Processing method of steel piston gas ring

A piston gas ring and processing method technology, applied in the direction of piston rings, engine components, machines/engines, etc., to achieve the effects of solving the machining process, saving process manufacturing costs, and low overall yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

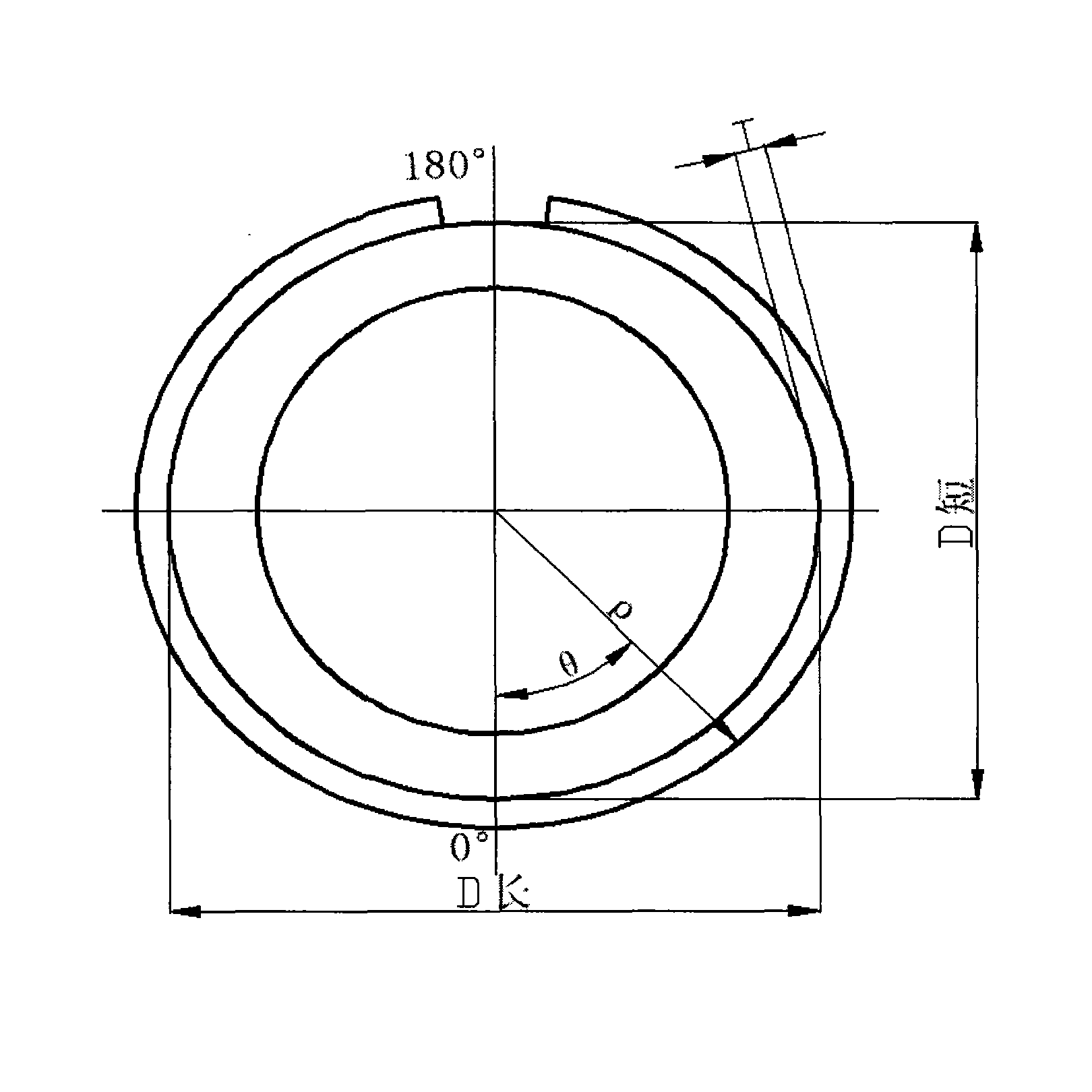

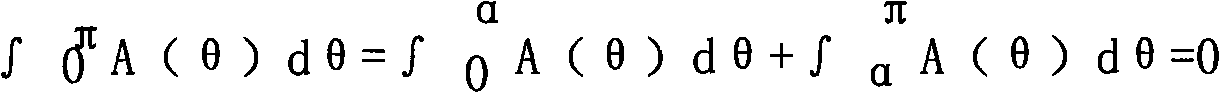

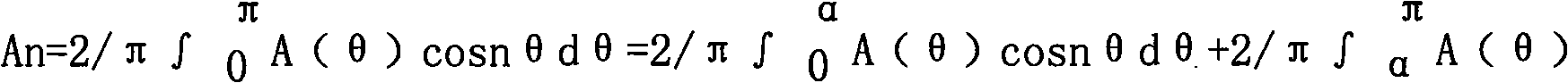

Image

Examples

Embodiment Construction

[0031] Take the single-cylinder diesel engine steel piston ring group as an example to further the present invention. The diesel engine steel piston ring set adopts the following combination: steel barrel ring (chrome-plated or nitrided) + steel cone ring (nitrided) + steel belt combined oil ring (chrome-plated or nitrided).

[0032] The selection of the surface treatment of the air ring must ensure long-lasting wear resistance, so the surface treatment layer must be thick and high in hardness, and it must be able to achieve or even exceed the effect of chrome plating. Nitriding treatment is used, and the nitriding performance is selected according to the characteristics of the nitriding process. 6Cr13Mo steel as the base material. Oil ring lining spring material is SUS304, coloring treatment, scraper ring is SWRH72A (NHC-54), hard chrome plated. Since the steel becomes brittle after nitriding, after nitriding the wiper ring reaches the thickness of the chromium layer, the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com