Patents

Literature

45 results about "Scandium chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Scandium(III) chloride is the inorganic compound with the formula ScCl₃. It is a white, high-melting ionic compound, which is deliquescent and highly water-soluble. Scandium(III) chloride is mainly of interest in the research laboratory. Both the anhydrous form and hexahydrate (ScCl₃•6H₂O) are commercially available.

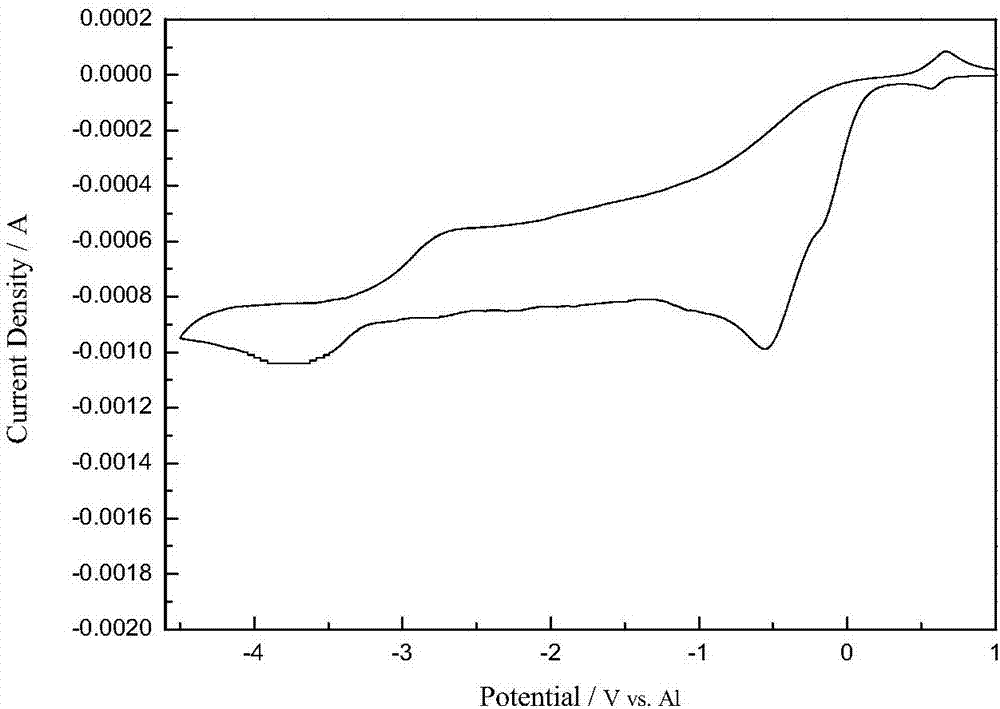

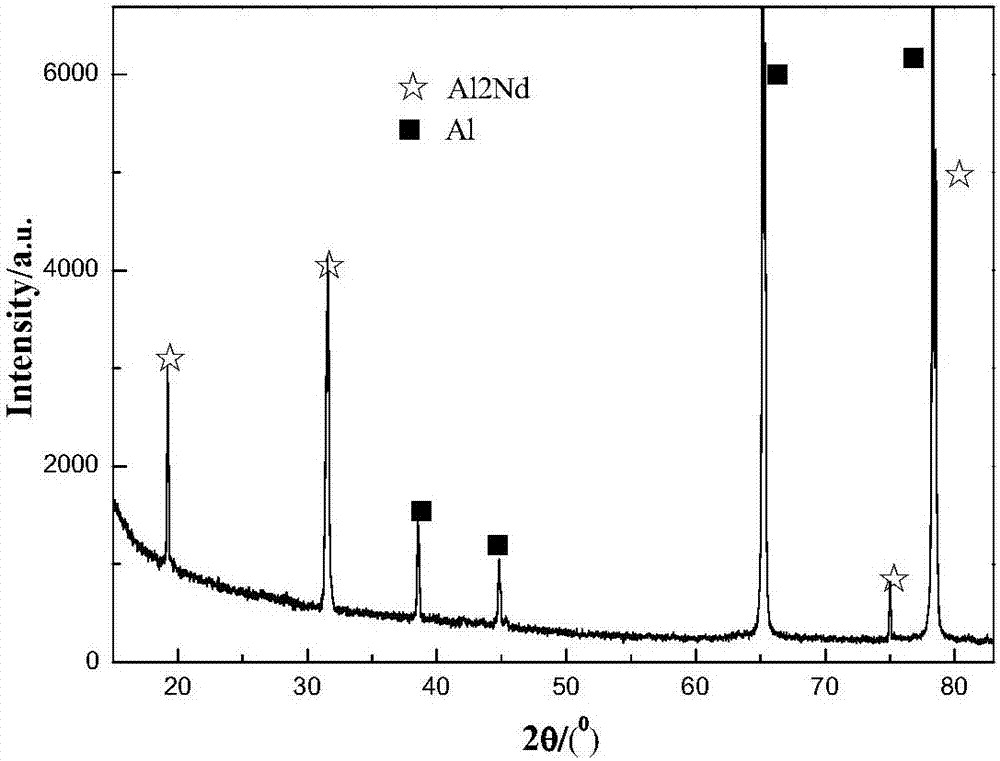

Method for preparing aluminum-based rare earth alloy through near-room-temperature electrolysis

The invention belongs to the field of low-temperature electrochemical extraction and particularly relates to a method for preparing an aluminum-based rare earth alloy through near-room-temperature electrolysis. The method for preparing the aluminum-based rare earth alloy through near-room-temperature electrolysis is an electrolytic method, and a electrolyte adopted by the electrolytic method is formed by rare earth chloride and ionic liquid, wherein the ionic liquid accounts for 96-98% of the total mass of the electrolyte, the rare earth chloride accounts for 2-4% of the total mass, and the rare earth chloride is one of neodymium chloride, lanthanum chloride, cerium chloride, scandium chloride, yttrium chloride, praseodymium chloride, samarium chloride, europium chloride, gadolinium chloride and terbium chloride. According to the technological for preparing the aluminum-based rare earth alloy through near-room-temperature electrolysis, operation is easy, and cost is low; and the technological reserve and theoretical support are provided for green extraction of the low-cost aluminum-based rare earth alloy.

Owner:NORTHEASTERN UNIV

Process using water tolerant lewis acids in catalytic hydration of alkylene oxides to alkylene glycols

ActiveUS20050014980A1Efficient preparationEfficient CatalysisOxygen-containing compound preparationOrganic compound preparationRare earthTriflic acid

Water tolerant Lewis acids are used in a process for the preparation of alkylene glycols by catalytic hydration of the corresponding alkylene oxide. The water tolerant Lewis acids can be a metal salt of a non-coordinating or weakly coordinating anion and a Group IIIB, rare earth or lanthanide, actinide or Group IVB cation. Optionally, carbon oxide may also be present. Examples of such water tolerant Lewis acids are scandium triflate, europium triflate, hafnium triflate, yttrium triflate, lanthanum triflate and ytterbium triflate. The catalyst may contain a coordinating anion instead, examples of which are scandium sulfate [Sc2(SO4)3], scandium chloride [ScCl3], scandium acetate [Sc(OAc)3] and scandium nitrate [Sc(NO3)3]. The catalysts may also contain both a non-coordinating or weakly coordinating anion and a coordinating anion, examples of which are scandium triflate sulfate [Sc(CF3SO3) (SO4)], scandium triflate chloride [Sc(CF3SO3)2Cl], scandium triflate acetate [Sc(CF3SO3)2(OAc)] and scandium triflate nitrate [Sc(CF3SO3)2(NO3)]

Owner:SAUDI BASIC IND CORP SA

Process using water tolerant Lewis acids in catalytic hydration of alkylene oxides to alkylene glycols

InactiveUS6916963B2Oxygen-containing compound preparationOrganic compound preparationRare earthTriflic acid

Water tolerant Lewis acids are used in a process for the preparation of alkylene glycols by catalytic hydration of the corresponding alkylene oxide. The water tolerant Lewis acids can be a metal salt of a non-coordinating or weakly coordinating anion and a Group IIIB, rare earth or lanthanide, actinide or Group IVB cation. Optionally, carbon oxide may also be present. Examples of such water tolerant Lewis acids are scandium triflate, europium triflate, hafnium triflate, yttrium triflate, lanthanum triflate and ytterbium triflate. The catalyst may contain a coordinating anion instead, examples of which are scandium sulfate [Sc2(SO4)3], scandium chloride [ScCl3], scandium acetate [Sc(OAc)3] and scandium nitrate [Sc(NO3)3]. The catalysts may also contain both a non-coordinating or weakly coordinating anion and a coordinating anion, examples of which are scandium triflate sulfate [Sc(CF3SO3) (SO4)], scandium triflate chloride [Sc(CF3SO3)2Cl], scandium triflate acetate [Sc(CF3SO3)2(OAc)] and scandium triflate nitrate [Sc(CF3SO3)2(NO3)].

Owner:SAUDI BASIC IND CORP SA

Production method of high purity aluminium scandium alloy

A technology for preparing high-purity Al-Sc alloy by use of three-layer molten aluminium refining electrolyzer features that the scandium chloride (or fluoride) is added to electrolyte (fluorochloride or fluoride), and then directly electrolyzed at 650-850 deg.C and under 4-7 V of working voltage. Its advantages are high quality and low cost.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Preparation technology of aluminum intermediate alloy

InactiveCN106987735ASolve the costSolve the problem of energy consumptionPotassiumSodium hexafluoroaluminate

The invention relates to the field of synthesis of aluminum intermediate alloys, in particular to a preparation technology of an aluminum intermediate alloy. According to the preparation technology of the aluminum intermediate alloy, aluminum ingots are fed into an electric induction furnace and molten, and the temperature of the molten aluminum is raised to 660-850 DEG C; then, magnesium fluoride, sodium hexafluoroaluminate, potassium hexafluoroaluminate and potassium chloride are mixed into a mixture, the mixture is fed into the electric induction furnace, and the temperature is raised to 750-1000 DEG C; one or two of scandium oxide and scandium chloride are added into the electric induction furnace to a reaction, and after the reaction is qualified, a slagging former is added to remove remaining fused salt on the surface of the alloy; the temperature of the alloy is kept at 760-900 DEG C, a rotating exhauster is used for feeding argon to conduct refining degassing; and then, the slagging former is added for secondary slagging treatment. By the adoption of the preparation technology of the aluminum intermediate alloy, the electric induction furnace is utilized, the chloride and the fluoride are mixed and then added to high-temperature molten aluminum with the surface covered with fused salt, the aluminum-scandium alloy is directly generated, and the problems that when the aluminum-scandium alloy is prepared through a mix-melting method, cost is high, the energy consumption is high, time is long, efficiency is low, and the quality is not stable are solved.

Owner:山东滨州华创金属有限公司

Chestnut shell active carbon and preparation method thereof

InactiveCN103551109AWell-developed pore structureWell-developed structureOther chemical processesCerium nitrateHazardous substance

Chestnut shell active carbon is prepared by the following raw materials by weight: 120-140 parts of chestnut shell, 3-5 parts of zinc chloride, 4-6 parts of Arabic gum, 4-6 parts of periston, 25-30 parts of bentonite, 10-15 parts of alumina, 20-25 parts of pumice, 2-4 parts of lanthanum chloride, 2-4 parts of cerium chloride, 2-4 parts of scandium chloride, 2-4 parts of yttrium chloride, 2-4 parts of praseodymium chloride, 1-3 parts of lanthanum nitrate, 1-3 parts of cerium nitrate, 1-2 parts of scandium nitrate, 1-2 parts of yttrium nitrate, 1-2 parts of praseodymium nitrate, 4-5 parts of modified diatomite, and a proper amount of water. Chestnut shell is used as a raw material, so as that the active carbon has advantages of developed aperture structure, big specific surface area, high adsorption speed, and good adsorption capability on various solutes and dissociation gases; lanthanum chloride is used for activation so as to form active carbon, which has big gaps and strong adsorption capability, is suitable for absorbing organic matters in air and water and removing harmful substances like formaldehyde, is low in cost, and is suitable for industrialization production.

Owner:BENGBU PIONEER FILTER

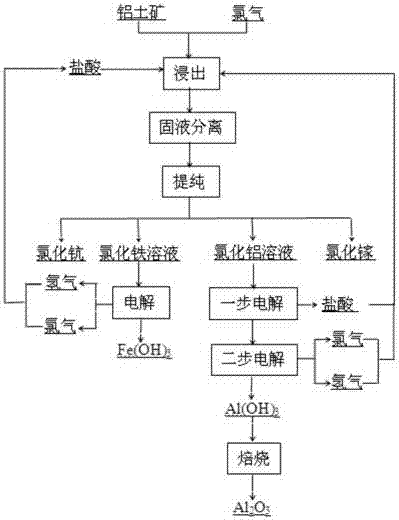

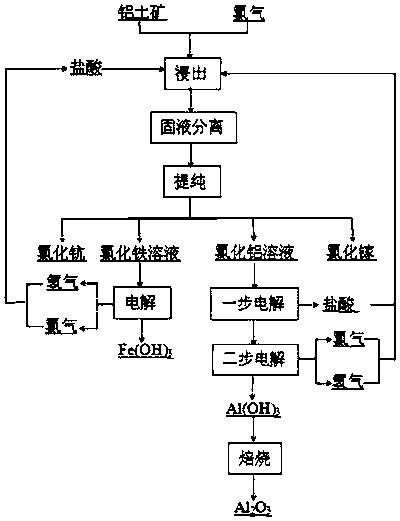

Method for preparing aluminum oxide through hydrochloric acid leaching and two-stage electrolysis of bauxite and comprehensively utilizing aluminum oxide

ActiveCN107128959AHigh degree of automationHigh purityAluminium compoundsRare earth metal chloridesAluminium chlorideElectrolysis

The invention relates to a method for preparing aluminum oxide through hydrochloric acid leaching and two-stage electrolysis of bauxite and comprehensively utilizing aluminum oxide. The method comprises the following steps: carrying out hydrochloric acid leaching, solid-liquid separation and purification on bauxite on bauxite, so as to obtain an iron chloride mixed solution and an aluminum chloride mixed solution; respectively separating and purifying the iron chloride mixed solution and the aluminum chloride mixed solution, so as to obtain scandium chloride, gallium chloride, an aluminum chloride water solution and an iron chloride water solution; setting electrolytic voltage and current density, and respectively carrying out two-stage electrolysis on the aluminum chloride water solution and the iron chloride water solution, so as to respectively obtain aluminum hydroxide, hydrogen and chlorine as well as iron hydroxide, hydrogen and chlorine; preparing a hydrochloric acid solution by using the generated hydrogen and chlorine, and returning the hydrochloric acid solution to a leaching stage for recycling; and roasting aluminum hydroxide, so as to obtain metallurgy level aluminum oxide or chemical aluminum oxide. Compared with a traditional acid method, the electrolysis method for recycling aluminum oxide in the bauxite and processing the bauxite has the advantages that the evaporation step and equipment, the concentration step and equipment are omitted, the operation is simplified, meanwhile, the cost is substantially lowered, and the product has relatively high purity.

Owner:NORTHEASTERN UNIV

Preparation method of scandium oxide for solid fuel battery

ActiveCN107082443AImprove the operating environmentDoes not affect purityRare earth metal oxides/hydroxidesFinal product manufactureNon toxicitySlurry

The invention relates to a preparation method of scandium oxide, in particular to a preparation method of scandium oxide for a solid fuel battery, and belongs to the technical field of inorganic chemistry. According to the method, firstly, scandium concentrate is firstly crushed and is then roasted; the cracking occurs after the fast quenching through cold water; then, ultrasonic-microwave treatment is performed in alkali liquid, so that the alkali-soluble impurities are removed; biogas slurry is used for mixed fermentation; weak acid environment is provided; the ball milling is matched; partial metal oxide impurities are removed; organic matters in the biogas slurry are removed after the drying; then, the cold diluted hydrochloric acid is used for soaking; metal oxide impurities such as ferric oxide are removed; then, hot diluted hydrochloric acid is used for dissolving the scandium oxide to form a high-purity scandium chloride solution; oxalic acid is used as a precipitator; after scandium oxalate precipitates are formed; roasting is performed. Therefore the high-purity scandium oxide for solid fuel battery can be obtained. The alkaline leaching is used for matching with the microbial fermentation and ball milling treatment; impurities in the scandium concrete can be removed, so that the product can be purified; in the preparation process, toxic extraction agents are not used; the production process achieves the environment-friendly effects and non-toxicity.

Owner:山西城市动力新能源有限公司

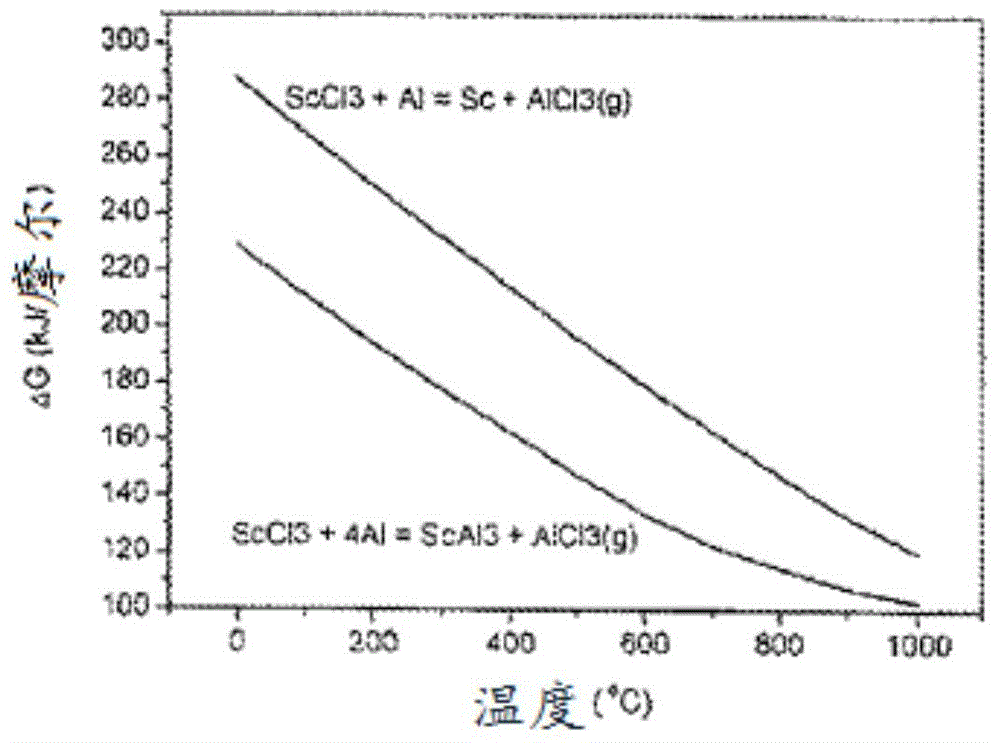

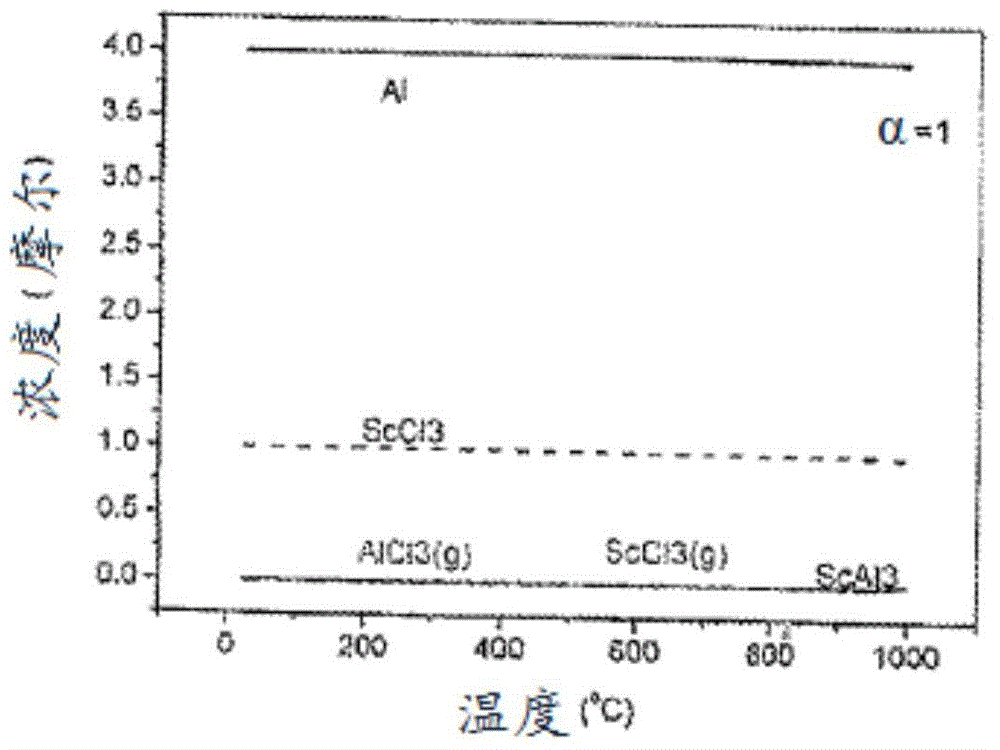

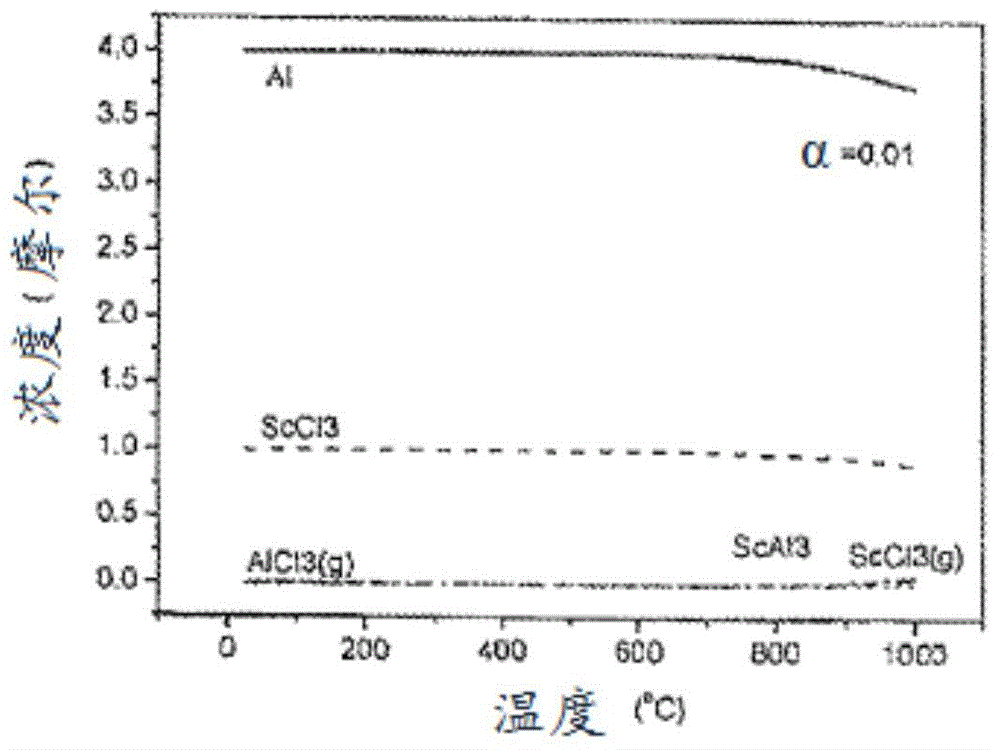

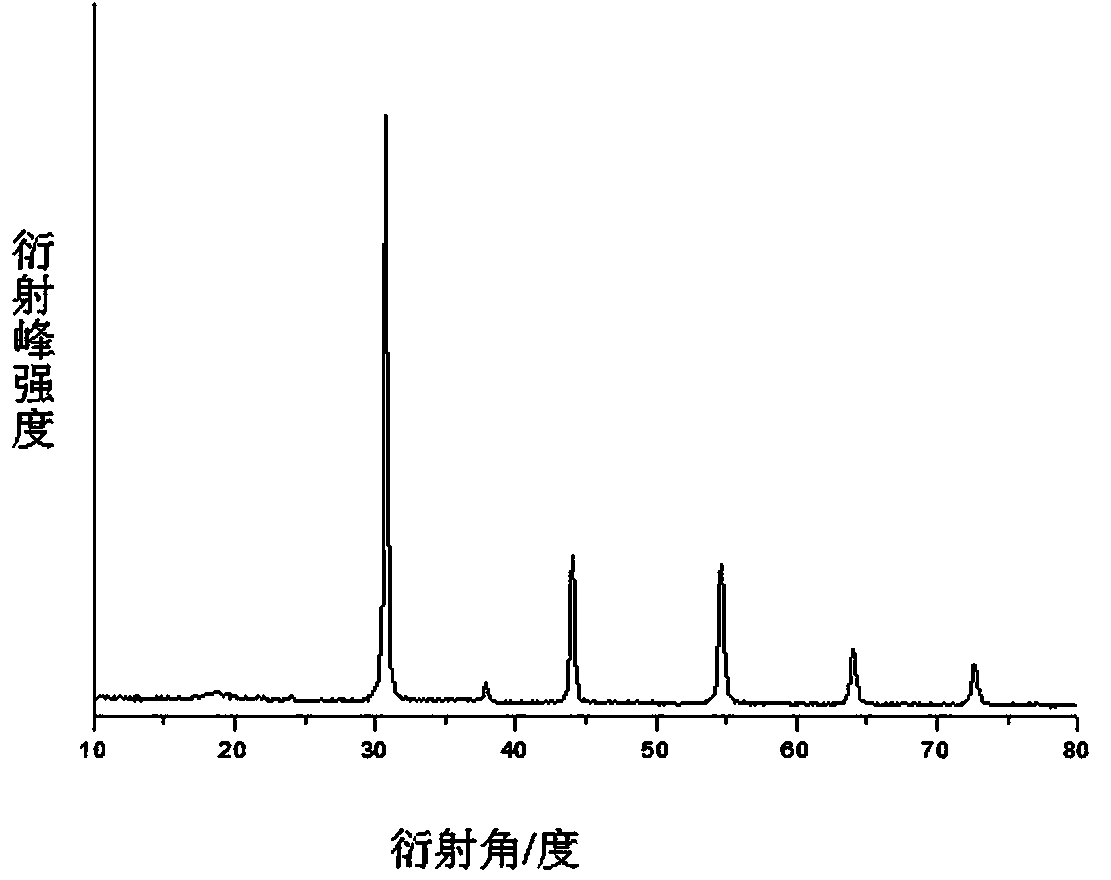

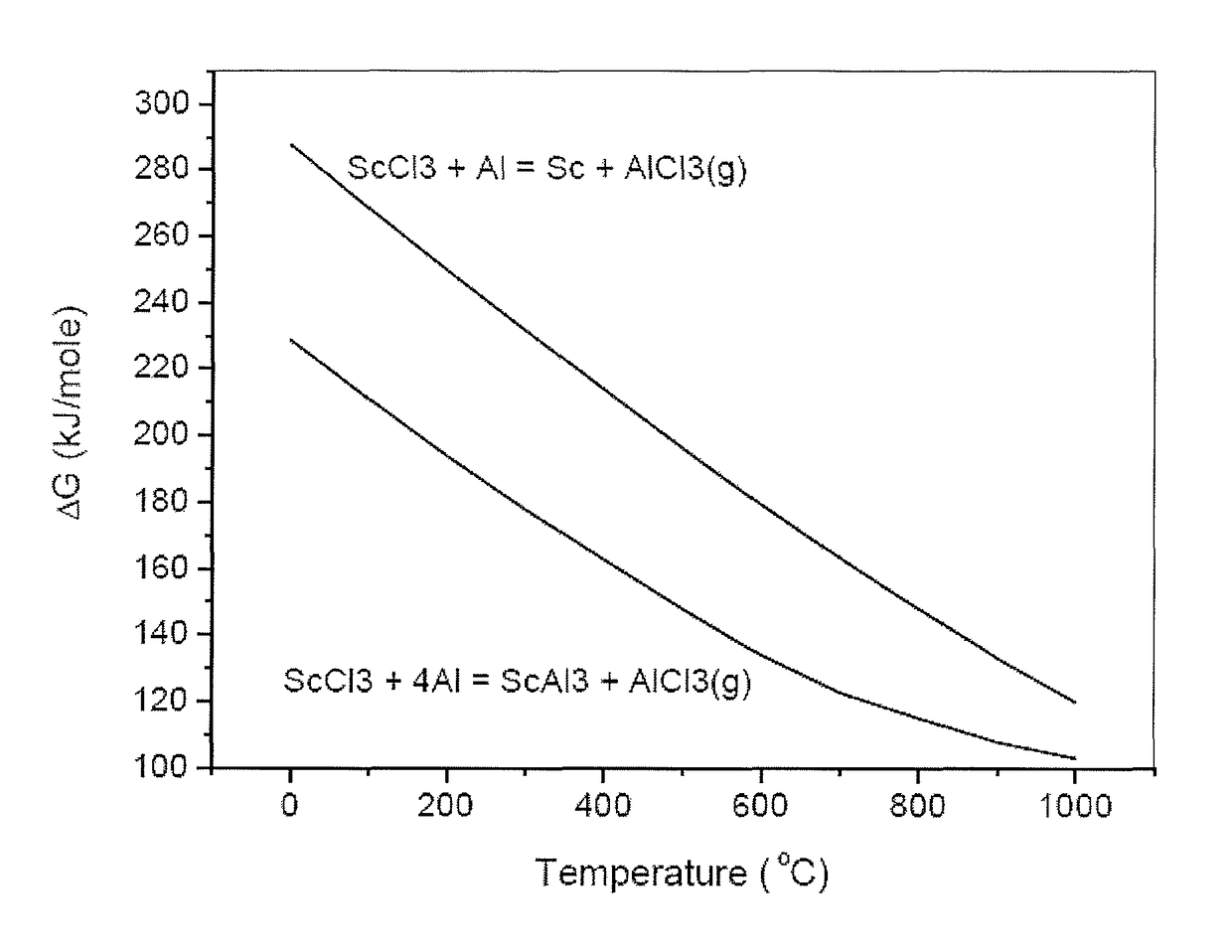

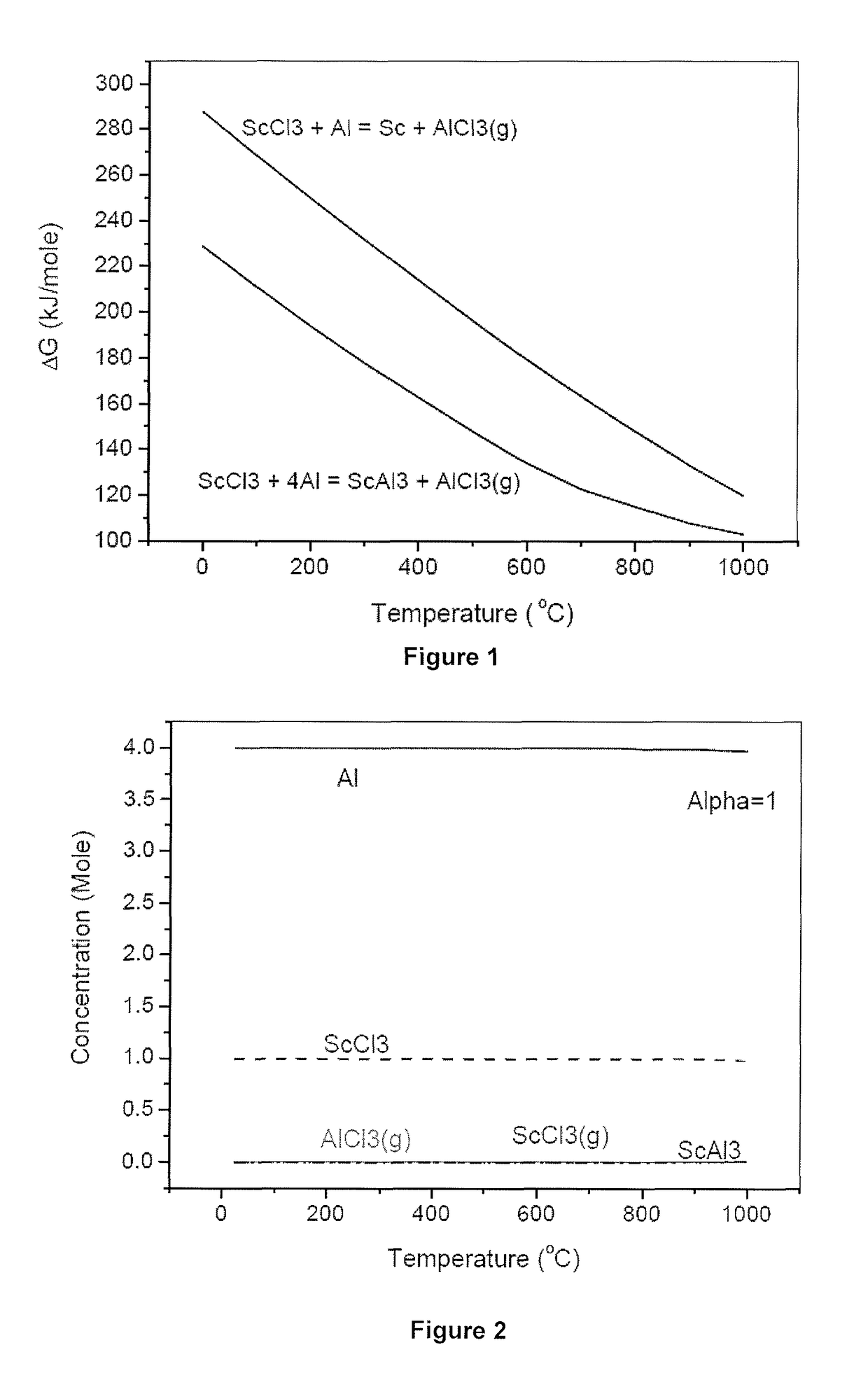

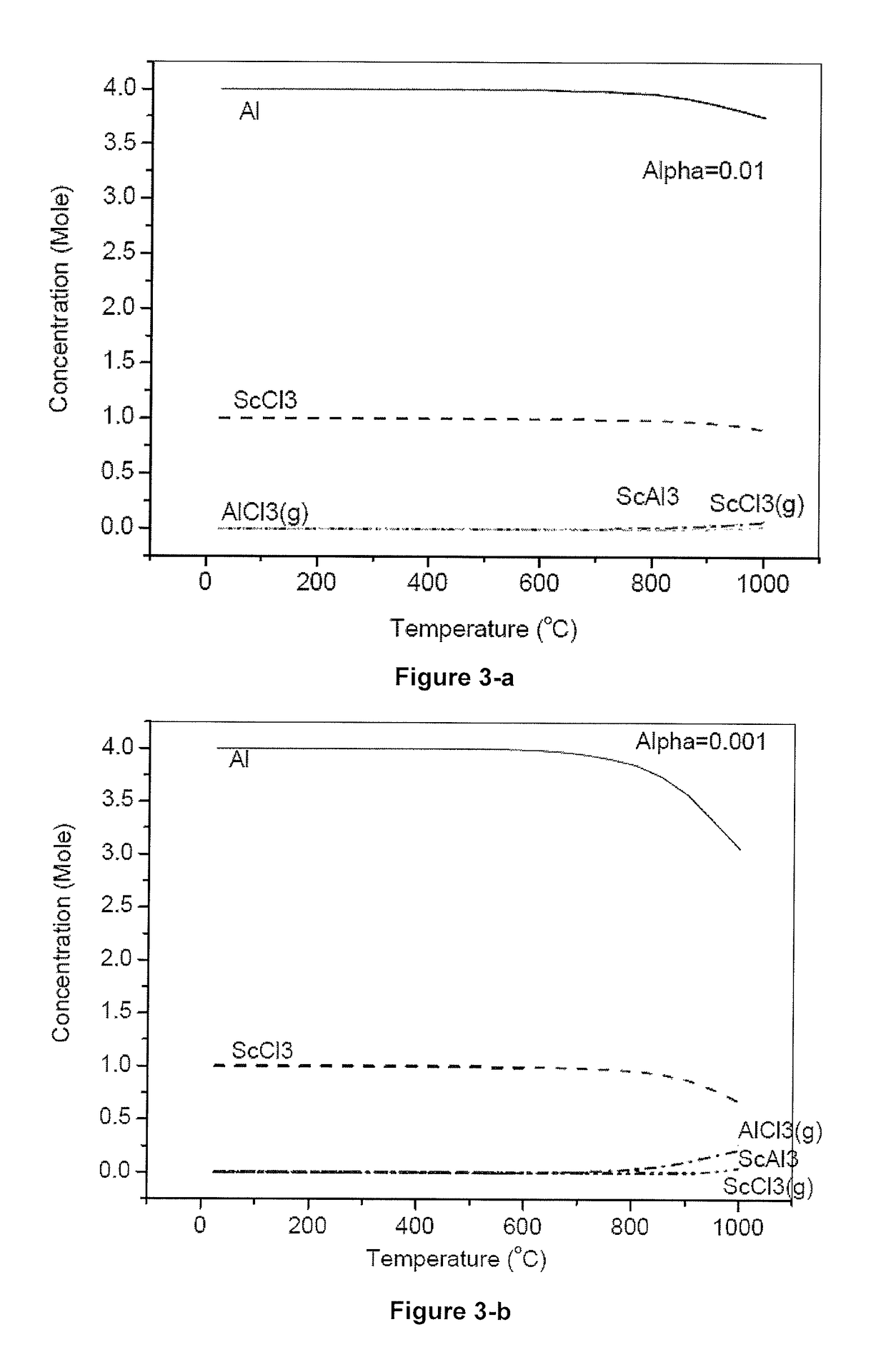

Production of aluminium-scandium alloys

A process for producing an aluminium-scandium based alloy from aluminium and scandium chloride, the process also producing aluminium chloride as a by-product and including the step of reducing scandium chloride in the presence of aluminium in a reaction zone and under reaction conditions which favour production of the aluminium-scandium based alloy.

Owner:COMMONWEALTH SCI & IND RES ORG

Production process of quarternary carbonate powder

InactiveCN1362360ACalcium/strontium/barium carbonatesCarbonate/bicarbonate preparationBarium titanateCarbonate

The production process of quaternary carbonate powder includes the following steps: firstly, making scandium oxide and hydrochloric acid produce reaction to produce scandium chloride, then making thescandium chloride, barium nitrate, strontium nitrate, calcium nitrate and sodium carbonate produce coprecipitation reaction to obtain quaternary carbonate, then making the obtained quaternary carbonate undergo the processes of centrifugal filtering, washing, drying and sieving to obtain the invented finished product. Said product can be coated on the cathode, its transmitted current density can be raised by aboev once as compared with cathode coated with ternary carbonate.

Owner:CAIHONG GRP ELECTRONICS CO LTD

Method for preparing barium scandium tantalate powder

InactiveCN104386750ASimple process routeReduce manufacturing costTantalum compoundsCross-linkBarium salt

The invention discloses a method for preparing barium scandium tantalate powder. The method comprises the steps of thoroughly dissolving a barium salt, a tantalum salt, a scandium salt and different cross-linking agents, which serve as raw materials, into a methanol-water mixture solution, then, carrying out cross-linking reaction at a certain temperature, then, mixing with a molten salt, grinding, so as to thoroughly mix uniformly, carrying out high-temperature reaction, then, cooling to room temperature, and then, carrying out water washing and drying, thereby obtaining the barium scandium tantalate powder, wherein the barium salt is either or a mixture of barium chloride and barium nitrate, the tantalum salt is either or a mixture of tantalum pentachloride and pentaethoxy tantalum, the scandium salt is either or a mixture of scandium chloride and scandium nitrate, the cross-linking agents are either or a mixture of urea and citric acid, and the molten salt is a mixture of sodium chloride and barium chloride. The method has the advantages that the preparation procedures are simplified, the preparation cost is low, the pollution to an environment cannot be caused, industrialized large-scale preparation is facilitated, and the prepared product can be applied to the fields of ferroelectrics, photoelectricity, photocatalytic hydrogen generation, fuel cells and the like.

Owner:BOHAI UNIV

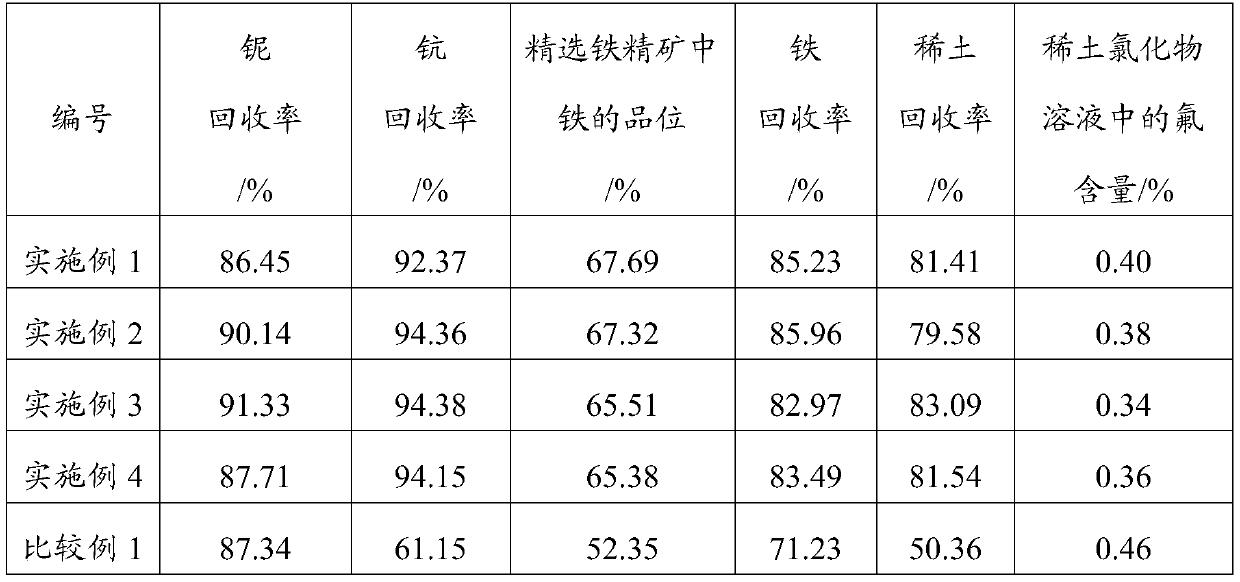

Treatment method for rare earth tailings

ActiveCN111363912AAchieve separationHigh recovery rateProcess efficiency improvementWet separationSlagNiobium

The invention discloses a treatment method for rare earth tailings. The treatment method comprises the following steps that firstly, pretreated rare earth tailings and calcium chloride containing inorganic matter are mixed, a mixed material is obtained, the mixed material is roasted at 480-750 DEG C, roasted smoke and roasted slag are obtained, the roasted smoke is cooled, and a niobium chloride containing product is obtained; secondly, the roasted slag is leached through water, then, solid-liquid separation is conducted, and a rare earth chloride solution and water leaching slag are obtained;thirdly, the water leaching slag is subjected to primary ore grinding and primary magnetic separation, roughing iron concentrates and roughing tailings are obtained, the roughing iron concentrates are subjected to secondary ore grinding and secondary magnetic separation, and finely-selected iron concentrates and finely-selected tailings are obtained; and fourthly, the roughing tailings and the finely-selected tailings are mixed, mixed tailings are obtained, the mixed tailings are leached through hydrochloric acid, then, solid-liquid separation is conducted, and a scandium chloride containingproduct is obtained, wherein the calcium chloride containing inorganic matter comprises calcium chloride, calcium oxide and blind coal. By means of the treatment method, respective recycling of iron,rare earth, niobium and scandium can be achieved.

Owner:BAOTOU RES INST OF RARE EARTHS

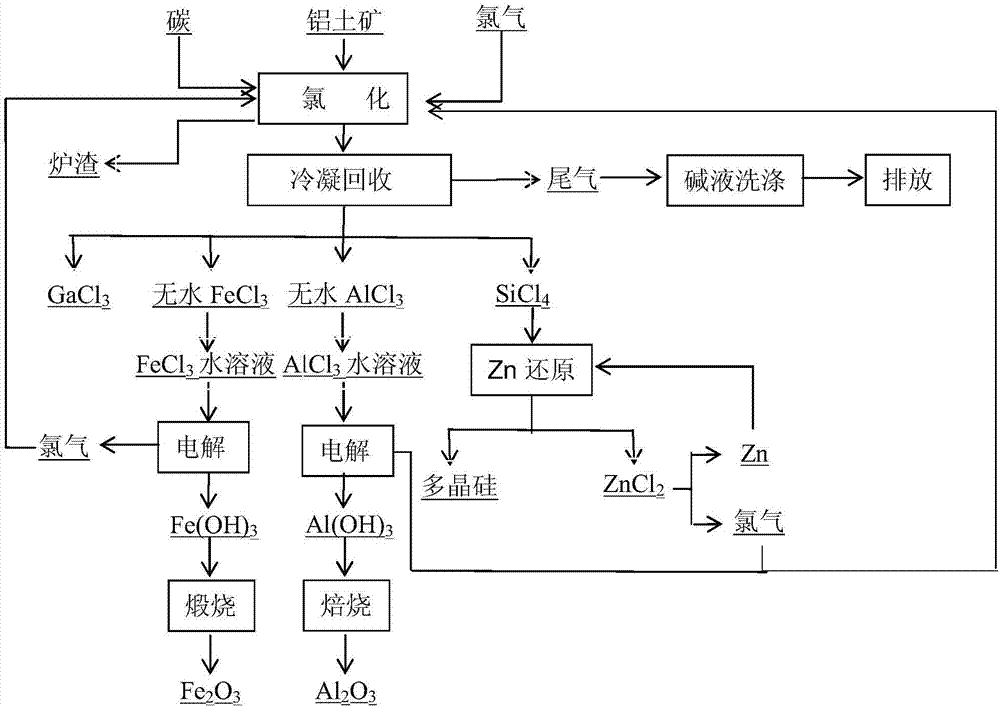

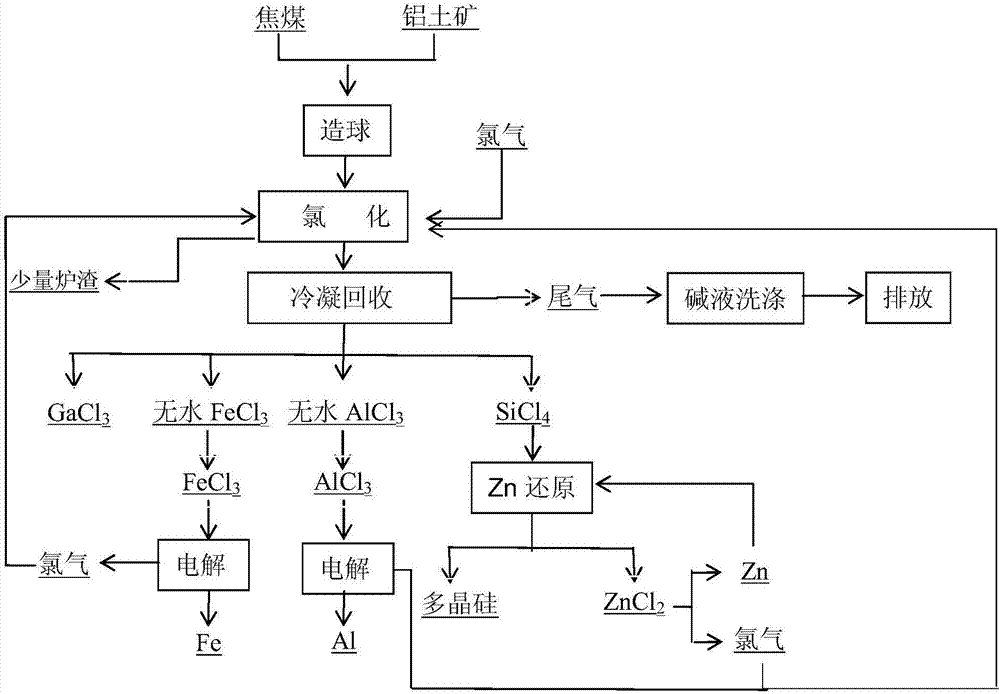

Method for chlorinating and electrolyzing bauxite to prepare alumina and comprehensively utilizing bauxite

InactiveCN107244682AReduce processing linksLow costZinc halidesPolycrystalline material growthFerric hydroxideAluminium chloride

A method for chlorinating and electrolyzing bauxite to prepare alumina and comprehensively utilizing bauxite comprises the following steps: chlorinating and separating chlorite to respectively obtain anhydrous aluminum chloride, anhydrous ferric chloride, silicon tetrachloride, titanium tetrachloride, scandium chloride and gallium chloride; converting the anhydrous aluminum chloride and the anhydrous ferric chloride into an aqueous aluminum chloride solution and an aqueous ferric chloride solution; electrolyzing the corresponding aqueous solutions at a controlled voltage and a controlled current density for a controlled electrolysis time to obtain aluminum hydroxide, ferric hydroxide, hydrogen and chlorine; returning the chlorine to the above chlorination section; calcining the aluminum hydroxide to obtain metallurgical grade / chemical grade alumina; calcining the ferric hydroxide to obtain iron red or other iron-containing products; rectifying and purifying the silicon tetrachloride to generate polysilicon and zinc chloride; refining the titanium tetrachloride to form a sponge titanium raw material; and enriching the scandium chloride in chloride residues to obtain a scandium extraction raw material. The method has the advantages of low cost, cheap and easily available raw materials, simple operating process, high automation degree, high product purity, and realization of recycling of zinc, chlorine and other raw materials.

Owner:NORTHEASTERN UNIV

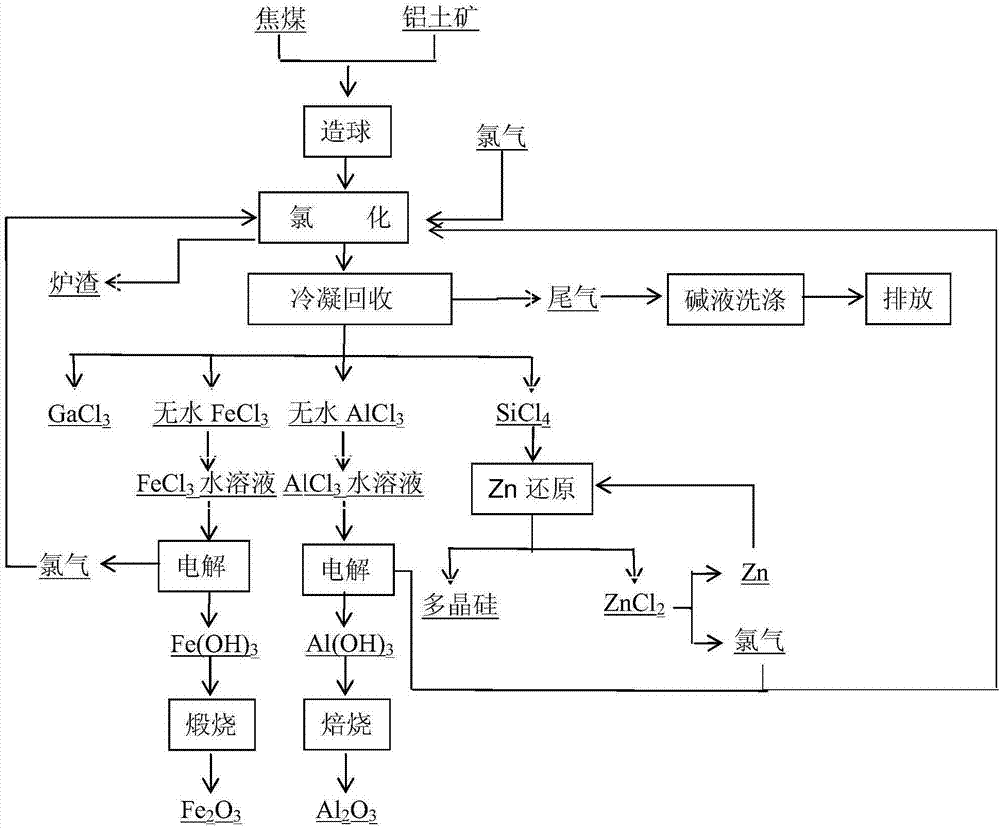

Method for preparing and comprehensively utilizing aluminum oxide by pelletizing, chloridizing and electrolyzing bauxite

ActiveCN107235499AReduce processing linksLow costAfter-treatment apparatusZinc halidesFerric hydroxideElectrolysis

The invention relates to a method for preparing and comprehensively utilizing aluminum oxide by pelletizing, chloridizing and electrolyzing bauxite. The method comprises the following steps: mixing bauxite, a carbon source and kaolin at a ratio; adding a binder and water, pelletizing and airing; chloridizing, separating and purifying, thereby obtaining anhydrous aluminum chloride, anhydrous ferric chloride, silicon tetrachloride, titanium tetrachloride, scandium chloride and gallium trichloride; converting anhydrous aluminum chloride and anhydrous ferric chloride into a corresponding chloride solution; controlling voltage and current density to electrolyze, thereby obtaining aluminum hydroxide, ferric hydroxide, hydrogen and chlorine; returning the chlorine to a chloridizing section; roasting aluminum hydroxide, thereby obtaining metallurgical / chemical aluminum oxide; roasting ferric hydroxide, thereby obtaining iron oxide red or other iron-containing products; purifying silicon tetrachloride; refining titanium tetrachloride, thereby obtaining a titanium sponge raw material; and enriching scandium chloride to serve as a scandium raw material. The method provided by the invention is low in cost, the raw materials are low-cost and are easily obtained, the complete chlorination is realized through pelletizing and chloridizing, the operation process is simple, the degree of automation is high, the product purity is high, and the raw materials, such as, chlorine and zinc, can be reused.

Owner:NORTHEASTERN UNIV

Silica-gel bionic bait outside coloring method

The invention discloses a silica-gel bionic bait outside coloring method. The silica-gel bionic bait outside coloring method comprises the following operation steps that 1, the surface of a prepared and formed silica-gel bionic bait is cleaned thoroughly, and then the silica-gel bionic bait is put in modification liquid for full soaking; 2, methyl methacrylate, butyl acrylate, 3-methoxyl methyl acrylate, deionized water, an emulgator and an initiator are mixed evenly, then the mixture is subjected to heat preservation treatment at the temperature of 88-92 DEG C for 3-4 hours, and then an acrylic emulsion is prepared; 3, promethium chloride and scandium chloride are added into water, then sodium naphthenate is added into the water, even mixing and stirring are performed, then the temperature of the mixture rises to 115-120 DEG C, and heat preservation treatment is performed to obtain rare earth naphthenates; 4, the acrylic emulsion, pigment, polyglycerol stearate, the rare earth naphthenates, a dispersing agent, xanthomonas campestris glue and sodium formaldehyde sulfoxylate are evenly mixed to obtain a silica-gel bionic bait coating. The silica-gel bionic bait prepared by adoptingthe method is excellent in water soaking resisting performance and quality, and a fading or color change phenomenon is not likely to occur.

Owner:界首市黑马渔具有限公司

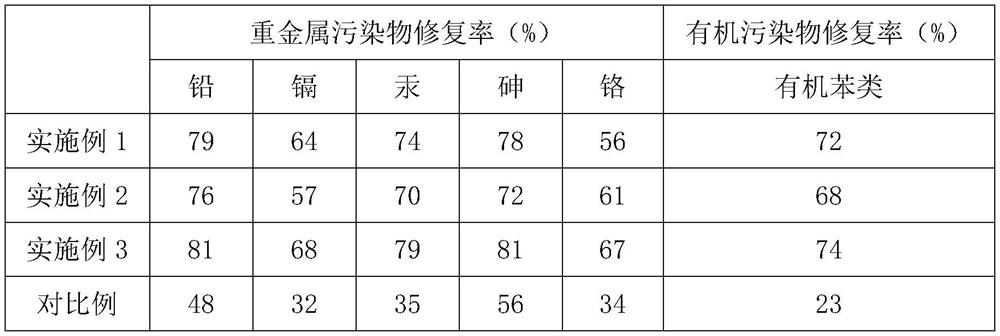

Garden soil ecological restoration agent and preparation method thereof

PendingCN114774132AImprove repair effectLarge specific surface areaOrganic fertilisersSoil conditioning compositionsWater chlorinationCarboxylic acid

The invention discloses a garden soil ecological restoration agent preparation method, which comprises: 1, washing vermiculite particles, grinding into powder, and screening; 2, dissolving diboron trioxide in an acid solution, and mixing with a scandium trichloride solution under the condition of an adhesive; 3, the solid mixture is placed in a tubular furnace to be subjected to high-temperature roasting treatment, and scandium diboride / expanded vermiculite is obtained; step 4, treating scandium diboride / expanded vermiculite by using dicarboxylic acid; step 5, carrying out acylating chlorination on the carboxylated scandium diboride / expanded vermiculite; 6, trimethoprem reacts with scandium diboride acylating chloride / expanded vermiculite, and the garden soil ecological restoration agent is obtained. The ecological restoration agent has a good restoration effect on soil, and inorganic pollutants and organic pollutants in the soil can be restored at the same time.

Owner:GUANGDONG BAILIN GARDEN CONSTR CO LTD

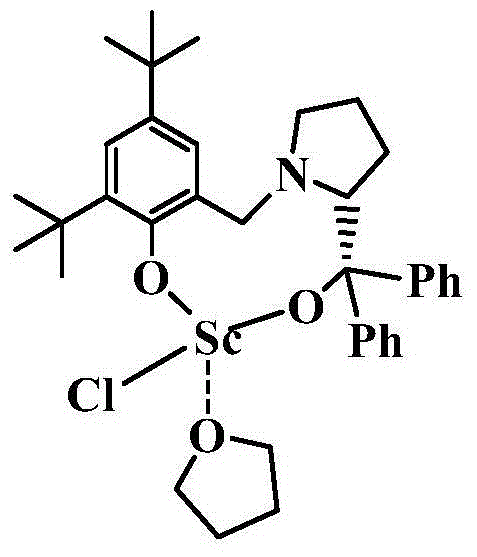

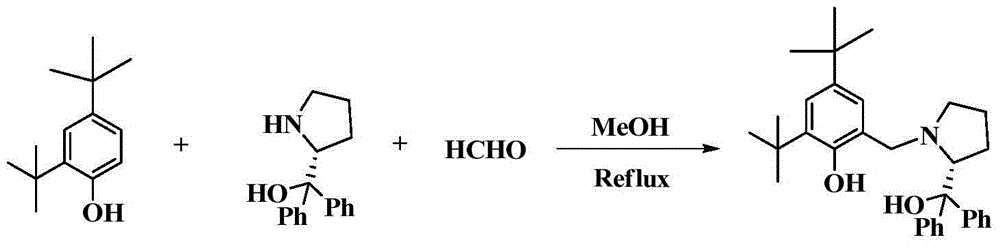

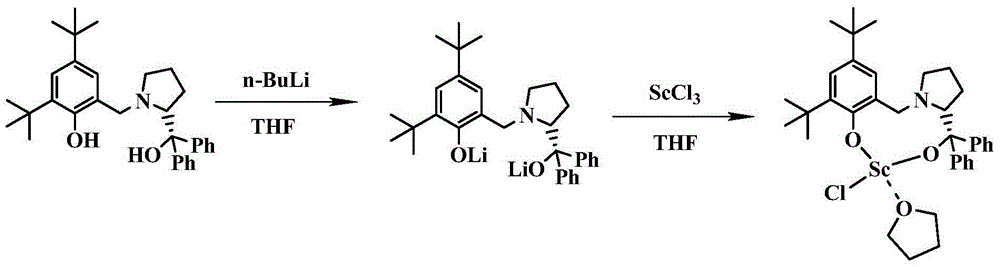

Chiral bridged aryloxyalkyloxy scandium chloride, and preparation method and application thereof

InactiveCN103951686AHigh catalytic activityHigh enantioselectivityOrganic-compounds/hydrides/coordination-complexes catalystsGroup 5/15 element organic compoundsHydrogenStructural formula

The invention discloses a chiral bridged aryloxyalkyloxy scandium chloride. The chiral bridged aryloxyalkyloxy scandium chloride is characterized in that the chiral bridged aryloxyalkyloxy scandium chloride has a general formula of LScCl(THF), and has a chemical structural formula shown in the specification, and L is (S)-2,4-di-tert-butyl-6-((2-(hydroxydiphenylmethyl)pyrrolidin-1-yl)methyl)-phenolate. The above compound has the advantages of simple synthesis, clear structure and high yield. The invention also provides a preparation method of the compound, and an application method of the compound in the catalysis of the asymmetric hydrogen phosphorization reaction of alpha, beta-unsaturated ketone as a catalyst. The application method has the advantages of mild conditions, high selectivity, good antipodal selectivity and wide substrate adaptation range.

Owner:ZHANGJIAGANG INST OF IND TECH SOOCHOW UNIV

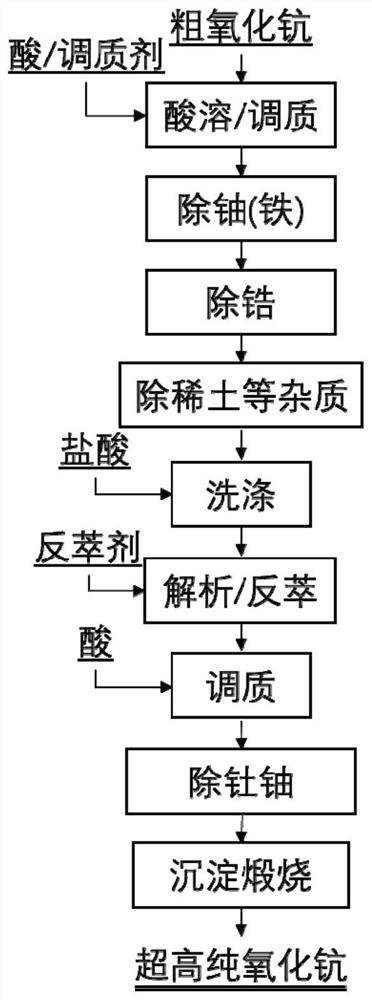

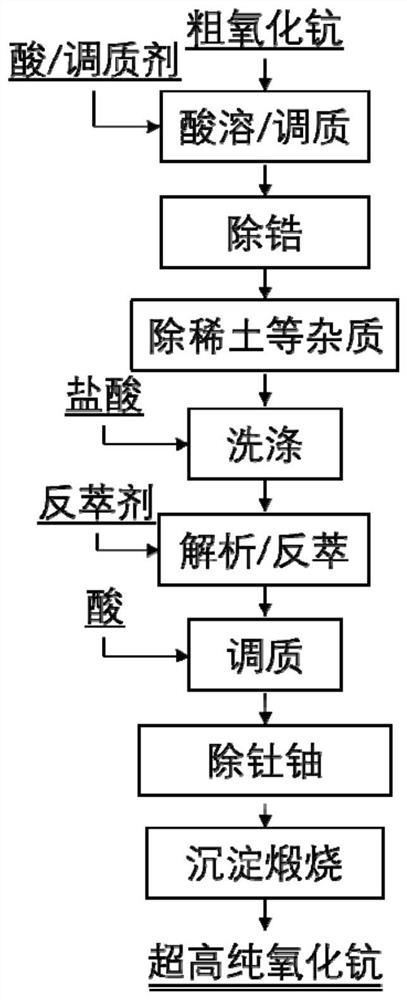

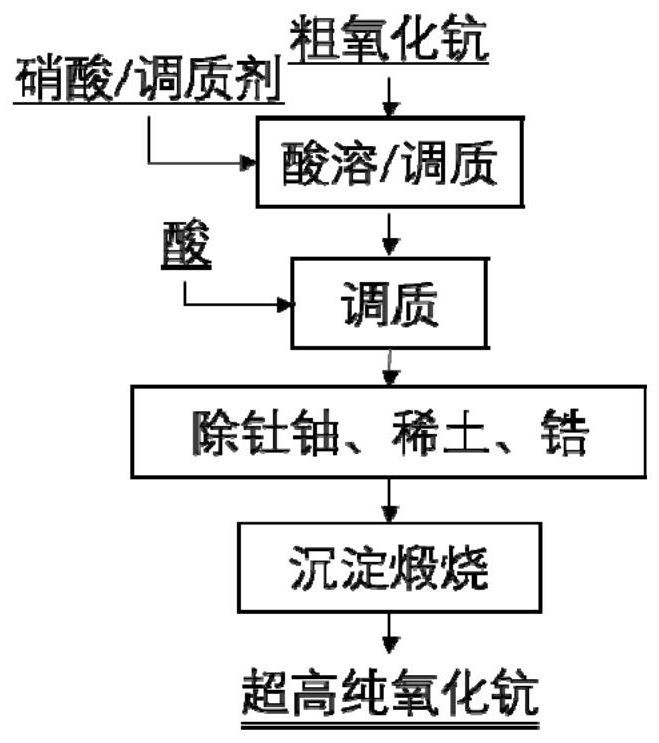

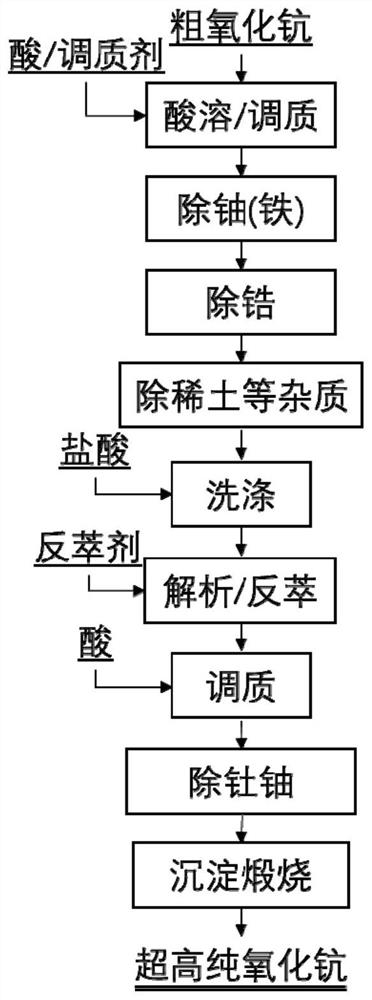

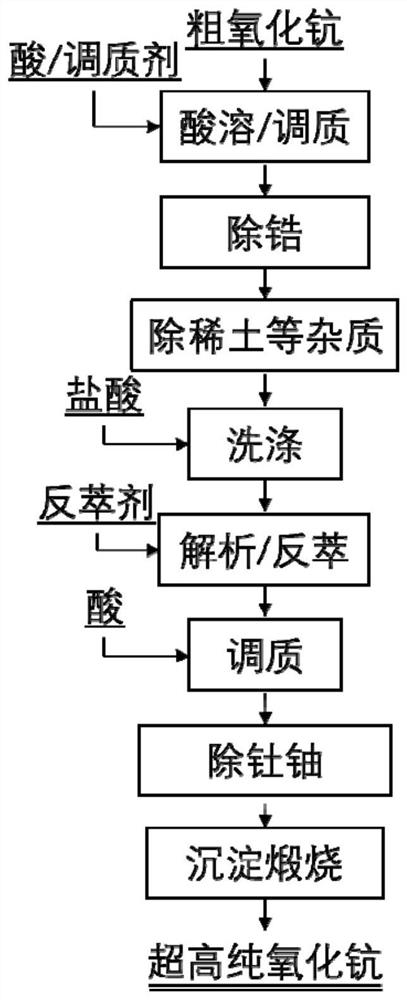

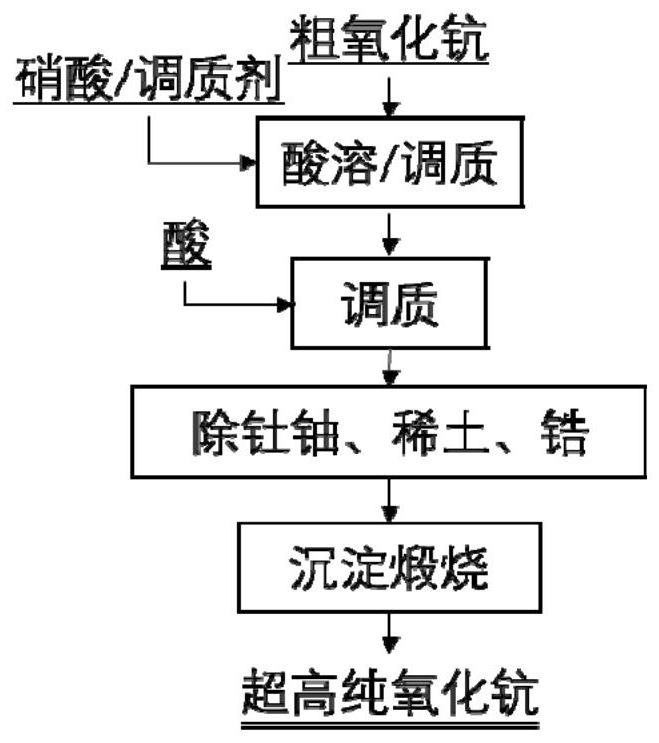

Preparation method and application of ultra-pure scandium oxide

ActiveCN113371751AAchieve removalReduce consumptionScandium oxides/hydroxidesRare earth metal compounds preparation/treatmentTrace elementAcid dissolution

The invention discloses a preparation method and application of ultra-pure scandium oxide. The preparation method comprises the following steps of: carrying out acid dissolution on coarse scandium oxide or scandium chloride; hardening and tempering by adopting strong acid, and purifying by adopting an extracting agent and / or extraction resin after hardening and tempering; and purifying and precipitating to obtain the ultra-pure scandium oxide. According to the method, rare earth impurity elements and common trace elements in scandium oxide can be removed, and deep removal of difficult-to-remove trace uranium and thorium elements and trace impurities including zirconium and titanium in scandium oxide can also be achieved; and the method is simple in operation process, has high practical operability, does not involve organic, weak base or strong base reverse extraction, does not cause scandium loss, and can reduce the initial equipment investment cost and energy consumption.

Owner:CHINA ENFI ENGINEERING CORPORATION

Method for producing high-purity metal scandium from low-purity scandium oxide enrichment

InactiveCN111172413AIncrease incomeHigh purityProcess efficiency improvementDistillationScandium fluoride

The invention discloses a method for producing high-purity metal scandium from low-purity scandium oxide enrichment. The method comprises the following steps that the low-purity scandium oxide enrichment is dissolved to obtain a solution A; the solution A is hydrolyzed, and filtrate is collected; ammonia sink is carried out, and scandium hydroxide precipitate is collected; the scandium hydroxide precipitate is dissolved to obtain a scandium chloride solution; industrial grade sodium fluoride is added into the scandium chloride solution, stirring is carried out for a certain time, and scandiumfluoride precipitate is obtained; high-temperature dehydration is carried out obtain scandium fluoride; reduced scandium is prepared to obtain the crude reduced metal scandium; and high-purity metal scandium is prepared, the crude reduced metal scandium is subjected to low-temperature distillation, high temperature distillation is carried out, and finally sub-high temperature distillation is carried out to obtain the high-purity metal scandium. The adopted raw materials are low-purity scandium oxide enrichment with the scandium oxide content of 3%-5%, the cost is low, and obtaining is easy; and the adopted method is simple to operate, and high-purity metal scandium can be obtained. According to the method, the production cost is reduced, large-scale industrialization is facilitated, and the income of enterprises is improved.

Owner:湖南金坤新材料有限公司

Production of aluminium-scandium alloys

A process for producing an aluminum-scandium based alloy from aluminum and scandium chloride, the process also producing aluminum chloride as a by-product and including the step of reducing scandium chloride in the presence of aluminum in a reaction zone and under reaction conditions which favor production of the aluminum-scandium based alloy.

Owner:COMMONWEALTH SCI & IND RES ORG

Method for preparing metal aluminum through bauxite pelletizing, chlorination and electrolysis and comprehensively utilizing bauxite

InactiveCN107236969AReduce processing linksLow costZinc halidesElectrolysis componentsElectrolysisMixed materials

A method for preparing metal aluminum through bauxite pelletizing, chlorination and electrolysis and comprehensively utilizing bauxite comprises the following steps that the bauxite, a carbon source and a kaolin ingredient are fetched according to a ratio and evenly mixed, so that a mixed material is obtained, and a binder and water are added to the mixed material, wherein the mass of the binder accounts for 1.0%-2.0% of the total mass of the mixed material, and the mass of the water accounts for 2.0%-5.0% of the total mass of the mixed material; even mixing is conducted, pelletizing and air drying are conducted; chlorination and separation are conducted on the pellets, so that anhydrous aluminum chloride, anhydrous ferric chloride, silicon tetrachloride, titanium tetrachloride, scandium chloride and gallium chloride are obtained; the anhydrous aluminum chloride is directly electrolyzed, so that metal aluminum and chlorine are obtained; the chlorine returns to the chlorination stage; the silicon tetrachloride is further purified; the titanium tetrachloride is refined to be used as a raw material of titanium sponge; and the scandium chloride is enriched in chlorination residues to be used as a scandium extraction raw material. According to the method, the cost is low, the raw materials are low in price and easy to obtain, through pelletizing chlorination, a chlorination reaction is complete, the operation process is easy, the automation degree of electrolysis is high, the prepared metal aluminum has high purity, and chlorine, zinc and other raw materials can be circularly utilized.

Owner:NORTHEASTERN UNIV LIAONING

A kind of hydrochloric acid leaching bauxite hydrochloric acid leaching step by step electrolysis to prepare alumina and its comprehensive utilization method

ActiveCN107128959BHigh degree of automationHigh purityAluminium compoundsElectrolysis componentsAluminium chlorideElectrolysis

A step-by-step electrolytic preparation of alumina by hydrochloric acid leaching of bauxite and a comprehensive utilization method, including the following steps: after hydrochloric acid leaching, solid-liquid separation and purification of bauxite, a ferric chloride mixed solution and an aluminum chloride mixed solution are obtained ; Separate and purify the aluminum chloride mixed solution and the ferric chloride mixed solution respectively to obtain scandium chloride and gallium chloride, as well as aluminum chloride and ferric chloride aqueous solutions; set the electrolysis voltage and current density to combine aluminum chloride and chloride The aqueous iron solution undergoes two-step electrolysis to obtain aluminum hydroxide, hydrogen and chlorine respectively; iron hydroxide, hydrogen and chlorine; the generated hydrogen and chlorine are prepared into hydrochloric acid solution and returned to the leaching section for recycling; aluminum hydroxide is roasted to obtain metallurgical grade alumina or the chemical aluminum oxide. The present invention uses an electrolytic method to recover alumina in bauxite. Compared with the traditional acid method, the present invention eliminates evaporation, concentration and equipment, simplifies operations, greatly reduces costs, and the product has higher purity.

Owner:NORTHEASTERN UNIV LIAONING

Preparation method and application of ultra-high purity scandium oxide

ActiveCN113371751BAchieve removalReduce consumptionScandium oxides/hydroxidesRare earth metal compounds preparation/treatmentTrace elementStrong acids

The invention discloses a preparation method and application of ultra-high-purity scandium oxide. The preparation method includes: acid-dissolving crude scandium oxide or scandium chloride; quenching and tempering with strong acid, and purifying by extracting agent and / or leaching resin after quenching and tempering; and obtaining ultra-high-purity scandium oxide by precipitation after purification. The invention can not only realize the removal of rare earth impurity elements and common trace elements in scandium oxide, but also realize the deep removal of difficult-to-remove trace uranium and thorium elements and trace impurities of zirconium and titanium in scandium oxide; and the operation process of the invention is simple and has strong performance. Practical, no organic, weak base or strong base stripping is involved, no scandium loss will be caused, and the initial equipment investment cost and energy consumption can be reduced.

Owner:CHINA ENFI ENGINEERING CORPORATION

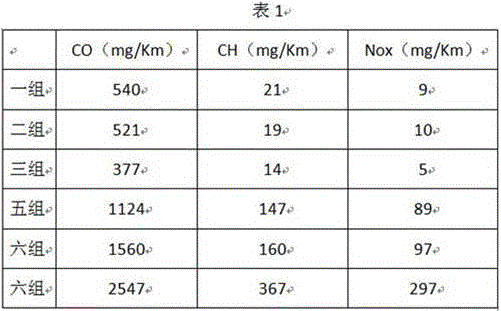

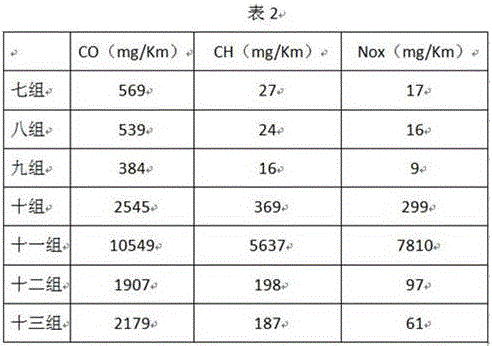

Three-way catalyst and preparation method thereof

InactiveCN106423298AImprove thermal stabilityReduce carbon depositionGas treatmentInternal combustion piston enginesRare-earth elementCross-link

The invention relates to the field of catalysts, in particular to a three-way catalyst and a preparation method thereof. The three-way catalyst comprises the following raw materials in parts by weight: 1-10 parts of lanthanum chloride, 1-10 parts of scandium chloride, 5-8 parts of polyvinylpyrrolidone, 20-30 parts of titanium dioxide, 15-25 parts of ceramics, 15-25 parts of silica gel, 1-5 parts of sodium sulfate, 4-8 parts of palladium sulfate, 5-7 parts of cerium chloride, 15-25 parts of zirconium dioxide, 15-20 parts of gamma-Al2O3 and 1-5 parts of a cross-linking agent. The three-way catalyst and the preparation method thereof provided by the invention have the benefits that through adding rare earth elements: lanthanum, scandium and cerium, the heat stability of B acid in the catalyst can be improved, so that the active tetragonal zirconium dioxide and titanium dioxide are more stable; the center strength and the density of surface acid are adjusted, the anti-toxic ability is increased, the mechanical strength is improved, and the carbon deposition phenomenon of the surface of the catalyst and the loss of heavy metals are delayed.

Owner:SHANDONG POLYTECHNIC COLLEGE

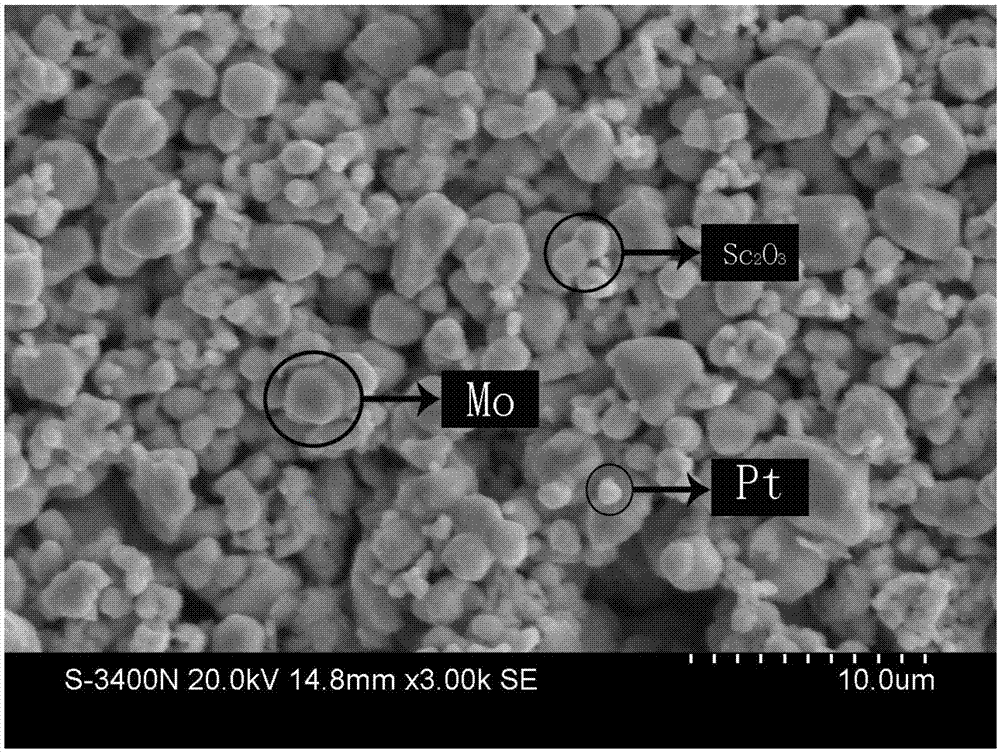

Fireproof filler based on molybdenum waste and fireproof coating

ActiveCN105440768ASolve the emission problemReduce pollutionFireproof paintsAnti-corrosive paintsIsobutanolFire prevention

The invention provides fireproof filler based on molybdenum waste and a fireproof coating. The fireproof coating comprises a film-forming agent, a carbonizing agent, a catalytic dehydration agent and a foaming agent and further comprises the fireproof filler based on molybdenum waste. According to the fireproof filler based on the molybdenum waste, sol is formed with molybdenum waste as a main material and chloroplatinic acid, scandium chloride hexahydrate, anhydrous isobutanol and diethanol amine as auxiliary materials, precursor sol is obtained after evaporation condensation, the precursor sol is dried at high temperature and ground, and the fireproof filler is prepared. The fire-retarding and corrosion-resistant fireproof coating which can effectively solve the problem of release of harmful gas in the heating process is provided to overcome defects about fireproof and corrosion-resistant effects and release of toxic and harmful gas decomposed during heating in the fire prevention process. With the adoption of the fireproof filler and the fireproof coating, environmental pollution can be reduced, and secondary recycling of the molybdenum waste can be realized.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Preparation method for scandium yttrium aluminate powder

InactiveCN104229858ASimple process routeReduce manufacturing costRare earth metal compoundsMetal/metal-oxides/metal-hydroxide catalystsMethanol waterFuel cells

The invention discloses a preparation method for scandium yttrium aluminate powder. The preparation method comprises the following steps: fully dissolving yttrium salts, scandium salts and different cross-linking agents as raw materials in a methanol and water mixing solution; then performing a cross-linking reaction on the mixture at certain temperature; mixing the reacted mixture with fused salts and grinding for fully and uniformly mixing the mixture; finally, performing high-temperature calcination treatment and washing drying to obtain the scandium yttrium aluminate powder, wherein the mole ratio of the yttrium salts to the scandium salts to the fused salts to the cross-linking agents is 1:1:2:10-200; the yttrium salts are one of yttrium chloride and yttrium nitrate or the mixture of the yttrium chloride and the yttrium nitrate; the scandium salts are one of scandium chloride or scandium nitrate or the mixture of the scandium chloride and the scandium nitrate; the cross-linking agents are one of urine or citric acid or the mixture of the urine and the citric acid. The preparation method disclosed by the invention has the advantages of simplicity, convenience, feasibility, high purity, low impurity content, low preparation cost of products and suitability for batch production. The prepared products can be applied to the fields of ferroelectricity, photoelectricity, photocatalysis, fuel cells and the like.

Owner:BOHAI UNIV

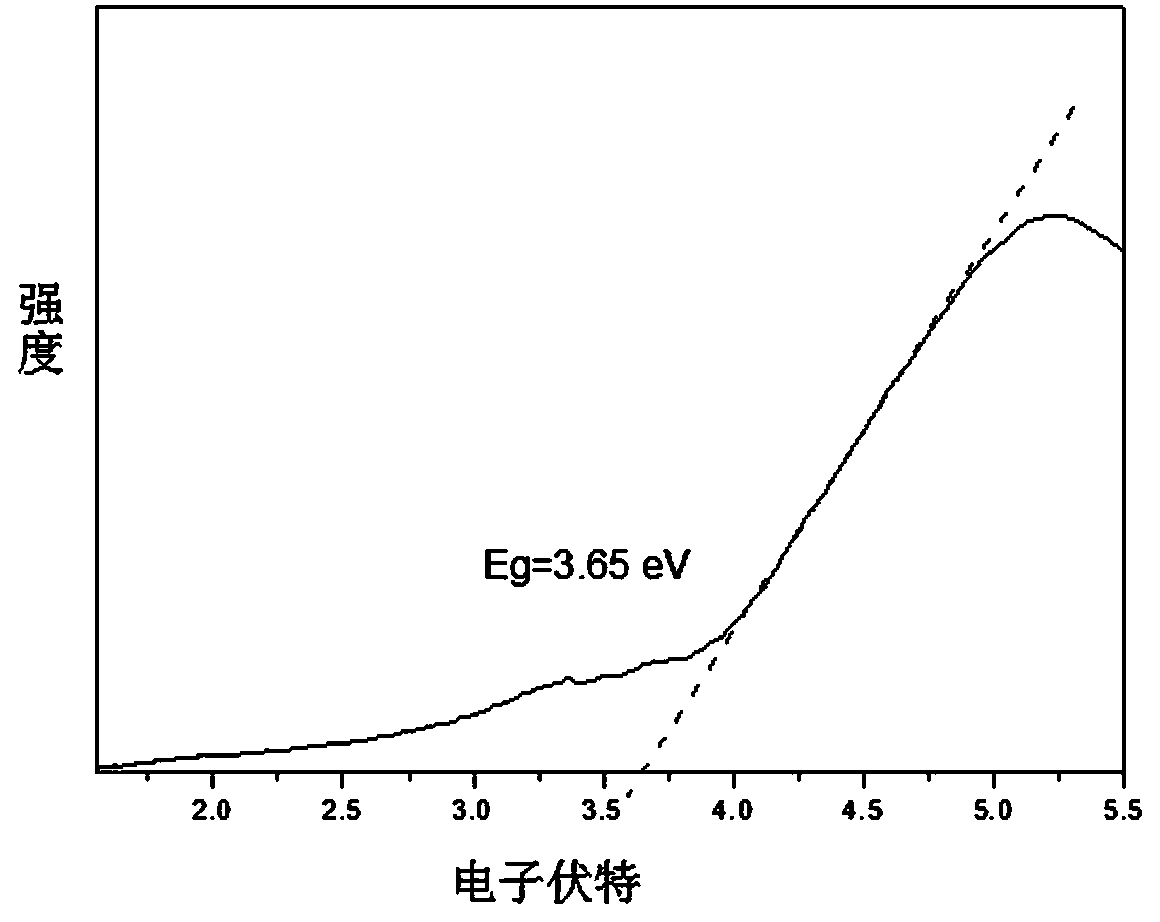

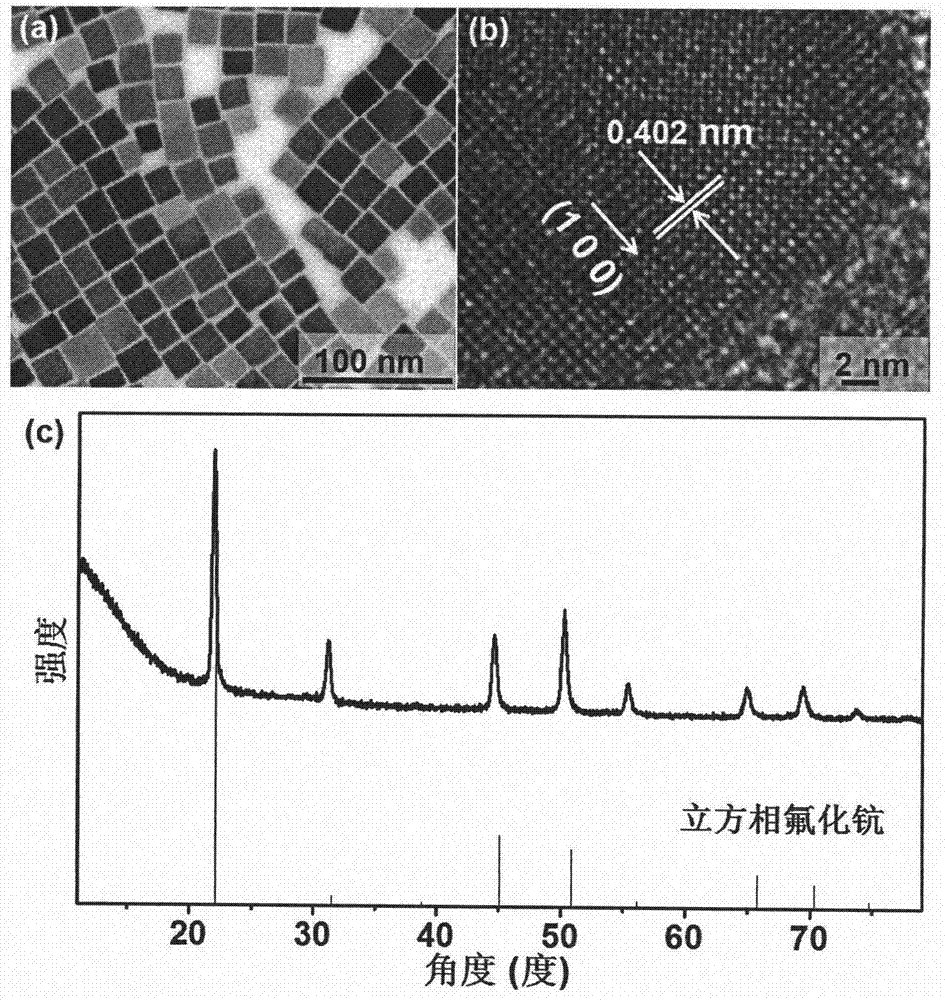

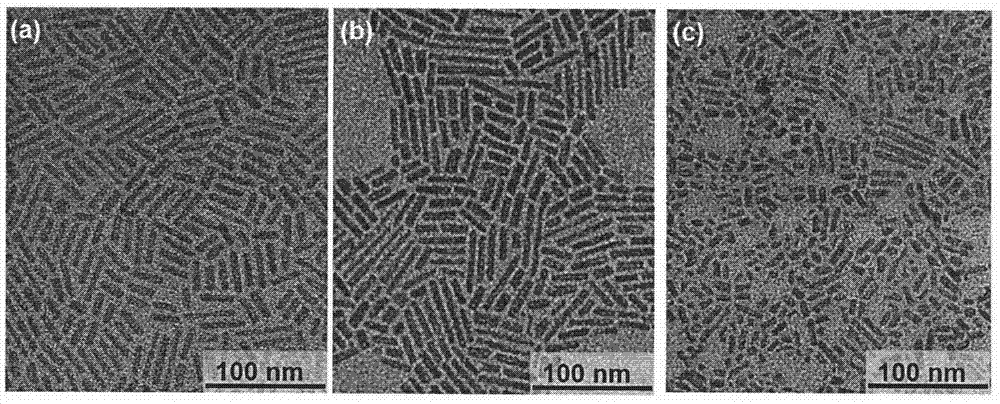

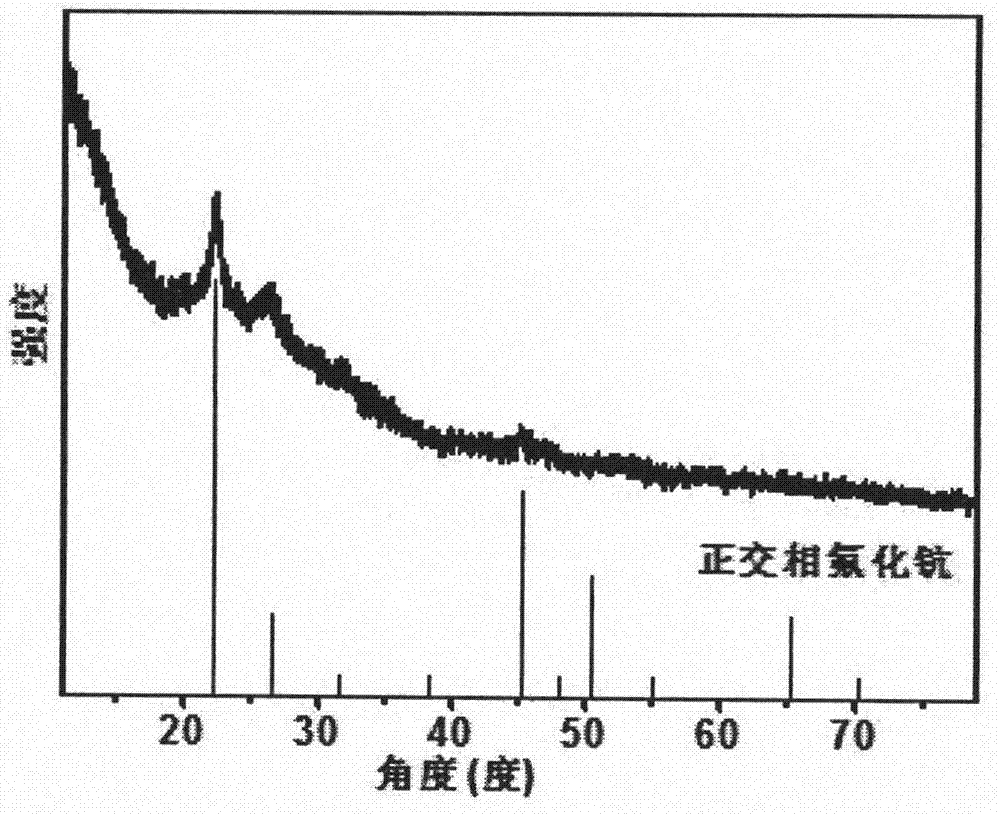

Method for preparing scandium fluoride nanocrystal and regulating crystalline phase at low temperature and normal pressure

InactiveCN107043120AMaterial nanotechnologyRare earth metal fluoridesReaction temperatureScandium fluoride

The invention belongs to the technical field of preparation of nanometer materials and in particular relates to controllable synthesis of scandium fluoride nanoparticles of three crystalline phases and crystalline phase control. The method comprises the following steps: taking anhydrous scandium chloride and ammonium fluoride as raw materials, taking oleate as a reaction solvent, and reacting at different temperatures for a certain time so as to obtain the scandium fluoride nanoparticles of different crystalline phases; and cleaning the reaction product with ethanol, performing centrifugal precipitation to obtain a purified sample, dispersing the sample in cyclohexane, and preserving for later use. In the preparation process, the scandium fluorides of three different crystalline phases can be obtained by changing the reaction temperatures only, and conversion from a tetragonal phase to an orthogonal phase or a cubic phase and conversion from the orthogonal phase to the cubic phase can be realized under the low-temperature normal-pressure conditions. According to the method disclosed by the invention, the scandium fluorides of three crystalline phases are prepared by thermal co-precipitation, mutual conversion of the crystalline phases under the low-temperature normal-pressure conditions can be realized, the method is simple in operation process and post-treatment, short in reaction period, low in cost, non-toxic and pollution-free, and fundamental research of a scandium nanometer material is greatly perfected.

Owner:NANJING TECH UNIV

Preparation method of iron-carbon micro-electrolysis filler for retarding formation of isolating layer through rare earth carbonization

PendingCN114084935AEnhance electrolytic conductivityImprove electrolysis efficiencyWater/sewage treatmentElectrolysisCarbonization

The invention discloses a preparation method of an iron-carbon micro-electrolysis filler for retarding formation of an isolating layer through rare earth carbonization. The preparation method comprises the following steps: mixing and sintering metal powder; grinding a mixed metal block; preparing paste; coating and carbonizing; and pelleting. The iron-carbon micro-electrolysis filler is reasonable in design, grains of an electrolytic coating are refined, uniform and compact, formation of large grains of the electrolytic coating is reduced, formation of an isolating layer is slowed down, the service life of the iron-carbon micro-electrolysis filler is prolonged, meanwhile, the used iron-carbon micro-electrolysis filler can be decomposed under the action of deliquescent scandium chloride powder in air, hardening after cleaning and stacking is avoided, the porous firmness performance of the surface of the iron-carbon micro-electrolysis filler can be improved by adopting a mold pelleting mode, the outermost surface of the iron-carbon micro-electrolysis filler does not contain metal elements, and the condition of bonding hardening between the iron-carbon micro-electrolysis filler caused by metal passivation can be avoided.

Owner:山东北方三潍环保科技有限公司

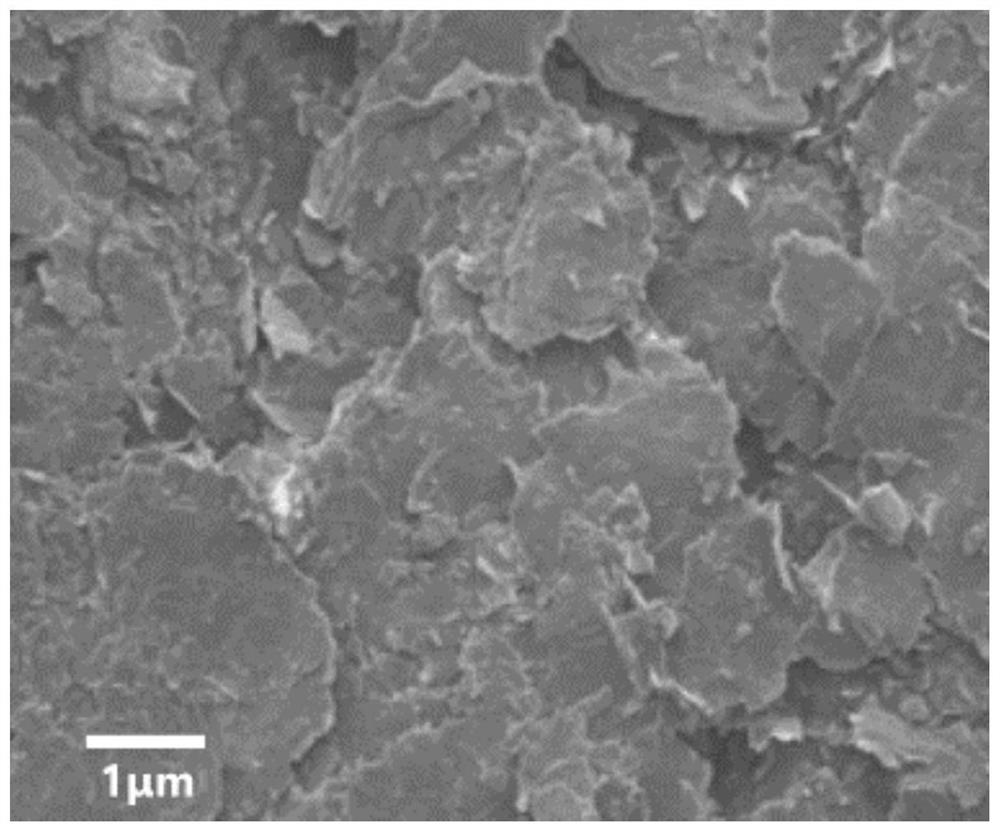

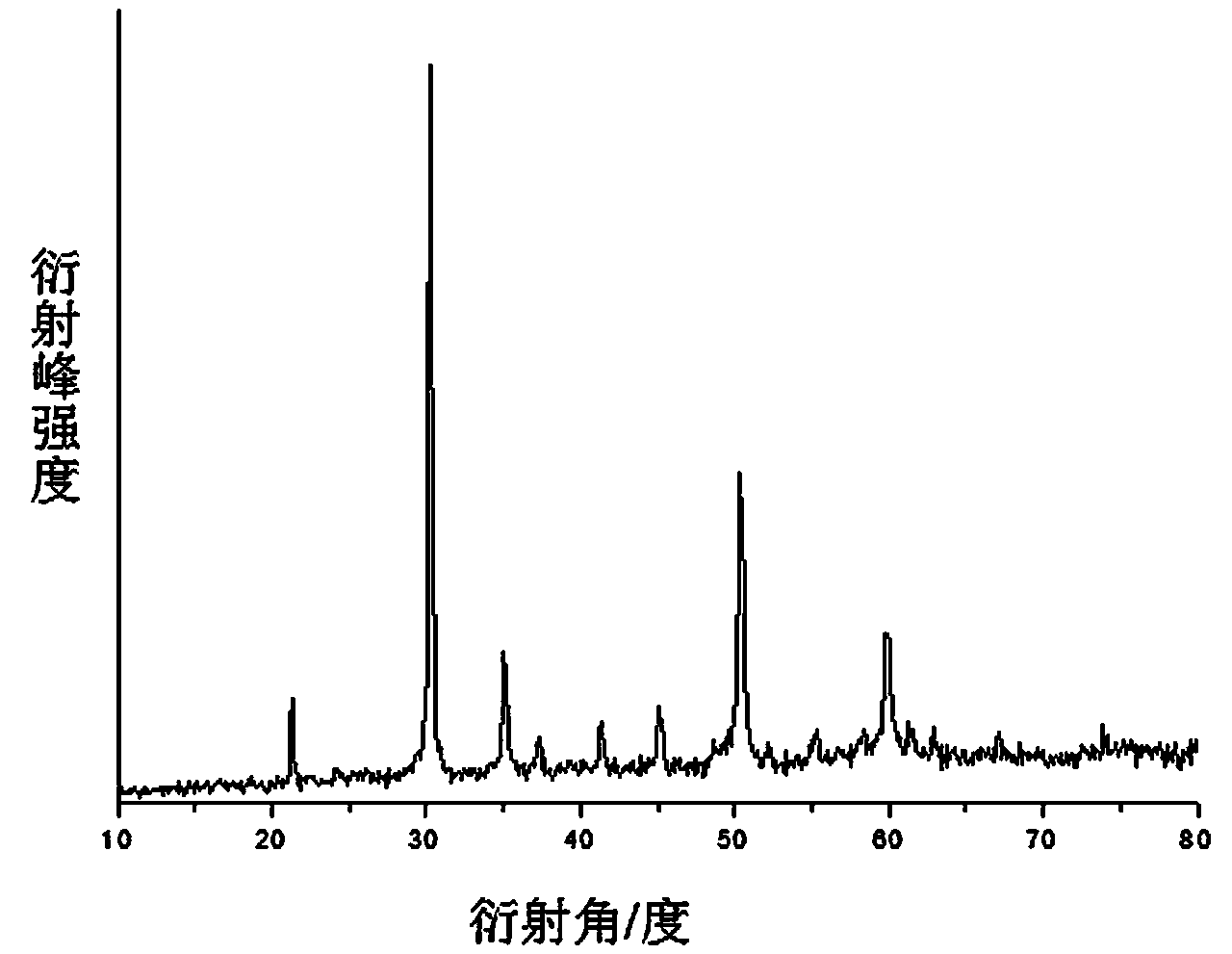

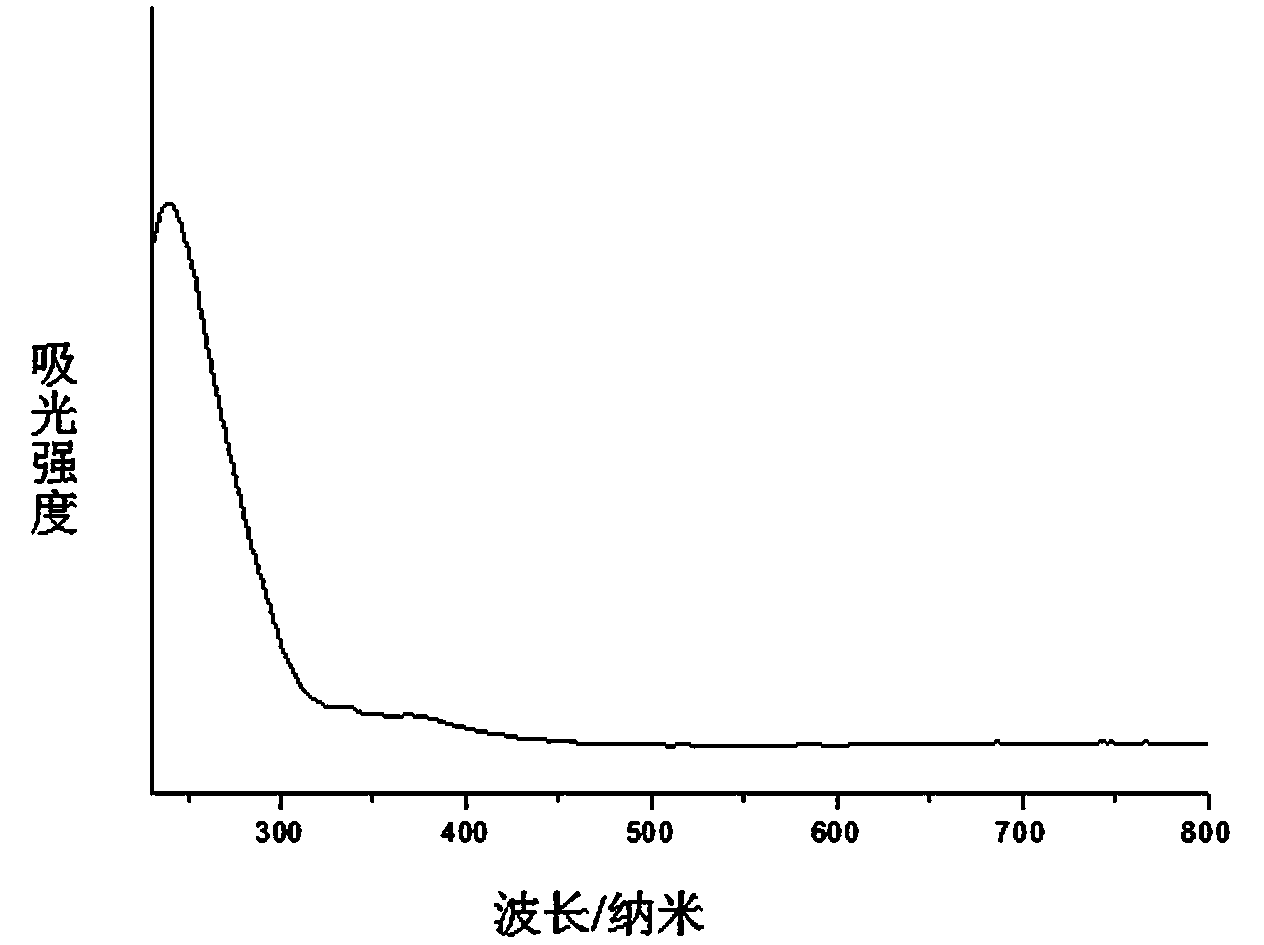

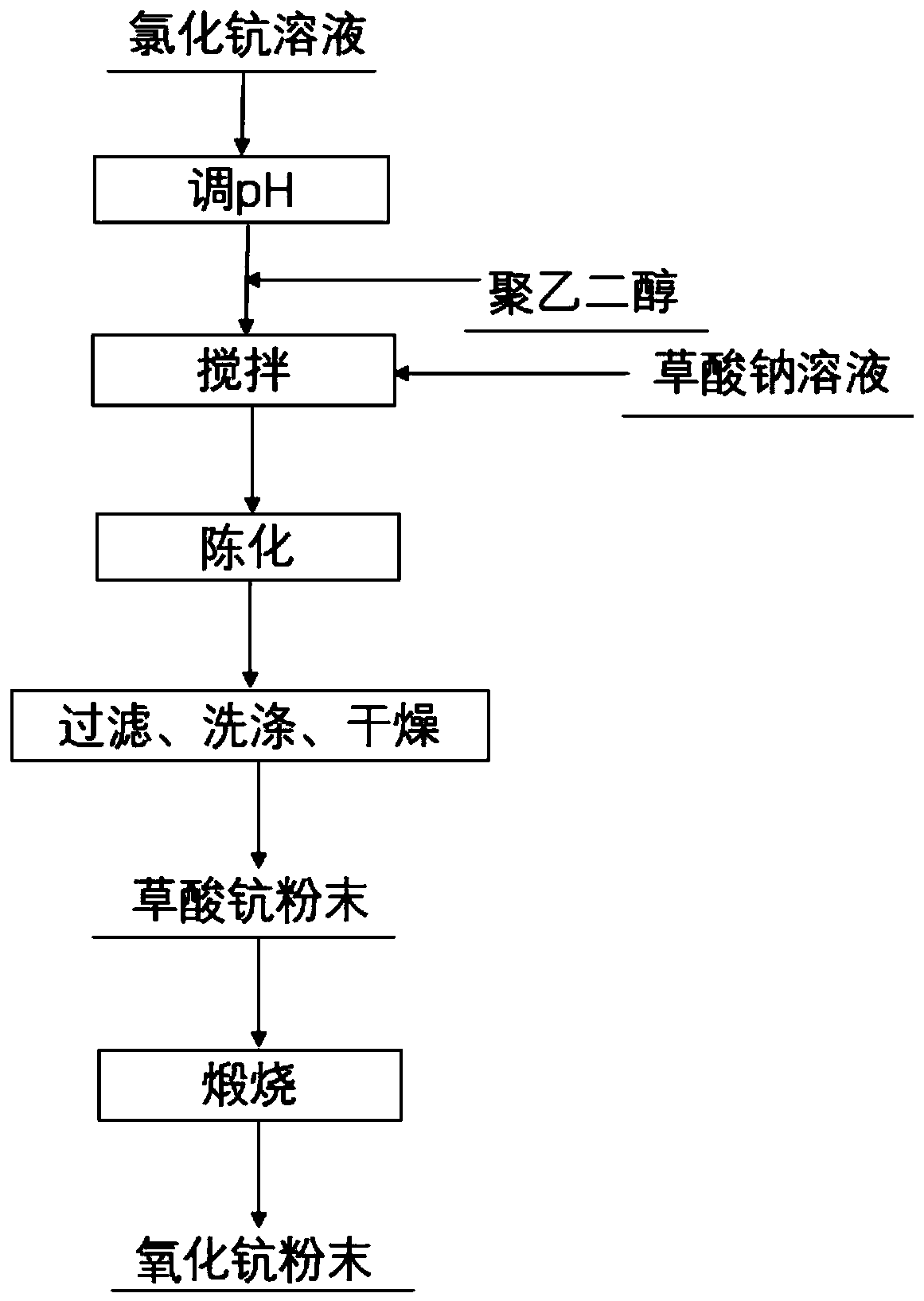

Method for preparing scandium oxide with various morphologies by liquid phase precipitation method

ActiveCN108163881BSimple methodConditions are easy to controlRare earth metal oxides/hydroxidesOperabilityScandium chloride

The invention discloses a method for preparing scandium oxide with various morphologies by using a liquid-phase precipitation method. The method for preparing scandium oxide with various morphologiesby using the liquid-phase precipitation method comprises the steps: regulating the pH value of a scandium chloride solution serving as a raw material, and adding a surfactant, wherein the mass ratio of the surfactant to the raw material is 0-1%; adding a precipitator containing oxalate ions into the scandium chloride solution, and after the reaction is completed, carrying out aging for 0-24h to obtain a precursor; filtering, washing and drying the precursor by using a natural filtering method to obtain scandium oxalate powder; and calcining the scandium oxalate powder at 650-900 DEG C for 1-3hto obtain scandium oxide powder. The scandium oxide powder with various morphologies can be obtained by using the method provided by the invention; and the method is simple, effective, easy to control conditions, strong in operability and capable of realizing industrialized application.

Owner:CENT SOUTH UNIV

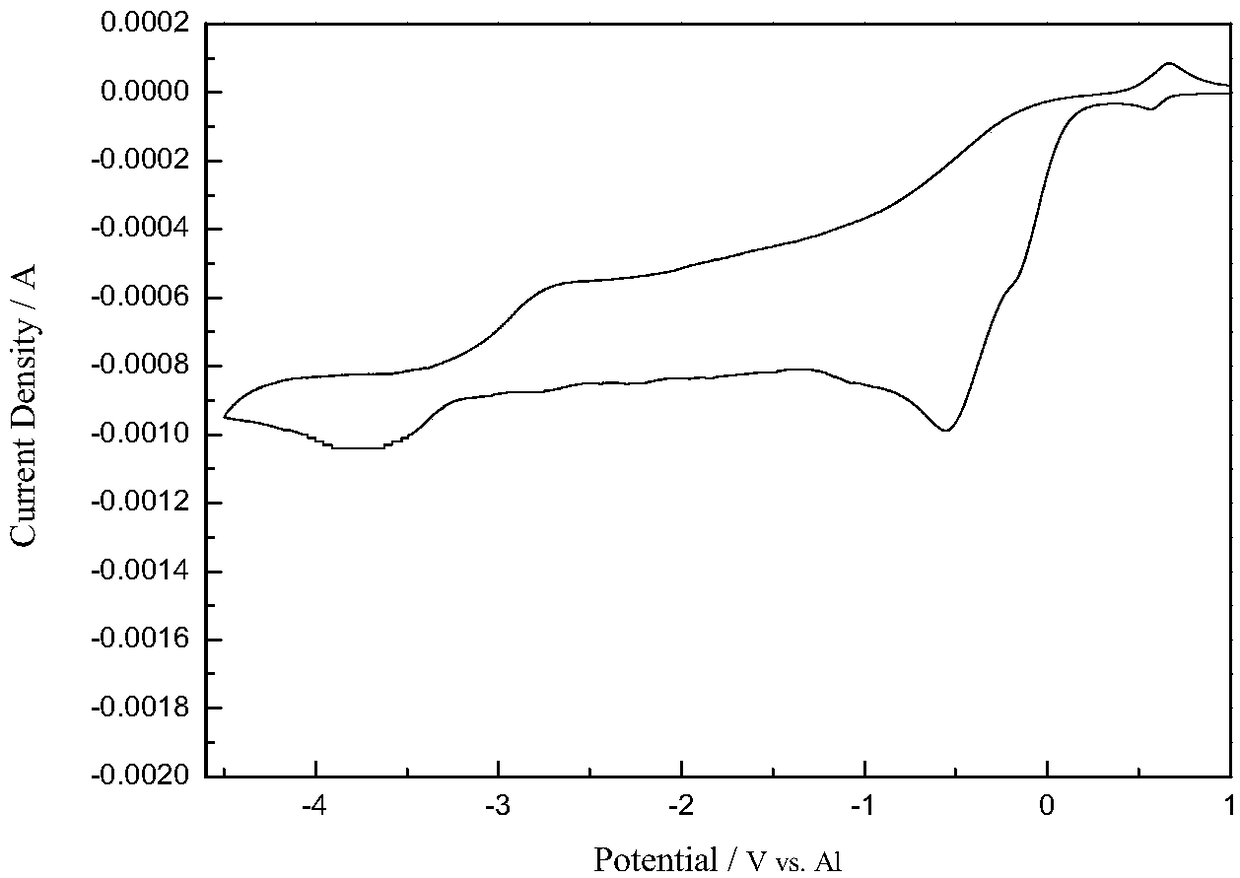

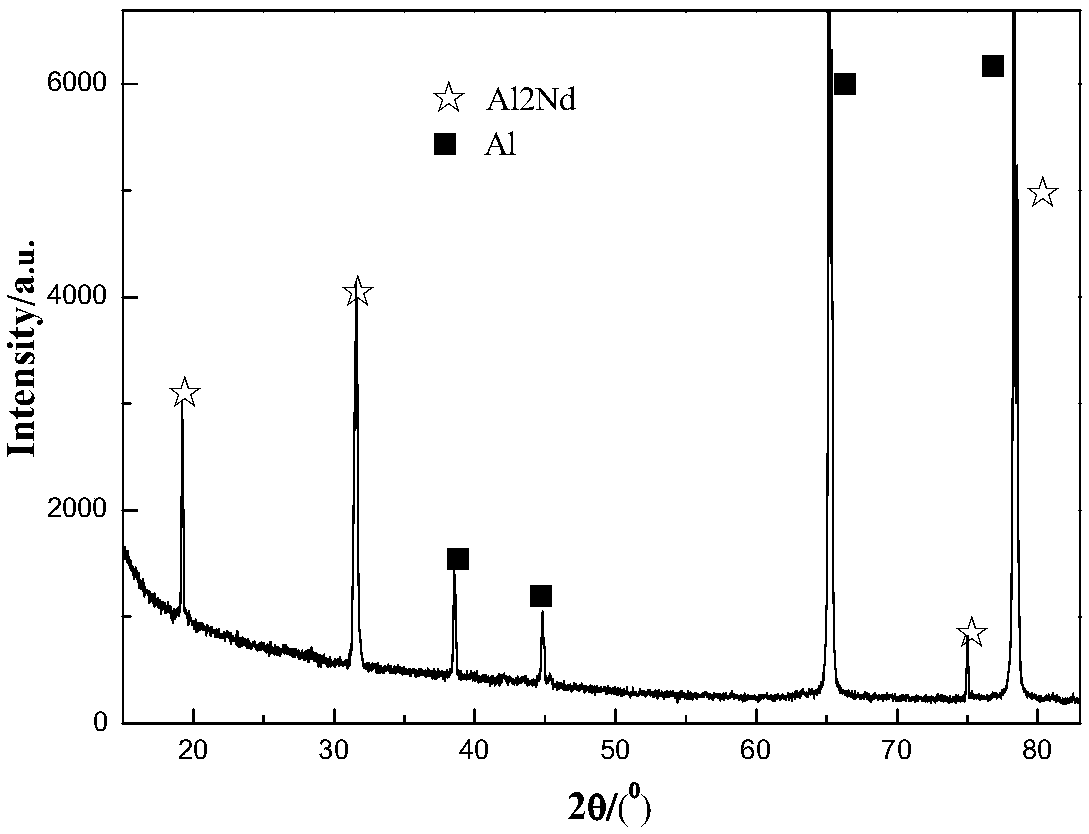

A method for preparing aluminum-based rare earth alloys by electrolysis near room temperature

The invention belongs to the field of low-temperature electrochemical extraction, and particularly relates to a method for electrolytically preparing aluminum-based rare earth alloys in a near room temperature environment. A method for preparing aluminum-based rare earth alloys by near room temperature electrolysis. The method is an electrolysis method. The electrolyte used in the electrolysis method consists of rare earth chloride and ionic liquid, wherein the ionic liquid accounts for 96 to 98% of the total mass of the electrolyte. , rare earth chloride accounts for 2% to 4% of the total mass. The rare earth chloride is neodymium chloride, lanthanum chloride, cerium chloride, scandium chloride, yttrium chloride, praseodymium chloride, samarium chloride, chloride Europium, one of gadolinium chloride and terbium chloride. The near room temperature electrolytic preparation process of aluminum-based rare earth alloys of the present invention has simple operation and low cost. Provide technical reserves and theoretical support for low-cost green extraction of aluminum-based rare earth alloys.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com