Ti-Zr-Cu-Be four-element amorphous composite with processing hardening capacity and preparation method thereof

An amorphous composite material and work hardening technology, applied in the field of amorphous composite materials, can solve the problems of second phase size and distribution preparation process sensitivity, weak amorphous forming ability, and limit practical application, etc., and achieve significant work hardening ability, Simple Ingredients, High-Intensity Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of Ti-Zr-Cu-Be amorphous composite material with dendritic phase volume fraction design value of 6%:

[0045] (1) Using metals with industrial grade purity as raw materials, according to Ti 59.5 Zr 38.3 Cu 2.2 Preparation of master alloy ① according to the composition ratio, specifically, firstly weigh and mix the constituent elements according to the composition ratio to obtain 100g of the metal mixture, put it into the electric arc furnace, and evacuate to 5×10 -4 Pa, then filled with high-purity argon, first smelt and absorb the titanium ingot, then smelt the metal mixture, and repeatedly smelt until the composition is uniform, the smelting current is 200A-700A, and the alloy is made to obtain the intermediate alloy ① ingot;

[0046] (2) Using metals with a purity of above industrial grade (including industrial grade) as raw materials, according to Ti 33.5 Zr 35.5 Cu 8.3 be 22.7 Preparation of master alloy ② according to the composition ratio, speci...

Embodiment 2

[0050] The difference from Example 1 lies in that: the dendrite phase volume fraction is different, and the smelting process is different.

[0051] In this embodiment, the design value of the volume fraction of the dendrite phase is 8% to 90%, as shown in Table 1. During the test, according to the design value of the dendrite phase volume fraction, different weights of master alloy ① and ② mixtures were weighed, and master alloy ingots were prepared by arc melting. When melting, the vacuum degree is 5×10 -3 Pa~5×10 -4 Pa, the melting current is 200A ~ 700A. Amorphous composite samples with dimensions of 6mm×10mm×60mm were prepared by induction melting casting method. During casting, the alloy melt temperature is in the range of 500-600°C above the liquidus line of the amorphous matrix.

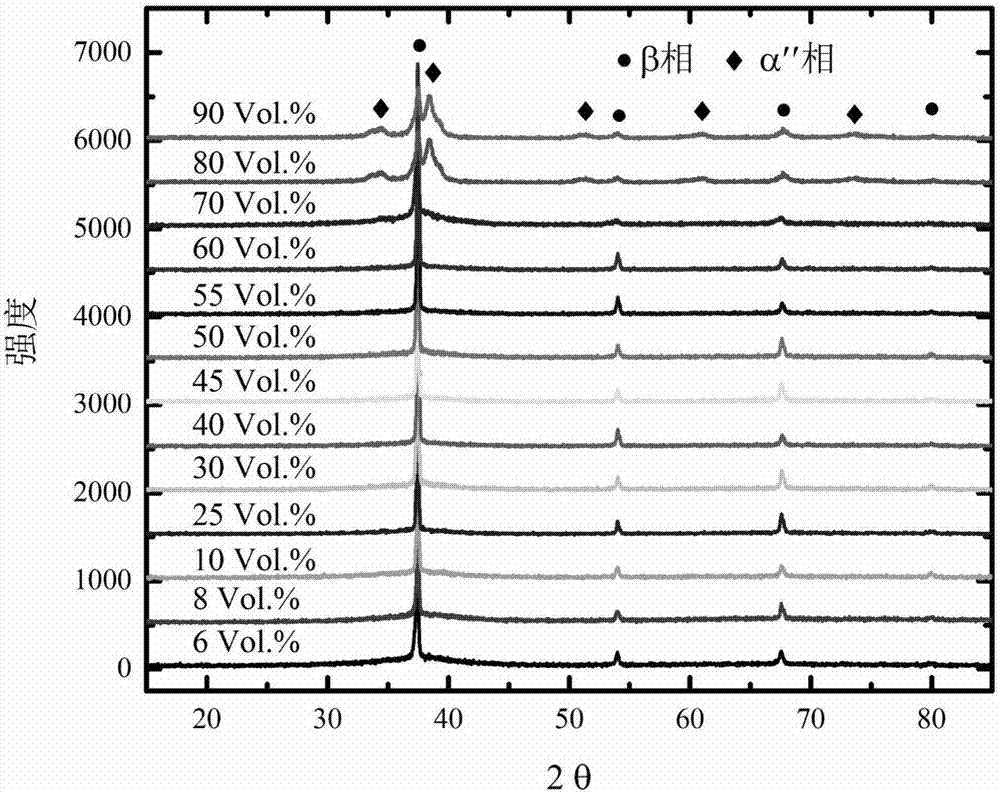

[0052] A sample of amorphous composite material with a size of 6mm×10mm×60mm was tested by X-ray analysis, such as figure 1 As shown, it shows that this series is an amorphous composite m...

Embodiment 3

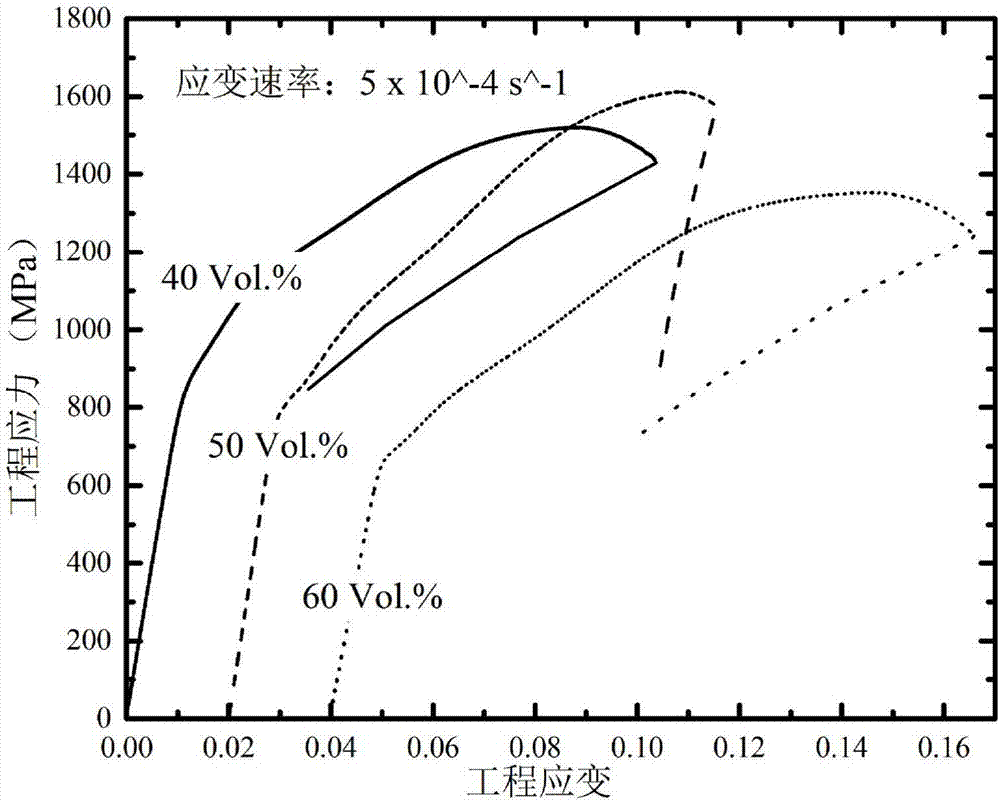

[0054] Using wire cutting, cut the tensile sample, and use the universal testing machine for tensile performance test, the strain rate is 5×10 -4 the s -1 . It can be found that the amorphous composite material has excellent tensile mechanical properties, the tensile strength is 1100MPa-1900MPa, the plasticity is 6%-15%, and remarkable work hardening ability. image 3 Tensile curves of amorphous composites with dendritic phase volume fractions of 40%, 50% and 60% are given. After tensile failure, the sample was detected by XRD and found to contain a large amount of martensitic phase, indicating that the amorphous composite material induced martensitic transformation during the deformation process, resulting in a significant work hardening ability of the amorphous composite material. Figure 4 The X-ray patterns of the amorphous composite material with a volume fraction of 45% before and after deformation are given.

[0055] The tensile sample of the amorphous composite mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com