Patents

Literature

544 results about "Axial deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

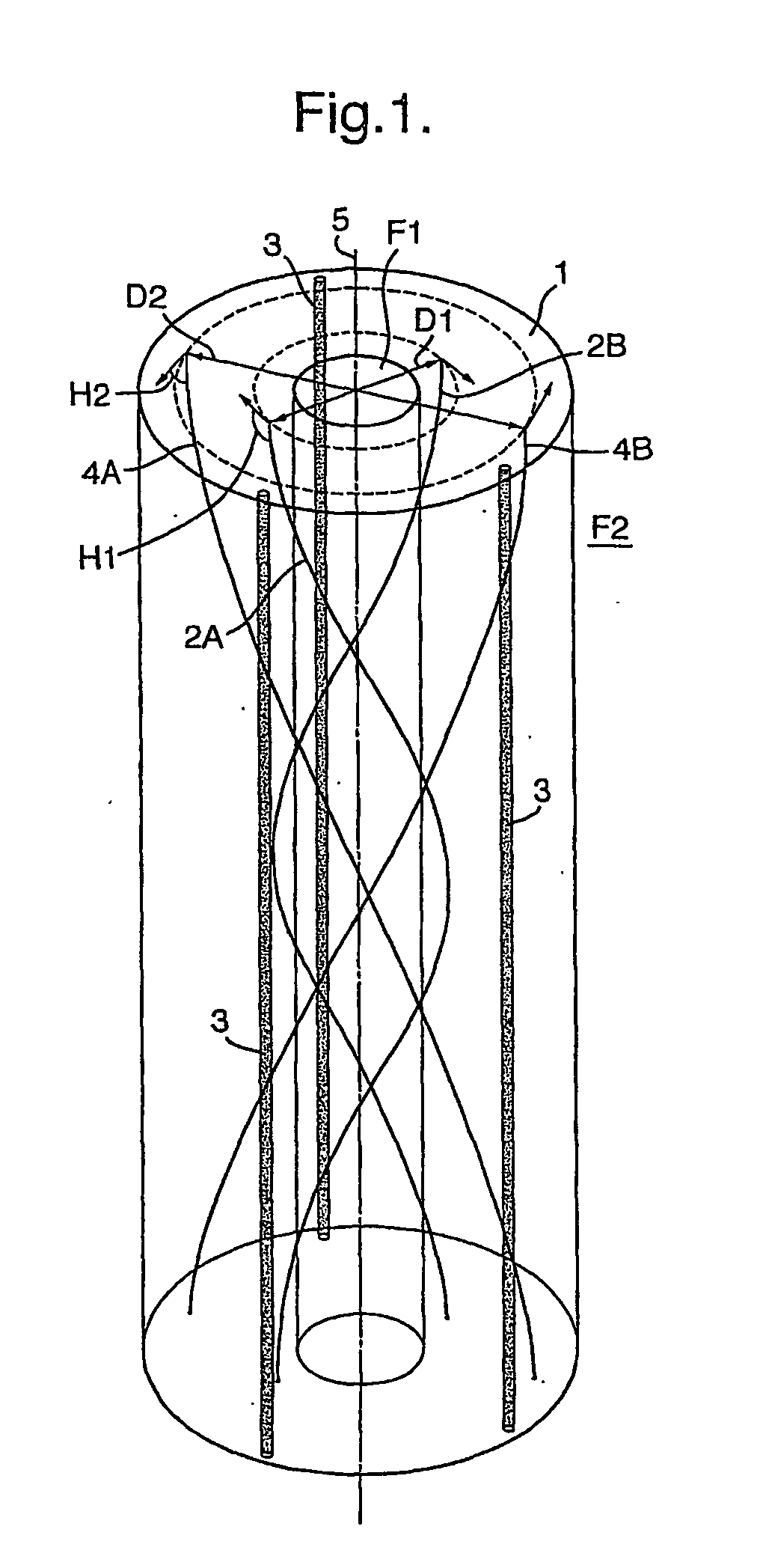

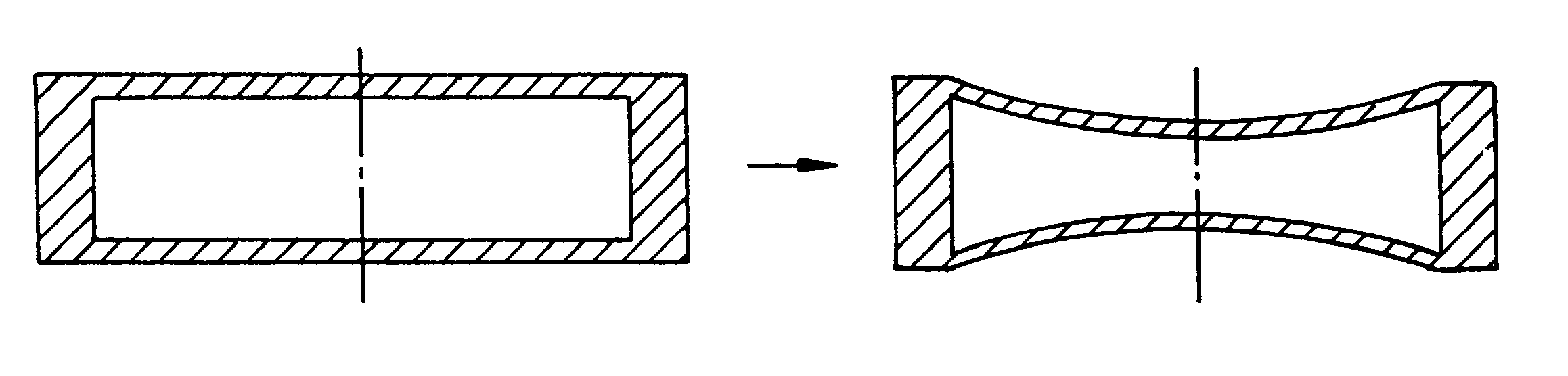

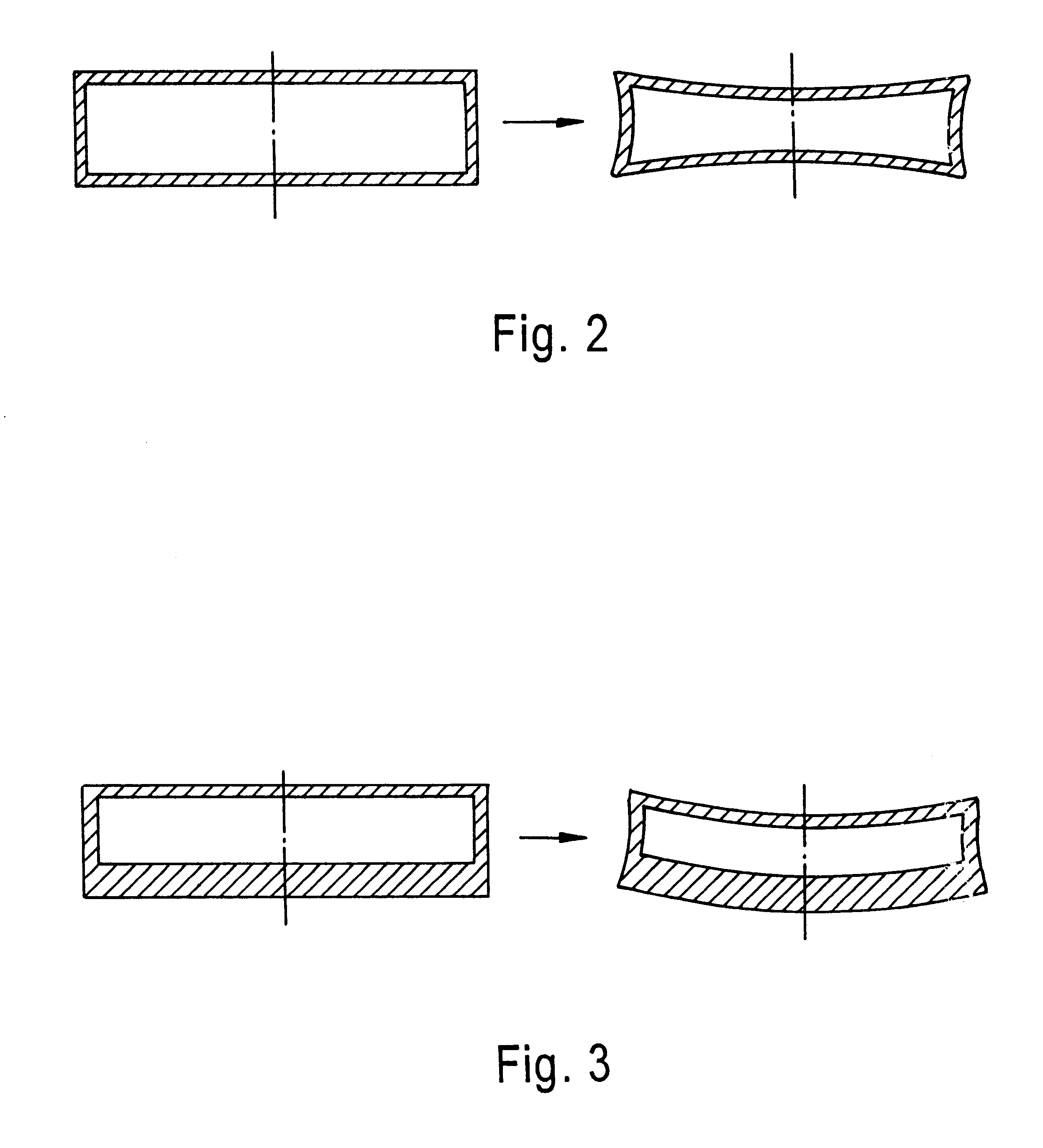

A direct consequence of part (b) of the definition 1 is the fact that axial deformation depends only on the variable, which represents the position of a particular cross-section on the longitudinal axis of the member. � The physical phenomenon described by definition 1 is illustrated in Figure 1, where the undeformed and deformed conditions of the linear member are presented.

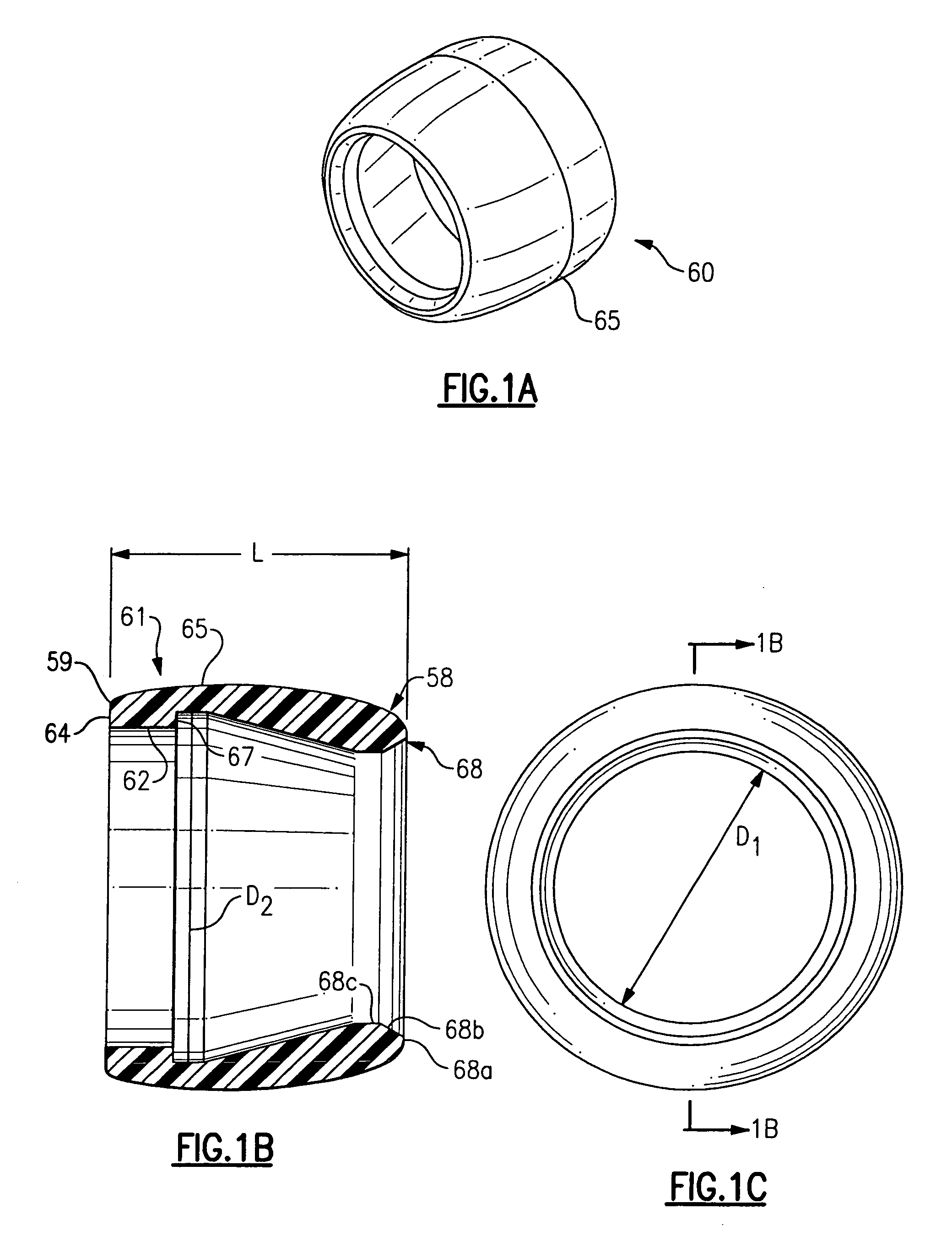

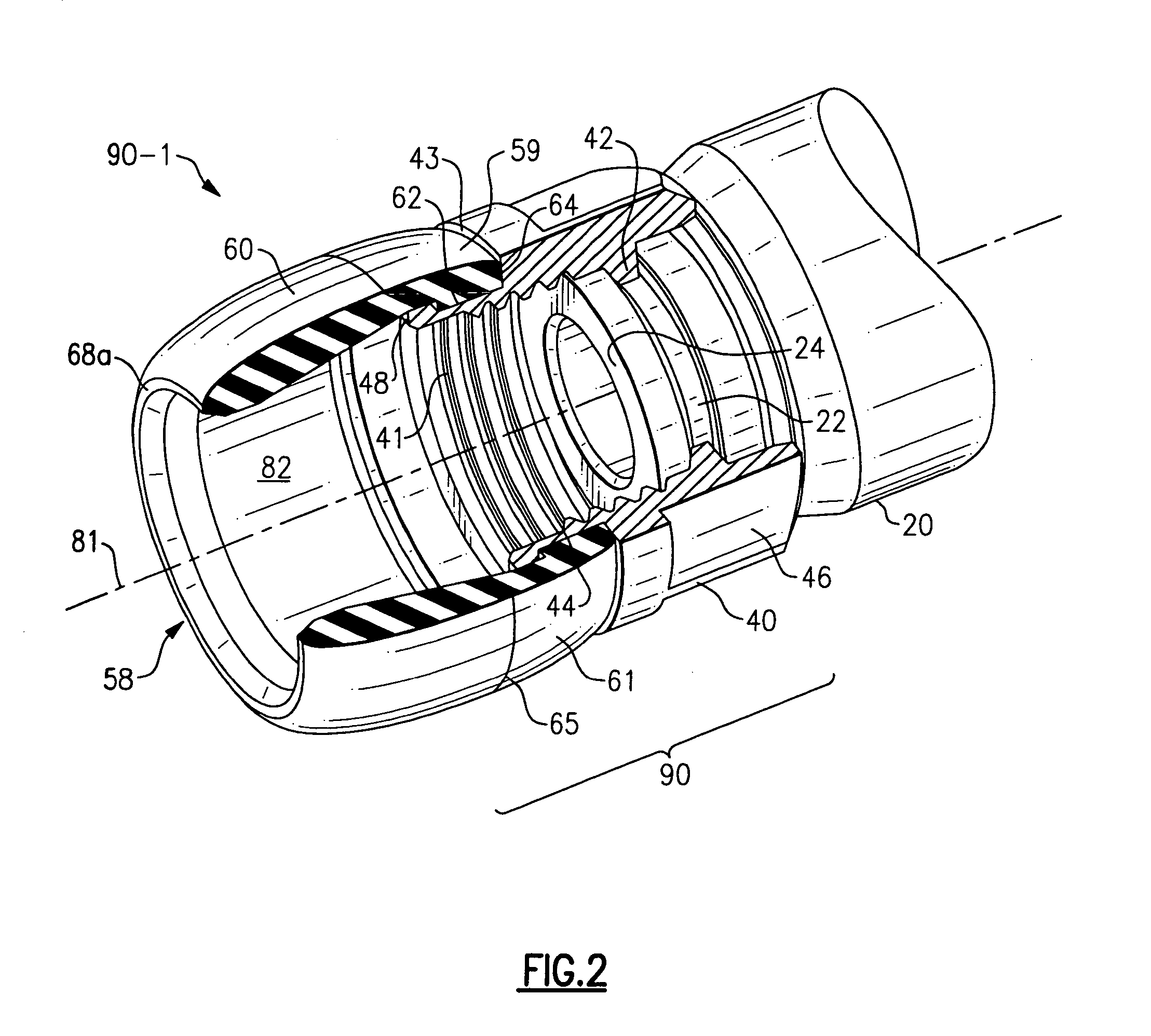

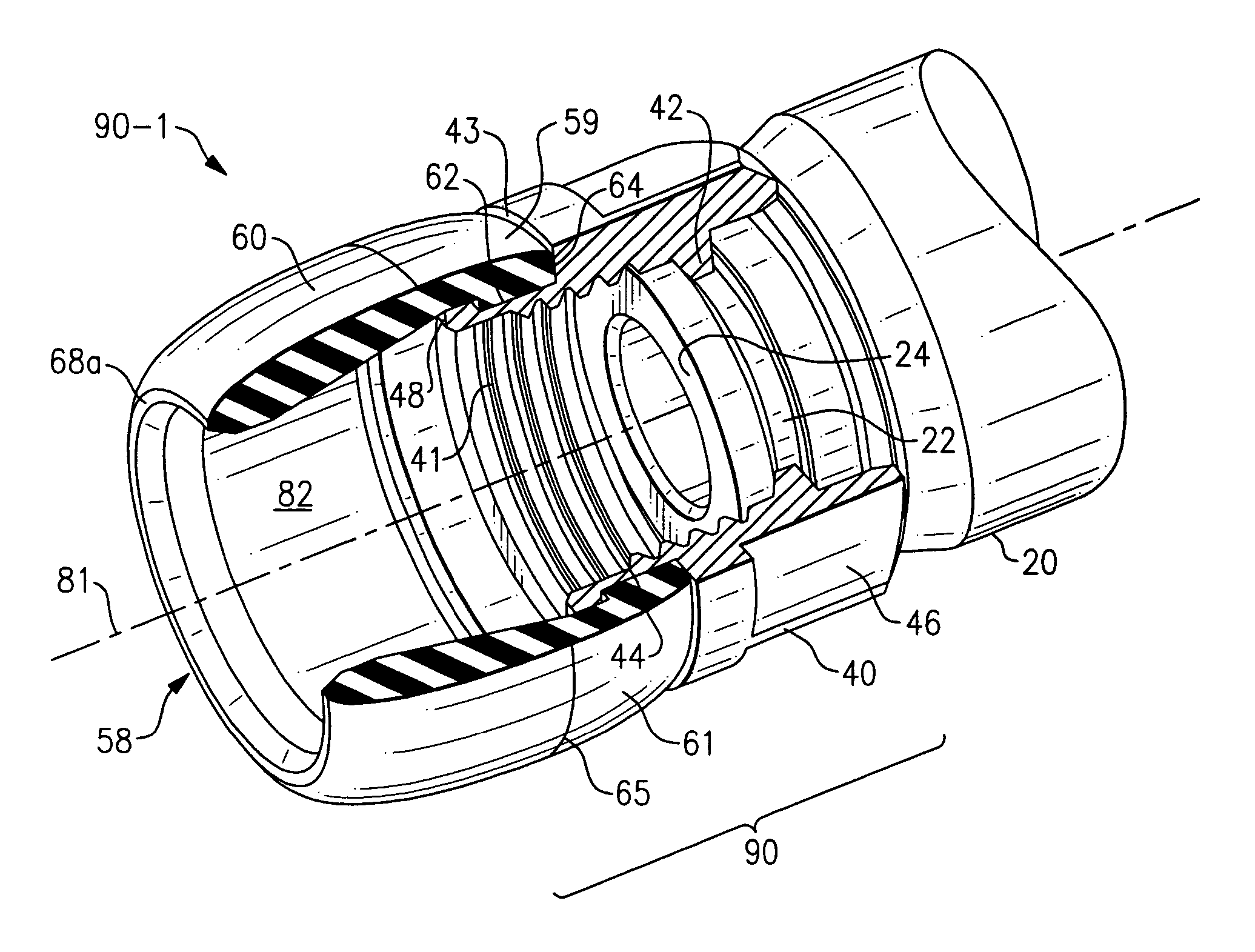

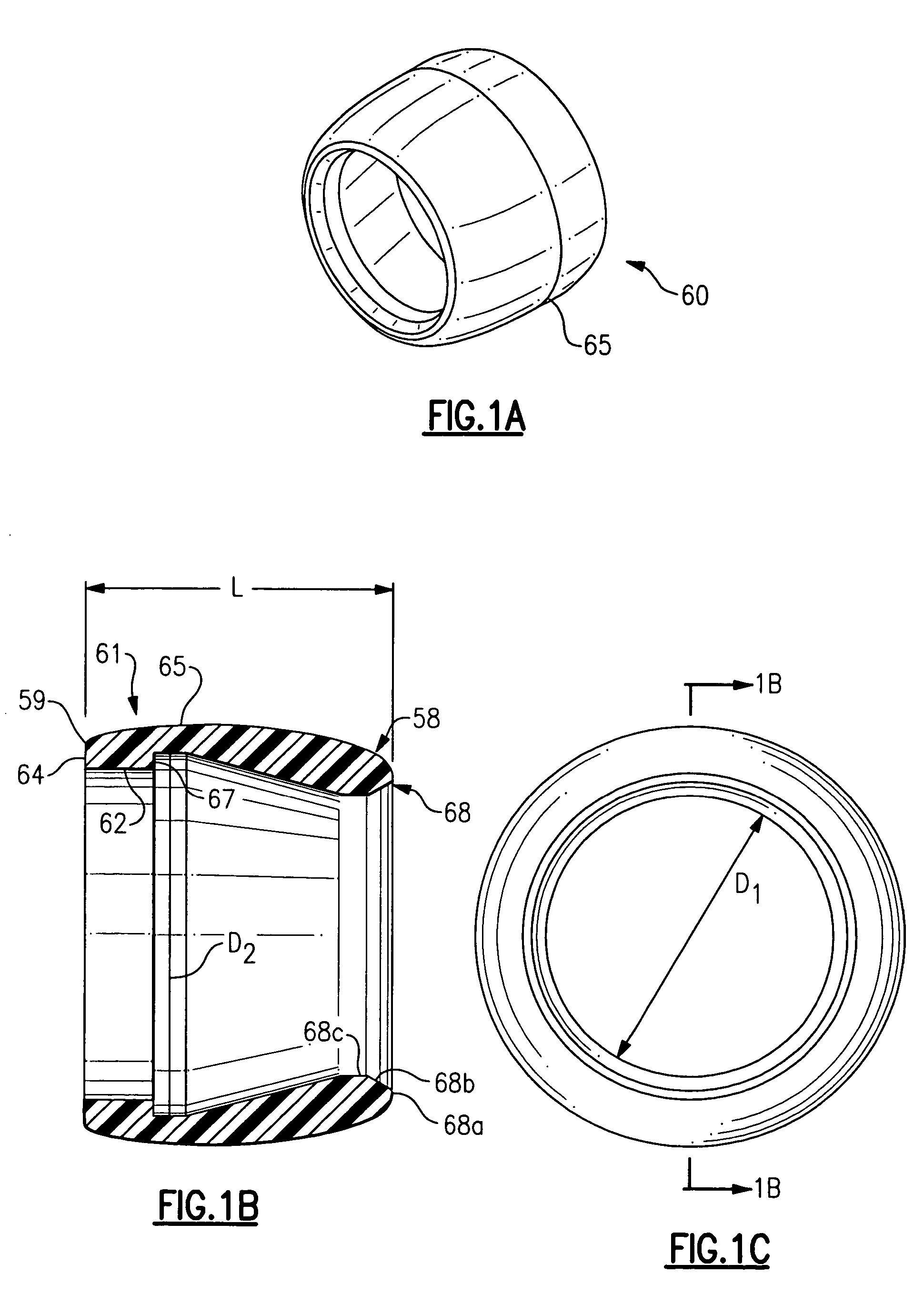

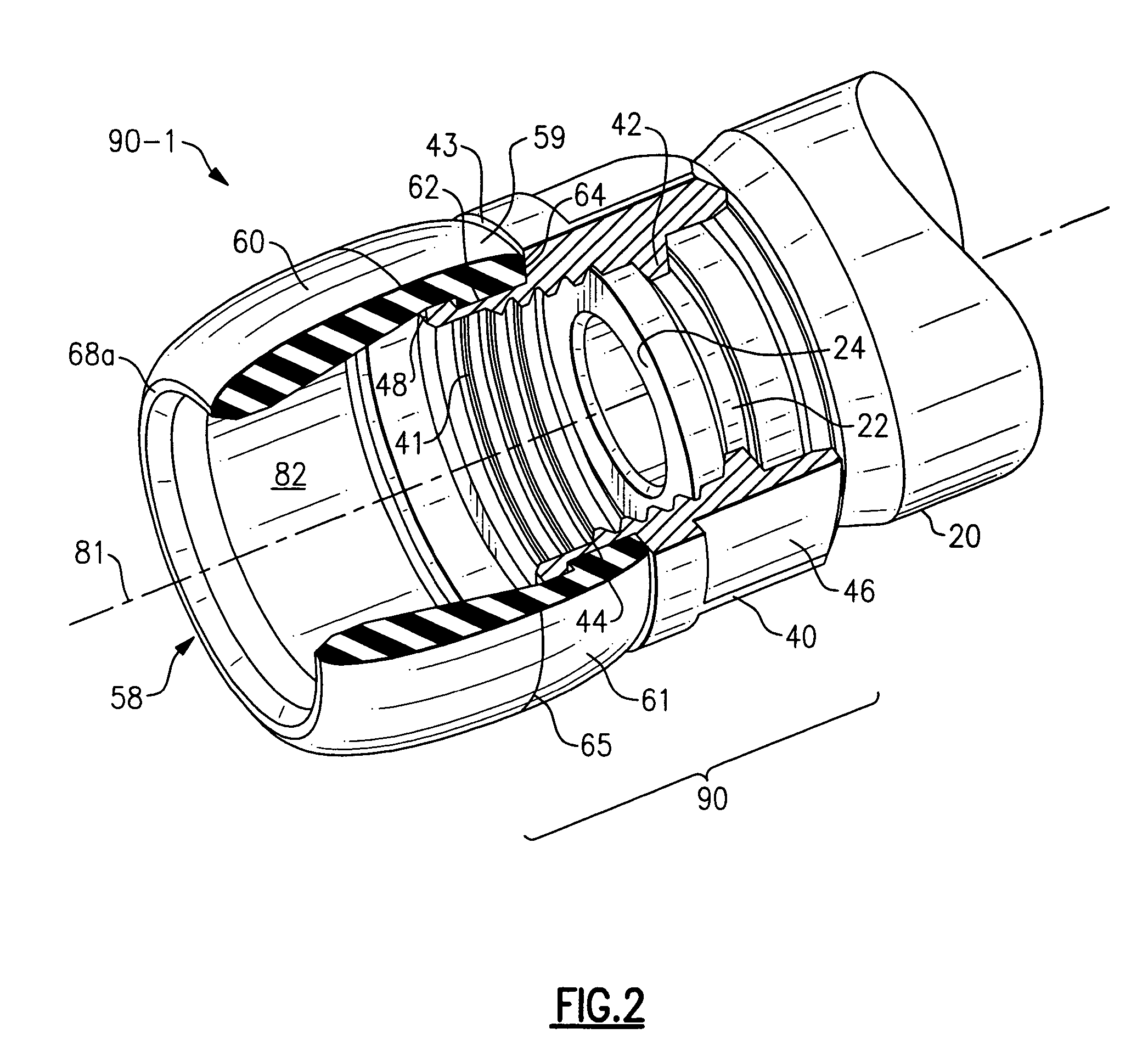

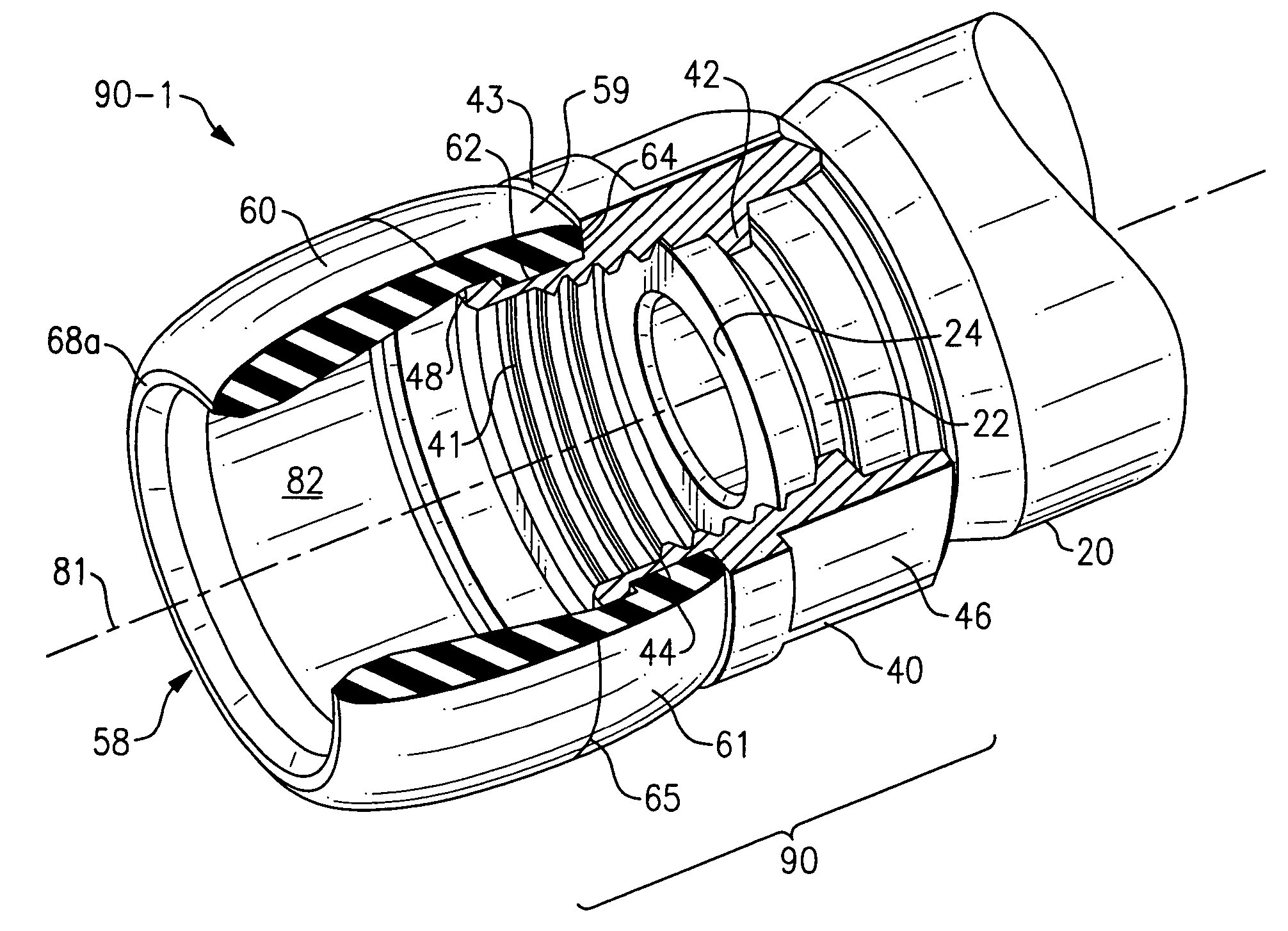

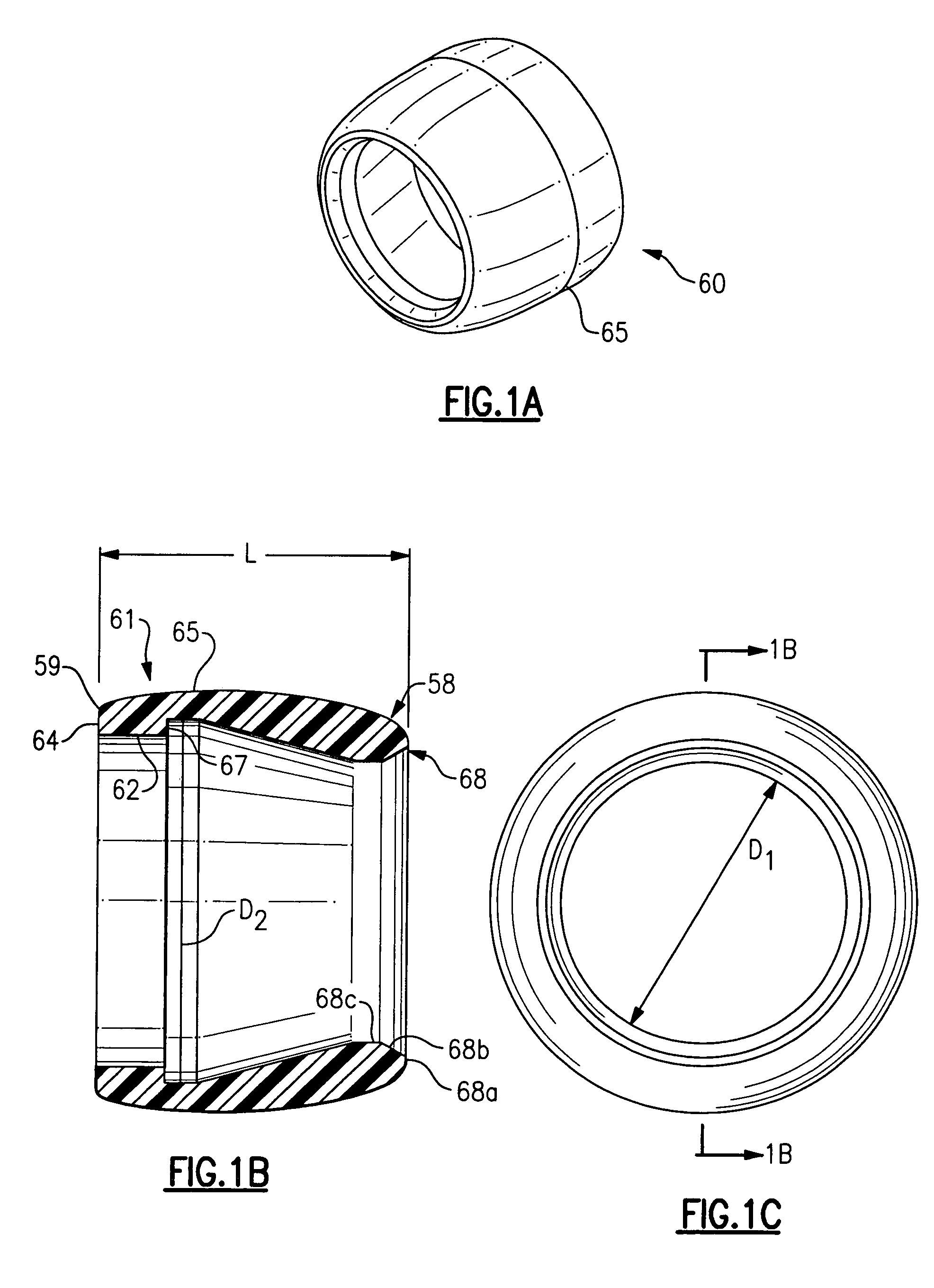

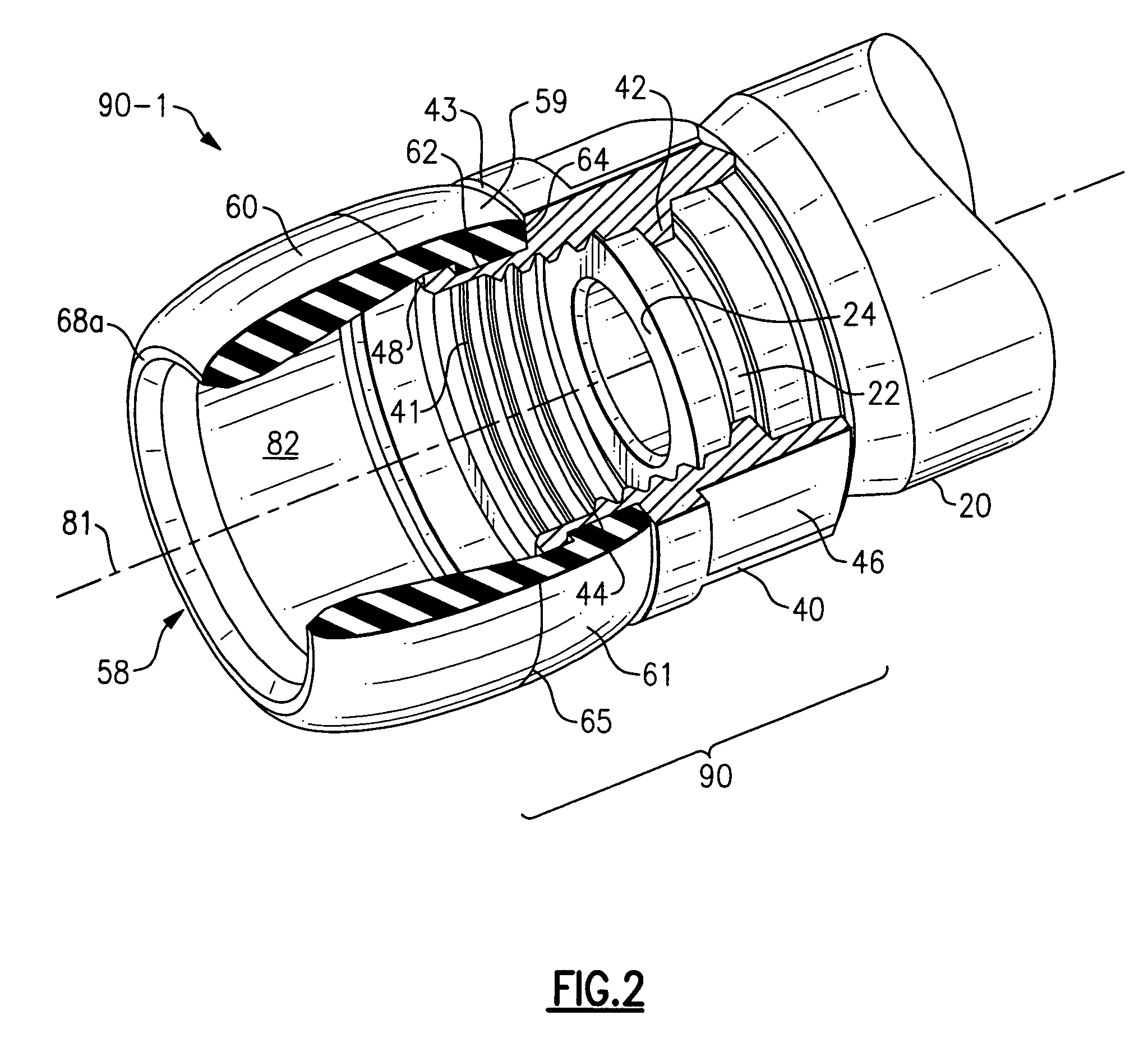

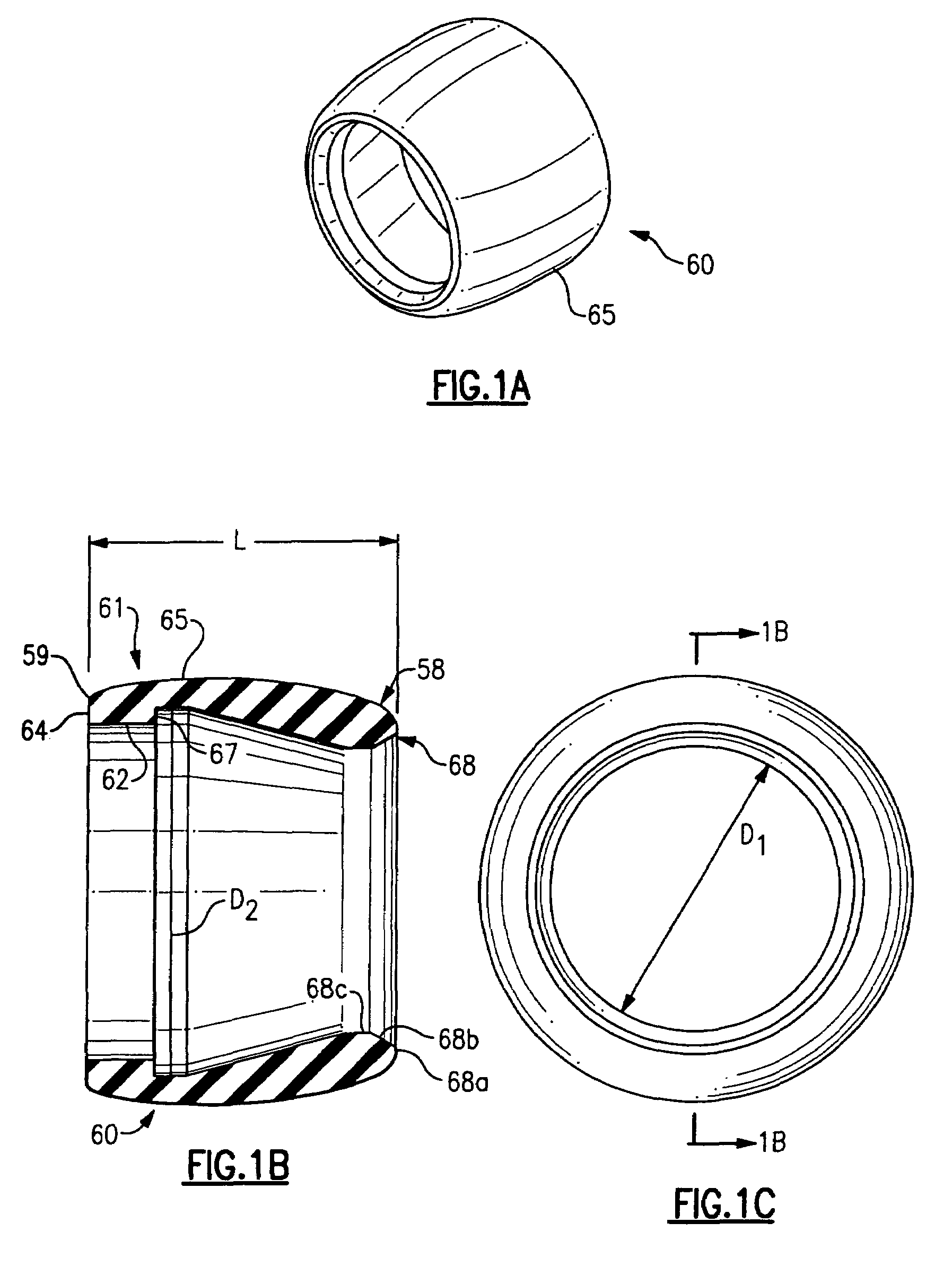

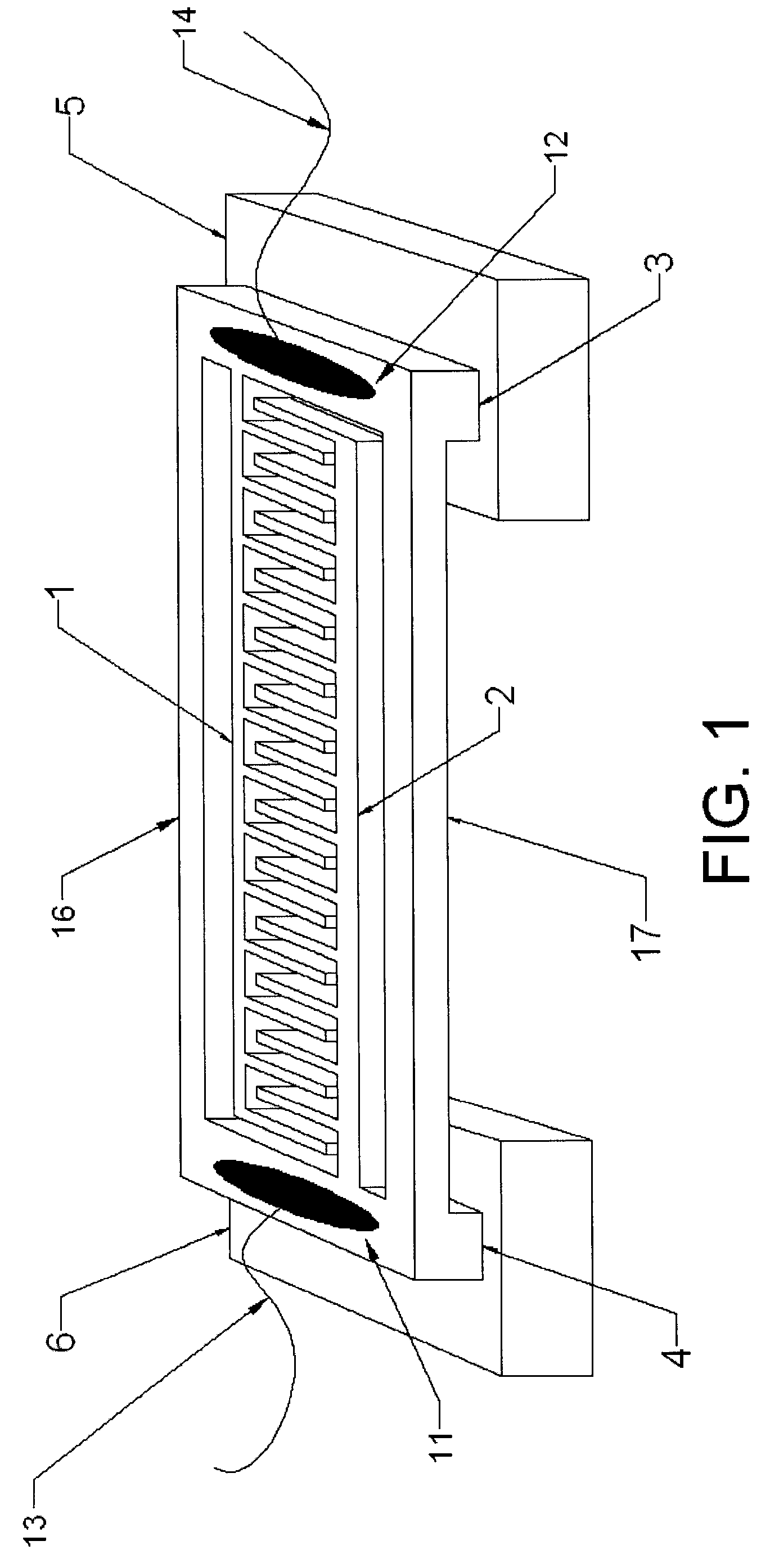

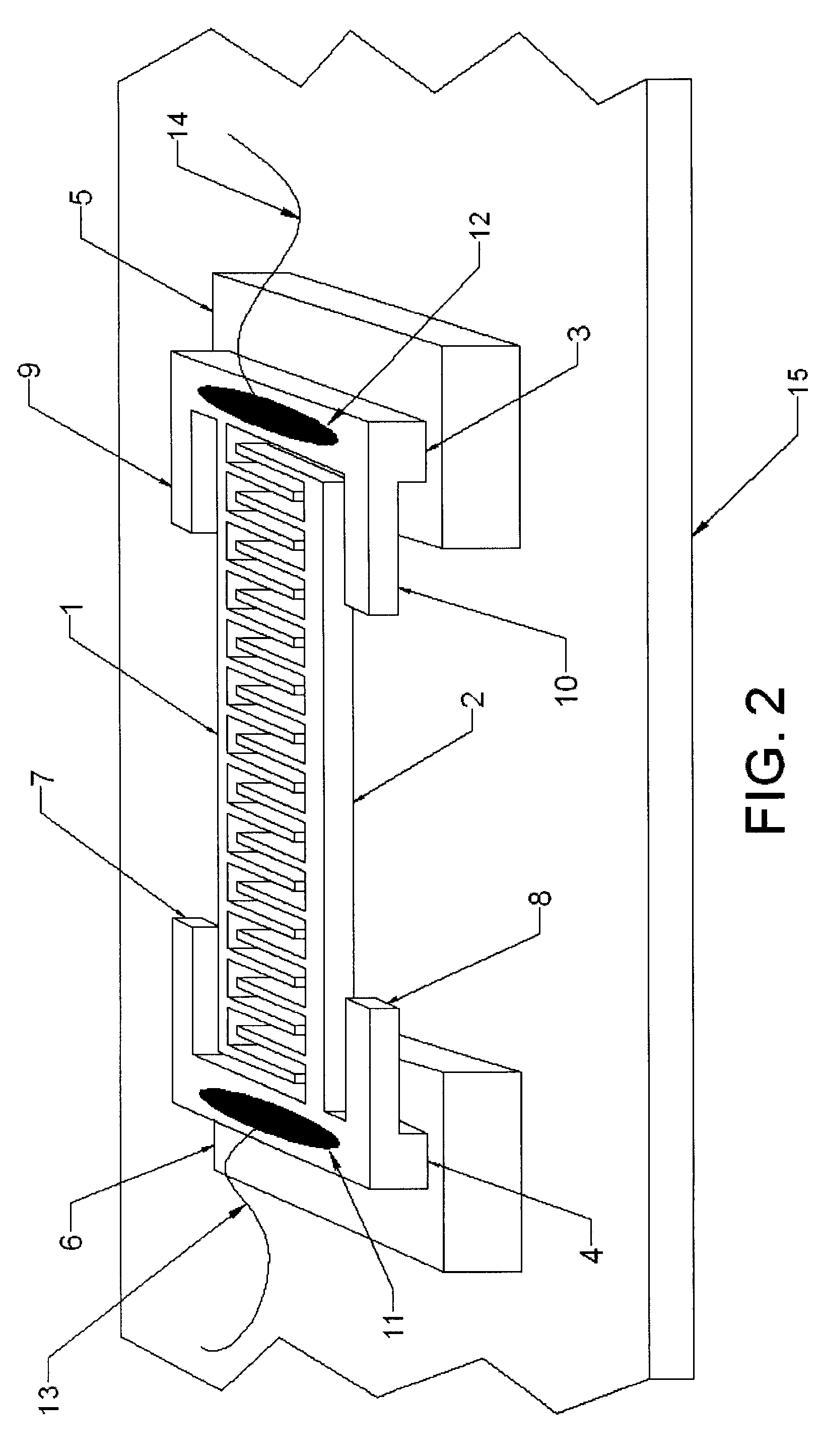

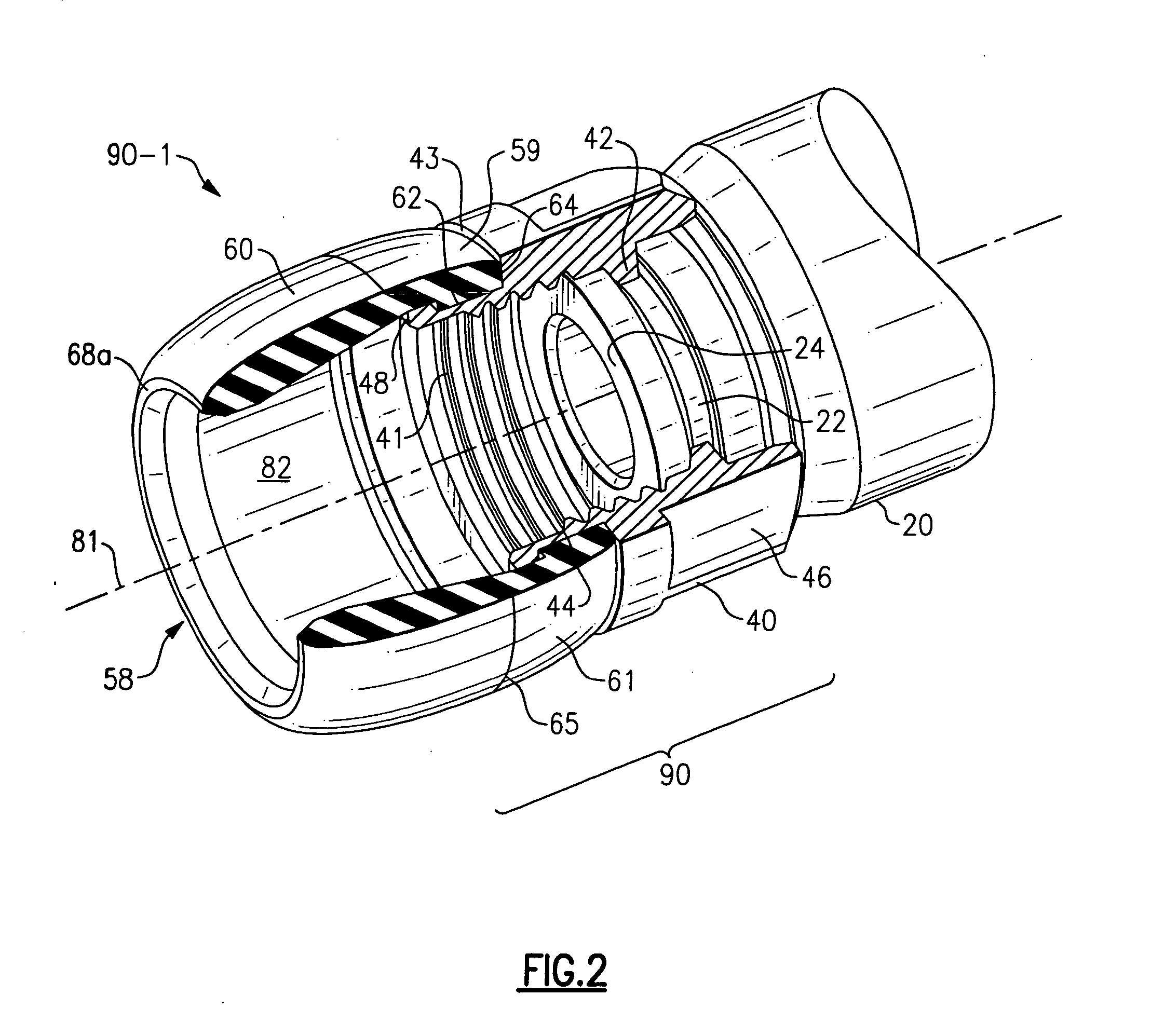

Nut seal assembly for coaxial cable system components

InactiveUS20070123101A1Electrically conductive connectionsSecuring/insulating coupling contact membersElastomerCoaxial cable

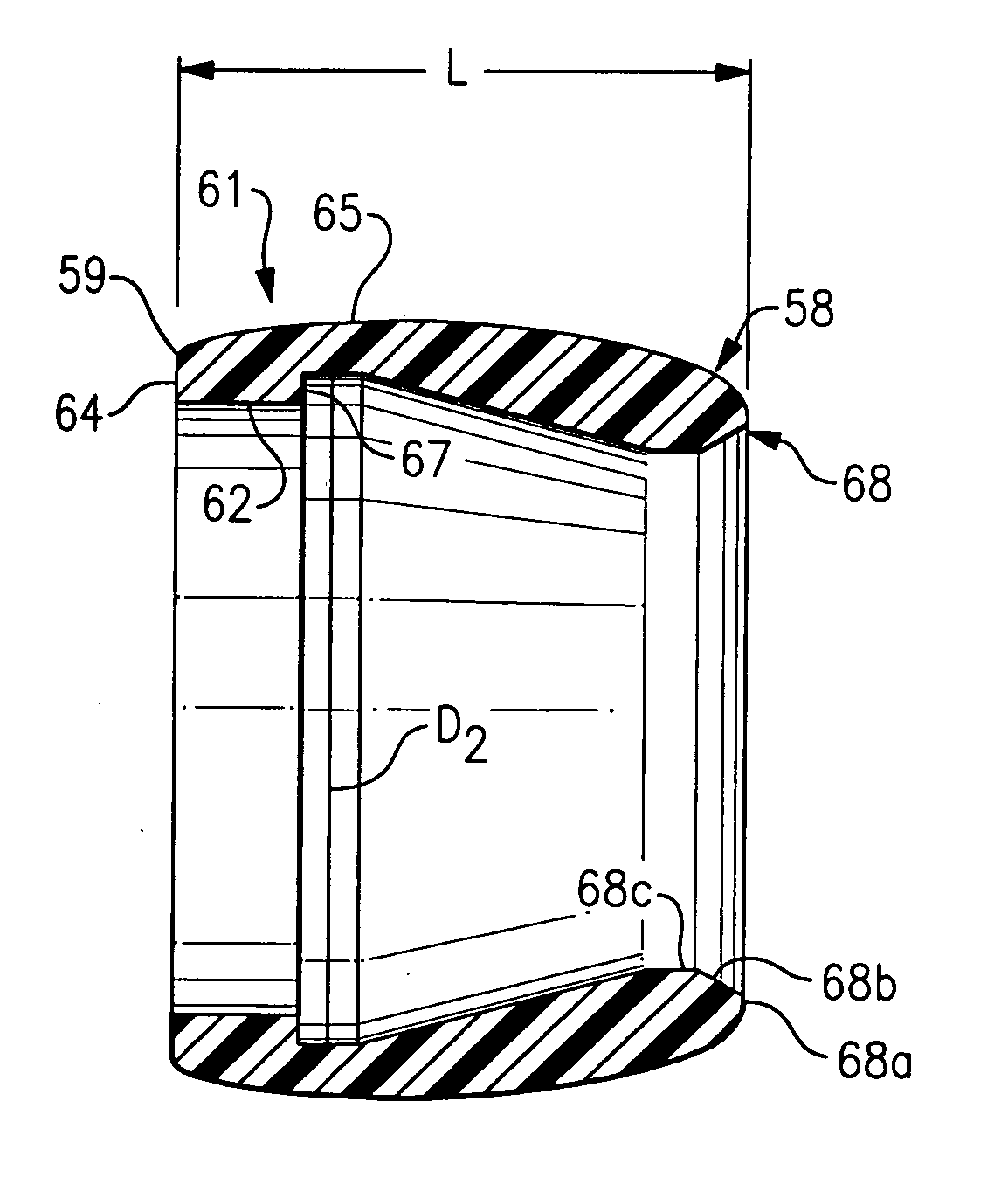

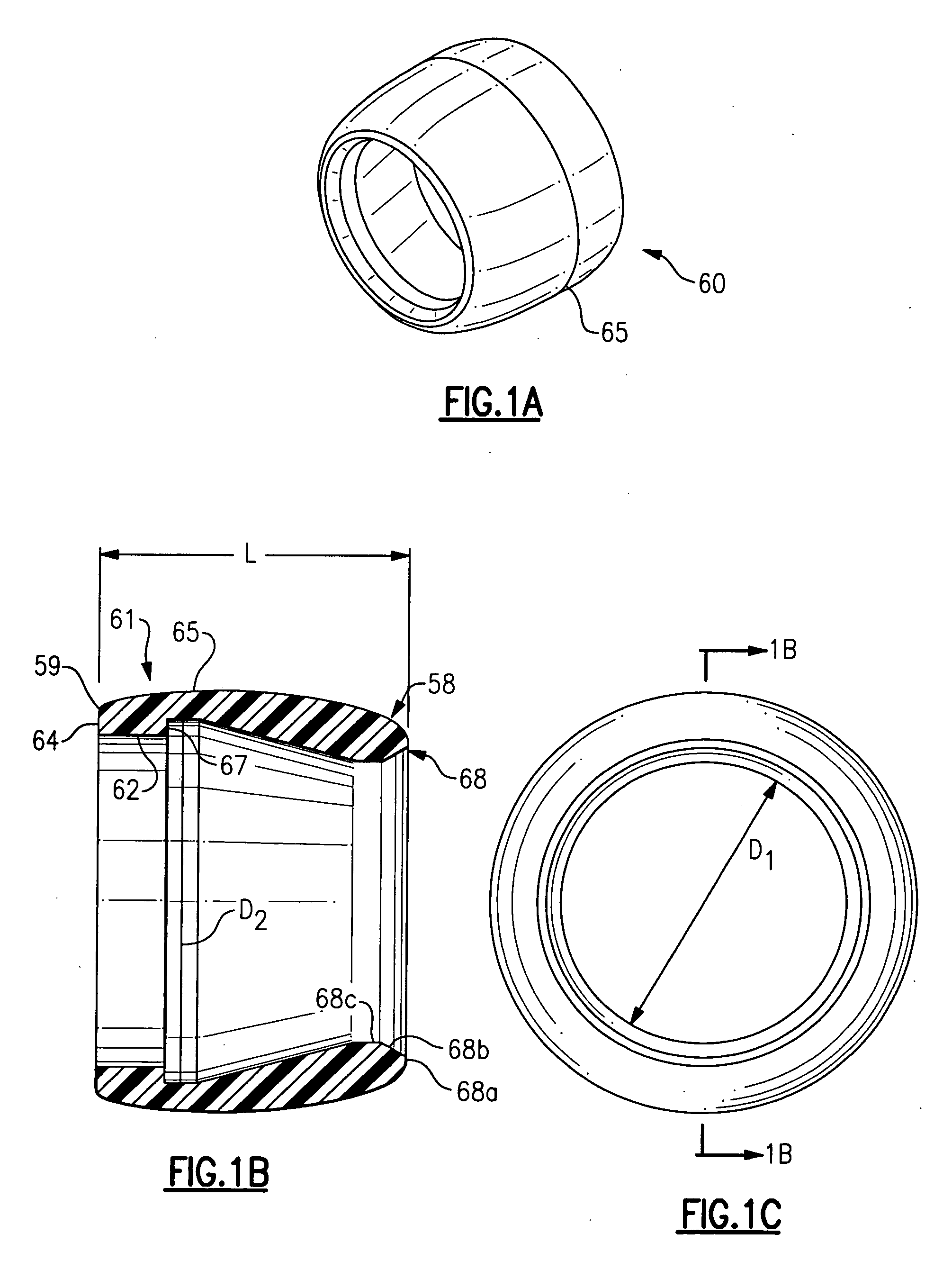

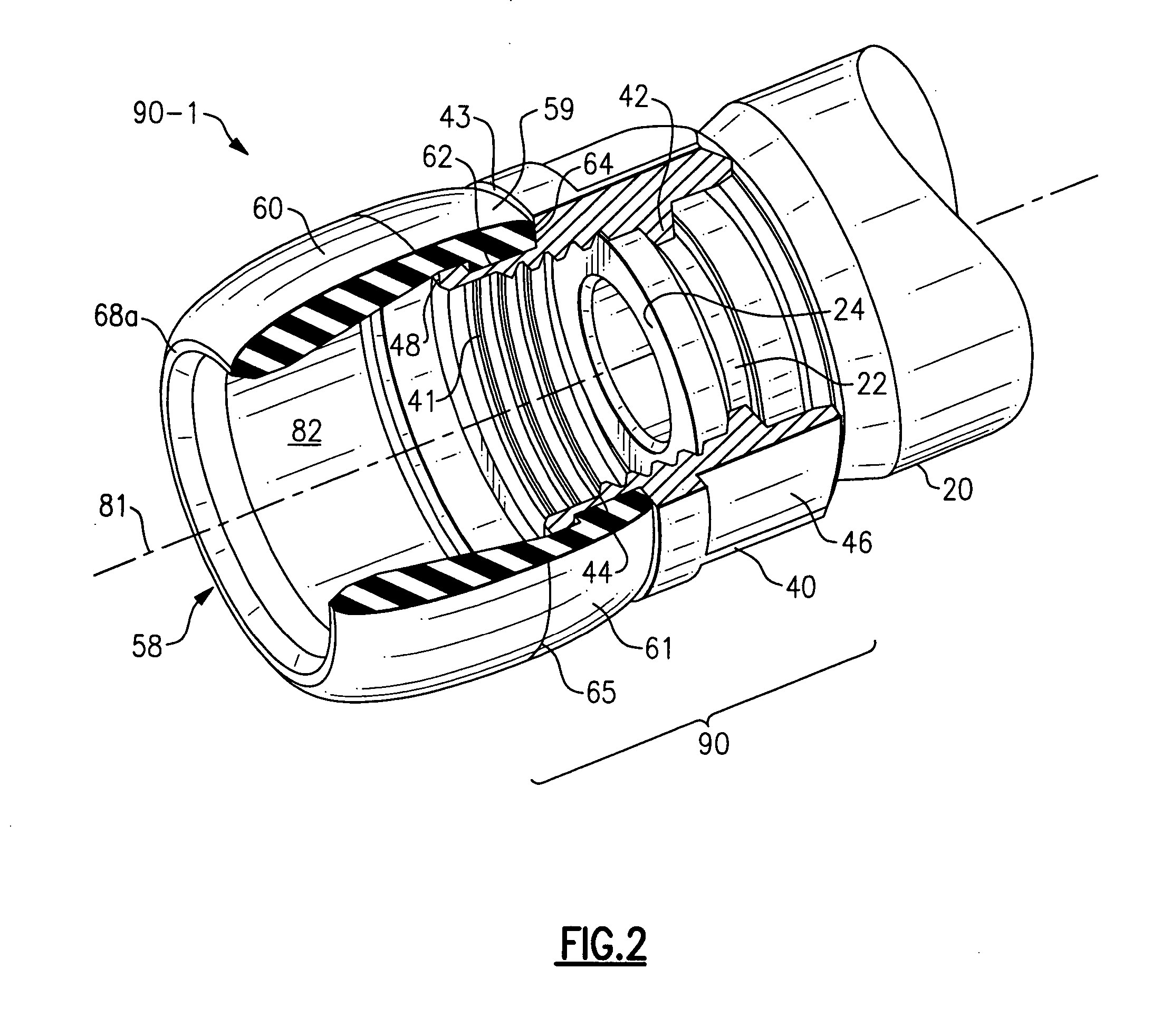

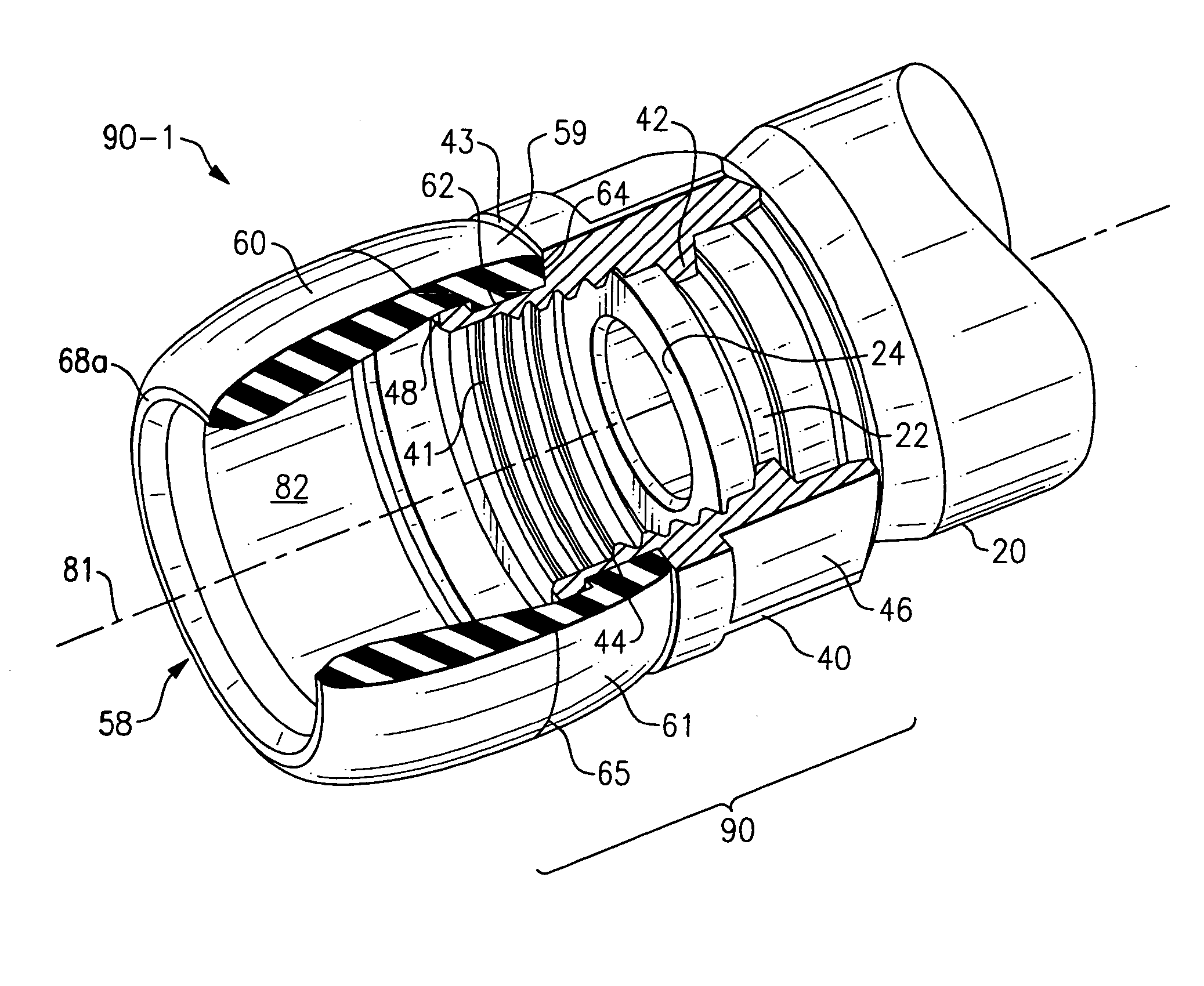

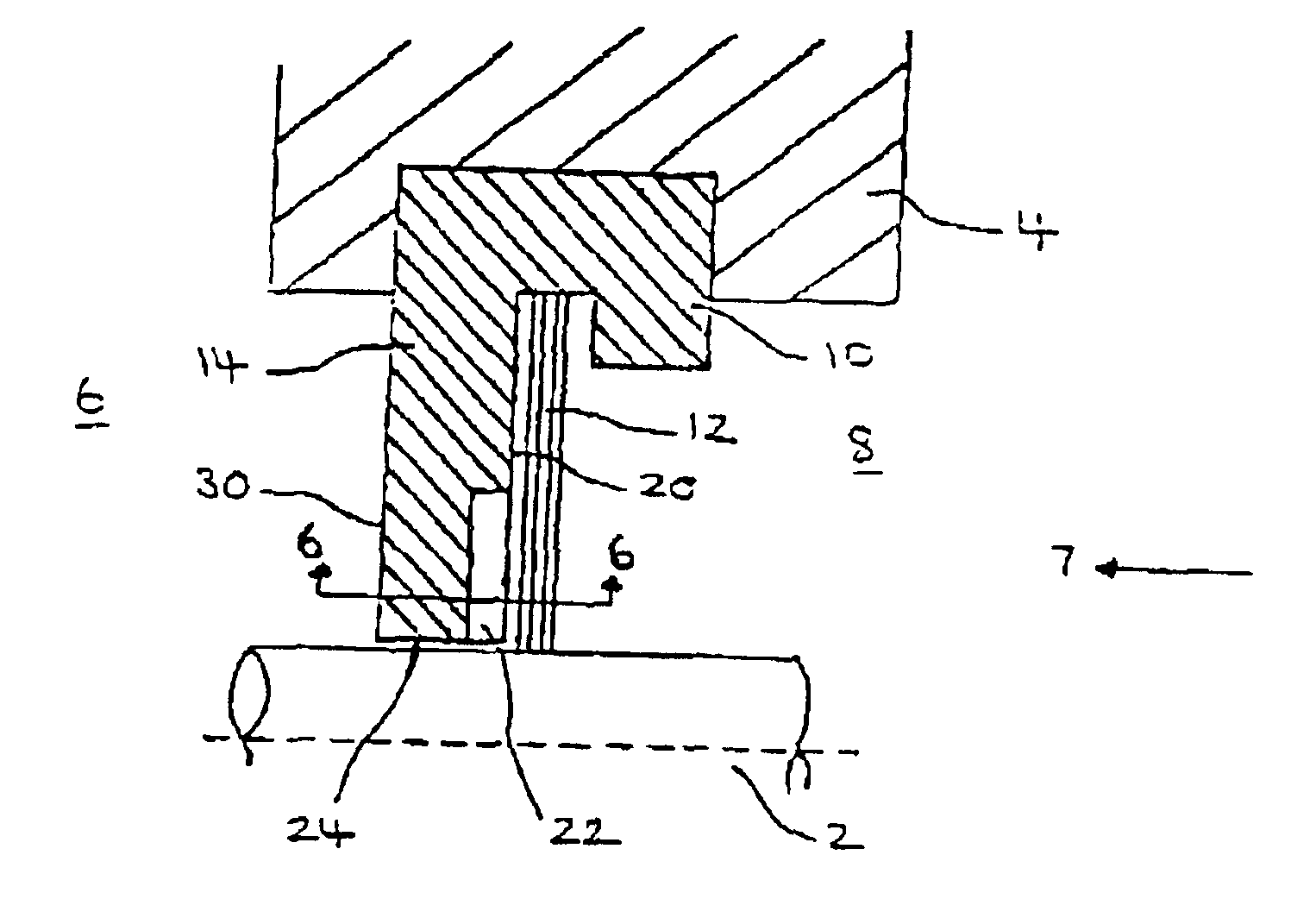

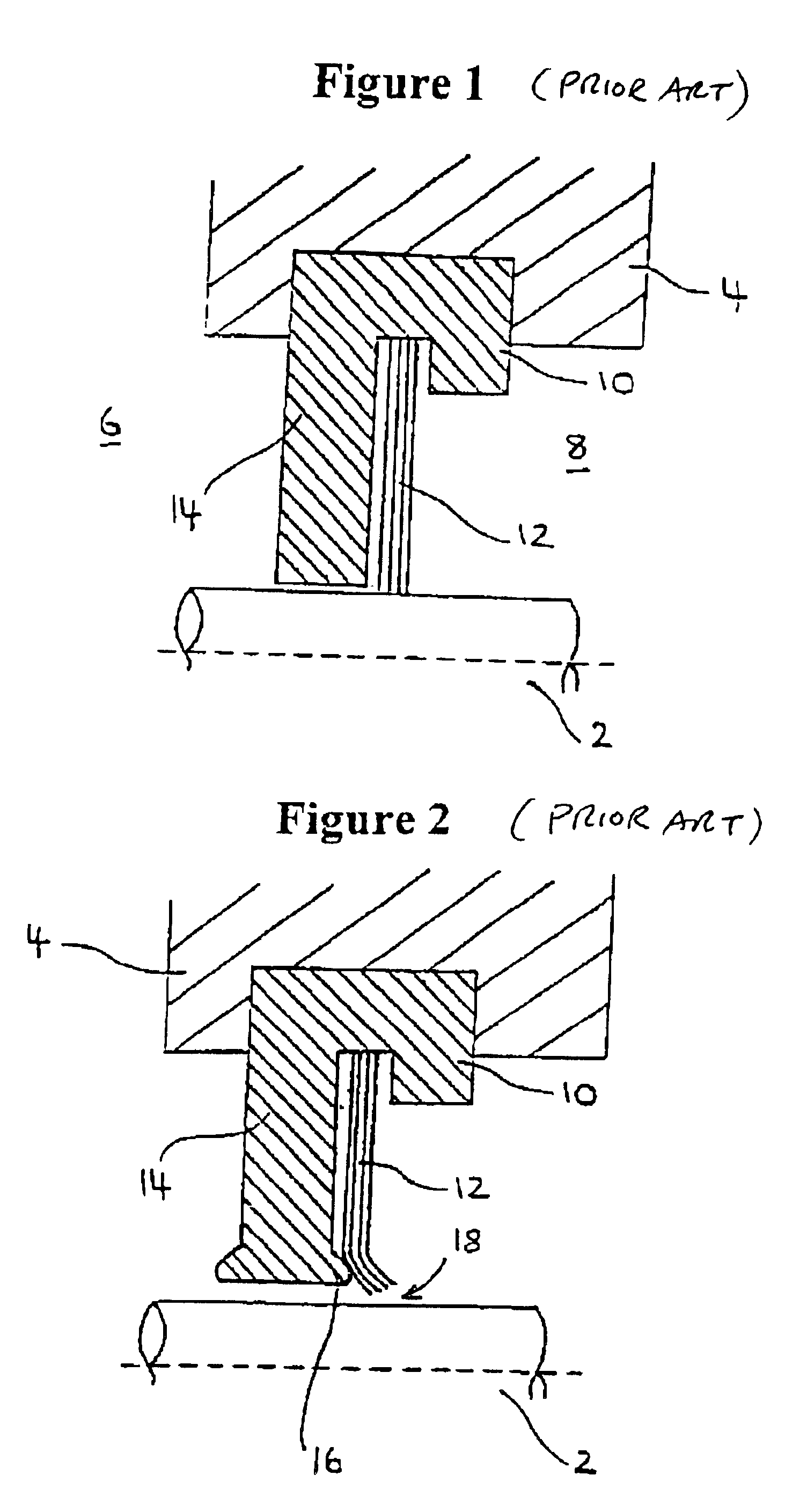

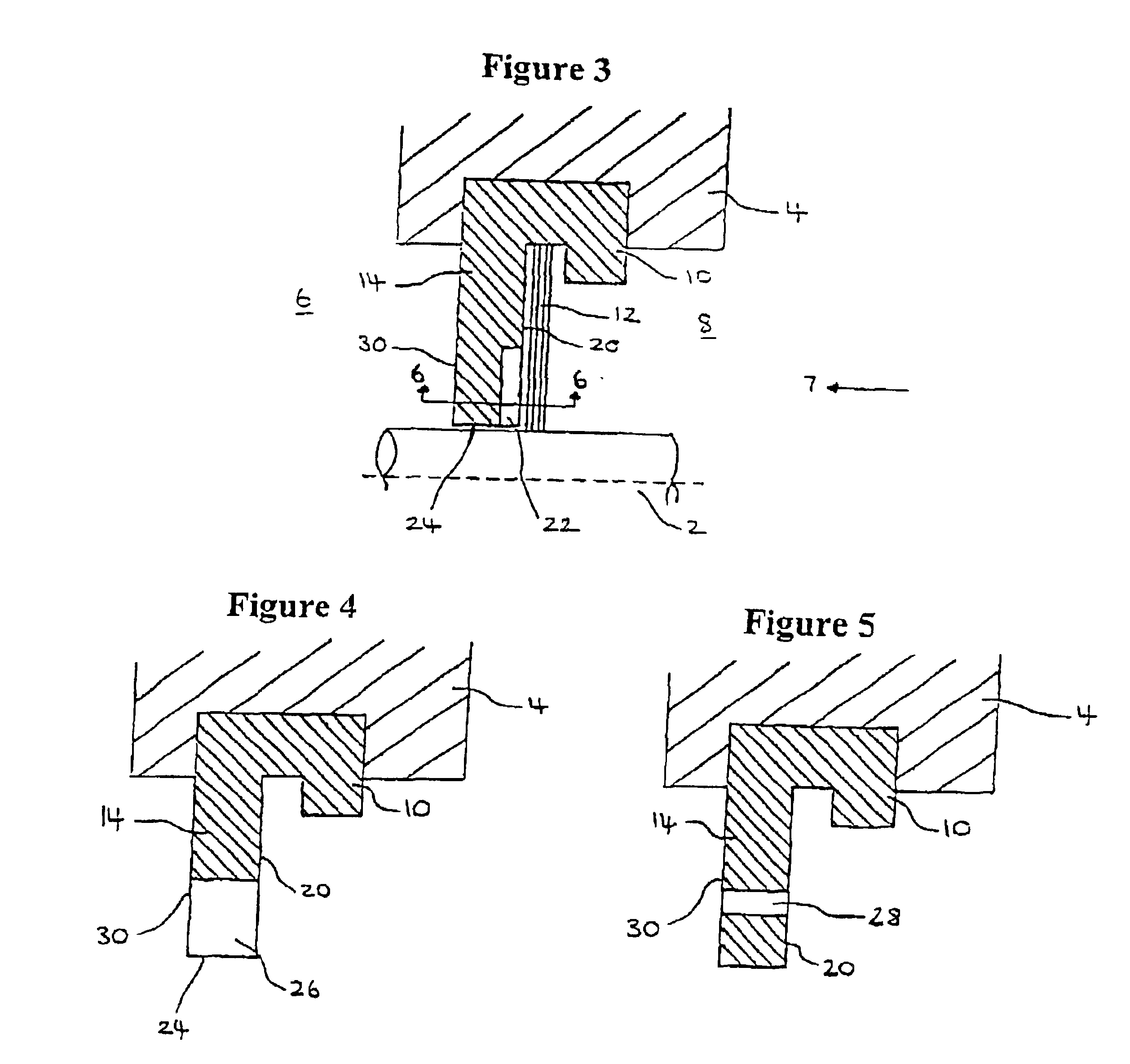

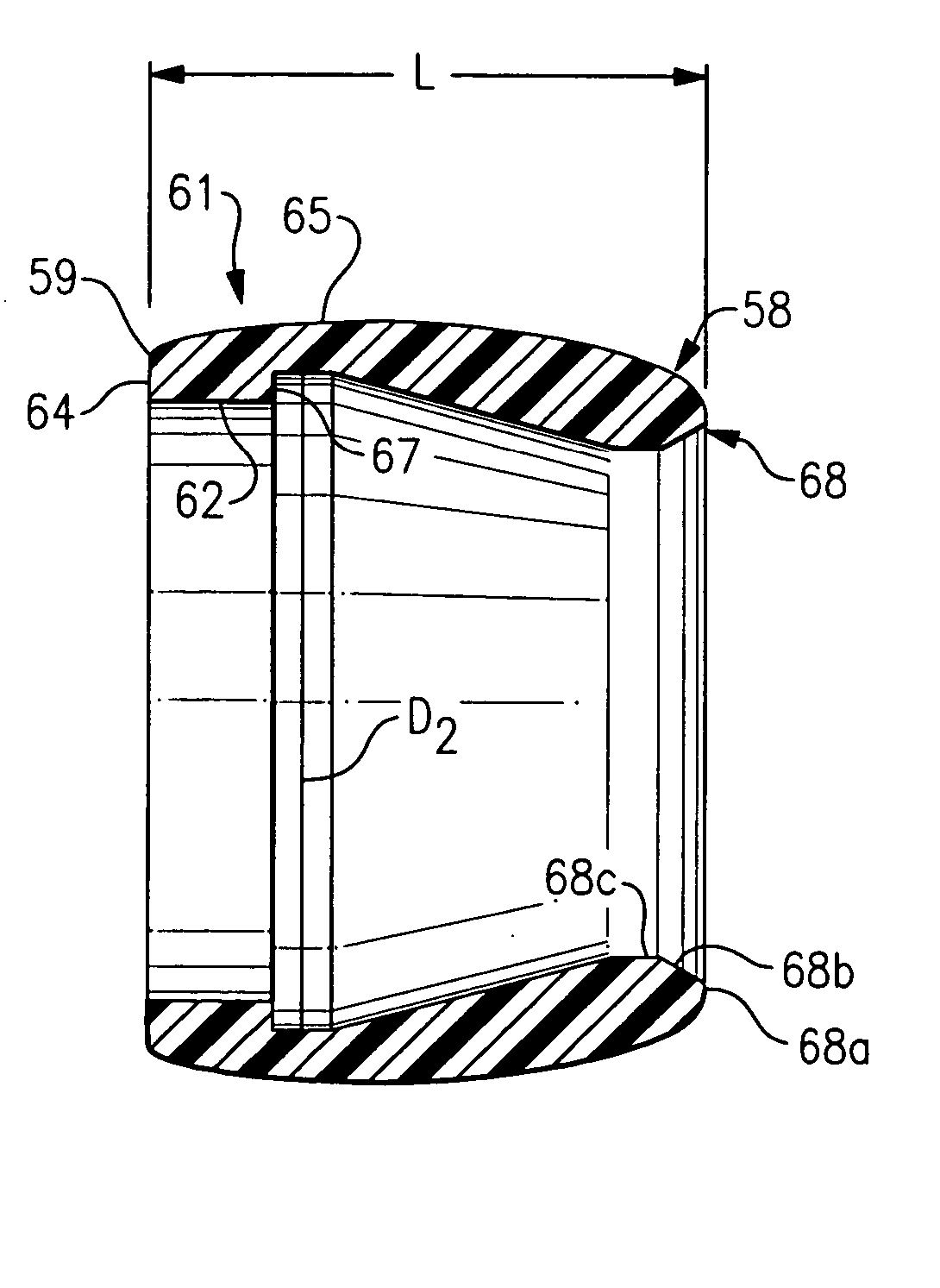

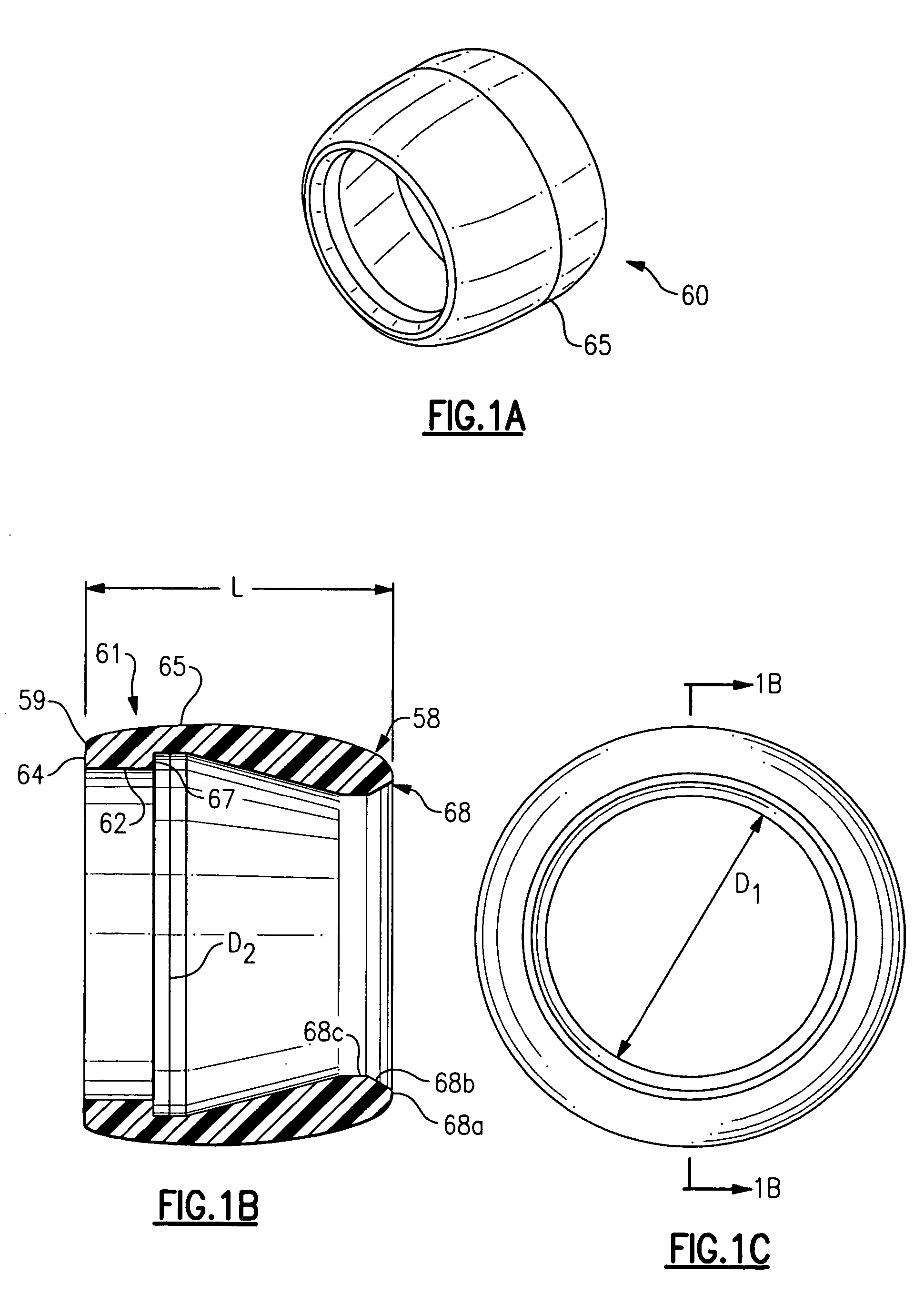

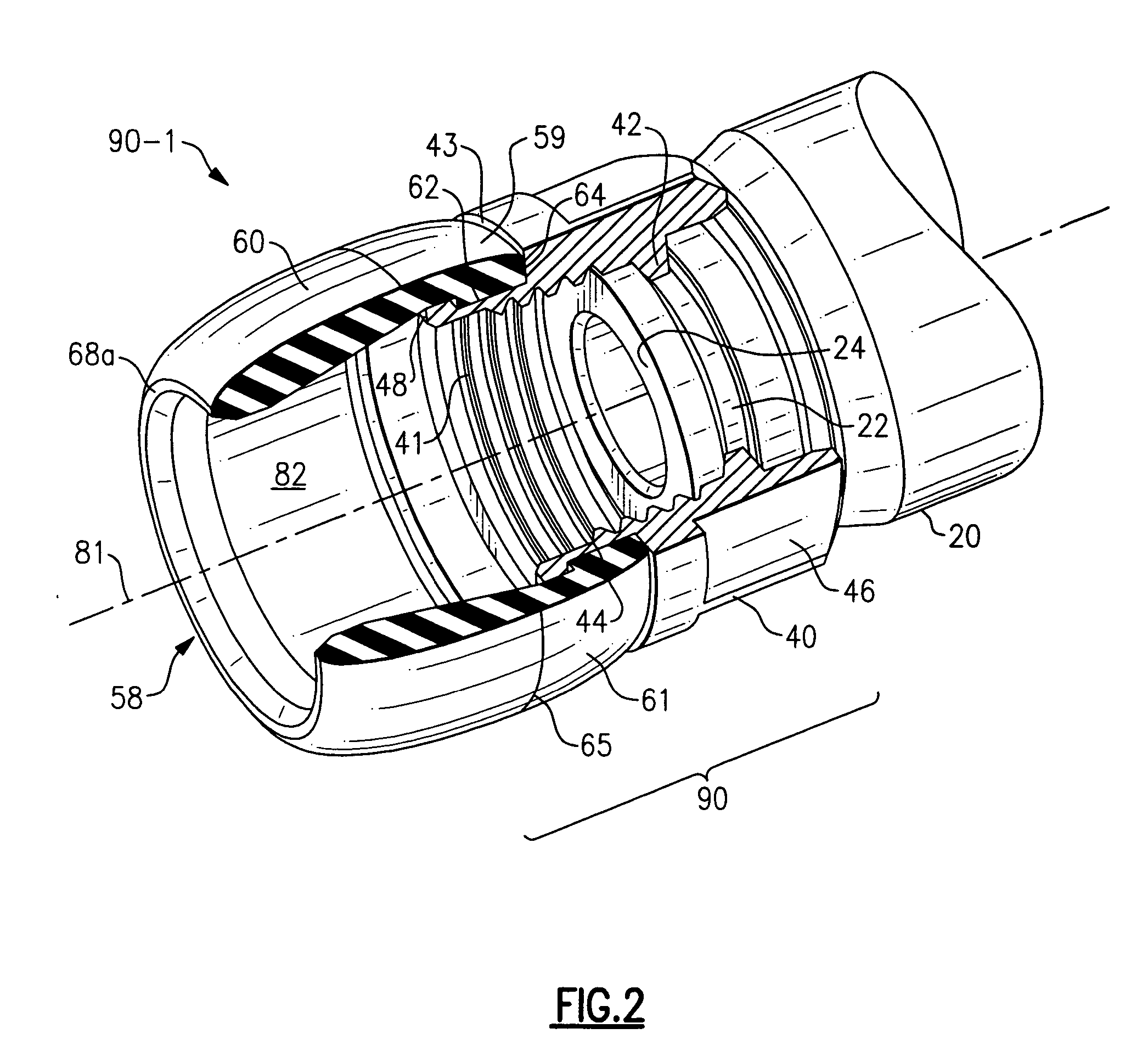

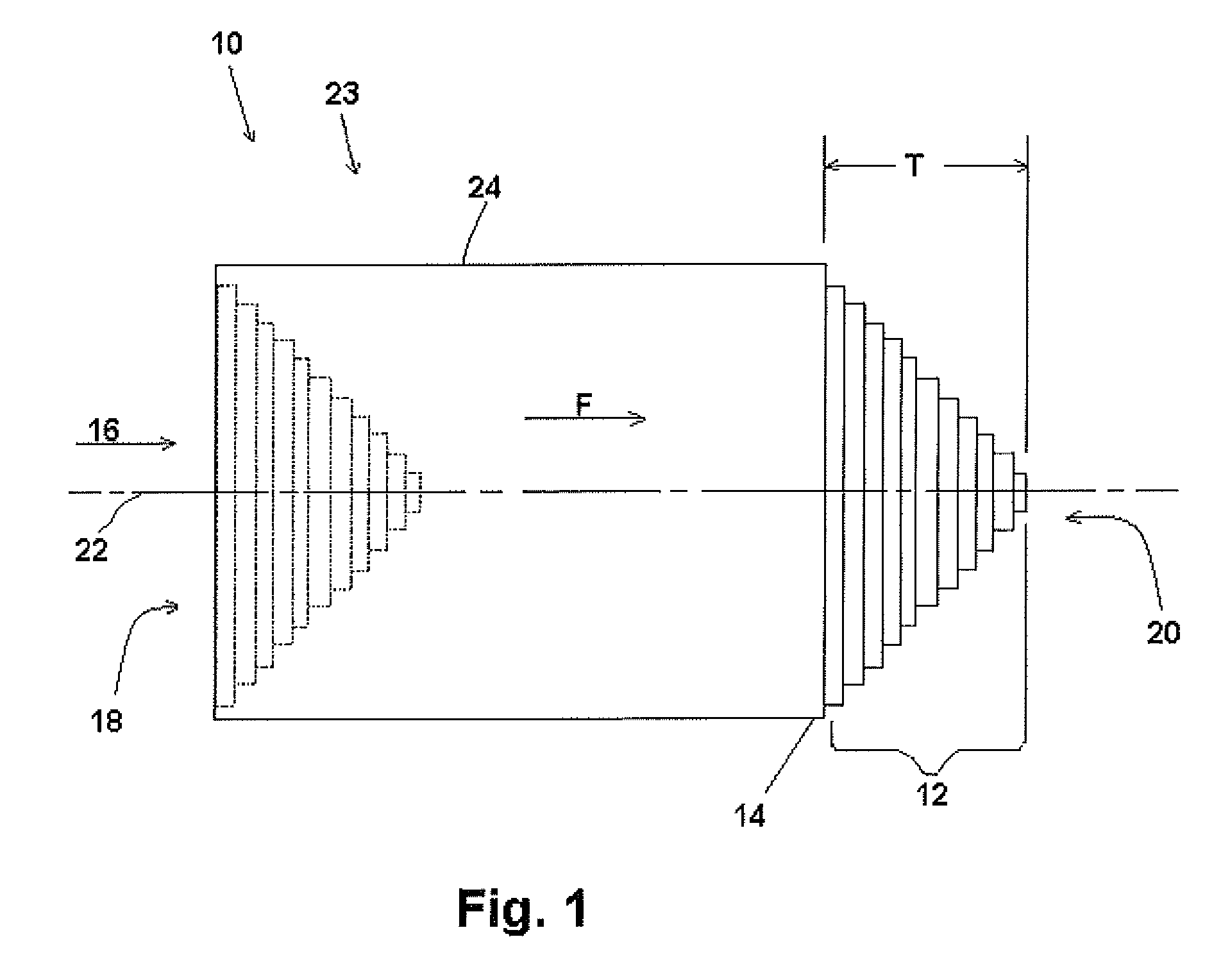

An integrated seal assembly is provided, as is a coaxial cable system component incorporating the seal assembly with a connector for coupling to an externally threaded port. The seal assembly includes a bellows-type seal formed at least partially of a conductive elastomer and having an elastically deformable tubular body and a plurality of sealing surfaces, and an integral joint-section intermediate an anterior end and a posterior end that assists in the axial deformation of the seal in response to axially-directed force. One of the sealing surfaces engages a corresponding surface of an internally threaded nut or housing. The component is engagable with an externally threaded port via the internally threaded connector. The anterior end of the seal fits over the port and a sealing surface of the seal is capable of sealing axially against a shoulder of the port while the seal body covers the otherwise exposed externally threaded port. Upon tightening of the nut on the port, the seal deflects in the axial direction to accommodate a variety of distances between the connector and the shoulder of the port. Additionally, the seal is capable of expanding to allow a second sealing surface to contact and seal against a variety of smooth outside diameters of the port. The versatility of the seal allows an operator to use one connector of a system component on a wide variety of externally threaded ports without the risk of a faulty seal at the connection or a poor connection due to an improper seal.

Owner:PPC BROADBAND INC

Nut seal assembly for coaxial cable system components

ActiveUS7097500B2Engagement/disengagement of coupling partsElectrically conductive connectionsCoaxial cableEngineering

Owner:PPC BROADBAND INC

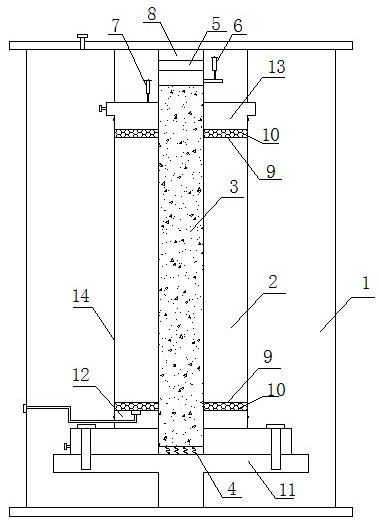

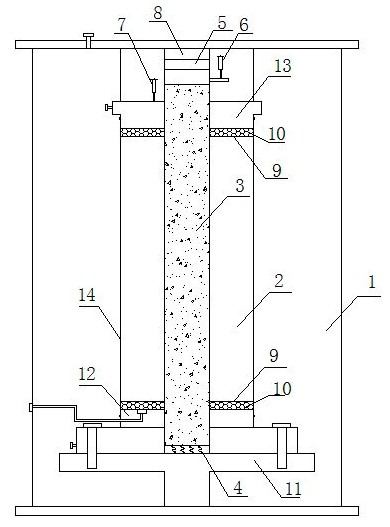

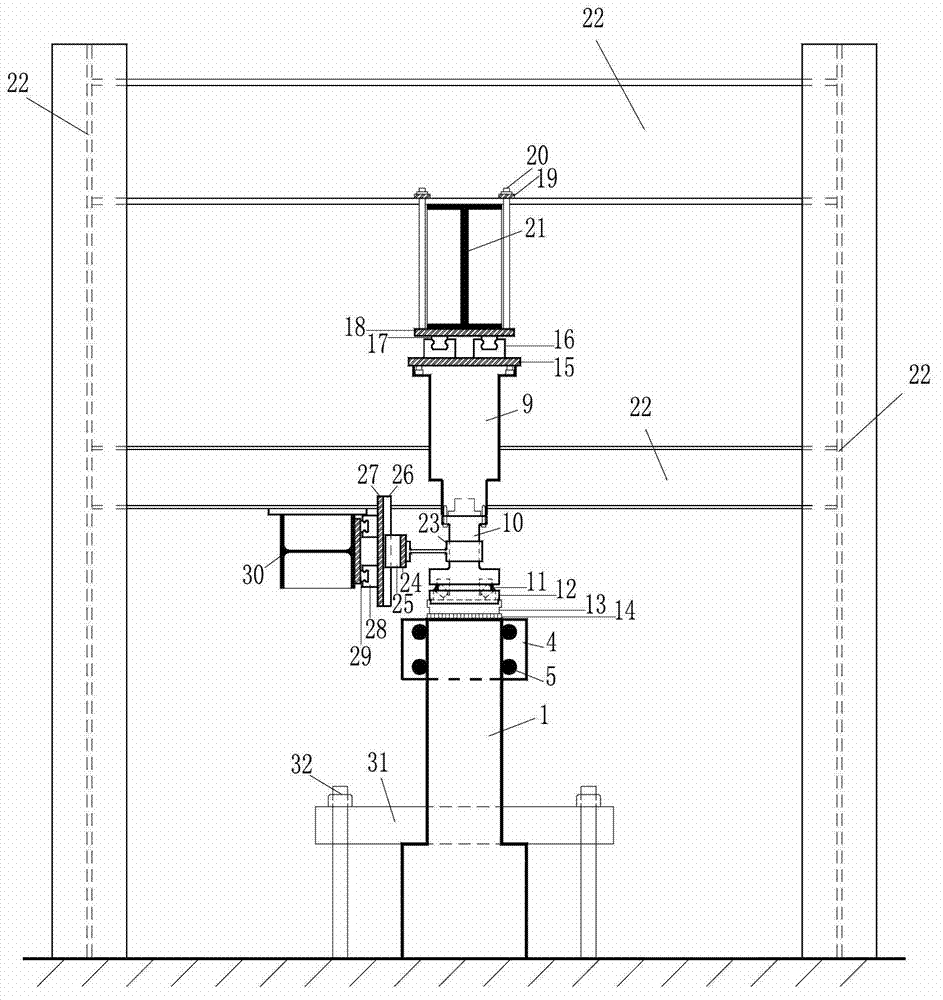

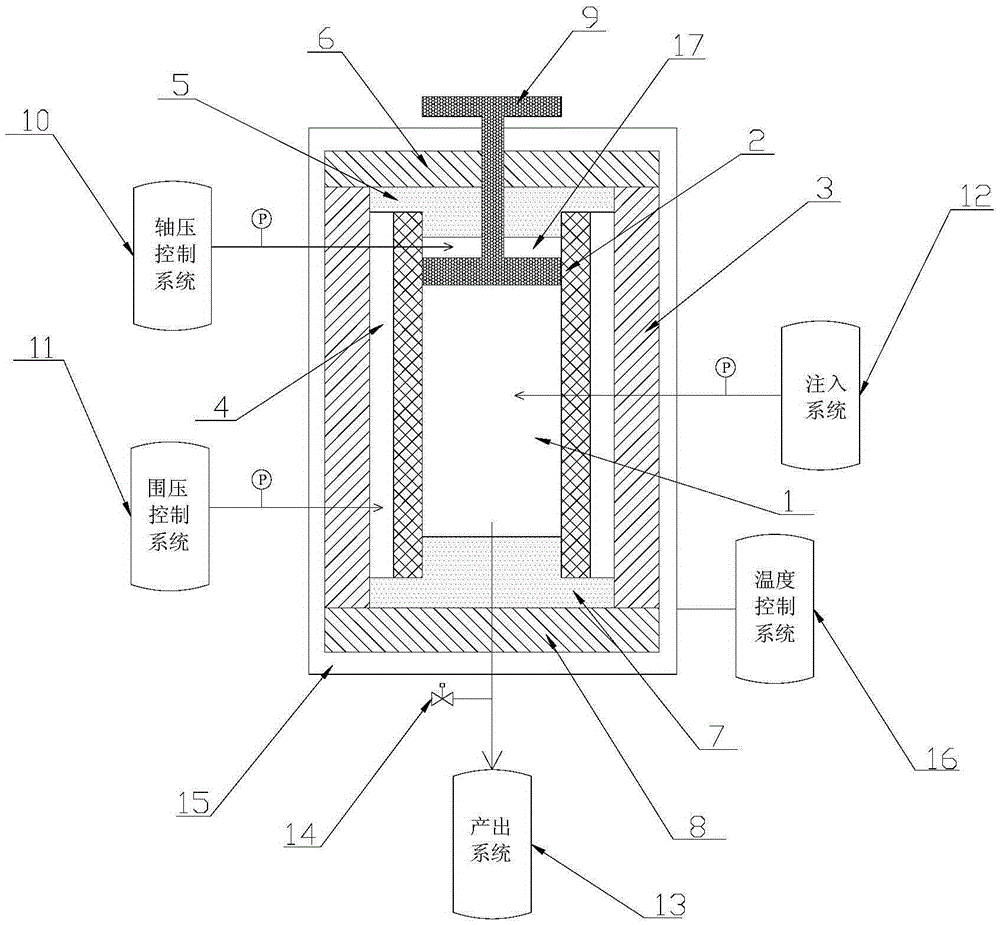

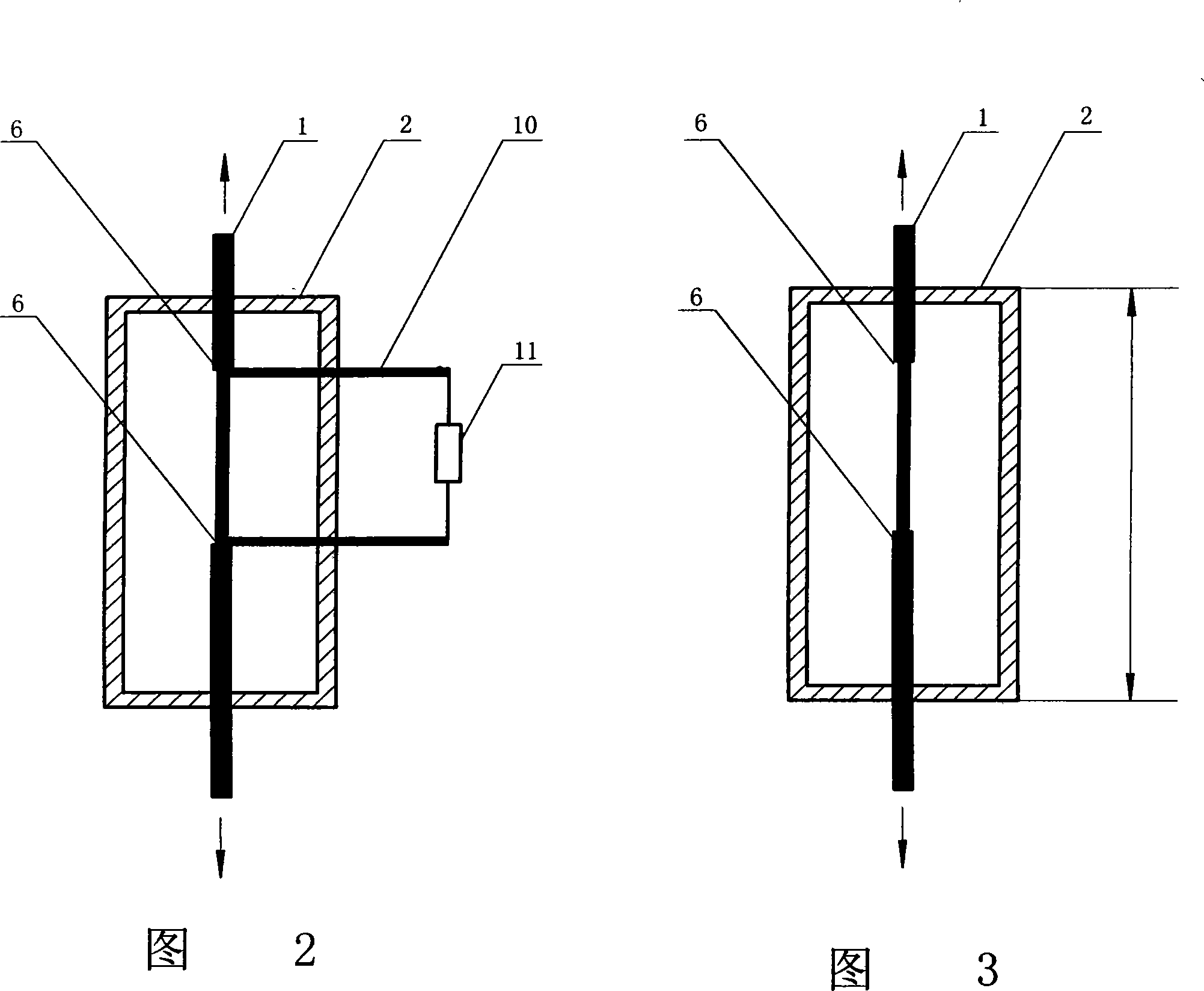

Device and method for testing mechanical properties of pile-soil contact surface

ActiveCN102628767ARealize moving up and downSimple structureMaterial strength using tensile/compressive forcesEngineeringFilter paper

The invention discloses a device for testing the mechanical properties of a pile-soil contact surface. The device is composed of a sealed pressure chamber, a hollow cylindrical soil sample, a solid cylindrical concrete pile sample and the like. The pile sample is prefabricated, and its diameter is equal to the internal diameter of the hollow cylindrical soil sample, and the two samples joint together closely. The lower end of the concrete pile sample is disposed on a pedestal through a spring assembly, and the upper end is connected to a stress loading system through a dowel bar, which is provided with a stress sensor and a displacement sensor I. The outside of the concrete pile sample is the hollow cylindrical soil sample. Filter paper and permeable stones are disposed at the lower end of the soil sample, and the lower end is positioned on the pedestal, while the upper end of the soil sample is provided with filter paper, permeable stones, a top cover and a displacement sensor II in order. During test, a confining pressure is exerted first for consolidating, and then a static (dynamic) load is exerted on the pile sample for measuring the axial deformation, pore water stress and the like of the pile and the soil. The device provided in the invention has a simple structure, is easy to realize, and can be used to measure the mechanical properties of a pile-soil contact surface under the action of a static (dynamic) load.

Owner:HOHAI UNIV

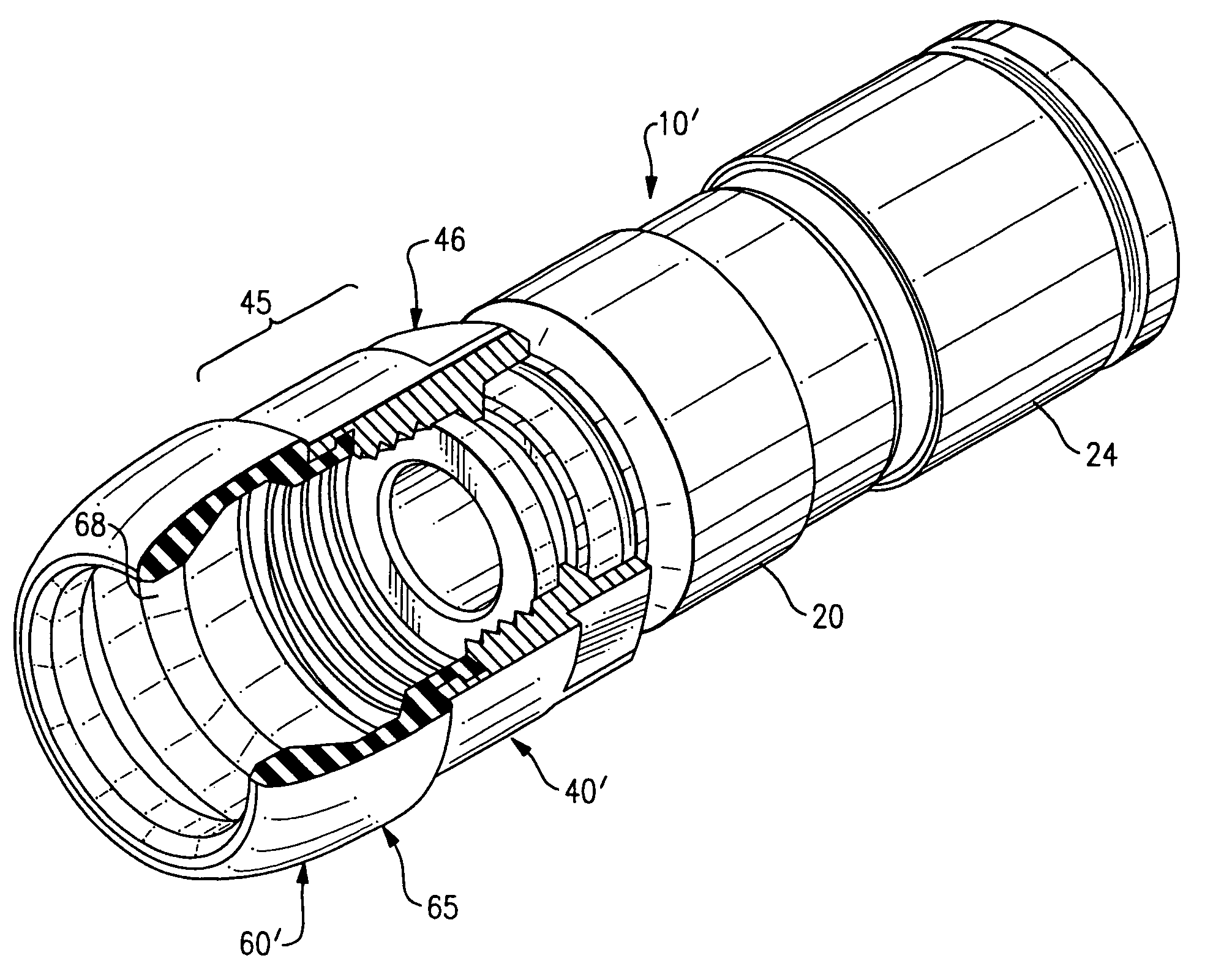

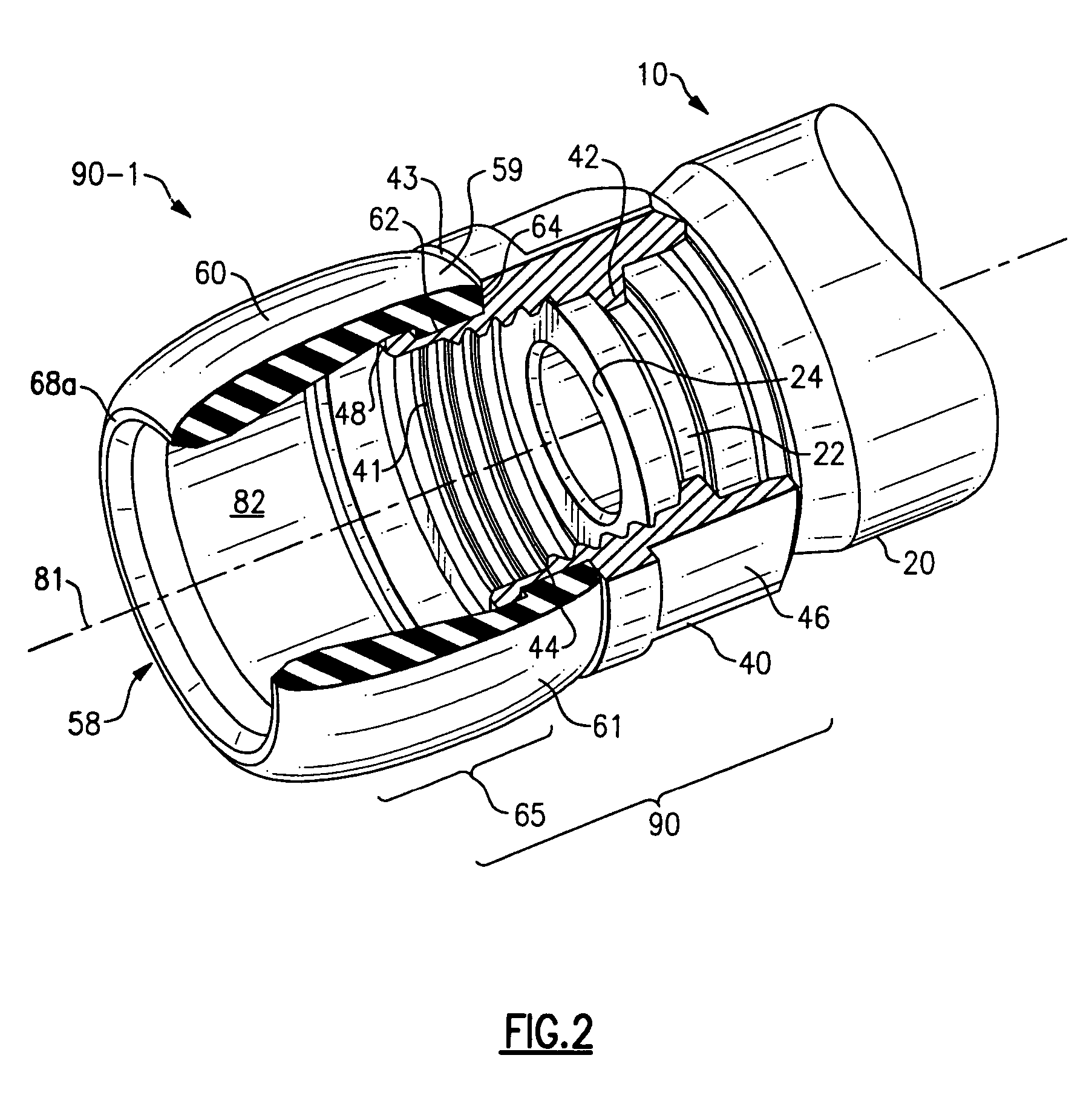

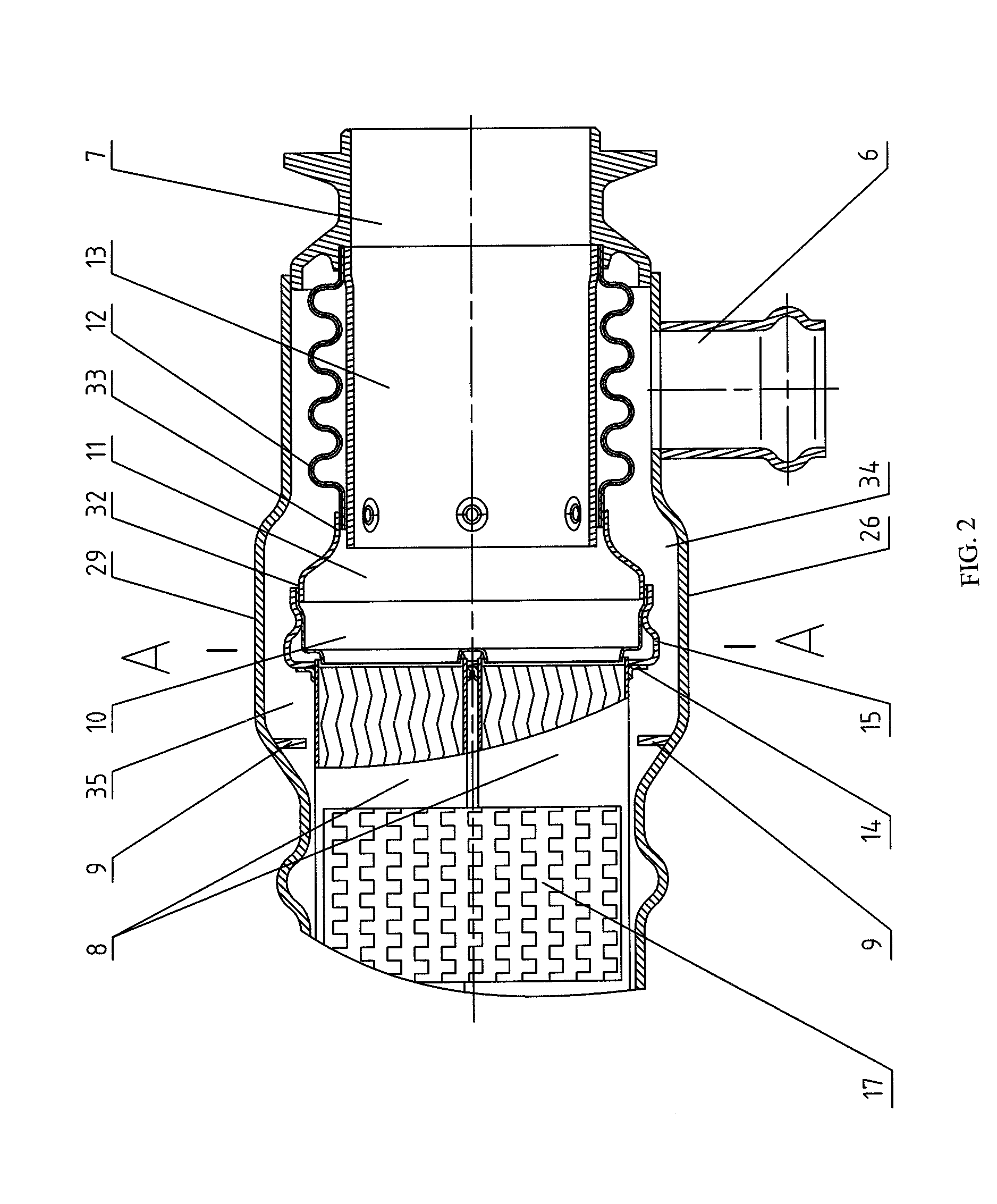

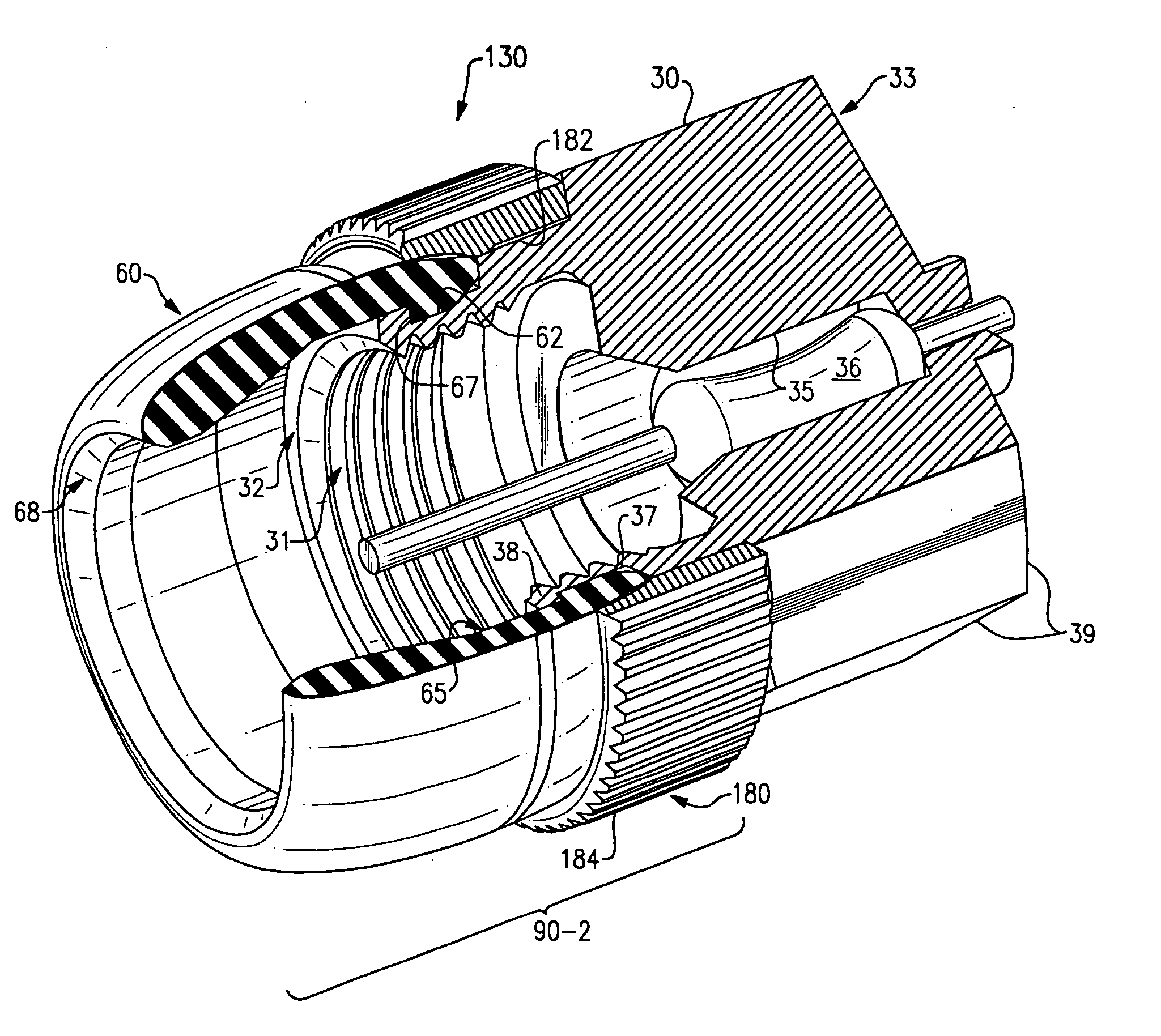

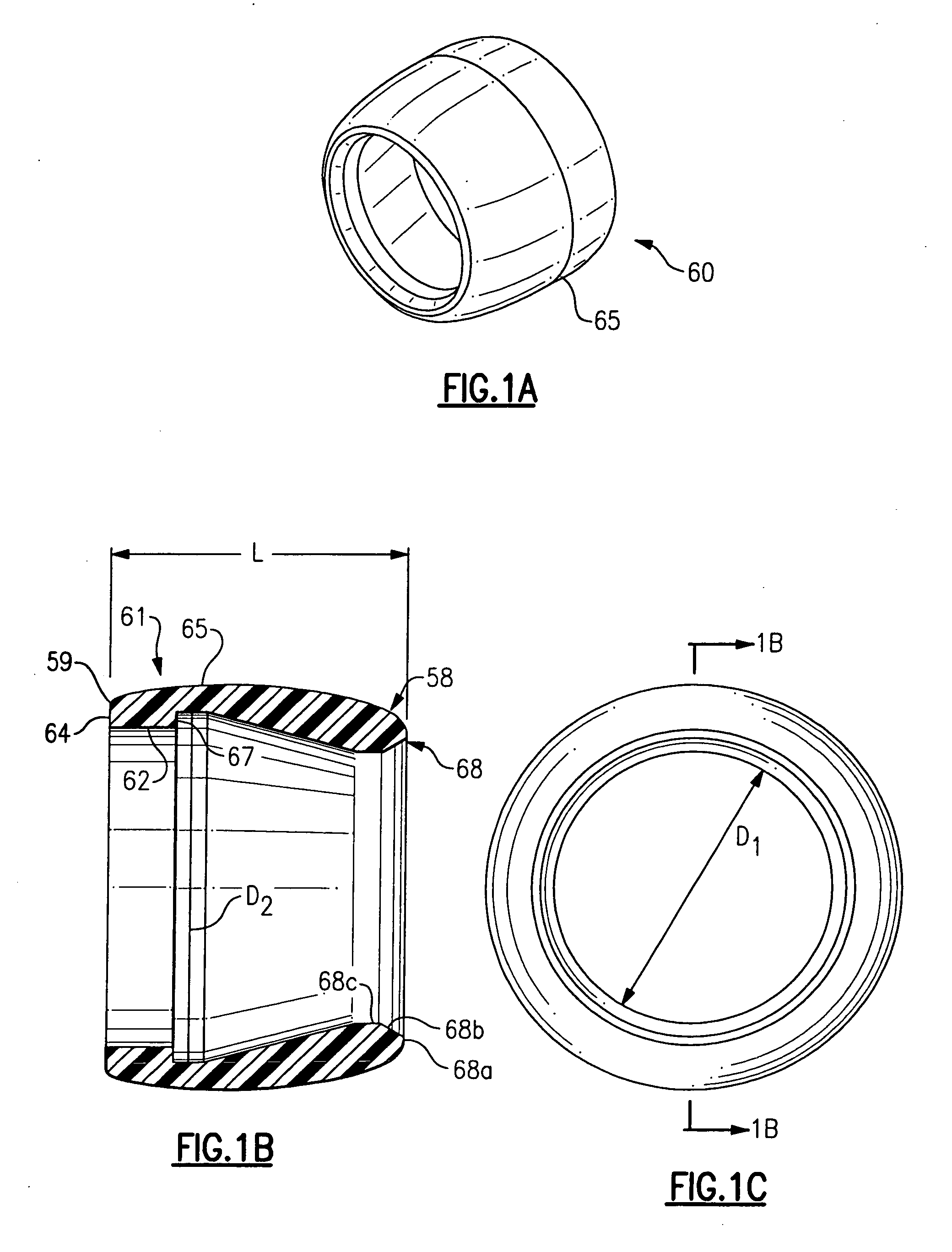

Nut seal assembly for coaxial connector

ActiveUS7186127B2Engagement/disengagement of coupling partsElectrically conductive connectionsCoaxial cableEngineering

An integrated seal assembly and a connector incorporating the seal assembly for connecting a coaxial cable to an externally threaded port. The seal assembly includes a bellows-type seal having an elastically deformable tubular body and a plurality of sealing surfaces, and an integral joint-section intermediate an anterior end and a posterior end that assists in the axial deformation of the seal in response to axially-directed force. One of the sealing surfaces is made to engage a corresponding surface of an internally threaded nut. The nut and attached seal form an integral seal assembly. A coaxial cable connector includes a connector body. One end of the body attaches a coaxial cable, the seal assembly being rotatably attached to the other end. The connector is engagable with an externally threaded port via the internally threaded nut component of the connector. The anterior end of the seal fits over the port and a sealing surface of the seal is capable of sealing axially against a shoulder of the port while the seal body covers the otherwise exposed externally threaded port. Upon tightening of the nut on the port, the seal deflects in the axial direction to accommodate a variety of distances between the connector and the shoulder of the port. Additionally, the seal is capable of expanding to allow a second sealing surface to contact and seal against a variety of smooth outside diameters of the port. The versatility of the seal allows an operator to use one connector on a wide variety of externally threaded ports without the risk of a faulty seal at the connection or a poor connection due to an improper seal.

Owner:PPC BROADBAND INC

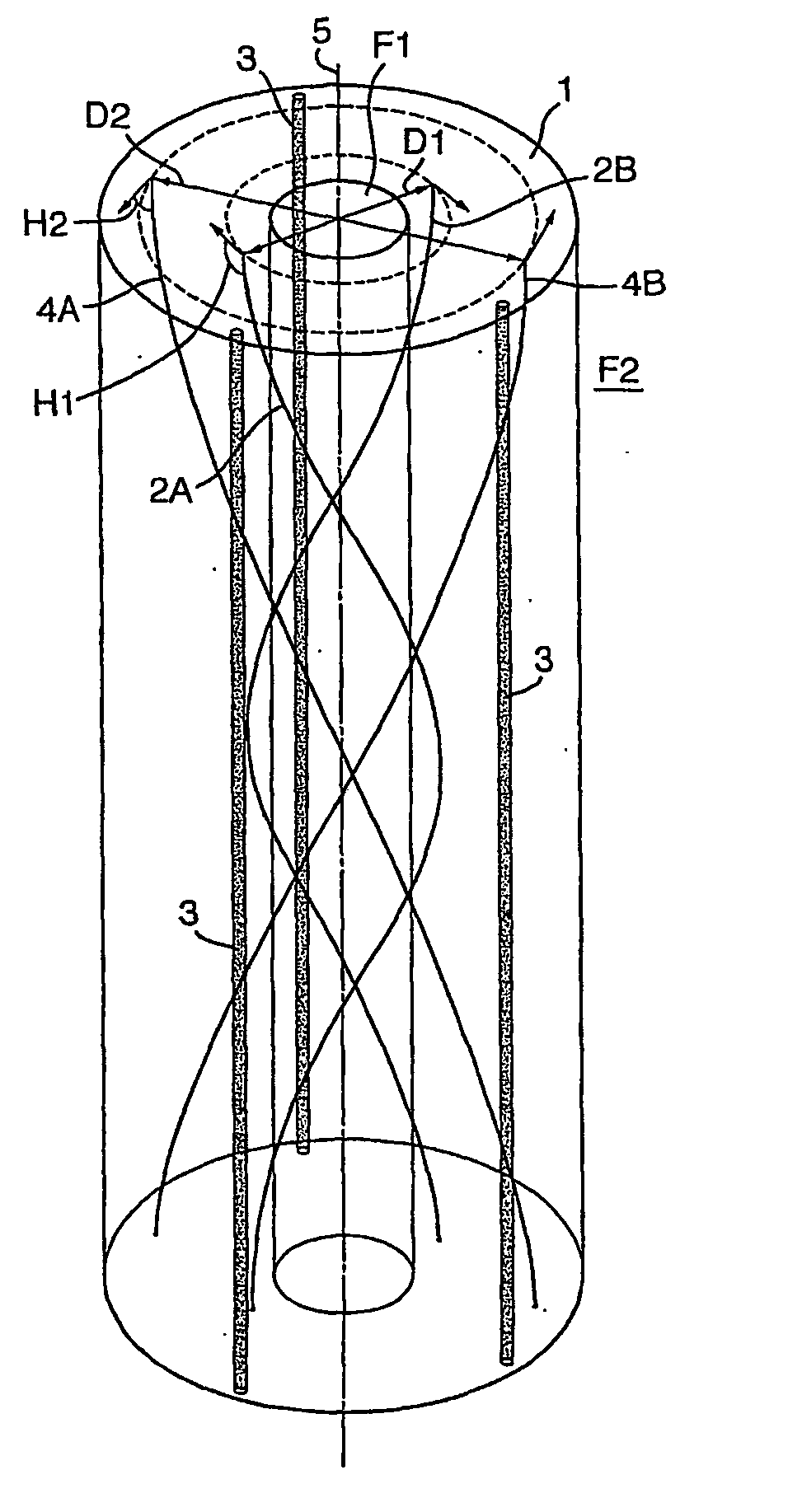

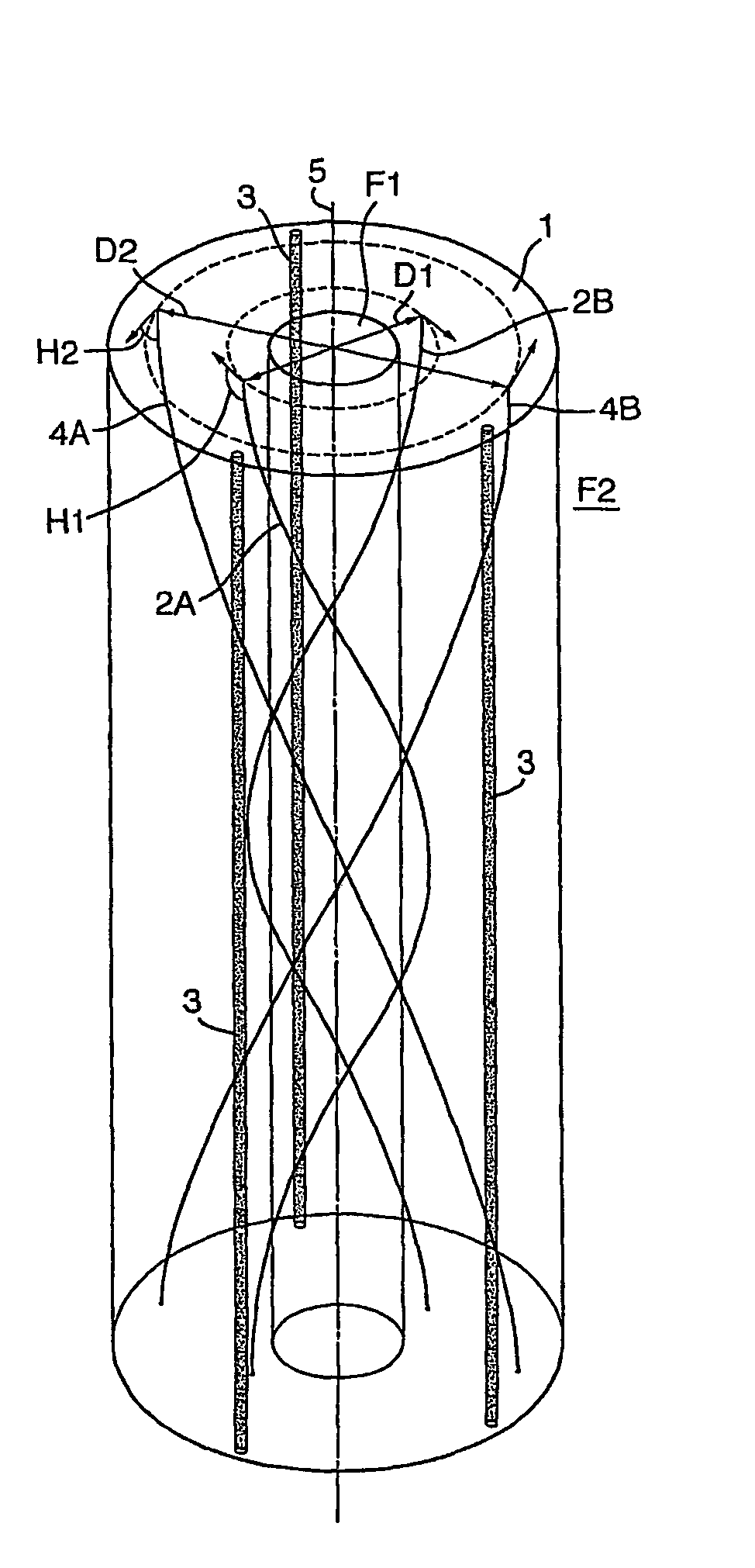

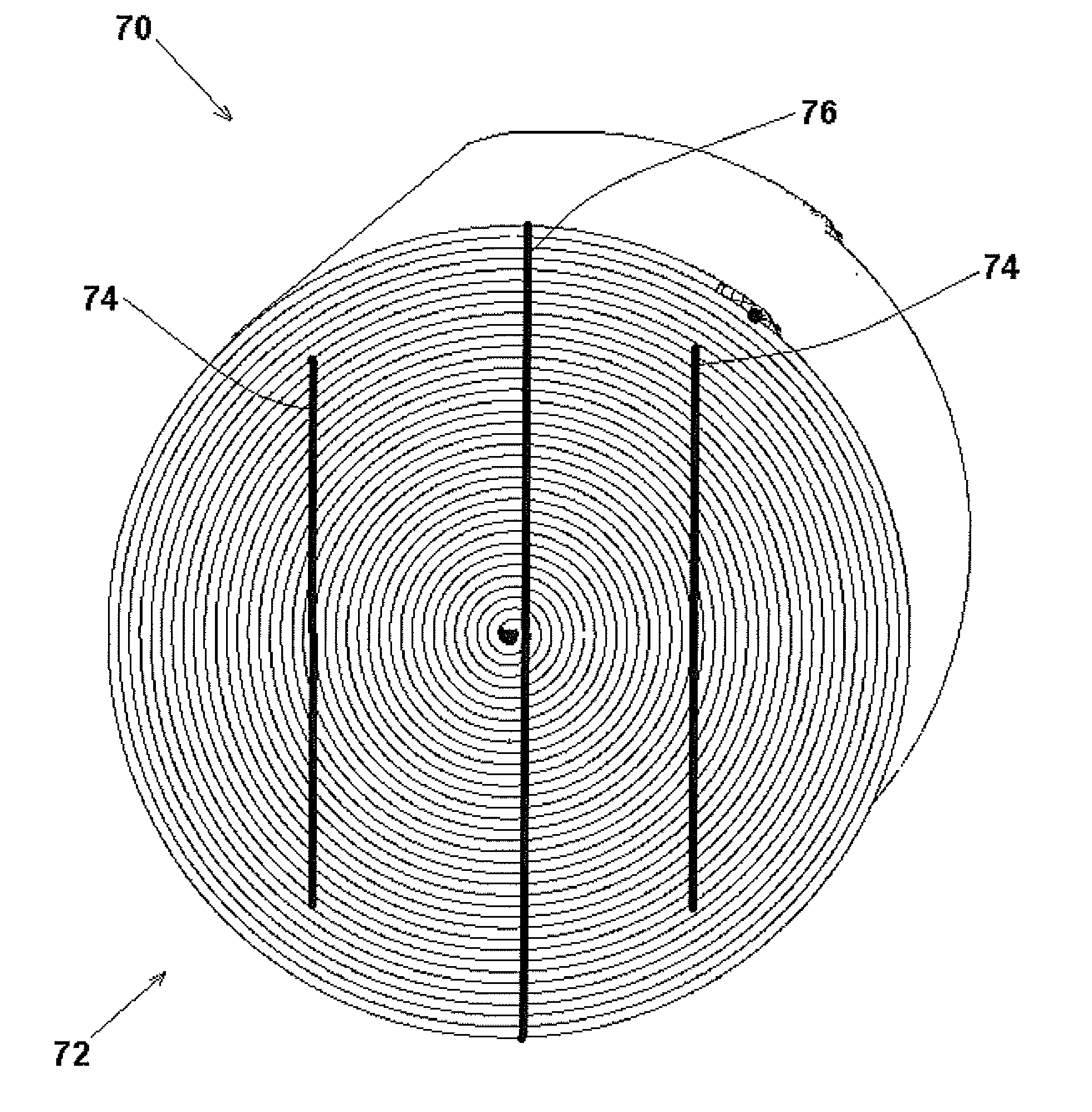

Coiled optical fiber assembly for measuring pressure and/or other physical data

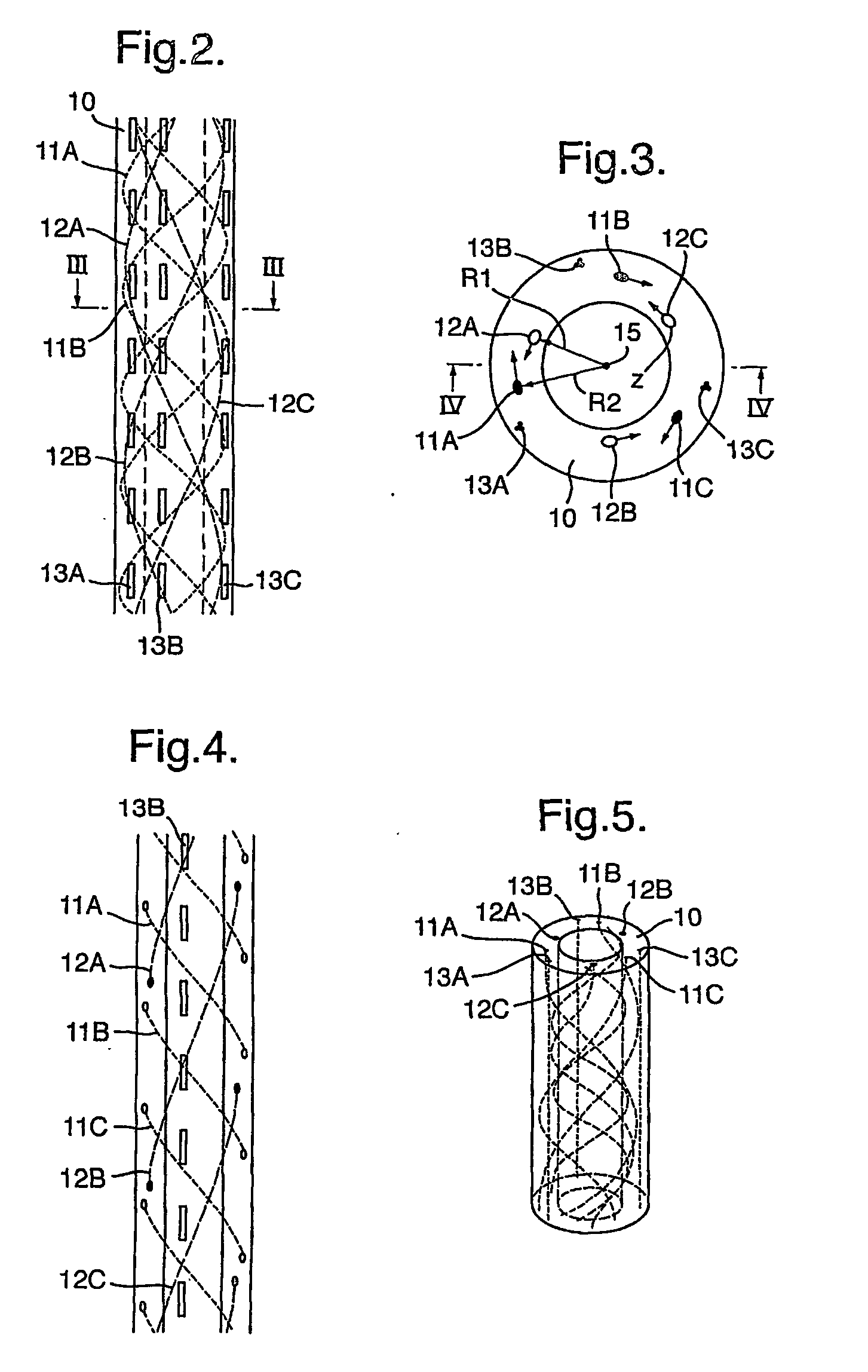

A method and system are disclosed for measuring pressure and other physical data such as the temperature, elongation, torsion and bending at any point along the length of an elongate carrier tube by means of one or more coiled optical fibers that are embedded in the wall the tube such that deformation of the carrier tube induces strain in each optical fiber. In use a pulsed laser light source transmits a sequence of light pulses of a selected wavelength from an upstream end of each fiber into a coiled substantially uniform light guide channel provided by the optical fiber and a light sensor assembly detects any shift in wavelength of the light pulses backscattered from various locations along the length of the light guide channel. A signal processing assembly then calculates a strain pattern along the length of the fiber, and a pressure difference between the interior and exterior of the tube, at various locations along the length of the carrier tube. Preferably several fibers are wound at different pitch angles and in different directions and at different diameters in the wall of the carrier tube and the signal processing assembly calculates bending, torsion and both radial and axial deformation of the carrier tube on the basis of a comparison of the strain patterns induced on different optical fibers.

Owner:SHELL USA INC

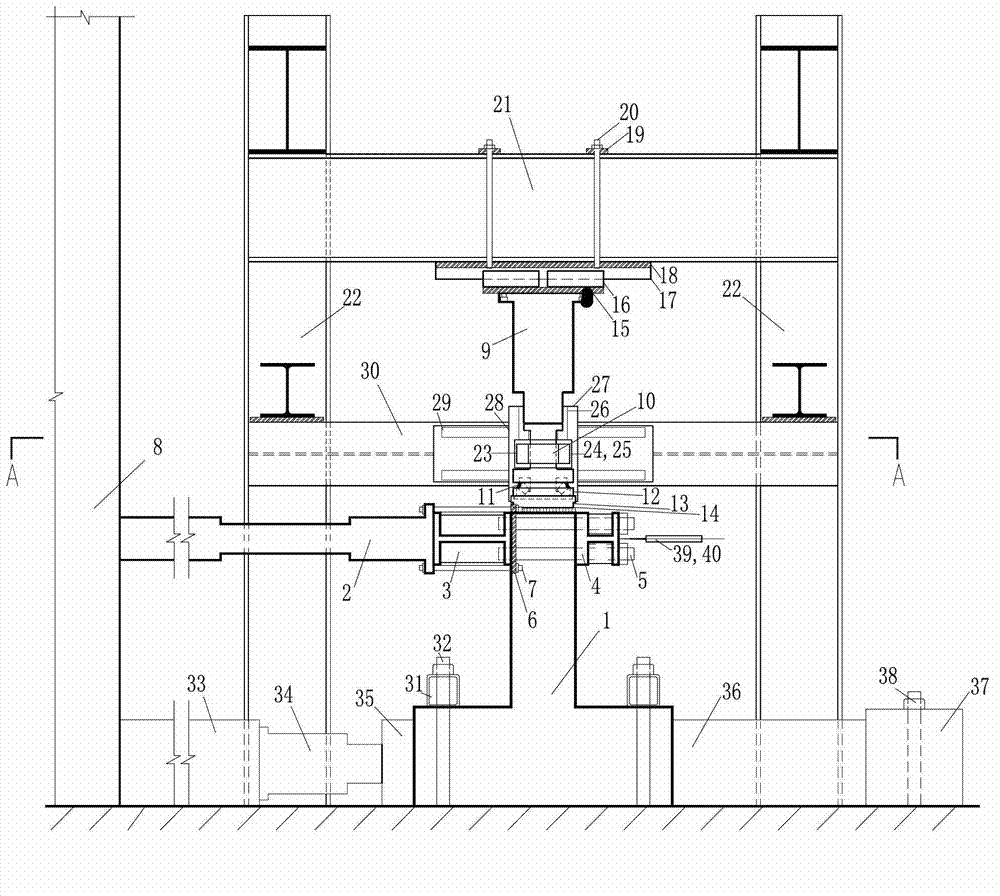

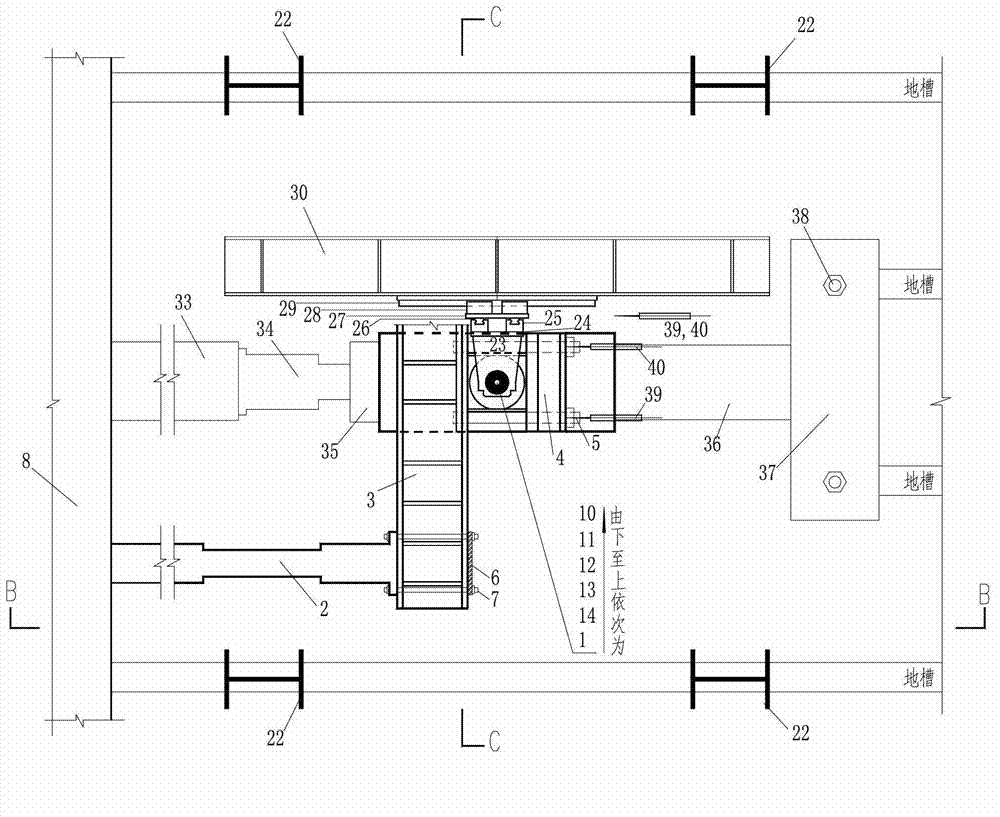

Component combined torsion experimental device and method

InactiveCN103115828AOvercome the disadvantages of inconsistent stress stateEasy to operateMaterial strength using steady torsional forcesEarthquake resistanceClassical mechanics

The invention discloses a component combined torsion experimental device comprising two counter-force frames which are fixed on a foundation terrace, a counter-force beam with two ends which are fixed at the upper ends of the counter-force frames and a counter-force wall fixed at the left side of the counter-force beam, wherein a component is fixed on the foundation terrace. The component combined torsion experimental device is characterized by further comprising a vertical force loading system for applying a vertical force to the component, a horizontal force loading system for applying a horizontal force to the component, a component top linear displacement guide system for meeting requirements of axial deformation, bending deformation and shearing deformation of the component, and a foundation displacement limiting system for fixing the position of the component. According to the experimental device and the method disclosed by the invention, the disadvantages of the existing similar experimental devices and methods are overcome; an experimental principle is scientific and an experimental process is simple to operate and control; the experimental device is convenient to assemble and can be used while being installed; and the experimental device can be circularly used and an experimental result meets a combined torsion performance of the structural component under the horizontal earthquake action, so as to provide experimental guarantees for disclosing a combined torsion mechanism and an anti-seismic property of the structural component.

Owner:TIANJIN YUANZHUO AUTOMATION EQUIP MFG CO LTD

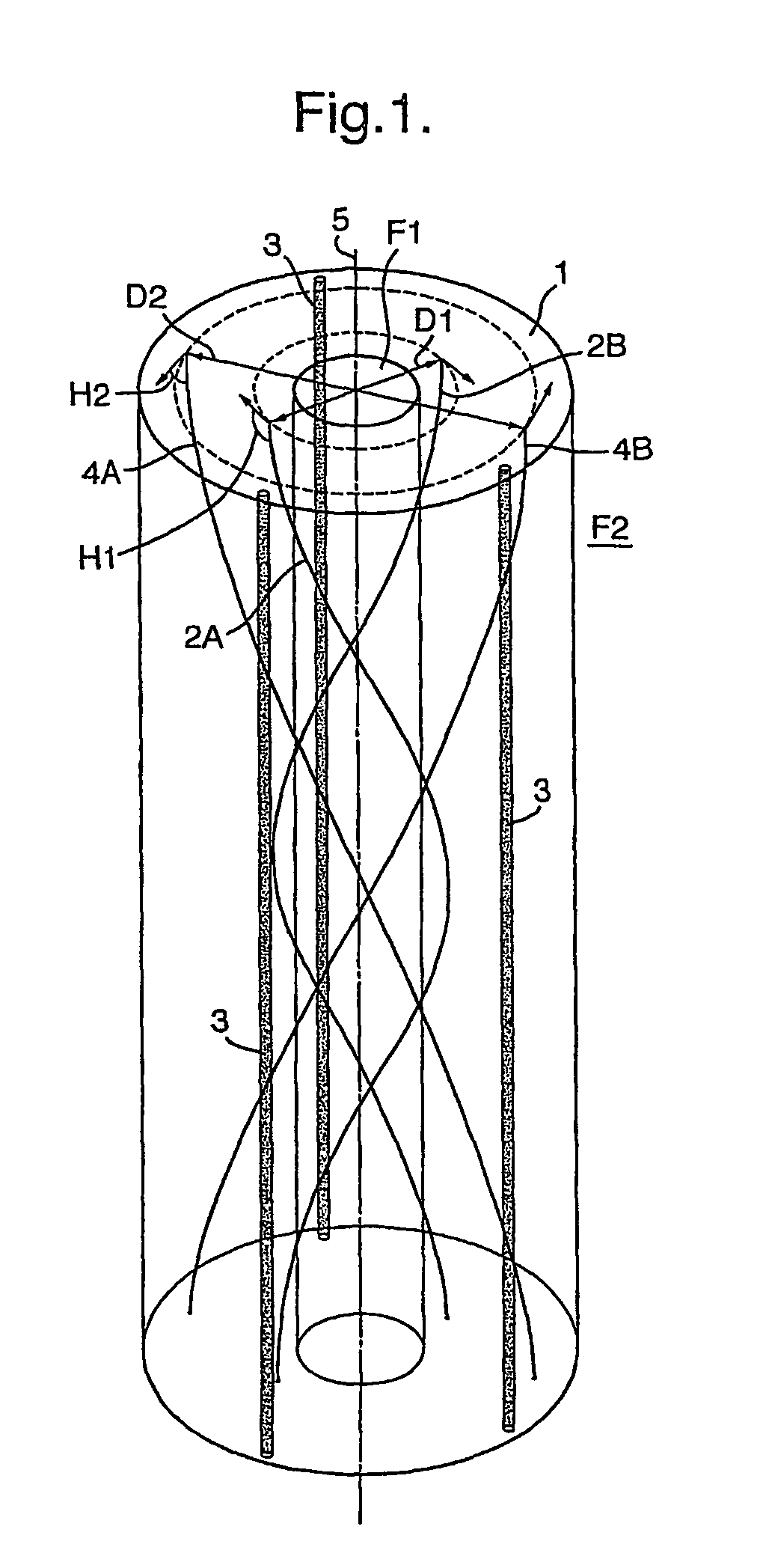

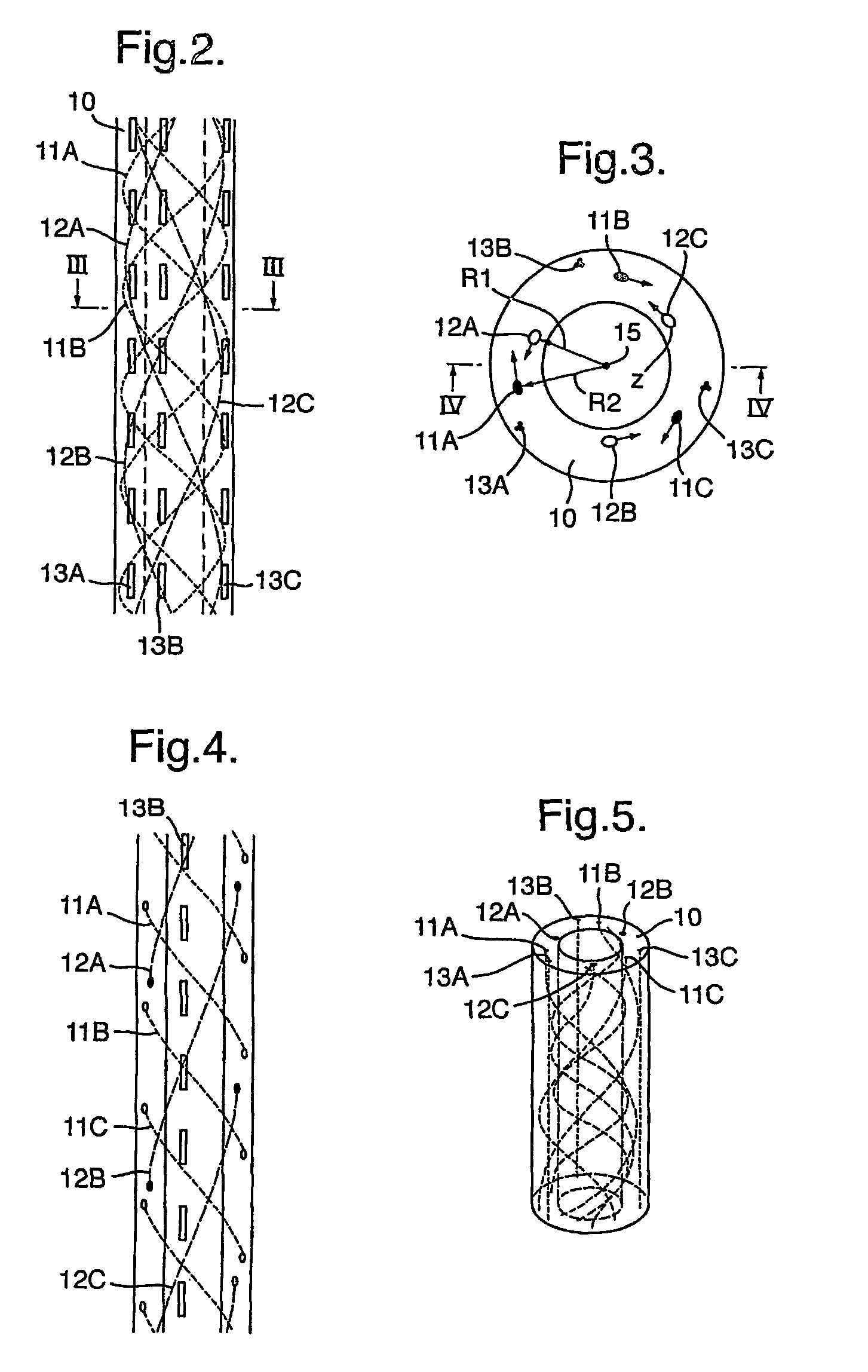

Coiled optical fiber assembly for measuring pressure and/or other physical data

A method and system are disclosed for measuring pressure and other physical data, such as the temperature, elongation, torsion and bending at any point along the length of an elongate carrier tube by means of one or more coiled optical fibers that are embedded in the wall the tube such that deformation of the carrier tube induces strain in each optical fiber. In use a pulsed laser light source transmits a sequence of light pulses of a selected wavelength from an upstream end of each fiber into a coiled substantially uniform light guide channel provided by the optical fiber and a light sensor assembly detects any shift in wavelength of the light pulses backscattered from various locations along the length of the light guide channel. A signal processing assembly then calculates a strain pattern along the length of the fiber, and a pressure difference between the interior and exterior of the tube, at various locations along the length of the carrier tube. Preferably several fibers are wound at different pitch angles and in different directions and at different diameters in the wall of the carrier tube and the signal processing assembly calculates bending, torsion and both radial and axial deformation of the carrier tube on the basis of a comparison of the strain patterns induced on different optical fibers.

Owner:SHELL USA INC

Nut seal assembly for coaxial cable system components

InactiveUS7354309B2Electrically conductive connectionsSecuring/insulating coupling contact membersElastomerCoaxial cable

An integrated seal assembly is provided, as is a coaxial cable system component incorporating the seal assembly with a connector for coupling to an externally threaded port. The seal assembly includes a bellows-type seal formed at least partially of a conductive elastomer and having an elastically deformable tubular body and a plurality of sealing surfaces, and an integral joint-section intermediate an anterior end and a posterior end that assists in the axial deformation of the seal in response to axially-directed force. One of the sealing surfaces engages a corresponding surface of an internally threaded nut or housing. The component is engagable with an externally threaded port via the internally threaded connector. The anterior end of the seal fits over the port and a sealing surface of the seal is capable of sealing axially against a shoulder of the port while the seal body covers the otherwise exposed externally threaded port. Upon tightening of the nut on the port, the seal deflects in the axial direction to accommodate a variety of distances between the connector and the shoulder of the port. Additionally, the seal is capable of expanding to allow a second sealing surface to contact and seal against a variety of smooth outside diameters of the port. The versatility of the seal allows an operator to use one connector of a system component on a wide variety of externally threaded ports without the risk of a faulty seal at the connection or a poor connection due to an improper seal.

Owner:PPC BROADBAND INC

Nut seal assembly for coaxial cable system components

ActiveUS7500874B2Two pole connectionsSecuring/insulating coupling contact membersCoaxial cableEngineering

An integrated seal assembly and a coaxial cable system component incorporating the seal assembly with a connector for coupling to an externally threaded port. The seal assembly includes a bellows-type seal having an elastically deformable tubular body and a plurality of sealing surfaces, and an integral joint-section intermediate an anterior end and a posterior end that assists in the axial deformation of the seal in response to axially-directed force. One of the sealing surfaces is made to engage a corresponding surface of an internally threaded nut or housing. The component is engagable with an externally threaded port via the internally threaded connector. The anterior end of the seal fits over the port and a sealing surface of the seal is capable of sealing axially against a shoulder of the port while the seal body covers the otherwise exposed externally threaded port. Upon tightening of the nut on the port, the seal deflects in the axial direction to accommodate a variety of distances between the connector and the shoulder of the port. Additionally, the seal is capable of expanding to allow a second sealing surface to contact and seal against a variety of smooth outside diameters of the port. The versatility of the seal allows an operator to use one connector of a system component on a wide variety of externally threaded ports without the risk of a faulty seal at the connection or a poor connection due to an improper seal.

Owner:PPC BROADBAND INC

Experimental device and method for simulating stratum deformation in NGH (natural gas hydrate) exploiting process

The invention discloses an experimental device for simulating stratum deformation in an NGH (natural gas hydrate) exploiting process. The experimental device comprises a reaction kettle, an axial pressure piston, a kettle outer jacket, an injection system, an axial pressure control system, an ambient pressure control system and an output system. The invention further discloses an experimental method for simulating the stratum deformation in the NGH exploiting process by adopting the experimental device. The method comprises the following steps: in a hydrate generation process, ice powder particles in proper particle size are prepared through an ice powder production system, ice powder is mixed with dried submarine sediment particles, and hydrate samples with different occurrence forms and different saturation degrees can be generated. Axial deformation quantity of a sample cavity as well as gas output, water output and sand output data is calculated in an exploiting experiment. According to the experimental device and the experimental method, the influence of the hydrate samples under various geological conditions and with different occurrence forms on the stratum deformation in a decomposition process can be simulated, basic data of the influence of decomposition of NGH on the stratum deformation are obtained, and the experimental foundation and basis are provided for real NGH exploiting.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

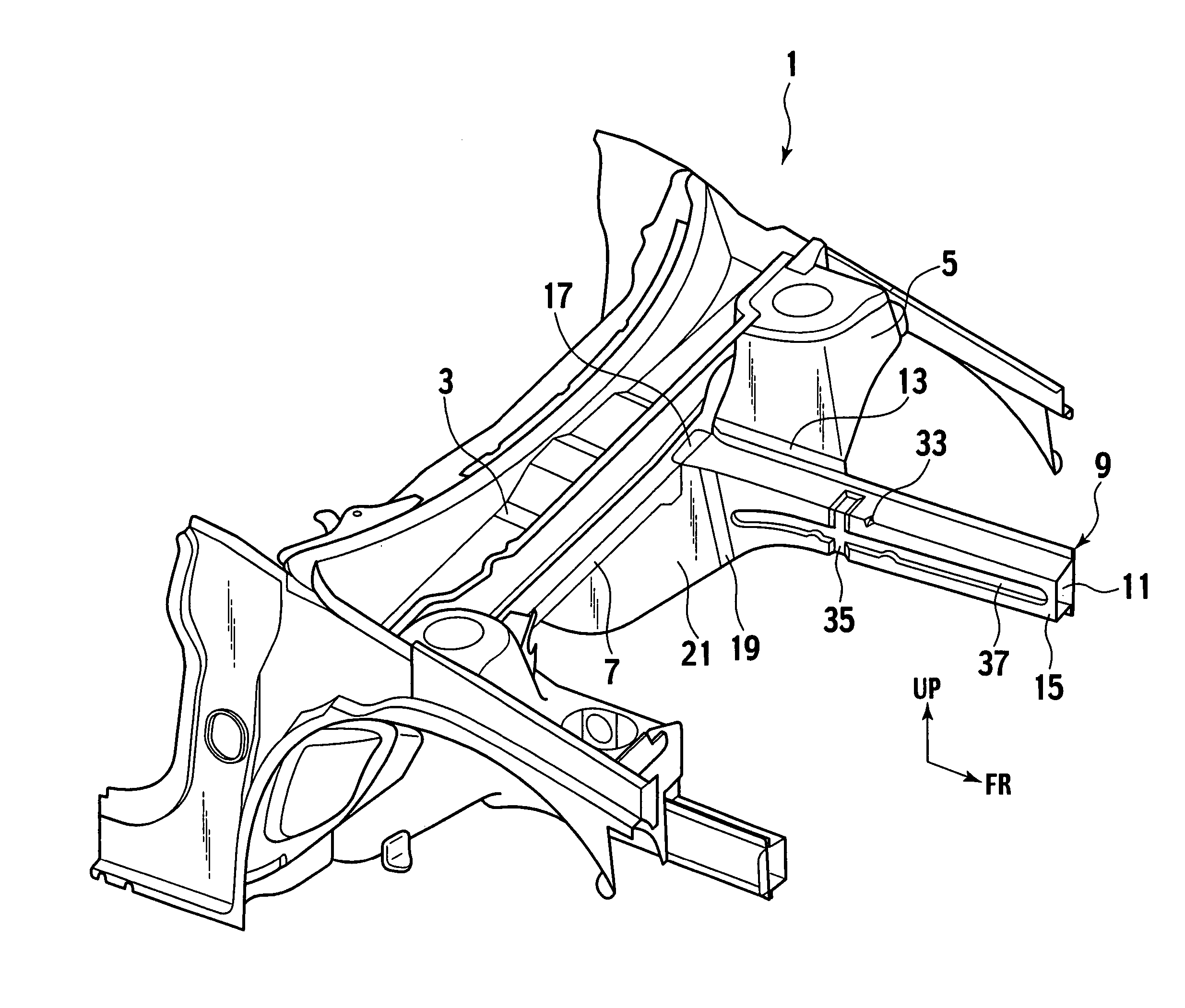

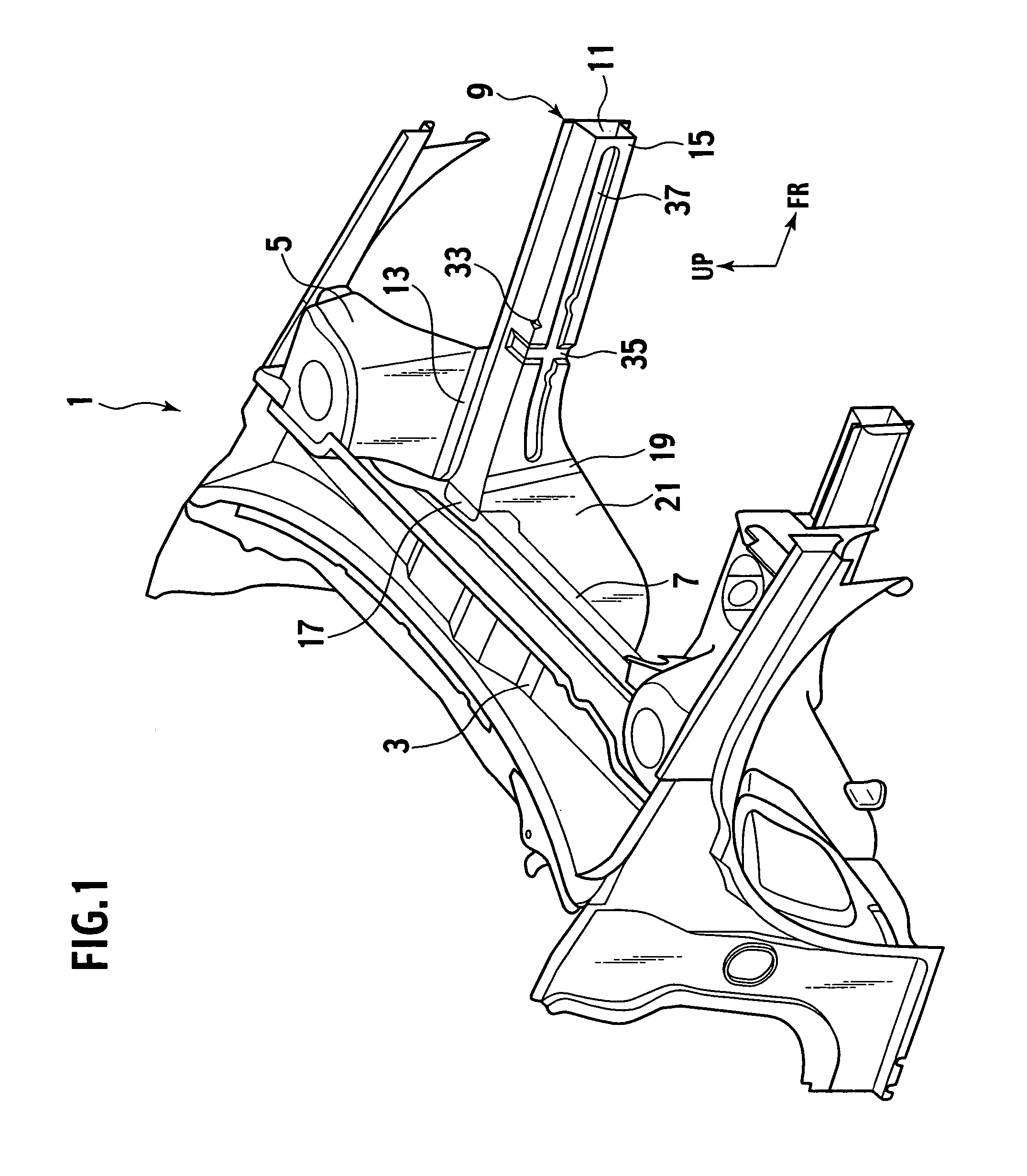

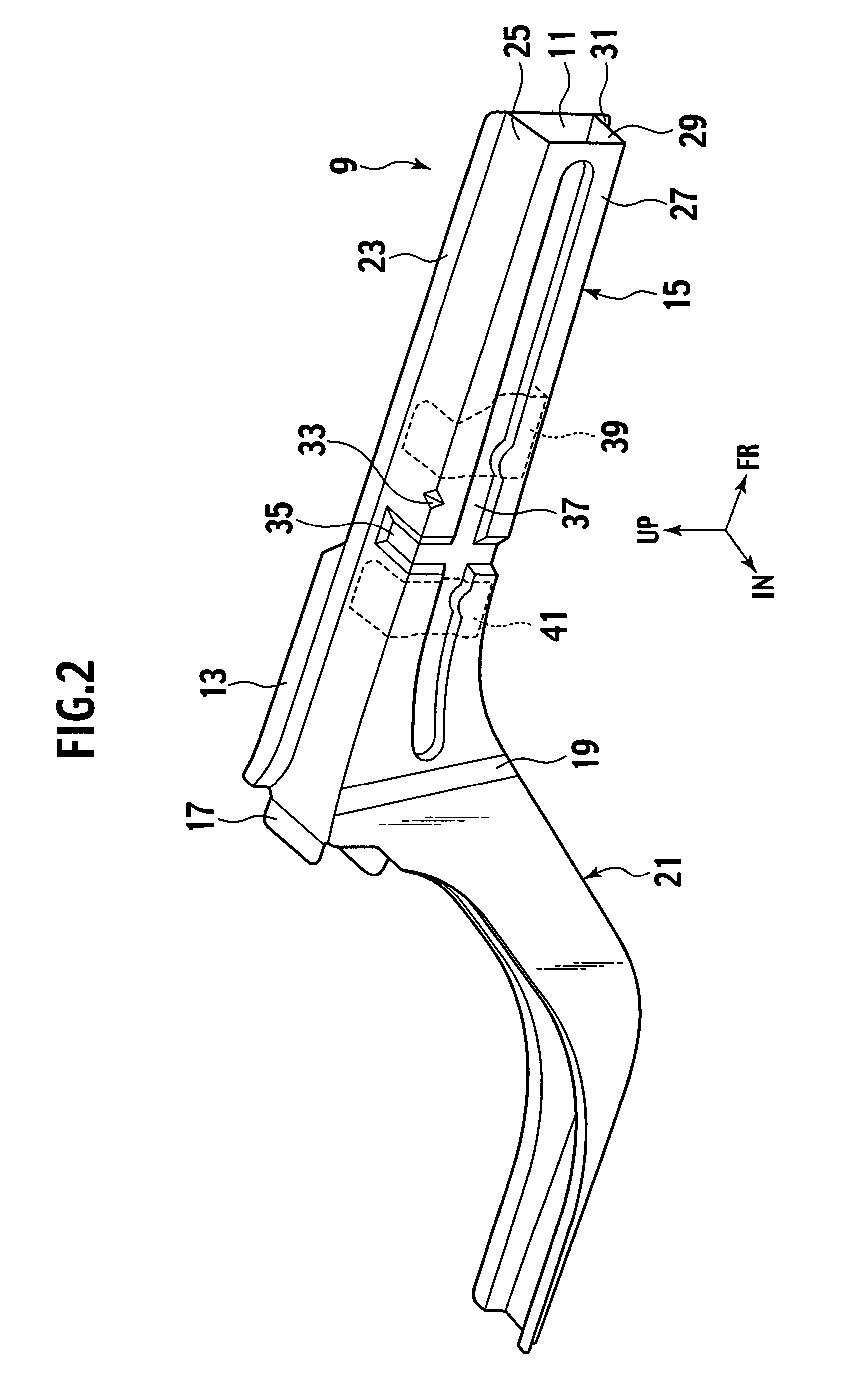

Impact energy absorbing structure of vehicle frame member

Owner:NISSAN MOTOR CO LTD

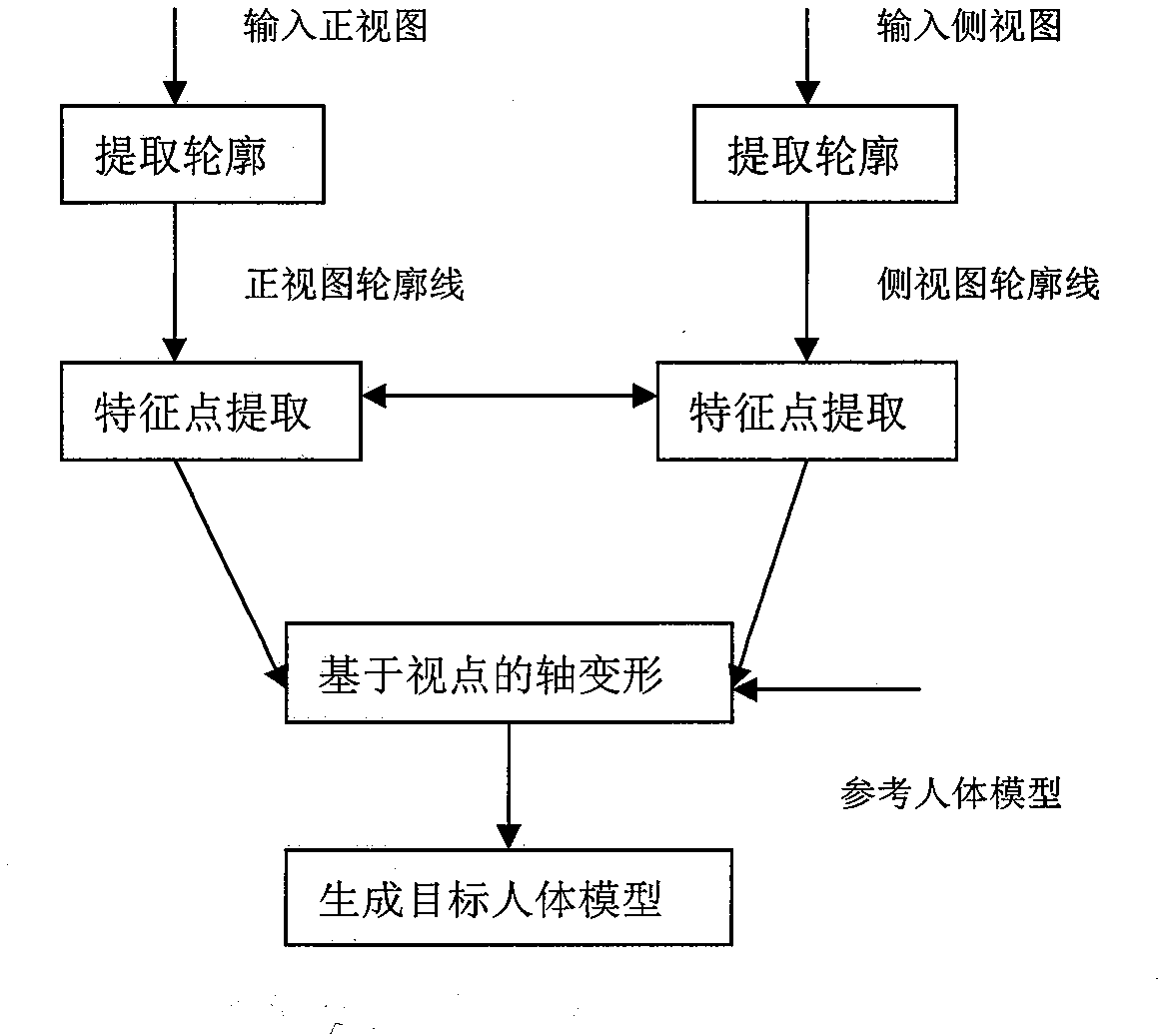

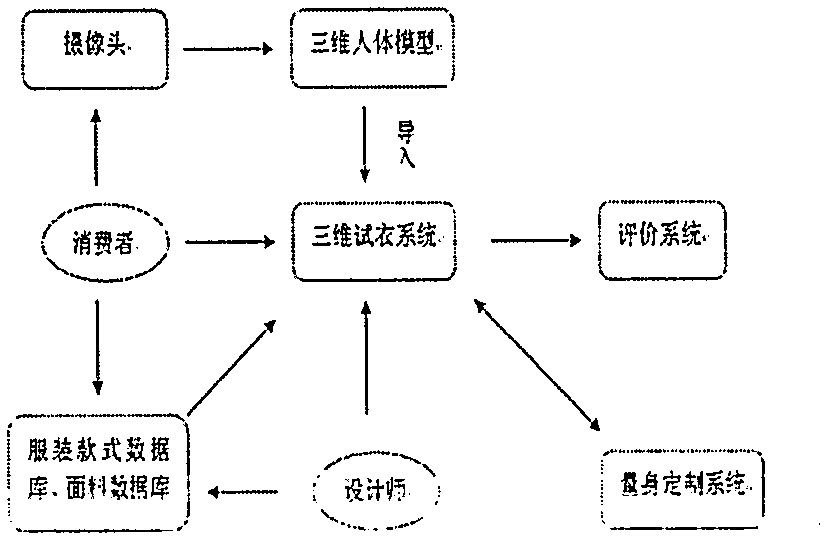

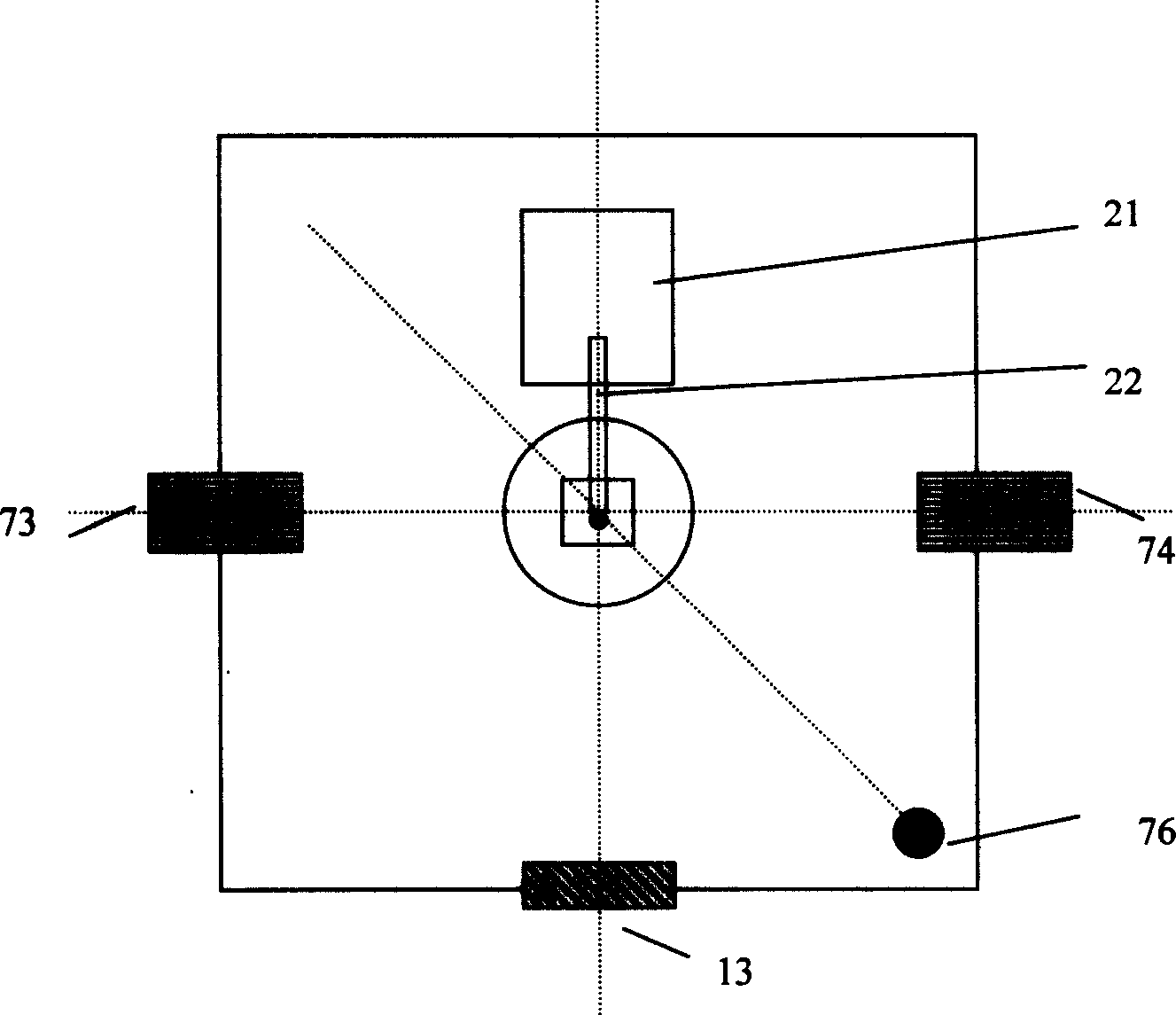

Three-dimensional virtual fitting system

InactiveCN103106586AImprove the design levelImprove efficiencyCommerceImage data processingHuman bodyPersonalization

The invention discloses a three-dimensional virtual fitting system and relates to the technical field of robot vision and digitized costume design. The three-dimensional virtual fitting system is characterized in that the object of costume three-dimensional virtual fitting is a three-dimensional human body model which is built through shooting and processing of a real human body. A customer is shot by a camera to obtain multiple groups of images; contour extraction and feature extraction are carried out on the images in a computer, based on axial deformation of viewpoints, with the human body model as reference, further factors including human body types and the like are considered, and the real-person human body model of the customer is finally obtained; the obtained model is input into the three-dimensional fitting system; through two-way selection, a style, cloth, design and color and the like of clothes are determined by the customer and a designer; the data are input into a 'custom-made system' to complete a costume design, an individual fashion sample is generated automatically and input back into the three-dimensional fitting system, and then a custom ready-to-wear is sewed in a virtual mode and worn on the real-person human body model to display an individual fitting effect intuitively; relative marking is carried out by an evaluation system, and scores can be a reference index for the customer and the designer; and the design level and design efficiency of the costume are greatly improved.

Owner:JIANGNAN UNIV

Deformable brush seal support

InactiveUS6840518B2Improve engine efficiencyAvoid damageEngine sealsLeakage preventionBristleEngineering

A brush seal is provided for sealing between a rotating shaft and a housing. The brush seal includes an annular rim or head portion coaxial with the shaft and mounted on the housing, an annular array of bristles extending from the head portion toward the shaft for contact with the shaft at their ends, and an annular bristle support plate extending from the head portion toward the shaft. The support includes voids arranged to accommodate radial deformation in the support due to rubbing contact between the support and the shaft without incurring any substantial accompanying axial deformation which would distort the bristles and cause deterioration of their sealing function.

Owner:ANSALDO ENERGIA SWITZERLAND AG

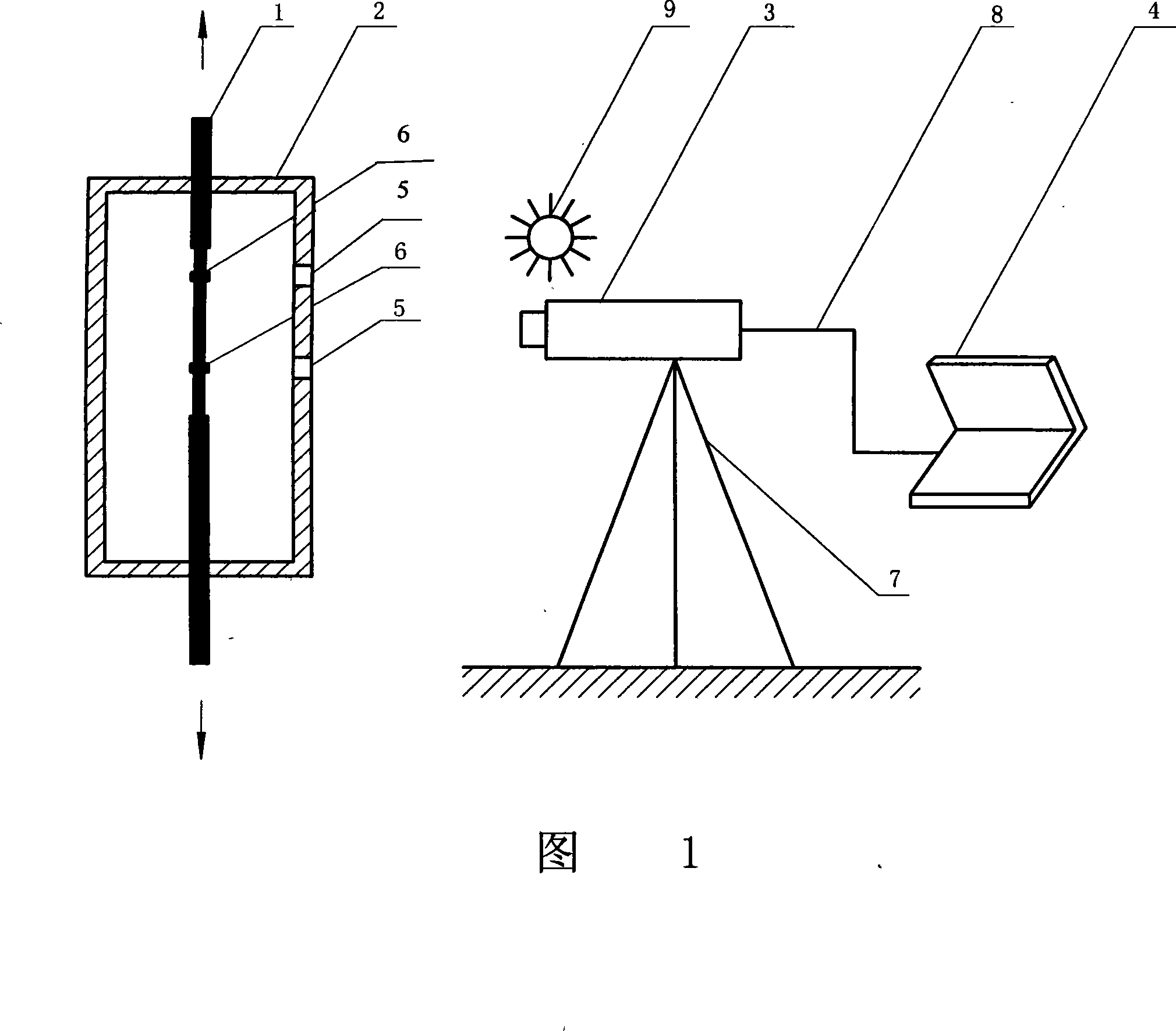

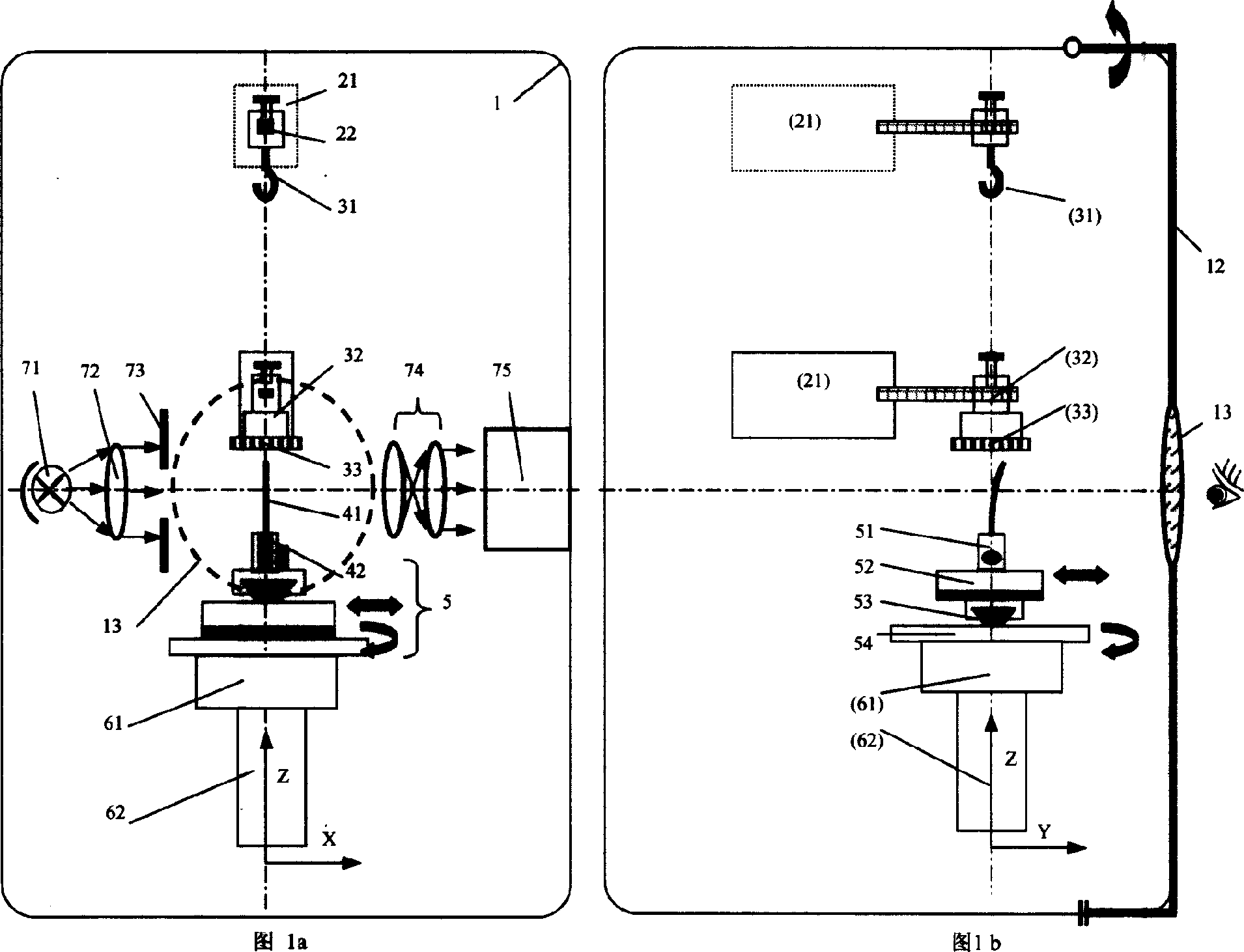

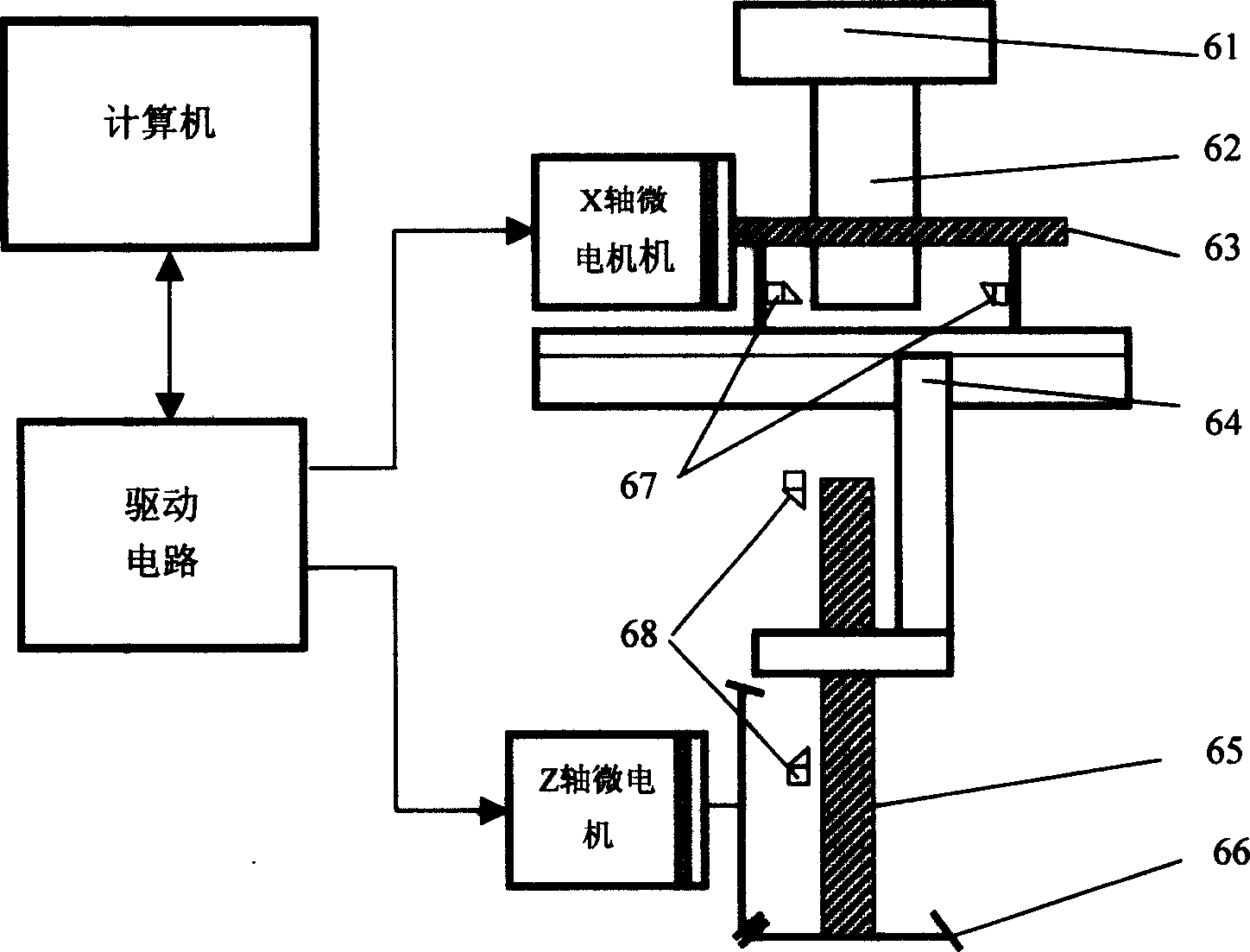

Method for measuring deformation of metallic material in hyperthermia mechanical test as well as observation instrument

InactiveCN101201245AImprove deformation measurement accuracyUsing optical meansStrength propertiesCouplingMetallic materials

The invention discloses a method of measuring deformation of metal material in the high-temperature mechanical test. First, a support is firmly erected in a safe distance from a heating furnace, a digital camera is mounted on the support, and the video output of the digital camera is connected to a computer by an information wire; two observation holes are opened on the wall of the heating furnace; two marks are made on a test piece right to the opposite of the observation holes of the furnace wall; the two marks on the test piece in the heating furnace are regarded as reference points; the feature information of the two reference points is recorded; coordinates of the two reference points in the image are determined by scanning; the distance between the reference points at the time is calculated; when the test piece expands by heat, deforms by stress or under heat-stress coupling action, the coordinates of the two reference points in the image are determined again, and the new distance between two reference points is calculated; in this way, the axial deformation of the test piece is observed; the method and the instrument of the invention can continuously track the axial deformation of the test piece in the high-temperature test to the steel, so as to effectively improve the precision of measuring the deformation of the test piece in the high-temperature test to the steel.

Owner:CHINESE PEOPLES ARMED POLICE FORCE ACAD

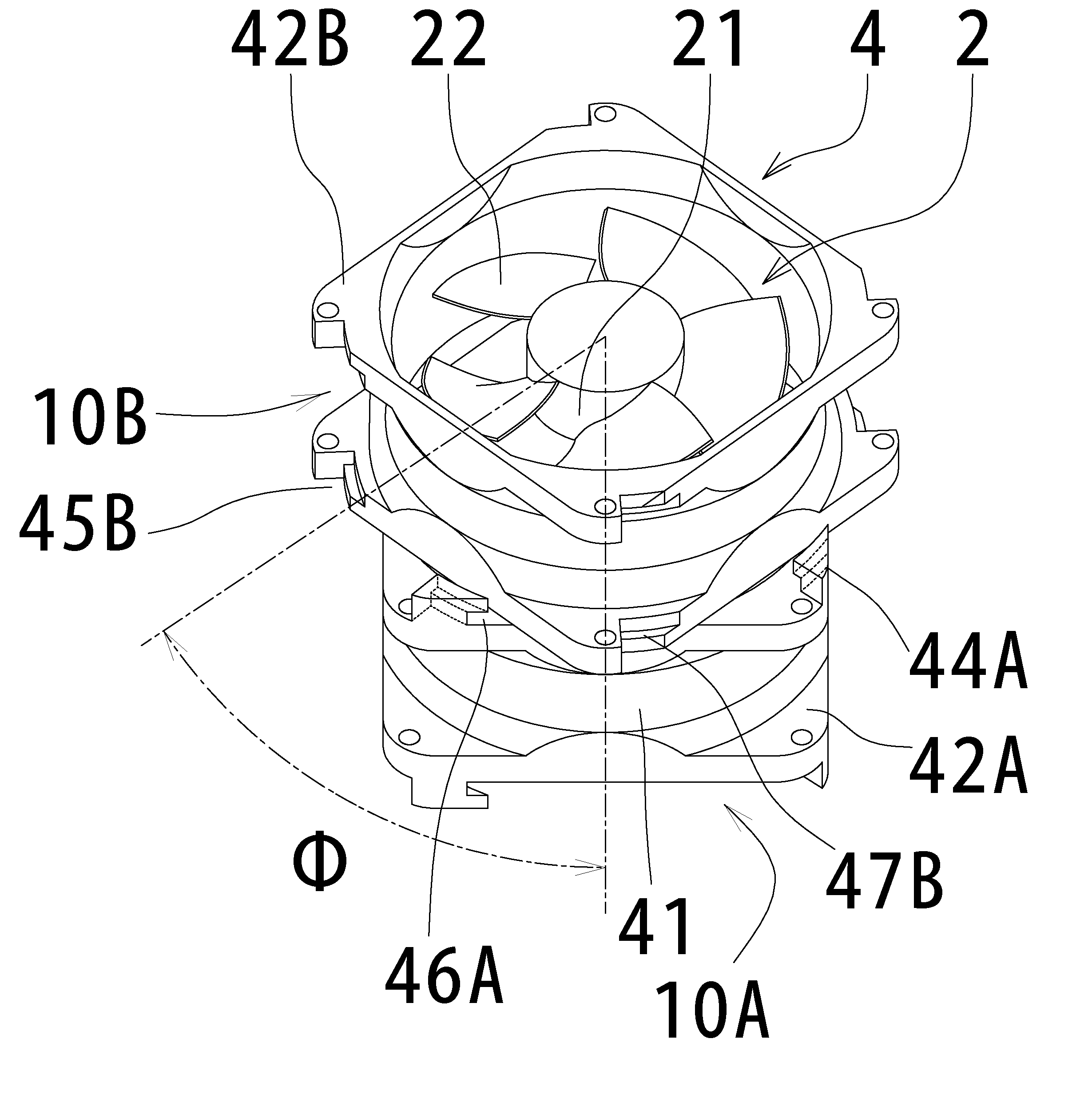

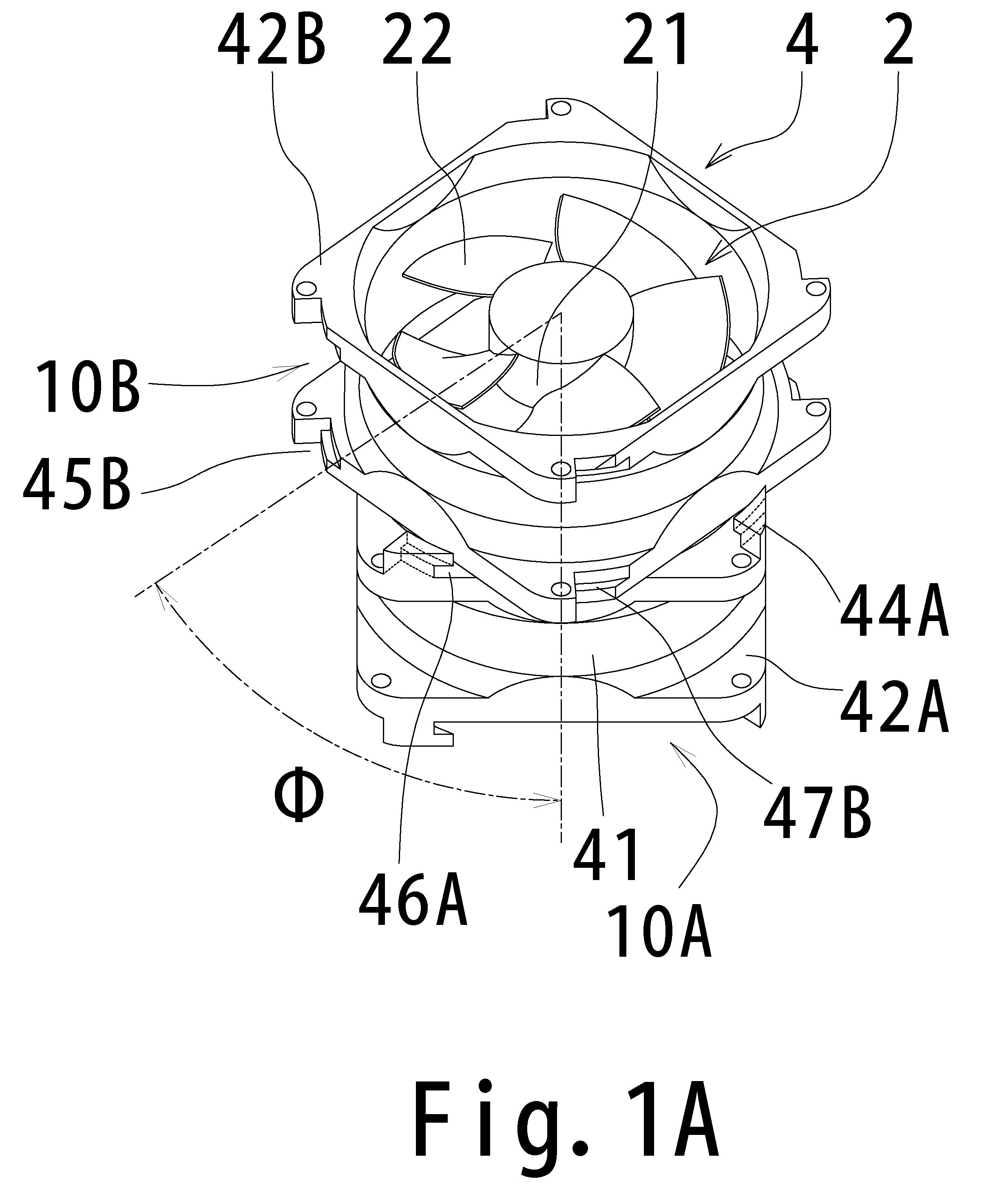

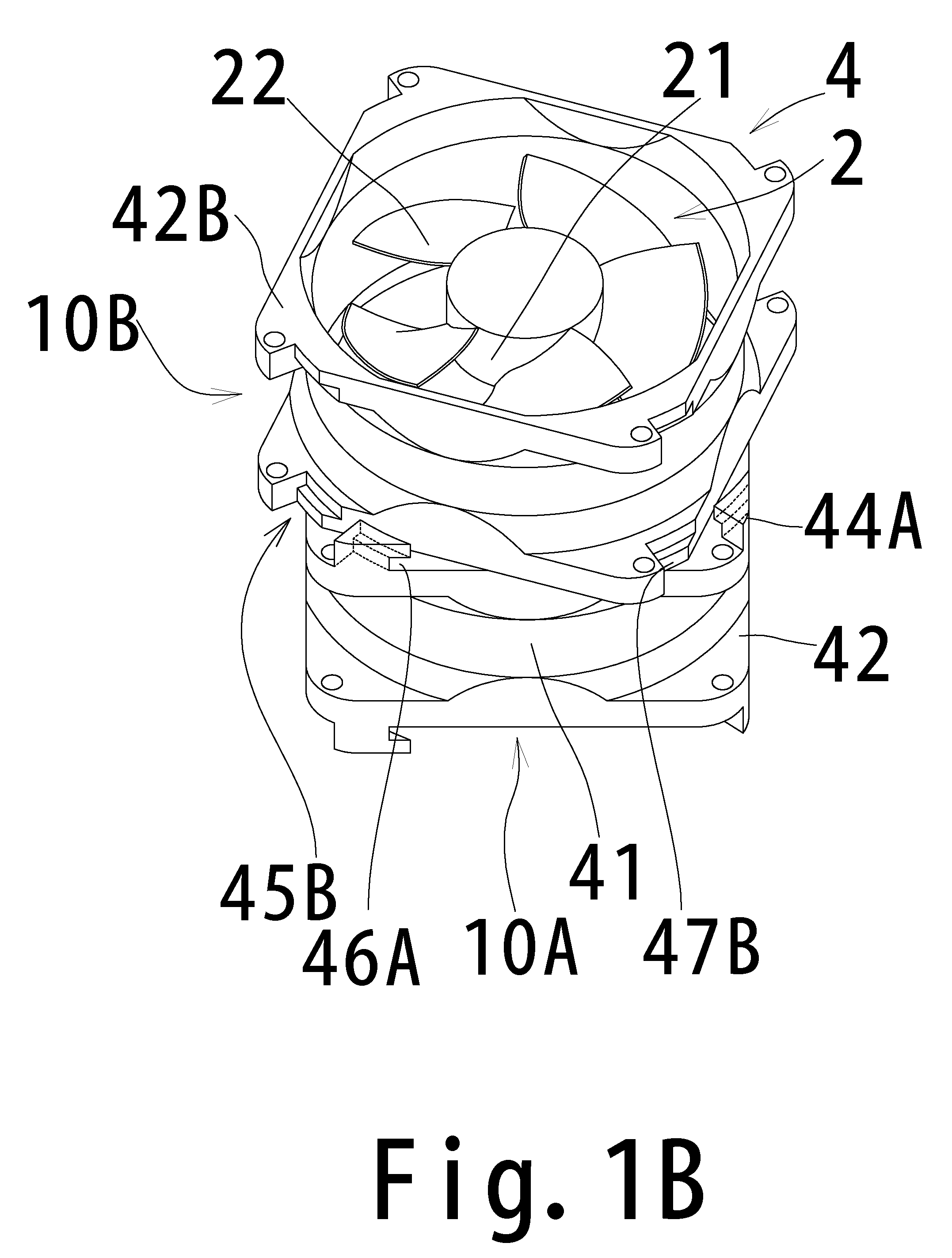

Housing assembly for use in fan unit and fan unit including the same

A housing assembly for a fan unit includes an upper housing having a lower engaging portion adjacent to its lower end surface and a lower housing having an upper engaging portion adjacent to its upper end surface. When one of the upper and lower housings rotates relative to the other about a center axis of the housings in a first direction with the opposing end surfaces of the housings in axial contact, the lower and upper engaging portions engage with each other. While the lower and upper engaging portions are in engagement, one of the lower and upper engaging portions presses the other in both axial directions to cause elastic axial deformation of the other; and one of the lower and upper engaging portions presses the other toward both the first direction and a second direction opposite thereto to cause elastic circumferential deformation of the other.

Owner:NIDEC CORP

Flow machine with rotor and stator

A flow machine with rotor and stator in axial structure in flow-oriented terms, at least in sections, having moving blades at the rotor and housing-fixed guide vanes, whereby the latter are arranged as at least one guide vane ring with an inner and an outer cover band. The at least one guide vane ring is implemented as self-bearing component part having a closed reinforcement at the inner cover band that reinforces the component part to resist jamming axial deformation, comprises a segmented outer cover band and is positioned in the housing over at least three cover band segments with bearing units that respectively allow radial relative movements. An air guide shell that guides a cooling air stream along the inside of the housing and is provided with openings for the housing-fixed bearing elements of the at least one guide vane ring is arranged between the housing and the outer cover band of the at least one guide vane ring.

Owner:DU BRO PRODS

Nut seal assembly for coaxial connector

ActiveUS20050176294A1Engagement/disengagement of coupling partsElectrically conductive connectionsCoaxial cableEngineering

An integrated seal assembly and a connector incorporating the seal assembly for connecting a coaxial cable to an externally threaded port. The seal assembly includes a bellows-type seal having an elastically deformable tubular body and a plurality of sealing surfaces, and an integral joint-section intermediate an anterior end and a posterior end that assists in the axial deformation of the seal in response to axially-directed force. One of the sealing surfaces is made to engage a corresponding surface of an internally threaded nut. The nut and attached seal form an integral seal assembly. A coaxial cable connector includes a connector body. One end of the body attaches a coaxial cable, the seal assembly being rotatably attached to the other end. The connector is engagable with an externally threaded port via the internally threaded nut component of the connector. The anterior end of the seal fits over the port and a sealing surface of the seal is capable of sealing axially against a shoulder of the port while the seal body covers the otherwise exposed externally threaded port. Upon tightening of the nut on the port, the seal deflects in the axial direction to accommodate a variety of distances between the connector and the shoulder of the port. Additionally, the seal is capable of expanding to allow a second sealing surface to contact and seal against a variety of smooth outside diameters of the port. The versatility of the seal allows an operator to use one connector on a wide variety of externally threaded ports without the risk of a faulty seal at the connection or a poor connection due to an improper seal.

Owner:PPC BROADBAND INC

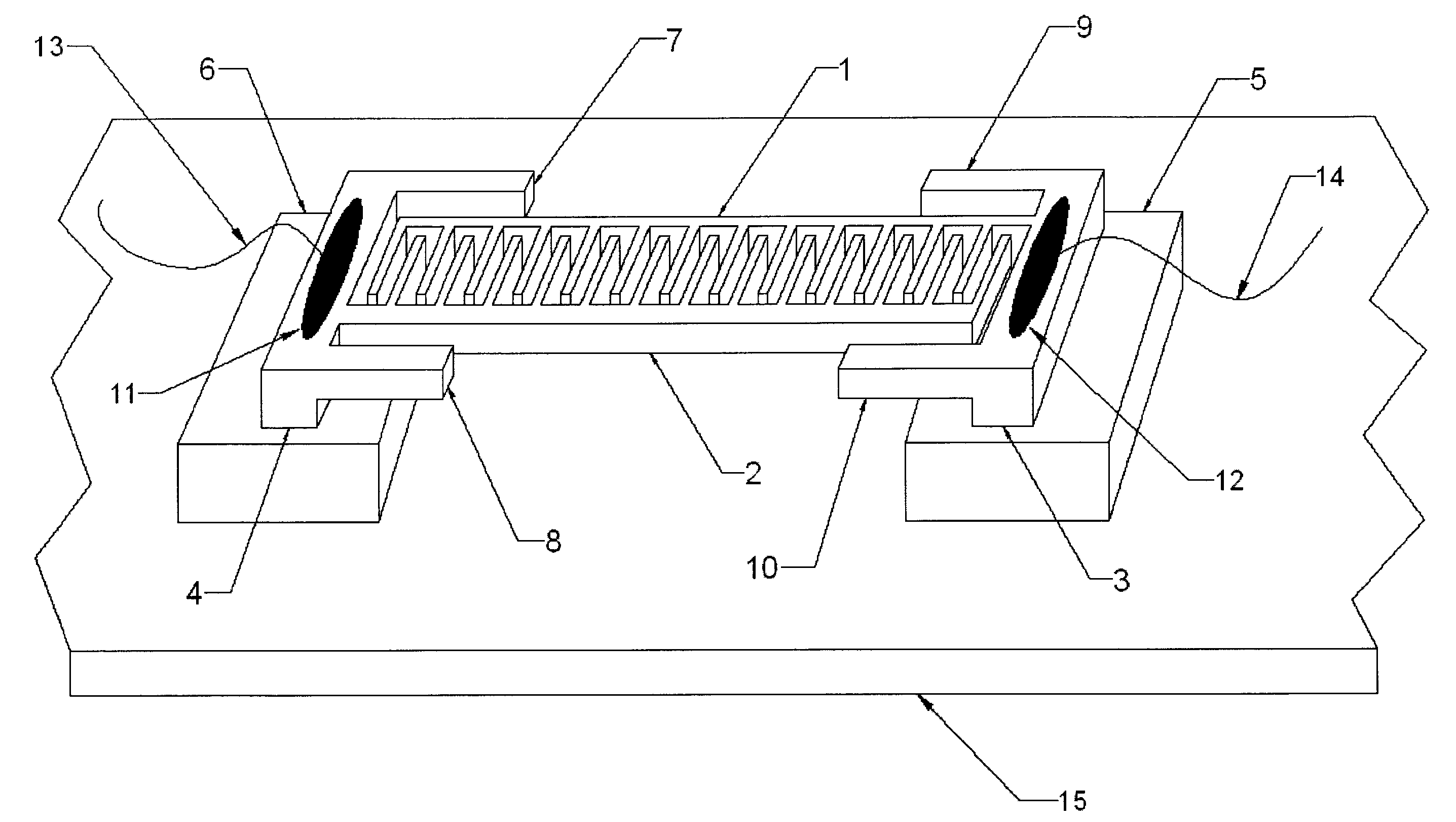

MEMS capacitive bending and axial strain sensor

ActiveUS7509870B2Easily be incorporated into current semi-conductor fabrication processLow powerForce measurementUsing electrical meansCapacitancePrimary operation

Owner:GLOBUS MEDICAL INC

Method of manufacturing articles of complex shape using powder materials, and apparatus for implementing this method

InactiveUS6210633B1Suppression of distortionMinimize radial shrinkageCeramic shaping apparatusClaywaresMaterials scienceHot isostatic pressing

The present invention offers a novel method of manufacturing articles of a complex shape by subjecting powder material to Hot Isostatic Pressing (HIP). The method involves manufacturing a capsule with at least one insert. The capsule is filled with outgassed powder. Thereafter, the powder in the capsule is subjected to hot isostatic pressing. The capsule is removed to produce a finished article, such as a bladed disk. The thickness of capsule walls is made variable so as to provide substantially unidirectional axial deformation of the powder during the Hot Isostatic Pressing.

Owner:LAB OF NEW TECH USA

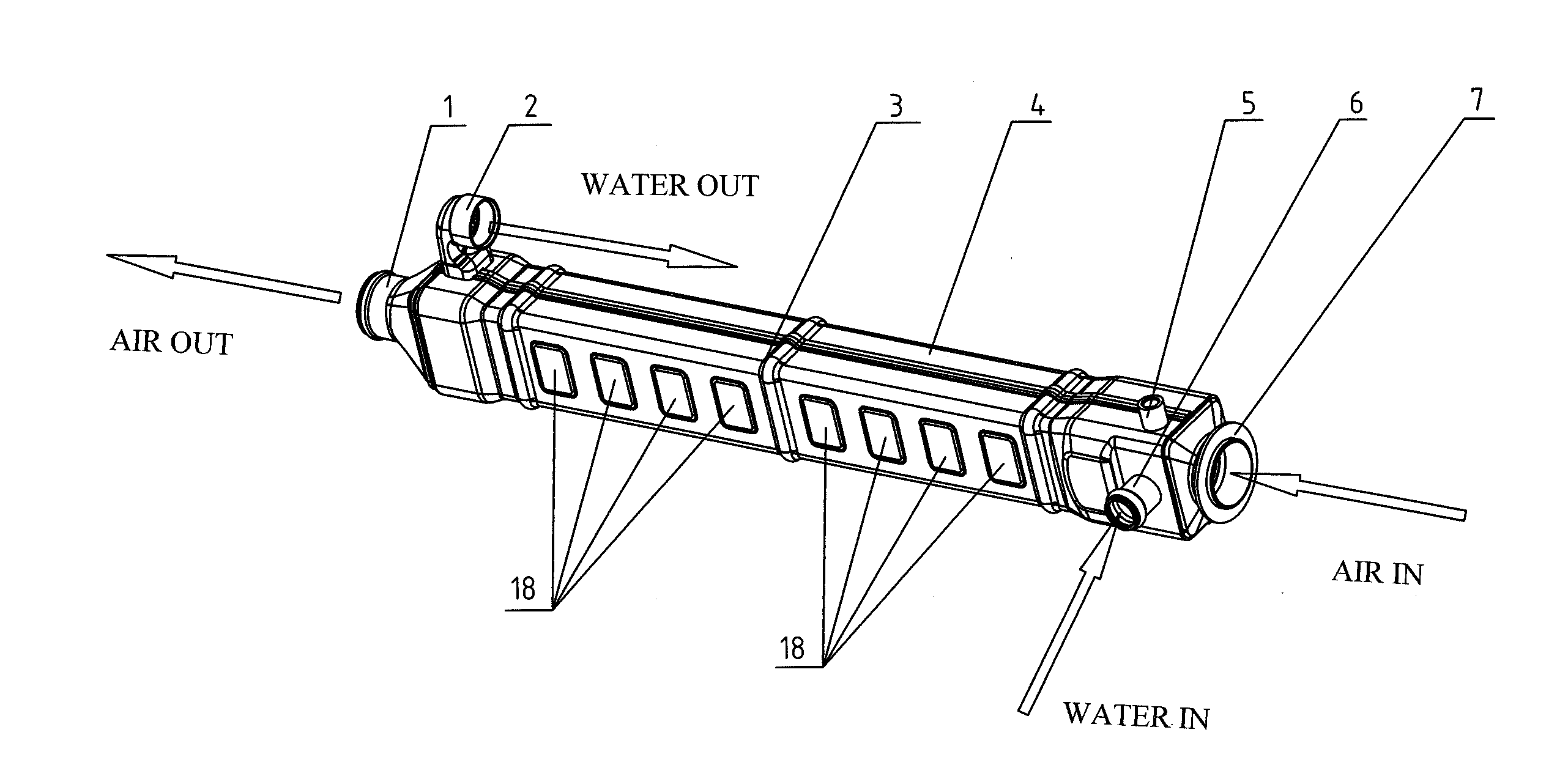

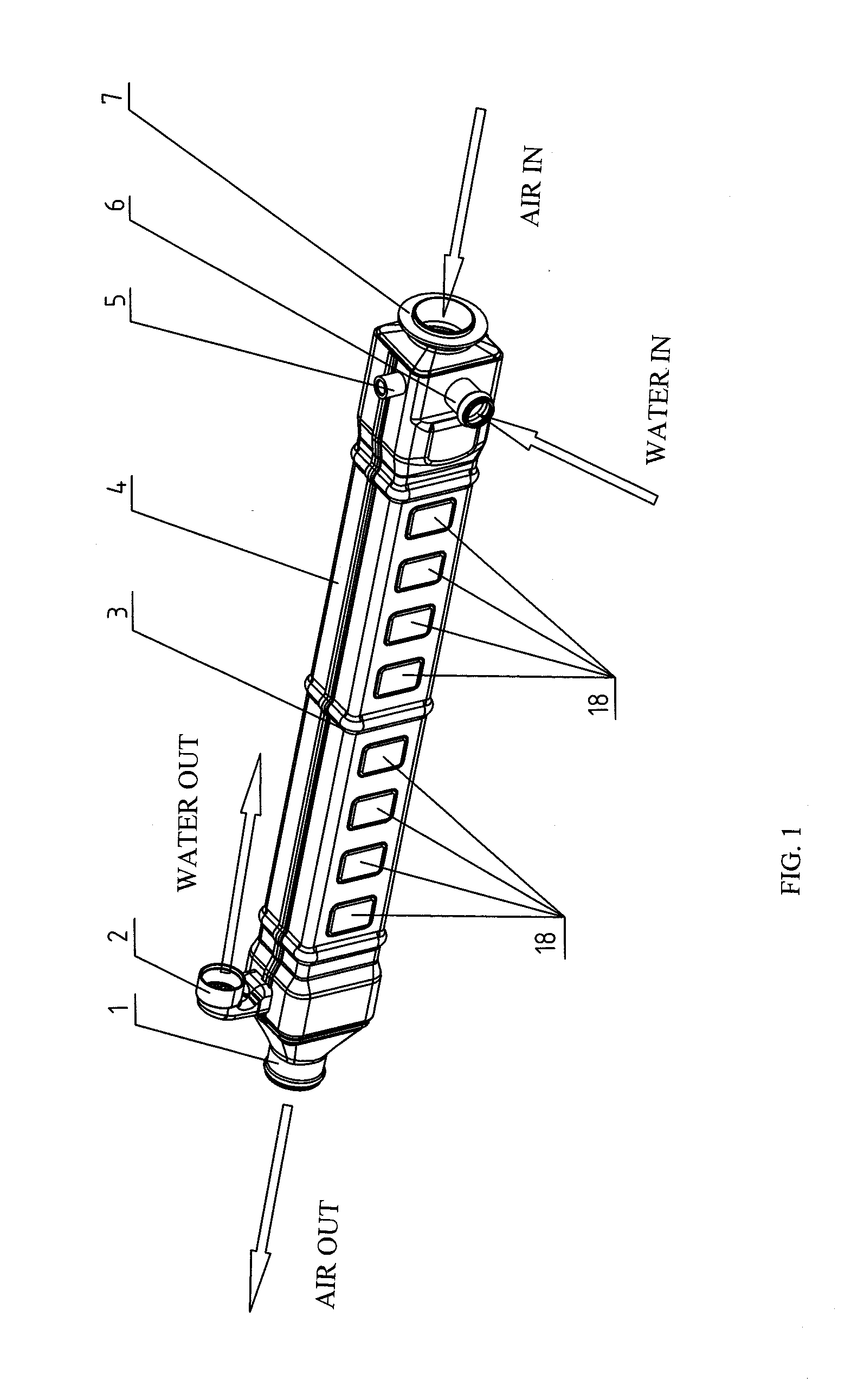

Plate-fin structure exhaust gas recirculation cooler with heat-insulation function

ActiveUS20140034028A1High strengthImprove cooling effectInternal combustion piston enginesNon-fuel substance addition to fuelEngineeringExhaust gas recirculation

The present invention discloses a plate-fin structure EGR cooler with heat-insulation function includes shell. The two ends of the shell are equipped with an air inlet flange and a discharge chamber. A water inlet pipe and a water outlet pipe are set on the shell near the air inlet flange and the discharge chamber. A cooling core assembly, an air chamber and a bellow are set in the shell. The main board at one end of the cooling core assembly is connected to the shell and the discharge chamber and the main board at another end is connected to one end of the air chamber. The other end of the air chamber is connected to one end of the bellow. The other end of the bellow is connected to the shell and the air inlet flange. A heat-insulating pipe connected to the air inlet flange is set within the bellow. Since the main board at the other side of the cooling core assembly is flexibly connected to the shell via the air chamber and the bellow, the axial deformation generated in the flat pipe unit can be transferred to and absorbed by the bellow through the air chamber and thus the axial heat stress generated from the heat deformation of the flat pipe unit is eliminated.

Owner:ZHEJIANG YINLUN MACHINERY

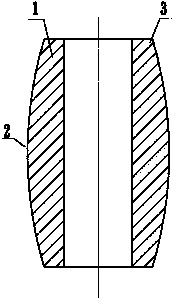

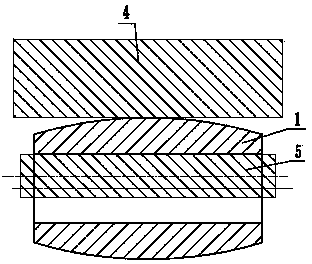

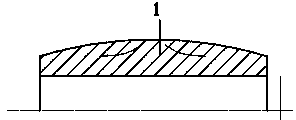

Rolling forming method of aluminum alloy high-tube thin-wall rings

ActiveCN104191166ASolve the assignment puzzleIncrease contact areaMetal rollingPunchingMaterials science

The invention discloses a rolling forming method of aluminum alloy high-tube thin-wall rings. The rolling forming method sequentially comprises the steps of upsetting of deformation aluminum alloy bars, punching, pre-rolling of ring blanks and final rolling of the rings, wherein after punching and before pre-rolling of the ring blanks, the steps of mandrel supporter broaching and end surface flattening are carried out on the punched ring blanks A (1). The rolling forming method has the advantages that the procedures of mandrel supporter broaching and end surface flattening are additionally carried out, the fillet size R of the punched ring blanks is decreased to be smaller than 15 mm, and therefore the distribution problem of axial deformation materials of the rings is solved; after the procedure of mandrel supporter broaching, bulging of the ring blanks is greatly reduced, the end surfaces are thickened, the contact area between the ring blanks and a home roll is increased in the external diameter direction, and unstability caused when rolling is directly carried out after punching of the ring blanks is greatly reduced.

Owner:GUIZHOU AVIATION TECHN DEV

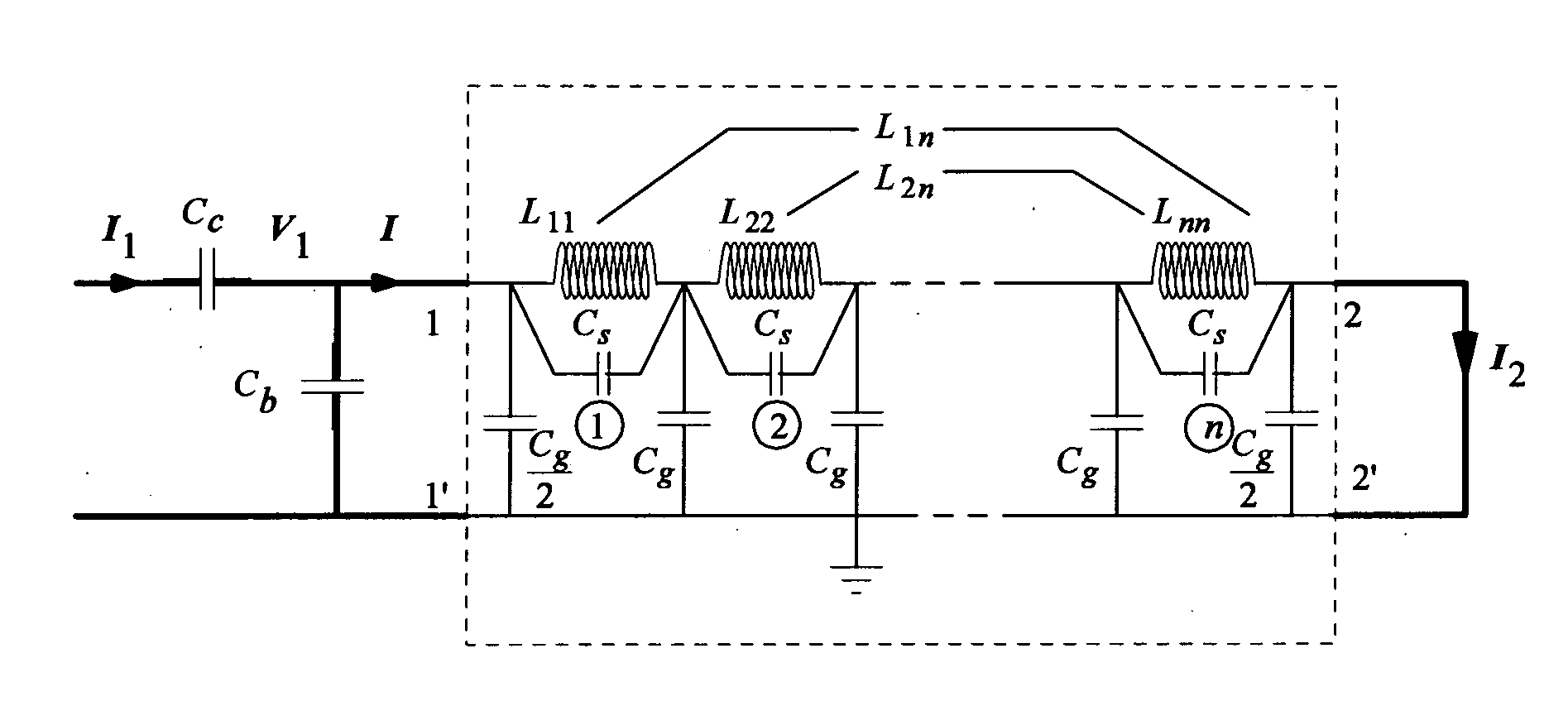

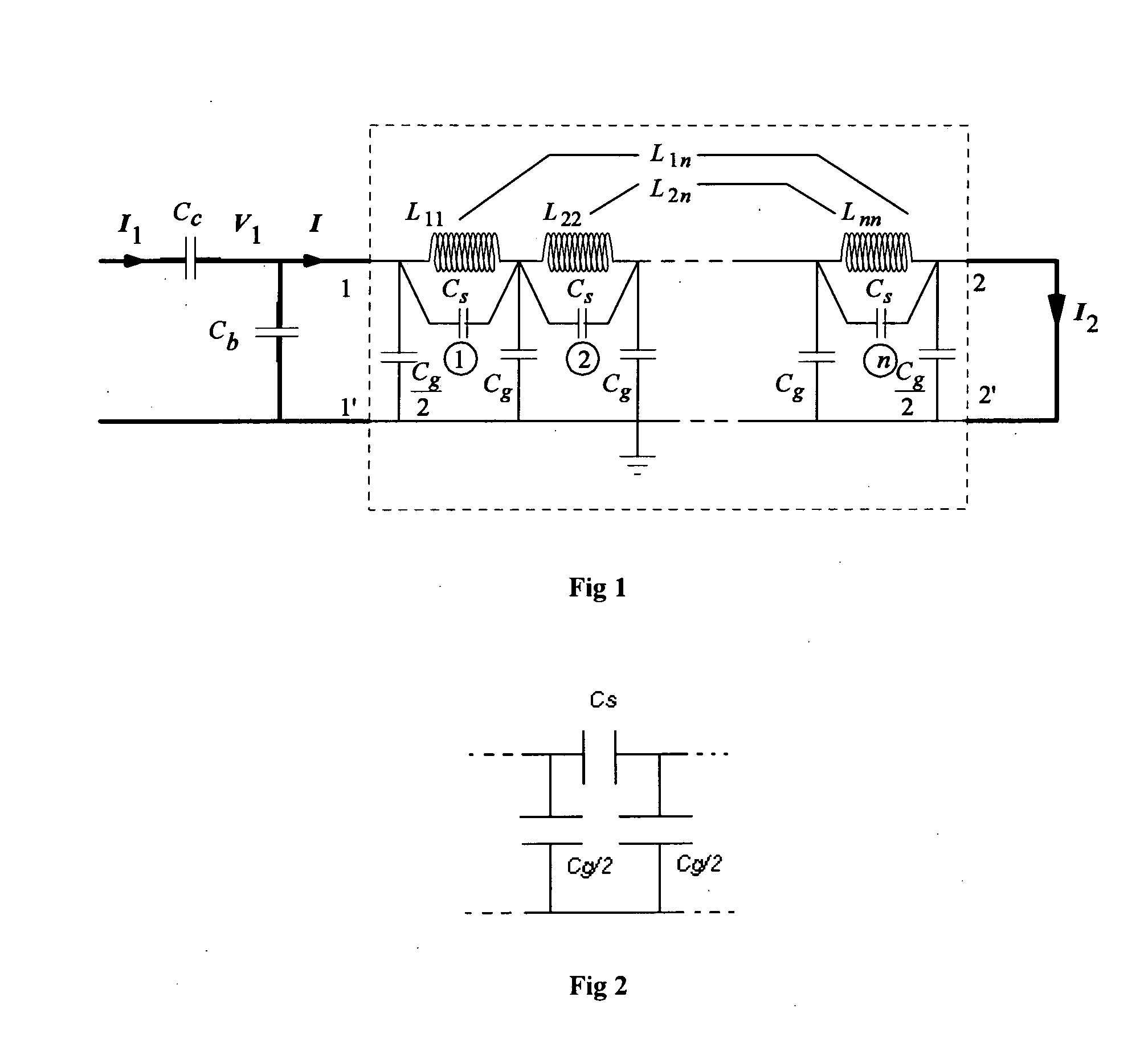

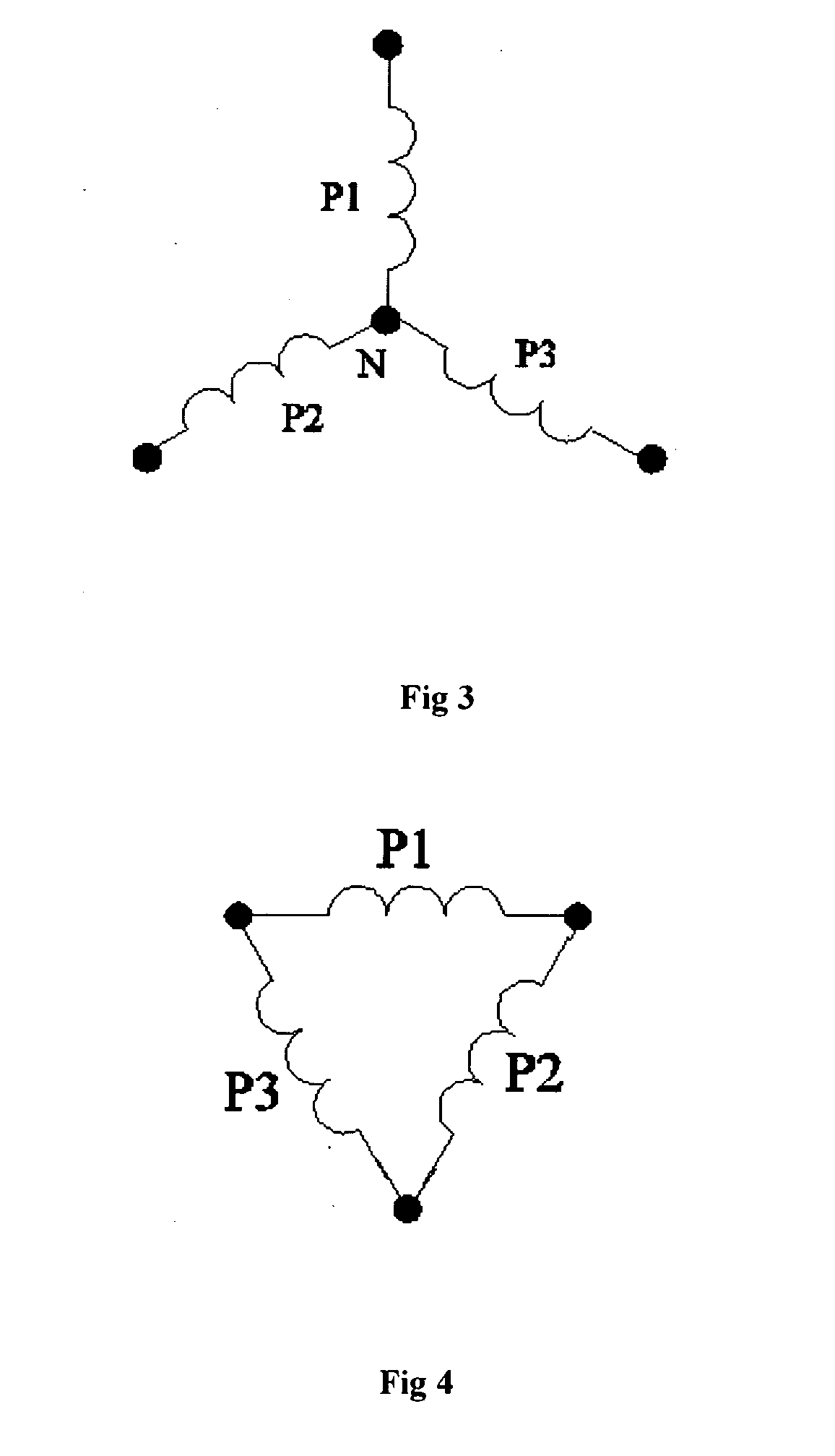

On-line diagnostic method for health monitoring of a transformer

InactiveUS20120130663A1Accurate and reliable processEfficiently determinedResistance/reactance/impedenceVoltage-current phase angleCapacitanceThree-phase

An on-line diagnostic method for health monitoring of a transformer. In the case of a single phase or three phase star connected transformer deformations in the winding are determined byrepresenting the transformer winding as a lumped parameter circuit and dividing the winding into at least two sections. A first set of fingerprint values are generated to determine the location of the deformed section of the winding and the type of deformation. A second set of finger print values are generated to determine the extent of deformation of the deformed section. The location and extent of radial or axial deformation or combination of both radial and axial deformation in the winding are then determined. The change in the capacitance of the bushing of the transformer connected at the line end of the winding is also determined. The state of the insulation system of the transformer is determined by detecting partial discharge pulses in the transformer winding. The change in the dielectric characteristics of the insulation system of the transformer is detected on the basis of phase angle difference.

Owner:INDIAN INSTITUTE OF TECHNOLOGY BOMBAY

Nut seal assembly for coaxial cable system components

ActiveUS20050176296A1Engagement/disengagement of coupling partsElectrically conductive connectionsCoaxial cableEngineering

An integrated seal assembly and a coaxial cable system component incorporating the seal assembly with a connector for coupling to an externally threaded port. The seal assembly includes a bellows-type seal having an elastically deformable tubular body and a plurality of sealing surfaces, and an integral joint-section intermediate an anterior end and a posterior end that assists in the axial deformation of the seal in response to axially-directed force. One of the sealing surfaces is made to engage a corresponding surface of an internally threaded nut or housing. The component is engagable with an externally threaded port via the internally threaded connector. The anterior end of the seal fits over the port and a sealing surface of the seal is capable of sealing axially against a shoulder of the port while the seal body covers the otherwise exposed externally threaded port. Upon tightening of the nut on the port, the seal deflects in the axial direction to accommodate a variety of distances between the connector and the shoulder of the port. Additionally, the seal is capable of expanding to allow a second sealing surface to contact and seal against a variety of smooth outside diameters of the port. The versatility of the seal allows an operator to use one connector of a system component on a wide variety of externally threaded ports without the risk of a faulty seal at the connection or a poor connection due to an improper seal.

Owner:PPC BROADBAND INC

Fiber compressive and flexural property measuring method and device

The invention is a method and device for measuring fiber compression flexural performance, refers to the measurement for cotton, fur, silk, hemp and chemical fiber, and other high performance fiber or fiber type material. The invention includes a force-shift measuring mechanism made up of high precision micro force sensor, multifunctional upper grip holder and the subjacent holder which can move in parallel and vertically, it can acquire the head end stress of fiber and fiber axial deformation data and simulate the puncture effect of human skin. The invention uses optical system to realize the synchronization, changes the deformation under pressure of fiber axial into digital image to be processed, acquires the fiber fineness, holding length, flexibility and curvature of each point and shift, and controls the measured parameter through the computer real-time collected data, measures the real-time pressure, flexibility, fiber bending shape and so on deformation curve and relative character parameter through theory model and algorithm software. It especially applies to axial compressing and bending performance measurement of convex fiber with diameter of 5-200ª–m and length of 1-25mm, and the stretching measurement of fiber with length of 0-150mm.

Owner:DONGHUA UNIV

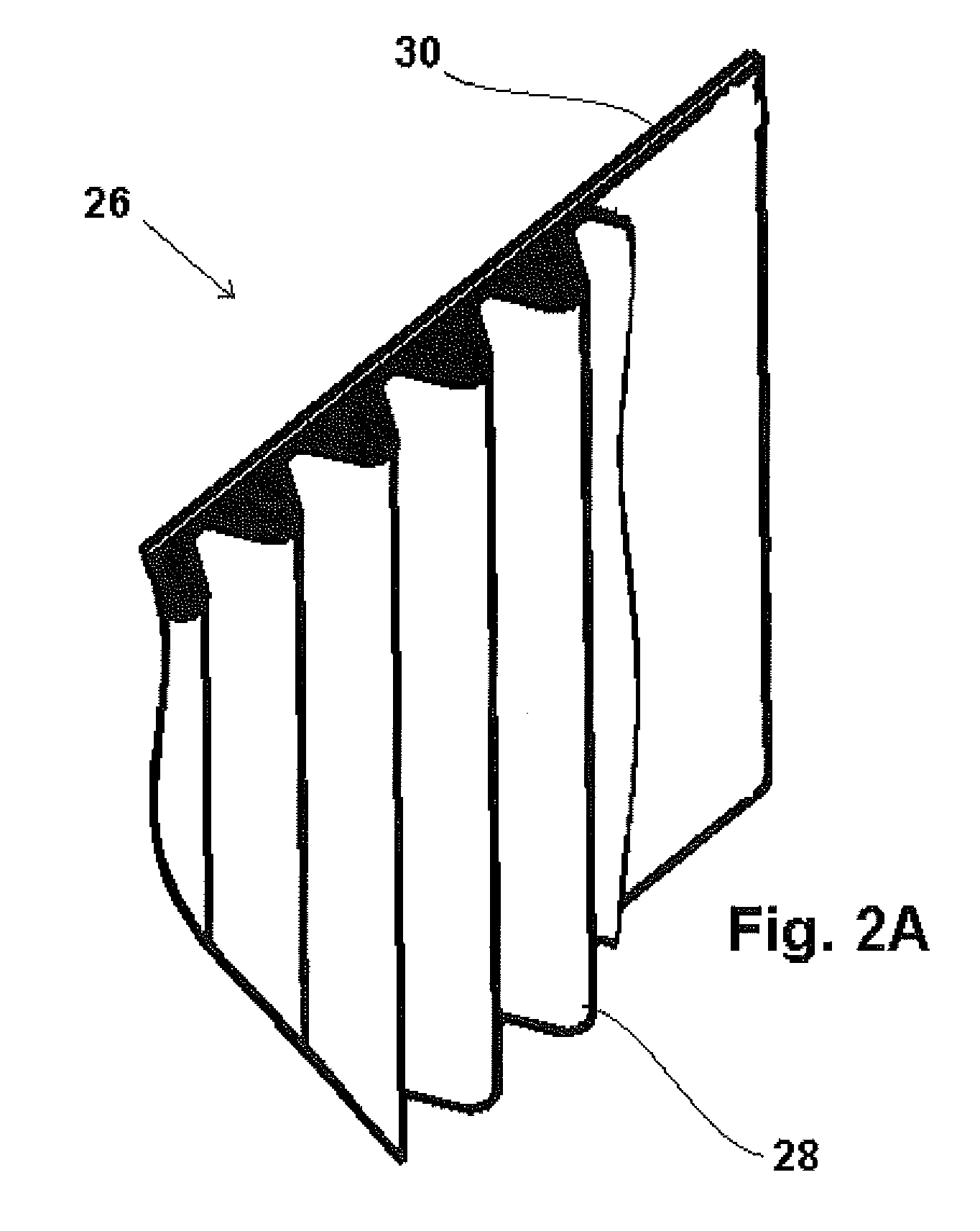

Reinforced filter element

The present invention provides one or more reinforcing members configured to act together with the adhesive bonding between filter media layers to further resist axial deformation forces such as induced by fluid flowing through the filter and thereby acting to retain the structural form and integrity of the filter element. Also disclosed is a method of reinforcing layers of a multilayer axial filter element against displacement of the layers.

Owner:MANN HUMMEL GMBH

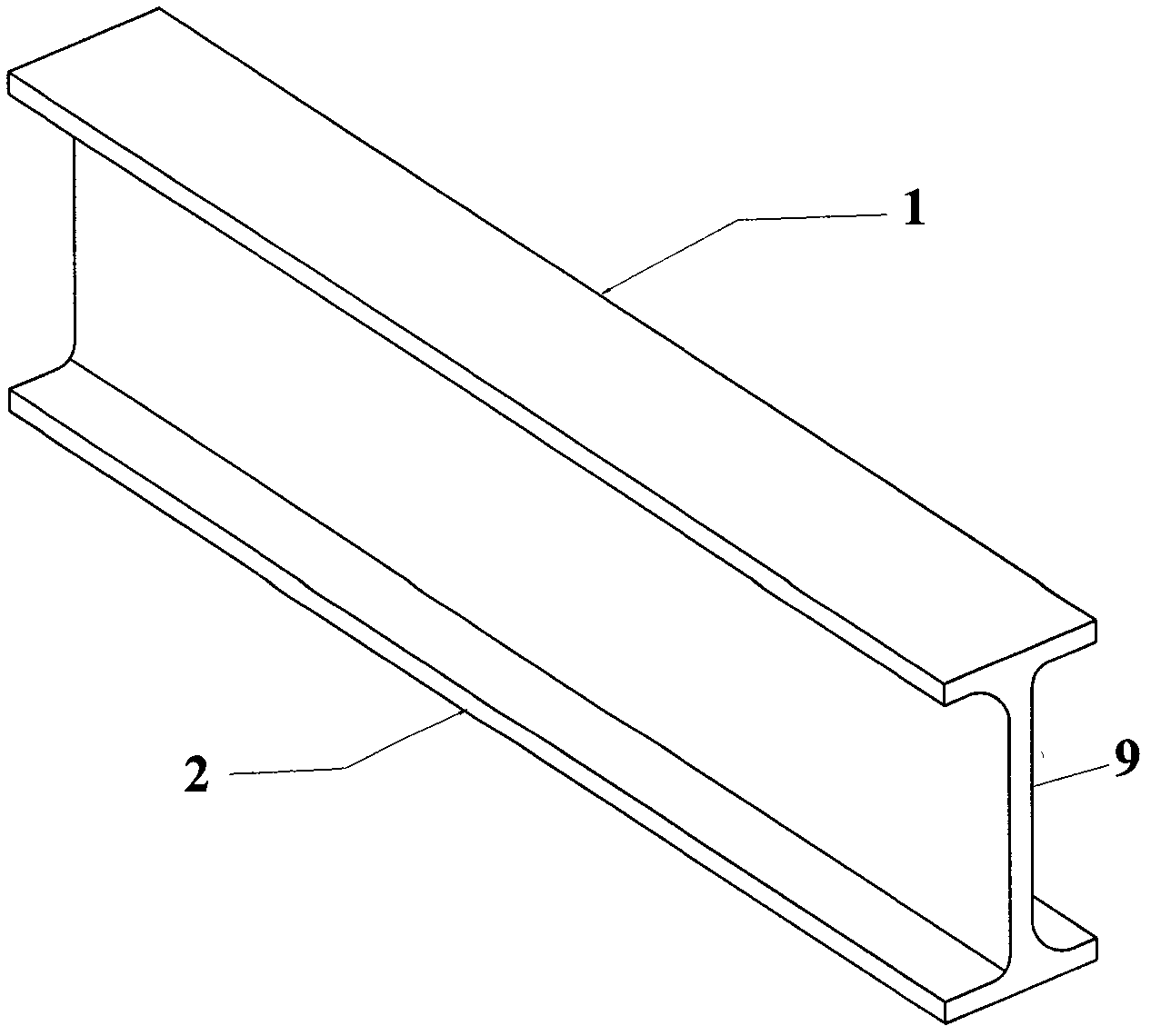

Closed metal support structure and construction method thereof

ActiveCN102505946AImprove efficiencyIncreased shear capacityUnderground chambersTunnel liningEngineeringRock tunnel

The invention relates to a closed metal support structure with an I-shaped section member of corrugated steel web plates. The I-shaped section member of the corrugated steel web plates comprises a top flange, a bottom flange and the corrugated steel web plates, wherein the corrugated steel web plates are welded with the top flange and the bottom flange. After each section of member is bent to be of a required shape of the support, the corrugated web plates are welded by an end plate, and the top flange and the lower flange are connected with a perforated cover board by bolts. According to the invention, after the corrugated steel web plates are connected by the end plate, the deformation of an axis of the support is generated; on the other hand, when the flanges bear an axial force, the axial deformation of the supported is adapted through adjusting the position of an adjusting screw in the hole, and the telescopic node connection manner is well adaptive to large deformation of soft rock. The closed metal support structure provided by the invention has the advantages of simple manufacturing and processing of the end plate and the cover board, convenience for installation, economy and reasonability, and capability of remarkably improving the comprehensive benefit. The closed metal support structure and the construction method thereof can be applied to the technical field of soft rock tunnel support.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

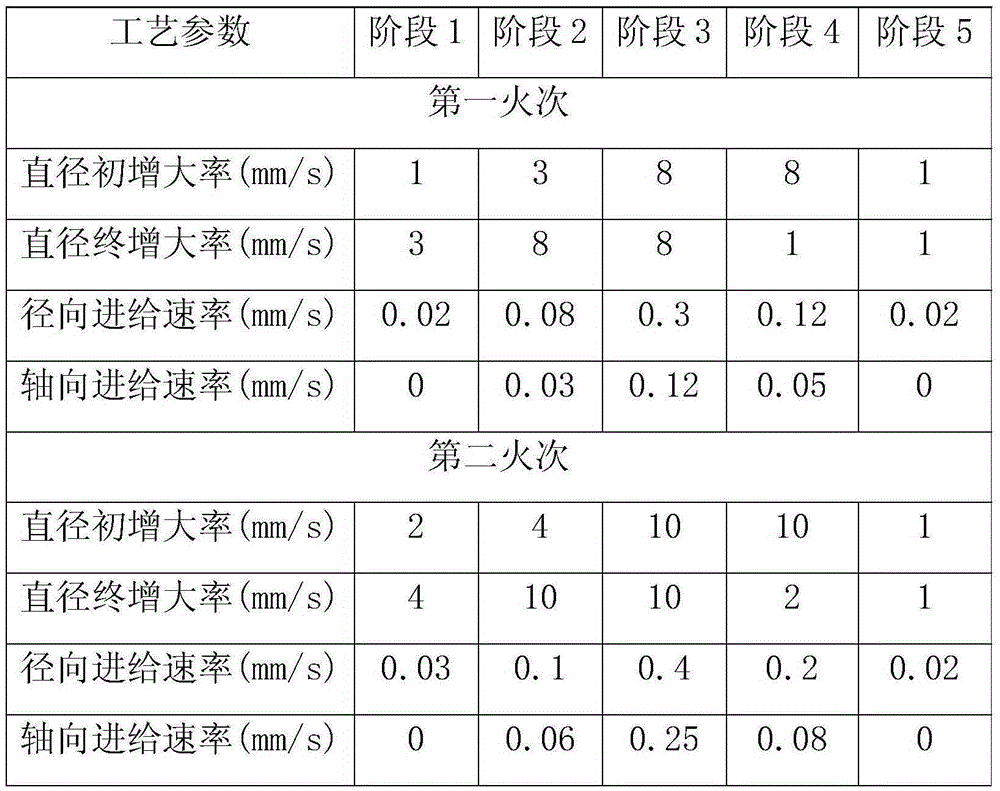

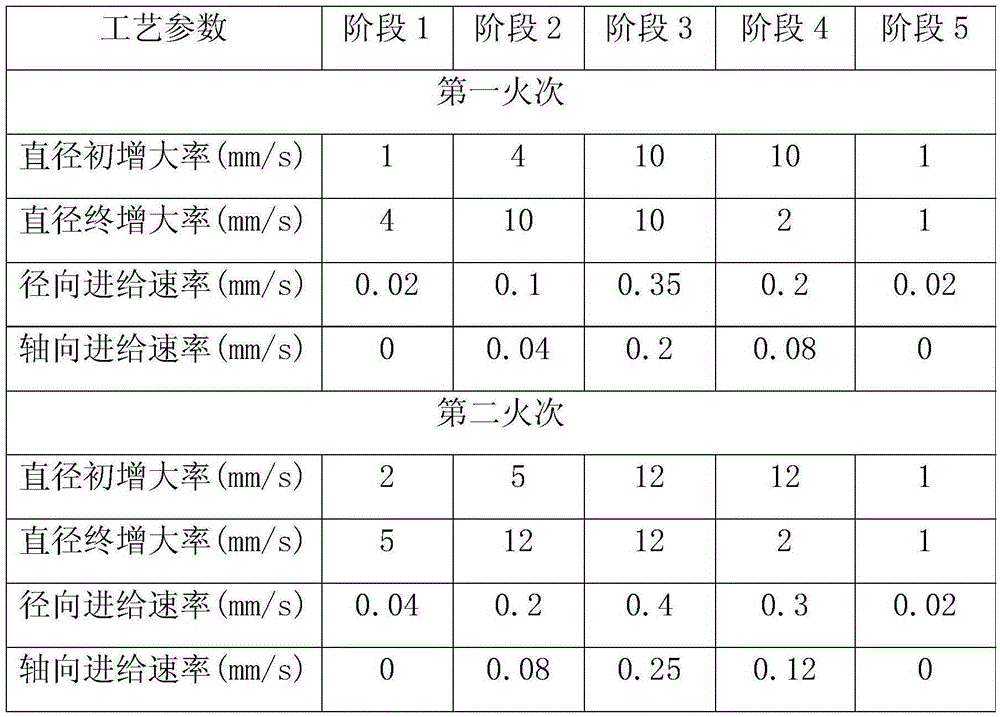

Rolling production method for integral aluminum alloy ring of super-large diameter

The invention belongs to the technical field of ring rolling forming and particularly relates to a rolling production method for an integral aluminum alloy ring of the super-large diameter. According to the technical scheme of the invention, a ring rolling forming technology is adopted, and through control over the rolling deformation temperature, the diameter increasement rate, the radial and axial feed rates, the radial and axial rolling reductions, the rolling ratio, the core roller diameter and the ring rolling heating number of an aluminum alloy ring piece of the super-large specification, the stable and continuous rolling process of the integral aluminum alloy ring of the super-large diameter is achieved, the size precision, the ovality and the radial and axial deformation quantities of the ring piece are effectively controlled, the product quality consistency is improved, the product percent of pass is increased, and technical index requirements of products are met.

Owner:CAPITAL AEROSPACE MACHINERY +1

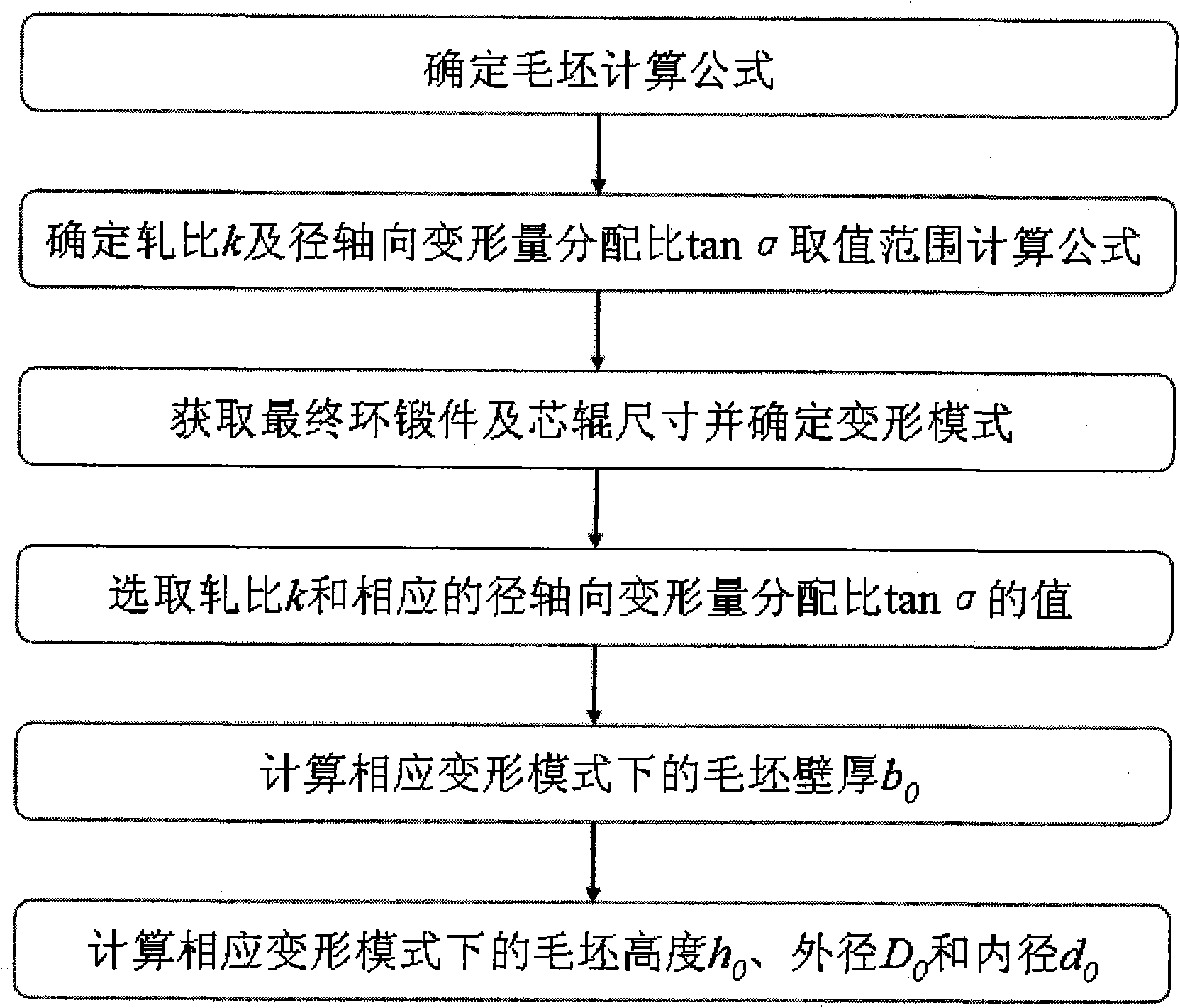

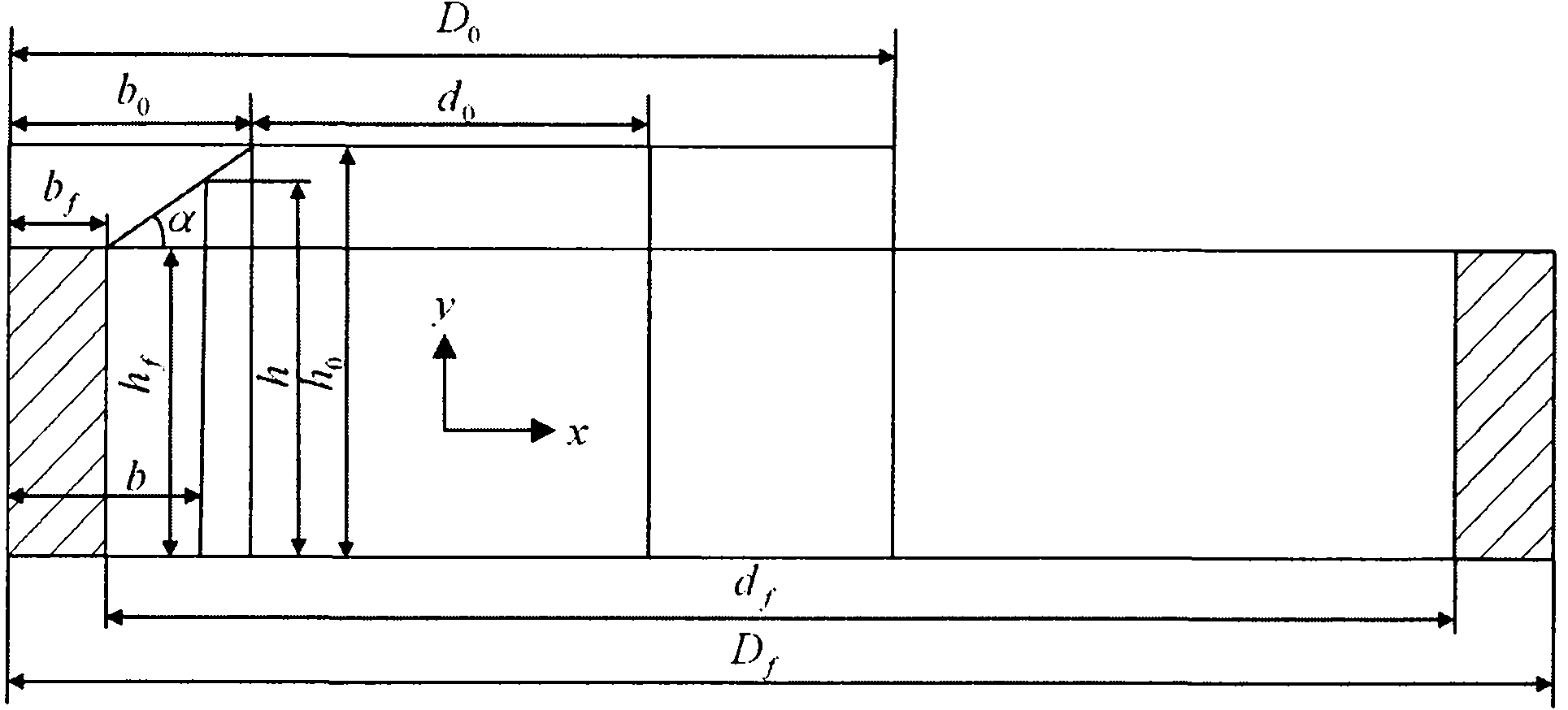

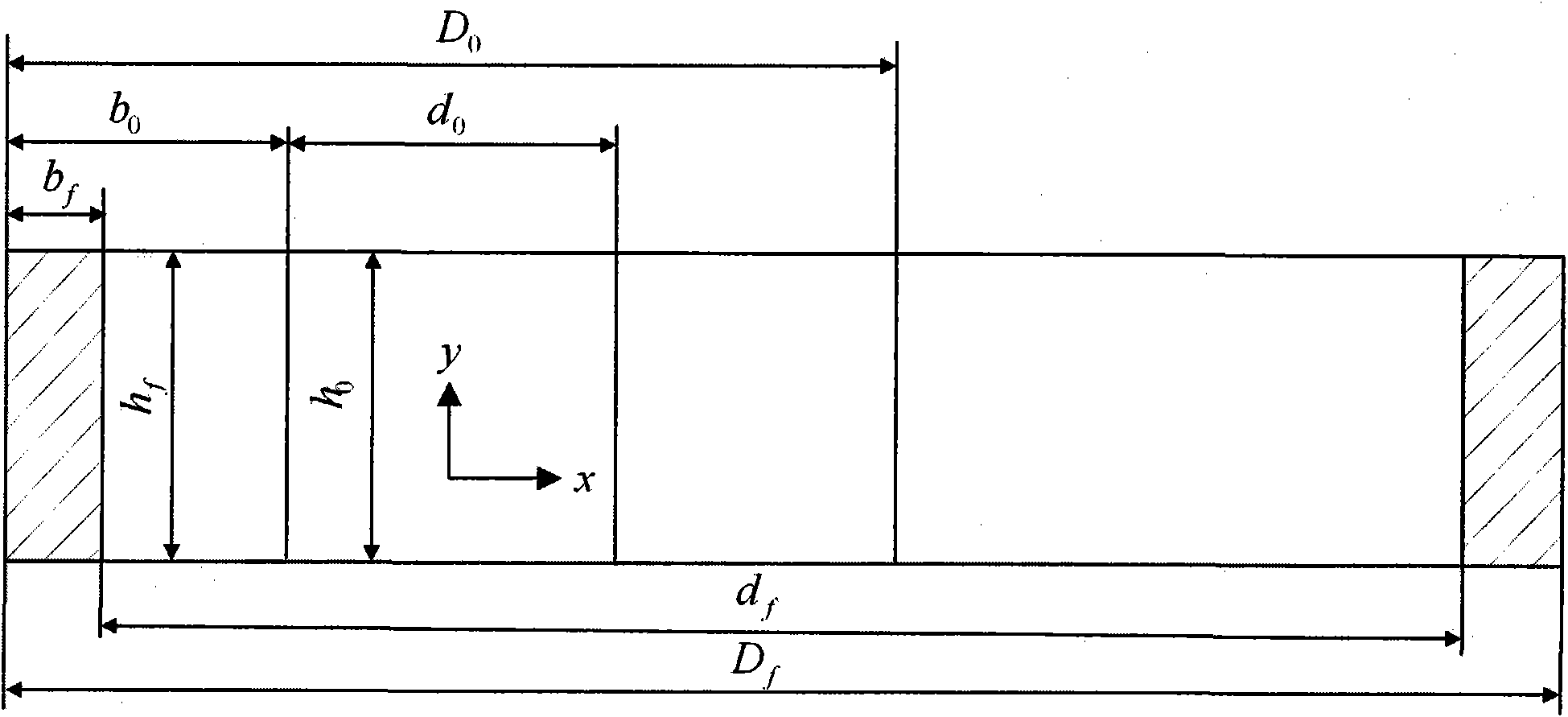

Method for determining dimensions of ring radially-axially rolled blank

InactiveCN101829686AImprove design efficiencyImprove product performanceRoll mill control devicesMetal rolling arrangementsMaterials scienceProduction cycle

The invention discloses a method for determining the dimensions of a ring radially-axially rolled blank, which comprises: firstly, determining a blank dimension calculation formula and the ranges of the values of a rolling ratio k and a radial-axial deformation distribution ratio tana and obtaining the outside diameter Df, inside diameter df, height hf and wall thickness bf of a ring forging and the diameter dm of a core roller; secondly, determining the deformation mode for ring radial-axial rolling; thirdly, calculating and determining the ranges of the values of the rolling ratio k and the radial-axial deformation distribution ratio tana according to the obtained dimensions of the ring forging and the core roller and the determined deformation mode; and finally, selecting a value of the rolling ratio k and the value of the corresponding radial-axial deformation distribution ratio tana according to determined ranges of the values and the deformation mode, calculating the wall thickness b0 of the blank in the corresponding deformation mode, and finally obtaining the height h0, outside diameter D0 and inside diameter d0 of the blank in the corresponding deformation mode. In the invention, for the rolling of a certain ring forging, a series of different rolling ratios k and radial-axial deformation distribution ratios tana of the blank can be designed, the design efficiency and product performance of the ring radially-axially rolled blank are improved, the production period is shortened, the production cost is reduced, and an important method and foundation are provided for researches on the optimization design of the rolling processes (including the rolling process of the blank).

Owner:NORTHWESTERN POLYTECHNICAL UNIV

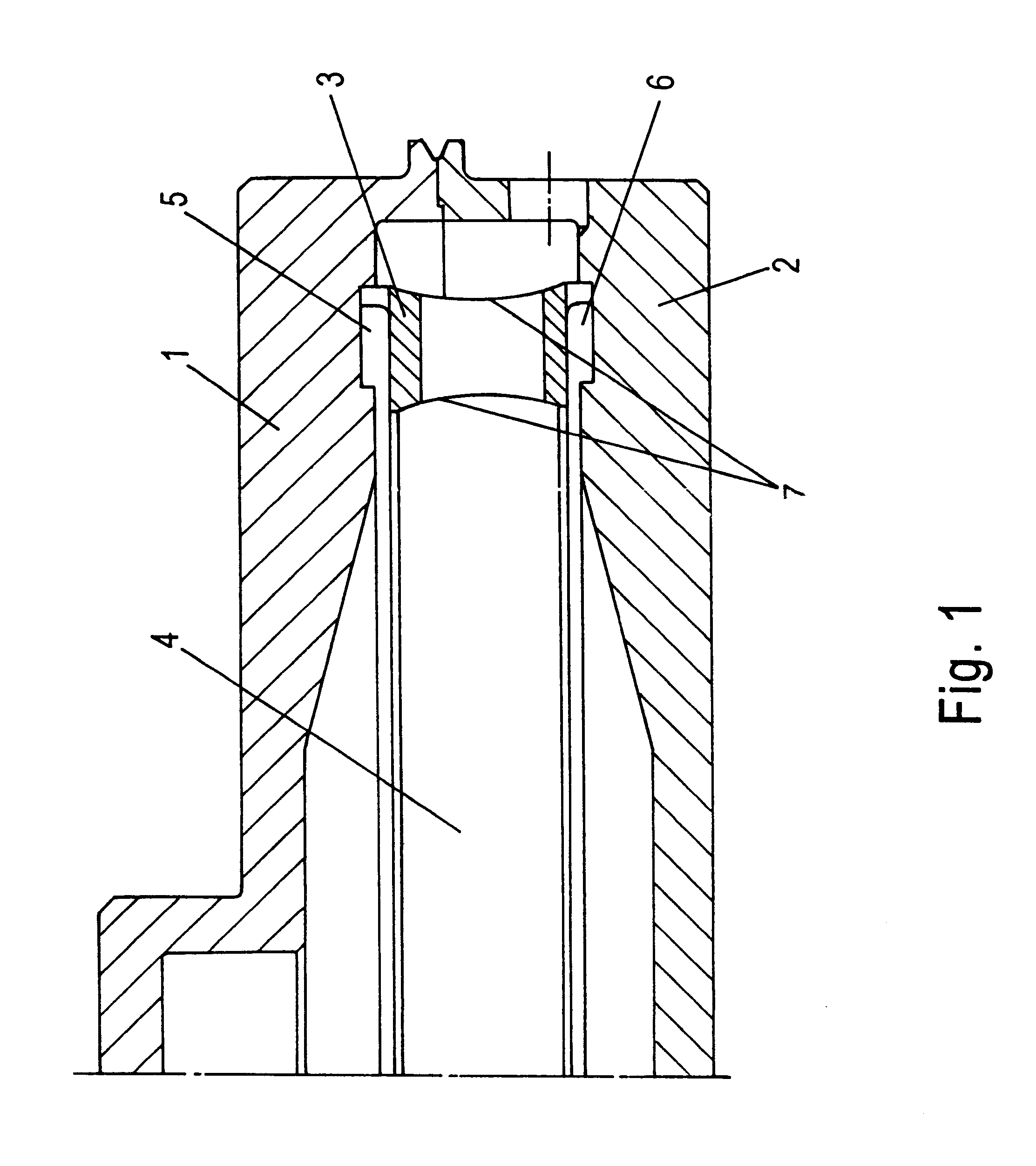

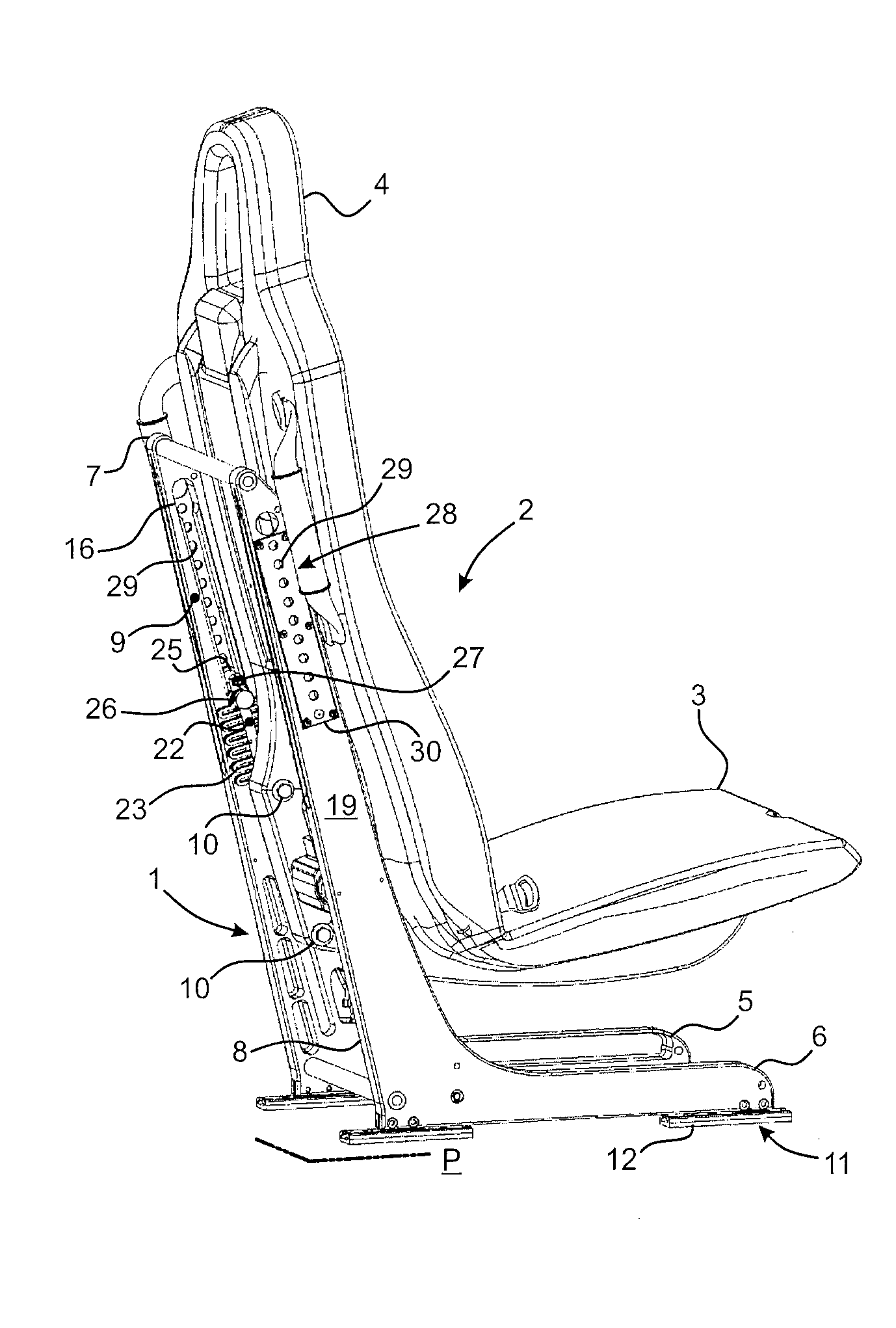

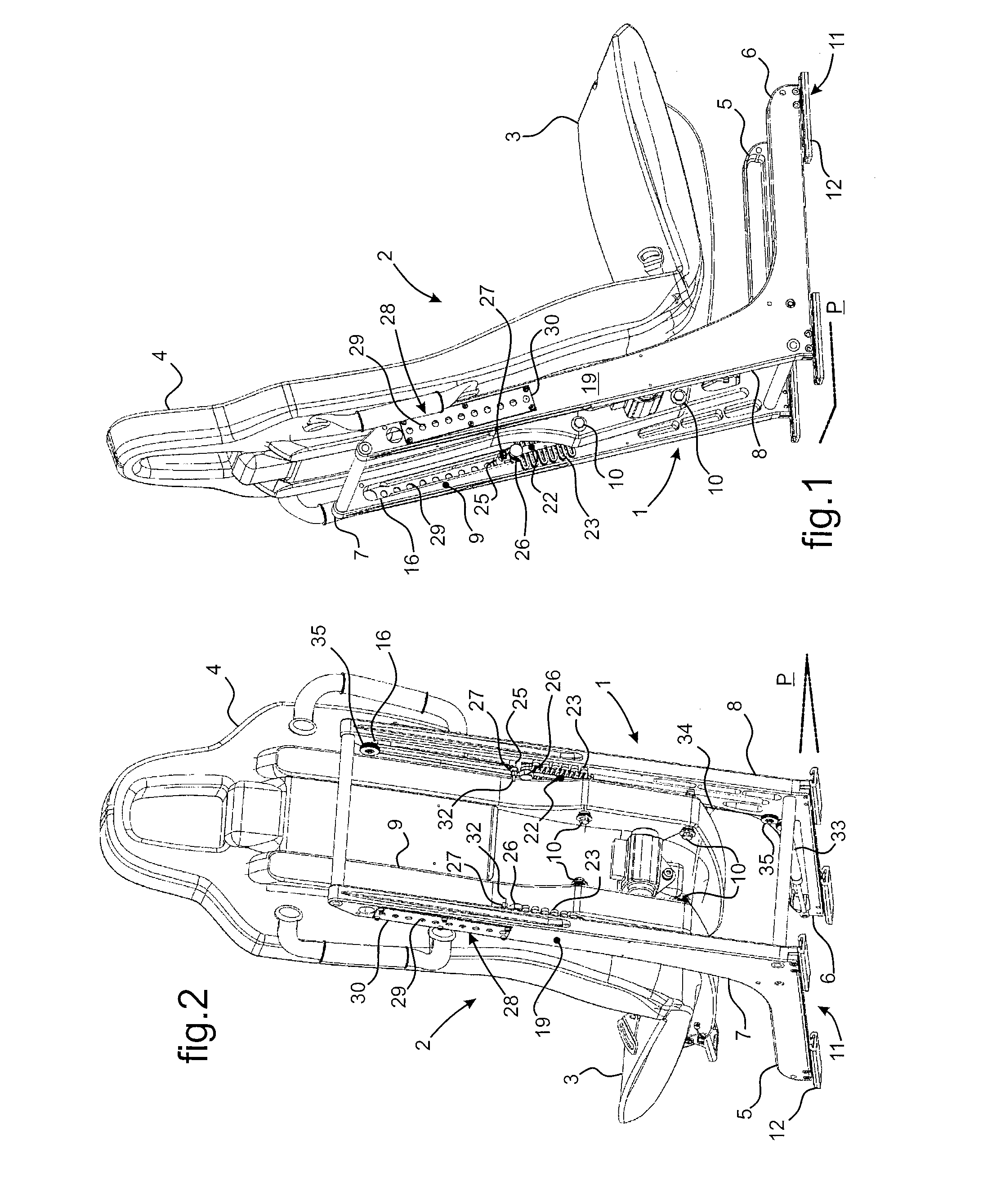

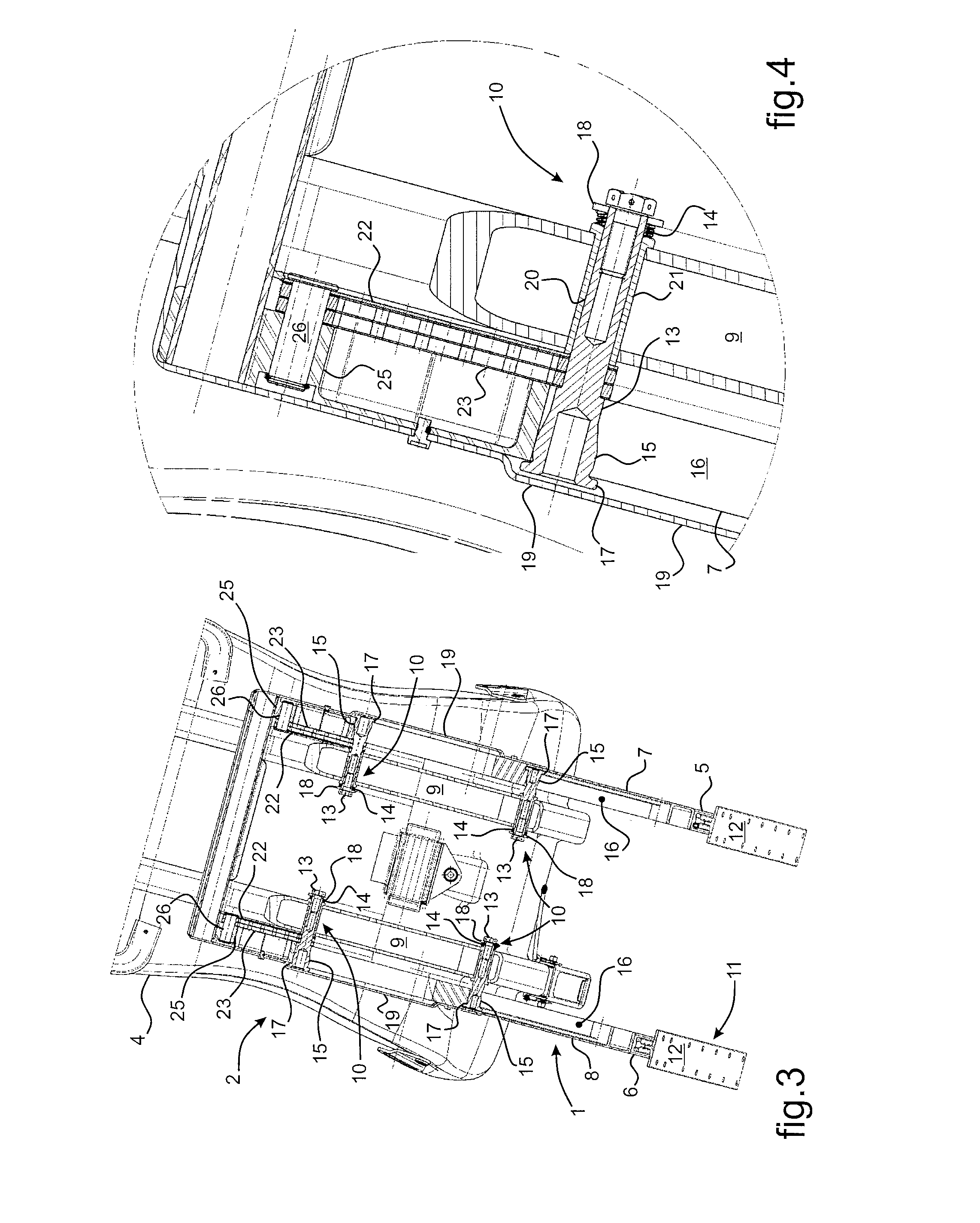

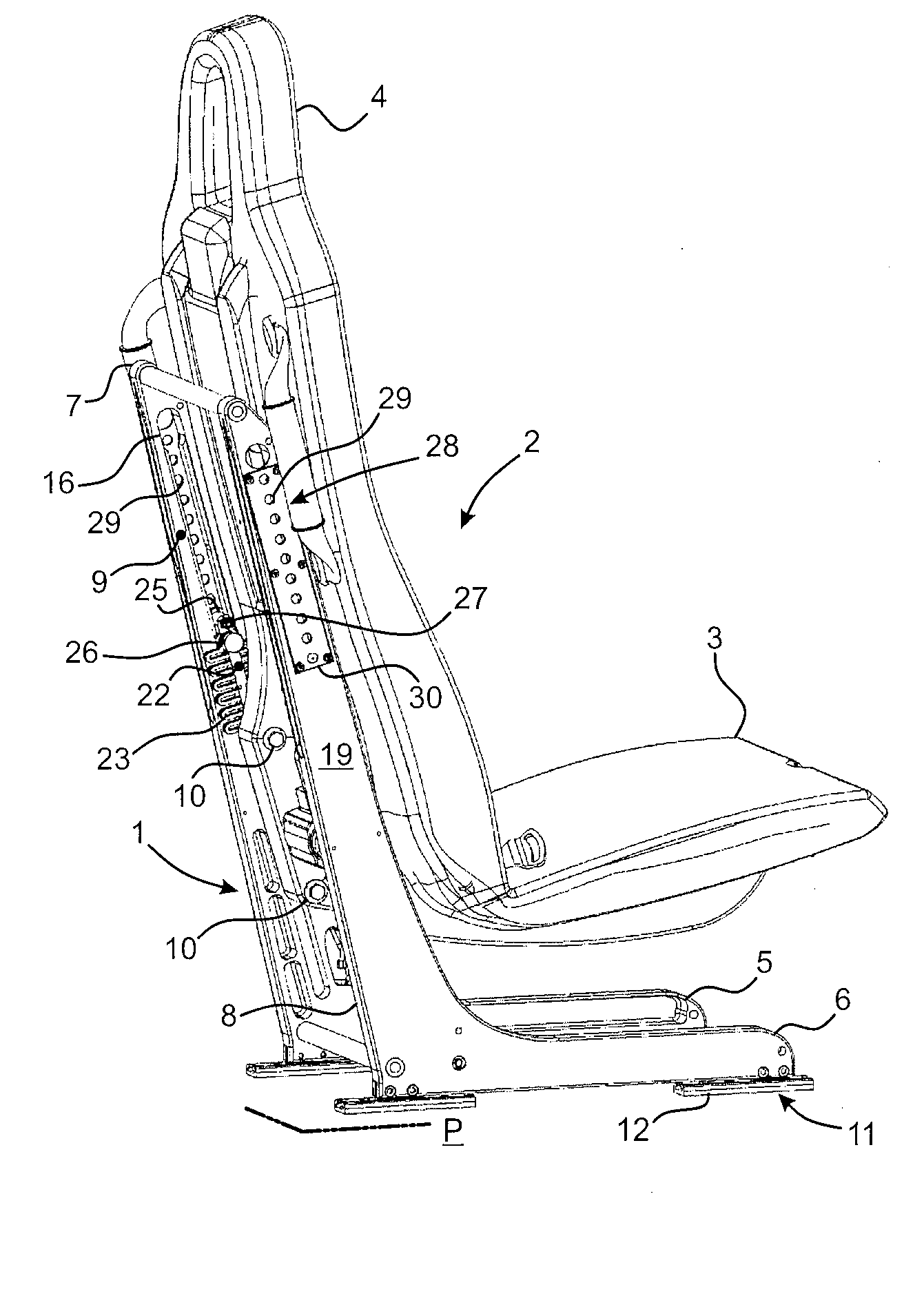

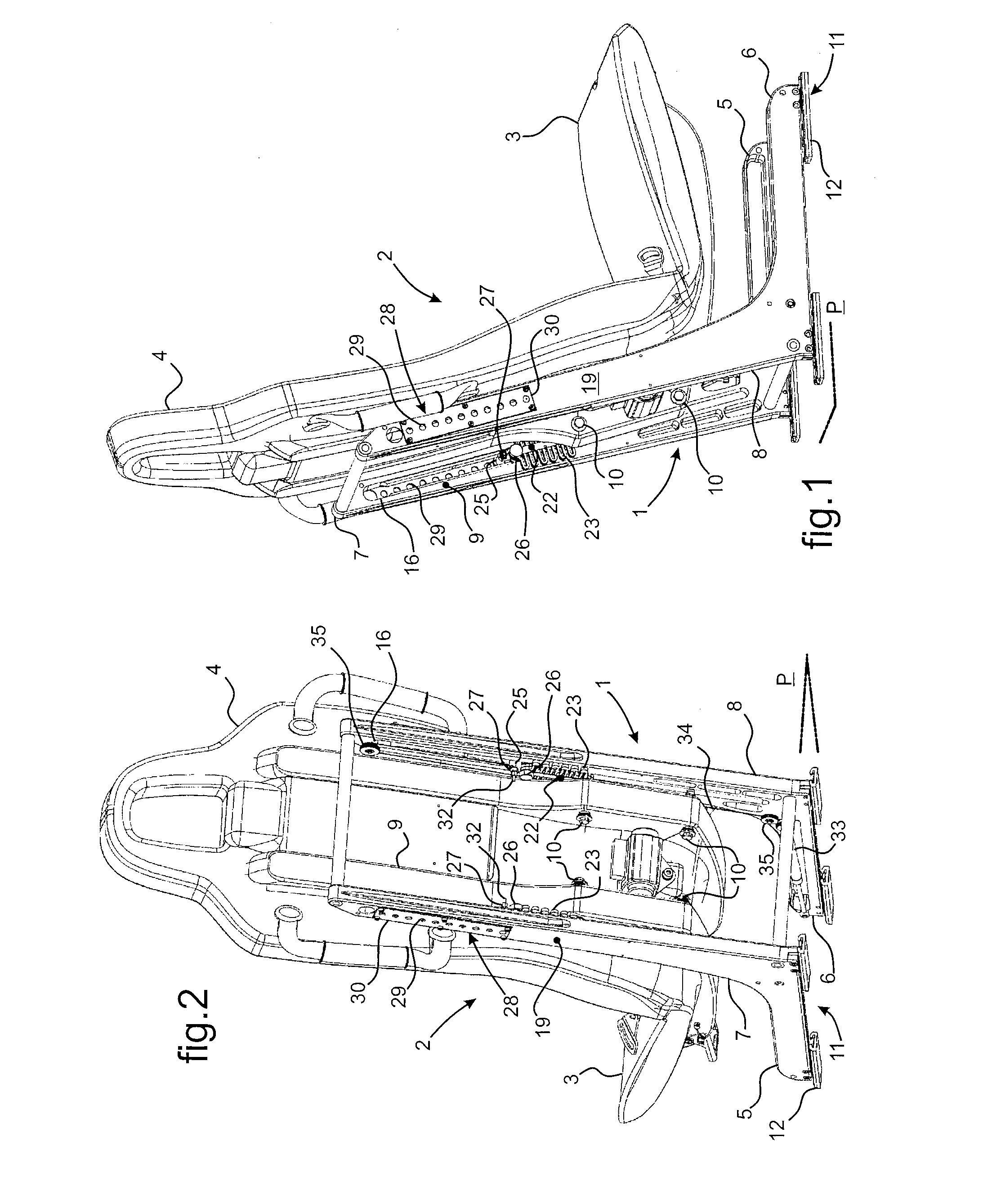

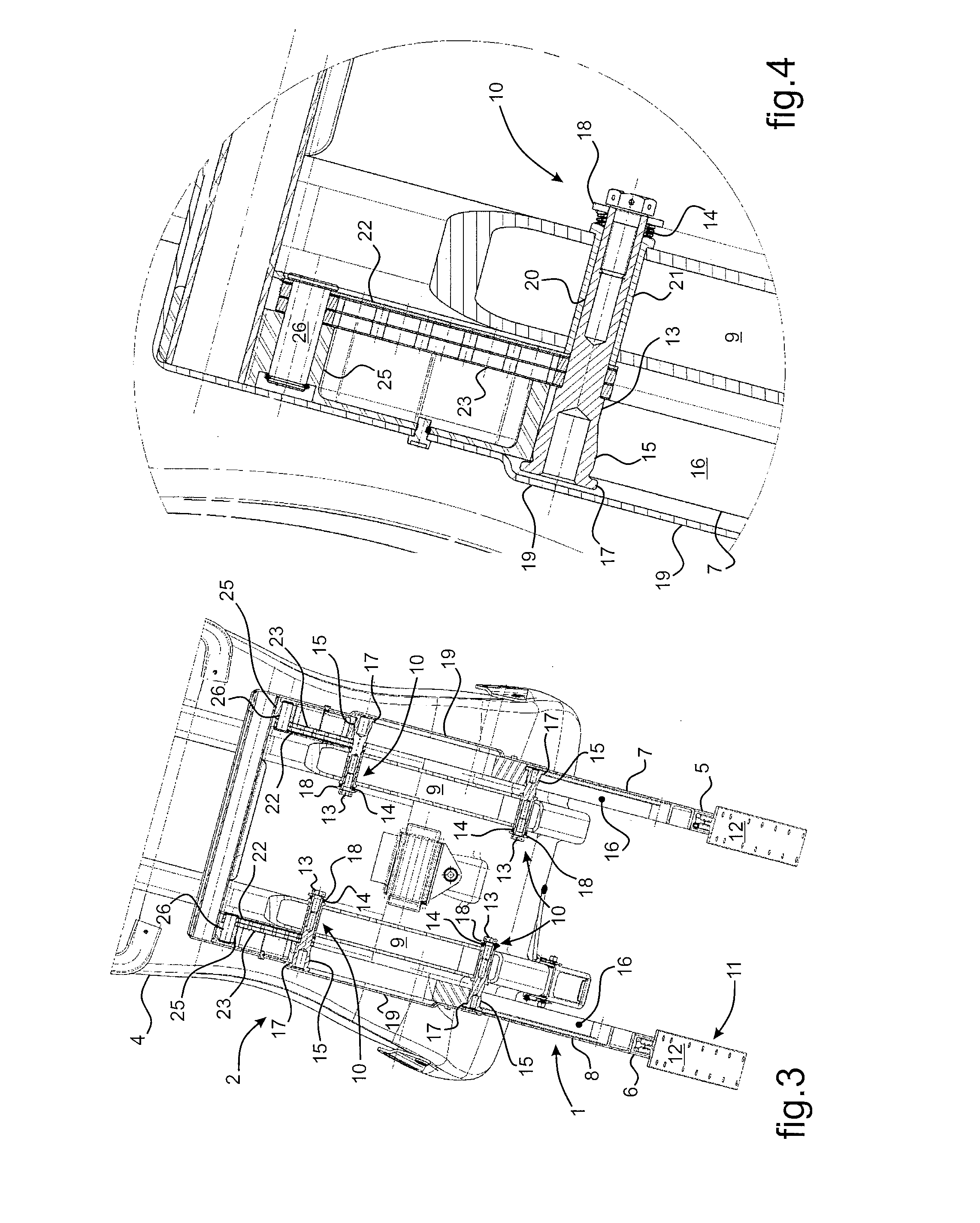

Seat for powered aircraft, the seat incorporating means for protecting its passenger in the event of a crash

ActiveUS8408643B2Convenient ArrangementEasy to implantVehicle seatsSeating arrangementsEngineeringBearing surface

A seat for a powered aircraft, the seat comprising a bucket (2) that is supported in hyperstatic manner on a stand. Leg members (7, 8) carry the bucket (2) via bolts (10). A first hinged mechanism for geometrically compensating deformation of the floor associates a ball-joint mounting of the bolts (10) on the leg members (7, 8) with an axial deformation arrangement of the bolts (10) between opposing axial bearing surfaces where they press against a strength member (9) of the bucket (2) and against the leg members (7, 8). A second energy-absorber mechanism associates fuses (22) with deformable support members (23) for the bucket (2), which members engage the bolts (10) and the leg members (7, 8) via slides (25) arranged to adjust the initial height position of the bucket (2).

Owner:EUROCOPTER

Seat for powered aircraft, the seat incorporating means for protecting its passenger in the event of a crash

ActiveUS20110079681A1Small sizeIncreasing weightSeating arrangementsPedestrian/occupant safety arrangementFlight vehicleEngineering

A seat for a powered aircraft, the seat comprising a bucket (2) that is supported in hyperstatic manner on a stand. Leg members (7, 8) carry the bucket (2) via bolts (10). A first hinged mechanism for geometrically compensating deformation of the floor associates a ball-joint mounting of the bolts (10) on the leg members (7, 8) with an axial deformation arrangement of the bolts (10) between opposing axial bearing surfaces where they press against a strength member (9) of the bucket (2) and against the leg members (7, 8). A second energy-absorber mechanism associates fuses (22) with deformable support members (23) for the bucket (2), which members engage the bolts (10) and the leg members (7, 8) via slides (25) arranged to adjust the initial height position of the bucket (2).

Owner:EUROCOPTER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com