Method for removing cyanogens-containing waste gas

A waste gas and removal technology, which is applied in the field of removing cyanide-containing waste gas and catalytic combustion method to remove cyanide-containing waste gas, can solve the problem of low specific surface area of alumina carrier, higher requirements for removal conditions, poor dispersion of active components, etc. problems, to achieve low-temperature activity, no by-products, and improve the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

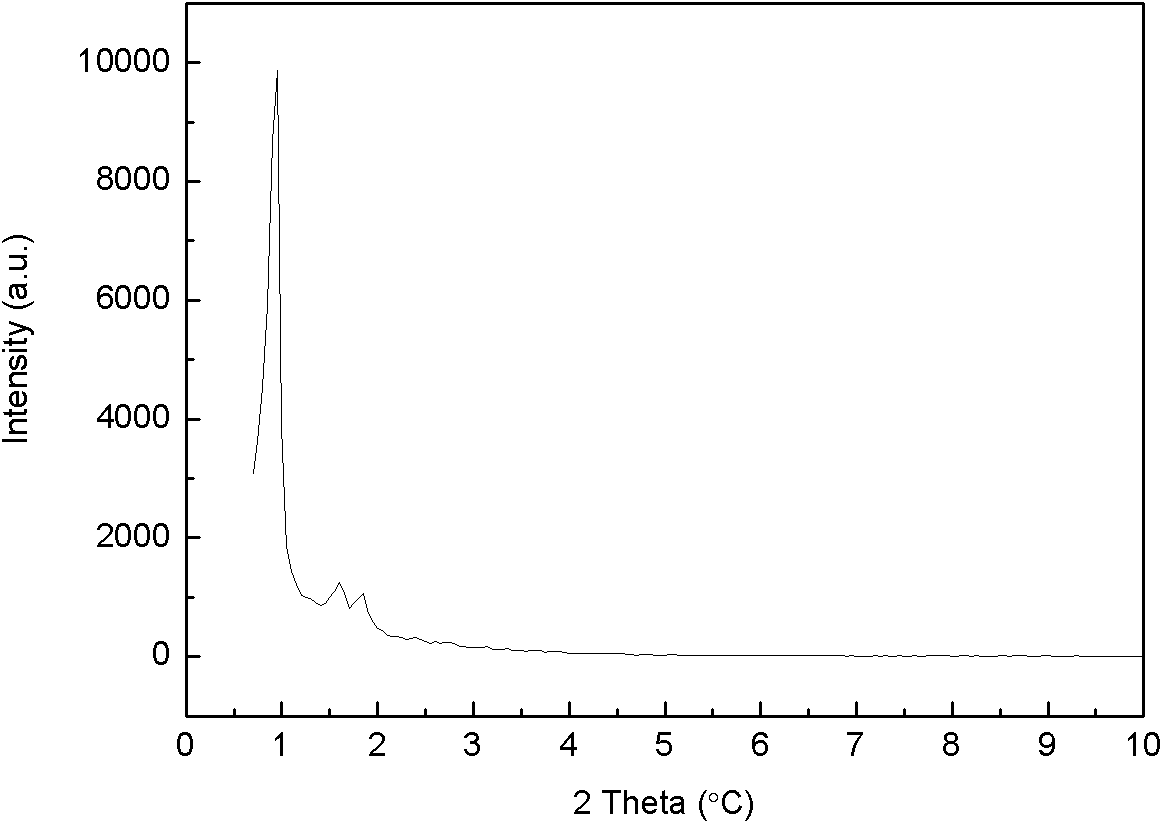

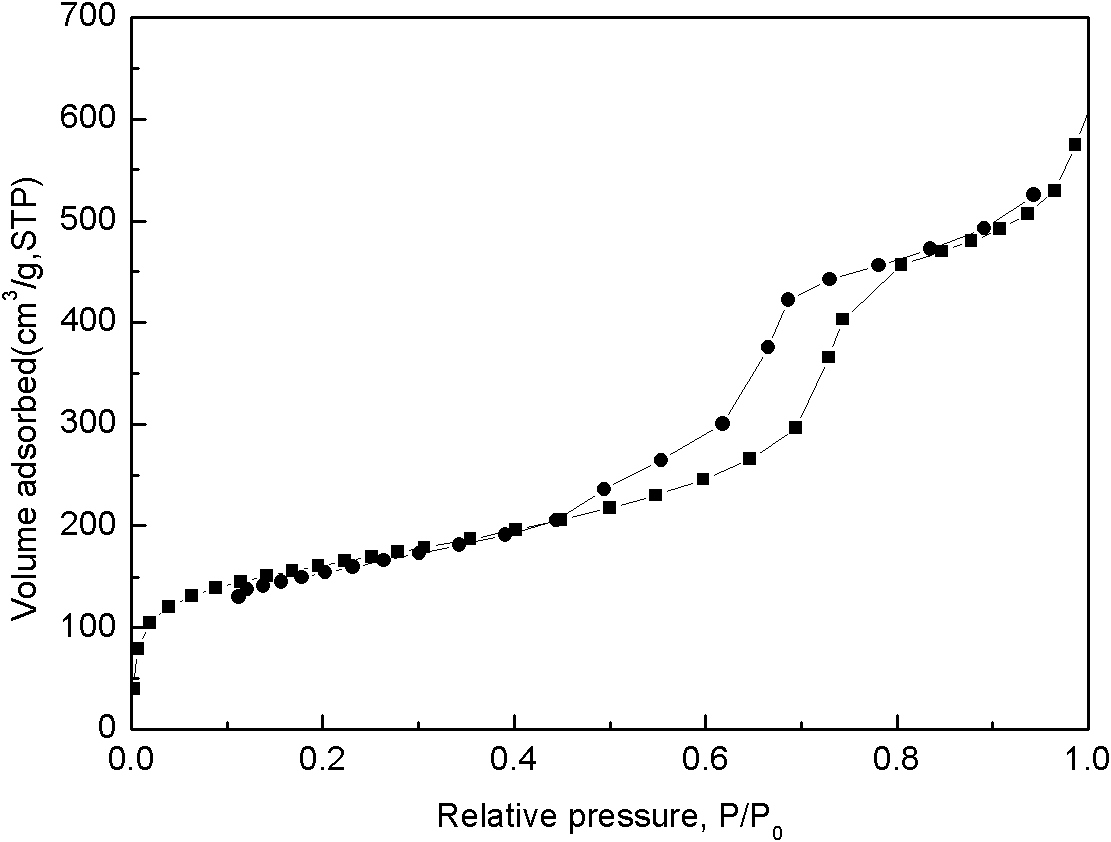

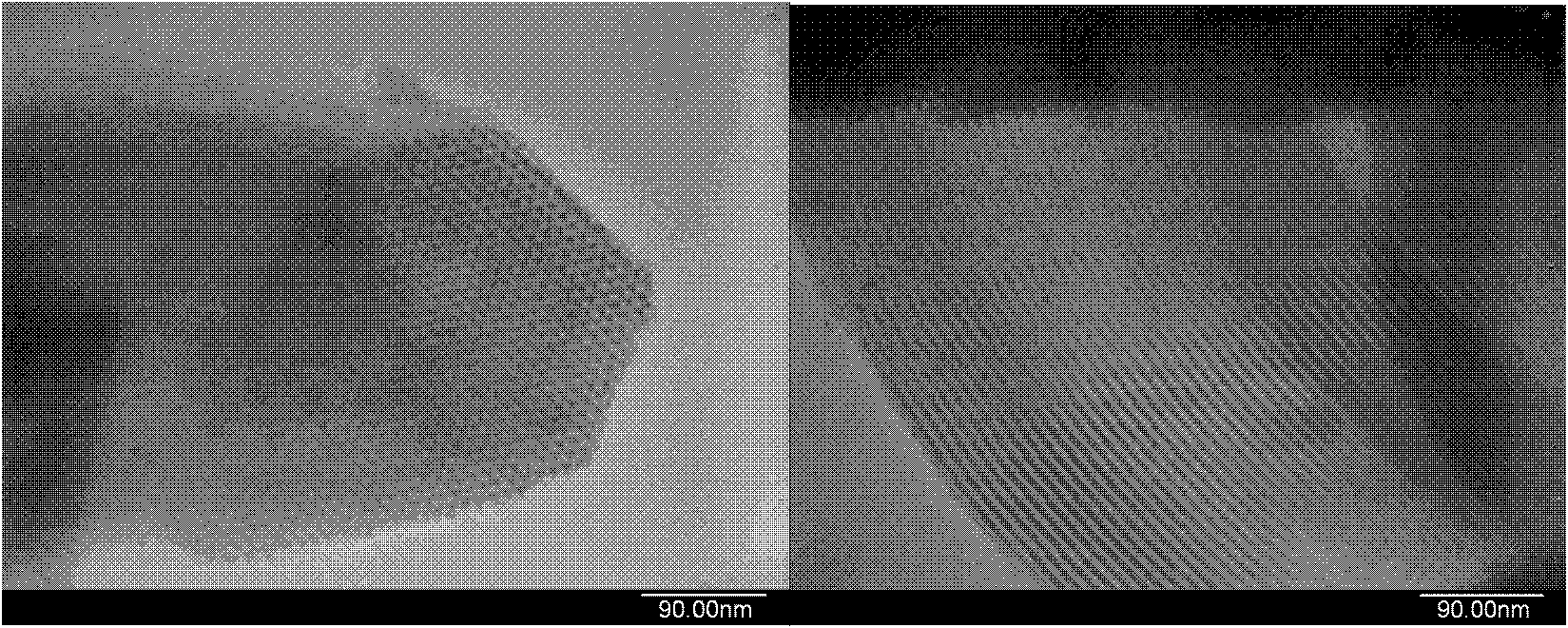

Embodiment 1

[0026] Embodiment 1: take by weighing 0.0756gCu (NO 3 ) 2 ·3H 2 O (chemically pure reagent), and dissolve it in water to form an impregnating solution, then weigh 1g of SBA-15 mesoporous molecular sieve and add it to the impregnating solution, stir in a water bath at 40°C for 24 hours, and then use a rotary evaporator to remove the impregnating solution. Finally, the above-mentioned supported catalyst was placed in an air atmosphere at a rate of 2 °C / min to 550 °C and calcined for 10 hours to obtain a Cu / SBA-15 catalyst with a mass fraction of 5% copper supported. The prepared catalyst was placed in a miniature fixed-bed quartz reactor, and then the reactor was heated to 450°C, and a CH 3 CN(1vol%), O 2 (5vol%) and N 2 (As a balance gas) mixed gas, the air velocity of the mixed gas is 20000h -1, using an American Nicolet Nexus 470 infrared spectrometer with a 2.4m optical path gas analysis cell for online gas quantitative analysis, so as to obtain the conversion rate of a...

Embodiment 2

[0027] Embodiment 2: take by weighing 0.1538gCr (NO 3 ) 3 9H 2 O, and dissolve it in water to make an impregnating liquid, then weigh 1g of SBA-16 mesoporous molecular sieve and add it to the impregnating liquid, stir in a water bath at 40°C for 24 hours, then use a rotary evaporator to remove the water in the impregnating liquid, and finally The above-mentioned supported catalyst was placed in an air atmosphere at a rate of 2 °C / min to 550 °C and calcined for 10 hours to obtain a Cr / SBA-15 catalyst with a mass fraction of 2% chromium supported. Put the prepared catalyst in a miniature fixed-bed quartz reactor, then raise the temperature of the reactor to 500°C, and pass through the reactor containing CH 3 CN(1vol%), O 2 (5vol%) and N 2 (As a balance gas) mixed gas, the air velocity of the mixed gas is 20000h -1 , using an American Nicolet Nexus 470 infrared spectrometer with a 2.4m optical path gas analysis cell for online gas quantitative analysis, so as to obtain the c...

Embodiment 3

[0028] Embodiment 3: take by weighing 0.0986gCo(NO 3 ) 2 ·6H 2 O, and dissolve it in water to form an impregnating liquid, then weigh 1g of KIT-5 mesoporous molecular sieve and add it to the impregnating liquid, stir in a water bath at 40°C for 24 hours, then use a rotary evaporator to remove the water in the impregnating liquid, and finally The above-mentioned supported catalyst was placed in an air atmosphere at a rate of 2 °C / min to 550 °C and calcined for 10 hours to obtain a Co / KIT-5 catalyst with a mass fraction of 2% cobalt. Put the prepared catalyst in a miniature fixed-bed quartz reactor, then raise the temperature of the reactor to 400°C, and pass through the reactor containing CH 3 CN(1vol%), O 2 (5vol%) and N 2 (As a balance gas) mixed gas, the air velocity of the mixed gas is 20000h -1 , using an American NicoletNexus 470 infrared spectrometer with a 2.4m optical path gas analysis cell for online gas quantitative analysis, so as to obtain the conversion rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com