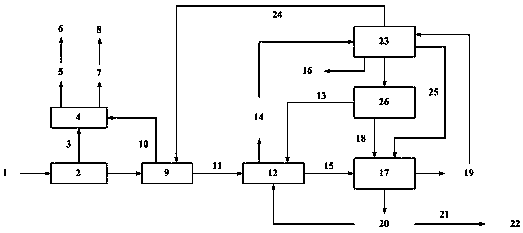

Patents

Literature

217 results about "Plasma gasification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plasma gasification is an extreme thermal process using plasma which converts organic matter into a syngas (synthesis gas) which is primarily made up of hydrogen and carbon monoxide. A plasma torch powered by an electric arc is used to ionize gas and catalyze organic matter into syngas, with slag remaining as a byproduct. It is used commercially as a form of waste treatment and has been tested for the gasification of municipal solid waste, biomass, industrial waste, hazardous waste, and solid hydrocarbons, such as coal, oil sands, petcoke and oil shale.

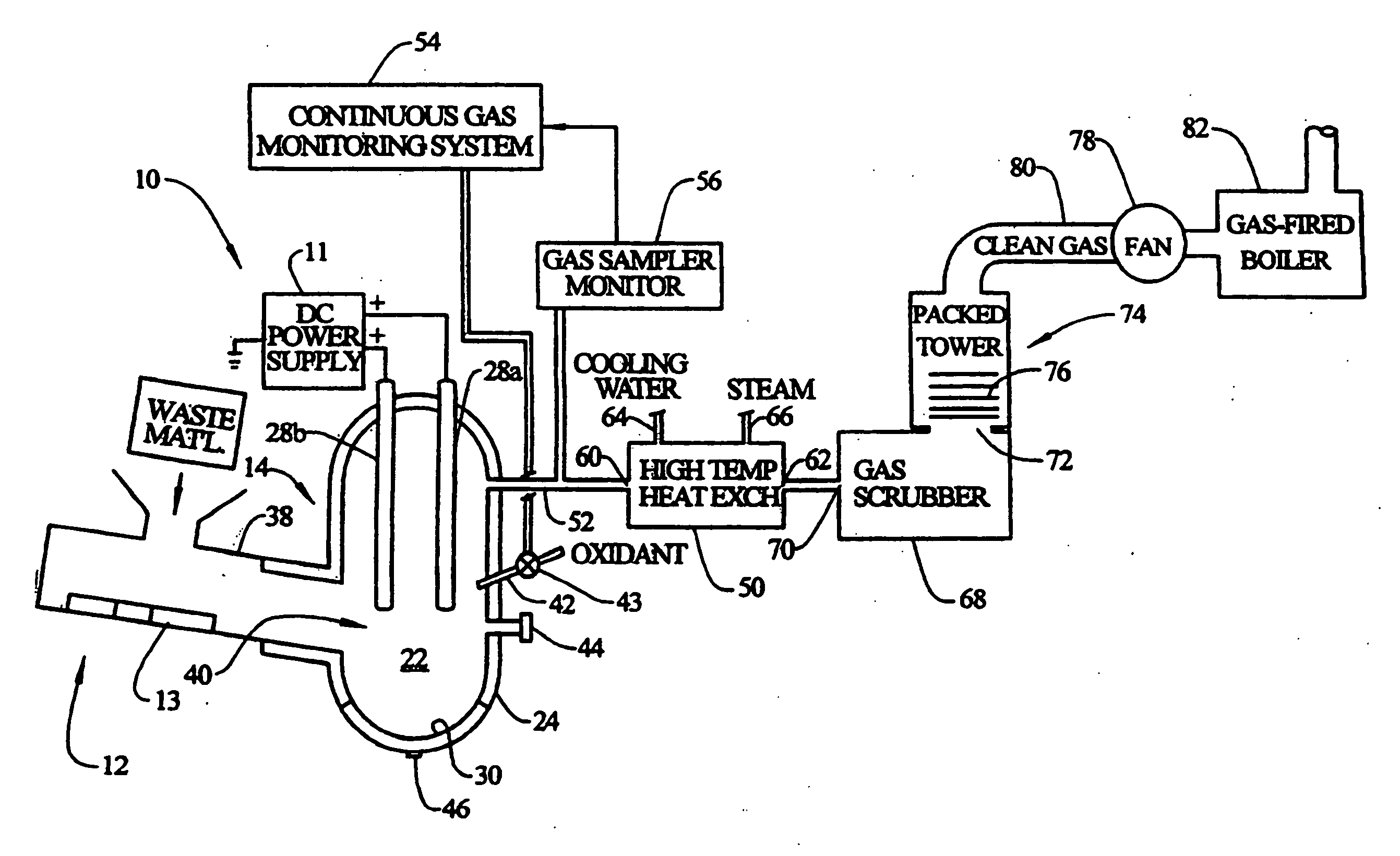

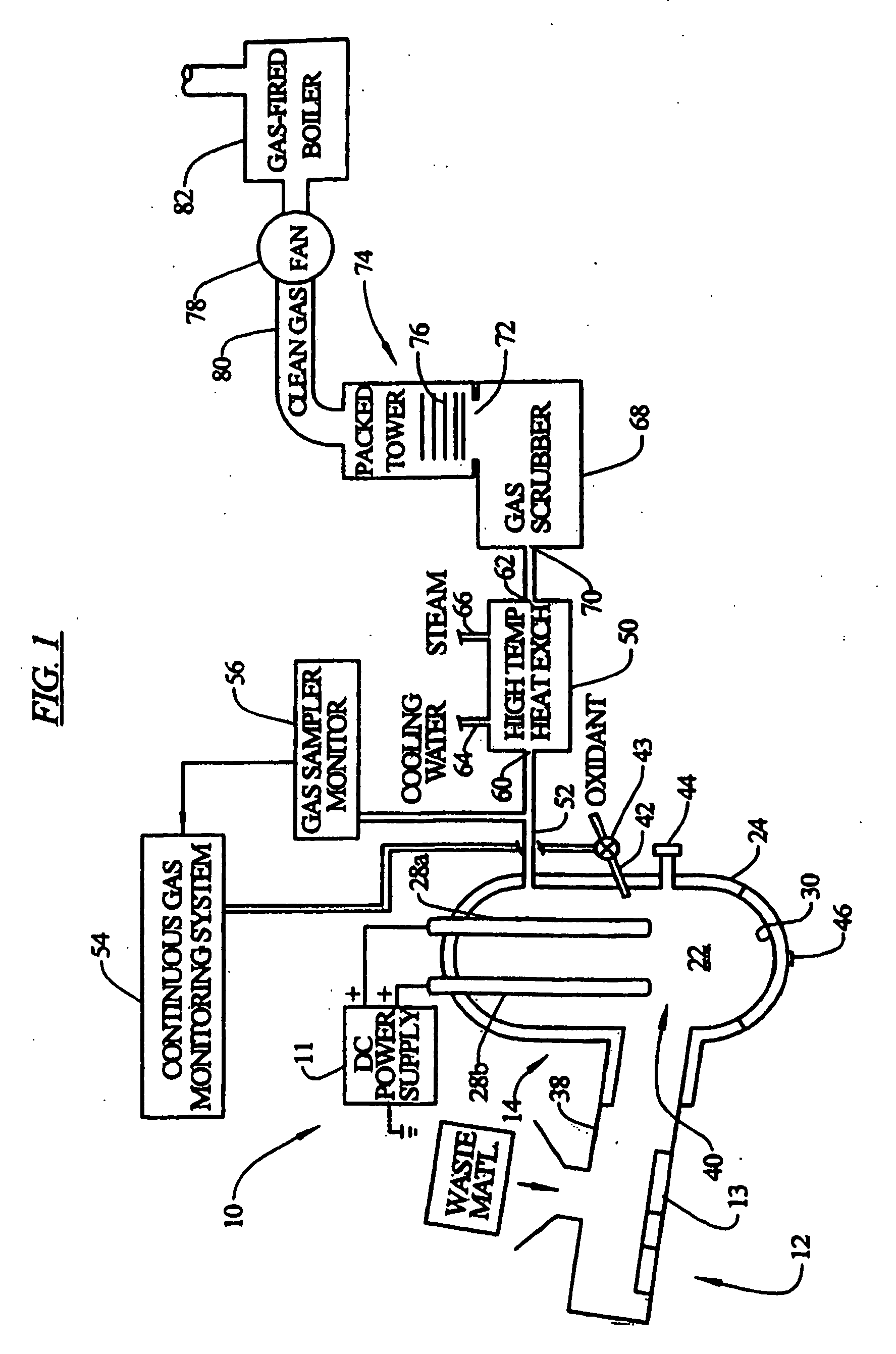

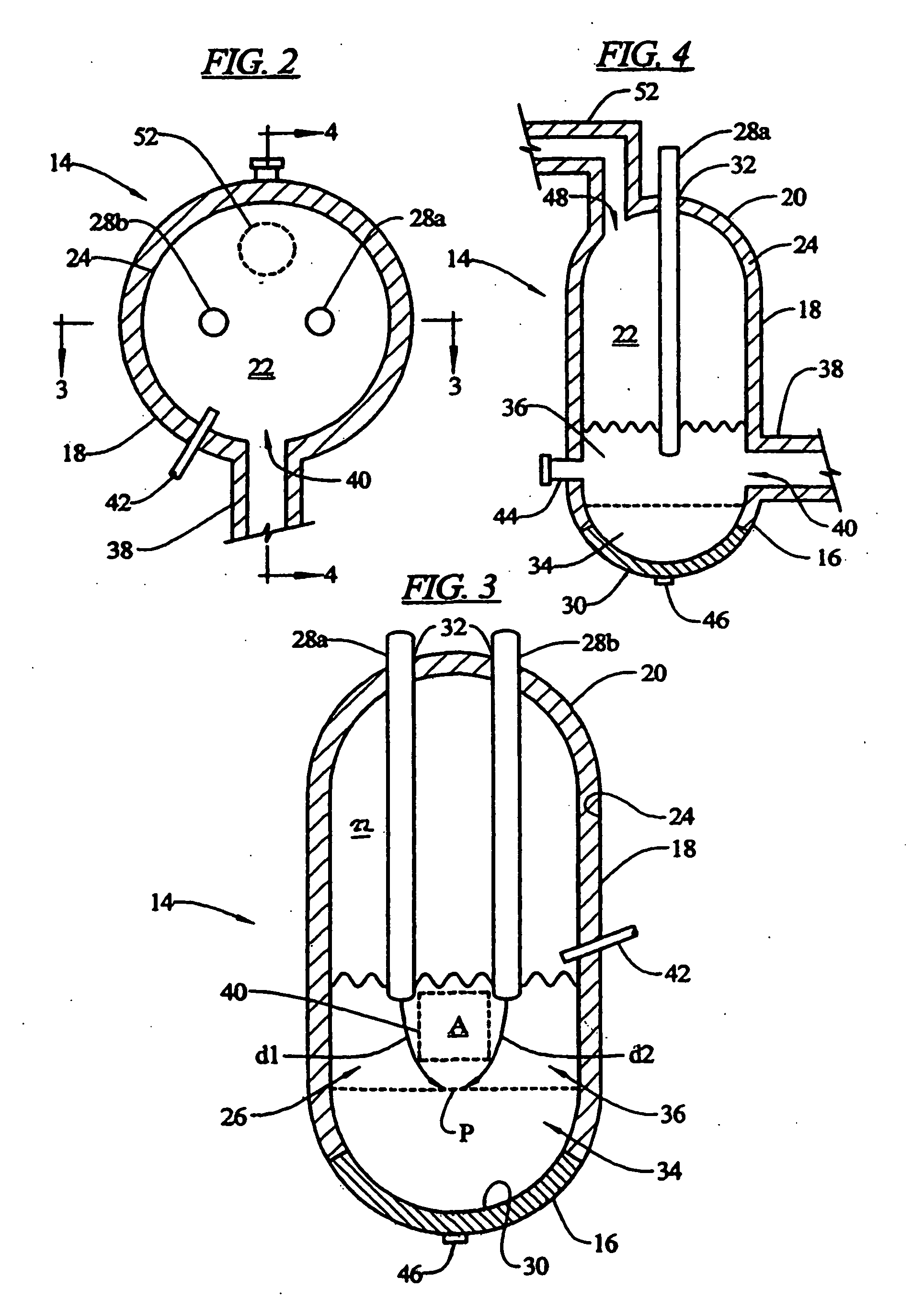

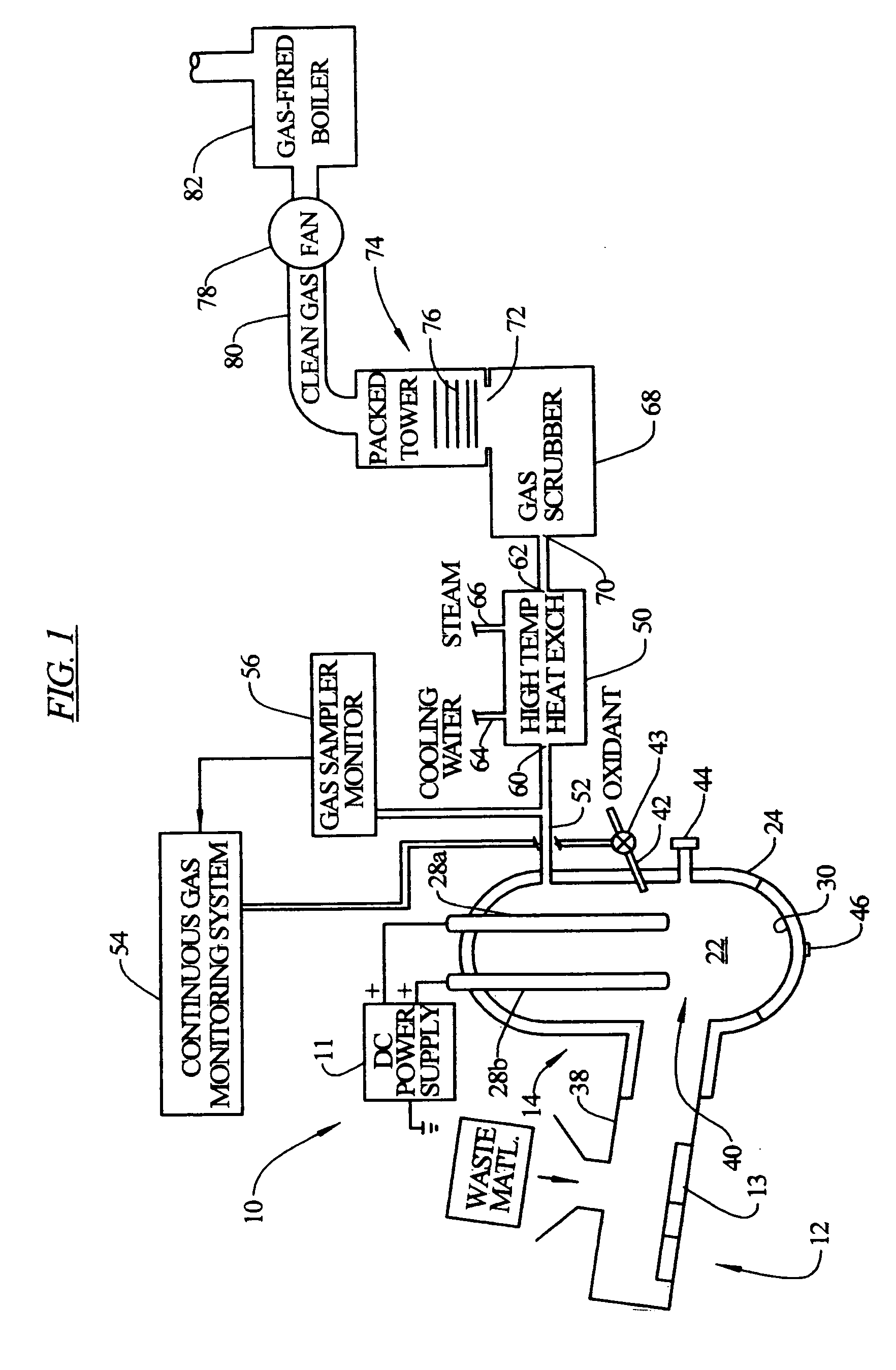

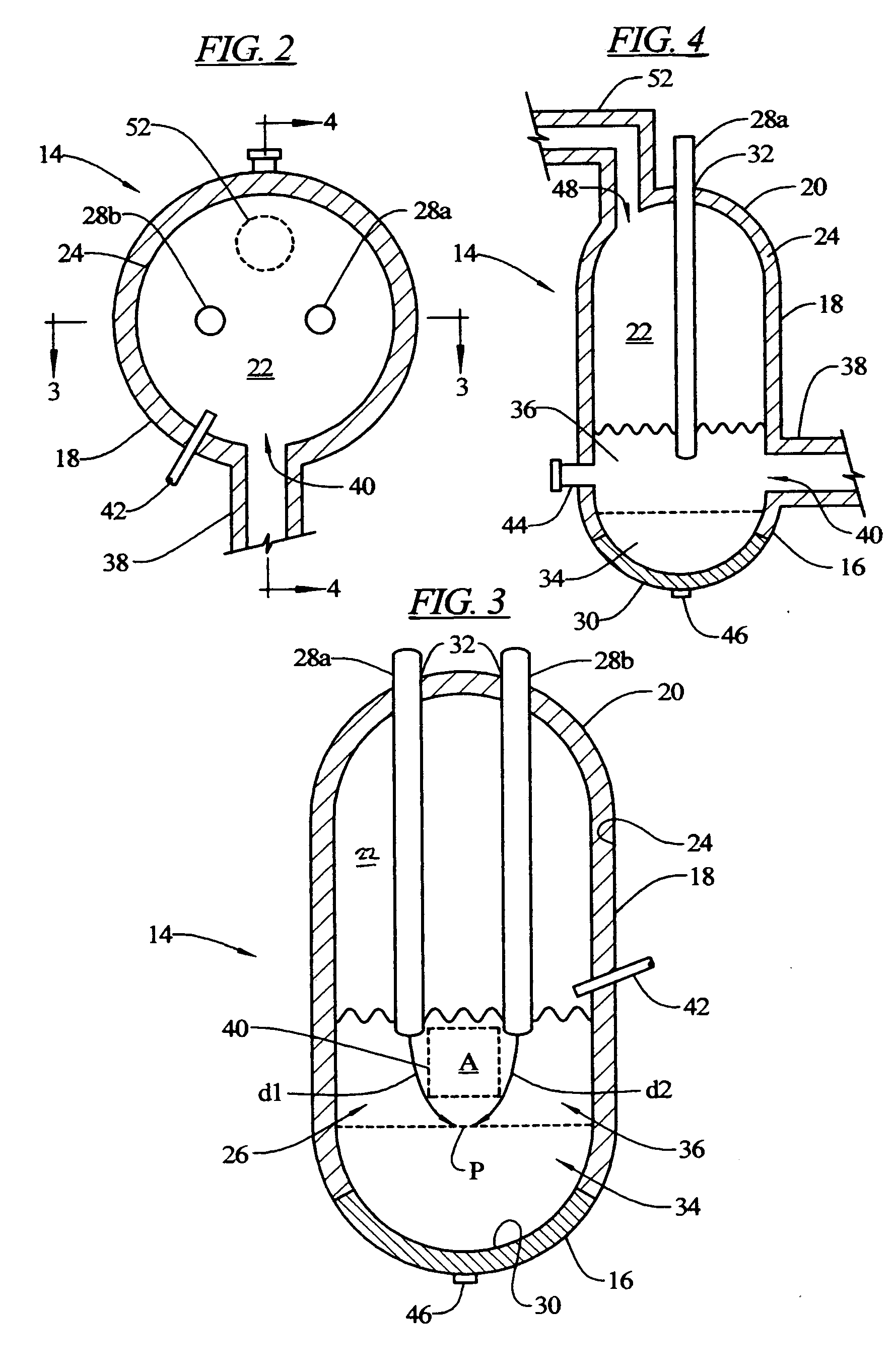

Method and apparatus for plasma gasification of waste materials

InactiveUS20070289509A1Simple and inexpensive in design and construction and operationHighly efficient and high reliabilityArc welding apparatusGasification processes detailsParticulatesHydrogen

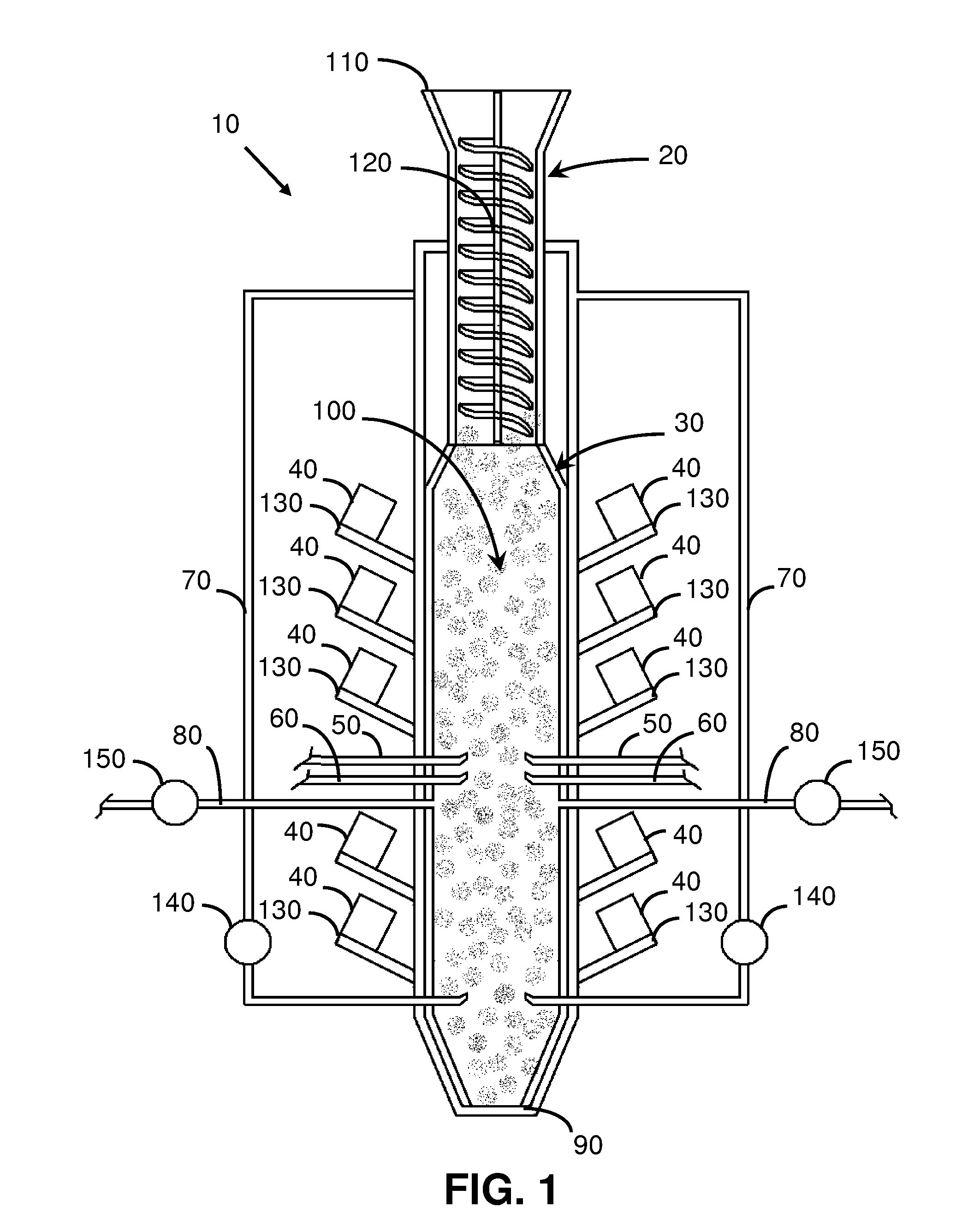

A method and apparatus for plasma gasification of waste materials consisting of organic and inorganic portions is provided which includes a refractory-lined reactor vessel, a feeder mechanism, and a DC electrode device. The refractory-lined reactor vessel has a processing chamber formed therein. The feeder mechanism feeds continuously waste materials into the processing chamber at a controlled feed rate. The DC electrode device is used for heating the processing chamber to a sufficient temperature so as to convert the organic portions of the waste materials to a synthetic gas consisting of hydrogen and carbon monoxide and to a carbon particulate, and to convert the inorganic portions of the waste materials to a molten material consisting of a lower metallic layer and a slag layer formed on top of the metallic layer.

Owner:PLASMA WASTE RECYCLING

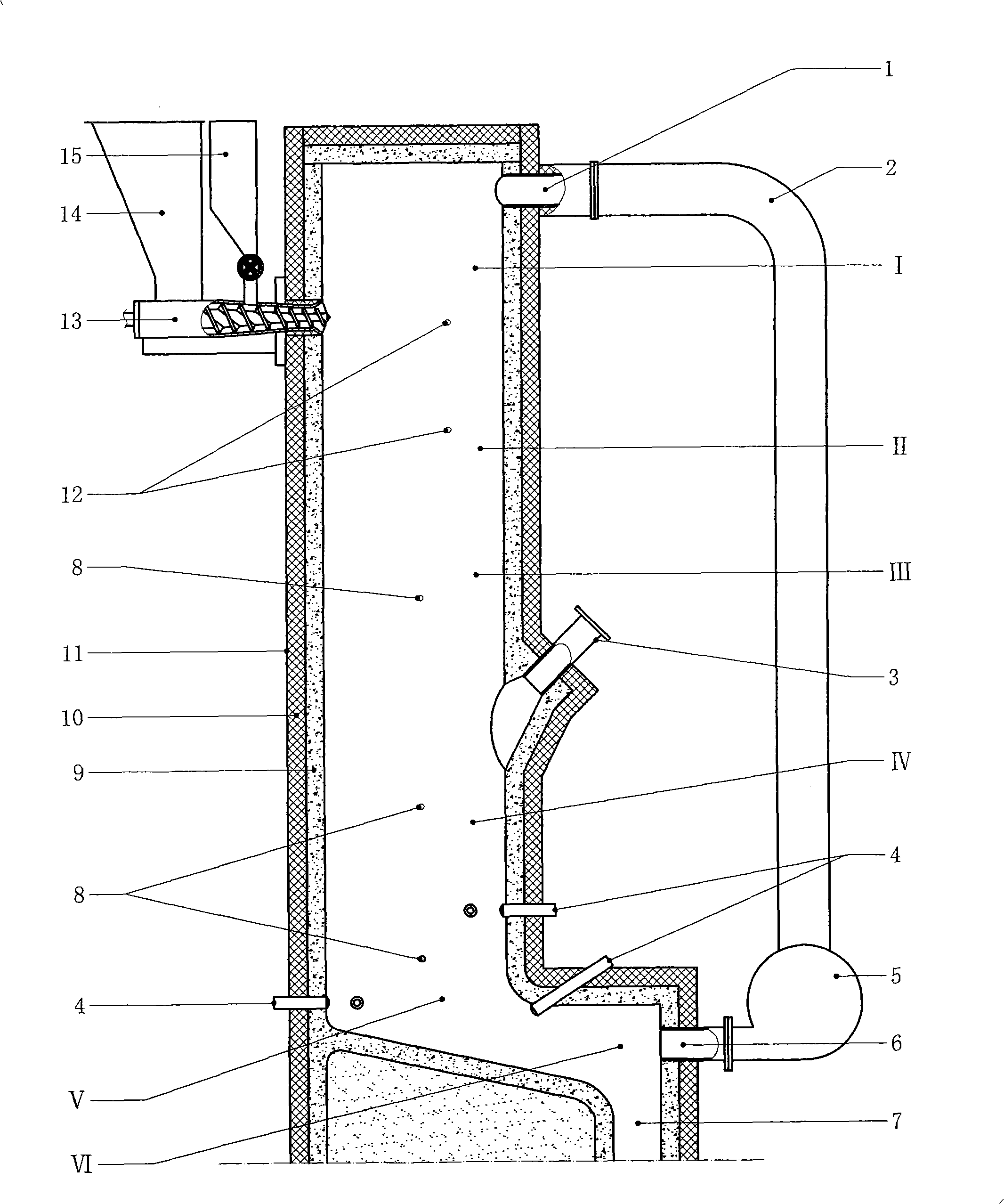

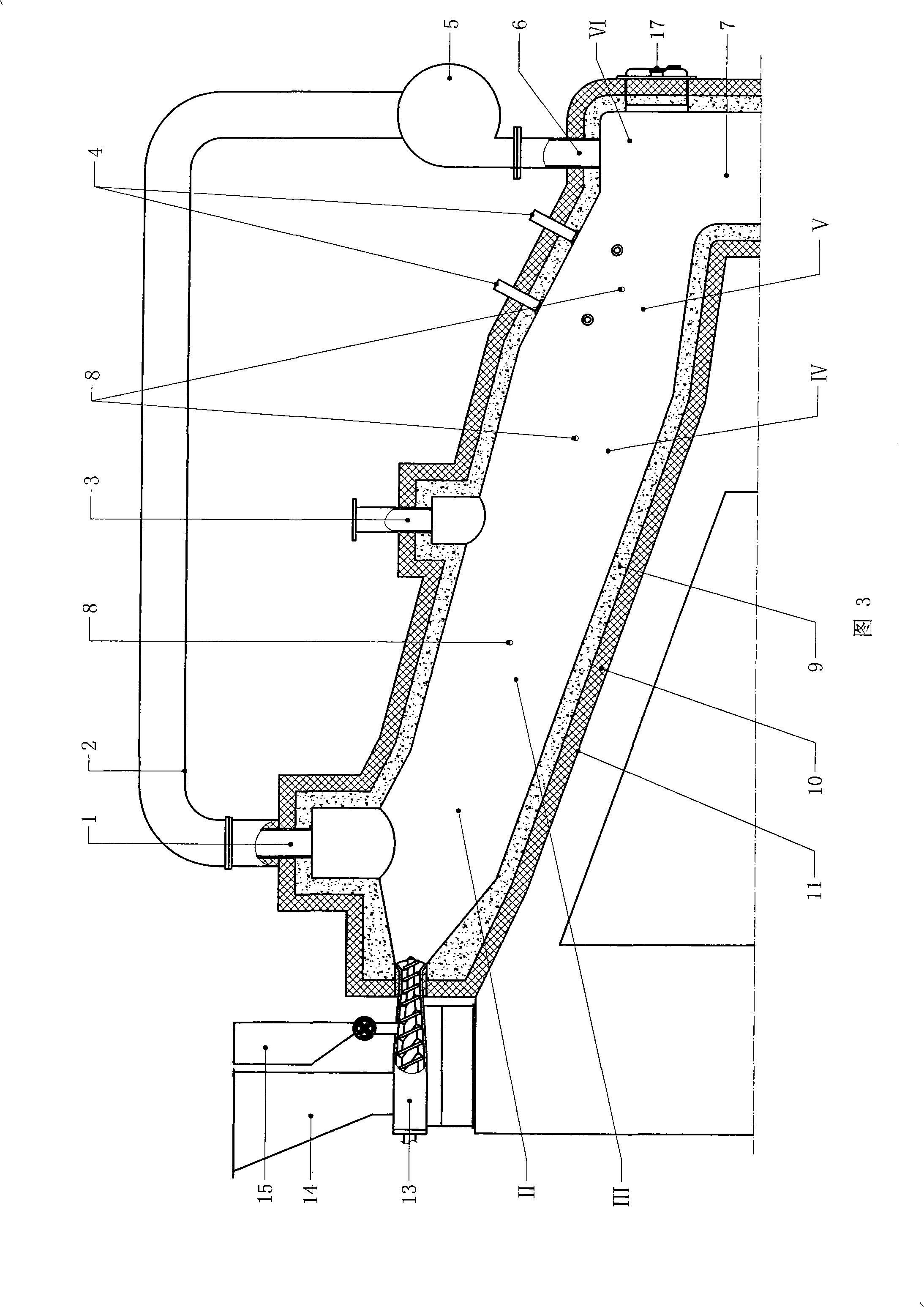

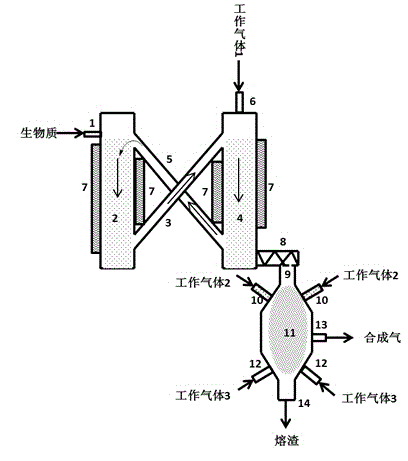

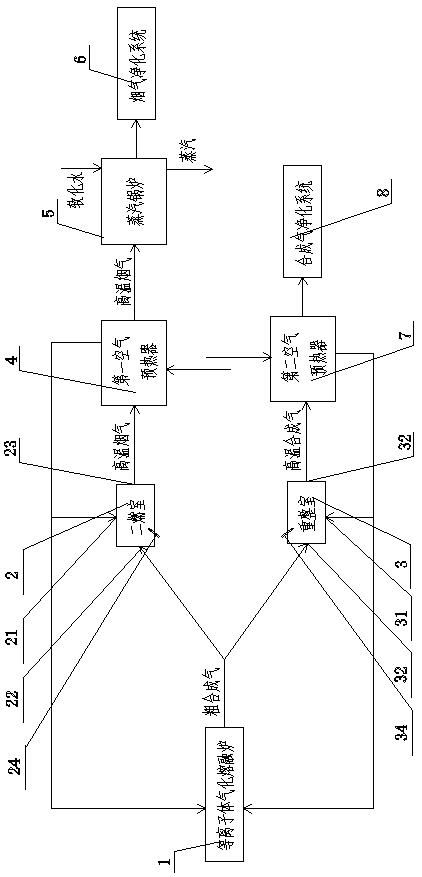

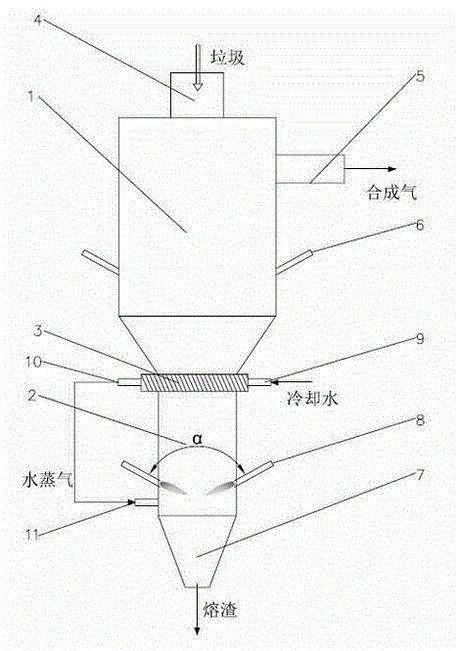

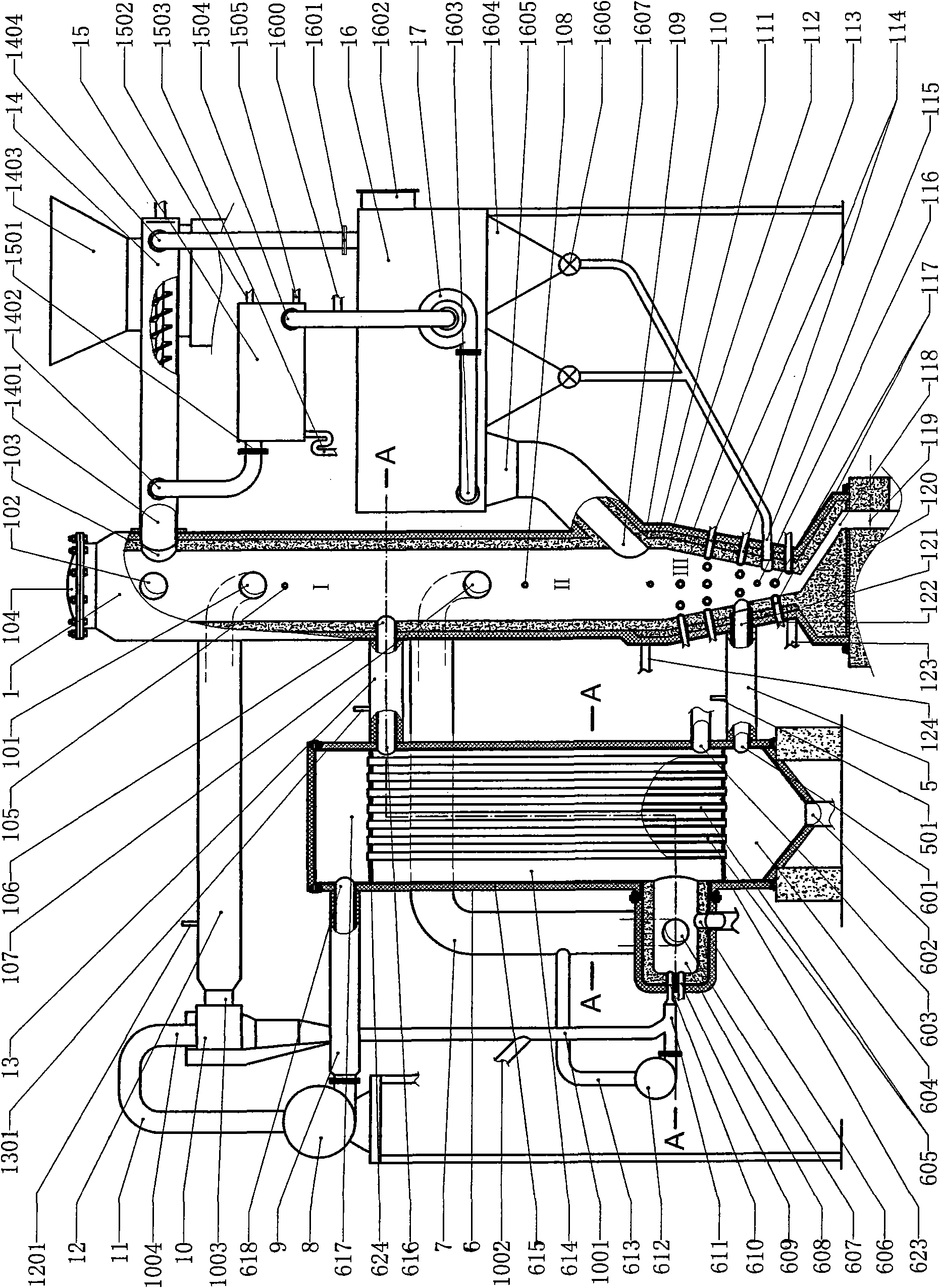

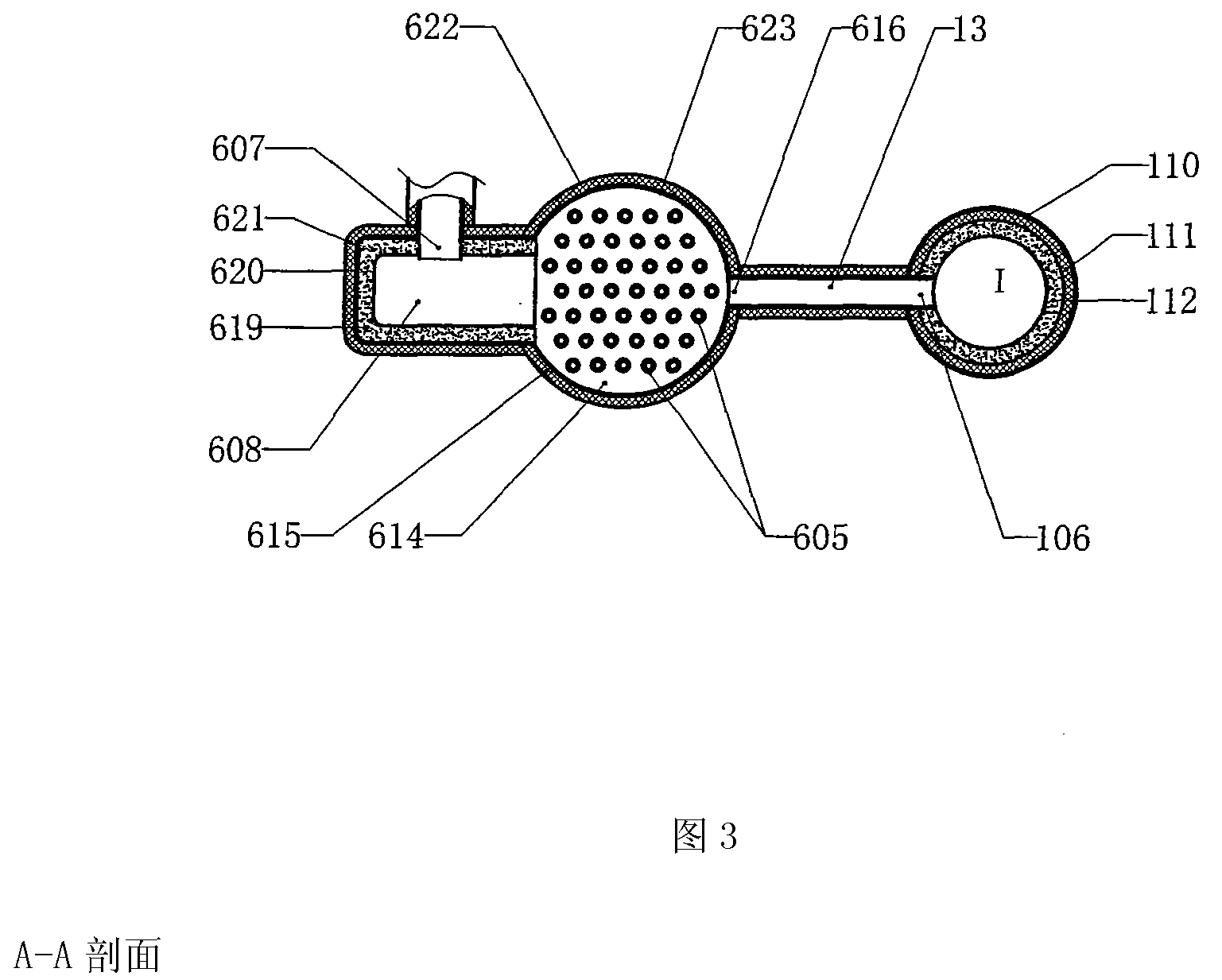

Two-stage plasma gasifying, melting and cracking method and device of waste containing organic matters

ActiveCN102000691ANo emissionsComplete gasificationSolid waste disposalGlass furnace apparatusGeneration rateHigh energy

The invention relates to a treatment method of waste containing organic matters, in particular to two-stage plasma gasifying, melting and cracking method and device of the waste containing organic matters, belonging to the field of gasifying, melting and cracking techniques. In the invention, the serious defects of high energy consumption of the waste containing organic matters and more flying ash during the plasma arc melting and cracking are solved, thereby thoroughly utilizing the energy of the organic matters and maximizing the treating efficiency, thoroughly cracking the tar, reducing the generation rate of Dioxin, obtaining synthesis gas with high quality and high heat value as much as possible, providing guarantee for the subsequent gasification power generation, the hydrogen energy recovery or the production of green liquid fuel, simultaneously finishing one-step recovery of noble metals and direct utilization of glass bodies in the field of building materials, laying foundation for the large-scale commercial development and application of the energy of the waste containing organic matters, and thoroughly solving the possible pollutant discharging problem in the gasifying process of the organic matters, particularly the dangerous waste.

Owner:HOOTECH

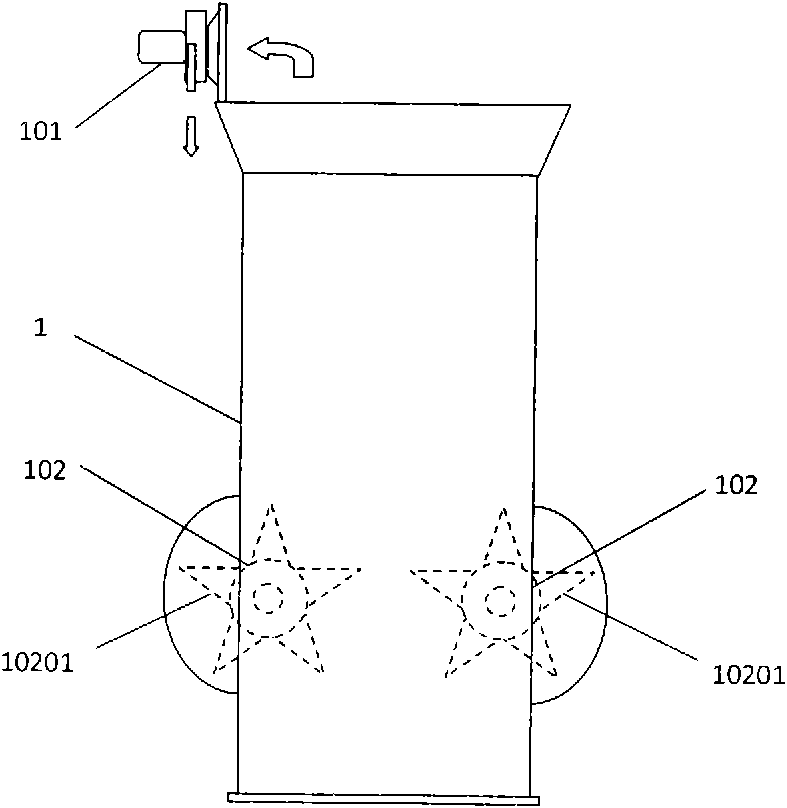

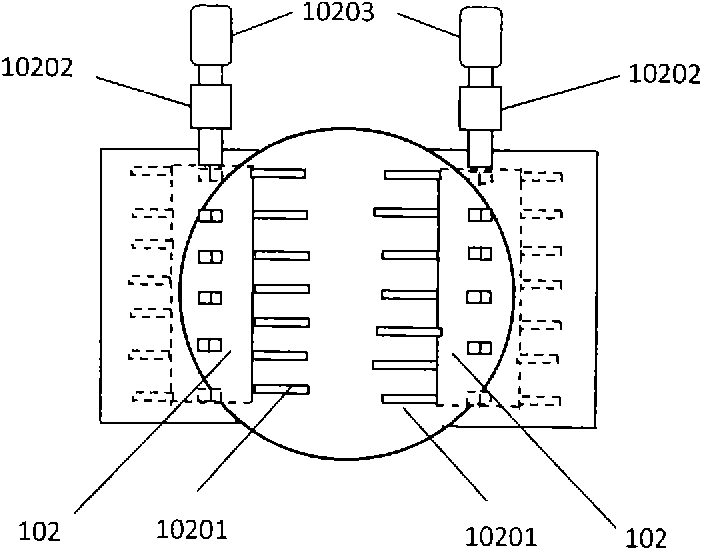

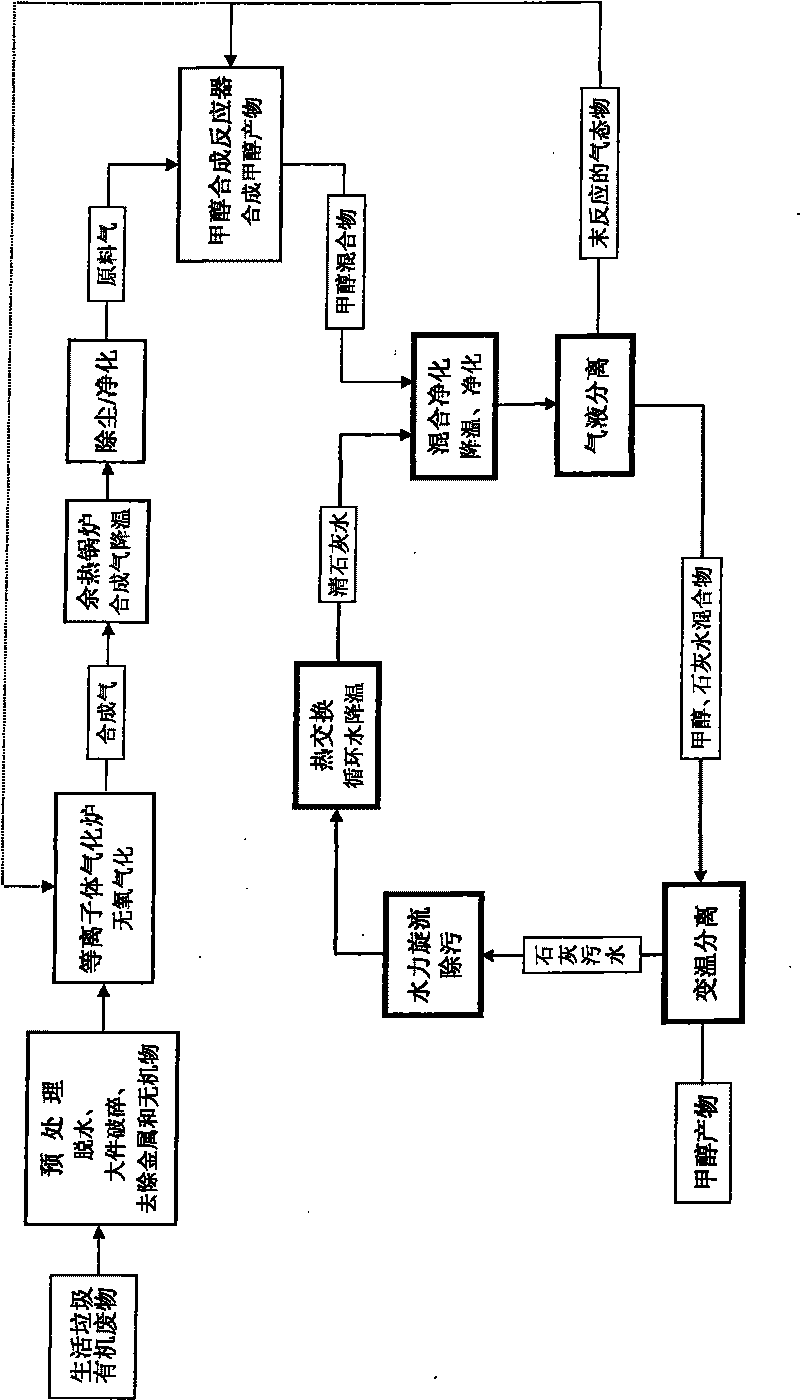

Process for gasification-liquefaction disposal of domestic garbage and organic waste

The invention discloses a process for gasification-liquefaction disposal of domestic garbage and organic waste, which relates to disposal technology of the domestic garbage and the organic waste. The process comprises the steps of: performing oxygen-free gasification on the domestic garbage or the organic waste in a plasma gasification furnace to produce hydrogen-rich syngas which does not contain oxygen and takes CO and H2 as main components, wherein the conditions of the formation of dioxin are avoided; then sending the hydrogen-rich syngas taken as feed gas into a methanol synthesis reactor to catalytically synthesize a methanol product after temperature reduction and dust removal / purification; then drawing the methanol product out of the reactor to mix with lime water for terminal purification operation; and using calcium hydroxide as an absorbent to ensure that pollutants and purities which are not eliminated in a dust removal / purification working procedure and comprise the dioxin are removed. The process almost has no the discharge of the pollutants during the whole disposal process, and is suitable for harmless disposal of municipal domestic waste, rural domestic refuse, medical waste, industrial polymer waste, agricultural and forestry waste, composting leftovers and refuse sorting field waste.

Owner:周开根

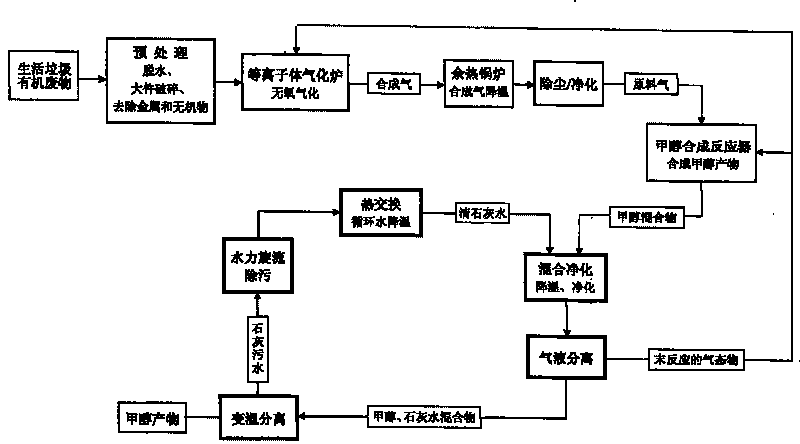

Gasification-liquefaction disposal method, system and equipment for household garbage

InactiveCN101823073ASolve pollutionEasy to removeWaste processingSolid waste disposalThermal energyClosed loop

The invention discloses a gasification-liquefaction disposal method, a system and equipment for household garbage, which relates to an organic waste disposal method and equipment for household garbage. The method of the invention comprises the following steps: pretreating household garbage, and delivering the pretreated household garbage into a plasma gasification furnace for gasification to generate hydrogen rich synthetic gas; then cooling, deacidifying and dedusting the hydrogen rich synthetic gas to separate CO2; then producing methanol in a methanol synthesis reactor; returning the separated CO2 to a gasification system to carry out carbonation reaction with calcium oxide to release heat for providing auxiliary heat energy for gasification, and simultaneously avoiding discharge of greenhouse gases to the environment; and returning tail gas to the plasma gasification furnace for remelting treatment, thus forming a closed-loop circulation production system. Disposal of the household garbage with zero discharge and no pollution is realized, the dioxin pollution problem is avoided, and the household garbage is converted to chemical raw materials and fuel needed by people. The invention is suitable for harmless and recycling disposal of the household garbage, industrial high polymer wastes, wastes produced by utilizing a composting method and waste in a garbage sorting site.

Owner:衢州市广源生活垃圾液化技术研究所

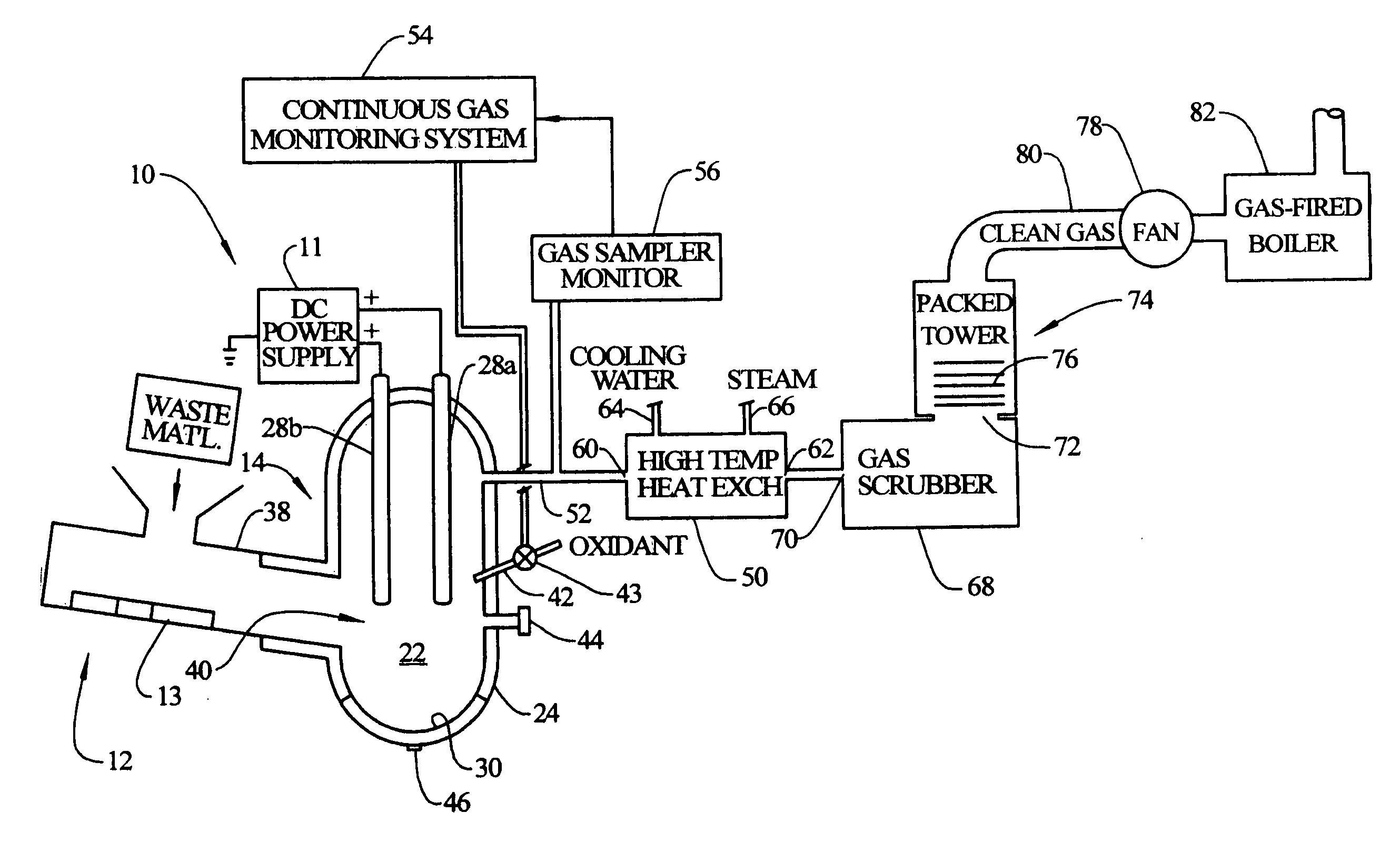

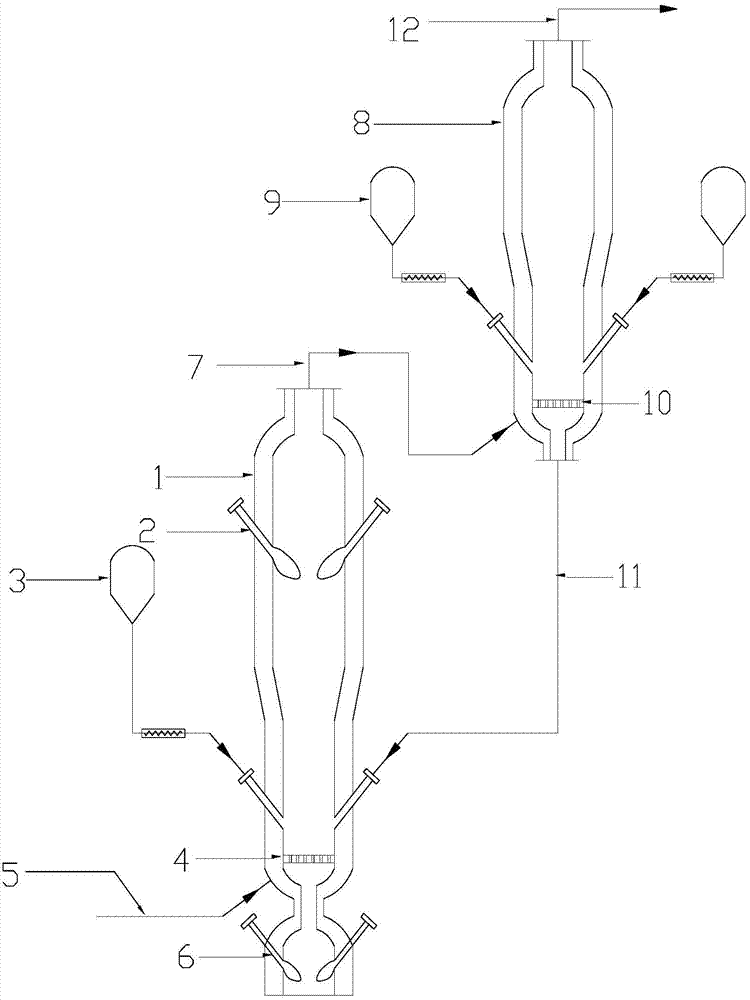

Method and apparatus for plasma gasification of waste materials

InactiveUS20060144305A1Simple and inexpensive in designSimple and inexpensive in and constructionEmission preventionHeat recoveryParticulatesHydrogen

A method and apparatus for plasma gasification of waste materials consisting of organic and inorganic portions is provided which includes a refractory-lined reactor vessel, a feeder mechanism, and a DC electrode device. The refractory-lined reactor vessel has a processing chamber formed therein. The feeder mechanism feeds continuously waste materials into the processing chamber at a controlled feed rate. The DC electrode device is used for heating the processing chamber to a sufficient temperature so as to convert the organic portions of the waste materials to a synthetic gas consisting of hydrogen and carbon monoxide and to a carbon particulate, and to convert the inorganic portions of the waste materials to a molten material consisting of a lower metallic layer and a slag layer formed on top of the metallic layer.

Owner:PLASMA WASTE RECYCLING

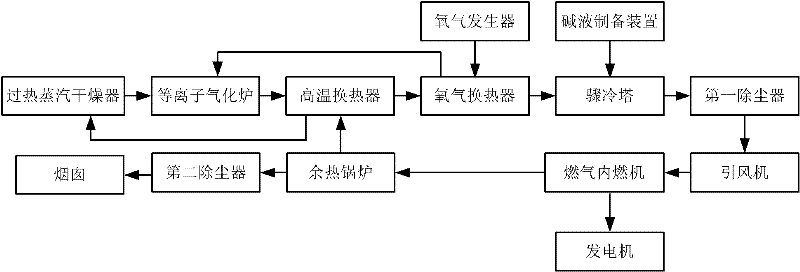

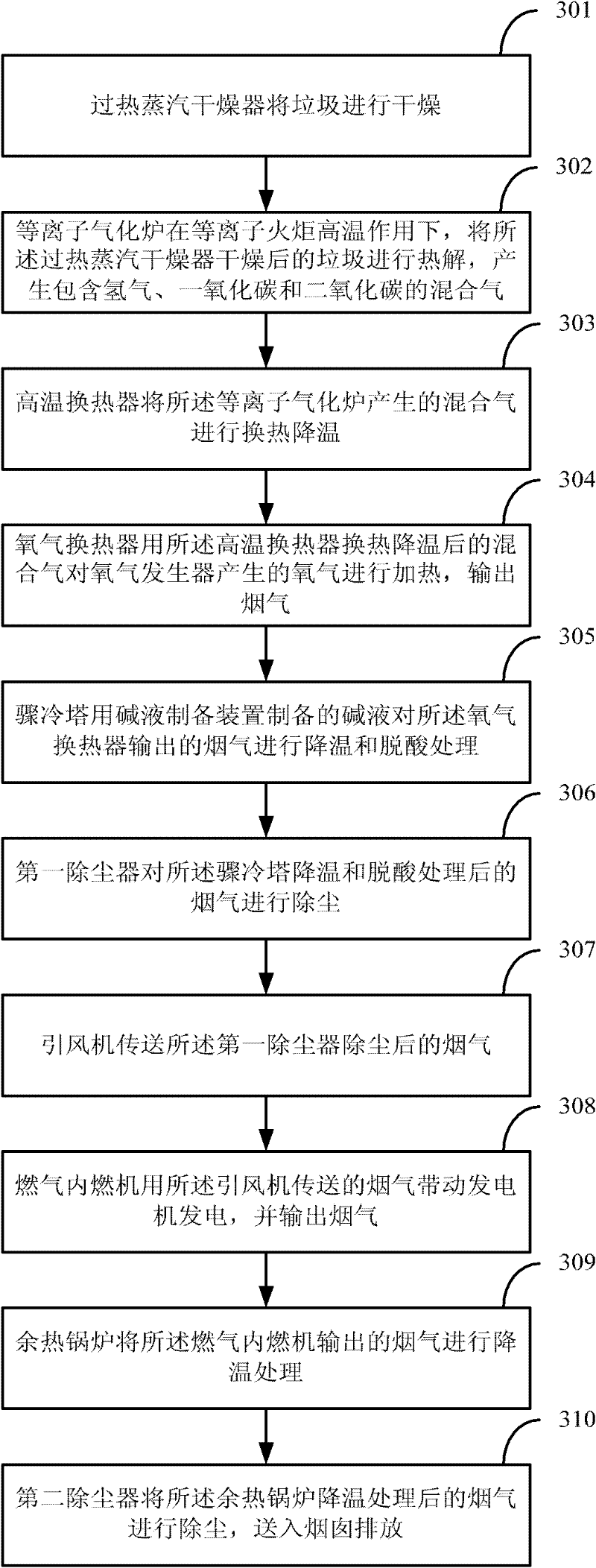

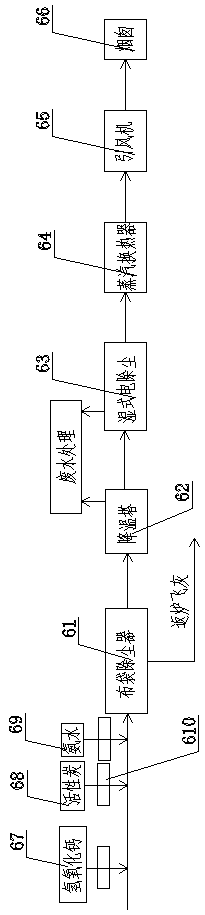

Plasma waste treatment system and method

InactiveCN102284467AIncrease profitImprove thermal efficiencySolid waste disposalRecuperatorInternal combustion engine

The invention discloses a plasma garbage treatment system and method, comprising: a superheated steam drier to dry garbage; a plasma gasification furnace pyrolyzing the dried garbage under the high temperature of a plasma torch to generate hydrogen, carbon monoxide and carbon dioxide Mixed gas; the high temperature heat exchanger performs heat exchange and cooling of the mixed gas; the oxygen heat exchanger uses the mixed gas after heat exchange and cooling to heat the combustion-supporting oxygen to output flue gas; the quench tower uses lye to cool the oxygen output from the oxygen heat exchanger The flue gas is cooled and deacidified; the first dust collector removes dust from the flue gas treated by the quenching tower; the induced draft fan transmits the flue gas after the first dust collector removes dust; the gas internal combustion engine uses the flue gas transmitted by the induced fan to drive the generator Generate electricity and output flue gas; the waste heat boiler cools the flue gas output by the gas-fired internal combustion engine; the second dust collector removes dust from the flue gas cooled by the waste heat boiler, and sends it to the chimney for emission. By adopting the invention, the waste heat utilization rate and thermal efficiency of waste treatment can be improved.

Owner:BEIJING ENERGY INVESTMENT HLDG

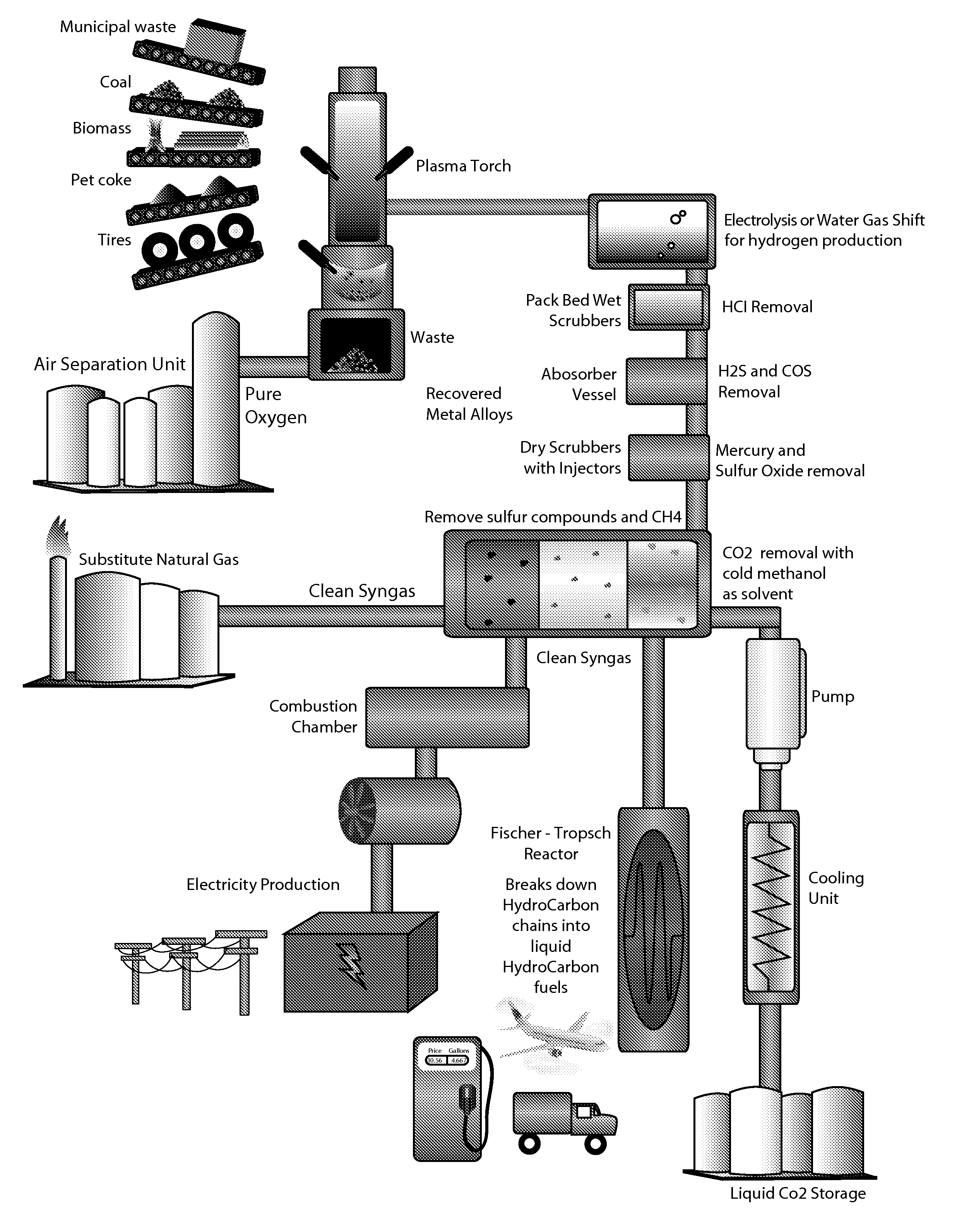

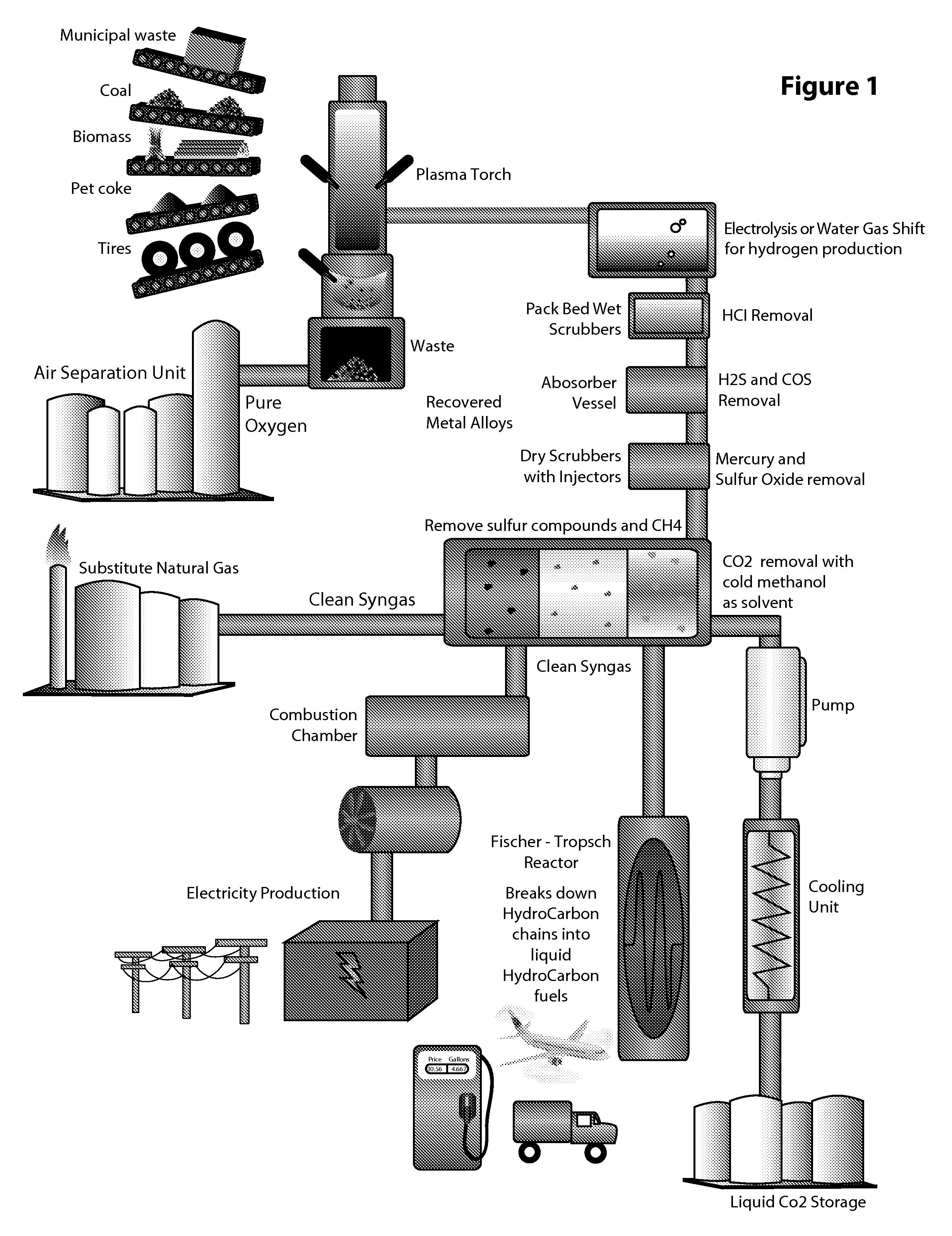

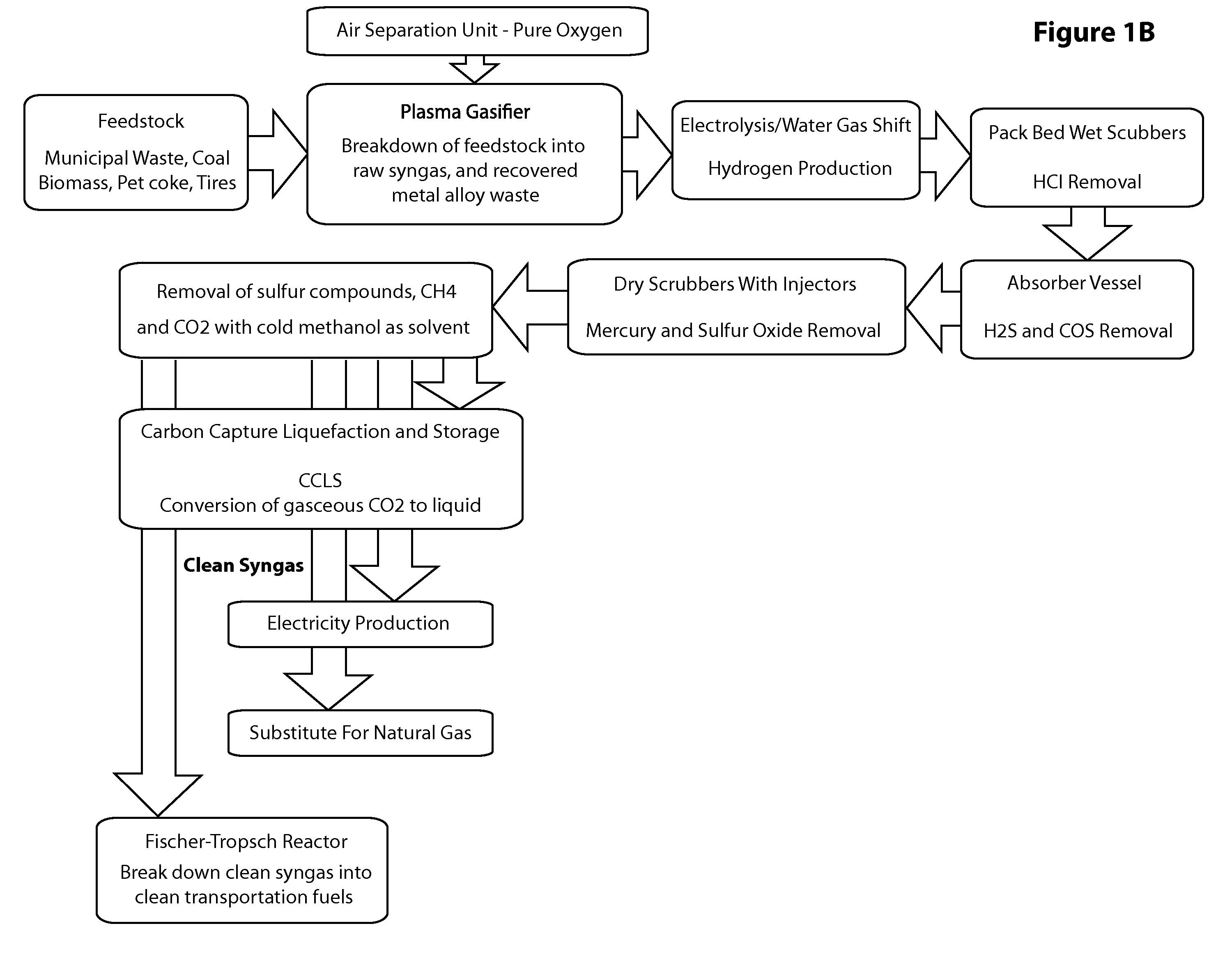

Waste Material, Coal, Used Tires and Biomass Conversion to Alternative Energy and Synthetic Fuels Solutions System with Carbon Capture and Liquefaction

ActiveUS20120032452A1Enhanced overall recoveryImprove powerCombustible gas catalytic treatmentBiofuelsEngineeringOxygen

The system contained within this application for non-provisional patent protection provides the ability to convert municipal solid waste materials, used tires, various biomass including wood chips and other agricultural waste, and the addition of coal into synthesis gas (syngas), with oxygen as plasma gas. The system will accommodate the possibility for variation in feedstock co-gasification of the various materials with plasma torches that will be embedded in a plasma gasification unit. One converted into synthesis gas (syngas), the syngas will be cleaned of acid gases and carbon dioxide (CO2). Carbon dioxide will be captured and converted for various industrial applications instead of being released into the atmosphere. Clean syngas generated by the system will become the gas fuel for various energy solutions including clean electricity, as substitute for natural gas, and ultra clean FT synthetic fuels.

Owner:KUKU LAI O

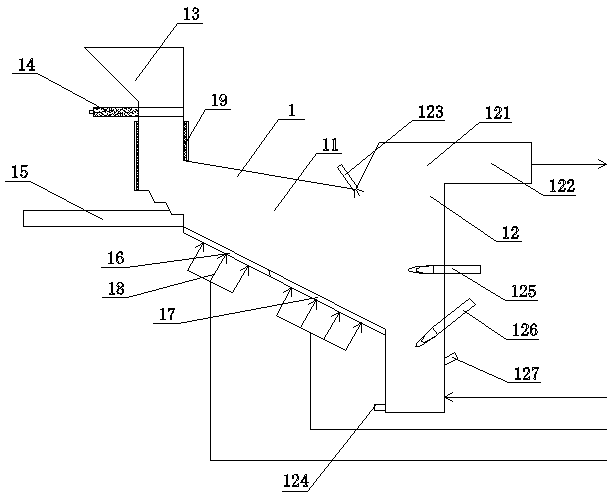

Plasma gasification equipment for changing garbage raw material to be syngas of high heat value

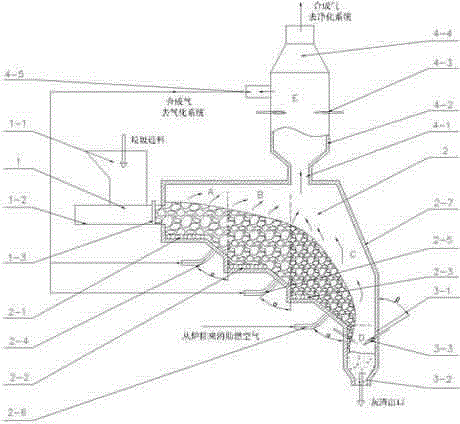

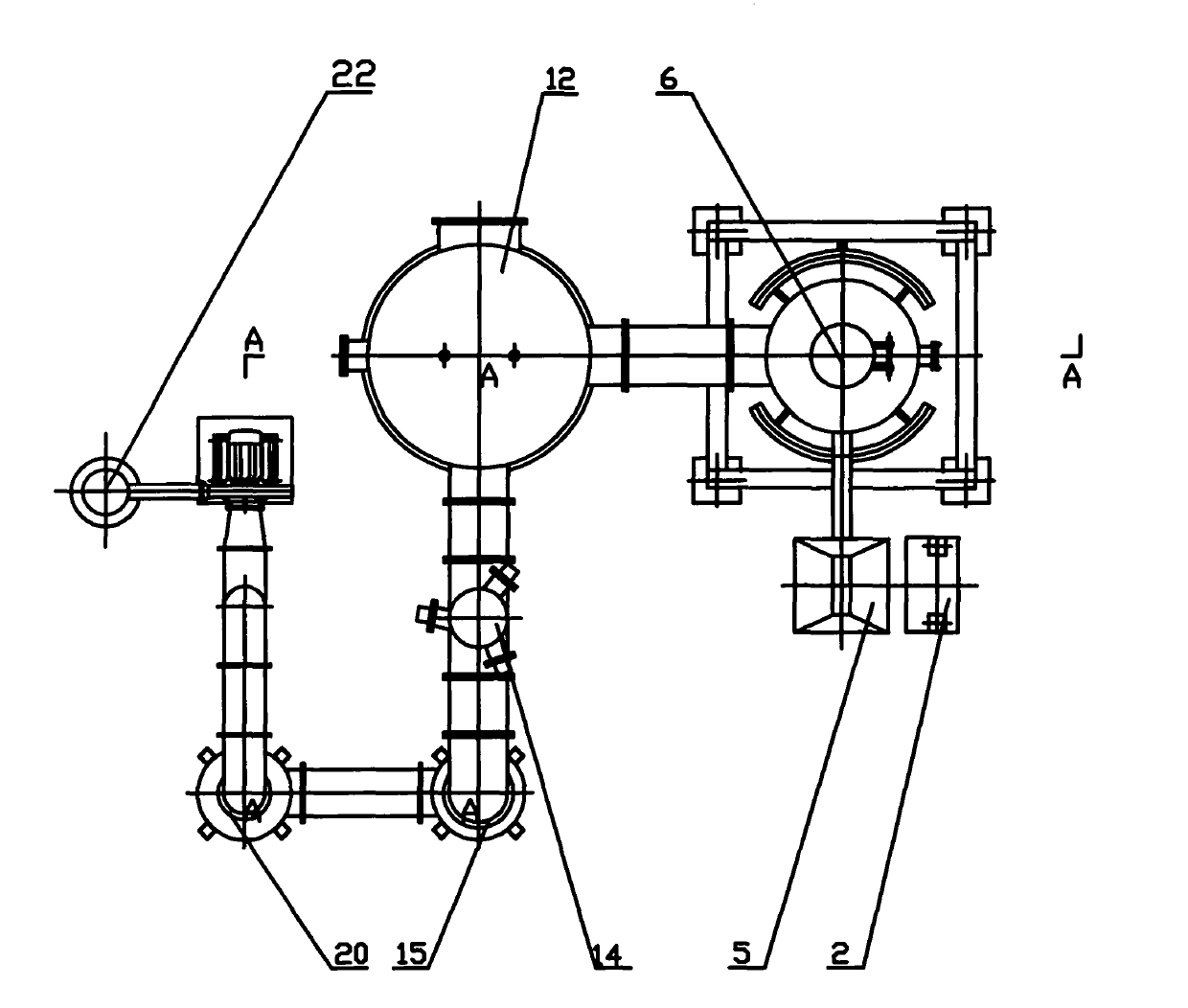

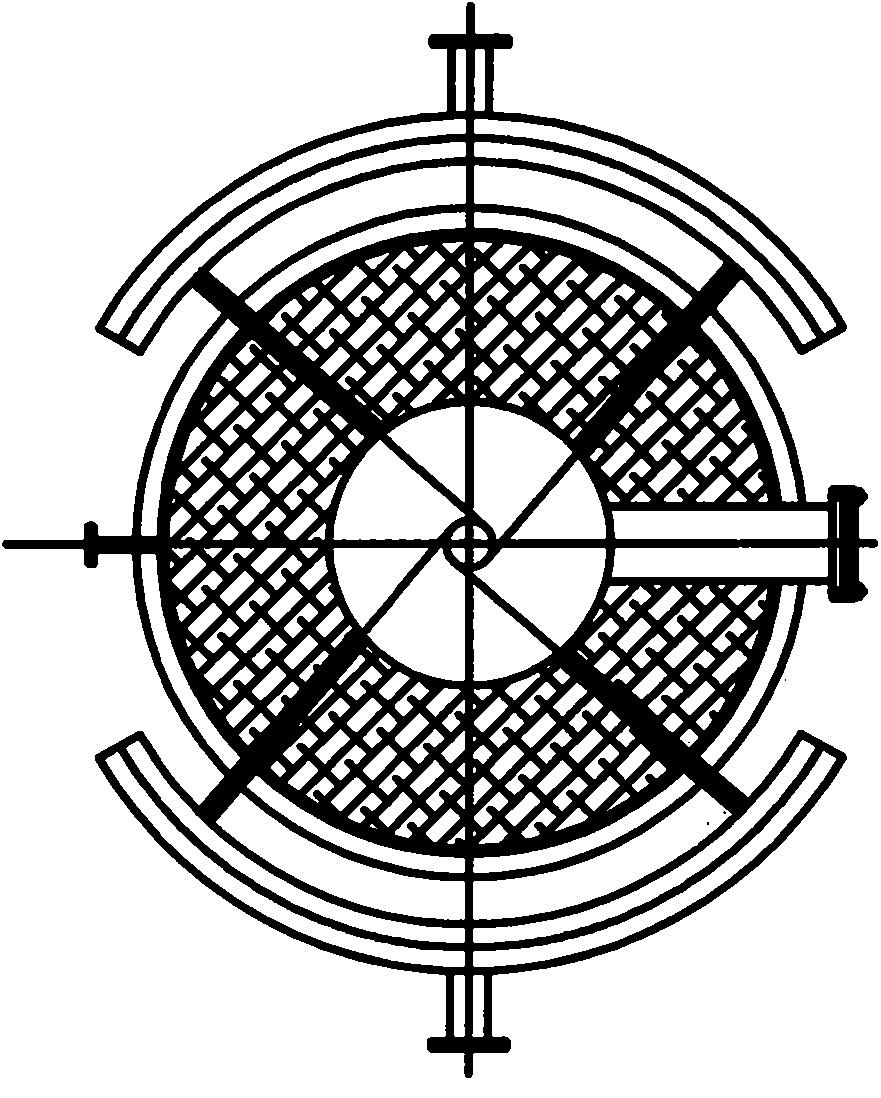

InactiveCN101306796AEliminate pollutionReduce tensionSolid waste disposalHydrogen productionFlue gasProcess engineering

A plasma gasification device for converting raw garbage materials to synthetic gas with high heat value relates to a gasification process device of garbage. The device mainly comprises a gasification reaction furnace, a circular air pipe, a circular blower, a plasma burner, and a screw feeder, wherein the gasification reaction furnace is divided into a baking zone, a pyrolysis zone, a gasification zone, a burning zone and an air chamber according to operation conditions, a flue gas output port is arranged above the baking zone, a synthetic gas output port is arranged at the joint site of the pyrolysis zone and the gasification zone, and a flue gas recirculation input port is arranged inside the air chamber; and a flue gas recirculation air pipe is connected between the flue gas output port and an induced draft port of the circular blower, the air outgoing port of the circular blower is connected with the flue gas recirculation input port, a plasma spray gun is installed on the side wall of the burning zone, and the discharge port of the screw feeder protrudes from the front part of the baking zone into the furnace. The inventive device can treat garbage and convert the garage into synthetic gas with high heat value, which can be used for producing secondary clean energy products, at the same time.

Owner:衢州市广源生活垃圾液化技术研究所

Method and apparatus for plasma gasification of carbonic material by means of microwave radiation

A method and apparatus for gasifying carbonic material in order to produce carbon monoxide and hydrogen; the method comprises the following steps: (a) providing carbonic material; (b) heating, by means of microwave radiation, the carbonic material provided until a plasma point cloud forms in the carbonic material; (c) causing the cloud of plasma points of carbonic material to react with superheated water vapour in order to produce a synthesis gas; and (d) purifying the produced synthesis gas by refeeding it through the cloud of plasma points in the carbonic material wherein it is broken up by microwave radiation of step (b) to achieve the generally complete transformation of the synthesis gas into carbon monoxide and hydrogen. Additionally the cloud of plasma points reacts with oxidation gas (air, oxygen or gas enriched with oxygen) in order to produce the synthesis gas.

Owner:ABA RES DE

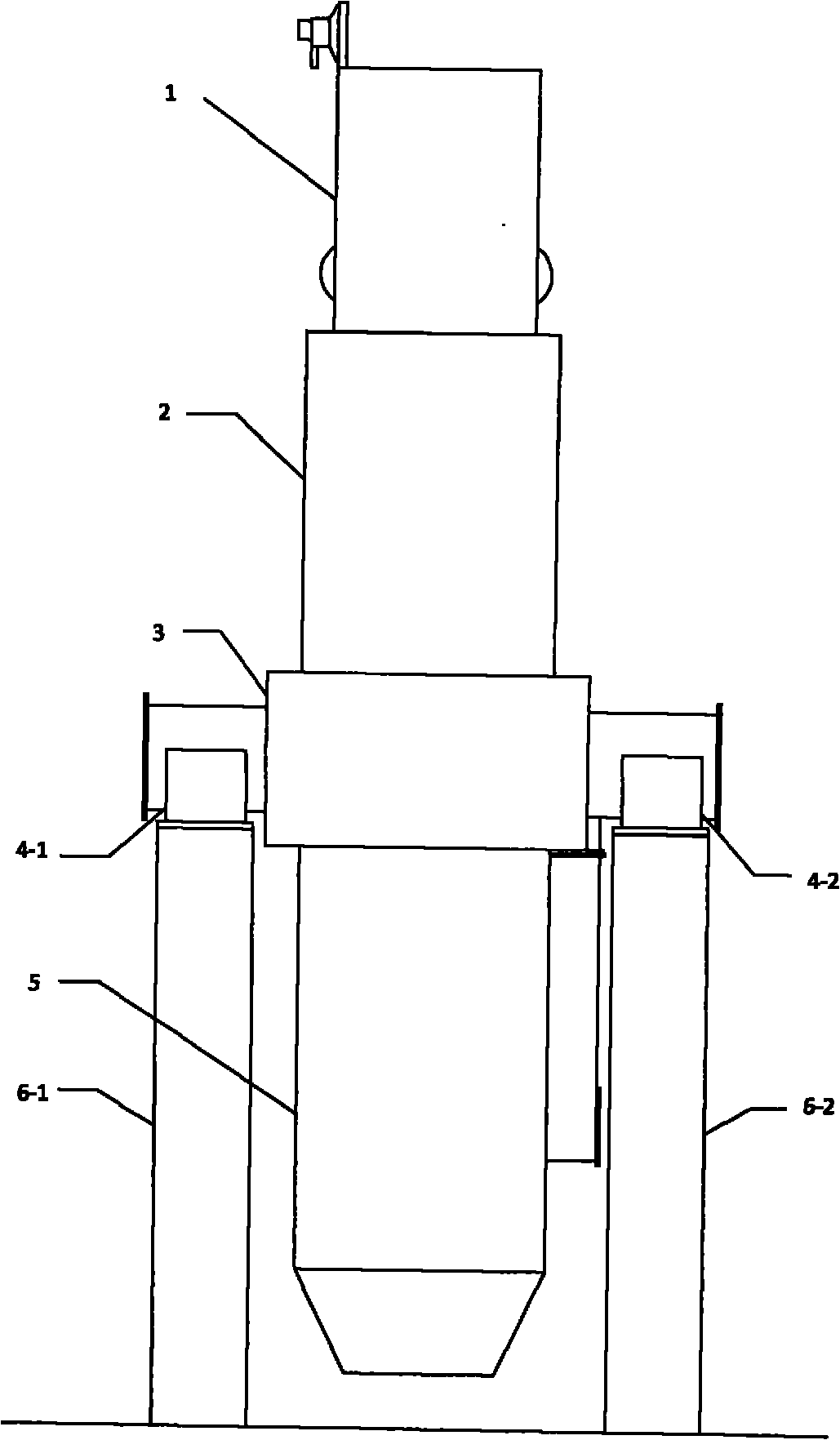

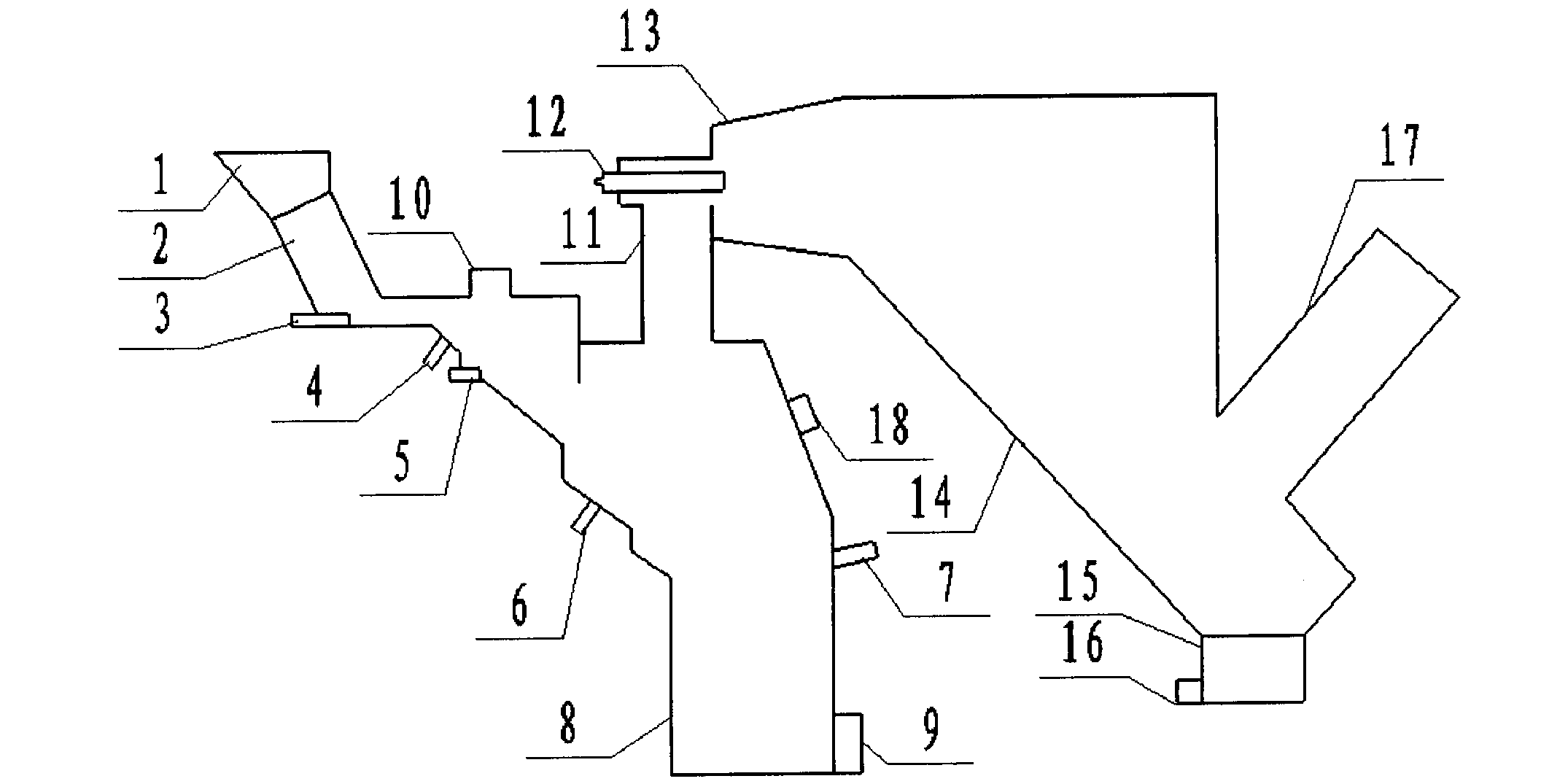

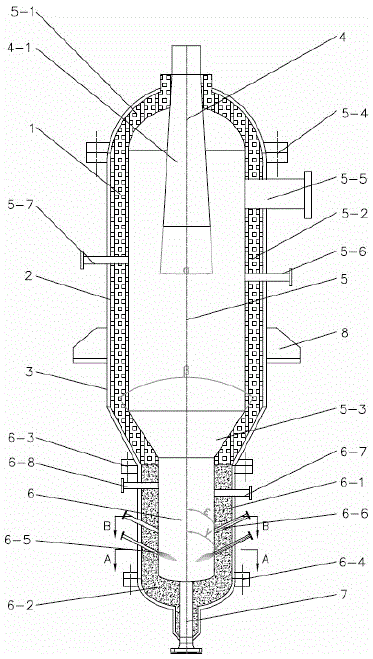

Plasma auxiliary-heating melting and gasifying reactor

ActiveCN104449875ASolve the emission problemFix issues that require reprocessingGasification processes detailsCombustible gas productionOperational costsReaction sequence

The invention relates to a plasma auxiliary-heating melting and gasifying reactor. The plasma auxiliary-heating melting and gasifying reactor comprises a feeder and a reaction chamber, wherein the feeder is connected with the reaction chamber; the reaction chamber sequentially comprises a drying area, a pyrolysis and gasification area, a burn-out area and an ash melting area according to a reaction sequence along a horizontal direction; the drying area is connected with the feeder through a charge port; the bottom of the pyrolysis and gasification area is lower than that of the drying area; the bottom of the burn-out area is lower than that of the pyrolysis and gasification area; the bottom of the ash melting area is lower than that of the burn-out area; the top of the burn-out area is connected with a synthesis gas reforming area through a throat opening; plasma torches are arranged in both the ash melting area and the synthesis gas reforming area. According to the plasma auxiliary-heating melting and gasifying reactor disclosed by the invention, the plasma torches are used as a high-quality external heat source for melting the ash generated after pyrolysis and gasification for household garbage, and the gasified synthesis gas is reformed, thus removing all harmful substances which are possibly generated by the household garbage in pyrolysis and gasification processes, reducing the one-time investment cost and operation cost of garbage plasma gasification, and enabling the synthesis gas to be purer.

Owner:中国东方电气集团有限公司

Oven gas generation of plasma gasified coke oven

InactiveCN1644661AEfficient conversionPromote conversionCombustible gas chemical modificationCoke ovensWater vaporDecomposition

This invention relates to a plasma tails treatment. Hot tails that contains steam and tar vapor from cokery is directly fed into a plasma gasifier to produce synthetic gas, reduced gas and fuel gas. Its procedure is short and easy to operate, has high heat efficiency and little pollution, and needs no catalyst, so as to eliminate toxic operation caused by catalyst decomposition.

Owner:TAIYUAN UNIV OF TECH

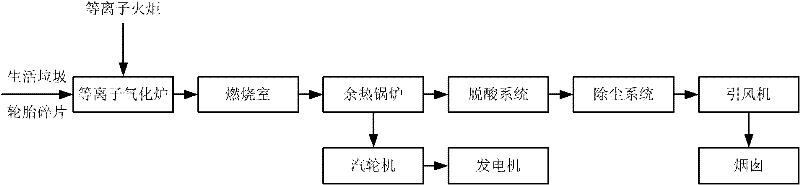

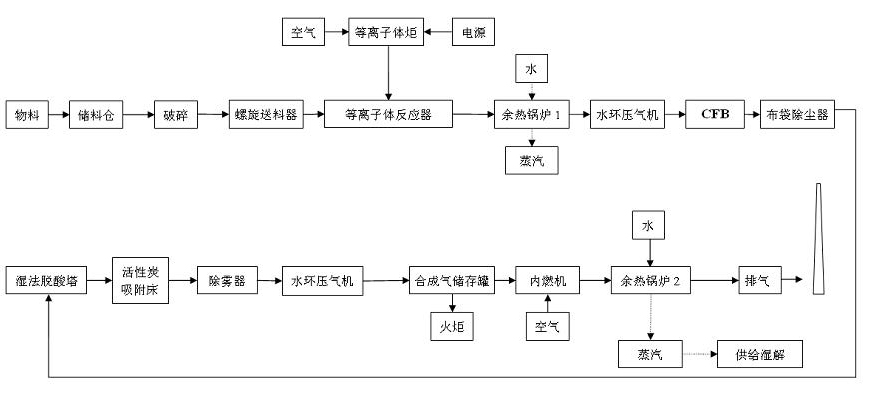

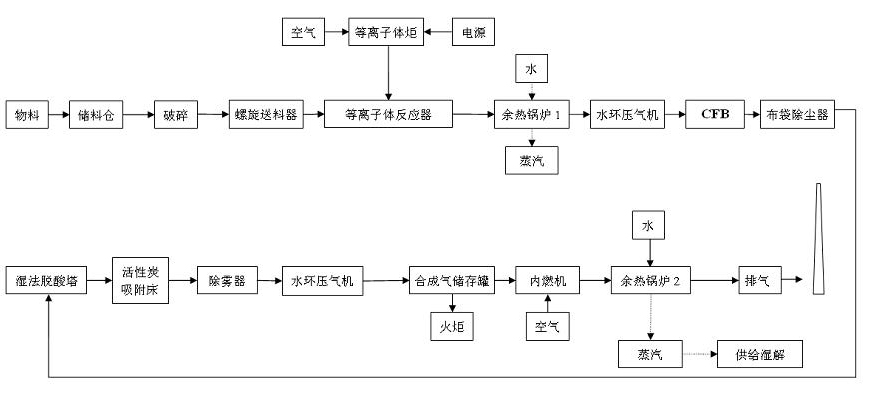

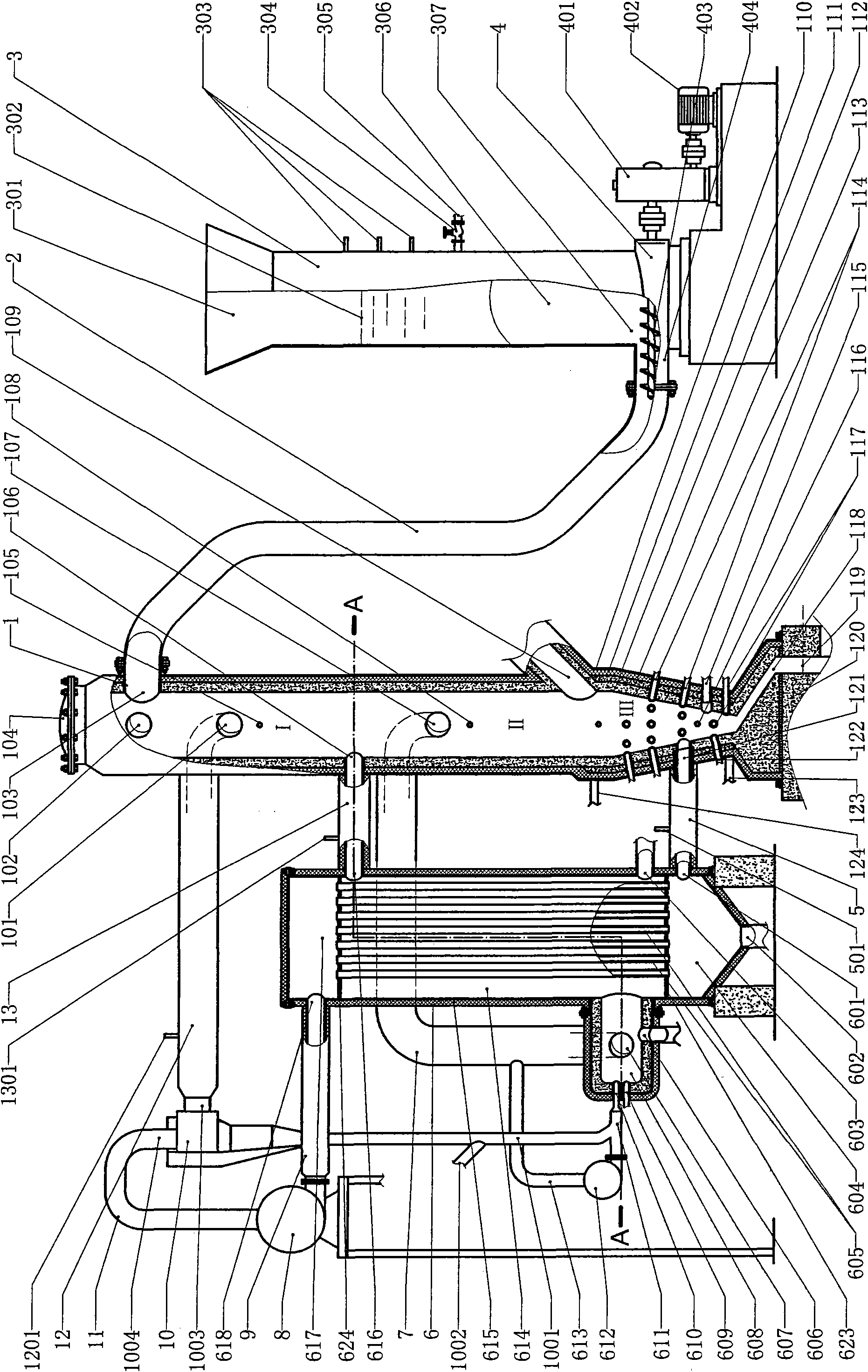

Power generation method and device adopting plasma gasification of household garbage and biomass

InactiveCN102061196AHigh capacity reduction ratioSmall footprintInternal combustion piston enginesEnergy inputWater vaporCogeneration

The invention discloses a power generation method and device adopting the plasma gasification of household garbage and biomass. The power generation device comprises a plasma torch and the working gas can be nitrogen, argon, water vapor or air. A plasma reactor converts household garbage or biomass to a synthesis gas, thus a defined amount of air or oxygen-enriched gas can be used to partly release the calorific value of the organic matter. The synthesis gas is cooled fast with a specially designed gas-water heat exchanger and steam can also be produced. The purification treatment of the synthesis gas adopts the dry process deacidification, the semi-dry process deacidification or the wet process deacidification while a bag filler is used for dedusting, or a small-scale reinforced wet-process spraying deacidification device is used in one device to complete deacidification and dedusting at the same time. An activated carbon adsorption bed is arranged after the deacidification and dedusting devices and used to adsorb heavy metals and dioxin organic pollutants. The clean synthesis gas and an internal combustion gas engine, small-scale gas turbine, steam turbine or centralized generator set are used for power generation; and the combined cycle of cogeneration can be adopted to produce liquid fuel.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Recycling treatment method and apparatus for oil-containing sludge

ActiveCN108328898AReduce contentReduce electric powerSludge treatment by de-watering/drying/thickeningWater contaminantsSlagOil sludge

The invention discloses recycling treatment method and apparatus for oil-containing sludge. The method includes steps of: 1) performing dehydration to the oil-containing sludge to separate an oil / water mixture, feeding the oil / water mixture to an oil-water separator to separate the water phase and the oil phase; 2) drying the dehydrated oil-containing sludge to discharge water and oil vapor, thusforming solid oil sludge; 3) sending the discharged water and oil vapor to the oil-water separator; 4) pyrolyzing the dried solid oil sludge to form pyrolysis gas, pyrolysis oil and pyrolysis charcoal; 5) performing plasma gasification to the pyrolysis charcoal to form synthetic gas and vitreous body slag; 6) performing heat exchange to the pyrolysis gas obtained in the step 4) and the synthetic gas in the step 5) and feeding the gas to a fuel power generation apparatus; 7) sending one part of the vitreous body slag, obtained in the step 5), to a pyrolysis furnace as a heat source, and coolingthe other part to room temperature to obtain a building material. The method can convert the oil-containing sludge into the vitreous body slag and synthetic gas without secondary pollution, thus achieving harmless treatment of the oil-containing sludge.

Owner:CHINA PETROLEUM & CHEM CORP +1

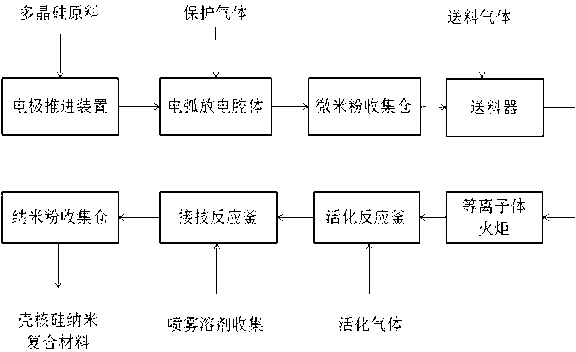

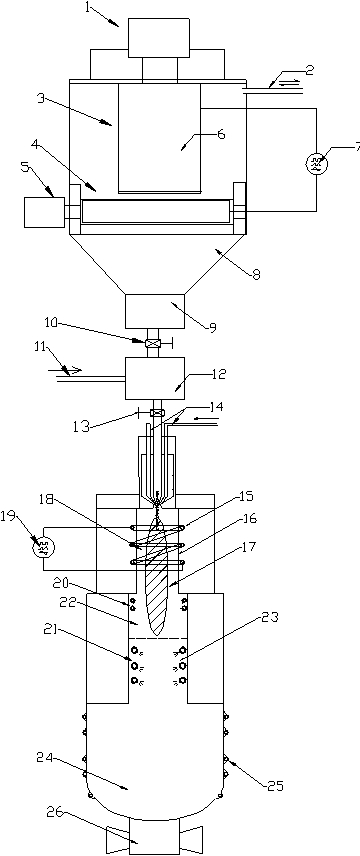

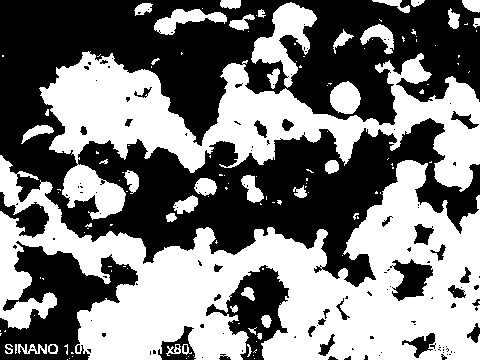

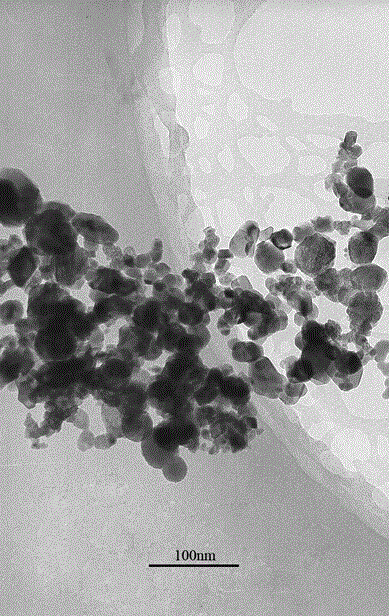

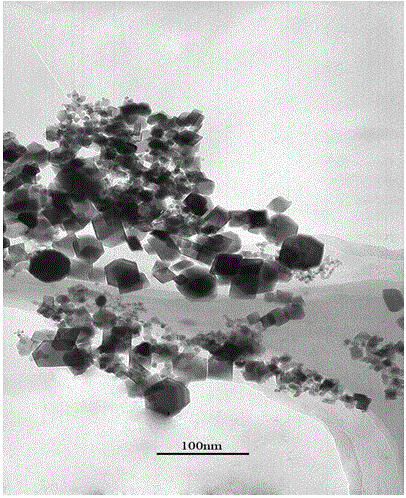

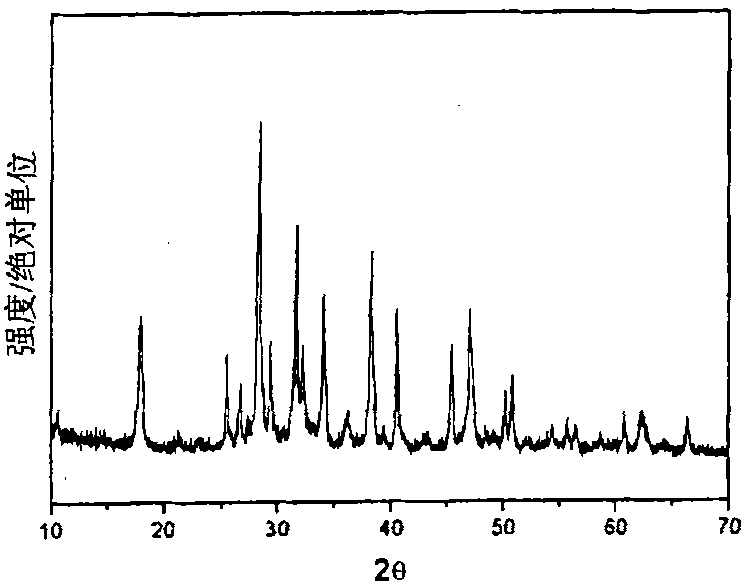

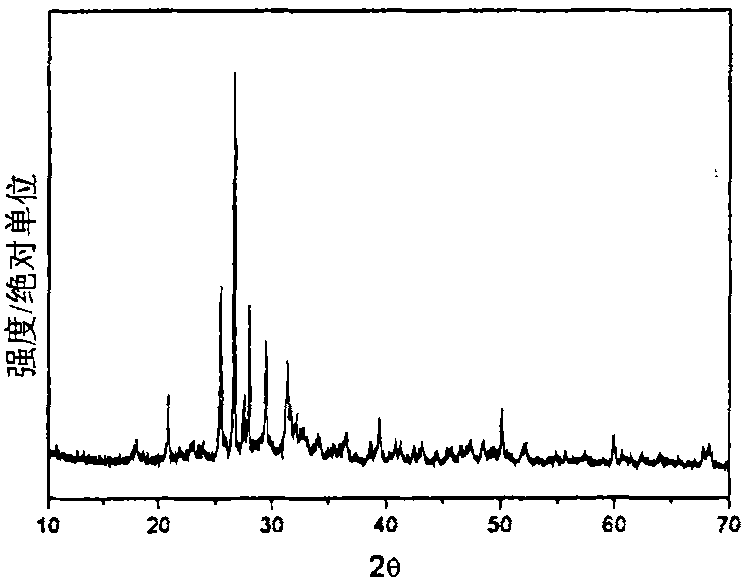

Preparation method of nanometer silicon composite material with core-shell structure

ActiveCN103311511AAvoid reunionPrevent oxidationCell electrodesNanotechnologyIngotBiological activation

The invention discloses a preparation method of a nanometer silicon composite material with a core-shell structure. A silicon rod of a high-purity semiconductor (9N-grade crystal silicon) or solar-grade (6N-grade crystal silicon) cast ingot is directly adopted, the content of phosphorus or boron as a semiconductor silicon doped element is strengthened through the approaches of arc discharge, high temperature plasma gasification, activation treatment and solution grafting, the conversion ratio and purity of a finished product are higher, and a silicon nanosphere has the core-shell structure, so that the prepared nanometer silicon composite material is not easy to agglomerate and oxidize, easy to store, simple and feasible in preparation method and suitable for large-scale production.

Owner:宁波革鑫新能源科技有限公司

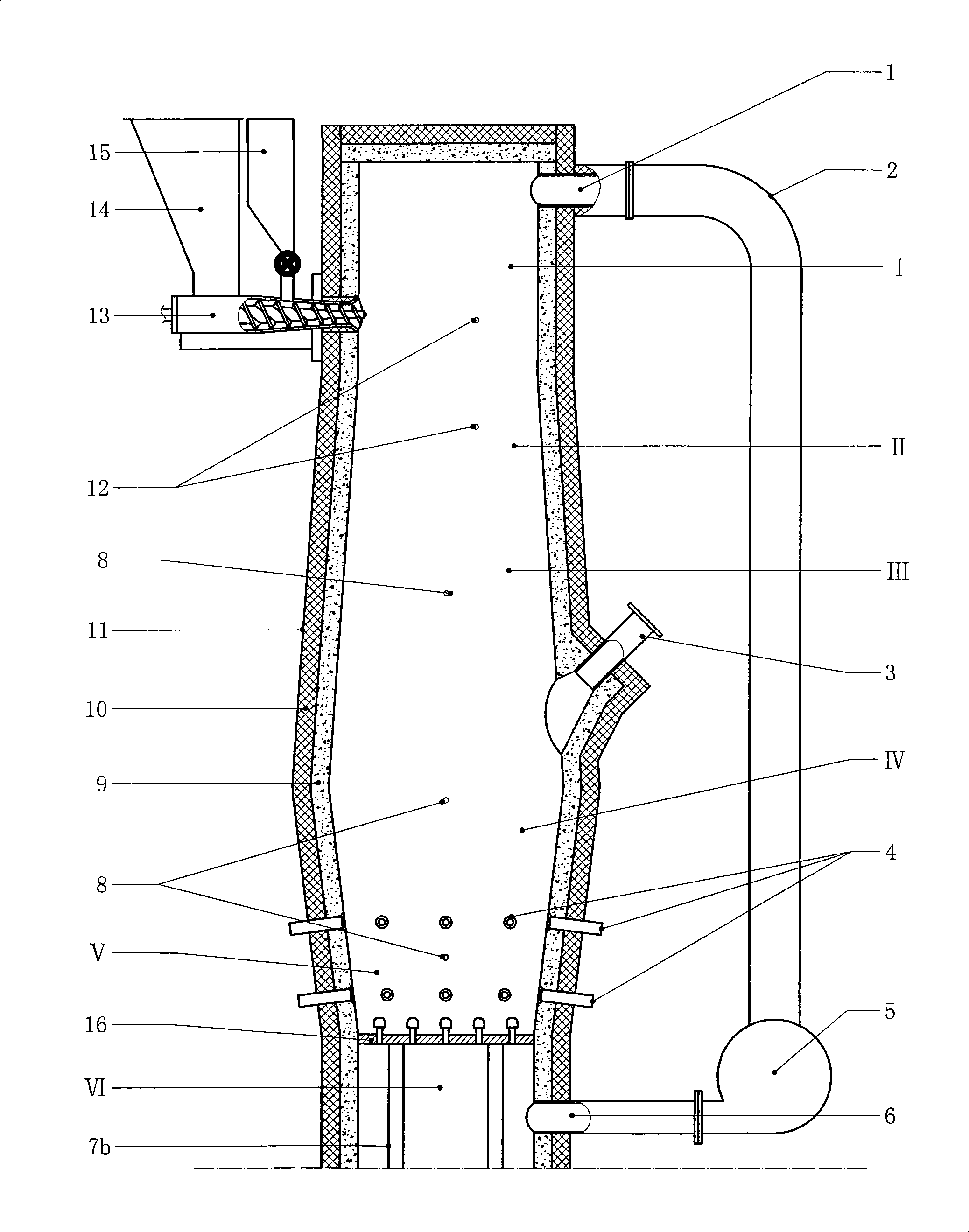

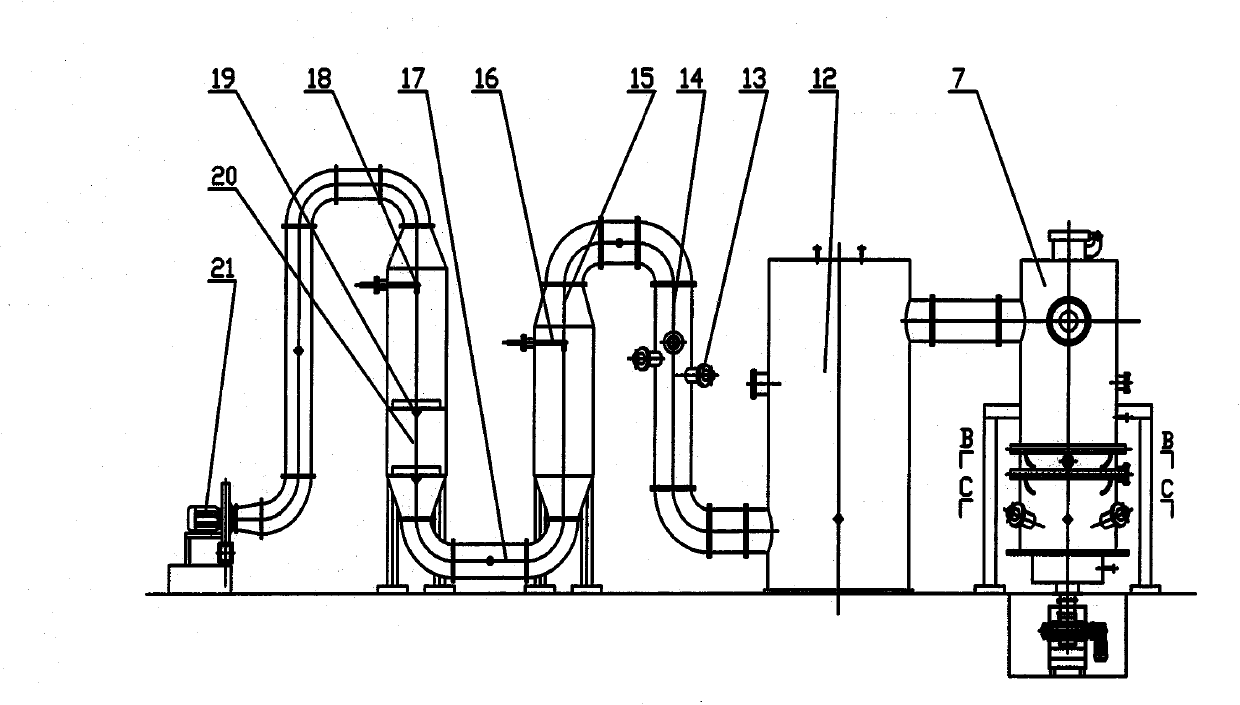

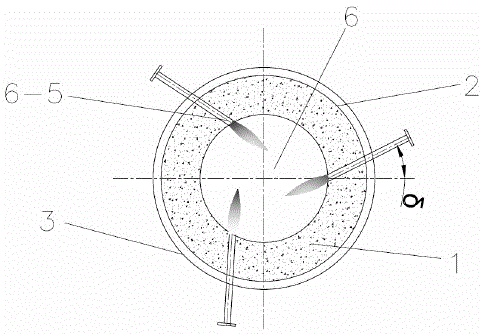

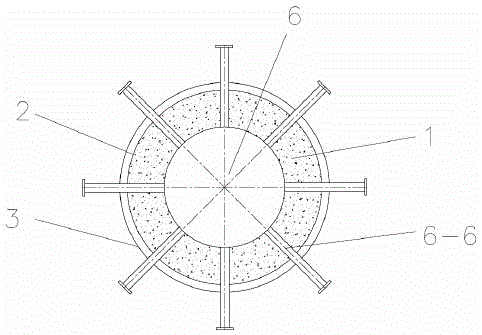

Plasma gasification refuse disposal method and device

ActiveCN102553880AEmission complianceEliminate pollutionSolid waste disposalPlasma technologyProcess engineering

The invention discloses a plasma gasification refuse disposal method and a device, comprising a pyrolysis gasification unit, a quench tower and a turbulent tower. A pyrolysis gasification furnace, an expansion reaction chamber, the quench tower and the turbulent tower are sequentially connected by a channel to form a vertically-alternate curve manifold gas channel. More than two of alternating-current plasma torches are arranged on the wall of the pyrolysis gasification furnace, and an air supply pipe is arranged on the alternating-current plasma torch. The axial lines of the alternating-current plasma torches are tangent with concentric circle taking the axial line of the pyrolysis gasification furnace as the center; a low-power alternating-current plasma torch is arranged on at least one of the expansion reaction chamber or the gas channel of the expansion reaction chamber and the quench tower to perform secondary pyrolysis. The quench tower is used for cooling gas, and the turbulent tower is used for desulfurizing and purifying gas. The invention uses the plasma technology to perform industrial gasification to the municipal solid waste so as to obtain usable gas; and the emission can achieve the environmental standards.

Owner:北京光耀环境科技有限公司

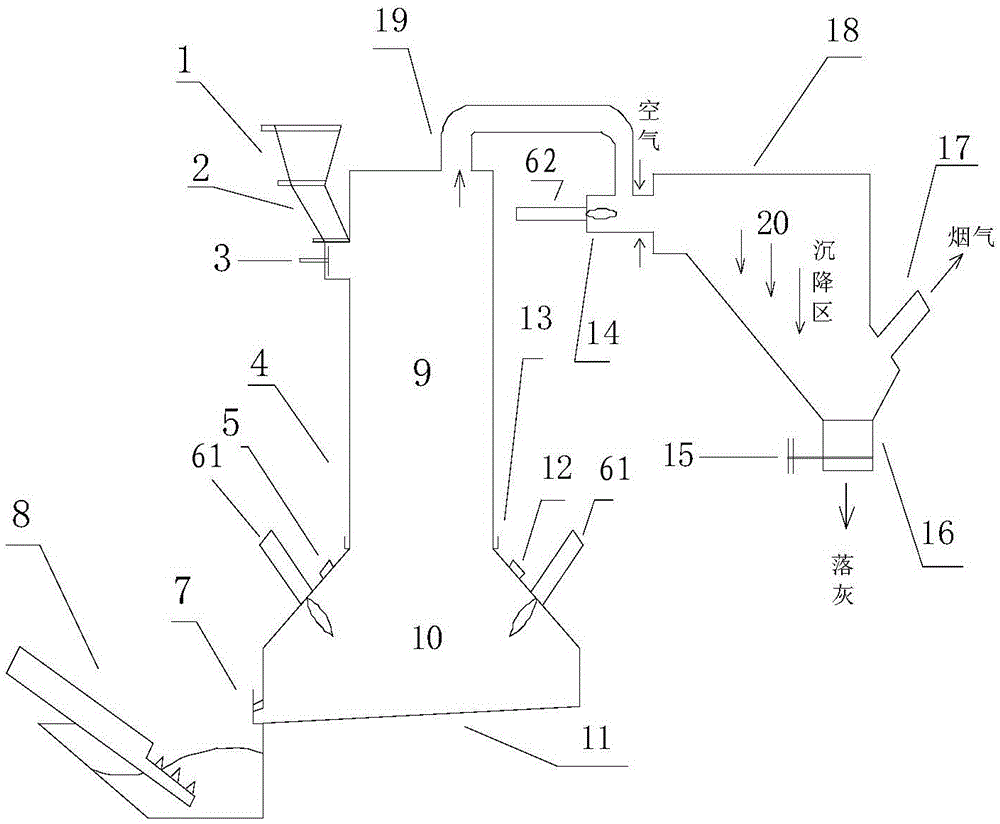

Medical waste plasma processing apparatus

ActiveCN104998888AEasy to flow outImprove gasification efficiencySolid waste disposalIncinerator apparatusCombustion chamberEnvironmental effect

The present invention discloses a medical waste plasma processing apparatus, including a feeding device, a plasma gasifier (4), a plasma secondary combustion chamber (18) and a deslagging device (8). The plasma gasifier (4) employs a vertical shaft furnace structure, and includes a garbage gasifier (9) on the upper part and an ash molten pool (10) on the lower part; the medical waste is sent into the plasma gasifier by the feeding device, and subjected to gasification, burning and melting treatment; the gasification synthetic gas formed in the garbage gasifier (9) enters a the plasma secondary combustion chamber (18); molten slag produced in the ash molten pool (10) is discharged into the deslagging device (8); and the gasification synthetic gas fully combusts in the plasma gasification secondary combustion chamber (18). The apparatus of the present invention has the advantages of high efficiency of treatment on medical waste, good environmental effect, and convenience for usage.

Owner:航天神洁(北京)科技发展有限公司 +1

Plasma waste gasification and pyrolysis equipment

ActiveCN104745235AImprove energy utilizationSolid waste disposalSpecial form destructive distillationEngineeringProcess engineering

The invention discloses plasma waste gasification and pyrolysis equipment. The plasma waste gasification and pyrolysis equipment comprises a plasma waste gasification furnace, a waste pyrolysis furnace and a waste automatic feeding device; a synthesis gas outlet is formed in the top of the gasification furnace; a gasification furnace top plasma torch is arranged on the top of the gasification furnace; feeding ports of a plurality of gasification furnace cabins are formed in the middle lower part of the gasification furnace; a gasification furnace air distribution plate is arranged below the feed ports, and a gasification bottom plasma torch is arranged on the bottom of the gasification furnace; a pyrolysis synthesis gas outlet is formed in the top of the pyrolysis furnace, a feed port of the pyrolysis furnace cabin is formed in the middle lower part of the pyrolysis furnace, a pyrolysis furnace air distribution plate is arranged below the feed port. Household garbage enters the gasification furnace from the gasification furnace cabin through feed ports, gasification media enter the gasification furnace through the gasification furnace air distribution plate and carry out gasification reaction with the garbage to generate synthesis gas; the synthesis output from the top of the gasification furnace enters the pyrolysis furnace through the pyrolysis furnace air distribution plate and then carries out pyrolysis reaction with the garbage entering from the pyrolysis furnace cabin.

Owner:SHANGHAI BOILER WORKS

Biomass pyrolysis gasification method

ActiveCN105586091ARelaxed size requirementsReduce preprocessing power consumptionCombustible gas productionMicrowave pyrolysisTar

The invention discloses a biomass pyrolysis gasification method which includes the following steps: 1) feeding a biomass raw material into a microwave pyrolysis reaction section to perform pyrolysis under microwave to generate gas, tar and semicoke as pyrolysis products; 2) respectively feeding the pyrolysis products and a first working gas into a microwave oriented gasification section to perform a gasification reaction to obtain a gasification product; 3) in the gasification product, separating gasified semicoke into two parts, wherein one part is spirally transported to the upper part of a microwave pyrolysis reaction section from the bottom of the microwave oriented gasification section so that this part of semicoke is mixed with the biomass raw material to perform microwave pyrolysis, and the other part of the semicoke is spirally transported to a plasma reaction section with a gas-phase volatile component in the gasification product; 4) performing a plasma gasification reaction to the material fed into the plasma reaction section to obtain high-quality synthetic gas which then is discharged out from a gas outlet while solid residues are discharged from the bottom of the plasma reaction section. The method is high in biomass gasification rate and carbon conversion rate. The synthetic gas is high in quality, can satisfy demand on synthetic liquid fuels and has excellent application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

Plasma gasification treatment system of solid organic waste

ActiveCN103013568AImprove gasification efficiencyEfficient conversionEnergy based chemical/physical/physico-chemical processesCombustible gas productionForming gasProcess engineering

The invention discloses a plasma gasification treatment system of solid organic waste, which comprises a feeding part, a drying device, a gasifier and a synthesis gas purification device, wherein the gasifier comprises a gasification plasma gun, and the synthesis gas purification device comprises a reheating plasma gun. With the adoption of the gasification treatment system, solid waste enters the gasification treatment system through the feeding part, and moisture in the solid waste is evaporated after the solid waste passes through the drying device; then the dried solid waste enters the gasifier, and gasification reaction is carried out on organic substances in the solid waste to produce synthesis gas and a polymer hydrocarbon composite under the action of the gasification plasma gun; and the synthesis gas and the polymer hydrocarbon composite produced by the gasifier enter the synthesis gas purification device, cracking is carried out on the polymer hydrocarbon substances to produce the synthesis gas under the action of the reheating plasma gun, fly ashes in the synthesis gas are removed through settlement of the synthesis gas, and then the purified synthesis gas is output. The system has high gasification efficiency, is stable to run and no-pollution.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

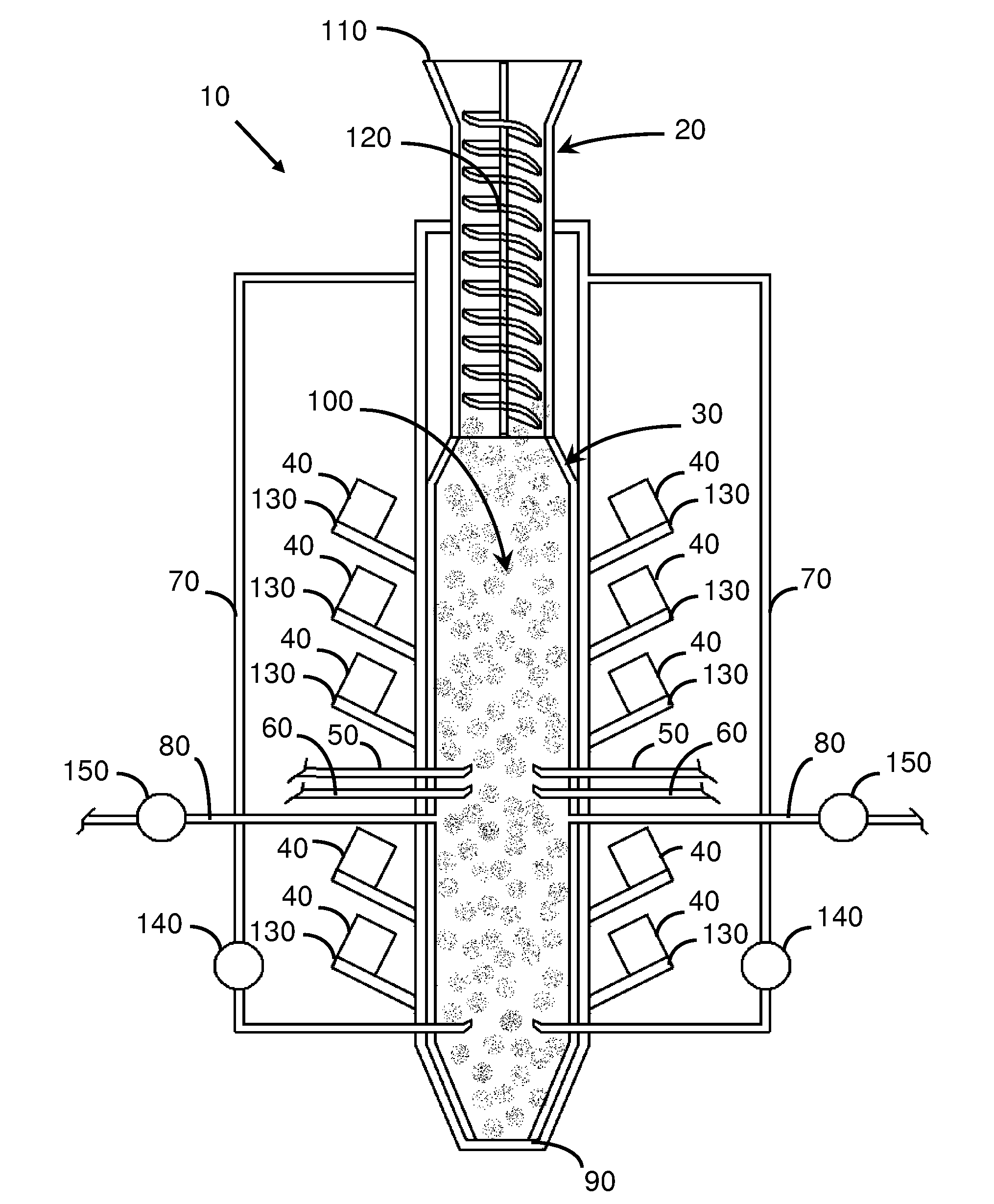

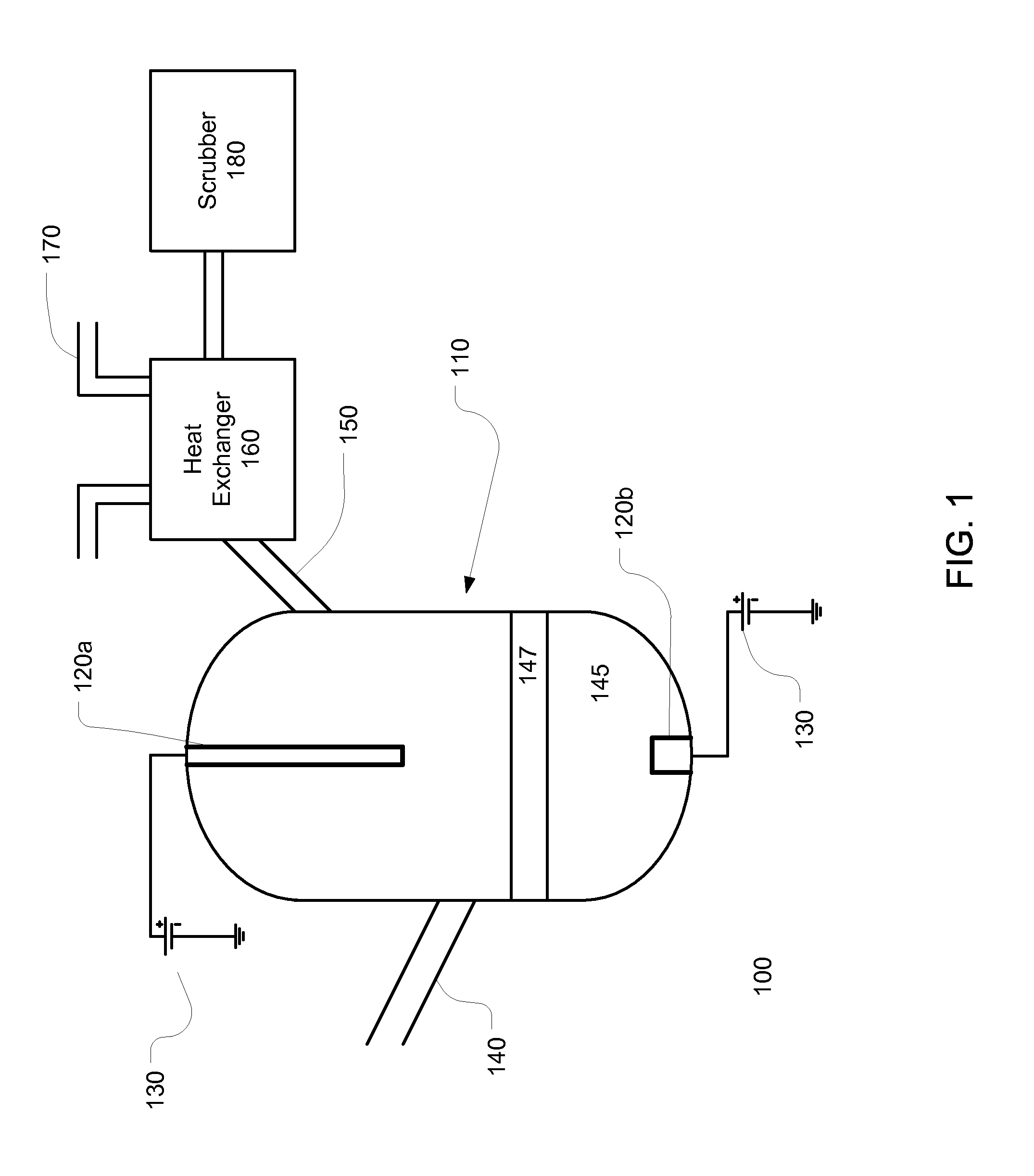

High pressure gasifier system using electrically assisted heating

ActiveUS20110126461A1Good and more complete processingIncrease temperatureGasifier electrodesEngine sealsElectricityMicrowave

The problems of the prior art are overcome by the apparatus and method disclosed herein. The reactor vessel of a plasma gasifier is operated at high pressure. To compensate for the negative effects of high pressure, various modifications to the plasma gasifier are disclosed. For example, by moving the slag, more material is exposed to the plasma, allowing better and more complete processing thereof. In some embodiments, magnetic fields are used to cause movement of the slag and molten metal within the vessel. An additional embodiment is to add microwave heating of the slag and / or the incoming material. Microwave heating can also be used as an alternative to plasma heating in a high pressure gasification system.

Owner:INENTEC

COMBINED PROCESSES FOR UTILIZING SYNTHESIS GAS with LOW CO2 EMISSION AND HIGH ENERGY OUTPUT

ActiveUS20140364517A1Reduce and eliminate emission of pollutantUse directlyCombustible gas catalytic treatmentBiofuelsSource materialHigh energy

A process and system for producing liquid and gas fuels and other useful chemicals from carbon containing source materials comprises cool plasma gasification and / or pyrolysis of a source material to produce synthesis gas using the produced synthesis gas for the production of a hydrocarbon, methanol, ammonia, urea, and other products. The process and system are capable of sequestering carbon dioxide and reducing NOx and SOx.

Owner:QUANTAFUEL AS

Plasma gasification and melting system for solid waste centralized processing

ActiveCN108097703AReduce the amount of dustPrevent regenerationWaste processingTransportation and packagingFuranCombustion chamber

The invention discloses a plasma gasification and melting system for solid waste centralized processing, and relates to the technical field of solid waste thermochemical treatment. The system comprises a plasma gasification and melting furnace, a synthesis gas outlet of the plasma gasification and melting furnace is connected with a secondary combustion chamber, a high-temperature smoke outlet ofthe secondary combustion chamber is sequentially connected with a waste heat recycling system and a smoke purifying system, and the synthesis gas outlet of the plasma gasification and melting furnaceis further connected with a reforming chamber, a high-temperature synthesis gas outlet of the reforming chamber is sequentially connected with a heat exchange system and a synthesis gas purifying system. The controlled oxygen combustion technology is adopted in the plasma gasification and melting furnace, the excessive air coefficient of primary air is about 0.3 to 0.5, the dust amount in rough synthesis gas can be effectively reduced, re-generation of toxic and harmful substances of dioxin and furan can be restrained, and the production of flying ash amount can be reduced.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

Domestic refuse plasma gasification reaction furnace

ActiveCN105018149ASolve the emission problemSolve processingSolid waste disposalCombustible gas productionHazardous substanceEngineering

The invention discloses a domestic refuse plasma gasification reaction furnace which comprises a pyrolysis gasification reaction chamber and an ash melting chamber, wherein the pyrolysis gasification reaction chamber comprises a top end socket, a middle cylinder and a bottom cone port, wherein a conical-pipe-shaped refuse inlet is embedded and installed in the top end socket; the middle cylinder is provided with a synthetic gas outlet; the mounting height of the synthetic gas outlet is greater than the base plane of the conical pipe; the ash melting chamber comprises a cylinder and a bottom end socket; the cylinder is uniformly provided with a plurality of plasma torch mounting ports on the same horizontal plane; the cylinder is also uniformly provided with a plurality of air inlets on another same horizontal plane; and air introduced through the air inlets is matched with heating of the plasma torches to perform secondary gasification. The plasma torches are used as the external heat source to melt the ash generated after domestic refuse pyrolysis gasification, thereby removing all the harmful substances which are possibly generated in the domestic refuse pyrolysis gasification process, lowering the disposable input cost and operating cost for refuse plasma gasification, and purifying the synthetic gas.

Owner:中国东方电气集团有限公司

Garbage plasma gasification furnace taking vapor as gasification medium

ActiveCN104479743AExtended service lifeReduce maintenance costsGasification processes detailsCombustible gas productionHigh energyWater vapor

The invention discloses a garbage plasma gasification furnace taking vapor as a gasification medium. The garbage plasma gasification furnace comprises an upper garbage gasification room and a low high-temperature vapor generating room, wherein water-cooling furnace arches which are arranged at intervals are arranged between the garbage gasification room and the vapor generating room; the garbage gasification room is separated from the high-temperature vapor generating room by virtue of the water-cooling furnace arches; two plasma torches are arranged along the peripheral direction of the inner wall of the high-temperature vapor generating room; low-temperature vapor is taken as a working gas of the plasma torches. According to the garbage plasma gasification furnace disclosed by the invention, the vapor plasmas are adopted to gasify the garbage, so that a high-temperature and high-energy environment is provided for the gasification reaction, and thus, the material heating rate is high and the reaction rate is high, the treatment efficiency is very high and some reactions which cannot be performed under the common gasification condition further can be generated.

Owner:中国东方电气集团有限公司

Calcium oxide and plasma body cooperative gasified domestic garbage gasification system and equipment

ActiveCN101880551ANo financial pressureReduce financial pressureOrganic compound preparationSolid waste disposalCo operativeWaste material

The invention provides a calcium oxide and plasma body cooperative gasified domestic garbage gasification system and equipment, which relate to solid organic waste disposal equipment. The gasification system consists of a plasma body gasification furnace, an air sealing material feeding device, a heat exchanger, a draught fan and a cyclone separator, wherein a material outlet of the air sealing material feeding device is connected to a material inlet of the gasification furnace, a thermolytical air outlet of the gasification furnace is connected to a carbonatation reaction chamber of the heat exchanger, a hot carrier outlet of the heat exchanger is connected to a hot carrier inlet of the gasification furnace, the hot carrier outlet of the gasification furnace is connected to the cyclone separator, the cyclone separator is connected to the draught fan, the draught fan is connected to a thermolytical air inlet of the heat exchanger, a thermolytical air outlet of the heat exchanger is connected to a thermolytical air inlet of the gasification furnace, and a synthesis air outlet is connected out at the engagement position of a thermolytical region and a gasification region. The system can realize the domestic garbage disposal without discharge or pollution, and is applicable to the harmless disposal of urban domestic garbage, rural domestic garbage, medical garbage, industrial high molecular waste materials and the like.

Owner:上海格灵迈环境科技有限公司

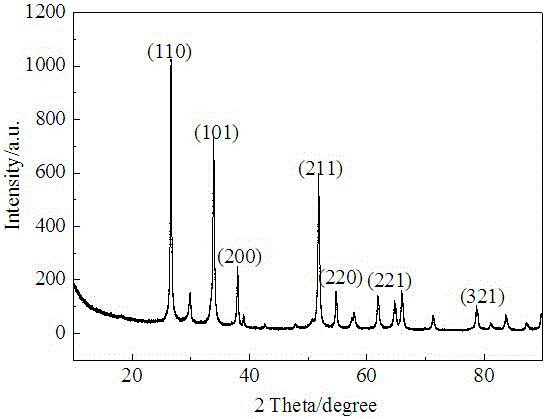

Technology for preparing nano-metallic oxide powder with DC (direct-current) plasma method

ActiveCN106044849ASimple processReduce manufacturing costGallium/indium/thallium compoundsNanotechnologyAtomic clusterOxygen

A technology for preparing nano-metallic oxide powder with a DC (direct-current) plasma method comprises steps as follows: a high-purity metal block is put into a smelting furnace and is melted, and a melt delivery tube connected with the smelting furnace is heated; a reaction chamber is subjected to vacuum pumping until the pressure reaches 2-10 MPa, cooling air is introduced into the reaction chamber, and cooling water is introduced into a reactor interlayer arranged in the reaction chamber; an arc plasma gasification system power source of a reactor is switched on, gasification current is adjusted to 10-2,000 A, and voltage is adjusted to 5-400 V; inert gas is introduced into the metal melt, the melt delivery tube is adopted for flow guidance, the gasification reaction is performed, and metal jet is formed; the metal jet is gasified under the action of arc plasma so as to form atomic clusters, the atomic clusters are subjected to a reaction with oxygen, oxide nanoparticles are formed, is condensed under cold-air negative pressure and enters a powder collecting chamber with cold air flow, and the nano-metallic oxide powder is obtained. The technology is simple, does not need a plasma source and has high yield, and the prepared nano-metallic oxide powder is not prone to agglomeration, is high in purity and facilitates large-scale production.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

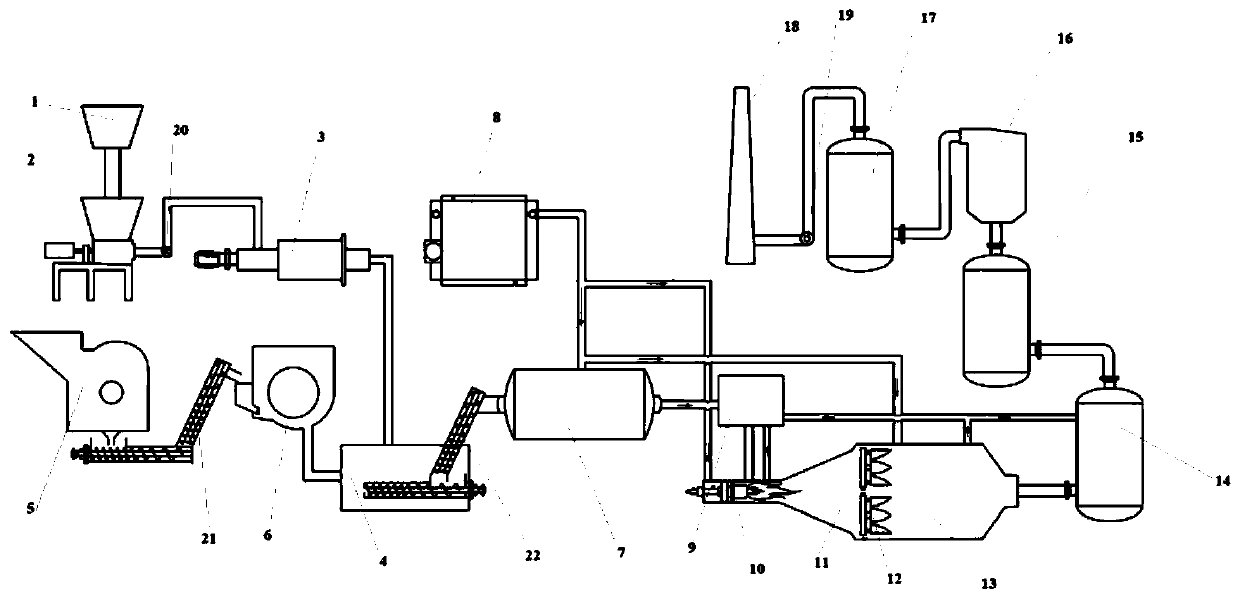

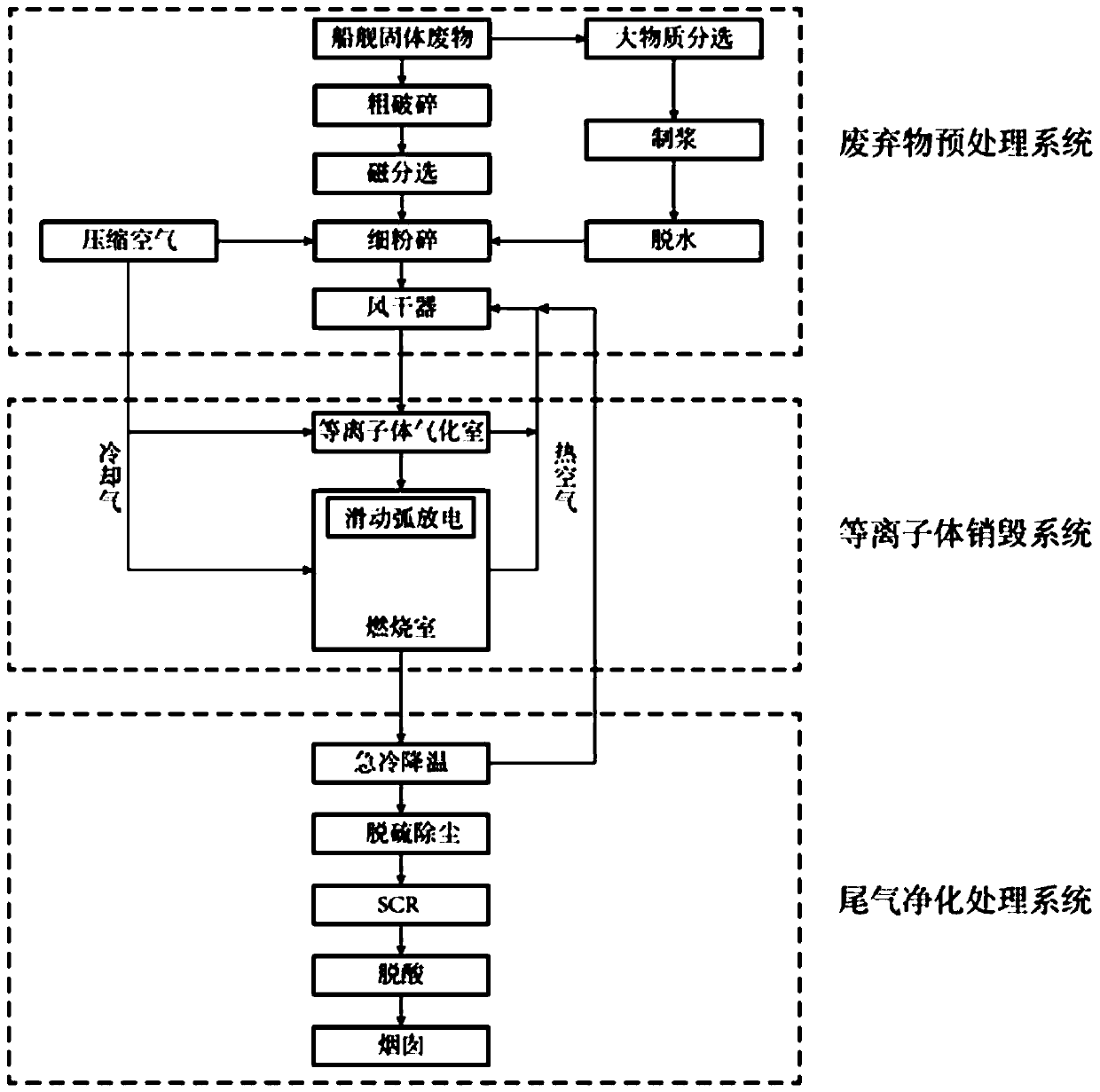

Multi-stage plasma processing method and multi-stage plasma processing system for solid waste of ship

ActiveCN110328214APromote gasificationReduce volumeSolid waste disposalTransportation and packagingCombustion chamberHigh energy

The invention discloses a multi-stage plasma processing method and multi-stage plasma processing system for solid waste of a ship, wherein combustible solid waste generated on the ship is coarsely crushed and then enters a transfer mixing bin, mixture of the transfer mixing bin is conveyed to a fine material crushing device and is further crushed into combustible micron-sized waste particles withthe particle size smaller than 15 [mu]m, and the water content of the combustible micron-sized waste particles is reduced to 4% or below; the waste particles are injected into a plasma vaporizing chamber in a gas conveying mode and are rapidly vaporized under the action of high-energy thermal plasma plume, and the waste particles are converted into low-heat-value crude synthesis gas; the generatedsynthesis gas flows into a combustion chamber, organic matter is completely converted into inorganic micromolecular matter such as carbon dioxide and water vapor under the auxiliary combustion of sliding arc discharge non-thermal plasma, and inorganic matter is converted into inert dust; and the gas flow processed by the combustion chamber is discharged after reaching the standard through tail gas purification measures such as quenching cooling, desulfurization and dust removal, denitrification, and deacidification.

Owner:SUN YAT SEN UNIV

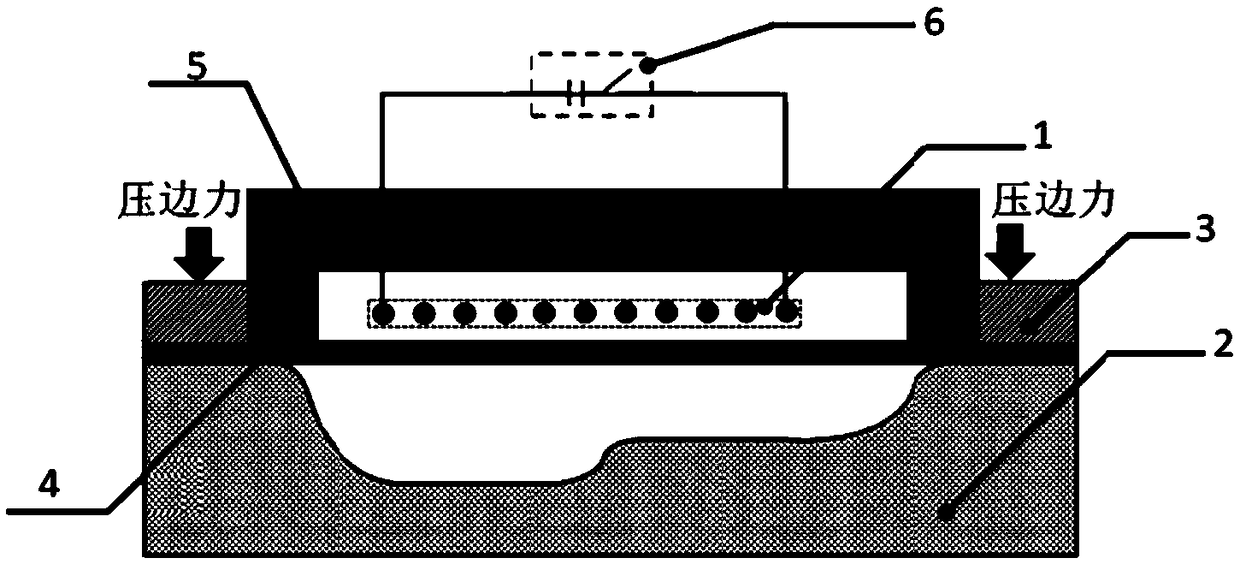

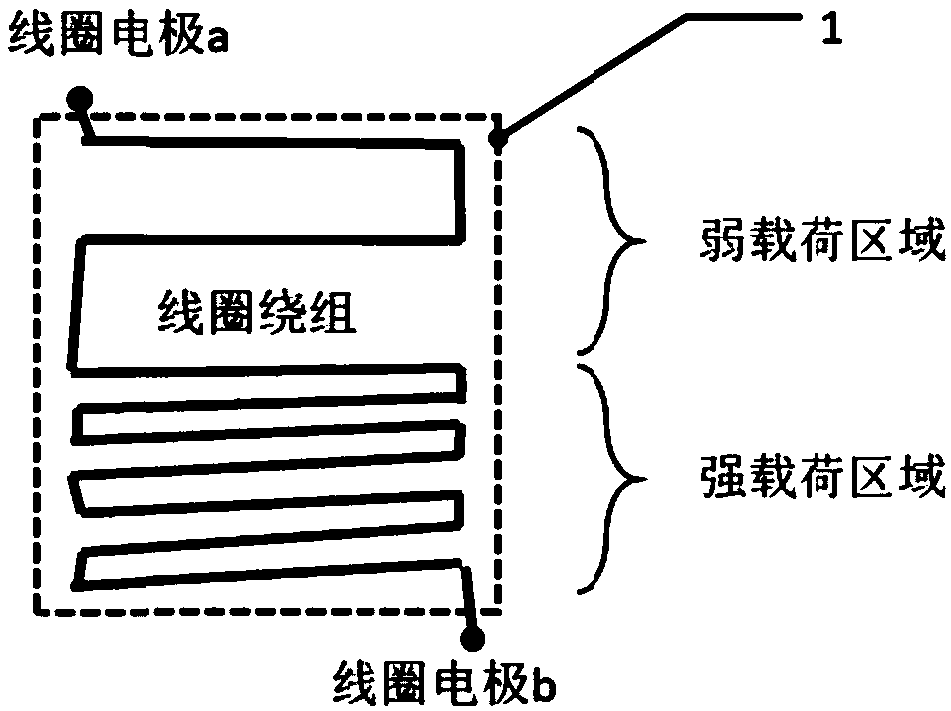

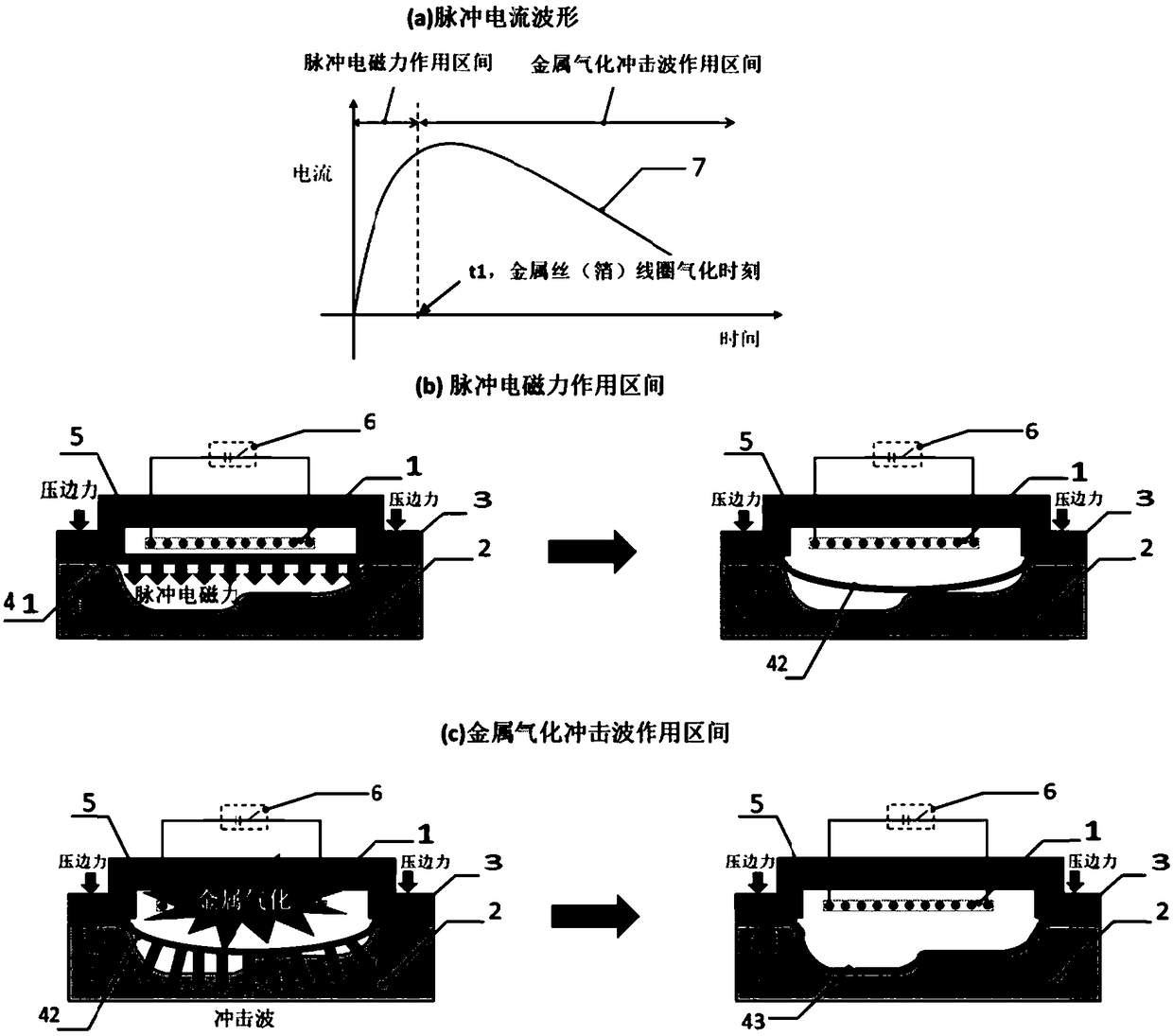

Metal forming device and method

The invention discloses a metal forming device and method. The device comprises a metal forming coil, a die, a power source, a blank holder and a constraint cavity for centralizing shock waves generated during high-temperature gasification of the metal forming coil. The die and a workpiece are oppositely put, blank holding force is applied to the flange region of the workpiece through the blank holder, and the forming coil is put between the workpiece and the constraint cavity and connected with the power source. During working, the forming coil senses pulse electromagnetic force in the workpiece region through pulse currents to drive the workpiece to deform; and meanwhile, joule heat is generated in the forming coil region through the pulse currents, the temperature exceeds the melting point of metal so that metal gasification can occur, plasma is generated, the shock waves are generated, and the workpiece is driven to further deform. Pulse electricity and the shock waves generated through through-flow metal plasma gasification are combined, high-speed pulse forming of the metal workpiece is achieved, the machining difficulty and cost of the forming coil are effectively reduced, the requirements of forming on the conductivity of the workpiece are lowered, and the forming capacity is remarkably improved.

Owner:HUAZHONG UNIV OF SCI & TECH

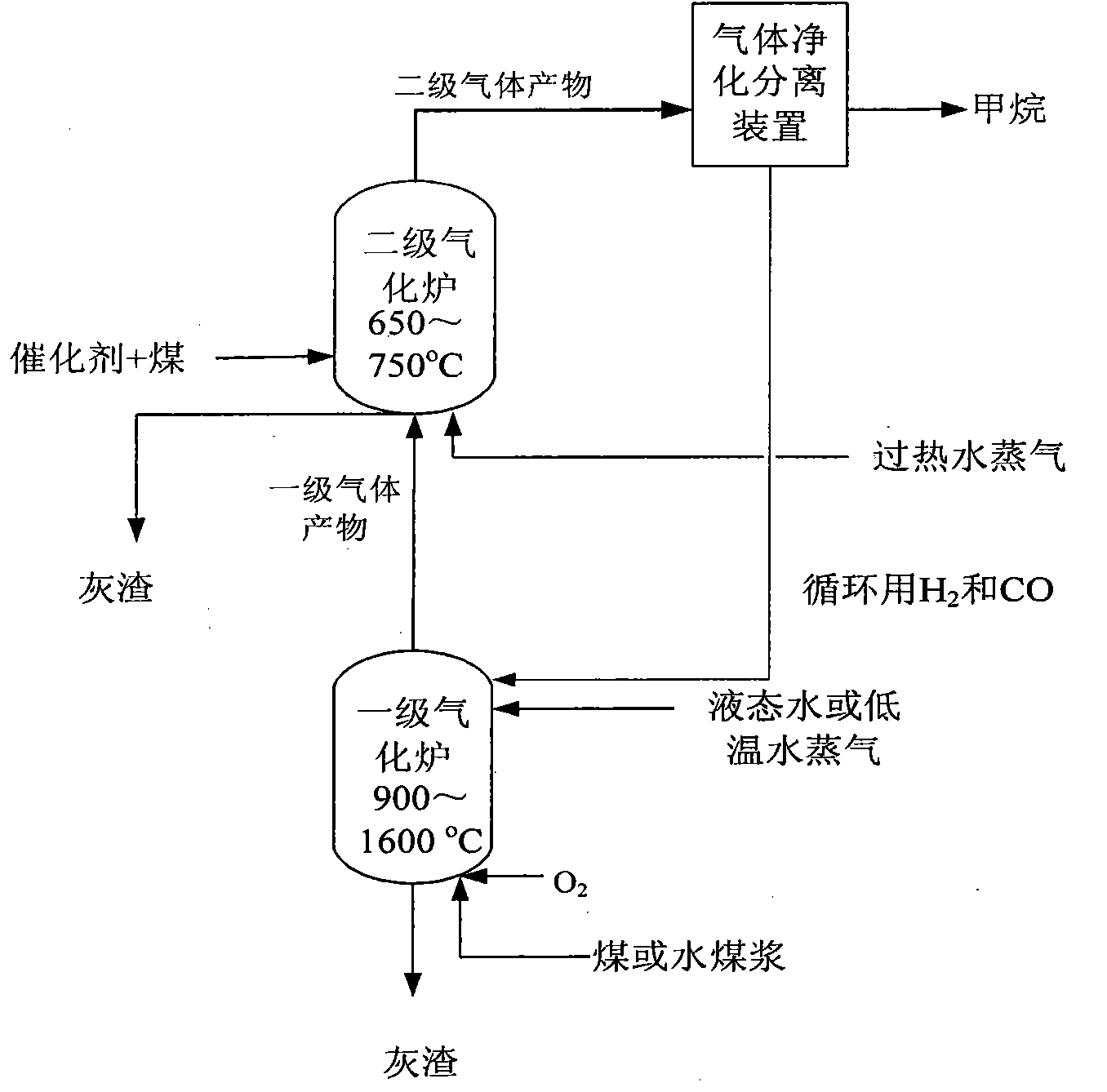

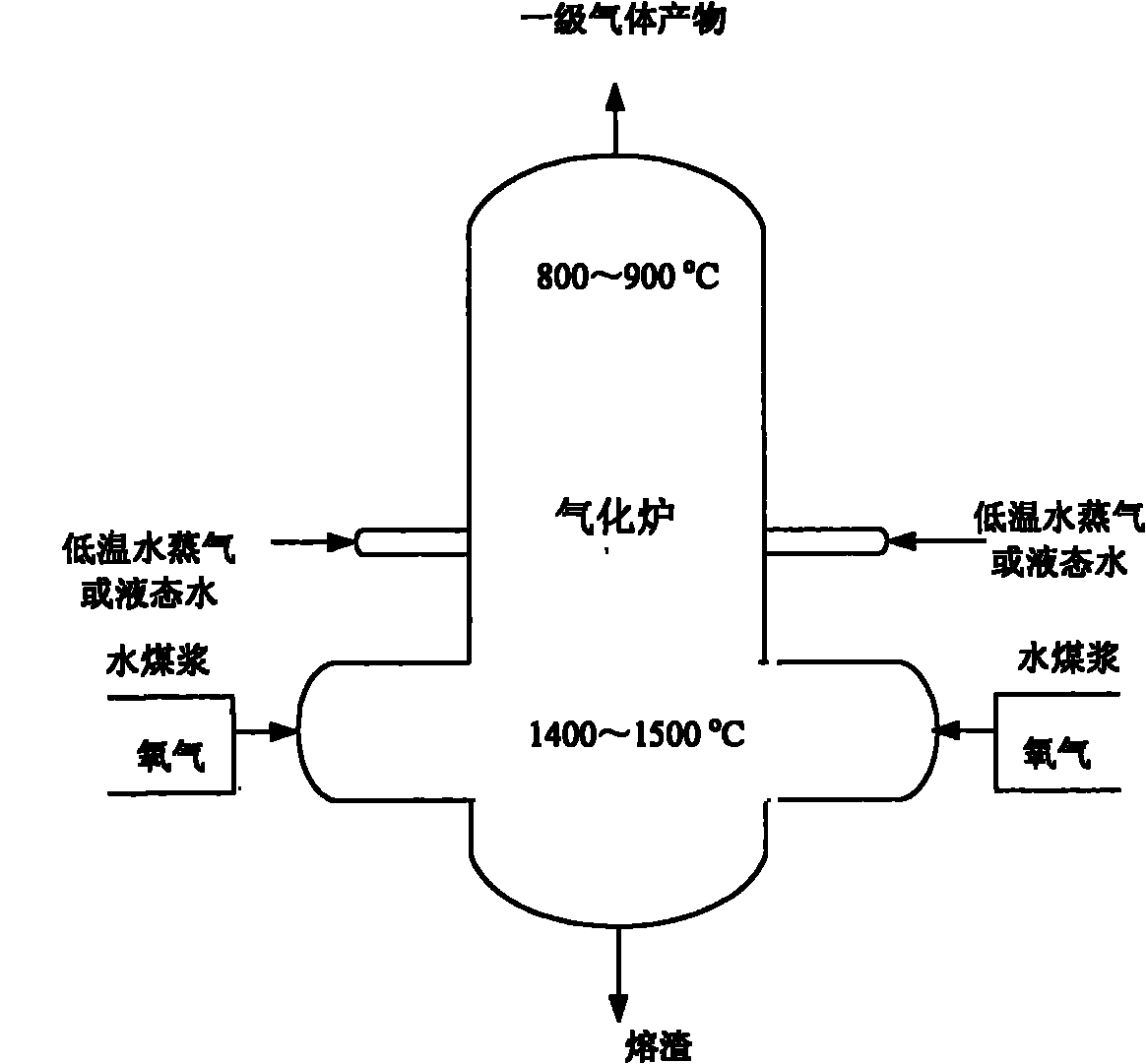

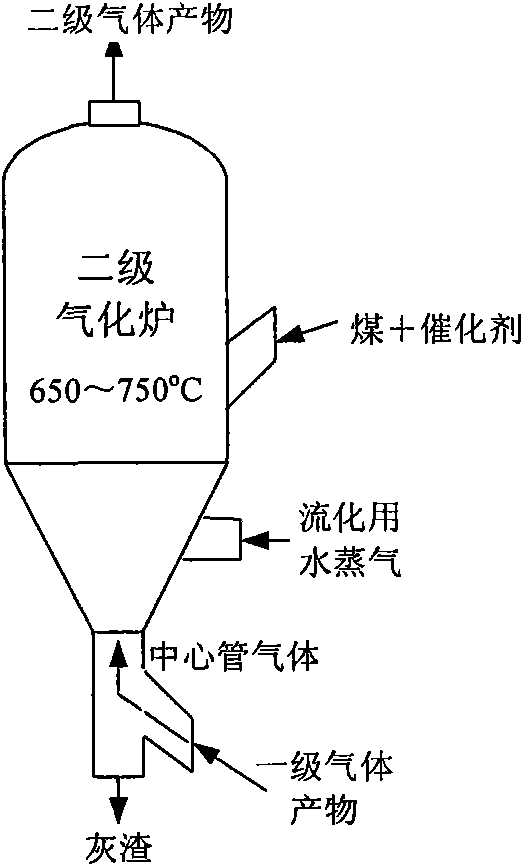

Coal gasification process for methane preparation by two stage gasification stove

The invention relates to a coal gasification process for methane preparation, including the following steps that: a. coal is reacted with oxygen containing gas in a first stage gasification stove to produce coal-gasified gas products containing CO, CO2, H2 and H2O; b. a coolant is fed to the coal-gasified gas products for cooling, and a first stage gas product is obtained; and c. the first stage gas product is fed to a second stage gasification stove and reacted with coal and a catalyst to form a second stage gas product containing methane.

Owner:ENN SCI & TECH DEV

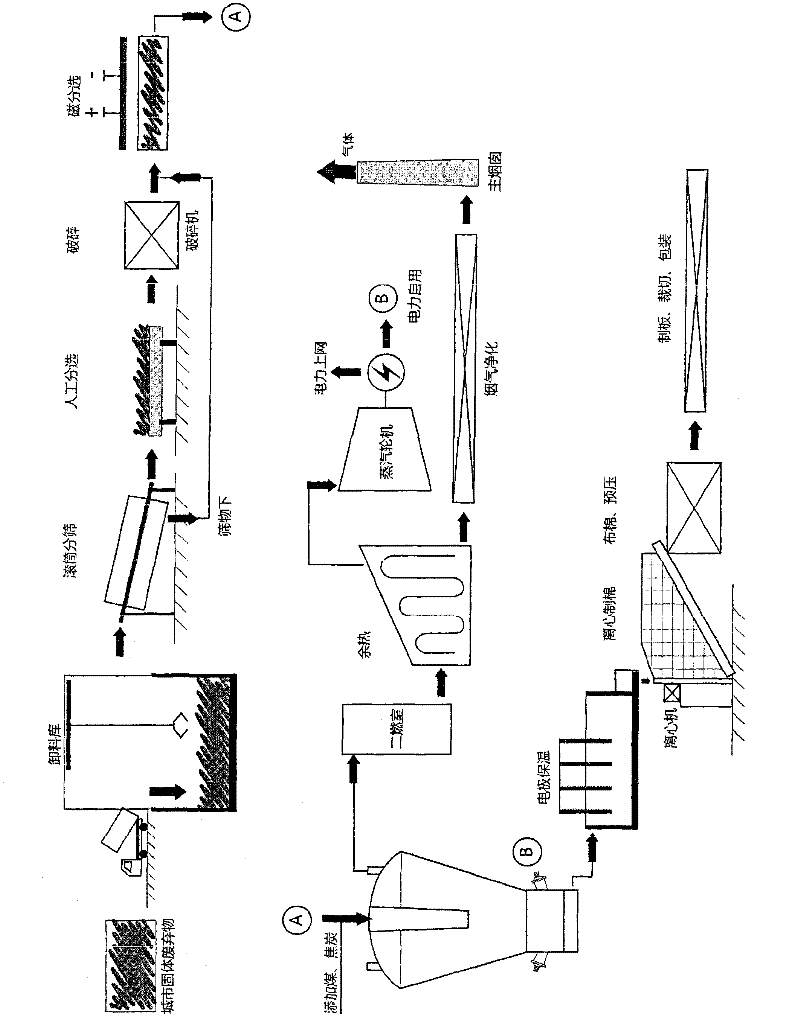

Method for producing mineral wool from solid waste by using plasma gasification furnace

The invention relates to the technical field of building material production, environmental protection, energy sources and the like, in particular to a method for directly producing a mineral wool product from hot slag produced by gasification of urban solid waste by using a plasma gasification furnace. The method comprises the following steps of: treating urban solid waste in the plasma gasification furnace to obtain glass-state hot slag; making the glass-state hot slag directly flow from the bottom of the plasma gasification furnace into a heat-preserving regulating reservoir through a heat-preserving discharging channel without cooling; adding mineral auxiliary materials into the heat-preserving regulating reservoir according to a hot slag parameter measured by an online detection device; and making regulated glass-state hot slag enter a mineral wool production system from the discharging hole of the heat-preserving regulating reservoir to obtain mineral wool. Compared with the mineral wool production method in the prior art, the method for producing mineral wool from urban solid waste by using the plasma gasification furnace has the advantages of environmental friendliness, energy saving, low economic cost and resource recycling.

Owner:AMERICAN GREEN ENERGY RESOURCE DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com