Patents

Literature

49 results about "Atomic cluster" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Atomic cluster concepts. Clusters of Atomic hosts under control of a Kubernetes master server is the expected operating arrangement of an Atomic environment. Kubernetes distributes and orchestrates the construction of pods on the Atomic hosts.

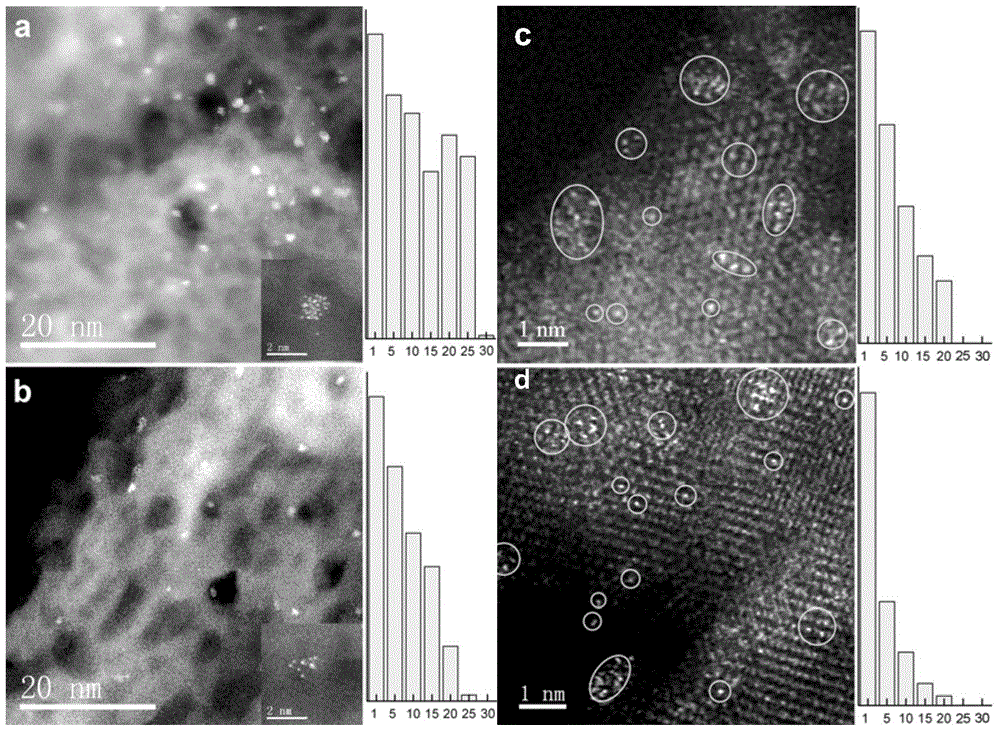

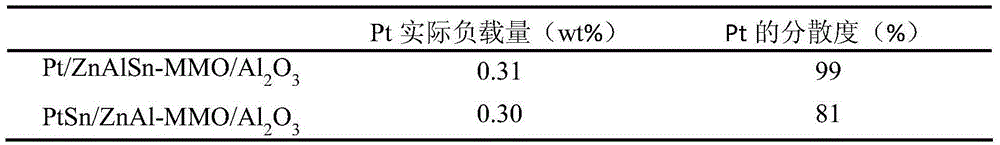

Method for controlling high dispersion of metal centers for catalysts by using auxiliaries

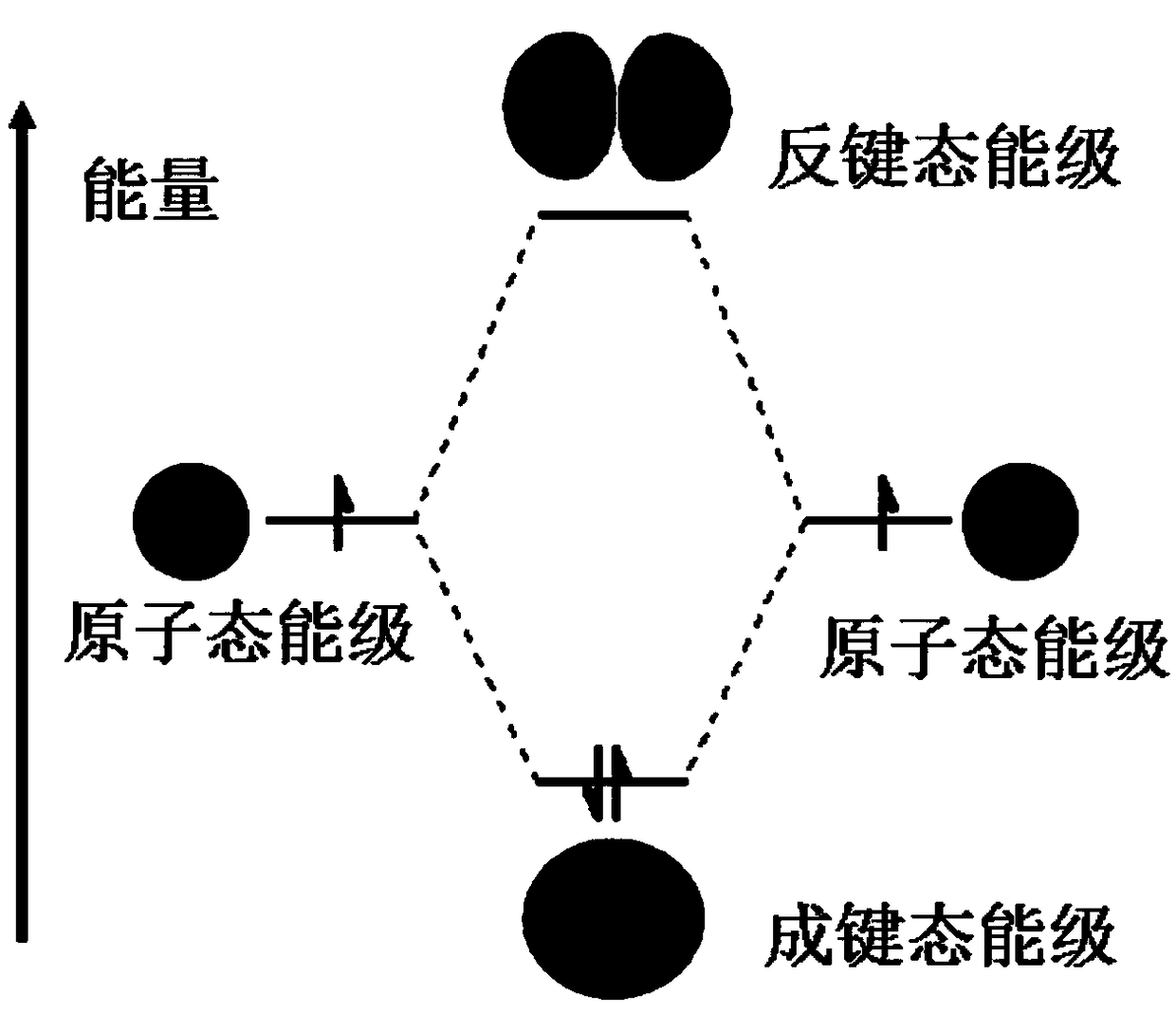

ActiveCN104148120AGood dispersionAchieve decentralizationCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsElectronic structureHydrotalcite

The invention relates to a method for controlling high dispersion of metal centers for catalysts by using auxiliaries, belonging to the technical field of supported catalyst controlling. Through uniform dispersion of layered double hydrotalcite precursor layer board cations, uniform doping, namely high dispersion of auxiliary metal ions in roasting oxides is realized, an electronic structure on a carrier surface is modulated, and the anchor points of Pt metal centers are provided. The method is easy to operate and control, the types and the content of the auxiliaries can be adjusted, and a control agent is not needed, so that single-atom-dispersed or atomic cluster Pt metal centers are obtained.

Owner:BEIJING UNIV OF CHEM TECH

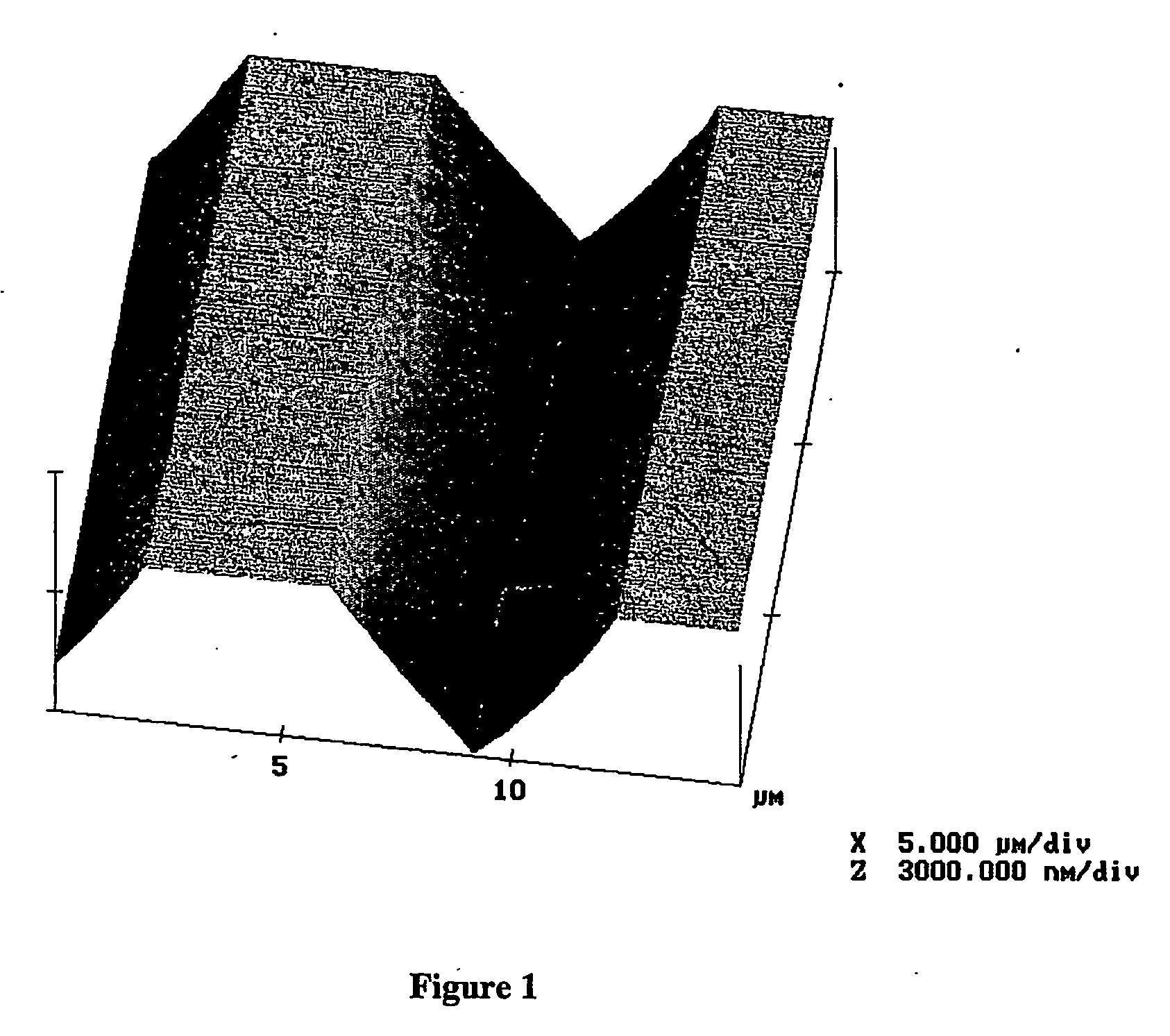

Etch masks based on template-assembled nanoclusters

InactiveUS20070051942A1Increase probabilityAvoid stickingMagnetic-field-controlled resistorsSolid-state devicesAtomic clusterNanoclusters

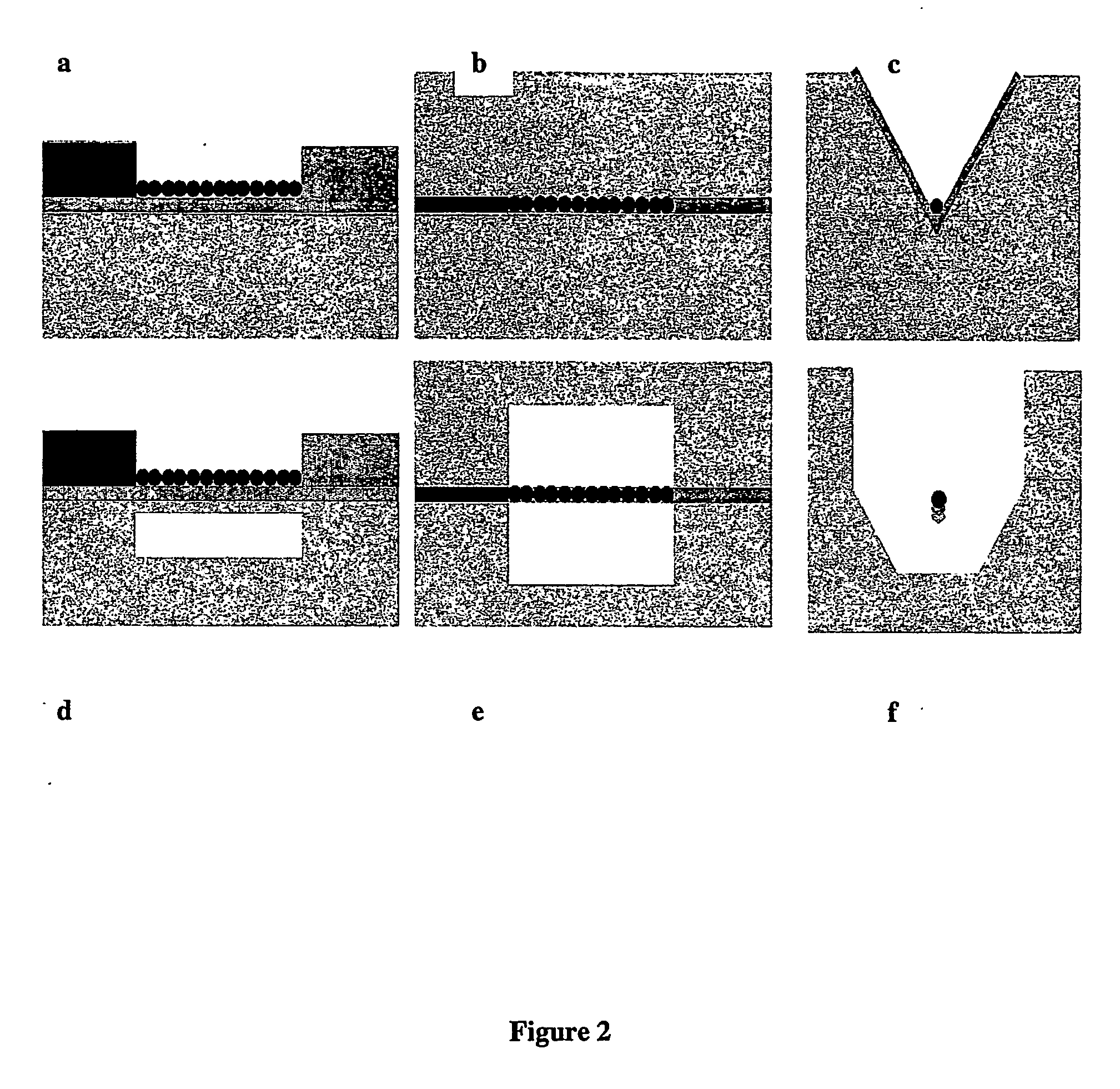

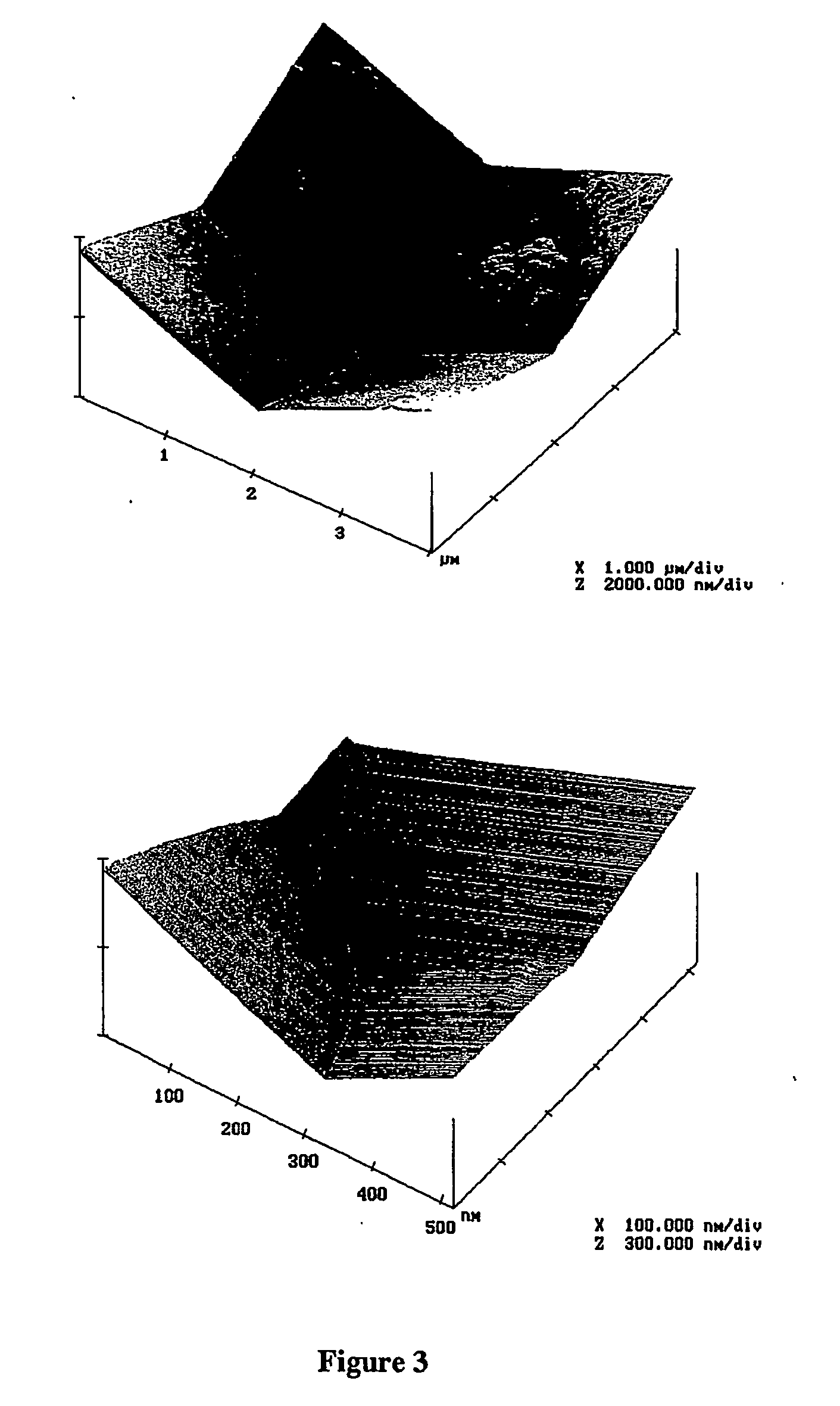

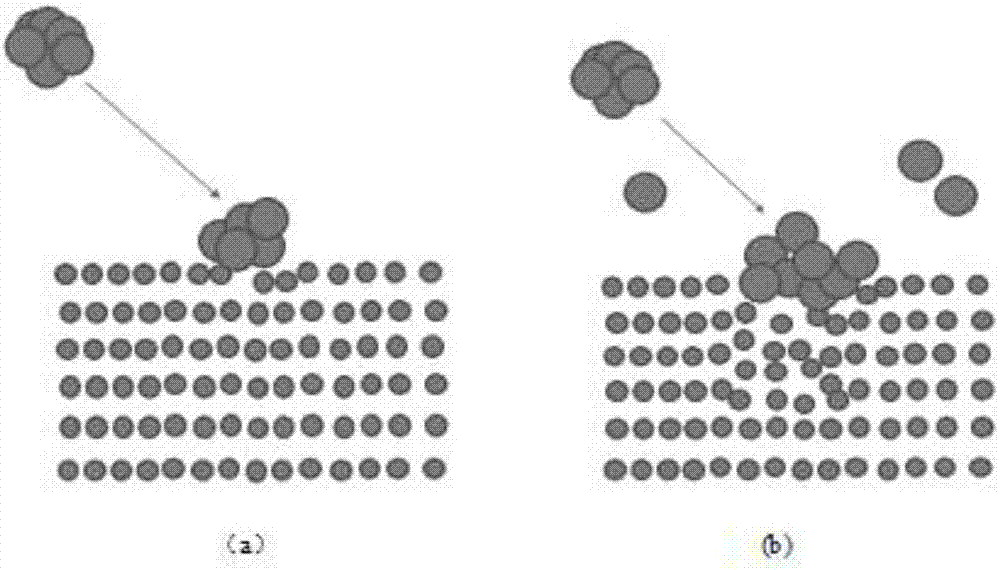

Nanoscale or mesoscale structures are fabricated on the surface of a substrate (e.g. silicon) by the aggregation of atomic clusters (e.g. antimony or bismuth) into V-grooves. These structures, preferably in the form of nanowires, are used as etching masks for the subsequent etching of the substrate. In an embodiment the V-grooves are metallised (e.g. with titanium or gold) prior to the deposition of the clusters. In this case the use of the nanostructures (e.g. antimony or bismuth) as an etching mask results in the formation of nanostructures of the underlying metal (e.g. titanium or gold). In this way the dimensions of the nanowires are transferred into the underlying metal film and the method allows fabrication of nanowires from materials (e.g. titanium or gold) that cannot be deposited as clusters.

Owner:NANO CLUSTER DEVICES

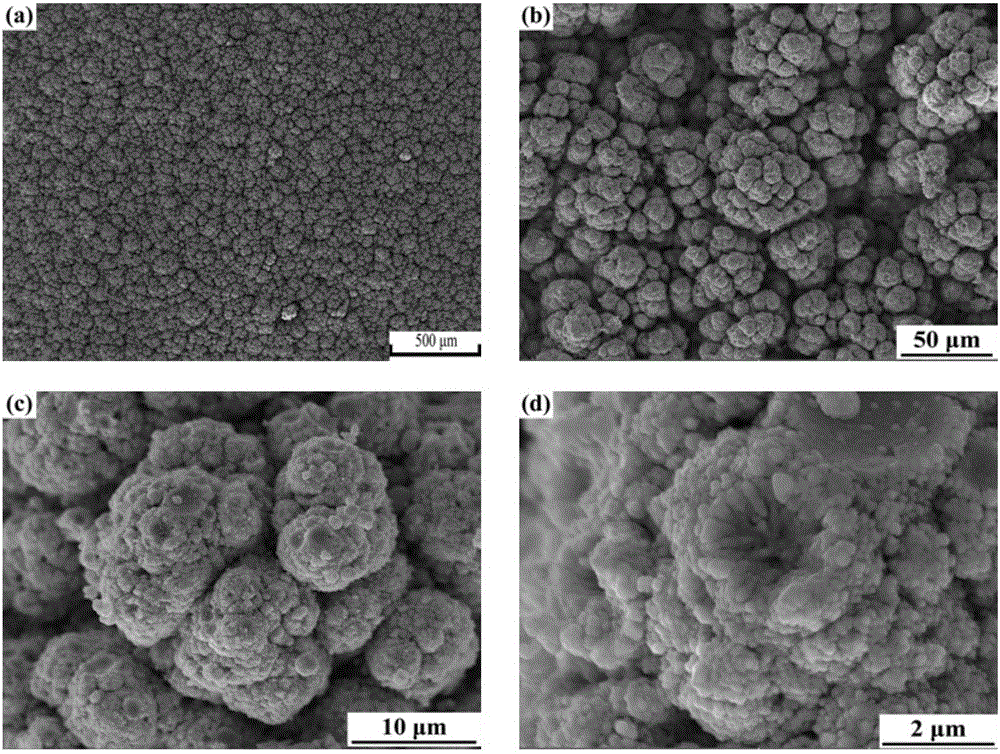

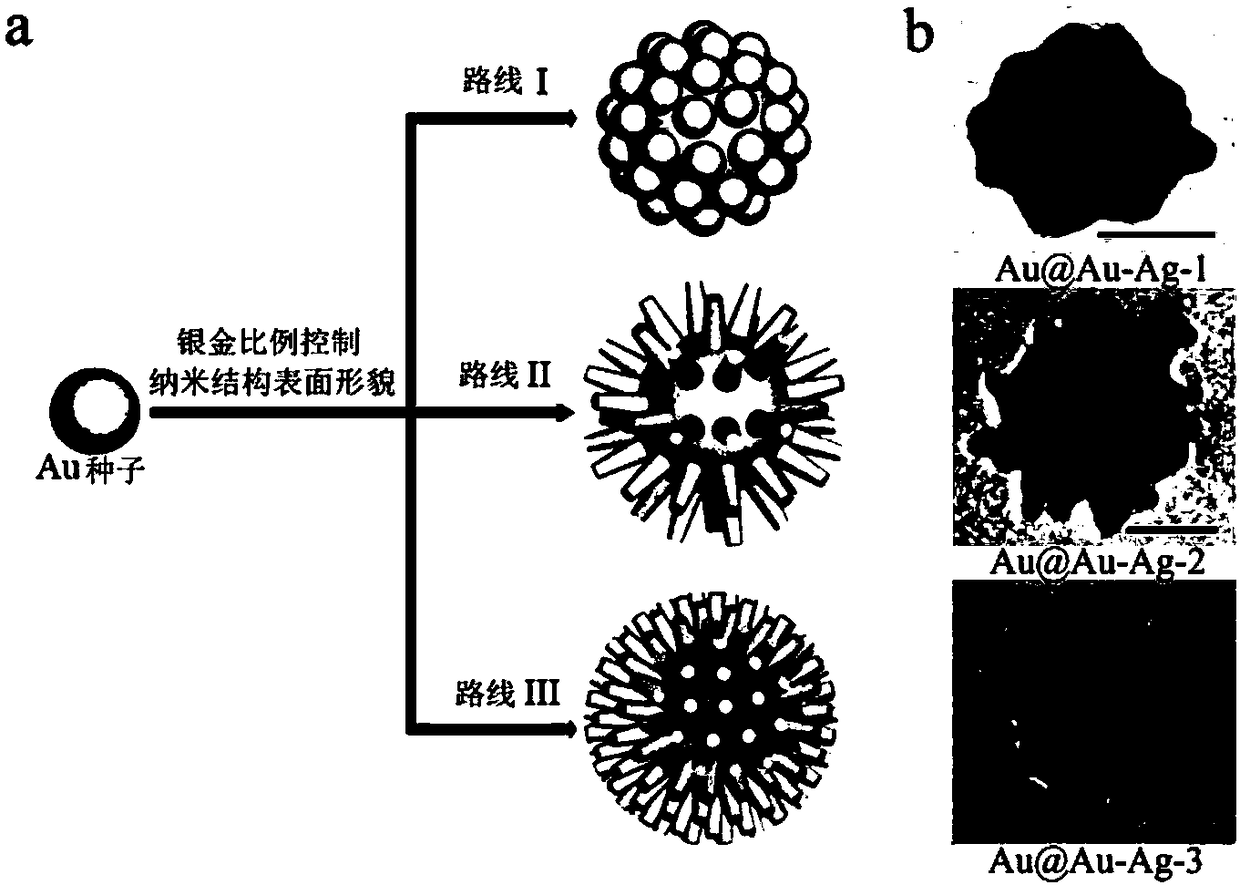

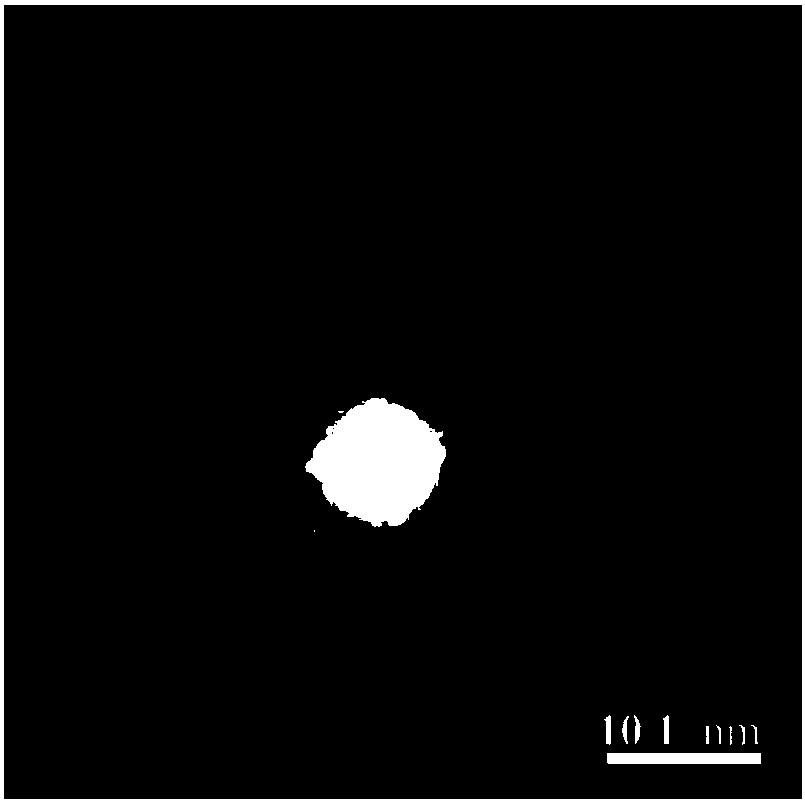

Preparation method of thorn-shaped or petal-shaped rough-surface gold-silver alloy nanometer material

InactiveCN106041119AFast growth rateEasy to operatePolycrystalline material growthNanotechnologyRough surfaceNanoparticle

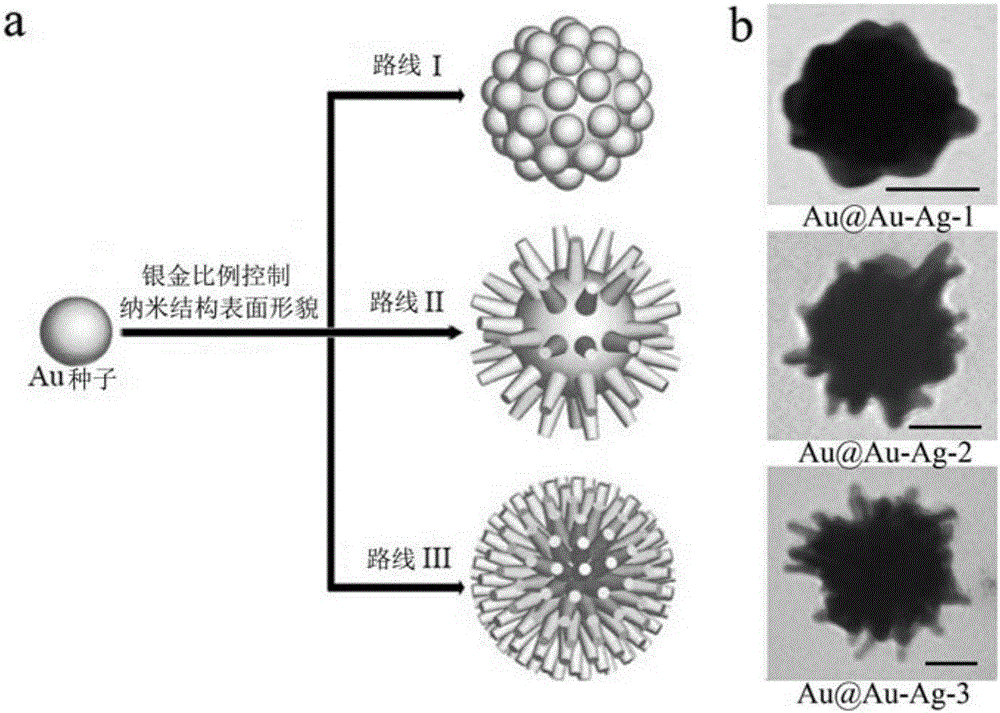

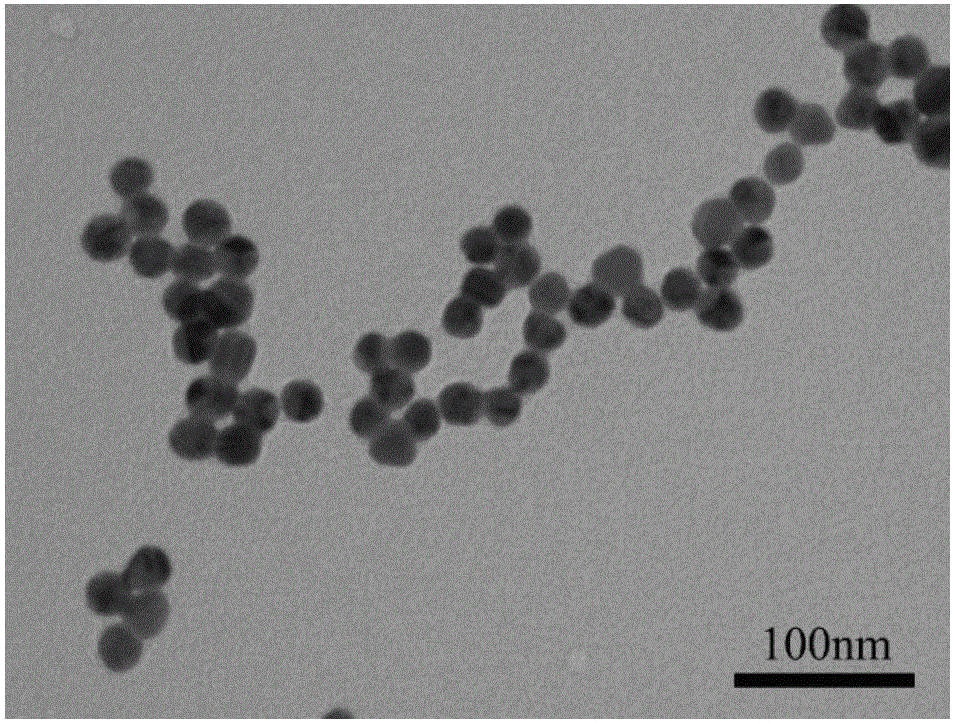

The invention provides a preparation method of a thorn-shaped or petal-shaped rough-surface gold-silver alloy nanometer material. The preparation method comprises the steps that gold nanoparticle seeds are prepared from a mixed solution of chloroauric acid and trisodium citrate; the gold nanoparticle seeds grow on the surfaces of gold nanoparticles through heterogeneous nucleation; and under the action of molecular synergistic adsorption of L-dopamine, stabilization of atomic clusters, reduction of gold ions and silver ions and underpotential deposition of silver atoms, the thorn-shaped or petal-shaped rough-surface gold-silver alloy nanometer material is prepared and formed. The preparation method is simple in process and effective; production cost can be lowered conveniently; the preparation method is suitable for large-scale production; and the prepared thorn-shaped or petal-shaped rough-surface gold-silver alloy nanometer material is of a unique bionic structure, large in specific surface area and capable of loading a great amount of active medicine and molecular dye. Therefore, the preparation method has wide application prospect in the fields such as SERS sensing, catalysis, diagnosis and treatment and adsorbing materials.

Owner:XI AN JIAOTONG UNIV

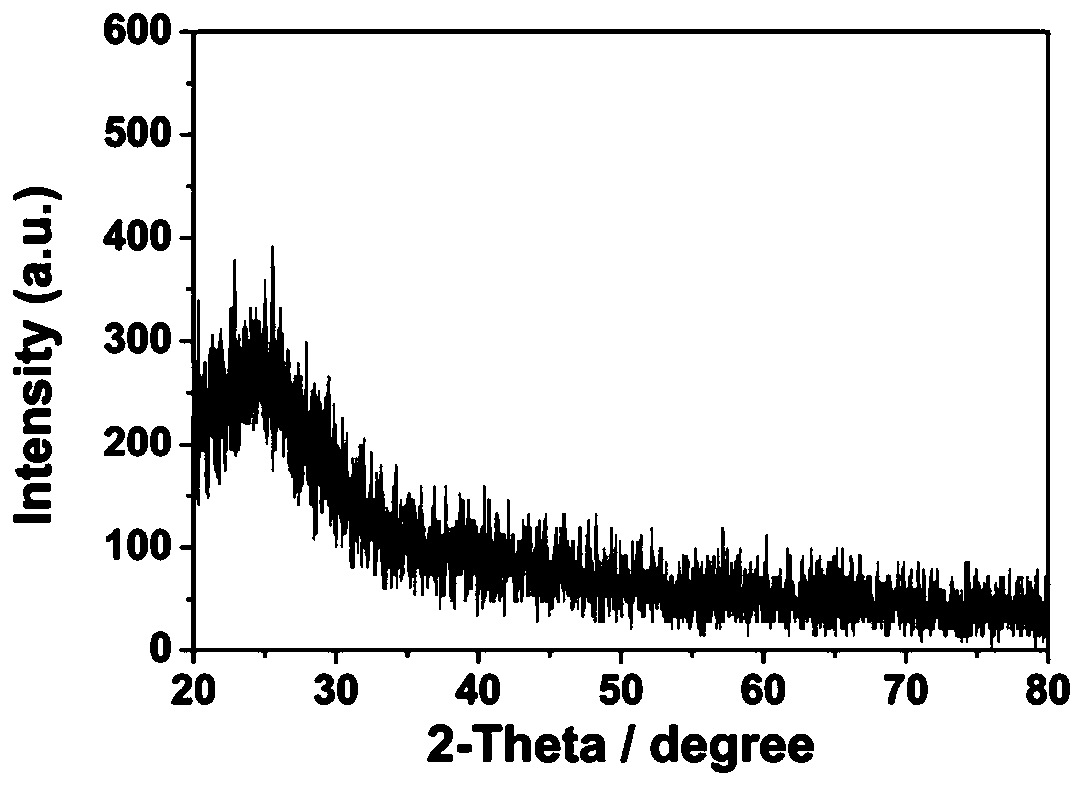

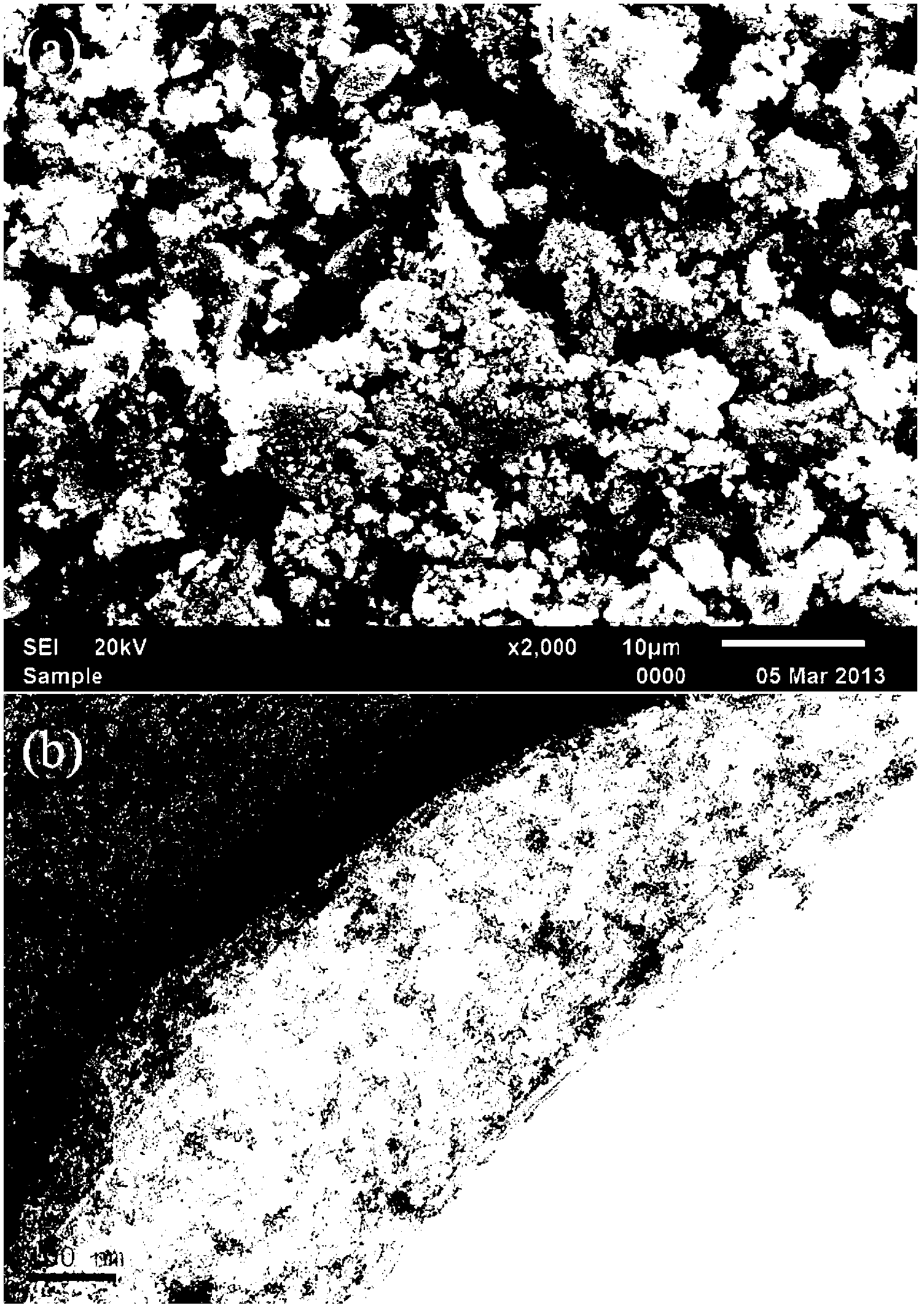

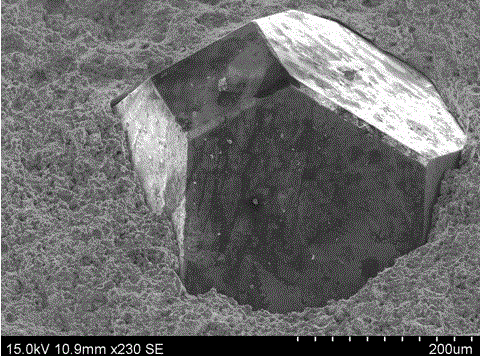

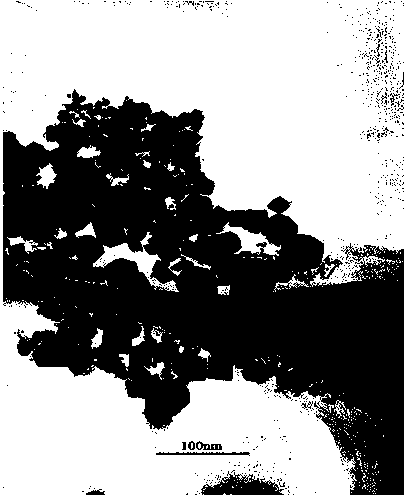

Method for preparing solid amorphous alloy thin strips with controllable microstructures

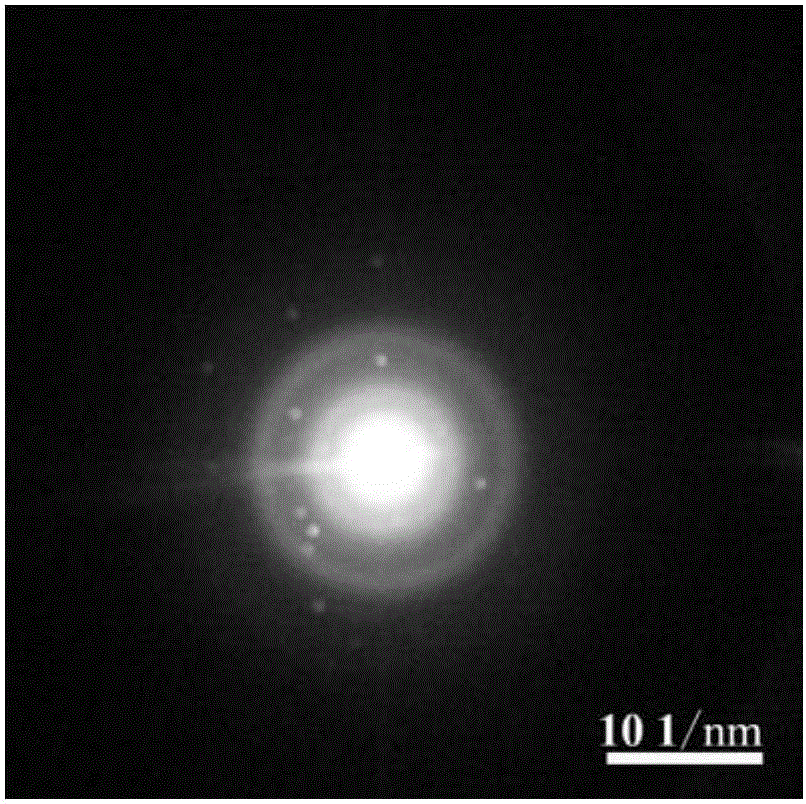

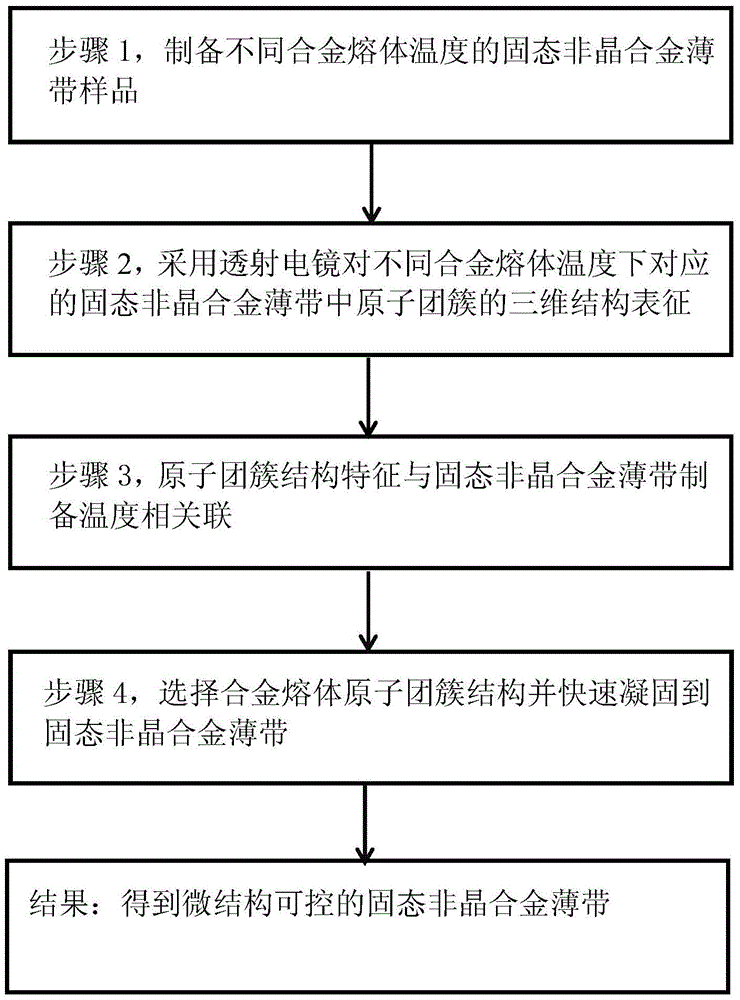

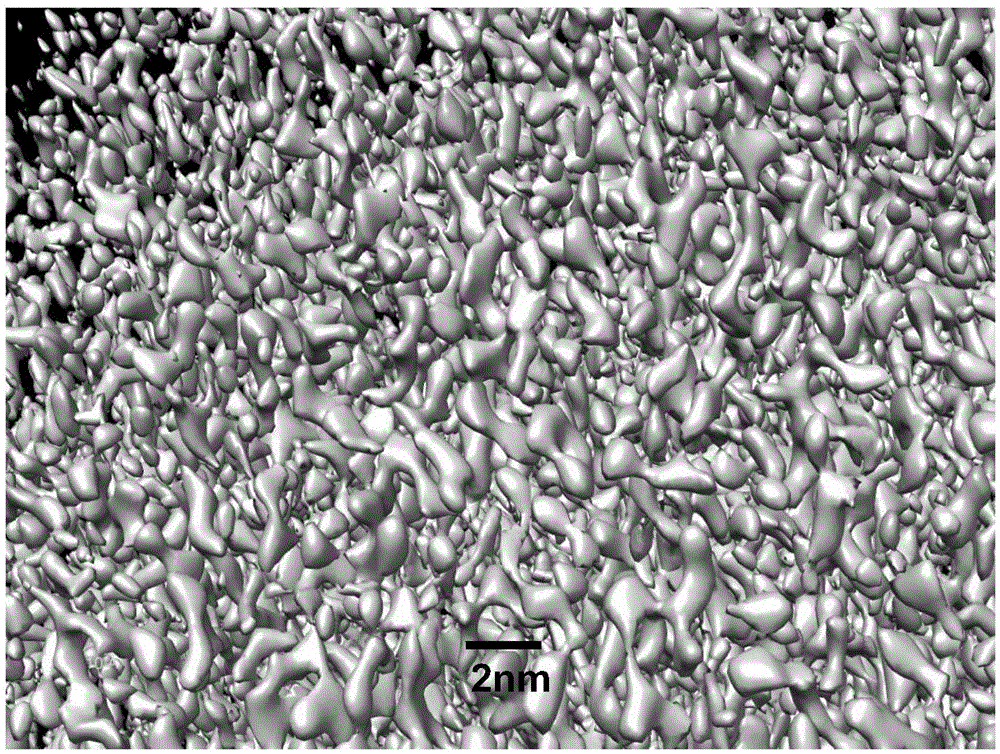

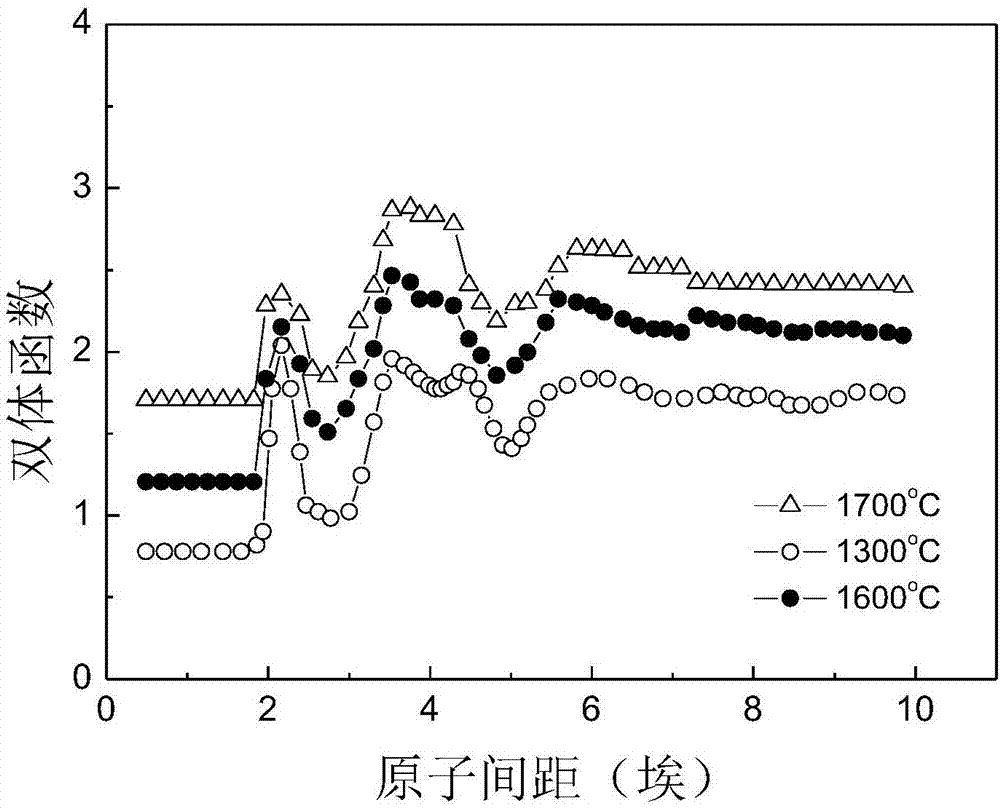

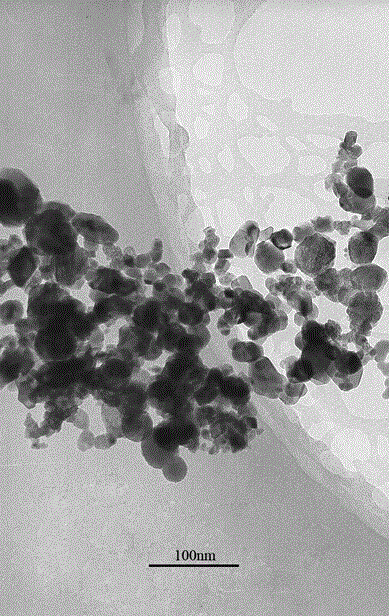

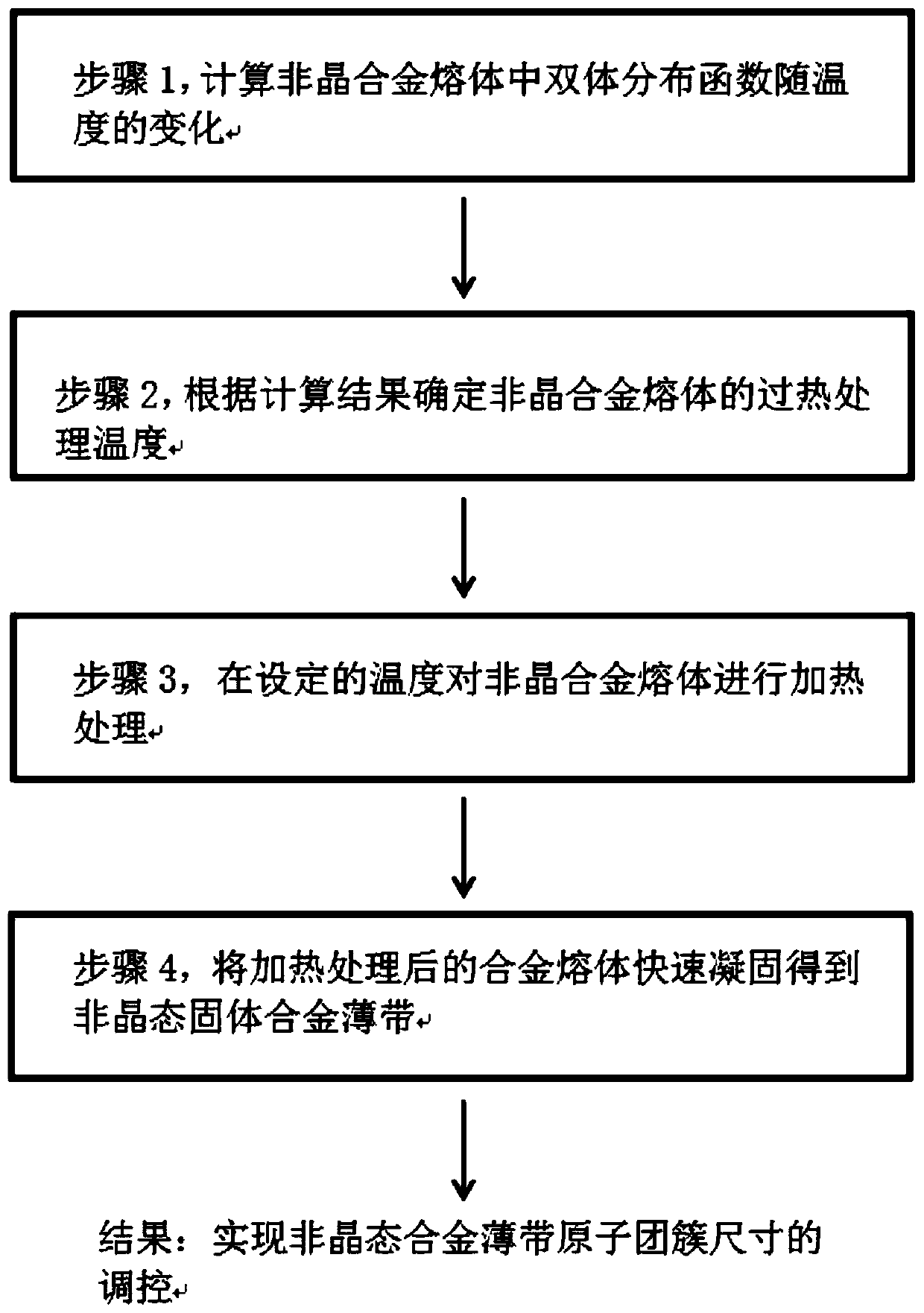

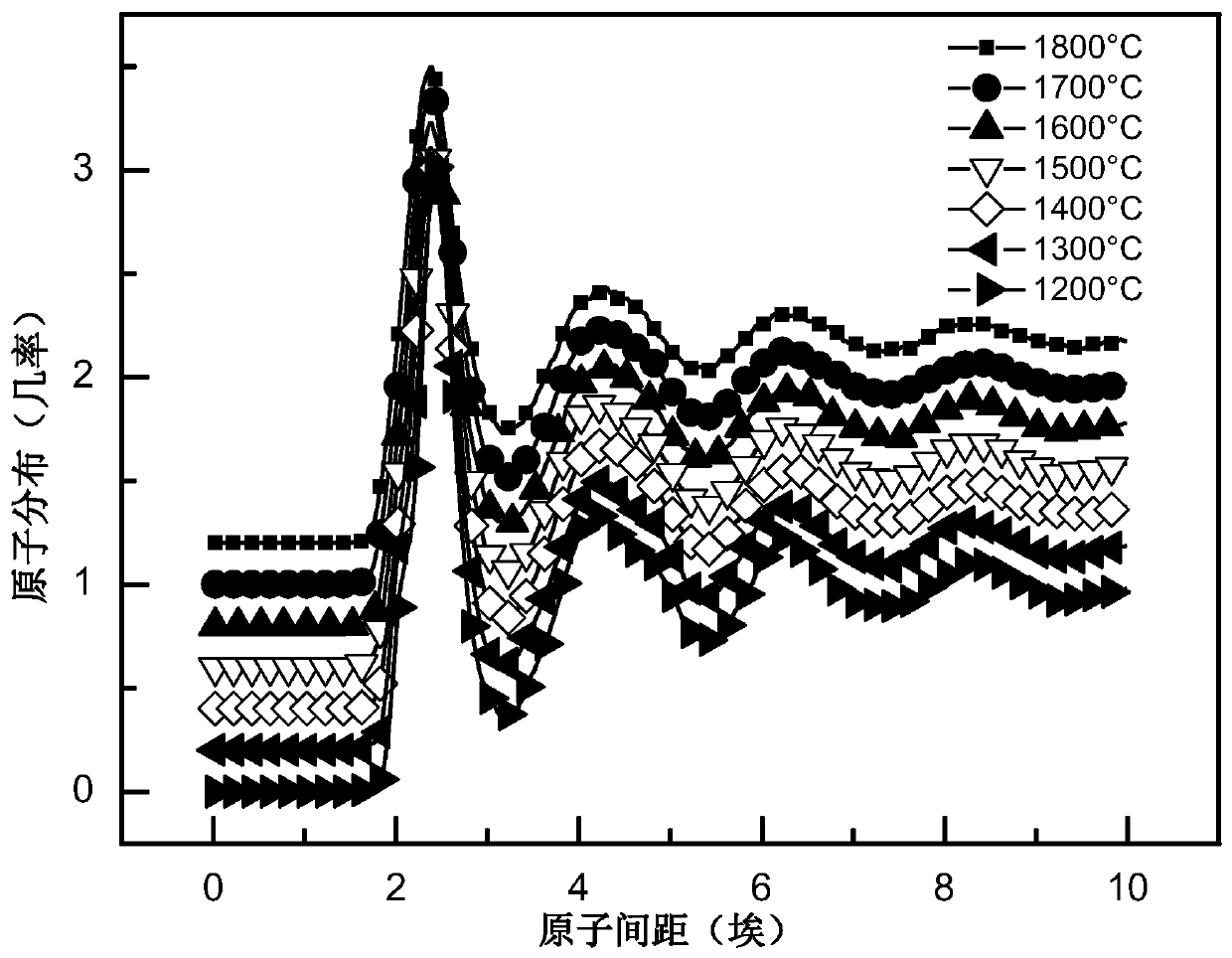

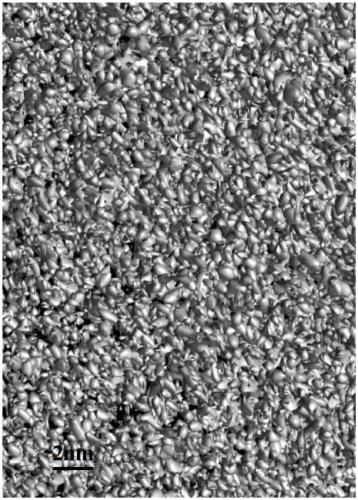

ActiveCN105624587ALower requirementTilt to achieveMaterial analysis by measuring secondary emissionAtomic clusterAlloy

The invention relates to a method for preparing solid amorphous alloy thin strips with controllable microstructures. The method is characterized by specifically comprising the steps that first, solid amorphous alloy thin strip samples at different alloy melt temperatures are prepared; second, the three-dimensional structures of atomic clusters in the solid amorphous alloy thin strips corresponding to different alloy melt temperatures are subjected to characterization by a transmission electron microscope; third, atomic cluster structure characteristics and the preparation temperatures of the solid amorphous alloy thin strips are related; fourth, the atomic cluster structures of alloy melt are selected and solidified to the solid amorphous alloy thin strips rapidly. According to the method, the microstructures of the solid amorphous alloy thin strips can be effectively controlled to achieve the designability and the controllability of the microstructures of the solid amorphous alloy thin strips and obviously improve the macroscopic physical performance of the solid amorphous alloy thin strips. The method for preparing the solid amorphous alloy thin strips with the controllable microstructures has the characteristics of being simple and convenient to implement, high in efficiency, low in cost, high in controllability and repeatability and high in technical reliability and the like, and is suitable for being widely applied in the technical field of preparation of metal functional materials.

Owner:江苏非晶电气有限公司 +2

Method for synthesizing high-performance metallic materials in low-temperature liquid phase

InactiveCN109014238AEfficient regulation of nucleationEffectively regulate growthMaterial nanotechnologyTransportation and packagingChemical synthesisElemental composition

The invention relates to a method for synthesizing high-performance metallic materials in a low-temperature liquid phase, and belongs to the field of material science and engineering technology and chemistry. The prepared metallic materials comprises monatomic, diatomic, polyatomic, atomic cluster or ultrafine nanoparticle and other materials composed of one or more metallic elements such as Ti, V, Cr, Mn, Cu, Zr, Nb, Mo, Ru, Rh, Pd, Ag, W, Re, Os, Ir, Pt and Au synthesized chemically in the low-temperature liquid phase.

Owner:TSINGHUA UNIV

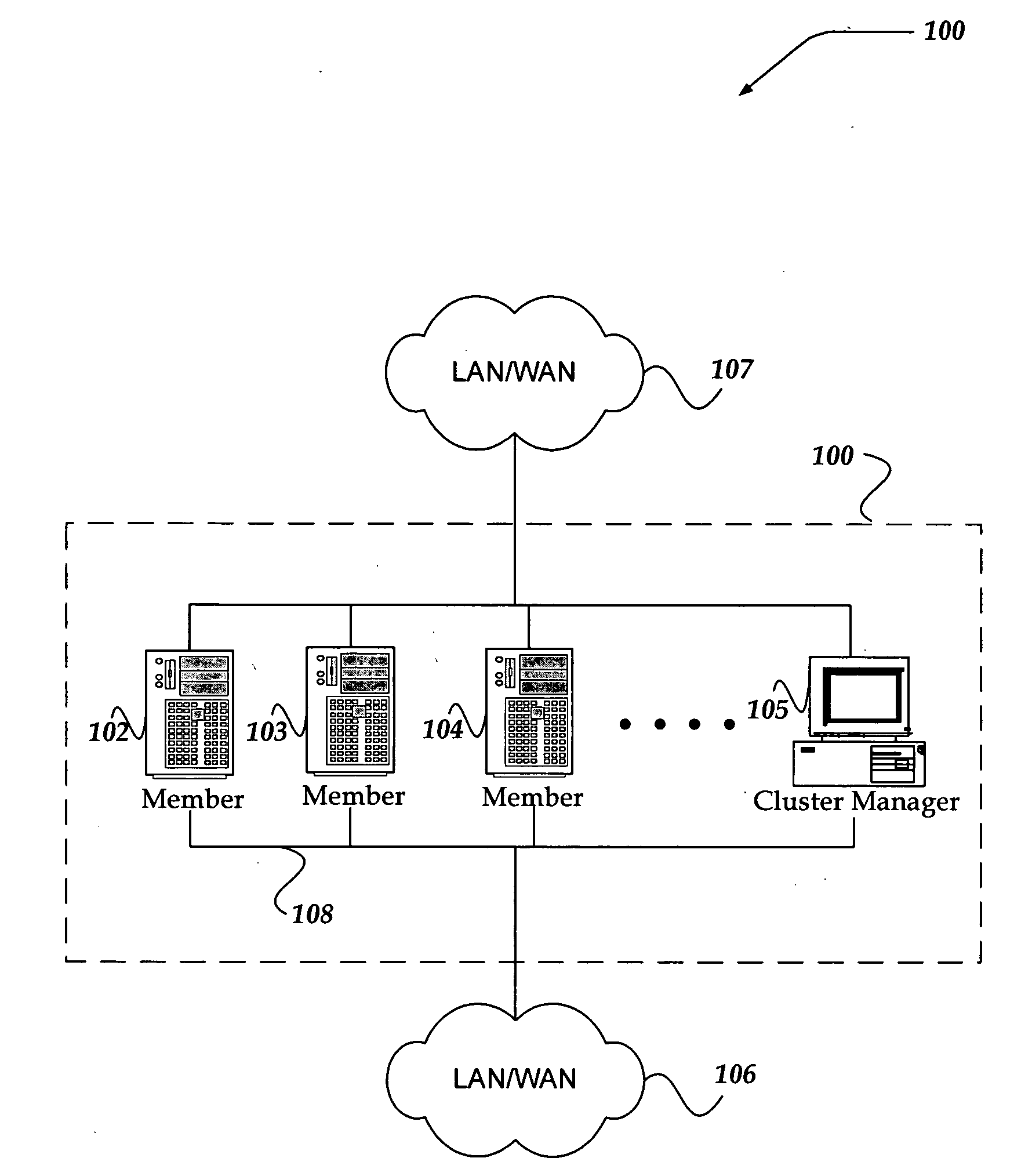

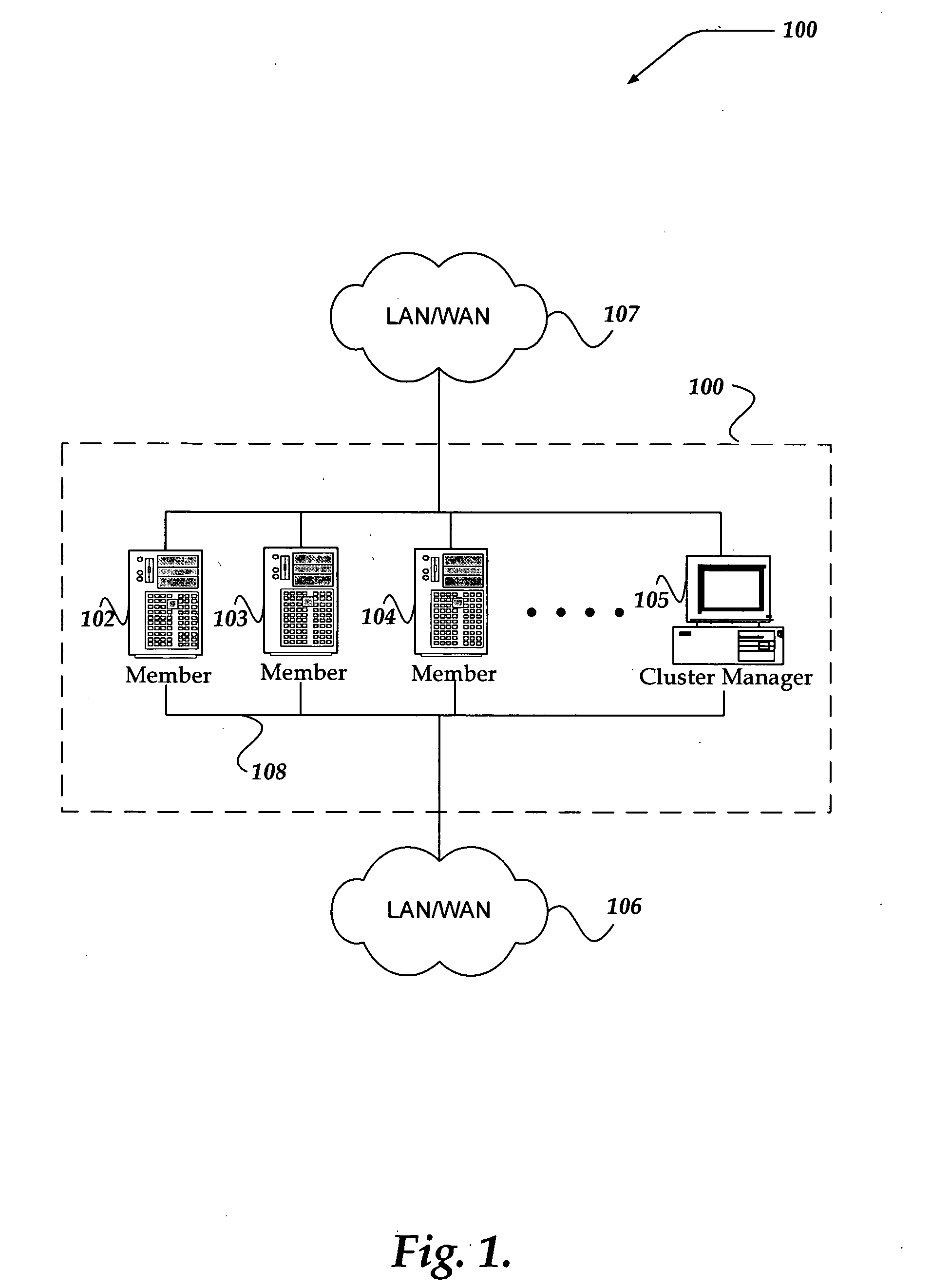

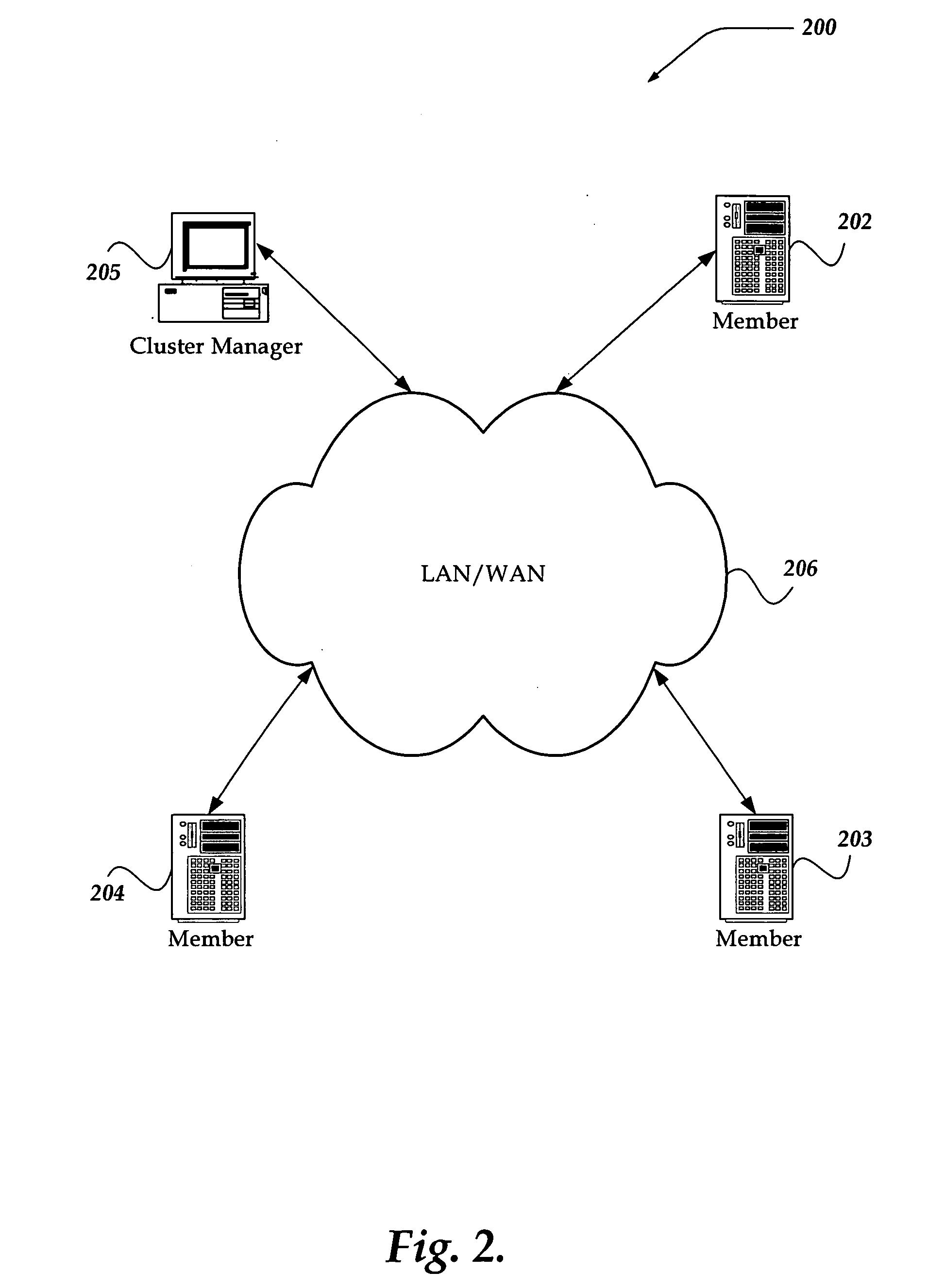

System and method for managing a change to a cluster configuration

An apparatus and method are directed to managing a configuration of a cluster of members. The invention employs an atomic cluster configuration approach that includes applying a change to the configuration uniformly across the members in the cluster. Each member within the cluster is initialized to a transaction mode. If all members are in the transaction mode, a change is provided to each member, which evaluates the received change. If the change is determined to be unacceptable for any of the members, the change is determined to be globally unacceptable, and is rejected for all the members in the cluster.

Owner:NOKIA INC

Electrode active material for lead-acid storage battery

InactiveCN106876666AHigh specific powerIncrease specific energyLead-acid accumulatorsCell electrodesTitanium nitrideAtomic cluster

The invention discloses an electrode active material for a lead-acid storage battery. The electrode active material comprises lead powder and a non-metallic titanium compound; the lead powder comprises one or more kinds of metal lead powder, ball-milling lead powder, Barton lead powder, Pb<2>O powder, PbO powder, Pb<2>O<3> powder, Pb<3>O<4> powder and PbO<2> powder; and the non-metallic titanium compound comprises one or more kinds of titanium sulfide, titanium nitride, titanium boride, titanium carbide, titanium hydride, titanium hydroxide, titanium silicide, a symbiotic blend of the abovementioned compounds on an atomic micro level or atomic cluster level, and doped compounds formed by doping the abovementioned compounds with one or more kinds of F, Sb, Sn, Ca, Bi, Co, Ca, Al, Mg, N, P, O and C. By virtue of the electrode active material for the lead-acid storage battery with an improved formula, the specific power, specific energy, charging-discharging efficiency, cycle life, low-temperature performance and the like of the lead-acid storage battery can be obviously improved.

Owner:杨春晓

Preparation method of nitrogen-doped carbon-supported monoatomic catalyst

ActiveCN109999883ARegulatory loadEasy to operateCatalyst activation/preparationFreeze-dryingFiltration

The invention relates to a preparation method of a nitrogen-doped carbon-supported monoatomic catalyst. The method comprises the following steps of: dissolving transition metal acetate in deionized water, and adding a pyrrole monomer into the deionized water dropwise to obtain a reaction precursor; transferring the reaction precursor into a reaction kettle to carry out a hydrothermal reaction, andcarrying out centrifugal separation on the product and freeze drying the product after the reaction is finished; adding a dried sample into a hydrochloric acid solution to remove oxides, carrying outsuction filtration separation on the product, washing and freeze drying the product; and placing the dried sample into a porcelain boat, carrying out heat treatment in a tubular furnace in a protective atmosphere, and naturally cooling to obtain the nitrogen-doped carbon-supported monoatomic catalyst. Due to the existence of a ligand in the precursor complex, metal ions can be effectively prevented from being agglomerated to generate atomic clusters in the preparation process. Besides, the monoatomic loading capacity can be regulated by regulating parameters such as pyrrole, acid treatment time and the like. The method is green, efficient and easy to operate, no precise and complicated equipment is needed, and the method is suitable for large-scale production.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of catalyst of sulfur containing transition metal atomic cluster compound for hydrodesulfurizing

InactiveCN1785517ARaw materials are easy to obtainLow priceCatalyst activation/preparationRefining to eliminate hetero atomsChemical reactionElectrolysis

A process for preparing the catalyst containing the S and the atom cluster compound of transition metal (Mo or W) and used for hydrodesulfurizing is disclosed. Said atom cluster compound of Mo or W is prepared from its oxide through electrolyzing in acid solution, sulfurizing, oxidizing, concentrating, separation and chemical reaction. Its advantage is high hydrodesulfurizing performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for improving corrosion resistance of 750MPa level ultrahigh strength aluminium alloy

The invention belongs to preparation technologies of ultrahigh strength aluminium alloys, and relates to a method for improving the corrosion resistance of a 750MPa level ultrahigh strength aluminiumalloy. The method comprises the steps that a deformed product is subjected to solid-solution quenching, then one to three times of subzero treatment is conducted, and at last aging treatment is conducted. A large amount of dislocations and subgrains which are in interaction can be formed through the method; grain boundary intermittent precipitated phases are promoted to be formed; the corrosion resistance can be obviously improved under the condition that the alloy strength level is maintained at the 750MPa level after aging; and meanwhile the organization structure is more stable. The methodis suitable for high-performance 750MPa level ultrahigh strength aluminium alloy plates or extruded profiles used in the fields of aviation, spaceflights and weapons. The plates or the extruded profiles after hot working are subjected to solid-solution treatment to form a supersaturated solid solution, a certain extent of recrystallization is controlled to be generated, a large amount of vacancies, atomic clusters, and dislocations and subgrains which are in interaction are formed in the subsequent subzero treatment process, the grain boundary organization structure of the alloy after artificial aging treatment is improved, and the intermittent precipitated phase structure is promoted to be formed.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Hot treatment process for remarkably improving comprehensive performance of aluminum alloy

ActiveCN103882354AMeet the requirements of large structural partsPractical application value of large industryAtomic clusterGrain structure

The invention relates to a hot treatment process for remarkably improving the comprehensive performance of aluminum alloy. According the hot treatment process, aluminum-copper-magnesium alloy in a solid solution state undergoes pre-aging treatment, asymmetric rolling deformation and secondary aging treatment; one part of atoms are segregated through pre-aging to form nanometer scale atomic clusters which block dislocation movement during subsequent deformation to form meshy dislocation cells or sub-boundary to refine grains; the other part of undecomposed solute atoms obtain vacancy / atomic cluster complex, G.P. zone, microtexture and special shearing texture under the strain action of subsequent deformation high shear stress; one part of fine grains grow with the aid of grain boundary migration due to the interaction of the compound textures during secondary aging to form a dual grain structure, so that the strength-plasticity coordination of the alloy is improved, and the toughness of the alloy is improved. The hot treatment process is simple, safely operated and conveniently, easily industrialized, and is a novel hot treatment technology with great application prospect; the comprehensive performance of the alloy is effectively improved through improving the microtexture of alloy according to the hot treatment process.

Owner:CENT SOUTH UNIV +1

Method for preparing powder material with electrochemical cathode

ActiveCN103233246AA new and convenient method for preparing powder materialsAtomic clusterLithium-ion battery

The invention relates to the field of new materials, and discloses a method for preparing a powder material with an electrochemical cathode. By using an inert electrode as an anode, a massive metal, semiconductor and alloy as a cathode, and a lithium salt / sodium salt / quaternary ammonium salt organic solution, pyrrole, quaternary ammonium salt or piperidine ionic liquid or strongly alkaline water solution as an electrolyte, strong cathode polarization is carried out under constant voltage; under the action of the strong cathode voltage, the massive metal, semiconductor and alloy surface forms an unstable intermediate Mx+Ny- (M+ is an electrolyte cation, and N represents metal, semiconductor or alloy) and becomes corroded; the intermediate is very unstable in the electrolyte, and is quickly decomposed to generate an atomic cluster; the atomic cluster continues aggregate to obtain a nanoparticle sol; and finally, the sol is centrifuged / washed, and dried to obtain the powder material. The prepared powder material can be widely used in the fields of lithium ion batteries, supercapacitors, (electric) catalysis, biosensing, photovoltaic devices, micro-electronics and the like.

Owner:CENT SOUTH UNIV +1

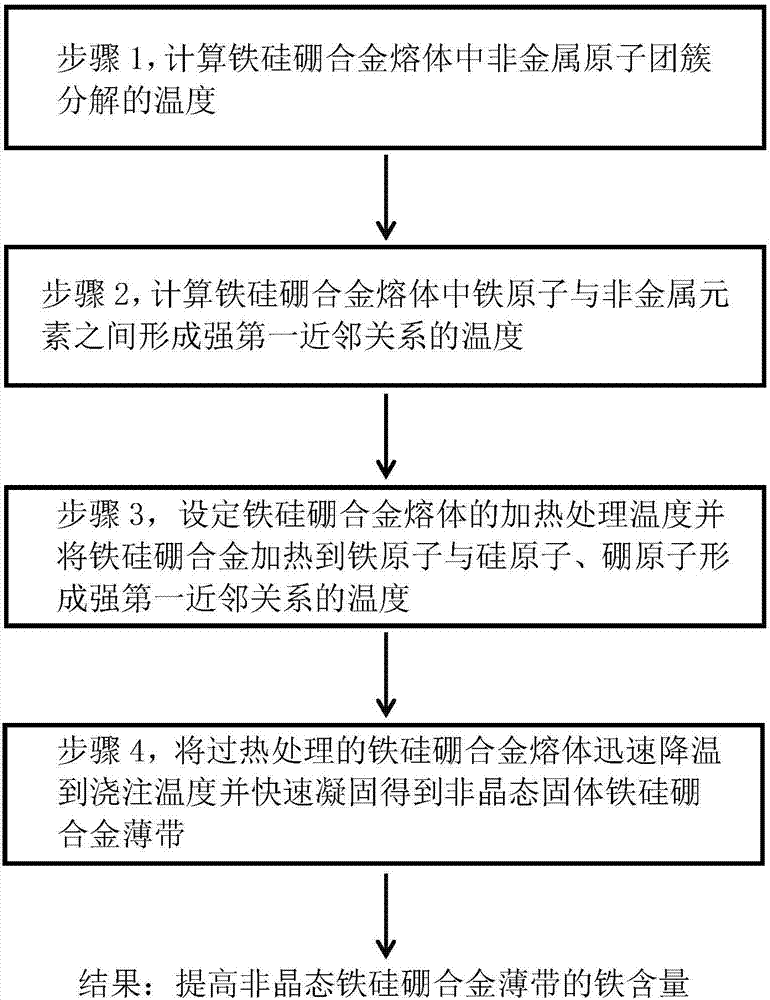

Technological method for increasing content of iron in thin amorphous Fe-Si-B alloy strip

ActiveCN107326158AHigh in ironEasy to implementHeat treatment process controlDecompositionAtomic cluster

The invention relates to a technological method for increasing the content of iron in a thin amorphous Fe-Si-B alloy strip. The method is characterized by comprising the steps as follows: S1, the decomposition temperature of nonmetallic atomic clusters in Fe-Si-B alloy melt is calculated; S2, the temperature for mainly forming the first neighborhood relation between iron atoms and nonmetallic elements in the Fe-Si-B alloy melt is calculated; S3, the heating treatment temperature of the Fe-Si-B alloy melt is set, the Fe-Si-B alloy is heated to the temperature at which the iron atoms form the strong first neighborhood relation with silicon atoms and boron atoms; S4, the heated alloy melt is quickly cooled to the set pouring temperature and is quickly solidified, and the thin amorphous solid alloy strip is obtained. With the method, the purpose of increasing the content of iron in the thin amorphous Fe-Si-B alloy strip can be achieved by regulating and controlling the microstructure of the amorphous Fe-Si-B alloy, so that the saturation magnetic induction intensity of the thin amorphous Fe-Si-B alloy strip can be increased.

Owner:南京腾元软磁有限公司 +2

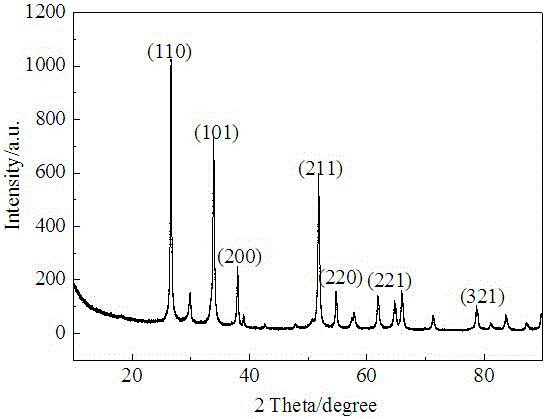

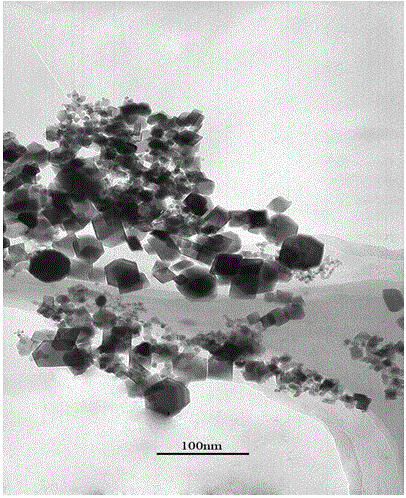

Technology for preparing nano-metallic oxide powder with DC (direct-current) plasma method

ActiveCN106044849ASimple processReduce manufacturing costGallium/indium/thallium compoundsNanotechnologyAtomic clusterOxygen

A technology for preparing nano-metallic oxide powder with a DC (direct-current) plasma method comprises steps as follows: a high-purity metal block is put into a smelting furnace and is melted, and a melt delivery tube connected with the smelting furnace is heated; a reaction chamber is subjected to vacuum pumping until the pressure reaches 2-10 MPa, cooling air is introduced into the reaction chamber, and cooling water is introduced into a reactor interlayer arranged in the reaction chamber; an arc plasma gasification system power source of a reactor is switched on, gasification current is adjusted to 10-2,000 A, and voltage is adjusted to 5-400 V; inert gas is introduced into the metal melt, the melt delivery tube is adopted for flow guidance, the gasification reaction is performed, and metal jet is formed; the metal jet is gasified under the action of arc plasma so as to form atomic clusters, the atomic clusters are subjected to a reaction with oxygen, oxide nanoparticles are formed, is condensed under cold-air negative pressure and enters a powder collecting chamber with cold air flow, and the nano-metallic oxide powder is obtained. The technology is simple, does not need a plasma source and has high yield, and the prepared nano-metallic oxide powder is not prone to agglomeration, is high in purity and facilitates large-scale production.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Method for spraying cracked selenium source on surface of substrate

InactiveCN102433550AHigh reactivityImprove photoelectric conversion efficiencyFinal product manufactureChemical vapor deposition coatingIndiumAtomic cluster

The invention relates to a method for spraying a cracked selenium source on the surface of a substrate. The method comprises the following steps: entering selenium steam into a high-temperature cracking chamber; penetrating the selenium steam through two layers of porous grid plates with uniformly distributed pores, the pore diameter of which is 0.2-0.5mm, in the high-temperature cracking chamber, so that the selenium source forms cracked selenium source; and spraying the cracked selenium source to the surface of the substrate so as to complete the process of spraying the cracked selenium source on the surface of the substrate. According to the method provided by the invention, the selenium steam is adopted to penetrate through the two layers of porous grid plates at high temperature, and a large Sen (n is more than or equal to 5) atomic cluster is cracked to form a small Sen (n is less than 5) atomic cluster, thereby increasing the quantity of high-activity Se2, improving the reaction activity of a selenium element, effectively improving the film-forming quality of a CIGS (copper indium gallium selenium) layer of a CIGS film solar battery and taking an positive effect on improvement of photoelectric conversion efficiency of the CIGS film solar battery; and the selenium steam with the small atomic cluster is directly sprayed to the surface of the substrate through spray orifices, so that a selenium material can sufficiently participate in the reaction film-forming process of the CIGS layer, thereby improving the utilization rate of the selenium material.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

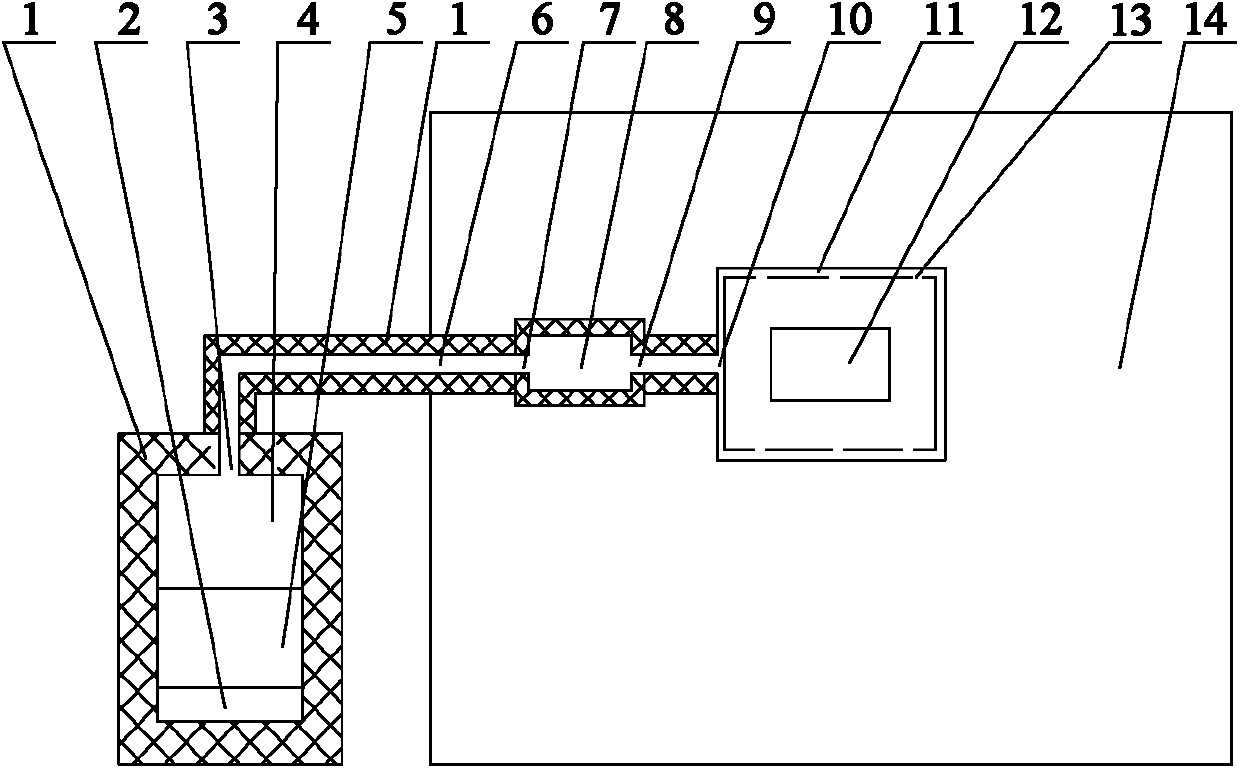

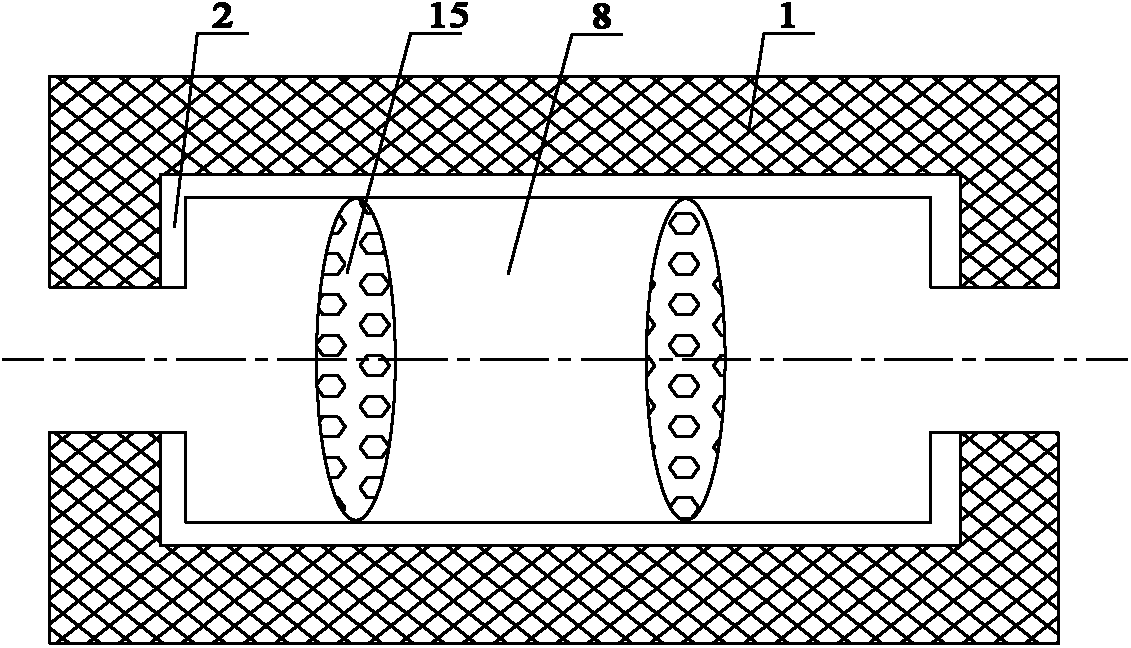

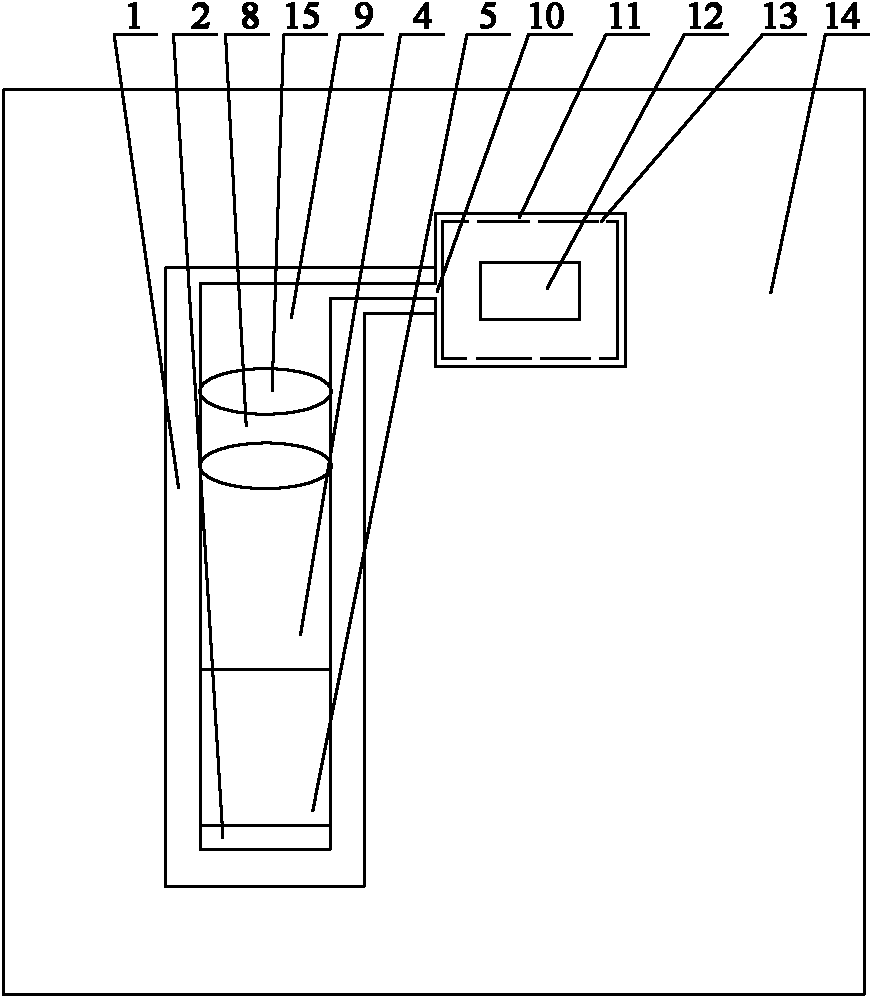

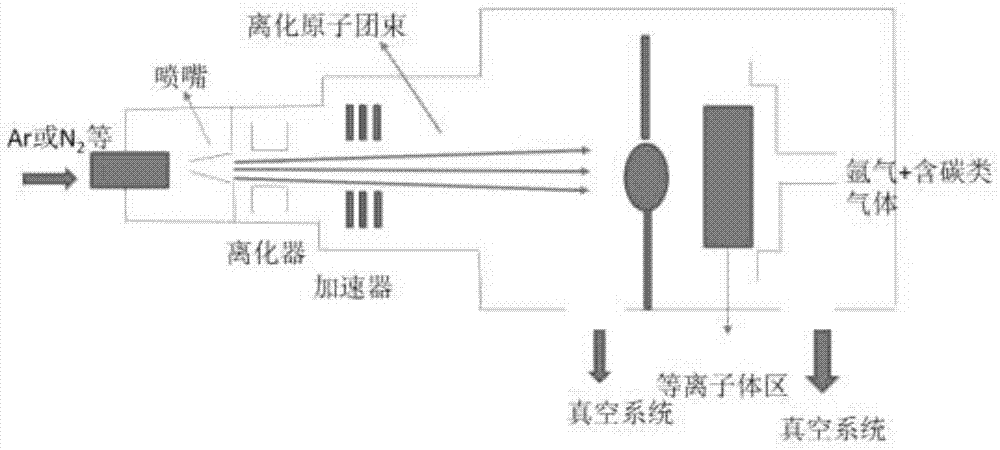

Method and system for assisting chemical vapor deposition to prepare DLC thin film through energy-loaded ionization atomic cluster

InactiveCN107541713AImprove mechanical propertiesImprove bindingChemical vapor deposition coatingOrganic baseAtomic cluster

The invention discloses a method and system for assisting chemical vapor deposition to prepare a DLC thin film through an energy-loaded ionization atomic cluster. The method comprises the steps that an inorganic or organic base plate is used as a base bottom, and before thin film deposition, the base bottom is sputter-cleaned, activated and flattened by using the energy-loaded ionization atomic cluster; and the DLC thin film is deposited on the surface of the base plate by using a PECVD method, meanwhile, the deposited DLC thin film is bombarded by using the energy-loaded ionization atomic cluster, and the highly-condensed DLC thin film is obtained. By means of the method, the density, abrasive resistance, rigidity and film / base binding force of the DLC thin film are greatly improved, thetechnology is easy to control, and the method can be applied toplated diamond thin films on the surafce of various tools and components.

Owner:SHANGHAI UNIV

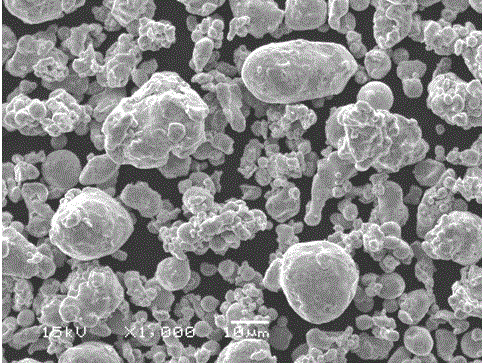

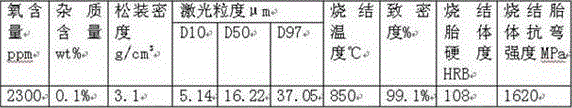

Rare-earth-regulated water-atomized Fe-Cu pre-alloyed powder special for ultra-hard material products and preparation method of rare-earth-regulated water-atomized Fe-Cu pre-alloyed powder

ActiveCN106222566AModulation of brittle wear propertiesMeet performance needsTransportation and packagingMetal-working apparatusSuperhard materialRare-earth element

The invention provides rare-earth-regulated water-atomized Fe-Cu pre-alloyed powder special for ultra-hard material products and a preparation method of the rare-earth-regulated water-atomized Fe-Cu pre-alloyed powder. Ultrafine iron and copper pre-alloyed powder is produced and prepared through a high-temperature liquid-state smelting and high-pressure water atomization method, and even and mechanical mixtures of Fe-Cu atomic clusters are formed inside powder particles; and double-component Fe-Cu basic pre-alloyed powder is produced and prepared by mainly using Fe, using soft-phase Cu in an auxiliary manner and adding the brittle phase forming element P and refined-grain rare earth elements (Ce and Y). The performance requirements of the ultra-hard products of different types can be well met, hard and brittle mass points such as Fe3P and Cu2P can be formed inside the alloy powder particles through the element P, dispersion distribution is achieved, the brittleness wear resistance of powder sintering tissues is regulated, and the improvement of the sharpness of tools is facilitated; and rare earth elements Ce and Y can refine powder crystalline grains, can improve the compactness and bending strength of the powder sintering tissues and is beneficial to the improvement of the holding force, for diamond, of the sintering tissues.

Owner:秦皇岛市雅豪新材料科技有限公司

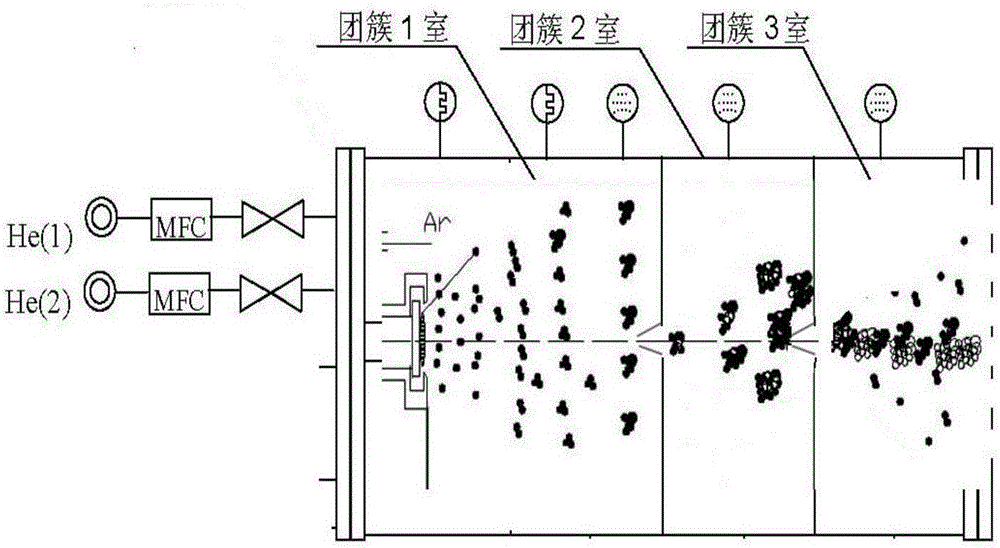

Nano processing method and equipment of atomic cluster beams aiming at organisms

ActiveCN106119802APromote growthVacuum evaporation coatingSputtering coatingMomentumRoom temperature

The invention relates to a nano processing method aiming at organisms on the basis of atomic cluster beams. Vacuum nano processing is performed on the organisms with high vapor pressure by utilizing the cluster beams, so that nano particles reach the surfaces of the organisms and functionally grow; the momentum of atomic cluster ions reaches 1.5*10<8> amu m / s; the organisms with high vapor pressure are solid materials of which the vapor pressure is 0.1 to 100 Pa at room temperature. A chamber I, a chamber II and a chamber III which are connected in series are formed in a generating device of the atomic cluster beams of the organisms; the growth of the atomic cluster beams at the same speed is realized by adjusting an opening angle of a nozzle between the chamber I and the chamber II or / and between the chamber II and the chamber III, and the opening angle of the nozzle is 5 to 35 degrees.

Owner:JIANGSU JICHUANG ATOMIC CLUSTER RES INST CO LTD

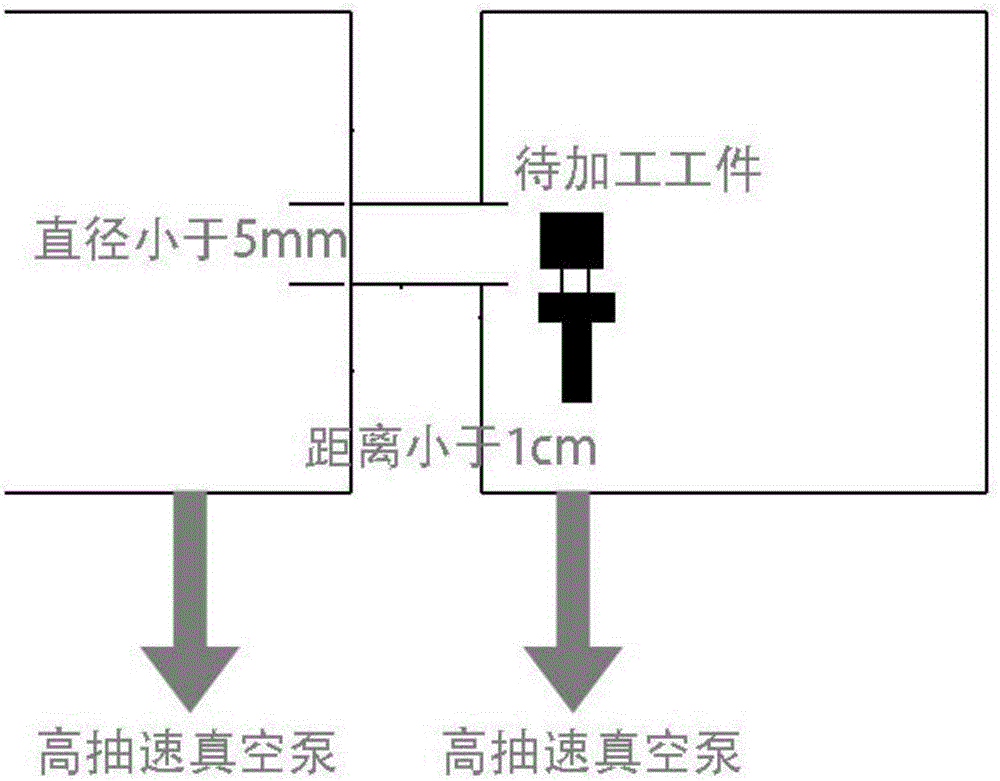

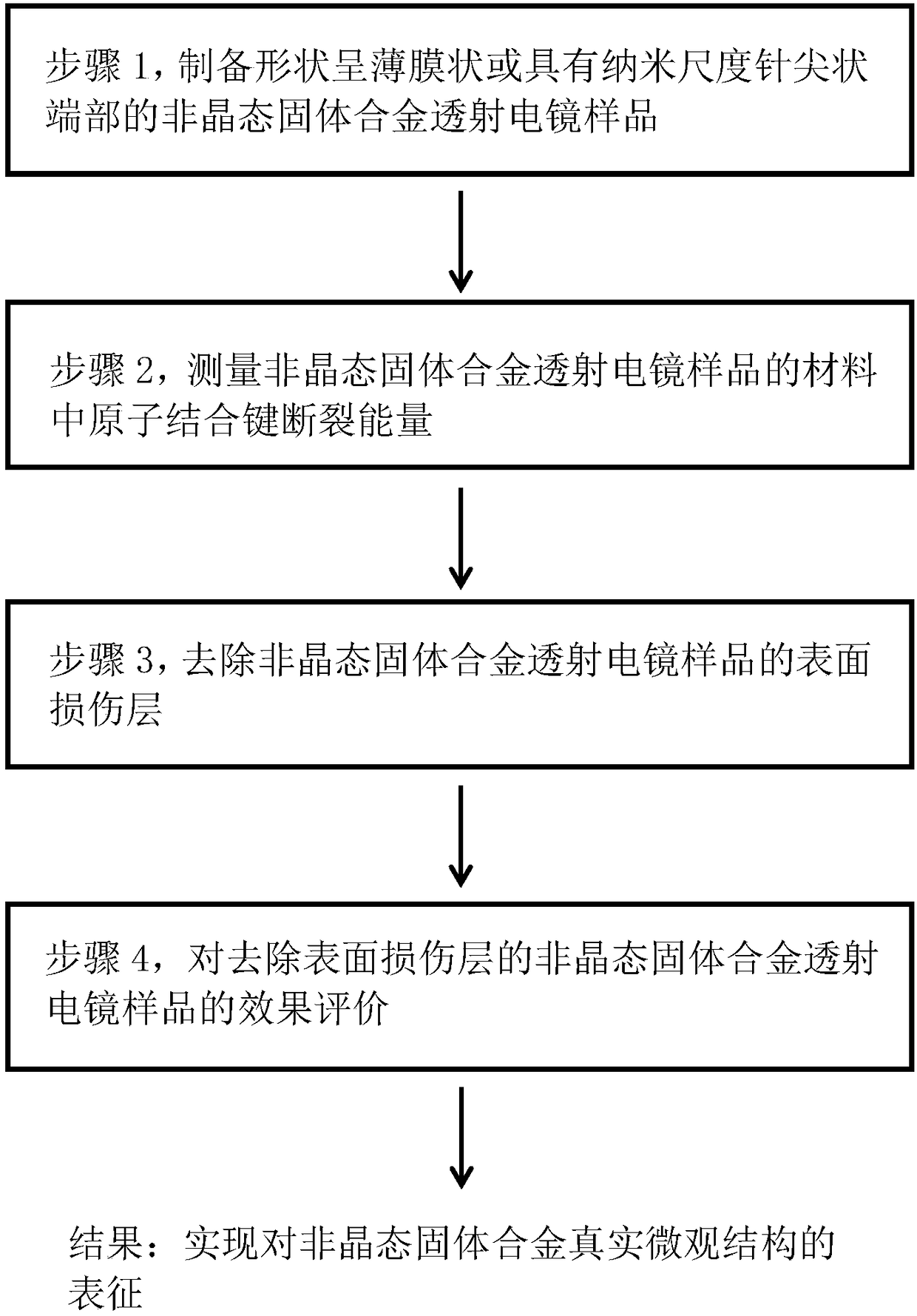

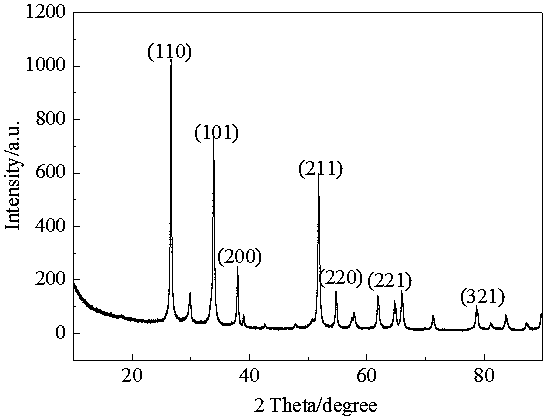

Technological method for refining three-dimensional reconstructed TEM (transmission electron microscope) sample of amorphous solid alloy and evaluation method

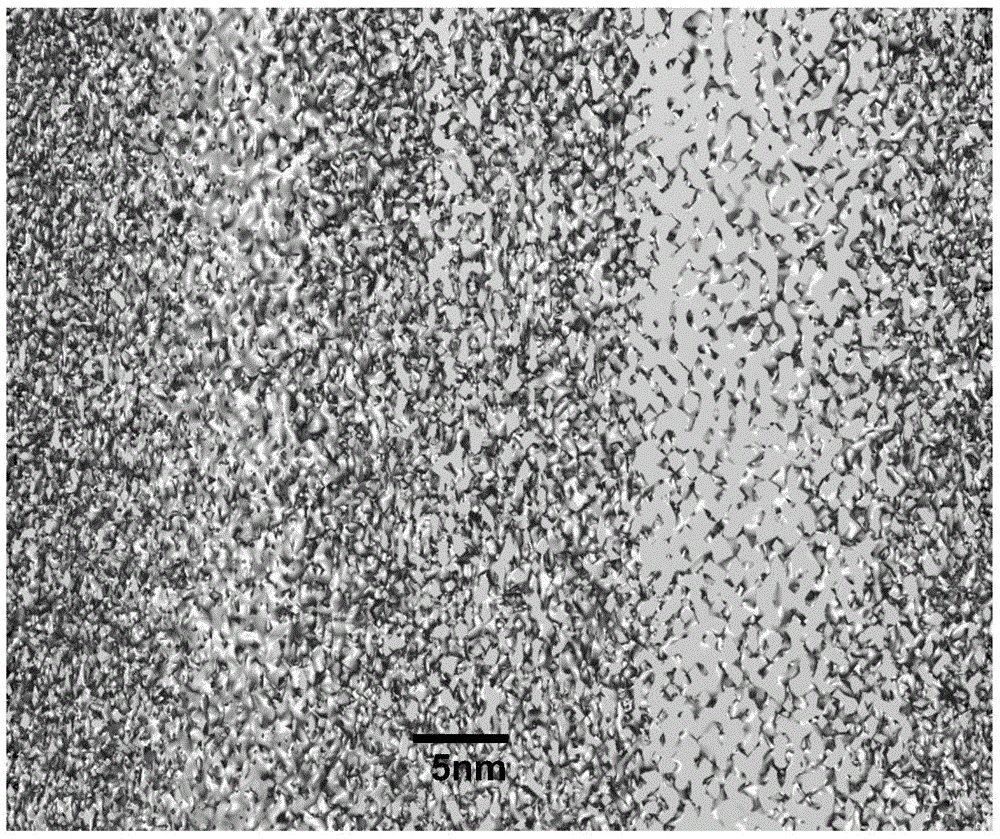

ActiveCN108181333AEfficient removalAccurate evaluationPreparing sample for investigationMaterial analysis by measuring secondary emissionAtomic clusterAlloy

The invention relates to a technological method for refining a three-dimensional reconstructed TEM (transmission electron microscope) sample of an amorphous solid alloy and an evaluation method. The technological method comprises the following steps: step 1, preparing a TEM sample, which is in a thin film shape or provided with a nanoscale needle-point end part, of the amorphous solid alloy; step2, measuring rupture energy of atomic bonds in the TEM sample of the amorphous solid alloy; step 3, removing a surface damage layer of the TEM sample of the amorphous solid alloy; step 4, evaluating the effect of the TEM sample of the amorphous solid alloy with the surface damage layer removed. The surface damage layer produced in the preparation process of the three-dimensional reconstructed TEMsample of the amorphous solid alloy can be removed, the effect of removal of the surface damage layer is evaluated accurately, guarantee is provided for accurate characterization of morphology and spatial distribution of atomic clusters of the amorphous solid alloy, and the foundation is laid for improving macroscopic performance of the amorphous solid alloy material.

Owner:南京腾元软磁有限公司 +2

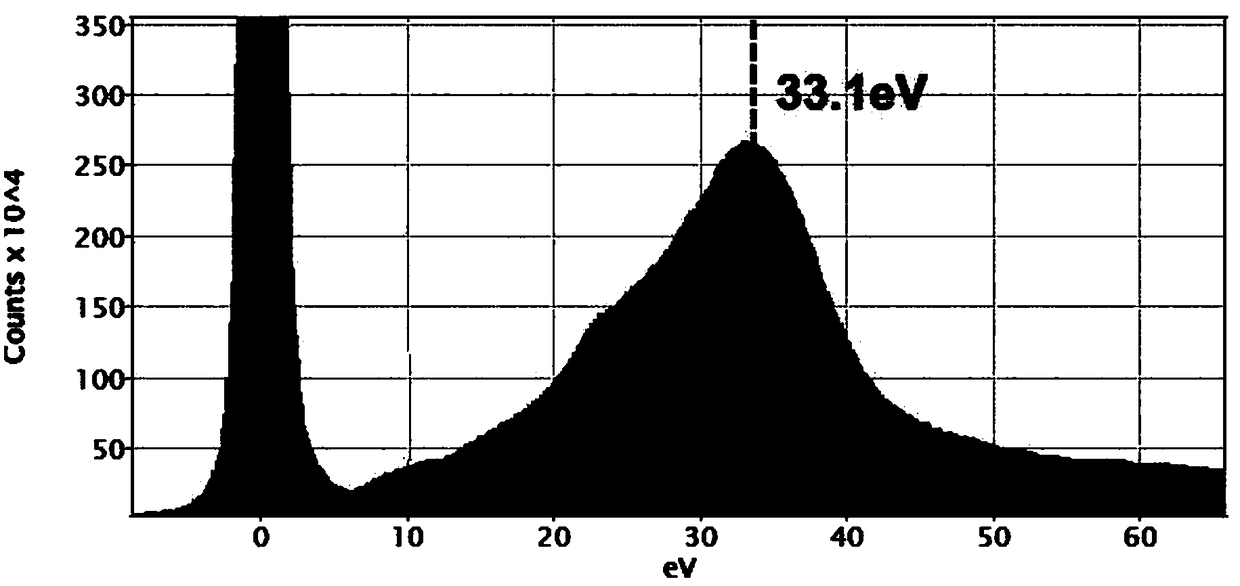

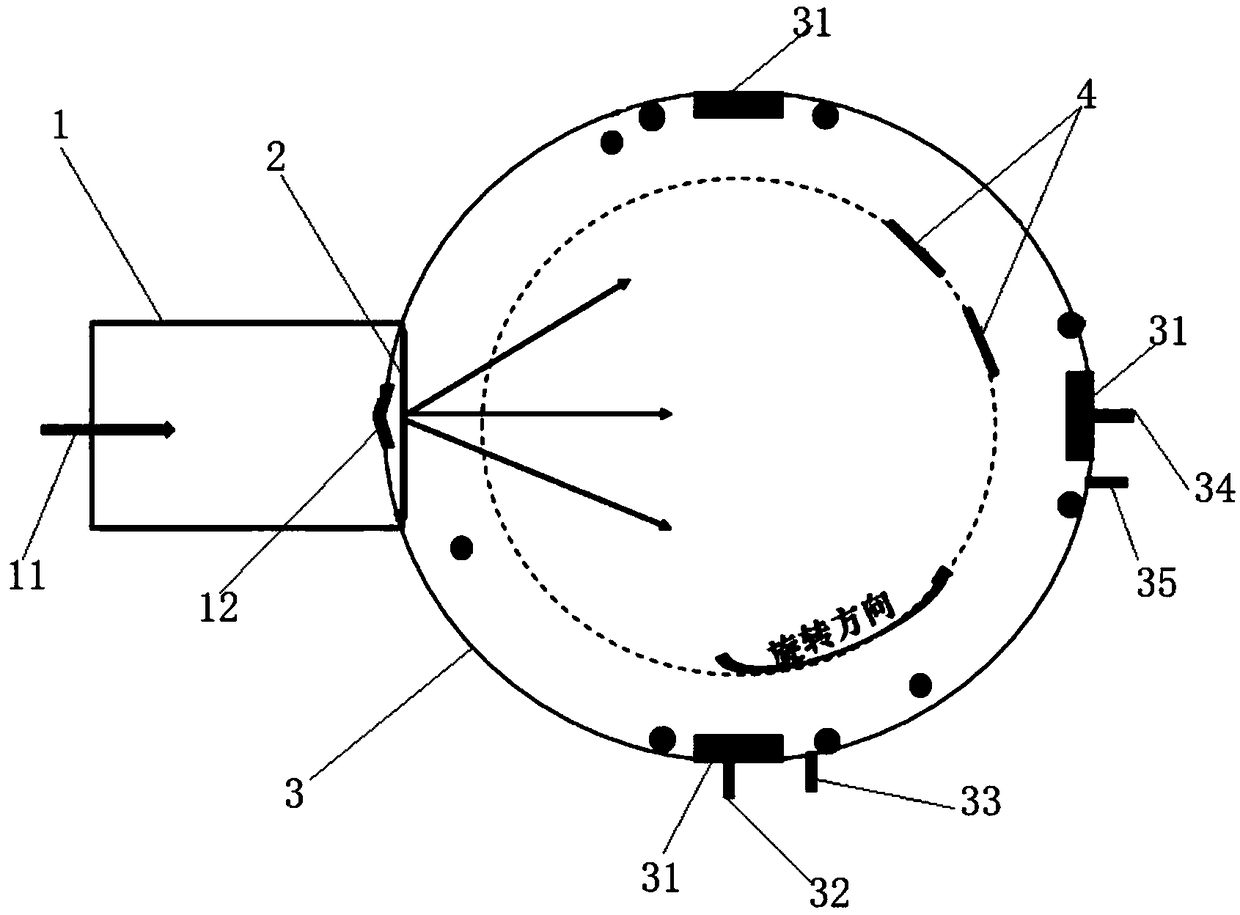

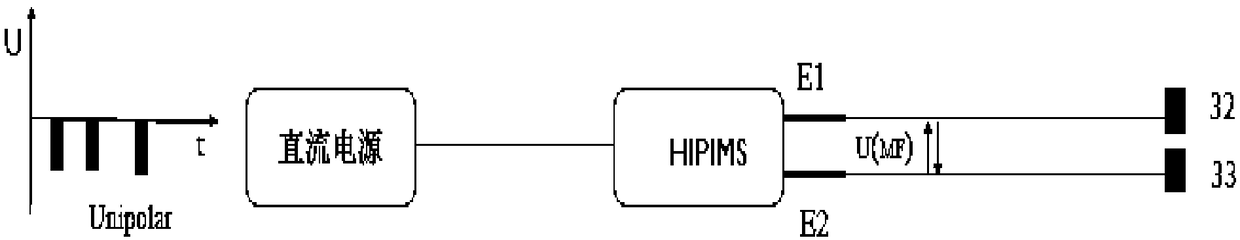

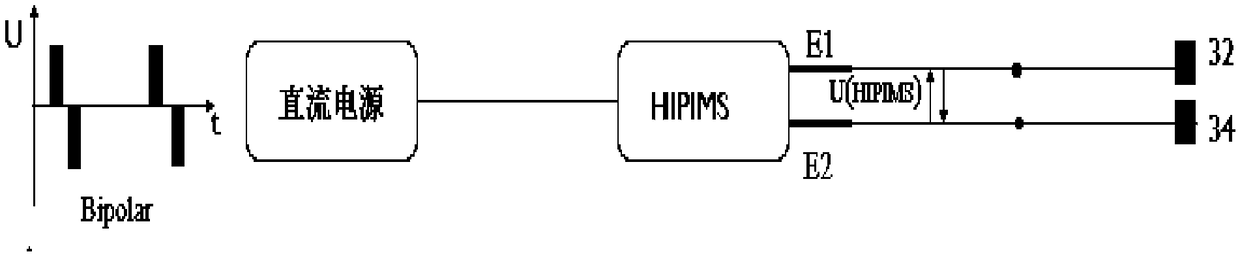

Method for preparing high-quality thin film by using ionized atom clusters and combining HIPIMS technology

InactiveCN109402555AImprove adhesion strengthImprove bindingVacuum evaporation coatingSputtering coatingSputteringGas phase

The invention discloses a method for preparing a high-quality thin film by using ionized atom clusters and combining an HIPIMS technology. The method is a PVD (physical vapor deposition) method for preparing the high-quality thin film by using the ionized atom clusters as sputtering gas and combining the HIPIMS technology; the film formation characteristic of high-power magnetron sputtering is exerted; the film formation deposition rate of the HIPIMS technology is exponentially improved; the high-quality thin film with excellent performance is obtained through preparation; inert gas is clustered through an atomic clustering device and is then ionized and guided out through an ionic device; a target material is bombarded under the effects of an electric field and an magnetic field, so thattarget material particles participate in a reaction on a base plate; the thin film is prepared. The method solves the problems that in the prior art, the quality of a film formed by a traditional PVDmethod is poor; that the combining force of the thin film produced by a CVD method is poor; that the mechanical performance is unstable.

Owner:昆山益固纳米科技有限公司

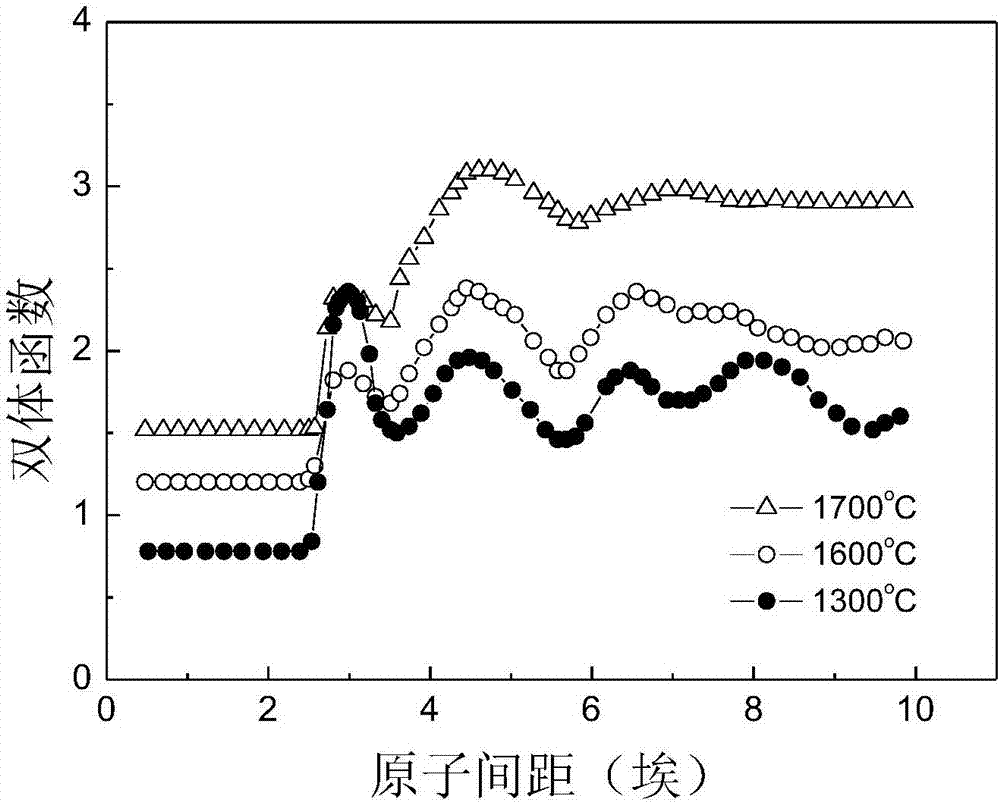

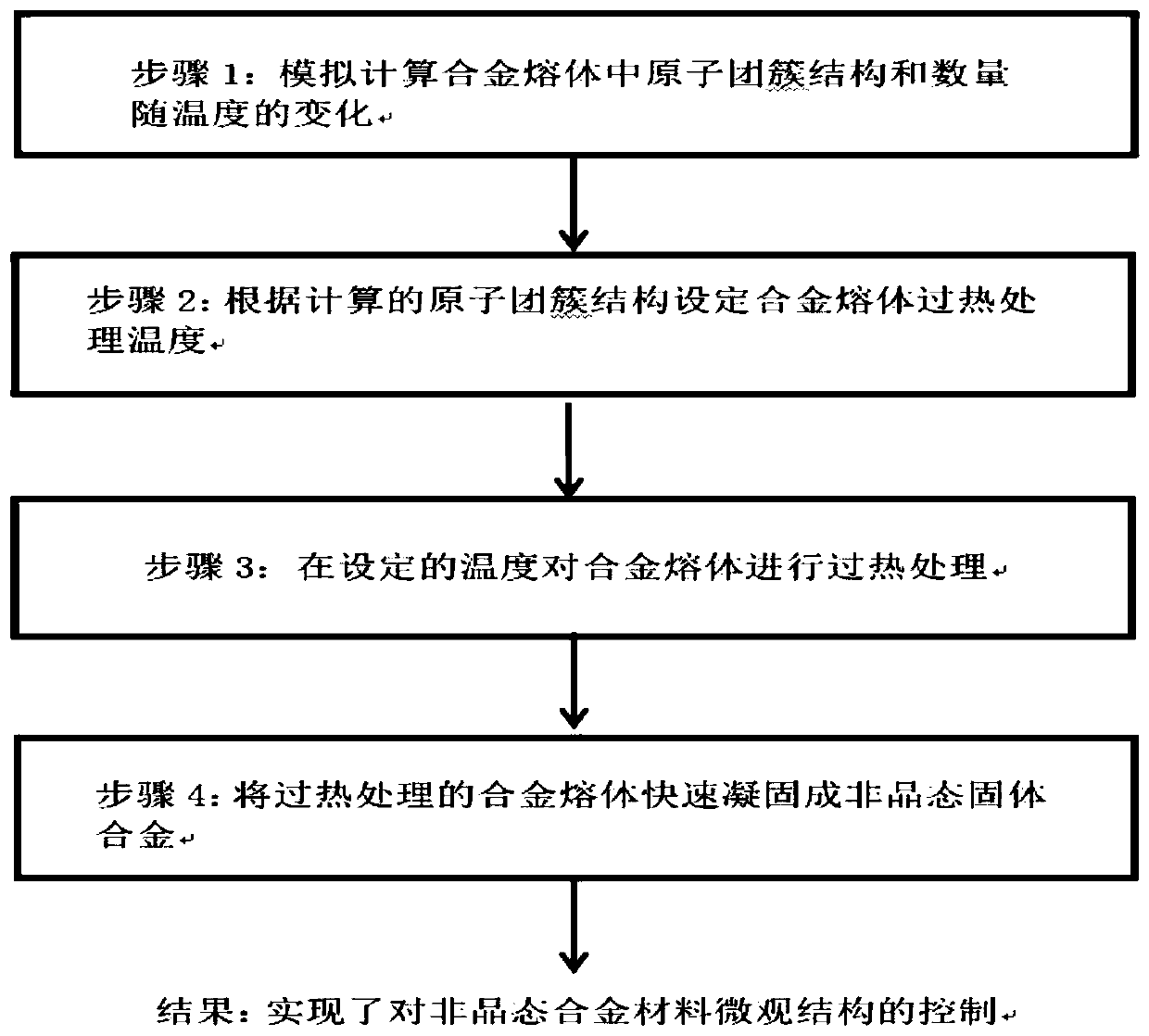

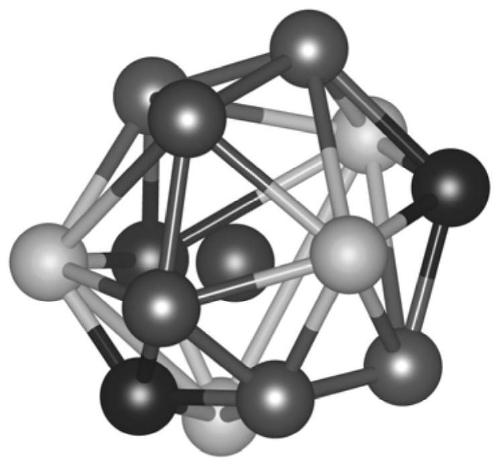

Method for adjusting microstructure of amorphous solid alloy by utilizing configuration and number of melt atomic clusters

InactiveCN109778084AImprove macro performanceStrong designabilityMolecular entity identificationComputational theoretical chemistryAtomic clusterAlloy

The invention discloses a method for adjusting the microstructure of amorphous solid alloy by utilizing the configuration and number of melt atomic clusters. The method comprises the following steps:carrying out analog calculation on the configuration and number of the atomic clusters in alloy melt, to be specific, according to the components of to-be-prepared alloy, calculating the configurationand number of atomic clusters in the alloy melt at different temperatures, and obtaining a calculating result that the configuration and number of the atomic clusters vary with the temperatures; carrying out superheat treatment on the alloy melt, to be specific, choosing required configuration and number of the atom clusters according to the calculating result, determining that the temperature corresponding to the chosen configuration and number of the atomic clusters is the superheat treatment temperature of the alloy melt, and carrying out heat preservation on the alloy melt at the superheat treatment temperature so as to obtain the superheat-treated alloy melt; and carrying out rapid solidification, to be specific, carrying out rapid solidification on the superheat-treated alloy melt to obtain the amorphous solid alloy. The invention creates a novel scheme for the controllable preparation of the microstructure of the amorphous solid alloy.

Owner:JIANGSU JICUI ANTAI CHUANGMING ADVANCED ENERGY MATERIALS RES INST CO LTD

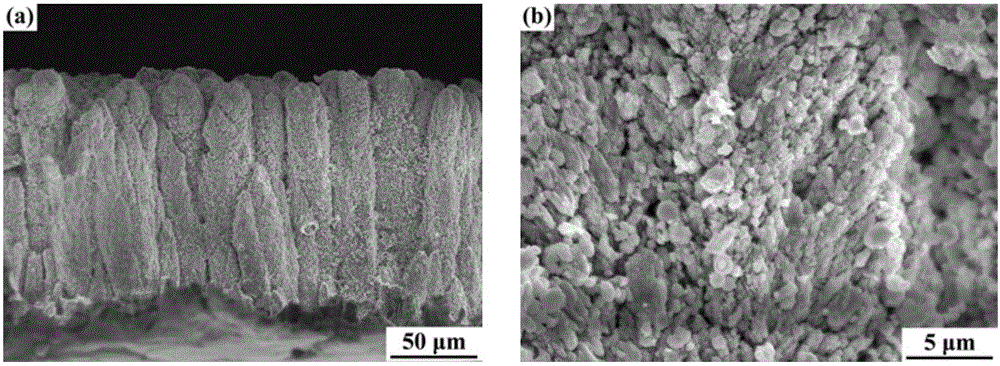

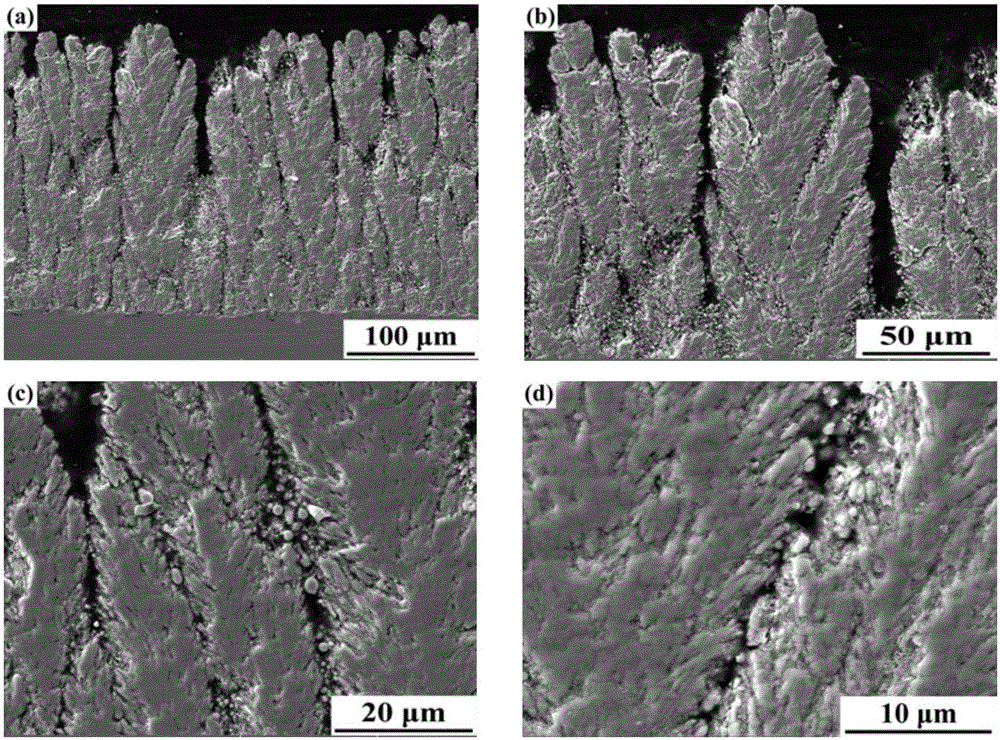

Preparation method for thermal barrier coating of high strain tolerance columnar structure

ActiveCN105839057AExtend your lifeWith flow-around characteristicsVacuum evaporation coatingSputtering coatingAtomic clusterAtmospheric pressure

The invention discloses a preparation method for a thermal barrier coating of a high strain tolerance columnar structure. The thermal barrier coating is of the columnar structure with intercolumnar pores and thus has high strain tolerance. The preparation method comprises the steps that under the chamber pressure of 10-5000 Pa, mixed beams containing coating material micro particles in the form of single atoms and / or atomic clusters serve as a deposition source, intermittent and / or continuous deposition is conducted on a workpiece of which the free path exceeds two times or above of the minimum free path of the coating material micro particles in the mixed beams, and the surface temperature is maintained or heat is preserved to be 0.2 times or above of the coating material melting point, so that the thermal barrier coating of the high strain tolerance columnar structure with the intercolumnar pores is prepared and obtained. Compared with a traditional thermal barrier coating, the thermal barrier coating prepared through the preparation method is of the high strain tolerance columnar structure with the intercolumnar pores, the stress caused by thermal mismatch can be effectively released, and the strain tolerance is improved, so that the service life of the thermal barrier coating is prolonged.

Owner:XI AN JIAOTONG UNIV

Process for preparing nanometer metal oxide powder by DC plasma method

ActiveCN106044849BSimple processReduce manufacturing costGallium/indium/thallium compoundsNanotechnologyAtomic clusterOxygen

A technology for preparing nano-metallic oxide powder with a DC (direct-current) plasma method comprises steps as follows: a high-purity metal block is put into a smelting furnace and is melted, and a melt delivery tube connected with the smelting furnace is heated; a reaction chamber is subjected to vacuum pumping until the pressure reaches 2-10 MPa, cooling air is introduced into the reaction chamber, and cooling water is introduced into a reactor interlayer arranged in the reaction chamber; an arc plasma gasification system power source of a reactor is switched on, gasification current is adjusted to 10-2,000 A, and voltage is adjusted to 5-400 V; inert gas is introduced into the metal melt, the melt delivery tube is adopted for flow guidance, the gasification reaction is performed, and metal jet is formed; the metal jet is gasified under the action of arc plasma so as to form atomic clusters, the atomic clusters are subjected to a reaction with oxygen, oxide nanoparticles are formed, is condensed under cold-air negative pressure and enters a powder collecting chamber with cold air flow, and the nano-metallic oxide powder is obtained. The technology is simple, does not need a plasma source and has high yield, and the prepared nano-metallic oxide powder is not prone to agglomeration, is high in purity and facilitates large-scale production.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

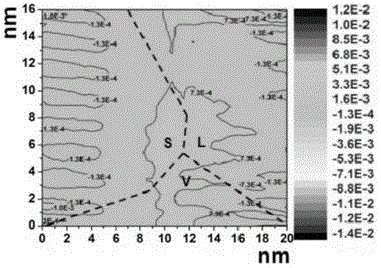

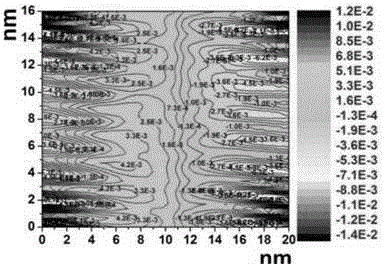

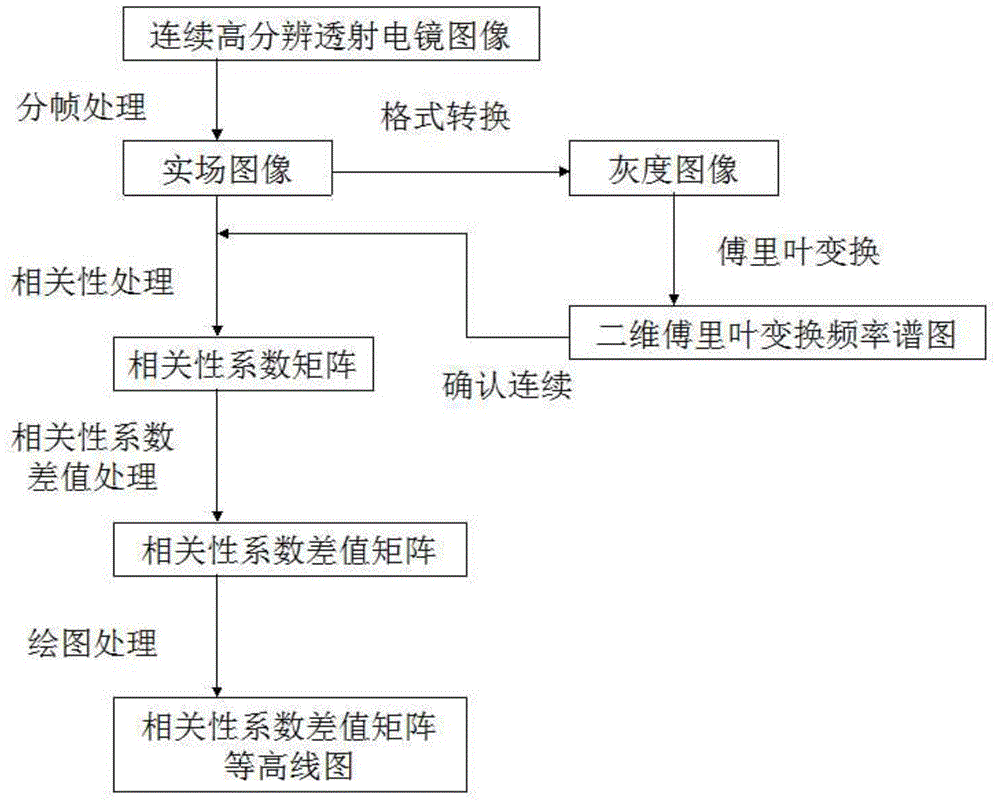

Analytical method suitable for continuous high-resolution transmission electron microscope images

ActiveCN104820994AEasy to distinguishAnalysis of resolved TEM images facilitatesImage analysisConventional transmission electron microscopeCorrelation coefficient

The invention discloses an analytical method suitable for continuous high-resolution transmission electron microscope images. The analytical method includes the following steps: framing processing is performed on continuous high-resolution dynamic images to obtain framed images; correlation processing is performed on the acquired framed images to obtain a correlation coefficient matrix; difference value processing is performed on the acquired correlation coefficient matrix to obtain a correlation coefficient difference value matrix; and the acquired correlation coefficient difference value matrix is converted to a contour map, different areas and boundaries between the areas are distinguished in a short time according to the range and the shape of contour lines, subtle motion changes of the continuous images are obtained according to changes in values of the contour lines and the average rate of change, and a transmission mechanism of energy is acquired. According to the analytical method suitable for the continuous high-resolution transmission electron microscope images, framing, conversion and correlation processing are performed on the images, the obtained correlation coefficient matrix that is calculated, the method converts atom or atomic cluster motion information that cannot be expressed quantitatively originally to information that can be analyzed quantitatively, an implementation process is relatively simple, and thus the method is easy to implement.

Owner:SHAANXI UNIV OF SCI & TECH

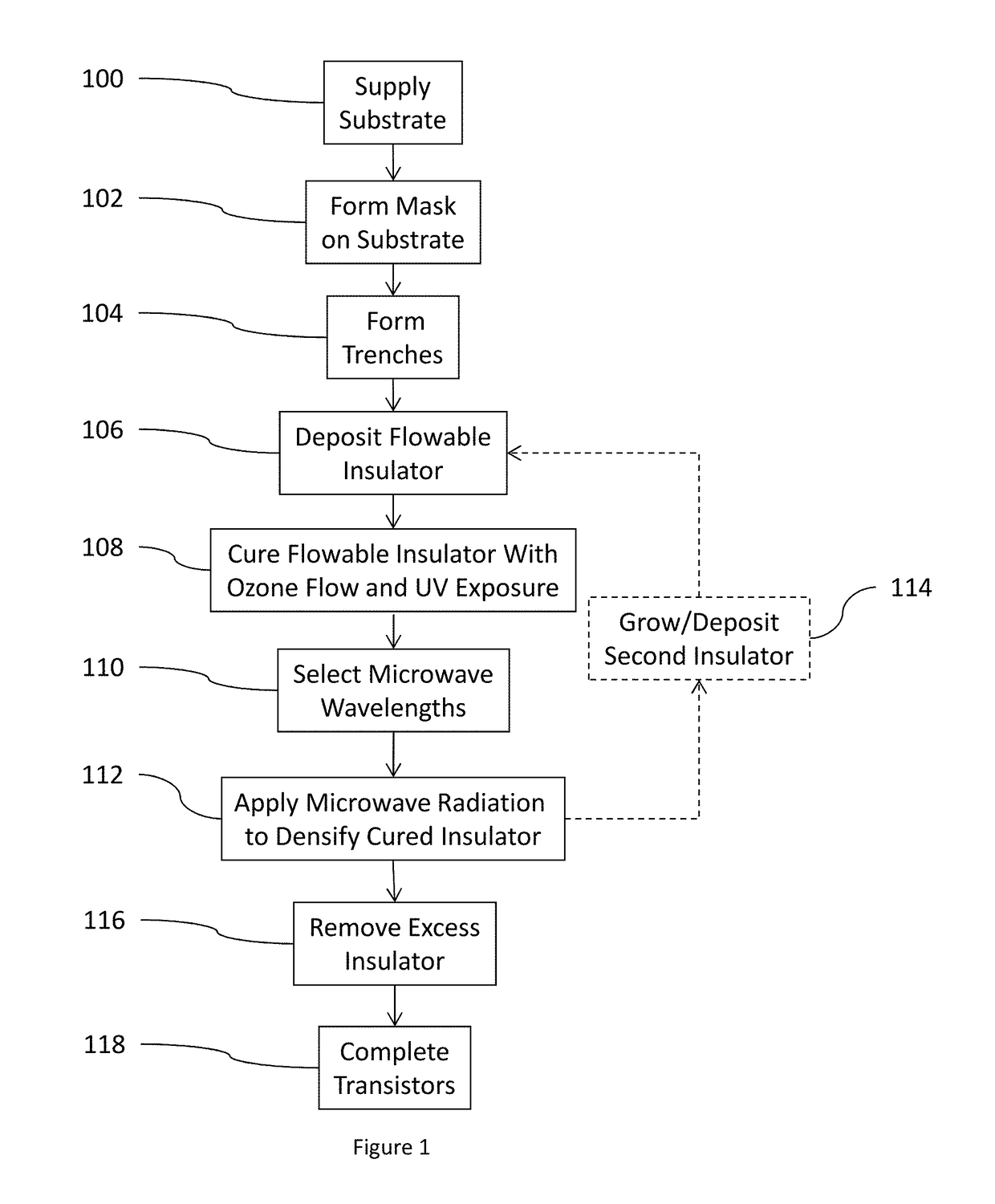

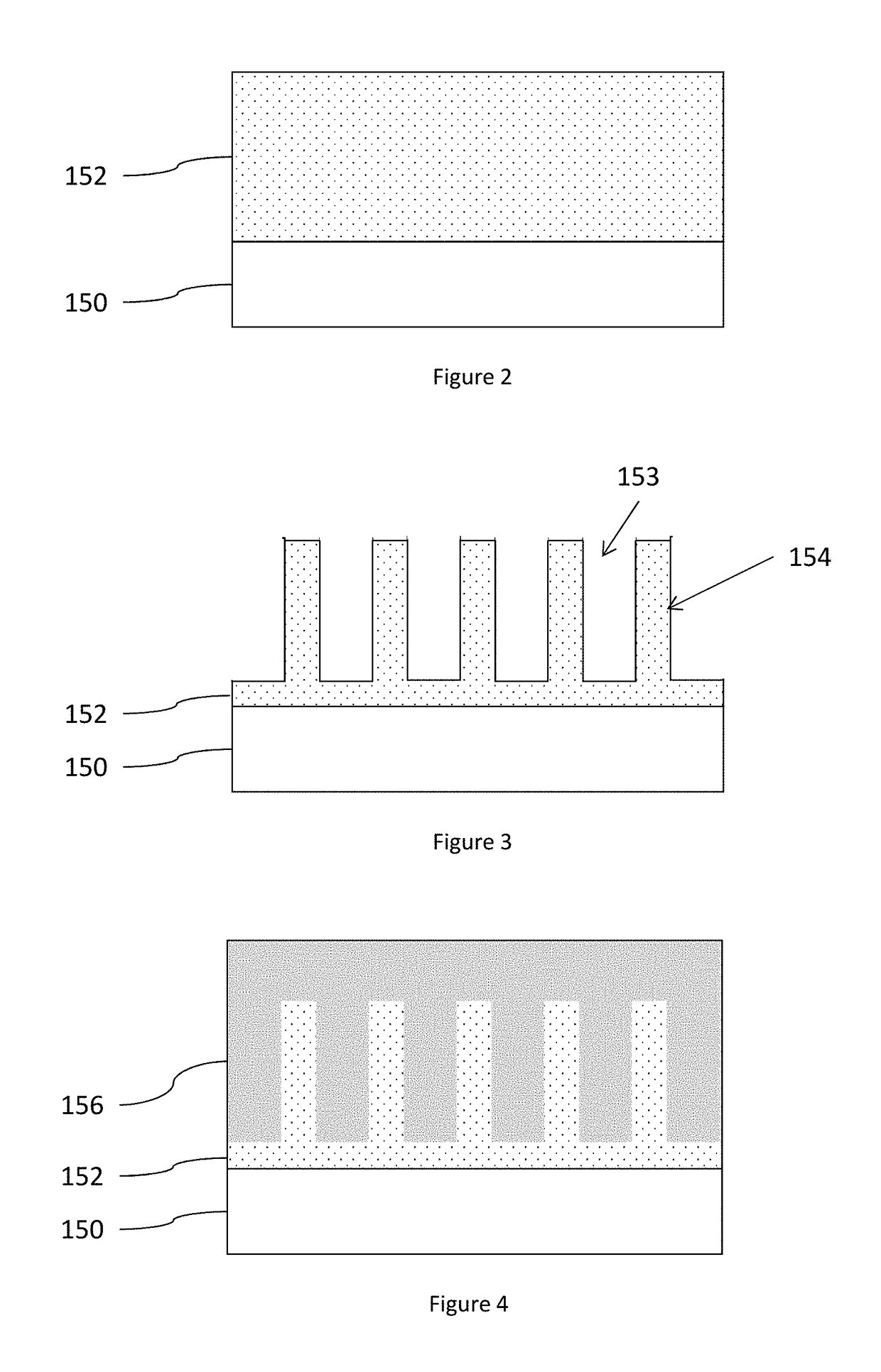

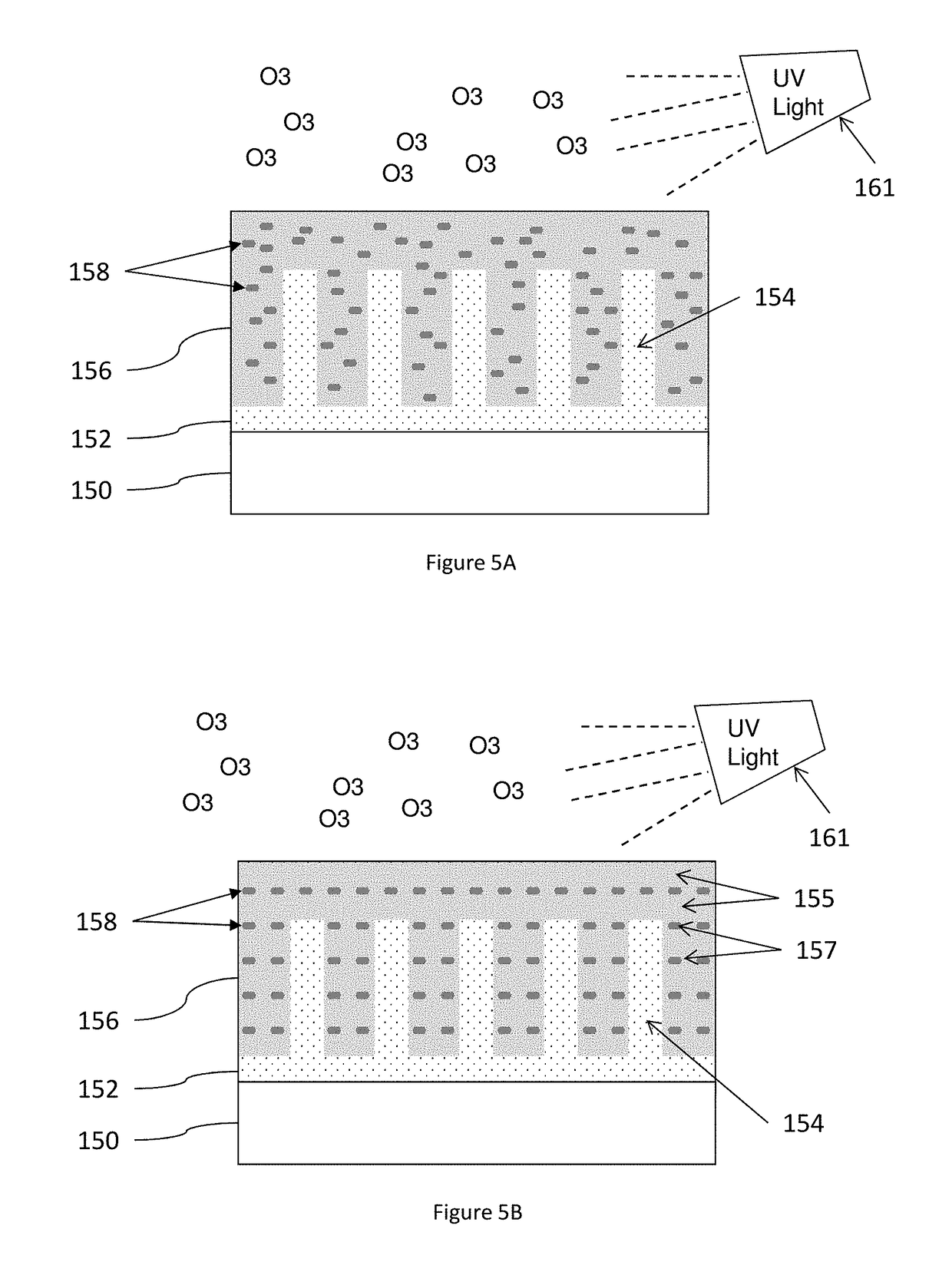

Microwave annealing of flowable oxides with trap layers

An insulator is formed by flowable chemical vapor deposition (FCVD) process. The insulator is cured by exposing the insulator to ultraviolet light while flowing ozone over the insulator to produce a cured insulator. The curing process forms nitrogen, hydrogen, nitrogen monohydride, or hydroxyl-rich atomic clusters in the insulator. Following the curing process, these methods select wavelengths of microwave radiation (that will be subsequently used during annealing) so that such wavelengths excite the nitrogen, hydrogen, nitrogen monohydride, or hydroxyl-rich atomic clusters. Then, these methods anneal the cured insulator by exposing the cured insulator to microwave radiation in an inert (e.g., non-oxidizing) ambient atmosphere, at a temperature below 500° C., so as to increase the density of the cured insulator.

Owner:GLOBALFOUNDRIES US INC

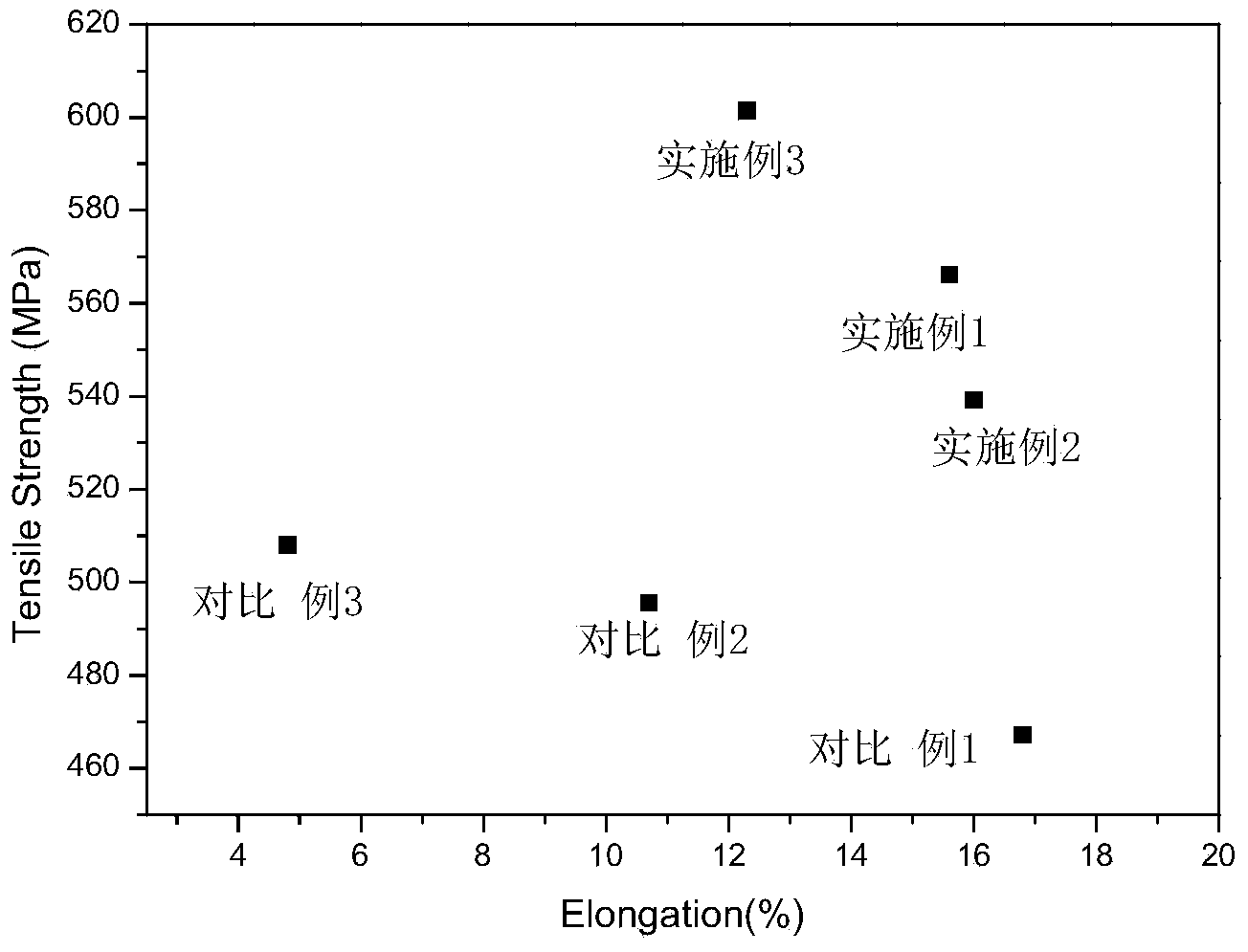

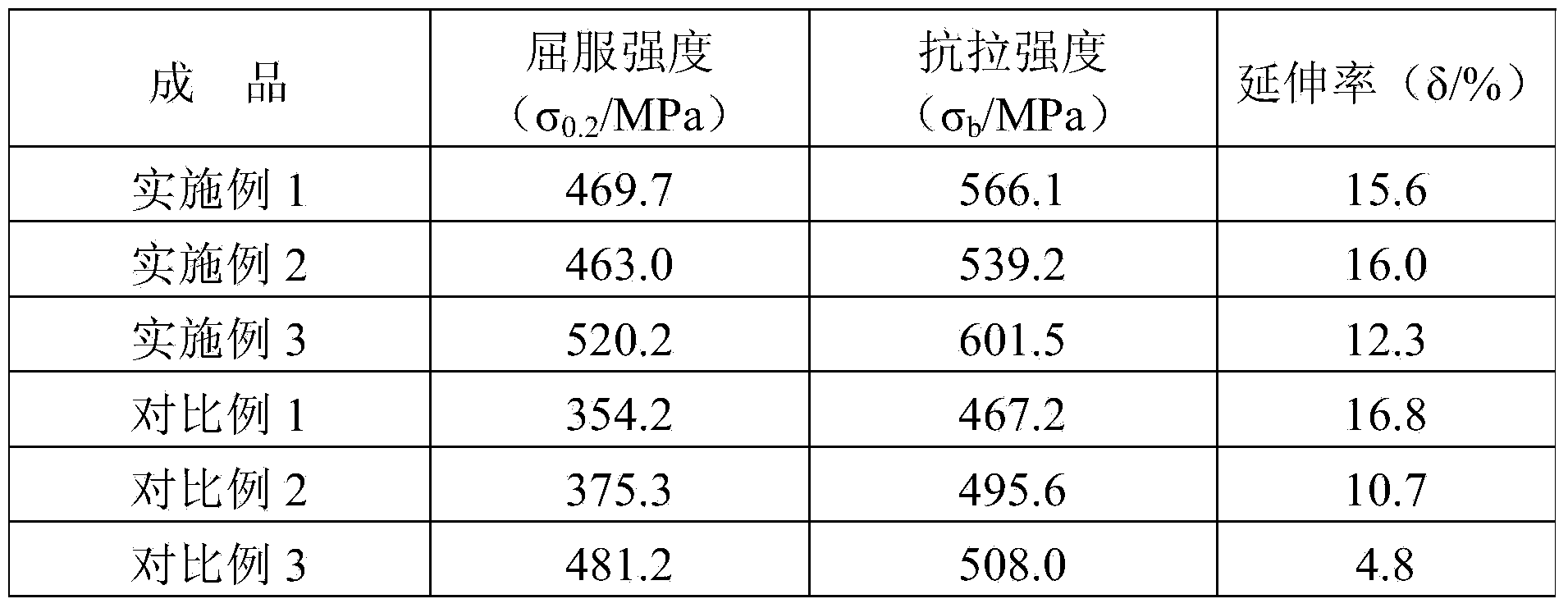

Method for strengthening VW93M magnesium alloy through atomic segregation and atomic clustering

The invention relates to a method for strengthening a VW93M magnesium alloy through atomic segregation and atomic clusters. The magnesium alloy comprises, by mass, Mg, 8.0-9.6% of Gd, 1.8-3.2% of Y, 0.3-0.7% of Zr, 0.02-0.5% of Ag, 0.02-0.3% of Er. The method comprises the steps of conducting rotary forging deformation on a VW93M magnesium alloy bar, controlling the initial rotary forging temperature to be 100-300 DEG C and the total deformation to be 10-80%, conducting oil lubrication in the rotary forging process, controlling the flow velocity of a lubricating agent to be 0.5-1.5 m3 / h and the feeding speed to be 3-6 mm / min, changing the feeding direction after each pass of deformation, wherein the concentration of Gd and Y elements of the grain boundary is 2-2.5 times greater than that of intragranular Gd and Y elements, the size of atomic clusters is 5-15 nm, and the obtained magnesium alloy has the yield strength greater than or equal to 530 MPa, the tensile strength greater than or equal to 610 MPa and the percentage elongation after fraction greater than or equal to 5%.

Owner:CENT SOUTH UNIV

Regulation method of amorphous alloy average atomic cluster size

The invention discloses a regulation method of an amorphous alloy average atomic cluster size. The regulation method of the amorphous alloy average atomic cluster size comprises the steps that amorphous alloy fused mass average atomic cluster size is calculated, specifically, the average atomic cluster sizes of amorphous alloy fused mass are calculated under different temperatures, the calculationresults of the average atomic cluster size changed with the temperature are acquired; super heating treatment is conducted on the alloy fused mass, specifically, the needed average atomic cluster size is chosen according to the calculation results, the temperature corresponding to the chosen average atomic cluster size is determined to be the super heating treatment temperature of the alloy fusedmass, heat preservation is conducted on the alloy fused mass under the super heating treatment temperature, and the alloy fused mass after the super heating treatment is acquired; and rapid solidification is conducted, specifically, the rapid solidification is conducted on the amorphous alloy fused mass after the super heating treatment, and an amorphous solid alloy is acquired. According to theregulation method of the amorphous alloy average atomic cluster size, a novel concept and a novel method of designing and preparation of an amorphous alloy microstructure are initiated, and the regulation method of the amorphous alloy average atomic cluster size has the characteristics of simpleness, convenience, high efficiency, low cost, high technology reliability and the like.

Owner:JIANGSU JICUI ANTAI CHUANGMING ADVANCED ENERGY MATERIALS RES INST CO LTD

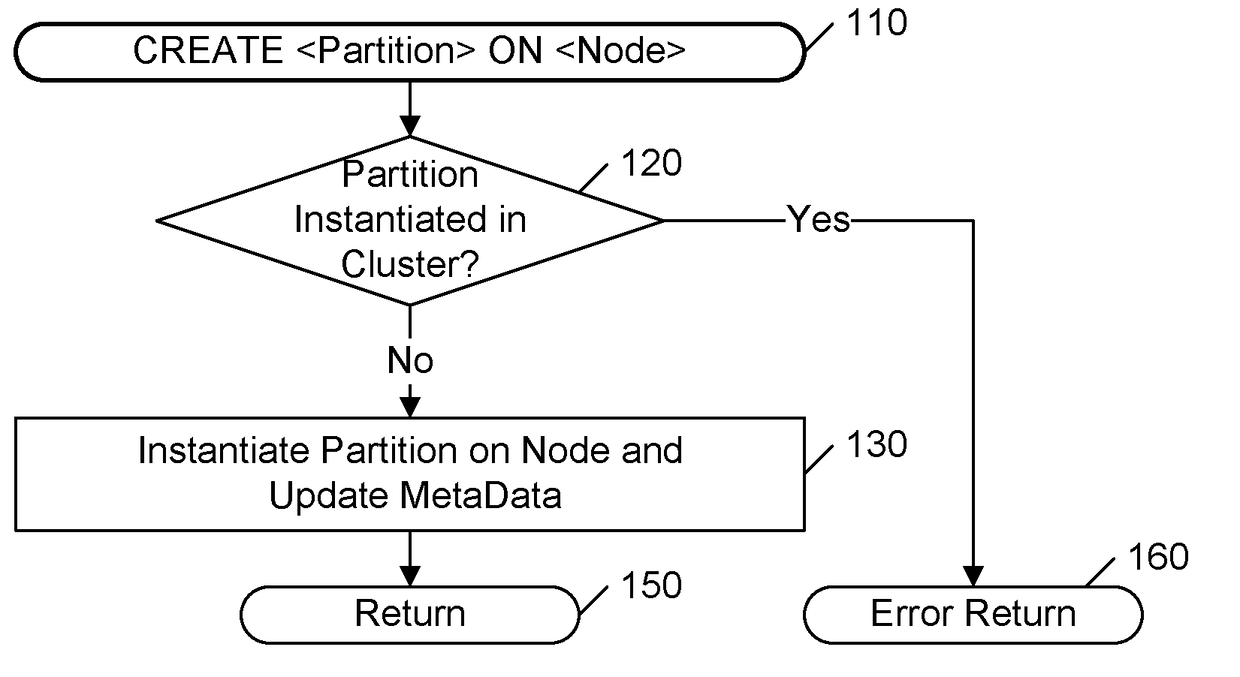

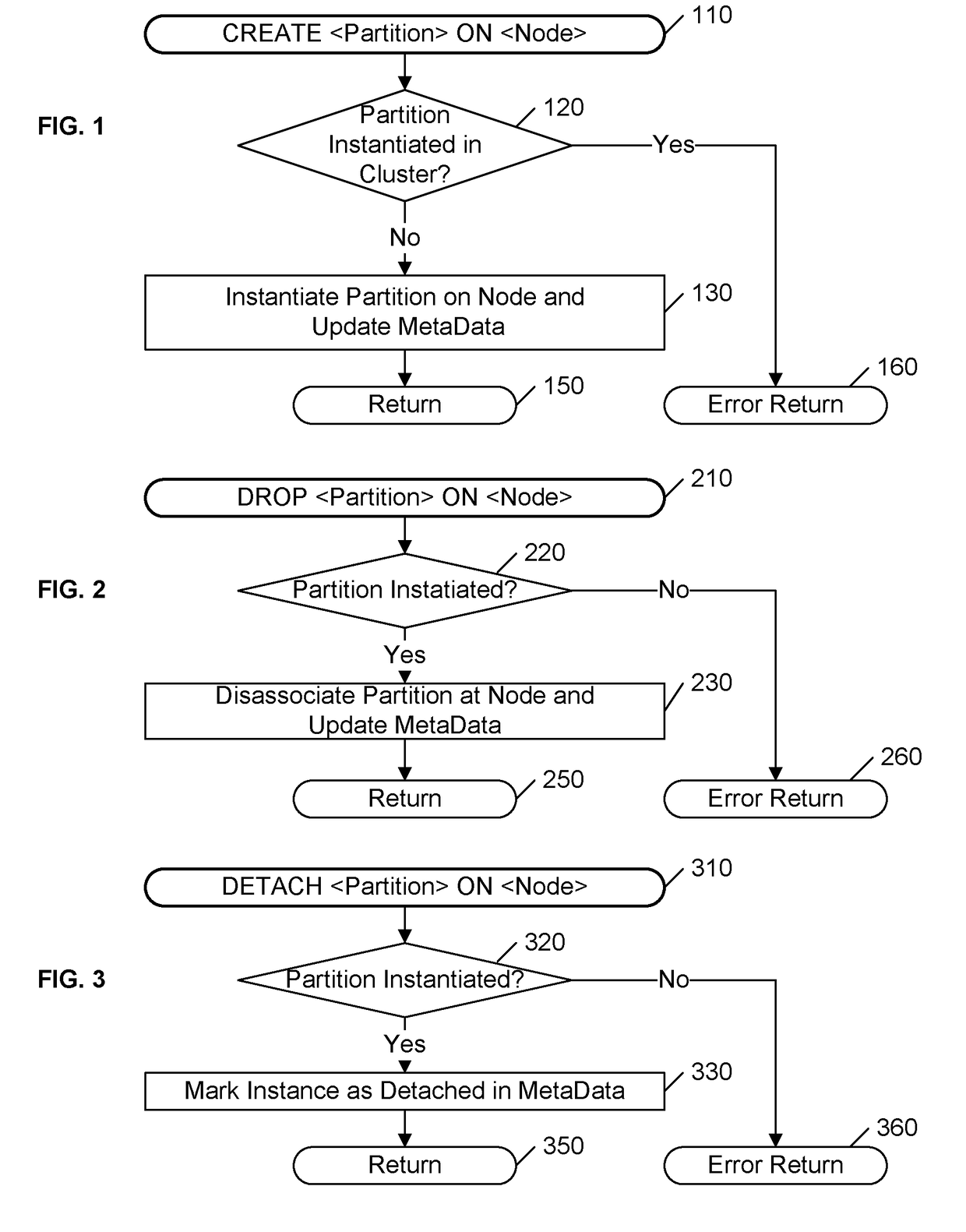

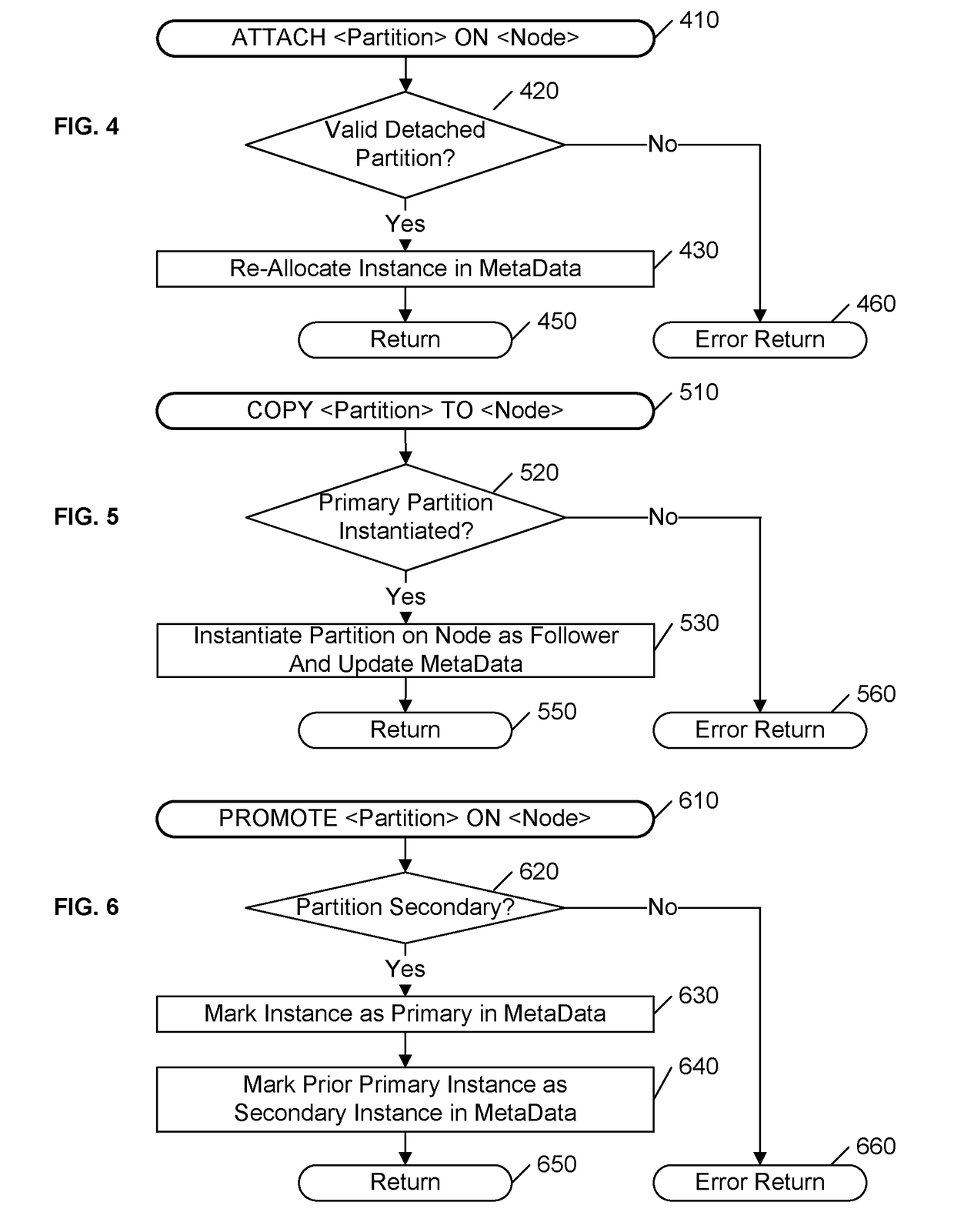

Atomic clustering operations for managing a partitioned cluster online

ActiveUS20170091301A1Improve reliabilityImprove performanceDatabase management systemsSpecial data processing applicationsFailoverClustered data

A set of six atomic primitives are provided for a database management system that may be used in combination to provide all of the common features and functions of a clustered database, including data failover, auto-healing, and elastic scaling. These six atomic primitives include CREATE, DROP, DETACH, ATTACH, COPY, and PROMOTE. Of particular note, it is shown that by maintaining appropriate metadata, including the status of each instance of each partition in the cluster, the versatility and reliability of this set of primitives is sufficient to implement each of the aforementioned data failover, auto-healing, and elastic scaling functions with high efficiency using a minimal number of these primitives. Each primitive is atomic (such that the cluster clearly in one state or another) and online (a workload of reads and writes is uninterrupted while the primitive runs), and each primitive is scoped to a single partition of data, thereby enabling parallel processing.

Owner:SINGLESTORE INC

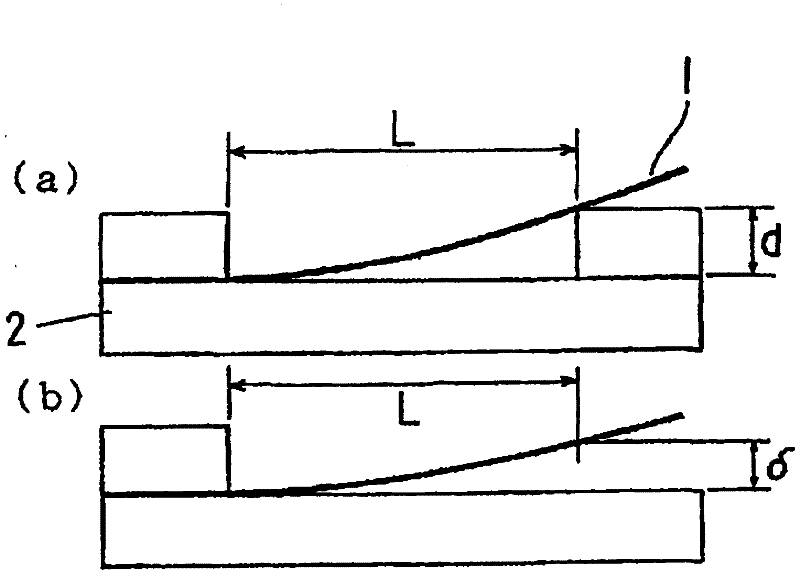

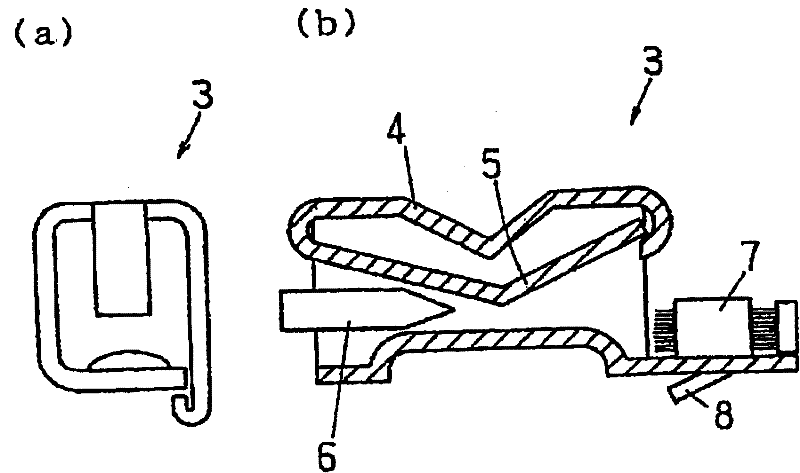

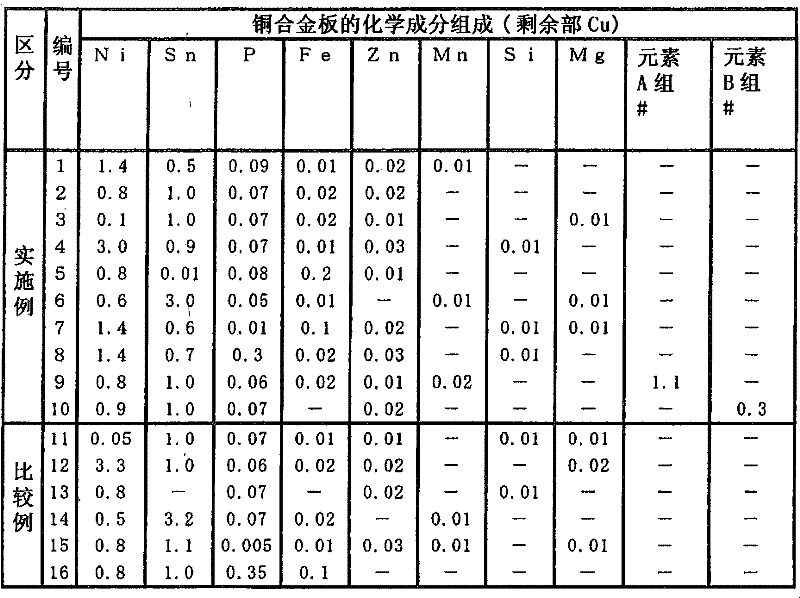

Copper alloy plate having excellent anti-stress relaxation properties

The invention provides a Cu-Ni-Sn-P alloy sheet satisfying the resistance property of stress relaxation in the direction perpendicular to the rolling direction and excellent in the other necessary properties as terminals and connectors. The invention relates to analloy sheet having a specific composition, which is made to contain specific atomic clusters containing at least any of an Ni atom or aP atom, as detected with a three-dimensional atom probe field ion microscope, in a specific density, by increasing the reduction ratio in the final cold rolling and by intentionally shortening the time for the rolling and the time to be taken before the final annealing at low temperature, and of which the necessary properties as a terminal or connector 3 are improved in that the resistance property of stress relaxation thereof in the direction perpendicular to the rolling direction is enhanced and the difference (anisotropy) in the resistance property of stress relaxation thereof between the parallel direction and the perpendicular direction to the rolling direction is reduced.

Owner:KOBE STEEL LTD

Preparation method of thorn-like and petal-like rough surface gold-silver alloy nanomaterials

InactiveCN106041119BFast growth rateEasy to operatePolycrystalline material growthNanotechnologyRough surfaceNanoparticle

The invention provides a preparation method of a thorn-shaped or petal-shaped rough-surface gold-silver alloy nanometer material. The preparation method comprises the steps that gold nanoparticle seeds are prepared from a mixed solution of chloroauric acid and trisodium citrate; the gold nanoparticle seeds grow on the surfaces of gold nanoparticles through heterogeneous nucleation; and under the action of molecular synergistic adsorption of L-dopamine, stabilization of atomic clusters, reduction of gold ions and silver ions and underpotential deposition of silver atoms, the thorn-shaped or petal-shaped rough-surface gold-silver alloy nanometer material is prepared and formed. The preparation method is simple in process and effective; production cost can be lowered conveniently; the preparation method is suitable for large-scale production; and the prepared thorn-shaped or petal-shaped rough-surface gold-silver alloy nanometer material is of a unique bionic structure, large in specific surface area and capable of loading a great amount of active medicine and molecular dye. Therefore, the preparation method has wide application prospect in the fields such as SERS sensing, catalysis, diagnosis and treatment and adsorbing materials.

Owner:XI AN JIAOTONG UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com