Wire and arc additive and laser shock peening composited manufacturing device and method

A technology of laser shock strengthening and additive manufacturing, which is applied in the direction of manufacturing tools, additive processing, laser welding equipment, etc. It can solve the problems affecting the mechanical properties of additive components and the residual tensile stress of materials, so as to improve the microstructure and mechanical properties , Eliminate cooling shrinkage, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

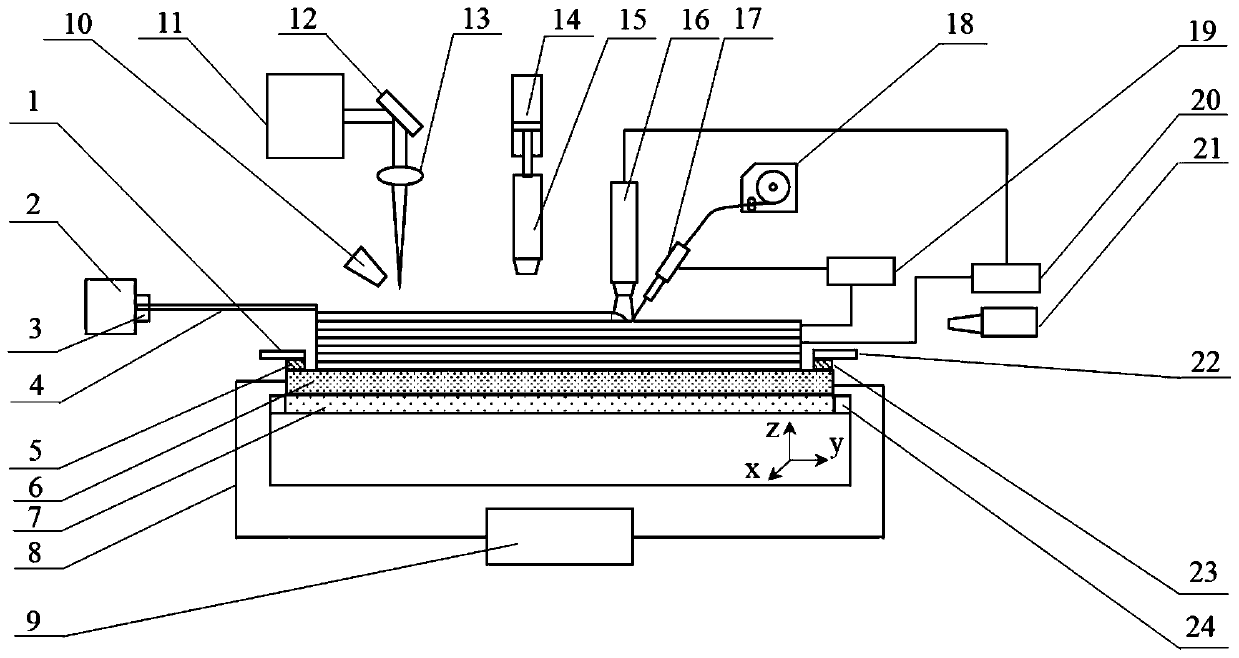

[0045] The compound manufacturing device of arc additive material and laser shock strengthening provided by the present invention includes: clamping device, arc additive manufacturing device, laser shock strengthening device, milling device, constrained layer laying device, temperature control system and control system; wherein, The control system is respectively connected to the arc additive manufacturing device, laser shock strengthening device, milling device, constrained layer laying device and temperature control system;

[0046]Among them, the clamping device is composed of a workbench 7, an insulating gasket and a clamp, and the arc additive manufacturing device is composed of a welding torch 16, a wire feeding mechanism 18, a contact tip 17, a welding power supply 20 and a welding wire heating power supply 19. By controlling the movement of the welding torch 16, the Metal is deposited to form additive components. The laser shock peening device is composed of a laser em...

Embodiment 2

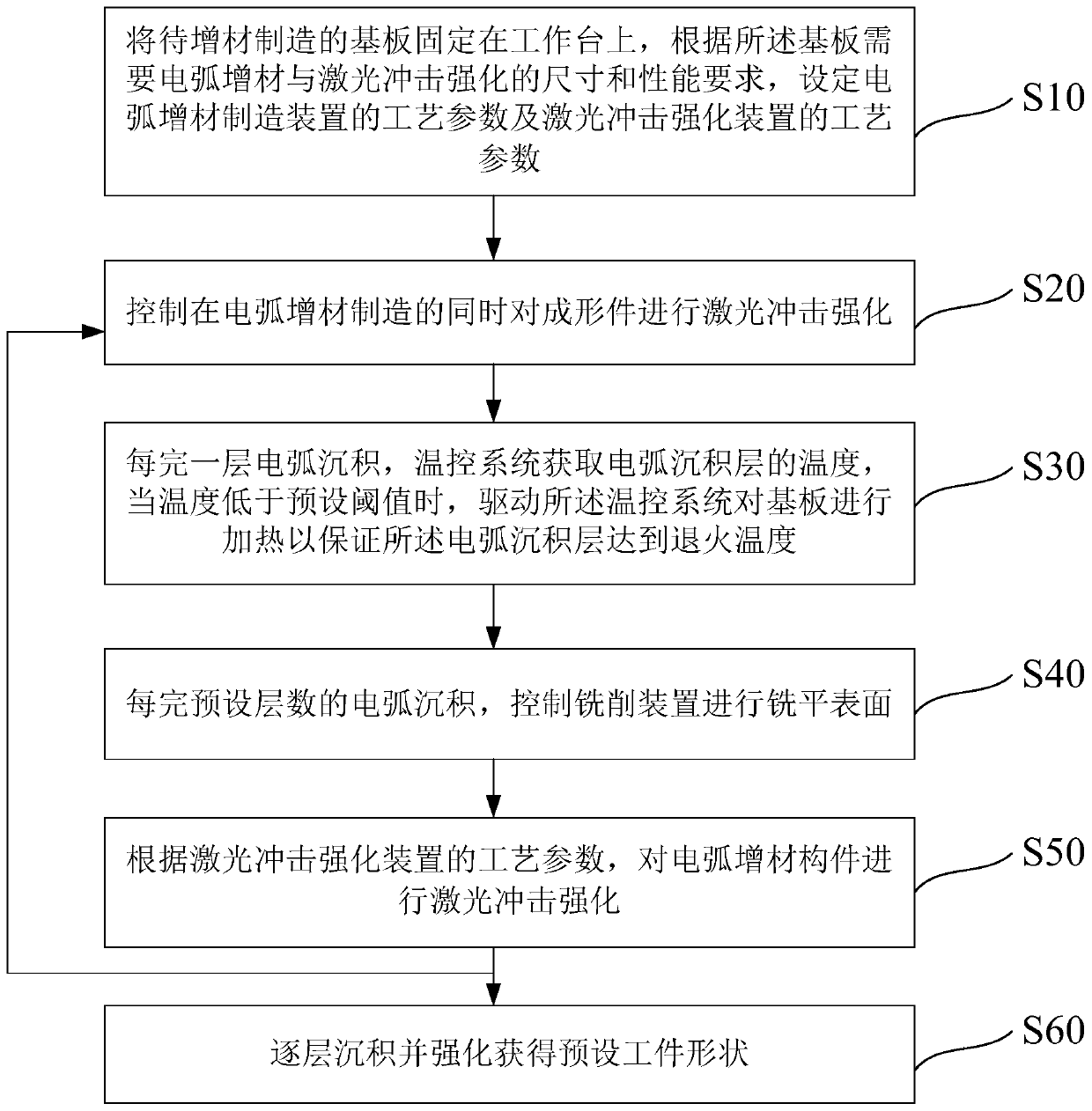

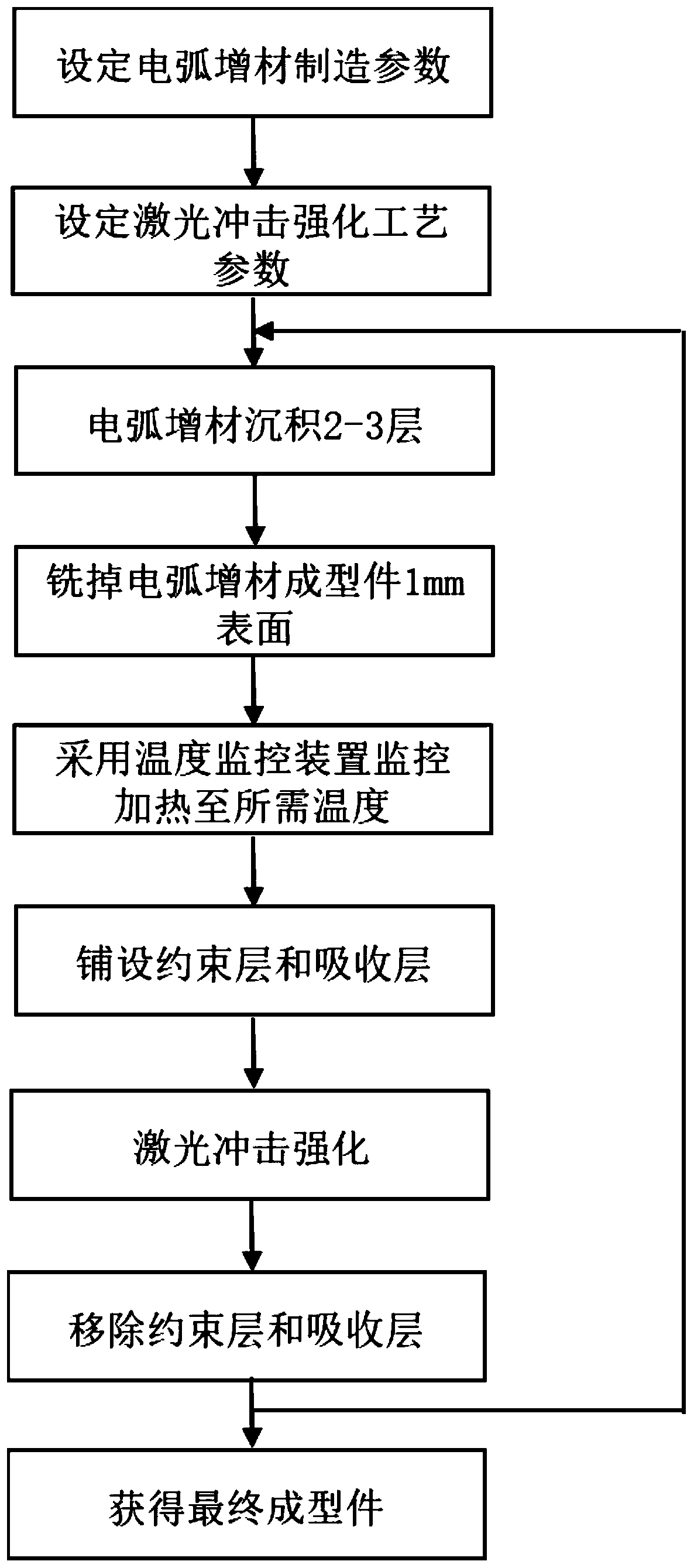

[0057] The embodiment of the present invention also provides a composite manufacturing method of arc additive manufacturing and laser shock strengthening, which can realize arc additive manufacturing and laser shock strengthening at the same time, so as to achieve efficient and rapid improvement of the internal microstructure of additive components, and improve the quality of additive components. The purpose of comprehensive mechanical properties.

[0058] refer to figure 2 shown, including the following steps:

[0059] S10, fixing the metal component to be additively manufactured on the substrate, and setting the process parameters of the arc additive manufacturing device and the laser shock peening device according to the size and performance requirements of the metal component;

[0060] S20, controlling laser shock peening of formed parts while arc additive manufacturing is in progress;

[0061] S30, after each layer of arc deposition, the temperature control system obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com