Soft magnetic high-entropy alloy powder and preparation method thereof

A high-entropy alloy and soft magnetic technology, applied in the field of high-entropy alloy powder, can solve problems such as undiscovered structure and performance research, and achieve high saturation magnetization, low coercive force, and good soft magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

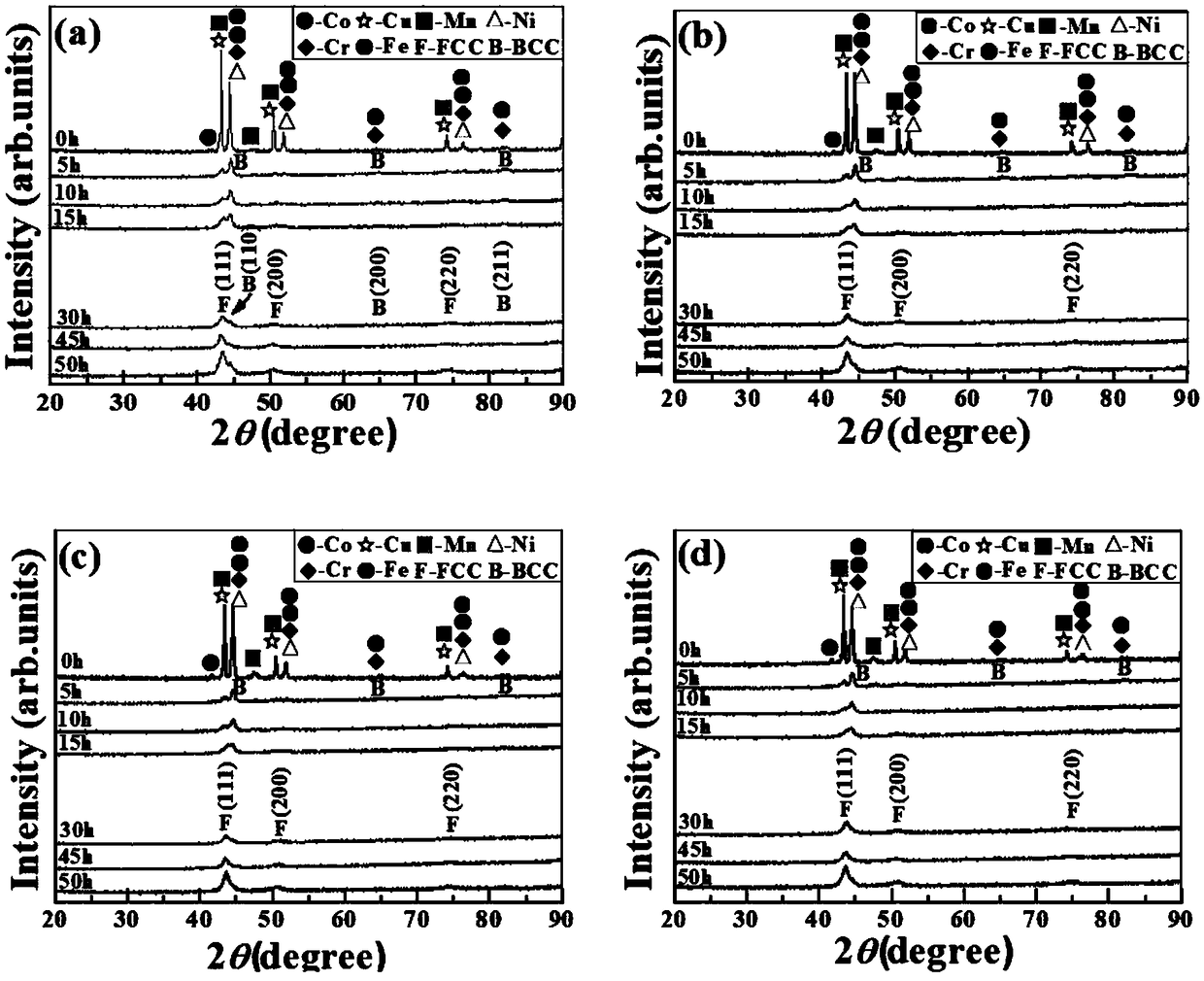

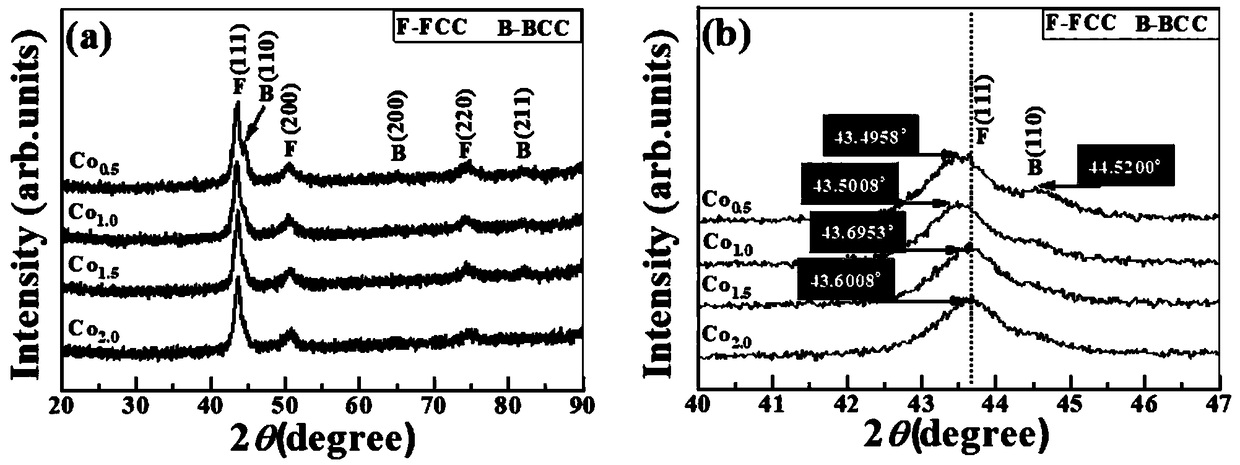

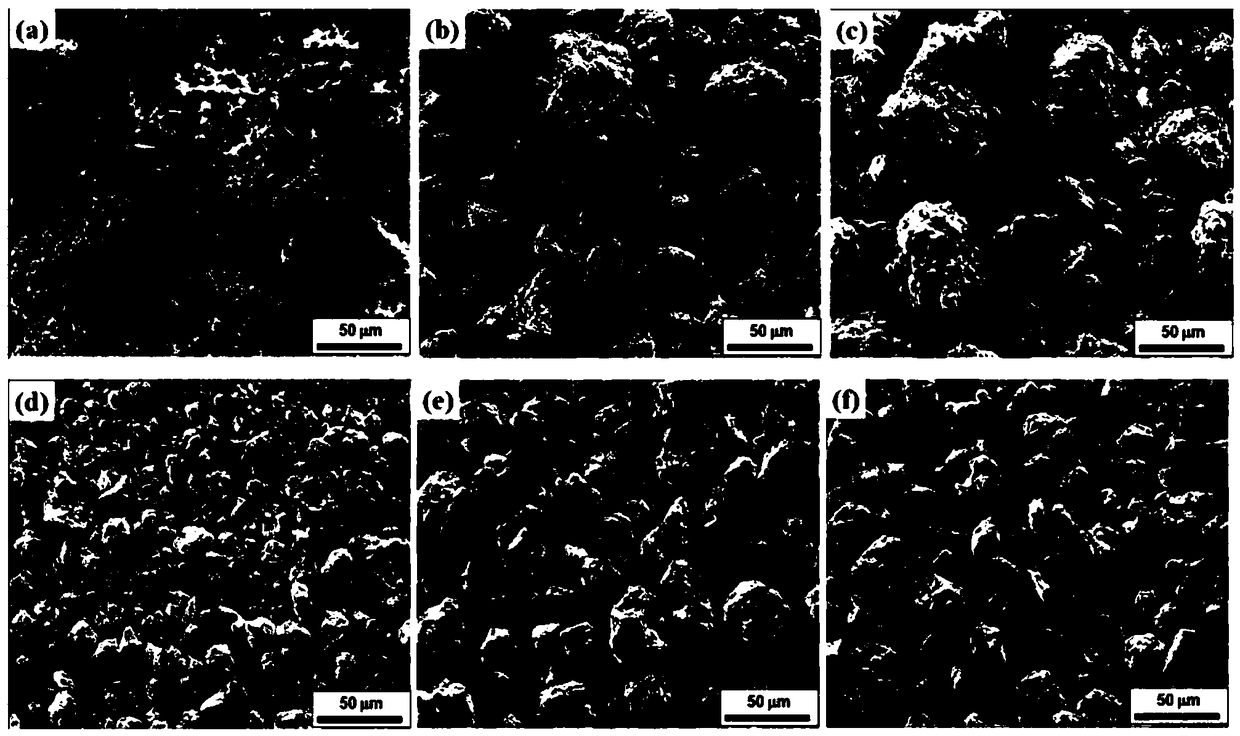

[0037] The preparation method of the described soft magnetic high entropy alloy powder of embodiment one to embodiment four, comprises the following steps:

[0038] (1) Weigh each alloy element powder on an electronic scale with an error of 0.1 mg according to the alloy composition shown in Table 1, then put it into a clean plastic bottle and mix it on a powder mixer for 5 hours at a speed of 200 rpm; The evenly mixed powder is put into a stainless steel ball mill tank, the ratio of ball to material is 10:1, the diameter of the stainless steel ball is 10mm and 5mm, the diameter of the two diameters of the stainless steel ball is 1:1, and two kinds of steel balls with different diameters are used in the The energy is higher and the efficiency is better during ball milling; then, the assembled ball mill jar is scrubbed with 99.999% high-purity argon gas for 5 minutes to avoid oxidation of the powder during ball milling. Finally, mechanical ball milling on the QM-WX4 type ball mi...

Embodiment 5

[0041] This example is basically the same and different from Example 1. The difference lies in: the preparation method of the soft magnetic high-entropy alloy powder, the dry milling time in step (1) is 45h, and then add the process inhibitor anhydrous ethanol, wet milling 5h, the mass ratio of absolute ethanol to alloying elements is 1:1.

Embodiment 6

[0043] This example is basically the same and different from Example 2. The difference lies in: the preparation method of the soft magnetic high-entropy alloy powder, the dry milling time in step (1) is 45h, and then add process inhibitor anhydrous ethanol, wet milling 5h, the mass ratio of absolute ethanol to alloying elements is 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com