Patents

Literature

429 results about "Super cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Supercooling. cooling of matter to temperatures below those of equilibrium phase transition that brings the matter to a new state of aggregation, or another crystalline modification that does not result in a phase transition. A supercooled material is in a state of metastable equilibrium. The phase transitions that are associated with loss...

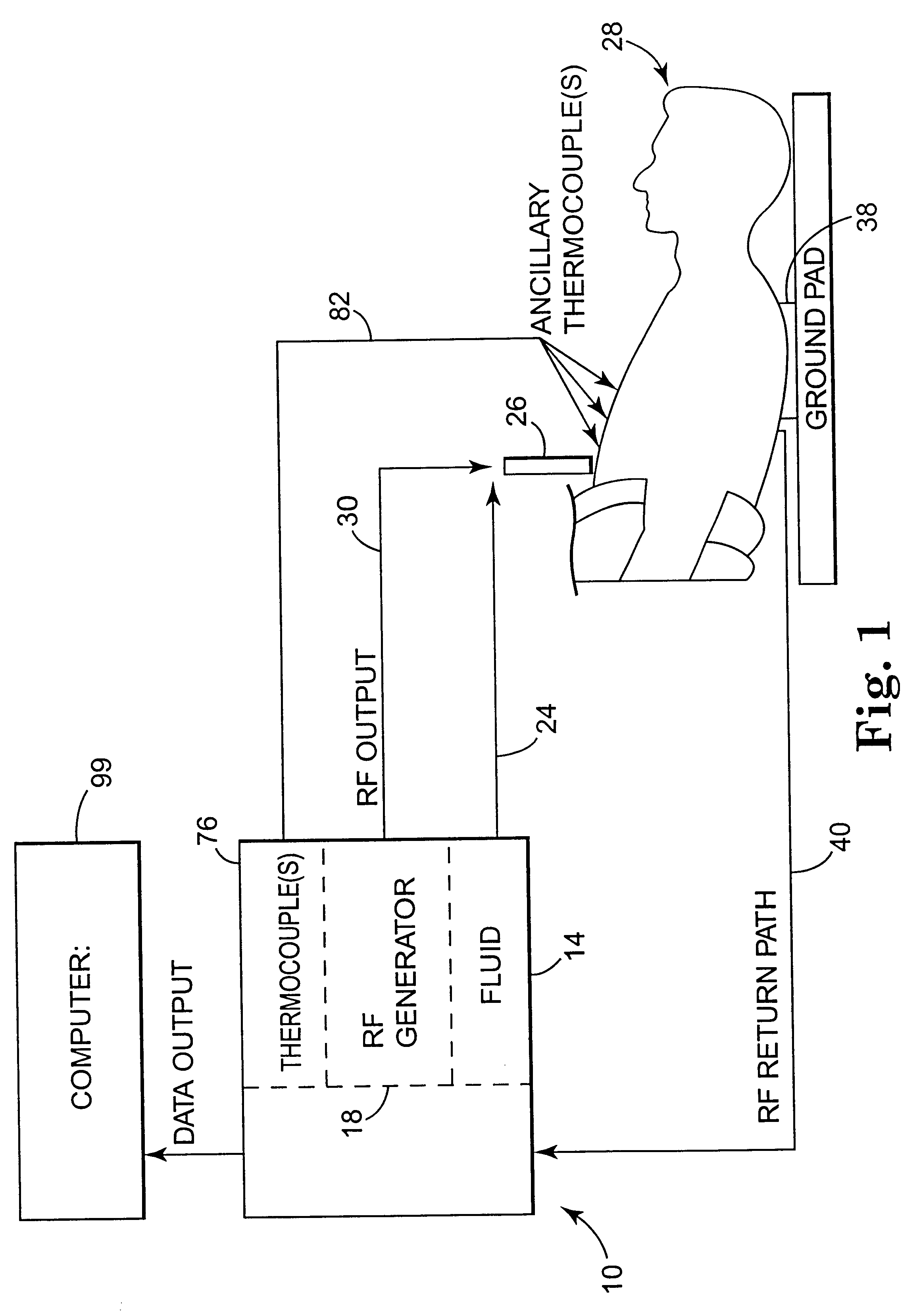

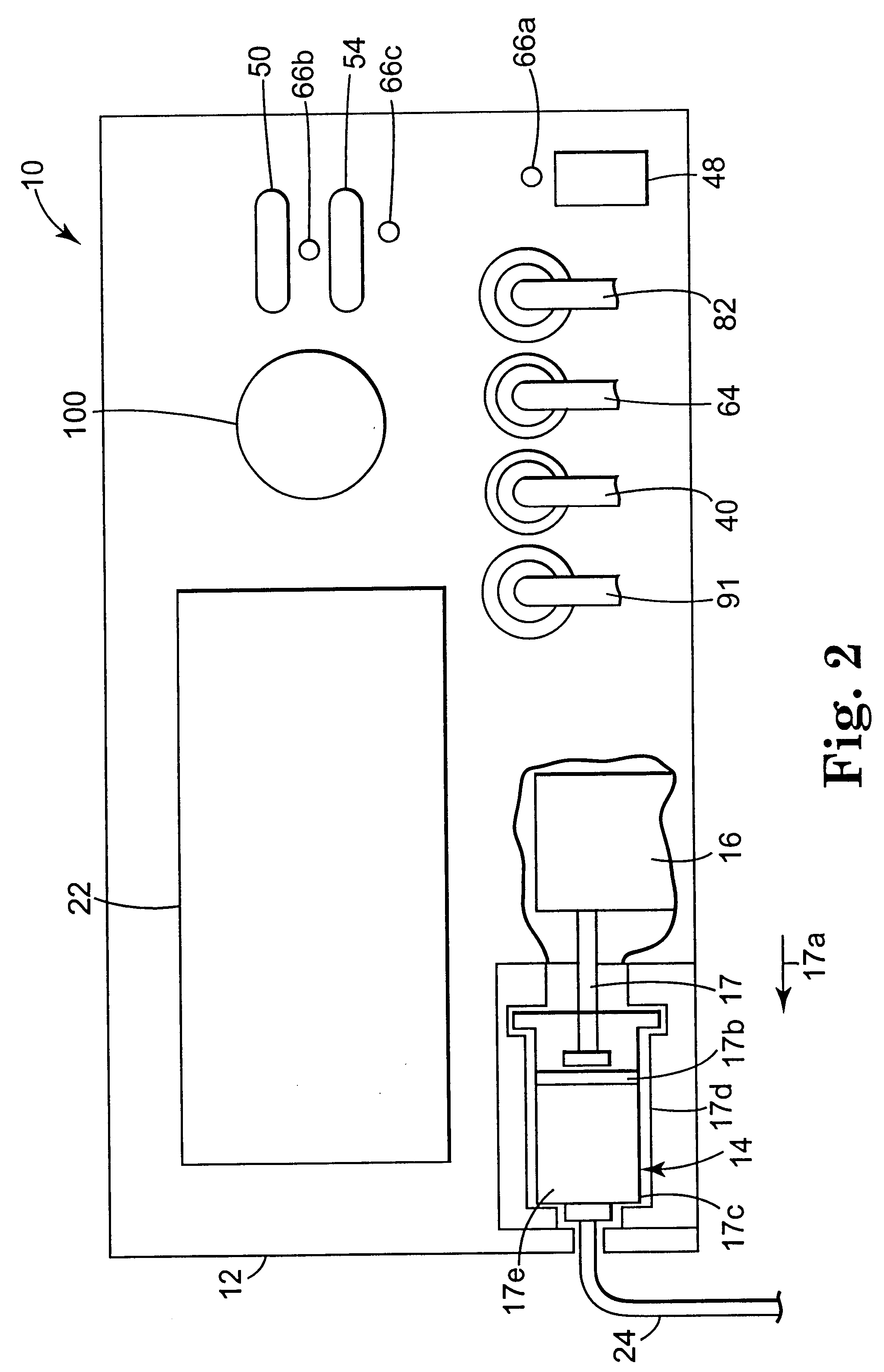

Apparatus and method for creating, maintaining, and controlling a virtual electrode used for the ablation of tissue

InactiveUS6537272B2Improving impedanceReduce the possibilitySurgical instruments for heatingTherapeutic coolingBlood Vessel TissueVascular tissue

The present invention provides an apparatus and a method for producing a virtual electrode within or upon a tissue to be treated with radio frequency alternating electric current, such tissues including but not limited to brain, liver, cardiac, prostate, breast, and vascular tissues and neoplasms. An apparatus in accordance with the present invention includes a source of super-cooled fluid for selectively providing super-cooled fluid to the target tissue to cause a temporary cessation of cellular or electrical activity, a supply of conductive or electrolytic fluid to be provided to the target tissue, and alternating current generator, and a processor for creating, maintaining, and controlling the ablation process by the interstitial or surficial delivery of the fluid to a tissue and the delivery of electric power to the tissue via the virtual electrode. A method in accord with the present invention includes delivering super-cooled fluid to the target tissue to cause a temporary cessation of cellular or electrical activity, evaluating whether the temporary cessation of cellular or electrical activity is the desired cessation of cellular or electrical activity, and if so, delivering a conductive fluid to the predetermined tissue ablation site for a predetermined time period, applying a predetermined power level of radio frequency current to the tissue, monitoring at least one of several parameters, and adjusting either the applied power and / or the fluid flow in response to the measured parameters.

Owner:MEDTRONIC INC

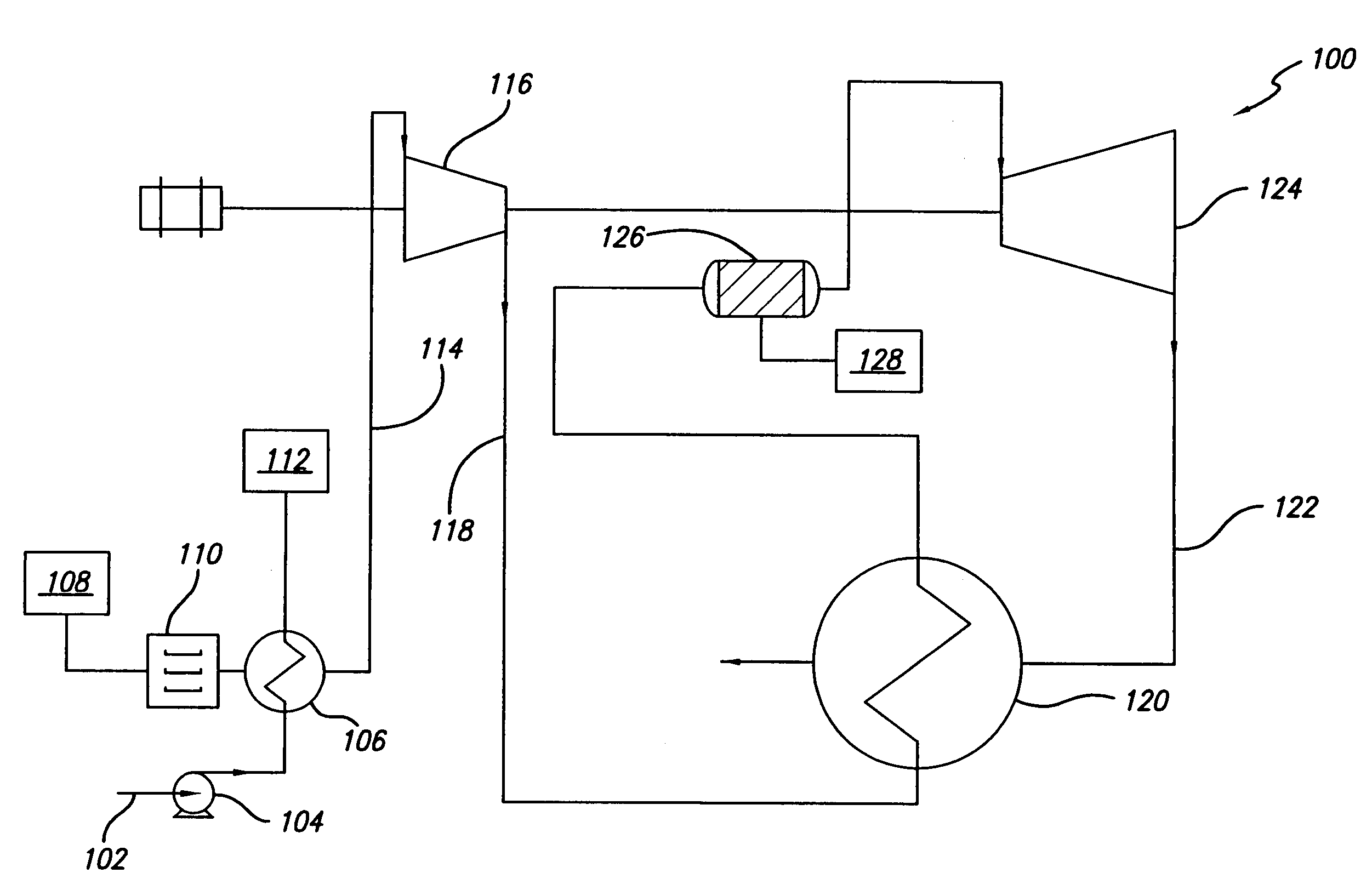

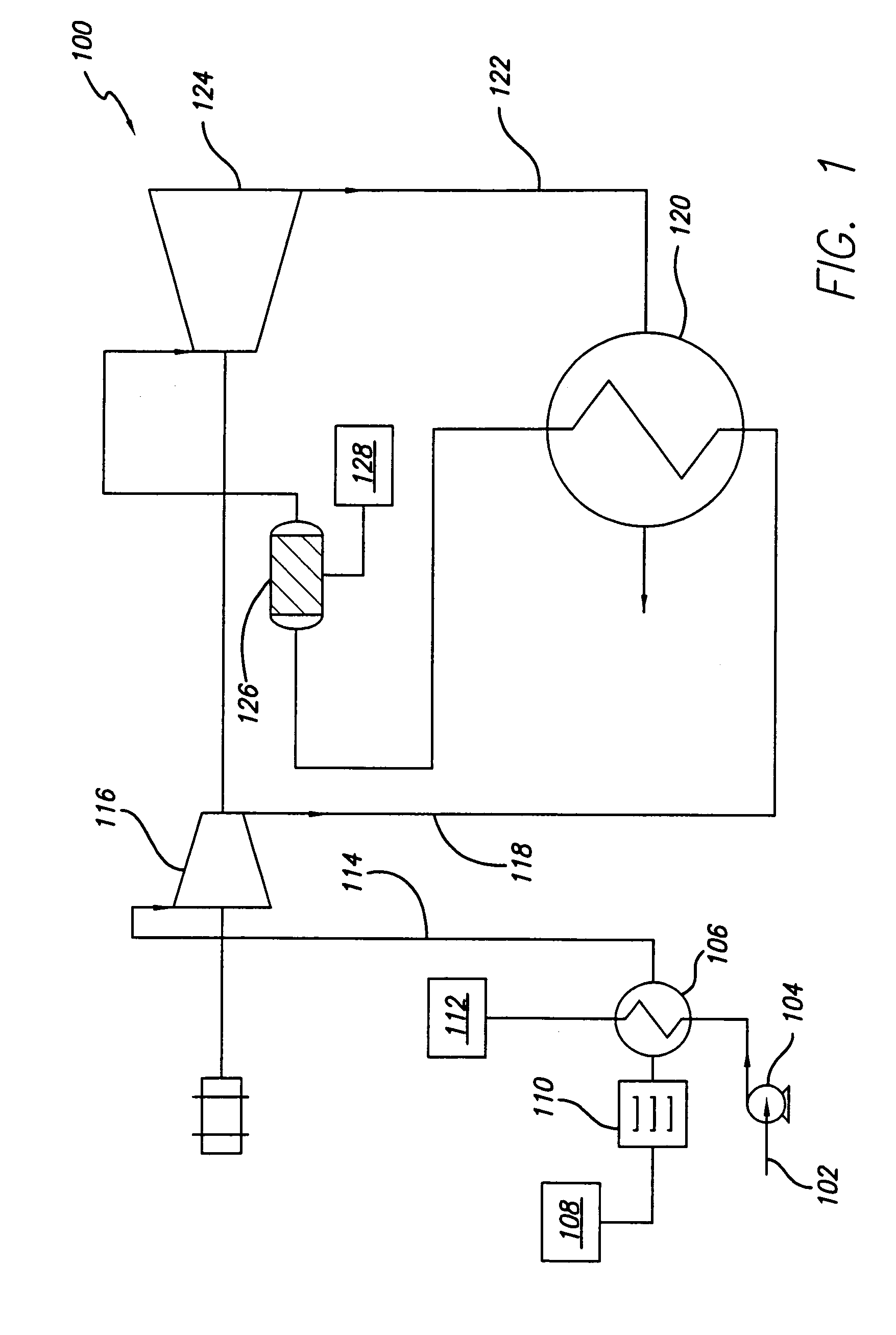

Vaporization of liquefied natural gas for increased efficiency in power cycles

InactiveUS7299619B2Easy to compressLess contaminantGas turbine plantsJet propulsion plantsCombustion chamberPower cycle

Owner:SIEMENS ENERGY INC

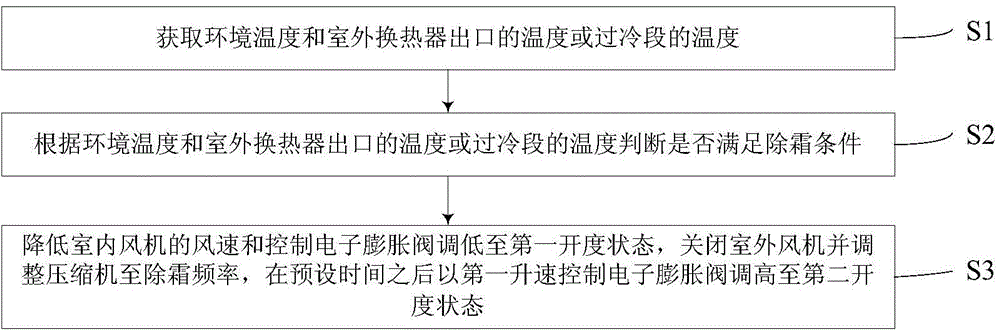

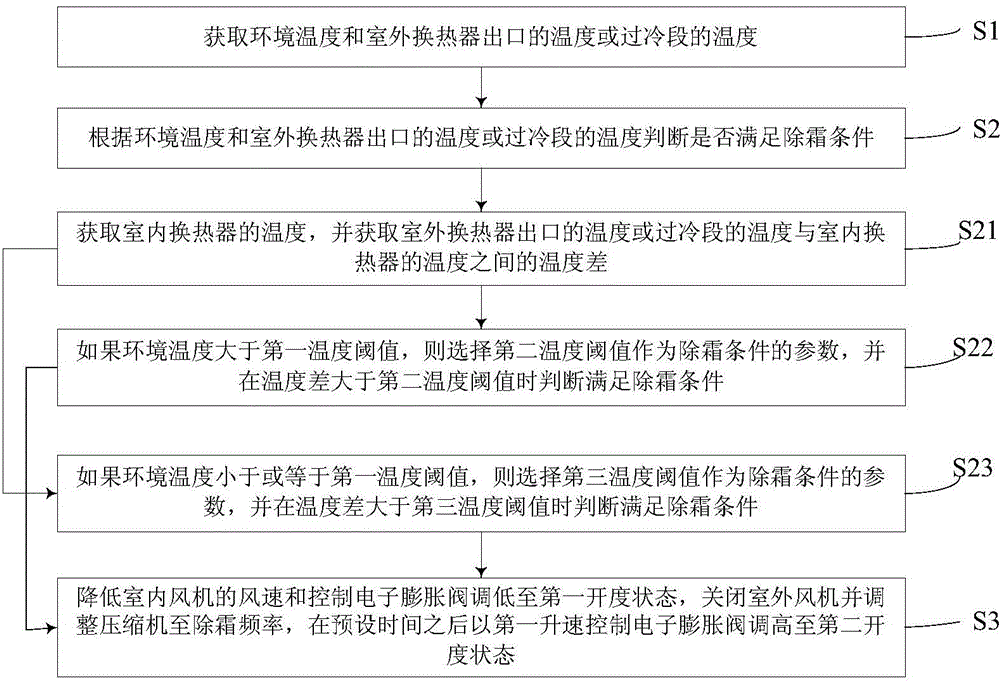

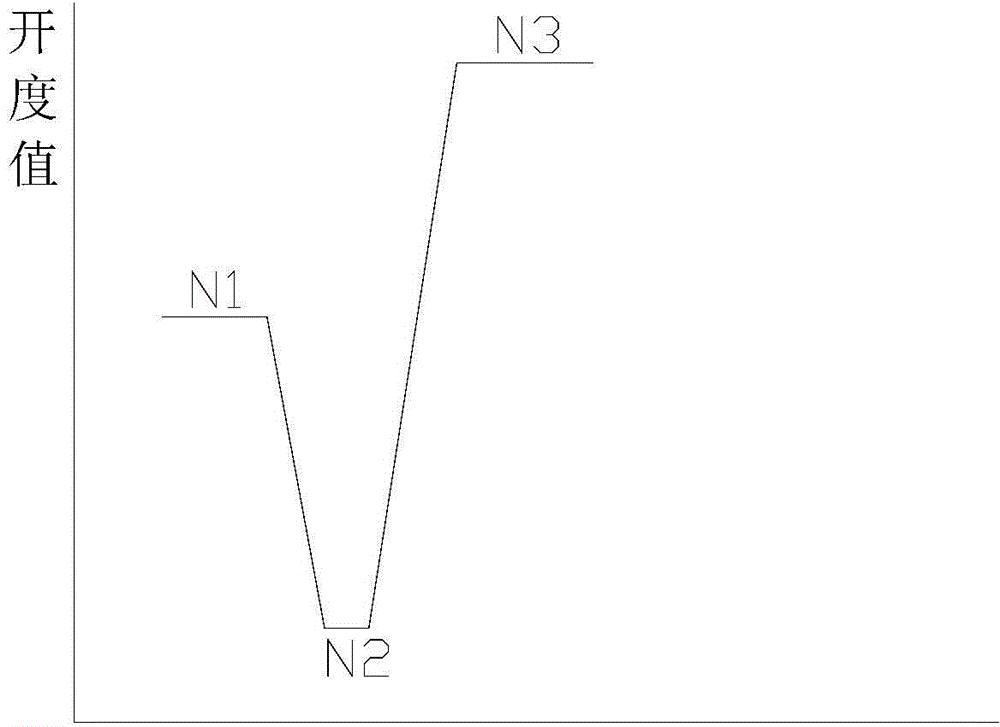

Air conditioner and defrosting control method thereof

ActiveCN104596032AReduce retentionImprove defrosting efficiencyMechanical apparatusSpace heating and ventilation safety systemsSuper coolingEngineering

The invention discloses a defrosting control method of an air conditioner. The control method comprises the following steps that environment temperature and the temperature of an outdoor heat exchanger outlet or the temperature of a super cooling section are obtained; whether the defrosting condition is met or not is judged according to the environment temperature and the temperature of the outdoor heat exchanger outlet or the temperature of the super cooling section; when the judgment result shows that the defrosting condition is met, the wind speed of an indoor fan is decelerated, an electronic expansion valve is controlled to be lowered to the first opening degree state, an outdoor fan is closed, a compressor is regulated to the defrosting frequency, after the preset time, and the first ascending speed is used for controlling the electronic expansion valve to be raised to the second opening degree state, wherein the opening degree value of the second opening degree state is greater than the opening value of the first opening degree state. The defrosting control method of the air conditioner has the advantages that the defrosting can be realized without stopping the compressor, the method is simple, and the reliability is high. The invention also provides the air conditioner.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

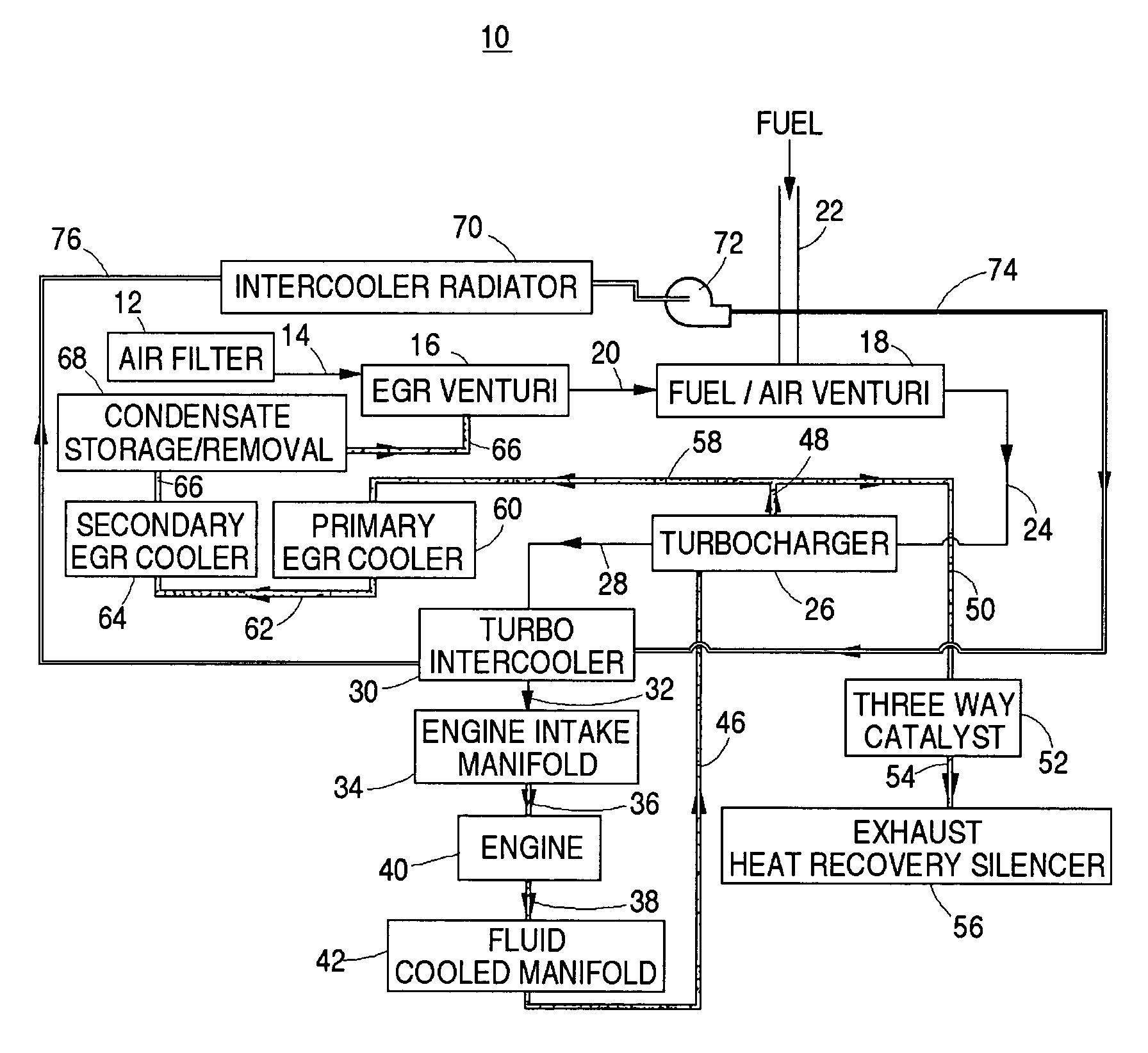

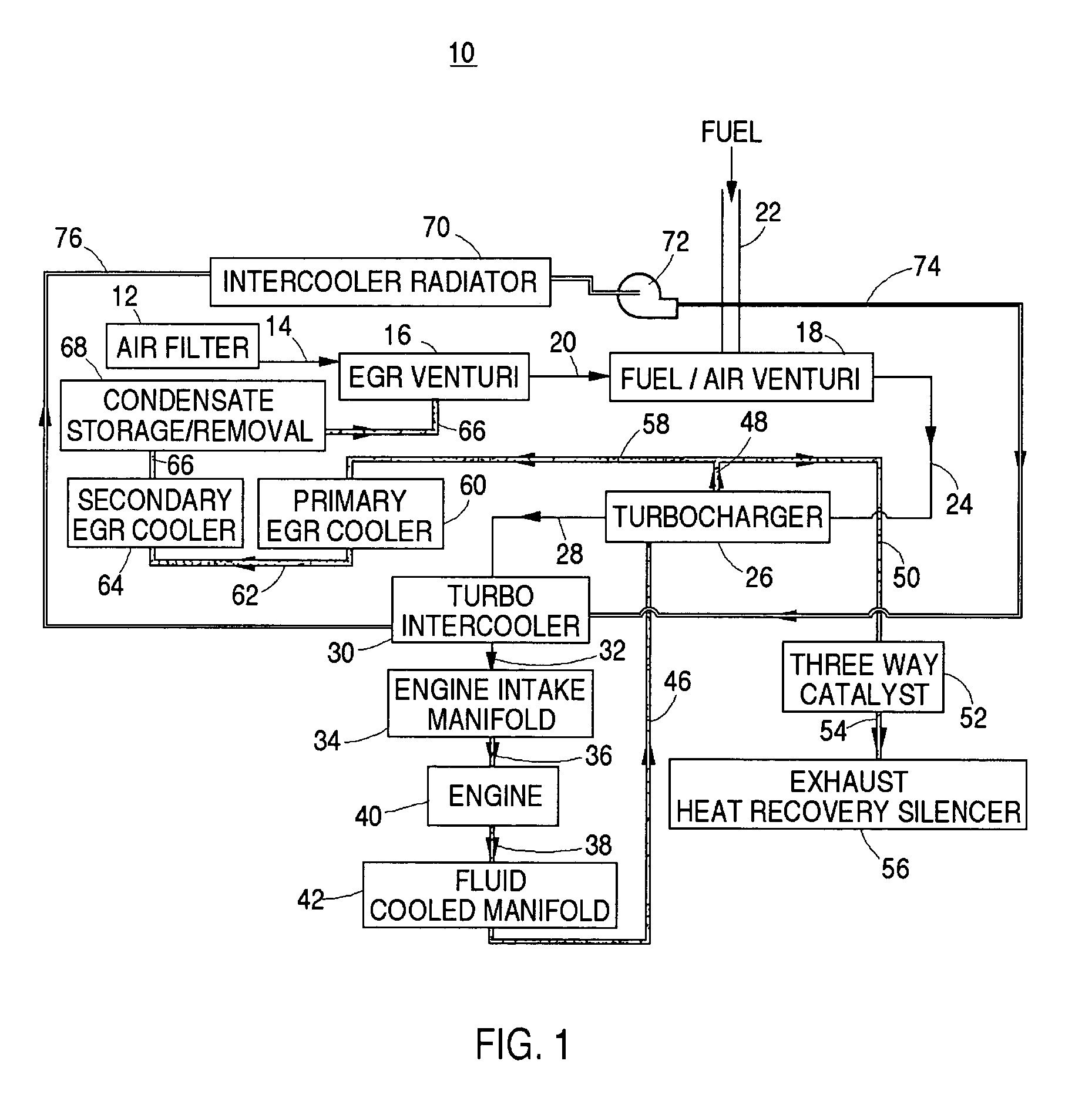

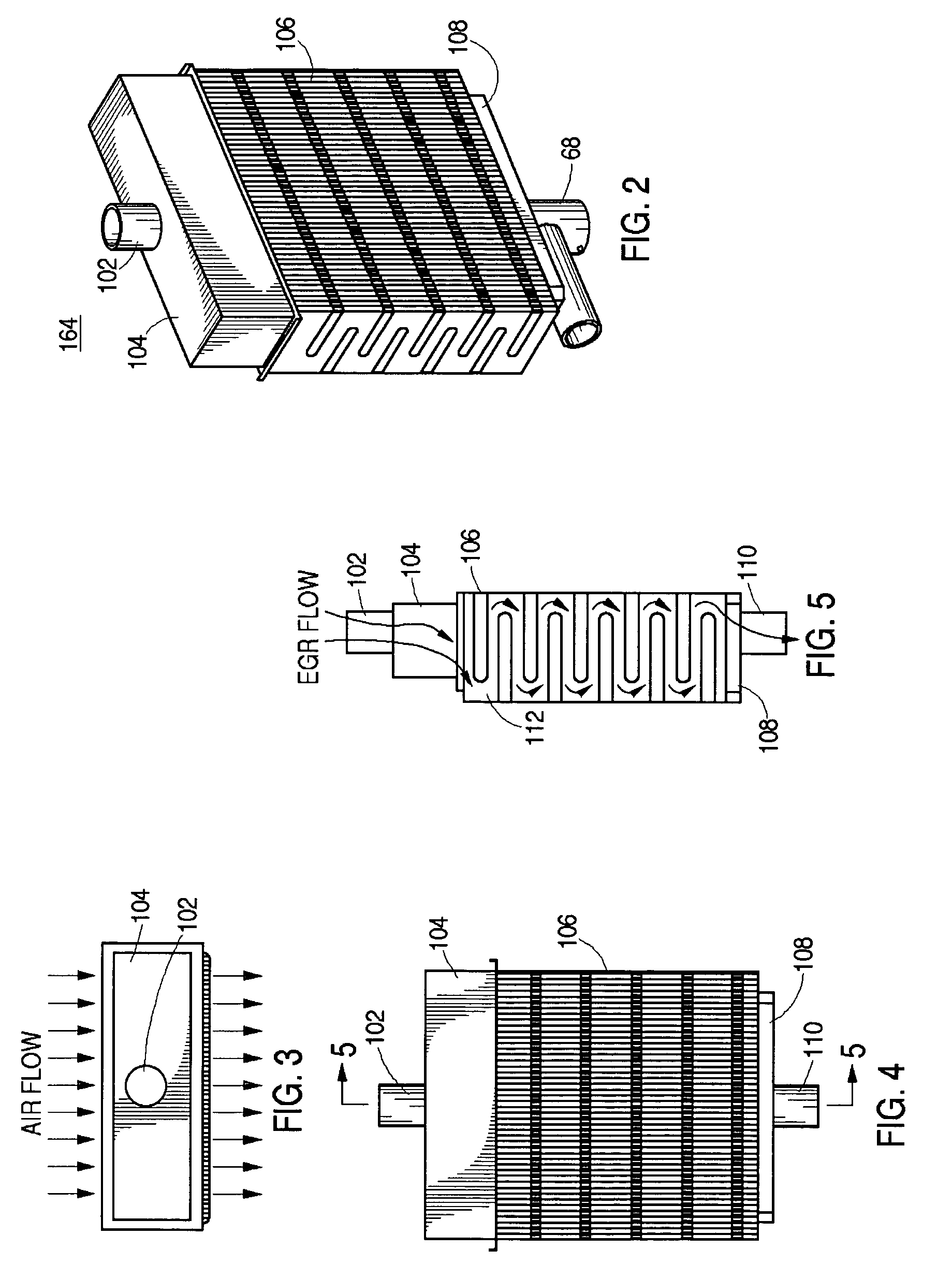

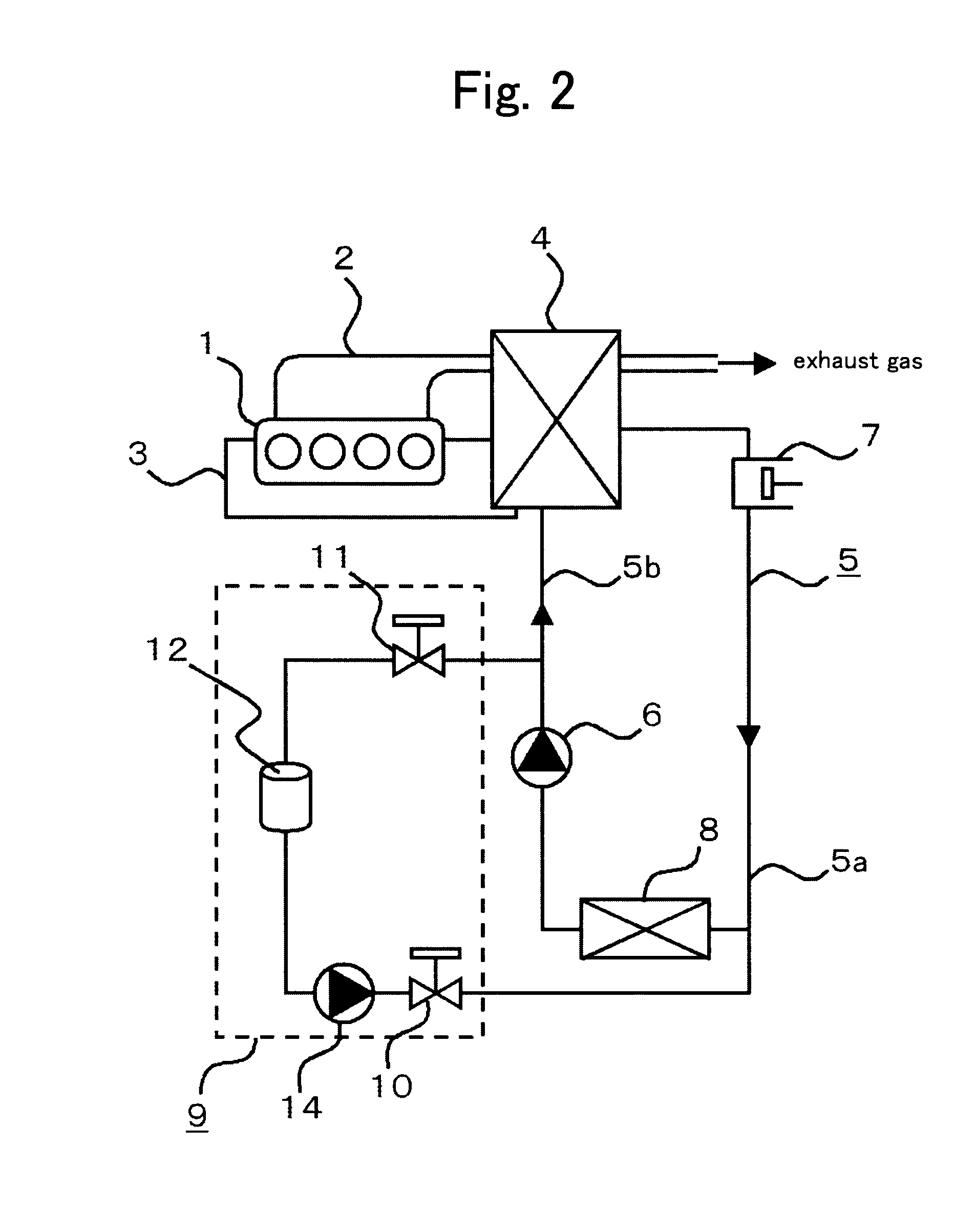

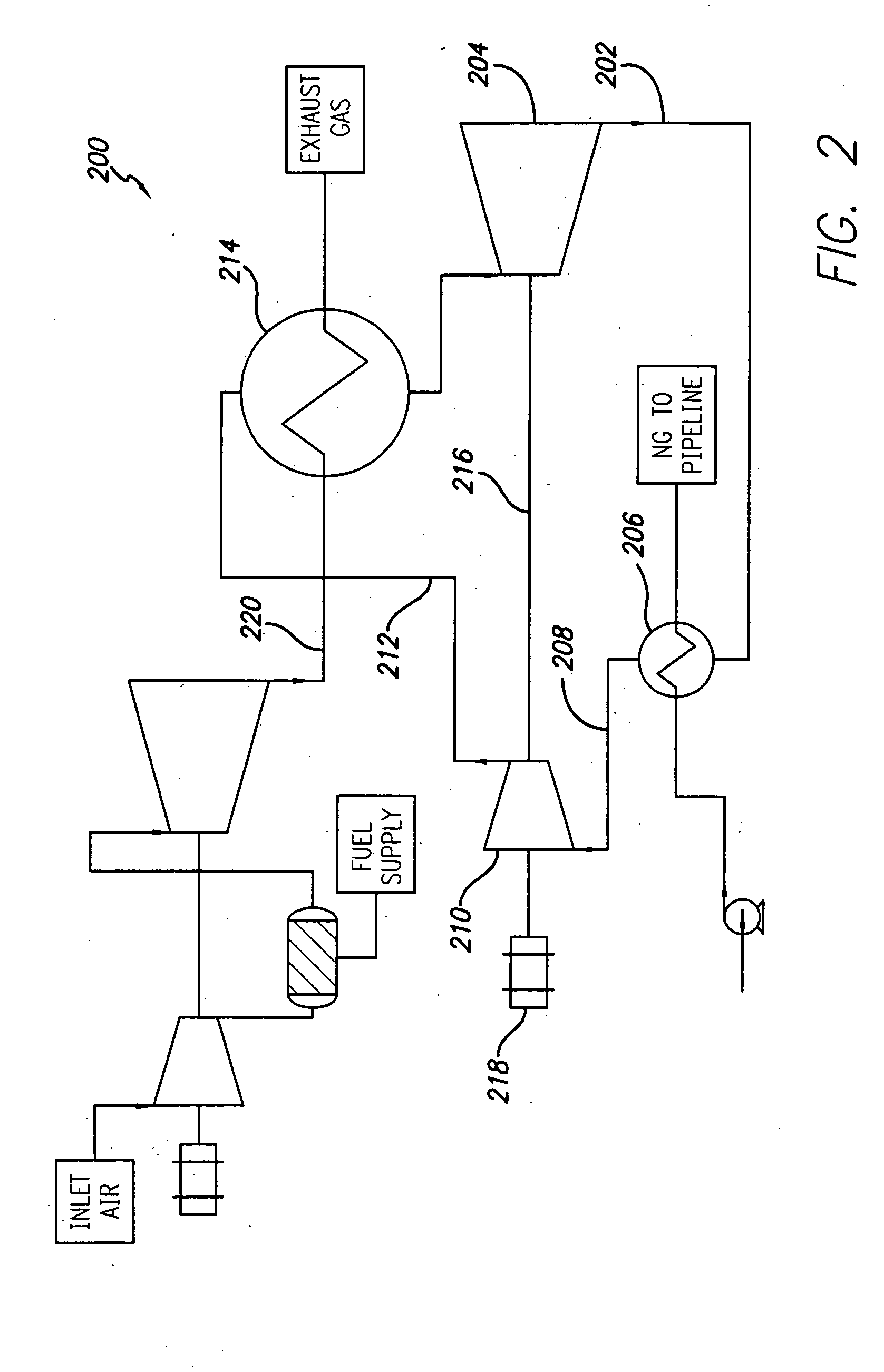

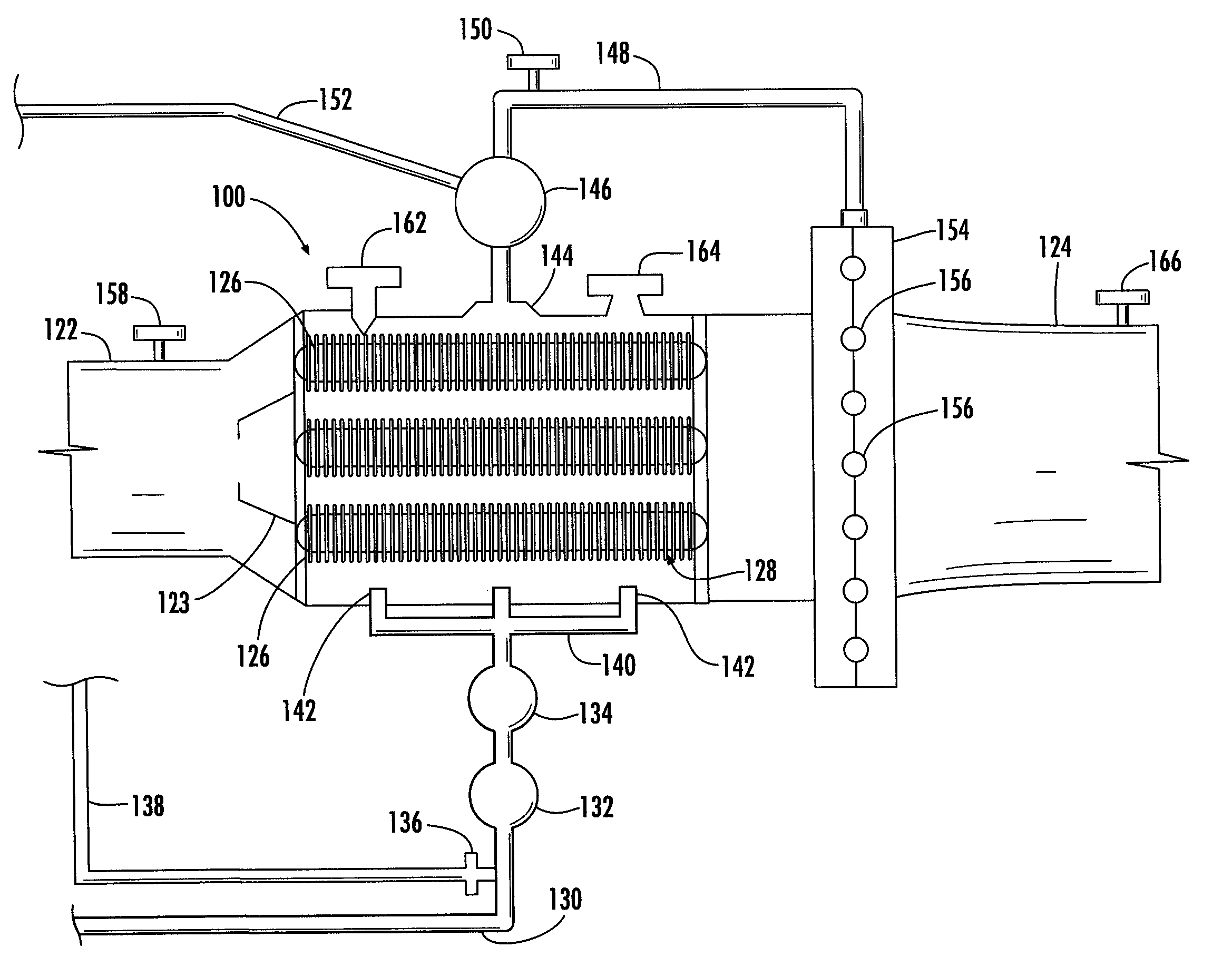

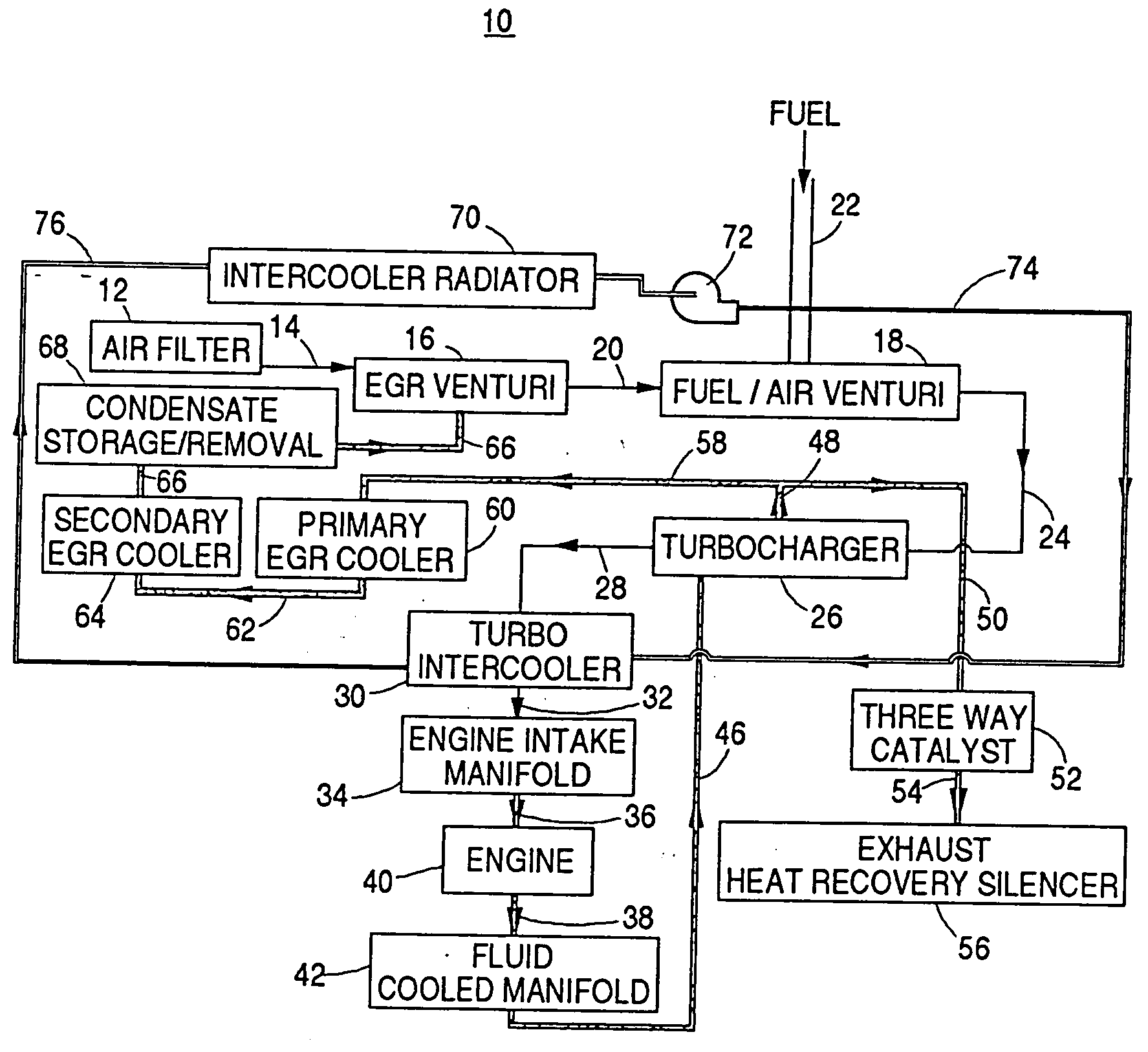

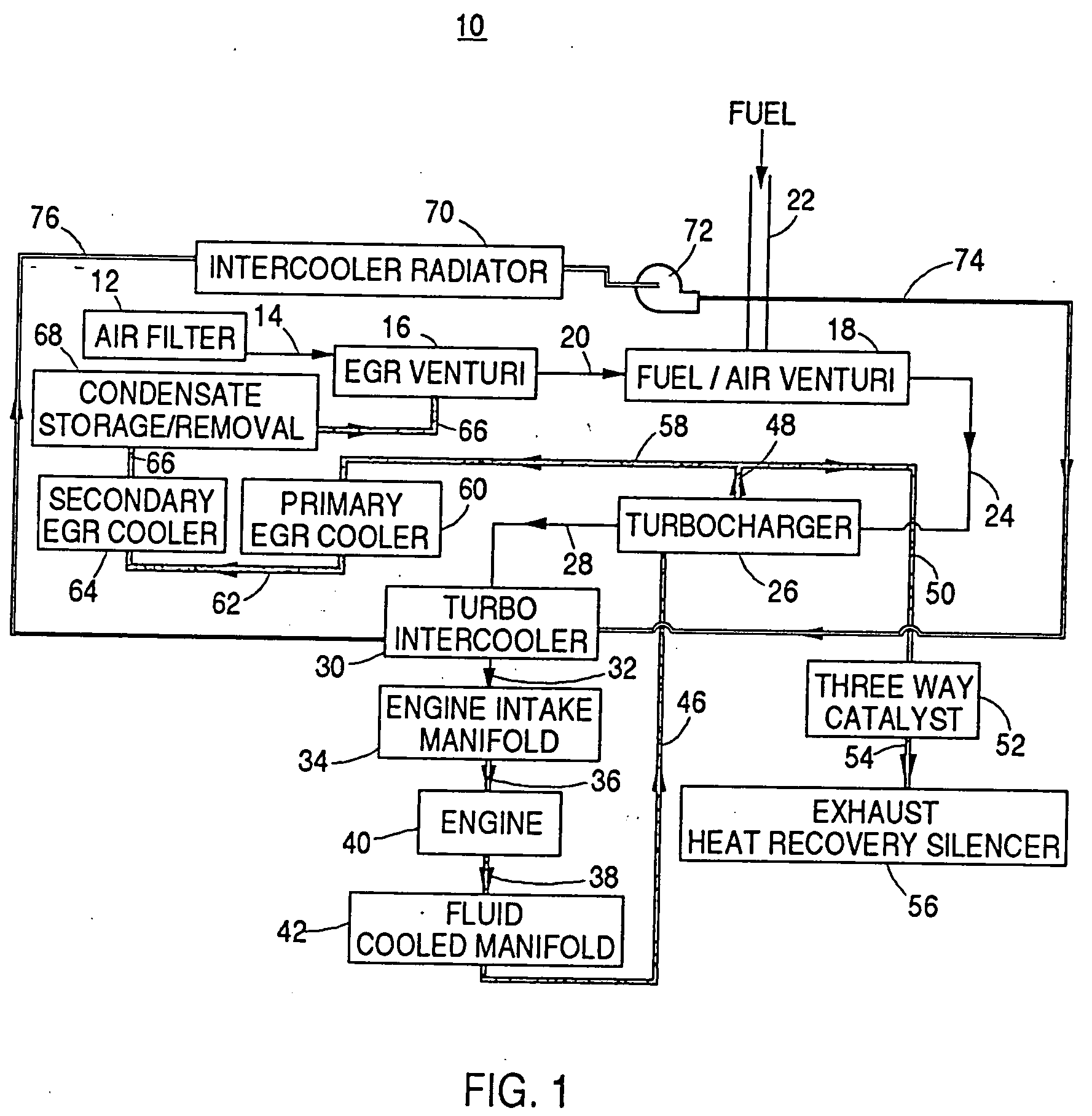

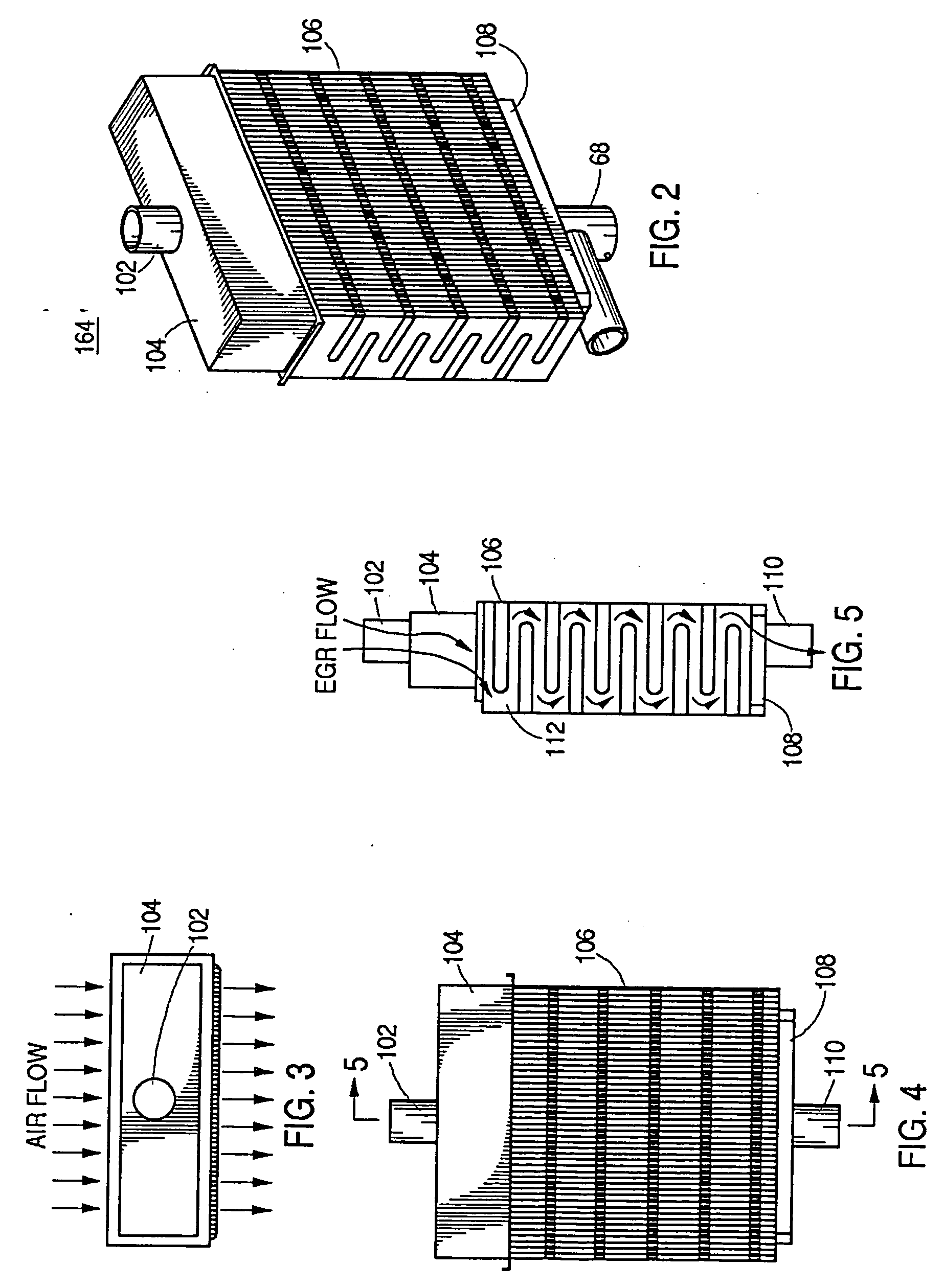

EGR cooling and condensate regulation system for natural gas fired co-generation unit

InactiveUS6978772B1Improve efficiencyReduce condensationNon-fuel substance addition to fuelInternal combustion piston enginesWater vaporCogeneration

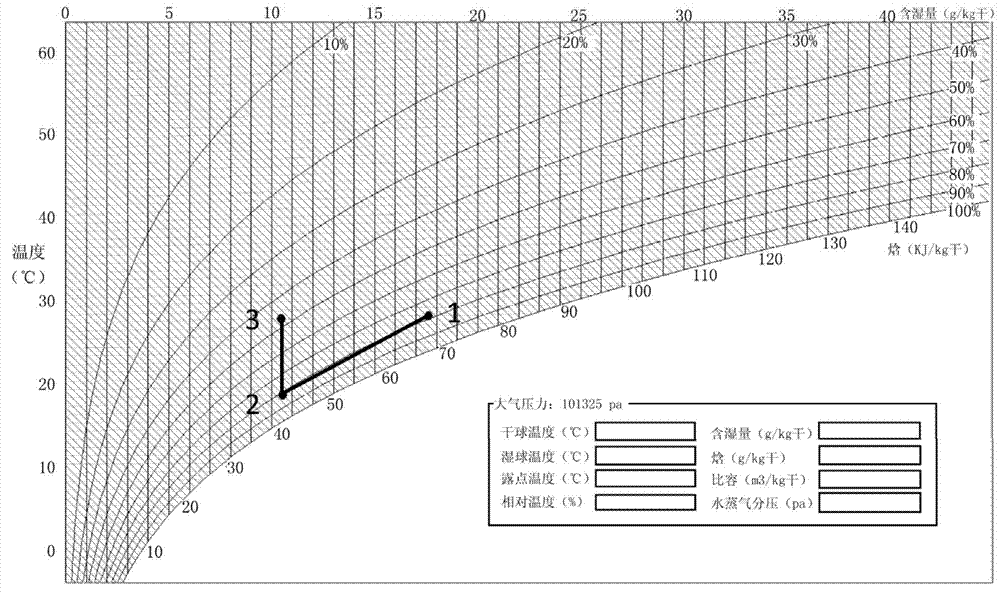

A recycled exhaust gas cooling and condensate regulation system for a natural gas fired internal combustion engine driven co-generation plant, which allows efficient exhaust recycled gas combustion while maintaining lower head temperatures to reduce thermal NOx emissions and delivering increased process / utility heat to a proximate co-generation client, is provided. The recycled exhaust gas cooling and condensate regulation system has primary and secondary, air-to-gas, exchanger units, coupled in series, such that the first unit, designed to take exhaust gas exiting the engine, cools the gas to a first exhaust gas temperature effectively super saturating the water vapor in the cooled exhaust gas; and, the second unit, designed to handle lower inlet temperatures, condenses the water vapor and super cools the exhaust gas to <130 F. In one embodiment, the engine intake mixture including the exhaust gas is supercharged. In another embodiment, a separate intercooler circuit is used to cool the compressed intake charge containing the recycled gas prior to entry into the intake engine manifold to further reduce head temperatures and control thermal NOx emissions.

Owner:CHAPEAU

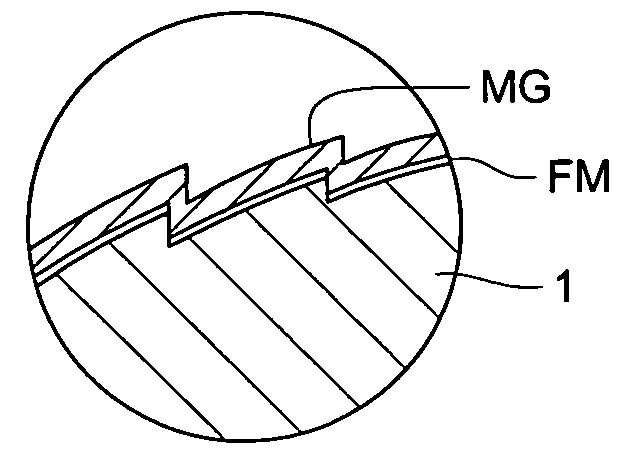

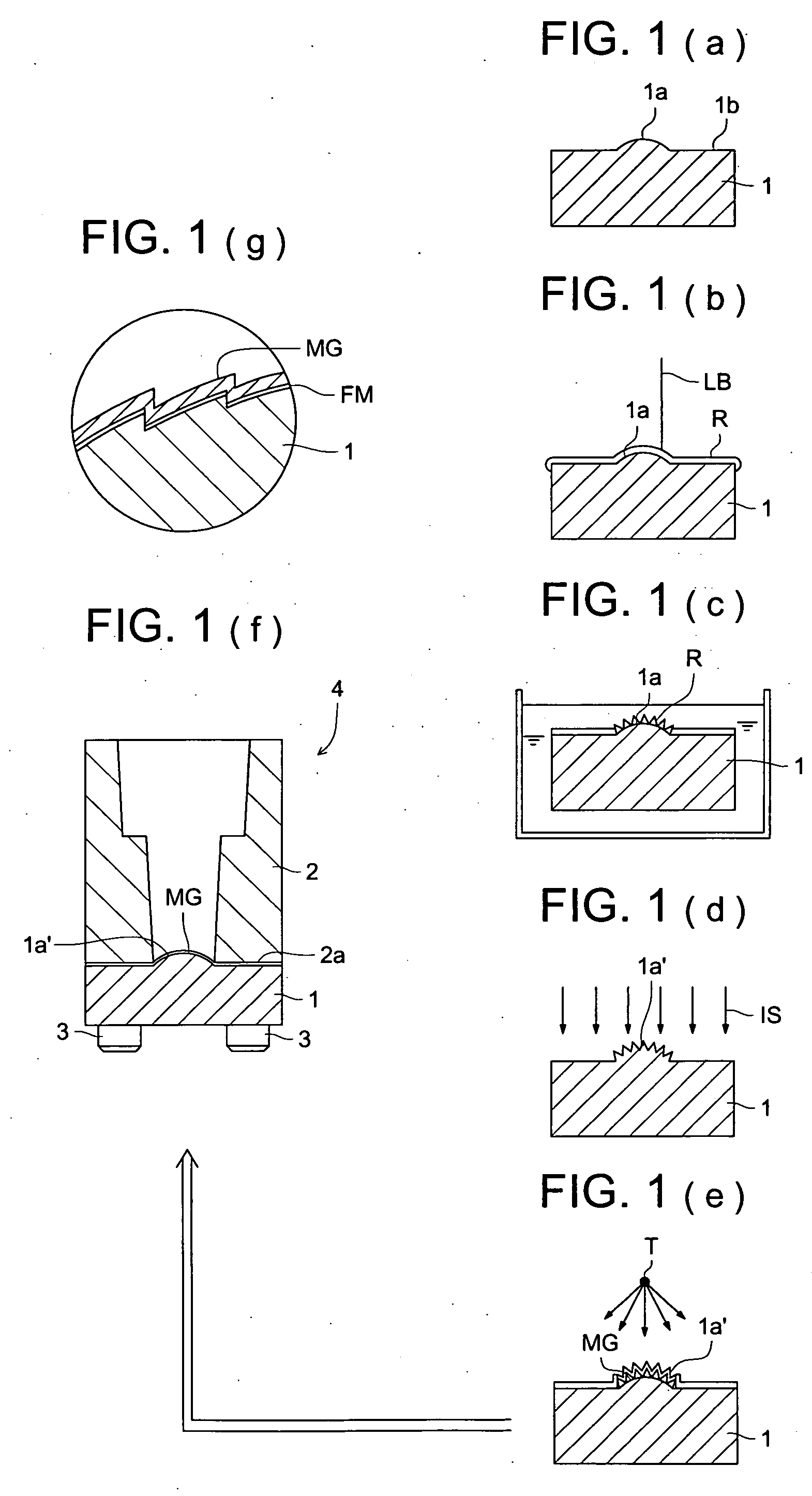

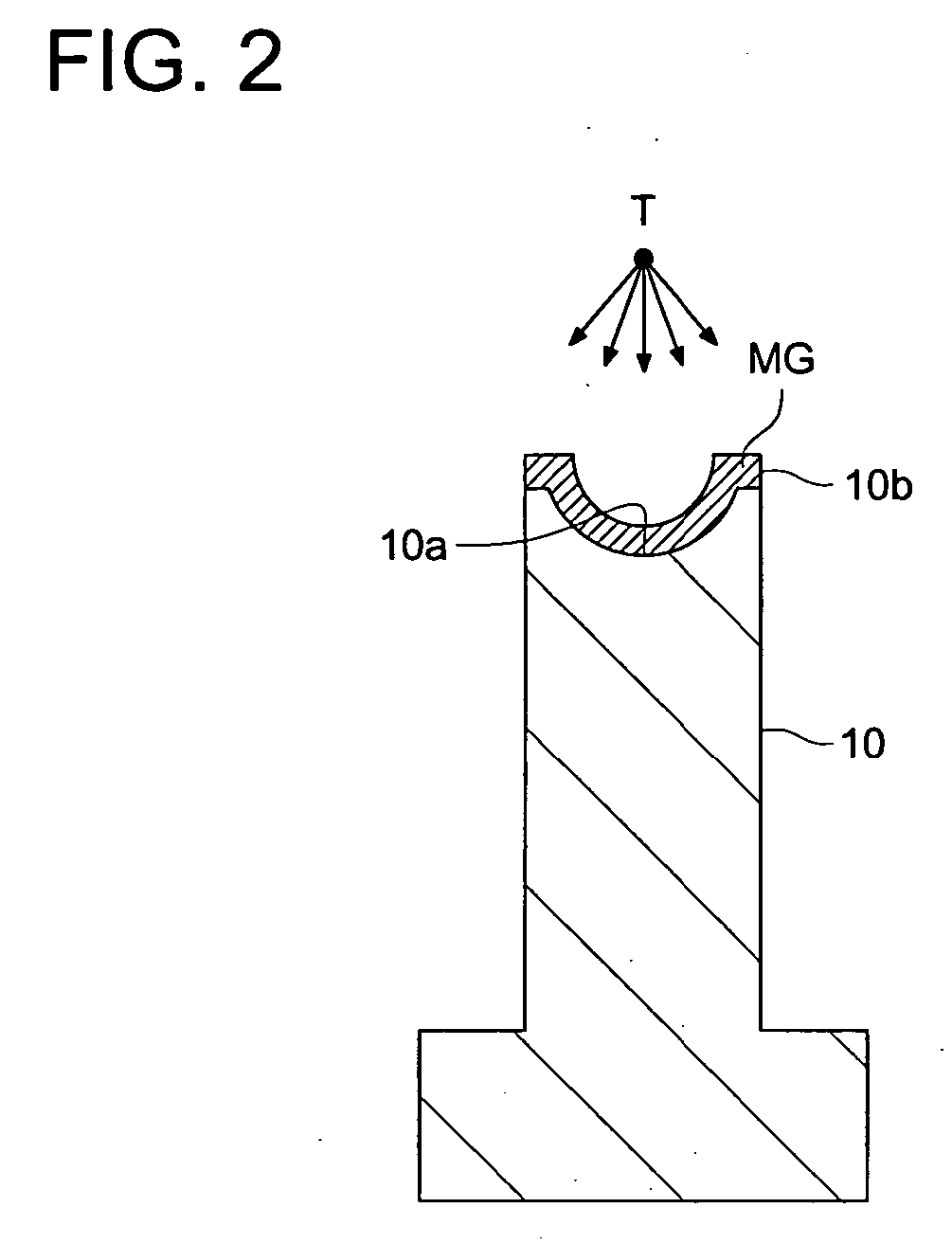

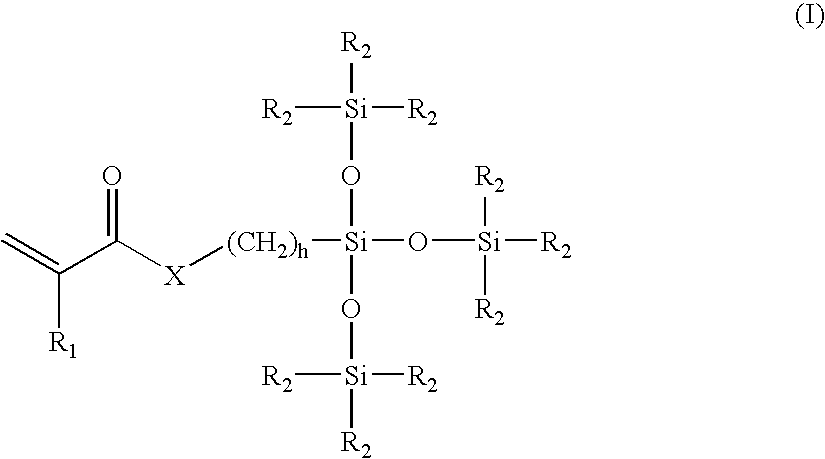

Manufacturing method of die for optical element molding

InactiveUS20050242454A1Reduce the possibilityPerformanceVacuum evaporation coatingAlcoholic beverage preparationSuper coolingVitrification

The invention relates to a manufacturing method of a die for molding an optical element. The manufacturing method comprising: forming the first film layer of an amorphous allow having a super-cooling liquid phase onto a master transfer surface of a master die for molding a molding transfer surface of the die; heating the first film layer more than a glass transition point of the amorphous alloy having the super-cooling liquid phase while a surface of the first film layer and a transferred surface of a base material of the die being faced and pressed; and peeling the first film layer from the master die and transferring the first film layer onto the base material of the die to form the molding transfer surface of the die.

Owner:KONICA MINOLTA OPTO

Use of a super-cooled fluid in lens processing

The present invention is a process for extracting pre-polymer from a polymer lens. The process comprises the step of contacting the lens with a super-cooled solvent for a period of time to increase the modulus of the contact lens. Thereafter the contact lens undergoes additional dry processing steps. By way of example, the dry processing steps include but are not limited to surface treatment, lens coating and polishing and / or edging of the contact lens.

Owner:BAUSCH & LOMB INC

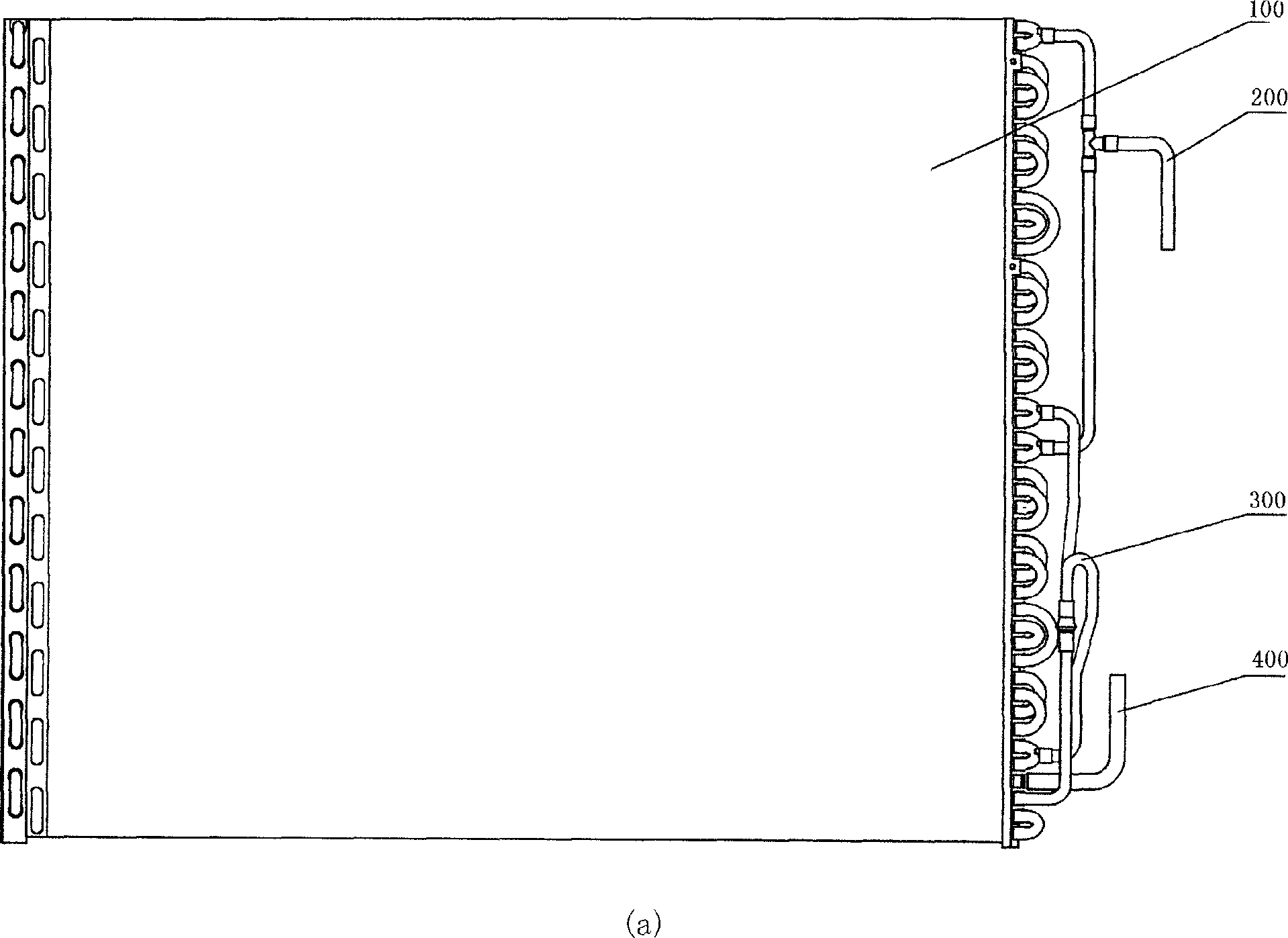

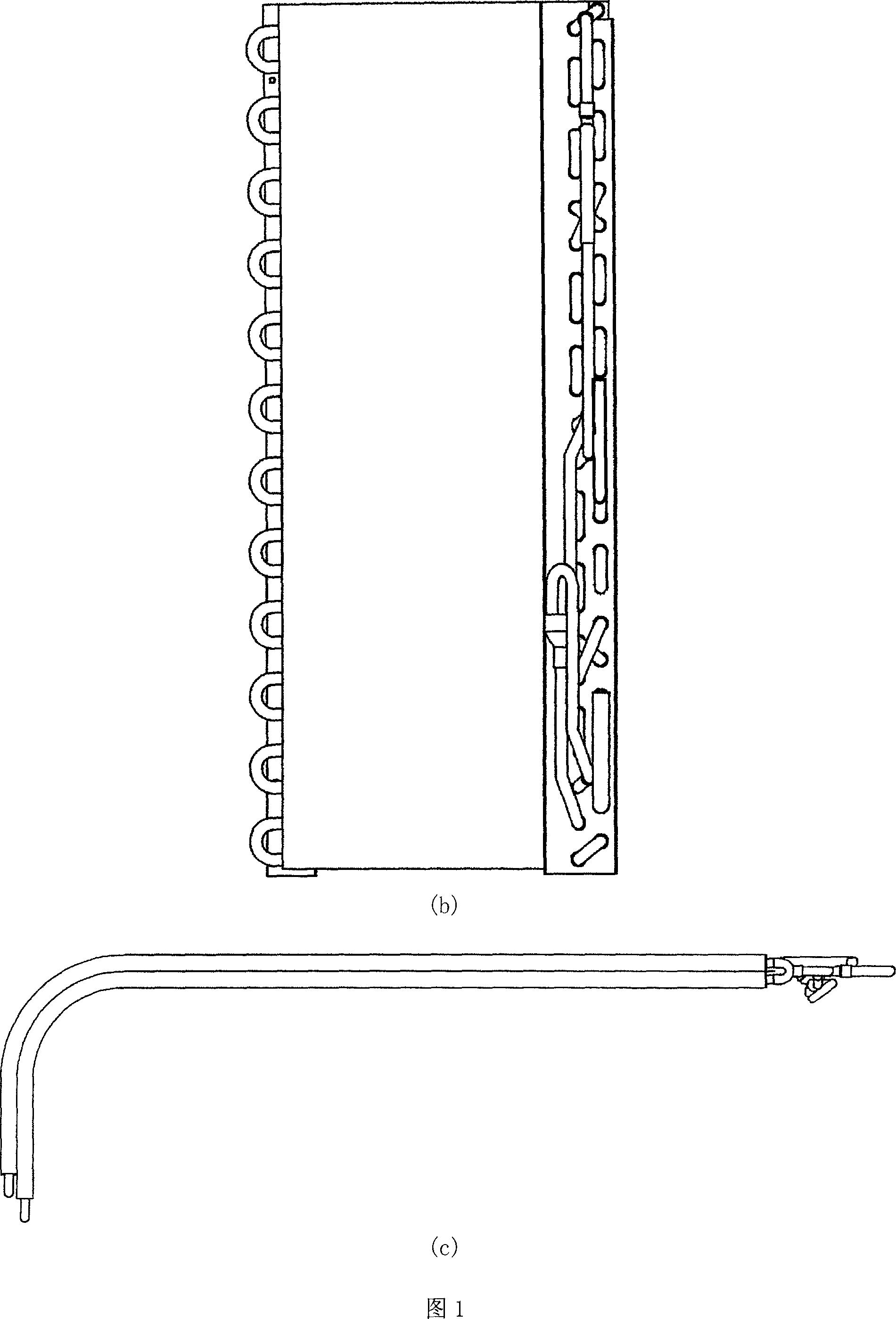

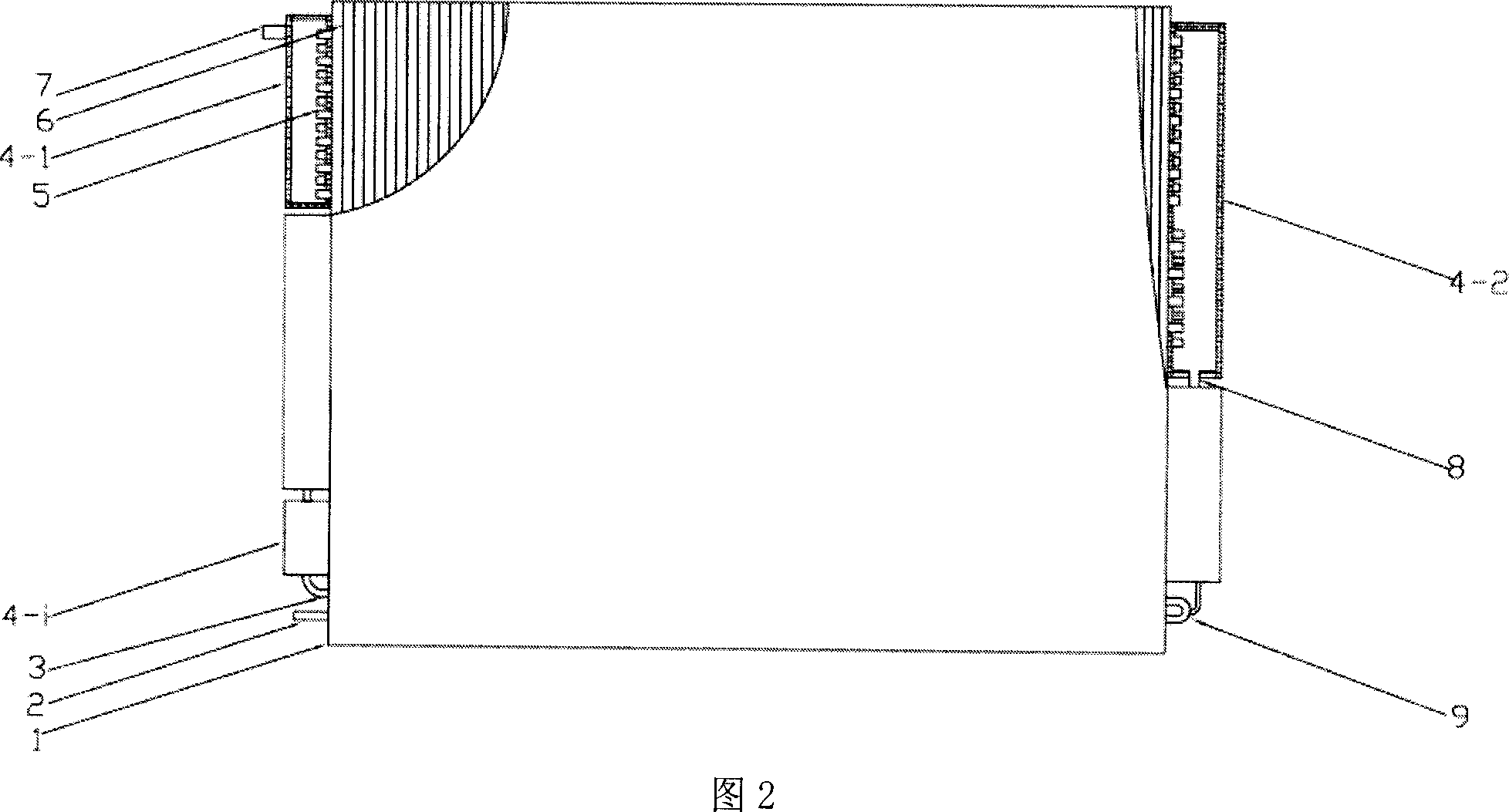

Liquid separating air condenser

InactiveCN1975311ANo steam leakage or short circuitReduce thicknessEvaporators/condensersSteam/vapor condensersCondensation processSuper cooling

A liquid-air-condenser belongs to thermal equipment technical fields. comprising steam inlet, heat exchange tube, fin, j cascade box, discharge pipe, three-limb tube, condensate outlet, single-pass pipe, shell; Steam from the steam inlet enter into the first cascade box and condense through the first group heat exchange tube, the vapor-liquid mixture flows into the second cascade box, vapor and liquid are separated: the liquid is ejected into the next cascade box by discharge pipes between cascade boxes , while steam enter into the next heat exchange tube group; collected by three-limb tube in the end and flow out through condensate outlet. The invention condense with stepped steam, separate by middle automatic vapor-liquid and drain fluid associate with super-cooling technology by the condensate concentrations, guarantee that each tube pass is entered with pure steam and cooled, effectively reduce the thickness of the liquid film in condensation process and eliminate the adverse biphasic flow pattern; compared with traditional condenser, save 30% material and reduce the condenser production and operation cost, and simple in production.

Owner:TSINGHUA UNIV

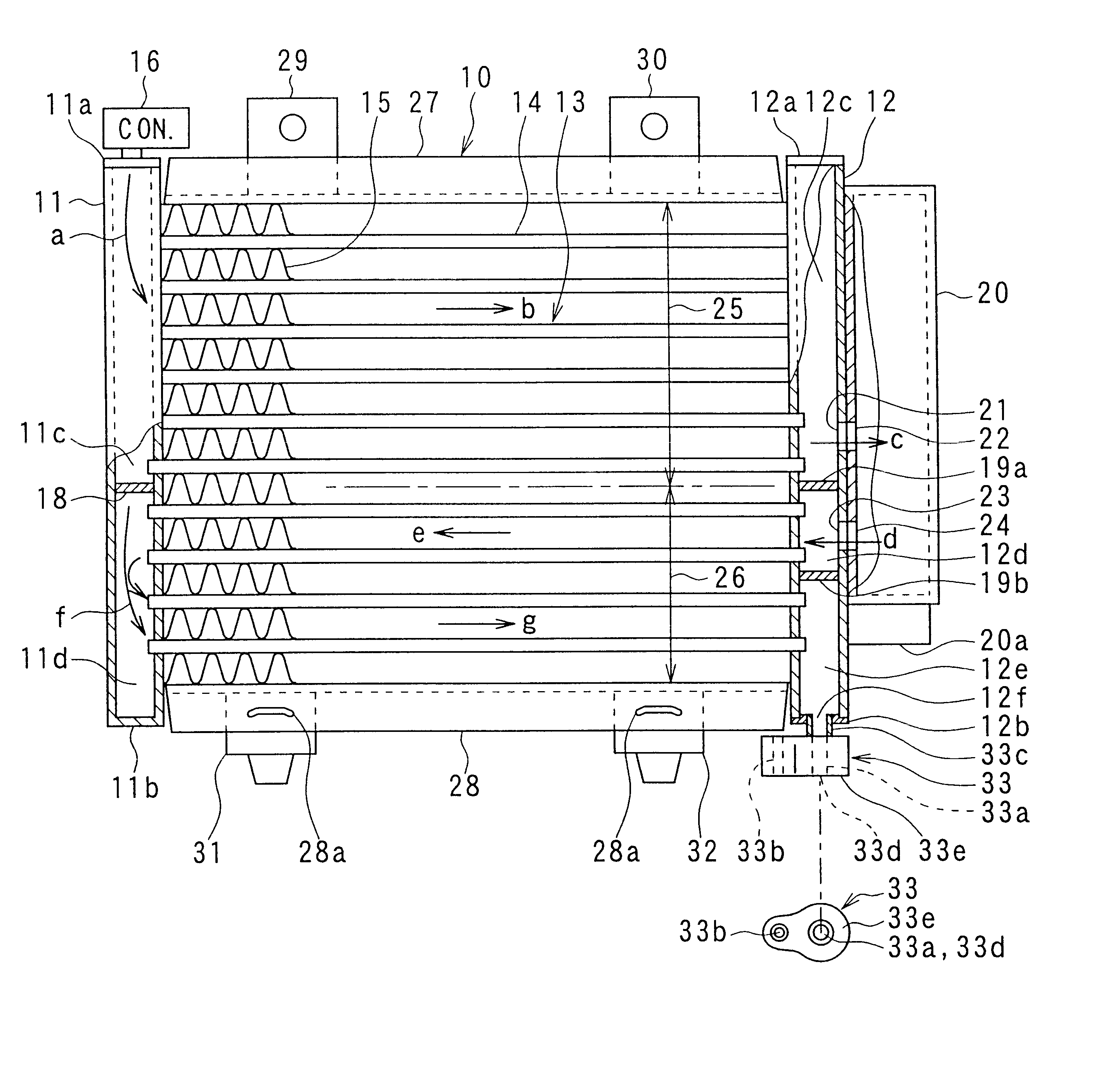

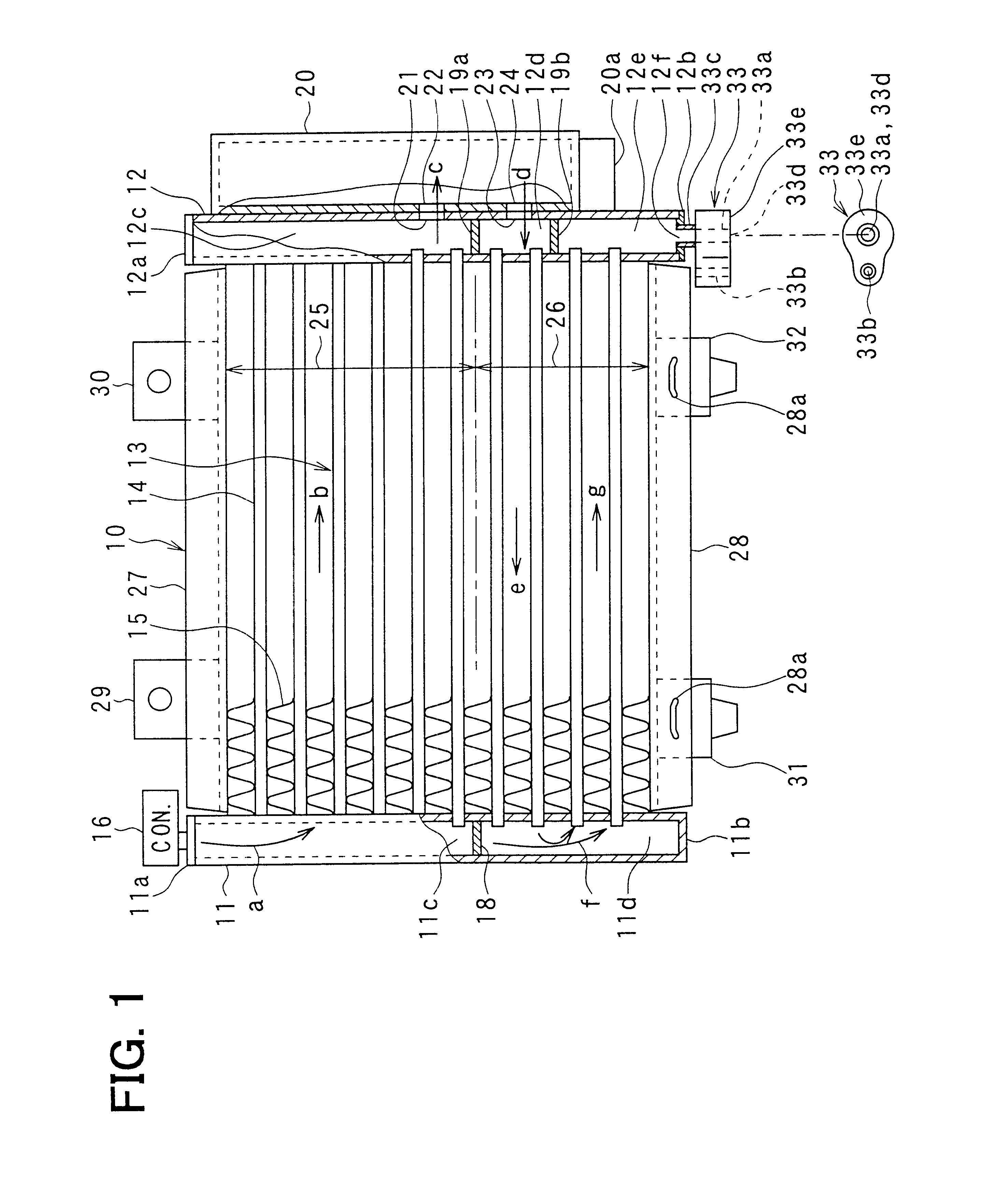

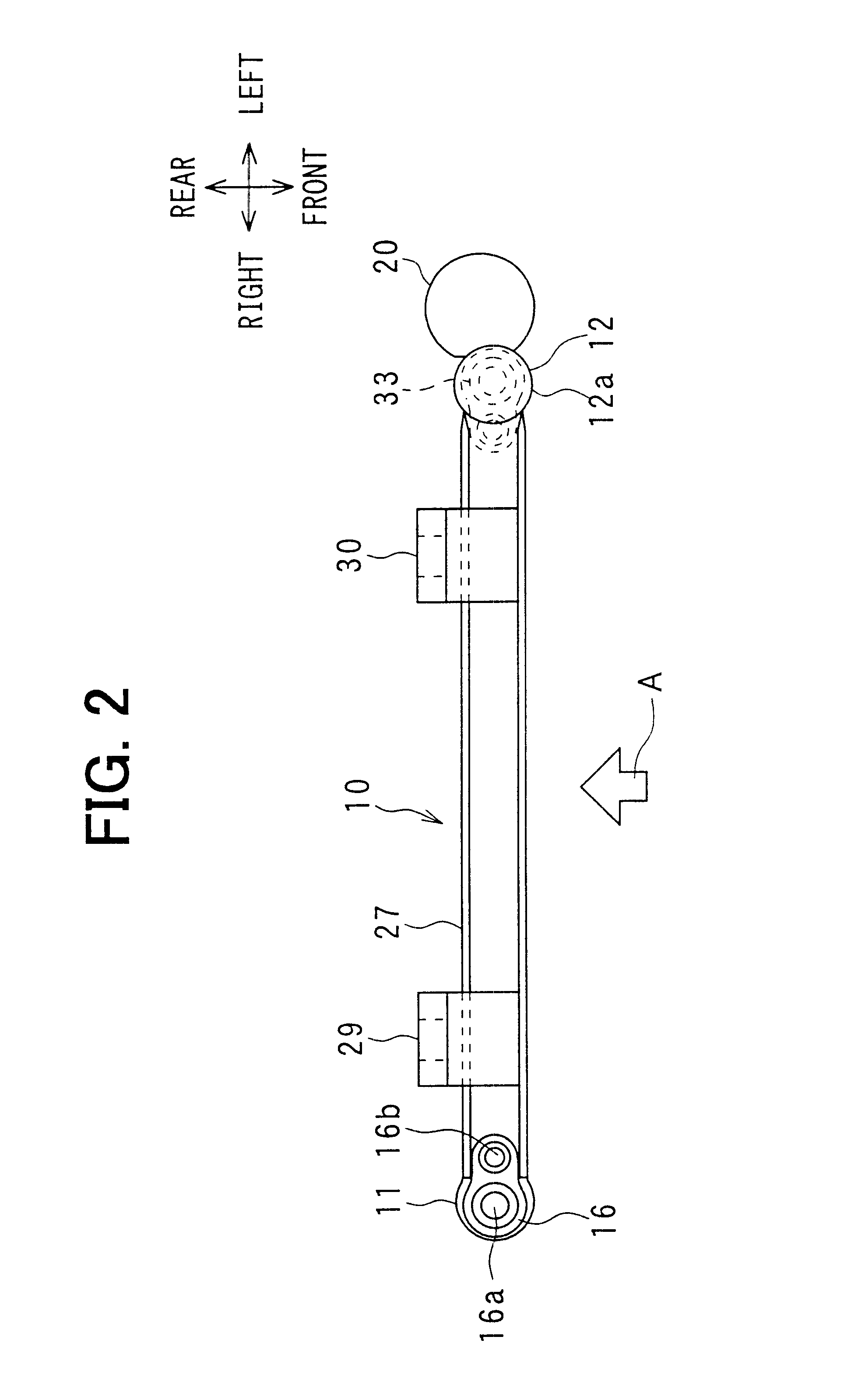

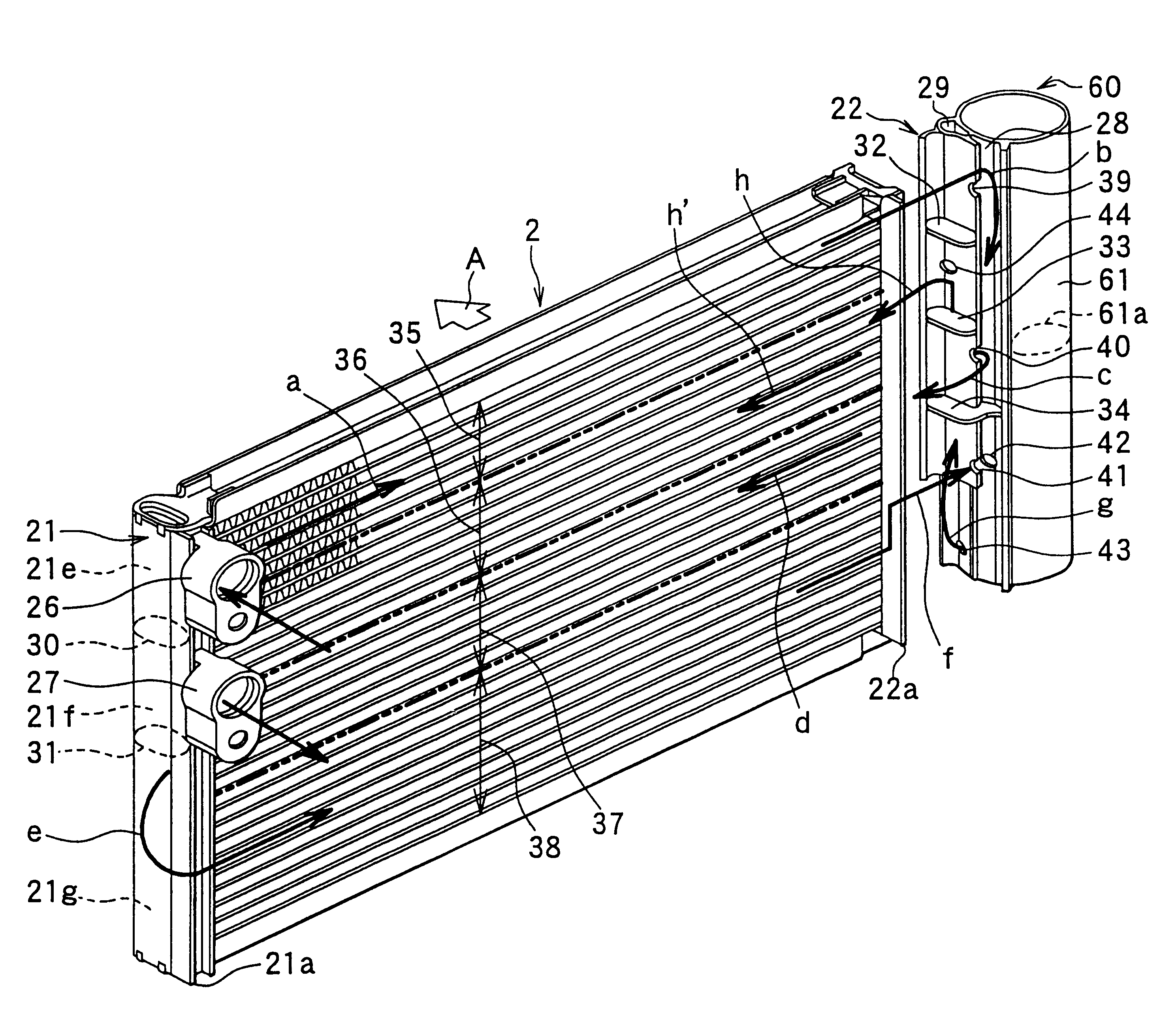

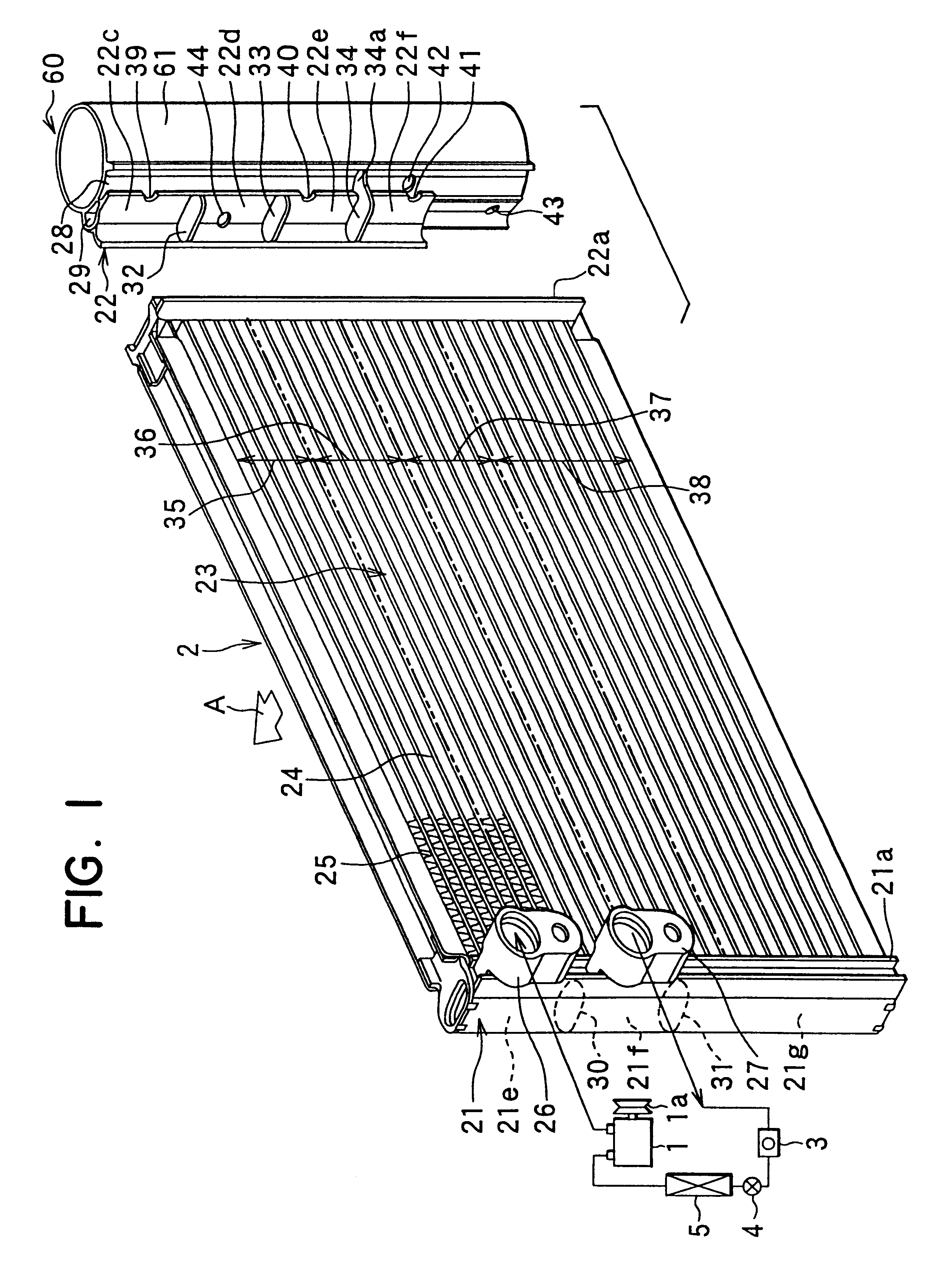

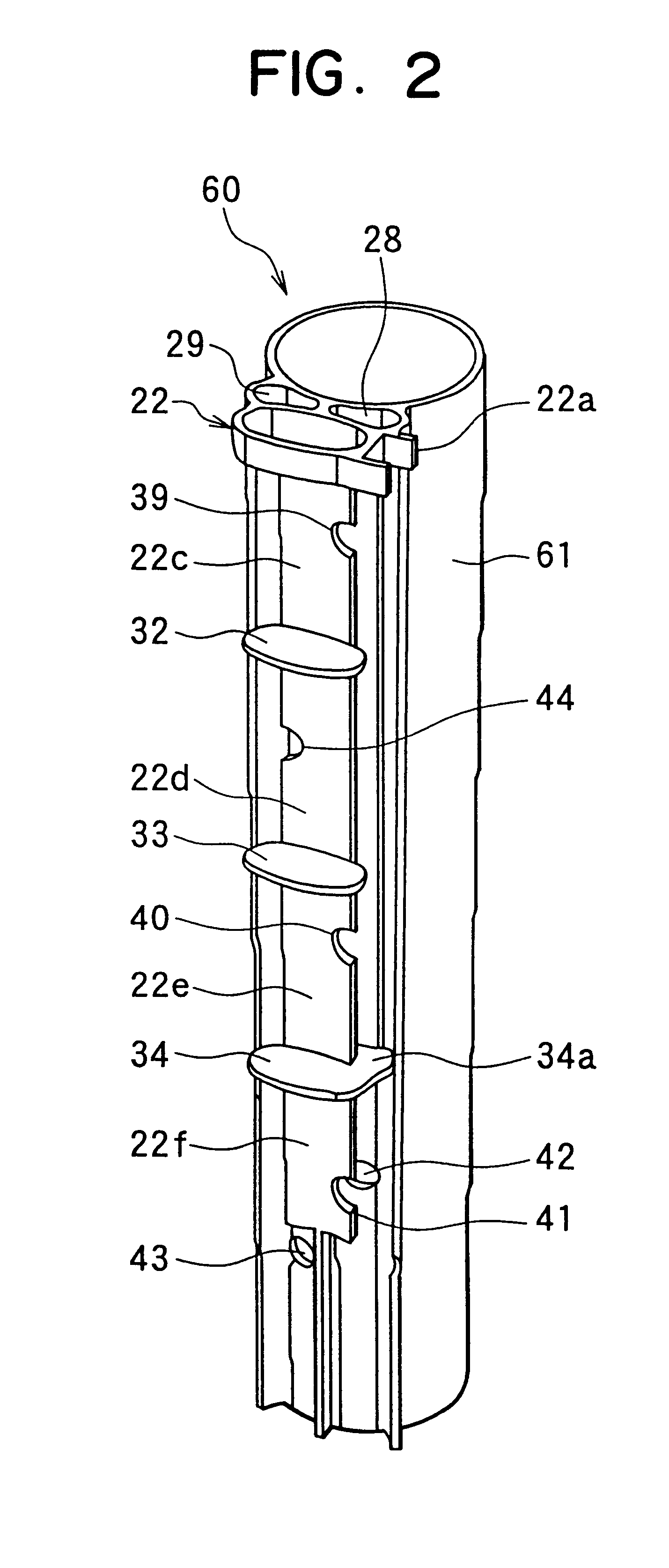

Receiver-integrated condenser for a vehicle

In a core portion of the receiver-integrated condenser, a condensing portion is disposed at an upper side of a super-cooling portion. A receiving unit is disposed at one end side of the core portion in a width direction, and refrigerant is U-turned in a refrigerant passage of the super-cooling portion at the other end side of the core portion in the width direction. In addition, a refrigerant outlet of the super-cooling portion is provided at the one end side of the core portion, a connector connected to the refrigerant outlet is disposed at a direct lower side of the refrigerant outlet, and the connector has a bottom surface used as a connecting surface connected with a pipe connector of a refrigerant pipe.

Owner:DENSO CORP

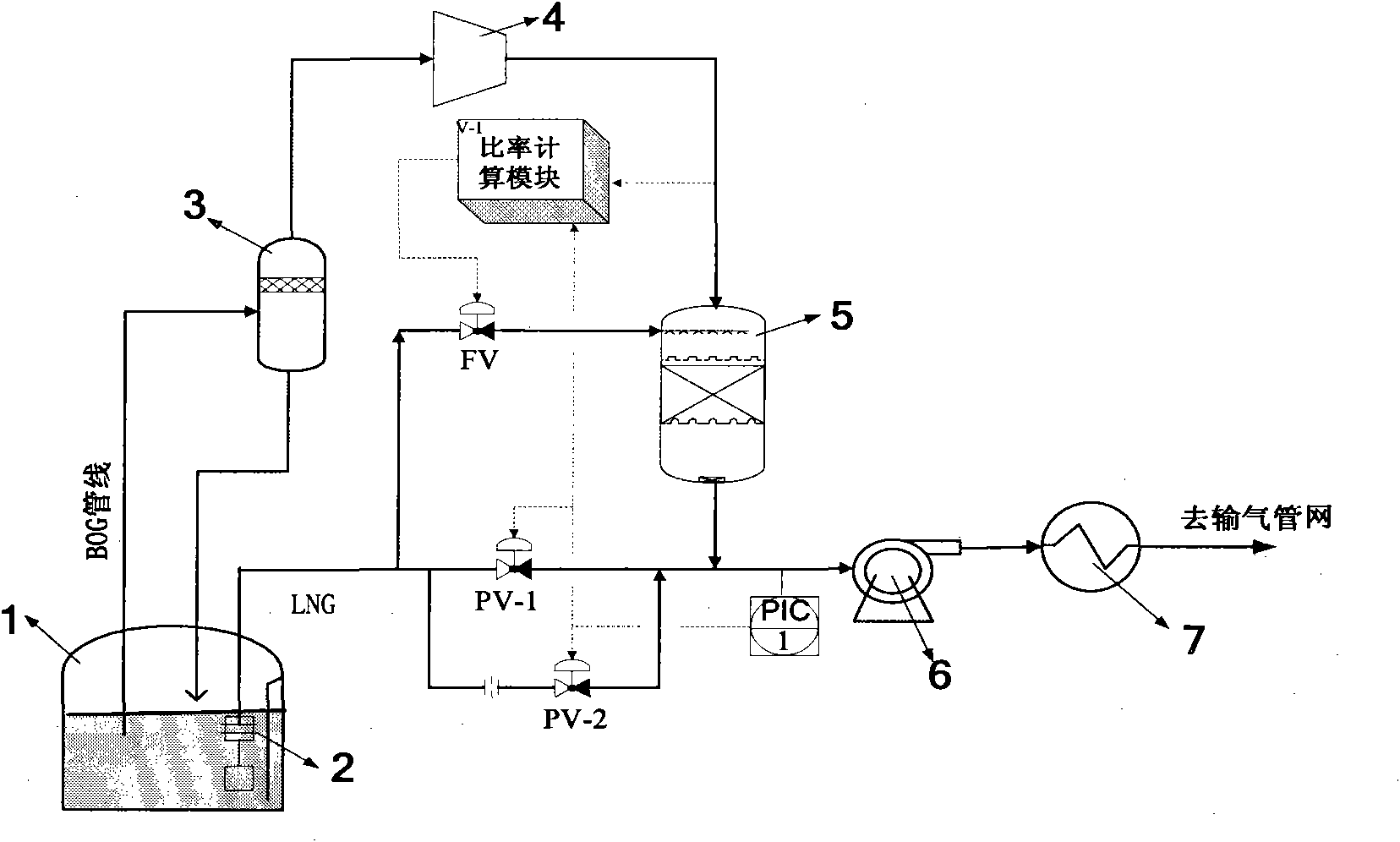

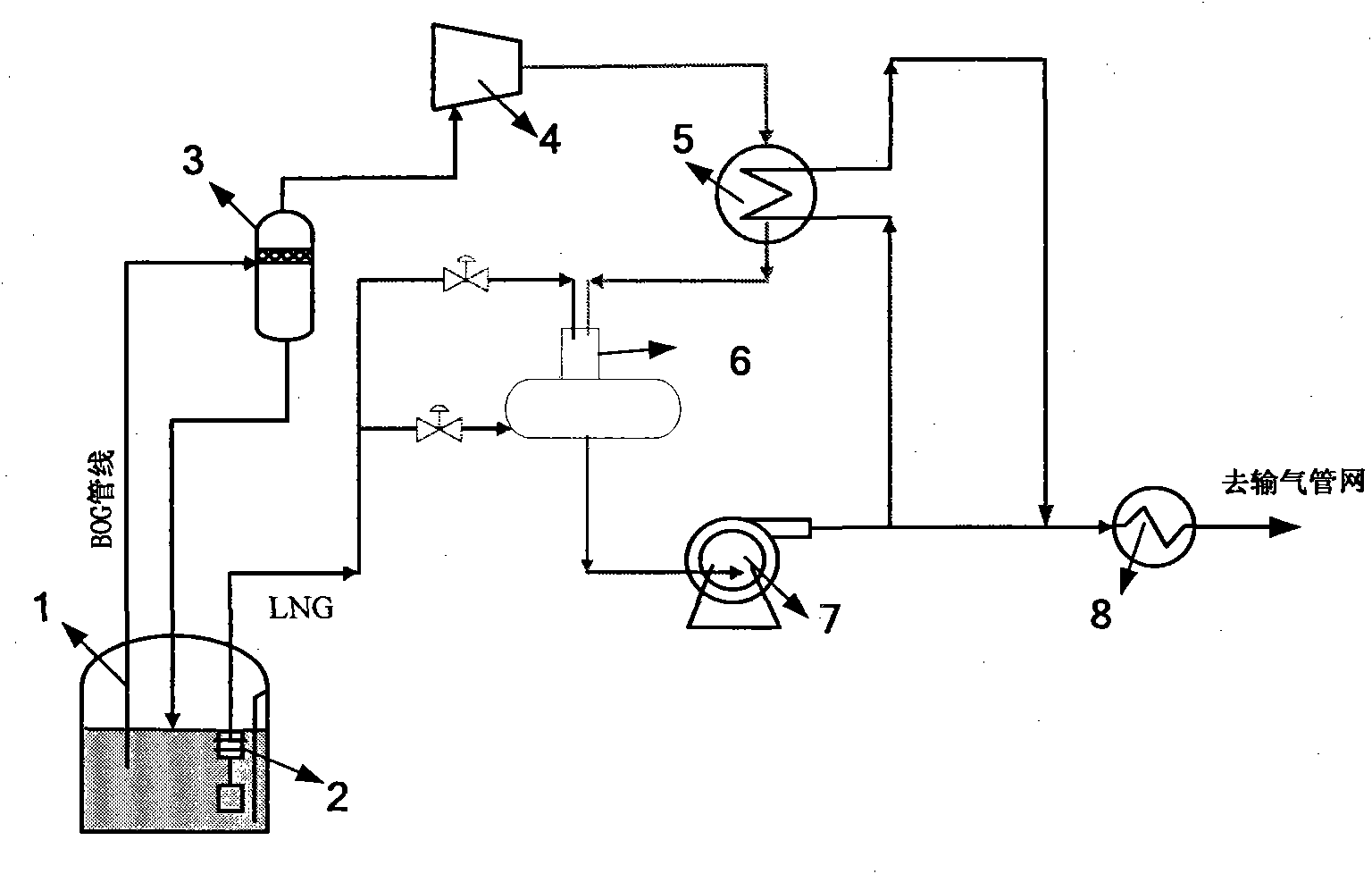

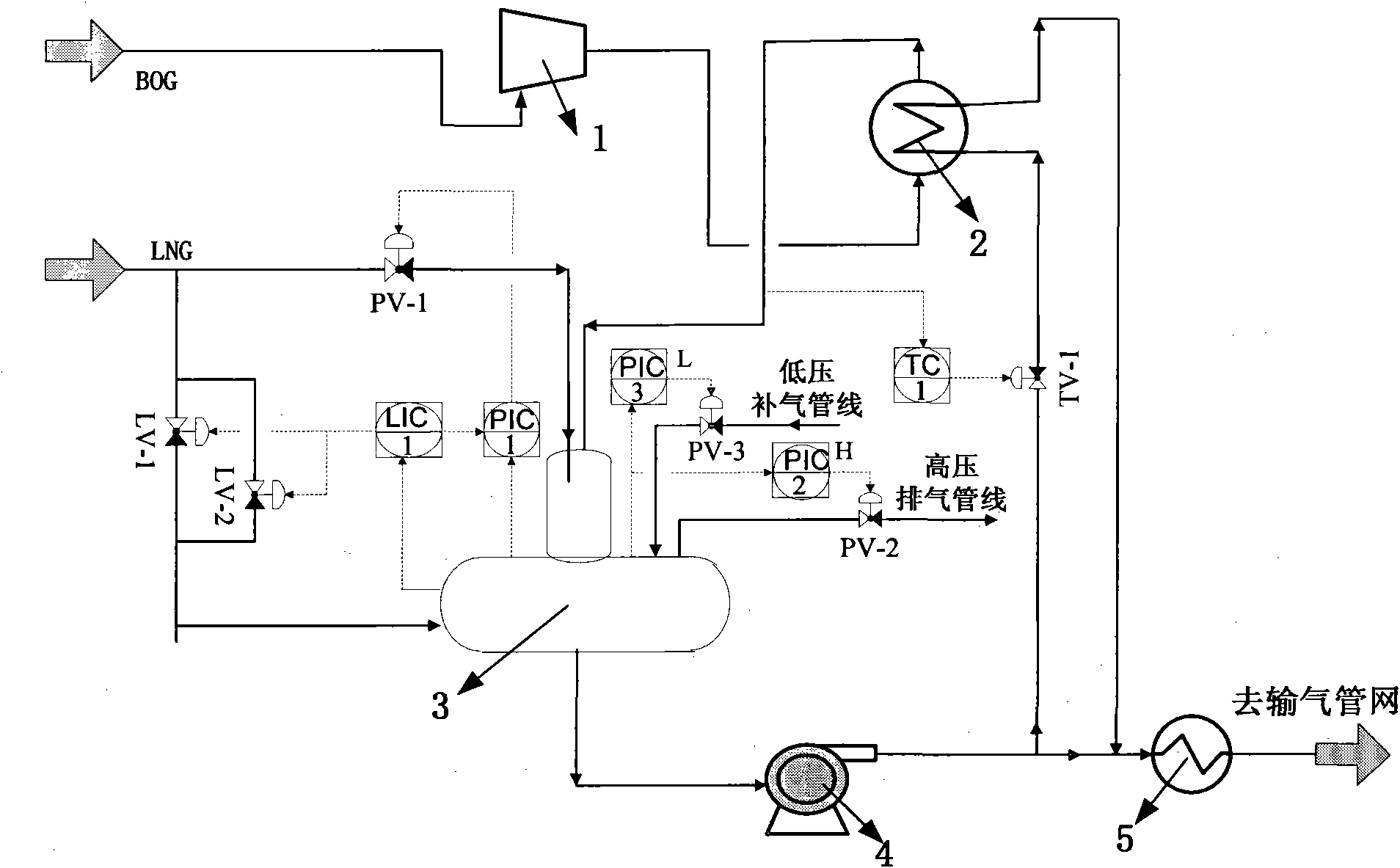

Re-condensation reclaiming system for evaporated gas of liquefied natural gas receiving station and reclaiming method thereof

ActiveCN101881549AReduce energy consumptionAdaptableSolidificationLiquefactionSuper coolingGas compressor

The invention discloses a re-condensation reclaiming system and a re-condensation reclaiming method for evaporated gas of a liquefied natural gas receiving station. The system comprises an evaporated gas compressor, an evaporated gas pre-cooling heat exchanger and a re-condenser, wherein the re-condenser consists of a vertical condensing tower and a high-pressure pump buffer tank; and the vertical condensing tower is positioned above the high-pressure pump buffer tank. The bottom of the high-pressure pump buffer tank is provided with a brace, and a crossed vortex breaker is arranged in the brace. The reclaiming method comprises the following steps of: (1) compressing the evaporated gas, (2) pre-cooling the evaporated gas, (3) condensing and super-cooling the evaporated gas and (4) conveying secondary pressure of LNG. The design of the buffer tank improves the running stability of a high-pressure pump; the re-condenser operates and controls the system more stably and simply; and the system and the method reduce the energy consumption, and have good adaptability to gas conveying load fluctuation.

Owner:佛山市天然气高压管网有限公司

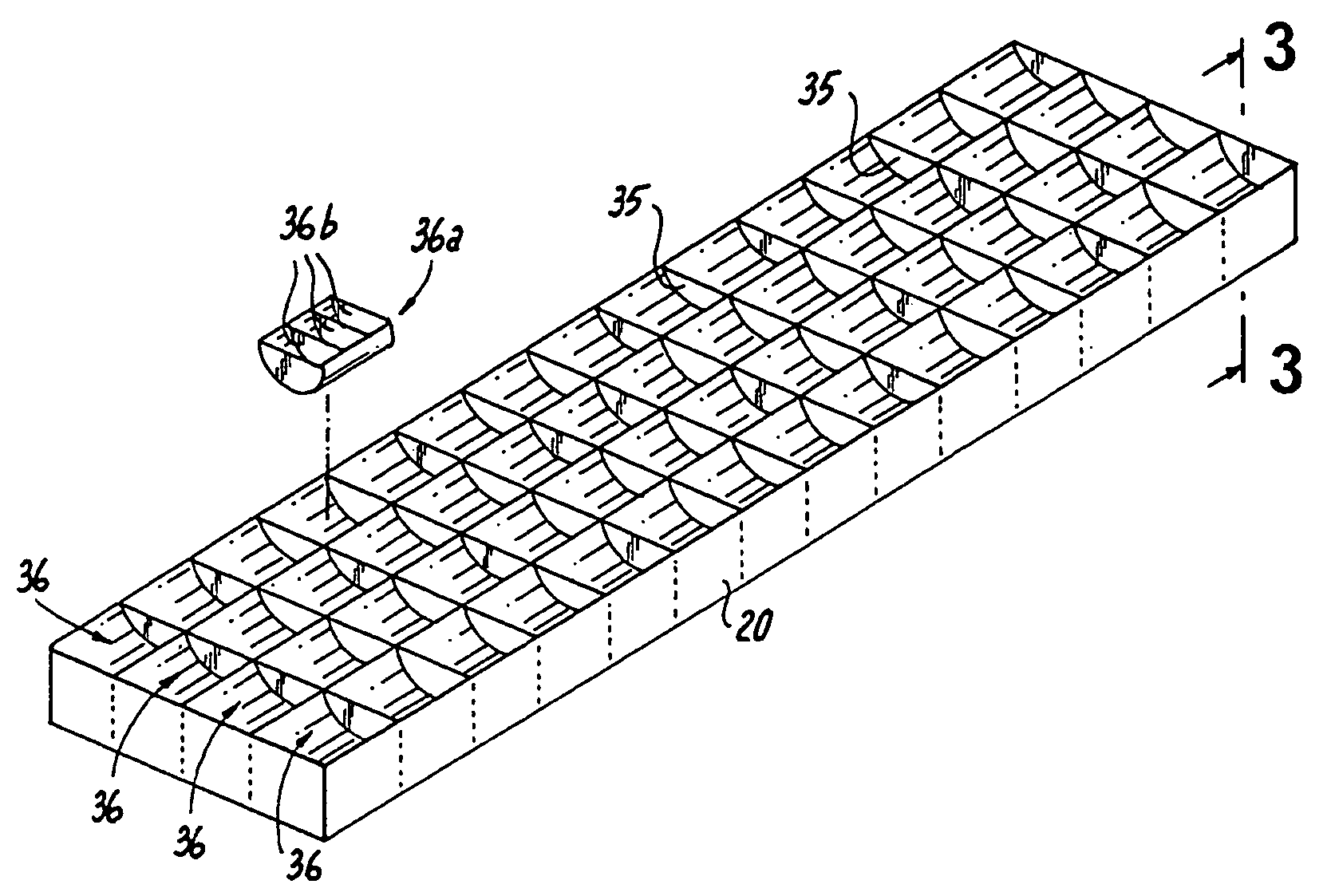

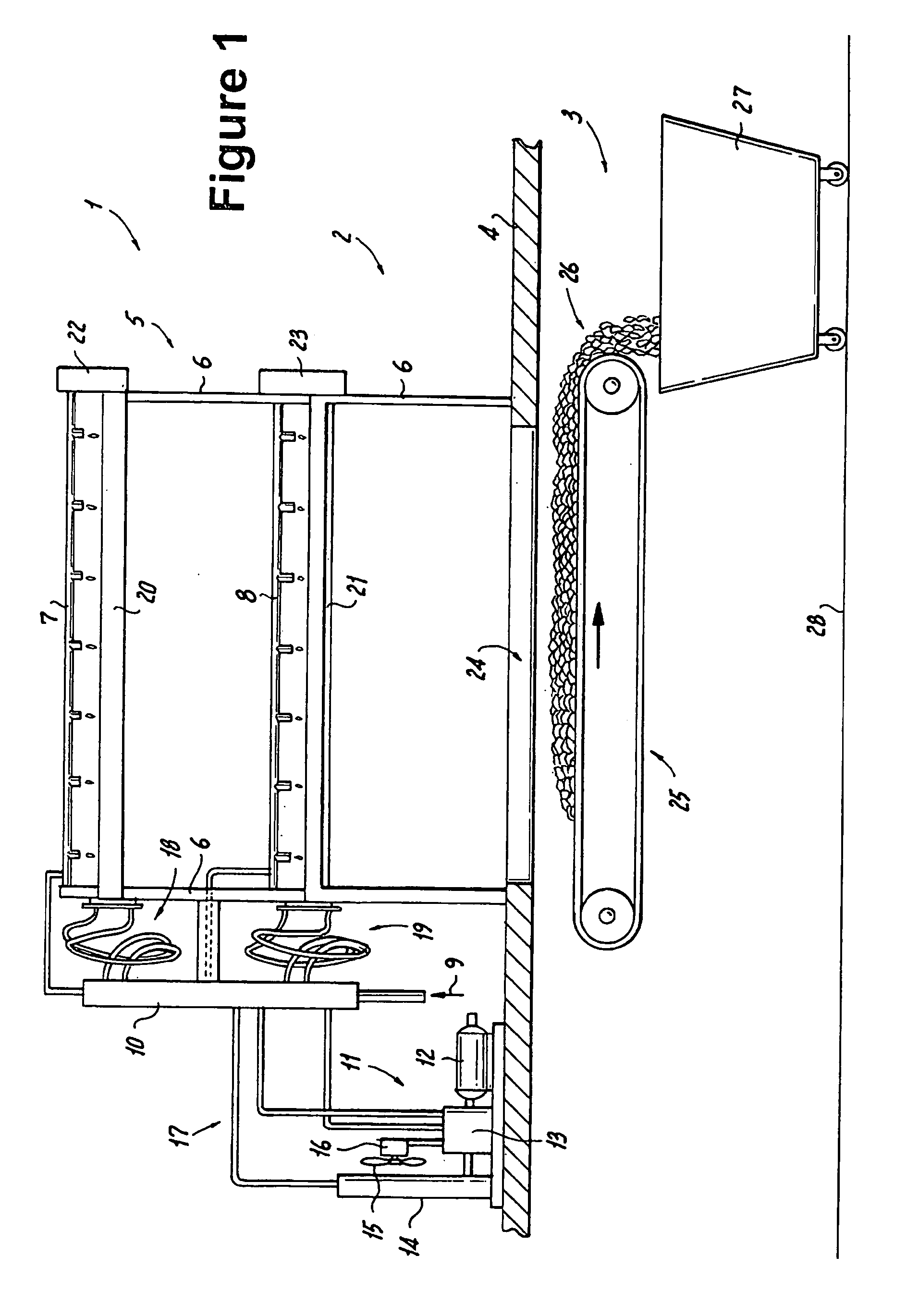

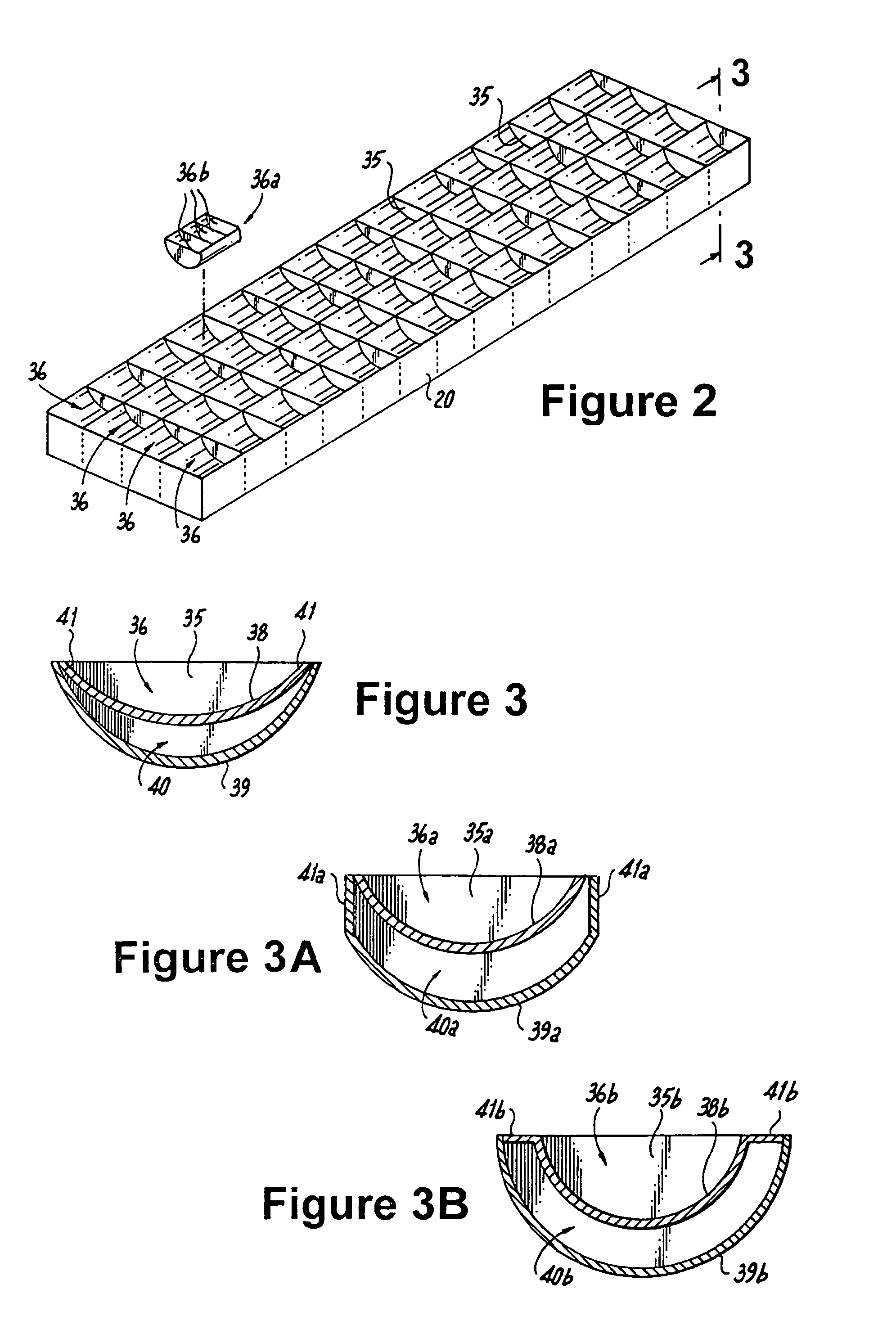

Liquid milk freeze/thaw apparatus and method

InactiveUS7059140B2Extended shelf lifeImprove disadvantagesLighting and heating apparatusIce productionSaline waterSuper cooling

A high throughput, short batch cycle commercial ice making machine produces salt containing, milk containing or beverage containing commercial ice, which resists melting in convenient sizes for mobile food carts, market produce, or fish displays. The machine introduces super-cooled liquid, that is in a liquid state while exposed to a temperature below freezing, into a batch of pre-formed hollow molds of one or more horizontally oriented ice forming freezing trays oriented horizontally. Using vapor compression refrigeration, the machine produces a plurality of supercooled ice segments in pockets within the freezing tray. The supercooled ice segments are rapidly subjected to a short, temporary contact with a high heat source from a sleeve integral with the freezing tray compartments, along a peripheral bottom surface of the ice segment accommodating freezing tray molds. This temporarily melts a bottom surface of each ice segment, lubricating it and loosening it. Then the machine rotates the freezing tray containing the batch of ice segments about its horizontally oriented axis to a vertically oriented dump position, thereby dumping the temporarily heated ice segments into the freezing tray. The ice cubes thus formed may be fresh water, salt water or beverage containing ice cubes.

Owner:ZEVLAKIS ANASTASSIA

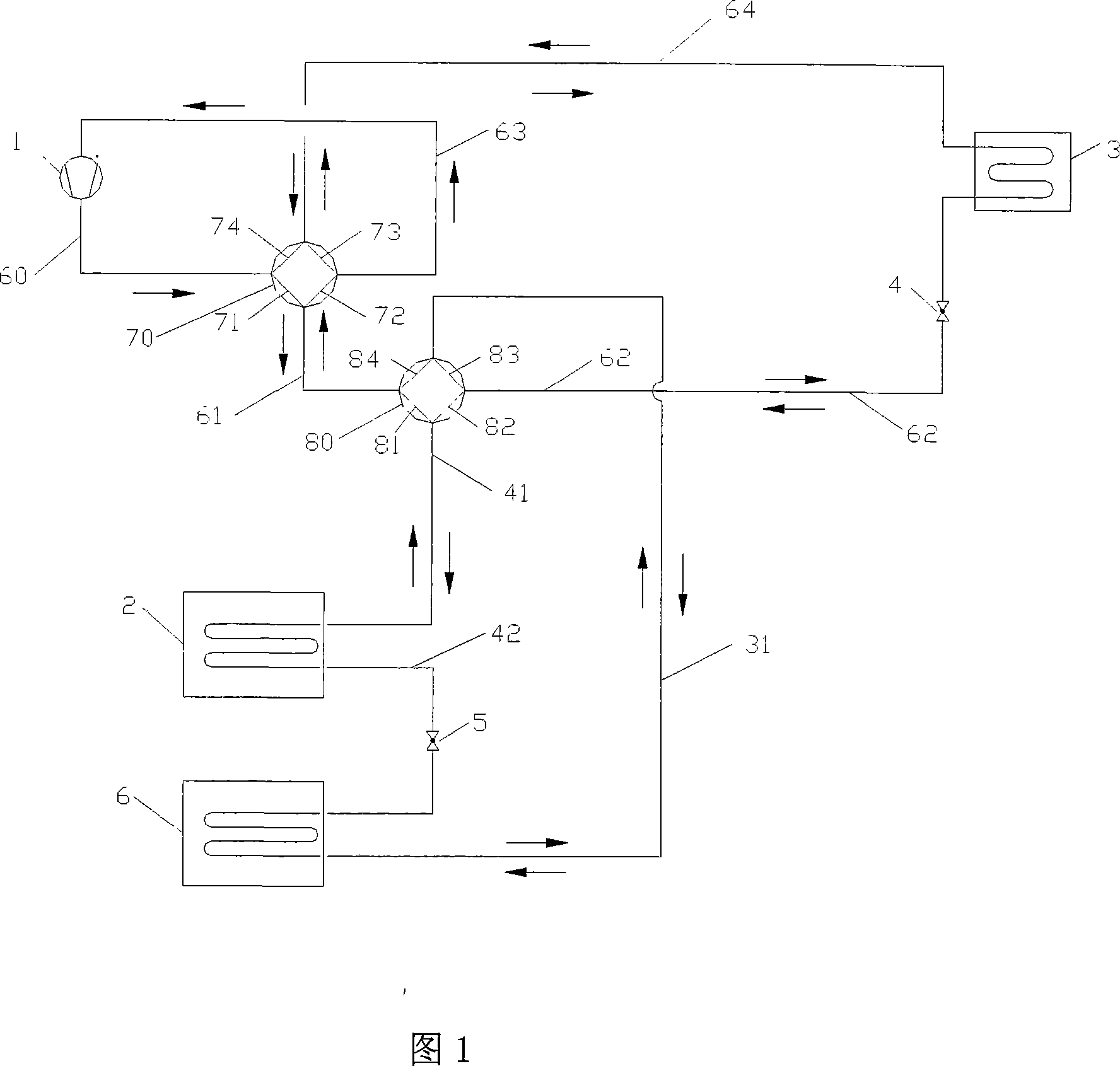

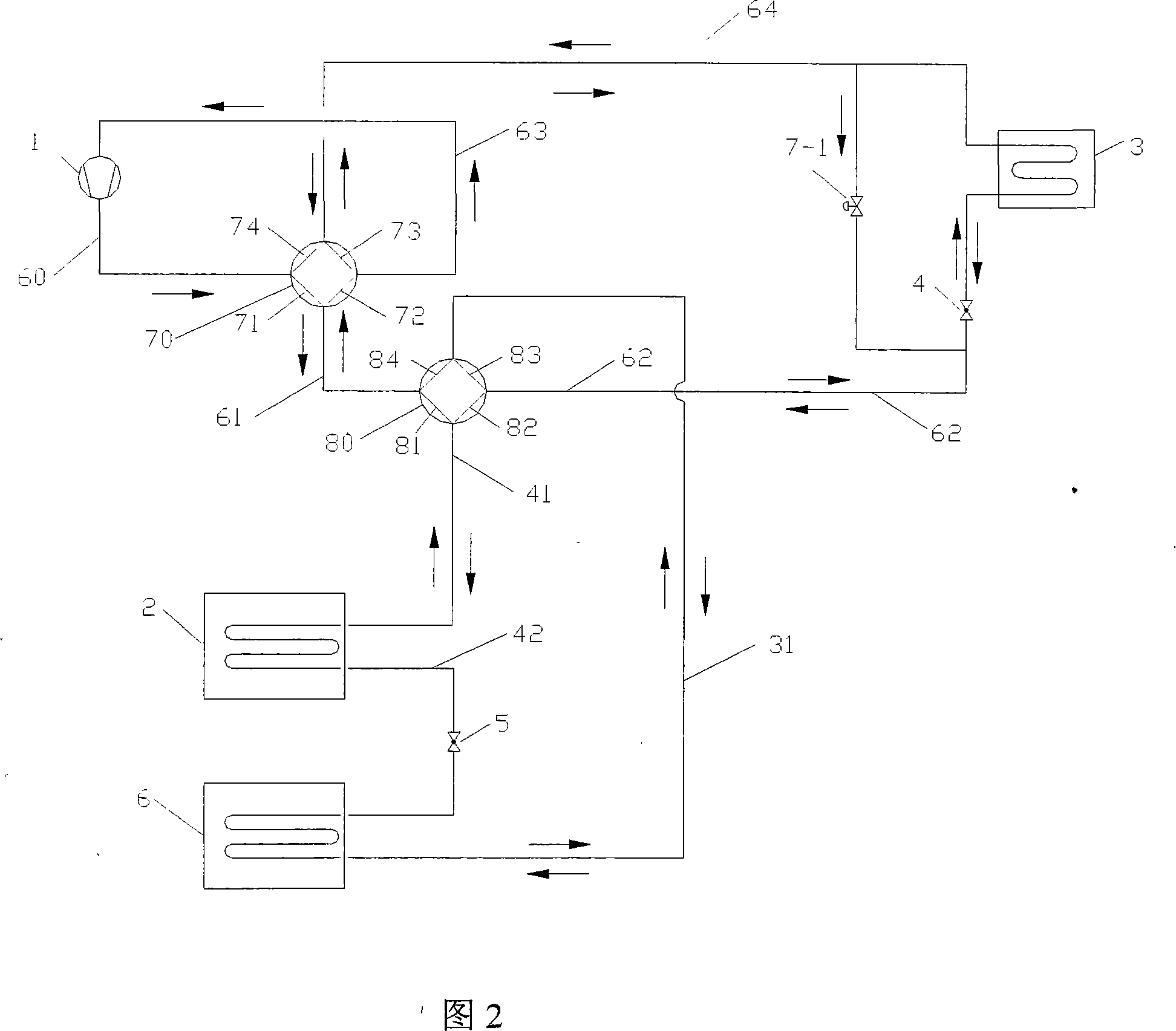

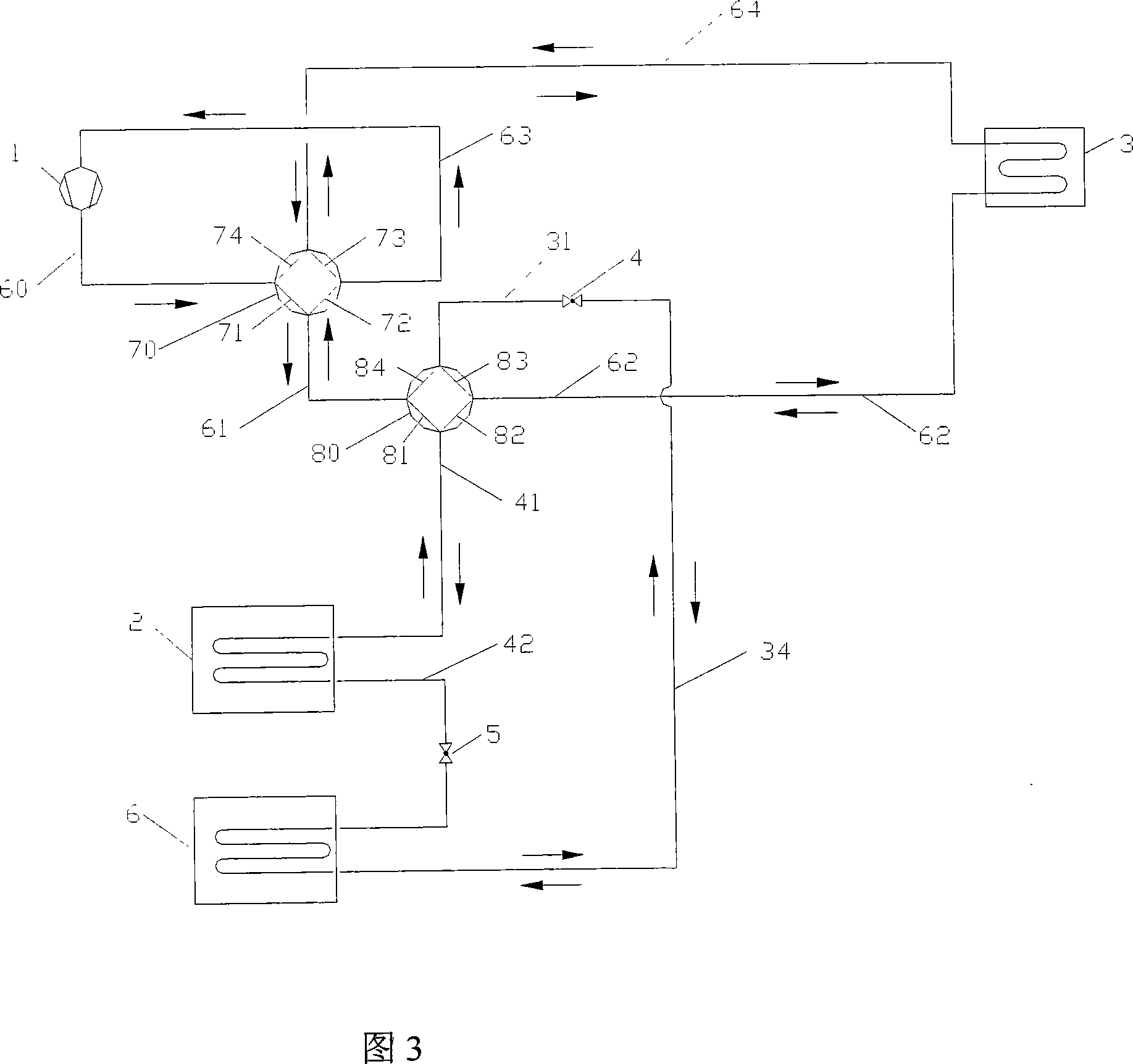

Dual-purpose heat pump device for winter and summer

InactiveCN101144662AImprove performanceAvoid canceling each other outHeat pumpsCorrosion preventionSuper coolingFour-way valve

The invention discloses a heat pump device which can be used both in summer and winter. The heat pump device comprises a compressor, a heat source side heat exchanger, a user side heat interchanger, a throttling mechanism and a four-way valve; and the heat pump device also comprises a second heat interchanger, a second throttling mechanism and a second four-way valve. The four-way valve is provided with four nodes, a four-way valve node is connected with the output end of the compressor through a pipeline, the four-way valve node is connected with the input end of the compressor through the pipeline, the four-way valve node is connected with one end of the user side heat interchanger through the pipeline, the four-way valve node is connected to the node of the four-way valve through the pipeline, the other node of the four-way valve is connected with the other ends of the user side heat interchanger in sequence through the pipeline and the throttling mechanism, the four-way valve node is connected with one end of the heat source side heat exchanger, and the other end of the heat source side heat exchanger is connected with the four-way valve node through the throttling mechanism and the second heat interchanger. The heat pump device produces the hot water to refrigerate or heat in the operation process. The recycling produces the low temperature afterheat. In the process of refrigeration cycle in summer and heating cycle in winter, the super cooling of a refrigeration agent can be realized. The invention is suitable for the industrial and civil use.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Receiver-integrated condenser

InactiveUS6397627B1Precise applicationPrecise punchingEvaporators/condensersClosure meansSuper coolingEngineering

In a receiver-integrated condenser, a super-cooling portion for cooling liquid refrigerant from a receiving unit is disposed between first and second condensing portions in a core portion in a vertical direction. Therefore, in an engine-idling, even when high-temperature air having passed through the receiver-integrated condenser is introduced again toward an upstream air side of the receiver-integrated condenser through a lower side of the receiver-integrated condenser, the high-temperature air is not introduced toward the arrangement position of said super-cooling portion, because the super-cooling portion is positioned at an upper side from the second condensing portion. Thus, super-cooling performance of refrigerant in the super-cooling portion of the core portion is prevented from being decreased even in the engine idling.

Owner:DENSO CORP

Detecting device for detecting icing by image and detecting method thereof

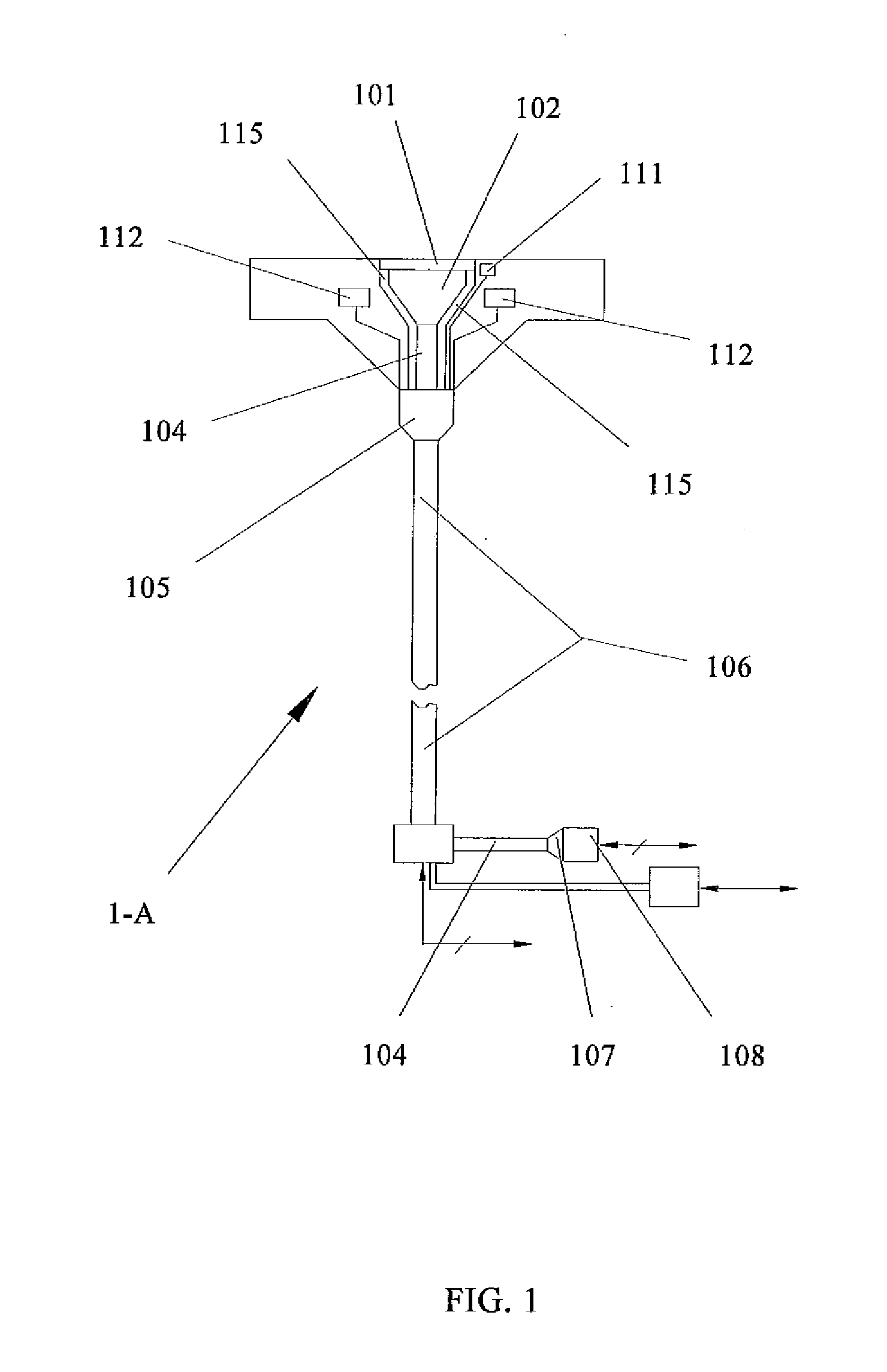

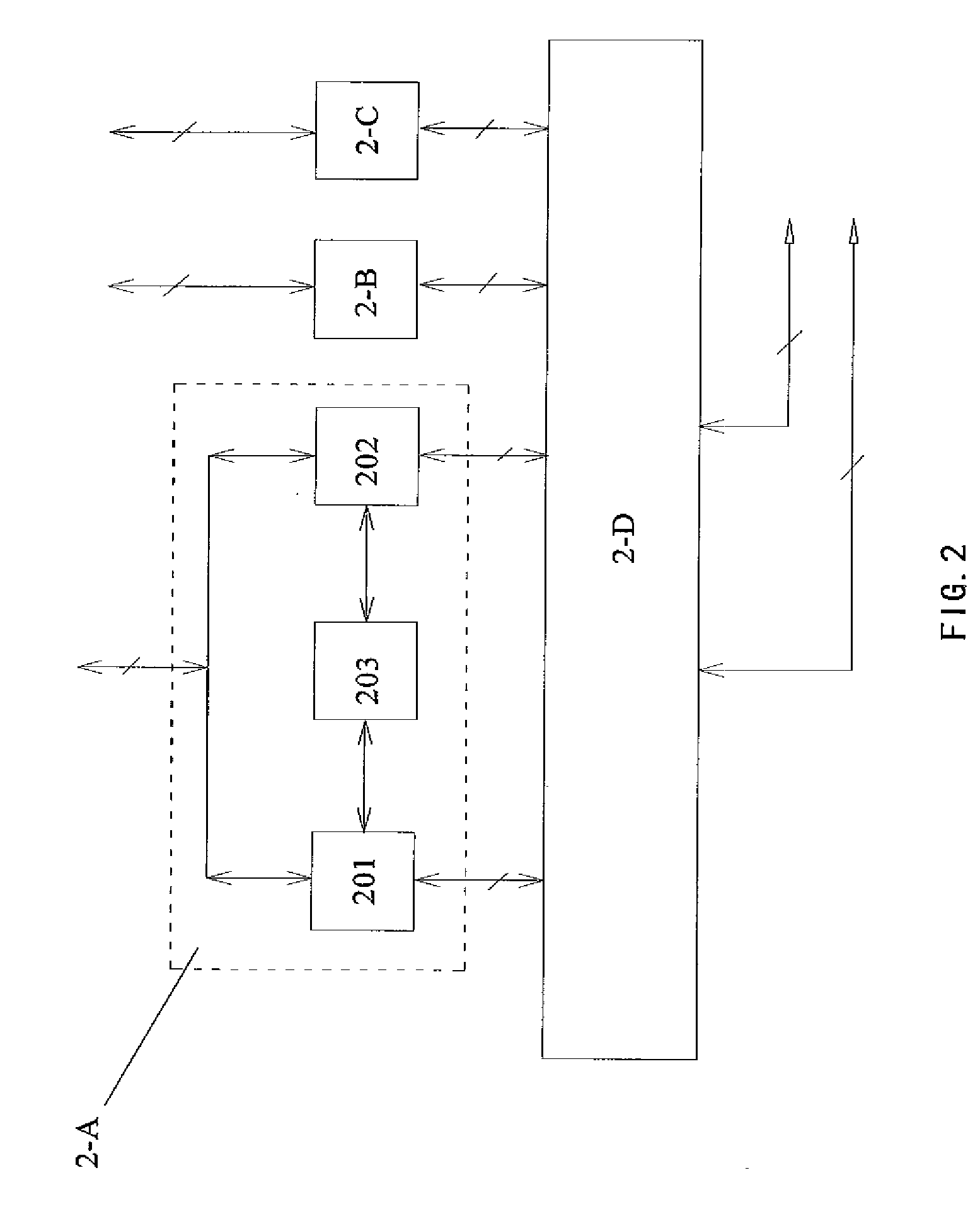

InactiveUS20130113926A1Avoid and reduce mistakeAccurate identificationImage enhancementImage analysisSuper coolingImaging processing

A detecting device for detecting icing by an image includes an image acquiring system (1-A) and an image processing system (2-A). The image acquiring system (1-A) can acquire an image of an object's surface. The image processing system (2-A) can analyze the image and obtain an icing condition of the object's surface. The detecting device is simple and reliable. It can identify the category of the icing effectively. So, it can improve the accurateness of the icing detection significantly and can accomplish the detection of the object's whole surface. Furthermore, it can detect an icing condition of a super-cooled large droplet. A method for detecting an icing condition of an object's surface using the detecting device is also provided.

Owner:COMAC +2

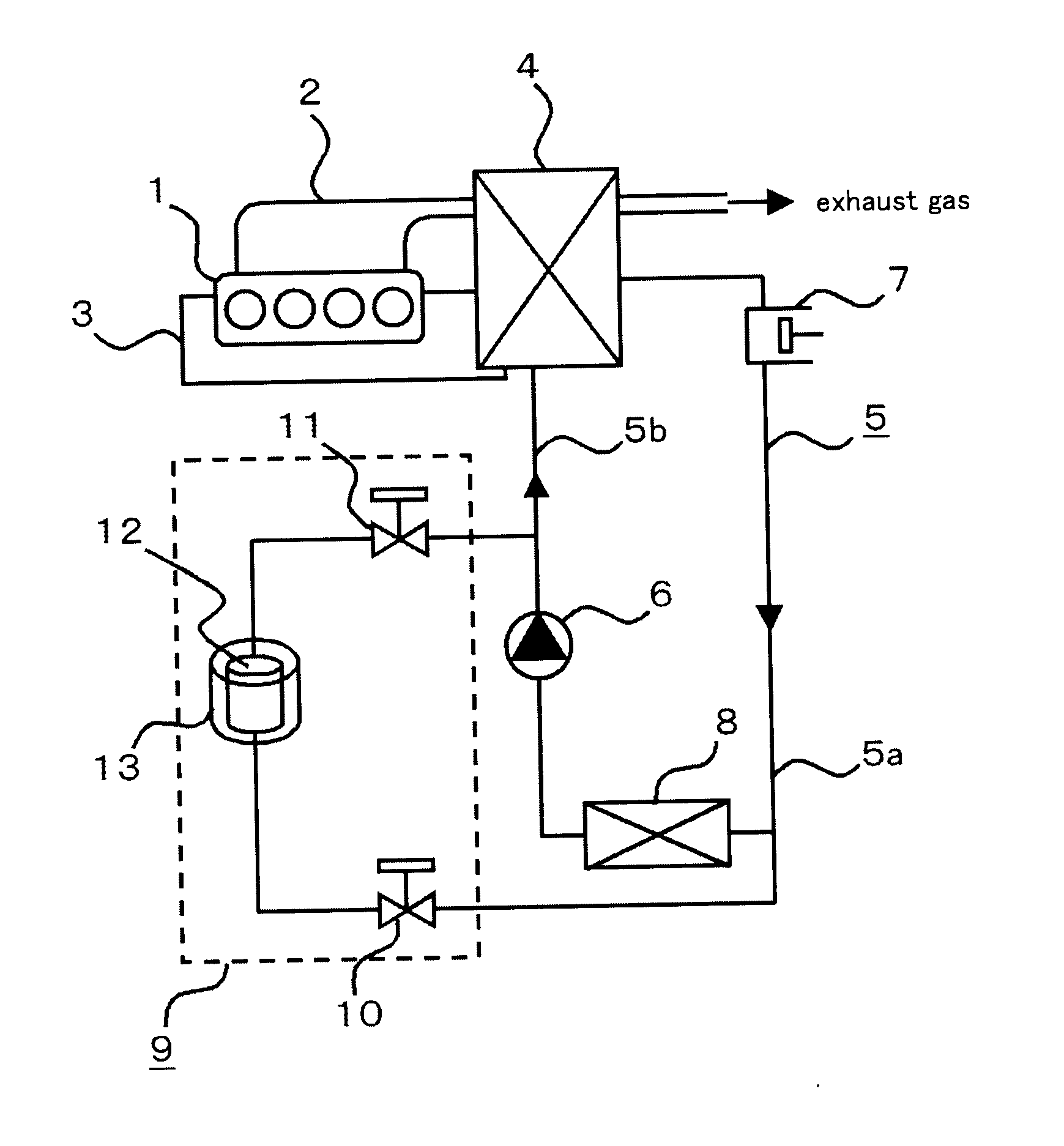

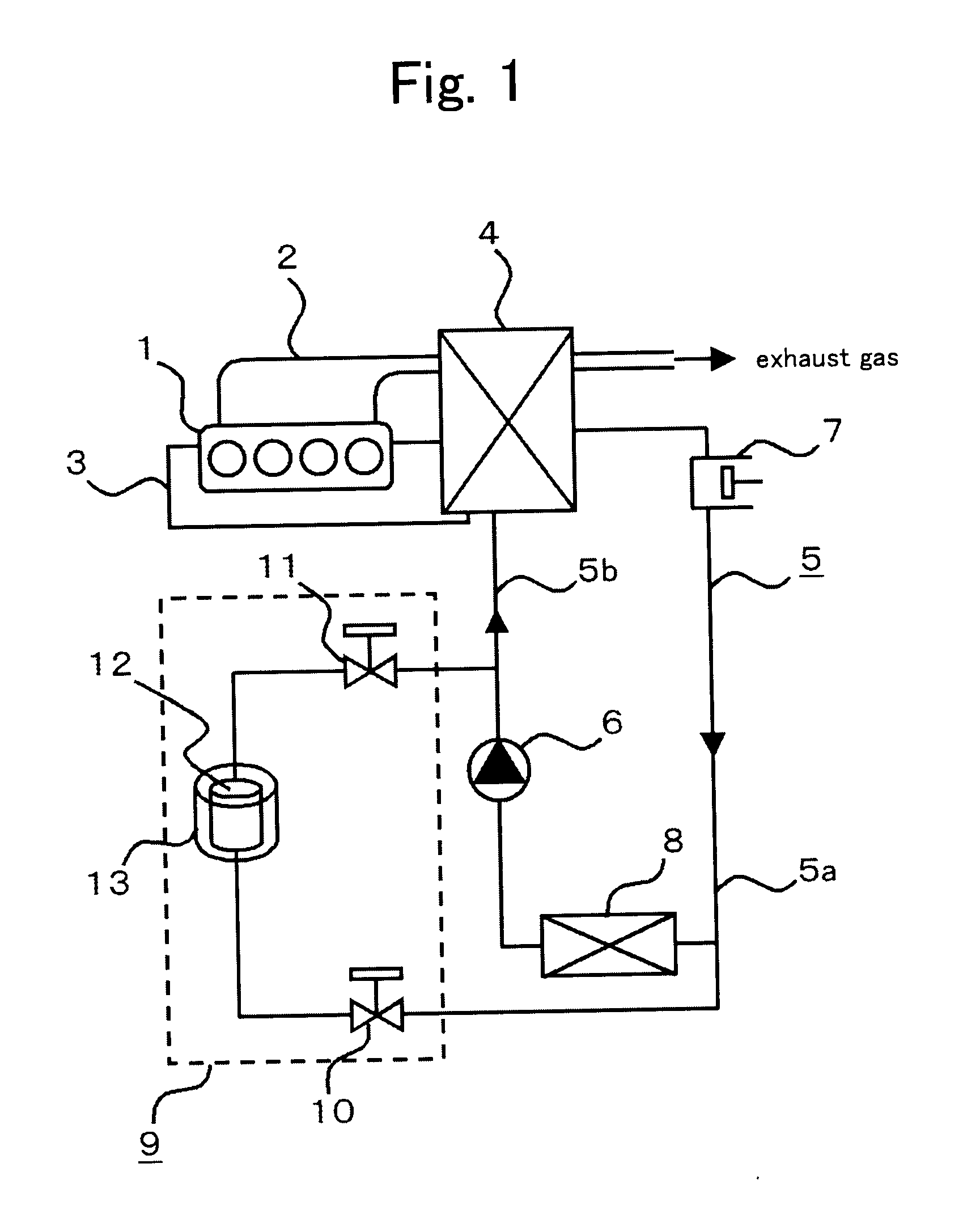

Exhaust heat recovery system

InactiveUS20110167818A1Easy to operateLow efficiencyInternal combustion piston enginesEngine componentsSuper coolingEngineering

In a case of a refrigerant amount being short when a Rankine cycle starts operating, because the pressure difference does not occur across a refrigerant pump, refrigerant cannot be injected from a bypass circuit to the Rankine cycle, and therefore super-cooling degree cannot be controlled. An exhaust heat recovery system is provided that can adjust the super-cooling degree even in the case of the pressure difference not occurring across the refrigerant pump. The system includes a refrigerant tank, for storing refrigerant, which is connected by pipes to the low-pressure circuit side and the high-pressure circuit side of the Rankine cycle through a low-pressure-side valve and a high-pressure-side valve, respectively, and a temperature adjuster for adjusting internal temperature of the refrigerant tank.

Owner:MITSUBISHI ELECTRIC CORP

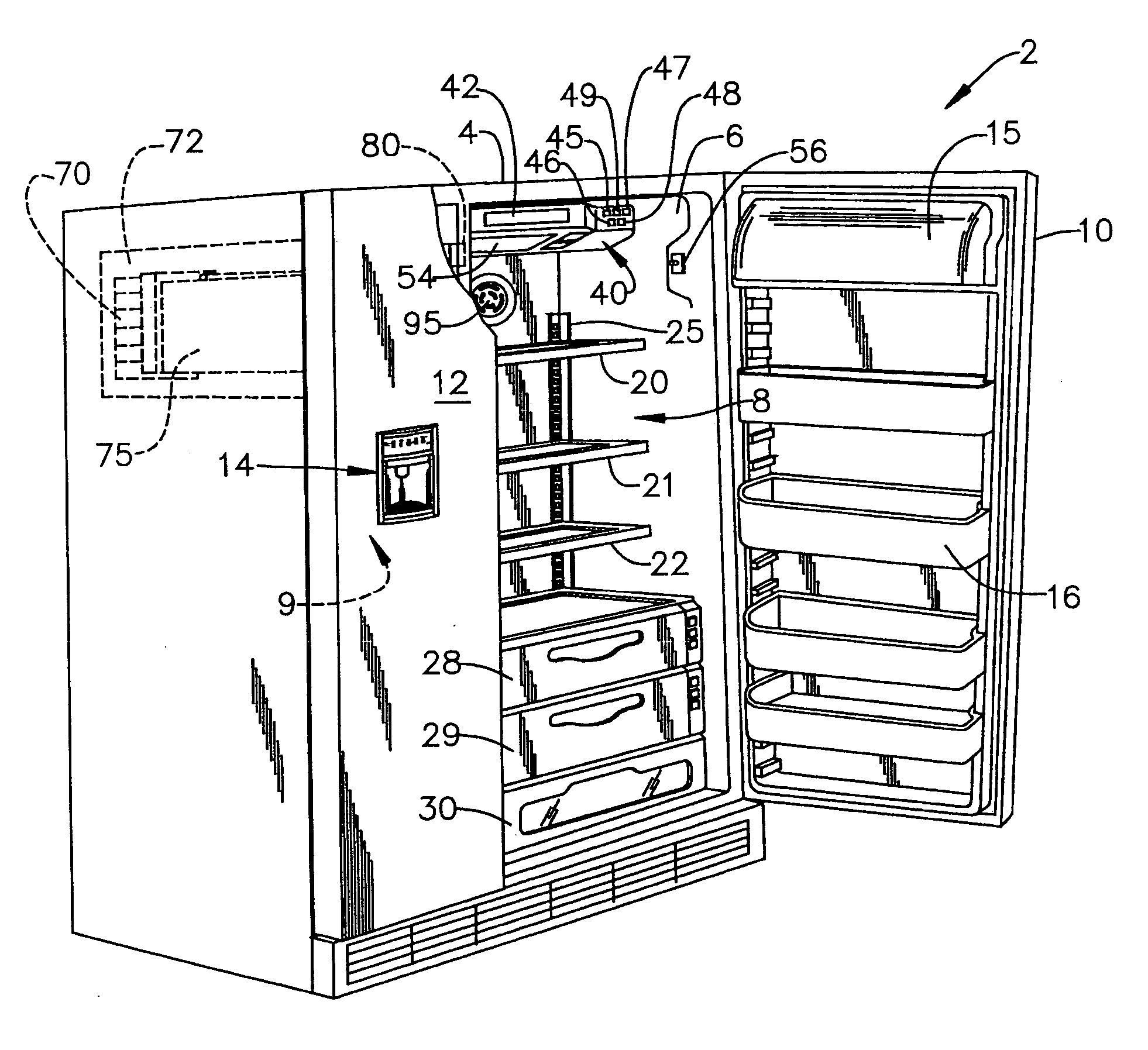

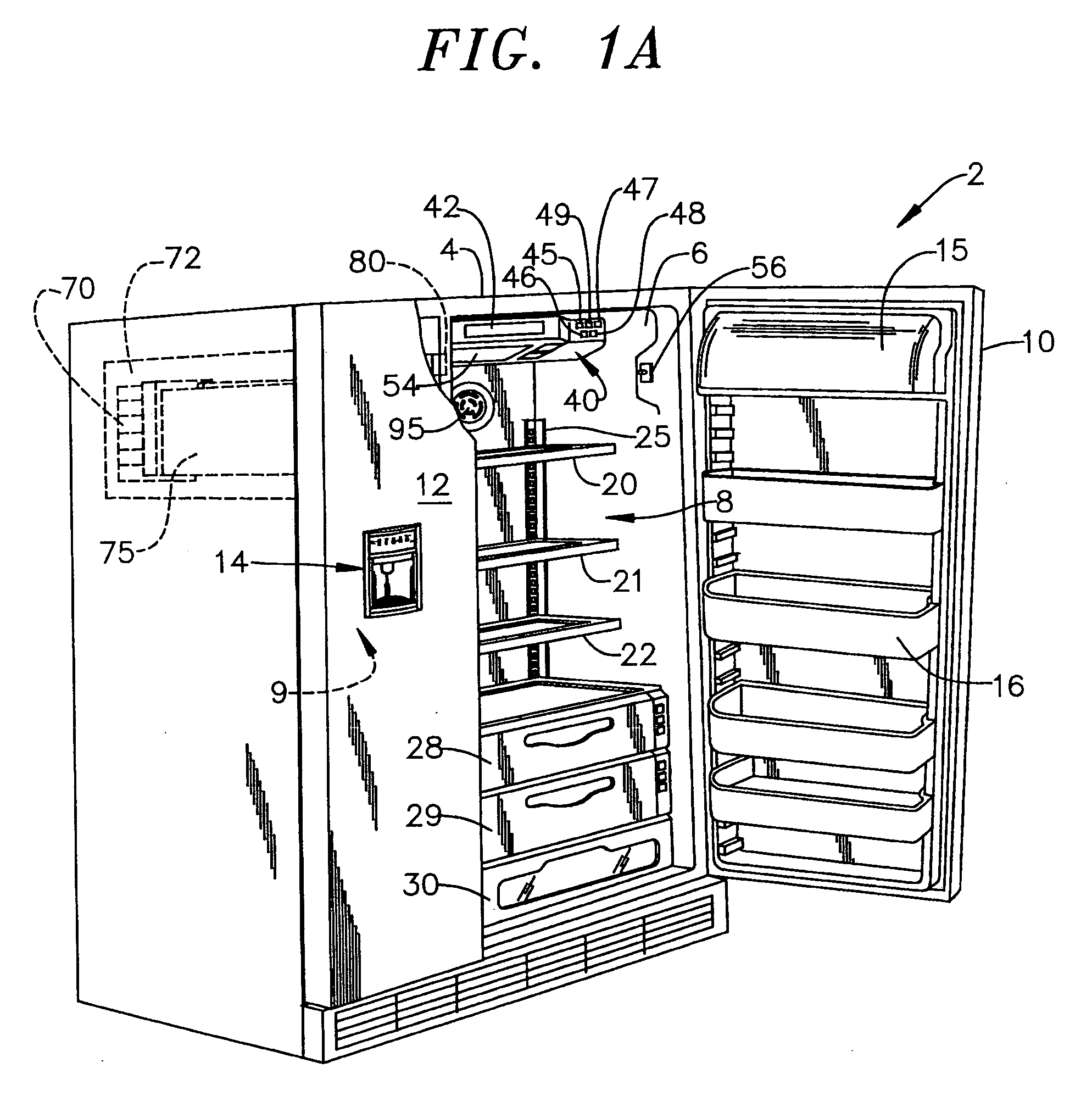

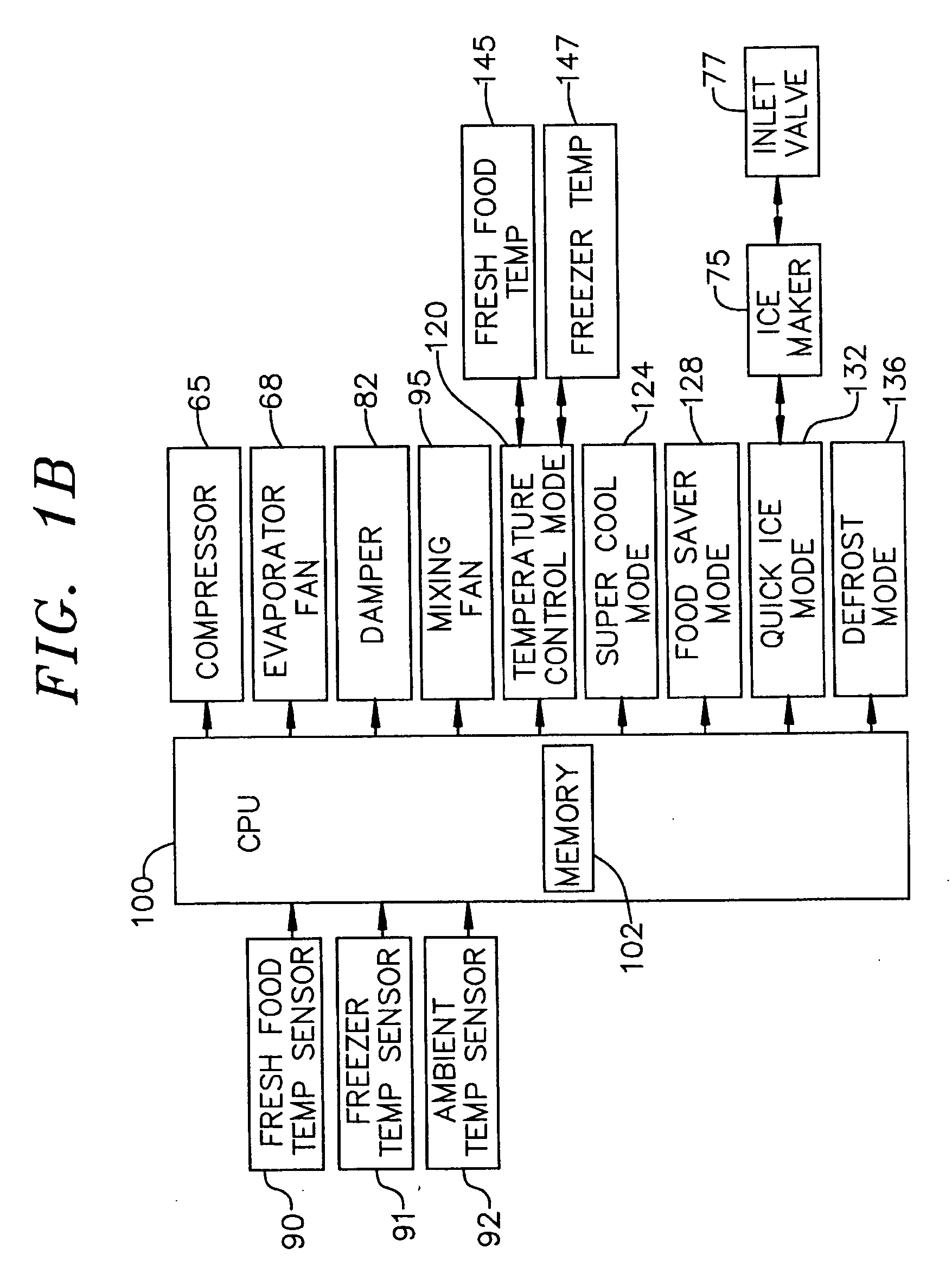

Control for a refrigerator

ActiveUS20070157645A1Reduce the temperatureIncrease temperatureDomestic refrigeratorsRefrigeration componentsSuper coolingFresh food

A refrigerator includes a fresh food compartment, a freezer compartment and a refrigeration system. A duct, exposed to the freezer compartment, leads into the fresh food compartment. A damper is arranged within the duct to selectively allow the passage of cooling air into the fresh food compartment. The refrigerator also includes an air mixing fan arranged in the fresh food compartment, a freezer mounted ice maker, a user interface having a plurality of control elements and a controller operatively associated with the user interface. The controller includes a memory having stored therein a plurality of operating parameters for controlling various aspects or features of the refrigerator, including a temperature control mode, a super cool mode, a food saver mode and a quick ice mode, which can be synergistically combined to efficiently operate the refrigerator.

Owner:MAYTAG

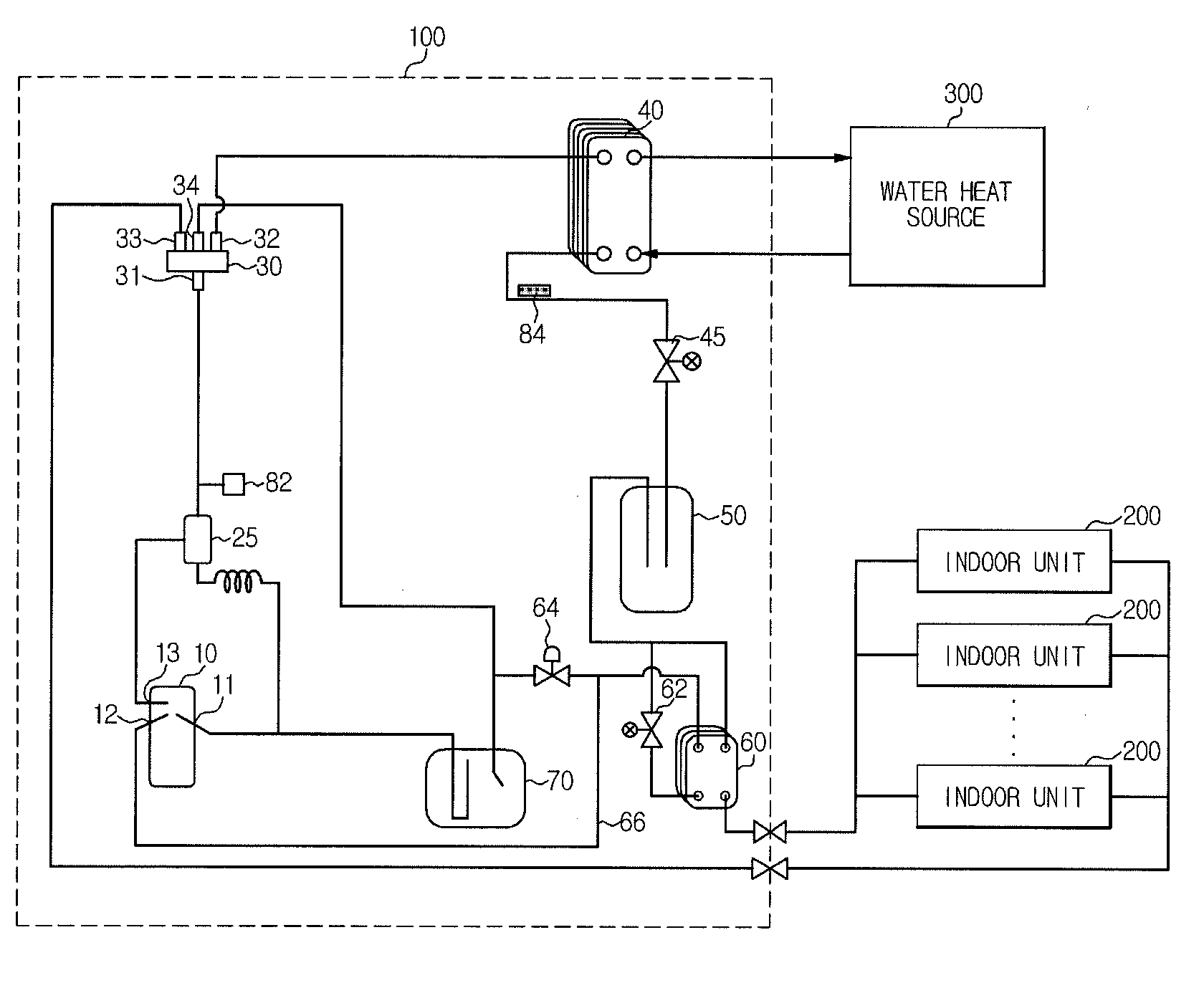

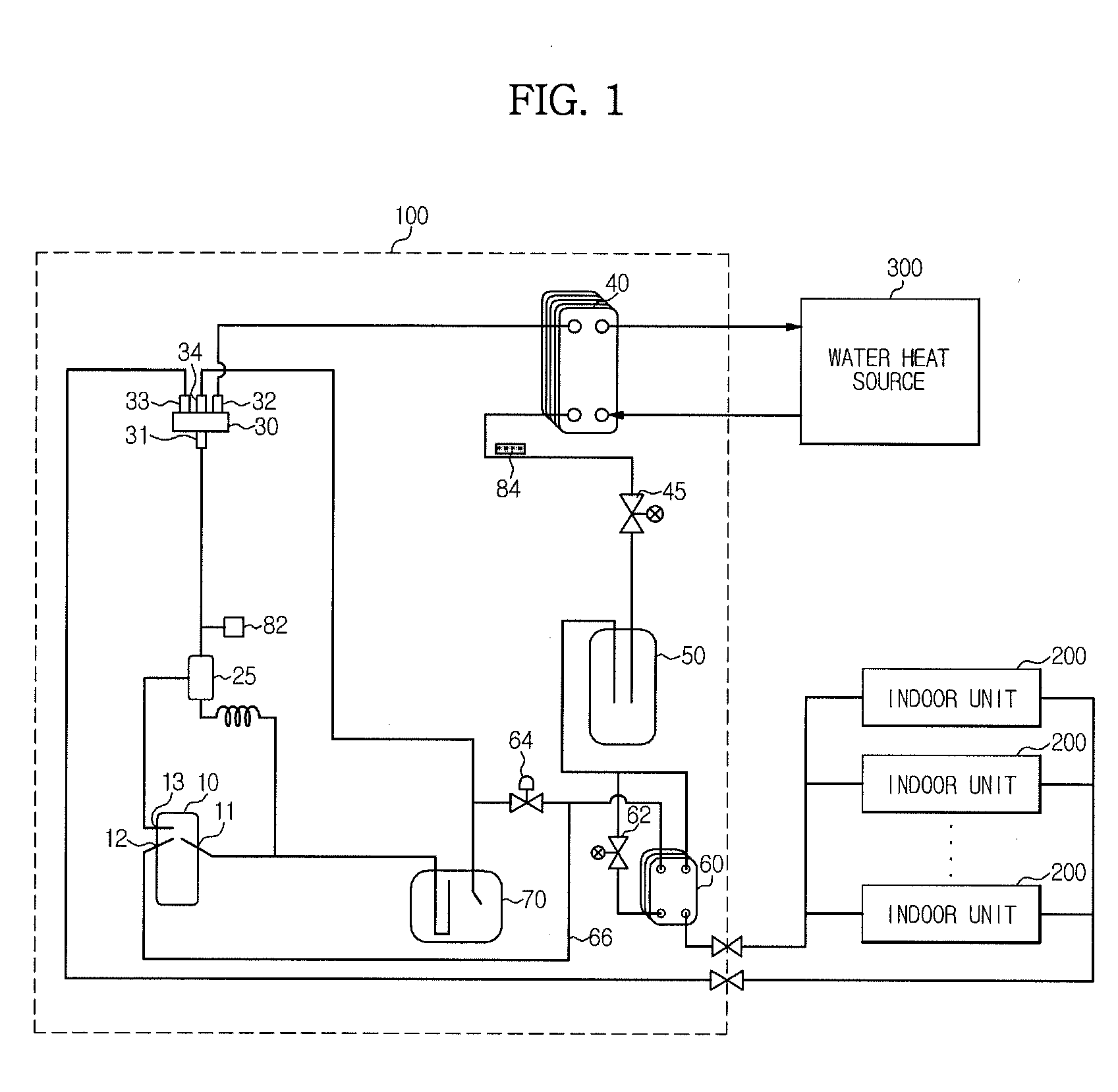

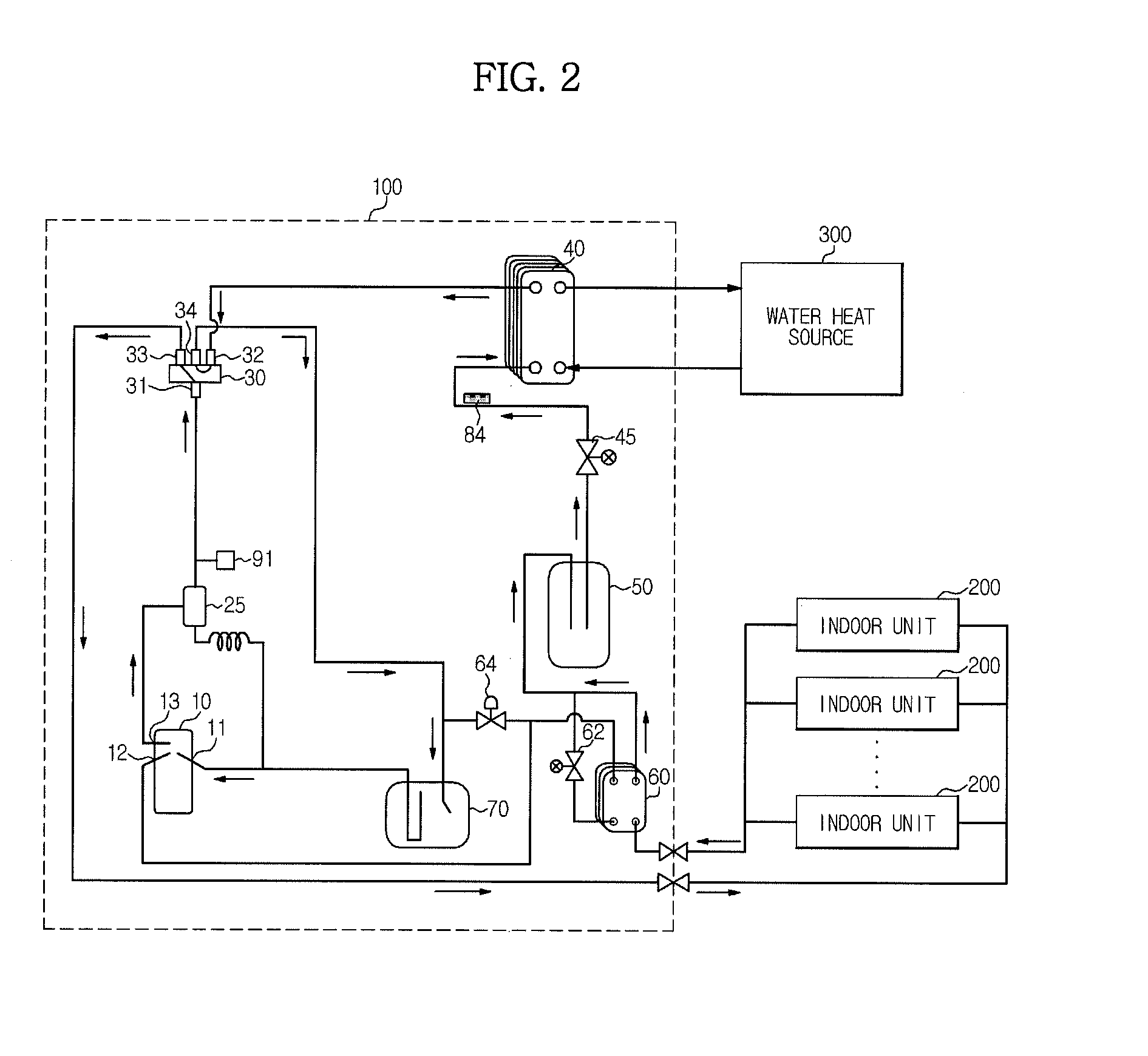

Air conditioner and control method thereof

InactiveUS20110192176A1Relieve stressReduce in quantityMechanical apparatusHeat pumpsSuper coolingWater source heat pump

Disclosed herein is a water-source heat-pump type air conditioner in which a receiver is connected to a super-cooler or economizer, and a control method of the air conditioner to reduce the quantity of liquid refrigerant collected in the receiver during a cooling / heating overload operation. When a cooling / heating overload operation occurs, an electric expansion valve associated with the super-cooler or the economizer is opened by a predetermined opening degree, to bypass high-pressure liquid refrigerant collected in the receiver, thereby preventing a rapid pressure increase due to a great quantity of liquid refrigerant collected in the receiver.

Owner:SAMSUNG ELECTRONICS CO LTD

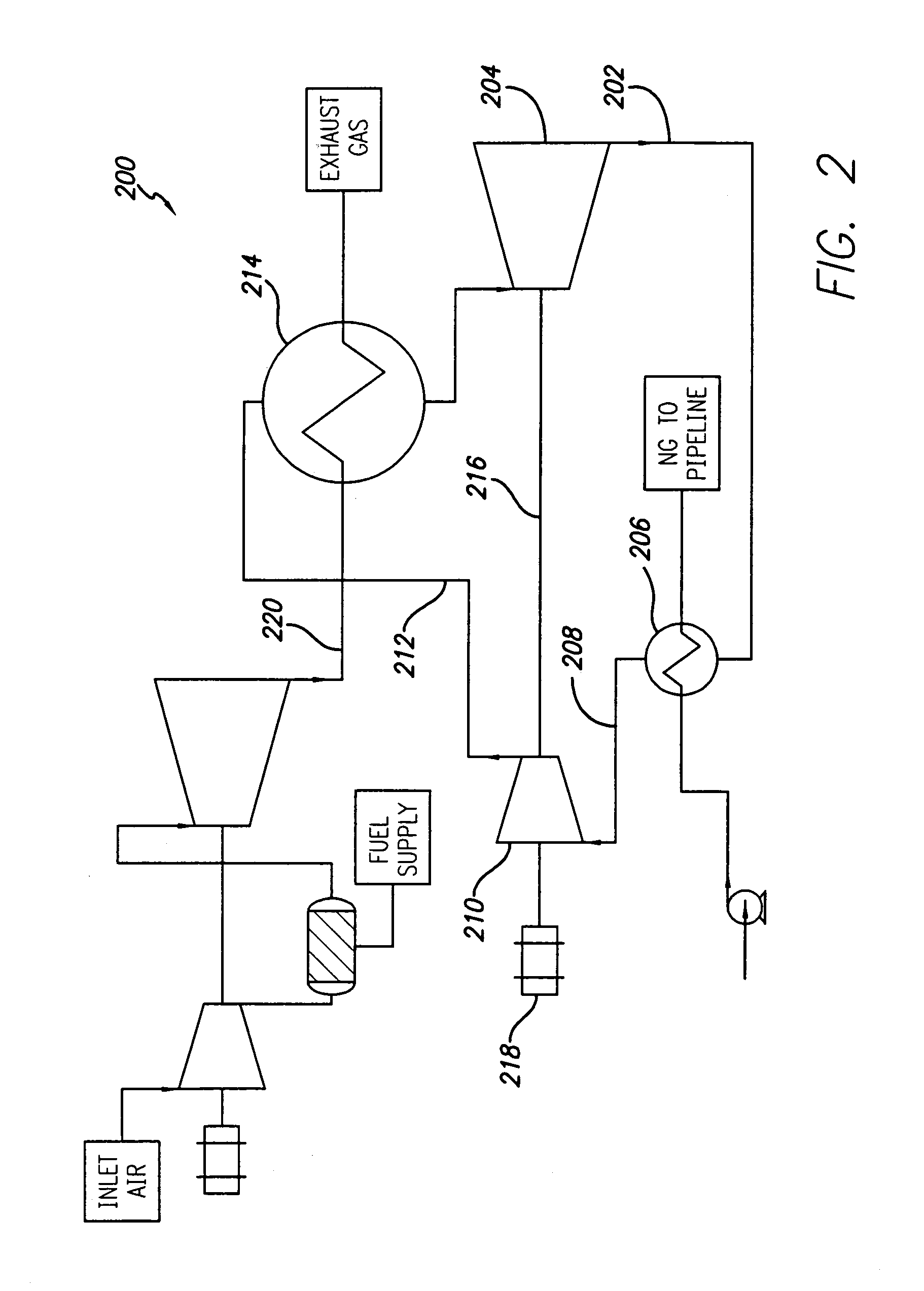

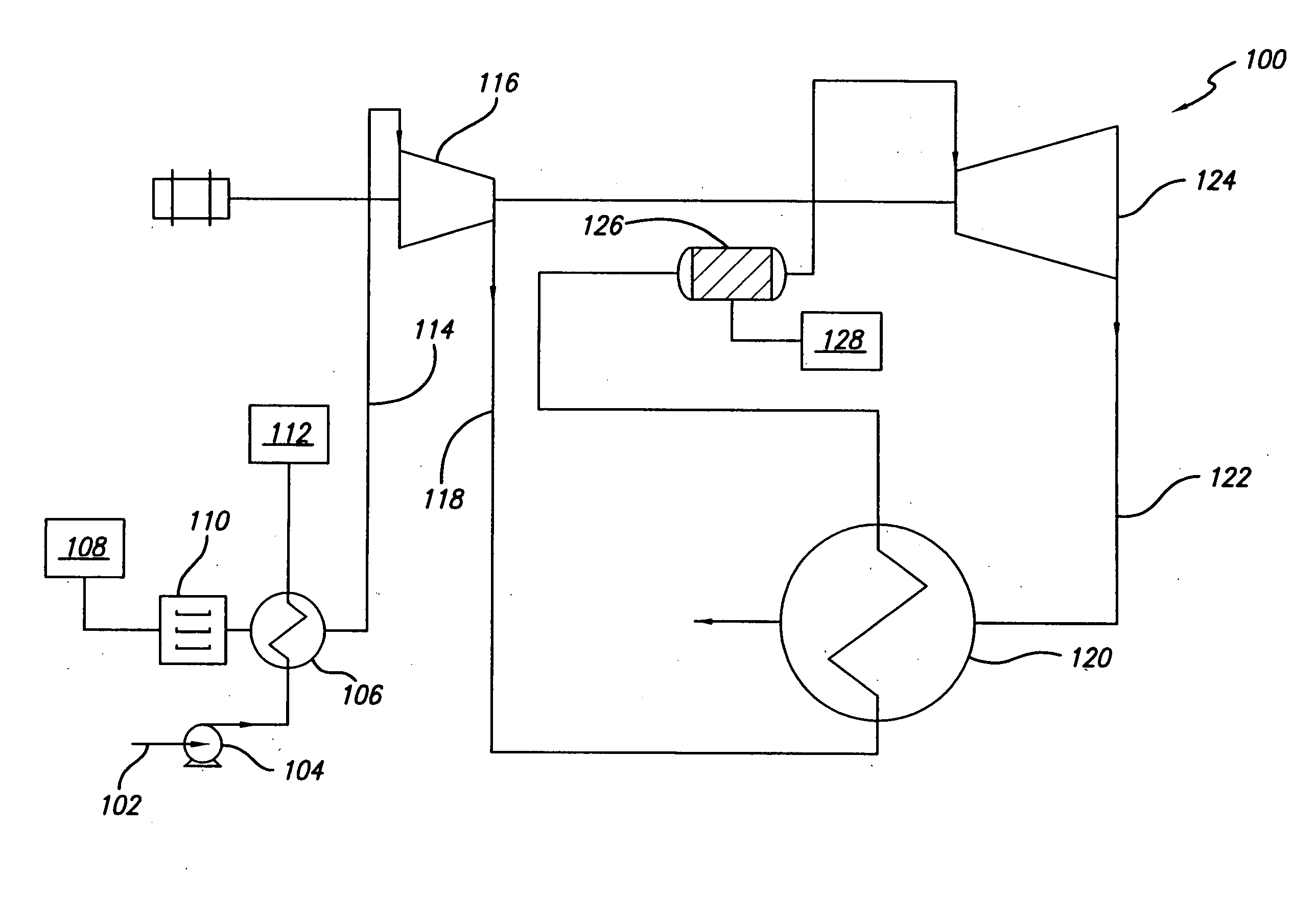

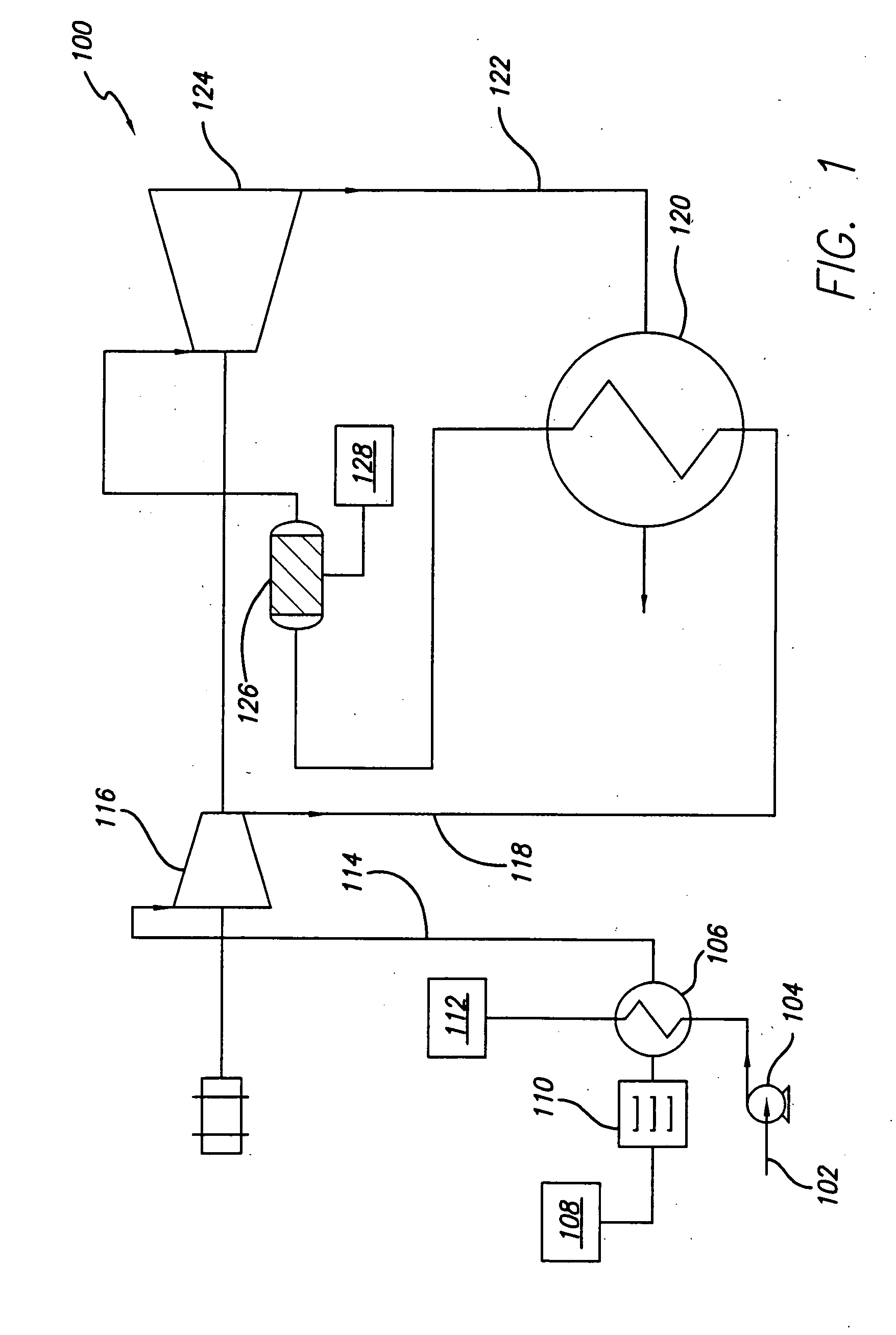

Vaporization of liquefied natural gas for increased efficiency in power cycles

InactiveUS20050223712A1Easy to compressLess contaminantGas turbine plantsJet propulsion plantsPower cycleCycle efficiency

A gas turbine cycle that utilizes the vaporization of liquefied natural gas as a source of inlet air chilling for a gas turbine. The cycle uses regeneration for preheating of combustor air and offers the potential of gas turbine cycle efficiencies in excess of 60%. The systems and methods permit the vaporization of LNG using ambient air, with the resulting super cooled air being easier to compress and / or having fewer contaminants therein. As the air is easier to compress, less energy is needed to operate the compressor, thereby increasing the efficiency of the system. A portion of the vaporized natural gas may be used as the combustion fuel for the gas turbine system, thereby permitting multiple turbines to be operated using a single topping cycle. In alternative embodiments, the vaporization of the LNG may be used as part of a bottoming cycle to increase the efficiencies of the gas turbine system.

Owner:SIEMENS ENERGY INC

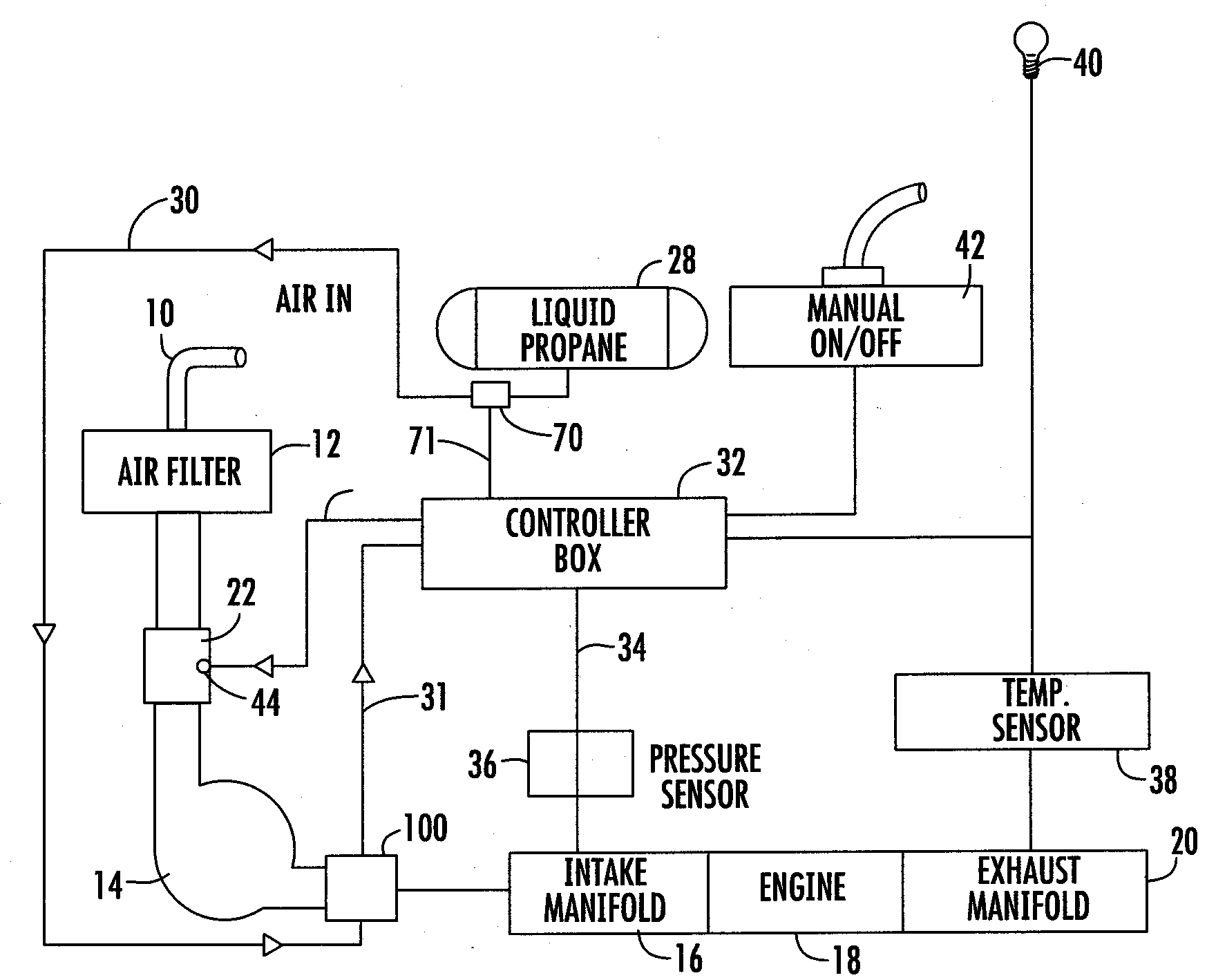

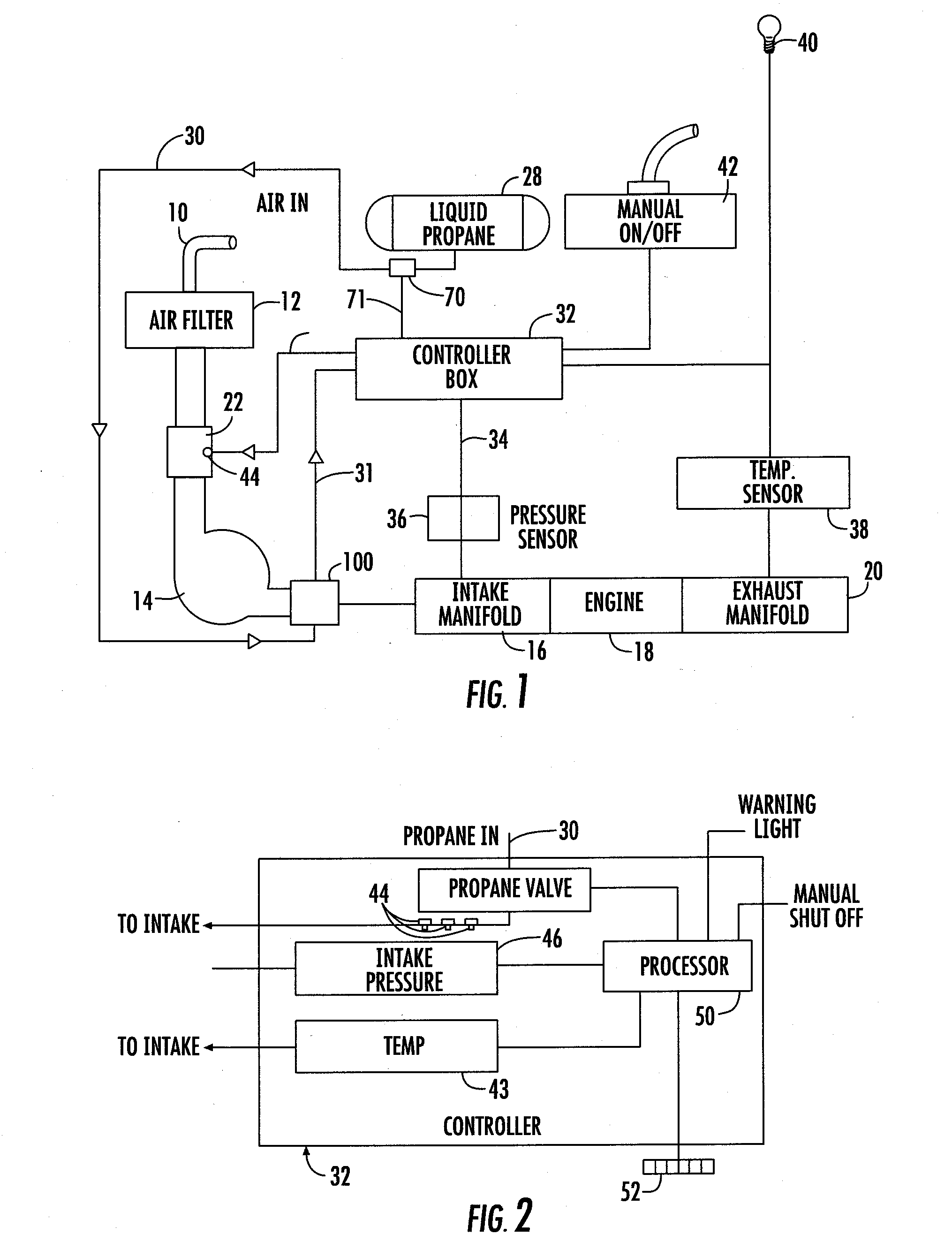

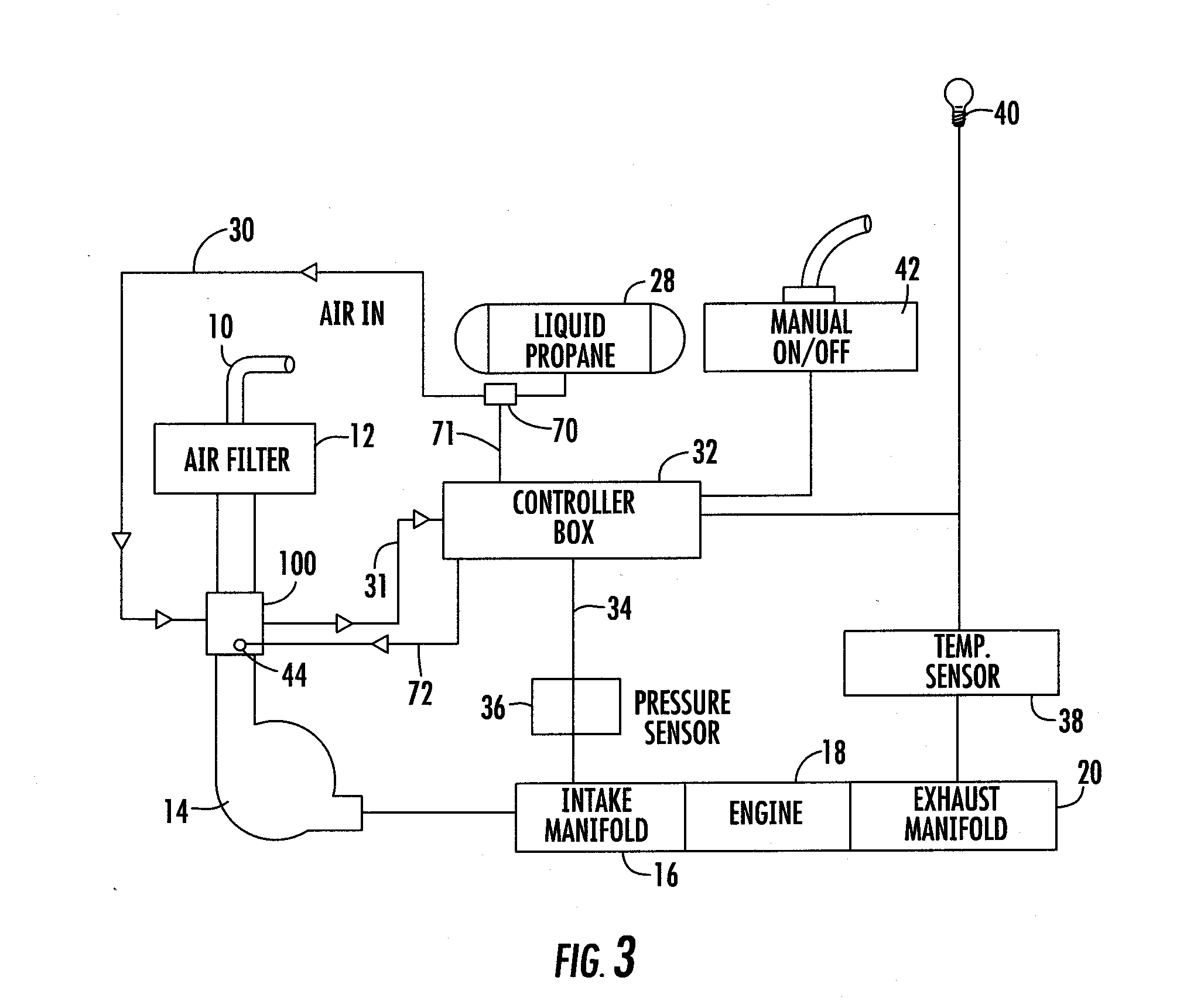

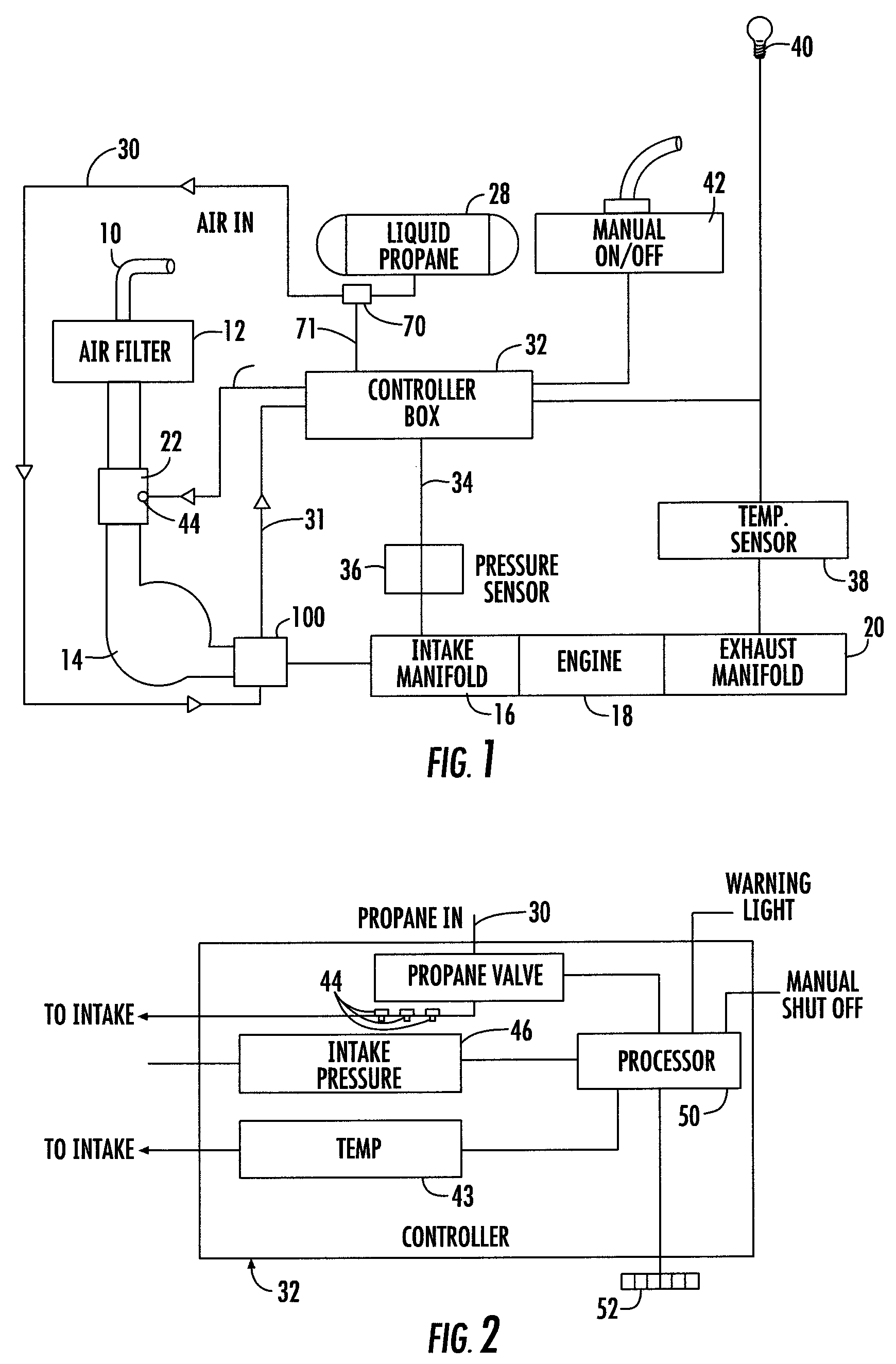

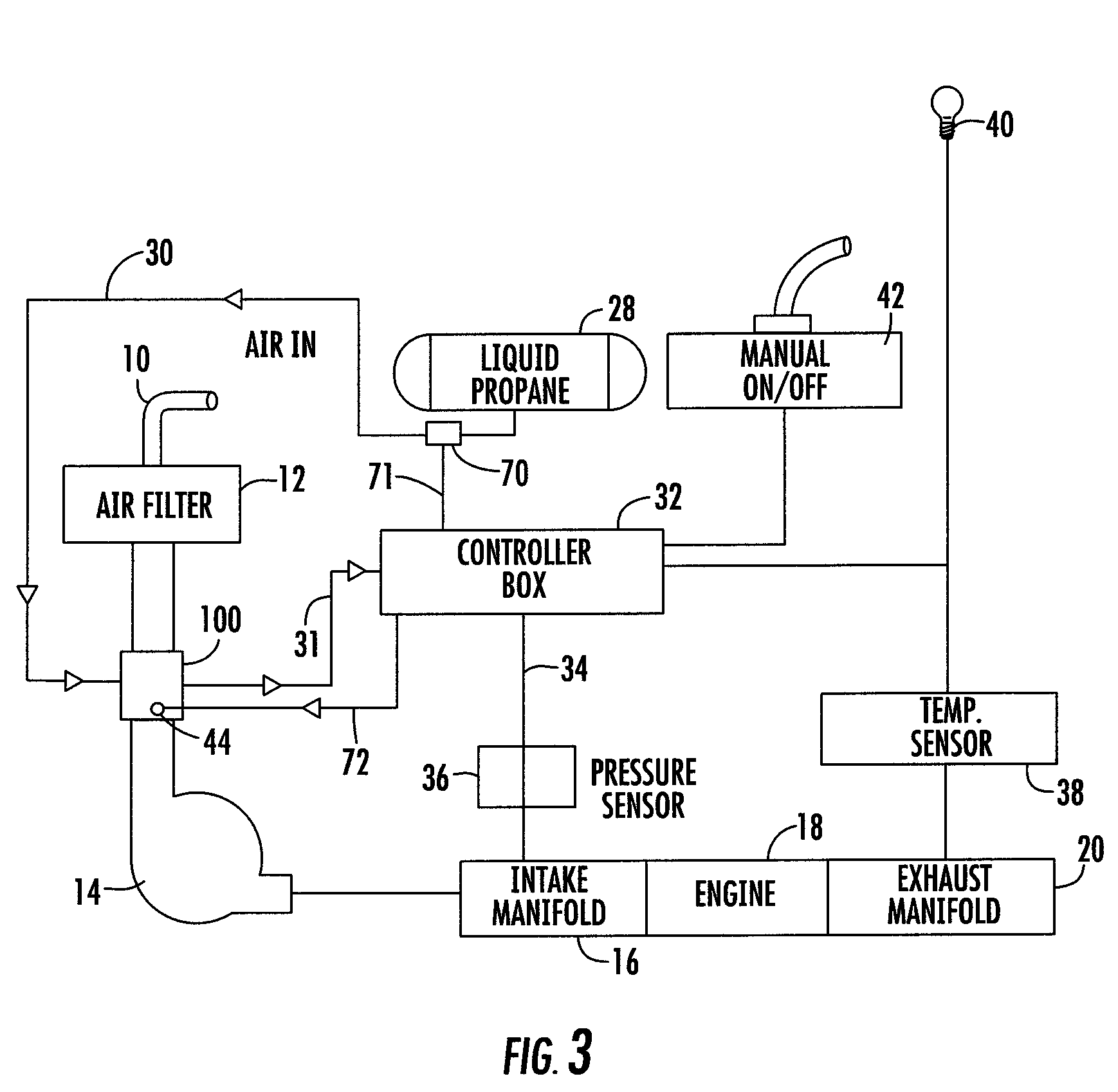

Super Cooled Air And Fuel Induction System For Internal Combustion Engines

ActiveUS20090126691A1Improved performance programmingMaximize fuel efficiencyElectrical controlInternal combustion piston enginesAlternative fuelsTurbocharger

The instant invention provides an apparatus and system for cooling the air charge of an internal combustion engine. More specifically, the instant invention provides an air-induction system suitable to provide cooled air charges to turbocharged, supercharged or naturally aspirated internal combustion engines to increase power output while reducing engine emissions. The system utilizes gaseous fuel stored as a liquid wherein the liquefied gaseous fuel is vaporized and warmed at least partially with heat removed from the intake air charge supplied to the engine from the turbocharger or supercharger. In a preferred embodiment, the compressed intake combustion air is first cooled in an aftercooler against an ambiently cooled coolant and is subsequently cooled further by the chiller of the instant invention which utilizes the change in phase, between liquid and gas, of the alternative fuel to cool the incoming air charge. The fuel, in the gaseous phase, is then supplied to the engine in a controlled manner for combustion by the engine. The operation of this system is measured and controlled by a control box mounted in the engine compartment.

Owner:DYNAMIC FUEL SYST

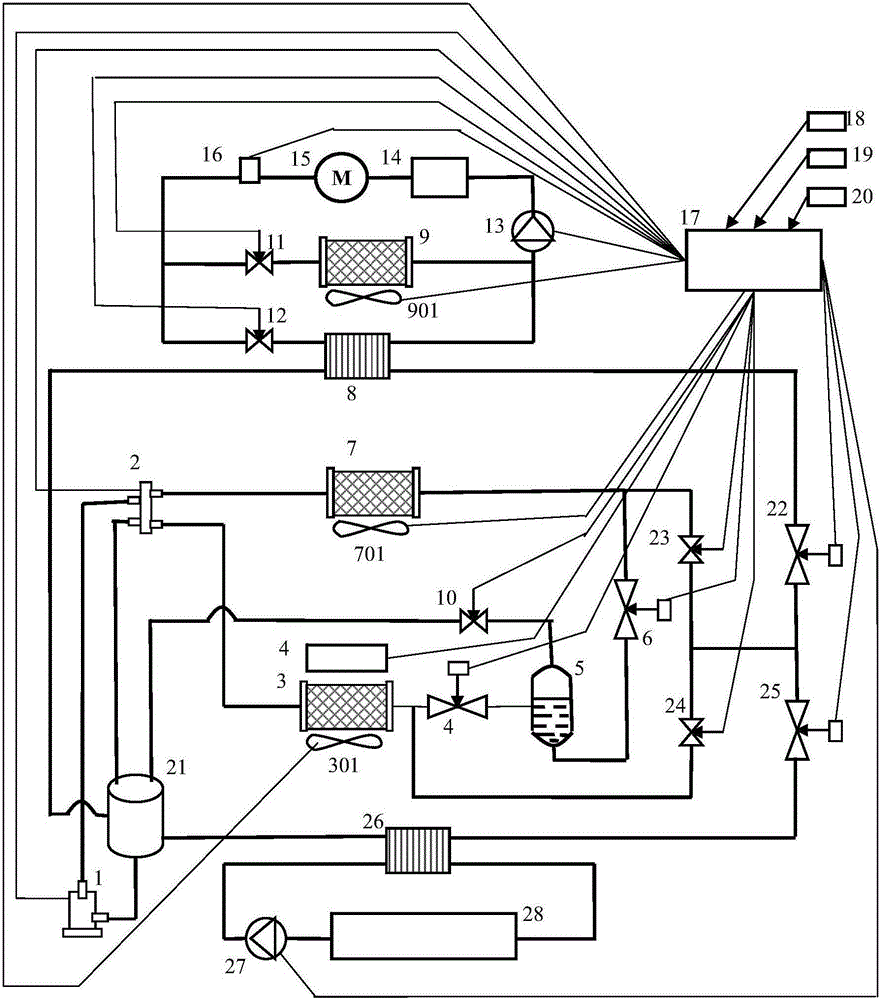

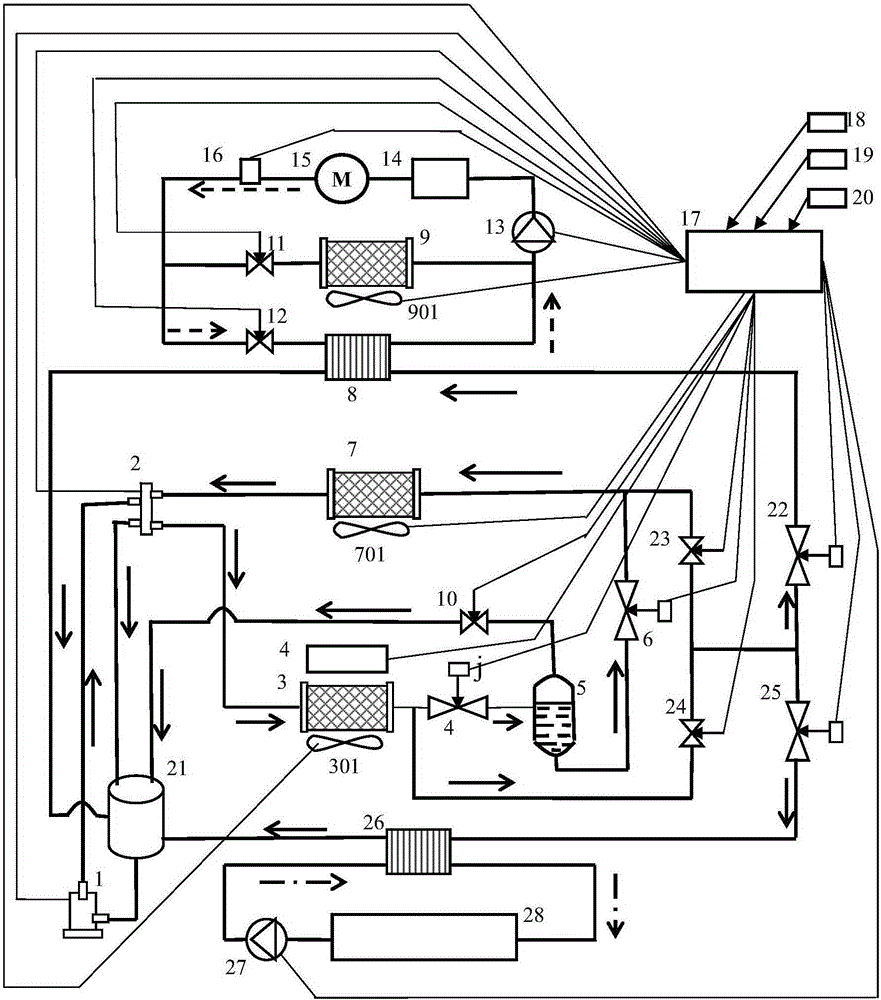

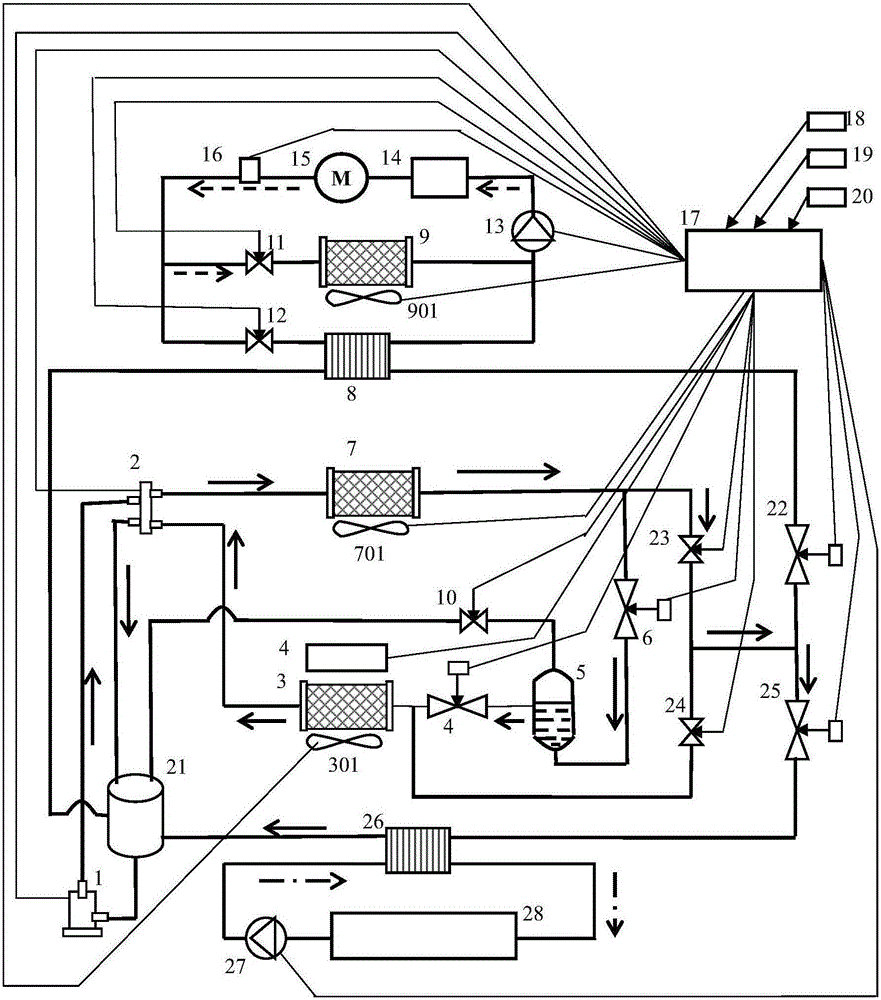

Flash evaporation super-cooling air-admission electric automobile waste heat recovery heat pump type integrated thermal management system

ActiveCN105216584AImprove energy efficiencyExtend the mileage of a single chargeAir-treating devicesHeat recovery systemsAutomatic controlSolenoid valve

The invention provides a flash evaporation super-cooling air-admission electric automobile waste heat recovery heat pump type integrated thermal management system. The system comprises an electric compressor, a four-way reversing valve, a vehicle interior air-conditioning heat exchanger, a first electronic expansion valve, a second electronic expansion valve, a third electronic expansion valve, a vehicle exterior air-conditioning heat exchanger, a driving motor waste heat recovery heat exchanger, a driving motor heat exchanger, a motor water pump, a flash evaporation super-cooling air-admission device, a first solenoid valve, a second solenoid valve, a third solenoid valve, a multi-inlet gas-liquid separator and a thermal management controller. By employing the integrated thermal management system, integrated thermal management on a vehicle power system and the vehicle interior thermal environment is carried out; waste heat of a driving motor of an electric automobile and a power battery system is recovered; flash evaporation super-cooling air-admission automatic control is realized; the energy efficiency of the system is improved; the load of the vehicle exterior heat exchanger during a heating process is reduced; the thermal safety of a driving motor system and the power battery system is guaranteed; and damage to the driving motor system and the power battery system is prevented. The integrated thermal management system is low in cost, is high-efficient and energy-saving, has reliable performance, and is convenient to maintain.

Owner:SHANGHAI JIAO TONG UNIV +1

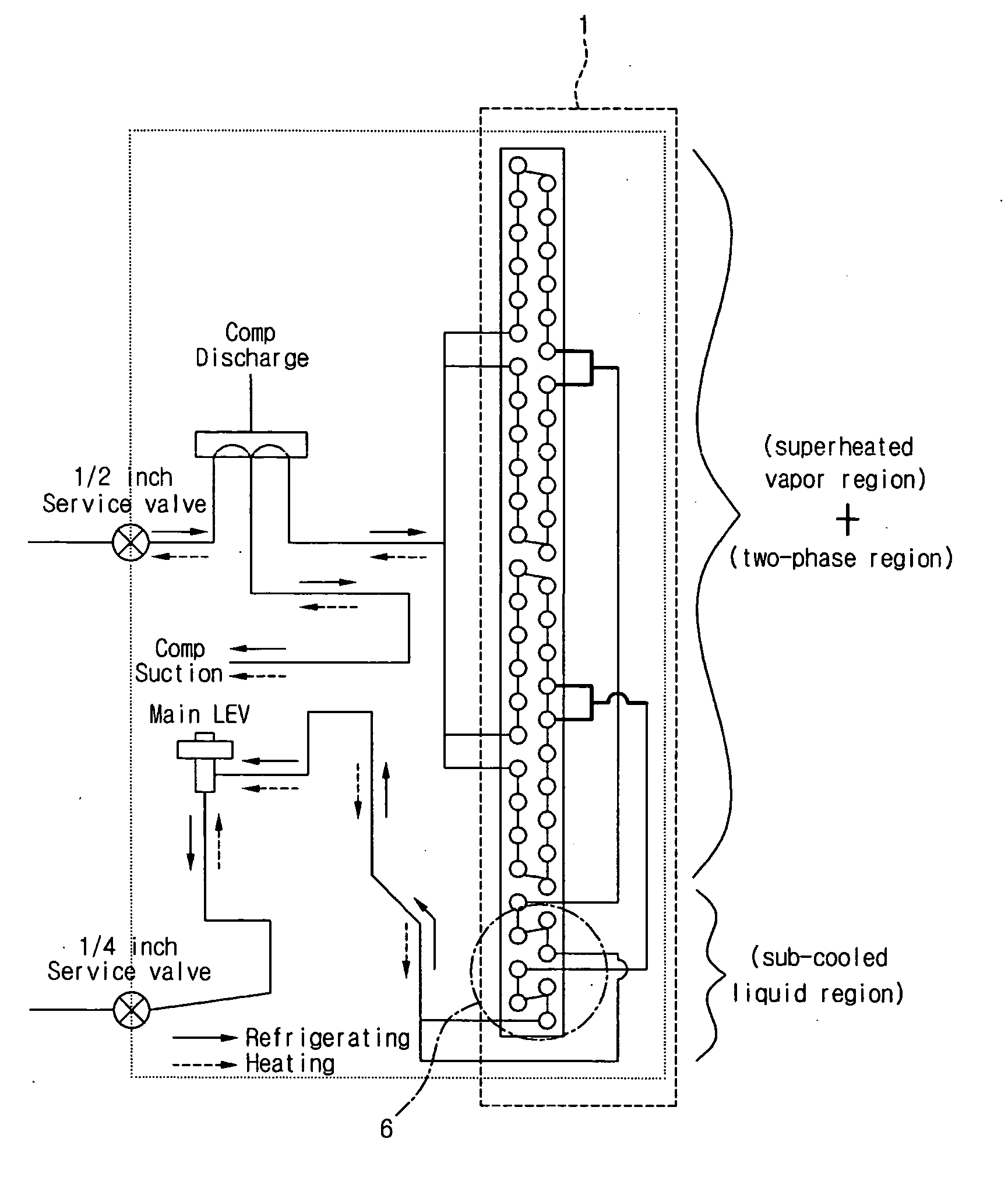

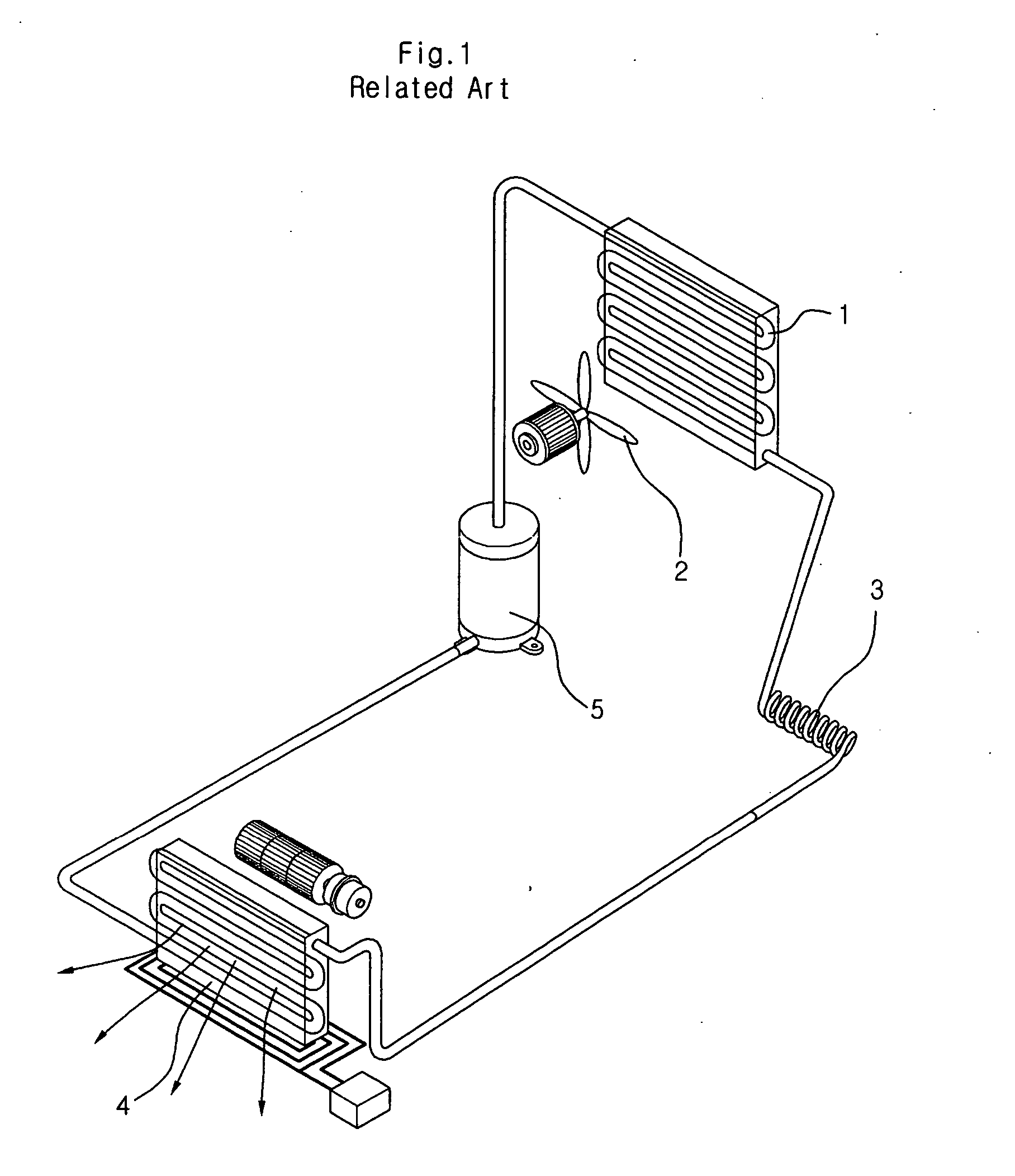

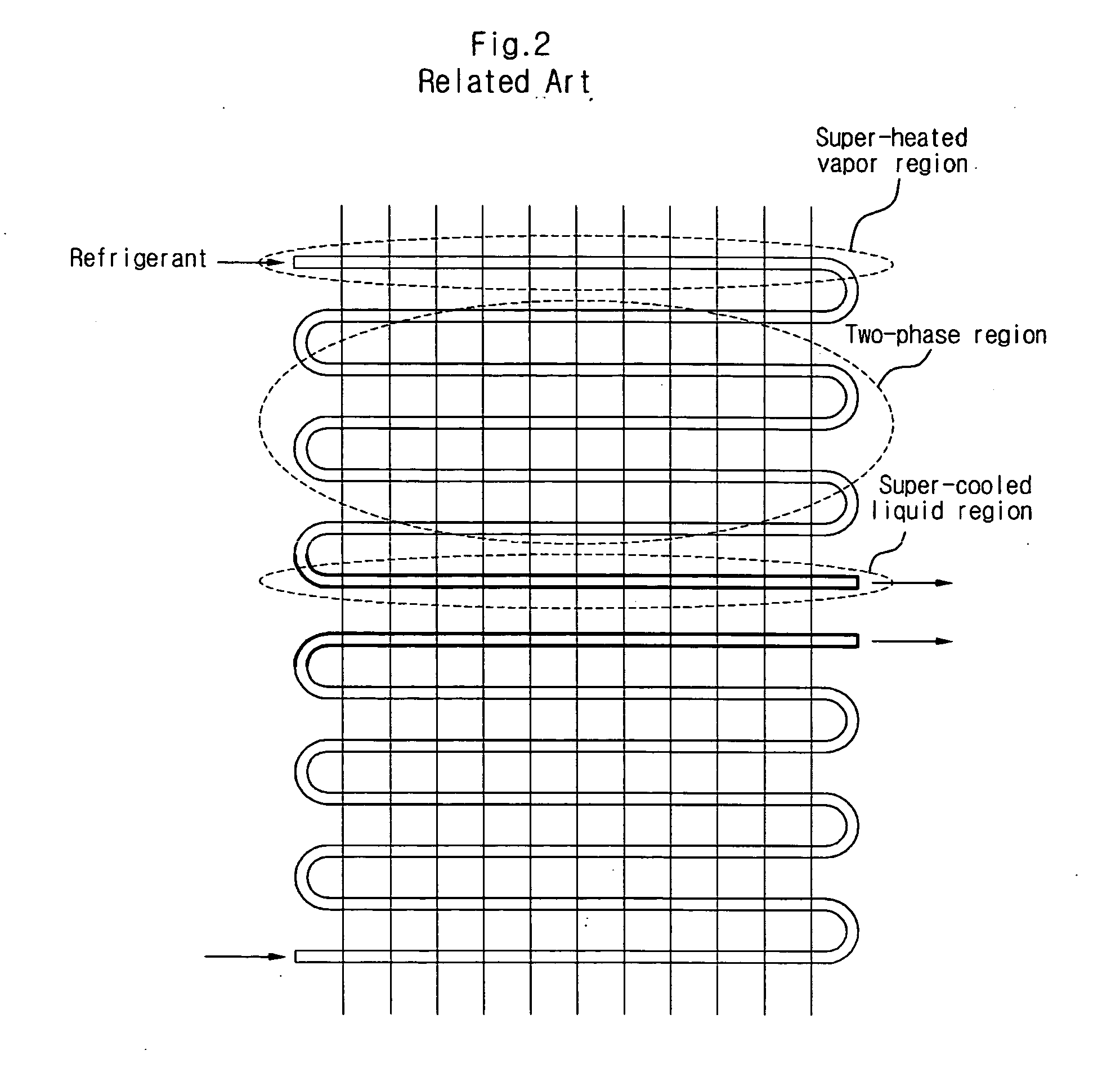

Condenser

InactiveUS20050044882A1Good air effectReduce electric powerCompression machines with non-reversible cycleEvaporators/condensersSuper coolingLiquid state

A condenser where a refrigerant introduced from a compressor is coexisting in super-heated vapor, two-phase and super-cooled liquid states combines a plurality of refrigerant paths within at least one of super-heated vapor and two-phase regions to output the refrigerant to the super-cooled liquid region, and provides a proper percentage of the super-cooled liquid region.

Owner:LG ELECTRONICS INC

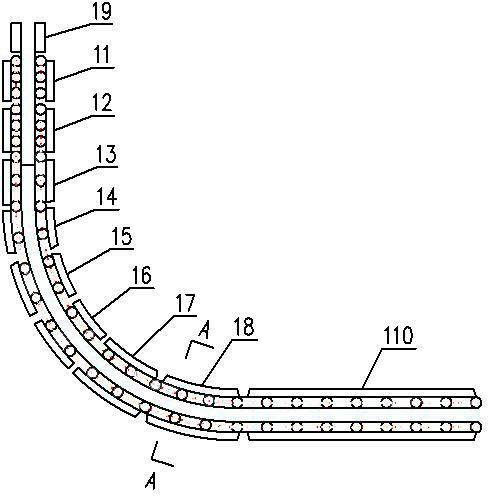

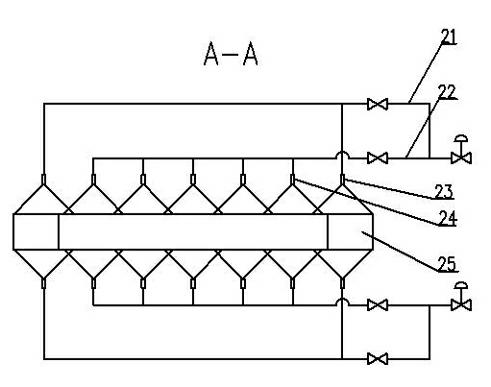

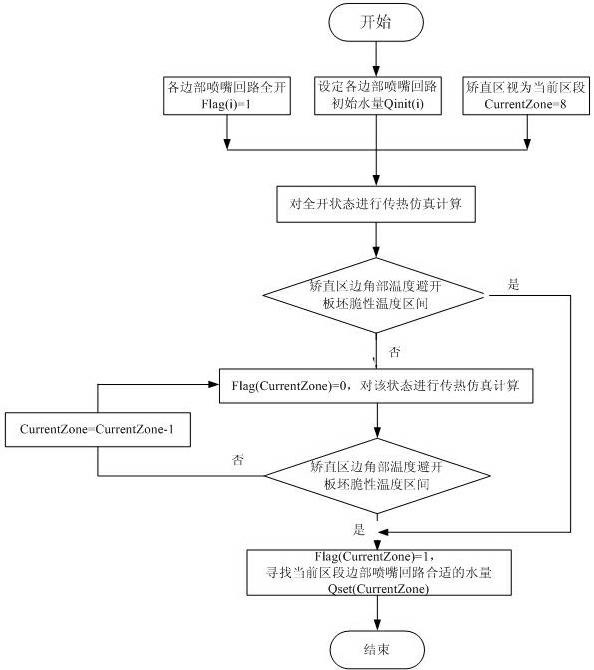

Method for controlling secondary cooling water spraying width during continuous casting of plate blank

The invention discloses a method for controlling secondary cooling water spraying width during continuous casting of a plate blank, which comprises the following steps: firstly, setting a plurality of secondary cooling sections in front of a straightening region of the plate blank; secondly, establishing a two-dimensional solidification and heat transfer simulation model of the plate blank through a computer; thirdly, utilizing the two-dimensional solidification and heat transfer simulation model to adjust the lectotype and the arrangement of a spray nozzle at the middle part of the wide surface of the plate blank; fourthly, determining the reasonable lectotype and the arrangement of the spray nozzles at the side parts by processing through the computer; fifthly utilizing the simulation model to determine the temperature distribution of the plate blanks with various width specifications through calculation; and sixthly, utilizing the model to calculate the flow rate of cooling water of a loop of the spray nozzle loop at the side part, which is arranged in an open state, and implementing the strategic cooling according to the calculated flow rate of the cooling water so as to enable the temperature on the surface of the plate blank to be uniform and prevent the corner part from being super-cooled. In the method, the simulation model is utilized for calculating the result, the situation of enabling the temperature at the side or corner part of the plate blank in the straightening region to be kept away from a brittleness temperature range is taken as the target, and the open / close state of each spray nozzle loop at the side part can be accurately determined, thereby enabling the control of the secondary cooling water spraying width to be more accurate, preventing the corner part of the plate blank from being super-cooled and avoiding the generation of cracks.

Owner:CISDI ENG CO LTD +1

Super cooled air and fuel induction system for internal combustion engines

ActiveUS7841322B2Use minimizedImprove performanceElectrical controlInternal combustion piston enginesSuper coolingAlternative fuels

Owner:DYNAMIC FUEL SYST

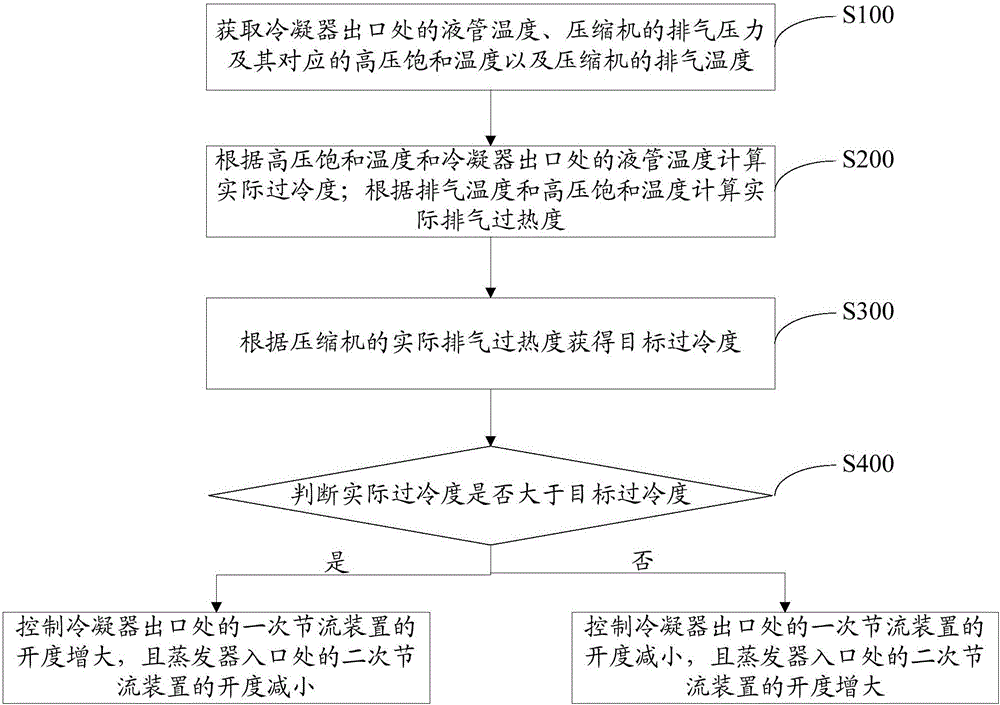

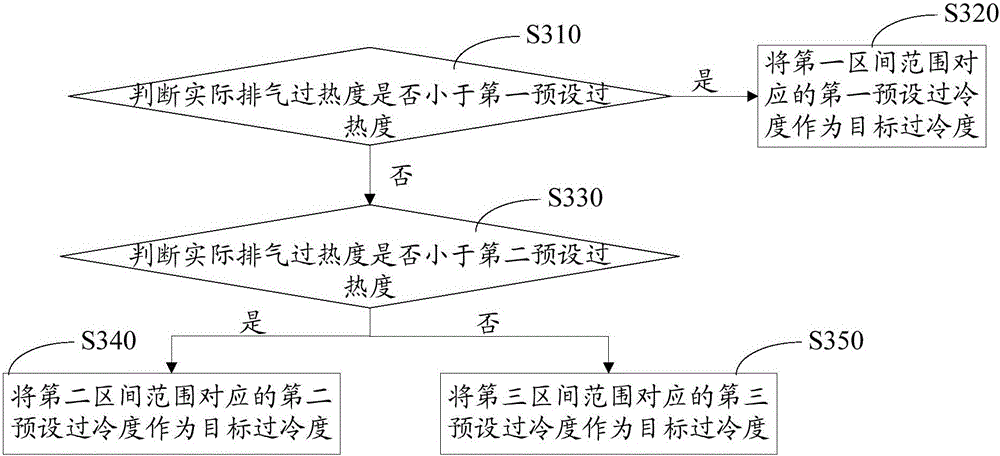

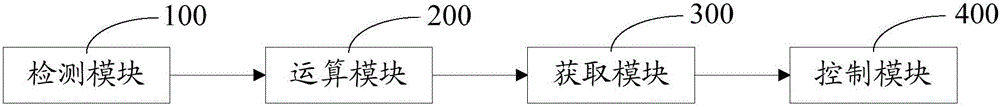

Control method of heat pump system and heat pump system

ActiveCN106196787APrevent liquid shockGuaranteed uptimeRefrigeration safety arrangementSuper coolingDischarge rate

The invention provides a control method of a heat pump system. The control method comprises steps as follows: the liquid pipe temperature at an outlet of a condenser, the discharge pressure of a compressor, the high-pressure saturation temperature corresponding to the discharge pressure and the discharge temperature of the compressor are acquired; the actual super-cooling degree is calculated according to the high-pressure saturation temperature and the liquid pipe temperature at the outlet of the condenser; the actual discharge superheat degree is calculated according to the discharge temperature and the high-pressure saturation temperature; the target super-cooling degree is acquired according to the actual discharge superheat degree of the compressor; whether the actual super-cooling degree is larger than the target super-cooling degree or not is judged, and if the actual super-cooling degree is larger than the target super-cooling degree, the actual super-cooling degree is reduced by adjusting the opening degree of a throttling device; and if the actual super-cooling degree is not larger than the target super-cooling degree, the actual super-cooling degree is increased by adjusting the opening degree of the throttling device. The invention further provides the heat pump system. With the control method of the heat pump system and the heat pump system, the accuracy of gas filling liquid detection and judgment of the system is improved, and the compressor is prevented from producing liquid impact, so that long-time reliable running of the compressor can be guaranteed.

Owner:GREE ELECTRIC APPLIANCES INC

EGR cooling and condensate regulation system for natural gas fired co-generation unit

InactiveUS20060130470A1Improve efficiencyReducing unwanted condensationNon-fuel substance addition to fuelInternal combustion piston enginesSuper coolingCombustion

A recycled exhaust gas cooling and condensate regulation system for a natural gas fired internal combustion engine driven co-generation plant, which allows efficient exhaust recycled gas combustion while maintaining lower head temperatures to reduce thermal NOx emissions and delivering increased process / utility heat to a proximate co-generation client, is provided. The recycled exhaust gas cooling and condensate regulation system has primary and secondary, air-to-gas, exchanger units, coupled in series, such that the first unit, designed to take exhaust gas exiting the engine, cools the gas to a first exhaust gas temperature effectively super saturating the water vapor in the cooled exhaust gas; and, the second unit, designed to handle lower inlet temperatures, condenses the water vapor and super cools the exhaust gas to <130 F. In one embodiment, the engine intake mixture including the exhaust gas is supercharged. In another embodiment, a separate intercooler circuit is used to cool the compressed intake charge containing the recycled gas prior to entry into the intake engine manifold to further reduce head temperatures and control thermal NOx emissions.

Owner:DORN GERALD R +1

Air conditioner dehumidifying system and control method thereof

ActiveCN103206748ARealize constant temperature and dehumidificationRealize warming and dehumidificationSpace heating and ventilation safety systemsLighting and heating apparatusSuper coolingFour-way valve

The invention discloses an air conditioner dehumidifying system which comprises an indoor unit and an outdoor unit. The outdoor unit comprises a compressor, a four-way valve, an outdoor heat exchanger, a first electronic expansion valve and a first one-way valve parallelly connected with the first electronic expansion valve, the indoor unit comprises a second electronic expansion valve, an indoor heat exchanger, a first electromagnetic valve and a dehumidifying coil, the first electromagnetic valve is parallelly connected with the second electronic expansion valve, the dehumidifying coil is arranged between the second electronic expansion valve and the indoor heat exchanger, and an electronic expansion valve is arranged between the dehumidifying coil and the indoor heat exchanger and is parallelly connected with a second electromagnetic valve. By the aid of the air conditioner dehumidifying system, a dehumidifying module and the dehumidifying coil are arranged between the second electronic expansion valve and the indoor heat exchanger, an air conditioner can realize constant-temperature dehumidifying, temperature rise dehumidifying and heating dehumidifying functions by controlling the electromagnetic valves and the electronic expansion valves, and the overall performance of the air conditioner is improved by the aid of secondary super-cooling technology.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +1

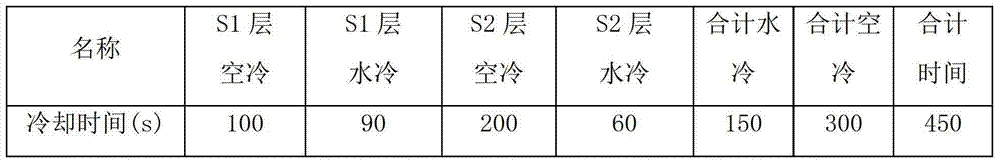

Method for formulating water-air alternate time-controlled quenching process

The invention provides a method for formulating a water-air alternate time-controlled quenching process. The method comprises the following steps of: step 1, predicating a structure composition of a part with required performance according to the performance detection part of an alloy steel piece and specific performance requirements; step 2, according to the super-cooled austenite isothermal cooling transformation curve or the super-cooled austenite continuous cooling transformation curve of a material, acquiring the longest cooling time or the minimum cooling speed which the structure needs to reach a certain temperature; step 3, dividing an alloy steel piece into a cooling speed control area and a slow cooling area along a section from the surface to the centre; step 4, determining the water-air alternation times of the cooling speed control area, and a water-cooling time and an air-cooling time each time; and step 5, determining the water-air alternation times of the slow cooling area, and a water-cooling time and an air-cooling time each time. With the adoption of the method provided by the invention, the alloy steel piece can obtain required performance or structure on the premise of avoiding cracking; and the method is suitable for a quenching treatment for the alloy steel pieces with various ingredients.

Owner:SHANGHAI JIAO TONG UNIV

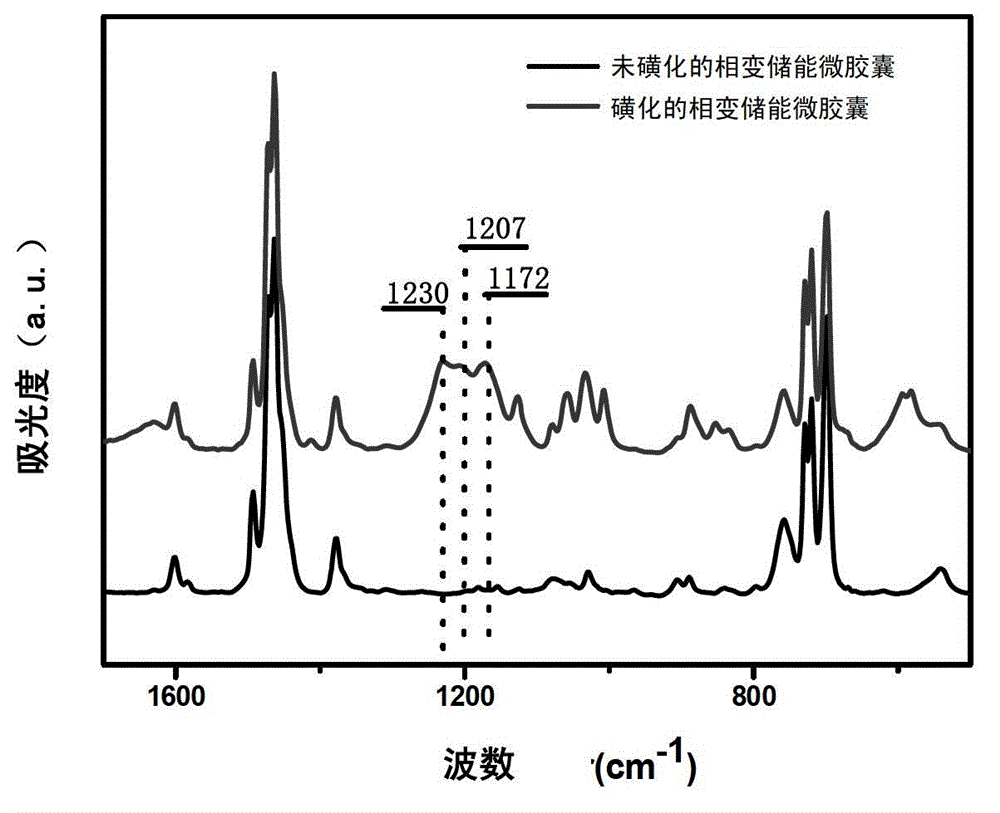

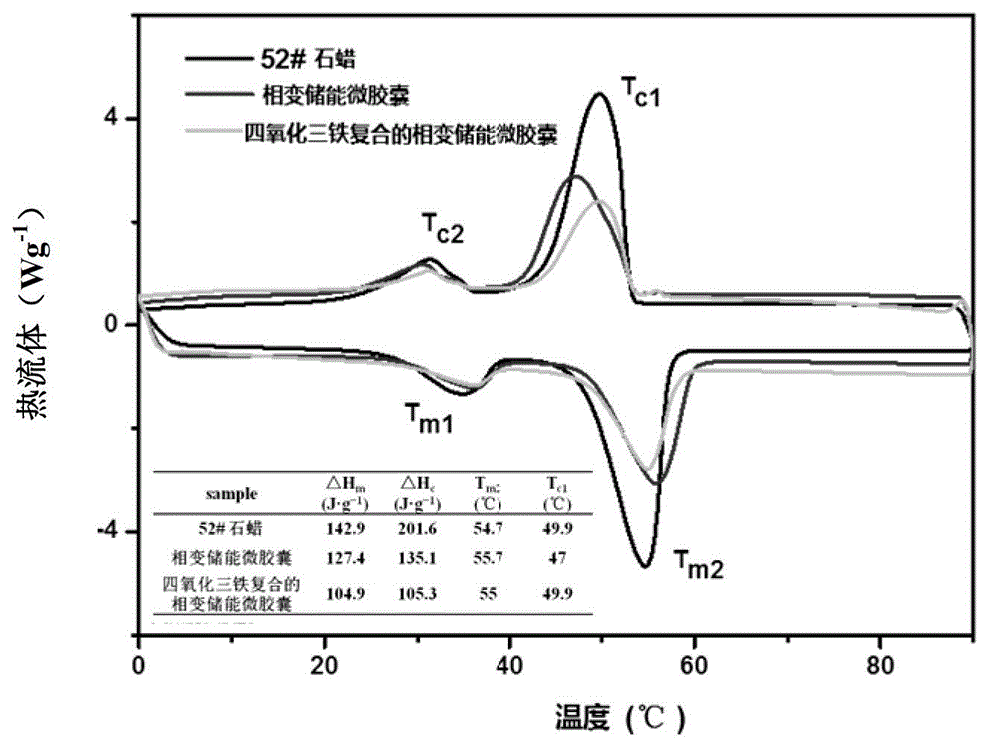

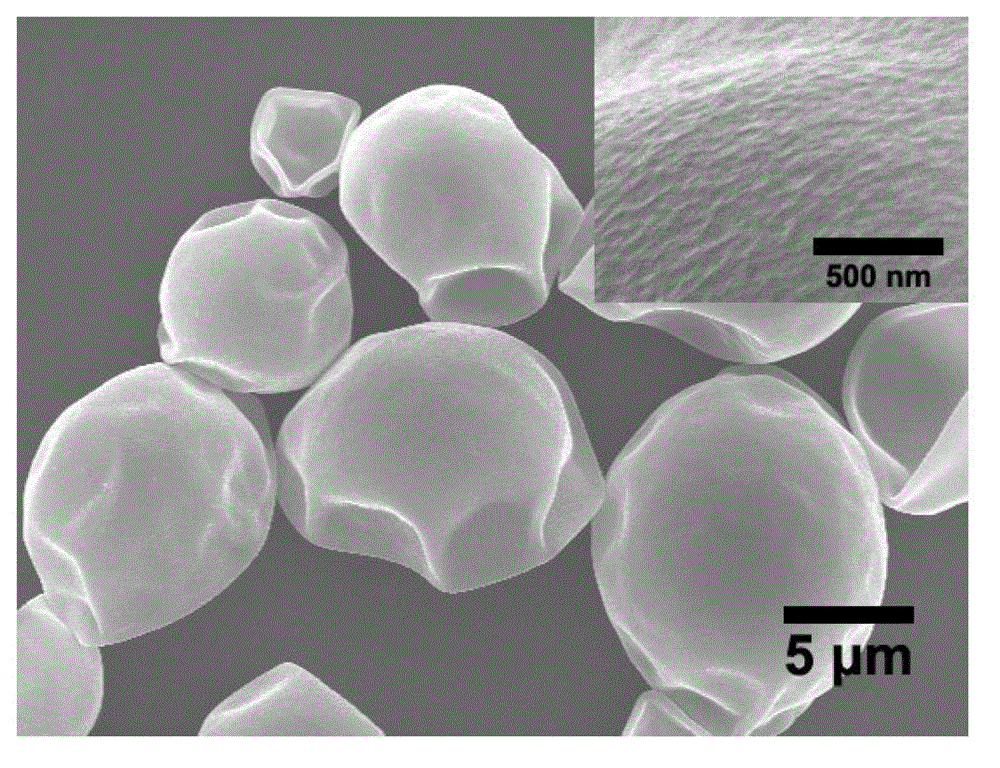

Phase change energy storage microcapsule and preparation method thereof

ActiveCN104031612AImprove thermal conductivityNo overcoolingHeat-exchange elementsMicroballoon preparationSuper coolingPhase change

The invention relates to a phase change energy storage microcapsule and a preparation method thereof, and especially relates to a phase change energy storage microcapsule having the advantages of no formaldehyde release, good heat conduction performance and no super cooling phenomenon, and a preparation method and an application thereof. The phase change energy storage microcapsule has a core-shell structure, wherein the whole shell of the phase change energy storage is compounded with metal or metal oxide particles. The phase change energy storage microcapsule has the advantages of no formaldehyde release, good heat conduction performance and no super cooling phenomenon.

Owner:中科世宇(北京)科技有限公司

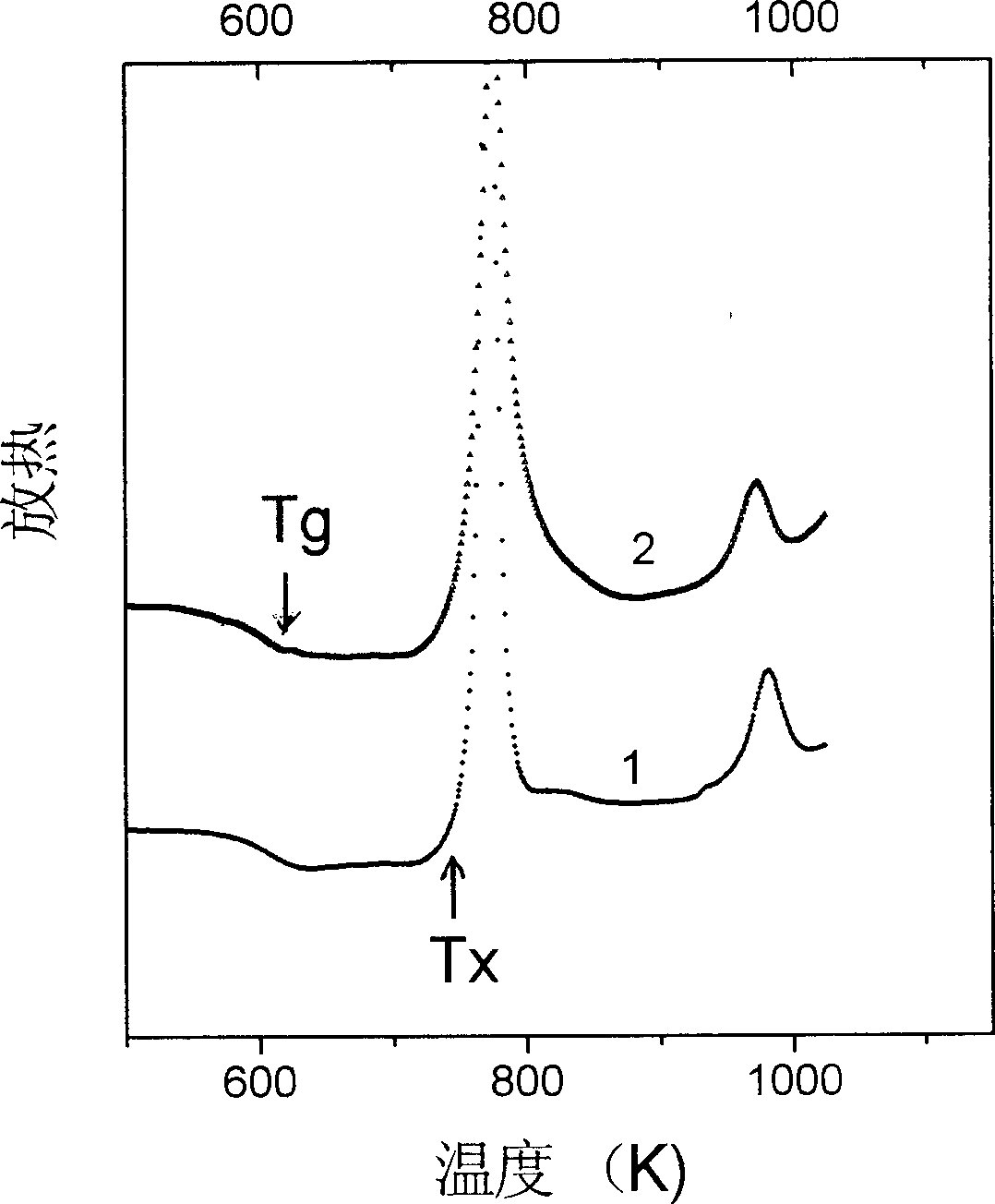

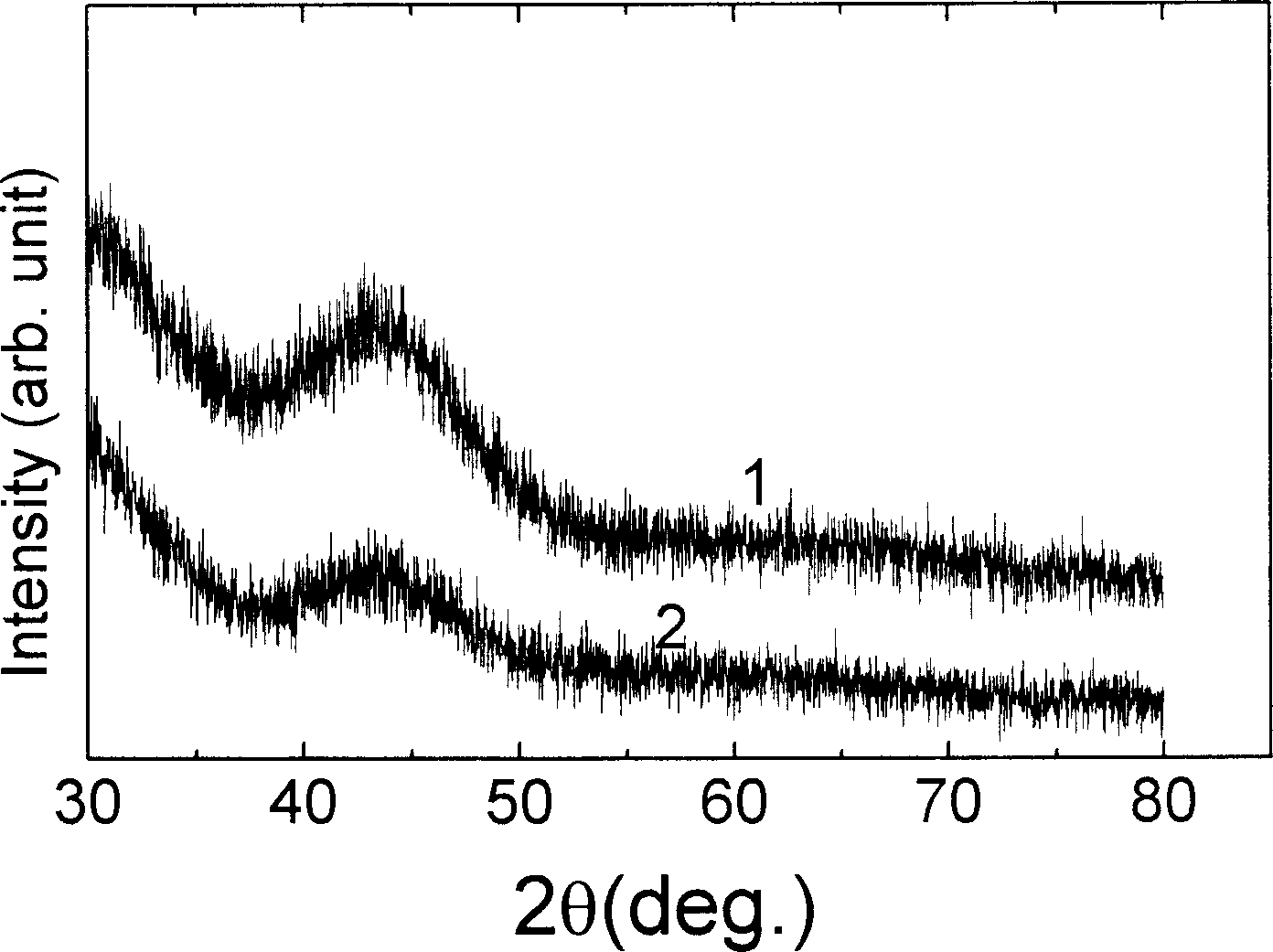

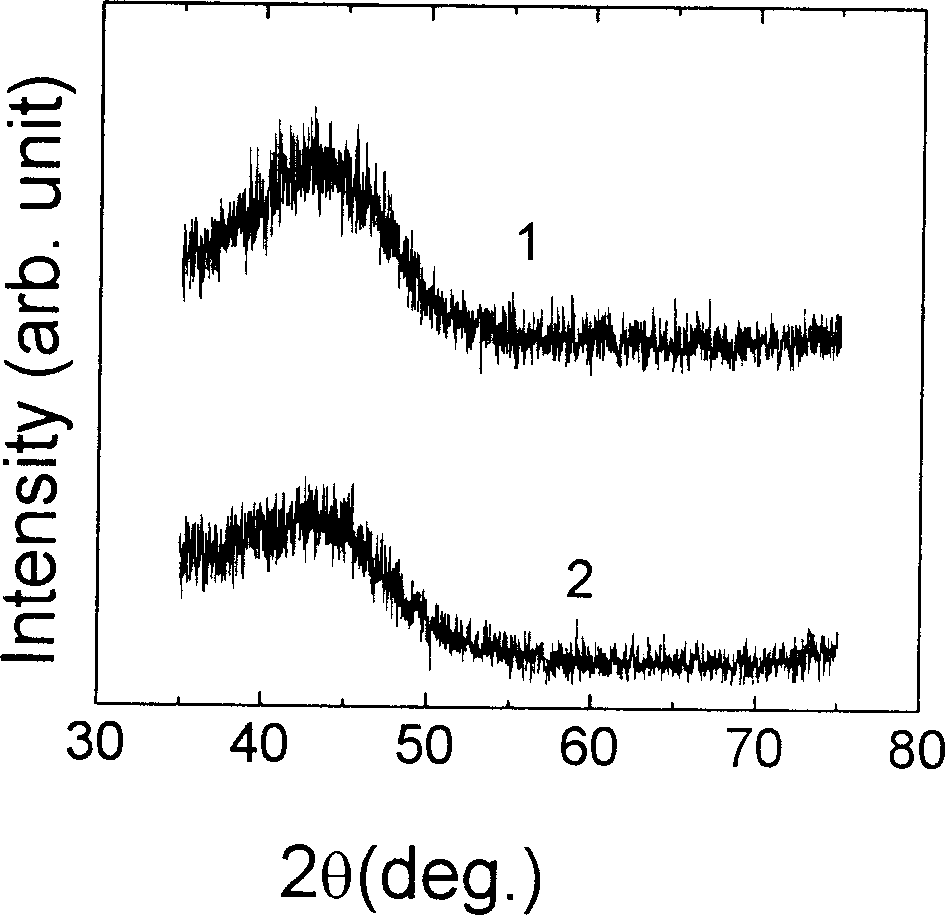

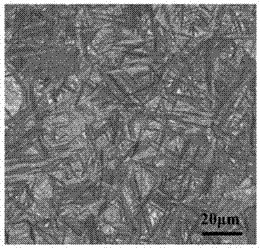

Rare earth iron base soft magnetic metallic glass having very large super cooling region

InactiveCN1442866AExcellent soft magnetic propertiesImprove thermal stabilityMagnetic materialsSuper coolingRare earth

A soft magnetic metal glass which consists of differential value for glass transforming temperature Tg and crystallization temperature Tx as over cooling section deltaTx=Tx-Tg, 50k to 110k rare earthiron-base metal glass has the composition of (Fel-aDa)-x-y-z-tTmyTnzLntBx, where element D is 1-2 kinds of Co and Ni, element Tm is 1-2 kinds of Nb, Mo, W, Zr, Cr, Ti, V, element Tn refers to one of Al, Cu, Si, C, Ln is 1-3 kinds of rare rarth element and the atomic ratios x,y,z,t and a are 21<x<35, 0.8<t<4.5, 0.1<2<2, 0.5<y<6 and 0íœaíœ13. The product of soft magnetic metal glass with the thickness below 4 mm can be made by the abrupt quenching process.

Owner:UNIV OF SCI & TECH BEIJING

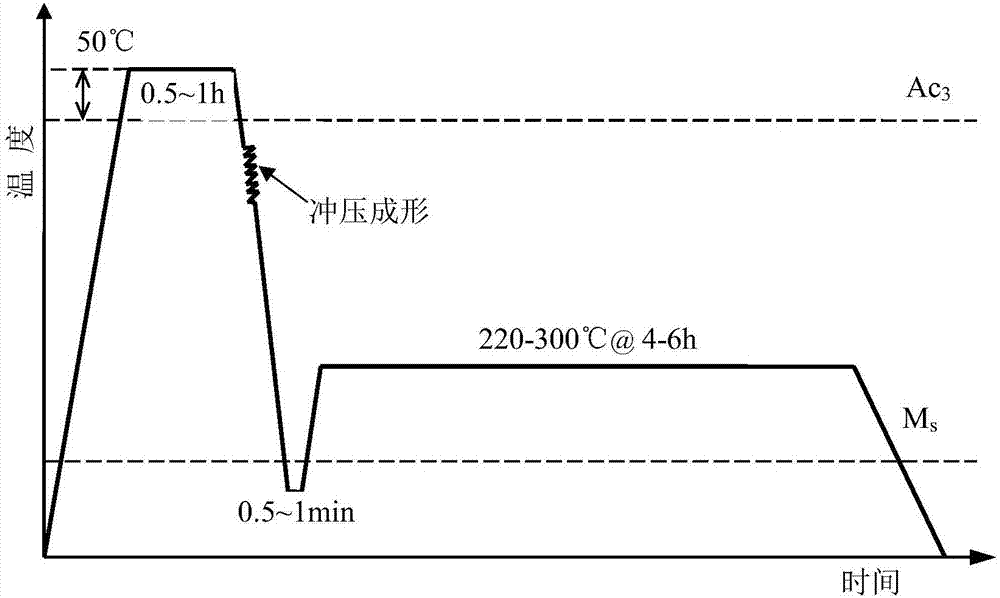

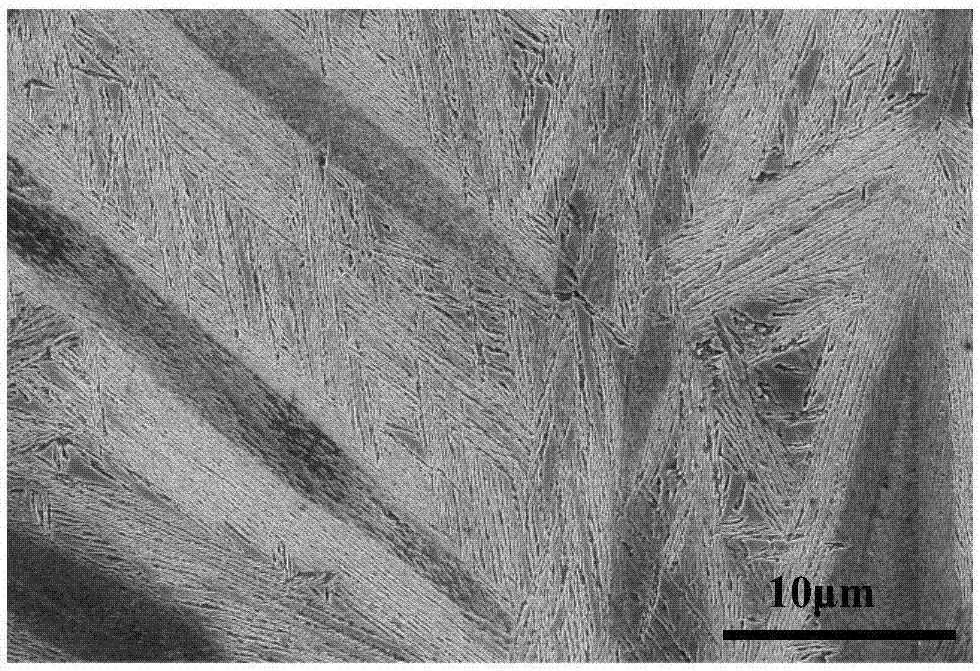

Preparation method for ultrahigh-strength thermoforming steel for car

The invention discloses a preparation method for ultrahigh-strength thermoforming steel for a car, and belongs to the technical field of high-strength steel. The preparation method comprises the following steps of: combining stamping forming with low-temperature bainite isothermal treatment; comprehensively utilizing refining technologies such as micro-alloy refining, controlled-rolling controlled-cooling refining, pre-deforming and low-temperature bainite isothermal treatment, thereby obtaining an ultra-fine structure which consists of carbide-free bainite, a little blocky type retained austenite and martensite with volume fraction smaller than 10%, and the ultra-fine structure has tensile strength of 1500-2200 MPa, and ductility of 10-20%. A preparation process for ultrahigh-strength steel comprises the following technological process: smelting, continuous casting, hot rolling, cutting, thermal stamping forming and low-temperature bainite isothermal treatment. During thermal stamping forming, a cut hot-rolled plate is re-heated to Ac3+50 DEG C for austenization, and heat is preserved for 0.5-1 hour, and then, the plate is immediately moved onto thermal stamping equipment to perform stamping forming; the quick cooling and quenching effect of a thermal stamping mould is utilized for cooling super-cooled austenite to a temperature lower than Ms point, is subjected to isothermal treatment for 0.5-1 minute, is quickly put into a salt-bath furnace or a resistance furnace of 200-300 DEG C to perform isothermal treatment for 4-6 hours, is subjected to isothermal bainite transformation, and is taken out for being air-cooled to the room temperature.

Owner:UNIV OF SCI & TECH BEIJING

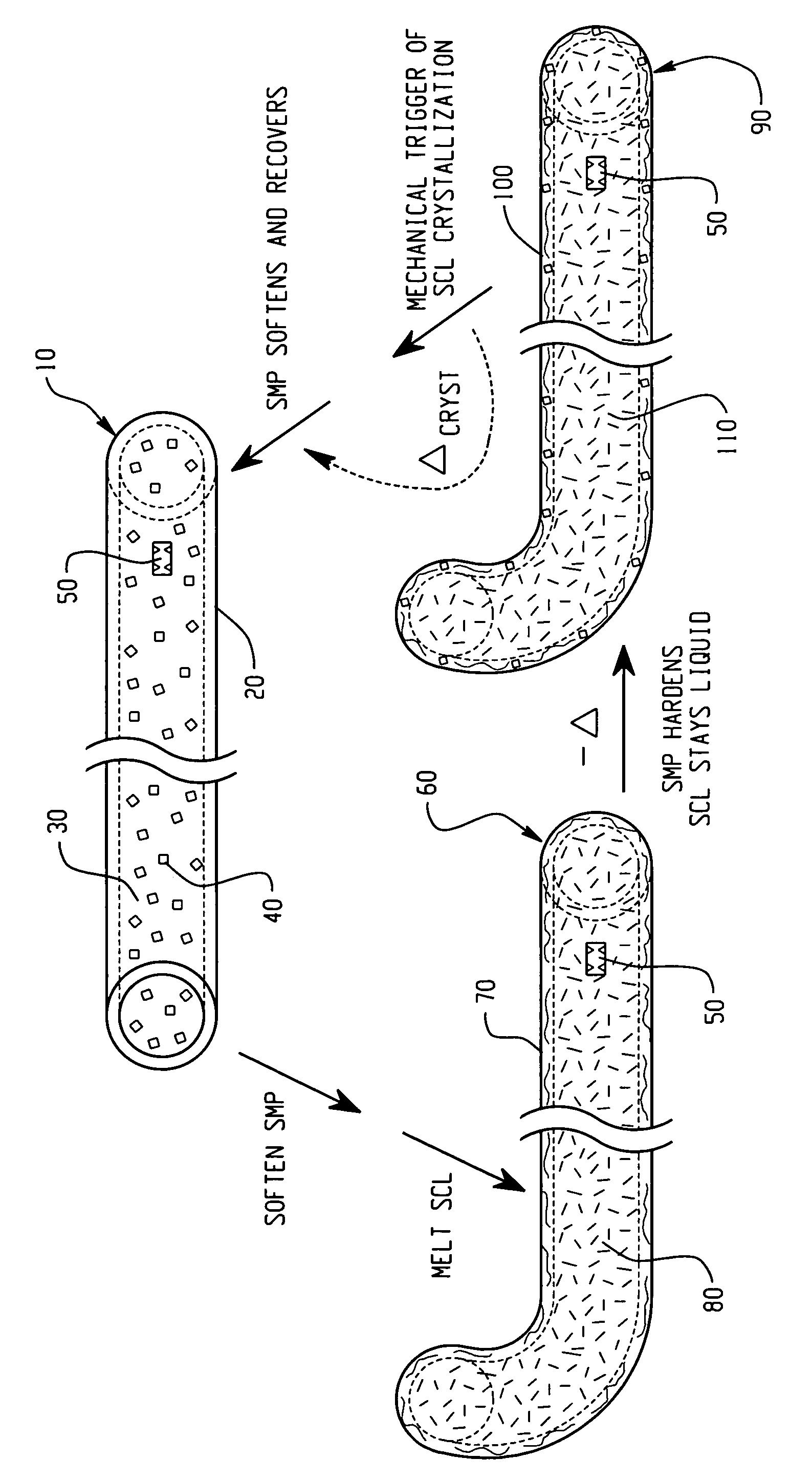

Mechanically activated shape memory device

Owner:UNIV OF CONNECTICUT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com