Patents

Literature

159 results about "Excessive Cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apparatus and method for cryogenic inhibition of hyperplasia

InactiveUS6355029B1Enhanced inhibitory effectEasy to controlCatheterSurgical instruments for coolingPercutaneous angioplastyBalloon catheter

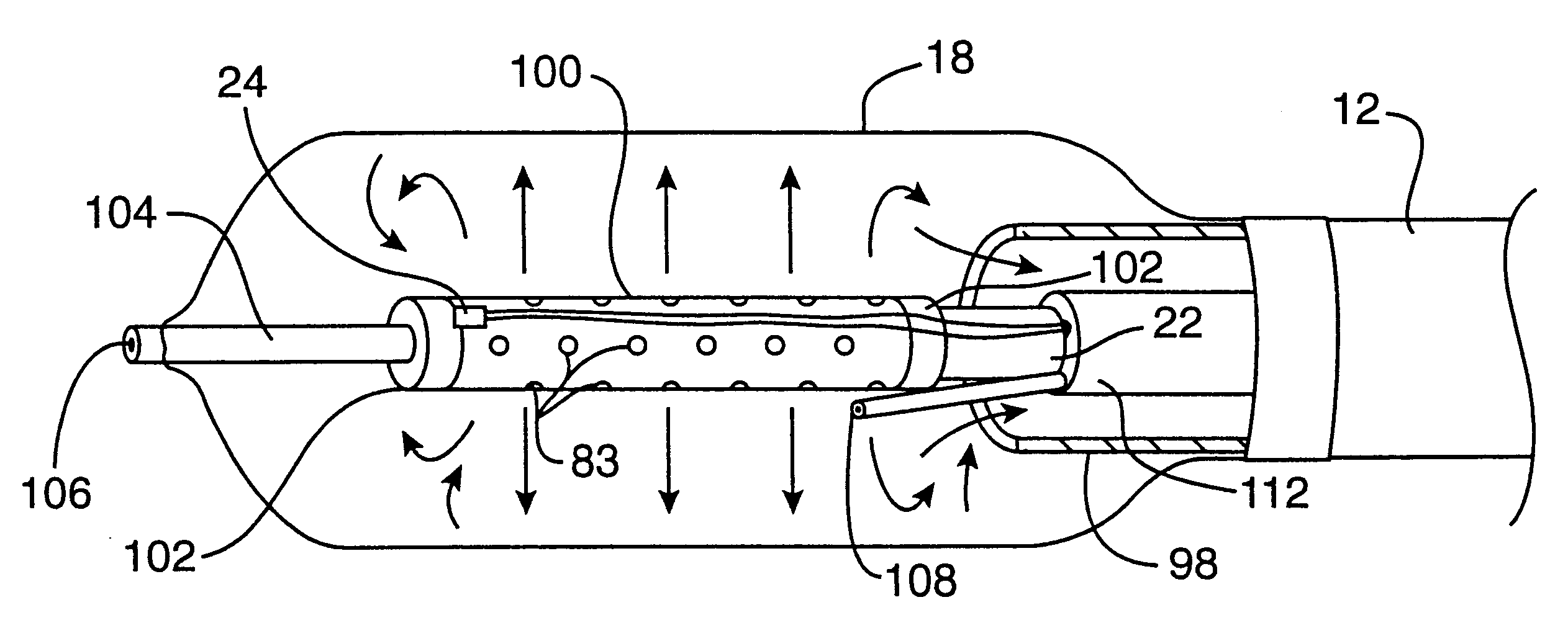

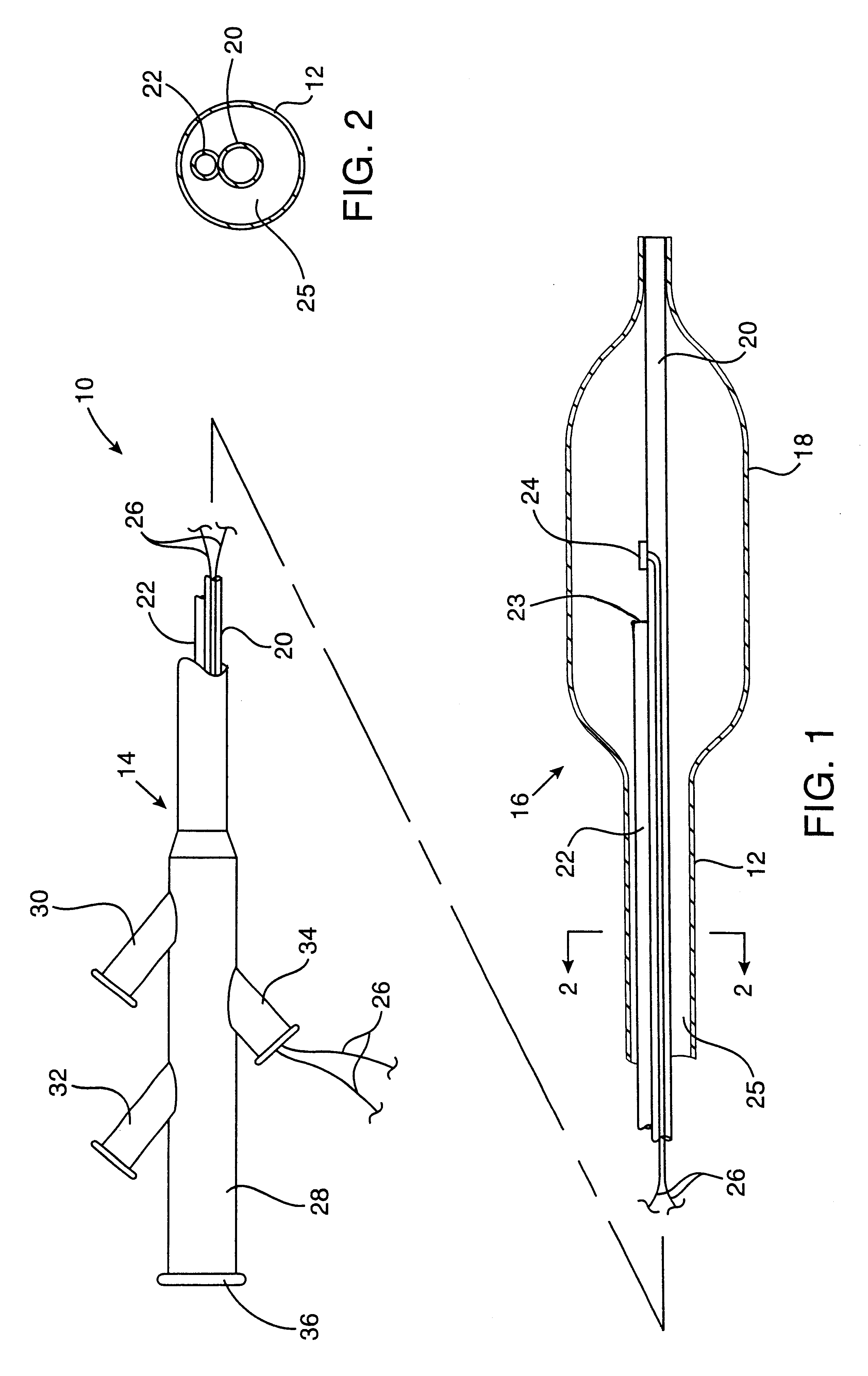

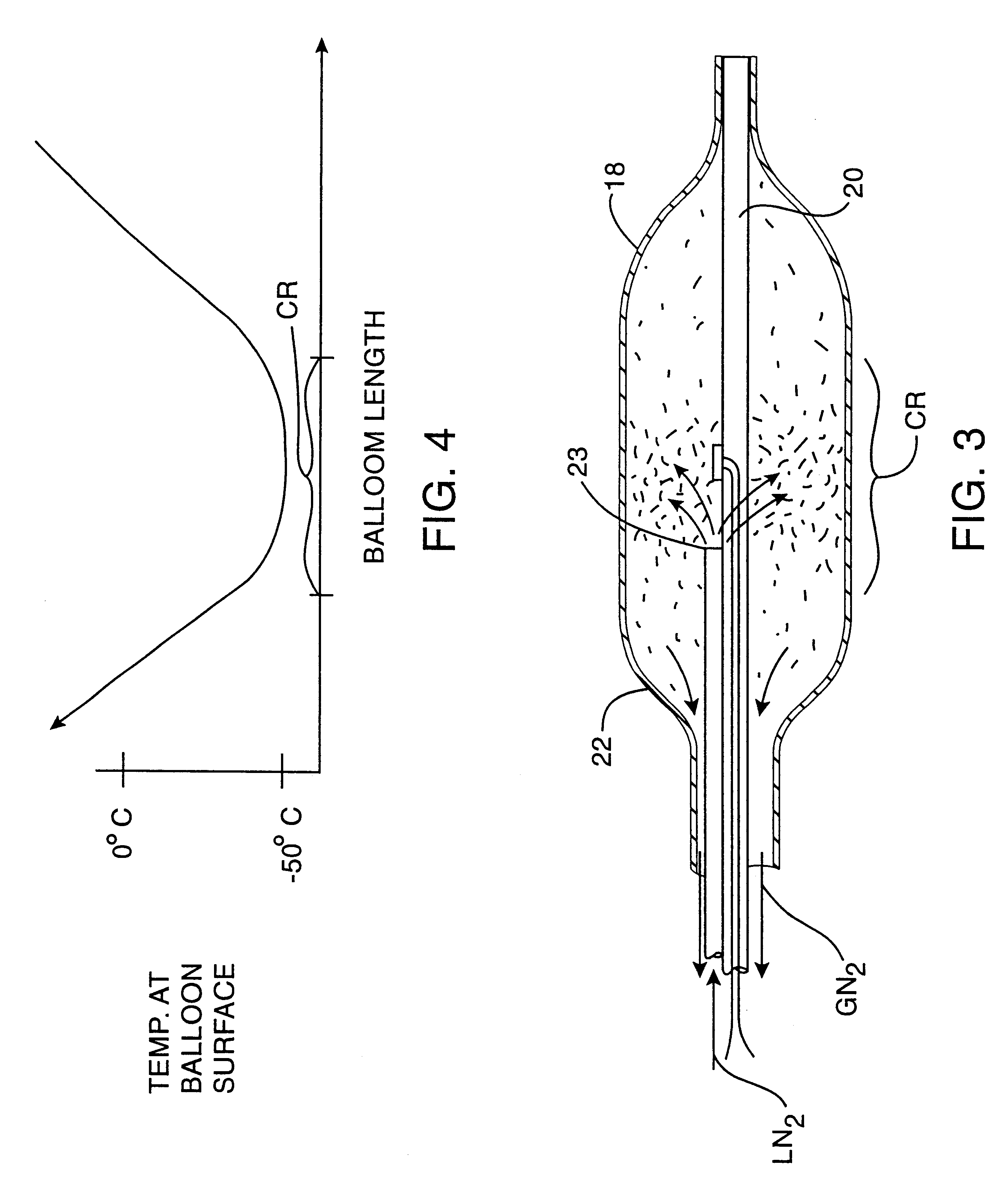

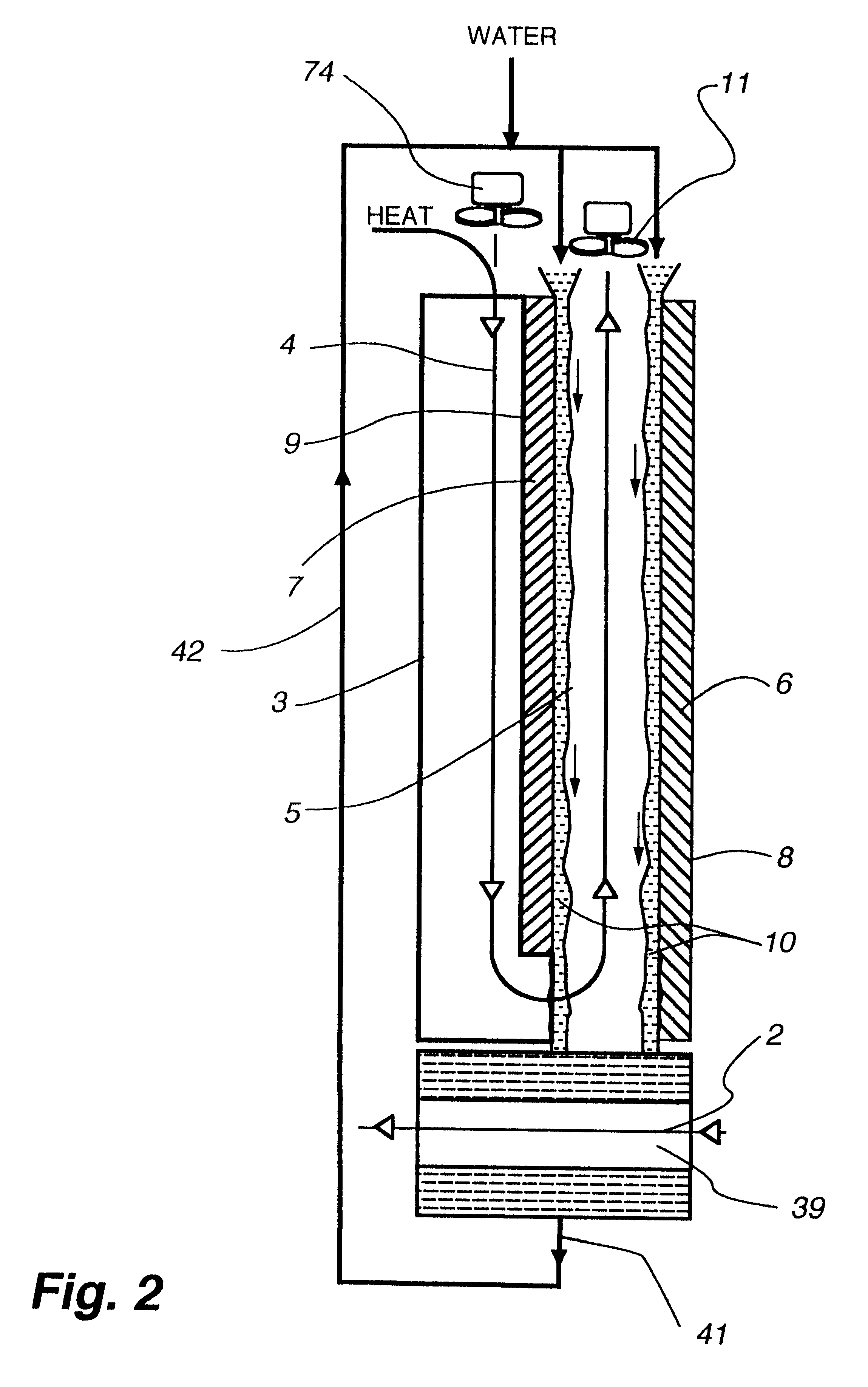

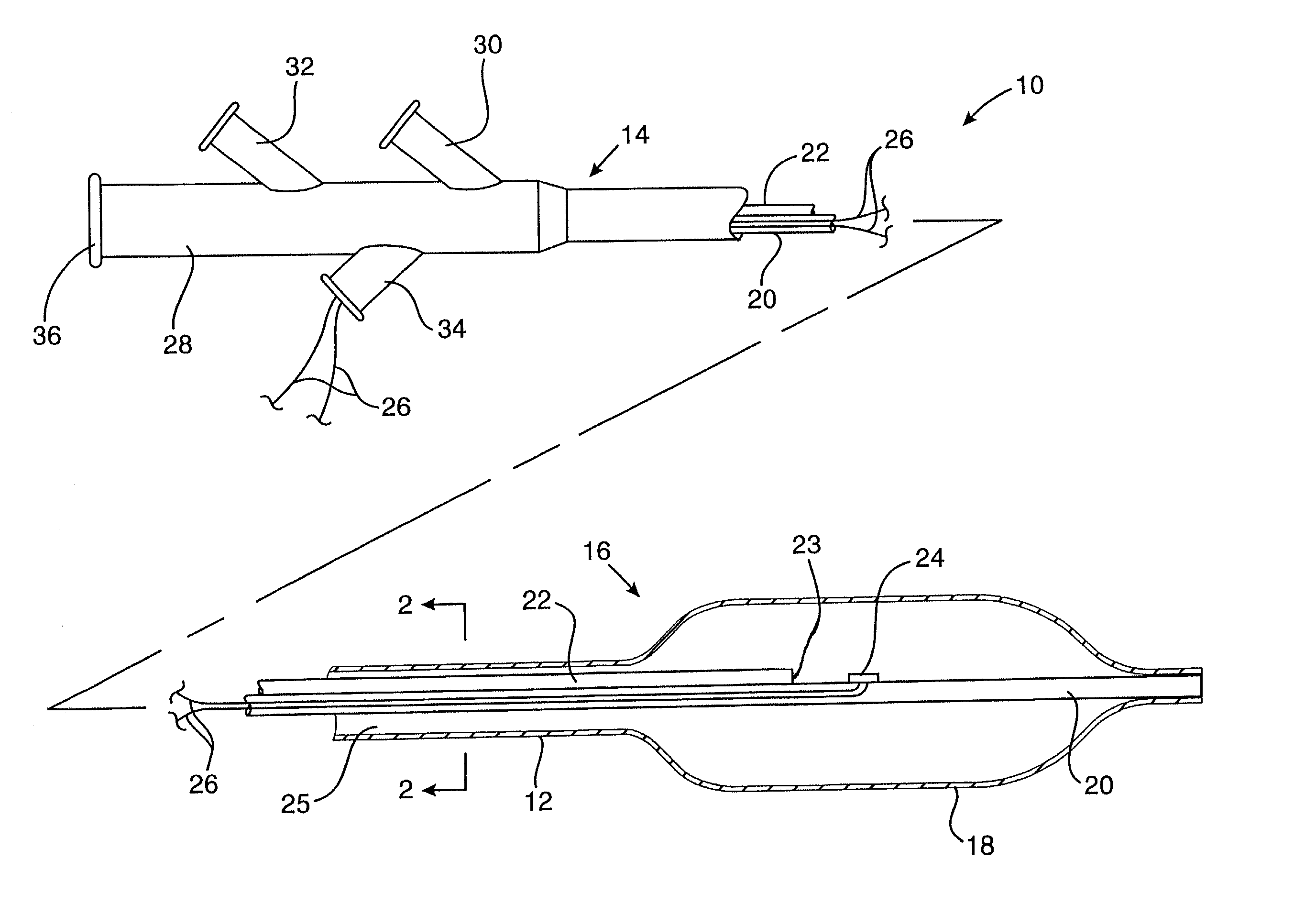

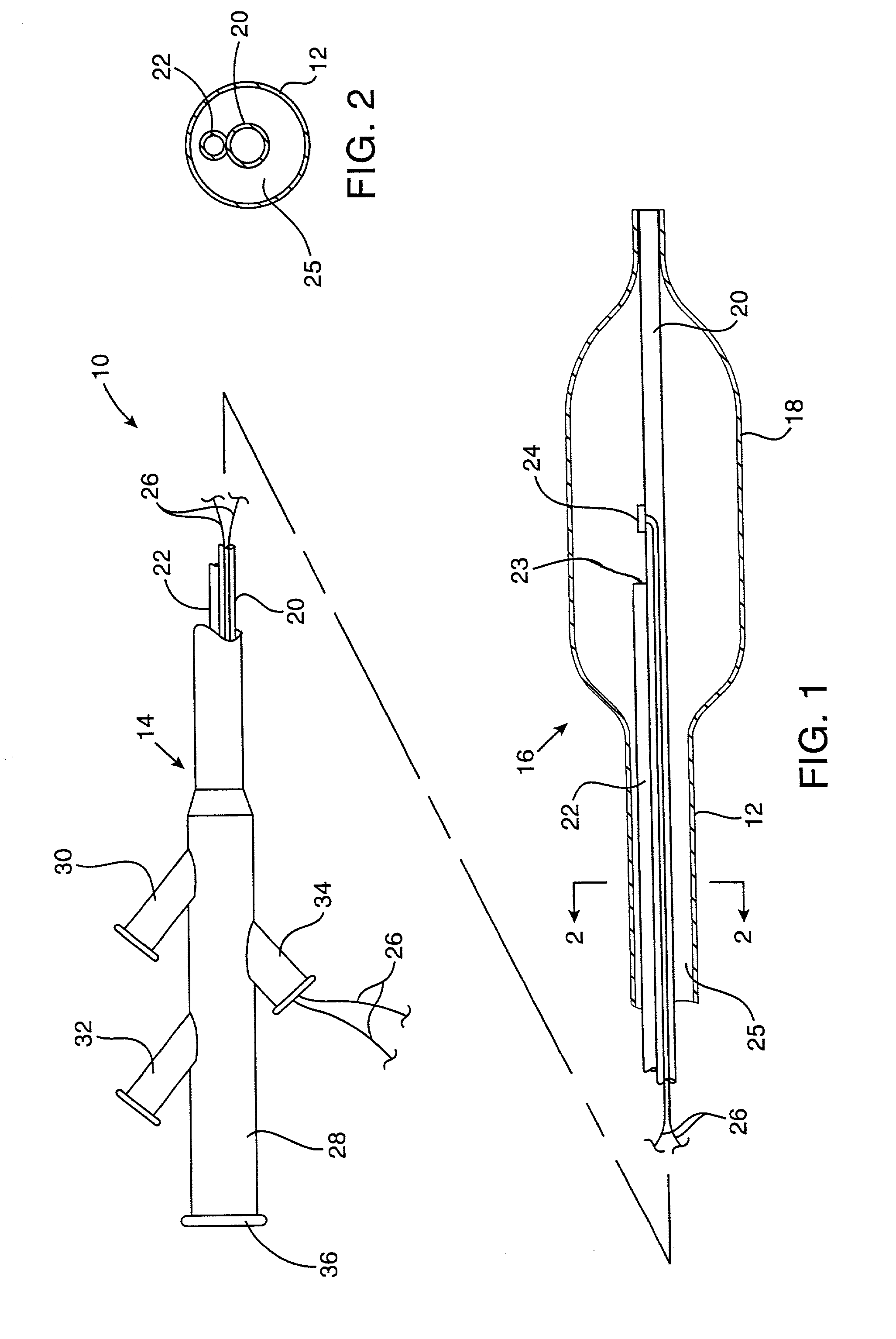

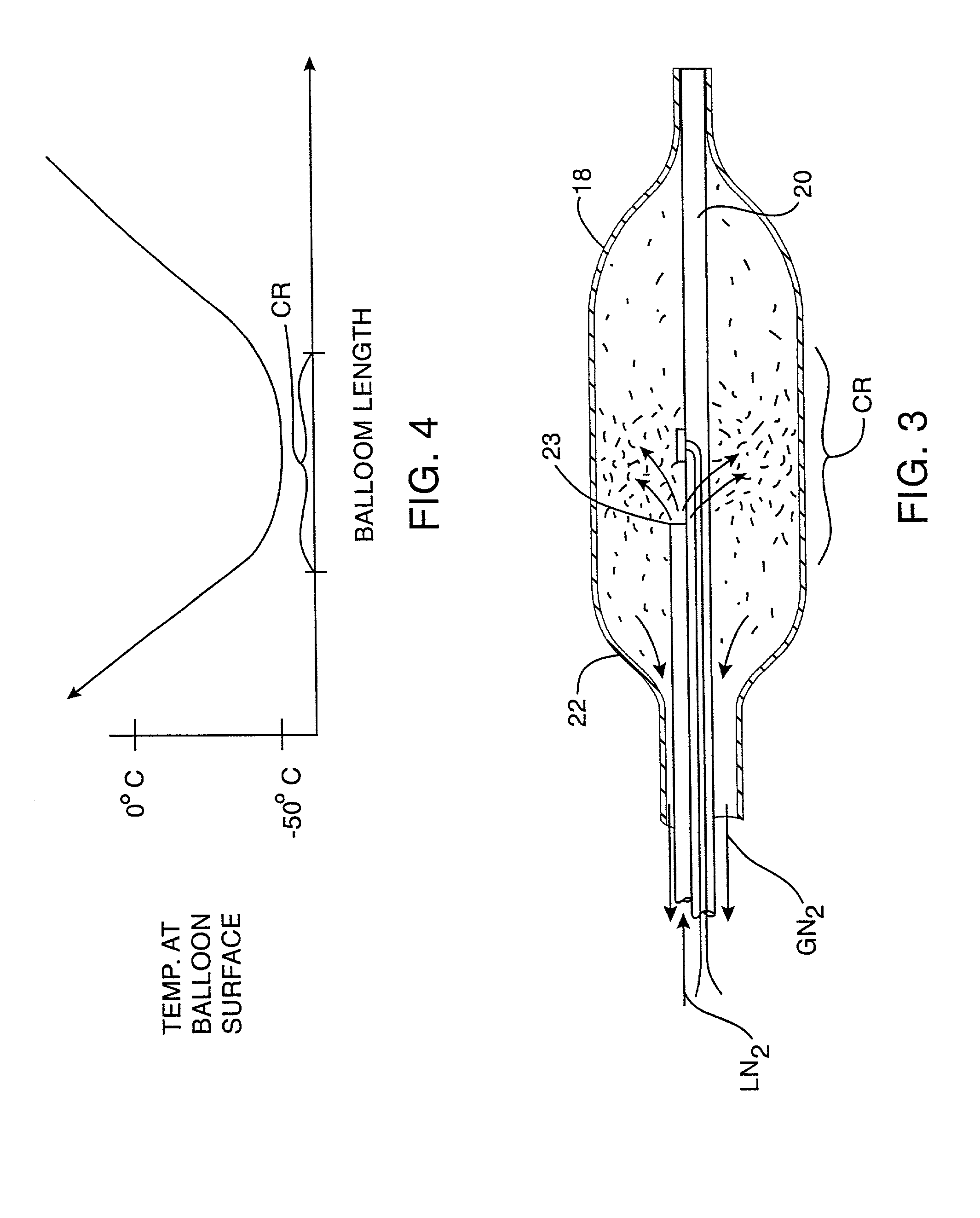

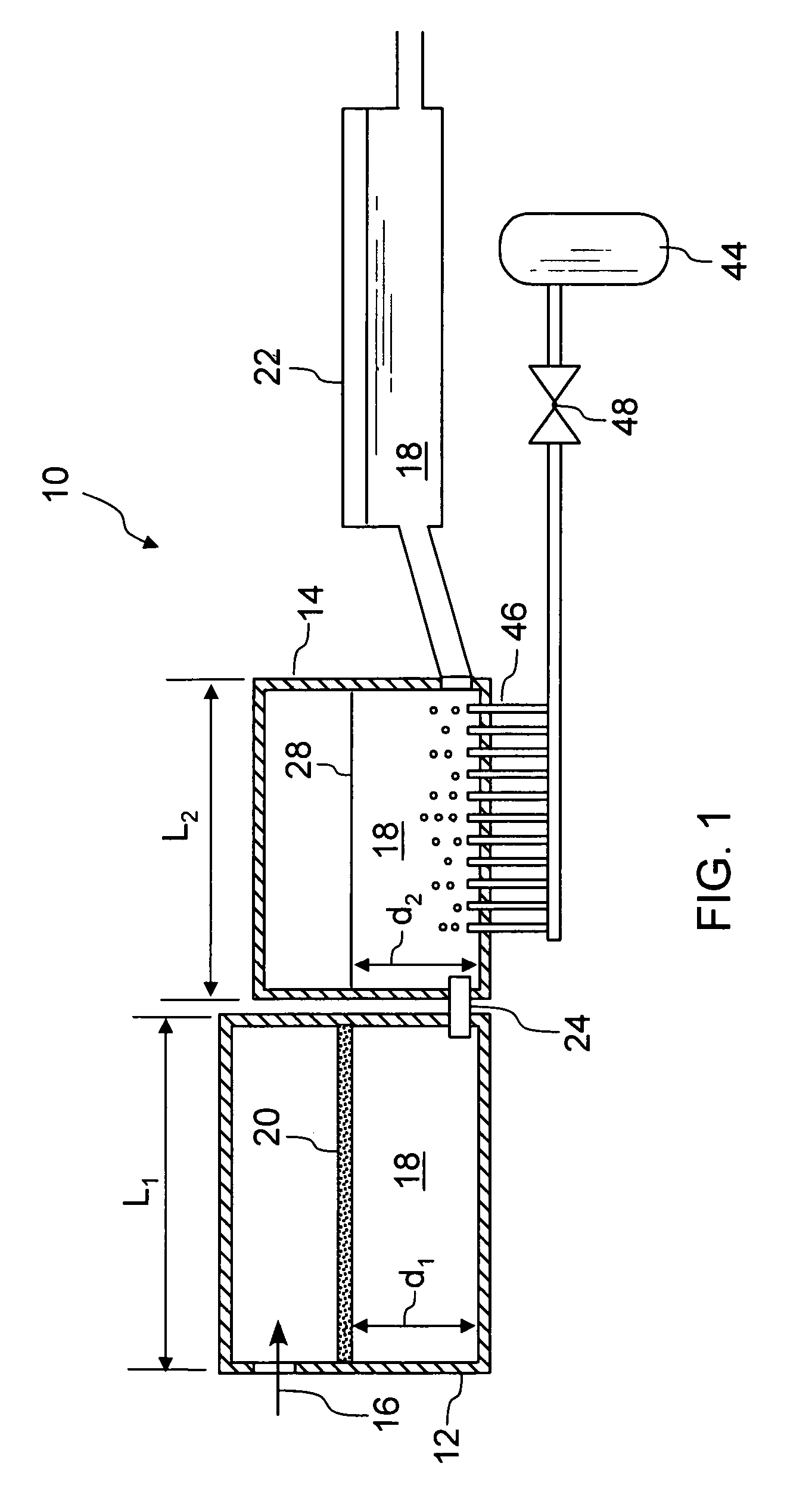

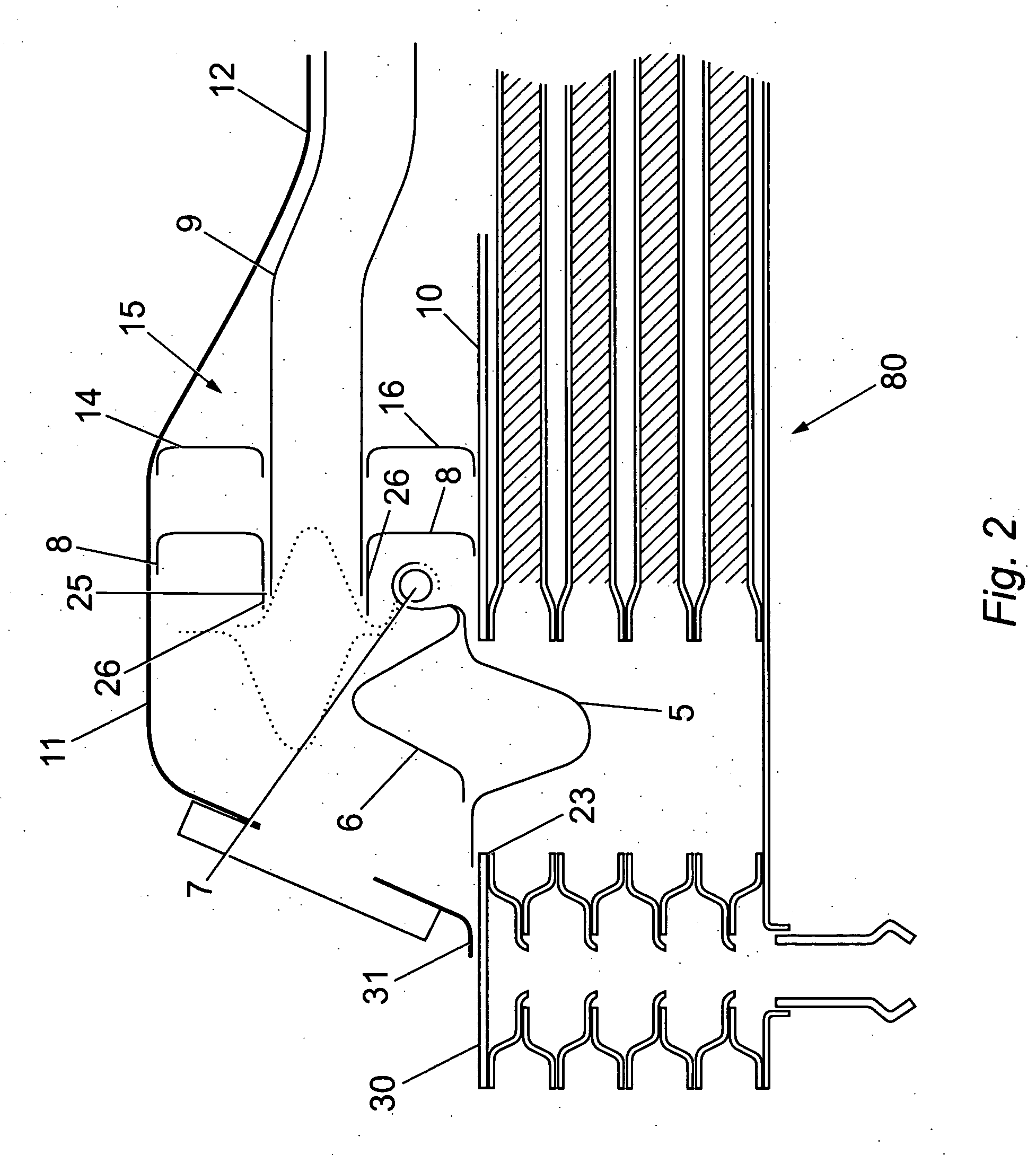

Post-angioplasty hyperplasia in blood vessels is treated using a cryosurgical balloon catheter. The balloon catheter is positioned at a target region within the blood vessel, and the balloon inflated by expanding a cryogenic fluid, such as liquid nitrogen, across an expansion orifice into a balloon. The balloon will be constructed so that cooling is achieved primarily in the central regions of the balloon, with the proximal and distal regions being less cold and acting to insulate adjacent regions of the blood vessel from excessive cooling.

Owner:BOSTON SCI SCIMED INC

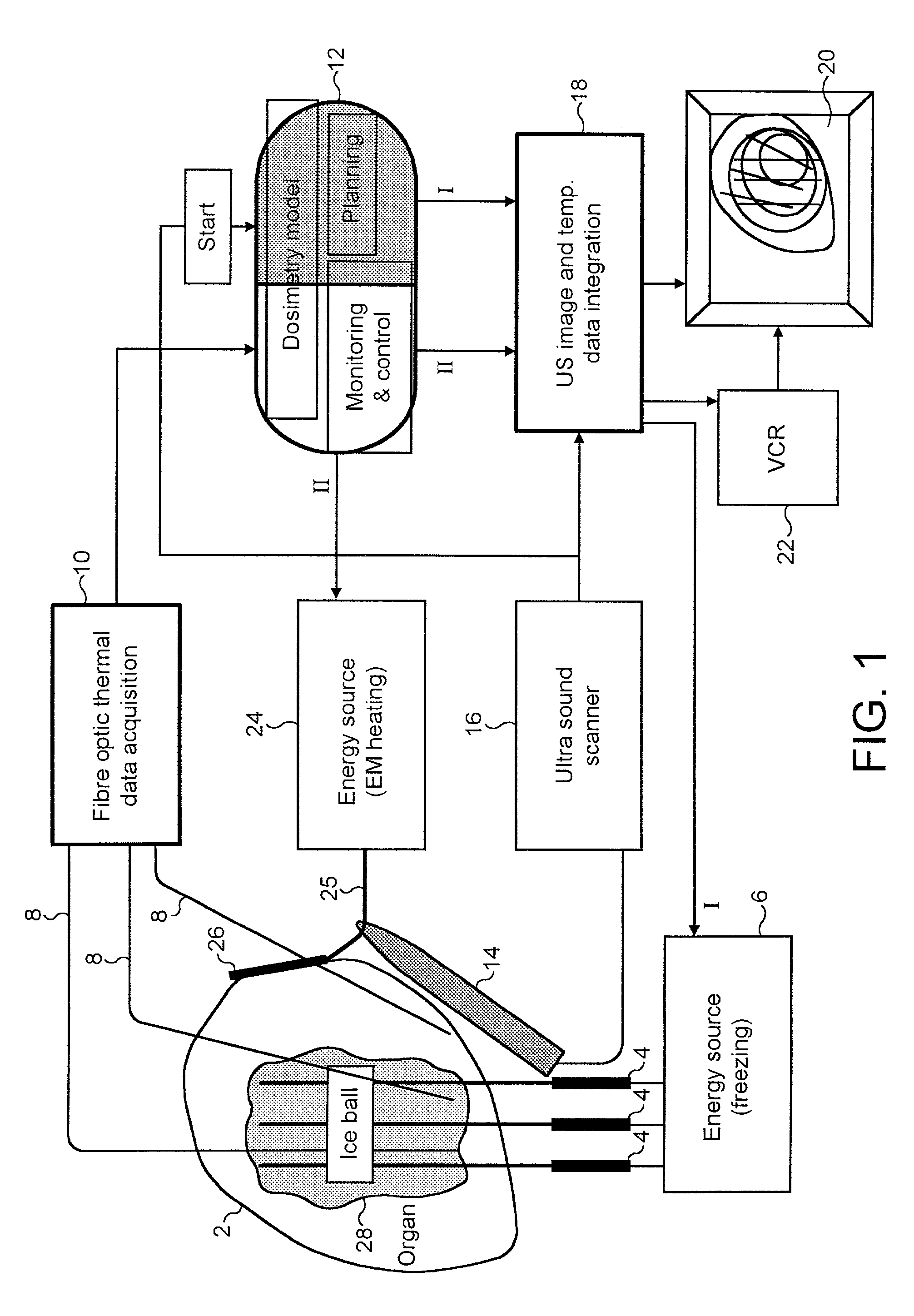

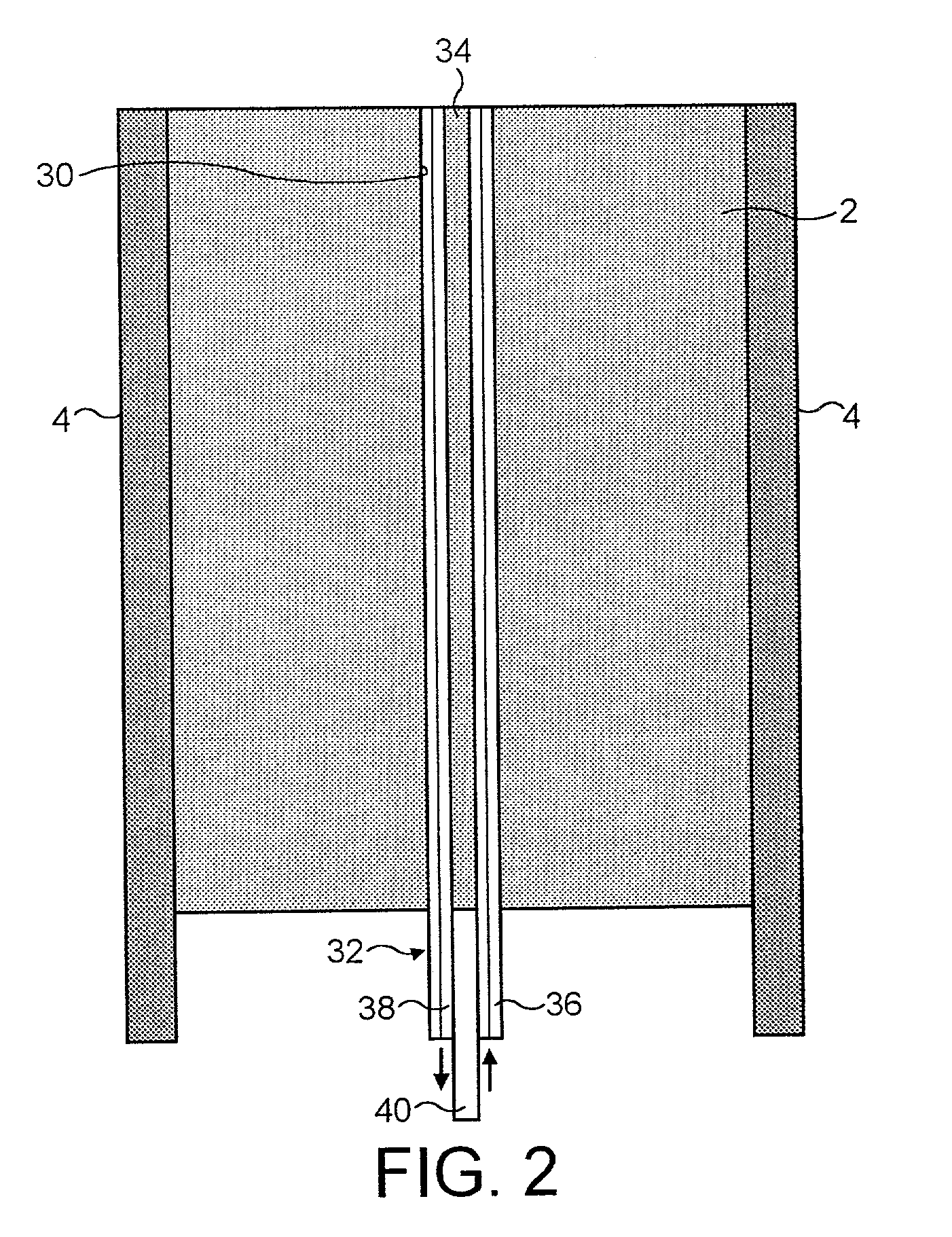

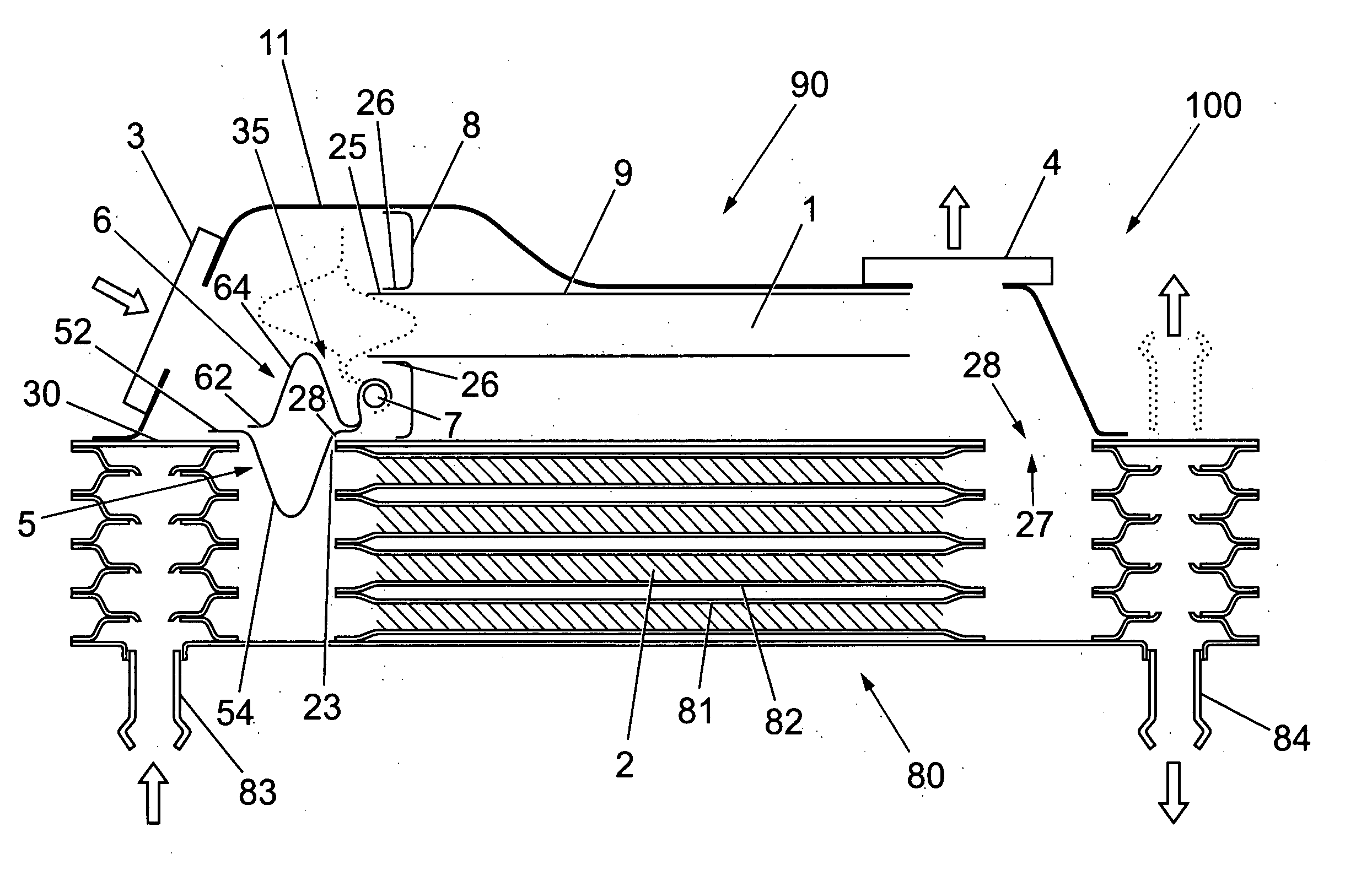

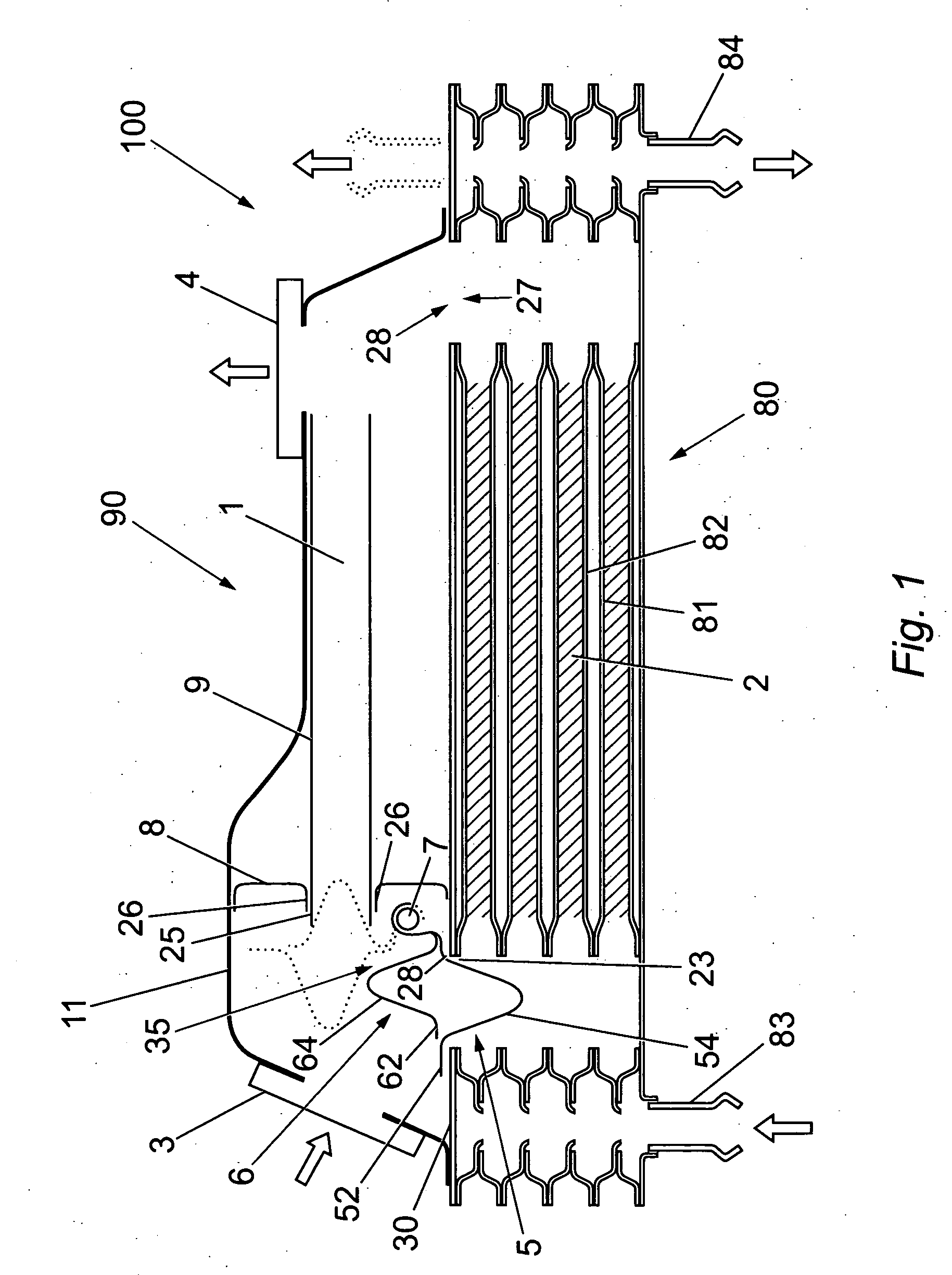

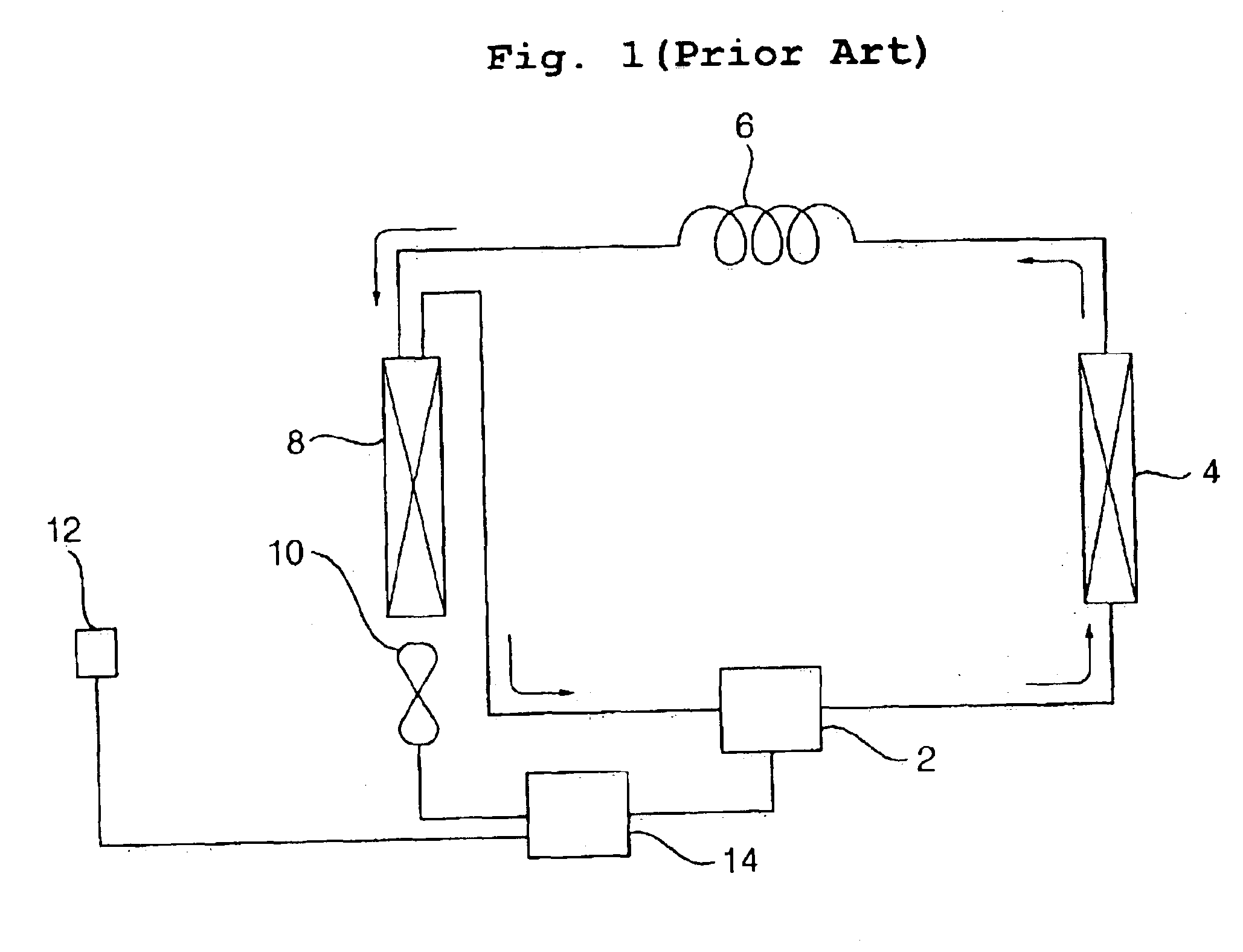

Cryosurgical apparatus and methods

InactiveUS7081111B2Easy to controlImprove reliabilityUltrasound therapyControlling energy of instrumentEngineeringAnimal body

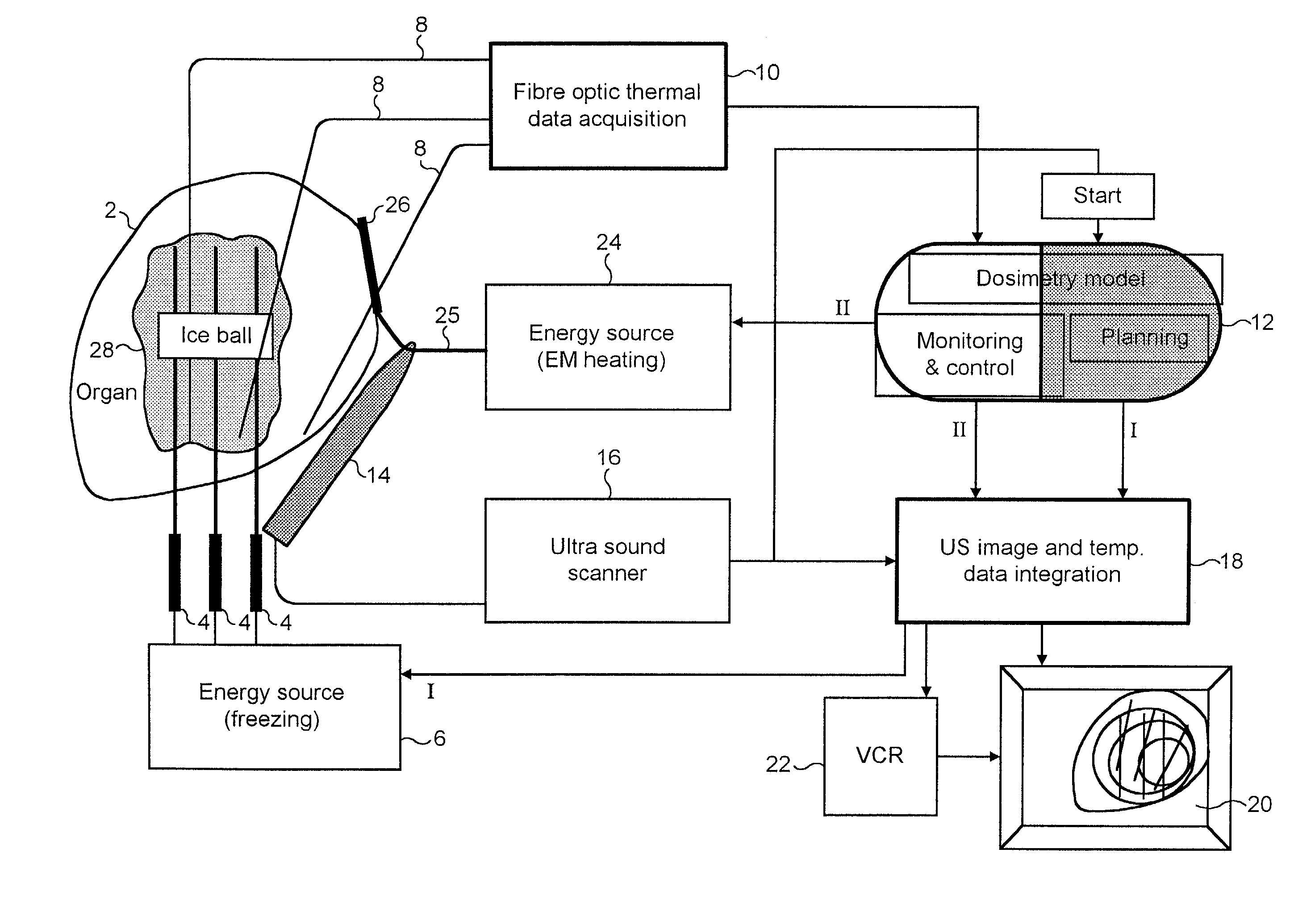

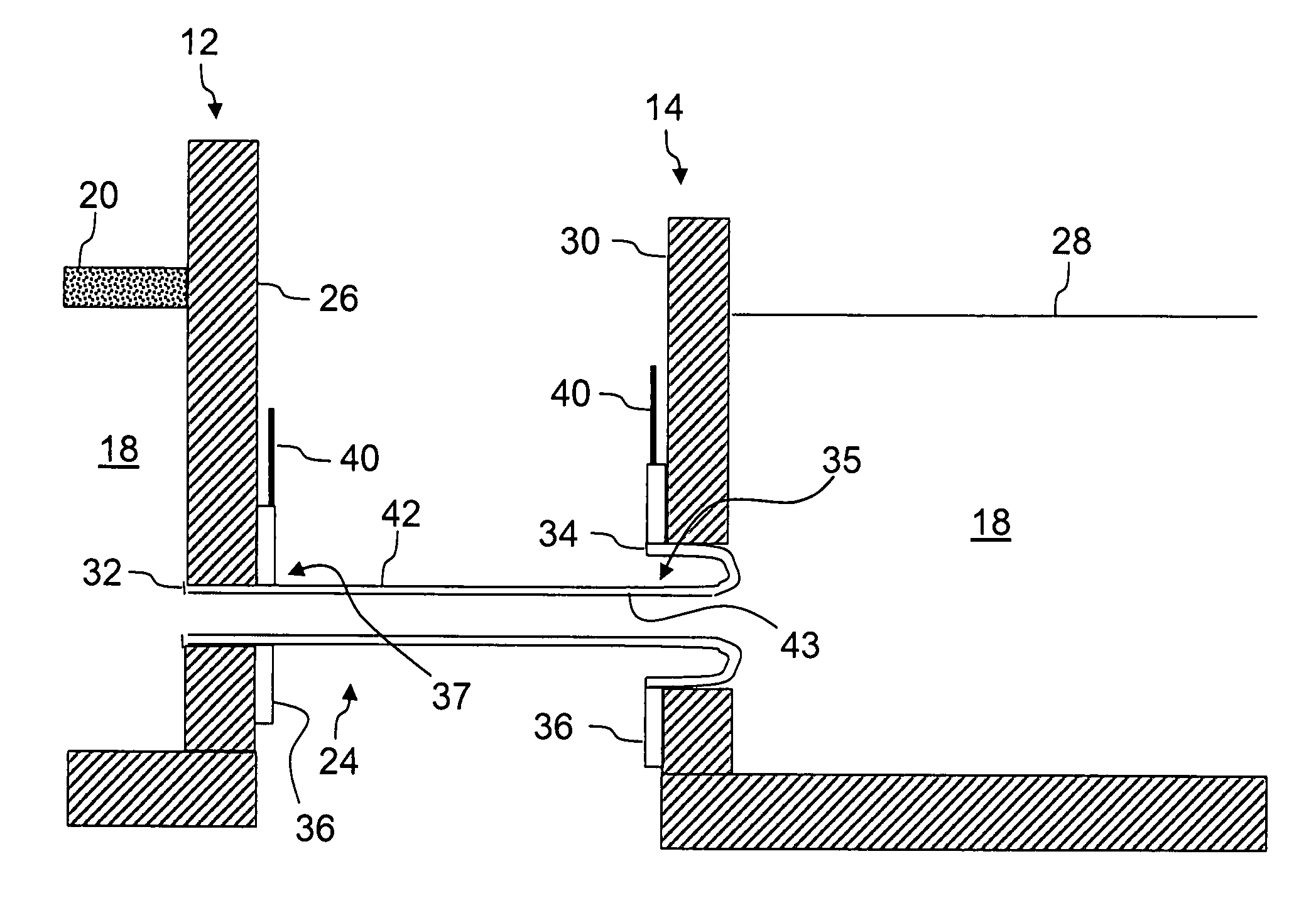

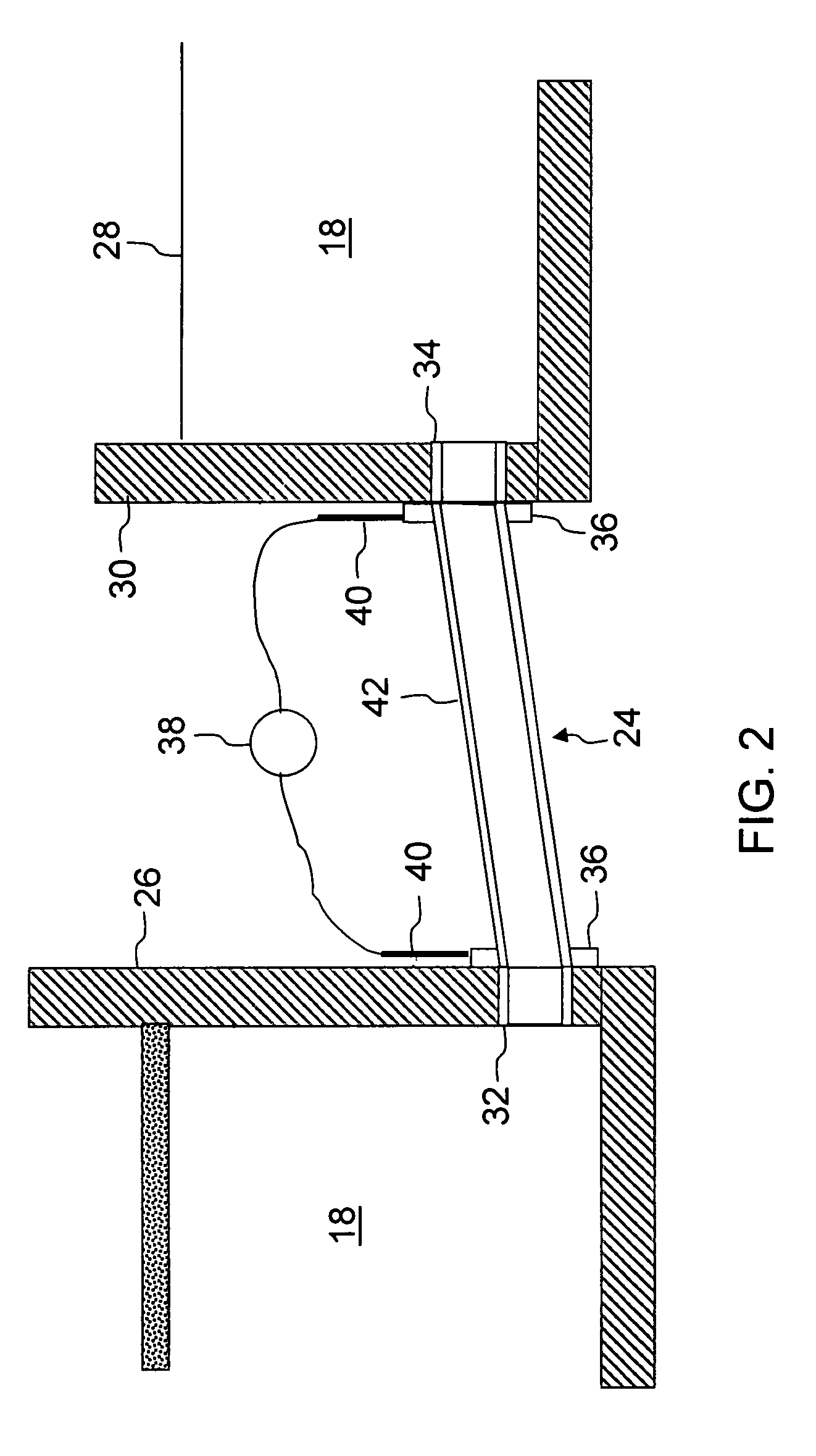

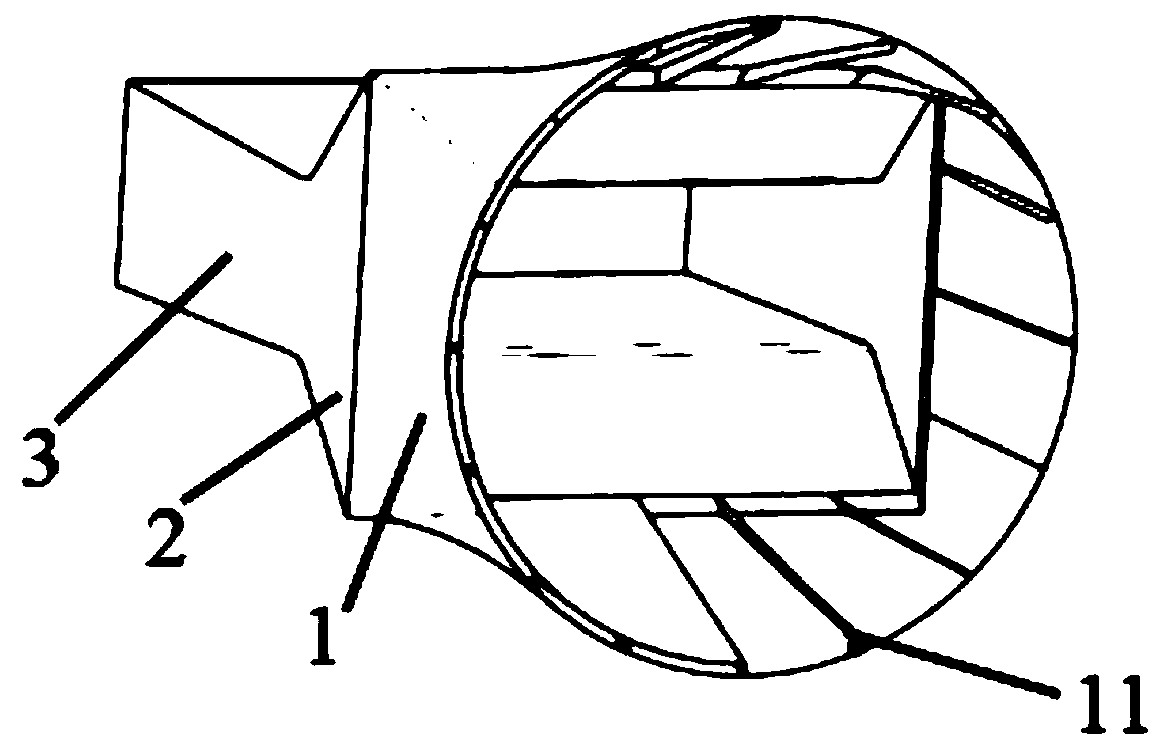

An apparatus for controlling the temperature of a part of a human or animal body 2 during a cryosurgical procedure is disclosed. The apparatus comprises a radiative energy transmitter 26 for radiating energy to a zone of the body 2 to be protected from excessive cooling. There is also provided a means 12 for controlling the energy radiated by said radiative energy transmitter 26. Preferably the radiative energy transmitter comprises an infra-red laser diode coupled to a diffuser 34 by an optical fibre 40.

Owner:MEDXENSE

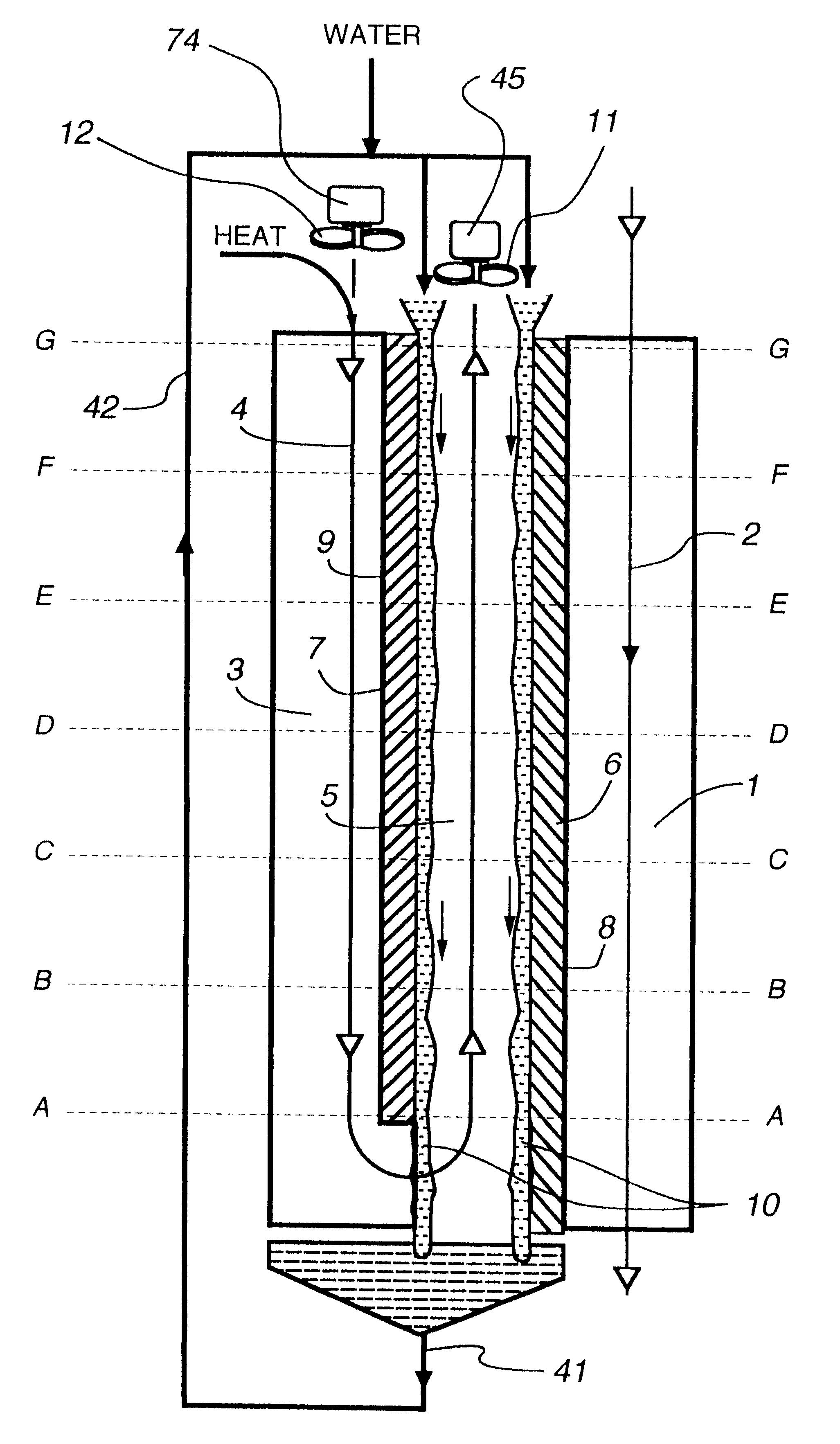

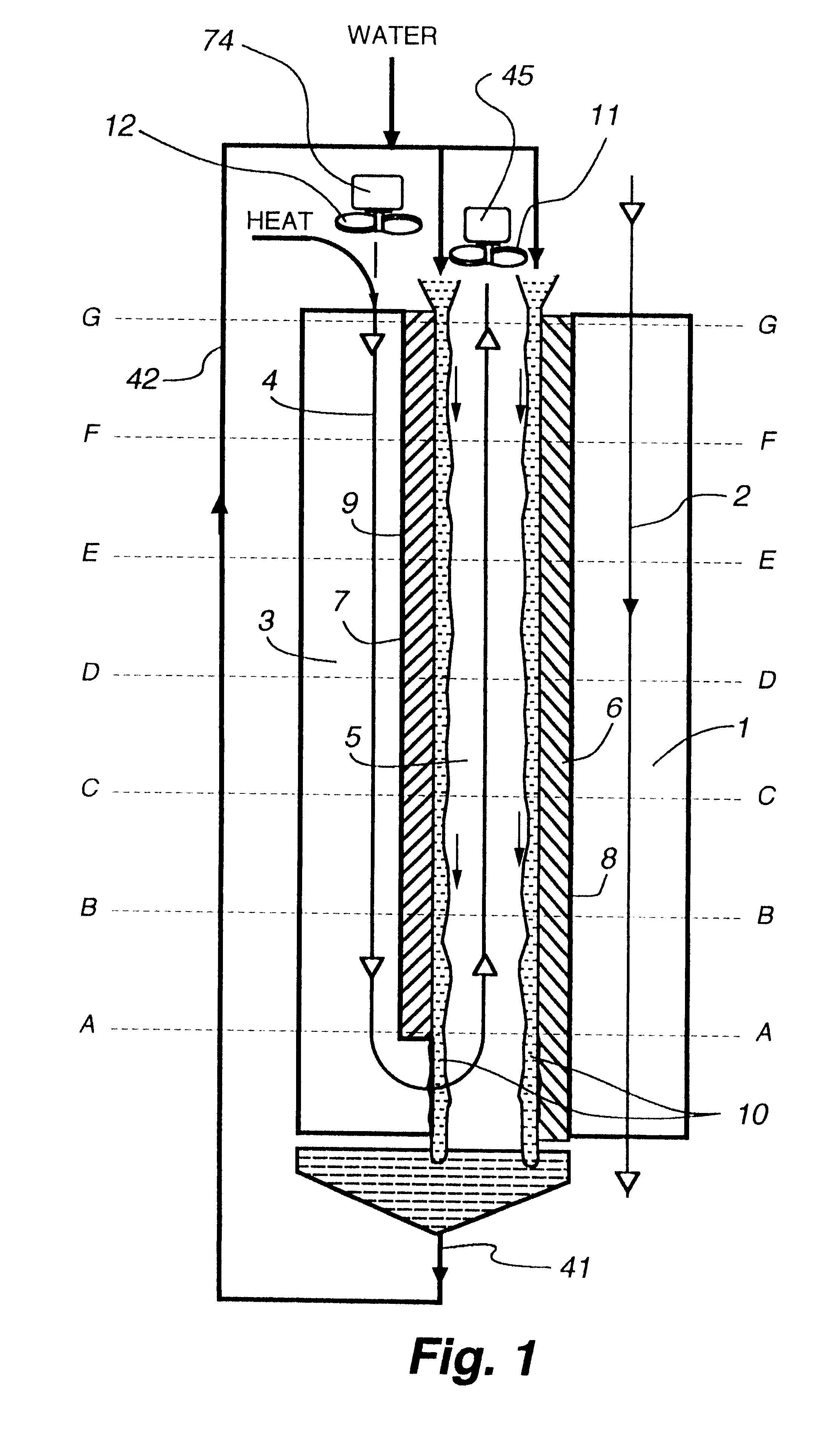

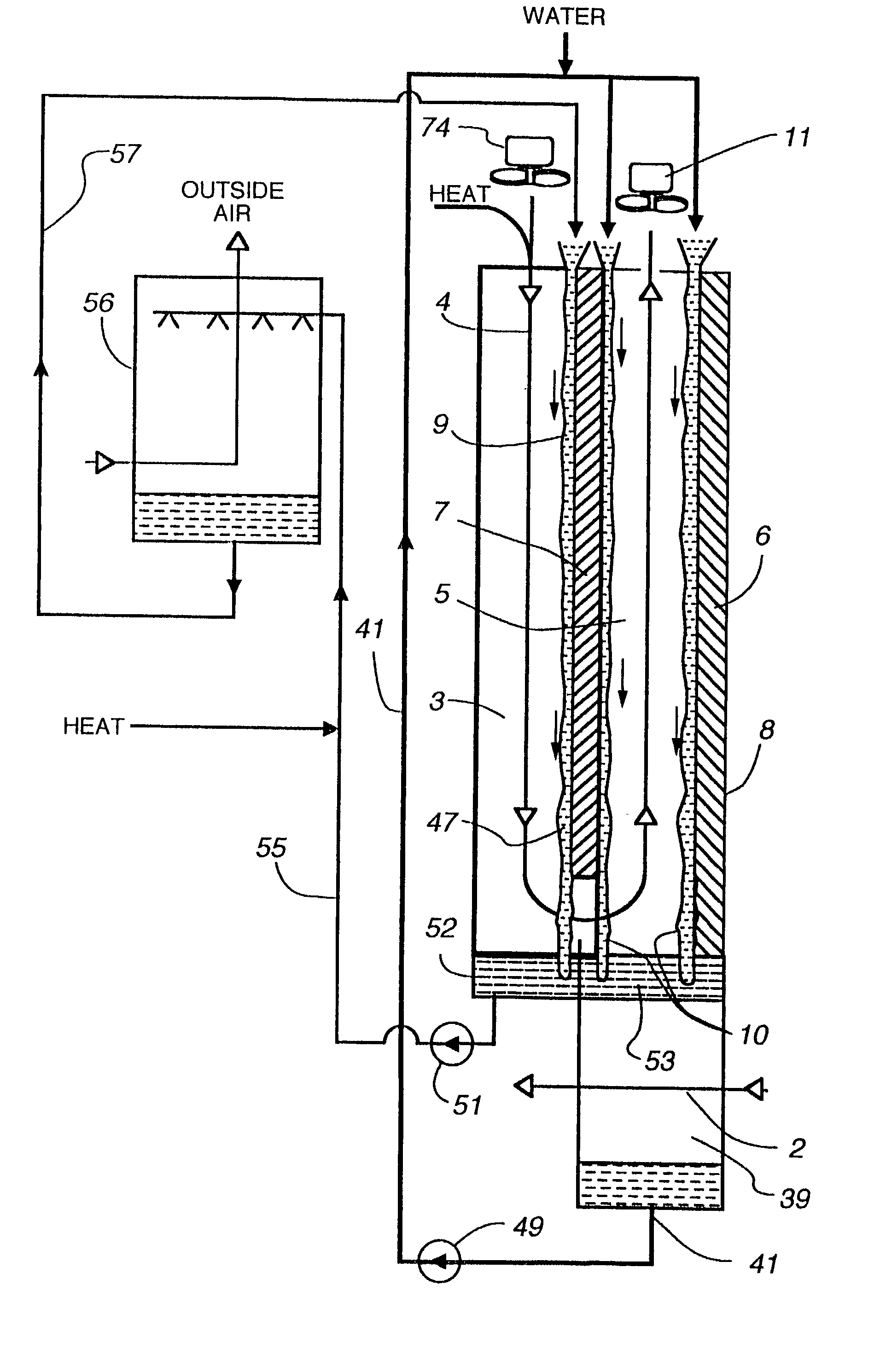

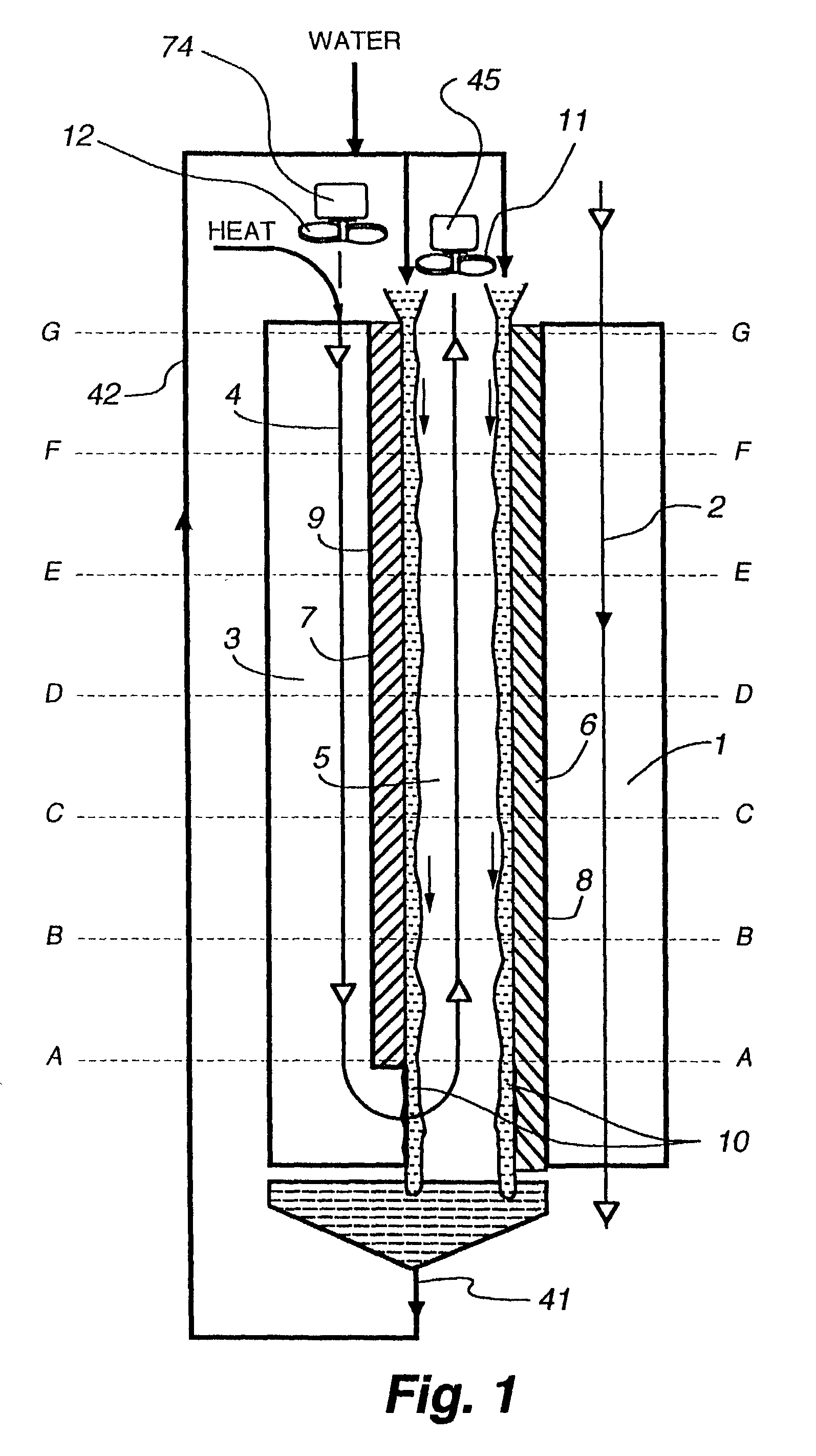

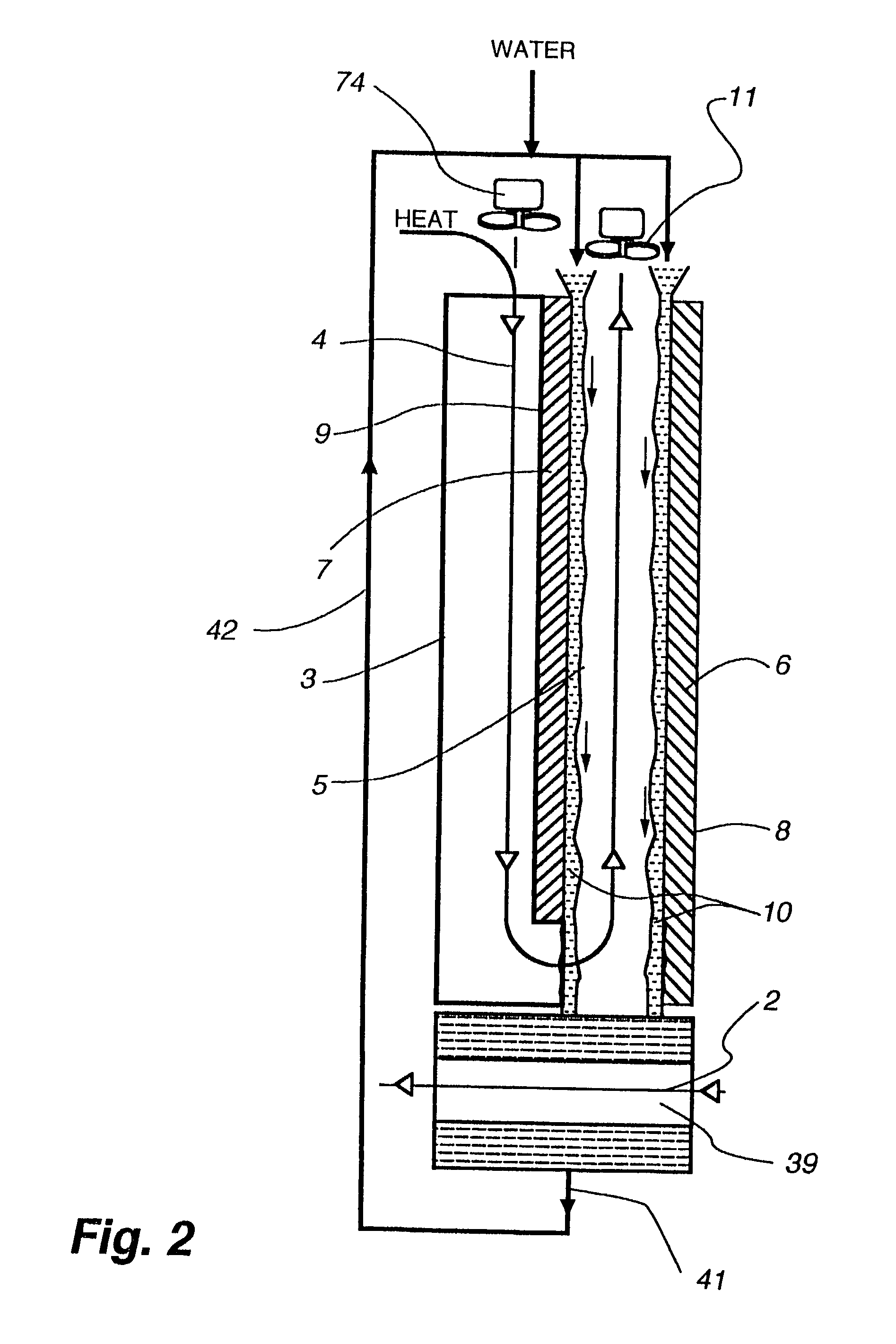

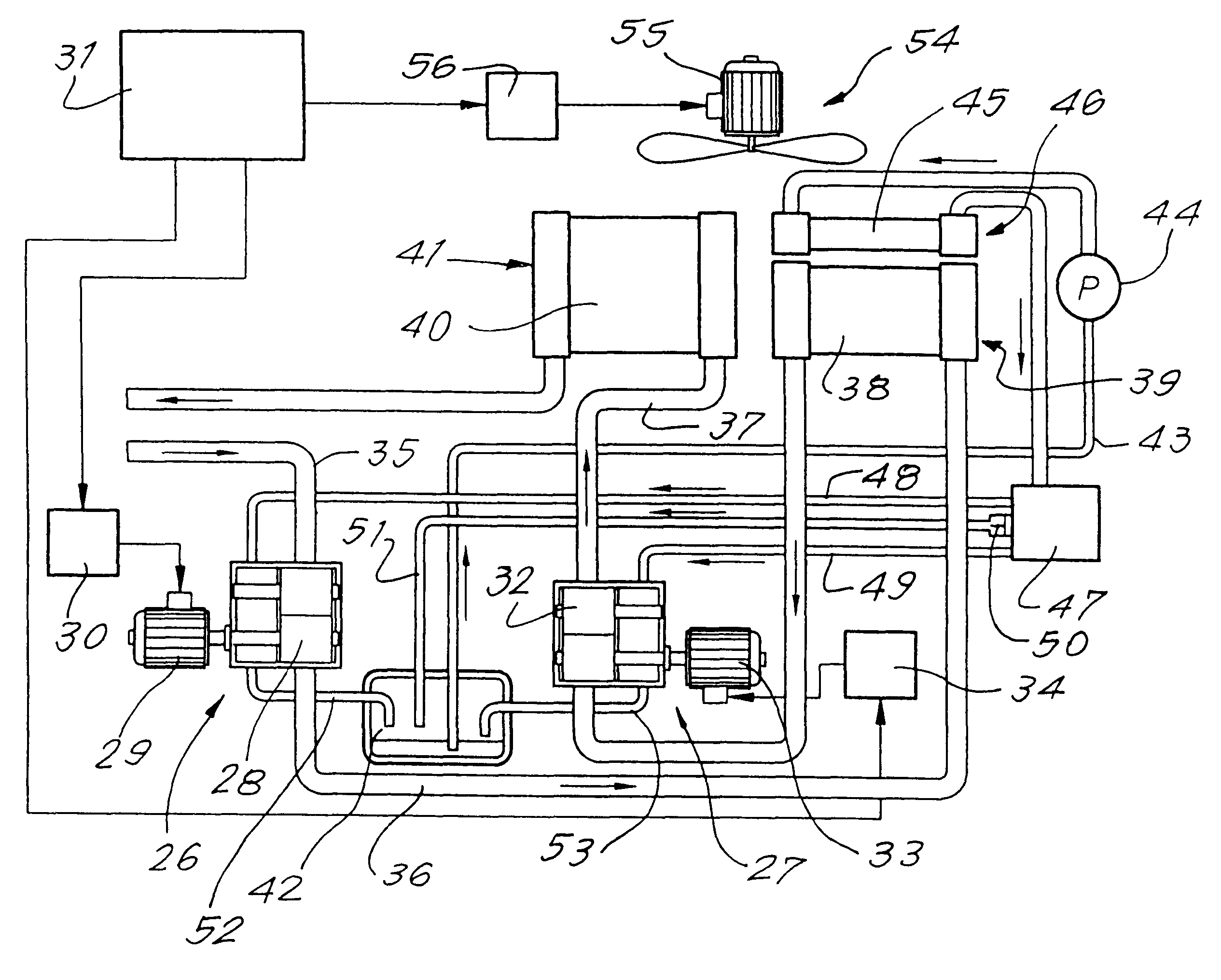

Method and apparatus of indirect-evaporation cooling

InactiveUS6497107B2Less energyHigh energy costFree-cooling systemsStationary conduit assembliesWorking fluidEvaporation

The within invention improves on the indirect evaporative cooling method and apparatus by making use of a working fluid that is pre-cooled with and without desiccants before it is passed through a Wet Channel where evaporative fluid is on the walls to take heat and store it in the working fluid as increased latent heat. The heat transfer across the membrane between the Dry Channel and the Wet Channel may have dry, solid desiccant or liquid desiccant and may have perforations, pores or capillary pathways. The evaporative fluid may be water, fuel, or any substance that has the capacity to take heat as latent heat. The Wet Channel or excess cooled fluid is in heat transfer contact with a Product Channel where Product Fluid is cooled without adding any humidity. An alternative embodiment for heat transfer between adjacent channels is with heat pipes.

Owner:F F SEELEY NOMINEES

Control unit and control method for reductant supply device

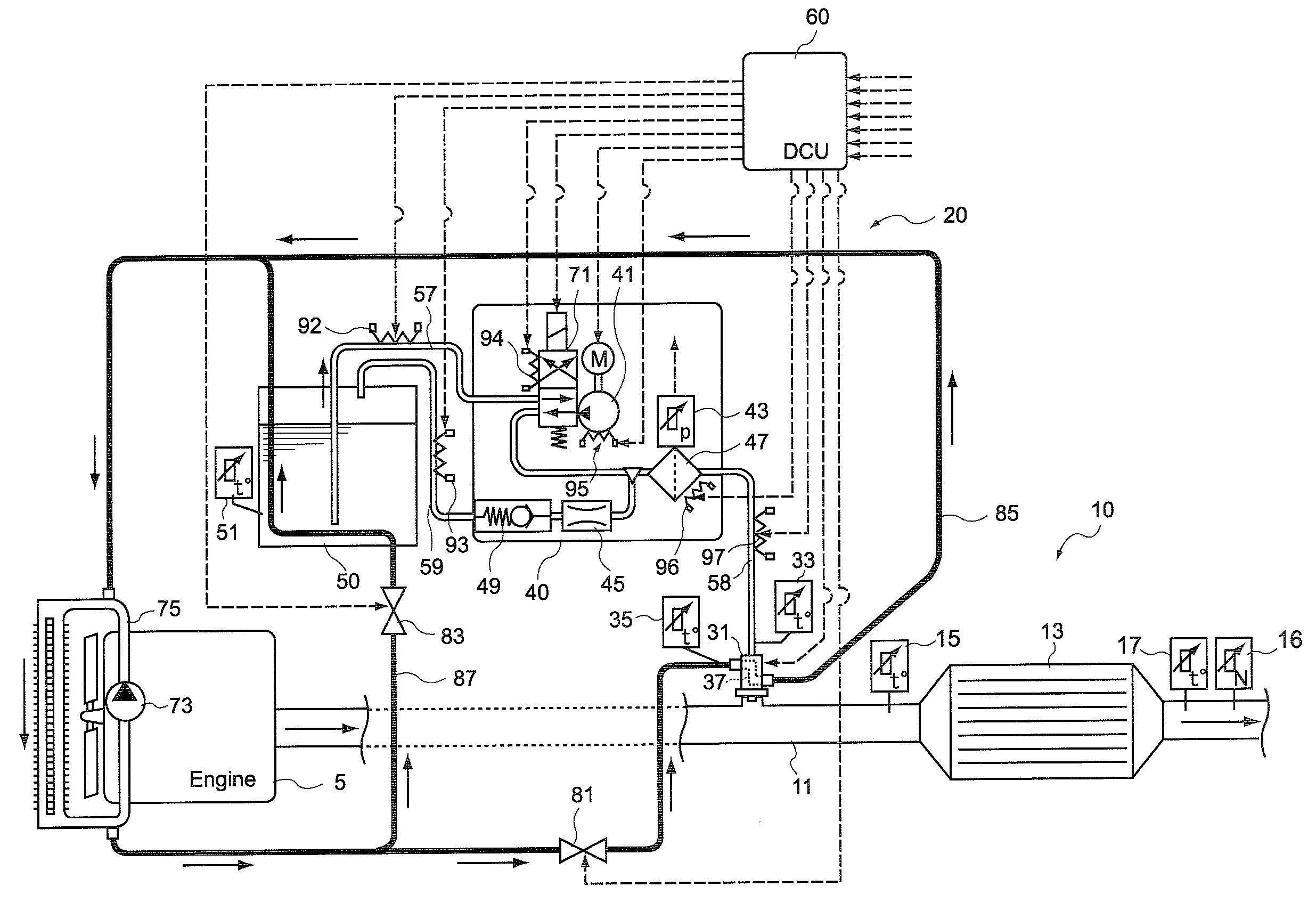

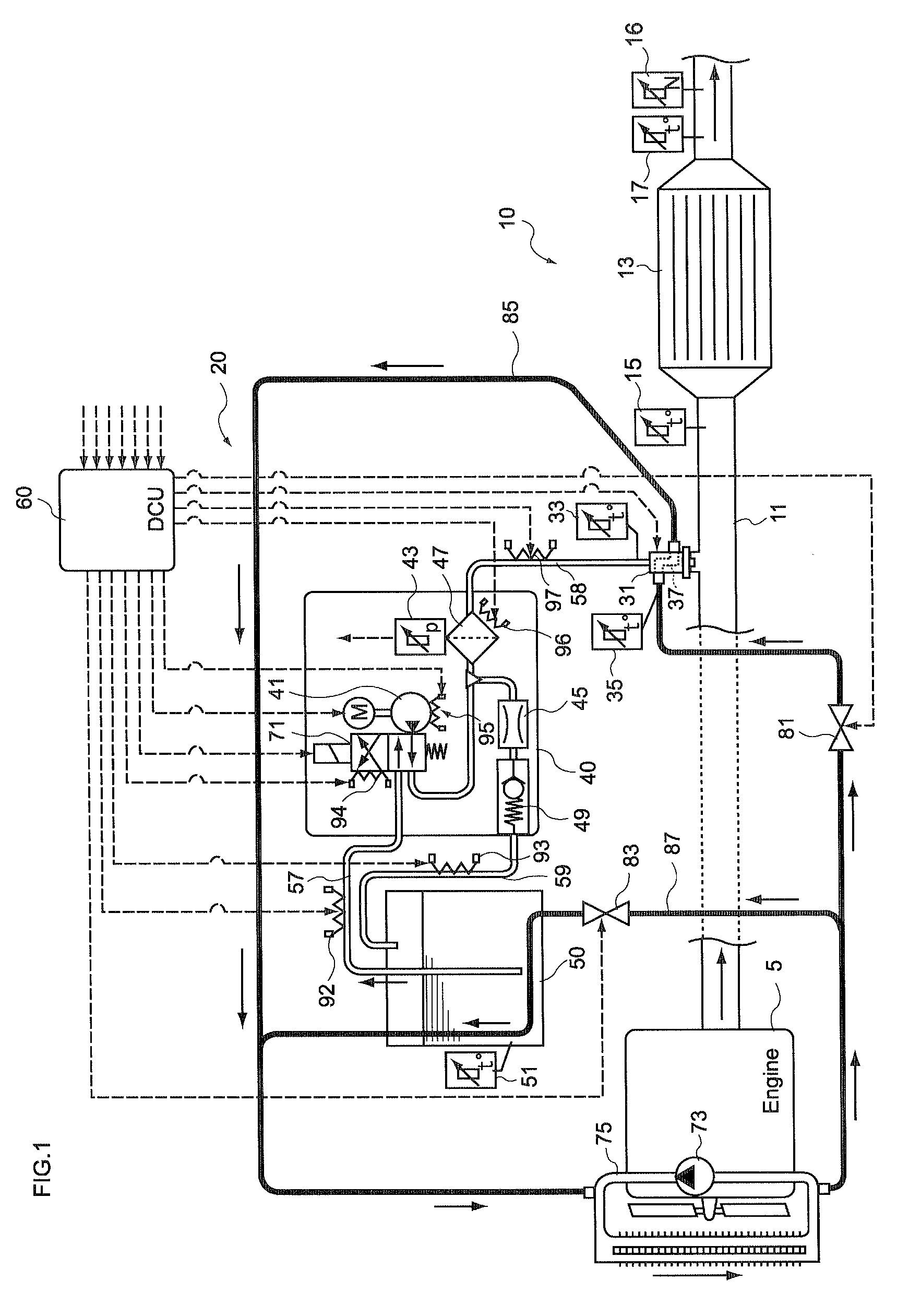

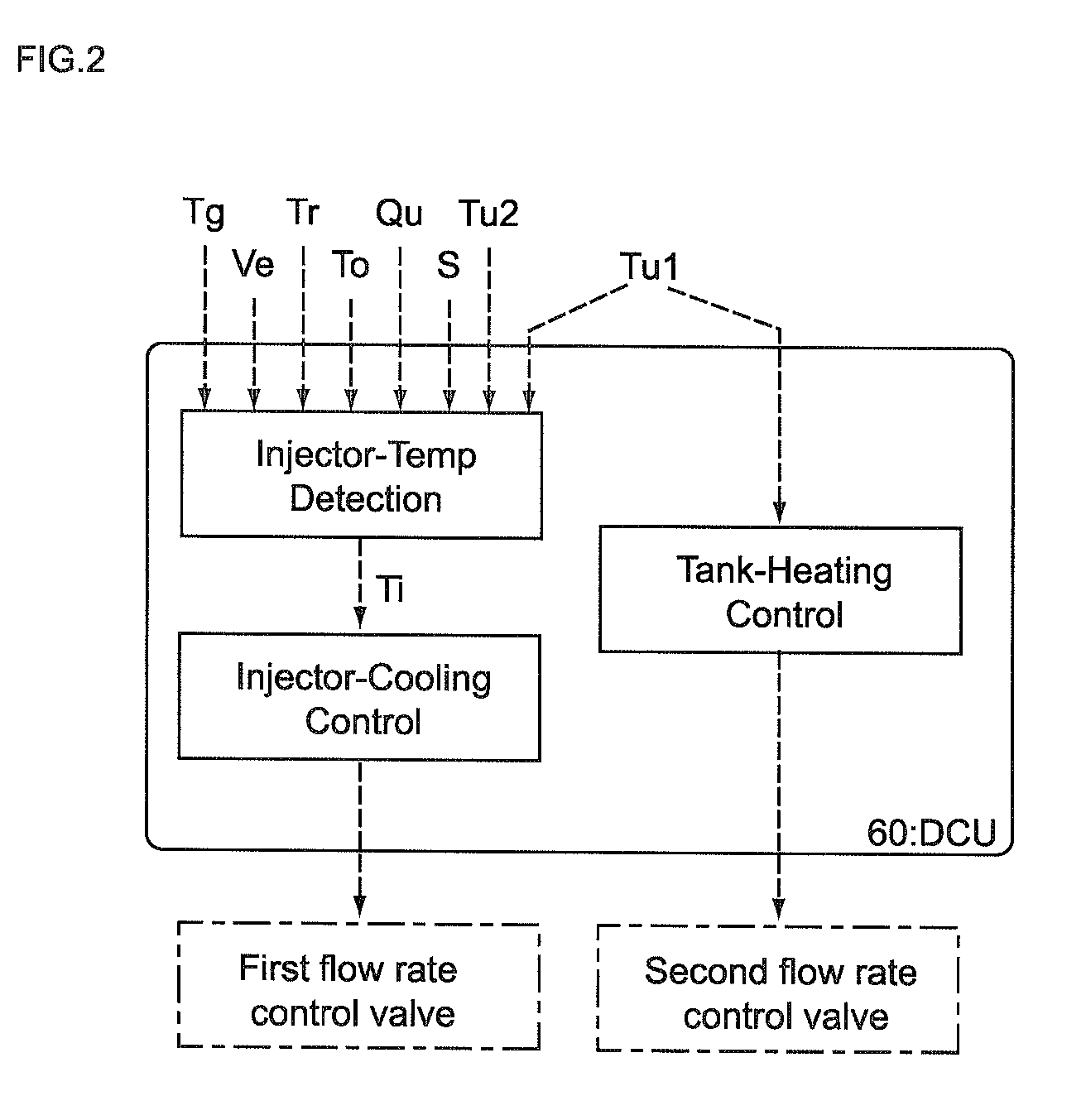

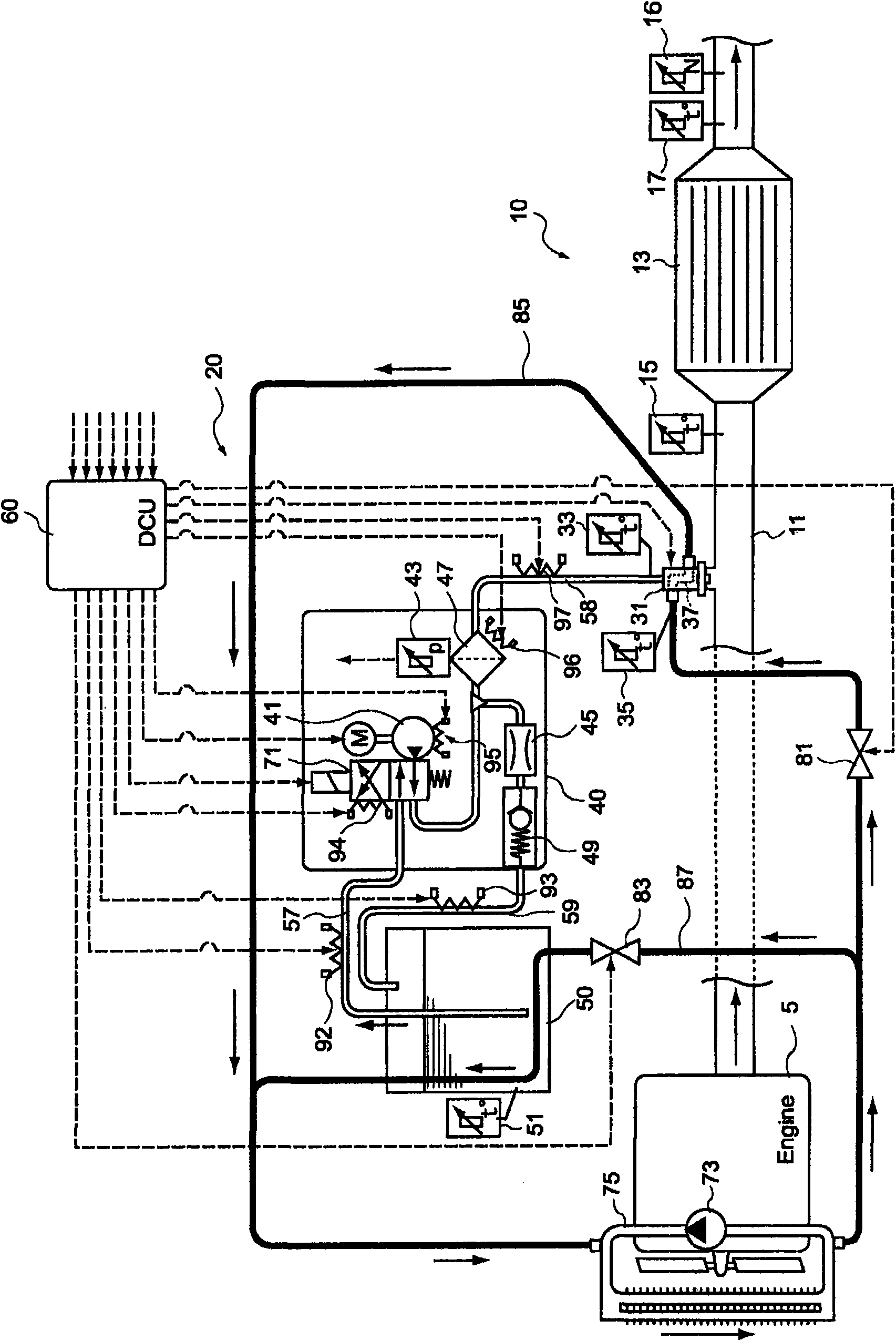

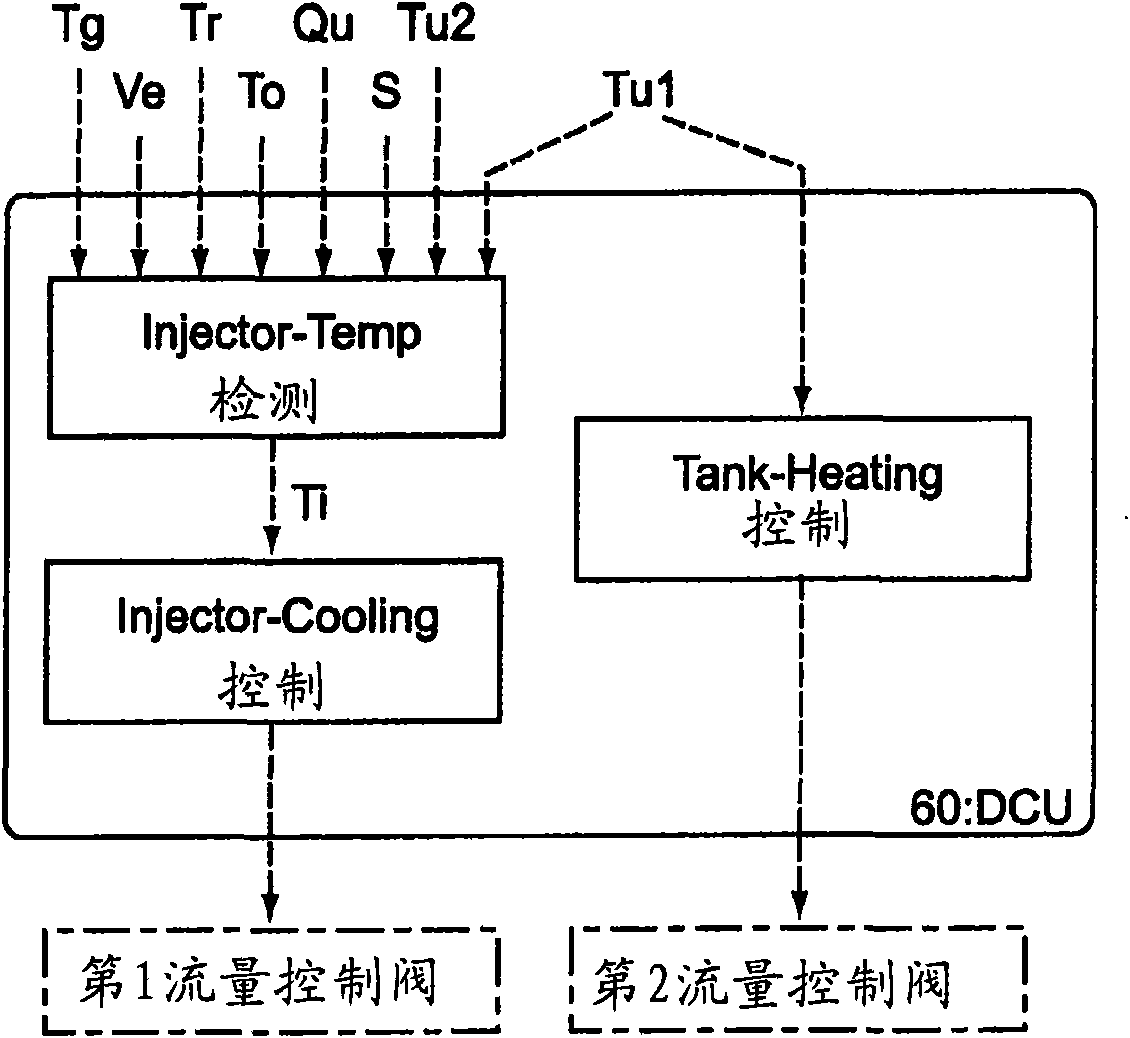

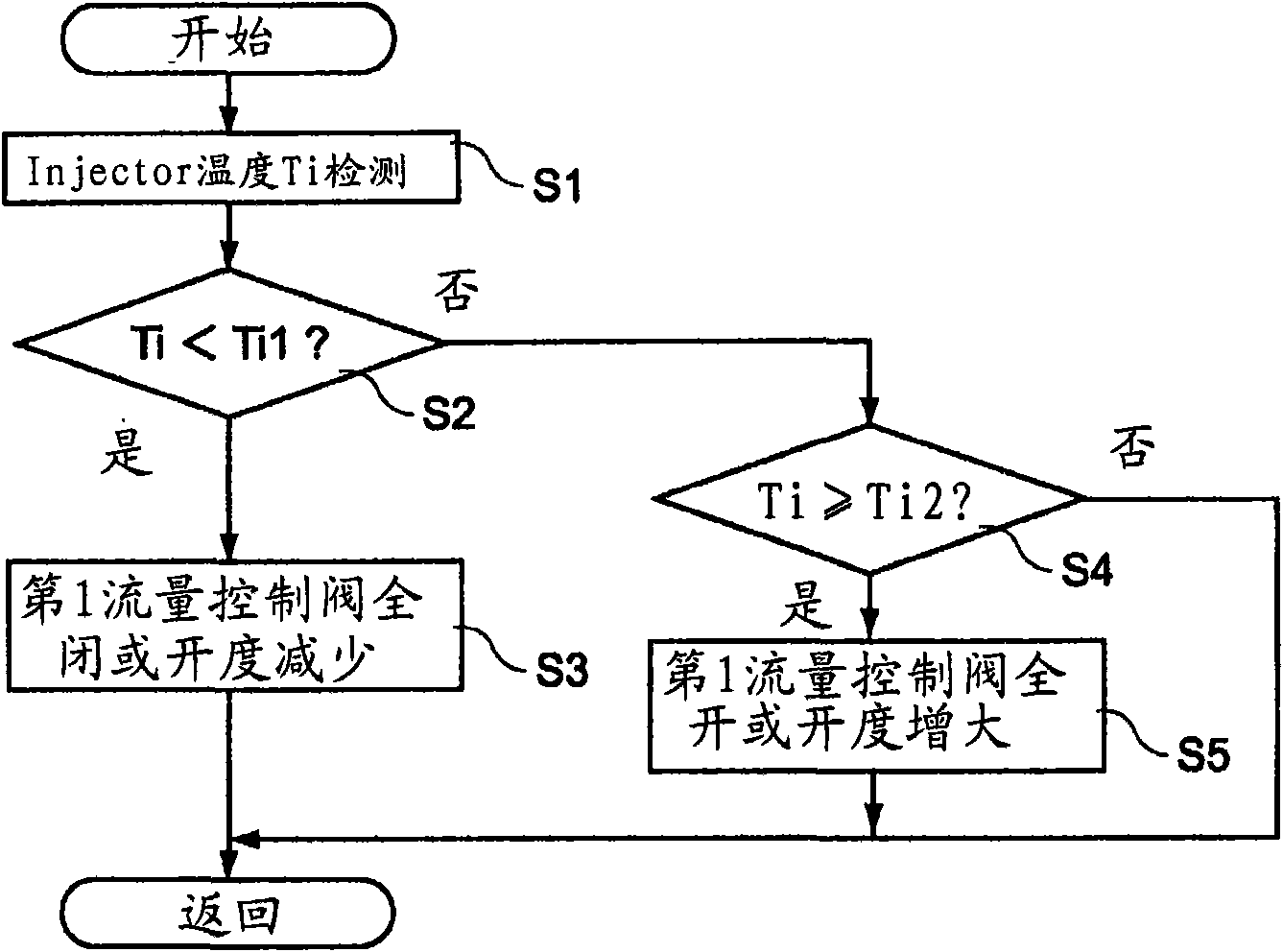

InactiveUS20100242439A1Prevent overcoolingImprove cooling effectLiquid coolingInternal combustion piston enginesEngineeringWater circulation

There are provided a reductant supply device and a control method for the reductant supply device, which can prevent heat damage of a reductant injection valve, and also prevent crystallization of urea solution due to excessive cooling of the solution reductant.The reductant supply device which is used in an exhaust gas purification device that injects and supplies, as a reductant, a urea solution to an exhaust gas upstream side of a reduction catalyst disposed in an exhaust gas passage of an internal combustion engine, and that reduces and purifies nitrogen oxides contained in exhaust gas using the reduction catalyst, the reductant supply device having a reductant injection valve that is fixed to an exhaust pipe on the exhaust gas upstream side of the reduction catalyst, includes: a cooling water circulation passage that circulates at least part of cooling water of the internal combustion engine to cool the reductant injection valve; flow rate control means for adjusting a flow rate of cooling water flowing through the cooling water circulation passage; temperature detection means for detecting a temperature of the reductant injection valve; and control means for controlling the flow rate control means based on the temperature of the reductant injection valve.

Owner:BOSCH CORP

Apparatus and method for cryogenic inhibition of hyperplasia

InactiveUS20020026182A1Enhanced inhibitory effectDiagnosticsCatheterPercutaneous angioplastyBalloon catheter

Post-angioplasty hyperplasia in blood vessels is treated using a cryosurgical balloon catheter. The balloon catheter is positioned at a target region within the blood vessel, and the balloon inflated by expanding a cryogenic fluid, such as liquid nitrogen, across an expansion orifice into a balloon. The balloon will be constructed so that cooling is achieved primarily in the central regions of the balloon, with the proximal and distal regions being less cold and acting to insulate adjacent regions of the blood vessel from excessive cooling.

Owner:BOSTON SCI SCIMED INC

Method of forming a glass melt

ActiveUS7454925B2Promote vigorous boilingReduce partial pressureCharging furnaceGlass furnace apparatusMolten glassExcessive Cooling

A method of forming a glass melt including heating a glass feed material in a first melting furnace to form a glass melt, flowing the glass melt into a second melting furnace through a refractory metal connecting tube, and further heating the glass melt in the second melting furnace. The refractory metal connecting tube is heated to prevent the molten glass from excessive cooling, and to ensure that the glass melt entering the second melting furnace is equal to or greater than the temperature of the glass melt in the second melting furnace. An apparatus for performing the method is also disclosed.

Owner:CORNING INC

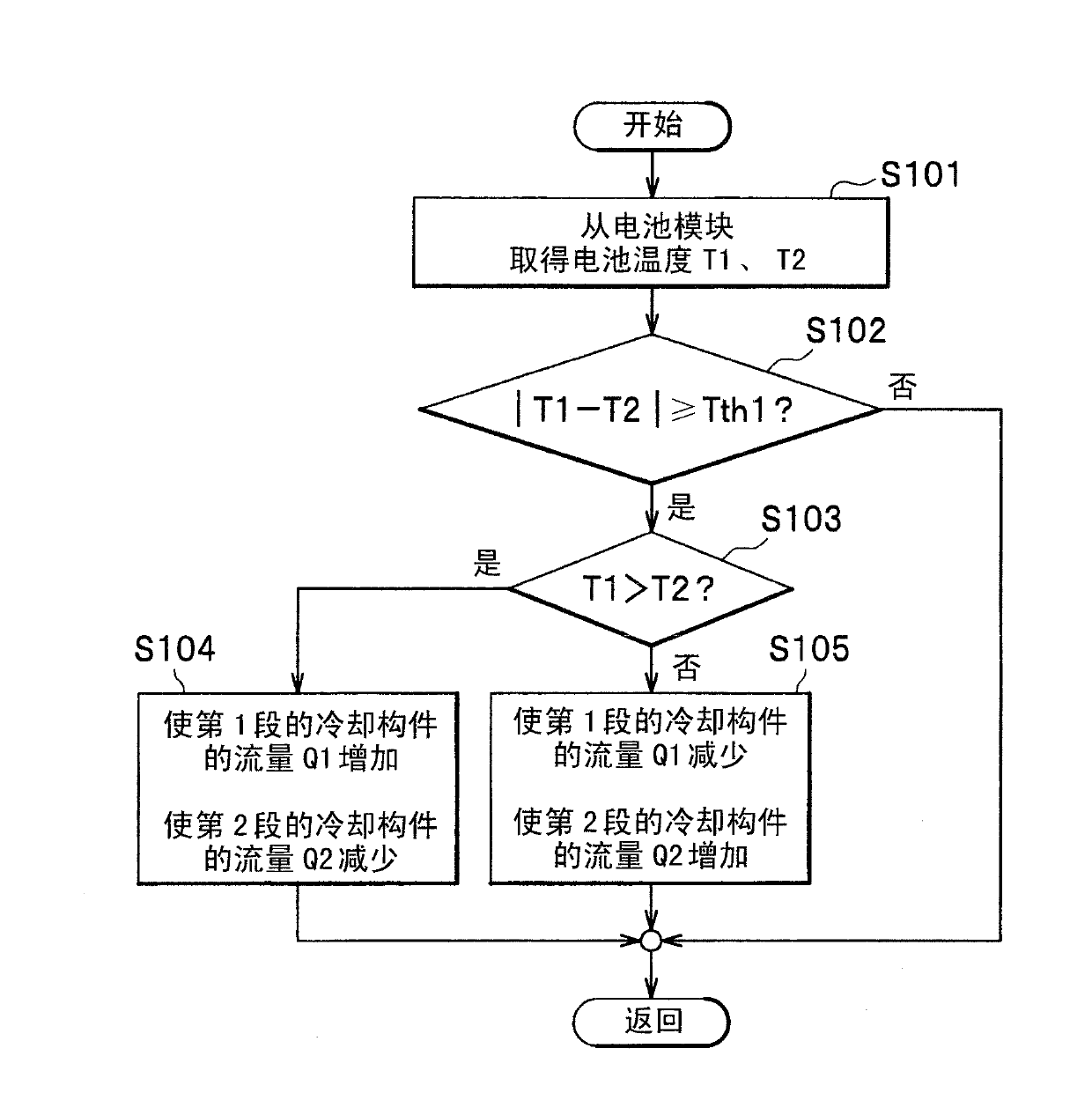

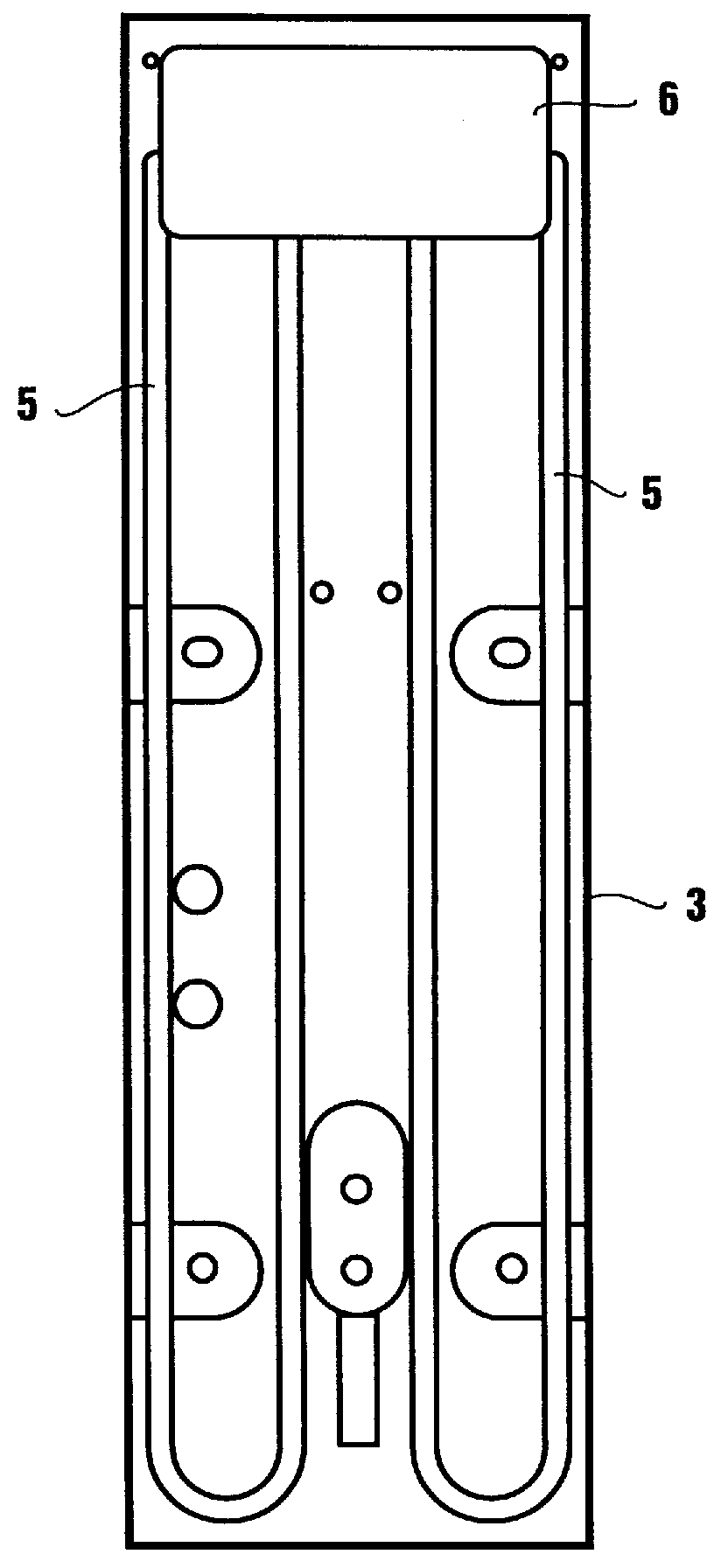

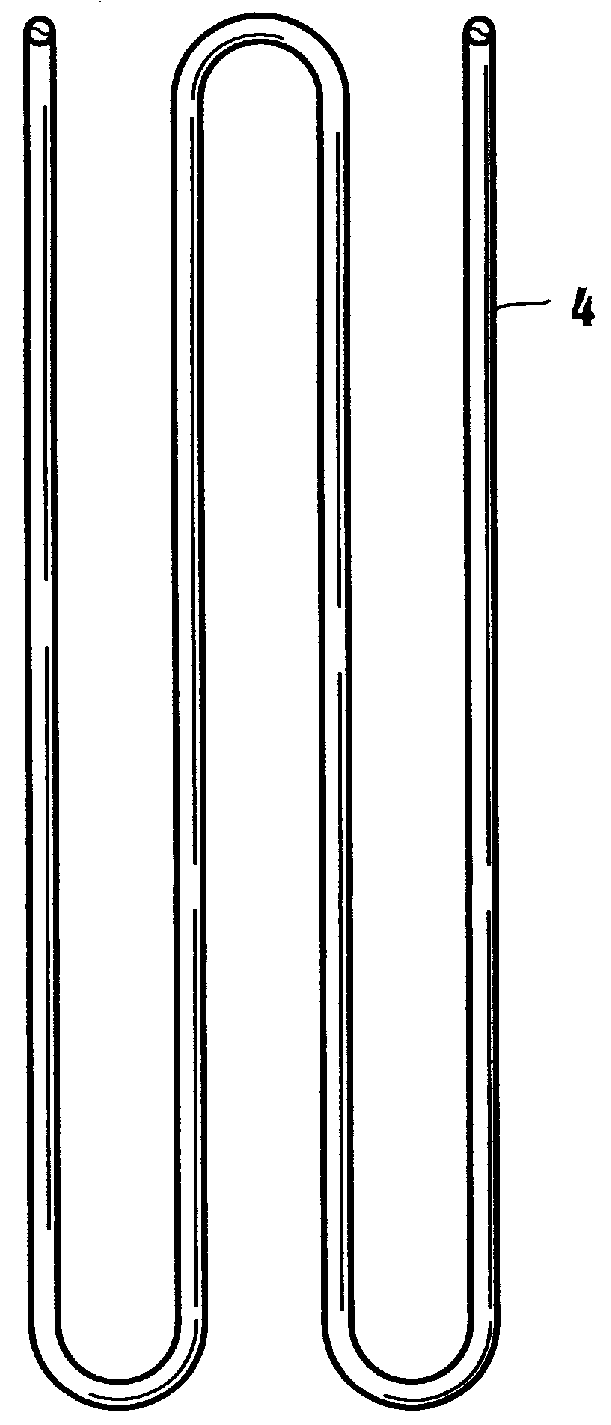

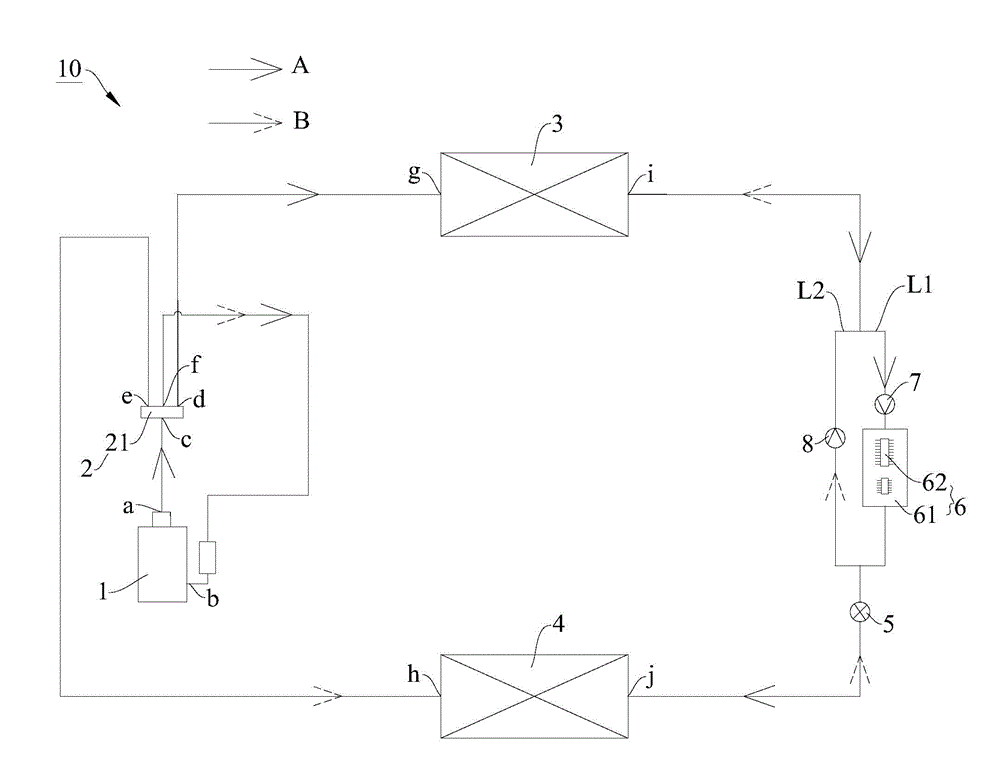

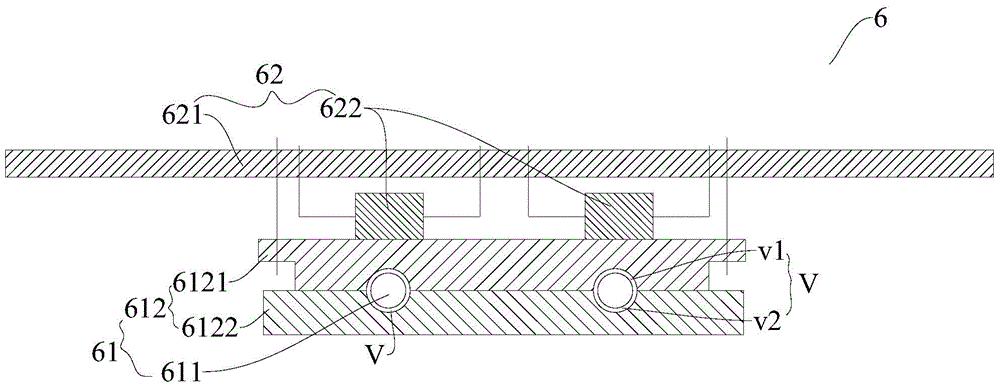

Battery system and temperature control method therefor

InactiveCN103311597ASuppress supercoolingSmall temperature deviationSecondary cellsCell component detailsTemperature controlEngineering

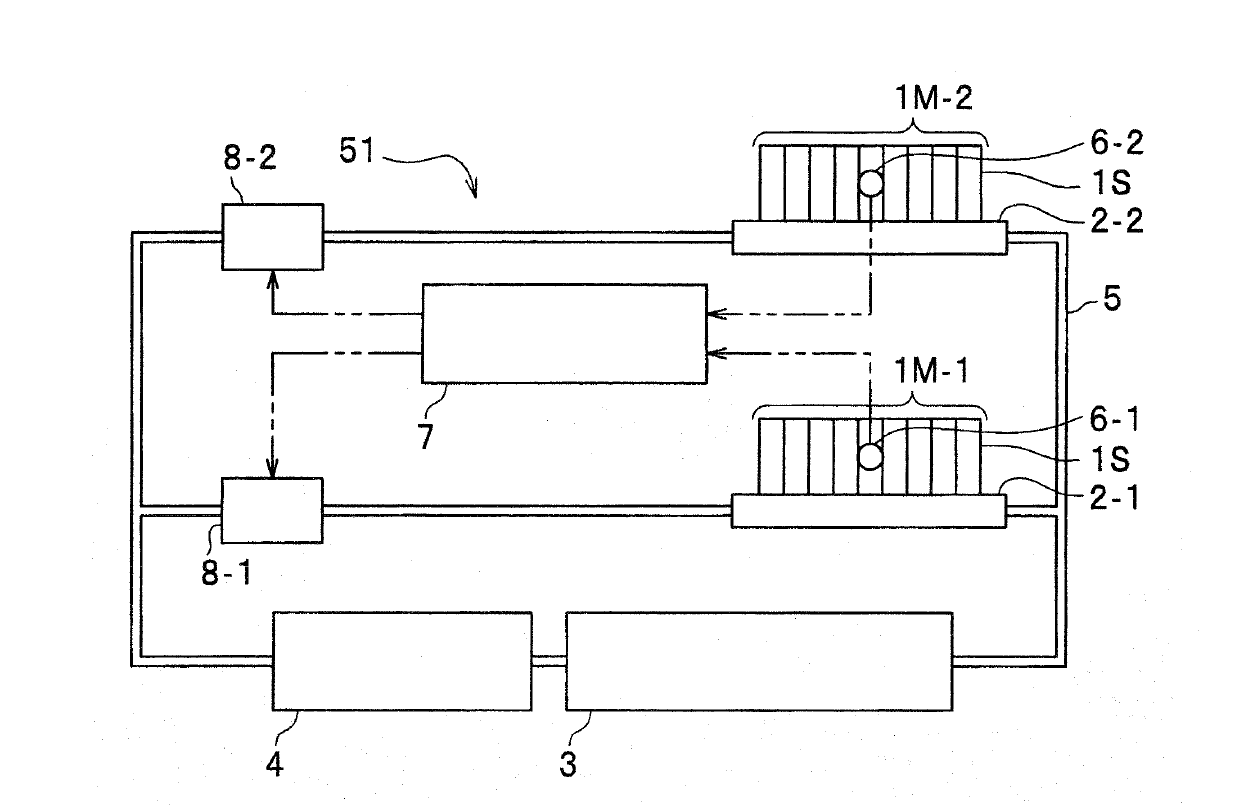

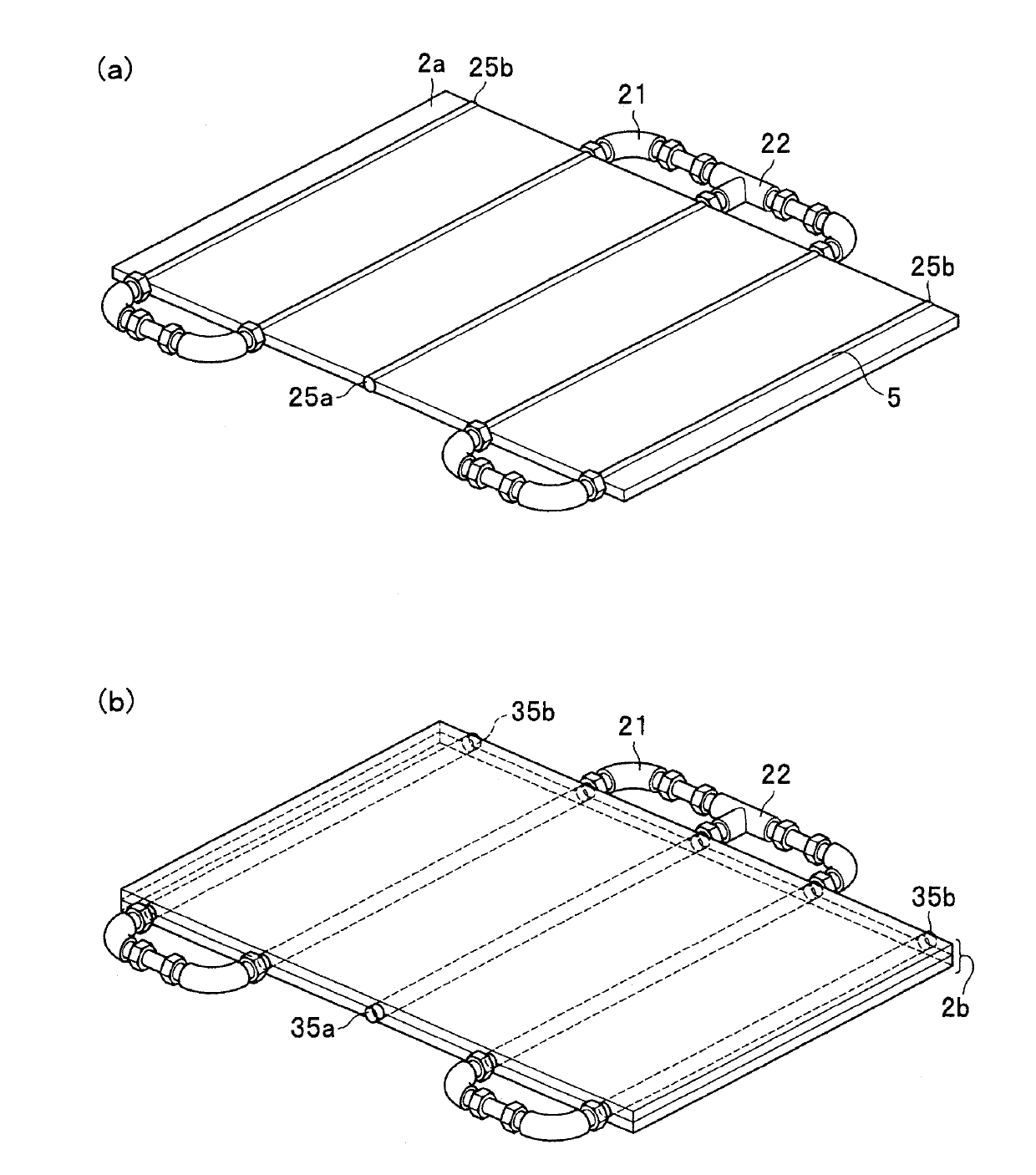

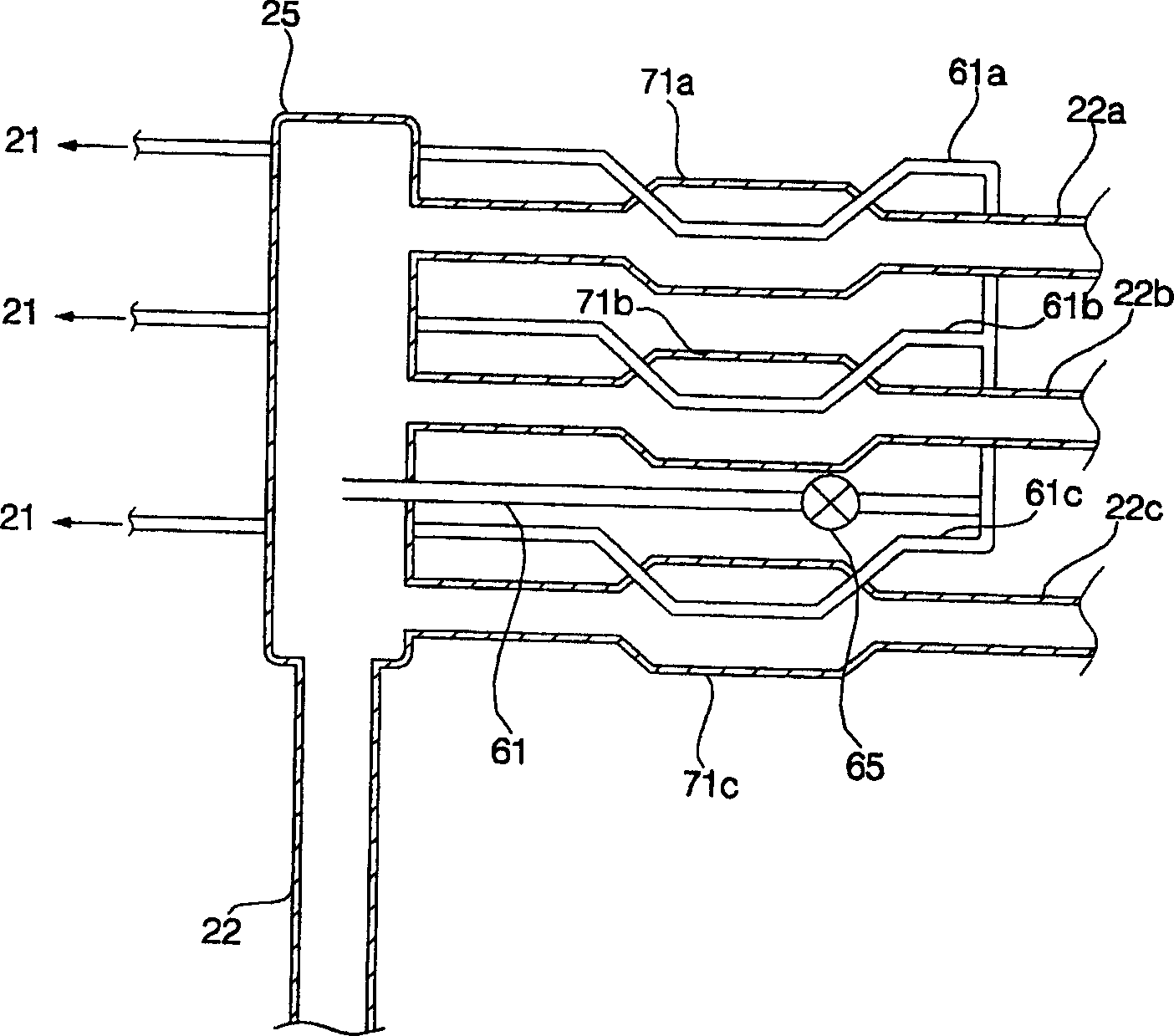

Provided are a battery system and temperature control method therefor capable of suppressing excessive cooling of a battery module, diminishing a temperature variance, and leveling the temperatures of plural battery modules. In the battery system including cooling units each of which is provided with a cooling plate (2-1, 2-2) which includes a flow channel through which a refrigerant flows and on which a battery module that is an object of temperature control (1M-1, 1M-2) is placed, and a flow rate adjustment device (8-1, 8-2) that adjusts the flow rate of the refrigerant that flows through the flow channel, temperature sensors (6-1, 6-2) that individually sense the temperatures of the battery modules, and a refrigerant circulation mechanism (4) that branches out the refrigerant into the flow channels accompanying the cooling units, and joins and circulates the refrigerants coming from the flow channels, a control unit (7) adjusts the refrigerant flow rates using the flow rate adjustment devices (8-1, 8-2) according to the temperatures, which are sensed by the temperature sensors (6-1, 6-2), for each of the cooling units.

Owner:HITACHI LTD

Method and apparatus of indirect-evaporation cooling

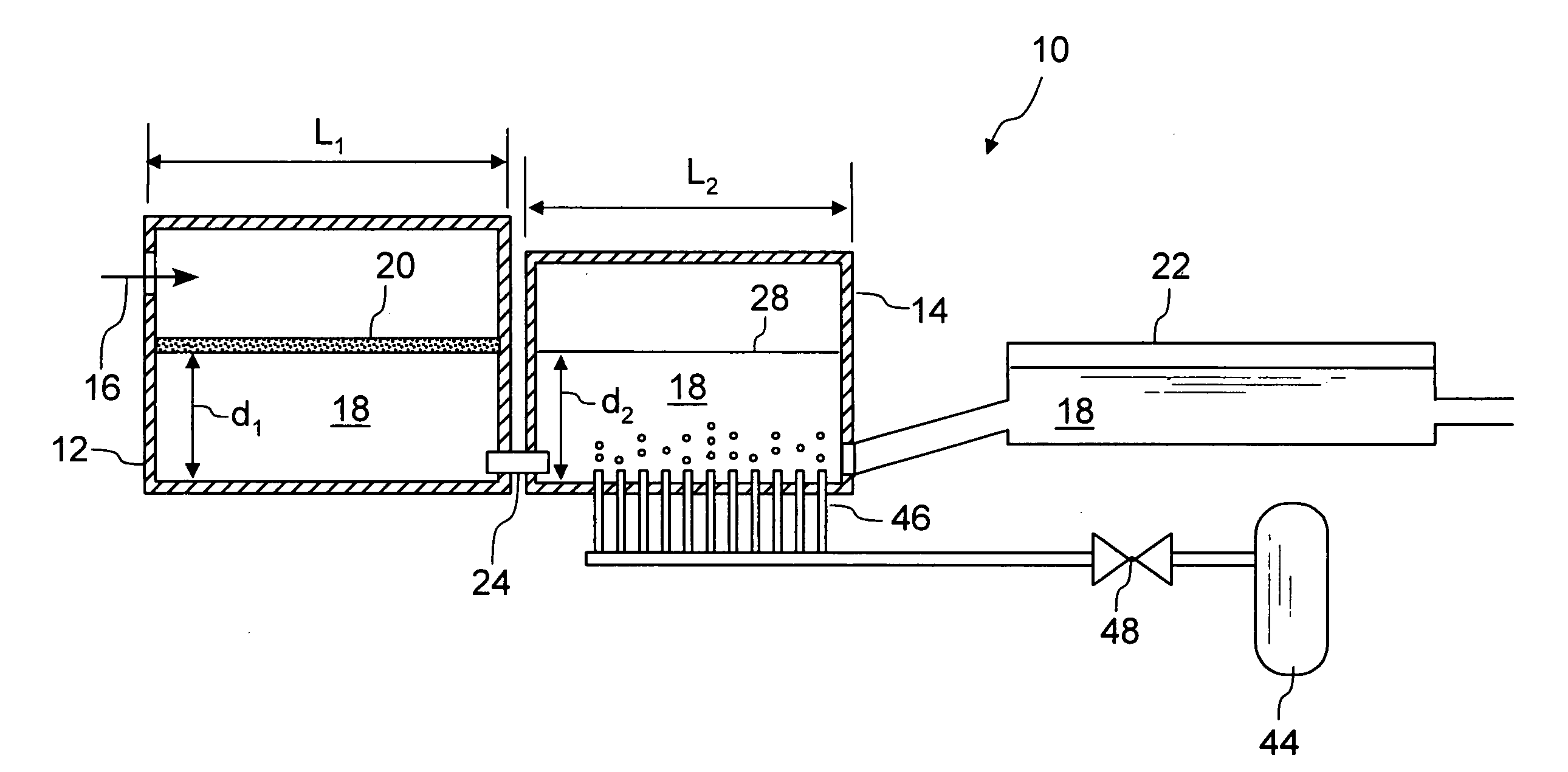

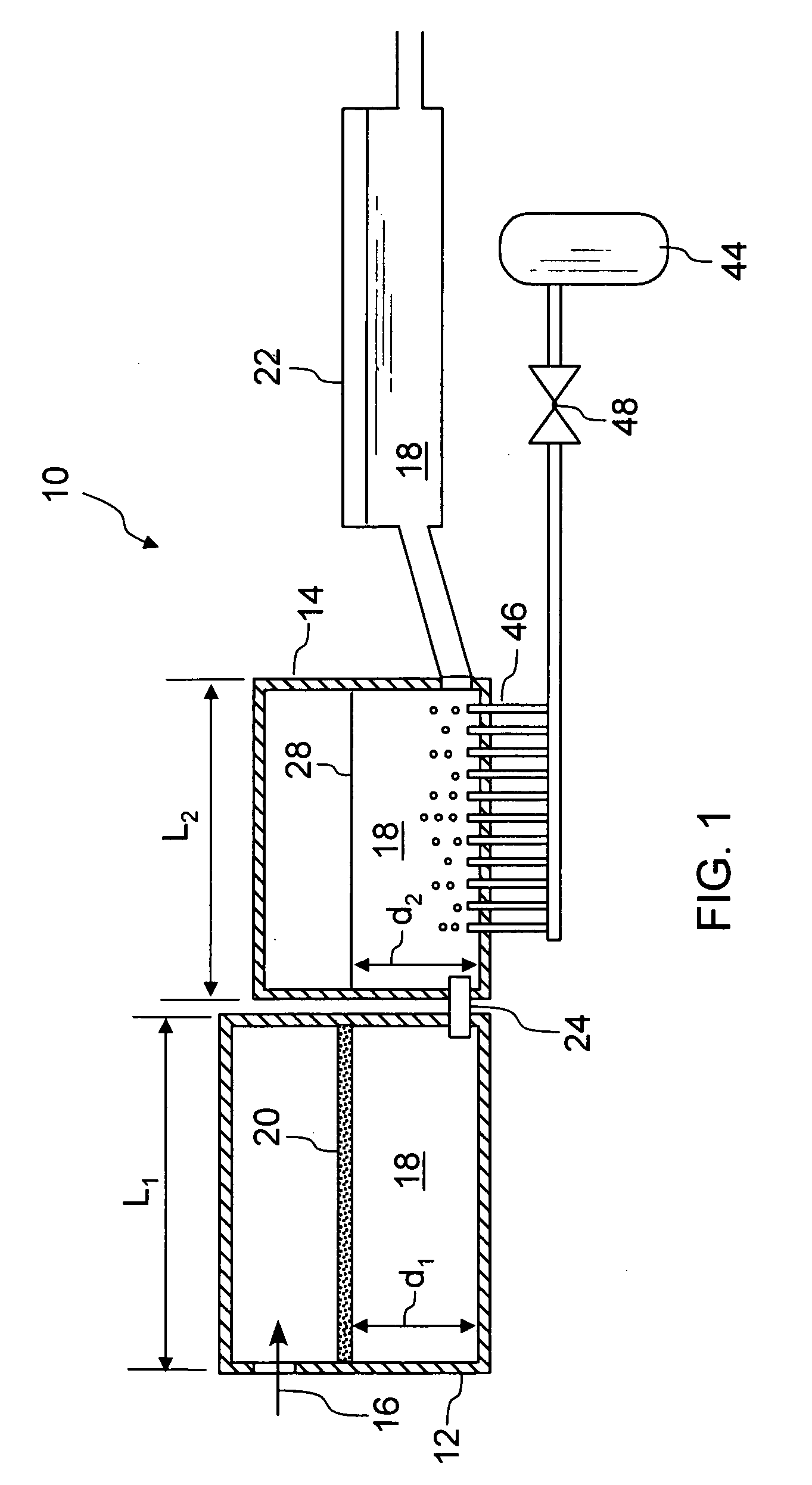

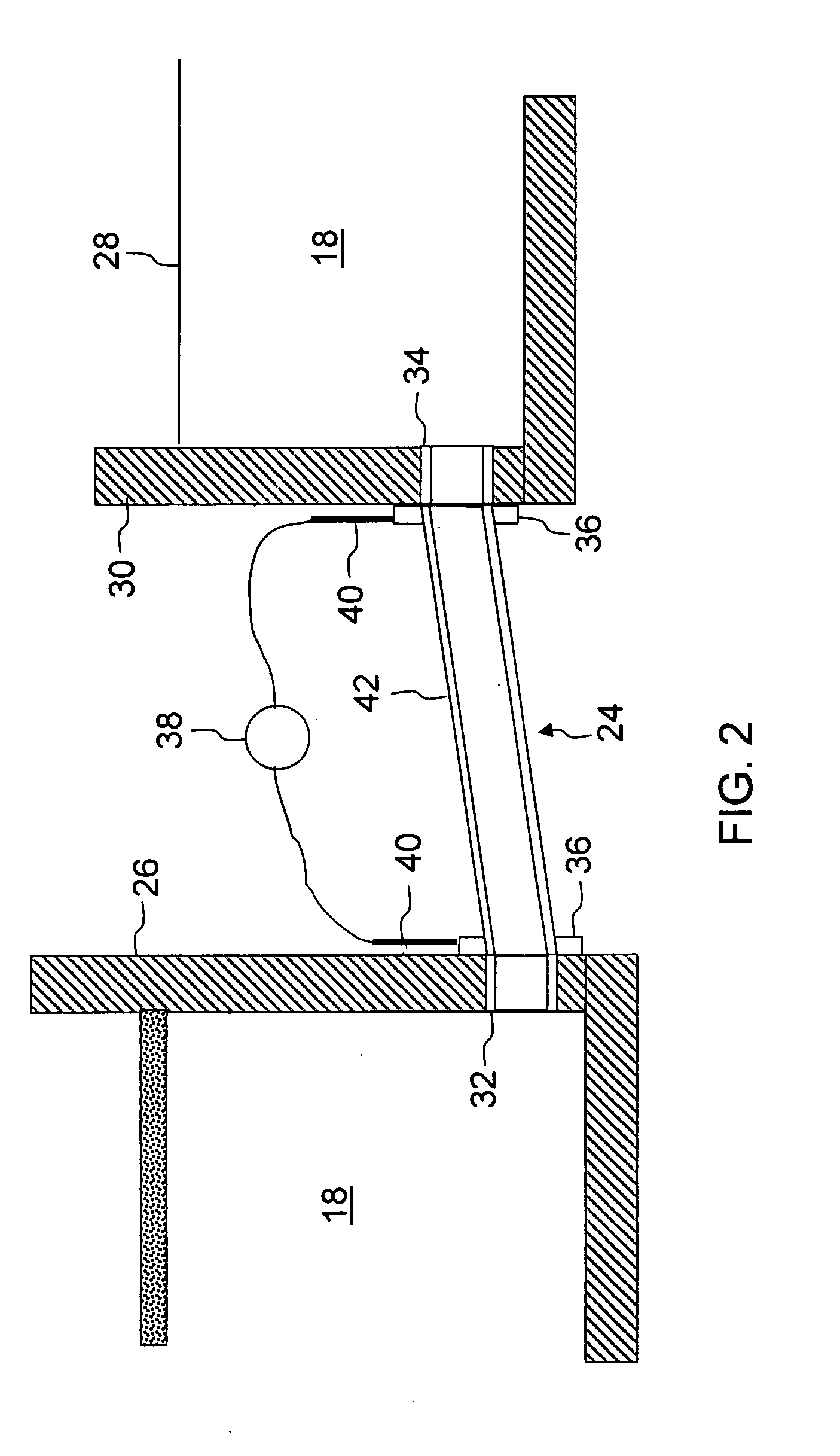

InactiveUS20030014983A1Economic securityFree-cooling systemsStationary conduit assembliesDesiccantHeat transmission

The within invention improves on the indirect evaporative cooling method and apparatus by making use of a working fluid that is pre-cooled with and without desiccants before it is passed through a Wet Channel where evaporative fluid is on the walls to take heat and store it in the working fluid as increased latent heat. The heat transfer across the membrane between the Dry Channel and the Wet Channel may have dry, solid desiccant or liquid desiccant and may have perforations, pores or capillary pathways. The evaporative fluid may be water, fuel, or any substance that has the capacity to take heat as latent heat. The Wet Channel or excess cooled fluid is in heat transfer contact with a Product Channel where Product Fluid is cooled without adding any humidity. An alternative embodiment for heat transfer between adjacent channels is with heat pipes.

Owner:MAISOTSENKO VALERIY +3

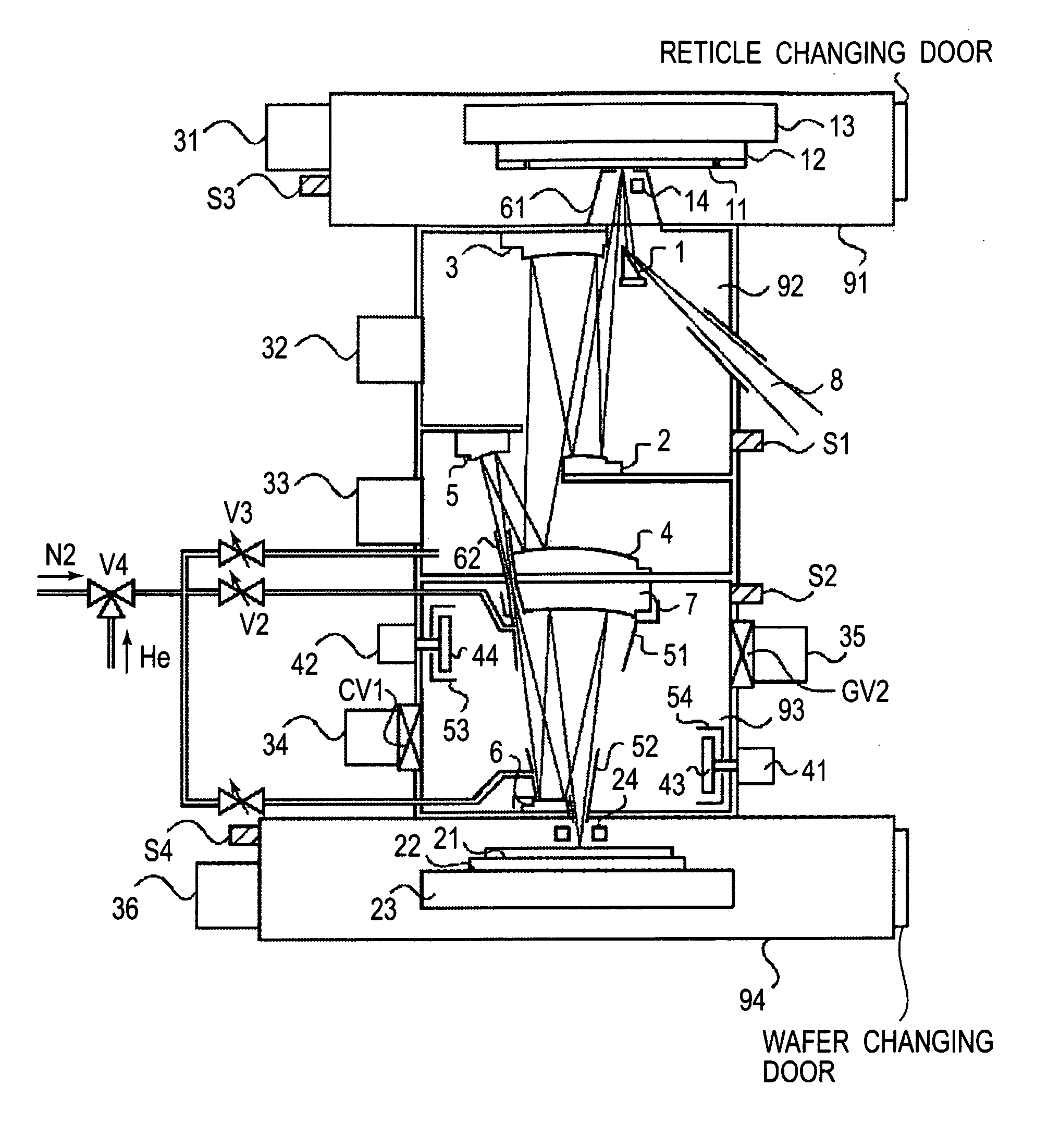

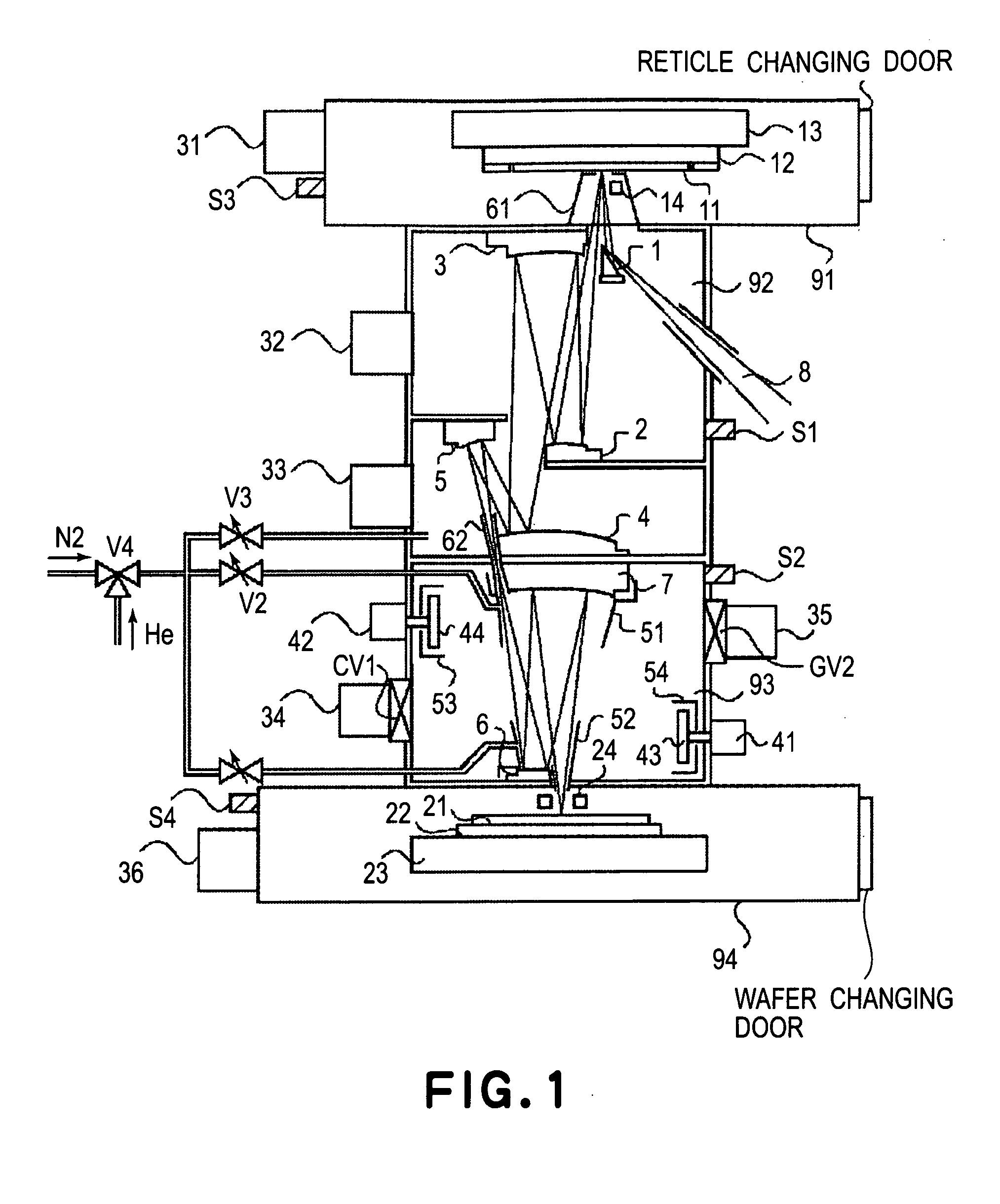

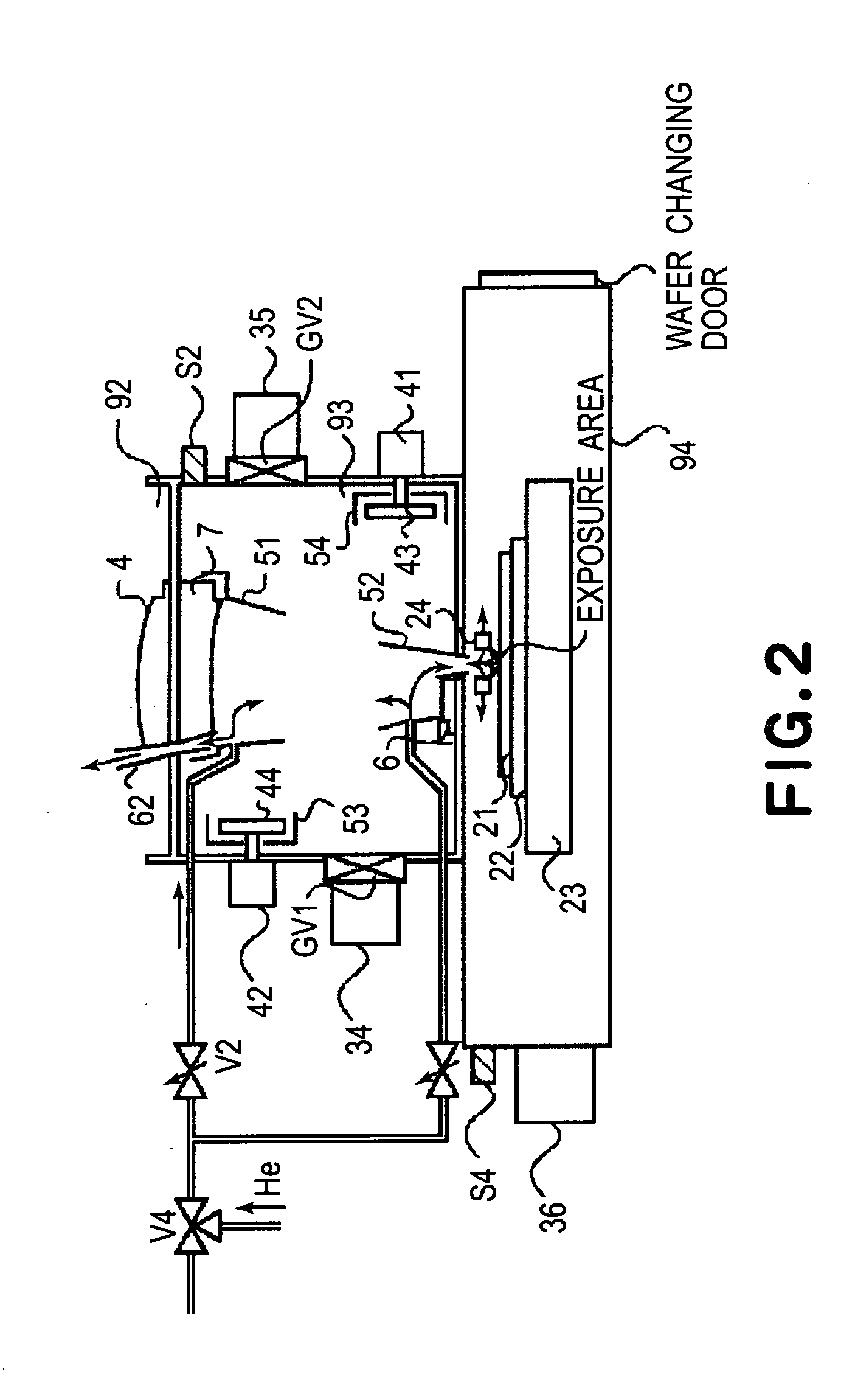

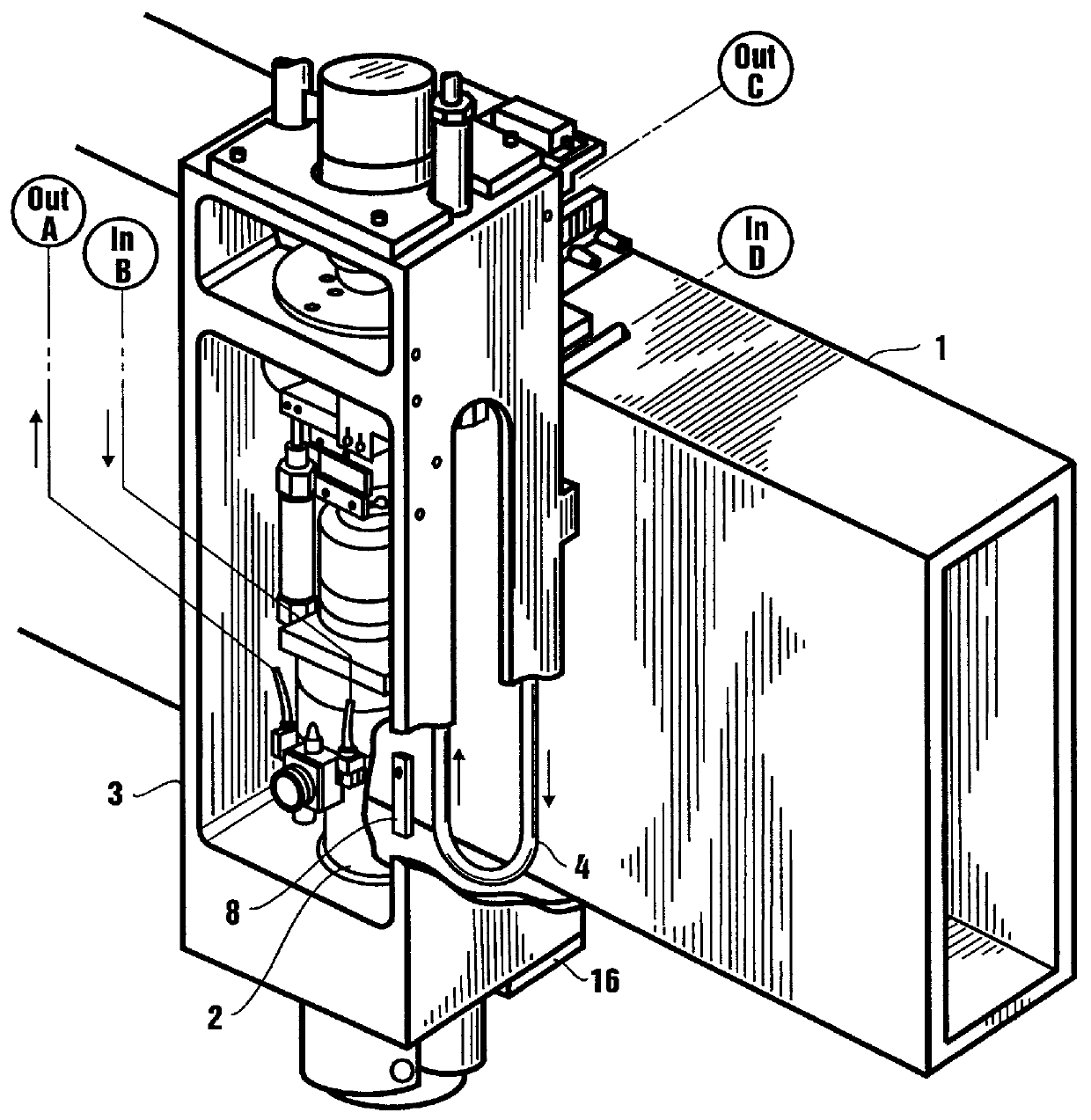

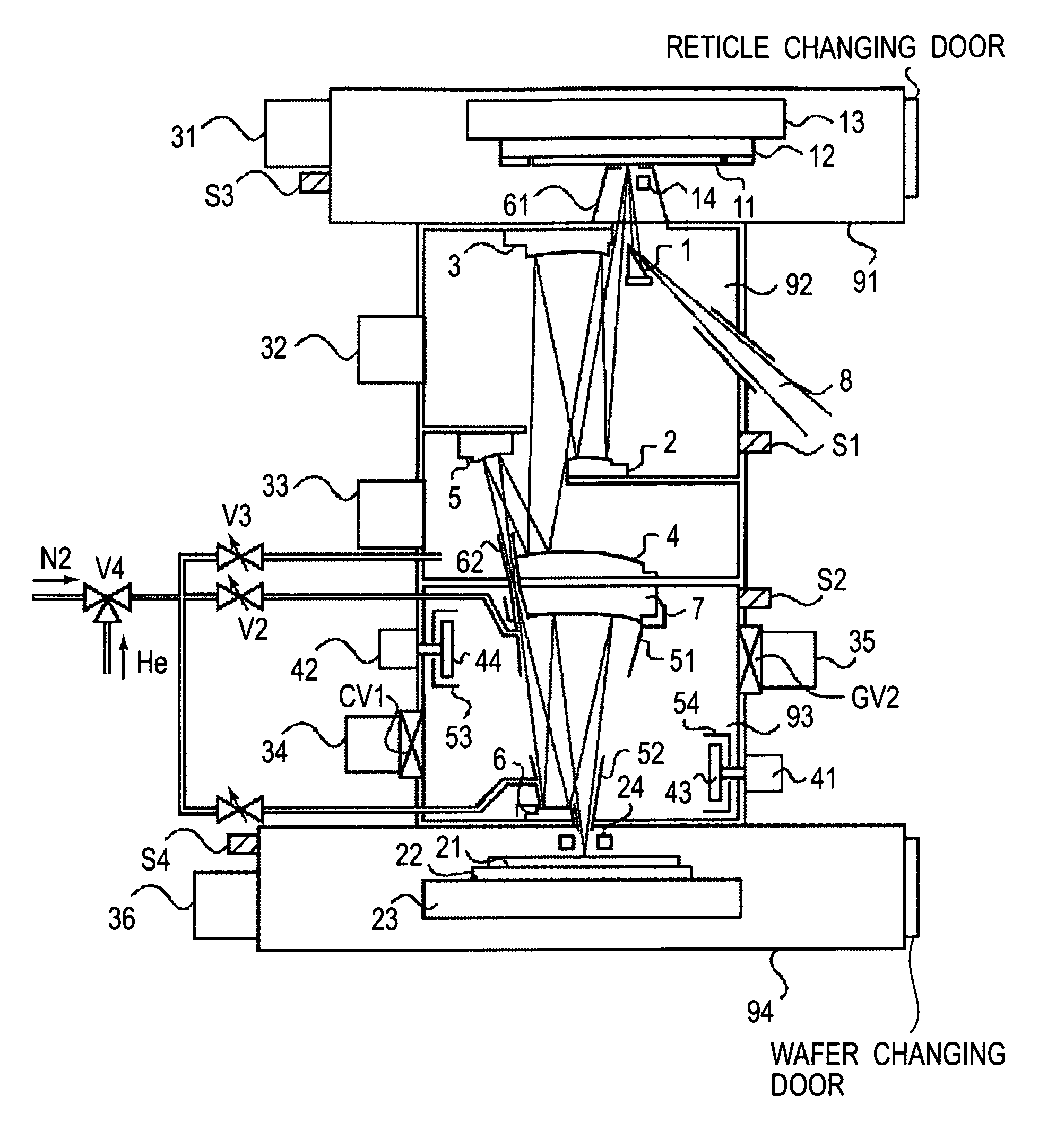

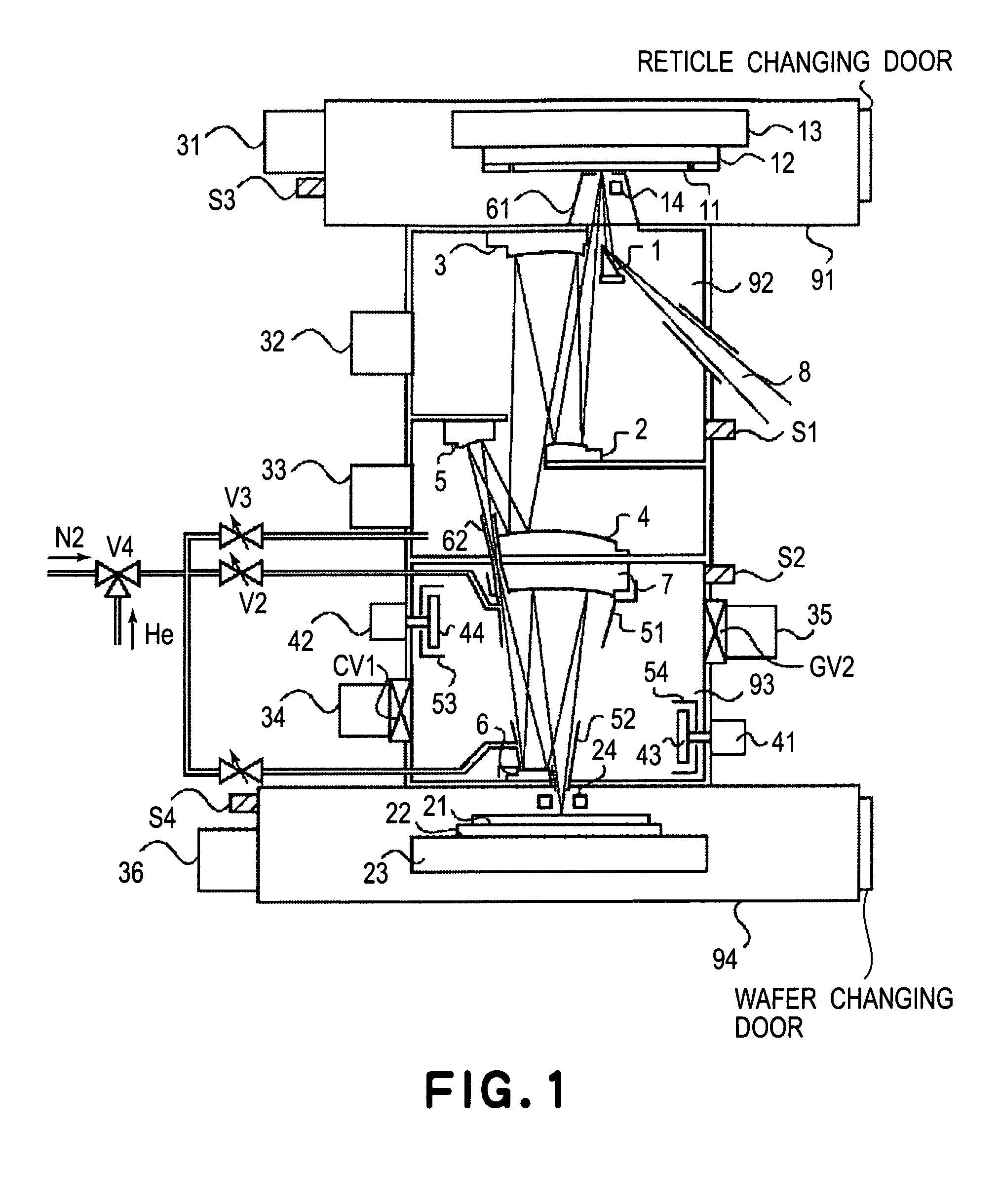

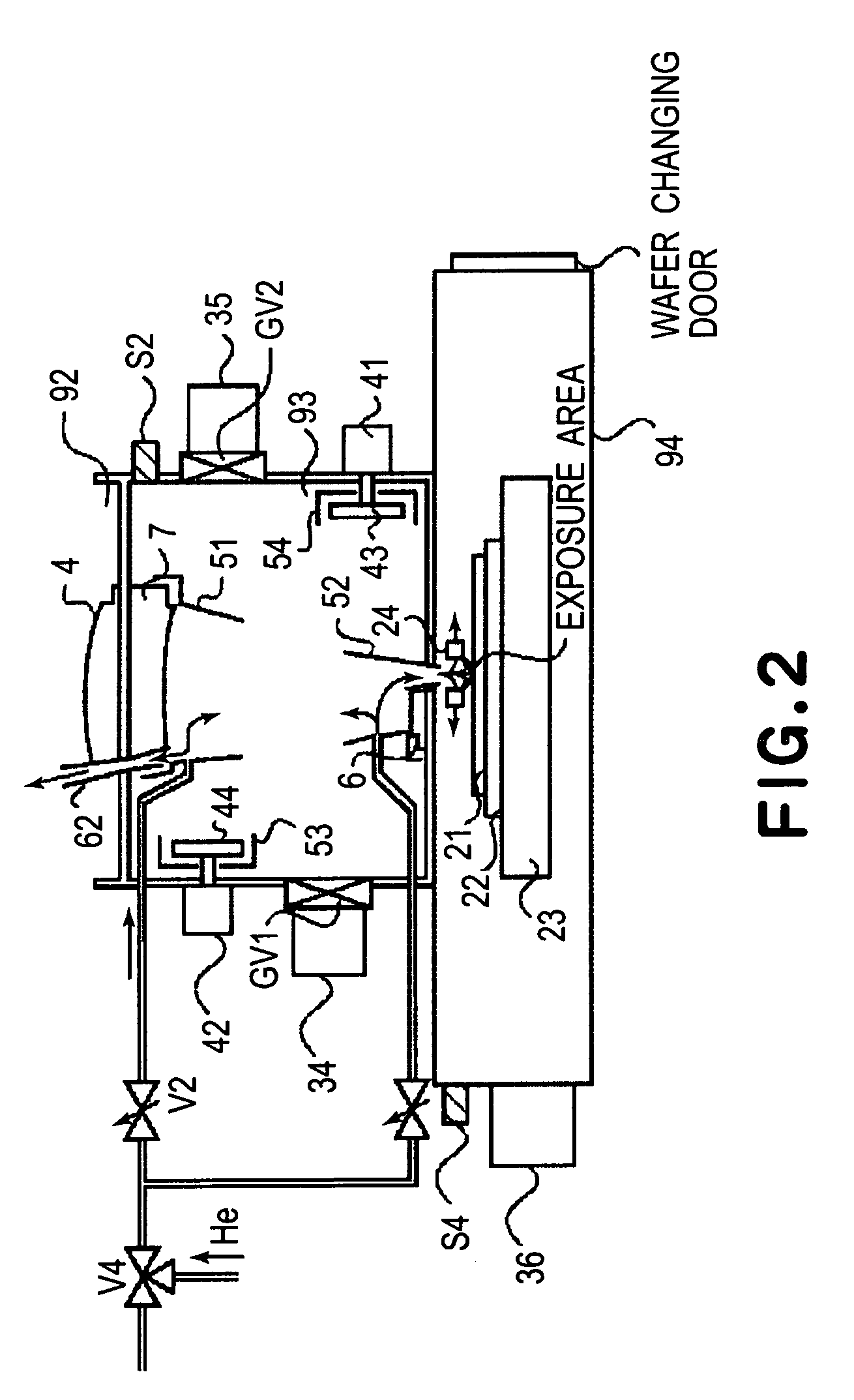

Exposure apparatus, and device manufacturing method using the same

InactiveUS20050110966A1Avoid radiationSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusOptoelectronicsRadiation shield

Disclosed is an exposure apparatus having a specific structure that includes a cold trap plate for attracting contaminant substances which might cause a decrease of reflectance of a mirror when adhered thereto, and a radiation shield member for preventing excessive cooling of the mirror or the like by the cold trap plate.

Owner:CANON KK

Thermal equalization system

In a thermal equalization system a machine tool carriage preferably of aluminum but which could be made of other lightweight materials, a drilling spindle housing is mounted on the carriage. At least one spindle housing is be mounted said carriage to service work pieces mounted on a tooling plate of the work table for said spindle. The chiller unit is used to provide coolant to the spindle to compensate for the heat generated by the spindle during drilling. When the spindle is not drilling, excessive cooling of the spindle can result. Accordingly, the instant invention also includes, a conductive rubber heating pad which is attached to the spindle structure to provide a heat source for the system to compensate for excessive cooling when the drill is not generating heat. The temperature control maintains the temperature between the spindle housing, carriage and work table thereby minimizing temperature expansion differentials between the drilling position and the worktable position.

Owner:EXCELLON AUTOMATION

Bypass for exhaust gas cooler

ActiveUS20060124114A1Eliminate fatigue failureInternal combustion piston enginesNon-fuel substance addition to fuelExhaust fumesChiller

An exhaust gas recirculation cooler, typically of the drawn cup design, with a bypass and control valve is disclosed. The control valve can direct a proportion of the exhaust gas to the cooler and a proportion to bypass the cooler depending on the input temperature of the exhaust gas and the required temperature of the exhaust gas. The proportion of the exhaust gas directed to the cooler / bypassing the cooler can be varied as required and so the temperature of the exhaust gas can be controlled. One benefit of certain embodiments of the invention is that engine damaging chemicals, such as sulphuric acid, which result from over-cooling the exhaust gas are reduced.

Owner:GARRETT TRANSPORATION I INC

Controller of reducing agent supply unit and method of controlling the same

InactiveCN101828011APrevent crystallizationPrevent sprayingLiquid coolingInternal combustion piston enginesTemperature controlNitrogen oxides

A reducing agent supply unit that prevents any heat damaging of reducing agent injection valve and also prevents any crystallization of urea solution by excessive cooling of liquid reducing agent; and a method of controlling the same. There is disclosed a reducing agent supply unit for use in an exhaust purification apparatus capable of feeding by injection a urea solution as a reducing agent on the along-exhaust upstream side of a reduction catalyst disposed along an exhaust path of internal combustion engine so as to attain reduction purification of any nitrogen oxides contained in exhaust gas by the reduction catalyst, which reducing agent supply unit has a reducing agent injection valve fixed to an exhaust pipe on the along-exhaust upstream side of the reduction catalyst. The reducing agent supply unit comprises a cooling water circulation path for circulating at least a portion of the cooling water of the internal combustion engine in order to cool the reducing agent injection valve; flow rate control means for regulating the flow rate of cooling water through the cooling water circulation path; temperature detection means for detecting the temperature of the reducing agent injection valve; and control means for controlling the flow rate control means on the basis of the temperature of the reducing agent injection valve.

Owner:BOSCH CORP

Method of forming a glass melt

ActiveUS20070151297A1Reduce partial pressurePromote vigorous boilingCharging furnaceTank furnacesMolten glassExcessive Cooling

A method of forming a glass melt including heating a glass feed material in a first melting furnace to form a glass melt, flowing the glass melt into a second melting furnace through a refractory metal connecting tube, and further heating the glass melt in the second melting furnace. The refractory metal connecting tube is heated to prevent the molten glass from excessive cooling, and to ensure that the glass melt entering the second melting furnace is equal to or greater than the temperature of the glass melt in the second melting furnace. An apparatus for performing the method is also disclosed.

Owner:CORNING INC

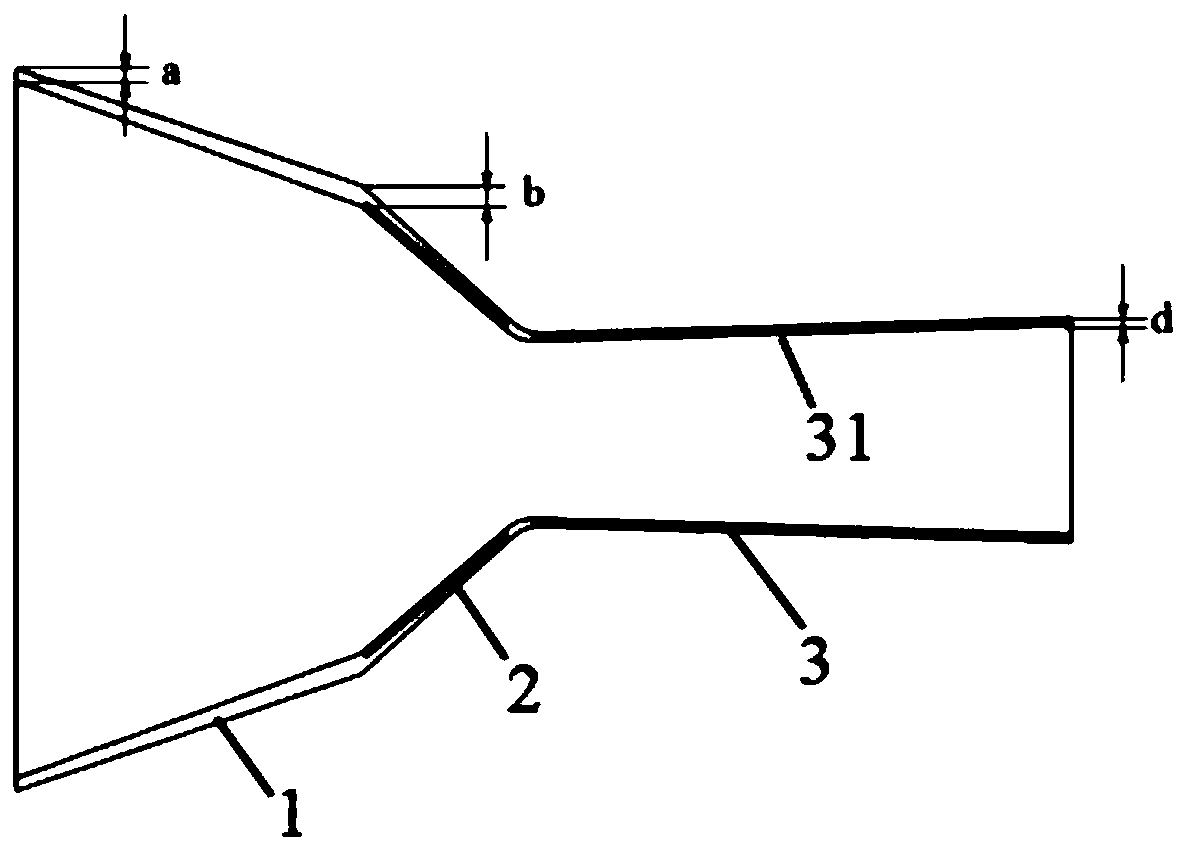

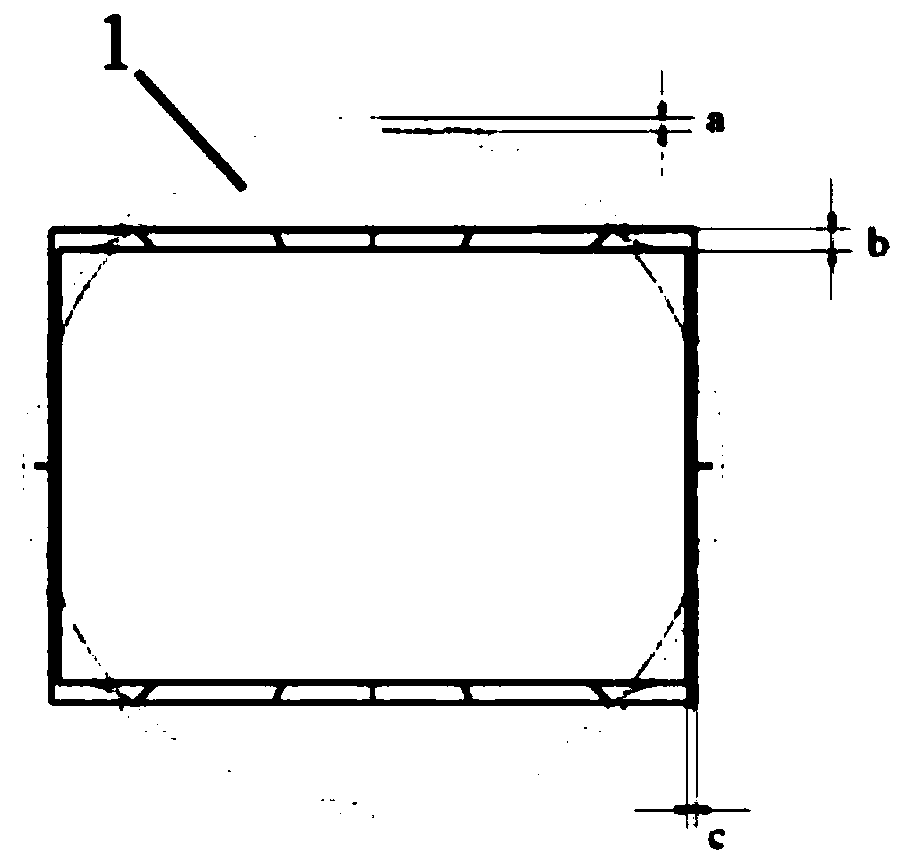

Cooling channel structure suitable for two-dimensional invisible spray pipe

ActiveCN111577481AAvoid Excessive Cooling EfficiencyReasonable distributionJet propulsion plantsCold airAviation

The invention belongs to the technical field of aero-engines, and particularly relates to a cooling channel structure suitable for a two-dimensional invisible spray pipe. The cooling channel structurecomprises a round-to-square section, a convergence section and an expansion section which are sequentially connected, and a first cooling channel is formed between a first inner wall and a first outer wall of the round-to-square section; a second cooling channel is formed between a second inner wall and a second outer wall of the convergence section, the second cooling channel communicates with the first cooling channel, the second inner wall comprises a convergence section upper-layer heat shield and a convergence section lower-layer heat shield, a first through hole is formed in the convergence section upper-layer heat shield, and a second through hole is formed in the convergence section lower-layer heat shield; and a third cooling channel is formed between a third inner wall and a third outer wall of the expansion section, the third cooling channel communicates with the second cooling channel, and the third inner wall comprises an expansion section heat shield. According to the cooling channel structure, air flow of the cooling channel of the round-to-square section of the spray pipe can be reorganized and, the cold air amount between a side wall and an adjusting piece is reasonably distributed, and excessive cooling efficiency and insufficient cold air amount of the adjusting piece caused by inflow of a large amount of cold air are avoided.

Owner:AECC SHENYANG ENGINE RES INST

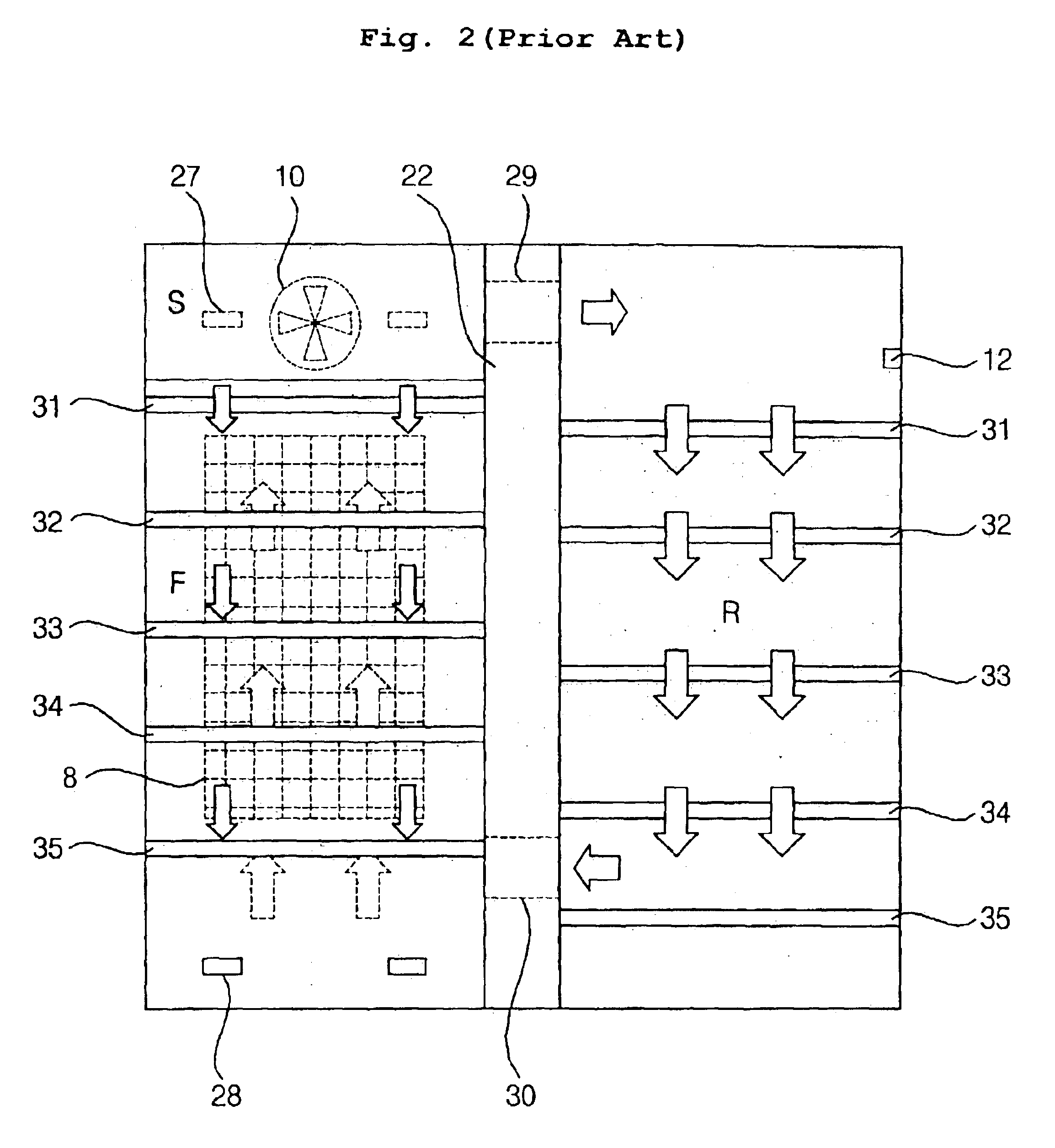

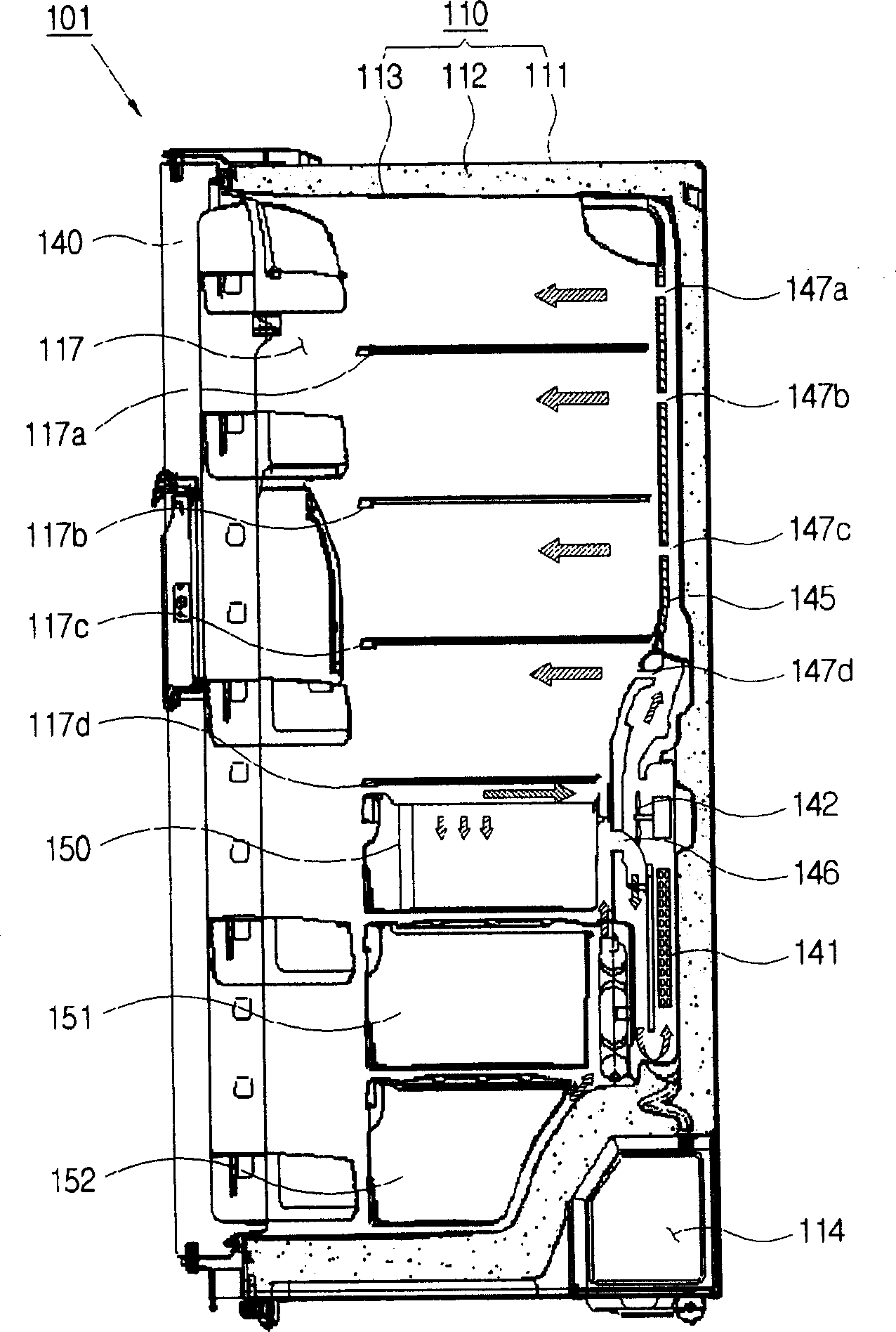

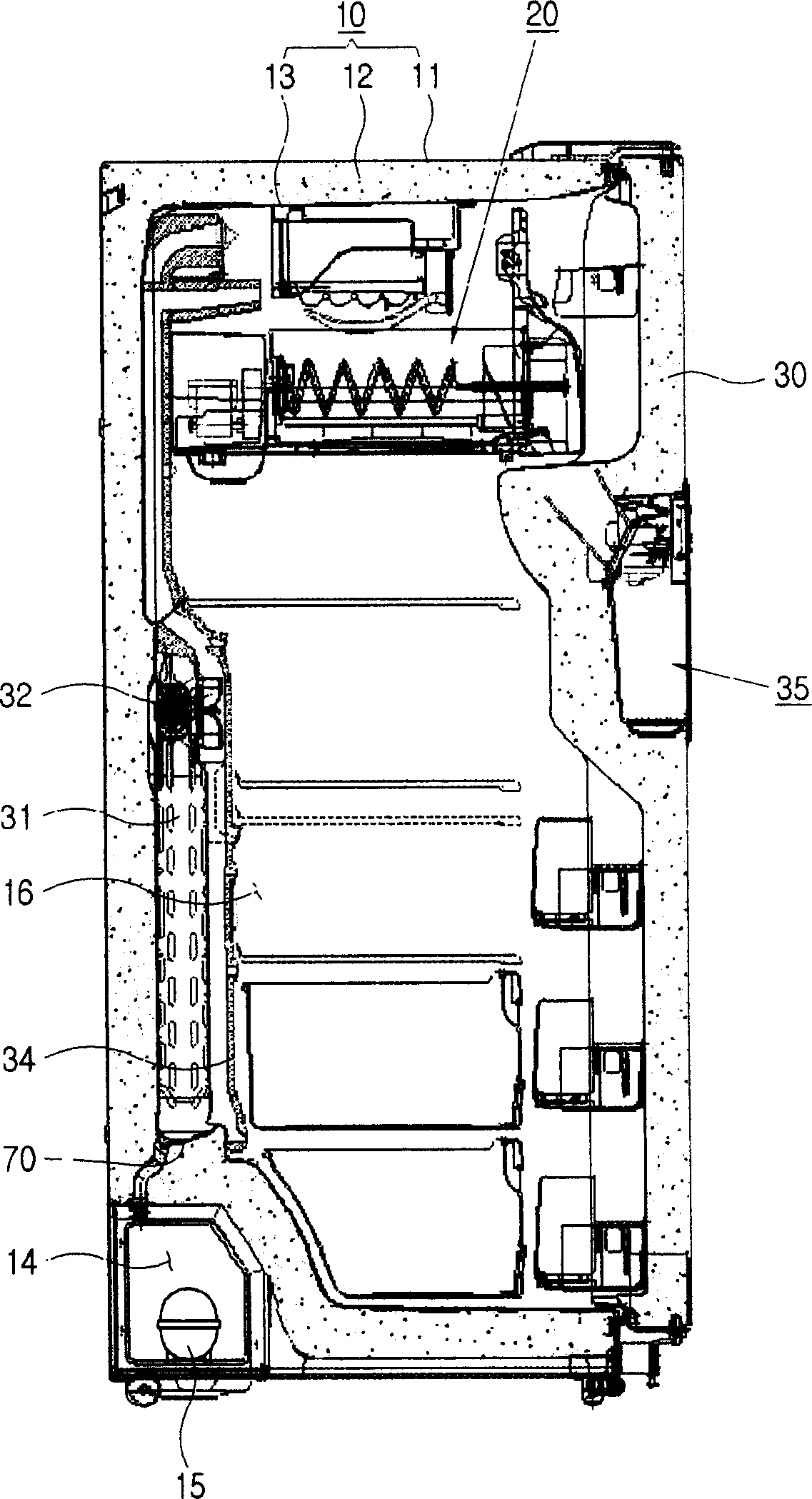

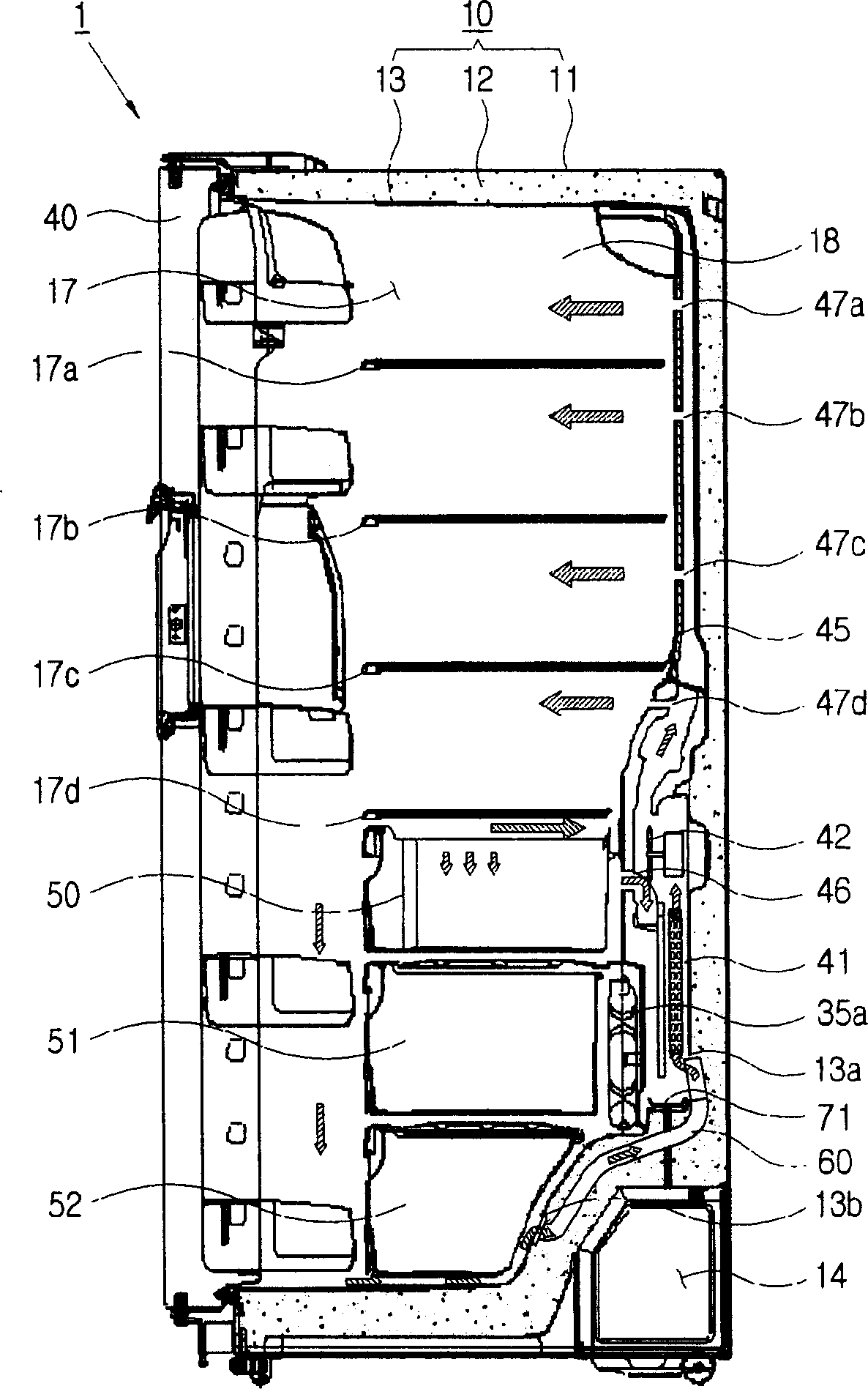

Refrigerator and method of controlling the same

InactiveUS6865899B2Easy to handleRapid coolingShow cabinetsLighting and heating apparatusCooling chamberCold store

Disclosed herein is a refrigerator that is capable of rapidly handling a load in a freezing chamber of the refrigerator or a refrigerating chamber of the refrigerator, and preventing stored goods in a rapid cooling chamber from being excessively cooled. The present invention also provides a method of controlling such a refrigerator. The refrigerator comprises a rapid cooling chamber mounted in at least one of the freezing and refrigerating chambers, a rapid cooling channel having one end communicating with an entering channel of the refrigerating chamber and the other end communicating with the rapid cooling channel, and a damper for controlling the flow of cool air passing through the entering channel of the refrigerating chamber and the rapid cooling channel. The damper is controlled on the basis of the load in the freezing or refrigerating chamber and a load in the rapid cooling chamber.

Owner:LG ELECTRONICS INC

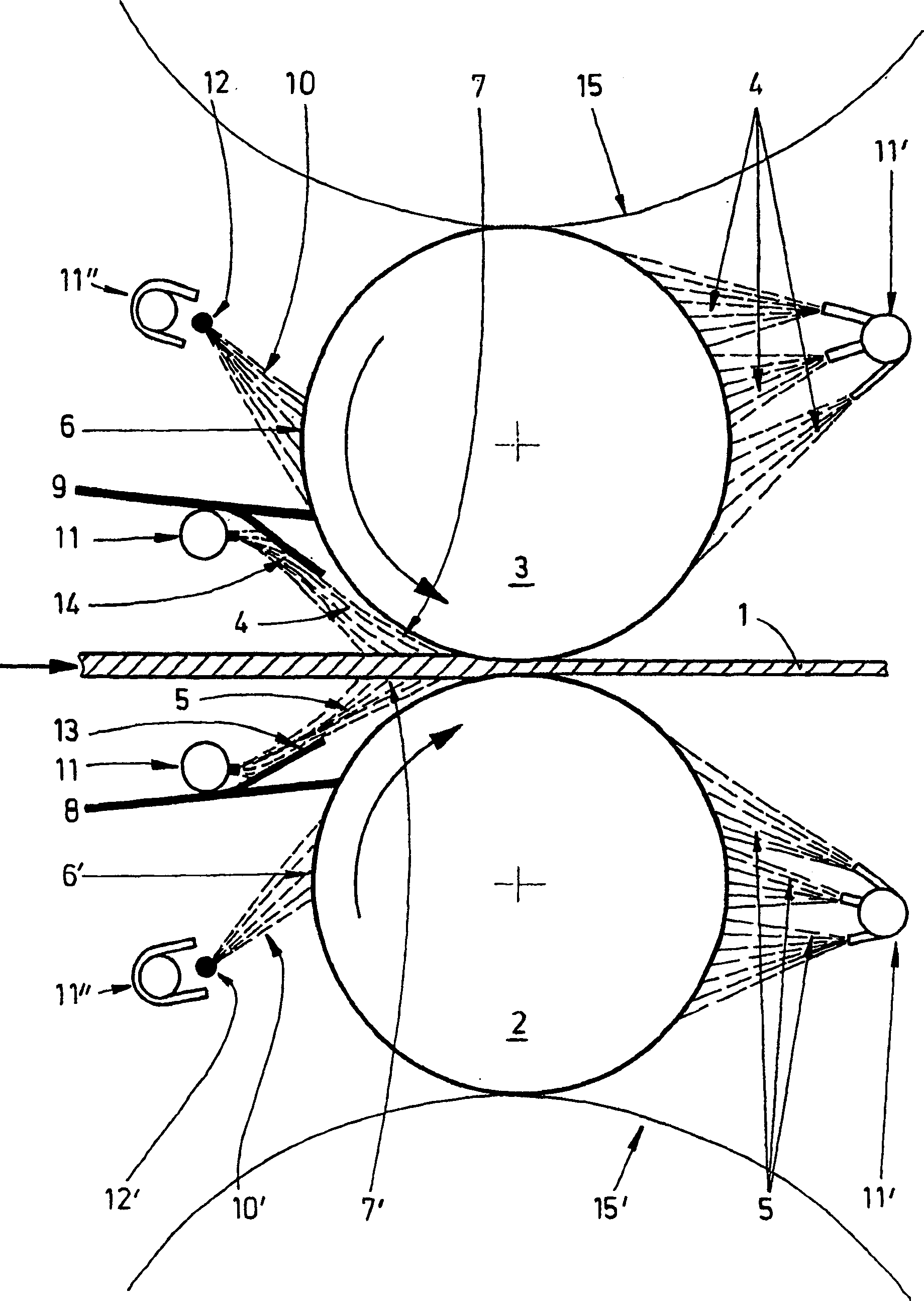

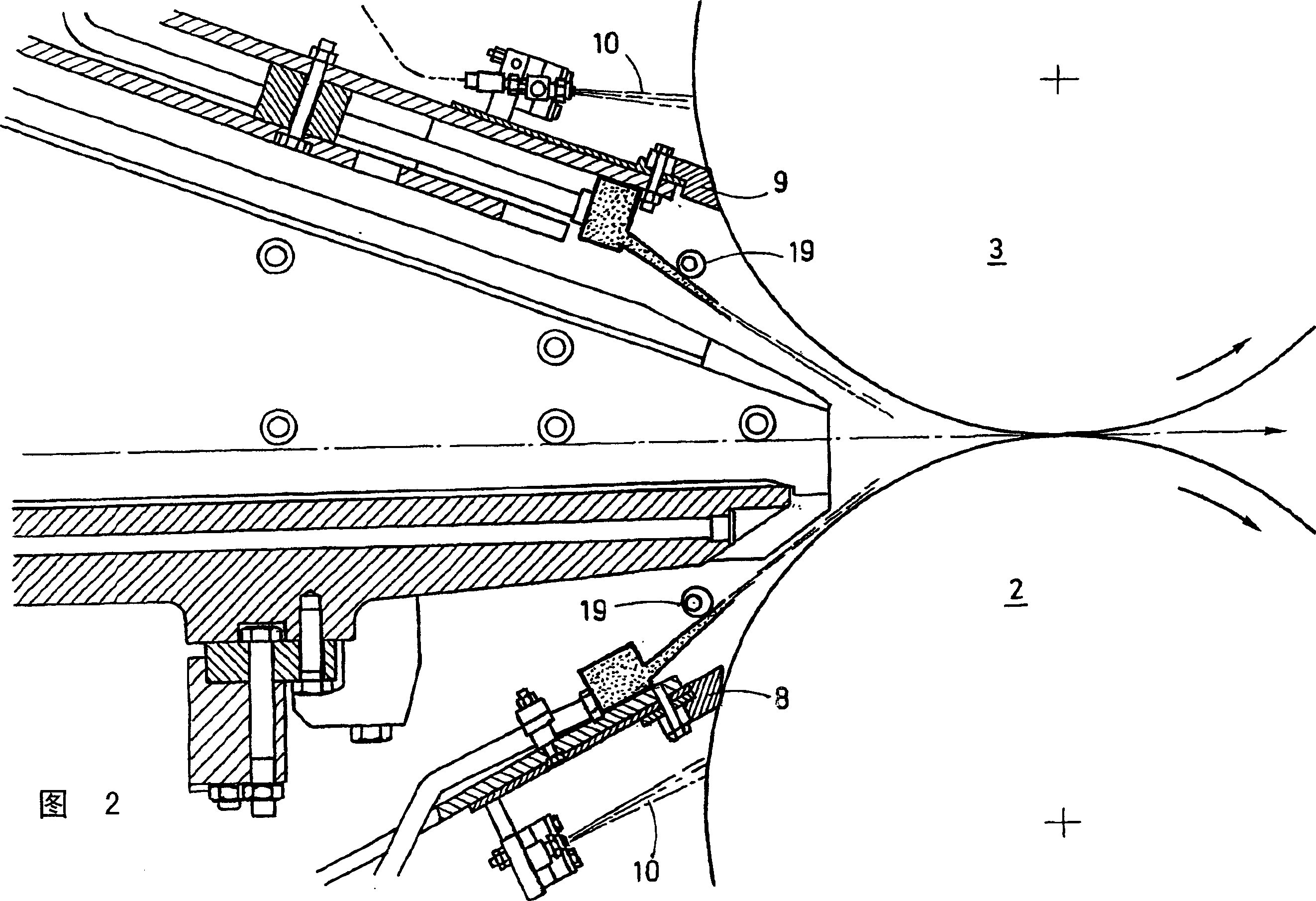

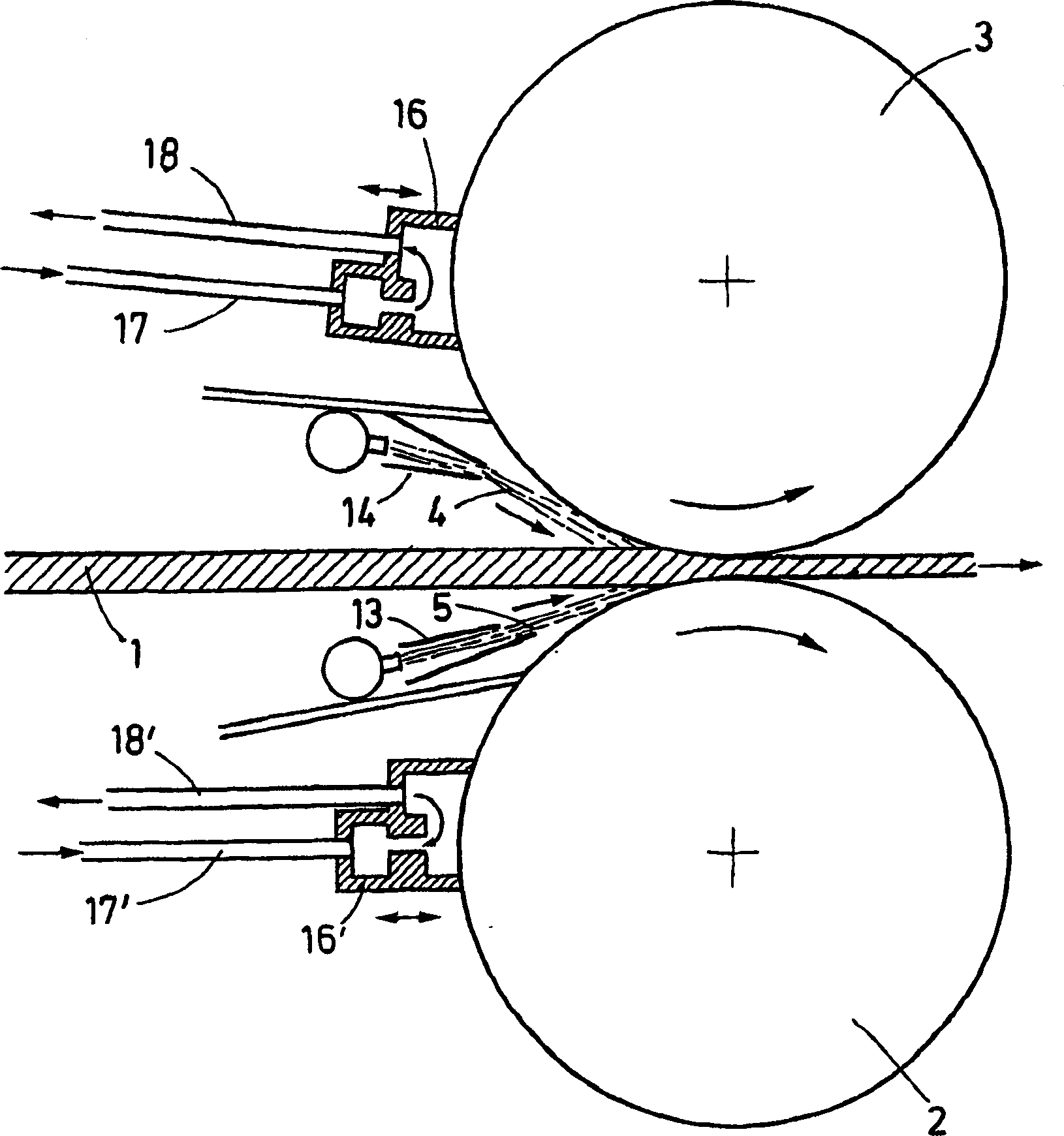

Method for cooling and lubricating rollers on rolling stand

InactiveCN1537035AIncrease stressPeeling suppressionRollsWork cooling devicesOil and greaseSuper cooling

The invention relates to a method and a device for cooling and / or lubricating rollers, in particular the working rollers (2, 3) on a rolling stand and a rolled strip (1), rolled between the above rollers and transported onwards, using water in the form of spray jets (4, 5) as cooling medium and oil, oil / air mix, oil / water mix, oil / air / water mix or grease mixtures as lubricant. In order to improve the lubricating and cooling effects, a combined application of super-cooling the strip and roller surfaces and roller lubrication on the input side of the stand is disclosed, in which both media, water and lubricant, are separately fed to the rollers (2, 3) and the rolled strip and applied to the roller surface at different application points. Separate reservoirs for water and lubricant and separate lines to the spraying bar (11) for water and the spraying bar (12) for the lubricant are provided.

Owner:SMS DEMAG AG

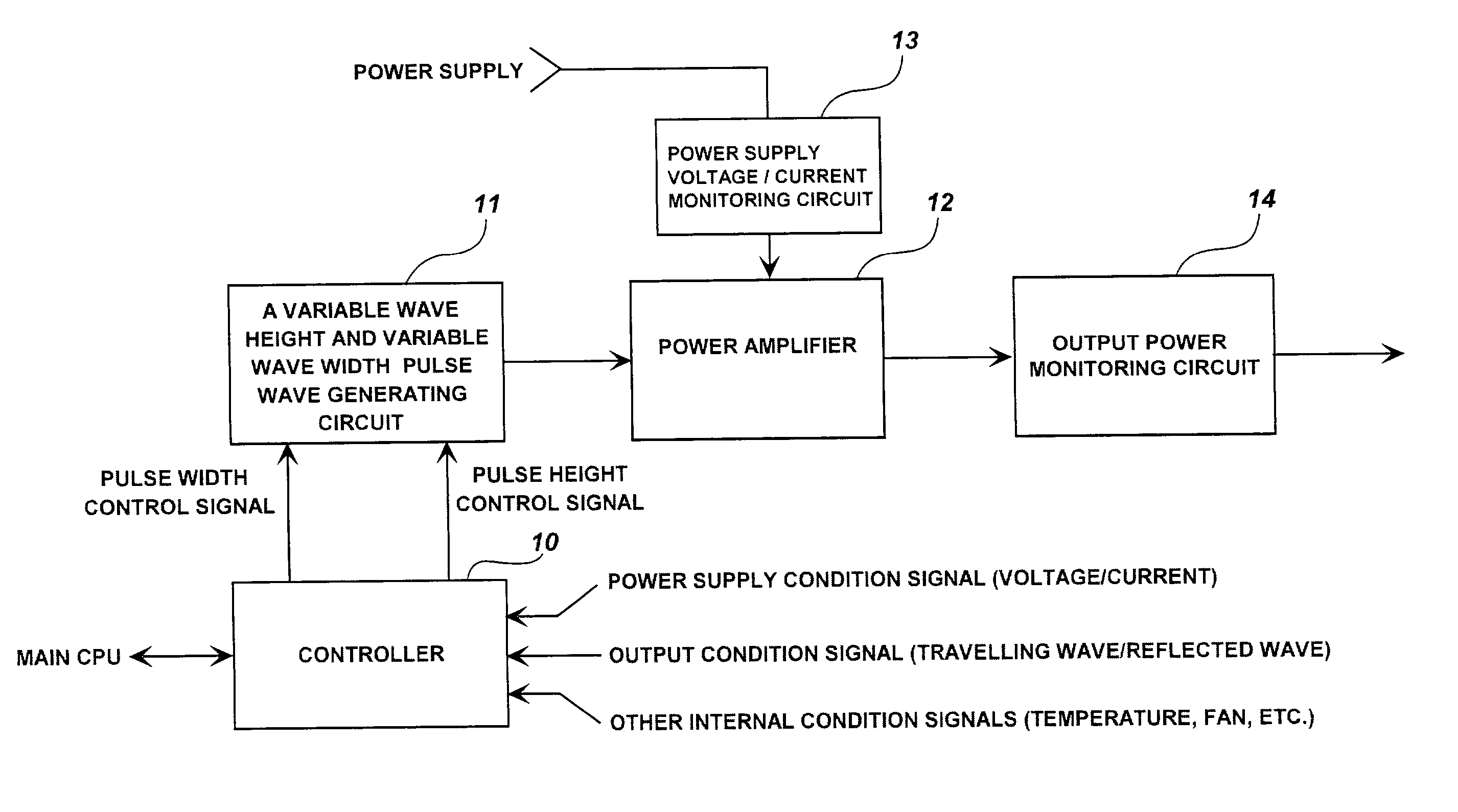

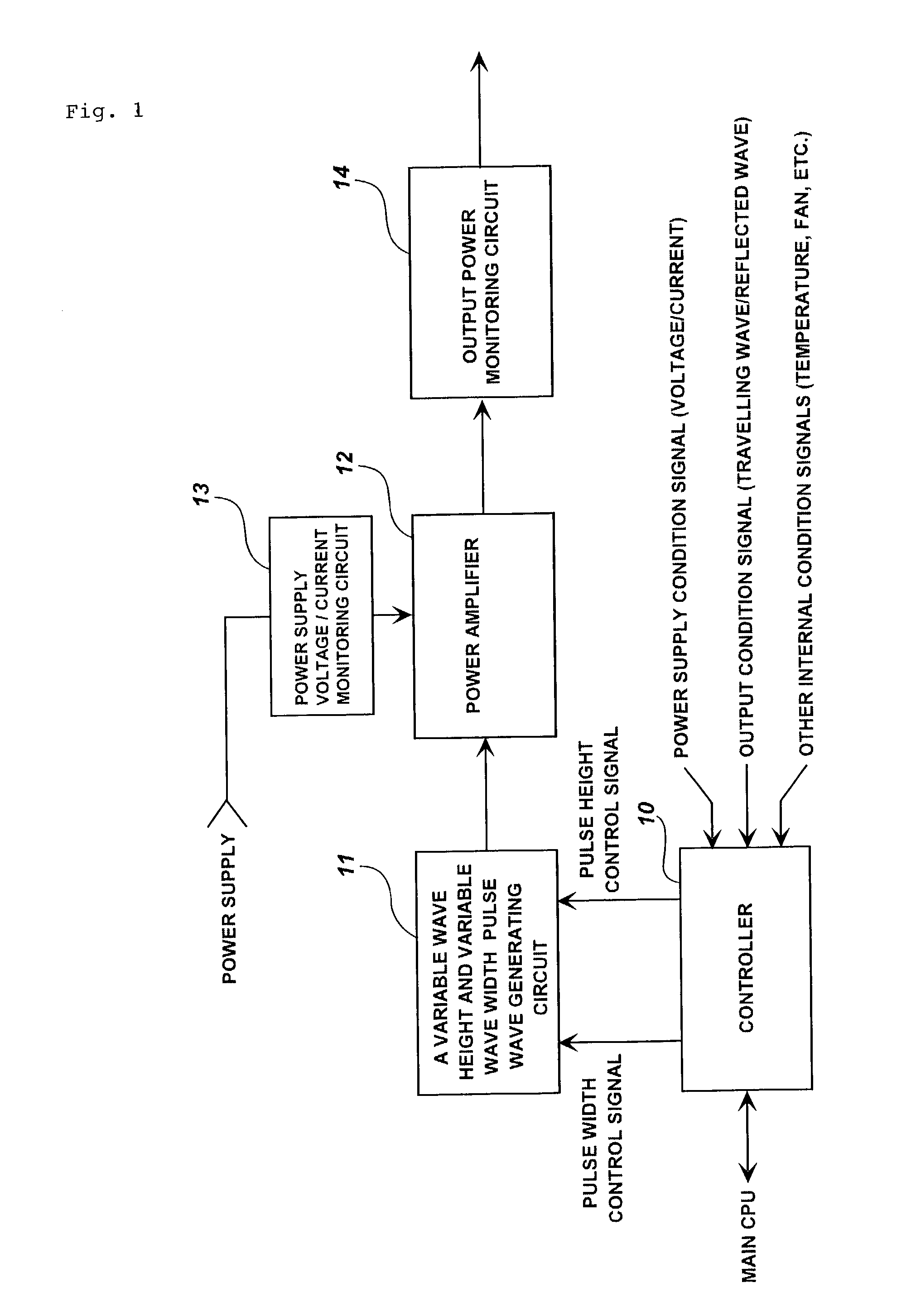

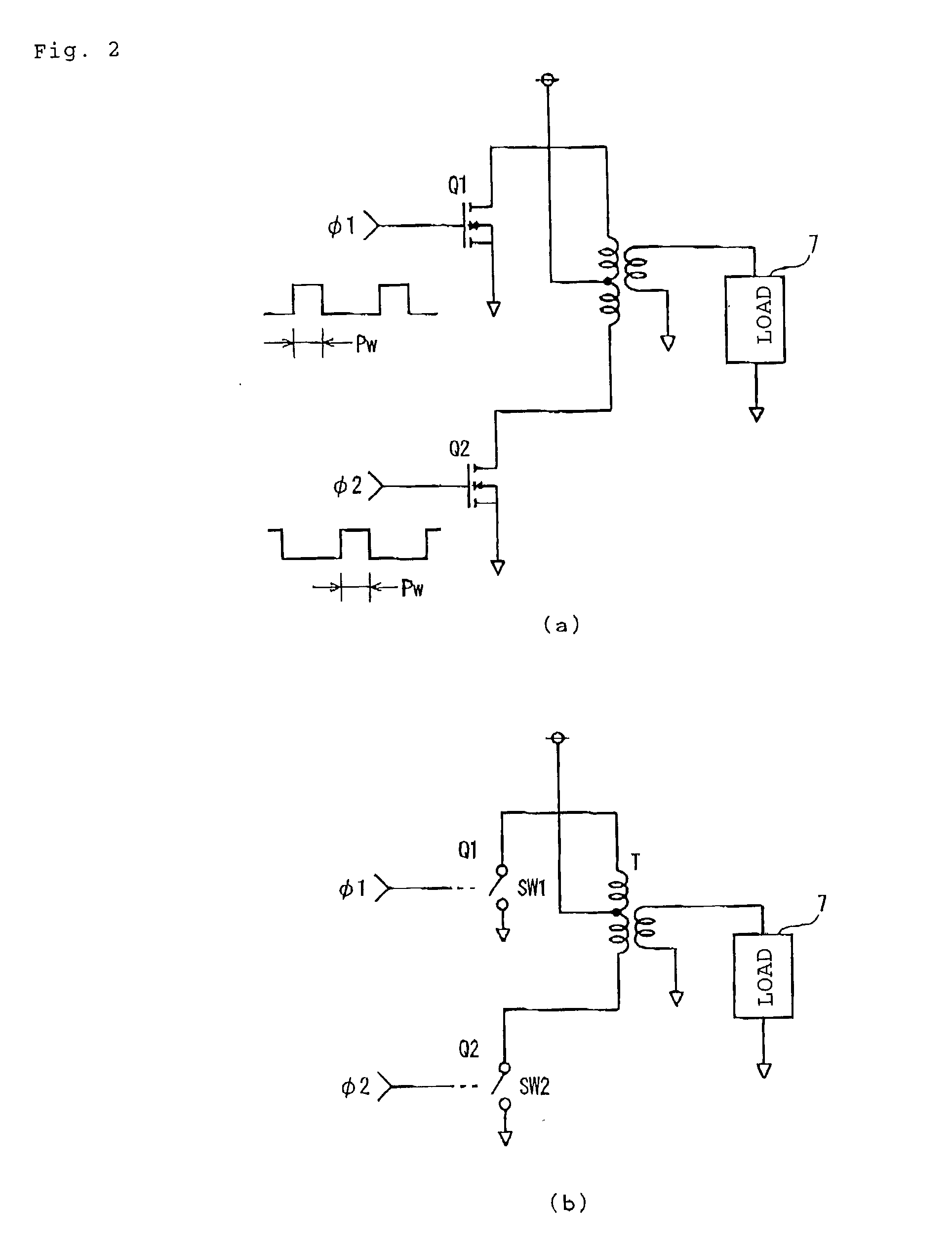

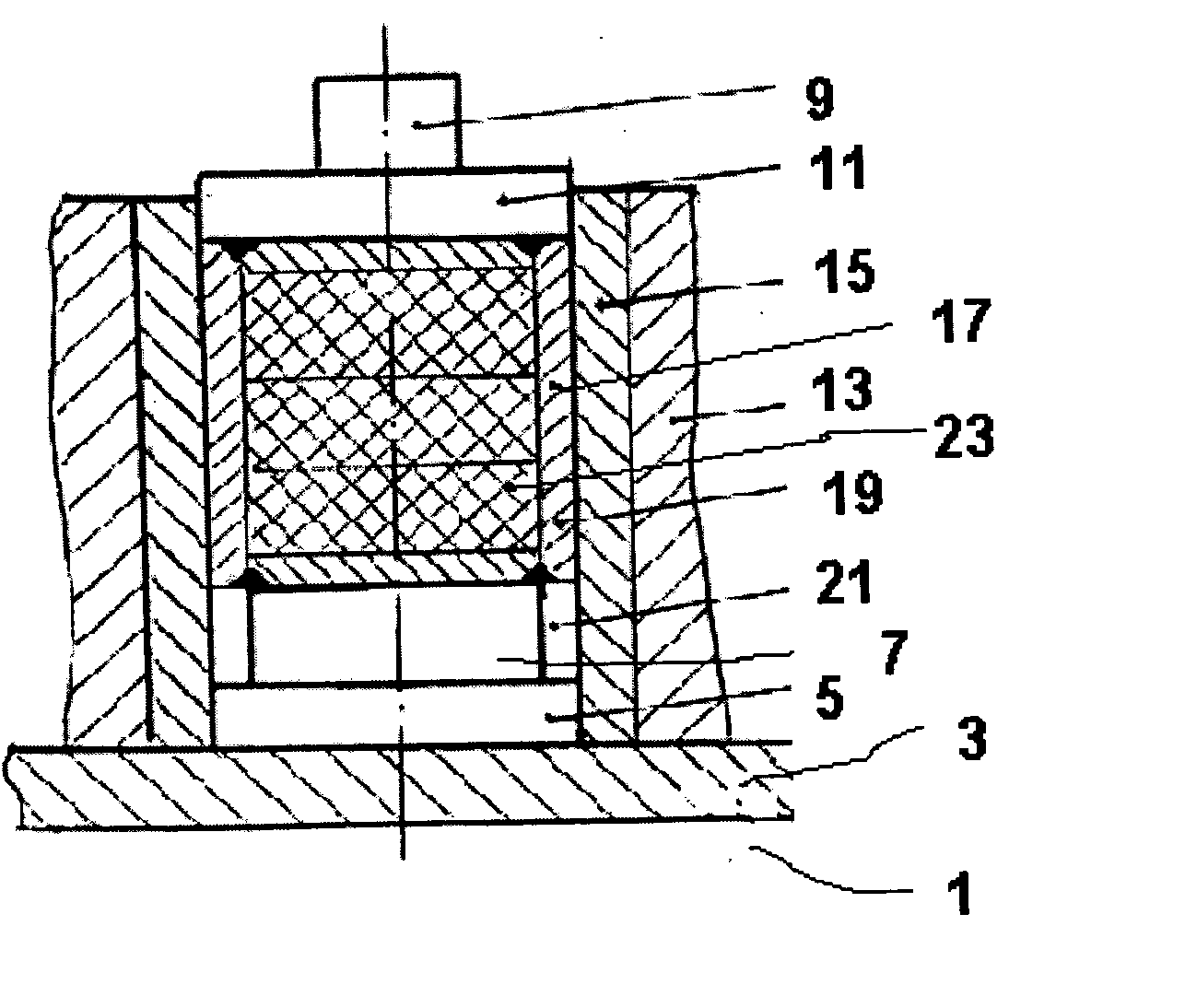

Radio frequency amplifier and method of driving the same

InactiveUS20030042977A1Not easily destroyedSimple powerPush-pull amplifiersPhase-splittersAudio power amplifierPulse height

The present invention relates to a radio frequency amplifier and a method of driving the radio frequency amplifier, and an object of the present invention is to provide a radio frequency amplifier and a method of driving the radio frequency amplifier which are excellent in the controllability at the time of a low power output while keeping the advantage of a high efficiency and give the heating generated by a power loss of such a degree that dewing generated due to over-cooling by the cooling system is not generated at the time of a low power output. The radio frequency amplifier is structured by a variable wave height and variable wave width pulse wave generating circuit 11 that generates a pulse wave (rectangular wave) having an arbitrary pulse height and pulse width, and a power amplifier 12 that is driven by the rectangular wave.

Owner:AGILENT TECH INC

Method and apparatus for forming billets from metallic chip scraps

InactiveUS20040067155A1Transportation and packagingMetal-working apparatusTitanium alloyMaterials science

The present invention relates generally to metallic chips recycling, particularly, titanium alloys metal chips, and more particularly to said chips to form billets that can then be used for producing consumable electrodes for obtaining secondary casting alloys, in blacksmith's work for obtaining forgings, extruded semi-finished products and the like. After the chips are crushed and cleaned, the chips are pressed into cylindrically shaped briquettes with relative density of 0.6, and placed into capsules. The capsules are heated and placed into a pressing rig apparatus. The pressing rig repetitively applies axial force to the capsule, resulting in briquettes having relative density of at least 0.95. In a preferred embodiment, the pressing rig is pre-heated to a temperature of at least 0.2 of the heated capsule temperature to avoid excessive cooling of the capsule during the hot deformation operation. In a preferred, the deformation effort is applied all over the surface of one of butt-ends of the capsule, and from the opposite butt-end of the capsule-over the surface the diameter of which is less than size. The pressing rig apparatus comprises a basis, a container, a mould, a compression ram, a principal press-washer and an autonomous press-washer. In a preferred embodiment, the diameter of one or both of the press-washers are less than the capsule diameter by two thicknesses of the capsule cowling, and wherein the press-washers form one or more chambers with the mould to receive the shed cowling during the hot deformation process.

Owner:GIRSHOV VLADIMIR LEONIDOVICH +4

Production technology of 7-series aluminum alloy tubular products

ActiveCN109554561AReduce air cooling speedLower the deoxidation temperatureManufacturing technologyDeoxygenation

The invention belongs to the technical field of aluminum alloy production and manufacture, and relates to a production technology of 7-series aluminum alloy tubular products. Aluminum alloy ingot casting is prepared from the following components in percentage by mass: 4.0-7.0% of Zn, 0.6-1.5% of Mg, 0.1-0.5% of Cu, less than or equal to 0.1-0.5% of Cr, less than or equal to 0.15-0.25% of Zr, lessthan or equal to 0.1% of Ti, less than or equal to 0.05% of single impurity, less than or equal to 0.15% of total impurities and the balance of Al. Sulfate and graphite are adopted to be added into molten aluminum liquid according to the mass fraction ratio of 1 to 9-3 to7 in the process of aluminum liquid refining, magnesium oxide and aluminum oxide in the aluminum liquid are removed, the deoxygenation temperature is 720+ / -5 DEG C, therefore, the air cooling speed of aluminum alloy profiles after extruded forming is 100 DEG C / min, and the problems that in the prior art, the production technology of 7-series aluminum alloy with no Mn element added has excessive cooling speed and is not easy to control are solved.

Owner:CHINA ZHONGWANG

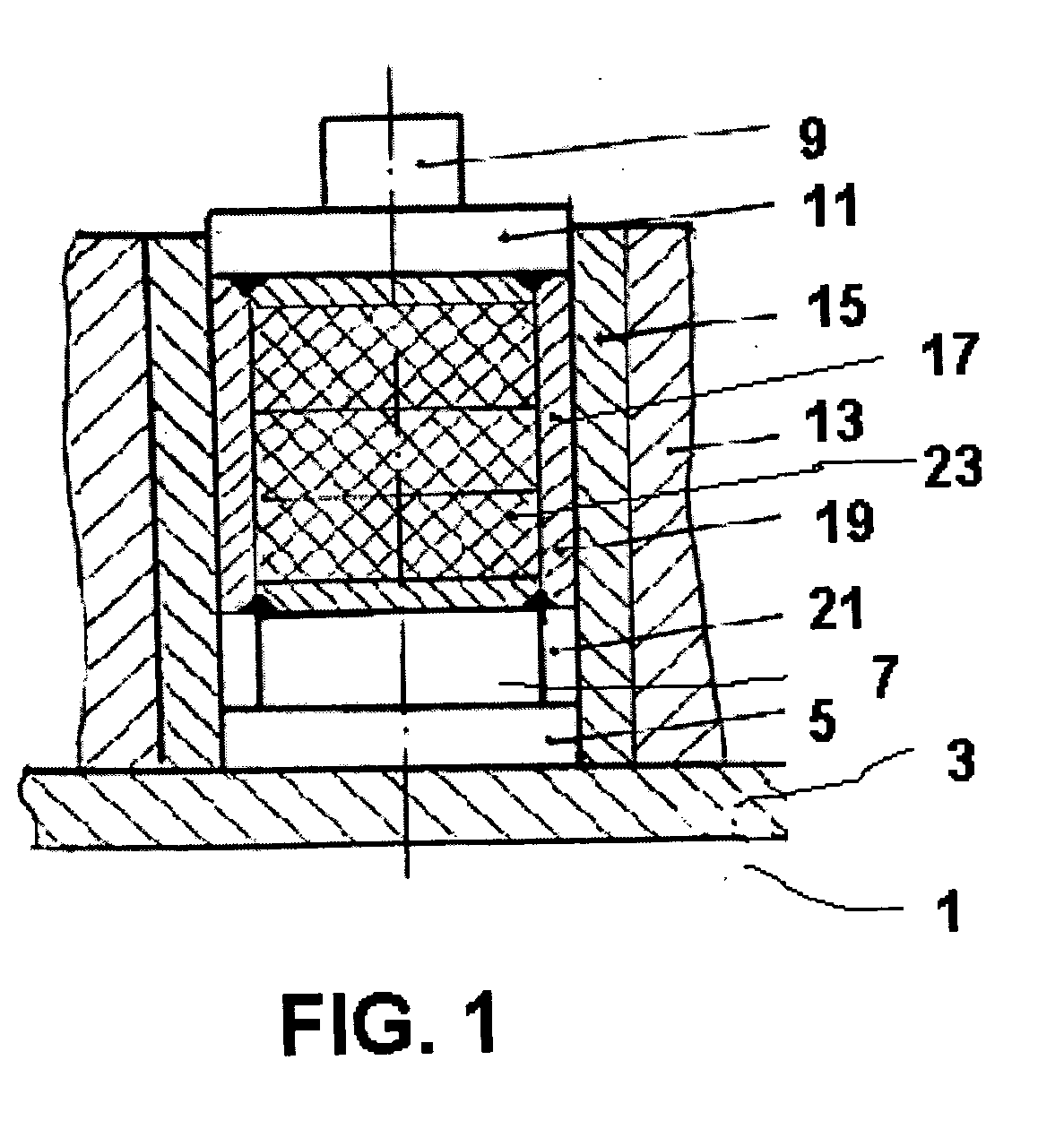

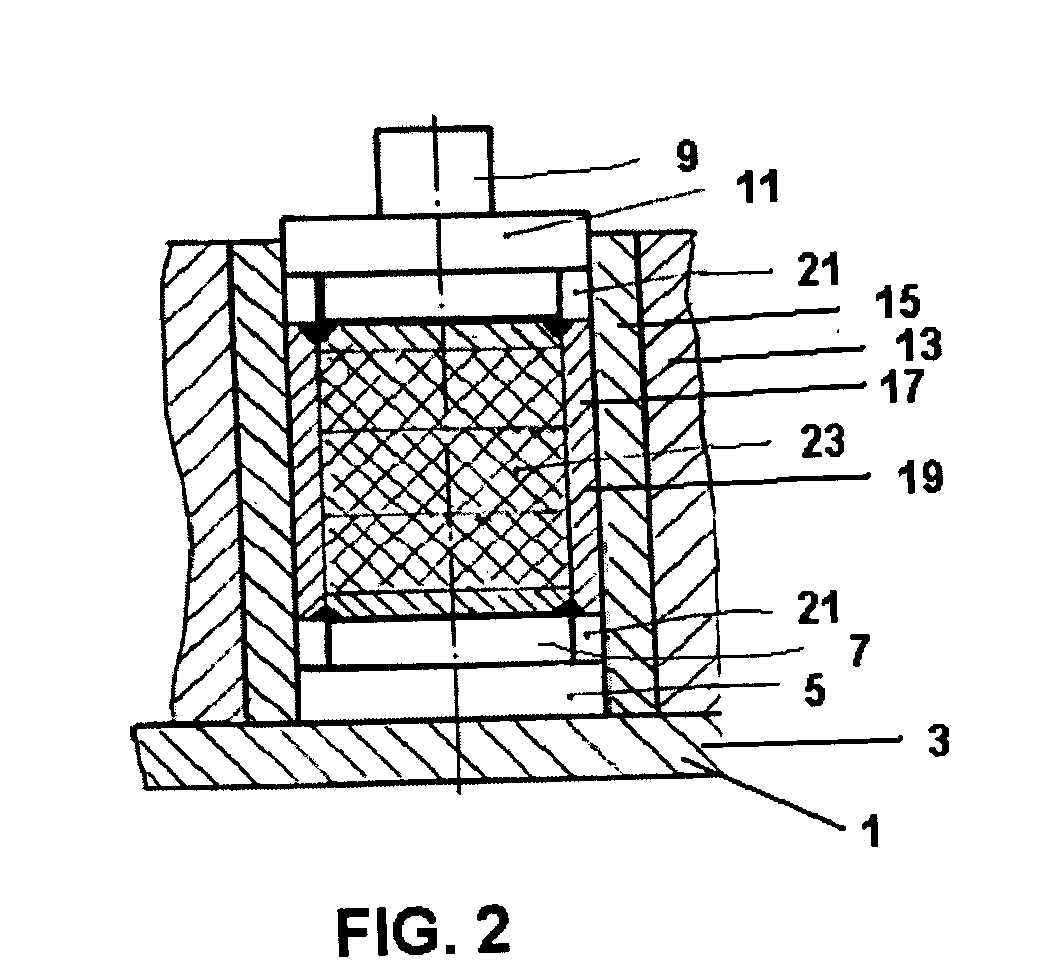

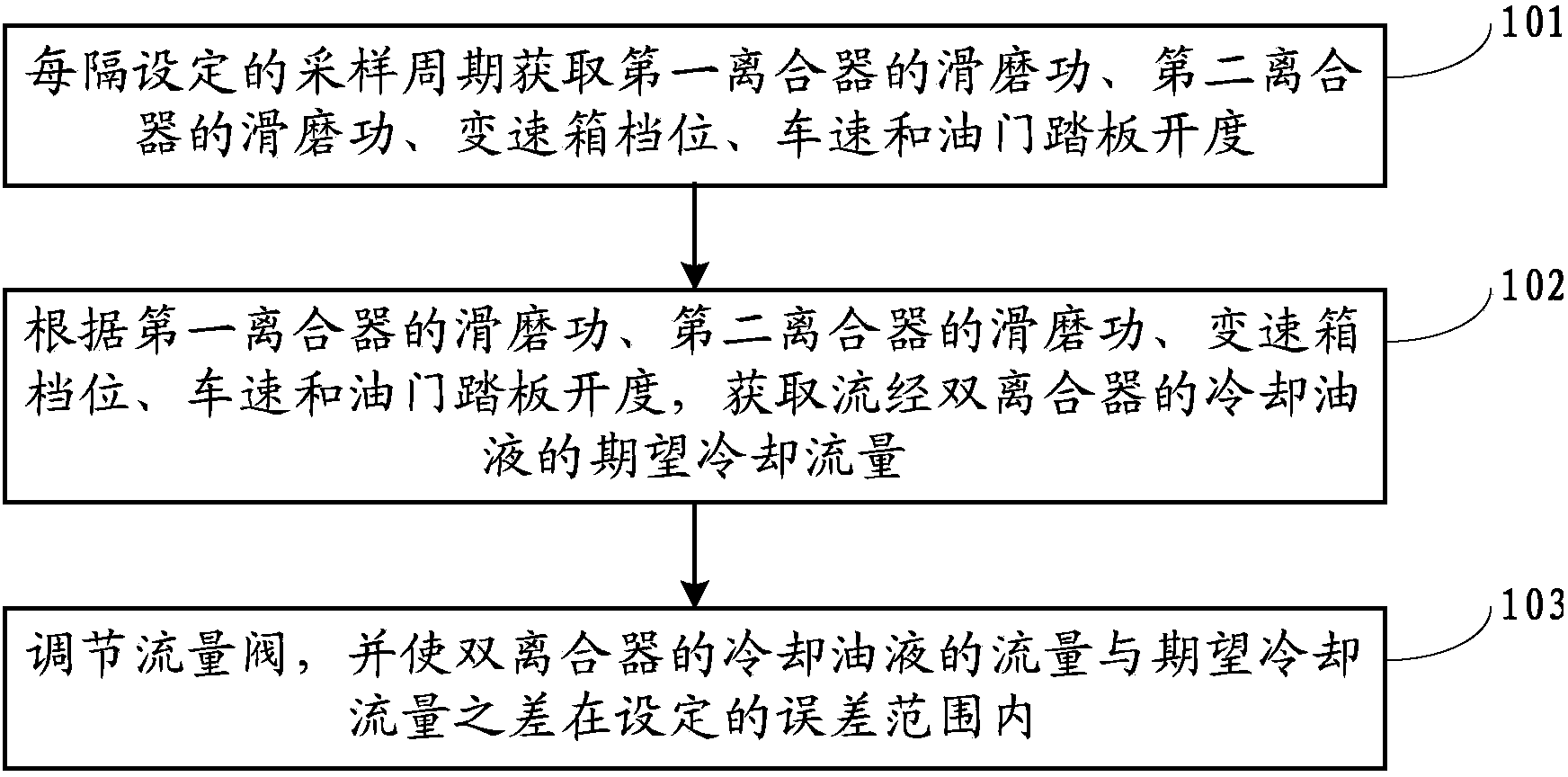

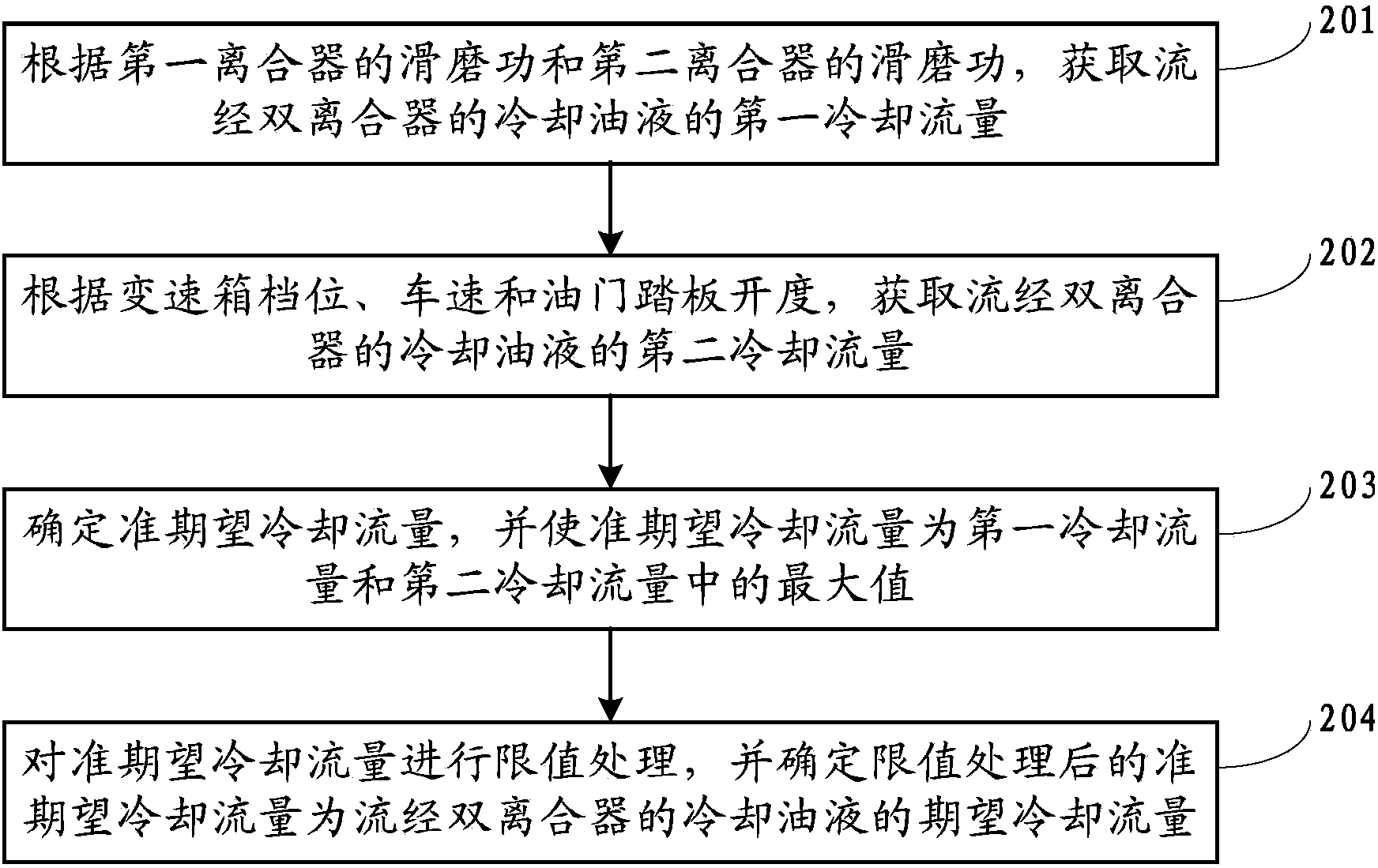

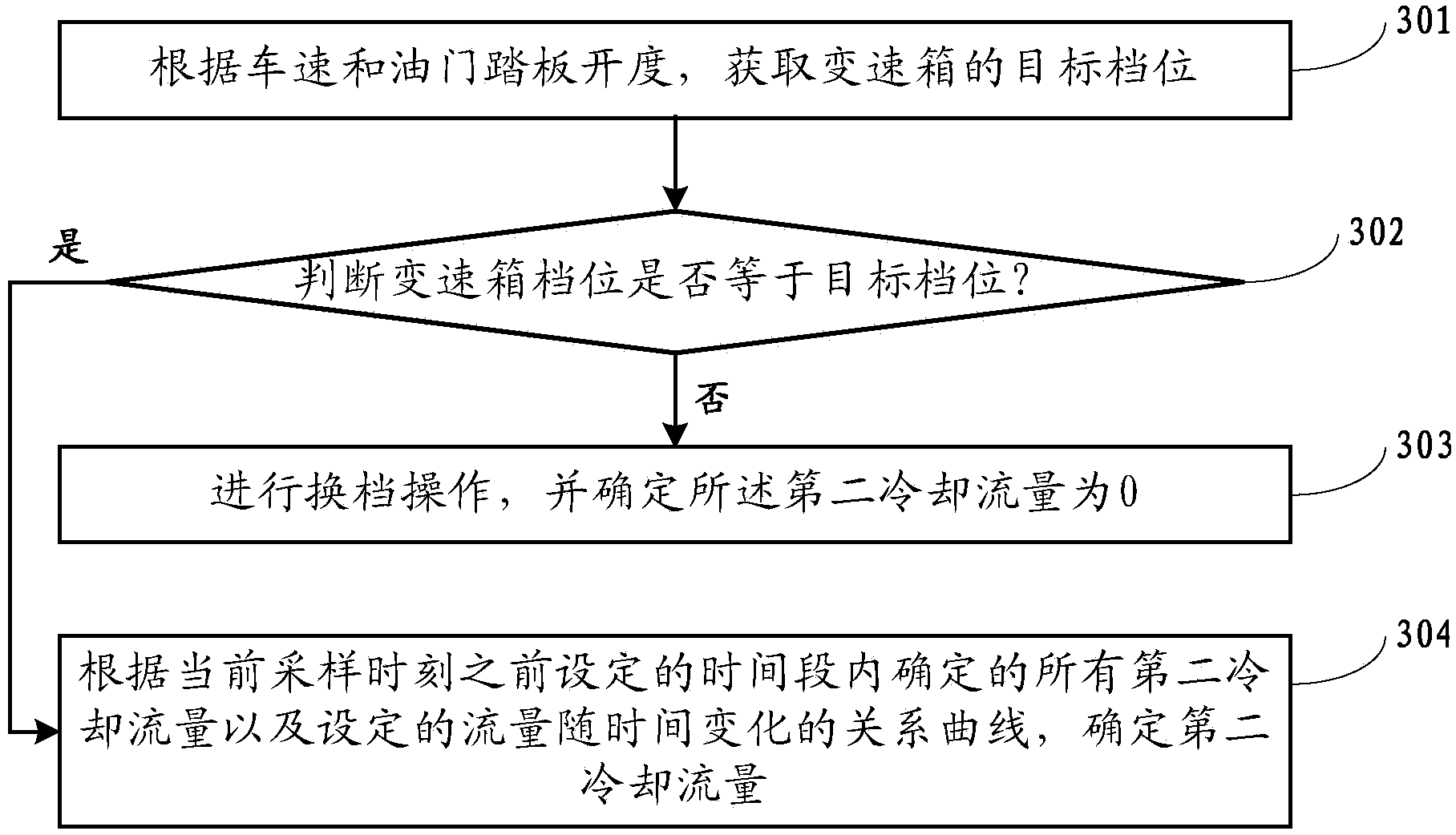

Dual clutch automatic transmission cooling flow control method and system

ActiveCN103821919ASufficient shift pressureExtended service lifeGear lubrication/coolingAutomatic transmissionOil temperature

The invention discloses a dual clutch automatic transmission cooling flow control method and a system. The dual clutch automatic transmission cooling flow control method comprises the following steps that work of slipping of a first clutch, work of slipping of a second clutch, a transmission gear, a speed and a accelerator pedal opening are obtained at every set sampling period; expected cooling flow of cooling oil flowing through the dual clutch is obtained based on work of slipping of the first clutch, work of slipping of the second clutch, the transmission gear, the speed and the accelerator pedal opening; flow valve is adjusted and differential flow between the flow of cooling oil of the dual clutch and the expected cooling flow is made in the set error range. According to the dual clutch automatic transmission cooling flow control method and the system, expected dual clutch cooling flow is codetermined by adopting work of slipping of the clutch, oil temperature of the dual clutch, oil temperature of the transmission and a shifting state, balanced relation between the cooling flow control and lubrication of the system is fully considered, so that moderate cooling flow can be appropriately provided to the dual clutch based on actual condition and adverse effects caused by excessive cooling and insufficient lubrication can be avoided.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

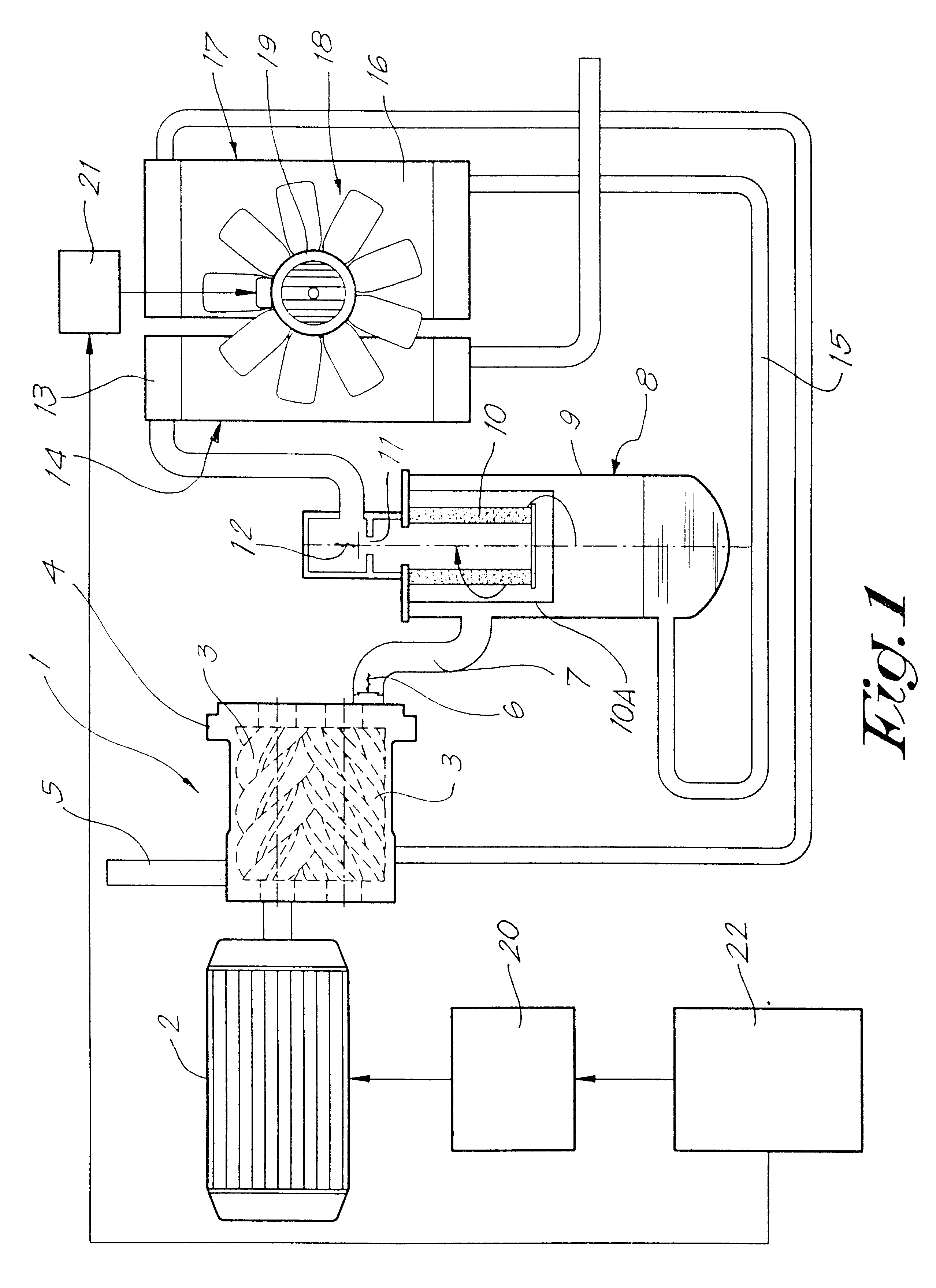

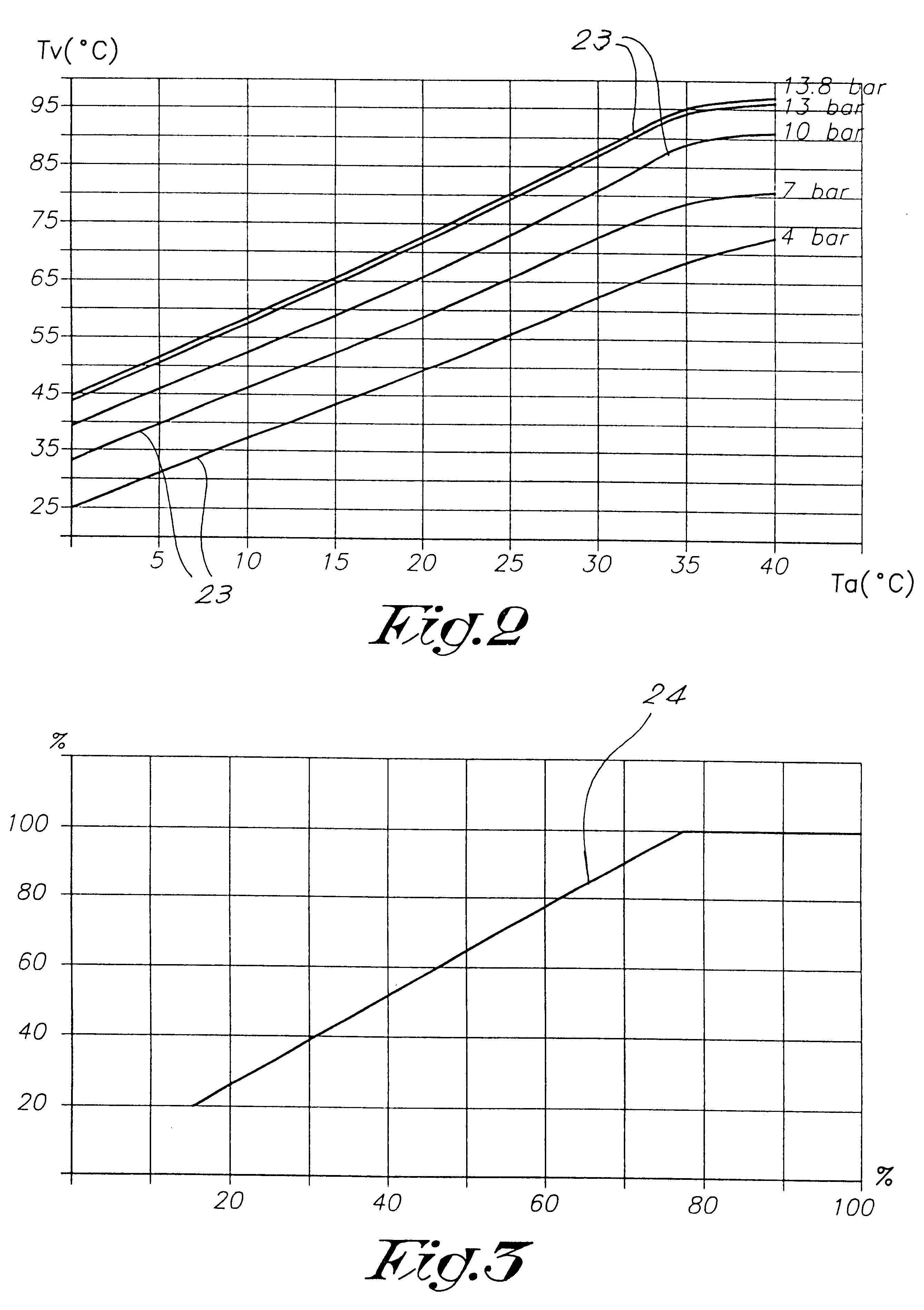

Method for regulating a fan in a compressor unit and compressor unit with fan regulated in such manner

A method for regulating a fan in a compressor unit which having at least one compressor element, a motor connected to the compressor element, and a cooler including at least one radiator and a fan cooperating therewith; driven by a motor. The motor of the compressor element is driven at a speed varying as a function of it's a load and the number of revolutions of the motor of the fan is regulated as a function of a selected lever of cooling, thereby mitigating condensation of moisture by excessive cooling. The unit includes a speed regulation device connected to the motor of the compressor element.

Owner:ATLAS COPCO AIRPOWER NV

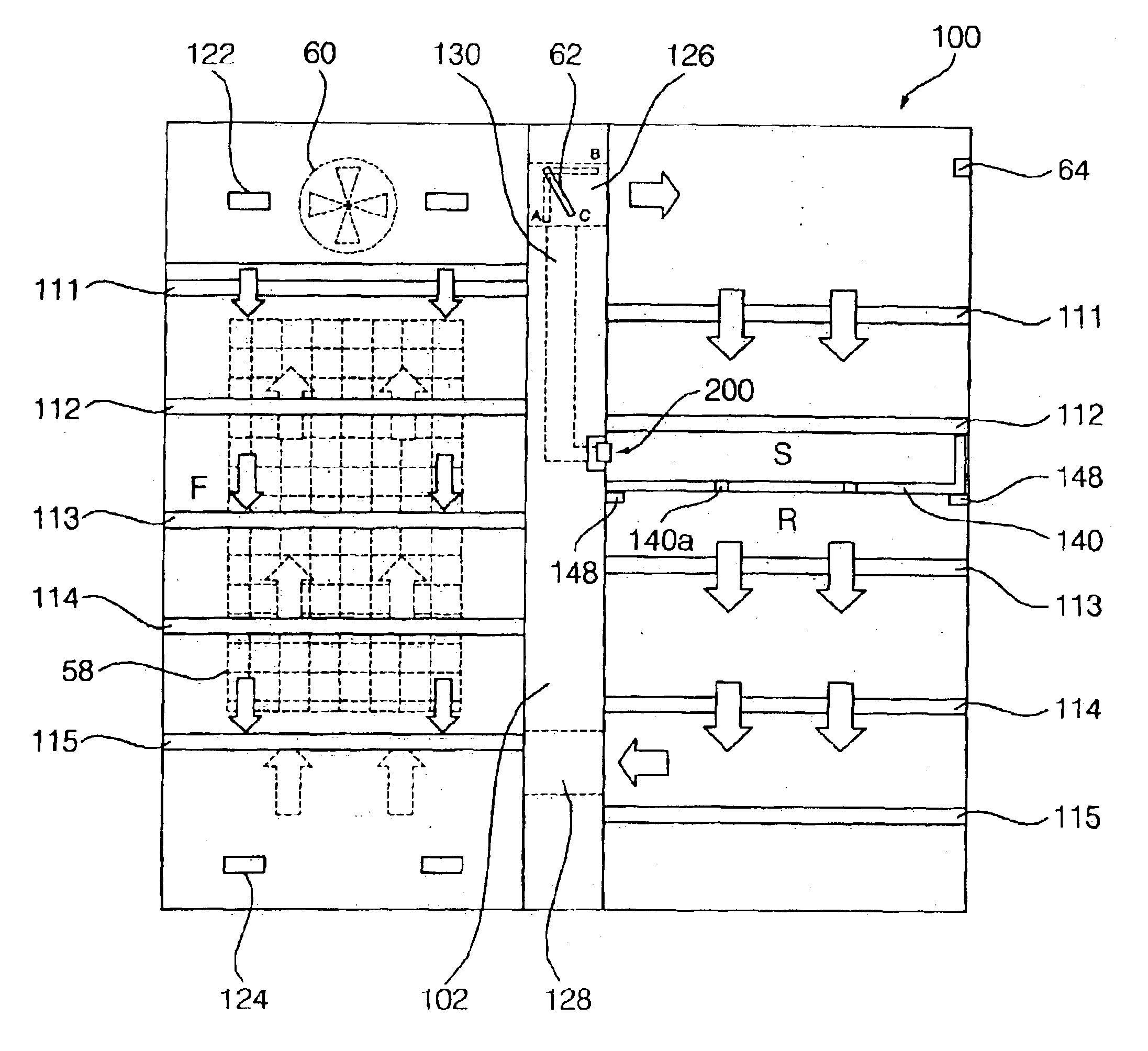

Refrigerator

A refrigerator is provided to prevent excessive cooling and freezing of a peripheral region of an evaporator in a refrigerator compartment by discharging cold air through a lower region of the refrigerator compartment. A refrigerator includes a refrigerator compartment duct(45), and a ventilation duct(60). The refrigerator compartment duct forms a cold air path between an evaporator(41) and the refrigerator compartment, and has a discharge port formed at the upper side of the evaporator. The ventilation duct is disposed to make the refrigerator compartment duct in communication with a lower region of the refrigerator compartment to flow the cold air therethrough. An evaporator of a freezer compartment is serially connected to the evaporator of the refrigerator compartment. When a refrigerator compartment fan is OFF and a freezer compartment fan is ON, the cold air generated from the evaporator of the refrigerator compartment is discharged to the refrigerator compartment through the ventilation duct.

Owner:SAMSUNG ELECTRONICS CO LTD

Exposure apparatus, and device manufacturing method using the same

InactiveUS7330236B2Avoid radiationSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusOptoelectronicsRadiation shield

Disclosed is an exposure apparatus having a specific structure that includes a cold trap plate for attracting contaminant substances which might cause a decrease of reflectance of a mirror when adhered thereto, and a radiation shield member for preventing excessive cooling of the mirror or the like by the cold trap plate.

Owner:CANON KK

Cooling/warming air conditioner

InactiveCN104482611AImprove work performanceGuaranteed reliabilityMechanical apparatusFluid circulation arrangementWork performanceClosed loop

The invention discloses a cooling / warming air conditioner which comprises a compressor, a reversing assembly, an outdoor heat exchanger, an indoor heat exchanger, a throttling element, a first refrigerant flowing channel and a second refrigerant flowing channel which are connected in parallel, an electric control radiator assembly, a first one-way valve and a second one-way valve. The compressor, the reversing assembly, the throttling element and the indoor heat exchanger are connected to form a closed loop system. The first refrigerant flowing channel and the second refrigerant flowing channel are connected between the outdoor heat exchanger and the throttling element in series respectively. The electric control heat radiator assembly comprises an electric control element and a radiating assembly connected onto the first refrigerant flowing channel in series. The first one-way valve is connected onto the first refrigerant flowing channel in series to be opened in one way during refrigeration, and the second one-way valve is connected onto the second refrigerant flowing channel in series to be opened during heating. A refrigerant can be utilized to dissipate heat of the electric control radiator assembly to further improve the working performance of the electric control element. Excessive cooling of the electric control element is avoided, and condensate water is prevented from being produced on the electric control radiator assembly.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

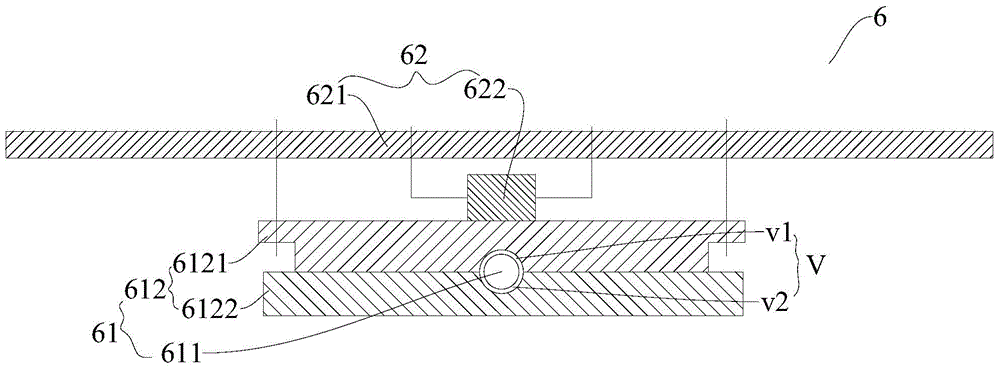

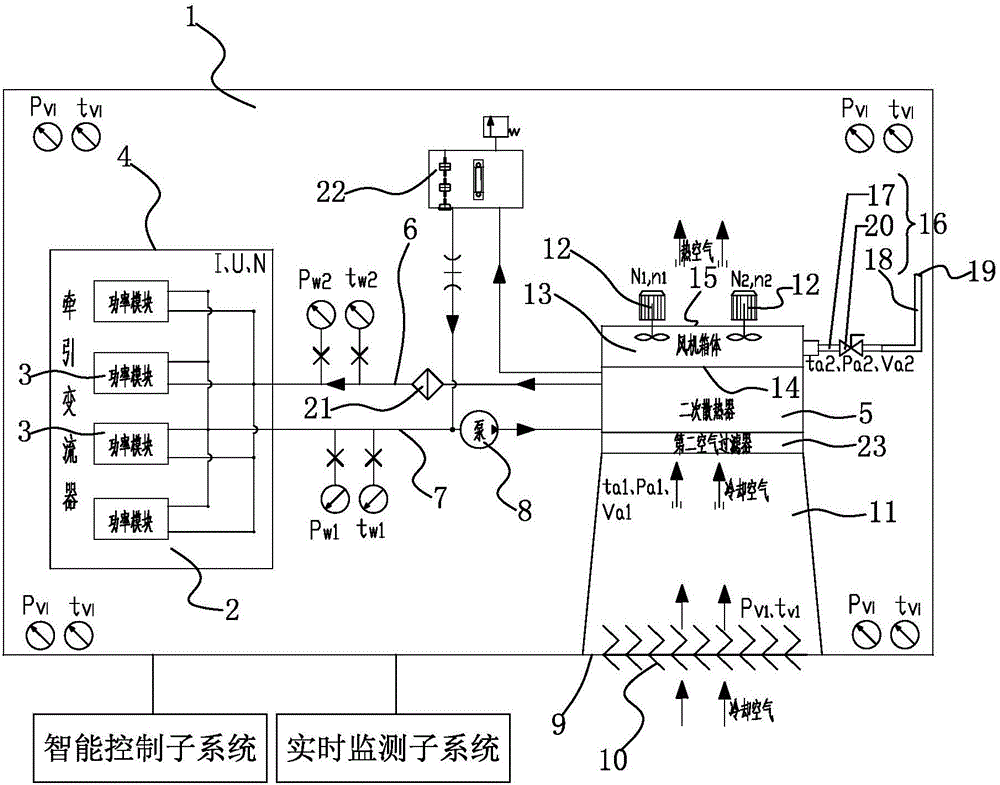

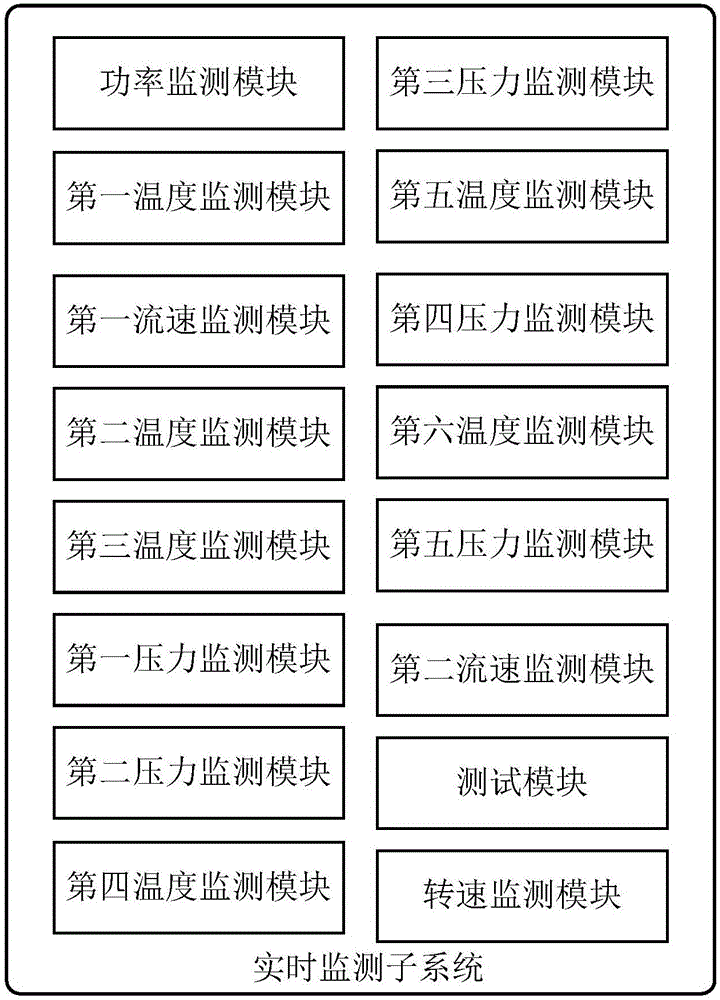

Intelligent cooling system for traction converter of electric multiple unit

ActiveCN106455418AMeet energy saving requirementsMeet environmental protection requirementsModifications using gaseous coolantsPower conversion systemsIntelligent lightingTraffic capacity

The invention discloses an intelligent cooling system for a traction converter of an electric multiple unit. The intelligent cooling system comprises a primary heat sink and a secondary cooling device, wherein the primary heat sink is used for installing a heat source part contained in the traction converter, the secondary cooling device is arranged in equipment compartment, heat generated by the heat source part is taken away by a cooling liquid flowing out of the primary heat sink, the secondary cooling device comprises a secondary heat sink and a pump, the secondary heat sink communicates with the primary heat sink through a cooling liquid circulation pipeline, the cooling liquid circulation pipeline comprises a liquid inlet pipeline and a liquid outlet pipeline, the pump is arranged on the liquid outlet pipeline, the cooling liquid flowing out of the primary heat sink passes through the liquid outlet pipeline and the pump and enters the secondary heat sink, the secondary heat sink is used for transferring the heat to cooling air from the cooling liquid, and the cooling liquid passes through the liquid inlet pipeline and returns to the primary heat sink after the heat is released. By the intelligent cooling system, the rotational speed of a draught fan and the flow quantity of the cooling air can be dynamically regulated according to a running environment and a working condition of the electric multiple unit so as to further control cooling intensity, and excessive cooling is prevented.

Owner:CRRC DALIAN INST CO LTD

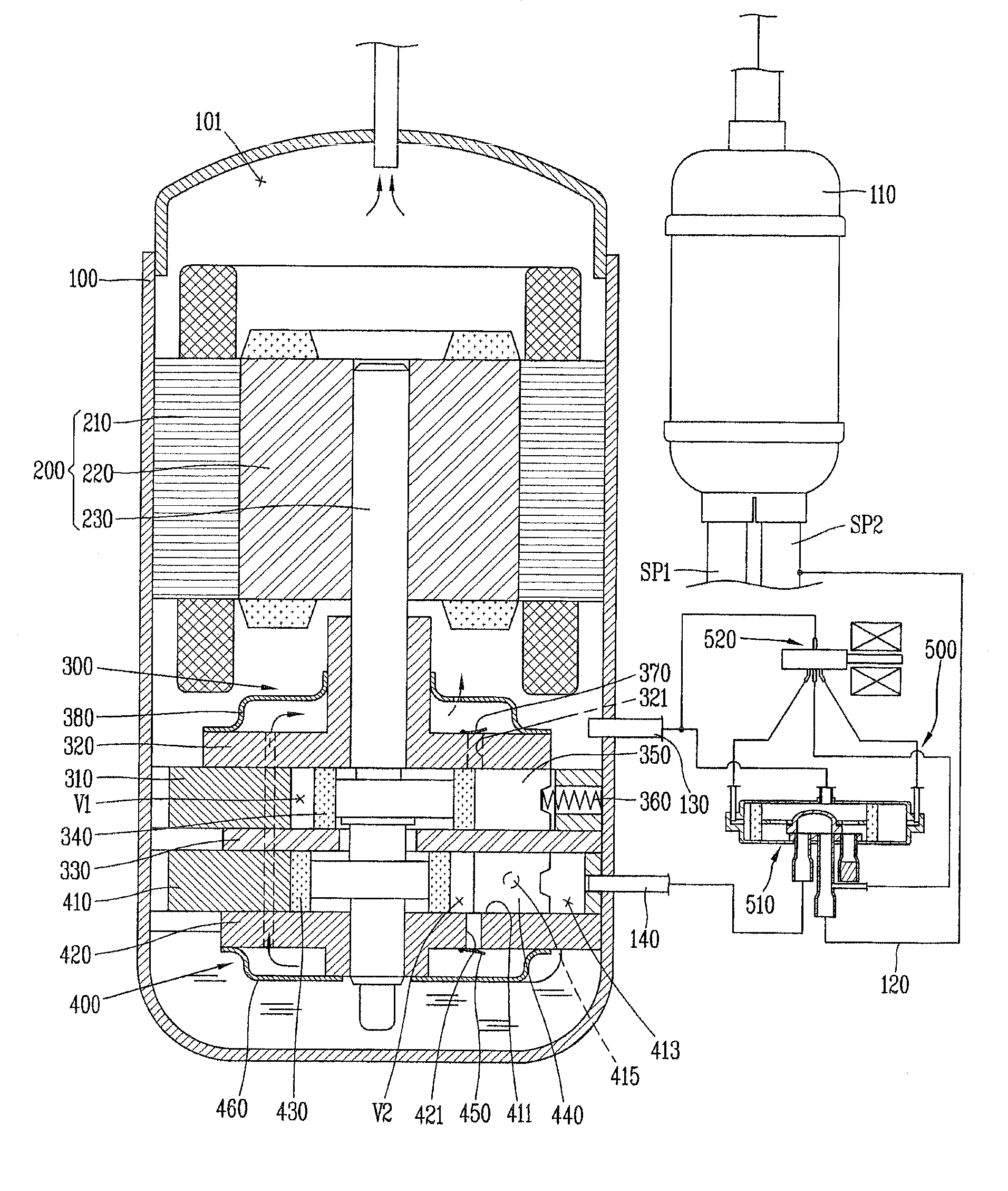

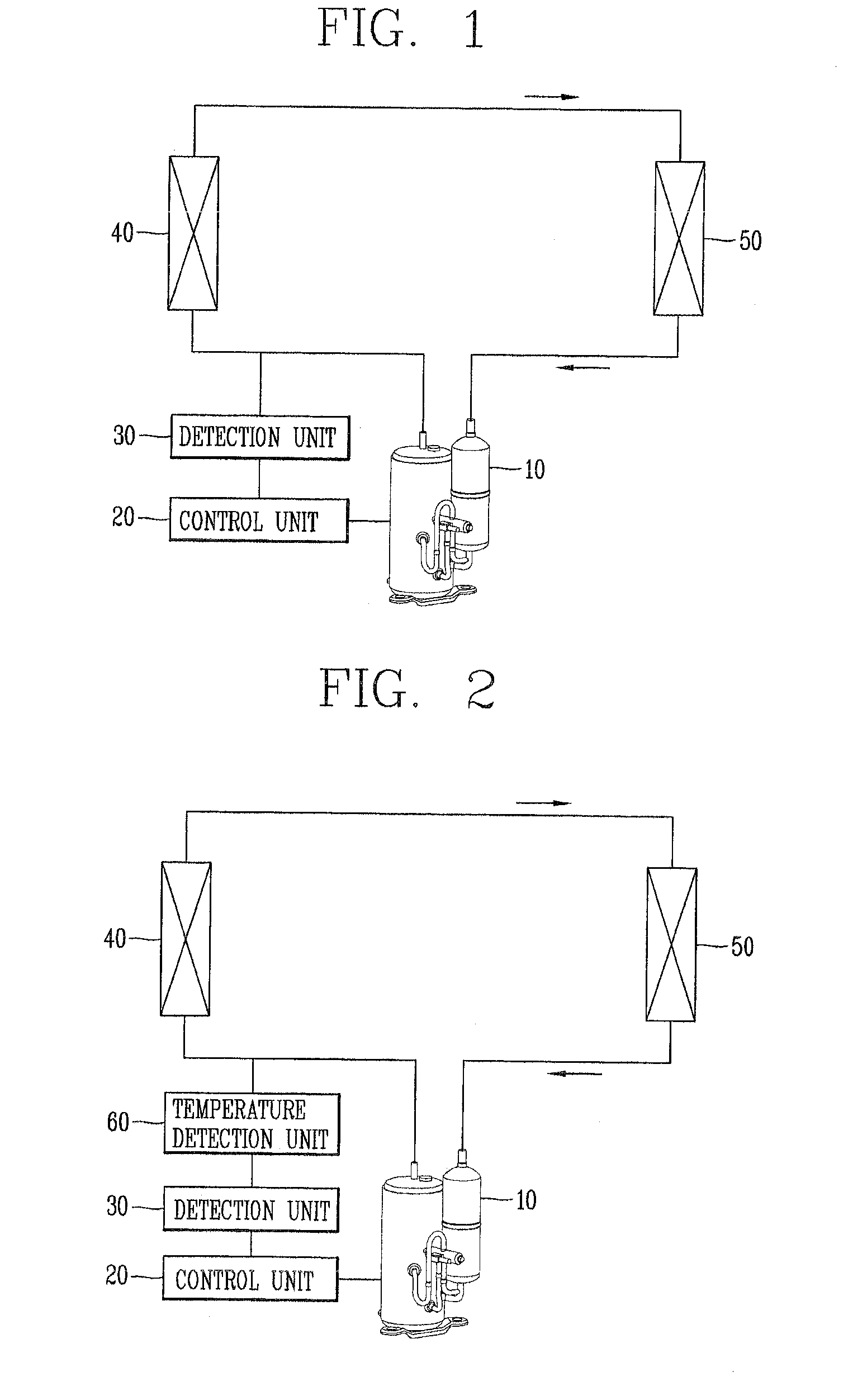

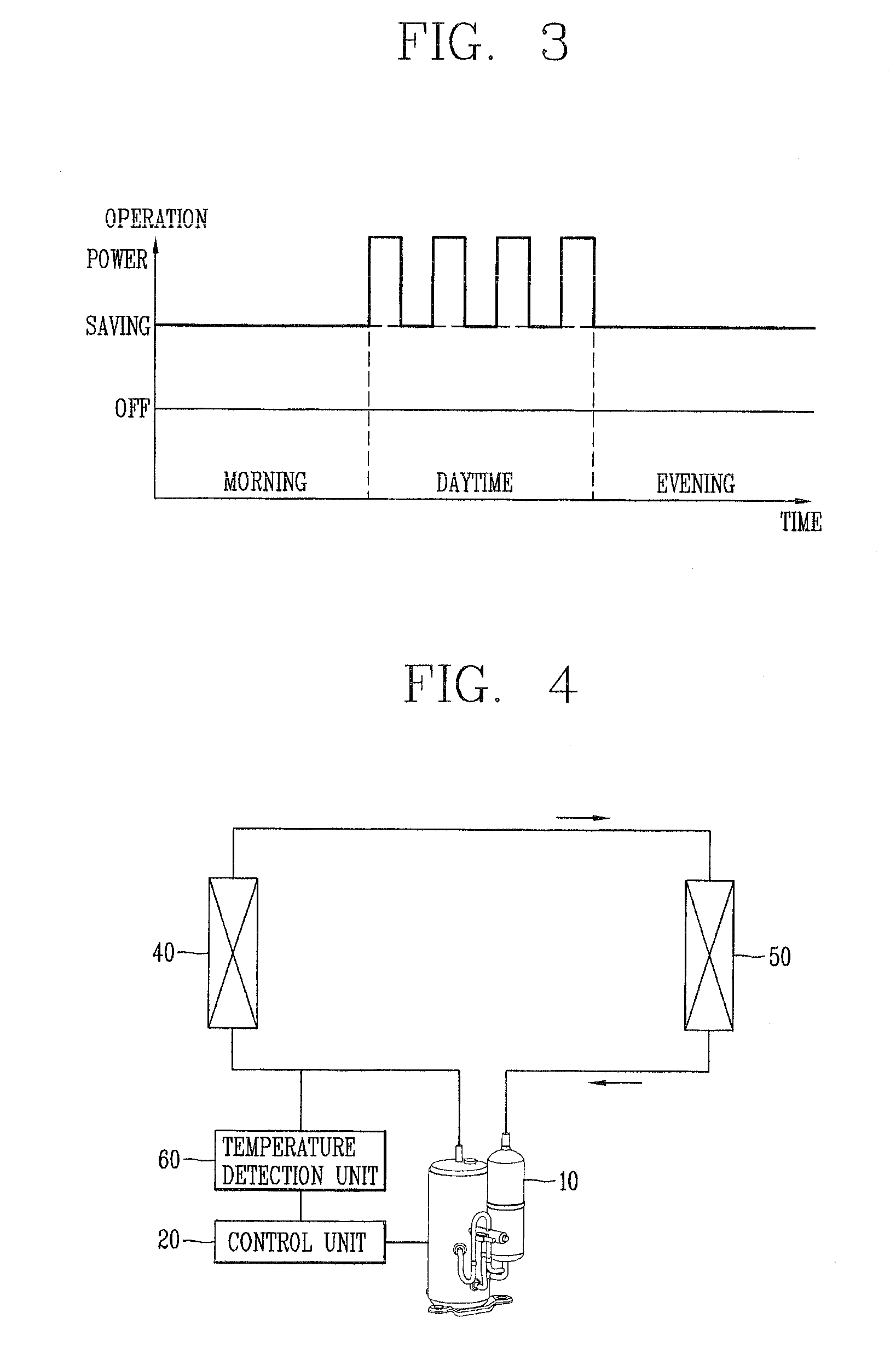

Compressor and air-conditioner having the same

ActiveUS20110120165A1Agreeable cooling operationReduce power consumptionRotary/oscillating piston combinations for elastic fluidsPump componentsTime domainLow voltage

A compressor and an air-conditioner having the same are disclosed. A compressor application voltage is detected, and the air-conditioner is operated in a pre-set operation mode according to the detection result, or the air-conditioner is operated in a pre-set operation mode in a certain time domain, thus continuously operate the compressor. Or, a compressor temperature or an ambient temperature is detected to operate the air-conditioner in a pre-set operation mode or operate the air-conditioner in a pre-set operation mode within a certain time domain, thus continuously operate the compressor. Accordingly, the compressor can be operated in a particular operation mode within a certain time slot regardless of an ambient temperature, whereby an excessive cooling operation cannot be performed at night to thus provide an agreeable cooling operation and reduce noise. The compressor is prevented from being stopped due to a low voltage, and because power of the compressor is not repeatedly turned on or off, power is consumption can be reduced and reliability can be improved.

Owner:LG ELECTRONICS INC

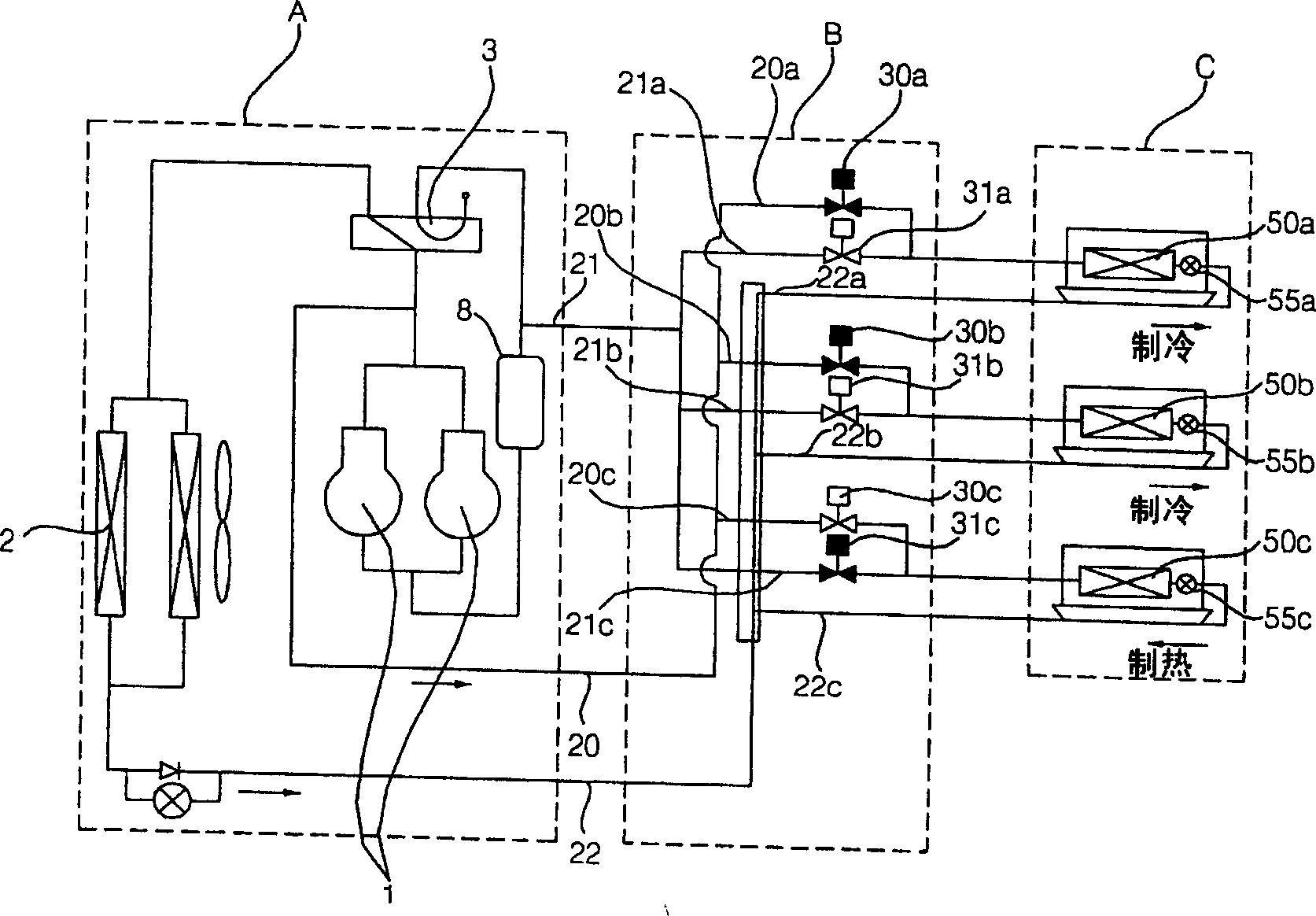

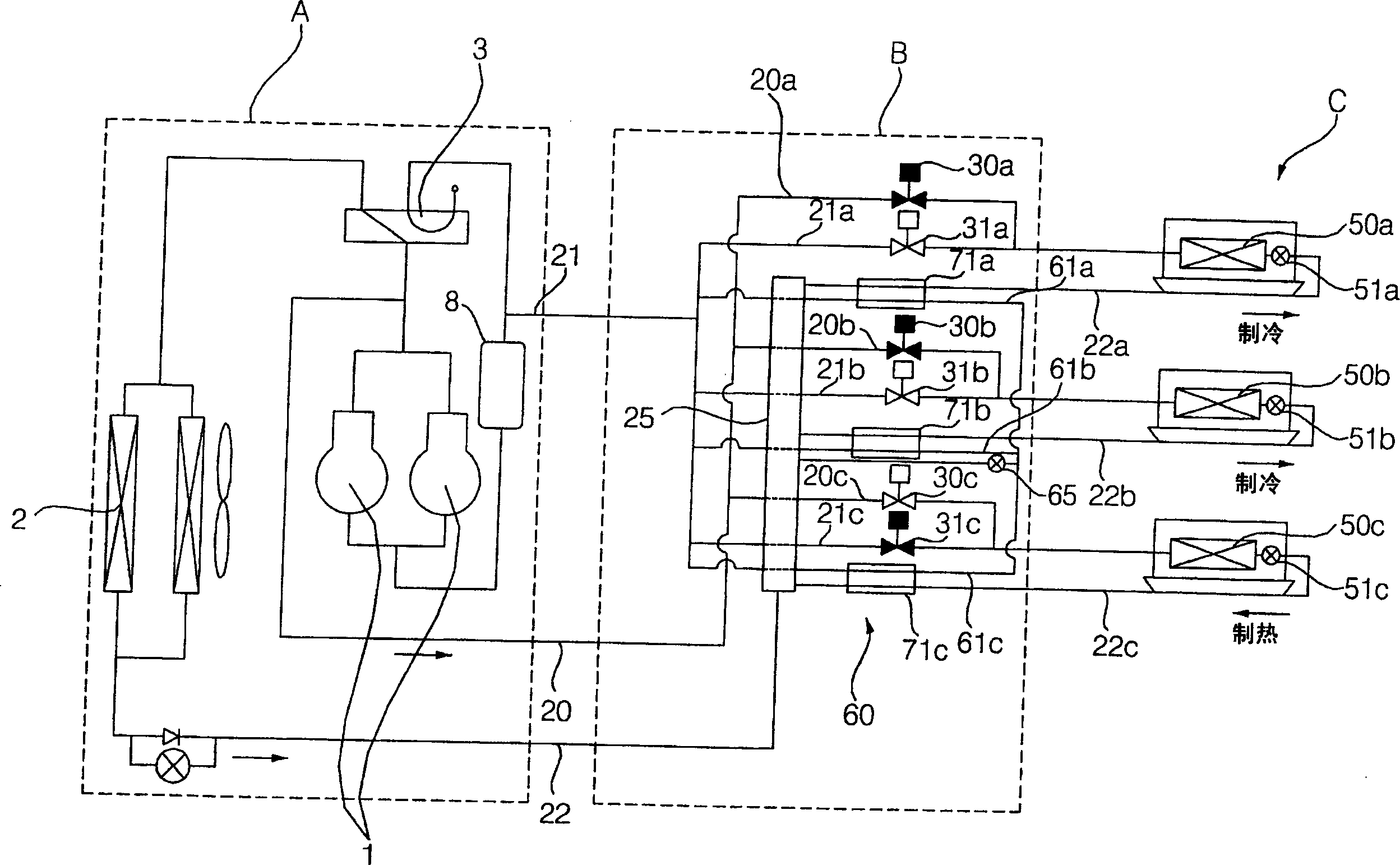

Supercooling apparatus of simultaneous cooling and heating type multiple air conditioner

InactiveCN1796905AImprove cooling effectReduce noiseMechanical apparatusCompression machines with several evaporatorsEngineeringRefrigerant

Disclosed herein is a supercooling apparatus of a simultaneous cooling and heating type multiple air conditioner. The supercooling apparatus comprises a liquid pipe header connected to an outdoor heat exchanger, a plurality of branch liquid pipes branched from the liquid pipe header and connected to a plurality of indoor heat exchangers, respectively, and a supercooling mechanism mounted at at least one of the branch liquid pipes for cooling refrigerant flowing to the indoor heat exchangers. The liquid refrigerant discharged from the heating-side indoor heat exchangers is supercooled by supercooling heat exchangers, and is then introduced into the cooling-side indoor heat exchangers. Consequently, noise generated from the cooling-side heat exchangers during the simultaneous cooling and heating operation is reduced, and cooling capacity of the multi air conditioner is improved.

Owner:LG ELECTRONICS INC

Power Saw Blade Cooling Arrangement

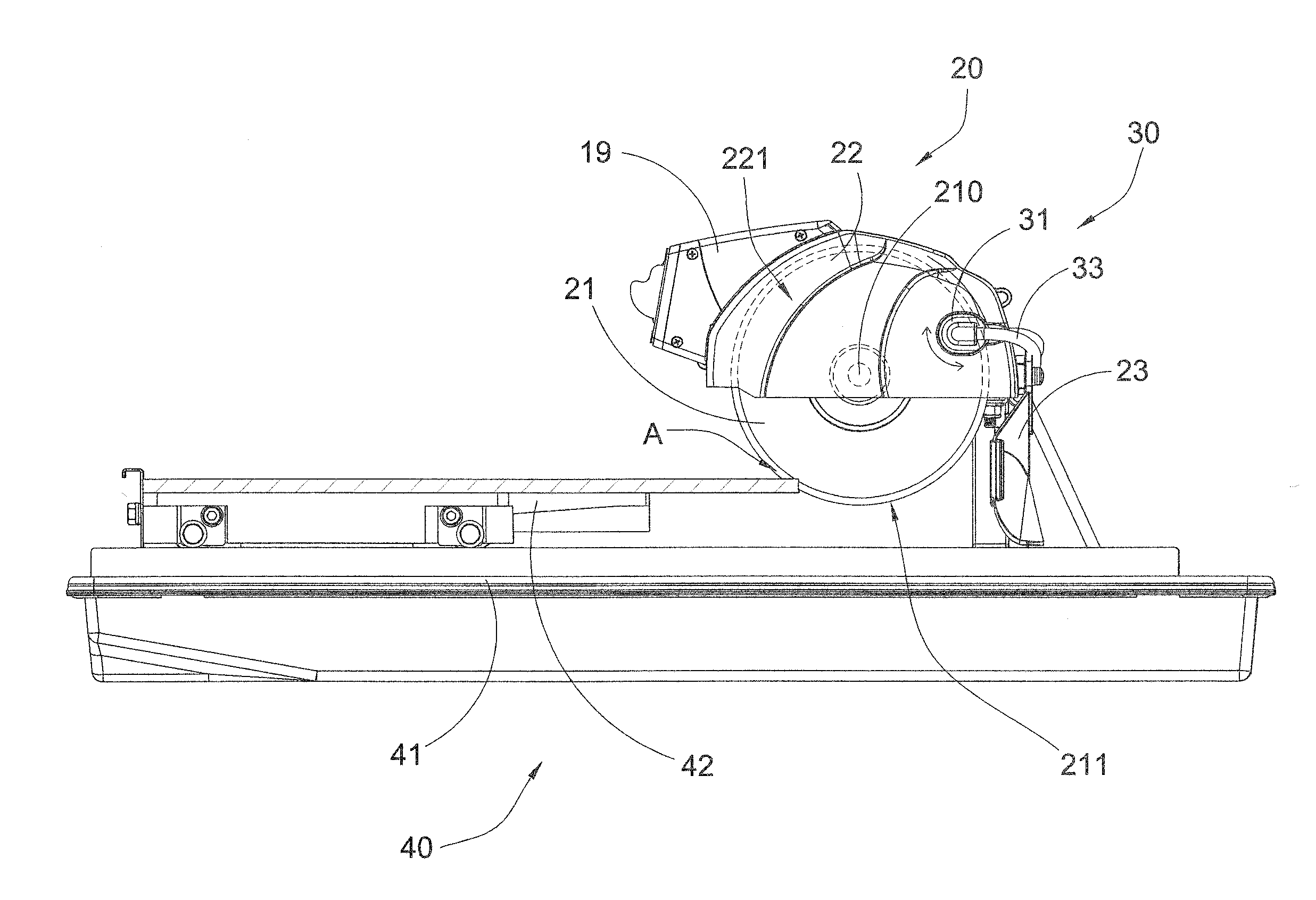

ActiveUS20170050338A1Minimizes dust formationMinimize moistureMetal sawing accessoriesWorking accessoriesKnife bladesCooling fluid

A cutting machine includes a motor assembly, a cutting blade powered by the motor assembly for cutting a work piece, and a cooling arrangement which includes a fluid nozzle unit for delivering cooling fluid onto a cutting edge portion of the cutting blade to ensure the cooling fluid to adhere on the cutting blade by means of adhesion and cohesion of the cooling fluid so as to cool the cutting blade during the cutting operation and to combine the cooling fluid with residual particles of the work piece after the work piece is cut. Therefore, no excessive cooling fluid is stayed on the cutting blade to minimize the formation of dust, and misting of the cooling fluid during the cutting operation.

Owner:LEE CHAO YING

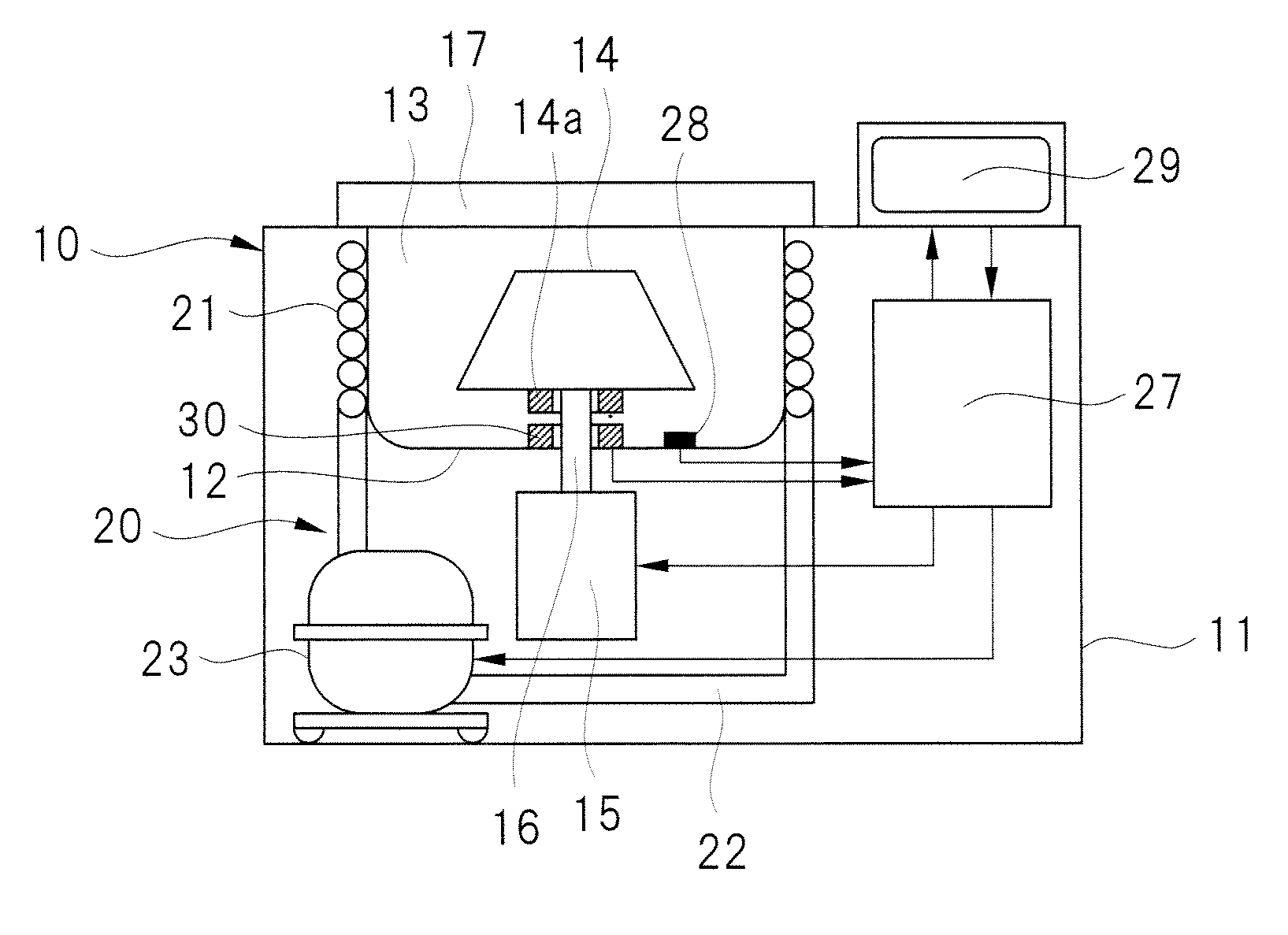

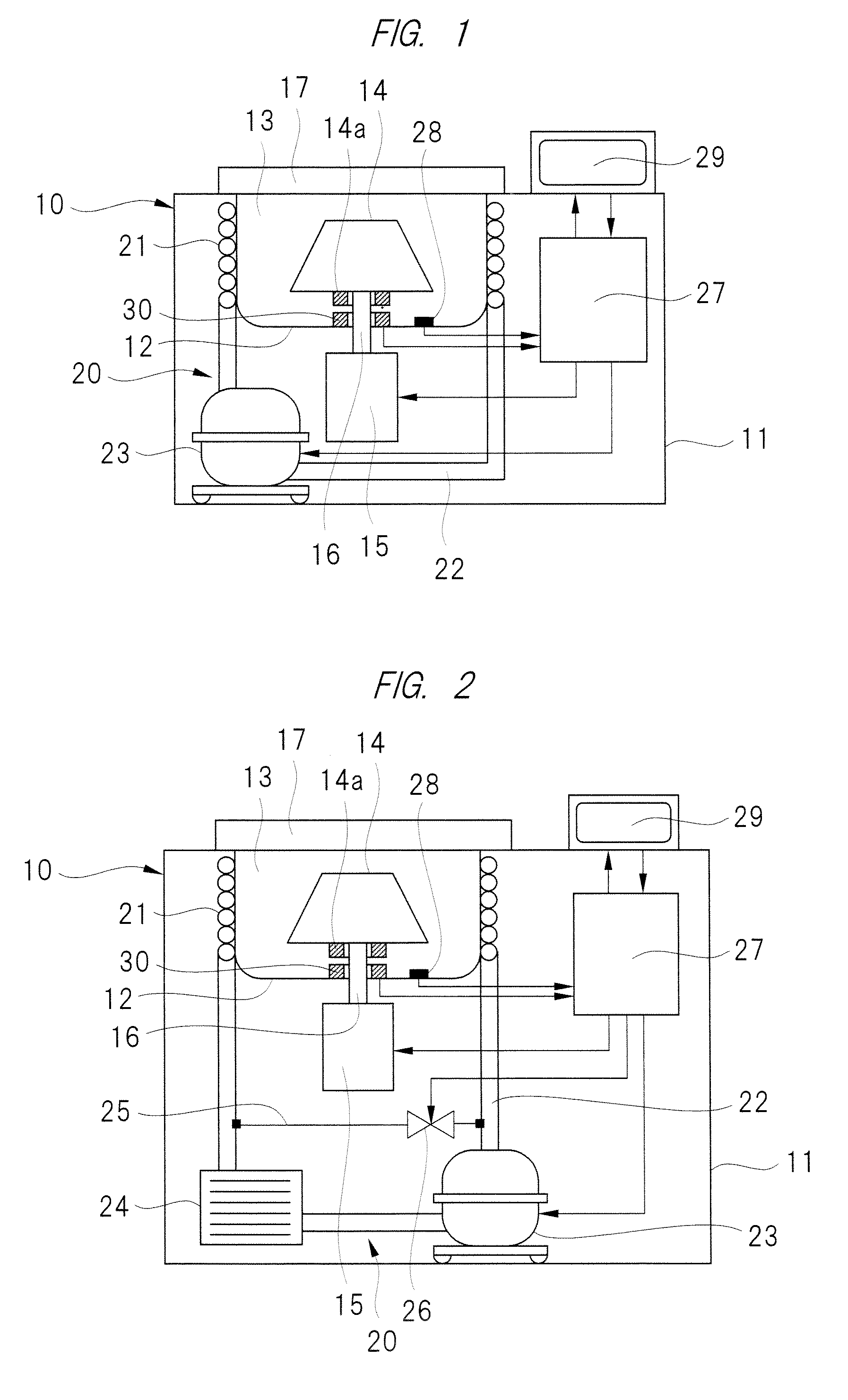

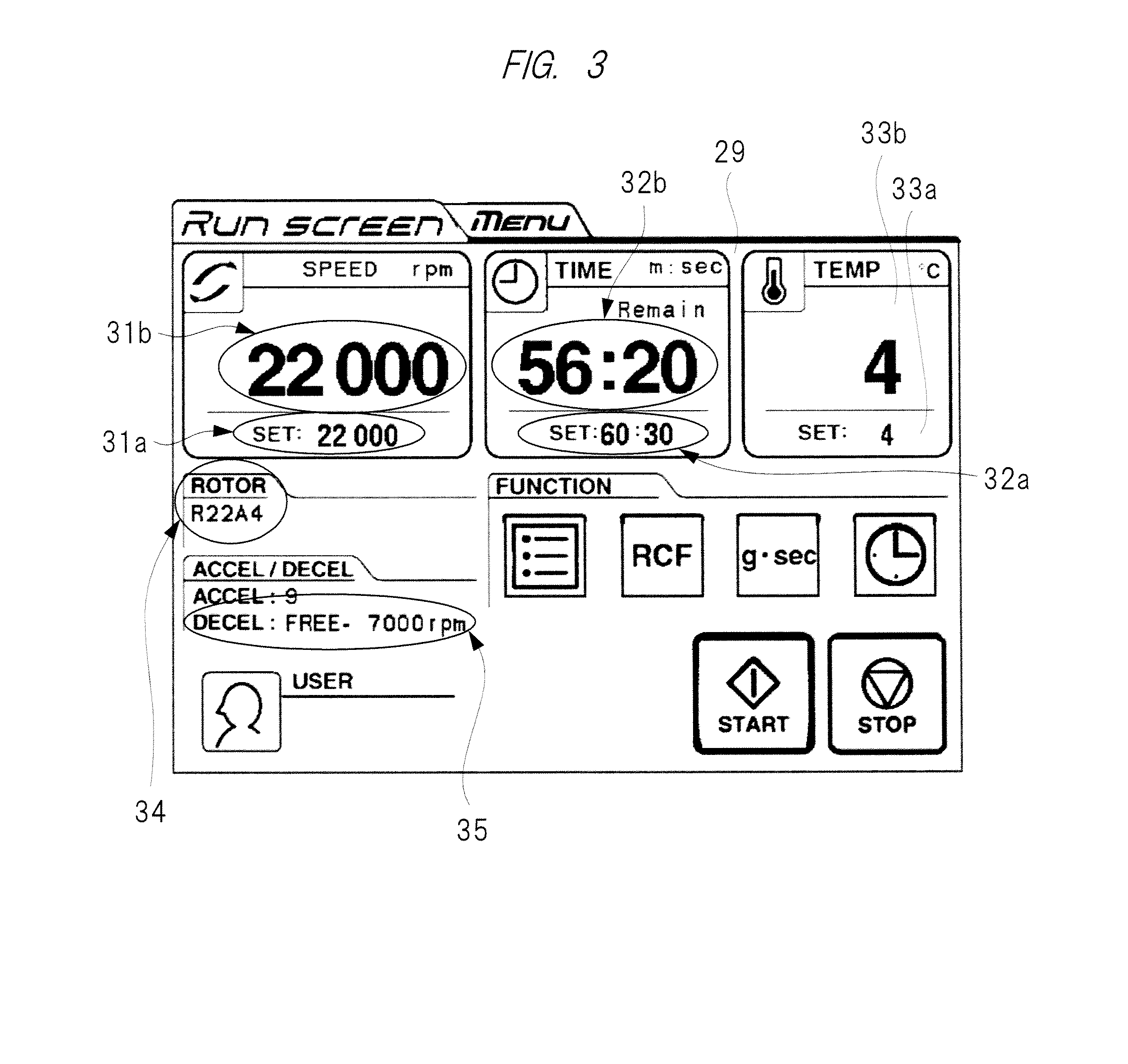

Centrifuge

Owner:EPPENDORF HIMAC TECH CO LTD

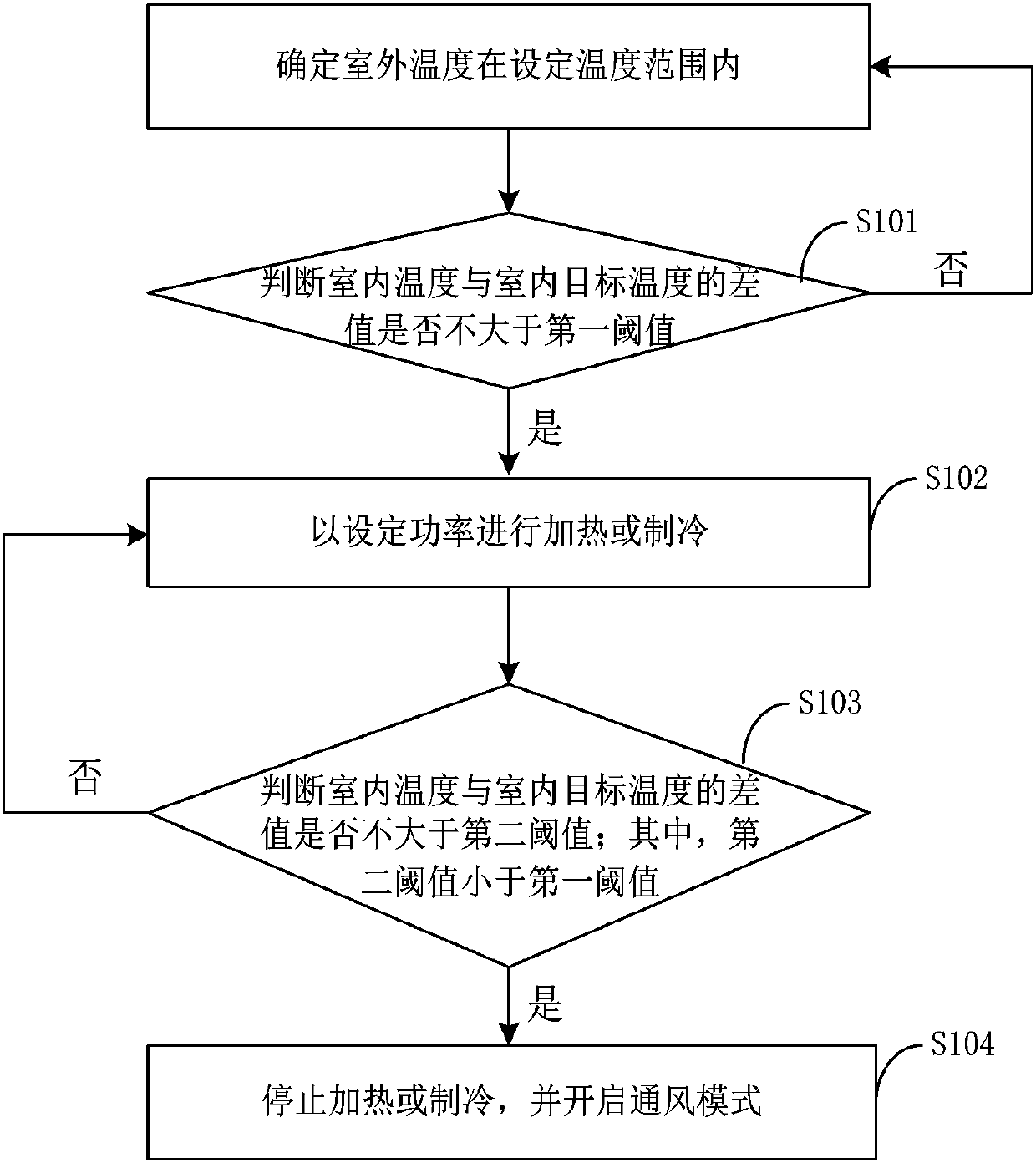

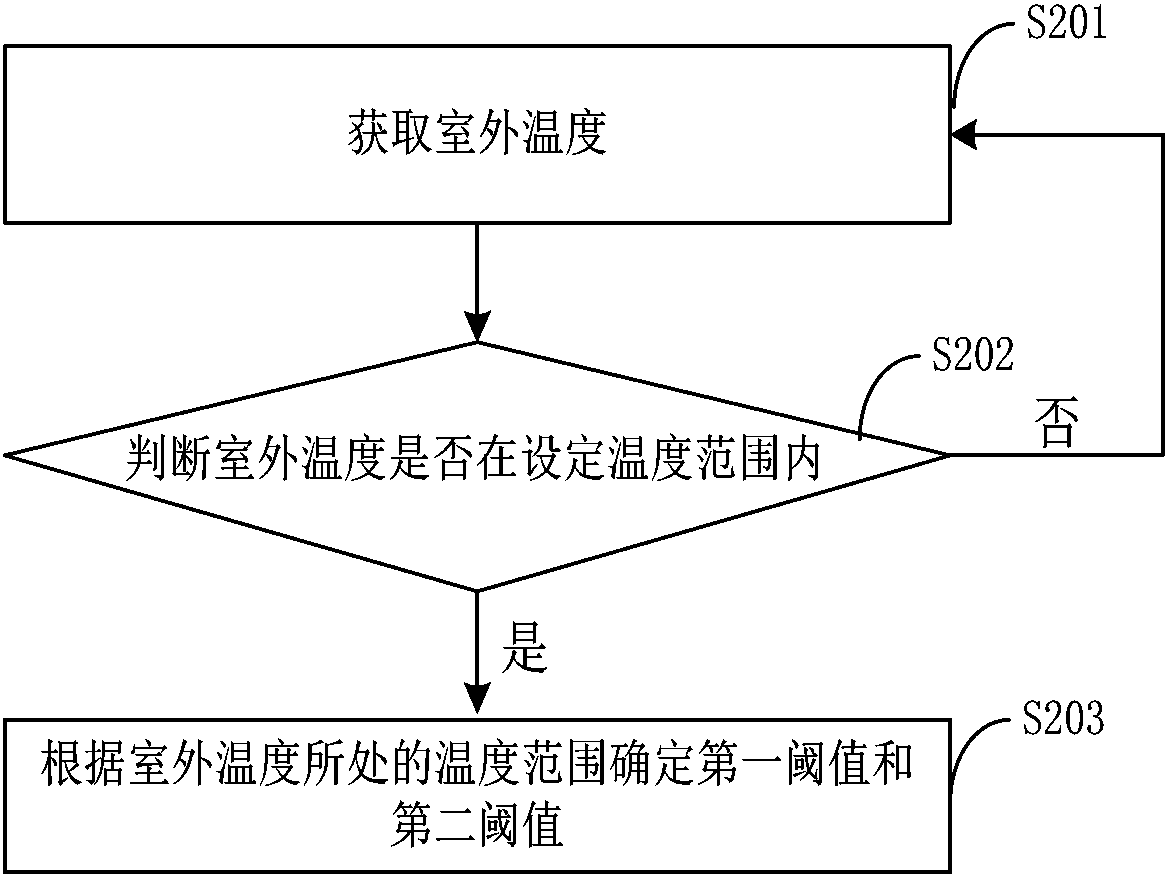

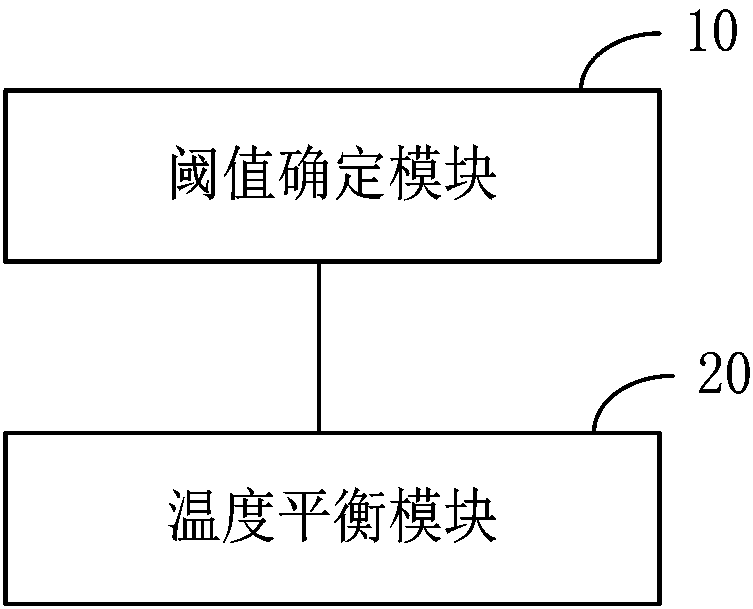

Air conditioner control method and device, electronic equipment and computer readable storage medium

ActiveCN109654691AAvoid frequent start and stopExtend your lifeMechanical apparatusSpace heating and ventilation safety systemsEngineeringVentilation mode

The invention provides an air conditioner control method and device, electronic equipment and a computer readable storage medium, and relates to the technical field of air conditioners. The air conditioner control method comprises the following steps that when the outdoor temperature is within a set temperature range, whether the difference value between the indoor temperature and the indoor target temperature is not larger than a first threshold value or not is judged; if yes, heating or refrigerating is carried out at the set power; the set power does not comprise the heating power during full-heat and the refrigeration power during full-cooling; the difference value between the indoor temperature and the indoor target temperature is not larger than a second threshold value or not is judged, and the difference value of the indoor temperature and the indoor target temperature is not larger than a second threshold value; the second threshold value is smaller than the first threshold value; and if yes, heating or refrigerating is stopped, and a ventilation mode is started. When the indoor temperature is close to the indoor target temperature, the heating power or the refrigeration power is limited, and heating is avoided due to excessive heating or excessive cooling, so that frequent starting and stopping of a compressor and a heater are avoided, the energy consumption is saved,and the service life of the compressor and the heater is prolonged.

Owner:NEW UNITED RAIL TRANSIT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com