Patents

Literature

45results about How to "Reduce process waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

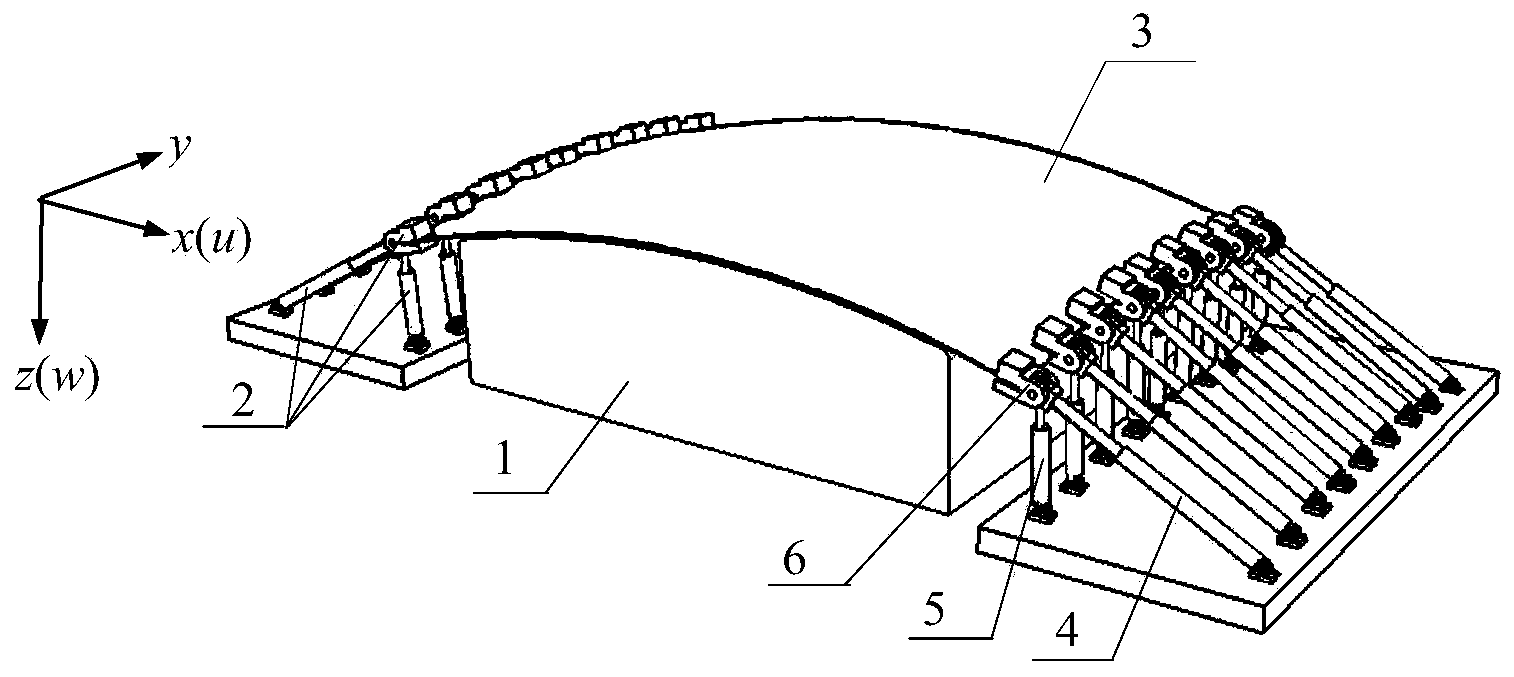

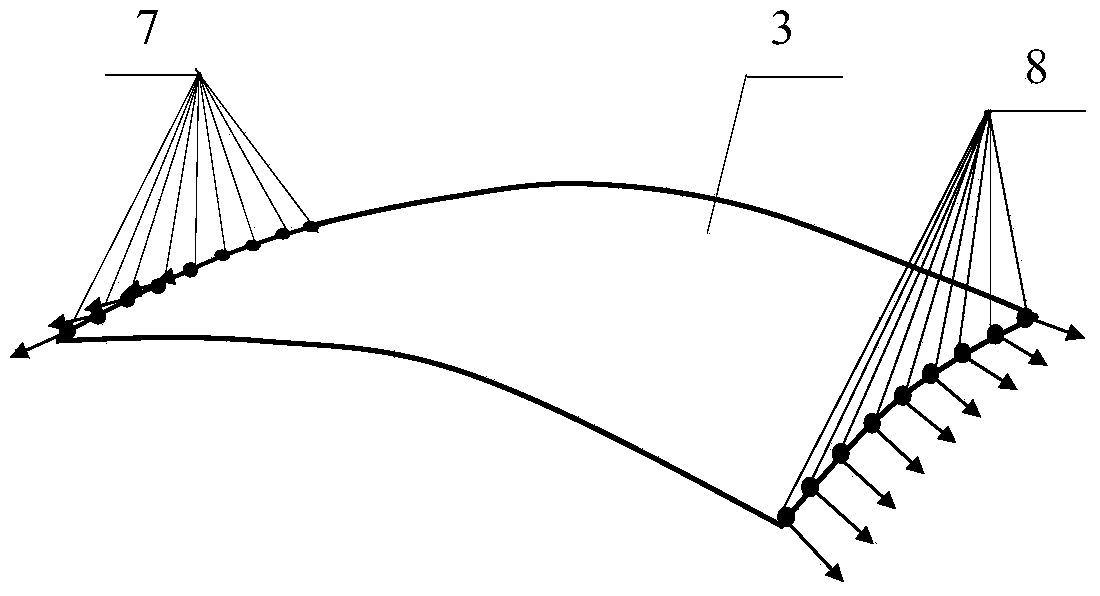

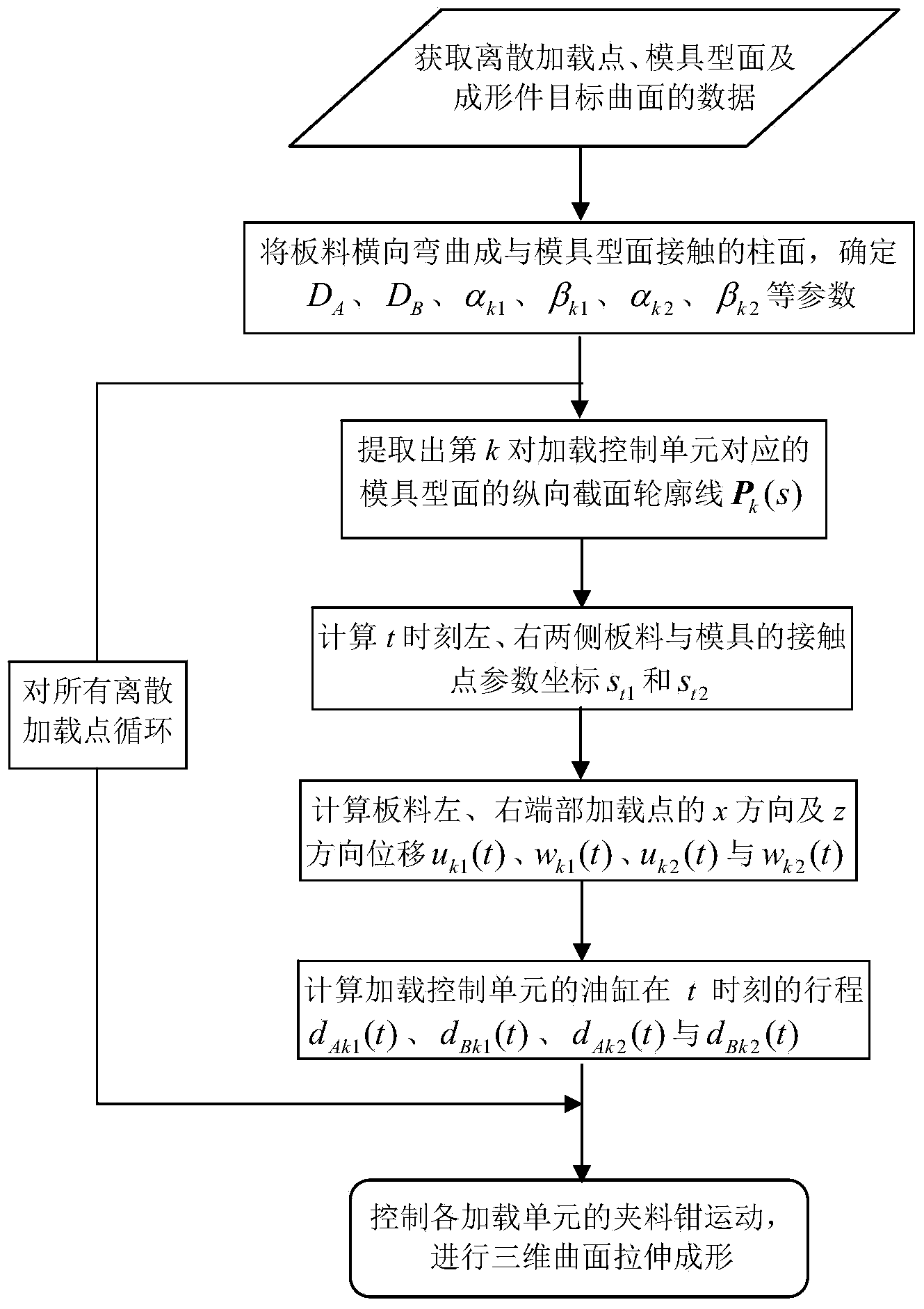

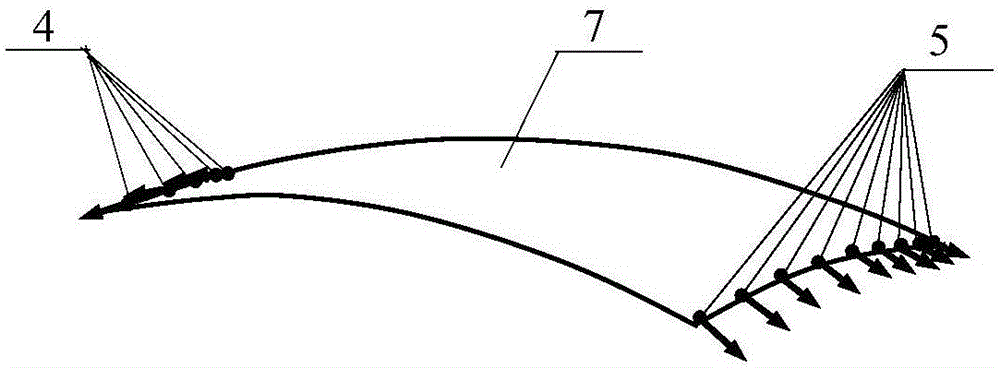

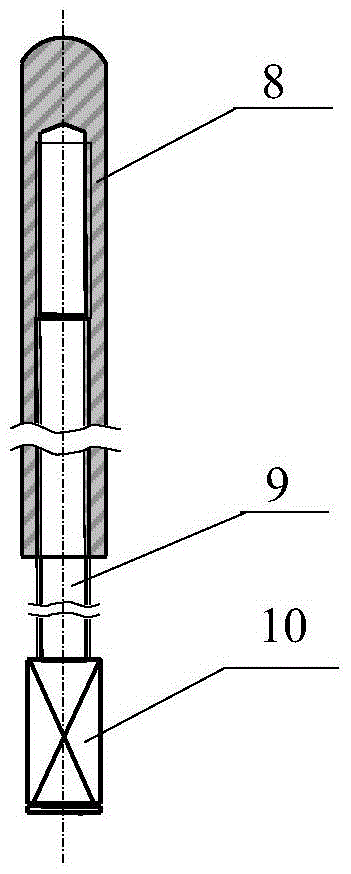

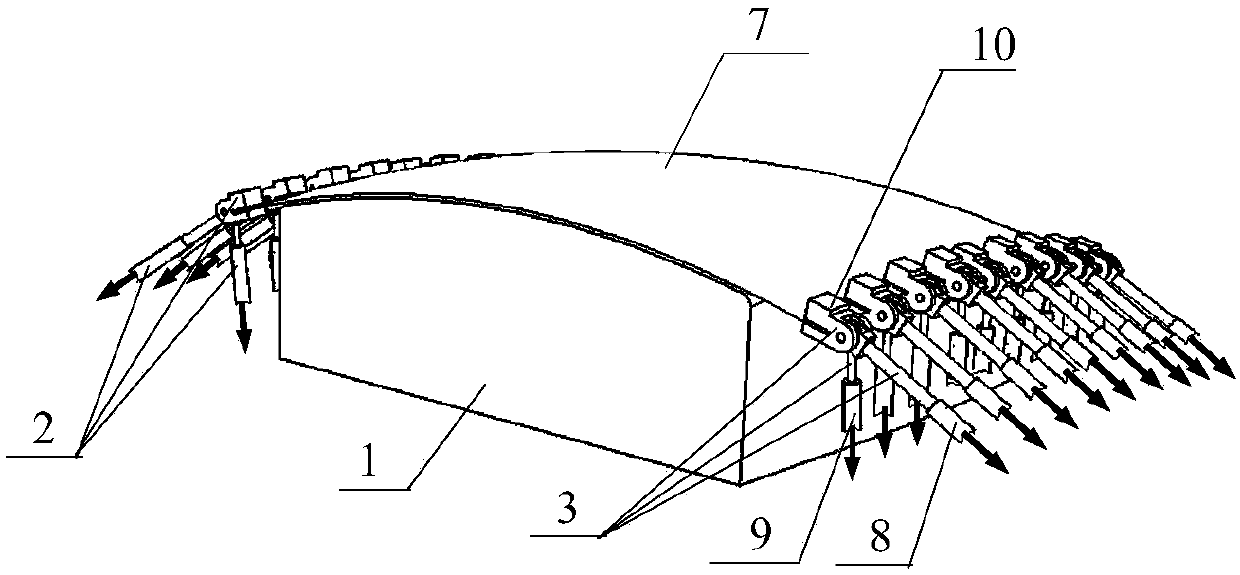

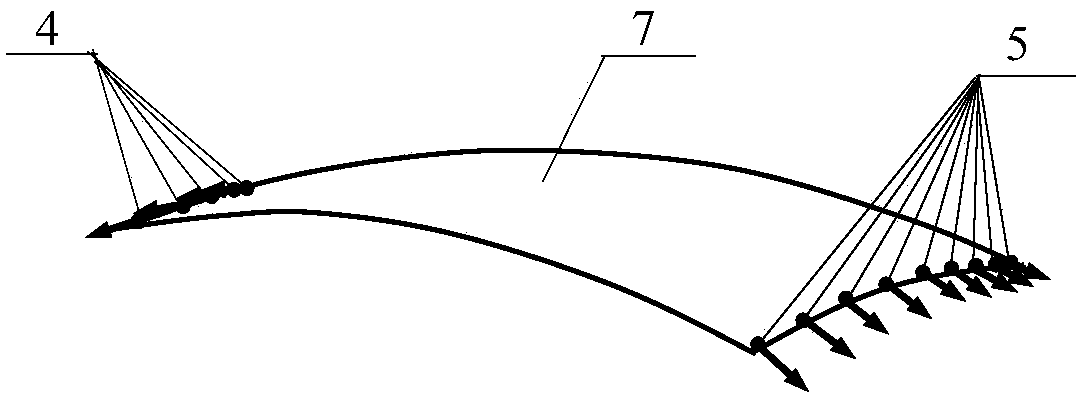

Method for forming three-dimensional curve surface by using discrete displacement loading mode

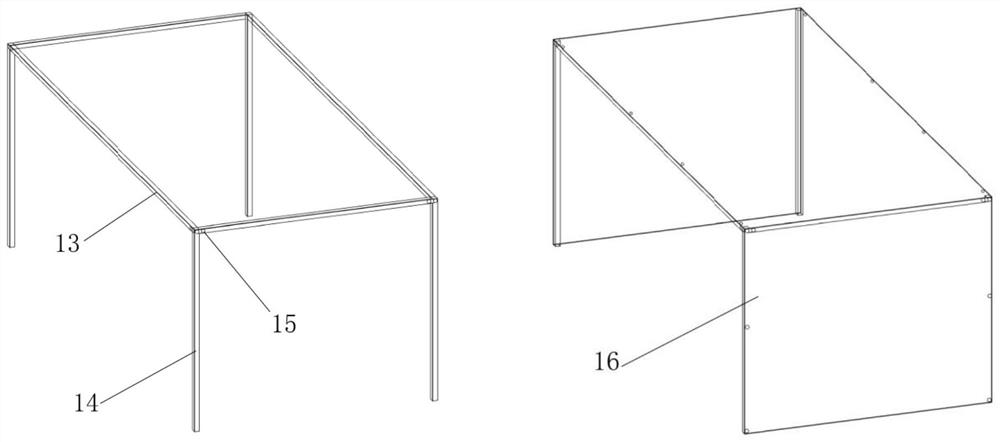

The invention relates to a method for forming a three-dimensional curve surface by using a discrete displacement loading mode, and belongs to the field of metal plastic processing. Uneven deformation is a main reason of various defects in formation of the three-dimensional curve surface. The formation process is controlled by adopting the discrete displacement loading mode; displacement loads are exerted to a series of discrete points at two ends of a panel by virtue of a loading control unit; the size and direction of each loading point displacement load change in real time. The invention provides a method for determining horizontal direction displacement and vertical direction displacement of each discrete loading point according to the target curve surface of a formed part. The homogenization of material deformation in the stretch forming process can be achieved by virtue of real-time control on each discrete point displacement; defects are avoided; formation of curve spare parts with large deformation is achieved; the laminating process of the panel can be improved; the process oddments are saved.

Owner:JILIN UNIV

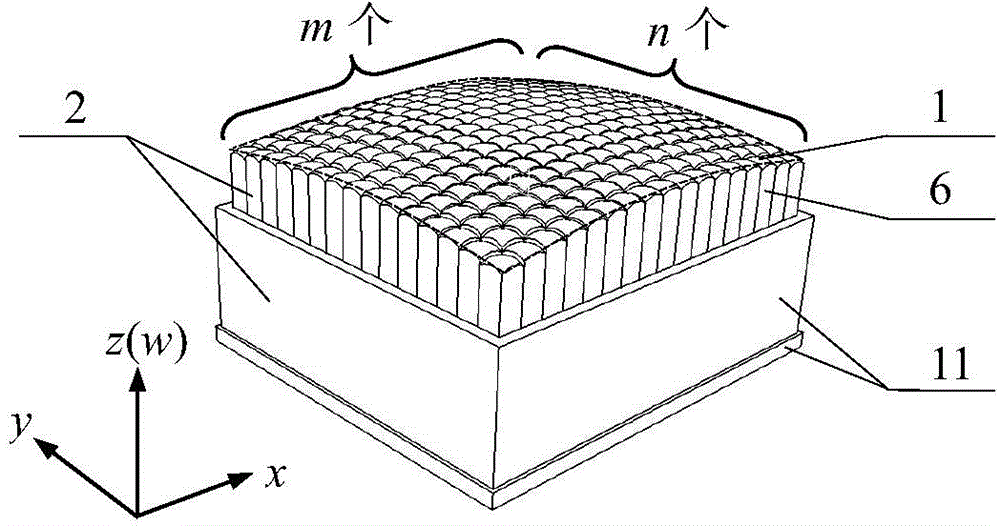

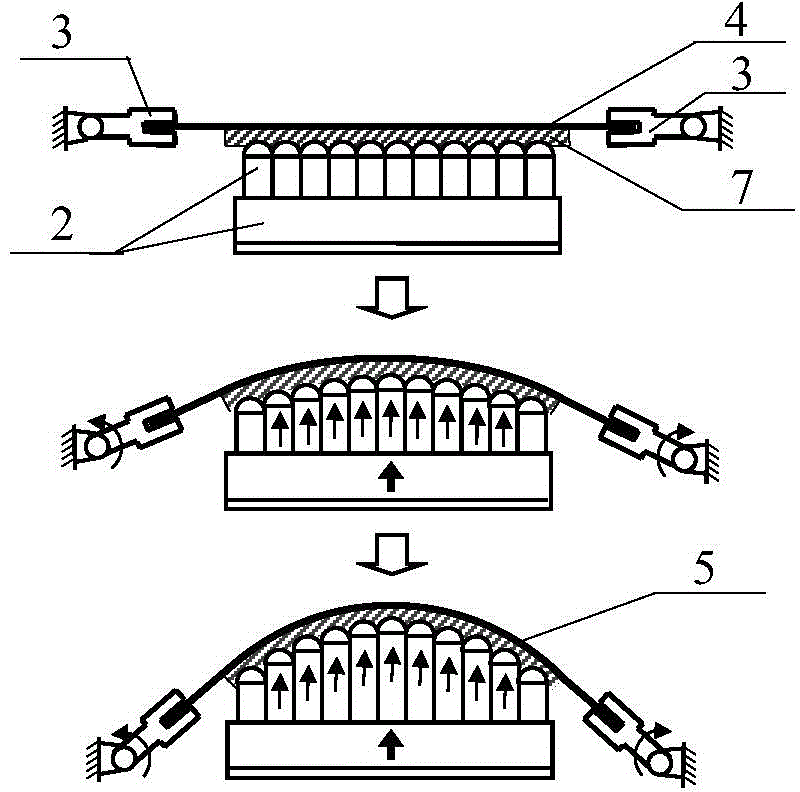

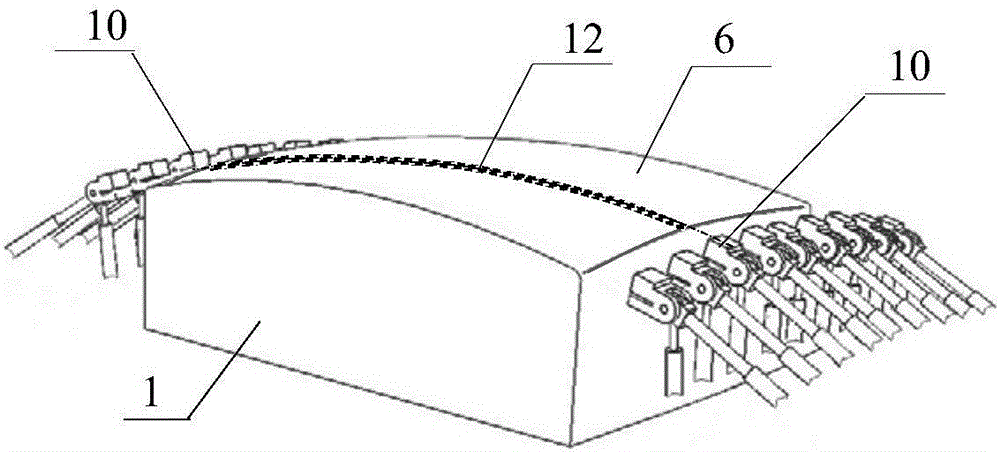

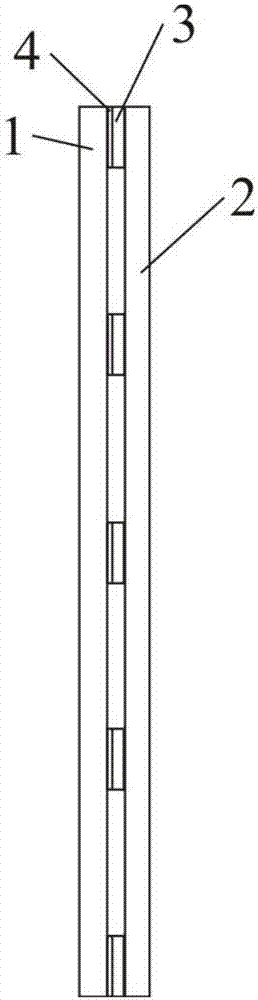

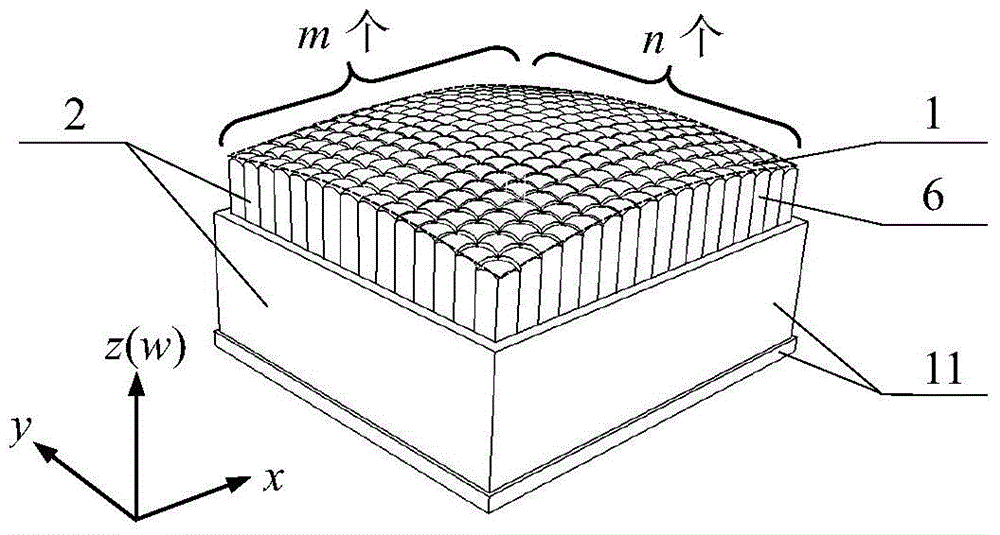

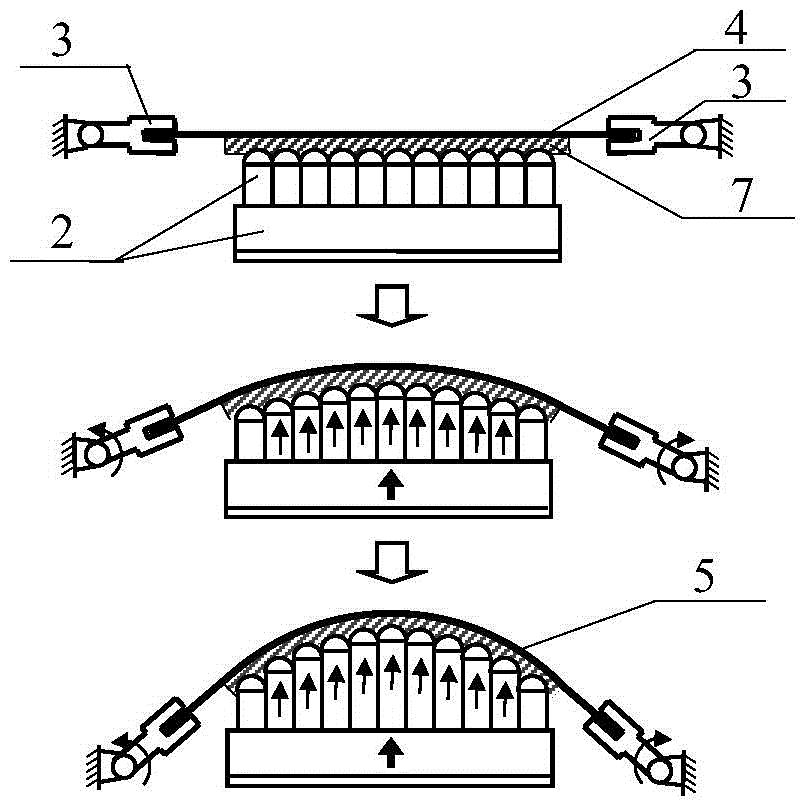

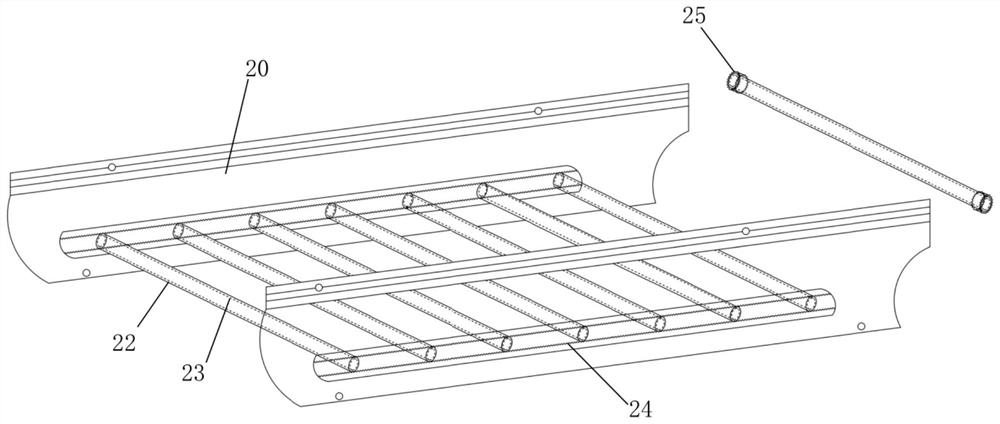

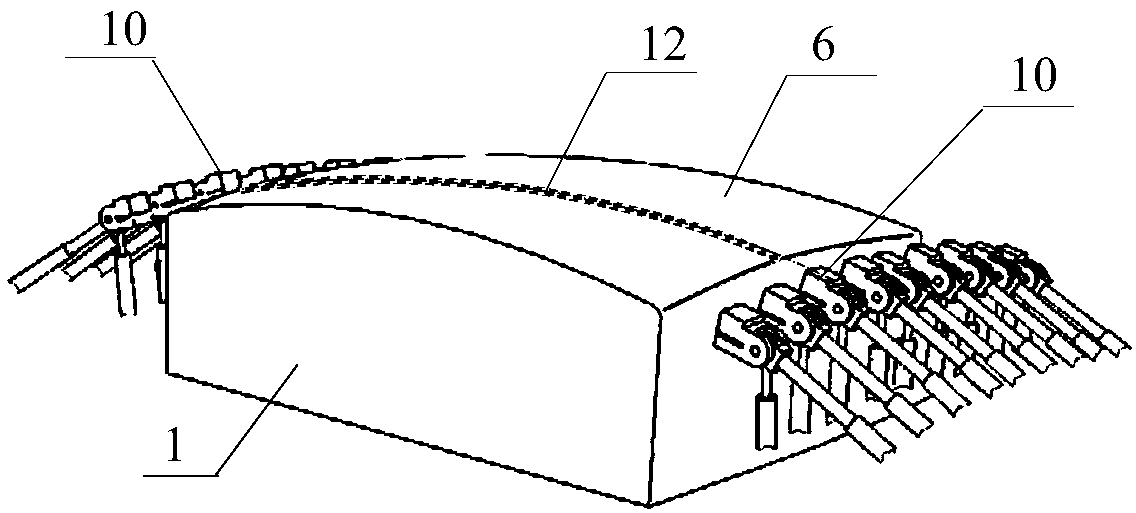

Three-dimensional curved surface stretch forming method based on surface-changing discrete mould

The invention provides a three-dimensional curved surface stretch forming method based on a surface-changing discrete mould, and belongs to the field of metal plastic machining. Nonuniform deformation of a plate in the stretch forming process is the main cause of kinds of defects. According to the method, based on the discrete mould, the forming process of a curved surface is controlled through the change of the mould surface. In the forming process, the plate is kept completely attached to the mould surface all the time, the continuous and uniform change of the mould surface makes the deformation of the plate more and more uniform, the forming defects are avoided, and a high-quality curved-surface part can be obtained through stretch forming. The discrete mould is composed of regularly-arrayed basic body units, and real-time control over the geometrical shape of the surface of the stretch forming mould is achieved by changing the height of the basic body units. Besides, in the stretch forming process, the plate is clamped by a clamp to rotate along with the change of the mould surface, the clamp does not need to move in the horizontal direction or height direction, and therefore a loading structure of stretch forming equipment can be simplified through the forming method.

Owner:JILIN UNIV

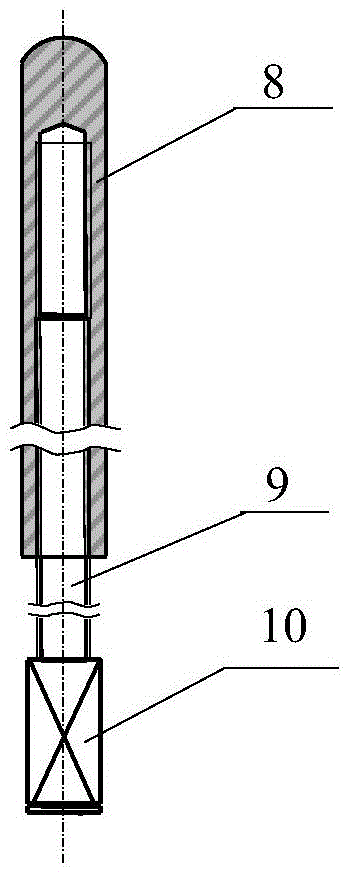

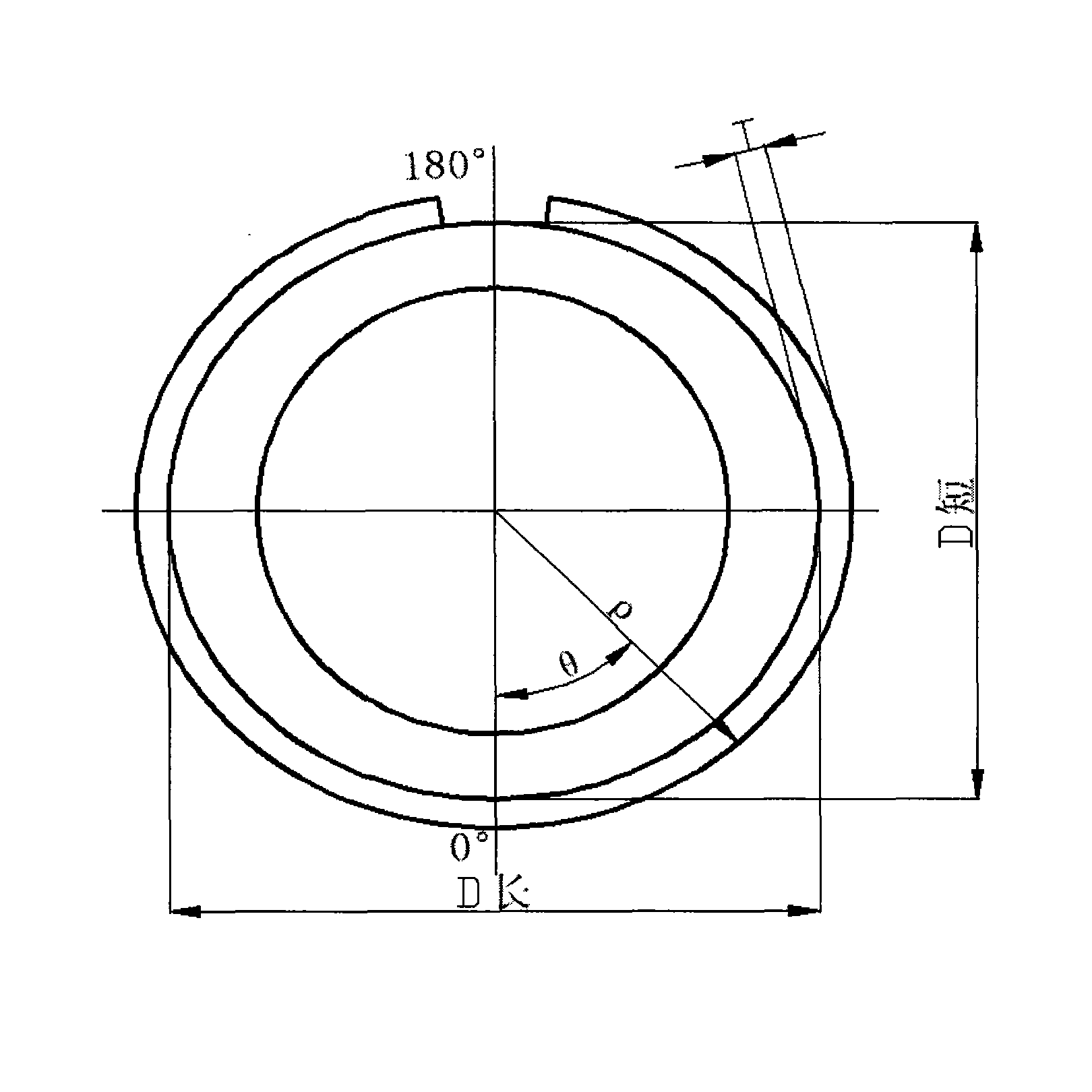

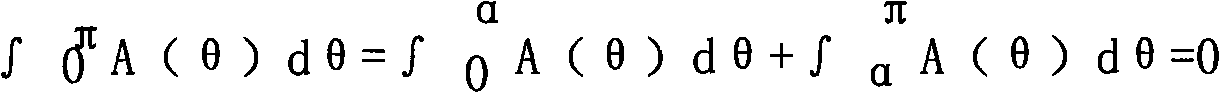

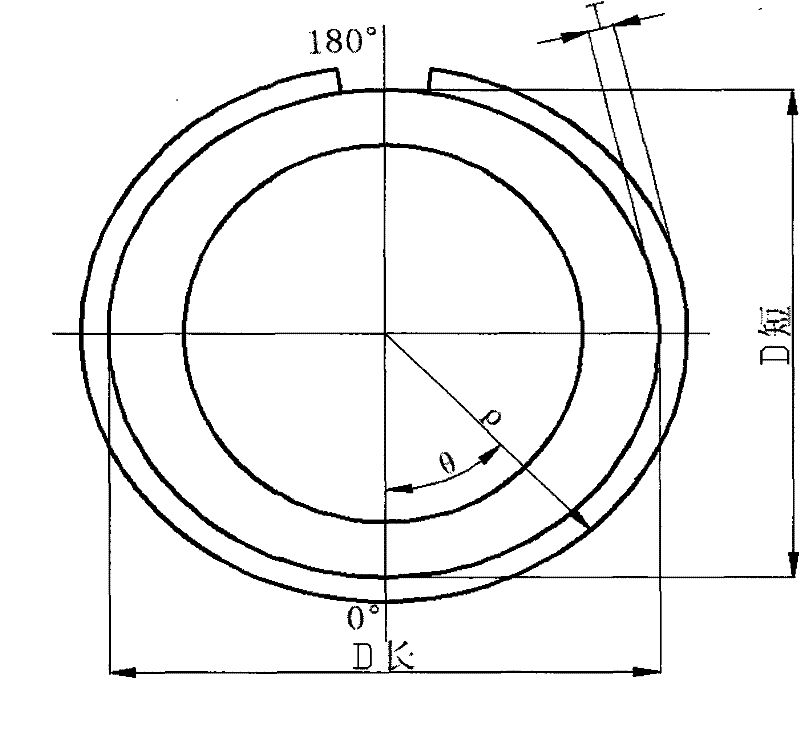

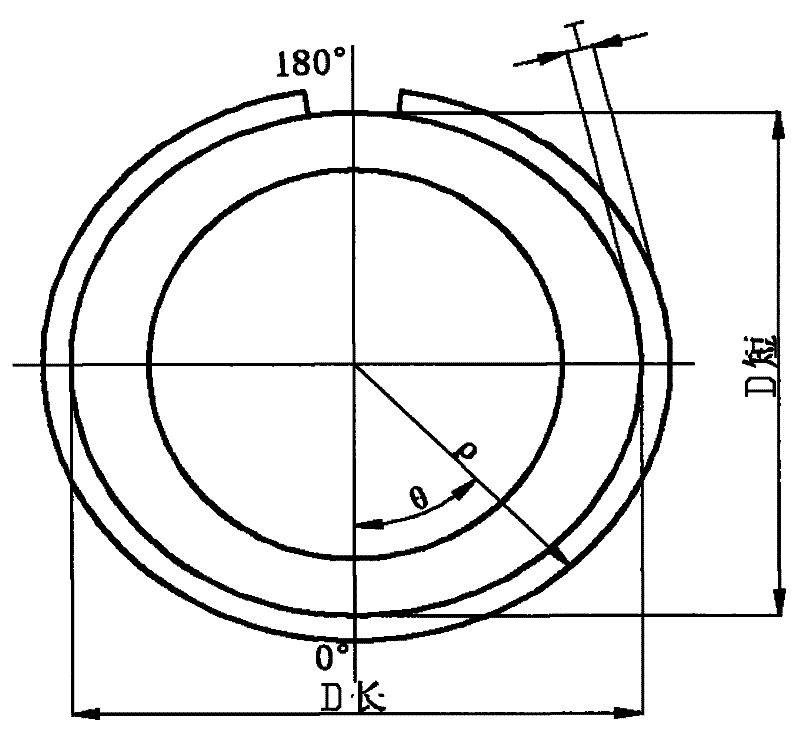

Processing method of steel piston gas ring

ActiveCN101649790ALow yieldSolve the cumbersome machining processPiston ringsMachines/enginesPliabilityProcess manufacturing

The invention discloses a processing method of a steel piston gas ring, which comprises the following steps: winding-destressing-grooving-shaping-top line trimming-flat surface grinding-excircle boning-chroming or nitriding-top line trimming-excircle boning-top line trimming-flat surface grinding; the size of a shaped blank rod is improved by calculating pressure distribution mold lines with different ovality requirements and fully considering the mold line change caused by nitriding shrinkage, thereby the problem of gas ring deformation after procedures, such as nitridation, and the like is greatly reduced, and the finished product ratio of the product is improved. Compared with the defects of long process routes, multi-workshop crossing processing and low comprehensive finished product ratio in the casting iron gas ring, the comprehensive finished product ratio of the steel gas ring processed by using the shaped blank rod can reach up to 95 percent. By utilizing the pliability characteristic of the steel and adopting a shaped steel winding and shaping process, the invention solves the fussy machining process of cast iron material, shortens the manufacturing period, also reduces the procedure waste simultaneously and saves the process manufacturing cost.

Owner:NANJING FAYN PISTON RING

UV drying curing system added on rotogravure printing machine

InactiveCN105269949AAvoid fire and other safety accidentsStrong production adaptabilityPrinting press partsUltravioletPulp and paper industry

The invention provides an UV drying curing system added on a rotogravure printing machine. The system comprises a rotogravure printing machine. The technical scheme is that the top of a longitudinal beam of the rotogravure printing machine is provided with a water-cooling shutter type ultraviolet cold light source drying curing system. The water-cooling shutter type ultraviolet cold light source drying curing system is formed by four sets of ultraviolet cold light sources, wherein three sets are parallel together and are installed on a mobile support, and the other independent set is installed on a fixed support. The front edge and the rear edge of the fixed support are provided with dancing rolls. A paper cooling roller is arranged on the rear of the mobile support. The system enhances production adaptive capacity of an original rotogravure printing machine, realizes a connecting line gravure multiple combination process, overcomes restrictions that a rotogravure printing machine cannot print cortex oil, ice points and snowflake, widens production range of the device, and satisfies more diverse technological requirements.

Owner:桂林澳群彩印有限公司

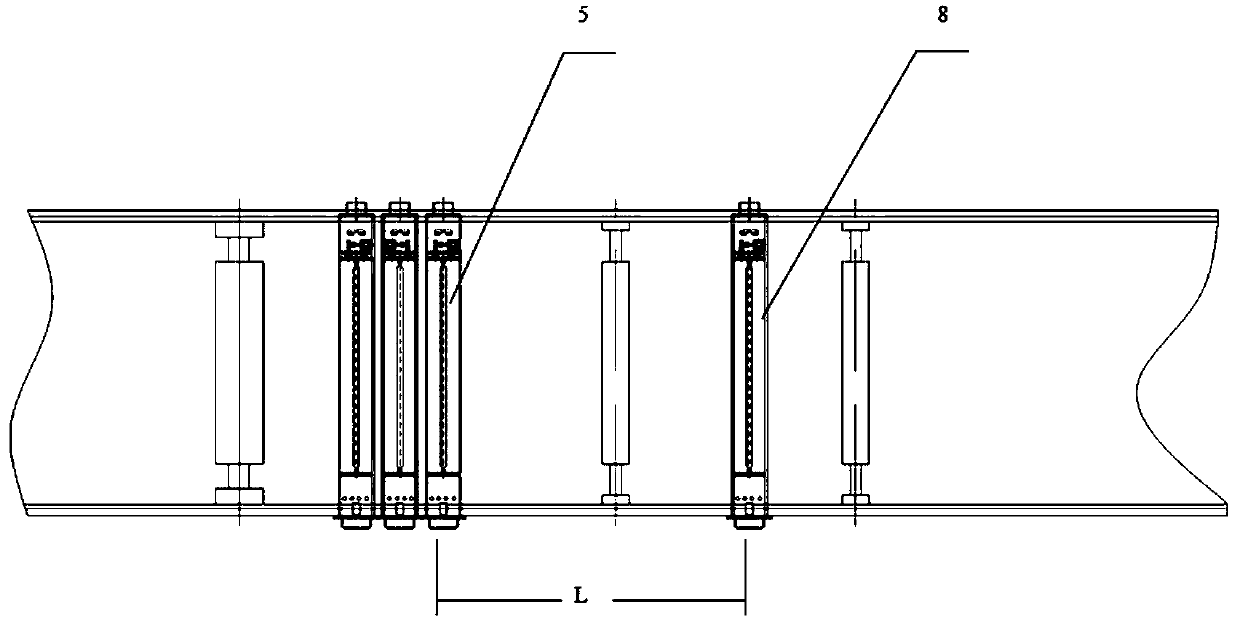

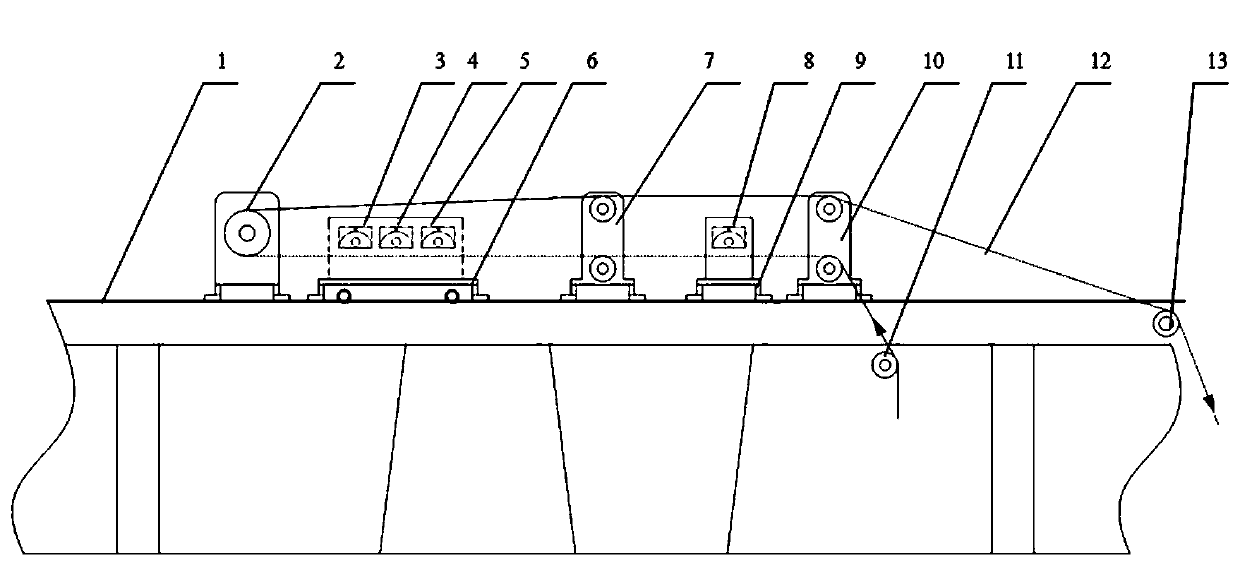

Three-dimensional curve stretch forming method based on multi-point force loading mode

The invention provides a three-dimensional curve stretch forming method based on a multi-point force loading mode, and belongs to the field of metal plastic machining. The multi-point force loading mode is adopted to control the plate stretch forming process; the stretch forming force is applied to a series of discrete points at two ends of a plate by loading control units arranged on two sides of a mold; and the magnitude and the direction of the stretch forming force applied by each loading point can be independently controlled. The invention provides a method for determining the stretch forming force of each discrete loading point according to molded surfaces of a stretch forming mold, realizes the stretch forming process of three-dimensional curve parts by minimum stretch deformation through real-time control of the stretch forming force in each discrete point, prevents generation of forming defects, obtains the curve parts with large deformations, can improve the mold pasting process of the plate, reduces residual materials in the stretch forming process, and saves the materials.

Owner:JILIN UNIV

Projection displaying screen and projection displaying system

The invention provides a projection displaying screen, and belongs to the technical field of projection displaying. The projection displaying screen comprises an optic mask, a backboard structure, andmagnetic stripes, wherein the backboard structure faces exactly the optic mask, the magnetic stripes are arranged between the optic mask and the backboard structure, are in magnetic attraction with the backboard, and are connected with the optic mask through double-sided foaming glue. The projection display screen can have good flatness, the bad phenomena of distortion, displacement, bending, protrusion, sinking, swelling and the like are avoided, and the watching effect of a user is improved; meanwhile, the thickness of the projection display screen can be reduced, and the ultrathin requirement of the user is met.

Owner:HISENSE VISUAL TECH CO LTD

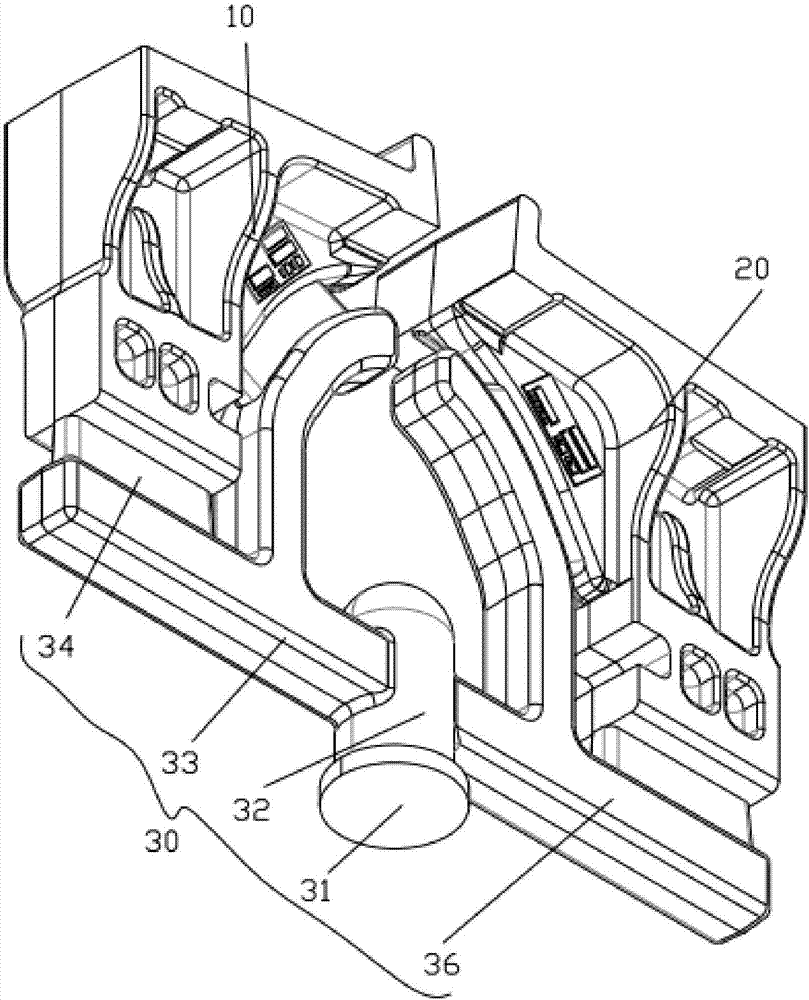

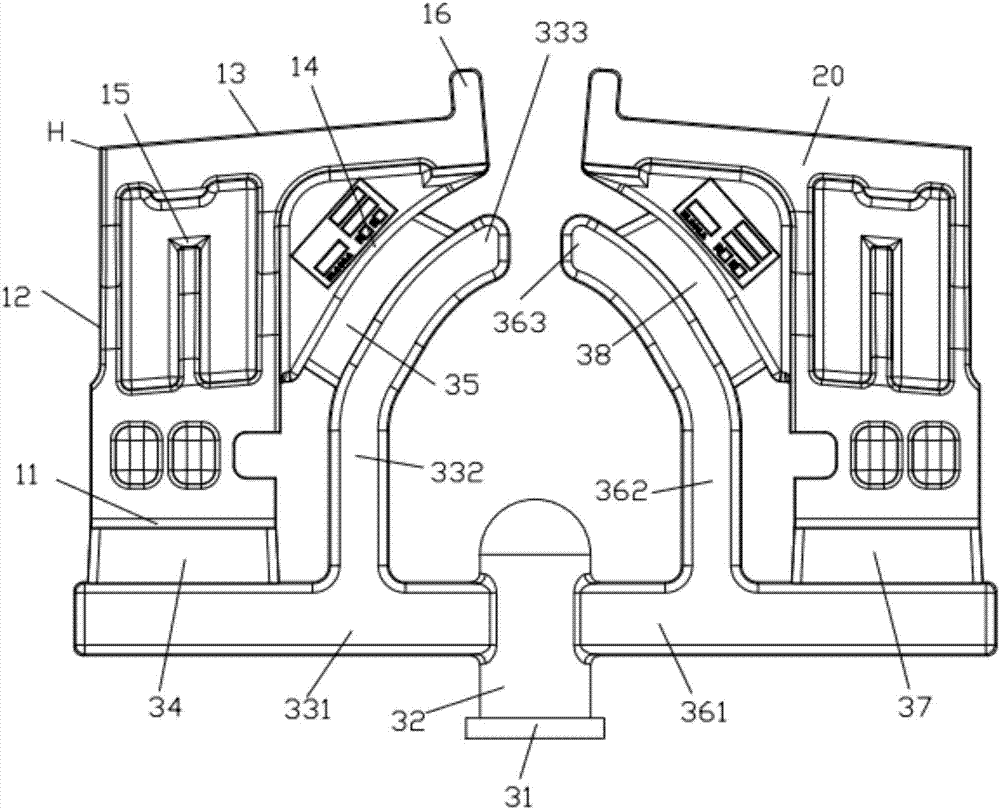

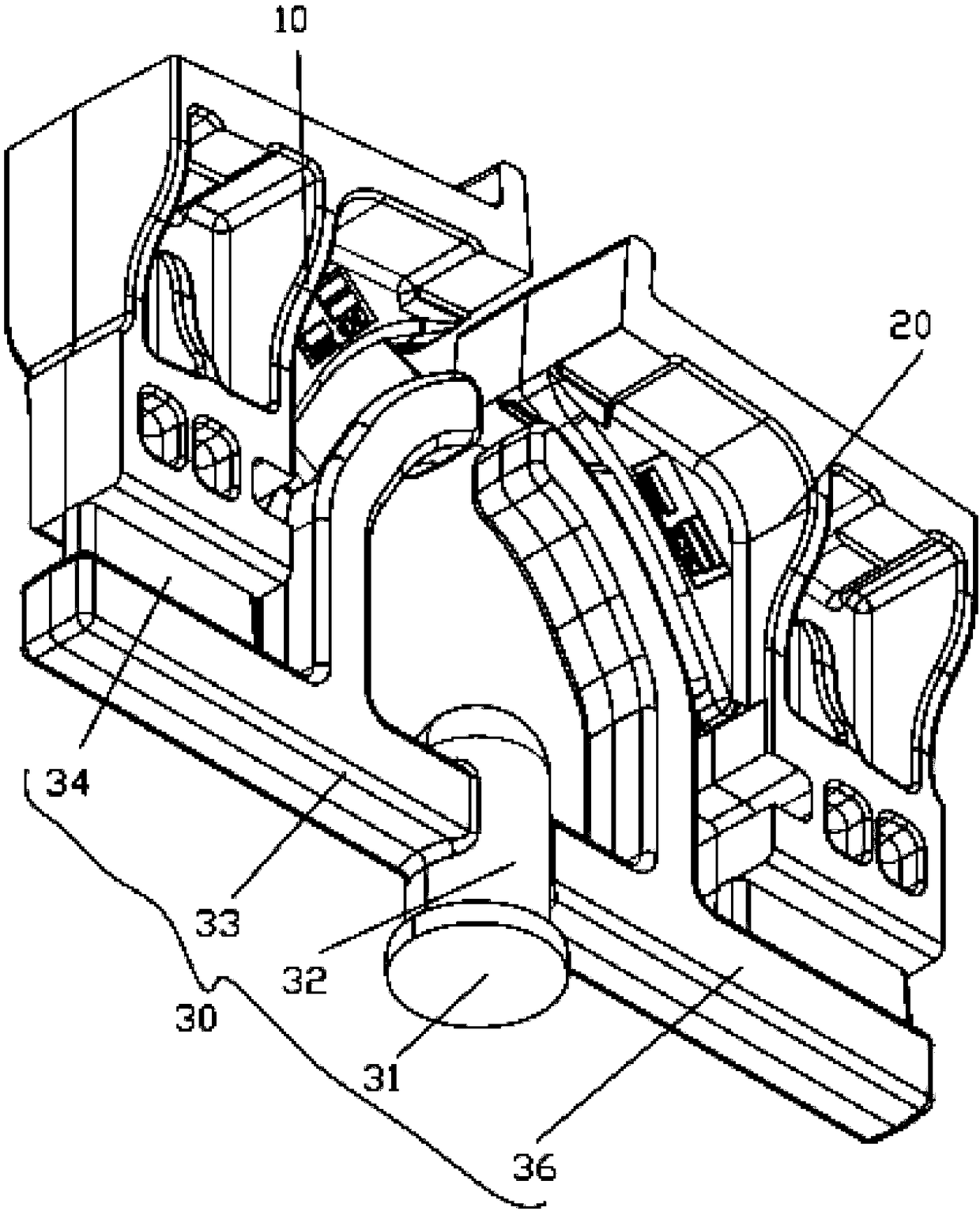

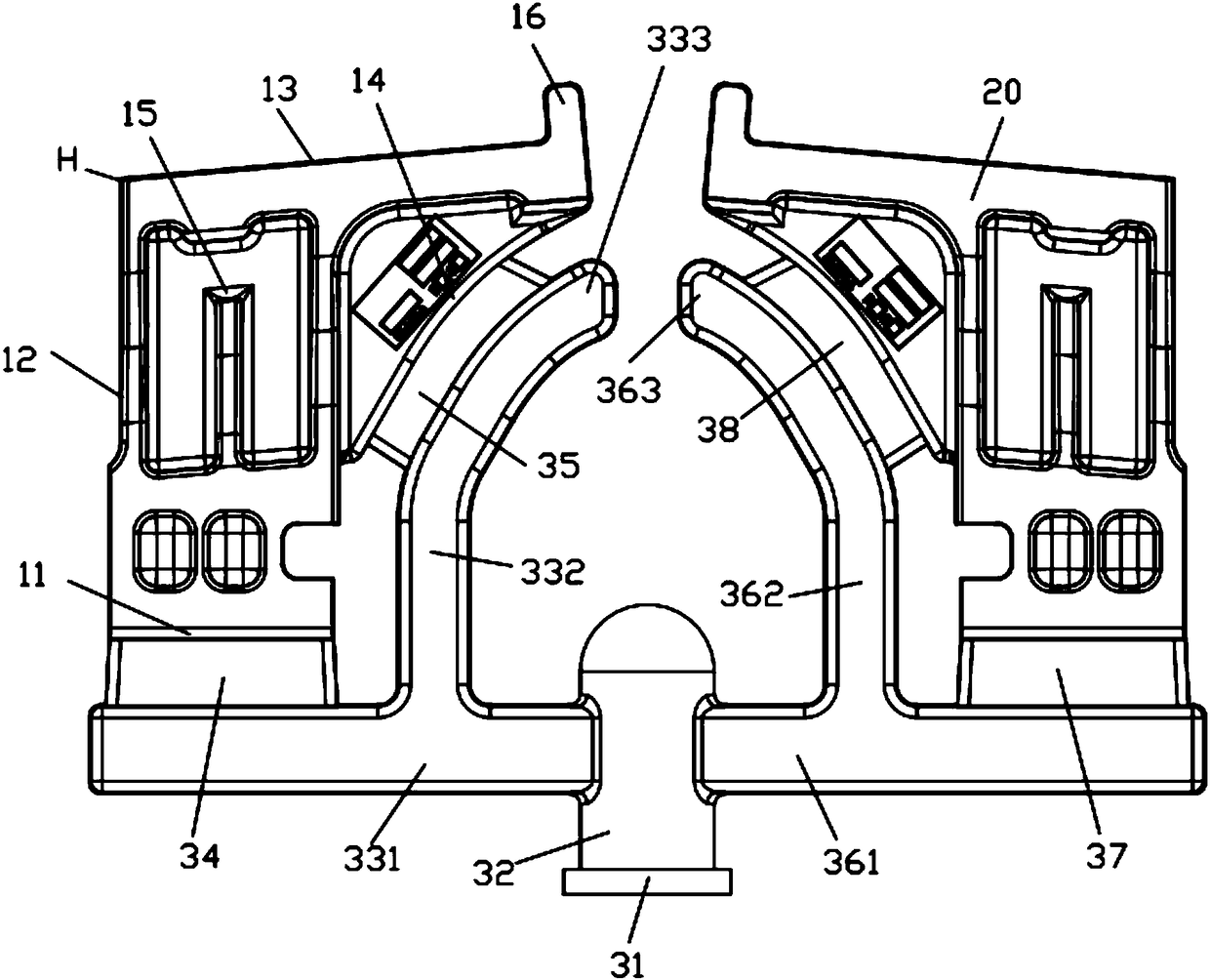

Large aluminum-magnesium alloy vibration reduction device casting system and casting method

The invention discloses a large aluminum-magnesium alloy vibration reduction device casting system which comprises a first vibration reducer cavity, a second vibration reducer cavity and a casting system body. The first vibration reducer cavity and the second vibration reducer cavity have a same structure; the casting system body comprises a filter, a straight pouring gate, a first transverse pouring gate, a first straight-edge inner pouring gate, a first arc-edge inner pouring gate, a second transverse pouring gate, a second straight-edge inner pouring gate and a second arc-edge inner pouring gate; one end of the first arc-edge inner pouring gate is connected with the first transverse pouring gate, the other end of the first arc-edge inner pouring gate communicates with an arc-edge cavity wall of the first vibration reducer cavity, one end of the second arc-edge inner pouring gate is connected with the second transverse pouring gate, and the other end of the second arc-edge inner pouring gate communicates with an arc-edge cavity wall of the second vibration reducer cavity. According to the large aluminum-magnesium alloy vibration reduction device casting system, two castings are adopted to be symmetrically cast and share one casting system, therefore, technological waste generated by at least one straight pouring gate is reduced, and the molding sand using amount is at least decreased by half.

Owner:宁夏维尔铸造有限责任公司

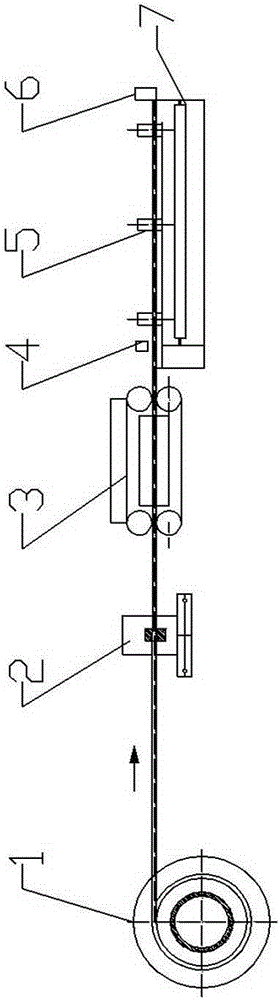

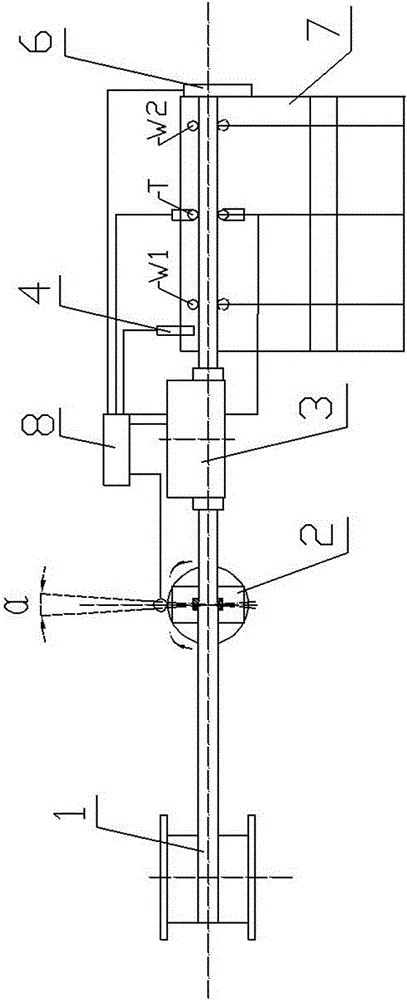

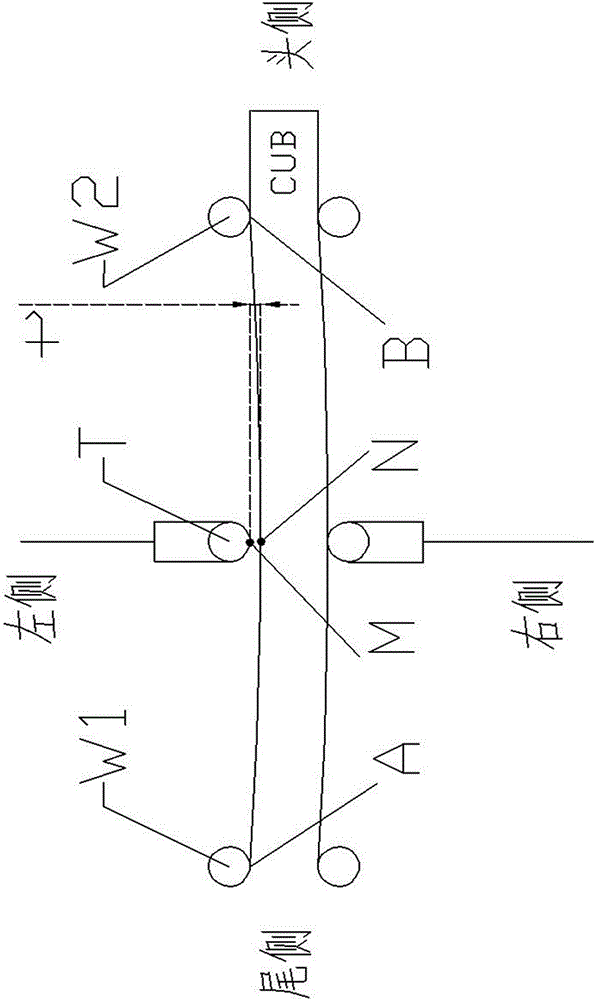

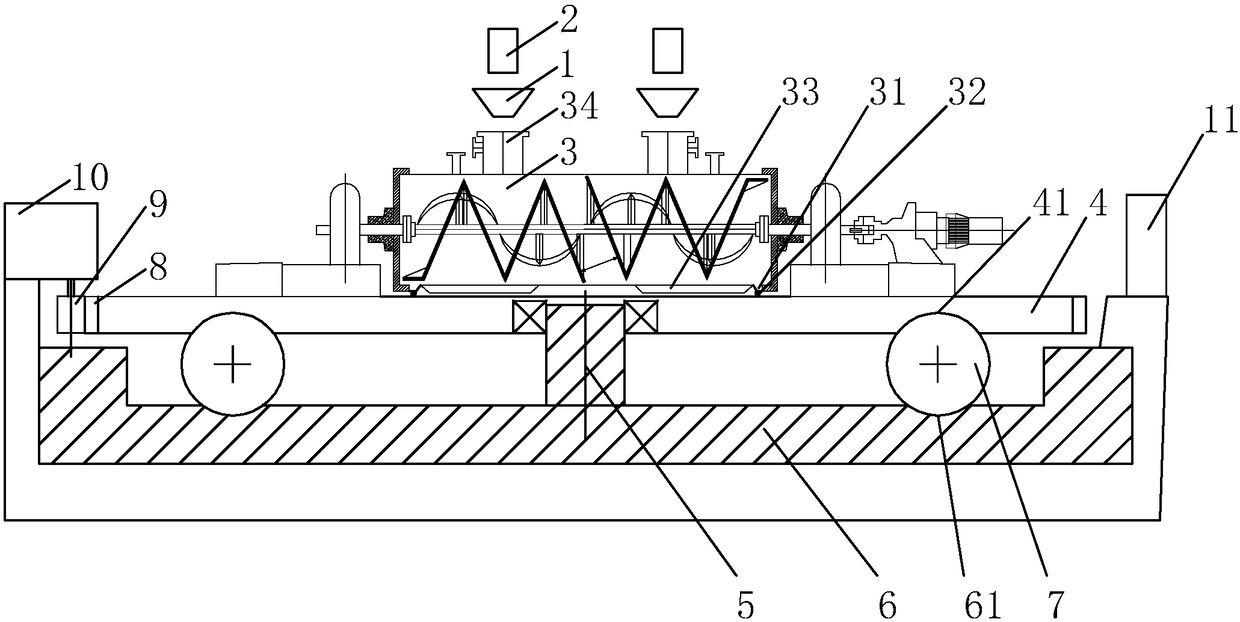

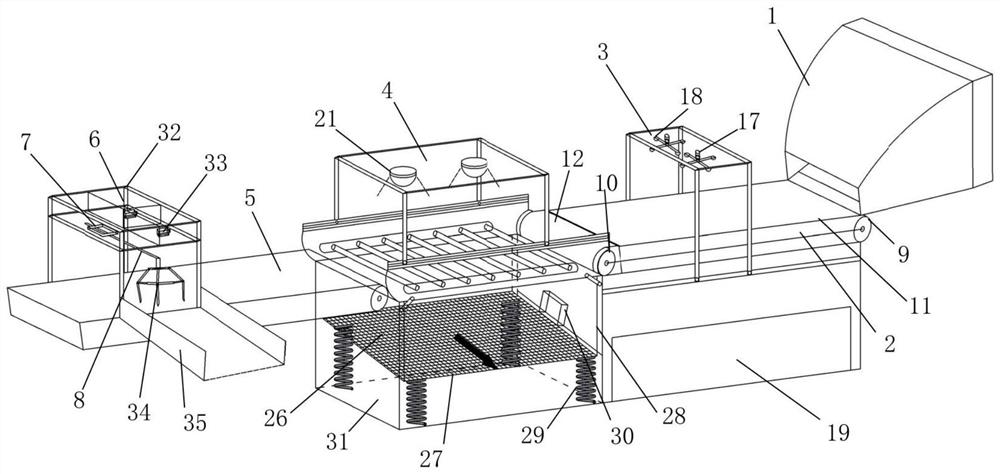

Drawing and straightening equipment of copper bars

ActiveCN105251789AReduce side bendingImprove quality and efficiencyMetal working apparatusEngineeringCopper

The invention relates to drawing and straightening equipment of copper bars. The drawing and straightening equipment comprises a drawing die capable of being deflected, a traction machine, a cutting machine, a curve measuring mechanism and a controller. The drawing die is connected with a servo motor and can be controlled by the controller to be deflected by an angle. The curve measuring mechanism is composed of two midpoint distance measurement sensors and two locating devices on the two sides of the midpoint distance measurement sensors. The two locating devices make contact with the copper bars and locate the section, located between the two locating devices, of the copper bars. The two midpoint distance measurement sensors are symmetrically arranged on the left side and the right side of the copper bars, and the peaks of the front ends of the midpoint distance measurement sensors are located on the midpoints of the connecting lines between the contact points, making contact with the copper bars, of the two locating devices. According to the drawing and straightening equipment, the data collected by the curve measuring mechanism are fed back to the controller, the controller drives the drawing die to be deflected by a small angle so that lateral bending can be reduced, correction is completed in the drawing process, additional straightening equipment and processes are not needed, and the quality and the production efficiency are improved.

Owner:湖南金龙国际铜业有限公司

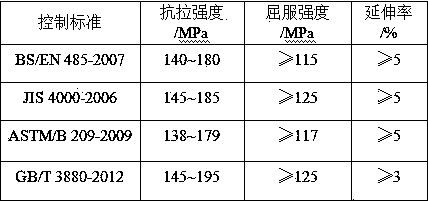

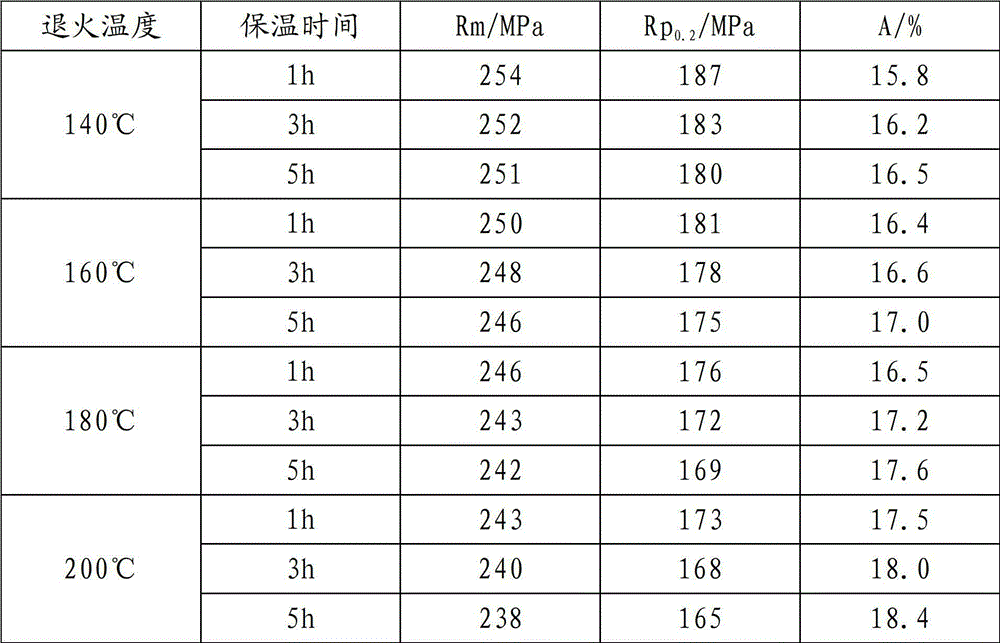

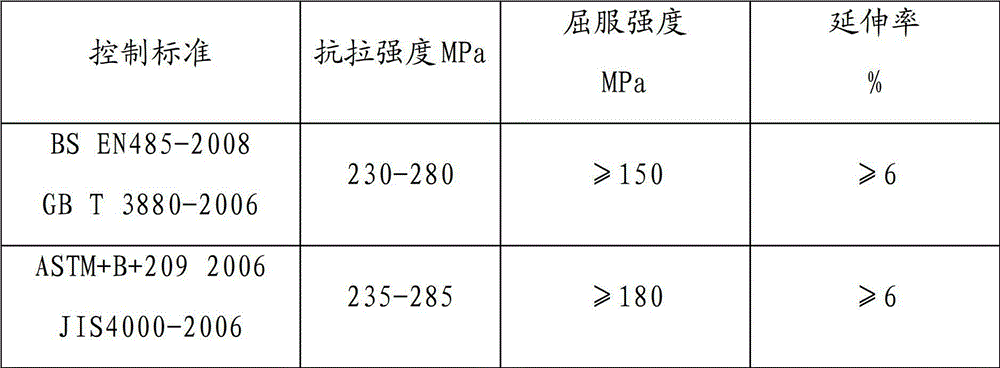

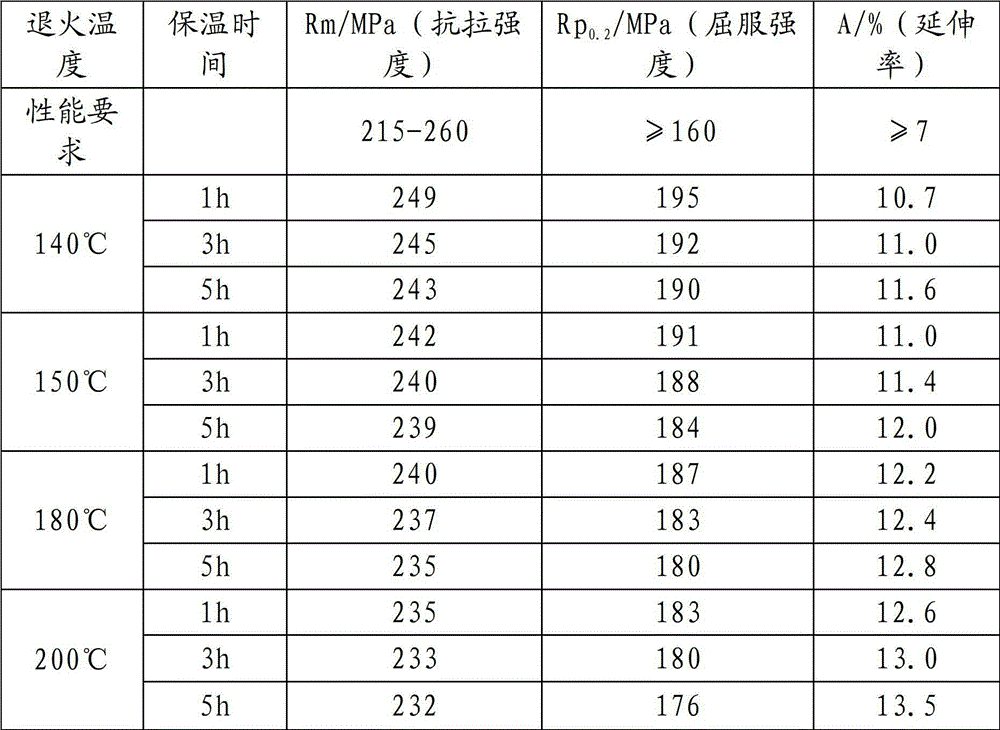

3003H14 aluminum alloy sheet and production method thereof

The invention provides a 3003H14 aluminum alloy sheet and a production method thereof. The 3003H14 aluminum alloy sheet comprises the following components in percentage by mass: less than or equal to0.20% of Si, 0.40-0.50% of Fe, less than or equal to 0.15% of Cu, 1.05-1.20% of Mn, less than or equal to 0.05% of Mg, less than or equal to 0.05% of Cr, less than or equal to 0.10% of Zn, 0.01-0.05%of Ti, less than or equal to 0.05% of other single impurity, less than or equal to 0.15% of all impurities in all and the balance being Al. The production method comprises the following steps: carrying out fusion casting, saw cutting, face-milling, ingot casting heating, hot rolling, cold rolling, cleaning, pulling straightening and transverse shear in sequence. The production method has the beneficial effects that the production method can ensure the performances of the product and shorten the production process; the mechanical properties are controlled by hot rolling plus one-pass cold rolling; and the 3003H14 aluminum alloy sheet product with the thickness of 2.0-4.0mm is produced, and the cost is saved.

Owner:CHINALCO RUIMIN

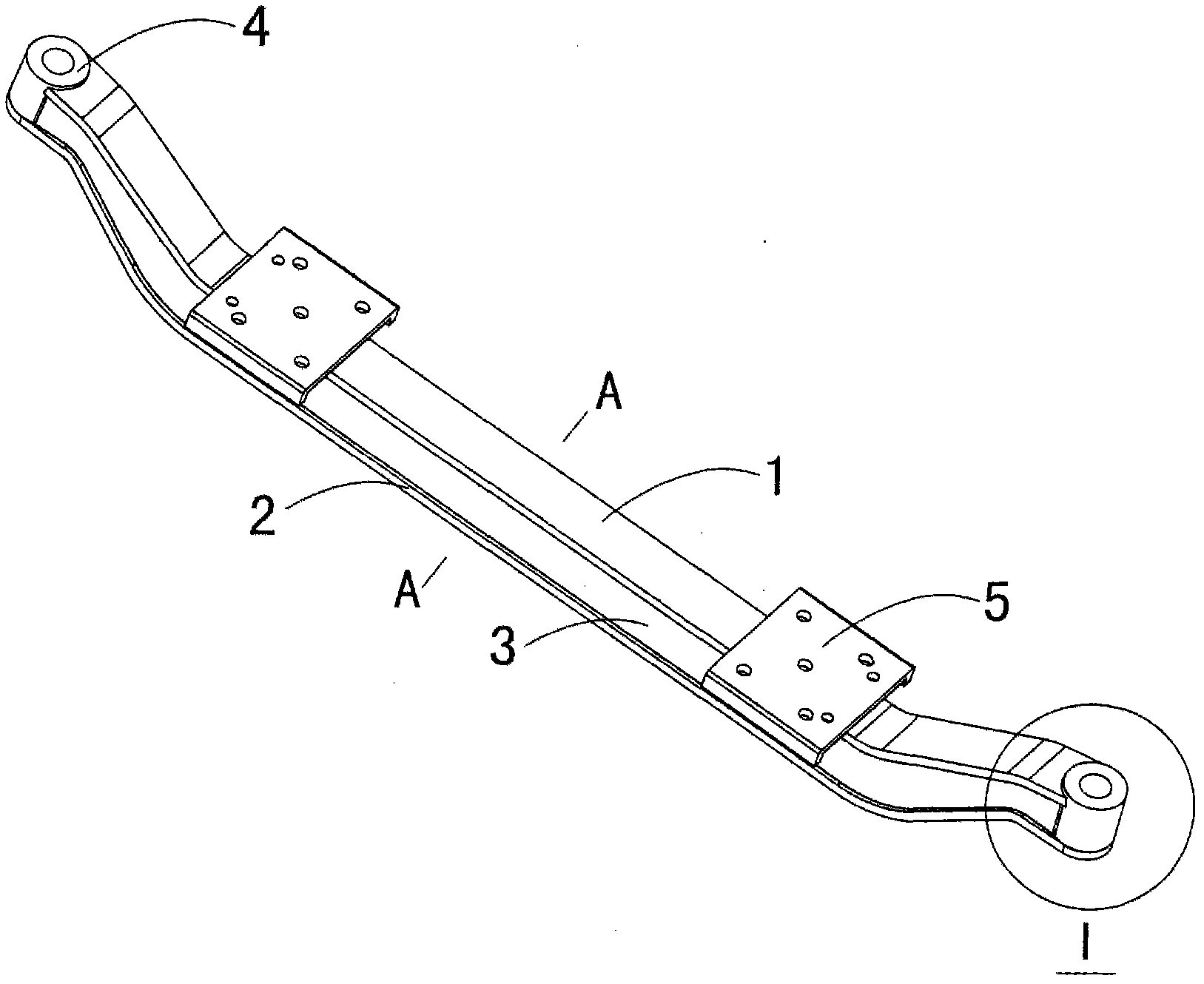

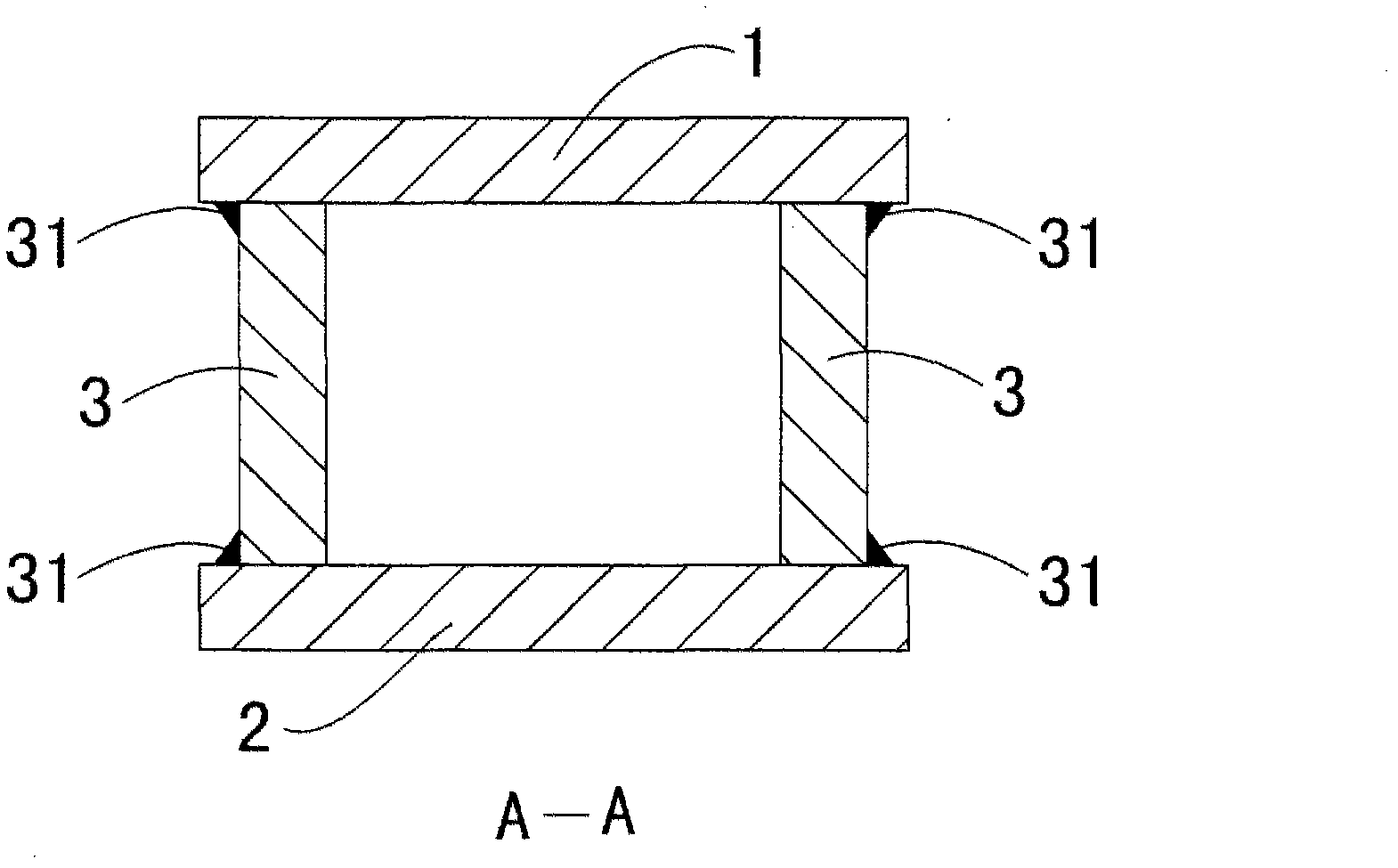

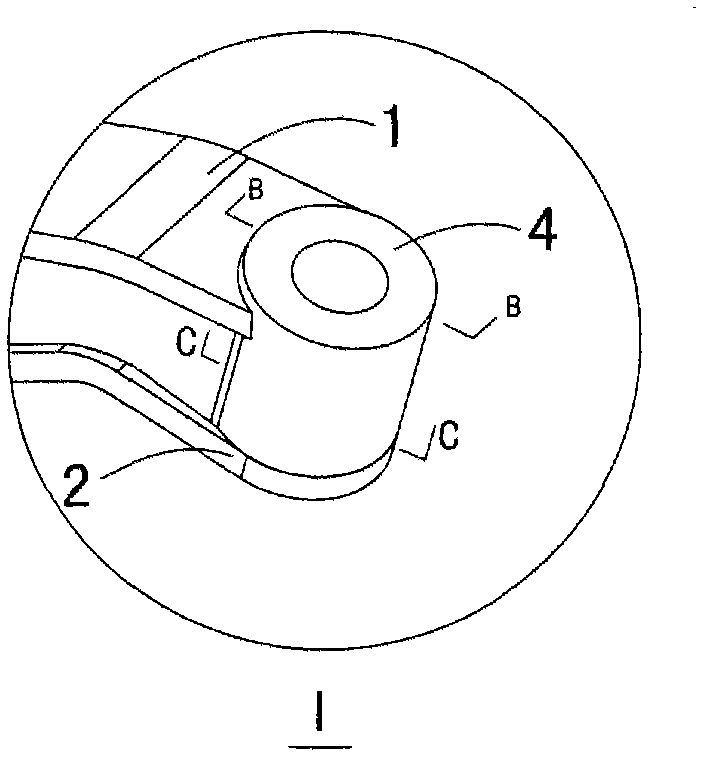

Welding type front axle beam and welding process thereof

ActiveCN102500943AReduce pollutionReasonable structureUnderstructuresWelding apparatusEngineeringMechanical engineering

The invention discloses a welding type front axle beam which is reasonable in structure and is simple in manufacturing process. The welding type front axle beam comprises an upper cover plate, a lower cover plate and a hollow tetragonal structure formed by welding two web plates, wherein the two web plates are arranged between the upper cover plate and the lower cover plate; and welding reserved positions at which the web plates are welded are arranged at the two sides of the upper cover plate and the lower cover plate. A welding process of the welding type front axle beam comprises the following steps of: welding the upper cover plate and the lower cover plate which are formed by being punched with the two web plates in a combined manner and carrying out down welding among the upper cover plate, the lower cover plate and the two web plates at the welding reserved positions; arranging pin seats at the positions of the two ends of the lower cover plate and carrying out down welding on the lower cover plate and the pin seats through welding grooves in the lower ends of the pin seats; forming craters between the two web plates and the pin seats and carrying out down welding at the craters; and carrying out down welding between the upper cover and the pin seats on the upper cover plate. The welding type front axle beam has the advantages of reasonable design, reliable performance, simple manufacturing process, low energy consumption, less environmental pollution and the like, and is suitable for popularization and application.

Owner:重庆康桥工业有限公司

Method for manufacturing beryllium bronze explosion-proof hammer

The invention relates to a method for manufacturing a beryllium bronze explosion-proof hammer. The method is characterized in that a metal casting mold is used for forming, and a metal column comprises an upper half mold and a lower half mold which are horizontally split; an upper casting mold half cavity is formed in the upper half mold, a lower casting mold half cavity corresponding to the uppercasting mold half cavity is correspondingly formed in the lower half mold, an upper half core is arranged in the center of the top surface of the upper casting mold half cavity, and a lower half coreis arranged in the center of the bottom surface of the lower casting mold half cavity; an exhaust channel is formed in the position, positioned on the parting surface of the upper half mold and the parting surface of the lower half mold, of the outer side of an explosion-proof hammer head cavity; an upper pressing head is arranged on the upper half mold; a material storage cavity is formed in thecenter of the lower half mold, and a lower pressing head is arranged at the bottom of the material storage cavity; and a flow channel is formed between the material storage cavity and the lower casting mold half cavity. The invention further relates to the method for manufacturing the beryllium bronze explosion-proof hammer by utilizing the metal casting mold, so that the problems that the density is low, the structure is thick and large, and blocks are prone to jumping in the using process in the process of producing the beryllium bronze explosion-proof hammer by an existing casting technology are solved.

Owner:HEBEI BOTOU SAFETY TOOLS CO LTD +1

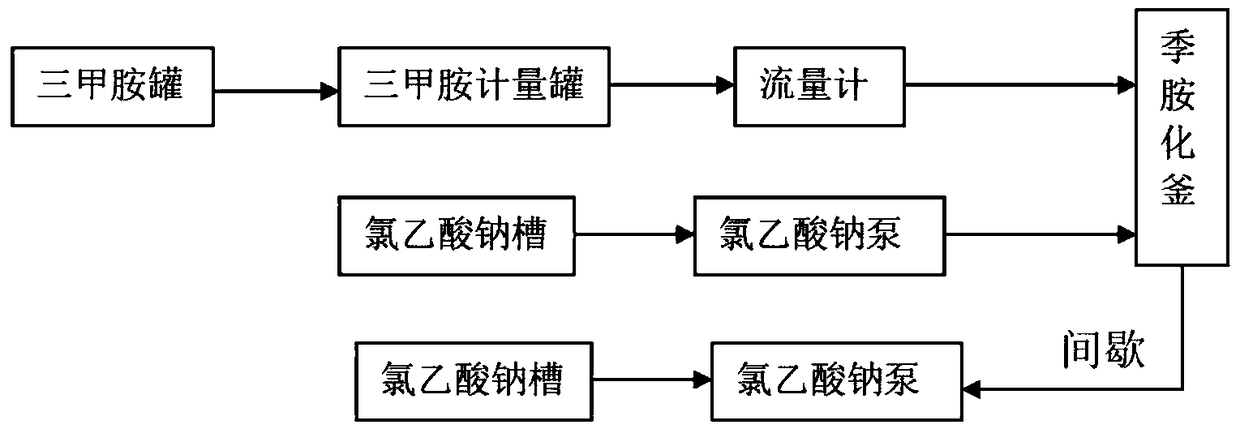

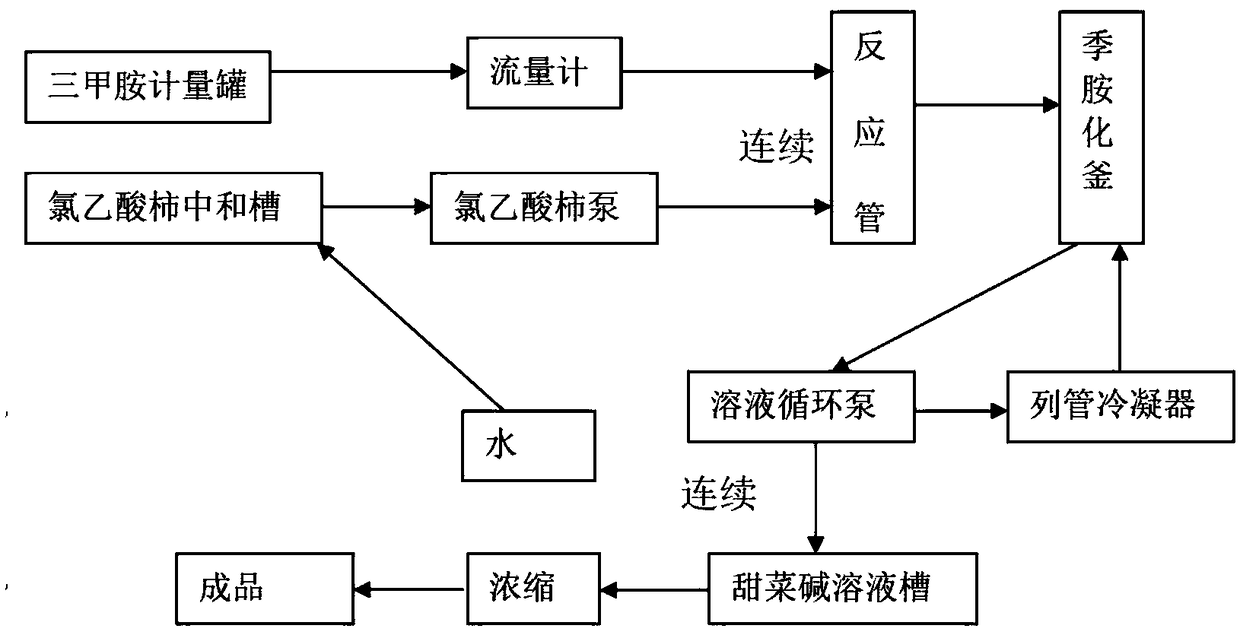

Betaine synthesis device and method

InactiveCN109134288AHigh purity of solutionImprove product profit and competitivenessRare earth metal chloridesOrganic compound preparationChemistryReaction tube

The invention discloses a betaine synthesis device and method, and relates to a preparation method of an additive product. The device comprises a reaction tube, a quaternization kettle, an amination liquid circulating pump and a betaine solution storage tank which are sequentially communicated through a pipeline, chloroacetic acid persimmon and trimethylamine feeding pipelines are arranged on thereaction tube, the amination liquid circulating pump is connected with a condenser through a circulating pipeline and then connected into a reactor, a PH (potential of hydrogen) meter is mounted on the circulating pipeline and performs continuous detection to control the feed quantity of an inlet and outlet system, materials react in the reactor and the reaction tube, the circulating pump performsforced circulation and cooling, and reaction heat of the system is removed. The device is high in use ratio, cerium chloride serving as a by-product is wide in application, can be used as a feed additive and can also serve as a raw material in the fields of medicines, military industries, fireworks and the like, products are high in additional value, the problem of formation of hydroxyacetic acidserving as a by-product in the production process is solved, and the yield and the purity of the product synthesis process are improved.

Owner:宜兴市天石饲料有限公司

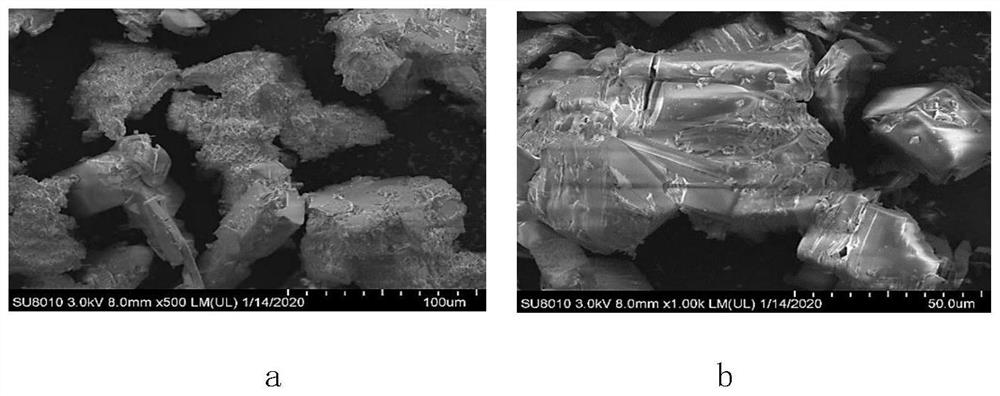

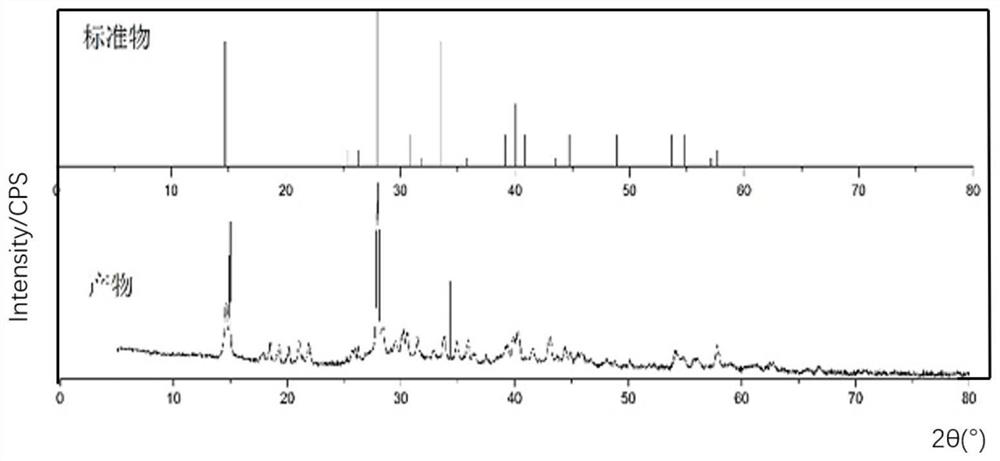

Method for synthesizing nuclear grade boric acid through hydrolysis of boron trifluoride

PendingCN113307281ANo wasteHigh purityFluorine/hydrogen-fluorideBoron-oxygen compoundsNuclear powerReaction temperature

The invention discloses a method for synthesizing nuclear-grade boric acid by hydrolyzing boron trifluoride, which comprises the following steps: (1) reacting boron trifluoride with boron 10 abundance of more than 96% with water, setting nitrogen or other inert gases as shielding gas or not, setting the molar ratio of boron trifluoride to water to be 10: 1-1: 100, the initial reaction temperature to be-20 to 100 DEG C, and the reaction time to be 0-40 hours, collecting a boric acid aqueous solution at the bottom of the reaction kettle, and absorbing generated hydrogen fluoride with water or alkali liquor; and (2) recrystallizing and purifying the boric acid obtained in the step (1), setting the crystallization temperature to be 0-50 DEG C, and setting the solution concentration to be 0-50%. The method disclosed by the invention is a process capable of directly obtaining the boron 10-enriched nuclear grade boric acid, the raw materials are easy to obtain, the process waste is less, and remarkable economic and environmental benefits are brought; and high temperature and high pressure are not needed, and energy waste is not caused, so that the overall cost of the process is reduced, the purity and yield of the product are improved, the purity of the synthesized boron-10-rich boric acid can reach 99.9%, the abundance of boron-10 is greater than 96%, and the boron-10-rich boric acid can be used for nuclear power station neutron protection.

Owner:TIANJIN UNIV

Three-dimensional Curved Surface Stretch Forming Method Based on Deformed Surface Discrete Die

The invention provides a three-dimensional curved surface stretch forming method based on a surface-changing discrete mould, and belongs to the field of metal plastic machining. Nonuniform deformation of a plate in the stretch forming process is the main cause of kinds of defects. According to the method, based on the discrete mould, the forming process of a curved surface is controlled through the change of the mould surface. In the forming process, the plate is kept completely attached to the mould surface all the time, the continuous and uniform change of the mould surface makes the deformation of the plate more and more uniform, the forming defects are avoided, and a high-quality curved-surface part can be obtained through stretch forming. The discrete mould is composed of regularly-arrayed basic body units, and real-time control over the geometrical shape of the surface of the stretch forming mould is achieved by changing the height of the basic body units. Besides, in the stretch forming process, the plate is clamped by a clamp to rotate along with the change of the mould surface, the clamp does not need to move in the horizontal direction or height direction, and therefore a loading structure of stretch forming equipment can be simplified through the forming method.

Owner:JILIN UNIV

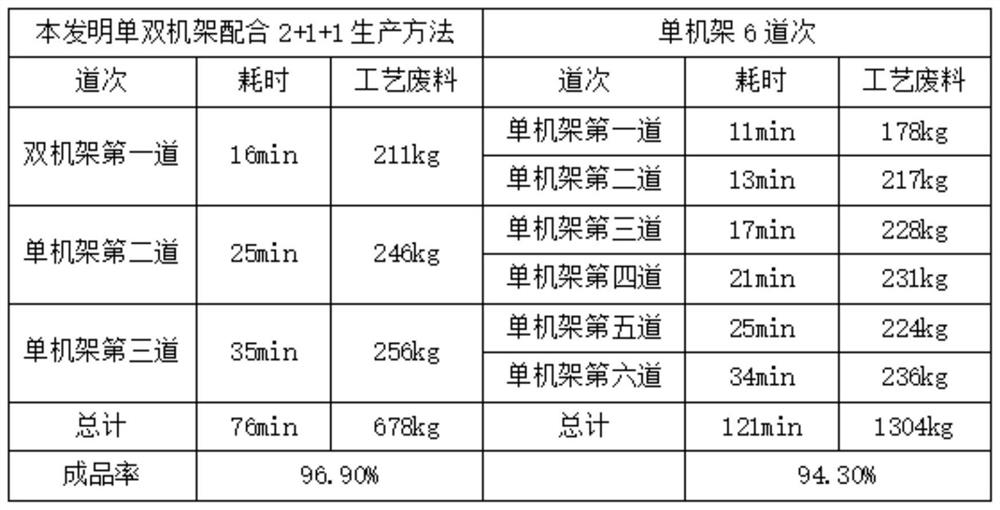

Short-process rolling method for cold-rolled 5052 alloy tank cover material

PendingCN112337969AShorten the timeReduce process wasteMetal rolling arrangementsAlloyContinuous rolling

The invention relates to the technical field of 5052 alloy tank cover cold rolling, in particular to a short-process rolling method for a cold-rolled 5052 alloy tank cover material. The short-processrolling method for the cold-rolled 5052 alloy tank cover material comprises a cast-rolling roll and further comprises the following steps that double-rack cogging is conducted, specifically, the cast-rolling roll is transferred to a double-rack cold rolling mill so as to be subjected to double-rack continuous rolling, and the thickness of a plate subjected to double-rack continuous rolling is converted into 0.55 to 0.85 mm; single-rack primary rolling is conducted, specifically, a strip rolled by the double-rack cold rolling mill is fed into one single-rack cold rolling mill, and the thicknessof the plate subjected to single-rack primary rolling is converted into 0.2 to 0.45 mm; and single-rack secondary rolling is conducted, specifically, the plate is fed into the other single-rack coldrolling mill again after being subjected to primary rolling through a single rack, and the thickness of the plate subjected to secondary rolling is converted into 0.18 to 0.26 mm. According to the short-process rolling method for the cold-rolled 5052 alloy tank cover material provided by the invention, the double-rack cold rolling mill and the two single-rack cold rolling mills are arranged and correspondingly adjusted, so that on one hand, the production efficiency can be greatly improved, on the other hand, due to reduction of process waste, the yield can be increased, and compared with a single-rack six-pass production mode, the production cost can be greatly reduced.

Owner:河南中孚高精铝材有限公司

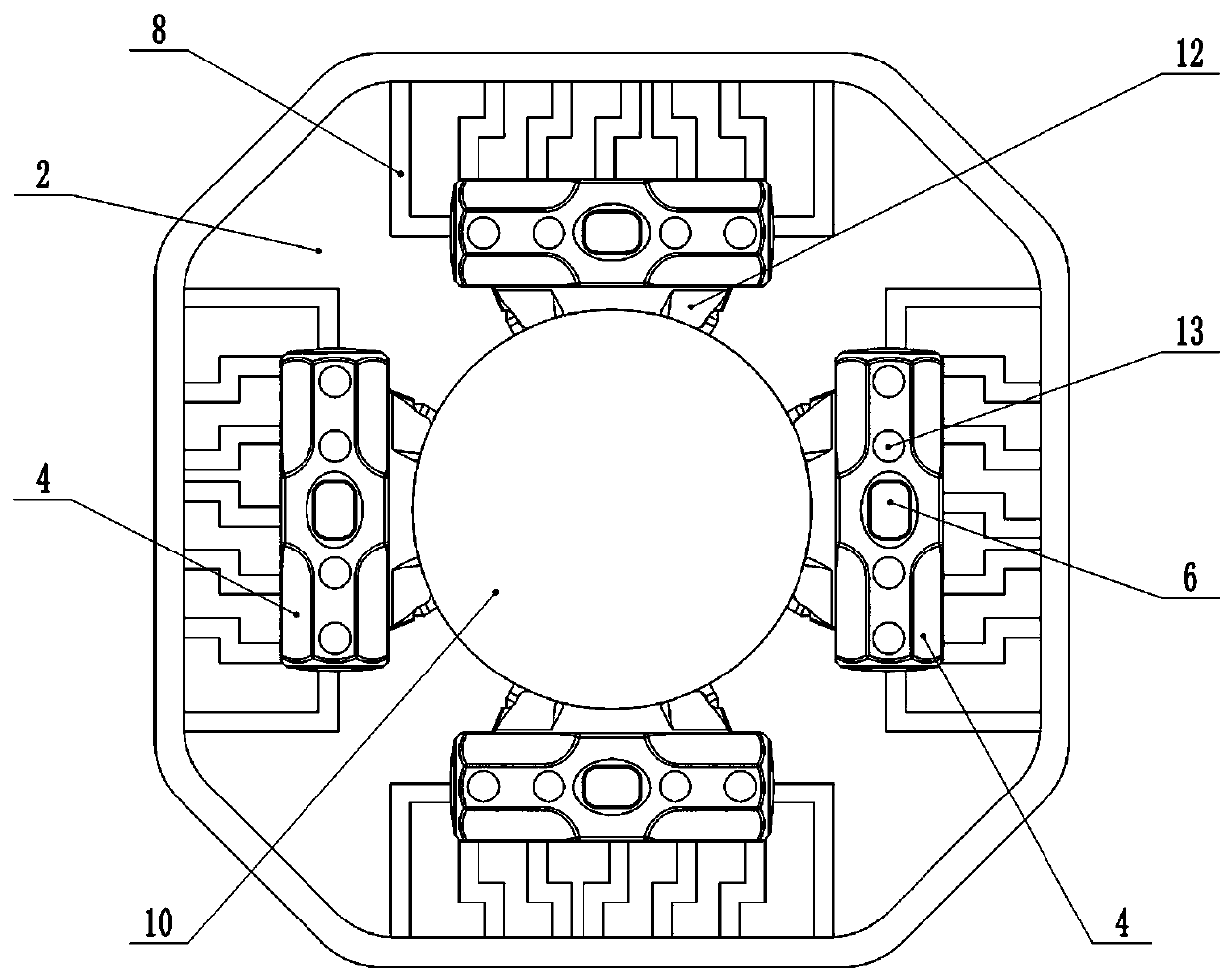

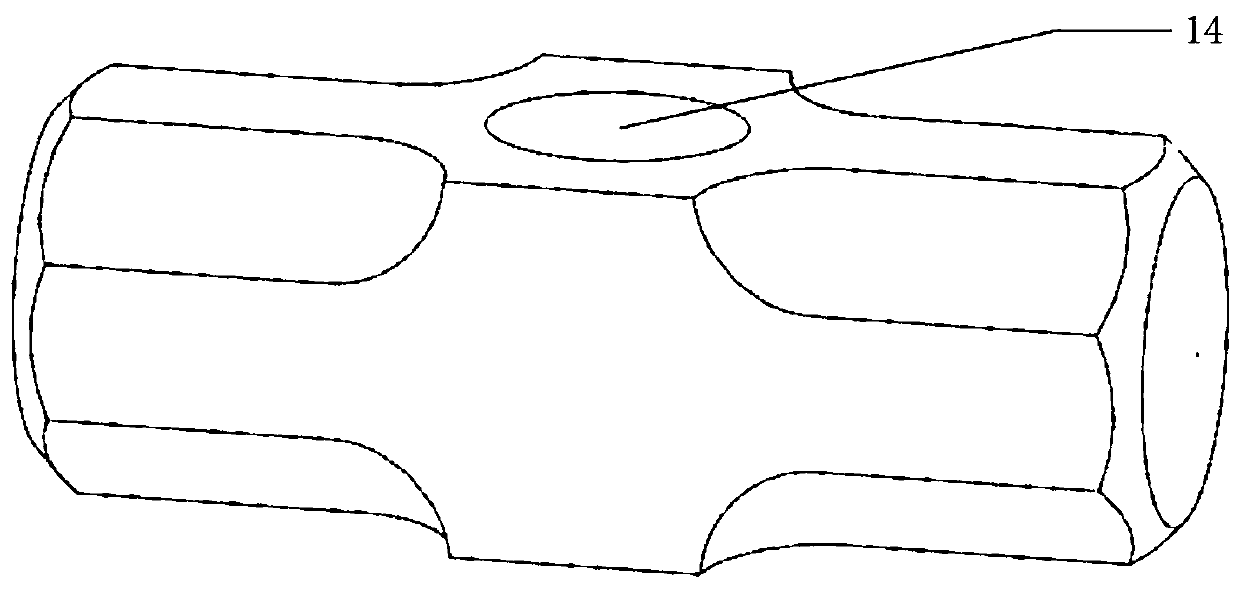

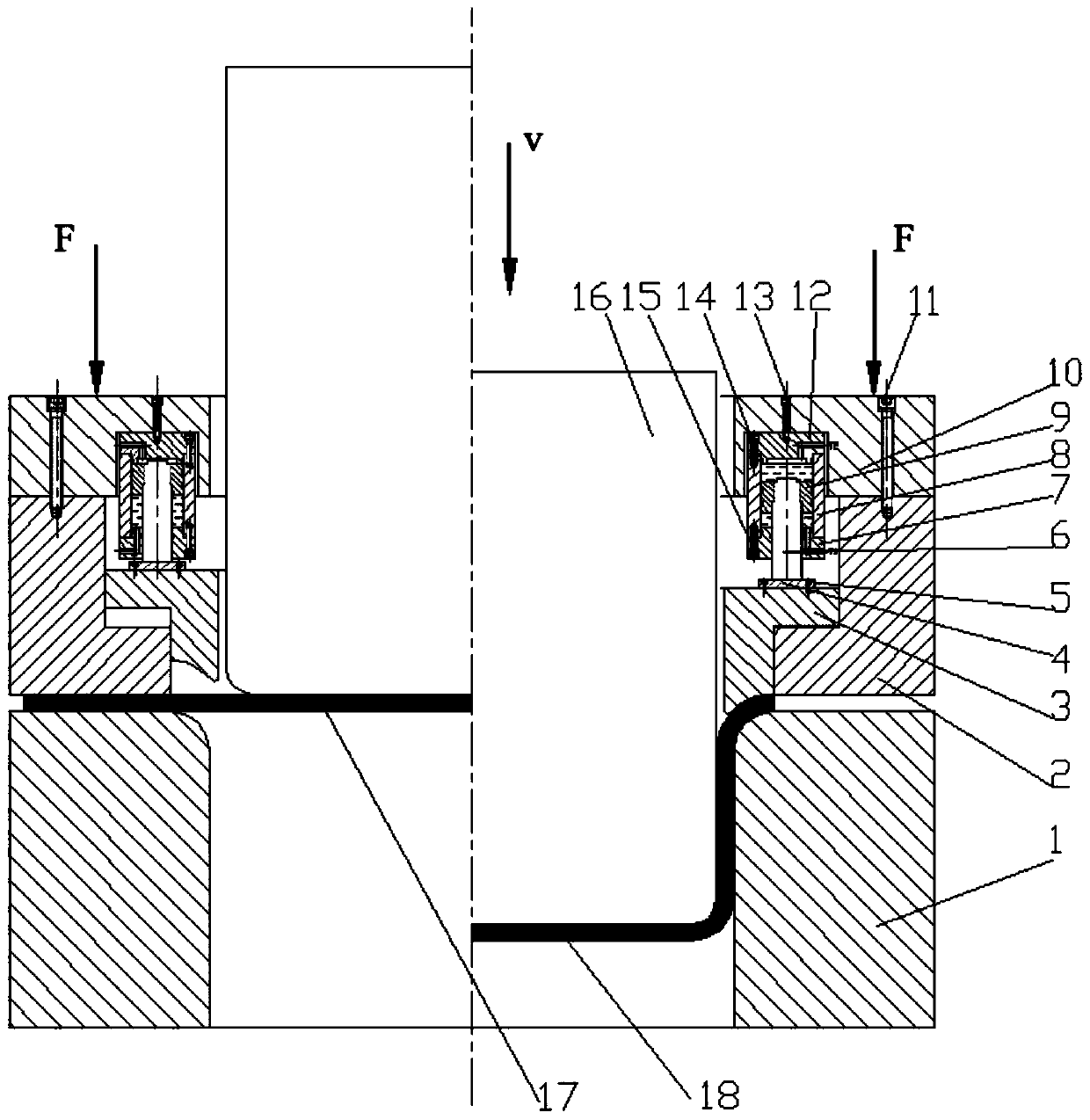

Device and method for divisional loading of blank holder force

The invention discloses a device and method for divisional loading of the blank holder force. The device comprises a female die, a plane blank holder, a round-angle zone blank holder, a blank holder fixing plate, a telescopic structure and a male die. According to the device and the method, an annular nested blank holder structure capable of realizing divisional application of the blank holder force to a plane zone and a round-angle zone is designed, in the deep-drawing process, before the plane zone is separated from the plane blank holder, the blank holder force is applied to round-angle zone materials through the round-angle zone blank holder, the round-angle zone materials which are used as process remaining materials originally and are about to be cut off are deformed continuously, most materials of the round-angle zone become effective areas of a deep-drawn part, thus the material utilization rate is increased, the formability and the wall-thickness uniformity of the part are improved, the forming passes are reduced even, and the die cost and the equipment cost are reduced.

Owner:HARBIN INST OF TECH

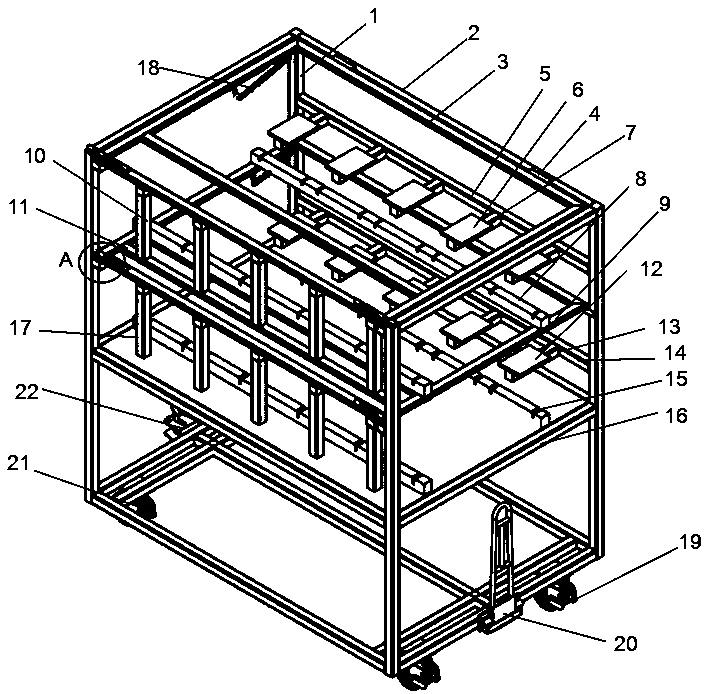

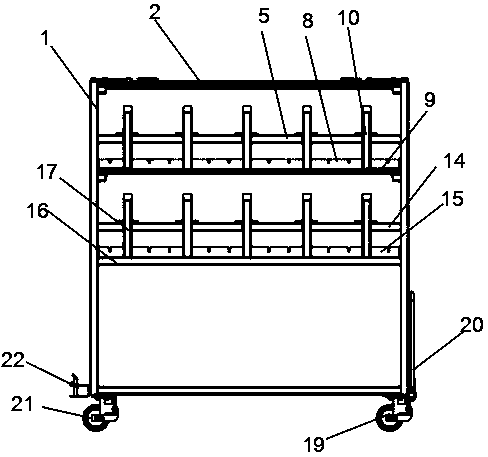

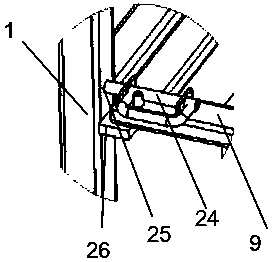

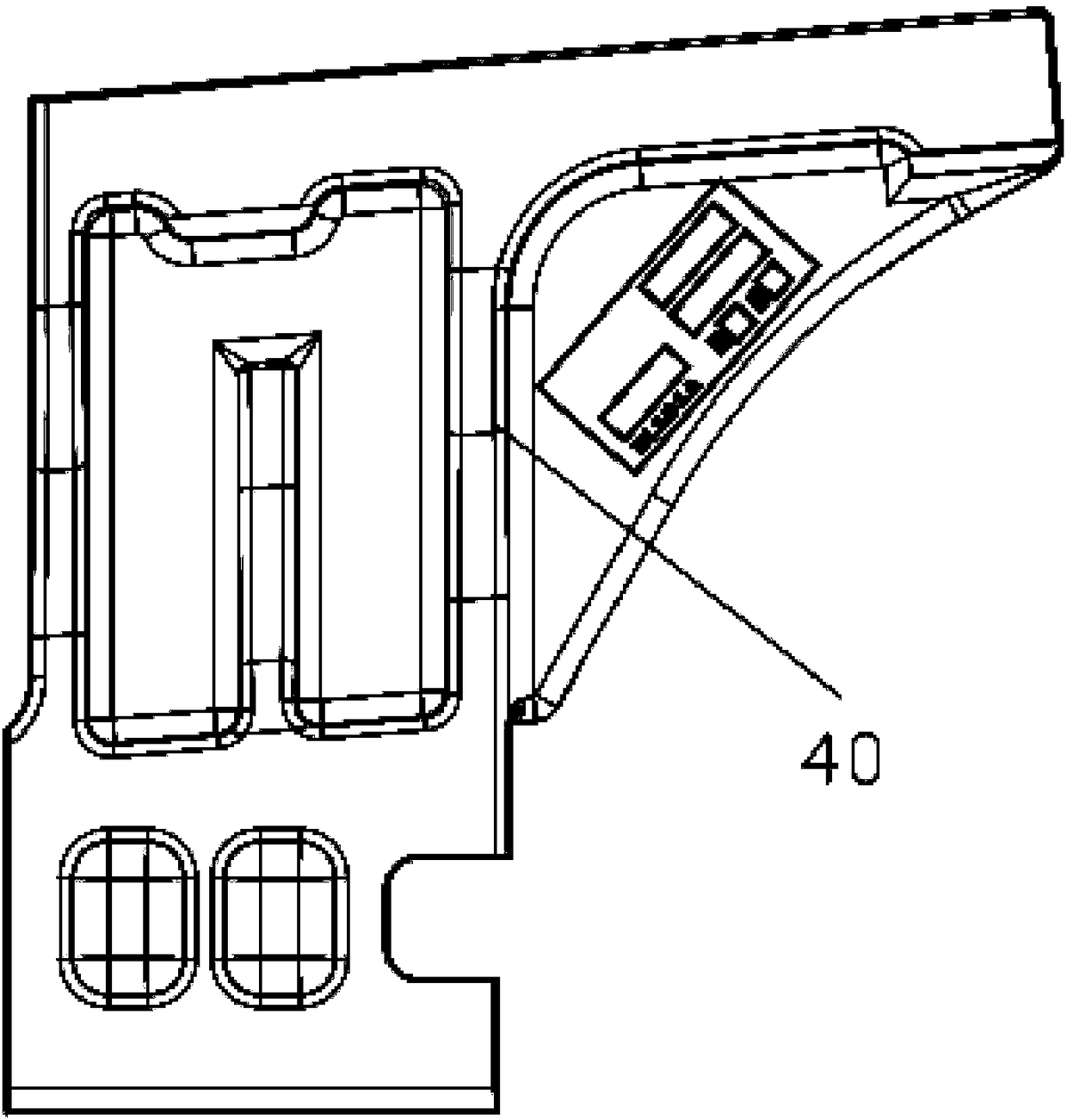

Appliance for turnover of automobile auxiliary instrument board assemblies

InactiveCN110395471AStable structureLow costPackage recyclingPackaging vehiclesHinge angleProduction line

The invention relates to an appliance for turnover of automobile auxiliary instrument board assemblies. The appliance comprise an appliance body, a movement mechanism, a placement layer and a top cover, wherein the appliance body is formed by the mutual welding of a cross beam and an upright post on the side and rear surfaces of the appliance body, the movement mechanism is composed of a wheel anda traction mechanism, the placement layer is internally fixed in the appliance body and is divided into a first placement layer and a second placement layer, and the connection between the first placement layer, the top cover and the appliance body is realized through hinges and gas springs. The appliance for the turnover of the automobile auxiliary instrument board assemblies has the advantagesof being stable in structure, reusable, and economical and environment-friendly; and in addition, the turnover from an manufacturer of the automobile auxiliary instrument board assemblies to a production line of an client can be realized, so that operators do not need to take out the automobile auxiliary instrument board assemblies from an appliance to other appliances for on-line operation, so that the visualization can be achieved, the safety is improved, the man-machine engineering is realized, and the working efficiency is improved.

Owner:SUZHOU SENZHONG AUTO PARTS CO LTD

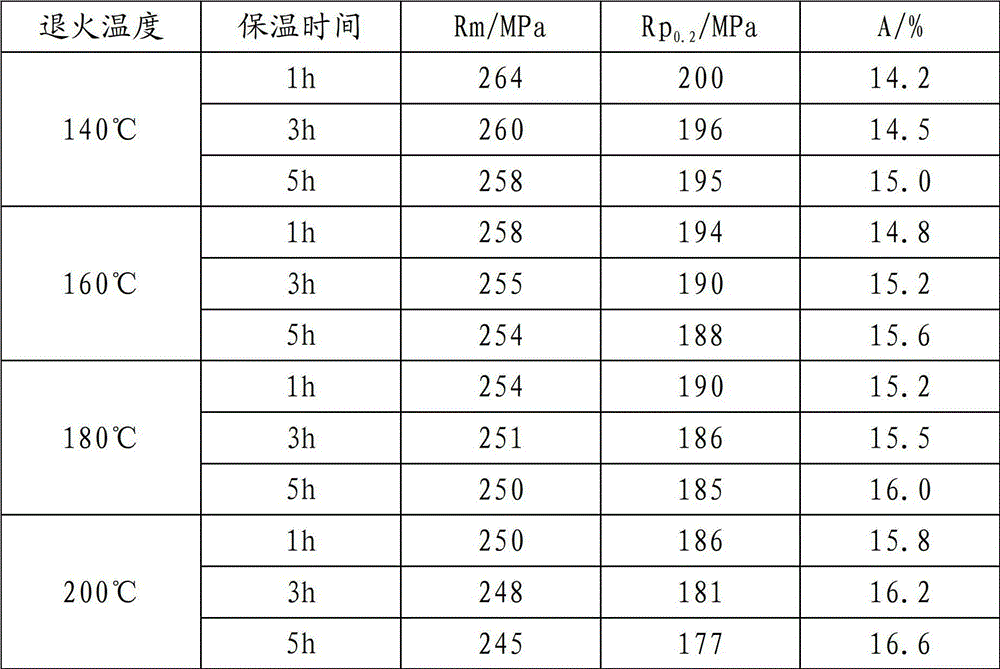

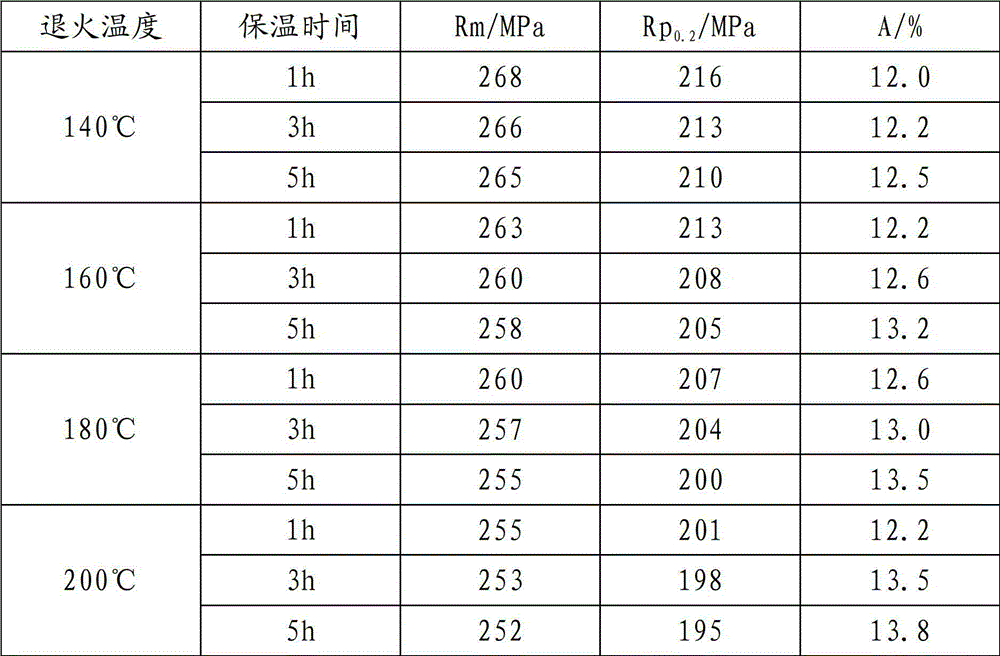

Production method of 5754-H24 aluminum alloy plate strip

Owner:ALUHOUSE TECHGD CO LTD

Synthesizing method for 4-oxethyl-1,1,1-trifluoro-butene-2-ketone

InactiveCN105237376ASimple processReduce process wasteOrganic compound preparationCarbonyl compound preparation by condensationKetoneDichloromethane

The invention relates to a synthesizing method for 4-oxethyl-1,1,1-trifluoro-butene-2-ketone. The method comprises the following steps that dichloromethane and pyridine are added in a reaction kettle, on the condition that the temperature is controlled at minus 10 DEG C-0 DEG C, trifluoroacetic acid is dropwise added, the dropwise adding time is controlled for 3-3.5 hours, and after dropwise adding is completed, stirring is performed for ten minutes; vinyl ethyl ether is added, on the condition that the temperature is controlled at minus 10 DEG C-0 DEG C, methylsulfonyl chloride is dropwise added, the dropwise adding time is controlled for 2 hours, after dropwise adding is completed, the temperature is slowly increased to 20 DEG C, and stirring is performed for staying overnight; filter pressing is performed on obtained products with a plate-and-frame filter press, and filter cakes are washed for two times with dichloromethane to collect pyridinium; normal-pressure desolventizing is performed on filtrate at 58 DEG C, the temperature is lowered to 20 DEG C to collect solvent, reduced-pressure distilling and desolventizing are performed at 58 DEG C to collect solvent to obtain crude products, reduced-pressure rectifying is performed on the crude products to collect overhead products, and the 4-oxethyl-1,1,1-trifluoro-butene-2-ketone is obtained. The synthesizing method for the 4-oxethyl-1,1,1-trifluoro-butene-2-ketone has the advantages of being simple and direct in technology, few in technology waste materials, high in yield and suitable for large-scale industrialized production.

Owner:JIANGSU REPONT PESTICIDE FACTORY

Au-base slicken solder and preparation method thereof

InactiveCN106695163AAccurate weight percentageConvenient, quick and accurate metering operationWelding/cutting media/materialsSoldering mediaImpurityMetal

The invention provides Au-base slicken solder and a preparation method thereof and belongs to the technical field of solder. The Au-base slicken solder is prepared from, by mass percent, the following raw materials: 8%-12% of Au, 1%-3% of Si, 10%-15% of Ge, 0.1%-0.8% of Ni, 0.3%-0.8% of Sb, 0.001%-0.003% of P, 0.001%-0.003% of S, 0.01%-0.05% of Fe, 0.01%-0.05% of Al and the balance Sn and unavoidable impurities. The Au-base slicken solder can enhance the oxidation resistance and the corrosion resistance of the solder better, improve the wettability and liquidity of the solder, reduce the melting point of the solder and the yield of solder splash, improve the welding performance, the metal plasticity, extension strength and other performance and is novel high-performance antioxidant Au-base slicken solder.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

Production method of 5754-H32 aluminum alloy plate strip

Owner:ALUHOUSE TECHGD CO LTD

Casting system of large aluminum-magnesium alloy vibration damping device

The invention discloses a large aluminum-magnesium alloy vibration reduction device casting system which comprises a first vibration reducer cavity, a second vibration reducer cavity and a casting system body. The first vibration reducer cavity and the second vibration reducer cavity have a same structure; the casting system body comprises a filter, a straight pouring gate, a first transverse pouring gate, a first straight-edge inner pouring gate, a first arc-edge inner pouring gate, a second transverse pouring gate, a second straight-edge inner pouring gate and a second arc-edge inner pouring gate; one end of the first arc-edge inner pouring gate is connected with the first transverse pouring gate, the other end of the first arc-edge inner pouring gate communicates with an arc-edge cavity wall of the first vibration reducer cavity, one end of the second arc-edge inner pouring gate is connected with the second transverse pouring gate, and the other end of the second arc-edge inner pouring gate communicates with an arc-edge cavity wall of the second vibration reducer cavity. According to the large aluminum-magnesium alloy vibration reduction device casting system, two castings are adopted to be symmetrically cast and share one casting system, therefore, technological waste generated by at least one straight pouring gate is reduced, and the molding sand using amount is at least decreased by half.

Owner:宁夏维尔铸造有限责任公司

Chemical raw material production equipment

PendingCN108311091AIncrease productivityReduce process wasteFeed devicesChemical/physical/physico-chemical moving reactorsPulp and paper industryCentrifugal force

The invention discloses chemical raw material production equipment. The chemical raw material production equipment comprises a feeding device, a reaction device and a material receiving device, wherein the feeding device comprises a hopper and a feeding pipe; the reaction device comprises a horizontal reaction kettle; a rotating device is arranged at the bottom part of the horizontal reaction kettle; the material receiving device is arranged beside the rotating device; the rotating device comprises a rotating platform which is flush with the ground of a workshop; the bottom part of the rotating platform is connected with a rotating shaft through a bearing; the lower end of the rotating shaft is fixedly arranged on a round basin type base. According to the chemical raw material production equipment disclosed by the invention, grooves for collecting waste residues are formed in the bottom parts of two ends of the inner part of the horizontal reaction kettle; meanwhile, during a reactiongenerating process, the rotating platform drives the horizontal reaction kettle to rotate, heavier granules coagulated during reaction can be thrown to the grooves formed in the two ends under the action of a centrifugal force, reaction and separation are simultaneously completed at a time, the production efficiency is greatly quickened, and waste of working procedures is reduced.

Owner:ZHEJIANG SHENGXIAO CHEM

Processing method of steel piston gas ring

Owner:NANJING FAYN PISTON RING

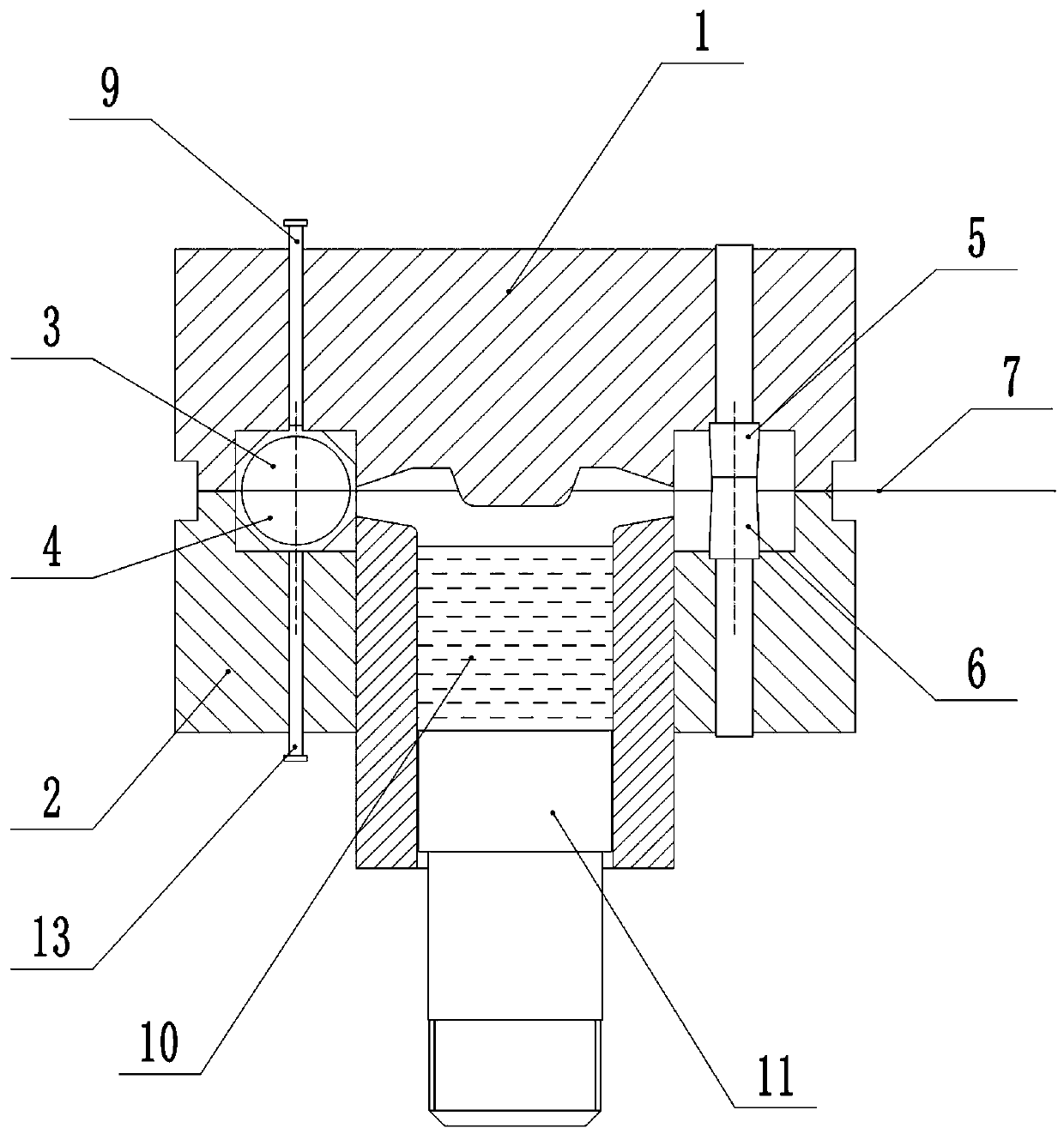

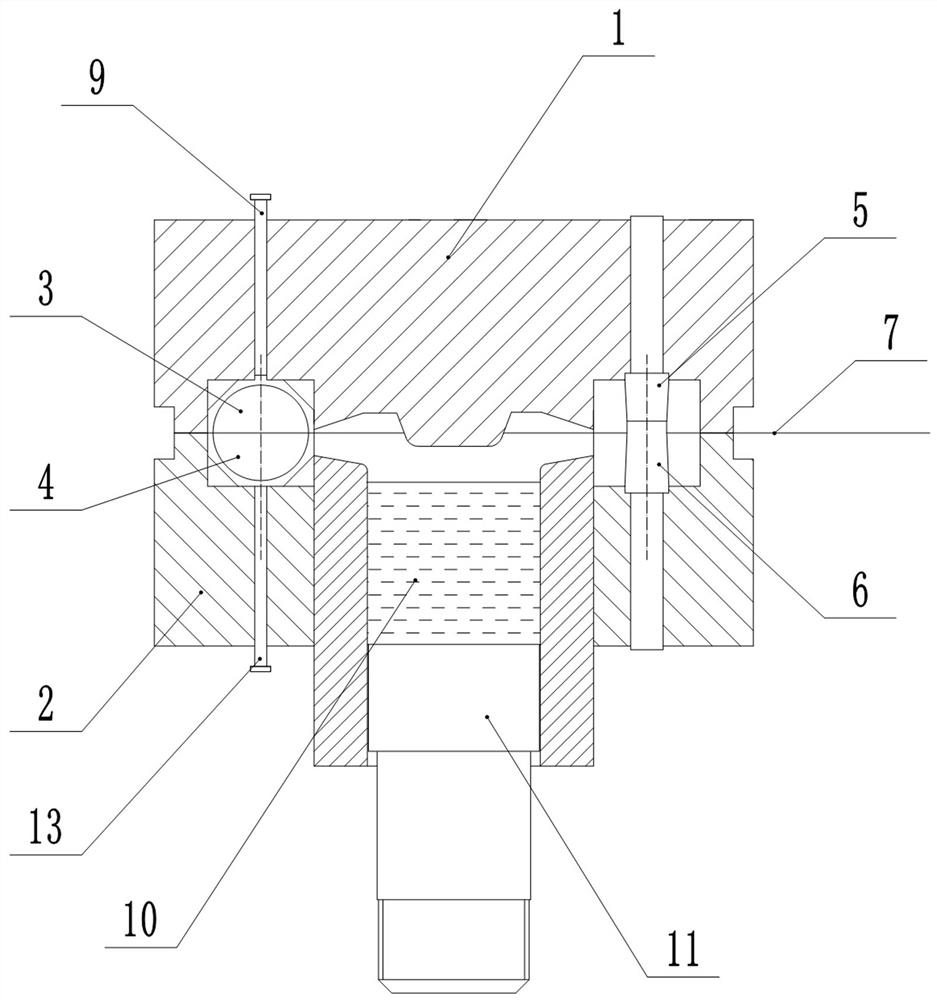

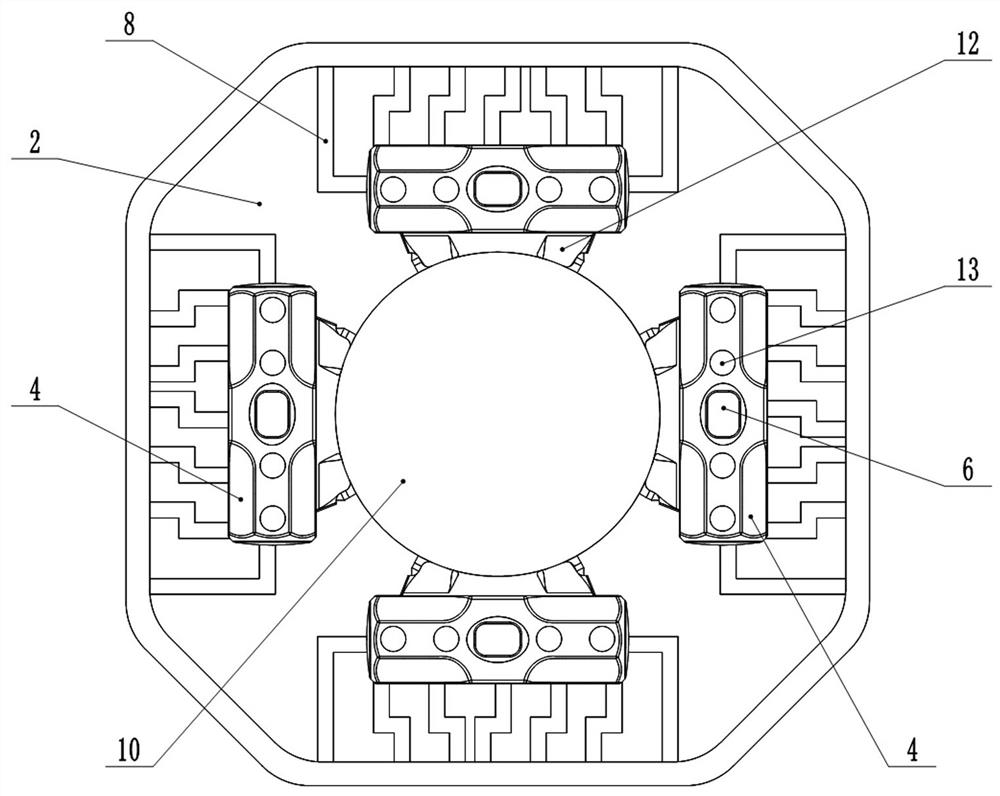

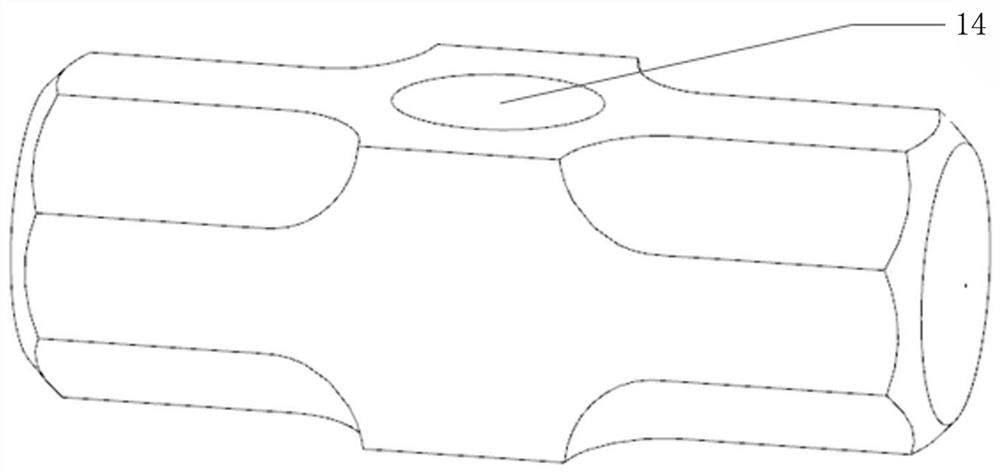

Metal casting mold and method for manufacturing aluminum bronze explosion-proof hammer

The invention relates to a metal mold for manufacturing an aluminum bronze explosion-proof hammer, which includes a horizontally divided upper half mold and a lower half mold; A lower mold half-cavity corresponding to the upper mold half-cavity is provided, an upper half-core is arranged in the center of the top surface of the upper mold half-cavity, and a lower half-core is arranged in the center of the bottom surface of the lower mold half-cavity; The outside of the explosion-proof hammer head cavity is located on the parting surface of the upper half and the lower half, and an exhaust channel is provided; the upper half is provided with an upper pressure head; the center of the lower half is provided with a material storage cavity, the bottom of the storage cavity is provided with a lower pressure head; a flow channel is provided between the storage cavity and the lower mold half cavity. The present invention also relates to a method for manufacturing an aluminum bronze explosion-proof hammer by using the above-mentioned metal casting mold, so as to solve the problems of low density, coarse structure and easy jumping during use of the aluminum bronze explosion-proof hammer produced by the existing casting technology.

Owner:HEBEI BOTOU SAFETY TOOLS CO LTD +1

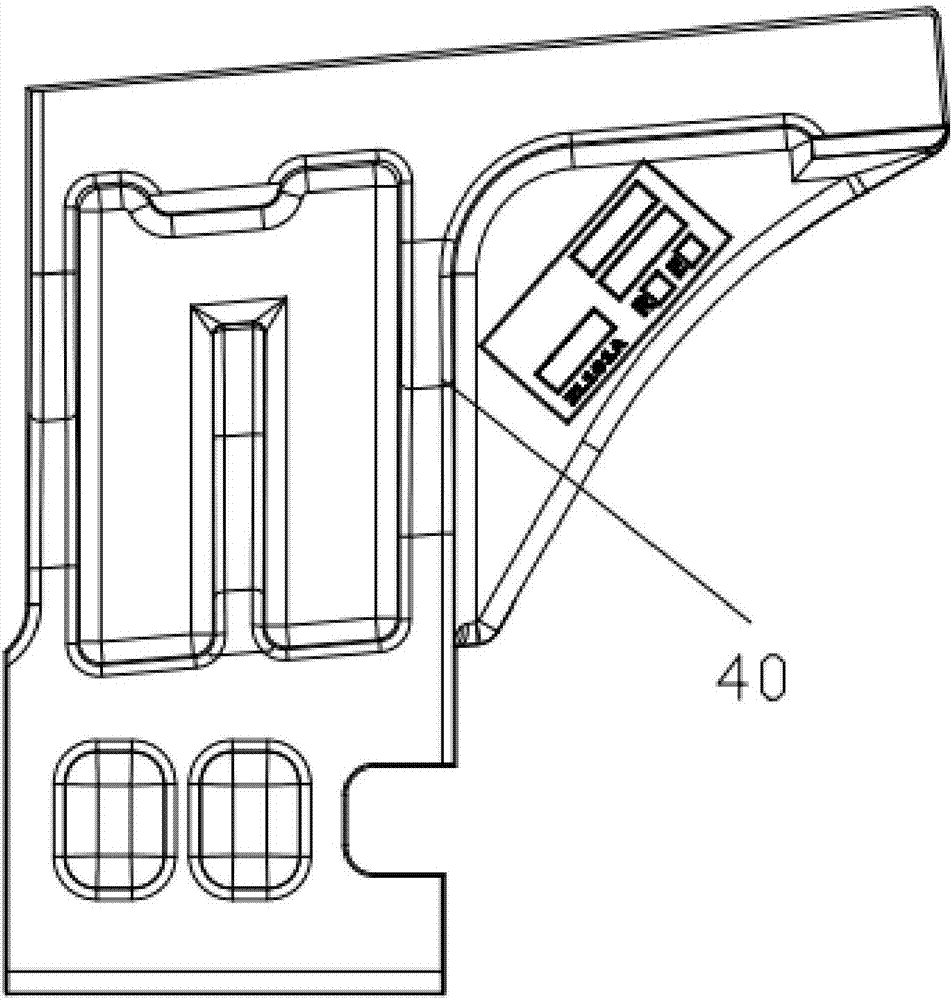

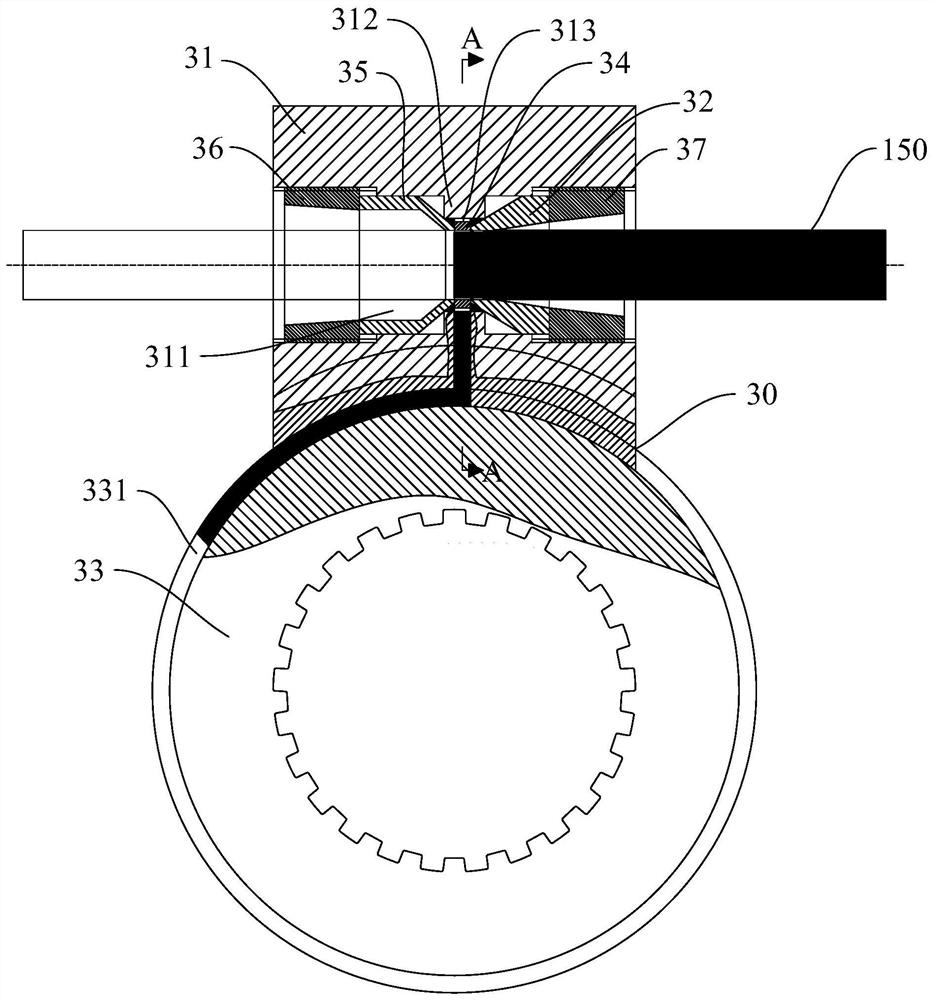

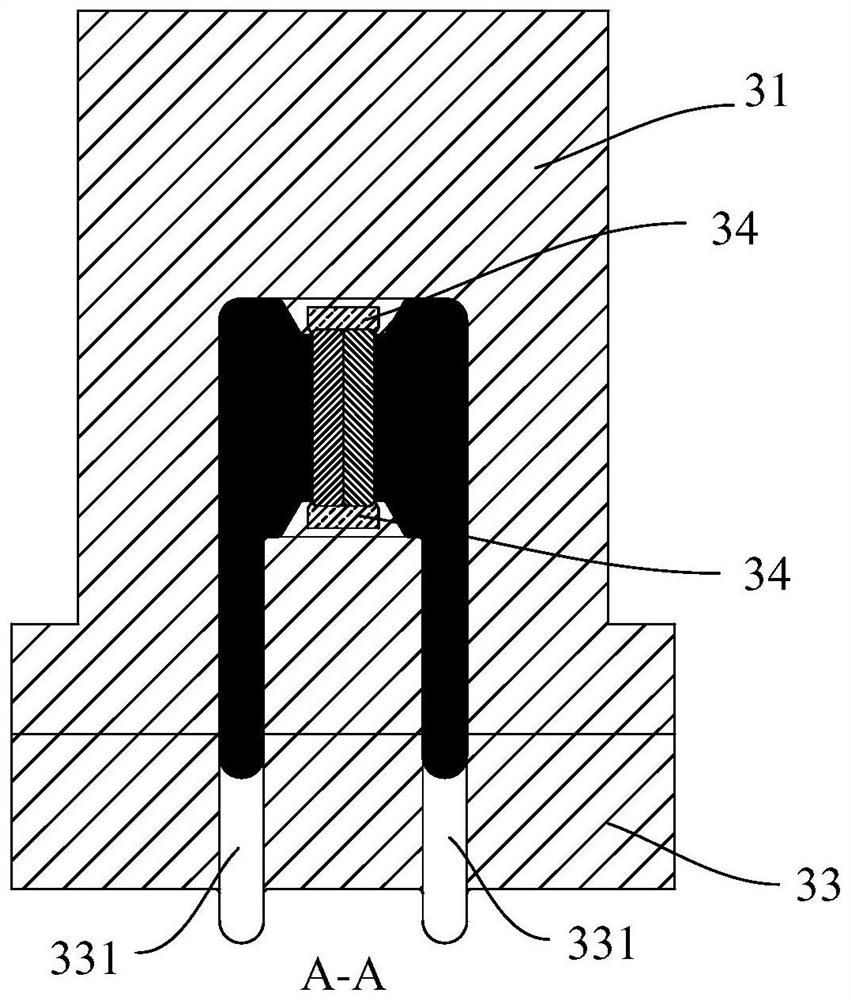

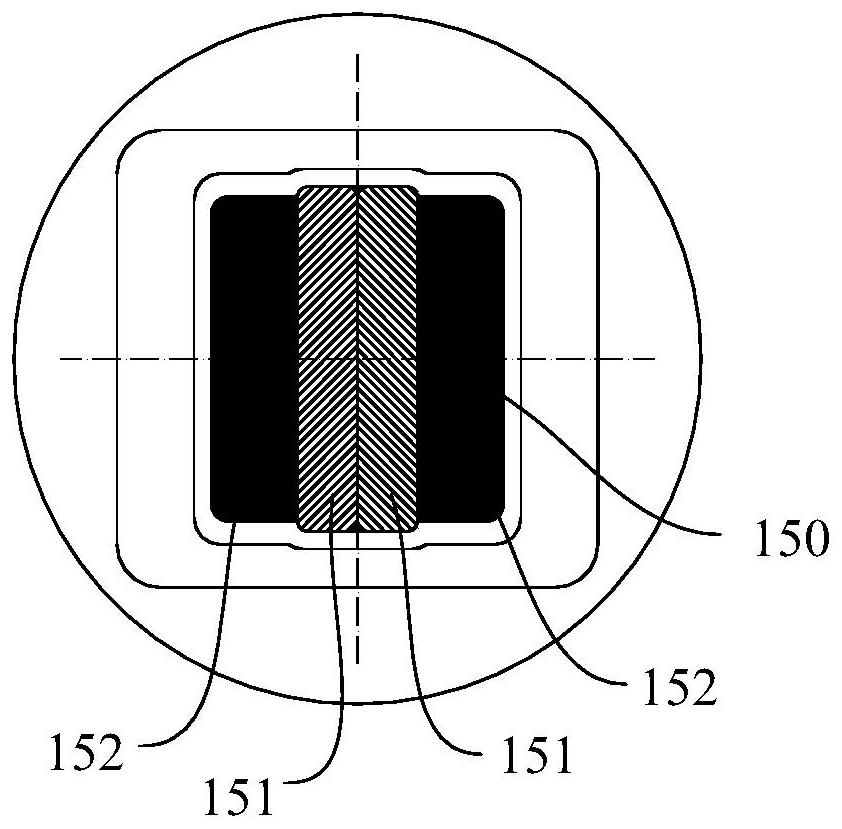

Copper-aluminum composite double-row continuous extrusion module and continuous extruder

PendingCN114054536AIncrease productivityReduce manufacturing costExtrusion diesMetal working apparatusMetallurgyAluminum can

The invention provides a copper-aluminum composite double-row continuous extrusion module and a continuous extruder, the copper-aluminum composite double-row continuous extrusion module comprises an extrusion die with an extrusion die cavity, an extrusion die mounted in the extrusion die cavity, and a double-groove extrusion wheel with extrusion grooves, the extrusion die cavity can allow double copper bars to enter, the extrusion die is provided with extrusion convex parts which are oppositely arranged up and down in the extrusion die cavity and a clamping groove formed between the two extrusion convex parts, the clamping groove is provided with two copper bar extrusion die cavities which are symmetrically arranged left and right, and the two copper bars are contained in the two copper bar extrusion die cavities respectively. Two extrusion grooves are formed in the double-groove extrusion wheel and are symmetrically distributed on the left side and the right side of the extrusion die cavity, and the tail ends of the two extrusion grooves extend to the outer sides of the two copper bar extrusion die cavities respectively. The copper-aluminum composite bar with one side made of copper and the other side made of aluminum can be continuously extruded and produced, the copper-aluminum composite bar is double in number, the production efficiency of the copper-aluminum composite bar is greatly improved, process waste is reduced, production procedures are reduced, energy consumption is reduced, and operators are reduced.

Owner:SHANGHAI ELECTRIC CABLE RES INST

High-precision intelligent separation system and method for underground coal gangue grading

PendingCN113000409AReduce initial temperature errorReduce mistakesSortingDust controlProcess engineering

The invention discloses a high-precision intelligent separation system for underground coal gangue grading, and relates to the field of coal-gangue separation. The high-precision intelligent separation system comprises an alignment feeding device, a first belt conveying device, a cooling dust removal device, a heating grading device, a second belt conveying device, an infrared recognition device, an intelligent sorting center and a coal-gangue separation device. Mined raw coal is conveyed by a belt after being aligned, is subjected to cooling dust removal and heating grading in sequence and then is subjected to infrared recognition, and coal-gangue separation is carried out under the action of the intelligent sorting center and the coal-gangue separation device. All the devices can be disassembled and reassembled, the environmental influence is small, assembly and disassembly are easy, the recognition precision is high, and the underground adaptability is high. The coal dressing process is optimized, and the occupied area of a chamber is reduced. Meanwhile, separated gangue can be directly subjected to underground backfilling, the coal-gangue separation efficiency is improved, the production cost is effectively saved, and the process waste is reduced.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Production method of 5052-H34 aluminum alloy plate strip

Owner:ALUHOUSE TECHGD CO LTD

Three-dimensional Surface Stretch Forming Method Based on Multi-point Force Loading Method

The invention provides a three-dimensional curve stretch forming method based on a multi-point force loading mode, and belongs to the field of metal plastic machining. The multi-point force loading mode is adopted to control the plate stretch forming process; the stretch forming force is applied to a series of discrete points at two ends of a plate by loading control units arranged on two sides of a mold; and the magnitude and the direction of the stretch forming force applied by each loading point can be independently controlled. The invention provides a method for determining the stretch forming force of each discrete loading point according to molded surfaces of a stretch forming mold, realizes the stretch forming process of three-dimensional curve parts by minimum stretch deformation through real-time control of the stretch forming force in each discrete point, prevents generation of forming defects, obtains the curve parts with large deformations, can improve the mold pasting process of the plate, reduces residual materials in the stretch forming process, and saves the materials.

Owner:JILIN UNIV

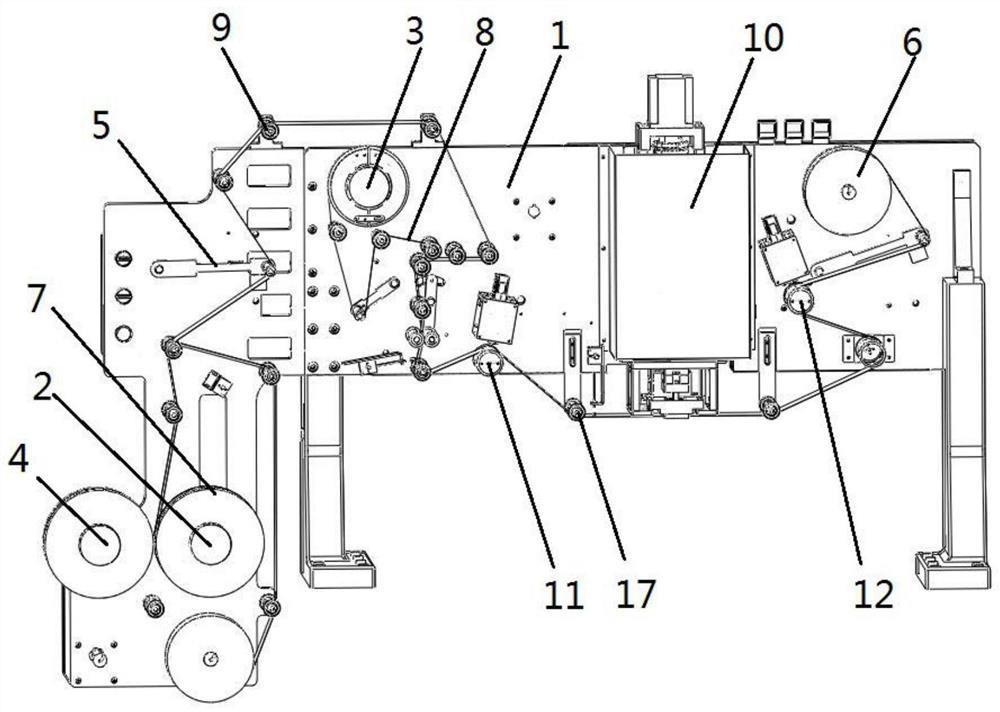

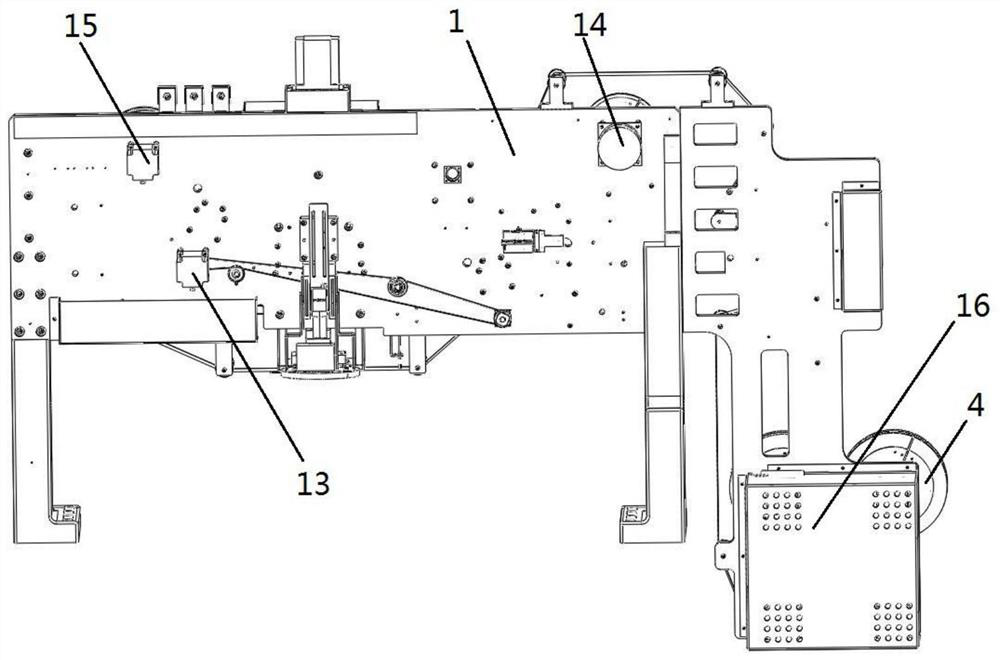

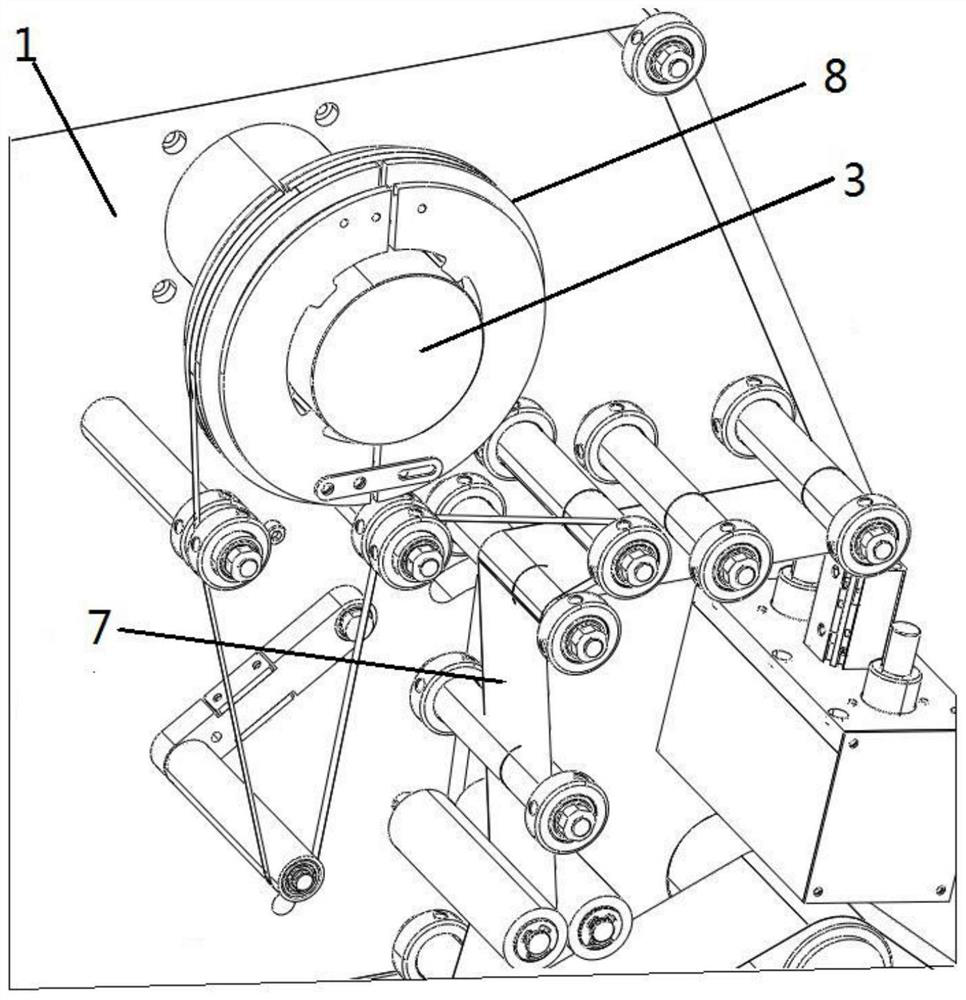

A fpc silver film pad pet slider mechanism

The invention provides an FPC silver film pad PET slider mechanism, the PET material roll is rolled on the second inflatable shaft, and the material belt of the silver film material is guided by multiple sets of guide wheels and passes through the second inflatable shaft. Put the PET material roll under the silver film material, and the front of the mounting plate is equipped with a U-axis mold rotation calibration and lamination mechanism. The waste of the silver film material is rolled into the silver film waste roll; the present invention puts a 2mm PET material at the bottom of the silver film material before punching and pasting, so that there is a 2mm wide part that is not pasted at any place. On FPC products, after the products are hot-pressed and oven-operated, the silver film protective film can be easily torn off by blowing air, which greatly improves the working efficiency, reduces process waste, and can carry out continuous automatic production operations, saving Cost and process control are easier to implement.

Owner:珠海韦田智科精密机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com