Low-cost high-saturation magnetic induction intensity iron-based amorphous soft magnetism alloy

An iron-based amorphous and soft magnetic alloy technology, applied in the direction of magnetic objects, magnetic materials, electrical components, etc., can solve the problems of thermal stability decline, easy to catch fire, and strips are prone to brittleness, etc., and achieve strong amorphous formation ability , high saturation magnetic induction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

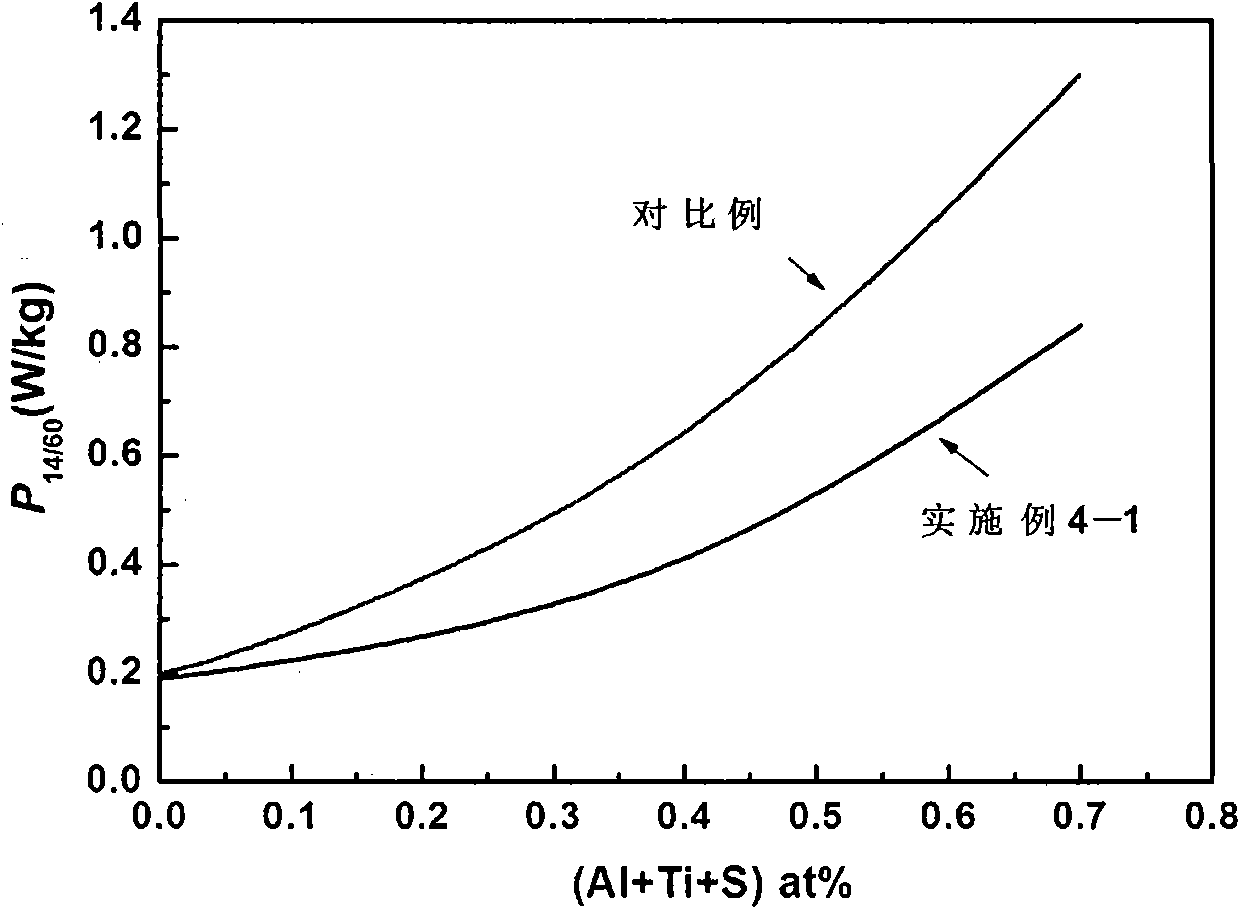

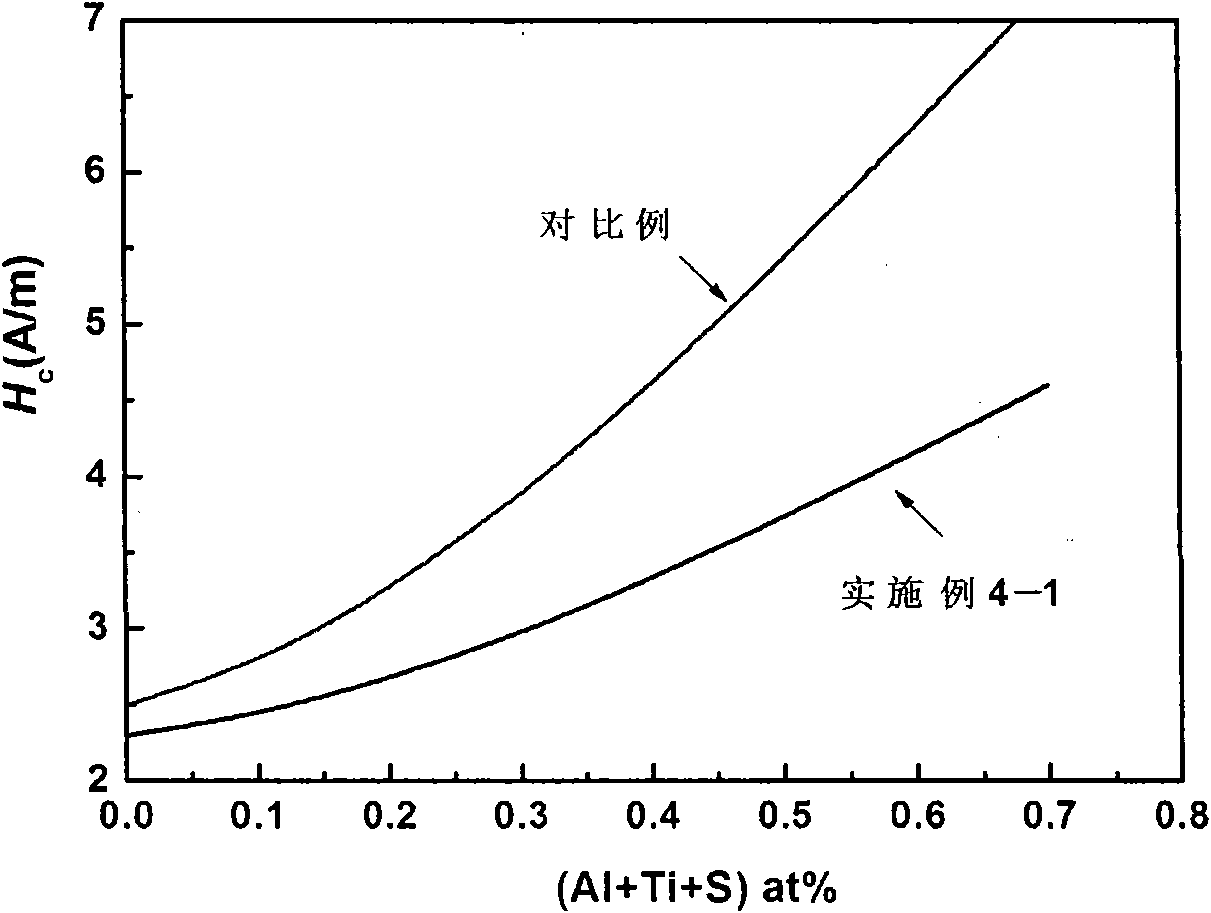

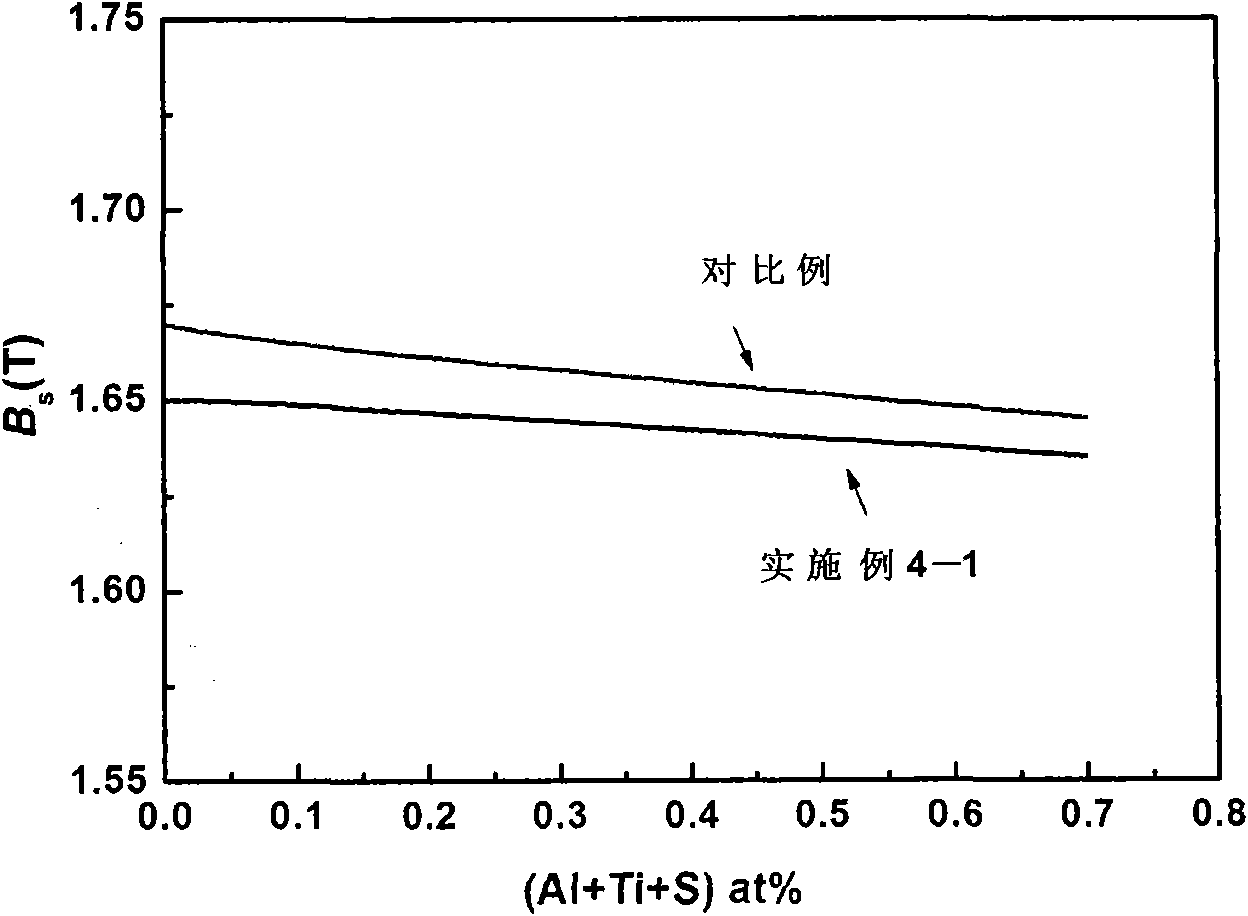

[0021] In the iron-based amorphous alloy with low cost and high saturation magnetic induction of the present invention, firstly, the Mn element can suppress the crystallization caused by impurity elements on the surface of the amorphous alloy, and improve the soft magnetic properties; secondly, the addition of Mn can effectively Inhibit strip embrittlement caused by impurity element S in the alloy, because Mn and S easily form MnS compound in molten steel. The inventors found that under the condition of rapid cooling and the presence of Sn and Sb elements in the present invention, MnS does not exist in the form of large block or chain inclusions, but in the form of tiny The particles are uniformly distributed inside the alloy, and thus the embrittlement and soft magnetic property deterioration caused by S elements are minimized; finally, when the Mn content is controlled below 0.5 at%, not only the surface quality of the amorphous alloy can be improved, It can also moderately ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com