Patents

Literature

169results about How to "Improve the ability to form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

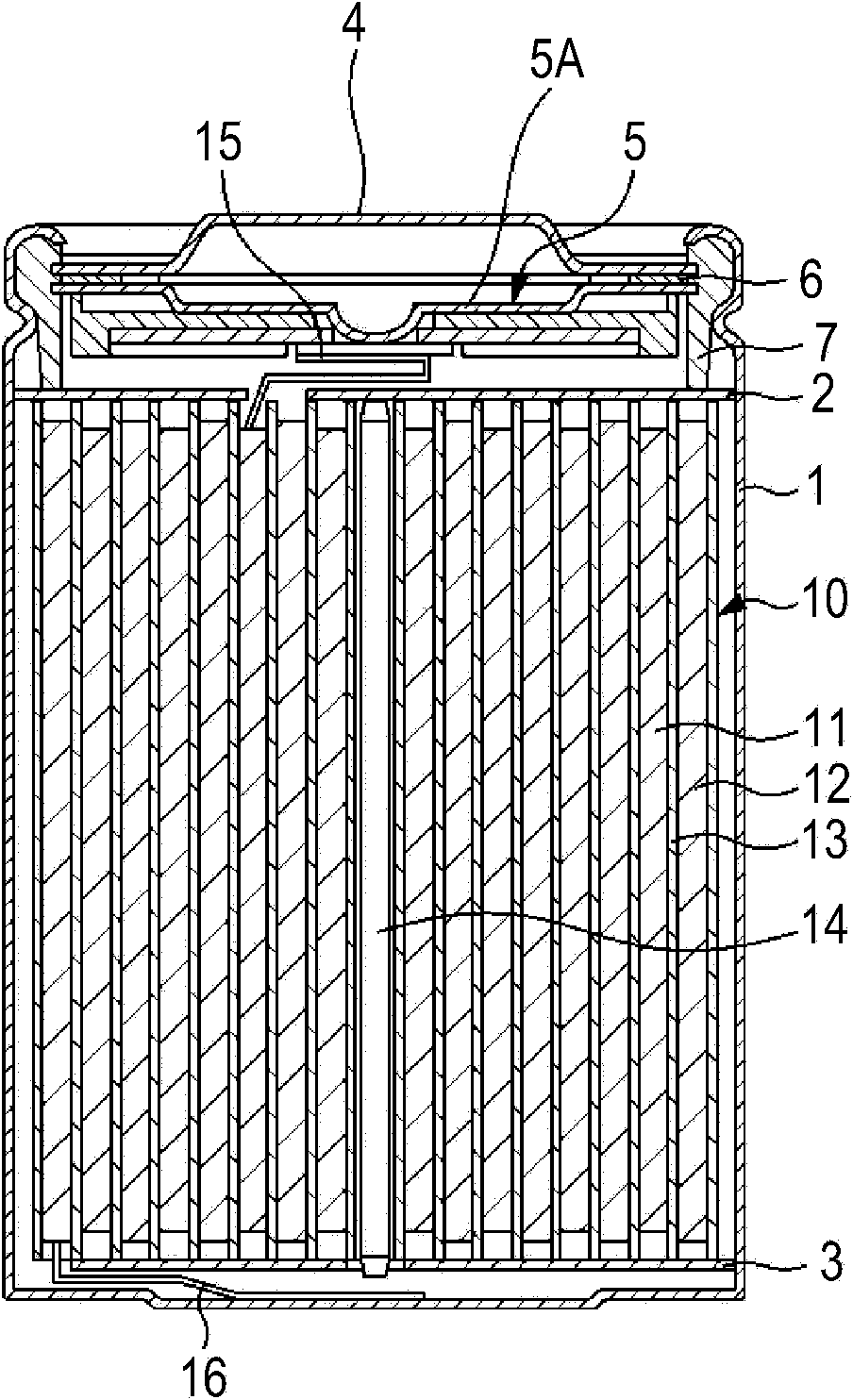

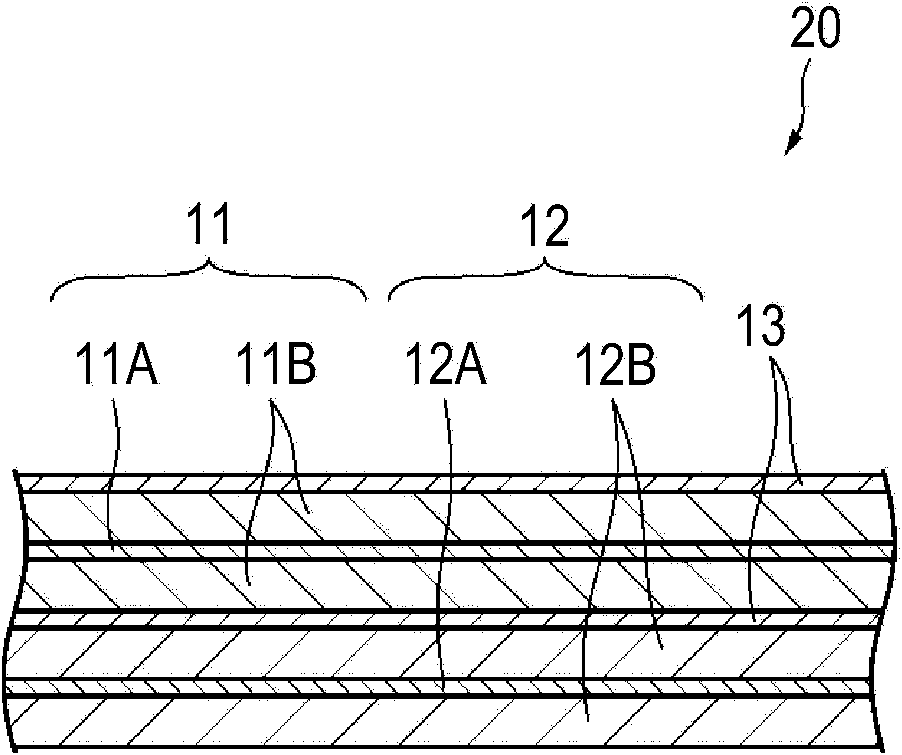

Nonaqueous electrolyte and nonaqueous electrolyte battery

ActiveCN102136604AImprove the ability to formReduce capacityPrimary cellsLi-accumulatorsHalogenSolvent

The present invention discloses a nonaqueous electrolyte and a nonaqueous electrolyte battery. The nonaqueous includes: a nonaqueous solvent containing 0.1% by volume or more and not more than 50% by volume of at least one member selected from the group consisting of a halogen element-containing chain carbonate represented by the following formula (1) and a halogen element-containing cyclic carbonate represented by the following formula (2); and an electrolyte salt containing a compound represented by the following formula (3) in an amount of 0.001 moles / L or more and not more than 0.5 moles / L relative to the nonaqueous solvent.

Owner:MURATA MFG CO LTD

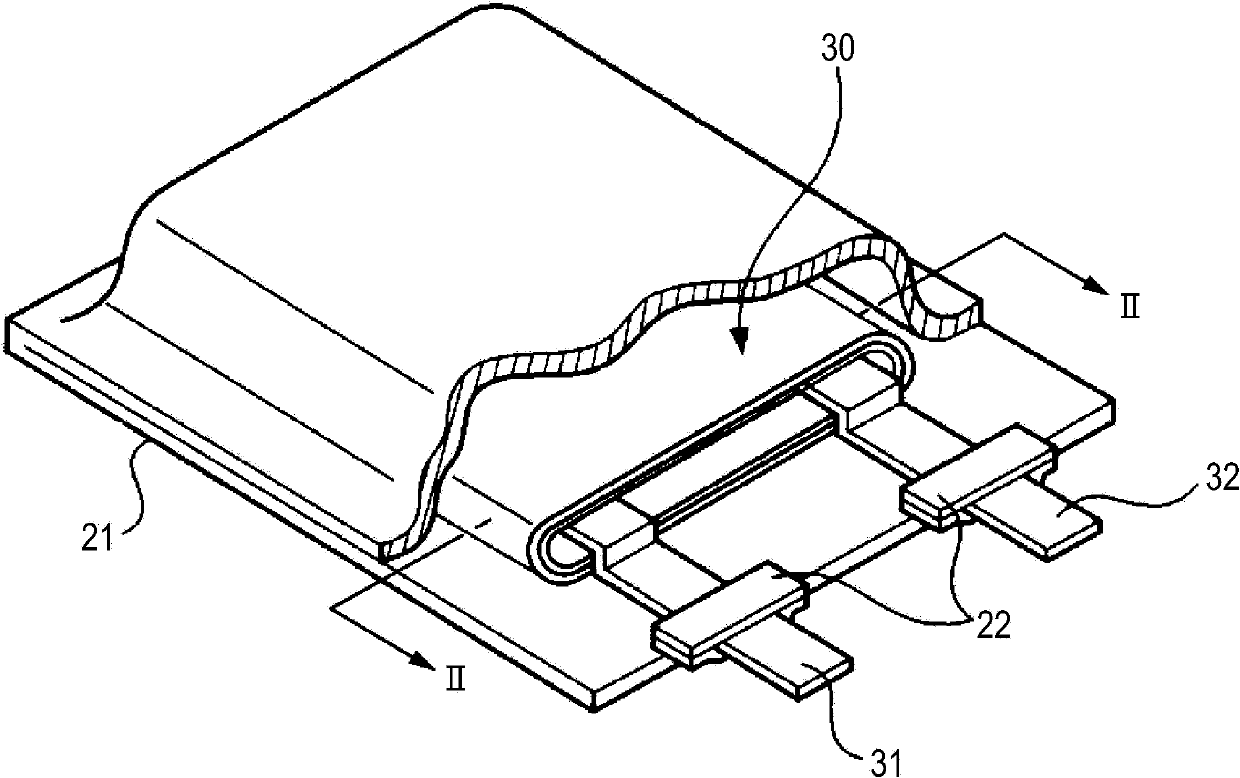

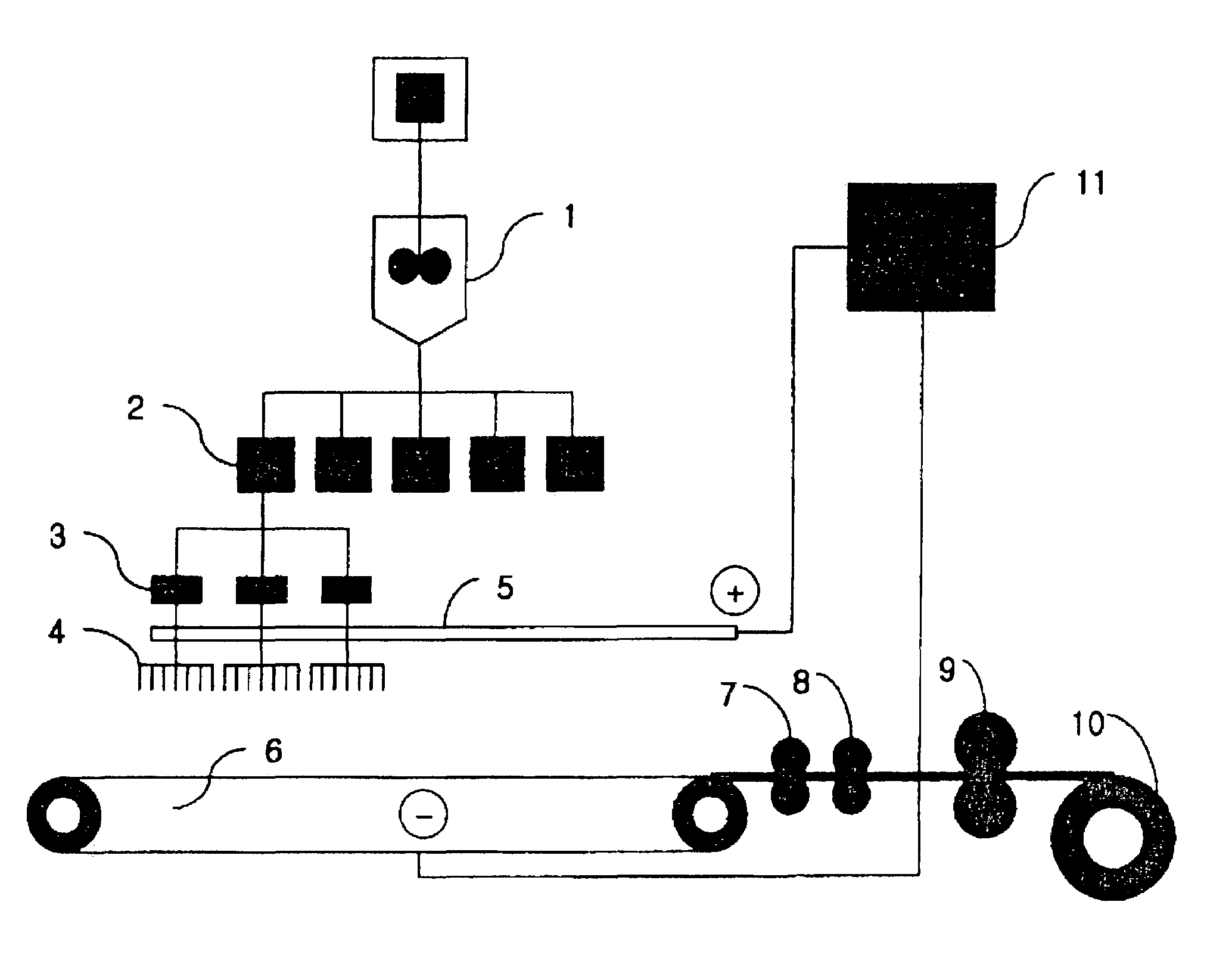

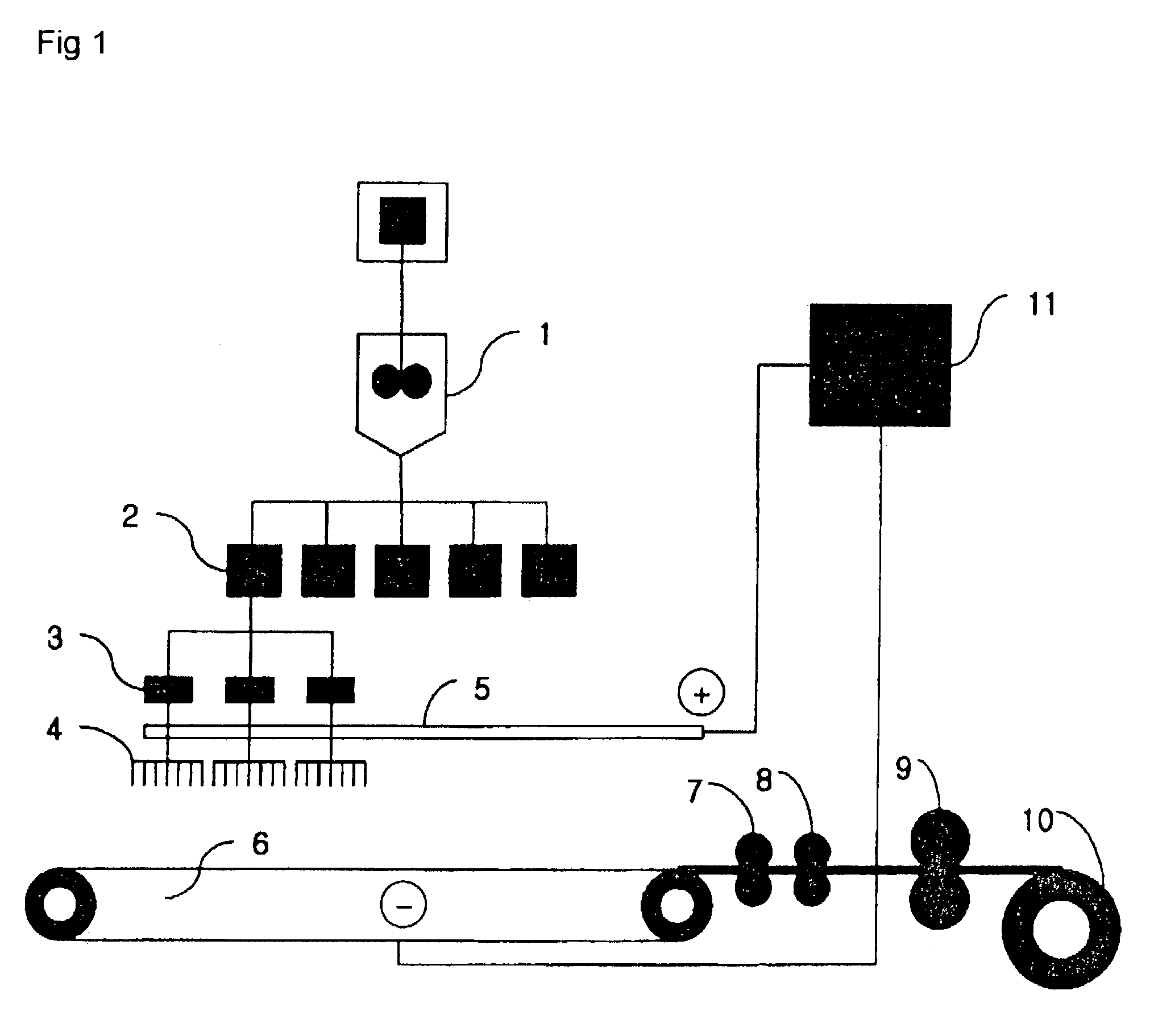

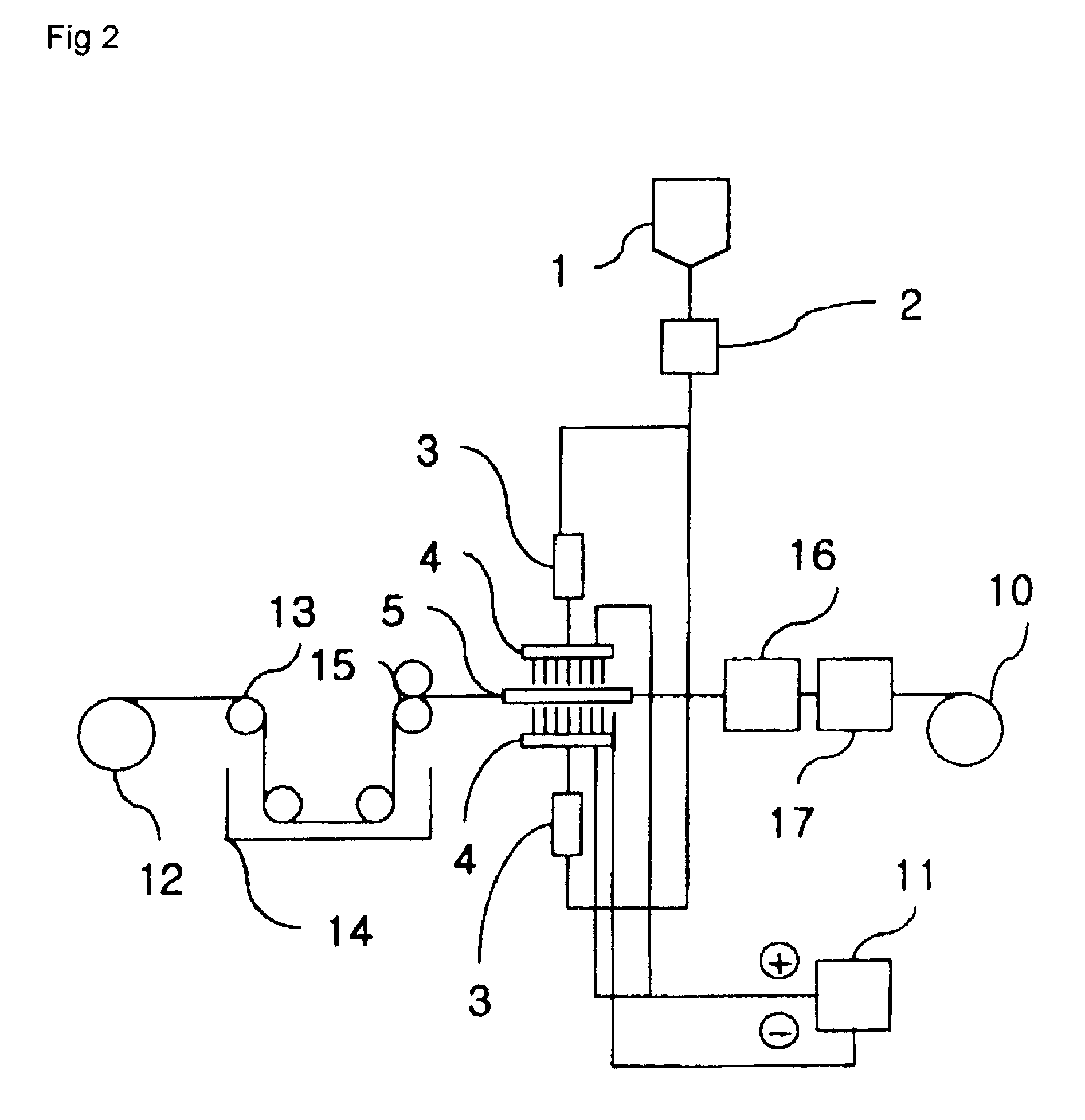

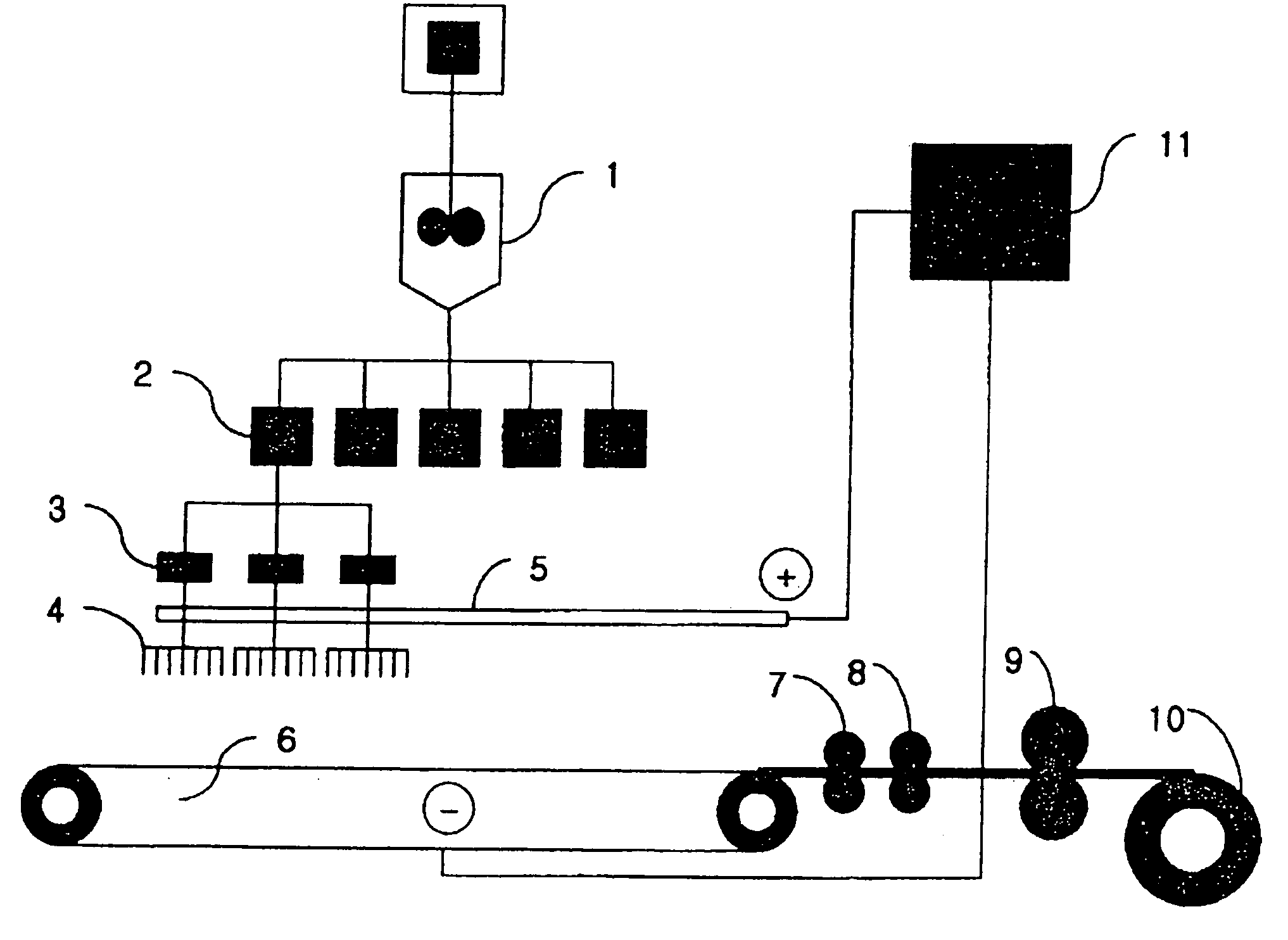

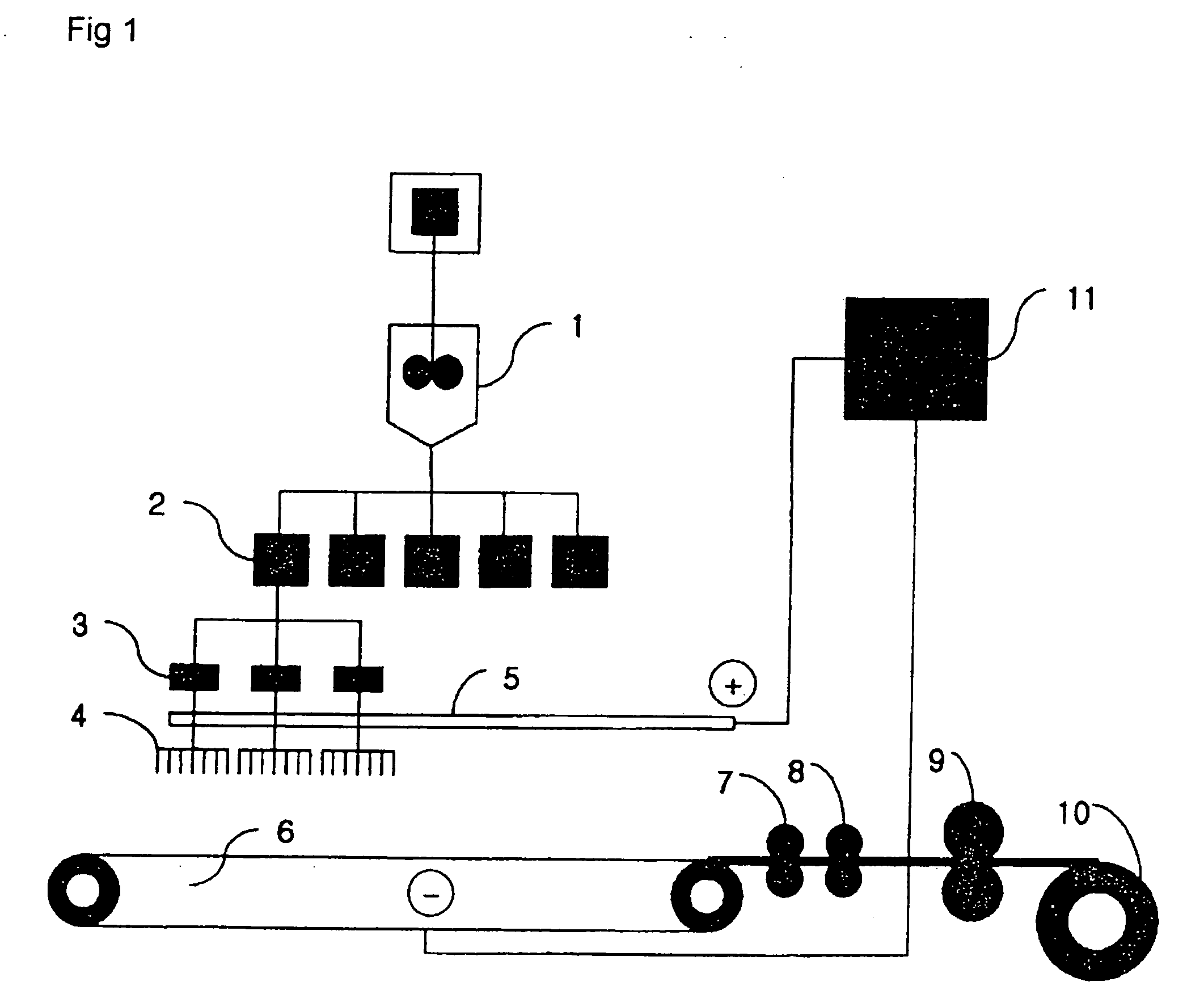

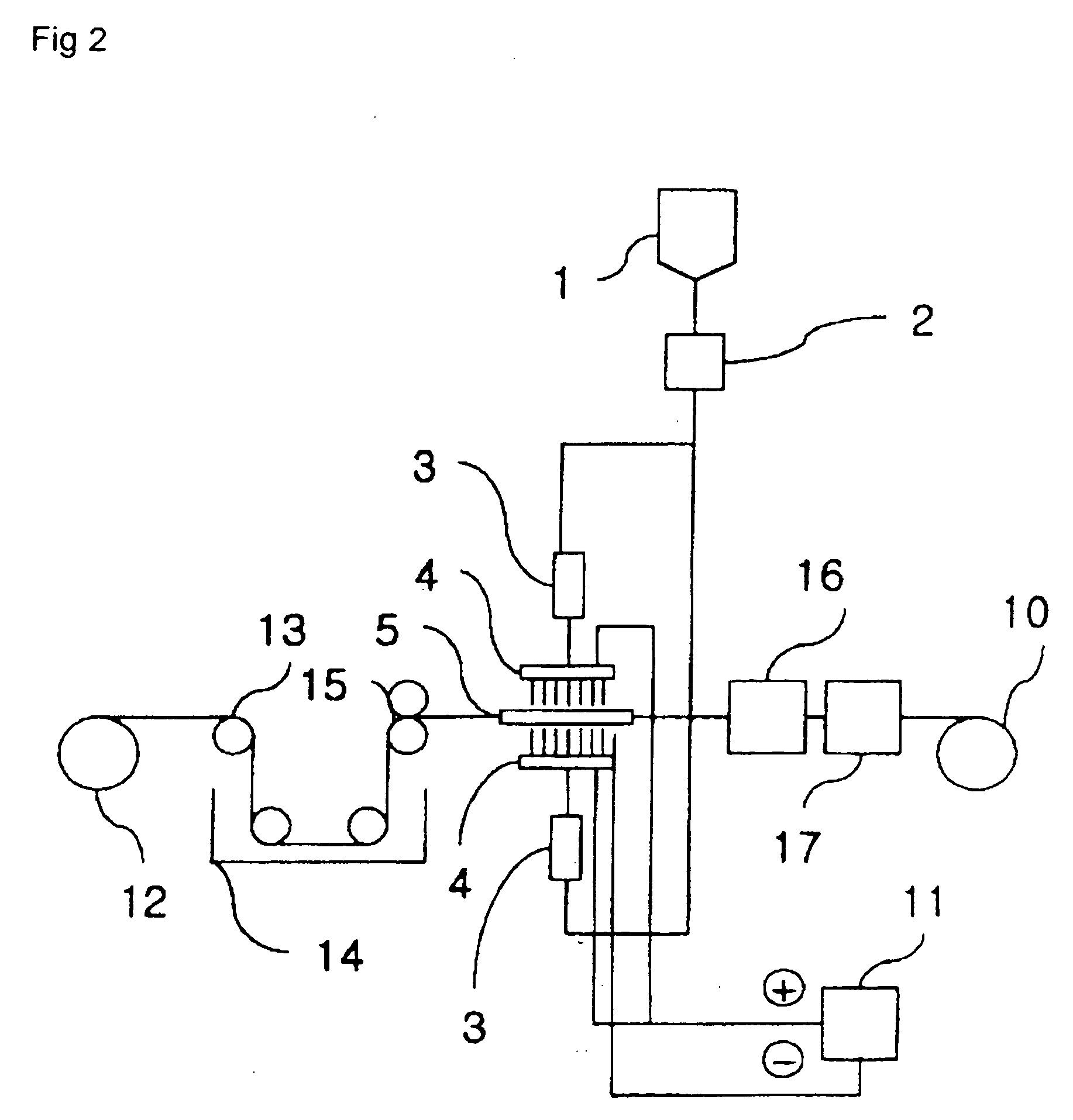

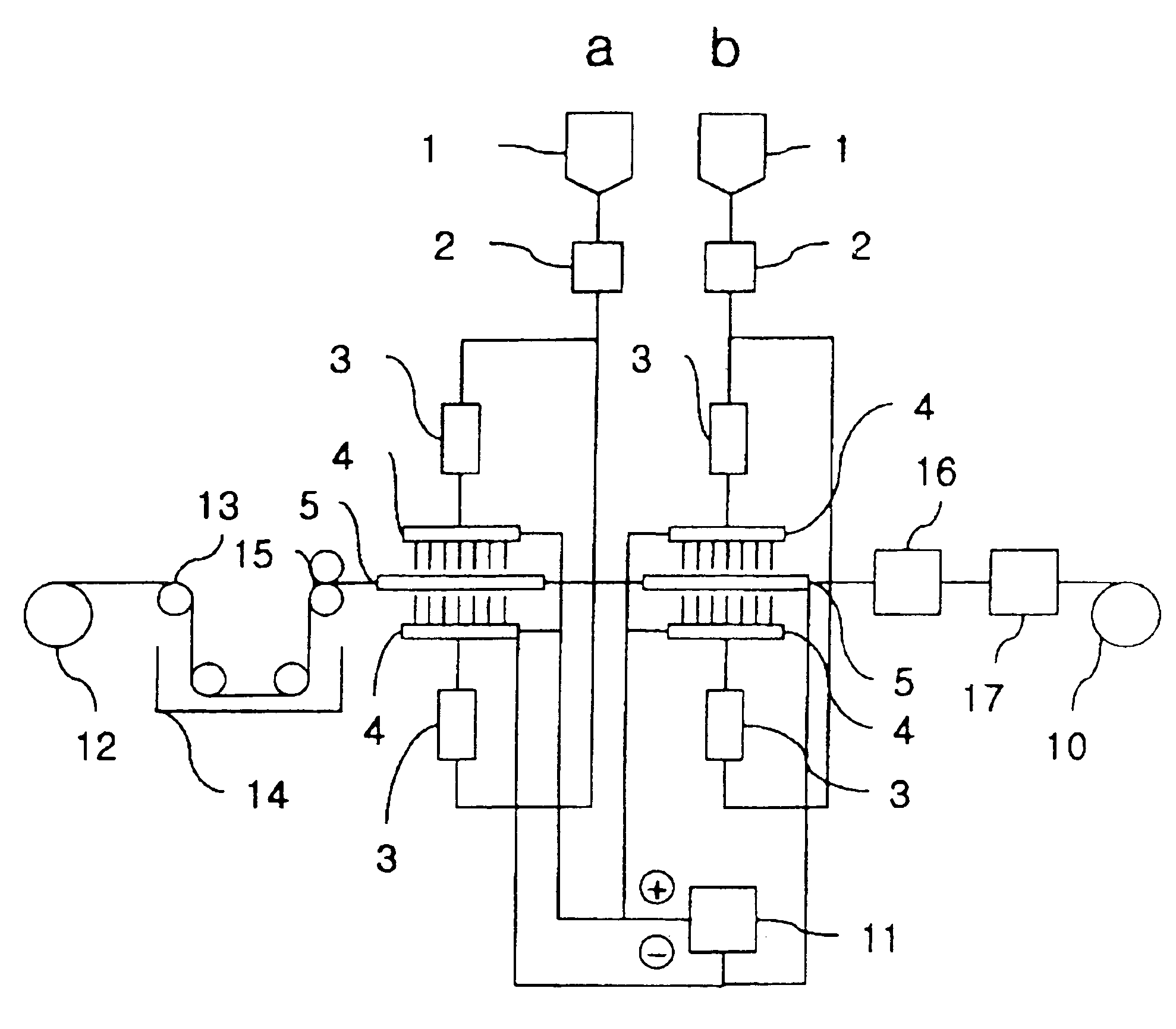

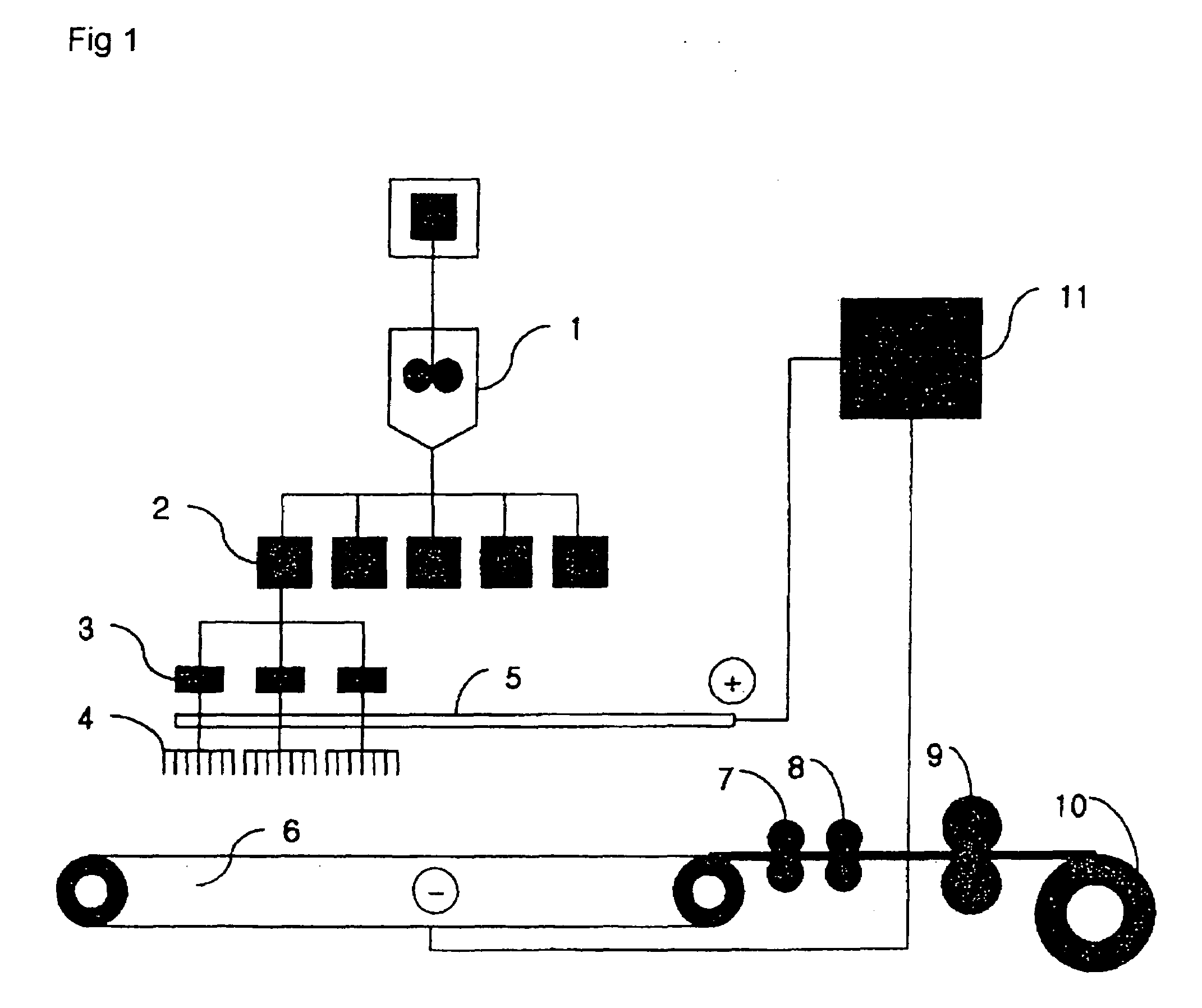

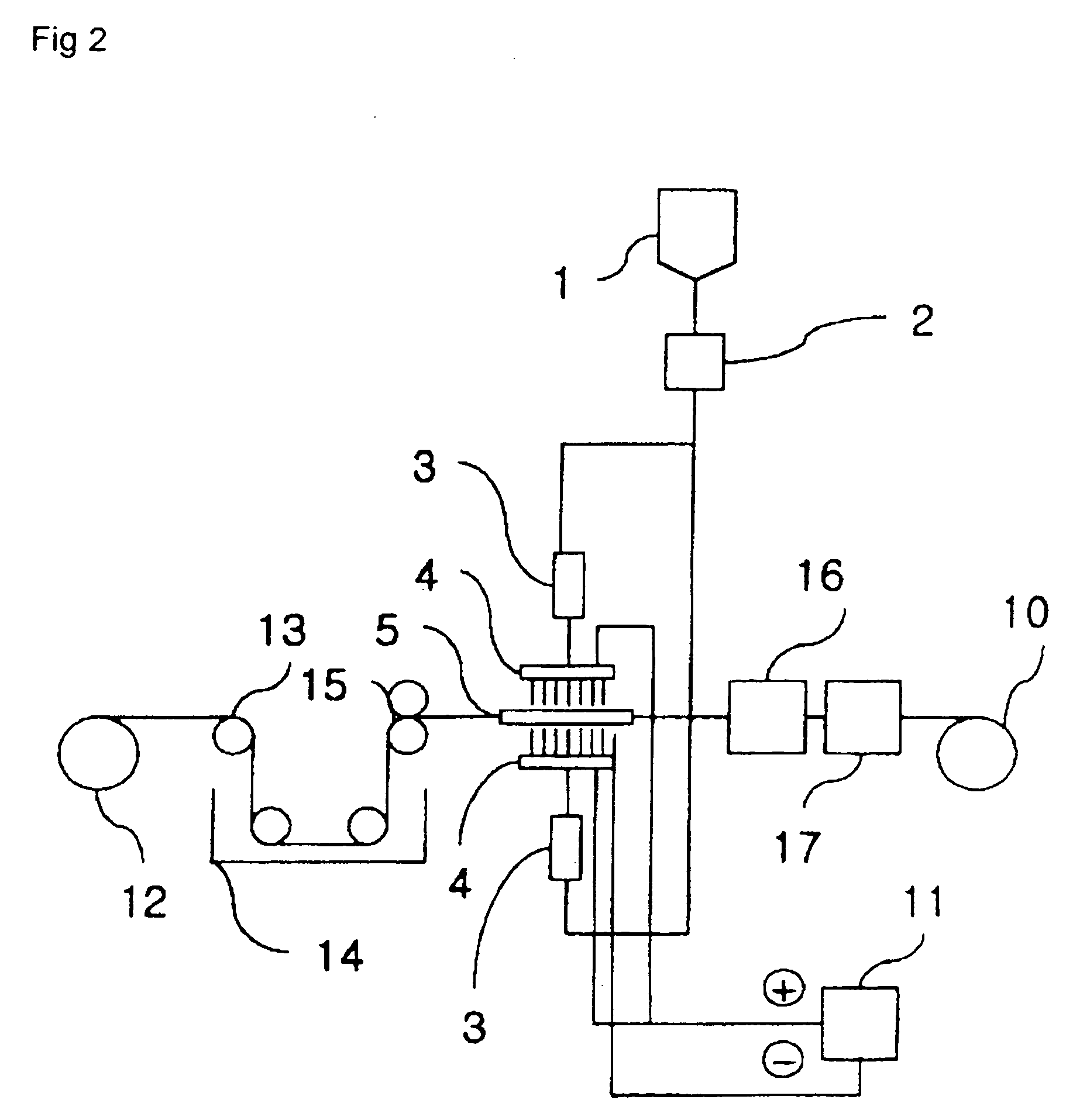

Electronic spinning apparatus

InactiveUS6991702B2Improve fiber performanceMaximizing electric forceMechanical working/deformationTurning machine accessoriesFiberVoltage generator

An electrospinning apparatus including a spinning dope main tank, a metering pump, a nozzle block, a collector positioned at the lower end of the nozzle block for collecting spun fibers, a voltage generator, a plurality of units for transmitting a voltage generated by the voltage generator to the nozzle block and the collector, said electrospinning apparatus containinga spinning dope drop device positioned between the metering pump and the nozzle block, the spinning dope drove device having(i) a sealed cylindrical shape,(ii) a spinning dope inducing tube and a gas inletting tube for receiving gas through its lower end and having its gas inletting part connected to a filter aligned side-by-side at the upper portion of the spinning dope drop device,(iii) a spinning dope discharge tube extending from the lower portion of the spinning dope drop device and(iv) a hollow unit for dropping the spinning dope from the spinning dope inducing tube formed at the middle portion of the spinning dope drop device.

Owner:FINETEX TECH GLOBAL +2

Electronic spinning apparatus, and a process of preparing nonwoven fabric using the same

InactiveUS20060048355A1Maximizing electric forceImprove the ability to formLamination ancillary operationsElectric discharge heatingVoltage generatorElectrospinning

An electrospinning apparatus including a spinning dope main tank, a metering pump, a nozzle block, a collector positioned at the lower end of the nozzle block for collecting spun fibers, a voltage generator, a plurality of units for transmitting a voltage generated by the voltage generator to the nozzle block and the collector, said electrospinning apparatus containing: a spinning dope drop device positioned between the metering pump and the nozzle block, the spinning dope drop device having (i) a sealed cylindrical shape, (ii) a spinning dope inducing tube and a gas inletting tube for receiving gas through its lower end and having its gas inletting part connected to a filter aligned side-by-side at the upper portion of the spinning dope drop device, (iii) a spinning dope discharge tube extending from the lower portion of the spinning dope drop device, and (iv) a hollow unit for dropping the spinning dope from the spinning dope inducing tube formed at the middle portion of the spinning dope-drop device.

Owner:FINETEX TECH GLOBAL

Electronic spinning apparatus, and a process of preparing nonwoven fabric using the same

InactiveUS7332050B2Maximizing electric forceImprove the ability to formLamination ancillary operationsElectric discharge heatingVoltage generatorElectrospinning

An electrospinning apparatus including a spinning dope main tank, a metering pump, a nozzle block, a collector positioned at the lower end of the nozzle block for collecting spun fibers, a voltage generator, a plurality of units for transmitting a voltage generated by the voltage generator to the nozzle block and the collector, said electrospinning apparatus containing:a spinning dope drop device positioned between the metering pump and the nozzle block, the spinning dope drop device having(i) a sealed cylindrical shape,(ii) a spinning dope inducing tube and a gas inlet tube for receiving gas through its lower end and having its gas inlet part connected to a filter aligned, side-by-side, at the upper portion of the spinning dope drop device,(iii) a spinning dope discharge tube extending from the lower portion of the spinning dope drop device, and(iv) a hollow unit for receiving the spinning dope from the spinning dope inducing tube provided at the middle portion of the spinning dope-drop device.

Owner:FINETEX TECH GLOBAL

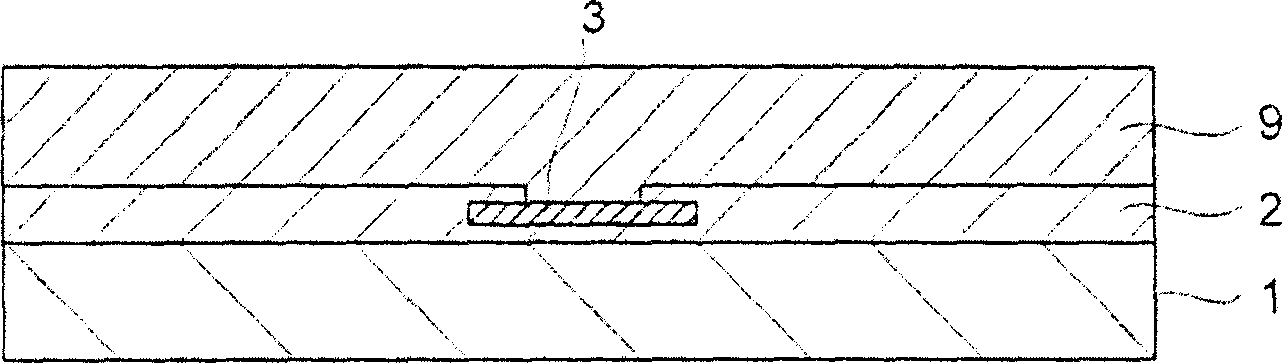

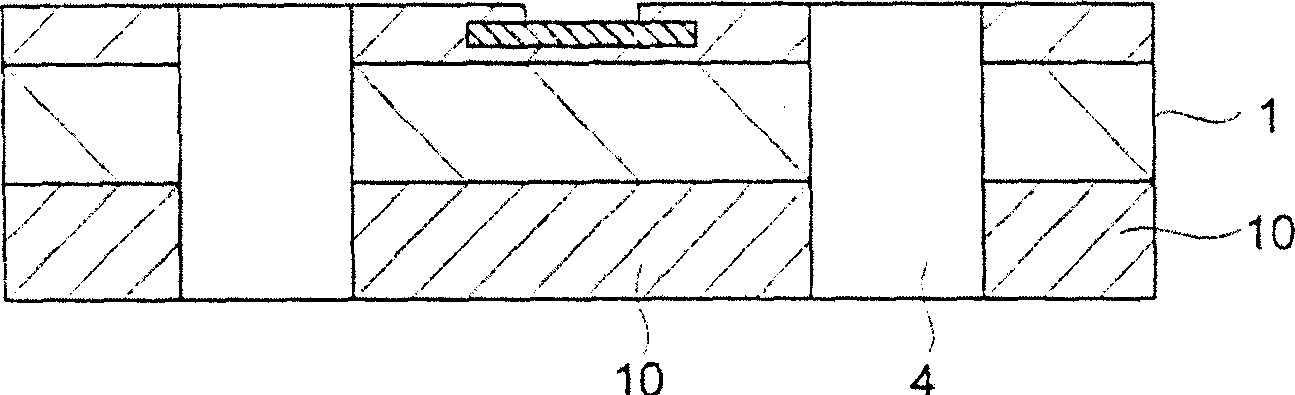

Semiconductor device and manufacturing method thereof

InactiveCN1758430AImprove the ability to formImprove insulation reliabilitySemiconductor/solid-state device detailsSolid-state devicesInsulation layerEngineering

A semiconductor device comprises a semiconductor substrate having an through hole, a first insulation resin layer formed on an inner surface of the through hole, a second insulation resin layer formed on at least one of front and rear surfaces of the semiconductor substrate, and a first conductor layer formed in the through hole to connect at least both front and rear surfaces of the semiconductor substrate and insulated from the inner surface of the through hole with the first insulation resin layer. A second conductor layer (wiring pattern) which is electrically connected to the first conductor layer in the through hole is further provided on the second insulation resin layer. The conductor layer formed in the through hole and constituting a connecting plug has a high insulation reliability. Therefore, a semiconductor device suitable for a multi-chip package and the like can be obtained. Further, since the forming ability of the conductor layer connecting the front and rear surfaces and the insulation layer is high, the manufacturing cost can be reduced.

Owner:KK TOSHIBA

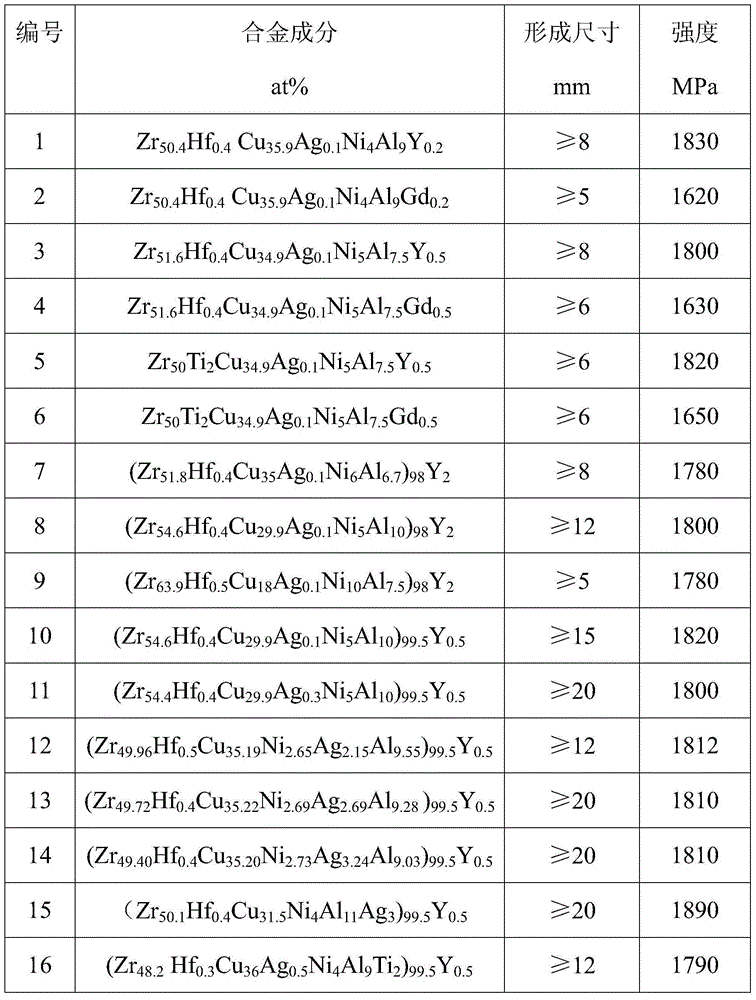

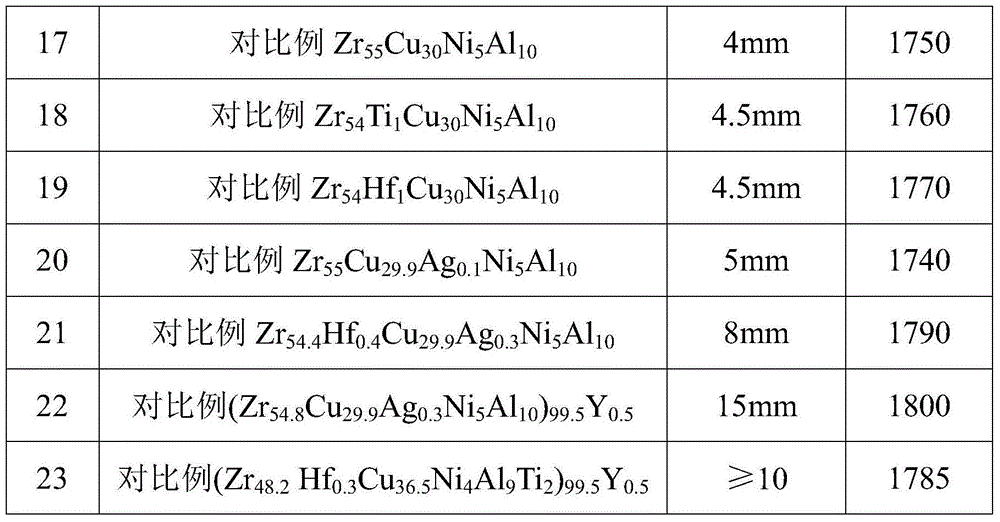

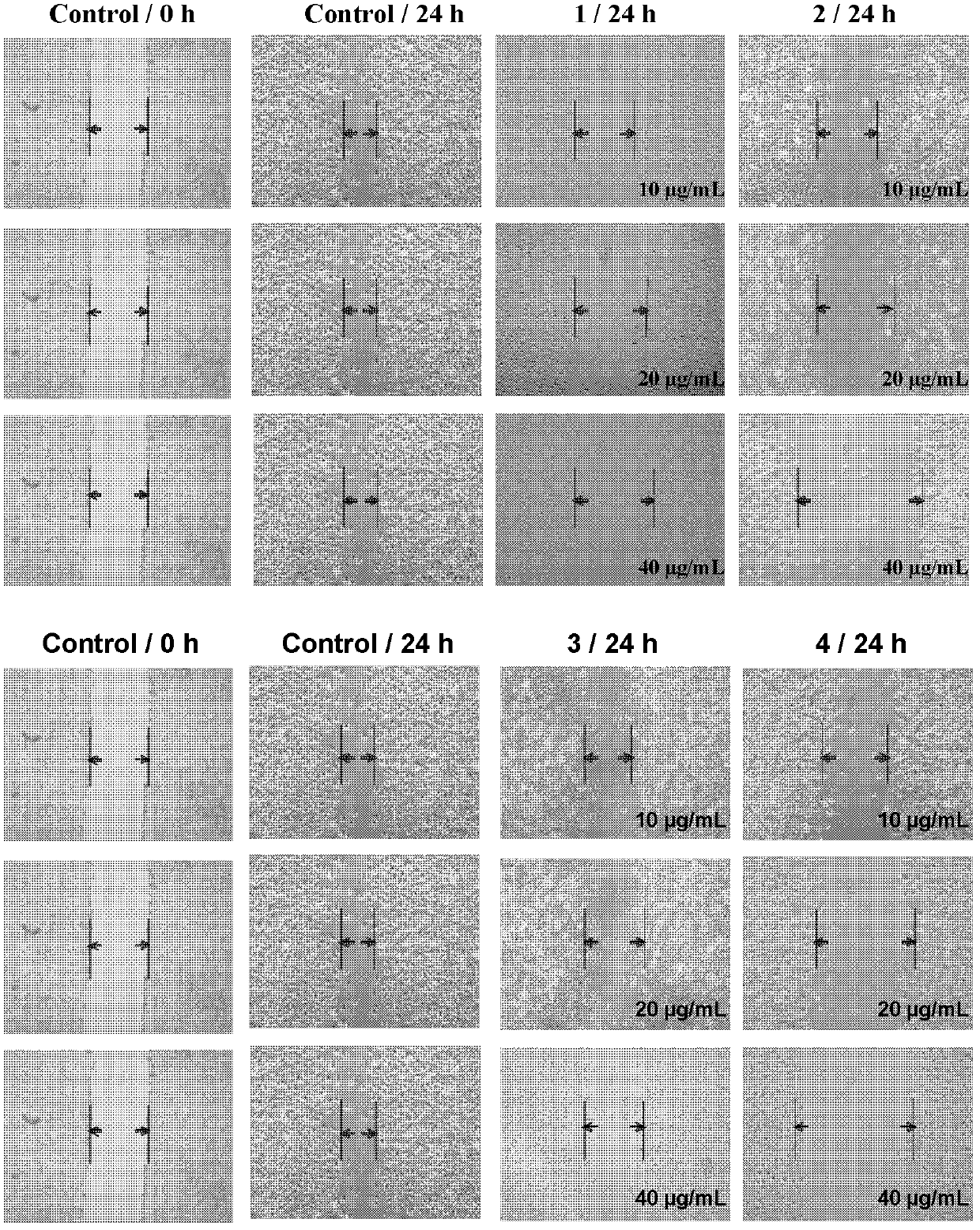

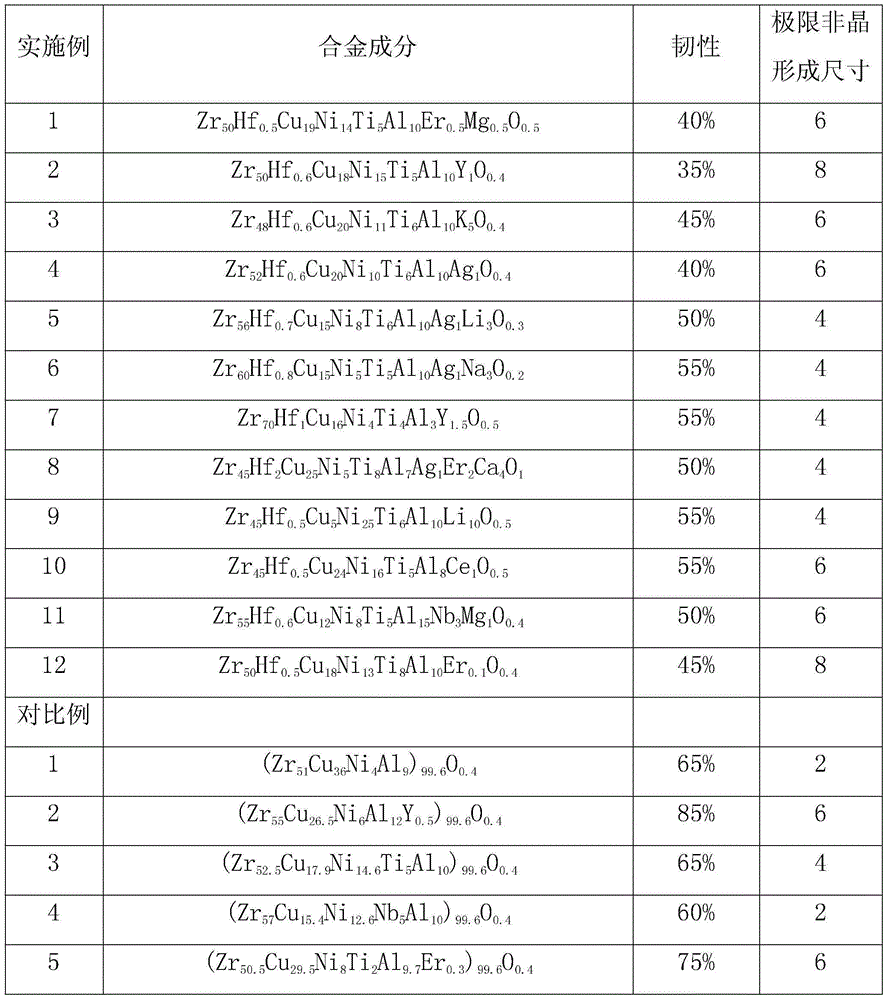

(ZrM)-(CuN)-Ni-Al-(Re) amorphous alloy, and preparation method and application thereof

ActiveCN104651756AImprove the ability to formImprove manufacturabilityRare-earth elementMechanical property

The invention discloses a (ZrM)-(CuN)-Ni-Al-(Re) amorphous alloy which comprises the following components in percentage by atom: 40-65% of Zr, 18-46% of Cu, 2-15% of Ni, 4-15% of Al, 0.1-3% of M(Hf, Ti or Hf+Ti), 0.05-3% of N (Ag) and 0.1-2% of rare-earth element RE (Y, Gd, Sc, Er or composition thereof). By adding small amounts of M, N and RE elements on the basis of the Zr-Al-Ni-Cu amorphous alloy, the alloy has the advantages of higher amorphous formation capacity, excellent manufacturability and favorable mold resistance, maintains the excellent mechanical properties of the Zr-Al-Ni-Cu amorphous alloy, and is an ideal material for preparing complex thin-wall parts in the fields of consumer electronics, medical care, automobiles and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Environment-friendly insulating paint for non-oriented silicon steel and preparation method of coating thereof

The invention relates to an environment-friendly insulating paint for non-oriented silicon steel and a preparation method of a coating thereof. The paint is prepared from the following components by weight percent: 10-30% of aluminium dihydrogen phosphate, 1-10% of coating color-developing agent, 0-10% of manganese dihydrogen phosphate, 0.5-1.5% of zinc oxide, 0.1-1% of magnesium oxide, 1-5% of silica sol, 1-5% of boric acid, 0.5-5% of titanate coupling agent, 0.1-0.4% of bismuth nitrate, 2-6% of organic solvent, 0.1-0.5% of other auxiliary agent and the balance of water, wherein the sum of all components is 100%. The environment-friendly insulating paint disclosed by the invention has the advantages that the coating is an environment-friendly coating free of chromate and the high-temperature treatment temperature can be up to 850 DEG C.

Owner:江阴市诺科科技有限公司 +1

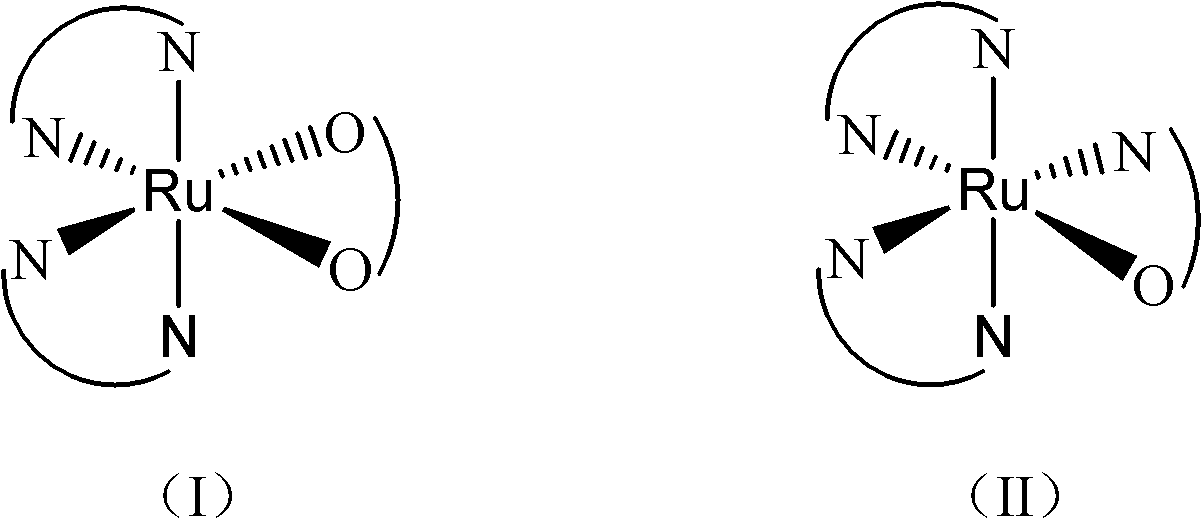

Ruthenium complex capable of inhibiting tumor angiogenesis and preparation method and application thereof

InactiveCN102516309AImprove stabilityImprove solubilityOrganic active ingredientsGroup 8/9/10/18 element organic compoundsSolubilityLithium chloride

The invention belongs to the field of chemical drugs, and discloses a ruthenium complex capable of inhibiting tumor angiogenesis and a preparation method and application thereof. The ruthenium complex provided by the invention has a structure shown in a formula I or II. The preparation method comprises the following steps of: dropwise adding a silver nitrate solution to a sodium salt solution, stirring and reacting, then filtering, washing and vacuum drying a precipitate, and thereby obtaining a ligand O-O; taking ruthenium chloride, L, and lithium chloride to be dissolved in N-, N-dimethyl formamide, heating and refluxing under the protection of argon atmosphere to obtain an intermeidate Ru (L2) Cl22 +; allowing the ligand O-O and the Ru (L2) Cl22 + to be dissolved in an ethanol / water mixed solvent, heating and refluxing to obtain the ruthenium complex shown in the formula I; and allowing the Ru (L2) Cl22 +, 8- hydroxyquinoline, and ammonium acetate to be dissolved in ethanol, and heating and refluxing under the protection of argon atmosphere to obtain the ruthenium complex shown in the formula II. The ruthenium complex has the advantages of good stability, uneasiness in hydrolysis, good solubility, low toxicity, and the ability to inhibit tumor angiogenesis, and is easily absorbed by the human body.

Owner:JINAN UNIVERSITY

High-voltage working electrolyte and preparation method thereof

The invention provides a high-voltage working electrolyte, which comprises the following raw materials by weight portion: 5.5-11 portions of solute, 80-88 portions of composite solvent, 0.1-2.5 portions of dehydrogenating agent, 0.1-1portion of waterproof combined additive, 0-2 portions of sparking voltage improving agent, 0.5-3 portions of anti-corrosion additive and 0.5-1 portion of high temperature stabilizer. The solvent is heated to 70-100 DEG C. The invention also provides a preparation method of the electrolyte, which comprises the followings steps: adding the sparking voltage improving agent, the high temperature stabilizer and the anti-corrosion additive, and uniformly mixing; heating to 120-130 DEG C, adding the solute, the dehydrogenating agent and the waterproof combined additive, holding at a temperature of 120-130 DEG C until a mixture is completely dissolved; and cooling and then obtaining the high-voltage working electrolyte. The process is simple, and the conditions are easy to control. The high-voltage working electrolyte provided by the invention has the advantages of high sparking voltage, high temperature resistance and long service life.

Owner:东莞宏强电子有限公司

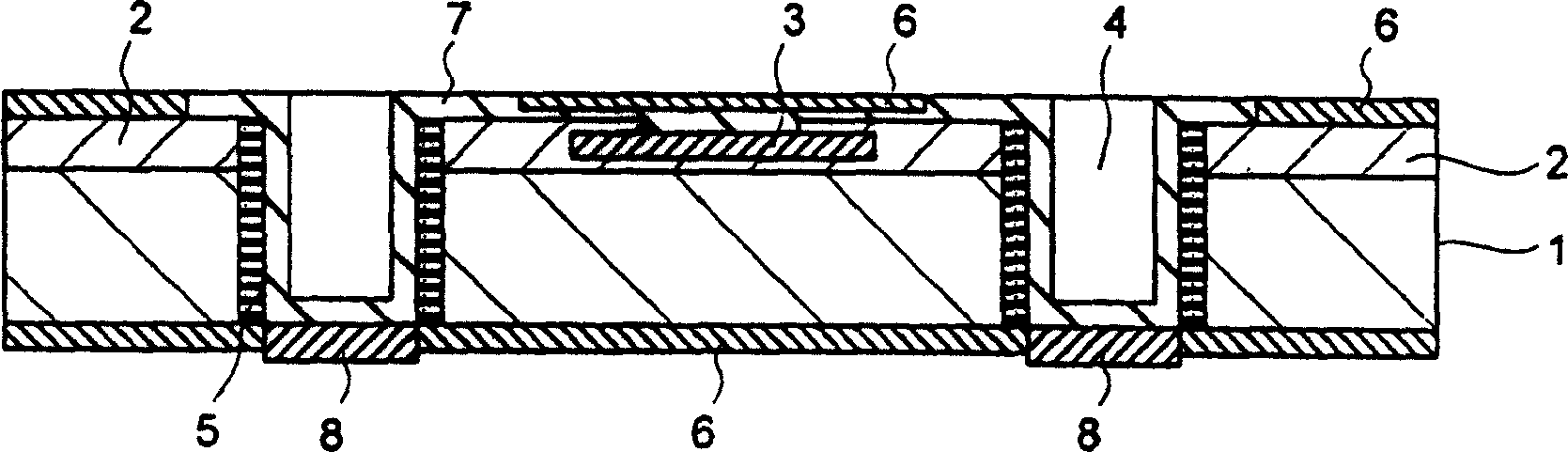

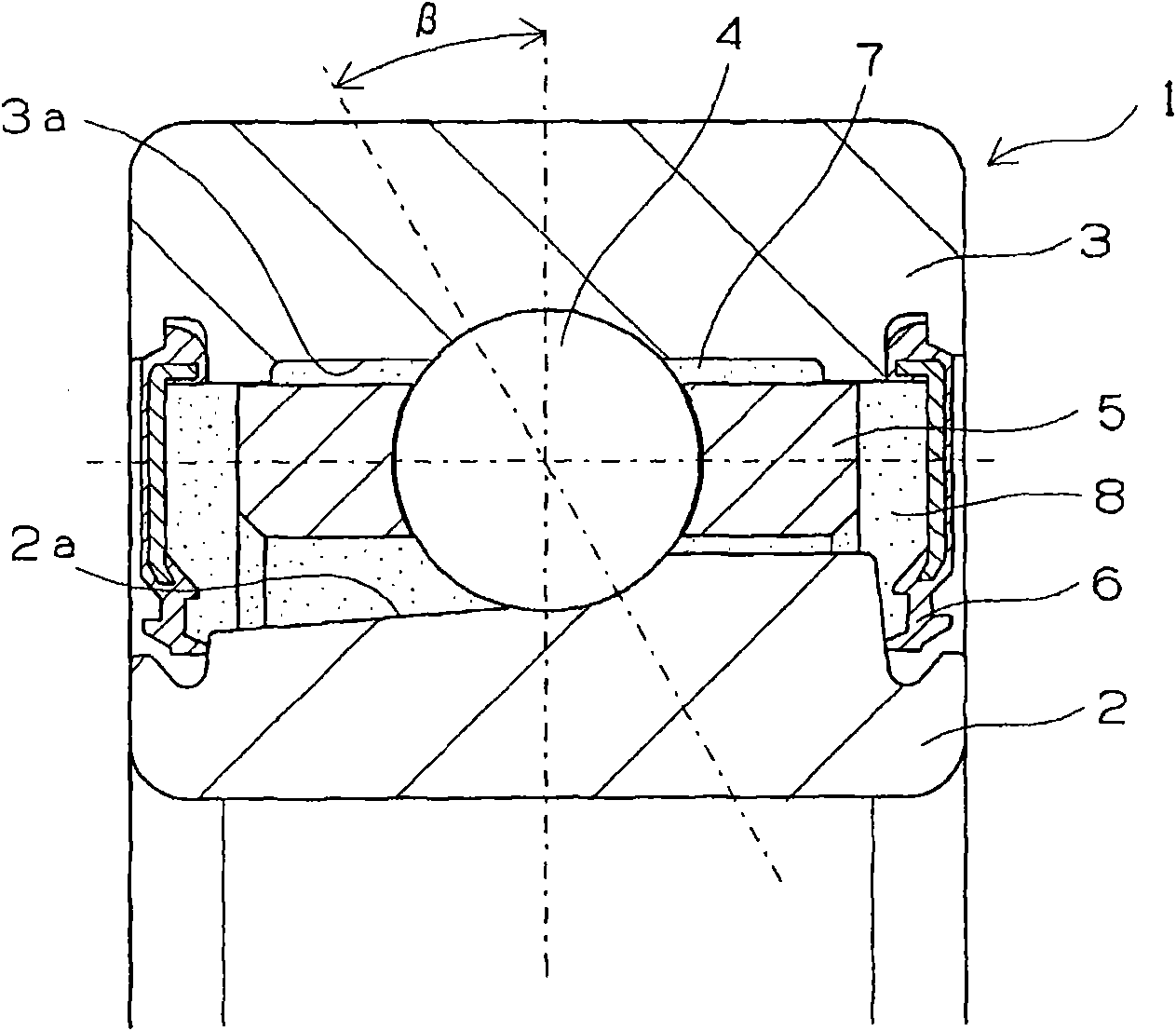

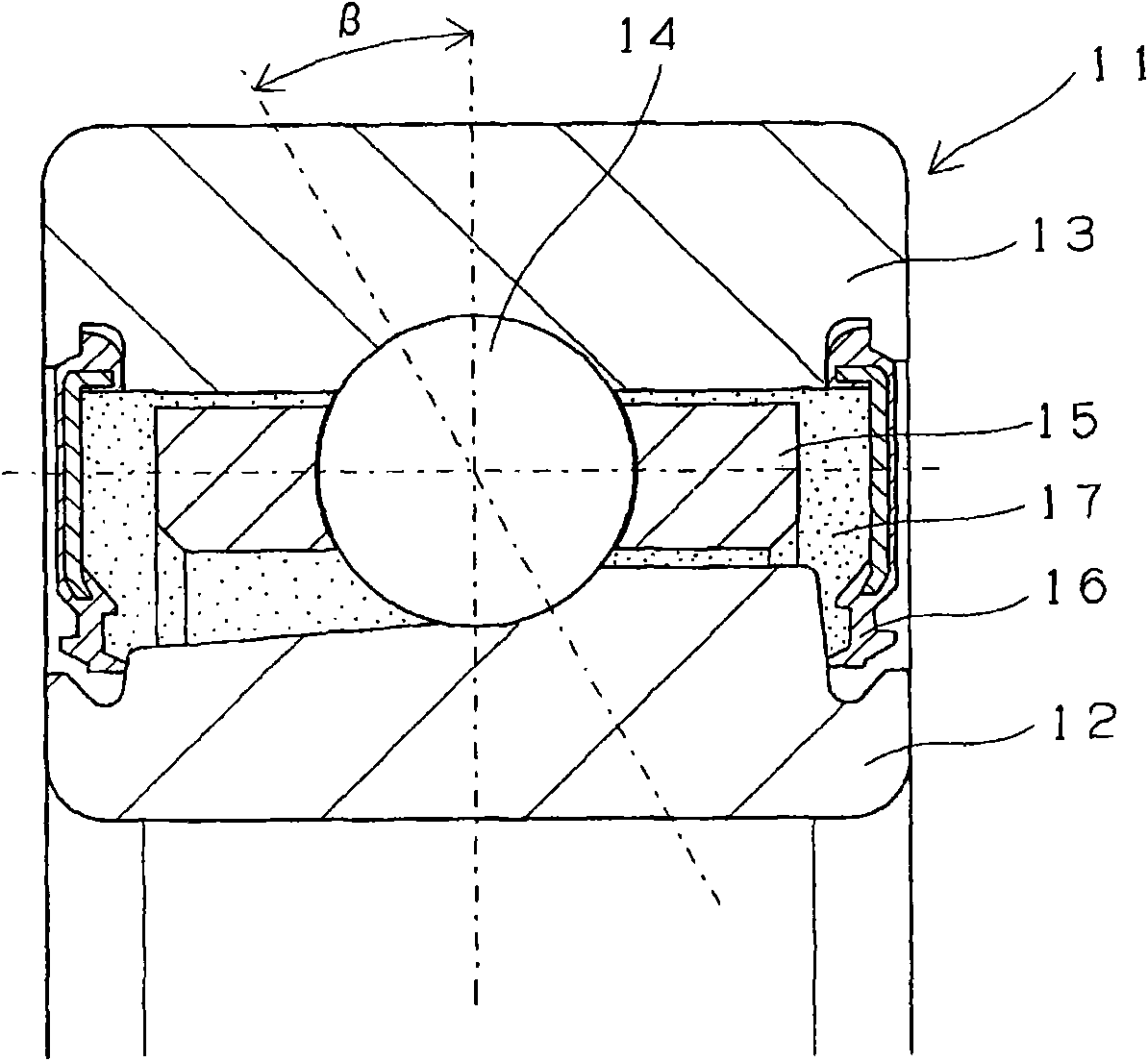

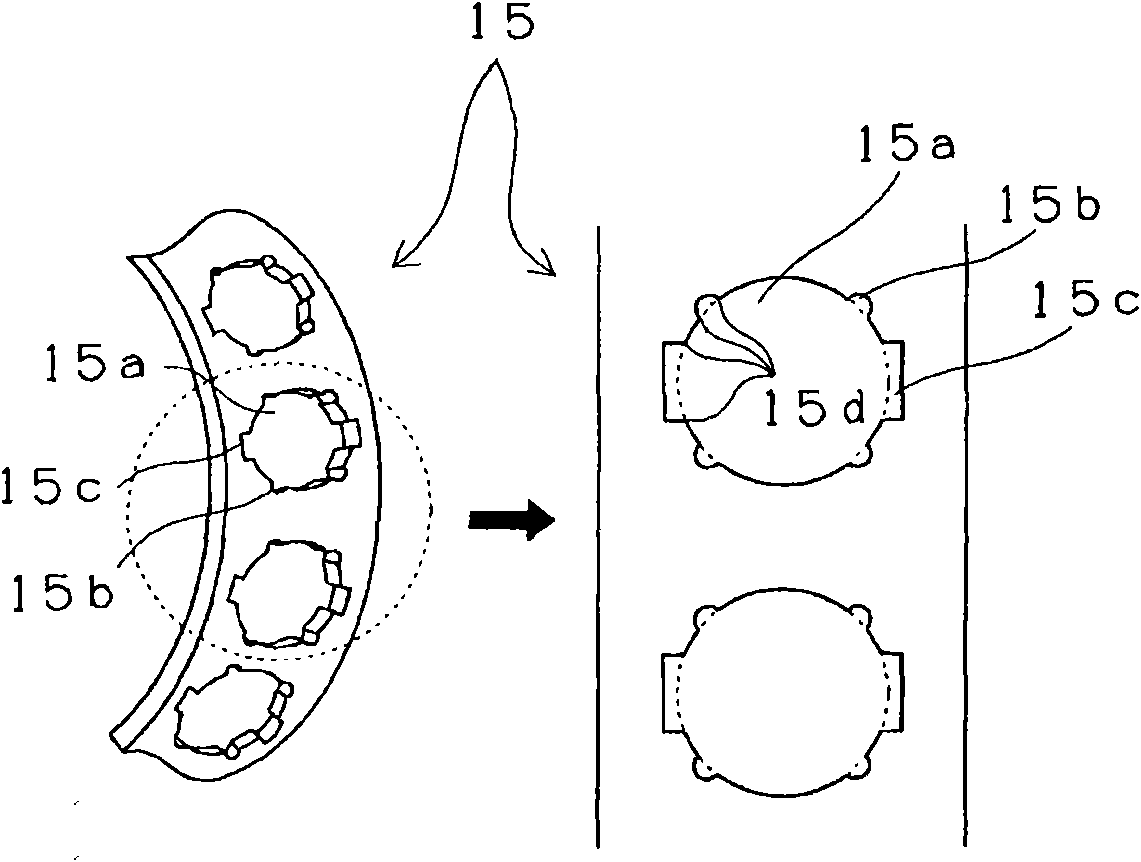

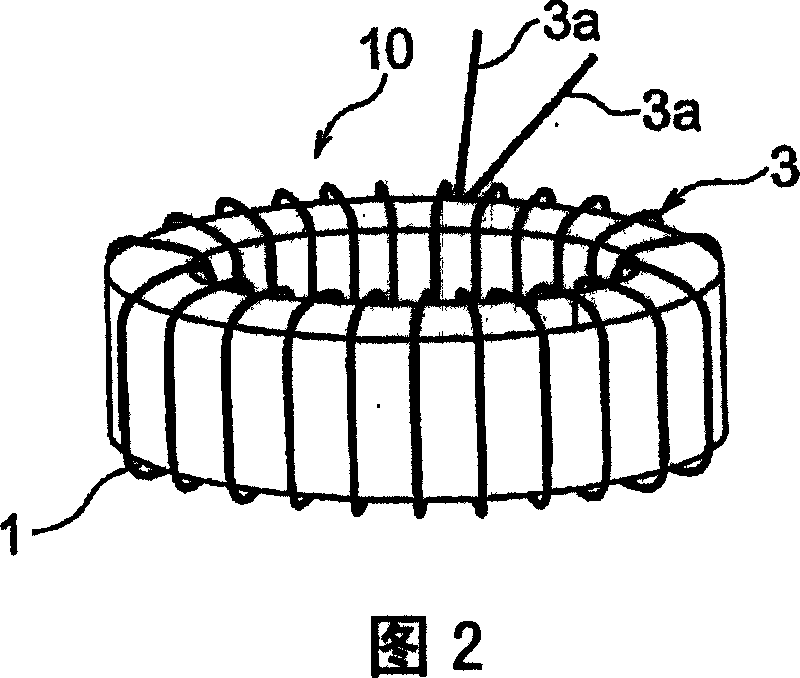

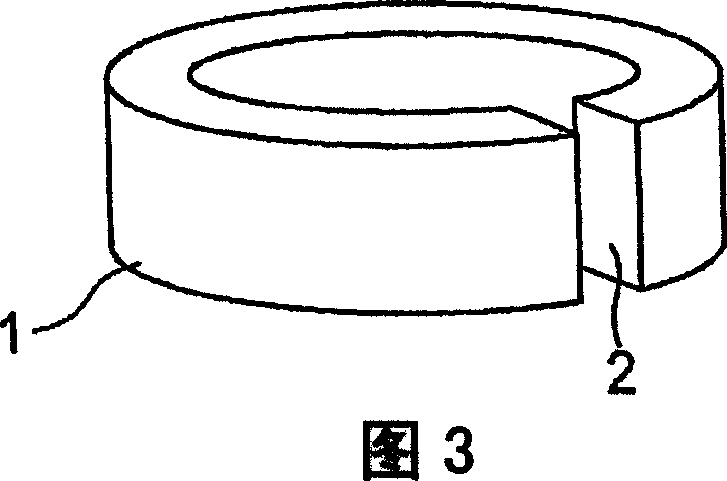

Grease for high-speed bearing and rolling bearing for high speed

InactiveCN101622333AMaintain load resistanceExcellent ability to supply oilBearing componentsThickenersEngineeringHigh velocity

A grease for high-speed bearing and rolling bearing for high speed that enable satisfactorily coping with a high-speed rotation of 170x10<4> or higher dmN value and enable realizing compaction of machine tool and cutback of operating costs. The grease is one comprising a mixture of urea grease containing a urea compound as a thickener and nonurea grease not containing the urea compound, wherein the urea compound is one obtained by reaction between a polyisocyanate component and a monoamine component, the monoamine component containing 50 mol% or more of at least one monoamine selected from among aliphatic monoamines and alicyclic monoamines based on all the monoamines. Rolling bearing for high speed (1) is one comprising inner ring (2), outer ring (3), multiple rolling elements (4) interposed between the inner ring (2) and the outer ring (3) and seal member (6), wherein the above grease (8) is hermetically introduced around the rolling elements(4).

Owner:NTN CORP

Amorphous soft magnetic alloy and inductance component using the same

InactiveCN101034609AHigh Amorphous Formation AbilityImprove the ability to formMagnetic materialsInductanceImpurity

To provide an amorphous soft magnetic alloy having a supercooled liquid region and excellent in amorphous-forming ability and soft magnetic properties, by selecting and optimizing an alloy composition, and to further provide a ribbon, a powder, a high-frequency magnetic core, and a bulk member each using such an amorphous soft magnetic alloy. The amorphous soft magnetic alloy has a composition expressed by a formula of (Fe1-alphaTMalpha)100-w-x-y-zPwBxLySiz, wherein unavoidable impurities are contained, TM is at least one selected from Co and Ni, L is at least one selected from the group consisting of Al, V, Cr, Y, Zr, Mo, Nb, Ta, and W, 0<=alpha0.98, 2<=w<=16 at %, 2<=x<=16 at %, 0 H01F 1 / 153 C22C 45 / 00 3 54 10 2007 / 2 / 2 101034609 2007 / 9 / 12 000000000 NEC Tokin Corp. Japan Urata Akiri Fujiwara Teruhiko Matsumoto Hiroyuki Yamada Yasunobu Inoue Akihisa zhangcheng xin 11021 The Patent Agency of the Chinese Academy of Sciences Inside the Chinese Academy of Sciences, No.52 Sanlihe Road, Fuwai, Beijing 100864 Japan 2006 / 2 / 2 2006-026210 Japan 2006 / 12 / 1 2006-326179

Owner:TOKIN CORP +1

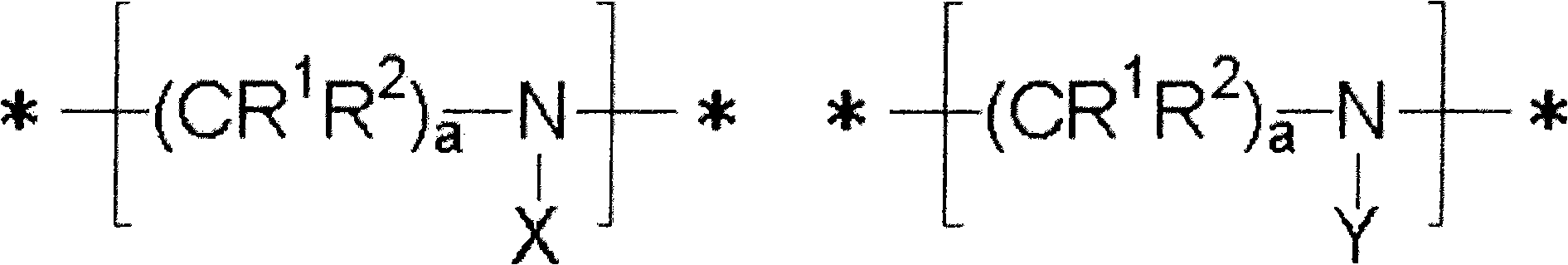

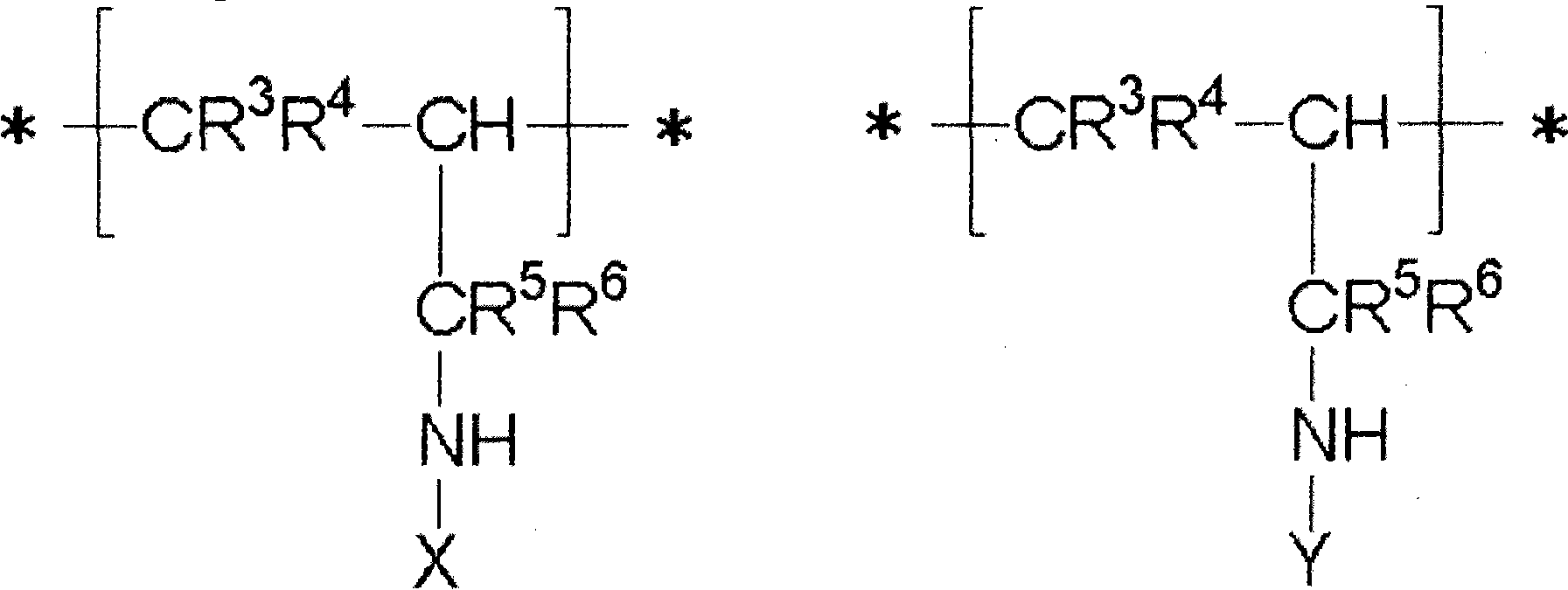

Resin, pigment dispersion liquid, coloring curable composition, color filter produced by using composition, and method for producing color filter

ActiveCN101925636ARealization of dispersibility and dispersion stabilityImprove the ability to formOptical filtersOrganic dyesOligomerSide chain

Disclosed is a resin having (i) a main chain portion containing a nitrogen atom, (ii) a group ''X'' having a functional group with a pKa of not more than 14 and bonded to a nitrogen atom in the main chain, and (iii) an oligomer chain or polymer chain ''Y'' having a number average molecular weight of 500-1,000,000, which forms a side chain.

Owner:FUJIFILM CORP

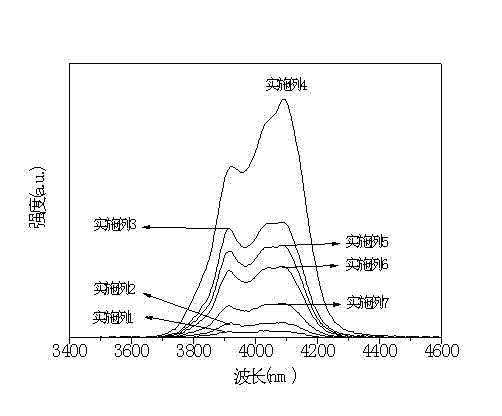

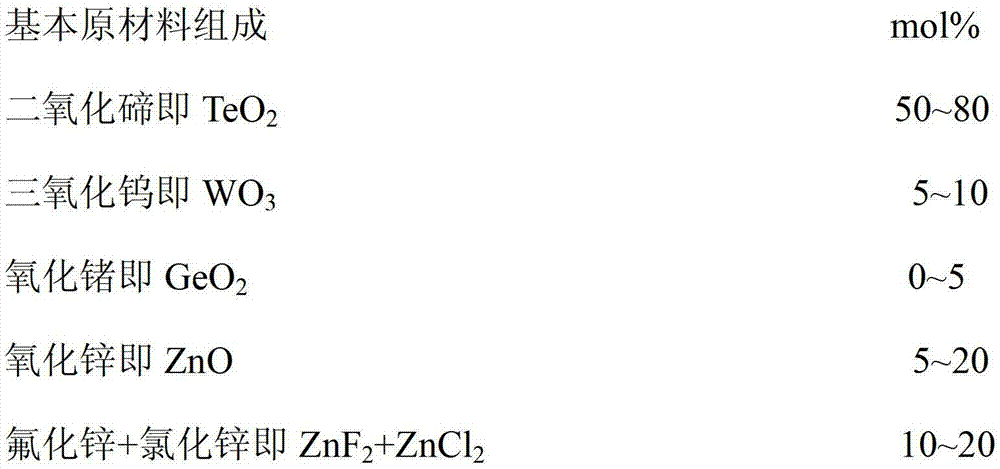

Method for preparing oxygen fluorine chlorine tellurate glass with intermediate infrared fluorescence output at 4 mu m

The invention relates to the technical field of intermediate infrared rare earth doped luminescent glass application, and aims at solving the technical problem of providing a method for preparing oxygen fluorine chlorine tellurate glass with intermediate infrared fluorescence output at 4 mu m. The glass is good in glass forming property, high in infrared light transmission rate, good in luminescence property and beneficial to output of fluorescence and laser of 4 mu m. The oxygen fluorine chlorine tellurate glass prepared by using a fusion method is tellurate glass which contains zinc fluoride and zinc chloride, and due to the appropriate amount of contains zinc fluoride and zinc chloride, the hydroxyl content and the phonon energy in the system are greatly reduced, so that the forming capability of the glass is effectively improved, the doping amount of rare earth ions is increased, and the fluorescence service lives of the rare earth ions are prolonged. By adopting the doping amount of the external doping rare earth ions, namely, Ho<3+> and Yb<3+>, the pumping efficiency of 980nm is greatly improved, and tests show that the oxygen fluorine chlorine tellurate glass has remarkable fluorescence output at 4 mu m.

Owner:CHINA ELECTRONICS TECH GRP NO 23 RES INST

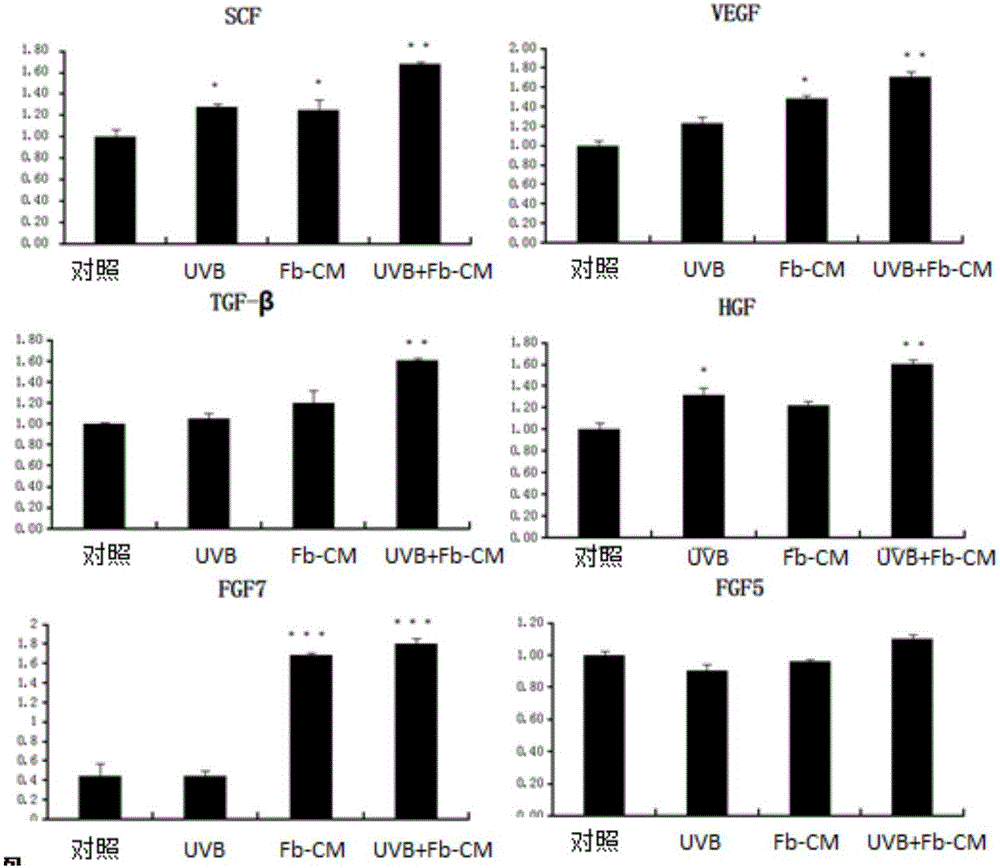

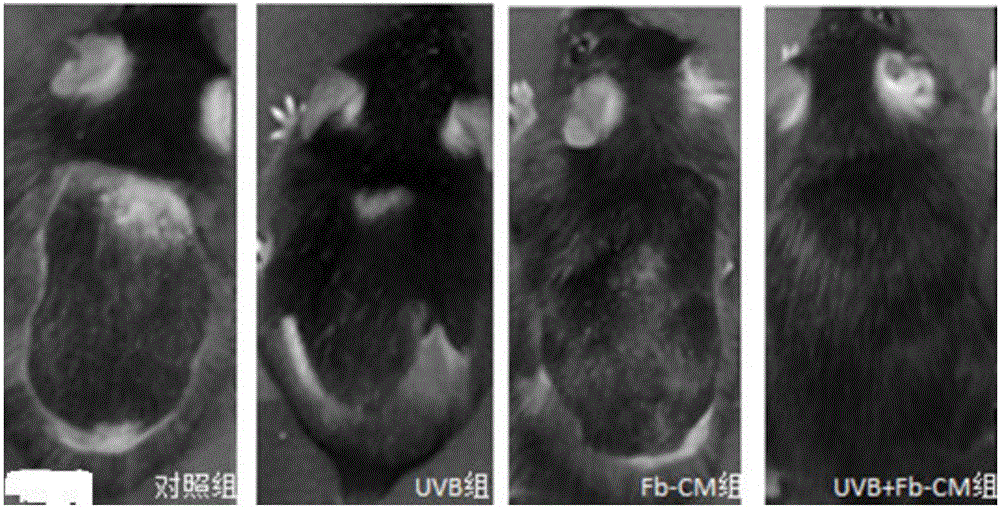

Preparation method of cell nutrient solution for promoting hair regeneration

InactiveCN106635973AGood regulationActivate the microenvironmentCosmetic preparationsHair cosmeticsNormal growthHair regeneration

The invention provides a preparation method of a cell nutrient solution for promoting hair regeneration. The preparation method mainly comprises three steps: 1) primary isolation of ADSCs (adipose-derived stem cells); 2) enlarged cultivation of the ADSCs; and 3) induced culture of the ADSCs. The cell nutrient solution prepared by the invention can solve the problem of alopecia from the point of cell regeneration; the ADSCs-conditioned medium (the nutrient solution), in a periodic hair follicle reconstruction process, can activate a stem cell microenvironment of hair follicle and can regulate and control the normal growth of the hair follicle; by conducting low-dose UVB radiation, ADSCs survival, migration and paracrine capacities can be significantly improved, and an angiogenesis capacity and a hair regeneration capacity can be also obviously improved; by cultivating the ADSCs with a fibroblast-conditioned medium, cell survival and metabolism processes in a body environment can be simulated, and the secretion of more cell factors, which are conducive to cell microenvironment regulation and control, from cells can be promoted; and meanwhile, the cell nutrient solution prepared by the method is convenient in cell preparation, broad in source and convenient for clinical popularization, and cells can be derived from fat wastes obtained from clinical liposuction and skin grafts removed in other surgical operations.

Owner:陕西佰瑞衡健康科技有限公司

Nanocrystalline magnetically soft alloy, amorphous magnetically soft alloy and preparation methods of nanocrystalline magnetically soft alloy and amorphous magnetically soft alloy

ActiveCN110670000AImprove high frequency permeabilityImproving the high and high frequency permeability of soft magnetic alloysInorganic material magnetismCrystallization temperatureFerromagnetism

The invention provides a nanocrystalline magnetically soft alloy, an amorphous magnetically soft alloy and preparation methods of the nanocrystalline magnetically soft alloy and the amorphous magnetically soft alloy. The nanocrystalline magnetically soft alloy comprises the compositions of Fe, Cu, Si, B, and Nb, and further comprises at least one element between Mn and Cr, wherein the atomic percentage content of each element at the at least one between the Mn and the Cr is not more than 3.5 at%. The antiferromagnetism of the Mn element and / or the Cr element is utilized, and a heat treatment mode of multi-stage rate annealing is combined, so that the high-frequency magnetic permeability of the magnetically soft alloy is improved, the high-frequency loss of the magnetically soft alloy is reduced, and the high-frequency magnetic performance of the magnetically soft alloy is improved; meanwhile, the crystallization temperature interval is narrower, and the heat treatment temperature interval is wider, so that the high-quality nanocrystalline magnetically soft alloy or the high-quality amorphous magnetically soft alloy are obtained favorably and the preparation cost is reduced; and inaddition, the oxidation resistance of the Mn element and / or the Cr element is further utilized, so that the tolerance of impurities is improved, the surface of an amorphous strip is prevented from being crystallized, the amorphous forming capacity is improved, and the high-quality magnetically soft alloy can be prepared through low-purity commercial raw materials.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +3

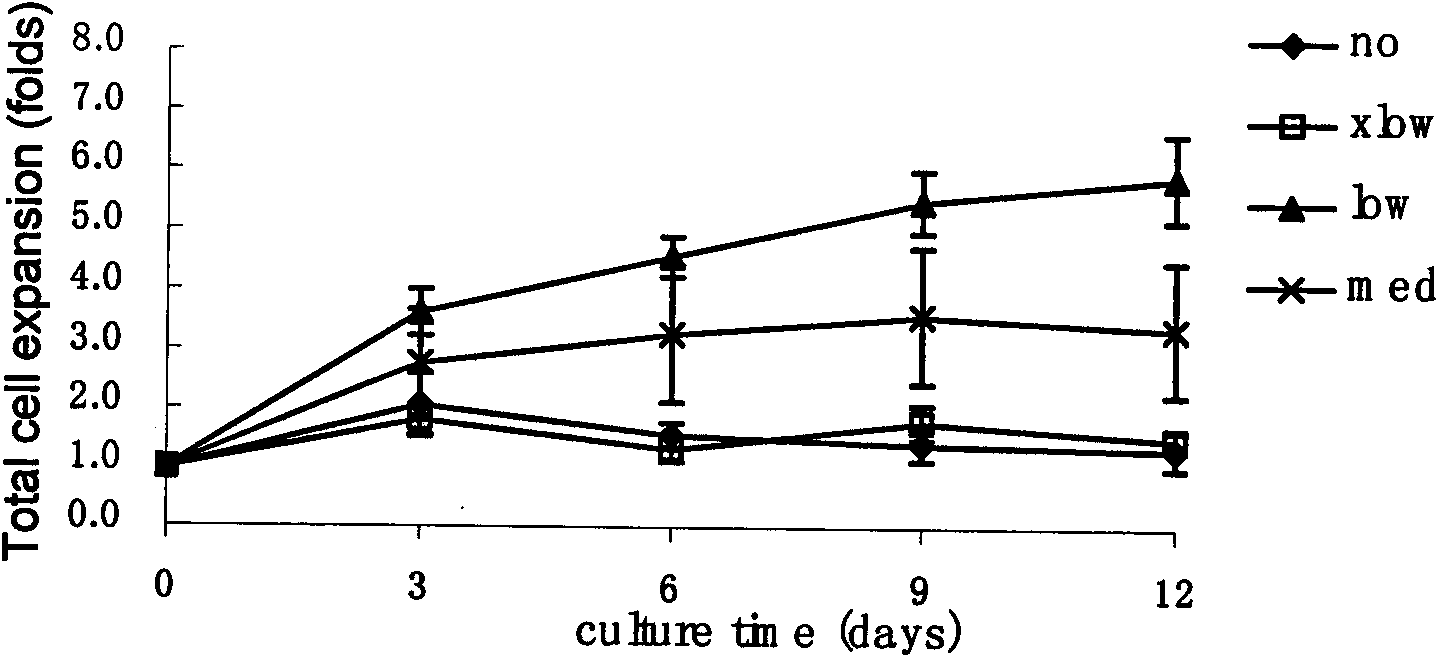

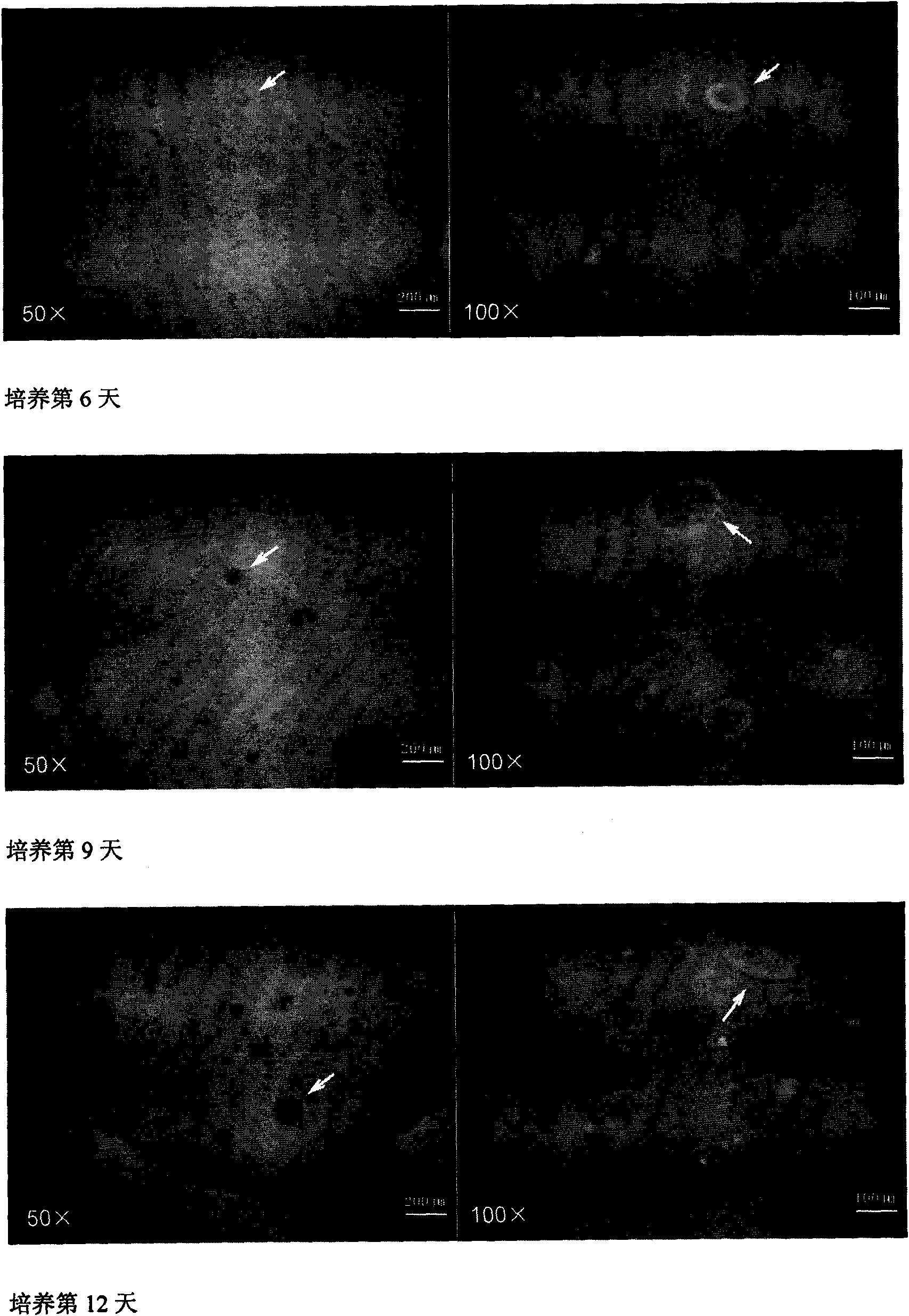

Method for culturing hematopoietic stem/progenitor cells

InactiveCN101597594AA large amountGood ability to rebuild bloodTissue cultureProgenitorBiotechnology

The invention belongs to the field of biotechnology, and relates to a method for expanding the hematopoietic stem / progenitor cells from umbilical cord blood in vitro by an alginate three-dimensional culture system. The method combines SCF, TPO and FL cytokines to support the expansion of the hematopoietic stem / progenitor cells in a single karyocyte of human umbilical cord blood, does not need adding other cytokines, and cultures the single karyocyte of human umbilical cord blood packaged in an alginate microsphere in a three-dimensional stationary culture system and a three-dimensional rotary culture system to observe the expansion effect of the single karyocyte of human umbilical cord blood packaged in the alginate microsphere in the rotary culture system. Compared with the conventional two-dimensional system, the three-dimensional culture system improves the total cells and obviously increases CD34+ cells under the condition of culturing low-concentration cytokines; and colony forming unit-granulocytes and macrophages of cells expanded in the three-dimensional culture system are cloned to form obviously increased cells, and the single karyocyte of human umbilical cord blood in a transplanted NOD / SCID mouse has better engraftment and reconstructs hemopoiesis.

Owner:AFFILIATED HUSN HOSPITAL OF FUDAN UNIV

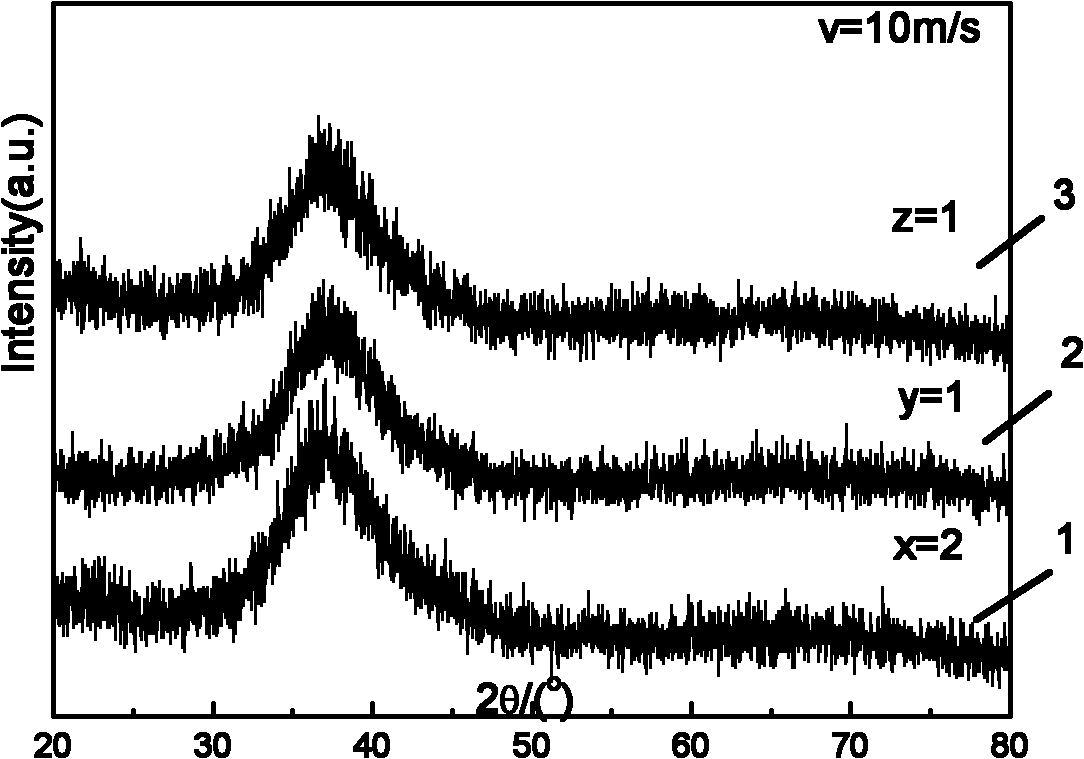

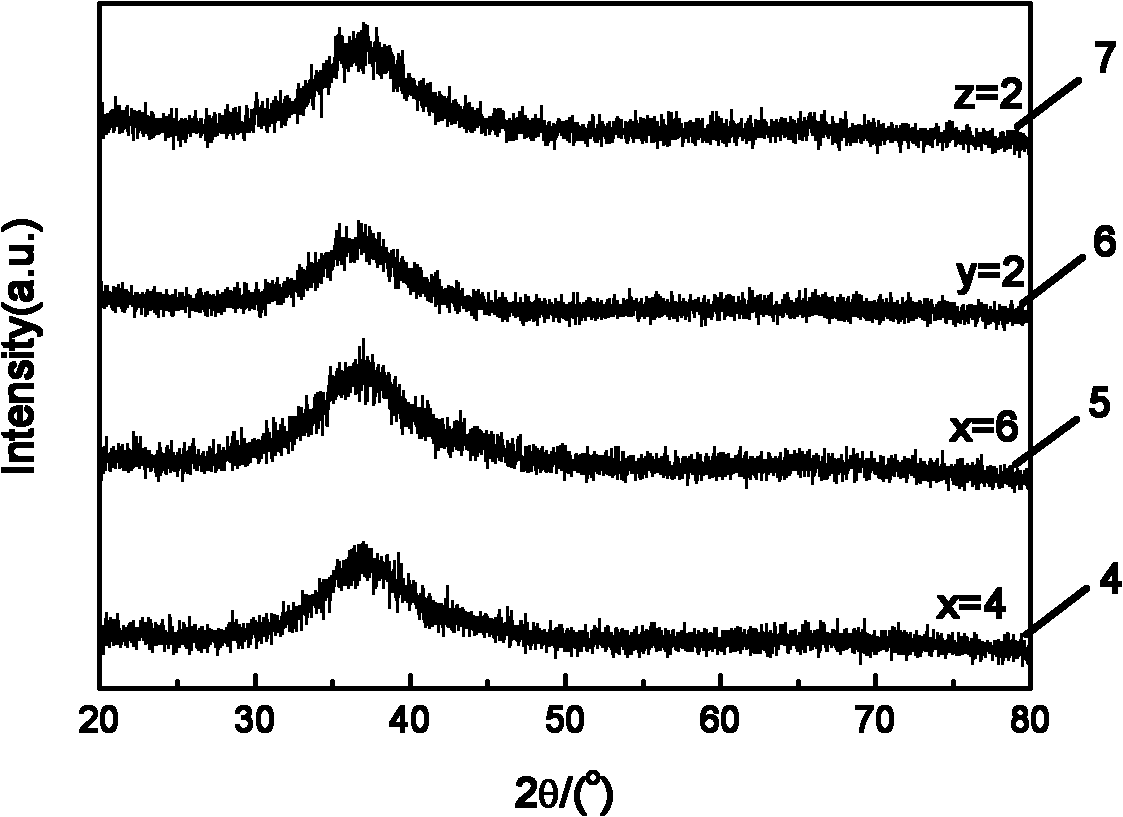

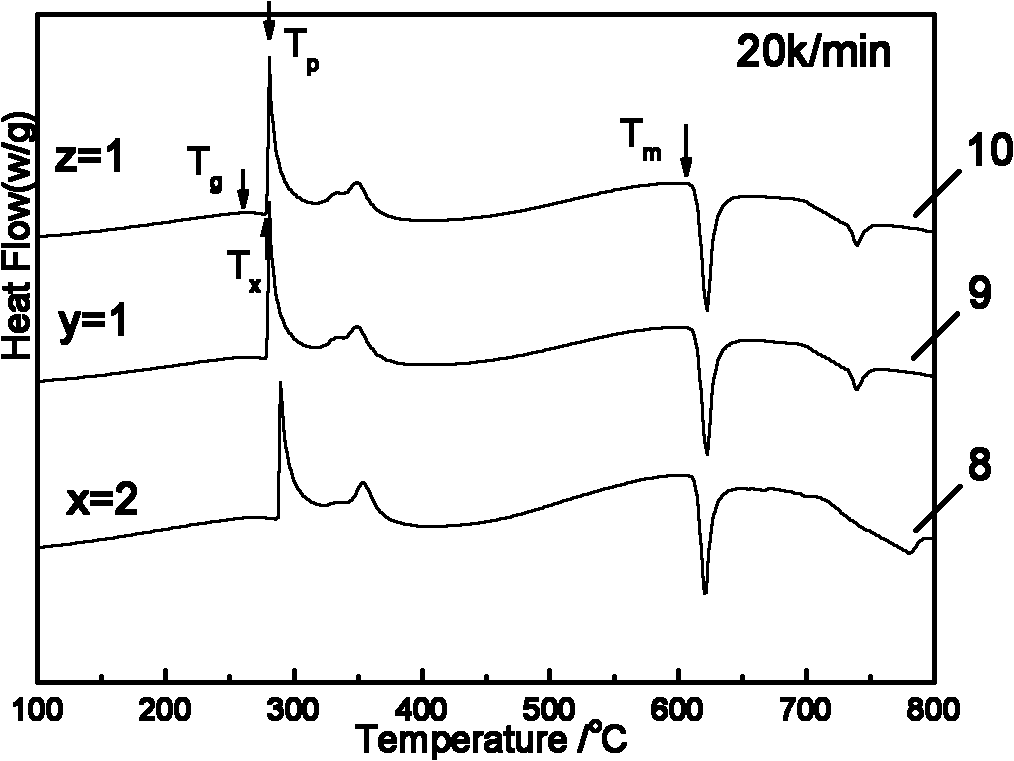

Al-Ni-Ce-La aluminum-based amorphous alloy and preparation method thereof

InactiveCN101838780AIncrease densityIncrease alloy viscosityVacuum induction meltingInjection pressure

The invention relates to an Al-Ni-Ce-La aluminum-based amorphous alloy which comprises the following components: Al84Ni10Ce(6-x)Lax(x=1 to 6, at.%), Al84Ni(10-y)Ce6Lay(y=1 to 3, at.%) and Al(84-z)Ni10Ce6Laz(z=1 to 3, at.%). A method for preparing the Al-Ni-Ce-La aluminum-based amorphous alloy comprises the following steps that: after preparing materials according to the nominal components of the alloy, under the protection of argon gas, a master alloy is prepared by vacuum arc melting or vacuum induction melting; and under the protection of Ar gas, an amorphous strip is prepared by spinning, the minimum linear speed of a copper roller when in spinning is 10m / s, the melt injection pressure is 0.07 to 0.08MPa, and the vacuum degree is 2 to 10-1Pa. The invention has the advantages of reasonable component ratio, strong amorphous forming capability, simple manufacturing method and low requirement on the vacuum degree.

Owner:CENT SOUTH UNIV

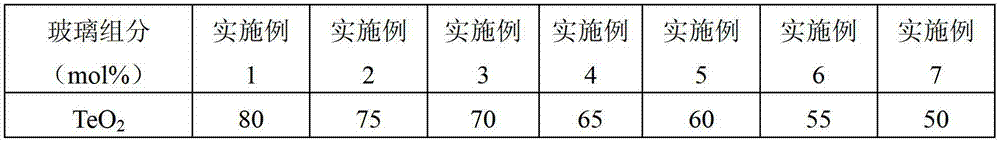

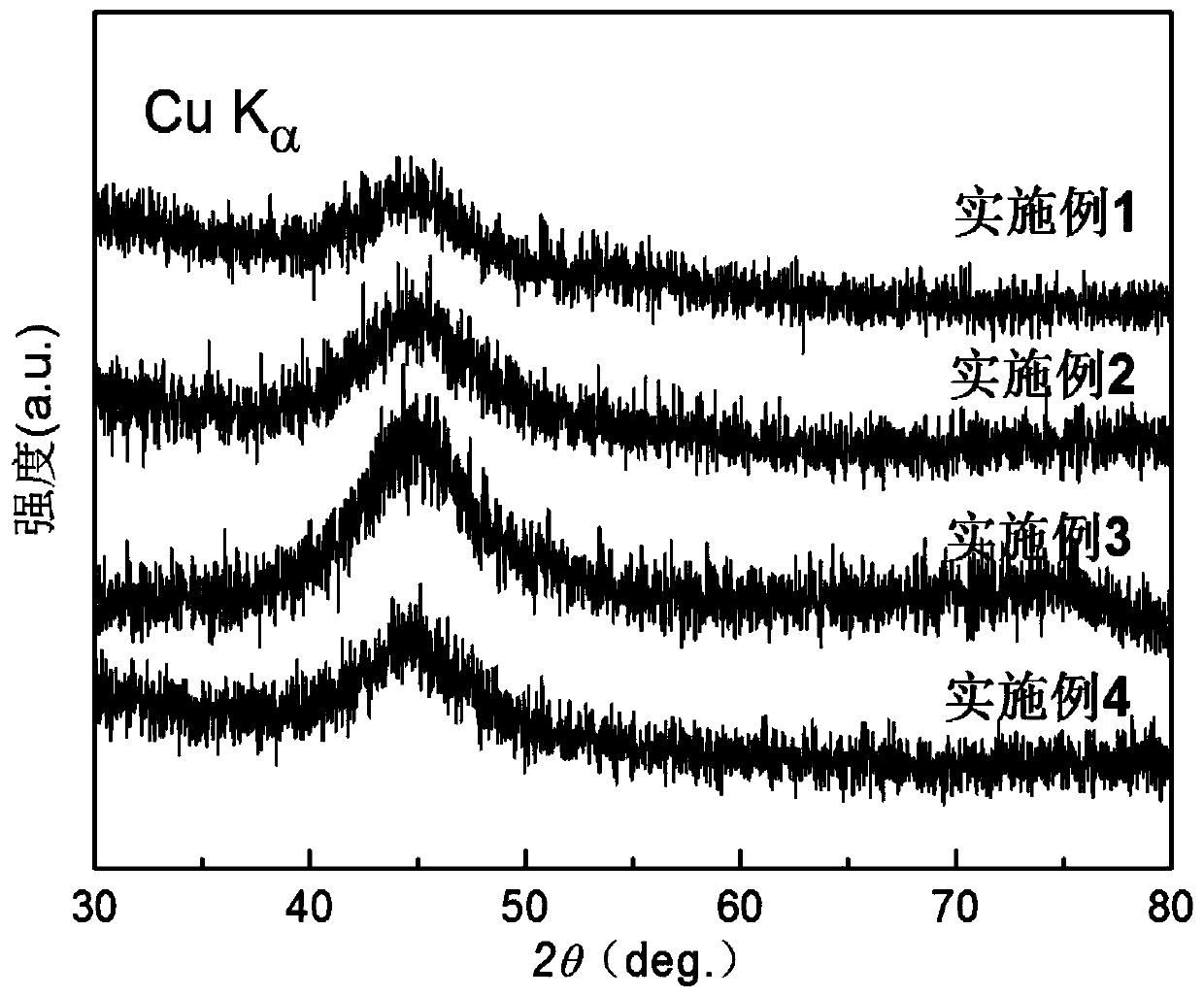

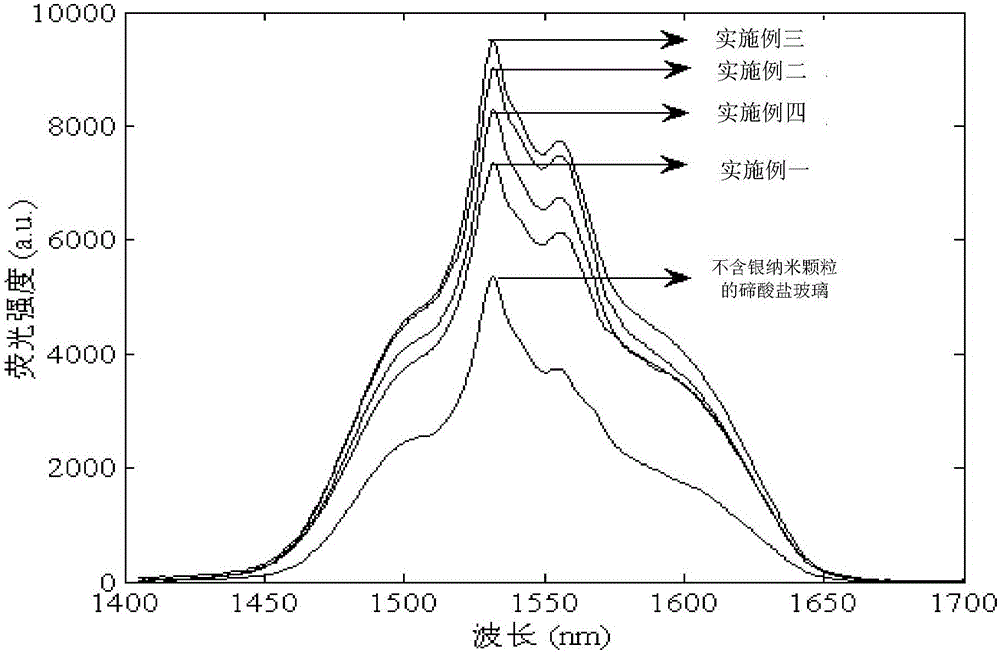

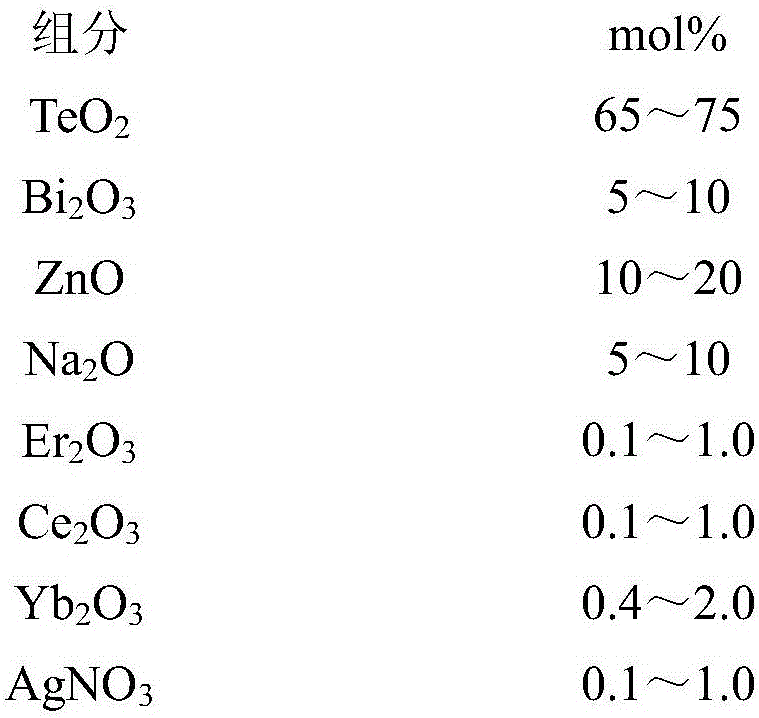

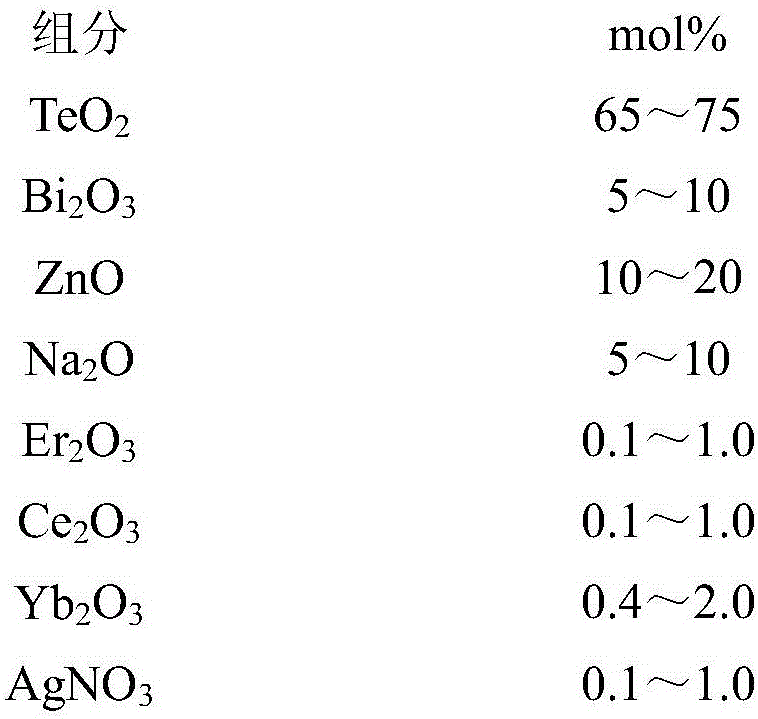

Er<3+>/Ce<3+>/Yb<3+> tri-doped tellurate glass containing silver nano particles and preparation method thereof

The invention discloses Er<3+> / Ce<3+> / Yb<3+> tri-doped tellurate glass containing silver nano particles and a preparation method thereof. The glass consists of the following components in percentage by mole: 65-75mol% of TeO2, 5-10mol% of Bi2O3, 10-20mol% of ZnO, 5-10mol% of Na2O, 0.1-1.0mol% of Er2O3, 0.1-1.0mol% of Ce2O3, 0.4-2.0mol% of Yb2O3 and 0.1-1.0mol% of AgNO3. The tellurate glass has the following advantages that by adopting tellurium oxide as a main component and adding bismuth oxide, zinc oxide and sodium oxide, the forming ability and physical-chemical stability of the glass are improved; due to the tri-doping way of rare earth Er<3+>, Ce<3+> and Yb<3+> ions, the sensitization among the rare earth ions is sufficiently utilized to improve the luminous efficiency of the rare earth Er<3+> ions under a commercial 980nm-wavelength semiconductor laser diode pump; and the fluorescence emission intensity of the doping Er<3+> ions in the 1.55mu m near infrared waveband is enhanced by the local field enhancement effect of the silver nano particles.

Owner:NINGBO UNIV

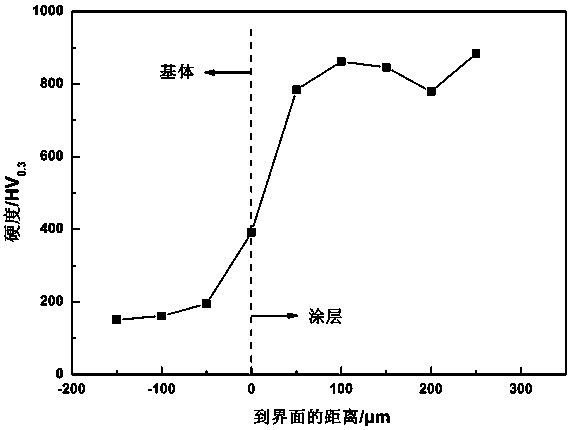

Iron based amorphous/alumina ceramic composite powder and preparation method and applications thereof

The invention discloses an iron based amorphous / alumina ceramic composite powder and a preparation method and applications thereof. The composite powder comprises following components in percentage byweight: 23.2 to 25.2 wt% of Cr, 3.3 to 4.5 wt% of B, 3.1 to 3.8 wt% of Si, 3.2 to 5.6 wt% of Nb, 1.8 to 2.8 wt% of Ni, 10.3 to 12.3 wt% of Mo, 1.5 to 2.0 wt% of Co, 3.2 to 4.2 wt% of Al2O3, and the balance being Fe. The raw materials are added into an induction cooker and then are heated and melted; the melted metals are atomized and dried, then the powder is sieved; the powder is used to preparea wear-resistant iron based amorphous / alumina ceramic composite protective coating, the coating is prepared by an ultrasonic flame spraying technology, and the obtained coating has the advantages ofhigh hardness, good binding strength, and excellent wear-resistant performance and can be used under severe work conditions such as a high parameter valve sealing surface.

Owner:HOHAI UNIV

Low-cost bulk amorphous alloy

The invention relates to the technical field of manufacturing of bulk amorphous alloy, in particular to low-cost bulk amorphous alloy. The chemical formula of the low-cost bulk amorphous alloy is Zra(Hf,Ti)bAlc(CuxNiy)d(Ag,Re)e(Li,Na,K,Si,Mg,Ca)fOg, wherein a, b, c, d, e, f and g are the percentage contents of corresponding atoms of all the elements in the amorphous alloy, 45<=a<=70, 5<=b<=10, 3<=c<=15, 20<=d<=40, 0<=e<=3, 0<=f<=10, 0.05<=g<=1 0.2<=x / y<=5, 0.1<=e+f<=10, and Re is one or more of rare earth elements. According to the low-cost bulk amorphous alloy, the sensitivity of a formula to the oxygen content is greatly reduced, so that the large bulk amorphous alloy suitable for industrial application can still be formed under the high oxygen content condition.

Owner:CHANGZHOU STREAM LIQUID METAL CO LTD

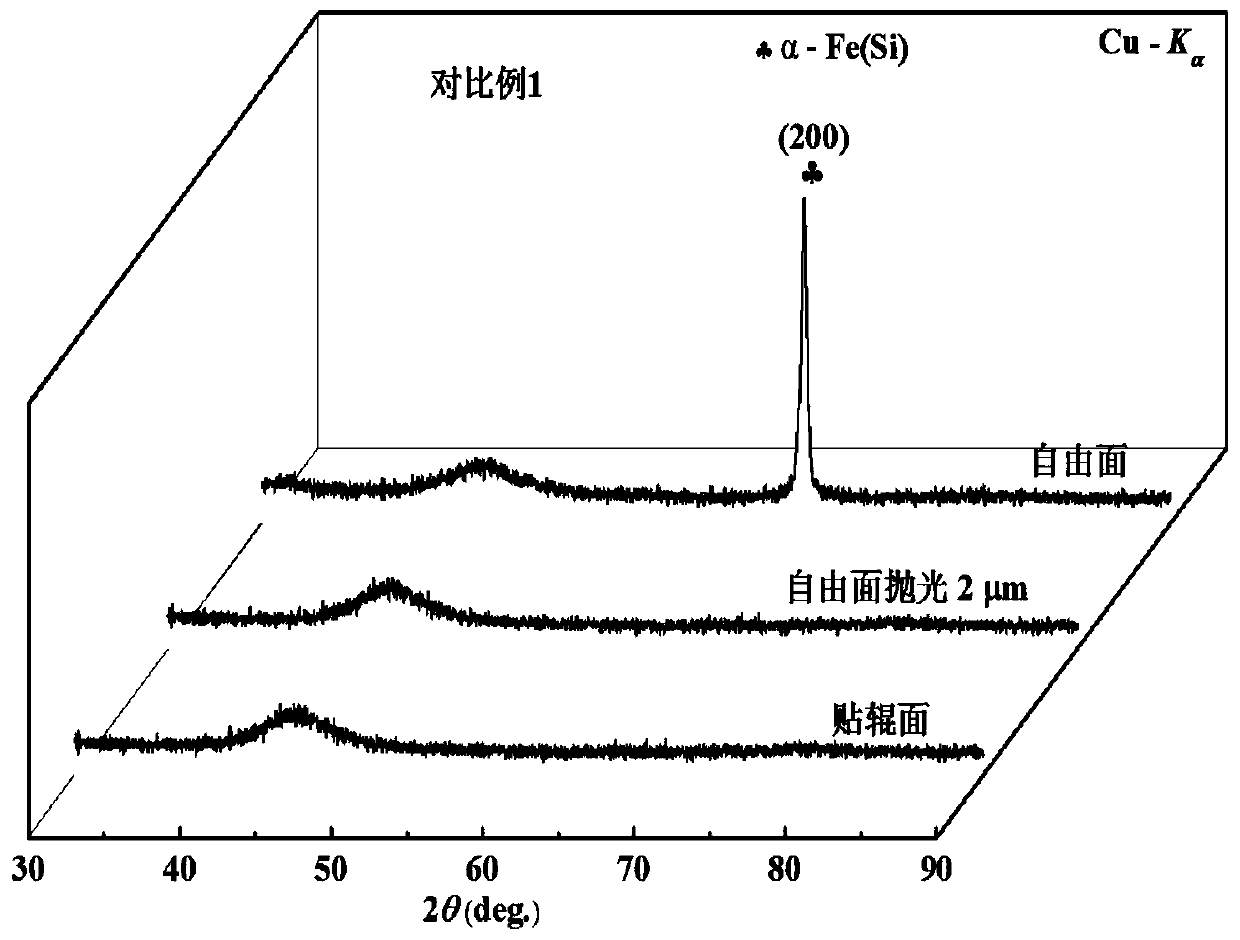

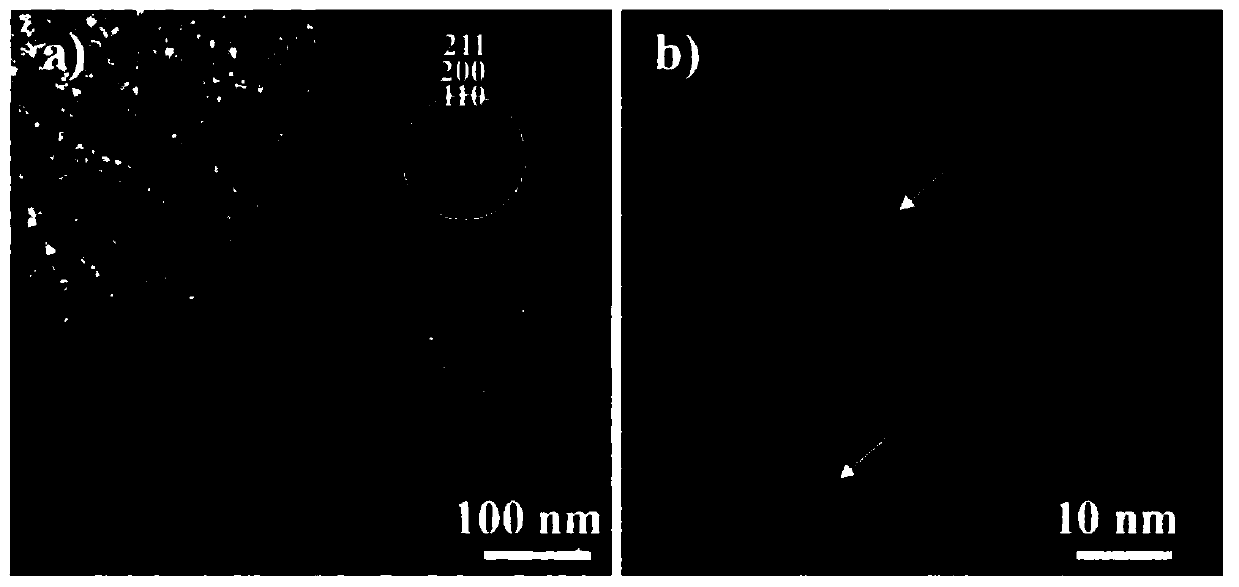

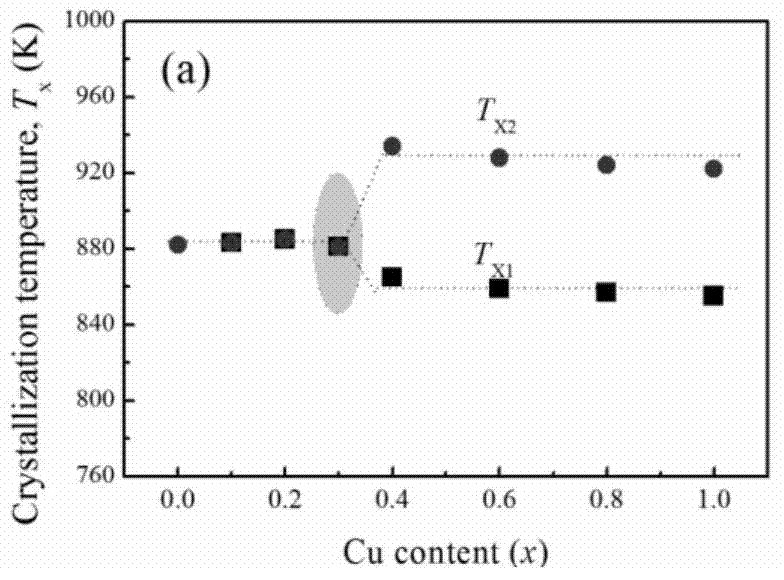

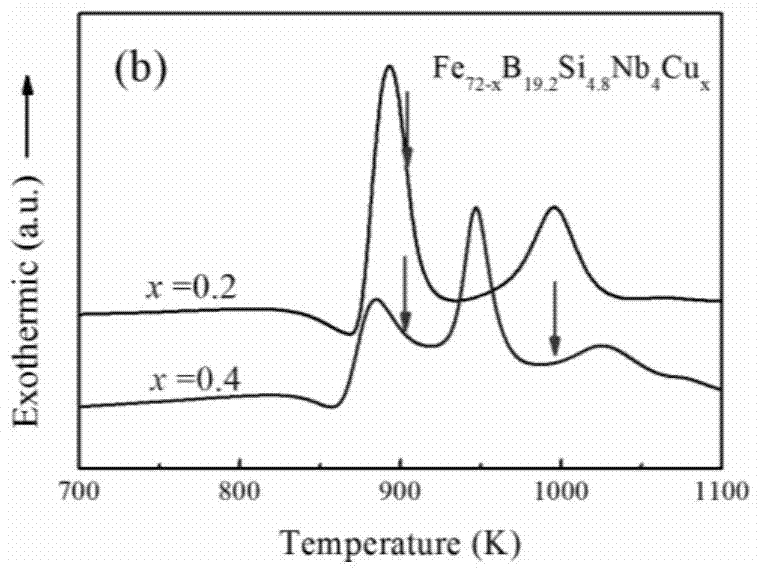

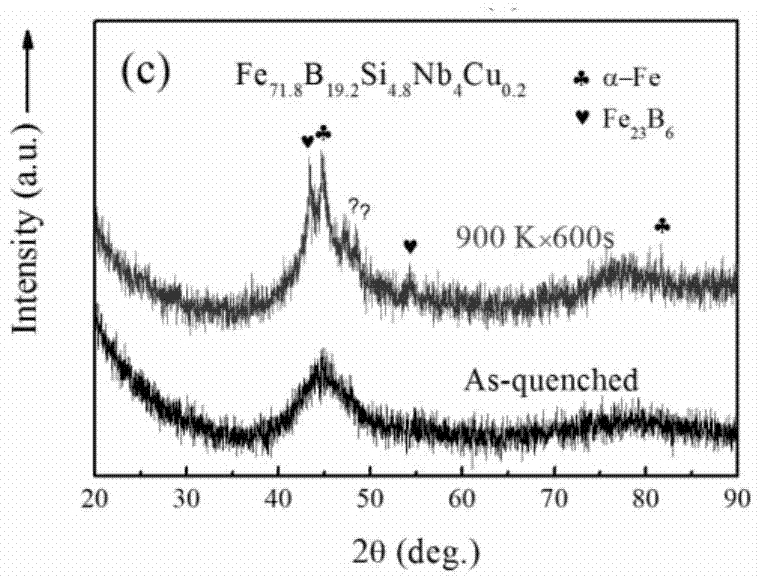

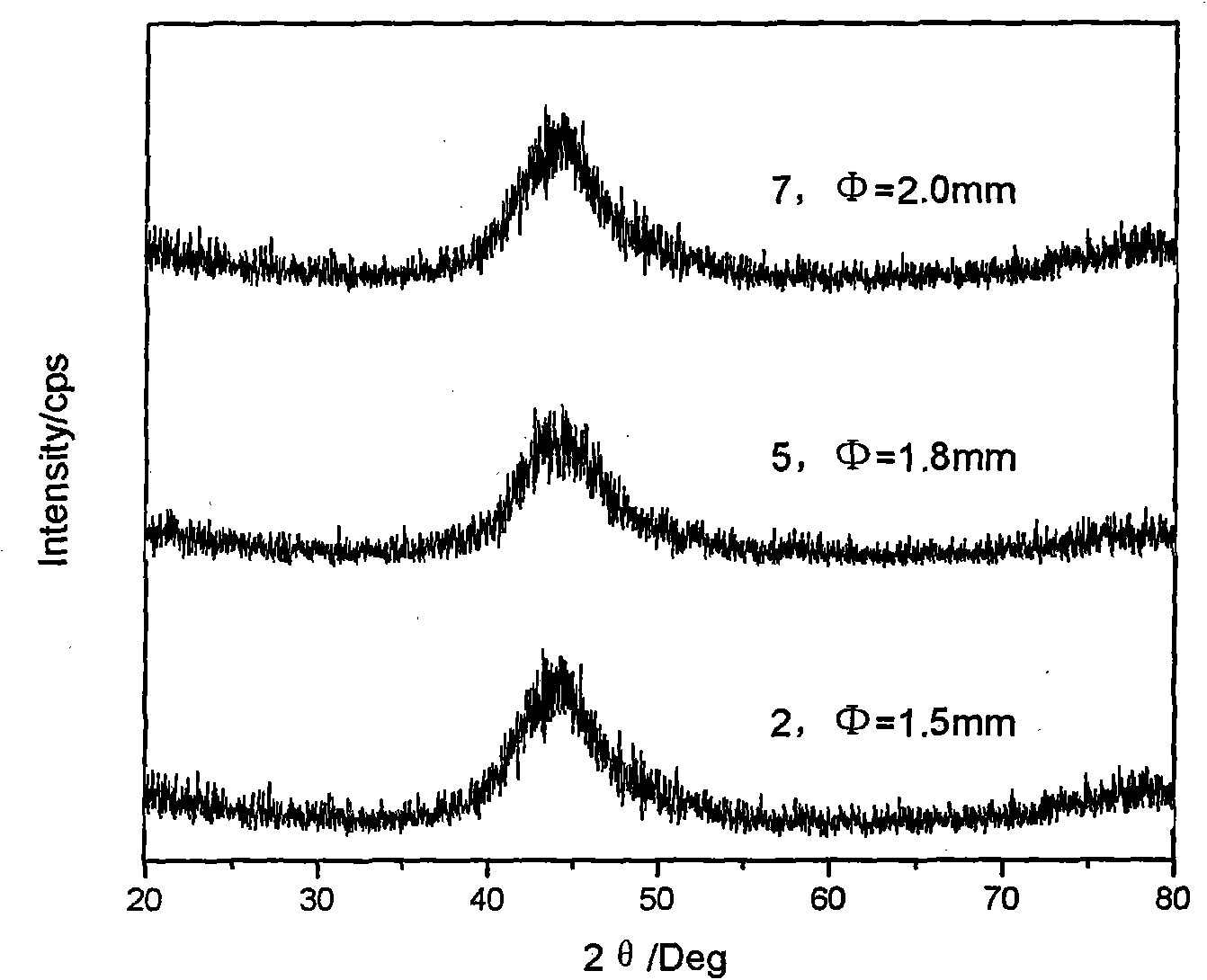

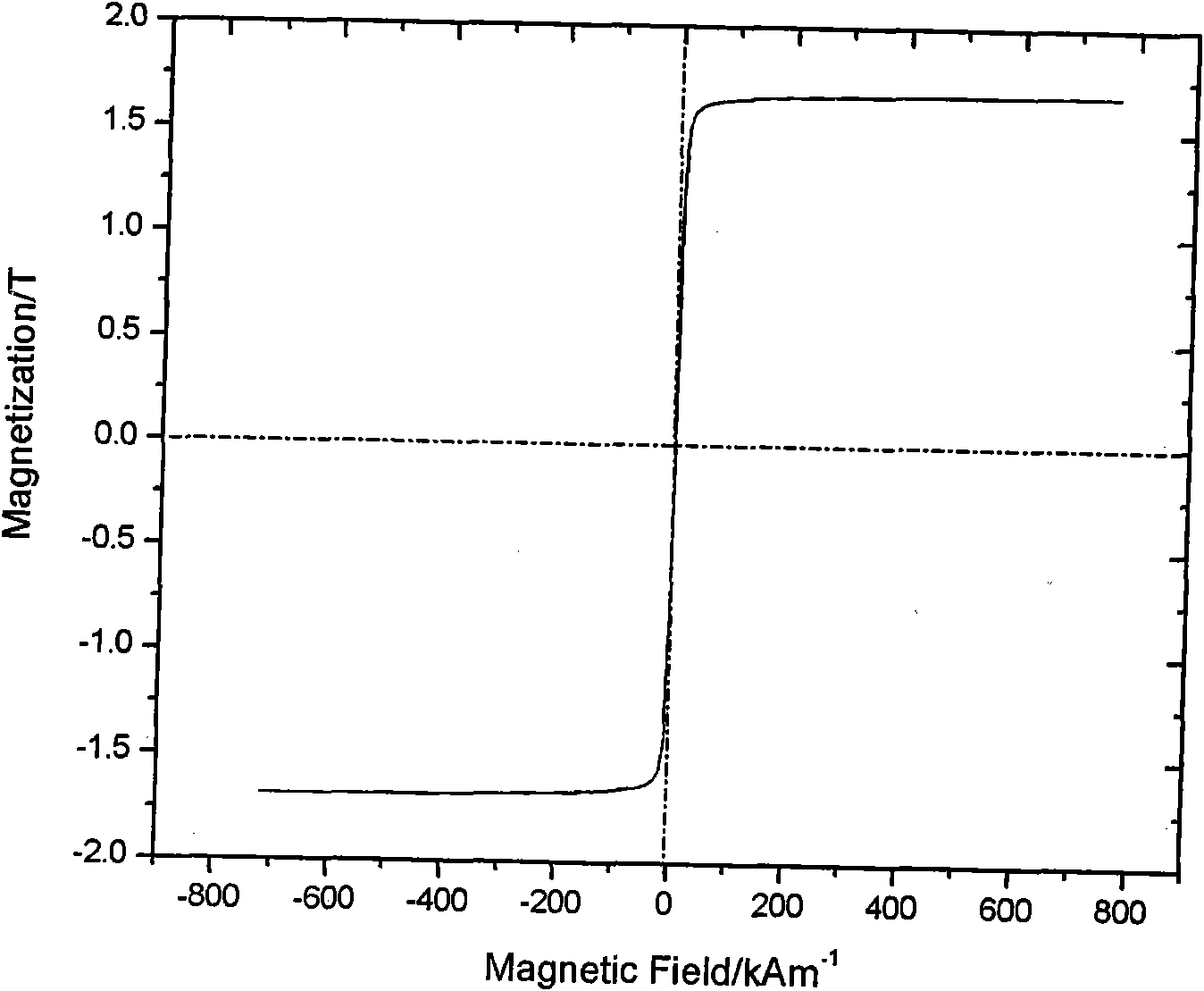

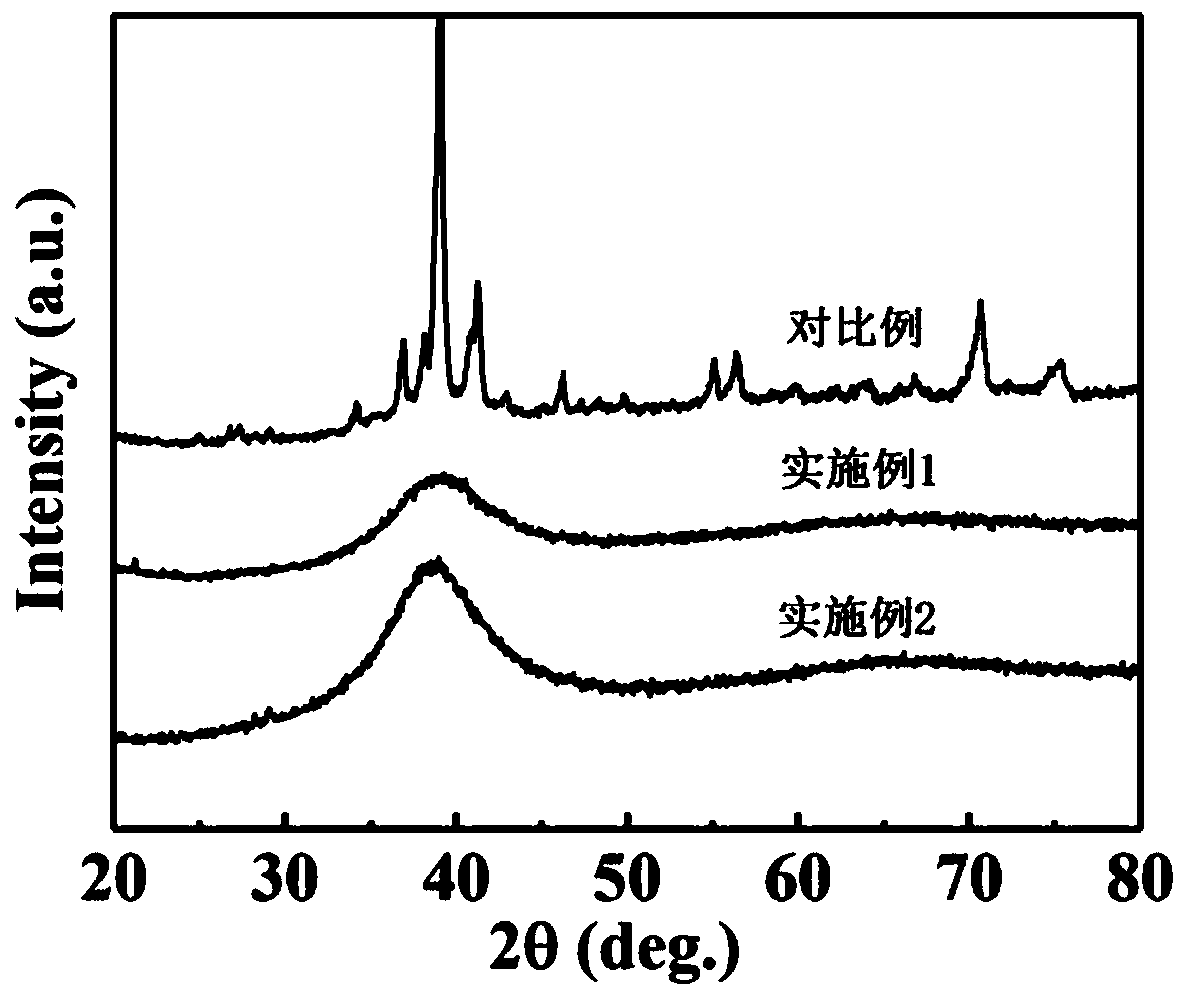

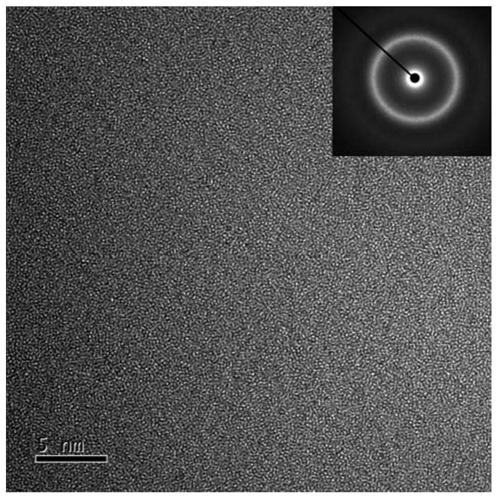

Preparation process for improving forming ability of Fe-base amorphous alloys

ActiveCN104264080ALow costEnhanced Amorphous Formation AbilityFoundry mouldsFoundry coresMagnetizationAlloy

The invention discloses a preparation process for improving the forming ability of Fe-base amorphous alloys, which belongs to the preparation method of Fe-based amorphous alloys. The process is low in cost, and simple and practicable, and can obviously increase the amorphous forming ability under the condition that the saturation magnetization is not reduced. According to the invention, stripped and blocky Fe-base amorphous alloy samples are respectively prepared by using a single-roll rapid quenching or copper mold casting method. The process specially comprises the following steps: under the protection of argon, adding a microelement into a Fe-base amorphous alloy, melting the obtained object in a reacting furnace in stoichiometric ratio, and rapidly cooling and solidifying the obtained product, so that a Fe-base amorphous alloy with high saturation magnetization and large amorphous forming ability is obtained, wherein the added microelement is a copper element, and the microelement accounts for 0.1-1.0% of the Fe-base amorphous alloy by total atomic percent. The process has the advantages that 1, an adopted Fe-base amorphous alloy preparation technology is simple and practicable, and low in cost; 2, the saturation magnetization is reduced while the amorphous forming ability is increased; and 3, the process is applicable to most of primary-phase non-alpha-Fe Fe-base amorphous alloy systems, thereby promoting the popularization and application of the Fe-base amorphous alloys.

Owner:CHINA UNIV OF MINING & TECH

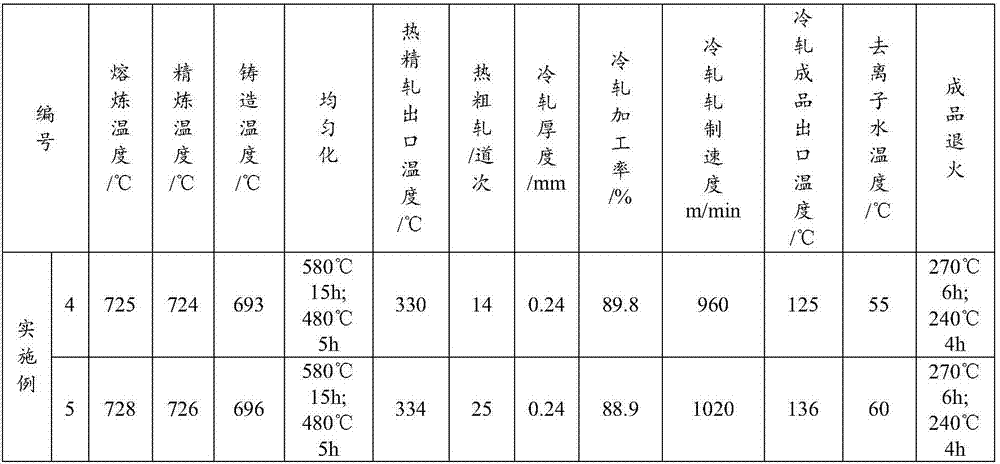

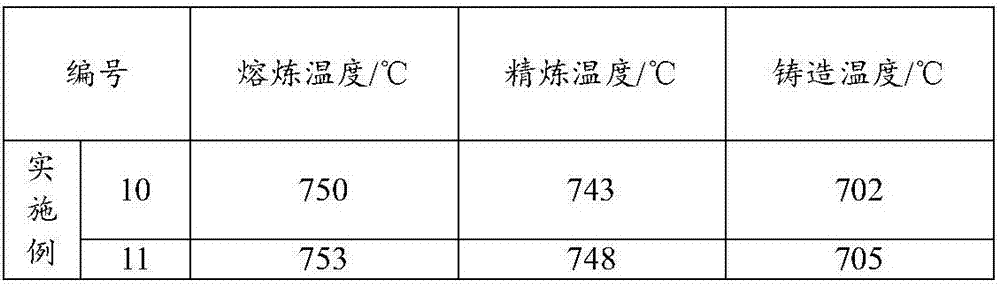

Aluminum alloy plate as well as production method and applications thereof

InactiveCN107058823AImprove the ability to formGuaranteed StrengthFlexible coversWrappersContinuous rollingImpurity

The invention discloses an aluminum alloy plate as well as a production method and applications thereof and belongs to the technical field of aluminum alloy plates. The aluminum alloy plate comprises the following components in percentage by weight: 0.15-0.25% of Si, 0.4-0.46% of Fe,0.16-0.18% of Cu, 0.84-0.92% of Mn, 1.17-1.23% of Mg, Cr less than or equal to 0.04%, 0.02-0.07% of Zn, Ti less than or equal to 0.02%, other single impurities less than or equal to 0.05%, other impurities less than or equal to 0.15% and the balance of Al. The aluminum alloy plate has an excellent forming performance. The production method of the aluminum alloy plate comprises the steps of smelting and casting, saw cutting and surface milling, uniformizing, hot continuous rolling, cold rolling, cleaning and annealing; and the production method is simple in process and is suitable for industrial production.

Owner:SHANDONG NANSHAN ALUMINUM +1

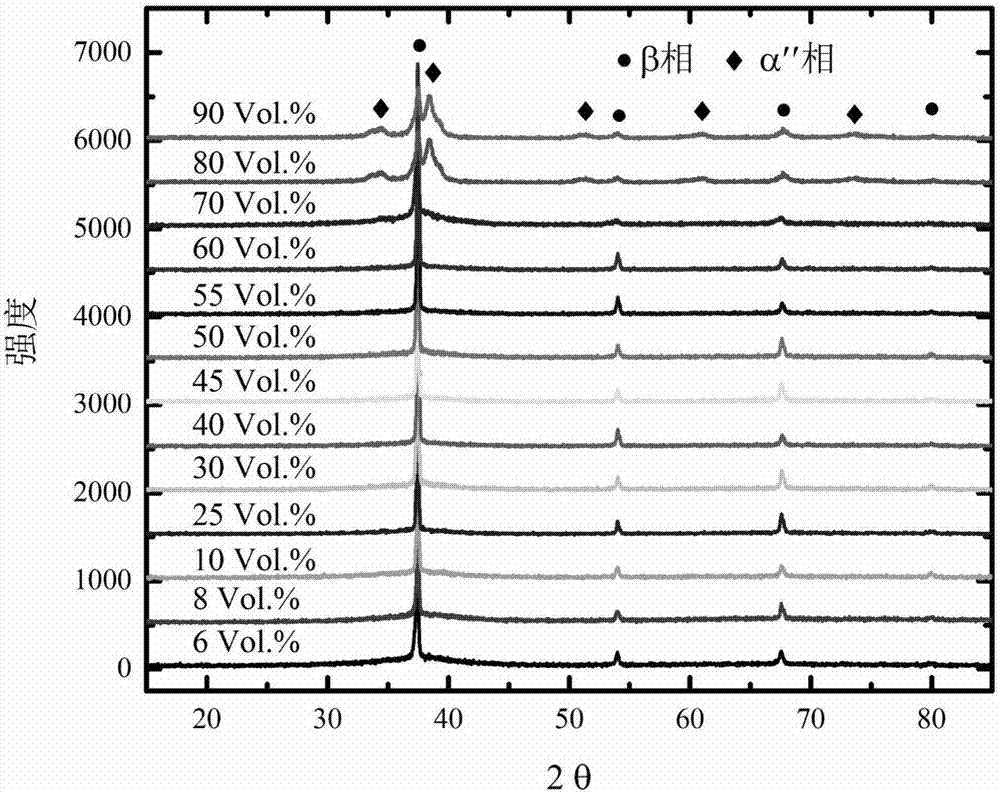

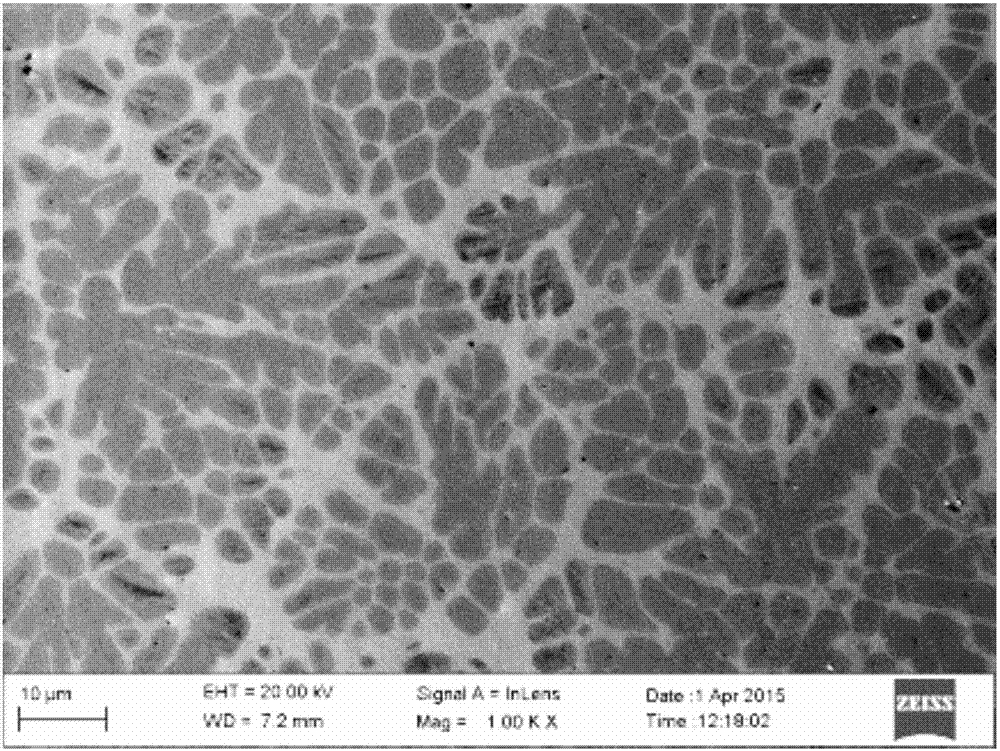

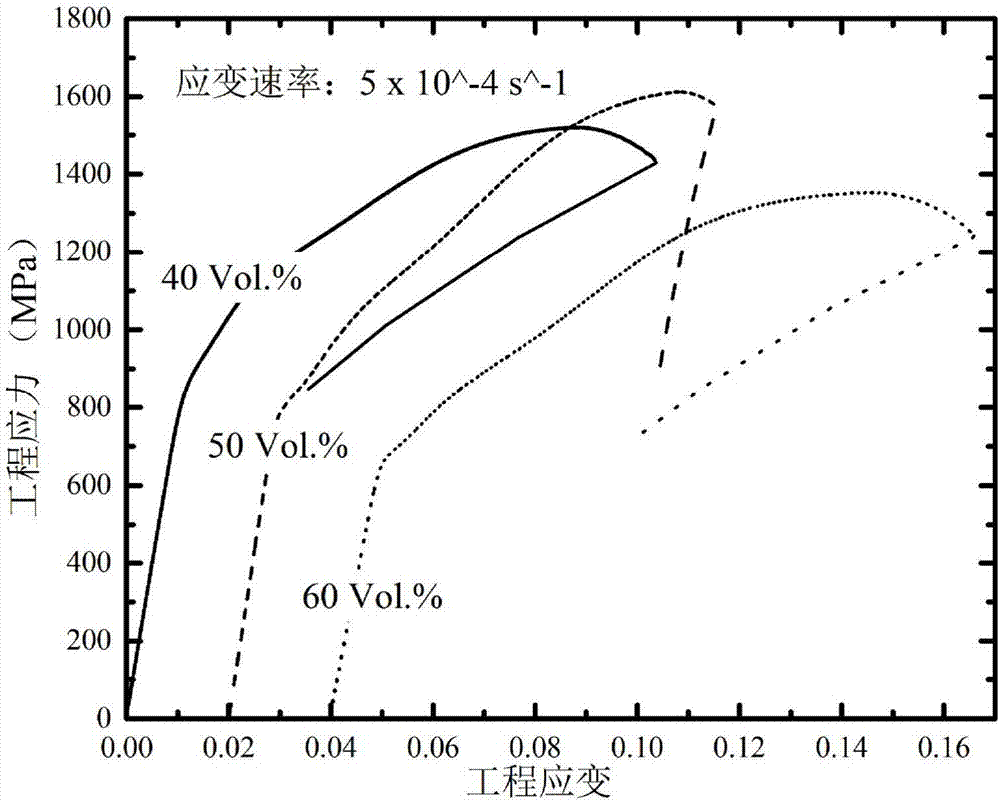

Ti-Zr-Cu-Be four-element amorphous composite with processing hardening capacity and preparation method thereof

ActiveCN107385365ASimple ingredientsImprove the ability to formMartensite transformationChemical composition

The invention discloses a Ti-Zr-Cu-Be four-element amorphous composite with the processing hardening capacity and a preparation method thereof. The composite is a type of amorphous alloy composite containing a dendritic crystal phase, wherein the dendritic crystal phase is prepared from the chemical components of 59-60 parts of Ti, 38-39 parts of Zr and 1-3 parts of Cu, the volume fraction of the dendritic crystal phase is 5-95%, and an amorphous matrix is prepared from the chemical components of 33-34 parts of Ti, 35-36 parts of Zr, 8-9 parts of Cu and 21-24 parts of Be. The dendritic crystal phase has the deformation-induced Martensite phase transformation characteristic, the composite shows excellent comprehensive mechanical properties of high strength, high plasticity, processing hardening and the like under the actions of tension and compression loads, for example, under the tension load, the processing hardening behavior is remarkable, the plastic deformation capacity is 6-15%, and the strength is 1100-1900 MPa. Meanwhile, by means of Martensite phase transformation, the composite has the super-elastic characteristic under the tension load through cyclic loading, for example, elastic deformation can be 2.7-3%. As for the composite, the chemical composition is simple, the chemical components of the second phase are relatively stable, and structural design and controllable preparation of the composite are facilitated.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing rhizoma drynariae/pig bone powder/chitosan compound bracket material

The invention adopts a method for preparing a medicated tissue engineering bracket material by a fully natural material, which overcomes the defects of slower growth of bone tissues at the initial period of implantation and weak synostosis at the initial period in the traditional tissue engineering bracket. The traditional Chinese medicines of rhizoma drynariae and pig bone type hydroxylapatite are introduced into the bracket to obtain a compound tissue engineering bracket material with excellent biological activity. The pig bone type hydroxylapatite is extracted from pig bones, has excellent biological activity and low production cost, is green and innoxious and is pulverized to reach a micron / nano state; the traditional Chinese medicine of the rhizoma drynariae has the functions of promoting the multiplication of osteoblast, accelerating the bone growth, diminishing inflammation and resisting bacteria and is prepared by an effective water extraction solvent method, a pulverization method and a spraying method; and the chitosan is used as a template and is prepared by a vacuum freeze drying method. The porosity of the bracket material is between 45% and 91%, the aperture is adjustable within a range of 40-500mu m, and the compressive strength can reach 0.1-5.6MPa. In the degradation process, the pH value of the bracket is between 6.77 and 7.50.

Owner:JIAMUSI UNIVERSITY

Fe-based amorphous soft magnetic alloy and preparation method thereof

InactiveCN101552071AHigh saturation magnetic inductionStrong Amorphous Formation AbilityMagnetic materialsChemical compositionPrecious metal

The invention discloses a Fe-based amorphous soft magnetic alloy, which comprises the following specific chemical compositions by atomic ratio: Fe(a)P(b)B(c)C(d)Si(e), and a+b+c+d+e=100, wherein the atom percentage content of b is 8-11, the atom percentage content of c is 0-3, the atom percentage content of d is 6-10, the atom percentage content of e is 0-3, and the balance is a. The alloy material does not contain precious metal elements, has excellent soft magnetic property, good amorphous forming ability and very high engineering application value, and can be widely used in the fields of structural materials, magnetic materials and the like; in addition, the alloy has the advantages of simple preparation method and very low production cost.

Owner:BEIHANG UNIV

Positve photosensitive painting composition, method for producing positive photosensitive resin and forming method of pattern

InactiveCN1469198AImprove the ability to formPhotosensitivity maintenanceWriting implementsSemiconductor/solid-state device manufacturingPositive typeChaetopyranin

The present application provides a positive type coating composition and forming method of pattern by using the said coating composition. The positive type sensitivity coating according to the present invention is characterized in that contains specific modified quinonediazido-sulfonamide as union based on the 100 parts by weight in one molecular, making the structure unit containing 0.1 to 0.9 mole concentration in 1 kg resin, and using the specific carboxylic sulfonamide derivative as the structure unit, which in 1 kg resin the structure unit containing 0.2 to 0.4 mole concentration positive type sensitivity resin with 1 to 50 parts by weight at least one component selected from the group of phenol resin phenol derivative and catechol.

Owner:KANSAI PAINT CO LTD

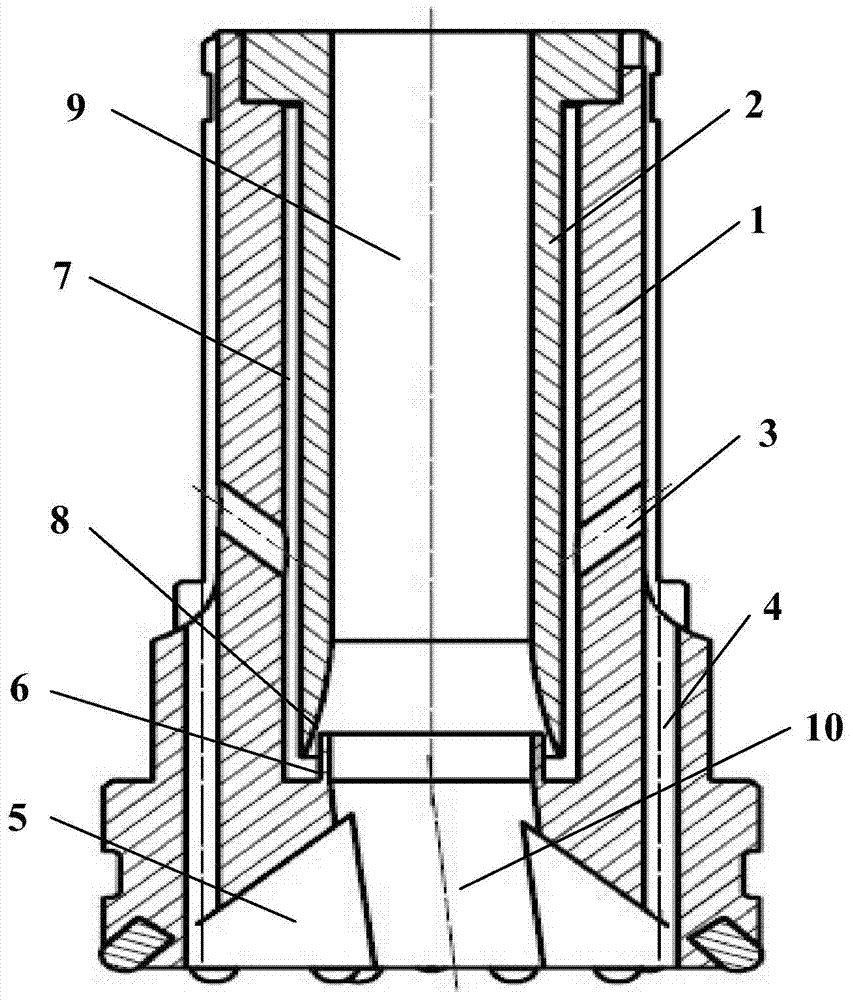

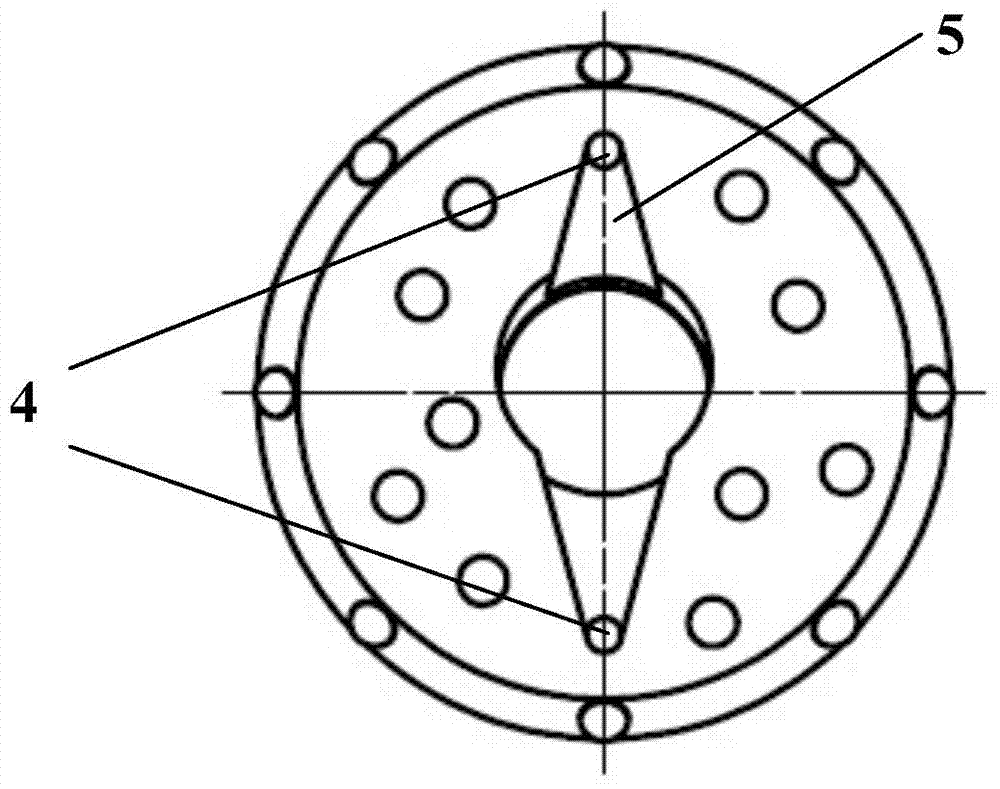

Strong suction type reverse-circulation coring drill bit

InactiveCN103967421AImprove the ability to formImprove drilling efficiencyDrill bitsCore removalRock coreDrill bit

The invention discloses a strong suction type reverse-circulation coring drill bit. An internal pipe is inserted into an inner chamber of a drill bit body; an annular space is formed between the outer wall of the internal pipe and the inner wall of the inner chamber of the drill bit body; the inner chamber of the internal pipe is a center passage of the drill bit body; an inner jet hole and a bottom jet hole are formed in the sidewall of the drill bit body; an eccentric passage and a pressurization groove are formed in the bottom of the drill bit body; the inner sidewall of the lower end of the internal pipe is an arc-shaped surface; an annular nozzle is formed between the arc-shaped surface and a circular bead which is arranged at the lower end of the drill bit body. The strong suction type reverse-circulation coring drill bit disclosed by the invention has the beneficial effects of being reasonable in structural design and beneficial for improving the drilling efficiency and core (sample) exploitation rate of a down hole hammer, and having great significances for improving the reverse circulation formation effect and guaranteeing safe, rapid and efficient running of a through down hole hammer.

Owner:JILIN UNIV +1

Block copper-based amorphous alloy and preparation method thereof

The invention relates to a large-block copper-based amorphous alloy and a preparation method thereof. The large-block copper-based amorphous alloy comprises the following components of, by atomic percent, 43-48 at.% of Zr, 5-10 at.% of Al, 0-2 at.% of Sn and the balance Cu. According to the large-block copper-based amorphous alloy and the preparation method thereof, the novel copper-based large-block amorphous alloy with the critical casting diameter of 3 mm in a Cu-Zr-Al system and a Cu-Zr-Al-Sn system is directly determined through combination of thermodynamic calculation and a binary eutectic ratio method; and the generation of a precipitation phase is inhibited by regulating and controlling the binary eutectic ratio, and the large-block amorphous alloy with the critical casting diameter of 5 mm and the large-block amorphous alloy with the critical casting diameter of 7 mm are obtained in the Cu-Zr-Al system and the Cu-Zr-Al-Sn system correspondingly.

Owner:TONGJI UNIV

Low-cobalt nickel nanocrystalline iron-base magnetically soft alloy material and preparation method thereof

InactiveCN102828110AExpand the range of amorphous formationHigh Curie temperatureMagnetic materialsCobalt metalAlloy

The invention provides a low-cobalt nickel nanocrystalline iron-base magnetically soft alloy material and a preparation method thereof. Under the condition of ensuring better soft magnetic property, the material not only reduces the high-price metal cobalt but also has good magnetic property. The preparation method has simple process and low production cost and is suitable for industrial production. The material comprises the following components by weight percent: 4-6.5% of Co, 5-8% of Ni, 3-5% of Gd, 0.01-0.05% of Ir, 0.1-0.5% of Tm, 0.1-0.5% of Dy, 2-4% of Al, 0.1-0.5% of P, 1-3% of B and the balance of Fe.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Preparation and application of amorphous nanocrystalline alloy

InactiveCN107686946AEnhanced Amorphous Formation AbilityPromotes grain refinementWater contaminantsWater/sewage treatmentQuenchingNanometre

The invention discloses preparation of an amorphous nanocrystalline alloy. The amorphous nanocrystalline alloy comprises the components of, by mass, 0.5-8% of Ni, 0.1-0.3% of Co, 1-2% of Cu, 0.01-0.03% of Nb, 3-11% of B, 2-9% of Si, 0.01-3.5% of C, 0.1-3% of P and the balance Fe, and the sum of the content of all the components is 100%. The amorphous nanocrystalline alloy is prepared in the modesthat a master alloy ingot is prepared through induction smelting and then is prepared into a strip belt through the single roll rotating quenching method, then the strip belt is cut to be with the required length and placed in a vacuum annealing furnace, vacuum pumping is conducted, and annealing treatment is conducted under protection of inert gas. The prepared amorphous nanocrystalline alloy canbe used in the field of azo dye wastewater treatment and can be reused, and the preparation cost is low.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com