Patents

Literature

256 results about "1-Octene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

1-Octene is an organic compound with a formula CH₂CHC₆H₁₃. The alkene is classified as a higher olefin and alpha-olefin, meaning that the double bond is located at the alpha (primary) position, endowing this compound with higher reactivity and thus useful chemical properties. 1-Octene is one of the important linear alpha olefins in industry. It is a colourless liquid.

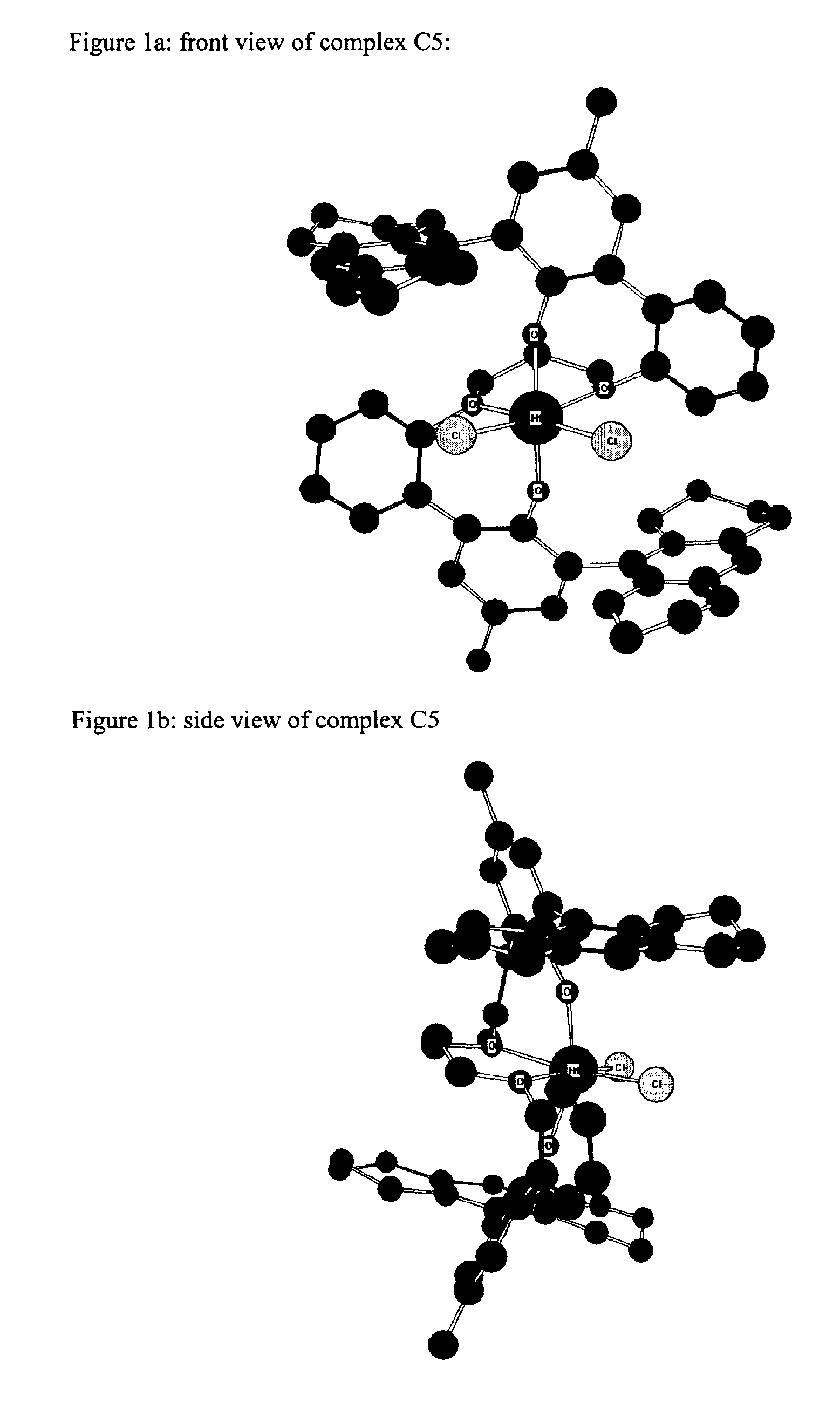

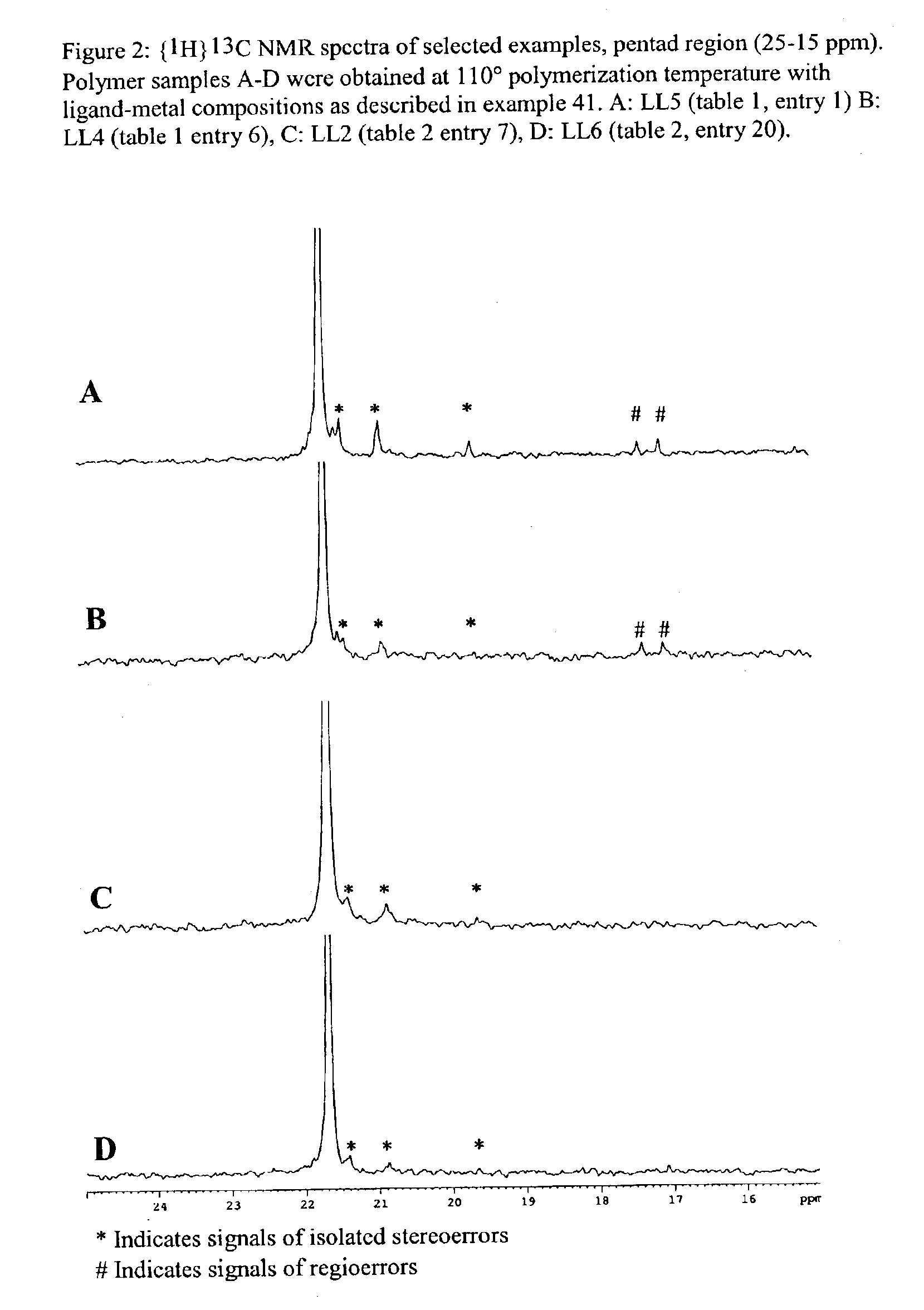

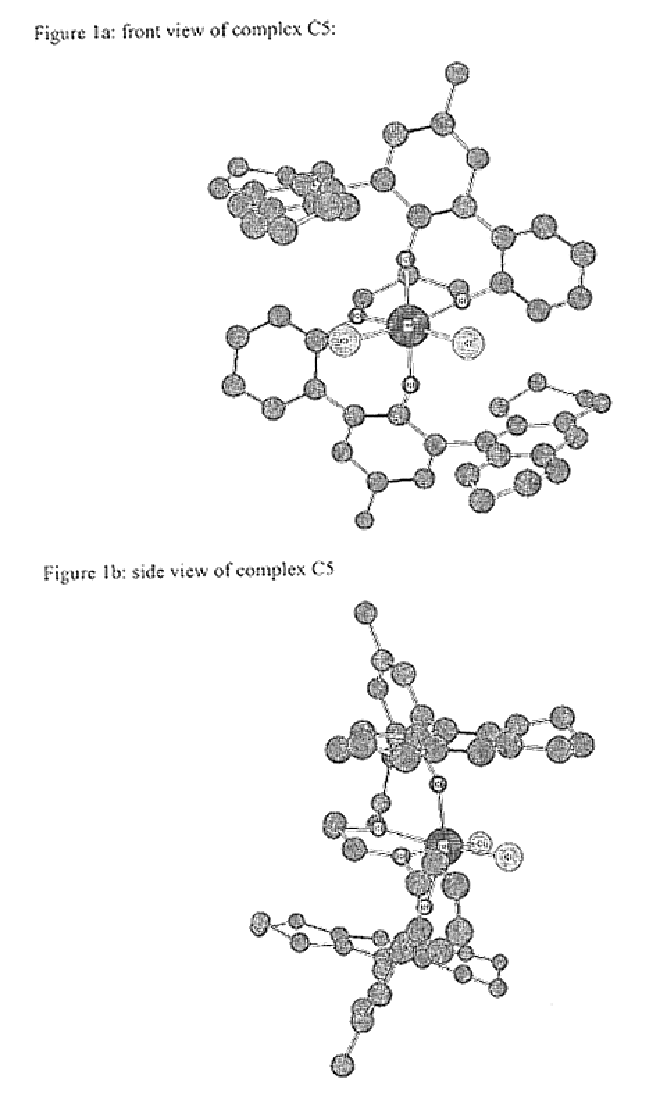

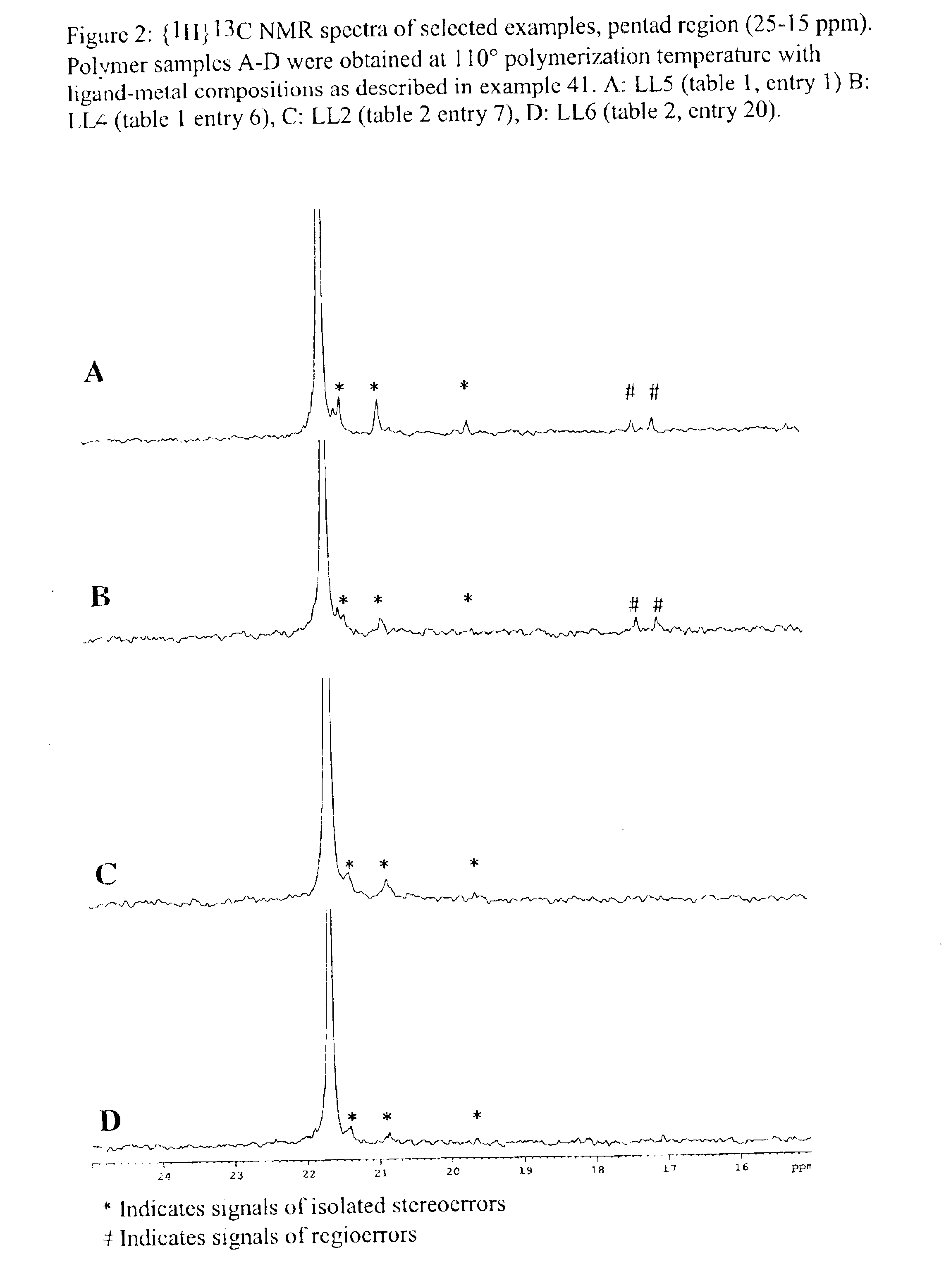

Bridged bi-aromatic ligands, catalysts, processes for polymerizing and polymers therefrom

InactiveUS6869904B2Improve catalytic performanceOrganic compound preparationGroup 4/14 organic compounds without C-metal linkages1-OctenePolypropylene

New ligands, compositions, metal-ligand complexes and arrays with bridged bis-aromatic ligands are disclosed that catalyze the polymerization of monomers into polymers. These catalysts with metal centers have high performance characteristics, including higher comonomer incorporation into ethylene / olefin copolymers, where such olefins are for example, 1-octene, propylene or styrene. The catalysts also polymerize propylene into isotactic polypropylene.

Owner:DOW GLOBAL TECH LLC

Catalyst composition of ethylene oligomerization and the application

ActiveCN101032695AHigh activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionAryl1-Octene

The present invention relates to catalyst composition for oligomerizing ethylene and its application. The catalyst composition includes complex of acetylacetone chromium, tetrahydrofuran chromium chloride and / or chromium isooctanate; ligand containing P and N; activator of methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; and promoter of X1R6X2, where, each of X1 and X2 is F, Cl, Br, I or alkoxyl, and R6 is alkyl or aryl group; with the molar ratio of the complex, the ligand, the activator and the promoter being 1 to 0.5-10 to 50-3000 to 0.5-10. The catalyst composition is used in oligomerizing reaction of ethylene to prepare 1-octene, and has high catalytic activity and high 1-octene selectivity.

Owner:PETROCHINA CO LTD

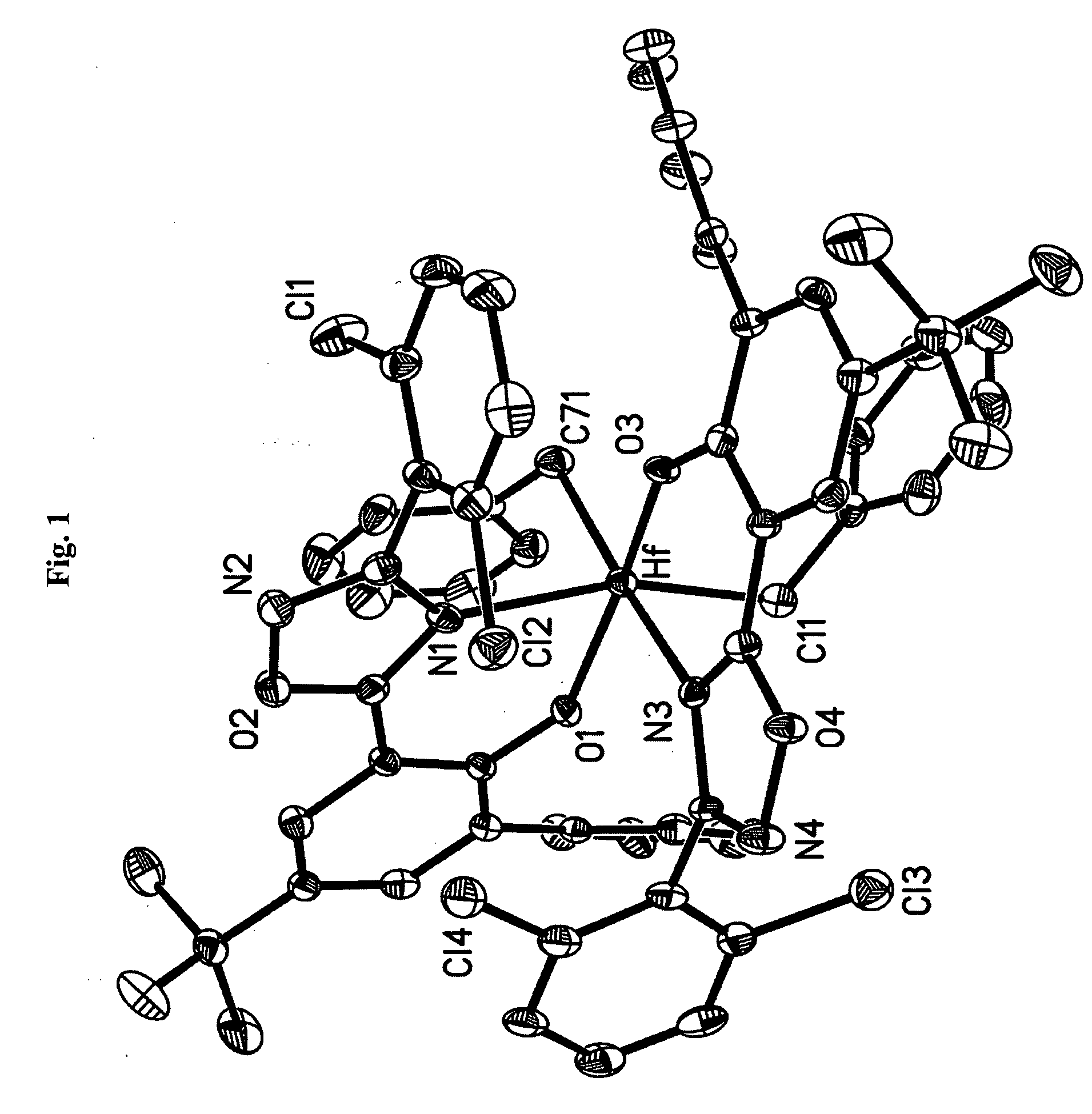

Substituted pyridyl amine complexes, and catalysts

InactiveUS6900321B2Improve catalytic performanceIncrease temperatureSilicon organic compoundsMacromolecular libraries1-OcteneHafnium

New ligands, compositions, metal-ligand complexes and arrays with pyridylamine ligands are disclosed that catalyze the polymerization of monomers into polymers. Certain of these catalysts with hafnium metal centers have high performance characteristics, including higher comonomer incorporation into ethylene / olefin copolymers, where such olefins are for example, 1-octene, isobutylene or styrene. Certain of the catalysts are particularly effective at polymerizing propylene to high molecular weight isotactic polypropylene in a solution process at a variety of polymerization conditions.

Owner:FREESLATE

Catalytic process for the oligomerization of olefinic monomers

InactiveCN101351424AGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsSilylene1-Octene

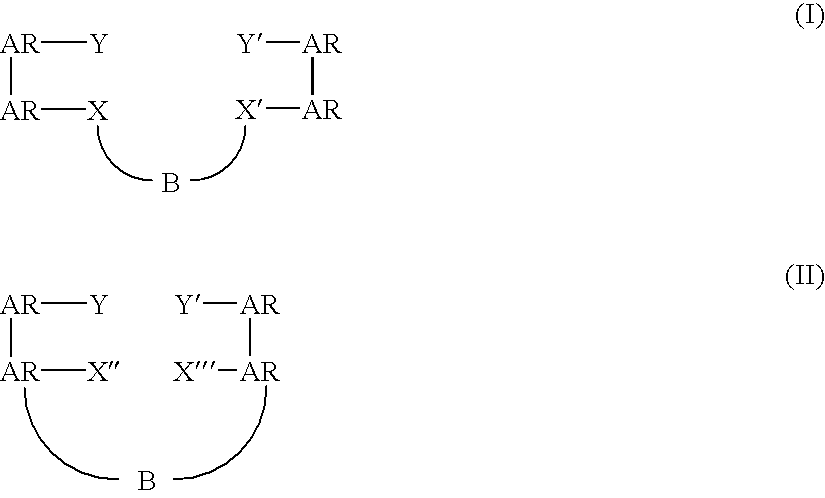

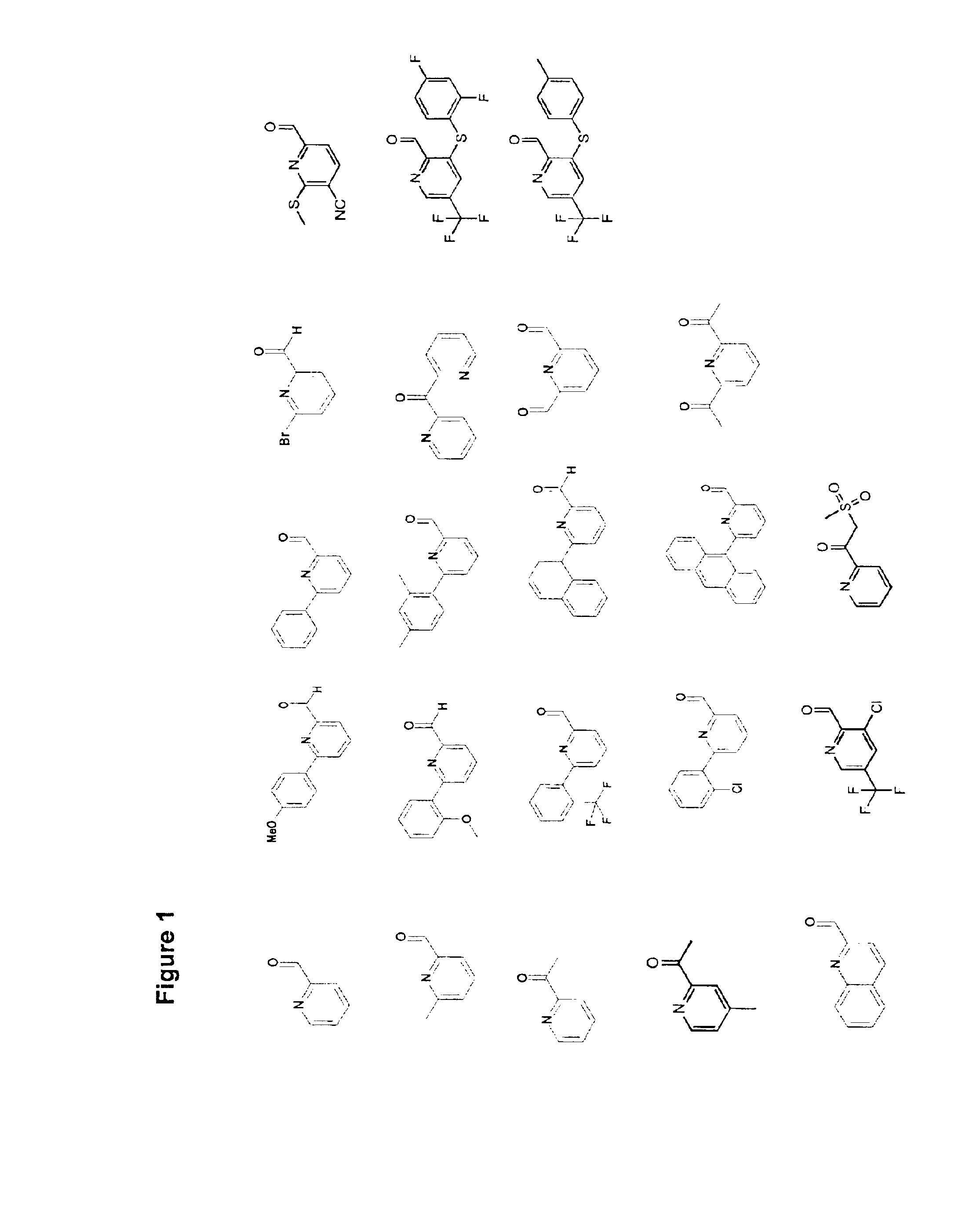

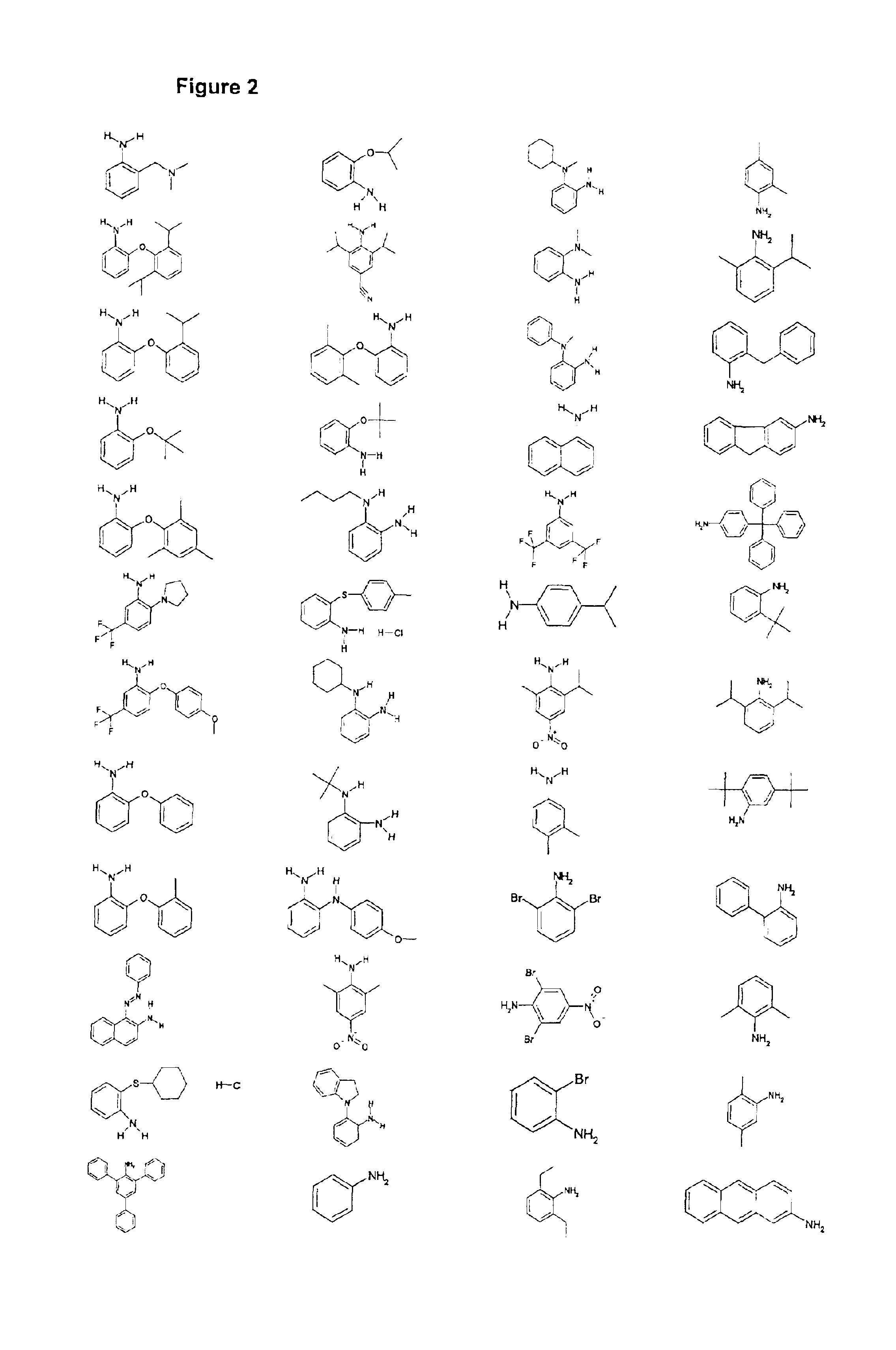

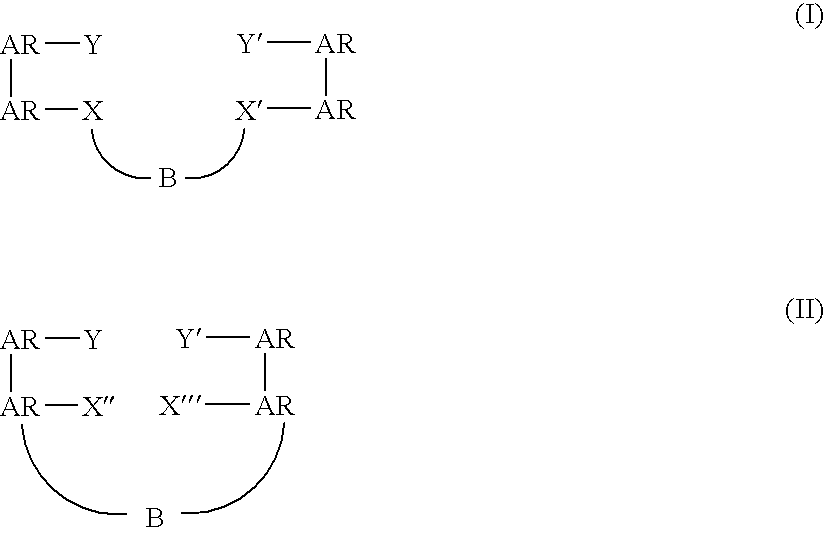

A process for the simultaneous trimerization and tetramerization of olefinic monomers , wherein the process comprises contacting at least one olefinic monomer with catalyst system comprising : a) a source of chromium, molybdenum or tungsten; b) a ligand having the general formula (I) ; (R<1>)2P-X-P (R<1>)m(R<2>)n wherein : X is a bridging group of the formula -N(R<3>)-, wherein R<3> is selected from hydrogen, a hydrocarbyl group, a substituted hydrocarbyl group, a heterohydrocarbyl group, a substituted heterohydrocarbyl group, a silyl group or derivative thereof; the R<1> groups are independently selected from an optionally substituted aromatic group bearing a polar substituent on at least one of the ortho-positions; and the R<2> groups are independently selected from hydrocarbyl, substituted hydrocarbyl, heterohydrocarbyl and substituted heterohydrocarbyl groups and c) a cocatalyst. The present invention further relates to a process for the simultaneous trimerization and tetramerization of ethylene to 1-hexene and 1-octene.

Owner:SHELL INT RES MAATSCHAPPIJ BV

Tandem tetramerisation-polymerisation of olefins

InactiveUS20060128910A1Improve catalytic performanceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon addition1-OctenePolyolefin

The invention provides a process for polymerising olefins to branched polyolefins in the presence of a polymerisation catalyst and a cocatalyst, wherein the cocatalyst produces 1-octene in a selectivity greater than 30%.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Heat-shrinkable multi-layer film

InactiveUS6146726AImprove sealingLow-temperature sealabilityWrappers shrinkageShrinkage connections1-OcteneCLARITY

The invention provides a heat-shrinkable multi-layer film comprising at least a thermoplastic resin layer as the outermost layer (A), a gas barrier resin layer as a core layer (B) and a sealing resin layer as the innermost layer (C), and optionally an adhesive layer between the individual layers, wherein (1) the sealing resin layer of the innermost layer (C) is a layer formed of a resin material (b) comprising a linear ethylene-1-octene copolymer (a) obtained by using a constrained geometry catalyst and having an 1-octene content not lower than 1 wt. % but lower than 20 wt. % and a density higher than 0.885 g / cm3 but not higher than 0.960 g / cm3, and (2) an intermediate layer (D1) formed of at least one resin (c) selected from the group consisting of polyamide resins, thermoplastic polyester resins and ethylene copolymer resins is provided between the outermost layer (A) and the core layer (B). The film has excellent sealing properties, clarity, mechanical strength, stretchability and bag-making property.

Owner:KUREHA KAGAKU KOGYO KK

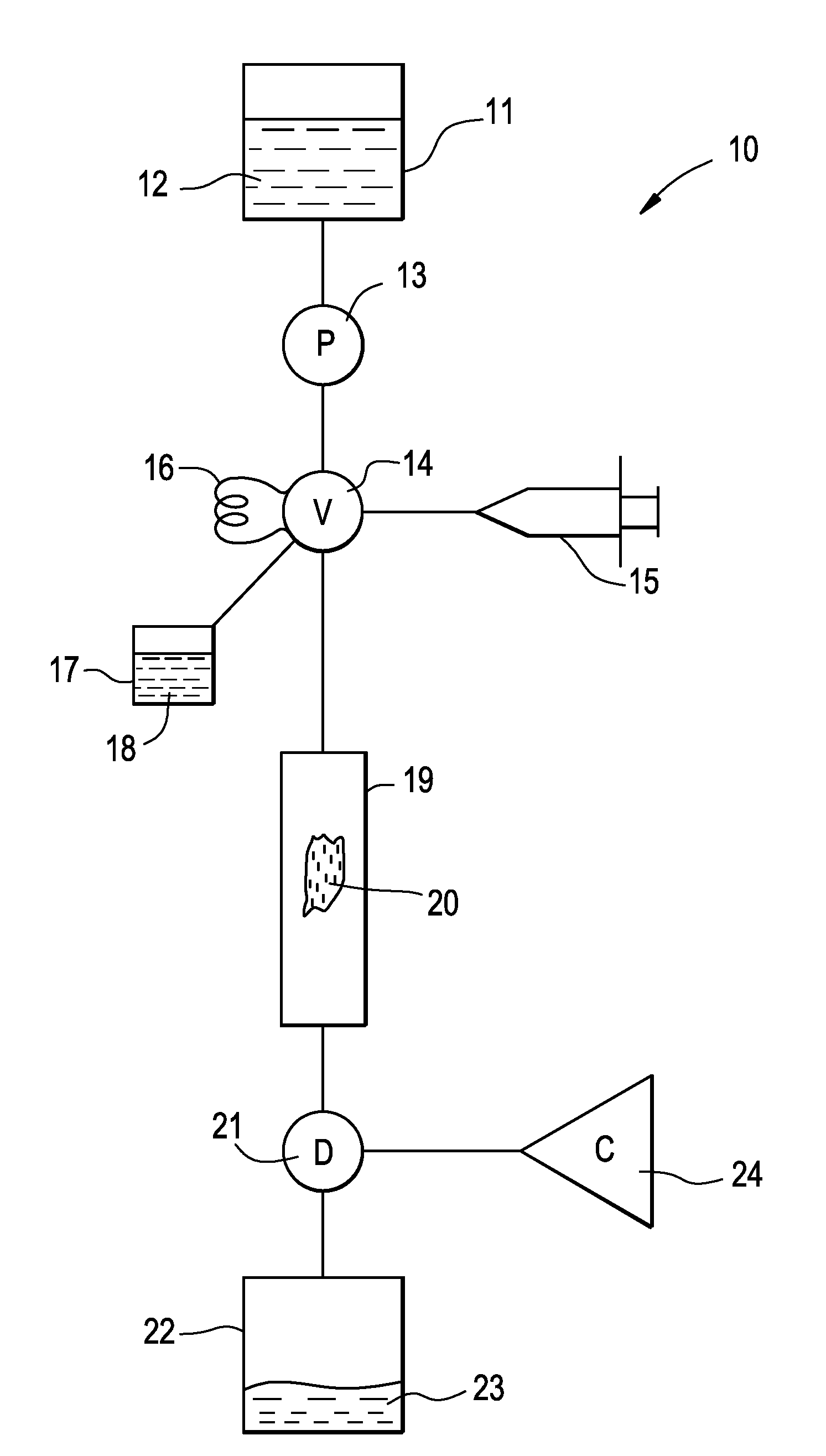

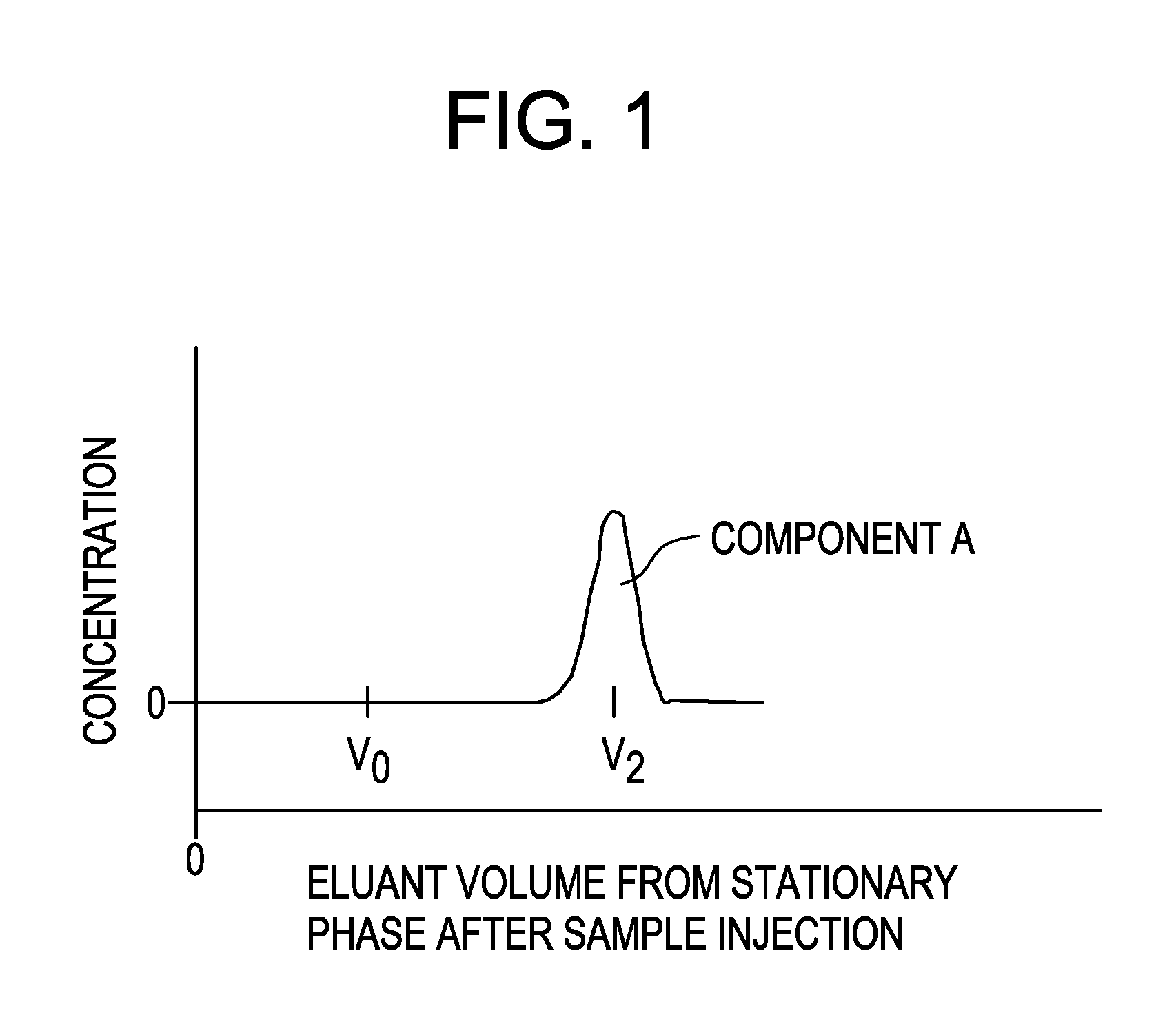

Chromotography of polyolefin polymers

ActiveUS20100093964A1Separation efficiency can be improvedIon-exchange process apparatusComponent separationPolyolefinPolymer science

Owner:THE DOW CHEM CO

High viscosity polyalphaolefins based on 1-hexene, 1-dodecene and 1-tetradecene

ActiveUS7547811B2Liquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon addition1-OcteneOctene

This invention relates to the use of olefin mixtures containing 1-hexene / 1-decene / 1-dodecene and, additionally, 1-octene or 1-decene to produce high viscosity polyalphaolefins (PAOs) having a viscosity of from about 40 cSt to about 100 cSt at 100° C. (ASTM D-445) and a number average molecular weight of between about 1200 to about 4000, particularly useful as lubricant base stocks.

Owner:EXXONMOBIL CHEM PAT INC

Methods for oligomerizing olefins

ActiveUS20060247399A1Organic-compounds/hydrides/coordination-complexes catalystsCatalystsChromium Compounds1-Octene

The present invention provides a method of producing oligomers of olefins, comprising reacting olefins with a catalyst under oligomerization conditions. The catalyst can be the product of the combination of a chromium compound and a heteroaryl-amine compound. In particular embodiments, the catalyst compound can be used to trimerize or tetramerize ethylene to 1-hexene, 1-octene, or mixtures of 1-hexene and 1-octene.

Owner:EXXONMOBIL CHEM PAT INC

Bridged bi-aromatic ligands, catalysts, processes for polymerizing and polymers therefrom

InactiveUS6841502B2Improve catalytic performanceOrganic compound preparationGroup 4/14 organic compounds without C-metal linkages1-OcteneAlkene

New ligands and compositions with bridged bis-aromatic ligands are disclosed that catalyze the polymerization of monomers into polymers. These catalysts with metal centers have high performance characteristics, including higher comonomer incorporation into ethylene / olefin copolymers, where such olefins are for example, 1-octene, propylene or styrene. The catalysts also polymerize propylene into isotactic polypropylene.

Owner:DOW GLOBAL TECH LLC

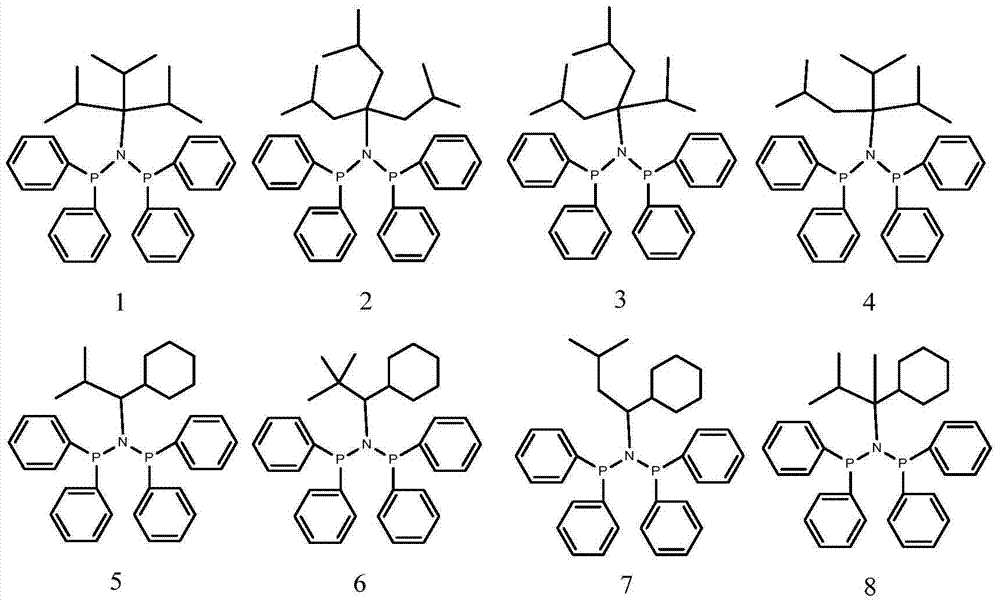

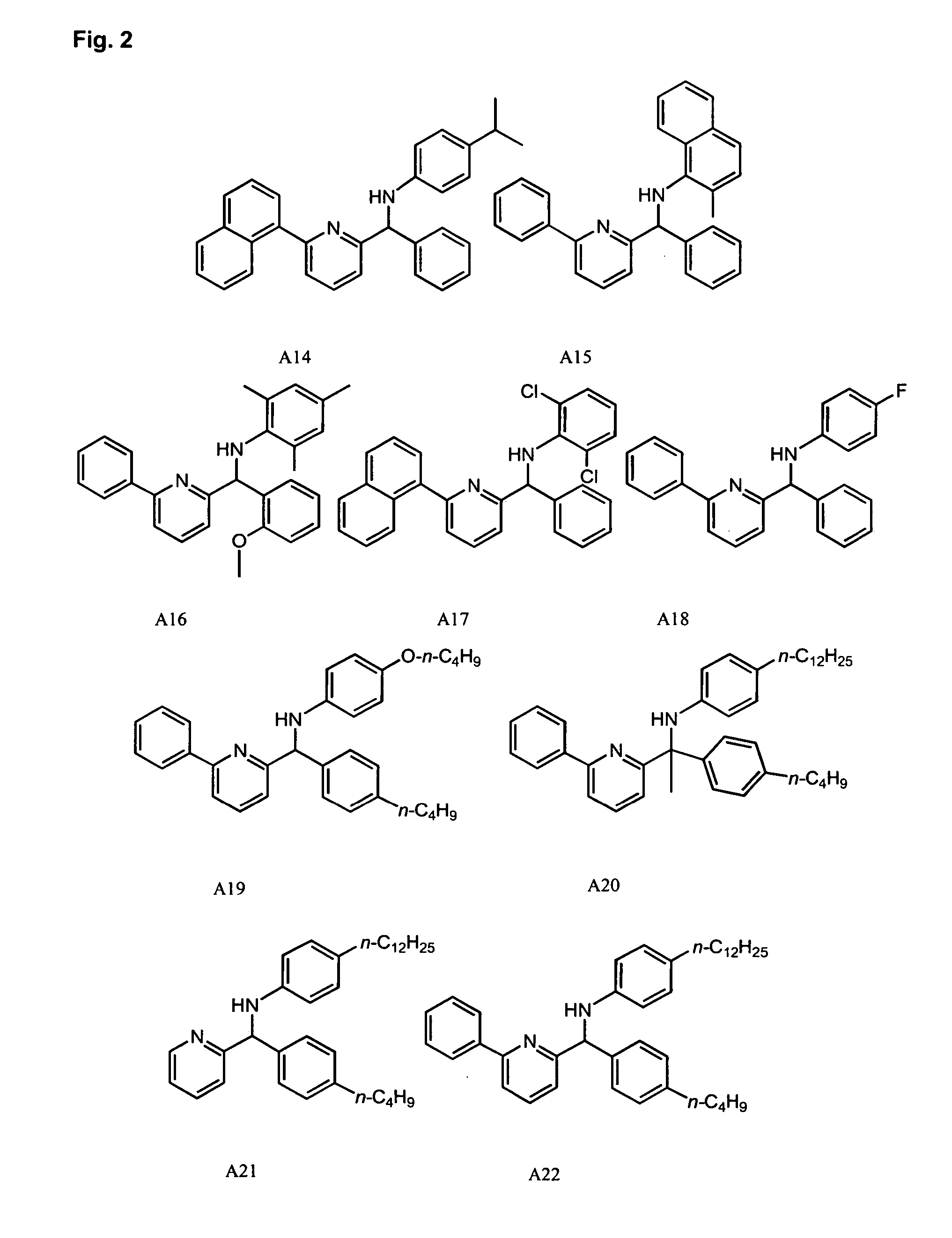

Catalyst composition for ethylene oligomerization and the use thereof

ActiveUS20070232481A1High activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionChromium Compounds1-Octene

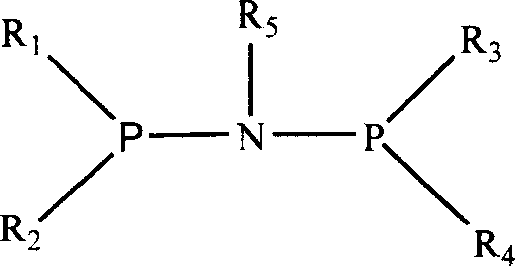

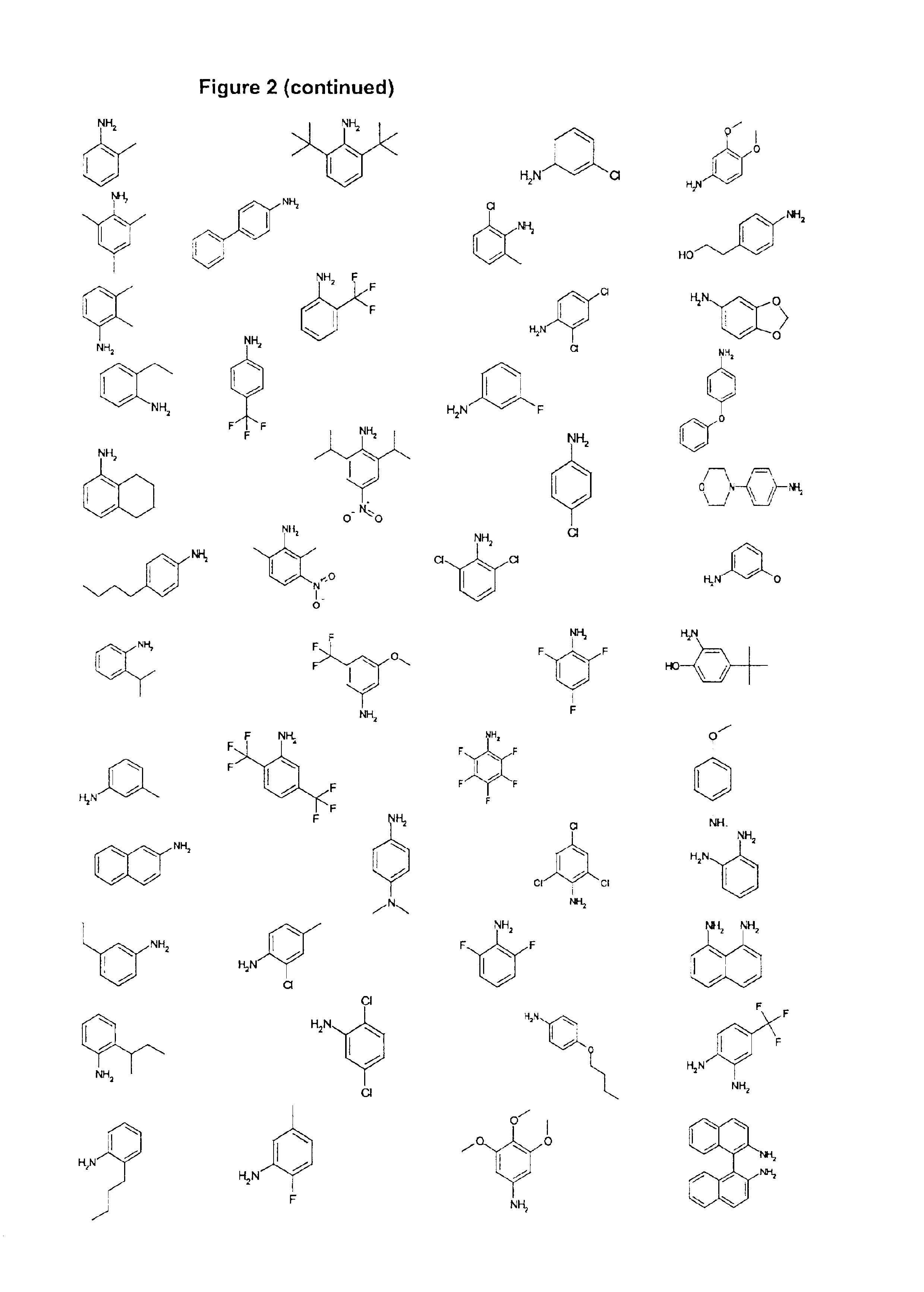

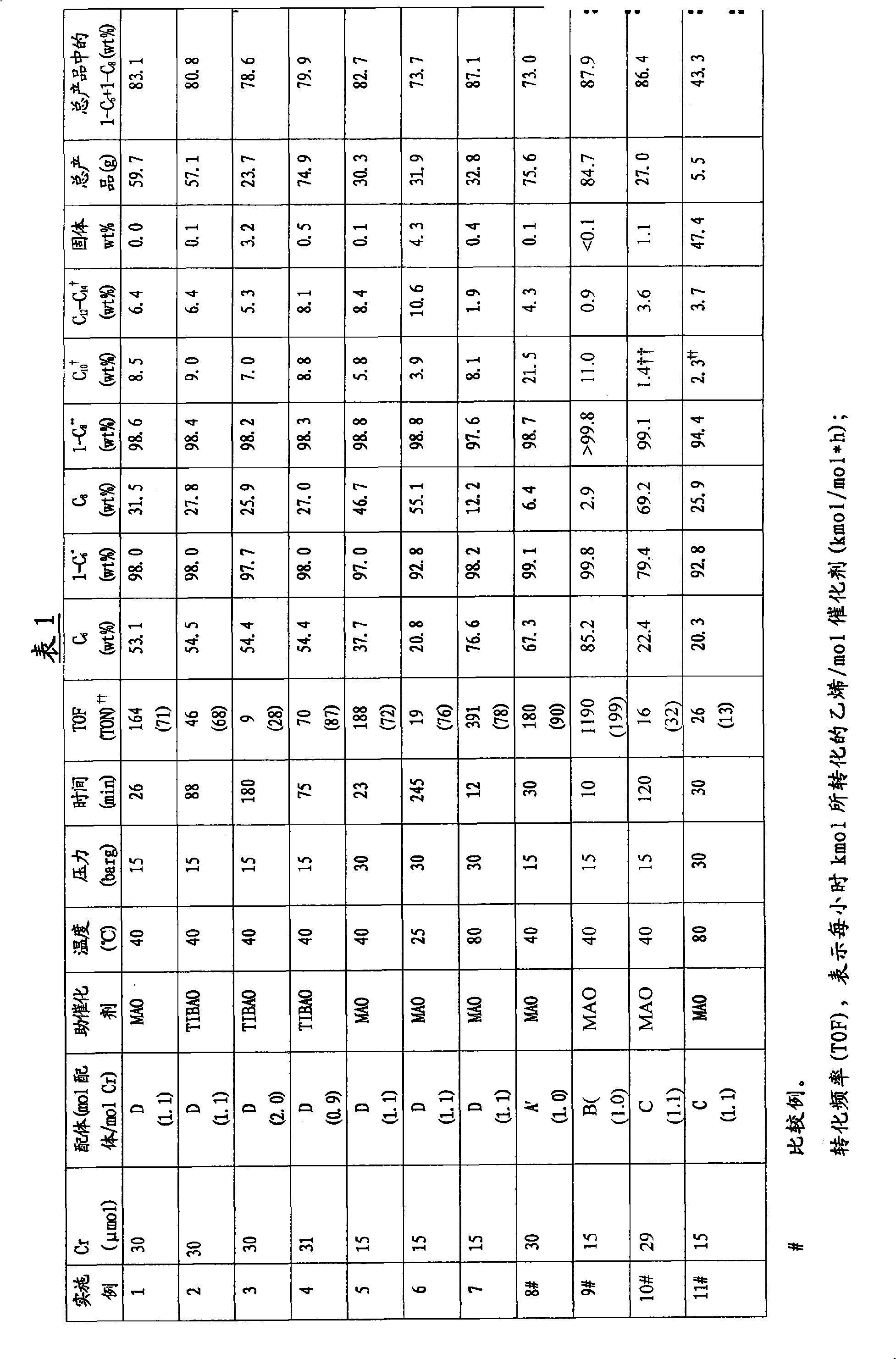

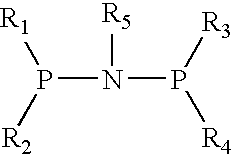

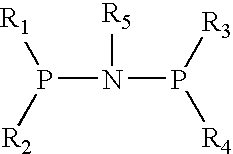

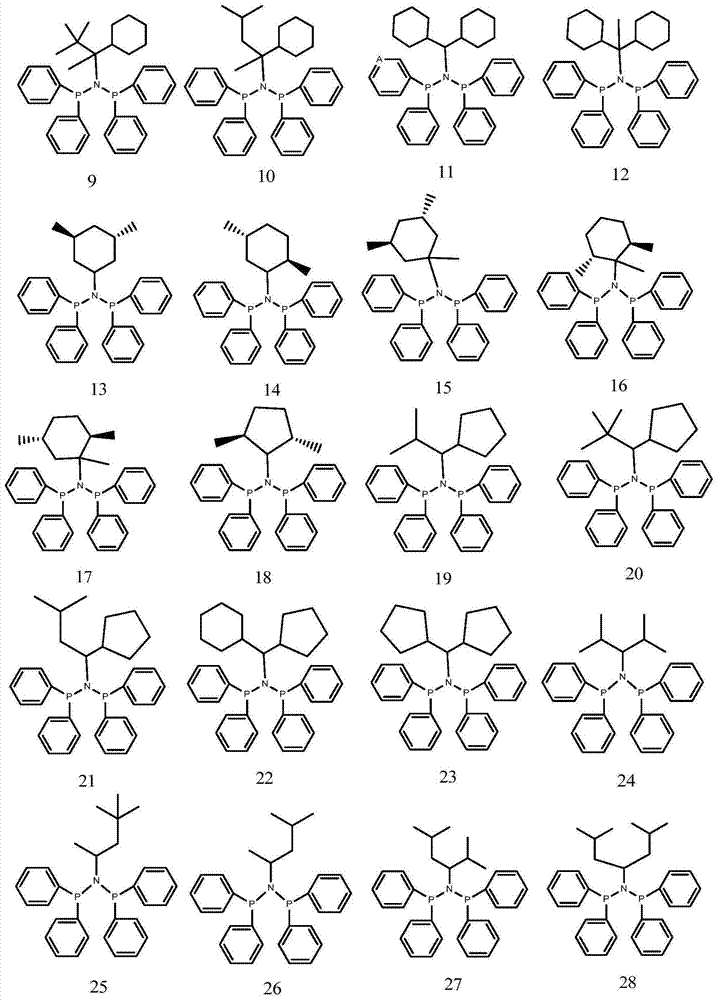

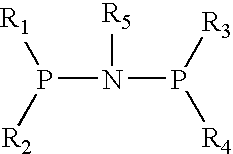

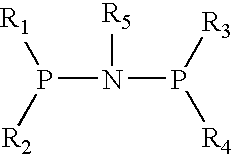

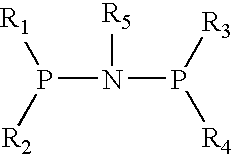

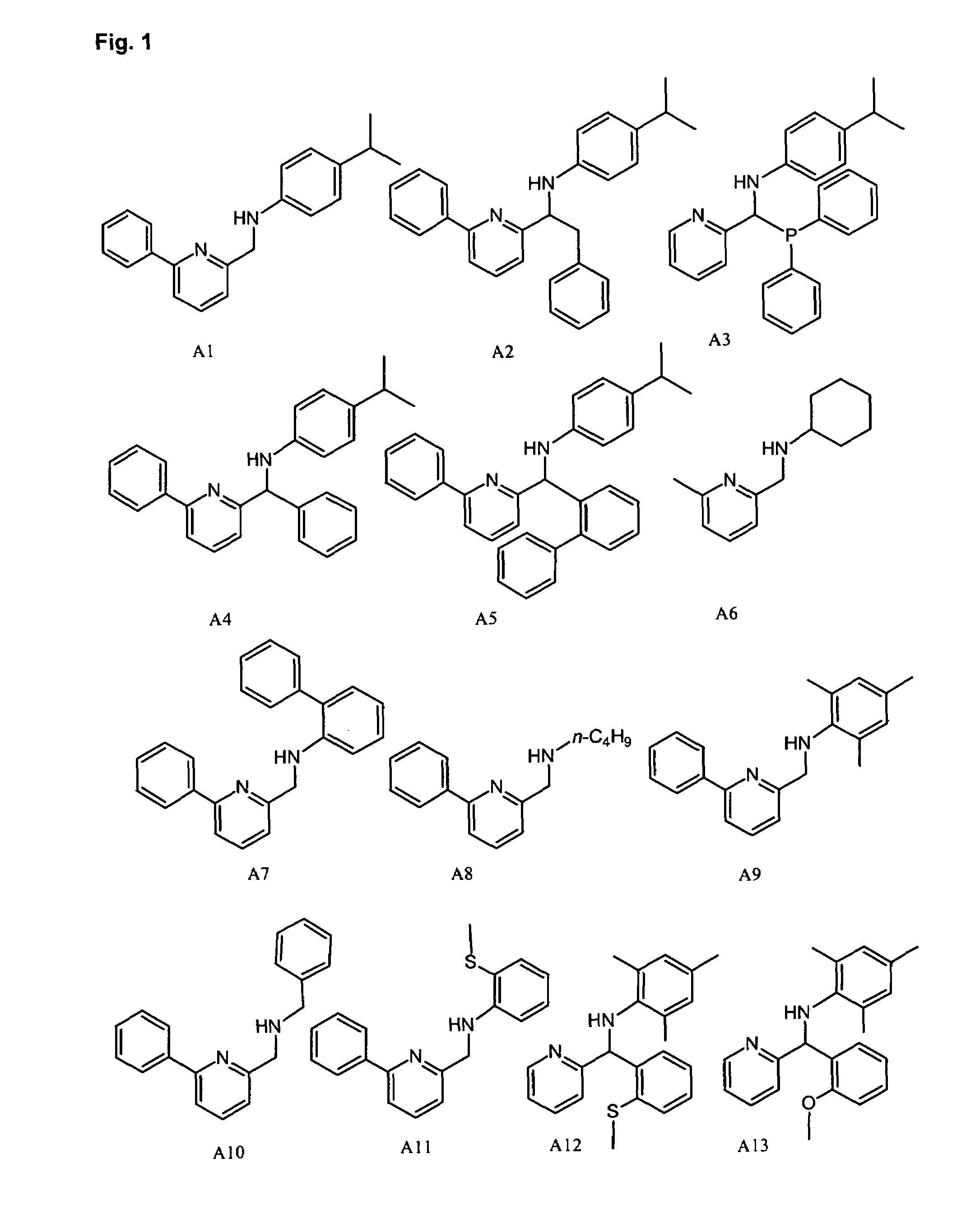

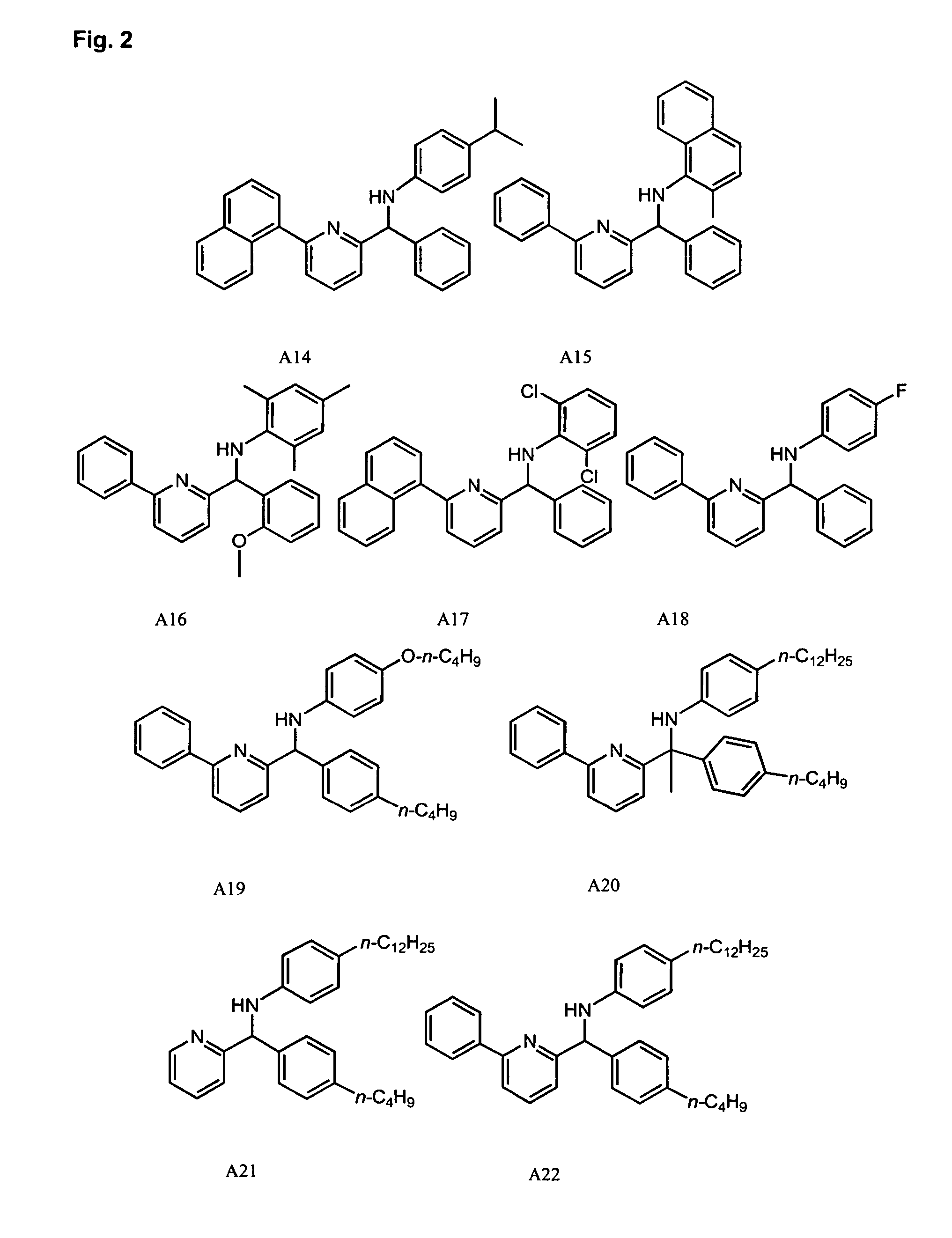

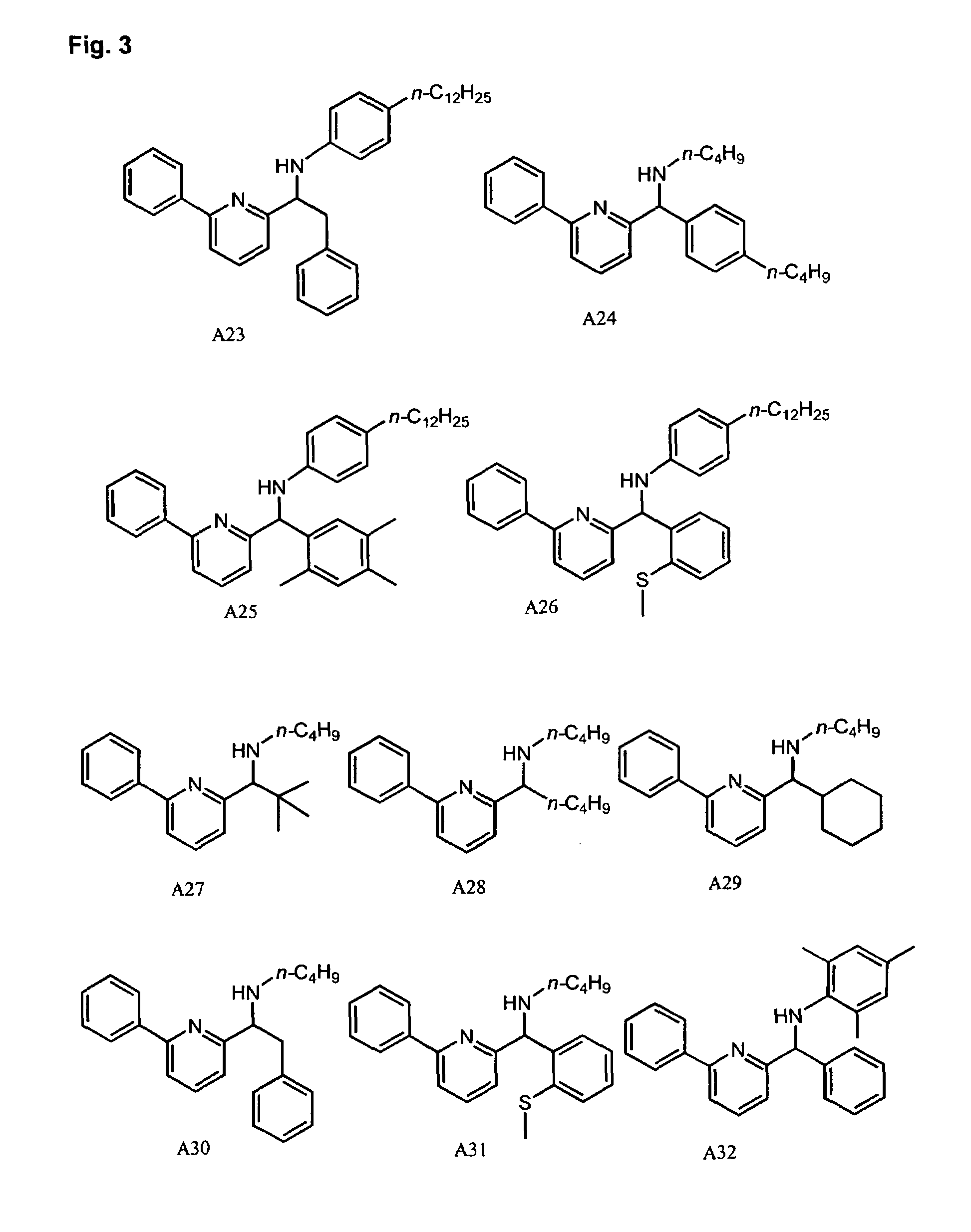

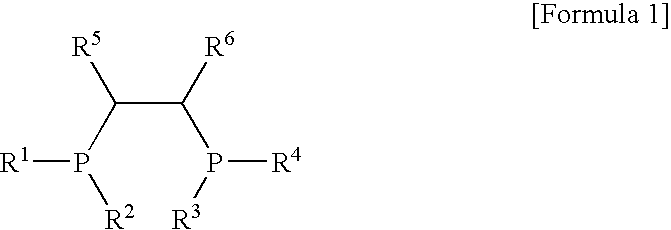

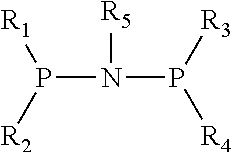

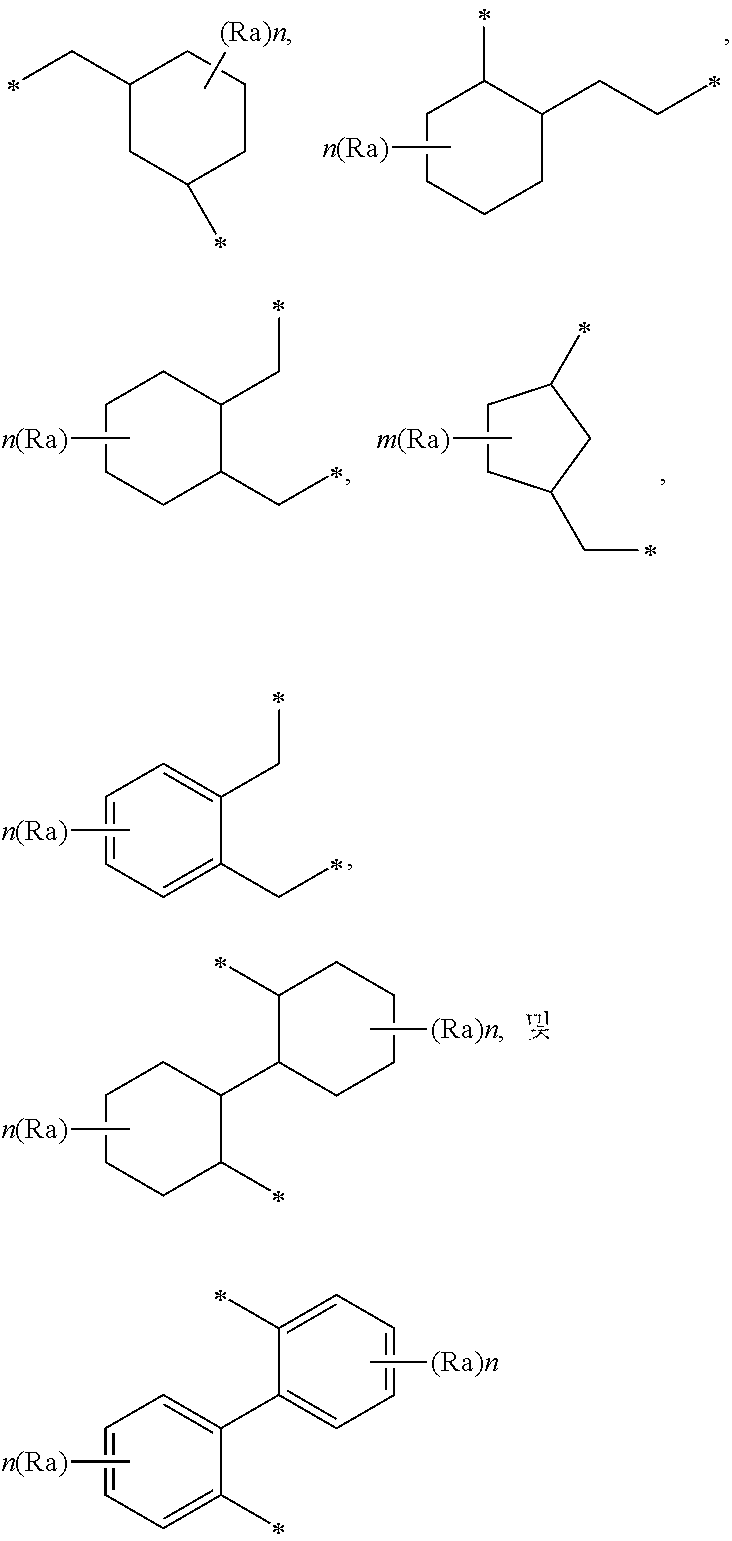

The present invention relates to a catalyst composition for ethylene oligomerization and the use thereof. Such catalyst composition includes chromium compound, ligand containing P and N, activator and accelerator; wherein the chromium compound is selected from the group consisting of acetyl acetone chromium, THF-chromium chloride and / or Cr(2-ethylhecanoate)3; general formula of the ligand containing P and N is shown as: in which R1, R2, R3 and R4 are phenyl, benzyl, or naphthyl. R5 is isopropyl, butyl, cyclopropyl, cyclopentyl, cyclohexyl or fluorenyl; the activatior is methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; general formula of the accelerator is X1R6X2, in which X1 and X2 are F, Cl, Br, I or alkoxyl, R6 is alkyl or aryl; the molar ratio of a, b, c and d is 1:0.5˜10:50˜3000:0.5˜10. After mixing the four components mentioned previously under nitrogen atmosphere for 10 minutes, they are incorporated to the reactor, or these four components are incorporated directly into the reactor. Then ethylene is introduced for oligomerization. Such catalyst can be used in producing 1-octene through ethylene oligomerization. It is advantageous in high catalysing activity, high 1-octene selectivity, etc. The catalytic activity is more than 1.0×106 g product·mol−1 Cr ·h−1, the fraction of C8 linear α-olefin is more than 70% by mass.

Owner:PETROCHINA CO LTD

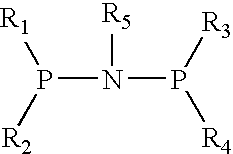

Ethylene oligomerization catalyst composition and application thereof

InactiveCN103285926AHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsArylAluminoxane

The invention relates to an ethylene oligomerization catalyst composition and an application thereof. The composition comprises the following components: a component a contains chromium acetylacetonate, tetrahydrofuran chromium chloride and / or chromium 2-ethylhexanoate; in the formula of a component b, R1, R2, R3 and R4 are phenyl, benzyl or naphthyl; and R5 is isopropyl, butyl, cyclopropyl, cyclopentyl, cyclohexyl or fluorenyl; a component c contains methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; a component d has a formula X1R6X2, wherein X1 and X2 are F, Cl, Br, I or alkoxy, and R6 is alkyl or aryl; in the formula of a component e, R is a linking group and selected from alkyl and derivatives thereof as well as aryl and derivatives thereof; and the molar ratio is 1: (0.5-10): (50-3000): (0.5-10): (0.5-10). The catalyst has the catalytic activity being more than 5.0*10<6>g mol<-1>Cr.h<-1>, and the mass of 1-hexene and 1-octylene is more than 93%.

Owner:PETROCHINA CO LTD

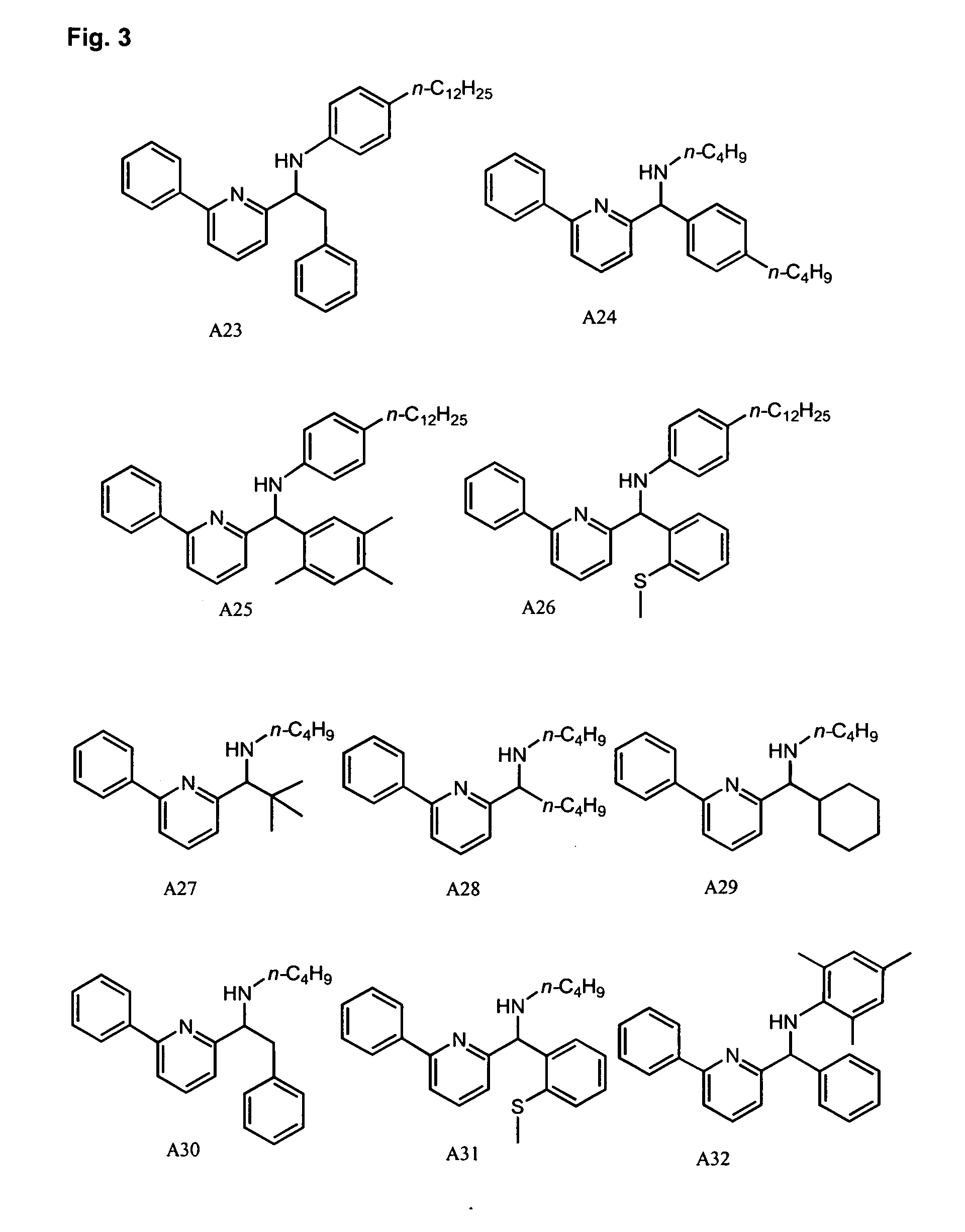

Methods for oligomerizing olefins

ActiveUS7414006B2Organic-compounds/hydrides/coordination-complexes catalystsCatalystsChromium Compounds1-Octene

The present invention provides a method of producing oligomers of olefins, comprising reacting olefins with a catalyst under oligomerization conditions. The catalyst can be the product of the combination of a chromium compound and a heteroaryl-amine compound. In particular embodiments, the catalyst compound can be used to trimerize or tetramerize ethylene to 1-hexene, 1-octene, or mixtures of 1-hexene and 1-octene.

Owner:EXXONMOBIL CHEM PAT INC

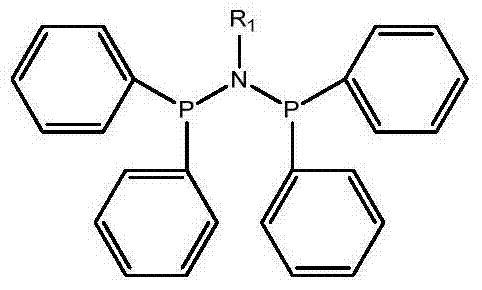

High-selectivity catalyst system used in trimerization and tetramerization of ethylene and use method thereof

ActiveCN104511311AIncreased co-selectivityHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsChromium Compounds1-Octene

The invention provides a high-selectivity catalyst system used in trimerization and tetramerization of ethylene and a use method thereof. The catalyst system includes three components: (1) a chromium compound, (2) a ligand, of which a general structure formula is (Ph2)P-N(R1)-P(Ph2), wherein R1 is a synthetic phenyl group, alkyl group or cycloalkyl group; and (3) an activating agent or a co-catalyst. According to the catalyst system, a conventional PNP chromium-series catalyst is improved so that a co-selectivity of 1-hexane and 1-octylene is increased, wax-like products are reduced and a high activity is maintained.

Owner:EAST CHINA UNIV OF SCI & TECH

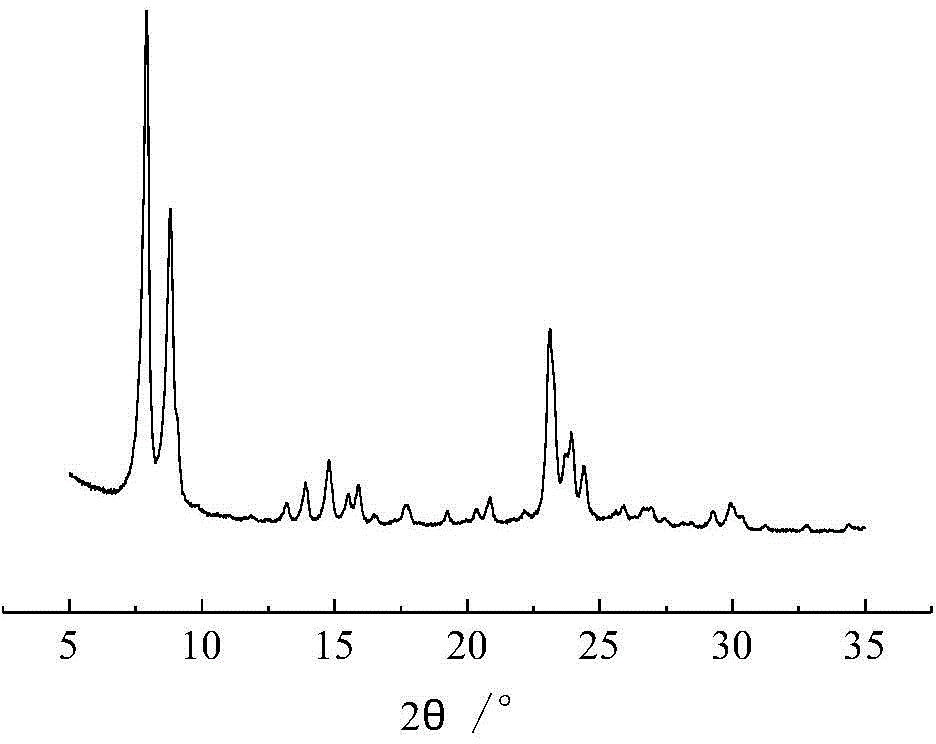

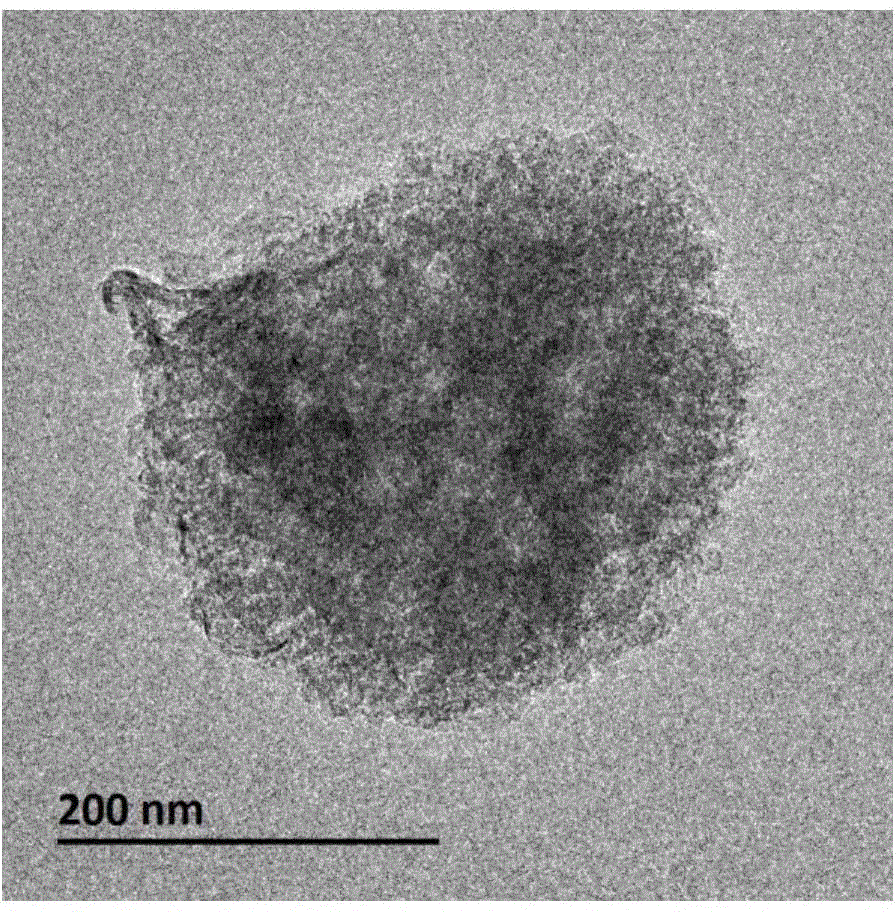

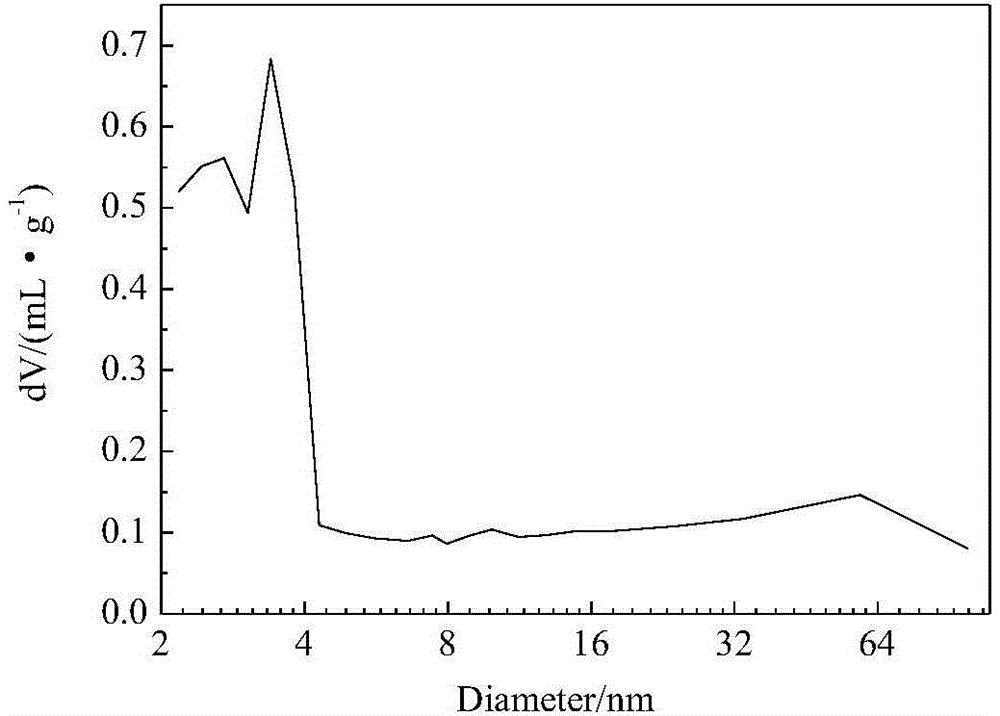

Hierarchical pore titanium-silicon molecular sieve and synthesis method thereof

ActiveCN106145151AHigh crystallinityPolymer compounds and/or modified natural polymer compounds produce particles with large crystallinityCrystalline aluminosilicate zeolitesMolecular sieve1-Octene

The invention discloses a hierarchical pore titanium-silicon molecular sieve and a synthesis method thereof. The particle size of the hierarchical pore titanium-silicon molecular sieve ranges from 250 nanometers to 350 nanometers, the relative crystallinity is not smaller than 45%, and the specific area is not smaller than 600 m<2> / g. The synthesis method includes the following steps that 1, a silicon source, a structure directing agent, a titanium source, water, a silylating reagent, a natural polymer compound and / or a modified natural polymer compound are mixed to be uniform according to a certain ratio, and a reaction mixture is obtained; 2, the reaction mixture obtained in the step 1 is crystallized for 1-240 h in a pressure-proof sealed container at the temperature of 90-230 DEG C and under self-generated pressure, and a crystallized product is obtained; 3, the crystallized product obtained in the step 2 is recycled. The hierarchical pore titanium-silicon molecular sieve has good catalytic activity in macromolecule reaction 1-octene oxidation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic oligomerization of olefinic monomers

A catalyst precursor composition comprising: a source of chromium, molybdenum or tungsten; a first ligand having the general formula (R1)(R2P—X—P(R3)(R4); and a second ligand having the general formula (R1′)(R2′)P—X′—P(R3′)(R4′). The present invention also relates to a catalyst system comprising the catalyst precursor composition of the present invention and a cocatalyst. The present invention further relates to a process for the trimerization and tetramerization of olefinic monomers, particularly the trimerization and tetramerization of ethylene to 1-hexene and 1-octene, wherein the process comprises contacting at least one olefinic monomer with the catalyst system of the present invention.

Owner:SHELL OIL CO

Catalyst composition for ethylene oligomerization and the use thereof

ActiveUS7786336B2High activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon addition1-OcteneAluminoxane

The present invention relates to a catalyst composition for ethylene oligomerization and the use thereof. Such catalyst composition includes chromium compound, ligand containing P and N, activator and accelerator; wherein the chromium compound is selected from the group consisting of acetyl acetone chromium, THF-chromium chloride and Cr(2-ethylhecanoate)3; general formula of the ligand containing P and N is shown as:in which R1, R2, R3 and R4 are phenyl, benzyl, or naphthyl. R5 is isopropyl, butyl, cyclopropyl, cyclopentyl, cyclohexyl or fluorenyl; the activatior is methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; the accelerator is selected from the group consisting of 1,1,2,2,-tetrachloroethane, 1,1,2,2-tetrabromoethane, 1,1,2,2-tetrafluoroethane, and compounds having a formula of X1R6X2, in which X1 and X2 are F, Cl, Br, I or alkoxyl, R6 is alkylene or arylene group; the molar ratio of chromium compound, ligand containing P and N, activator and accelerator is 1:0.5˜10:50˜3000:0.5˜10. After mixing the four components mentioned previously under nitrogen atmosphere for 10 minutes, they are incorporated to the reactor, or these four components are incorporated directly into the reactor. Then ethylene is introduced for oligomerization. Such catalyst can be used in producing 1-octene through ethylene oligomerization. It is advantageous in high catalysing activity, high 1-octene selectivity, etc. The catalytic activity is more than 1.0×106 g product·ma−1 Cr·h−1, the fraction of C8 linear α-olefin is more than 70% by mass.

Owner:PETROCHINA CO LTD

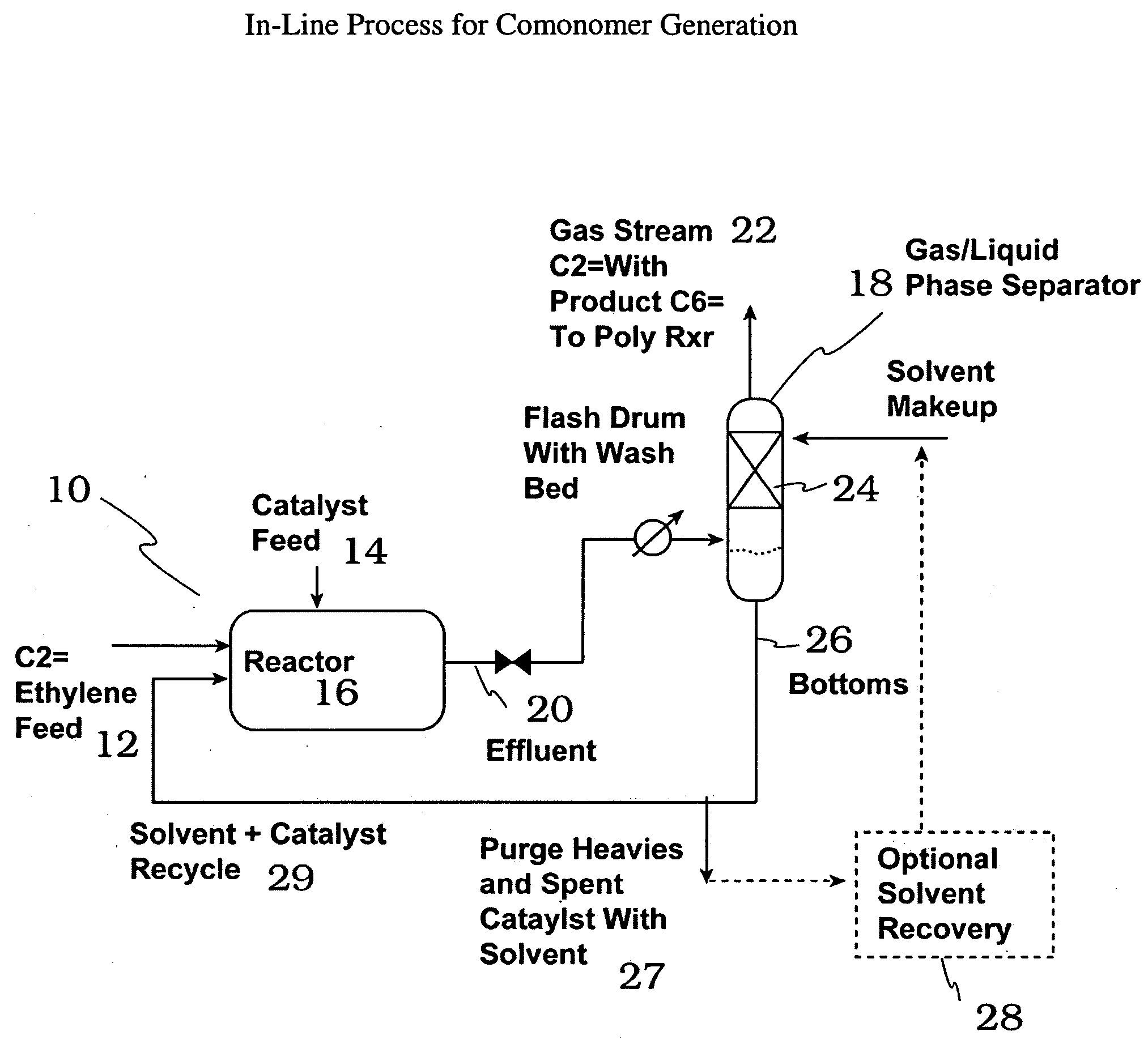

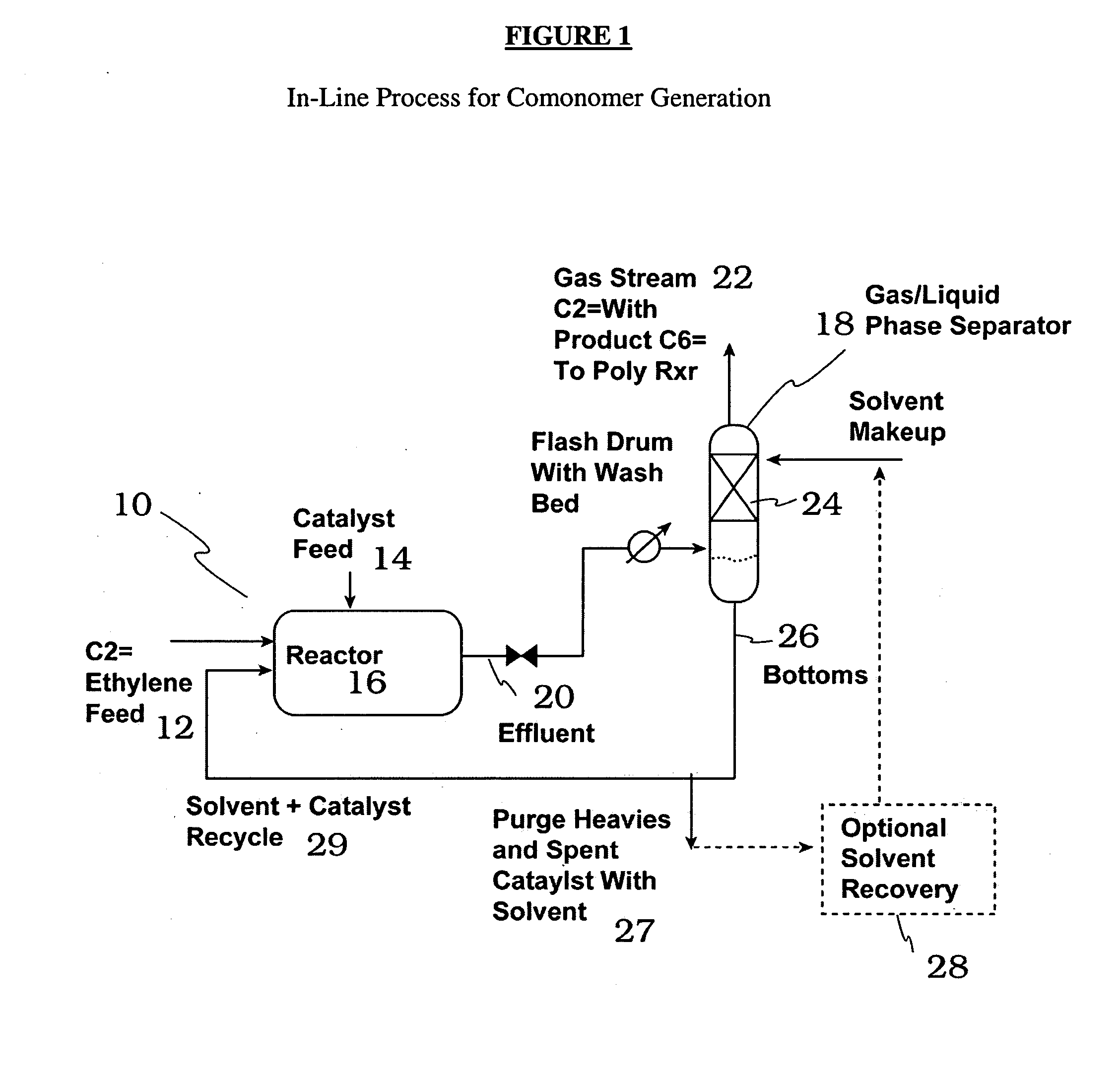

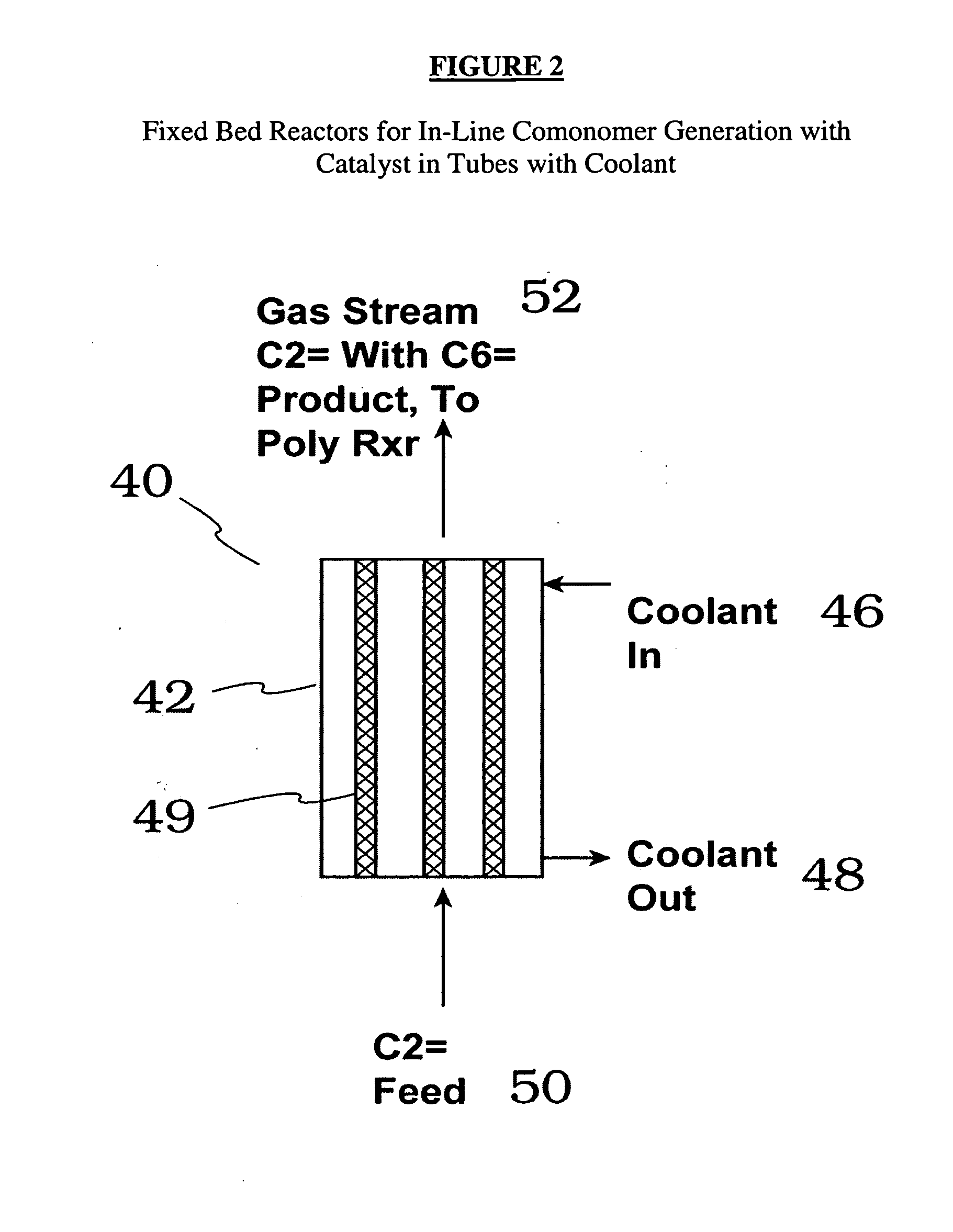

In-line process for generating comonomer

InactiveUS20070185364A1Substantial capitalSubstantial operational cost savingHydrocarbons from unsaturated hydrocarbon additionHydrocarbons1-OcteneSolvent

The present invention relates to an in-line method for generating comonomer, such as 1-hexene or 1-octene, from monomer, such as ethylene. The comonomer generated is directly transported, without isolation or storage, to a polyethylene polymerization reactor. The in-line method for generating comonomer includes the steps of providing an in-line comonomer synthesis reactor and a downstream gas / liquid phase separator prior to a polyethylene polymerization reactor; feeding ethylene monomer and a catalyst in a solvent to the comonomer synthesis reactor; reacting the ethylene monomer and the catalyst in solvent under reaction conditions to produce an effluent stream including ethylene monomer and comonomer; passing the effluent stream from the comonomer synthesis reactor to the downstream gas / liquid phase separator to separate a gas stream from a bottom stream, wherein the gas stream is a mixture of ethylene monomer, and comonomer; and passing the gas stream to the polyethylene polymerization reactor to provide the necessary comonomer input. The in-line method is useful in the production of LLDPE, and other branched polyethylene based polymers. Some benefits include process simplification and reduced capital and operating costs.

Owner:EXXONMOBIL CHEM PAT INC

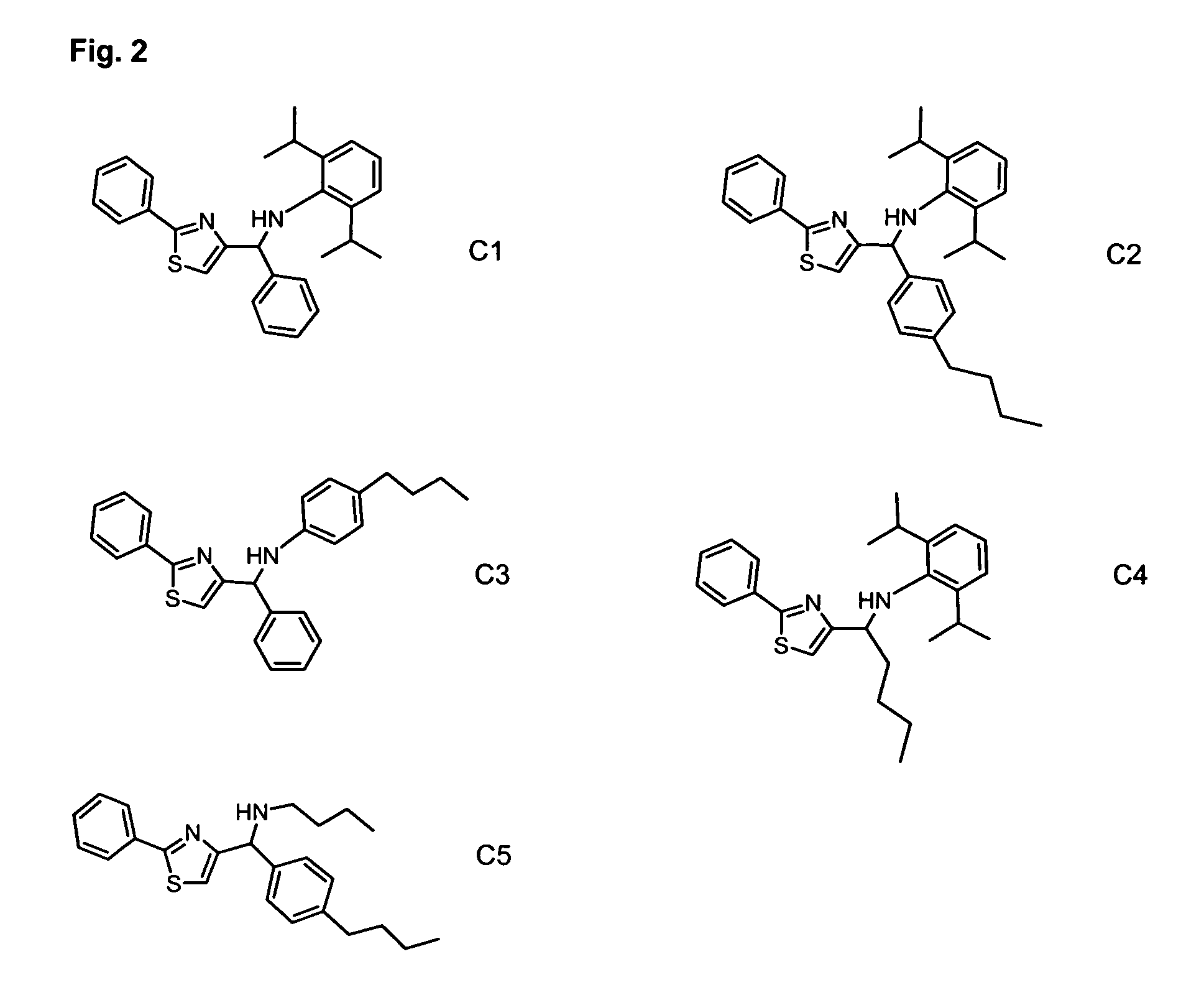

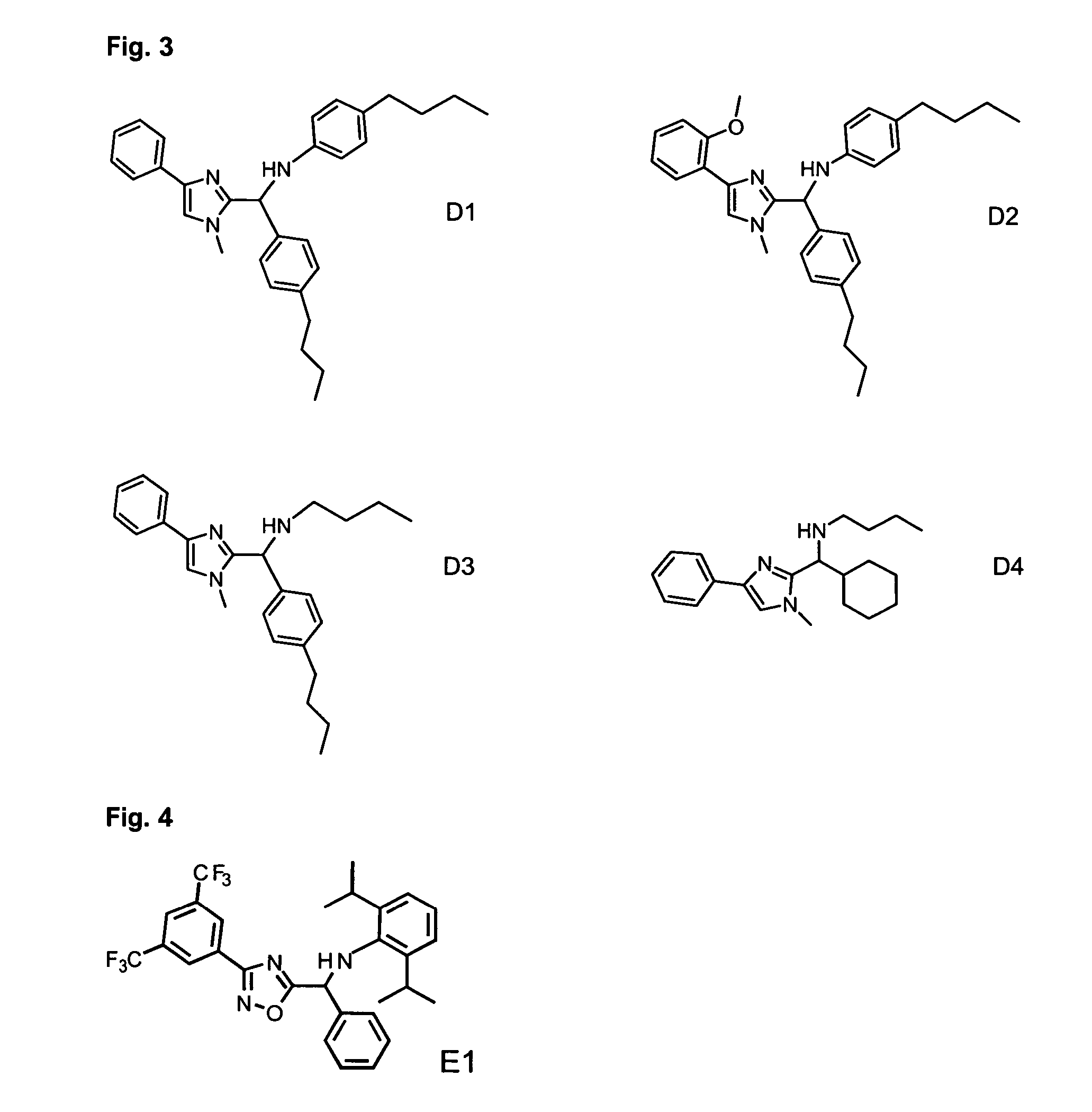

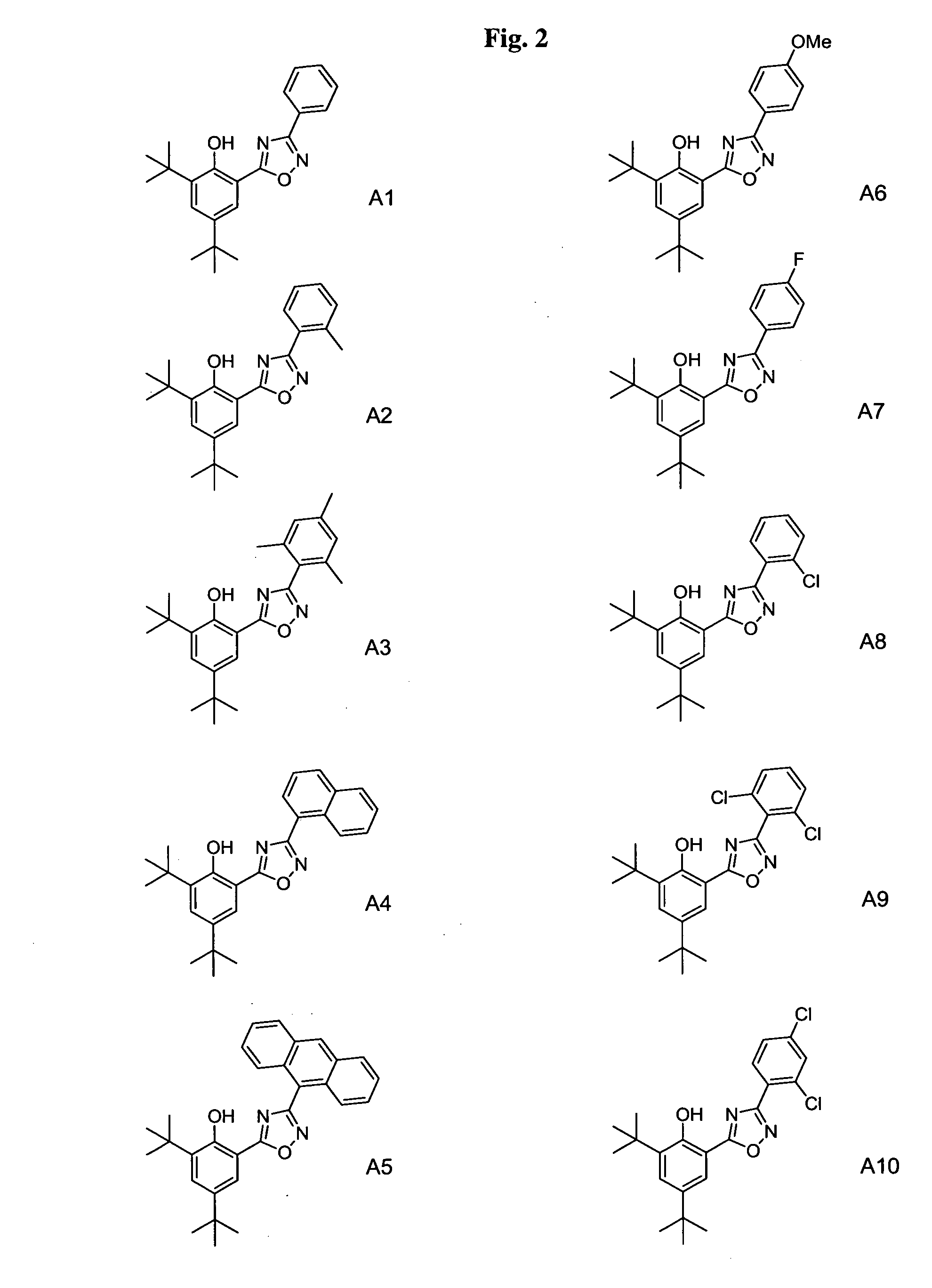

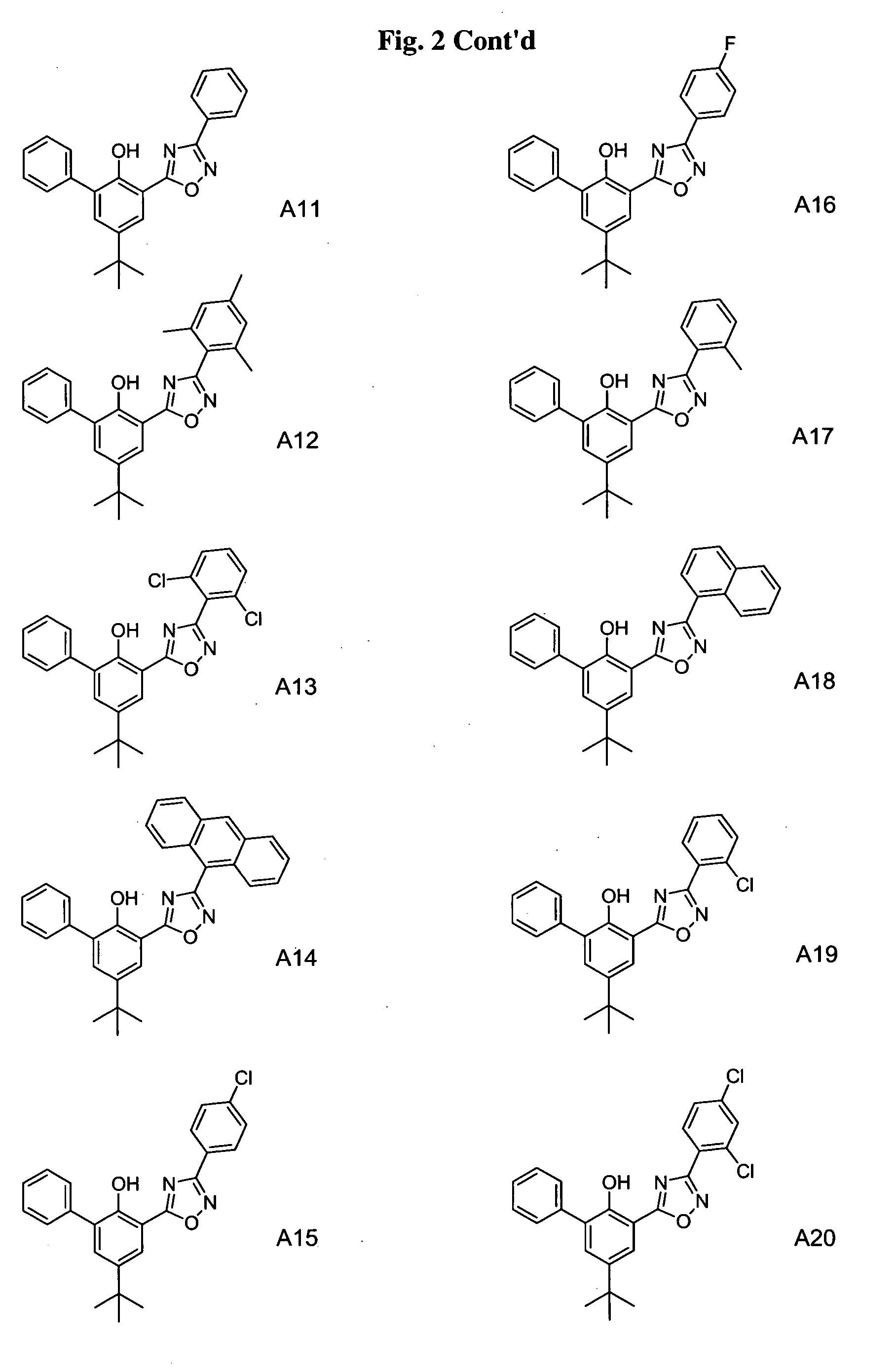

Phenol-heterocyclic ligands, metal complexes, and their uses as catalysts

InactiveUS20060135713A1High activityHigh melting pointGroup 4/14 organic compounds without C-metal linkagesGroup 8/9/10/18 element organic compounds1-OctenePHENOL LIQUID

Ligands, compositions, and metal-ligand complexes that incorporate phenol-heterocyclic compounds are disclosed that are useful in the catalysis of transformations such as the polymerization of monomers into polymers. The catalysts have high performance characteristics, including high comonomer incorporation into ethylene / olefin copolymers, where such olefins are for example, 1-octene, propylene or styrene. The catalysts particularly polymerize styrene to form polystyrene.

Owner:FREESLATE

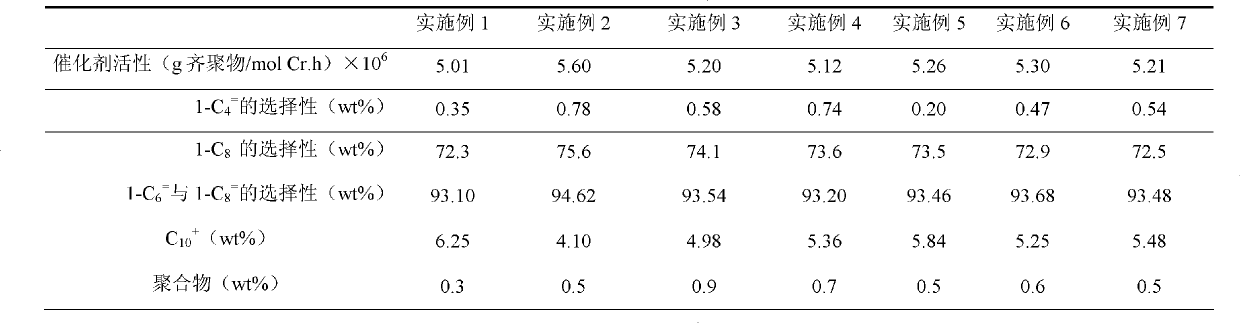

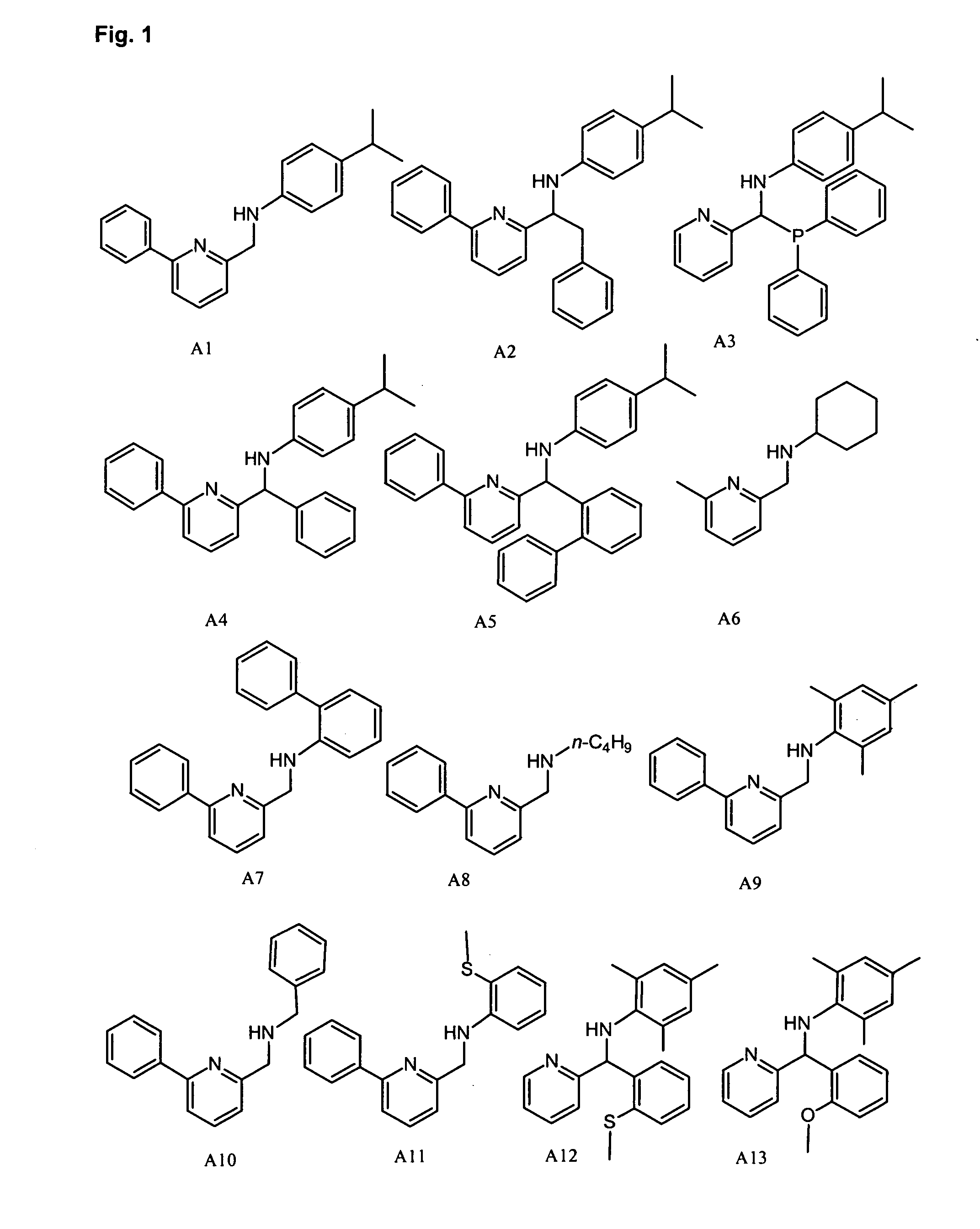

Methods for oligomerizing olefins

ActiveUS20060247483A1Organic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionChromium CompoundsOligomer

The present invention provides a method of producing oligomers of olefins, comprising reacting olefins with a catalyst under oligomerization conditions. The catalyst can be the product of the combination of a chromium compound and a pyridyl amine or a heteroaryl-amine compound. In particular embodiments, the catalyst compound can be used to trimerize or tetramerize ethylene to 1-hexene, 1-octene, or mixtures of 1-hexene and 1-octene.

Owner:EXXONMOBIL CHEM PAT INC

Methods for oligomerizing olefins

ActiveUS7425661B2Organic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionOligomer1-Octene

The present invention provides a method of producing oligomers of olefins, comprising reacting olefins with a catalyst under oligomerization conditions. The catalyst can be the product of the combination of a chromium compound and a pyridyl amine or a heteroaryl-amine compound. In particular embodiments, the catalyst compound can be used to trimerize or tetramerize ethylene to 1-hexene, 1-octene, or mixtures of 1-hexene and 1-octene.

Owner:EXXONMOBIL CHEM PAT INC

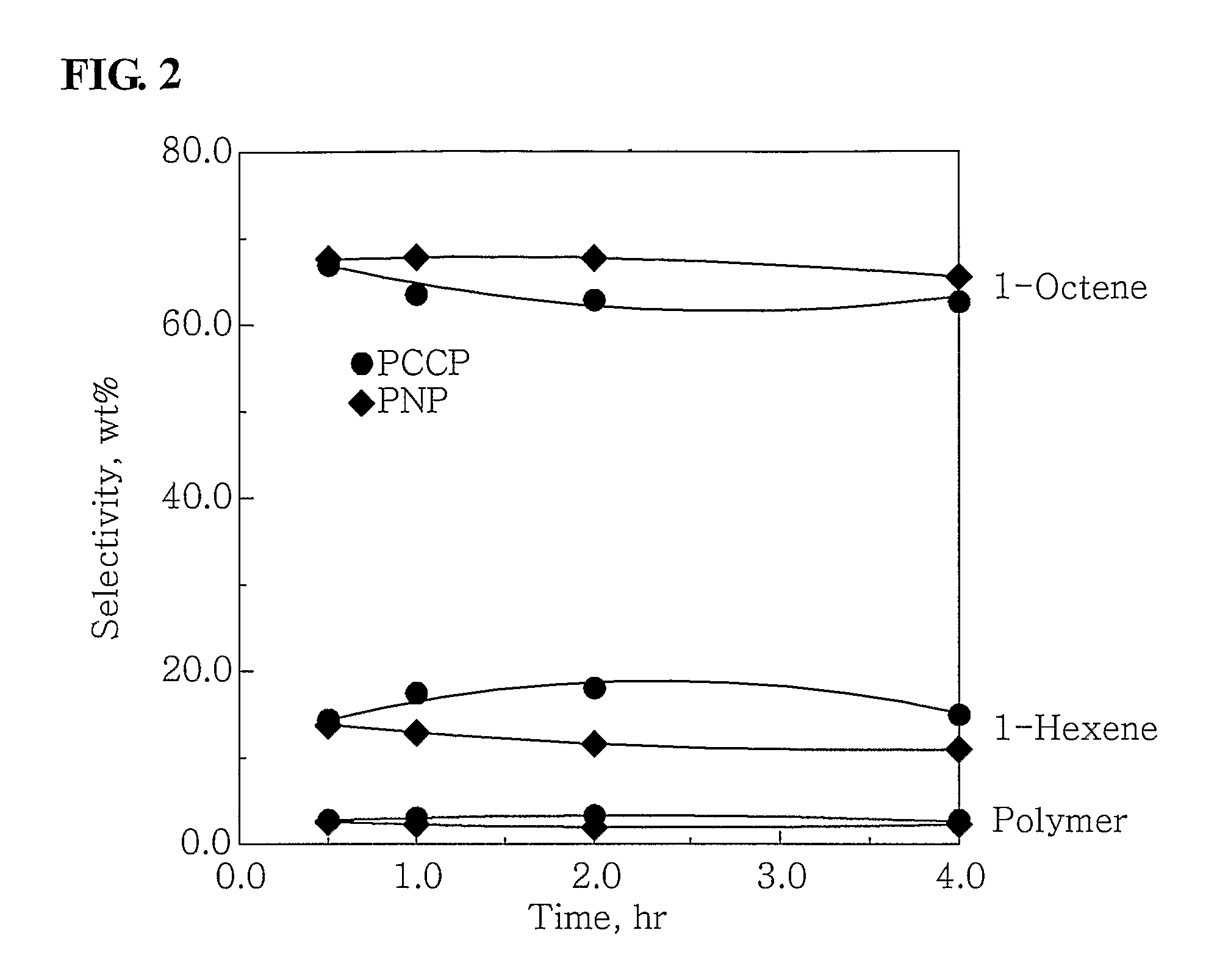

Ethylene tetramerization catalyst systems and method for preparing 1-octene using the same

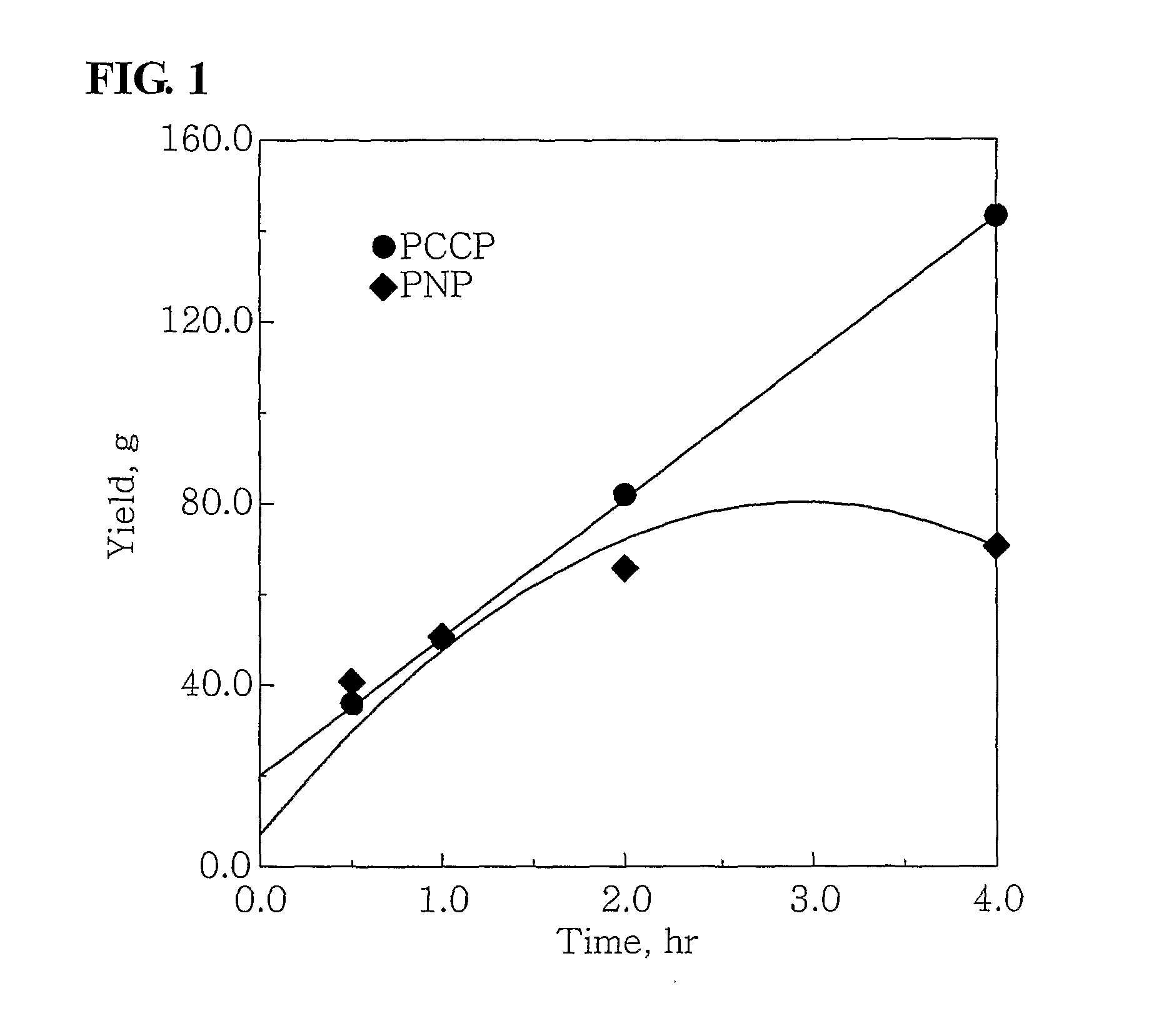

ActiveUS8609924B2Reduce rateHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon addition1-OcteneHigh activity

Disclosed herein is a method of preparing 1-octene at high activity and high selectivity while stably maintaining reaction activity by tetramerizing ethylene using a chromium-based catalyst system comprising a transition metal or a transition metal precursor, a cocatalyst, and a P—C—C—P backbone structure ligand represented by (R1)(R2)P—(R5)CHCH(R6)—P(R3)(R4).

Owner:SK GEO CENTRIC CO LTD

High viscosity polyalphaolefins based on 1-hexene, 1-dodecene and 1-tetradecene

ActiveUS20070225533A1Improve low temperature performanceHigh viscosityLiquid hydrocarbon mixtures productionHydrocarbons from unsaturated hydrocarbon addition1-OcteneOctene

This invention relates to the use of olefin mixtures containing 1-hexene / 1-decene / 1-dodecene and, additionally, 1-octene or 1-decene to produce high viscosity polyalphaolefins (PAOs) having a viscosity of from about 40 cSt to about 100 cSt at 100° C. (ASTM D-445) and a number average molecular weight of between about 1200 to about 4000, particularly useful as lubricant base stocks.

Owner:EXXONMOBIL CHEM PAT INC

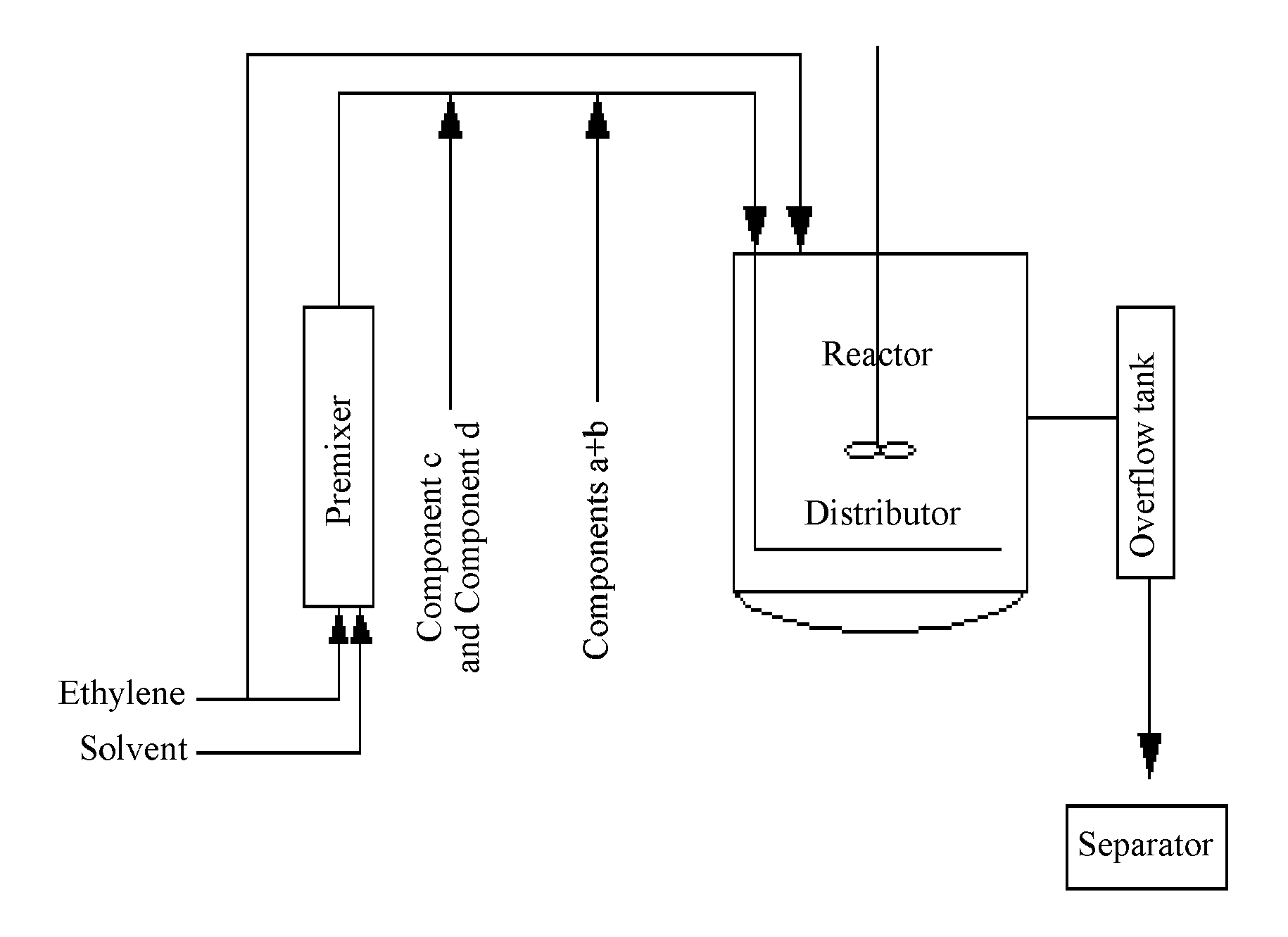

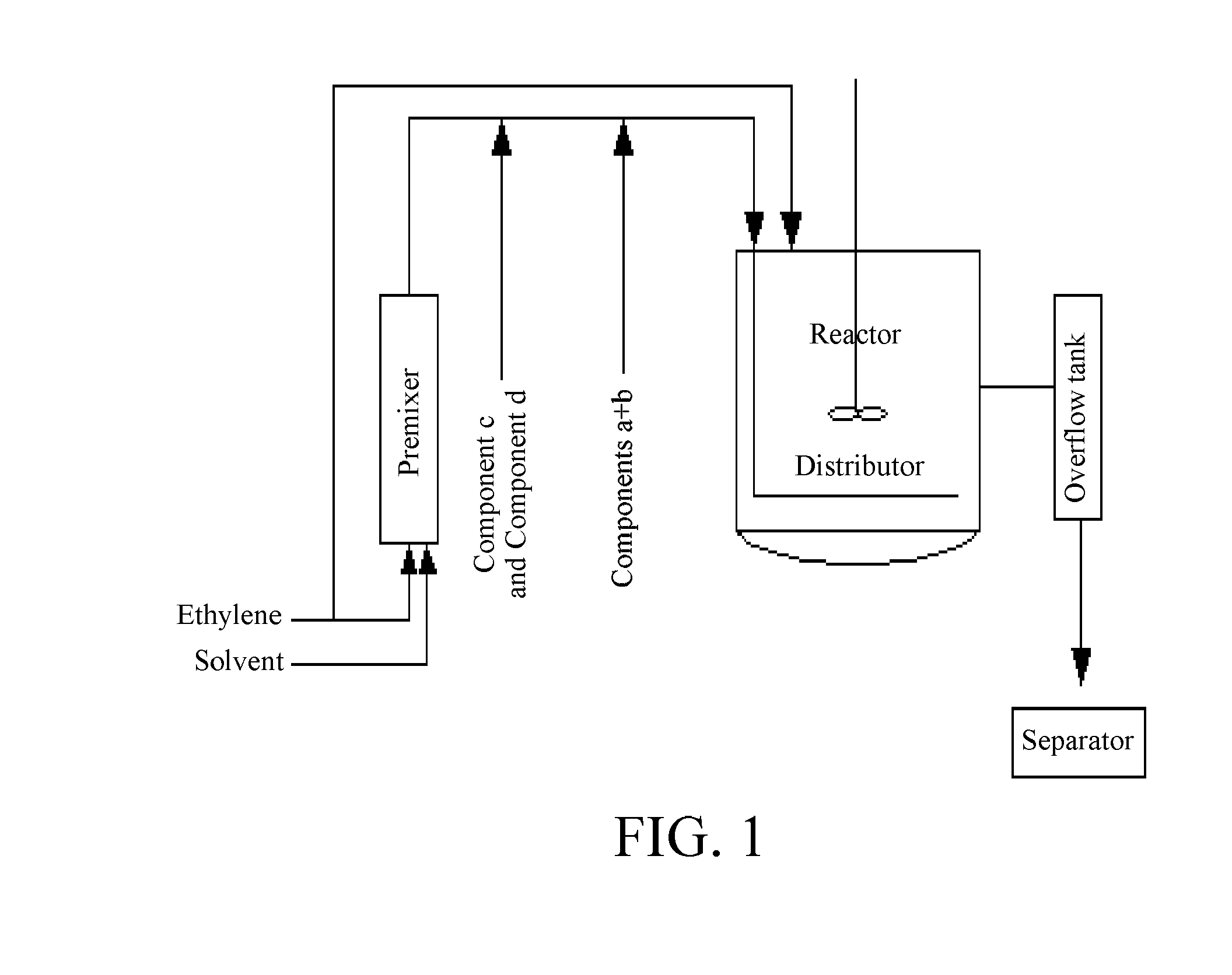

Method for Preparing 1-Octene by Oligomerization of Ethylene

InactiveUS20130090508A1Short reaction timeHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon addition1-OcteneProduct gas

Disclosed is a method for preparing 1-octene in the presence of a catalyst system for ethylene oligomerization, which includes: premixing a part of ethylene gas as raw material with a solvent, mixing with the components a+b, c and d of the catalyst system, and then sending in a reactor; directly sending the rest of ethylene gas in the reactor; discharging the resultant liquid from the upper part of the reactor into an overflow channel; adding a catalysis stopping agent to the overflow channel; and then separating the resultant liquid. The advantages of the method are high selectivity of 1-octene and high catalytic activity.

Owner:PETROCHINA CO LTD

Ligand compound, catalyst system for olefin oligomerazation, and method for olefin oligomerization using the same

ActiveUS20160122371A1High catalytic activityHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon addition1-Octene1-Hexene

This disclosure relates to a ligand compound, a catalyst system for olefin oligomerization, and a method for olefin oligomerization using the same. The catalyst system for olefin oligomerization according to the present invention has excellent catalytic activity, and yet, exhibits high selectivity to 1-hexene and 1-octene, thus enabling efficient preparation of alpha-olefin.

Owner:LG CHEM LTD

Method for producing 1-octene

InactiveUS7030286B2High purityHigh yieldOrganic compound preparationOrganic chemistry methods1-OcteneOctene

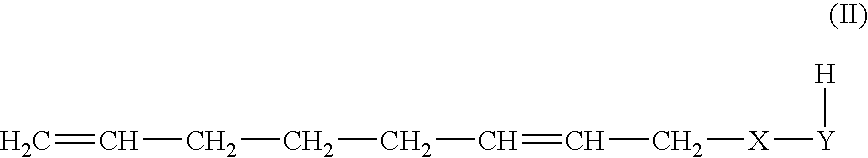

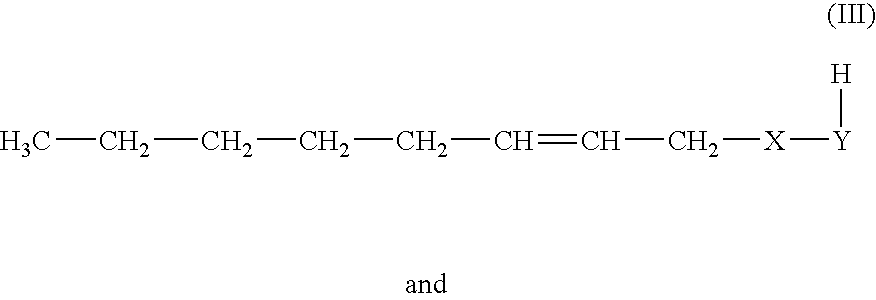

The invention relates to a process for preparing 1-octene by reacting 1,3-butadiene with a telogen of the formula H—X—Y—H, where X is O, N, S or P and Y is C, N or Si and X and Y bear, depending on their valence, further substituents, in the presence of a telomerization catalyst to form a telomer of the formula H2C═CH—CH2—CH2—CH2—CH═CH—CH2—X—Y—H, partially hydrogenating the telomer to form a 1-substituted 2-octene of the formula H3C—CH2—CH2—CH2—CH2—CH═CH—CH2—X—Y—H and dissociating the 1-substituted 2-octene to give 1-octene.

Owner:OXENO OLEFINCHEMIE GMBH

Tandem tetramerisation-polymerisation of olefins

InactiveUS7323524B2Improve catalytic performanceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionPolyolefin1-Octene

The invention provides a process for polymerising olefins to branched polyolefins in the presence of a polymerisation catalyst and a cocatalyst, wherein the cocatalyst produces 1-octene in a selectivity greater than 30%.

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

Propylene polymer compositions

The invention relates to propylene polymer compositions comprising 45-79 parts per weight of a propylene homo- or copolymer, 10-27 parts per weight of a first elastomeric ethylenepropylene copolymer, 5-22 parts per weight of a second elastomeric ethylene-propylene copolymer, 1-15 parts per weight of an elastomeric ethylene-1-octene copolymer and 5-15 parts per weight of inorganic filler. The propylene polymer compositions are suitable for injection molding of large articles, which do not show flow marks and which have a good impact strength / stiffness ratio.

Owner:BOREALIS TECH OY

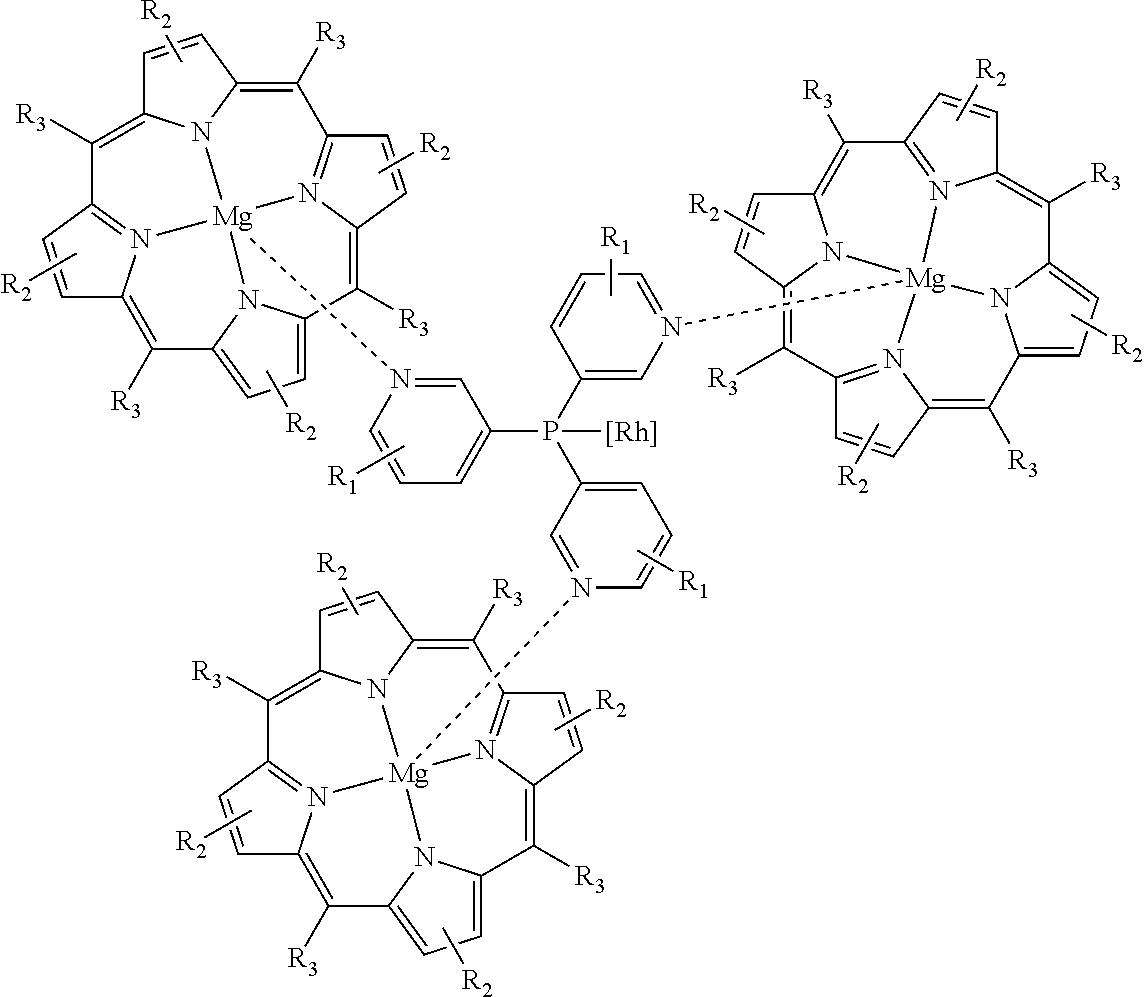

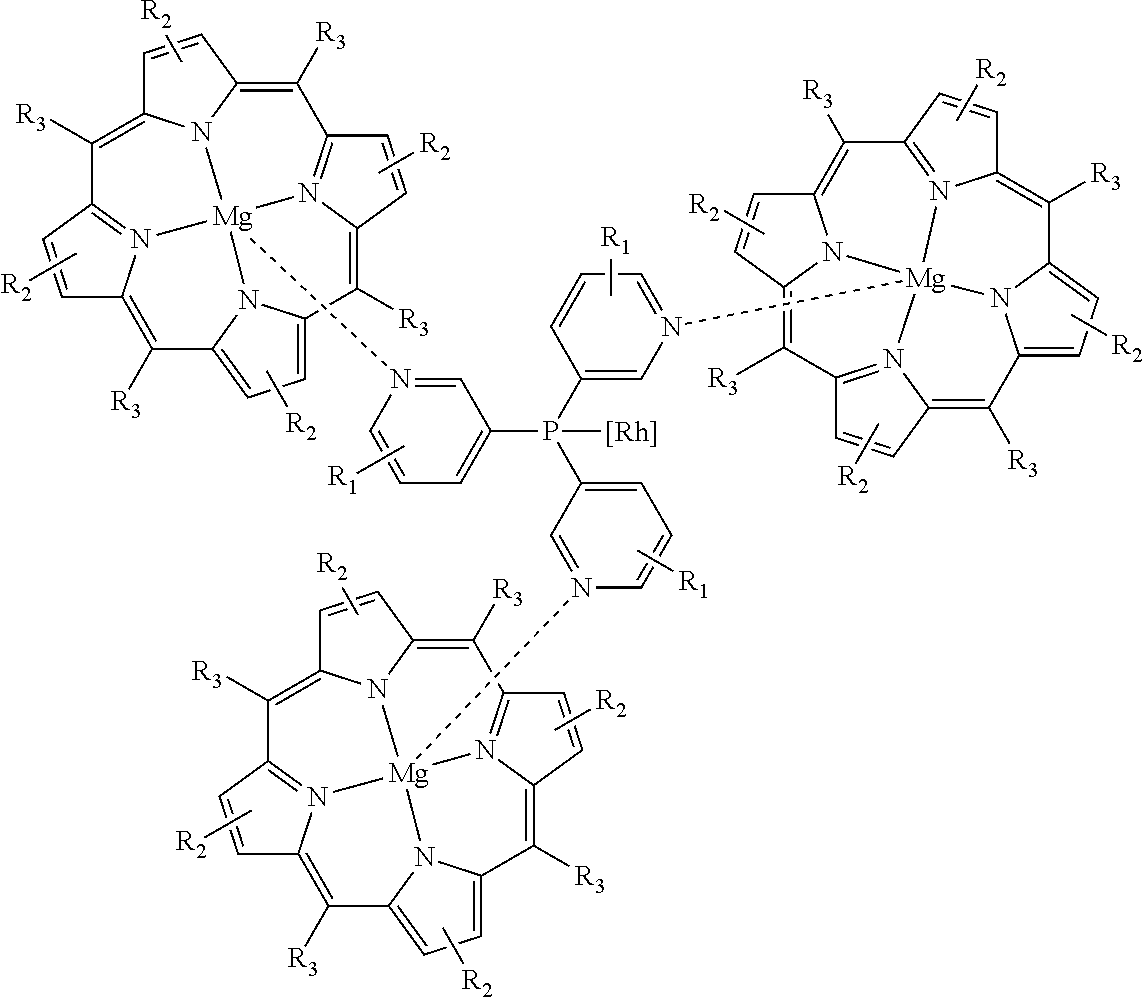

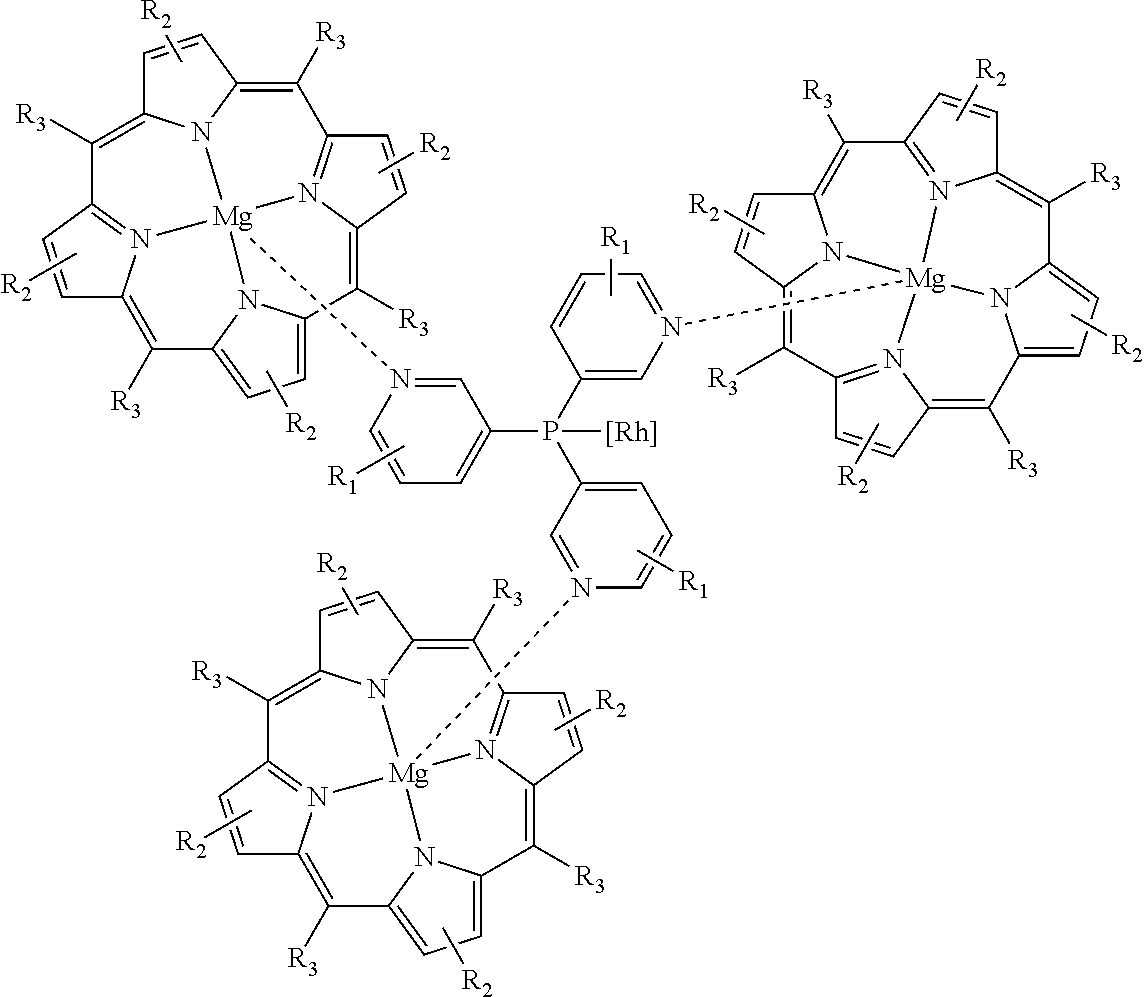

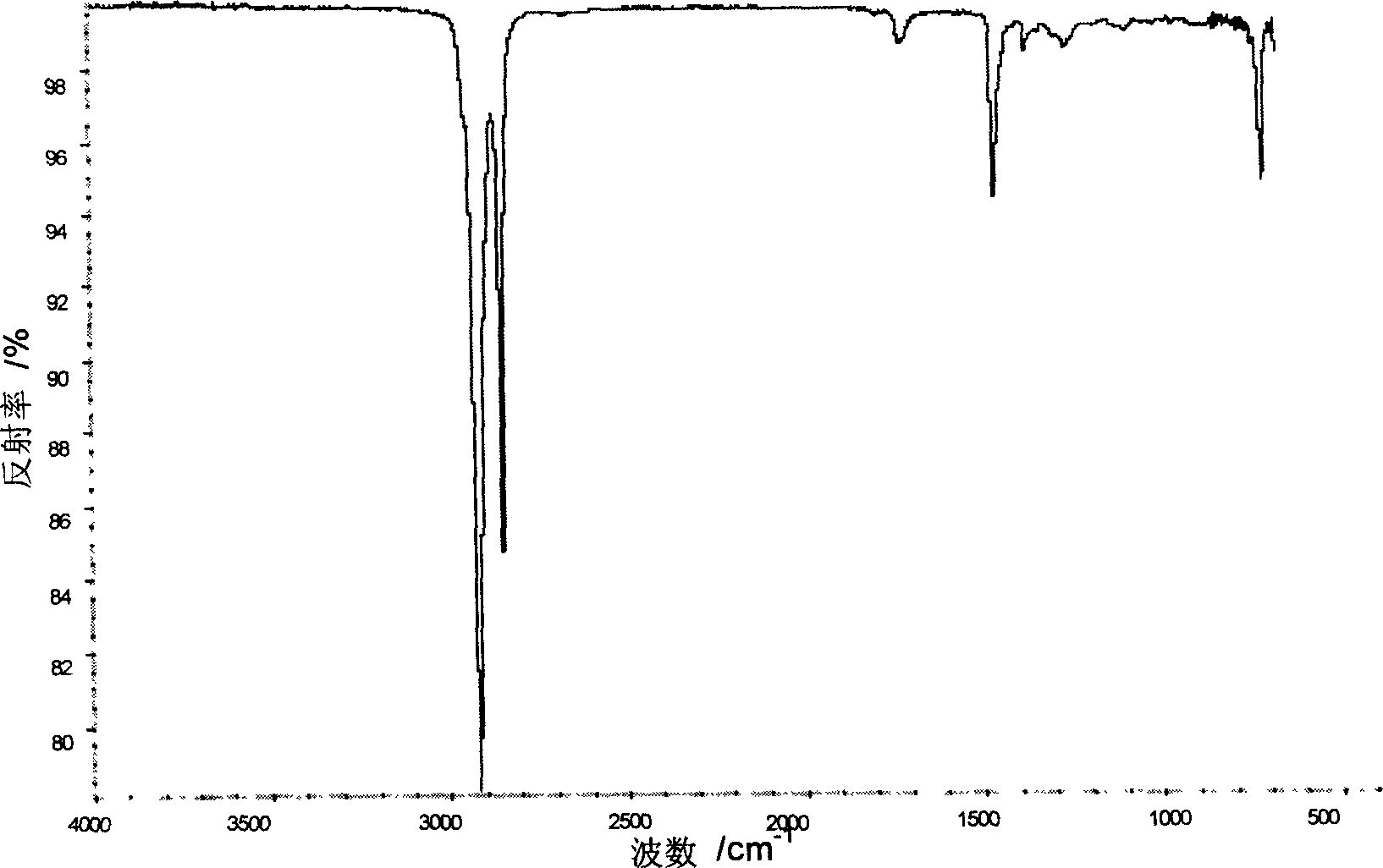

Catalysts and process for producing aldehydes

ActiveUS8710275B2Organic compound preparationOrganic-compounds/hydrides/coordination-complexes catalysts1-OctenePorphyrin

Modification of a unique supramolecular assembly of a pyridylphosphine ligand and a metal centered porphyrin complex is shown to give unprecedented selectivities to branched aldehydes via rhodium catalyzed hydroformylation of propylene and 1-octene. Use of magnesium in the porphyrin center provides the highest reported concentrations of iso-butyraldehyde and 2-methyl-octanal.

Owner:EASTMAN CHEM CO

Tenacity reinforced nylon and its preparing method

The present invention relates to toughened nylon with maleic anhydride grafted vinyl-1-octene copolymer as toughening agent and its preparation process. The toughened nylon consists of nylon 60-90 wt%, maleic anhydride grafted vinyl-1-octene copolymer 10-30 wt%, polyolefin 0-10 wt%, and assistant 0.02-2 wt%, with the assistant being calcium stearate or stearic cid. Using maleic anhydride grafted vinyl-1-octene copolymer as toughening agent can reach high toughening effect while producing less strength decrease of the nylon alloy.

Owner:SHANGHAI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com