Flat magnetic powder and preparation method thereof

A magnetic powder, flat technology, applied in the field of flat magnetic powder and its preparation, can solve the problems to be improved, increase energy consumption, reduce production efficiency, etc., to reduce skin effect, reduce flattening time, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Using pure iron powder with an average particle size of 40 μm and an average axial ratio of 3 as raw material, add 12 g of iron powder raw material into a stainless steel ball mill tank, use absolute ethanol as a ball mill medium, and mill for 2 hours; the ball milled powder is placed in an oven for After drying, vacuum anneal in a tube furnace for 30 minutes at an annealing temperature of 500°C to eliminate stress and defects caused by ball milling; put the annealed powder back into the tube furnace, and feed high-purity ammonia and high-purity Pure hydrogen gas mixture, control the flow rate of ammonia and hydrogen to 1:1 through the flow meter, the total flow rate is 200ml / min, heat up to 600°C under normal pressure, keep warm for 5 hours, and then cool to room temperature with the furnace to obtain flat Fe 4 N magnetic powder.

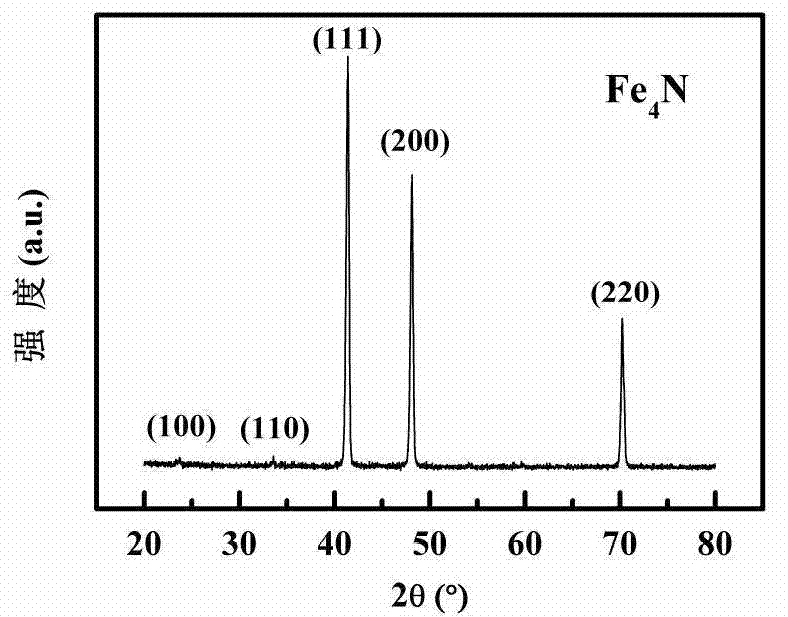

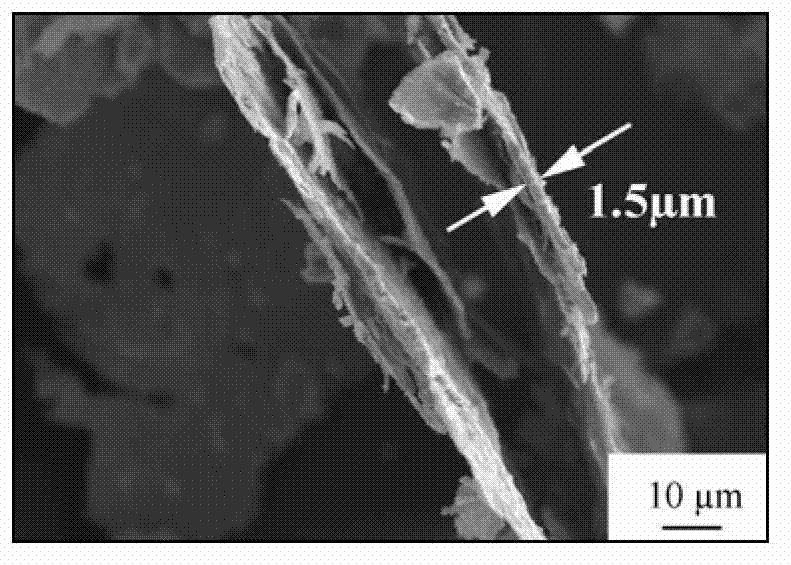

[0018] The XRD pattern of the powder that present embodiment makes is as figure 1 As shown, that is, when the raw material is pure iron po...

Embodiment 2

[0020] Using the same pure iron powder as in Example 1 as a raw material, 12g of iron powder raw material was added to a stainless steel ball milling tank, and absolute ethanol was used as a ball milling medium for 30 minutes of ball milling; Vacuum annealing in a tube furnace for 30 minutes at an annealing temperature of 500°C to eliminate the stress and defects caused by ball milling; put the annealed powder back into the tube furnace, and inject a mixture of high-purity ammonia and high-purity hydrogen, The flow rate of ammonia and hydrogen is controlled by a flow meter to be 1:1, the total flow rate is 200ml / min, the temperature is raised to 600°C under normal pressure, and the temperature is kept for 5 hours, then cooled to room temperature with the furnace, and the flat Fe 4 N magnetic powder.

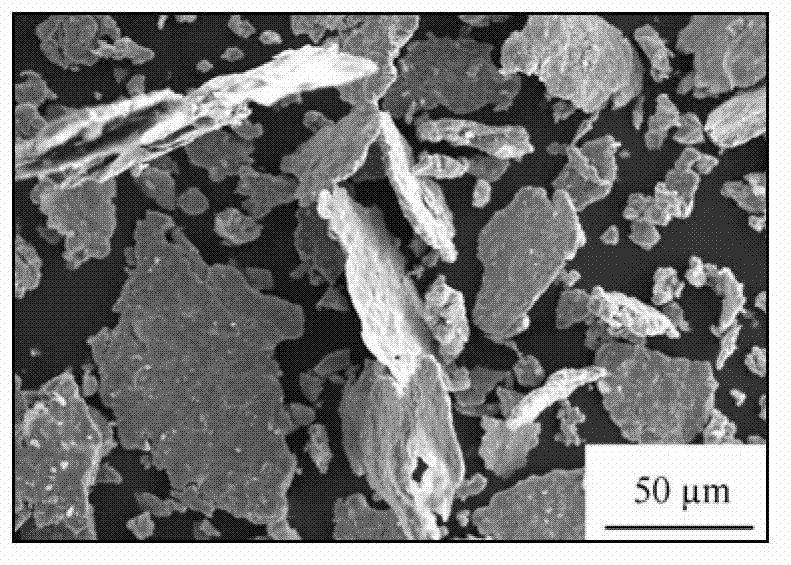

[0021] The phase of the powder obtained in this example is the same as in Example 1, which is pure phase γ'-Fe 4 N; The SEM topography of the powder obtained in this embodiment ...

Embodiment 3

[0023] Take by weighing the Fe that embodiment 1 and embodiment 2 make 4 Each 1.8g of N powder is uniformly mixed with 10wt% paraffin wax after heating and melting; then, press molding on a press to obtain a ring-shaped sample, the pressure used is about 170MPa, the outer diameter of the sample is about 18mm, the inner diameter is about 6mm, and the thickness is about is 3mm; the complex magnetic permeability of the material is measured by a vector network analyzer (Agilent E4991A, US), the test frequency range is 1M~1GHz, and its magnetic spectrum is as follows Figure 4 shown.

[0024] As can be seen from the figure, the cutoff frequency (corresponding to the maximum value of the imaginary part of the magnetic permeability) of the sample corresponding to Example 2 is about 23MHz, while the corresponding cutoff frequency of Example 1 is significantly improved, about 100MHz, and the permeability The real part and imaginary part are also higher than that of Embodiment 2 in mos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com