Patents

Literature

126results about "Rare earth metal chlorides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

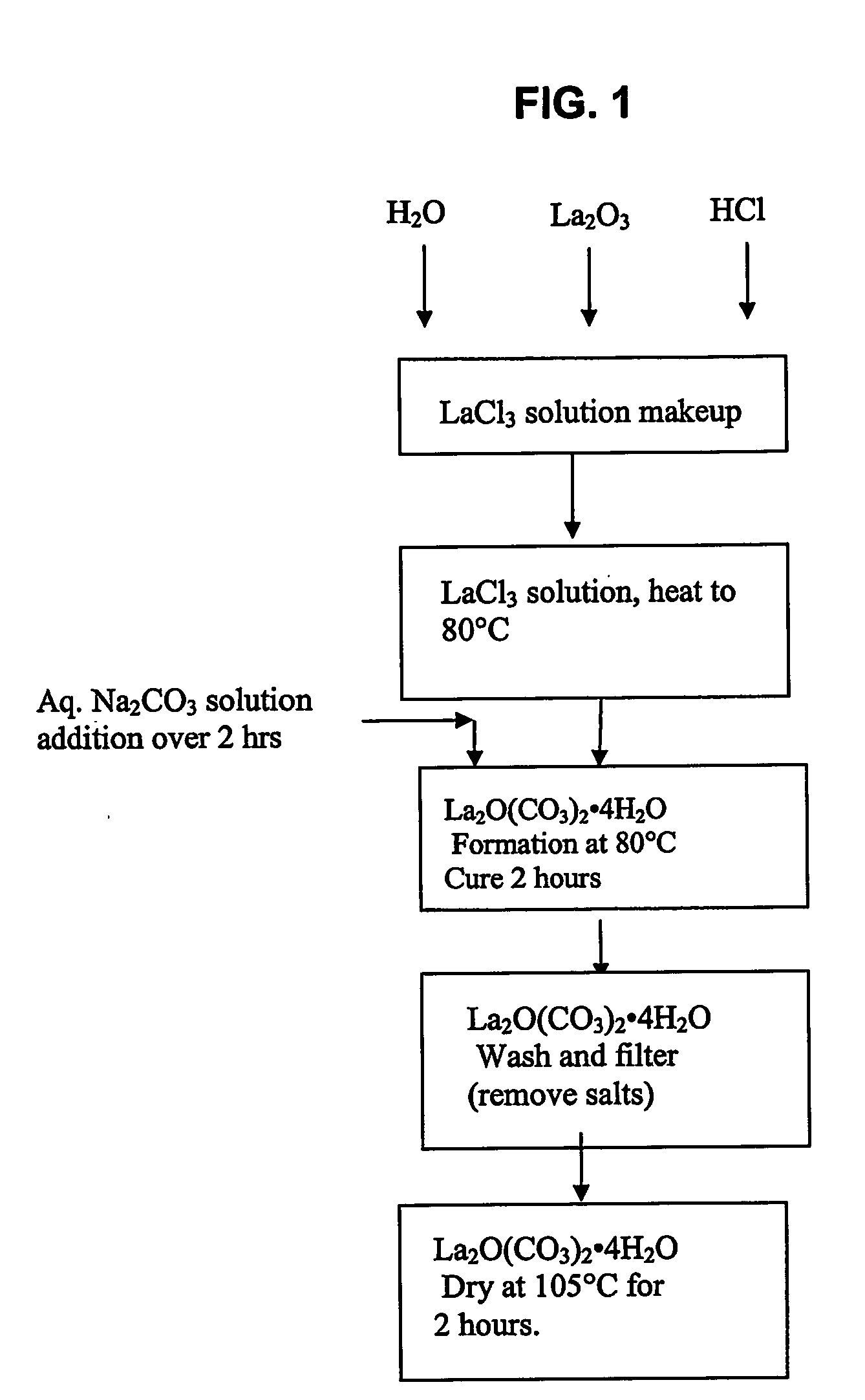

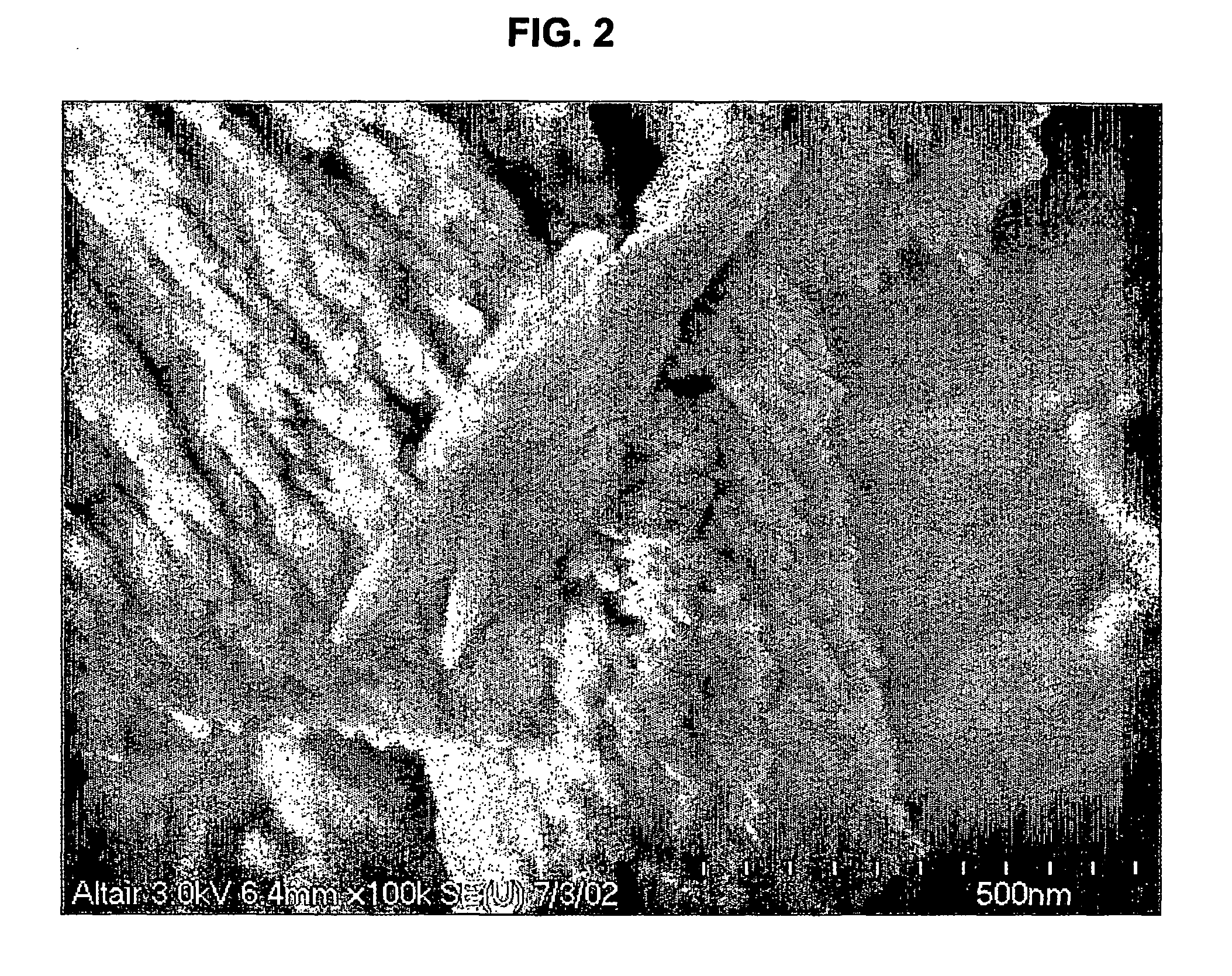

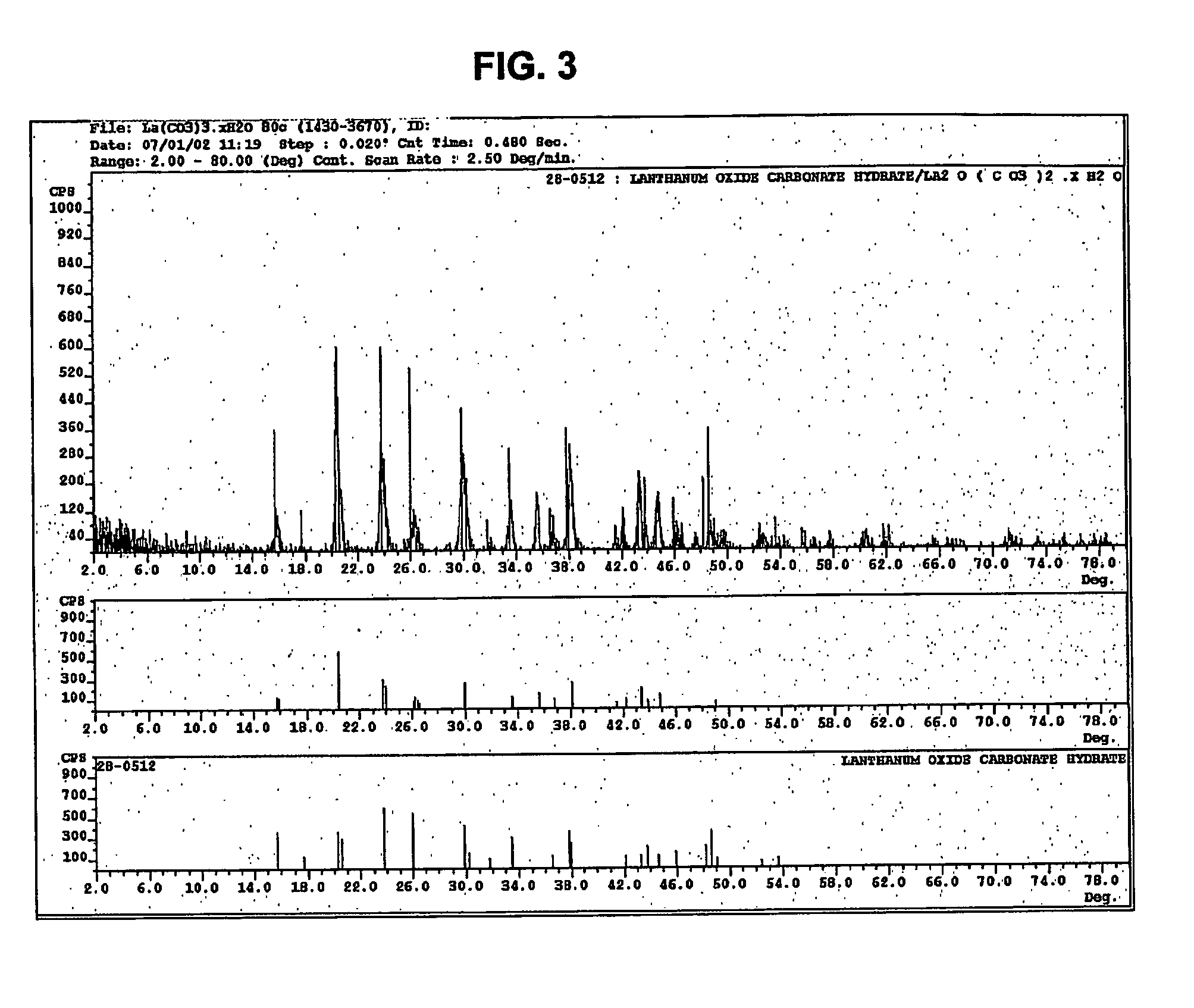

Rare earth compositions and structures for removing phosphates from water

InactiveUS20070149405A1Easy to makeEasy to solveHeavy metal active ingredientsBiocidePhosphateRare earth

A rare-earth compound selected from the group consisting of rare earth anhydrous oxycarbonate and rare earth hydrated oxycarbonate, with a surface area of at least 10 m2 / g, suitable for the removal of phosphate from water.

Owner:SPECTRUM PHARMA INC

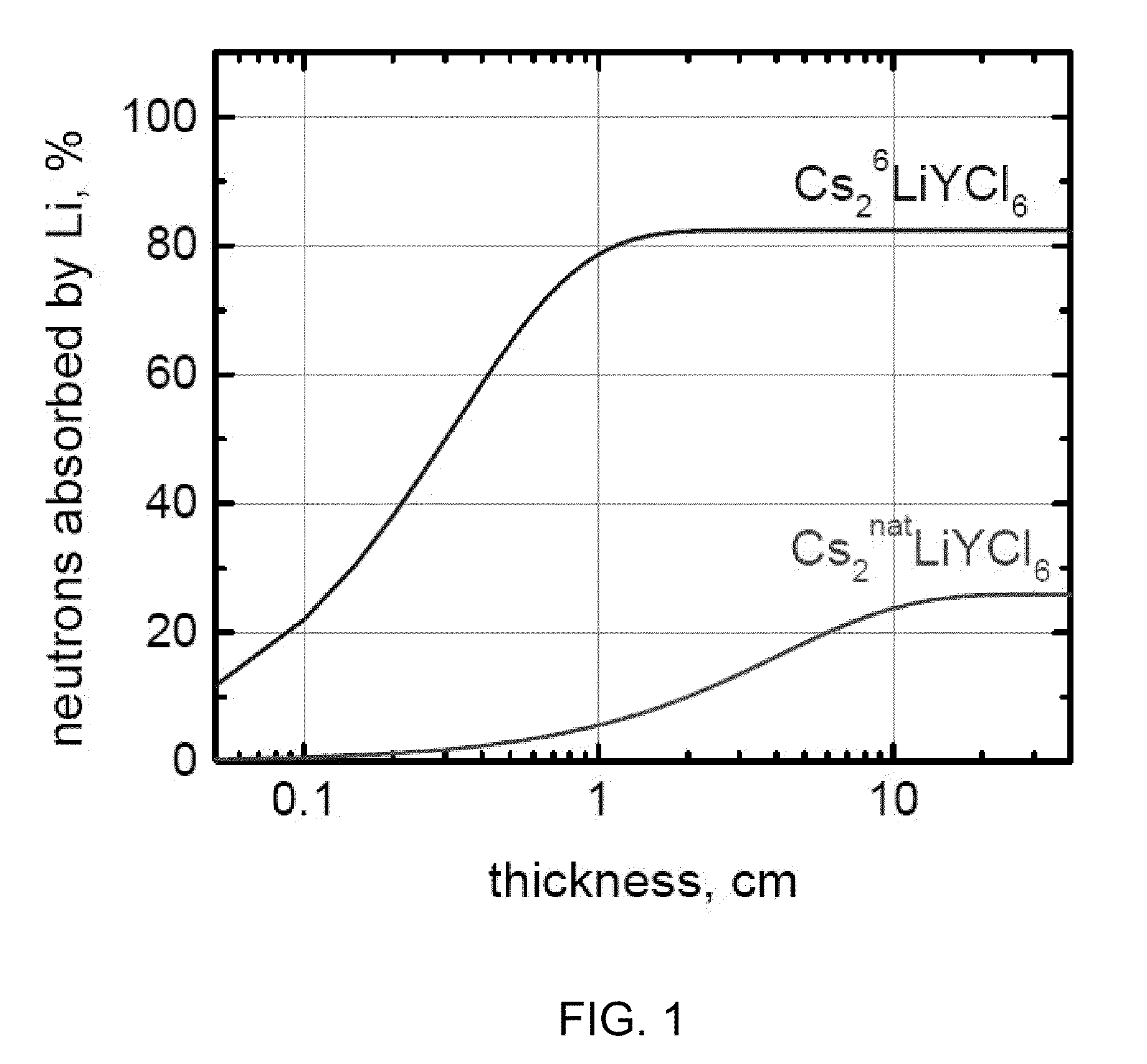

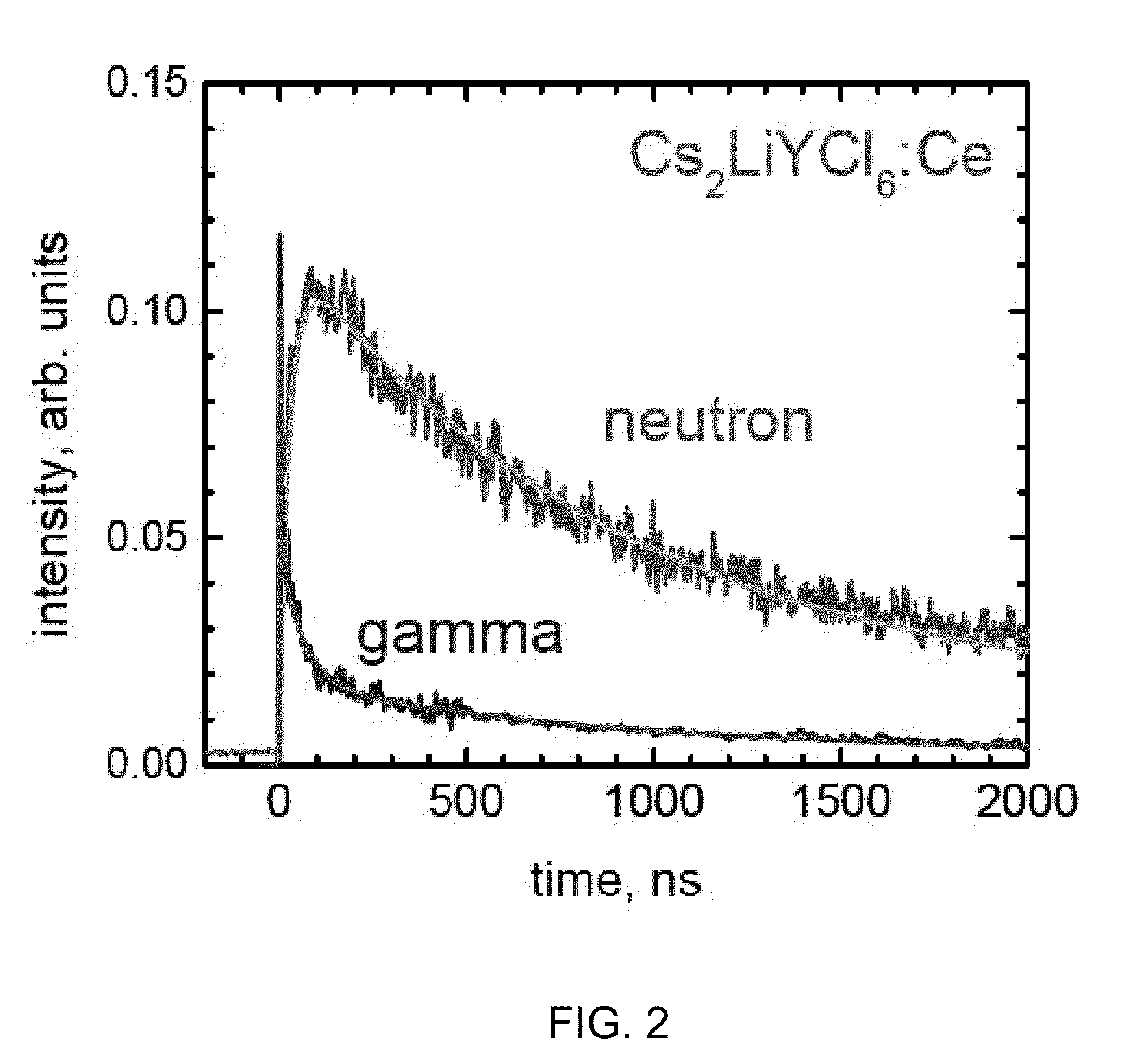

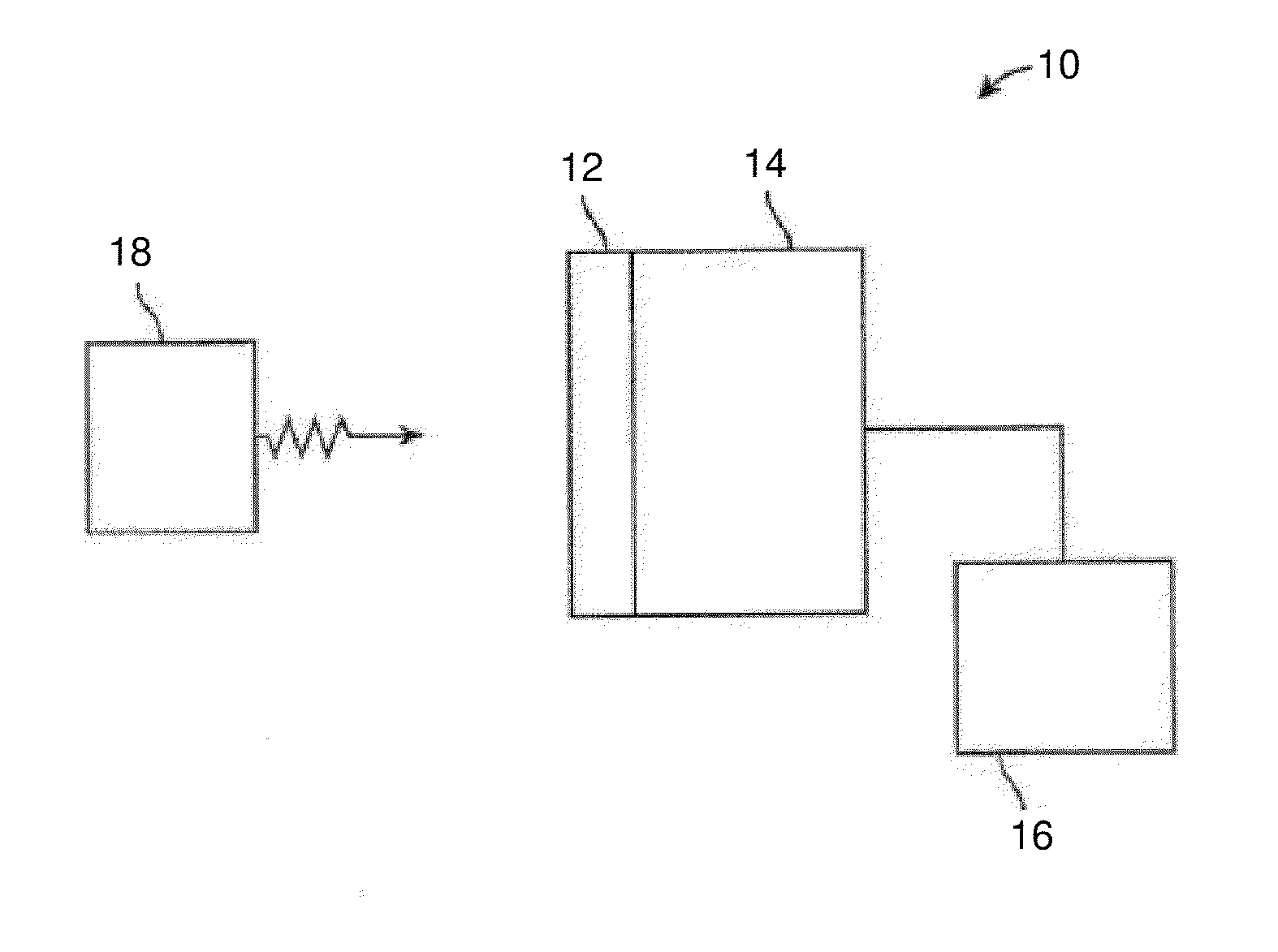

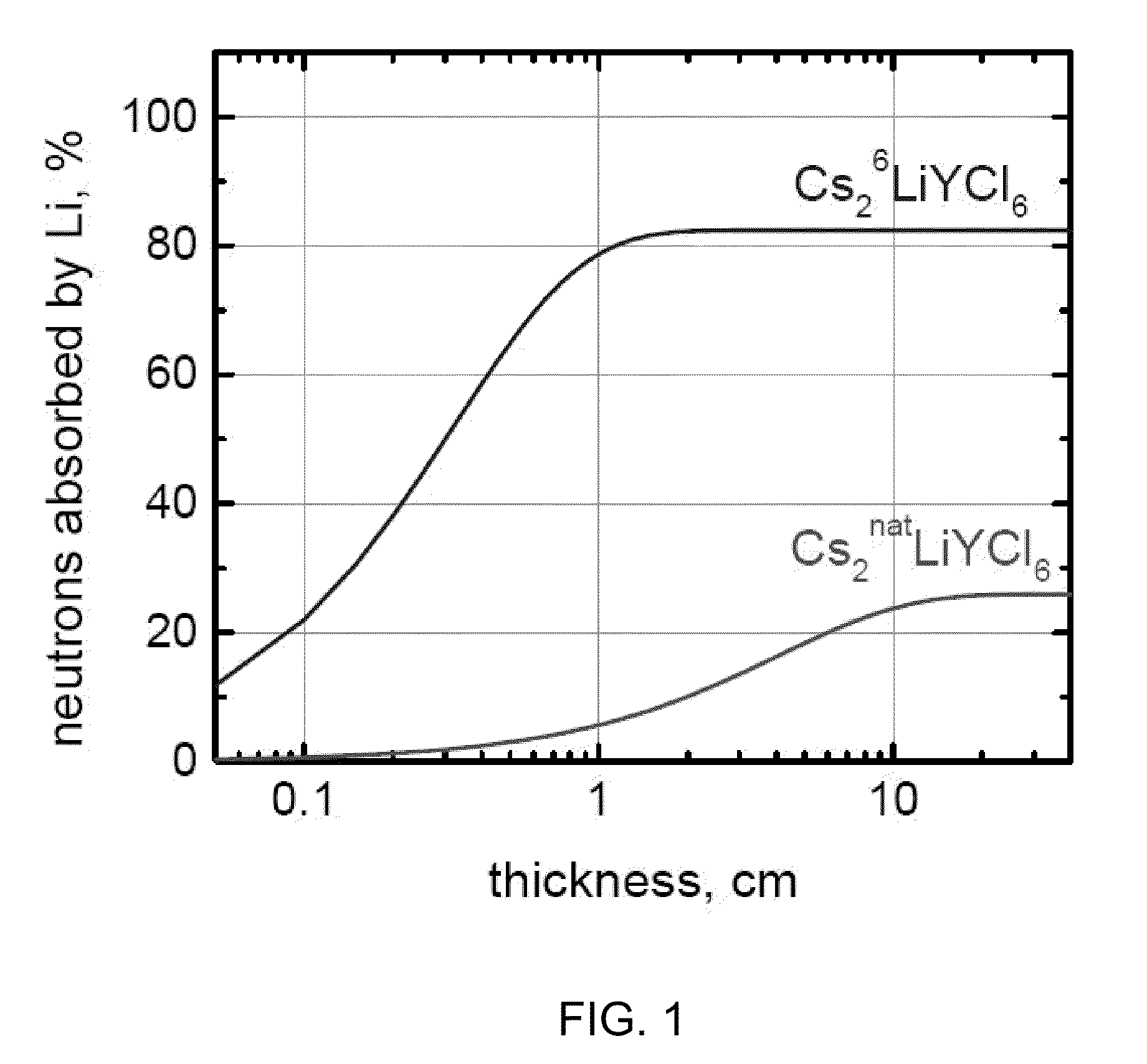

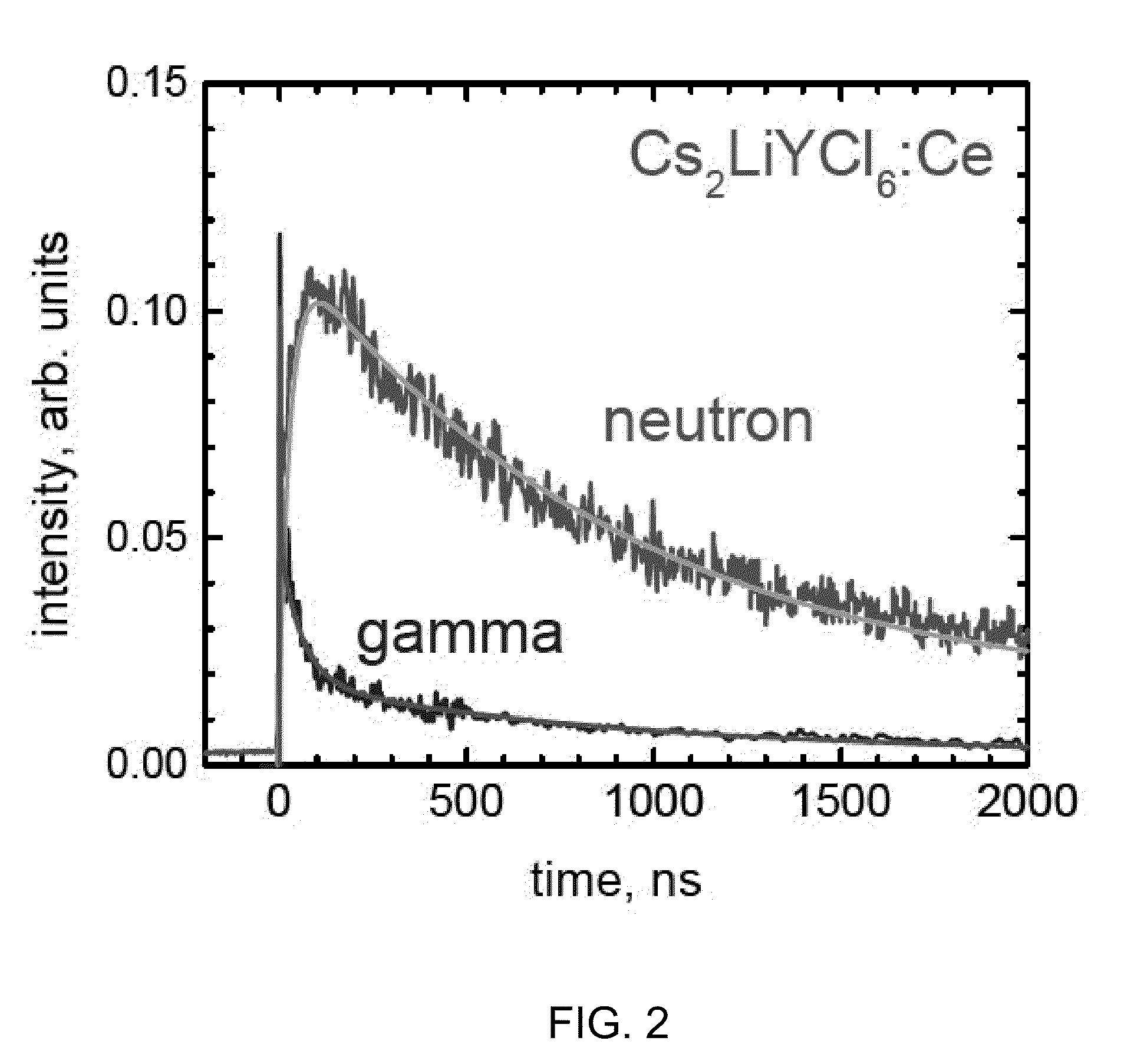

CsLiLn HALIDE SCINTILLATOR

ActiveUS20110024635A1Maintain good propertiesImprove light outputPolycrystalline material growthRare earth metal chloridesScintillatorAnalytical chemistry

Li-containing scintillator compositions, as well as related structures and methods are described. Radiation detection systems and methods are described which include a Cs2LiLn Halide scintillator composition.

Owner:RADIATION MONITORING DEVICES

Method for recovering rare earth, aluminum and silicon from rare earth-containing aluminum and silicon wastes

ActiveCN106319218AReduce dosageEfficient separationRare earth metal oxides/hydroxidesRare earth metal chloridesAluminum IonAluminium hydroxide

The invention provides a method for recovering rare earth, aluminum and silicon from rare earth-containing aluminum and silicon wastes. The method comprises the following steps: 1, carrying out acid dipping on the rare earth-containing aluminum and silicon wastes by using an aqueous inorganic acid solution to obtain silicon-rich residues and an acid dipping solution containing rare earth ions and aluminum ions; 2, adding an alkaline substance to the acid dipping solution containing rare earth ions and aluminum ions to control the pH value of the acid dipping solution to be 3.5-5.2, and carrying out solid-liquid separation to obtain an aluminum hydroxide-containing precipitate and a rare earth-containing filtrate; and 3, reacting the aluminum hydroxide-containing precipitate with sodium hydroxide to obtain a sodium metaaluminate solution and aluminum and silicon residues, and using the rare earth-containing filtrate to prepare a rare earth compound product. Aluminum and rare earth are dissolved in the acid, segmented alkaline transfer is carried out, the aluminum ions are precipitated to obtain aluminum hydroxide and the rare earth ions which are separated from the aluminum hydroxide, and excess sodium hydroxide is added to convert aluminum hydroxide into the sodium metaaluminate solution, so simultaneous and high-efficiency recycling of the rare earth and aluminum is realized, the use amount of sodium hydroxide is greatly reduced, and the recovery cost is reduced.

Owner:GRIREM ADVANCED MATERIALS CO LTD

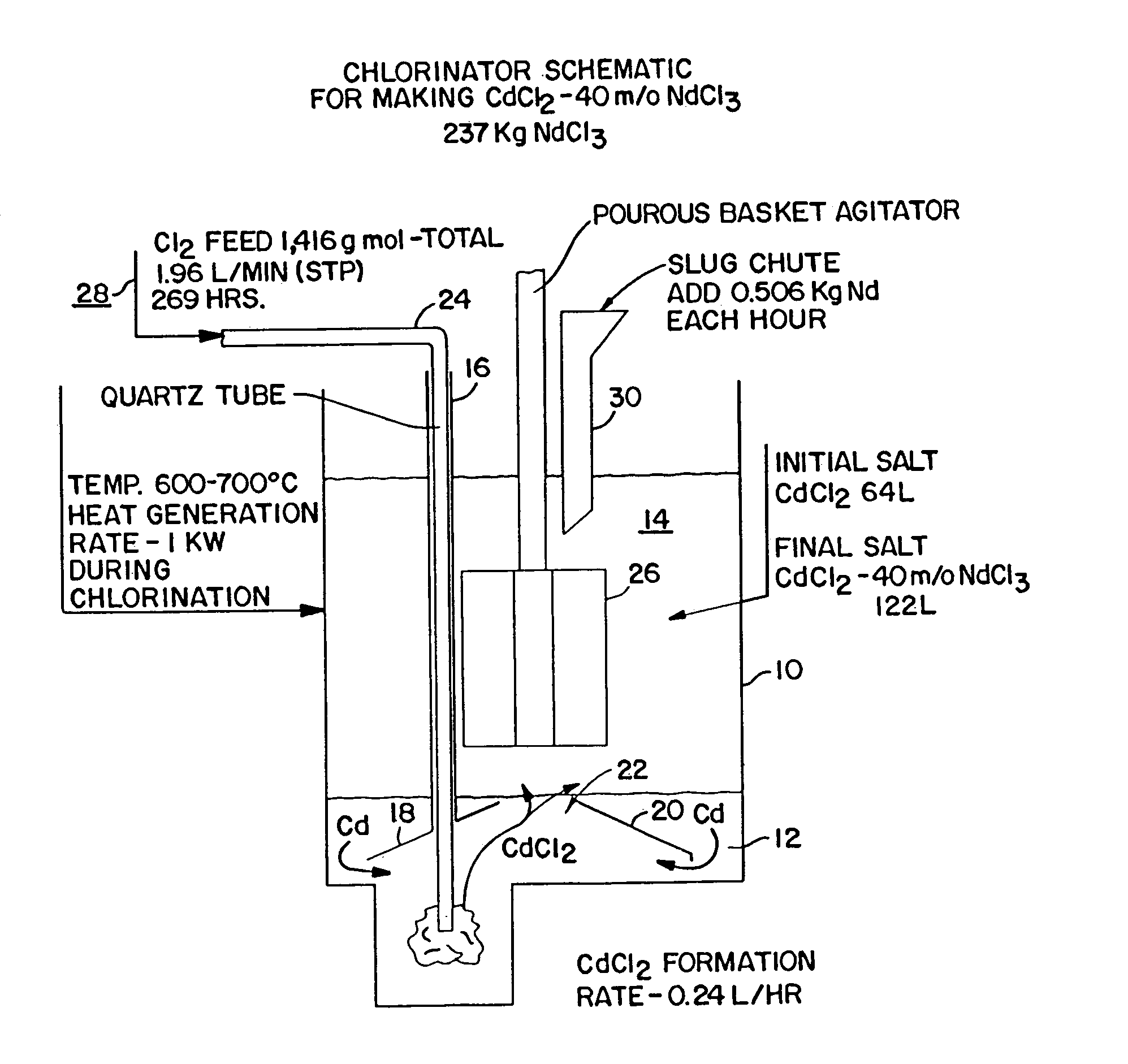

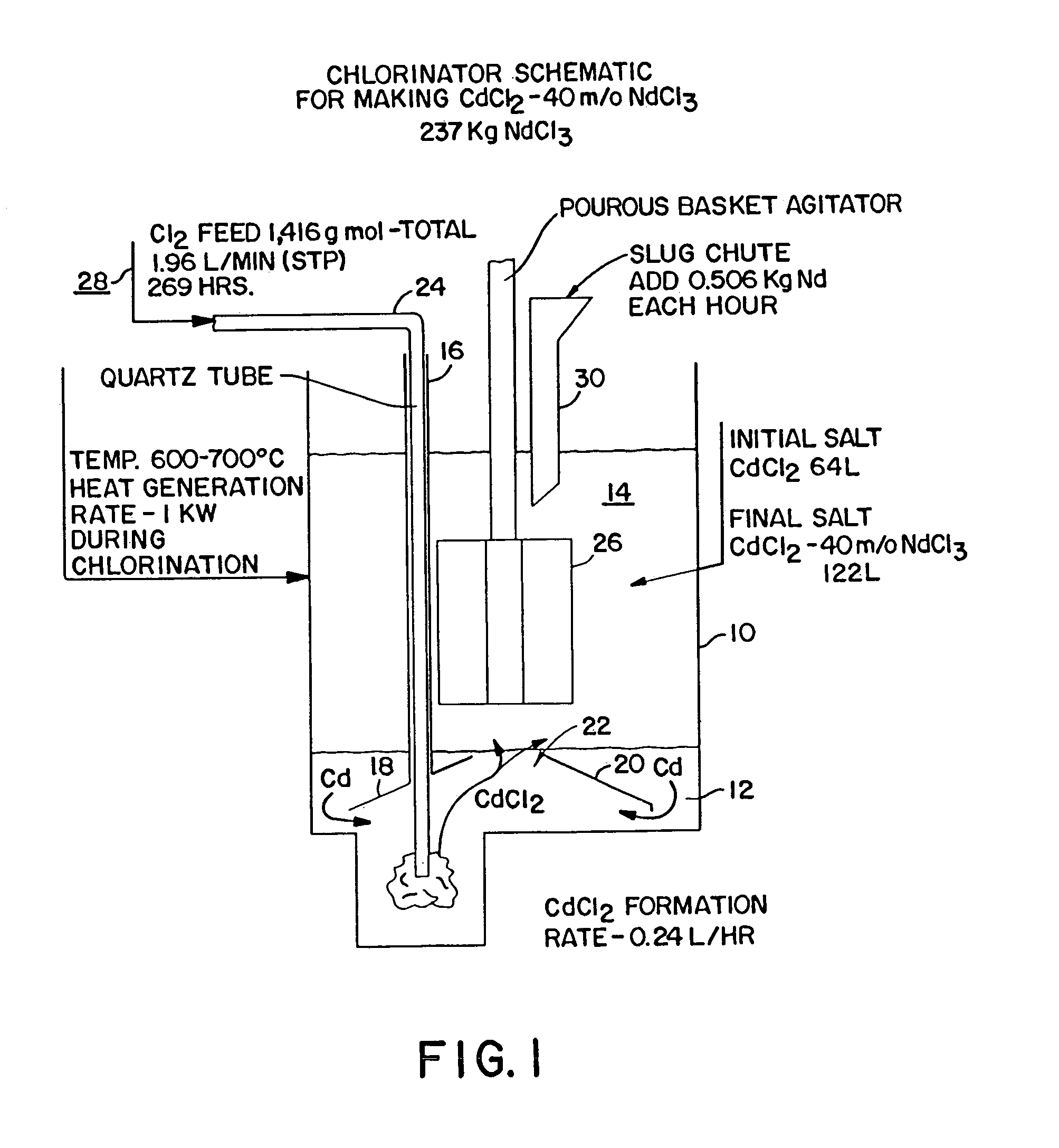

Apparatus and method for making metal chloride salt product

InactiveUS7217402B1Low densityRare earth metal chloridesChloride preparationMetal chlorideDistillation

A method of producing metal chlorides is disclosed in which chlorine gas is introduced into liquid Cd. CdCl2 salt is floating on the liquid Cd and as more liquid CdCl2 is formed it separates from the liquid Cd metal and dissolves in the salt. The salt with the CdCl2 dissolved therein contacts a metal which reacts with CdCl2 to form a metal chloride, forming a mixture of metal chloride and CdCl2. After separation of bulk Cd from the salt, by gravitational means, the metal chloride is obtained by distillation which removes CdCl2 and any Cd dissolved in the metal chloride.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Inorganic scintillating material, crystal scintillator and radiation detector

InactiveUS8629403B2Short decay timeGood energy resolutionPolycrystalline material growthRare earth metal chloridesDopantChemical composition

A new inorganic scintillating material is provided represented by the formula Ln(1-m-n)HfnCemA(3+n), where A is Br or Cl, or I, or a mixture of at least two halogens of the group, Ln is an element from the group: La, Nd, Pm, Sm, Eu, Gd, Tb, Lu, Y. A new crystal scintillator is also provided represented by the formula Ln(1-m)CemA3:n.Hf4+, where Ln(1-m)CemA3 represents the chemical composition of the matrix material, A is Br, or Cl, or I, or a mixture of at least two halogens from the group, Ln is an element from the group: La, Nd, Pm, Sm, Eu, Gd, Tb, Lu, Y; Hf4+ is a dopant. A radiation detector comprising a scintillating element based on the novel inorganic scintillating material is also provided.

Owner:OBSHCHESTVO S OGRANICHENNOY OTVETABTVENNOSTYU SCINTILLYATSIONNYE TEKHNOLOGII RADIATSIONNOGO KONTROLYA

Method for extracting and separating light rare earth element

InactiveCN102851501ASmall membrane sizeLow investment costRare earth metal chloridesRare earth metal compounds preparation/treatmentRare-earth elementAqueous solution

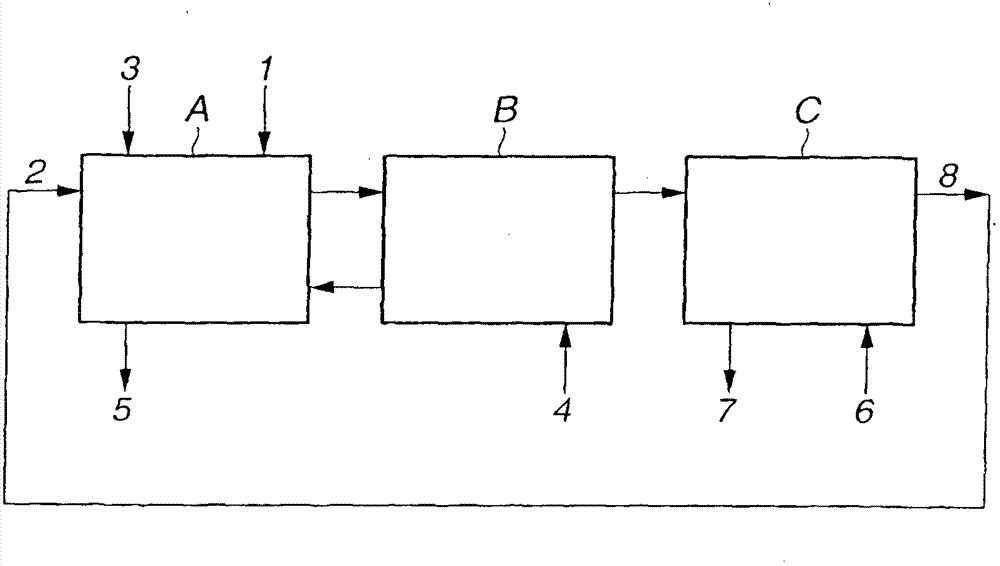

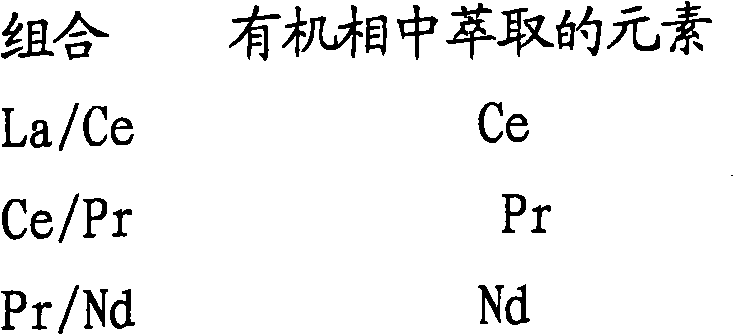

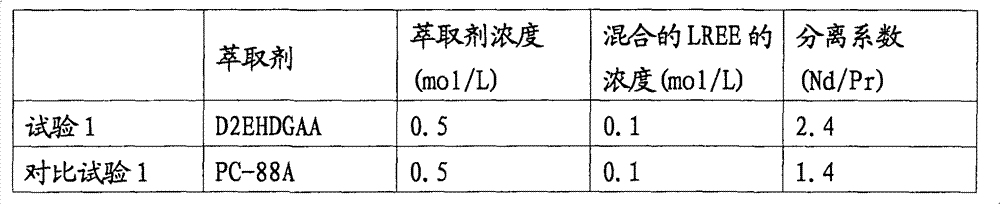

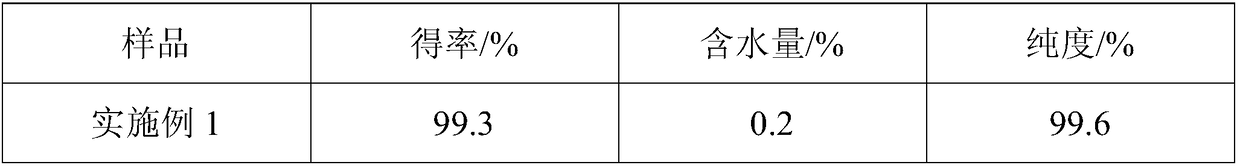

A target light rare earth element is separated from an aqueous solution containing two or more of La, Ce, Pr and Nd by contacting an organic phase containing an extractant with the aqueous solution in a counter-current flow multistage mixer-settler while adding an alkaline solution thereto, and contacting the organic phase with an acid aqueous solution for back-extracting the target element. The extractant is a dialkyl diglycol amic acid having formula: R1R2NCOCH2OCH2COOH, wherein R1 and R2 are alkyl, at least one having at least 6 carbon atoms.

Owner:SHIN ETSU CHEM CO LTD

Preparation method of anhydrous cerium chloride

InactiveCN108455650AAdequate responseReduce hydrolysis reactionRare earth metal chloridesCeriumCombined use

The invention provides a preparation method of anhydrous cesium chloride. The preparation method is characterized in that cerium oxide is taken as a raw material, reaction is conducted by using ammonium chloride solid, then dried hydrogen chloride gas enters, heating is conducted until the reaction is completed, and products are dried to obtain anhydrous cesium chloride. By the combined use of theammonium chloride and the hydrogen chloride gas, and by the combination and the proportioning of the using amount of reactants, the synergistic effect of the ammonium chloride and the hydrogen chloride is achieved to adjust the position relationship of each reactant, to make the reaction more complete, the yield of the reaction product is high, drying is conducted under an inert atmosphere by reducing pressure to prevent the occurrence of redox side reaction, improve the product purity, and the preparation method is safe and effective, and the products are pure.

Owner:上海泰坦科技股份有限公司

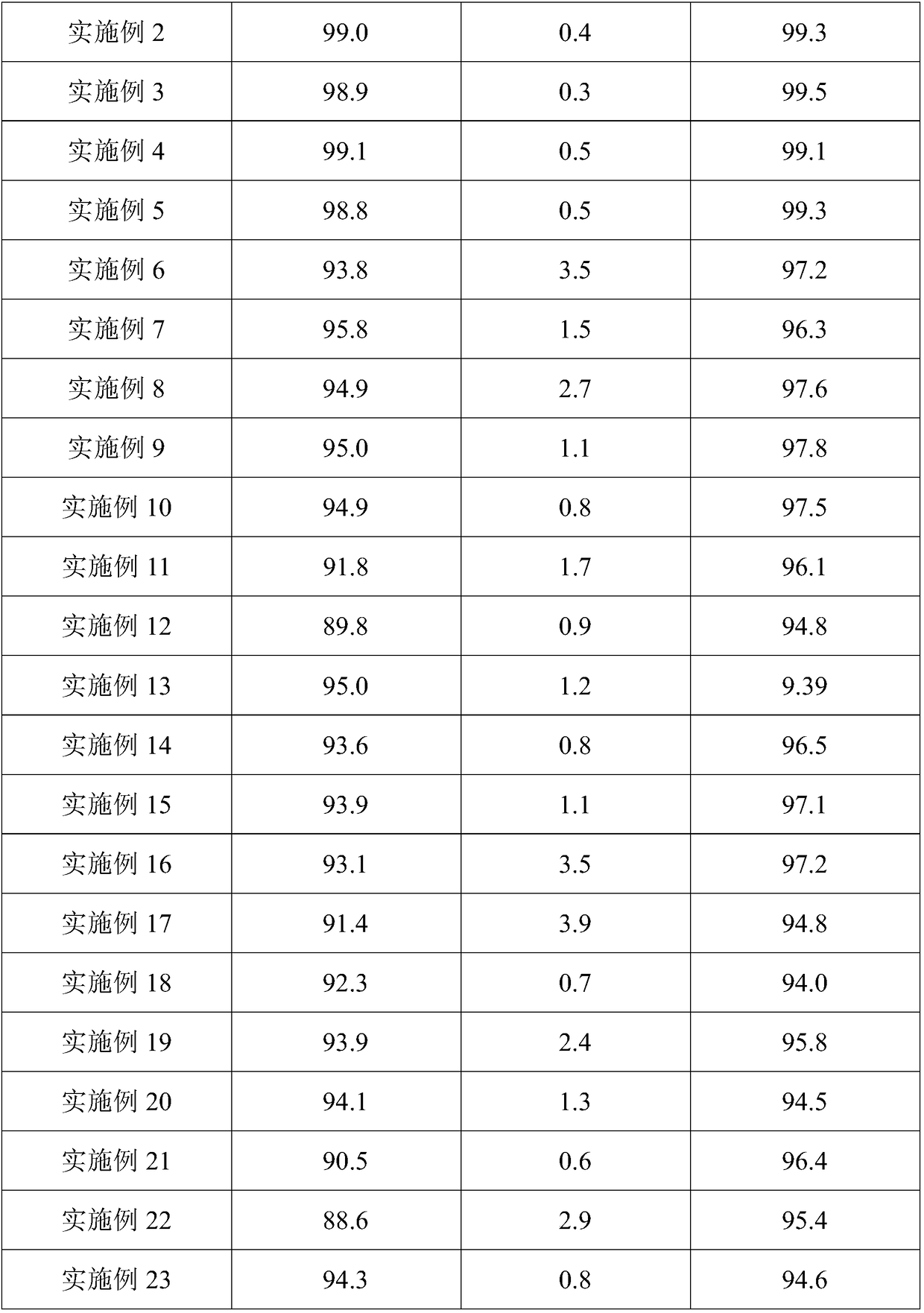

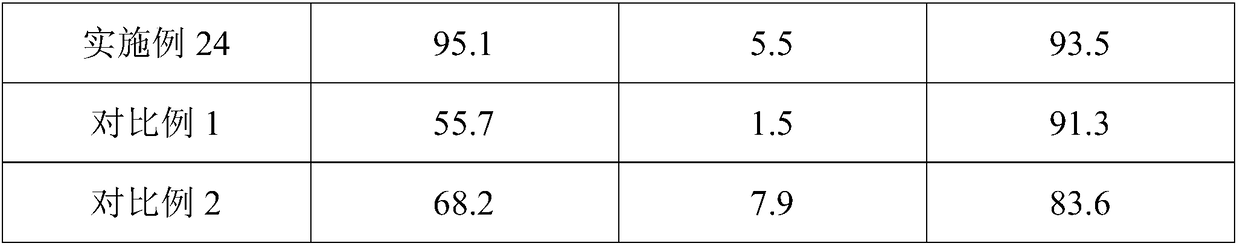

Method for low-calcium high-grade mixed type rare-earth concentrate circulating slurrying decomposition

InactiveCN109536746AReduce consumptionSolve problems such as knotsRare earth metal chloridesProcess efficiency improvementDecompositionSlag

The invention relates to a method for low-calcium high-grade mixed type rare-earth concentrate circulating slurrying decomposition, and belongs to the field of hydrometallurgy. The method comprises the following steps that an absolute excess low-concentration sulfuric acid solution is adopted, fluorine-carbon cerium ore in a low-calcium high-grade mixed concentrate is rapidly decomposed by a slurrying reaction under the heating condition; and after the reaction, acid leaching slag is soaked in water to dissolve calcium sulfate and rare earth sulfate into water immersion liquid, and impuritiesare removed in the water immersion liquid to form phosphorus-iron-thorium slag. After the acid leaching liquid supplements sulfuric acid, new ore is recycled, and the concentrated alkali liquor is used for decomposing water leaching slag and the phosphorus-iron-thorium slag. The alkali wastewater is crystallized and recycled, and the sodium phosphate is recycled. The method is suitable for low-calcium high-grade mixed type rare-earth concentrate treatment, fluorine and phosphorus resources in the mixed rare-earth concentrate can be recycled, sulfuric acid, sodium hydroxide, energy consumptionand the like are reduced to the theoretical consumption, the problems that the concentrated sulfuric acid and the rare-earth concentrate are subjected to solid-solid-solid-phase reaction equipment crusting and the like are solved, and industrialization is easy to realize.

Owner:BAOTOU RES INST OF RARE EARTHS +1

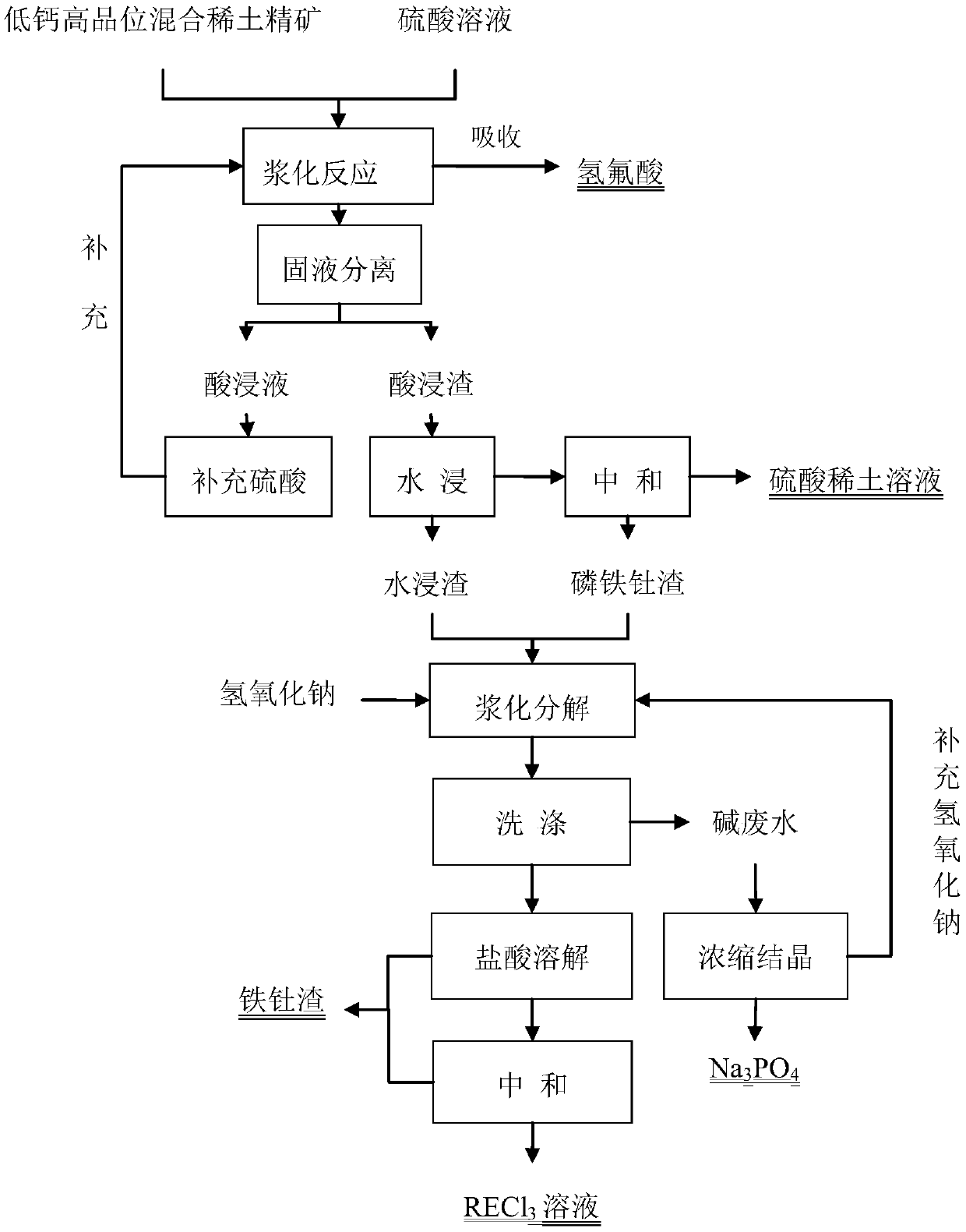

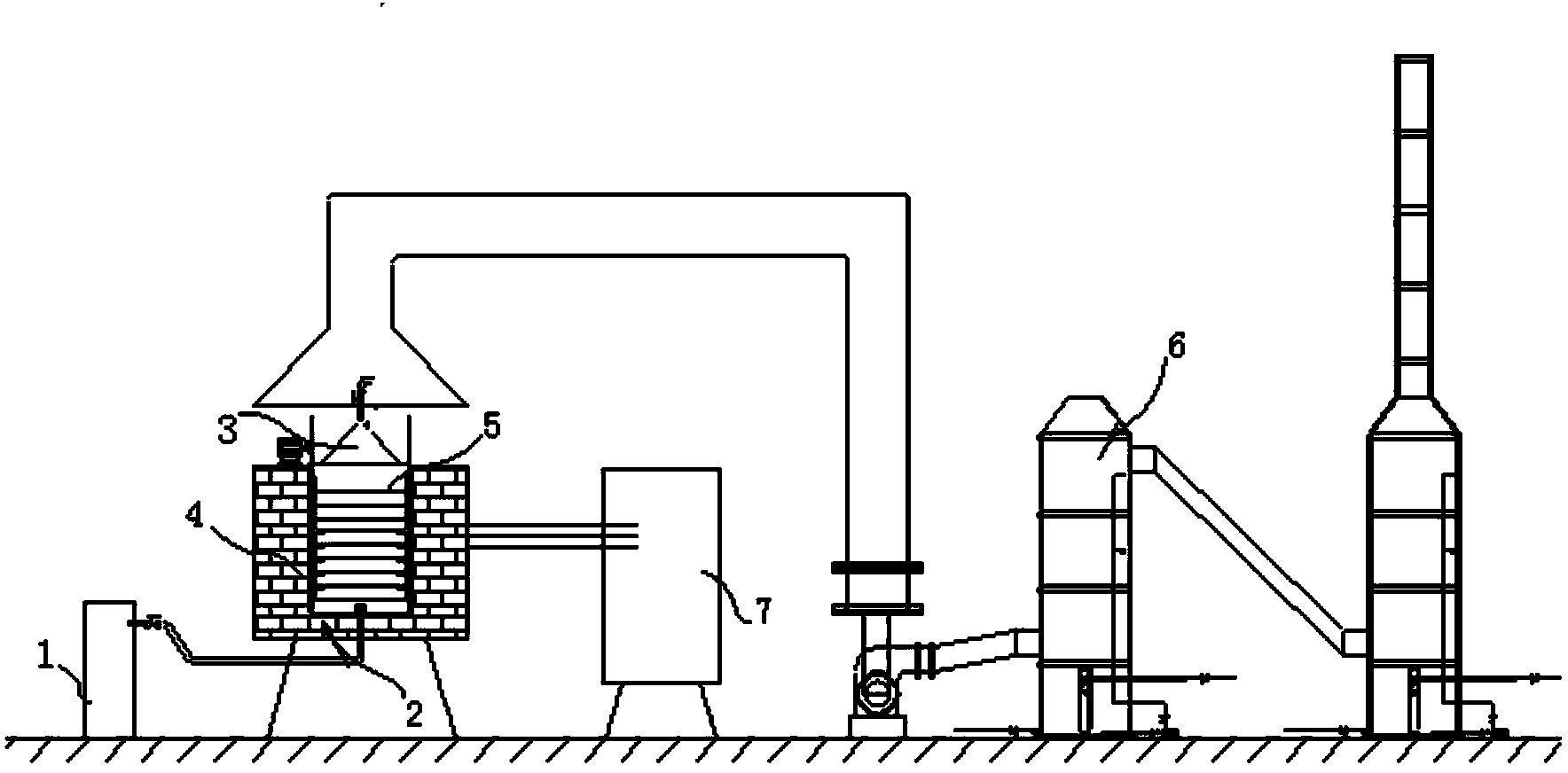

Method and device for preparing anhydrous rare earth chloride through gas phase method

The invention provides a method for preparing anhydrous rare earth chloride through a gas phase method. According to the method, hydrogen chloride gas is directly used to chlorinate a rare earth oxide serving as a raw material to prepare anhydrous rare earth chloride. The method comprises the following steps: putting the rare earth oxide in a chlorination furnace and heating to 350-650 DEG C; introducing hydrogen chloride gas into the chlorination furnace to chlorinate the rare earth oxide; holding the temperature for 20-35h then stopping, thus obtaining the chlorinated anhydrous rare earth chloride; in the chlorination process, absorbing the hydrogen chloride tail gas (discharged by the chlorination furnace) by a lime solution through an acid mist absorption device and emptying the hydrogen chloride tail gas. When used for preparing anhydrous rare earth chloride, the method is capable of inhibiting generation of chlorinated rare earth oxides; and the purity of the prepared anhydrous rare earth chloride product is higher than 98.00% and the yield of rear earth is higher than 99.5%.

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST

CsLiLn halide scintillator

ActiveUS8440980B2Maintain good propertiesImprove light outputPolycrystalline material growthRare earth metal chloridesScintillatorAnalytical chemistry

Li-containing scintillator compositions, as well as related structures and methods are described. Radiation detection systems and methods are described which include a Cs2LiLn Halide scintillator composition.

Owner:RADIATION MONITORING DEVICES

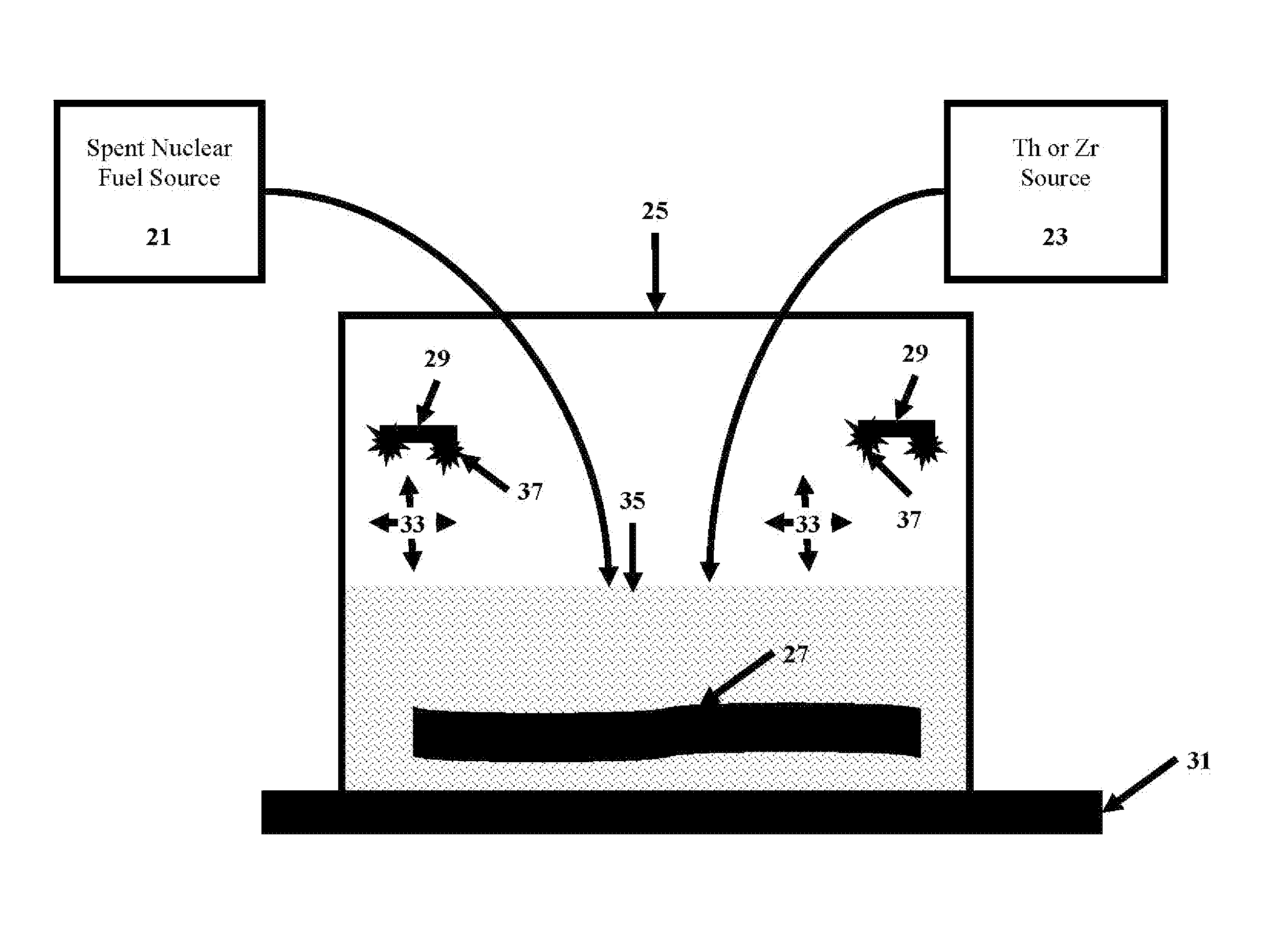

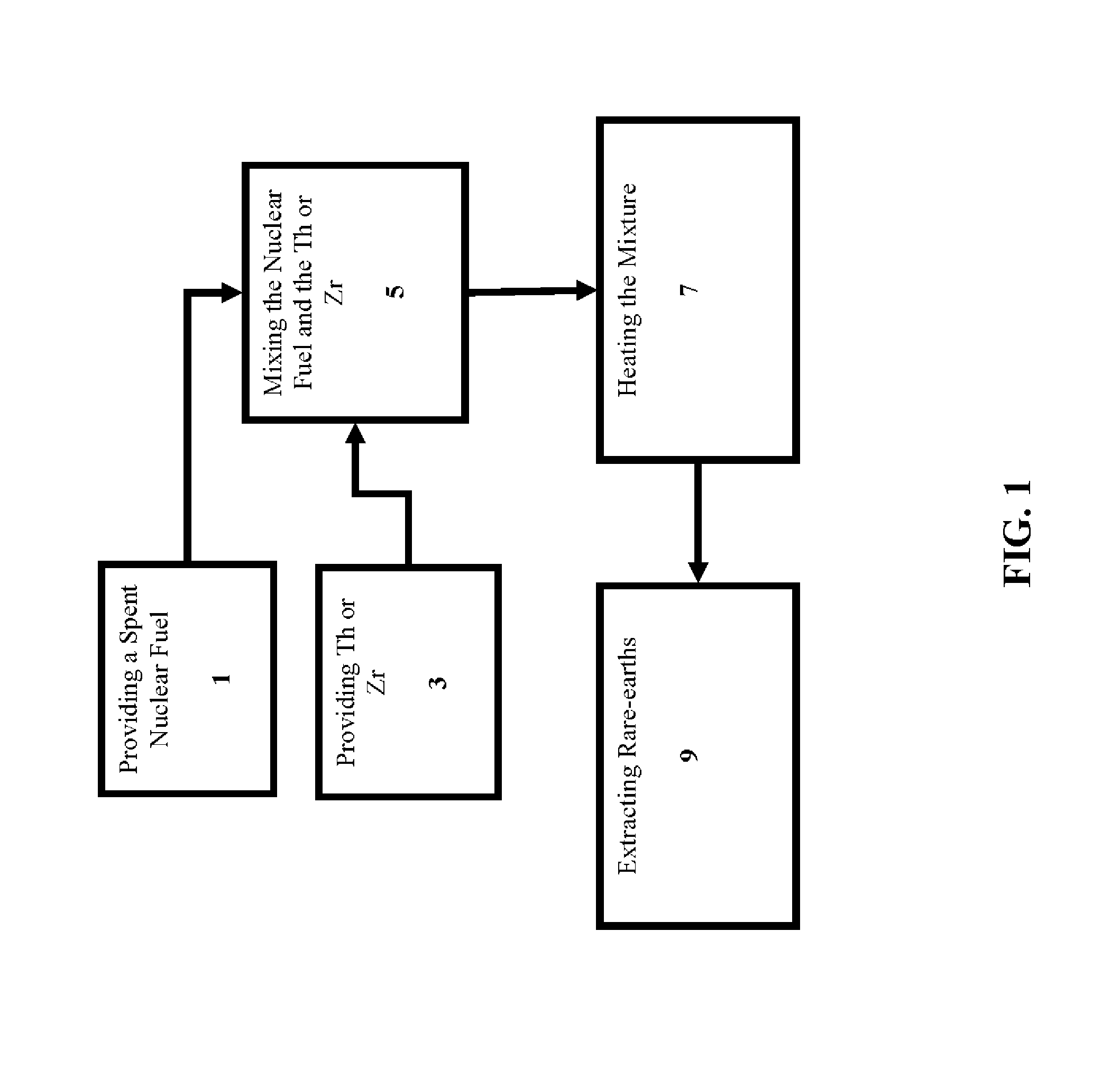

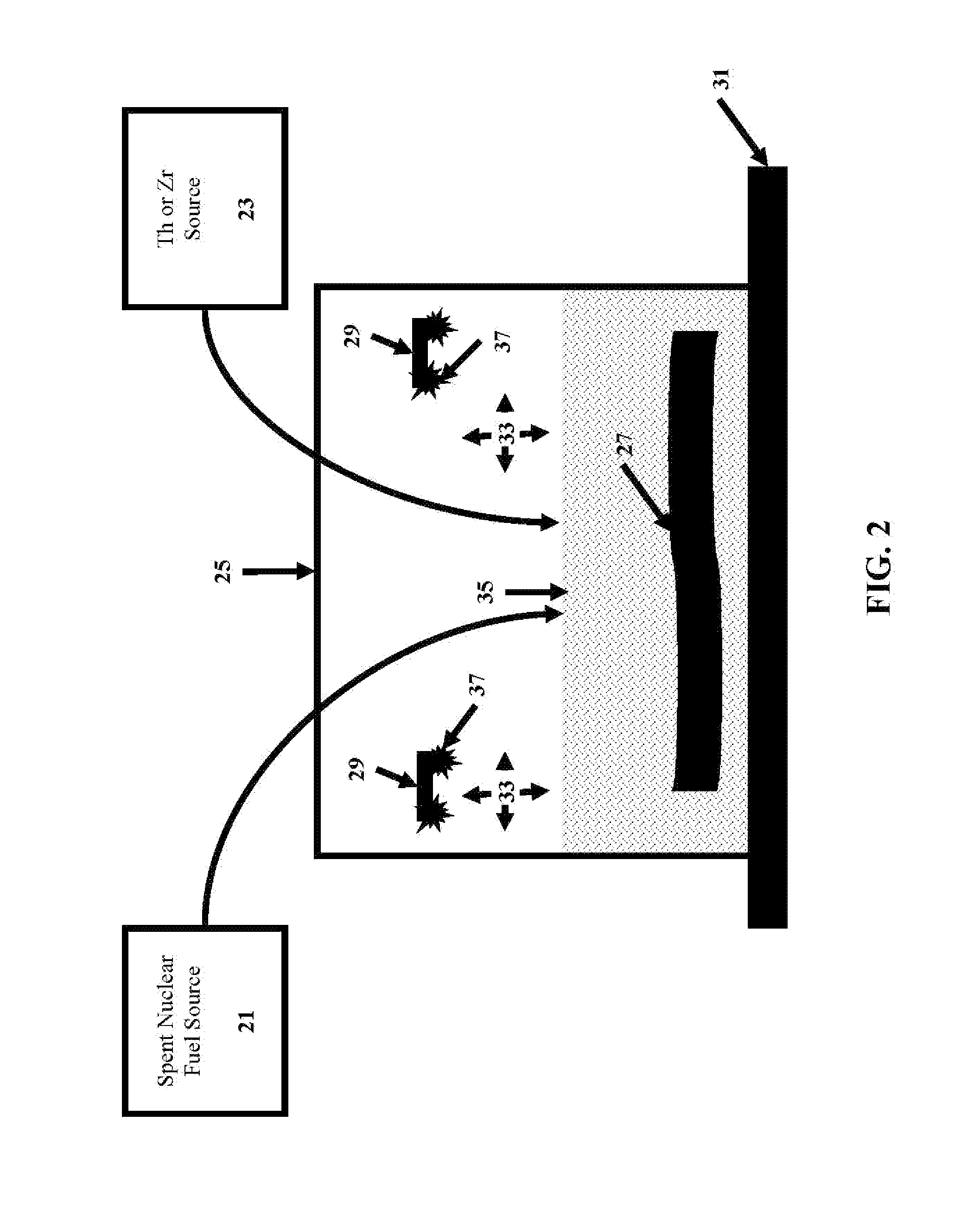

Separation of the rare-earth fission product poisons from spent nuclear fuel

ActiveUS9428401B1Specific isotope recoveryRare earth metal chloridesOxidation reductionRedox cycling

A method for the separation of the rare-earth fission product poisons comprising providing a spent nuclear fuel. The spent nuclear fuel comprises UO2 and rare-earth oxides, preferably Sm, Gd, Nd, Eu oxides, with other elements depending on the fuel composition. Preferably, the provided nuclear fuel is a powder, preferably formed by crushing the nuclear fuel or using one or more oxidation-reduction cycles. A compound comprising Th or Zr, preferably metal, is provided. The provided nuclear fuel is mixed with the Th or Zr, thereby creating a mixture. The mixture is then heated to a temperature sufficient to reduce the UO2 in the nuclear fuel, preferably to at least to 850° C. for Th and up to 600° C. for Zr. Rare-earth metals are then extracted to form the heated mixture thereby producing a treated nuclear fuel. The treated nuclear fuel comprises the provided nuclear fuel having a significant reduction in rare-earths.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Method for preparing mixed rare earth chloride from Bayan Obo rare earth ore concentrates

InactiveCN109097559AReduce energy consumptionSave resourcesPolycrystalline material growthRare earth metal chloridesDecompositionRare earth

The invention discloses a method for preparing mixed rare earth chloride from Bayan Obo rare earth ore concentrates. The method comprises the following steps: mixing the Bayan Obo rare earth ore concentrates with concentrated sulfuric acid at a mass ratio ranging from 1:0.7 to 1:1.5, and carrying out three-section roasting on the mixture to obtain roasted rare earth ores; carrying out leaching andpurification on the obtained roasted rare earth ores, carrying out filtering and deslagging on the leached and purified ores, and carrying out extraction transformation on a filtrate obtained throughthe filtering to obtain a raffinate and a loaded organic phase; and carrying out back extraction on the loaded organic phase through hydrochloric acid to obtain a mixed rare earth chloride solution.The method provided by the invention has the advantages that through the low-temperature external-heating roasting and countercurrent movements of a heat source and materials, energy consumption can be effectively reduced; through the three-section roasting method, sufficient decomposition of the rare earth ore concentrates can be further promoted, so that the materials can be prevented from adhering to a kiln, and can be more sufficiently roasted to effectively reduce exhaust emissions; and through the continuous leaching and the countercurrent purification, the rare earth ore concentrate recovery rate can be effectively improved.

Owner:西安西骏新材料有限公司

Preparation method for anhydrous rare-earth chloride

The invention provides a preparation method for an anhydrous rare-earth chloride (REC13). The preparation method comprises the following steps: S1) utilizing hydrochloric acid to dissolve a rare earthoxide, thereby forming a rare-earth chloride solution; S2) adding ammonium chloride into the dissolved rare-earth chloride solution; S3) stir-frying under a heating condition, thereby acquiring a solid mixture of rare-earth chloride containing crystal water and ammonium chloride; S4) transferring the stir-fried solid mixture into a sublimation device, rising temperature to 390 DEG C from 80 DEG Cin the manner of gradient temperature rise, and meanwhile, vacuumizing and heating, and removing ammonium chloride and crystal water of the rare-earth chloride in turn in the vacuumizing and heatingprocess, thereby acquiring the high-purity anhydrous rare-earth chloride. The method provided by the invention has the characteristics of simple and safe production process, no side reaction, high purity of prepared anhydrous rare-earth chloride and being beneficial to large-scale production.

Owner:LANZHOU UNIVERSITY

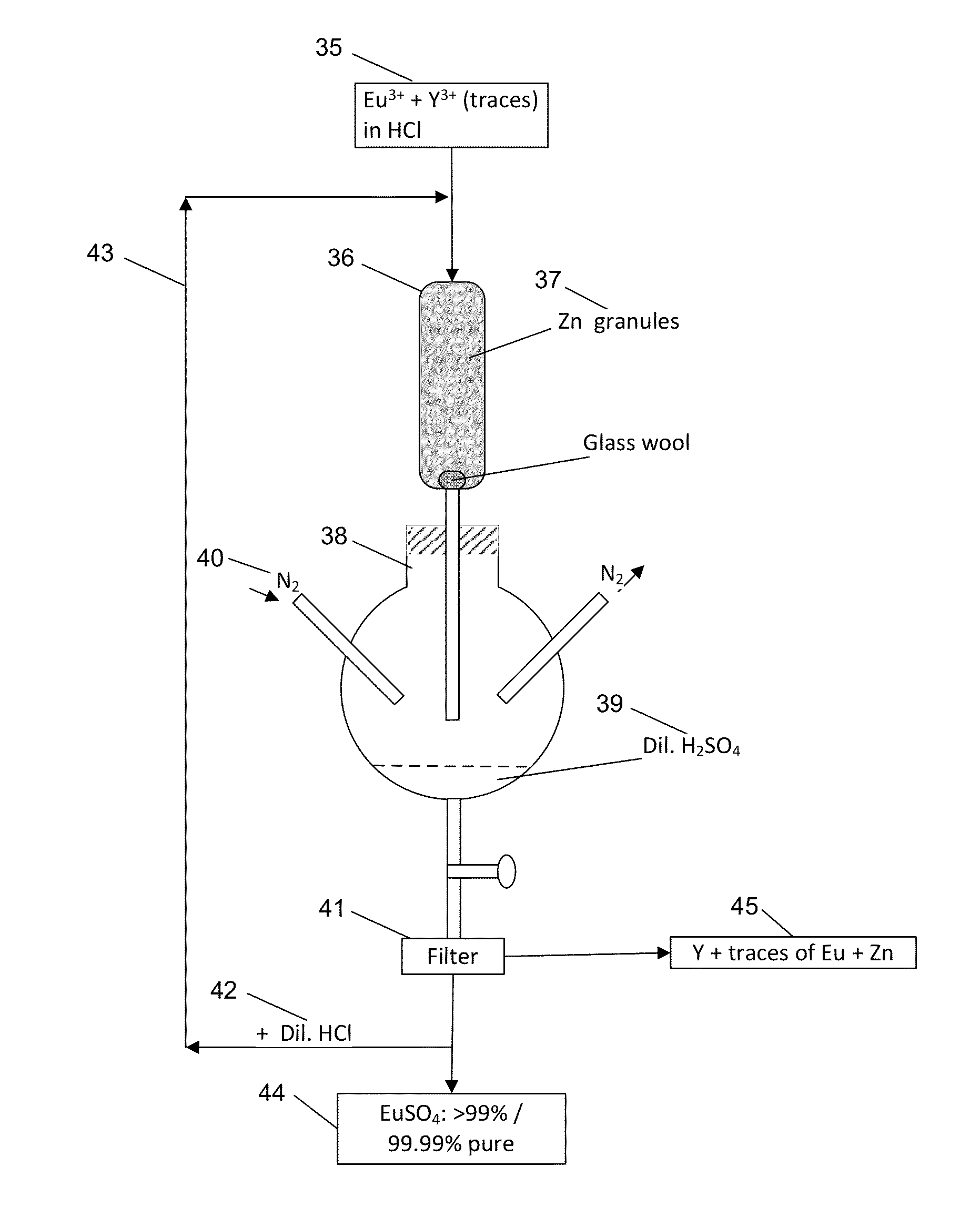

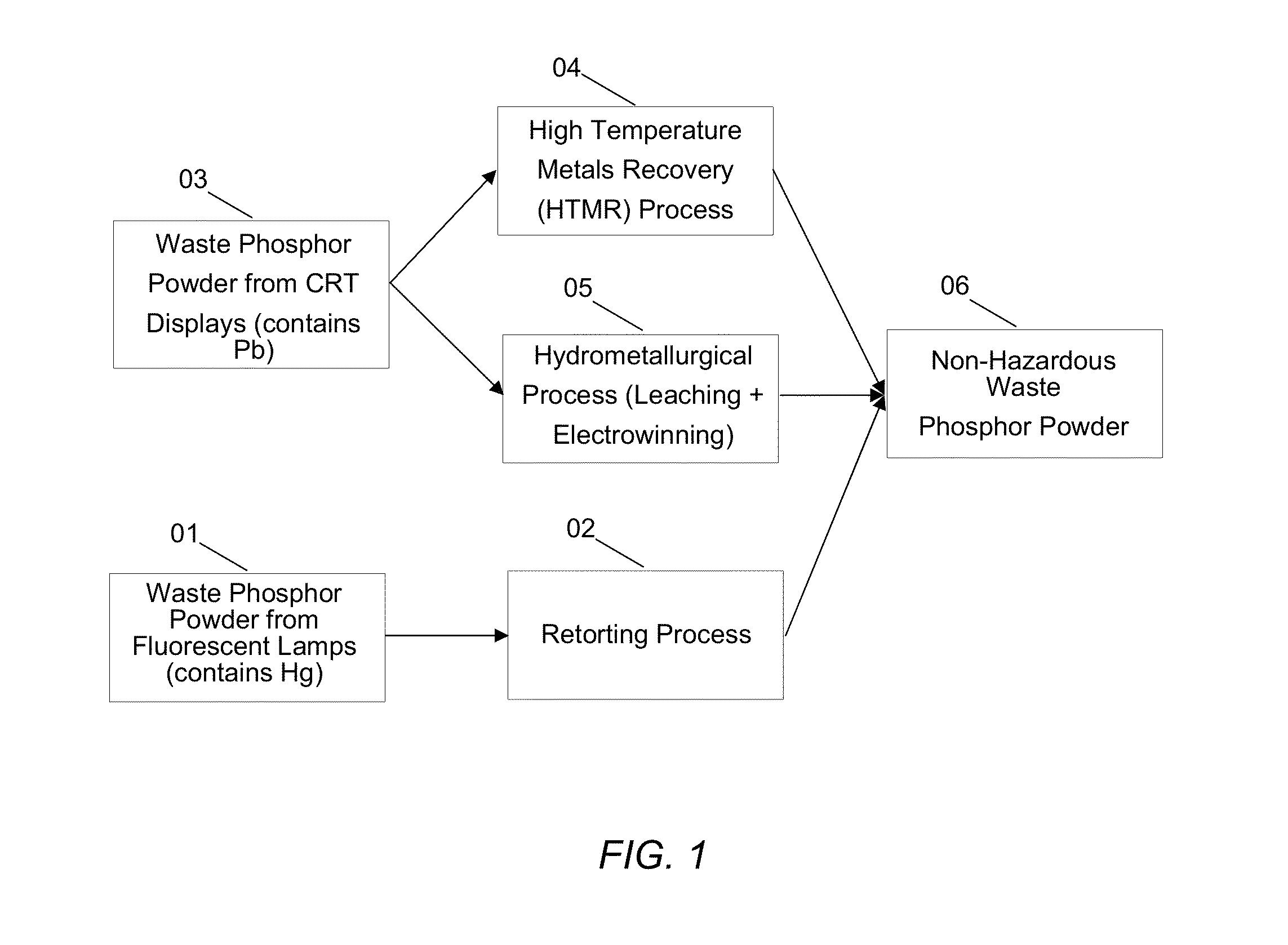

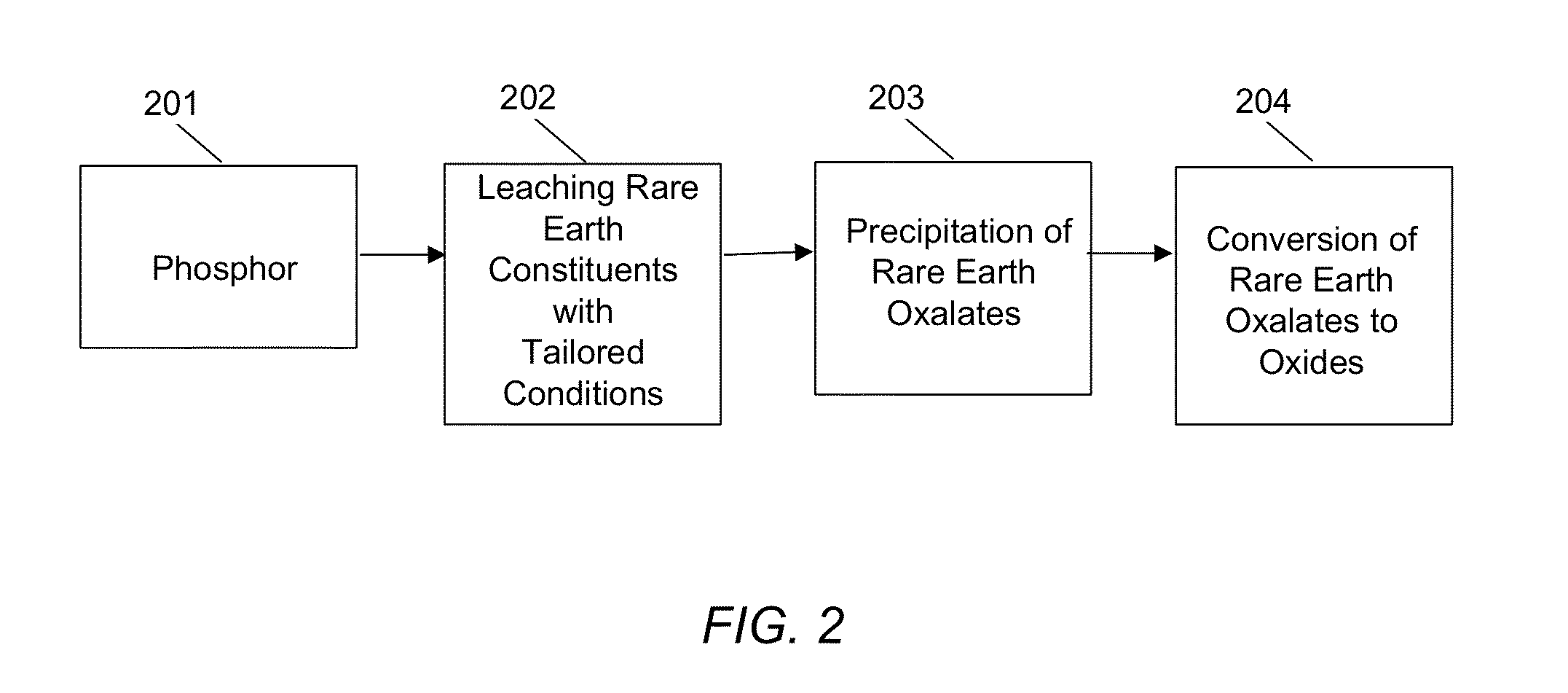

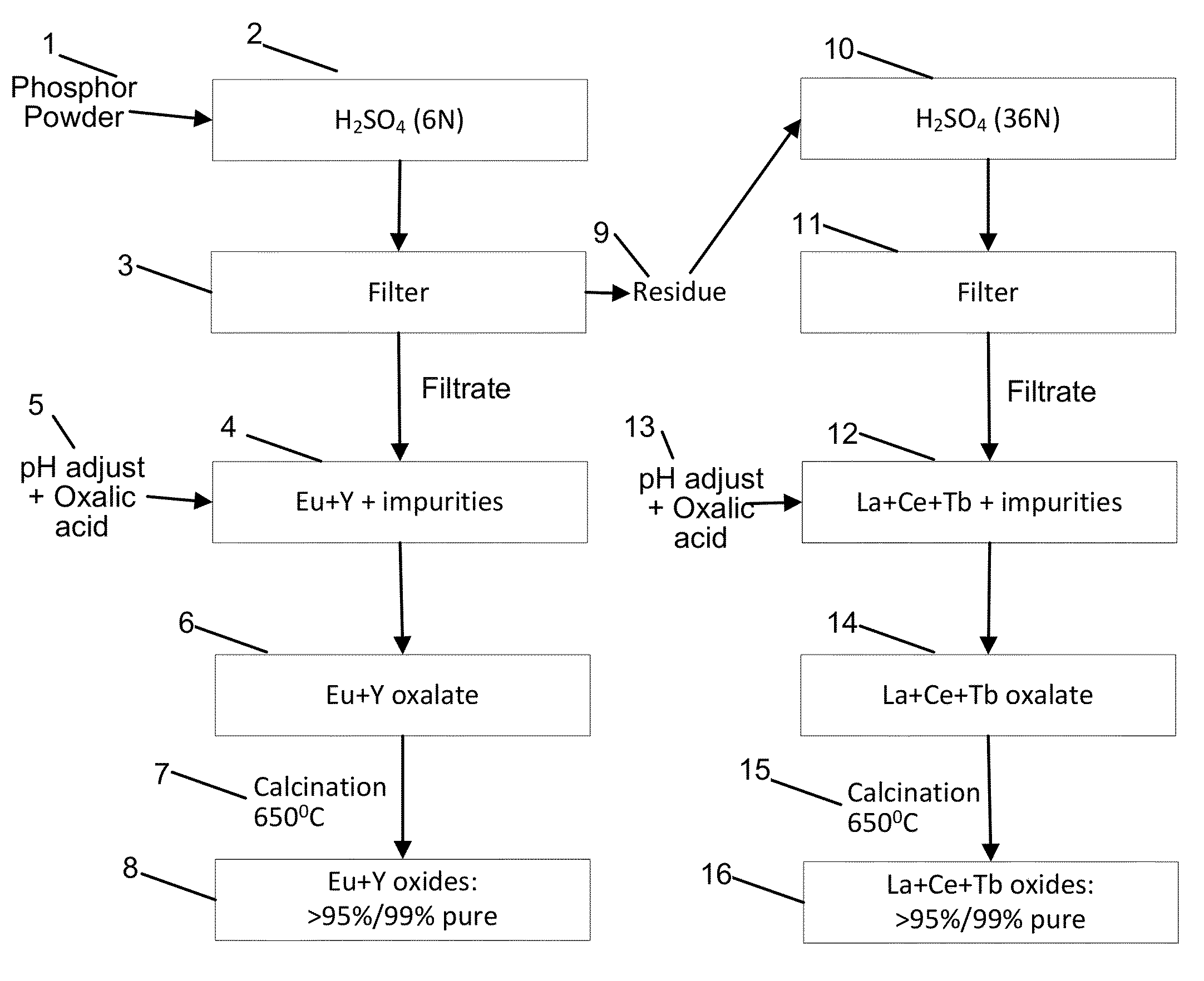

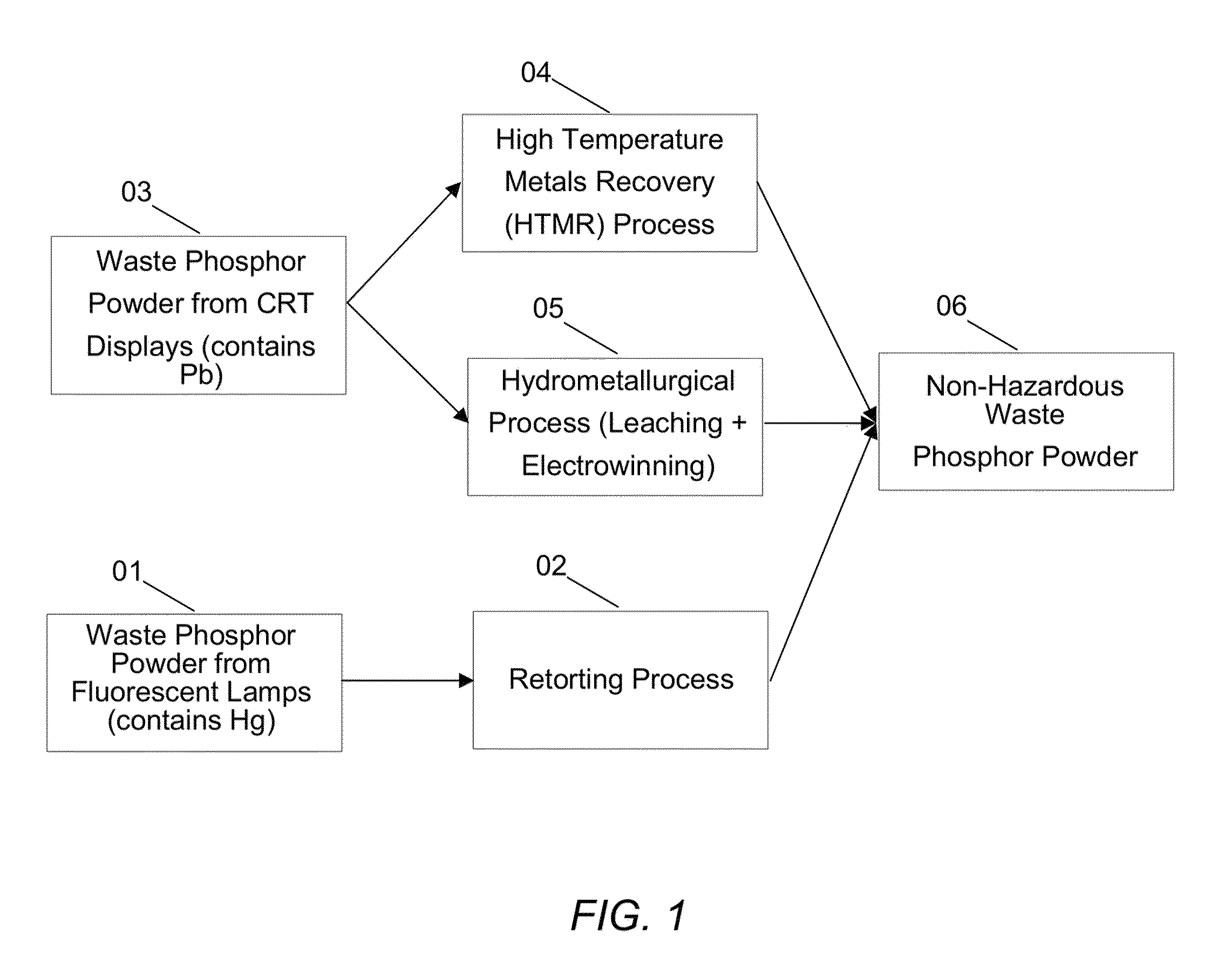

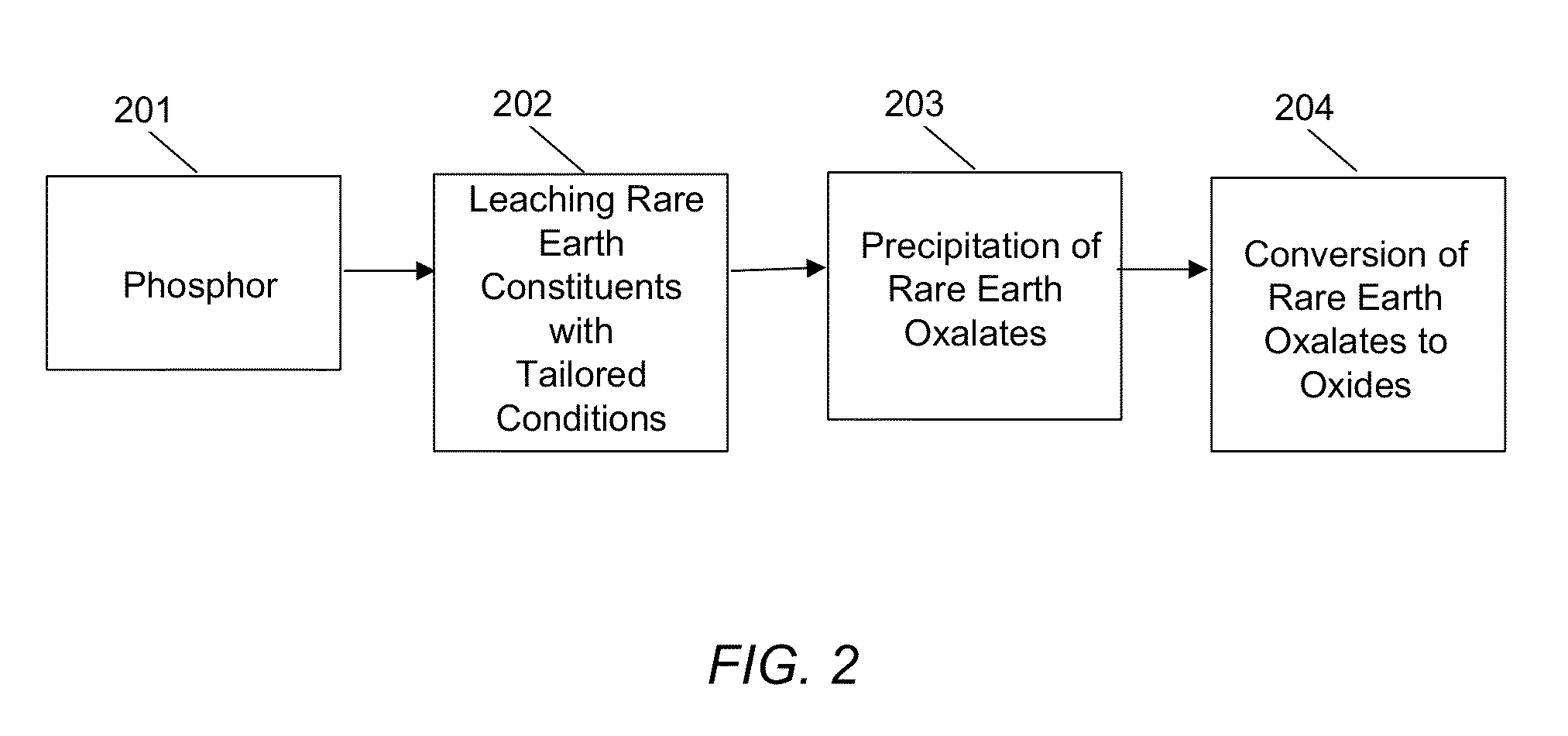

Rare earth recovery from phosphor

InactiveUS20130156660A1Efficient methodEfficient and effectivePhysical/chemical process catalystsRare earth metal chloridesPhosphorRare earth

A method is described to produce high purity rare earth oxides of the elements La, Ce, Tb, Eu and Y from phosphor, such as waste phosphor powders originating in various consumer products. One approach involves leaching the powder in two stages and converting to two groups of relatively high purity mixed rare earth oxides. The first group containing Eu and Y is initially separated by solvent extraction. Once separated, Eu is purified using Zn reduction with custom apparatus. Y is purified by running another solvent extraction process using tricaprylmethylammonium chloride. Ce is separated from the second group of oxides, containing La, Ce and Tb by using solvent extraction. Subsequently, La and Tb are separated from each other and converted to pure oxides by using solvent extraction processes. A one-stage leaching process, wherein all rare earths get leached into the solution and subsequently processed, is also described.

Owner:REENEWAL

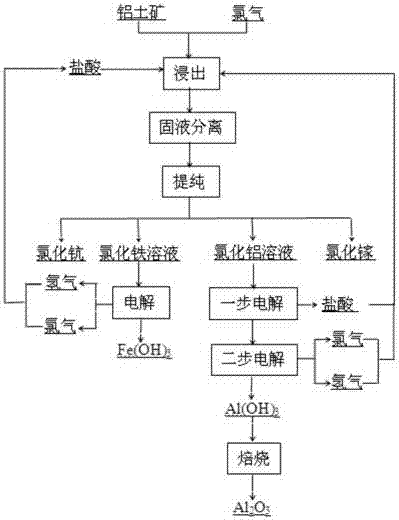

Method for preparing aluminum oxide through hydrochloric acid leaching and two-stage electrolysis of bauxite and comprehensively utilizing aluminum oxide

ActiveCN107128959AHigh degree of automationHigh purityAluminium compoundsRare earth metal chloridesAluminium chlorideElectrolysis

The invention relates to a method for preparing aluminum oxide through hydrochloric acid leaching and two-stage electrolysis of bauxite and comprehensively utilizing aluminum oxide. The method comprises the following steps: carrying out hydrochloric acid leaching, solid-liquid separation and purification on bauxite on bauxite, so as to obtain an iron chloride mixed solution and an aluminum chloride mixed solution; respectively separating and purifying the iron chloride mixed solution and the aluminum chloride mixed solution, so as to obtain scandium chloride, gallium chloride, an aluminum chloride water solution and an iron chloride water solution; setting electrolytic voltage and current density, and respectively carrying out two-stage electrolysis on the aluminum chloride water solution and the iron chloride water solution, so as to respectively obtain aluminum hydroxide, hydrogen and chlorine as well as iron hydroxide, hydrogen and chlorine; preparing a hydrochloric acid solution by using the generated hydrogen and chlorine, and returning the hydrochloric acid solution to a leaching stage for recycling; and roasting aluminum hydroxide, so as to obtain metallurgy level aluminum oxide or chemical aluminum oxide. Compared with a traditional acid method, the electrolysis method for recycling aluminum oxide in the bauxite and processing the bauxite has the advantages that the evaporation step and equipment, the concentration step and equipment are omitted, the operation is simplified, meanwhile, the cost is substantially lowered, and the product has relatively high purity.

Owner:NORTHEASTERN UNIV

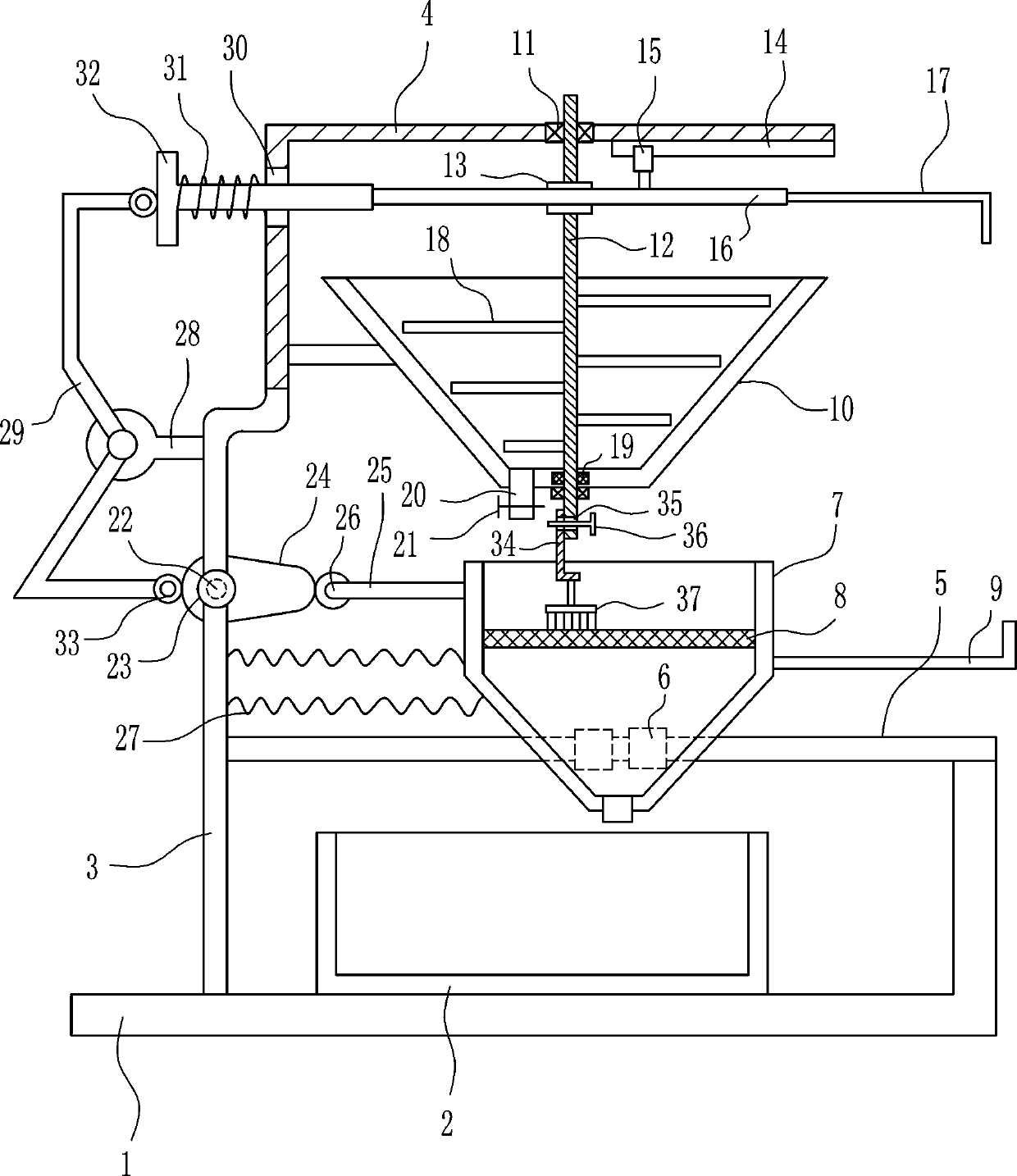

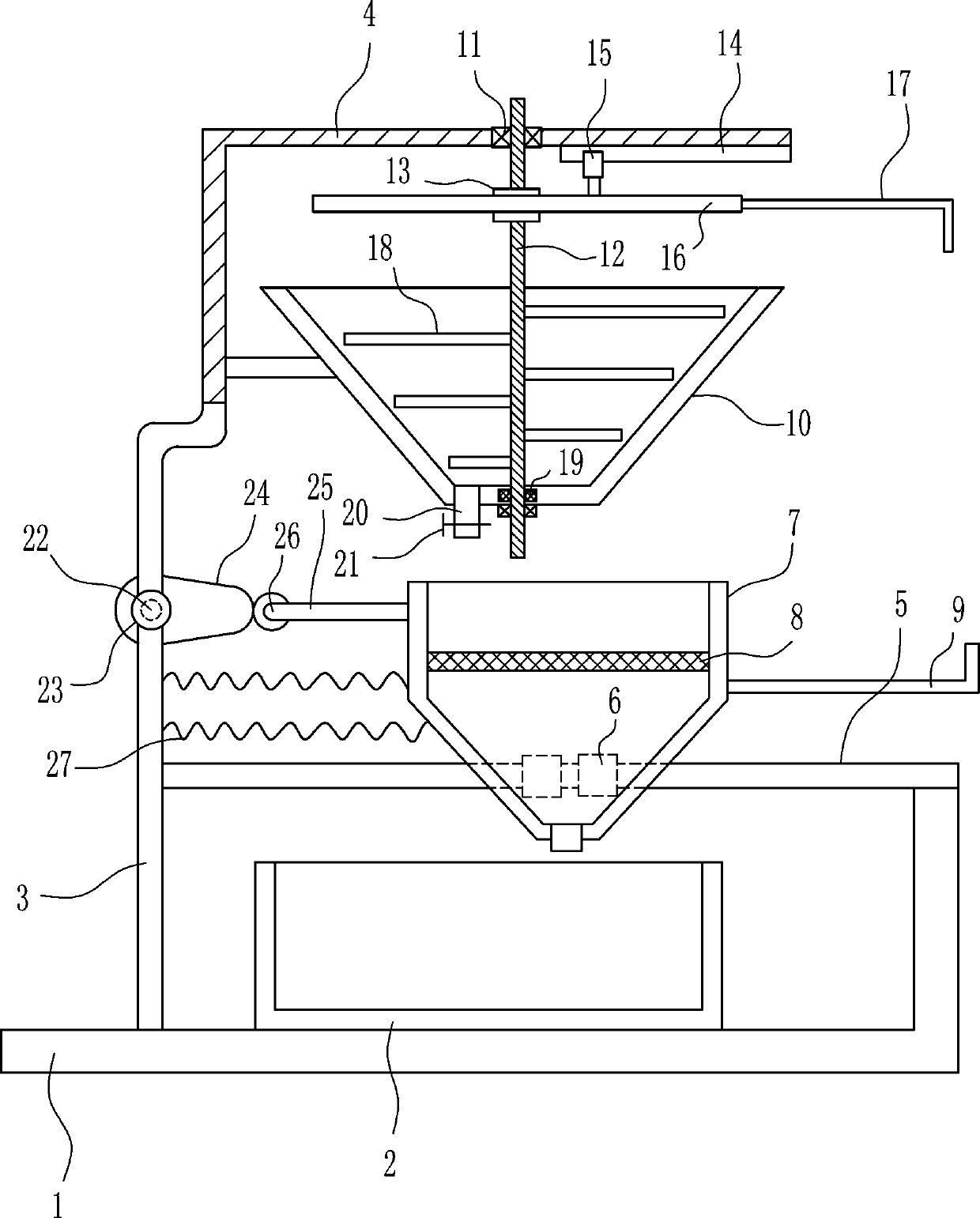

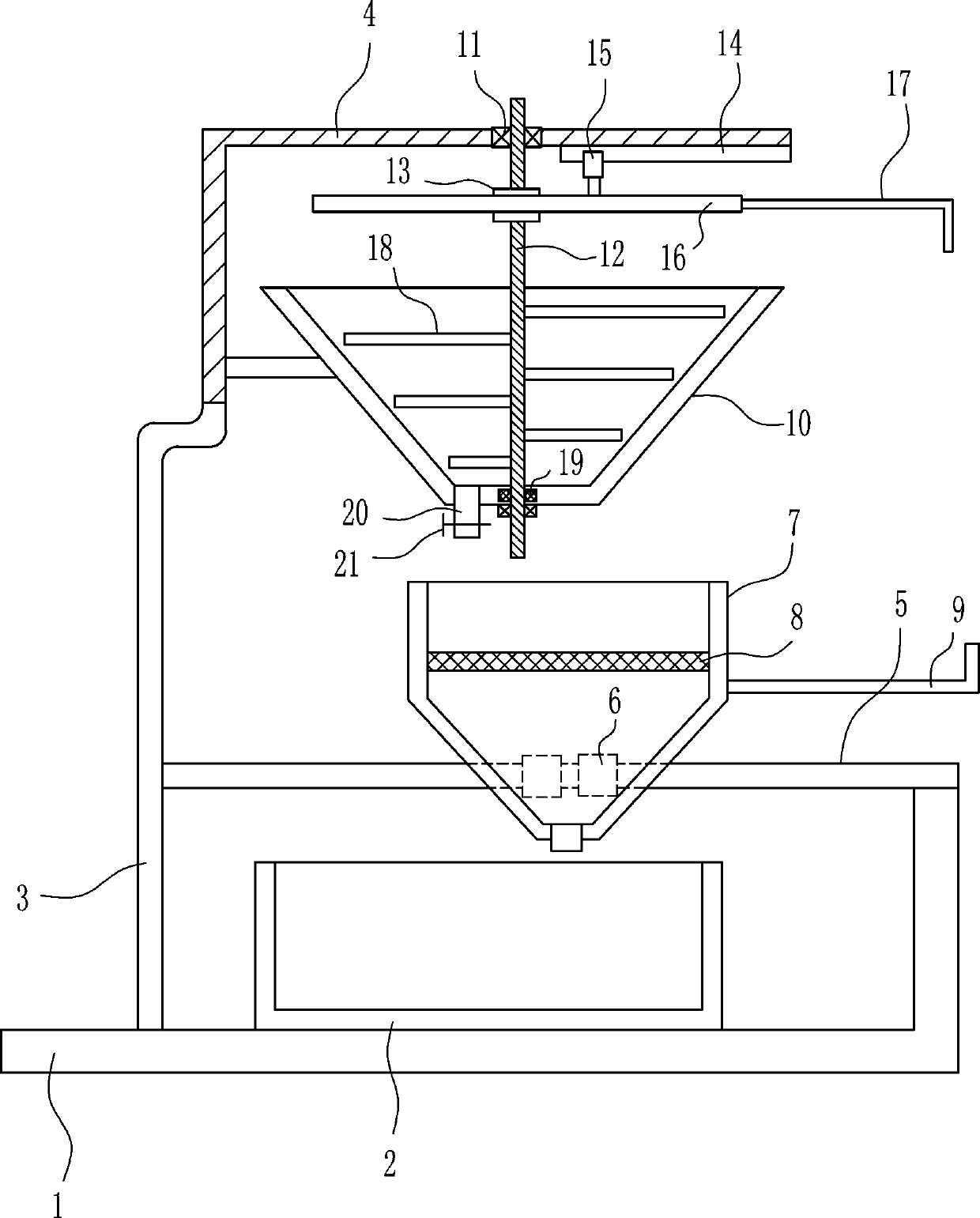

Rare earth chloride solution movable filtration equipment for producing rare earth chloride carbonate

InactiveCN109589669ASave human effortEasy to operateRare earth metal chloridesTransportation and packagingFiltrationRare earth

The invention relates to filtration equipment, in particular to rare earth chloride solution movable filtration equipment for producing rare earth chloride carbonate. Therefore, the technical problemis to provide the rare earth chloride solution movable filtration equipment for producing rare earth chloride carbonate which can continuously stir the rare earth chloride solution in a process of filtering a rare earth solution, enables impurities in the rare earth chloride carbonate to be difficultly deposited and cannot block a filtration device. The rare earth chloride solution movable filtration equipment for producing the rare earth chloride carbonate comprises a mounting frame, a collection frame, a first mounting rod, a second mounting rod, a guide rail, guide sleeves, a movable screening frame, a screening mesh, a first pull rod, a stirring box, a first bearing base and the like; and the collection frame is mounted in the middle of the bottom part of the mounting frame. Accordingto the rare earth chloride solution movable filtration equipment for producing the rare earth chloride carbonate disclosed by the invention, the effects that the rare earth chloride solution can be continuously stirred in the process of filtering the rare earth solution, the impurities in the rare earth chloride solution are difficultly to deposit and the filtration device cannot be blocked are achieved.

Owner:罗美婷

Preparation method of rare earth halide

ActiveCN111186853AIncrease oxygen contentAvoid pollutionRare earth metal chloridesRare-earth elementHalogen

The invention provides a preparation method of rare earth halide. The method comprises the following steps: heating LnX3.nNH4X powder in a rare earth oxide crucible to obtain rare earth halide LnX3, wherein the rare earth element in the LnX3.nNH4X powder is the same as the rare earth element in the rare earth oxide crucible, Ln is selected from La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, Sc and Y, X is halogen, and n is more than 0 and less than or equal to 12. According to the preparation method provided by the invention, the high-purity, anhydrous and oxygen-free rare earth halide can be obtained; and the anhydrous high-purity rare earth halide obtained by the method can be used for growing high-purity blocky single crystals or fibrous single crystals with excellent scintillation performance.

Owner:北京梦晖科技有限公司

Preparation method of anhydrous rare earth chloride

The invention provides a preparation method of anhydrous rare earth chloride (REC13). The method comprises the steps of S1, dissolving a rare earth oxide with hydrochloric acid to form a rare earth chloride solution; S2, adding ammonium chloride into the dissolved rare earth chloride solution; S3, parching the mixture until the mixture is thoroughly dried under a heating condition to obtain a solid mixture of the rare earth chloride containing crystal water and the ammonium chloride; S4, transferring the parched solid mixture into a sublimation device, raising the temperature from 80 DEG C to390 DEG C in a gradient heating mode, and simultaneously carrying out vacuuming heating operation, wherein in the vacuuming heating process, the crystal water of the ammonium chloride and the rare earth chloride are sequentially removed, so that the high-purity anhydrous rare earth chloride is obtained. The method has the advantages that the production process is simple and safe, no side reactionhappens, the purity of the prepared anhydrous rare earth chloride is high, and large-scale production is facilitated.

Owner:LANZHOU UNIVERSITY

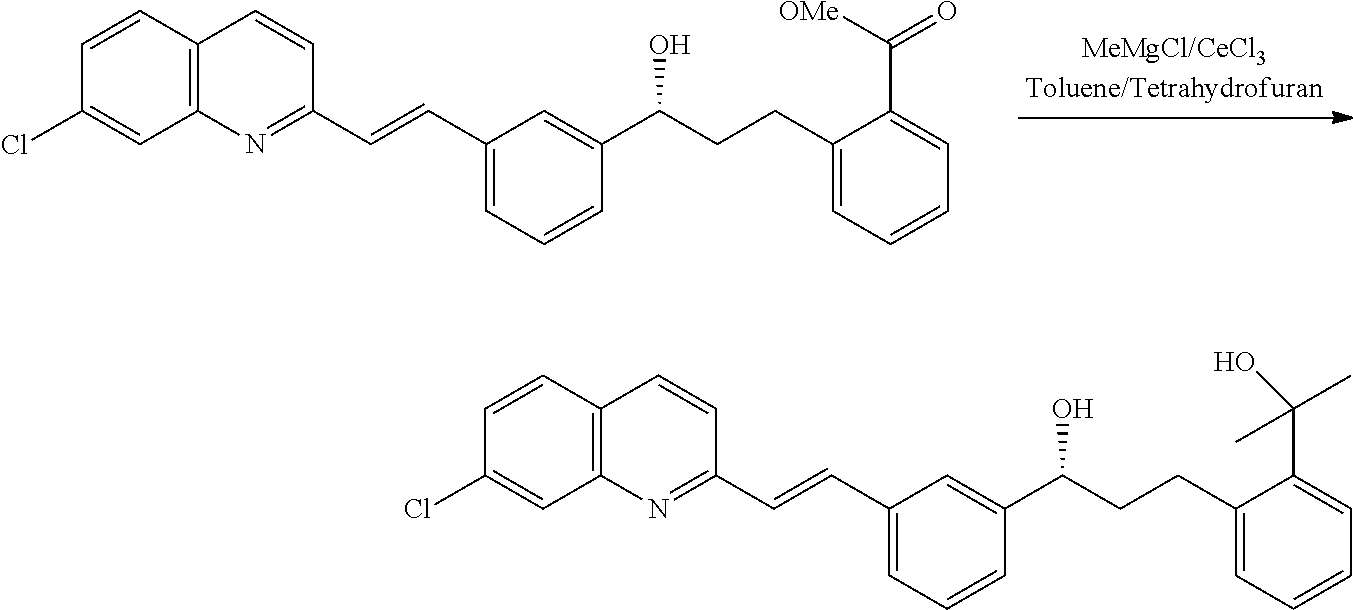

Rare earth recovery from phosphor

InactiveUS8524176B2Efficient and effectiveRare earth metal chloridesPhysical/chemical process catalystsPhosphorRare earth

A method is described to produce high purity rare earth oxides of the elements La, Ce, Tb, Eu and Y from phosphor, such as waste phosphor powders originating in various consumer products. One approach involves leaching the powder in two stages and converting to two groups of relatively high purity mixed rare earth oxides. The first group containing Eu and Y is initially separated by solvent extraction. Once separated, Eu is purified using Zn reduction with custom apparatus. Y is purified by running another solvent extraction process using tricaprylmethylammonium chloride. Ce is separated from the second group of oxides, containing La, Ce and Tb by using solvent extraction. Subsequently, La and Tb are separated from each other and converted to pure oxides by using solvent extraction processes. A one-stage leaching process, wherein all rare earths get leached into the solution and subsequently processed, is also described.

Owner:REENEWAL

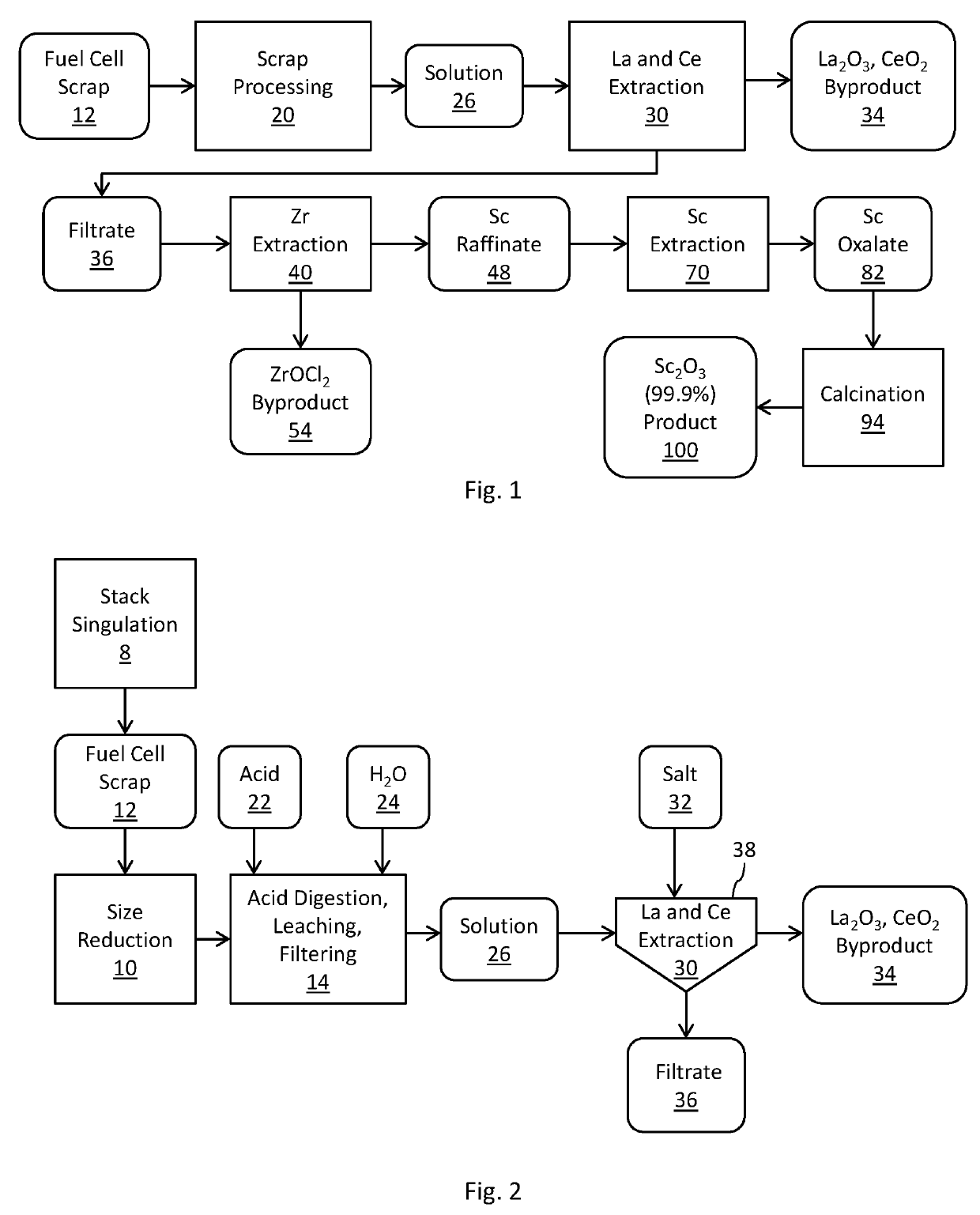

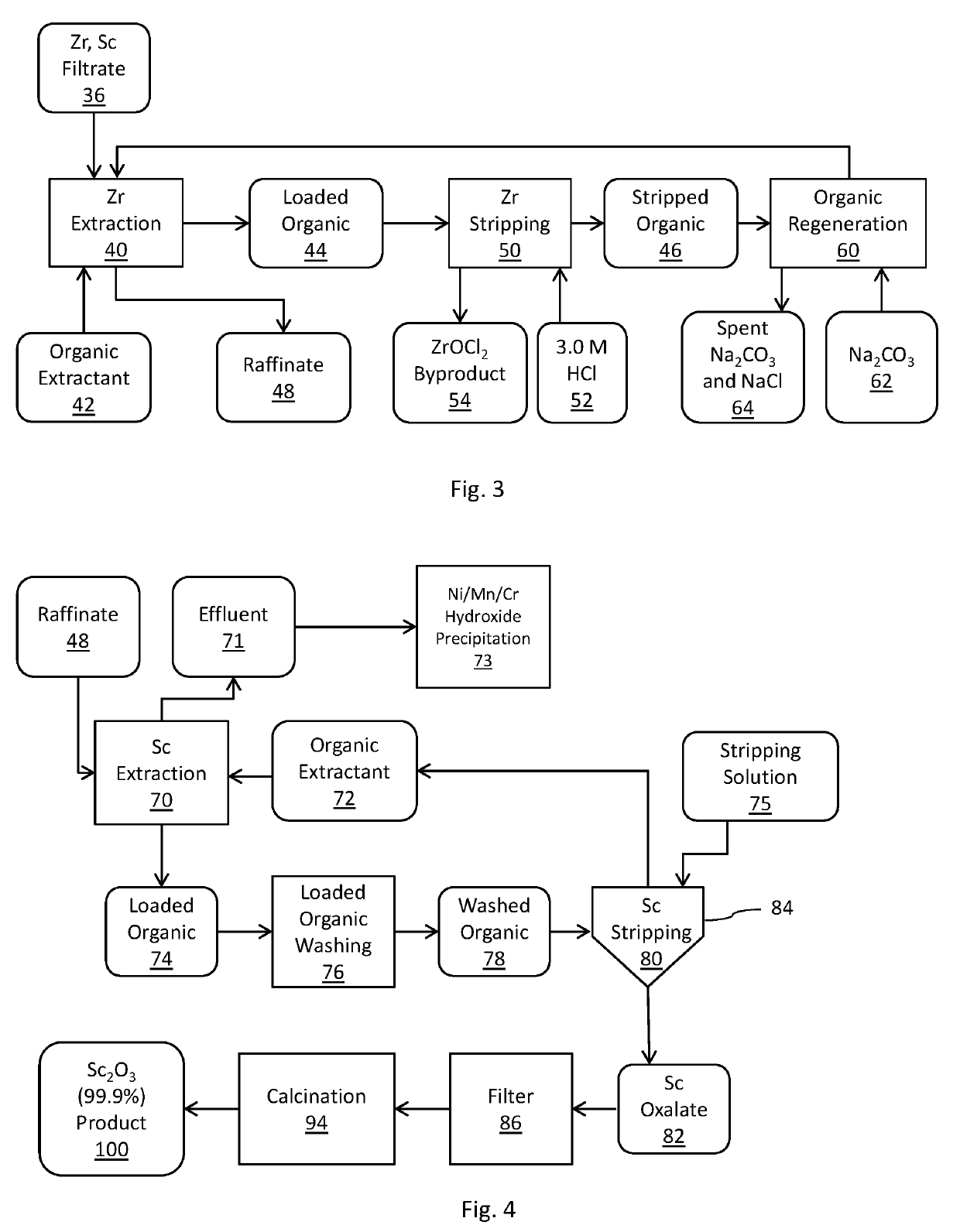

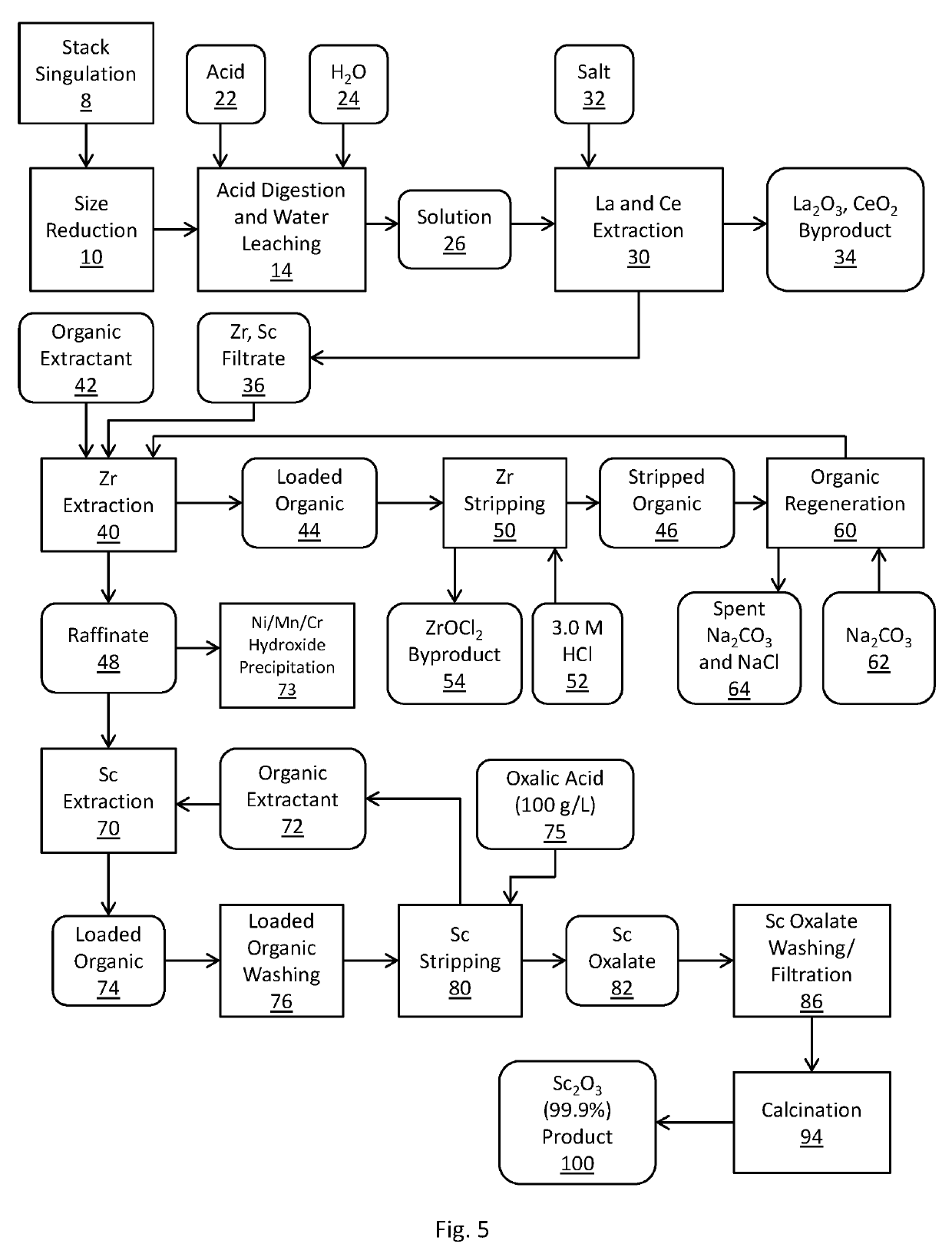

Method of recovering metal compounds from solid oxide fuel cell scrap

A method of recovering metal compounds from solid oxide fuel cell scrap includes processing the solid oxide fuel cell scrap to form a powder, digesting the processed scrap, extracting lanthanum oxide and cerium oxide from a solution containing the digested processed scrap, extracting a zirconium compound from the solution after extracting the lanthanum oxide and cerium oxide, and extracting scandium compound from the solution extracting the zirconium compound from the solution.

Owner:BLOOM ENERGY CORP

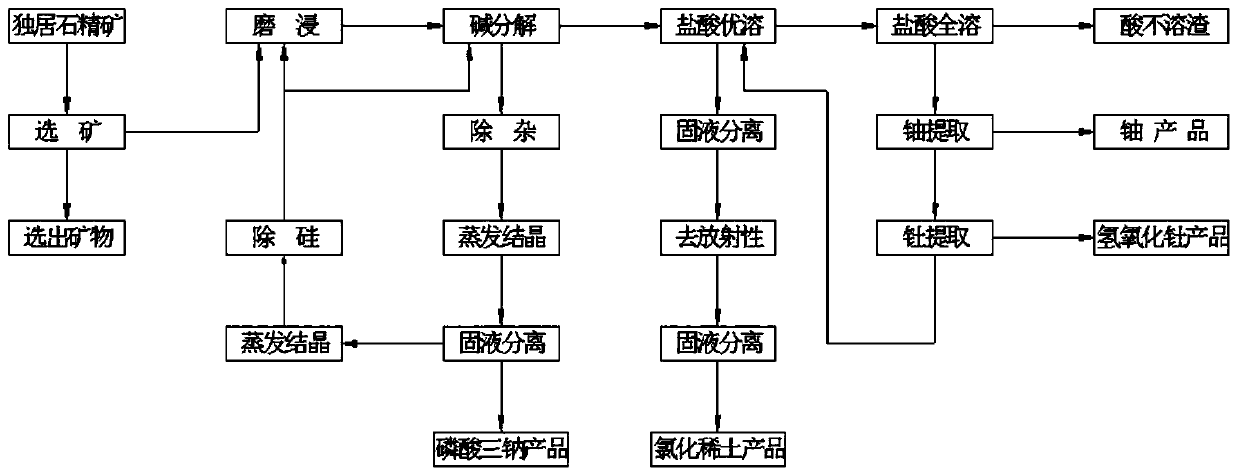

Process method for smelting and separating uranium, thorium and rare earth from monazite concentrate

ActiveCN111020242ASolve problems such as being abandonedHigh recovery rateRare earth metal chloridesRadium compoundsTrisodium phosphateMagnetic separation

The invention provides a process method for smelting and separating uranium, thorium and rare earth from monazite concentrate. The process method comprises the following steps that the monazite concentrate is used as a raw material, the steps of crushing by wet ball mill and iron removal by magnetic separation, alkali decomposition transformation, preparation of trisodium phosphate product, alkalicake adding hydrochloric acid for solubilization, preparation of rare earth chloride mixture product, adding hydrochloric acid to optimal solution slag for full dissolution, extraction of uranium byamines and preparation of uranium products, extraction of thorium by acidic phosphorus containing compounds and preparation of crude thorium products and wastewater treatment are adopted, and the recovery rate of valuable resources such as uranium, thorium, rare earth is greater than 95%. After the thorium is extracted, the raffinate water phase is returned to the optimal solution to recover the rare earth chloride mixture, most of the production process water is directly returned and recycled, and a small part of wastewater is returned to the system for utilization after comprehensive treatment, so that zero discharge of the wastewater is realized. The process is reliable, the chemical materials are common, and the consumption is low. The use of solitary stone resources is ensured for green, environmental protection, efficient and clean production, and the process method has obvious social benefits and economic benefits.

Owner:湖南中核金原新材料有限责任公司

Rare earth production wastewater treatment method

InactiveCN106145443ALarge amount of processingSimplified processing stepsWater treatment parameter controlRare earth metal chloridesSodium bicarbonateRare-earth element

The invention discloses a rare earth production wastewater treatment method, which comprises the following steps that (1) rare earth production wastewater is introduced into a settling pool; supernate passes through an impurity filter; particle impurities are removed; (2) a mixture of sodium carbonate and sodium bicarbonate is added into wastewater subjected to impurity removal, so that rare earth elements precipitate; solid and liquid are separated; hydrochloric acid is added into a solid phase to obtain rare earth chloride; (3) the separated liquid phase in the second step is introduced into the settling pool; alkali is added into the settling pool; the pH value is regulated to 10 to 13; after still standing, the wastewater is introduced into an intermediate water box in an overflowing mode; the wastewater in the intermediate water box is pumped and lifted into an ammonia gas exhaust device by a lifting pump; ammonia nitrogen in the ammonia gas exhaust device is converted into ammonia gas; ammonia gas is pumped into a gas liquid separator by a vacuum pump; discharged water treated by the ammonia gas exhaust device is detected, and is directly discharged through a water discharge pipe when ammonia nitrogen reaches standards. The treatment quantity is great; the treatment steps are simple; the industrial application can be realized.

Owner:LESHAN DONGCHEN ADVANCED MATERIAL

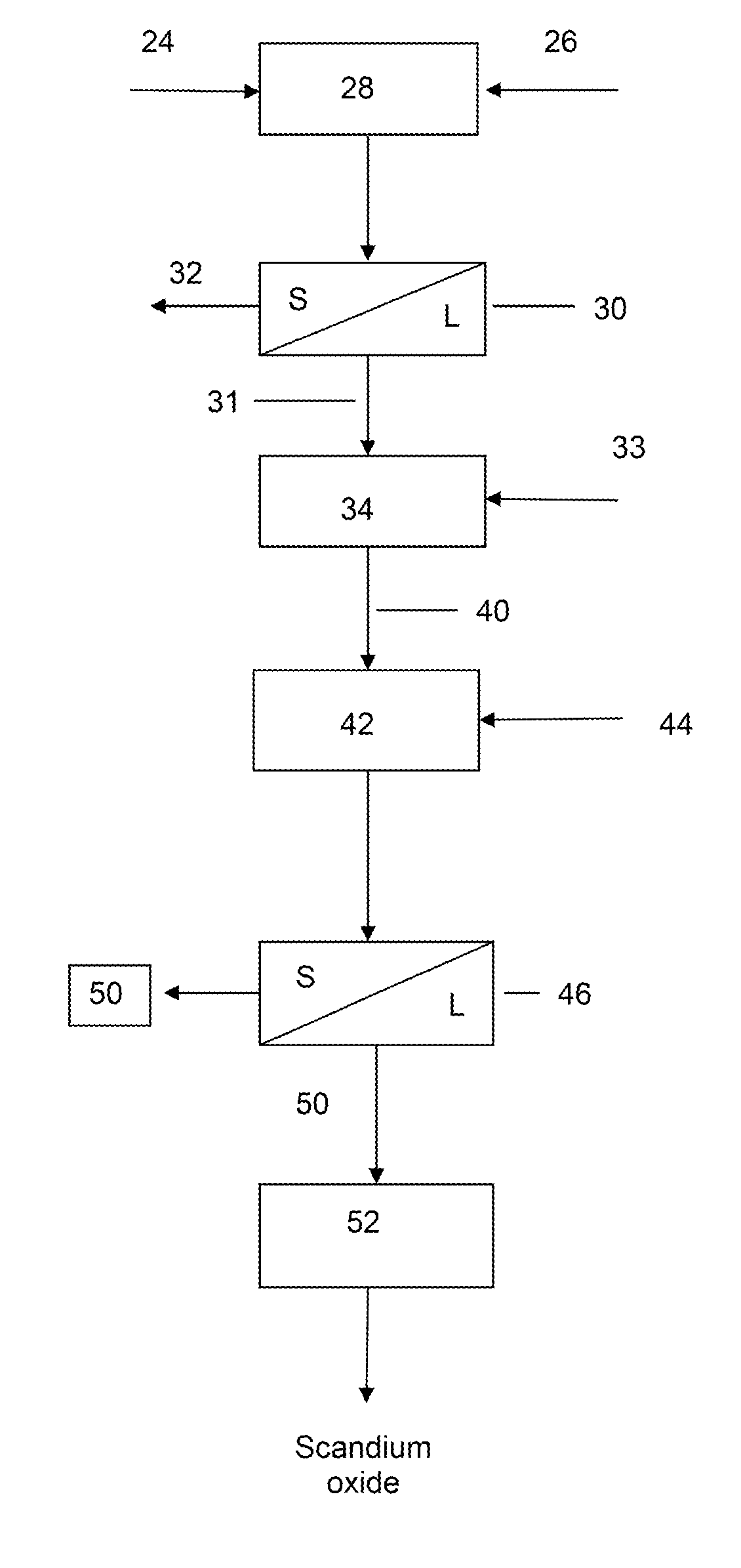

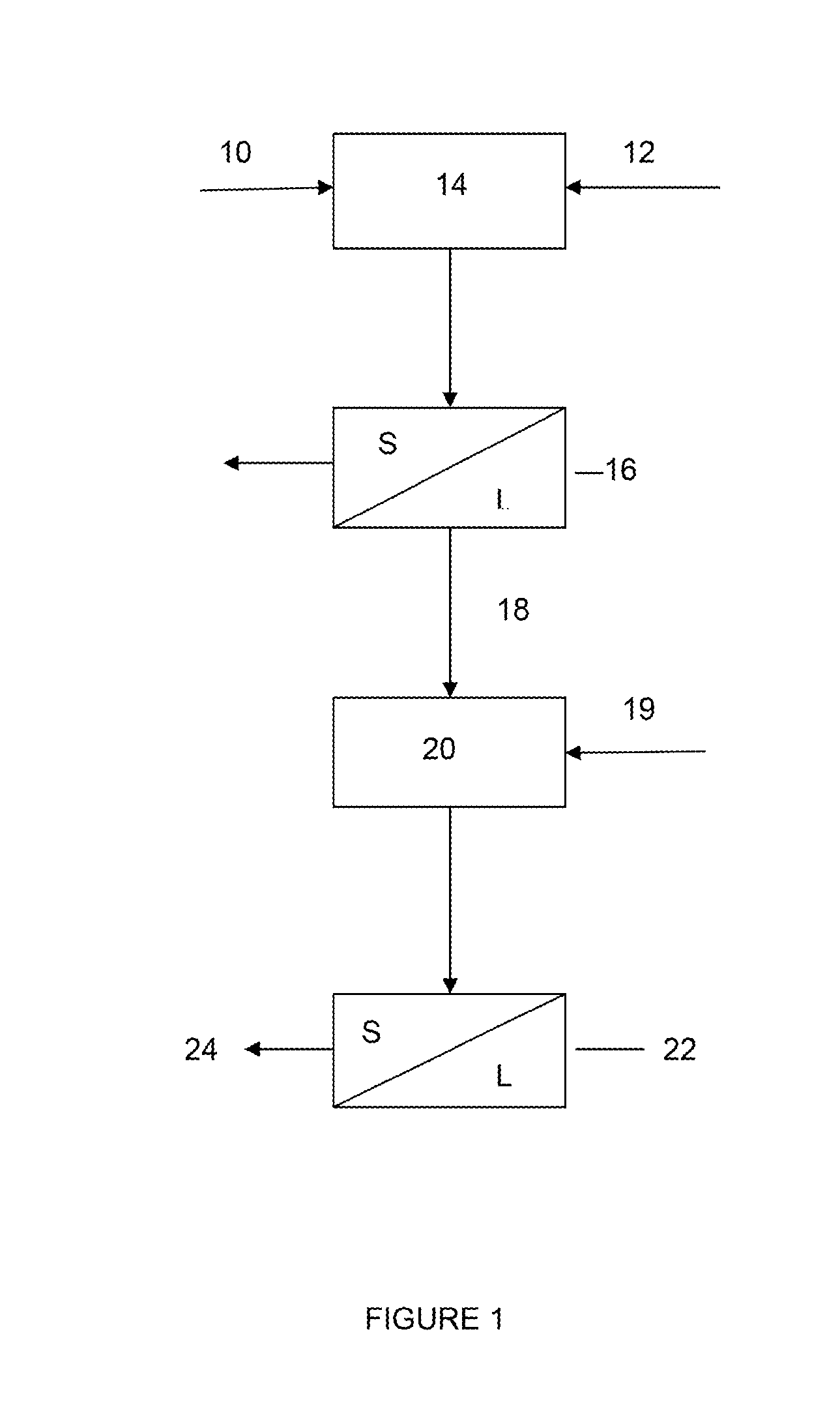

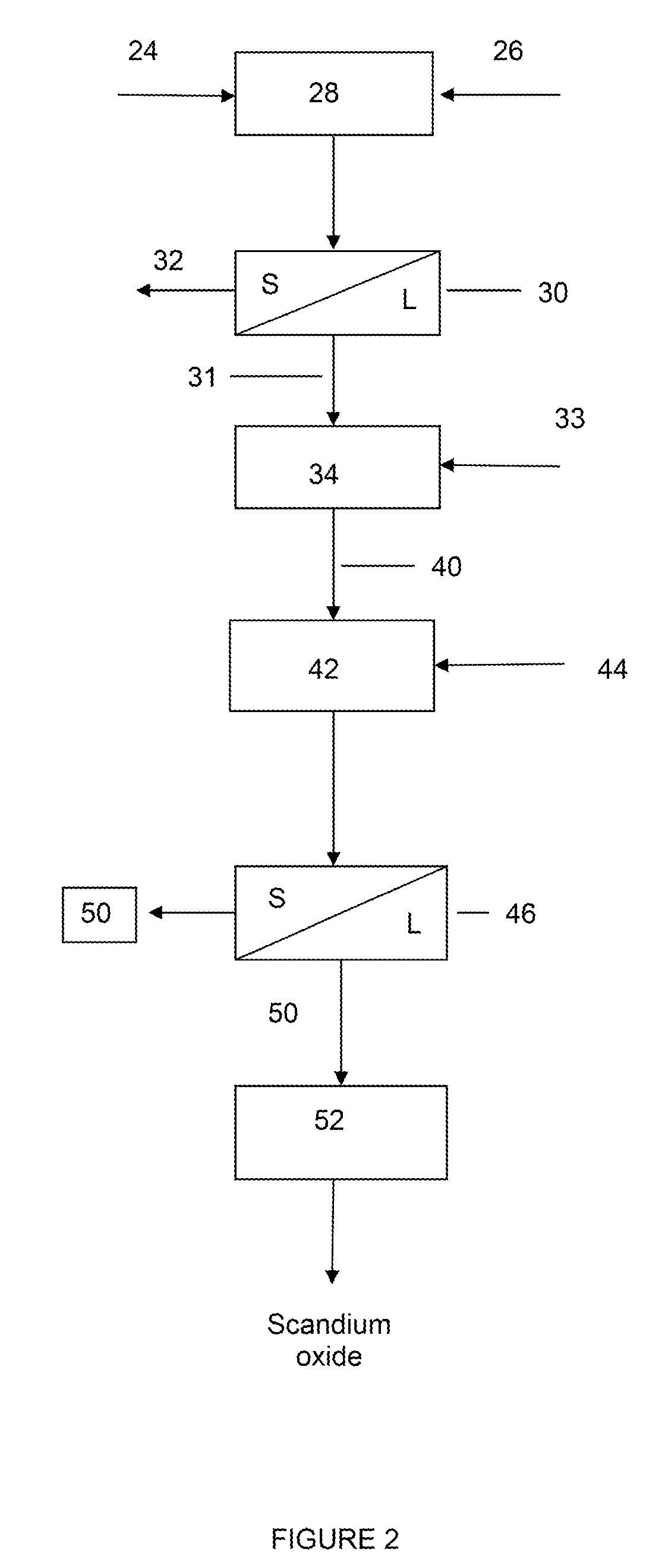

Method for producing a solid scandium-containing material of enhanced scandium content

ActiveUS20150368755A1Raise the ratioReduce contentRare earth metal chloridesGroup 3/13 organic compounds without C-metal linkagesHydrogenCarbamate

A method for producing a solid scandium-containing material comprises providing an aqueous solution containing carbonate ions, carbamate ions, hydrogen carbonate (HCO3+) ions, or mixtures thereof, contacting the aqueous solution with a scandium containing material containing one or more impurities to produce a scandium-loaded solution and a depleted scandium containing material, separating the depleted scandium containing material from the scandium loaded solution, treating the scandium loaded solution to cause precipitation of a solid scandium-containing material whilst avoiding or minimising precipitation of impurities present in the aqueous solution, and separating the solid scandium-containing material from the solution. In another embodiment, a high purity scandium containing is produced by contacting a solid material containing scandium with an acid to form a scandium loaded solution, separating the scandium loaded solution from any solids, adding additional acid to the scandium loaded solution to reduce the pH and precipitating a high purity scandium oxalate material by adding oxalic acid to the solution.

Owner:ELEMENT 21 PTY LTD

Preparation method of anhydrous yttrium chloride

The invention provides a preparation method of anhydrous yttrium chloride. The preparation method includes the steps that yttrium oxide is used as a raw material to react with solid ammonium chloride,then dry hydrogen chloride gas is introduced, heating is performed until the reaction is complete, and a product is fluidized, dried, baked and dewatered to obtain anhydrous yttrium chloride. Throughcombined use of ammonium chloride and hydrogen chloride gas and combination with the proportion amount of the reactants, a synergistic effect of ammonium chloride and hydrogen chloride is achieved; the positional relationship of all the reactants is adjusted, so that the reaction is more complete, and the yield of the reaction product is high; fluidized drying and baking are sequentially performed, so that the occurrence of redox side reactions is prevented, the product purity is improved, the production method is safe and effective, and the product is pure.

Owner:上海泰坦科技股份有限公司

Preparation method of anhydrous lanthanum chloride

InactiveCN107500334AInhibition of hydrolysisReduce pollutionRare earth metal chloridesChlorideLanthanum

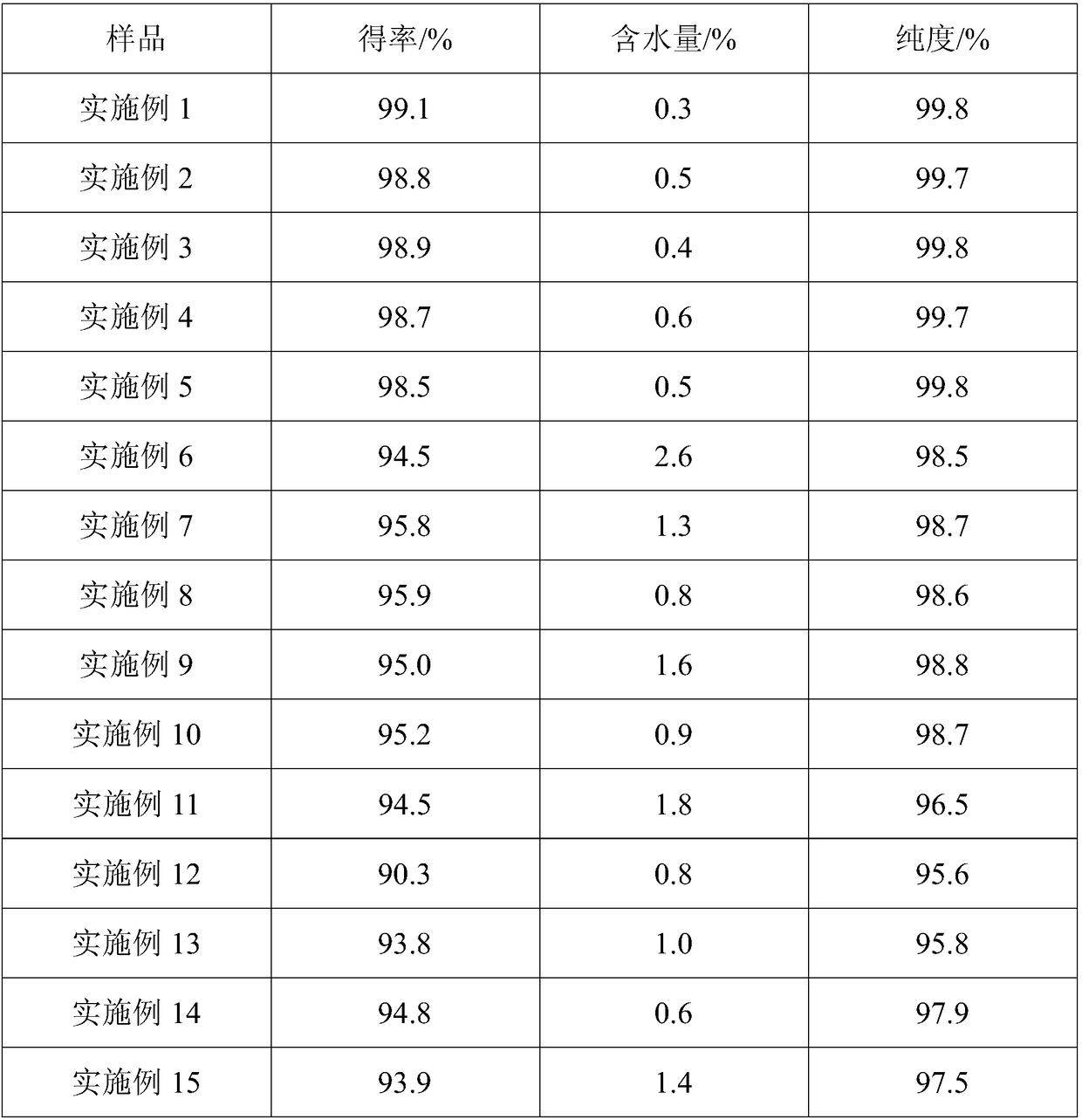

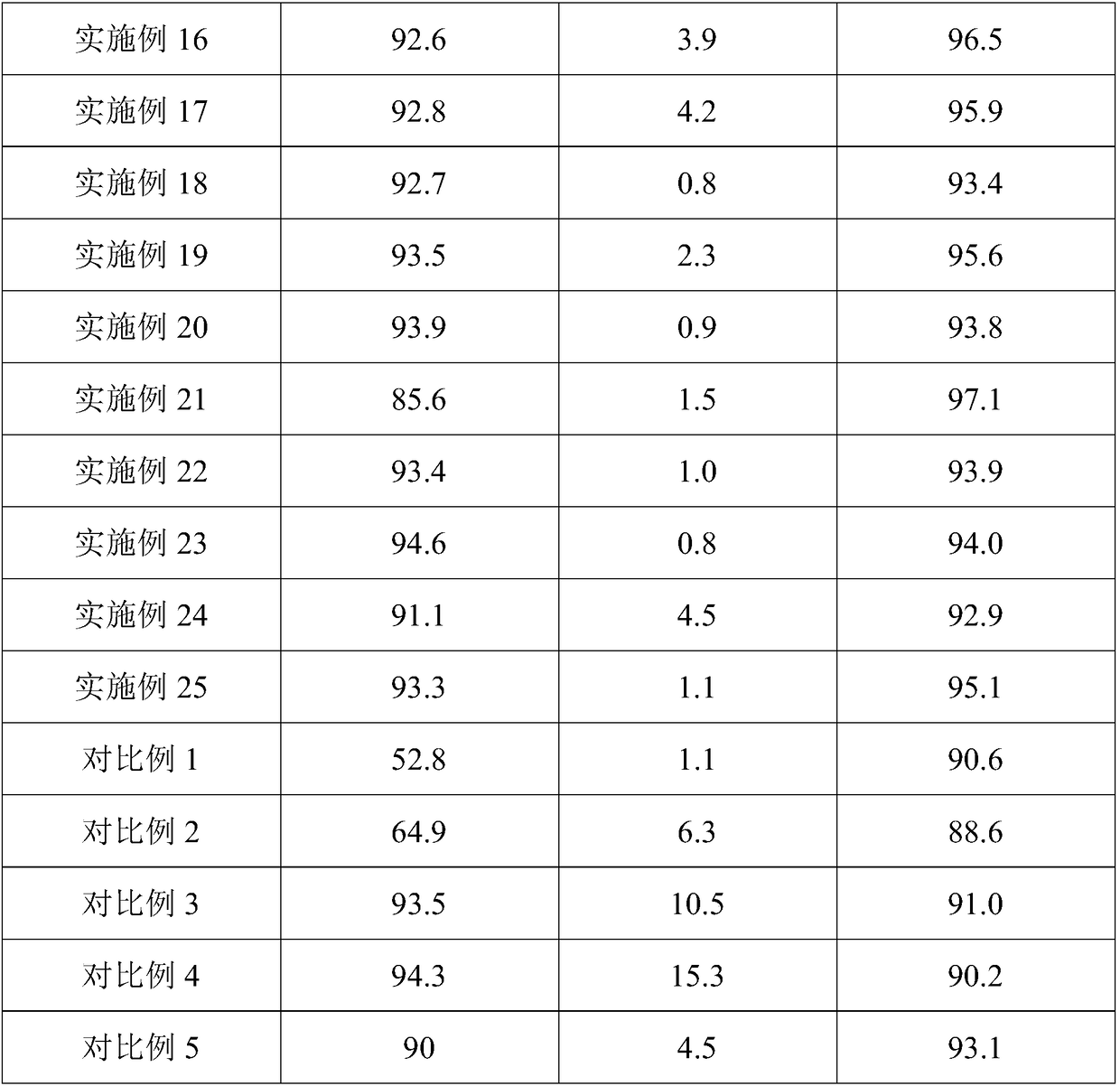

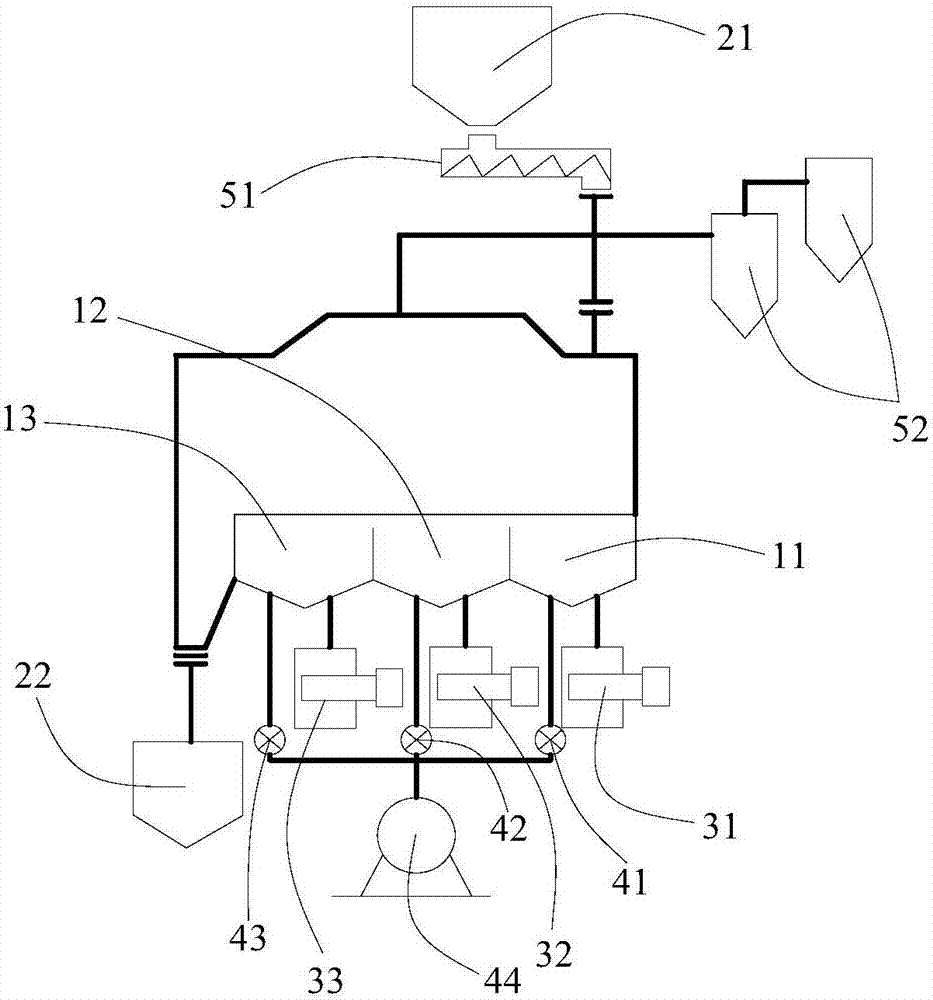

The invention discloses a preparation method of anhydrous lanthanum chloride. The preparation method comprises the following steps: S1, carrying out first-section fluidization dehydration on lanthanum chloride heptahydrate at 60 DEG C to 100 DEG C to obtain a lanthanum chloride trihydrate crude product; S2, carrying out second-section fluidization dehydration on the lanthanum chloride trihydrate crude product at 120 DEG C to 130 DEG C to obtain a lanthanum chloride monohydrate crude product; S3, carrying out third-section fluidization dehydration on the lanthanum chloride monohydrate crude product at 140 DEG C to 160 DEG C to obtain the anhydrous lanthanum chloride, wherein the three sections of fluidization dehydration are carried out in a hydrogen chloride gas atmosphere. According to the preparation method of the anhydrous lanthanum chloride, disclosed by the invention, the lanthanum chloride heptahydrate is subjected to sectioned fluidization dehydration and a hydrogen chloride protection gas atmosphere is provided, so that a hydrolysis effect in a process of dehydrating an intermediate product lanthanum chloride monohydrate into the anhydrous lanthanum chloride is effectively inhibited and the purity of a product is greatly improved; the preparation method of the anhydrous lanthanum chloride has the advantages of low dehydration temperature, low preparation cost and good dehydration effect.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

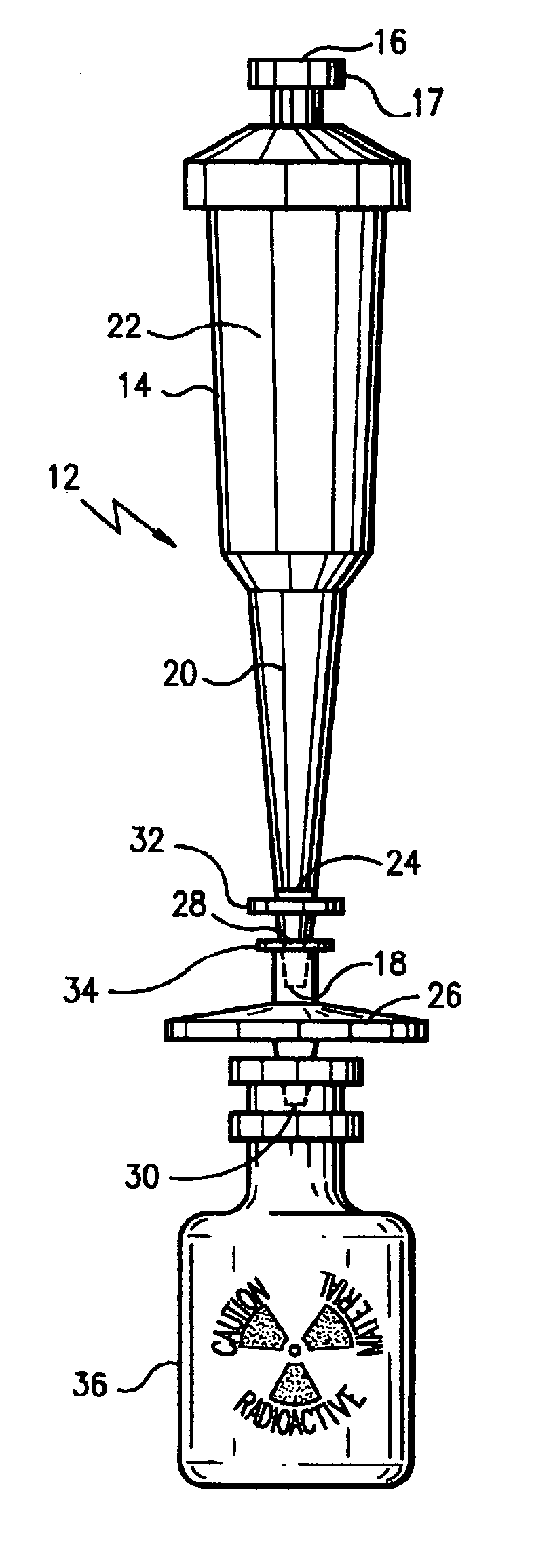

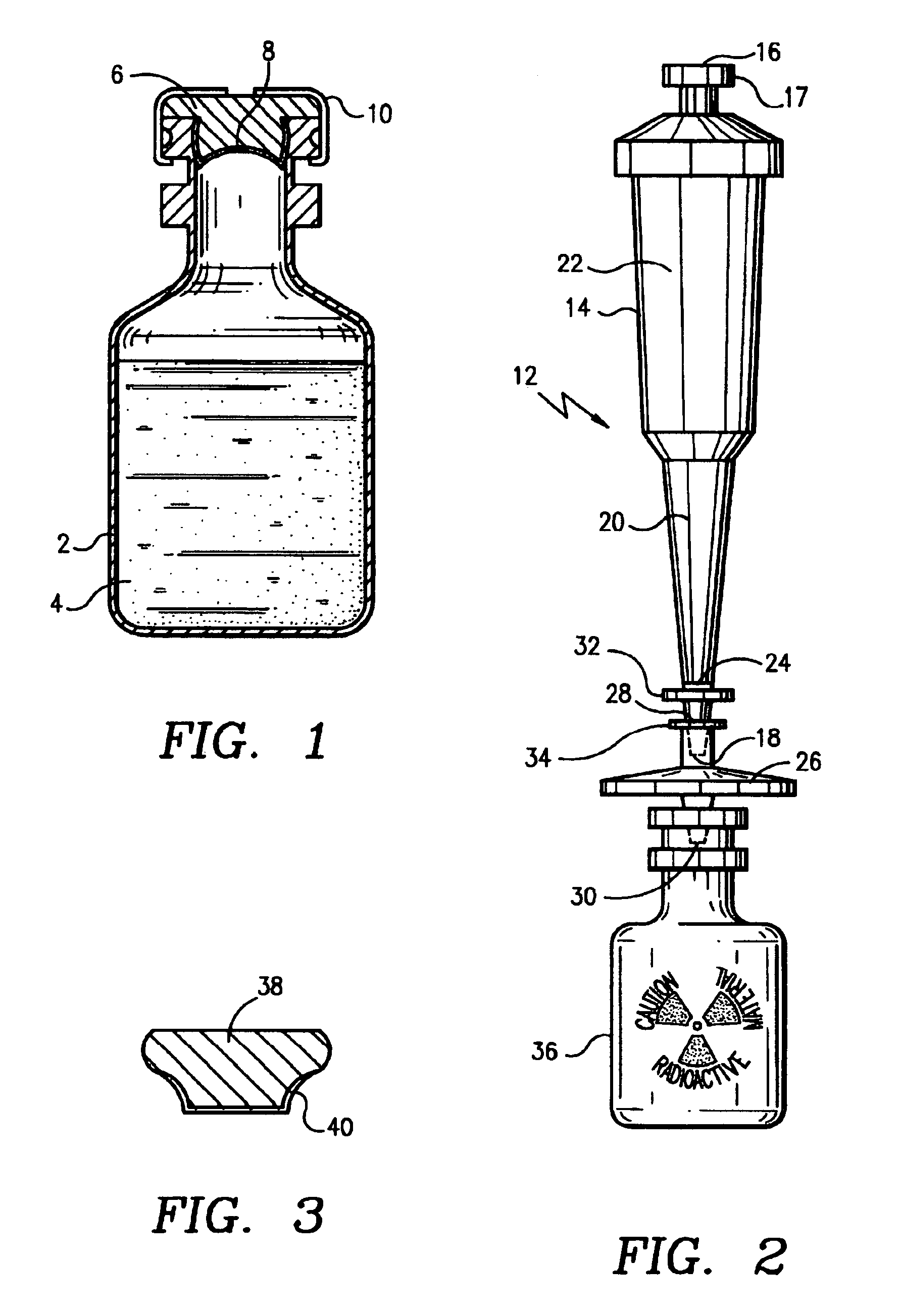

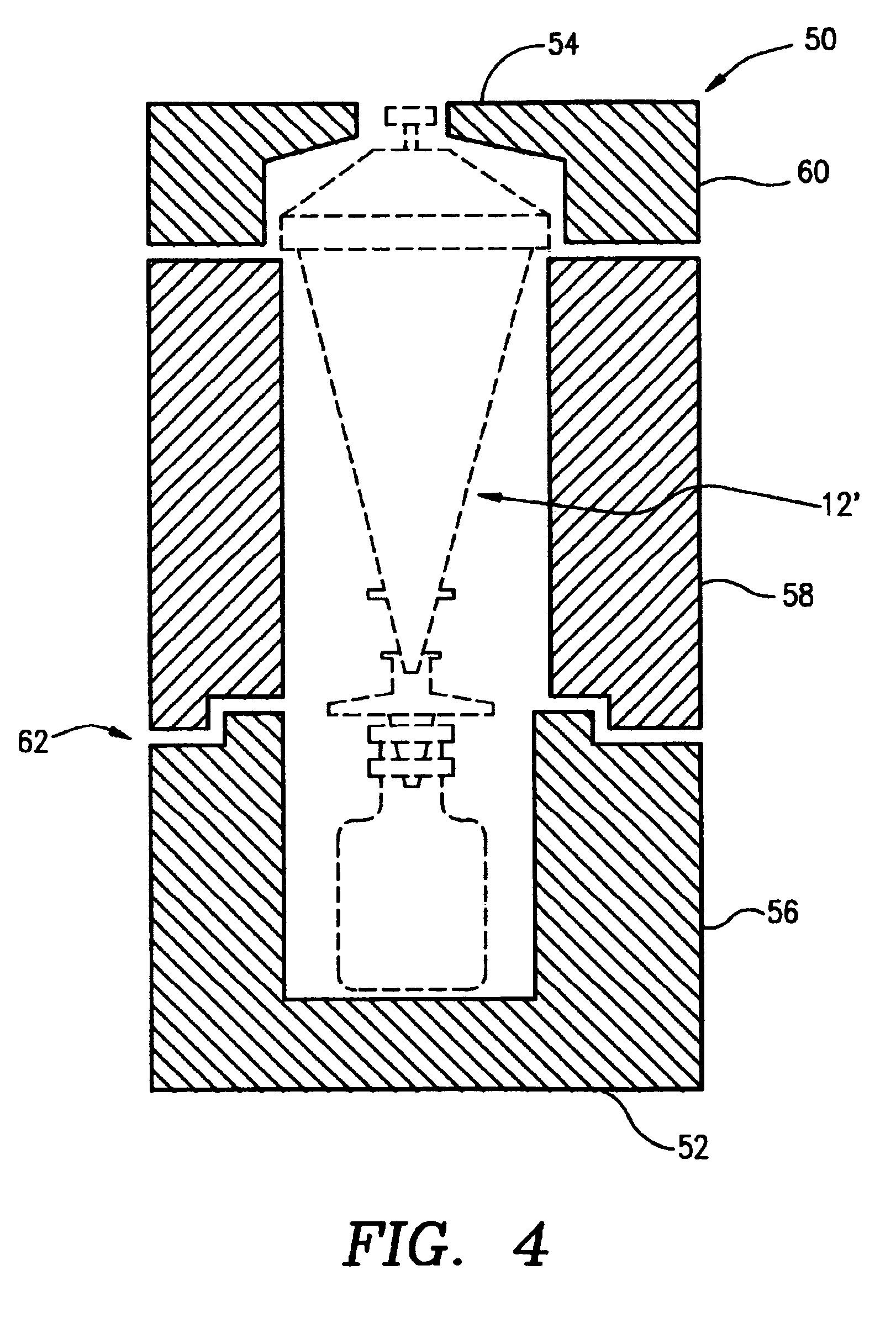

Purification of Lutetium 177

ActiveUS7244403B1Easy to emptyReduce wasteRare earth metal chloridesTransuranic element compoundsLutetiumHafnium

Undesirable metal cation contaminants, including hafnium, can be reduced from a solution containing Lutetium-177 on a bed of an anion exchange resin. The thus purified solution can be stored and transported in a polypropylene vial, to prevent the possibility of hafnium entering the solution from a glassware wall and of Lutetium from being lost from the solution by chemically reacting with a glassware wall. The vial can be sealed with a rubber stopper which has a polytetrafluoroethylene coating facing the solution to prevent the possibility of contaminants which could interfere with later uses of the Lutetium-177 from leaching into the solution from the rubber stopper. Recipients of the Lutetium-177-containing vial can be provided with a prepackaged column of the anion exchange resin to enable such recipients to remove the hafnium which accumulated in the solution as a product of radioactive decay during shipment.

Owner:ISO TEX DIAGNOSTICS

Preparation method of high-purity anhydrous rare earth chloride

ActiveCN112010339AFully chlorinatedReduce generationRare earth metal chloridesRare earth metal compounds preparation/treatmentWater chlorinationProcess engineering

The invention relates to the technical field of preparation of rare earth materials, in particular to a preparation method of high-purity anhydrous rare earth chloride. The preparation method comprises the following steps: (1) mixing rare earth oxide and ammonium chloride, and carrying out heating for a reaction to obtain a mixture A; (2) mixing the mixture A with hydrochloric acid to obtain a solution B; (3) concentrating and drying the solution B to obtain a solid C; and (4) carrying out programmed heating on the solid C to obtain the product. The method has the advantages of high yield, high purity and low water content.

Owner:内蒙古中科蒙稀新材料有限责任公司

Process For Preparing Anhydrous Rare Earth Metal Halides

Processes of preparing anhydrous rare earth metal halides are provided. In some embodiments, the rare earth metal halide is cerium (III) chloride. In other embodiments, the rare earth metal halide is lanthanum chloride.

Owner:ARCH PHARMALABS LTD

Preparation method of high-purity anhydrous rare earth chloride

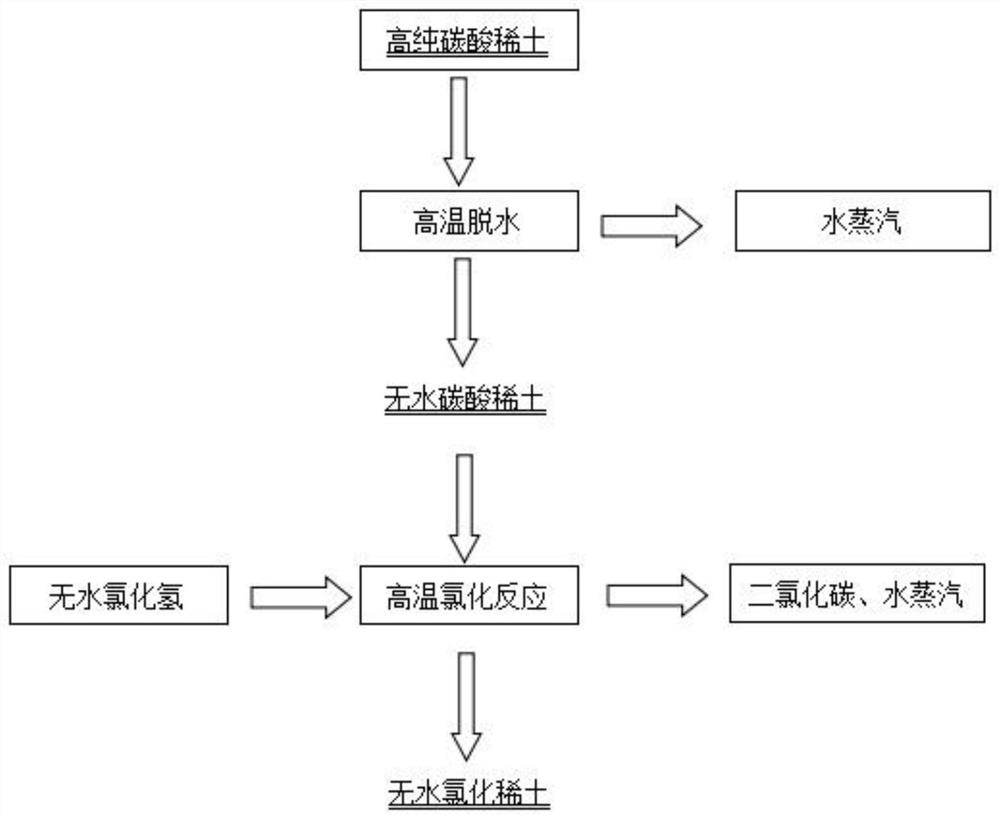

ActiveCN112607761AHigh purityReduce process production costsRare earth metal chloridesRare earth metal compounds preparation/treatmentReaction rateWater chlorination

The invention discloses a preparation method of high-purity anhydrous rare earth chloride, which comprises the following steps: heating and dehydrating high-purity water-containing rare earth carbonate under micro negative pressure to obtain a raw material anhydrous rare earth carbonate; putting the crude anhydrous rare earth carbonate obtained in the previous step into a rotary atmosphere furnace for micro-negative pressure suction, and gradually raising the temperature step by step; after the technical requirements are met, slowly opening an anhydrous hydrogen chloride storage tank, and giving a flow rate according to the technical requirements, so that anhydrous rare earth carbonate is subjected to chlorination reaction under pure anhydrous hydrogen chloride; introducing anhydrous hydrogen chloride gas of which the theoretical amount is 105-130%, controlling the reaction rate to be 1kg-20kg / h ventilation, and cooling to room temperature under the protection of nitrogen after the ventilation is finished; sucking the reacted product into a storage container for inspection under the protection of dry nitrogen by using a vacuum suction machine, and collecting the finished anhydrous rare earth chloride under the condition of isolating water and oxygen. The method is low in process cost, simple in process control, environment-friendly, safe and easy for industrial production.

Owner:包头市明芯科技有限公司

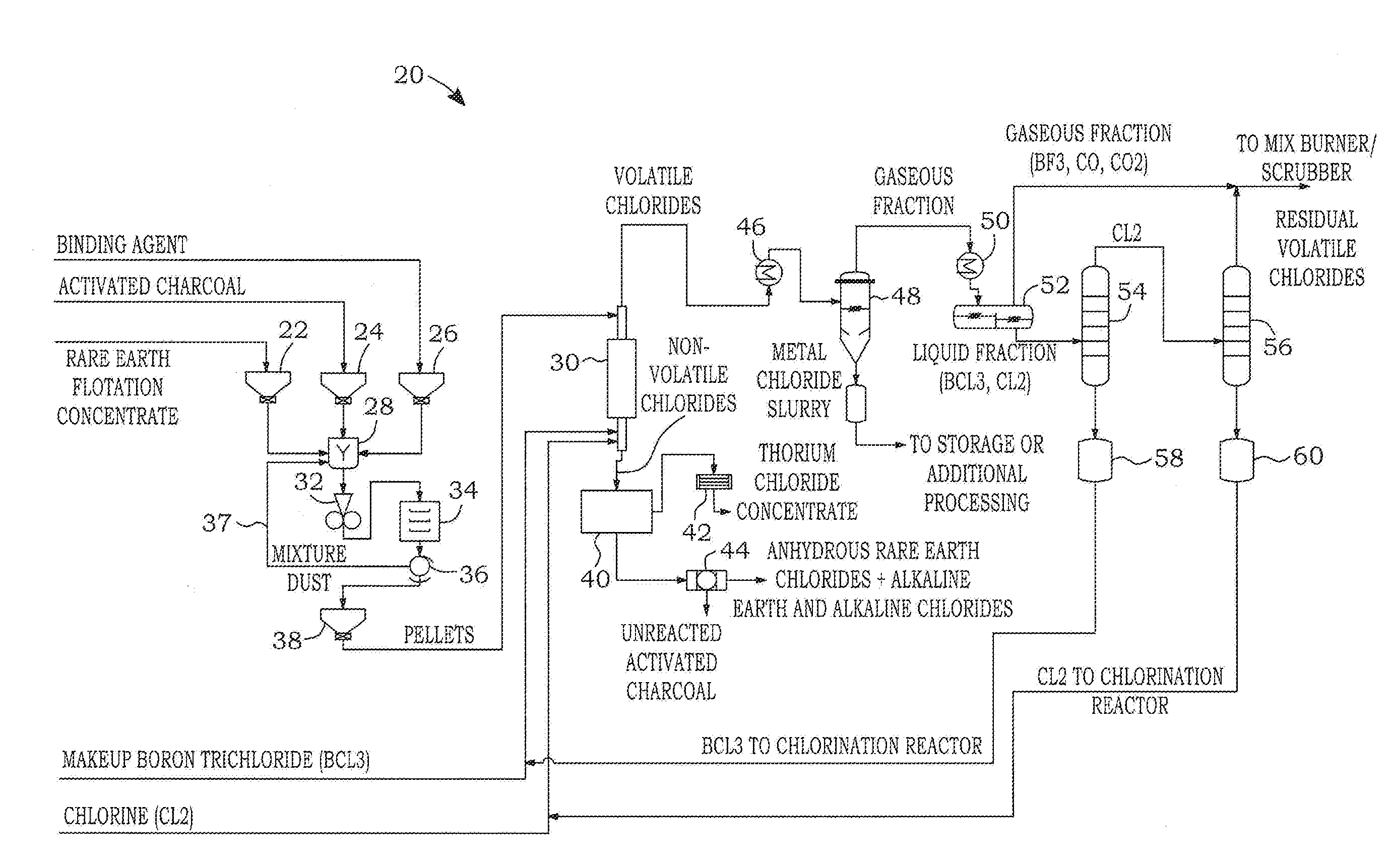

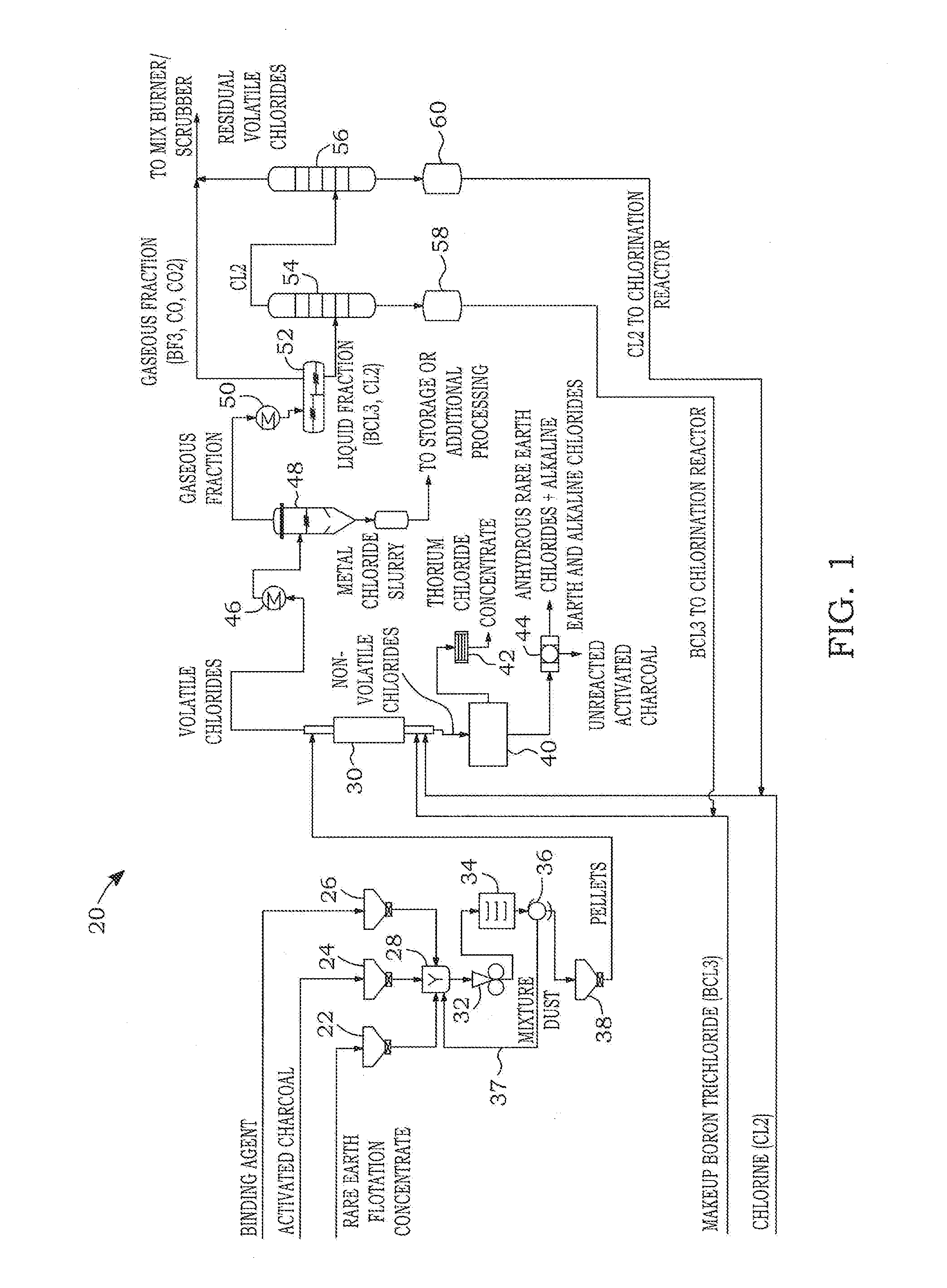

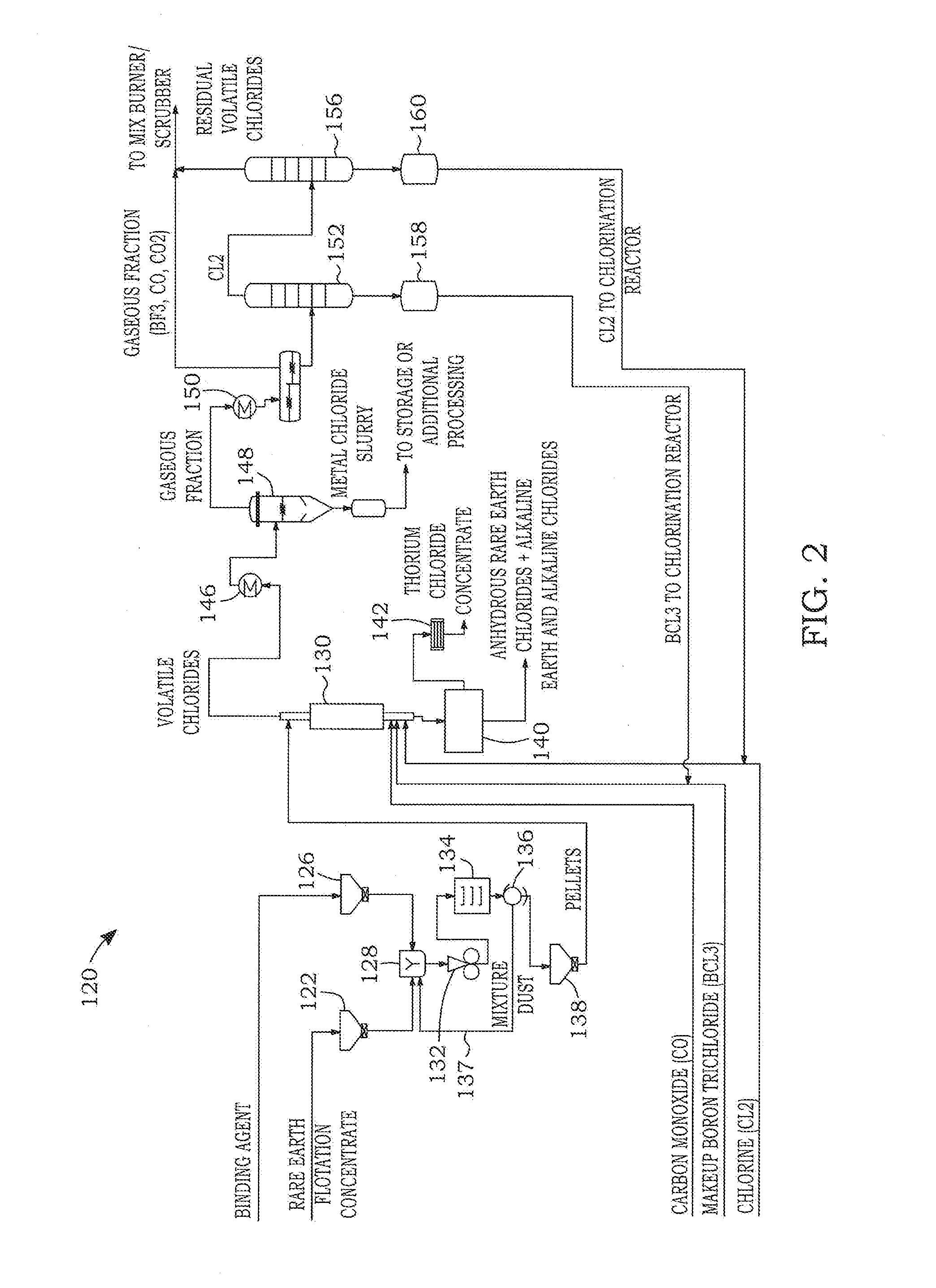

Dry chlorination process to produce anhydrous rare earth chlorides

A process for producing at least one rare earth chloride from an ore containing the at least one rare earth comprises: contacting the ore containing the at least one rare earth with reactants comprising a carbonaceous reducing agent, chlorine, and a boron-containing Lewis acid in a chlorination reactor to produce a gaseous product and a non-volatile chloride mixture comprising the at least one rare earth chloride.

Owner:NIOBEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com