Patents

Literature

328 results about "Ovality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

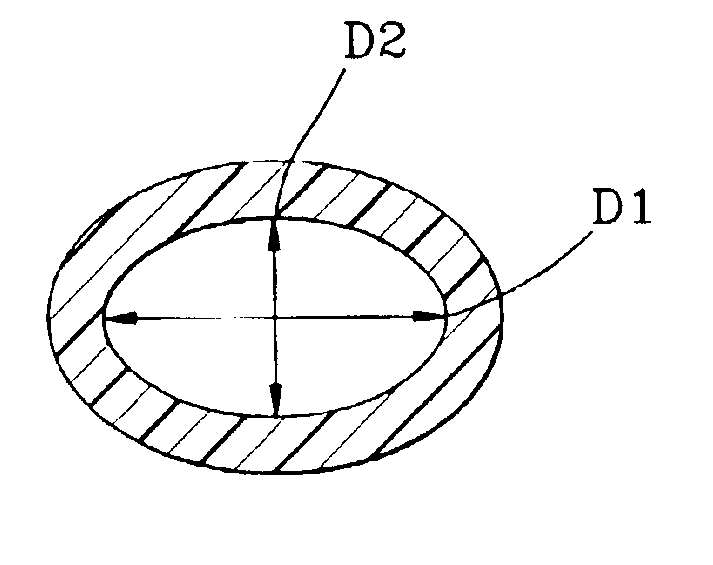

In telecommunications and fiber optics, ovality or noncircularity is the degree of deviation from perfect circularity of the cross section of the core or cladding of the fiber. The cross-sections of the core and cladding are assumed to a first approximation to be elliptical. Quantitatively, the ovality of either the core or cladding is expressed as , where a is the length of the major axis and b is the length of the minor axis. The dimensionless quantity so obtained may be multiplied by 100 to express ovality as a percentage. Alternatively, ovality of the core or cladding may be specified by a tolerance field consisting of two concentric circles, within which the cross section boundaries must lie.

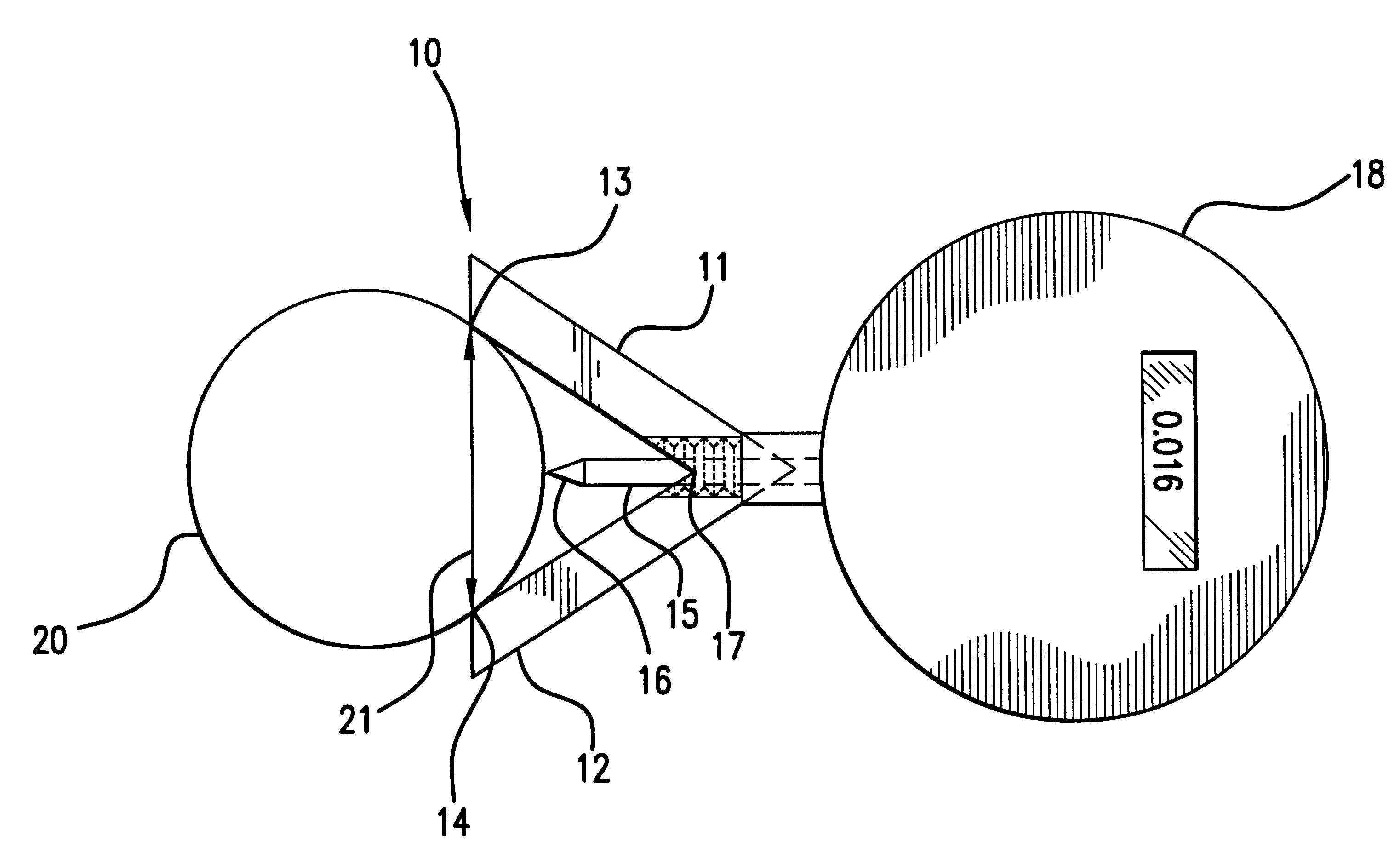

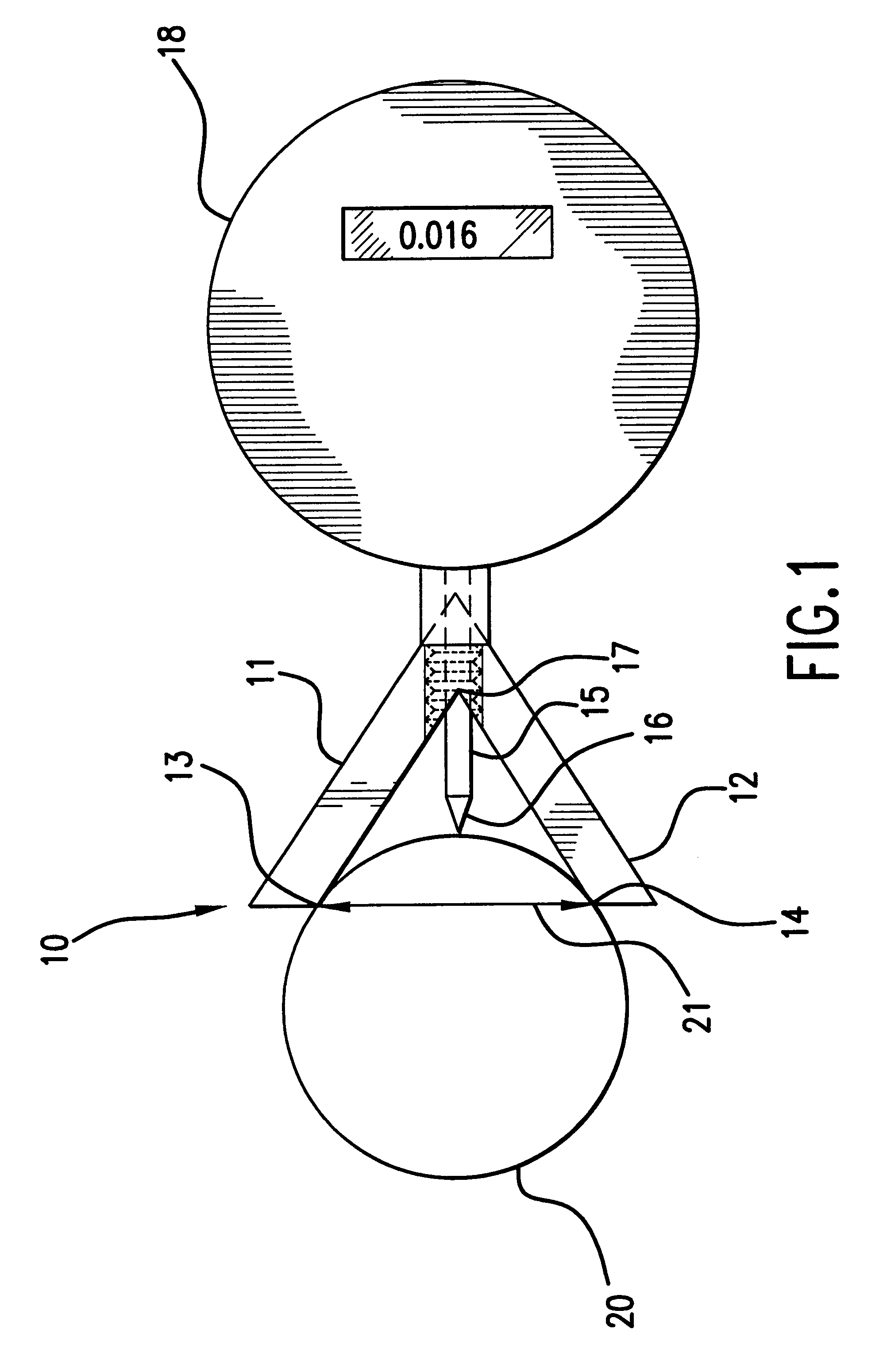

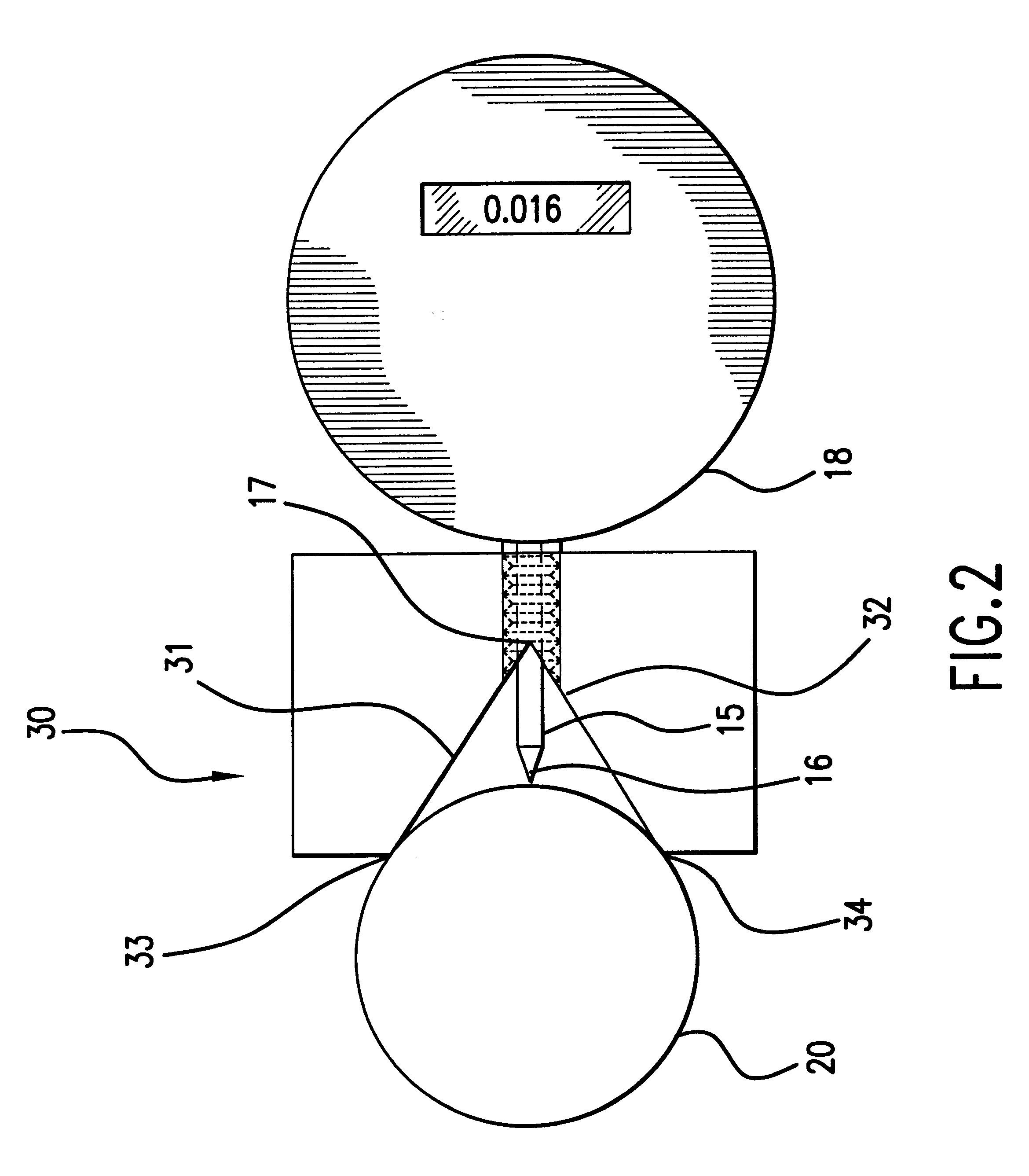

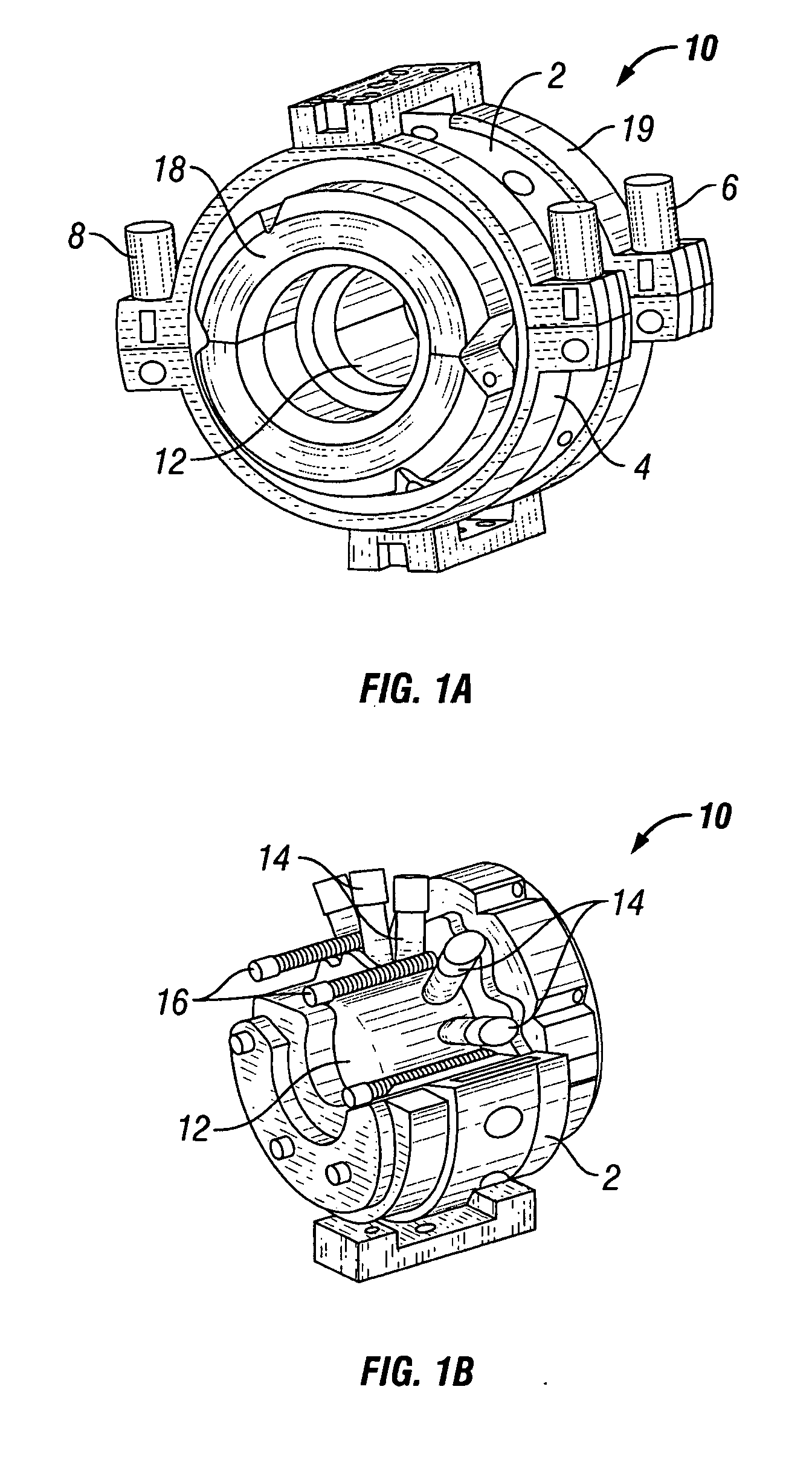

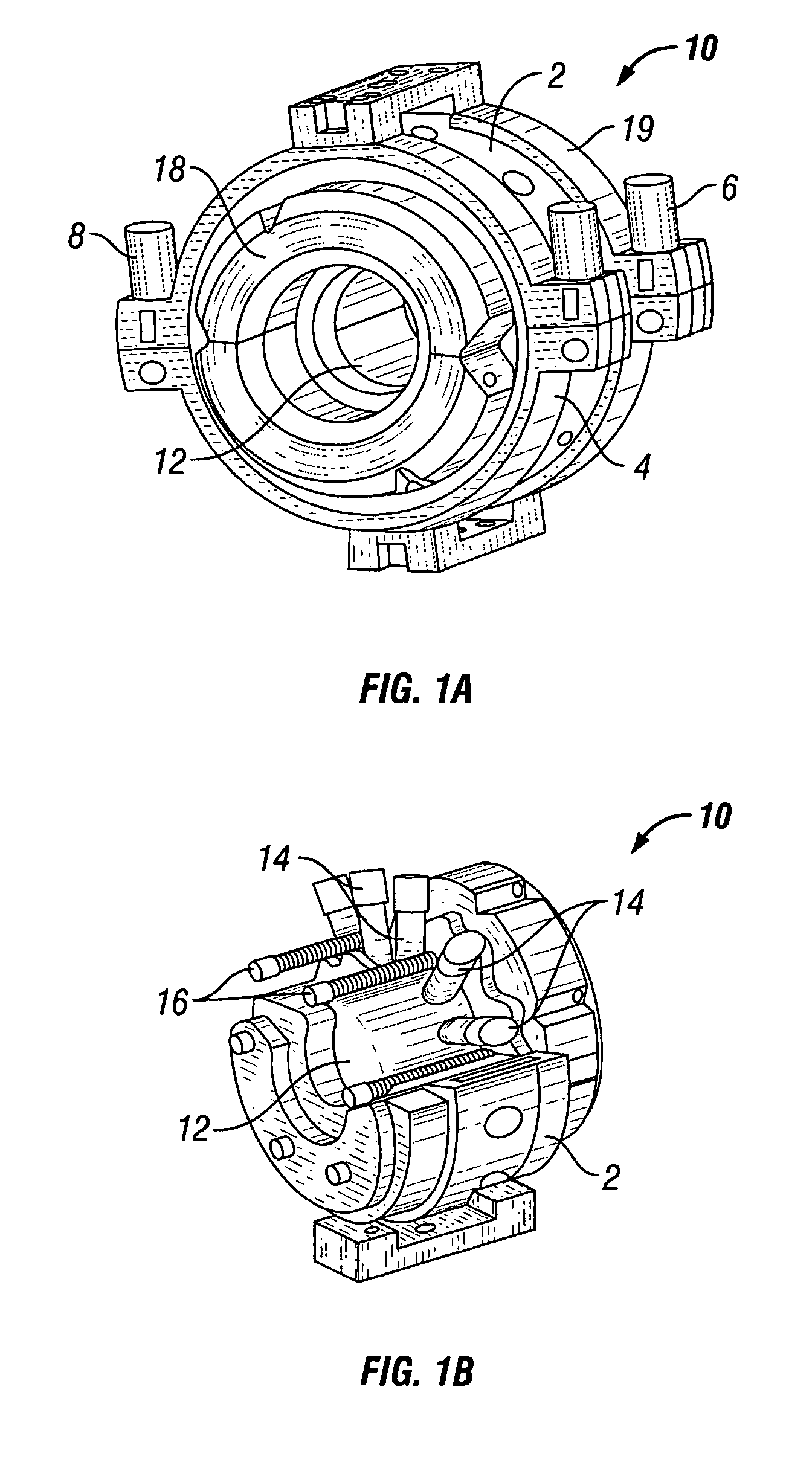

Ovality measurement method and apparatus

InactiveUS6272762B1Mechanical counters/curvatures measurementsElectric/magnetic contours/curvatures measurementsEngineeringOvality

An ovality measurement tool for measurement of ovality of a circumferentially deformable cylindrical element having a cylindrical element support, a sensing element for traversing the circumference of the cylindrical element, which sensing element is movable radially with respect to the cylindrical element, and a readout device for reading the amount of movement of the sensing element as it traverses the circumference of the cylindrical element.

Owner:GAS TECH INST

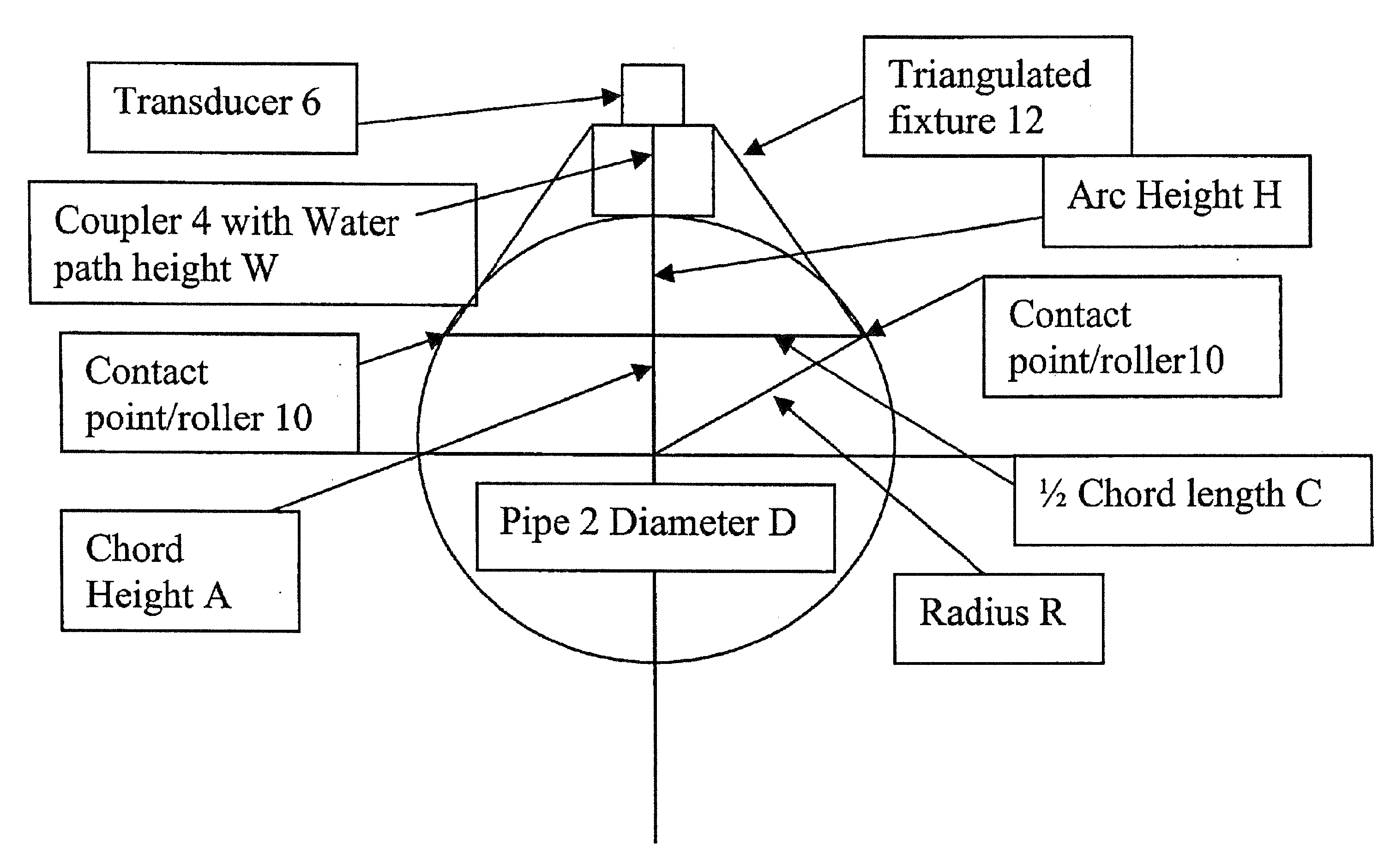

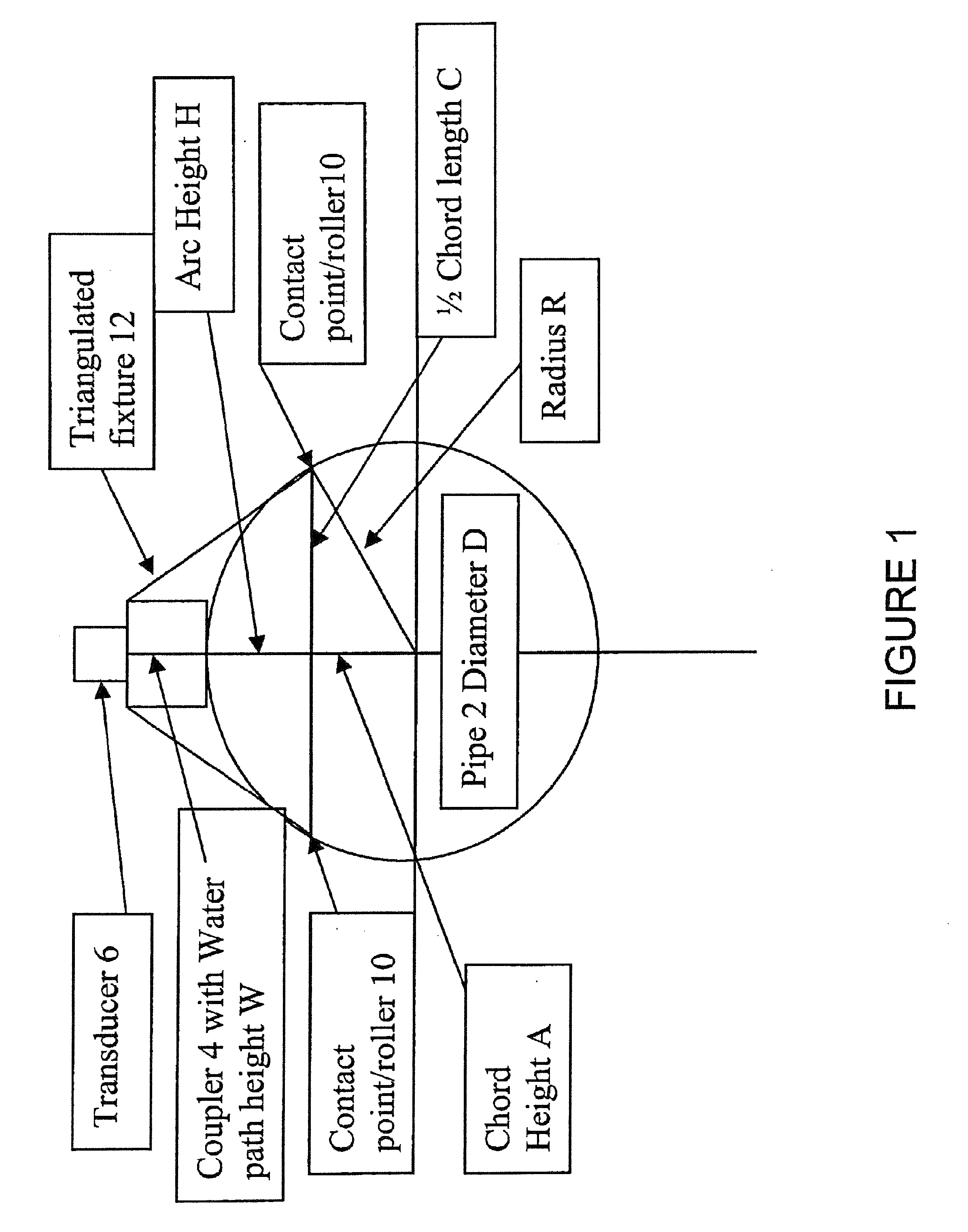

Method and apparatus for measuring wall thickness, ovality of tubular materials

InactiveUS20080071496A1Using subsonic/sonic/ultrasonic vibration meansDigital computer detailsPosition dependentOvality

The wall thickness and ovality of a tubular are simultaneously determined. The theoretical radius of a pipe is computed from a measurement of its circumference. An ultrasonic device conventionally used to measure the wall thickness of tubulars is adapted to also measure the maximum and minimum diameters and ovality by equipping or utilizing existing ultrasound inspection device with contact surfaces which contact the tubular at a fixed distance apart and at a known distance from the surface of the ultrasonic transducer. The contact surfaces define a chord of known length on the tubular under test. The mean radius of the tubular may be computed from multiple water path measurements around the circumference relative to a known fixture. The maximum and minimum diameter and ovality are calculated from the measured differences in distance from the surface of the tubular to the ultrasonic transducer and the theoretical circle. Wall thickness and ovality may be correlated relative to position by using the same apparatus for both measurements.

Owner:CUDD PRESSURE CONTROL

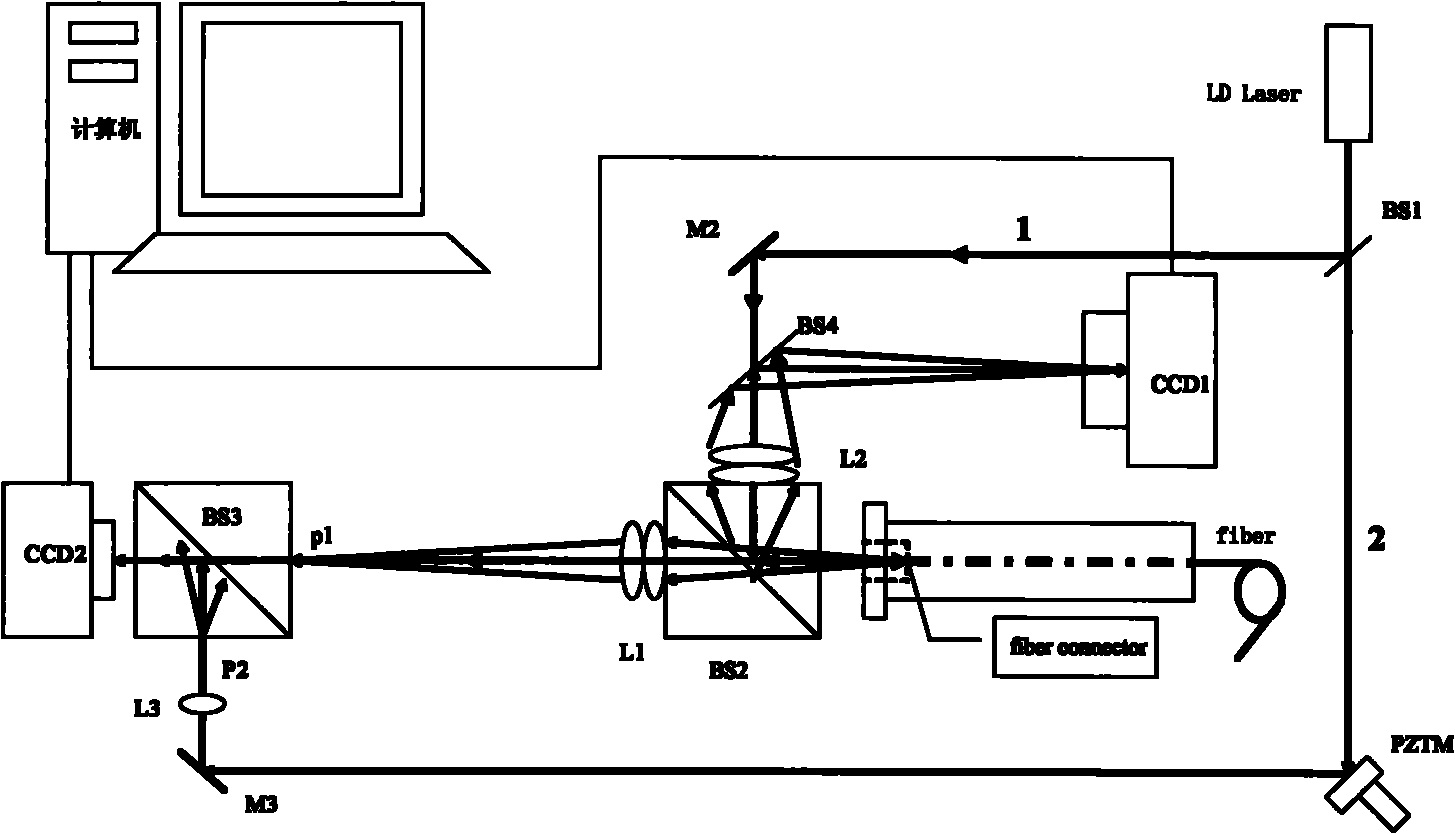

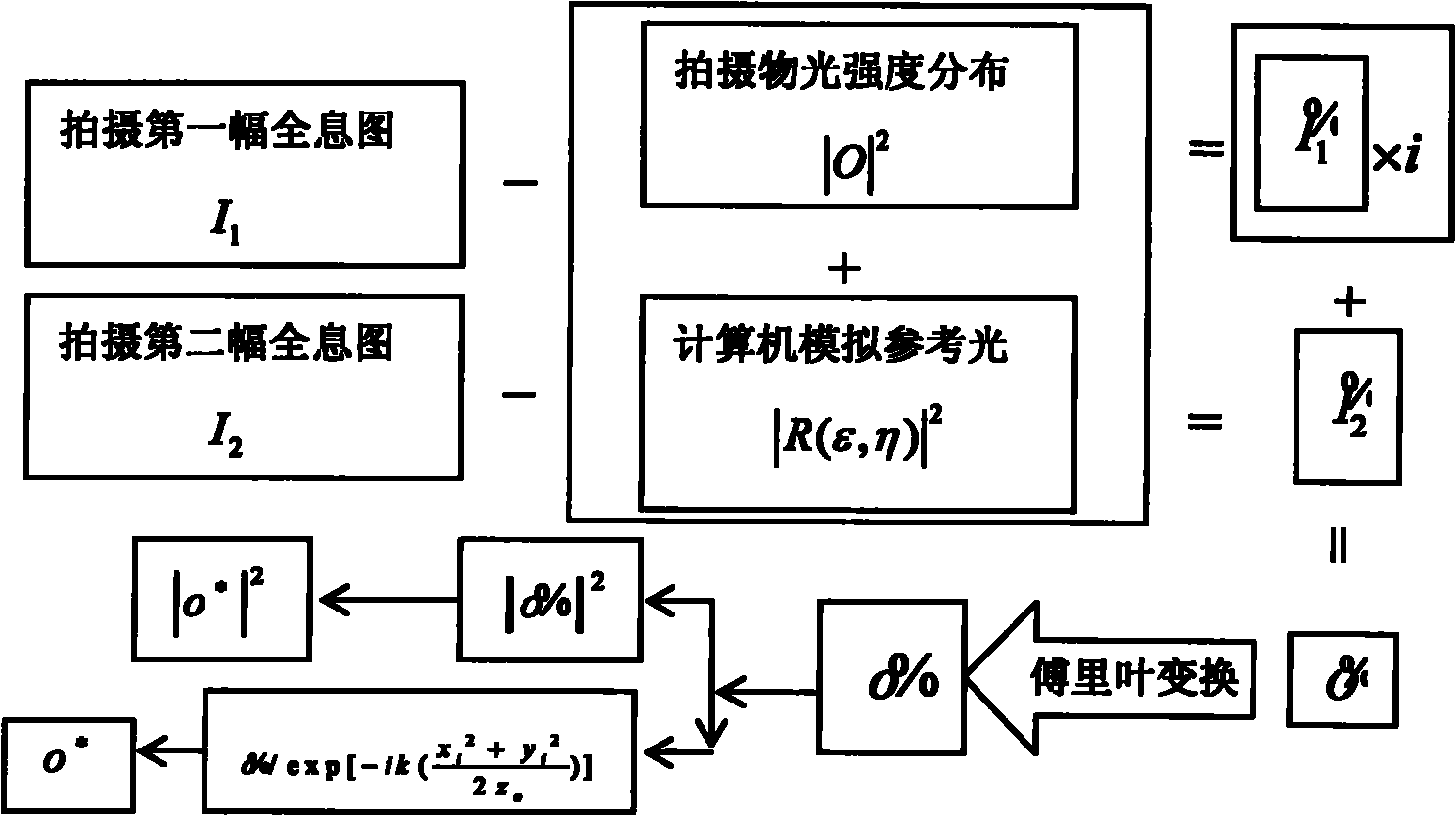

Method and device for detecting end surface of optical fiber connector

InactiveCN101852587AEnough contrastImprove anti-interference abilityUsing optical meansOptical apparatus testingFiberBeam splitting

The invention relates to a detector for the end surface of an optical fiber connector. In the detector, an optical signal of a laser source is split into a reference light path and an object light path, wherein reference light is focused and reflected to enter into a photoelectric converter and then transmitted into a computer through a USB interface; object light is reflected and focused, and then enters to the end surface of a detected optical fiber connector on an optic fiber connector holder through a light incidence port of the optical fiber connector; the transmitted object light and the reflected reference light which are reflected and amplified by the optical signal interferes on the symmetrical surface of the incidence surface of a beam-splitting mirror on which the detected optical fiber is reflected, and then the transmitted object light and the reflected reference light are acquired by another photoelectric converter and transmitted into the computer through the USB interface; and after the optical signal is acquired, the computer carries out de-noising on a hologram by using software and reconstitutes a three-dimensional hologram according to a two-step phase shift method. The invention can not only detect parameters of ovality, concentricity, and the like of a connector fiber core and a connector cover, but also reconstitute the three-dimensional topography on the surface of the end surface fiber core area and monitor the surface appearance and the height of the fiber core; in addition, the invention has high detection accuracy, small system size and high automation degree and is friendly in a user interface and convenient to use.

Owner:ZHEJIANG NORMAL UNIVERSITY

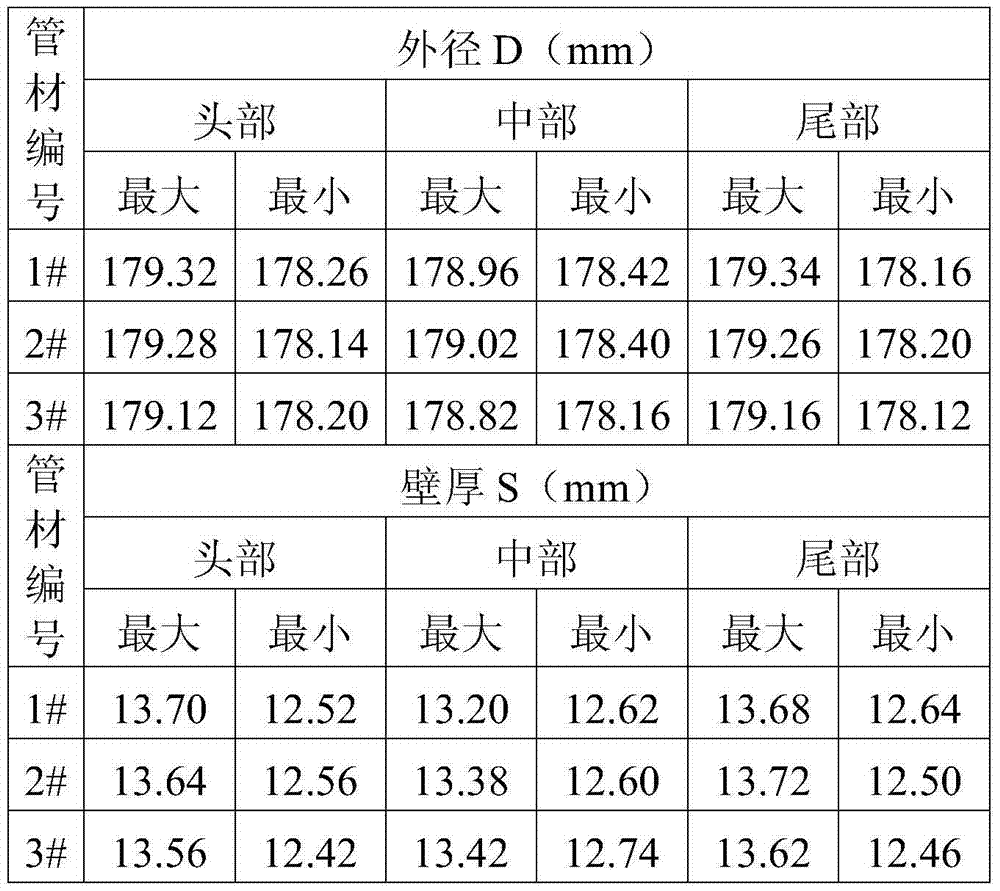

TC4 titanium alloy seamless tube and production method thereof

ActiveCN103934269AGood mechanical propertiesReasonable processTemperature control deviceMetal rolling arrangementsReduction ratePunching

The invention provides a TC4 titanium alloy seamless tube and a production method thereof. The method comprises the steps of heating a round billet of a TC4 titanium alloy to 920-980 DEG C; conducting on-line hot centering on the round billet; conducting cross piercing, wherein controlling the total diameter reduction rate to be 9-16%, controlling the before-head reduction rate to be 2.5-11%, controlling the ovality coefficient to be 1.13-1.20, and controlling the punching rate to be 0.2-0.5m / s; conducting precise skew rolling to form a pierced billet, enabling the total diameter reduction rate to be 12-18%, enabling the ovality coefficient to be 1.08-1.15, enabling the tube rolling rate to be 0.3-0.4m / s; controlling the temperature of the pierced billet to be 860-940 DEG C, sizing and conducting air cooling to obtain the TC4 titanium alloy seamless tube. By means of the production method, the TC4 titanium alloy seamless tube with the excellent mechanical property can be obtained, production efficiency is high, mass production can be achieved, and the yield can reach 90% and more.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

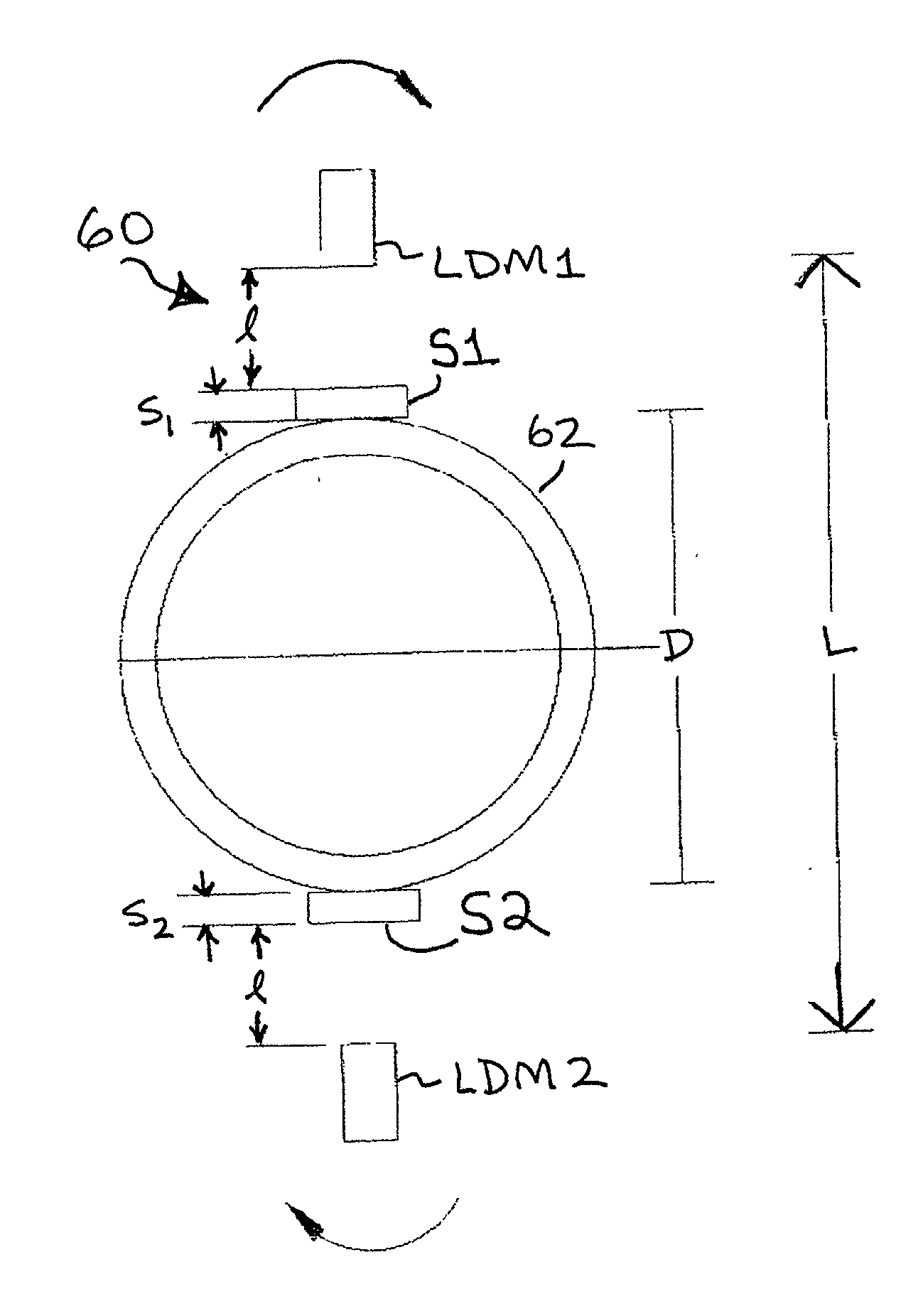

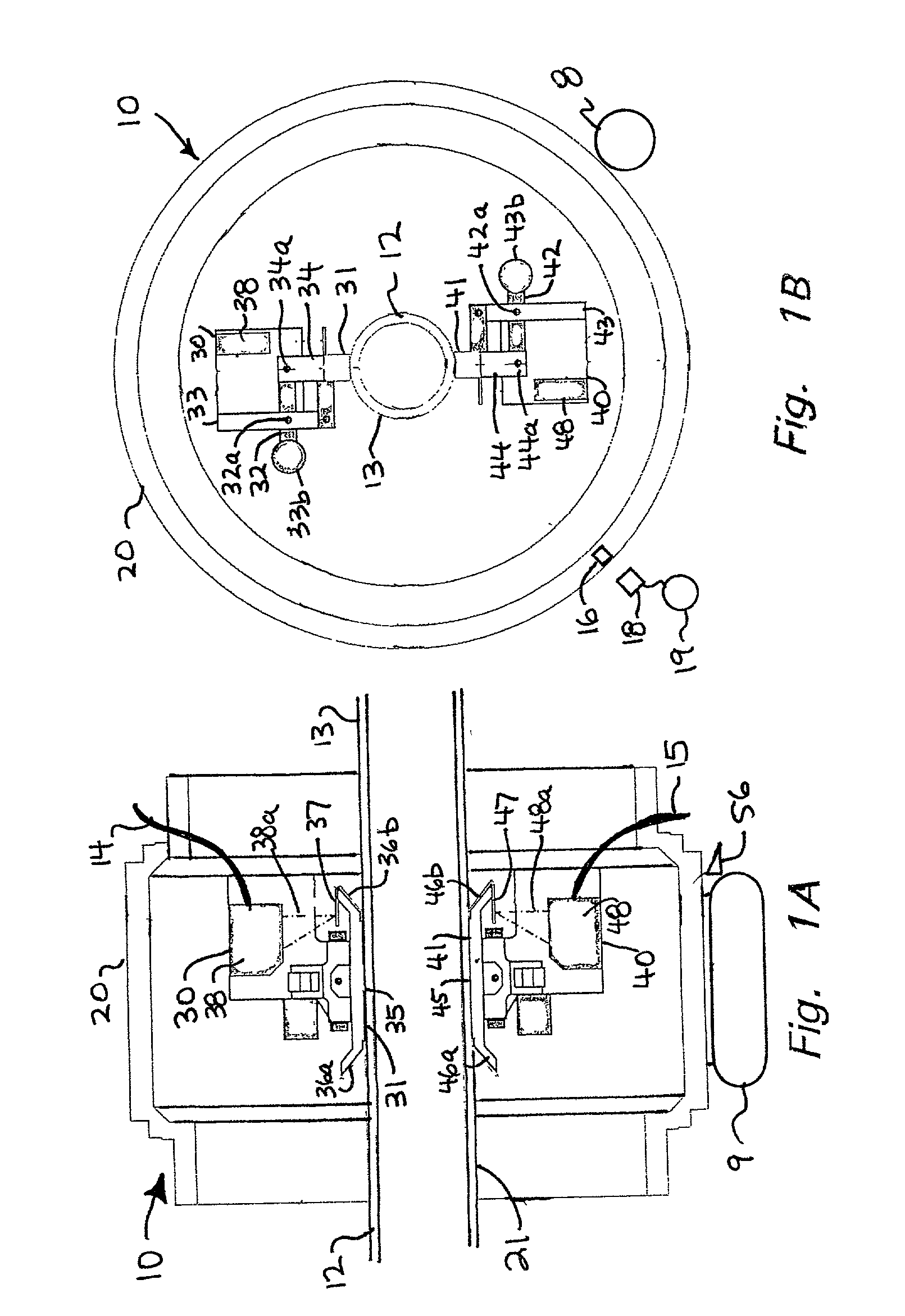

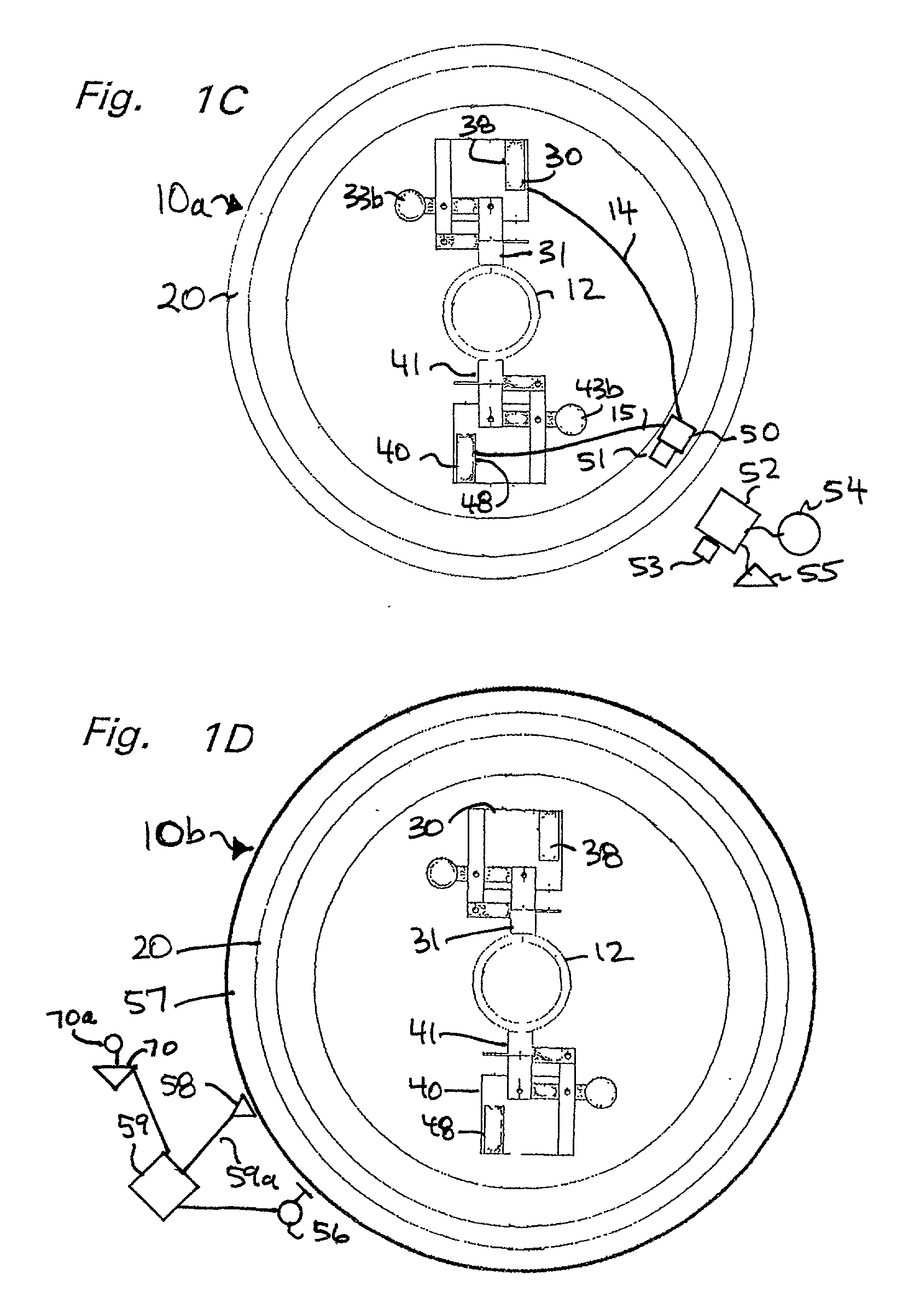

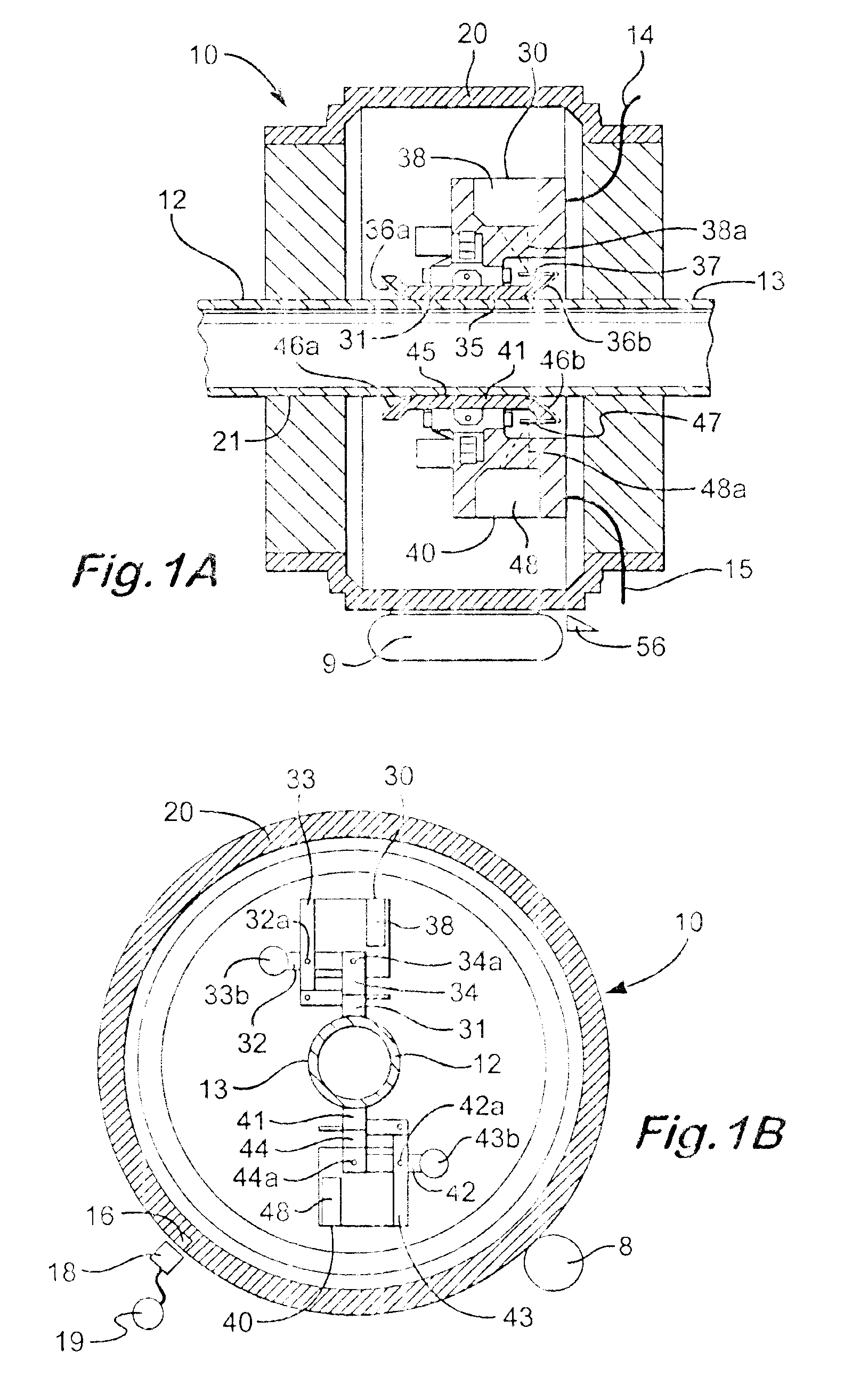

Tubular ovality testing

InactiveUS20030189713A1Eliminate the effects ofAccurate centerInvestigating moving sheetsUsing mechanical meansLinear variable differential transformerProcess equipment

A system for measuring diameter (inner and / or outer) of a tubular, the system in at least certain aspects including at least one linear distance measuring device with respect to which a tubular to be measured is movable, the at least one linear distance measuring device including a detector for detecting a surface of the tubular, the detector movably mounted to mount apparatus, the detector movable longitudinally along the surface of the tubular and movable axially in response to variation in diameter of the tubular, a rotatable head rotatable with respect to the tubular either outside of it or within it, the mount apparatus secured to the rotatable head, at least one signal production apparatus secured to the mount apparatus or head, and in communication with the linear distance measuring device, the at least one signal production apparatus for producing a signal indicative of distance between said detector and a known point, and transmitting apparatus for transmitting said signals to processing equipment for determining diameter of the tubular; and in certain aspects the linear distance measuring device is a laser device, electronic measurement device, acoustic measurement device, infrared measurement device, or linear variable differential transformer device.

Owner:VARCO I P INC

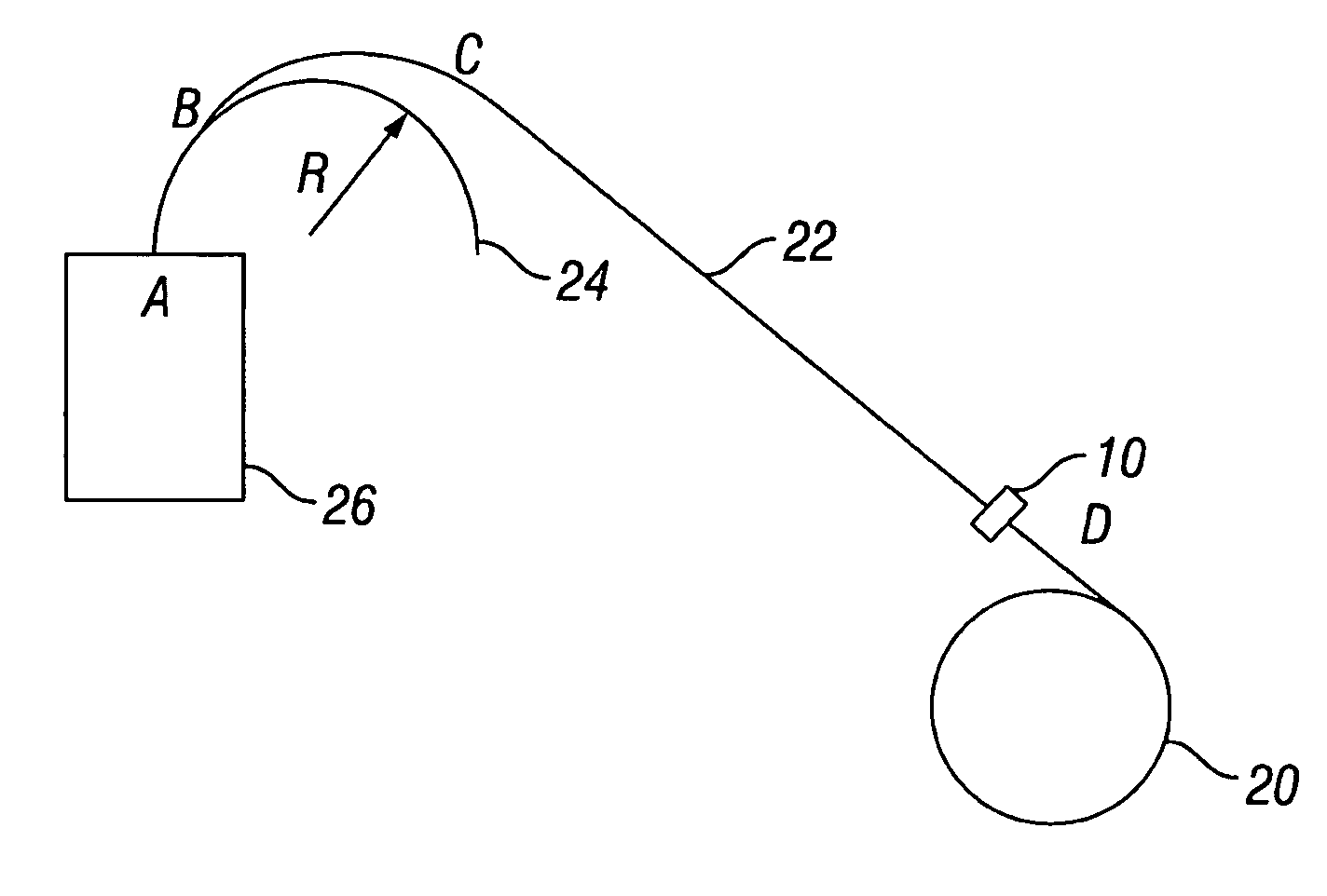

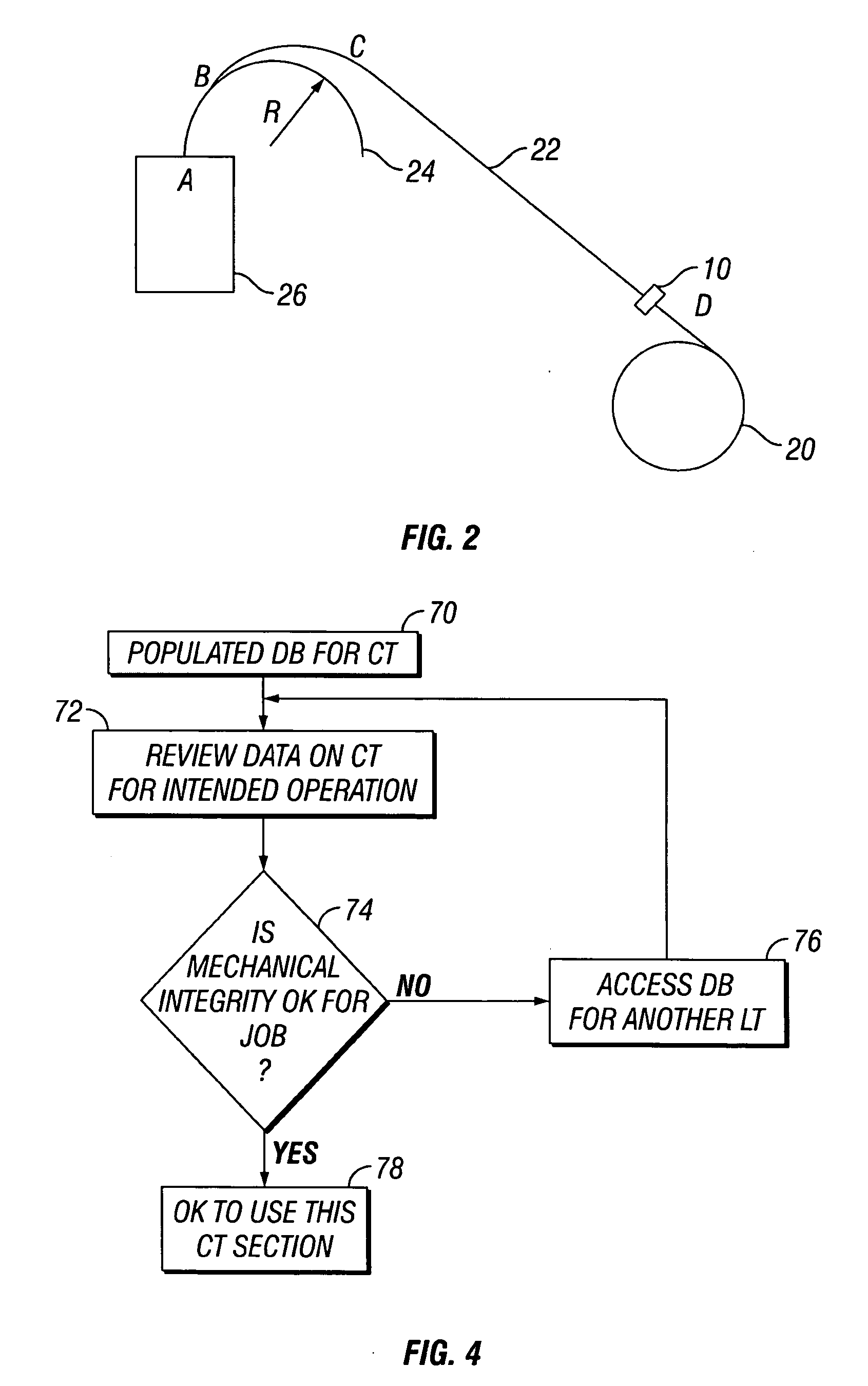

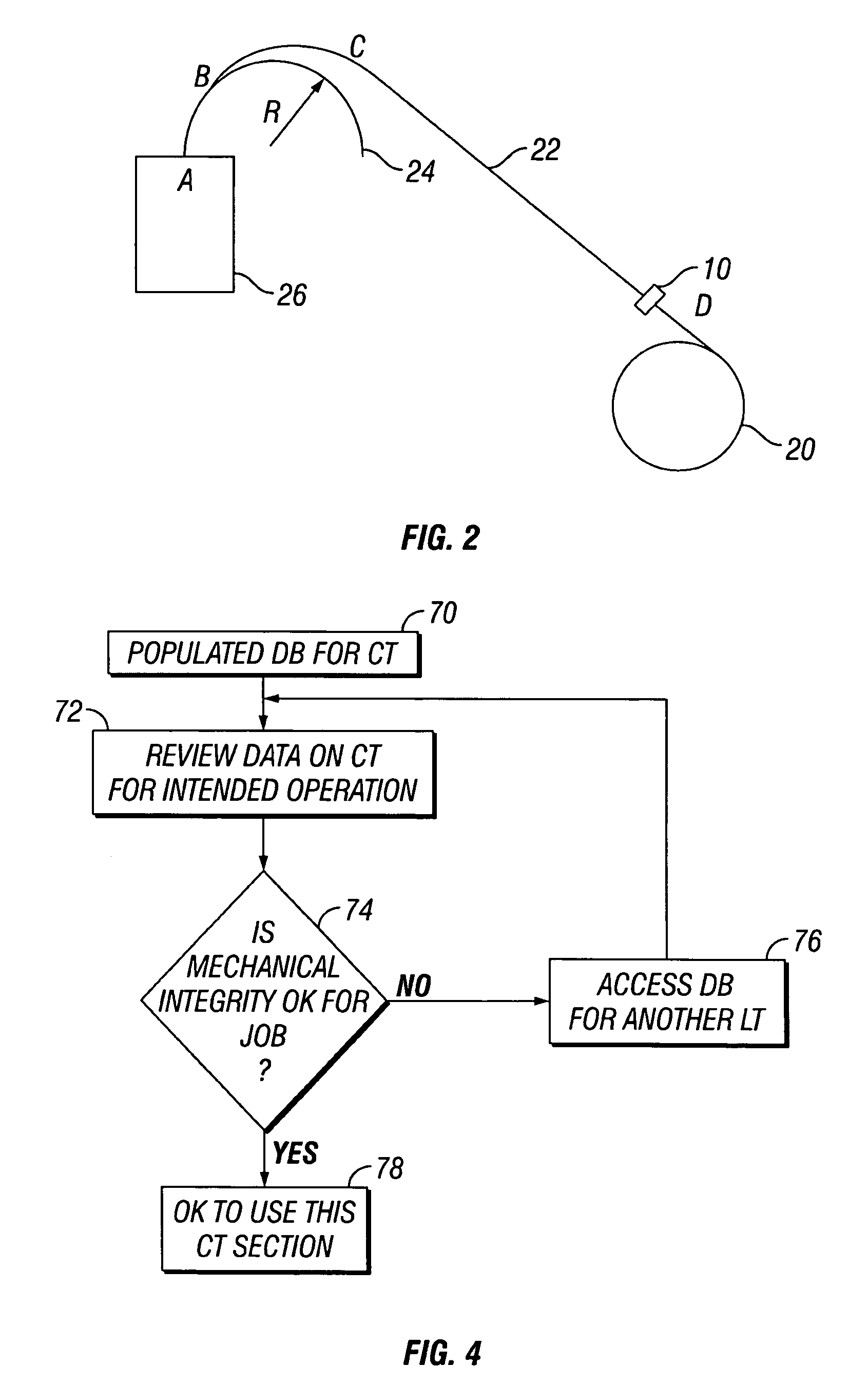

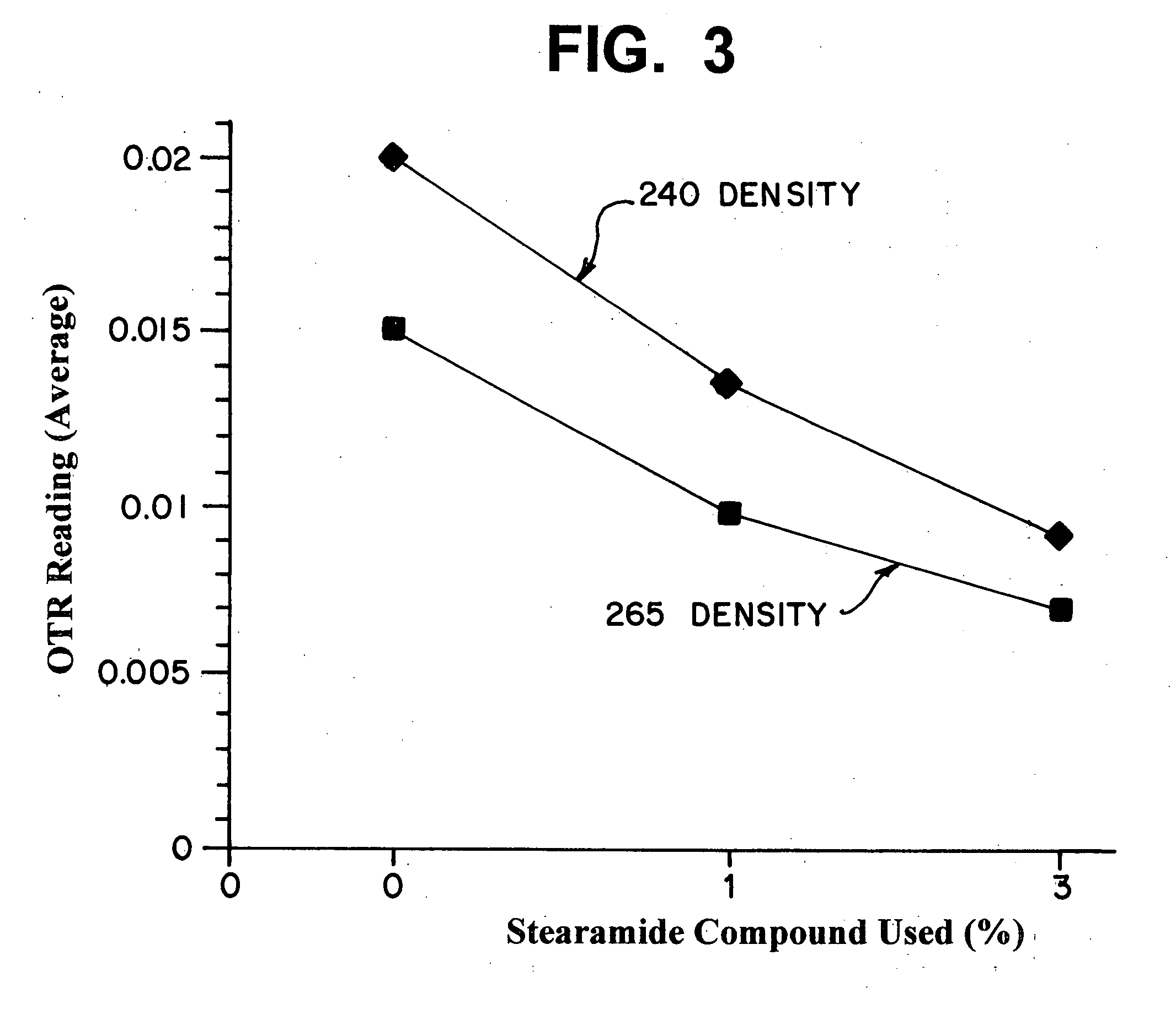

Methods of using coiled tubing inspection data

ActiveUS20060096753A1Reduce and overcome problemReducing and eliminating riskEarth drilling toolsSurveyReal-time dataCoiled tubing

Methods for generating geometric databases of coiled tubing inspection data and using the data in job design, real time monitoring and automated feedback control of operations are described. One method includes creating a grid of spatial positions on a length of coiled tubing as it traverses through an inspection apparatus having a plurality of sensors for detecting defects in the coiled tubing. Real time data may be compared to historical or nominal data for the coiled tubing. Another method includes monitoring, in real time or near real time, the status of tubing dimension (thickness, diameter, ovality, shape) during a coiled tubing operation, such as acidizing, fracturing, high pressure operations, drilling, and wellbore cleanouts. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims.

Owner:SCHLUMBERGER TECH CORP

Construction process of wind power tower tube

InactiveCN107876943AGuaranteed accuracyReduce reworkFinal product manufactureWelding accessoriesNumerical controlElectricity

The invention relates to a construction process of a wind power tower tube. The construction process comprises the procedures of sectioned tube section manufacturing, tower tube flange installation, and tower tube assembly; sectioned tube section manufacturing comprises the procedures of factory inspection of raw materials, material reinspection, pretreatment of a steel plate, numerical control cutting blanking, dimensional inspection, groove machining, circle rolling, group-welding of longitudinal joints, circle rectifying, measuring of tube section ovality, 100%UT detection and T-shaped seam100%MT detection; tower tube flange installation is achieved through the procedures of flange detection, tower tube detection, flange fixing, tube body installation, welding measuring, bottom flangeassembly, tube body connection, bolt connection, tube body positioning welding and detection after welding jointly; and tower tube assembly comprises the procedures of grouping of tube sections and flange nipples, inspection, welding, 100% UT detection, inspection, drawing of position lines of inner parts, inspection, group-welding of the inner parts, anticorrosion treatment, assembly of the innerparts, packing and forwarding. The construction process has the advantage of being high in precision.

Owner:NANTONG BLUE ISLAND OFFSHORE CO LTD

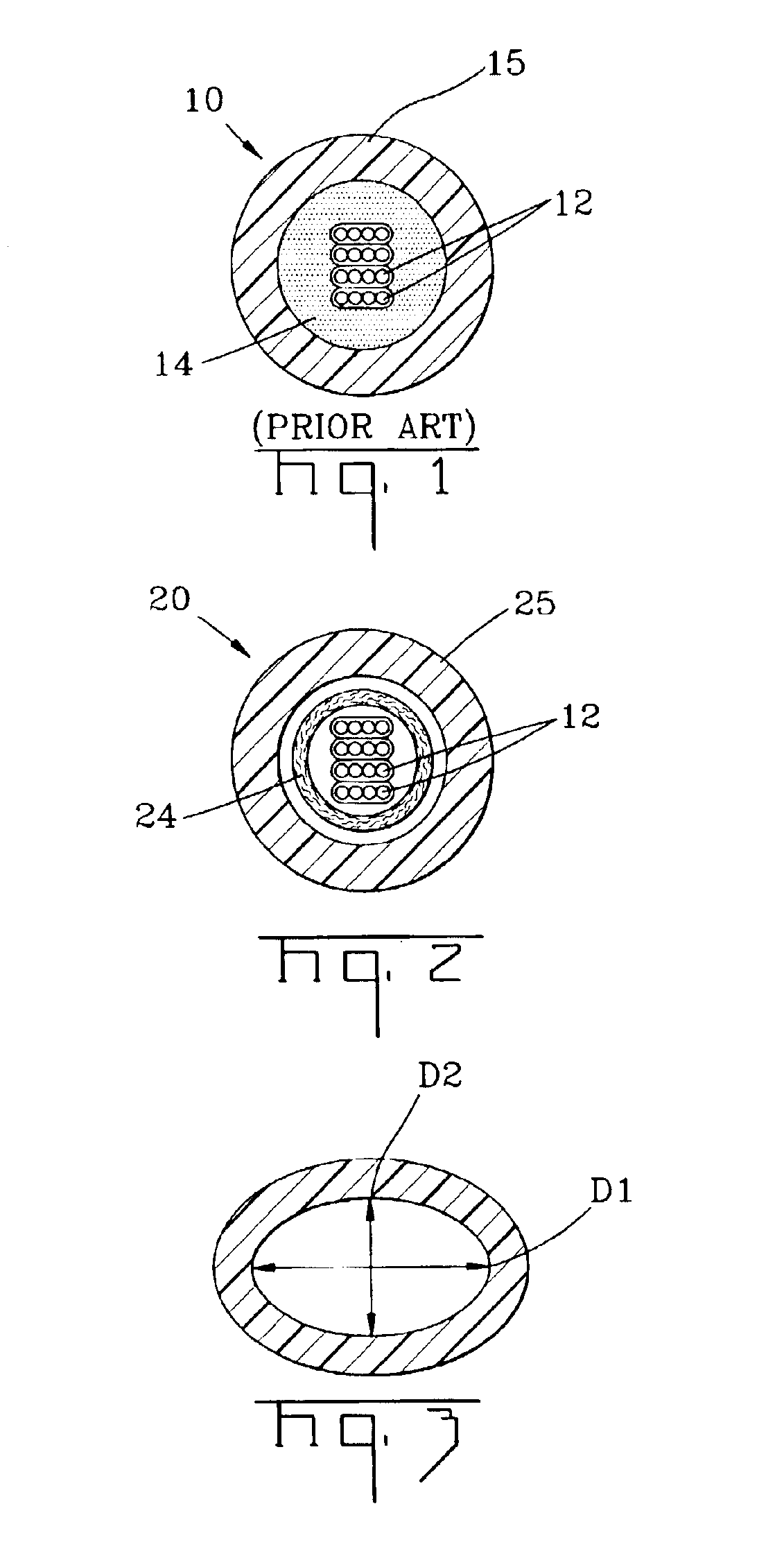

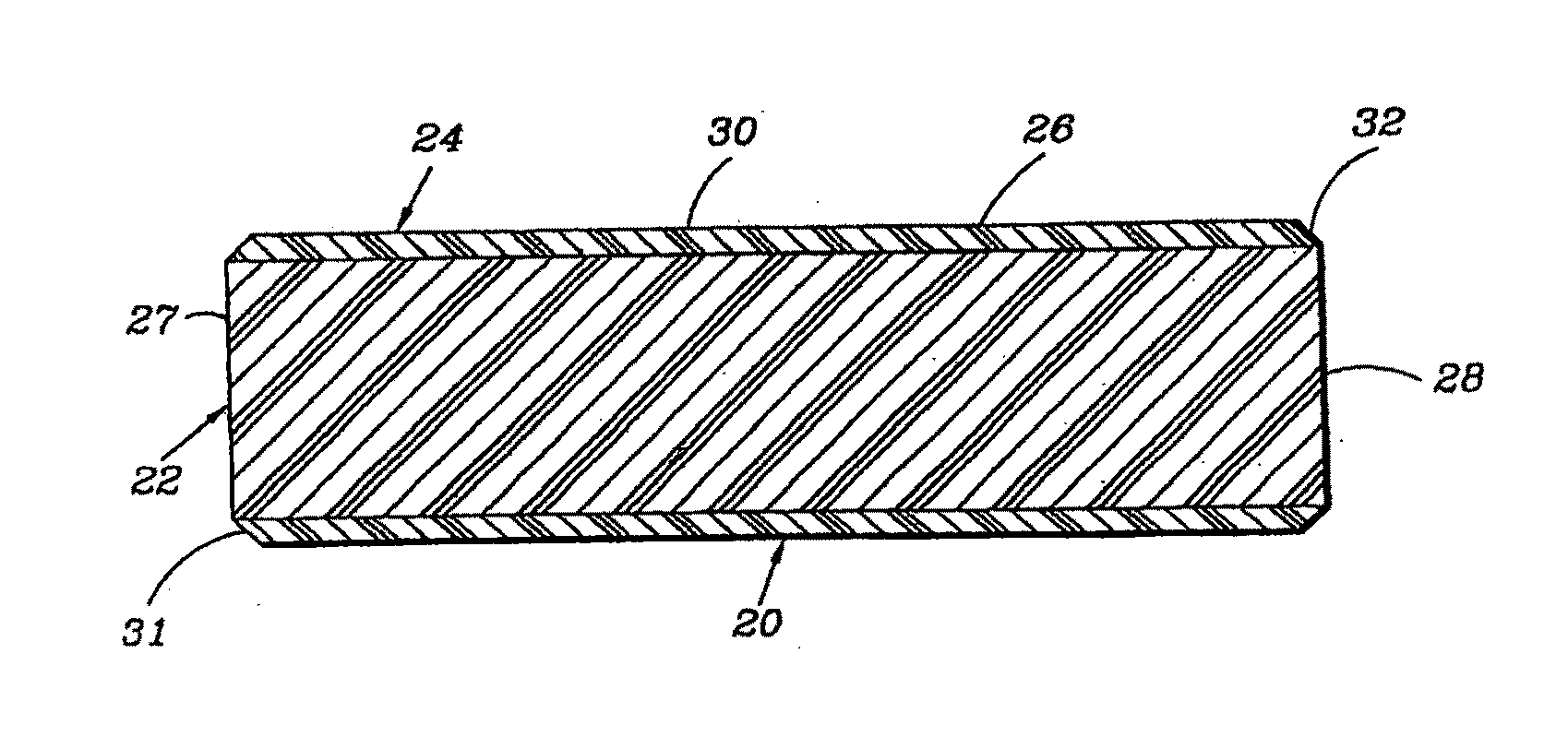

Dry tube fiber optic assemblies, cables, and manufacturing methods therefor

A fiber optic dry tube assembly and a method of manufacturing the same includes at least one optical waveguide and a tube. The tube houses at least a portion of the at least one optical fiber and is formed from a bimodal polymeric material. The tube has an average ovality of about 10 percent or less. In other embodiments, the bimodal polymeric material that forms the tube has a melt index of about 1.0 g / 10 minutes or less, a melt strength in the range of about 8 cN to about 35 cN at 190° C,. and / or a polydisperity of about 7 or greater. Additionally, the dry tube assemblies of the present invention can form a portion of a cable.

Owner:CORNING OPTICAL COMM LLC

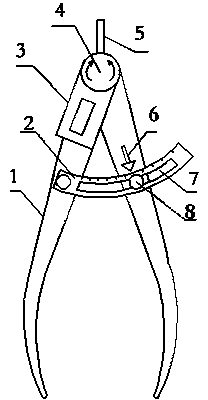

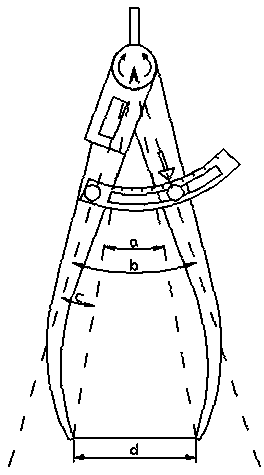

Direct-reading type calipers for measuring ovality of pipeline

InactiveCN103837067AGuaranteed reliabilityAvoid compromising accuracyMechanical counters/curvatures measurementsLarge distanceCalipers

The invention provides a pair of direct-reading type calipers for measuring the ovality of a pipeline. The pair of direct-reading type calipers comprises a calipers body which comprises two calipers legs with the ends hinged to each other through a hinge pin; a rotation angle sensor used for detecting relative rotation angle signals of the two calipers legs is arranged on the hinge pin, a digital display box is arranged on one calipers leg, an integrated circuit board is arranged in the digital display box, a microprocessor used for processing and calculating the angle signals sent by the rotation angle sensor and obtaining a space value between the ends of the two calipers legs is integrated on the integrated circuit board, and a display screen connected with the microprocessor through signals is arranged on the digital display box. The direct-reading type calipers have the advantages that when the direct-reading type calipers are clamped on a bent pipe or an elbow of the pipeline, the number is read without the requirement for taking the direct-reading type calipers out of the pipeline, the angle value is directly read, the calipers legs of the calipers are fastened at largest distance points, and the phenomenon that due to the fact that the distance between the two calipers legs changes, the accuracy of the value is influenced is avoided. An electronic mode and a mechanical mode are used for measuring the angle and errors are reduced.

Owner:STATE GRID CORP OF CHINA +1

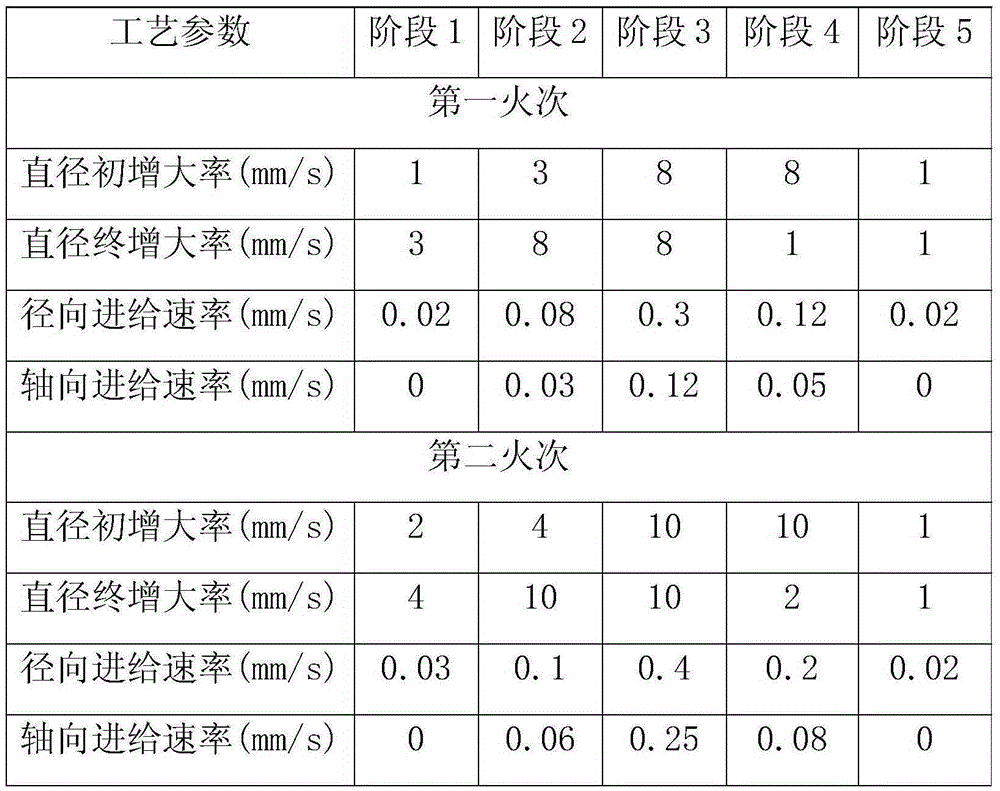

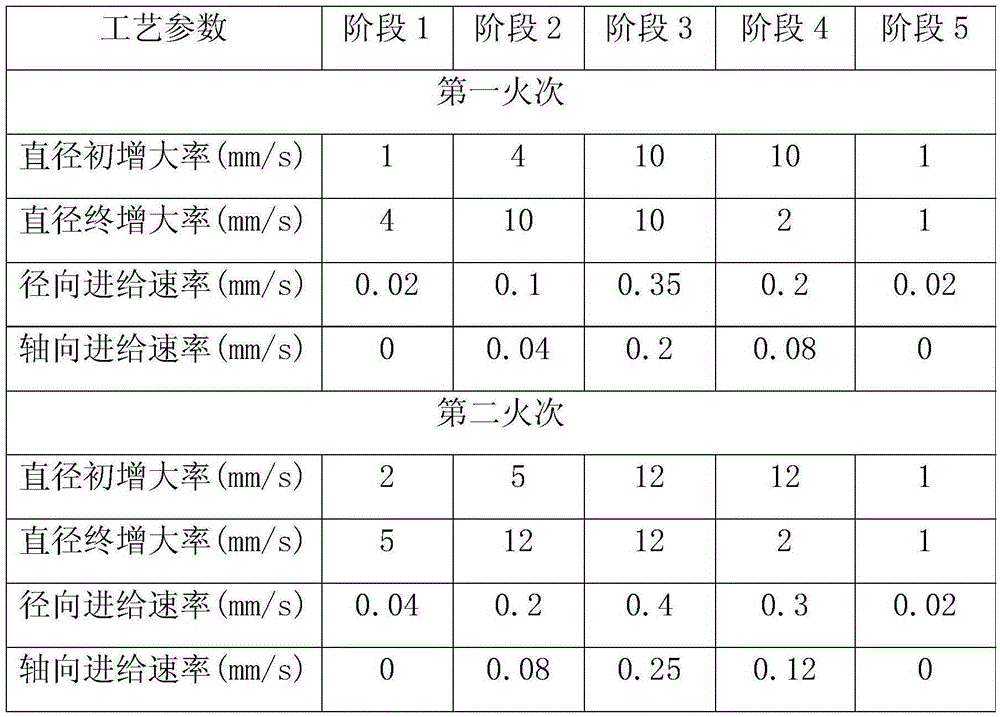

Rolling production method for integral aluminum alloy ring of super-large diameter

The invention belongs to the technical field of ring rolling forming and particularly relates to a rolling production method for an integral aluminum alloy ring of the super-large diameter. According to the technical scheme of the invention, a ring rolling forming technology is adopted, and through control over the rolling deformation temperature, the diameter increasement rate, the radial and axial feed rates, the radial and axial rolling reductions, the rolling ratio, the core roller diameter and the ring rolling heating number of an aluminum alloy ring piece of the super-large specification, the stable and continuous rolling process of the integral aluminum alloy ring of the super-large diameter is achieved, the size precision, the ovality and the radial and axial deformation quantities of the ring piece are effectively controlled, the product quality consistency is improved, the product percent of pass is increased, and technical index requirements of products are met.

Owner:CAPITAL AEROSPACE MACHINERY +1

Chromium 23 nickel 6 ferrite-austenitic stainless steel pipe and fabrication process thereof

ActiveCN101353769AEasy to useHigh tensile strengthRoll mill control devicesWork treatment devicesChemical industryManufacturing technology

The invention relates to a Cr 23 Ni 6 ferrite-austenitic stainless steel which is manufactured from stainless steel materials containing components by weight percentage as follows: 22 percent to 24 percent of Cr, 5 percent to 7 percent of Ni, 3 percent to 4 percent of Mo, 0.15 percent to 0.25 percent of N, less than or equal to 0.03 percent of C and 1 percent to 2 percent of Mn, and the rest is Fe. The manufacturing technology of the Cr 23 Ni 6 ferrite-austenitic stainless steel of the invention is characterized in that: in hot piercing process, the hot piercing temperature is controlled to be 1150 DEG C to 1200 DEG C; the prior compression coefficient of a piercing plug is controlled to be 5 percent; the reduction of roller waist is controlled to be 12 percent and the ovality is controlled to be 1.08 to 1.11; in cold drawing / cold rolling process, cold deformation quantity is controlled to be below 50 percent; in heat treatment process, the solid solution temperature of products is controlled to be 1080 DEG C to 1100 DEG C and the solid solution temperature of finished products is controlled to be 1050 DEG C to 1100 DEG C. The Cr 23 Ni 6 ferrite-austenitic stainless steel has good chloride stress corrosion resistance, good pit corrosion resistance, high tensile strength and yield strength and good corrosion fatigue resistance and erosion corrosion resistance, and is widely used in the fields such as petroleum industry, chemical industry, natural gas industry and marine shipping and the like.

Owner:上上德盛集团股份有限公司

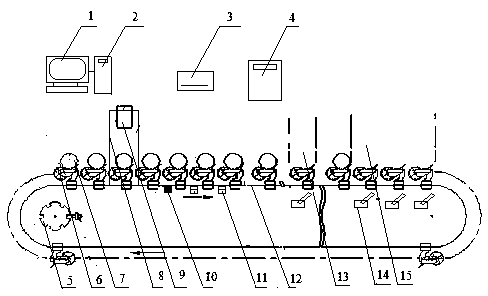

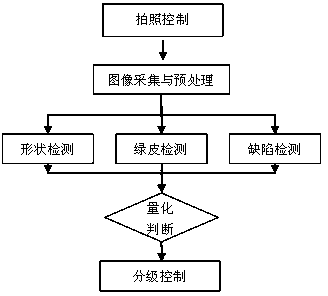

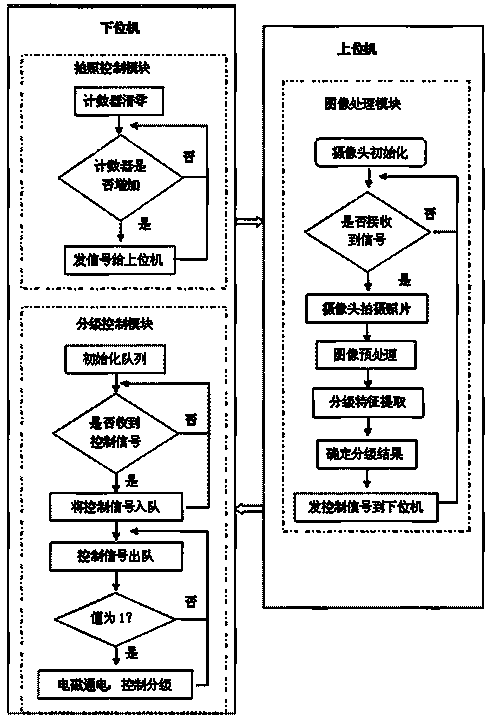

Intelligent potato sorting method and apparatus

The invention discloses an intelligent potato sorting method and apparatus, comprising a mechanical potato sorting apparatus, a potato grading control method and a potato appearance quality detection method. A potato intelligent grading apparatus is formed by additionally installing a computer vision detection device and an intelligent grading control device on the basis of the mechanical potato sorting apparatus. The potato grading control method comprises a shooting control unit and a grading control unit. The potato appearance quality detection method comprises the following steps: image acquisition and preprocessing; shape detection; green skin detection; and defect detection. The shapes of potatoes are graded by calculating ovality by using an approximate ellipse method according to national standards of China and external characteristics of the potatoes; the phenomenon of green skin is detected by using the values of an R component and an H component according to color characteristics; defects are detected by using automatic threshold segmentation and are determined according to the area ratio of the defects. The grading apparatus and grading method provided by the invention overcome the disadvantages of subjectivity, low efficiency and the like of artificial detection, enable quantitative detection to be more objective and scientific, are applicable to quality grading and commerce circulation of produced potatoes and improve production efficiency.

Owner:QINGDAO AGRI UNIV +2

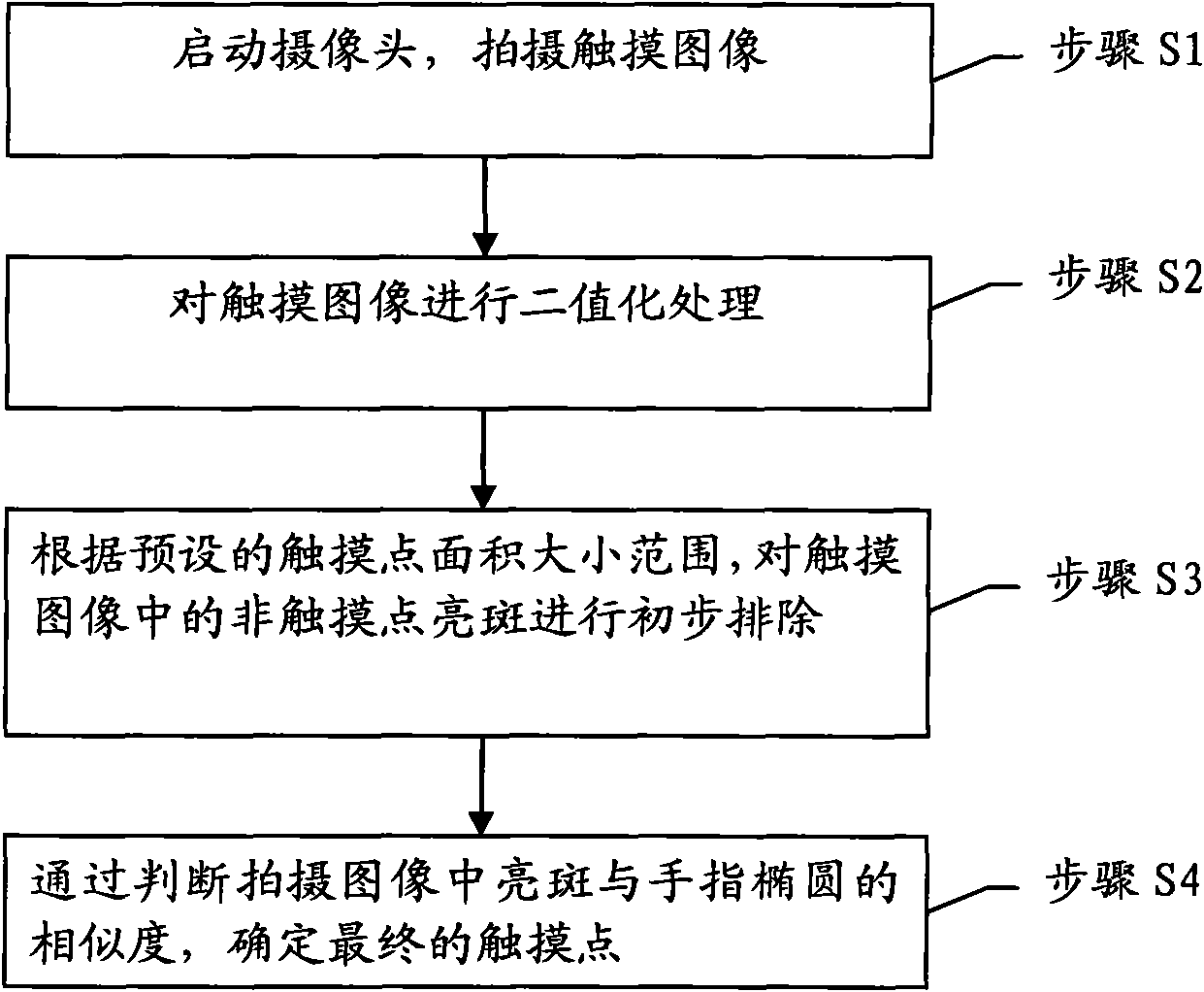

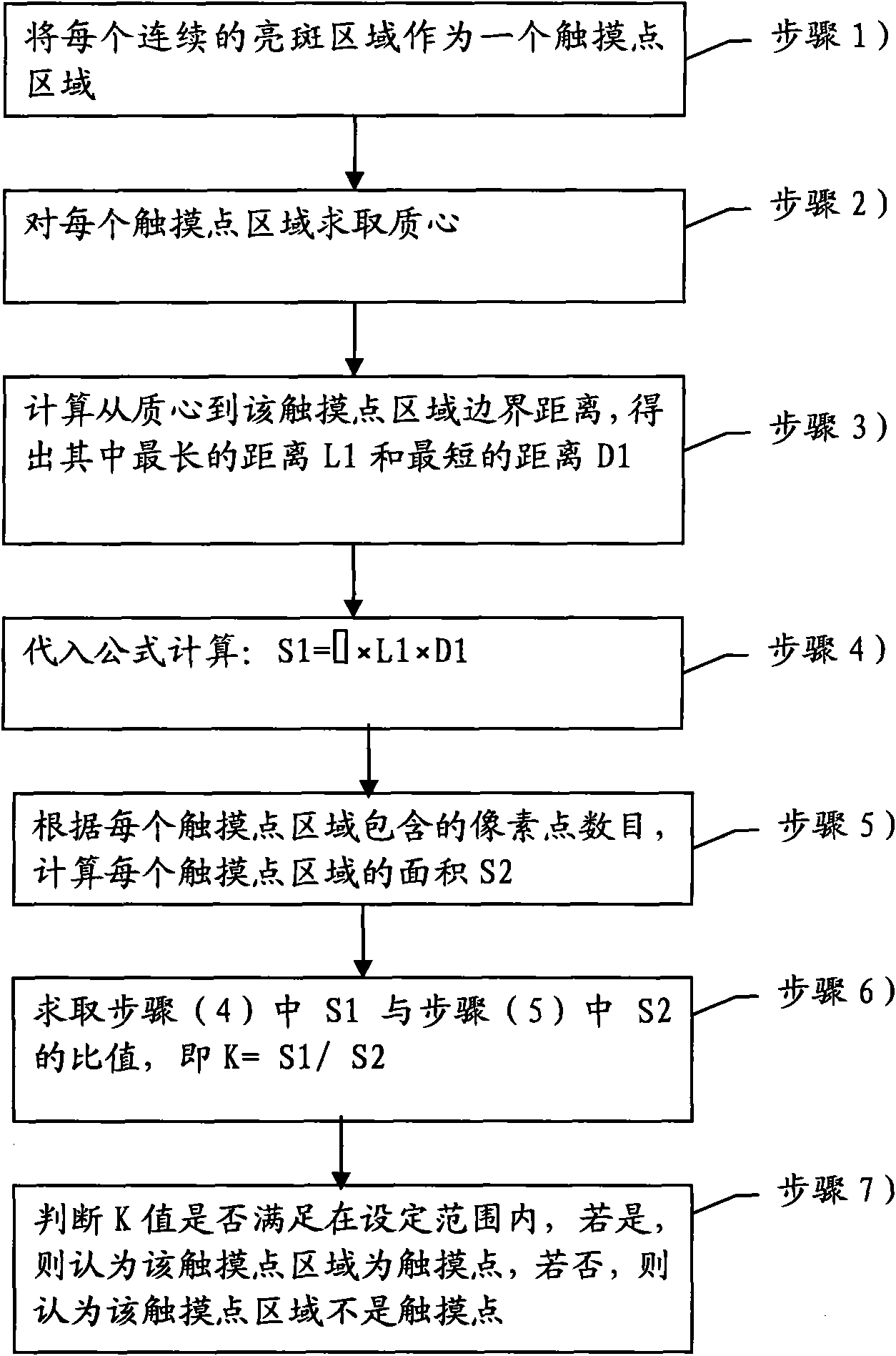

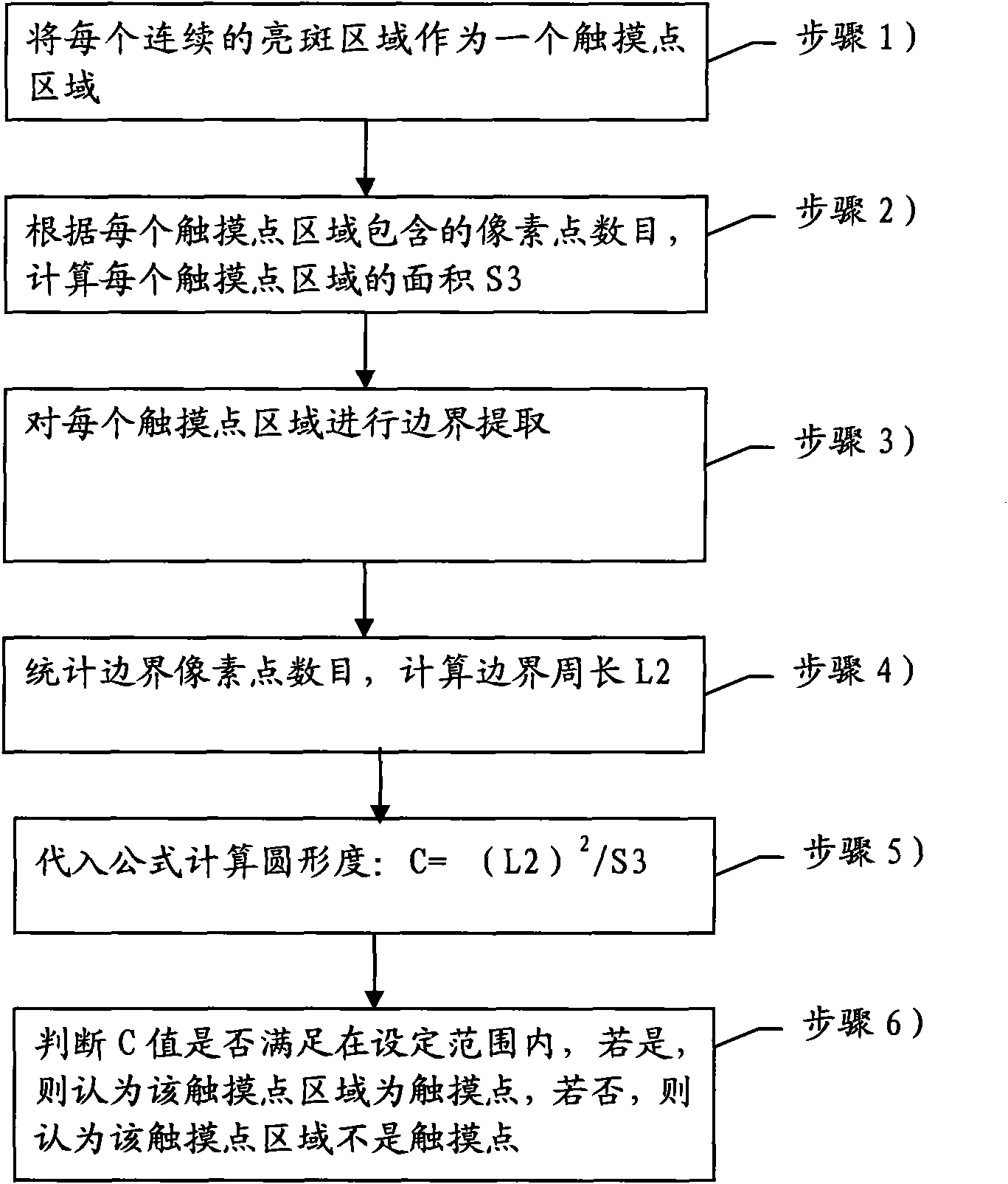

Anti-interference touch identification method and device

ActiveCN101976334AEfficient identificationAvoid misjudgmentCharacter and pattern recognitionInput/output processes for data processingPattern recognitionIdentification device

The invention discloses an anti-interference touch identification method comprising the following steps of: (S1) starting a camera to shoot a touch image; (S2) carrying out binaryzation processing on the touch image; (S3) carrying out the primary elimination on non-touch point bright spots in the touch image; and (S4) determining a final touch point through judging the similarity of the bright spots in the taken image and the finger ovality. The invention also provides an anti-interference touch identification device comprising an image shooting unit, an image preprocessing unit and a similarity judgment unit. The invention can effectively identify the real touch point and avoids the mistake judgment caused by non-touch point interference, such as the mistake judgment caused by the reason that sleeves or other devices on the body touch a touch panel. Simultaneously, the invention also has the advantages of simple operation, high processing speed and the like.

Owner:南通卓效自动化有限公司

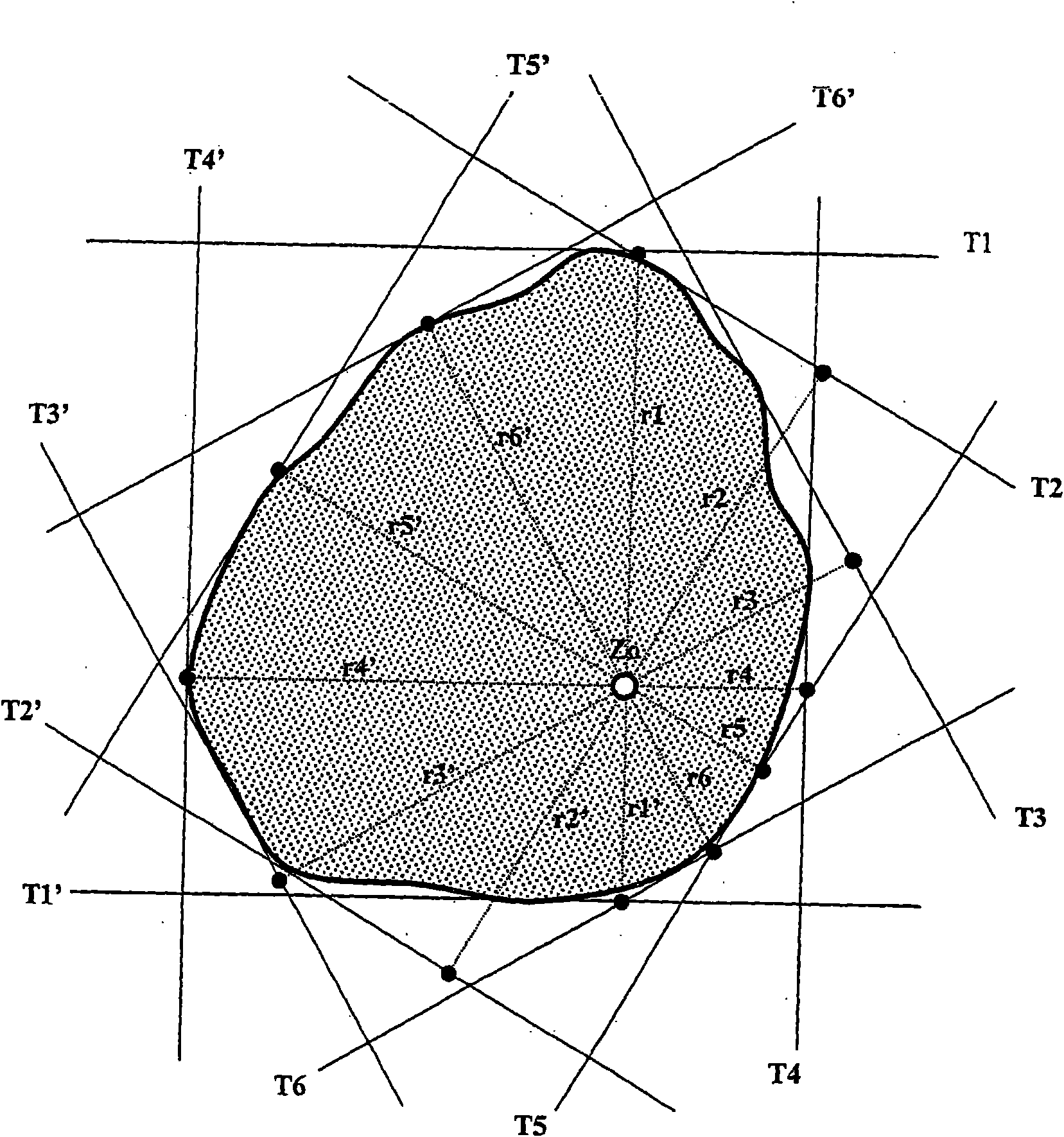

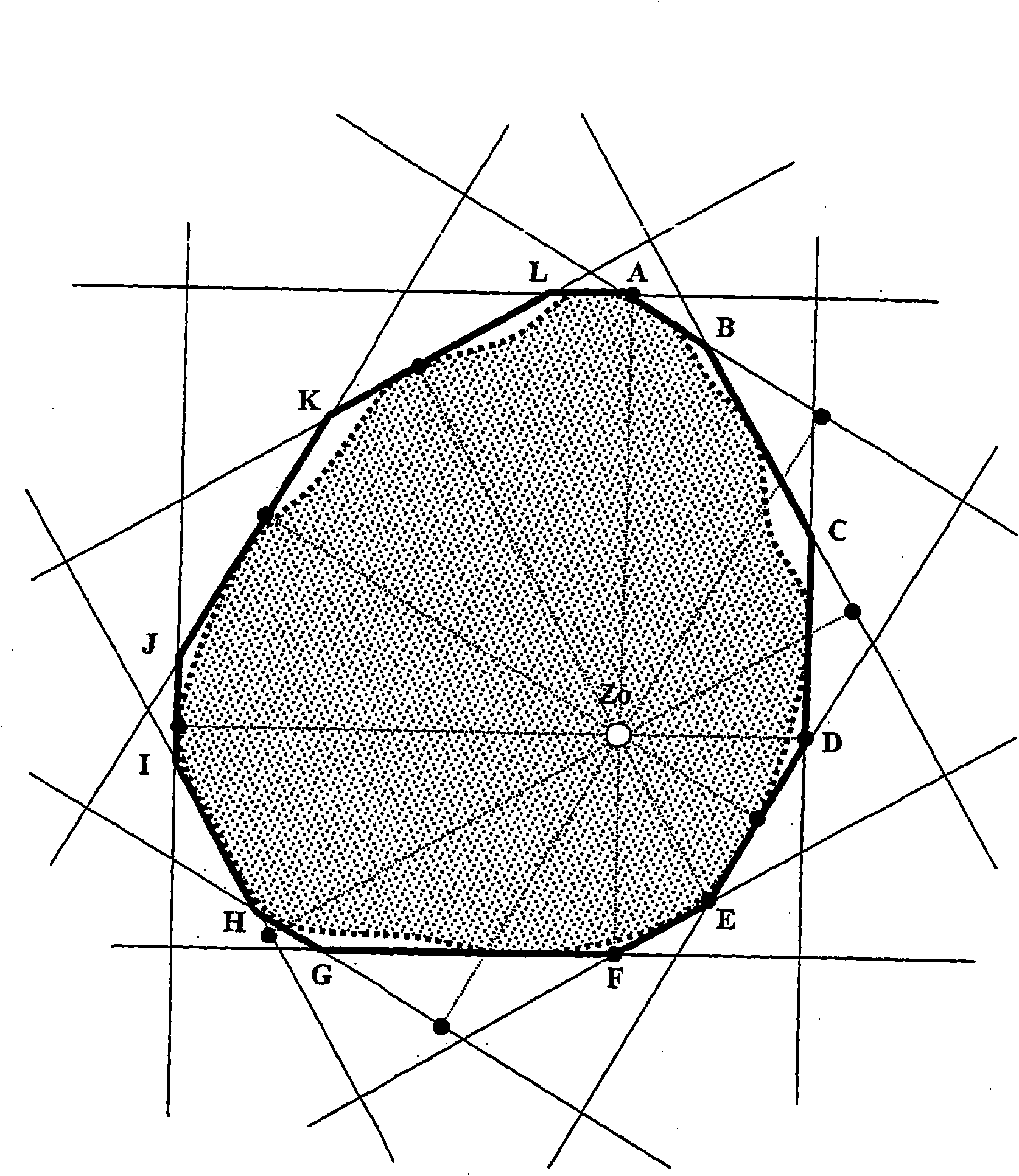

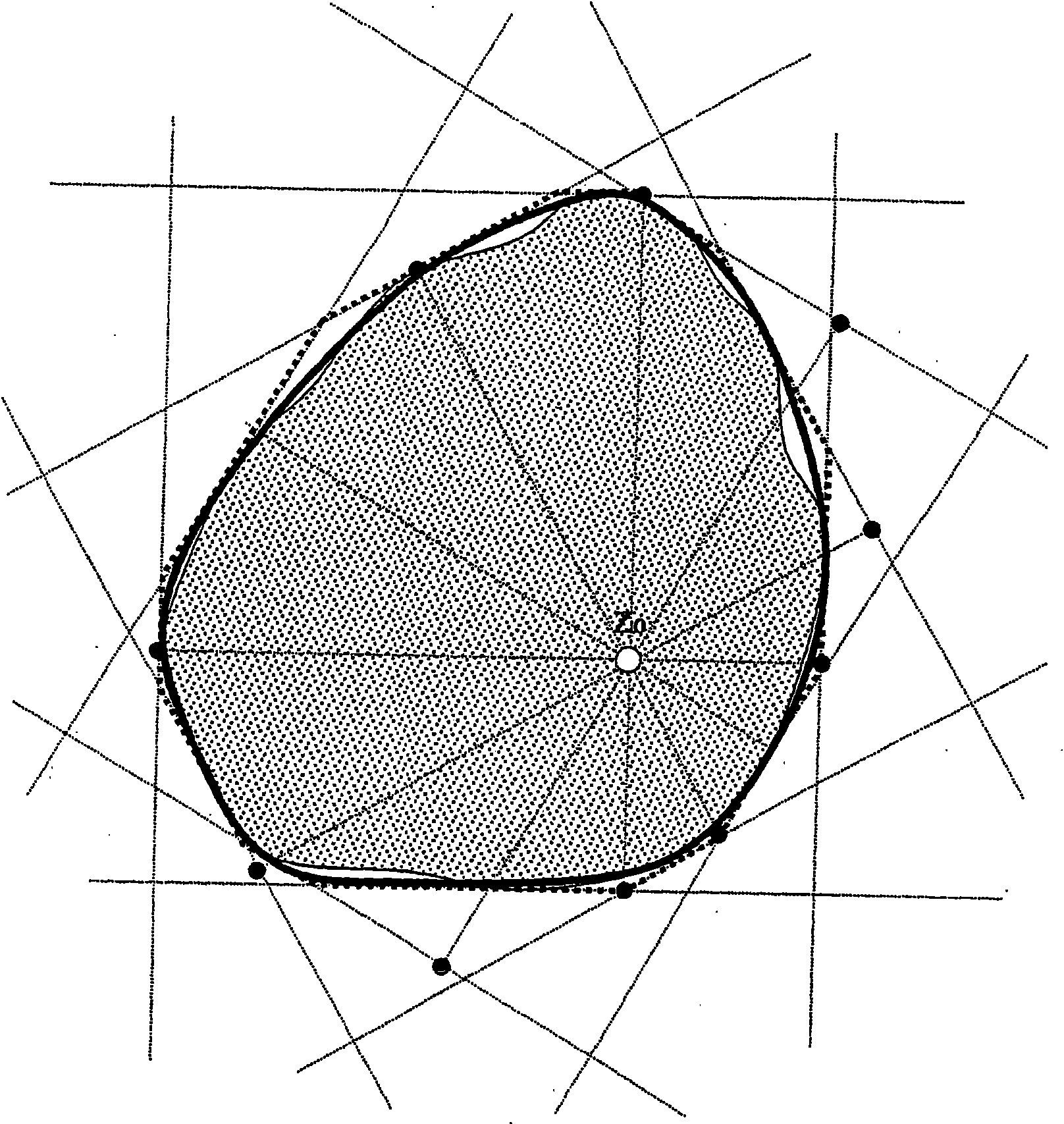

Method for measuring the shpericity of spherical profiles

The invention relates to a method for measuring the sphericity or for measuring the shape deviation of spherical profiles in rolling trains that displace in the longitudinal direction thereof. According to the invention, at least three shadow edges that are adjacent to the spherical profile that is to be measured, that surrounds said spherical profile and that forms a polygon are produced and measured in a known manner, with the aid of a measuring device having at least two laser scanners that respectively comprise a light-sensitive sensor and a laser, and the corresponding tangents are calculated from said result. Said method is characterised in that a) prior to measurment, a centre (Z0) in the measuring field of the measuring device is calibrated and determined provided that said type ofcentre (Z0) has not already determined, b) perpendiculars (r1, - r6') from the centre (Z0) to the tangents (T1, bis T6' ) and also the distance from the centre (Z0) to the tangents (T1 - T6' ) is calculated, c) the corner points (A - K) of the polygon surrounding the spherical profile are calculated, a contour is determined, d) a reference circuit is determined in relation to the contour such that i) the quadratic shape deviation of the contour reaches a minimum in relation to said reference circuit, ii) said reference circuit represents the smallest possible circuit that adapts to the contour, iii) said reference circuit representing the largest possible circuit that adapts to the contour, or iv) the reference circuit together with an additional circuit that is concentric to the reference circuit surrounds the contour at a minimal radial distance, e) the diameter (Dref) of the reference circuit is calculated and the reference centre (Zp) is determined from the position in the cavitythat represents the centre point of the reference circuit and f) at least two vectors are calculated from said reference centre (Zp) to the contour and the ovality is determined from said data.

Owner:ZUMBACH ELECTRONICS

Process for bending X100 steel grade large-caliber bent pipe through intermediate frequency induction heating

The invention discloses a process for bending an X100 steel grade large-caliber bent pipe through intermediate frequency induction heating, which comprises the following steps of: (1) selecting raw materials meeting the standard; (2) performing a thermal simulation experiment; (3) bending; (4) correcting to round the end of the bent pipe; (5) machining a groove; (6) performing thermal treatment, namely reasonably tempering, and eliminating the stress of the bent pipe by using a natural gas thermal treatment furnace; (7) performing surface treatment; and (8) detecting a finished product, wherein process parameters are that: the pushing temperature is between 960 and 990 DEG C, the pushing speed is 25mm / min, the cooling speed is 600 DEG C / min, the cooling water temperature is less than or equal to 40 DEG C, and the tempering temperature is between 500 and 530 DEG C. A straight pipe section and a bending section are wholly heated and tempered, so that the uniformity and consistency of the whole performance index of the bent pipe are ensured; the bent pipe does not have an obvious tissue transition region, so that the stress defect caused by different tissues is overcome; and the ovality of a bent part of the bent pipe is controlled by controlling the width of a heating strip, so that the product has a good appearance size.

Owner:河北恒通管件集团有限公司

Methods of using coiled tubing inspection data

ActiveUS7357179B2Reduce and overcome problemReducing and eliminating riskEarth drilling toolsSurveyReal-time dataCoiled tubing

Methods for generating geometric databases of coiled tubing inspection data and using the data in job design, real time monitoring and automated feedback control of operations are described. One method includes creating a grid of spatial positions on a length of coiled tubing as it traverses through an inspection apparatus having a plurality of sensors for detecting defects in the coiled tubing. Real time data may be compared to historical or nominal data for the coiled tubing. Another method includes monitoring, in real time or near real time, the status of tubing dimension (thickness, diameter, ovality, shape) during a coiled tubing operation, such as acidizing, fracturing, high pressure operations, drilling, and wellbore cleanouts. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims.

Owner:SCHLUMBERGER TECH CORP

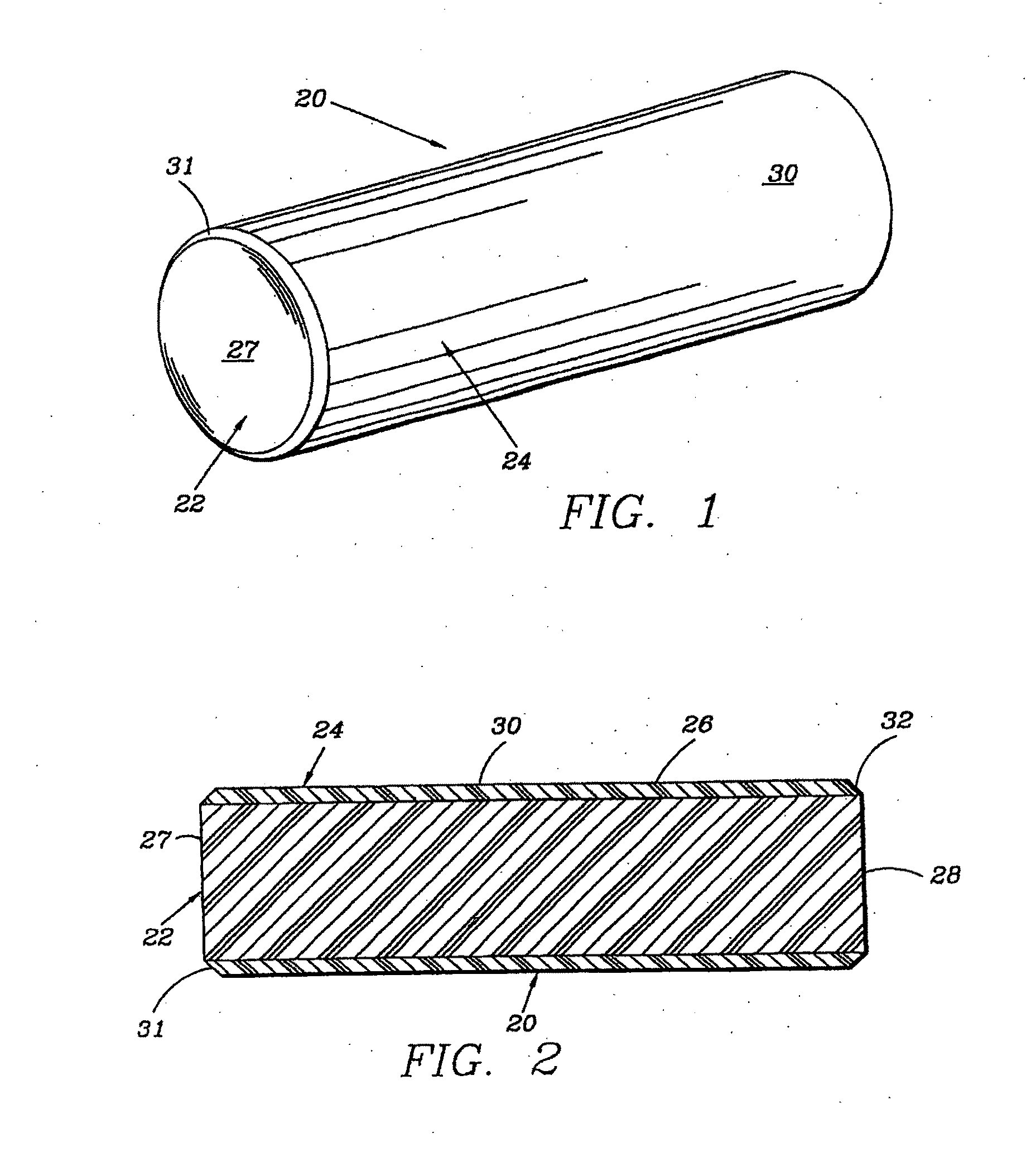

Synthetic closure

By providing a synthetic closure which comprises at least one thermoplastic polymer and, as an additive, at least one fatty acid derivative, in particular a fatty acid ester or a fatty acid amide such as a stearamide, a synthetic closure is attained which achieved substantially enhanced properties. In particular, it has been found that the oxygen transfer rate of the closure is reduced substantially, thus reducing unwanted oxidation of wine. Furthermore, the use of a fatty acid derivative additive improves the performance characteristics of synthetic corks, such as extraction force, ovality control, diameter control and length control.

Owner:VINVENTIONS USA LLC

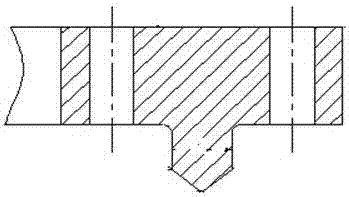

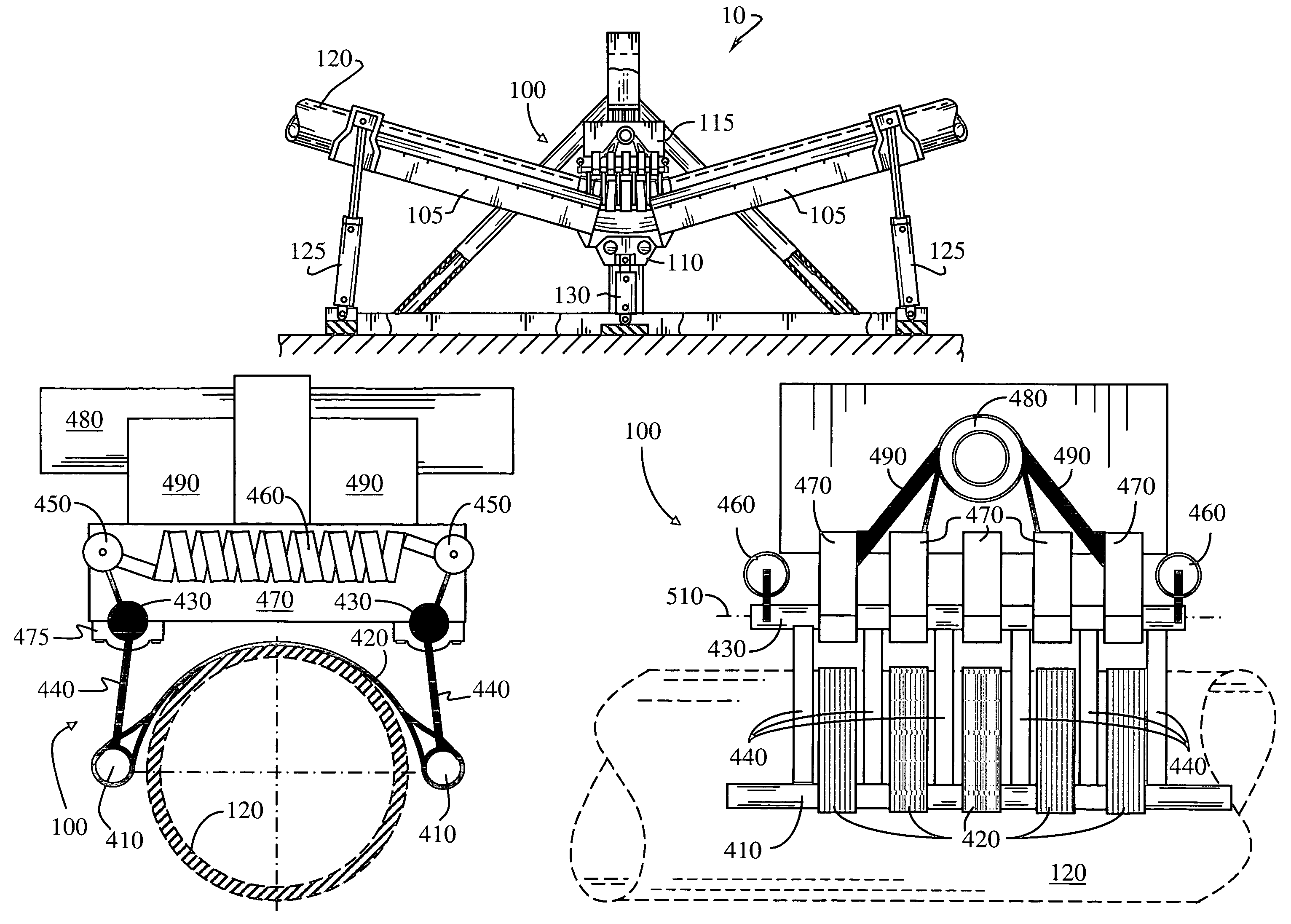

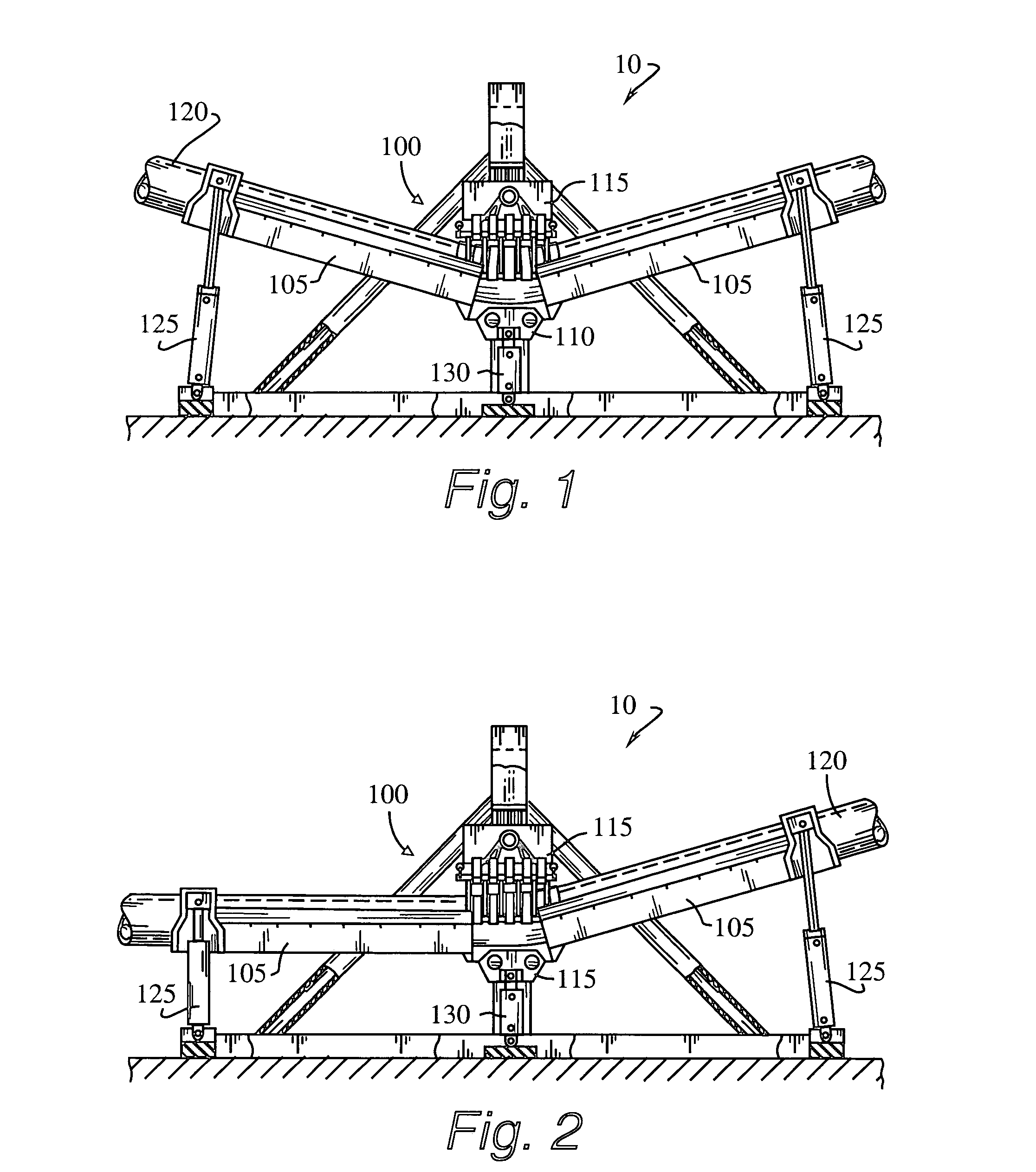

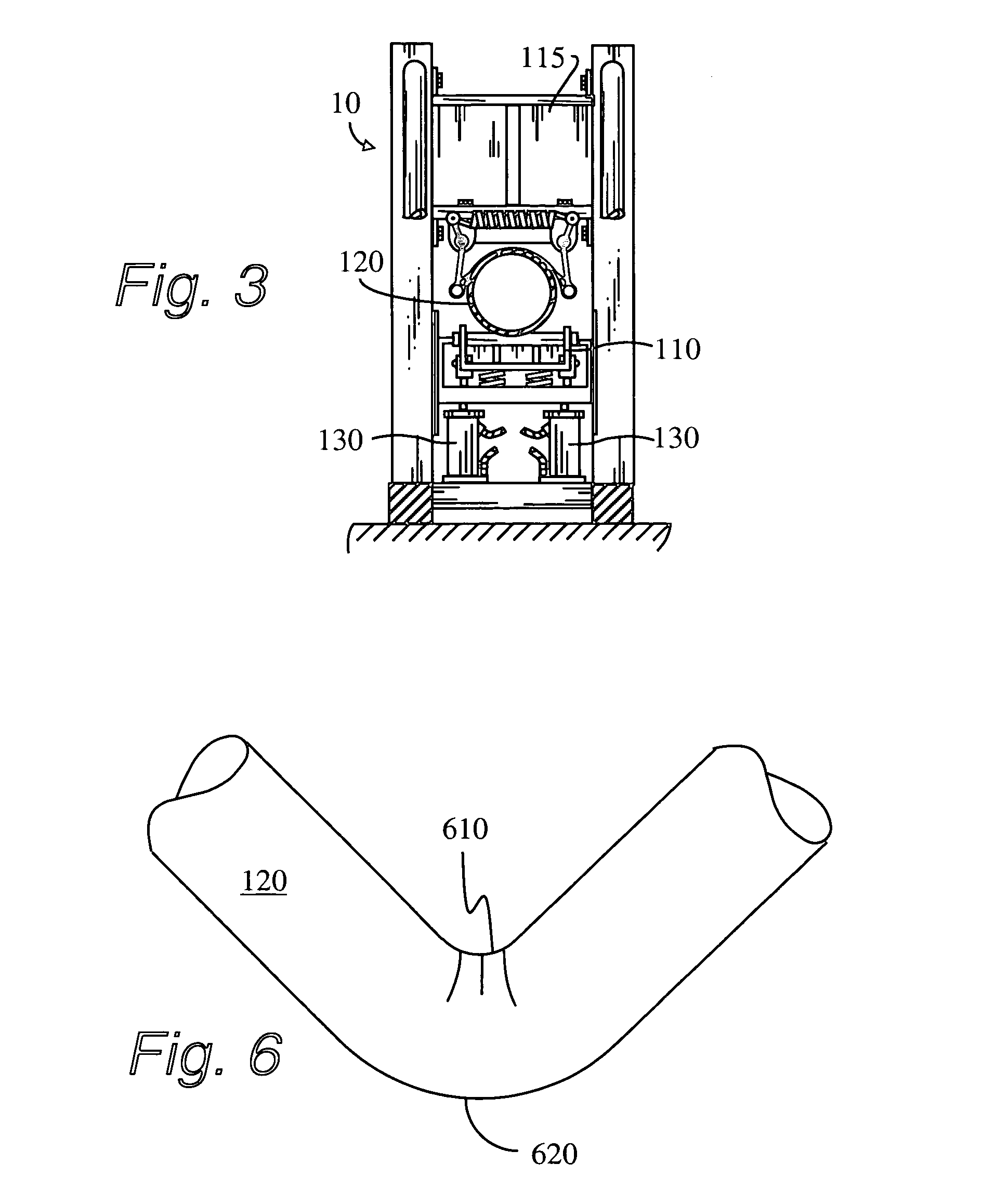

Pipe bending apparatus

An improved pipe bending apparatus comprising a plurality of belts supporting the minor radius of the bend. The belts cannot support stresses sufficient to allow concentrated stress to cause the pipe walls to collapse. The belts are affixed to a framework that forces the belts into the sides of the pipe, thereby providing support to maintain ovality of the pipe cross-section.

Owner:THEENER RONALD E

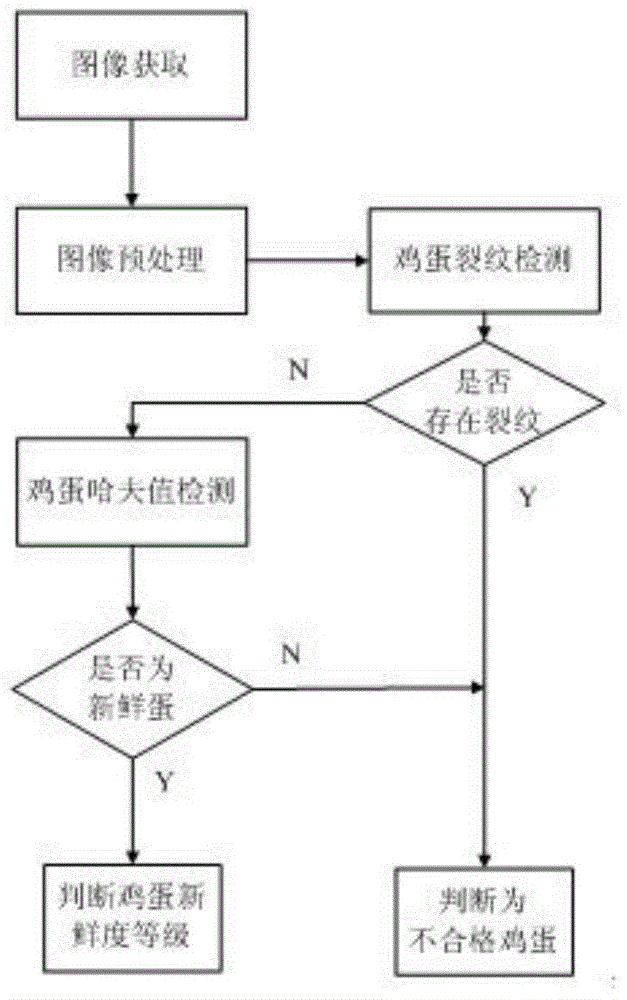

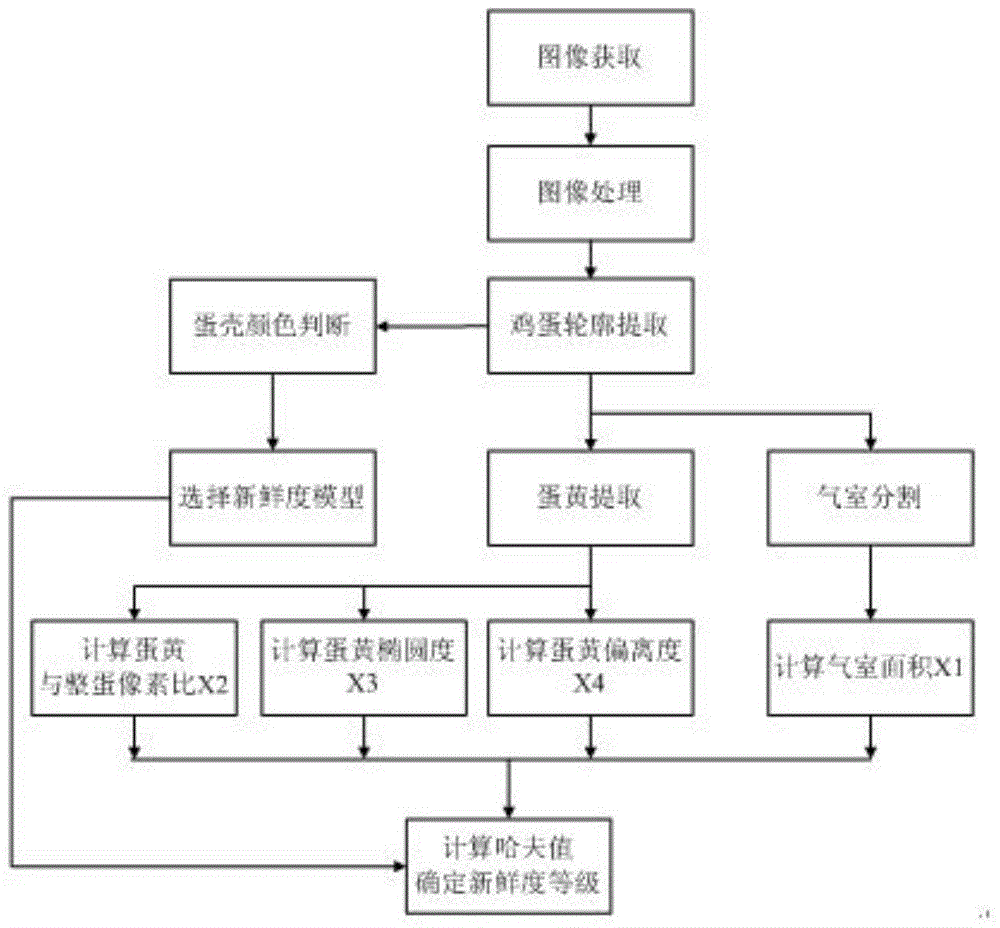

Egg freshness nondestructive testing system based on Android system and egg freshness nondestructive testing method

InactiveCN104535588AImprove accuracyApplicable useOptically investigating flaws/contaminationAnimal scienceReal-time testing

The invention provides an egg freshness nondestructive testing system based on an Android system and an egg freshness nondestructive testing method. By utilizing the egg freshness nondestructive testing system and the testing method, a target can be subjected to real-time testing, the speed is high, and the testing accuracy is high. The testing method comprises the following steps: firstly determining whether an egg has a crack, then fractionizing freshness testing to four different testing items of air chamber area, ratio of egg yolk pixel to whole egg pixel, egg yolk ovality and egg yolk deviation, training to obtain effect weight to the freshness of the different testing items, namely a freshness model, and synthesizing to obtain a Half value of the tested egg. By utilizing the egg freshness nondestructive testing system and method, the freshness of the egg can be directly provided, and the egg freshness nondestructive testing system has testing instantaneity and high testing stability and accuracy and is suitable for an egg consumer to use.

Owner:HOHAI UNIV CHANGZHOU

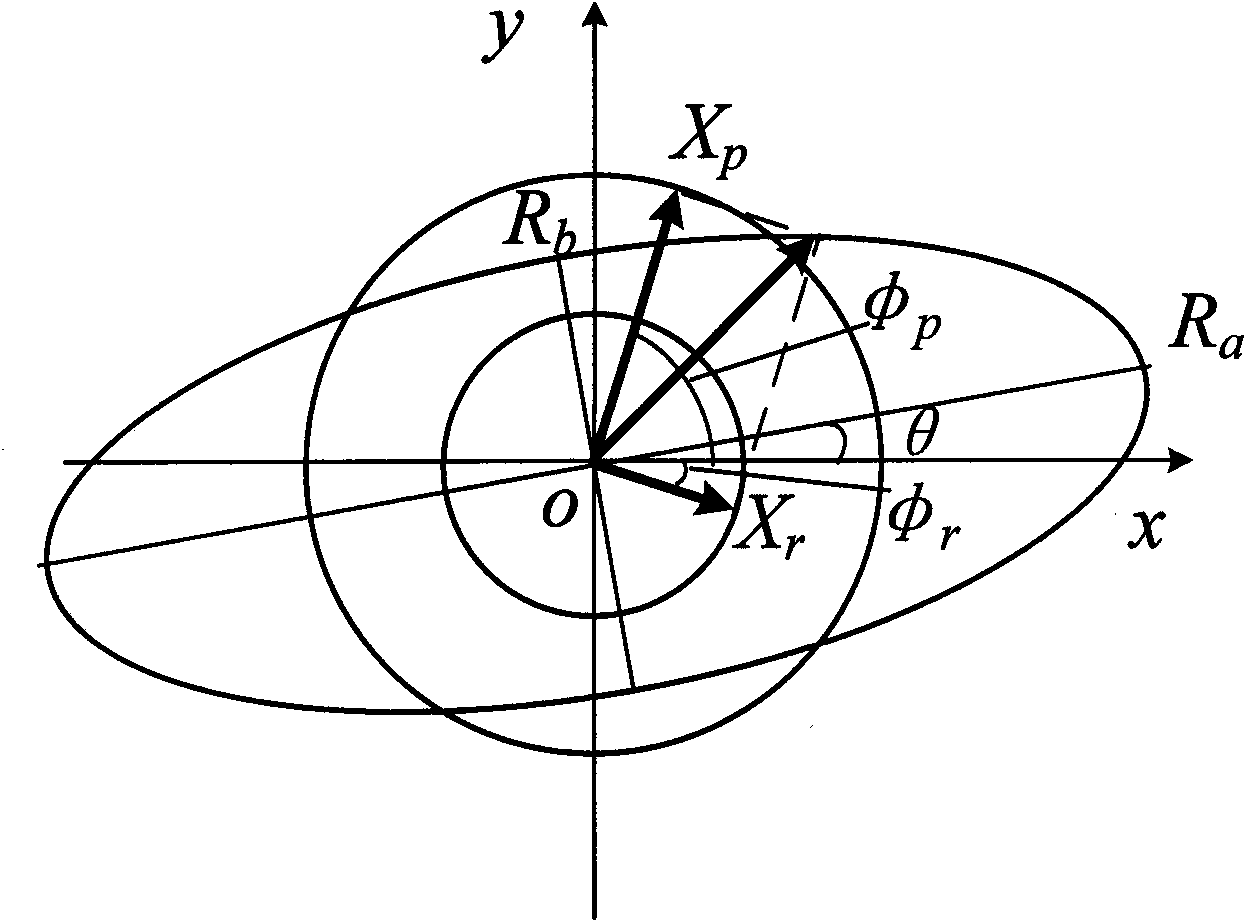

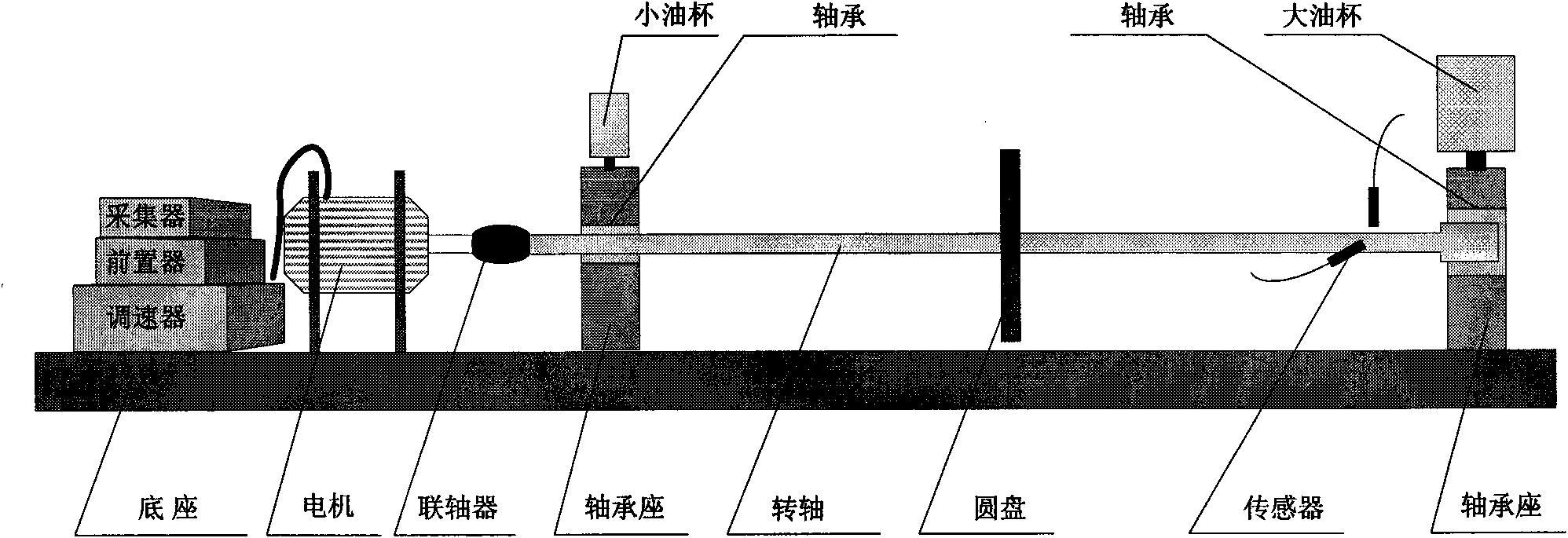

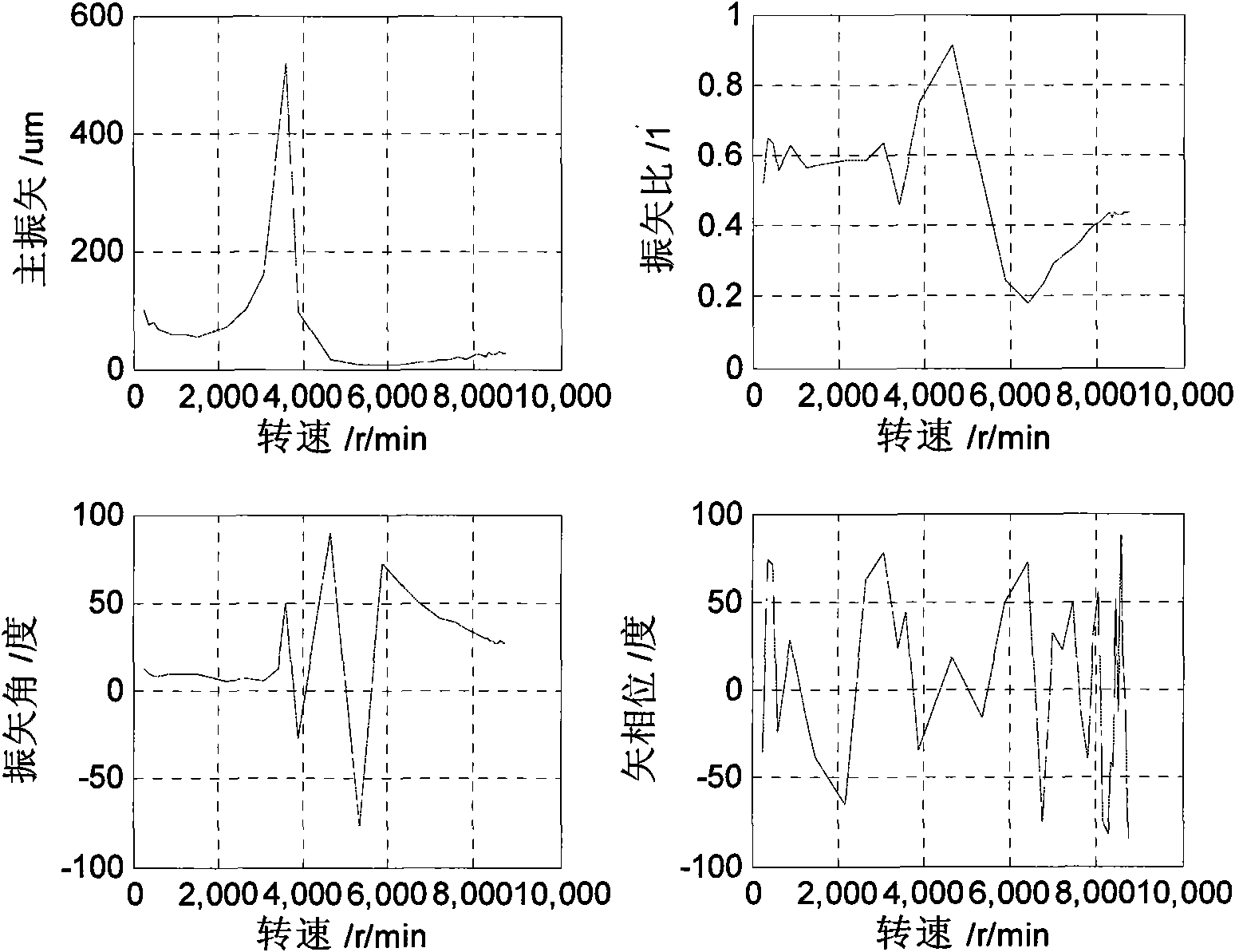

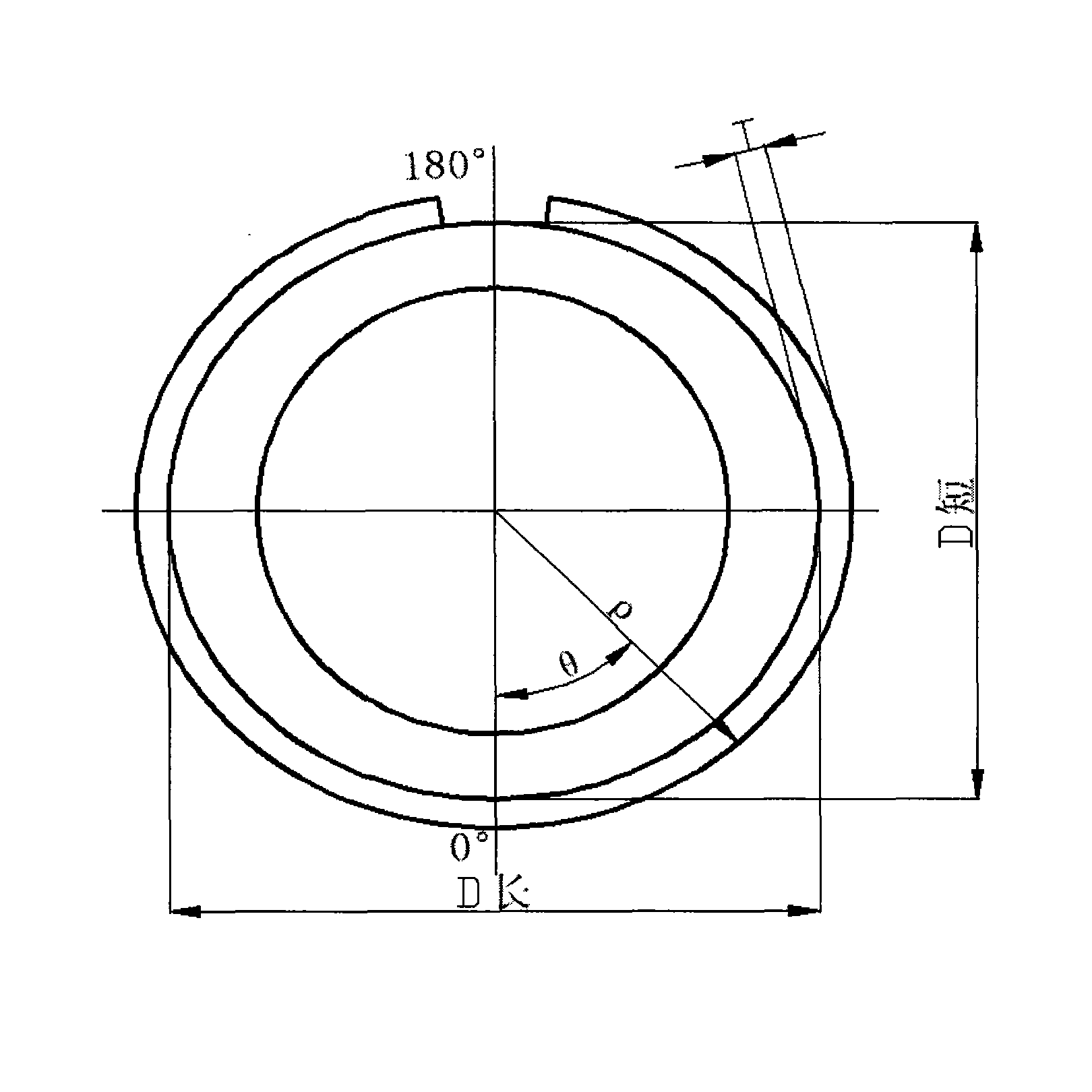

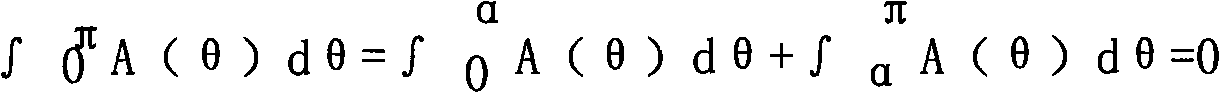

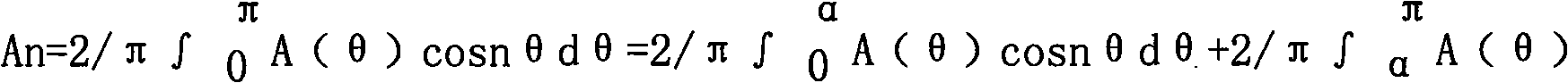

Analytical method of rotor transient signal

ActiveCN101561312AEasy to identifyMake up for limitationsMachine part testingSubsonic/sonic/ultrasonic wave measurementUltimate tensile strengthPhase point

The invention discloses an analytical method of a rotor transient signal, which comprises the following steps: 1) two orthogonal current vortex displacement sensors are arranged on a rotor section to collect a vibration signal of a rotor relative to a bearing support, the direction of the sensor from X to Y is consistent with the rotation direction of the rotor, and an equal rotary speed signal is adopted for collection and a key phase signal is used for simultaneous complete alternation sampling; 2) signals collected are processed with anti-alias filtering, low-pass filtering and the like to remove unnecessary interference noise signals; 3) the computation of main vibration vector, vibration vector ratio, vibration vector angle and vector phase is conducted, complex FFT conversion is adopted and one-time FFT computation is utilized to obtain such characteristic parameters; 4) a relational graph of each parameter relative to rotation speed or other variables is drawn; and 5) a main vibration vector graph is used for expressing the vibration strength change of measuring points under a single frequency, a vibration vector ratio graph is used for expressing the ovality change of the single frequency vortex track of measuring points, a vibration vector angle graph is used for expressing the change of maximum vibrating direction, and a vector phase graph is used for expressing the change of a vibration vector and a reference phase point.

Owner:郑州恩普特科技股份有限公司

Processing method of steel piston gas ring

ActiveCN101649790ALow yieldSolve the cumbersome machining processPiston ringsMachines/enginesPliabilityProcess manufacturing

The invention discloses a processing method of a steel piston gas ring, which comprises the following steps: winding-destressing-grooving-shaping-top line trimming-flat surface grinding-excircle boning-chroming or nitriding-top line trimming-excircle boning-top line trimming-flat surface grinding; the size of a shaped blank rod is improved by calculating pressure distribution mold lines with different ovality requirements and fully considering the mold line change caused by nitriding shrinkage, thereby the problem of gas ring deformation after procedures, such as nitridation, and the like is greatly reduced, and the finished product ratio of the product is improved. Compared with the defects of long process routes, multi-workshop crossing processing and low comprehensive finished product ratio in the casting iron gas ring, the comprehensive finished product ratio of the steel gas ring processed by using the shaped blank rod can reach up to 95 percent. By utilizing the pliability characteristic of the steel and adopting a shaped steel winding and shaping process, the invention solves the fussy machining process of cast iron material, shortens the manufacturing period, also reduces the procedure waste simultaneously and saves the process manufacturing cost.

Owner:NANJING FAYN PISTON RING

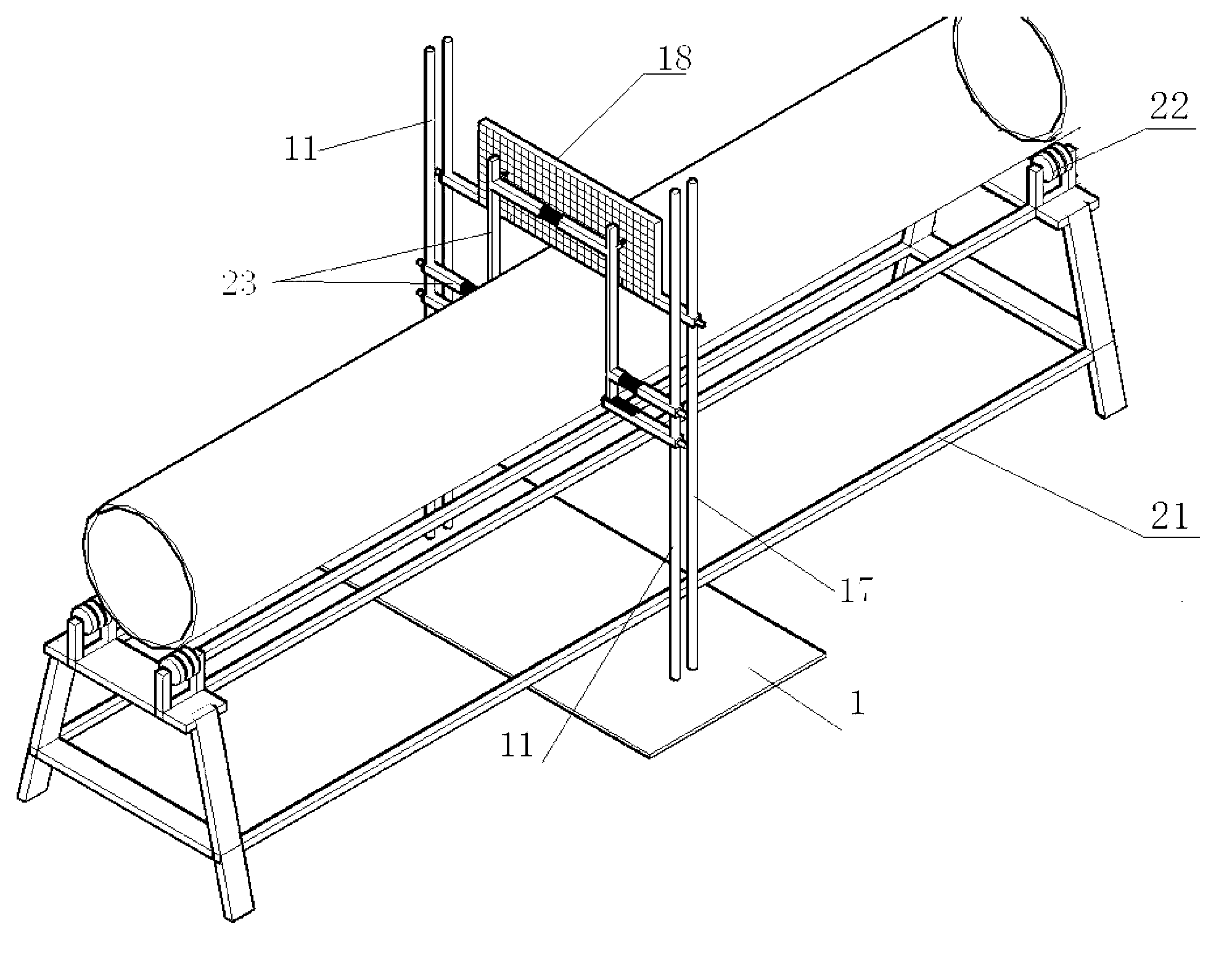

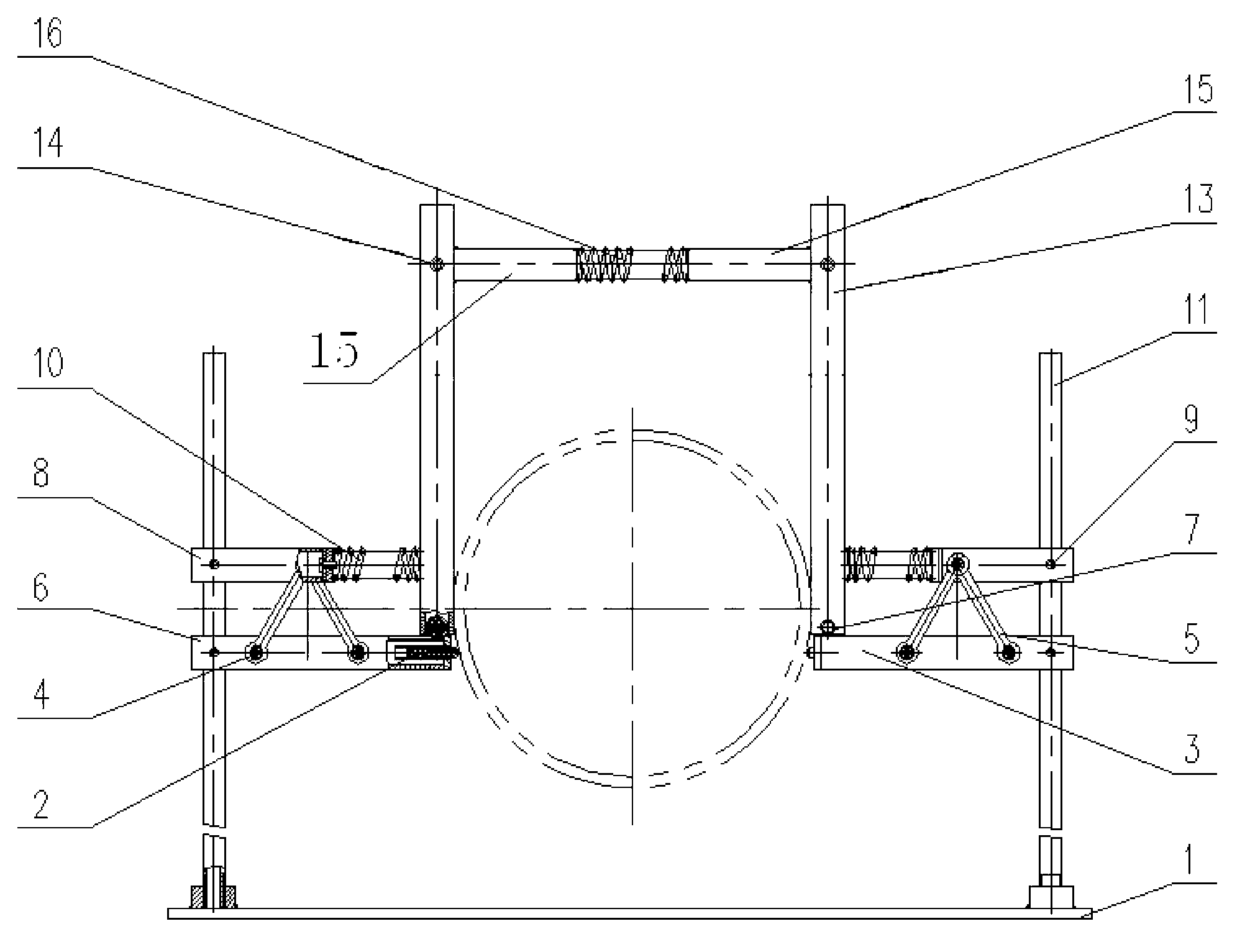

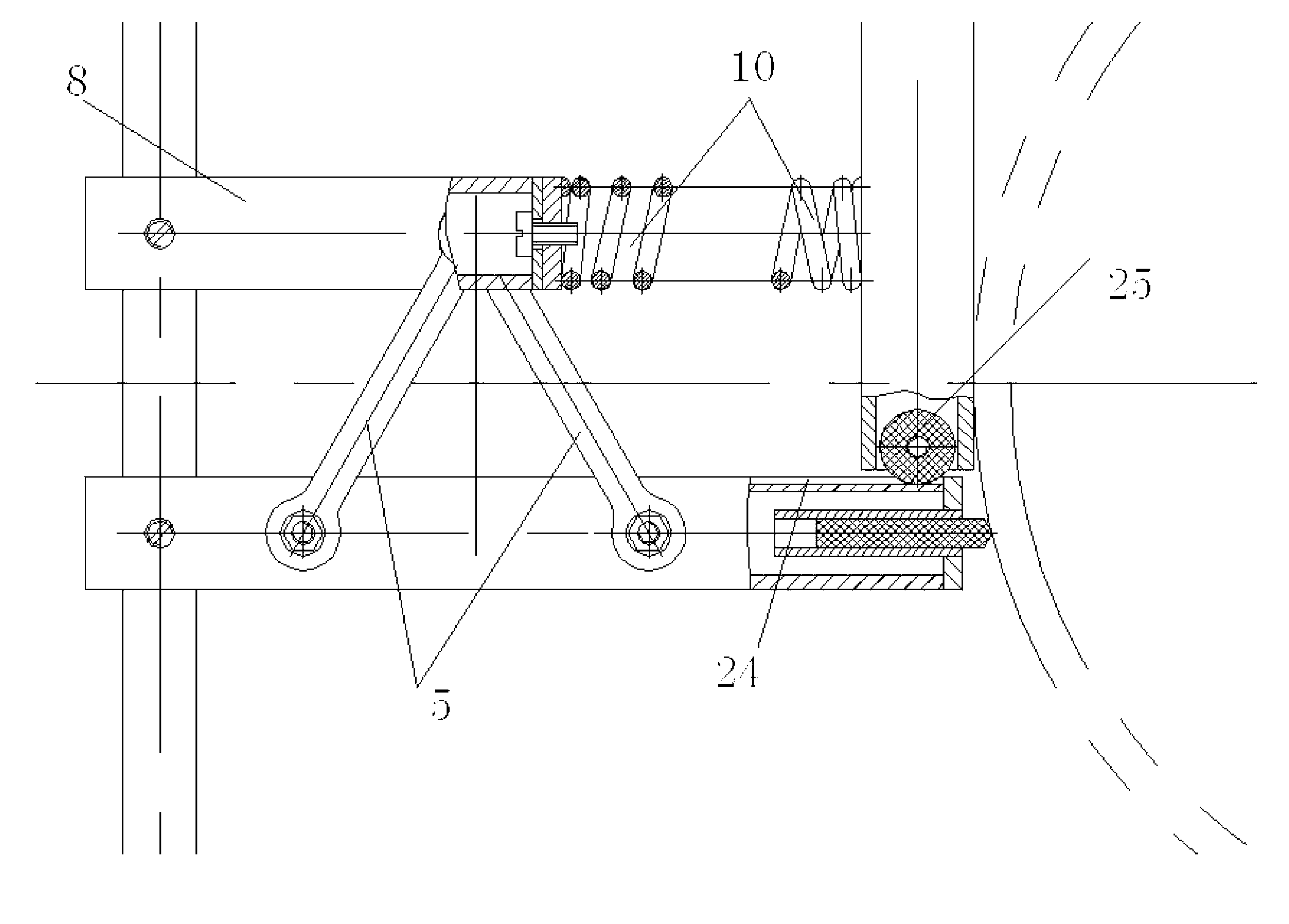

Device for measuring pipe ovality

ActiveCN102937404AUniform measurement accuracyUnified AffordabilityMechanical counters/curvatures measurementsLong axisEngineering

The invention belongs to the technical field of pipe production and laying installation and relates to a device for measuring pipe ovality. The device comprises a drawing board connected onto a drawing board column and an ovality measuring mechanism connected onto a measuring column. The drawing board column and the measuring column are vertically fixed. The ovality measuring mechanism comprises two vertical rods connected through a horizontal beam with a horizontal spring. The lower portion of the ovality measuring mechanism is connected onto the measuring column on the same side through an upper beam and a lower beam respectively. One end of the lower beam is vertically fixed on the measuring column on the same, a guide groove is axially arranged on the upper portion of the other end of the lower beam, and the lower ends of the vertical rods are installed in the guide groove through balls. The upper beam is provided with a demarcation spring, and the upper ends of the two vertical rods are respectively fixedly connected with a marking pen pointing to the drawing board. By means of the device, measurement workers can conveniently and directly read length of a long shaft and a short shaft on the section of a pipe, and simultaneously determines the position of endpoints of the long shaft. The device achieves quality checking of the large-diameter pipe.

Owner:TIANJIN UNIV

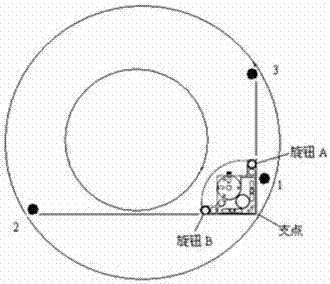

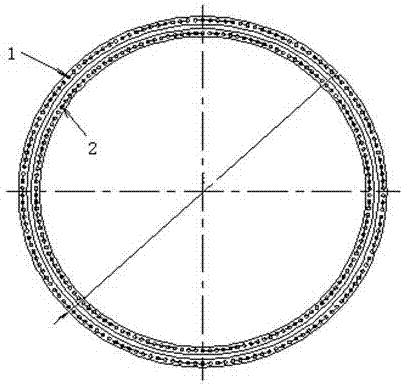

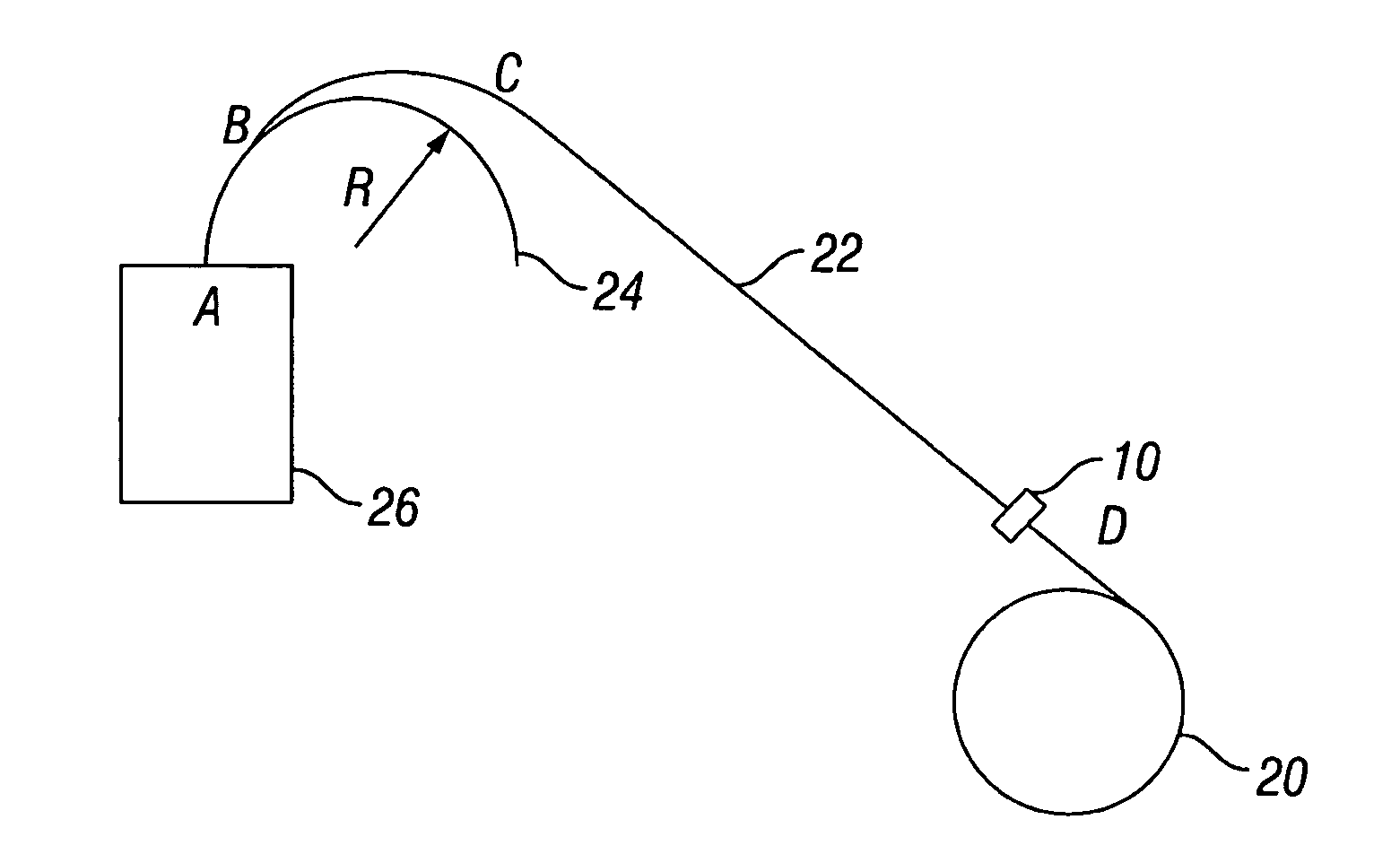

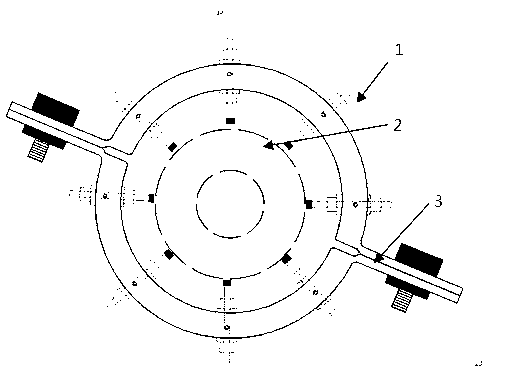

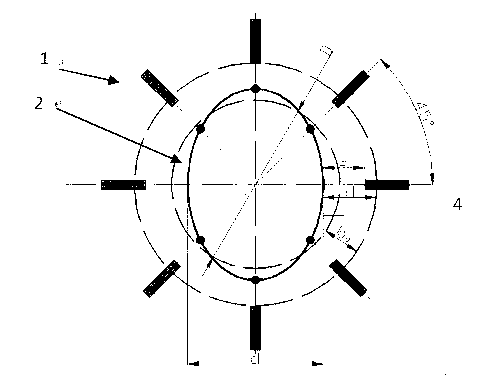

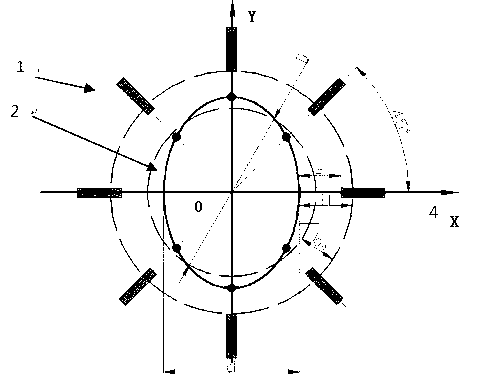

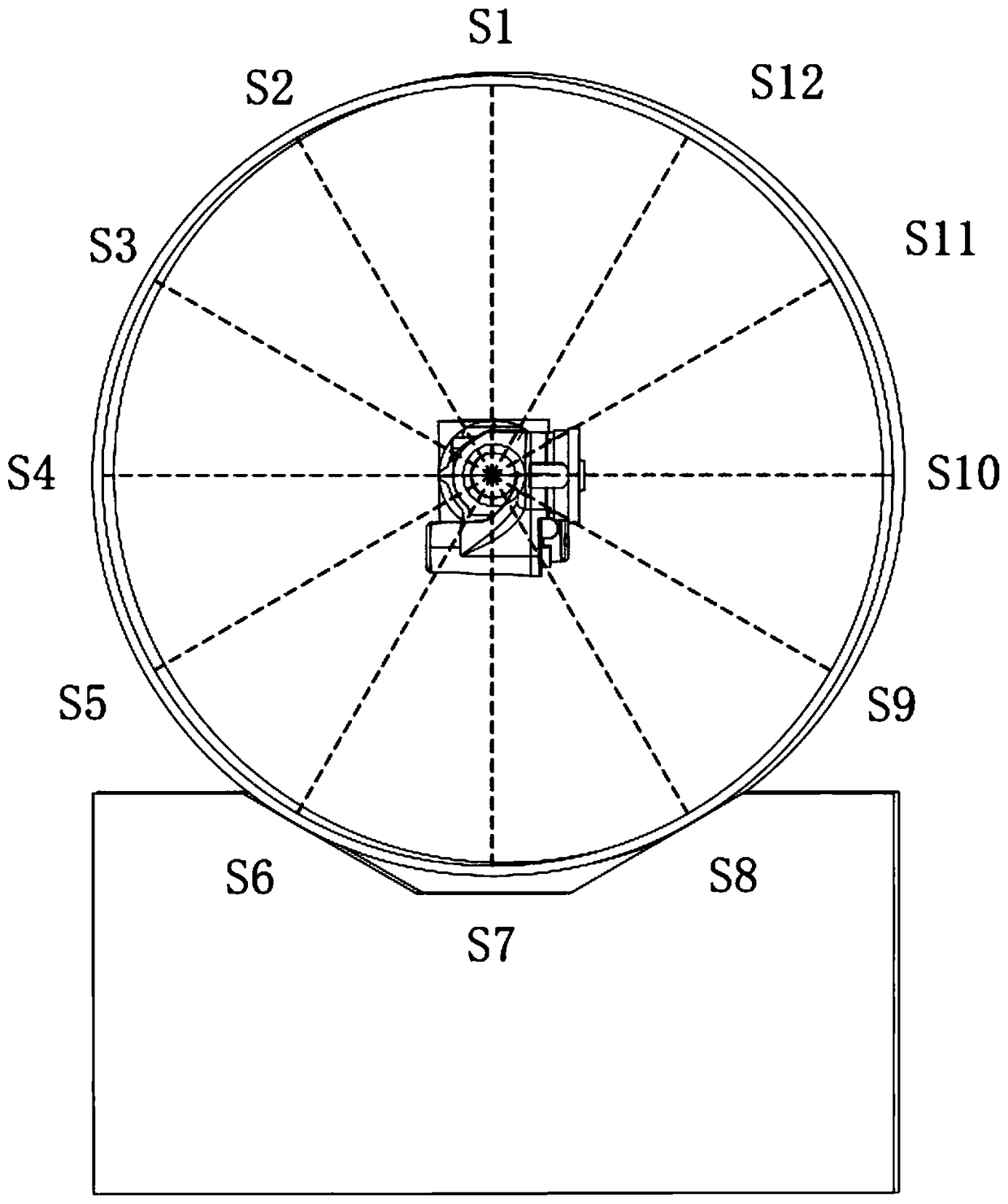

Coiled tubing ovality testing method

ActiveCN103063126AAchieve losslessRealize non-contactElectric/magnetic contours/curvatures measurementsContinuous measurementStraight tube

The invention relates to the technical field of coiled tubing testing, and discloses a coiled tubing ovality testing method. Lift-off heights of eight points of the same circumference of a certain position of coiled tubing are detected by means of the adoption of a displacement sensor, and then ovality of the coiled tubing on the position is calculated. Compared with a magnetic flux leakage testing method and an ultrasonic testing method, the coiled tubing ovality testing method can achieve undamaged, contactless and continuous measurement, cannot be subjected to influences of non-electrical-conductivity sundries of the surface of the coiled tubing, and is suitable for coiled tubing in various specifications or straight pipes and bent pipes made of other materials.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

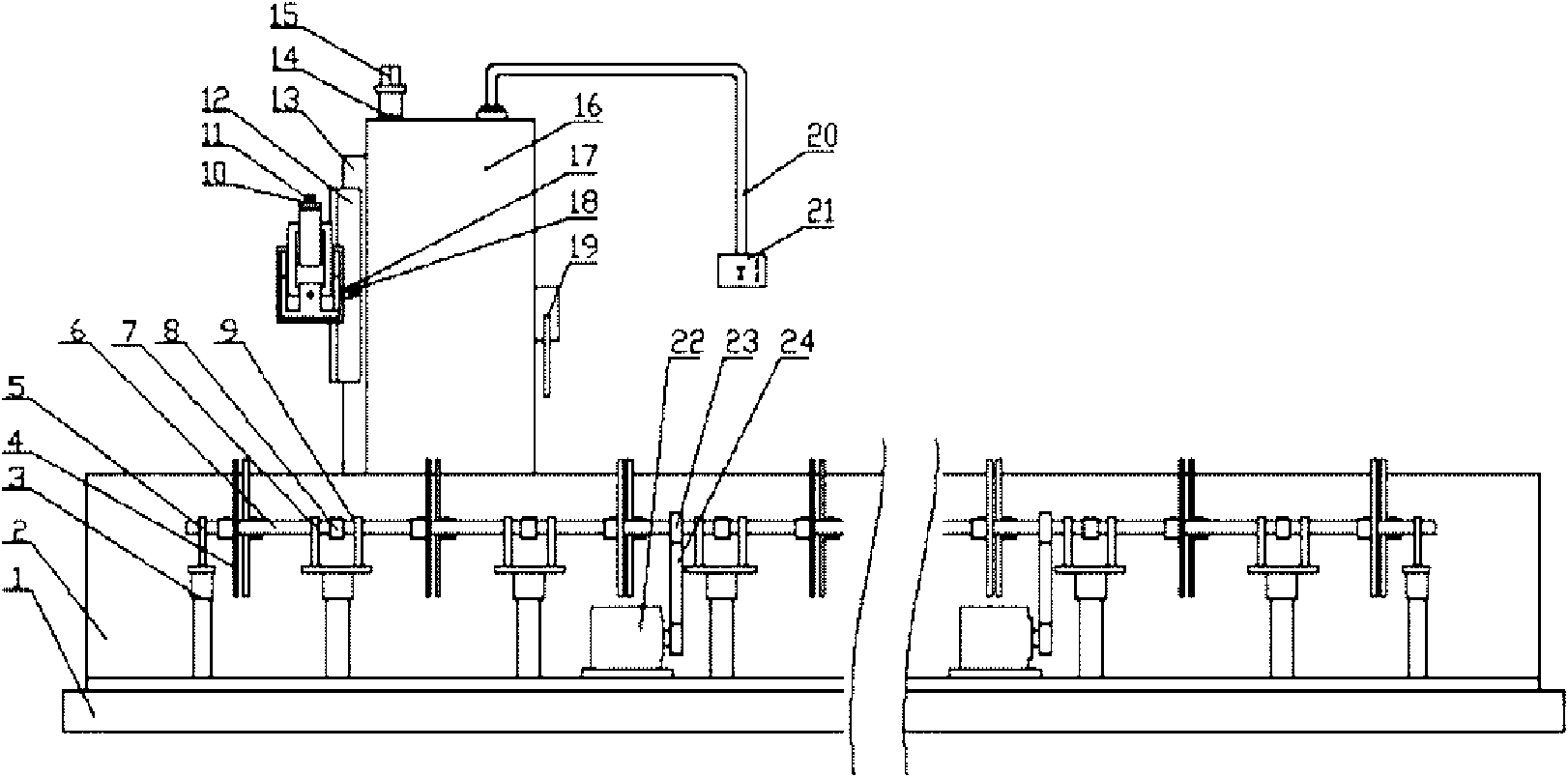

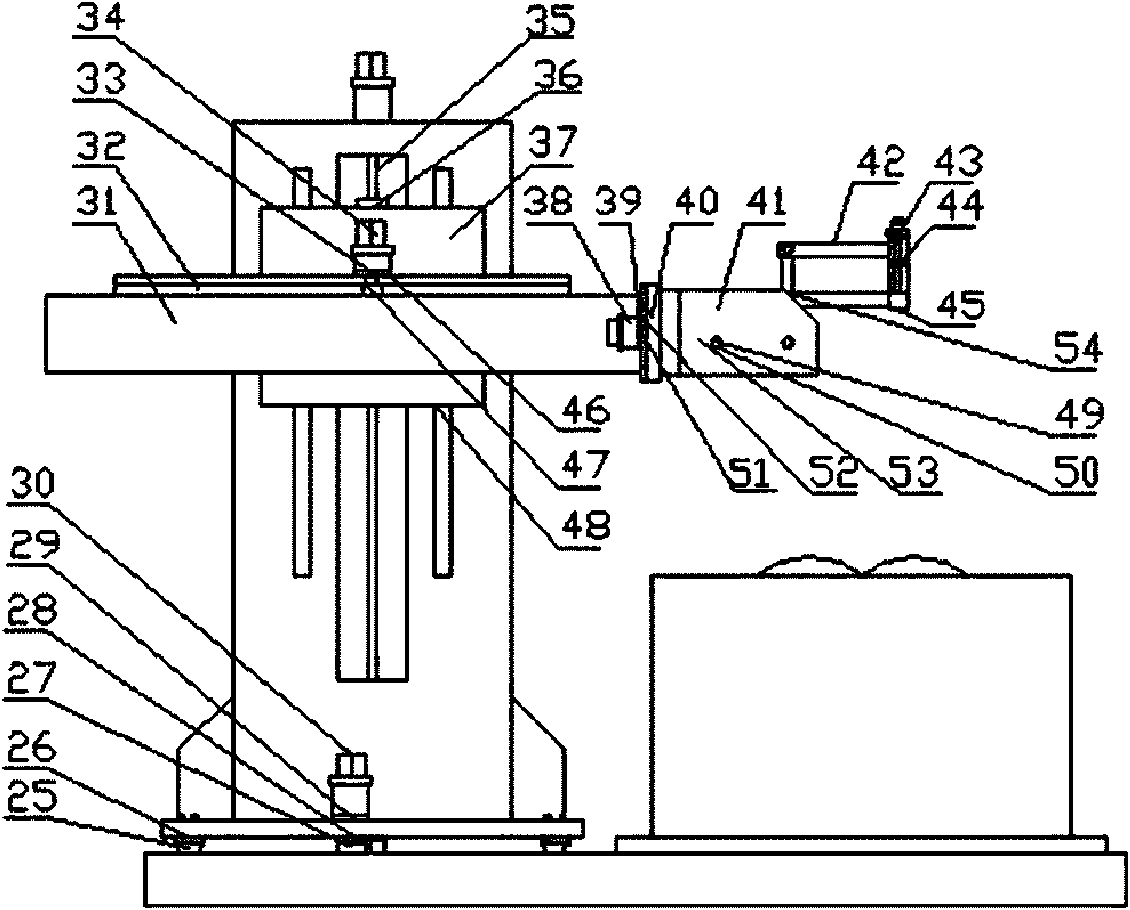

Cutting machine of seven-axis numerical control pipeline intersecting line

InactiveCN101664844AShorten the development cycleReduce development costsPlasma welding apparatusGas flame welding apparatusSocial benefitsNumerical control

The invention relates to a cutting machine of a seven-axis numerical control pipeline intersecting line in the technical field of numerical control cutting, comprising a base, a cutting gun body, a friction wheel device, a mobile device, a rotating device, a swinging device, a cutting saw seat and an ovality compensating mechanism, wherein the friction wheel device is connected with the base; thecutting gun body is movably arranged on the base; the mobile device, the rotating device and the swinging device are respectively and movably arranged on the cutting gun body; the cutting saw seat isfixedly arranged at the output tail end of the cutting gun body; and the ovality compensating mechanism is fixedly arranged on the cutting gun body. The cutting machine can adapt to the requirements of various processing tasks, ensure cutting quality and cutting precision, improve efficiency, save materials and have good economic and social benefits.

Owner:SHANGHAI JIAO TONG UNIV

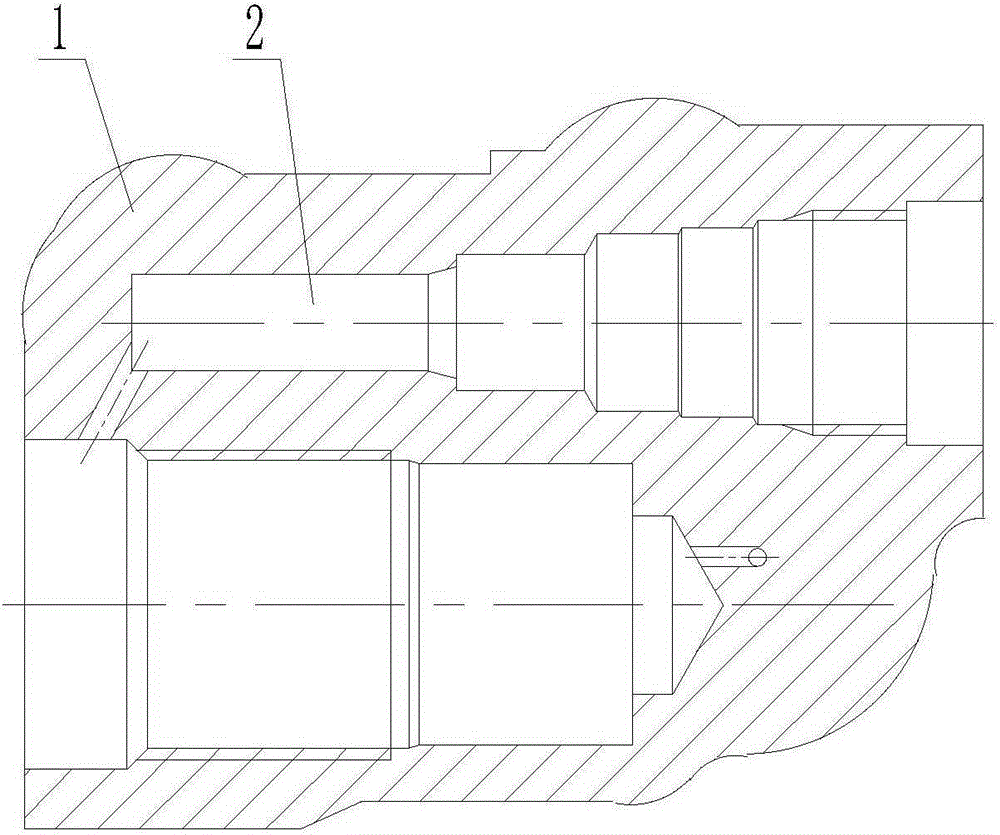

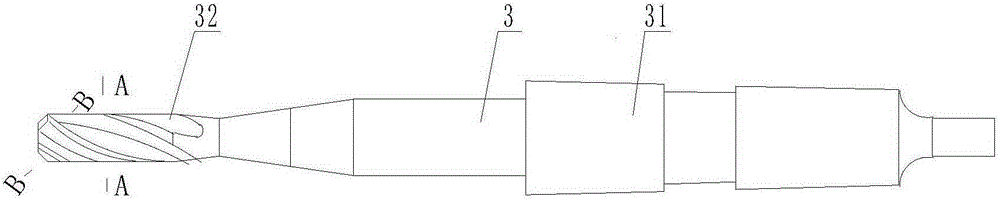

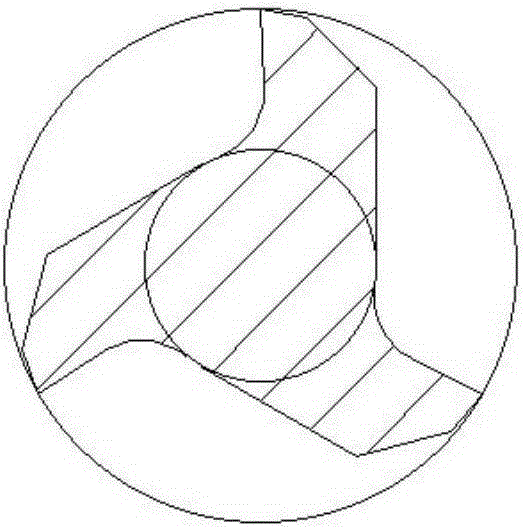

Efficient machining method of precise valve hole

The invention discloses an efficient machining method of a precise valve hole; and the method comprises such steps as drilling, broaching, rough reaming, finish reaming, no-edge reaming and extrusion of a chip extruding hole and inspection. The efficient machining method can effectively solve such problems as incapability of achieving the precision requirement, low product pass percent, long machining period, low efficiency, high labor intensity, high waste rate and high machining cost in machining of the precise valve hole in the prior art; the product pass percent is greatly improved; the roughness Ra of the machined hole reaches 0.8-0.4 micron; the ovality error is within 0.01-0.02 mm; the taper error is within 0.01-0.025 mm; the hole size precision can be controlled within 0.01 mm; and the product pass percent reaches above 99%.

Owner:贵州凯星液力传动机械有限公司

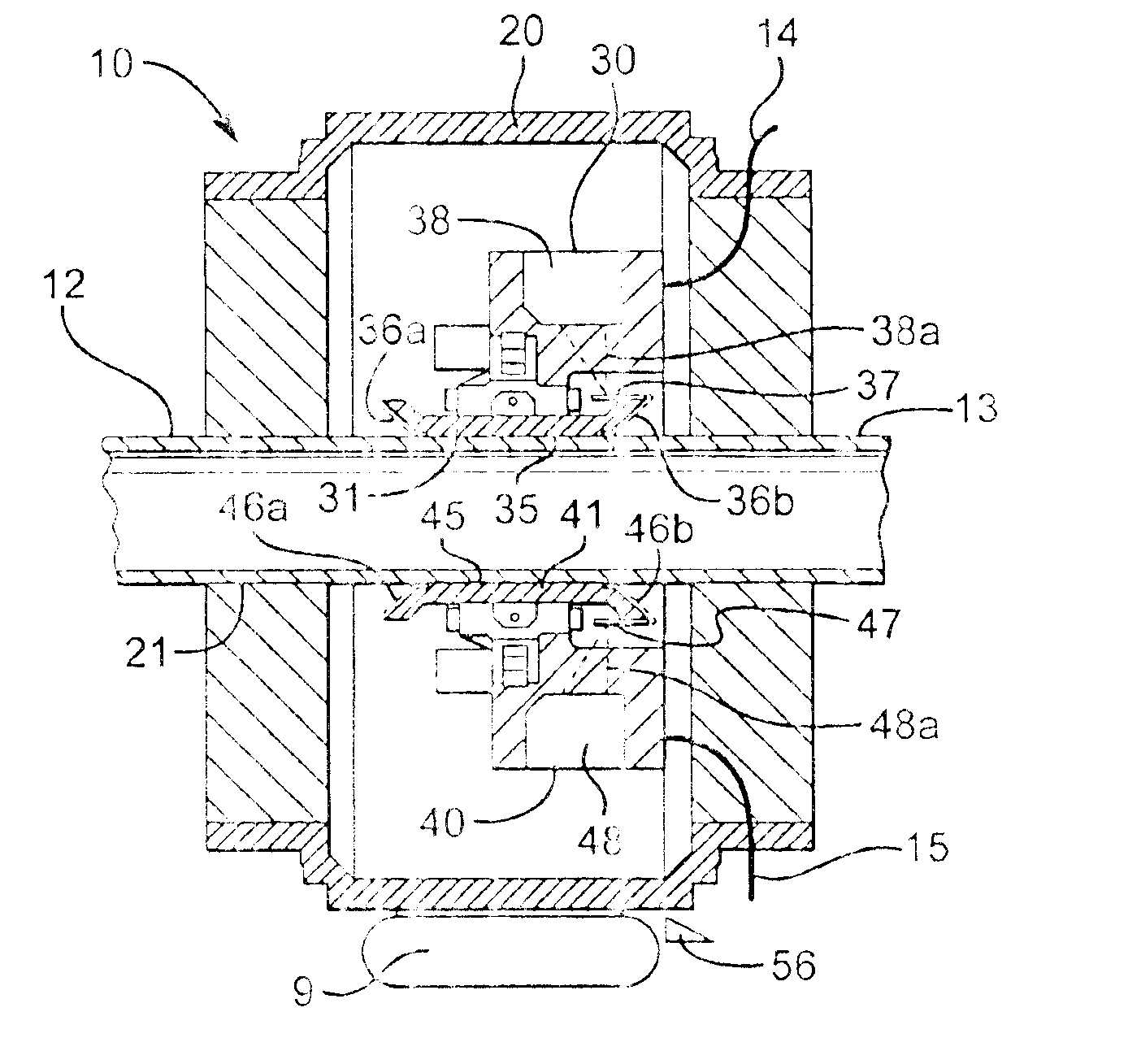

Tubular ovality testing

InactiveUS6862099B2Investigating moving sheetsUsing mechanical meansLinear variable differential transformerMeasurement device

A system for measuring diameter (inner and / or outer) of a tubular, the system in at least certain aspects including at least one linear distance measuring device with respect to which a tubular to be measured is movable, the at least one linear distance measuring device including a detector for detecting a surface of the tubular, the detector movably mounted to mount apparatus, the detector movable longitudinally along the surface of the tubular and movable axially in response to variation in diameter of the tubular, a rotatable head rotatable with respect to the tubular either outside of it or within it, the mount apparatus secured to the rotatable head, at least one signal production apparatus secured to the mount apparatus or head, and in communication with the linear distance measuring device, the at least one signal production apparatus for producing a signal indicative of distance between said detector and a known point, and transmitting apparatus for transmitting said signals to processing equipment for determining diameter of the tubular; and in certain aspects the linear distance measuring device is a laser device, electronic measurement device, acoustic measurement device, infrared measurement device, or linear variable differential transformer device.

Owner:VARCO I P INC

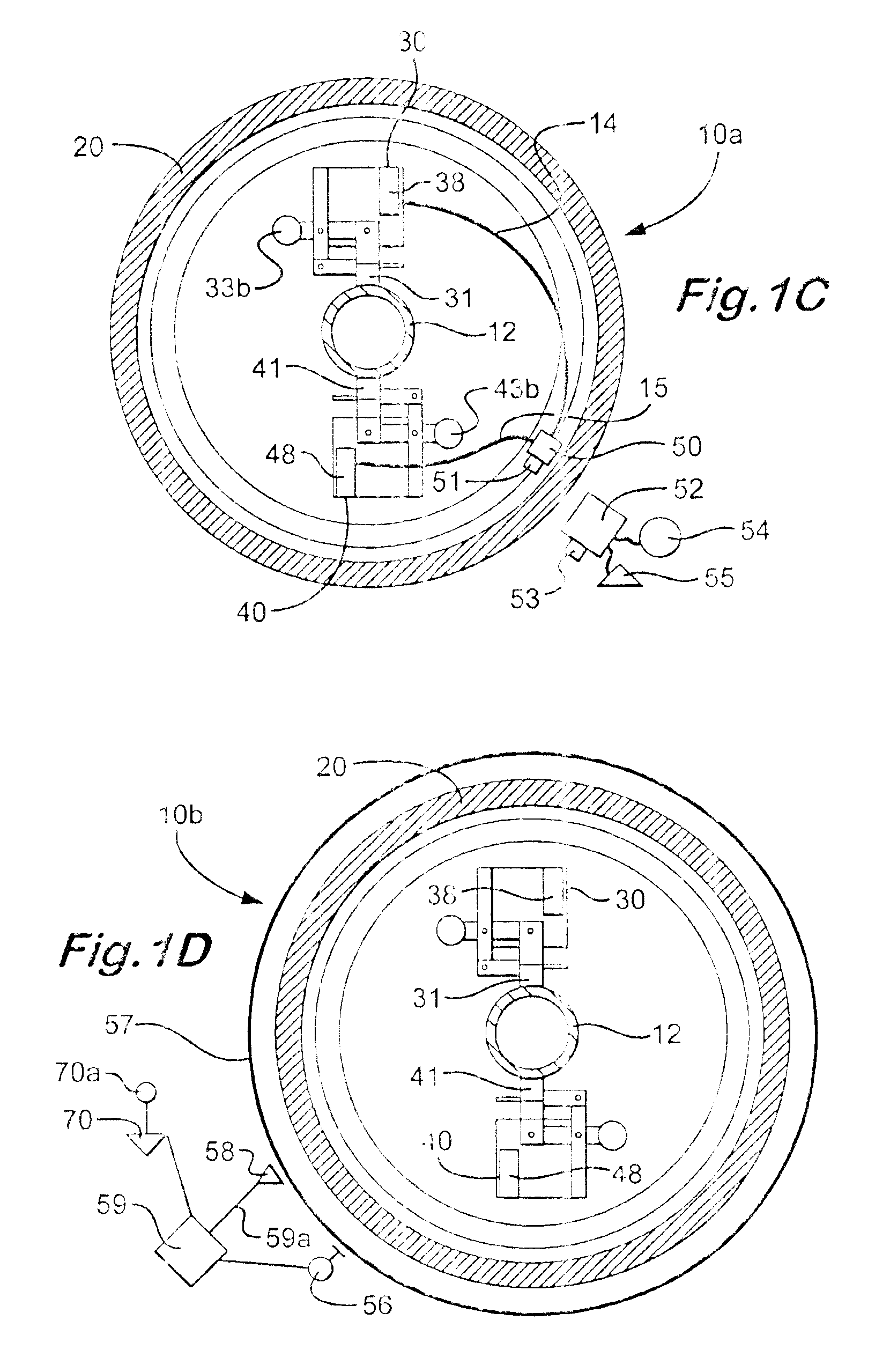

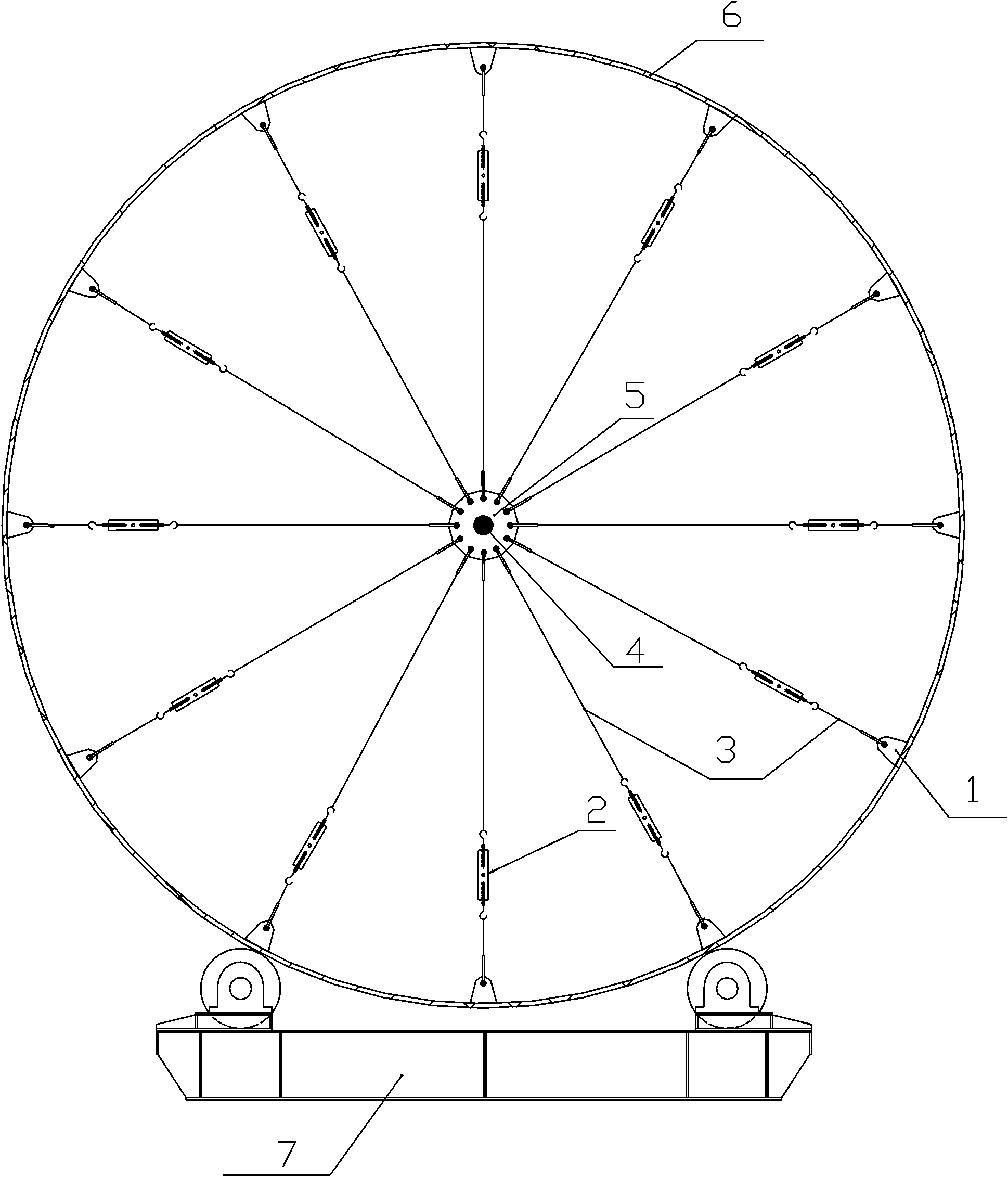

Method for preventing deformation of guyed assembling and welding large-scale horizontal storage tank shell section

The present invention relates to the field of an assembling and welding device of large-scale horizontal tanks, in particular to a method for preventing deformation of guyed assembling and welding a large-scale horizontal storage tank shell section. The method is characterized by comprising the following steps of: connecting adjustable stay cables in the internal wall of the shell section after assembling an arc-shaped shell board of the shell section, tightening the stay cables, applying a deformation reacting force, then assembling and welding. The method adopts the steel wire ropes and a screwing device to connect the internal parts of the horizontal storage tank, and prevents the deformation through tightening the steel wire ropes. The method can quickly adjust the screwing device to adjust the tightening force of the steel wire ropes according to the states in the field, thereby further adjusting the deformation quantity; simultaneously, the method can directly adjust parts of the large-scale horizontal storage tank whose ovality exceeds the standard for meeting the requirements of the construction technology. The device can be conveniently detached and reused.

Owner:WUHAN YIYE STEEL STRUCTURE

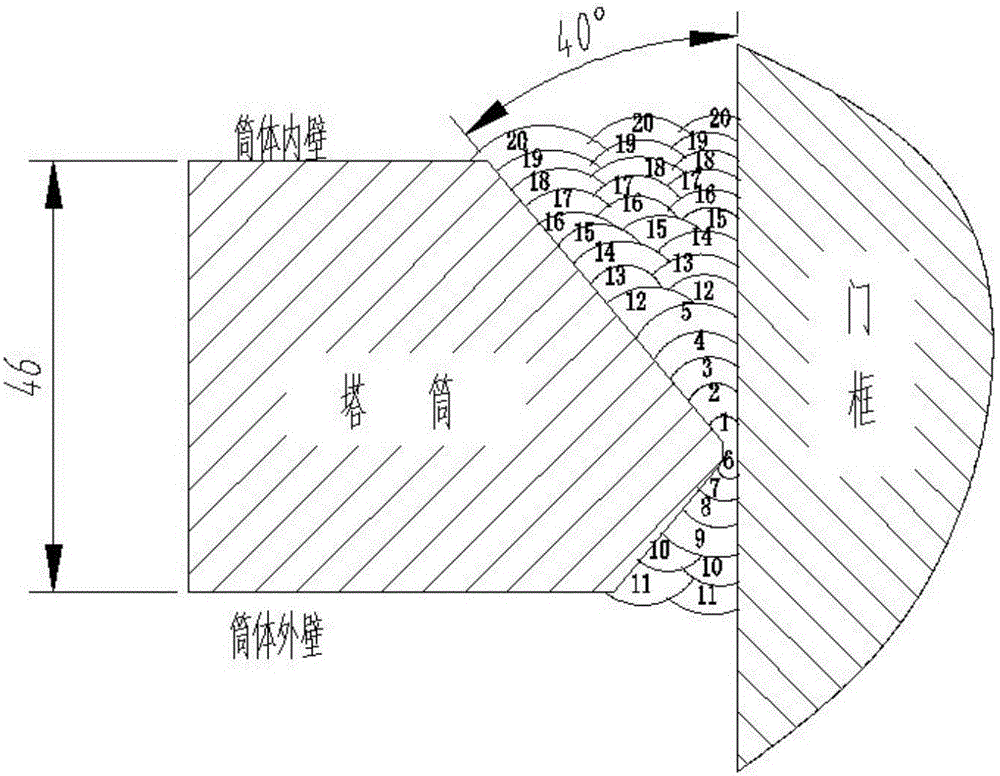

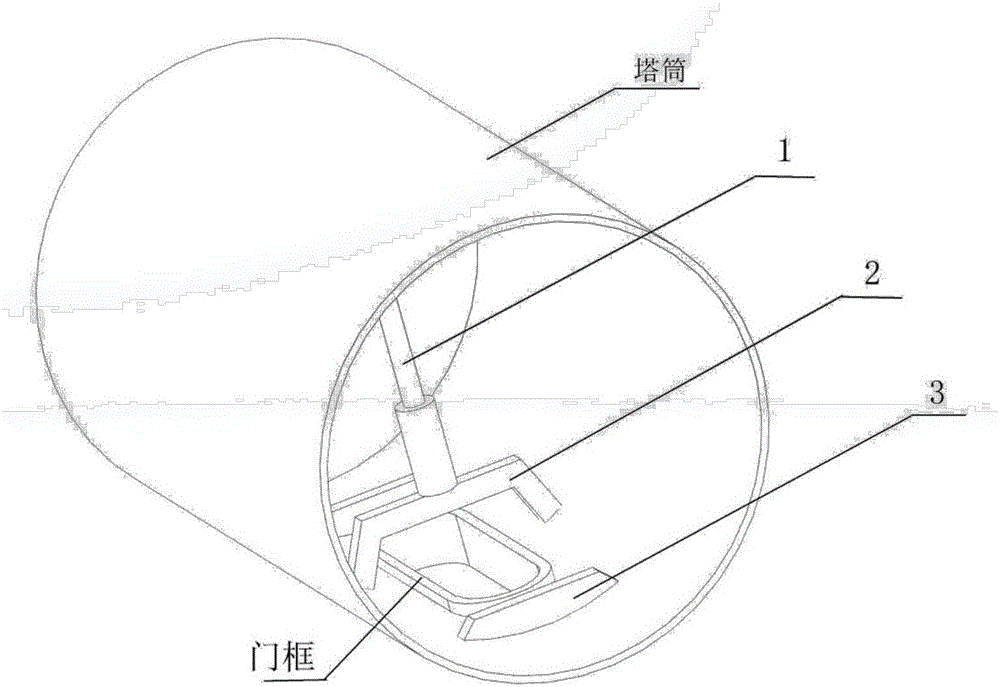

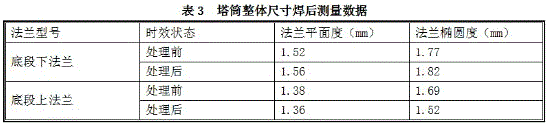

Method for welding door frame of ultra-low-temperature high-power wind turbine tower

ActiveCN106002008AReduce mistakesIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesElectricityStress concentration

The invention discloses a method for welding a door frame of an ultra-low-temperature high-power wind turbine tower. The method comprises the following five main steps: preparing materials of the door frame; cutting a door hole; mounting an anti-deformation tool; welding corner weld of the door frame and the tower; and carrying out stress relief treatment after welding. Stress concentration of a welding region of the door frame and the tower under the working condition of ultra-low temperature and the condition of high-power generation requirements can be eliminated, defects of welding cracks and lamellar tearing are avoided, and requirements of impact energy at the low temperature of minus 40 DEG C are met; influences of stress concentration to yield of flatness and ovality of a flange of the tower is avoided; and first-pass yield of inspection and acceptance of the tower is improved.

Owner:SINOHYDRO BUREAU 4 JIUQUAN NEW ENERGY EQUIPCO

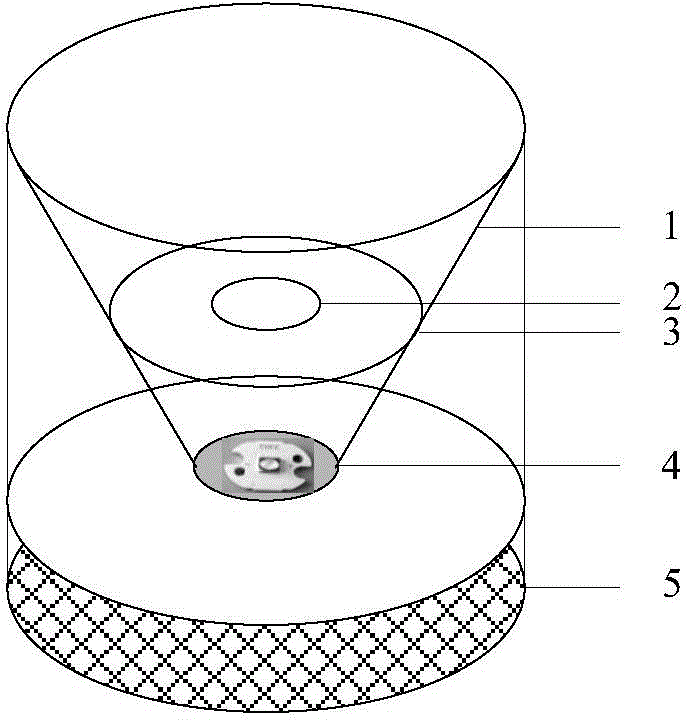

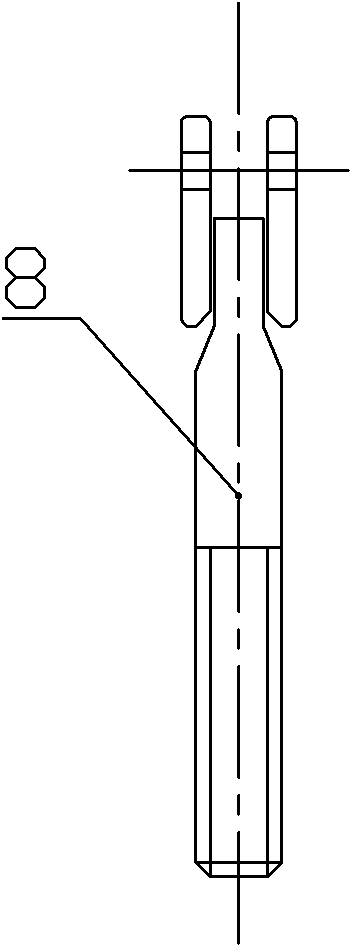

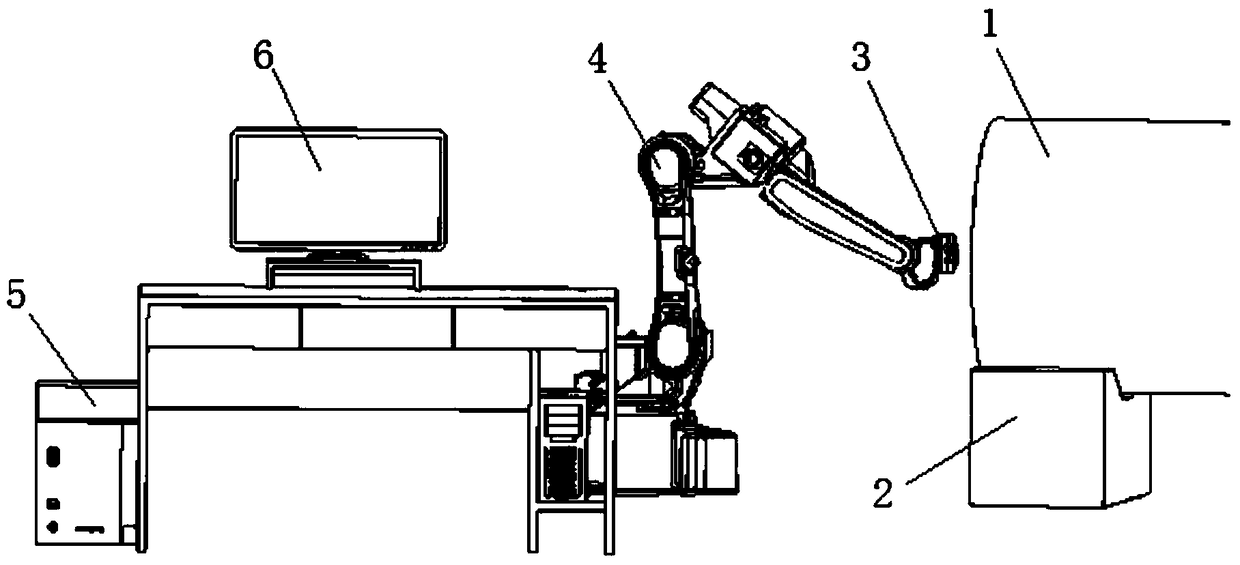

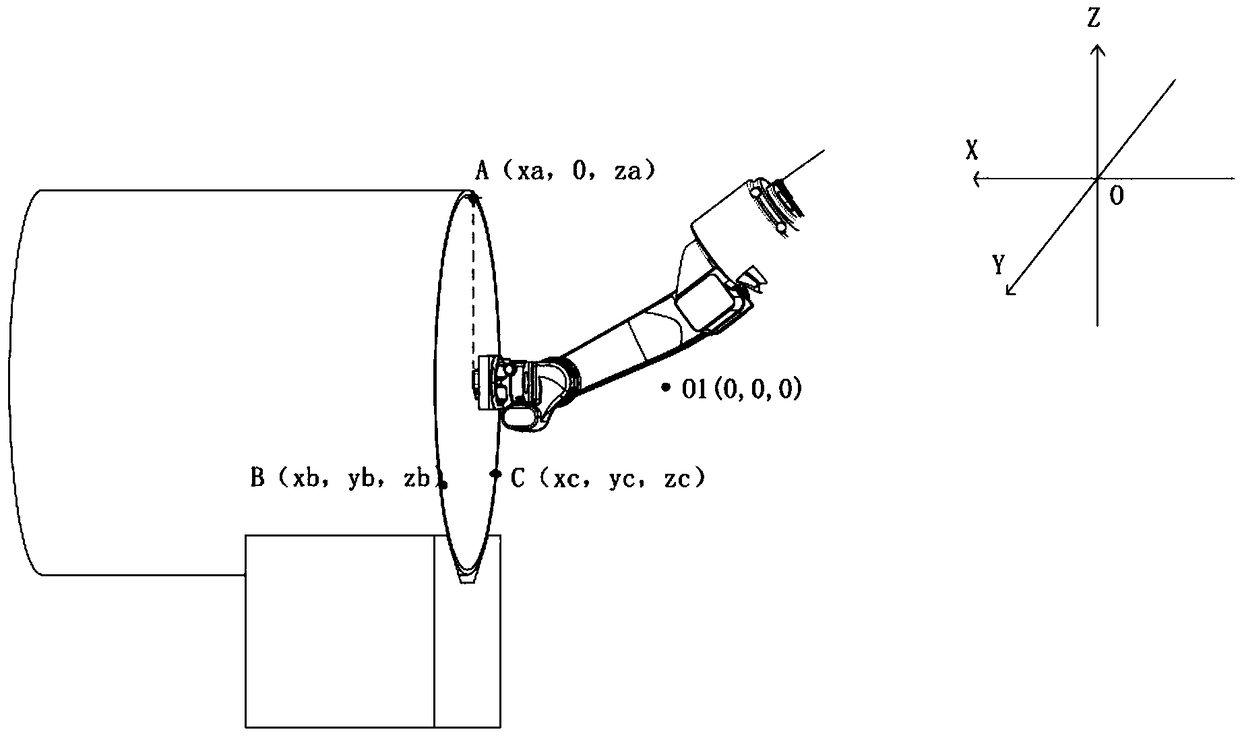

Automatic detection equipment for ovality of pipeline as well as detection method thereof

InactiveCN109186487AEasy to measureImprove accuracyProgramme-controlled manipulatorUsing optical meansLaser rangingAutomatic test equipment

The invention relates to automatic detection equipment for ovality of a pipeline as well as a detection method thereof. The detection equipment comprises an industrial robot and a V-shaped device usedfor fixing the pipeline, the industrial robot is connected with an industrial control computer in a communication way, the tail end of the industrial robot is connected with a laser ranging device, and the industrial control computer controls the industrial robot to act and receive data acquired by the laser ranging device in the communication way. The detection method comprises the following steps: firstly, automatically adjusting attitude by the industrial robot, so that the laser ranging device can enter the pipeline and is vertical to a measured surface of a vertical pipeline; secondly, inserting the laser ranging device into the pipeline and rotating for one circle by virtue of the tail end of the industrial robot, measuring coordinate values of multiple points in circumferential direction, and storing a calculation result in the industrial control computer; and thirdly, calculating and fitting an elliptical curve by virtue of the industrial control computer, and obtaining lengthdata of a long axis and a short axis of the elliptical curve. The detection equipment provided by the invention fits the elliptical curve for obtaining the ovality in a way of measuring the multiplecoordinate points inside the pipeline, measurement accuracy and efficiency are higher, and operation is simpler.

Owner:WUHU ANPU ROBOT IND TECH RES INST +1

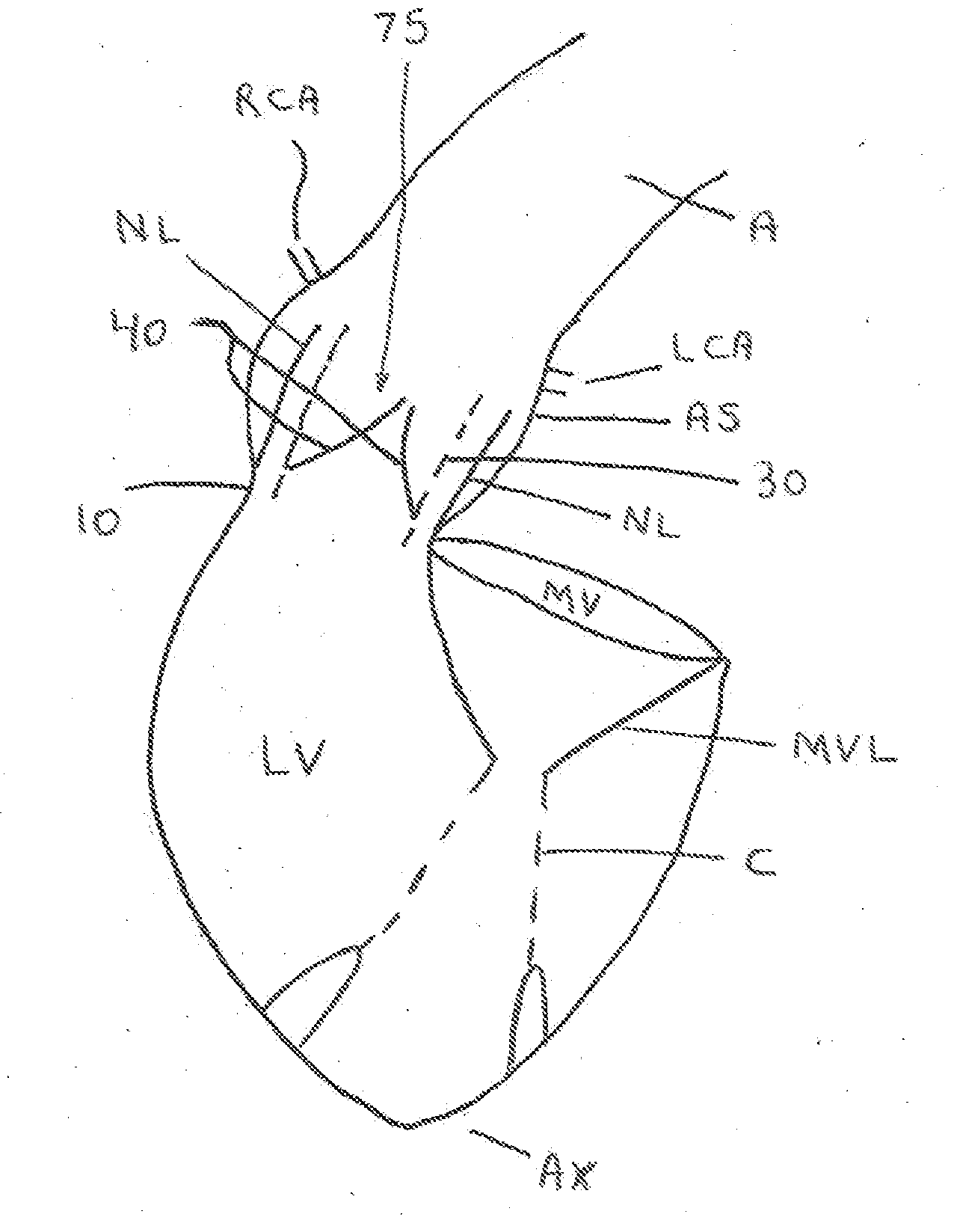

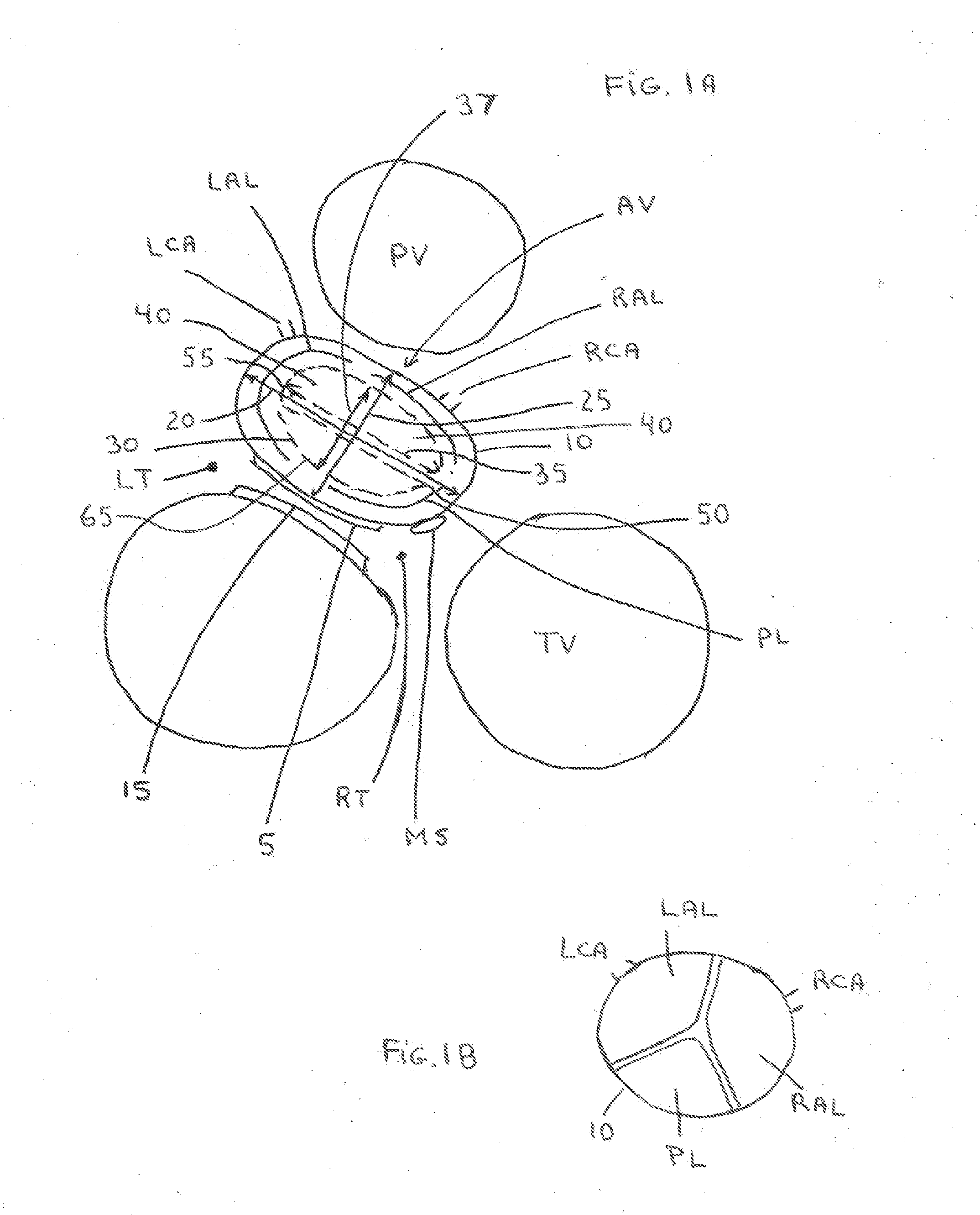

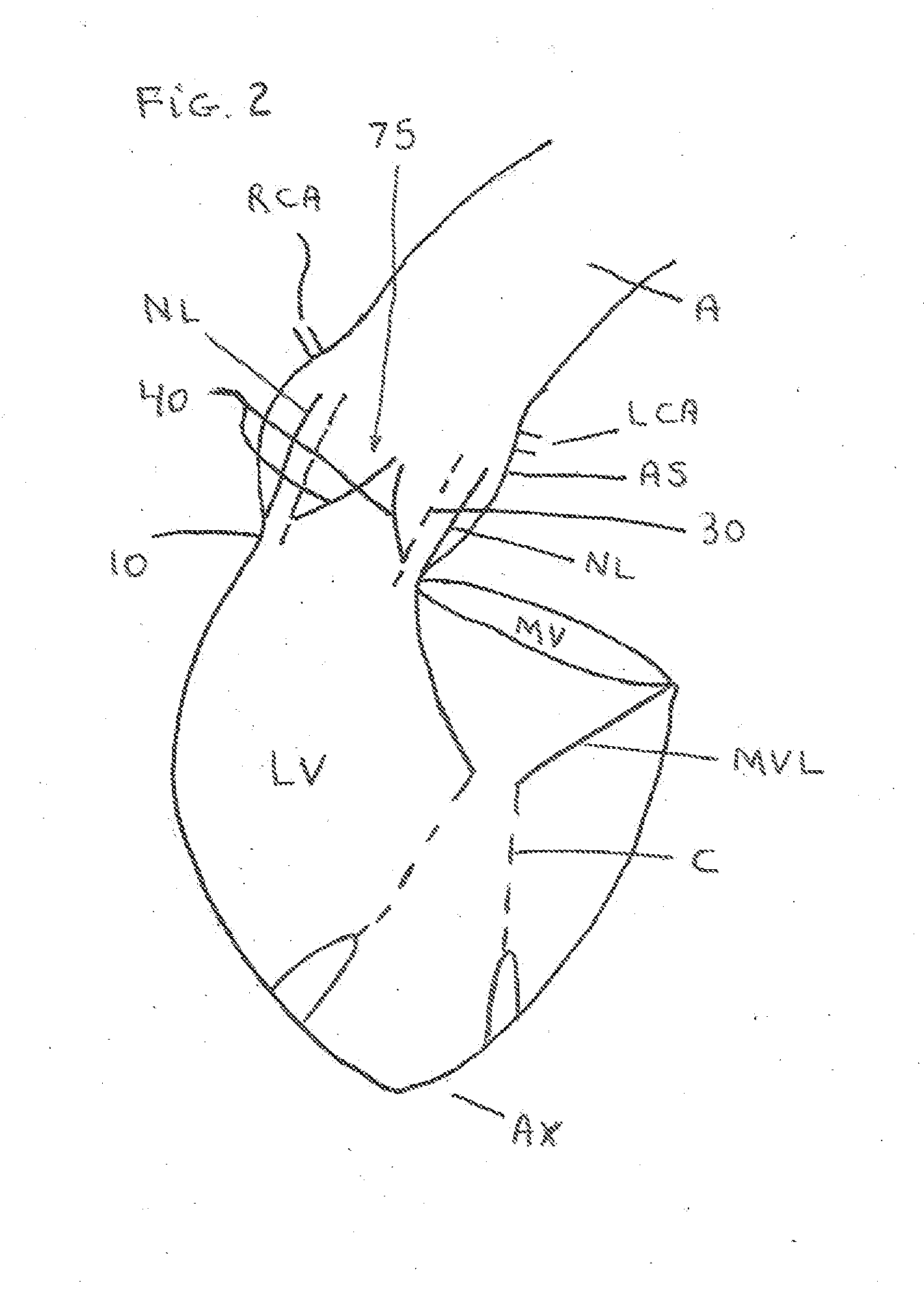

Oval Aortic Valve

InactiveUS20130023980A1Soft flexureLarge external forceHeart valvesBlood vesselsLoop of HenleMitral valve leaflet

An oval valve for use in transcutaneous aortic (TAVI) or mitral valve implantation or for direct access valve implantation. The oval leaflet frame or stent provides a better seal with the oval native annulus to reduce perivalvular leaks. The valve leaflets are a bileaflet configuration to provide improved leaflet coaptation independent of the amount of ovality of the native valve annulus. The bileaflet configuration is less dependent upon the diameter and perimeter of the native valve annulus and provides leaflet coaptation without intravalvular leakage.

Owner:DRASLER WILLIAM JOSEPH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com