Plasma auxiliary-heating melting and gasifying reactor

An auxiliary heating, melting and gasification technology, applied in gasification process, manufacture of combustible gas, petroleum industry, etc., can solve the problems of equipment cost increase, extremely high power, uneven distribution of temperature field, etc., to avoid pyrolysis gasification, Increased service life and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

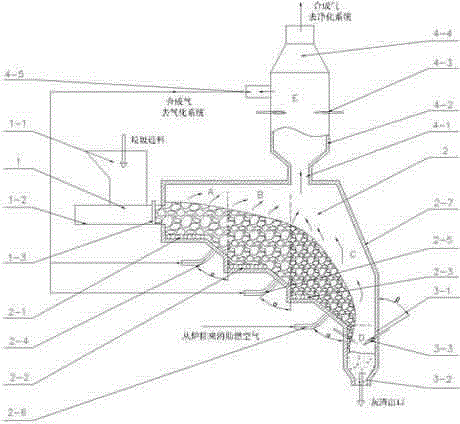

[0029] Such as figure 1 As shown, a plasma-assisted heating melting gasification reactor for converting municipal solid waste into synthesis gas and inert slag products according to the present invention includes a feeder 1, a reaction chamber 2, and a gasification reaction chamber Chamber furnace wall 2-7, the feeder 1 is connected with the reaction chamber 2, and the reaction chamber 2 sequentially includes a drying area A with an additional circulating thermal synthesis gas along the horizontal direction according to the reaction sequence, and a drying area with an additional circulating thermal synthesis gas. And the pyrolysis and gasification zone B with steam added, the burnout zone C with heated air, the ash melting zone D with a plasma generator, and the drying zone A through the feed port 1-1 of the reaction furnace and the feed materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com