Patents

Literature

3777 results about "Iron based" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron-based superalloys are characterized by high temperature as well as room-temperature strength and resistance to creep, oxidation, corrosion, and wear. Wear resistance increases with carbon content. Maximum wear resistance is obtained in alloys 611, 612, and 613, which are used in high-temperature aircraft bearings...

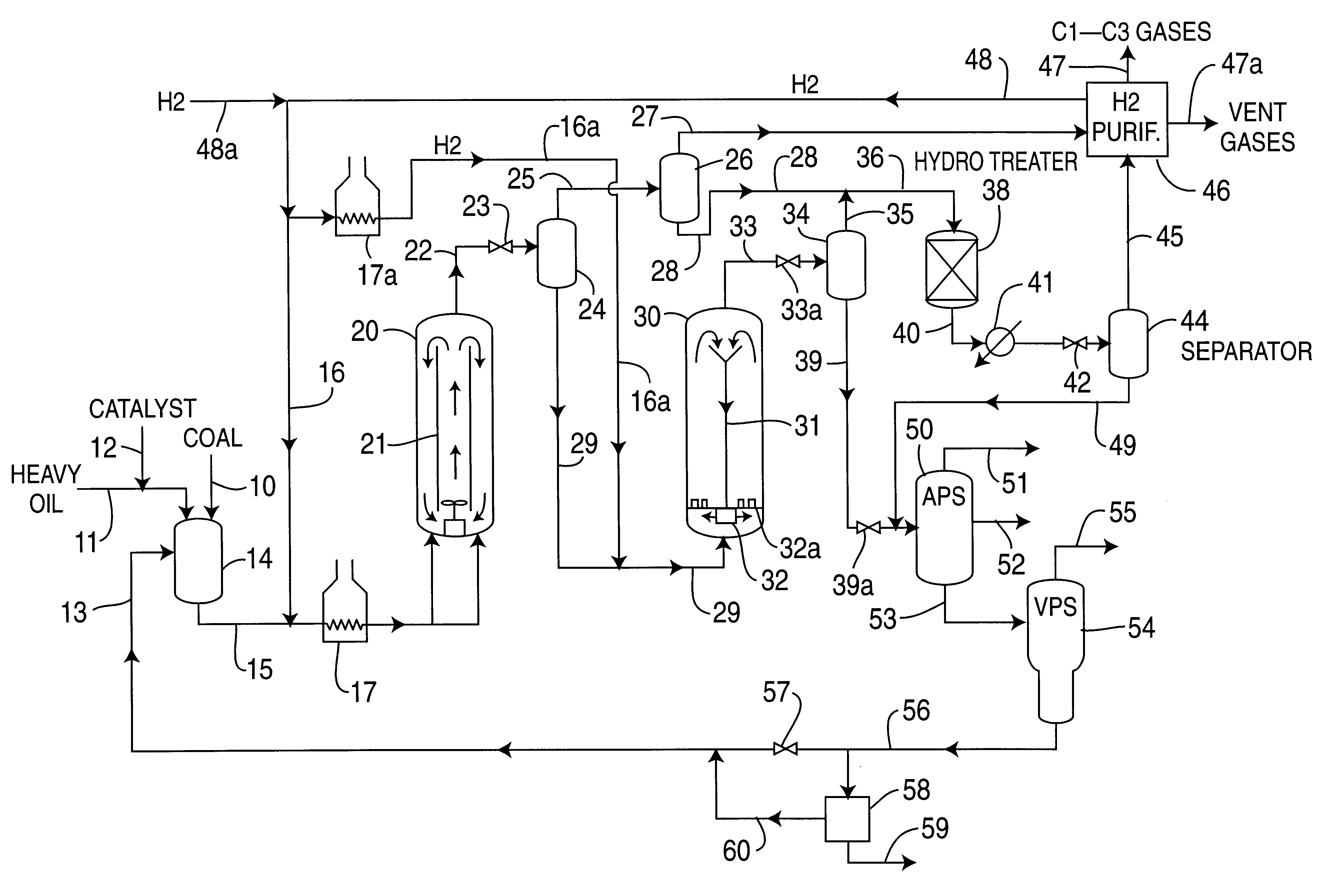

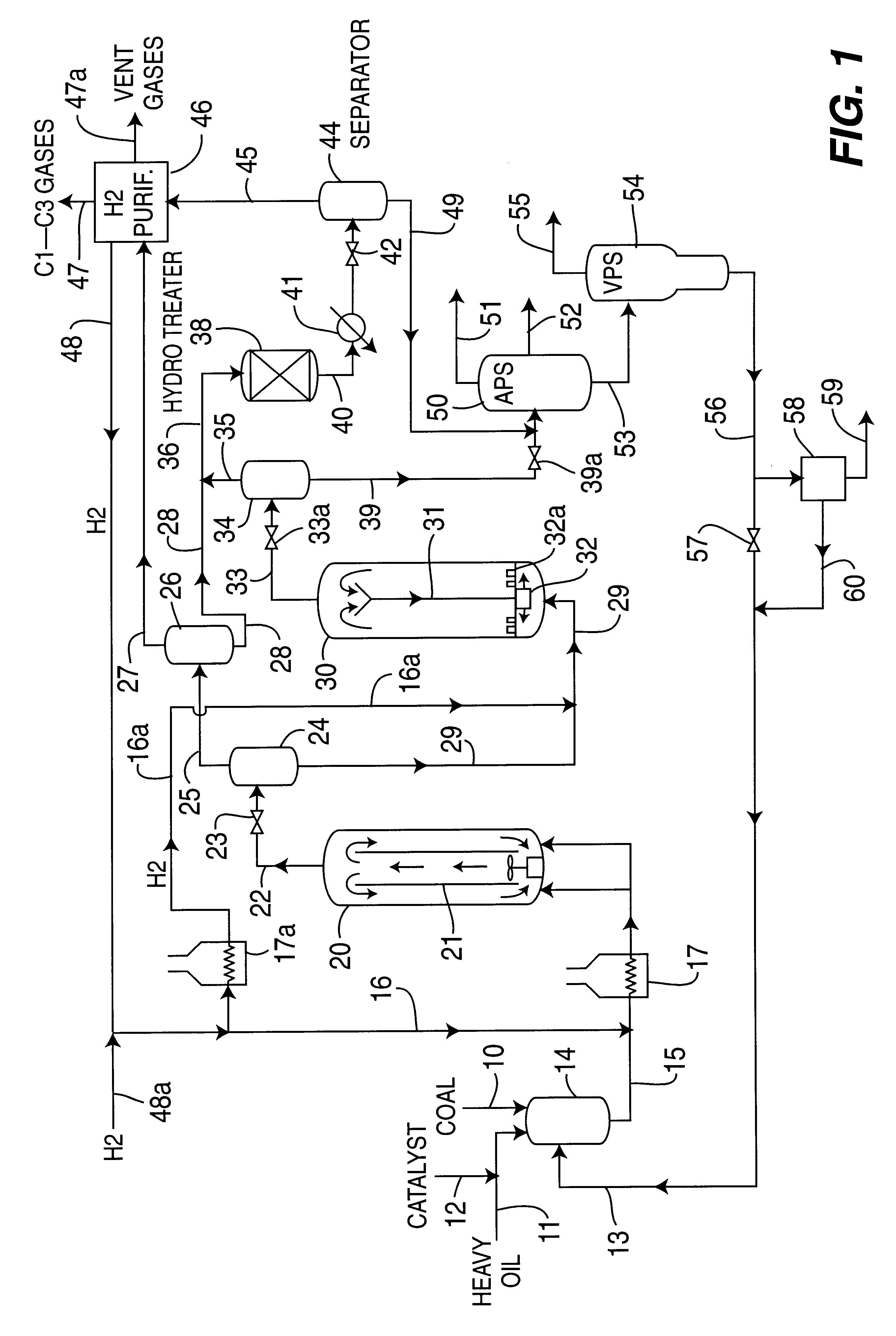

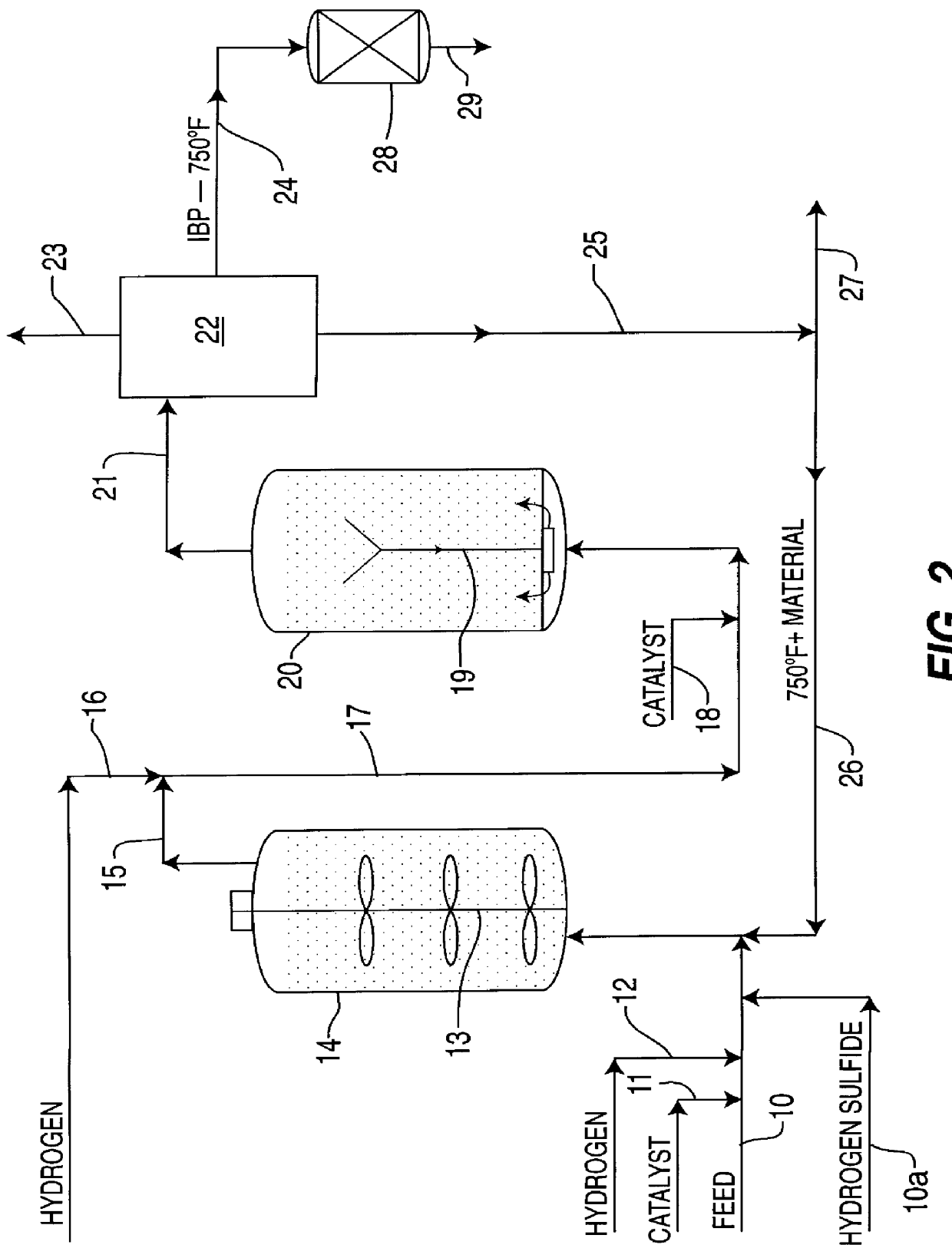

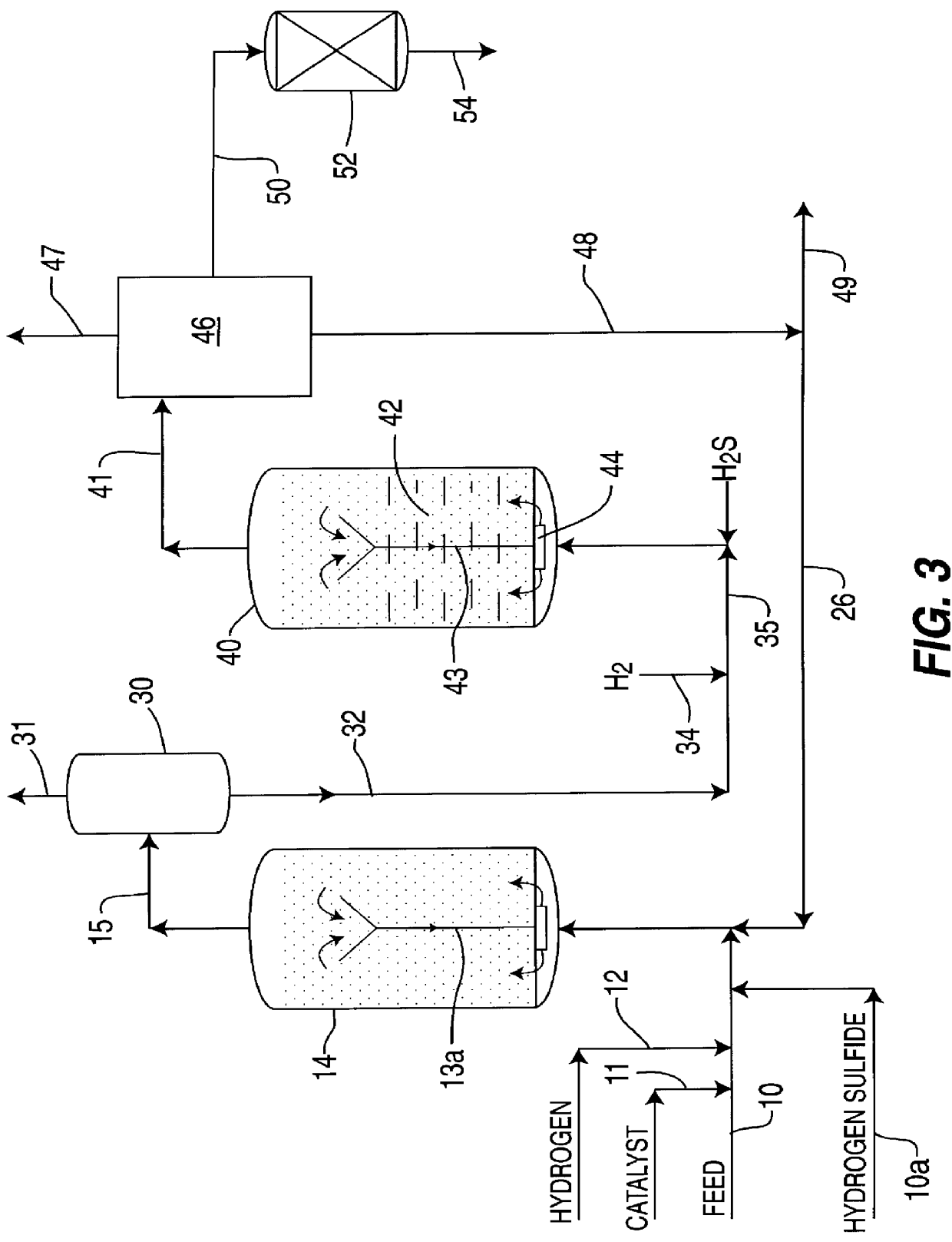

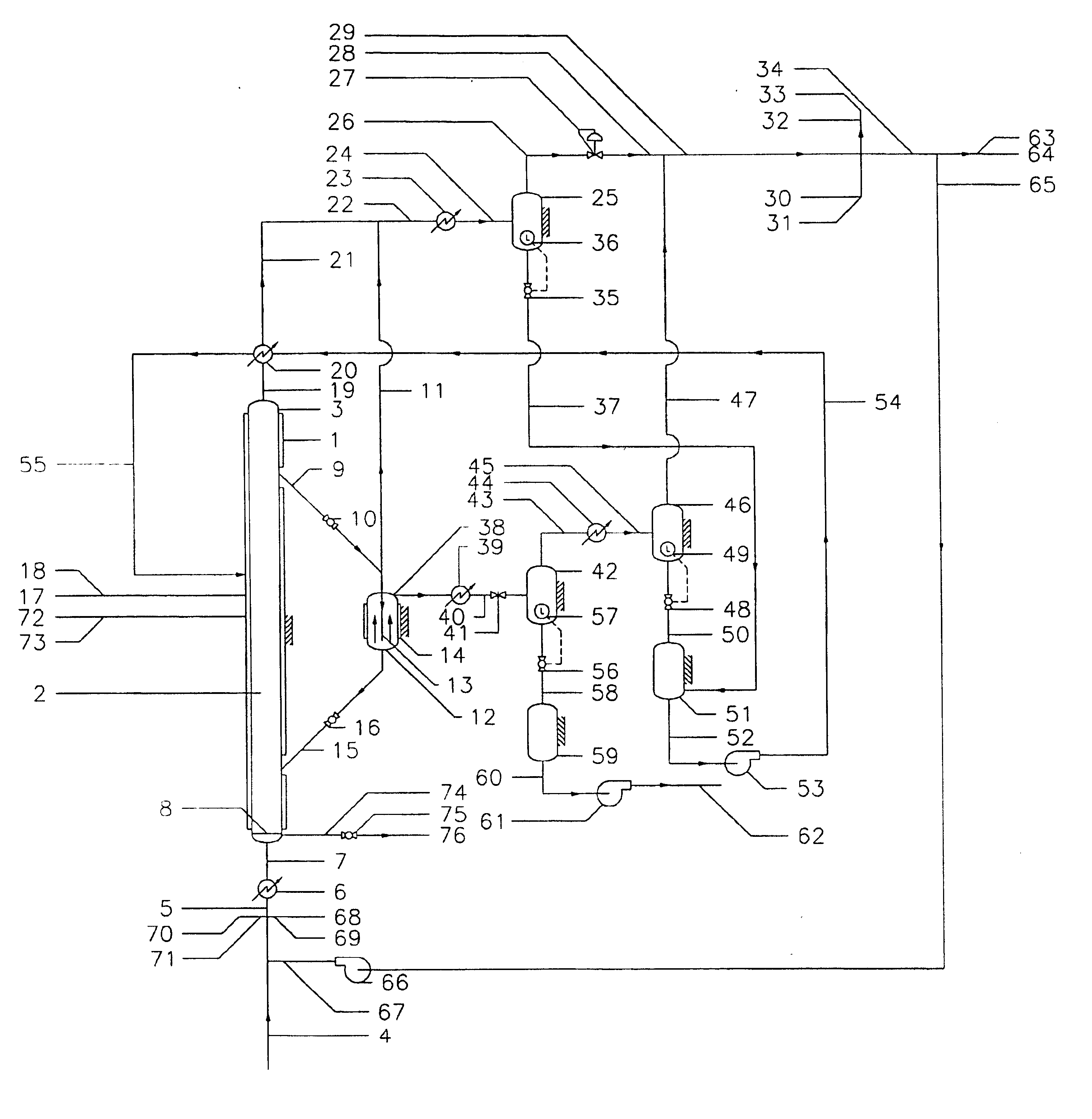

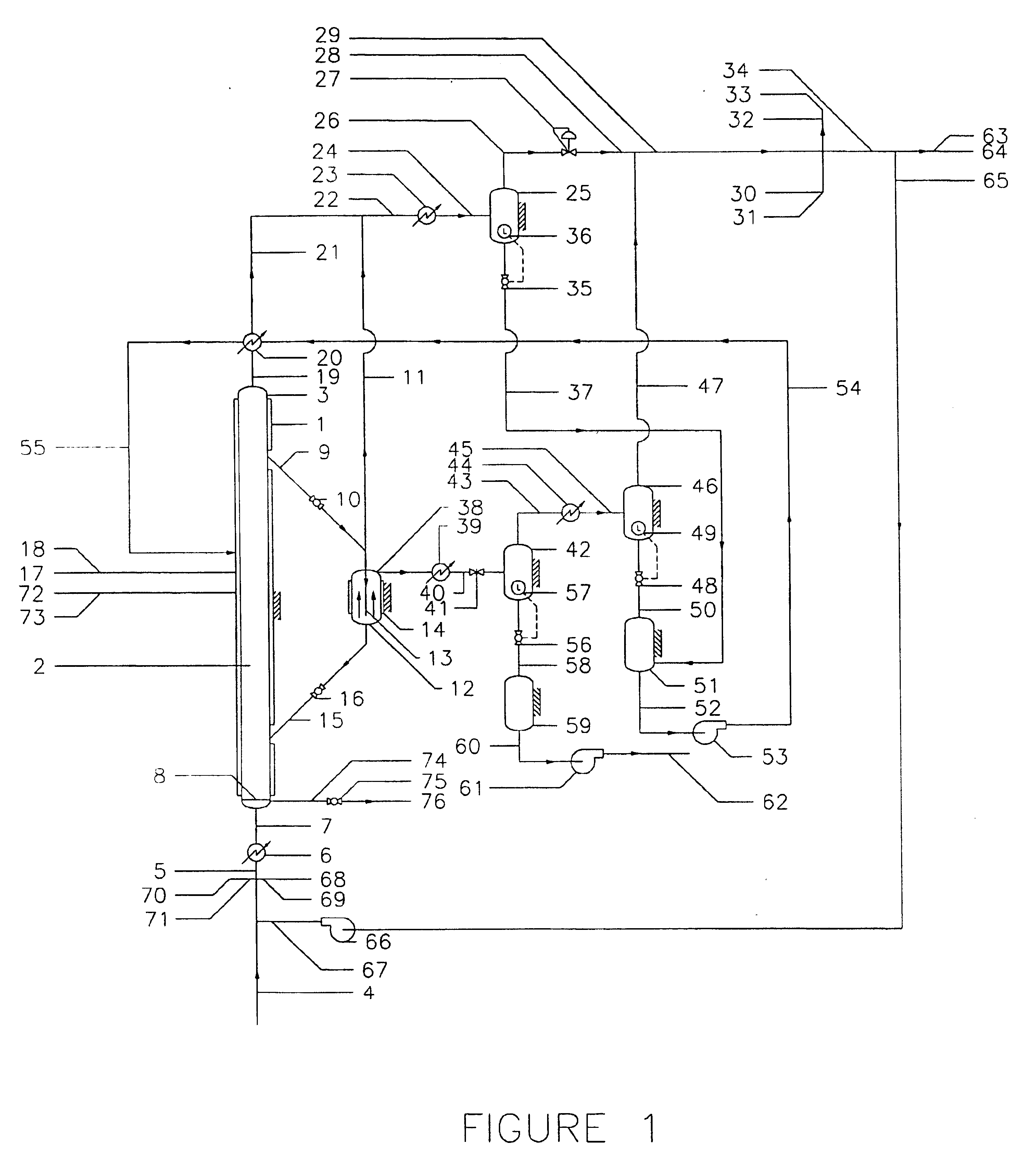

Catalytic multi-stage process for hydroconversion and refining hydrocarbon feeds

InactiveUS6190542B1Improve distillation yieldQuality improvementCatalyst activation/preparationLiquid hydrocarbon mixture productionLiquid productDistillates petroleum

A multi-stage catalytic hydrogenation and hydroconversion process for heavy hydrocarbon feed materials such as coal, heavy petroleum fractions, and plastic waste materials. In the process, the feedstock is reacted in a first-stage, back-mixed catalytic reactor with a highly dispersed iron-based catalyst having a powder, gel or liquid form. The reactor effluent is pressure-reduced, vapors and light distillate fractions are removed overhead, and the heavier liquid fraction is fed to a second stage back-mixed catalytic reactor. The first and second stage catalytic reactors are operated at 700-850.degree. F. temperature, 1000-3500 psig hydrogen partial pressure and 20-80 lb. / hr per ft.sup.3 reactor space velocity. The vapor and light distillates liquid fractions removed from both the first and second stage reactor effluent streams are combined and passed to an in-line, fixed-bed catalytic hydrotreater for heteroatom removal and for producing high quality naphtha and mid-distillate or a full-range distillate product. The remaining separator bottoms liquid fractions are distilled at successive atmospheric and vacuum pressures, low and intermediate-boiling hydrocarbon liquid products are withdrawn, and heavier distillate fractions are recycled and further upgraded to provide additional low-boiling hydrocarbon liquid products. This catalytic multistage hydrogenation process provides improved flexibility for hydroprocessing the various carbonaceous feedstocks and adjusting to desired product structures and for improved economy of operations.

Owner:HEADWATERS CTL

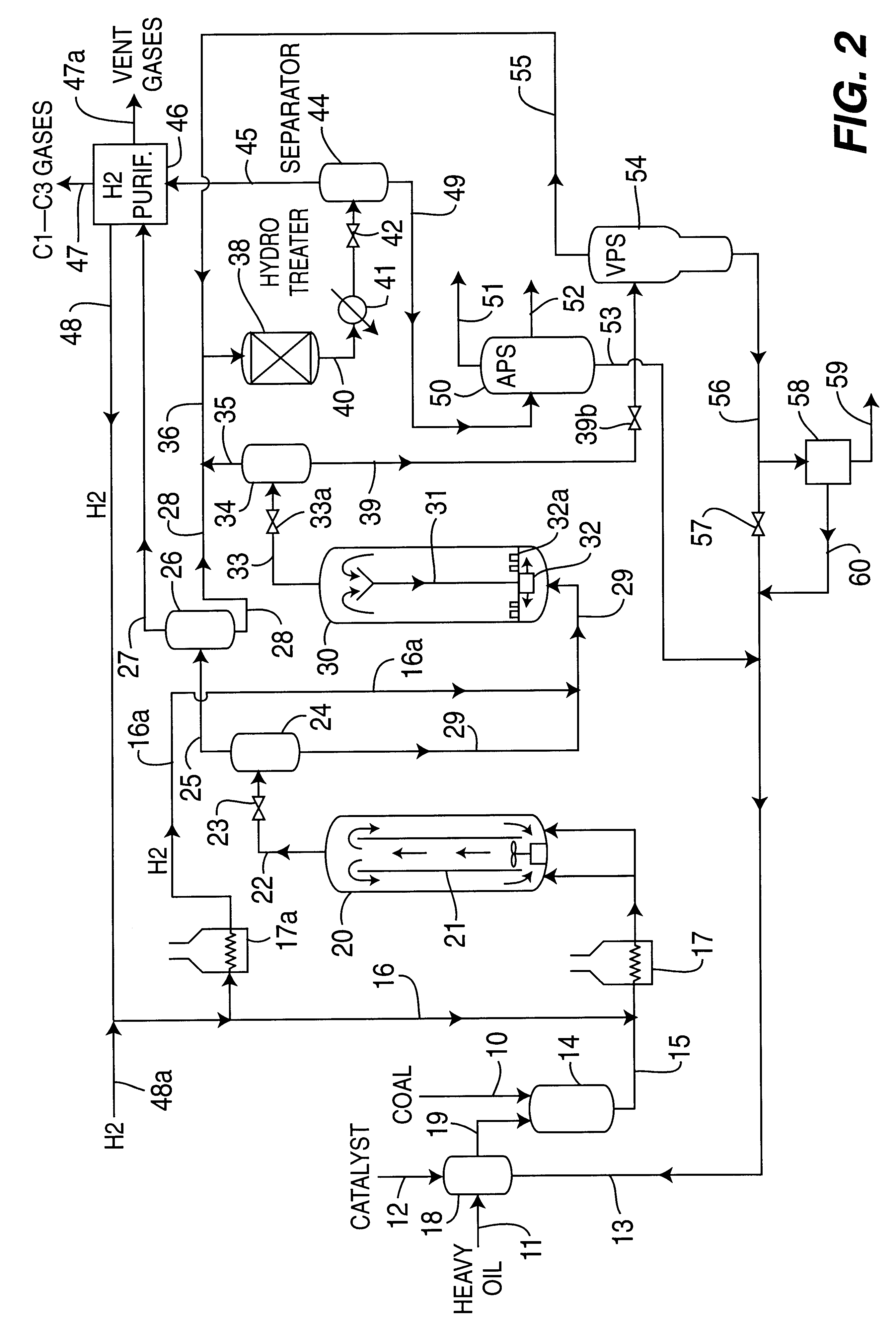

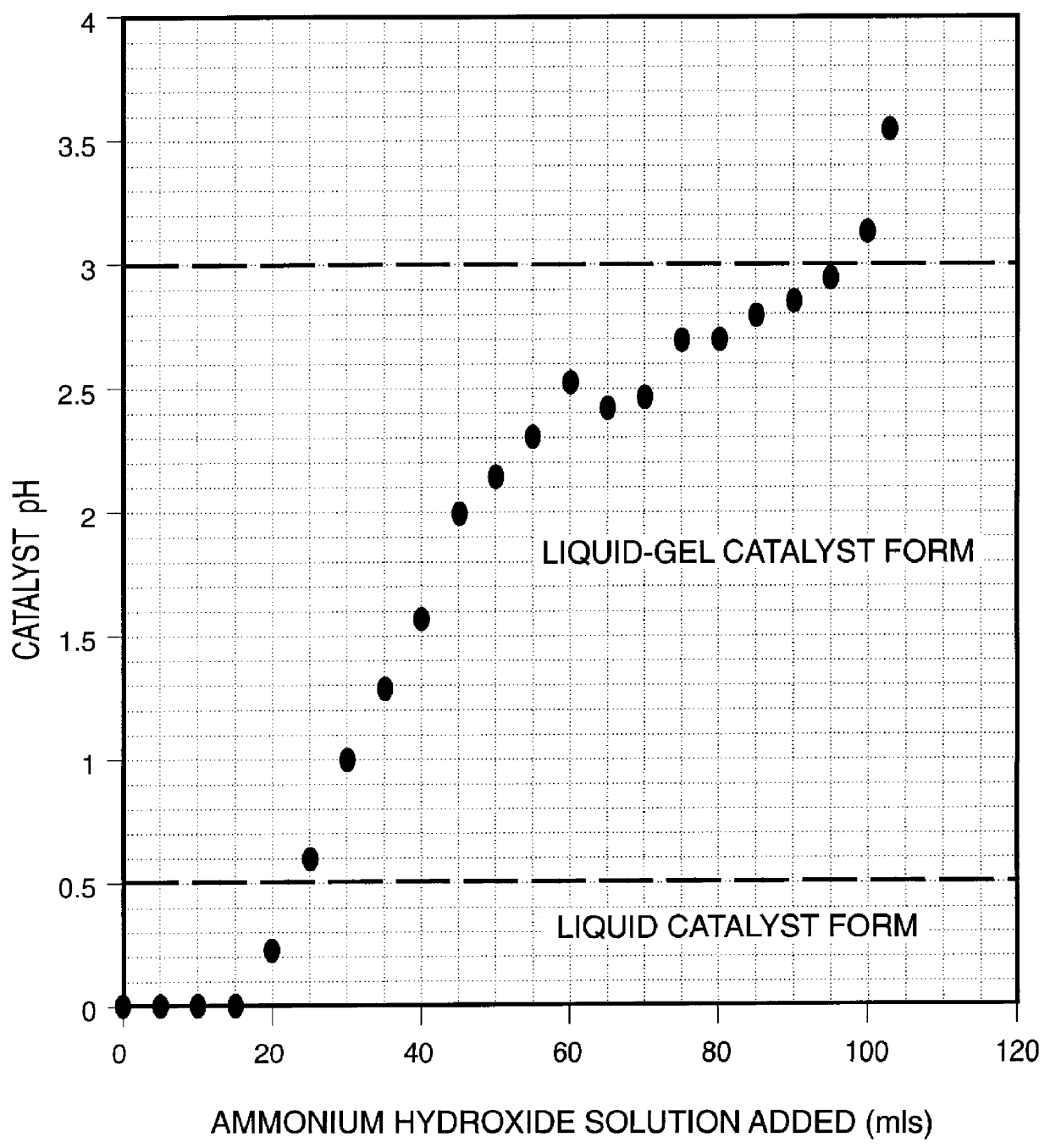

Iron-based ionic liquid catalysts for hydroprocessing carbonaceous feeds

InactiveUS6139723AIncrease hydrocracking ability of catalystIndirect and direct heating destructive distillationCatalyst activation/preparationLiquid productIron salts

A highly dispersed iron-based ionic liquid or liquid-gel catalyst which may be anion-modified and metals-promoted has high catalytic activity, and is useful for hydrocracking / hydrogenation reactions for carbonaceous feed materials. The catalyst is produced by aqueous precipitation from saturated iron salt solutions such as ferric sulfate and ferric alum, and may be modified during preparation with anionic sulfate (SO42-) and promoted with small percentages of at least one active metal such as cobalt, molybdenum, palladium, platinum, nickel, or tungsten or mixtures thereof. The resulting catalyst may be used in a preferred ionic liquid form or in a liquid-gel form, and either fluidic form can be easily mixed and reacted with carbonaceous feed materials such as coal, heavy petroleum fractions, mixed plastic waste, or mixtures thereof. The invention includes methods for making the ionic liquid or liquid-gel catalyst, and processes for using the fluidic catalysts for hydroprocessing the carbonaceous feed materials to produce desirable low-boiling hydrocarbon liquid products.

Owner:HEADWATERS CTL

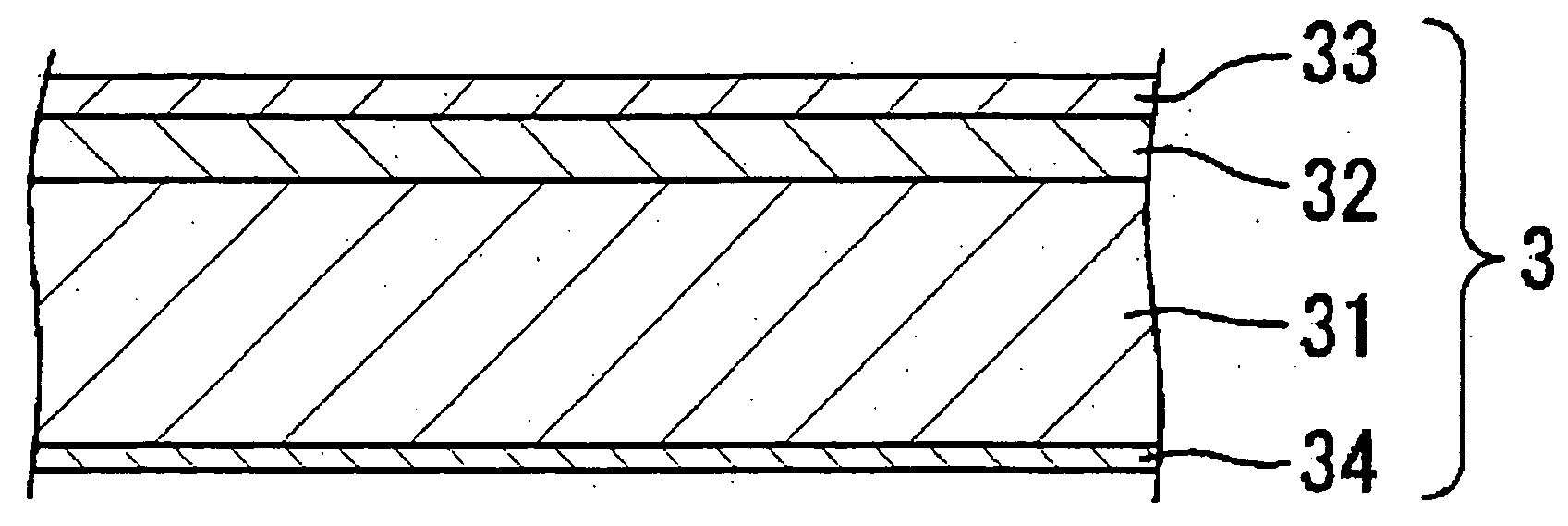

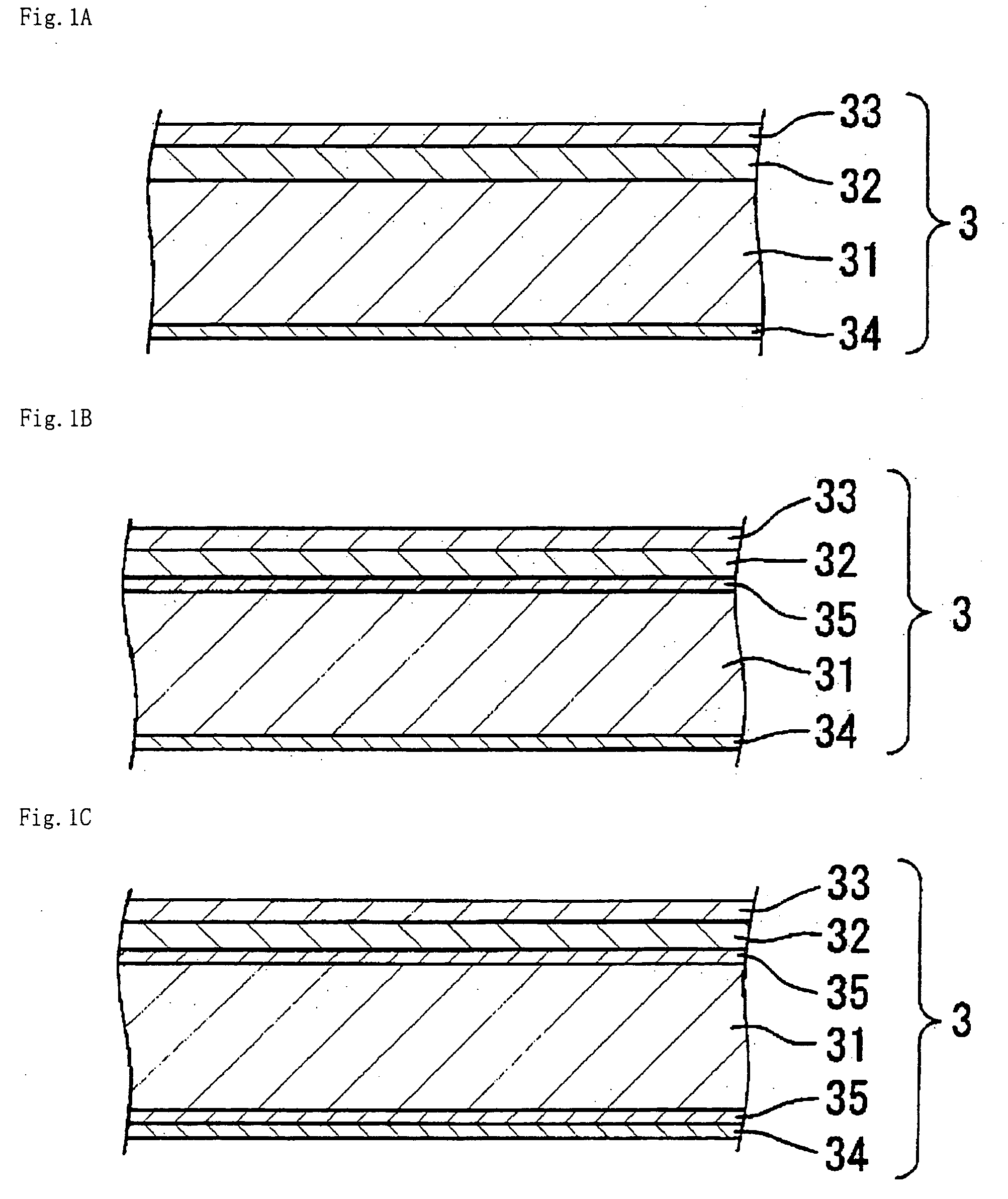

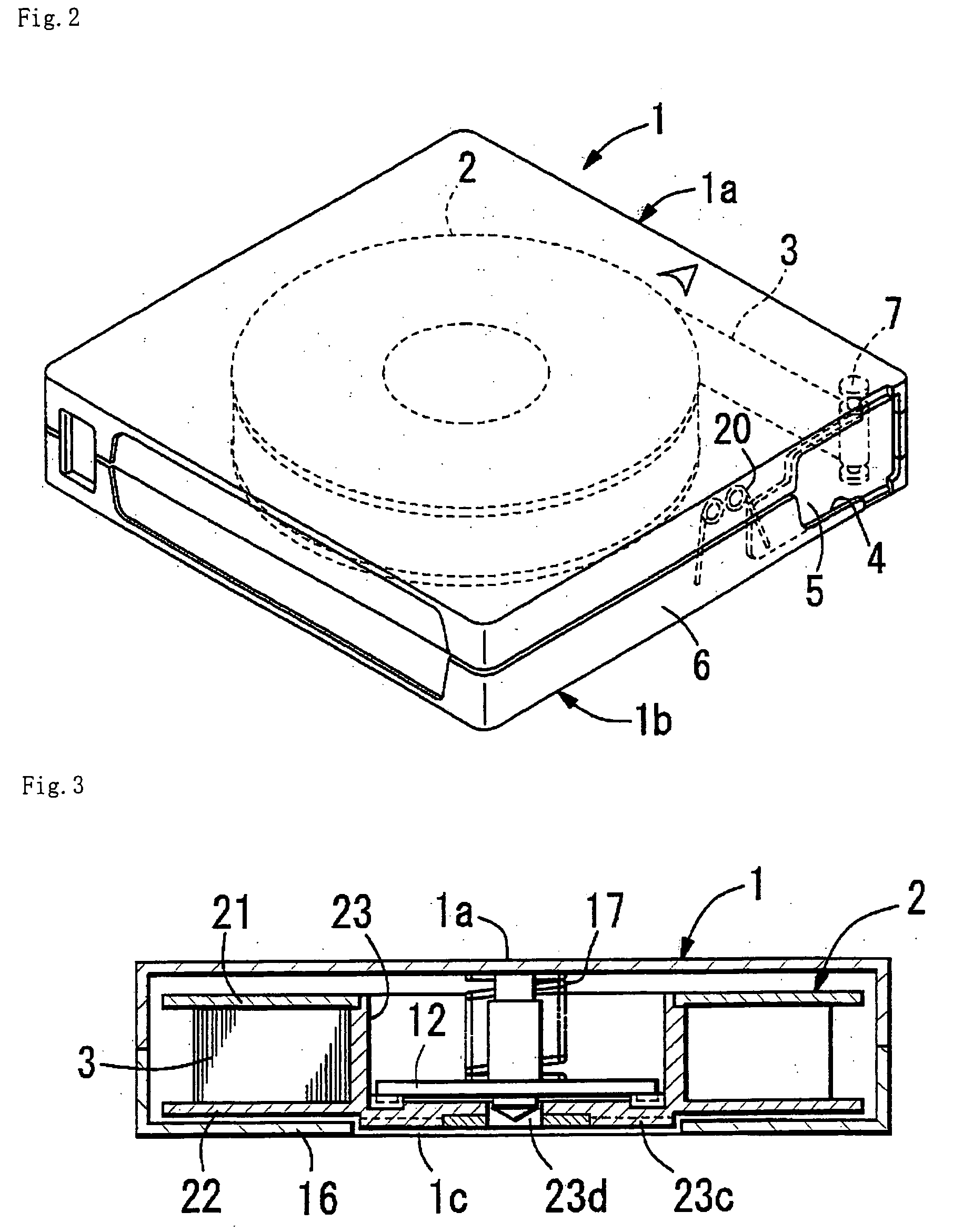

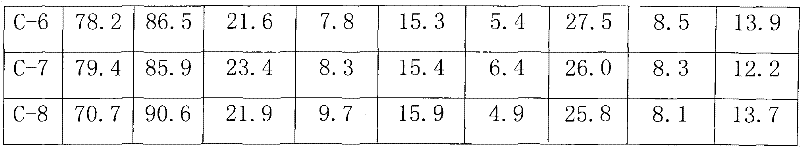

Magnetic tape and magnetic tape cartridge

InactiveUS20050153170A1Improved in performanceGood dimensional stabilityMaterials with ironLayered productsMagnetic tapeThermal expansion

There is provided a magnetic tape comprising a non-magnetic support, and a primer layer and a magnetic layer both formed on a surface of the non-magnetic support, and a backcoat layer formed on the other surface of the non-magnetic support, wherein the magnetic layer contains magnetic powder which comprises needle-like iron-based magnetic particles, and has a thickness of 0.09 μm or less; and the primer layer contains non-magnetic powder which comprises plate-like non-magnetic oxide particles with an average particle size of 10 to 100 nm. Further, the thermal expansion coefficient of the magnetic layer in the tape widthwise direction is (0 to 8)×10−6 / ° C., and the humidity expansion coefficient of the magnetic layer in the tape widthwise direction is (0 to 10)×10−6 / % RH; and the amount of edge weave which is formed on either of the edges of the tape serving as the side of reference for the feeding of the tape is 0.8 μm or less. This magnetic tape is excellent in performance for recording / reproducing signals with short wavelengths and hardly causes a decrease in reproducing output due to off-track.

Owner:HITACHT MAXELL LTD

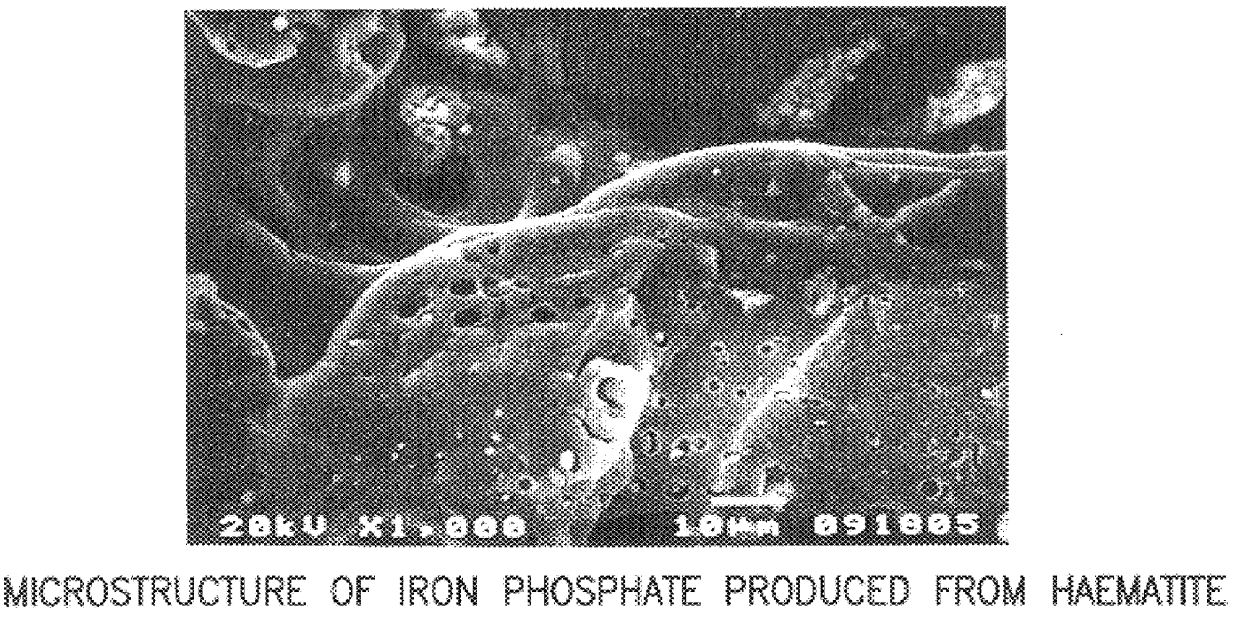

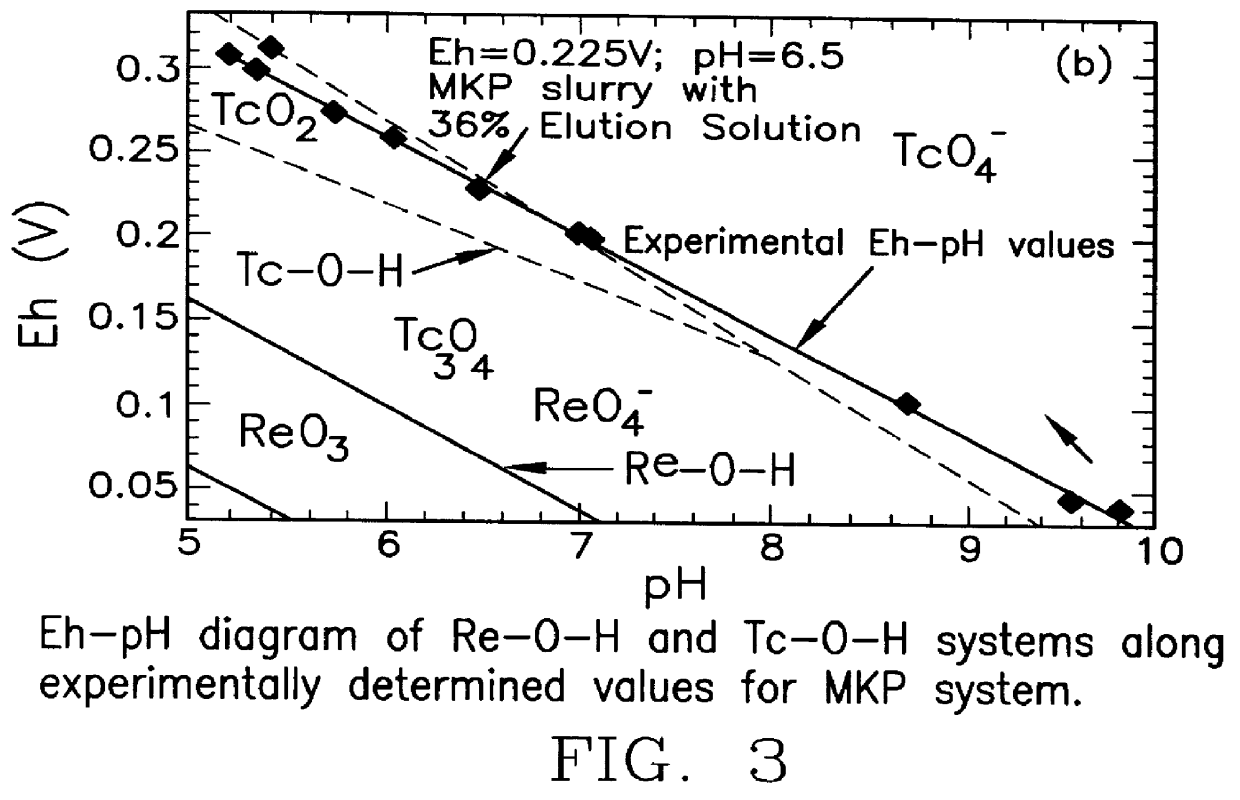

Method for producing chemically bonded phosphate ceramics and for stabilizing contaminants encapsulated therein utilizing reducing agents

Known phosphate ceramic formulations are improved and the ability to produce iron-based phosphate ceramic systems is enabled by the addition of an oxidizing or reducing step during the acid-base reactions that form the phosphate ceramic products. The additives allow control of the rate of the acid-base reactions and concomitant heat generation. In an alternate embodiment, waste containing metal anions are stabilized in phosphate ceramic products by the addition of a reducing agent to the phosphate ceramic mixture. The reduced metal ions are more stable and / or reactive with the phosphate ions, resulting in the formation of insoluble metal species within the phosphate ceramic matrix, such that the resulting chemically bonded phosphate ceramic product has greater leach resistance.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

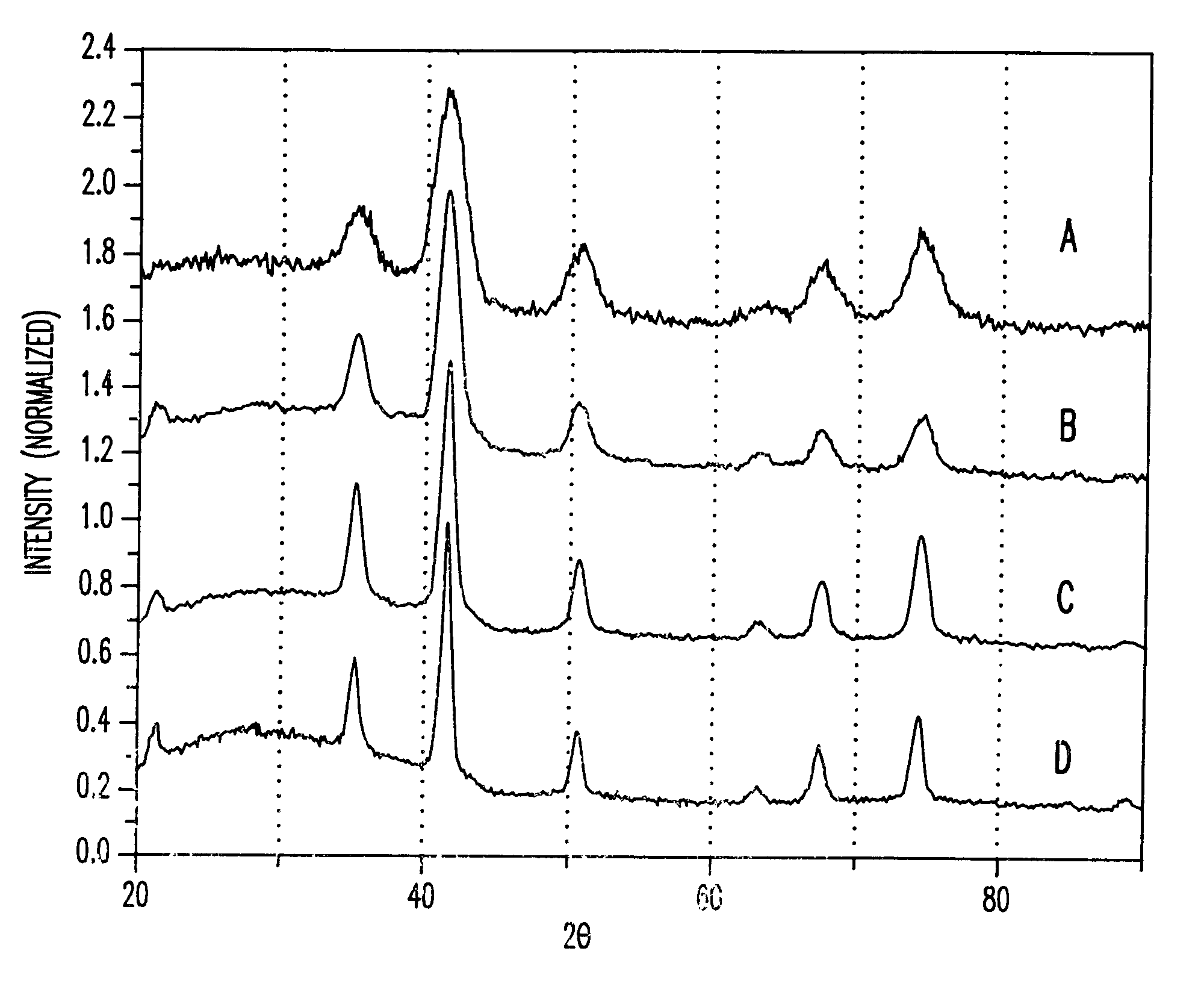

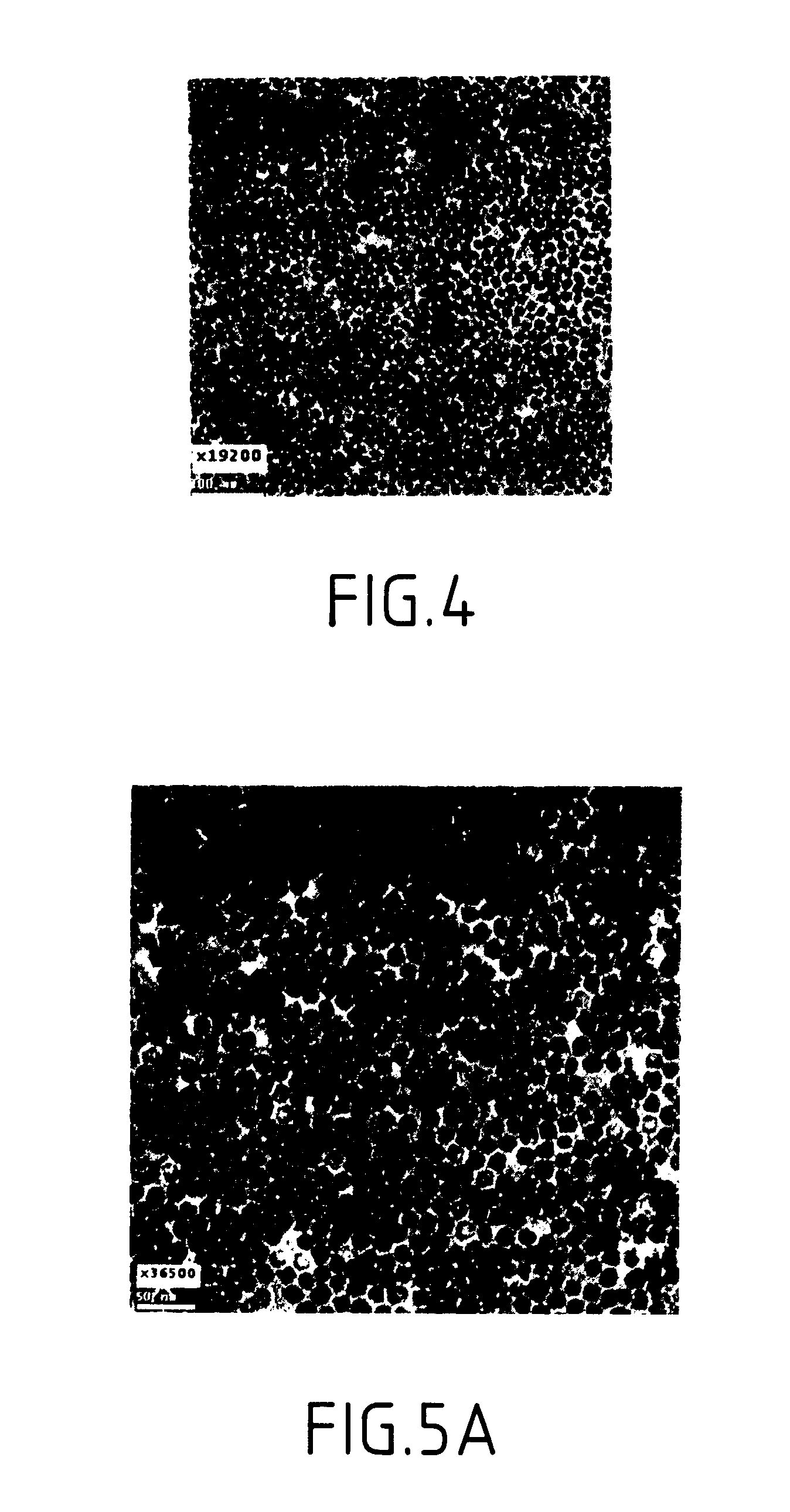

Synthesis of magnetite nanoparticles and the process of forming Fe-based nanomaterials

InactiveUS6962685B2Small sizeNarrow size distributionMaterial nanotechnologyNanomagnetismIron saltsMagnetite Nanoparticles

A method and structure for making magnetite nanoparticle materials by mixing iron salt with alcohol, carboxylic acid and amine in an organic solvent and heating the mixture to 200–360 C is described. The size of the particles can be controlled either by changing the iron salt to acid / amine ratio or by coating small nanoparticles with more iron oxide. Magnetite nanoparticles in the size ranging from 2 nm to 20 nm with a narrow size distribution are obtained with the invention. The invention can be readily extended to other iron oxide based nanoparticle materials, including M Fe2O4 (M=Co, Ni, Cu, Zn, Cr, Ti, Ba, Mg) nanomaterials, and iron oxide coated nanoparticle materials. The invention also leads to the synthesis of iron sulfide based nanoparticle materials by replacing alcohol with thiol in the reaction mixture. The magnetite nanoparticles can be oxidized to γ-Fe2O3, or α-Fe2O3, or can be reduced to bcc-Fe nanoparticles, while iron oxide based materials can be used to make binary iron based metallic nanoparticles, such as CoFe, NiFe, and FeCoSmx nanoparticles.

Owner:INT BUSINESS MASCH CORP

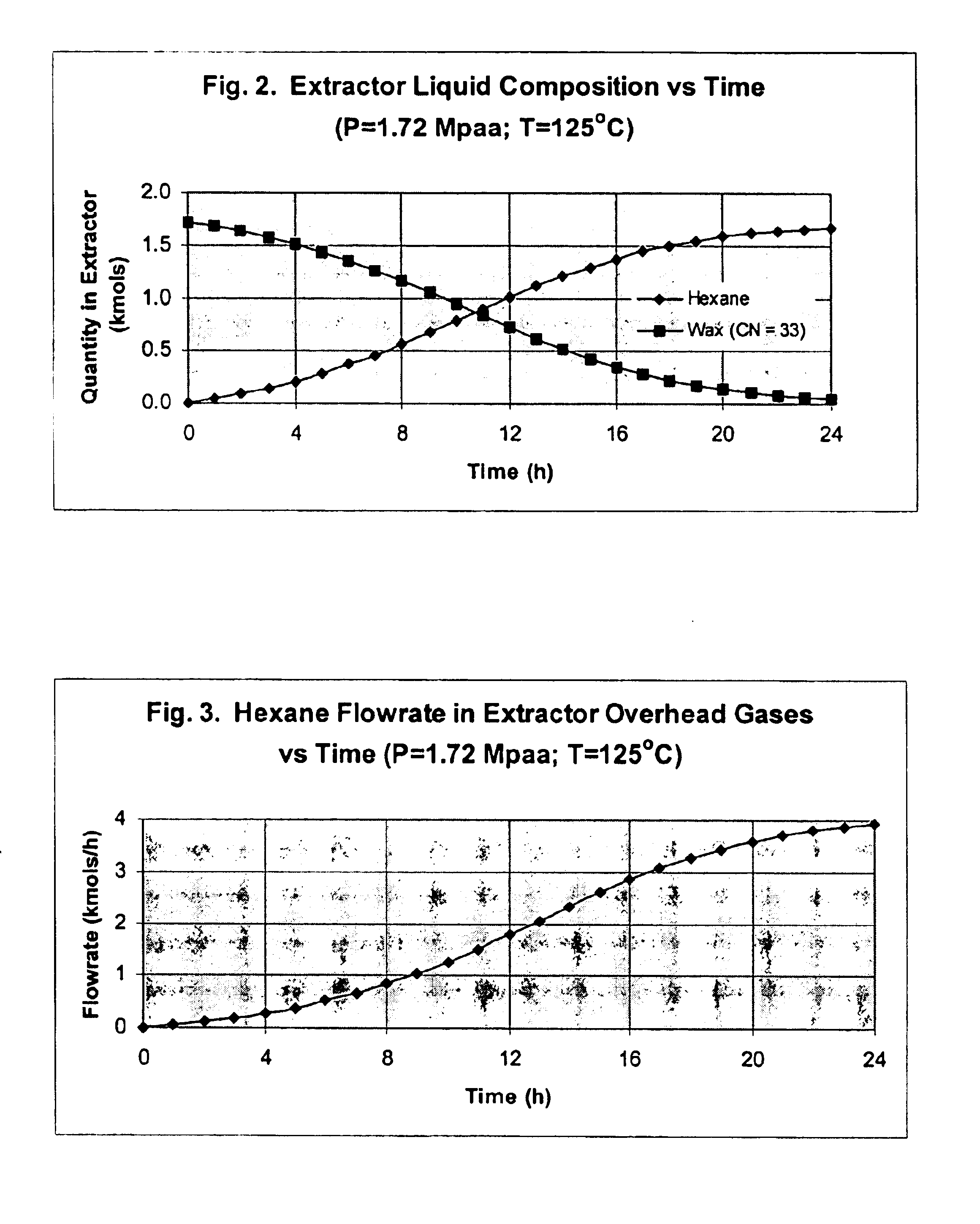

Method and apparatus for regenerating an iron-based Fischer-Tropsch catalyst

ActiveUS6838487B1Reduce concentrationMaintain standardOrganic compound preparationOther chemical processesWaxContinuous flow

Solvent extraction is used to remove wax and contaminants from an iron-based Fischer-Tropsch catalyst in a natural circulation continuous-flow system. The wax-free catalyst is then subjected to controlled oxidation to convert the iron to its initial oxidized state, Fe2O3. Reactivation of the oxide catalyst precursor is carried out by addition of synthesis gas.

Owner:RES USA LLC

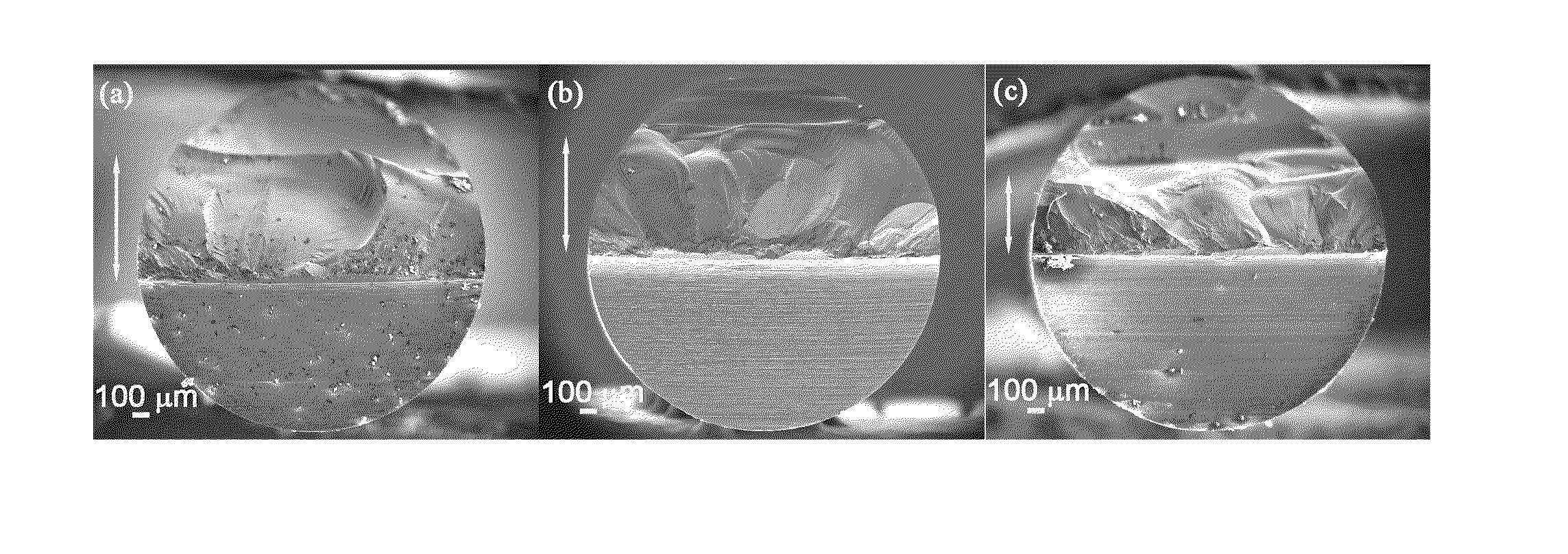

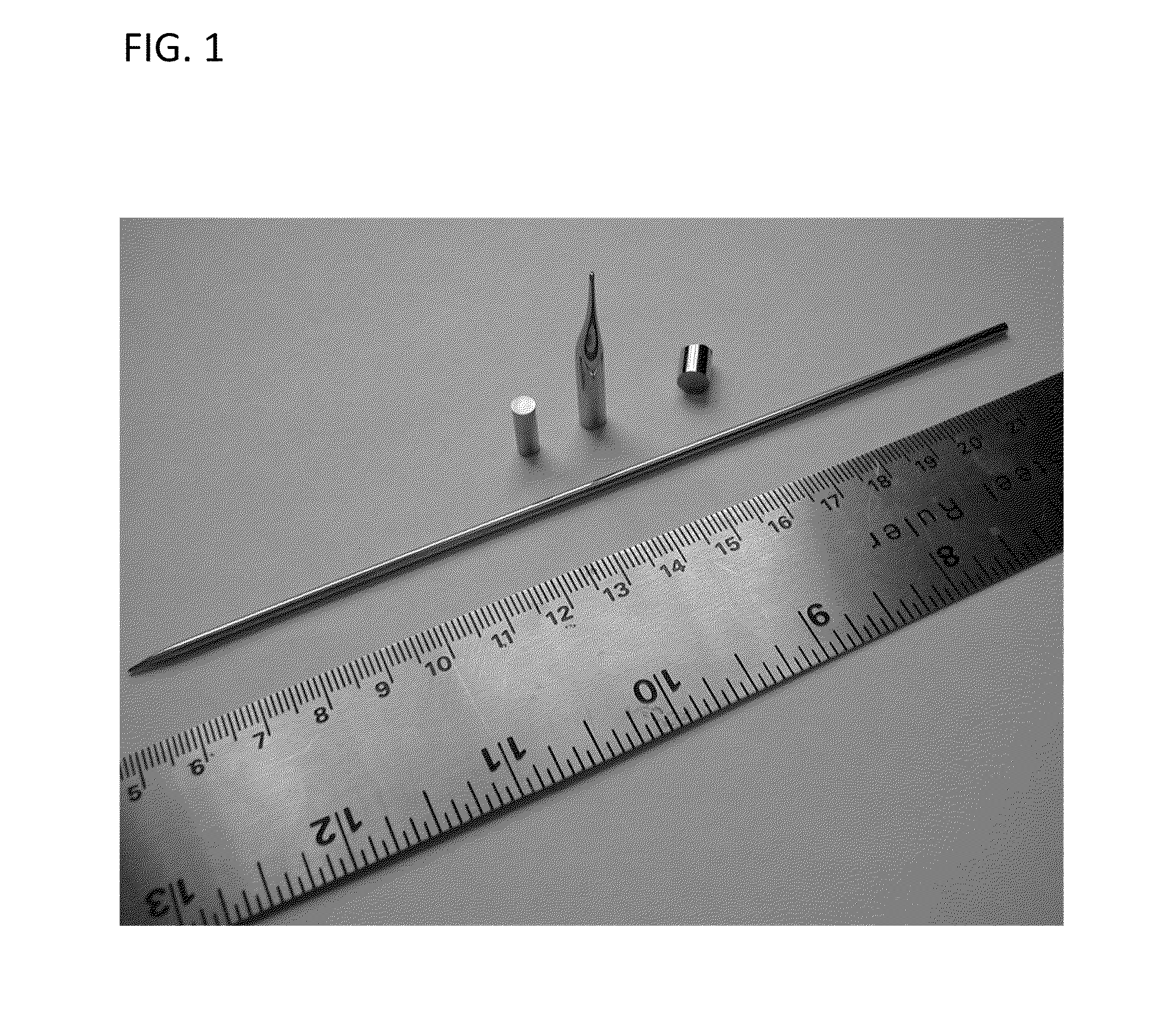

Tough iron-based bulk metallic glass alloys

A family of iron-based, phosphor-containing bulk metallic glasses having excellent processibility and toughness, methods for forming such alloys, and processes for manufacturing articles therefrom are provided. The inventive iron-based alloy is based on the observation that by very tightly controlling the composition of the metalloid moiety of the Fe-based, P-containing bulk metallic glass alloys it is possible to obtain highly processable alloys with surprisingly low shear modulus and high toughness.

Owner:CALIFORNIA INST OF TECH

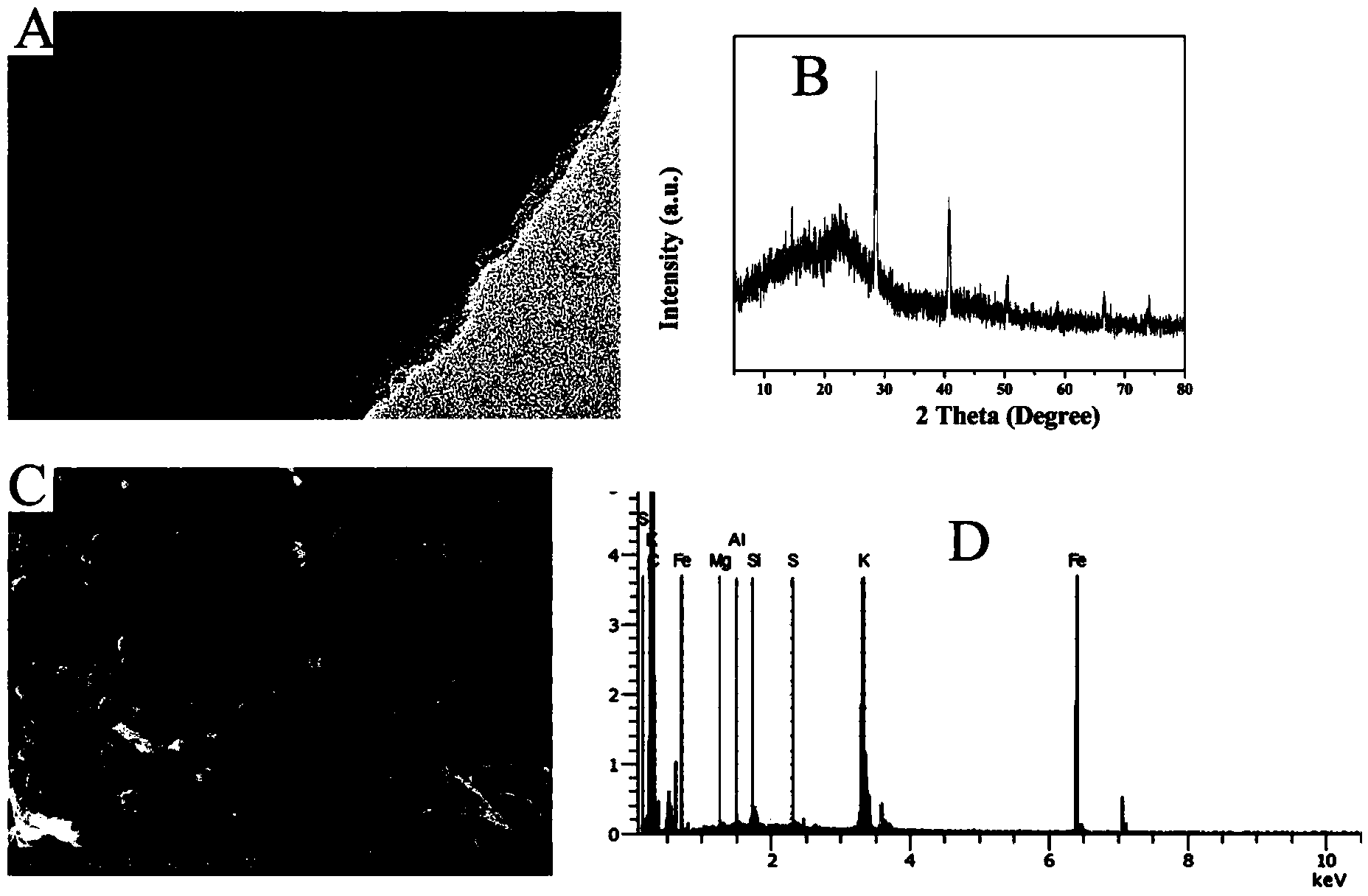

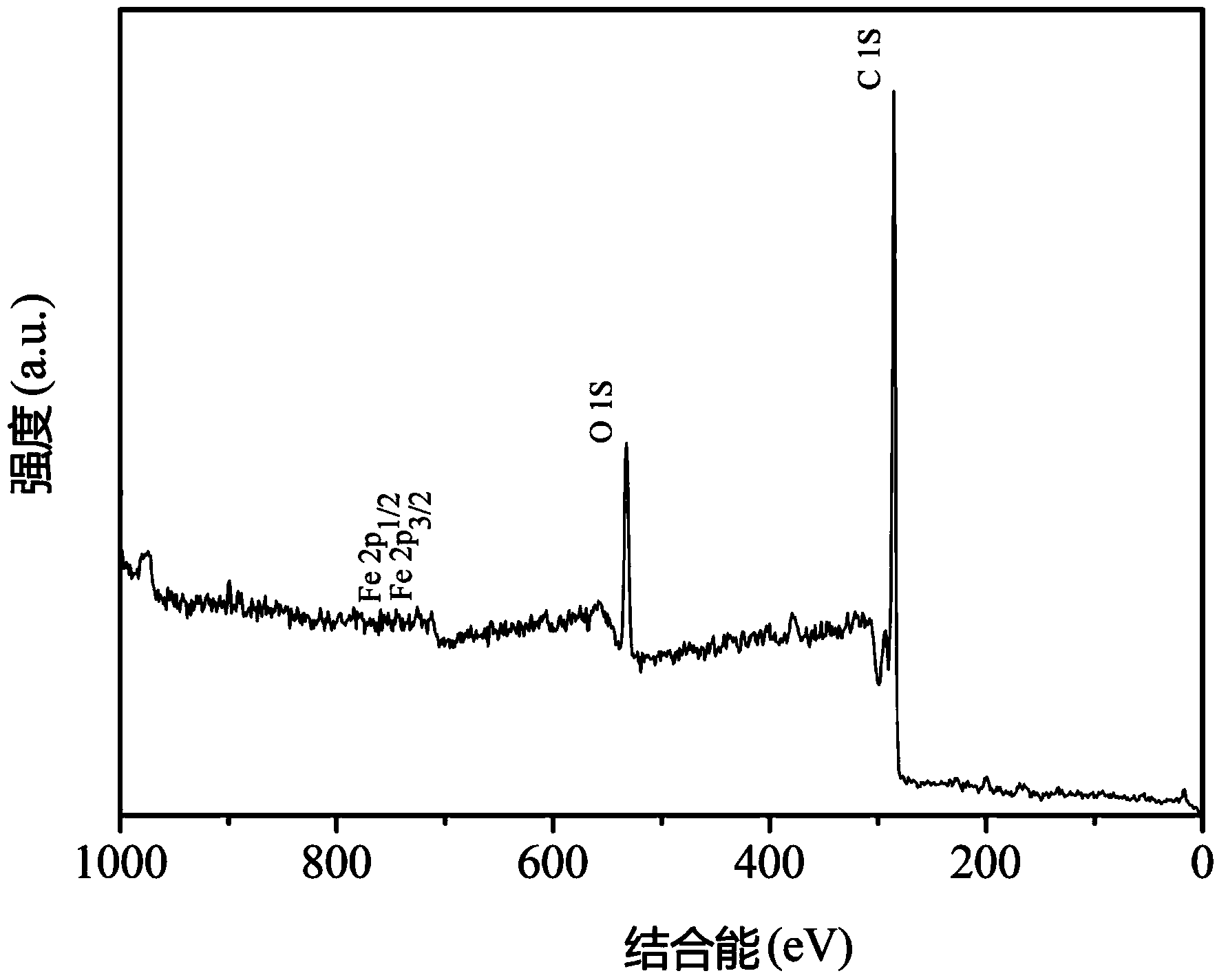

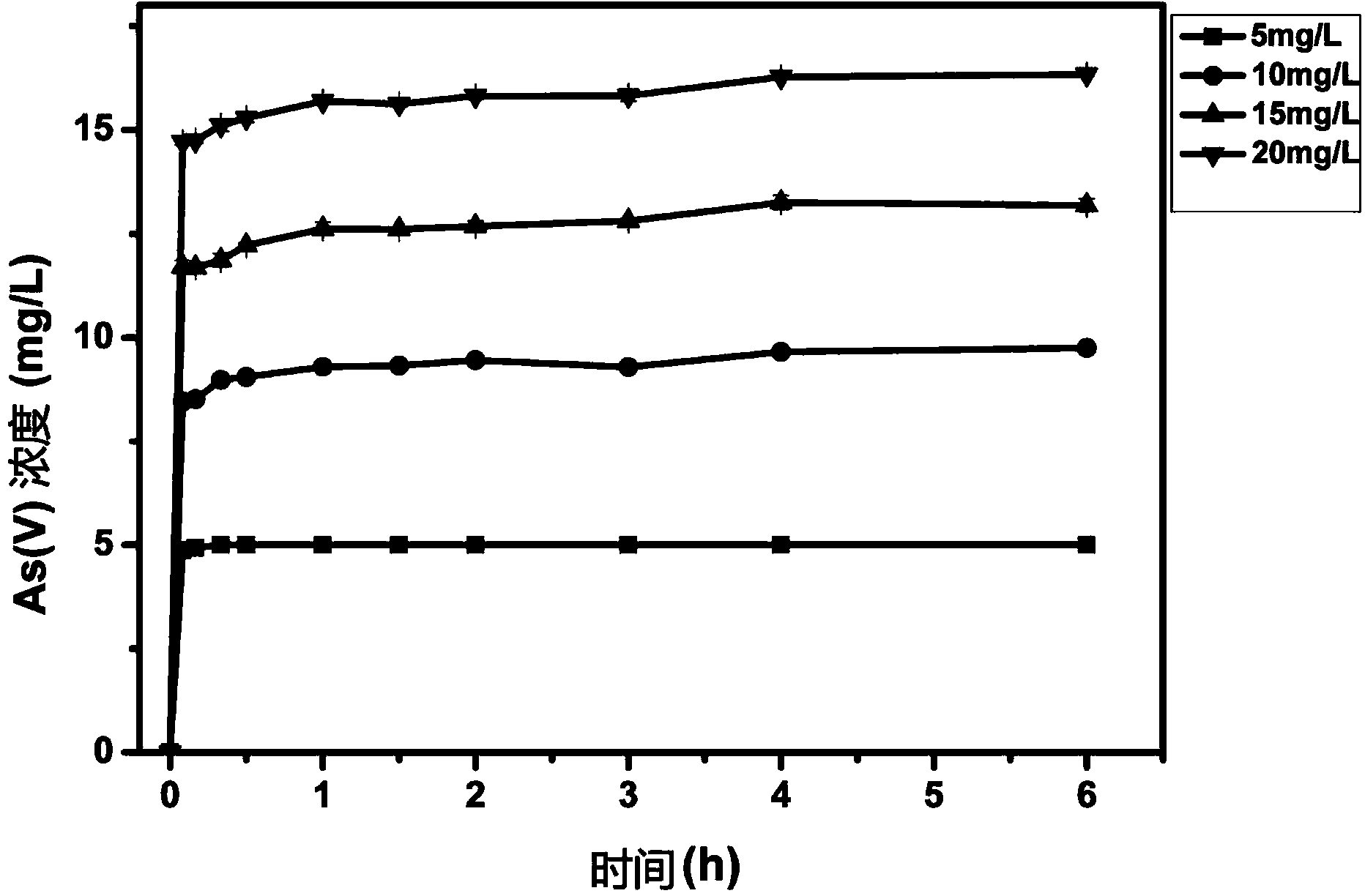

Iron-based bio-char material, preparation process thereof, and application thereof in soil pollution treatment

ActiveCN104388094AImprove performanceReduced bioavailabilityTransportation and packagingContaminated soil reclamationCarbonizationSoil heavy metals

The invention relates to the technical field of soil heavy metal remediation, and specifically discloses a method for preparing an iron-based bio-char material, a prepared iron-based bio-char material, and a method for applying the iron-based bio-char material in treating soil heavy metal pollution. According to the material, biomass is adopted as a raw material; a high-temperature carbonization method is adopted; during the bio-char preparation process, an iron-containing compound is added, such that iron is doped according to a certain ratio, and the iron-based bio-char material with special structure and function is formed. The material has the advantages of simple preparation process, low production cost, and short production period. The obtained iron-based bio-char material has a unique effect in repairing arsenic-cadmium composite polluted soil. With the material, bio-availability of arsenic and cadmium in soil can be effectively reduced, arsenic and cadmium contents in agricultural products planted in the arsenic-cadmium composite polluted soil can be greatly reduced, and no toxic or side effect is caused on crops. The material is safe to apply, and can be used in a large scale in treatment of arsenic-cadmium composite polluted soil.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

Laser fusing and coating process for wear resistant and etch-resistant coating of hydraulic support column cylinder and piston rod

ActiveCN101338427AExcellent wear resistance and corrosion resistanceImprove wear resistanceMetallic material coating processesWear resistantRoom temperature

A laser cladding process of the wear-resisting anticorrosive coating of a hydraulic pressure support pillar cylinder barrel or a piston rod cylinder barrel comprises procedures as follows: the surfaces of the standing pillar cylinder barrel and the piston rod cylinder barrel are pretreated; the surfaces of the standing pillar cylinder barrel and the piston rod cylinder barrel are decreased, de-rusted and cleaned up by alcohol under room temperature; alloying powder is chosen and an automatic powder feeder is adjusted; the iron base alloying powder with good wear-resisting anticorrosive property and sound metallurgy compatibility with a matrix is selected and the iron base alloying powder contains major constituents, including Fe, C, Cr, Ni, Mo, Si, N, Nb, Ta and B; and at last, the automatic powder feeder is adjusted. Adjusting the automatic powder feeder can lead the alloying powder from an automatic feeding end to a laser melting pool and feeding amount is adjusted so that the thickness of the alloying coating reaches 0.6mm to1.2mm. The alloying coating of the invention is even and dense and has good wear-resisting anticorrosive property. Compared with galvanization, the wear-resisting anticorrosive property and the service life of the standing pillar cylinder barrel and the piston rod manufactured by the invention are greatly improved.

Owner:CHONGQING JIANGLU LASER TECH

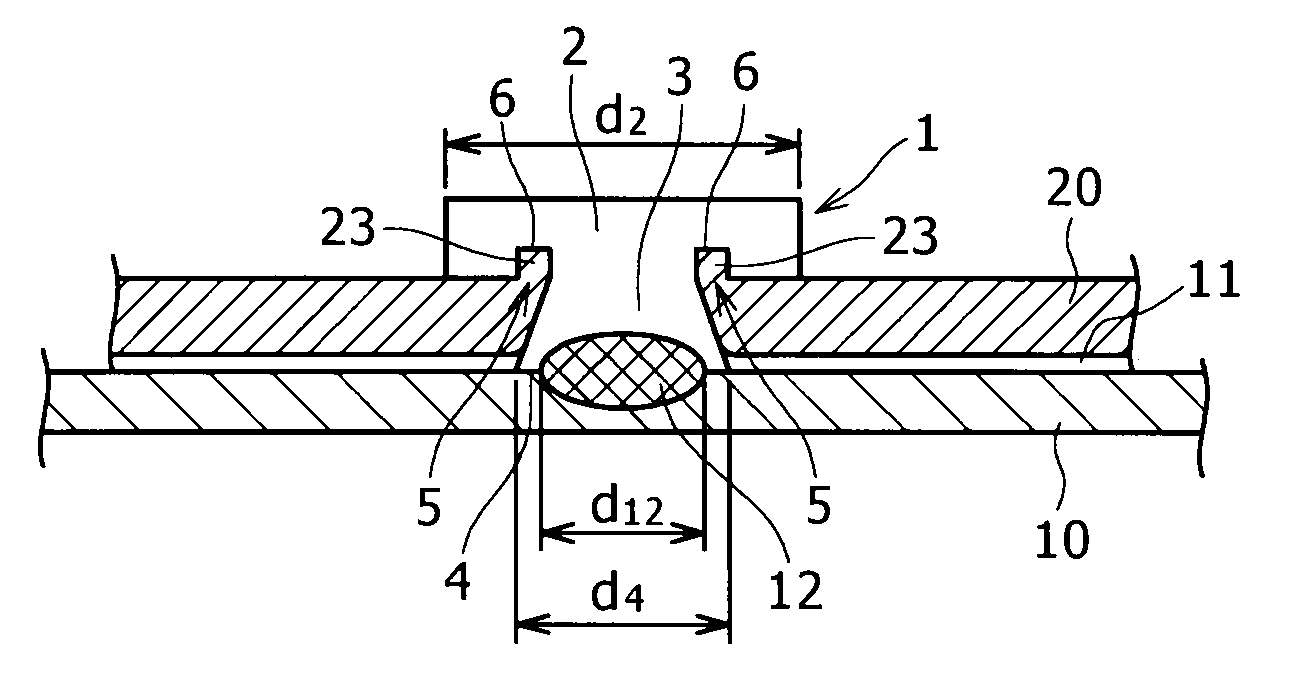

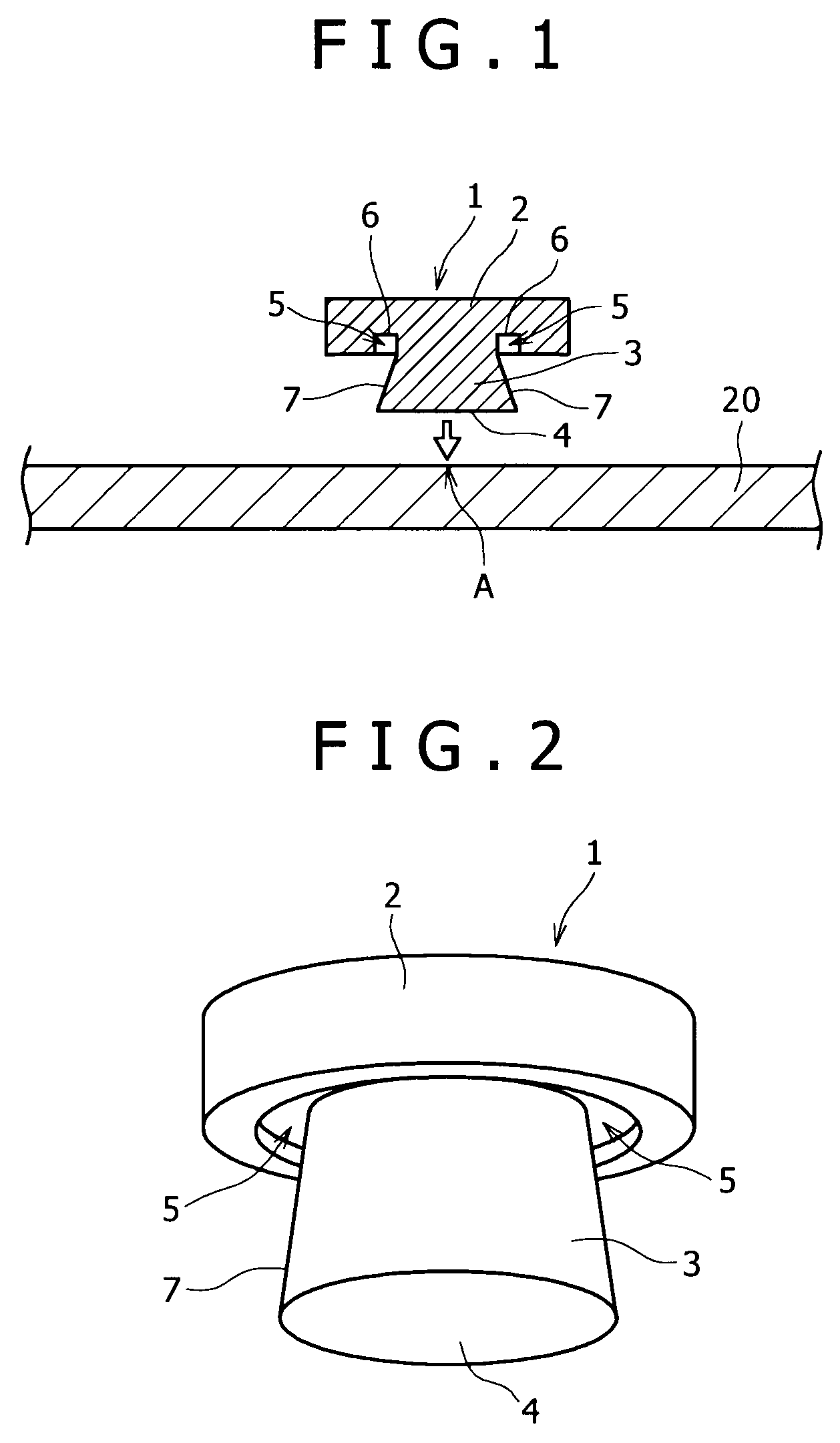

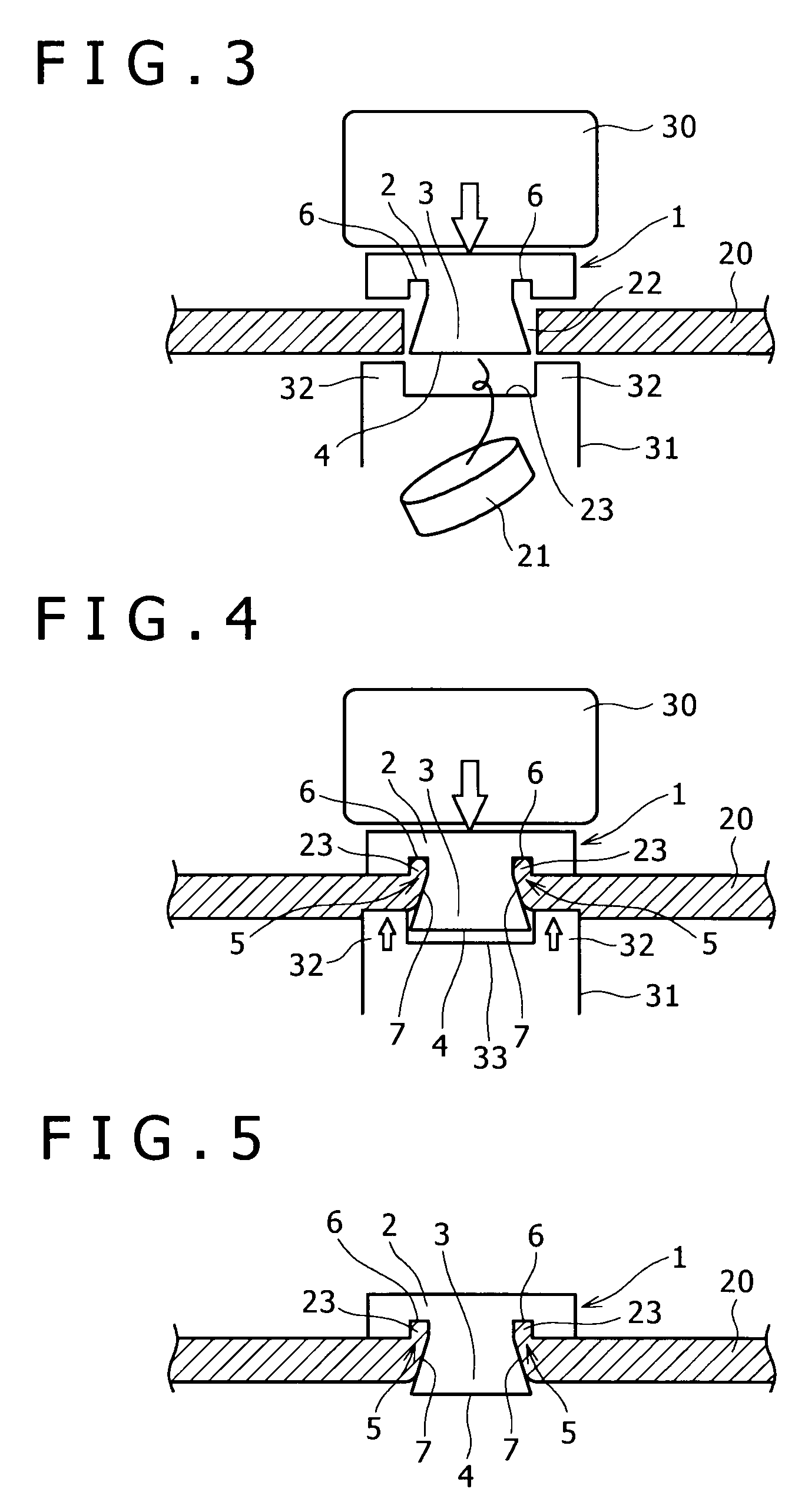

Method for joining dissimilar metals of steel product and light metal product with each other

InactiveUS20090294410A1Overcome limitationsImprove joint strengthShrinkage connectionsSheet joiningSpot weldingUltimate tensile strength

There is provided method for joining dissimilar metals of a steel product and a light metal product with each other, wherein the light metal product and a rivet made of an iron-base metal are connected with each other beforehand in a previous process preceding spot welding, and subsequently, the rivet and the steel product are spot welded with each other. Then, a cavity for use in clinching the light metal product is formed, and upon the stem of the rivet is embedded into the light metal product to penetrate therethrough, light metal is caused to undergo plastic flow into the cavity of the rivet, for clinching the light metal product to be thereby clinched with the rivet whereupon spot welding for forming a weld nugget only within the scope of an interface between the stem of the rivet, and the steel product is carried out. Thus, the present invention can implement the spot welding between iron—iron similar metals, without a constraint on, and a problem with conditions applicable to the spot welding and a high joint strength can be obtained owing to the synergistic effect of the spot welding and connection by clinching of the aluminum alloy product with the iron-base rivet, added thereto.

Owner:KOBE STEEL LTD

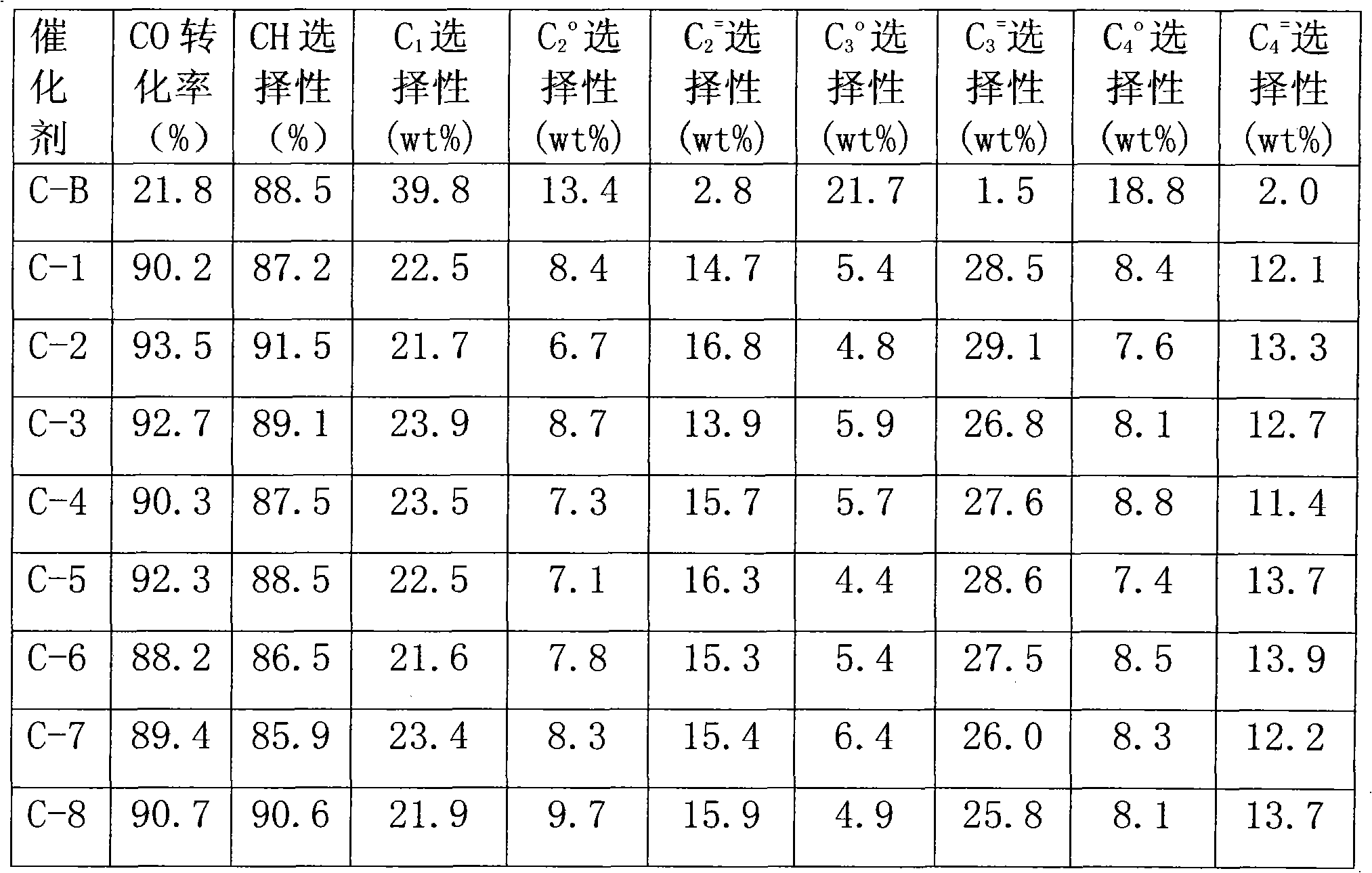

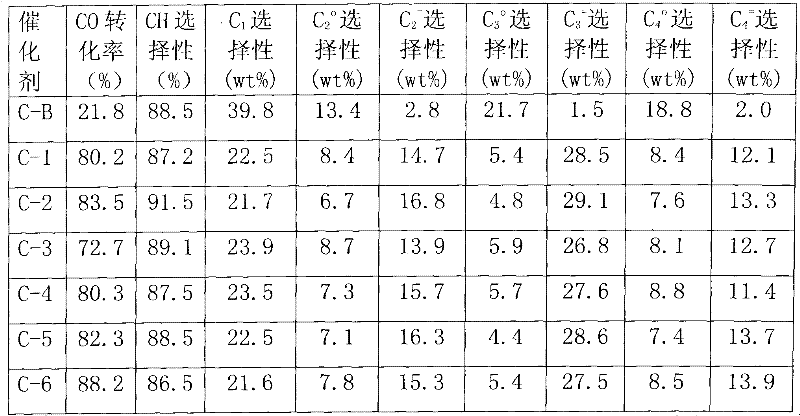

Method for preparing low-carbon olefine catalyst by loading iron-based synthetic gas

ActiveCN102441383AOvercoming strong interactionsHigh activityHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsSilica gelSurface modification

The invention discloses a method for preparing a low-carbon olefine catalyst by a loading iron-based synthetic gas, which comprises the following steps of: firstly carrying out surface modification on a silica gel carrier by using silica gel as a carrier, and then loading a metal auxiliary agent and an active component Fe by using an immersion method, wherein the surface modification method of the silica gel carrier comprises the following step of carrying out immersion treatment by using the acidic solution of sugar. After the silica gel carrier adopted is modified, the strong interaction between the carrier and the active component is overcome, and the activity and the selectivity of the catalyst are improved. The catalyst prepared by using the method is suitable for a reaction process of producing low-carbon olefines of ethylene, propylene, butane and the like by the synthetic gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Laser fusing and coating process of wear resistant and anticorrosion alloy coatings at surface of slide plate of railroad turnout

InactiveCN101338425ANo pollution in the processImprove productivityMetallic material coating processesNumerical controlWear resistant

A laser cladding process of an exterior wear-resisting anti-corrosive alloy coating of a slide chair of a railway switch comprises processes as follows: firstly, the surface of the slide chair is pre-heated, which means the surface of the slide chair is degreased and de-rusted under room temperature; and the surface is cleaned up by alcohol; then alloy powder is prefabricated, which means iron-base, nickel-base or cobalt base alloy powders that are ready for cladding are preplaced on the processed surface of the slide chair, and a scraping straightedge provided with a rail is used for adjusting the pretreated metal powder so that the alloy powder can be distributed on the surface of the slide chair evenly and has proper thickness to meet the thick requirement of the coating after cladding; and finally, the slide chair is hardened by the laser cladding; the laser of CO2 gas is adopted; a numerical control machine is used as a working table and the surface of the slide chair is hardened by the laser cladding. The laser cladding process has the characteristics of no pollution, high production rate, low energy consumption, the little finishing allowance of cladding coating and low combined cost.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

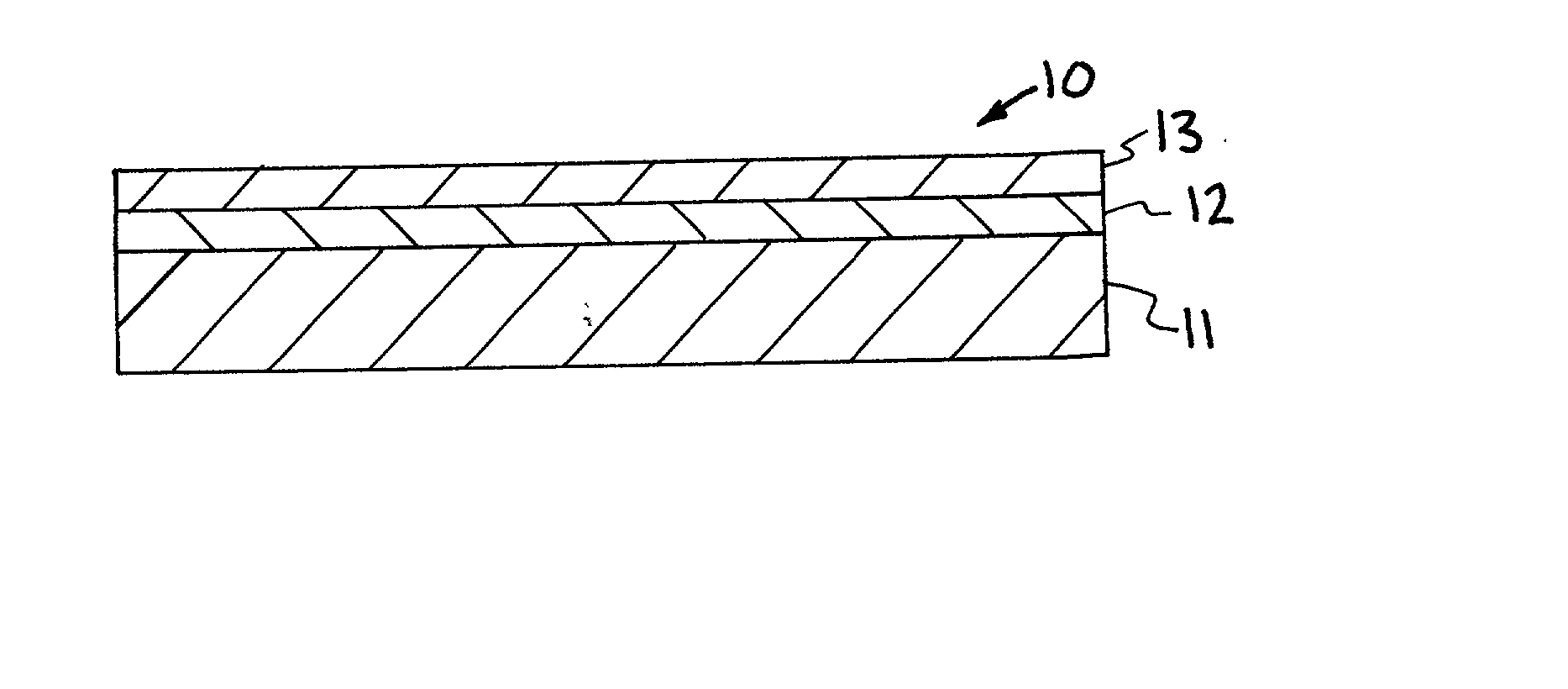

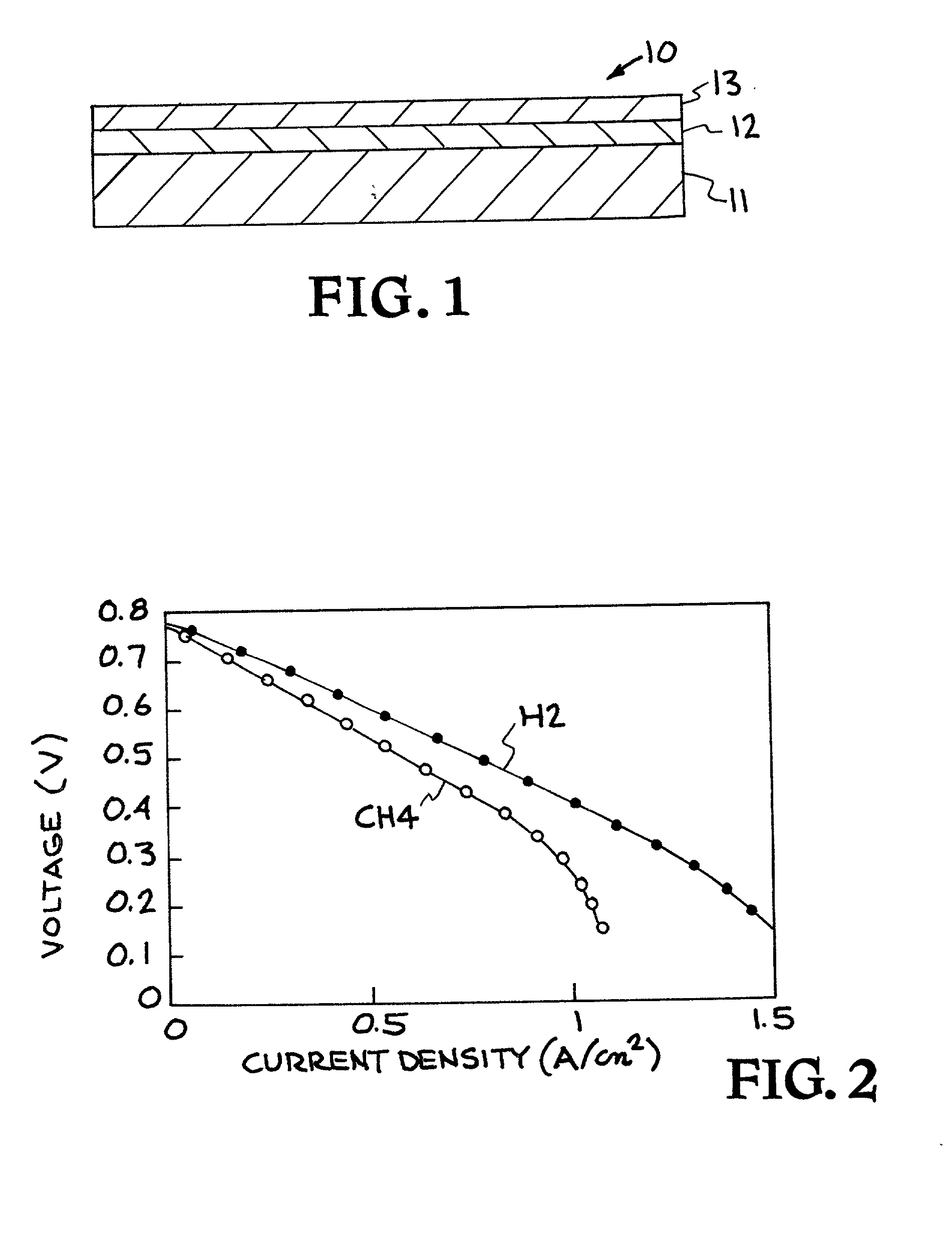

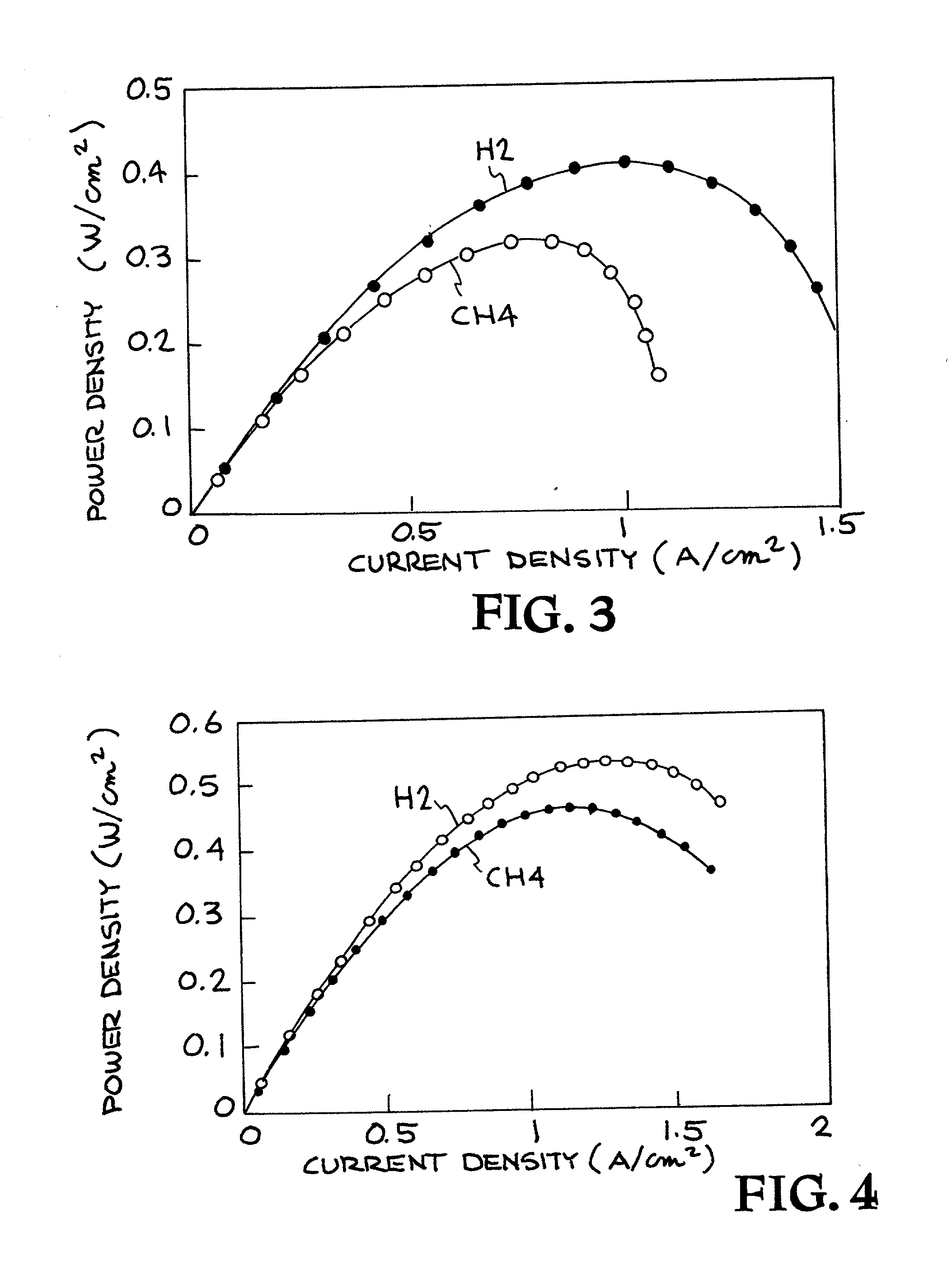

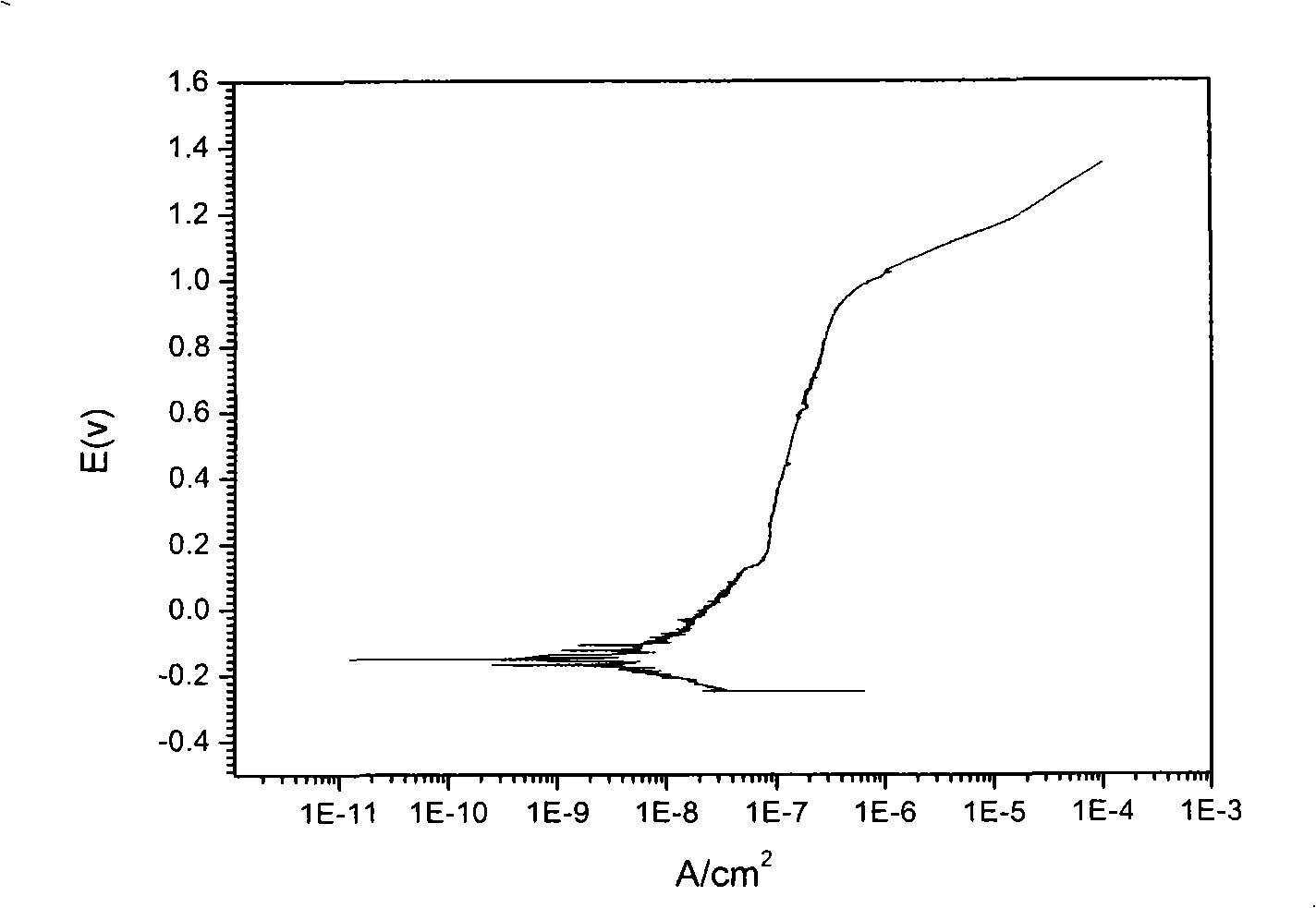

Ceria-based solid oxide fuel cells

InactiveUS20020127455A1Improve power densityMore option for sealingCell electrodesFuel cell auxillariesCerium(IV) oxideCobalt

High-performance intermediate temperature solid oxide fuel cells (SOFCs). The SOFCs are ceria-based structures that can achieve a power output of 300 mW / cm.sup.2 at an operating temperature below 600.degree. C. By way of example, the fuel cell as an anode made of NiO / doped-ceria, a thin film of doped-ceria and / or doped zirconia electrolyte is deposited on the anode, and a cathode of cobalt iron based material, such as (La, Sr)(Co, Fe)O.sub.3 or cobalt, ion, magnesium based material, is deposited on top of the electrolyte, and can operate at a temperature of 550.degree. C. The various layers may be deposited by colloidal spray deposition or aerosol spray casting.

Owner:RGT UNIV OF CALIFORNIA

Method for joining dissimilar metals of steel product and light metal product

InactiveCN101590598AOvercome limitationsRemove constraintsShrinkage connectionsSheet joiningMetallic materialsSpot welding

There is provided method for joining dissimilar metals of a steel product and a light metal product with each other, wherein the light metal product and a rivet made of an iron-base metal are connected with each other beforehand in a previous process preceding spot welding, and subsequently, the rivet and the steel product are spot welded with each other. Then, a cavity for use in clinching the light metal product is formed, and upon the stem of the rivet is embedded into the light metal product to penetrate therethrough, light metal is caused to undergo plastic flow into the cavity of the rivet, for clinching the light metal product to be thereby clinched with the rivet whereupon spot welding for forming a weld nugget only within the scope of an interface between the stem of the rivet, and the steel product is carried out. Thus, the present invention can implement the spot welding between iron-iron similar metals, without a constraint on, and a problem with conditions applicable to the spot welding and a high joint strength can be obtained owing to the synergistic effect of the spot welding and connection by clinching of the aluminum alloy product with the iron-base rivet, added thereto.

Owner:KOBE STEEL LTD

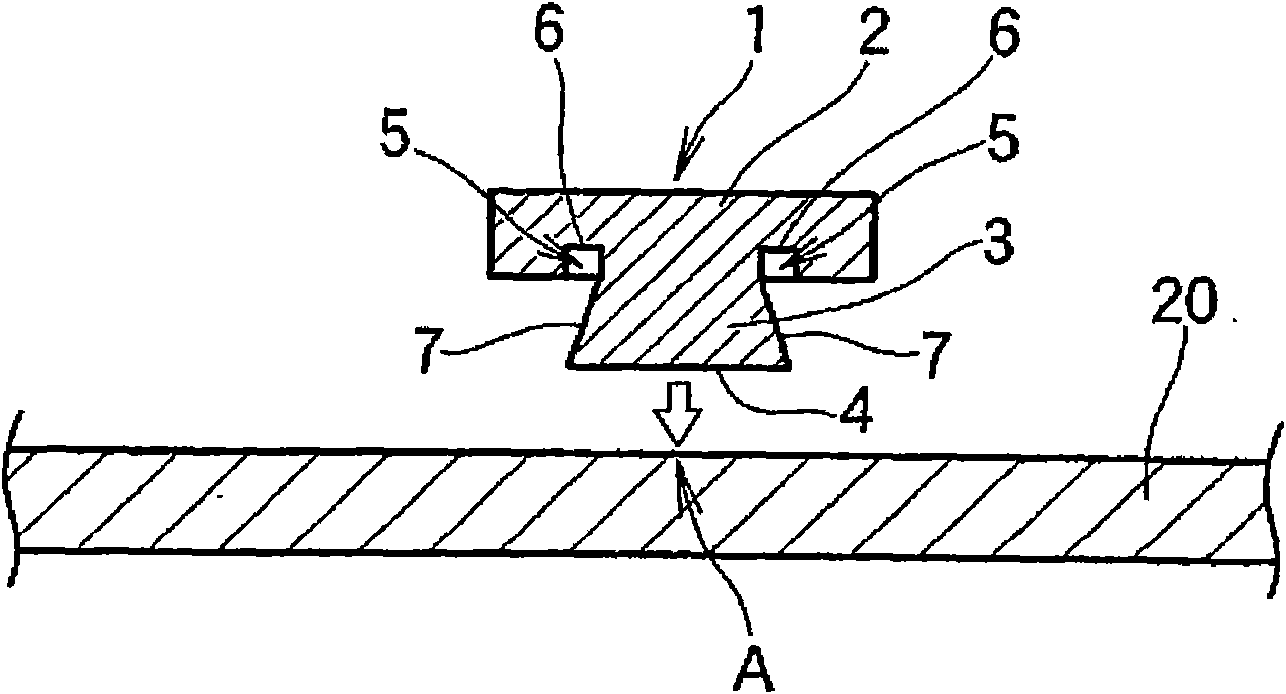

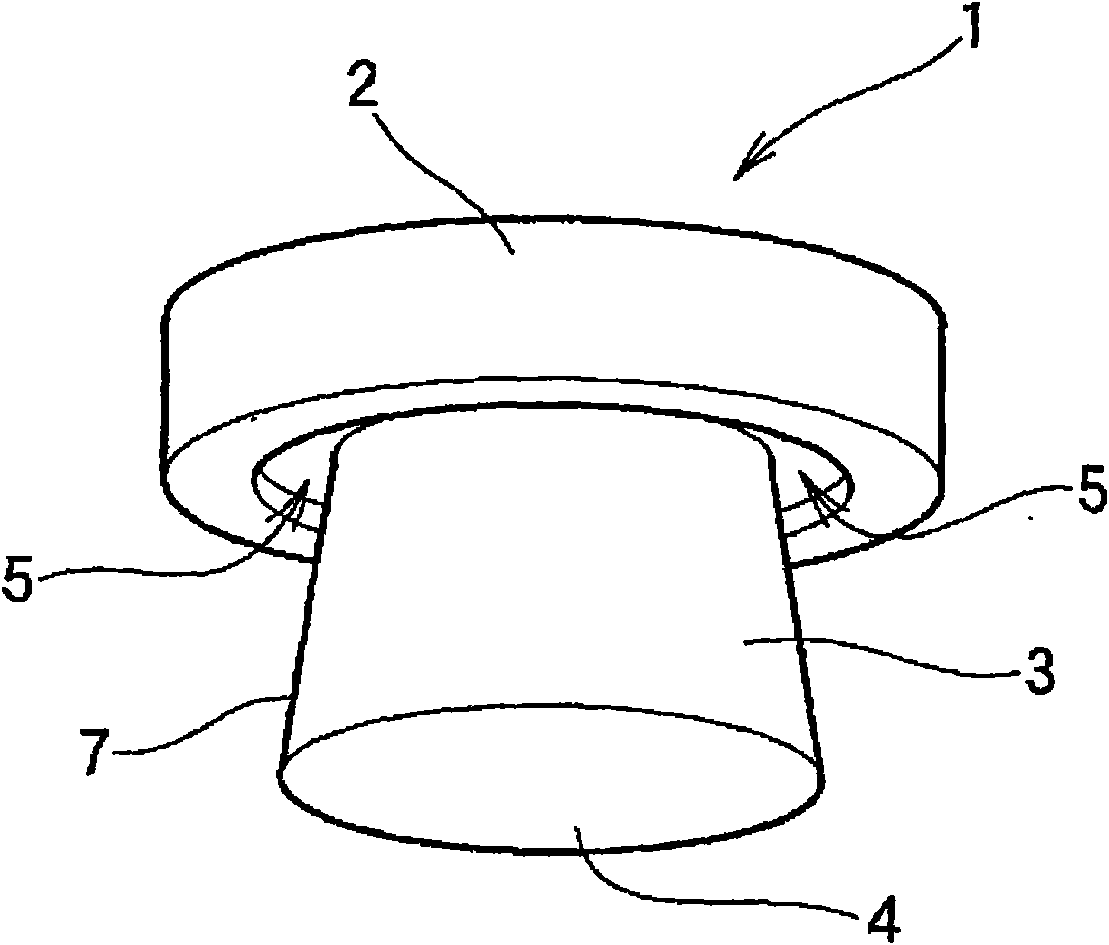

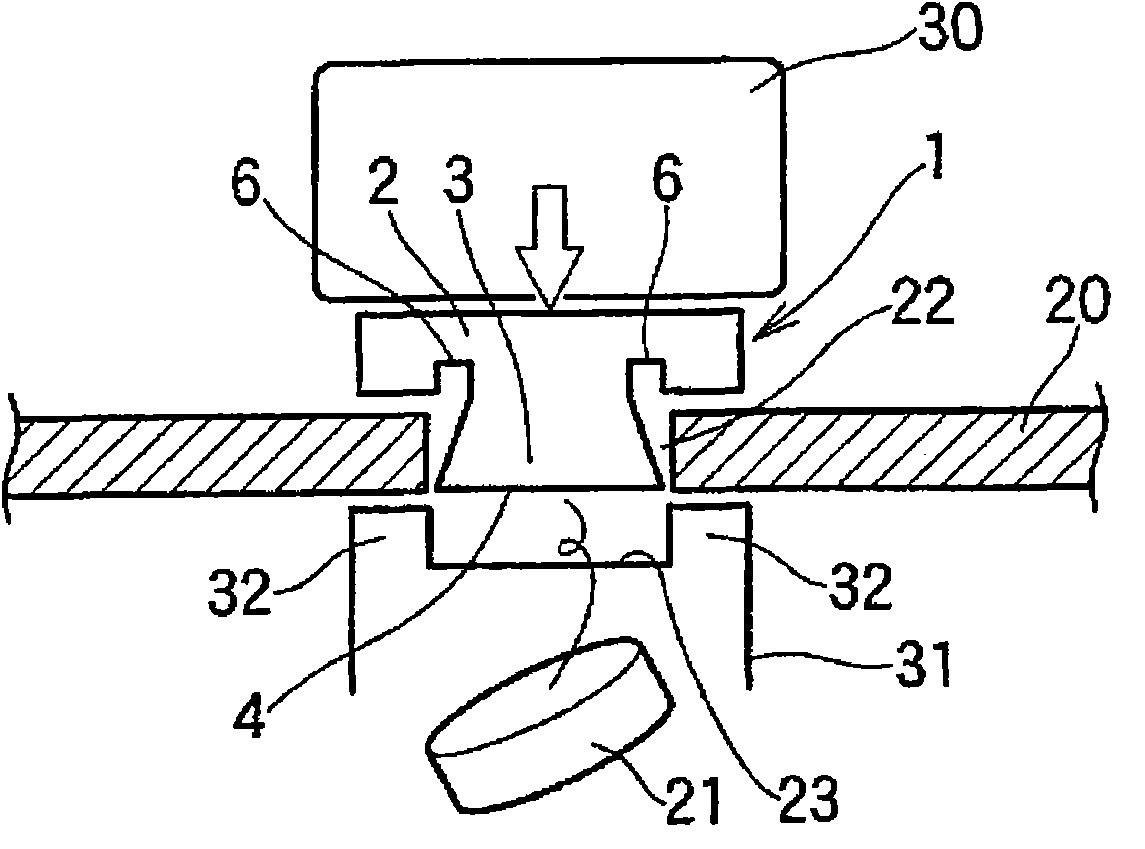

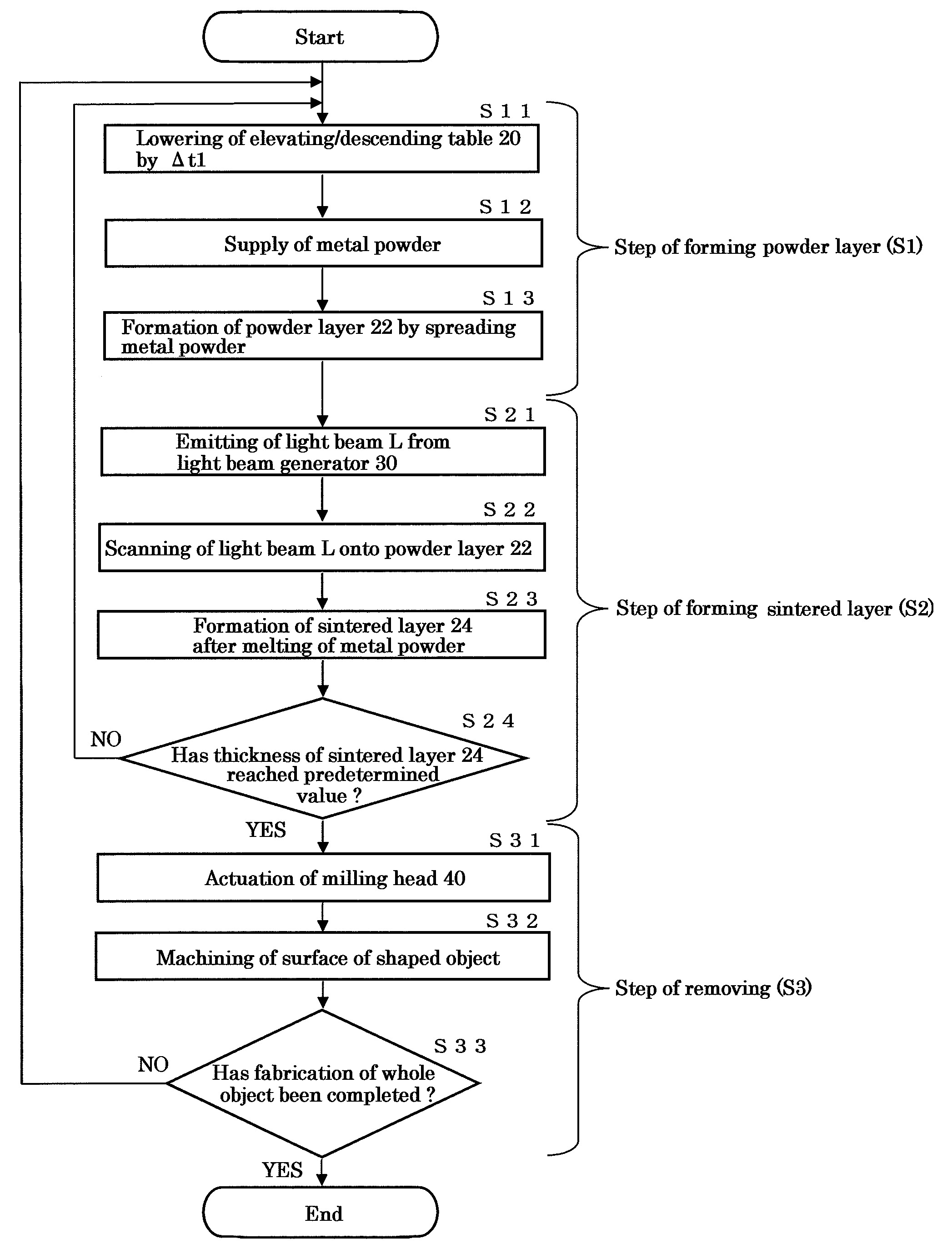

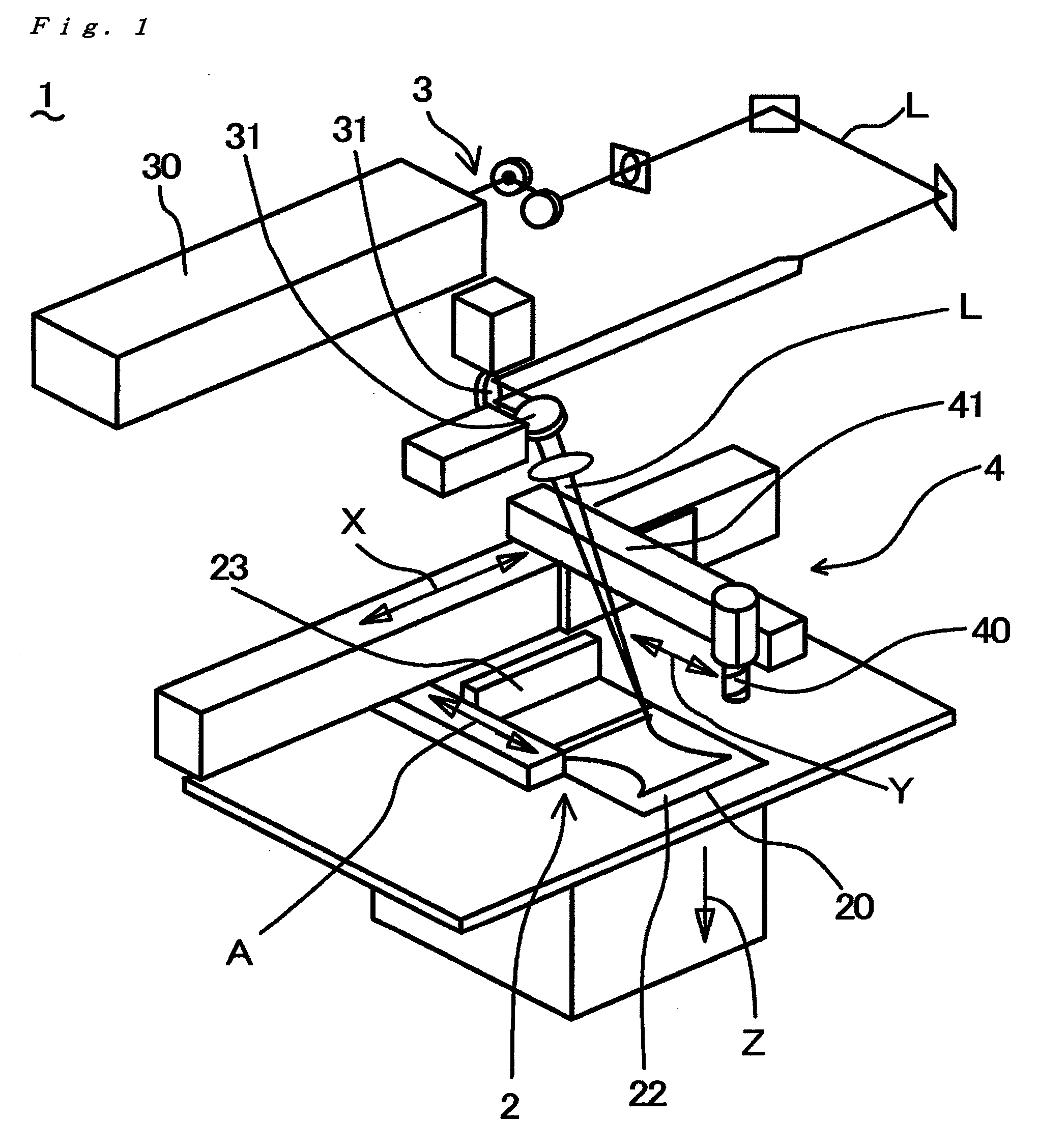

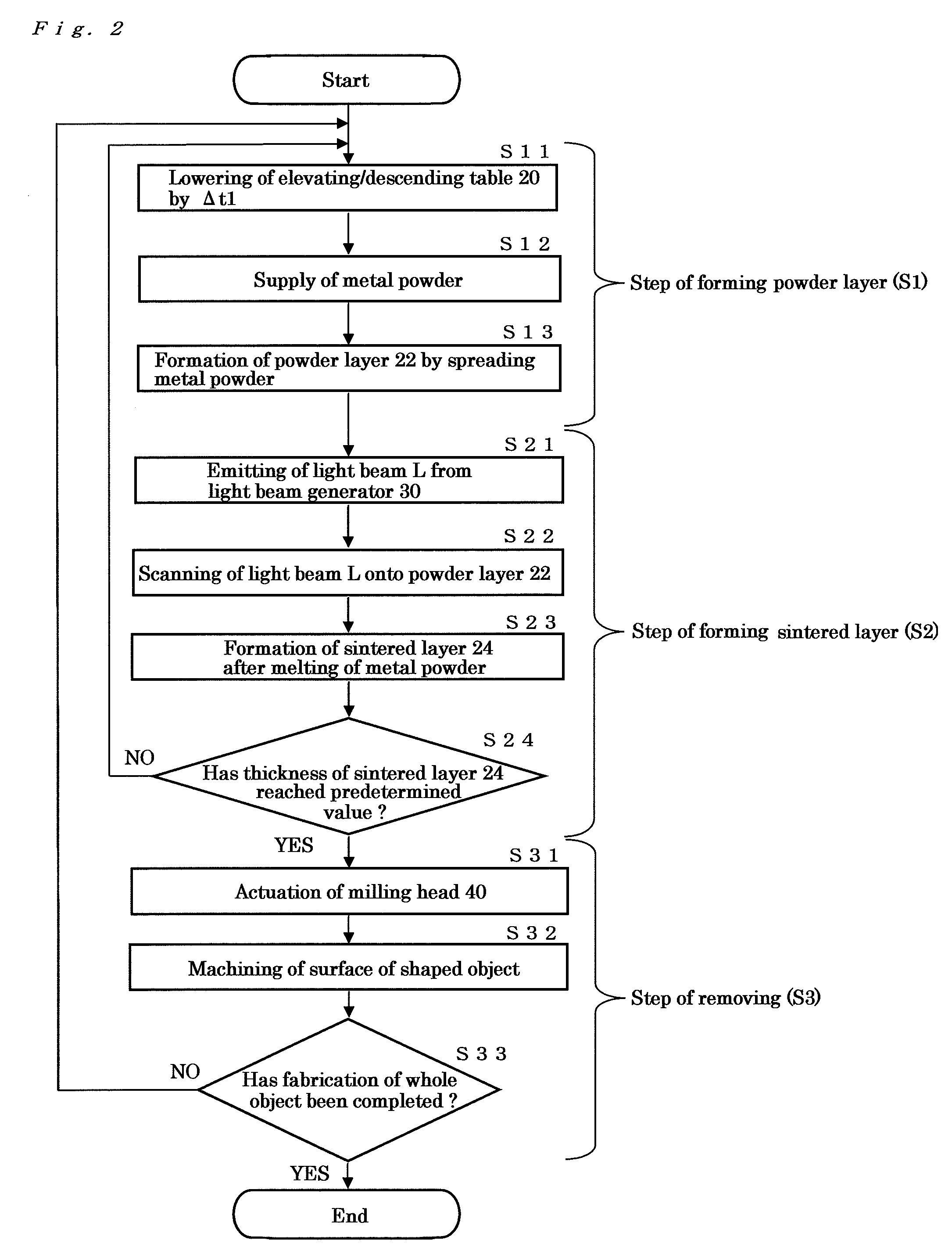

Metal powder for metal laser-sintering and metal laser-sintering process using the same

InactiveUS20110123383A1Reduce resistanceEliminate attachmentAdditive manufacturing apparatusTransportation and packagingAlloyGraphite

A metal powder for use in a metal laser-sintering wherein a three-dimensional shaped object is produced by irradiating a powder layer of the metal powder with a light beam to form a sintered layer and thereby laminating the sintered layers. The metal powder of the present invention is characterized in that it comprises an iron-based powder and at least one kind of powder selected from the group consisting of a nickel powder, a nickel-based alloy powder, a copper powder, a copper-based alloy powder and a graphite powder; and the iron-based powder has been annealed. In such metal powder, the iron-based powder is in a softened state due to the annealing treatment thereof. Accordingly, the use of the metal powder in a metal laser-sintering process makes it possible to reduce a machining resistance attributable to the residual metal powder adherent to the surface of the shaped object, which leads to an achievement of an extended lifetime of a machining tool.

Owner:PANASONIC CORP

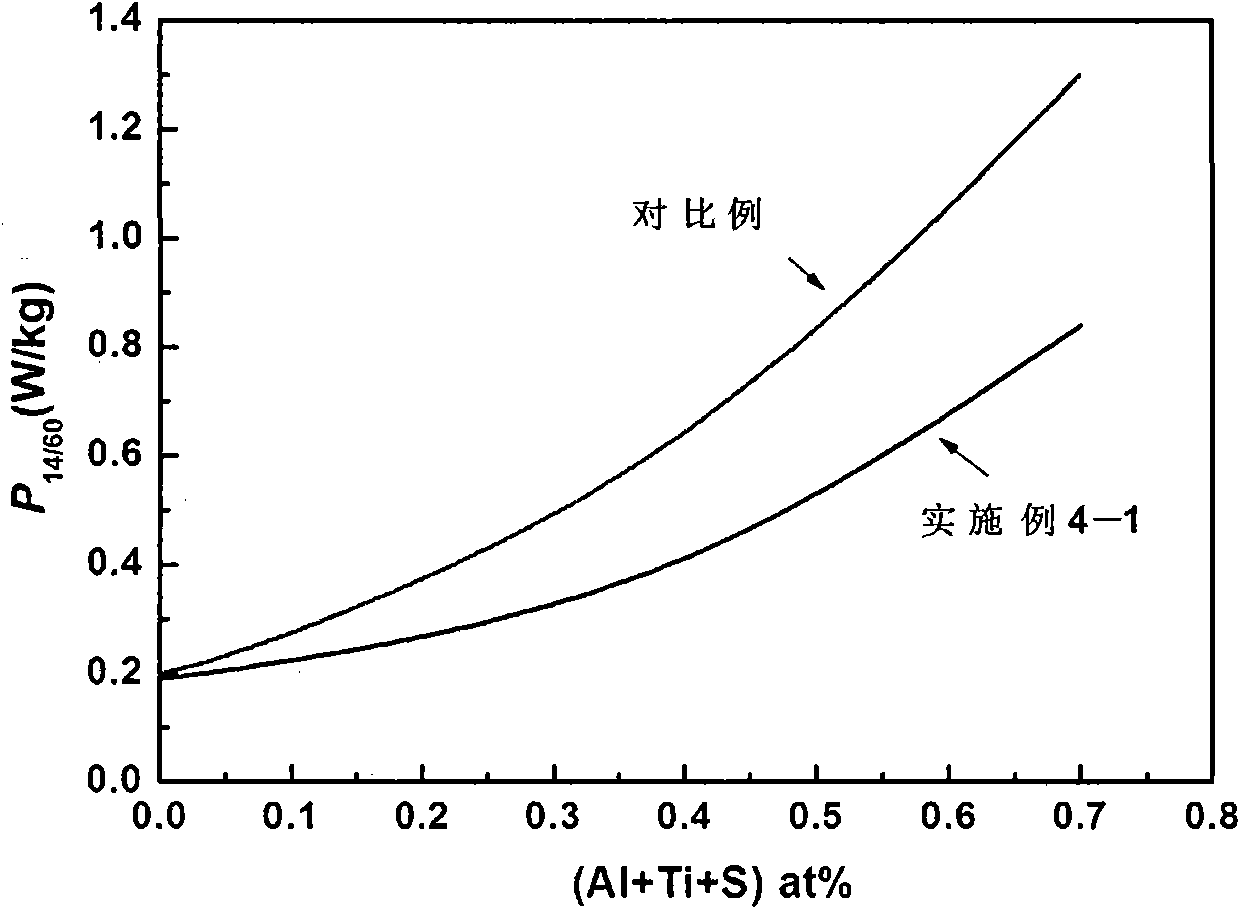

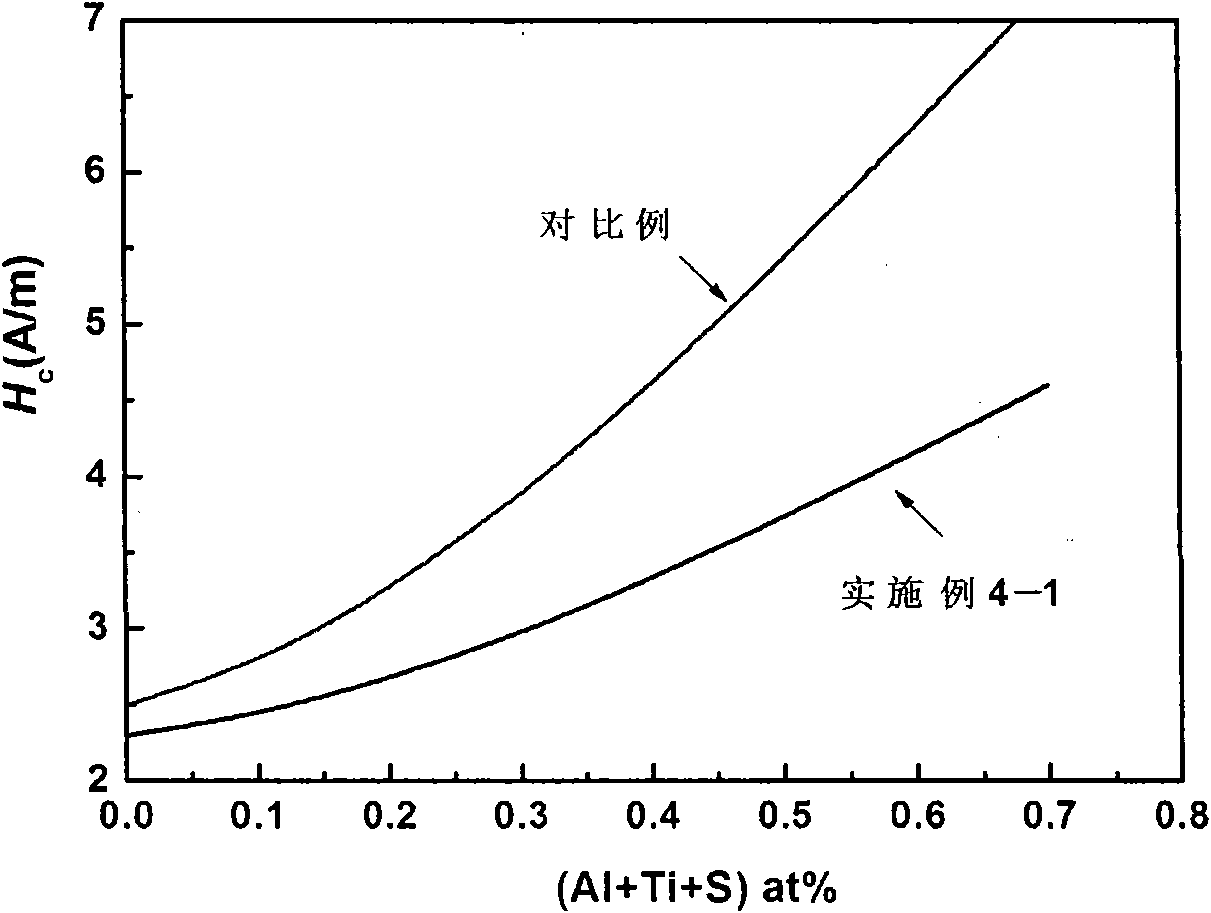

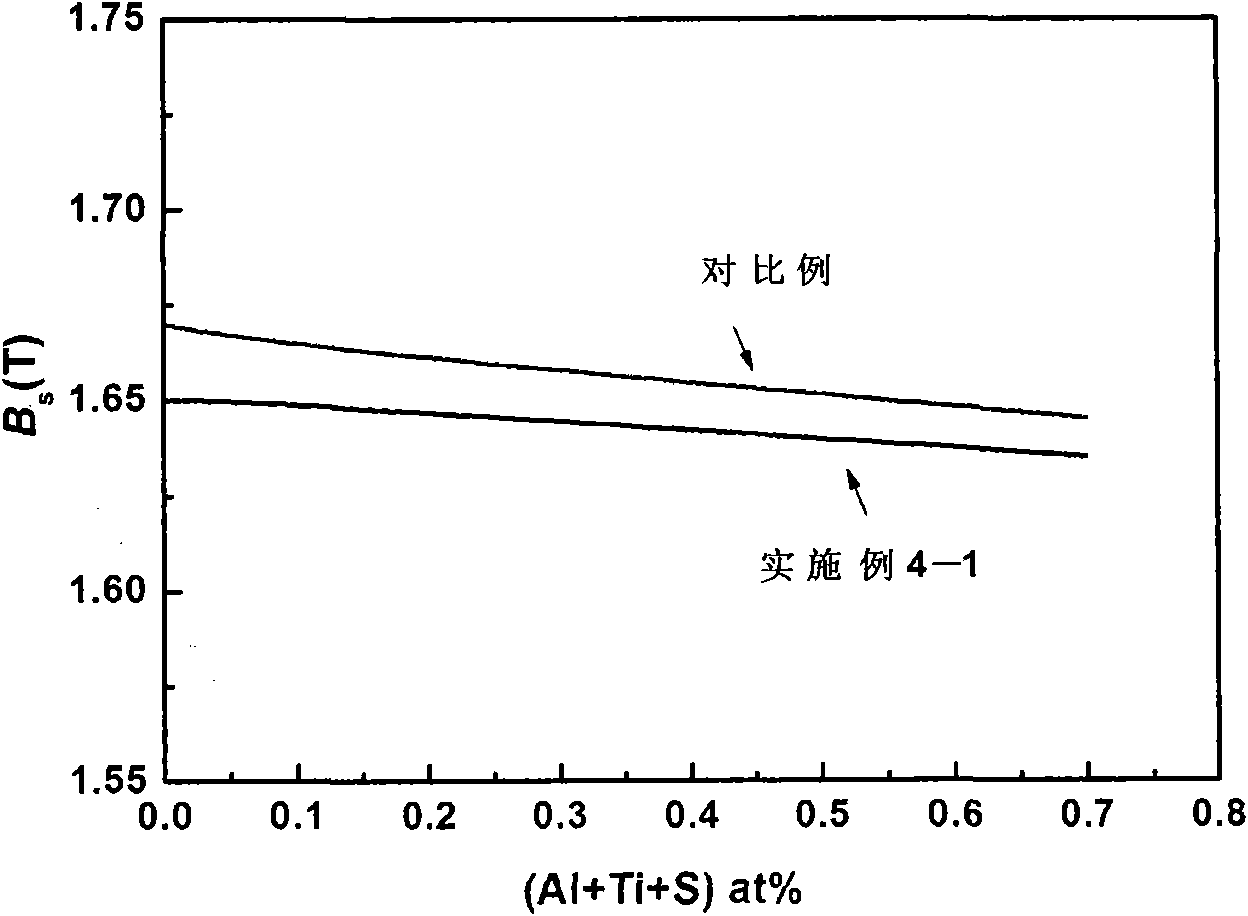

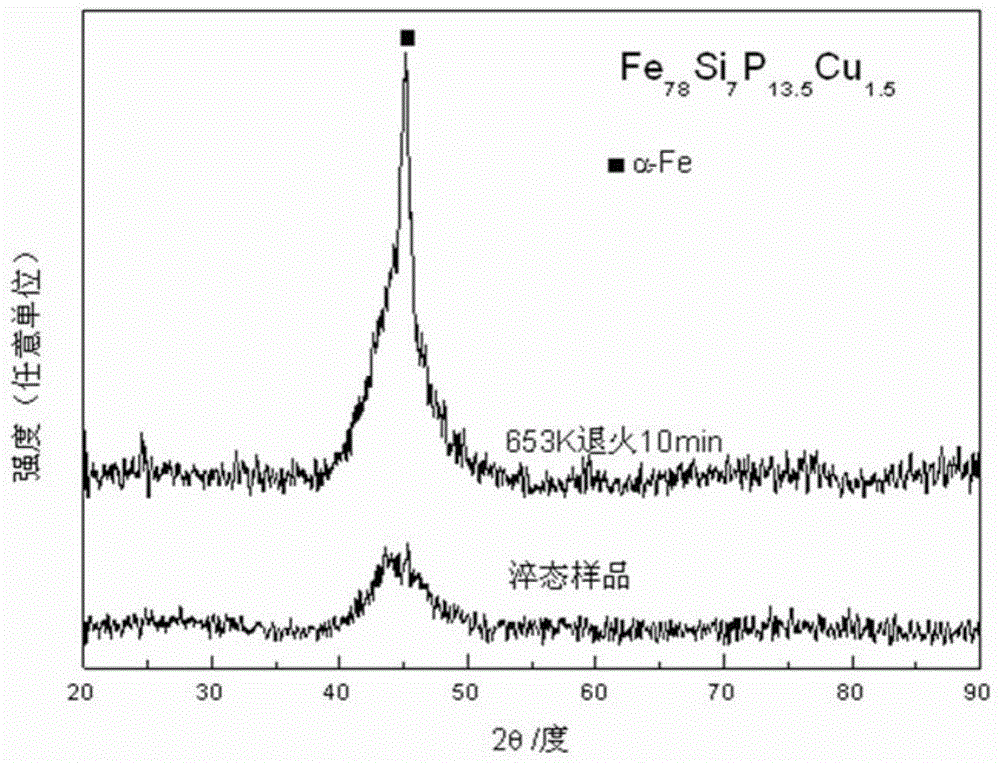

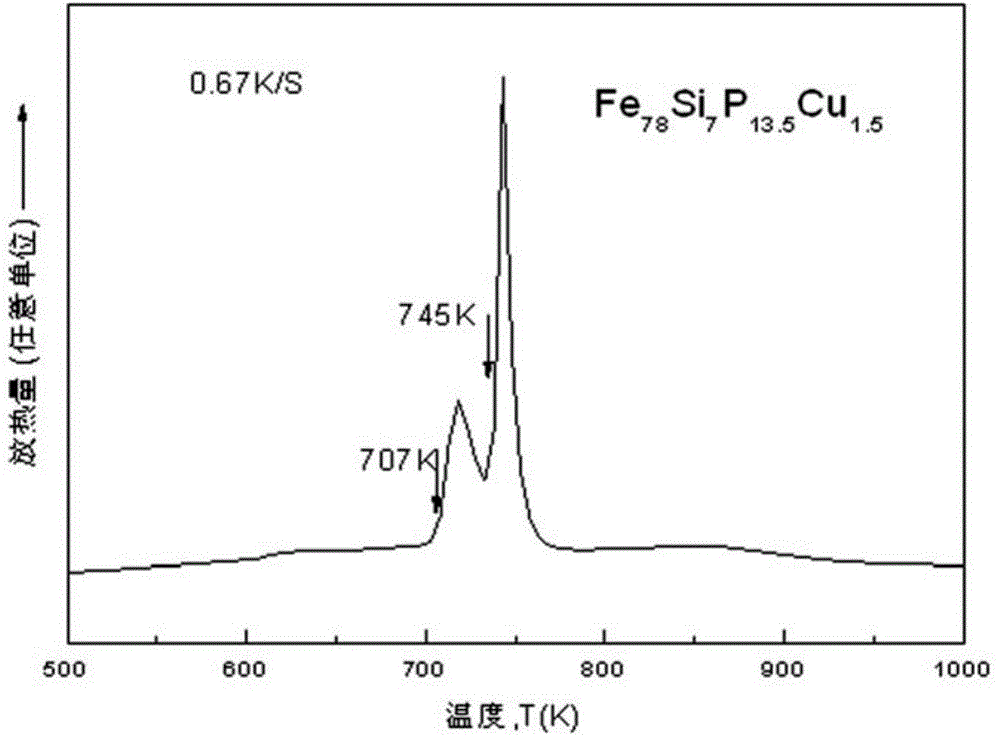

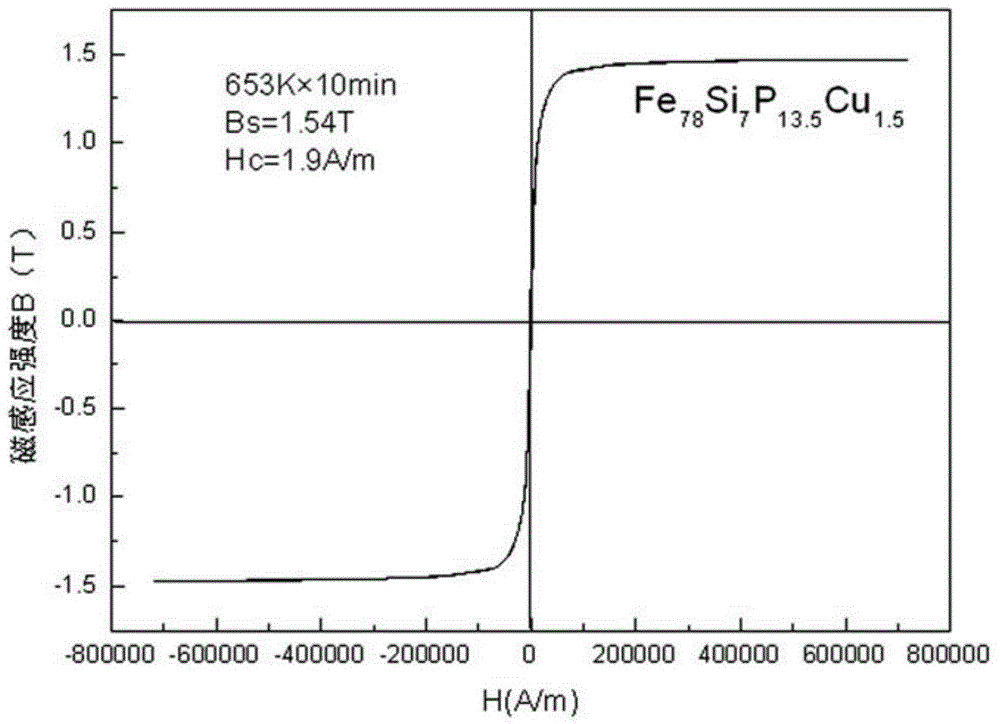

Low-cost high-saturation magnetic induction intensity iron-based amorphous soft magnetism alloy

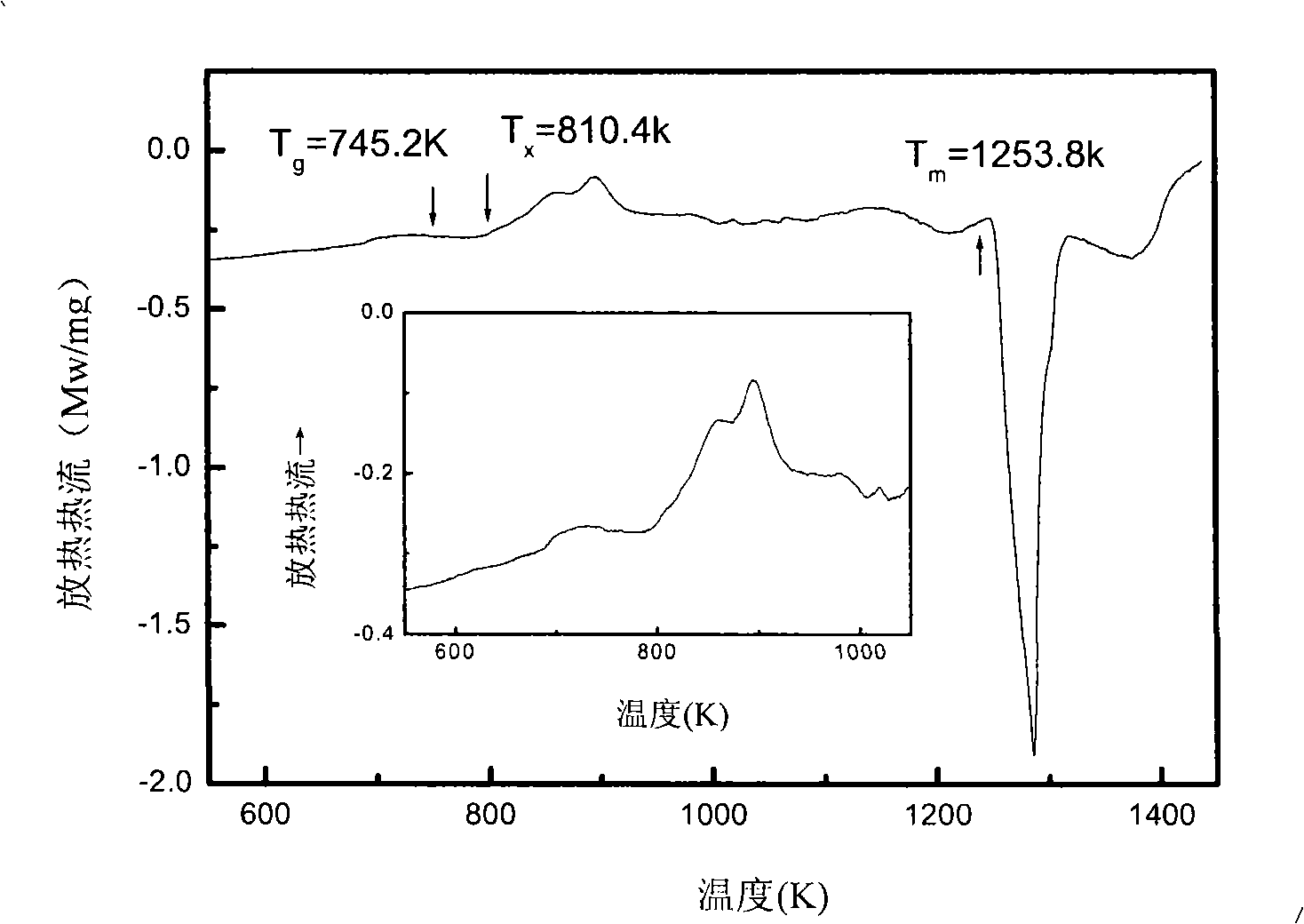

ActiveCN101840764AStrong Amorphous Formation AbilityHigh saturation magnetic inductionMagnetic materialsIron basedMagnetism

The invention provides a low-cost high-saturation magnetic induction intensity iron-based amorphous soft magnetism alloy. The alloy comprises the following ingredients in percentage by atoms: 0 to 15 of Si, 3 to 20 of B, 0.001 to 12 of P, 0.001 to 5 of C, 0.0001 to 0.1 of Al, 0.001 to 0.5 of Mn, 0.0001 to 0.5 of Sb, 0.0001 to 0.1 of Ti, 0.0001 to 0.5 of S, 0.0001 to 0.5 of Sn, 0.0003 to 0.2 of W and the balance of Fe and unavoidable impurities. The soft magnetism alloy of the invention has the characteristics of strong amorphous forming capability, high saturation magnetic induction intensity, low cost and the like. After the alloy is annealed, the saturation magnetic induction intensity is higher than 1.6 T, and the coercive force is lower than 5A / m.

Owner:AT&M AMORPHOUS TECH CO LTD

Method of manufacture and treatment of wood with injectable particulate iron oxide

InactiveUS20060075923A1Reduces UV-promoted degradation of the wood substrateAppearance hasFireproof paintsBiocideParticulatesPreservative

A wood preservative includes injectable particles comprising one or more sparingly soluble iron salts. The iron-based particles are sufficiently insoluble so as to not be easily removed by leaching but are sufficiently soluble to exhibit toxicity to primary organisms primarily responsible for the decay of the wood. Wood or a wood product may be impregnated with iron-based particles of the invention.

Owner:OSMOSE

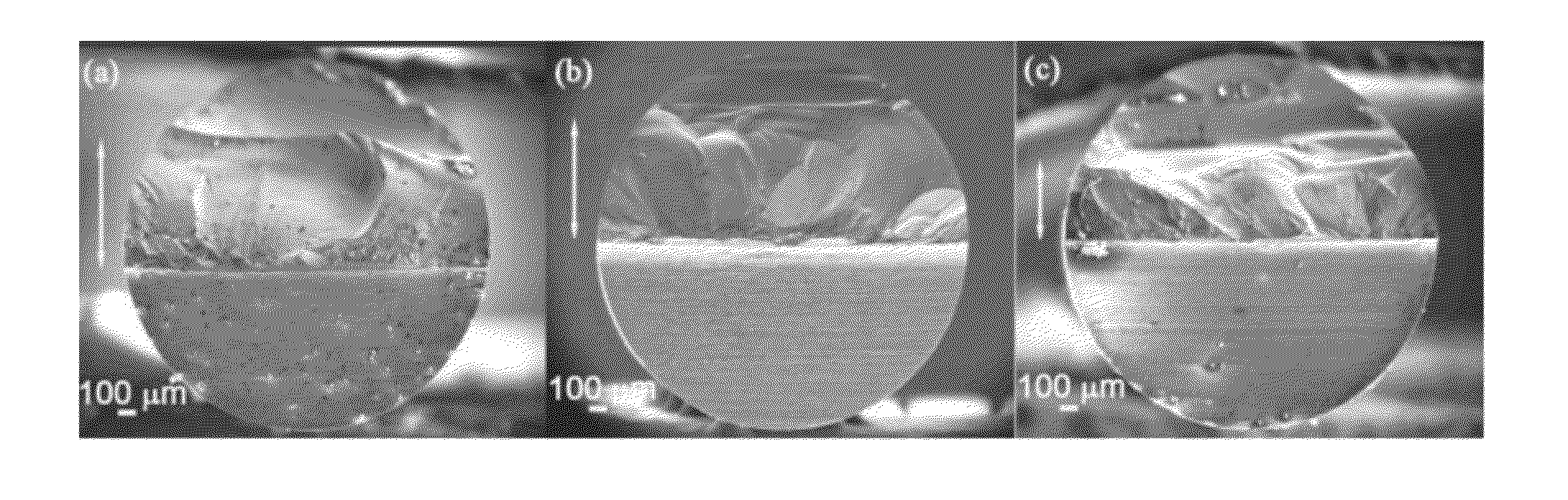

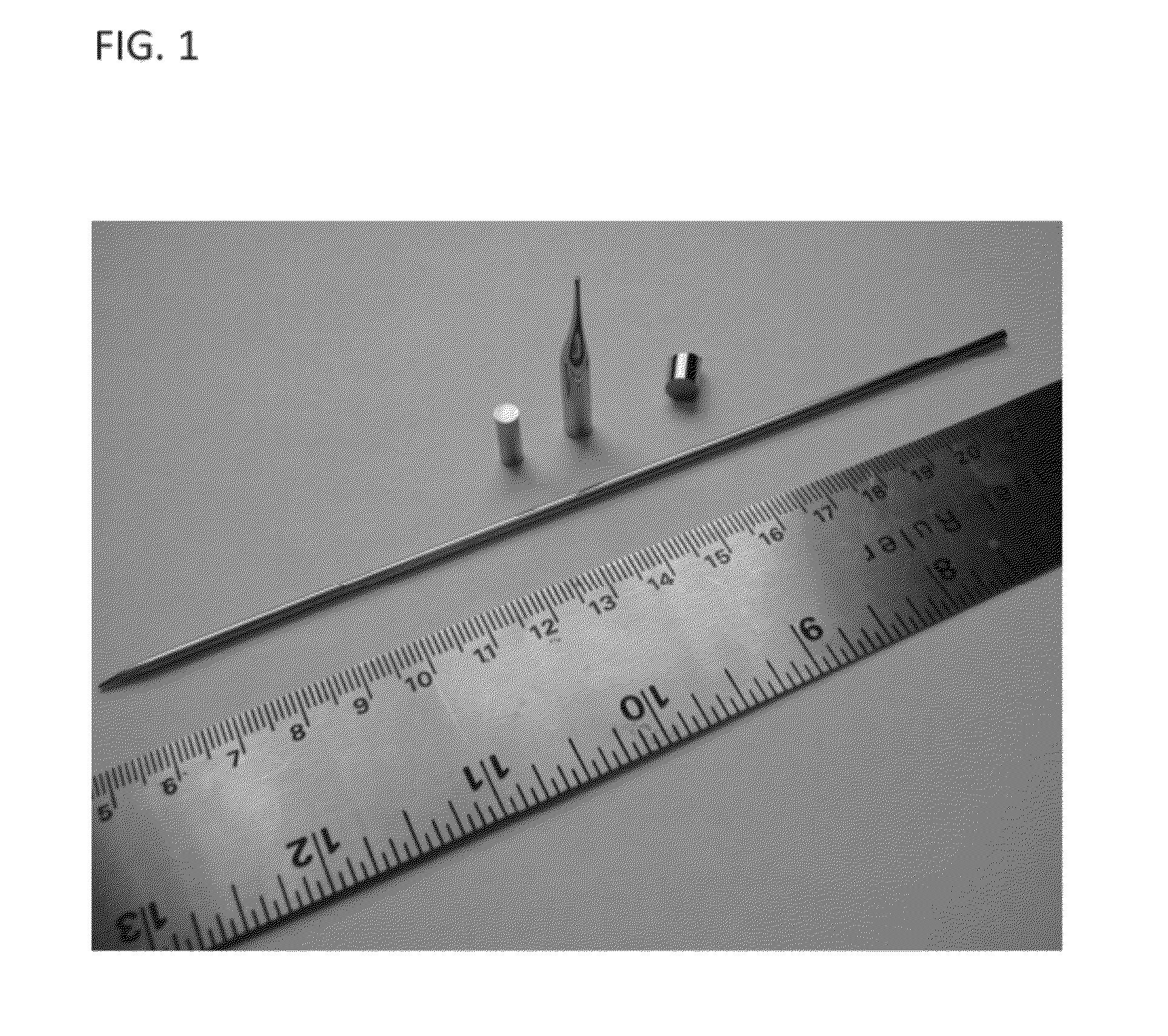

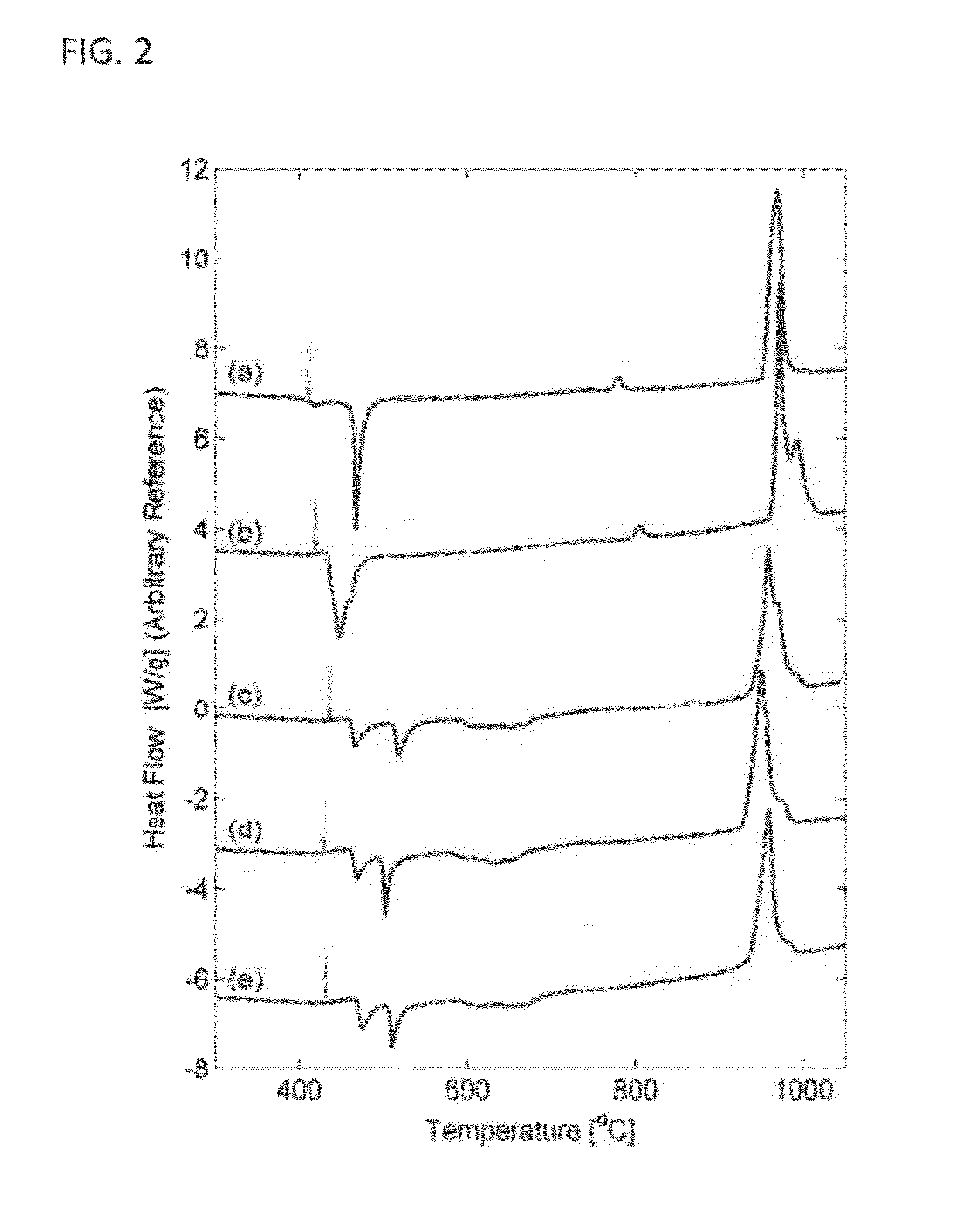

Tough iron-based bulk metallic glass alloys

A family of iron-based, phosphor-containing bulk metallic glasses having excellent processability and toughness, methods for forming such alloys, and processes for manufacturing articles therefrom are provided. The inventive iron-based alloy is based on the observation that by very tightly controlling the composition of the metalloid moiety of the Fe-based, P-containing bulk metallic glass alloys it is possible to obtain highly processable alloys with surprisingly low shear modulus and high toughness. Further, by incorporating small fractions of silicon (Si) and cobalt (Co) into the Fe—Ni—Mo—P—C—B system, alloys of 3 and 4 mm have been synthesized with high saturation magnetization and low switching losses.

Owner:CALIFORNIA INST OF TECH

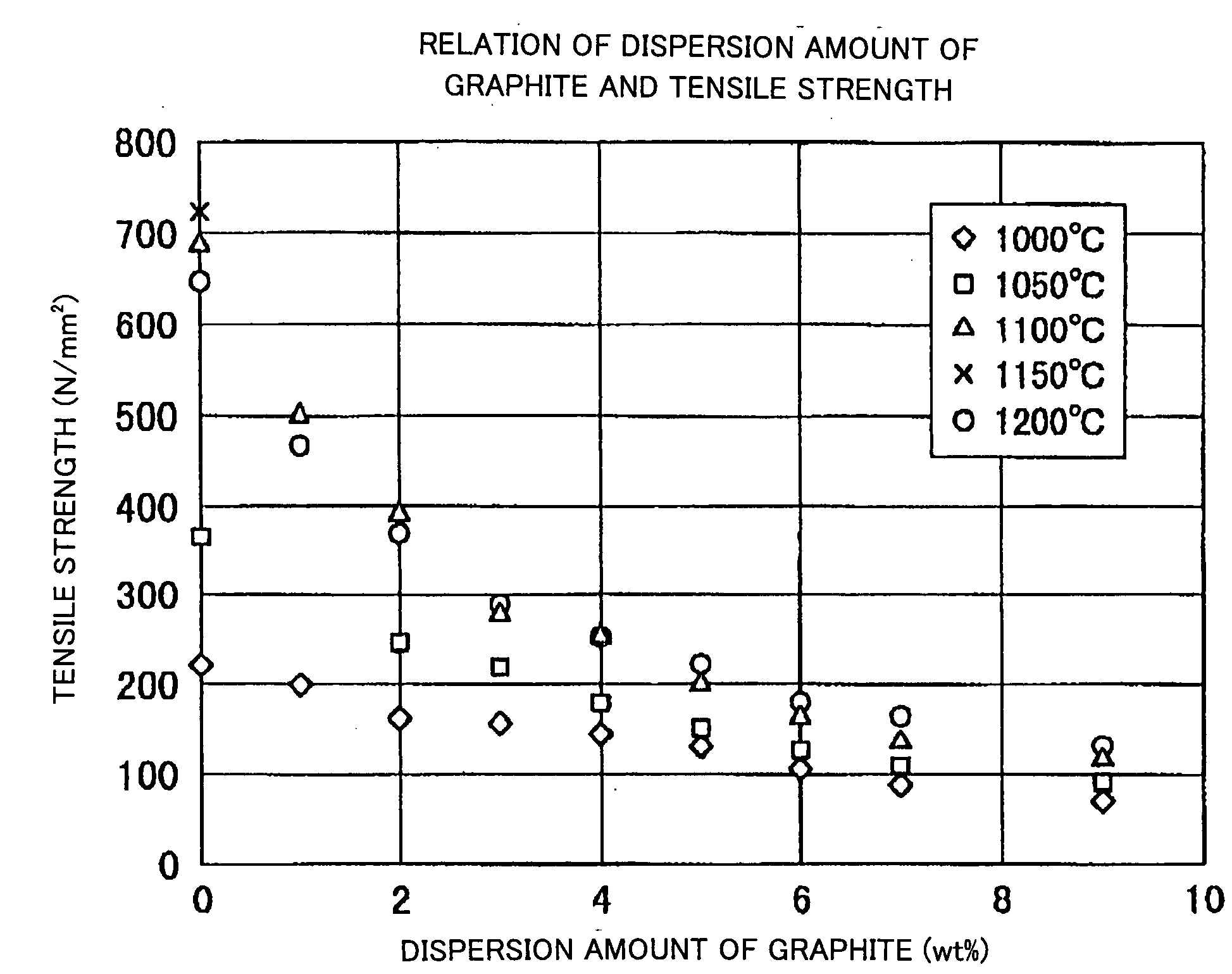

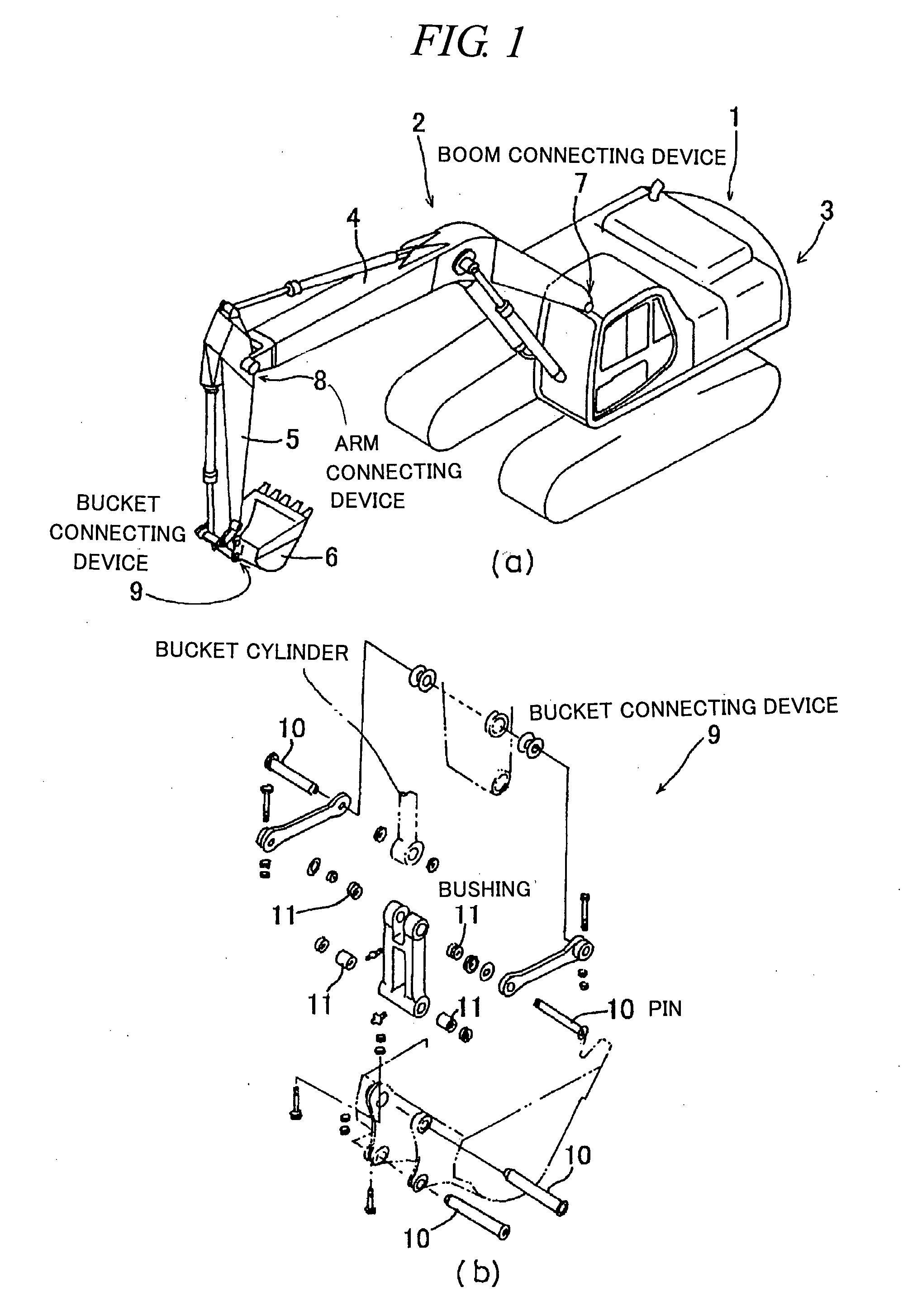

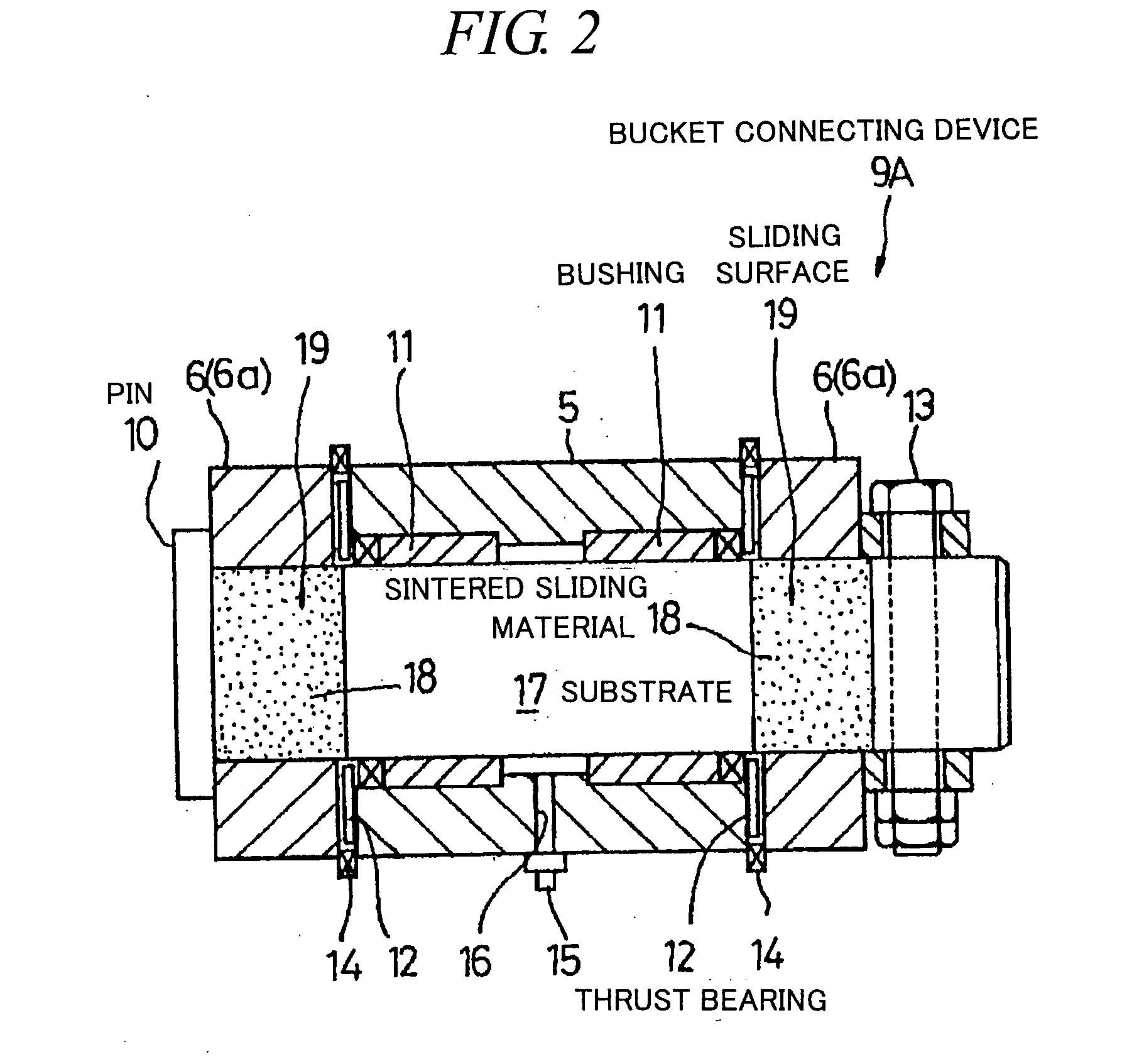

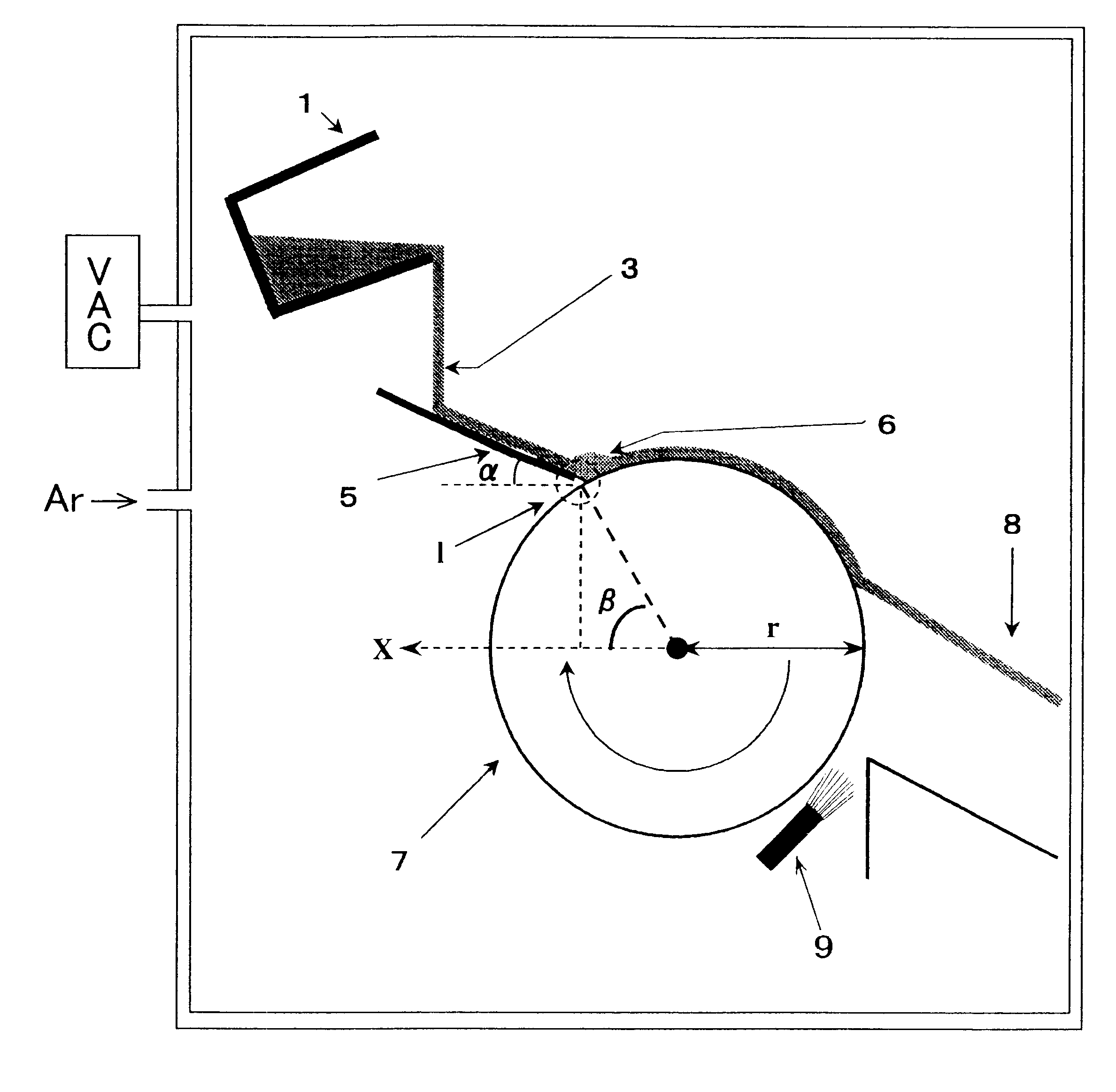

Sintered Material, Ferrous Sintered Sliding Material, Producing Method of the Same, Sliding Member, Producing Method of the Same and Coupling Device

InactiveUS20080146467A1Excellent abrasion resistanceReduce necessityBearing componentsPowder mixtureGraphite particle

The iron-based sintered sliding material comprises: a sintered structure which contains 10-50 wt. % copper and 1-15 wt. % carbon and has been formed by sintering a powder mixture obtained by mixing at least one of an Fe—Cu alloy powder containing copper in an amount which is the solid solubility or larger and is 5-50 wt. %, excluding 50 wt. %, and an Fe—Cu—C alloy powder containing copper in an amount which is the solid solubility or larger and is 5-50 wt. %, excluding 50 wt. %, and containing carbon in an amount of 0-5 wt. %, excluding 0 wt. %, with a graphite powder and at least one of a copper powder and a copper alloy powder; and graphite particles dispersed in the sintered sliding material in an amount of 1-14 wt. % or 3-50 vol. %.

Owner:KOMATSU LTD

Iron-based alloy powder for high strength and toughness laser deposited coating

InactiveCN101974724AGood workmanshipMetallic material coating processesLaser beam welding apparatusHardnessAlloy coating

The invention discloses iron-based alloy powder for a high strength and toughness laser deposited coating in the technical field of alloy materials. The iron-based alloy powder comprises the following components: 0.60 to 1.00 percent of C, 0.35 to 0.70 percent of Si, 0.30 to 0.60 percent of Mn, 5.00 to 7.00 percent of Cr, 2.50 to 4.00 percent of Ni, 1.50 to 2.50 percent of Mo, 1.00 to 1.50 percent of W, 0.70 to 1.00 percent of V, 0.20 to 0.40 percent of Ti, 0.50 to 0.70 percent of B, 0.20 to 0.40 percent of Nb, 0.10 to 0.30 percent of Ce and the balance of Fe. The iron-based laser deposited alloy coating without cracks in large area can be obtained without pre-heating and post thermal treatment, the deposited alloy coating has high hardness which reaches 62 to 67HRC, and the yield strength reaches 1,700 to 2,000MPa.

Owner:SHANGHAI JIAO TONG UNIV

Method of making material alloy for iron-based rare earth magnet

InactiveUS6695929B2Good reproducibilityUniform structureNanomagnetismInorganic material magnetismRare-earth elementRare-earth magnet

A melt of an iron-based rare earth material alloy, represented by (Fe1-mTm)100-x-y-zQxRyMz, is prepared, wherein T is Co and / or Ni; Q is B and / or C; R is selected from Y (yttrium) and the rare earth elements; M is selected from Al, Si, Ti, V, Cr, Mn, Cu, Zn, Ga, Zr, Nb, Mo, Ag, Hf, Ta, W, Pt, Au and Pb; 10<=x<=30 at %; 2%<=y<10 at %; 0<=z<=10 at % and 0<=m<=0.5. The melt is fed onto a guide to form a flow of the melt thereon and move the melt onto a melt / chill roller contact region, where the melt is rapidly cooled by the chill roller to make a rapidly solidified alloy. An oxygen concentration of the melt yet to be fed onto the guide is controlled at about 3,000 ppm or less in mass percentage.

Owner:SUMITOMO SPECIAL METAL CO LTD

Alloy powder special for laser-remelted high hardness crackless iron-base alloy

InactiveCN101381869AHigh strengthHigh hardnessMetallic material coating processesThermal sprayingNiobium

The invention belongs to the technical field of alloy material, and relates to an improvement on the prior art, in particular to special alloy powder for laser cladding of high-hardness crack-free iron-based alloy. The formula of the alloy powder comprises the following compositions in weight percentage: 0.3 to 0.5 of C, 1.2 to 2.0 of Si, 0.4 to 1.0 of B, 1.5 to 2.5 of Ni, 1.0 to 1.5 of Cr, 1.0 to 1.5 of Mn, 1.5 to 2.5 of Mo, 0.15 to 0.7 of V, and 0.15 to 0.7 of Nb, the balance being Fe; and the total weight of the compositions is 100 percent. The special alloy powder can obtain the iron-based alloy with large area, large thickness and no crakes for laser cladding without preheating and subsequent heat treatment, has high strength, hardness and wear resistance and good plastic toughness of a cladding layer, and has lower cost compared with most of hot spraying self melting alloy powder and the prior laser cladding special iron-based alloy powder.

Owner:东莞市豪恩新材料技术有限公司

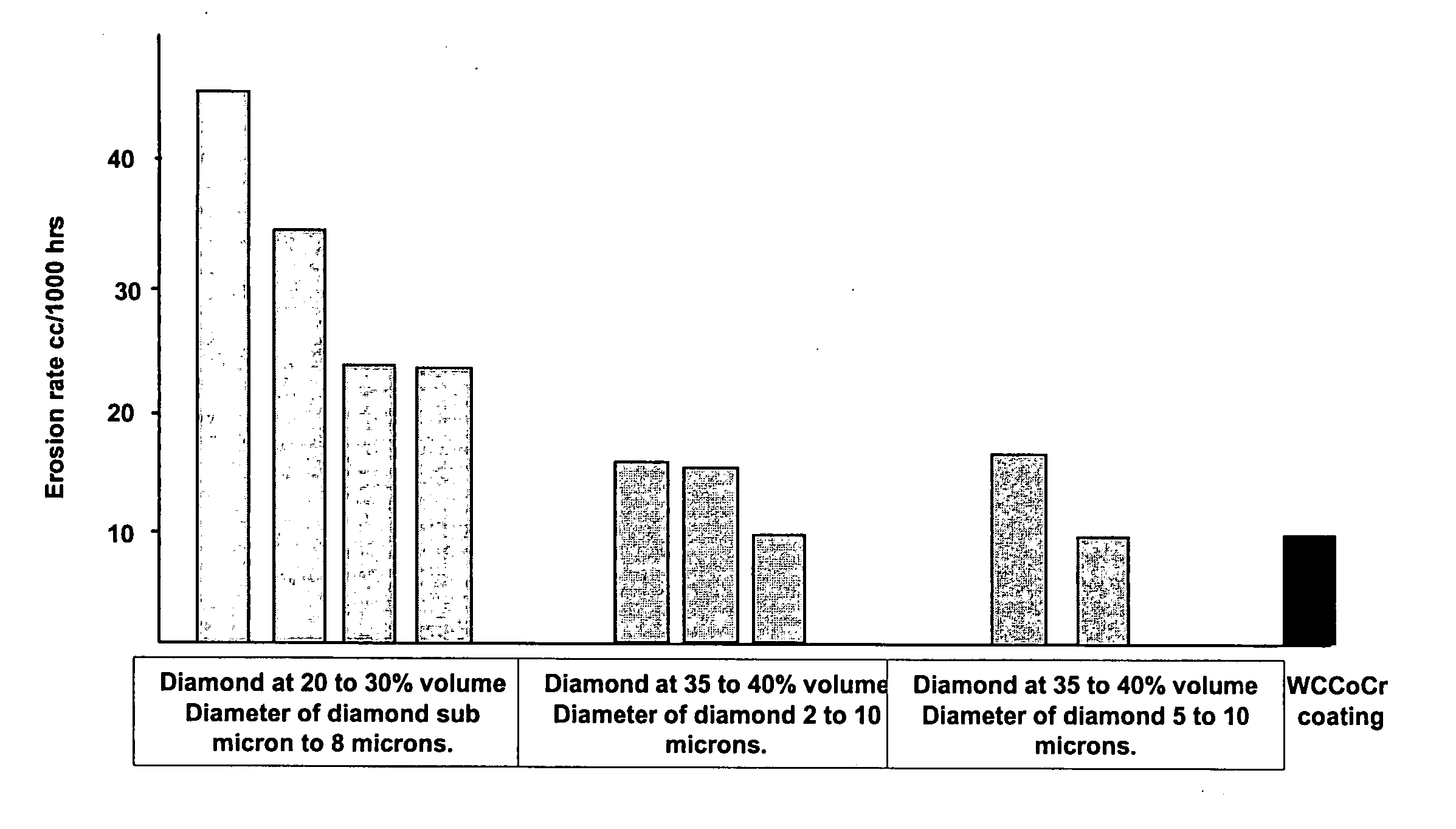

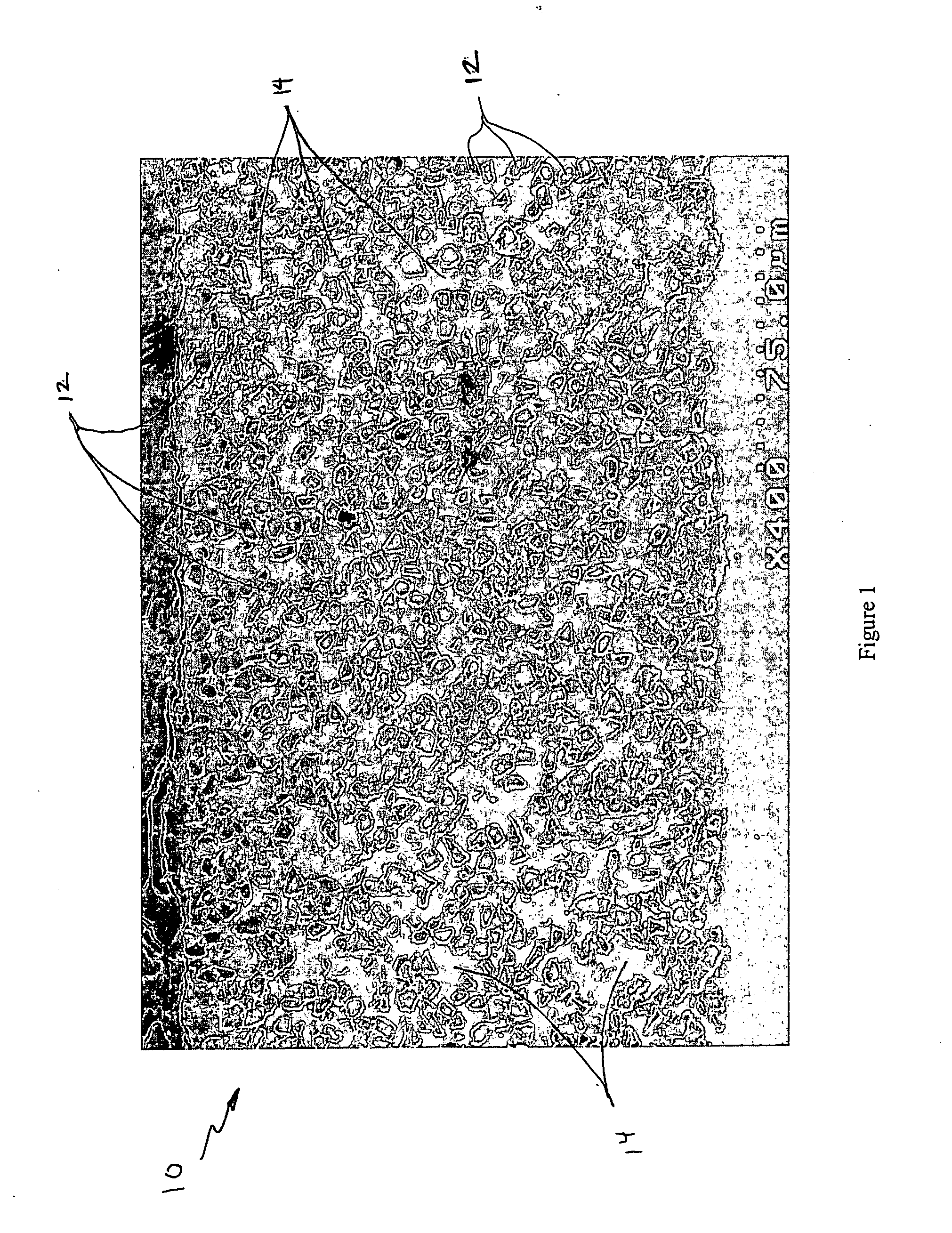

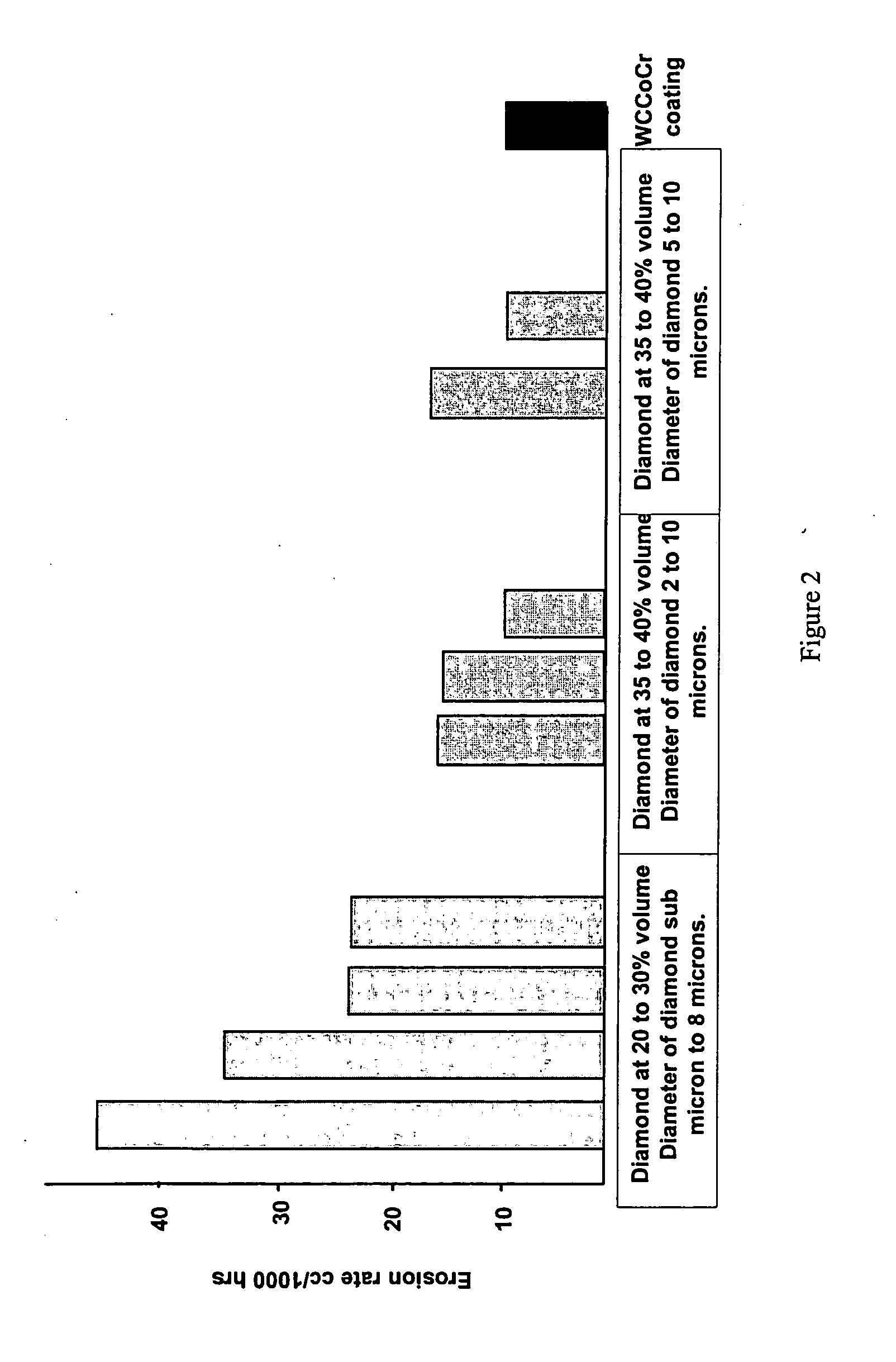

Erosion resistant coatings and methods thereof

Erosion resistant coating compositions include hard particles in a metal matrix such as nickel-based, cobalt-based and iron-based matrices applied by a plating process for complex geometry or hard to access component surfaces or by thermal spray processes for line of sight applications. These materials and processes are especially suited for providing erosion resistance to hydroelectric turbine components.

Owner:GENERAL ELECTRIC CO

Iron based amorphous alloy material and uses thereof

The invention relates to a Fe-based amorphous material, the composition of the material is expressed by atomic ratio as follows: Fe100-a-b-c-d-eNiaCrbPcTdDe, wherein, a is 0.5-8, b is 5-26, c is 3-15, d is 8-20 and e is 0-8; T is one or more of B, C and Si, and D is five or less of Y, V, Zr, Mo, Nb, Cu, Al, Ga, Sn, W and Mn. The material can be in the form of powder, strip, wire and block material.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

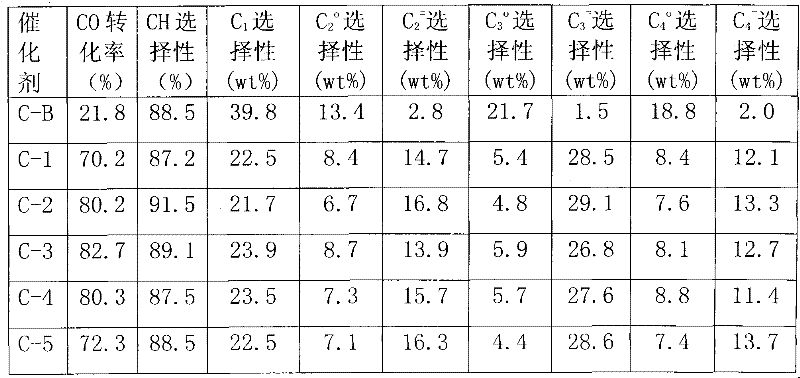

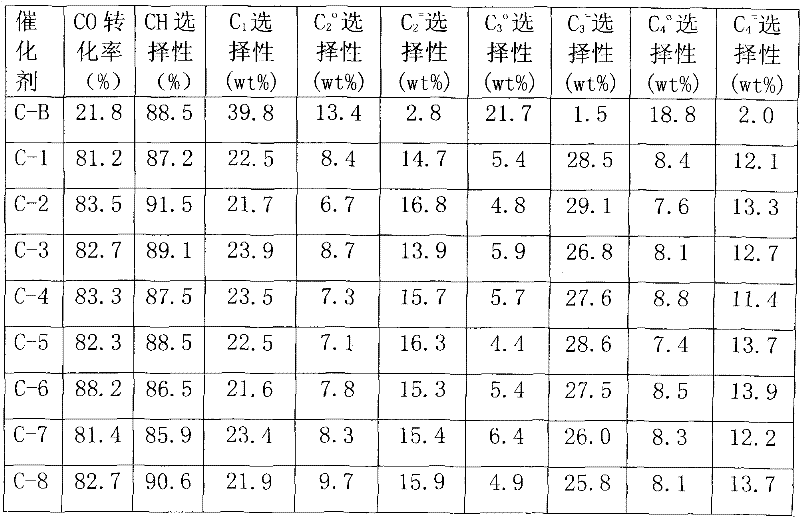

Preparation method of catalyst in process of producing light olefins by high-activity load type iron-based synthesis gas

ActiveCN102441400AOvercoming strong interactionsHigh activityCatalyst carriersHydrocarbon from carbon oxidesActive componentHigh activity

The invention discloses a preparation method of a catalyst in a process of producing light olefins by high-activity load type iron-based synthesis gas. The preparation method comprises the steps of: with silicon gel as a carrier, firstly, carrying out surface modification on the silicon gel carrier, and then loading a metal additive and an active component Fe by adopting an immersion method, wherein an ammonium salt-containing buffer solution is adopted for immersion in the surface modification method of the silicon gel carrier. After the adopted silicon gel carrier is modified, the strong interaction function between the carrier and the active component is overcome, and the activity and the selectivity of the catalyst are improved. The catalyst prepared by adopting the preparation methodis suitable for a reaction process for producing light olefins such as ethylene, propylene, butylene and the like by using the synthesis gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing low-carbon olefine catalyst by loading iron-based synthetic gas

ActiveCN101940958AOvercoming strong interactionsHigh activityHydrocarbon from carbon oxidesCatalyst activation/preparationActive componentSilica gel

The invention discloses a method for preparing a low-carbon olefine catalyst by a loading iron-based synthetic gas, which comprises the following steps of: firstly carrying out surface modification on a silica gel carrier by using silica gel as a carrier, and then loading a metal auxiliary agent and an active component Fe by using an immersion method, wherein the surface modification method of the silica gel carrier comprises the following step of carrying out immersion treatment by using the acidic solution of sugar. After the silica gel carrier adopted is modified, the strong interaction between the carrier and the active component is overcome, and the activity and the selectivity of the catalyst are improved. The catalyst prepared by using the method is suitable for a reaction process of producing low-carbon olefines of ethylene, propylene, butane and the like by the synthetic gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Iron-based nanocrystalline soft-magnetic alloy with excellent high-frequency performance and preparation method thereof

ActiveCN104087833AHigh saturation magnetic inductionImprove thermal stabilityMagnetic materialsRare-earth elementNanocrystalline silicon

The invention discloses iron-based nanocrystalline soft-magnetic alloy with excellent high-frequency performance and a preparation method thereof. The expression of the alloy is FeaSibPcCuxMy, wherein a, b, c, x and y respectively represent the atomic percent content of corresponding compositions and satisfy the following conditions: 70<=a<=85, 5<=b<=15, 5<=c<=18, 0.0001<=x<=3, 0<=y<=5, a+b+c+x+y=100%, and M is one or more of Zr, Ti, Ta, Hf, Nb, V, W, Mo, Mn, Cr, Re, Zn, In, As, Sb, Bi, Ca, platinum group elements, rare earth elements, N, Sn, Ge, Ga and Al. The alloy is a nanocrystalline soft-magnetic alloy band prepared by employing a single-roller quick-cooling method under the conditions of high vacuum and argon protection. The alloy does not contain B elements, is good in soft magnetic property, high in thermal stability, low in high-frequency loss and low in magnetostriction coefficient.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Method for preparing low-carbon olefin catalyst by high-activity-stability carrier-type iron-based synthetic gas

ActiveCN102441384AHigh activityHigh selectivityHydrocarbon from carbon oxidesCatalyst activation/preparationWater vaporActive component

The invention discloses a method for preparing a low-carbon olefin catalyst by high-activity-stability carrier-type iron-based synthetic gas. Silica gel is taken as a carrier, and a metal promoter and an active component Fe are loaded by adopting an immersion method, wherein the used silica gel carrier is firstly subjected to hydrothermal treatment, and the condition for the hydrothermal treatment is that 50%-100% water vapor is used for carrying out the hydrothermal treatment for 0.5-20h at the temperature of 150-600 DEG C. After the silica gel carrier used in the method disclosed by the invention is subjected to the hydrothermal treatment, the strong interaction between the carrier and the active component is overcome, and thus, the activity and the selectivity of the catalyst are improved. The catalyst prepared by the method disclosed by the invention is applicable to the reacting processes of preparing the low-carbon olefins, such as ethylene, propylene, butylene and the like, from the synthetic gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

Abrasion resistant iron base sintered alloy material for valve seat and valve seat made of iron base sintered alloy

InactiveUS6139599AAbrasion resistance of the sintered alloy material is remarkably increasedIncrease resistanceMachines/enginesSlide valveCarbideHardness

A valve seat made of an iron base sintered alloy for internal combustion engines comprises of hard particles of hardness 700-1300 Hv dispersed by 3-20% by volume in a matrix phase comprising comprising of a 5-40% psarlite phase, a 20-60% fine carbide dispersed phase, and a 5-20% high alloy diffusd phase. The hard paricles are preferably selected from a group of Mo-Ni-Cr-Si-Co intermetallic compound particles, Cr-Mo-Co intermetallic compound particles, and Fe-Mo alloy particles. The iron base sinteed alloy is conpised of, by weight, C: 0.2-2.0%, Cr: 1.0-9.0%, Mo: 1.0-9.0%, Si: 0.1-1.0%, W: 1.0-50%, V: 0.2-3.0%, one or more Cu, Co and Ni of 0.5-10.0% in total, and the remainder substantial Fe.

Owner:NIPPON PISTONRING CO LTD

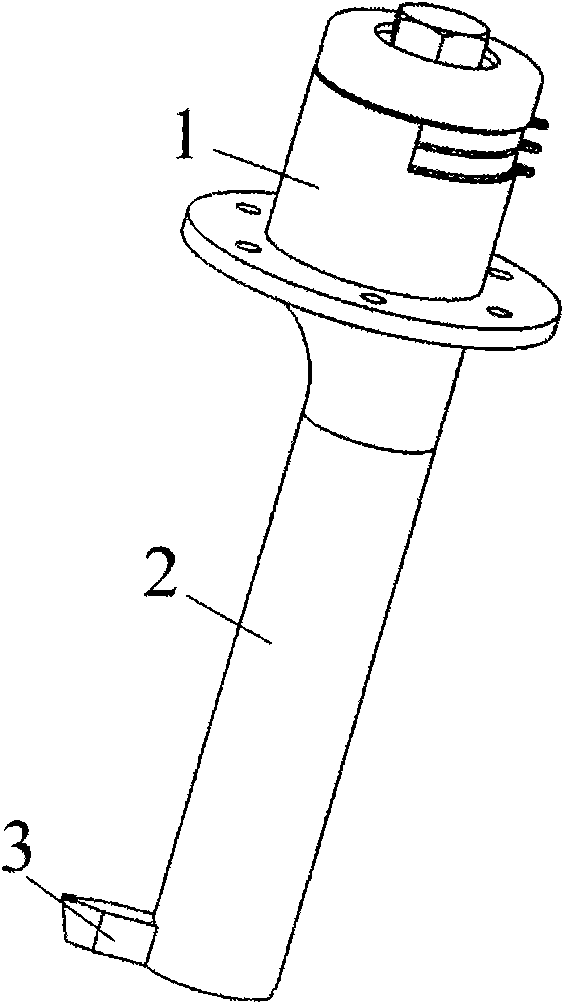

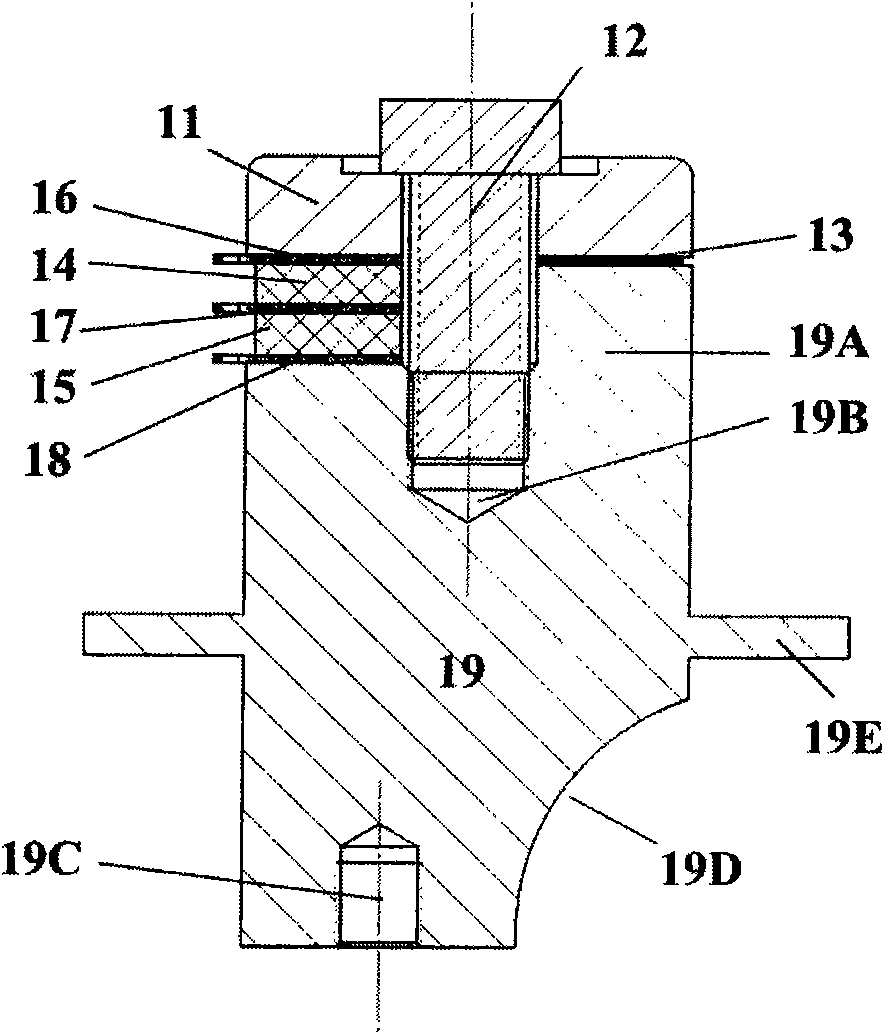

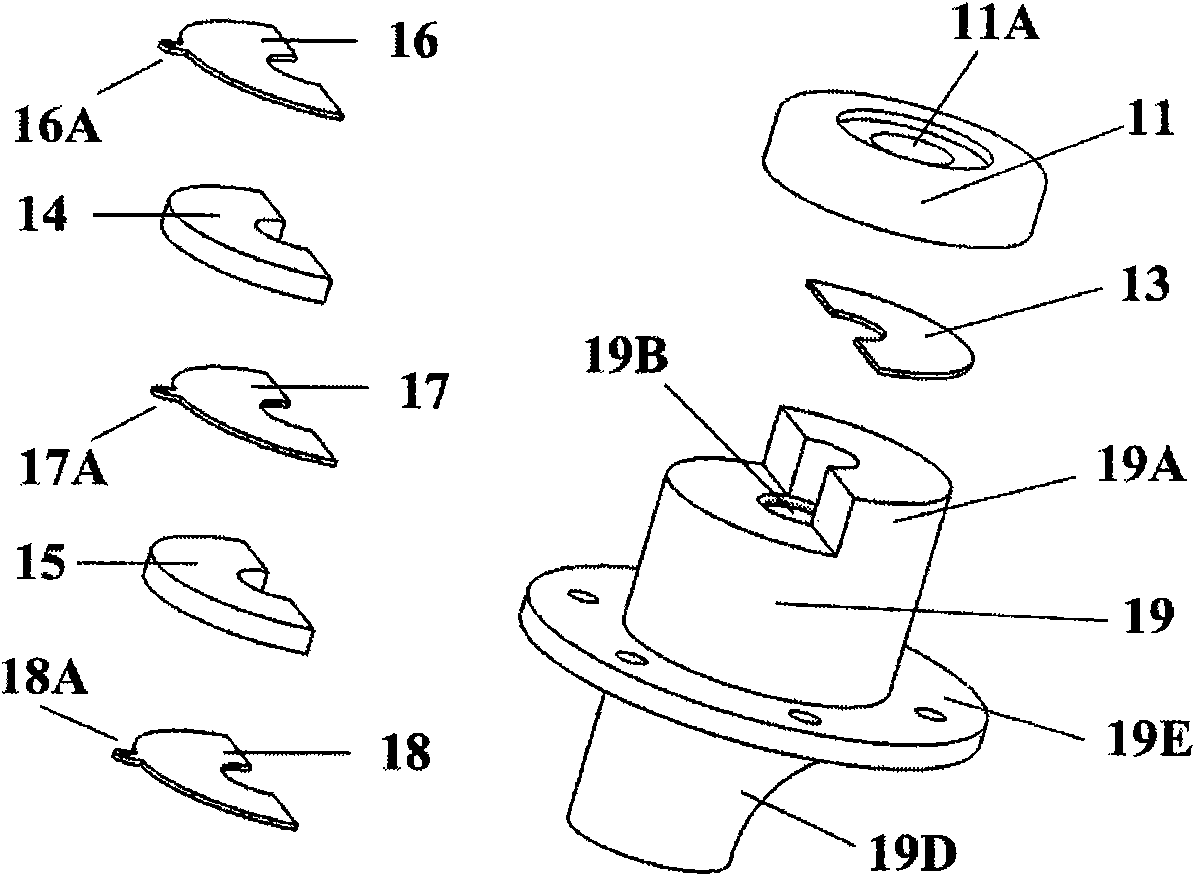

Elliptical ultrasonic vibration auxiliary cutting device with adjustable track

InactiveCN101804575AEasy to wearReduce wearMechanical vibrations separationFeeding apparatusTransformerEngineering

The invention relates to an elliptical ultrasonic vibration auxiliary cutting device with an adjustable track, which consists of a transducer, an amplitude transformer and a cutter, wherein the transducer adopts a basic structure of a longitudinal vibration sandwiched piezoelectric chip, has revolution asymmetric characteristic structures of an overlapping structure of semicircular ring-shaped piezoelectric ceramic chips and electrode chips separately, an off-axis type catenary variable-amplitude structure and the like, and initiates and strengthens flexural vibration when longitudinal vibration is output; the amplitude transformer is a cylindrical bar with uniform cross sections, and a relative angle between the amplitude transformer and a front cover plate is adjustable; and the cutter is installed in an offset way in the radial direction at the tail end of the amplitude transformer, and the offset degree can be adjusted. The working frequency of the invention is higher than 20kHz and can better achieve the ultrasonic machining effect; the elliptical cutting track is long, the minor axis proportion is reasonable, so that the advantages of elliptical cutting can be fully used; the elliptical track can be adjusted to better adapt to machining of different machining materials and different cutting consumption; and single-point diamond ultraprecise cutting can be hopefully expanded to machining of iron-based materials and optical crisp and hard materials.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com