Patents

Literature

376results about How to "Achieve strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

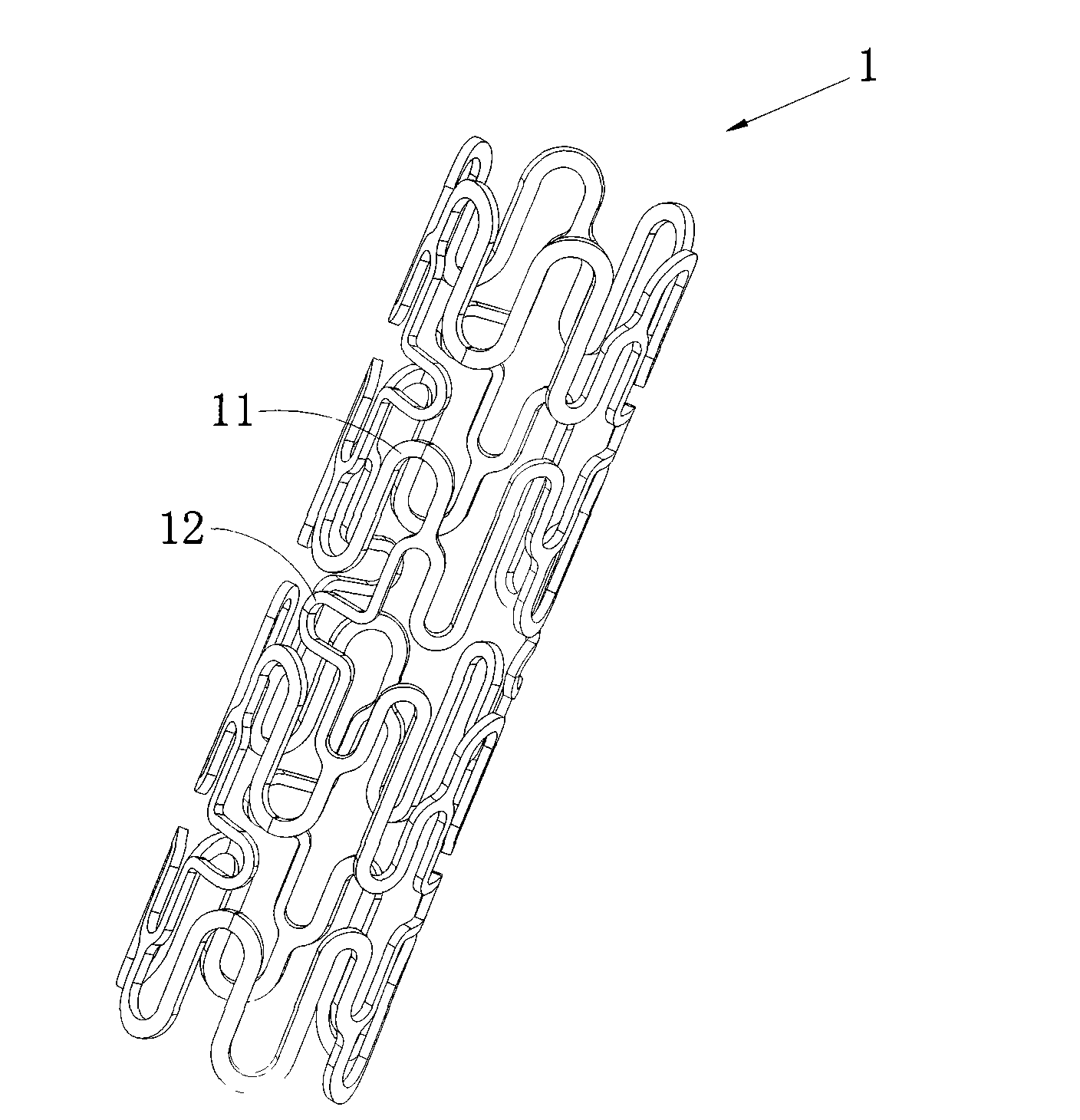

Human body absorbable blood vessel support and its manufacturing method

ActiveCN101549170AHigh strengthFast absorptionStentsSolid state diffusion coatingHuman bodyUltimate tensile strength

The present invention provides a method for manufacturing human body absorbable blood vessel support, including the following steps: (1) support forming; (2) cleaning and pre-polishing the support; (3) performing surface alloying treatment to the support; (4) performing fine finish to the support after surface treatment. The invention also provides a human body absorbable blood vessel support, theinvention adopts a surface alloying technique so that the support has a compound diffusion layer with adjustable penetration depth, thereby improving the support intensity and simultaneously quickening the corrosion speed of the support and shortening the support absorption cycle. The yield strength and elongation rate can be modulated in a prodigious scope by controlling the distribution, shapeand depth of the composite diffusion layer, to reach the intensity and absorption cycle required by the support.

Owner:BIOTYX MEDICAL (SHENZHEN) CO LTD

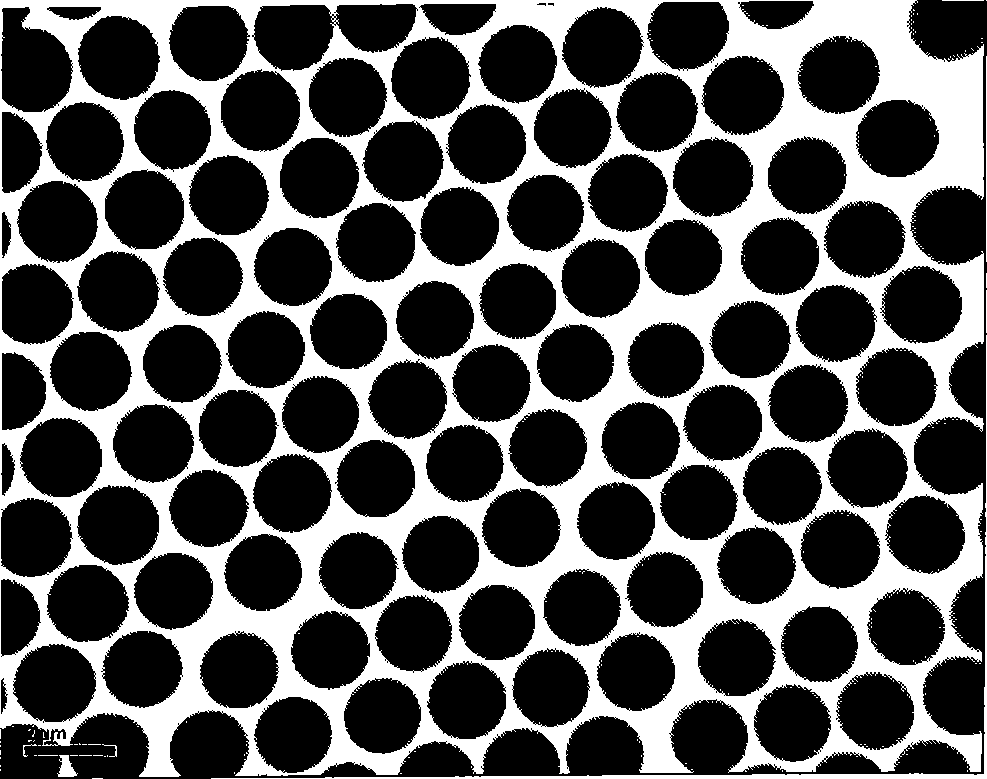

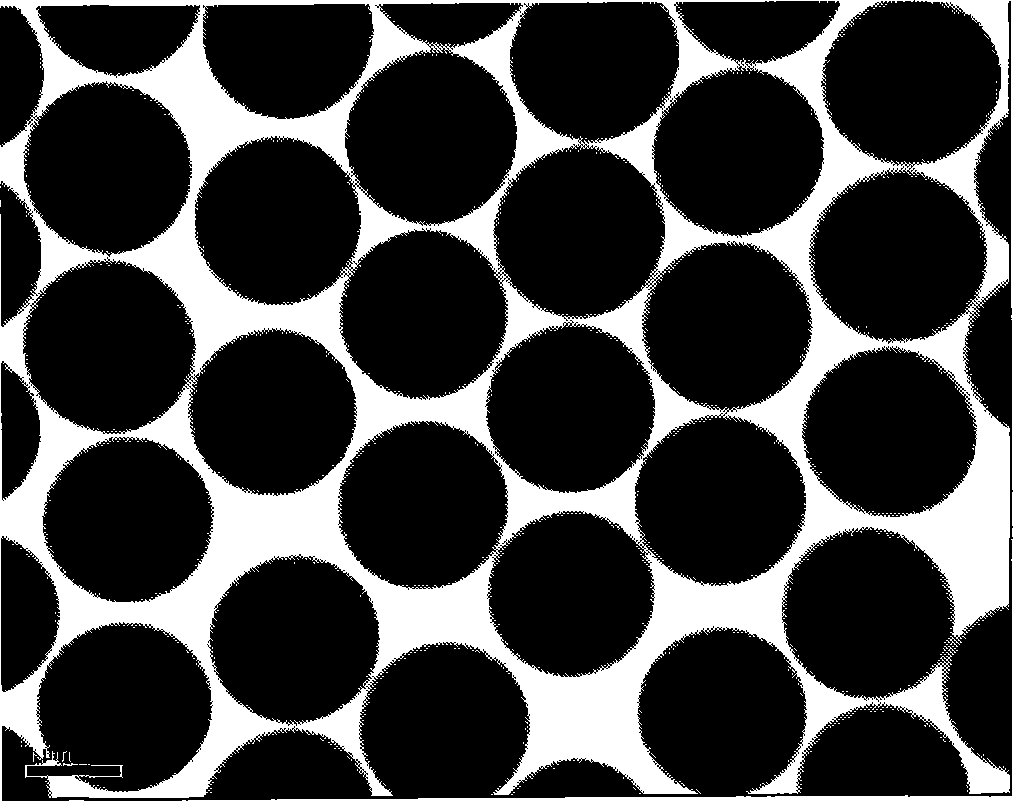

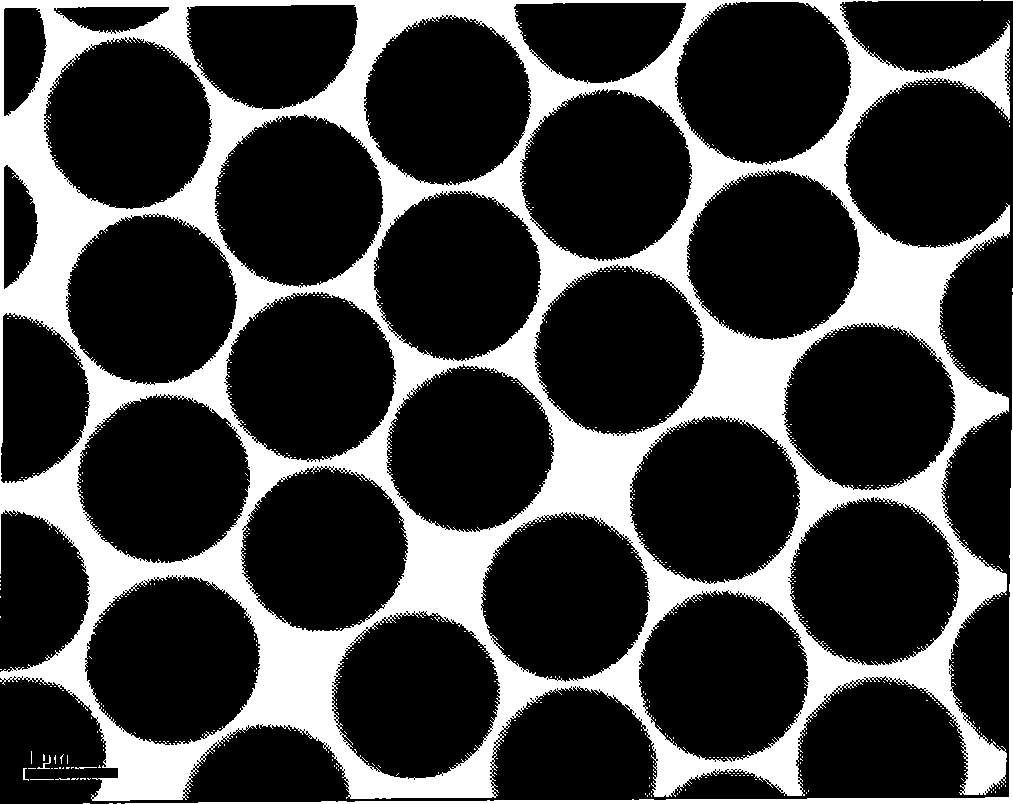

Process for producing cross-linked polymer microsphere with even grain diameter

The invention relates to a preparation method of crosslinked polymer microphere with uniform particle size. By adopting the process of dispersion and polymerization, styrene or acrylic ester is taken as a monomer; a monodisperse crosslinked polymer microphere with uniform particle size is prepared by steric hindrance dispersant and multi-functional crosslinker. The microphere has regular spherical and solid, a smooth surface, no damage or defect, and the strength and flexibility meet the requirements of producing ACF.

Owner:杜天鹏

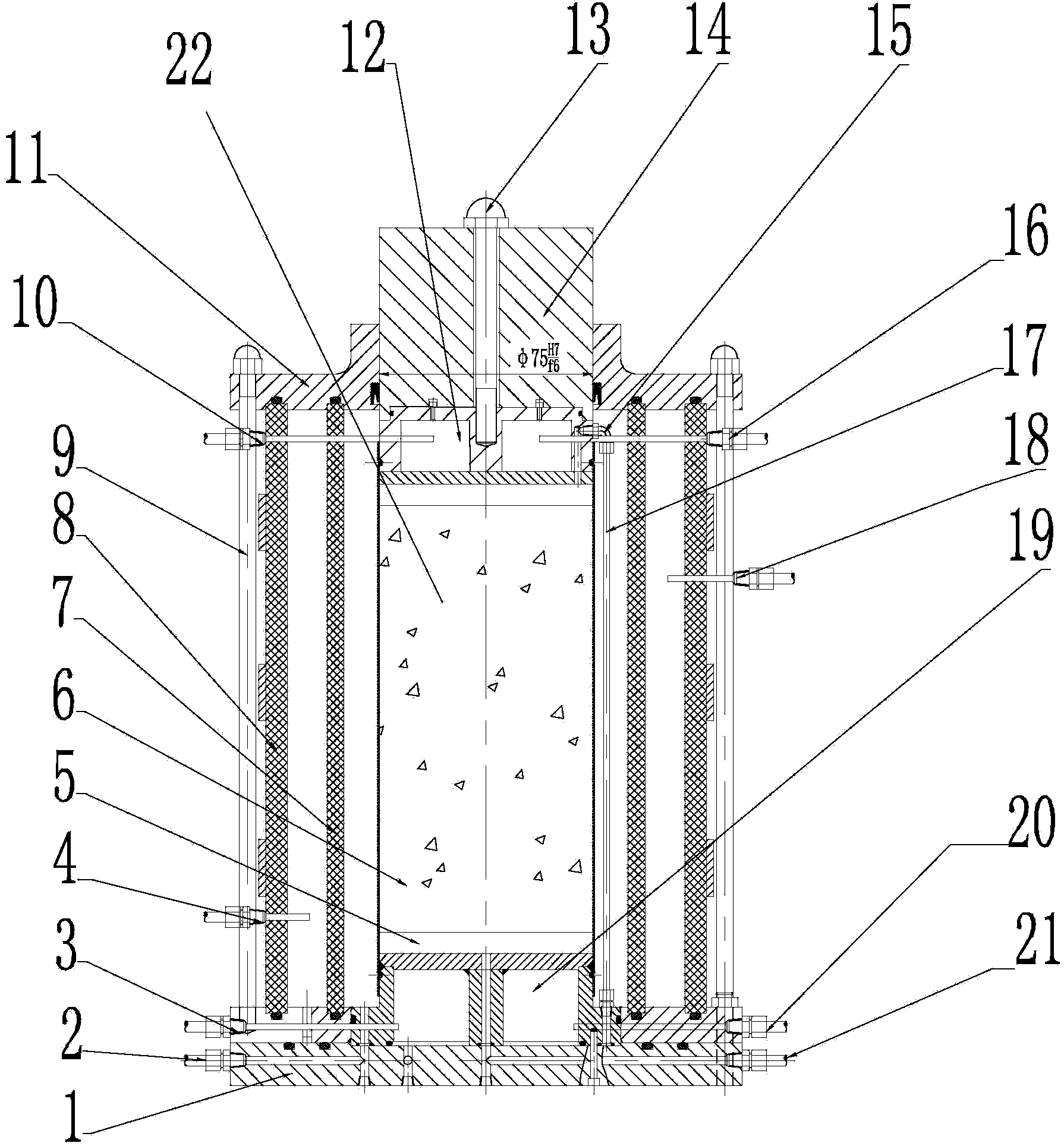

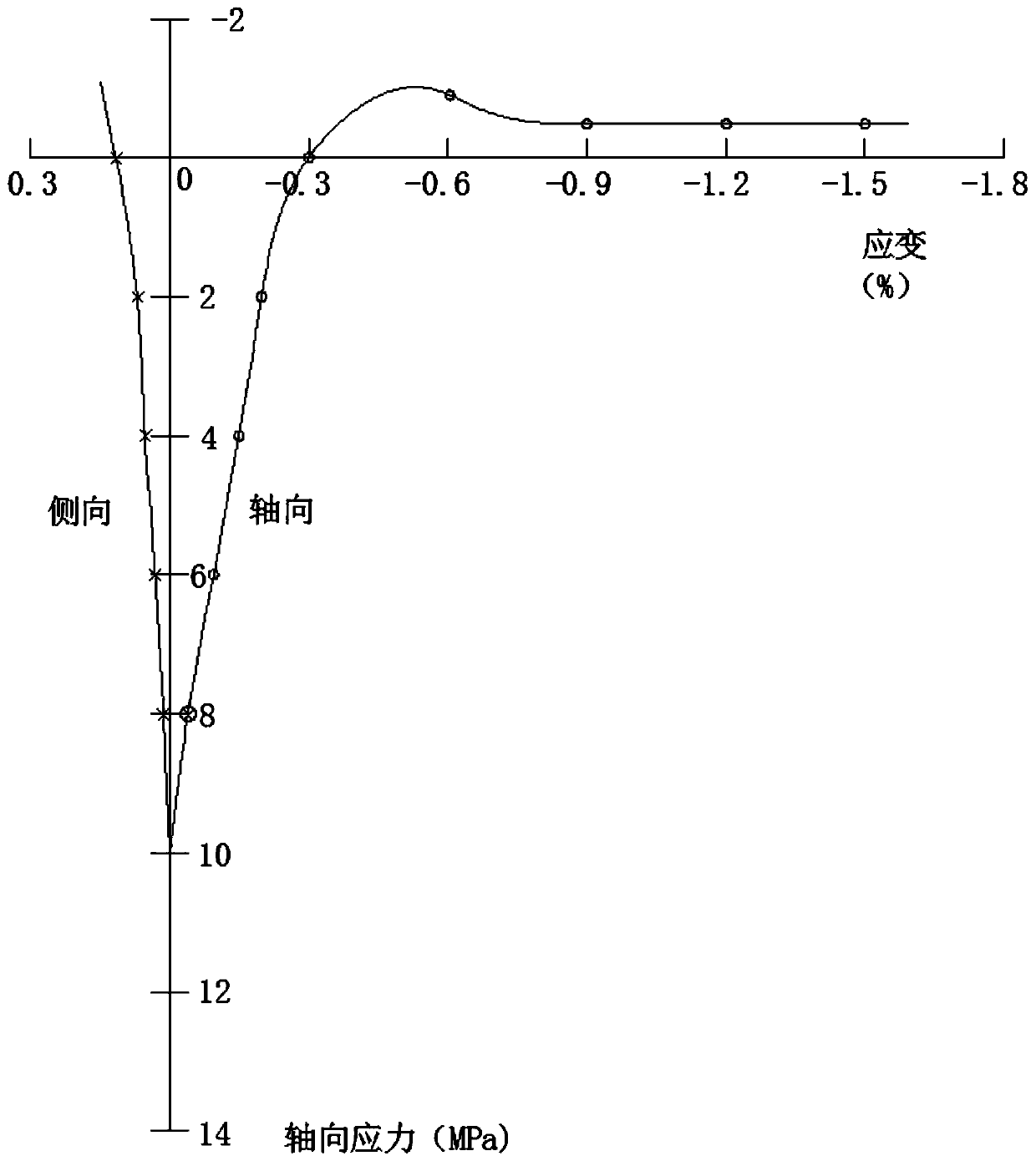

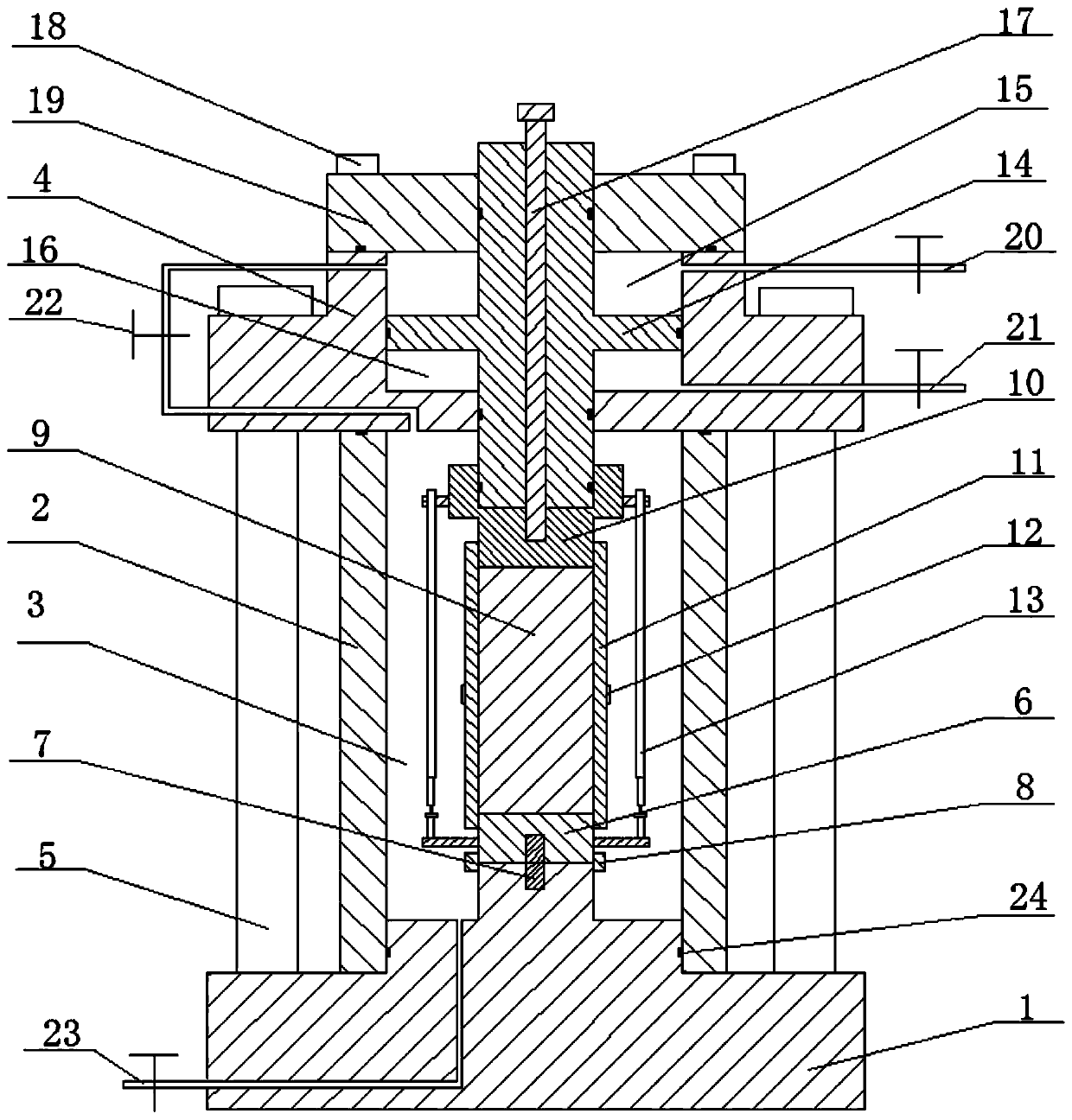

Low-temperature dynamic triaxial apparatus

InactiveCN103728185ATemperature controlFreeze-thawMaterial strength using tensile/compressive forcesPore water pressureEngineering

The invention relates to the field of civil engineering, and particularly to a low-temperature dynamic triaxial apparatus. A confining pressure direct interface and a pore water pressure measuring interface are respectively formed in the side surface of a chassis, a footwall cold bath loop inlet and a footwall cold bath loop outlet are respectively formed in the side surface of a footwall base, an interior shaft chamber is arranged above the footwall base, a hanging wall cap is arranged at the top part of the interior shaft chamber, an exterior shaft chamber is arranged at the periphery of the interior shaft chamber, a cold bath loop chamber is arranged at the periphery of the exterior shaft chamber, a peripheral cold bath loop inlet and a peripheral cold bath loop outlet are respectively formed in the side surface of the cold bath loop chamber, a hanging wall cold bath loop inlet and a hanging wall cold bath loop outlet respectively penetrate the exterior shaft chamber, the cold bath loop chamber and two sides of hanging wall cap, a piston is arranged above the hanging wall cap and is fixed through a ball screw, and a pressure chamber upper cover is arranged at the periphery of the piston. The low-temperature dynamic triaxial apparatus has the following advantages that the temperatures of the top end and the bottom of the soil sample can be controlled, the soil sample freezing process can be simulated, the freezing and thawing state of the soil sample is kept, the temperatures of different parts of the soil sample are monitored, and the deformation and the strength of the soil sample are measured.

Owner:BEIJING JIAOTONG UNIV

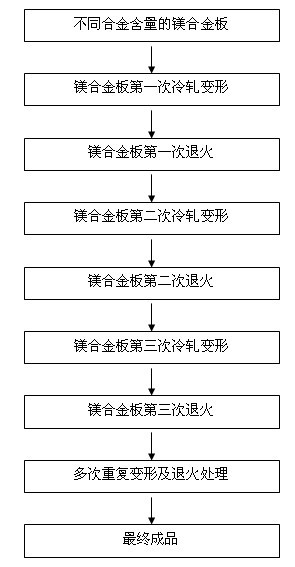

Method for refining crystal grains of magnesium alloy plate

InactiveCN101985729AImprove strength and plasticityIncrease productivityAlloy elementMagnesium alloy

The invention relates to a method for refining crystal grains of a magnesium alloy plate, in particular to a preparation method for refining the crystal grains of the magnesium alloy plate by a circular cold rolling-annealing method. In the method, the magnesium alloy plate with refined crystal grains is obtained by repeatedly circulating cold rolling deformation and annealing according to such a rule that next cold rolling deformation is more than previous deformation and next annealing temperature is lower than the previous processing temperature, wherein the magnesium alloy plate comprises 0.1 to 10 weight percent of alloy element; and the size of the crystal grains of the magnesium alloy plate is greatly refined through several cold rolling deformation and annealing processes. The method is low in cost and simple in operation, can be used for mass production and is a method for economically and effectively preparing the magnesium alloy plate; and the magnesium alloy plate prepared by the method has the characteristics of low cost, high strength and plasticity and the like, and can be widely applied to various fields such as automobiles, aviation, communication, buildings and the like.

Owner:CHONGQING UNIV

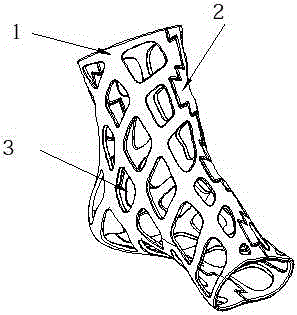

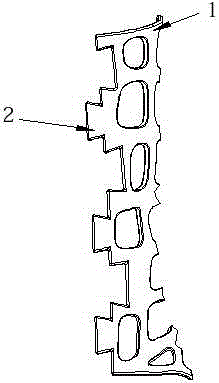

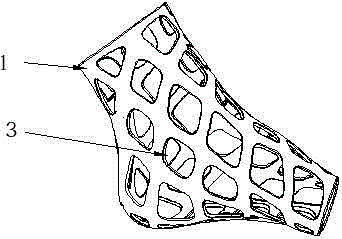

3D-printing-based customized external foot fixation protector

InactiveCN105250064AAchieve lightweightAchieve strengthAdditive manufacturing apparatusFractureAnkleItching

The invention discloses a 3D-printing-based customized external foot fixation protector. The 3D-printing-based customized external foot fixation protector comprises protectors at left and right portions, dual-dovetail-groove fasteners distributed on the edges of the protectors and air vents distributed in the surfaces of the protectors; the protector is realized through a 3D printing technology on the basis of CT data of a foot of a patient and is printed as left and right portions crossing an ankle, and the protectors at the left and right portions are fixed through the dual-dovetail-groove fasteners. The 3D-printing-based customized external foot fixation protector can be optimally customized aiming at different wounds of different patients, has the advantages of light weight, good air permeability, convenience in installation, simplicity in use and reliable fixation, facilitates the rehabilitation activities of the patient, prevents skin aging, itching and the like, and greatly improves the comfort of the patient during rehabilitation.

Owner:SHANGHAI UNIV

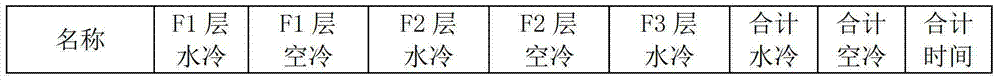

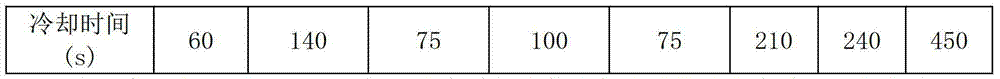

Method for formulating water-air alternate time-controlled quenching process

The invention provides a method for formulating a water-air alternate time-controlled quenching process. The method comprises the following steps of: step 1, predicating a structure composition of a part with required performance according to the performance detection part of an alloy steel piece and specific performance requirements; step 2, according to the super-cooled austenite isothermal cooling transformation curve or the super-cooled austenite continuous cooling transformation curve of a material, acquiring the longest cooling time or the minimum cooling speed which the structure needs to reach a certain temperature; step 3, dividing an alloy steel piece into a cooling speed control area and a slow cooling area along a section from the surface to the centre; step 4, determining the water-air alternation times of the cooling speed control area, and a water-cooling time and an air-cooling time each time; and step 5, determining the water-air alternation times of the slow cooling area, and a water-cooling time and an air-cooling time each time. With the adoption of the method provided by the invention, the alloy steel piece can obtain required performance or structure on the premise of avoiding cracking; and the method is suitable for a quenching treatment for the alloy steel pieces with various ingredients.

Owner:SHANGHAI JIAO TONG UNIV

Composite enhanced hydrolysis-resistant thermoplastic polyurethane elastomer and its preparation method

The invention provides a composite enhanced hydrolysis-resistant thermoplastic polyurethane elastomer composition comprising a thermoplastic polyurethane elastomer body and nano silica, and the composition is characterized in that: the surface of the nano silica is modified by coating of a silane coupling agent, the weight ratio of nano silica to silane coupling agent is 25:1-15:1, and the silane coupling agent is gamma-glycidoxypropyltrimethoxysilane. A preparation method of the composition is as follows: the surface of the nano silica is coated with the silane coupling agent gamma-glycidoxypropyltrimethoxysilane containing epoxy groups, and then the nano silica is combined with the thermoplastic polyurethane elastomer (TPU) body, on the one hand, dispersity of the nano SiO2 in TPU can be improved, and adverse effects caused by agglomeration can be inhibited; on the other hand, the initial mechanical properties and hydrolysis resistance of TPU material can be effectively improved, stable mechanical properties of TPU products can be maintained, and the TPU products have broad application prospects.

Owner:SINOTEX INVESTMENT & DEV CO LTD

Method for treating inorganic solid waste and application

InactiveCN1480264AImprove performanceQuality improvementSolid waste disposalEnvironmental engineeringMagnetic separation

A process for reclaiming the inorganic solid waste (waste silicon, waste concrete blocks, coal gangue, and slags) includes crushing to less than 400 mm for granularity, removing impurities, breaking to less than 80 mm for granularity to obtain the reclaimed aggregate, classifying, magnetic dressing, flushing dressing, and floatation. Said reclained aggregate can be used for road bed or concrete.

Owner:王剑

Carburized and high-frequency hardened part having high strength

ActiveCN101285158AReduce generationImprove solubilitySolid state diffusion coatingFurnace typesMechanical componentsHigh intensity

Owner:AISIN AW CO LTD

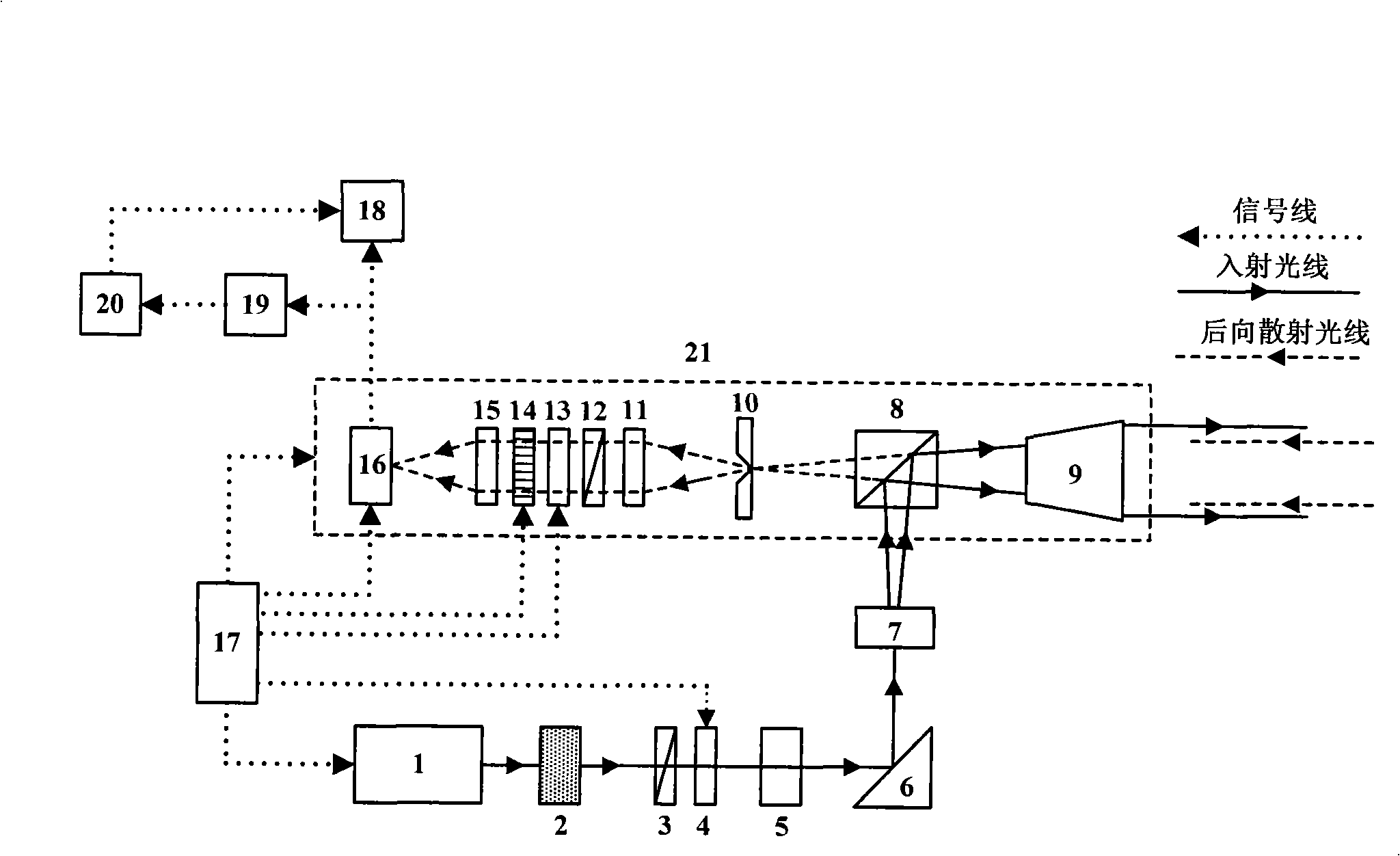

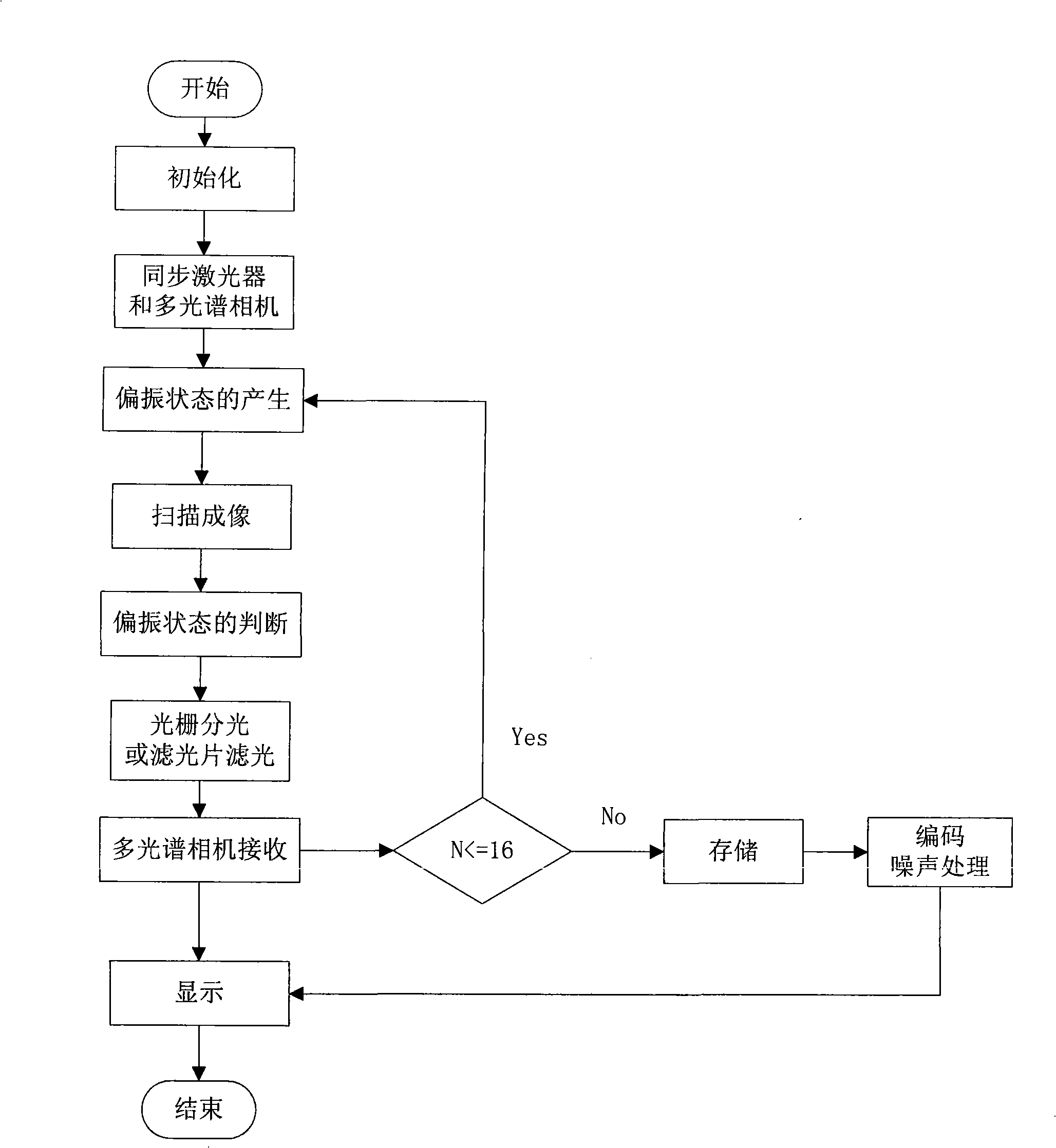

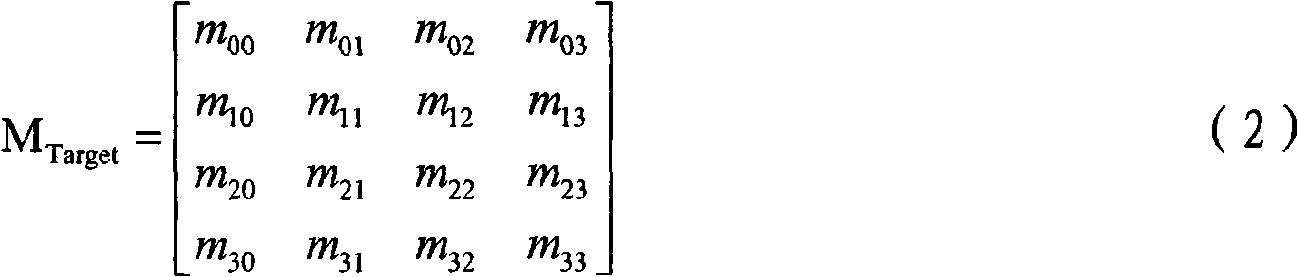

Fast multispectral remote sensing polarization imager

InactiveCN101526621AImprove detection and identification capabilitiesFast measurementElectromagnetic wave reradiationTime intensityTelescope

The invention relates to a fast multispectral remote sensing polarization imager. A system can work under an active mode and a passive mode and can improve the detectability of a target by controlling the polarization state and the wavelength of incident light. The system essentially consists of an emitting part, a receiving part, a controlling part and an image processing part. The emitting part essentially consists of a multi-wavelength pulse light source, a polarization module and a beam shaping, collimating and beam expanding part. The receiving part consists of a scanning and receiving telescope, the polarization module and a multispectral camera. A control system essentially controls the polarization state of the emitting part and the receiving part and obtains images under various polarization modes. The image processing part realizes the pseudo-color coding of an intensity image and a polarization degree image. The polarization state of the incident light can be adjusted by a fast adjustable liquid crystal wave plate; imaging range is enlarged in a way of scanning and receiving; and finally the noise is eliminated by image processing, so as to realize a pseudo-color coding image with exact real-time intensity and polarization degree.

Owner:BEIHANG UNIV

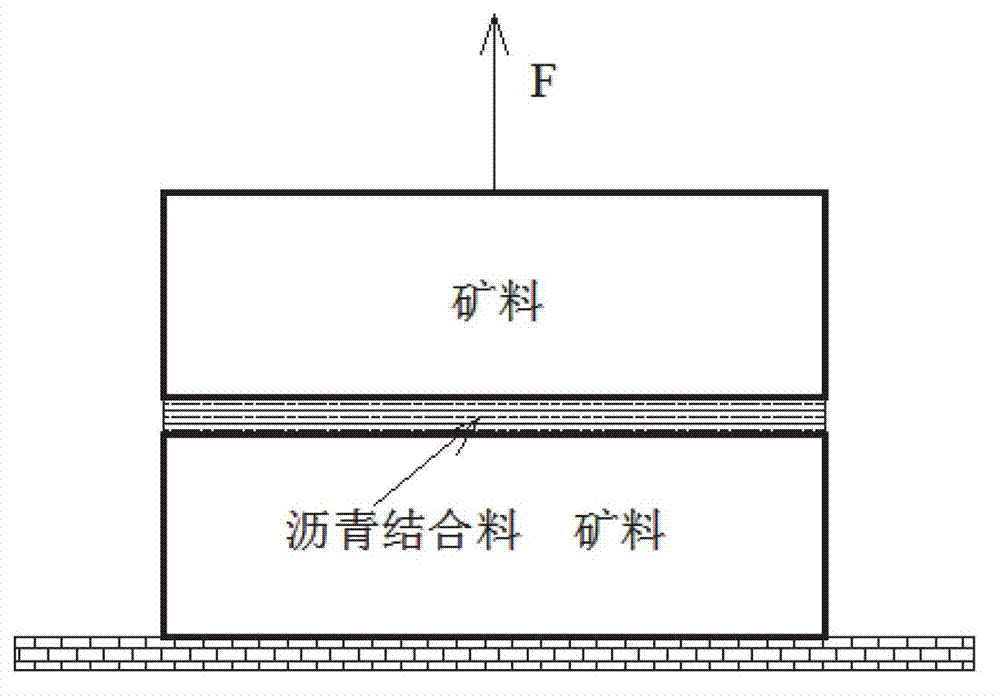

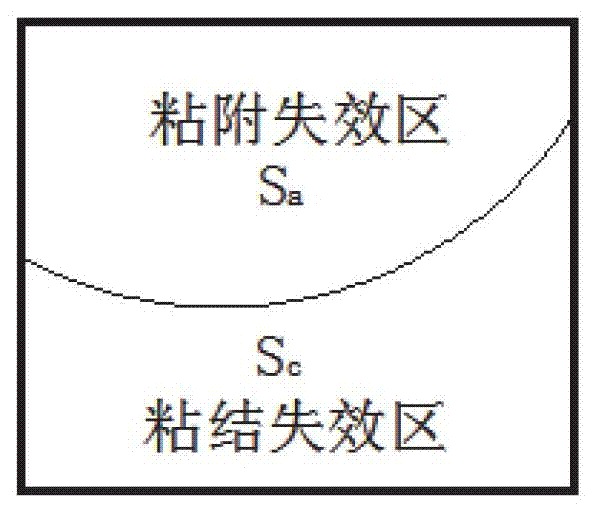

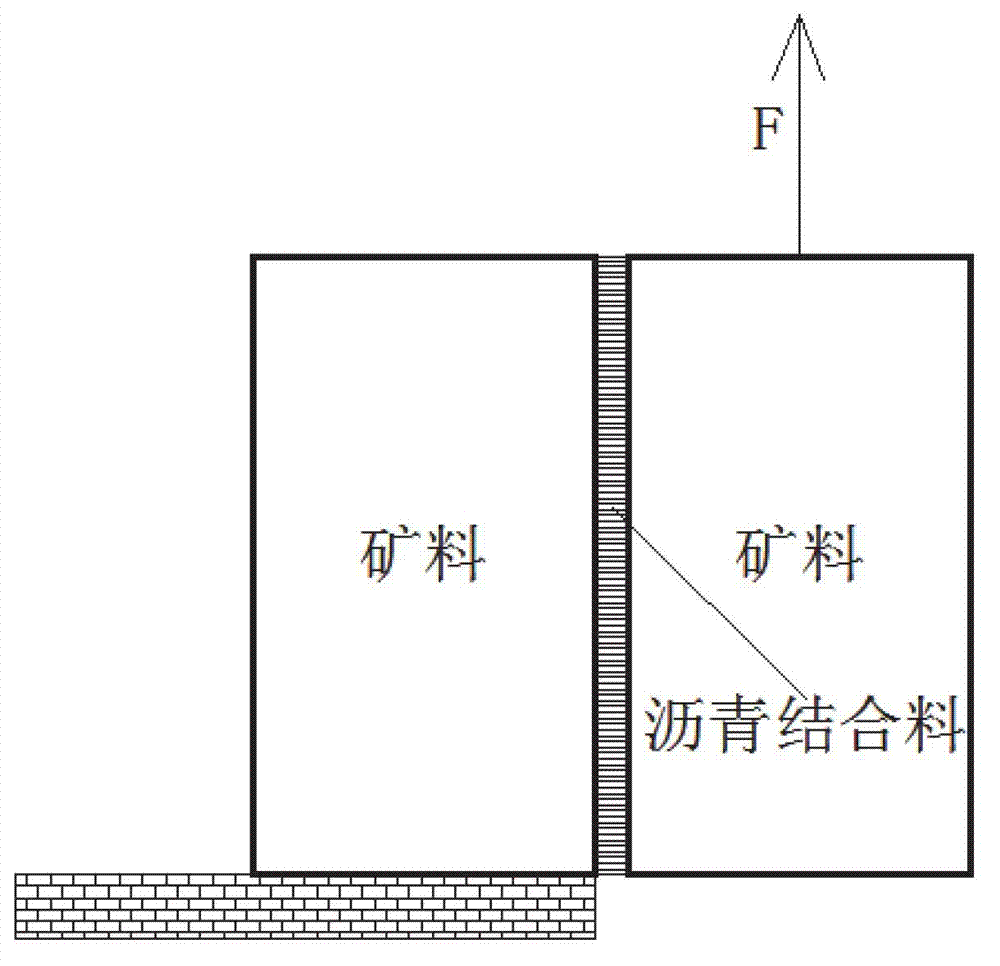

Quantitative testing method for microscopic strengths of mixture-mineral aggregate contact surfaces

InactiveCN102830062AAchieve strengthAchieving Adhesion StrengthUsing mechanical meansMaterial analysisThin layerBonding strength

The invention discloses a quantitative testing method for the microscopic strengths of mixture-mineral aggregate contact surfaces. The quantitative testing method comprises the following steps of: reading a stretching or shear failure load; calculating an adhesion failure region area, a bonding failure region area and a mineral aggregate contact surface area on the contact surface of a mineral aggregate test model; within a thick-layer oil film scope, testing and analyzing the fundamental relation between the bonding strength of a bonding material and the thickness of the oil film, and calculating the bonding strength of the bonding material under the conditions of a thin-layer oil film and a medium-thick-layer oil film; and then calculating the overall stretching or shearing strength of the contact surface of the mineral aggregate test model, the stretching or shearing adhesion strength of the surfaces of asphalt and the mineral aggregate and the stretching or shearing bonding strength of the asphalt bonding material. The quantitative testing method for the microscopic strengths of the mixture-mineral aggregate contact surfaces provided by the invention realizes quantitative tests on the microscopic strengths including the adhesion strength between the asphalt and the mineral aggregate, the bonding strength of the asphalt bonding material and the overall strength of the mineral aggregate contact surface at different temperatures and different mechanical effects (stretching effect and shearing effect).

Owner:JILIN UNIV

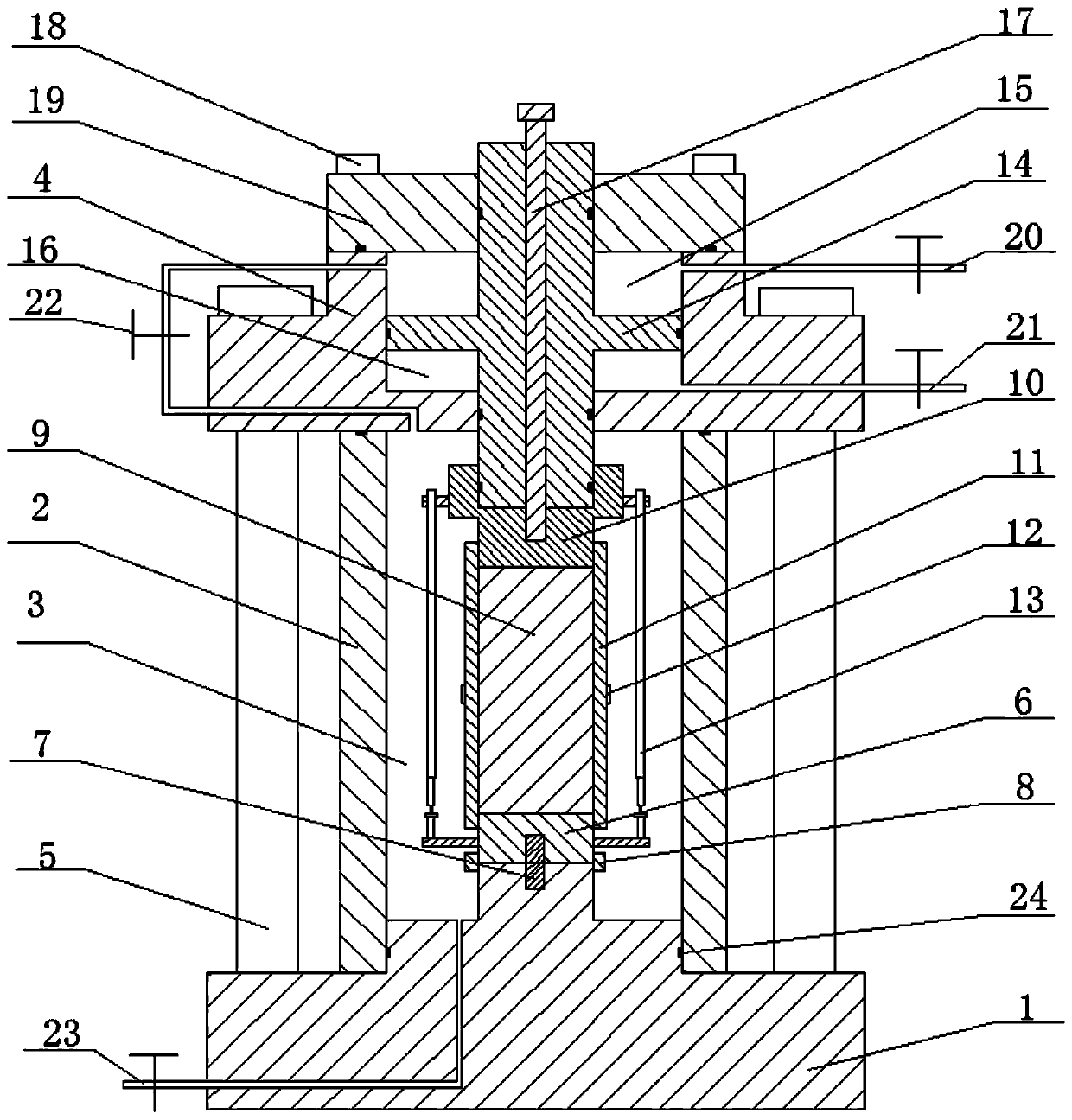

Rock triaxial direct stretching indoor experimental device and method

PendingCN109855973AMake up tensile strengthMake up for mechanicsMaterial strength using tensile/compressive forcesRock engineeringStress path

The invention relates to a rock triaxial direct stretching indoor experimental device. The device includes a base, a confining pressure cylinder, a confining pressure chamber, a confining pressure cover plate, long pull rod bolts, a sample lower base, a fixing screw, a first sealing sleeve, a rock sample, a sample upper base, a sample sealing sleeve, a lateral deformation gauge, an axial deformation gauge, a piston, a confining pressure self-balancing chamber, a tension application chamber, a pull rod, short bolts, a cover body, a confining pressure self-balancing chamber inlet, a tension applying chamber inlet, a communication valve, a confining pressure chamber inlet and a sealing ring. According to the rock triaxial direct stretching indoor experimental device of the invention, appliedrepresentative confining pressure is obtained through calculation according to deep engineering in-situ ground stress; the direct tensile strength and deformation characteristics of rock under different confining pressures can be obtained through the device of the invention, so that the tensile strength criterion of the rock can be obtained through calculation; and therefore, the current cognitiveblank of the tensile strength and mechanical behavior of rock under triaxial tensile stress paths can be filled, the evaluation of the triaxial tensile mechanical strength and deformation behavior ofthe rock is realized, and services can be provided for the safety of deep rock engineering.

Owner:NORTHEASTERN UNIV

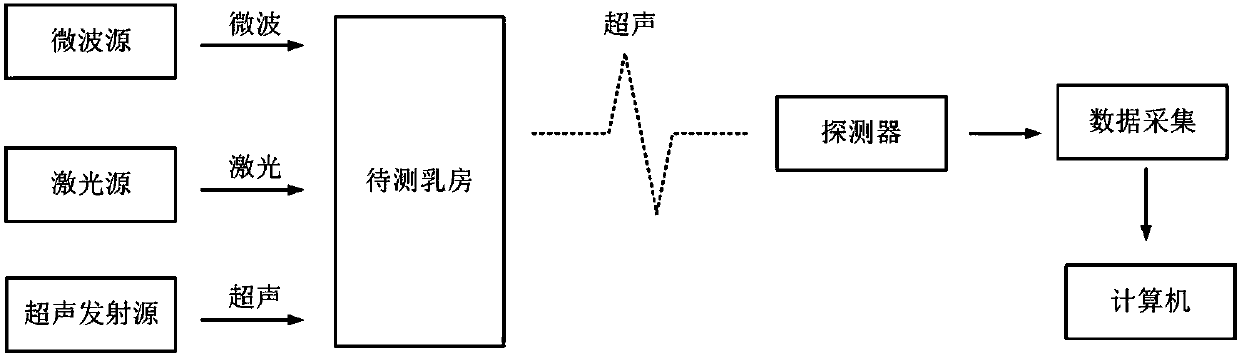

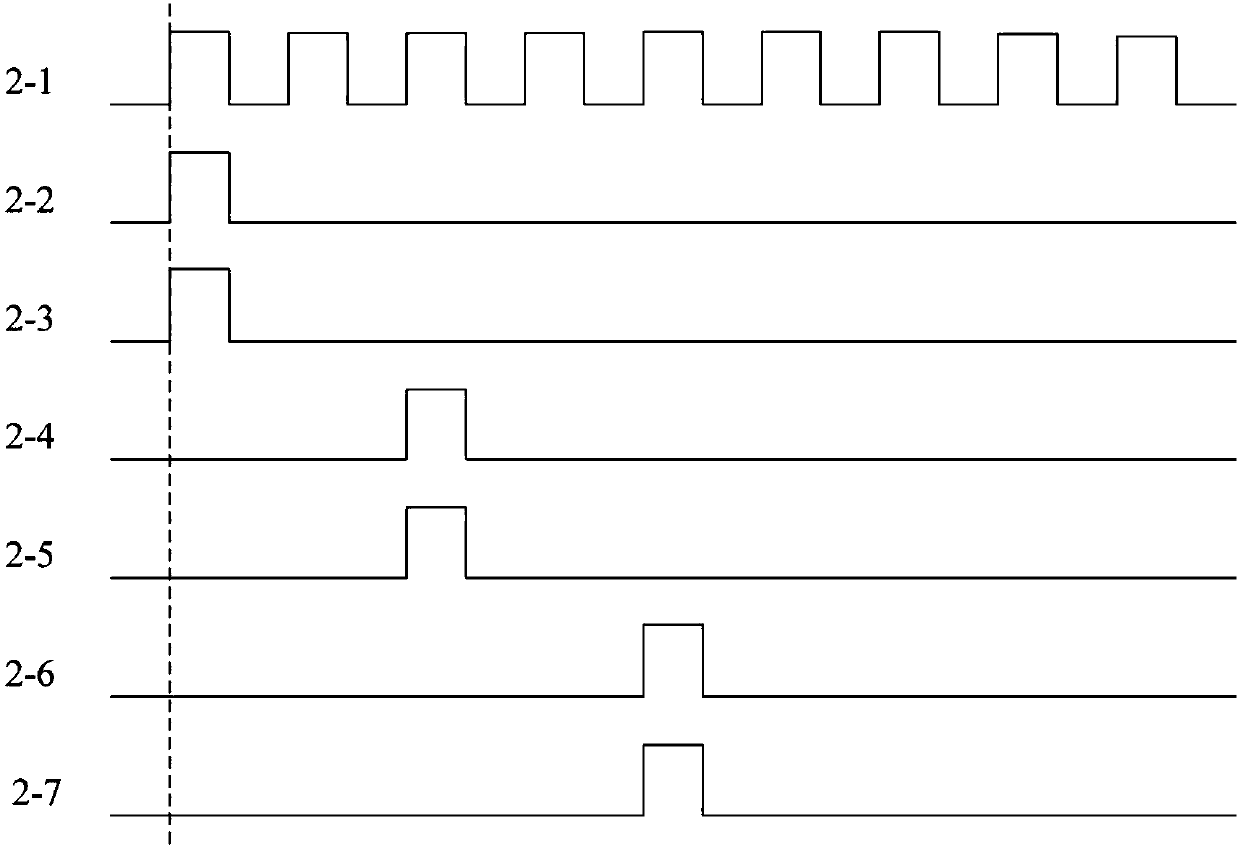

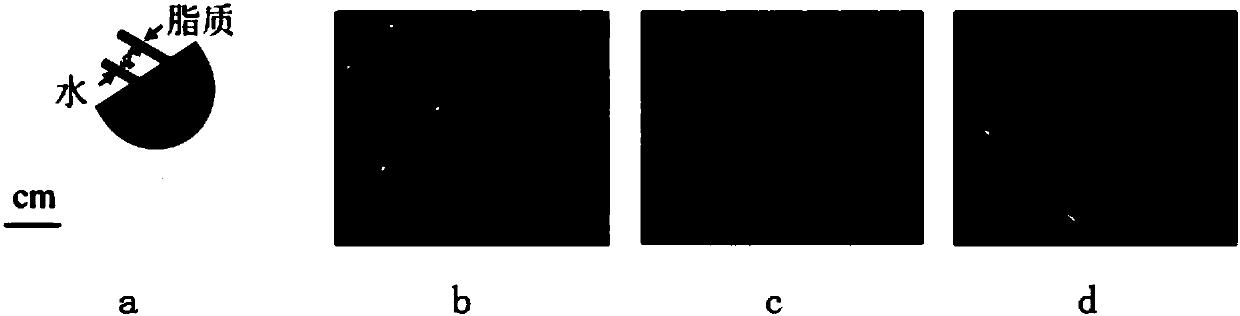

Thermoacoustic, photoacoustic and ultrasonic three-mode breast tumor detection device and method

InactiveCN107713990AImprove spatial resolutionImprove image contrastDiagnostic signal processingOrgan movement/changes detectionSonificationData acquisition

The invention relates to a thermoacoustic, photoacoustic and ultrasonic three-mode breast tumor detection device and a thermoacoustic, photoacoustic and ultrasonic three-mode breast tumor detection method. The thermoacoustic, photoacoustic and ultrasonic three-mode breast tumor detection device comprises a pulse train generator, a microwave source, a laser source, an ultrasonic emitting source, acoupler, a detector, a data acquisition module and an image processing module, wherein a tissue to be detected is placed inside the coupler; energy of the microwave source, the laser source and the ultrasonic emitting source is radiated into the coupler; generated thermoacoustic, photoacoustic and ultrasonic signals are jointly received by the detector; then, the signals are acquired by the data acquisition module and transmitted into the image processing module; the image processing module reconstructs thermoacoustic, photoacoustic and ultrasonic images by a back-projection algorithm to obtain three-mode images; finally, the three-mode images are superposed and synthesized on the same image. The thermoacoustic, photoacoustic and ultrasonic three-mode breast tumor detection device integrates the advantages of respective single modes in one system, and can not only eliminate misdiagnosis of breast edema, inflammation and fibroadenoma, but also improve the accuracy of early breast cancerdetection through combination of multiple parameter indexes.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Compound deoxidant for solid steel

The composite deoxidant for killed steel contains (wt%) 40-70% of active lime and 30-60% of aluminium, also contains 5-15% of one or several substances selected from fluorite, silica and salt and one or several deoxidizing substances selected from silicon, manganese, barium, magnesium, calcium or its alloy. The described composite deoxidant is a kind of pellet whose diameter is 20-30 mm. Said composite oxide is easy to aggregate in the molten steel, and can be quickly floated upwards into slag, so that it can prevent Al2O3 produced by using aluminium to make deoxidation from being aggregated at steel ladle gate and can eliminate pouring fault of blocking gate.

Owner:谢廷声

Sealing material for solid oxide fuel cells

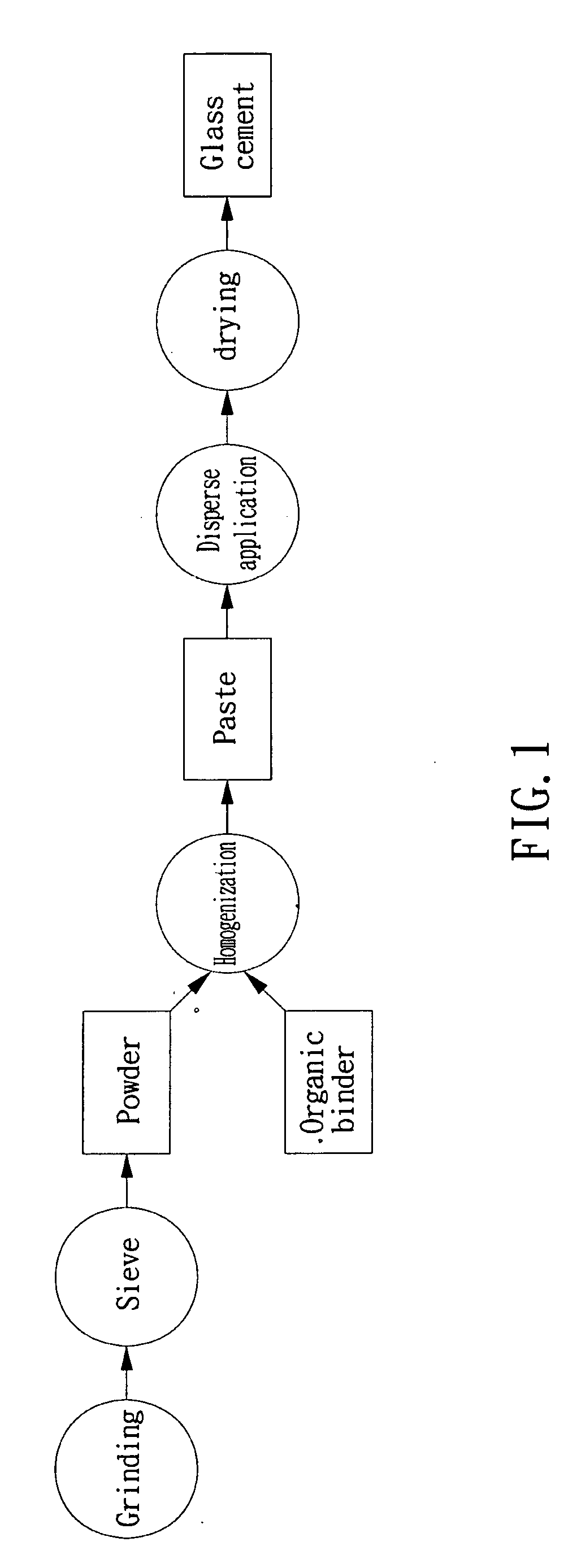

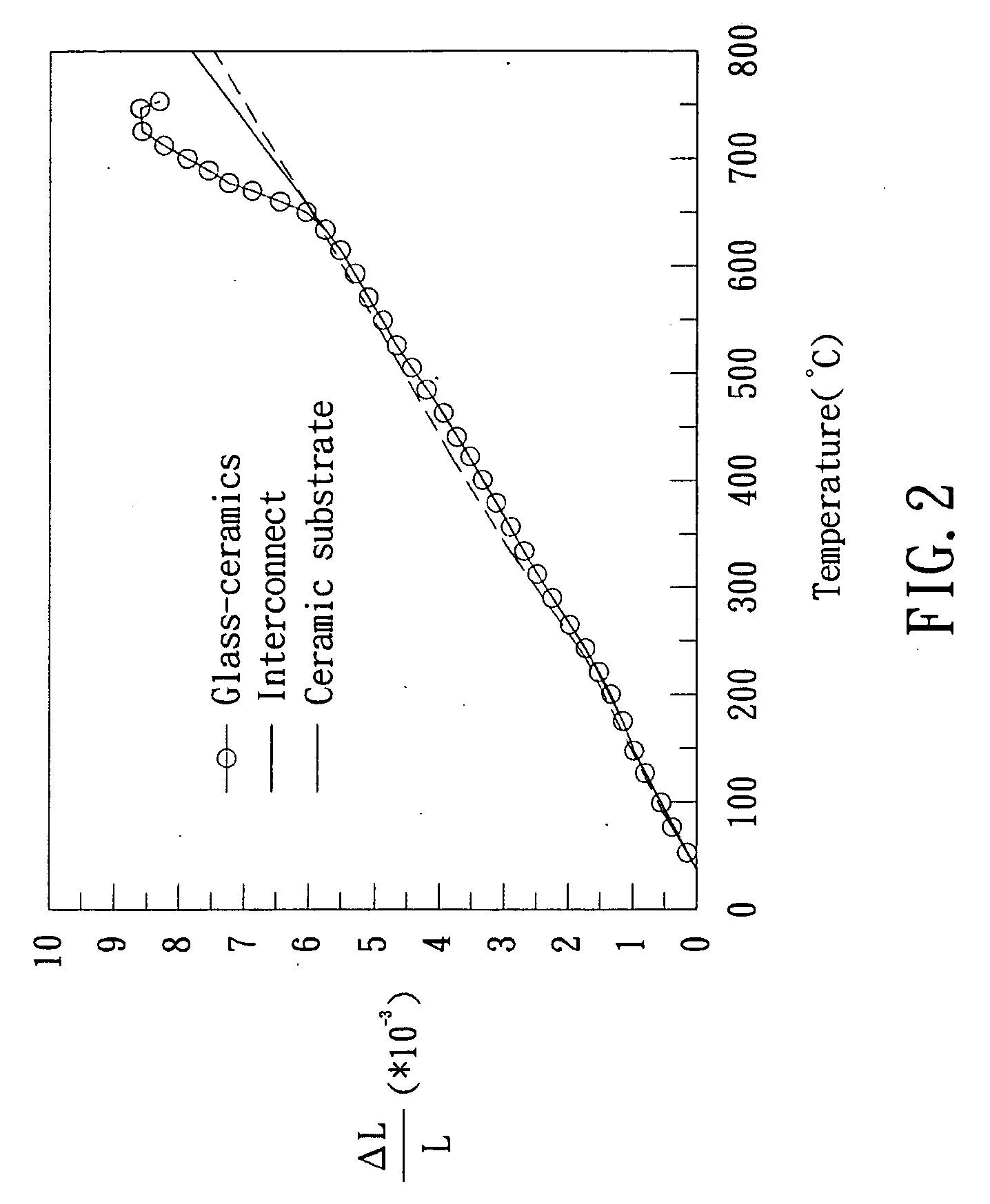

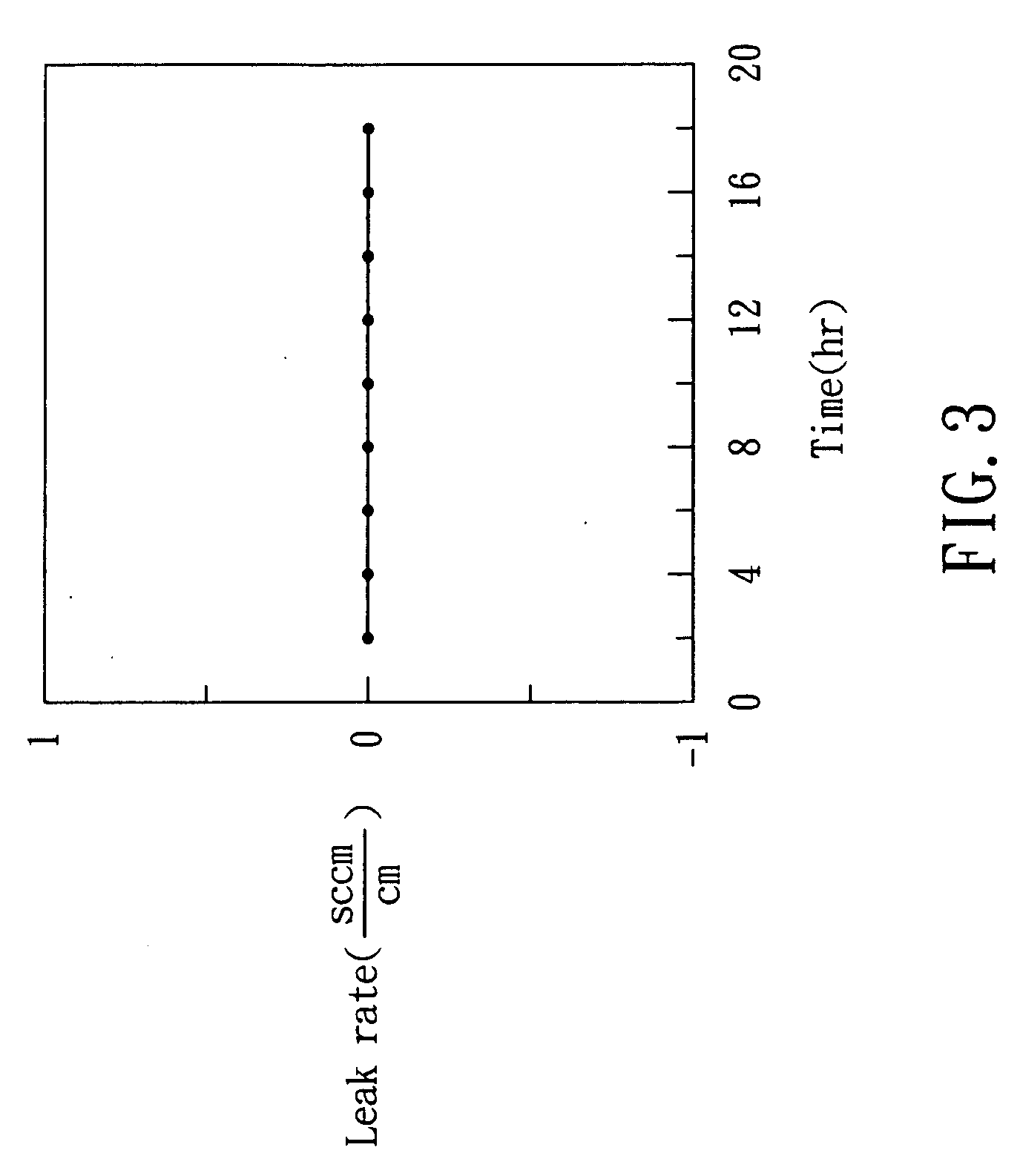

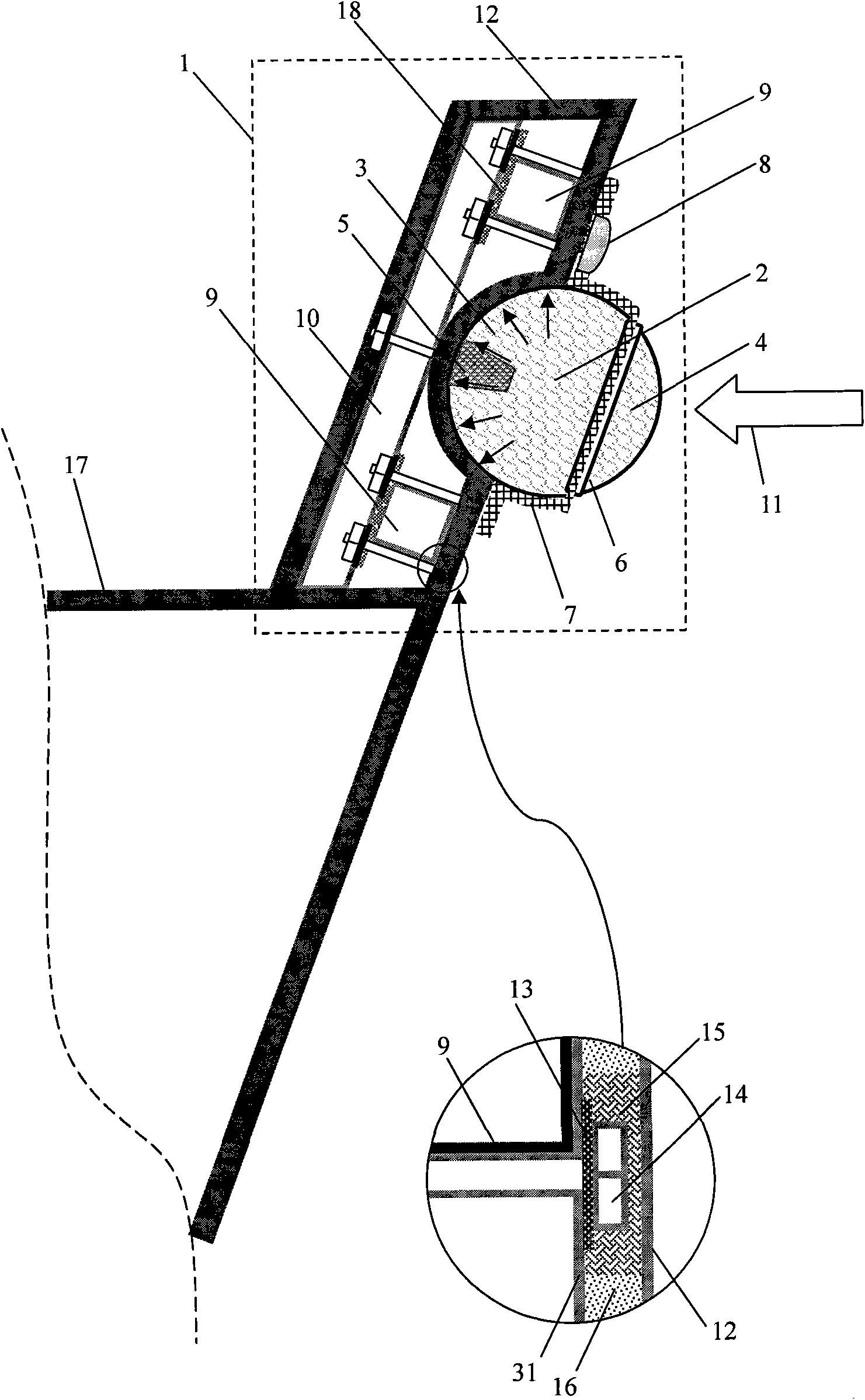

ActiveUS20090061282A1Quickly room temperatureAchieve strength and dimensional and chemical stabilityFuel cells groupingCell component detailsPlasticizerPolyethylene glycol

A sealing material for solid oxide fuel cells is provided, which is composed of around 60% to 80% by weight of glass, around 20% to 30% by weight of alcohol, around 0.5% to 3% by weight of ethyl celluloid as a binder, and around 0.01% to 0.1% by weight of polyethylene glycol as a plasticizer.

Owner:INST NUCLEAR ENERGY RES ROCAEC

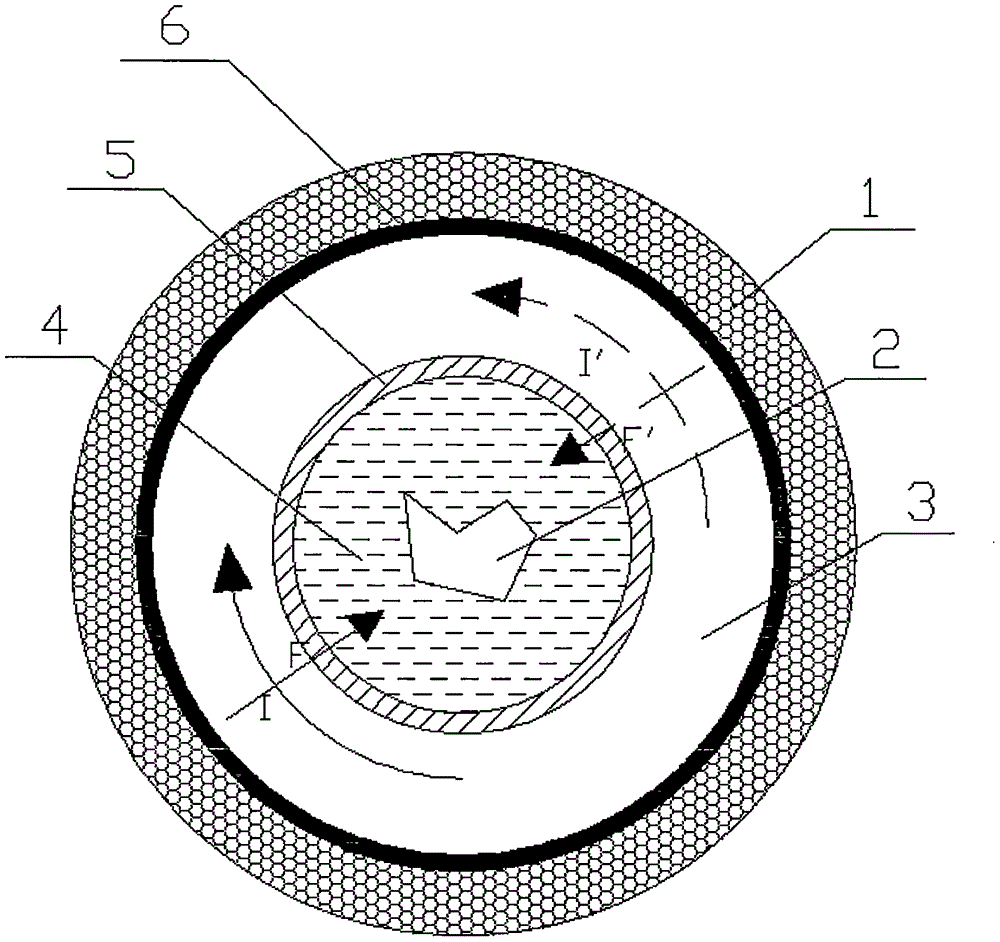

Anti-collision method of ship made of composite materials and hull structure

ActiveCN101898621AImprove protectionImprove rigidityVessel cleaningHull partsHull structureMarine engineering

The invention discloses an anti-collision method of a ship made of composite materials and a hull structure. The invention is mainly characterized in that sandwich plates (12) made of the composite materials are used as the outer walls of the hull, an integrated anti-collision bulwark (1) is adopted, the hull is in a 'cage type' structure, annular reinforced ribs are arranged on the side surfaces of the hull, and an energy-absorbing bow is adopted. The hull structure has the characteristics of light weight and high strength, and simultaneously, the overall anti-collision performance of the ship made of the composite materials is effectively improved through the comprehensive anti-collision structure design. When the ship has a collision on a front surface or a side surface, the comprehensive passive safety protection hull structure provided by the invention can effectively buffer an impact force caused by the collision of the ship, has good energy-absorbing effect and strong anti-deformation capacity, and is favorable for preventing or reducing casualties and property loss caused by the collision of the ship. The invention is especially suitable for the anti-collision design of the ship made of composite materials and has better application and popularization prospects.

Owner:SHENZHEN HISPEED BOATS TECH

Plane prototyping photo-curing three-dimensional printing method capable of controlling workpiece strength

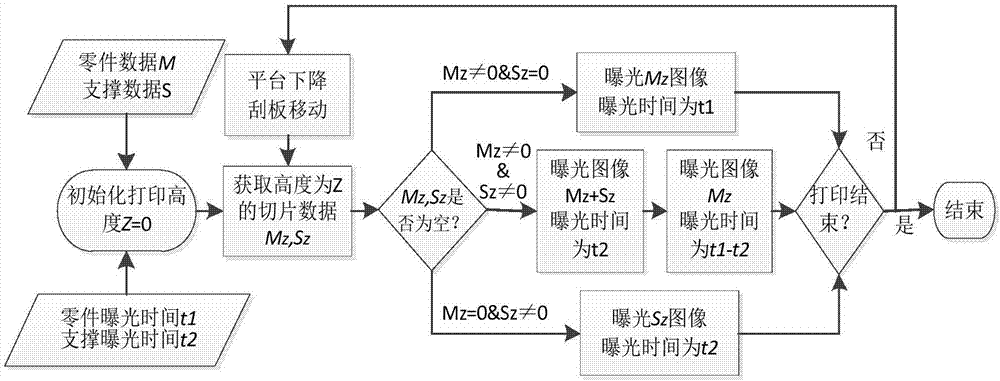

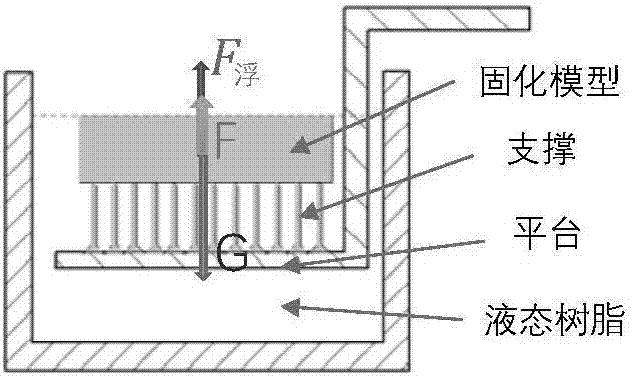

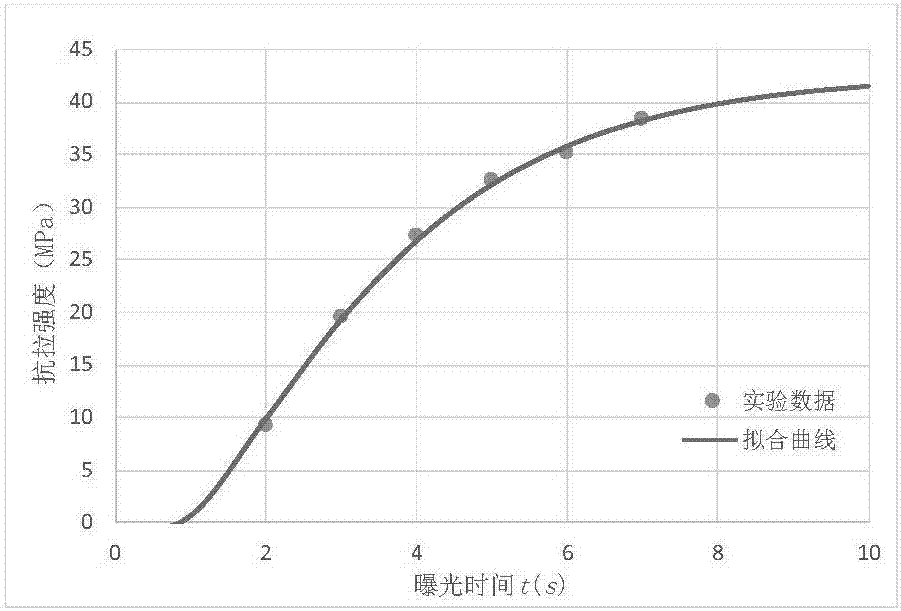

InactiveCN107263862AImprove surface qualityChange intensityAdditive manufacturing apparatus3D object support structuresSerializationUltimate tensile strength

The invention relates to a plane prototyping photo-curing three-dimensional printing method capable of controlling workpiece strength, and belongs to the technical field of plastic processing. The method includes the following implementation steps that (1) initialization is conducted, and a digital model generation technology is used for generating a workpiece digital model; (2) the strength of the part digital model and the strength of a supporting digital model are set, and exposure time of the workpiece digital model is determined; (3) the workpiece digital model in the step (1) is subjected to slicing operation; (4) a z-layer two-dimensional slice of the workpiece digital model is judged, and the exposure time is subjected to difference control according to the z-layer two-dimensional slice; and (5) the slicing layer z value of a two-dimensional image in the step (4) is judged so as to determine whether printing needs to be completed or not. By the adoption of the method, in the plane prototyping photo-curing three-dimensional printing process, the exposure time difference can be controlled through software differences according to the curing characteristic of a photosensitive resin material, and the workpiece strength can achieve gradient distribution and serialization only through one material.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Process for brewing yellow wine with high alcohol content

InactiveCN101544940AHigh alcohol contentAchieve strengthMicroorganism based processesAlcoholic beverage preparationMonascusChemistry

The invention discloses a process for brewing yellow wine with high alcohol content, which comprises the following steps that: 25 kilograms of steamed sticky rice, 38 kilograms of water and 1.5 kilograms of Gutian red yeast rice are poured to a wine jar, evenly stirred, fermented for 2 to 3 months at a temperature of between 8 and 35 DEG C till the mixture is fully fermented; then lees in the mixture is separated by a squeezing method to obtain the clear yellow wine; 18 kilograms of the steamed sticky rice, 38 kilograms of the clear yellow wine and 1 kilogram of the Gutian red yeast rice are poured to the wine jar once again, evenly stirred and fermented for 15 days at a temperature of between 4 and 25 DEG C; the jar is sealed, moved to a shade, fermented for 2 to 3 months; the leavening is subjected to filter pressing, wine decoction and clarification to finally obtain a finished product, namely the yellow wine with the high alcohol content; and the alcohol content is between 21 and 23 percent vol. The yellow wine achieves the rigidity of white wine, is nutritious and healthy and has mellower mouthfeel.

Owner:陈清

Rare-earth composite wall heat-insulating layer and heat-insulating layer material preparation method

InactiveCN101215858AHigh strengthImprove insulation effectCovering/liningsClimate change adaptationInfraredRare earth

The invention relates to a heat-insulating layer of a rare earth complex wall body and the manufacturing method of heat-insulating layer material, which belongs to the field of architectural materials. The invention is characterized in that the process for preparation comprises mixing rare earth rubber powder by weight ratio that rubber powder: water = 1:1 to 1.5, adding polyphenyl particles into material which is mixed, the proportion is that rubber powder: EPS particles = 1 kg: 8 L, continuously mixing for 5-10 min to make rare earth rubber powder EPS particle heat-insulating material, mixing rare earth trowel finish sand with water according to the proportion that rare earth trowel finish sand: water = 1: 1 into slurry, making rare earth trowel finish sand slurry, and brushing rare earth rubber powder EPS particle heat-insulating material, trowel finish sand slurry, standard net cloth, rare earth trowel finish sand slurry, flexible putty and face coat on the base layer of the wall body in turn. The invention has good heat-insulating property, strong binding power, high compression strength, good water resistance and flame proof, which is antiseptic, noncorrosive, nontoxic, tasteless and pollution-free, has the function of absorbing ultraviolet ray and infrared ray, and has quick coagulate speed, rapid increase of the strength of materials, and the construction procedure is rapid, timesaving and laborsaving.

Owner:包头市科强新型材料有限公司

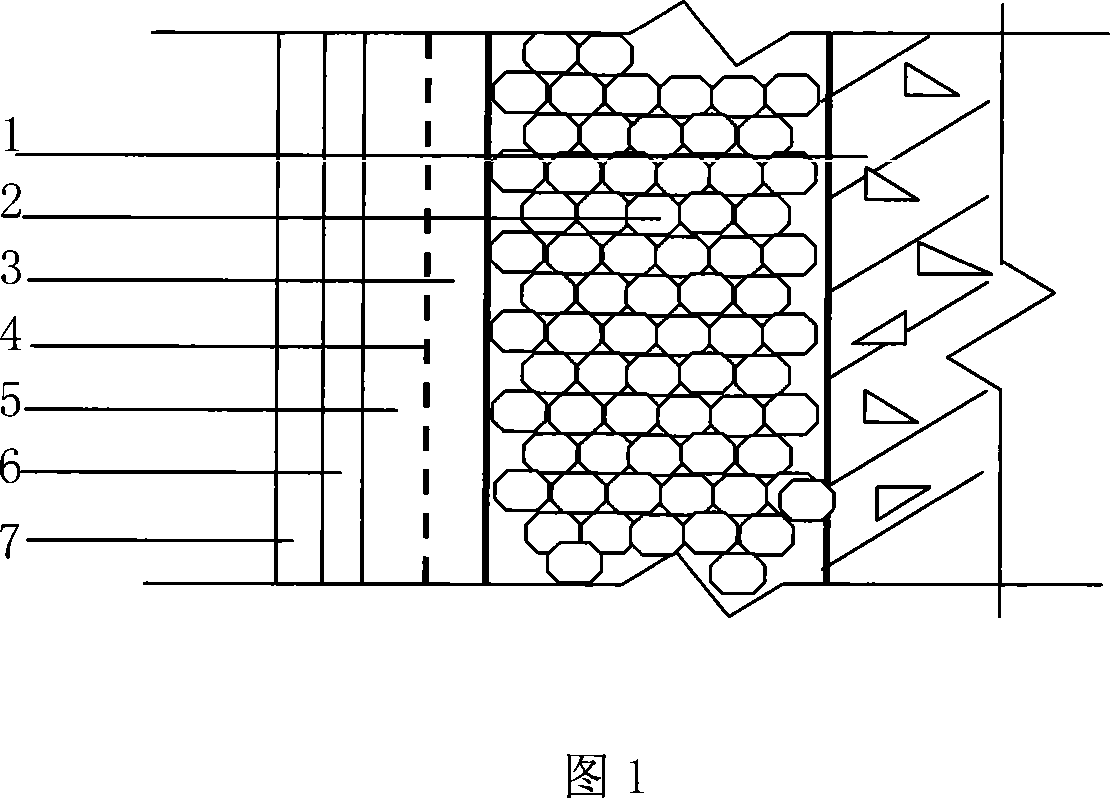

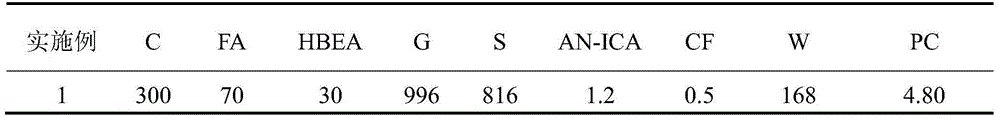

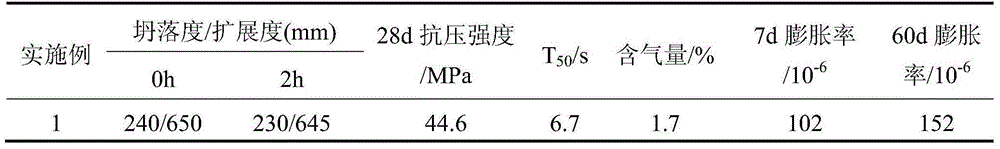

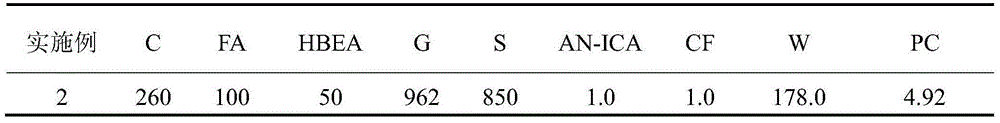

C30 self-compaction microexpanded concrete-filled steel tube and preparation method thereof

ActiveCN105084836ASolve the "out of the air" problemImprove cementing performanceSolid waste managementCelluloseCoal

The invention discloses a C30 self-compaction microexpanded concrete-filled steel tube and belongs to the field of building materials. The C30 self-compaction microexpanded concrete-filled steel tube is prepared by taking cement, coal ash, composite expansion agents, gravel, river sand, tackifying plasticity-maintaining ultra-dispersed additive, internal maintaining materials, micro-grade modified degreasing cotton cellulose and water as raw materials. The number of binding materials adopted in the C30 self-compaction microexpanded concrete-filled steel tube is small, and the C30 self-compaction microexpanded concrete-filled steel tube has the advantages of being good in self-compaction performance, low in gas content and high in durability, being slightly expanded and the like, is suitable for compact pouring of intensely reinforced large-pipe-diameter thin-wall steel tube concrete-filled steel tube underwater piles with complex shapes and a small section size, string tube pumping pouring of upper and lower concrete-filled steel tubes of concrete-filled steel tube truss bridges and high-throwing vibration-free pouring of concrete-filled steel tube pier studs. The problem of disengaging of the concrete-filled steel tube can be effectively solved, and wide application prospects are achieved.

Owner:WUHAN UNIV OF TECH

Method for improving mechanical dephosphorization of iron scale of low-carbon cold heading steel wire rod

ActiveCN102699055AGuaranteed shiftMeet the requirements of the transformationWork treatment devicesMetal rolling arrangementsTemperature controlWire rod

A method for improving the mechanical dephosphorization of iron scale of a low-carbon cold heading steel wire rod belongs to the technical field of steel rolling. Processing steps and control technical parameters are as follows: finish rolling inlet temperature is controlled to be 920 DEG C-950 DEG C, and the finish rolling temperature rising range is controlled to be 80 DEG C-100 DEG C; the spinning temperature is controlled to be 880 DEG C-920 DEG C; the opening times and a heat holding cover of an air cooling line and the opening degree of a fan are regulated, the cooling rate of the phase front section of a spun steel wire rod is controlled to be 2-3 DEG C / s; the temperature of the spun steel wire rod is controlled to be 760 DEG C-740 DEG C when the spun steel wire rod enters the heat holding cover, and the heat holding cover is uncovered at the temperature being 620 DEG C-600 DEG C; and the temperature of the spun steel wire rod is controlled to be 580 DEG C-600 DEG C when the spun steel wire rod is discharged from the heat holding cover, the fan is additionally arranged when the spun steel wire rod is discharged from the heat holding cover, the cooling rate of the spun steel wire rod passing through a temperature zone being 5000 DEG C-400 DEG C rapidly is controlled to be 3-5 DEG C / s, and the passing time is controlled to be 15-25s. The method has the advantages that the phase structure conversion phenomenon in an FeO layer in the iron scale on surface of a hot rolling steel wire rod is reduced obviously, the mechanical dephosphorization is improved obviously, and the wire breaking rate and the loss of a die in the user pulling process are reduced.

Owner:SHOUGANG CORPORATION

Double-liquid double-metal oil quenching hammer and machining method thereof

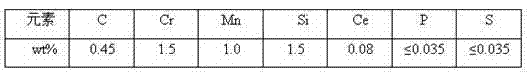

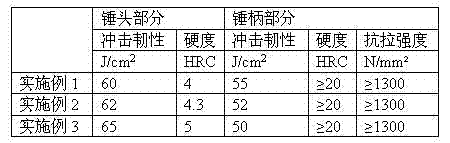

ActiveCN103667870ASimple processReasonable ingredientsFurnace typesHeat treatment furnacesFerrosiliconCarbon alloy

The invention discloses a double-liquid double-metal oil quenching hammer and a machining method thereof. The machining method comprises the following steps: matching waste steel, pig iron, ferrochromium, ferromanganese and ferrosilicon as furnace materials according to chemical component content of a hammer head part and a hammer handle part of a product, respectively putting the materials into a sensing furnace to be smelted, casting and shaping, performing thermal treatment so as to obtain the double-liquid double-metal oil quenching hammer. The double-liquid double-metal oil quenching hammer has the advantages of simple process, reasonable material matching and low production cost; as a high-chromium iron material is added into an alterant with ferroboron, ferrotitanium, ferrovanadium and rare earth silicon to cast the hammer head part, a low-carbon alloy steel material is added into an alterant with rare earth lanthanum and cerium, ferrosilicon particles, rare earth magnesium and ferroboron to cast the hammer handle part, and the requirements on hardness and wear-resistance of the hammer part and on hardness, toughness and wear-resistance of the hammer handle part can be met through thermal treatment at one step.

Owner:BEIPIAO JINSHIDA MACHINERY MFR

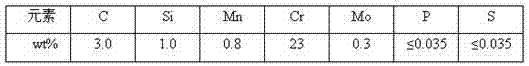

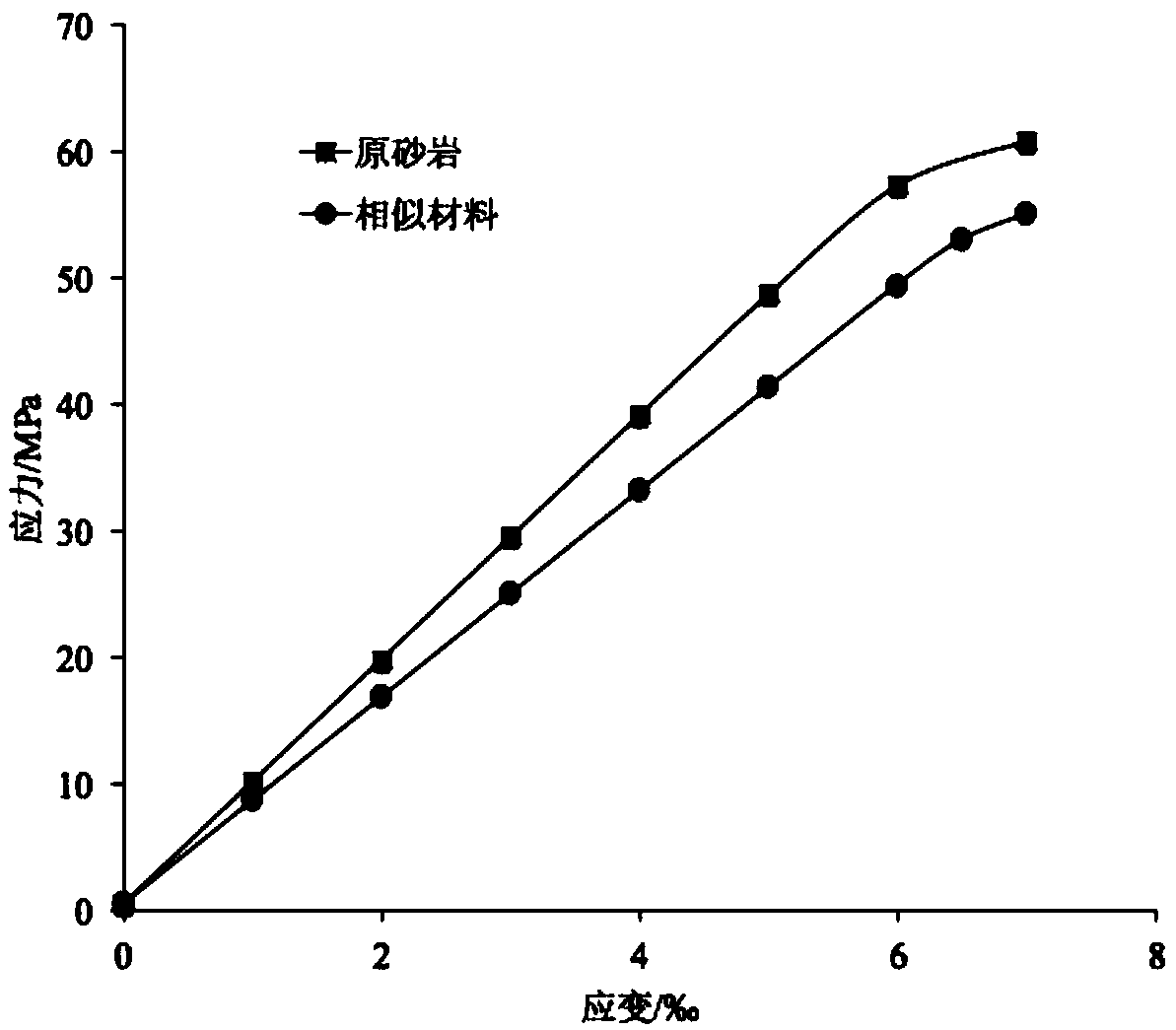

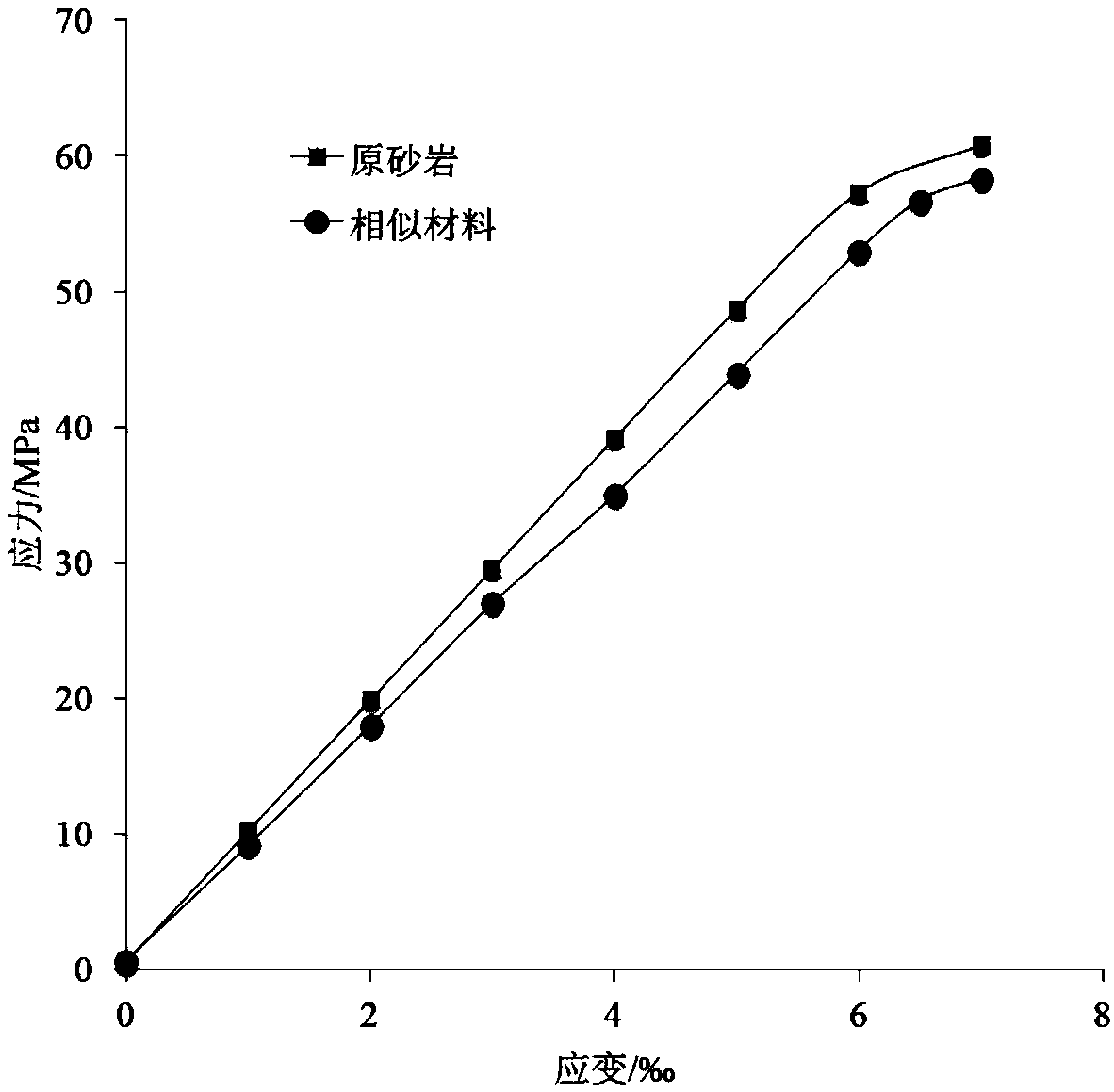

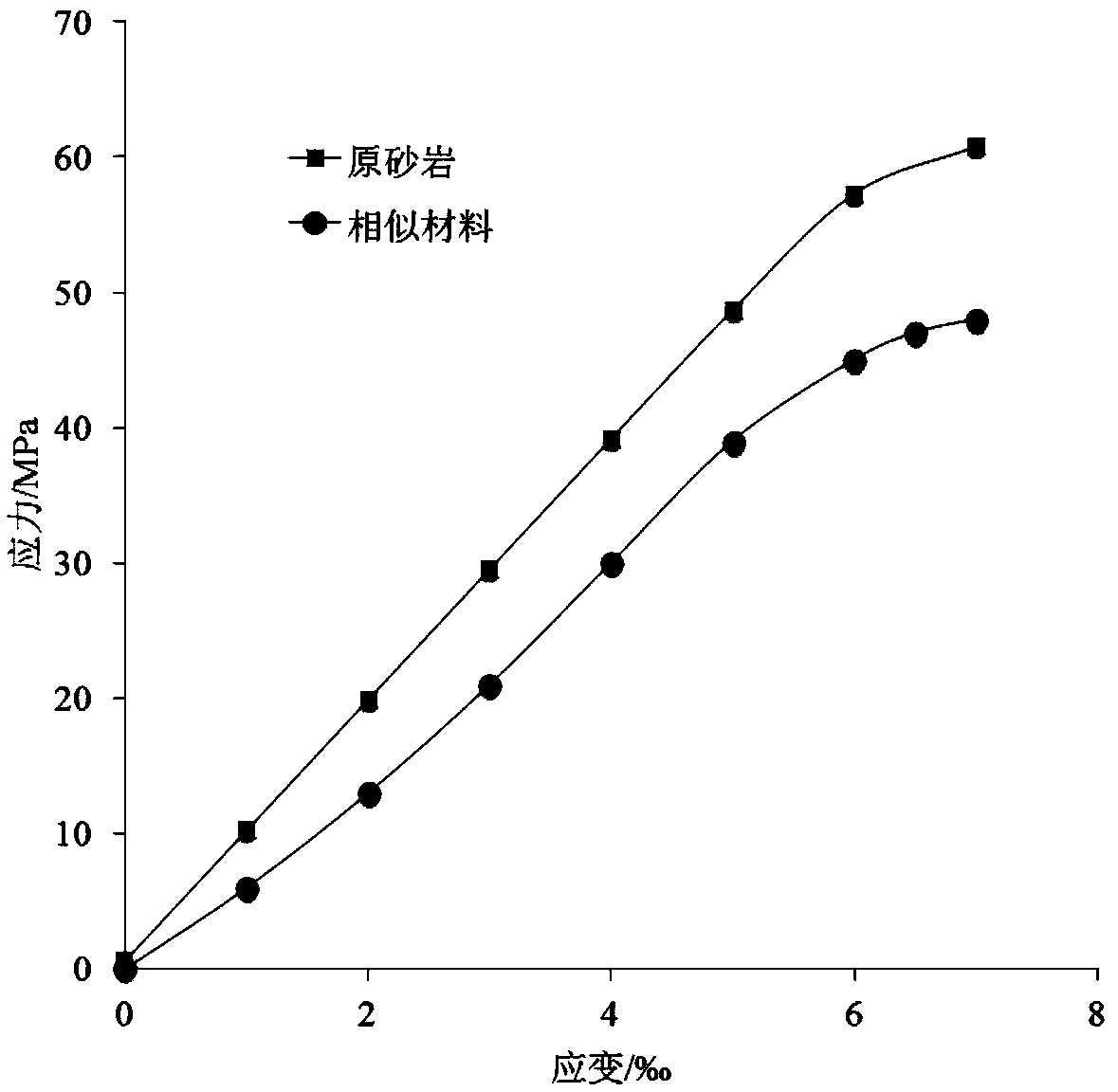

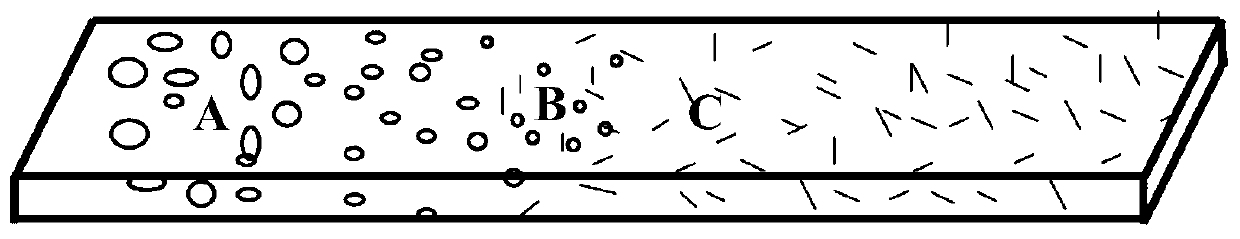

Sandstone similar material and preparation method thereof

InactiveCN109020364AImprove brittlenessHigh strengthSolid waste managementPreparing sample for investigationMechanical propertyWater reducer

The invention provides a sandstone high-strength high-brittleness similar material and a preparation method thereof. Raw materials comprise quartz sand, silicon powder, cement, distilled water and a water reducer. based on physical and mechanical properties and microscopic features of protolith, a method of regulating material properties by using aggregate is adopted, quartz sand is selected to improve brittleness of the material, and silicon powder is selected to raise strength of the material. Thereby, brittleness and strength of the sandstone similar material are achieved, and main physicaland mechanics parameters (density, elastic modulus, cohesion, internal friction angle, uniaxial compressive strength, tensile strength and Poisson's ratio, etc.) of the similar material and protolithmeet the similarity theory. Features of sandstone in rock slope of Xinjiang Tianshan highway are successively simulated. The types of required materials are less, and the cost is low. The manufactureefficiency is high. The material of the invention has wide practicality.

Owner:HUBEI ENG UNIV

Method for preparing TC21 titanium alloy gradient structure with high strength and toughness

The invention provides a method for preparing a TC21 titanium alloy gradient structure with high strength and toughness. The method for preparing the TC21 titanium alloy gradient structure with high strength and toughness comprises the steps of applying pulse current on a TC21 titanium alloy bar or a panel, and utilizing resistance for locally heating; through controlling the parameters such as pulse voltage, the pulse current and pulse frequency, producing a temperature gradient in a TC21 titanium alloy bar-shaped sample or plate-shaped sample; and through controlling the width of the temperature gradient and the heat preservation time, finally obtaining the gradient structure at room temperature. According to the method for preparing the TC21 titanium alloy gradient structure with high strength and toughness provided by the invention, without the need for changing the alloy compositions, an integrated structure part containing an original material structure, a transition area gradient structure and a lamellar structure can be produced, so that the performance advantages of the original material are reserved, and meanwhile, a combination property of the material is improved. The method is simple to operate, equipment is simple and easy, the method is environmental-friendly and economical, the production efficiency is improved, the energy consumption is reduced, and the methodhas a larger industrial promotion value.

Owner:XIAN UNIV OF TECH

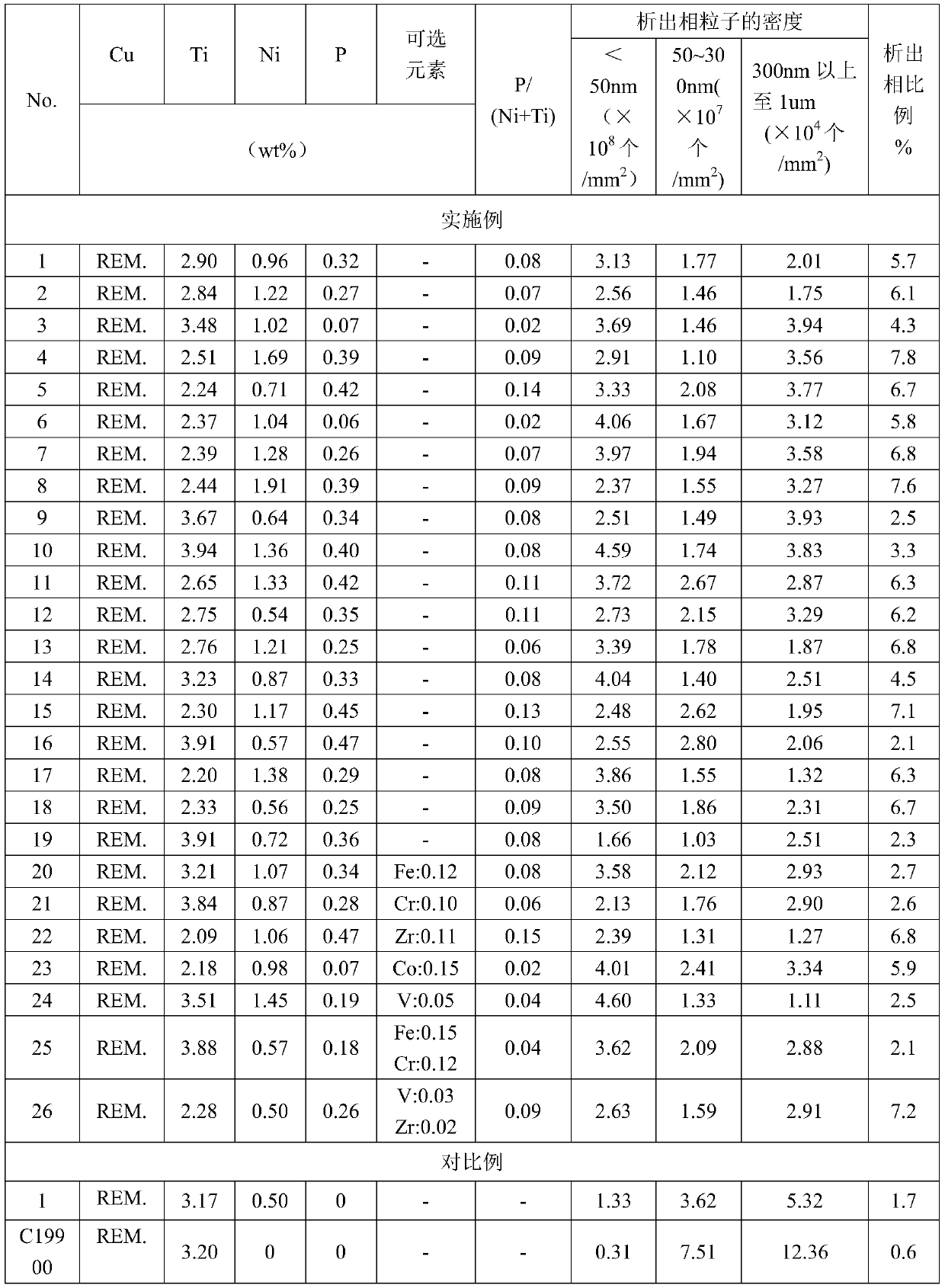

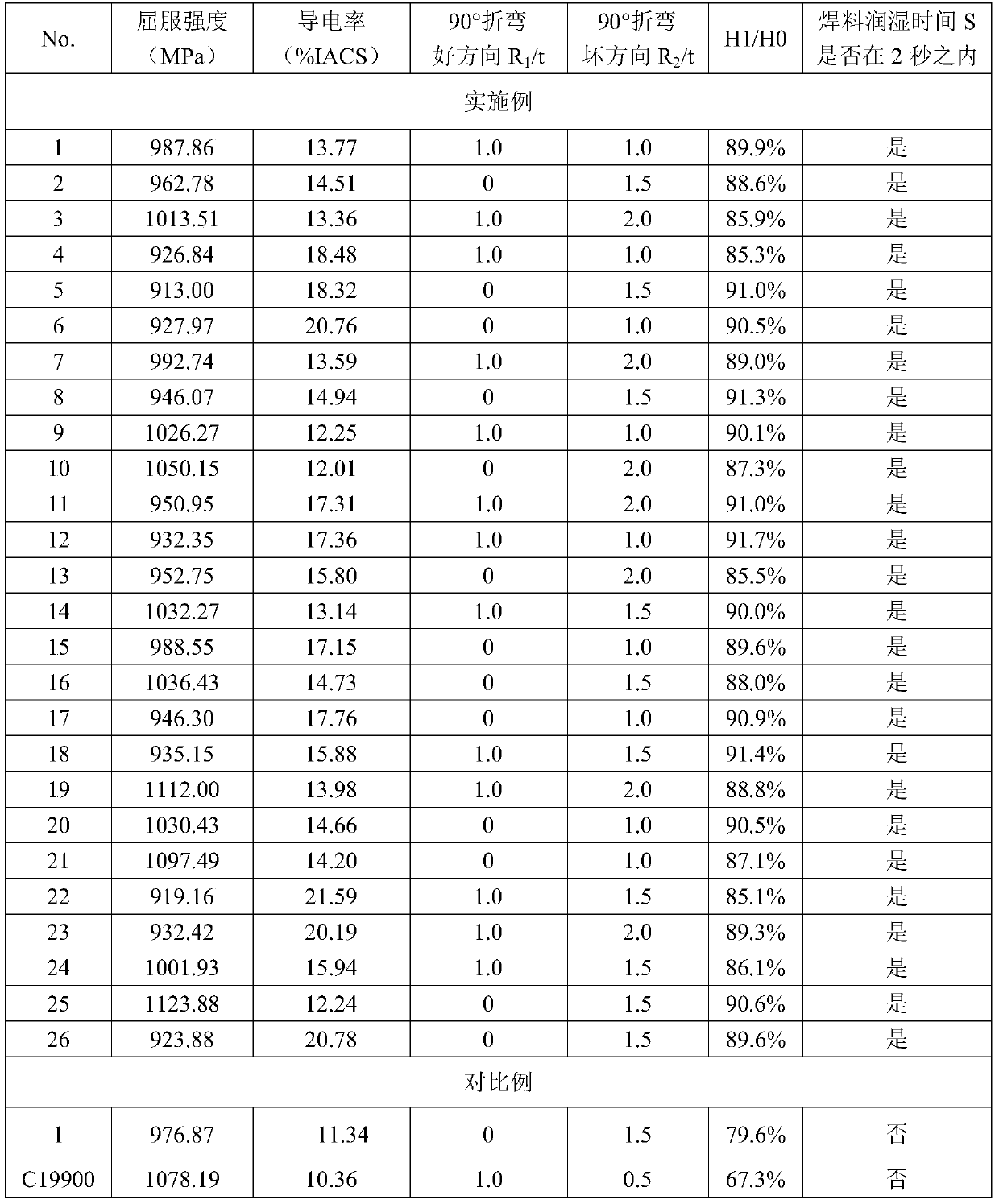

Aging-reinforced titanium-copper alloy and preparation method thereof

The invention relates to an aging-reinforced titanium-copper alloy. The aging-reinforced titanium-copper alloy is characterized by being prepared from the compositions in percentage, by weight, 2.0-4.0% of Ti, 0.5-2.0% of Ni, 0.05-0.5% of P and the balance copper and unavoidable impurities. By controlling the matching ratio of Ni to P to Ti, the yield strength of the aging-reinforced titanium-copper alloy is up to 900-1150 MPa, the conductivity is up to 12-22% IACS, and excellent bending machinability, high-temperature softening resistance and welding properties are obtained. The aging-reinforced titanium-copper alloy is especially applicable to the fields of connectors, terminals, relays and the like.

Owner:NINGBO POWERWAY ALLOY MATERIAL +1

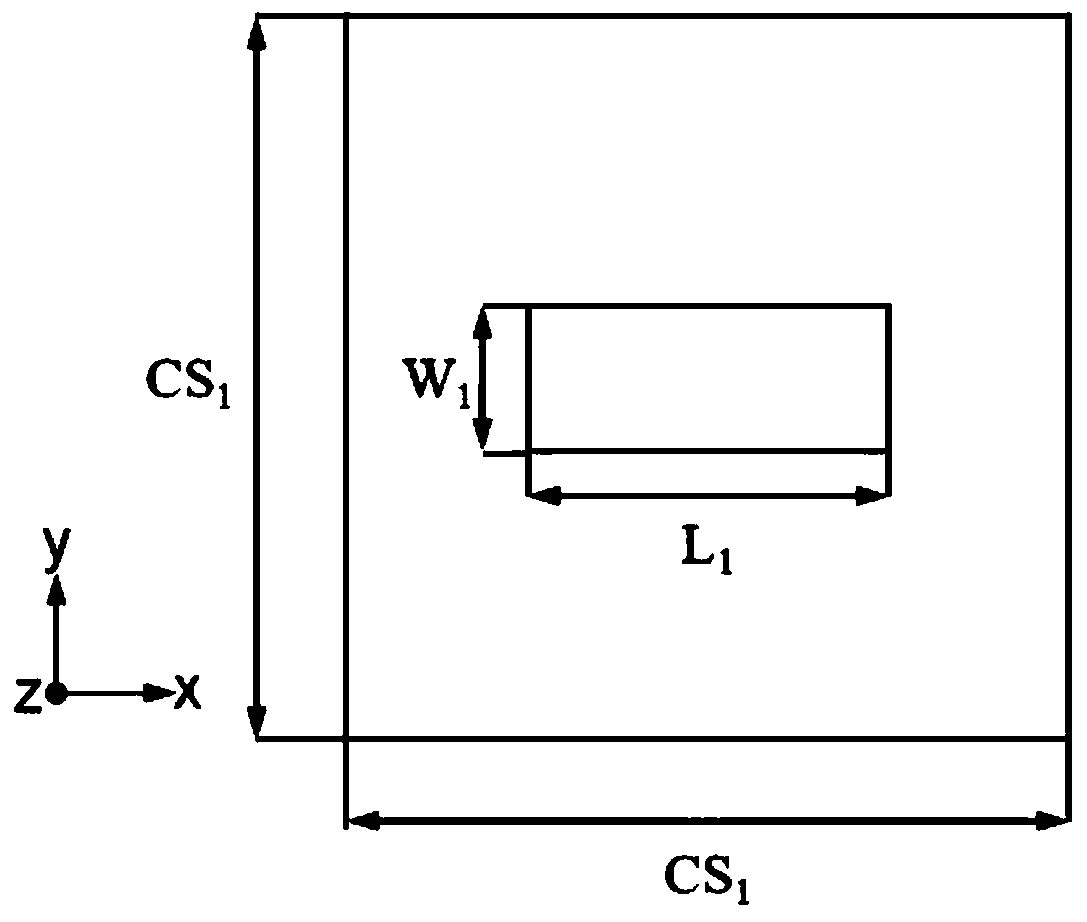

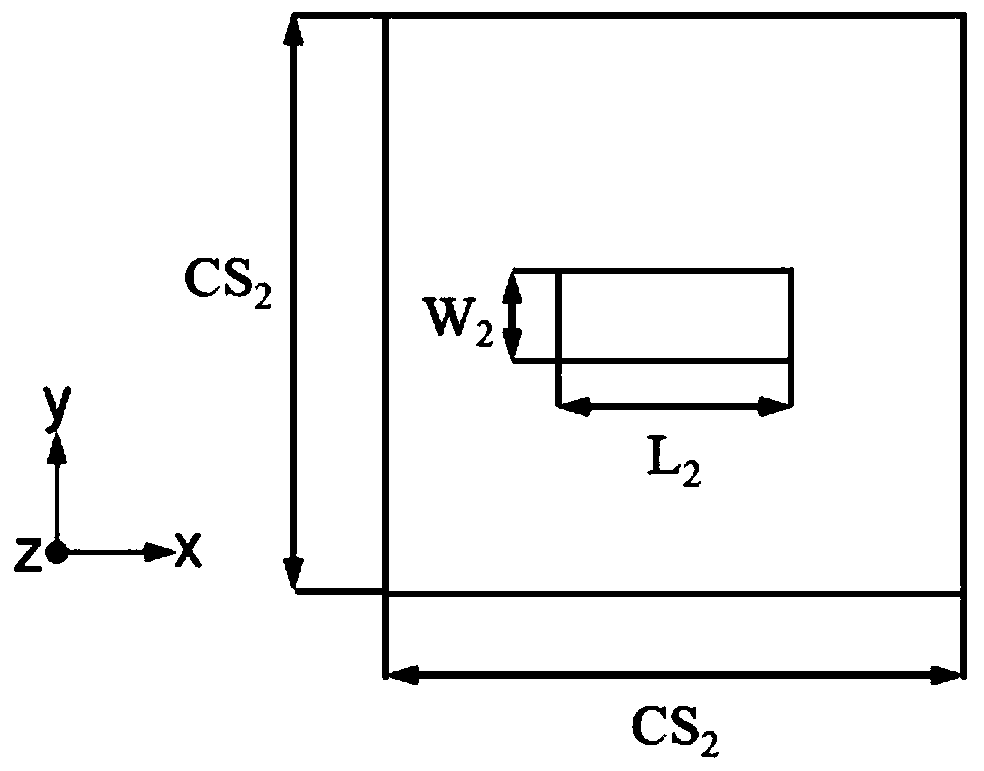

Color printing device based on metal nano brick array and printing method

ActiveCN110568526AImplement storageRealize the display effectOptical light guidesSpectral responseBrick

The invention discloses a color printing device based on a metal nano brick array and a printing method. A metal nano brick array structure comprises a substrate and a nano brick array on the substrate. On the basis of a metal surface plasma resonance effect, a polarization separation structure can be designed through specific nano brick sizes; and on the basis of anisotropic characteristics of ametal nano brick-air mixing layer structure, metal nano brick structures with different spectral responses can be designed by changing the duty ratio and sizes of the metal nano bricks. The metal nanobricks with different geometric dimension parameters can serve as polarizers of blue light, green light and red light wave bands, also have functions of light filtering and polarizing beam splittingand are used for realizing the color nano-printing function. The nano brick array can be widely applied to the fields of compact display, optical counterfeiting prevention, information encryption, light storage and the like and can be manufactured only through a simple one-time photolithography technique, thereby having the outstanding advantages of being flexible in design, simple to process, compact in structure and the like.

Owner:WUHAN UNIV

Device for increasing clamping force of magnetorheological fluid flexible fixture

ActiveCN106141708AEnhanced static yield stressAbility to control clamping forcePositioning apparatusMetal-working holdersPower flowMagnetorheological fluid

The invention relates to a device for increasing clamping force of a magnetorheological fluid flexible fixture. Magnetorheological fluid increases the clamping force of the flexible fixture in the application field of the flexible fixture to guarantee normal workpiece machining. The device mainly consists of an electromagnetic coil, a machined workpiece, an extension electric conducting ring, the magnetorheological fluid, an extension insulation container and an insulation isolation ring. When the electromagnetic coil is electrified, the magnetorheological fluid generates a magnetorheological effect, so that the magnetorheological fluid instantly changes from a low-viscosity and high-fluidity newtonian fluid to a high-viscosity and low-fluidity Bingham fluid to form a chain in a magnetic field direction to clamp the workpiece with an irregular shape; meanwhile, current is conducted to the extension electric conducting ring; an electrifying conductor is suffered from ampere force in a magnetic field; the current direction and the magnetic field direction are adjusted according to a left-hand rule, so that the generated force extrudes the magnetorheological fluid in the center direction of the device; and the chain in the magnetorheological fluid is continuously thickened by extruding, so that the workpiece is firmly clamped to guarantee normal machining.

Owner:嘉兴彩虹光学膜片科技有限公司

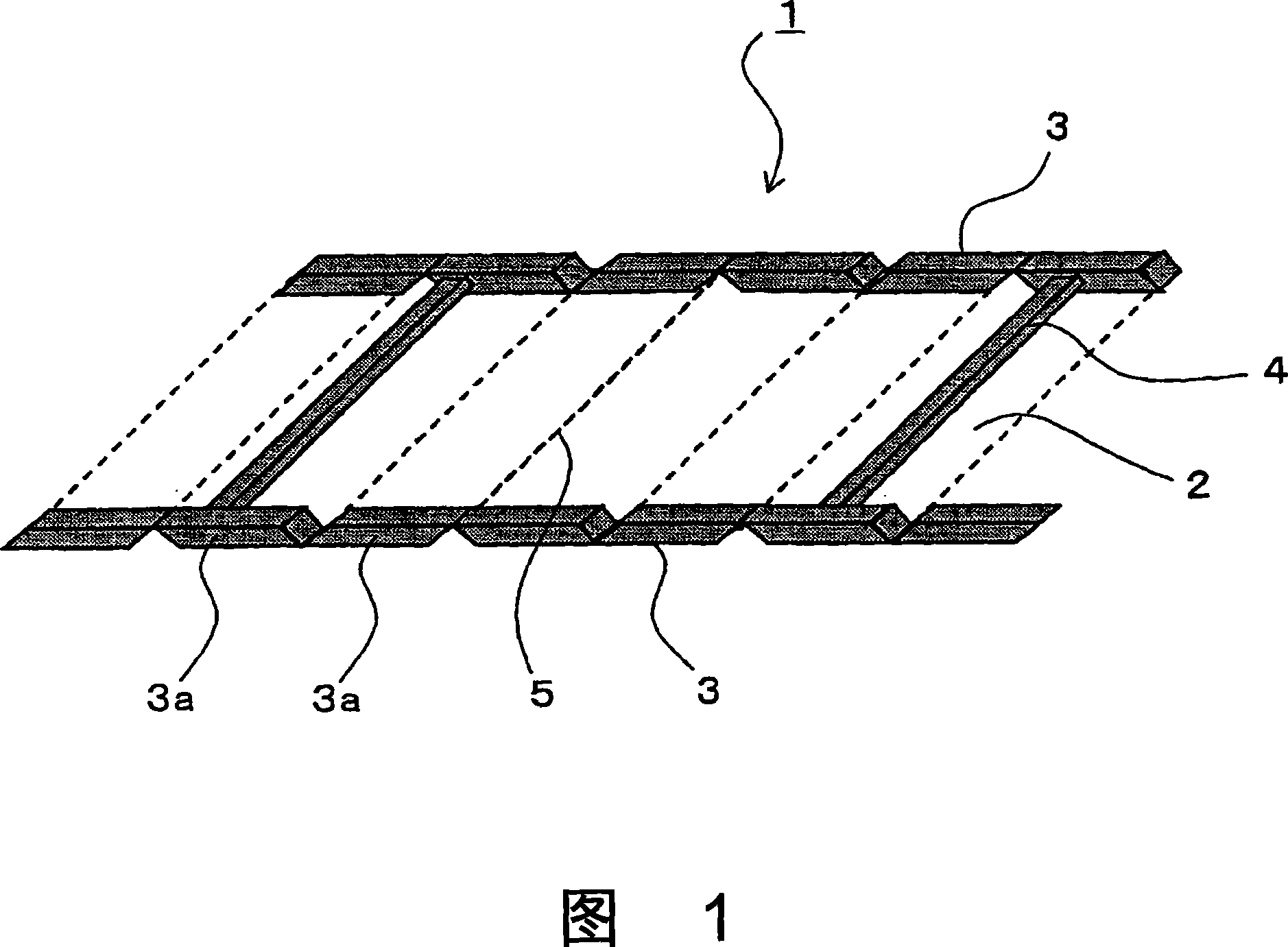

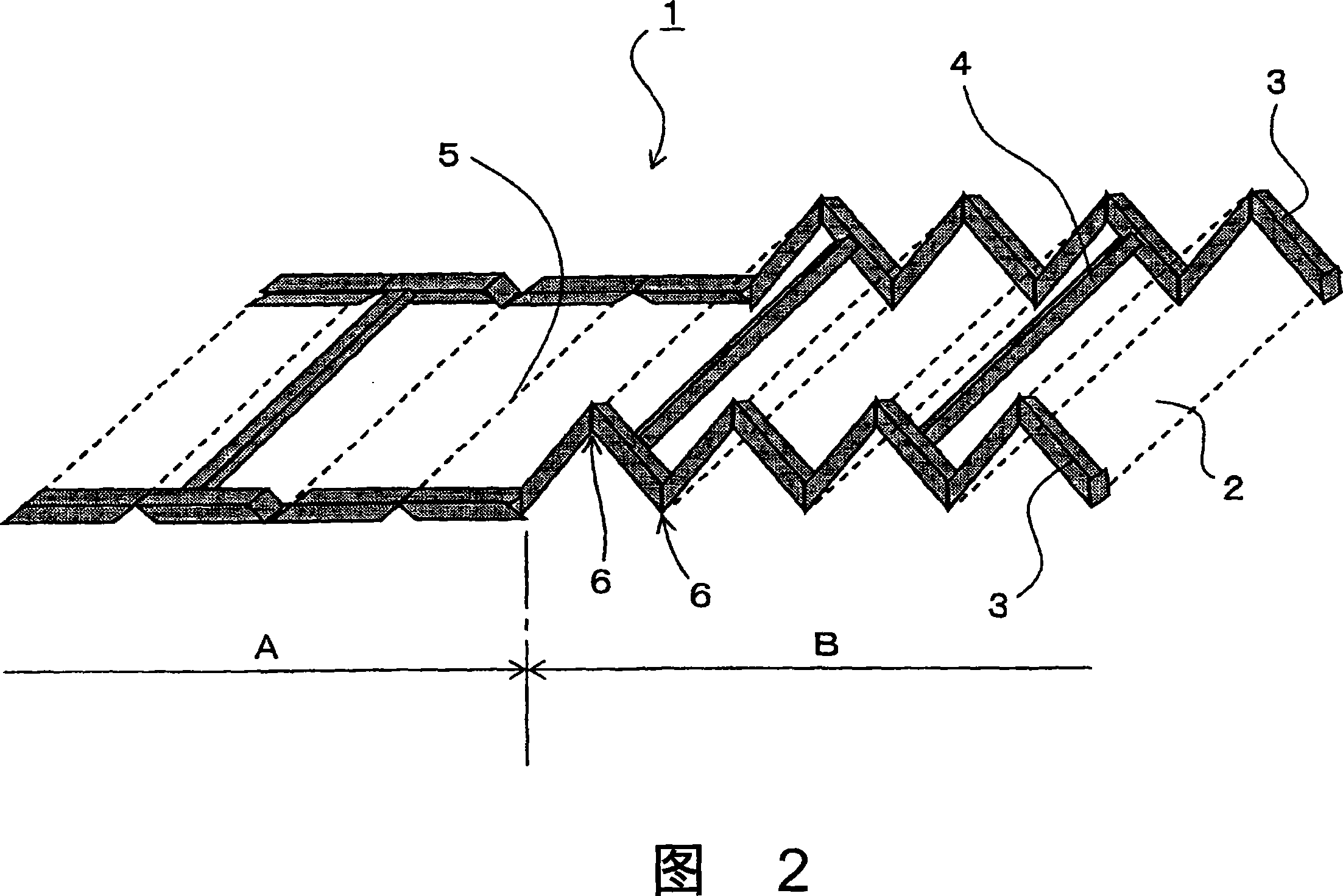

Filter

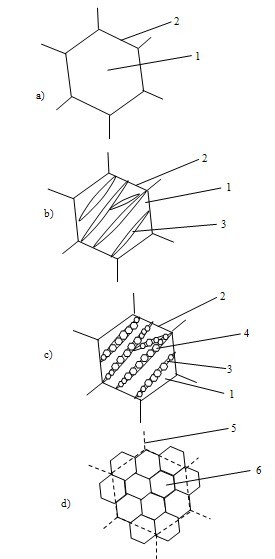

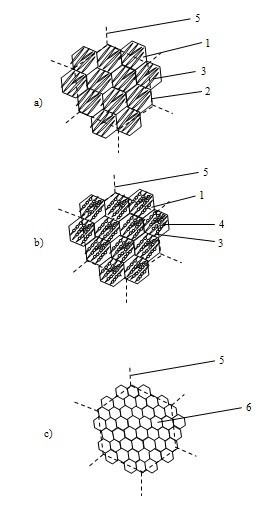

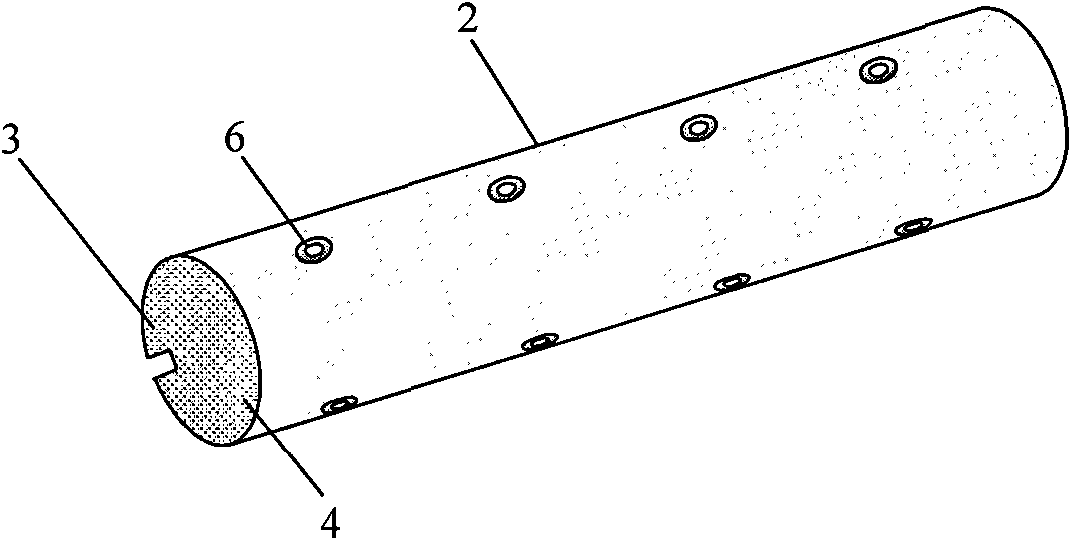

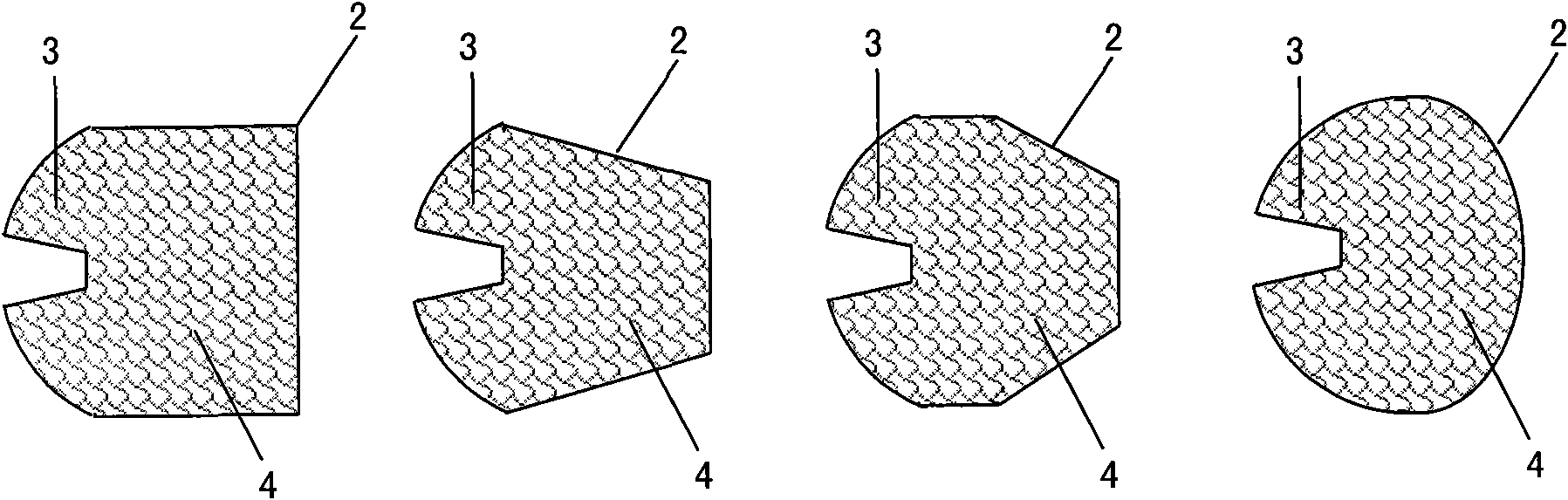

InactiveCN101091857ASimple structureAchieve strengthAir-treating devicesDispersed particle filtrationFilter materialEngineering

Disclosed is a filter (1) comprising a sheet-like filter material (2) capable of being folded in a pleat form, two filter frame members (3) each provided on each side of the filter material (2) and each free to be expended and folded in the longitudinal direction of filter material (2), and a plurality of support members (4) appropriately arranged in the longitudinal direction of the filter material (2) and each of which extends between two filter frame members (3) in the transverse direction of the filter material (2). By this invention, provided is a filter excellent in attachment and detachment property in a small space, and having a sufficient strength at a simple structure, and which can be manufactured at a reduced cost.

Owner:SANDEN CORP

Process of modifying calcium silicate plate with water-base epoxy resin

InactiveCN101066852AAchieve strengthMeet the requirements of autoclave curingWater basedCalcium silicate

The present invention relates to method of modifying calcium silicate plate with water-base epoxy resin. Water-base epoxy resin emulsion and curing agent are used in modifying calcium silicate plate product or material. The modified material consists of calcium silicate plate product 100 weight portions, water-base epoxy resin emulsion 3-10 weight portions, and curing agent 20-25 wt% of the water-base epoxy resin emulsion. The modified calcium silicate plate has excellent performances, including waterproof performance, shock resistance, compression strength and bending strength, higher than that of common calcium silicate plate, and is suitable for use in building.

Owner:GUANGDONG UNIV OF TECH

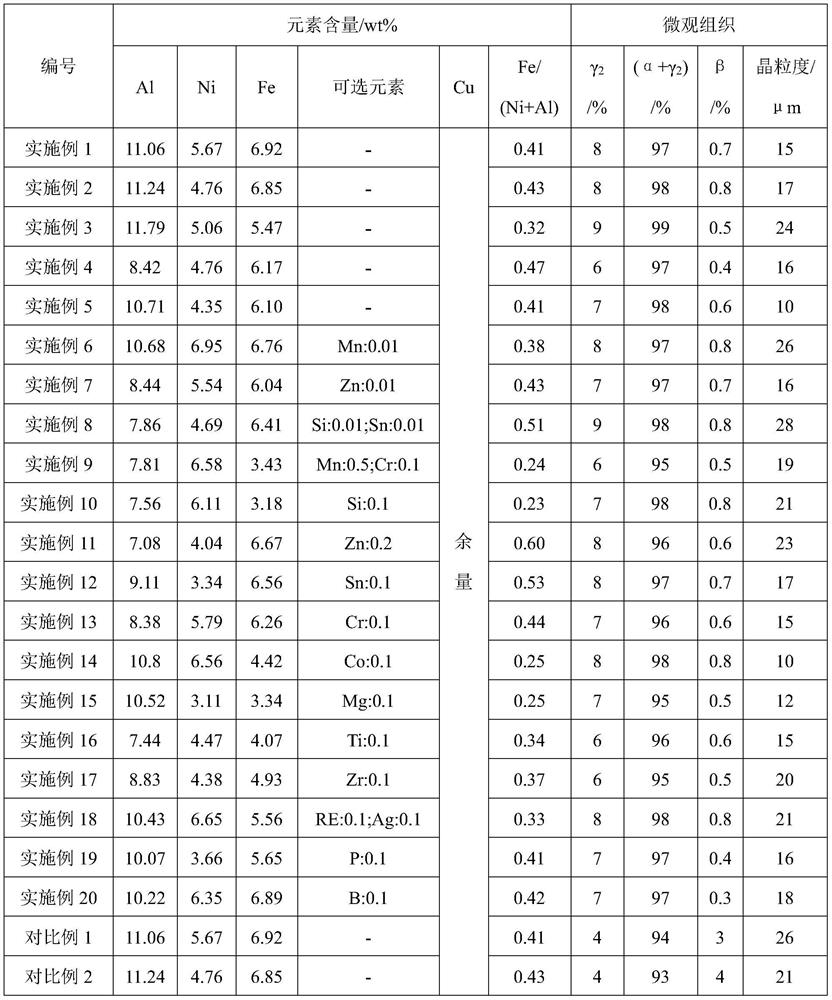

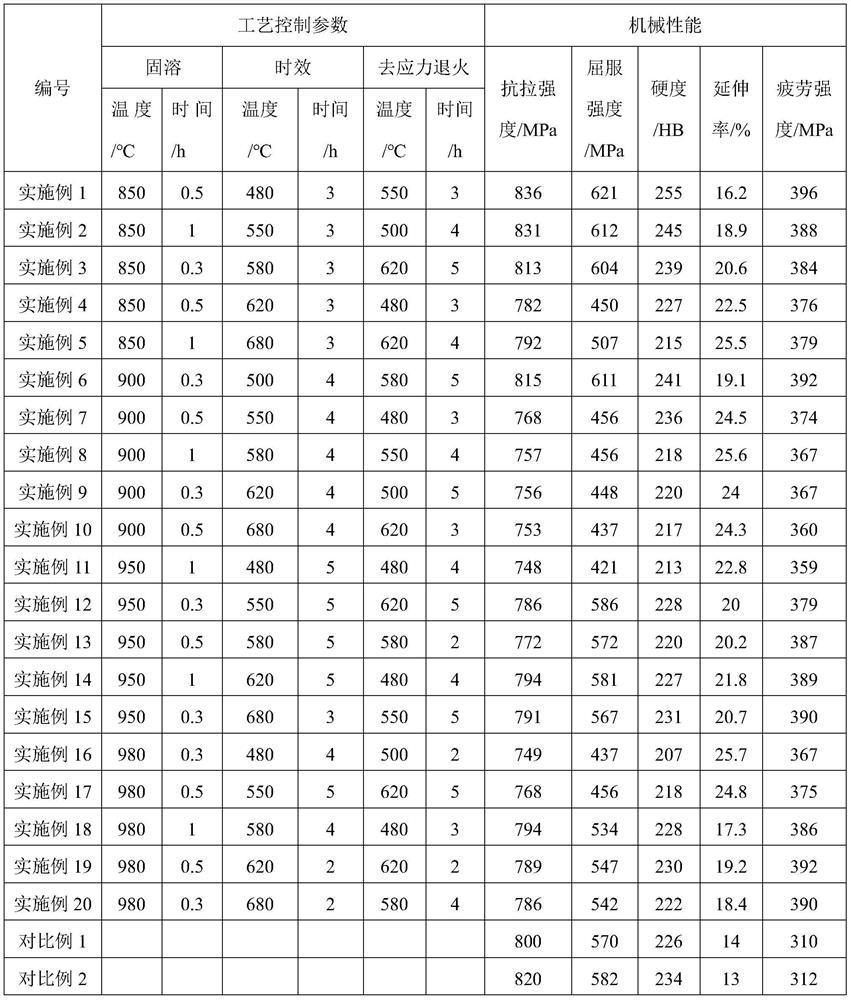

Aluminum bronze and preparation method thereof

The invention discloses aluminum bronze. The aluminum bronze is characterized by comprising the following components in percentage by mass: 7.0-12.0% of Al, 3.0-7.0% of Ni, 3.0-7.0wt% of Fe, 0-1.0wt%of Mn, 0-1.0wt% of Zn, 0-0.5wt% of Si, 0-0.5wt% of Sn, and the balance Cu and inevitable impurities; and a microstructure of the aluminum bronze contains an alpha phase and a gamma 2 phase. The aluminum bronze has the tensile strength of not less than 740MPa, the yield strength of not less than 400MPa, the ductility of not less than 15% and the hardness of not less than 200HB; when the stretchingcycle times are 107 times, the fatigue strength is 355-400MPa; and the aluminum bronze can satisfy the requirements of structural parts, wear resisting parts, corrosion resisting parts and the like working in such places as mechanical industry, ship and ocean industry, petrochemical industry and electric industry on comprehensive performances of the aluminum bronze.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com