Patents

Literature

285results about How to "Good soft magnetic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

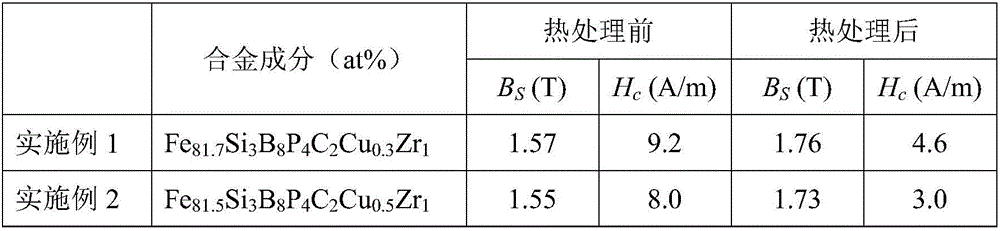

Iron-based nano-crystalline magnetically-soft alloy having high saturation magnetic induction intensity

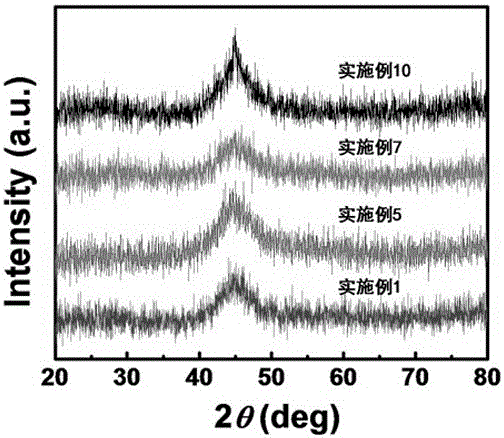

InactiveCN101840763AReasonable design of ingredientsStrong Amorphous Formation AbilityMagnetic materialsAtomic compositionCoercivity

The invention provides an iron-based nano-crystalline magnetically-soft alloy having high saturation magnetic induction intensity. The iron-based nano-crystalline magnetically-soft alloy is characterized in that the atomic composition thereof by percentage (%) is shown in the following formula: FeTaBbCucCdMe, wherein T represents at least one selected from Zr, Ti, Ta, Hf, Nb, V, W, Mo and Cr; M represents at least one selected from P, Si, N, Sn, Ge, Ga and Al; the subscripts, i.e., a to e in the formula, indicate the atomic percentage (%) and meet the following conditions: a is larger than or equal to 0.002 and less than or equal to 5, b is larger than or equal to 2 and less than or equal to 18, c is larger than or equal to 0.02 and less than or equal to 5, d is larger than or equal to 0.002 and less than or equal to 3, and e is larger than or equal to 0.02 and less than or equal to 20; and Fe and other unavoidable impurities constitute the balancing amount. The magnetically-soft alloy of the invention has the characteristics of high glass-forming ability, high saturation magnetic induction intensity and good soft magnetic performance; and particularly, the saturation magnetic induction intensity of the annealed alloy is higher than 1.5T, and the coercive force thereof is lower than 15A / m.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

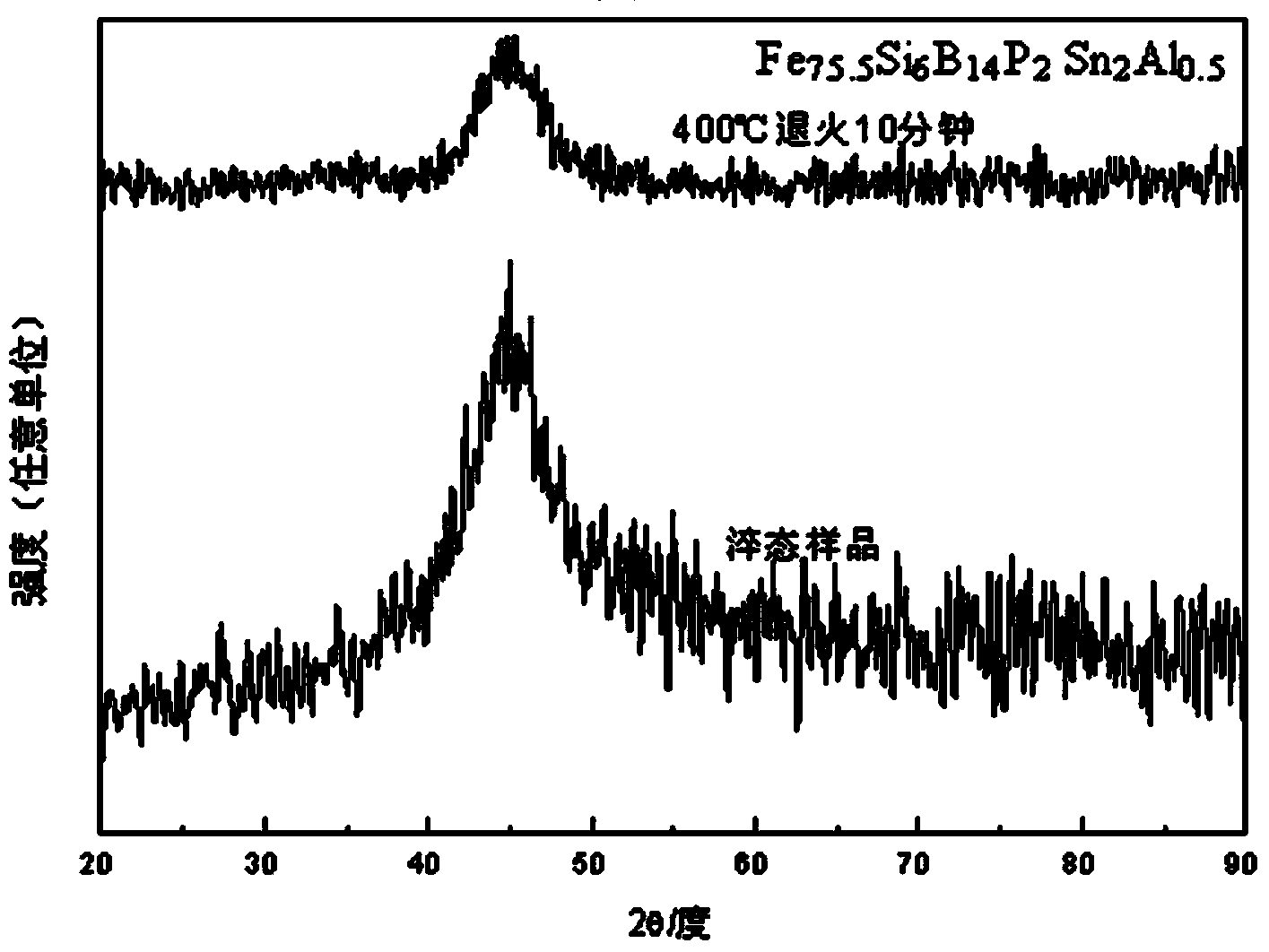

Iron-based amorphous magnetically soft alloy with uniform element distribution and preparation method thereof

ActiveCN104073749AImprove thermal stabilityHigh saturation magnetic inductionMagnetic materialsTransformerMaterials science

The invention discloses an iron-based amorphous magnetically soft alloy with uniform element distribution and a preparation method thereof. The expression of the alloy is FeaSibBcPdMe, a, b, c, d and e in the expression represent the atomic percent contents of corresponding components respectively, and meet the following conditions: a is not less than 70 and not greater than 84, b is not less than 2 and not greater than 10, c is not less than 5 and not greater than 18, d is not less than 0.001 and not greater than 8, e is not less than 0.0001 and not greater than 2.5, a+b+c+d+e=100%, and M is one or more of C, N, Sn, Ge, Ga, Al, S, Te, Be, Pb, Mg and Cu. The amorphous strip prepared from the alloy under a high vacuum and argon shield has the characteristic of uniform element distribution, particularly solves the problem of non-uniform distribution of element P in the amorphous alloy, has excellent magnetically soft performance, and is suitable for transformers, engines, power generators, magnetic sensors and the like.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

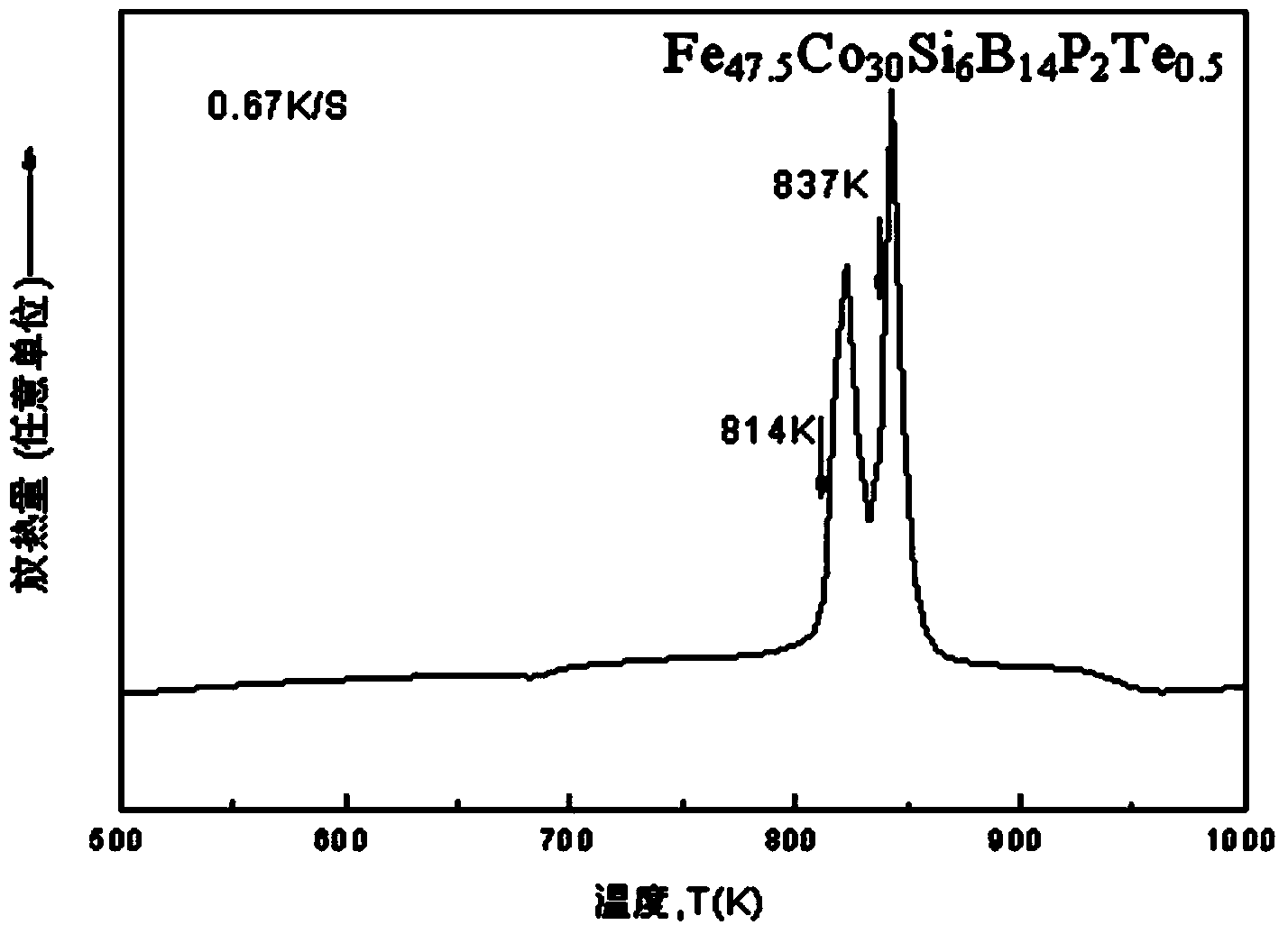

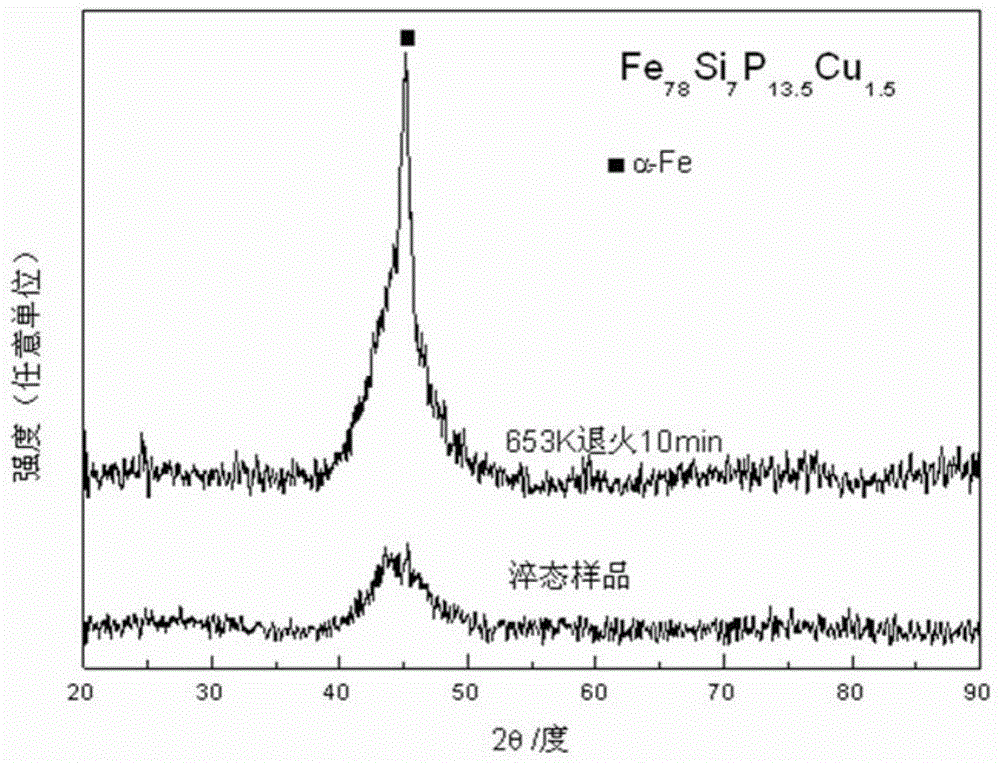

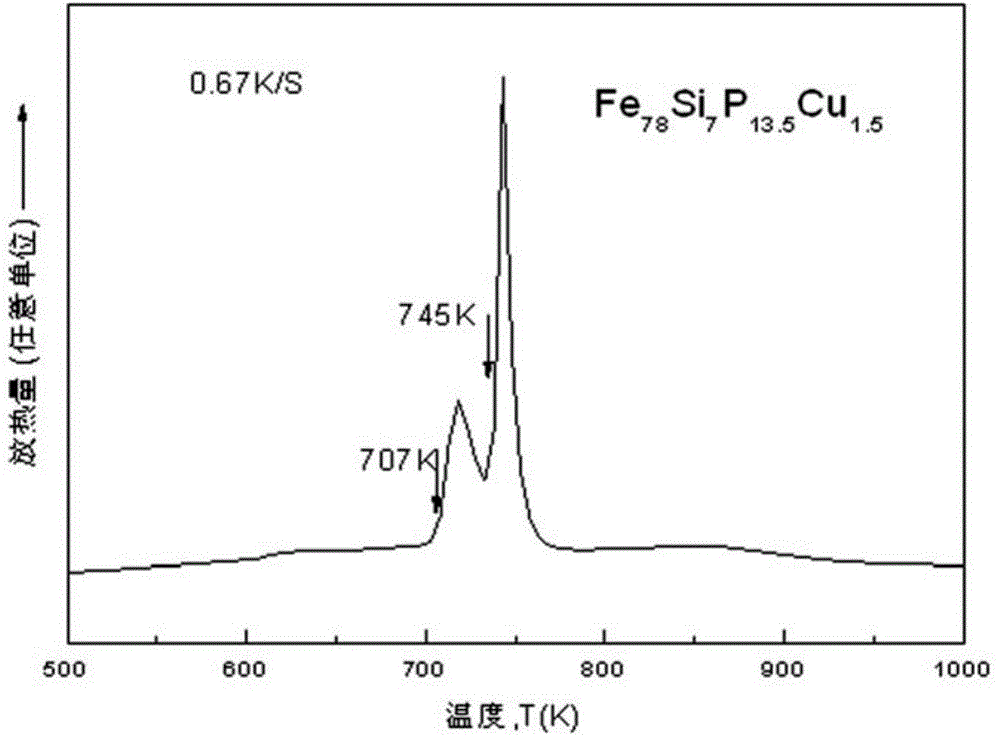

Iron-based nanocrystalline soft-magnetic alloy with excellent high-frequency performance and preparation method thereof

ActiveCN104087833AHigh saturation magnetic inductionImprove thermal stabilityMagnetic materialsRare-earth elementNanocrystalline silicon

The invention discloses iron-based nanocrystalline soft-magnetic alloy with excellent high-frequency performance and a preparation method thereof. The expression of the alloy is FeaSibPcCuxMy, wherein a, b, c, x and y respectively represent the atomic percent content of corresponding compositions and satisfy the following conditions: 70<=a<=85, 5<=b<=15, 5<=c<=18, 0.0001<=x<=3, 0<=y<=5, a+b+c+x+y=100%, and M is one or more of Zr, Ti, Ta, Hf, Nb, V, W, Mo, Mn, Cr, Re, Zn, In, As, Sb, Bi, Ca, platinum group elements, rare earth elements, N, Sn, Ge, Ga and Al. The alloy is a nanocrystalline soft-magnetic alloy band prepared by employing a single-roller quick-cooling method under the conditions of high vacuum and argon protection. The alloy does not contain B elements, is good in soft magnetic property, high in thermal stability, low in high-frequency loss and low in magnetostriction coefficient.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Fe-based nanocrystalline soft magnetic alloy with strong amorphous forming ability and preparing method of Fe-based nanocrystalline soft magnetic alloy

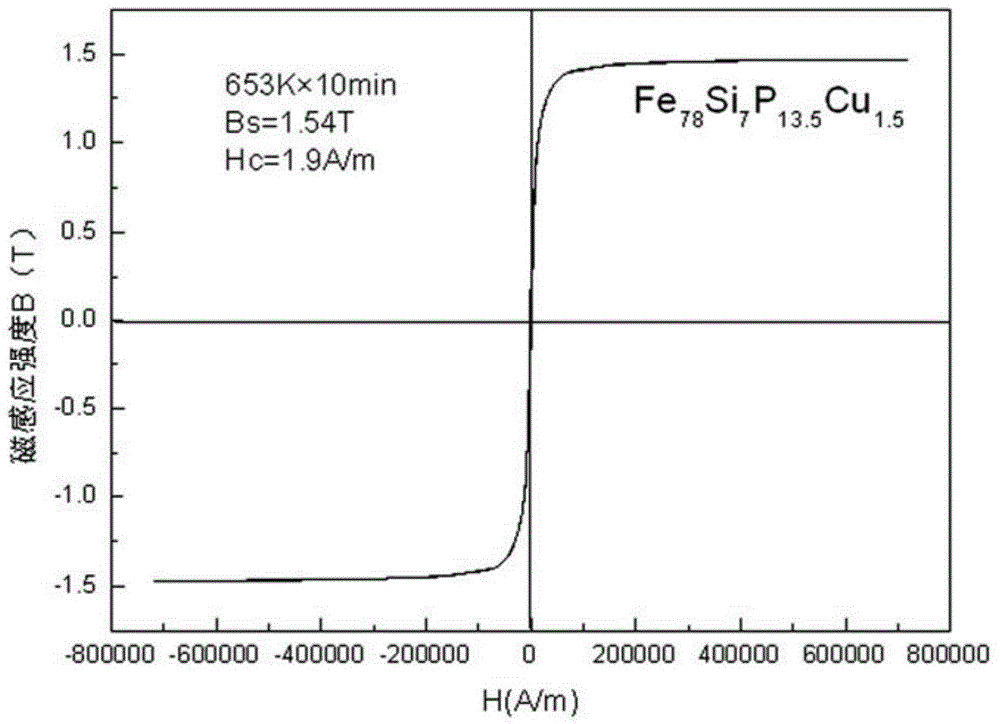

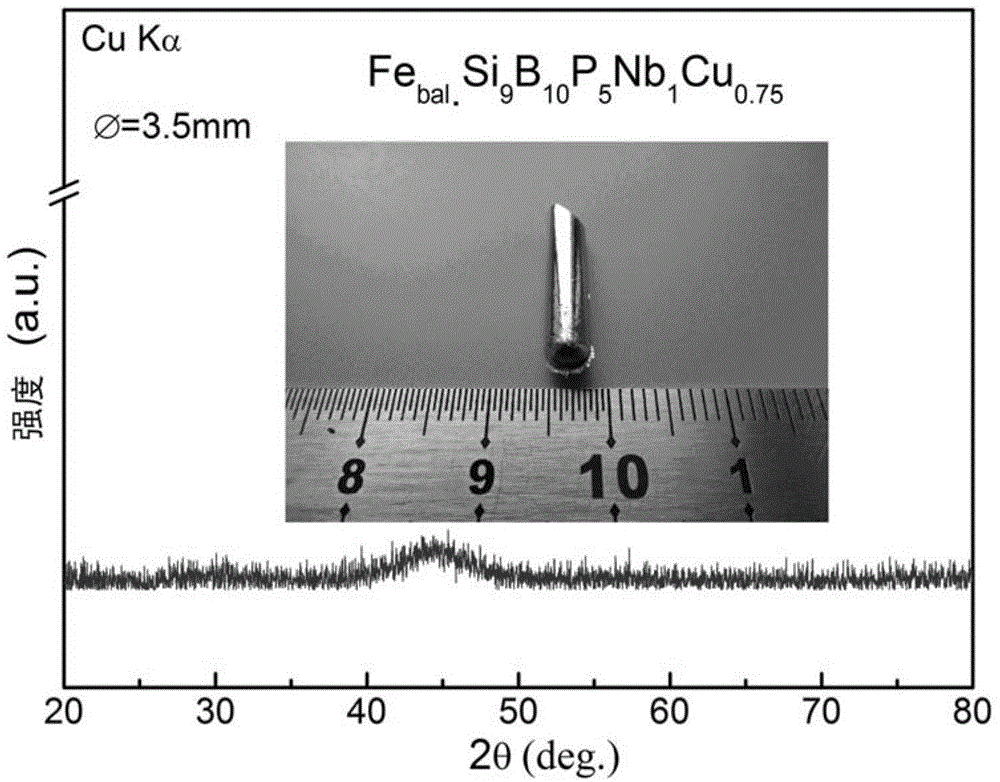

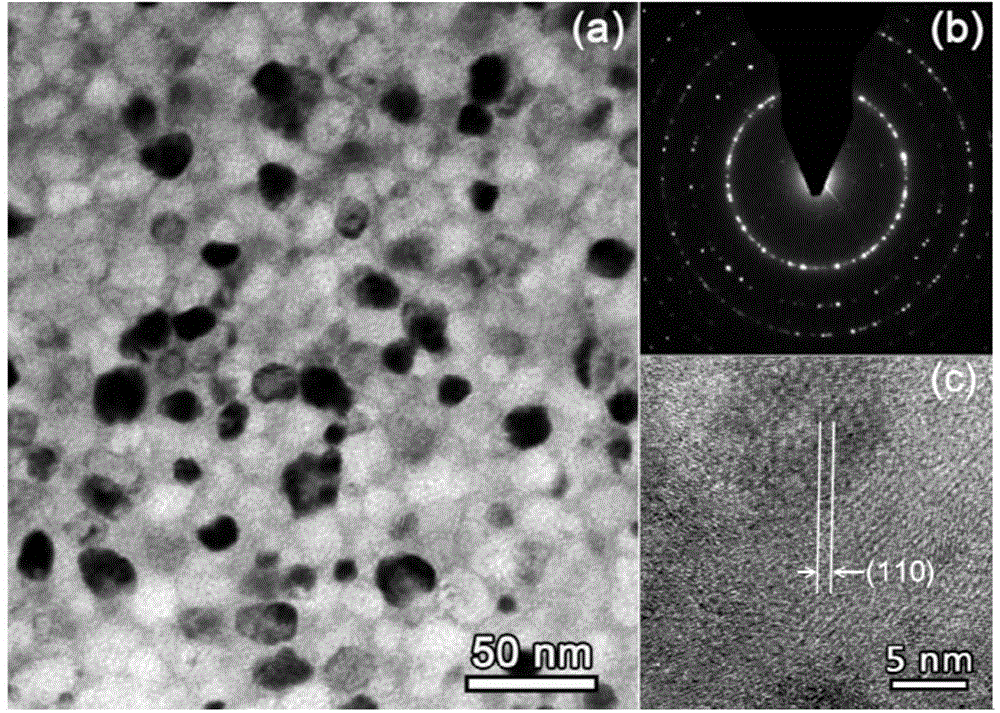

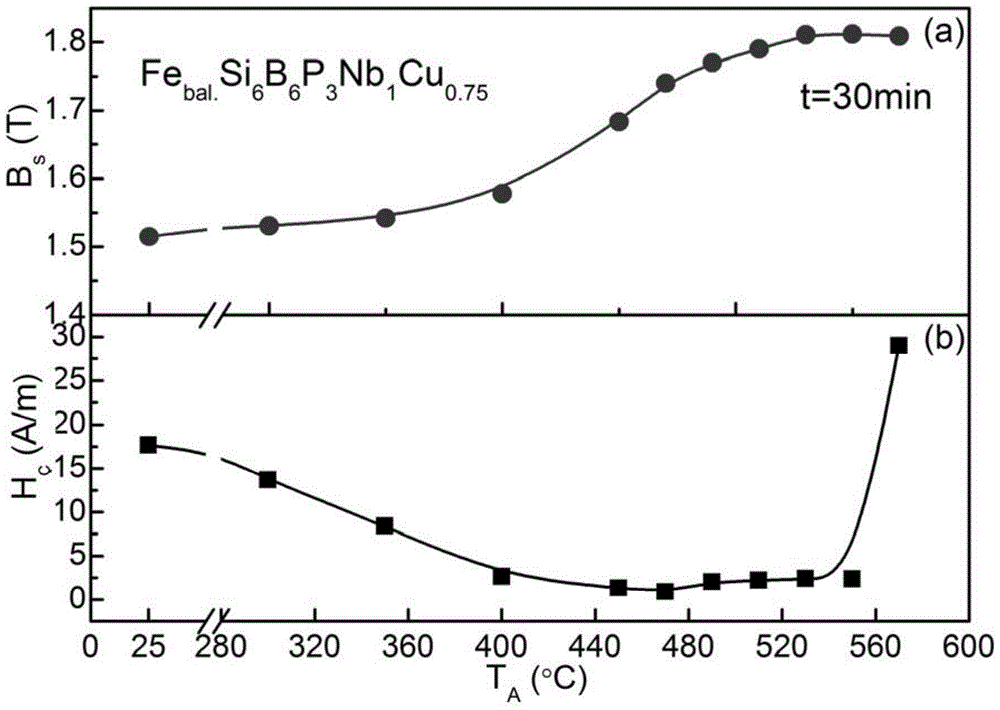

ActiveCN104934179AHigh saturation magnetic inductionLow coercivityMagnetic materialsCopper moldMagnetic alloy

The invention discloses a Fe-based nanocrystalline soft magnetic alloy with strong amorphous forming ability and a preparing method of the Fe-based nanocrystalline soft magnetic alloy. The alloy has an expression of Fe<x>SiBP<c>Nb<d>Cu<e>, wherein in the expression, each of the x, the a, the b, the c, the d and the e shows the atomic percentage content of the corresponding ingredient, and meets the following conditions that the a is greater than or equal to 0.5 but smaller than or equal to 12; the b is greater than or equal to 0.5 but is smaller than or equal to 15; the c is greater than or equal to 0.5 but smaller than or equal to 12; the d is greater than or equal to 0.1 but smaller than or equal to 3; the e is greater than or equal to 0.1 but smaller than or equal to 3; the x is greater than or equal 70 but smaller than or equal to 85; and the sum of the x, the a, the b, the c, the d and the e is 100 percent. The soft magnetic alloy has the advantages that an ordinary copper mold casting method can be used for preparing a Fe-based amorphous alloy with the critical dimension being 3.5mm; after the annealing; the saturation flux density is greater than 1.5T; and the coercive force value is smaller than 1A / m.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

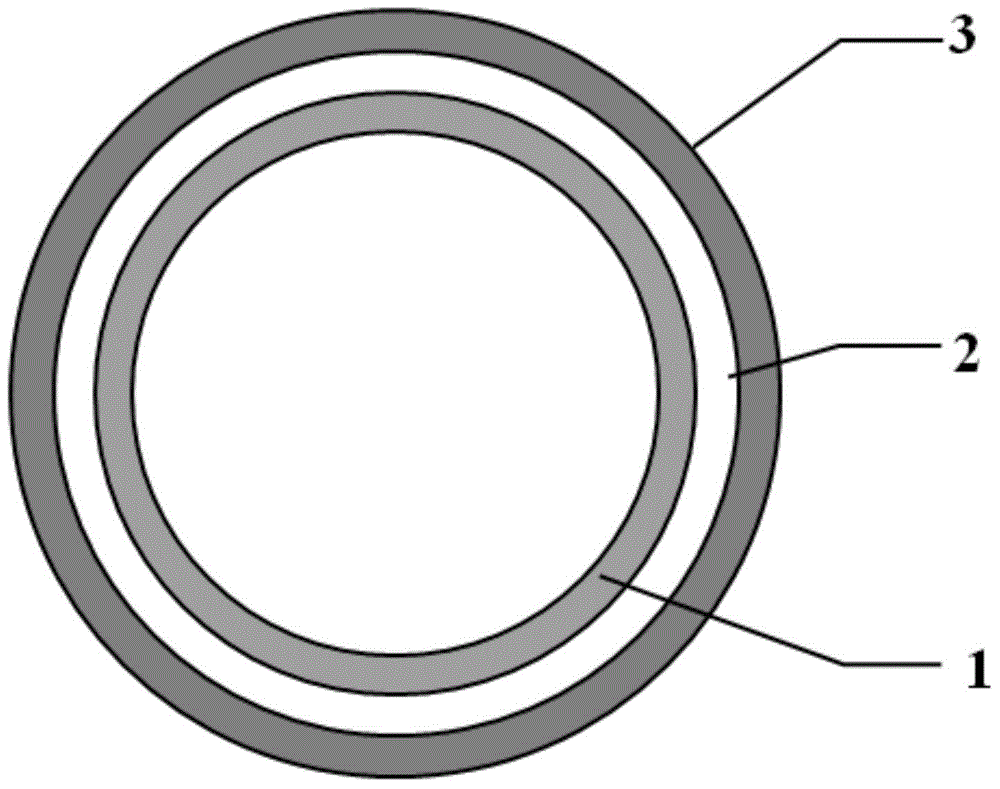

Magnetic nano T102 composite photocatalysis and preparation method

InactiveCN1562464ANot easy to interactReduce interactionPhysical/chemical process catalystsMethyl orangeMagnetic field

A magnetic composite nano-TiO2 photocatalyst able to be recovered magnetically is prepared by sol-gel method. It is composed of Fe3O4 as core, SiO2 as isolating layer and TiO2 as coated layer. It has excellent soft magnetic property, high photocatalyst activity, and high degradability to methyl orange.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

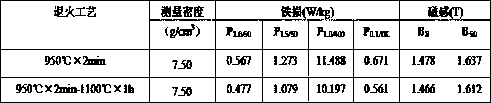

Production method of oriented high-silicon-steel thin plates

The invention relates to a production method of oriented high-silicon steel thin plates, which belongs to the technical field of metal material production. The process comprises the following steps of: 1. obtaining cylindrical crystals grown in (100) directions by adopting a directional solidification method, and wherein the solidification rate is controlled between 0.6 and 15 mm / min and the temperature gradient is controlled between 60 and 400K / cm; 2. heating plate blanks at the heating temperature between 800 DEG C and 1300 DEG C, and then hot rolling the plate blanks to obtain sheet steel of 1.0-4.0mm; 3. carrying out annealing heat treatment and acid washing on the hot rolled plate blanks, and warm rolling the hot rolled plate blanks to obtain 0.4-0.8mm; and 4. carrying out heat treatment on warm rolled plates, and carrying out multiple cold rolling and secondary recrystallization annealing to obtain the oriented high-silicon steel. The production method has the advantages that the directional solidification method is utilized for controlling organization and crystal grain orientation from the material production source, a cold rolling method is used for producing alloy oriented plate materials, and the soft magnetic performance of the high-silicon steel is greatly improved. Produced cold rolled thin plates have good plate shapes.

Owner:UNIV OF SCI & TECH BEIJING

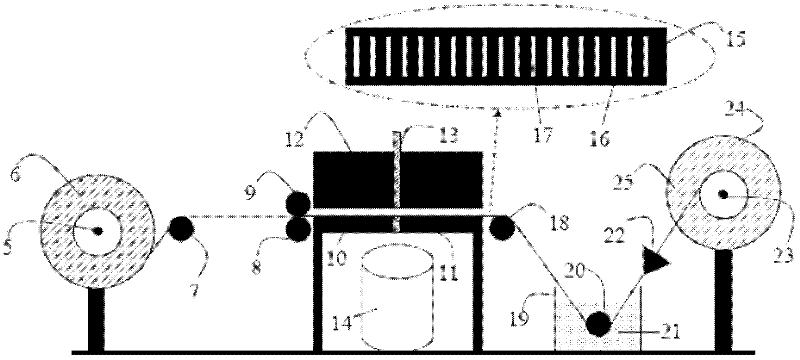

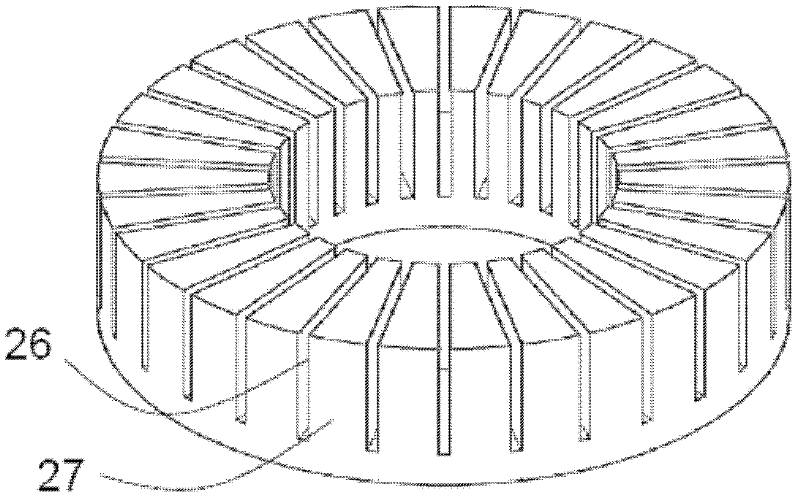

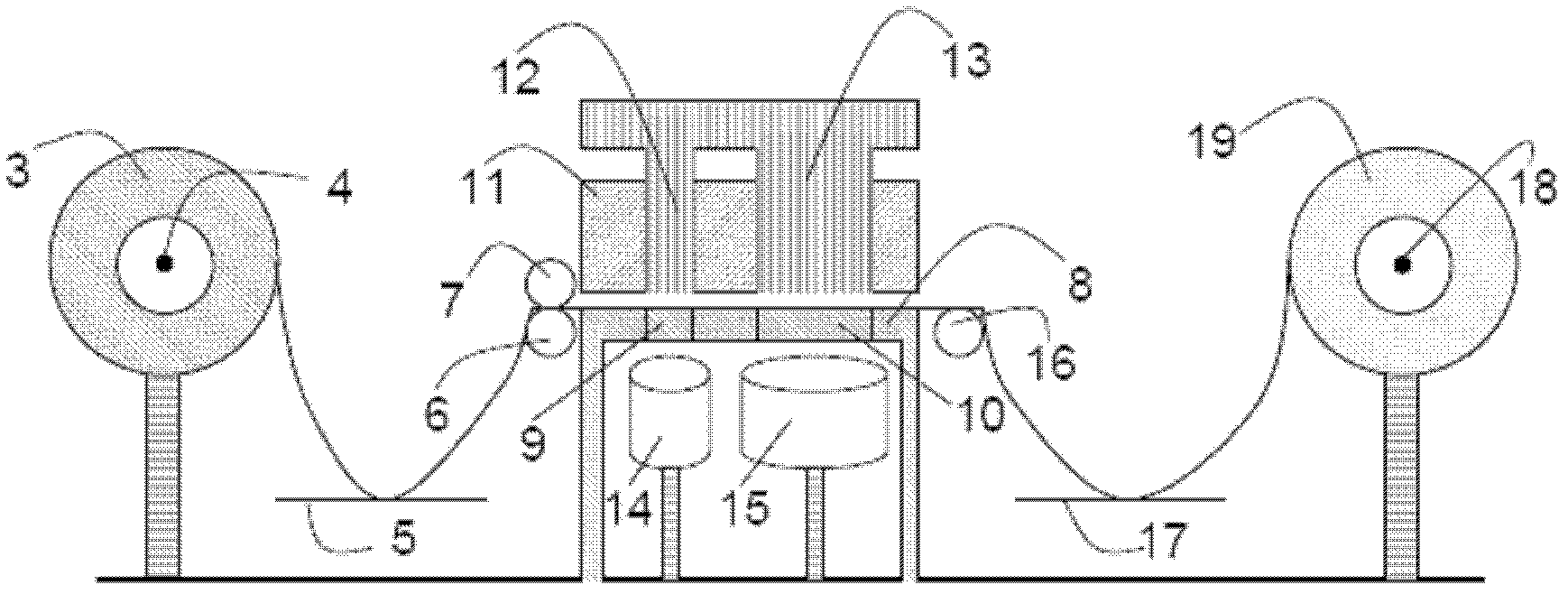

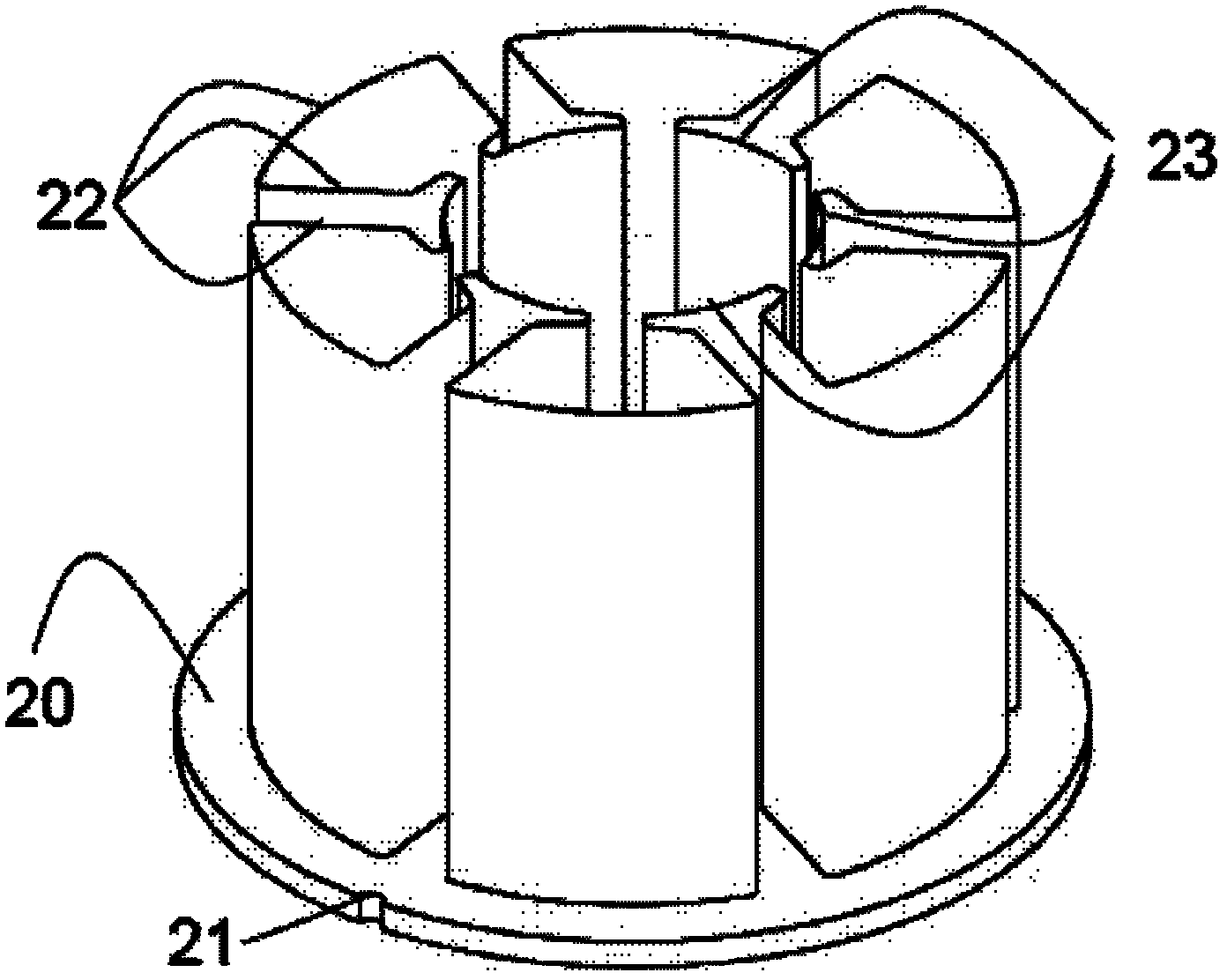

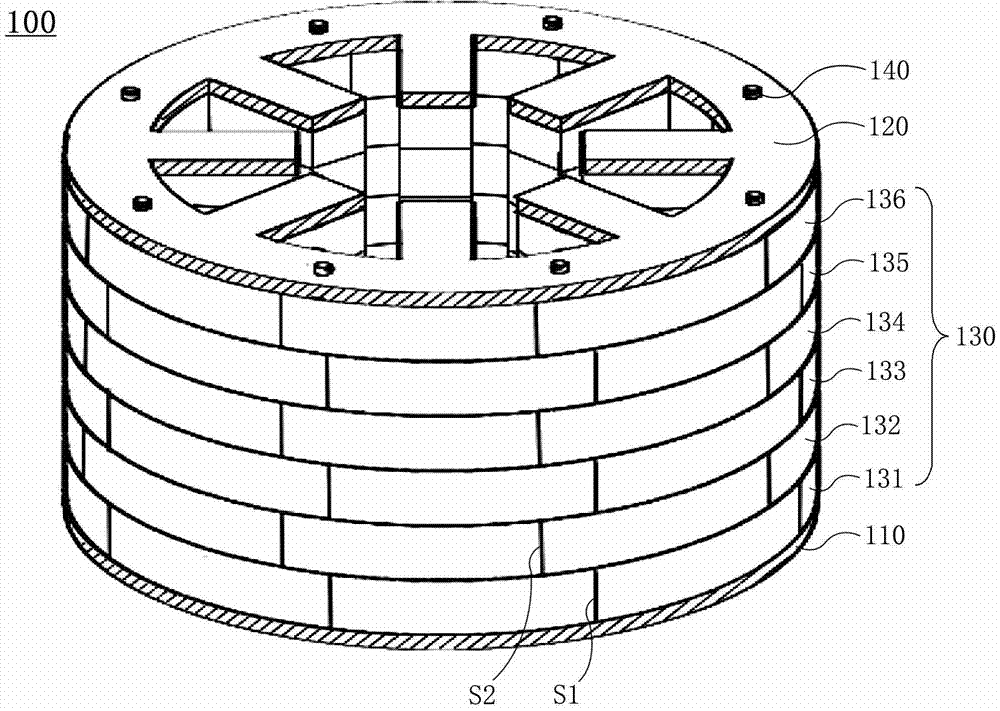

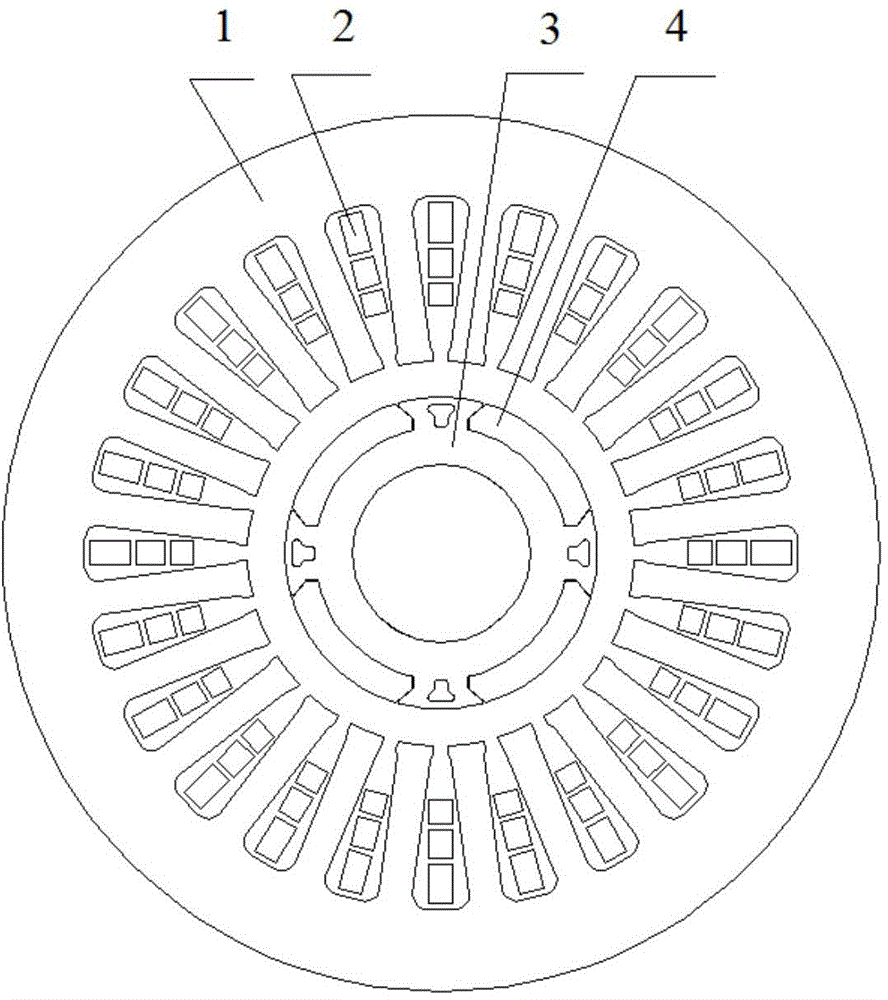

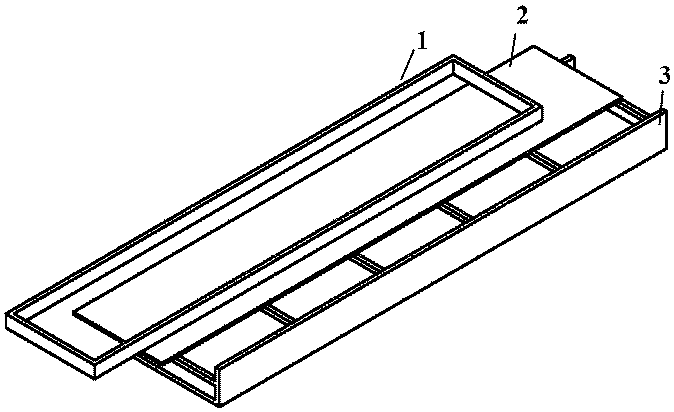

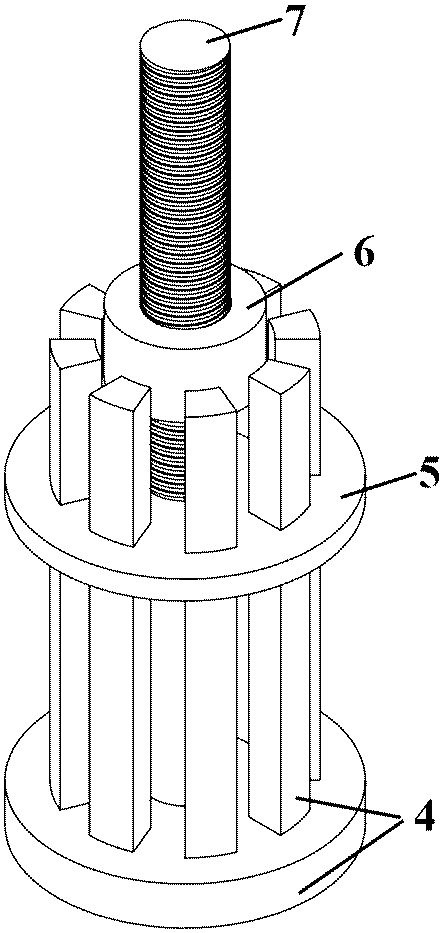

Amorphous, microcrystalline or nano-crystalline alloy stator iron core for axial magnetic flux motor and manufacture method for stator iron core

ActiveCN102510141AImprove production efficiency and core yieldEliminate resin thermosetting molding processMagnetic circuit stationary partsManufacturing stator/rotor bodiesHigh power densityMagnetic flux

The invention discloses an amorphous, microcrystalline or nano-crystalline alloy stator iron core for an axial magnetic flux motor and a manufacture method for the stator iron core. The manufacture method includes the steps: firstly, rolling and cutting a coiled amorphous, microcrystalline or nano-crystalline alloy wide band into an alloy strip coil (6) which is twice as high as that of the finished iron core, then uniformly punching a plurality of strip slots (17) in the middle of the alloy strip coil at intervals with the same equipment, performing insulation coating treatment and further coiling the alloy strip coil on an inner core (24) of the iron core, wherein the strip slots (17) are as same as open slots (26) in width, and the length of each strip slot (17) is twice of the depth of each open slot (26); next, adding an iron core outer-circumference protecting layer on the outer circumference face of the coiled alloy strip coil, then transversely halving the alloy strip coil into two identical alloy iron cores along the axial perpendicular plane of the alloy strip coil; and finally, carrying out high-temperature annealing treatment on the iron cores formed by processing. The stator iron cores prepared by the method are more excellent in performance, and particularly applicable to a high-speed motor, a high-power density motor and a high-torque density motor.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

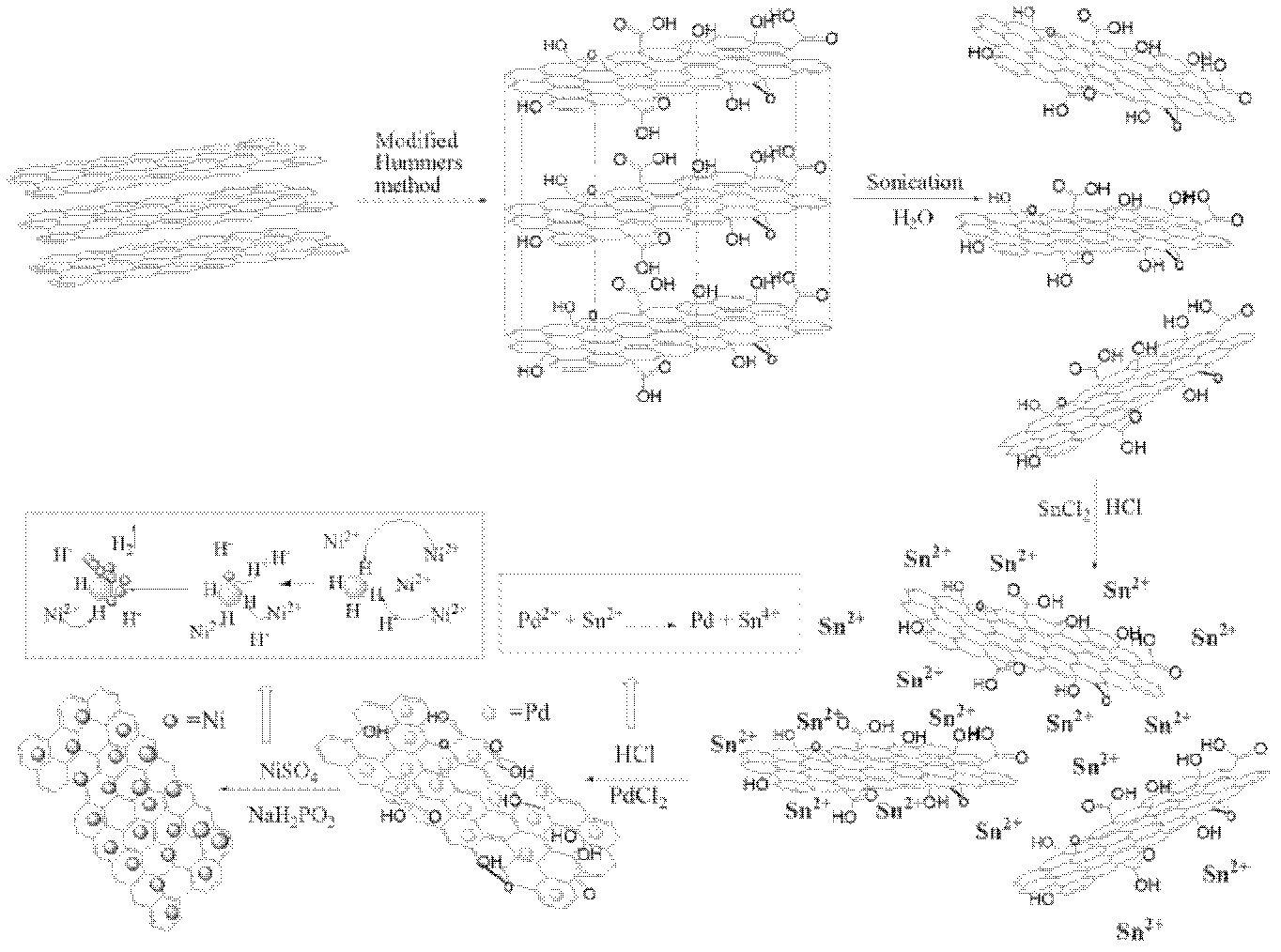

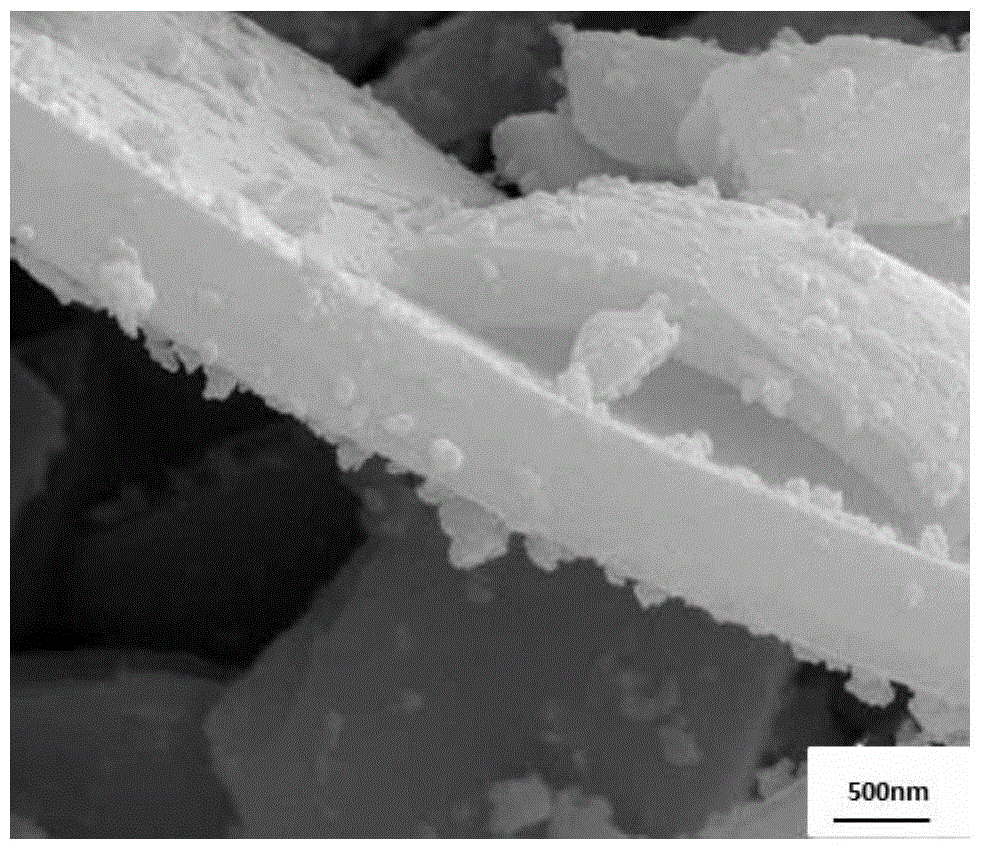

Surface nano-nickel particle modified graphene nano material and preparation method thereof

InactiveCN102583348AGood soft magneticPrevent restackingGrapheneInorganic material magnetismCvd grapheneChemical plating

The invention discloses a surface nano-nickel particle modified graphene nano material and a preparation method of the nano material, belonging to the field of nano material preparation technology. The preparation method can be used for preparing surface nano-nickel particle modified graphene by the steps of preparation of graphite oxide, preparation of graphene oxide and pretreatment. According to the invention, the surface nano-nickel particle modified graphene is prepared by a chemical plating method, so that the particle size and the crystal form of surface nano-nickel particles can be effectively controlled, and the graphene oxide part can be reduced when metal particles are deposited; and graphene sheet layers are prevented from being stacked again by the deposition of nickel particles on the surface of the graphene; and the graphene has excellent soft magnetism so as to be magnetized under the minimal additional magnetic field.

Owner:BEIHANG UNIV

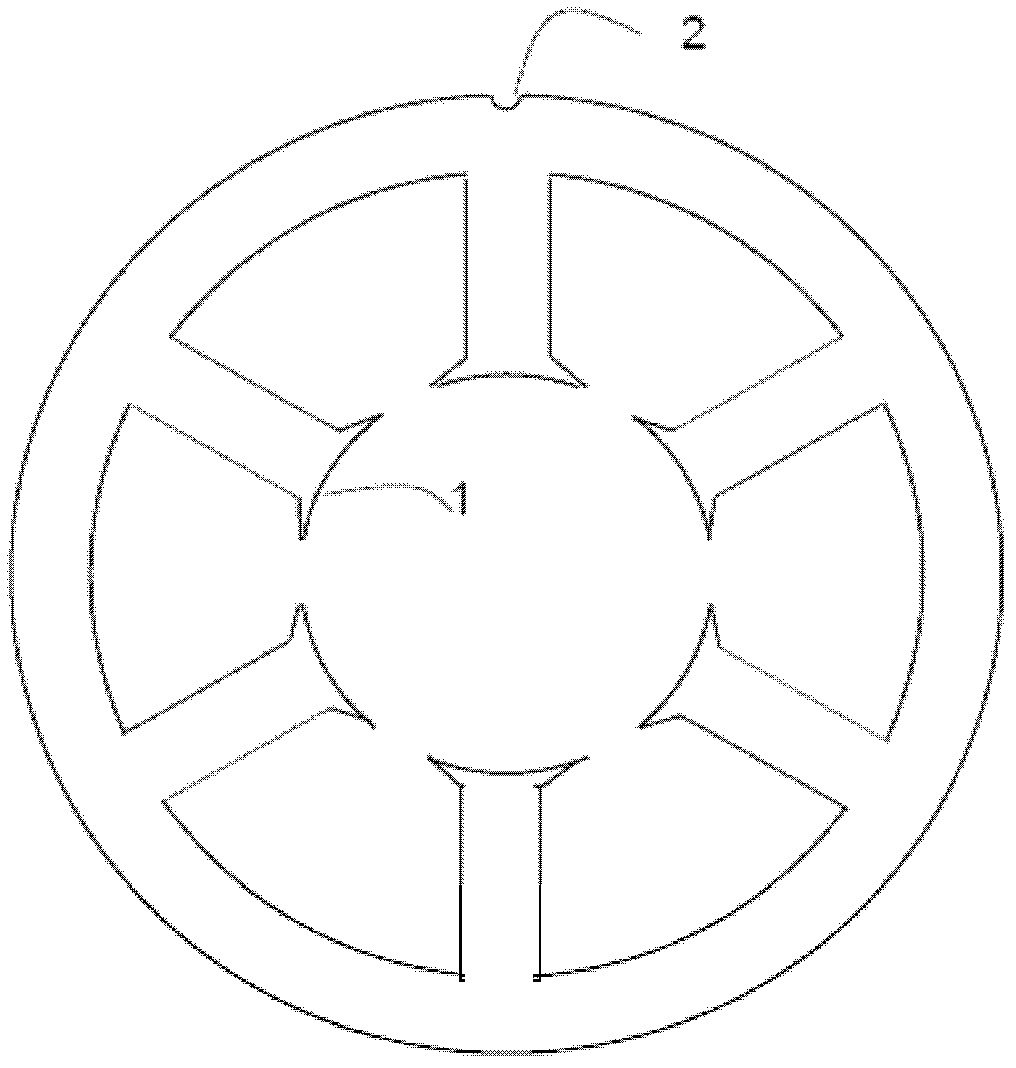

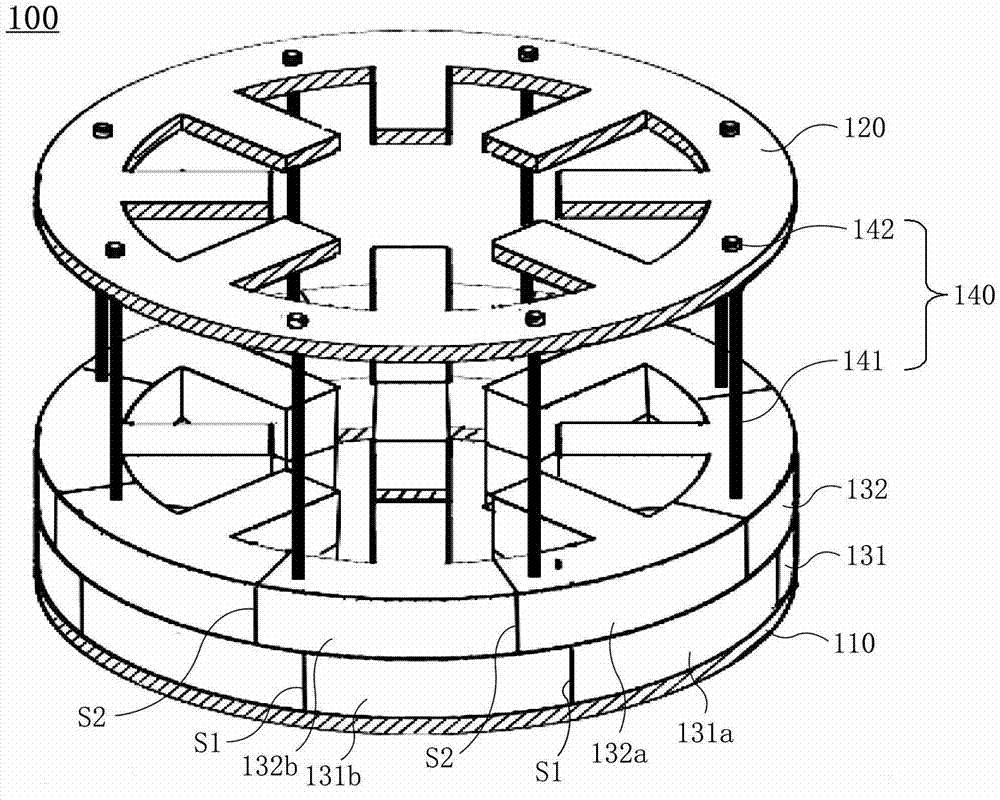

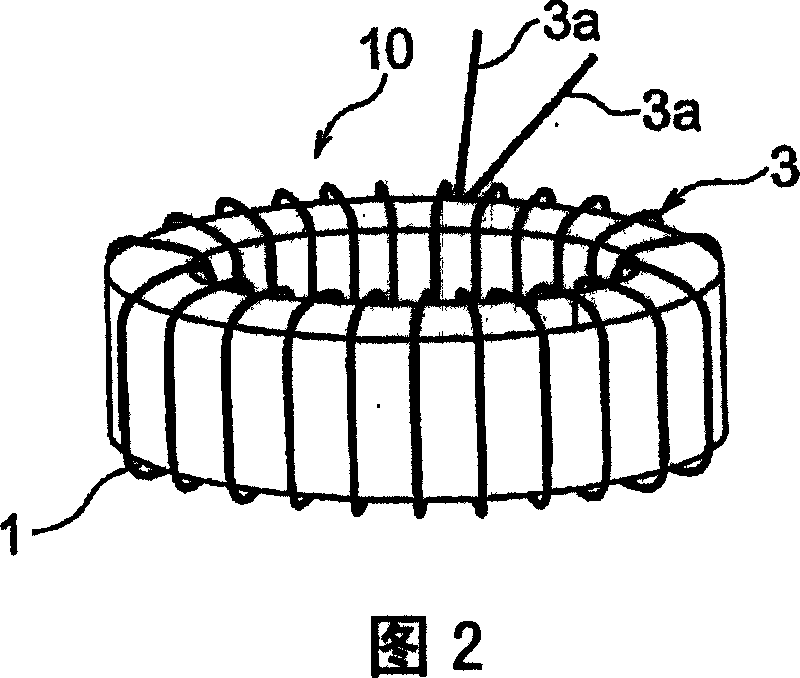

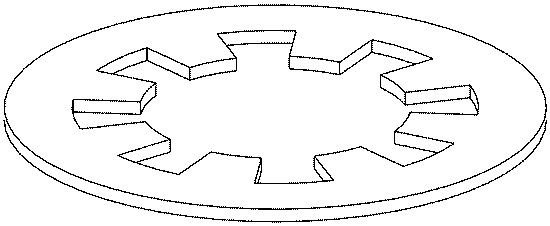

Protective box type amorphous, microcrystal or nano-crystal alloy stator core for motor and preparation method thereof

ActiveCN102361374AShort production processEnergy saving productionManufacturing stator/rotor bodiesDip-coatingNanocrystal

The invention belongs to the field of magnetic circuit parts of motors, and discloses a protective box type amorphous, microcrystal or nano-crystal alloy stator core for a motor and a preparation method thereof. The method comprises the following steps of: stamping a coiled alloy strip (3) to form a plurality of same annular stamped sheets, wherein the tooth ends of inner teeth (1) of the stampedsheets are positioned on the same circumference and the outer side of each stamped sheet is provided with at least one positioning groove (2); stacking the plurality of annular stamped sheets in a protective box with open upper end, putting the stamped sheets and the protective box into insulated coating solution together and performing insulated dip-coating treatment; taking out the stamped sheets and the protective box together, performing compactness treatment on the annular stamped sheets, fixing an upper end panel of the protective box and the inner center surface together, and forming the stator core; and performing integral annealing treatment on the stator core of the sealed protective box. By the method, the process problems that the stator core is easily damaged to drop residue and cracks among layers, the performance declines because the adhesive stress cannot be eliminated and the like are solved, and the performance of the stator core is greatly improved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

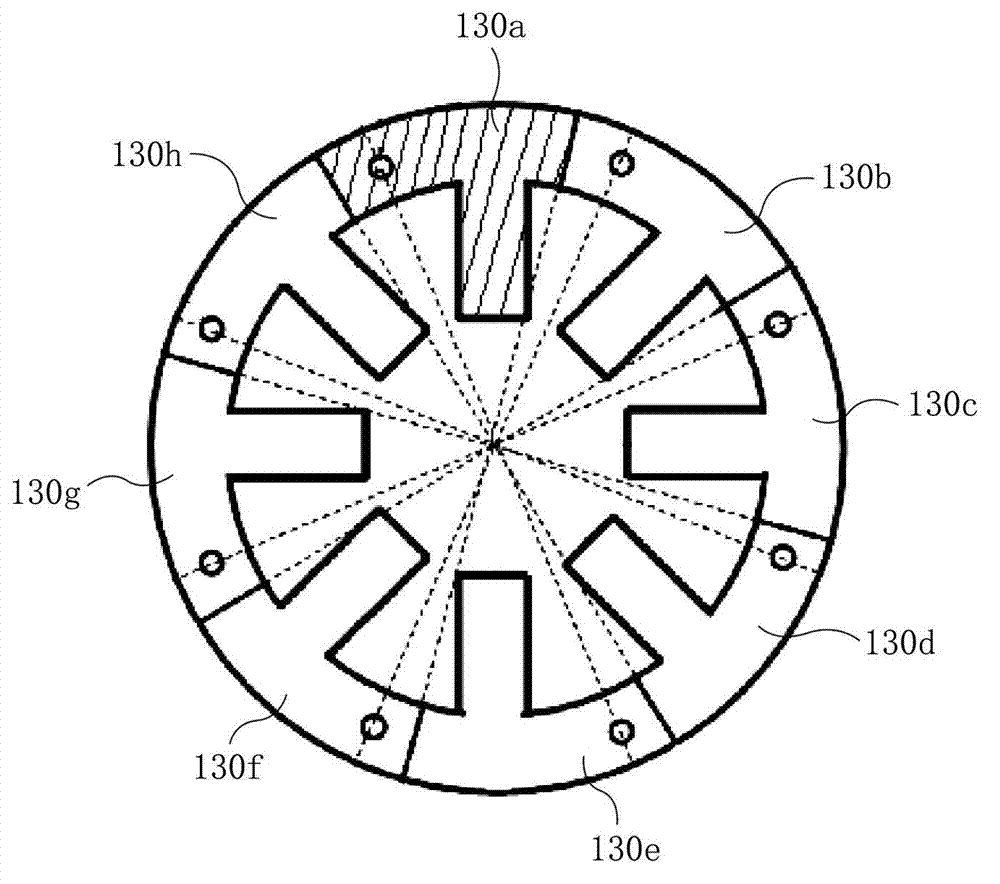

Stator core and manufacturing method thereof

InactiveCN102868241AGood soft magneticStable structureMagnetic circuit stationary partsManufacturing stator/rotor bodiesEngineeringStator

The invention provides a stator core and a manufacturing method thereof. The stator core comprises a lower end plate, an upper end plate, a plurality of laminated bodies and a plurality of connection members, wherein the laminated bodies are laminated between the lower end plate and the upper end plate; the connection members are penetrated through the laminated bodies and are connected with the lower end plate and the upper end plate; each laminated body comprises a plurality of laminated body units which are sequentially arranged in the circumferential direction and form a circumference; each laminated body unit comprises a yoke part and an inner tooth; the yoke part is an arc-shaped flat piece or plate; the inner tooth is a flat piece or plate and extends from the yoke part to the circle center of the yoke part; at least one of the yoke part and the inner tooth comprises a hole; adjacent laminated body units among the multiple laminated body units of each laminated body form joint seams; each connection member comprises a rod; the rod is penetrated through the hole of the laminated body unit; the lower end of the rod is fixed to the lower end plate, and the upper end of the rod is fixed to the upper end plate; the yoke parts of the multiple laminated bodies overlap along the direction of the rod; the inner teeth of the multiple laminated bodies overlap along the direction of the rod; and the multiple joint seams of the adjacent laminated bodies among the multiple laminated bodies do not overlap.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Fe-based amorphous and nanocrystalline soft magnetic alloy ribbon and preparation method thereof

InactiveCN105261435AHigh saturation magnetic inductionGood soft magneticInductances/transformers/magnets manufactureMagnetic materialsTransformerThermal stability

The invention provides a Fe-based amorphous and nanocrystalline soft magnetic alloy ribbon. Components of the Fe-based amorphous and nanocrystalline soft magnetic ribbon are as shown in FeSiB<c>P<d>Cu<e>Me<f>, wherein a, b, c, d, e and f respectively represent the content of Fe, Si, B, P, Cu and Me in the alloy ribbon on the basis of mass fractions of atoms; a is less than or equal to 90 and greater than or equal to 80; b is less than or equal to 5 and greater than or equal to 0.5; c is less than or equal to 12 and greater than or equal to 5; d is less than or equal to 9 and greater than or equal to 1; e is less than or equal to 2 and greater than or equal to 0.3; f is less than or equal to 3 and greater than or equal to 0.3; and a+b+c+d+e+f=100. According to the Fe-based amorphous and nanocrystalline soft magnetic alloy ribbon, by addition of microelements, the Fe-based amorphous and nanocrystalline soft magnetic alloy ribbon with high saturation flux density can be obtained without a heat treatment; and the alloy ribbon can be prepared in high vacuum or argon protection, has excellent soft magnetic property and high heat stability and is suitable for a transformer, an engine, a motor, a generator, a magnetic sensor and the like.

Owner:WANGWEI NEW MATERIALS (PIZHOU) CO LTD

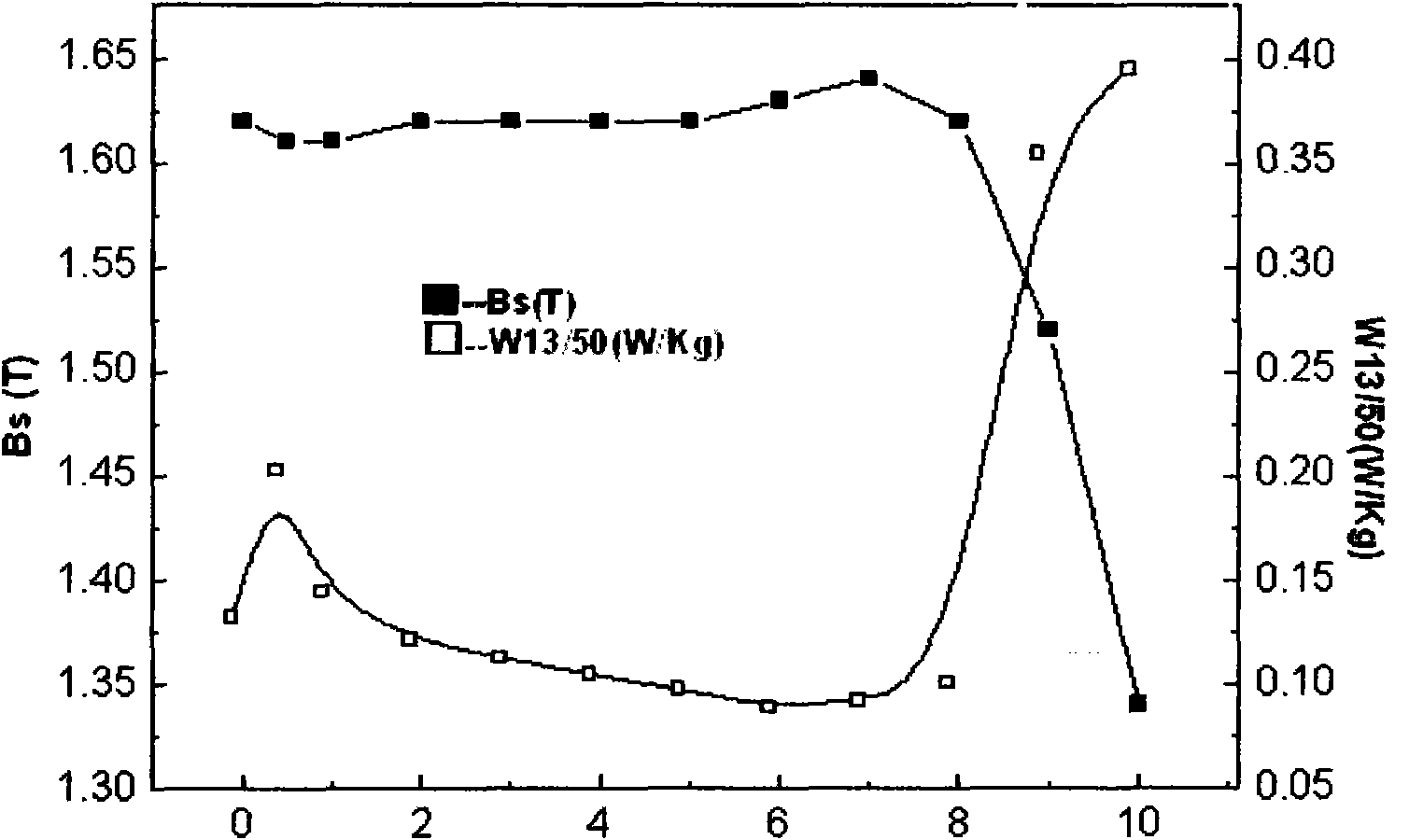

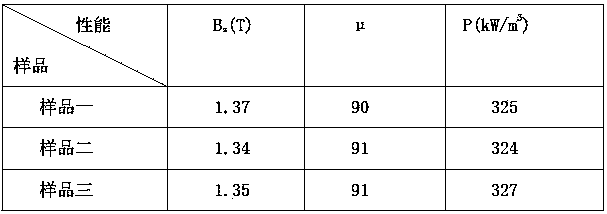

Iron-based amorphous alloy with high soft magnet performance and low cost and manufacturing method thereof

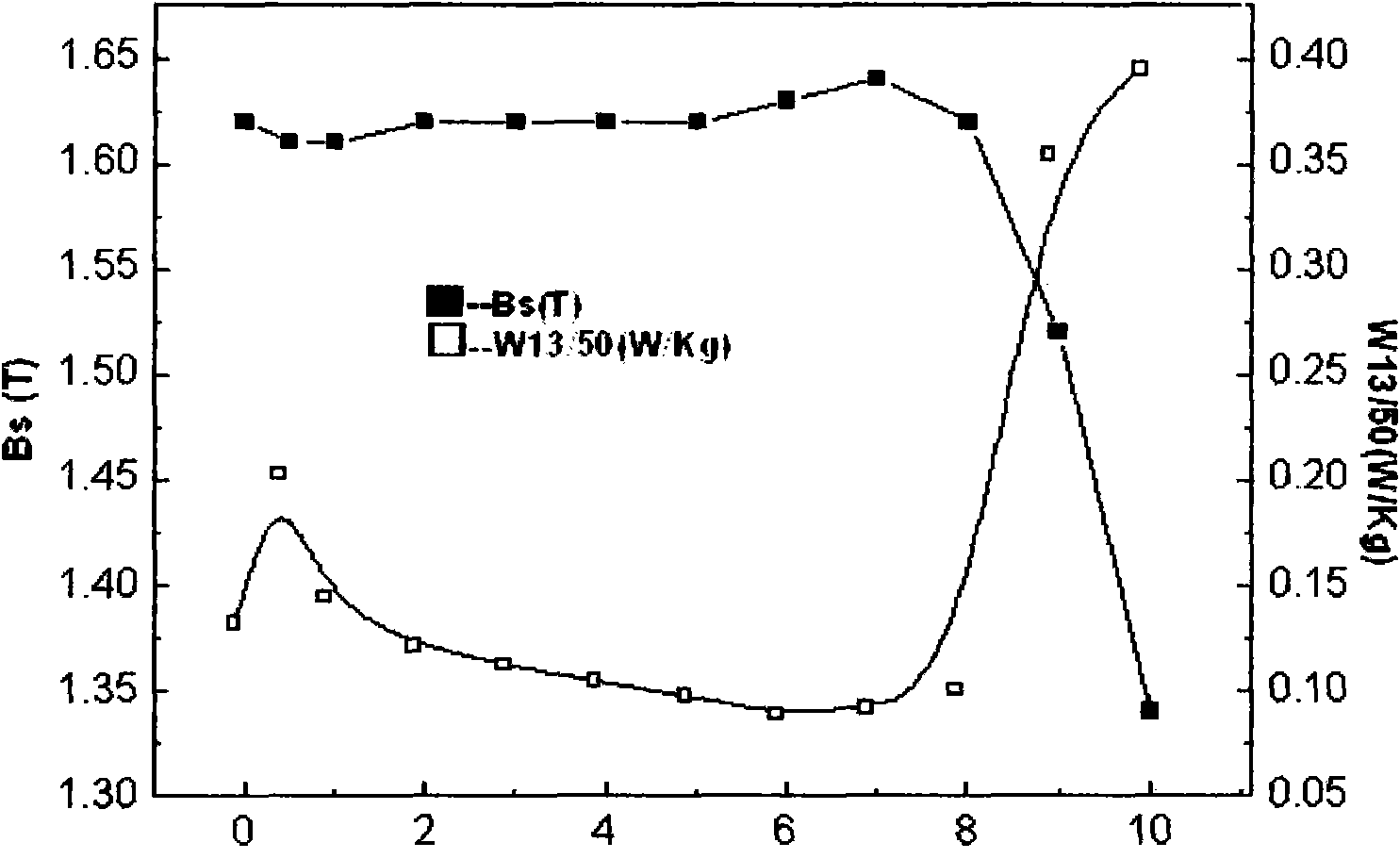

InactiveCN101800109AReduce manufacturing costGood soft magneticFurnace typesMagnetic materialsSoft magnetCurie temperature

The invention discloses an iron-based amorphous alloy with high soft magnet performance and low cost and a manufacturing method thereof. The iron-based amorphous alloy comprises the following components expressed at the atomic ratio: Fe (100-x-y-z-w) BxSiyCzPw, wherein x is 4-20, y is 3.5-5, z is 1.8-2.3, w is 0-10, and the balance is Fe; x+y+z+w is 19-23, preferably 19-20.5 or 20.5-23, more preferably 20-20.5; P is used for replacing parts of B, w is preferably 1-7, and x+w is 11-20 preferably; the components of the iron-based amorphous alloy expressed at the atomic ratio are preferably 79.5 of Fe, 12 of B, 3.5 of Si, 2 of C and 3 of P, or 79.5 of Fe, 13 of B, 3.5 of Si, 2 of C and 2 of P or 79.5 of Fe, 11 of B, 3.5 of Si, 2 of C and 4 of P; and the high-saturation magnetic induction strength Bs of the iron-based amorphous alloy is 1.3-1.64 T, iron loss is P13 / 50<0.3W / kg. Curie temperature variation is 381-418 DEG C. In the component proportioning of the alloy, cheap P is used for replacing parts of elements B so as to greatly lower manufacturing cost and keep favourable soft magnetic performance at the same time.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

Amorphous soft magnetic alloy and inductance component using the same

InactiveCN101034609AHigh Amorphous Formation AbilityImprove the ability to formMagnetic materialsInductanceImpurity

To provide an amorphous soft magnetic alloy having a supercooled liquid region and excellent in amorphous-forming ability and soft magnetic properties, by selecting and optimizing an alloy composition, and to further provide a ribbon, a powder, a high-frequency magnetic core, and a bulk member each using such an amorphous soft magnetic alloy. The amorphous soft magnetic alloy has a composition expressed by a formula of (Fe1-alphaTMalpha)100-w-x-y-zPwBxLySiz, wherein unavoidable impurities are contained, TM is at least one selected from Co and Ni, L is at least one selected from the group consisting of Al, V, Cr, Y, Zr, Mo, Nb, Ta, and W, 0<=alpha0.98, 2<=w<=16 at %, 2<=x<=16 at %, 0 H01F 1 / 153 C22C 45 / 00 3 54 10 2007 / 2 / 2 101034609 2007 / 9 / 12 000000000 NEC Tokin Corp. Japan Urata Akiri Fujiwara Teruhiko Matsumoto Hiroyuki Yamada Yasunobu Inoue Akihisa zhangcheng xin 11021 The Patent Agency of the Chinese Academy of Sciences Inside the Chinese Academy of Sciences, No.52 Sanlihe Road, Fuwai, Beijing 100864 Japan 2006 / 2 / 2 2006-026210 Japan 2006 / 12 / 1 2006-326179

Owner:TOKIN CORP +1

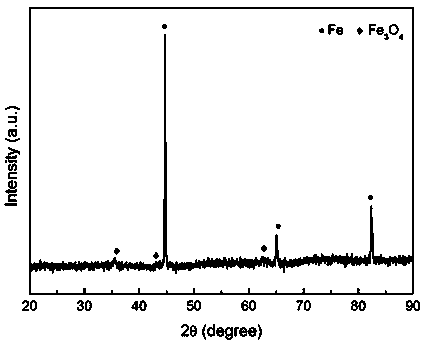

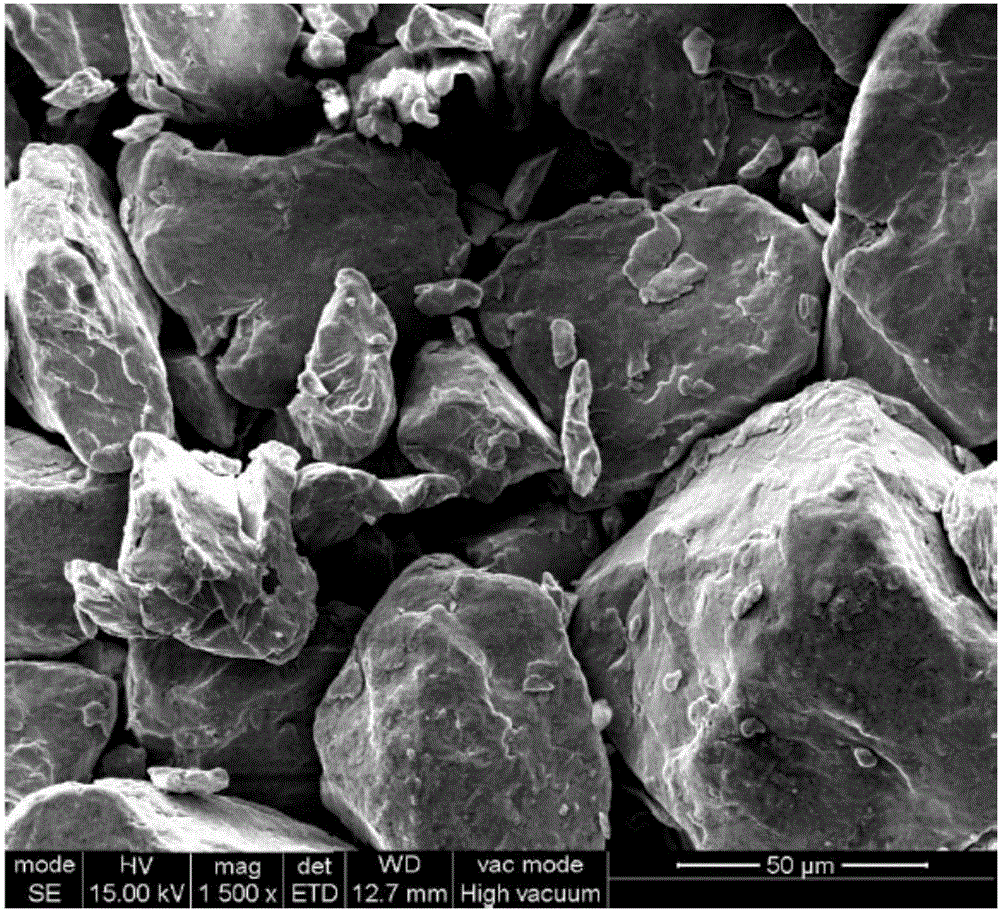

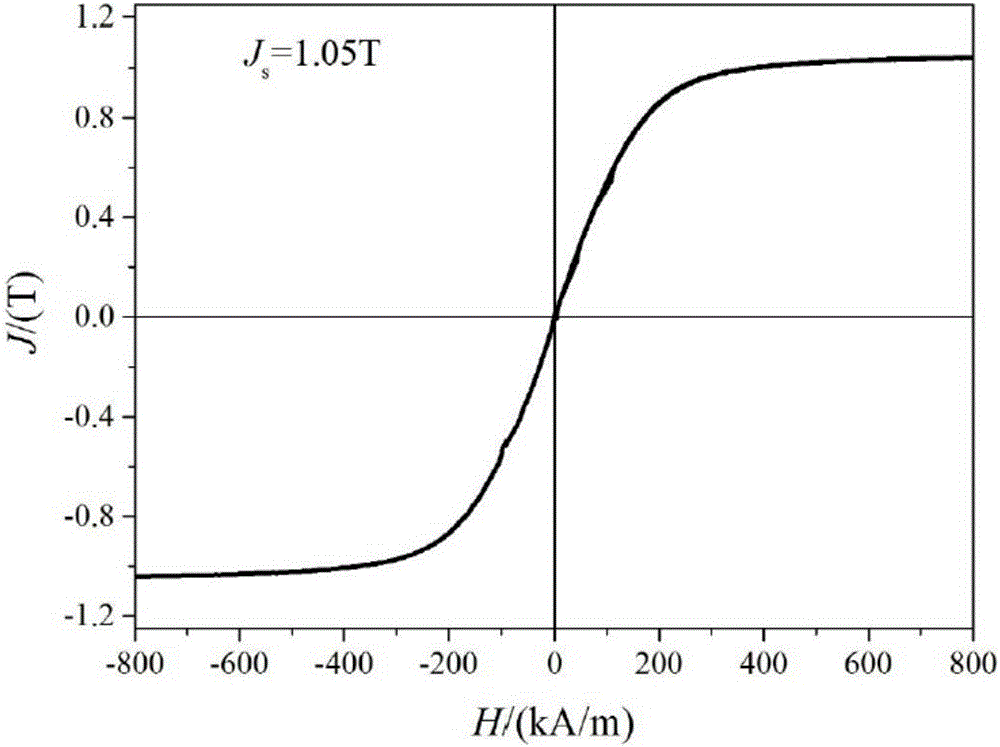

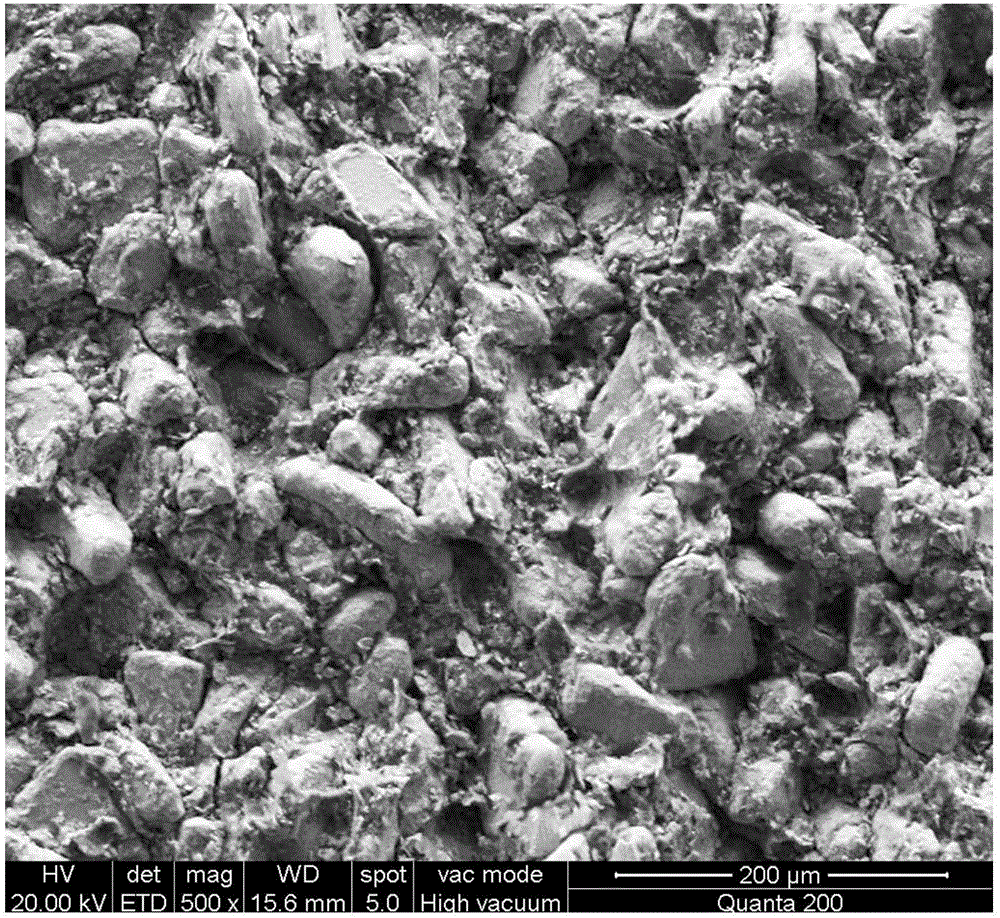

Preparation method of soft magnetic composite material

ActiveCN104028762ANo magnetic dilutionImprove permeabilityInorganic material magnetismCompression moldingFerrous

The invention discloses a preparation method of a soft magnetic composite material. The surface of soft magnetic alloy powder is coated with a coating layer with a sol-gel method, wherein the coating layer is formed by nanometer Fe3O4 particles with the uniform sizes; the processes of bonding, compression molding and heat treatment are carried out, and the novel soft magnetic composite material is prepared. The preparation method has the advantages that the surface of the soft magnetic alloy powder can be uniformly coated with Fe3O4 prepared with the sol-gel method; the Fe3O4 with ferrimagnetism serves as an insulating coating agent, so that a magnetic dilution phenomenon occurring when a traditional non-magnetic material serves as a coating agent is avoided, and higher magnetic conductivity and magnetization intensity can be obtained.

Owner:ZHEJIANG UNIV

Fe-Ai-Al powder core annular magnet and preparation method thereof

ActiveCN106158340AImprove permeabilityGood soft magneticTransportation and packagingMetal-working apparatusAl powderNano al2o3

The invention discloses a Fe-Ai-Al powder core annular magnet and a preparation method thereof. The preparation method comprises the following steps: (1) pouring original Fe-Ai-Al alloy powder into an acetone solution containing a coupling agent and uniformly stirring; putting the uniformly-stirred alloy powder into a vacuum drying box and drying; (2) adding an insulating additive into the dried powder; after uniformly stirring, drying again, wherein the insulating additive is a mixture of organic silicon resin, nano aluminum oxide and kaolin; (3) pressing the prepared mixed powder into a magnet ring; and (4) keeping the heat of the magnet ring at 350 DEG C-450 DEG C for 20min-40min, carrying out heat treatment and cooling along a furnace to obtain Fe-Ai-Al magnetic powder core. The magnetic powder core disclosed by the invention has good properties, a simple preparation process and low cost and is applicable to industrial production.

Owner:SOUTH CHINA UNIV OF TECH

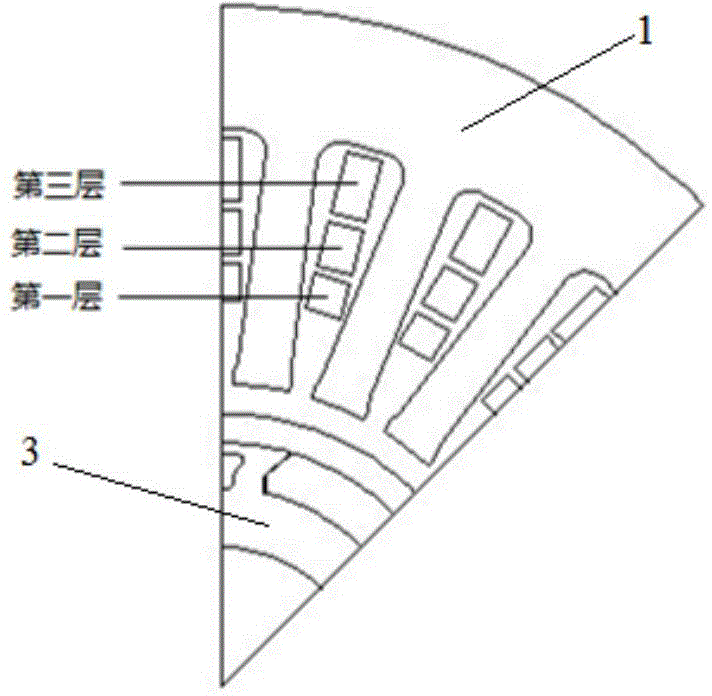

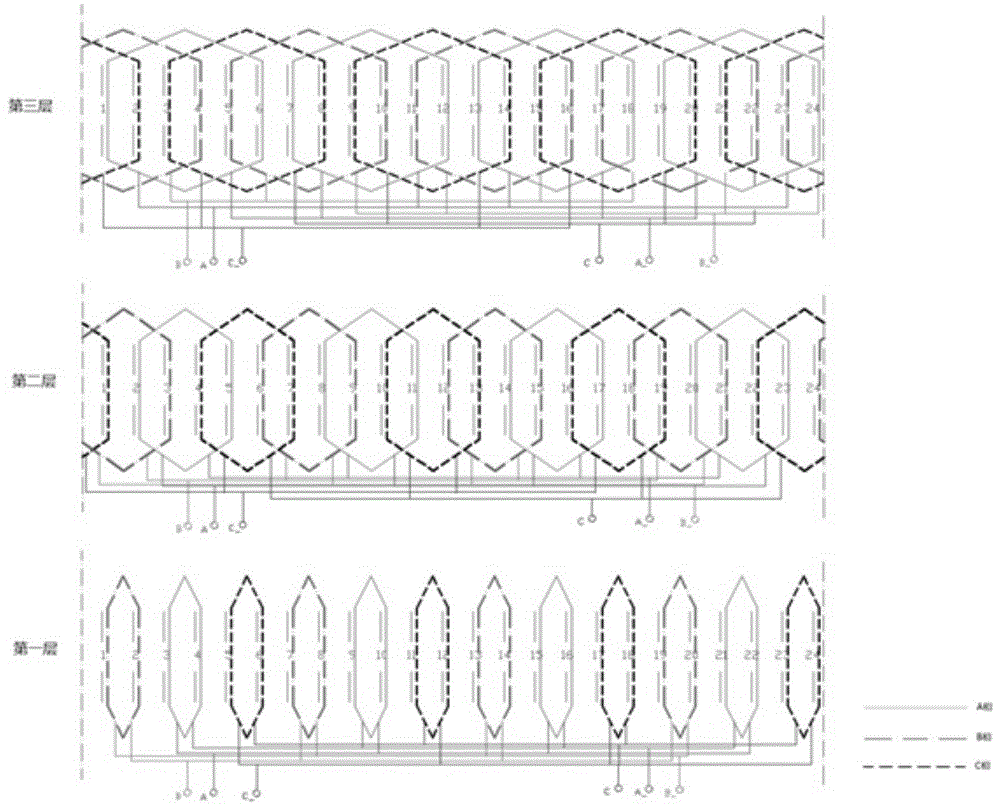

High-speed electric machine electromagnetism structure for air compressor

ActiveCN104795909AIncrease speedImprove power densityMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetConductor Coil

The invention relates to a high-speed electric machine electromagnetism structure for an air compressor. The high-speed electric machine electromagnetism structure for the air compressor comprises a stator core, a stator winding which is arranged on the stator core, a rotor core and a permanent magnet which is clamped on the surface of the rotor core; a plurality of stator grooves are uniformly formed in the circumference of the stator core; the stator winding is arranged inside the stator grooves in a connecting mode of three-layer low harmonic wave concentric winding; a plurality of wedge-shaped grooves are uniformly distributed along the circumference of the surface of the rotor core; a wedge-shaped arm is arranged between the adjacent two wedge-shaped grooves; air magnetic separation holes which are used for improving the gap flux density amplitude are formed in the wedge-shaped arm; permanent magnets are clamped in the wedge-shaped grooves. Compared with the prior art, the high-speed electric machine electromagnetism structure for the air compressor has the advantages of being compact in integral structure, high in rotation speed, high in mechanical intensity, small in harmonic loss and the like.

Owner:TONGJI UNIV

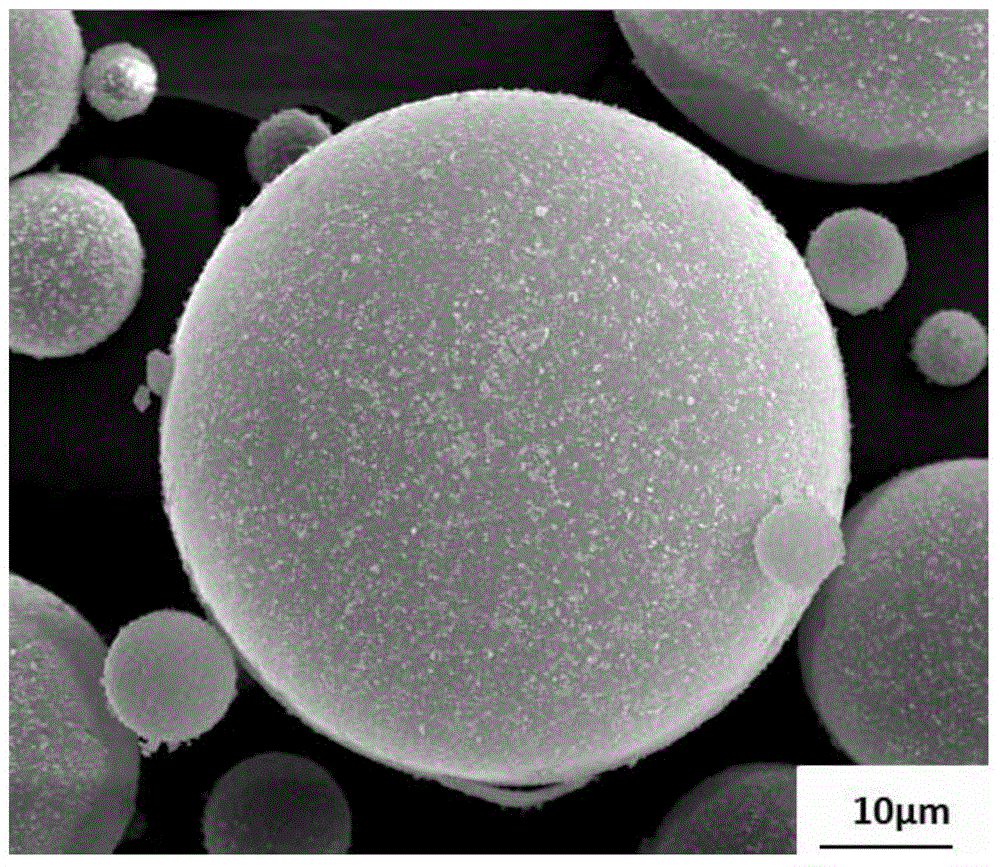

High saturation magnetic induction intensity iron-based amorphous soft magnetic composite material and manufacturing method thereof

InactiveCN104036904AHigh saturation magnetic inductionImprove self-fluxingMagnetic materialsCompression moldingElectron

The invention discloses a high saturation magnetic induction intensity iron-based amorphous soft magnetic composite material and a manufacturing method of the composite material. The atomic ratio expression of the alloy composition forming the amorphous soft magnetic composite material is Fe100-a-b-c-dREaMbPcSd, wherein 0<a<=8, 10<=b<=25, 0<c<=10, 0<d<=0.5, RE is one or a mixture selected from Y, La, Eu, Gd, Dy, Ho, Er, Tm, Yb and Lu, and M is one or a mixture selected from C, Si and B. The manufacturing method of the iron-based amorphous soft magnetic composite material includes the technical steps of alloy smelting, atomizing and pulverizing, insulating cladding, compression molding and heat treating. The iron-based amorphous soft magnetic composite material prepared through the method is high in saturation magnetic induction intensity and can be applied to electronic devices high in power and frequency.

Owner:ZHEJIANG UNIV

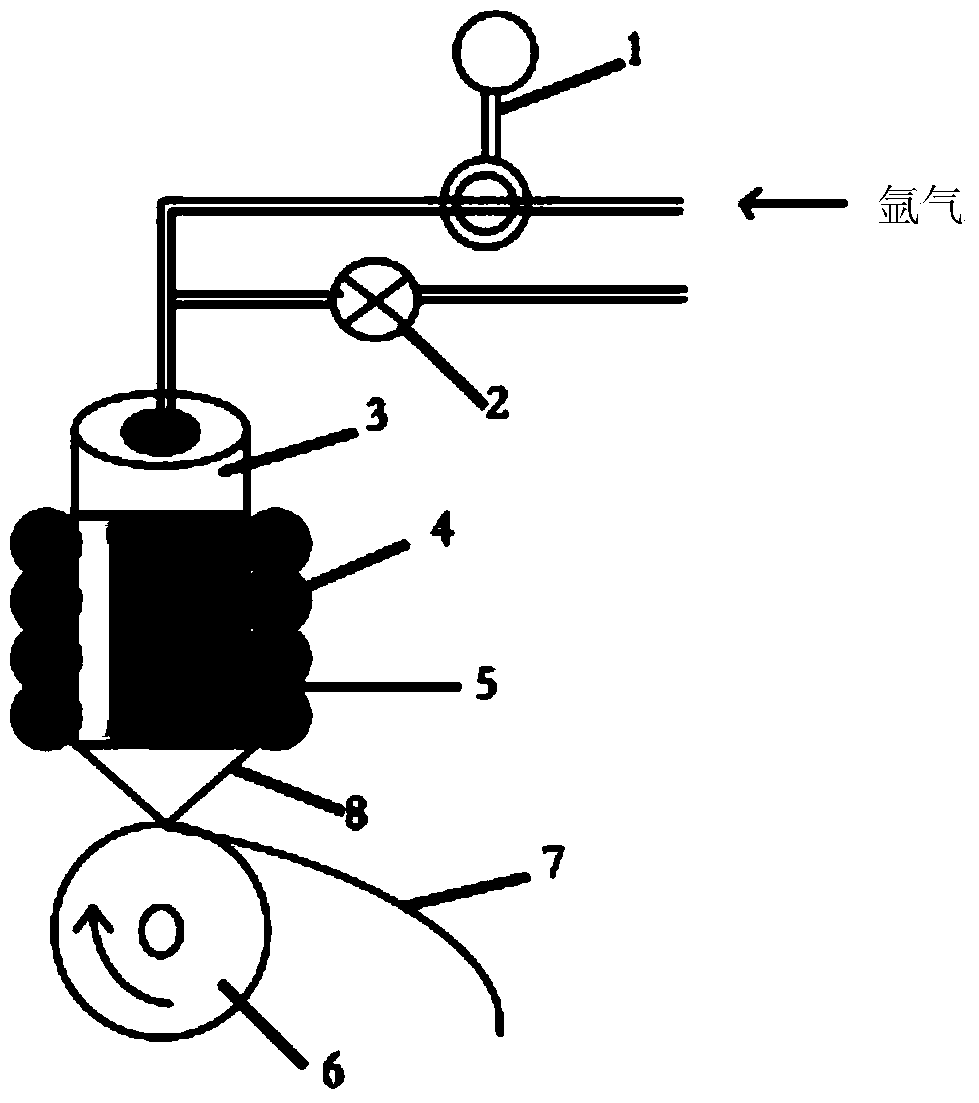

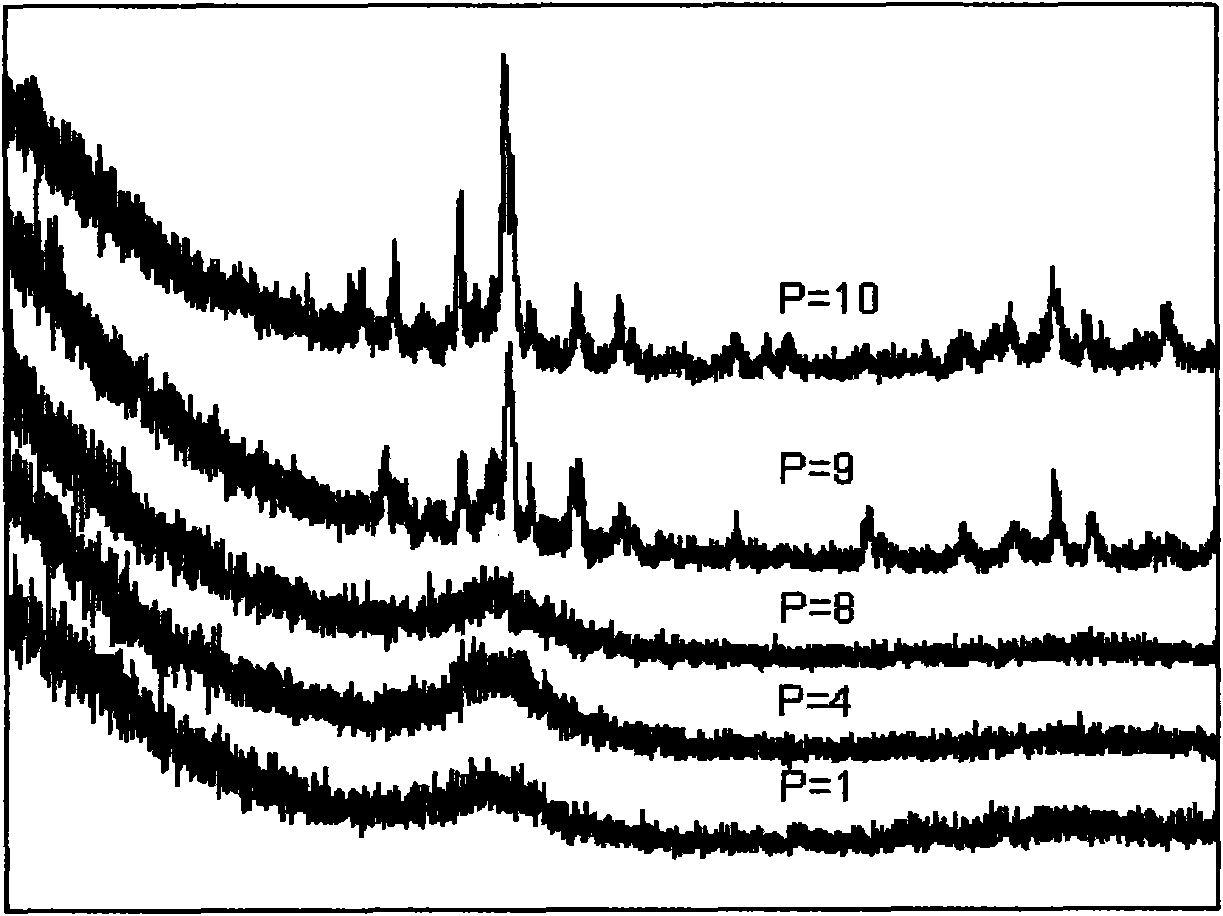

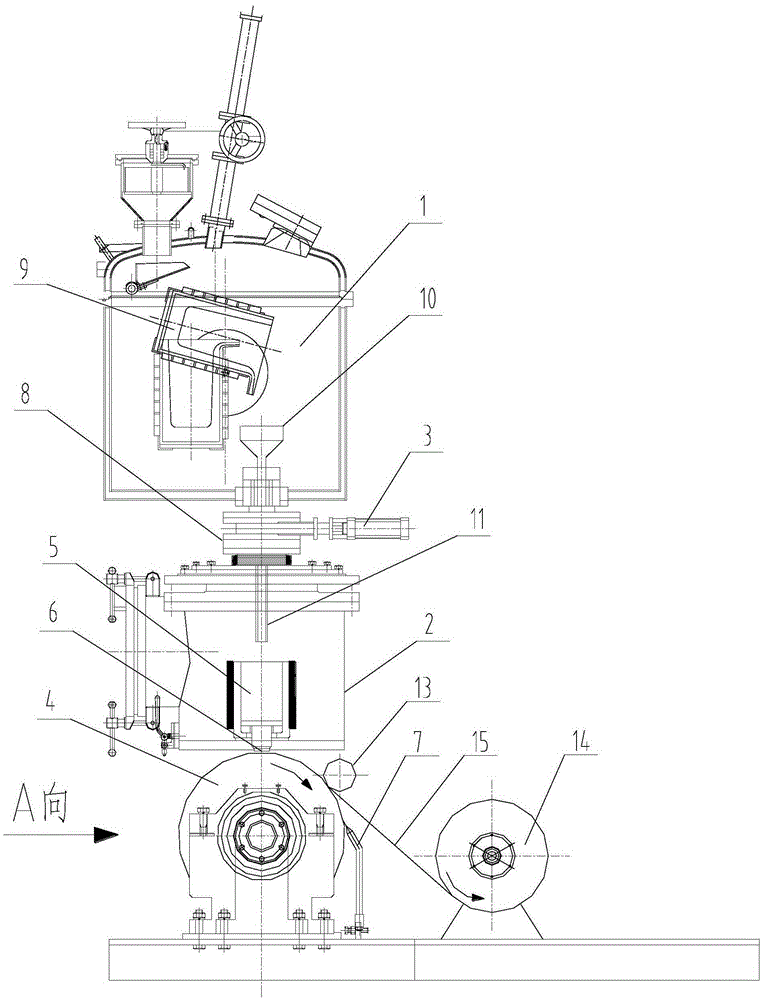

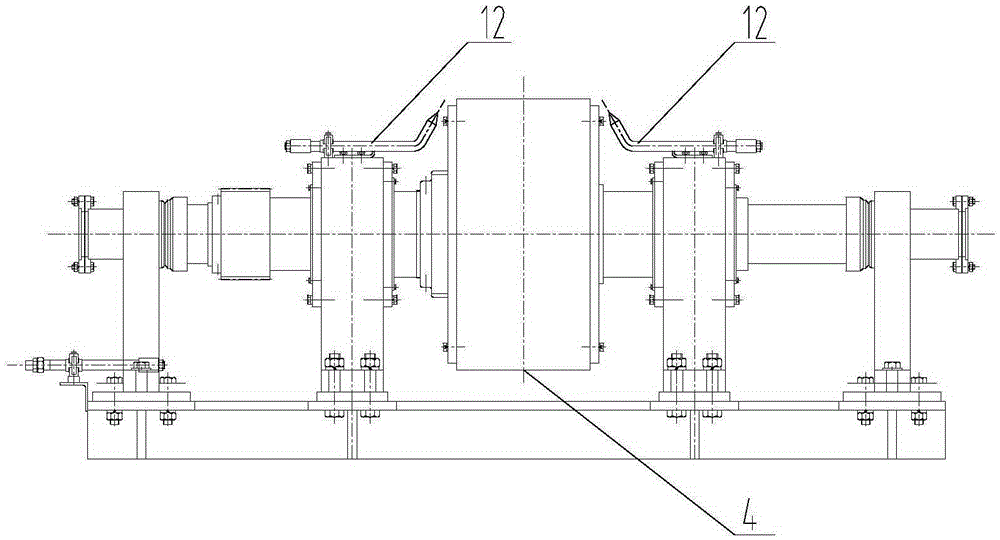

Method for preparing high silicon thin steel strip through single-roller melt spinning method

The invention discloses a method for preparing a high silicon thin steel strip through a single-roller melt spinning method. The method comprises the steps of 1) feeding high silicon steel mother alloy into a vacuum furnace for vacuum melting, and preheating a heat preservation ladle; 2) introducing a protective gas into the vacuum furnace and the heat preservation ladle till positive pressure is reached, opening a gate valve when the air pressure inside the vacuum furnace approaches the air pressure inside the heat preservation ladle, lowering the whole heat preservation ladle to a working position above a crystallization roller, turning on the crystallization roller, and releasing a puddle protective gas; 3) pouring molten silicon steel obtained through smelting into a spray ladle inside the heat preservation ladle, and turning on a gas stripping device, so as to enable molten steel to flow from a nozzle slot at the bottom of the spray ladle to the rotating crystallization roller below a nozzle to be quenched to form the thin strip; and 4) after the molten steel is poured completely, closing the gate valve, increasing the pressure of the protective gas inside the heat preservation ladle, and controlling the molten steel inside the spray ladle to be quickly and uniformly sprayed from the nozzle to the crystallization roller through a pressure closed-loop control till the strip spraying is over. The method has the advantages that the forming property of strip spraying is good, the strip width range is large, and a finished product is good in shape and magnetism.

Owner:武汉钢铁有限公司

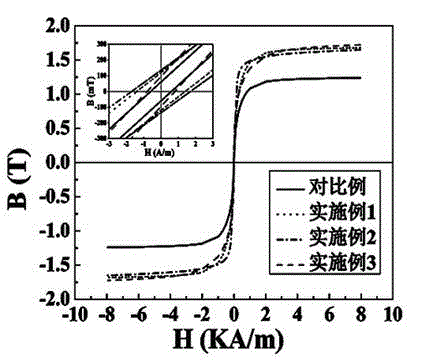

High-performance ferric-based nano-crystalline soft magnetic alloy and preparation method thereof

InactiveCN102945719AGood soft magneticSuitable for mass productionMagnetic materialsChemical compositionChemical element

The invention provides a high-performance ferric-based nano-crystalline soft magnetic alloy and a preparation method thereof, and belongs to the field of preparation of soft magnetic alloy of functional materials. Chemical elements of the nano-crystalline soft magnetic alloy can be represented by FeaPbCcSidAleCrfCug, wherein a, b, c, d, e and f are the atomic percentage of corresponding elements, which are in a range as follows: b is 4-10, c is 5-9, c is 0-6, e is 0.5-1, f is 0.3-0.5, g is 0-2, and a is (100-b-c-d-e-f-g). A soft magnetic amorphous alloy ribbon made by a rotary quenching method according to an ingredient proportion requirement of the invention is provided with good amorphous forming ability and annealing process performance, and particularly can keep a rather low coercive force within a rather wide annealing temperature range. And the nano-crystalline soft magnetic alloy provided by the invention has a great potential application prospect because of relatively low cost and excellent soft magnetic performance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

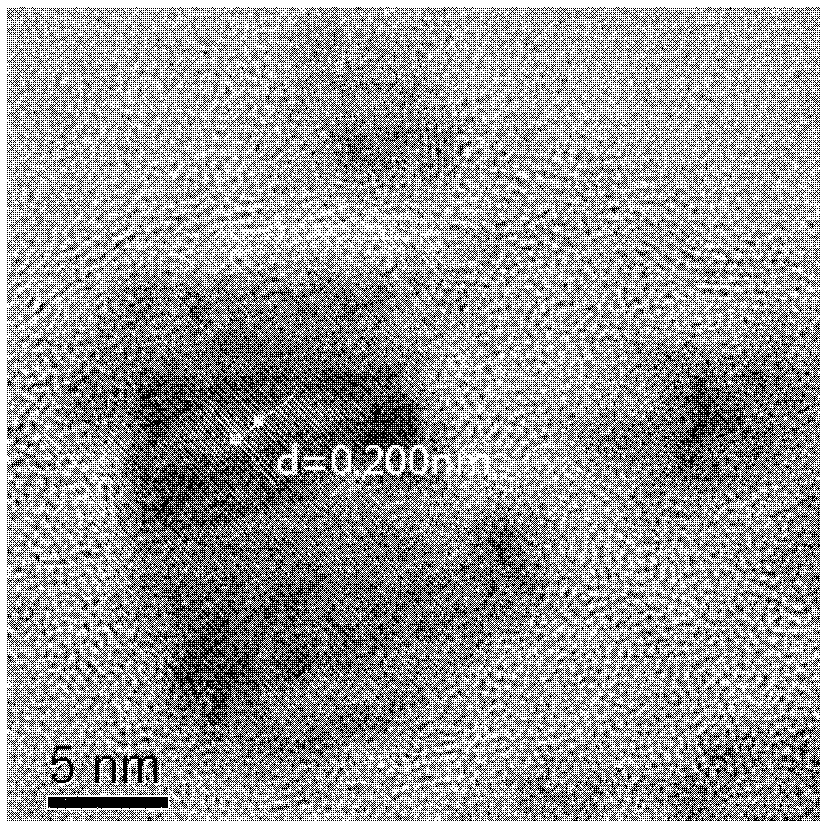

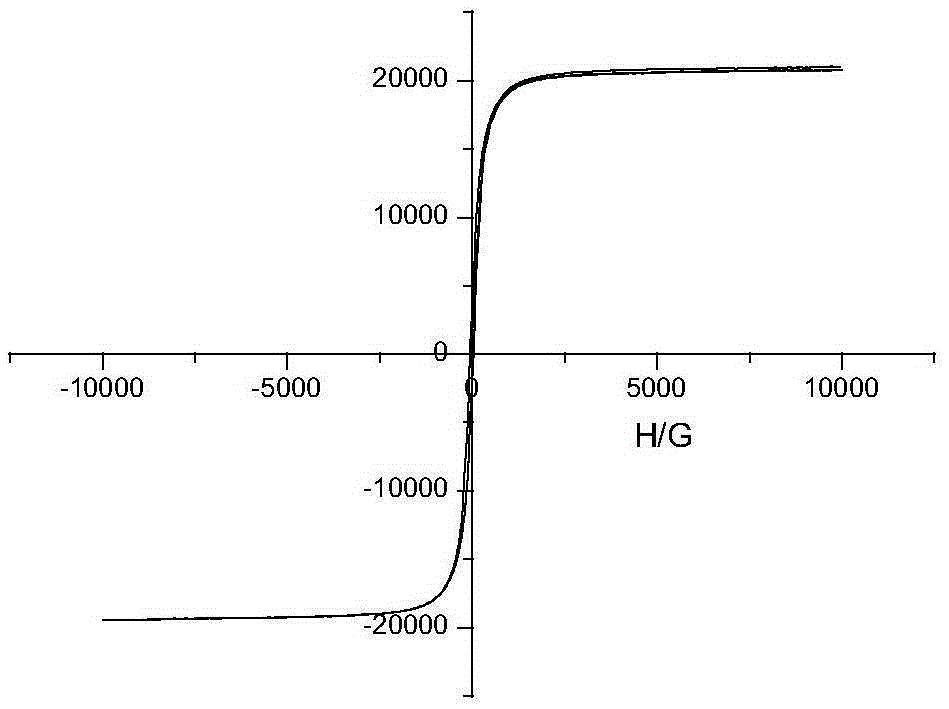

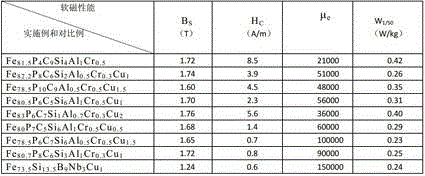

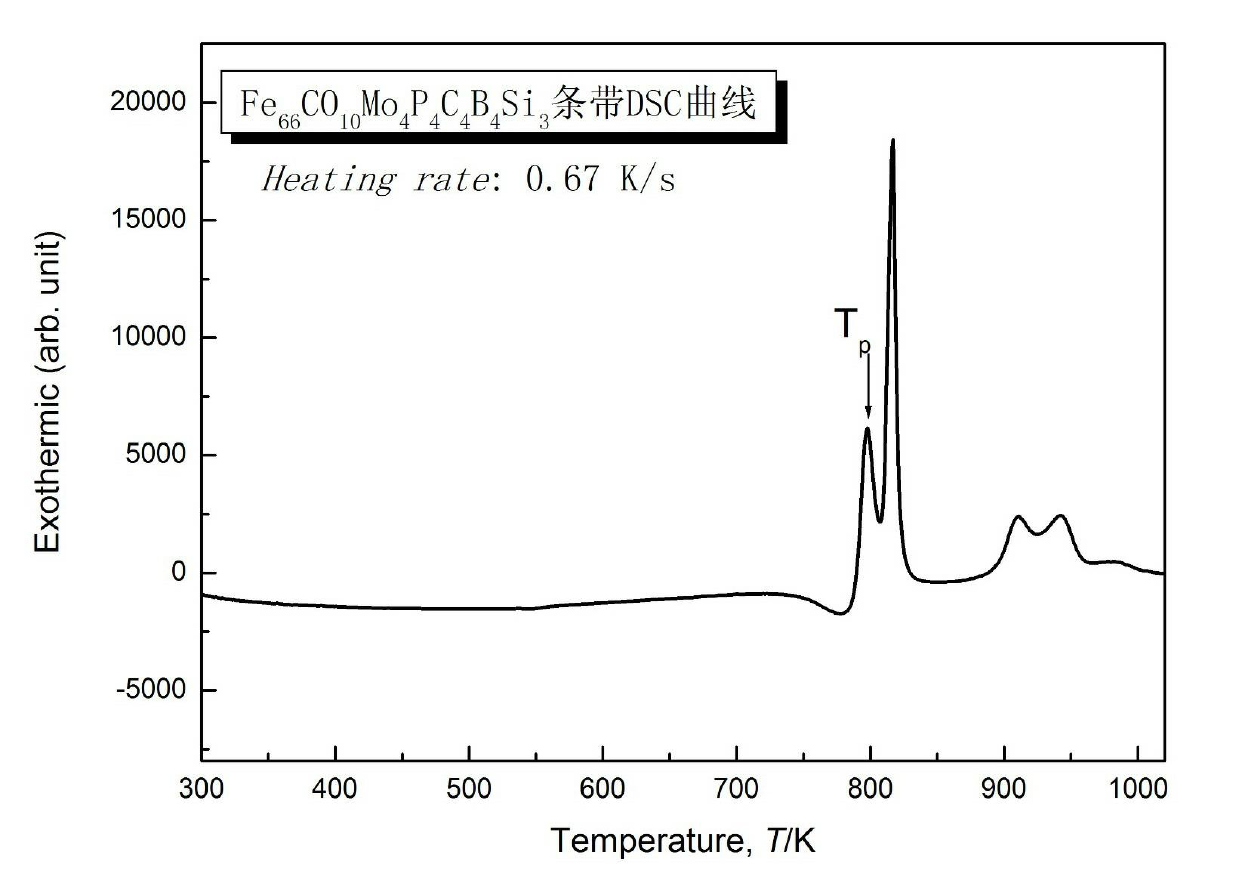

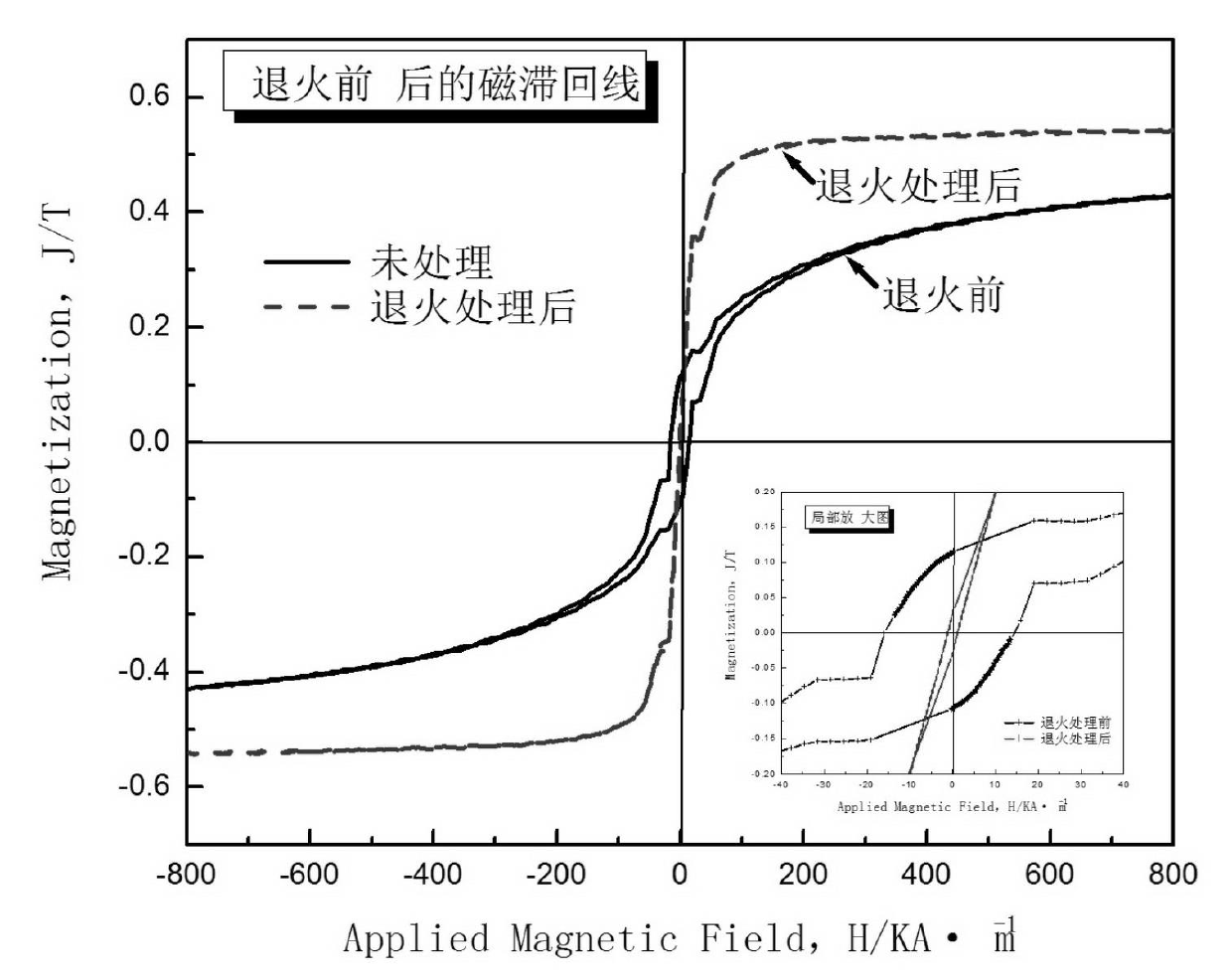

Preparation method of Fe66Co10Mo4P4C4B4Si3 block soft-magnetic nanocrystalline/amorphous composite material

The invention relates to a preparation method of a Fe66Co10Mo4P4C4B4Si3 block soft-magnetic nanocrystalline / amorphous composite material, comprising the following steps: annealing a Fe66Co10Mo4P4C4B4Si3 block amorphous alloy in vacuum at a first crystallization peak temperature Tp and preserving heat for a specific time, after annealing, putting the annealed alloy in a cooling medium to fast coolto room temperature. According to the invention, nanocrystallization of the Fe base block amorphous alloy can be realized, and the soft magnetic property can be improved obviously. The method provides a novel technological process of the Fe66Co10Mo4P4C4B4Si3 block soft-magnetic nanocrystalline / amorphous composite material.

Owner:ZHENGZHOU UNIV

Preparation method of motor iron cores

InactiveCN106033919AIron core with excellent soft magnetic propertiesFast productionManufacturing stator/rotor bodiesProcessing accuracyInternal stress

The invention discloses a preparation method of motor iron cores. The preparation method mainly comprises the steps that 1, a soft magnetic metal strip is laminated and fixed; 2, lamination is cut by lasers to obtain strip slices; 3, the strip slices are stacked to a certain thickness, and atmosphere annealing is conducted; 4, the strip slices are immersed into a bonding agent for curing, and paint spraying is conducted. The preparation method has the advantages the motor iron cores are prepared through laser cutting, the machining precision is high, no rough edge exists, small internal stress is generated, and the motor iron cores in complex shapes can be machined. By preparing the motor iron cores through the laser method, the production technology can be simplified, the machining speed is increased, the cost is reduced, and the method has a wide application prospect in the field of high-speed motor manufacturing.

Owner:白国华

Amorphous-nanocrystalline composite magnetic power core and production method thereof

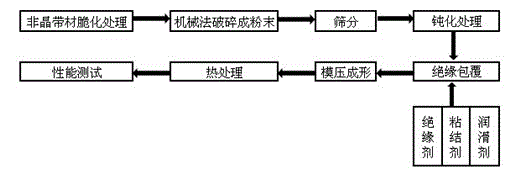

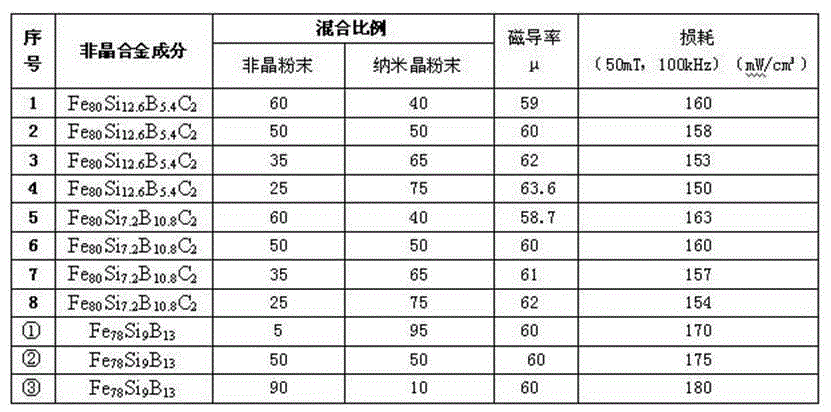

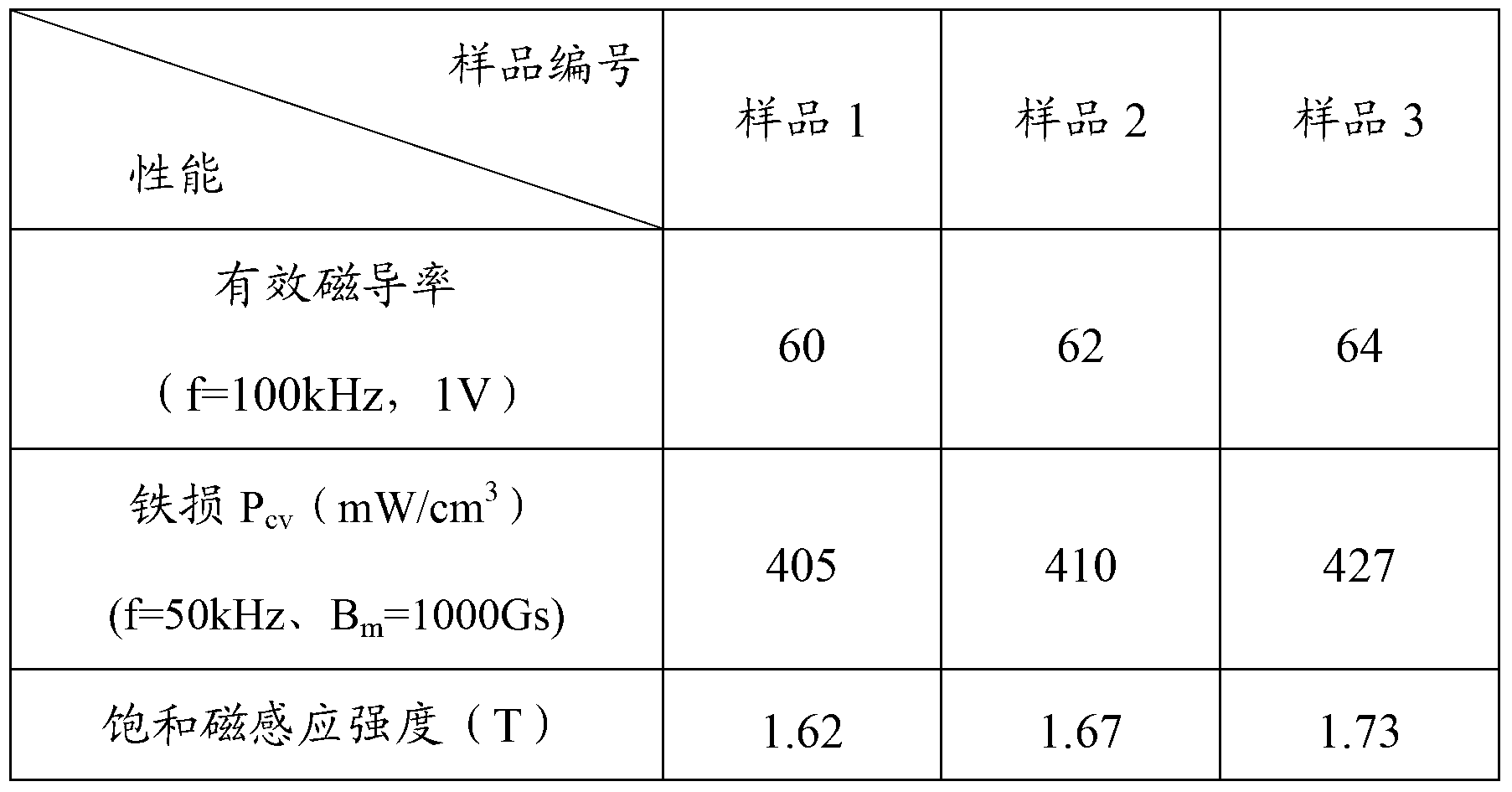

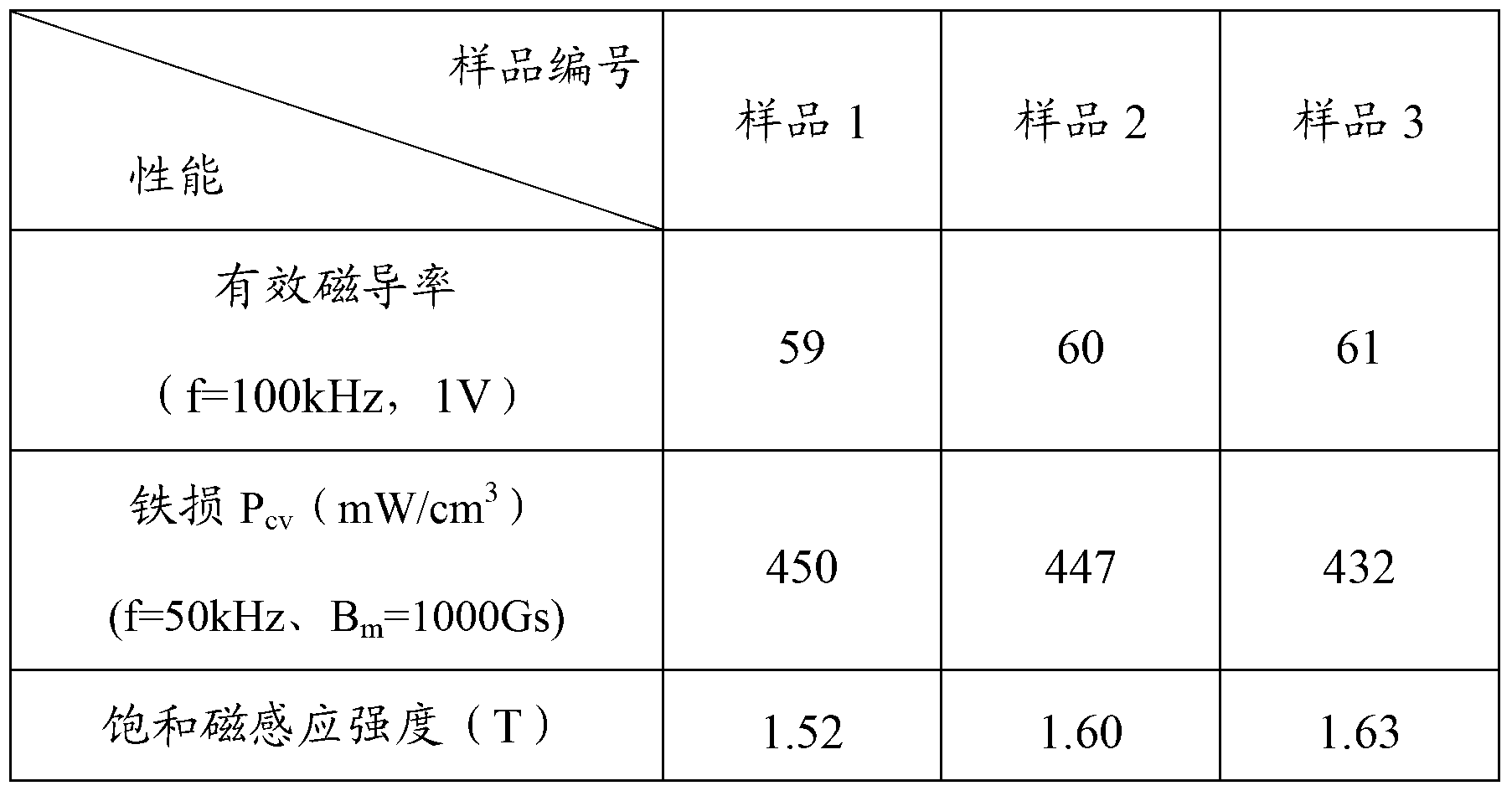

ActiveCN103559974AImprove magnetic propertiesImprove mechanical propertiesInorganic material magnetismInductances/transformers/magnets manufactureInorganic oxideNanocrystalline composites

The invention belongs to the field of function materials and particularly relates to an amorphous-nanocrystalline composite magnetic power core and a production method thereof. The amorphous-nanocrystalline composite magnetic power core is mainly made of iron-based amorphous powder, iron-based nanocrystalline powder, organic binder, and insulating agent. The insulating agent is a mixture of inorganic oxide, carbide and nitride. The organic binder and the insulating agent account for 0.5-2wt% and 0.5-4wt% of total weight of the two powders respectively. The production method includes: amorphous strip embrittlement, mechanical breaking for powdering, screening, passivation and insulation coating, die pressing, and heat treatment. The amorphous-nanocrystalline composite magnetic power core has excellent soft magnetic properties, thermal stability and mechanical strength under medium and high frequencies, and can be massively used for various inductive components, such as filters, current regulators and energy storage components, on various switch power modules.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

High-saturation magnetic induction density iron cobalt-based nanocrystal soft magnetic powder core and preparation method thereof

InactiveCN103310937AGood soft magneticSimple processInductances/transformers/magnets manufactureMagnetic materialsMagnetic powderCurie temperature

The invention discloses a preparation method of a high-saturation magnetic induction density iron cobalt-based nanocrystal soft magnetic powder core. The compositions of the magnetic powder core meet the following molecular formula: FeaCobSicBdueMf, wherein M is C, P, Cr or Mn, and subscripts a, b, c, d, e and f are atomic percentages of corresponding elements respectively and meet the conditions that a is not less than 5 and not more than 82, b is not less than 5 and not more than 82, c is not less than 3 and not more than 15, d is not less than 4 and not more than 13, e is not less than 0.4 and not more than 1.5, f is not less than 2 and not more than 8, and the sum of a, b, c, d, e and f is equal to 100. The prepared magnetic powder core is higher in saturation magnetic induction density and Curie temperature and excellent in comprehensive soft magnetic performance.

Owner:ZHEJIANG UNIV +1

Ferrum-based amorphous nanocrystalline soft magnetic alloy and preparation method and application thereof

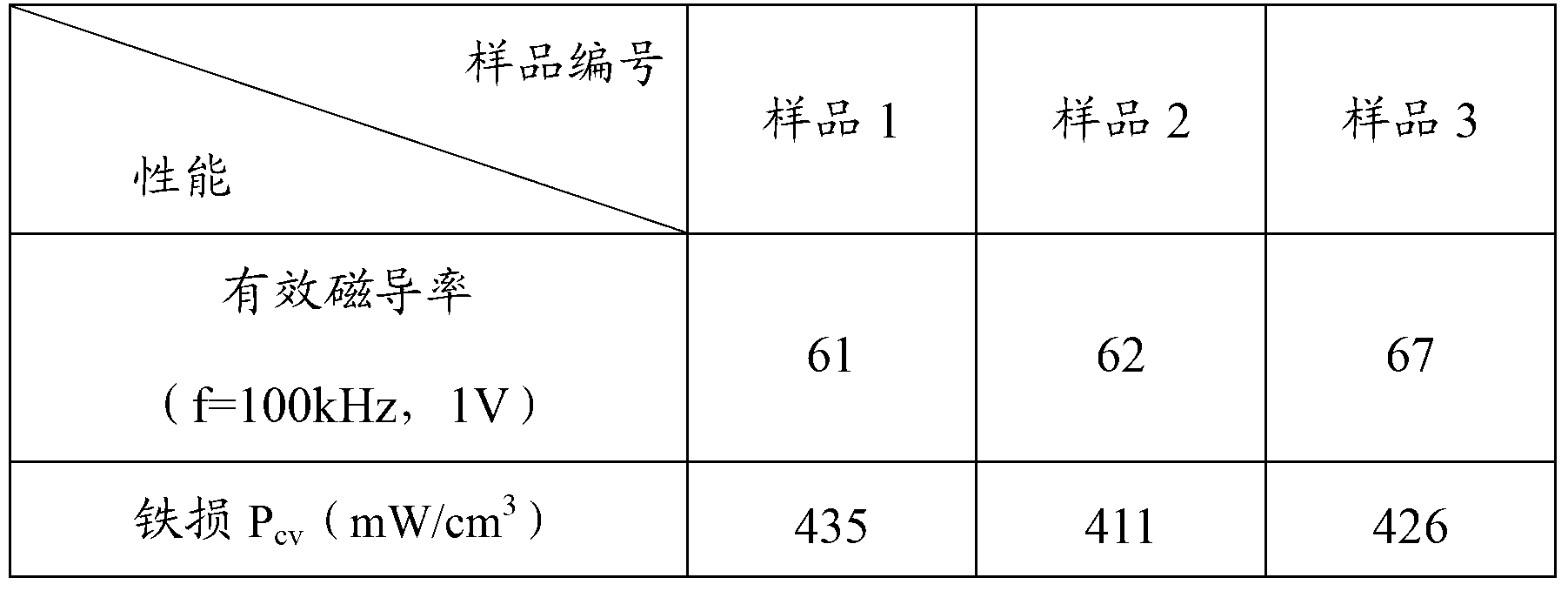

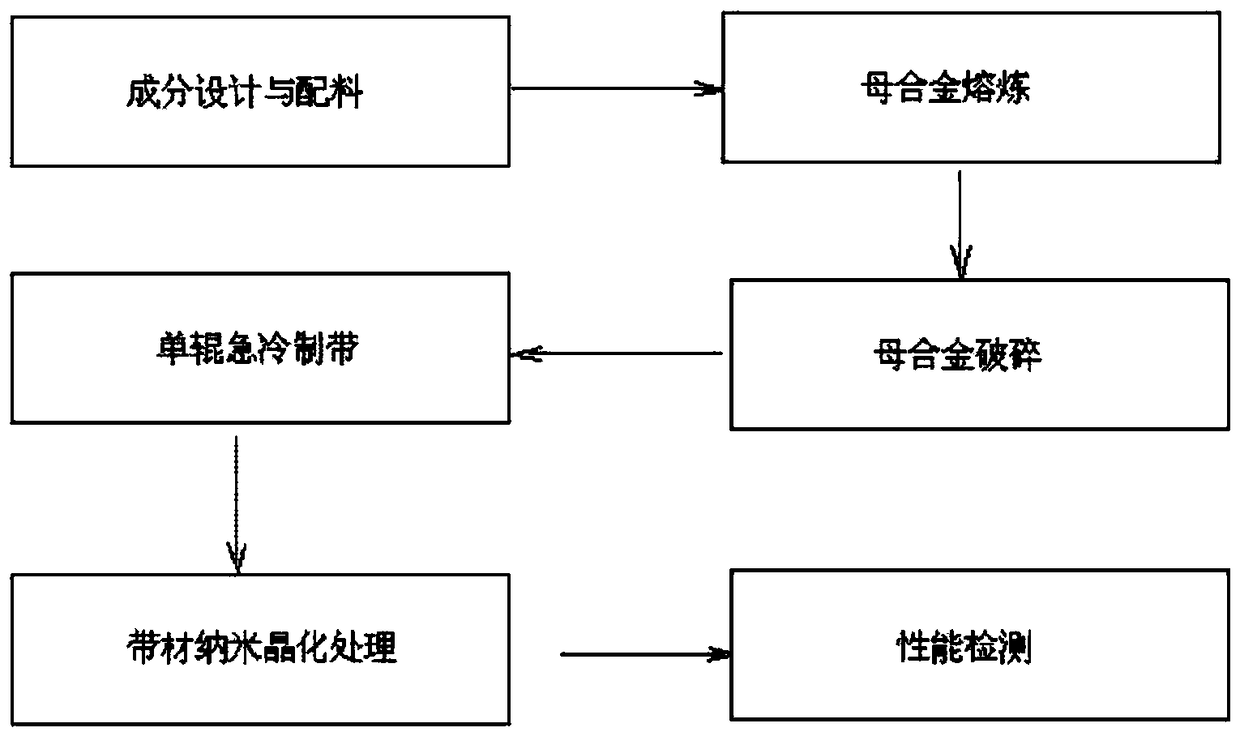

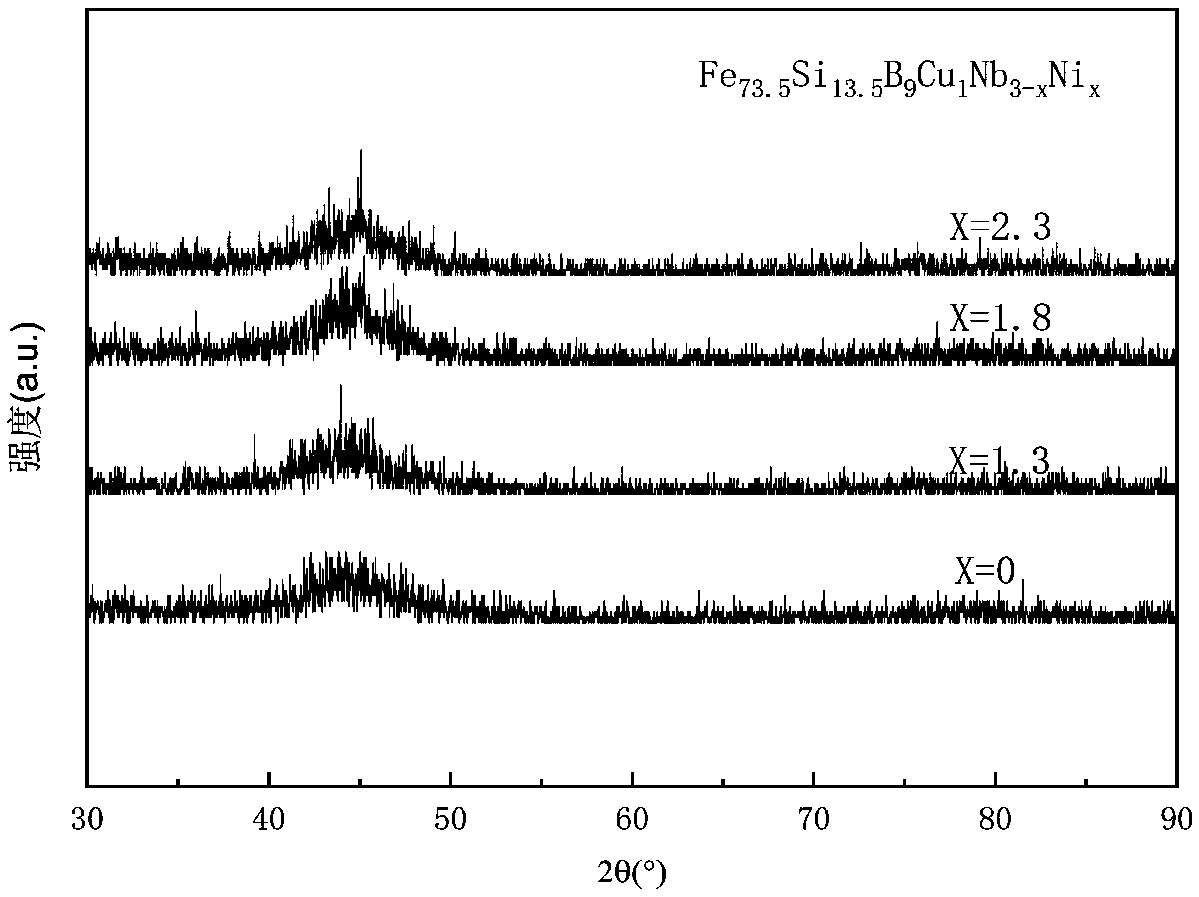

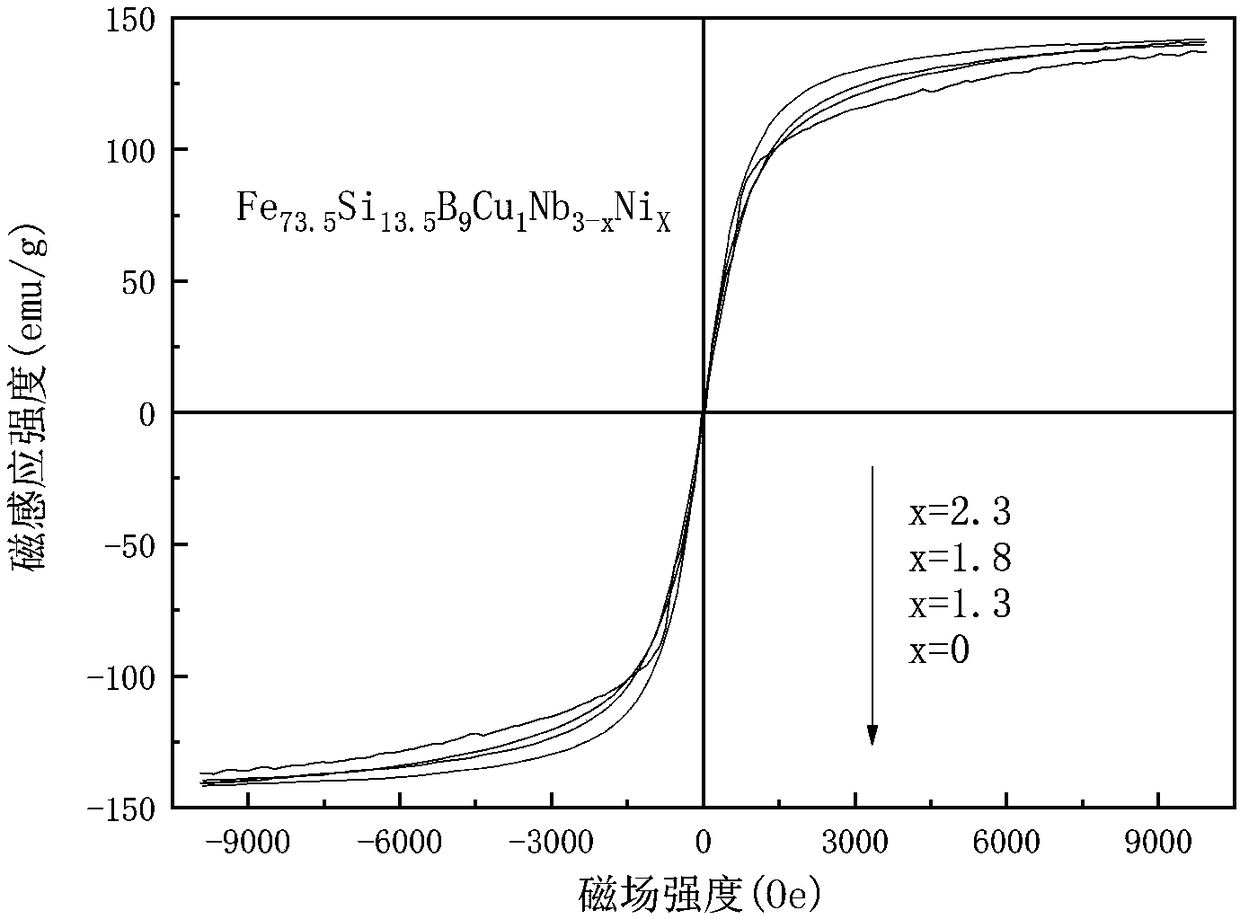

InactiveCN109440021AHigh saturation magnetic inductionLow coercivityInductances/transformers/magnets manufactureMagnetic materialsNiobiumIngot

The invention belongs to the technical field of soft magnetic alloy function materials and discloses a ferrum-based amorphous nanocrystalline soft magnetic alloy and a preparation method and application thereof. The molecular formula of the ferrum-based amorphous nanocrystalline soft magnetic alloy is Fe73.5Si13.5B9Gu1Nb3-xNix, wherein the x is equal to 0, 1.3, 1.8 or 2.3. The preparation method comprises the steps that an alloy ingot is obtained after smelting of ferrum, silicon, boron source, copper, niobium and nickel; the alloy ingot is cleaned after being crushed, then strip-throwing is performed, and an amorphous alloy strip is obtained; and under the condition of vacuum or a protective atmosphere, the ferrum-based amorphous nanocrystalline soft magnetic alloy is obtained after the amorphous alloy strip is subjected to heat treatment with the temperature being 430-450 DEG C. An experiment result shows that, the prepared ferrum-based amorphous nanocrystalline soft magnetic alloysare all of completely-amorphous structures and have high saturation magnetic induction strength, low coercive force and other excellent soft magnetic properties, furthermore, the use amount of the expensive metal element Nb is reduced, and the material cost is significantly lowered.

Owner:GUANGDONG UNIV OF TECH

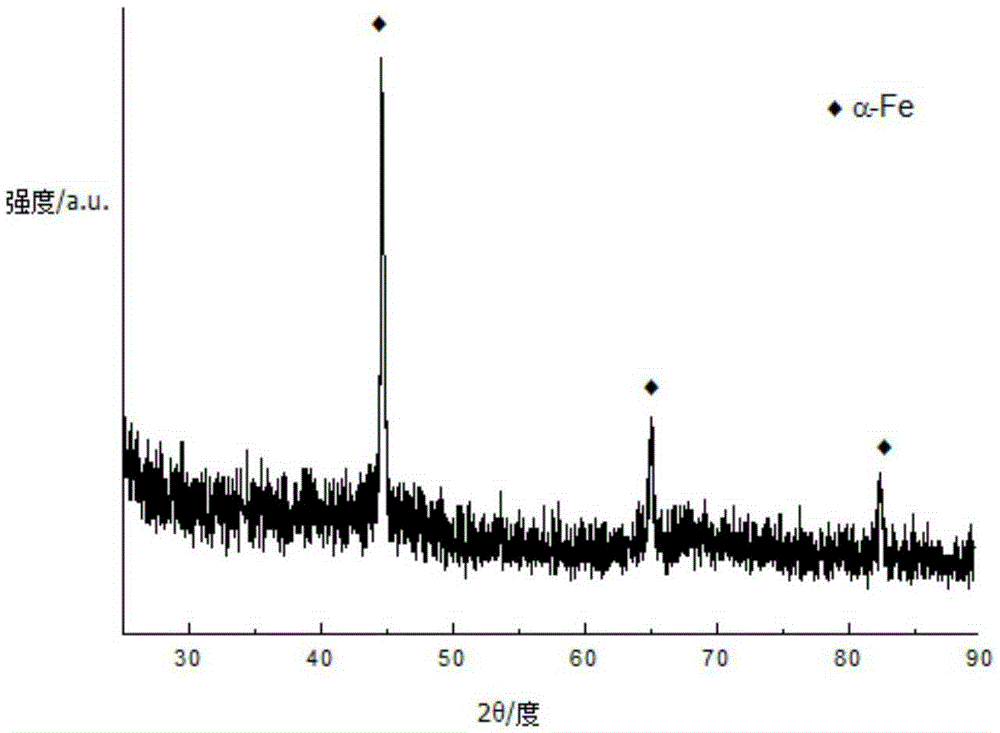

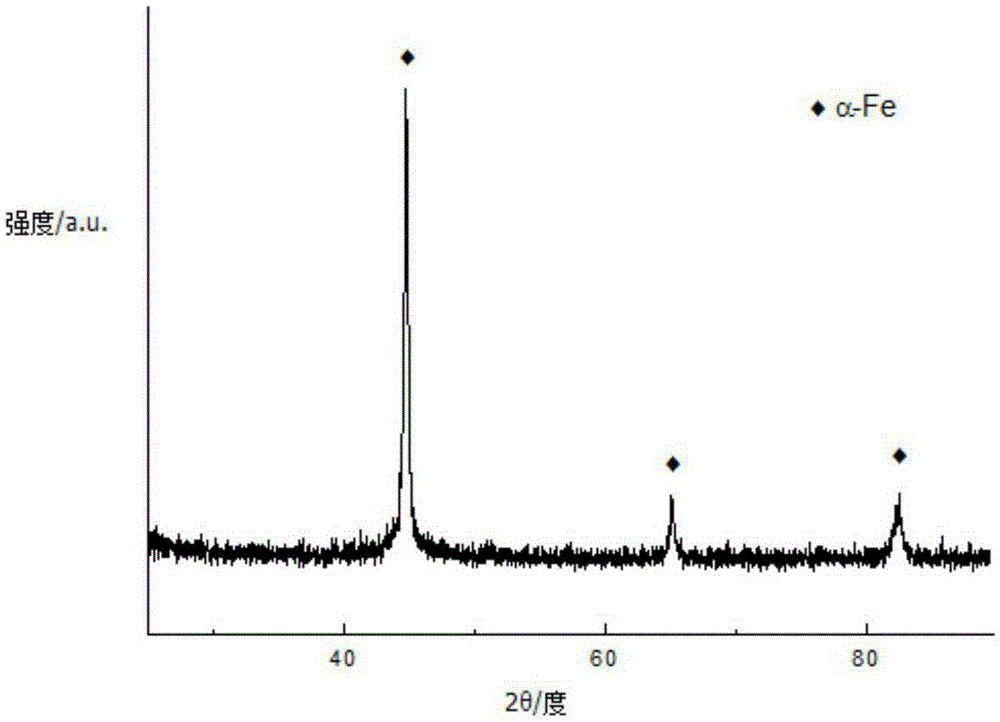

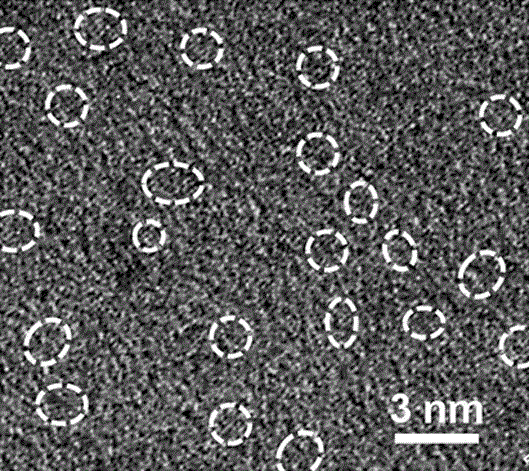

Iron-based sub-nanometer magnetically soft alloy and preparing method thereof

ActiveCN106756488AGood soft magneticPrevent Performance Deterioration SituationsMagnetic materialsQuenchingMicrostructure

The invention discloses an iron-based sub-nanometer magnetically soft alloy. The component expression of the alloy is FeaSibBcPdCeCufMg, wherein M represents one or several elements of Ti, Zr and Hf, and the subscripts of a, b, c, d, e, f and g are the atom percents of the corresponding elements, and the following conditions are met and include that a is larger than or equal to 78 and smaller than or equal to 86, b is larger than or equal to 2 and smaller than or equal to 9, c is larger than or equal to 4 and smaller than or equal to 10, d is larger than 0 and smaller than or equal to 5, e is larger than 0 and smaller than or equal to 3, f is larger than or smaller than or equal to 2, g is larger than 0 and smaller than or equal to 5, and the sum of a, b, c, d, e, f and g is 100. According to the alloy, a large number of alpha-Fe grains and atom clusters with the sub-nanometer dimension being lower than 5 nm are dispersed and distributed in a belt prepared through a single-roll melt fast quenching method, the belt has high saturation magnetic induction intensity, low losses, high permeability and other good soft magnetic properties. After the above quenched-state belt is subjected to heat treatment under proper conditions, a large number of alpha-Fe grains with the sub-nanometer dimension can be further precipitated, and the soft magnetic property is further improved. Due to the novel and unique microstructure, fast heat treatment is adopted in a crystallization technology for the series of alloys, and the industrial production efficiency can be obviously improved.

Owner:NINGBO ZHONGKE BIPULASI NEW MATERIAL TECH CO LTD

Alloying-based high-silicon thin steel strip and preparation method thereof

The invention relates to an alloying-based high-silicon thin steel strip and preparation method thereof. The technical scheme of the alloying-based high-silicon thin steel strip is as follows: the silicon content of the high-silicon thin steel strip is 5.5-7.0wt%, the copper content is 0.05-2.5wt%, and the rest is iron and other unavoidable impurity. The preparation method is as follows: using ingot iron, commercial silicon and pure copper as raw materials and burdening according to the chemical component of the high-silicon thin steel strip, smelting the raw materials in a medium-frequency vacuum induction furnace, casting at 1300-1650 DEG.C to form casting blank, forging the casting blank at 750-1250 DEG.C to form a slab with thickness of 10-20mm, hot-rolling the slab at 700-1250 DEG.C to form a thin strip with thickness of 0.6-0.8mm, and finally warm-rolling the thin strip at 150-750 DEG.C to 0.2-0.3mm. The alloying-based high-silicon thin steel strip provided by the invention is low in cost, simple in process and capable of utilizing the existing apparatus, the fragility of the prepared alloying-based high-silicon thin steel strip is obviously improved, the plasticity is obviously improved, the strip shape is good and the magnetic performance is excellent.

Owner:WUHAN UNIV OF SCI & TECH

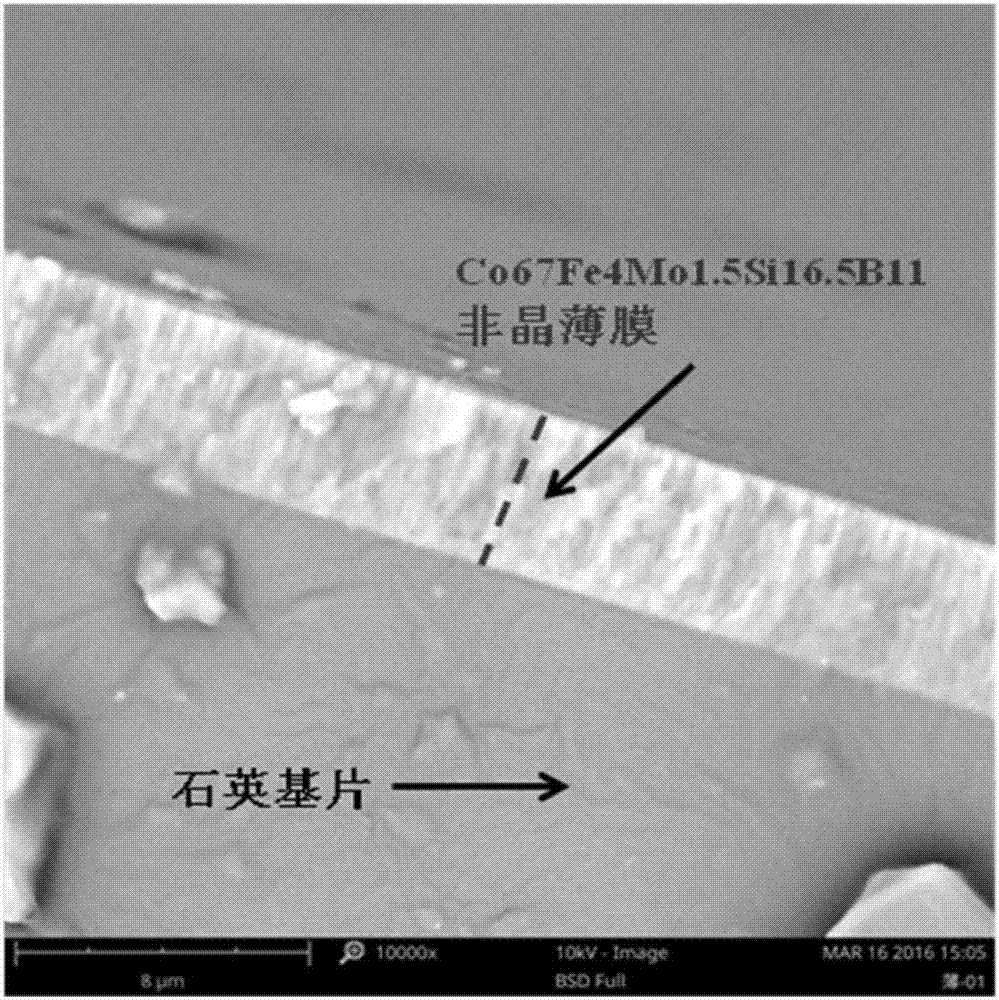

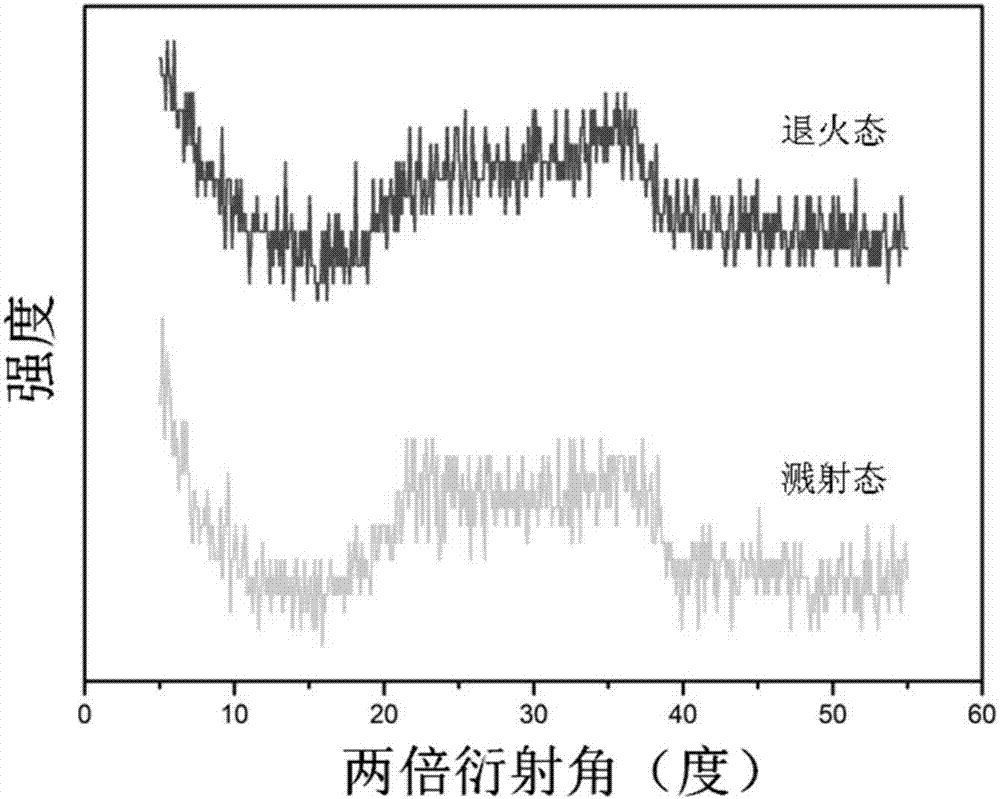

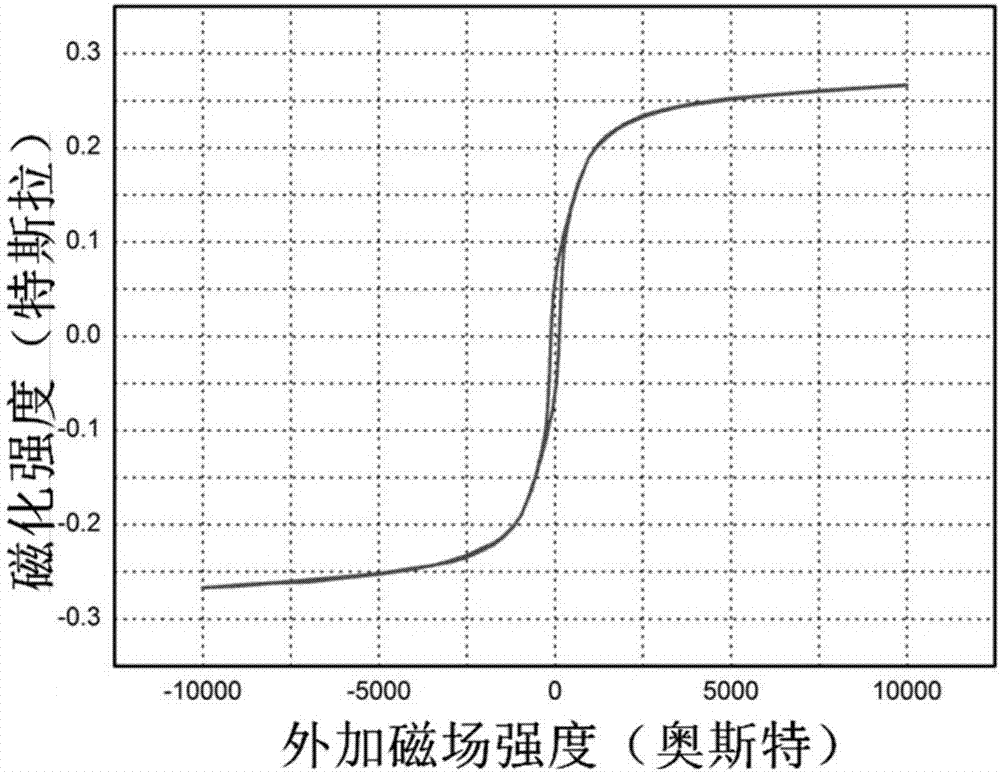

Intermittent direct-current (DC) magnetron sputtering preparation method of amorphous cobalt-based magnetic film

InactiveCN107043914AAvoid uniformityOvercoming production inefficienciesVacuum evaporation coatingSputtering coatingMagnetizationAlloy

The invention relates to an intermittent direct-current (DC) magnetron sputtering preparation method of an amorphous cobalt-based magnetic film. The method comprises the steps as follows: (1) a cast Co67FexMo(5.5-x)SiyB(27-y) (x is larger than 2 and smaller than 5, and y is larger than 10 and smaller than 17) crystalline alloy is used as a target material, quartz is used as a substrate, a pure metal buffer layer is sputtered on the quartz substrate firstly, and the temperature of the substrate is controlled to range from 50 DEG C to 70 DEG C with the intermittent DC magnetron sputtering method; the magnetron sputtering technology is as follows: the sputtering power ranges from 120 W to 180 W, the argon flow ranges from 40 ml / min to 200 ml / min, the argon partial pressure ranges from 0.4 Pa to 1.2 Pa; (2) annealing treatment is performed on a sputtering-state film as follows: the sputtering-state Co67FexMo(5.5-x)SiyB(27-y) film is arranged in a vacuum annealing furnace, the temperature of 300-430 DEG C is kept for 1 h with the gradient temperature increase method, and the film is cooled with the furnace; and the prepared film is high in amorphous degree, and the saturated magnetization intensity reaches 0.27 T. the preparation method suitable for different types of magnetic films is convenient to operate, short in production cycle, low in equipment requirement and easy to industrialize.

Owner:WUHAN UNIV OF TECH

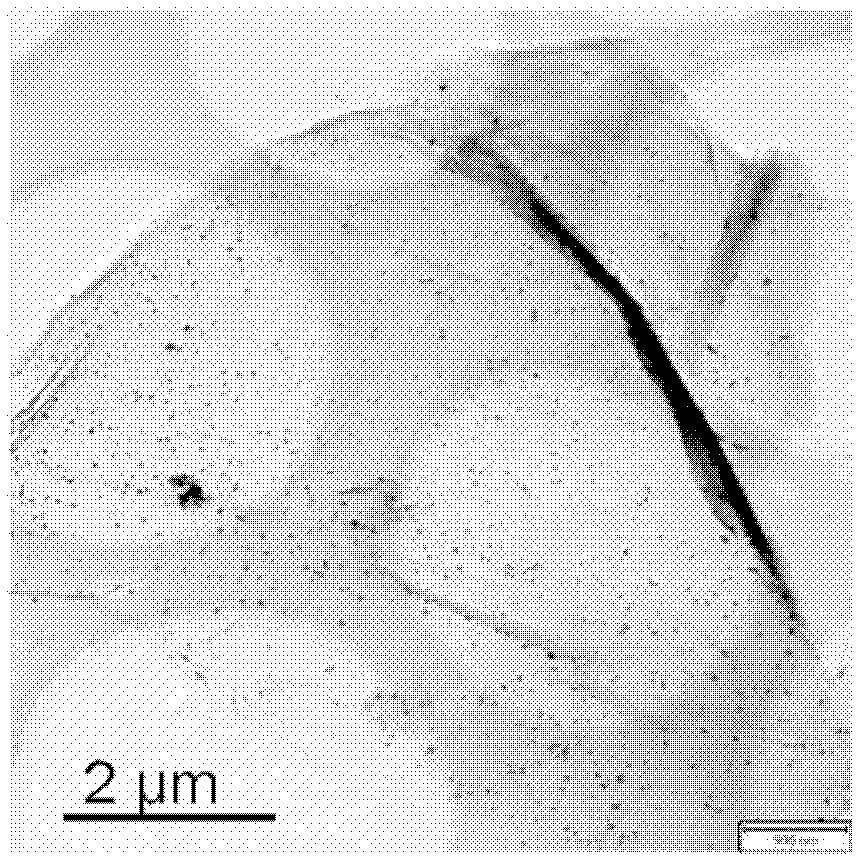

Hollow microsphere/Ni-Fe-P/Cu composite coating and preparation method thereof

ActiveCN104018139AGood soft magneticImprove permeabilityMaterial nanotechnologyLiquid/solution decomposition chemical coatingChemical platingMicrosphere

The invention provides a hollow microsphere / Ni-Fe-P / Cu composite coating and a preparation method thereof, relating to a hollow microsphere composite coating and a preparation method thereof. The hollow microsphere / Ni-Fe-P / Cu composite coating comprises a matrix hollow microsphere, an amorphous Ni-Fe-P soft magnetic coating and a nano Cu conductive coating from inside to outside. The method comprises the following steps: I. washing; II sensitizing with SnCl2; III. activating with PdCl2; IV. chemical plating of Ni-Fe-P; V. chemical plating of Cu. The hollow microsphere composite coating has light weight, high permeability, high conductivity and multiple interfaces, and thus the hollow microsphere composite coating can be used for preparing electromagnetic shielding coatings with good shielding property, wide frequency range and light weight. Besides, the hollow microsphere composite coating can be also applied in the field of wave absorption and is applied in the field of hollow microsphere surface chemical plating.

Owner:HARBIN INST OF TECH

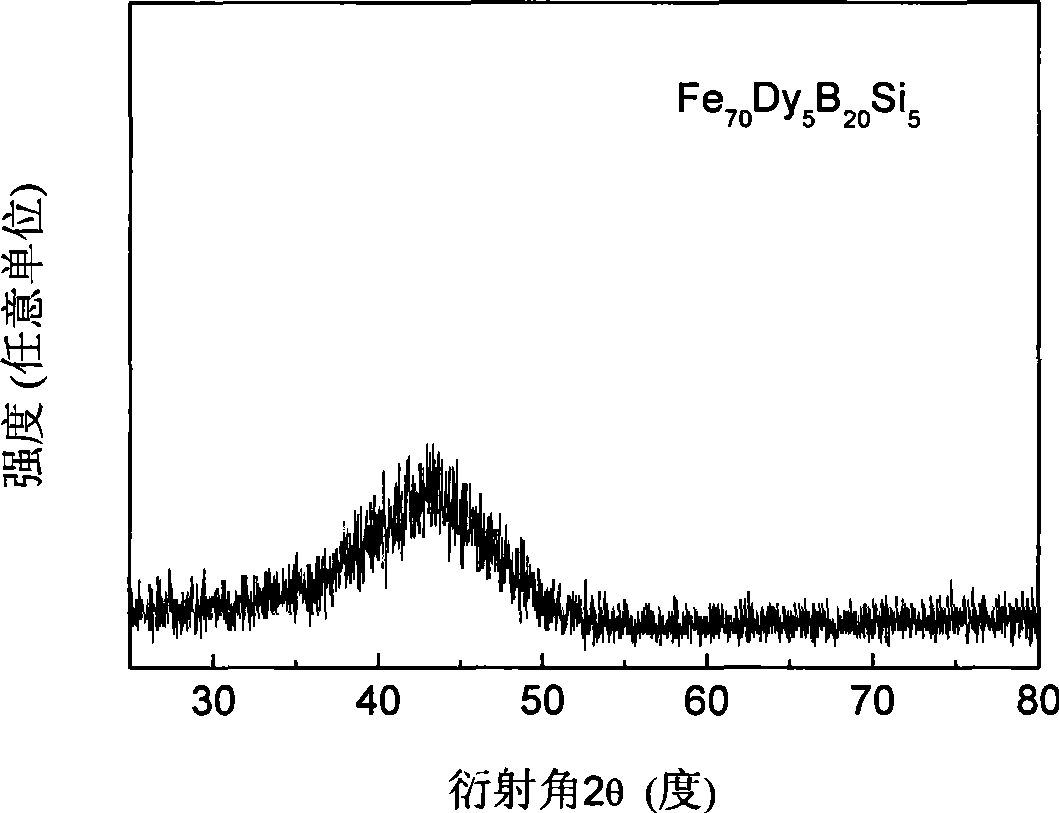

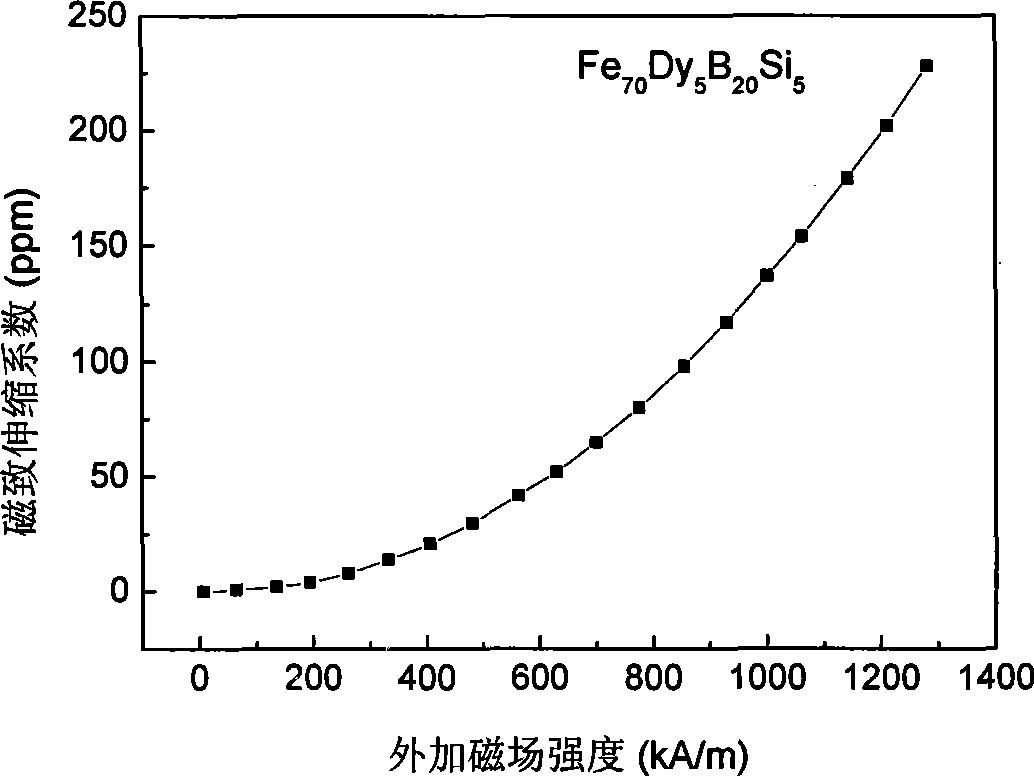

High magnetostriction iron based amorphous alloy and preparation thereof

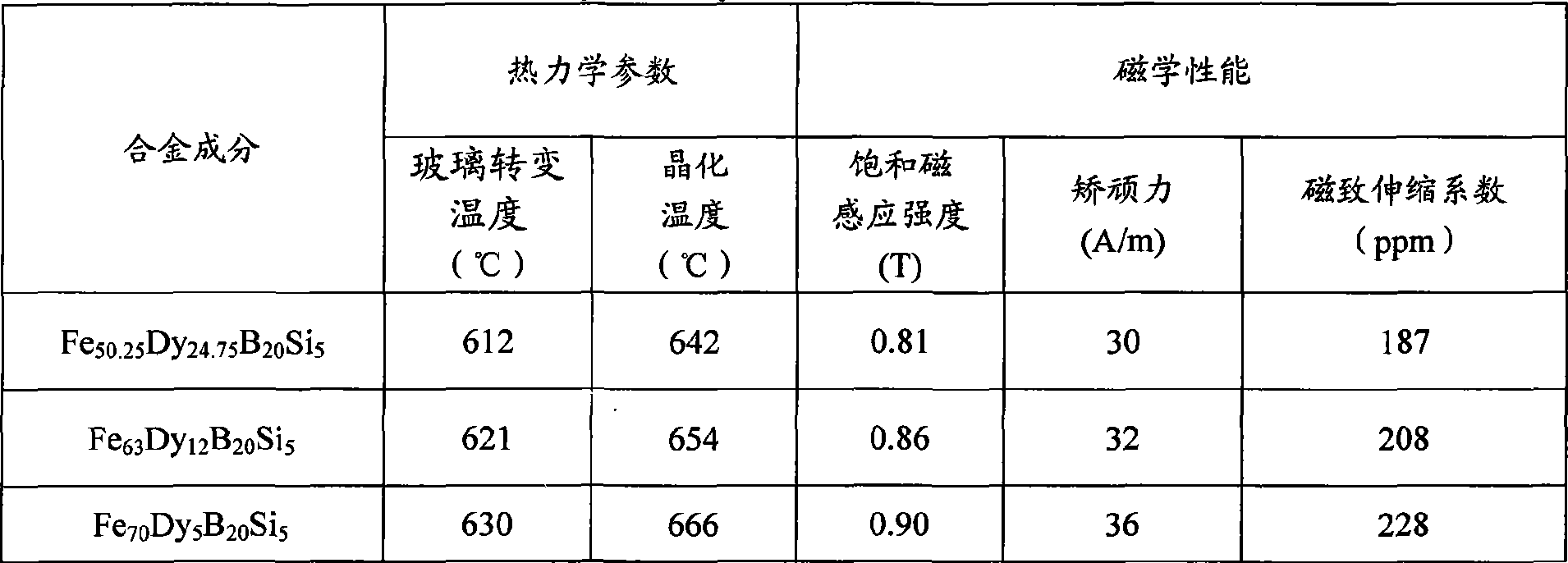

InactiveCN101503784AHigh magnetostriction coefficientImprove thermal stabilityMagnetizationThermal stability

The invention discloses a high magnetostriction iron base amorphous alloy and a preparation method thereof. The high magnetostriction iron base amorphous alloy has the following chemical molecular formula: Fe100-x-y-zDyxBySiz, wherein x, y and z are the atom percent of a Dy element, a B element and a Si element respectively, 100-x-y-z is the atom percent of a Fe element, x is more than or equal to 5 and less than or equal to 25, y is more than or equal to 20 and less than or equal to 25, and z is more than or equal to 0 and less than or equal to 10. The preparation method comprises the following steps: mixing industrial pure metal raw materials and an FeB alloy according to an alloy formulation, carrying out the magnetic suspension induction smelting on the raw materials and the FeB alloy to obtain a mother alloy, and then preparing an amorphous thin belt through a single roller melt-spun method. The iron base amorphous alloy material has a high magnetostriction coefficient of 228 ppm, excellent soft magnetization performance, high thermal stability, and a good amorphous formation capability. Simultaneously, the alloy material has simple preparation method and can be widely applied to the aspects of soft magnetization materials and structural materials in the fields of information, communication, computer, and the like.

Owner:ZHEJIANG UNIV +1

Large-plasticity cobalt-based bulk amorphous alloy with high amorphous forming ability and preparing method large-plasticity cobalt-based bulk amorphous alloy

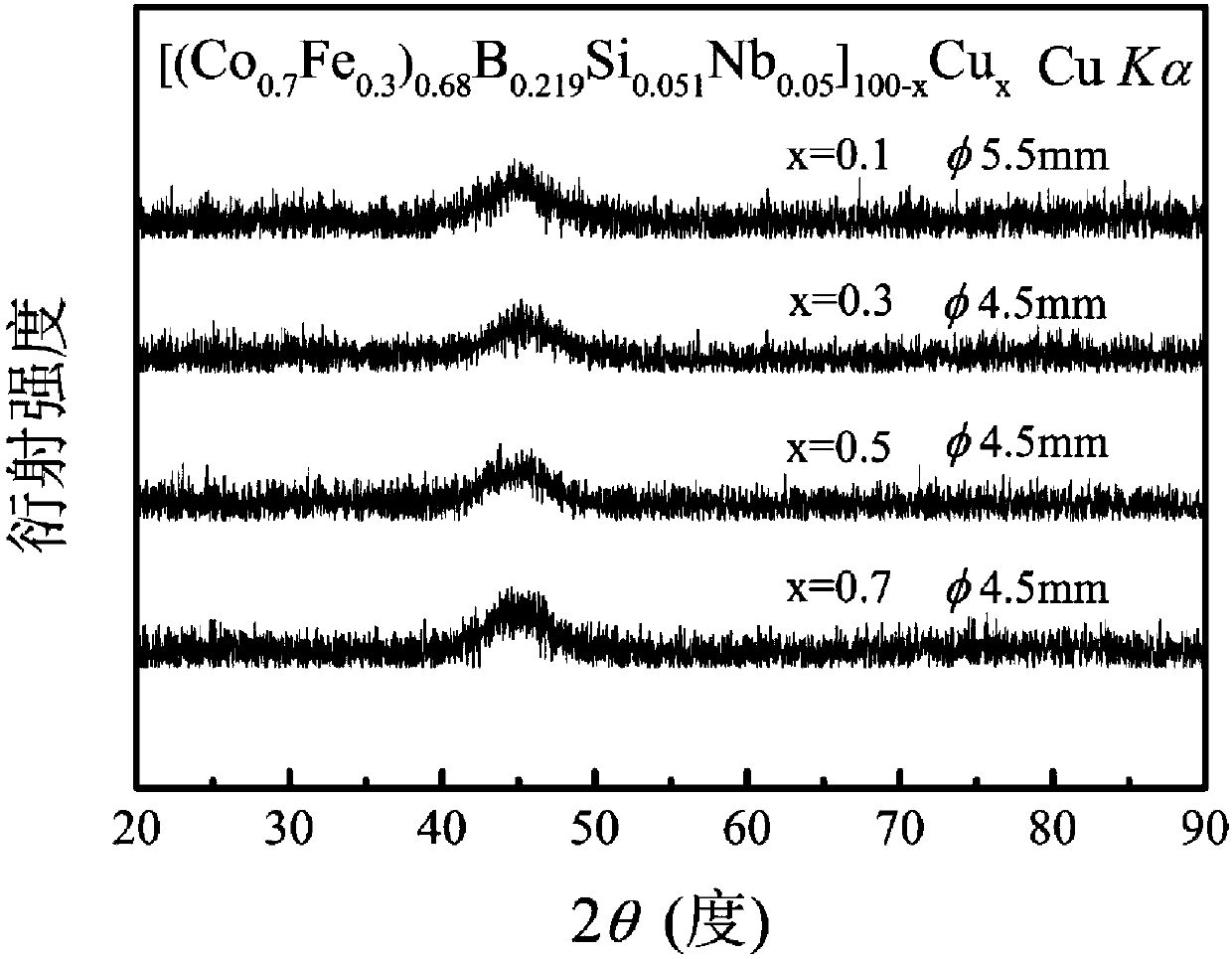

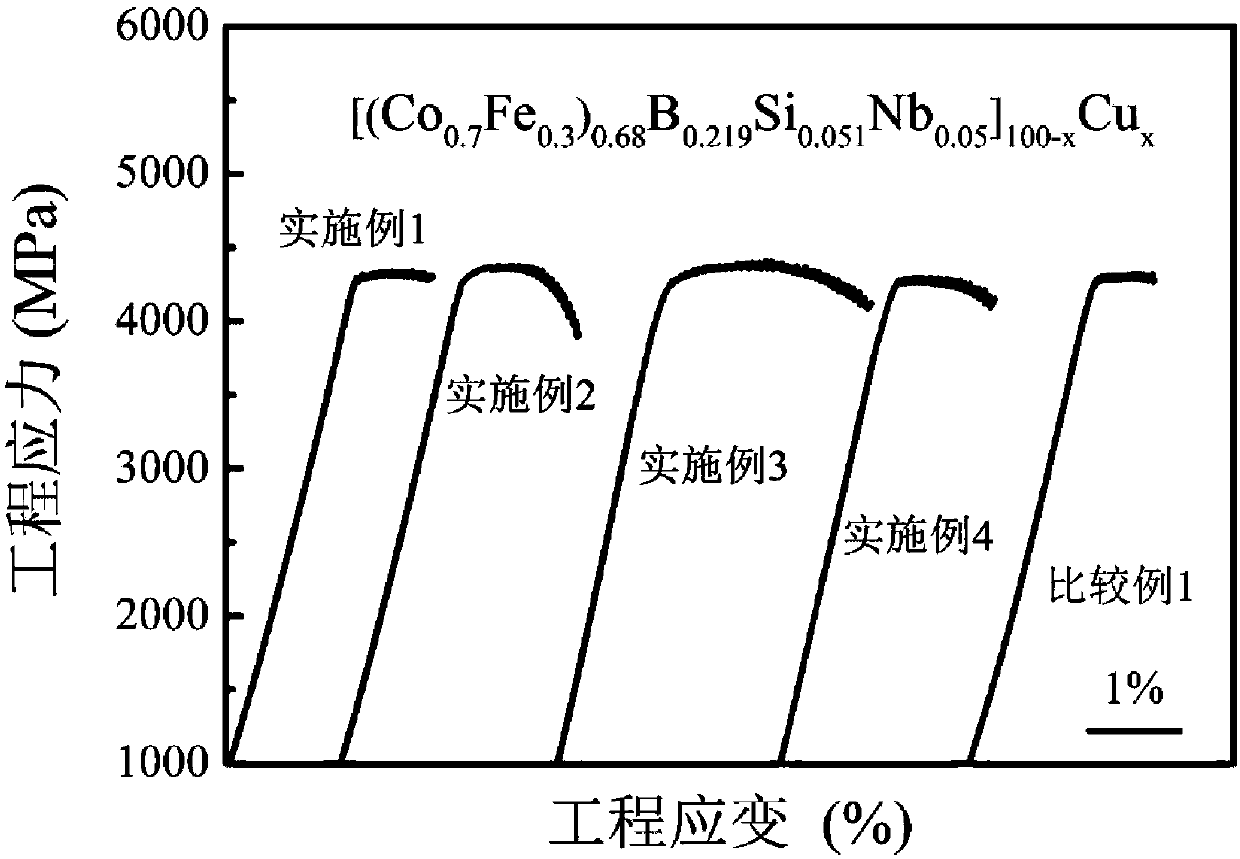

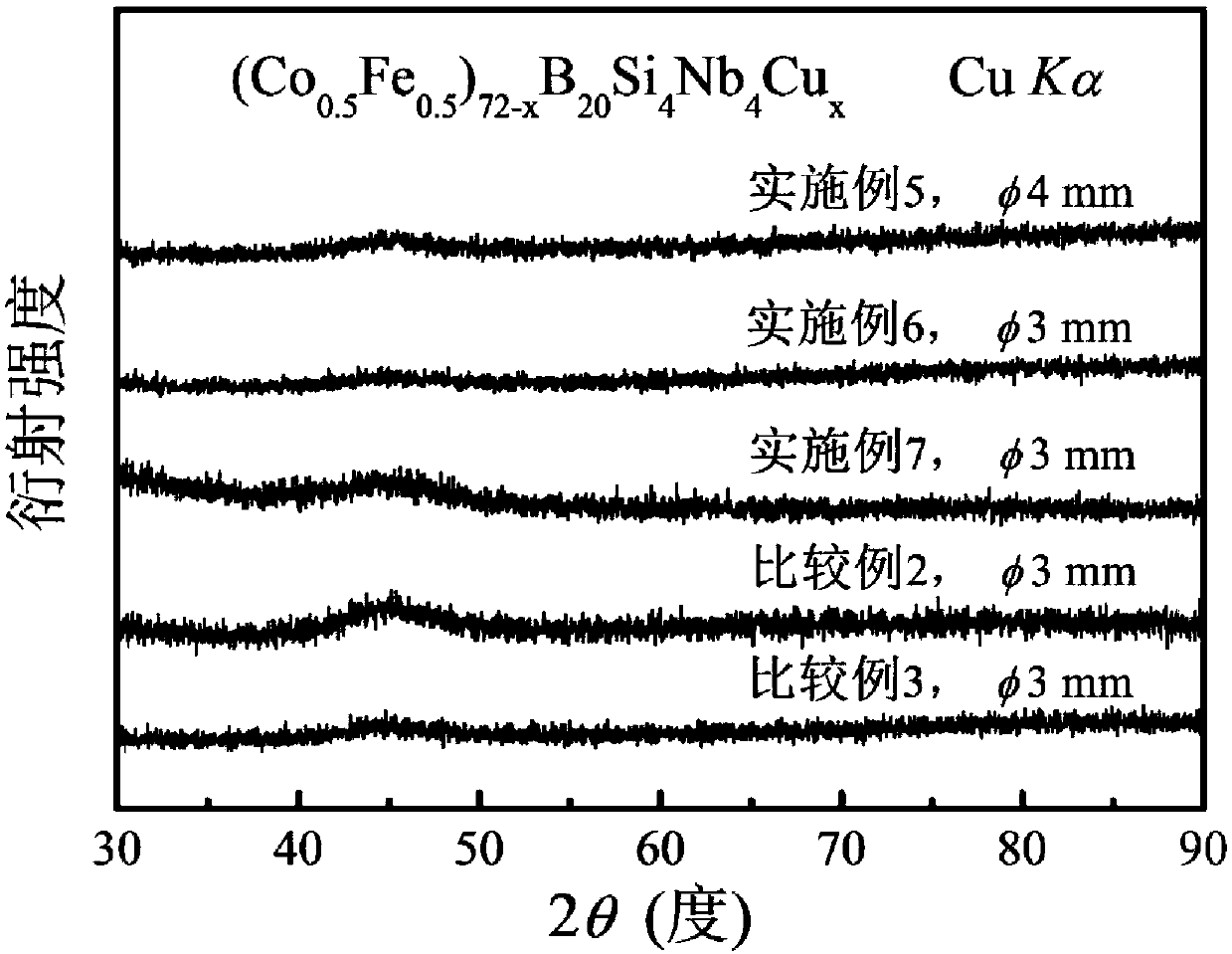

InactiveCN107829047AStrong ability to inhibit crystallizationImprove thermal stabilityBreaking strengthRare-earth element

The invention provides a large-plasticity cobalt-based bulk amorphous alloy with high amorphous forming ability. The molecular formula of the bulk amorphous alloy is CoaFebBxSiyNbcCud, in the formula,a, b, c, d, x and y show atomic percents of corresponding alloying elements, wherein a is larger than or equal to 35 and smaller than or equal to 48, b is larger than or equal to 20 and smaller thanor equal to 36, c is larger than or equal to 4 and smaller than or equal to 5, d is larger than or equal to 0.1 and smaller than or equal to 0.9, x is larger than or equal to 20 and smaller than or equal to 24, y is larger than or equal to 4 and smaller than or equal to 5.5, a+b is larger than or equal to 65 and smaller than or equal to 71.9, and a+b+c+d+x+y is equal to 100. Compared with the prior art, the alloy has the obviously beneficial effects that the high amorphous forming ability, the outstanding plastic deformation capacity and the excellent soft magnetic property are achieved, the maximum critical diameter reaches 3 mm-5.5 mm, the breaking strength is 4060 MPa-4400 MPa, the plastic deformation capacity is 1%-3.7%, the saturation magnetization is 0.72 T and above, and the coercive force is 0.81A / m-1.41 A / m; and the alloy does not contain rare earth elements and easy volatile elements, the preparing process is simple, and the good application prospect is achieved. The invention further provides a preparing method of the above alloy.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com