Patents

Literature

906 results about "Vacuum annealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum Annealing. Vacuum annealing alters the physical properties of rare earth alloys and metal alloys. Depending on the materials and the conditions, vacuum annealing can be used to alter strength, ductility or other properties.

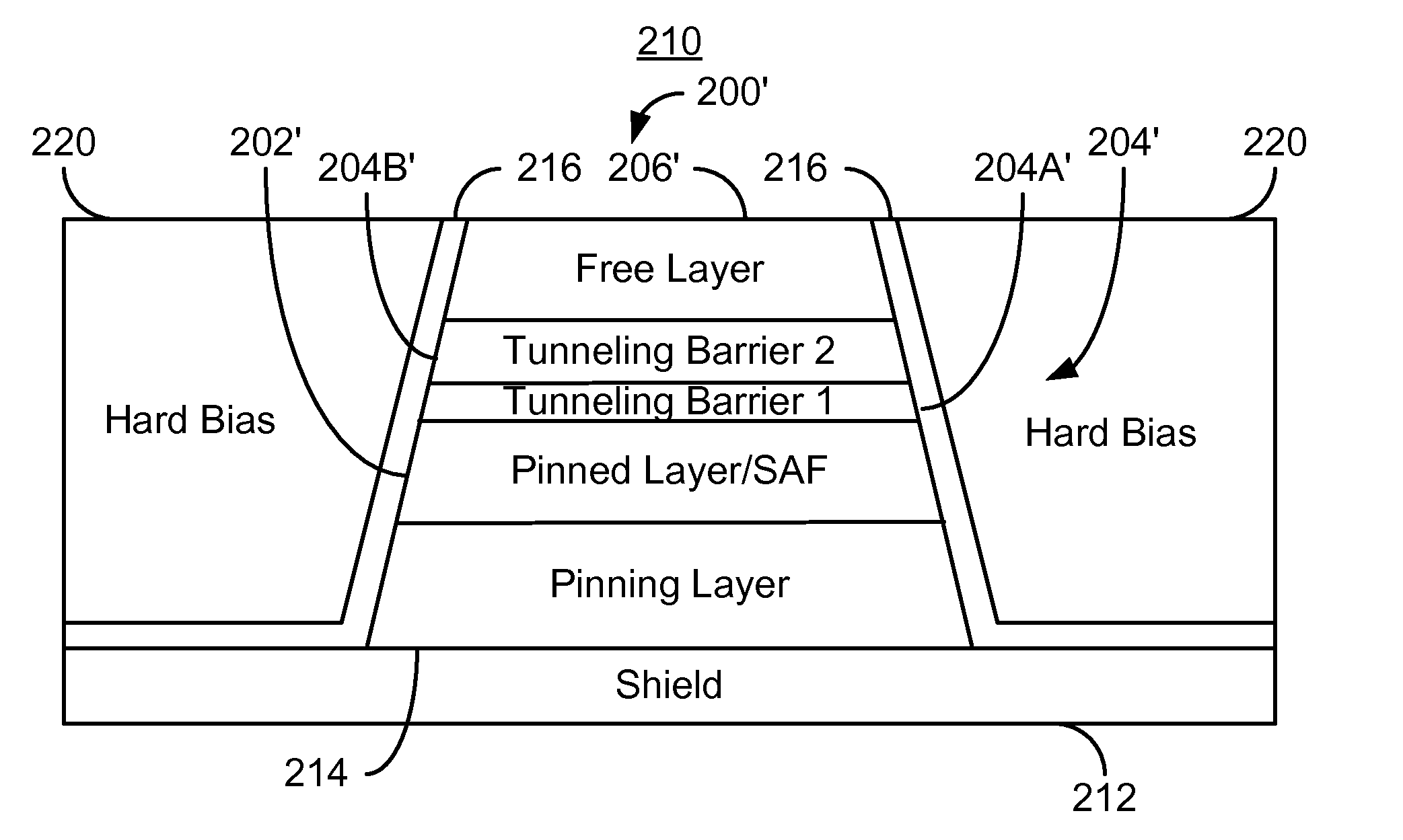

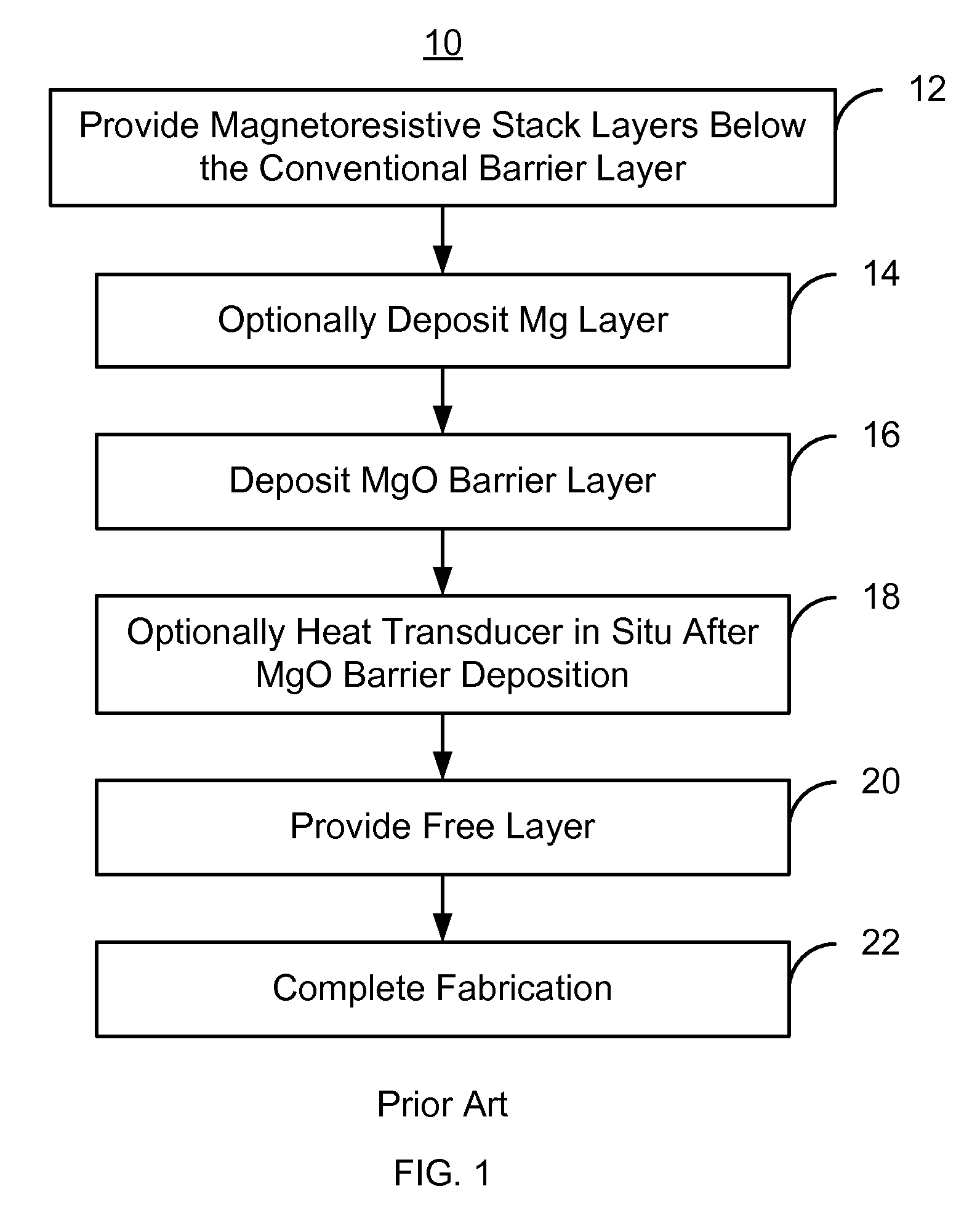

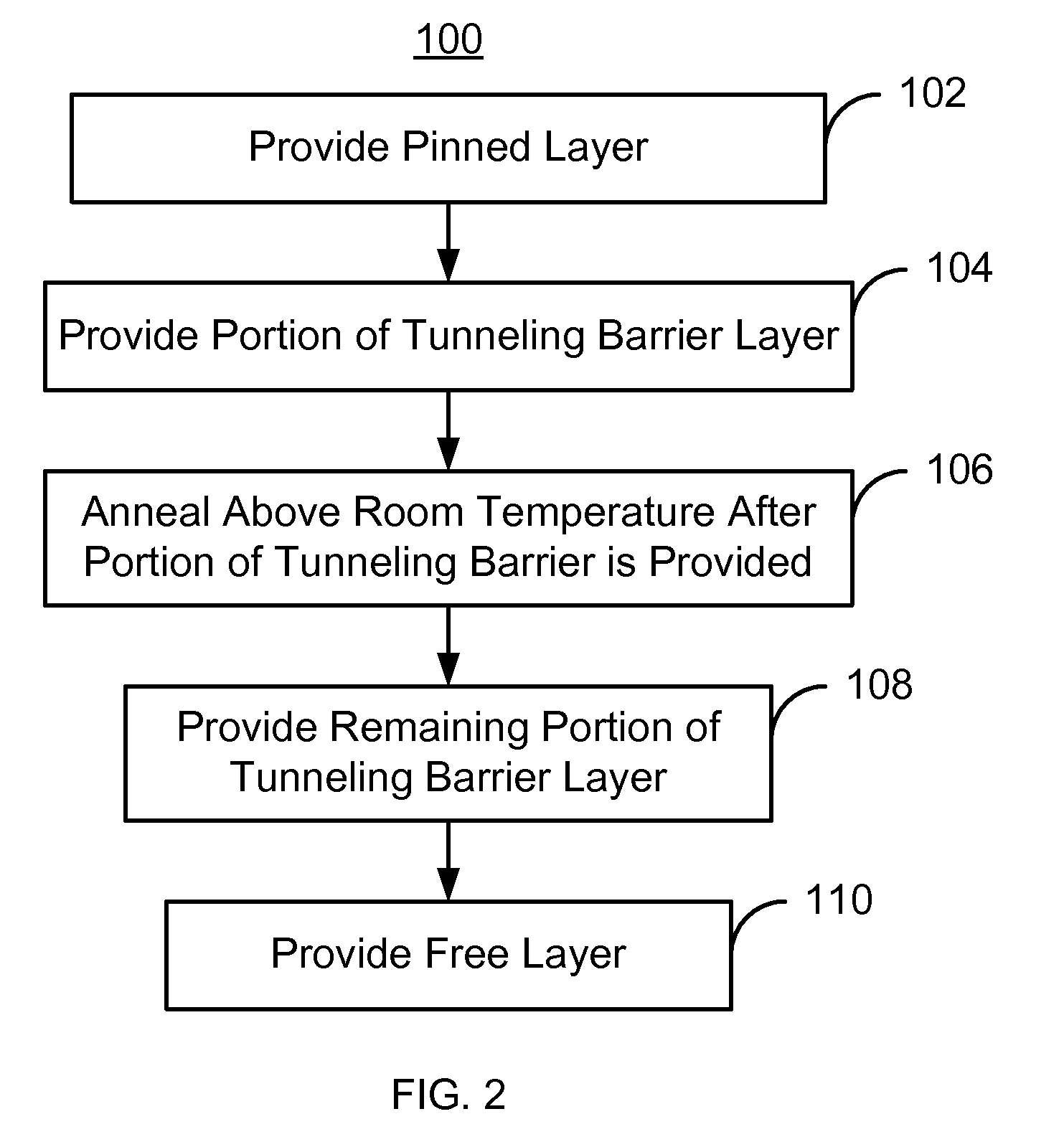

Method for providing a magnetic recording transducer

Owner:WESTERN DIGITAL TECH INC

Solar selective coating having higher thermal stability useful for harnessing solar energy and a process for the preparation thereof

InactiveUS20070196670A1Easy to optimizeImprove thermal stabilitySolar heat devicesVacuum evaporation coatingAbsorptanceEngineering

The present invention provides an improved solar selective multilayer coating having higher thermal stability and a process for the preparation thereof. Solar selective coatings having higher thermal stability are useful in solar steam generation, solar steam turbines to produce electricity and also on automobile engine components. In the present invention, a tandem stack of three layers of TiAlN, TiAlON and Si3N4 is deposited on metal and non-metal substrates at room temperature using a planar reactive direct current magnetron sputtering process. The first two layers function as the absorber and the third antireflection layer further enhances the coating's absorptance. The solar selective coatings were annealed in air and vacuum to test the thermal stability at different temperatures and durations. The coatings of the present invention deposited on copper substrates are stable in air up to a temperature of 625° C. for a duration of 2 hours and exhibit higher solar selectivity in the order of 9-10 and these coating also show no change in the absorptance and the emittance values even after vacuum annealing at 600° C. for 3 hours. Coatings deposited on copper substrates showed no significant degradation in the optical properties even after continuous heating in air at 525° C. for 50 hours. The solar selective coatings of the present invention exhibit high hardness, high oxidation resistance, chemical inertness and stable microstructure.

Owner:COUNCIL OF SCI & IND RES

Method for preparing high-purity molybdenum titanium sputtering target

InactiveCN101956159AHigh purityHigh densityVacuum evaporation coatingSputtering coatingImpurityElectron

The invention discloses a method for preparing high-purity molybdenum titanium sputtering targets, and relates to a method for preparing molybdenum titanium sputtering targets used in the electronic and photovoltaic field, which is characterized in that the preparation process comprises the following steps: taking ammonium dodecamolybdate as a raw material, preparing high-purity molybdenum powder through two sections of a hydrogen reductive method; carrying out cold isostatic pressing on the high-purity molybdenum powder to press into a molybdenum plate green body; presintering in vacuum; sintering into a molybdenum plate at high temperature at the atmosphere of hydrogen; processing the sintered molybdenum plate into a molybdenum target body by adopting a pressure processing manner of firstly forging and then rolling; vacuum annealing to process into the finished product of molybdenum titanium sputtering target according to a specific specification machine. The preparation method of the invention has low cost, simple operation and low equipment requirements; the prepared molybdenum titanium sputtering target has high purity, low impurity content, high density, uniform particle size and specific crystallization orientation.

Owner:JINDUICHENG MOLYBDENUM CO LTD

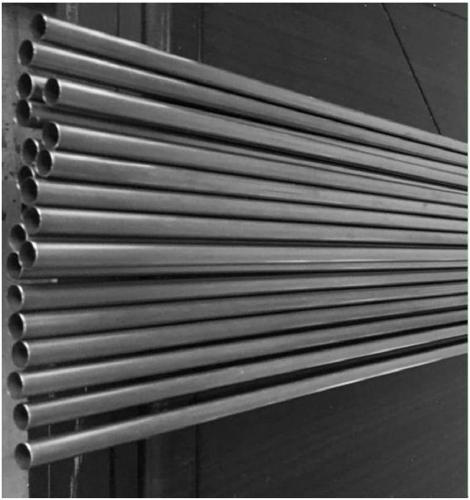

Titanium alloy TC4 cold-rolled tube and production method thereof

ActiveCN101824564AHigh strengthLow costRoll force/gap control deviceFurnace typesOxygenTitanium alloy

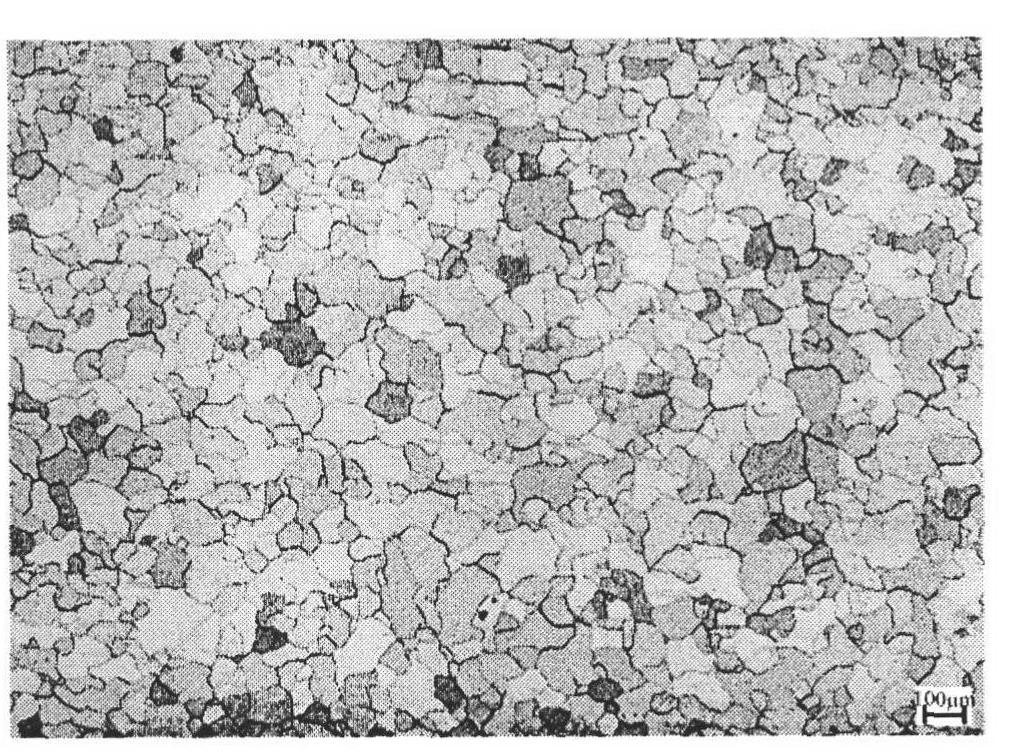

The invention relates to a titanium alloy, in particular to a titanium alloy TC4 cold-rolled tube and a production method thereof. By weight, the composition of the alloy is as follows: the balance of Ti, 5.5 percent to 6.75 percent of Al, 3.5 percent to 4.5 percent of V, less than or equal to 0.1 percent of Fe, less than or equal to 0.1 percent of C, less than or equal to 0.03 percent of N, less than or equal to 0.015 percent of H and less than or equal to 0.15 percent of O. The specification of the TC4 cold-rolled tube is outer diameter multiplied by wall thickness (however, the ratio of the outer diameter to the wall thickness is larger than 2). In the process of cold-rolling the titanium alloy tube, lubricant is added on the inner and the outer surfaces of the tube blank and the semi-finished tube, rolling is then carried out, the tube is annealed in oxygen after each rolling pass, a single edge is inwardly sheared by 0mm to 0.8mm, scale cinder and flaws are completely removed before the last one to two passes, the tube is washed by alkali and acid or acid and then by water and then rolled before a finished product is produced after 1 to 16 rolling passes, the rolled finished product is annealed in oxygen or vacuum, and the annealed finished product is washed by alkali and acid or acid again. The performance of the titanium alloy (TC4) cold-rolled tube is good, the metallographic structure is uniform, and the surface quality of the tube is good.

Owner:忠世高新材料股份有限公司

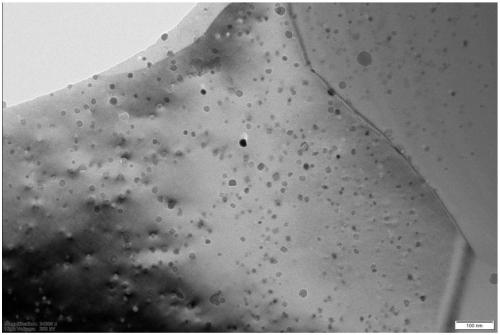

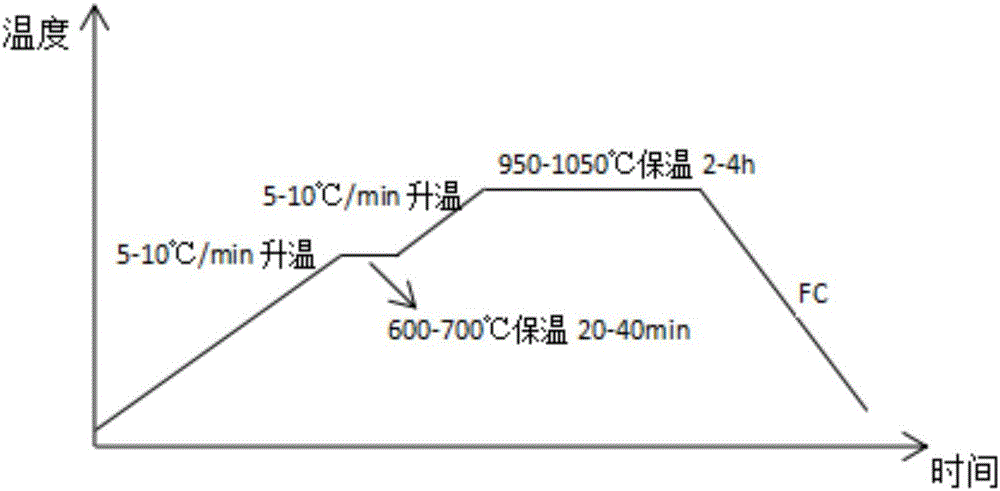

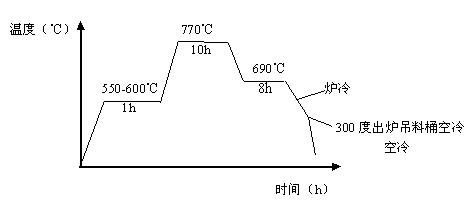

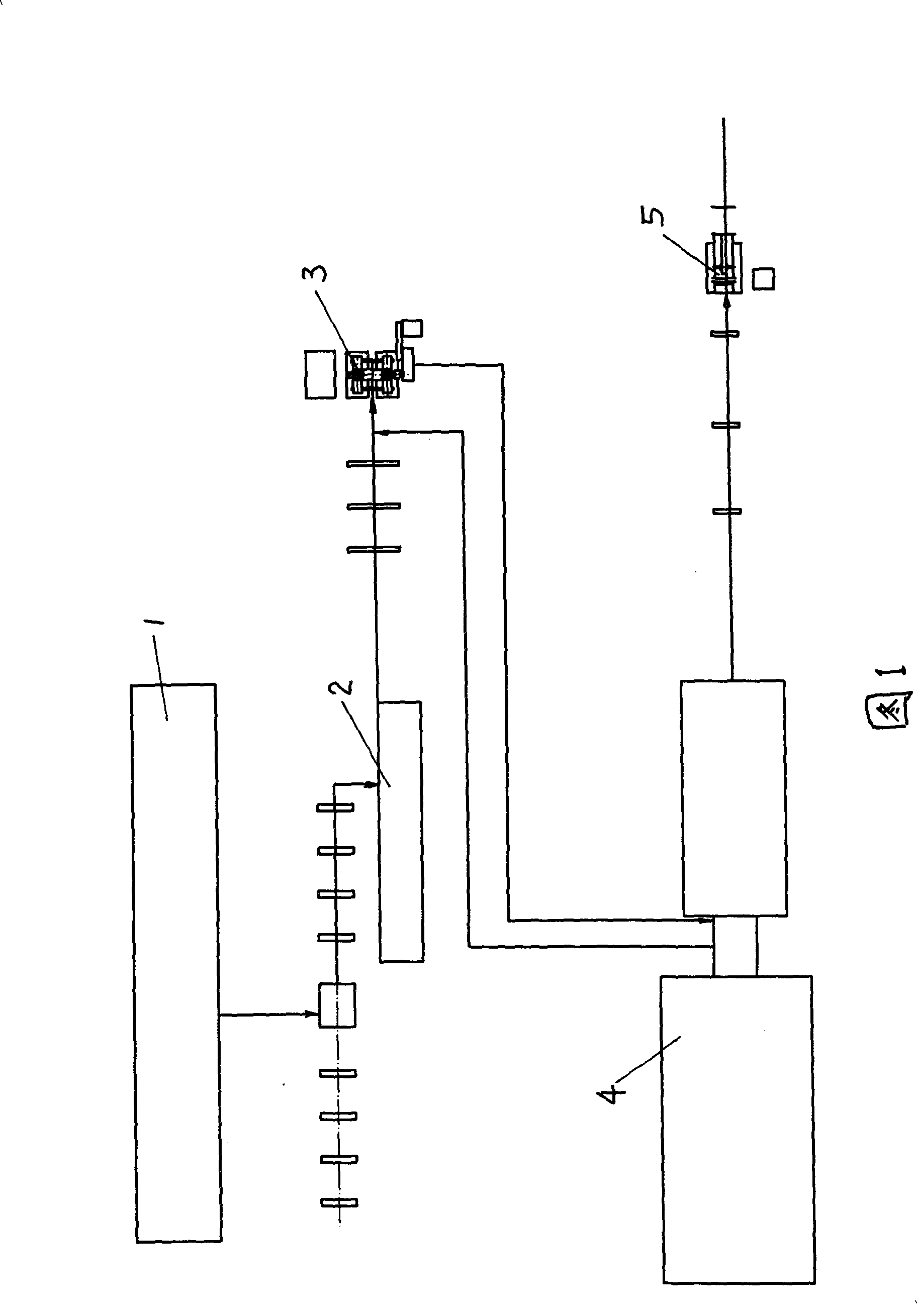

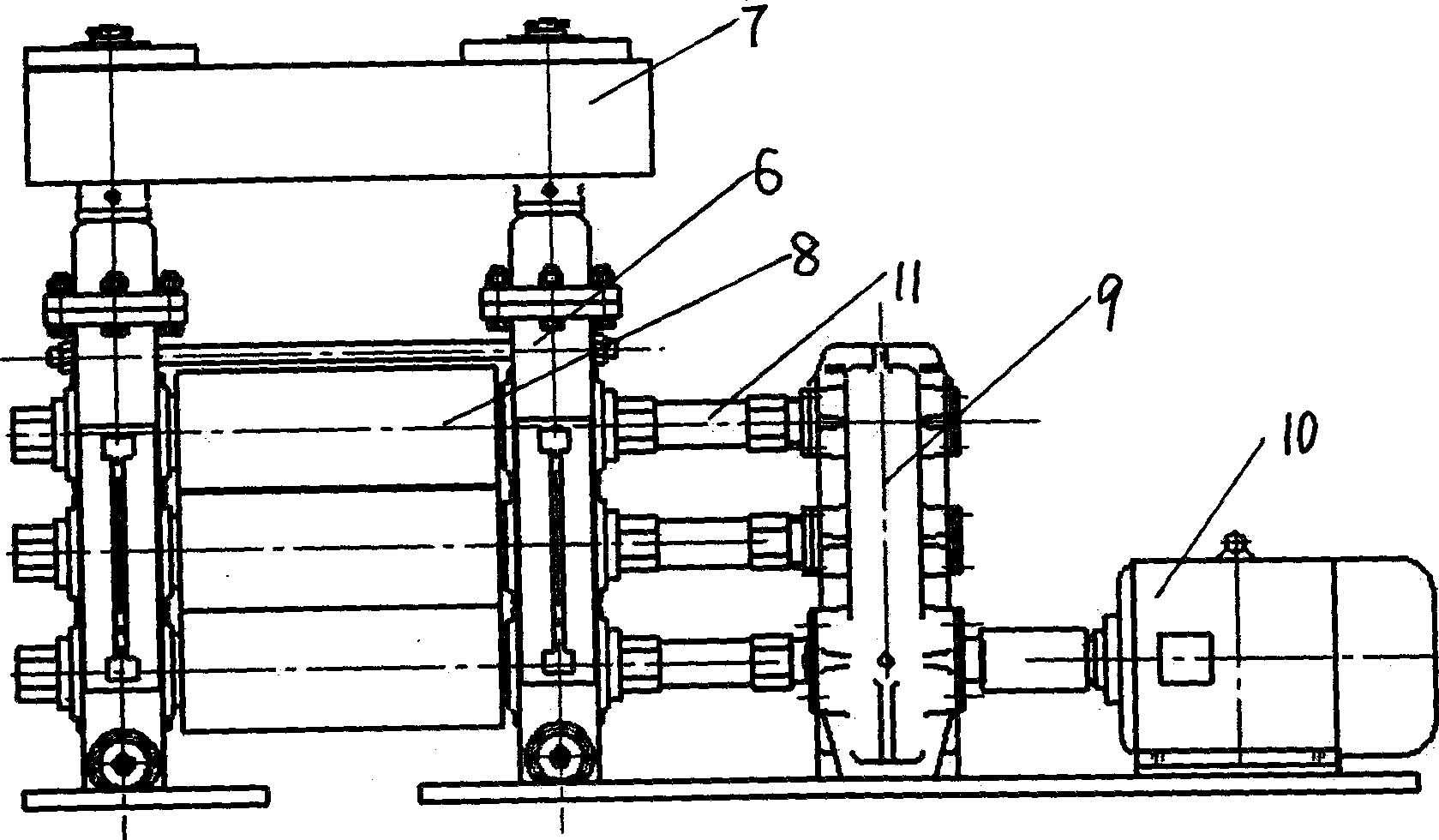

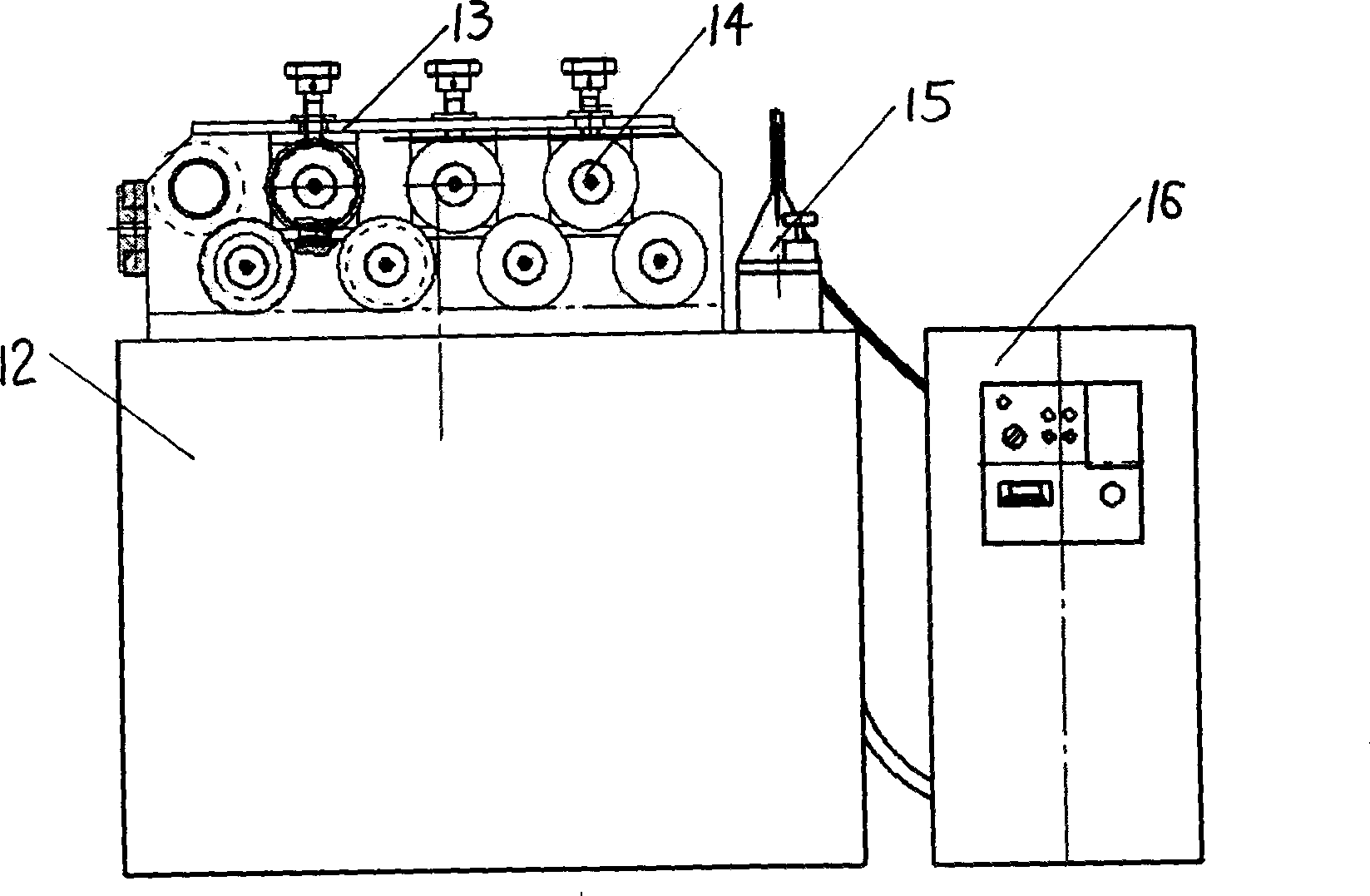

Current transformer iron core of amorphous and nano-crystalline magnetically soft alloy and preparation method thereof

ActiveCN105047348AReduce magnetic lossReduce lossTransformers/inductances magnetic coresInductances/transformers/magnets manufactureChemical compositionAlloy

The invention discloses a current transformer iron core of amorphous and nano-crystalline magnetically soft alloy and a preparation method of the current transformer iron core. The chemical component atomic percent of the iron core is FeaSibBcMdCueM'f, wherein a is not more than 85 and is not less than 65; b is not more than 25 and is not less than 5; c is not more than 15 and is not less than 0; d is not more than 15 and is not less than 0; e is not more than 5 and is not less than 0, and f is not more than 1 and is not less than 0, and a plus b plus c plus d plus e plus f equals to 100, and M is at least one of Nb, Mo or V, and M' is at least one of Sn, Al, Y and Sb. The preparation method comprises the steps as follows: preparing materials according to atomic percent and smelting to prepare a mother alloy; then crushing the prepared mother alloy to re-melt and covering steel-making slagging constituent to prevent oxidation and deslagging; preparing amorphous alloy ribbons with the re-melted mother alloy by using a single roll rapid solidification ribbon preparation method under ordinary pressure, and finally winding the amorphous alloy ribbons as the amorphous iron core, and performing isothermal annealing crystallization in a vacuum annealing furnace to obtain the amorphous and nano-crystalline magnetically soft alloy of a mutual inductor iron core. The iron core of the invention has high saturation flux density, high permeability, and low magnetic loss so that the mutual inductor has ultrahigh precision and accuracy class.

Owner:NEW MATERIALS TECH JIANGSU AMORPHD +1

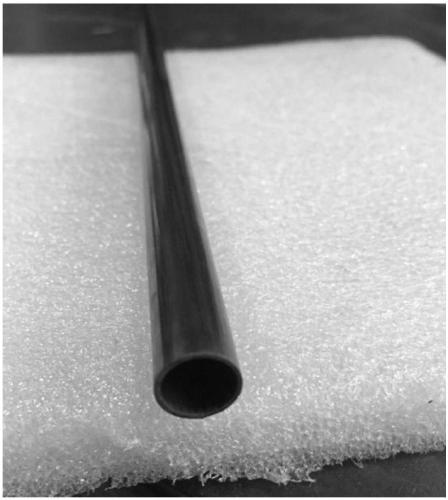

Preparation process of sputtered rotary molybdenum-sodium-alloy tubular target

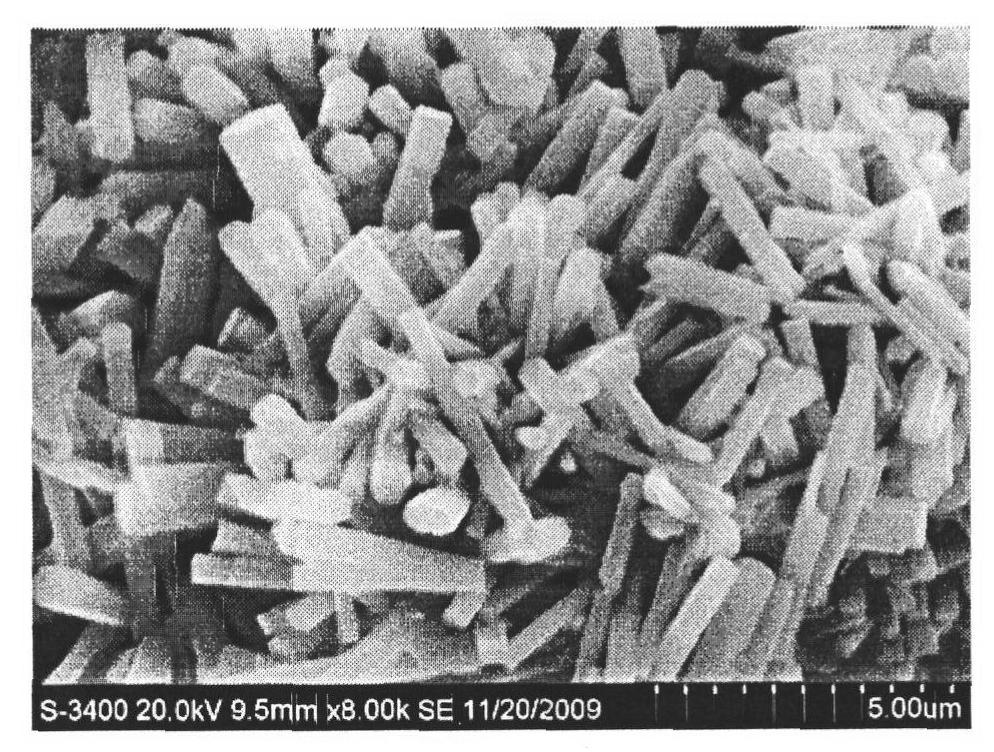

ActiveCN103045925AHigh densitySmall grain sizeVacuum evaporation coatingSputtering coatingSodium molybdateNiobium alloy

The invention discloses a preparation process of a sputtered rotary molybdenum-sodium-alloy tubular target. The preparation process comprises the following steps of: (1) preparing materials, wherein used powder comprises molybdenum powder and sodium molybdate powder, the physical property of the powder is as follows: the Mo content of the molybdenum powder is at least 99.95% with the granularity of 3-5 microns, and the sodium molybdate content of the sodium molybdate powder is at least 99.0% with the granularity of 20-40 microns; (2) blending the powder: weighing the molybdenum powder and the sodium molybdate powder proportionately, controlling the mass percentage content of the molybdenum powder to be 90-99% and that of the sodium molybdate powder to be 1-10%; (3) carrying out mechanical alloying: synthesizing nanometer molybdenum-sodium alloy powder; (4) filling into a die; (5) carrying out cold isostatic pressing; (6) sintering; (7) forging; (8) performing vacuum annealing; and (9) mechanically processing to obtain the sputtered rotary molybdenum-sodium-alloy tubular target. A produced molybdenum-niobium-alloy tubular target has characteristics of uniform elements, no segregation, fine grain size and high purity, completely meets requirements of CIGS (Copper Indium Gallium Selenide) photovoltaic cells and increases the use efficiency of the cells.

Owner:LUOYANG SIFON ELECTRONICS

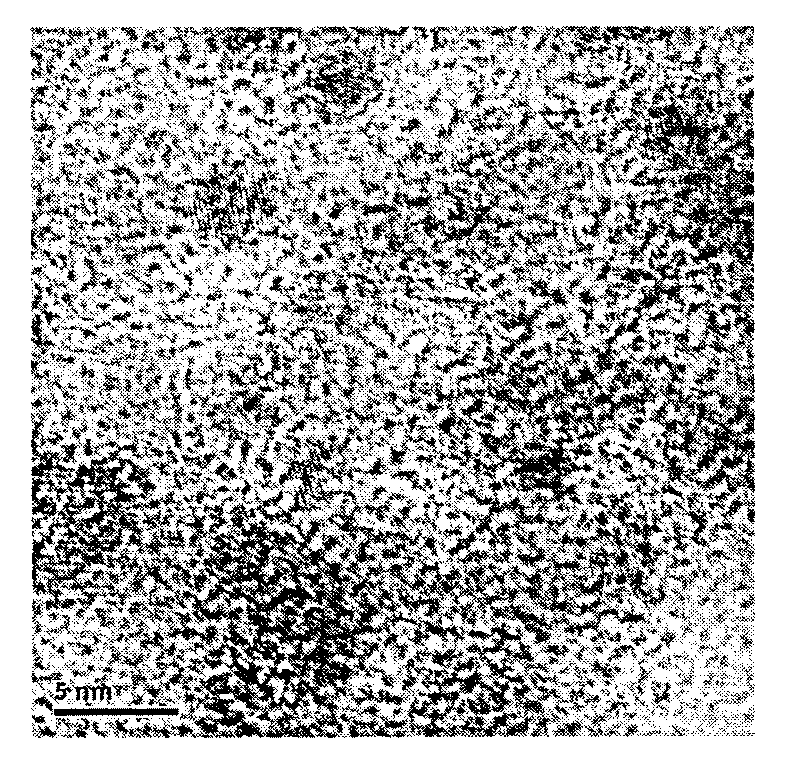

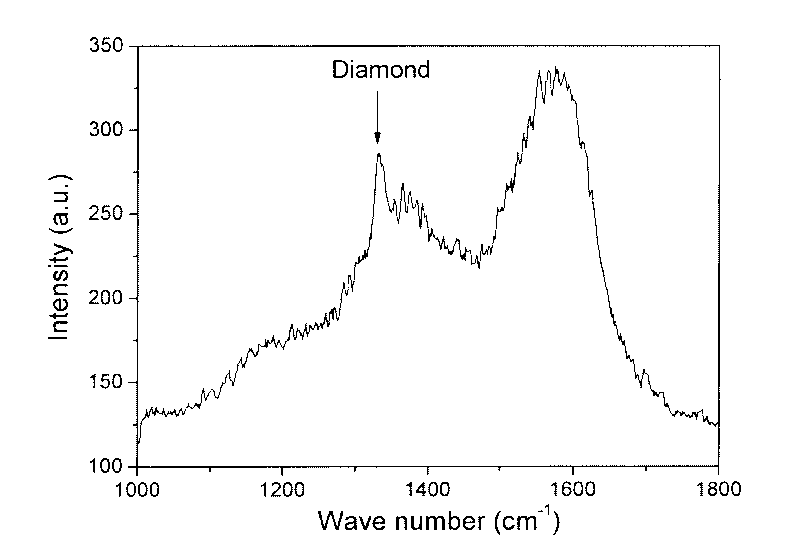

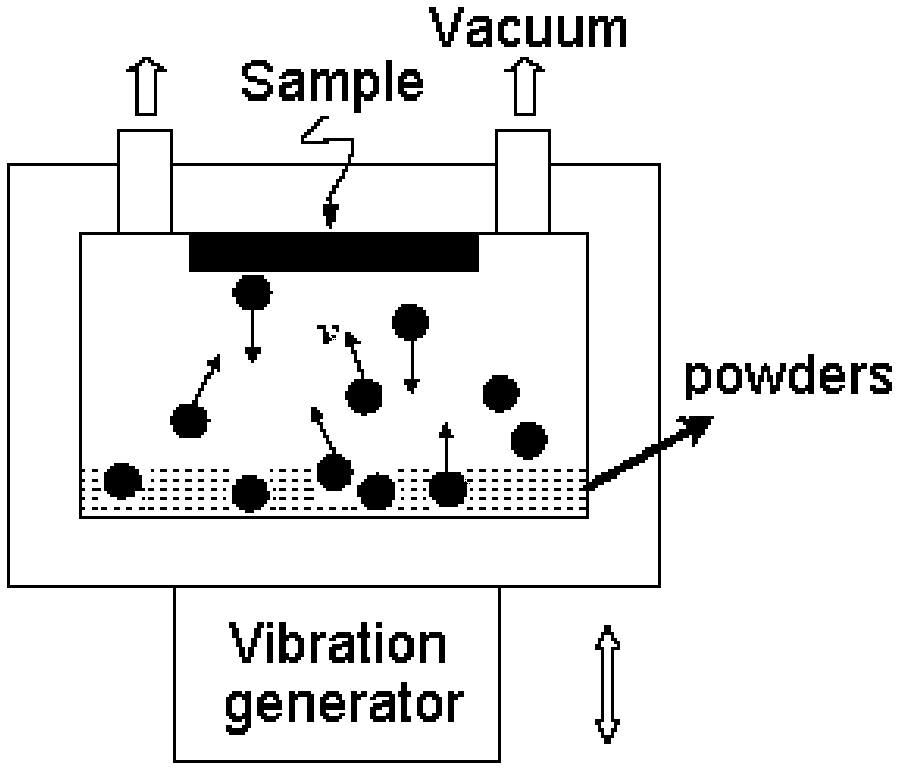

N-type nano-diamond film and preparation method

ActiveCN101717913ALow resistivityImprove mobilityVacuum evaporation coatingSputtering coatingPhosphoniumGas phase

The invention provides an n-type nano-diamond film and a preparation method. The preparation method comprises the following steps: injecting donor impurity ions into a nano-diamond film by adopting an ion injection method; and performing vacuum annealing on the film to obtain the n-type nano-diamond film. The method uses the ion injection method to finish the step of doping, so that the phosphonium ions or oxonium ions of which the injected dose is 1,014 to 1,016 cm-2 are doped to nano-diamond crystal grains and crystal boundaries, and the defect that impurities are centralized in the crystal boundaries but cannot enter diamond crystal grains in the processes of chemical vapor deposition and doping is avoided; and after the vacuum annealing at the temperature of between 700 and 1,000 DEG C, the n-type diamond film which has lower resistivity and higher Hall mobility is obtained. Therefore, the n-type nano-diamond film has very important scientific significance and engineering value for the application of the film in the field of semiconductor devices, field emission displays, electrochemistry and the like.

Owner:ZHEJIANG UNIV OF TECH

Method for modifying surface of metal material by using surface mechanical attrition treatment

InactiveCN102560508AExtended service lifeHigh hardnessSolid state diffusion coatingSteel ballCost savings

The invention discloses a method for modifying the surface of a metal material by using surface mechanical attrition treatment. The method comprises the following steps of: putting infiltration medium element powder into a closed container, performing surface mechanical attrition treatment on the metal material by using a super-hard abrasion-resistant stainless steel ball, and performing vacuum annealing treatment on the metal material subjected to the surface mechanical attrition treatment. By performing the surface mechanical attrition treatment on the metal material in the infiltration medium powder and using the high dispersion performance of the nano material and the promoting effect of the later annealing treatment on the dispersion, the surface of the metal material is modified and strengthened, the surface performance of the metal material is remarkably promoted; and the method has the advantages of simple process, convenience in operation and cost saving.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

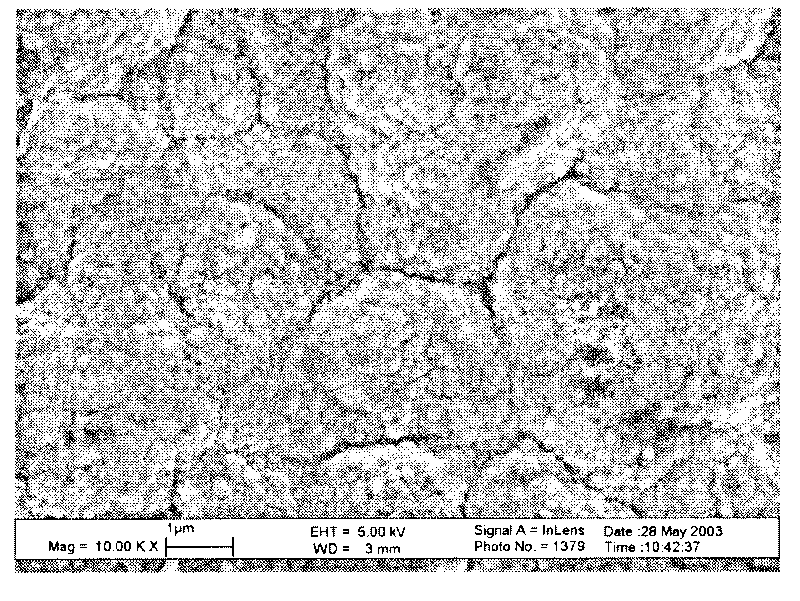

Preparation method of oxide dispersion strengthened FeCrAl alloy pipe

The invention provides a preparation method of an oxide dispersion strengthened FeCrAl alloy pipe, belongs to the technical field of nuclear power pipe preparation, particularly discloses a preparation method of an ODS (oxide dispersion strengthened) FeCrAl alloy pipe for a nuclear fuel canning material, and aims to realize localization of a high-strength ODS-FeCrAl alloy thin-walled pipe. The preparation method of the ODS FeCrAl alloy pipe adopts a cold rolling and pass thermal treatment process, and is characterized in that the rolling speed is controlled to 100-600 r / min, and the pipe deformation is controlled to 0%-50%. Each pass of thermal treatment mode adopts a vacuum annealing mode, the annealing temperature is 700-1150 DEG C, and the heat insulation time is 30-90 minutes. The preparation method does not influence the granular size and the dispersion state of a Y-Al-O oxide strengthening phase in the ODS FeCrAl alloy, the prepared pipe is of fine-crystalline-grain and uniform-texture crystal structure, and the ODS pipe has excellent strength and creep resistance and high oxidation resistance and irradiation swelling performance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +3

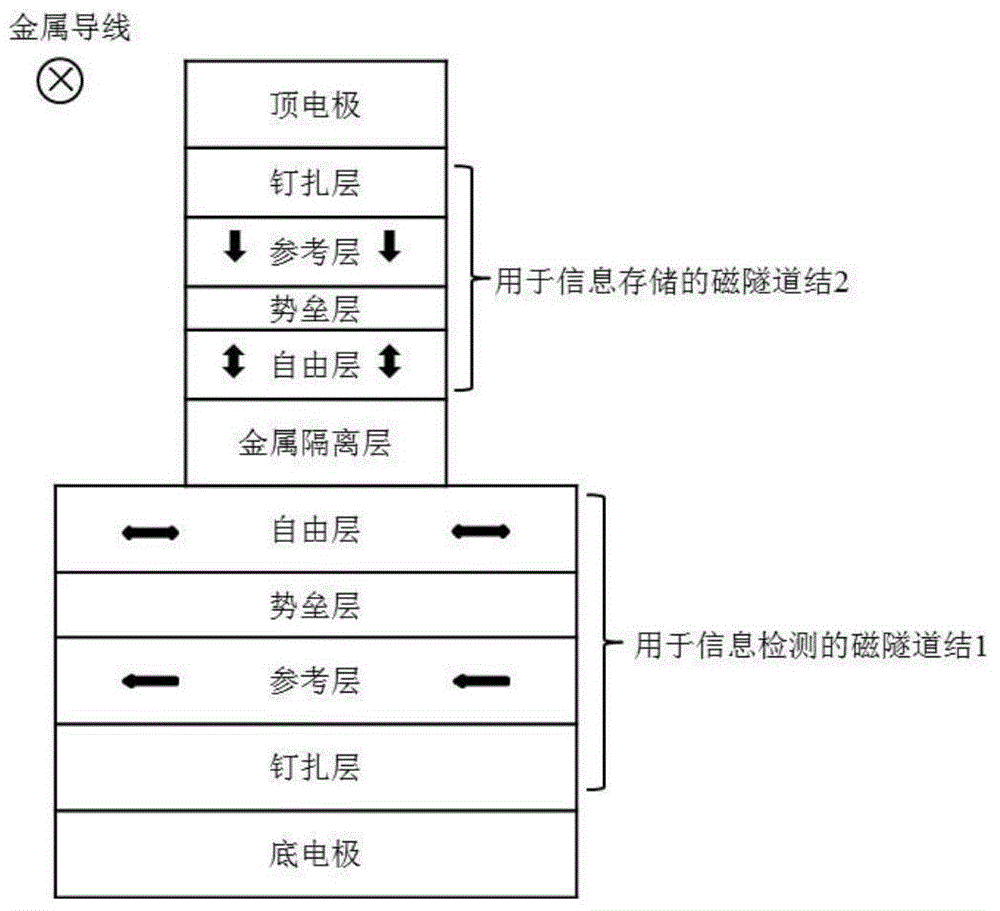

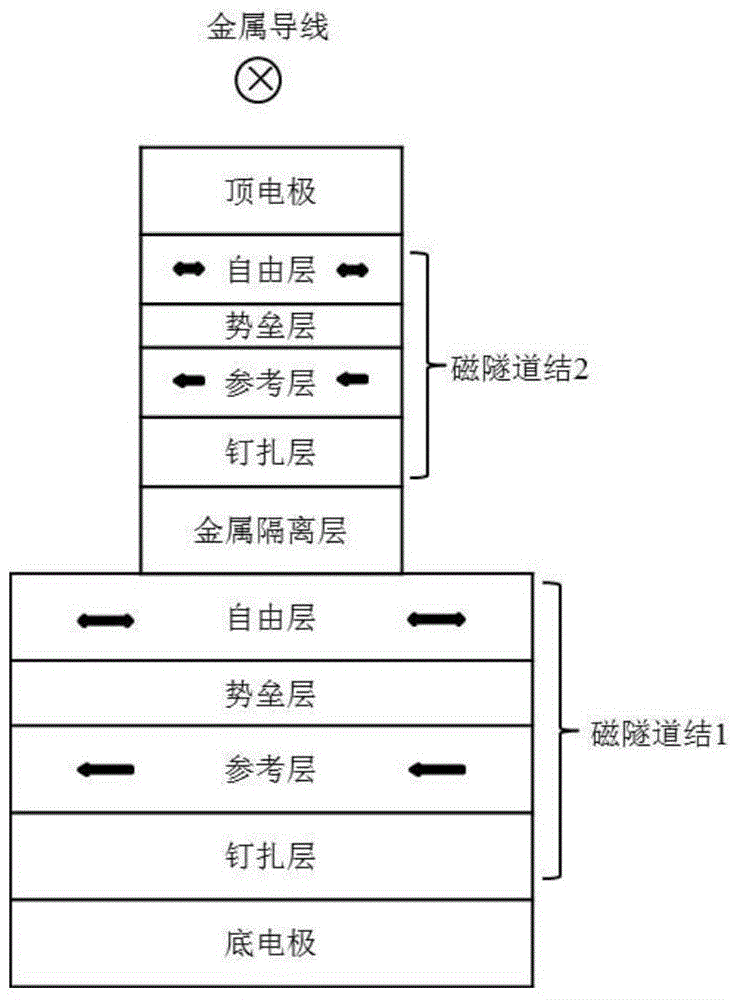

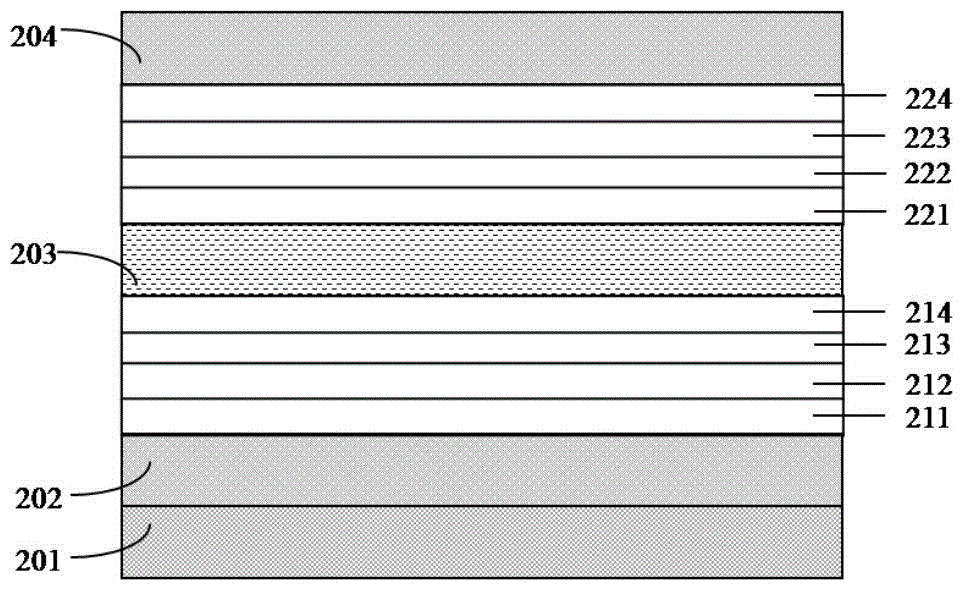

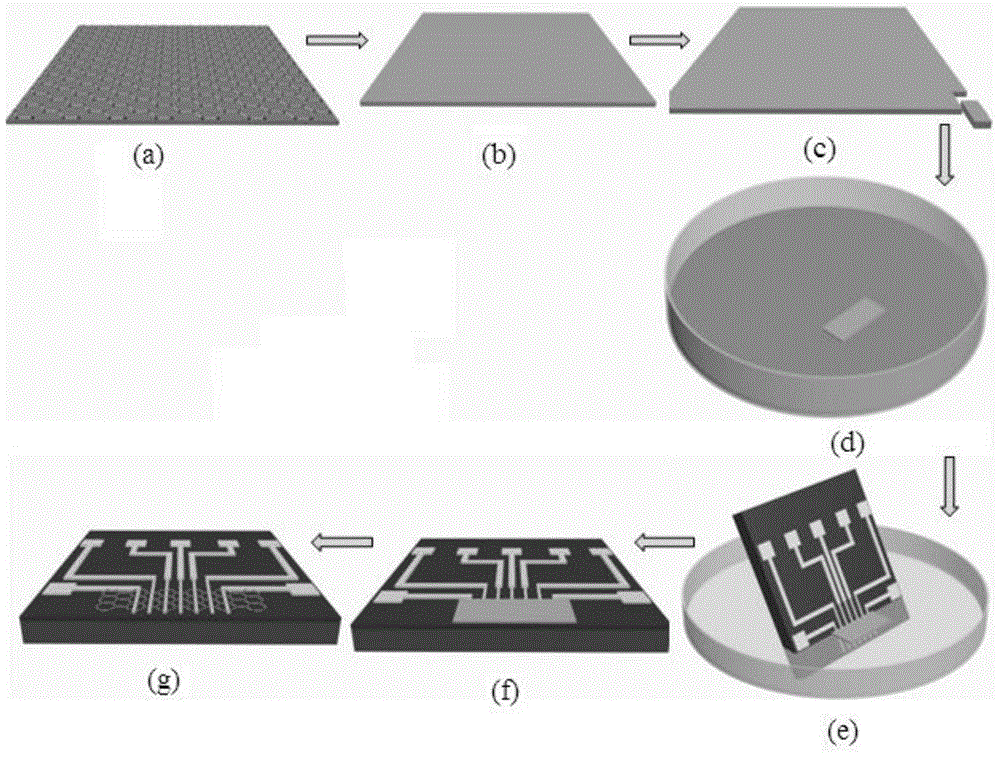

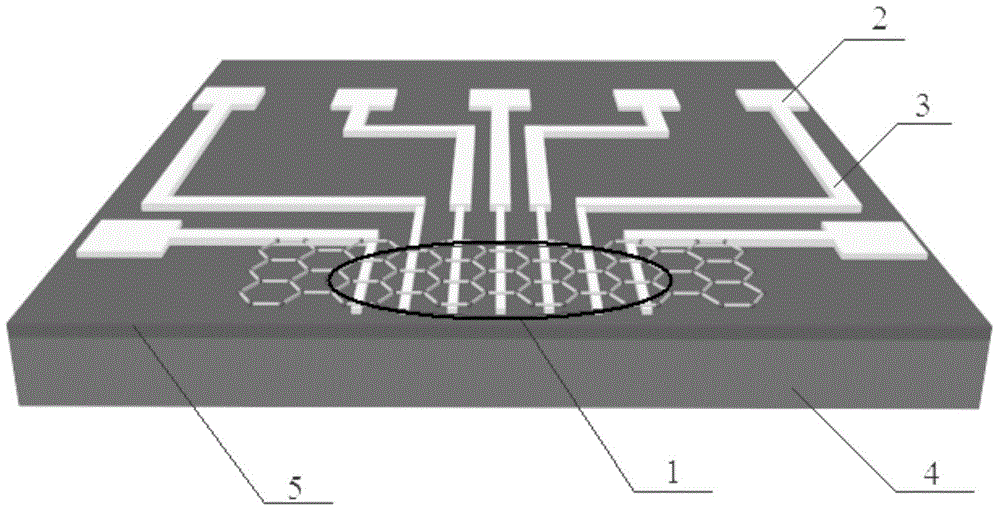

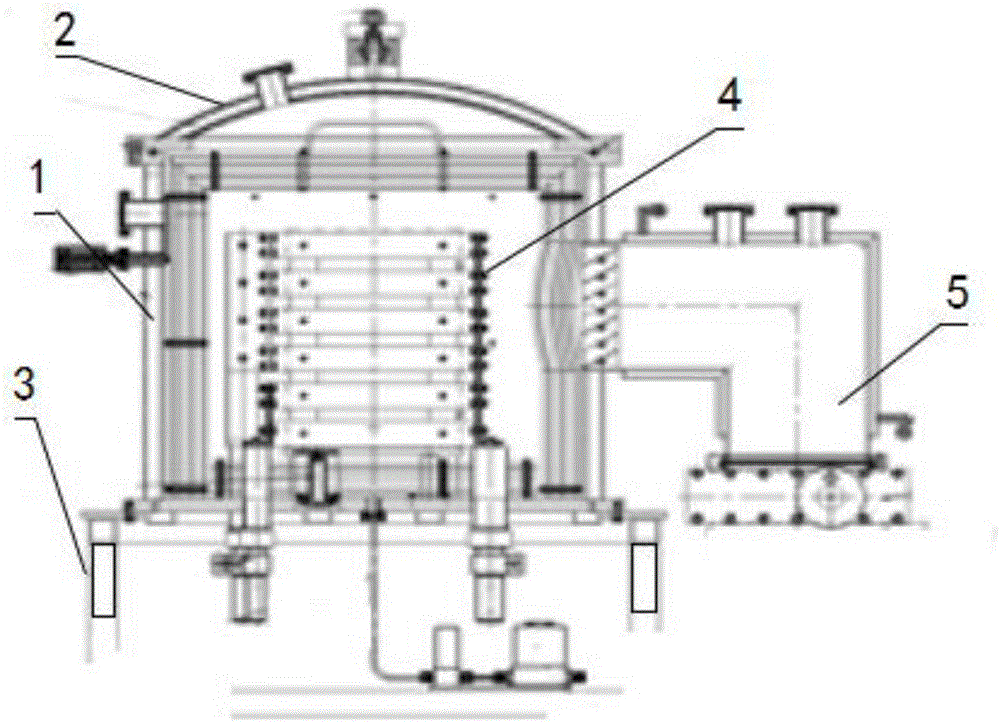

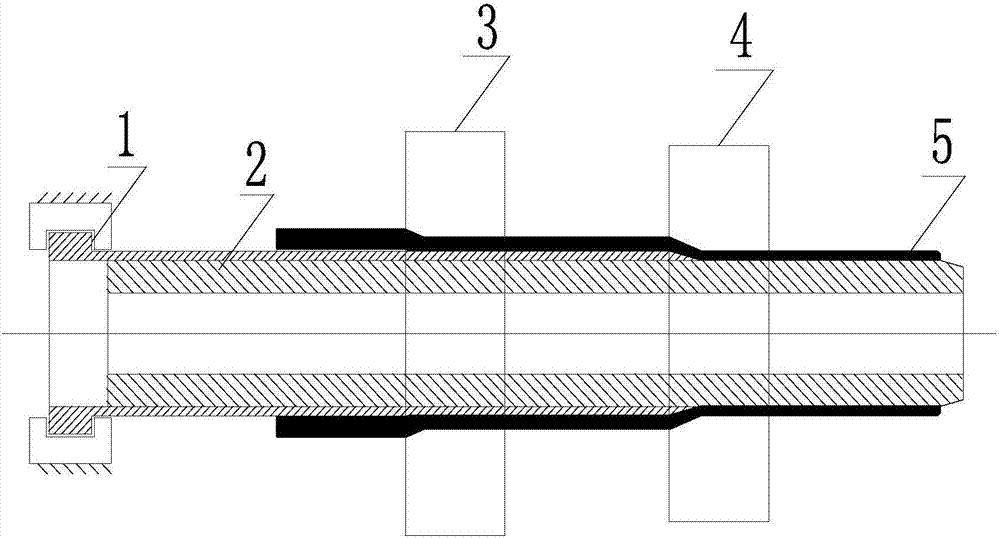

Information sensing and storing device and fabrication method thereof

ActiveCN104134748ARealize the detection functionRealize the storage functionMagnetic-field-controlled resistorsGalvano-magnetic device manufacture/treatmentSputteringMetallic electrode

An information sensing and storing device has a dual-MTJ (Magnetic Tunnel Junction) structure, and comprises a bottom electrode, an MTJ 1, a non-ferromagnetic metal isolation layer, an MTJ 2 and a top electrode sequentially from bottom to top, wherein a metal wire is arranged at one side of the device. A fabrication method of the information sensing and storing device comprises the five steps of: 1, depositing a magnetic multi-layer film material on a substrate; 2, performing annealing through an ultrahigh magnetic field vacuum annealing apparatus to fix the magnetization direction of a reference layer; 3, finishing shape fabrication of the dual-MTJ structure by using traditional nanometer device processing technologies such as photoetching, etching and magnetron sputtering; 4, depositing an isolation layer at the outer side of the dual-MTJ structure, and configuring the metal wire near the dual-MTJ structure through the technologies such as photoetching, etching and inlaying; and 5, forming a metal electrode at the top of the dual-MTJ structure by using the processing technologies such as photoetching, etching and inlaying for subsequent integration or test.

Owner:BEIHANG UNIV

Method for preparing zirconium metal filaments

The invention discloses a method for preparing zirconium metal filaments. The method comprises the steps of firstly, preparing zirconium ingots and forging bar billets; secondly, rolling the bar billets into bars and machining and removing surface scales; thirdly, drawing the bars to obtain wires; fourthly, performing acid cleaning to the wires and then carrying out vacuum annealing; fifthly, carrying out multi-path drawing on the wires after vacuum annealing, and then performing vacuum annealing to the drawn wires; sixthly, carrying out acid pickling, prefilming, electroplating and flushing on the wires subjected to vacuum annealing sequentiall, and then drying; seventhly; seventhly, bundling the dried wires and loading into copper tubes and compounding on a broaching machine so as to obtain composite tubes, and drawing after vacuum annealing; and eighthly, carrying out acid pickling on the drawn composite tubes to remove copper and oxidation films, flushing with deionized water, and naturally drying to obtain the zirconium fiber filaments. According to the method, the bundling and drawing process is adopted to prepare the zirconium fiber filaments, and the zirconium composite tube cannot be fractured during the bundling and drawing process due to selection of proper zirconium-copper cross section ratio.

Owner:西安西部新锆科技股份有限公司

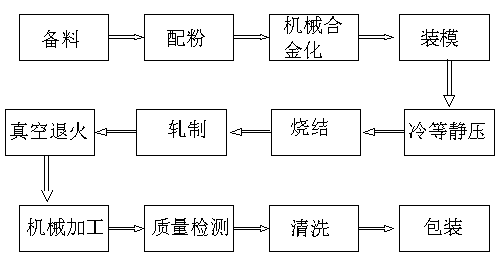

Molybdenum-tungsten alloy sputtering target material for flat panel display and preparation method thereof

InactiveCN103255379AHigh strengthHigh densityTemperature control deviceVacuum evaporation coatingProduction lineDisplay device

The invention relates to a molybdenum-tungsten alloy plane sputtering target material, and in particular relates to a molybdenum-tungsten alloy sputtering target material for a flat panel display and a preparation method thereof. The target material is prepared from 80-96.5% of molybdenum powder and 3.5-20% of tungsten powder. The preparation method comprises the steps of material preparation, powder blending, mechanical alloying, die filling, isostatic cool pressing, sintering, hot rolling, vacuum annealing and mechanical processing. According to the molybdenum-tungsten alloy sputtering target material and the preparation method thereof provided by the invention, the preparation technology is simple, the requirements for equipment are not high, the investment cost is lower, the prepared target material has good density, and the relative density exceeds 99%; meanwhile, through the technology provided by the invention, the molybdenum-tungsten alloy grain is refined, and the grain structure is optimized; and when the product is used for coating, the uniformity and quality of the film are greatly improved, and the requirements of a flat panel display coating production line for the sputtering target material are met.

Owner:LUOYANG SIFON ELECTRONICS

Techniques for Perovskite Layer Crystallization

ActiveUS20160035917A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMetal halidesVacuum annealing

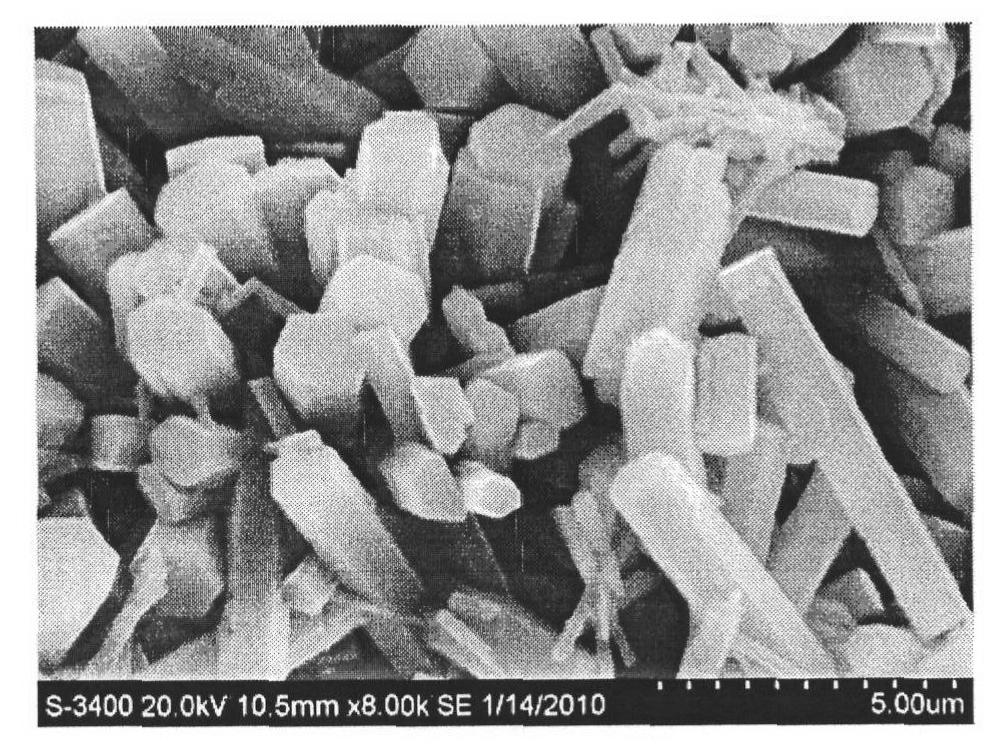

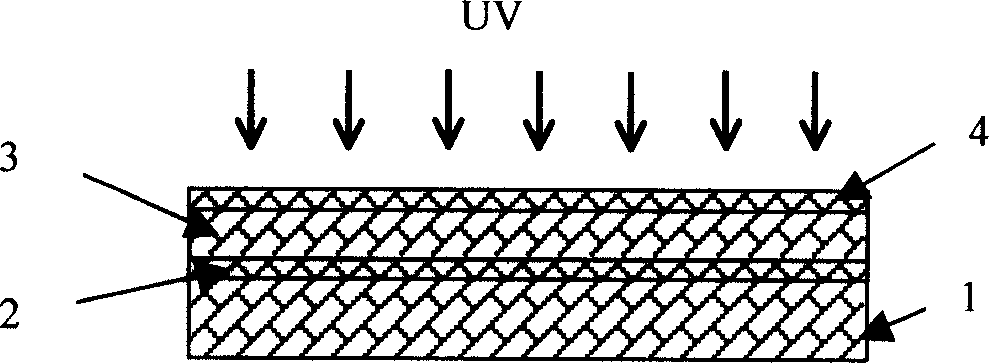

Vacuum annealing-based techniques for forming perovskite materials are provided. In one aspect, a method of forming a perovskite material is provided. The method includes the steps of: depositing a metal halide layer on a sample substrate; and vacuum annealing the metal halide layer and methylammonium halide under conditions sufficient to form methylammonium halide vapor which reacts with the metal halide layer and forms the perovskite material on the sample substrate. A perovskite-based photovoltaic device and method of formation thereof are also provided.

Owner:IBM CORP

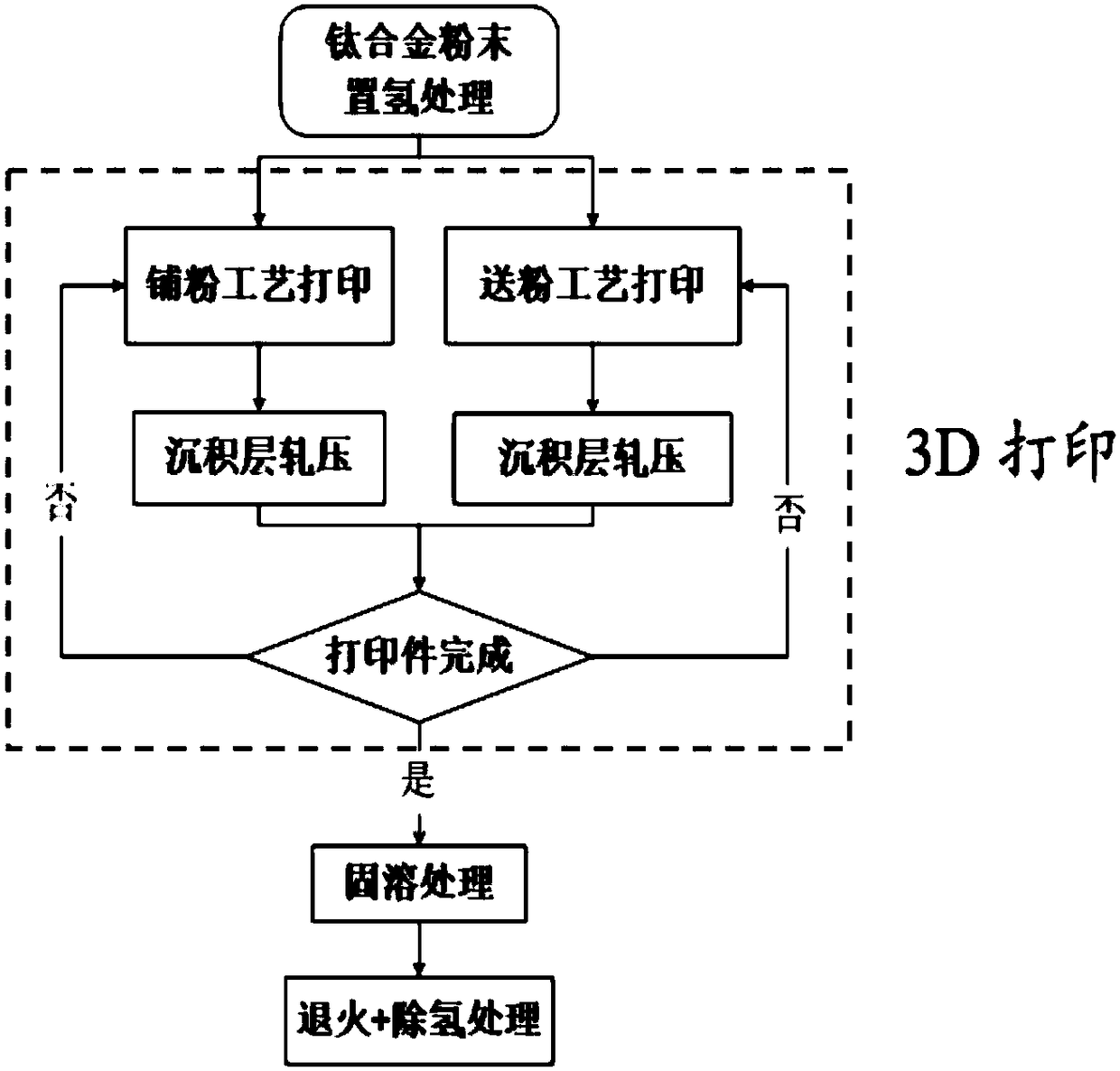

Hydrogen treatment roll compacting compound technology for improving additive manufacturing titanium alloy structure

ActiveCN108580884AFacilitated DiffusionIncrease subcoolingAdditive manufacturing apparatusTransportation and packagingCyclic processChemical composition

The invention provides a hydrogen treatment roll compacting compound technology for improving an additive manufacturing titanium alloy structure. The hydrogen treatment roll compacting compound technology for improving the additive manufacturing titanium alloy structure comprises the steps of during an additive manufacturing process, carrying out hydrogen treatment on titanium alloy powder, and roll compacting a printing piece layer by layer, so that the printing piece with structure being refined is prepared through a circulation process of printing-roll compacting-printing-roll compacting; and finally removing temporary alloying element hydrogen through vacuum annealing, so that the change of chemical components of a final material is avoided. During the process, the printing piece structure is refined and improved by utilizing hydrogen and the dislocation defects are increased by roll compacting at the same time, so that the capability of nucleation is reduced, the nucleation rate is improved, and the aims of refining grains and improving the structure without changing the alloy components are achieved.

Owner:SHANGI INST FOR ADVANCED MATERIALSNANJING CO LTD

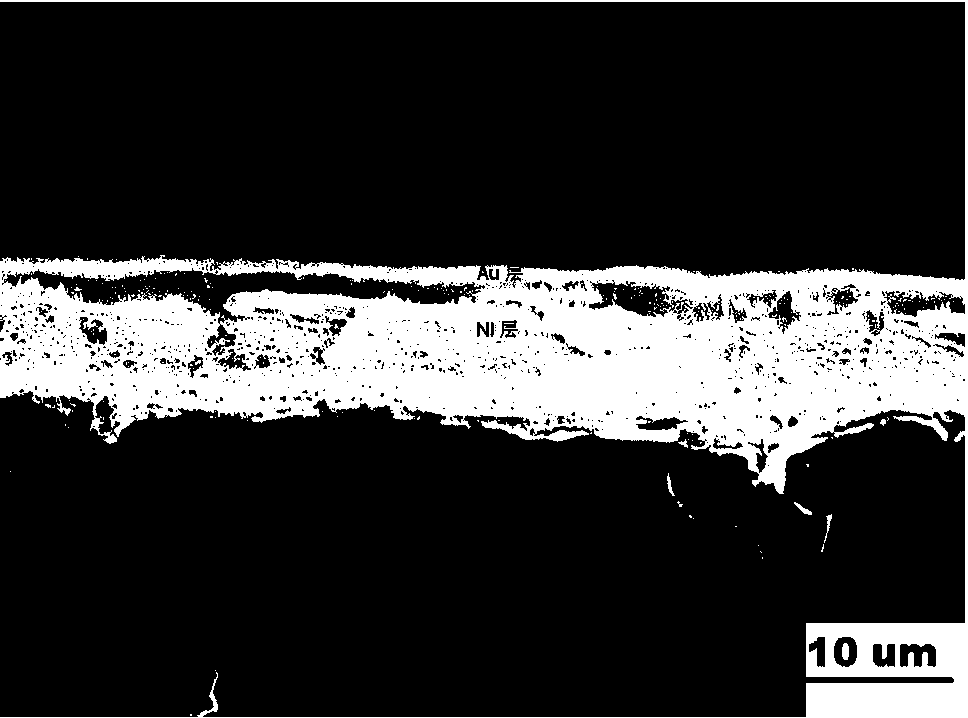

Surface gold plating method of diamond and copper composite material

InactiveCN104195603ATo achieve the purpose of micro-coarseningLiquid/solution decomposition chemical coatingChemical platingSolderability

The invention relates to a surface gold plating method of a diamond and copper composite material. The method specifically comprises the following steps: degreasing and deoiling the diamond and copper composite material; carrying out alkaline deoiling; micro-etching; acid-activating; sensitization activating; acidic chemical nickel-plating; vacuum annealing treatment; alkaline chemical plating; electro nickelling; and electrogilding to form a gold material layer which is 2-3 mu m thick on the surface of the diamond and copper composite material. By adopting a sensitive-active two-step method, a palladium salt center with catalytic activity is formed on the surface of a diamond and copper composite material test piece. Good solid solution diffusion is formed between an acidic chemical nickel-plating layer and a substrate is formed by means of a vacuum thermal treatment method, so that the interface bonding force is enhanced. The adhesive force is enhanced between the surface plating layers of the diamond and copper composite material by means of a method of three-step nickel plating to form multiple layers of combined nickel, so that the stress of the plating layer is released. By plating gold with cyanogen gold salt as an electroplating gold salt formula, the obtained plating layer is excellent in appearance quality and excellent in weldability.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Preparation method of graphene field-effect transistor biosensor

ActiveCN104535635AKeep Superior PerformanceImprove cleanlinessMaterial analysis by electric/magnetic meansPolymethyl methacrylateSingle layer graphene

The invention belongs to a preparation method of a biosensor, and relates to a preparation method of a graphene field-effect transistor biosensor. The preparation method comprises the following steps: (1) preparing a single-layer graphene copper plate; (2) preparing devices on a substrate layer of a sensor; (3) performing directional transfer on graphene; and (4) heating to bake the sensor, removing PMMA (polymethyl methacrylate) with acetone, performing vacuum annealing, and modifying the graphene with probes to obtain the graphene field-effect transistor biosensor. According to the preparation method provided by the invention, large-scale preparation of the biosensor based on CVD (chemical vapor deposition) graphene can be realized, the copper etching time is short, and the preparation method is simple and quick and can greatly lower the manufacturing cost; and in the preparation process, the PMMA polymer is used only once (in the traditional method, the PMMA polymer is used for more times, at least three times), thus greatly improving the surface cleanliness of the graphene, retaining the intrinsic high performance of the graphene and being more beneficial to subsequent probe modification.

Owner:HUBEI UNIV OF CHINESE MEDICINE

A kind of preparation method of nano rare earth oxide doped molybdenum alloy electrode material

The invention relates to a preparation method of a molybdenum alloy electrode material doped with nano rare oxides. According to the preparation method, molybdenum powder is used as a raw material, the molybdenum powder and nano rare oxide powder are uniformly mixed by adopting a solid-solid doping method, wherein the nano rare oxides are lanthana oxide, cerium oxide or mixed rare earth oxide; and then the molybdenum alloy electrode material doped with different kinds and contents of nano rare earth oxides is prepared through adopting the processes of sieving, pressing and forming, sintering,forging and vacuum annealing heat treatment under certain temperature. The preparation method disclosed by the invention and the heat treatment process are simple and feasible; and the molybdenum alloy electrode material doped with the nano rare earth oxides, which is prepared by using the method disclosed by the invention, has the characteristics of uniform tissues, high compactness, high strength, high recrystallization temperature, high elongation rate, favorable deep processing performance, and the like.

Owner:XIAN FULAI ELECTRICAL ALLOY

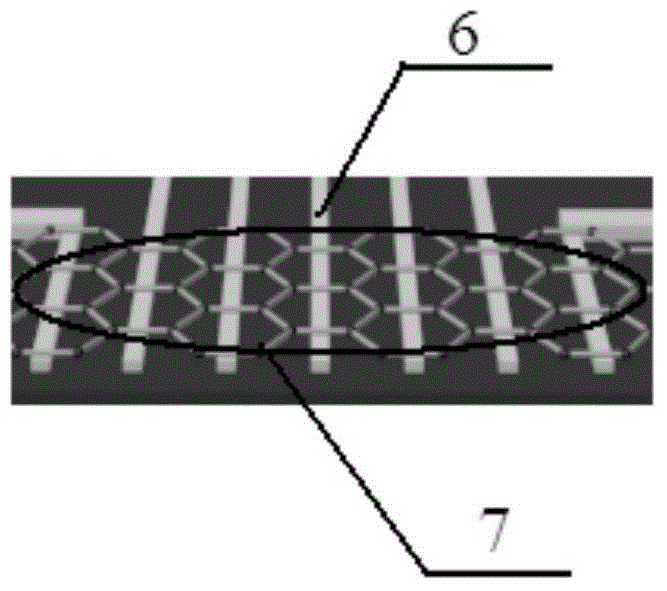

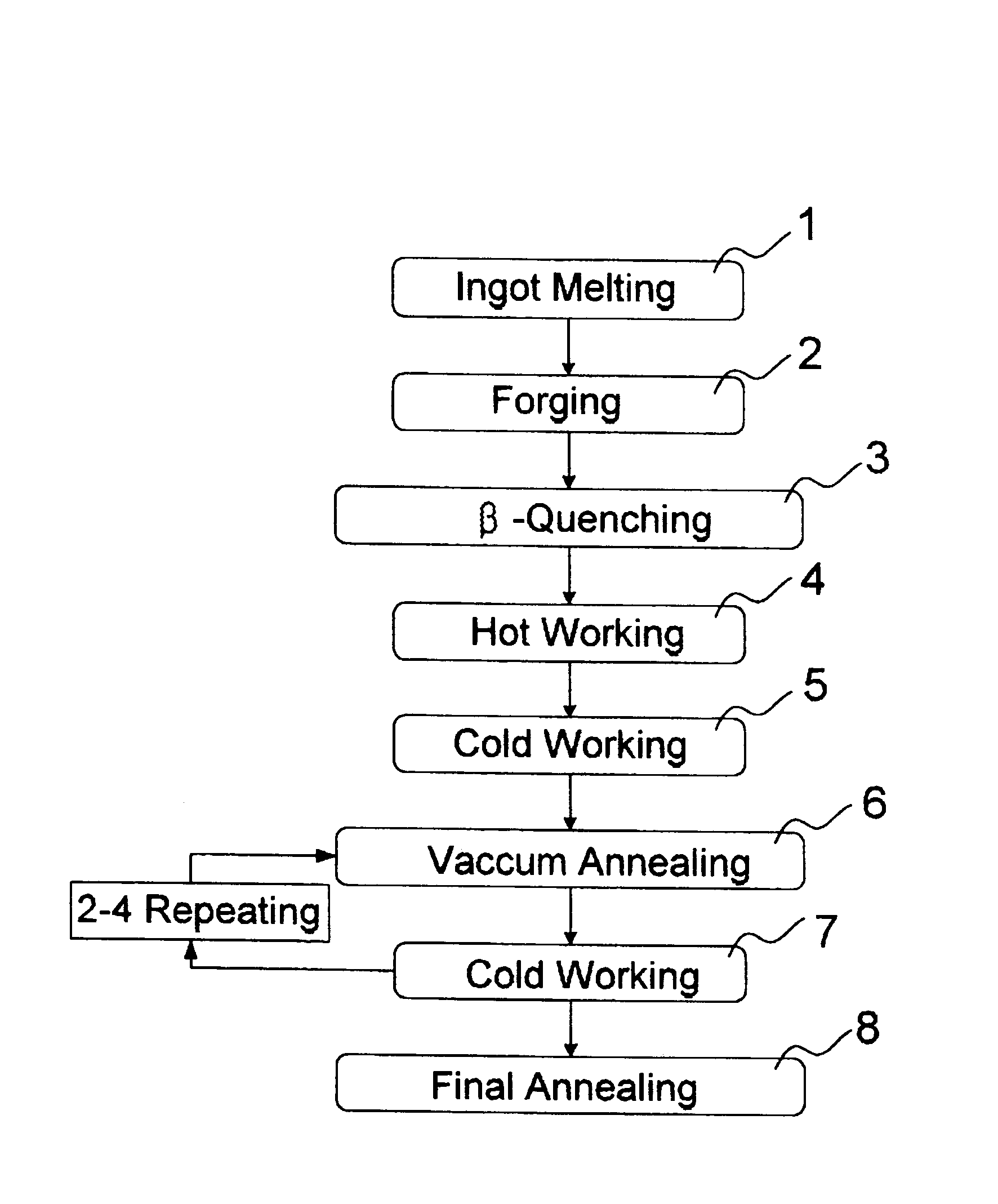

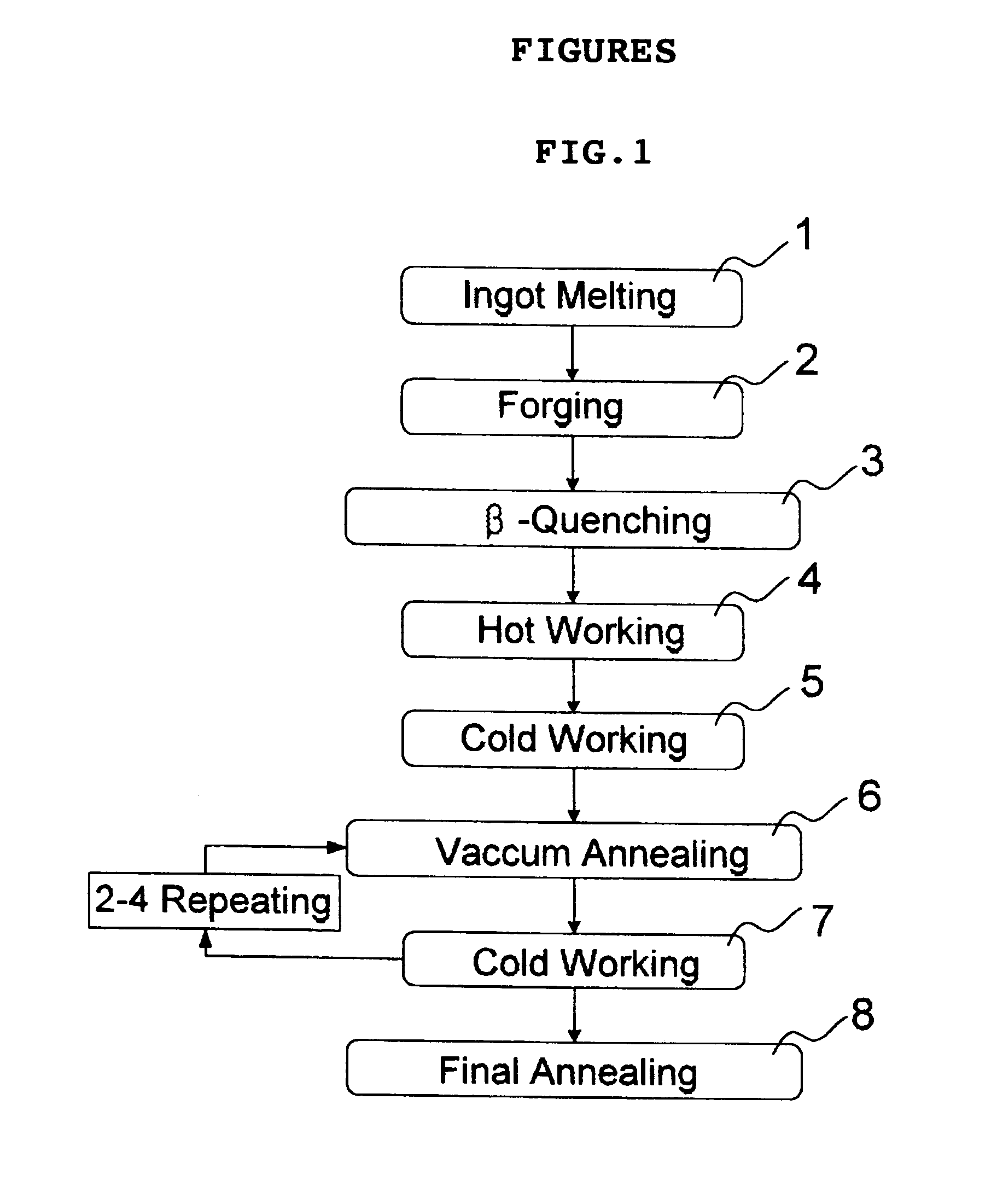

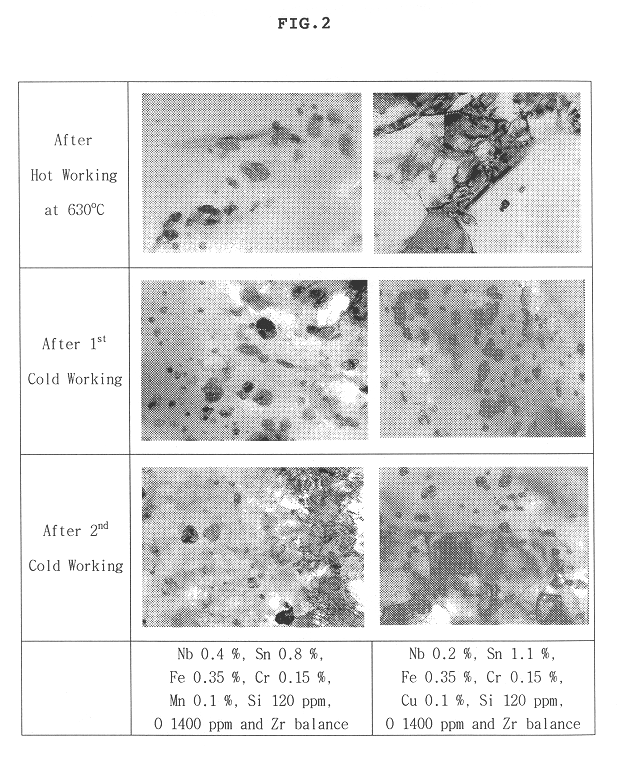

Method for manufacturing a tube and a sheet of niobium-containing zirconium alloy for a high burn-up nuclear fuel

Disclosed is a method for manufacturing a tube and a sheet of niobium-containing zirconium alloys for the high burn-up nuclear fuel. The method comprises melting Nb-added zirconium alloy to ingot; forging the ingot at beta phase range; beta-quenching the forged ingot after solution heat-treatment at 1015-1075° C.; hot-working the quenched ingot at 600-650° C.; cold-working the hot-worked ingot in three to five passes, with intermediate vacuum annealing; and final vacuum annealing the cold-worked ingot at 440-600° C., wherein temperatures of intermediate vacuum annealing and final vacuum annealing after beta-quenching are changed so as to attain the condition under which precipitates in the alloy matrix are limited to an average diameter of 80 nm or smaller and the accumulated annealing parameter (SIGMA A) is limited to 1.0x10-18 hr or lower.

Owner:KEPCO NUCLEAR FUEL CO LTD +1

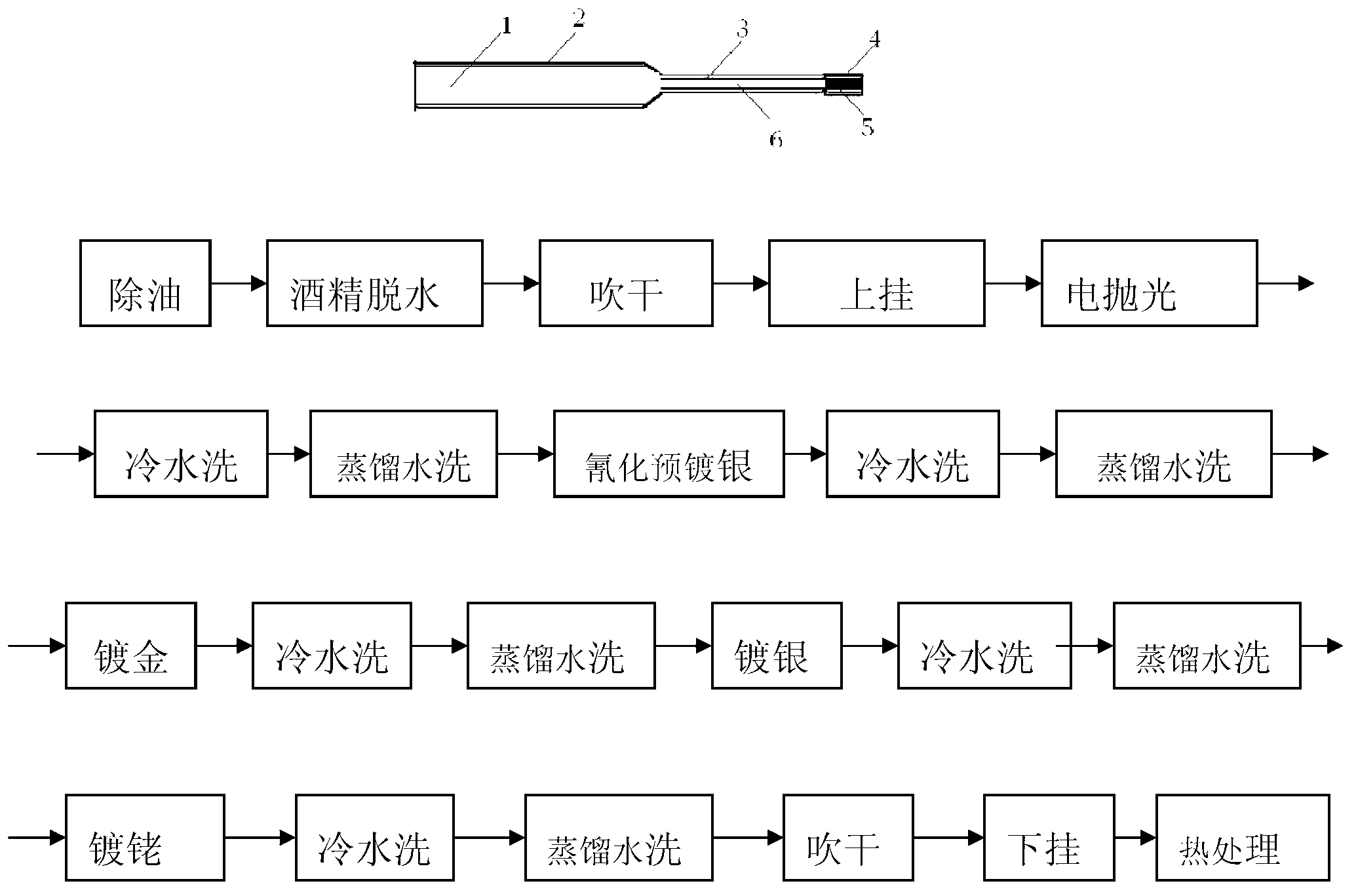

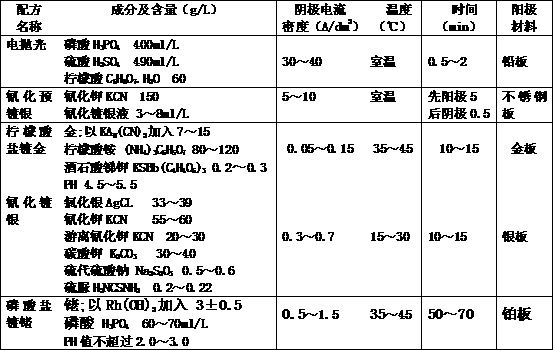

Gold-silver-rhodium multilayer composite plating process

The invention provides a gold-silver-rhodium multilayer composite plating process. According to the process, a rhodanizing coating does not crack, bubbling, peeling and falling off of each plating can be avoided, platings are well combined and do not discolor, the service life is high, and movement of a silver plating can be effectively constrained at a high temperature. According to the technical scheme, a cyaniding pre-silver-plating process is added before gold plating, a 3ml / L-8ml / L of cyaniding silver plating solution is added in a cyaniding tank, a reversing power supply is adopted after cyaniding, and a thin silver layer is plated reversely in the solution, after the cyaniding pre-silver-plating process, citrate is adopted for gold plating; after the gold plating, silver is plated through cyaniding, rhodium is plated through phosphate, after the rhodium plating, vacuum annealing heat treatment is performed at the temperature of 900-950 DEG C to evenly coat the three precious metal of the gold, the silver and the rhodium on the surface of a part. According to the process, under the condition that a rhodium plating of a contact type switching element such as a reed switch can not be welded, one end of a workpiece can be welded with a wire or sealed with glass, and bubbles, cracks and air tightness problems are not easy to cause.

Owner:四川泛华航空仪表电器有限公司

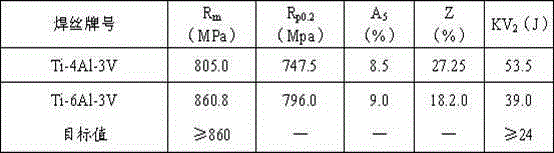

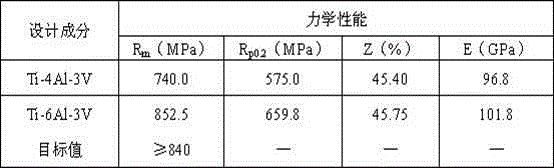

Special Ti-6Al-3V welding wire for Ti-6Al-4V ELI titanium alloy and machining process of special Ti-6Al-3V welding wire

InactiveCN104923968AImprovement and improvement of mechanical propertiesHigh tensile strengthWelding/cutting media/materialsWelding/soldering/cutting articlesMetallic aluminumTitanium alloy

The invention provides a special Ti-6Al-3V welding wire for Ti-6Al-4V ELI titanium alloy and a machining process of the special Ti-6Al-3V welding wire. The special Ti-6Al-3V welding wire includes the alloy components of, by weight, 5.5-6.75% of Al, 2.5-4.5% of V, smaller than 0.20% of Fe, smaller than 0.13% of O and the balance Ti. The machining process of the special Ti-6Al-3V welding wire includes the following steps that a, the raw material weight ratio of Al-V intermediate alloy to pure metal aluminum to titanium sponge is calculated according to the design components of the welding wire, and the raw materials are smelted into ingots through vacuum arc remelting; b, the ingots are forged into bar billets; c, the bar billets are rolled into bars; d, the bars are rolled into wire billets; e, the wire billets are stretched; f, the wire billets are straightened, descaled, polished and ground; g, the wire billets are thermally treated and then stretched into wires; h, vacuum annealing is conducted on the wires after alkaline washing and acid washing are conducted on the wires; i, the wires are straightened and then cut into straight wires; j, the straight wires are ground into finished products. Through the adjustment of the content of main alloy elements and impurity elements and the reasonable production process, the titanium welding wire with better mechanical performance matching performance with the Ti-6Al-4V ELI titanium alloy is produced, and the performance of a weld joint of the welding wire can meet the index requirements of a manned cabin.

Owner:BAOJI TITANIUM IND CO LTD

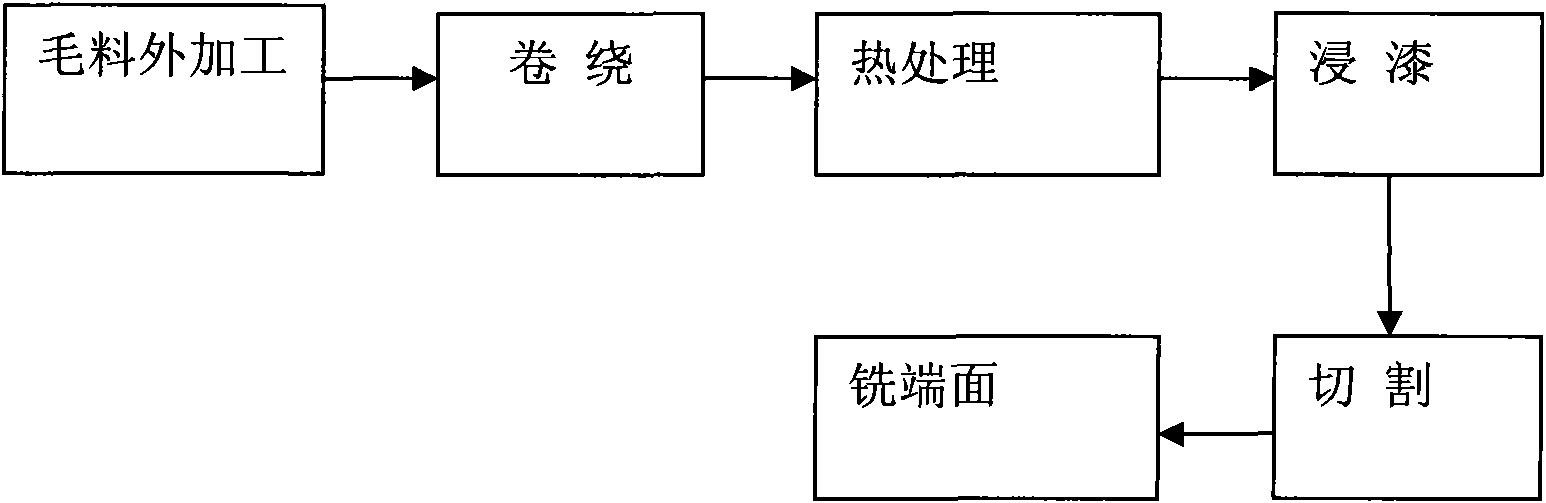

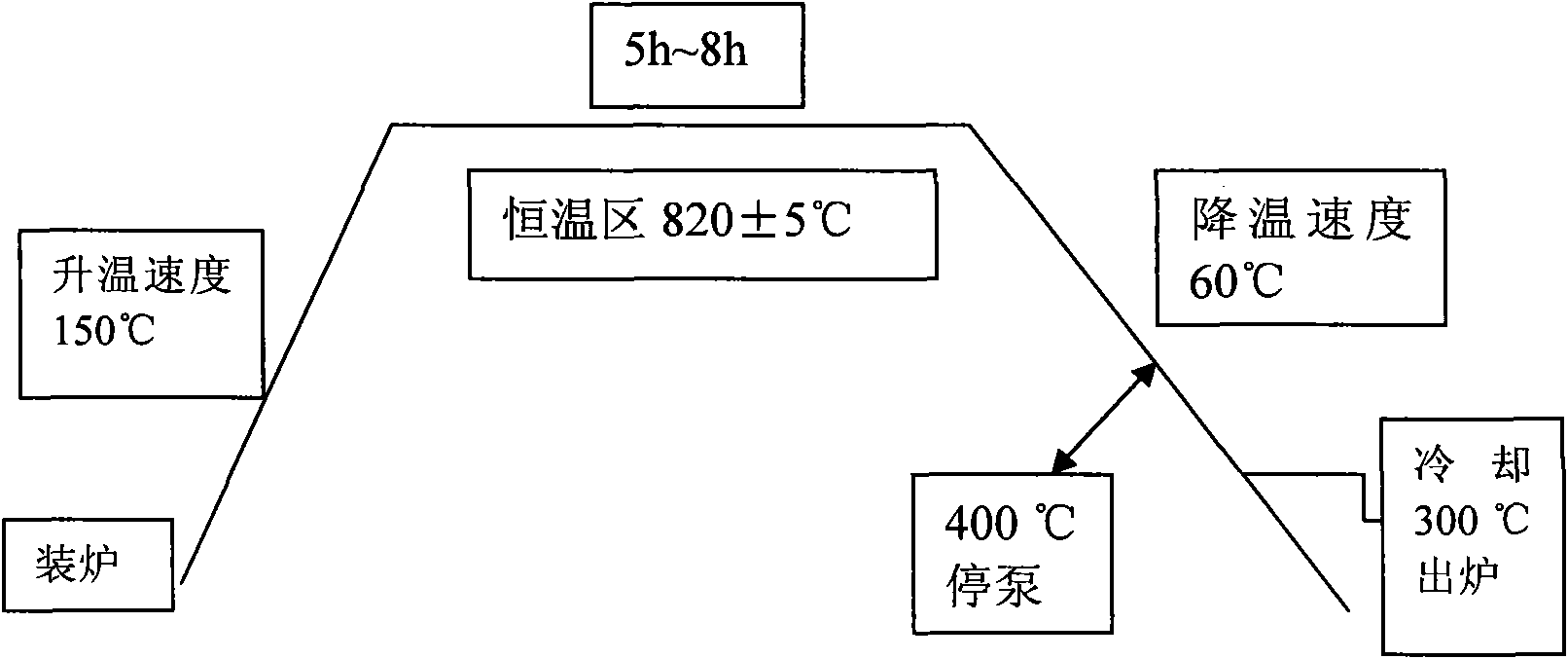

Processing method for silicon steel ribbon iron core of direct current electric transmission and transformation radio-frequency reactor

InactiveCN101599358AReduce volumeReduce weightTransformers/inductances detailsInductances/transformers/magnets manufactureMagnetic amplifierWork in process

The invention relates to the technology of power transformer, pulse transformer, magnetic amplifier and converter, in particular to a processing method for silicon steel ribbon iron core of direct current electric transmission and transformation radio-frequency reactor. According to the technical scheme provided by the invention, the processing method for the silicon steel ribbon iron core of direct current electric transmission and transformation radio-frequency reactor includes the following steps: a, winding, namely the silicon steel ribbon is wound into an iron core; b, heat treatment, namely the iron core primary product is annealed under vacuum; c, dipping paint, namely vacuum dipping paint is carried out on the iron core semifinished product; d, cutting, namely the iron core semifinished product after dipping paint is loaded into a cutting clamp of a cutting machine in a lying way, the cutting machine is started to begin cutting with the cutting speed of 200-300 r / min. The invention can improve the quality of product.

Owner:无锡希恩电气有限公司

Selective laser melting material additive manufacturing IN718 component, system, and heat treatment method and device

ActiveCN106180719AReduce residual stressCorrosiveAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingAlloy

The invention relates to a selective laser melting material additive manufacturing IN718 component, a system, and a heat treatment method and device. According to the IN718 component, during selective laser melting molding, the laser power ranges from 275 W to 800 W, the spot diameter ranges from 0.1 mm to 0.2 mm, the scanning speed ranges from 900 mm / s to 1400 mm / s, and the thickness of a powder laying layer ranges from 0.04 mm to 0.08 mm; the heat treatment method comprises the steps that the molded IN718 component is placed in a vacuum heat treatment furnace to be subject to vacuum annealing heat treatment. The heat treatment device comprises the vacuum heat treatment furnace. The system for the selective laser melting material additive manufacturing IN718 component comprises a 3D printer and further comprises the vacuum heat treatment furnace arranged behind the working procedure of the 3D printer. According to the system and the heat treatment method and device, residual stress generated in the printing process of the IN718 alloy component can be removed, a structure is obviously homogenized, corrosion resistance, toughness and the like are well improved, and the requirement of aerospace products for the IN718 alloy structural component can be met.

Owner:飞而康快速制造科技有限责任公司

Method for producing microelectromoulding metal mould

InactiveCN1715455AReduce internal stressGood side wall verticalityElectroforming processesMicro structureHigh surface

The microelectromolding metal mold making process belongs to the field of micro machine building technology. The microelectromolding metal mold making process includes the steps of: pre-treatment of mold base, making microelectromolding mother mold, microelectromolding, post-treatment and detection. The present invention adopts so-called 'no-back board growth process', in which micro structure pattern is electromolded directly on nickel substrate via ultraviolet irradiation on photoetching mask. During making microelectromolding mother mold, one seed layer is added between the SU-8 photoresist and the substrate; and in the post-treatment, vacuum annealing is adopted. The microelectromolding metal mold made in the method of the present invention has the merits of high side wall verticality and high surface smoothness. The present invention is suitable for fine machining of organic polymer, including plastic.

Owner:DALIAN UNIV OF TECH

Method for producing copper-clad aluminum bar

The invention relates to a method for producing a copper-clad aluminum bar. The method comprises the following steps of: removing oxidation layers from the surfaces of a copper belt and an aluminum bar; feeding the copper belt and the aluminum bar into a cladding machine for molding and welding; rolling and tightening by using a cold-rolling mill; saw-cutting according to a required size, and continuously feeding copper-clad aluminum bar materials which are cut off into an intermediate-frequency heating furnace for pre-heating; feeding the copper-clad aluminum bar materials into a continuous heating furnace; operating the copper-clad aluminum bar materials through a roller bed and then feeding the copper-clad aluminum bar materials into a hot-rolling mill for finish rolling and cooling; drawing and setting the rolled copper-clad aluminum bar materials, and performing fixed-length saw-cutting according to a process; putting the copper-clad aluminum bar materials which are subjected to the fixed-length cutting into a vacuum annealing furnace, performing bright annealing, and thus obtaining a finished product; and putting the finished product on an automatic packaging line, packaging the finished product and then warehousing. By coating a copper layer outside an aluminum core, the method for producing the copper-clad aluminum bar has the advantages of low cost, continuous production, short process flow, high production efficiency, mechanical operation and high bonding strength of interfaces; and requirements of electric equipment can be met.

Owner:孙华桥

Method for preparing high aspect ratio metal microgratings on metal substrate

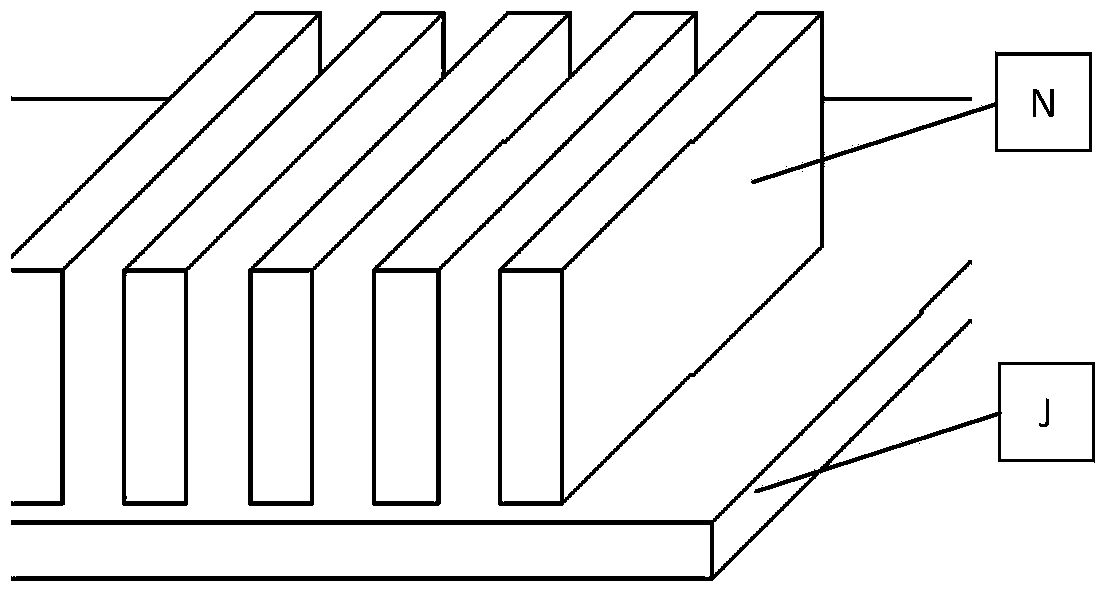

InactiveCN103913789ASolution depthSolve the fragile baseDiffraction gratingsElectroforming processesBinding forceWidth ratio

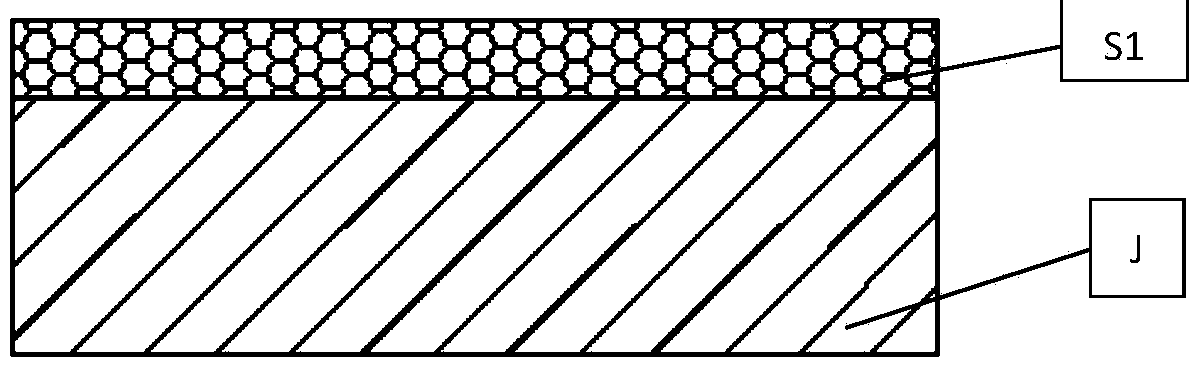

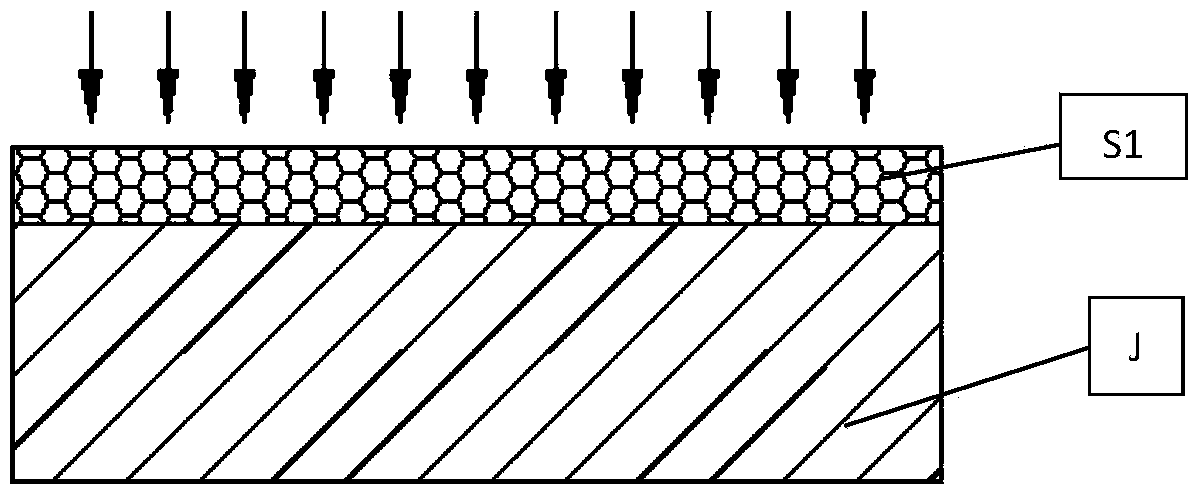

The invention discloses a method for preparing high aspect ratio metal microgratings on a metal substrate, and belongs to the micro-manufacturing technical field. A UV-LIGA technology is adopted, the photolithography technological processes such as two-time photoresist homogenizing, layered exposure and one-time developing are executed on a high-purity nickel plate substrate J to obtain an SU-8 photoresist film, and then the metal microgratings can be manufactured through micro electroforming nickel N after micro electroforming treatment; a line width compensating method is used for solving the problem that line width is decreased due to swelling; in the photoresist removing process, a 'ultrasound-soaking-ultrasound-soaking' circulating method is used for removing photoresist; in annealing operation, vacuum annealing is adopted to remove residual stress, and the binding force between the substrate and the metal gratings is improved. The method for preparing high aspect ratio metal microgratings on the metal substrate has the advantages that when the method is used for preparing the metal microgratings on the metal substrate J, the depth-to-width ratio is large, dimensional precision is high, mechanical strength is high, the preparation technology is simple, and cost is low.

Owner:DALIAN UNIV OF TECH

Power battery hydrogen storage electrode alloy and preparation method thereof

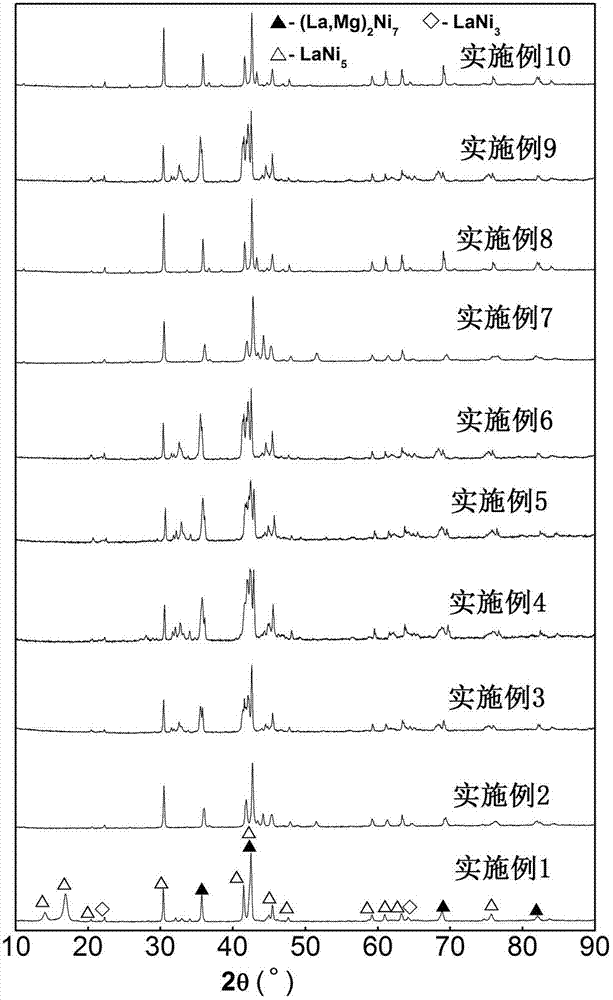

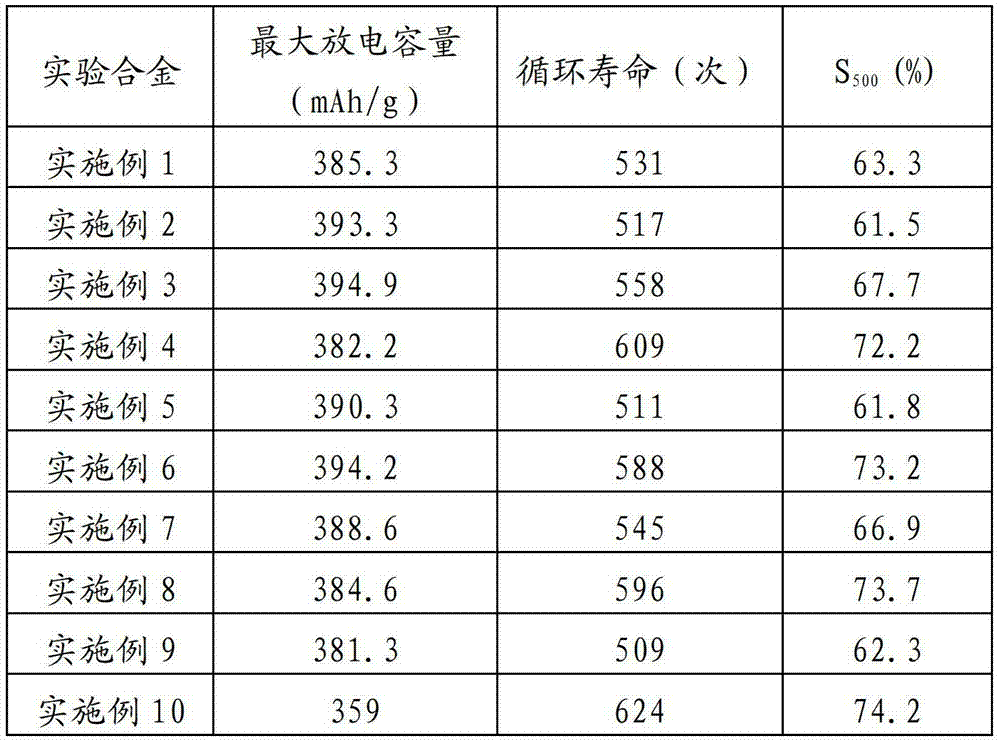

ActiveCN103165873AImprove electrochemical cycle stabilityStrong anti-powdering abilityAlkaline accumulator electrodesRare-earth elementElectrochemistry

The invention provides a power battery hydrogen storage electrode alloy and a preparation method of the power battery hydrogen storage electrode alloy. The power battery hydrogen storage electrode alloy is formed by low magnesium multi-rare-earth components, the chemical formula is RE1-xMgxNiyAlz, wherein 0.15<=x<=0.2, 3.3<=y<=3.8, and 0.05<=z<=0.15, and the rare earth elements (RE) are at least two elements selected from La, Ce, Sm, Y and Nd. The preparation method is that in inert gas shielding, induction heating smelting is adopted, melting alloy is poured into a tundish and sprayed on the surface of a water-cooling copper roller rotating at a certain speed through a nozzle at the bottom of the tundish to obtain rapid-quenching alloy, and then vacuum annealing is carried out in a vacuum heat treatment furnace. Combined action of the rare earth elements is fully used, the power battery hydrogen storage alloy is prepared by adoption of vacuum melting, the inert gas shielding and the rapid-quenching technology, electrochemical cycling stability of the alloy is improved, and the power battery hydrogen storage electrode alloy and the preparation method of the power battery hydrogen storage electrode alloy have the advantages that the technology is easy to master and suitable for mass production.

Owner:CENT IRON & STEEL RES INST

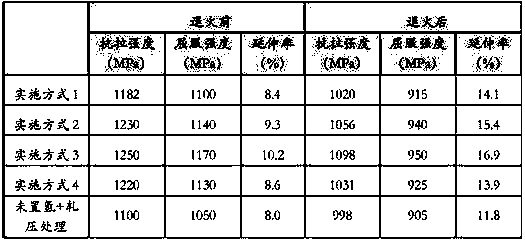

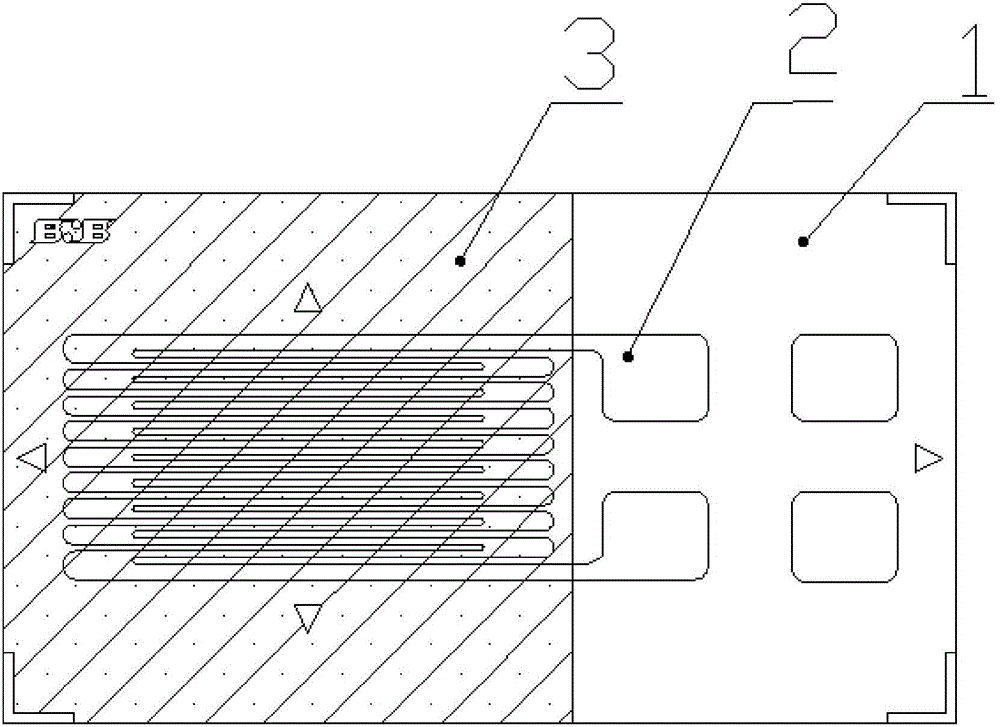

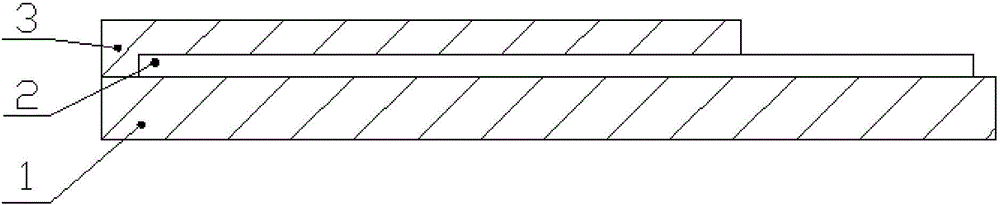

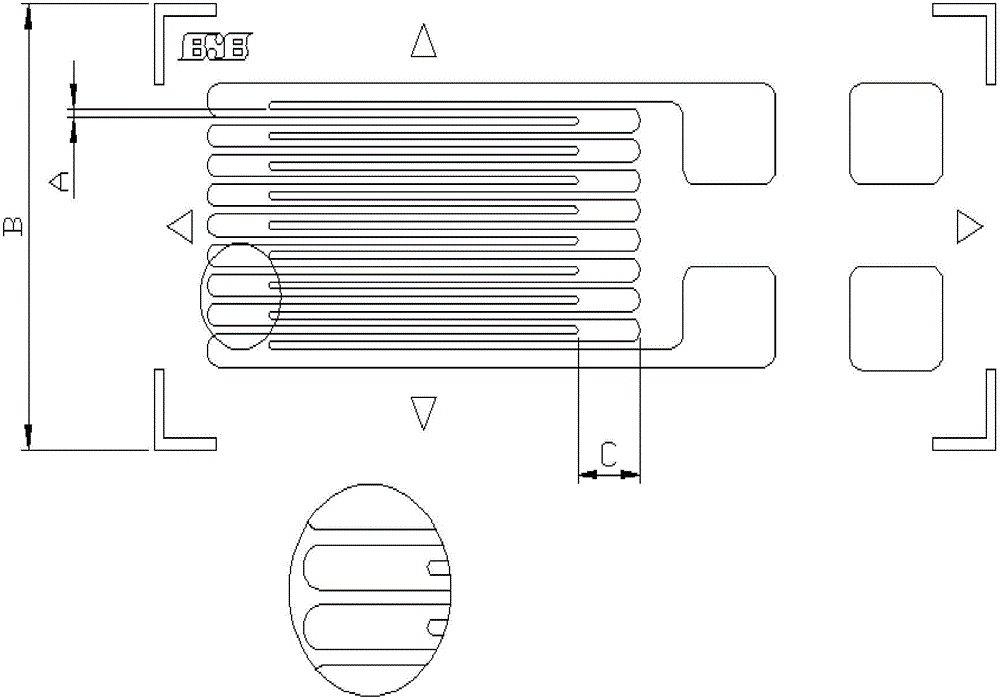

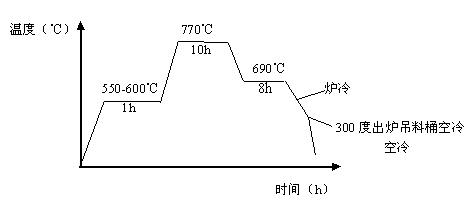

Strain meter for plastic deformation test and manufacturing and calibration method thereof

ActiveCN103604363ANot easy to break and damageImprove ductilityElectrical/magnetic solid deformation measurementAlloyVacuum annealing

The invention provides a strain meter for a plastic deformation test and a manufacturing and calibration method of the strain meter. The strain meter comprises a substrate, a sensitive grid and a sealing layer, wherein the sensitive grid is obtained by subjecting constantan and tinsel alloy formed in a cold rolling mode to vacuum annealing at 350-550 DEG C for three to six hours. The sensitive grid of the strain meter is obtained by subjecting the constantan and tinsel alloy formed in the cold rolling mode to vacuum annealing, and is good in ductility and elongation and capable of completely meeting measurement requirements of plastic deformation, so that the sensitive grid is not prone to rupture failures in the plastic deformation process.

Owner:ZHONGHANG ELECTRONICS MEASURING INSTR

Rotor manufacture process

InactiveCN102005870AFine grainImprove product qualityManufacturing stator/rotor bodiesNumerical controlNitrogen

The invention relates to a rotor manufacture process comprising the following process lines: (1) blanking: blanking by adopting a numerical control band sawing machine with the verticality of not larger than 0.5; (2) annealing: vacuumizing by adopting a well-type vacuum annealing furnace and inflating nitrogen to protect annealing, wherein the annealed oxidized and decarburized single edge is not larger than 0.1, and the annealed material hardness HB is 113-120; (3) making a blank: making a blank by adopting a digital control lathe of CK6130, wherein the height error is controlled within 0.5; (4) carrying out the lubricating process as follows; (5) preforming: extruding by adopting a hydraulic press of 2000kN with the extrusion force P of 90 T, wherein the dimension accuracy is -0.05 to 0.05 and the surface roughness is 3.2; and (6) forming and extruding: extruding by adopting the hydraulic press of 2,000kN with the extrusion force P of 80 T, the cycloid accuracy of -0.05 to 0.05 and the extrusion velocity of not smaller than 4 pieces per min, wherein the extrusion length is 150 mm, the surface roughness is 1.6, and the extruded hardness HB is 200-210.

Owner:镇江中虎弹簧有限公司

Copper coated aluminum bus bank production method and apparatus

InactiveCN101364459AReduce consumptionThe process steps are simpleSingle bars/rods/wires/strips conductorsCable/conductor manufactureAcid washingOxidation resistant

The invention belongs to a production method of a compound metal bus bar, particularly to a production method of a copper-clad aluminum bus bar, which comprises the following steps: (1) pretreatment of raw materials: acid washing a copper tube as a raw material, polishing, and placing an aluminum rod into the copper tube; (2) heat treatment before deformation: placing the raw material which is subjected to drawing into a vacuum annealing furnace for annealing; and (3) rolling the copper and the aluminum with fresh metal surface together under high pressure by using different lanes irreversible constant rolling speed hot rolling technique. The production method has the advantages of simple process, wide process conditions and easy operation. The obtained copper-clad aluminum bus bar has the same electrical conduction performance, oxidation resistance and other performances as those of a pure copper bus bar, while having remarkably reduced cost and copper consumption, which achieves resources saving purpose for countries being short of copper resources.

Owner:大连松辽玻璃钢船艇有限公司

Method for hot rolling of large-opening-diameter titanium and titanium alloy thin-wall seamless pipe through jacket core bar

ActiveCN107052076AReduce manufacturing costQuality improvementMetal rolling arrangementsTitanium alloyMechanical property

The invention discloses a method for hot rolling of a large-opening-diameter titanium and titanium alloy thin-wall seamless pipe through a jacket core bar. According to the method, a vacuum self-consuming arc furnace is used for secondary smelting to form a casting ingot; the casting ingot is subject to two-heating-number forging to form the bar; scaling machining is carried out; three-roller (or two-roller) skew rolling punching is used for making a seamless pipe blank; for pipe materials with the special property needs, the pipe blank subject to sand blasting, acid pickling, polishing and grinding and the like is subject to further cold rolling and other deep machining, a finished product pipe with the more excellent property is obtained, the pipe is subject to acid pickling treatment, and the large-opening-diameter thin-wall seamless pipe is obtained; finally, the finished product pipe is subject to vacuum annealing treatment and polishing fixed-size packaging. The large-opening-diameter thin-wall titanium and alloy seamless pipe manufactured through the method is excellent in mechanical property, the method is mainly used for fields of pressure containers, industrial pipelines, condensers, well drilling parts and the like in the industries of petroleum, chemical engineering, ocean and the like, and the needs of the anti-corrosion pipe can be met.

Owner:安徽宝泰特种材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com