High saturation magnetic induction intensity iron-based amorphous soft magnetic composite material and manufacturing method thereof

A soft magnetic composite material, iron-based amorphous technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problem of low saturation magnetic induction intensity of amorphous magnetic powder cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The steps of a preparation method of an iron-based amorphous soft magnetic composite material are as follows:

[0036] Step 1: Mix industrial pure iron, polysilicon, phosphorus iron alloy, rare earth RE and alloy M according to the atomic ratio;

[0037] Step 2: Melting the prepared raw materials under the protection of argon, the melting temperature is 1200°C, using the water mist method to make amorphous powder, the pressure is 20 MPa, and the particle size of the prepared amorphous powder is less than 200 μm;

[0038]Step 3: Classify the obtained amorphous powder into -400 mesh, -300 mesh, -200 mesh, and -100 mesh, and then perform particle size ratio. The mass percentage of the mixed powder is: -100 ~ +200 mesh, accounting for 20 %~40%, -200~+300 mesh accounts for 25%~50%, -300 mesh accounts for 10%~30%, and the rest is -400 mesh;

[0039] Step 4: Use phosphoric acid passivation process for insulation treatment, the amount of phosphoric acid used is 0.4% of the wei...

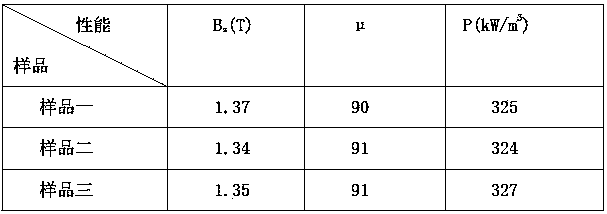

Embodiment 1

[0043] Put Fe, Y, P, Si, B, C and S in accordance with Fe 75 Y 1 P 5.8 Si 5 B 12 C 1 S 0.2 The atomic ratio is used for batching. Put the prepared raw materials into the crucible of the vacuum melting furnace, and carry out melting under the atmosphere of argon. Use the water spray method to crush the master alloy into a size smaller than 200

[0044] μm amorphous powder, the water pressure is 20 MPa. For the particle size ratio of the amorphous powder, the mass percentage content of the mixed powder is: -100 ~ +200 mesh accounts for 40%, -200 ~ +300 mesh accounts for 30%, -300 mesh accounts for 20%, -400 mesh accounts for 10% . The mixed amorphous powder was passivated by phosphoric acid, the amount of phosphoric acid was 0.4% of the mass of the magnetic powder, and the passivation treatment was carried out at 50 °C for 1 h. Add xylene-diluted silicone resin to the powder after passivation treatment, the addition of silicone resin is 2% of the mass of the magnetic p...

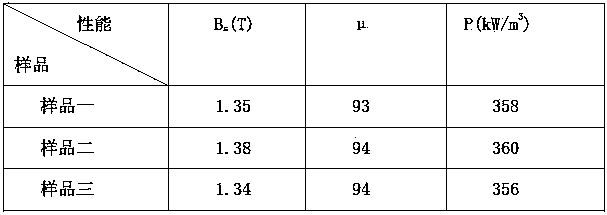

Embodiment 2

[0047] Fe, Y, Dy, P, Si, B, C and S are classified according to Fe 75 Y 1 Dy 1 P 5.8 Si 5 B 10 C 2 S 0.2 The atomic ratio is used for batching. will match

[0048] The raw materials are put into the crucible of the vacuum melting furnace and smelted in an argon atmosphere. The master alloy was pulverized into amorphous powder with a size of less than 200 μm by water spray method, and the water pressure was 20 MPa. For the particle size ratio of the amorphous powder, the mass percentage content of the mixed powder is: -100 ~ +200 mesh accounts for 30%, -200 ~ +300 mesh accounts for 30%, -300 mesh accounts for 30%, -400 mesh accounts for 10% . The mixed amorphous powder was passivated by phosphoric acid, the amount of phosphoric acid was 0.4% of the mass of the magnetic powder, and the passivation treatment was carried out at 50 °C for 1 h. Add xylene-diluted silicone resin to the powder after passivation treatment, the addition of silicone resin is 2% of the mass of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com