Method for improving corrosion resistance of 750MPa level ultrahigh strength aluminium alloy

A corrosion-resistant, ultra-high-strength technology, which is applied in the field of ultra-high-strength aluminum alloy preparation, can solve the problems that solid solution and aging cannot be well eliminated, the level of ultra-high strength cannot be reached, and the bonding strength of grain boundaries is reduced, so as to improve the grain boundary. Boundary morphology and organizational structure, good application requirements, and the effect of improving corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

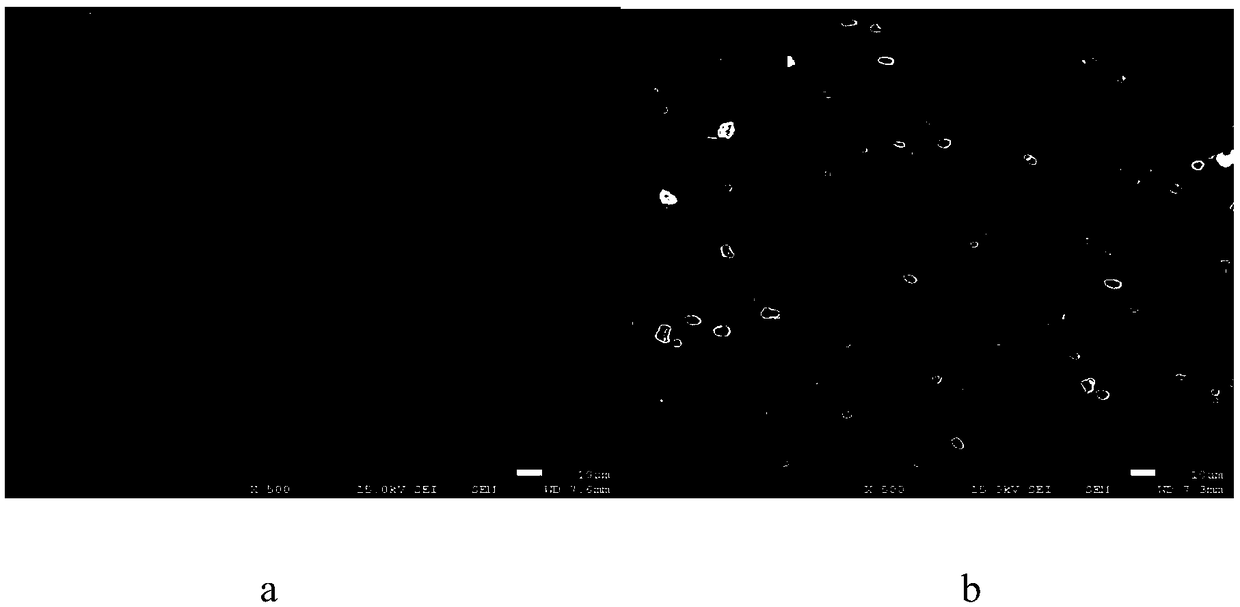

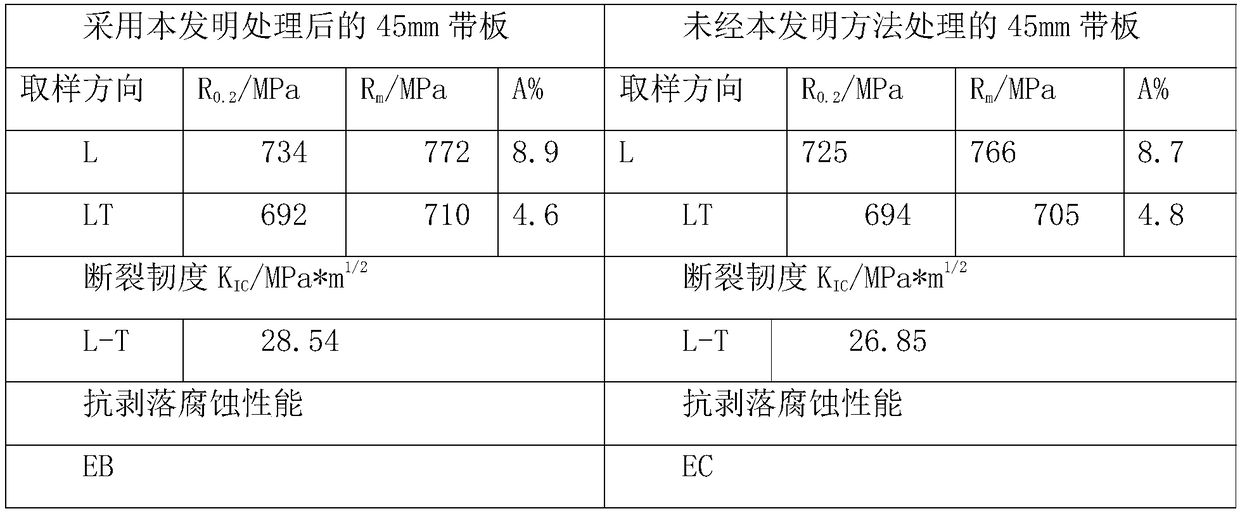

Embodiment 1

[0021] Using the method for improving the corrosion performance of 750MPa-level ultra-high-strength aluminum alloy deformed products involved in the present invention, the alloy components and weight percentages are: Zn 10.5%, Cu 1.72%, Mg 1.95%, Zr 0.11%, Sc 0.10%, Ti0. 06%, Si 0.06%, Fe 0.08%, the balance is Al, the extruded strip with a thickness of 45mm is solution treated, the solution temperature is 470°C, the holding time is 150min, and the room temperature water quenching. After quenching, pre-stretch the strip at 2.0%, and then carry out cryogenic treatment: from room temperature to -160°C, the cooling rate is 20°C / h, keep the temperature for 20h, then warm up to room temperature, the heating rate is 15°C / h, and then Carry out artificial aging treatment: 100°C / 10h+135°C / 15h. The tensile, fracture toughness and exfoliation corrosion properties of the strip were measured, and compared with the properties of the strip after the same solid solution, pre-stretching and agi...

Embodiment 2

[0026] Using the method for improving the corrosion performance of 750MPa-level ultra-high-strength aluminum alloy deformed products involved in the present invention, the alloy components and weight percentages are: Zn 11.3%, Cu 1.94%, Mg 2.16%, Zr 0.10%, Sc 0.12%, Ti0. 05%, Si 0.07%, Fe 0.06%, the balance is Al, the extruded strip with a thickness of 45mm is solution treated, the solution temperature is 470°C, the holding time is 150min, and the room temperature water quenching. After quenching, the strip is pre-stretched by 2.0%, and then subjected to two cryogenic treatments: from room temperature to -170°C, the cooling rate is 20°C / h, and the temperature is kept for 22h, and then the temperature is raised to room temperature, and the heating rate is 15°C / h , and then carry out artificial aging treatment: 100°C / 12h+140°C / 18h. The tensile, fracture toughness and exfoliation corrosion properties of the strip were measured, and compared with those of the strip after the same ...

Embodiment 3

[0031]Adopting the method for improving the corrosion performance of 750MPa-level ultra-high-strength aluminum alloy deformed products involved in the present invention, the alloy composition and weight percentage are: Zn 11.5%, Cu2.04%, Mg 1.76%, Zr 0.12%, Sc 0.15%, Ti0 .06%, Si 0.04%, Fe 0.08%, the balance is Al, and the extruded strip with a thickness of 45mm is solution treated. The solution temperature is 470°C, the holding time is 150min, and the room temperature water quenching. After quenching, the strip plate is pre-stretched by 2.0%, and then subjected to three cryogenic treatments: from room temperature to -175°C, the cooling rate is 20°C / h, and the temperature is kept for 18h, and then the temperature is raised to room temperature, and the heating rate is 15°C / h. Then carry out artificial aging treatment: 110°C / 15h+135°C / 15h. The tensile, fracture toughness and exfoliation corrosion properties of the strip were measured, and compared with those of the strip after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com