Fireproof filler based on molybdenum waste and fireproof coating

A technology of fireproof coatings and fireproof fillers, applied in the field of fireproof coatings, fireproof fillers and fireproof coatings, can solve the problems of smoke generation rate, total smoke generation rate and CO generation rate reduction, reduce smoke poison release, endanger life and other problems, and achieve adhesion Good performance, reduce environmental pollution, increase the effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a fireproof coating, which is composed of the following raw materials: 20g of film-forming agent, 20g of char-forming agent, 10g of catalytic dehydrating agent, 20g of foaming agent, and 30g of fireproof filler based on molybdenum waste.

[0037] The film-forming agent is sodium silicate; the char-forming agent is pentaerythritol; the catalytic dehydrating agent is ammonium polyphosphate; and the foaming agent is melamine.

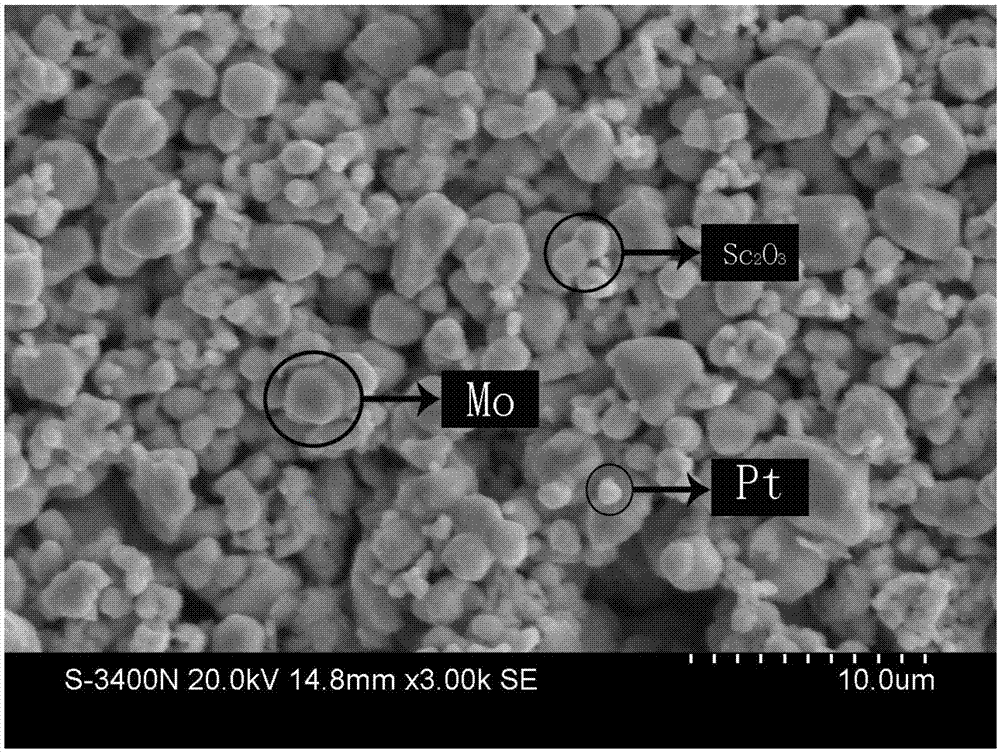

[0038]Among them: the specific preparation process of fireproof filler based on molybdenum waste is as follows: add molybdenum waste, chloroplatinic acid and scandium chloride hexahydrate into anhydrous isobutanol, heat to 60 ° C ~ 70 ° C, then add diethanolamine and water, Adjust the pH value in the range of 7.5 to 8 with ammonia water, stir to form a sol, and obtain a stable, uniform, and transparent precursor gel after evaporation and coagulation, dry the precursor gel at 300 to 400 ° C, and obtain a molybdenum-based gel a...

Embodiment 2

[0047] This embodiment provides a fireproof coating, which is composed of the following raw materials: 60g of film-forming agent, 10g of char-forming agent, 5g of catalytic dehydrating agent, 15g of foaming agent, and 10g of fireproof filler based on molybdenum waste.

[0048] The film-forming agent is sodium silicate; the char-forming agent is pentaerythritol; the catalytic dehydrating agent is ammonium polyphosphate; and the foaming agent is melamine.

[0049] Wherein: the specific preparation process of the fireproof filler based on molybdenum waste is the same as that of Example 1.

[0050] The preparation method of the fireproof coating is to mix the raw materials evenly according to the proportion, and grind them to the particle size meeting the specifications. Refer to Table 2 for the performance test results of the fire retardant coating prepared in this embodiment.

Embodiment 3

[0052] This embodiment provides a fireproof coating, which is composed of the following raw materials: 60g of film-forming agent, 10g of char-forming agent, 5g of catalytic dehydrating agent, 15g of foaming agent, and 10g of fireproof filler based on molybdenum waste.

[0053] The film-forming agent is silica sol; the char-forming agent is ammonium polyphosphate; the catalytic dehydrating agent is diamine hydrogen phosphate; the foaming agent is urea.

[0054] Among them: the specific preparation process of the fireproof filler based on molybdenum waste is basically the same as that of Example 1, and the preparation method of the fireproof coating is to mix the raw materials evenly according to the proportion, and grind to the particle size that meets the specification requirements. Refer to Table 2 for the performance test results of the fire retardant coating prepared in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com