Tenacity reinforced nylon and its preparing method

A nylon and toughening technology, applied in the field of toughened nylon and its preparation, can solve the problems of reducing the strength of nylon alloys, and achieve the effect of reducing the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

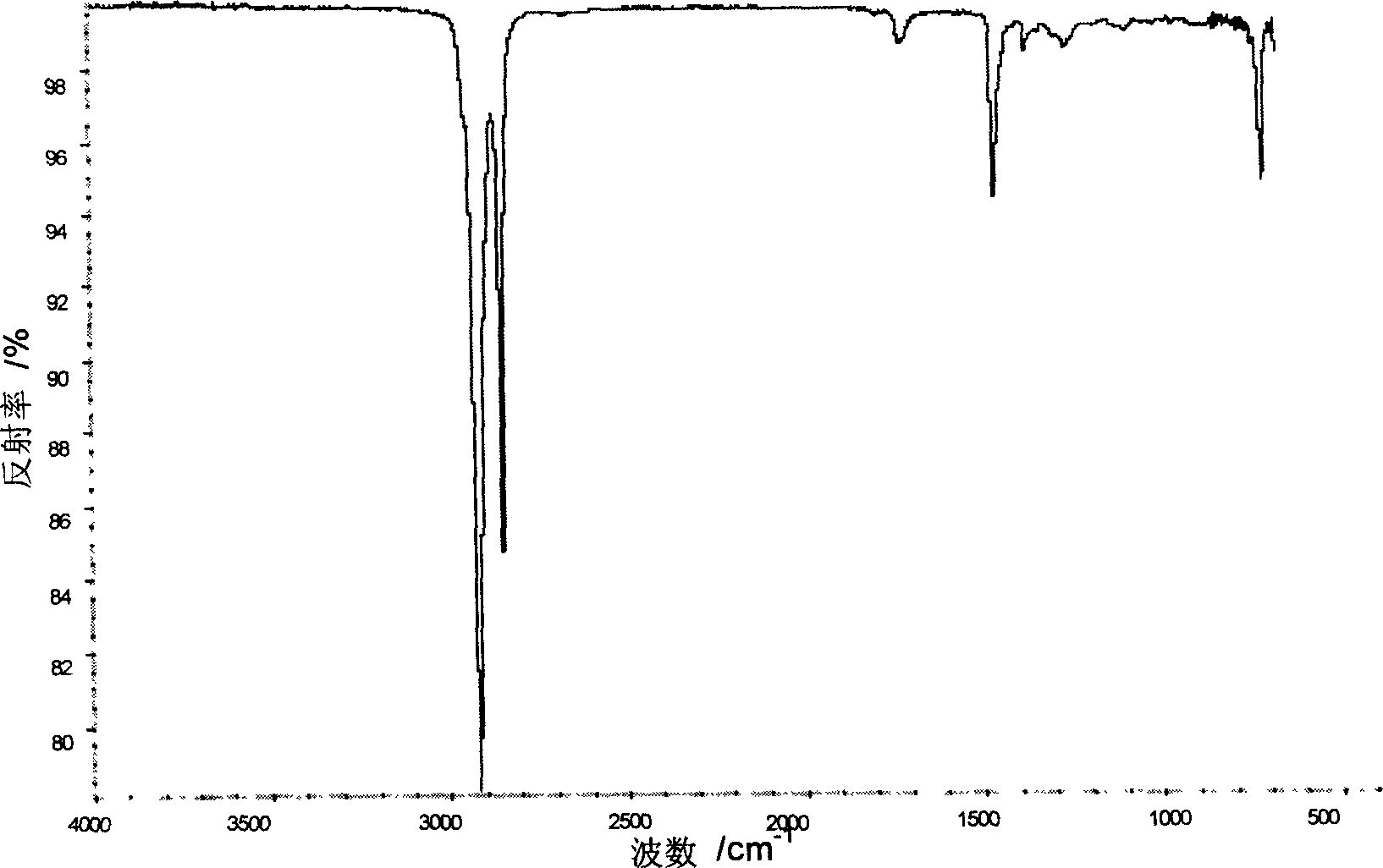

Image

Examples

Embodiment Construction

[0016] The process conditions used in the following embodiments are: control the temperature of each section of the screw: the feeding section is 180°C, the plasticizing shear section is 230°C-240°C, and the head is 230°C; the screw speed is controlled at 120rmp, and the reaction of the material in the screw is controlled. The residence time is 70-100s. Put the pre-mixture according to the formula into a twin-screw extruder for extrusion, water cooling, pelletizing, and drying. Splines were prepared by injecting standard dimensions. The samples were tested for tensile strength, bending strength and notched Izod impact strength according to GB / T1040, GB9341 and GB1843 respectively; the composition and proportioning of each embodiment are shown in Table 1.

[0017] Example / parts by weight

[0018] In Table 1, EPDM-g-MAH is ethylene-propylene rubber grafted with maleic anhydride, and POE-g-MAH is ethylene-1-octene copolymer grafted with maleic anhydride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com