Patents

Literature

257results about How to "Reduce skin effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

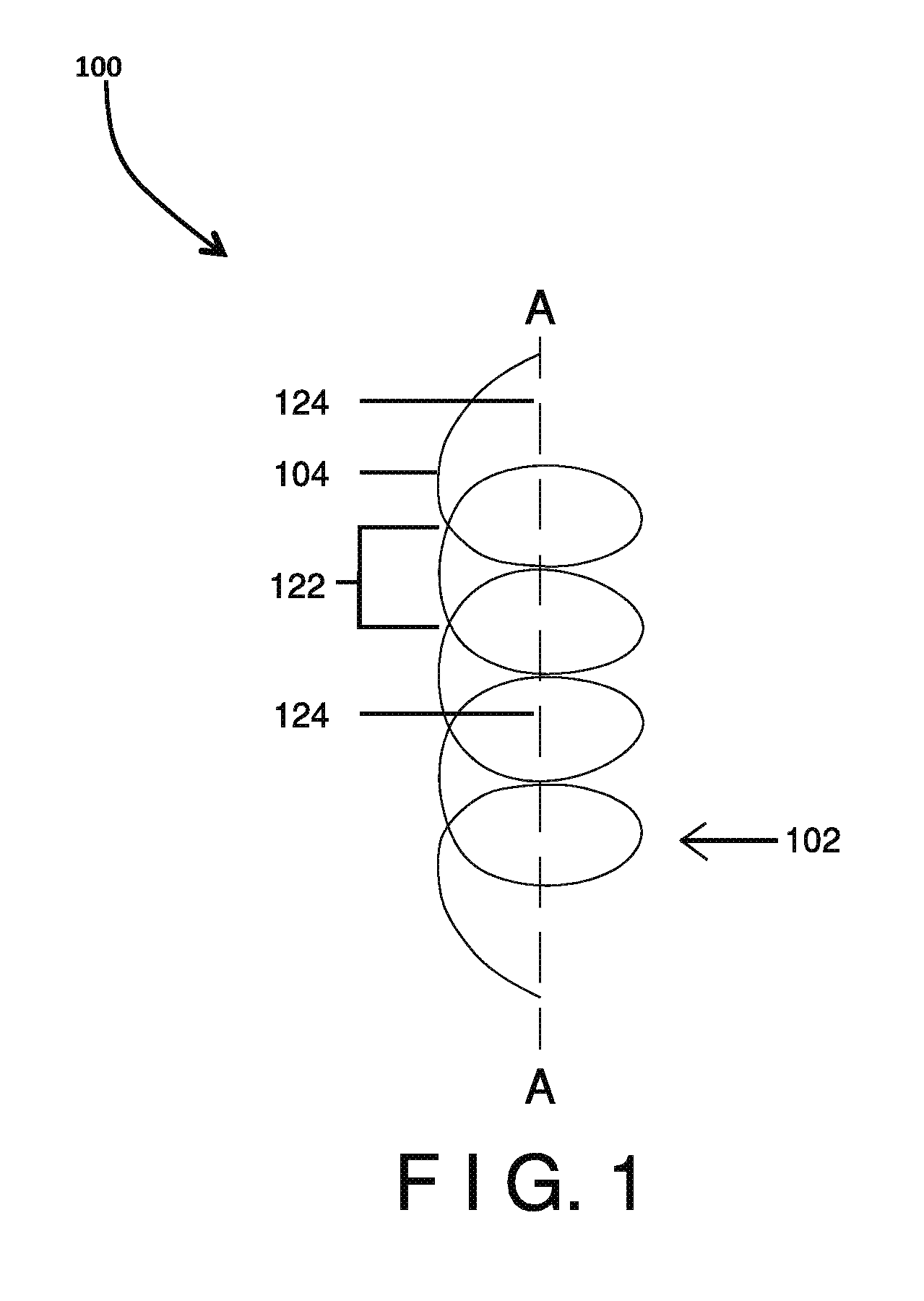

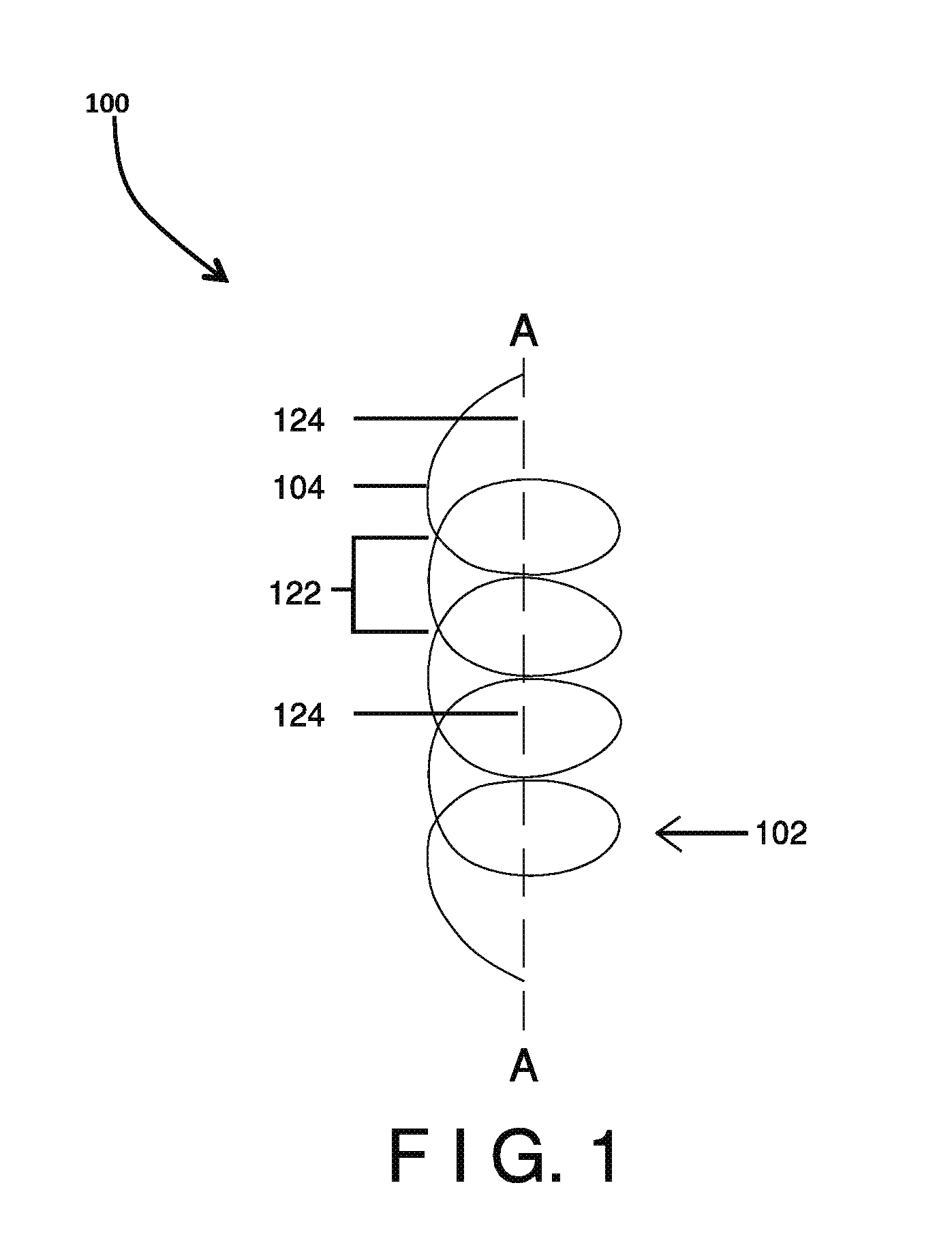

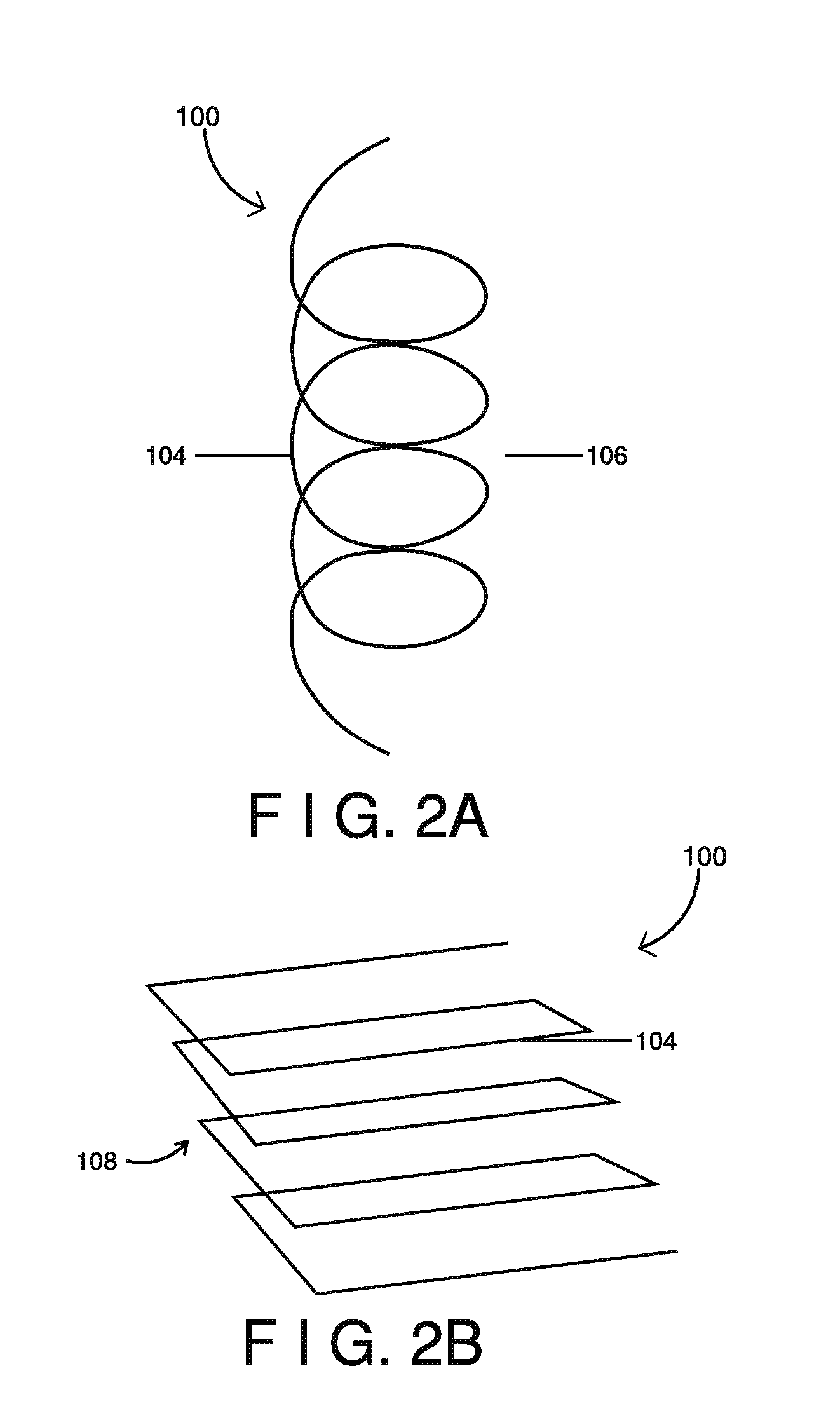

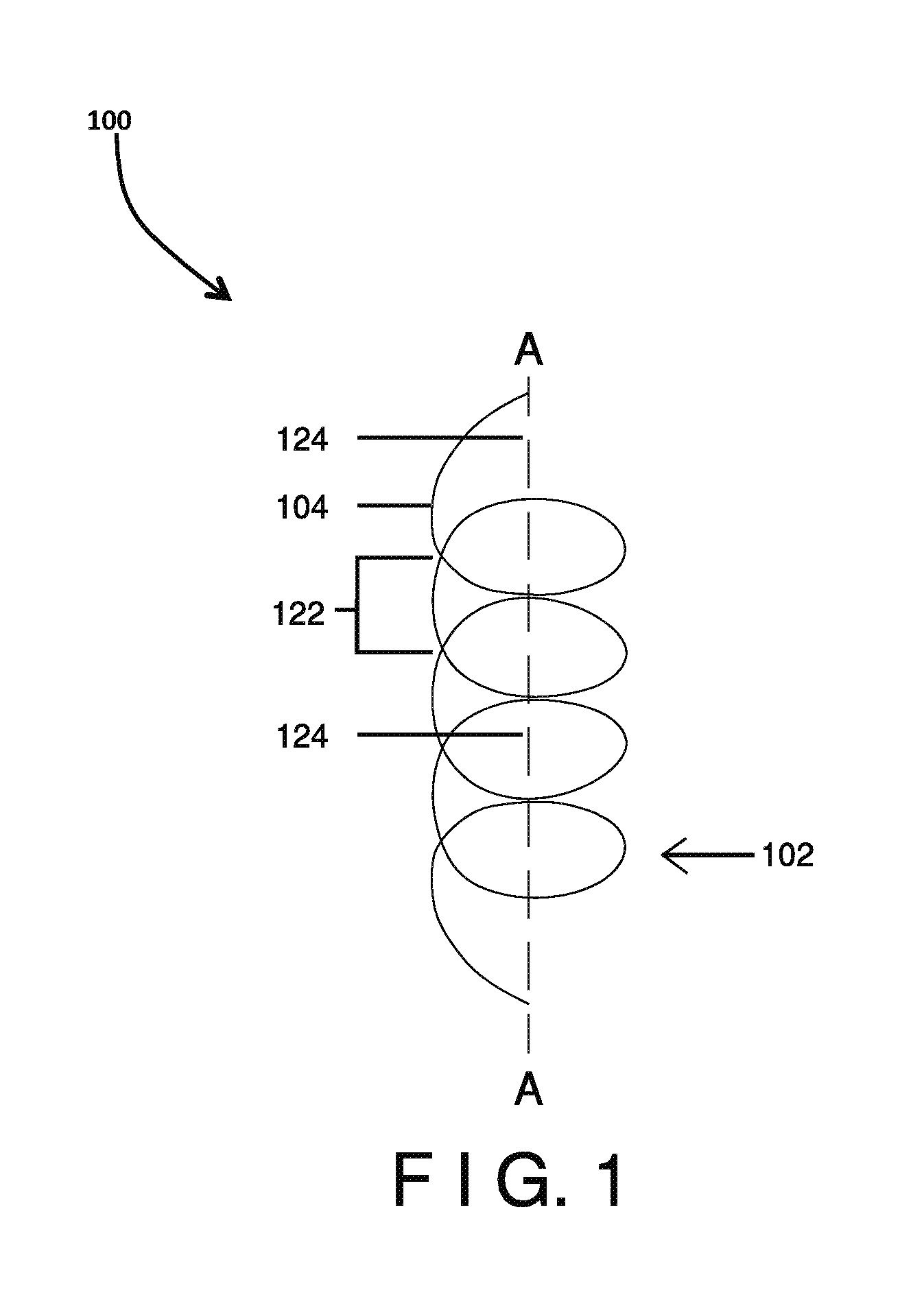

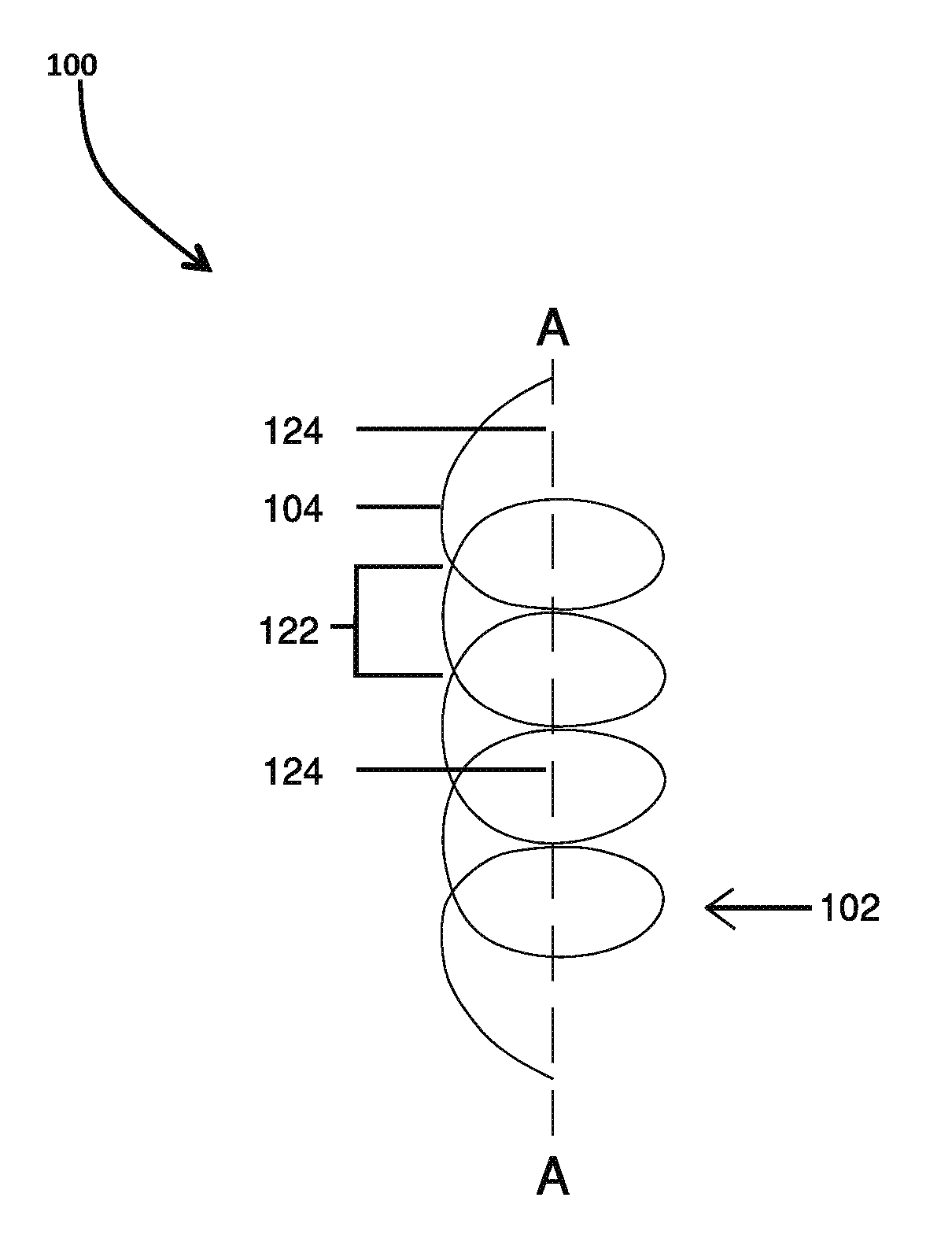

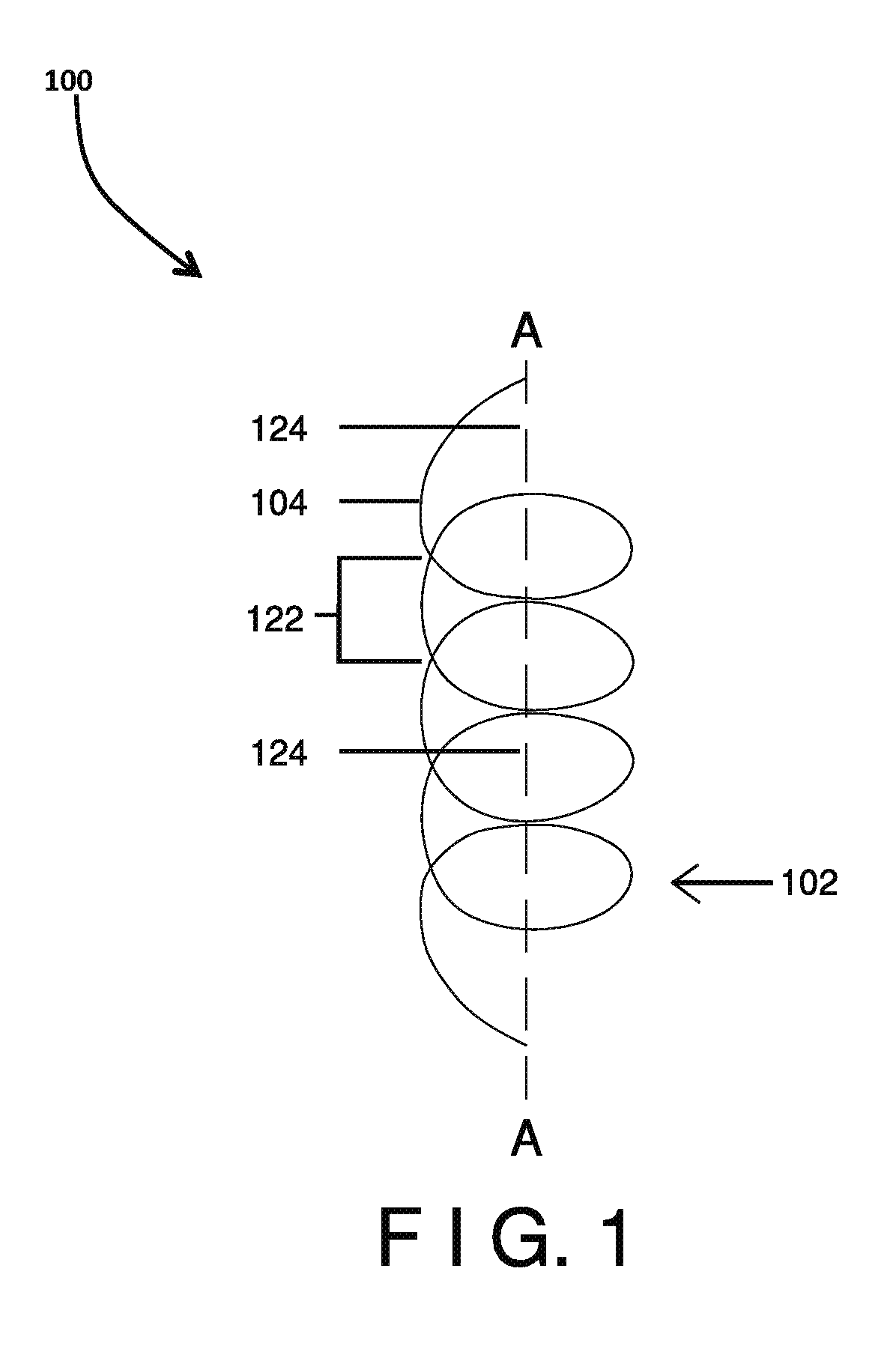

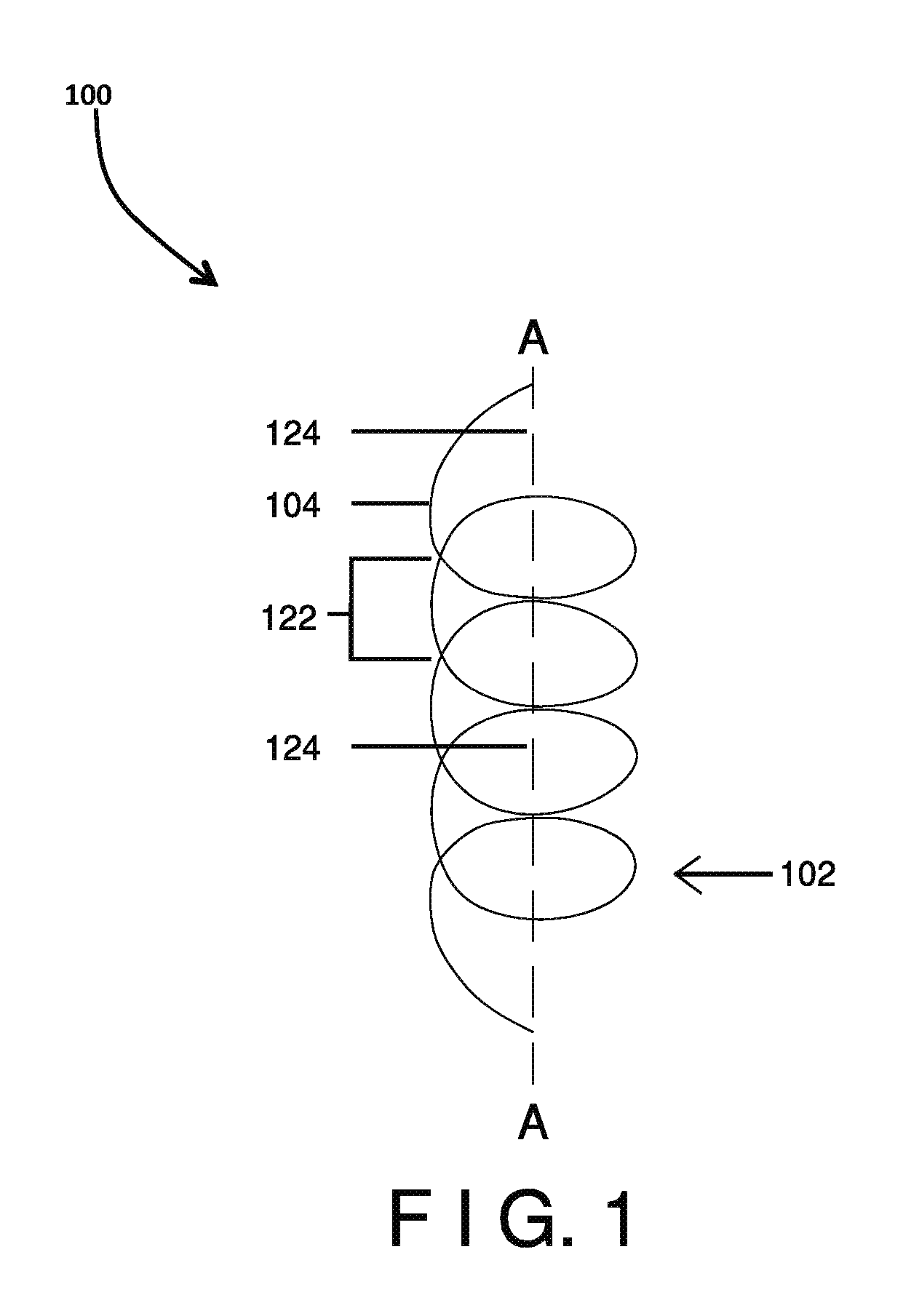

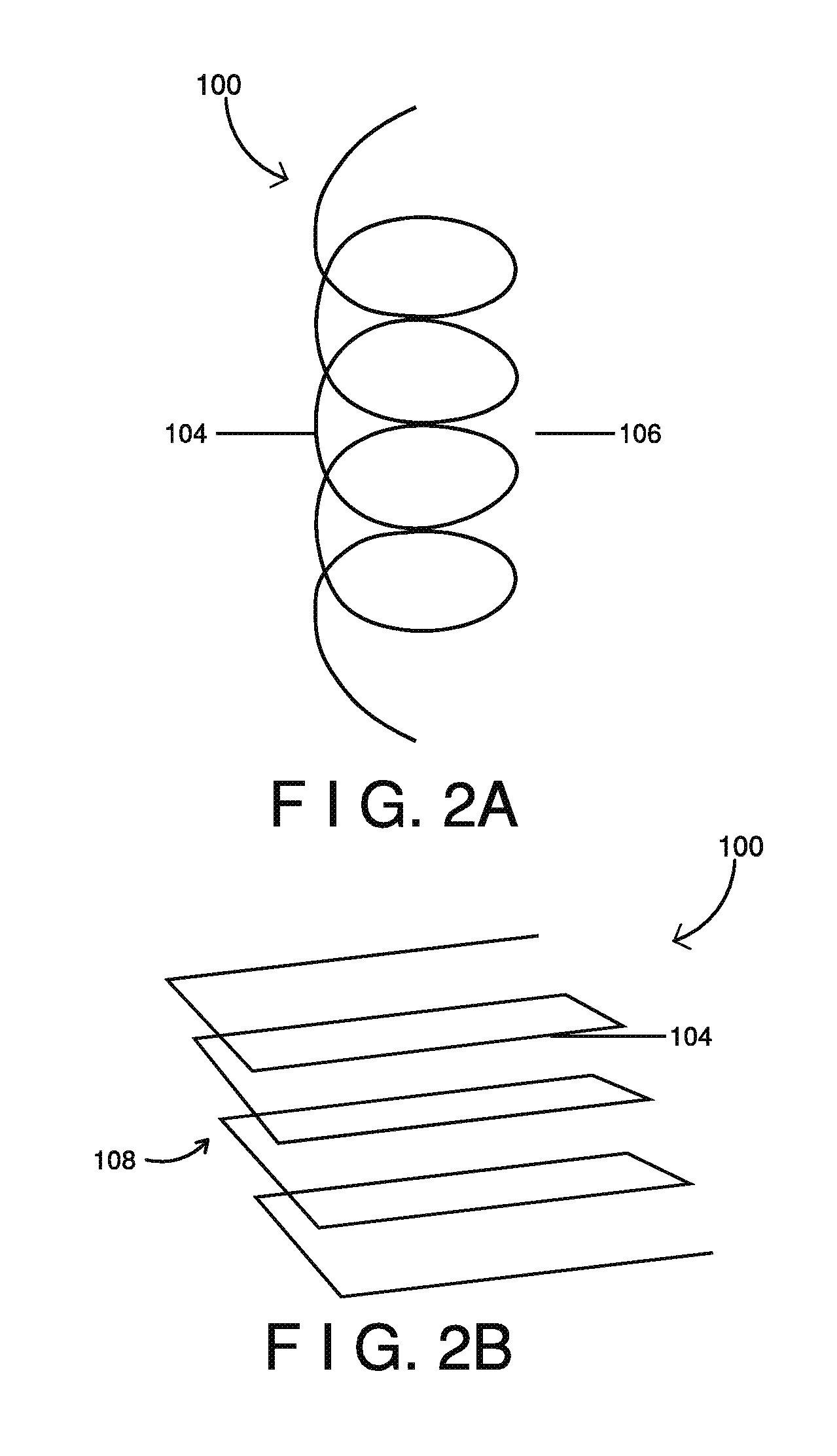

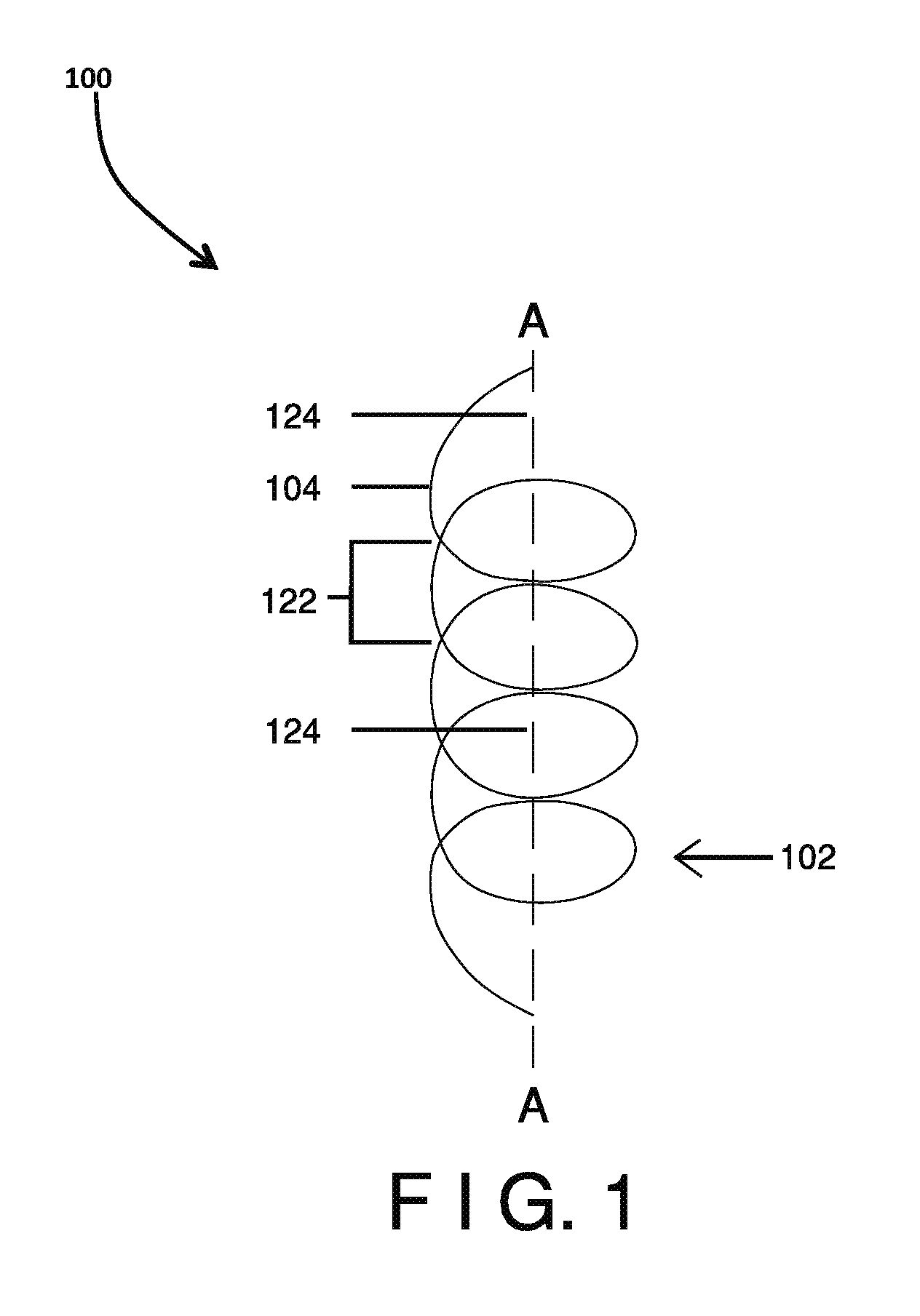

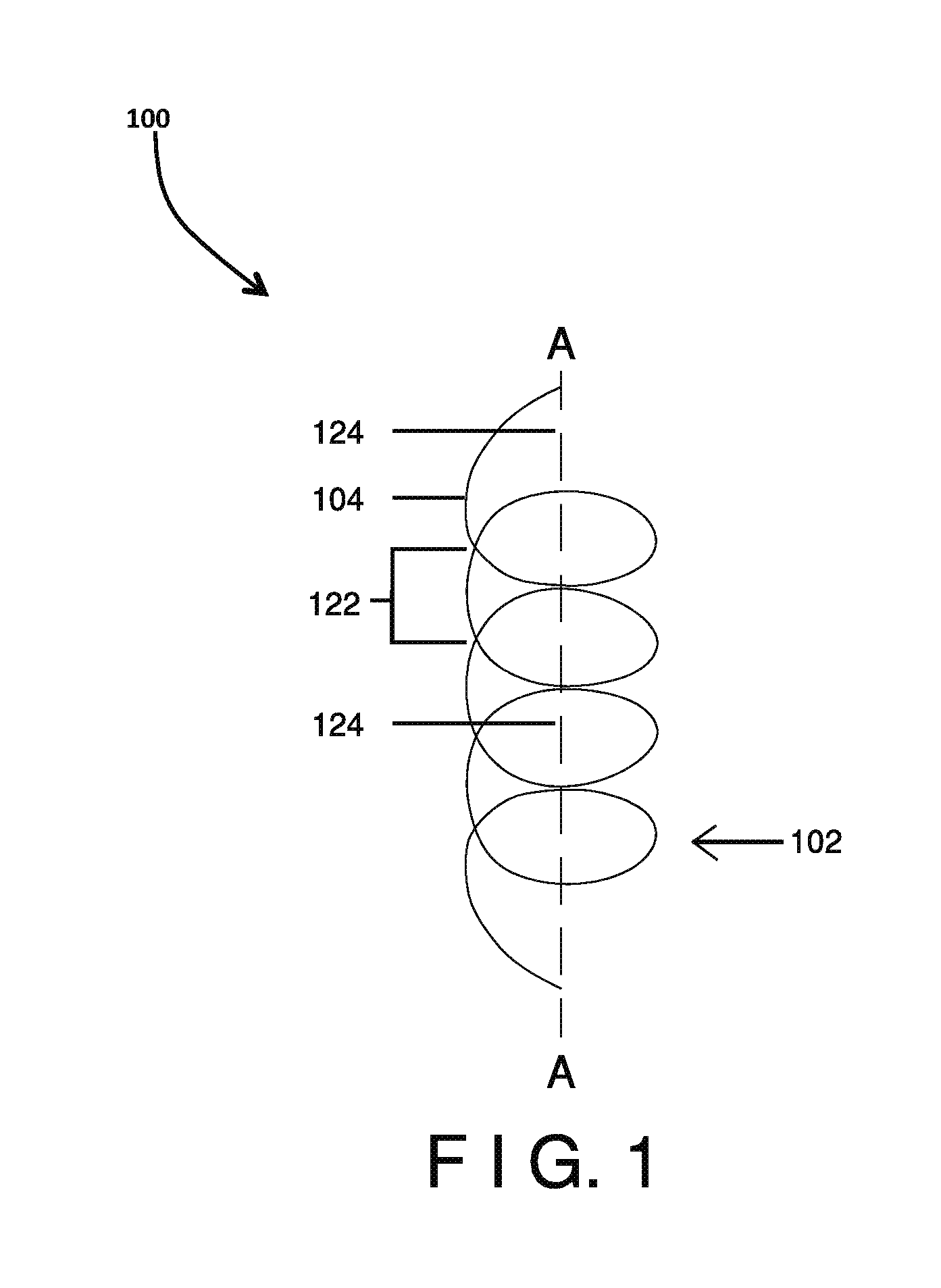

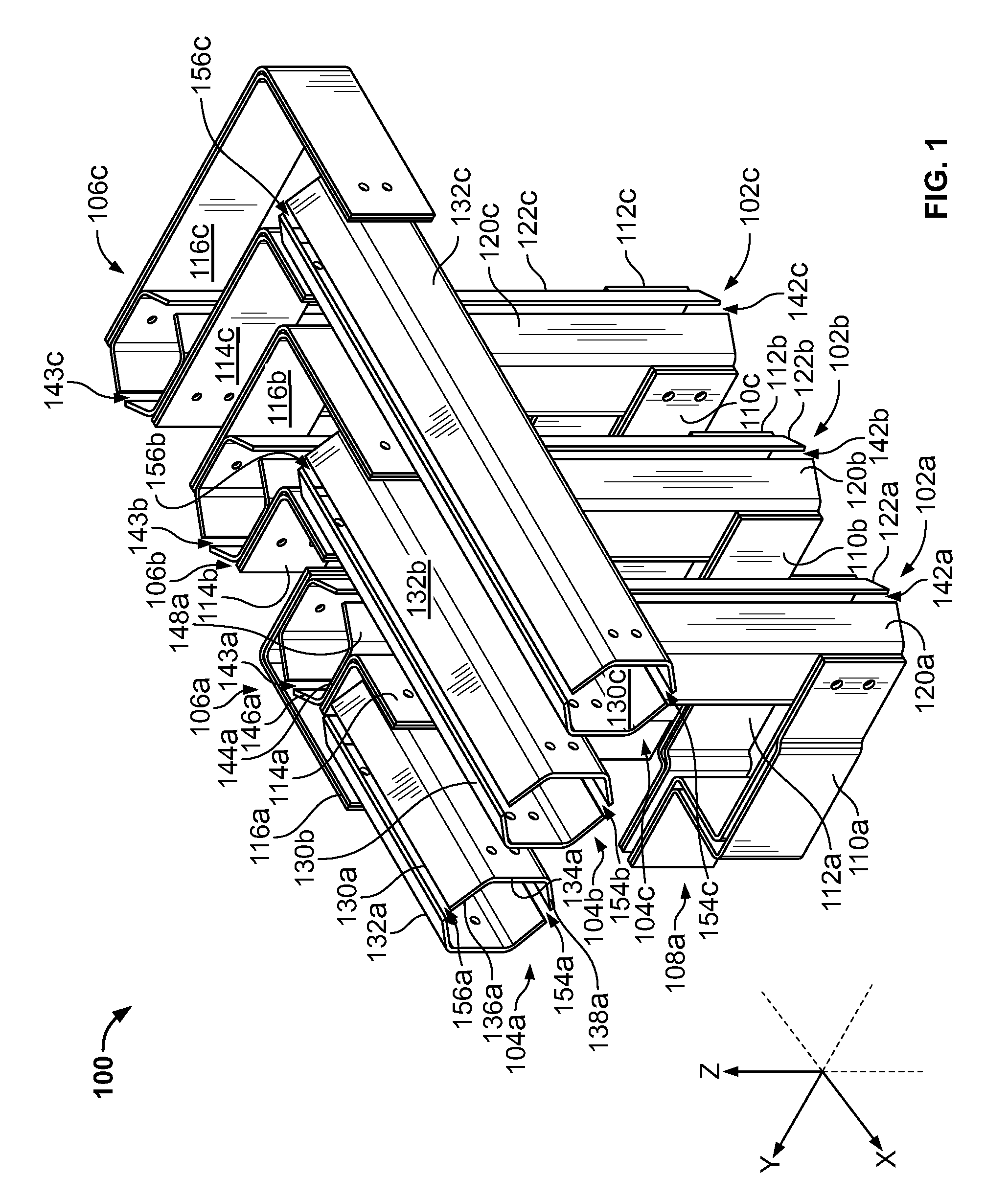

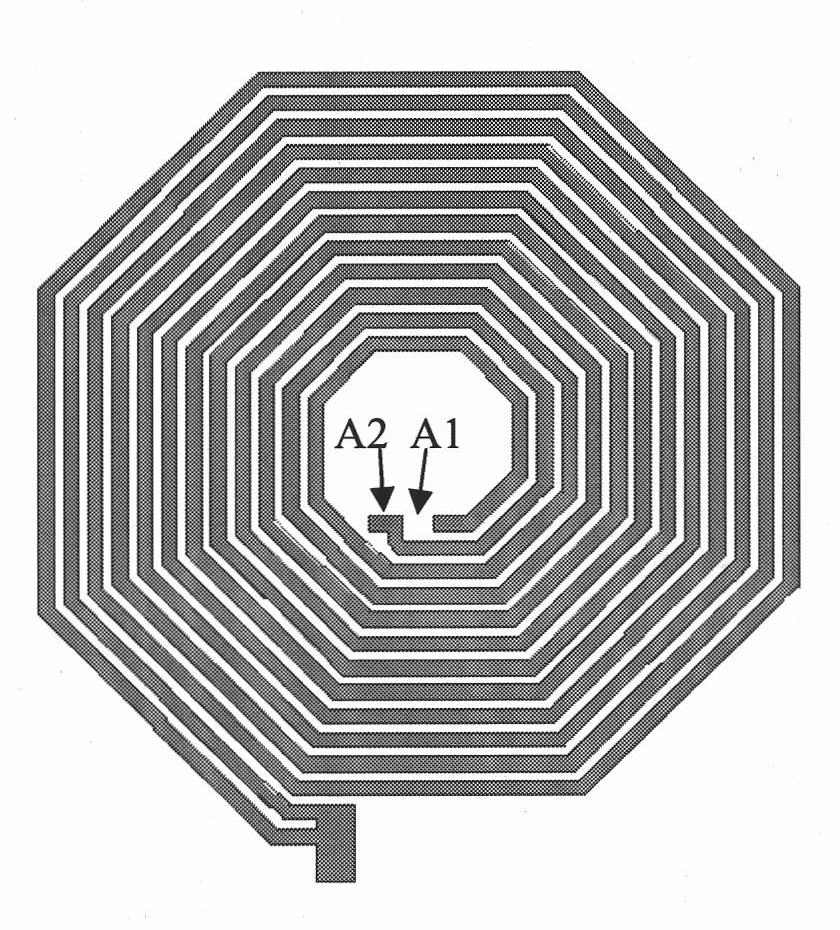

Printed circuit board coil

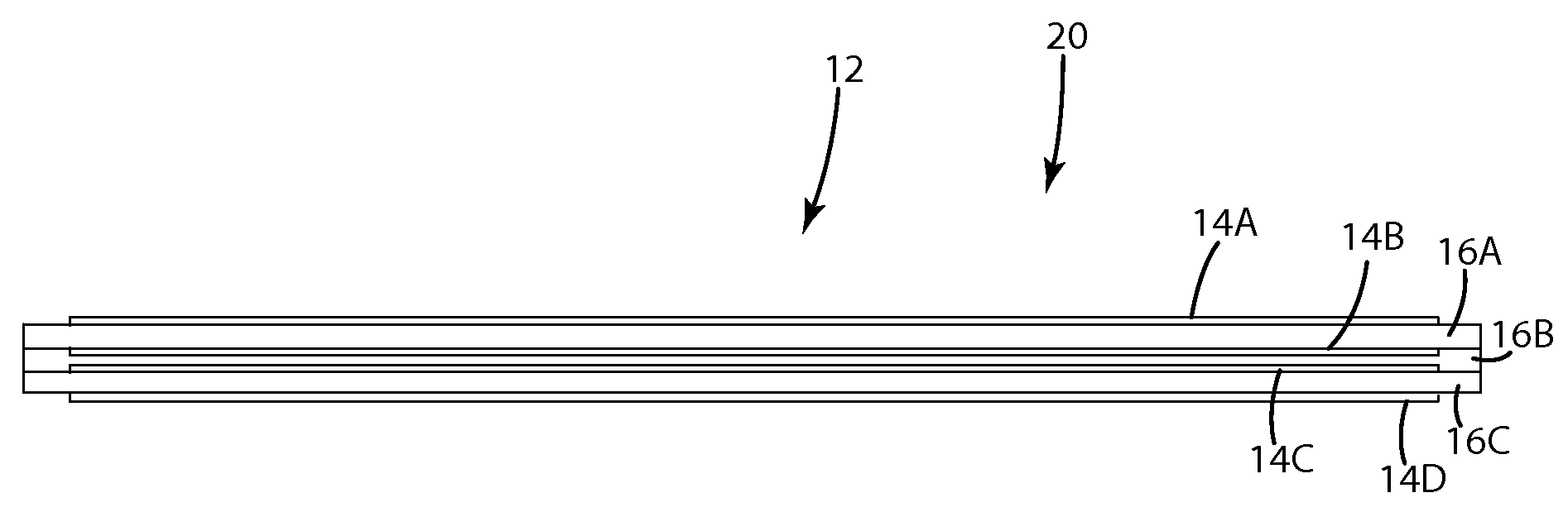

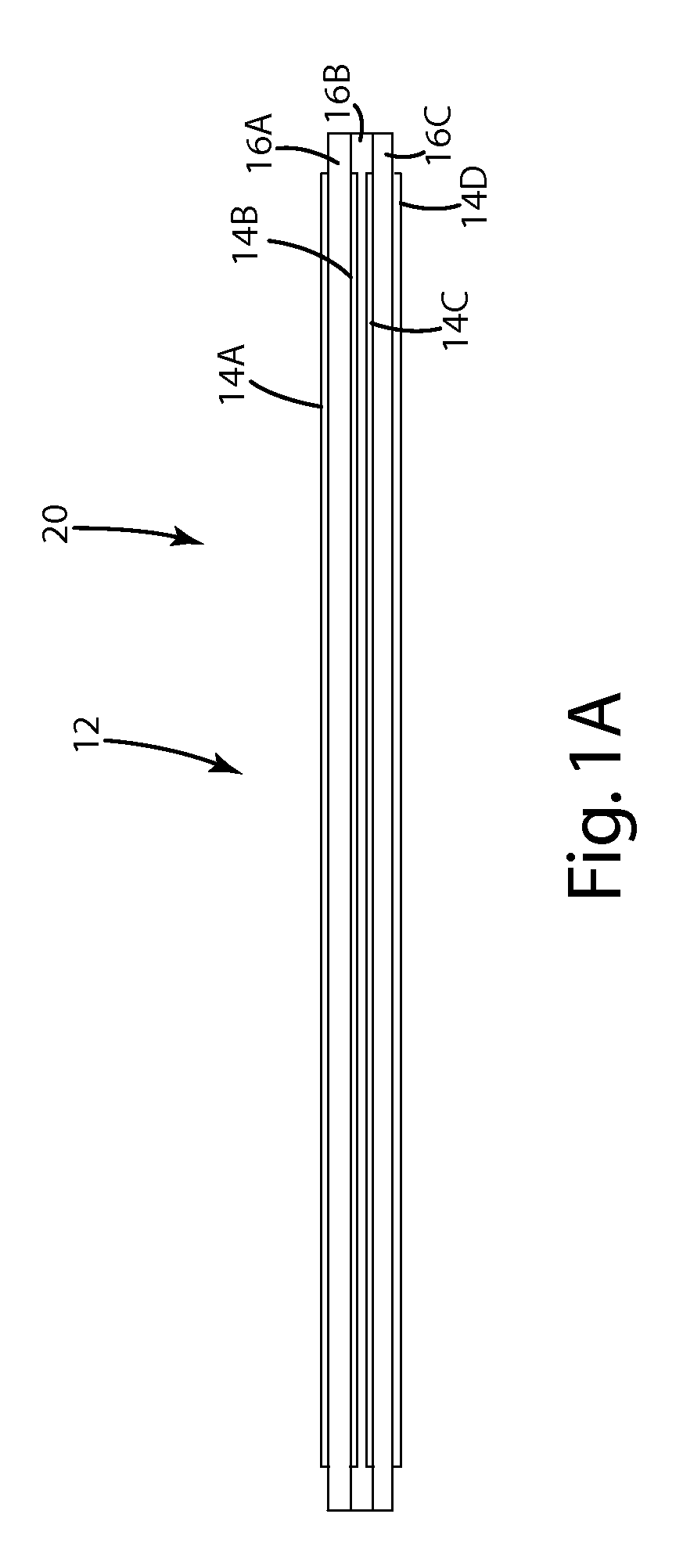

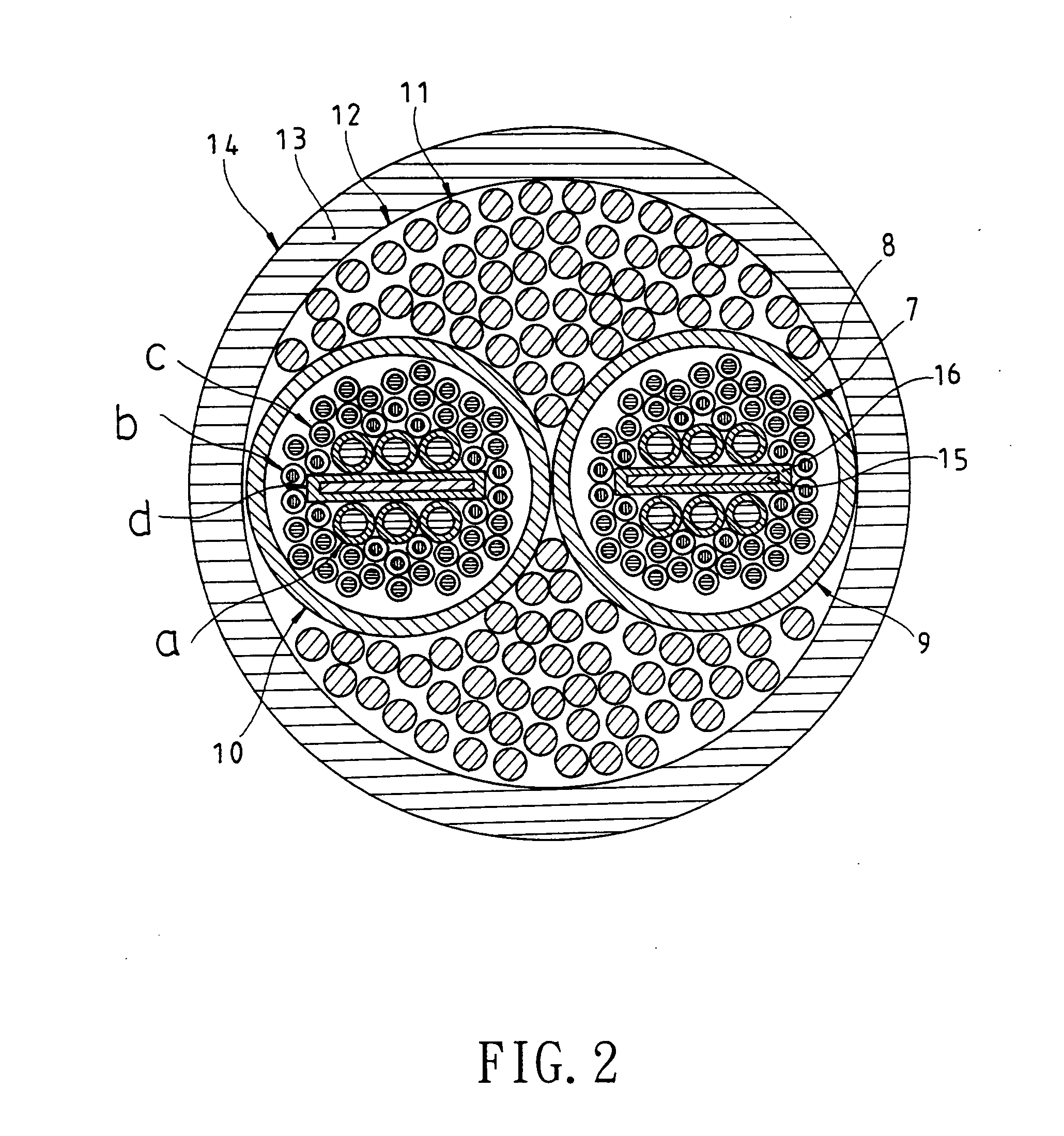

ActiveUS20090085706A1Reduce skin effectReduce lossTransformersTransformers/inductances coils/windings/connectionsElectrical conductorLitz wire

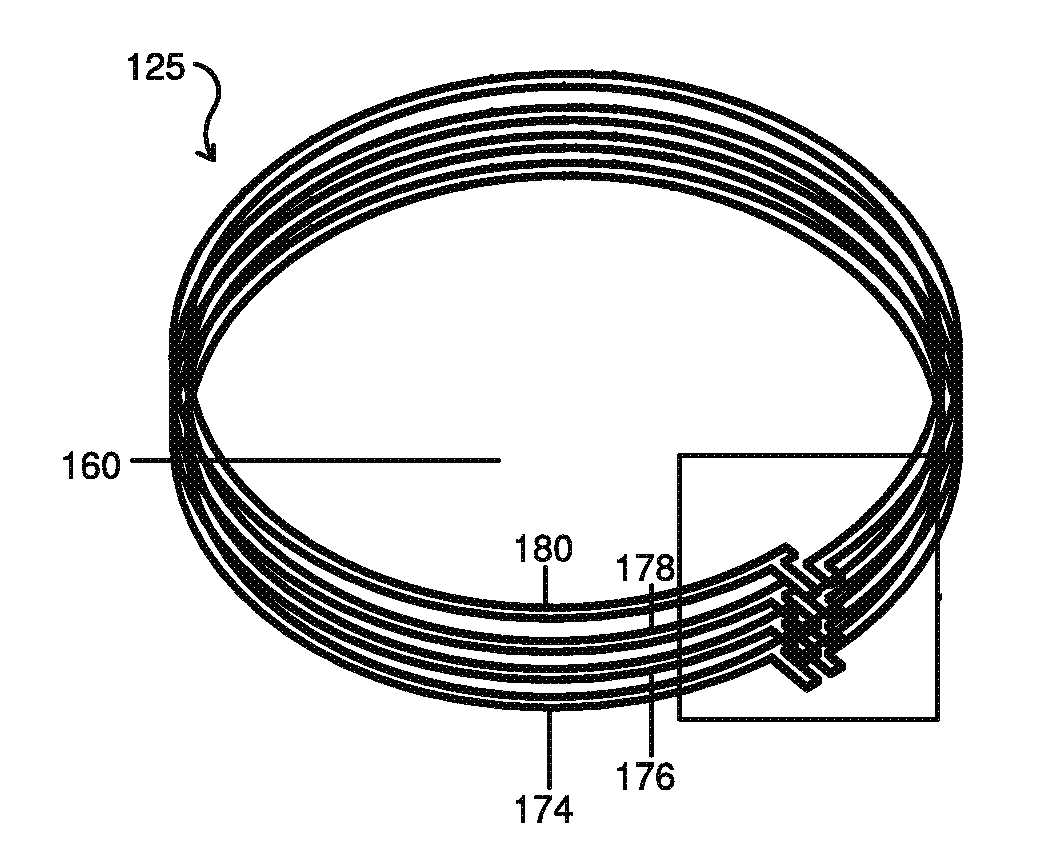

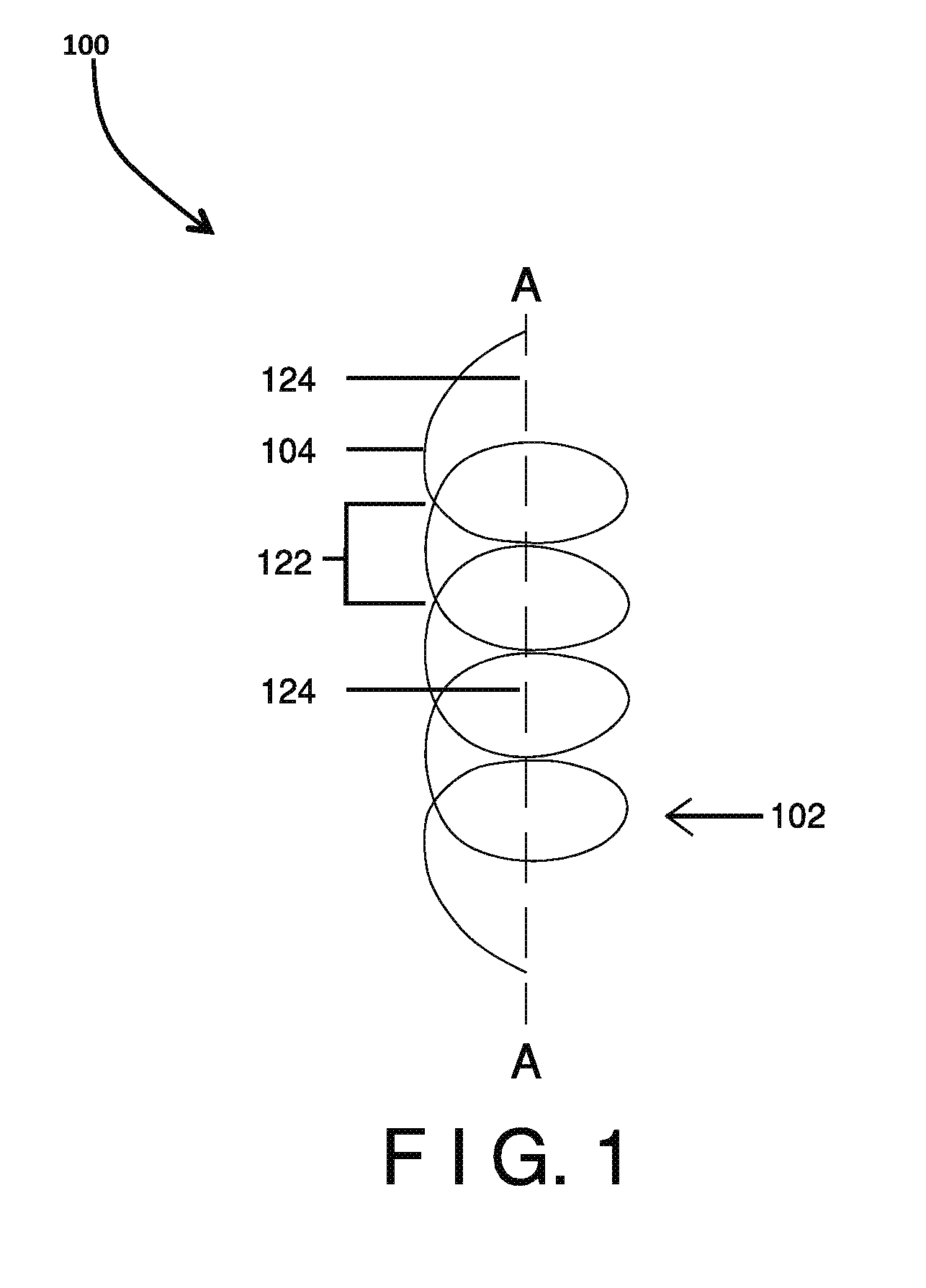

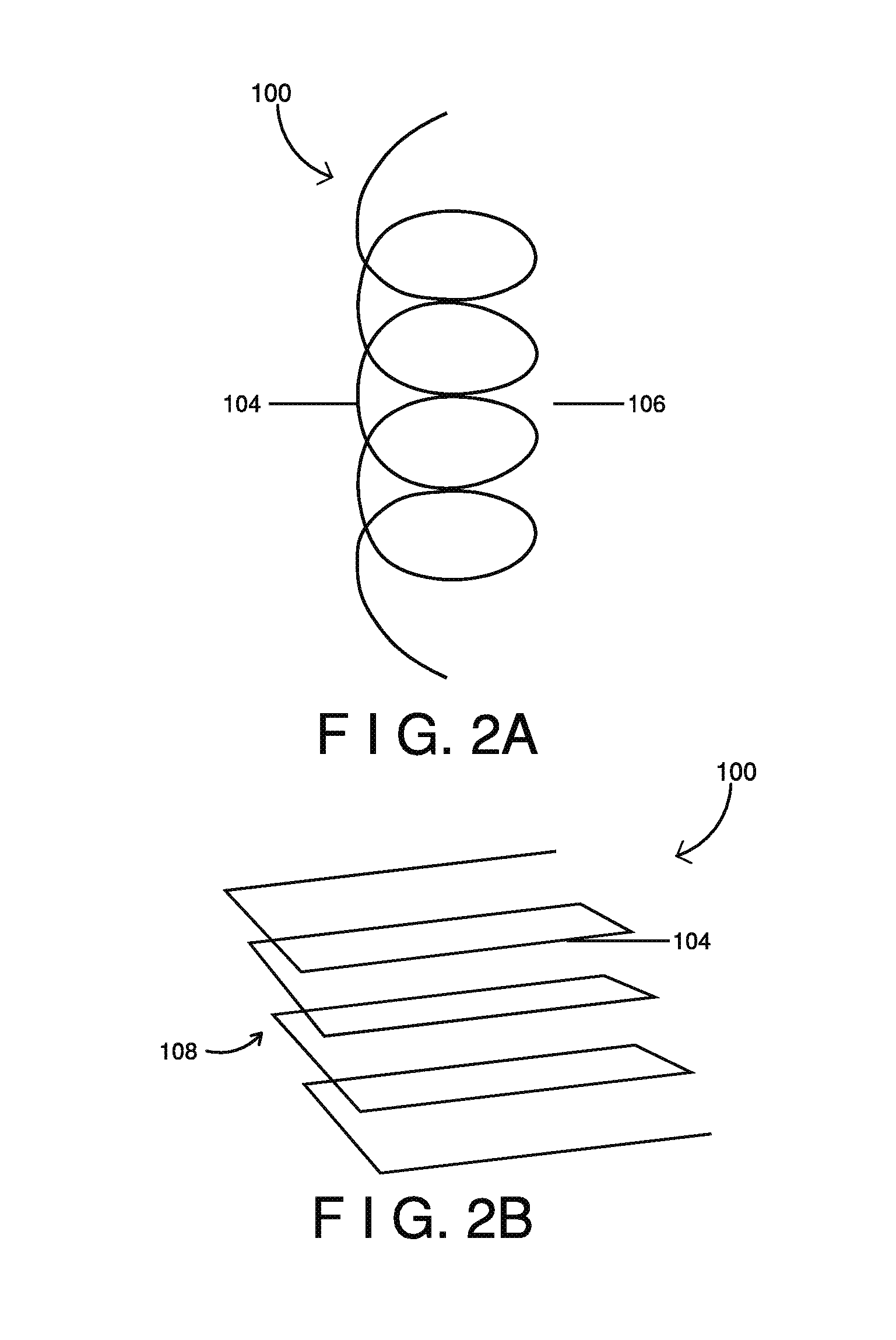

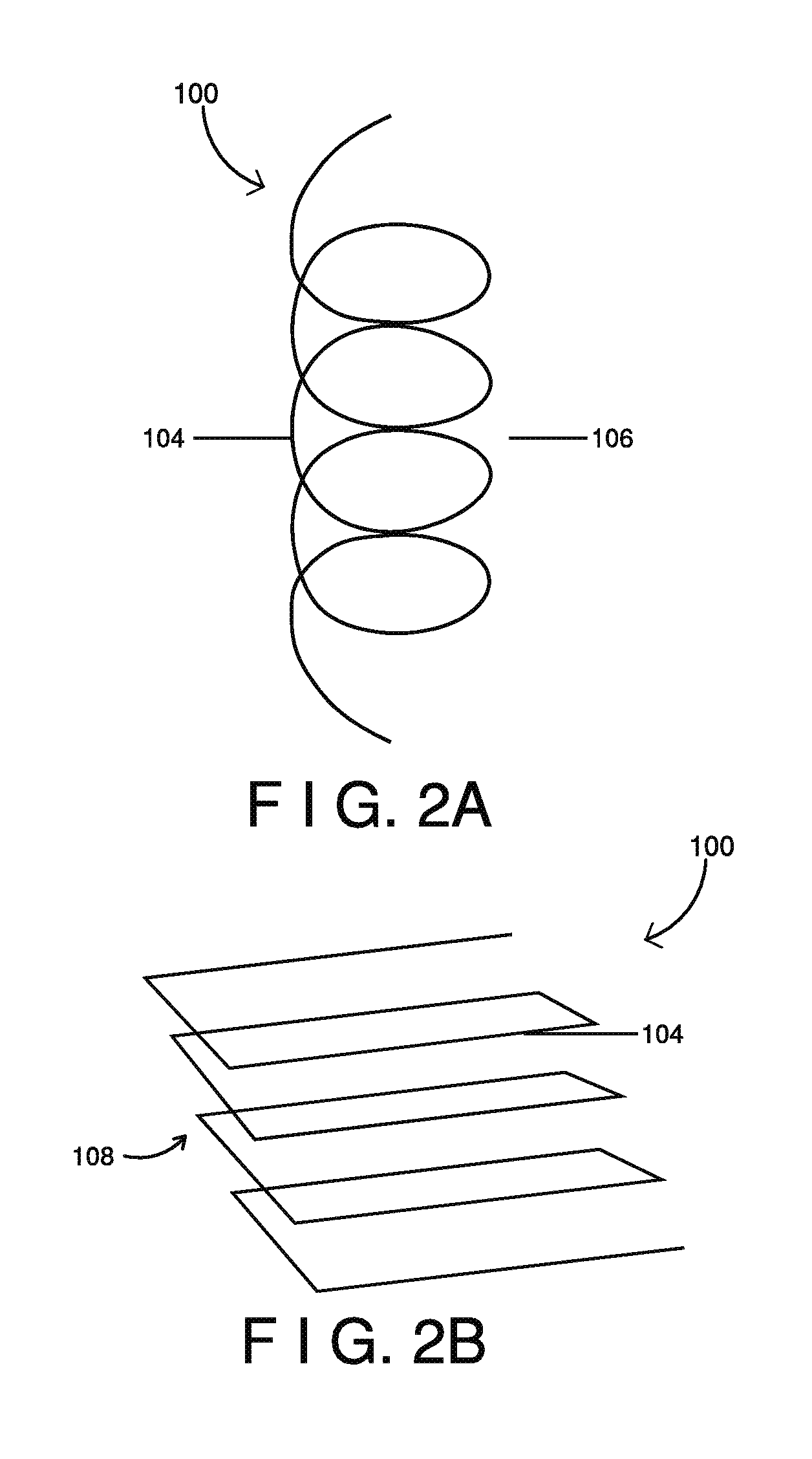

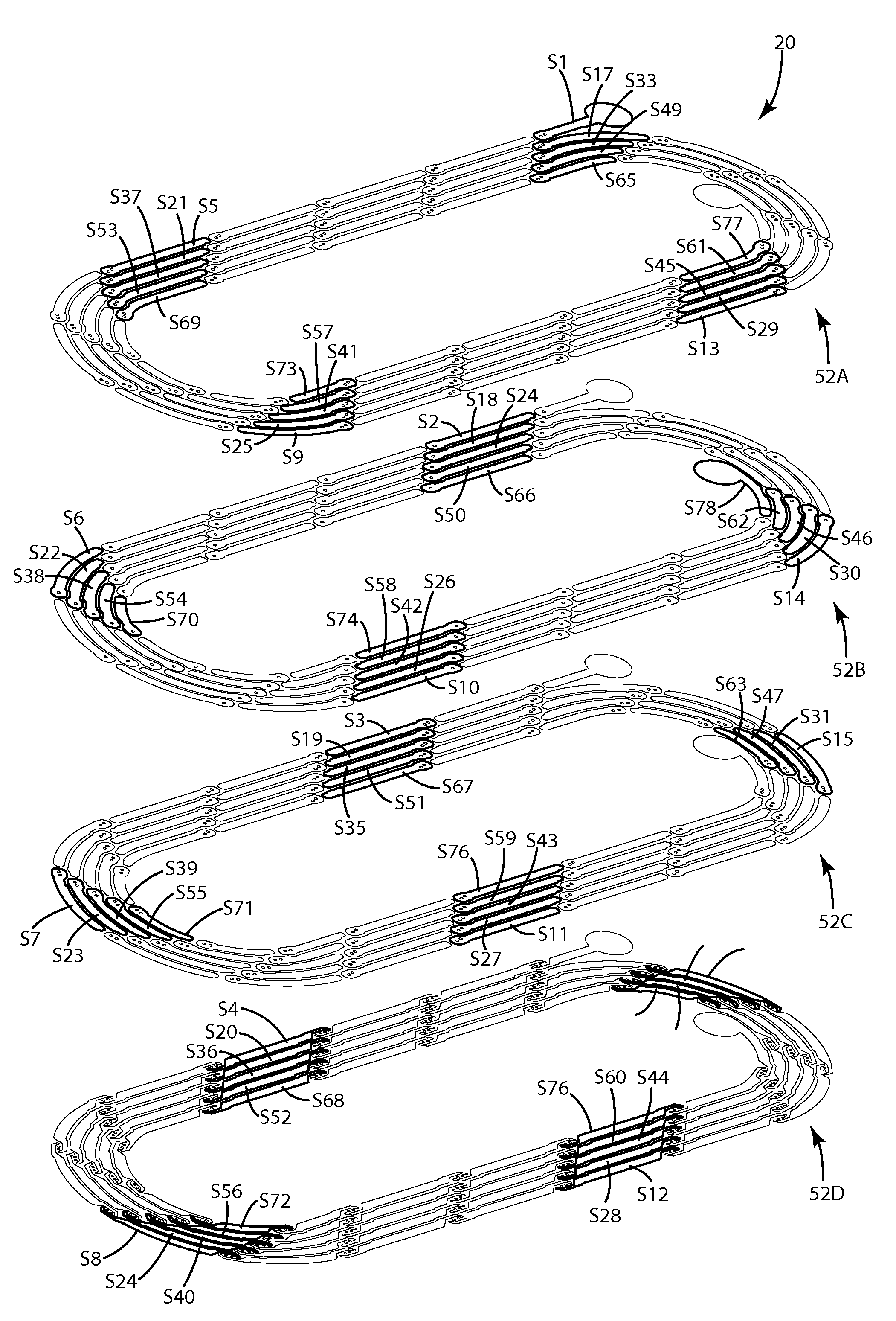

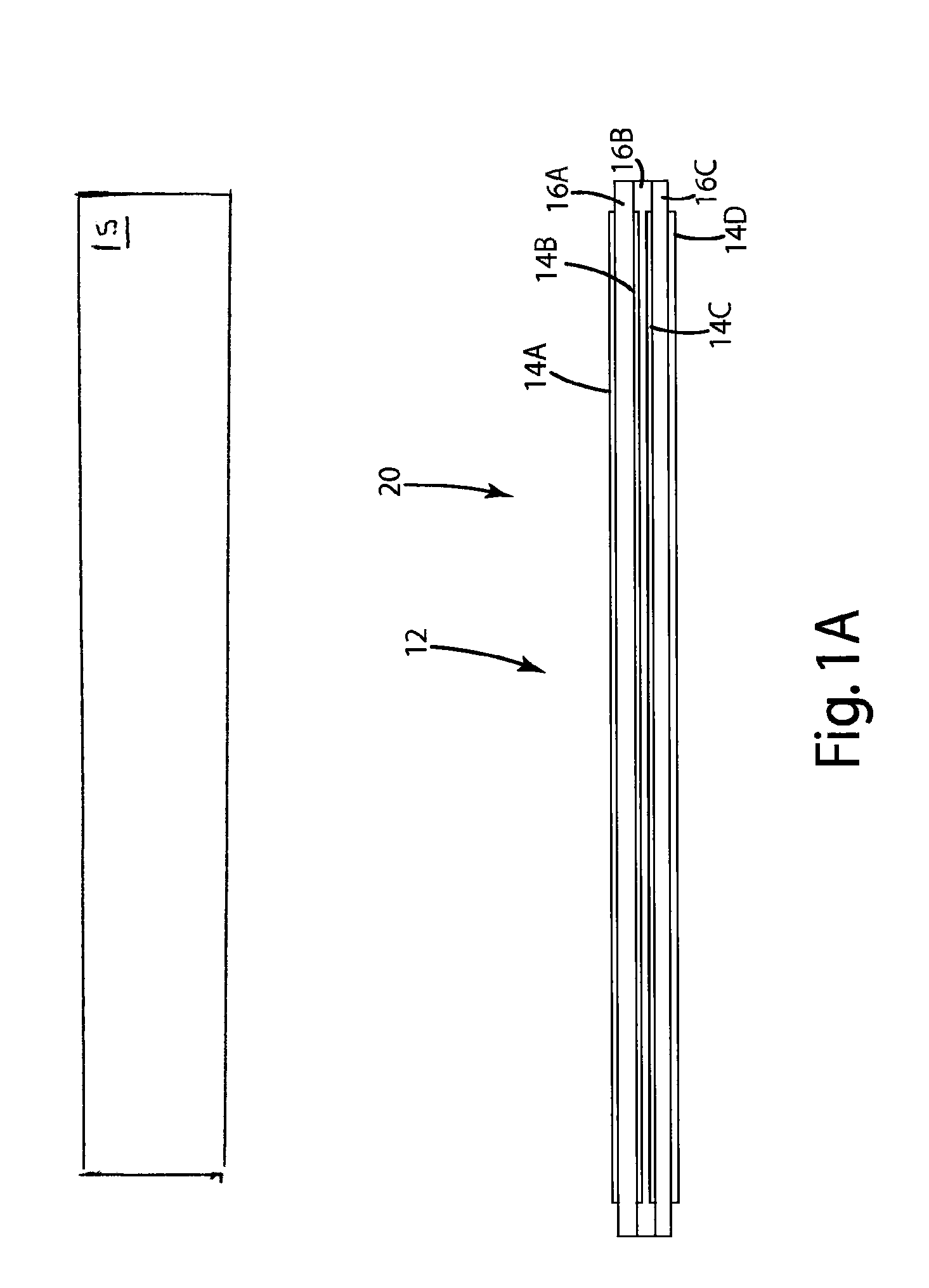

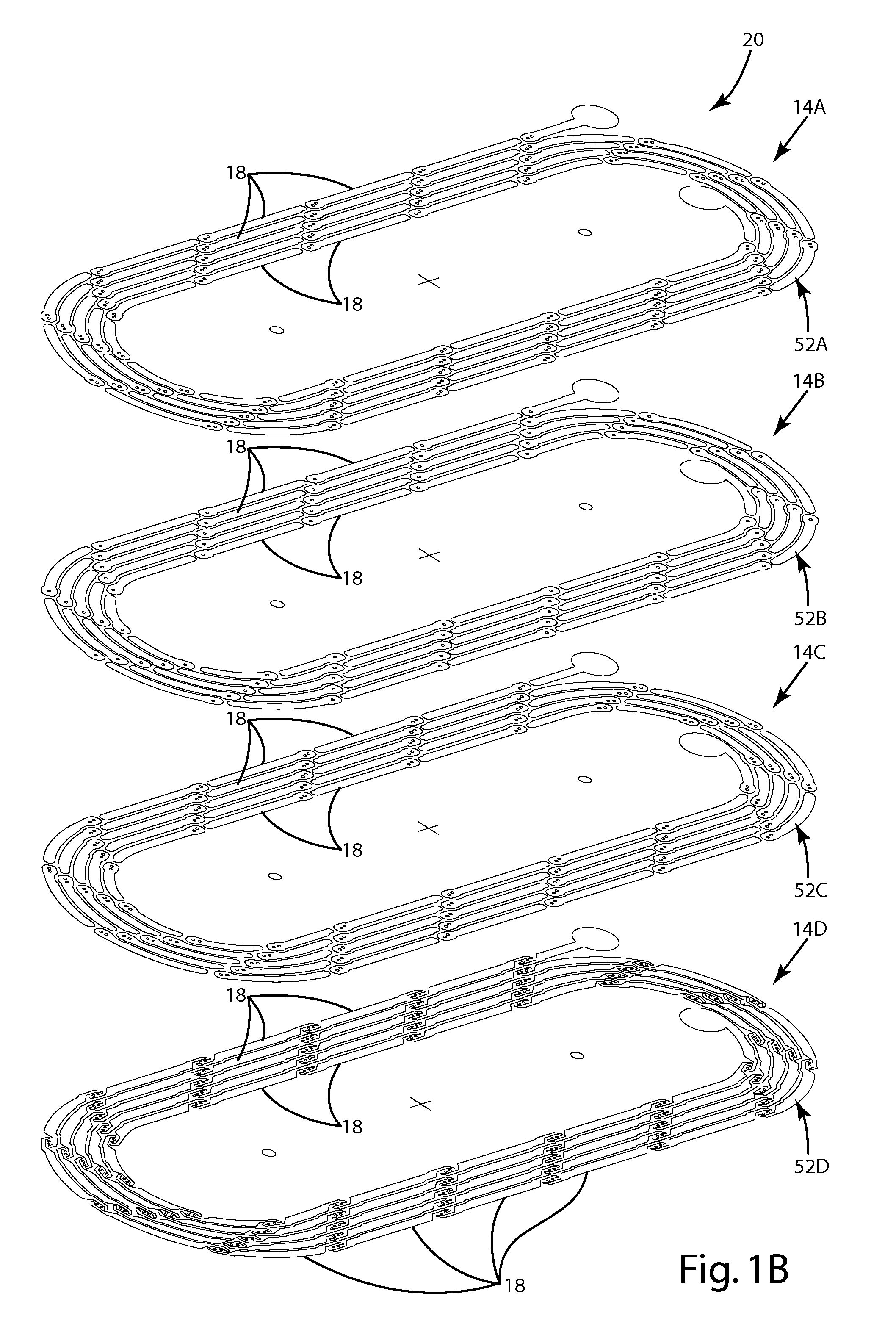

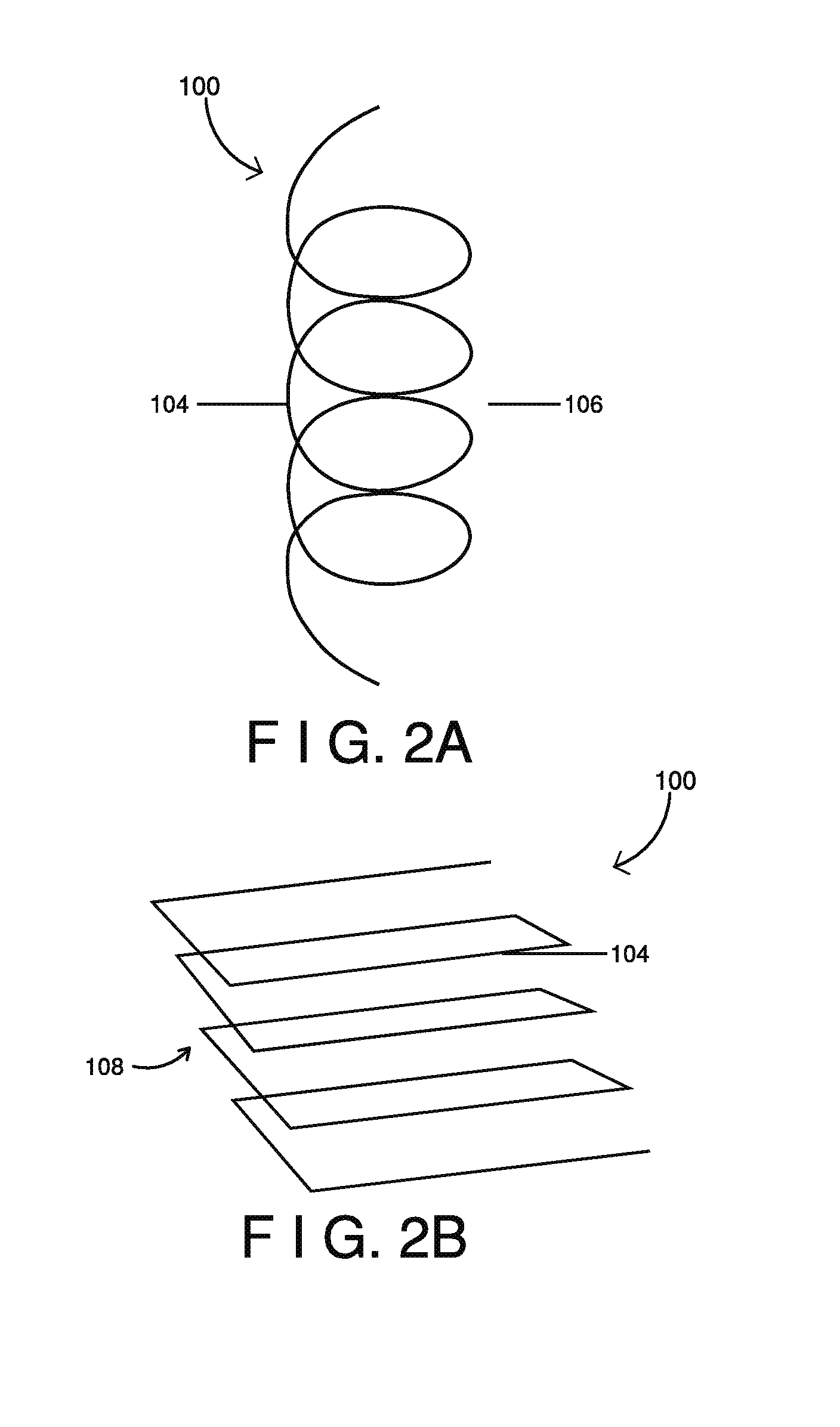

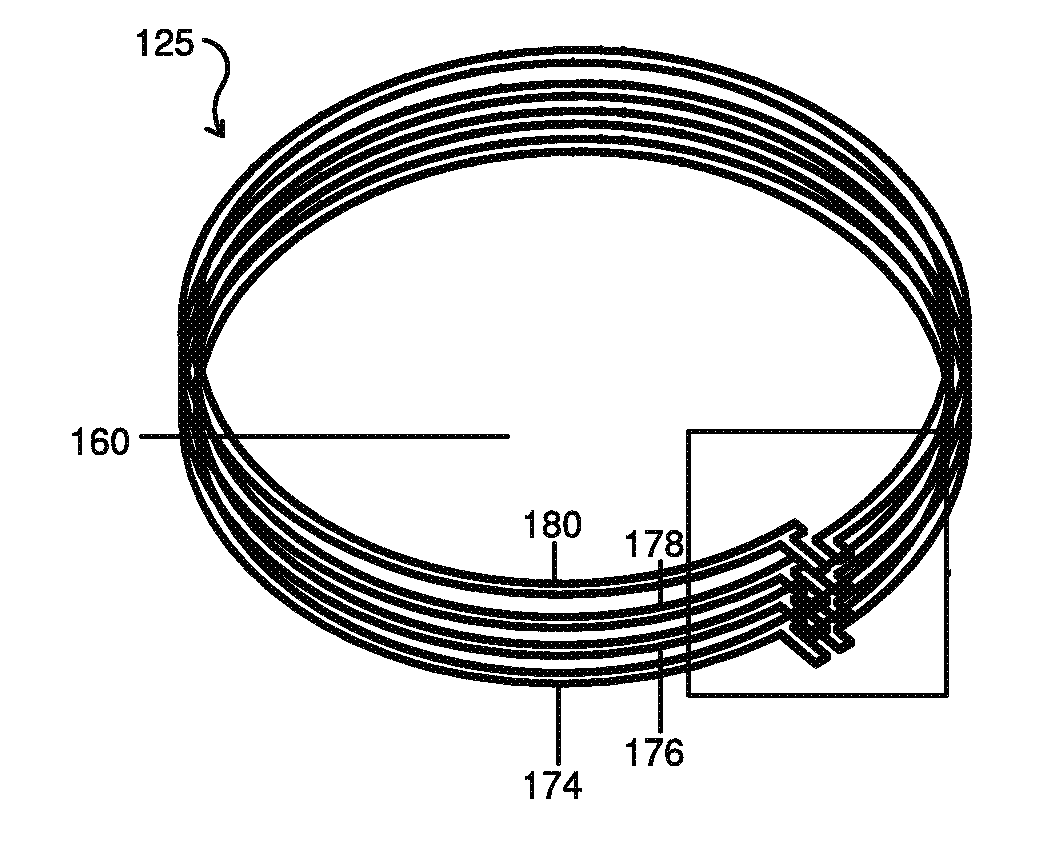

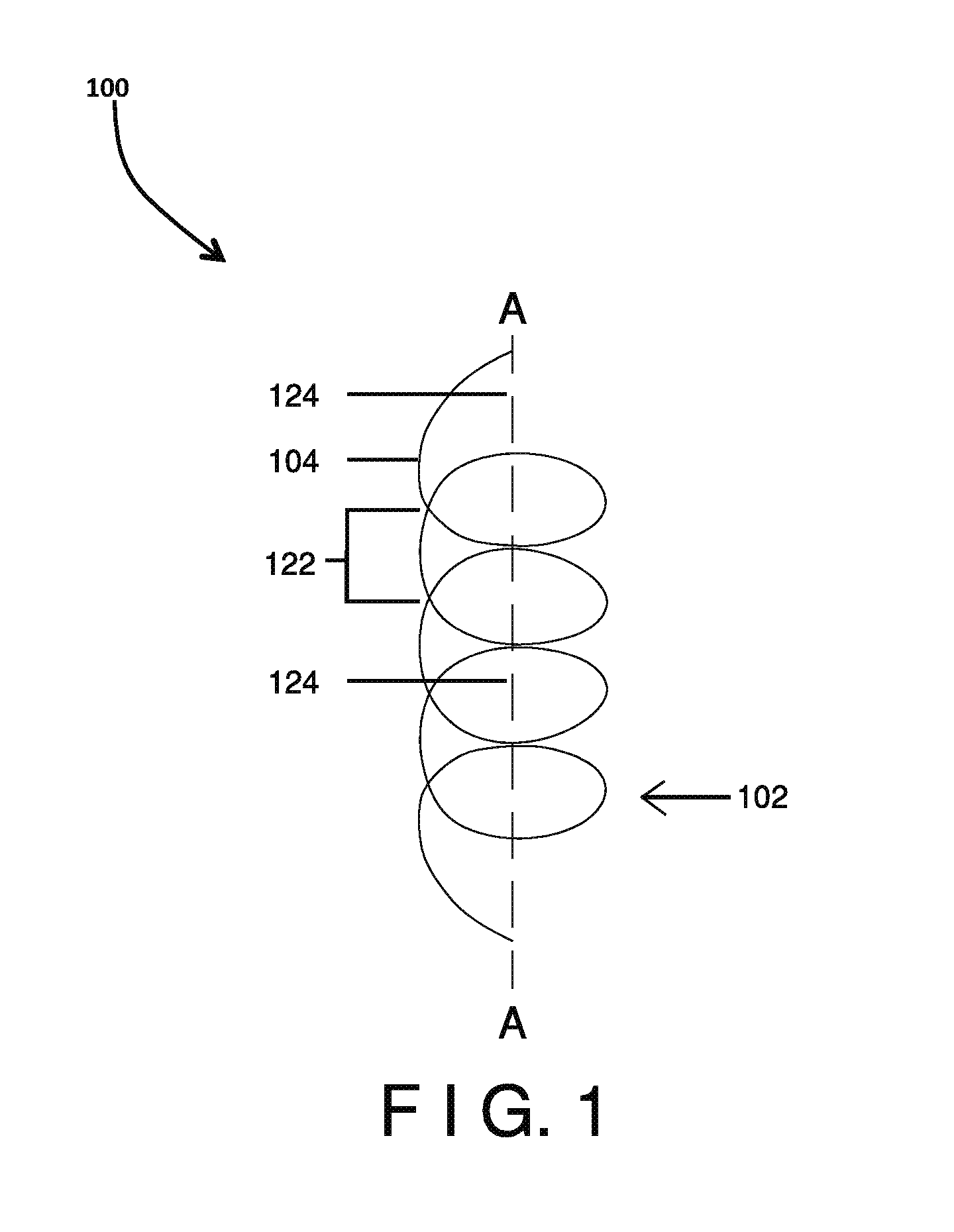

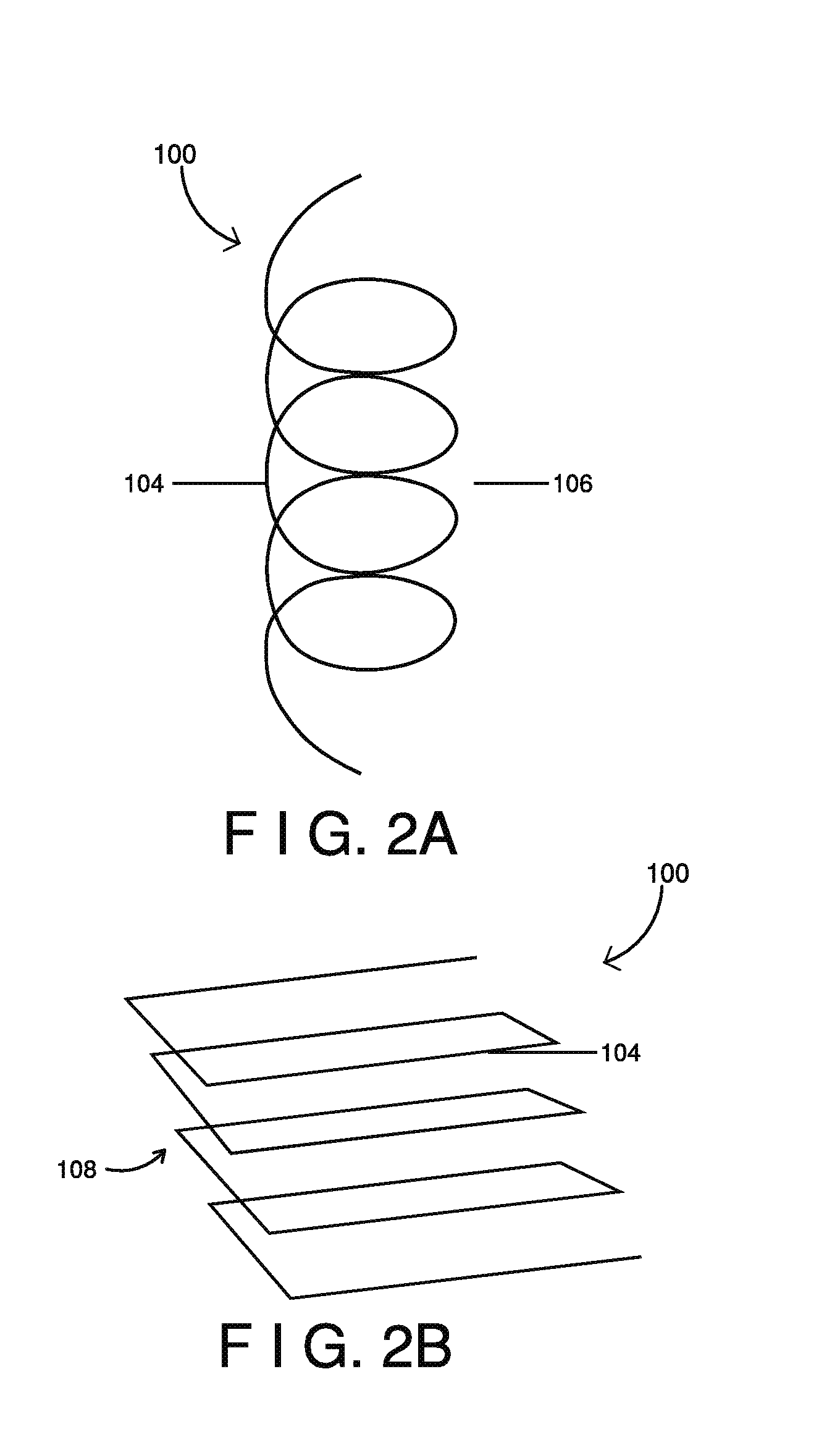

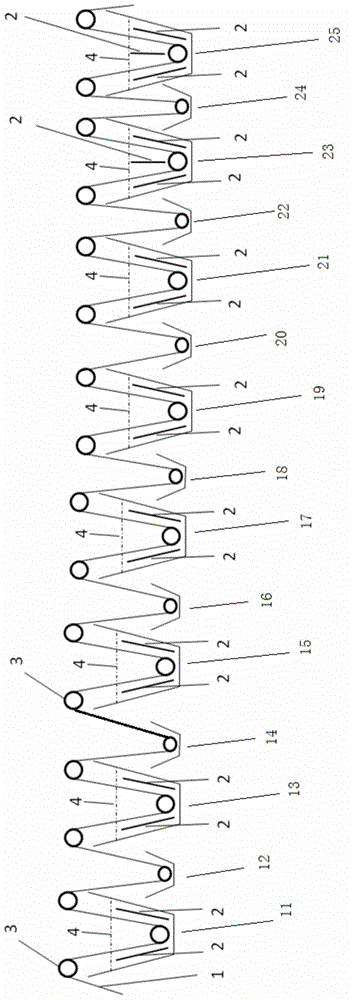

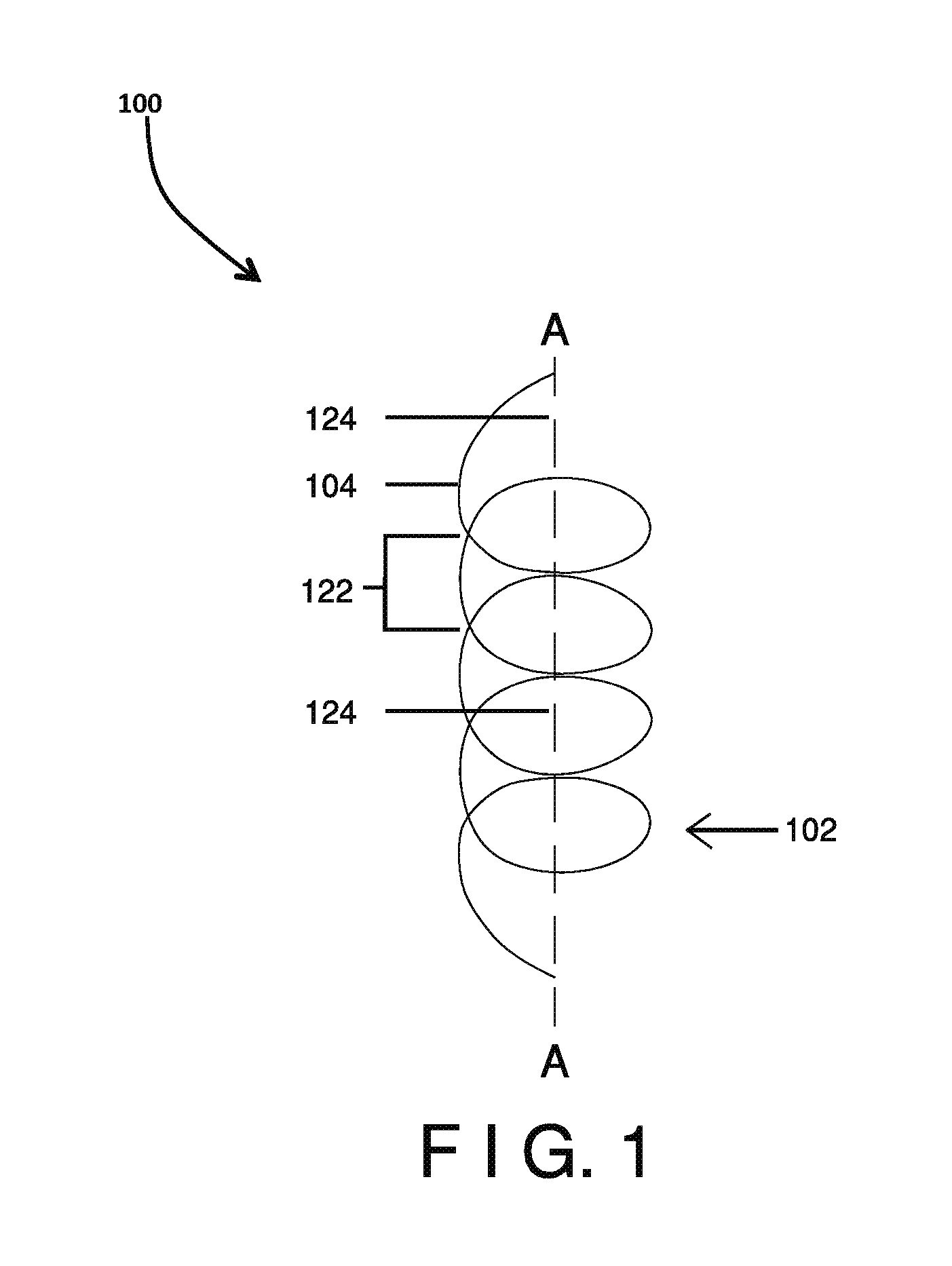

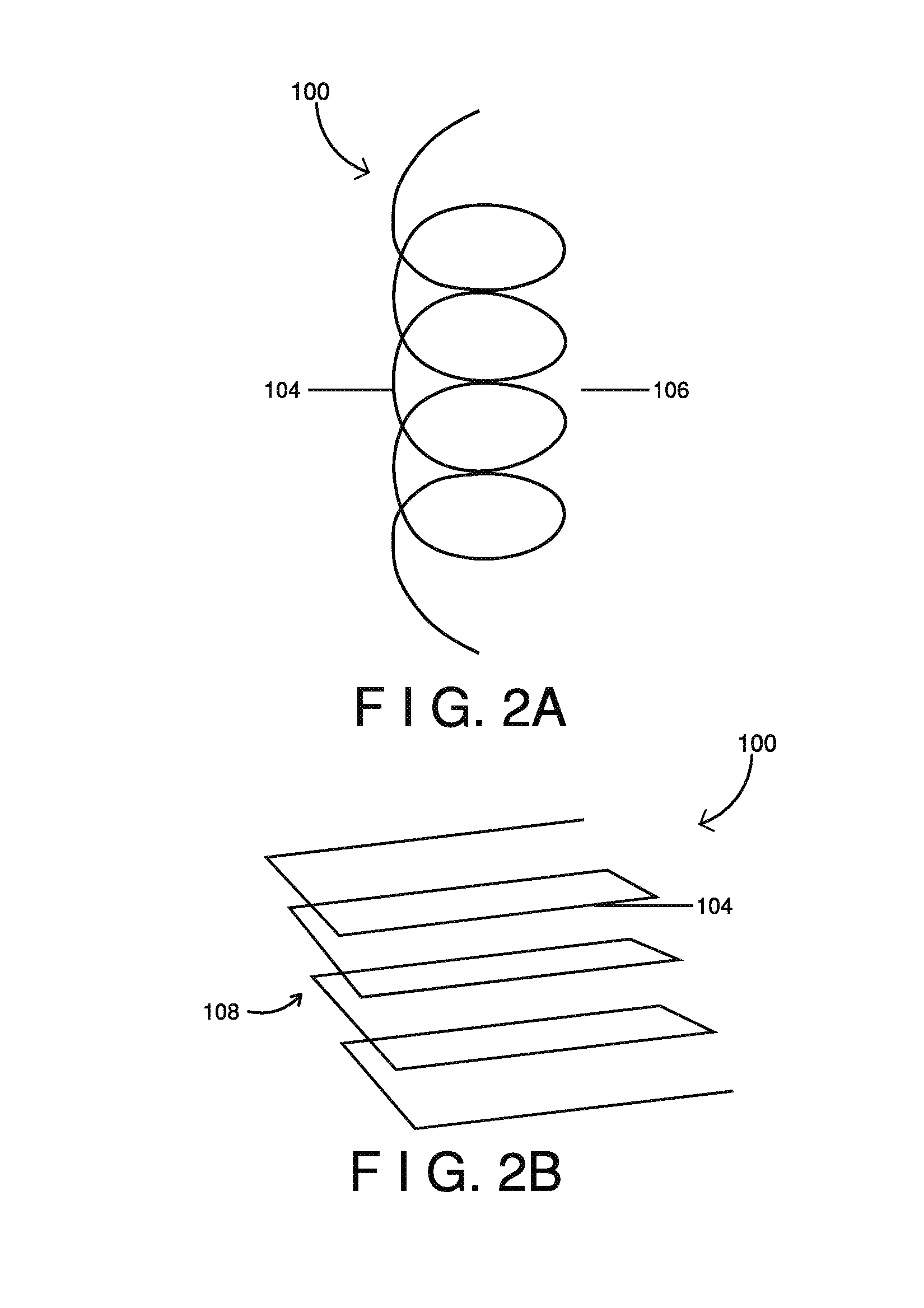

A multilayer printed circuit board (“PCB”) coil that simulates a coil formed from litz wire. The PCB includes a plurality of alternating conductor and insulating layers interconnected to cooperatively form the coil. Each conductor layer includes a trace that follows the desired coil shape and is divided into a plurality of discrete conductor segments. The segments are electrically connected across layers to provide a plurality of current flow paths (or filaments) that undulate between the layers in a regular, repeating pattern. The coil may be configured so that each filament spends a substantially equal amount of time in proximity to the paired coil and therefore contributes substantially equally to the self or mutual inductance of the coil. Each conductor layer may include a plurality of associated traces and intralayer connector that interconnected so that each filament undulates not only upwardly / downwardly, but also inwardly / outwardly in a regular, repeating pattern.

Owner:PHILIPS IP VENTURES BV

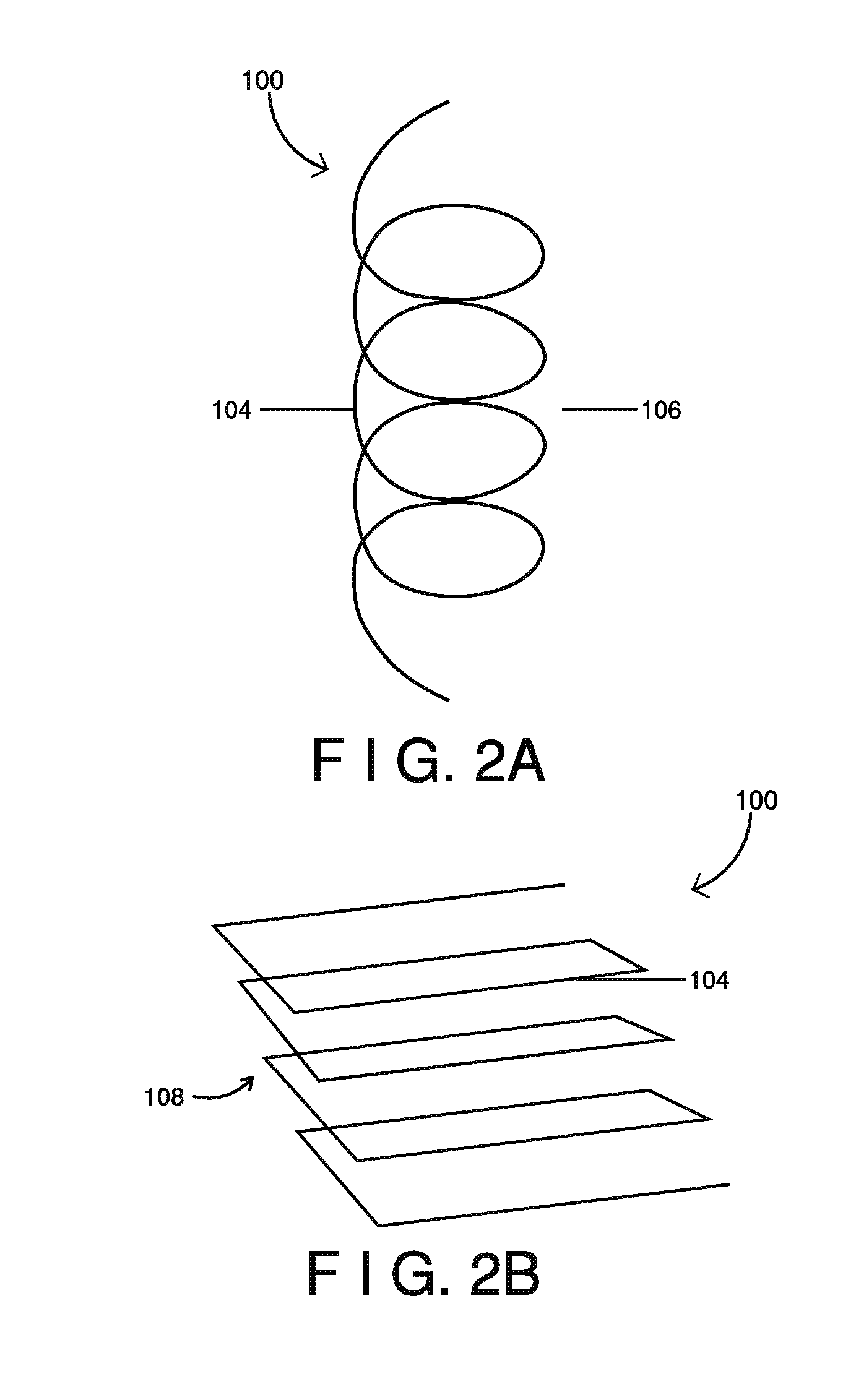

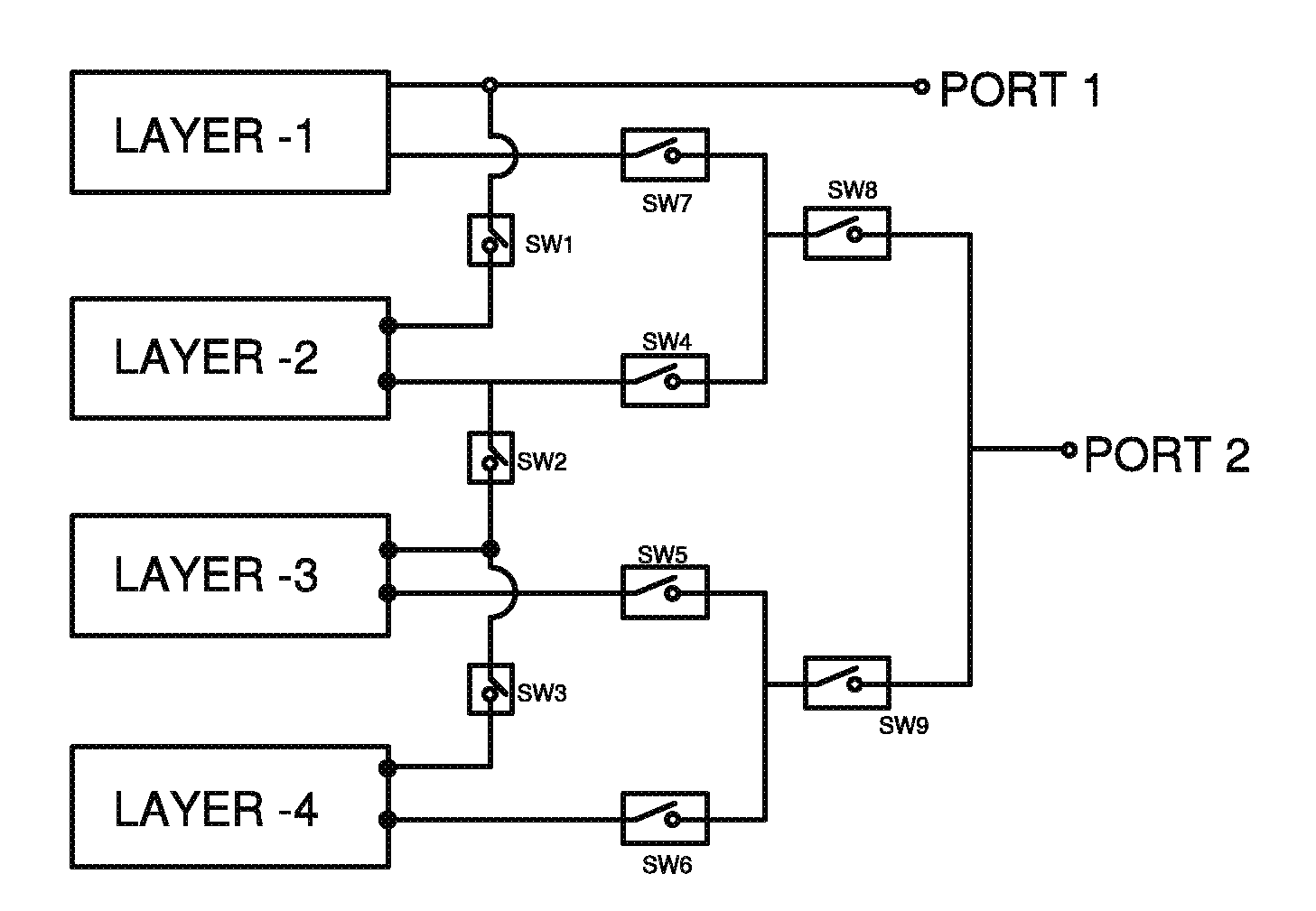

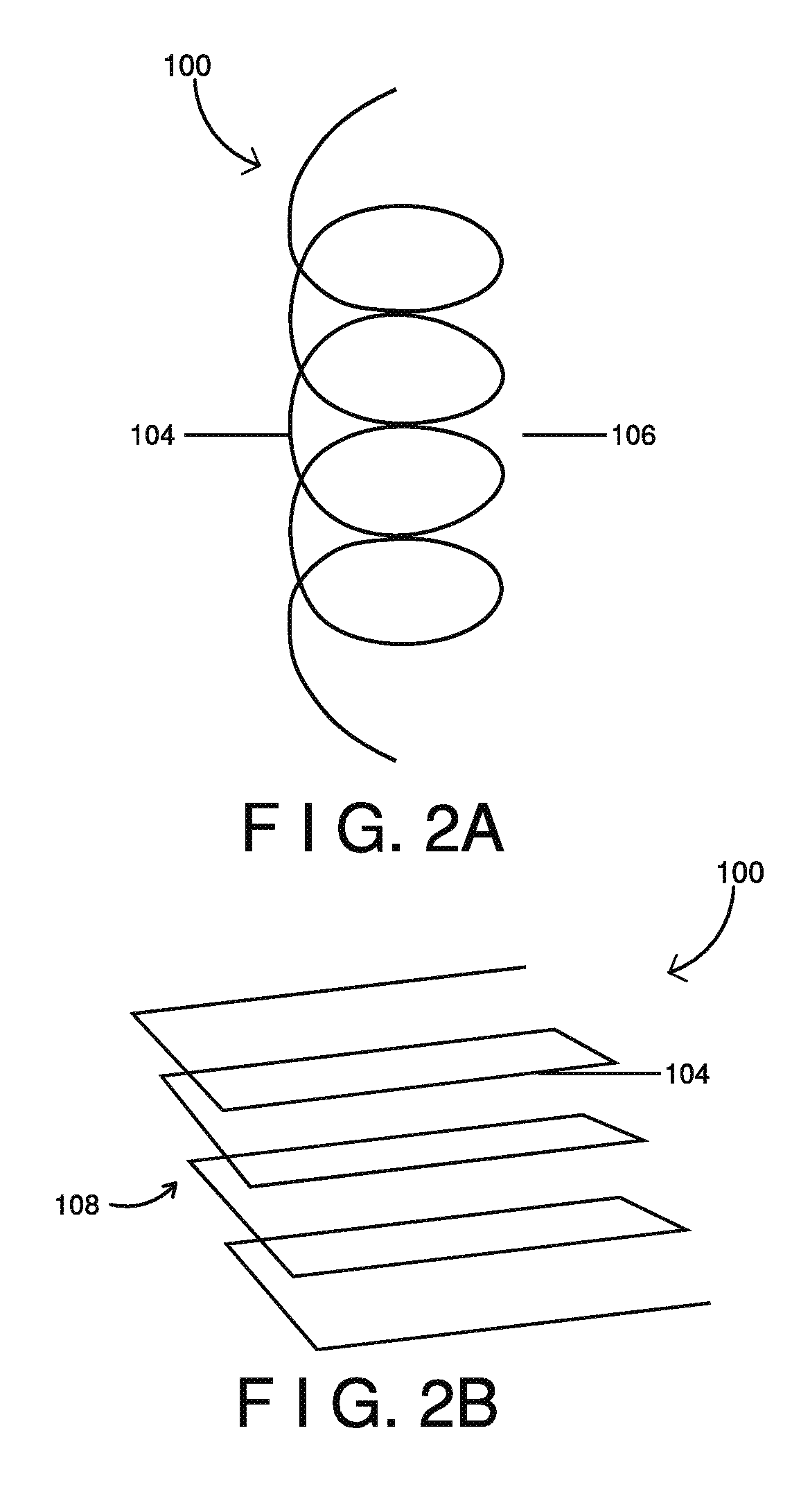

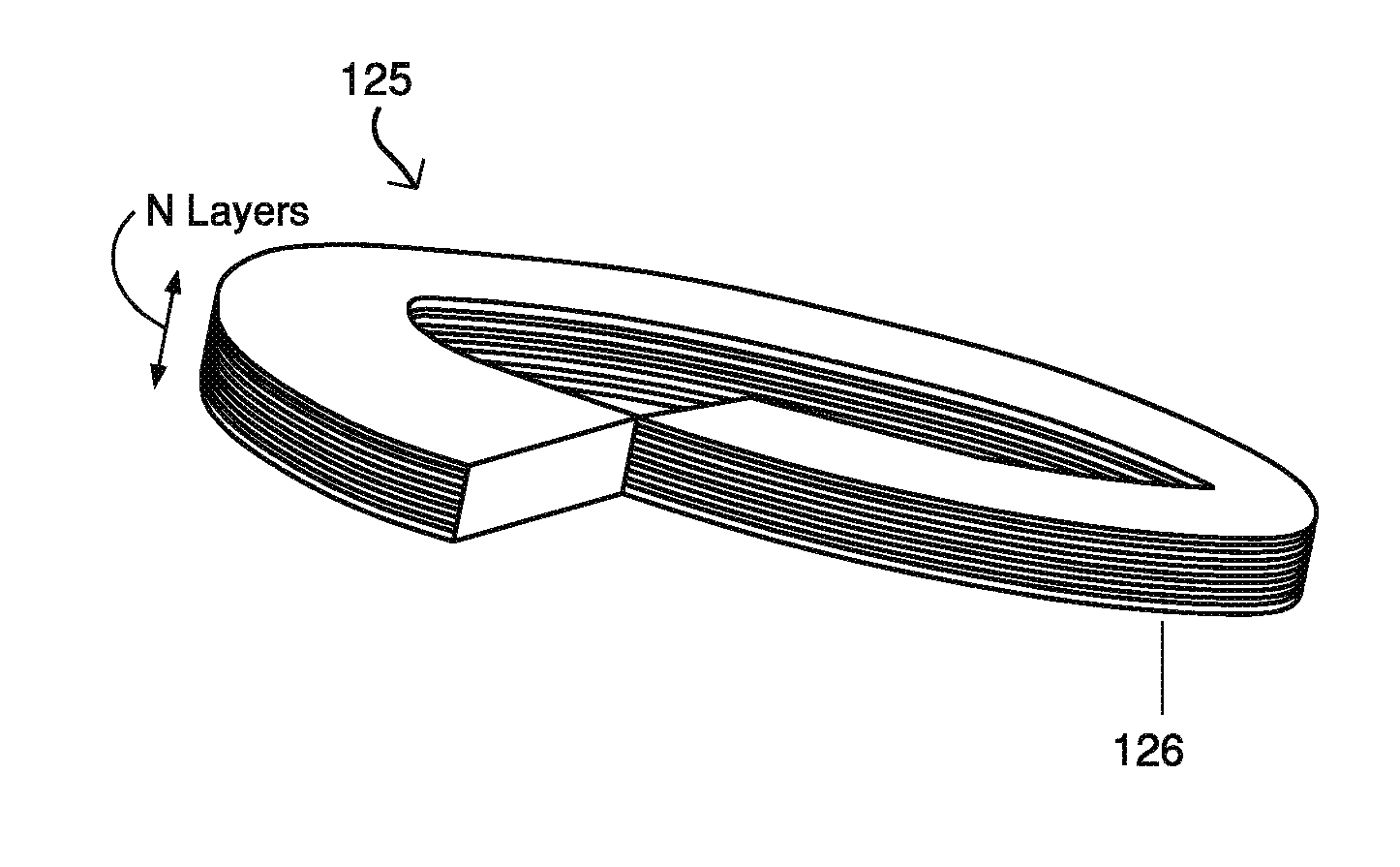

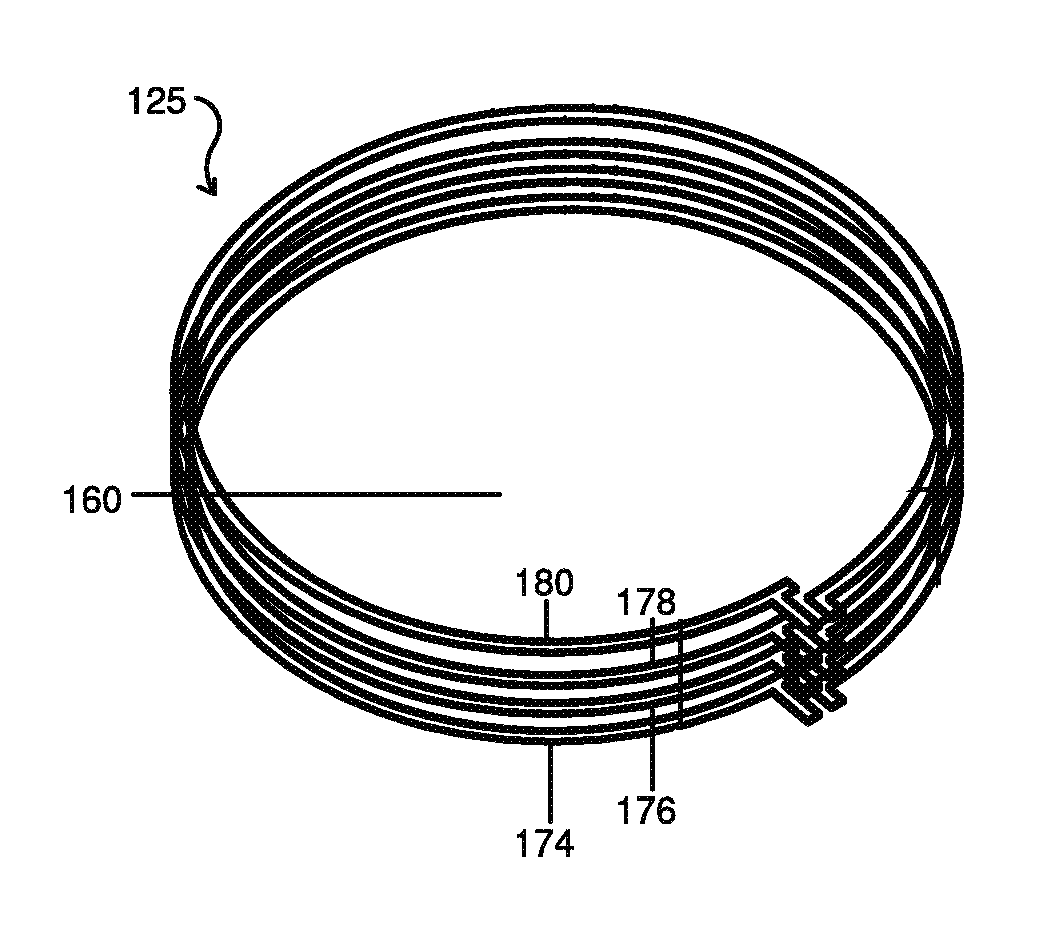

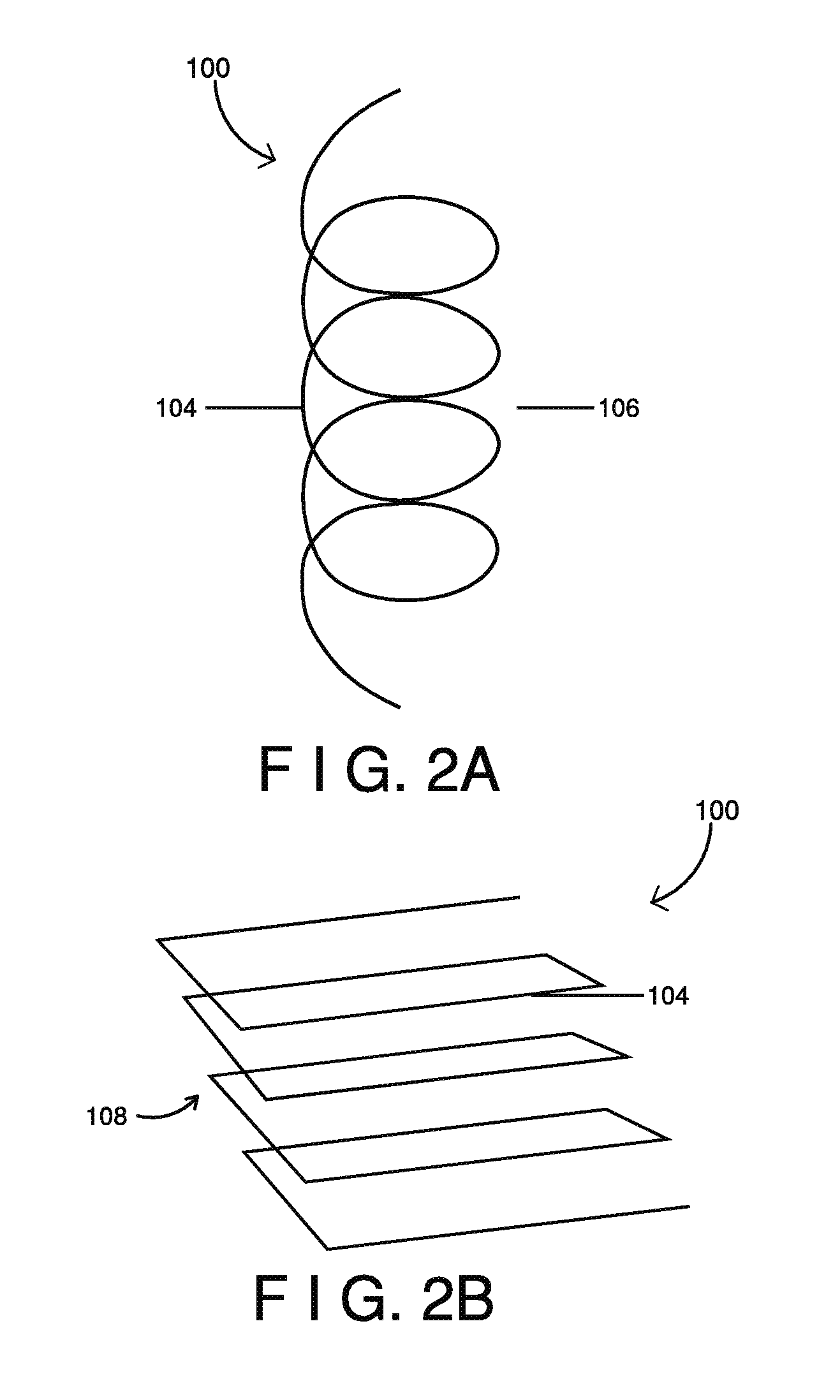

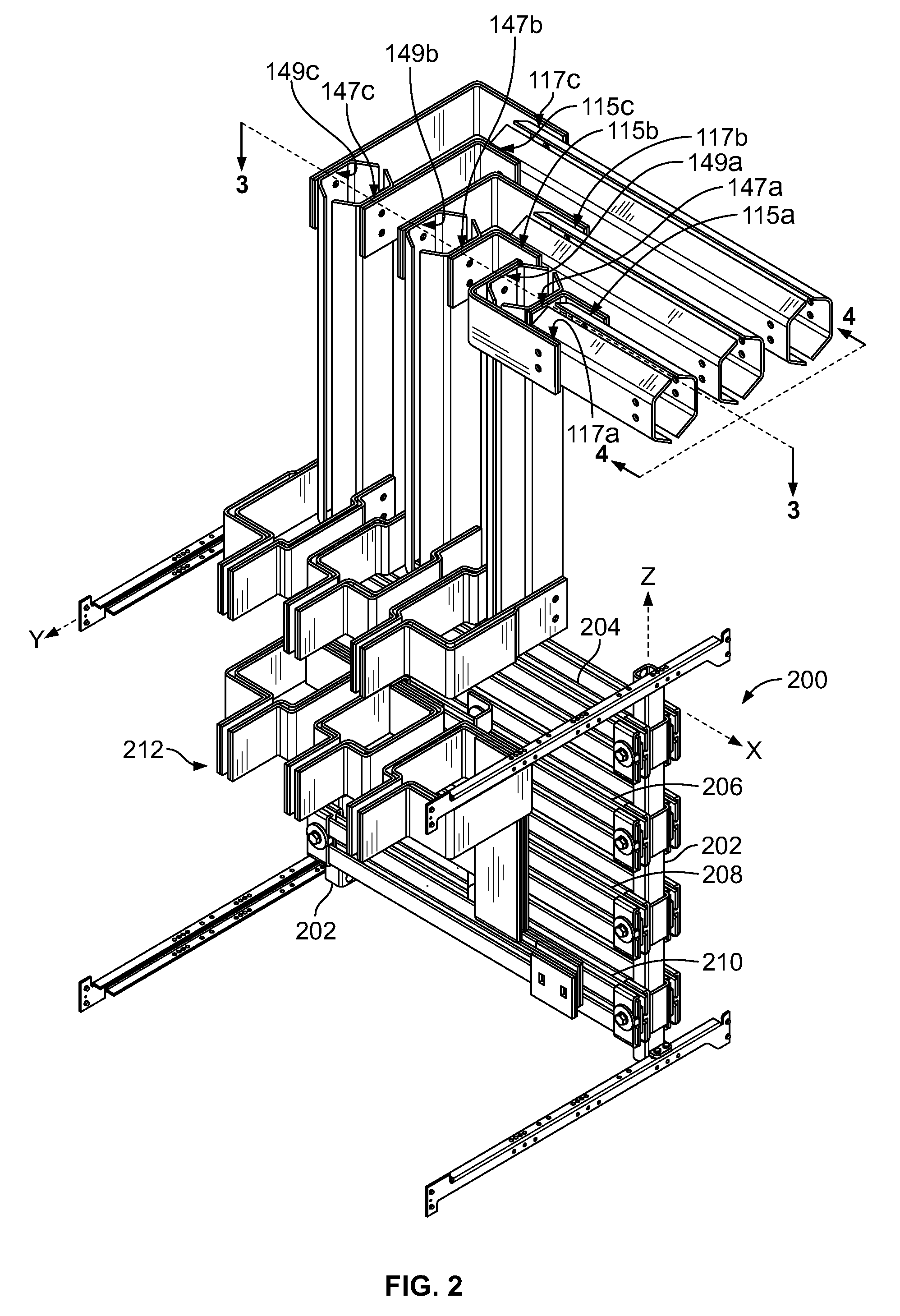

Method for manufacture of multi-layer-multi-turn high efficiency inductors

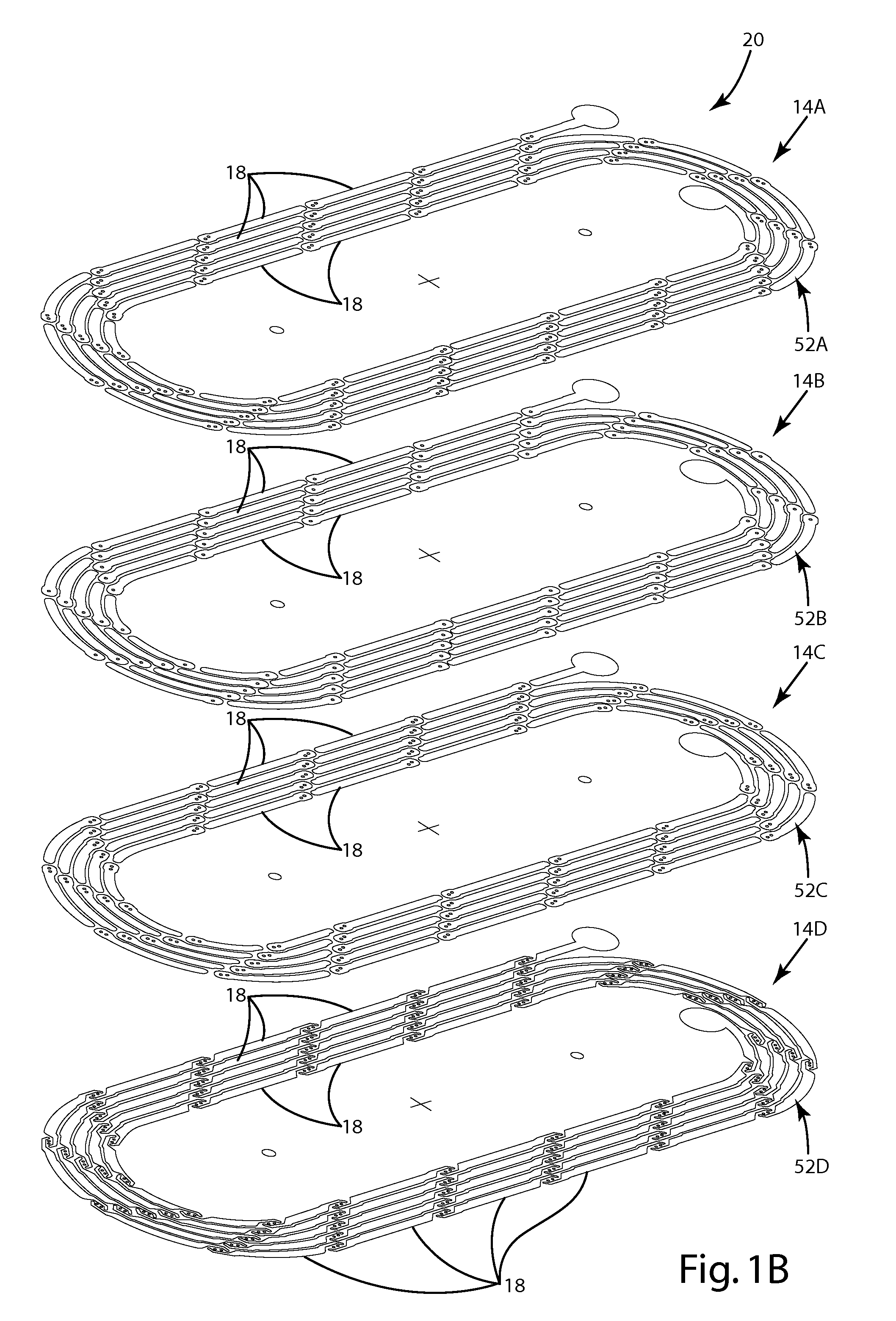

ActiveUS20130199027A1Low quality factorReduction of resistance lossInternal electrodesTransformers/inductances coils/windings/connectionsRadio frequencyInductor

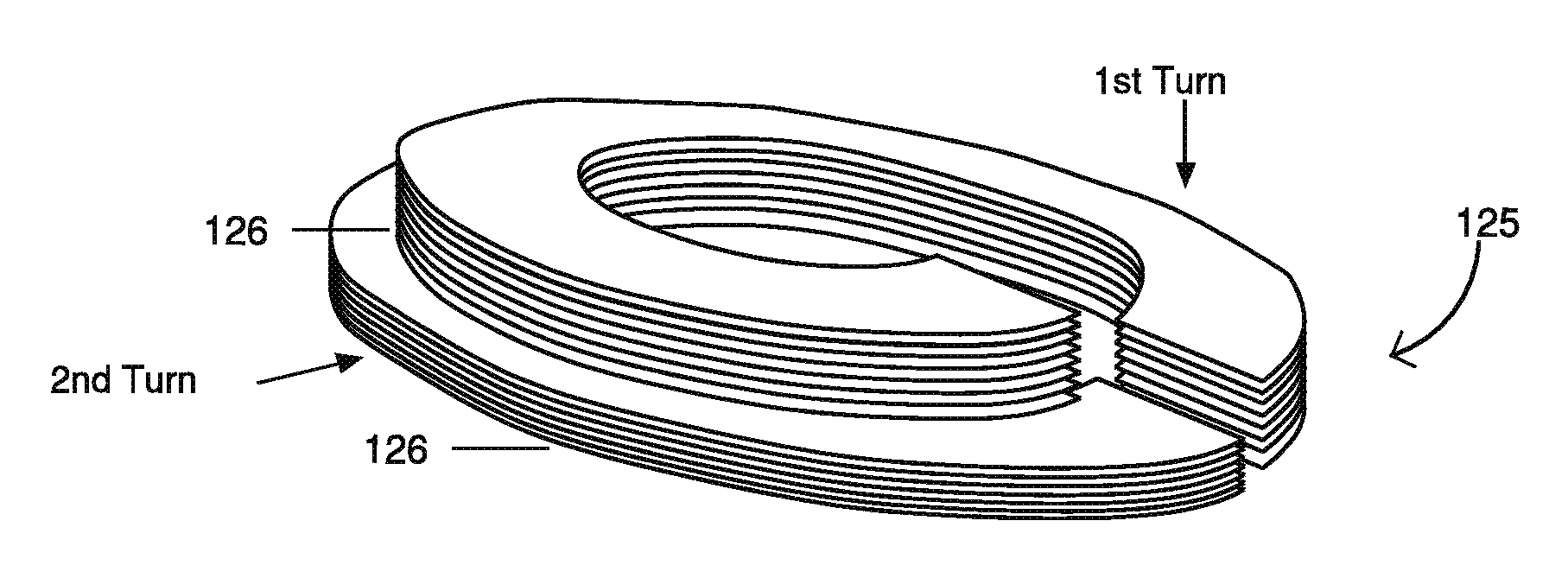

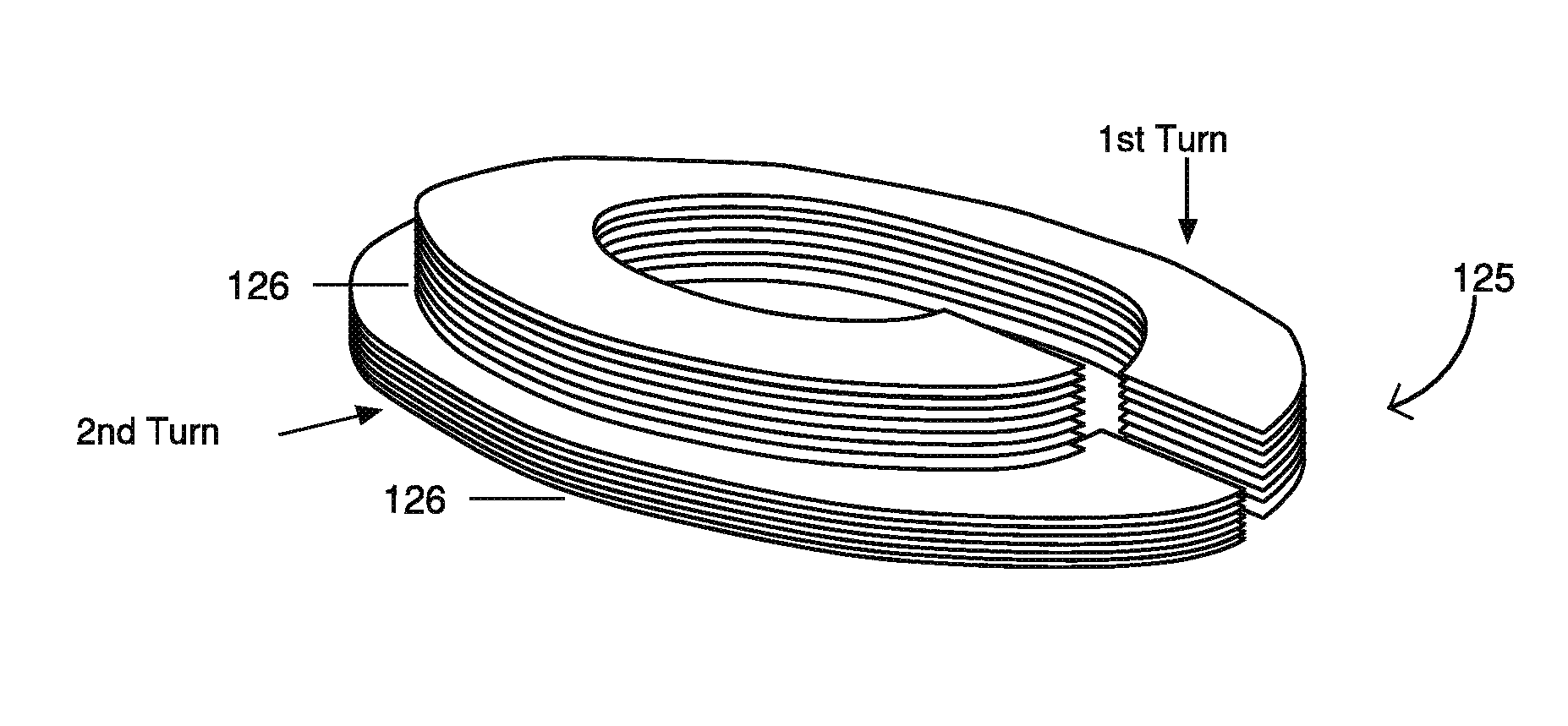

A multi-layer, multi-turn structure for an inductor having a plurality of conductor layers separated by layers of insulator is described. The inductor further comprises a connector electrically connected between the conductor layers. The structure of the inductor may comprise a cavity therewithin. The structure of the inductor constructed such that electrical resistance is reduced therewithin, thus increasing the efficiency of the inductor. The inductor is particularly useful at operating within the radio frequency range and greater.

Owner:NUCURRENT INC

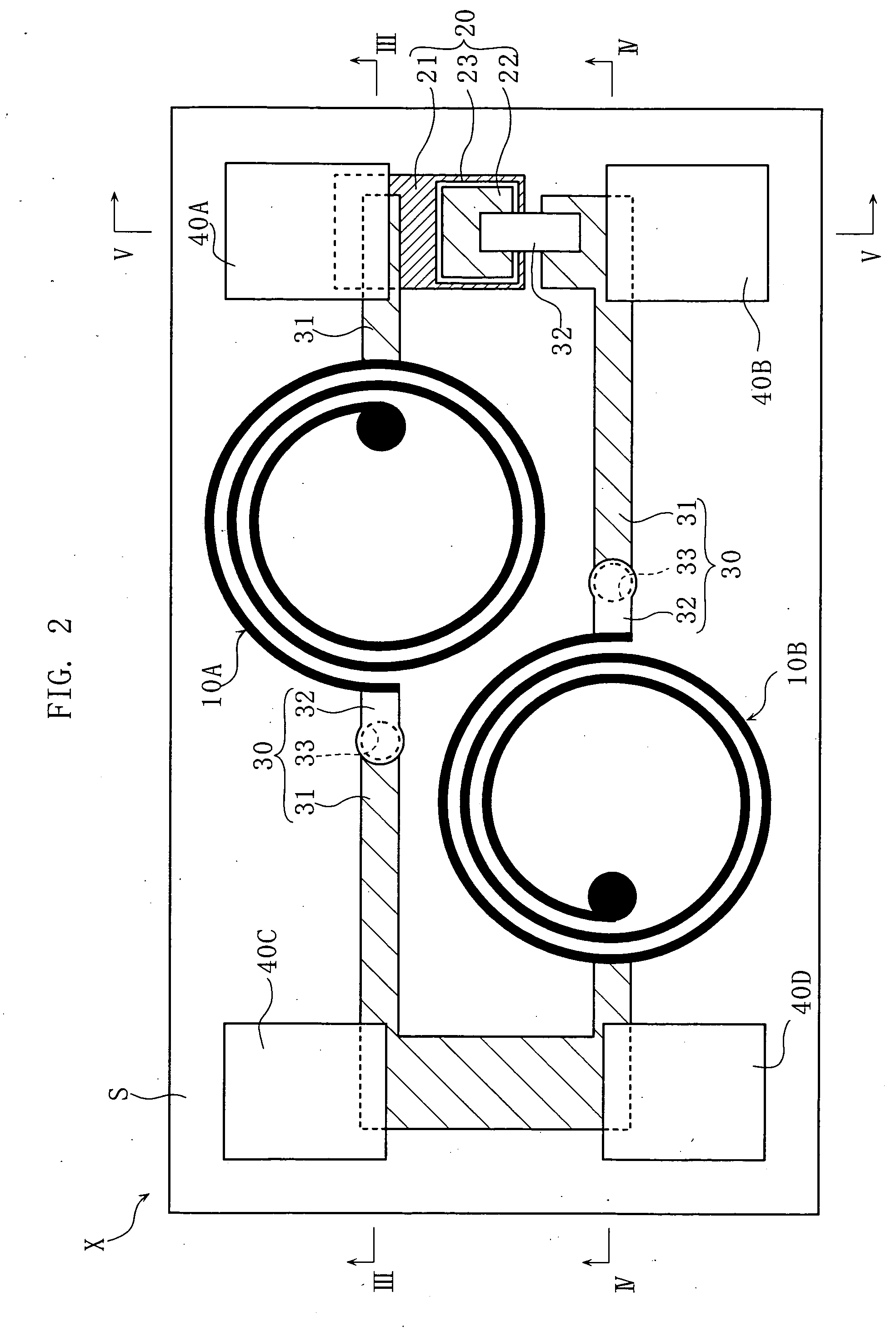

Integrated electronic device and method of making the same

ActiveUS20070045773A1Small sizeReduce skin effectMultiple-port networksSemiconductor/solid-state device detailsInductorInductance

An integrated electronic device includes a substrate, passive components, pads for external connection, and three-dimensional wiring. The passive components includes a multi-stage coil inductor provided on the substrate. The multi-stage coil inductor has a plurality of coils disposed in several layers. Mutually adjacent coil wires are spaced-apart from each other. The three-dimensional wiring includes a first wiring portion which extends on the substrate, a second wiring portion which extends off the substrate but along the substrate, and a third wiring portion connecting with the first wiring portion and the second wiring portion.

Owner:TAIYO YUDEN KK

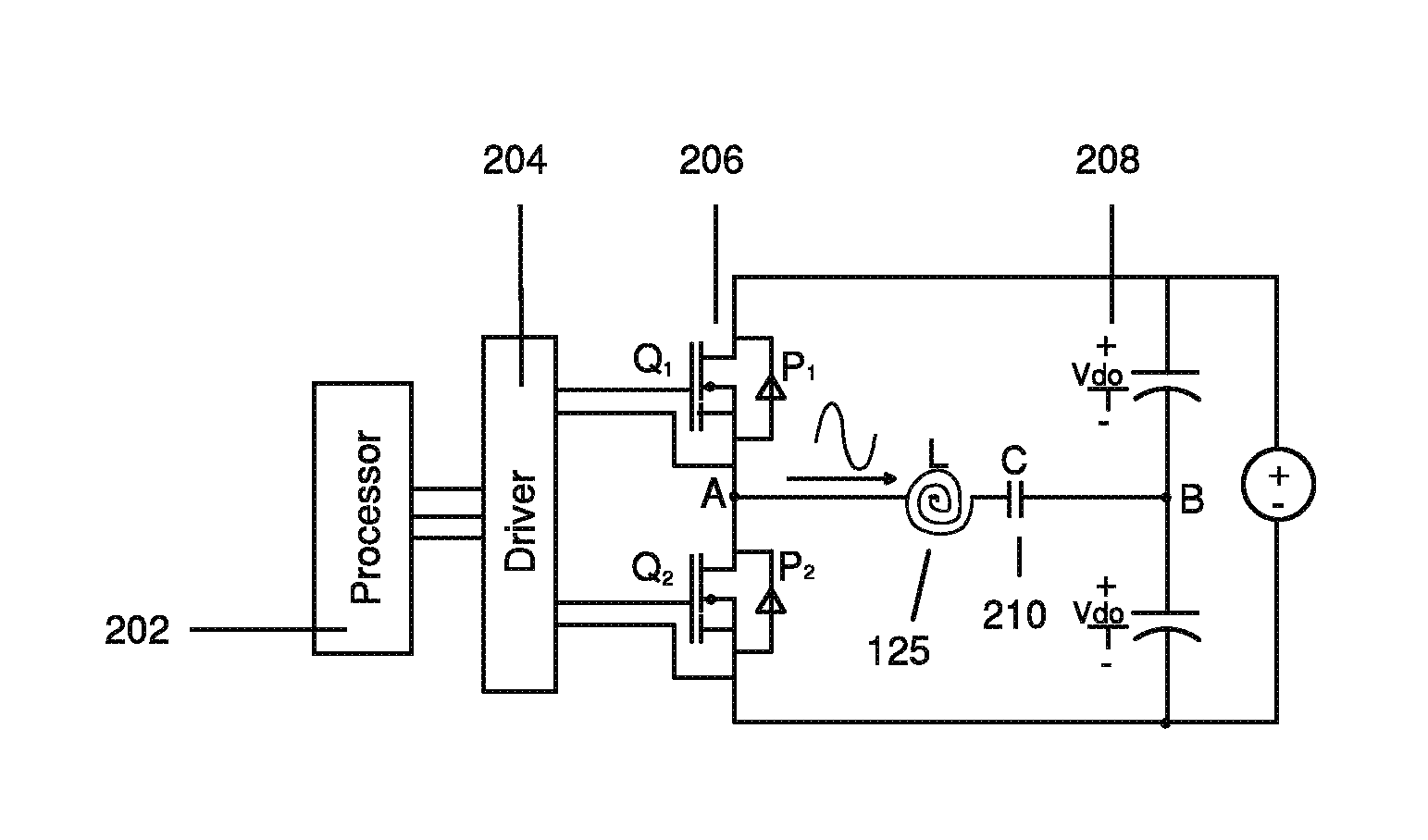

Systems using multi-layer-multi-turn high efficiency inductors

ActiveUS20130208390A1Higher resistive lossIncrease qualify factorTransformers/inductances coils/windings/connectionsInternal electrodesElectrical resistance and conductanceElectricity

Owner:NUCURRENT INC

Method for manufacture of multi-layer-multi-turn high efficiency inductors with cavity

ActiveUS20130205582A1Higher resistive lossIncrease qualify factorMultiple-port networksInternal electrodesElectrical resistance and conductanceElectrical conductor

A multi-layer, multi-turn structure for an inductor having a plurality of conductor layers separated by layers of insulator is described. The inductor further comprises a connector electrically connected between the conductor layers. The structure of the inductor may comprise a cavity therewithin. The structure of the inductor constructed such that electrical resistance is reduced therewithin, thus increasing the efficiency of the inductor. The inductor is particularly useful at operating within the radio frequency range and greater.

Owner:NUCURRENT INC

Multi-layer-multi-turn structure for tunable high efficiency inductors

ActiveUS20130200969A1Low quality factorReduction of resistance lossTransformers/inductances coils/windings/connectionsInternal electrodesRadio frequencyInductor

A multi-layer, multi-turn structure for an inductor having a plurality of conductor layers separated by layers of insulator is described. The inductor further comprises a connector electrically connected between the conductor layers. The structure of the inductor may comprise a cavity therewithin. The structure of the inductor constructed such that electrical resistance is reduced therewithin, thus increasing the efficiency of the inductor. The inductor is particularly useful at operating within the radio frequency range and greater.

Owner:NUCURRENT INC

Multi-layer-multi-turn high efficiency inductors for an induction heating system

ActiveUS20130200070A1Higher resistive lossLower quality factorTransformers/inductances coils/windings/connectionsInternal electrodesElectrical resistance and conductanceElectricity

A multi-layer, multi-turn structure for an inductor having a plurality of conductor layers separated by layers of insulator is described. The inductor further comprises a connector electrically connected between the conductor layers. The structure of the inductor may comprise a cavity therewithin. The structure of the inductor constructed such that electrical resistance is reduced therewithin, thus increasing the efficiency of the inductor. The inductor is particularly useful at operating within the radio frequency range and greater.

Owner:NUCURRENT INC

Printed circuit board coil

ActiveUS7973635B2Reliable and easily implementedImprove coiling efficiencyTransformersTransformers/inductances coils/windings/connectionsElectrical conductorLitz wire

A multilayer printed circuit board (“PCB”) coil that simulates a coil formed from litz wire. The PCB includes a plurality of alternating conductor and insulating layers interconnected to cooperatively form the coil. Each conductor layer includes a trace that follows the desired coil shape and is divided into a plurality of discrete conductor segments. The segments are electrically connected across layers to provide a plurality of current flow paths (or filaments) that undulate between the layers in a regular, repeating pattern. The coil may be configured so that each filament spends a substantially equal amount of time in proximity to the paired coil and therefore contributes substantially equally to the self or mutual inductance of the coil. Each conductor layer may include a plurality of associated traces and intralayer connector that interconnected so that each filament undulates not only upwardly / downwardly, but also inwardly / outwardly in a regular, repeating pattern.

Owner:PHILIPS IP VENTURES BV

Multi-layer-multi-turn high efficiency inductors with cavity structures

ActiveUS20130200976A1Higher resistive lossLower quality factorInternal electrodesTransformers/inductances coils/windings/connectionsElectrical resistance and conductanceElectrical conductor

A multi-layer, multi-turn structure for an inductor having a plurality of conductor layers separated by layers of insulator is described. The inductor further comprises a connector electrically connected between the conductor layers. The structure of the inductor may comprise a cavity therewithin. The structure of the inductor constructed such that electrical resistance is reduced therewithin, thus increasing the efficiency of the inductor. The inductor is particularly useful at operating within the radio frequency range and greater.

Owner:NUCURRENT INC

Method for operation of multi-layer-multi-turn high efficiency tunable inductors

ActiveUS20130201589A1Higher resistive lossLower quality factorInternal electrodesTransformers/inductances coils/windings/connectionsElectrical resistance and conductanceElectrical conductor

A multi-layer, multi-turn structure for an inductor having a plurality of conductor layers separated by layers of insulator is described. The inductor further comprises a connector electrically connected between the conductor layers. The structure of the inductor may comprise a cavity therewithin. The structure of the inductor constructed such that electrical resistance is reduced therewithin, thus increasing the efficiency of the inductor. The inductor is particularly useful at operating within the radio frequency range and greater.

Owner:NUCURRENT INC

Method for operation of multi-layer-multi-turn high efficiency inductors

ActiveUS20130200722A1Higher resistive lossLower quality factorInternal electrodesTransformers/inductances coils/windings/connectionsElectrical resistance and conductanceElectrical conductor

A multi-layer, multi-turn structure for an inductor having a plurality of conductor layers separated by layers of insulator is described. The inductor further comprises a connector electrically connected between the conductor layers. The structure of the inductor may comprise a cavity therewithin. The structure of the inductor constructed such that electrical resistance is reduced therewithin, thus increasing the efficiency of the inductor. The inductor is particularly useful at operating within the radio frequency range and greater.

Owner:NUCURRENT INC

Method for operation of multi-layer-multi-turn high efficiency inductors with cavity structure

ActiveUS20130208389A1Higher resistive lossIncrease qualify factorTransformers/inductances coils/windings/connectionsInternal electrodesElectrical resistance and conductanceElectricity

A multi-layer, multi-turn structure for an inductor having a plurality of conductor layers separated by layers of insulator is described. The inductor further comprises a connector electrically connected between the conductor layers. The structure of the inductor may comprise a cavity therewithin. The structure of the inductor constructed such that electrical resistance is reduced therewithin, thus increasing the efficiency of the inductor. The inductor is particularly useful at operating within the radio frequency range and greater.

Owner:NUCURRENT INC

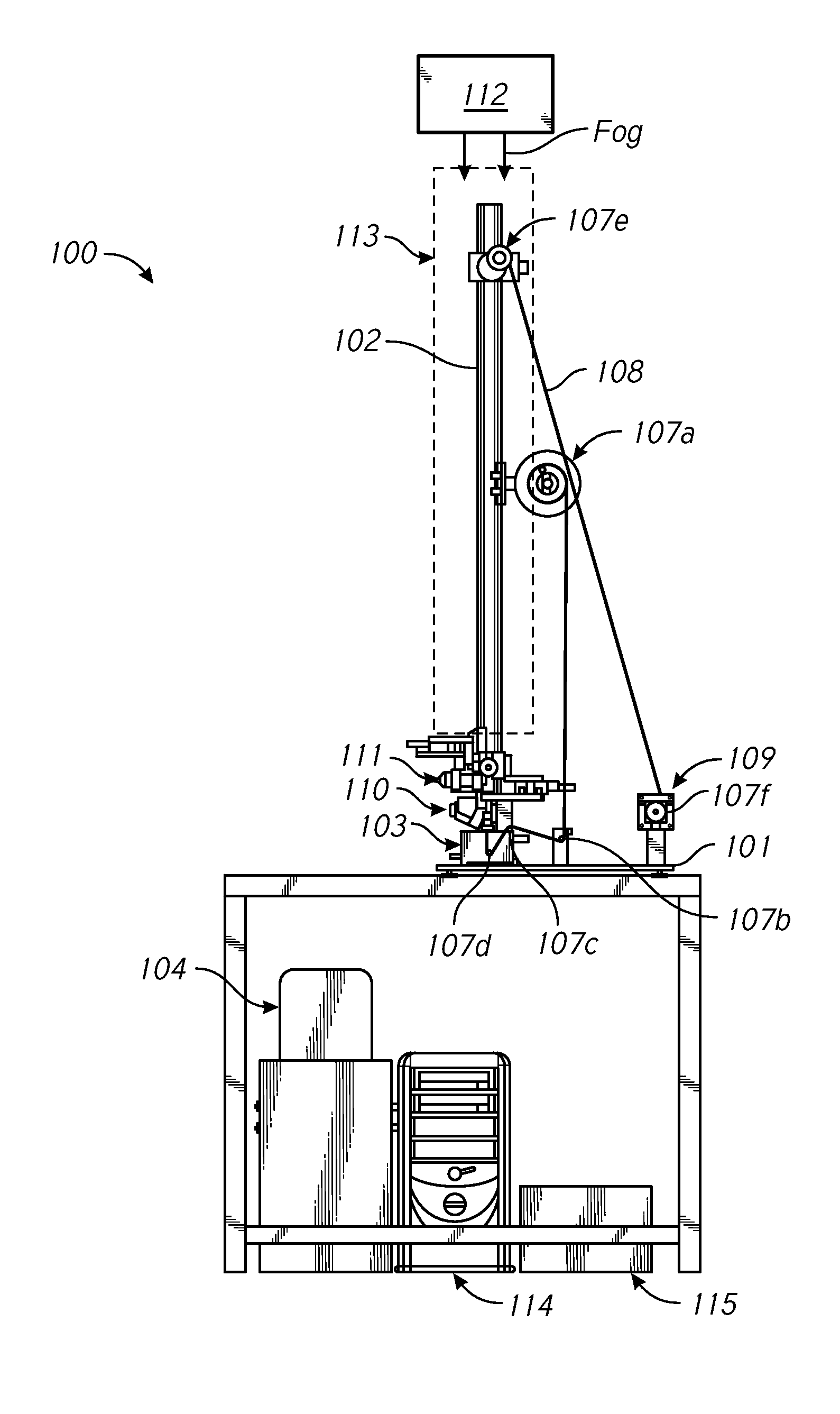

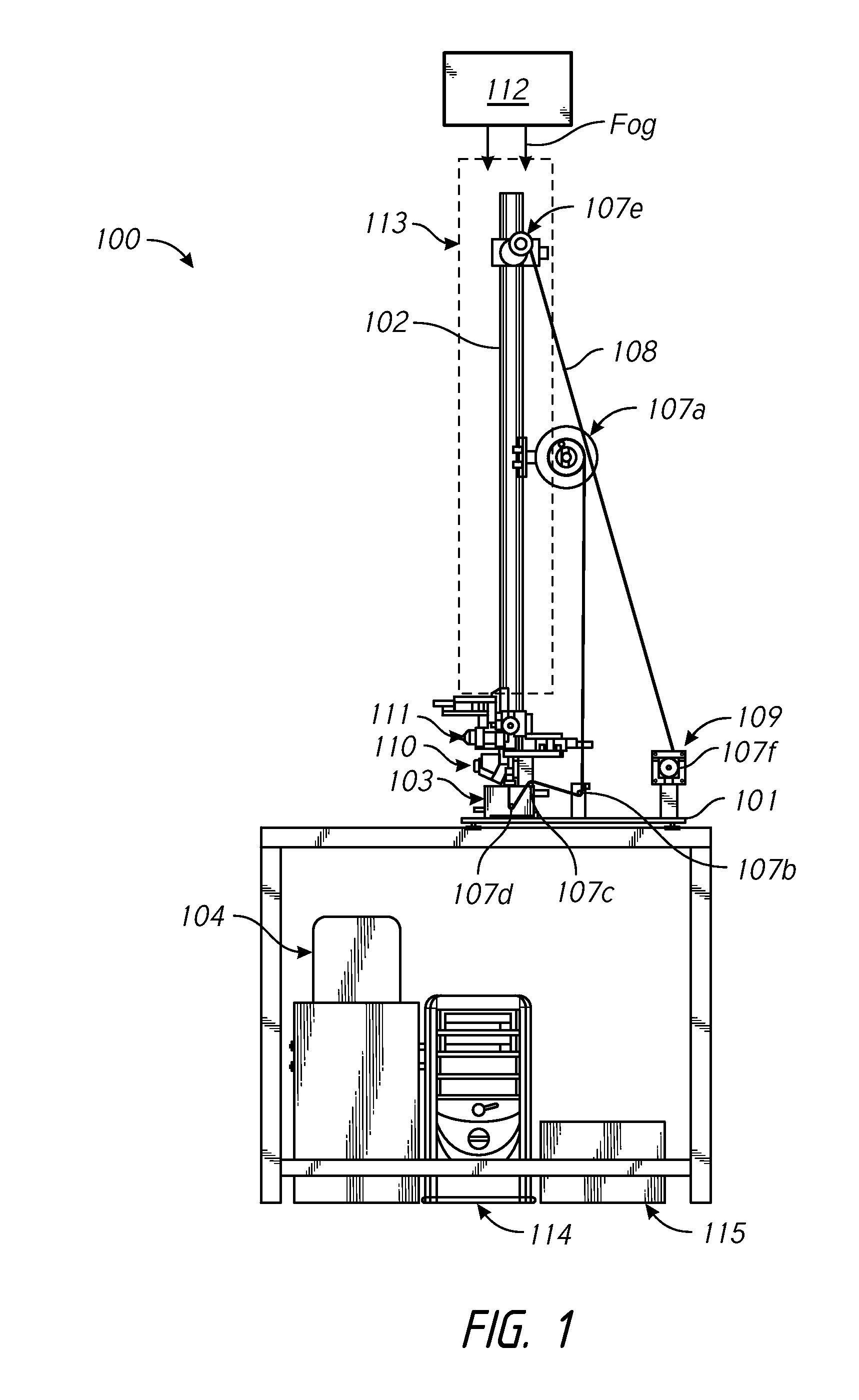

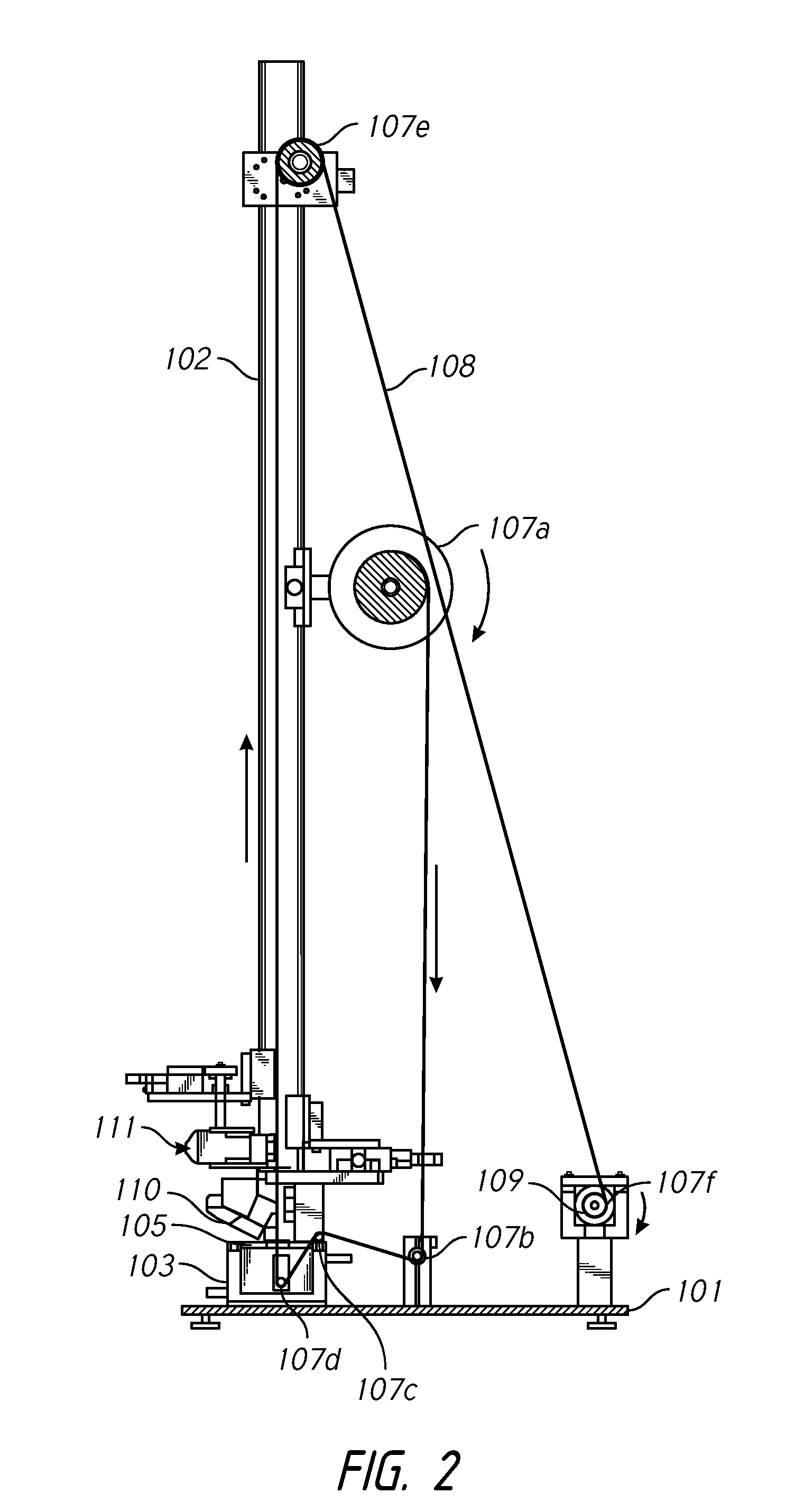

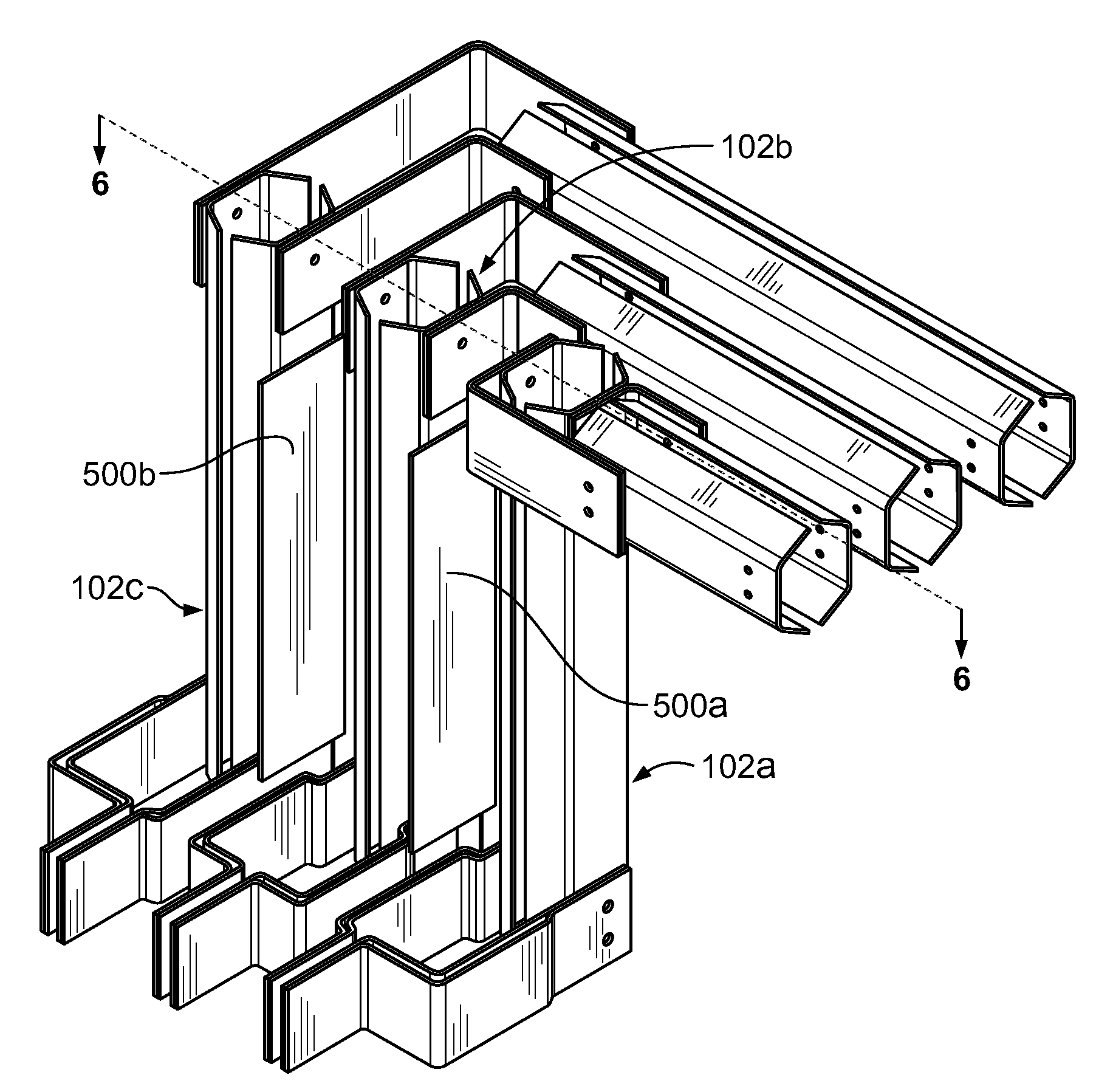

Intraocular shunt manufacture

ActiveUS20140287077A1Reduce skin effectUniform shapeLiquid surface applicatorsEye surgeryOphthalmologySurgery

An intraocular shunt can be manufactured using a system that includes a liquid bath and a wire, which is moved through the bath. When moved through the bath, the wire is coated with a material, such as gelatin. For example, the liquid bath can have a top layer, including water, and a bottom layer, including gelatin. The coated wire passes through an aperture formed in a plate component of the system. The gelatin can be dried on the wire in a humidity-controlled space, thereby forming the shunt.

Owner:AQUESYS INC

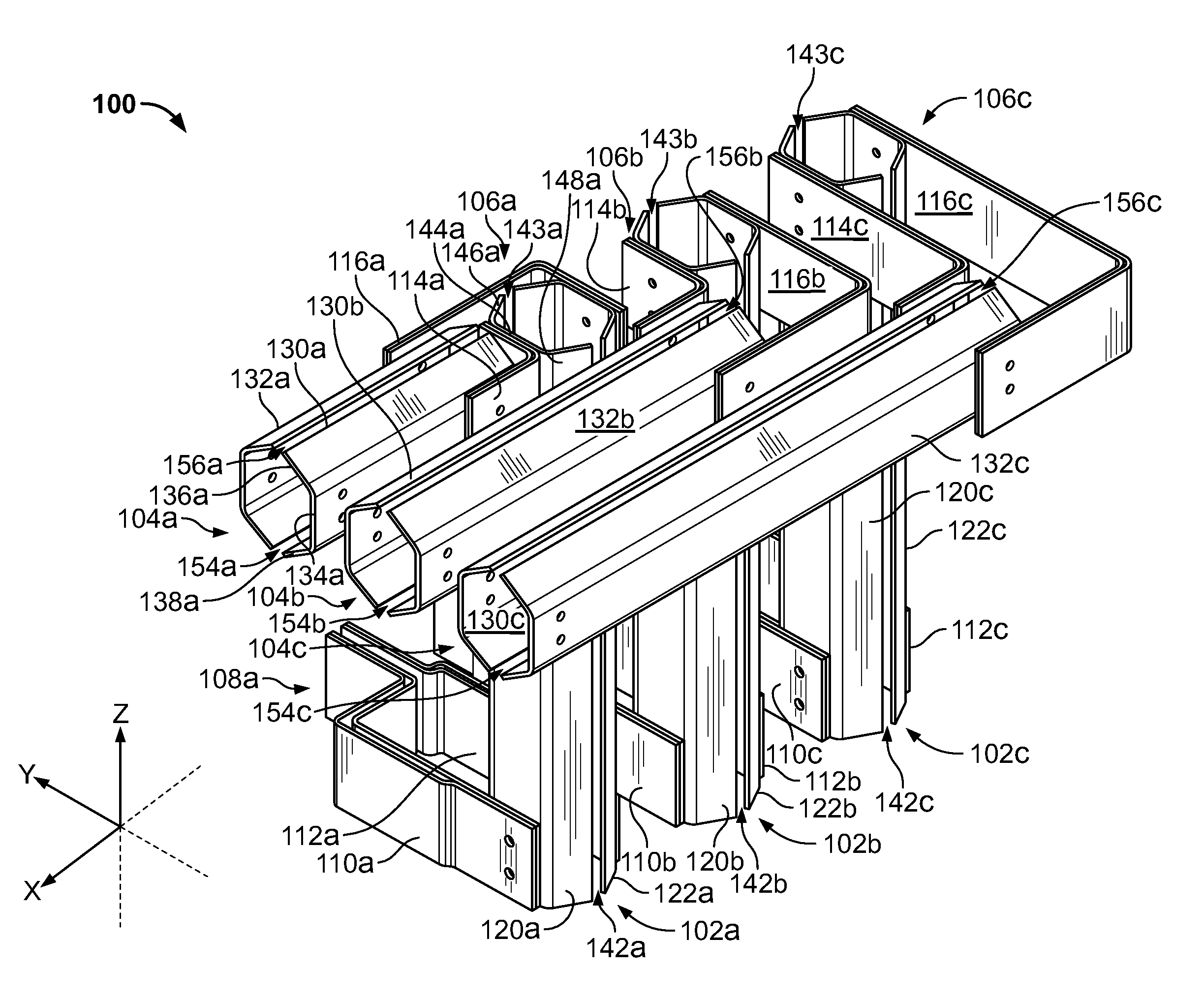

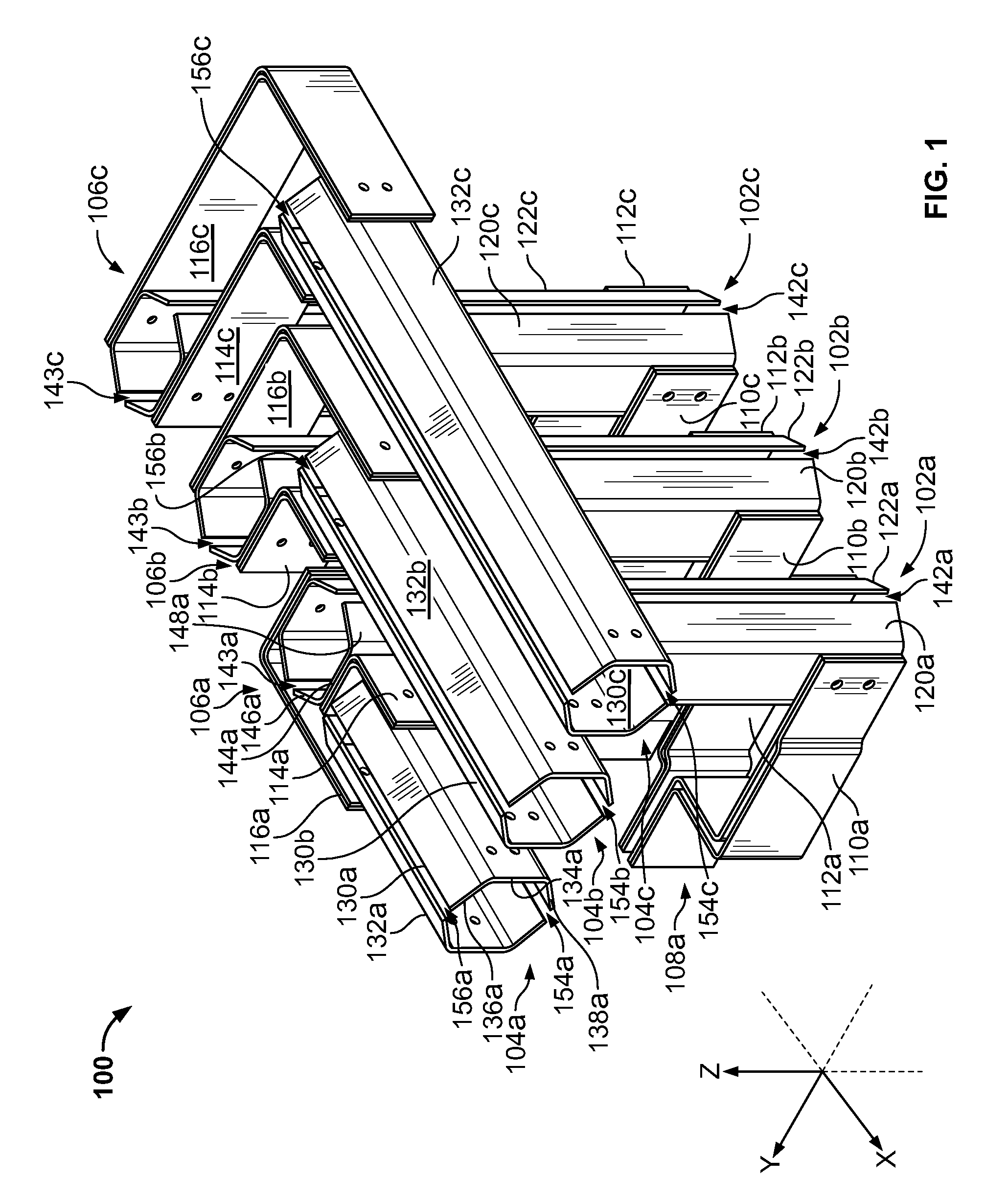

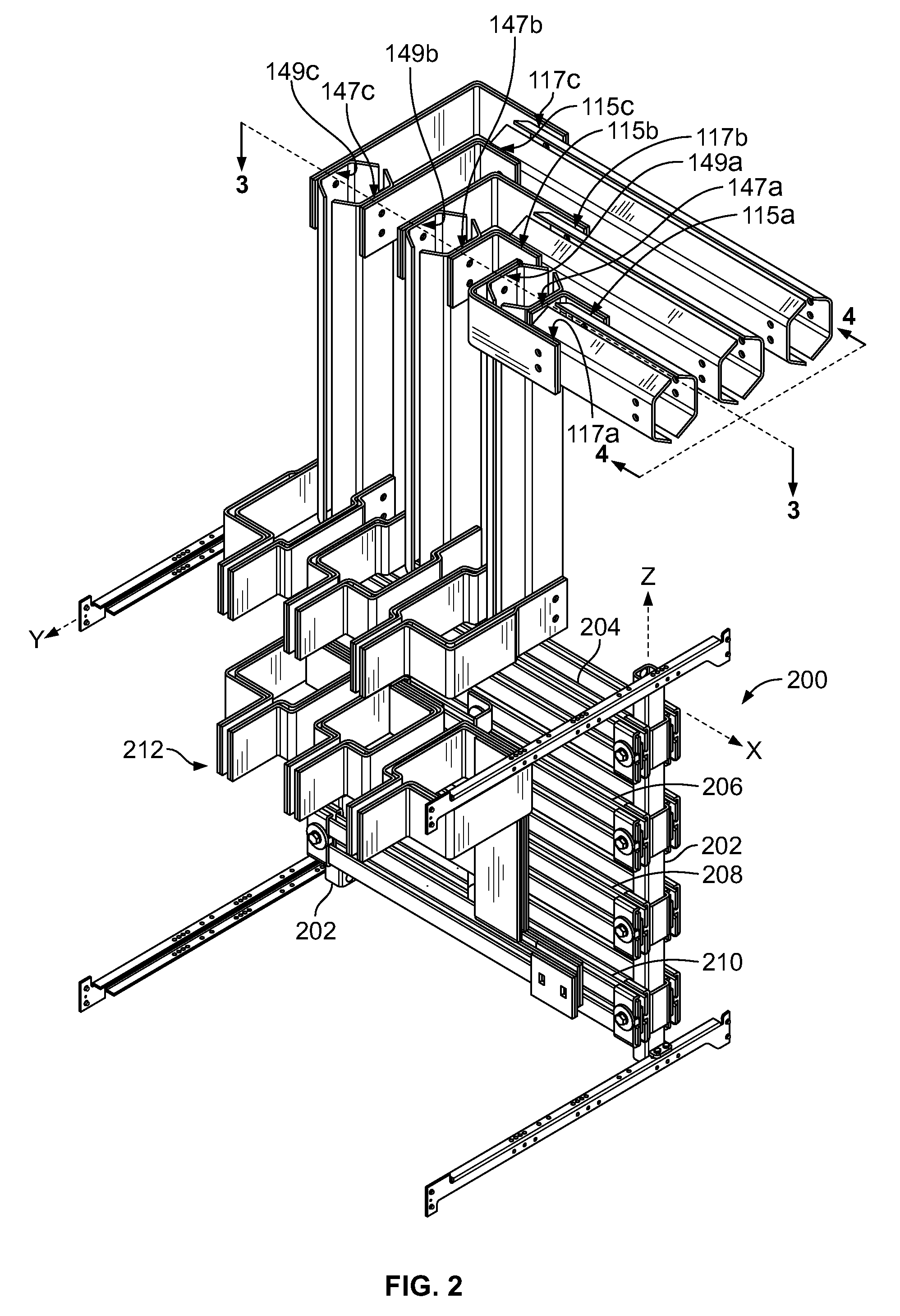

Efficient high-ampacity bowl-shaped tubular conductors

ActiveUS20100051342A1Better currentAccelerated dissipationBus-bar/wiring layoutsMagnetic/electric field screeningIsosceles trapezoidBusbar

A high ampacity busbar includes a pair of oppositely facing bowl-shaped conductors, each of whose cross sections resembles half of a hexagon or an open isosceles trapezoid, separated by an air gap in both horizontal and vertical configurations. The air gap increases cooling efficiency by natural convection by exposing more surface area of the conductors directly to the air flow within the electrical distribution equipment cabinet. As a result, the overall temperature of the bus system is reduced. The shaped conductors have smoother transitions presented to the electrical current between the bends of the conductors. These smooth transitions improve current distribution throughout the conductor, reducing skin effects. As a result of improved thermal dissipation and reduced skin effects, the amount of copper needed to maintain the same ampacity is significantly reduced. Magnetic shields can be placed between adjacent busbars, reducing proximity effects.

Owner:SQUARE D CO

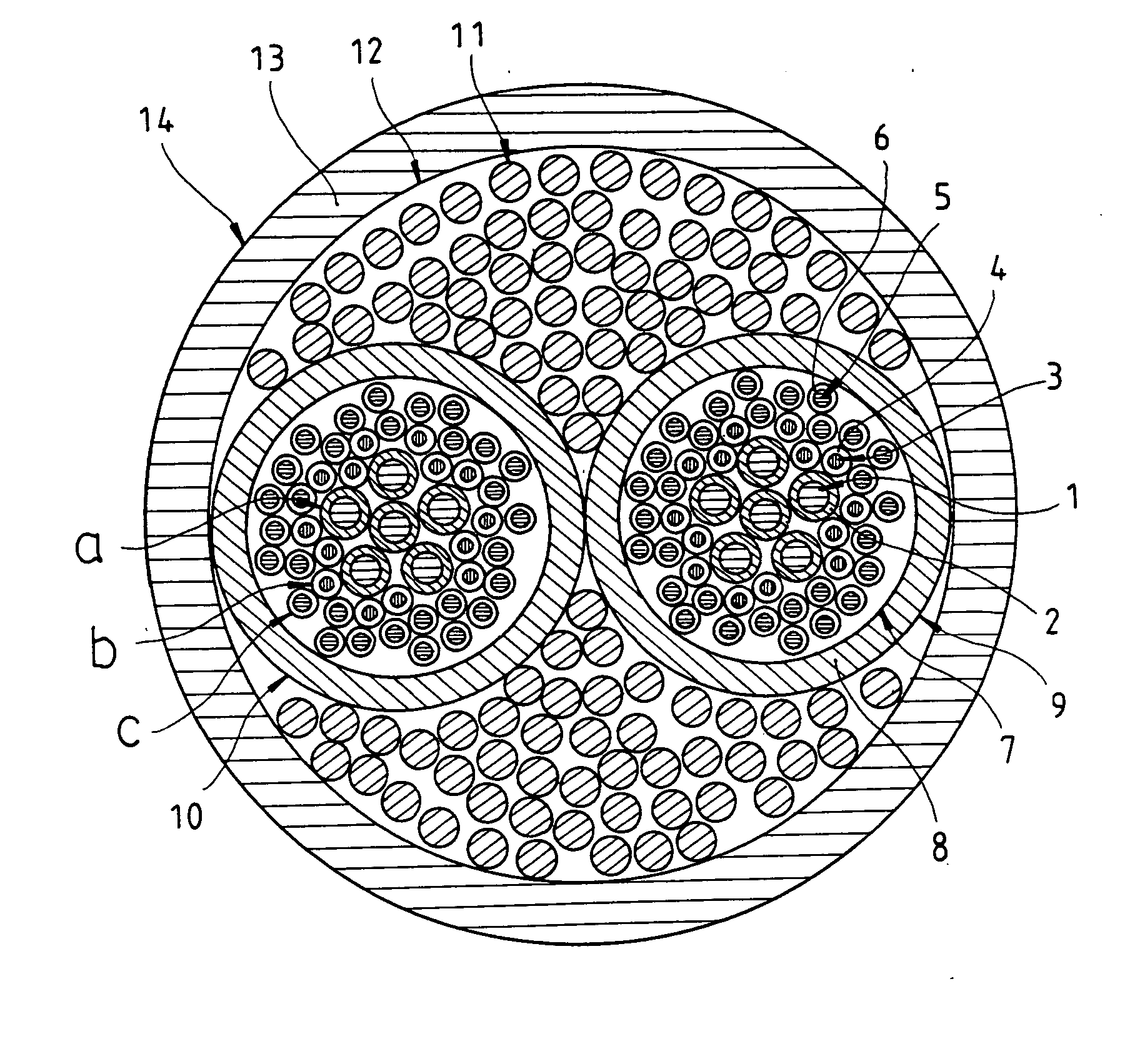

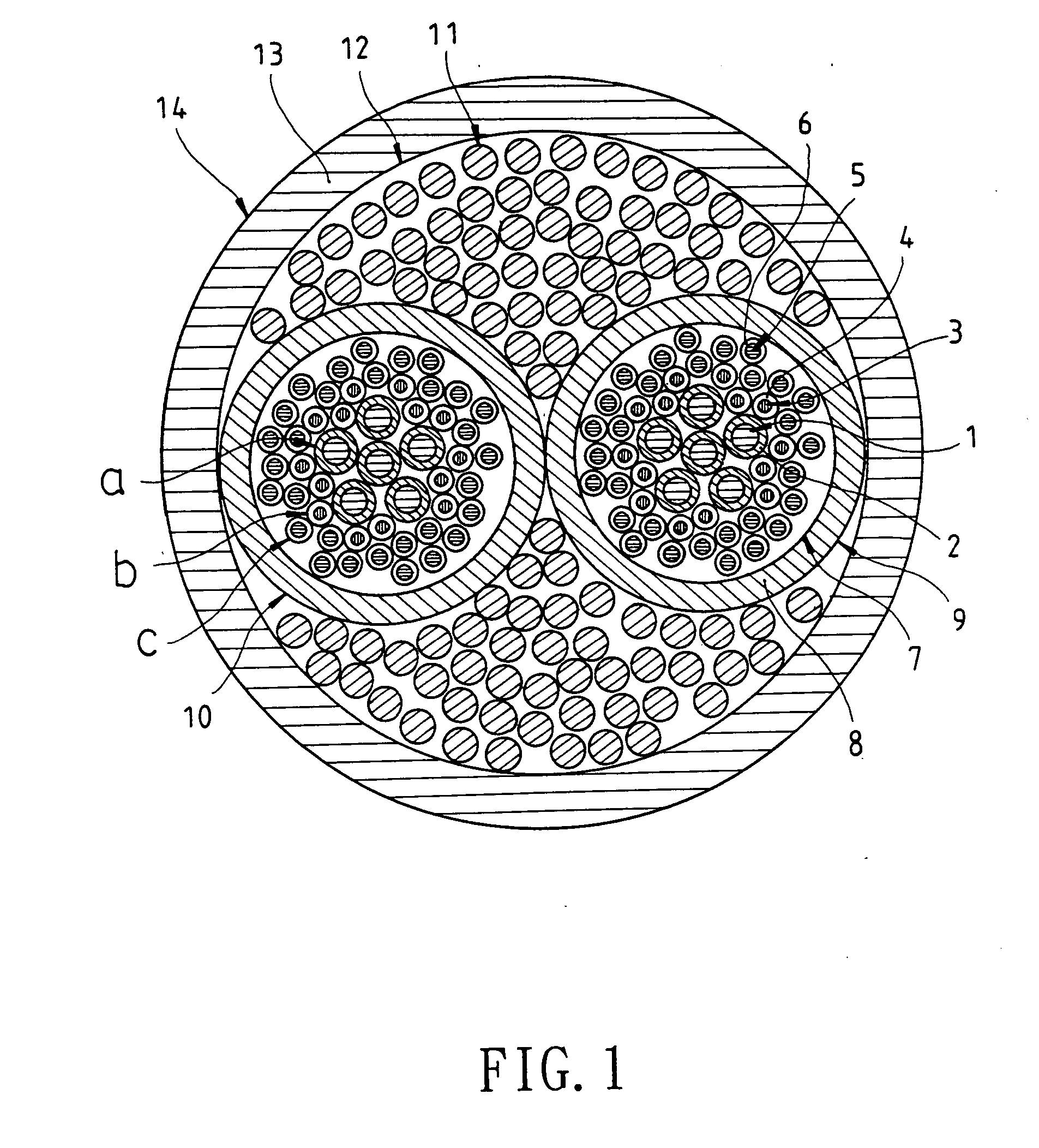

Structure of audio signal cable

ActiveUS20050011667A1High speedIncrease distanceNon-insulated conductorsInsulated cablesElectrical conductorSkin effect

An improved structure of audio signal cable, the features of which are that the audio signal cable is comprised of arrayed solid and tinsel wire conductors. After each of the conductors are insulated and bundled, they are placed into a surrounding insulation. The solid conductors are of a circular and a flat, thin shape. The solid conductors are of differing larger and smaller diameters and, furthermore, disposed in unequal quantities. The smaller diameter tinsel wires are twisted to increase distance and enlarge their surface area to reduce skin effect for better high frequency transmission, while the larger diameter conductors enable the rapid conveyance of low frequencies. As such, the present invention achieves the synchronous phasing of high and low frequency signals.

Owner:VICTOR JAY

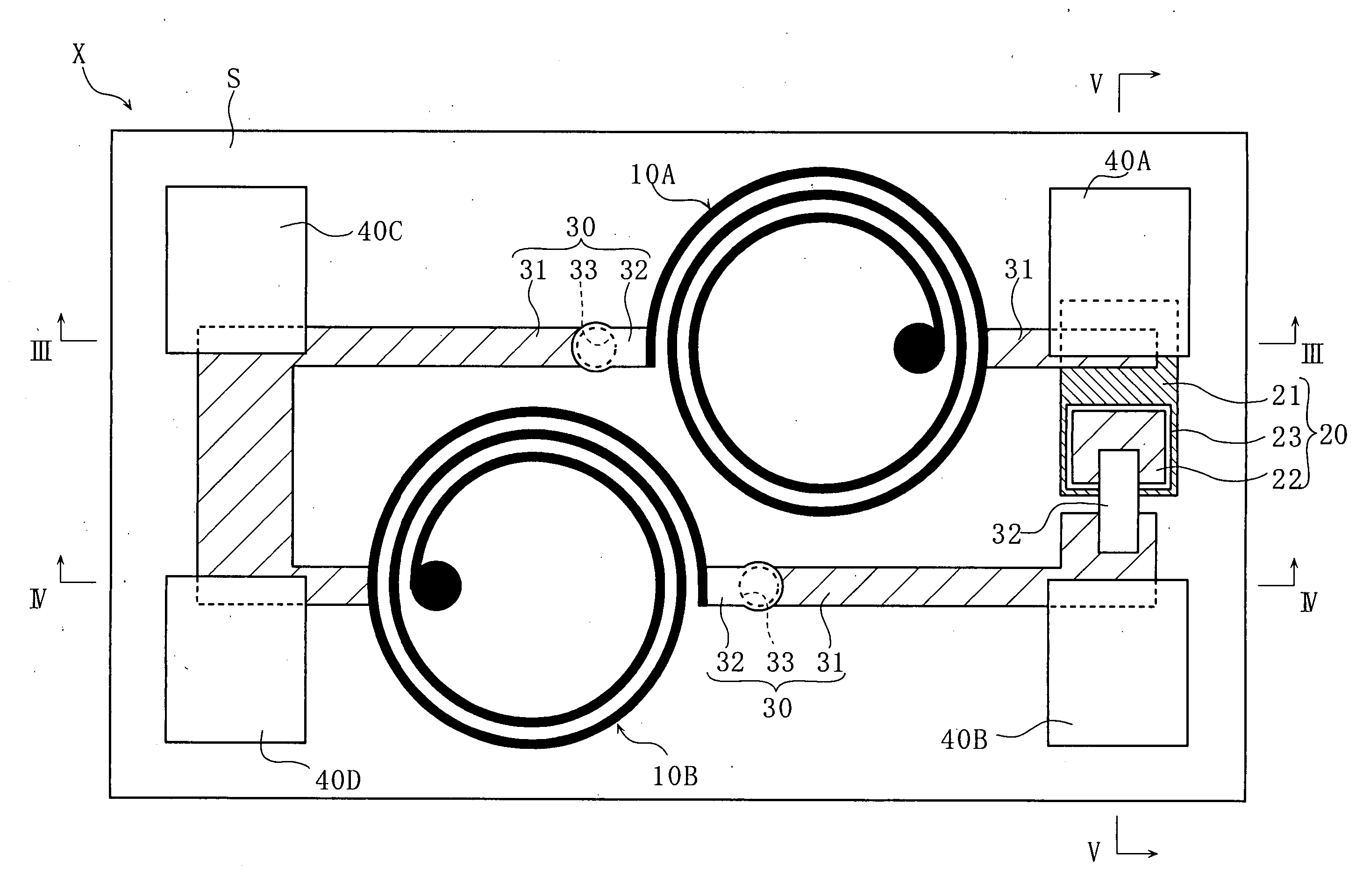

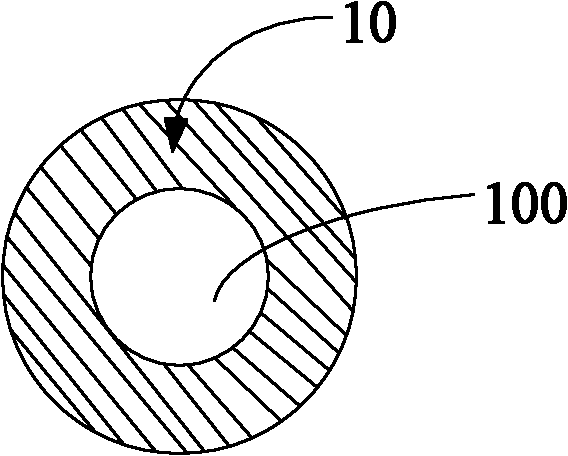

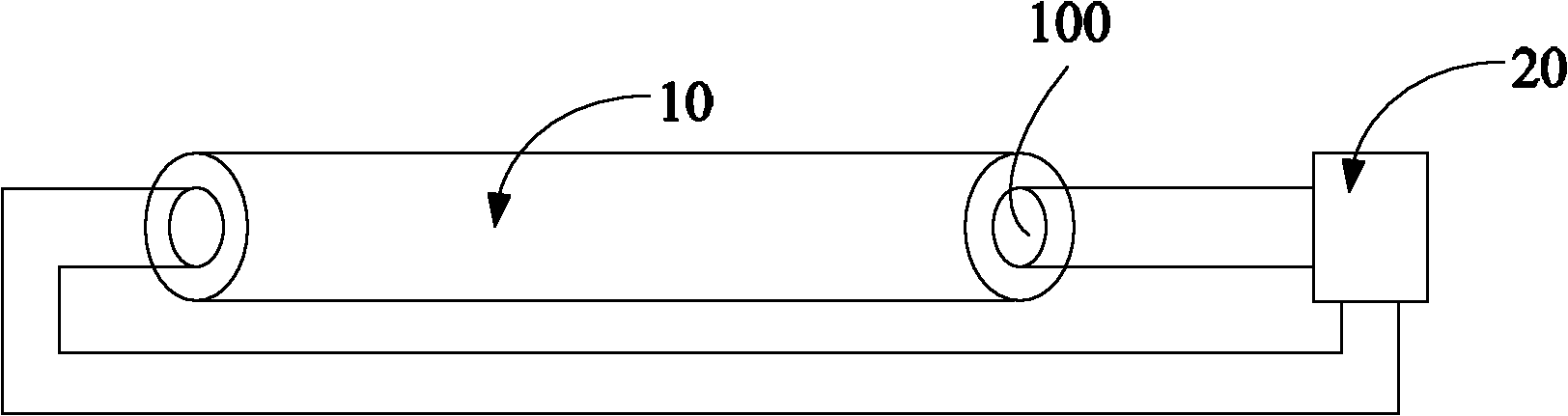

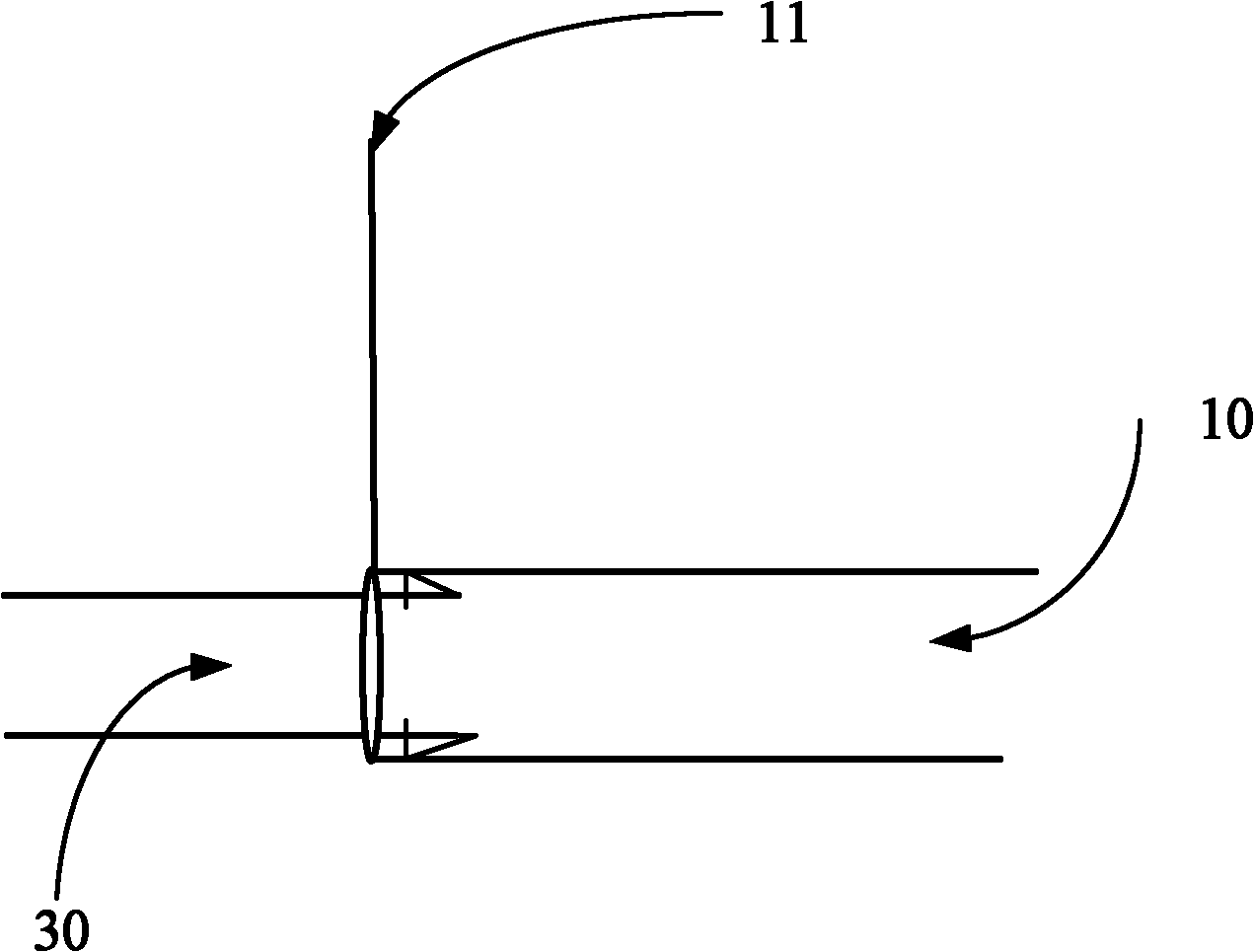

Coil of magnetic resonance imaging system, and cooling device and method thereof

ActiveCN102110510AReduce heating powerIncrease the cross-sectional areaDiagnostic recording/measuringSensorsSkin effectConductive materials

The invention relates to a coil of a magnetic resonance imaging system, and a cooling device and a cooling method thereof. The coil of the magnetic resonance imaging system is formed by winding a hollow wire which is made of a magnetic compatible conducting material. In the coil of the magnetic resonance imaging system, and the cooling device and the cooling method thereof, the coil is formed by winding the hollow wire, and the cross sectional area of a cylindrical coil is increased; a conductor skin effect is reduced due to the increase of the cross sectional area, so that the radiating power of the coil is reduced, and the effect of generating less heat is achieved; and the hollow wire is made of the magnetic compatible conducting material, so that the influence on a magnetic field is reduced and the performance of a gradient coil is improved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Efficient high-ampacity bowl-shaped tubular conductors

ActiveUS7786384B2Better currentAccelerated dissipationBus-bar/wiring layoutsElectrically conductive connectionsIsosceles trapezoidBusbar

A high ampacity busbar includes a pair of oppositely facing bowl-shaped conductors, each of whose cross sections resembles half of a hexagon or an open isosceles trapezoid, separated by an air gap in both horizontal and vertical configurations. The air gap increases cooling efficiency by natural convection by exposing more surface area of the conductors directly to the air flow within the electrical distribution equipment cabinet. As a result, the overall temperature of the bus system is reduced. The shaped conductors have smoother transitions presented to the electrical current between the bends of the conductors. These smooth transitions improve current distribution throughout the conductor, reducing skin effects. As a result of improved thermal dissipation and reduced skin effects, the amount of copper needed to maintain the same ampacity is significantly reduced. Magnetic shields can be placed between adjacent busbars, reducing proximity effects.

Owner:SQUARE D CO

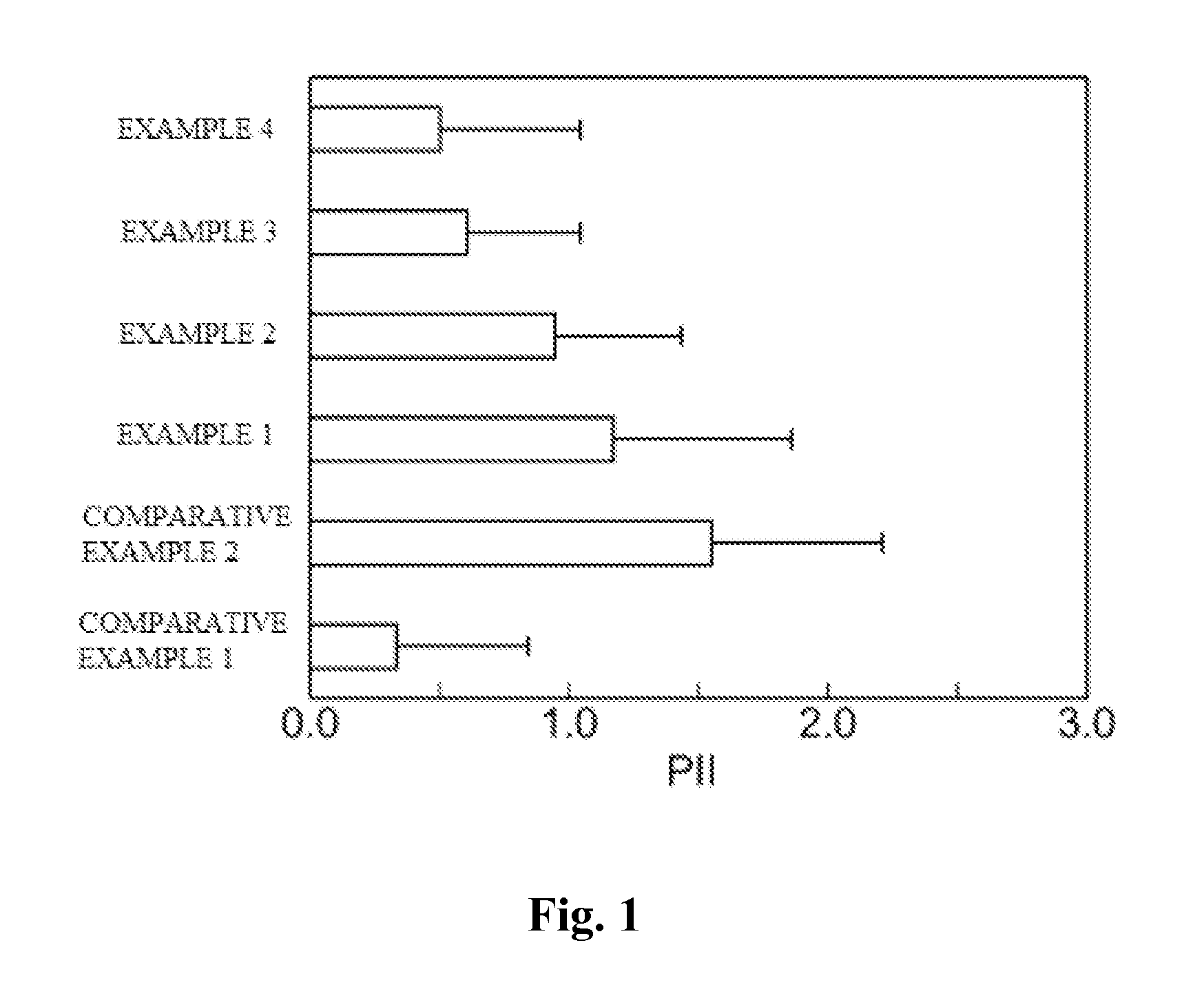

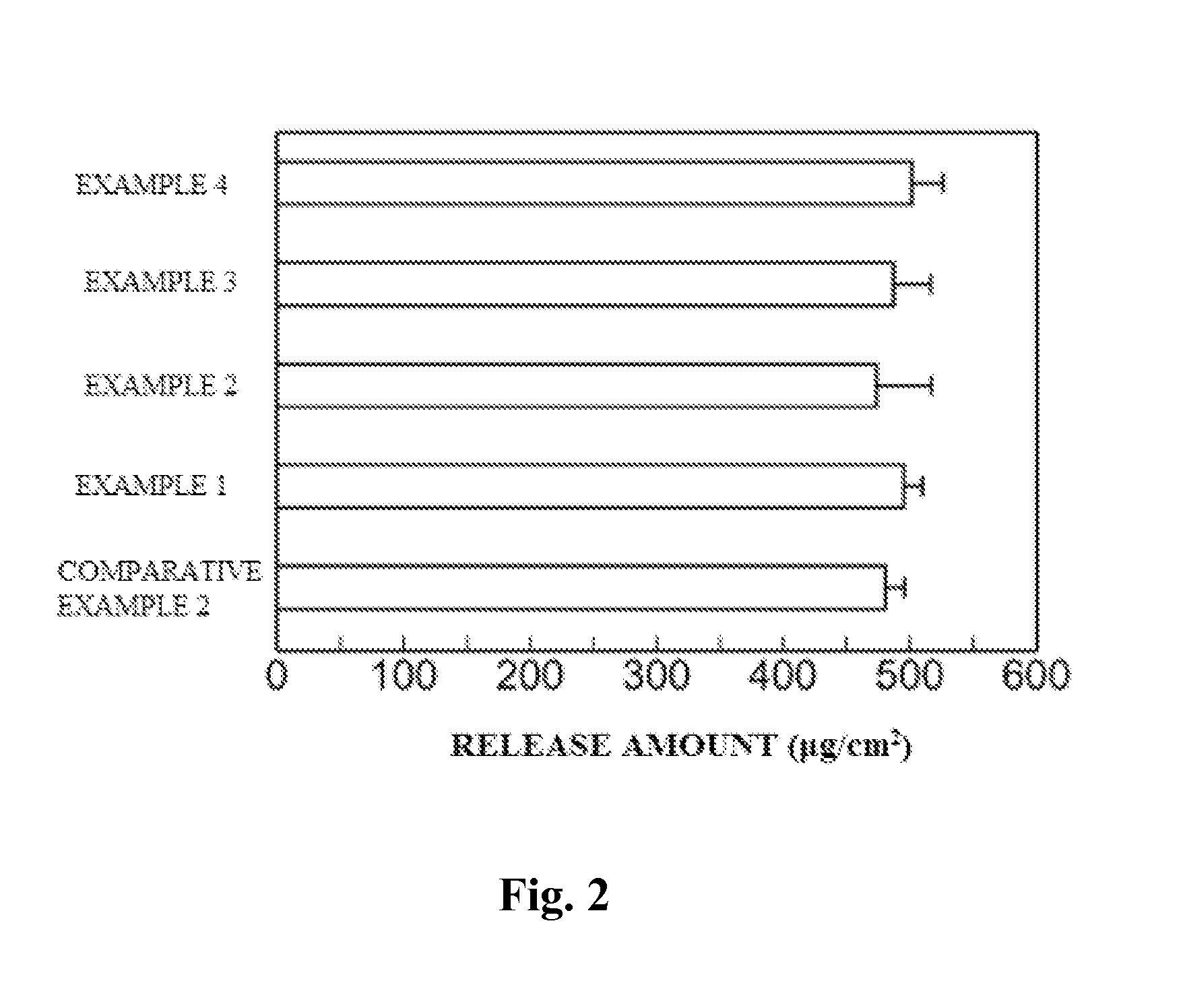

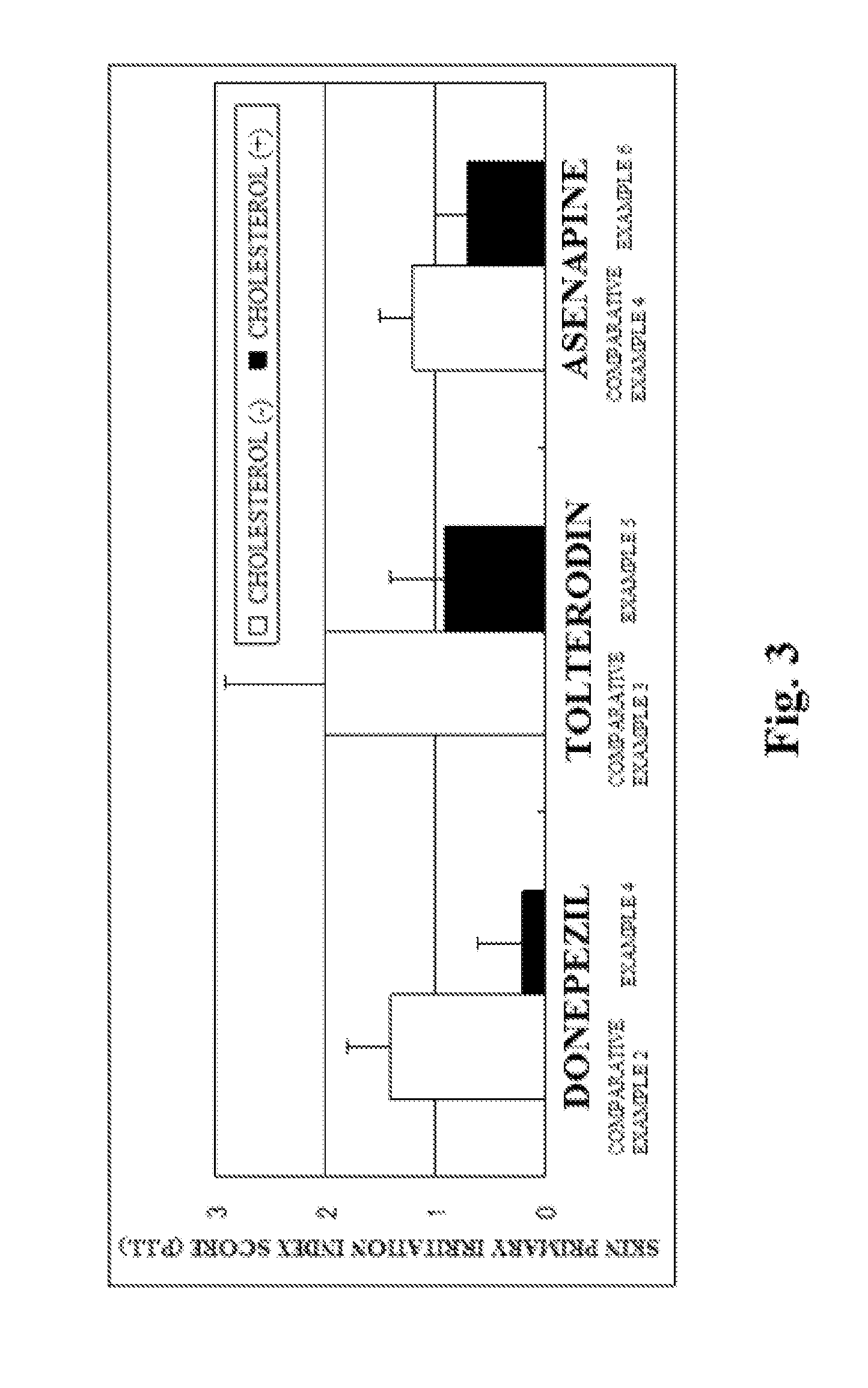

Skin irritation suppressant and transdermal preparation

InactiveUS20130053357A1Sufficient reduction effectReduce skin effectOrganic active ingredientsBiocideCholesterol derivativeCitalopram

Provided is a skin irritation suppressant for transdermal preparations, having a sufficient reduction effect of skin irritation due to a drug. Also provided is a transdermal preparation comprising the skin irritation suppressant. One embodiment of the invention is a skin irritation suppressant for suppressing the skin irritation due to a drug and a pharmaceutical ingredient to be used in a transdermal preparation other than the drug, the skin irritation suppressant comprising a sterol compound selected from the group consisting of cholesterol, cholesterol derivatives and cholesterol analogs, and the drug is one or more basic drugs selected from the group consisting of tolterodine, asenapine, bisoprolol, risperidone, nicotine and citalopram, and their pharmaceutically acceptable salts.

Owner:HISAMITSU PHARM CO INC

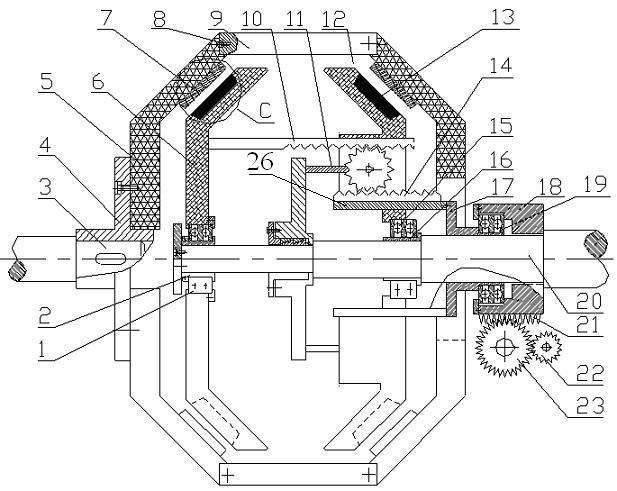

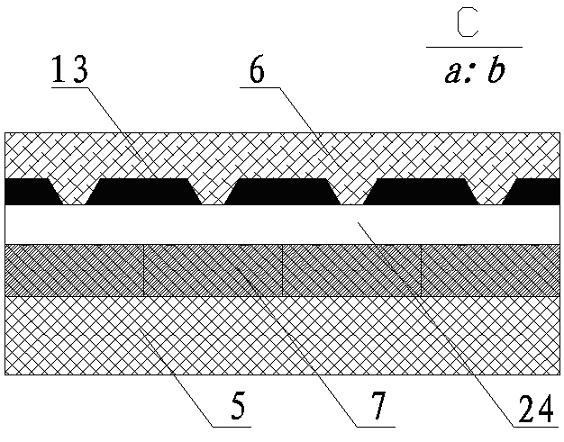

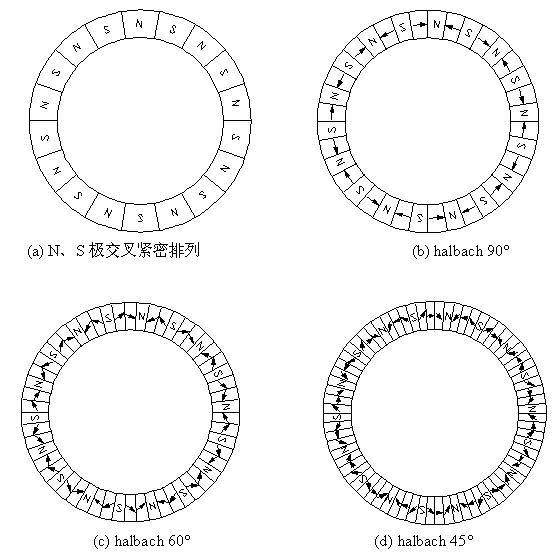

A Wedge Disc Adjustable Speed Magnetic Coupling

InactiveCN102290964ARapidly changing magnetic flux densityReduce eddy current lossDynamo-electric gearsCircular discMagnetic tension force

The invention relates to the technical field of mechanical transmission, in particular to a wedge-shaped disc-type adjustable-speed magnetic coupling. The shaft coupling of the present invention includes a driving disc device, a driven disc device and a speed regulating mechanism. Among them, both the driving and driven discs adopt wedge-shaped disc structure, the purpose of which is to simultaneously change the facing area and the size of the air gap between the permanent magnet and the conductor, quickly adjust the magnetic flux of the air gap magnetic field, and control the output speed and speed better and faster. The size of the torque. At the same time, the axial movement of the driving rack (21) is controlled by the speed regulating mechanism, so that the square bearing base (18) can also move accordingly, and then the lower rack (14) and the right side are pushed by the two-way thrust ball bearing (19). The wedge-shaped driven disk moves, and now the motion is passed to the upper rack (10) by the gear (12), so that the upper and lower racks drive the corresponding left and right wedge-shaped discs to move toward or away from each other. That is to say, the distance between the master and slave discs can be changed at any time during the operation of the coupling, thereby changing the torque and speed of the driven shaft, and achieving the purpose of stepless speed regulation.

Owner:JIANGSU UNIV

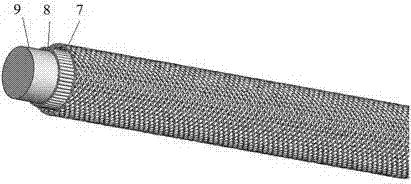

Composite graphite grounding material with low skin effect and preparation method for composite graphite grounding material

ActiveCN103500595AImprove mechanical propertiesImprove densification performanceBraided wire conductorsCarbon-silicon compound conductorsYarnSkin effect

The invention discloses a composite graphite grounding material with a low skin effect and a preparation method for the composite graphite grounding material. The composite graphite grounding material is shaped into a rope or a stranded wire, and comprises a flexible inner core, a second outer composite graphite yarn layer and an outermost composite graphite yarn braided layer, wherein the flexible inner core is wrapped by the second outer composite graphite yarn layer; the second outer composite graphite yarn layer is wrapped by the outermost composite graphite yarn braided layer. The composite graphite grounding material has the advantages of high corrosion resistance, high electrical conductivity, high flexibility, low skin effect, low cost, easiness for transportation, high precision of bonding with soil and the like; the composite graphite grounding material is low in cost, so that the composite graphite grounding material can be prevented from being artificially stolen and damaged, and is applied to all engineering fields of transformer substations, overhead power transmission line towers, high-rise buildings and the like with electrical grounding requirements.

Owner:WUHAN HONGMEN ELECTRICAL TECH CO LTD

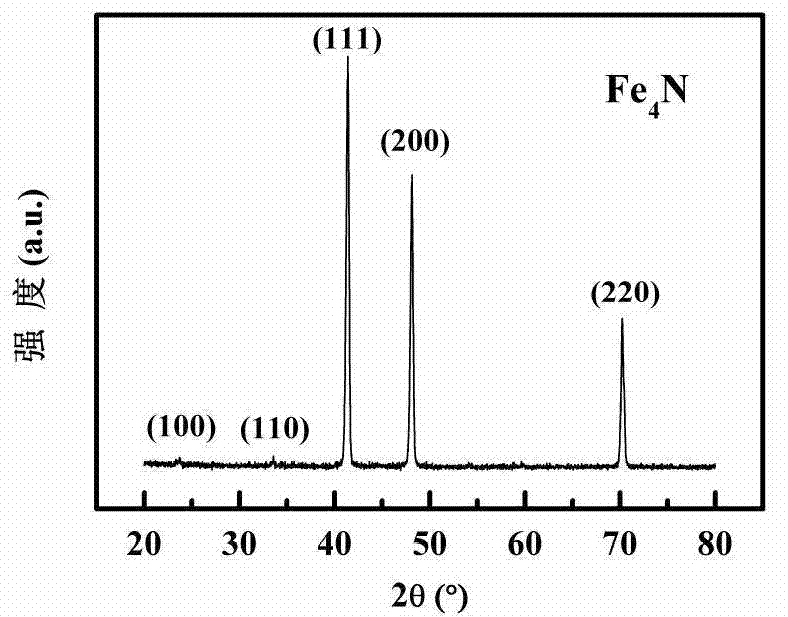

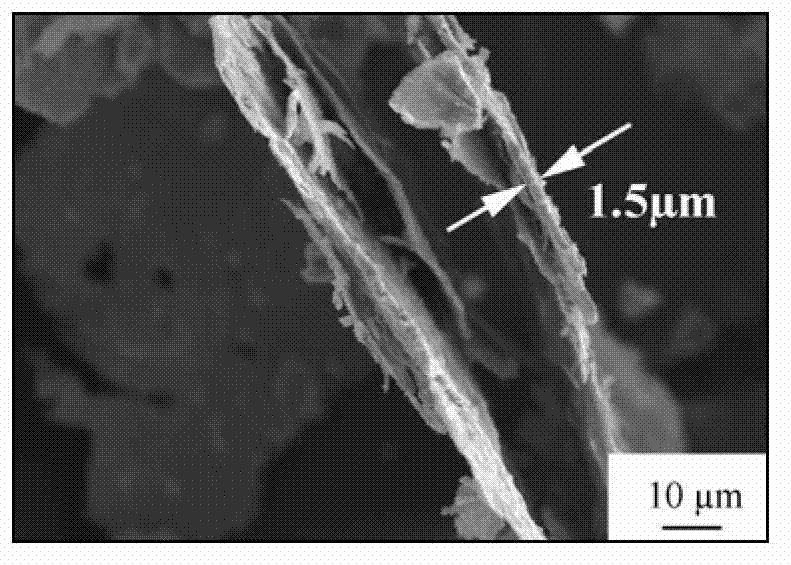

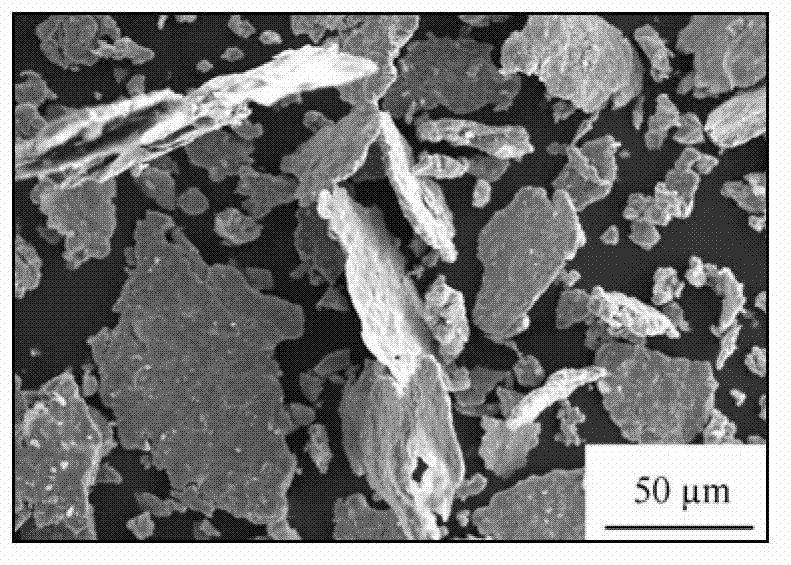

Flat magnetic powder and preparation method thereof

The invention belongs to the technical field of magnetic powder and relates to flat magnetic powder and a preparation method thereof. The main phase of the magnetic powder is gamma'-Fe4N, the thickness of the powder is 0.1-9 micrometers, and the radium-thickness ratio is 10-200. The method includes: taking pure iron powder lower in hardness as a raw material, adopting the ball-milling method for flattening treatment, nitriding in a gas mixture of ammonia / hydrogen, and controlling technical parameters such as the thickness and the flatness of the powder by adjusting process conditions such as grain size and ball-milling time of the powder to realize control on electromagnetic performances such as cutoff frequency of the powder. The flat magnetic powder effectively reduces skin effect of a Fe4N material and is in favor of high-frequency application of the Fe4N material, and the preparation method is simple, flattening time is substantially lowered, production efficiency is improved, and control on micro-topography and the electromagnetic performances of the powder can be realized.

Owner:BEIJING UNIV OF TECH

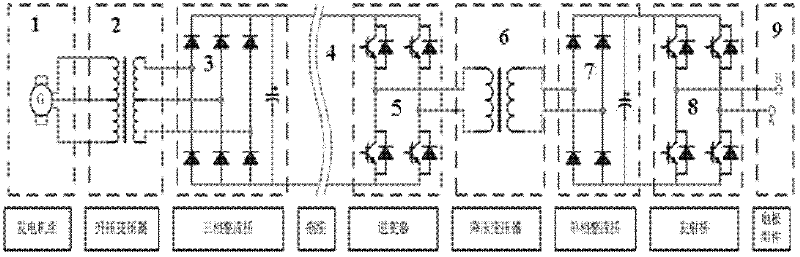

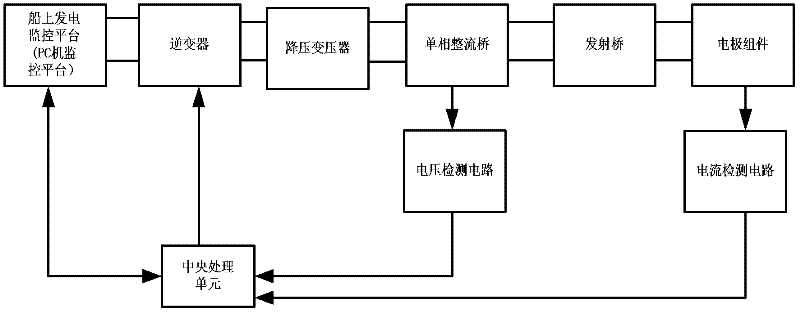

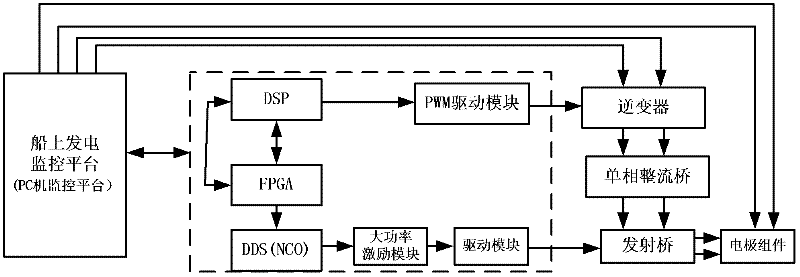

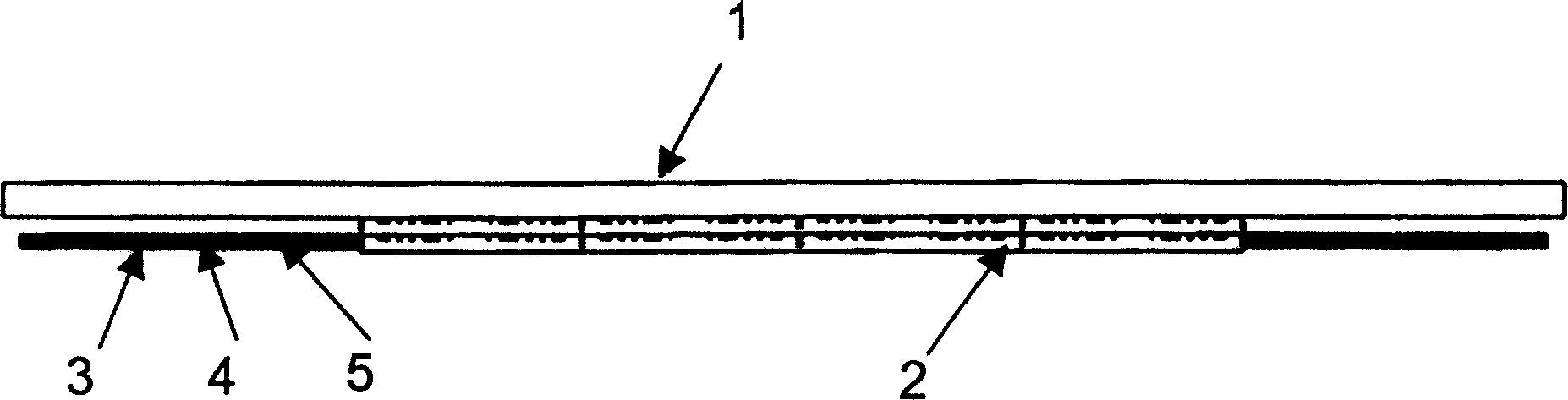

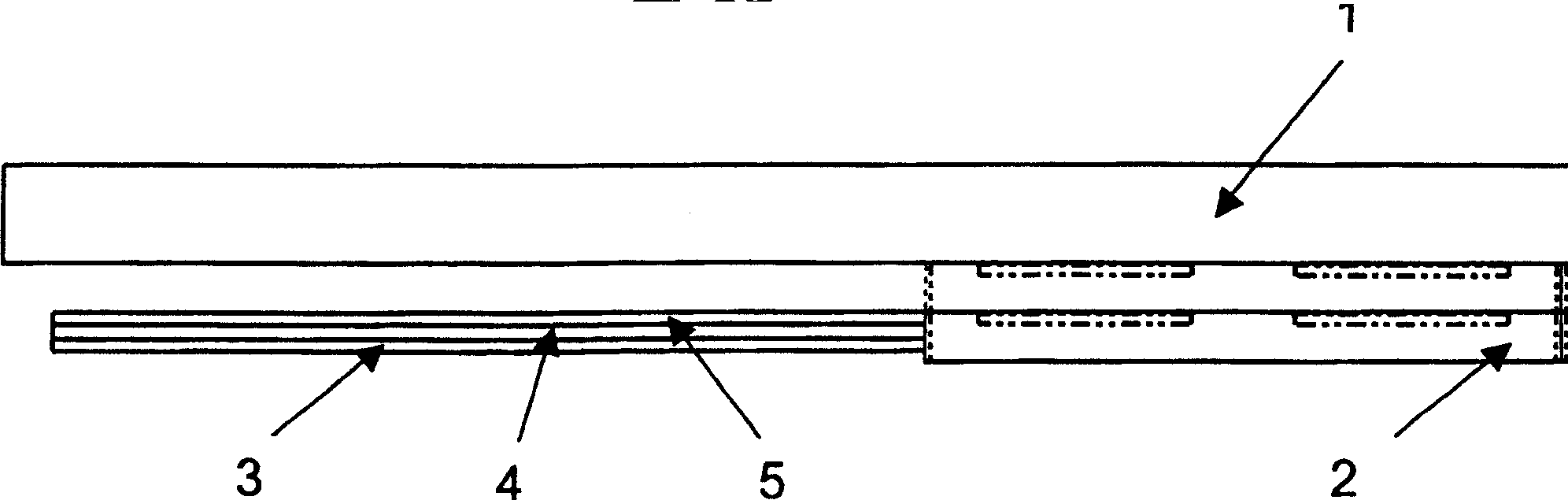

Method for launching marine controlled-source electromagnetic exploration system

InactiveCN102590866AHigh voltageImprove linearityWater resource assessmentElectric/magnetic detectionCost (economic)Engineering

The invention relates to a method for launching a marine controlled-source electromagnetic exploration system. One generator unit, two inverters, two rectifier and filter circuits, one control circuit, one voltage detection circuit, one current detection circuit as well as a tow cable and an electrode assembly are included, wherein the generator unit provides a three-phase power supply to the system; the inverter and rectifier circuits are used for finishing AC-DC and DC-AC conversions of the power supply in the signal transmission and emission process; the transformer is used for transforming voltage grade and is convenient for signal transmission and emission; the voltage detection circuit and the current detection circuit are used for realizing real-time detection of output voltage and current and provide real-time signals for the control circuit; and the control circuit is a central processing unit. According to the method for launching the marine controlled-source electromagnetic exploration system, disclosed by the invention, the signal transmission reliability of the system is improved, the requirement on the cable is reduced and the economic cost is reduced.

Owner:BEIJING UNIV OF TECH

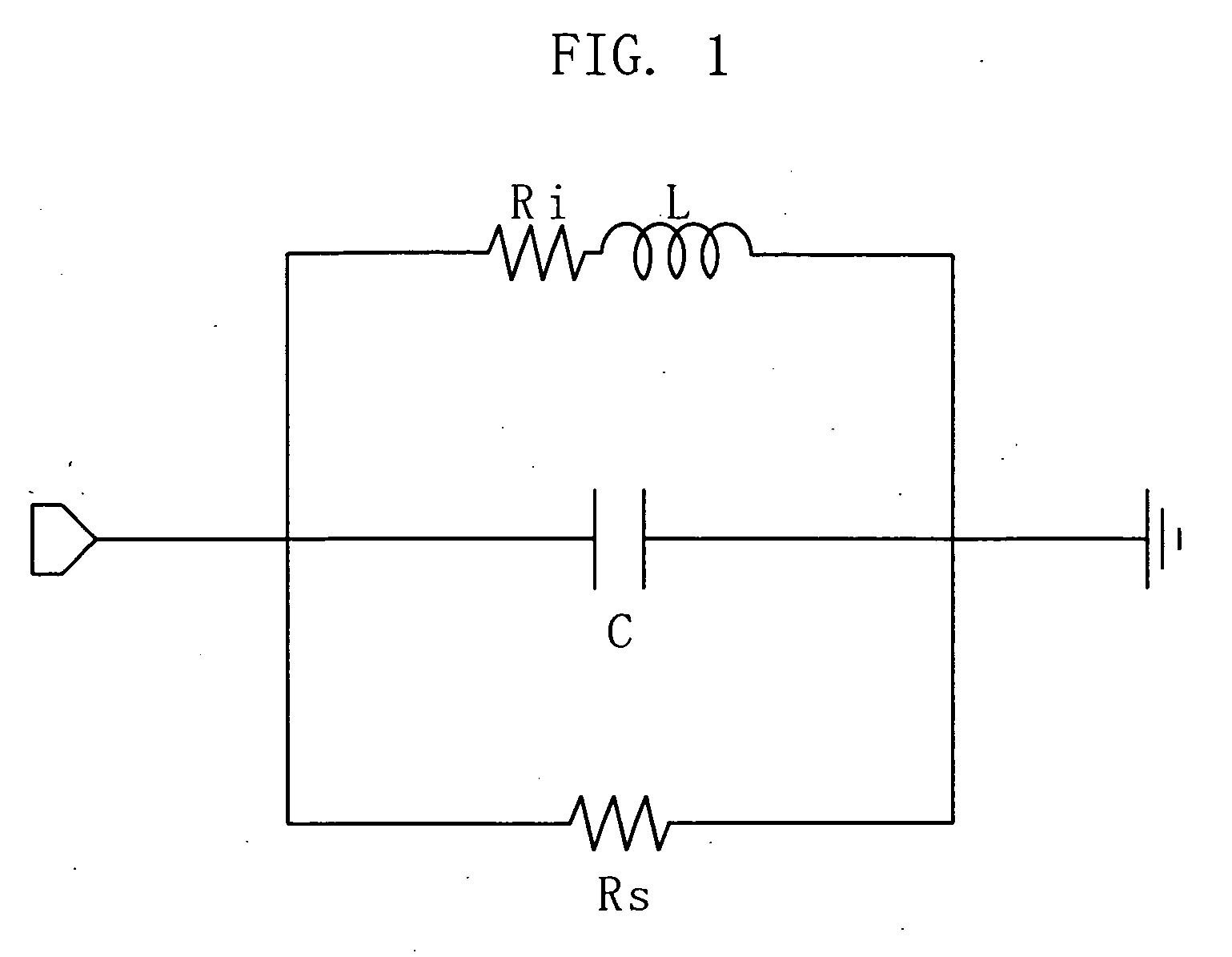

Transmitter head and a system for contactless energy transmission

InactiveCN1762082AAchieving a high degree of protection (safety)Reduce skin effectTransformersMagnetic-bias transformersEngineeringMechanical engineering

Owner:SEW-EURODRIVE GMBH & CO KG

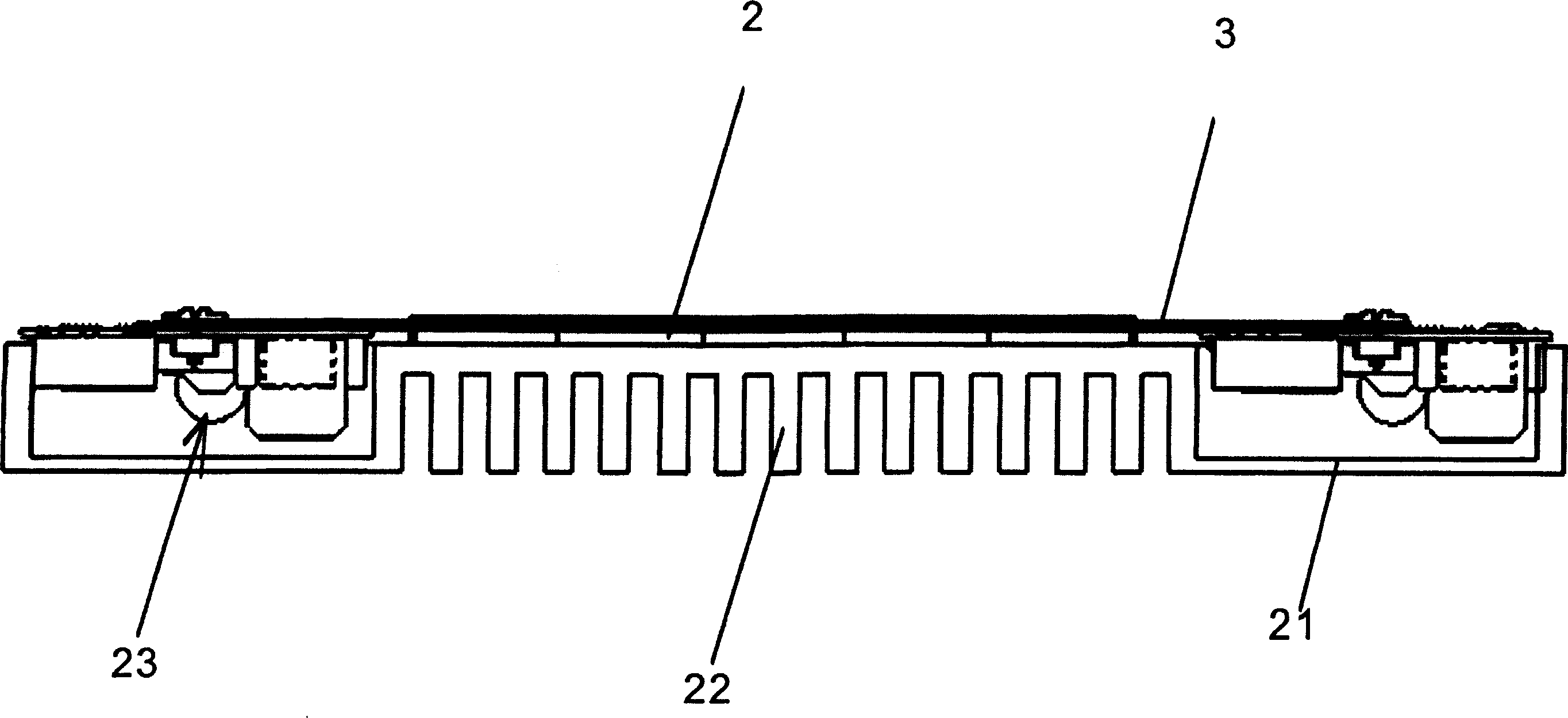

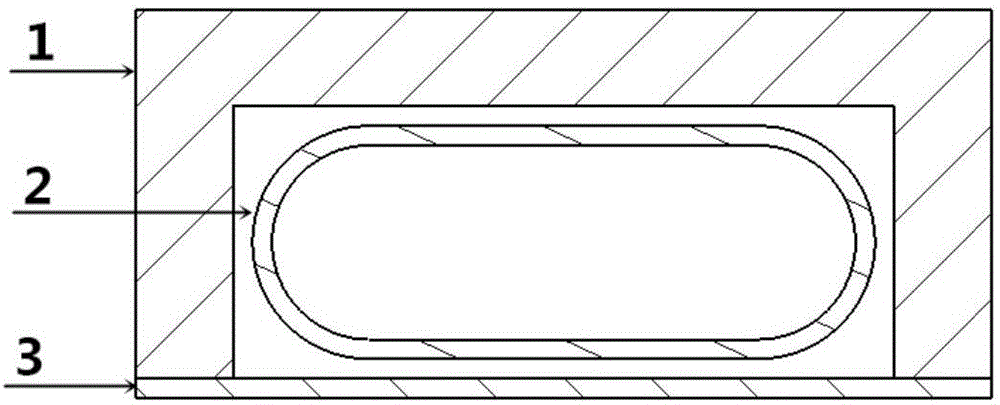

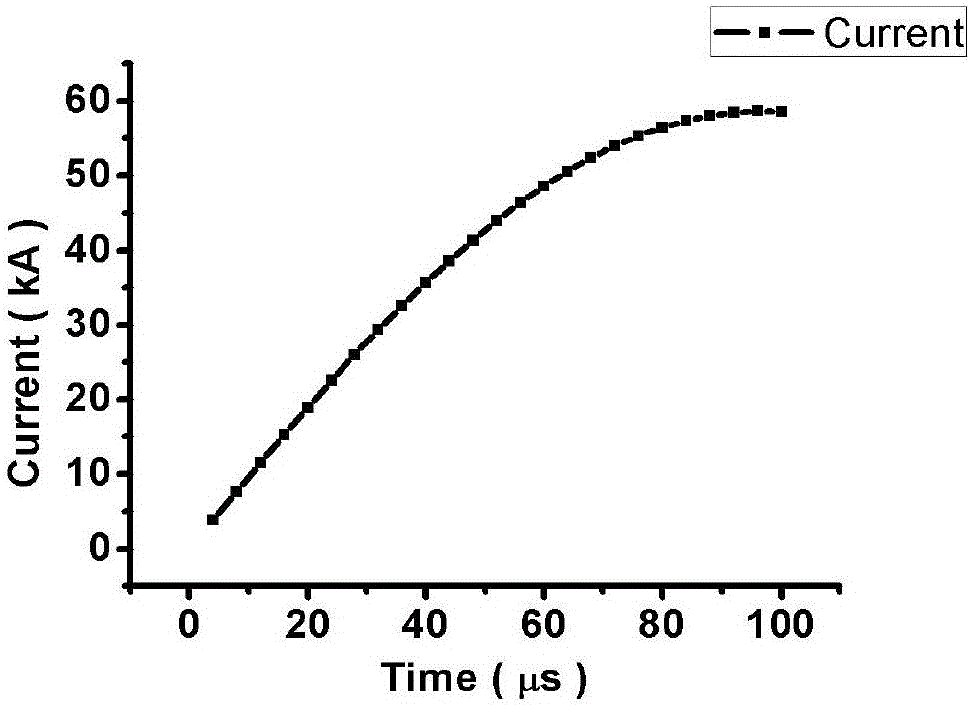

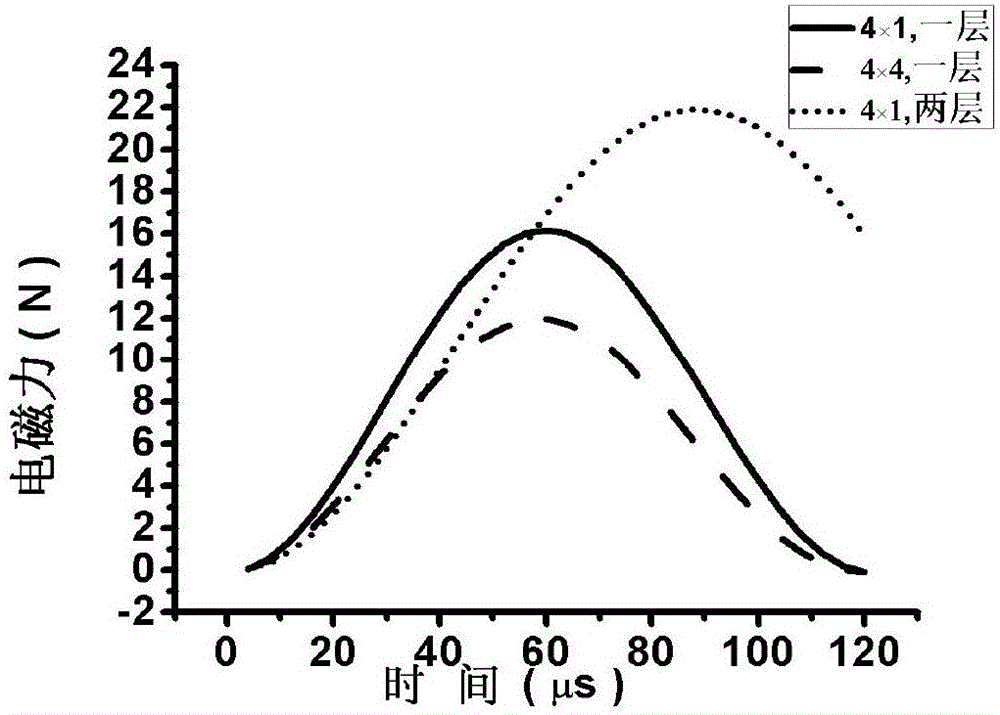

Uniform-pressure electromagnetic forming device, uniform-pressure coil and obtaining method thereof

ActiveCN106807824AHigh strengthImprove forming efficiencyCoils manufactureCoilsEddy currentEngineering

The invention provides a uniform-pressure electromagnetic forming device, a uniform-pressure coil and an obtaining method thereof. The uniform-pressure electromagnetic forming device comprises a conductive channel, a coil and a workpiece. The U-shaped conductive channel is formed in an upper-portion surrounding coil of the coil, the workpiece is arranged below the coil, and the workpiece and the conductive channel form a current loop. The coil comprises a lead, an epoxy plate and a reinforcing material. A framework composed of the epoxy plate provides supporting for the lead. The reinforcing material is arranged on the outer side of the lead to serve as an outer reinforcing layer and used for providing enough strength. During work, eddy current is sensed in the workpiece and the conductive channel due to the influence of changing current in the coils, and the current loop is formed. Due to the fact the coil is formed by winding multiple layers and turns of thinner red copper leads, an electromagnetic force exerted in the workpiece is large, and the forming efficiency is higher. For ensuring the strength of the coil, the reinforcing material is wound and reinforced in the coil lead winding direction and the winding direction perpendicular to the lead respectively, and high-strength and efficient uniform-pressure electromagnetic forming is achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for manufacturing high-roughness electronic copper foil for ceramic-based high-frequency electronic copper-clad plate

ActiveCN105050331AImprove high temperature oxidation resistanceIncrease roughnessCircuit precursor manufactureRough surfaceSkin effect

The present invention discloses a method for manufacturing a high-roughness electronic copper foil for a ceramic-based high-frequency plate. The method comprises the procedures of crude foil, first roughening, second roughening, first curing, second curing, third curing, blackening, galvanizing, passivation, coupling agent spraying and drying. The copper foil rough surface roughness of the crude foil process of the invention is greatly improved, the contact area of the copper foil rough surface and resin is greatly increased, the problem of low peel strength caused by poor resin mobility is solved, the uniformity of a rough surface copper tooth of the copper foil produced by the production process is good, the consistency is high, a skin effect caused by a large copper tooth fluctuation is reduced, and the loss in the signal transmission process is reduced.

Owner:ANHUI TONGGUAN COPPER FOIL +1

Method for manufacture of multi-layer-multi-turn high efficiency inductors

ActiveUS9300046B2Higher resistive lossIncrease qualify factorInternal electrodesTransformers/inductances coils/windings/connectionsElectricityElectrical resistance and conductance

A multi-layer, multi-turn structure for an inductor having a plurality of conductor layers separated by layers of insulator is described. The inductor further comprises a connector electrically connected between the conductor layers. The structure of the inductor may comprise a cavity therewithin. The structure of the inductor constructed such that electrical resistance is reduced therewithin, thus increasing the efficiency of the inductor. The inductor is particularly useful at operating within the radio frequency range and greater.

Owner:NUCURRENT INC

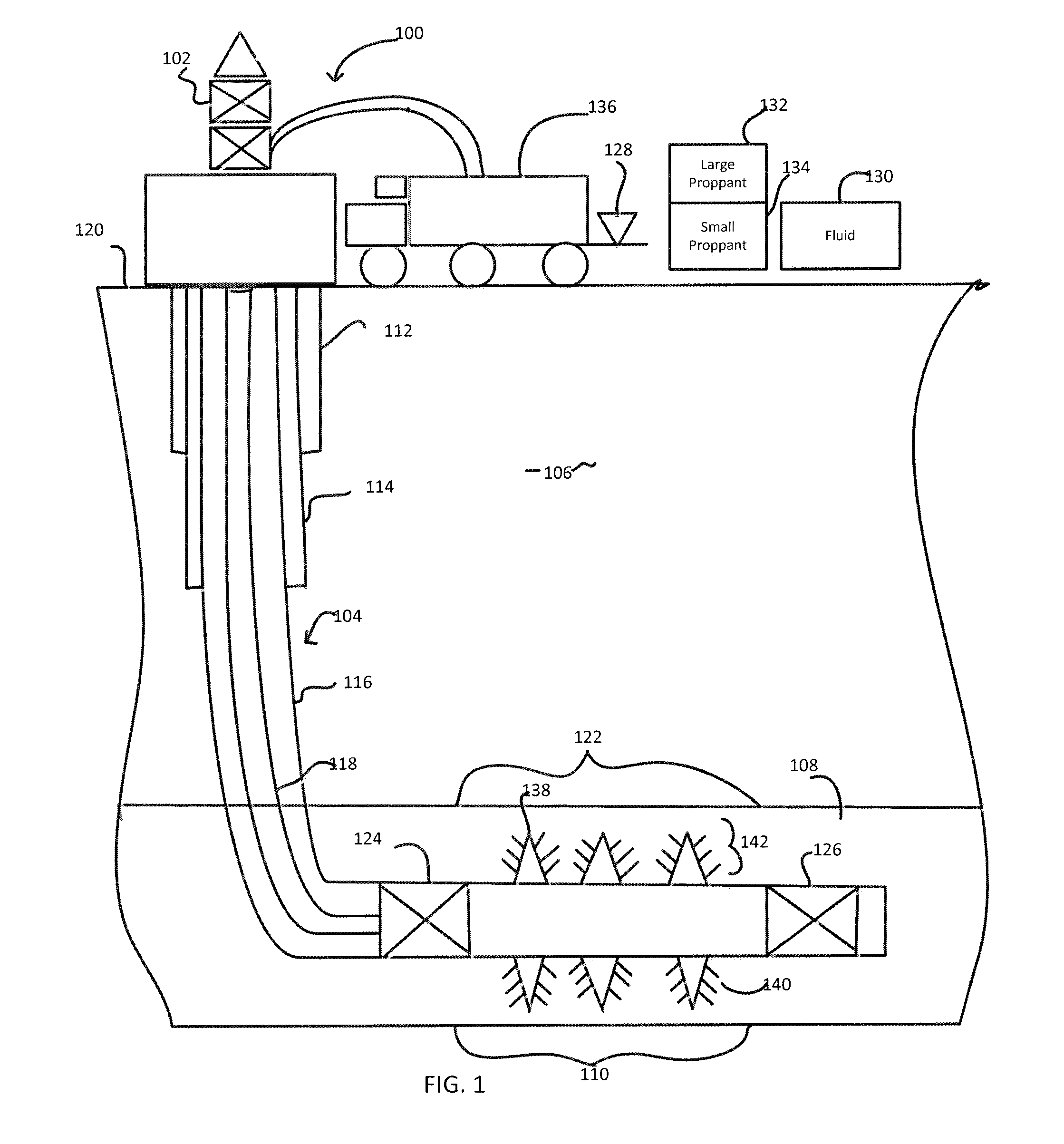

Nano-proppants for fracture conductivity

InactiveUS20160355727A1Increase the extension lengthImprove conductivityFluid removalDrilling compositionMetallurgyFracturing fluid

Methods of hydraulic fracturing are disclosed. One method of hydraulic fracturing which is performed on a geologic stratum includes using a nano-proppant dominantly formed of particles having an average diameter of less than 1 μm dispersed in a fracturing fluid. A material for use in hydraulic fracturing may include a fracturing fluid and a nano-proppant dominantly formed of particles having an average diameter of less than 1 μm dispersed in the fracturing fluid.

Owner:UNIVERSITY OF KANSAS

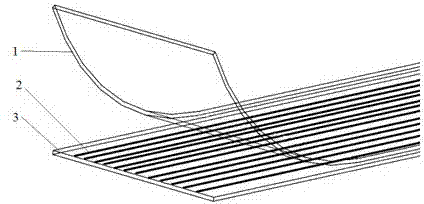

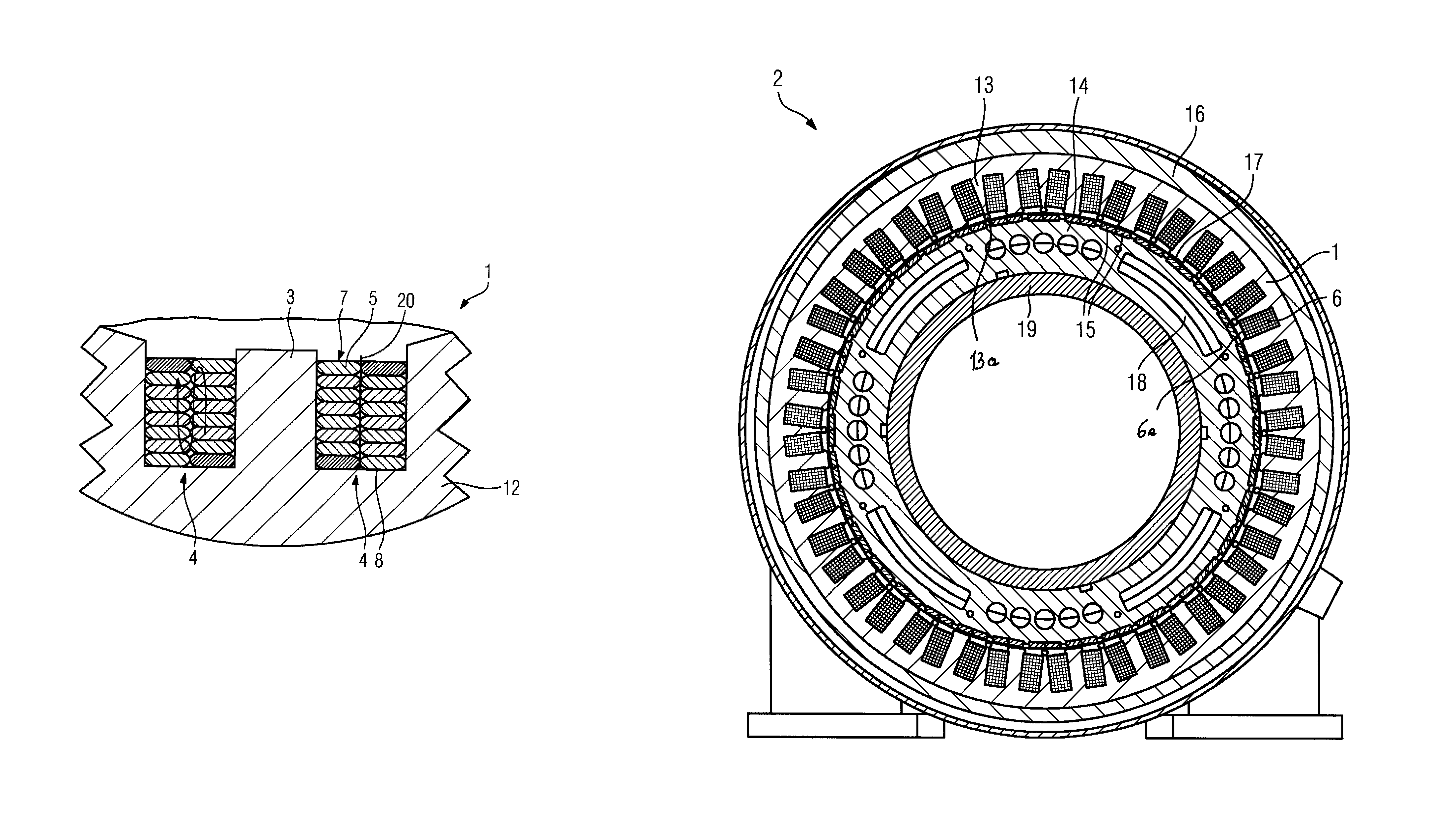

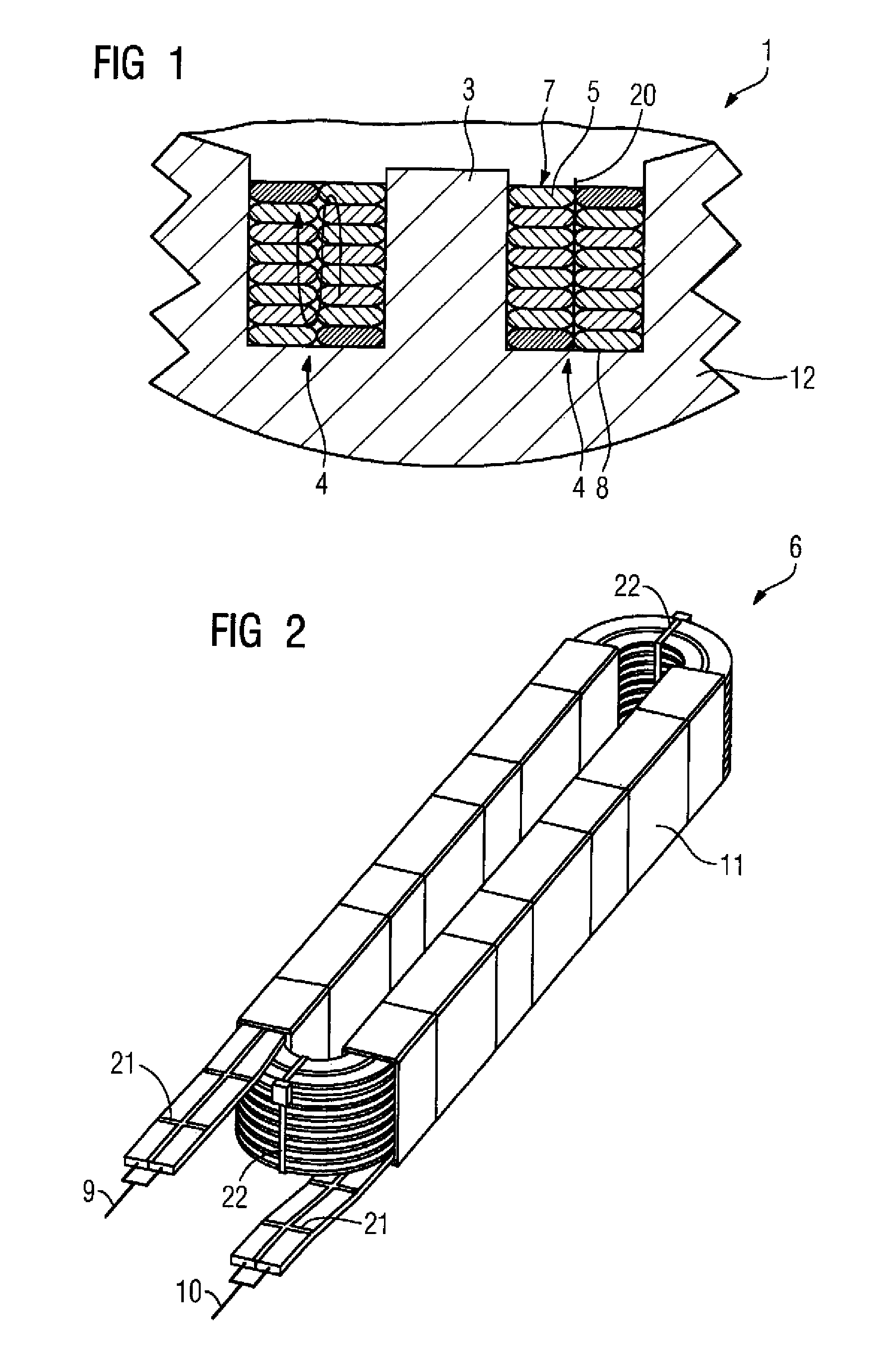

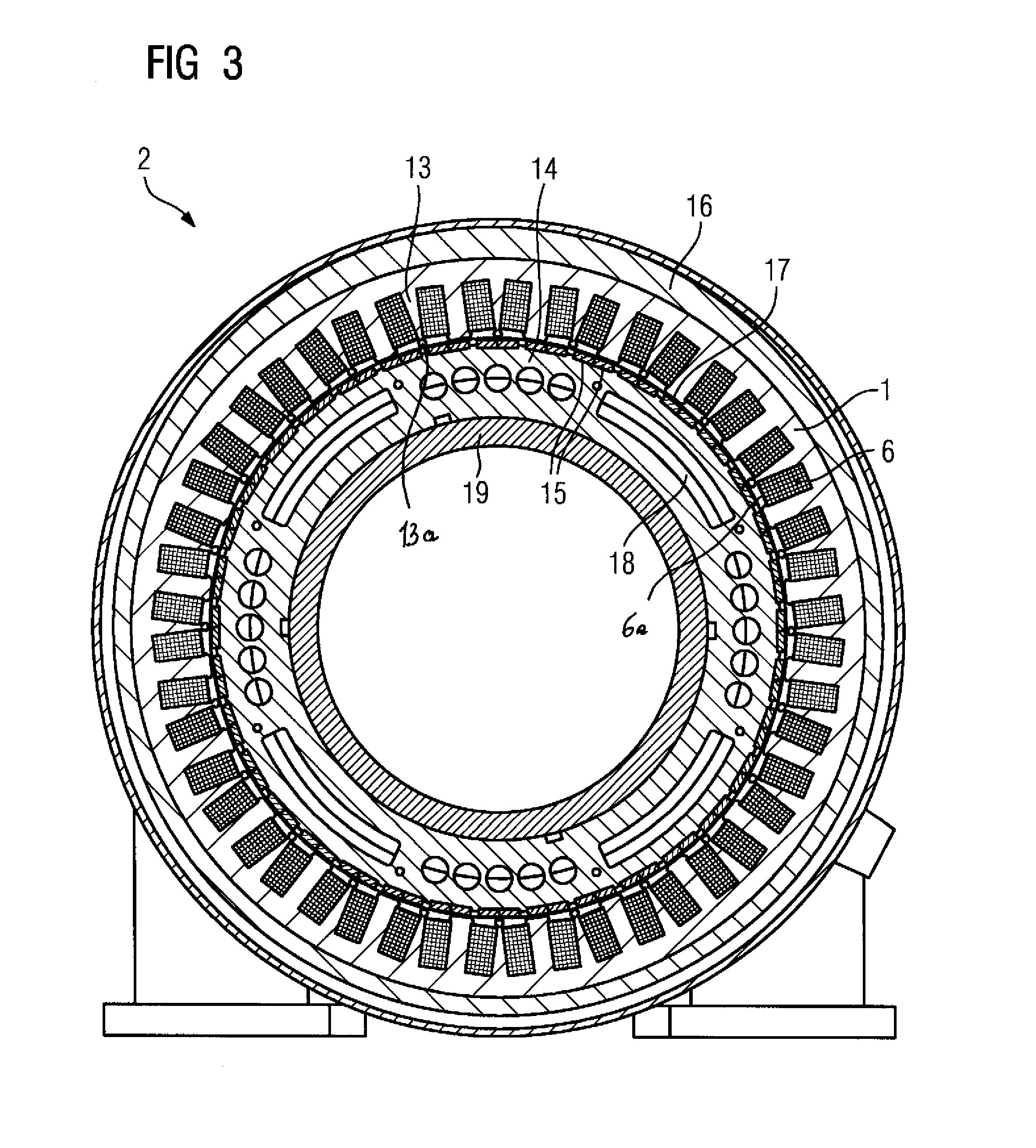

Permanent magnet synchronous machine with flat-wire windings

InactiveUS7646131B2Reduce production complexityIncreased copper filling factorMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet synchronous machineSynchronous motor

According to the invention, an improved copper filling in the slots (4) of a permanently-stimulated synchronous motor (2) may be achieved, whereby such a motor is disclosed, comprising a stator (1), with parallel-edged slots (4), provided with a winding system of flat wires (5), whereby the flat wires (5) each enclose a tooth (3) and are embodied as a tooth coil (6). The flat wires (5) are wound edgewise such that the narrower side of the flat wire (5) faces the tooth (3) and each tooth coil (6) comprises at least two layers of flat wires (5).

Owner:SIEMENS AG

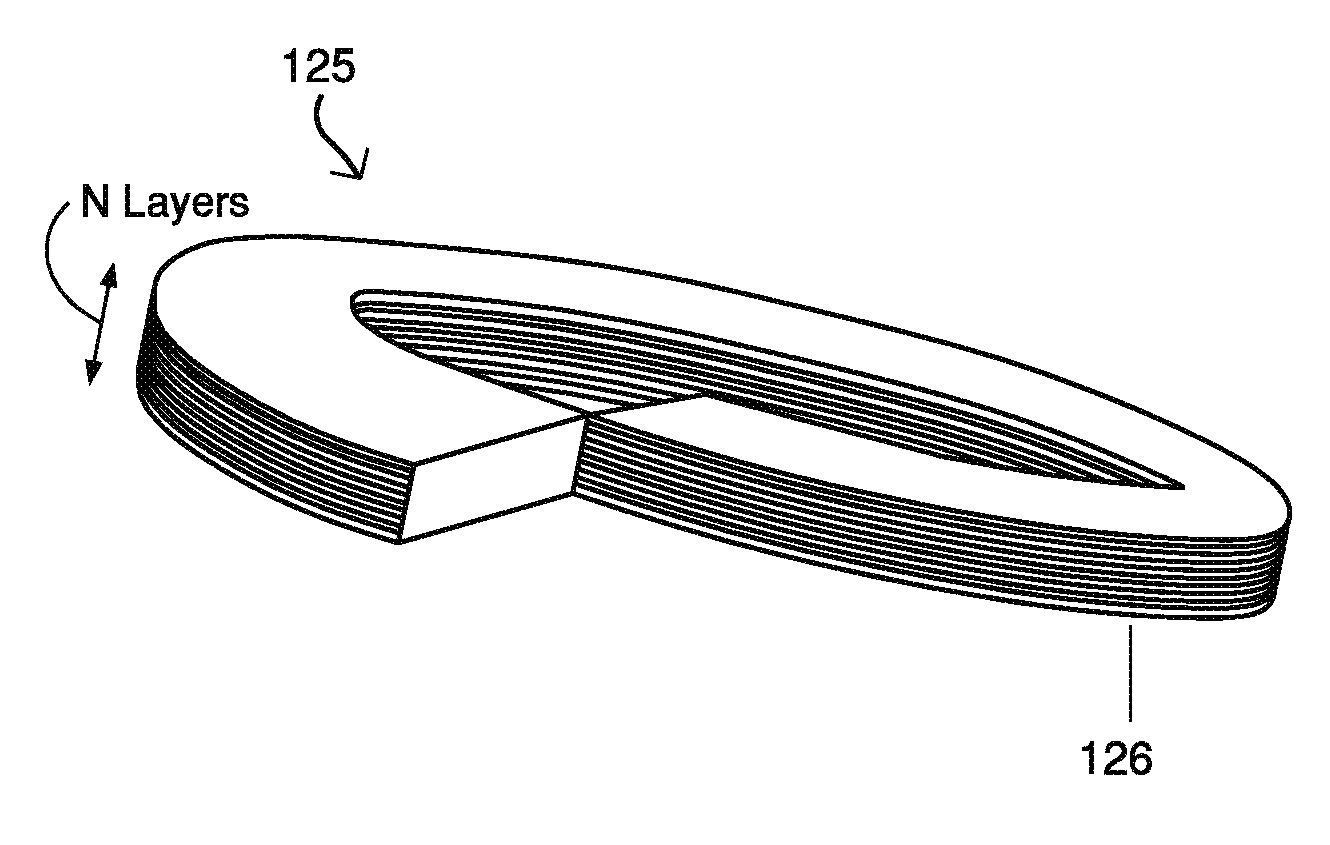

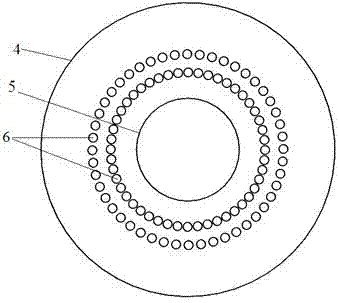

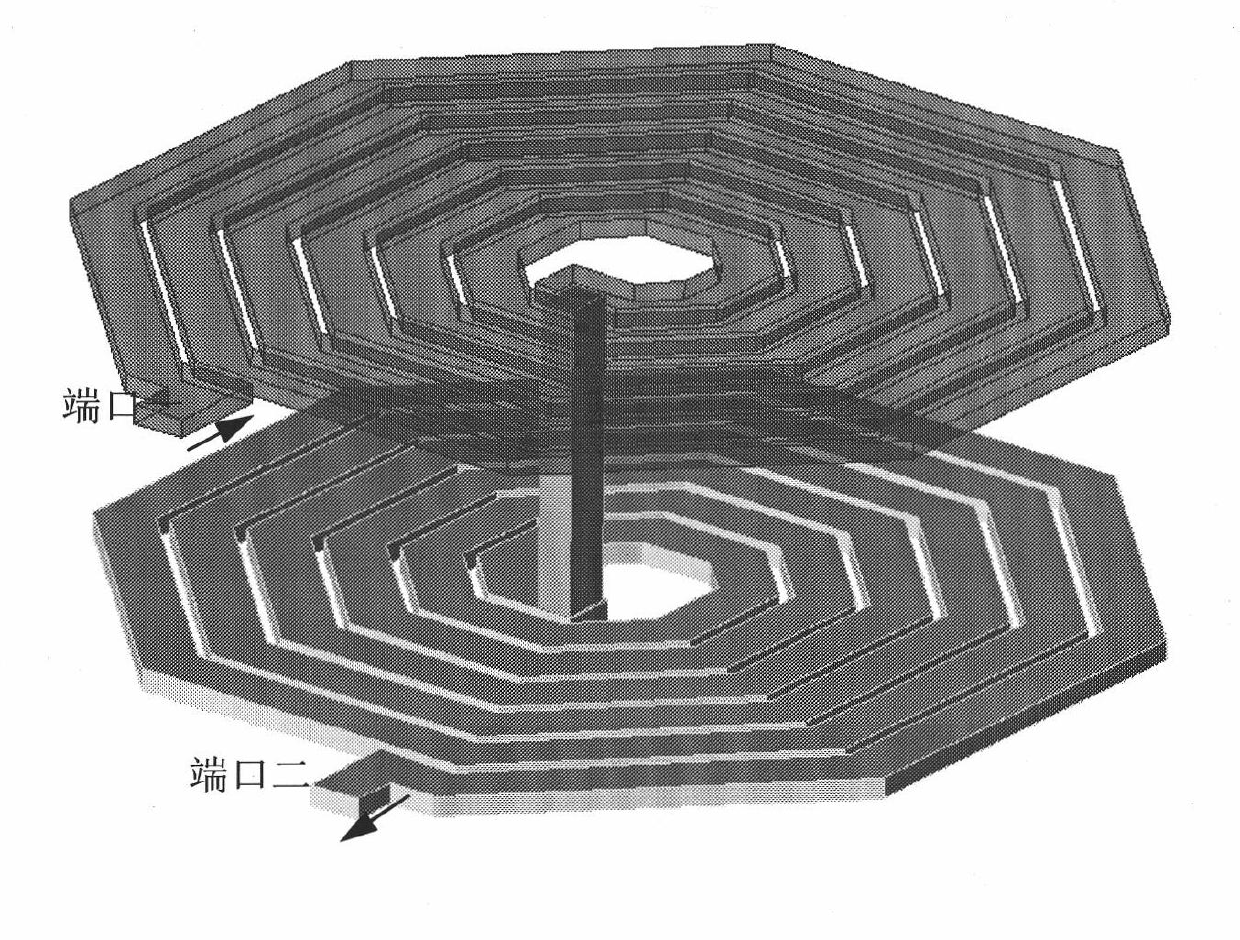

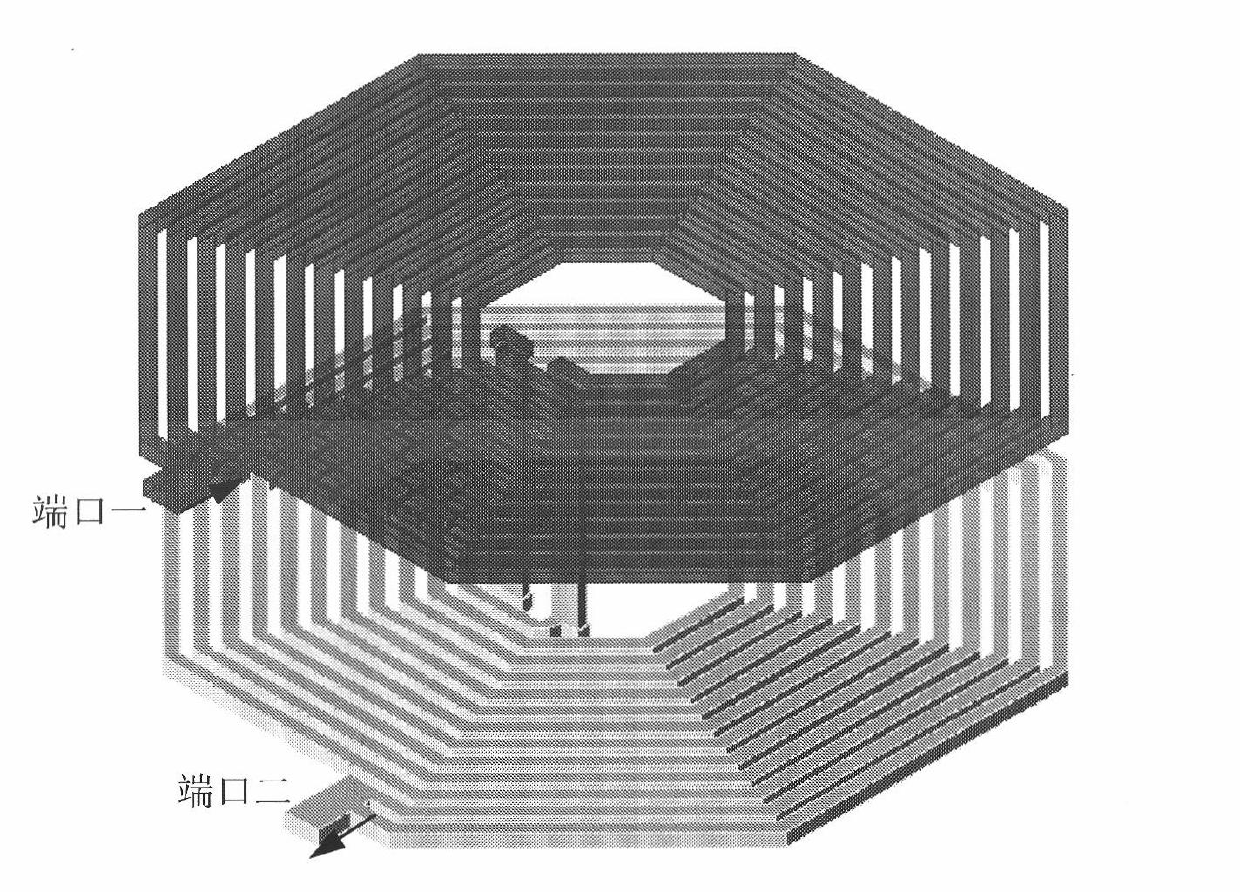

Multi-path laminated inductor with inner path and outer path current compensation function

InactiveCN102087909AReduce skin effectIncrease the inductance valueSemiconductor/solid-state device detailsTransformers/inductances coils/windings/connectionsCross connectionPower flow

The invention discloses a multi-path laminated inductor with an inner path and outer path current compensation function. The multi-path laminated inductor has a multilayer structure and comprises an upper layer metal coil and a lower layer metal coil, wherein slotted parts of patterns of the upper layer metal coil and the lower layer metal coil are coincident with each other; each metal coil consists of a plurality of paths of metal wires; the path of metal wire inside the first layer of metal coil is wound to the other layer of metal coil, and is turned and connected to form an outer path of metal wire; the path of metal wire inside the other layer of metal coil is wound to the first layer of metal coil, and is turned and connected to form an outer path of metal wire; and the upper layer metal coil is interconnected with the lower layer metal coil. The invention provides a multi-coil laminated inductor with a new structure; and the influence of skin effect and proximity effect is reduced by dividing the plurality of paths and cross-connecting the upper layer metal and the lower layer metal. In the inductor, the inductance under the same area condition is improved to the great extent, and a higher inductance quality factor is effectively kept.

Owner:SHANGHAI HUA HONG NEC ELECTRONICS

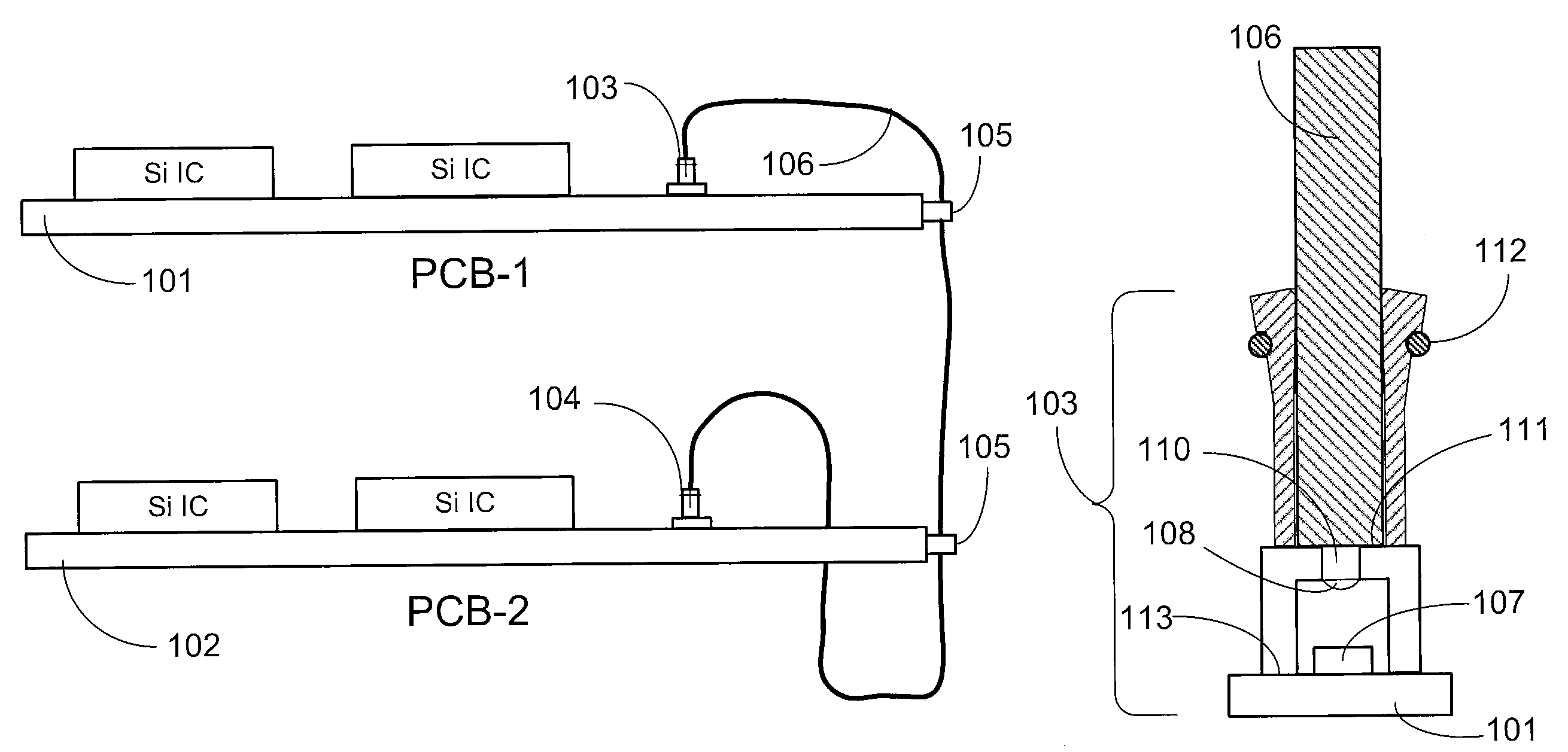

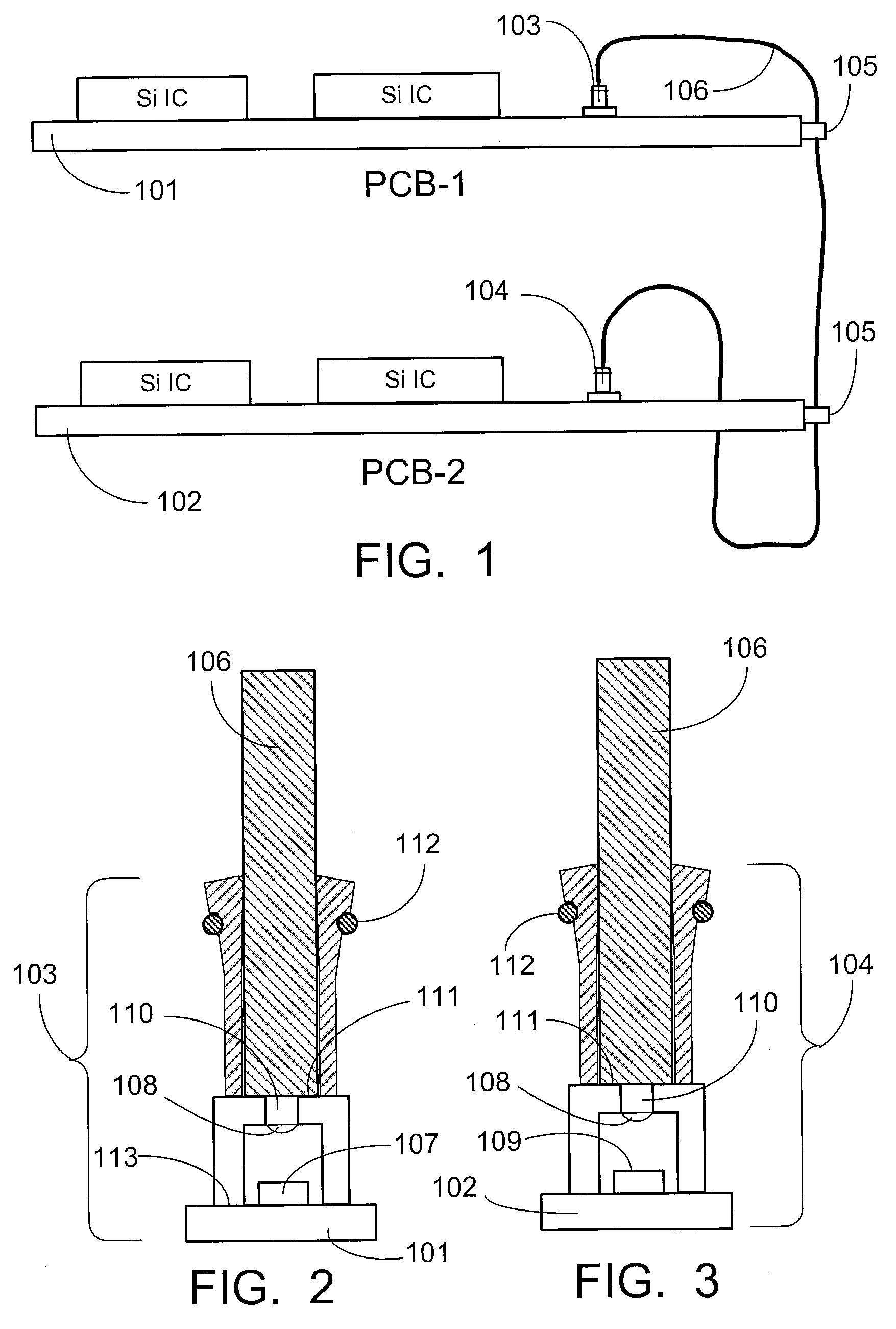

Optical interconnect solution

ActiveUS7901144B2Avoid connection failureFirmly connectedCircuit optical detailsCoupling light guidesElectricityComputer module

A low-cost, high-speed optical interconnect replacement for current electrical interconnects on printed circuit boards is provided. The invention achieves its goal by including an optical transmitter module or optical receiver module mounted in close proximity to a modulator used to encode optical signals from electrical impulses or decode optical signals to electrical impulses. A bare optical fiber is then used to transmit the signal from an optical encoding source to an optical receiver, providing a high-speed method of replacement for traditional electrical interconnects.

Owner:II VI DELAWARE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com