Method for preparing aluminum oxide through hydrochloric acid leaching and two-stage electrolysis of bauxite and comprehensively utilizing aluminum oxide

A hydrochloric acid leaching and bauxite technology, applied in aluminum compounds, rare earth metal compounds, chemical instruments and methods, etc., can solve the problems of long process, high energy consumption, inability to comprehensively utilize, etc., to save a lot of costs and product purity. High, improve the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

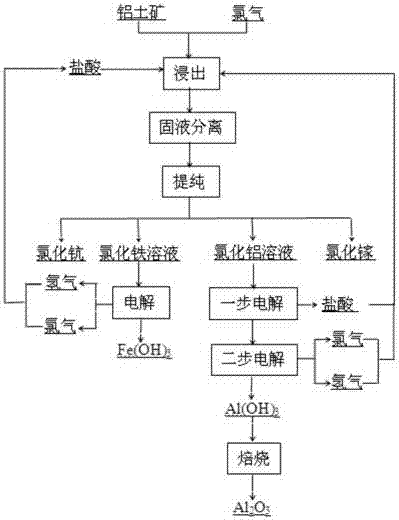

[0052] A kind of bauxite hydrochloric acid leaching step-by-step electrolytic preparation of alumina and its comprehensive utilization method, the process flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0053] (1) Mix bauxite trihydrate and hydrochloric acid with a mass concentration of 36% according to the solid mass and liquid volume ratio of 1:1, send it into the reactor and heat it to 50°C, the reaction time is 1h, and carry out solidification after the reaction cools down. Liquid separation and purification treatment, respectively to obtain aluminum chloride mixed solution and ferric chloride mixed solution;

[0054] (2) Separate and purify the aluminum chloride mixed solution and the ferric chloride mixed solution obtained in step (1) respectively to obtain scandium chloride with a purity of 98.5% and gallium chloride with a purity of 98.5%, and aqueous aluminum chloride and Ferric chloride aqueous solution;

[0055] (3) The ...

Embodiment 2

[0061] A kind of bauxite hydrochloric acid leaching step-by-step electrolytic preparation of alumina and its comprehensive utilization method, the process flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0062] (1) Mix bauxite and hydrochloric acid with a mass concentration of 5% according to the solid mass to liquid volume ratio of 1:20; mix them, send them into the reactor and heat them to 250°C, the reaction time is 10h, and the reaction is carried out after cooling down Solid-liquid separation and purification treatment to obtain aluminum chloride mixed solution and ferric chloride mixed solution respectively;

[0063] (2) Separate and purify the aluminum chloride mixed solution and the ferric chloride mixed solution obtained in step (1) respectively to obtain scandium chloride with a purity of 98.5% and gallium chloride with a purity of 98.5%, and aqueous aluminum chloride and Ferric chloride aqueous solution;

[0064] (3) The ...

Embodiment 3

[0070] A kind of bauxite hydrochloric acid leaching step-by-step electrolytic preparation of alumina and its comprehensive utilization method, the process flow chart is as follows figure 1 As shown, it specifically includes the following steps:

[0071] (1) Bauxite monohydrate and hydrochloric acid with a mass concentration of 36% are mixed according to the solid mass to liquid volume ratio of 1:5, and heated to 100°C in the reactor, and the reaction time is 3h, and solidification is carried out after the reaction cools down. Liquid separation and purification treatment, respectively to obtain aluminum chloride mixed solution and ferric chloride mixed solution;

[0072] (2) Separate and purify the aluminum chloride mixed solution and the ferric chloride mixed solution obtained in step (1) respectively to obtain scandium chloride with a purity of 98.5% and gallium chloride with a purity of 98.5%, and aqueous aluminum chloride and Ferric chloride aqueous solution;

[0073] (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com