Patents

Literature

188 results about "Supersaturated solid solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

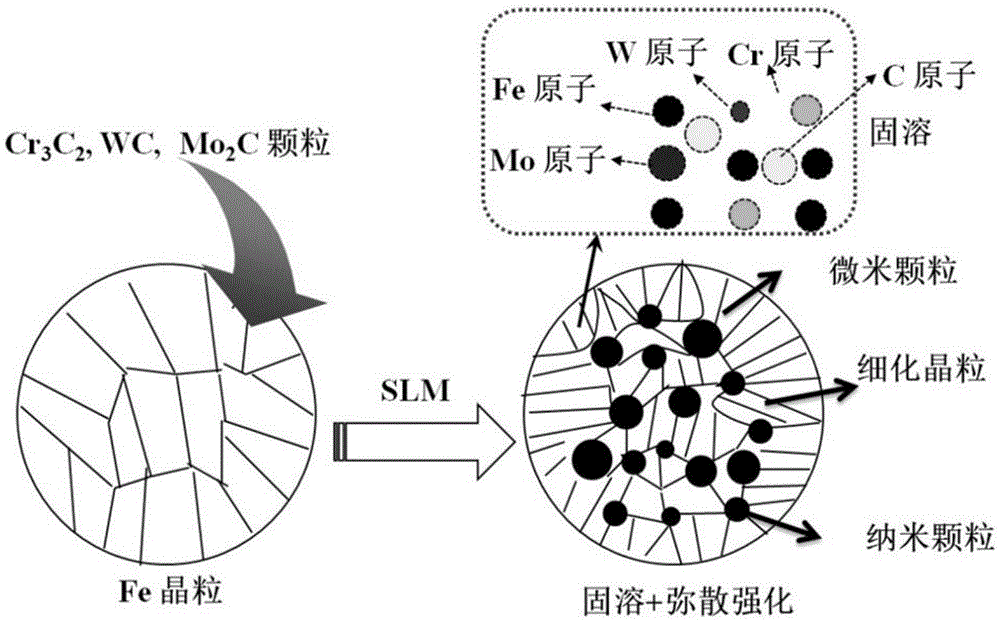

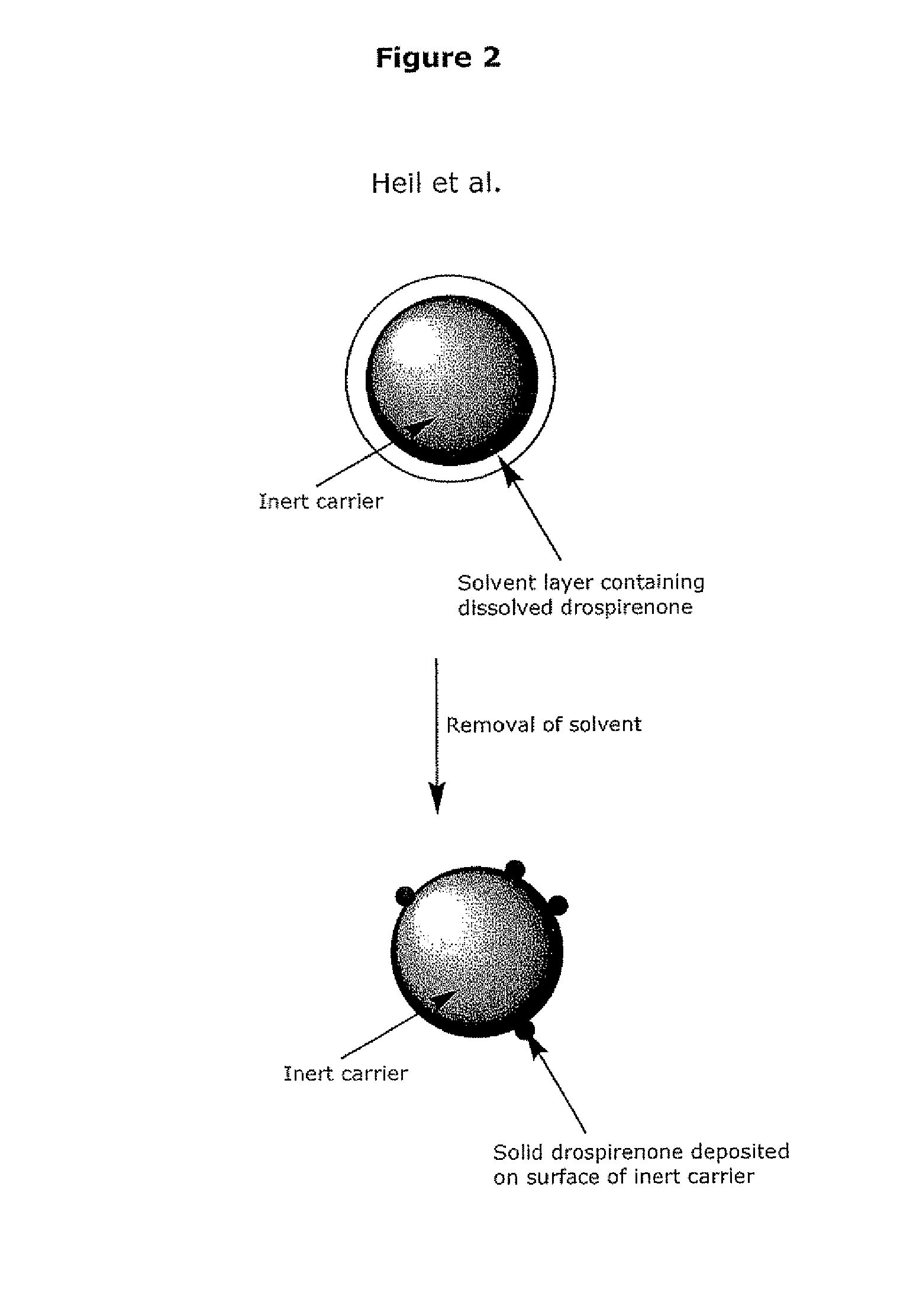

Stabilised supersaturated solids of lipophilic drugs

Methods for improving solubility and bioavailability of lipophilic compounds are described. Particularly, described are stabilized superstaturated solid solutions, particularly in power form, of lipophilic drugs, such as steroidal molecules.

Owner:BAYER INTELLECTUAL PROPERTY GMBH

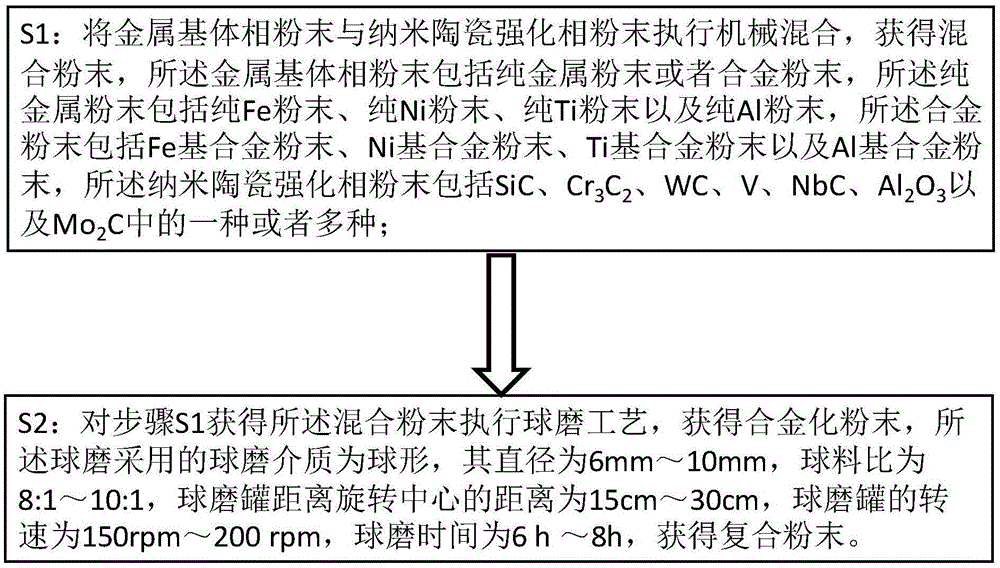

Method for preparing composite powder for 3D printing, product and application

ActiveCN105583401ANo microscopic cracksSuper full noAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSupersaturated solid solution

The invention discloses a method for preparing a composite powder for 3D printing, and belongs to the technical field of material additive manufacturing. The method comprises the following steps: S1, executing mechanical mixing on a metal matrix phase powder and a nano-ceramic strengthening phase powder to obtain a mixed powder; and S2, executing a ball-milling process on the mixed powder to obtain an alloyed powder, wherein a ball-milling medium used in ball-milling is spherical and has a diameter of 6-10mm, a ball-to-powder ratio is 8: 1 to 10: 1, a distance from a ball-milling tank to a rotary centre is 15-30cm, a rotational speed is 150-200rpm, a ball-milling time is 6-8h, and the composite powder is obtained. The invention further provides a method for using the composite powder prepared by the above-mentioned method for 3D printing forming for parts. The composite powder prepared by the method disclosed by the invention is free from micro-cracks and the problem of supersaturated solid solution, and has no high internal stress; and the parts prepared by virtue of the composite powder disclosed by the invention through a selective laser melting forming method have good comprehensive performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Stabilised supersaturated solids of lipophilic drugs

Owner:BAYER INTELLECTUAL PROPERTY GMBH

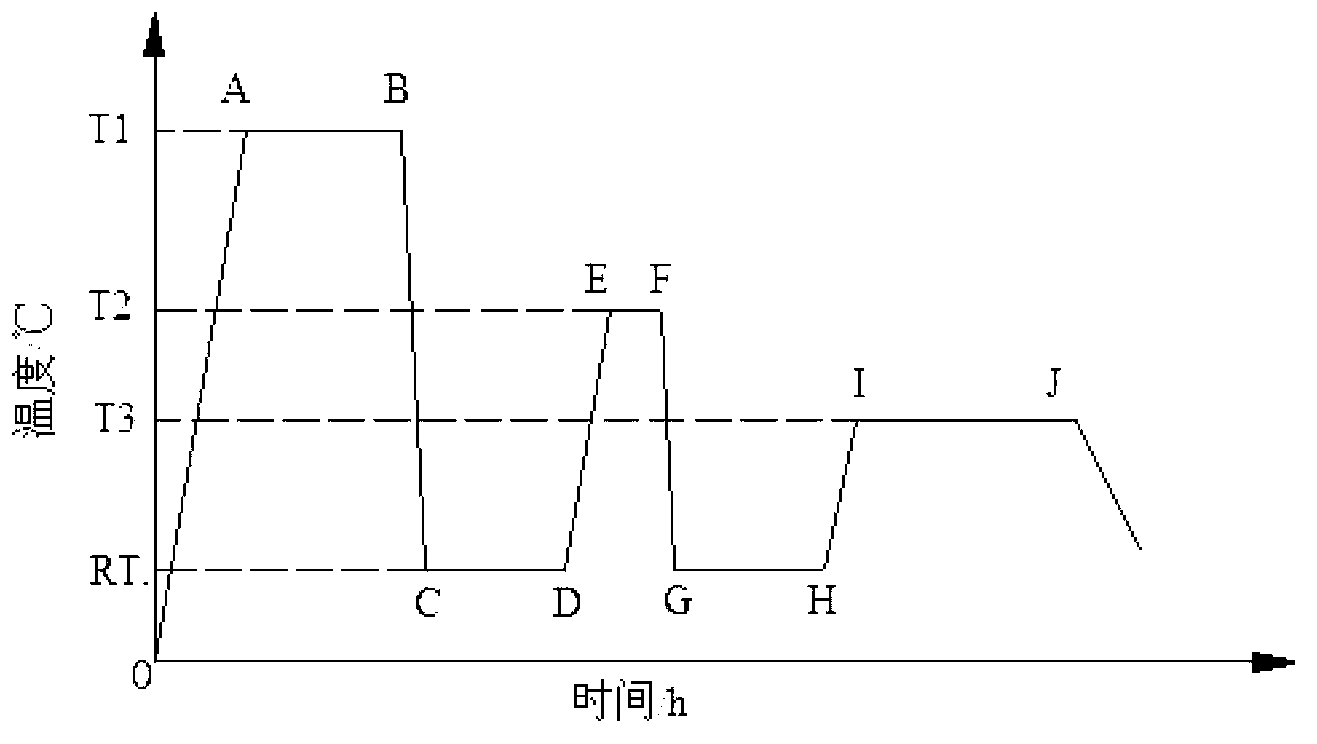

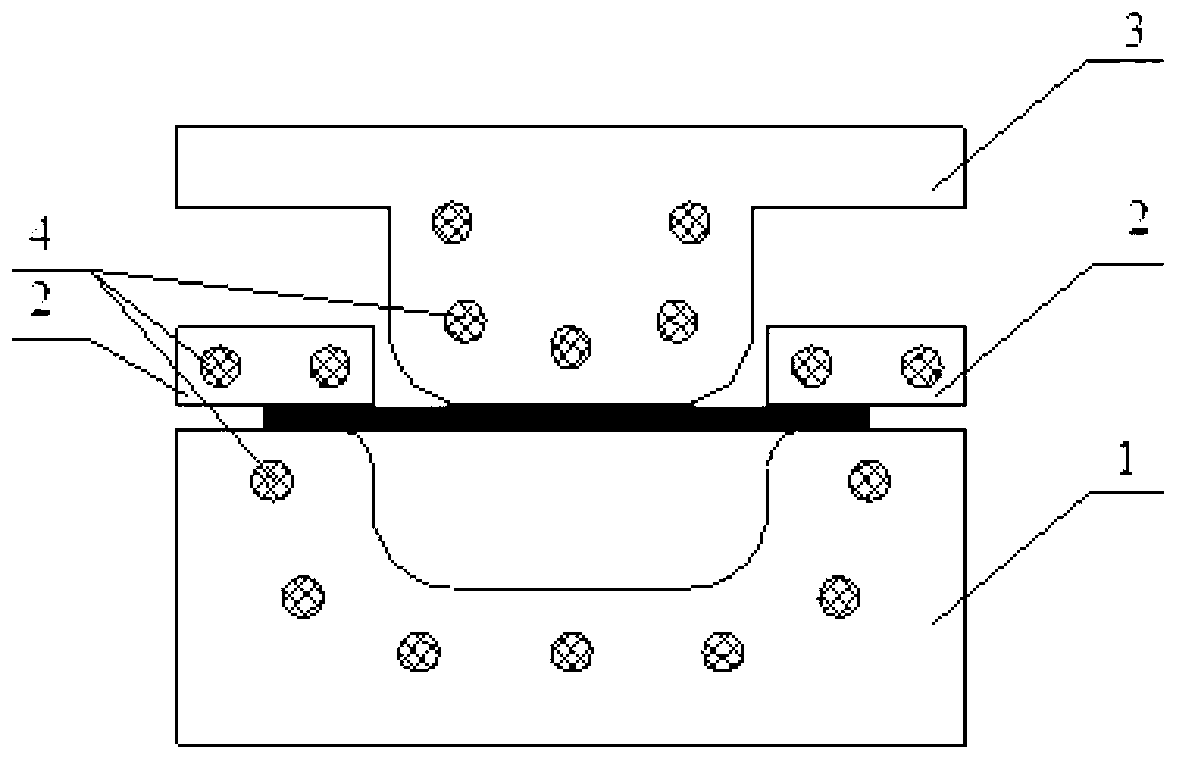

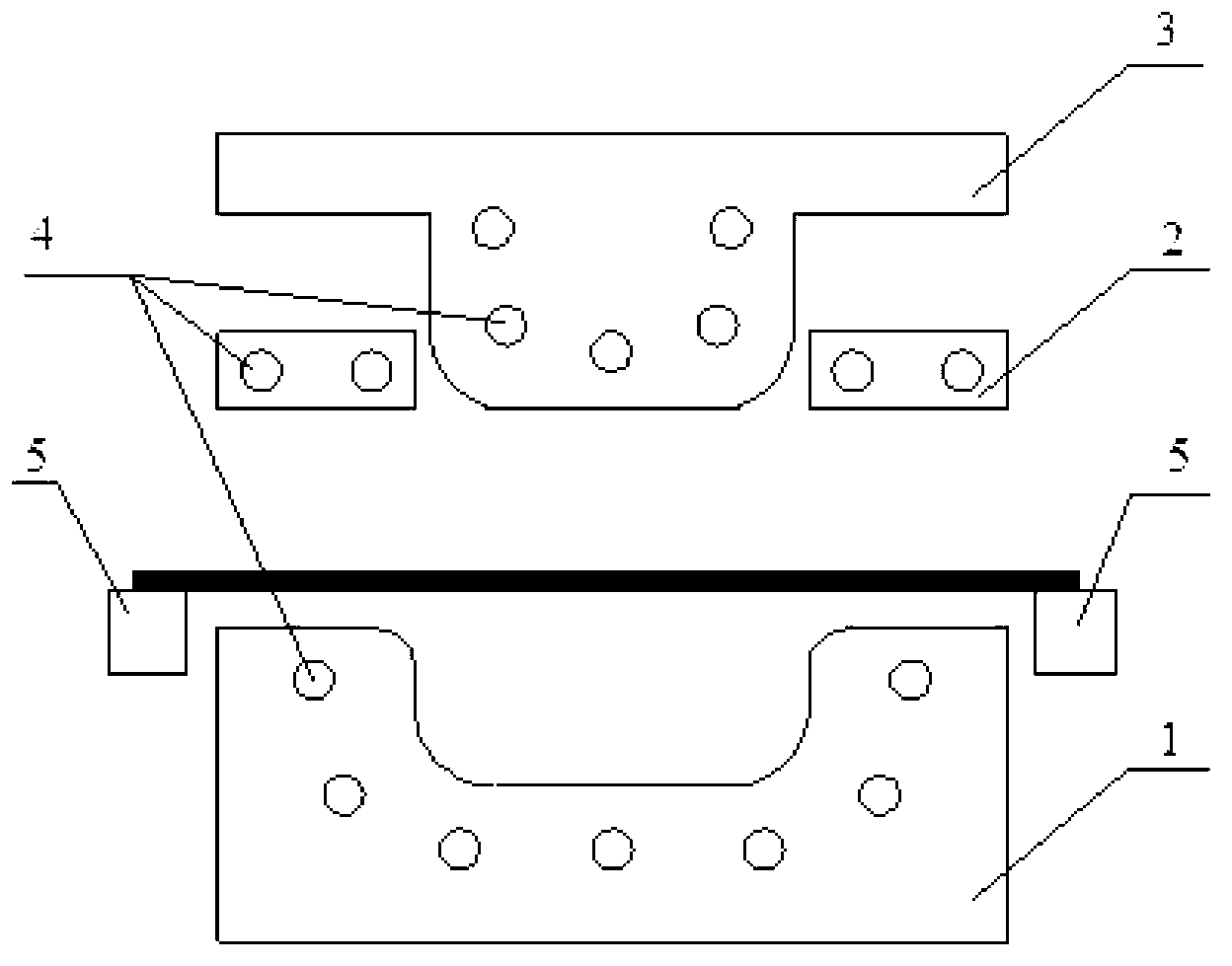

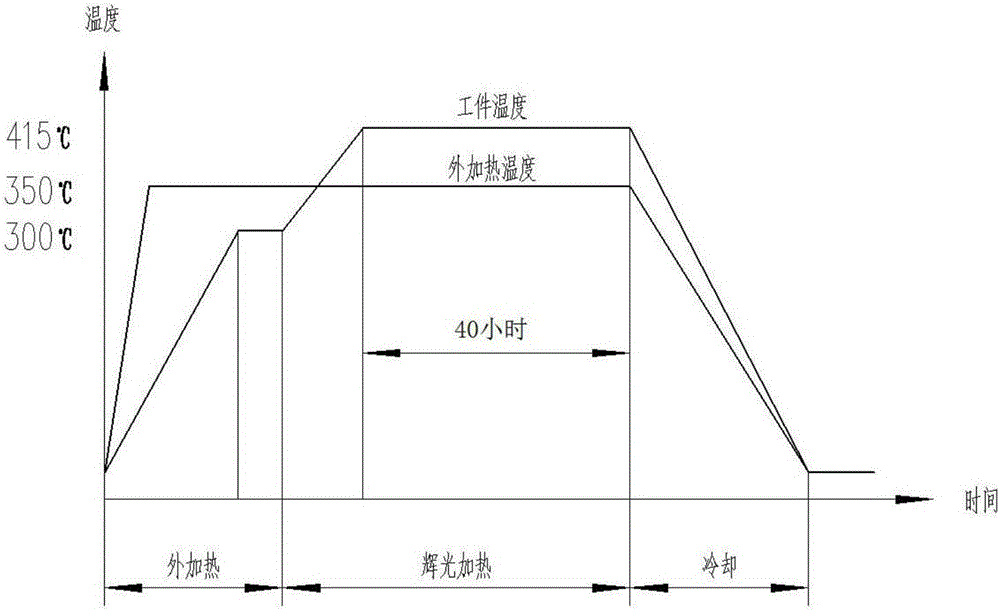

Heat forming method for aluminum alloy sheet metal part after solid solution and water quenching

InactiveCN102974675AGuaranteed shape and size accuracyAvoid quick transfersShaping toolsSize changeSupersaturated solid solution

The invention discloses a heat forming method for an aluminum alloy sheet metal part after solid solution and water quenching, relates to a heat forming method for a heat-treatable strengthening aluminum alloy sheet metal part and aims at solving the technical problems that existing heat-treatable strengthening aluminum alloy is large in shape and size change in the process of heat treatment after the heat-treatable strengthening aluminum alloy is formed first, heat melting forming and cold mold quenching technique requires transfer locating and forming to be fast, in an aluminum alloy sheet metal part cold-hot compound mold forming method, control on temperature of an aluminum alloy slab is difficult, in-mold cooling and quenching speed after forming is slow and not beneficial for obtaining a supersaturated solid solution, requirements for forming equipment are high, and the like. The forming method includes the flowing steps: carrying out the solid solution and the water quenching to the aluminum alloy slab, then, placing the aluminum alloy slab in a hot-state mold to carry out secondary heating, and carrying out aging treatment after pressing forming. According to the heat forming method for the aluminum alloy sheet metal part after the solid solution and the water quenching, the requirements for the forming equipment are not high, precision of shape and size of the aluminum alloy sheet metal part is high, strength is greatly improved, and the heat forming method for the aluminum alloy sheet metal part after the solid solution and the water quenching is suitable for the heat-treatable strengthening aluminum alloy such as 2000 series aluminum alloy, 6000 series aluminum alloy and 7000 series aluminum alloy.

Owner:HARBIN INST OF TECH

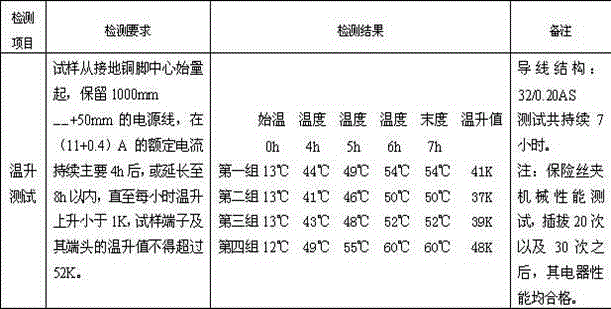

Elastic brass alloy and preparation method thereof

The invention relates to an elastic brass alloy material. The material comprises the following components in percentage by weight: 70 to 71 percent of copper, 24 to 25 percent of zinc, 2 to 3 percent of aluminum, 1 to 3 percent of nickel and 0.5 to 1 percent of chromium. A preparation method comprises the following steps of: smelting; performing hot rolling; performing solid solution treatment; annealing, and performing cold rolling; and performing ageing treatment. The chromium element of which the solid solubility is reduced with the reduction of temperature is added into a metal matrix, a supersaturated solid solution is formed through high temperature sold solution quenching treatment, and is decomposed through ageing treatment to form a large number of fine dispersed Cr particles, and the particles are dispersedly distributed in the matrix to form a precipitated phase, so that the strength, electrical conductivity and elasticity of an alloy are improved. An elastic brass alloy strip prepared by the method meets the technical requirements on temperature rise, electrical performance and the like after being made into a fuse clip, can replace scarce tin phosphorus bronze and is applied to related fields.

Owner:JINTIAN COPPER GROUP CORP NINGBO

Manufacturing technology of novel hobbing cutter with laser cladding WC wear-resistant coating

ActiveCN103737273AImprove wear performanceInhibit sheddingMetallic material coating processesNumerical controlHobbing

The invention relates to a manufacturing technology of a novel hobbing cutter with a laser cladding WC wear-resistant coating. The manufacturing technology comprises the following steps: (1) manufacturing the hobbing cutter with a forging method, wherein the hobbing cutter is made of alloy steel; (2) carrying out peel removal cleaning treatment on surfaces to be machined of the intertooth space of an alloy cutter; (3) using a transverse flow CO2 laser, taking a numerical control machine tool as a workbench, and carrying out cladding wear-resistant strengthening treatment on the intertooth space of a cutter ring cutter, wherein the thickness of the WC cladding layer is 1.5-2.5mm; (4) carrying out performance detection on a composite coating. A laser surface cladding technology is adopted, and the tissues of a cladding coating mainly consist of carbides and a supersaturated solid solution superfine casting-state structure, wherein spherical tungsten carbide ceramics are of ultra-high hardness and uniformly distributed on a binding phase with extremely high hardness level, and also achieves an inhibition effect on abrasion, and the grinding resistance between hobbing cutter edges can be effectively improved; the binding phase is good in tenacity and high in strength, the formation of cracks can be effectively reduced, and the wear resistance and corrosive resistance of the hobbing cutter is improved, and the service life of the hobbing cutter is prolonged.

Owner:江苏点金激光科技有限公司

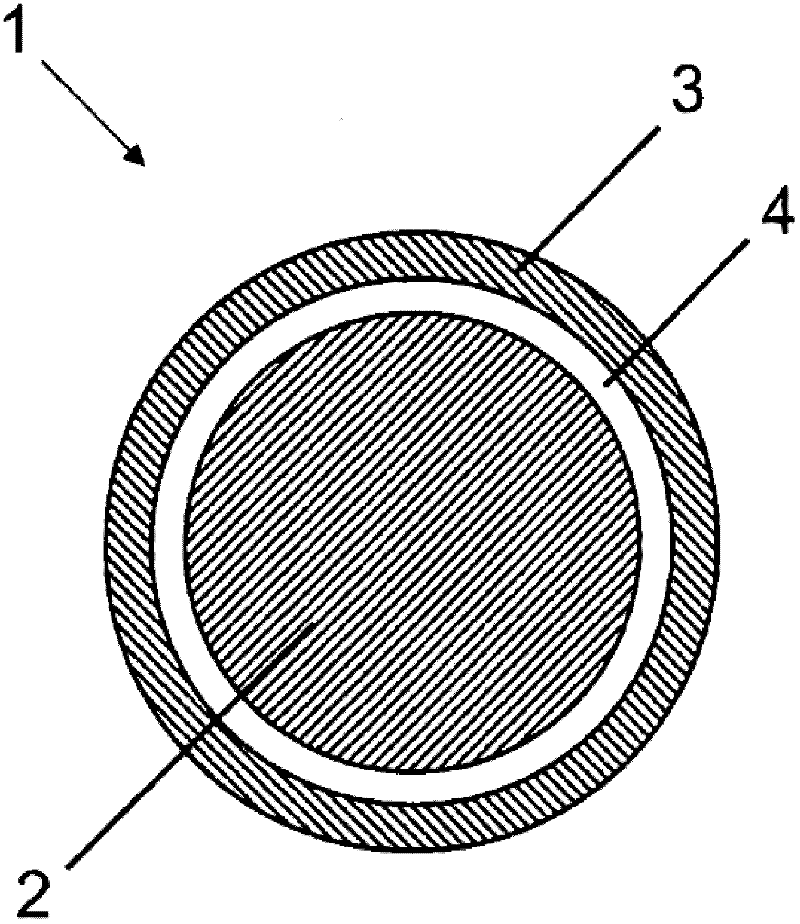

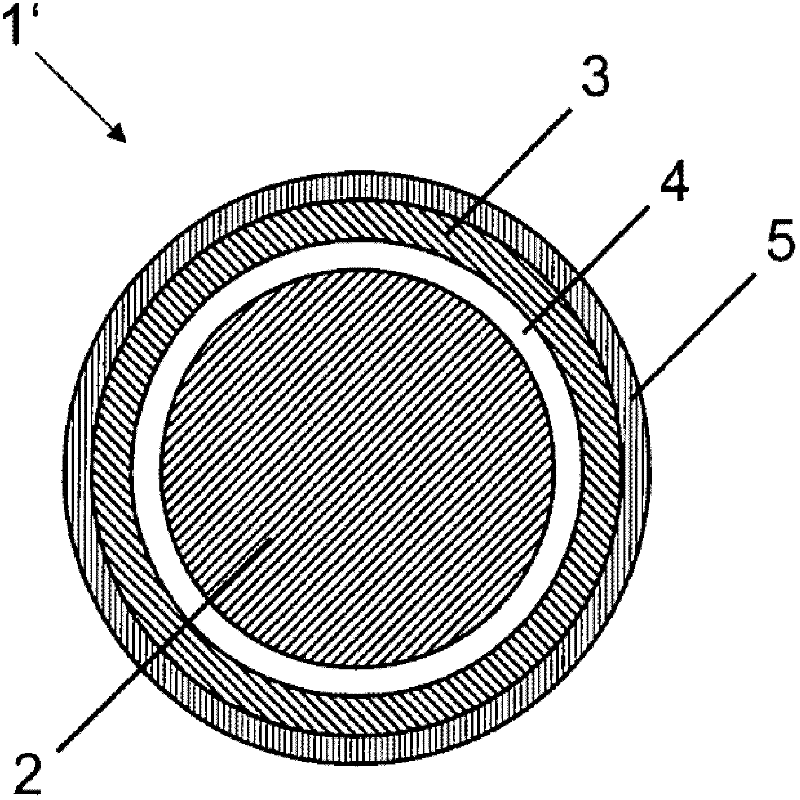

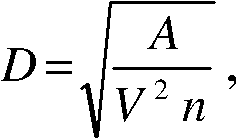

Wire electrode for electric discharge cutting processes

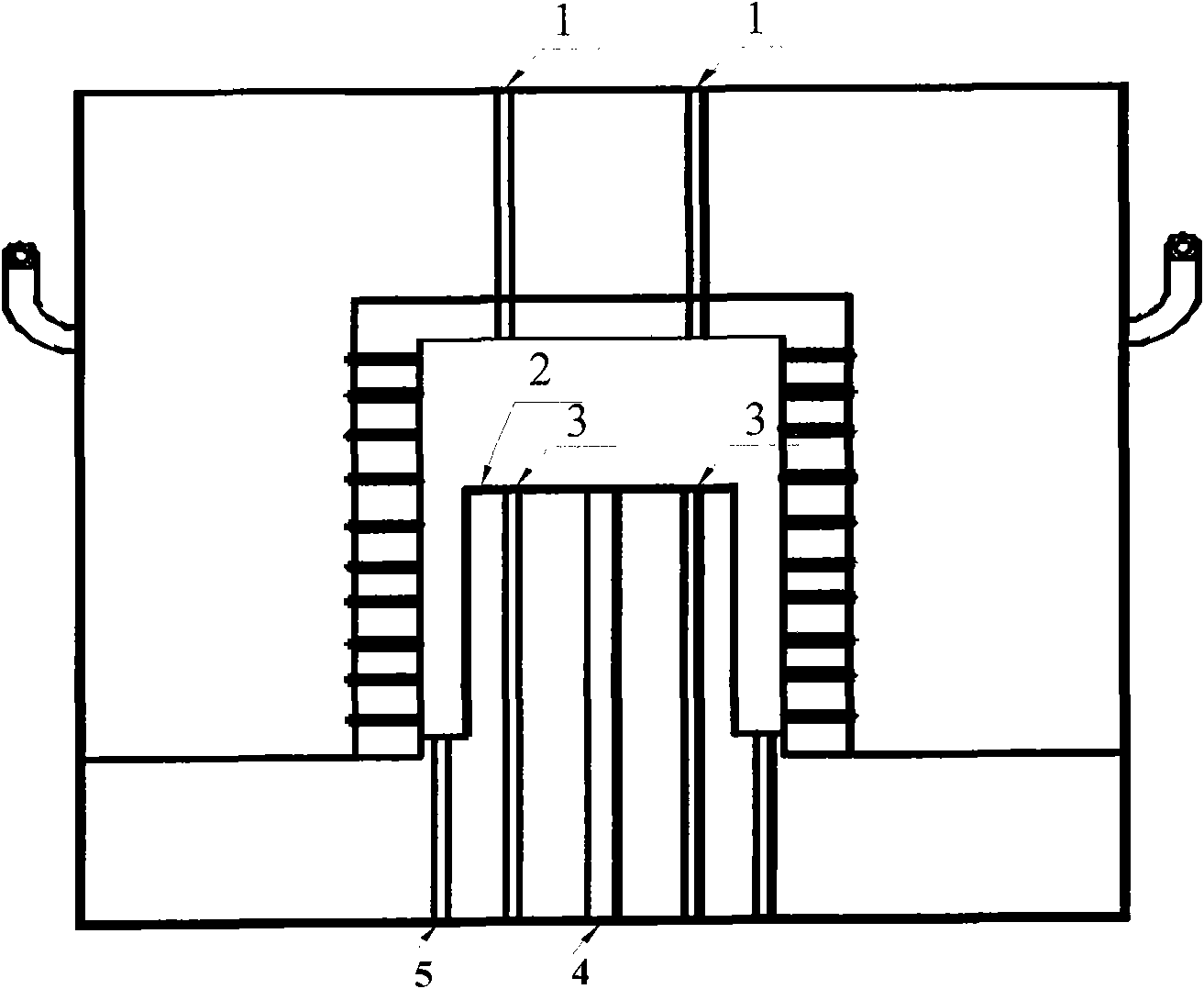

ActiveCN102239024AImprove corrosion resistanceImprove cutting effectElectrical-based machining electrodesThin material handlingElectric dischargeBeta phase

The invention relates to a wire electrode (1, 1') for electric discharge cutting processes and a method for the production thereof. The wire electrode (1, 1') has a core (2) containing a metal or a metal alloy, and a coating (3, 4; 3, 4, 5) that surrounds the core (2) and includes one or more coating layers (3, 4, 5), at least one (3) of which contains a phase mixture of beta-brass and / or beta'-brass and gamma-brass. In said at least one coating layer (3) containing beta-brass and / or beta'-brass and gamma-brass, the beta-phase and / or beta'-phase and the gamma-phase are arranged next to each other in a fine-grained structure in which the mean size of the beta-brass and / or beta'-brass grains and the gamma-brass grains amounts to a maximum of 5 [mu]m relative to the cross-section extending perpendicular to the longitudinal axis of the wire electrode (1, 1'). In order to produce the wire electrode (1, 1'), a wire is used that has a coating layer predominantly containing gamma-brass, and a homogenizing step is carried out in which the gamma-brass is substantially transformed into a beta-brass having a minimum zinc concentration of 51 percent by weight at temperatures exceeding 600 DEG C, and the wire (1, 1') is finally cooled, a process during which zones of gamma-brass are separated from the supersaturated solid solution of beta-brass.

Owner:BERKENHOFF GMBH

Method of consolidating precipitation-hardenable alloys to form consolidated articles with ultra-fine grain microstructures

InactiveUS20060278308A1Low costEasy to useTransportation and packagingMetal-working apparatusUltra fineSupersaturated solid solution

A method by which consolidated articles can be produced from nanocrystalline materials to have mechanical properties that can be improved through thermal treatment. The method entails machining a body to produce polycrystalline chips having nanocrystalline microstructures, and then consolidating the chips to form a consolidated article having mechanical properties that exceed that of the body from which the chips were formed. In particular, consolidation of nanocrystalline chips formed by machining a supersaturated solid-solution body causes precipitation of a fine dispersion of precipitates in the consolidated article, with the potential for certain properties to even improve during consolidation or subsequent thermal treatment of the consolidated article.

Owner:PURDUE RES FOUND INC

High-efficiency short-process preparation method of high-strength high-conductivity copper alloy

ActiveCN111363948AHigh strengthHigh crystal defectsIncreasing energy efficiencyElectro conductivitySupersaturated solid solution

The invention discloses a high-efficiency short-process preparation method of a high-strength high-conductivity copper alloy. The method comprises the following steps that (a), horizontal continuous casting is carried out to obtain an as-cast initial blank of the copper alloy, and alloy elements in the as-cast initial blank are kept in a supersaturated solid solution state; and (b), after the as-cast initial blank obtained in the step(a) is peeled, continuous extrusion, cold machining and aging annealing treatment are directly and sequentially carried out to obtain the copper alloy, and the alloy elements of the blank are kept in the supersaturated solid solution state in the continuous extrusion process. According to the method for continuously preparing the high-strength high-conductivity copper alloy, the process can be shortened, the energy consumption and the cost are reduced, the product forming rate is increased, and the high strength and the high conductivity of the copper alloy are guaranteed.

Owner:ZHEJIANG UNIV

Two-stage solid solution heat treatment method of copper chromium zirconium system alloy

The present invention relates to a two-stage solid solution heat treatment method of copper chromium zirconium system alloy, and belongs to the field of non-ferrous metal heat treatment. According to the method, cast-condition copper chromium zirconium system alloy can be processed by one or a plurality of processes of extrusion, forging, rolling and drawing; first-stage solid solution heat treatment of the processing-condition copper chromium zirconium system alloy is performed; and second-stage solid solution heat treatment of the processed copper chromium zirconium system alloy is performed. The two-stage solid solution heat treatment method of the copper chromium zirconium system alloy overcomes the shortcomings of common single stage solid solution heat treatment processes, and can obtain relatively pure supersaturated solid solution. By subsequent thermomechanical treatment process of the copper chromium zirconium system alloy prepared by the method, the strength can be improved by about 20-50MPa compared with that of a alloy processed by the single-stage solid solution treatment process, and the conductivity can be at the same level or improved more compared with that of the alloy processed by the single-stage solid solution treatment process.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

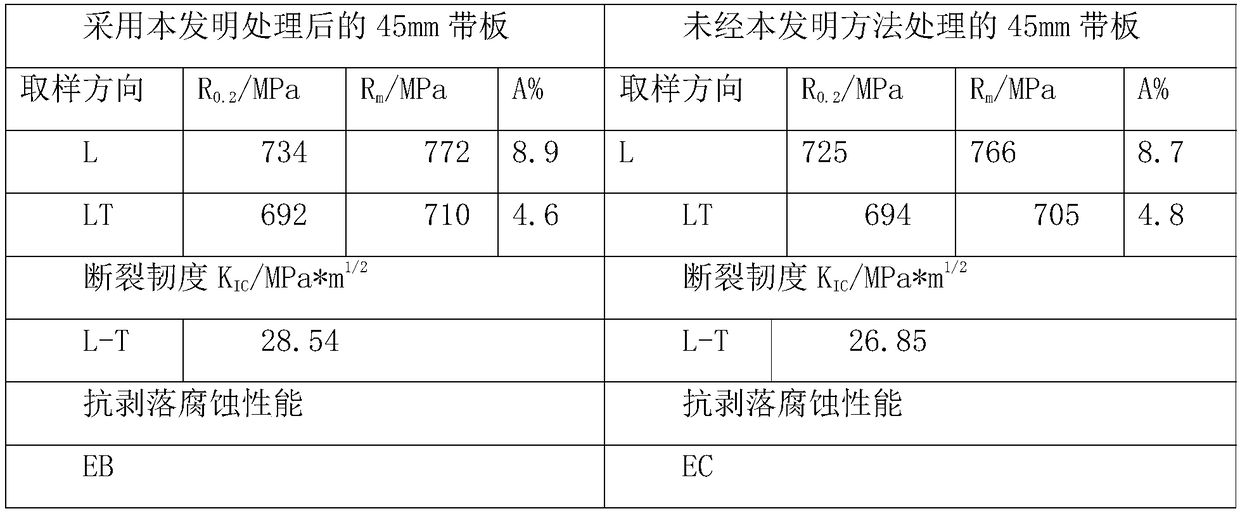

Method for improving corrosion resistance of 750MPa level ultrahigh strength aluminium alloy

The invention belongs to preparation technologies of ultrahigh strength aluminium alloys, and relates to a method for improving the corrosion resistance of a 750MPa level ultrahigh strength aluminiumalloy. The method comprises the steps that a deformed product is subjected to solid-solution quenching, then one to three times of subzero treatment is conducted, and at last aging treatment is conducted. A large amount of dislocations and subgrains which are in interaction can be formed through the method; grain boundary intermittent precipitated phases are promoted to be formed; the corrosion resistance can be obviously improved under the condition that the alloy strength level is maintained at the 750MPa level after aging; and meanwhile the organization structure is more stable. The methodis suitable for high-performance 750MPa level ultrahigh strength aluminium alloy plates or extruded profiles used in the fields of aviation, spaceflights and weapons. The plates or the extruded profiles after hot working are subjected to solid-solution treatment to form a supersaturated solid solution, a certain extent of recrystallization is controlled to be generated, a large amount of vacancies, atomic clusters, and dislocations and subgrains which are in interaction are formed in the subsequent subzero treatment process, the grain boundary organization structure of the alloy after artificial aging treatment is improved, and the intermittent precipitated phase structure is promoted to be formed.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

7-series aluminum alloy for container and machining process thereof

The invention belongs to the technical field of aluminum alloy machining and manufacturing and relates to a 7-series aluminum alloy for a container and a machining process thereof. The machining process comprises the steps of material mixing, smelting, casting, soaking, saw cutting and face milling, heating, hot rolling, solution quenching and artificial ageing. By changing alloy components, the main low-melting-point phases of an aluminum alloy cast ingot before homogenizing treatment belong to MgZn2, the diffusion velocity of Mg and Zn in an Al matrix at high temperature is high, and the MgZn2 phases can be rapidly dissolved. Thus, grains can be protected against abnormal growth without overburning within the soaking temperature range of 440-500 DEG C. After the aluminum alloy cast ingotis subjected to homogenizing heat treatment, the big low-melting-point phases are dissolved and disappears or is in a rounded spherical and are rolled and crushed into fine soluble phases, the high supersaturated solid solution creation condition is provided for short-time solution quenching treatment of a finished product, and then an aluminum alloy plate with good plate shape and strength matching degree is obtained.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

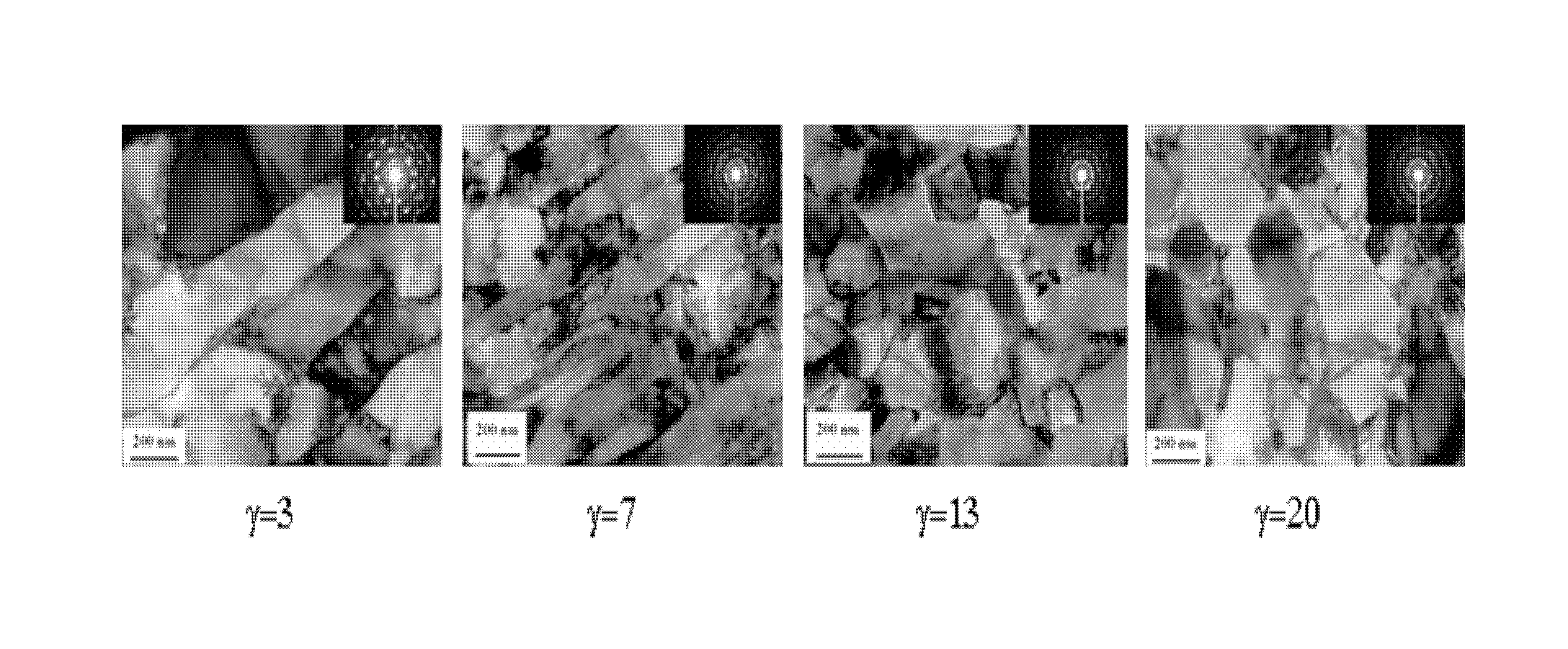

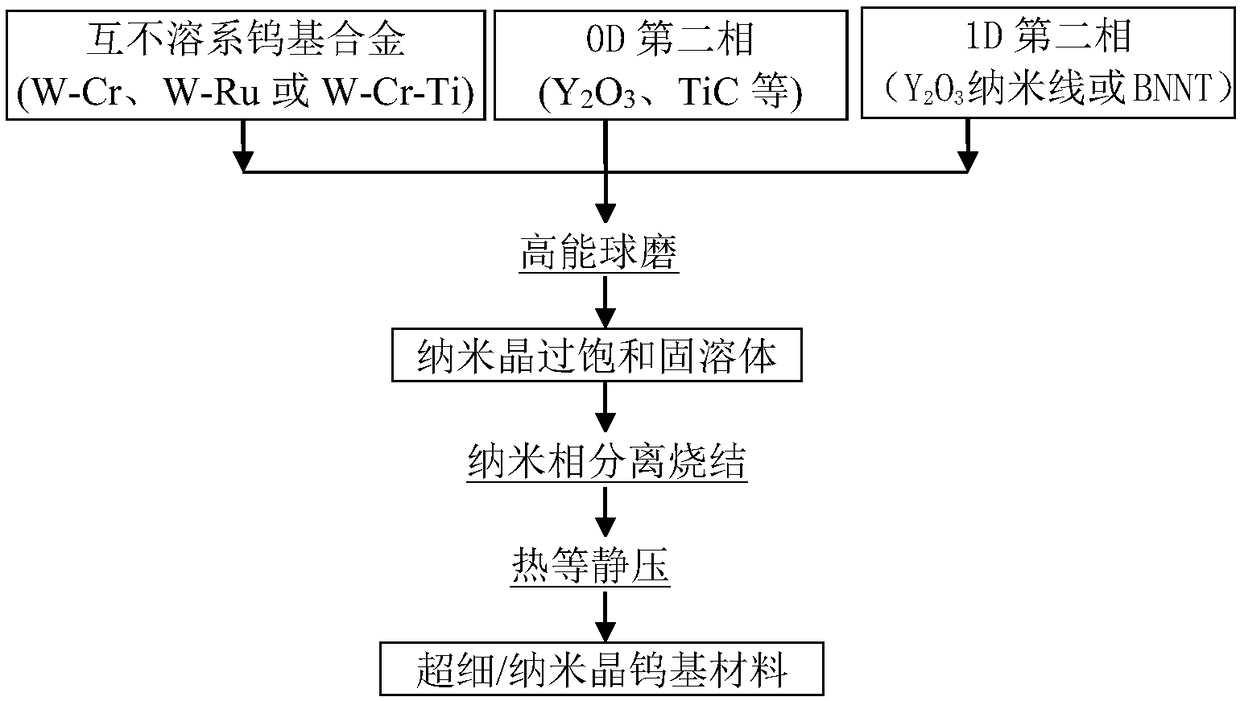

Method for preparing tungsten material through nanophase separation and sintering

The invention provides a method for preparing a tungsten material through nanophase separation and sintering. According to the method, mechanical alloying powder with the features of nanocrystalline grain structures and a supersaturated solid solution is prepared through high-energy ball milling and then is densified through pressureless sintering and unsheathed hot isostatic pressure technologiesto obtain a tungsten matrix composite. In the sintering process, nanocrystalline grains and the supersaturated solid solution are subjected to phase separation, nano precipitated phases are preferentially precipitated on the necks of the nanocrystalline grains and the surfaces of powder particles to form a quick migration channel, sintering densification is promoted, and the sintering temperatureis lowered. Along with rising of the sintering temperature, the nano precipitated phases are diffused to a tungsten matrix, and a grain boundary element enrichment region is left. Grain growth can beeffectively suppressed through comprehensive utilization of a grain boundary element segregation region and secondary phases. The method has the advantages that solid phase sintering is conducted inthe sintering process; the sintering temperature is low; the secondary phases are prevented from growing obviously in the high-temperature sintering process; the method is suitable for preparing a large-size fine grain tungsten matrix material; the prepared tungsten matrix material is almost fully densified, uniform in texture structure and excellent in comprehensive mechanical performance.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of superfine grain nano-structure oxide dispersion strengthened steel

The invention discloses a preparation method of superfine grain nano-structure oxide dispersion strengthened steel. The preparation method comprises the following steps of: performing ball-milling mechanical alloying on alloy powder which is prepared by an atomization method or pure metal element powder in a corresponding constituent element ratio, metal Ti powder and Y2O3 powder in a nanometer scale in vacuum or under Ar gas protection so as to form solid solution alloy powder which is rich in supersaturated Y, Ti and O; and putting the supersaturated solid solution alloy powder into a mould, and performing solidification sintering in spark plasma sintering equipment so as to obtain the superfine grain nano-structure oxide dispersion strengthened steel, wherein sintering environment can be vacuum or inert gas; a sintering temperature is between 800 and 1,200 DEG C; heat preserving time is between 1 and 15min; and pressure is between 10 and 200MPa. The grain size of the alloy is refined from a micron level to a level which is equal to or less than 500 nanometers by the method, the characteristic microstructure and the irradiation resistance performance of the nano-structure oxide dispersion strengthened steel are maintained, and the alloy strength and the high temperature creep strength are greatly improved, so that the using requirement of core parts of an advanced nuclear reactor on the high temperature resistance and the irradiation resistance of materials are met.

Owner:NORTHEASTERN UNIV

Method of preparing Nb3AL superconducting wire by adopting high energy ball milling method

ActiveCN103093898AAvoid breakingAvoid askingSuperconductors/hyperconductorsSuperconductor devicesHigh energyNiobium

The invention discloses a method of preparing an Nb3AL superconducting wire by adopting a high energy ball milling method. The method comprises four steps: preparing niobium aluminum supersaturation solid solution, preparing an Nb3AL superconducting wire single core wire precursor, preparing an Nb3AL superconducting wire split conductor precursor and heat treatment. The method of preparing the Nb3AL superconducting wire solves the problem that Nb3AL prepared with the prior art is easy to break, and avoids the situation that the precursor is easy to break in high temperature by adopting traditional fast heating and fast cooling processing and requirements on the particularity of heating equipment. An obtained superconducting wire is even in ingredients, good in performance, cost is effectively reduced, and mass production can be carried out conveniently.

Owner:西部超导材料科技股份有限公司

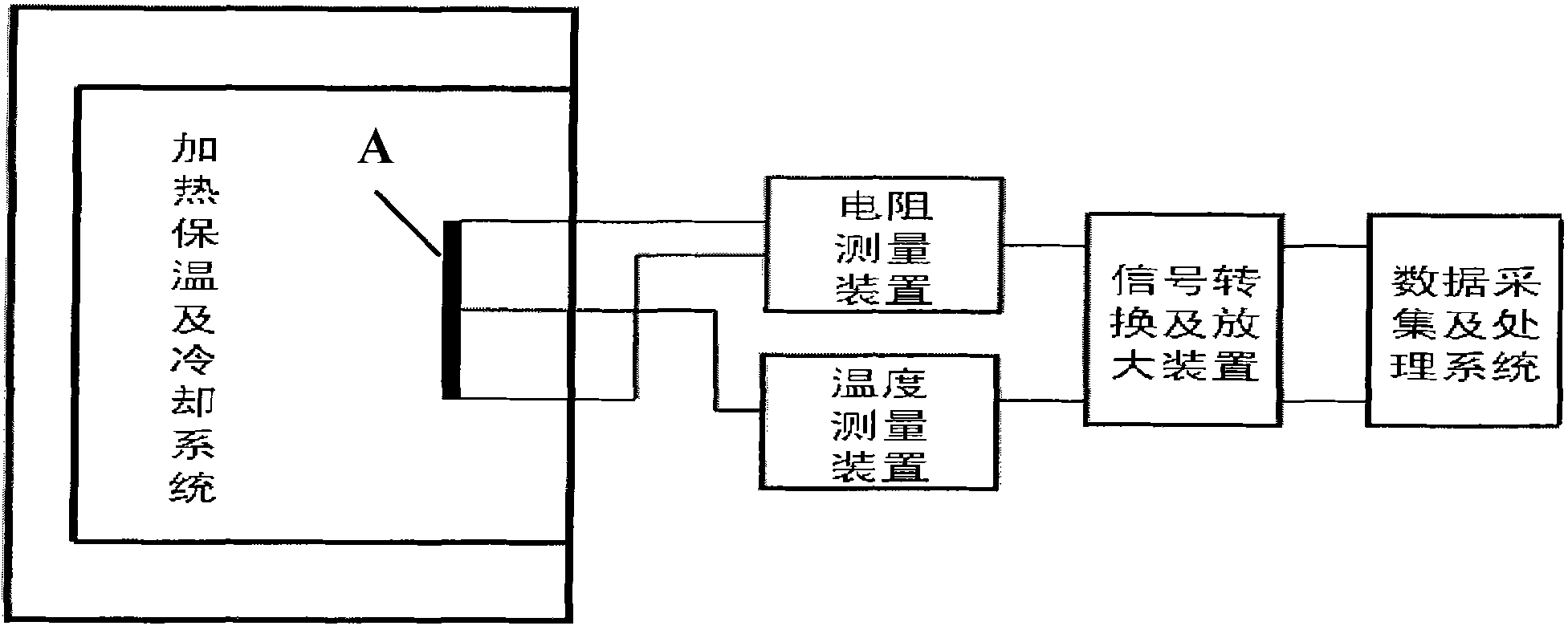

Method and device for measuring continuous cooling phase transformation points of aluminum alloy

InactiveCN101776627AVersatileEasy to operateInvestigating phase/state changeElectrical resistance and conductanceTemperature curve

The invention provides a method and a device for measuring the continuous cooling phase transformation points of aluminum alloy. The method comprises the following steps of automatically collecting the data of resistance, temperature and time in real time by utilizing a computer, drawing a voltage-temperature curve or a resistance-temperature curve of an aluminum alloy sample according to the measured data, and then obtaining the cooling phase transformation points according to the drawn curve. The device comprises a heating insulation and cooling system, a dynamic voltage measuring system, a temperature measuring system, a signal amplifying and converting system and a data collecting and processing system which are sequentially connected. The device can be used for obtaining the curve of voltage changing along with the temperature in the continuous cooling process of a supersaturated solid solution, thereby judging the phase transformation points of the alloy. The invention has the advantages of wide cooling test range, high measuring precision, high speed and simple operation, and can carry out heating, insulation, cooling, and the voltage and temperature real-time measurement and collection on aluminum alloy materials.

Owner:CENT SOUTH UNIV

Preparation method of Cr2Nb phase-containing high-strength high-conductivity high-temperature-resistant copper alloy

ActiveCN111534710AShorten the diffusion distanceIncrease the speed of diffusionAdditive manufacturing apparatusIncreasing energy efficiencyCold airIngot casting

The invention discloses a preparation method of a Cr2Nb phase-containing high-strength high-conductivity high-temperature-resistant copper alloy, and belongs to the technical field of copper alloy preparation. The preparation method comprises the following steps that an Nb element is introduced on the basis of a traditional chromium-zirconium-copper material, and Nb powder and Cr powder are fullyactivated before ingot casting to obtain an unbalanced supersaturated solid solution, so that a Cr2Nb phase is easier to form in a copper alloy cast ingot. According to the preparation method, a process of combining atomization powder preparation and 3D printing is adopted, and low-temperature argon high-pressure cold air flow is adopted for carrying out cold casting treatment on metal liquid drops in the atomization powder preparation process, so that it is guaranteed that the Cr2Nb phase is fine and is in a sufficient supersaturated state, and the dispersion strengthening effect of a precipitated phase is improved; and the advantages of 3D printing are fully utilized, parts in complex shapes can be prepared, and the prepared parts have the advantages of being high in strength and excellent in high-temperature resistance.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

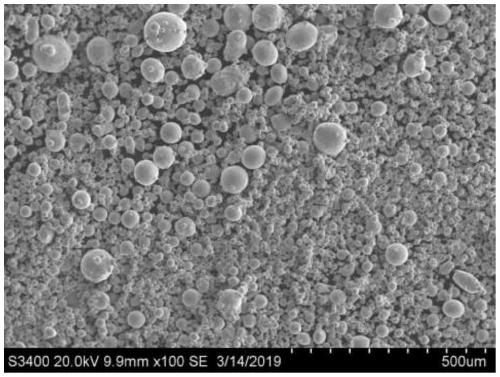

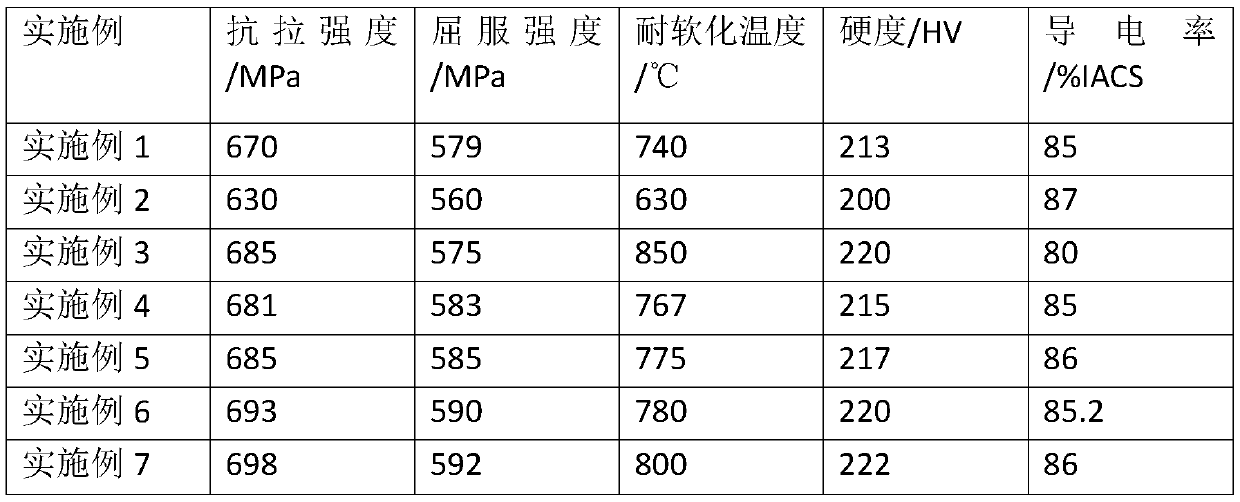

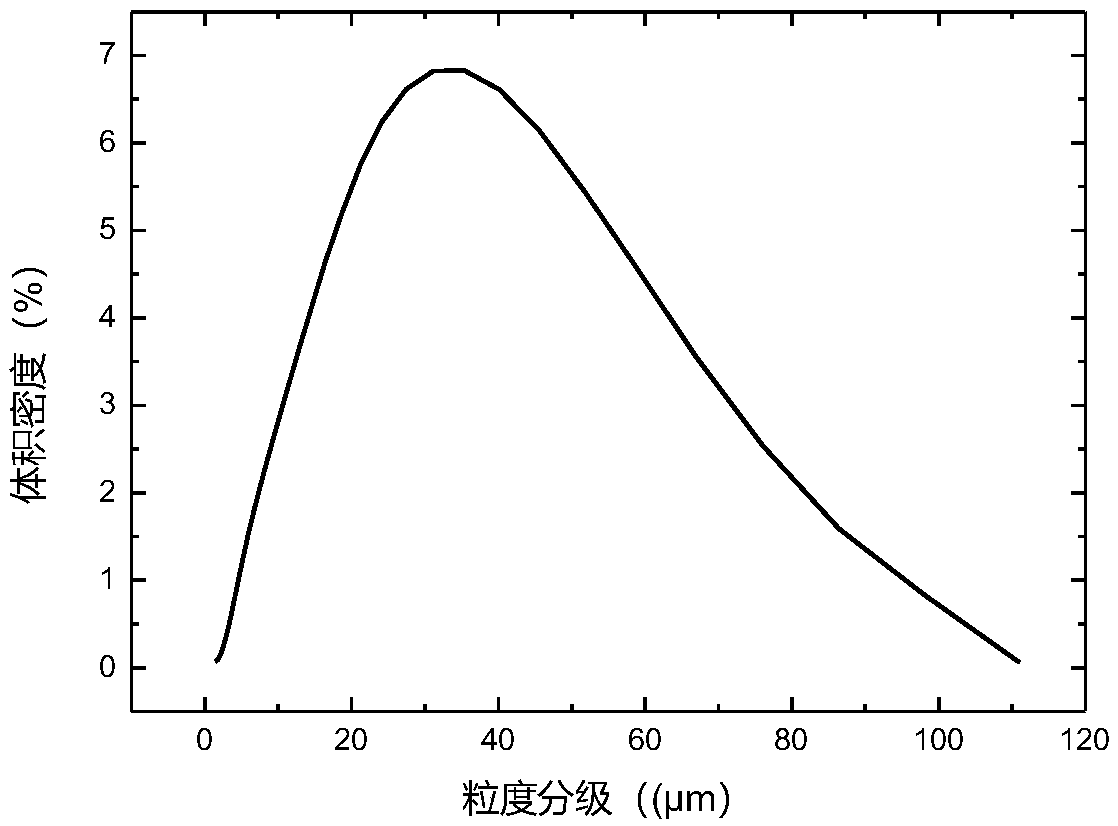

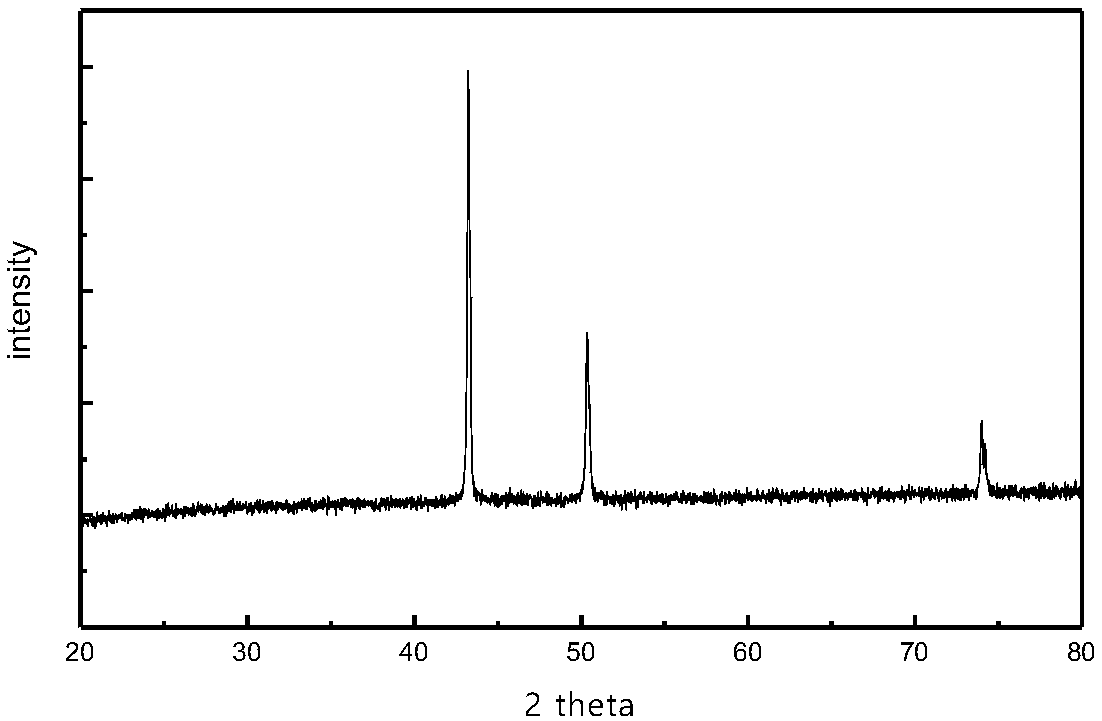

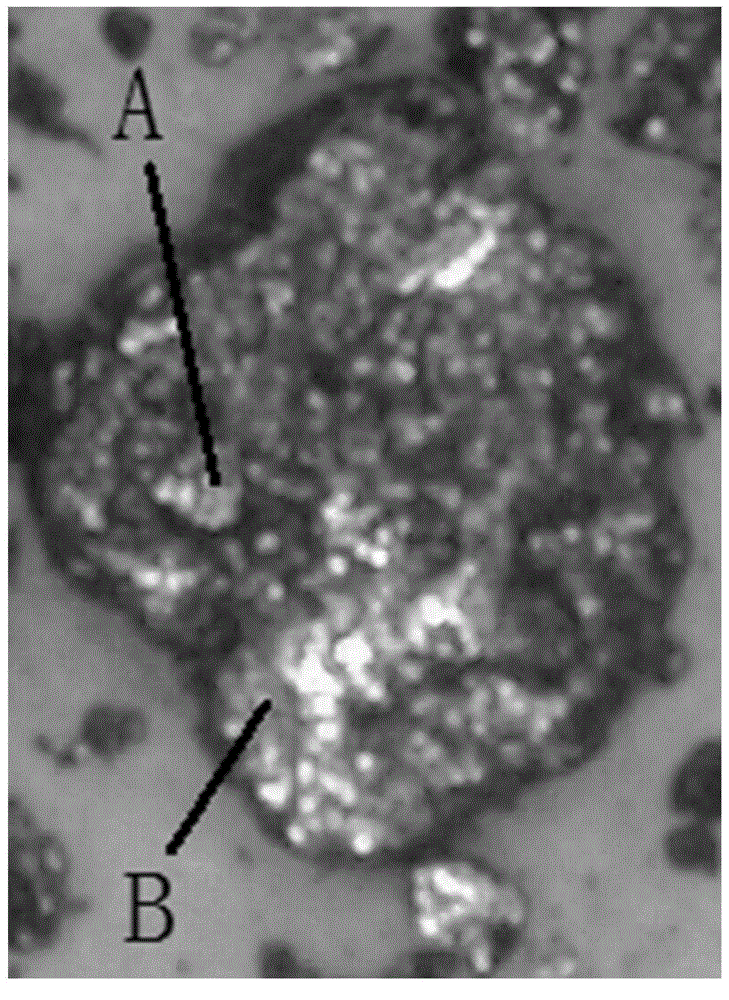

High-performance copper alloy and high-performance copper alloy powder preparation method

The invention relates to a high-performance copper alloy and a high-performance copper alloy powder preparation method. The high-performance copper alloy comprises Cu, Cr, Zr and M, wherein the mass percentage of Cr is 0.1-5.0% , and the mass percentage of Zr is 0.1-5.0% . M is composed of at least two of Mg, Ag, B, Ga, Si, Li, Ti, Fe and Mn and Re, wherein the mass percentage of the M is 0.05-0.5%, and RE is selected from at least three of Ce, La, Yb, Pr, Nd and Sm. Cu-Cr-Zr-M copper alloy powder is prepared through gas atomization, the powder is supersaturated solid solution which is uniformin ingredient and fine in micro-structure. The preparation technology is simple, the obtained powder is fine in particle, uniform in particle size distribution and good in sphericity degree. A blockymaterial made of the powder has the features of excellent electrical properties and mechanical properties.

Owner:CENT SOUTH UNIV

Preparation method of mechanical alloying copper-tungsten alloy powder

The invention discloses a preparation method of mechanical alloying copper-tungsten alloy powder. Atomized copper powder and crystallized tungsten powder are selected as raw materials; a ball milling medium, in particular a volatile organic solvent as the ball milling medium is added for wet grinding; the wet grinding enables powder grains to be fine; the components are uniform; the powder oxidized degree is reduced; the increment of forming density is facilitated; a mechanical alloying method with a high ball-material ratio is adopted, so that tungsten particles are embedded in copper particles through high-energy collision under the condition of normal temperature to form supersaturated solid solution alloy powder; and finally, the ball milling medium is removed to obtain the mechanical alloying copper-tungsten alloy powder. The tungsten-copper alloy powder, obtained by the method, has such characteristics as larger particles, uniform components, excellent forming capacity, excellent flowing performance, easy formation and easy segregation; and the preparation method is simple in process and easy to operate.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

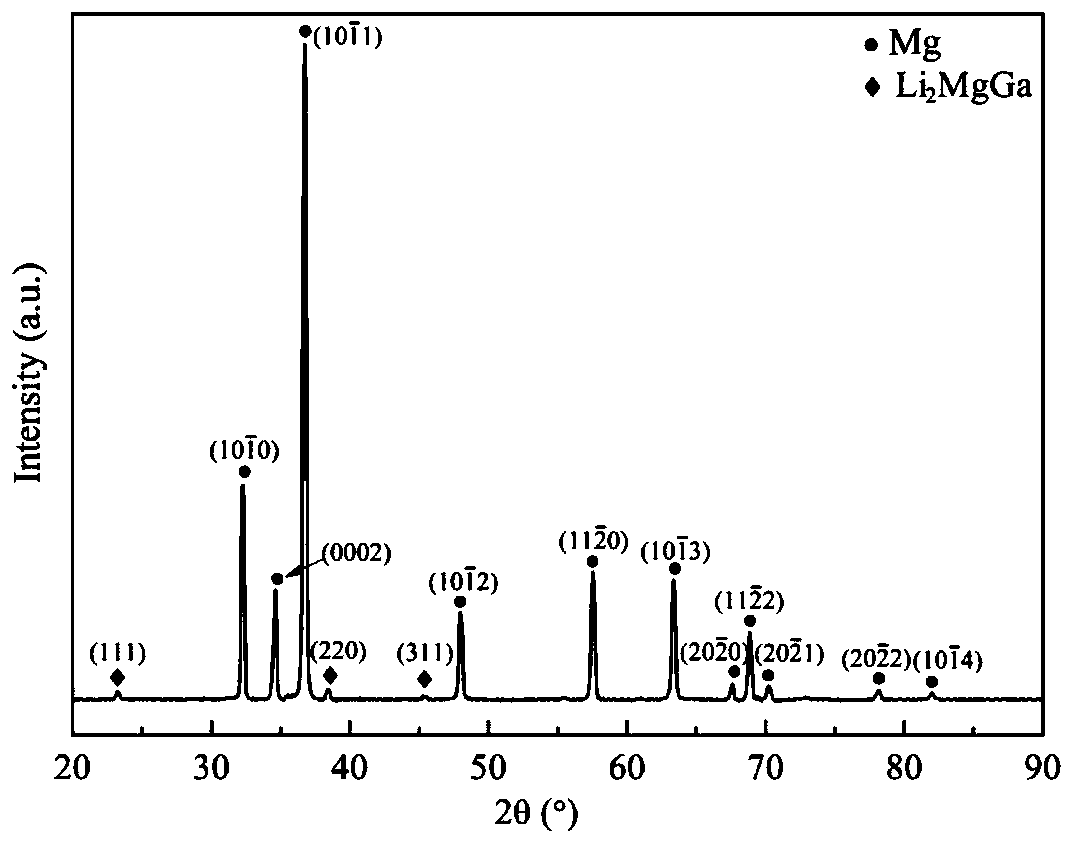

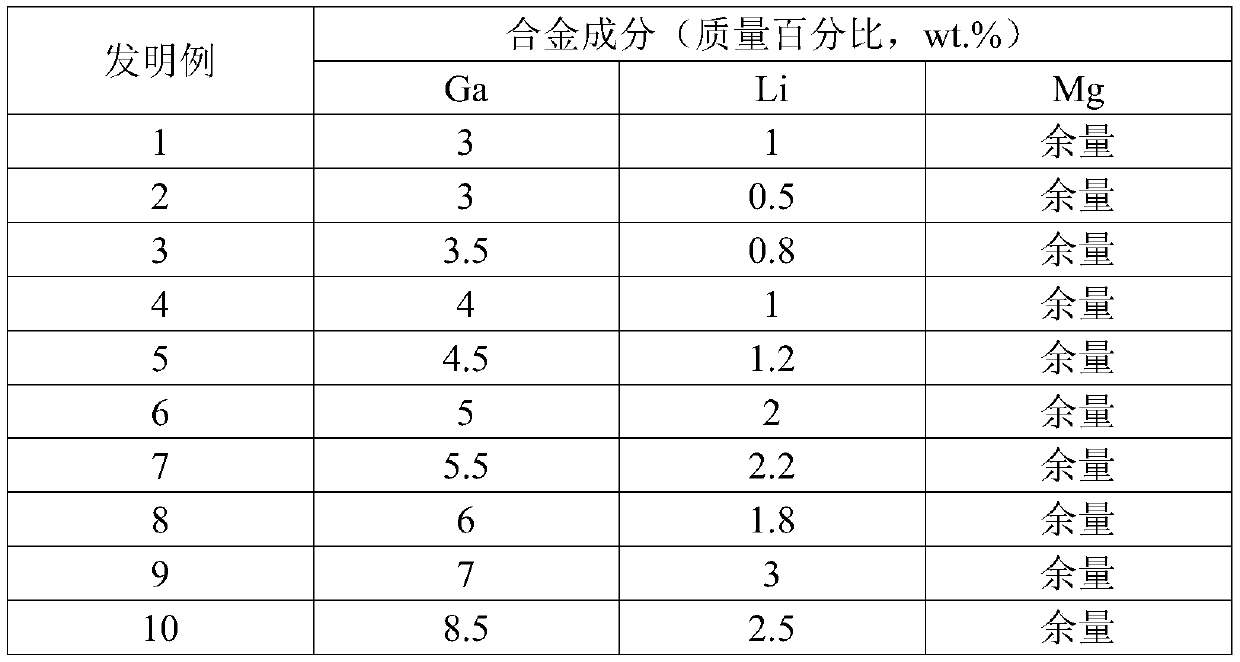

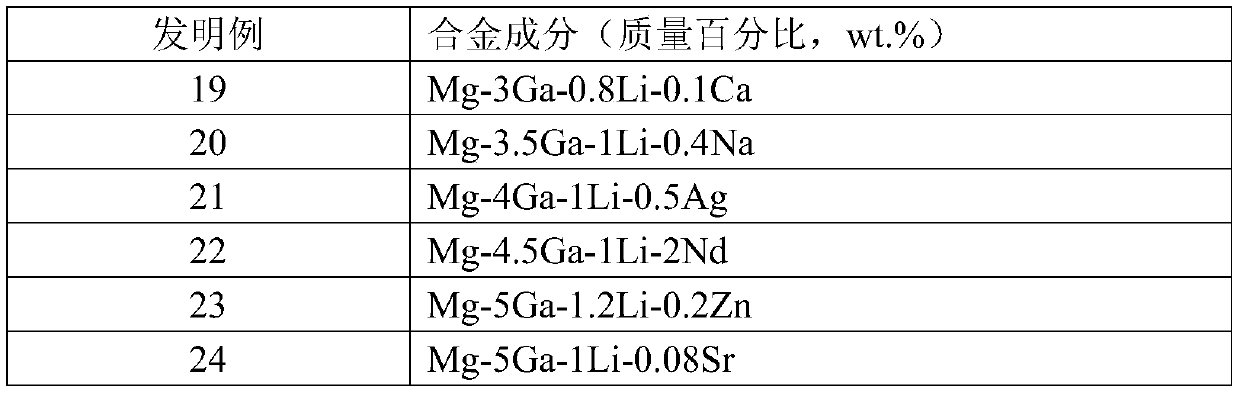

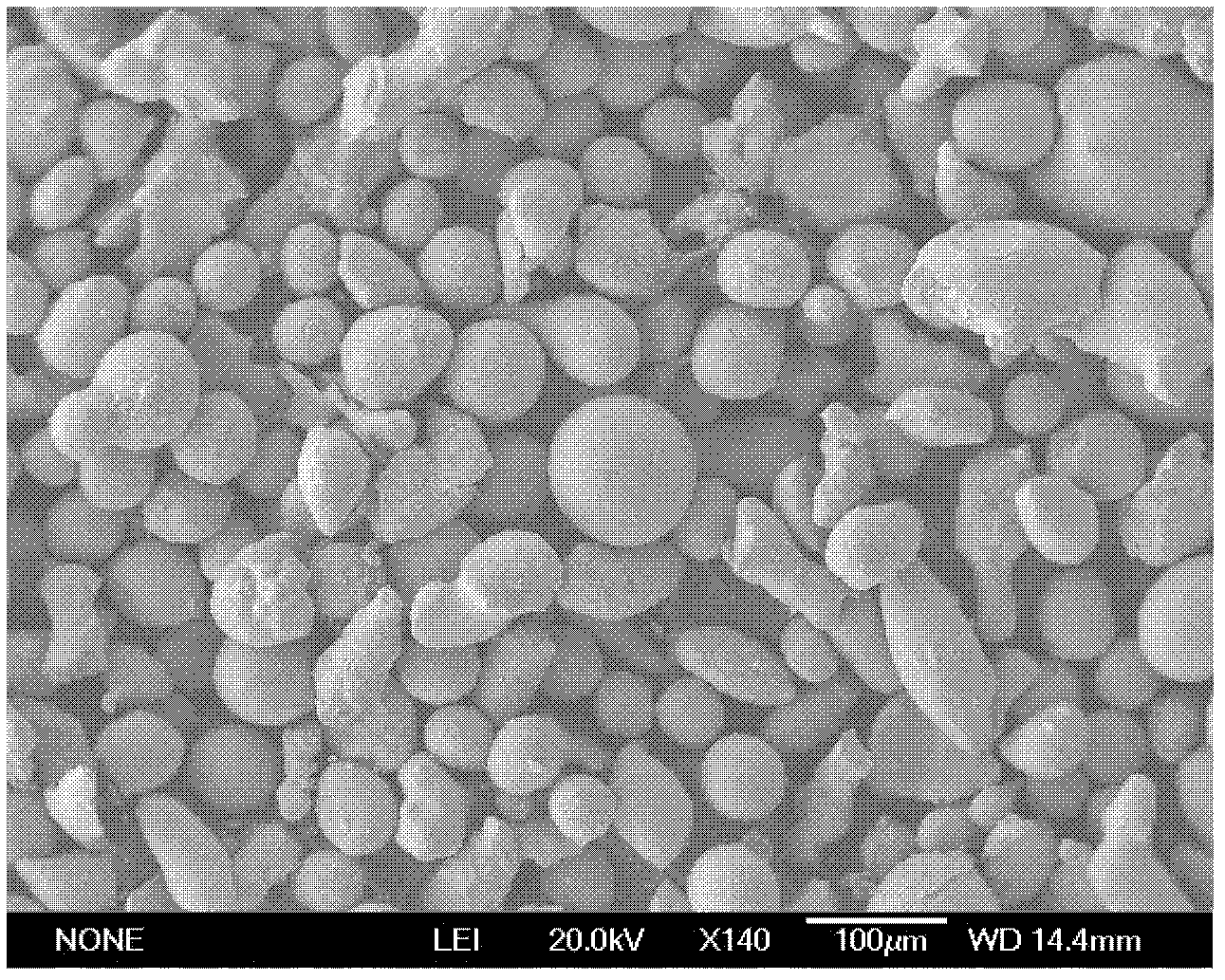

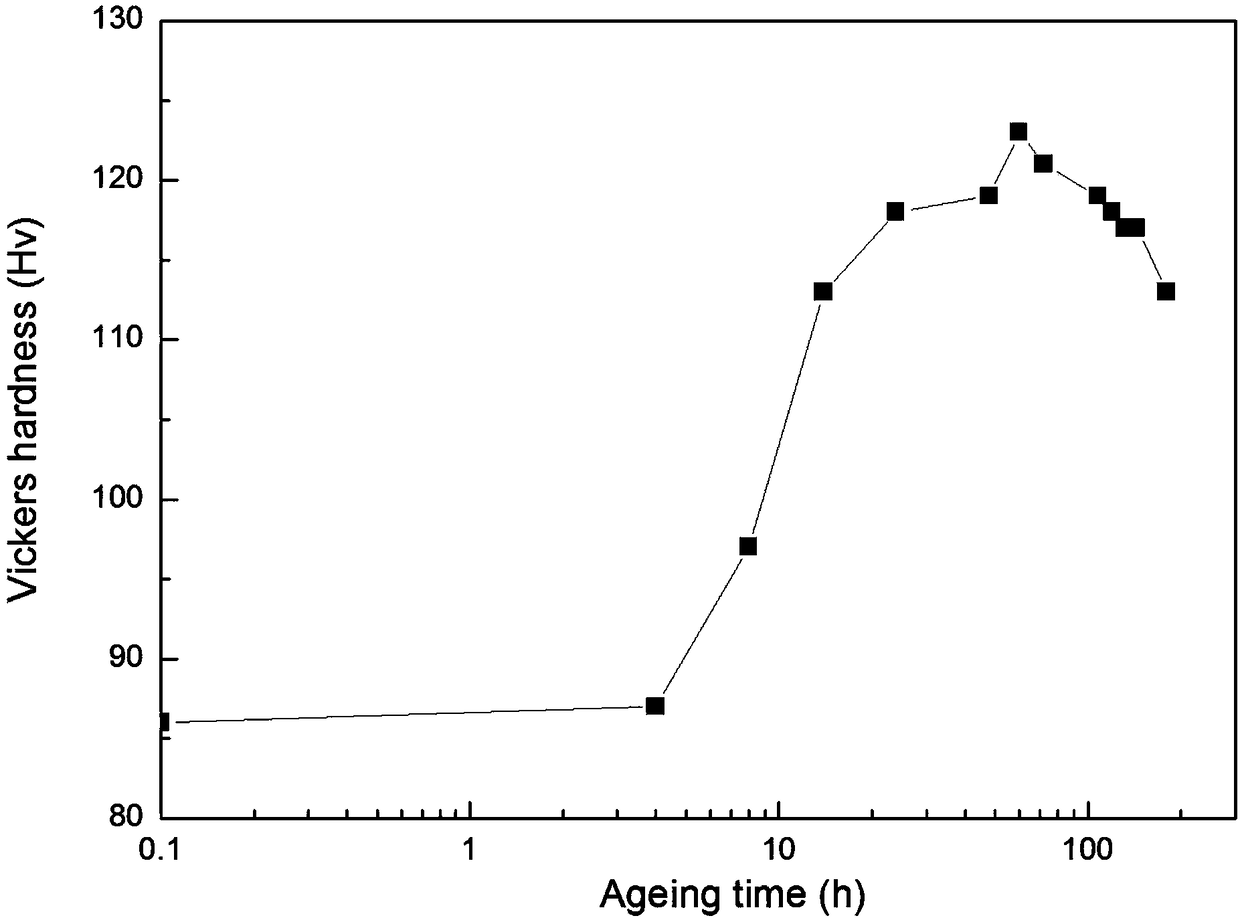

High-strength high-ductility Mg-Ga-Li-series magnesium alloy capable of quickly realizing ageing strengthening and preparation method thereof

ActiveCN110983135AFast formingReach peak age hardnessAdditive manufacturing apparatusSurgeryRare-earth elementSupersaturated solid solution

The invention provides a high-strength high-ductility Mg-Ga-Li-series magnesium alloy capable of quickly realizing ageing strengthening and a preparation method thereof. The alloy is prepared from thefollowing components in percentage by weight: 3-8.5% of Ga, 0.5-3% of Li and the balance Mg; and the alloy further can contain at least one of Zn, Ca, Sr, Si, Zr, a rare-earth element Re, Mn, Ag, Cuand Na. The alloy provided by the invention can be quickly formed by an additive manufacturing (3D printing) technology, further can be subjected to solid-solution thermal treatment to obtain an Mg-based supersaturated solid solution, and can achieve an ageing strengthening value within 20 hours through quick aging thermal treatment. The high-strength high-ductility Mg-Ga-Li-series magnesium alloyhas room-temperature tensile yield strength higher than 200 MPa, and has elongation higher than 10%. The alloy takes a Mg-Ga-Li ternary phase of a nano scale as a main precipitated phase, is remarkable in ageing strengthening effect, is good in overall performance, and further can be used as a biomedical material for manufacturing a body implant medical device except from being used as a common structure and a high-temperature creep-resistant material.

Owner:UNIV OF SCI & TECH BEIJING

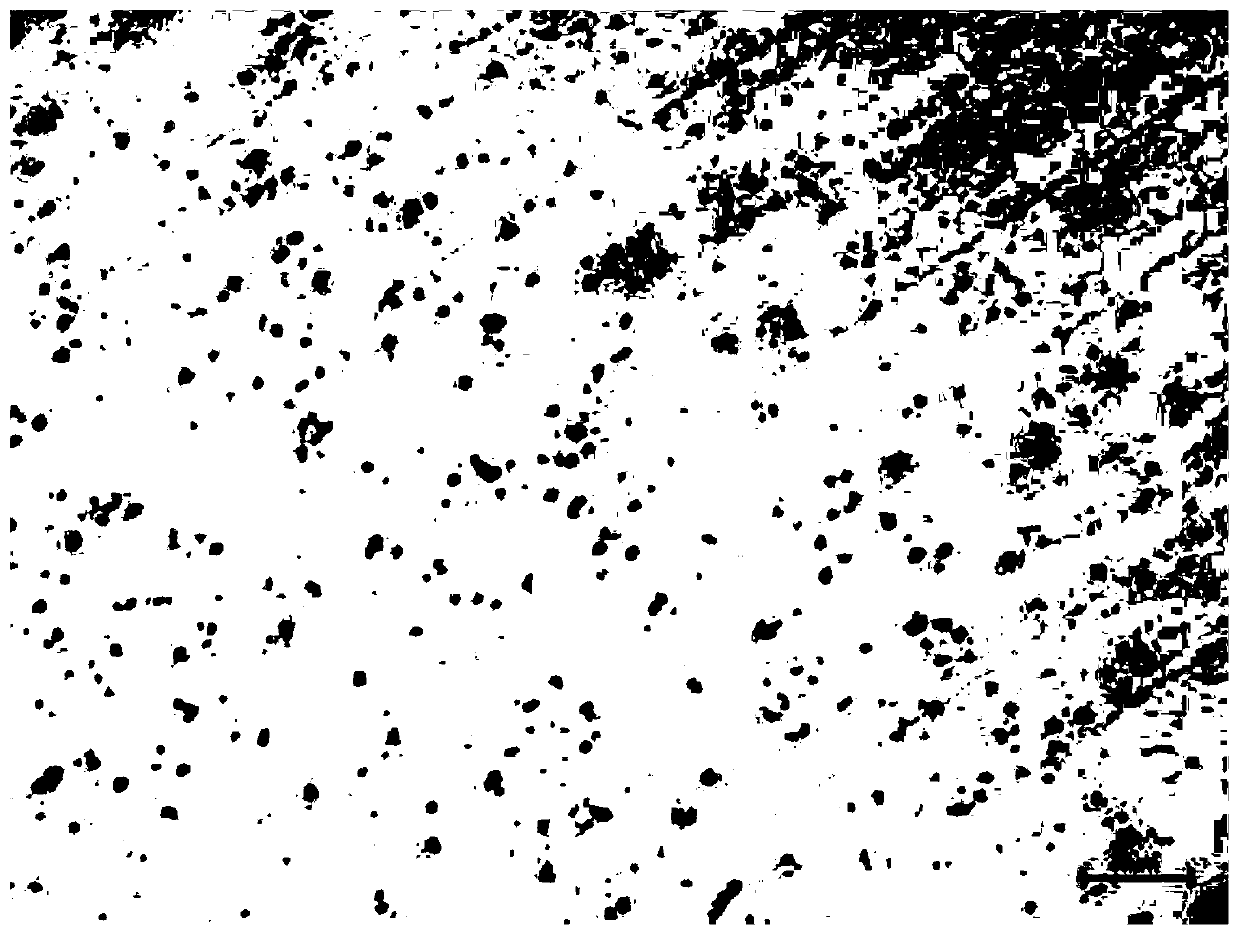

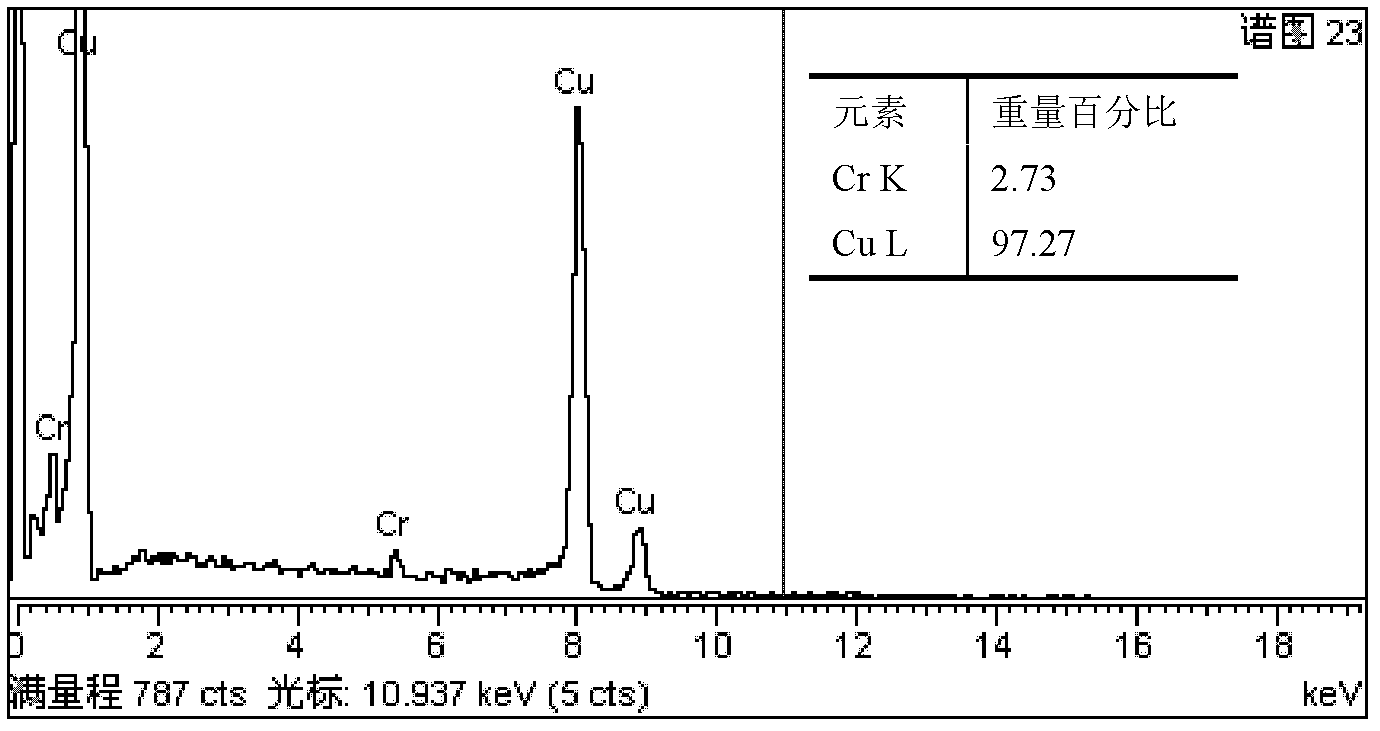

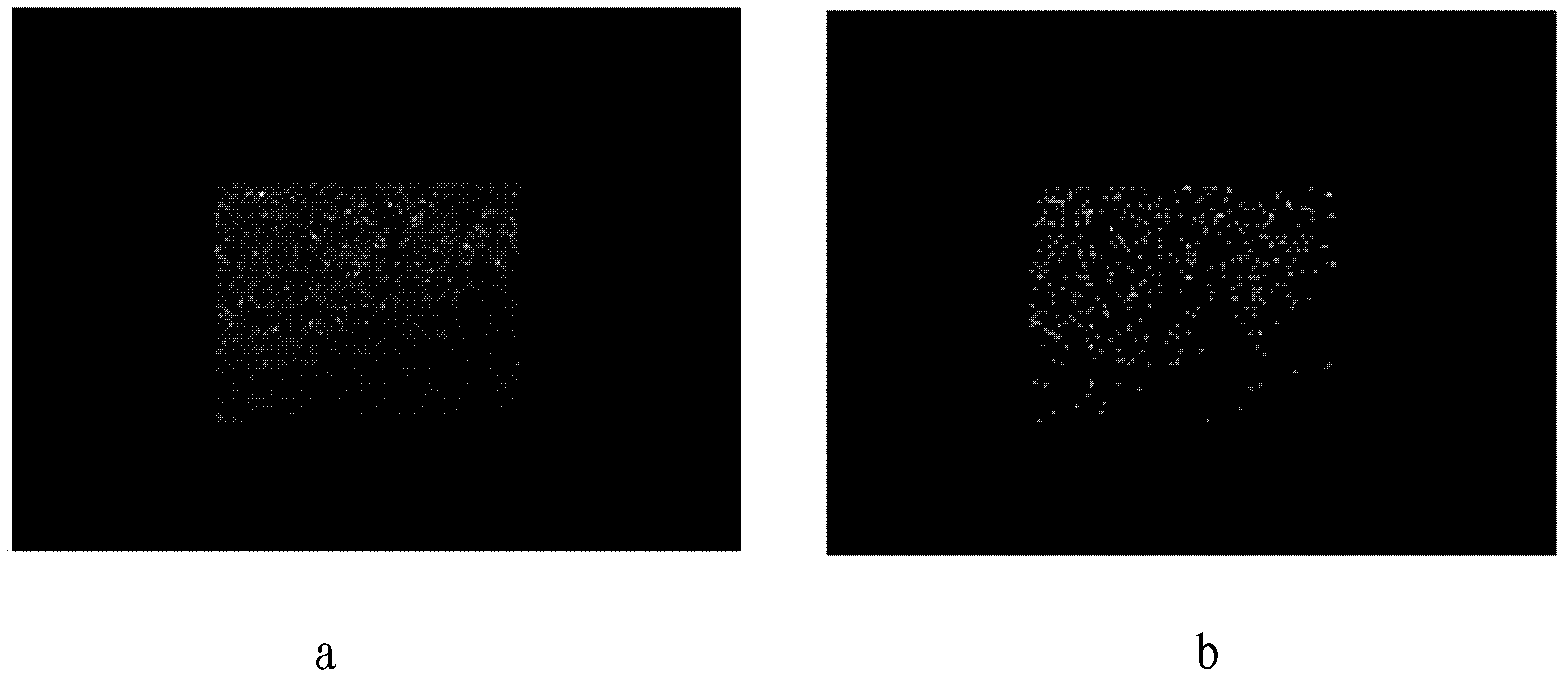

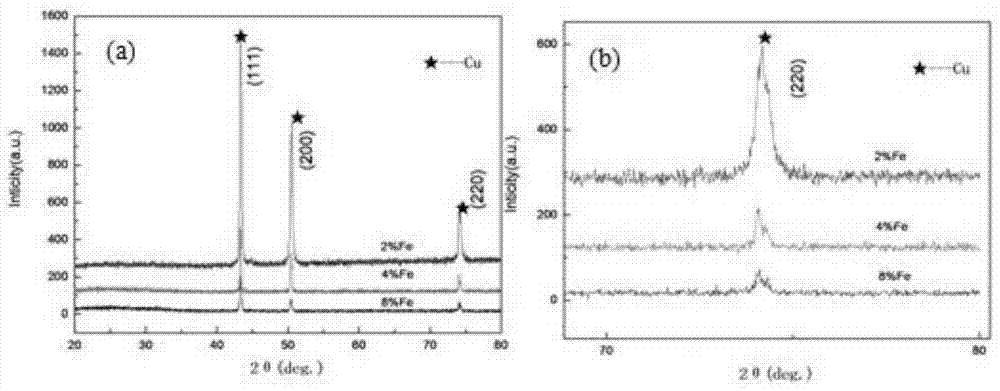

Preparation method of CuCr alloy powder with low chromium content

The invention discloses a preparation method of CuCr alloy powder with low chromium content. The preparation method comprises the steps of: weighing copper block and chromium block according to mass percent, melting the copper block utilizing a medium-frequency induction smelting furnace, adding the chromium block to molten copper, then adding a certain amount of slag-forming agent and covering agent, and after copper and chromium are sufficiently mixed, atomizing with high-purity nitrogen as atomization gas, thus the melt is dispersed into small liquid drops and the liquid drops fall to an atomization barrel holding water for cooling and solidifying. The CuCr alloy powder prepared by the method is a supersaturated solid solution, has fine solidified structure, and can realize powder sintering easily; in the CuCr alloy powder, Cr phase component segregation is reduced and Cr is uniformly distributed on a substrate; and the problem that impurities are introduced during mechanical alloying is solved.

Owner:XIAN UNIV OF TECH

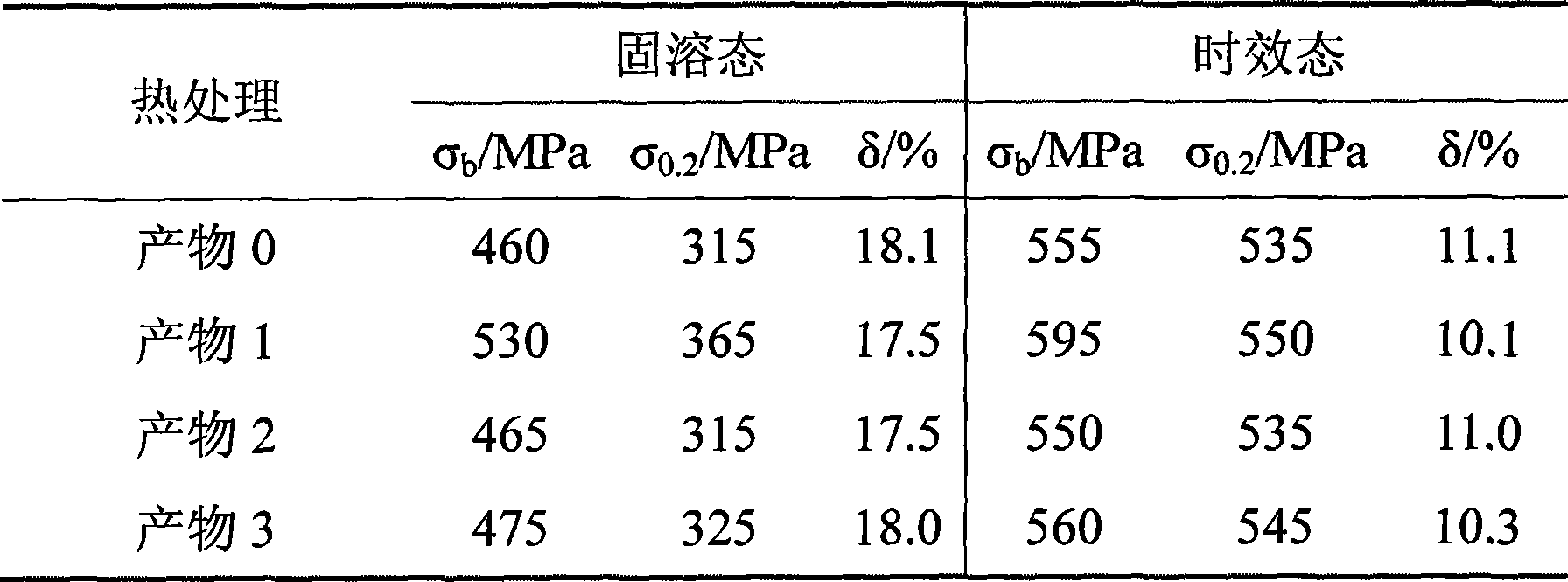

Thermal treatment method for Al-Zn-Mg-Sc-Zr alloy

A heat treatment method of Al-Zn-Mg-Sc-Zr alloy comprises such five steps as hot rolling, first solution, cold rolling, second solution and aging. During the first solution, a second-phase is dissolved in a base to obtain supersaturated solution, thus effectively improving the alloying effects of Sc and Zr and at the same time softening the alloy to provide fully softened organism for later cold rolling with comparatively large deformation; the later cold rolling can smash the undissolved coarse phase, thus is beneficial for the coarse phase to be dissolved in the matrix during the second solution, improves the supersaturation level of the base, lowers the probability of the occurrence of cracks during the alloy deformation, and at the same time lays a foundation for aging to precipitate more strengthening phases. Compared with the conventional heat treatable alloy, when the cold rolling deflection of the alloy treated by the method of the invention is 50.0%, the tensile strength and yield strength of the alloy in solution state are respectively improved by 70MPa and 50MPa and the tensile strength and yield strength of the alloy in aging state are respectively improved by 40MPa and 35MPa. The method of the invention is simple in technique and convenient in operation, is applicable to industrial application and provides a new processing method for the improvement of the property of aerospace materials.

Owner:CENT SOUTH UNIV

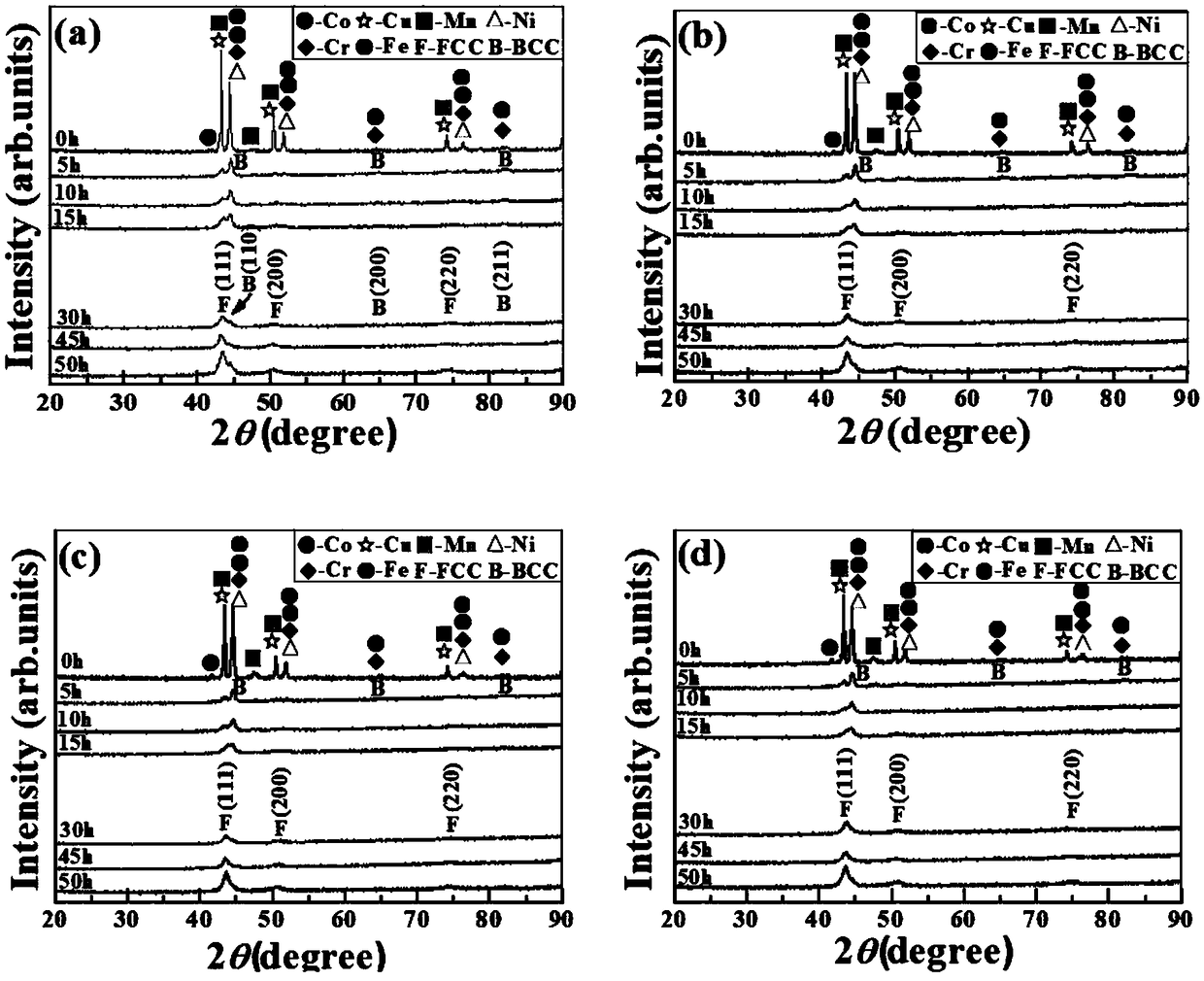

Soft magnetic high-entropy alloy powder and preparation method thereof

ActiveCN109175346AHigh saturation magnetizationLow coercivityHigh entropy alloysSupersaturated solid solution

The invention provides soft magnetic high-entropy alloy powder and a preparation method thereof. The soft magnetic high-entropy alloy powder is prepared by Co, Cr, Cu, Fe, Mn and Ni with a mole ratioof 0-2: 1: 1: 1: 1: 1; all alloying elements of the soft magnetic high-entropy alloy powder form nanocrystalline oversaturated solid solution structures with FCC structures as main components; the atomic percentages of all element contents approximate nominal components; the magnetic strength of the high-entropy alloy powder is 21-52 emu / g; the coercivity is 14-63 Oe; and the residual magnetism rate Mr / Ms is 3-16%. The high-entropy alloy powder prepared by mechanical alloying achieves higher saturated magnetic strength, lower coercivity and better soft magnetic property.

Owner:HENAN INST OF ENG +1

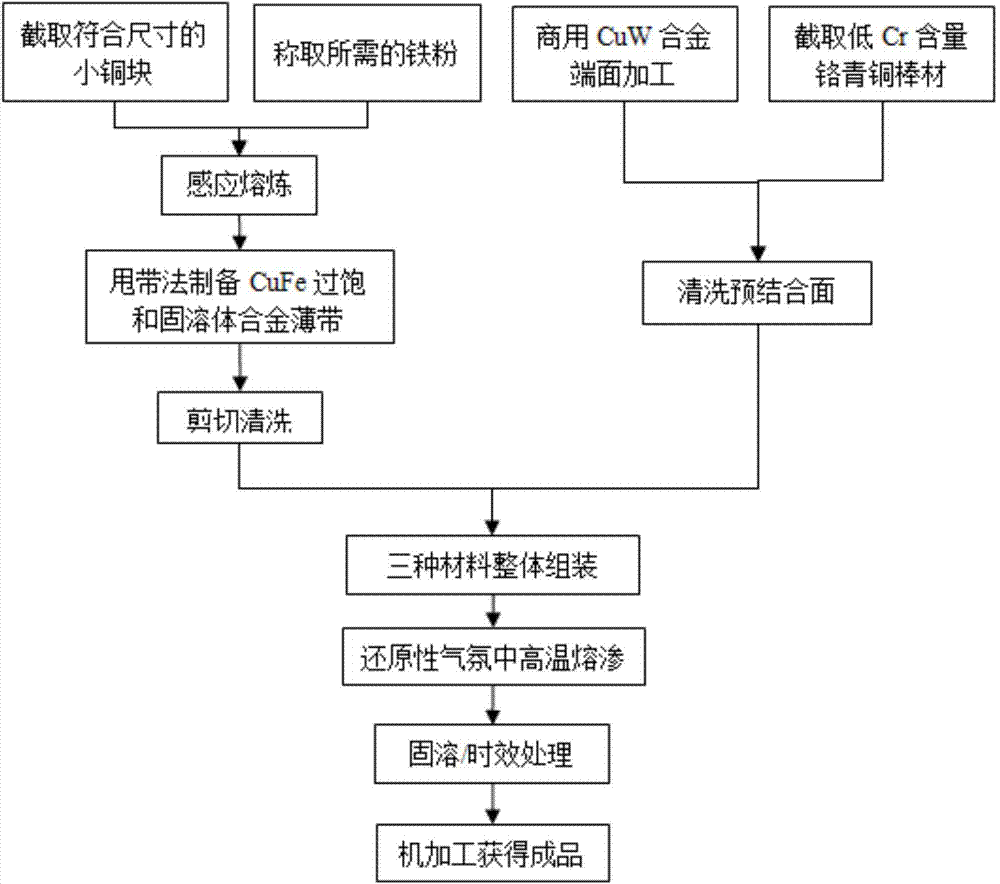

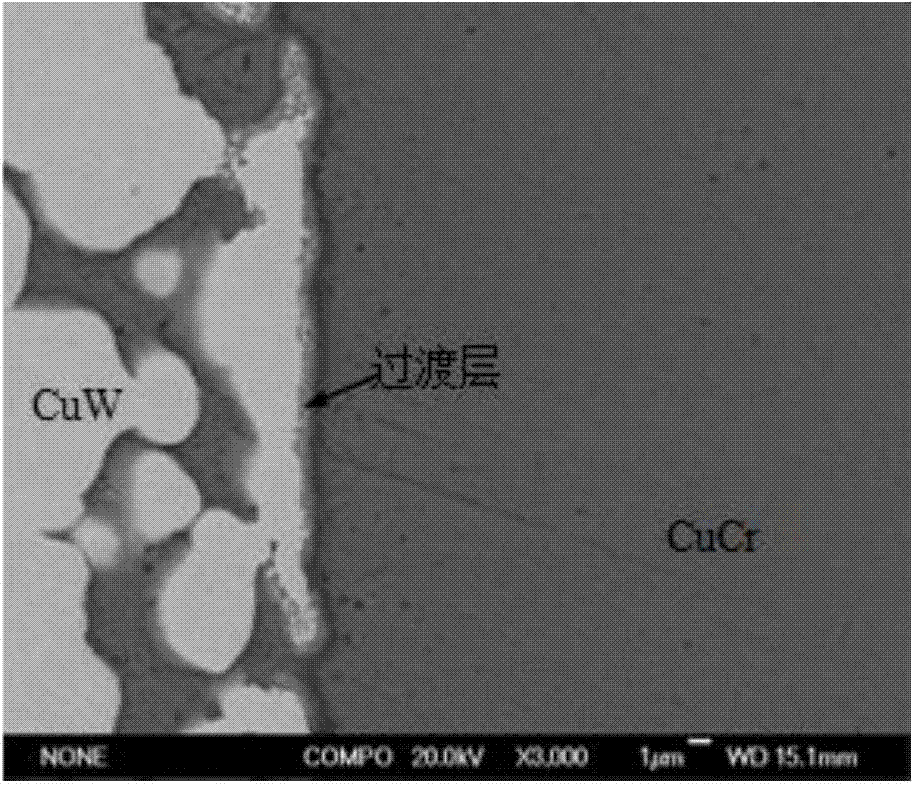

Preparation method of CuW/CuCr composite material

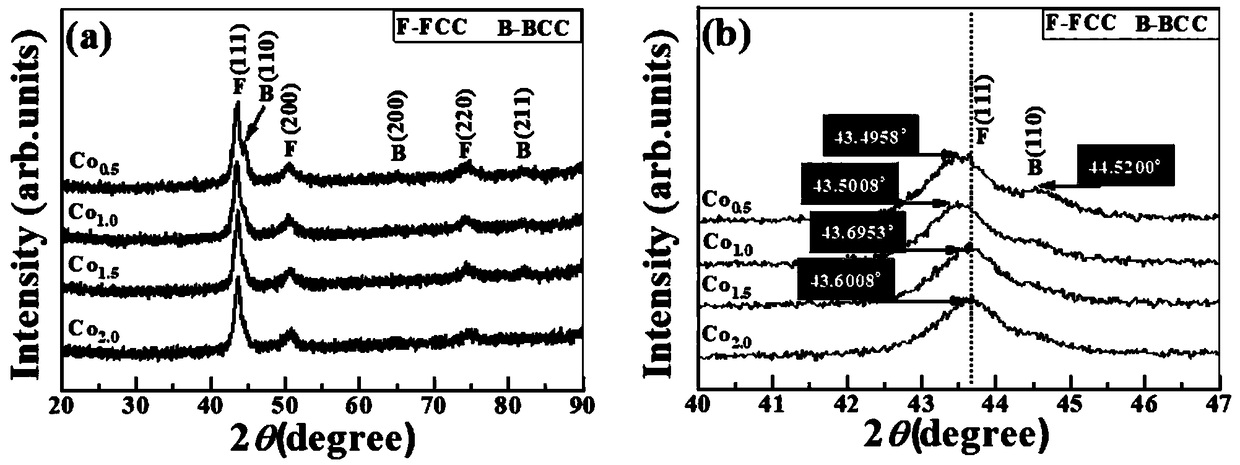

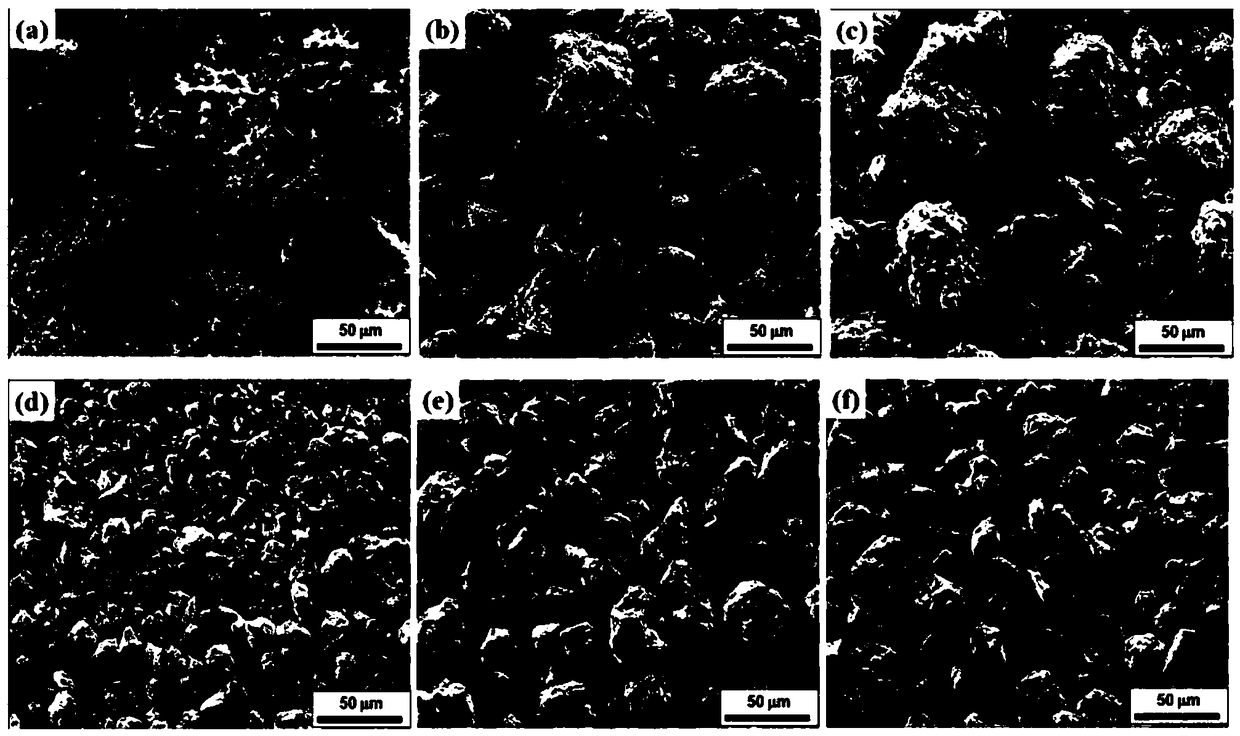

InactiveCN104505286AImprove bindingImprove the bonding strength of the interfaceElectric switchesInterface bondSupersaturated solid solution

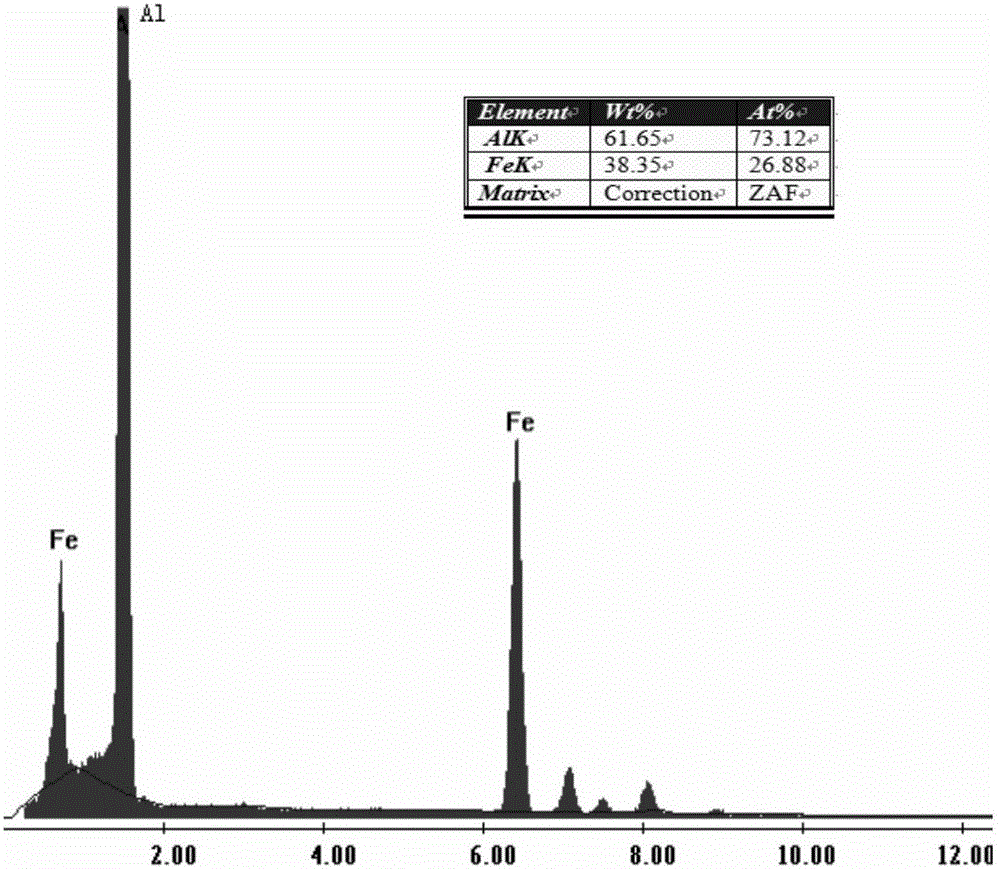

The invention discloses a preparation method of CuW / CuCr composite material. A CuFe supersaturated solid solution alloy thin strip is prepared firstly, then the CuFe supersaturated solid solution alloy thin strip is arranged between a CuW alloy and a CuCr alloy to be sintered and infiltrated, and finally solid solution and aging treatment is performed on the material after sintering and infiltration so that the CuW / CuCr composite material of which the bonding surface is metallurgically bonded is obtained. The invention provides the preparation method of the CuW / CuCr composite material. The Cu / W phase interface is enhanced via introducing the CuFe alloy thin strip so that metallurgical bonding between a framework W and matrix phase Cu is realized, bonding force between the framework and the matrix phase is enhanced, interface bonding strength of the CuW / CuCr material is enhanced, problems that interface bonding strength of the CuW / CuCr heterogeneous material prepared by the existing methods is low and the CuW end falls off due to the fact that the whole material is liable to break along the bonding surface can be solved, and thus the technology is simple and cost is low.

Owner:XIAN UNIV OF TECH

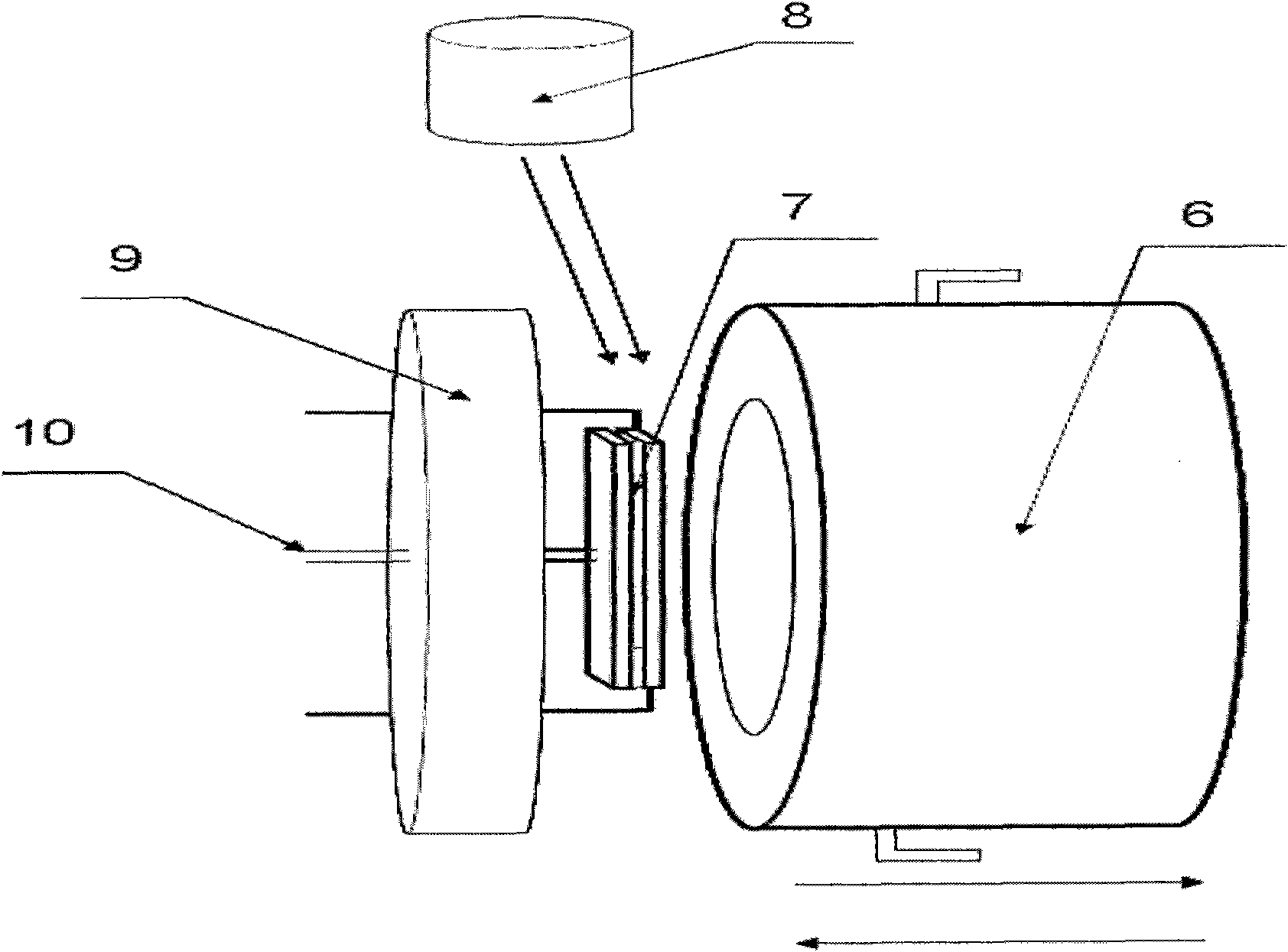

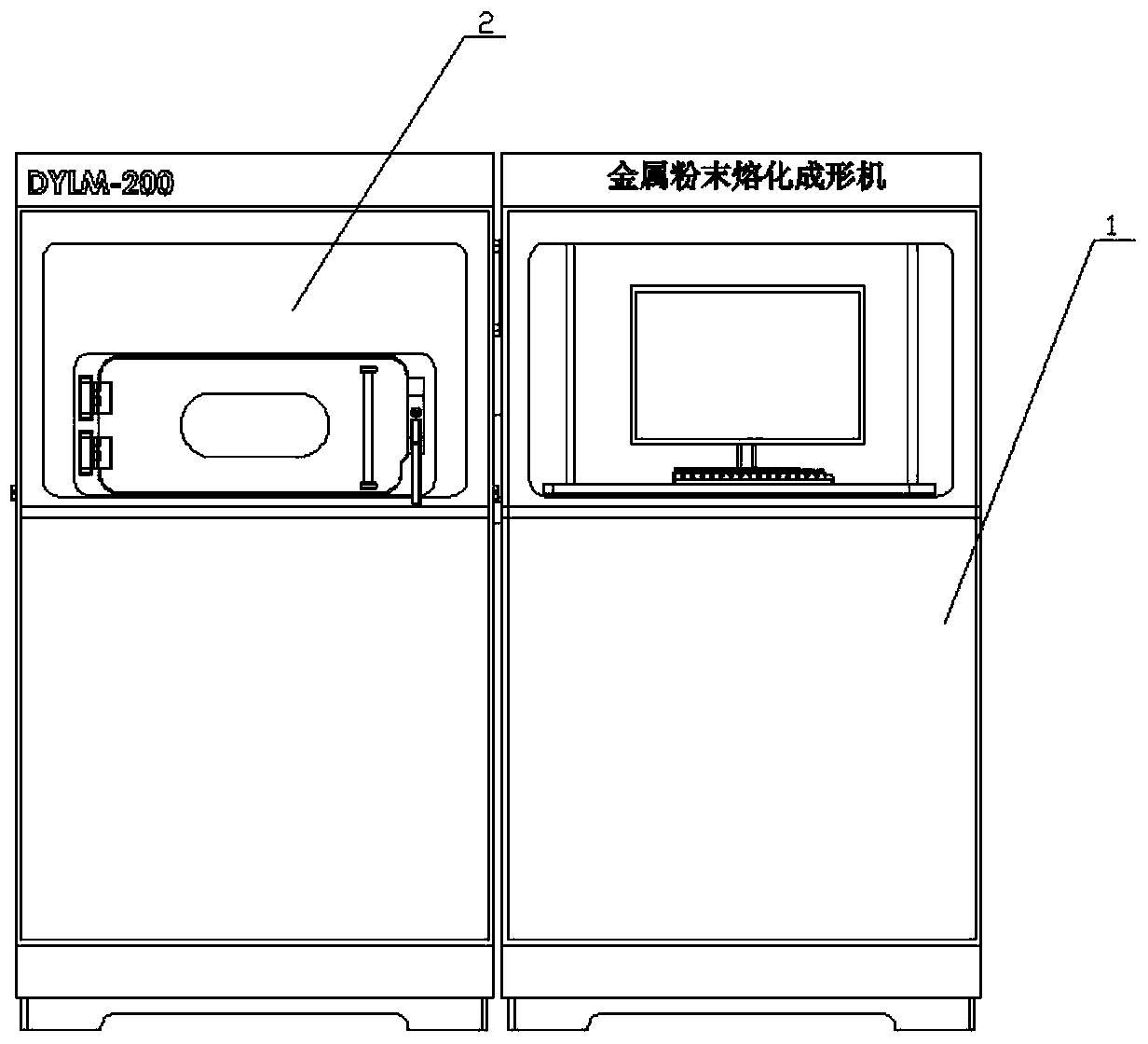

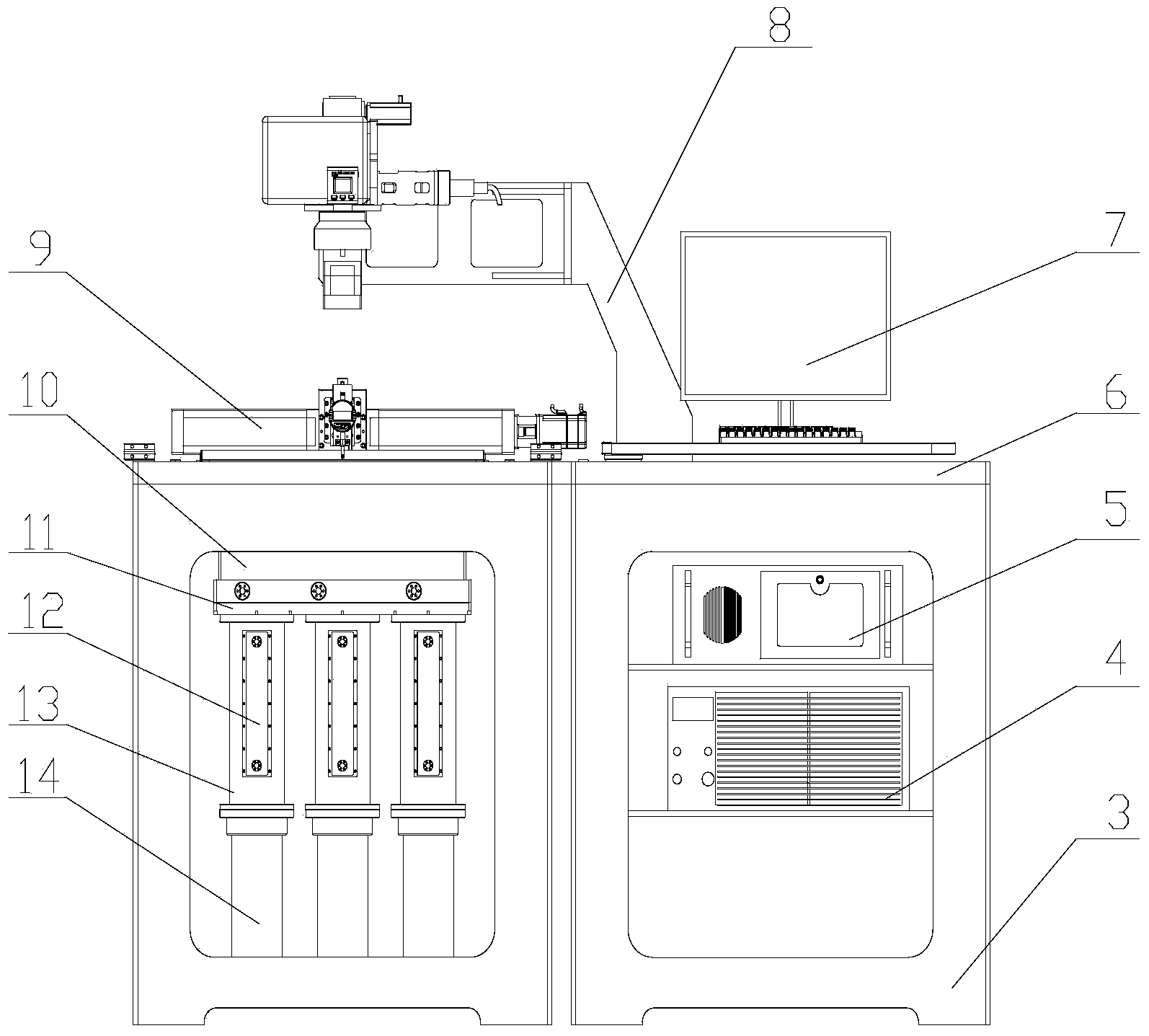

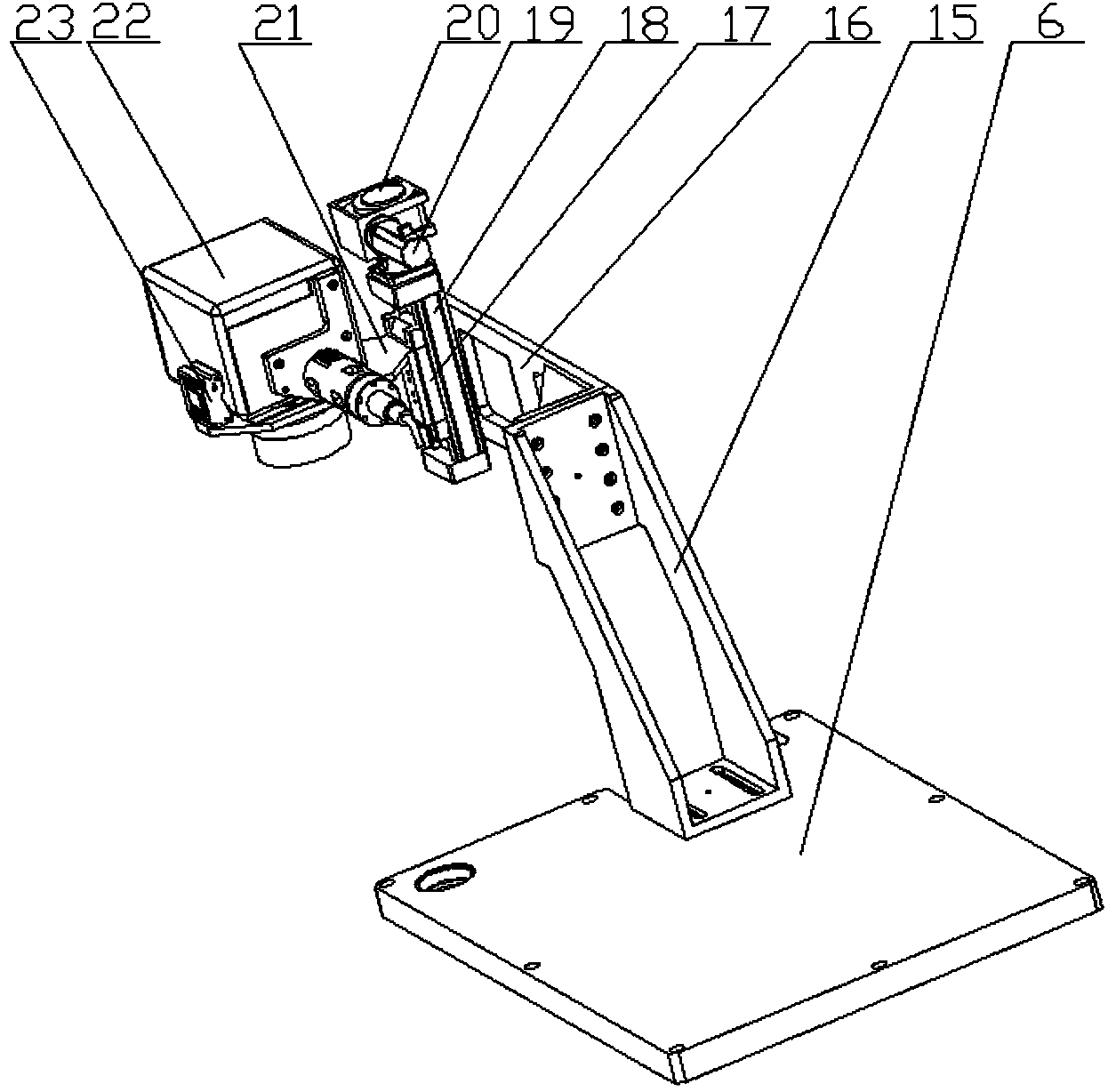

Novel metal powder melting and quick-molding machine

The invention relates to a novel metal powder melting and quick forming machine which comprises a frame, a control system, a laser galvanometer scanning device, a powder laying device, a three-cylinder body and a laser, wherein the control system, the laser galvanometer scanning device, the powder laying device, the three-cylinder body and the laser are all arranged on the frame, the laser galvanometer scanning device is in optical connection with the laser, and the laser galvanometer scanning device, the powder laying device, the three-cylinder body and the laser are all connected to the control system. The novel metal powder melting and quick forming machine has the advantages that a nonequilibrium supersaturated solid solution and uniform and fine metallographic structures can be obtained, the density of a formed part is close to 100%, the mechanical performance is equivalent to that of a forging part, the processing time and cost can be obviously reduced, and the development cycle of a new product is shortened. The novel metal powder melting and quick forming machine greatly adapts to the requirements of quick, individuated and flexible development of the modem manufacturing industry and has a broad application prospect in the manufacturing fields of aviation, aerospace, medicine, molds, weaponry and the like.

Owner:HARBIN FORWEDO MULTI DIMENSIONAL INTELLIGENT EQUIP CO LTD

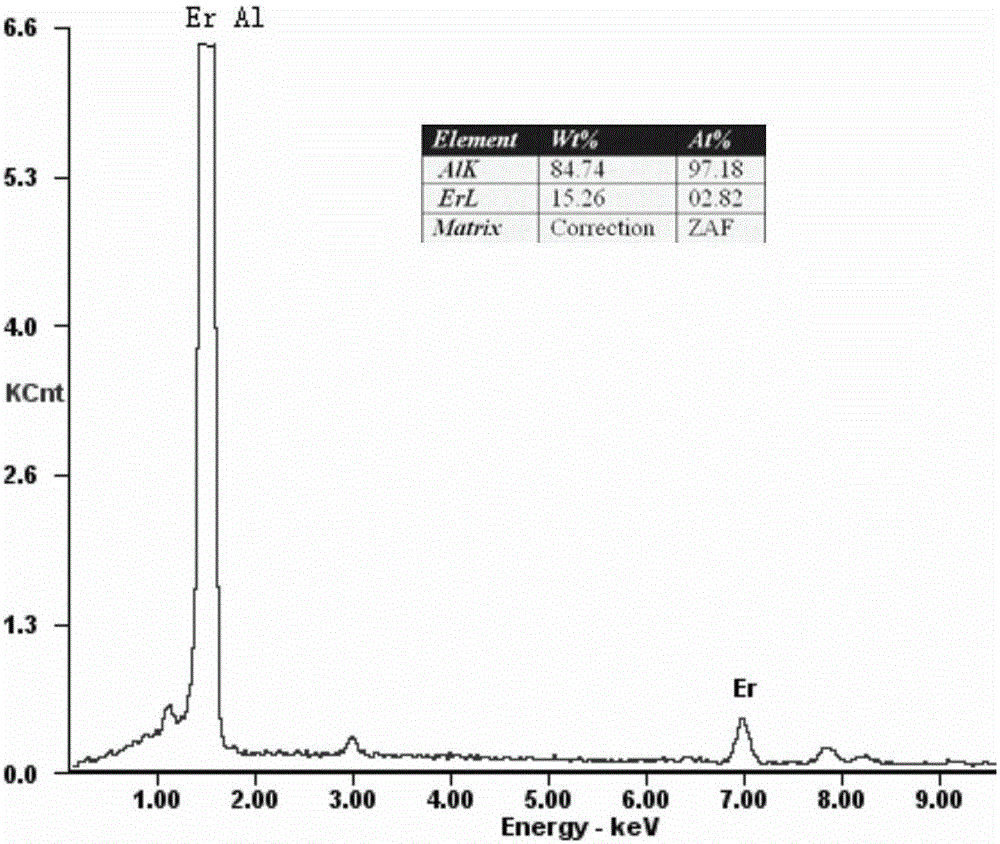

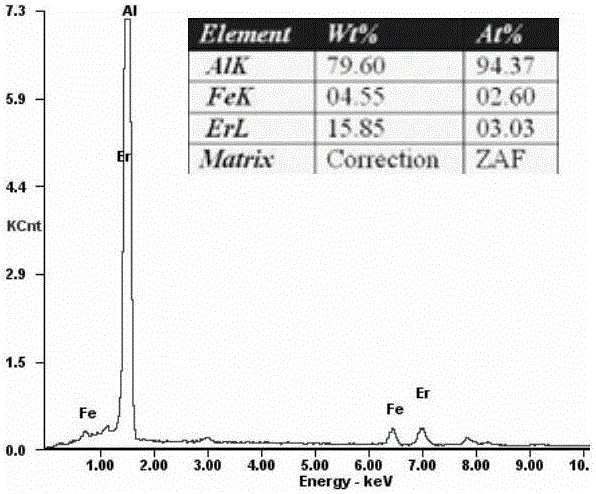

Light high-conductivity and heat-resistant aluminum conductor and preparation method thereof

ActiveCN105734353AImprove conductivityOo fullConductive materialMetal/alloy conductorsElectricityHeat resistance

The invention discloses a light high-conductivity and heat-resistant aluminum conductor and a preparation method thereof. The aluminum conductor is composed of, by weight, 0.035-0.06% of B, 0.1-0.2% of Zr, 0.1-0.3% of Er, inevitable impurities and the balance Al. The technological process comprises the steps of smelting, on-the-spot fast component analyzing, refining, rapid cooling casting, blank annealing, extruding and drawing. The added B element has the refining and modifying effects and mainly has the effect of promoting supersaturated solid solutions containing Zr and Er to separate out Al3(Er and Zr) ternary composite phases; the Al3(Er and Zr) composite phases are nano particles which are coherent with a matrix and have shell-core structures, are dispersed in the aluminum matrix and can greatly improve the electricity conductivity and the heat resistance of the aluminum conductor; the density of obtained monofilaments is smaller than or equal to 2.71 g / cm<3>, the electricity conductivity of the monofilaments is greater than or equal to 62%IACS, the short-time heat-resistance temperature of the monofilaments reaches 230 DEG C, the long-term heat-resistance temperature of the monofilaments reaches 210 DEG C, and the tensile strength of the monofilaments is greater than or equal to 165 MPa; the economic benefits are remarkable, the energy is greatly saved, and the environmental friendliness is high.

Owner:CENT SOUTH UNIV

Magnesium alloy strengthened with rare earth samarium and preparation method of magnesium alloy

InactiveCN108220730ASolve the costly status quoGood solid solution strengtheningRare earthSolid solution strengthening

The invention provides a magnesium alloy strengthened with rare earth samarium. The magnesium alloy is prepared from, by mass percent, 5.0% to 6.0% of Y, 2.5% to 3.5% of Sm, 0.4% to 0.8% of Zr and thebalance magnesium. According to the novel high-strength magnesium alloy, the rare earth Sm is selected for alloying the magnesium alloy, the maximum solid solubility of Sm in magnesium is higher thanthat of Nd with a good strengthening effect in magnesium. Due to the fact that Y and Sm are added, a large number of Mg24(Y,Sm)5 phases and Mg41(Sm,Y)5 phases are generated in the magnesium alloy, the precipitated phases can be completely redissolved into a base body in the solid solution treatment process, a supersaturated solid solution is formed, and then the supersaturated solid solution is subjected to artificial aging; and in the artificial aging process, the hardness is greatly improved, a very good solution strengthening and aging strengthening effect is achieved, and more excellent mechanical performance is achieved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

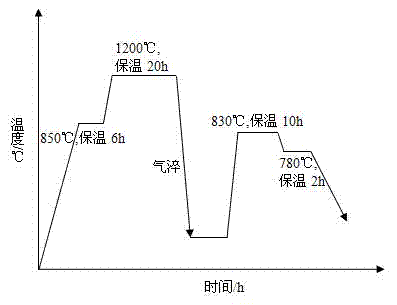

Rare earth-containing Cu-Ni-Fe alloy inert anode material and heat treatment method thereof

The invention discloses a rare earth-containing Cu-Ni-Fe alloy inert anode material and a heat treatment method thereof, and relates to an aluminum electrolysis alloy inert anode material, and a heat treatment method suitable for the high-temperature molten salt aluminum electrolysis alloy inert anode material. The inert anode material comprises 35-65mass% of Cu, 20-35mass% of Ni and 15-30mass% of Fe, and the sum of the mass percentages of the above three elements is 92.5-99.9%. The heat treatment method of the inert anode material comprises the following steps: carrying out heating, heat insulation and strong cooling quenching for homogenization heat treatment to obtain a uniform supersaturated solid solution structure, and carrying out two-stage ageing heat treatment to obtain a fine and uniform second phase dispersed and distributed on an anode matrix. The uniformly dispersed anode matrix structure has a stationary voltage in the electrolytic process, and has a good high-temperature oxidation resistance and a good electrolyte corrosion resistance, and the impurity content in an electrolysis aluminum product is lower than 0.5%.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for producing 6000 series aluminum alloy

InactiveCN106319409AHigh extrusion deformation strengthening effectNarrows or disappears in widthDissolutionIngot

The invention discloses a method for producing a 6000 series aluminum alloy, and the method includes (1), alloy ingot preparation; (2), pre aging treatment; (3), cold extrusion deformation; and (4), re aging treatment. Firstly through the control of the pre aging, characteristics of certain properties, quantities, sizes, shapes and distribution of matrix and grain boundary precipitate phases can be pre formed; by the control of extrusion speed and extrusion ratio for cold extrusion deformation, the matrix precipitate phase is deformed to induce dissolution to form a supersaturated solid solution, and the grain boundary precipitate phase breaks to form a continuous distribution state; and finally, re aging is controlled for re precipitation of a strengthening phase from the matrix supersaturated solid solution, so that precipitation strength effect can be further obtained on the basis of cold extrusion deformation strengthening, and dislocation accumulation ability can be improved; full spheroidization and discontinuous distribution of the grain boundary precipitate phase can be promoted, and elimination of the susceptibility to intergranular corrosion can be realized.

Owner:张家港市丰乐汽车设备有限公司

Preparation method for 304 austenite stainless steel rotary blades of juicer

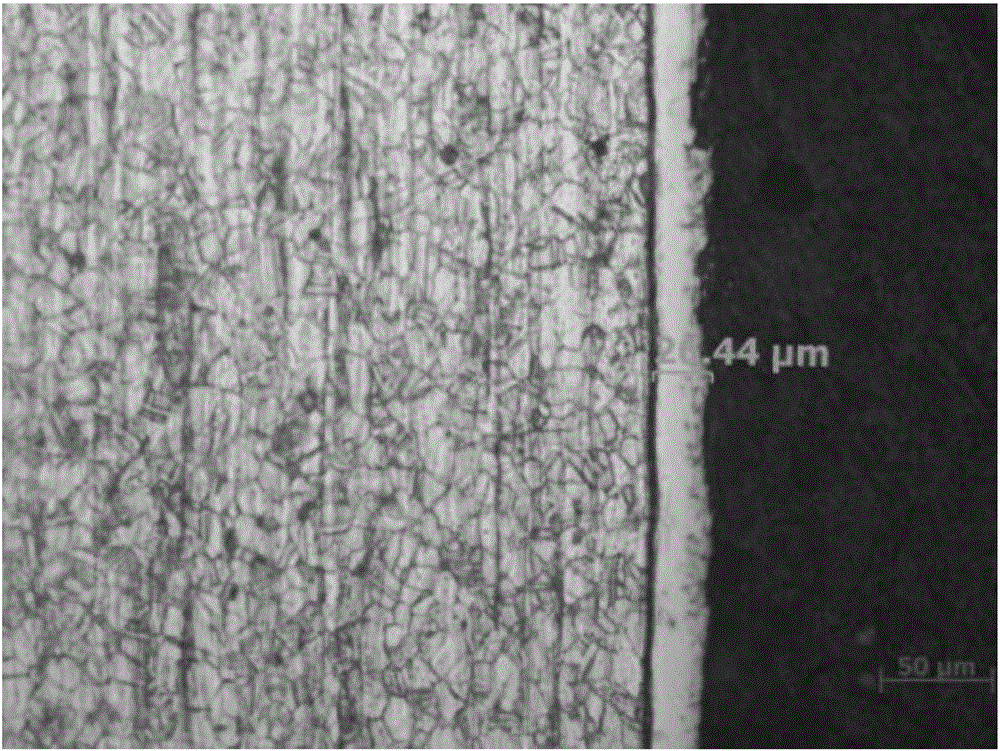

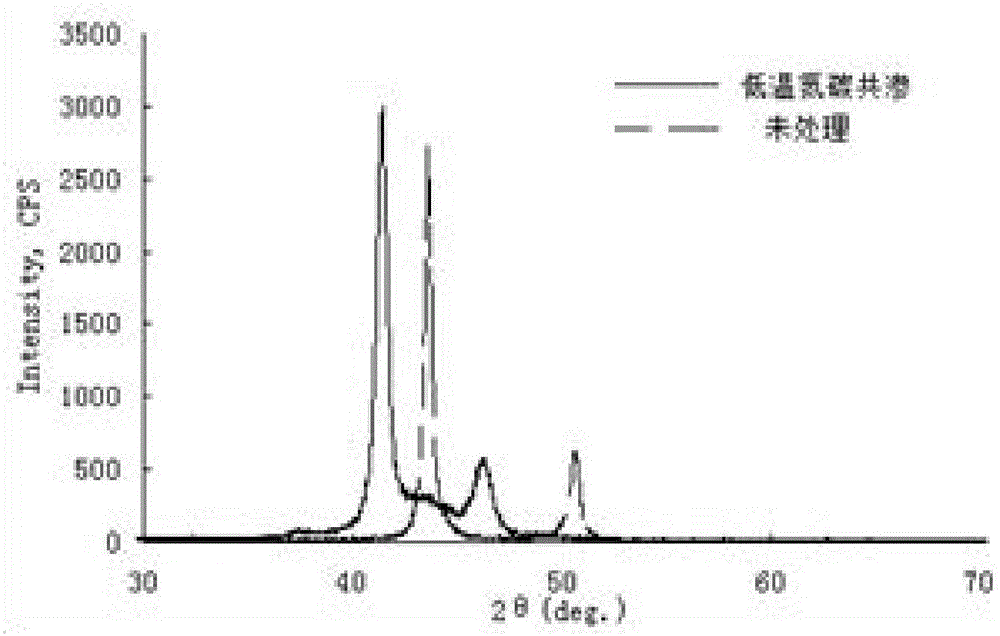

ActiveCN106756762AHigh hardnessImprove corrosion resistanceSolid state diffusion coatingNitrogenSupersaturated solid solution

The invention relates to a plasma nitrocarburizing technique for 304 austenite stainless steel rotary blades of a juicer. After the 304 austenite stainless steel rotary blades are subjected to plasma nitrocarburizing treatment, and hardened layers with the thicknesses being more than 15 [mu]m are generated on the surfaces of the stainless steel rotary blades and oversaturation solid solutions (S phases) of nitrogen and carbon in austenite. The 304 austenite stainless steel rotary blades have high hardness and corrosion resistance, and various technical indices all exceed food mechanical standard requests.

Owner:QINGDAO AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com