Fe-based amorphous soft magnetic alloy and preparation method thereof

A technology of iron-based amorphous alloy and soft magnetic alloy, which is applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of insufficient amorphous forming ability, low saturation magnetization, and affecting the application of iron-based amorphous, and achieves Excellent amorphous forming ability, high saturation magnetic induction, and good soft magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

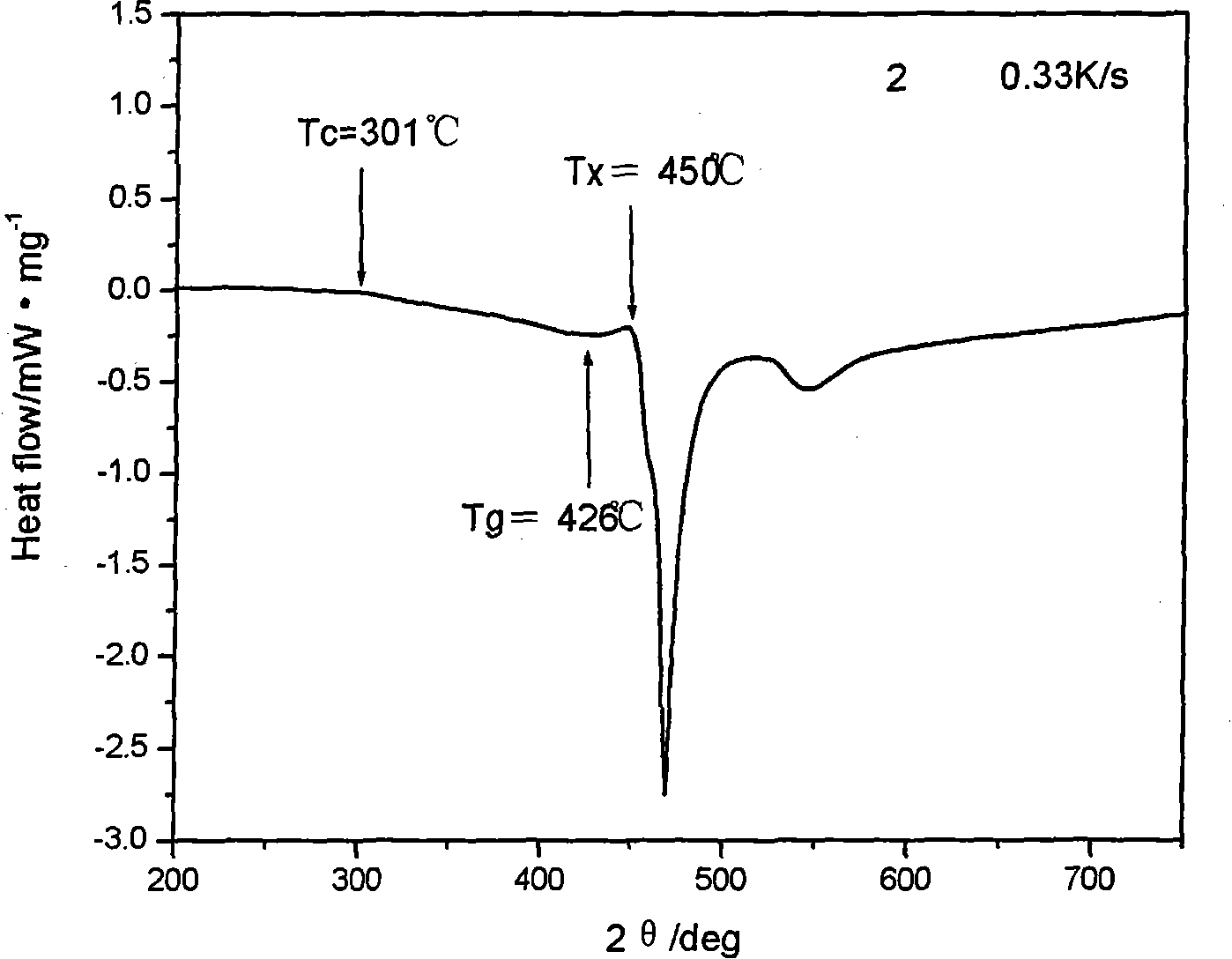

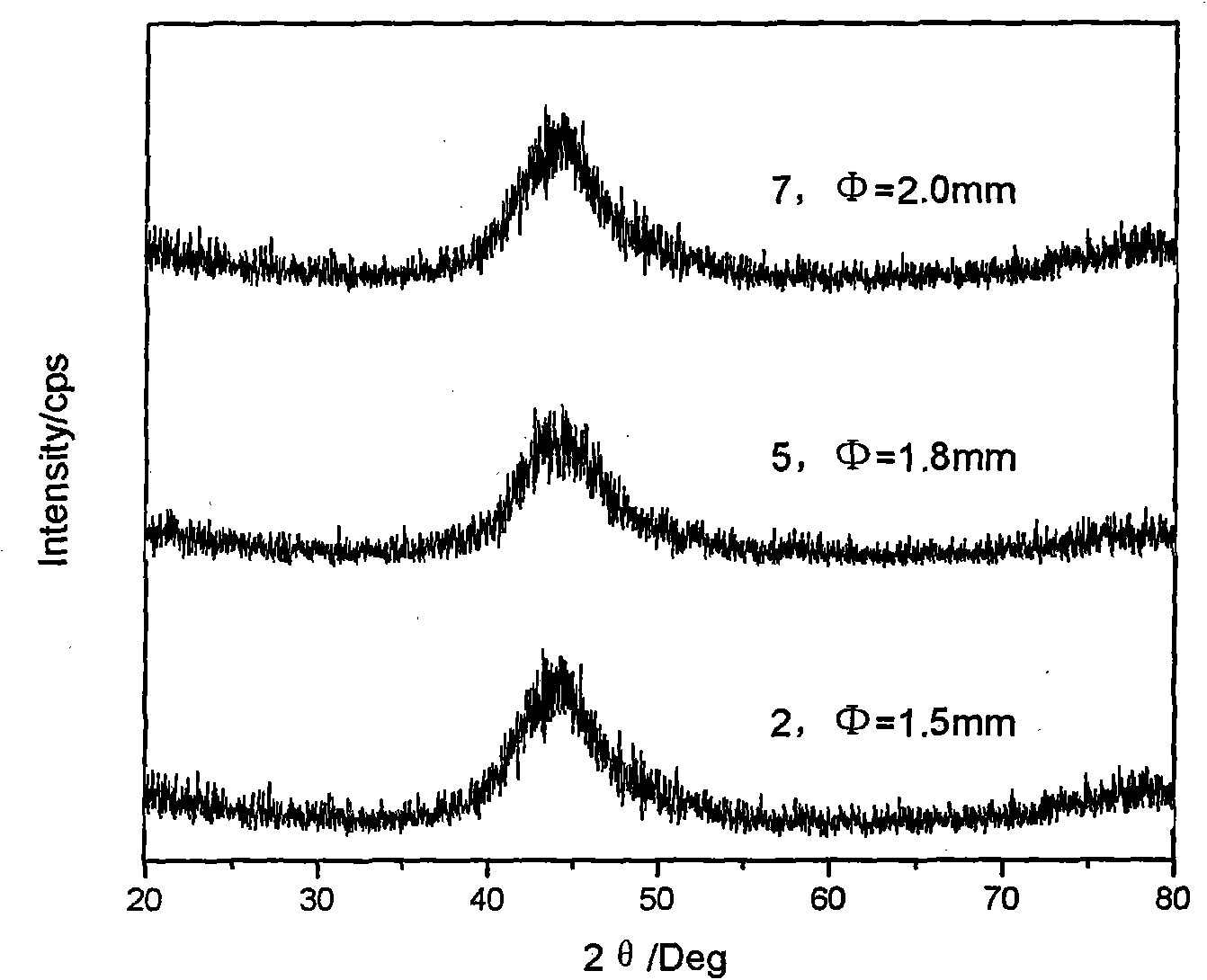

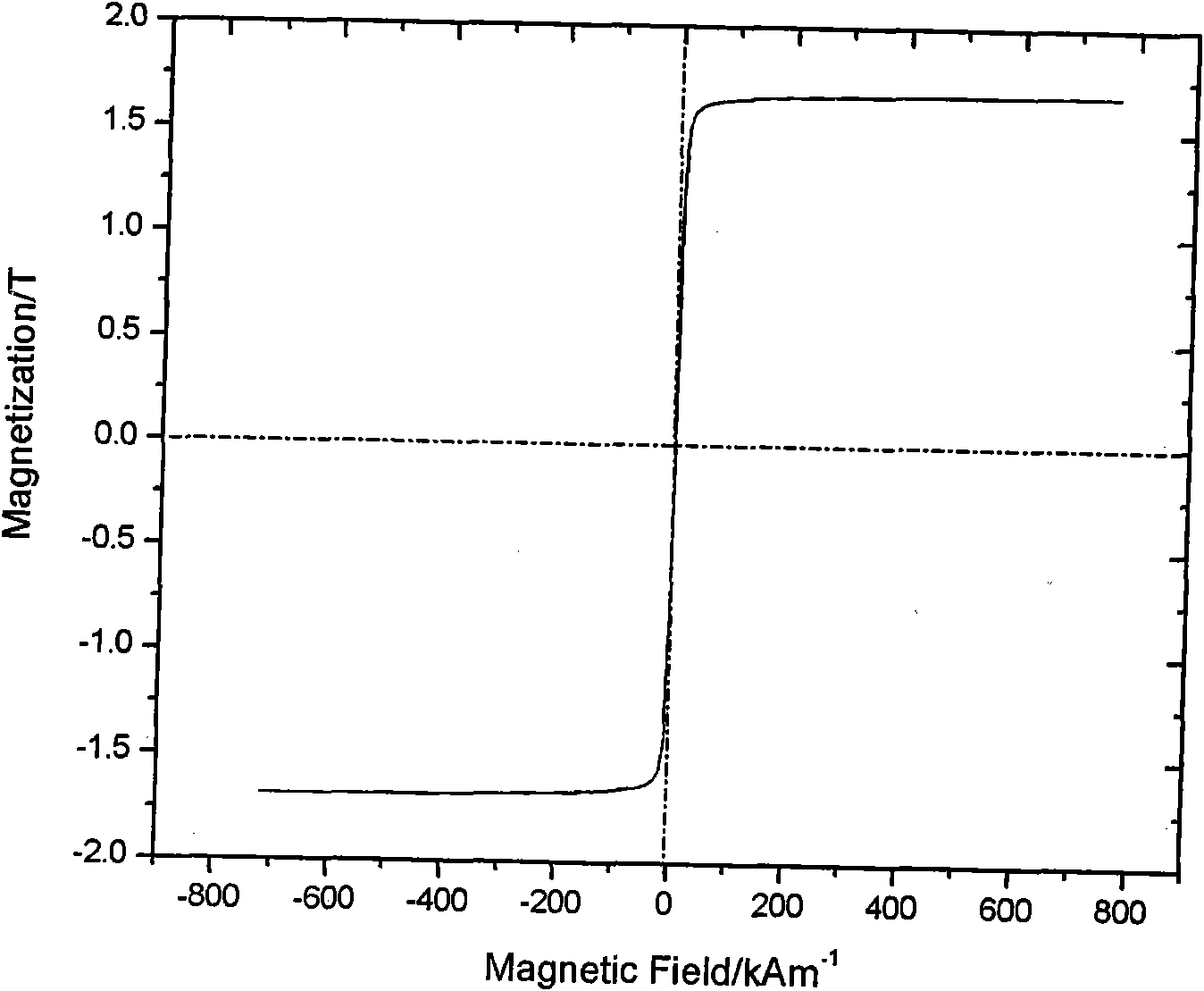

[0023] Preparation of Fe 79 P 11 C 10 Amorphous alloy

[0024] Step 1: Press Fe 79 P 11 C 10 Chemical composition ratio for batching

[0025] Press Fe 79 P 11 C 10 Calculate and weigh the corresponding raw material quality, where P is added through FeP, and the purity of other elements is industrial grade;

[0026] Step 2: Melting to prepare Fe 79 P 11 C 10 Master Alloy

[0027] Put the raw materials of the target ingredients weighed in step 1 into the vacuum high-frequency induction smelting furnace, and vacuumize to 1-5×10 -3 Pa, filling pressure is 0.02-0.09MPa argon protective gas; adjust current 15-25A, smelting temperature 1000-1600℃, smelting for 5-10min, then take out with furnace cooling to obtain Fe 79 P 11 C 10 master alloy.

[0028] Step 3: Preparation of Fe 79 P 11 C 10 Amorphous alloy:

[0029] Put the master alloy prepared in step 2 into the induction furnace of the rapid solidification device, and vacuumize to 1-5×10 -3 Pa, filling pressur...

Embodiment 2

[0032] Preparation of Fe 80 P 11 C 9 Amorphous alloy

[0033] Step 1: Press Fe 80 P 11 C 9 Chemical composition ratio for batching

[0034] Press Fe 80 P 11 C 9 Calculate and weigh the corresponding raw material quality, where P is added through FeP, and the purity of other elements is industrial grade;

[0035] Step 2: Melting to prepare Fe 80 P 11 C 9 Master Alloy

[0036] Put the raw materials of the target ingredients weighed in step 1 into the vacuum high-frequency induction smelting furnace, and vacuumize to 1-5×10 -3 Pa, filling pressure is 0.02-0.09MPa argon protective gas; adjust current 15-25A, smelting temperature 1000-1600℃, smelting for 5-10min, then take out with furnace cooling to obtain Fe 80 P 11 C 9 master alloy.

[0037] Step 3: Preparation of Fe 80 P 11 C 9 Amorphous alloy:

[0038] Put the master alloy prepared in step 2 into the induction furnace of the rapid solidification device, and vacuumize to 1-5×10 -3 Pa, filling pressure is 0.0...

Embodiment 3

[0041] Preparation of Fe 81 P 11 C 8 Amorphous alloy

[0042] Step 1: Press Fe 81 P 11 C 8 Chemical composition ratio for batching

[0043] Press Fe 81 P 11 C 8 Calculate and weigh the corresponding raw material quality, where P is added through FeP, and the purity of other elements is industrial grade;

[0044] Step 2: Melting to prepare Fe 81 P 11 C 8 Master Alloy

[0045] Put the raw materials of the target ingredients weighed in step 1 into the vacuum high-frequency induction smelting furnace, and vacuumize to 1-5×10 -3 Pa, filling pressure is 0.02-0.09MPa argon protective gas; adjust current 15-25A, smelting temperature 1000-1600℃, smelting for 5-10min, then take out with furnace cooling to obtain Fe 81 P 11 C 8 master alloy.

[0046] Step 3: Preparation of Fe 81 P 11 C 8 Amorphous alloy:

[0047] Put the master alloy prepared in step 2 into the induction furnace of the rapid solidification device, and vacuumize to 1-5×10 -3 Pa, filling pressure is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetic induction | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

| Saturation magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com