Patents

Literature

113 results about "Constantan" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Constantan is a copper–nickel alloy also known as Eureka, Advance, and Ferry. It usually consists of 55% copper and 45% nickel. Its main feature is the low thermal variation of its resistivity, which is constant over a wide range of temperatures. Other alloys with similarly low temperature coefficients are known, such as manganin (Cu [86%] / Mn [12%] / Ni [2%] ).

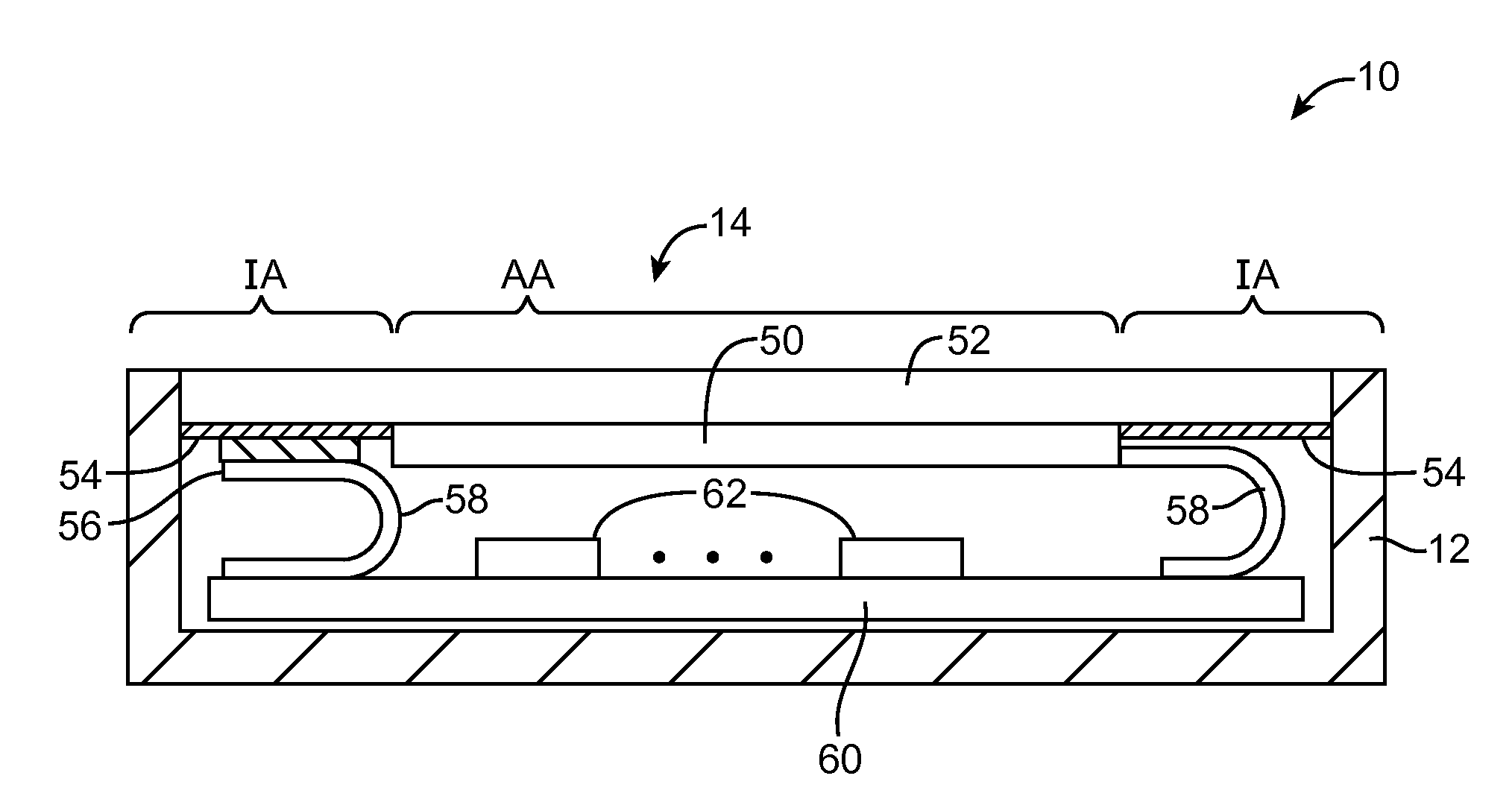

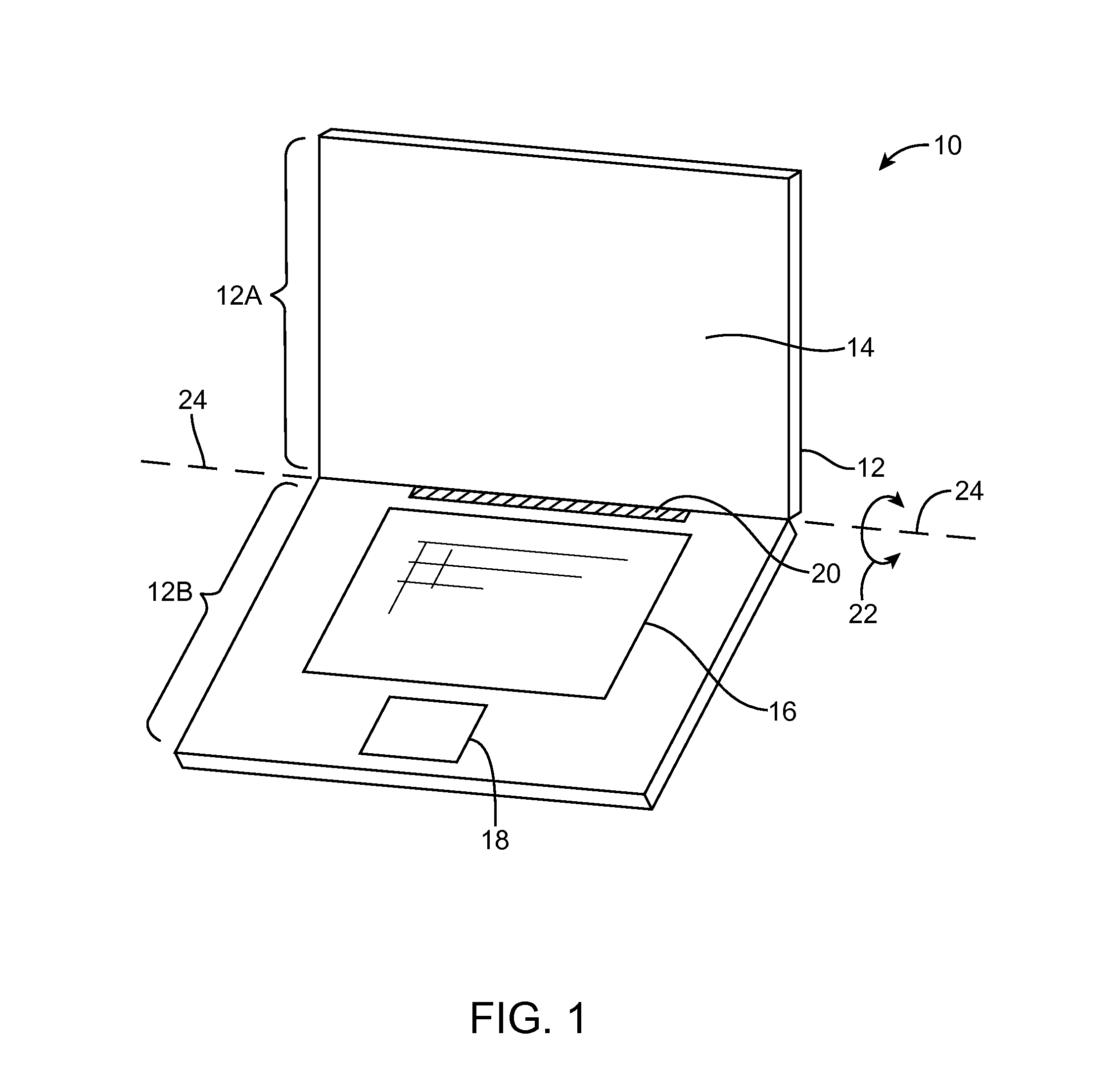

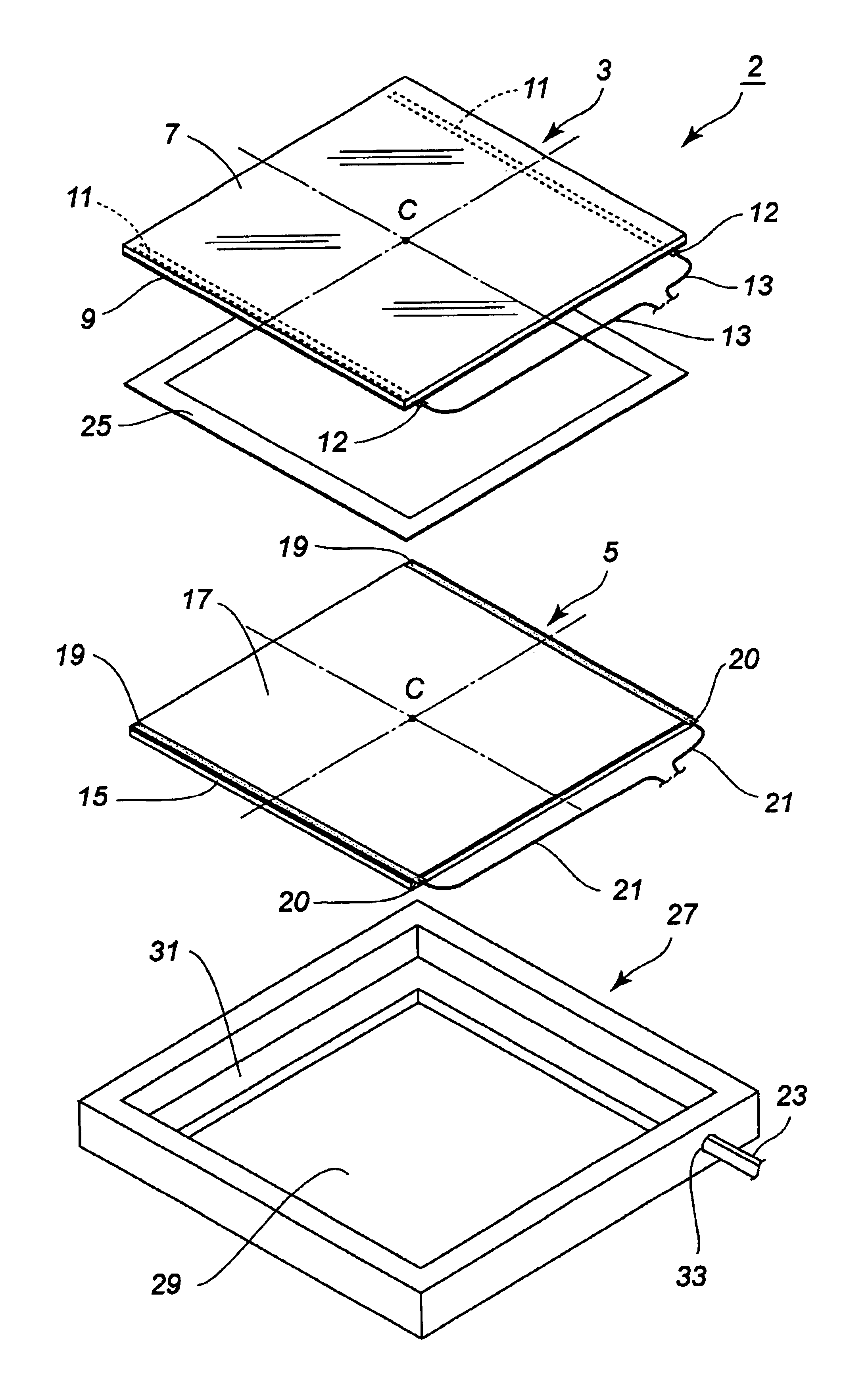

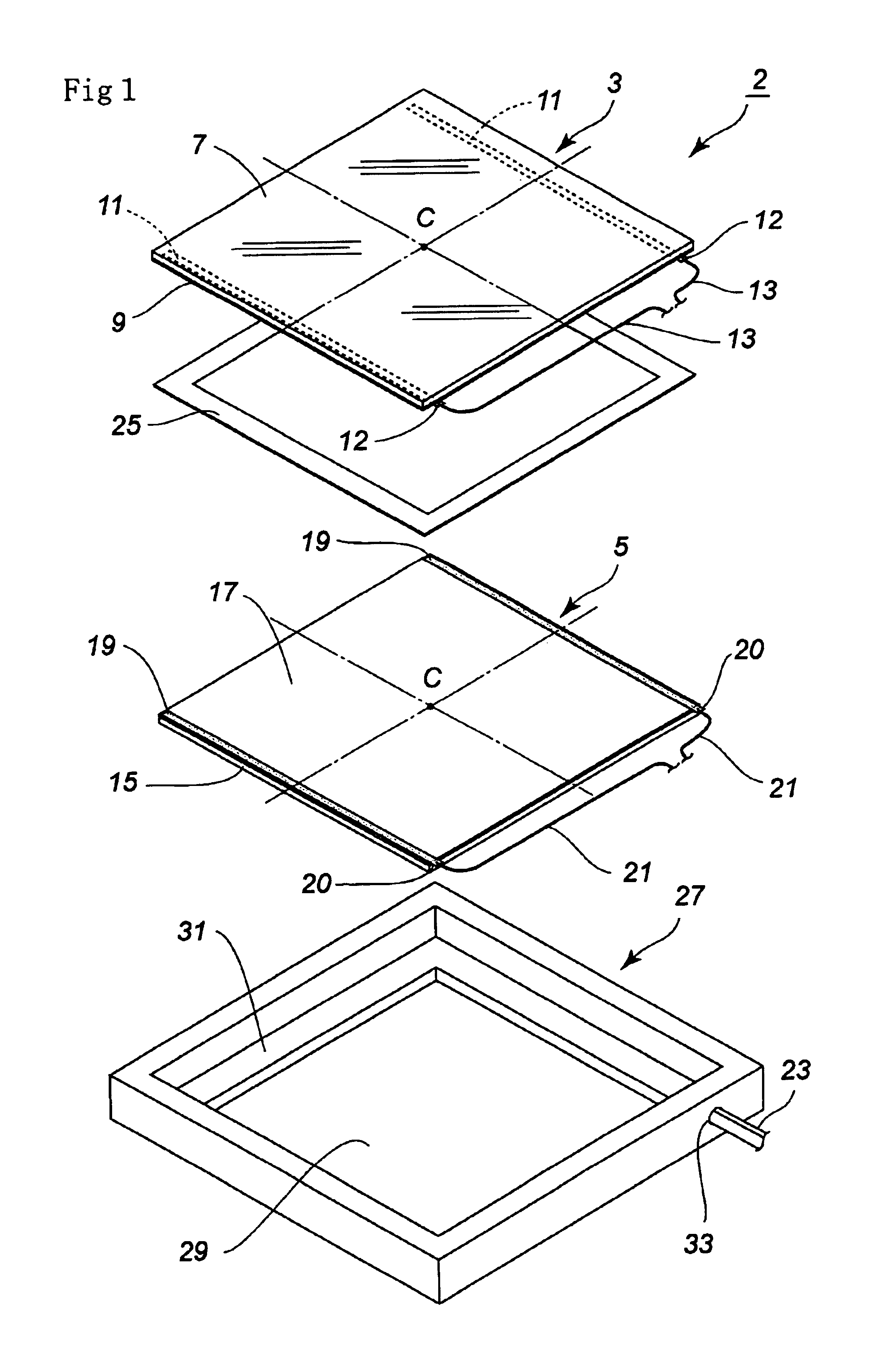

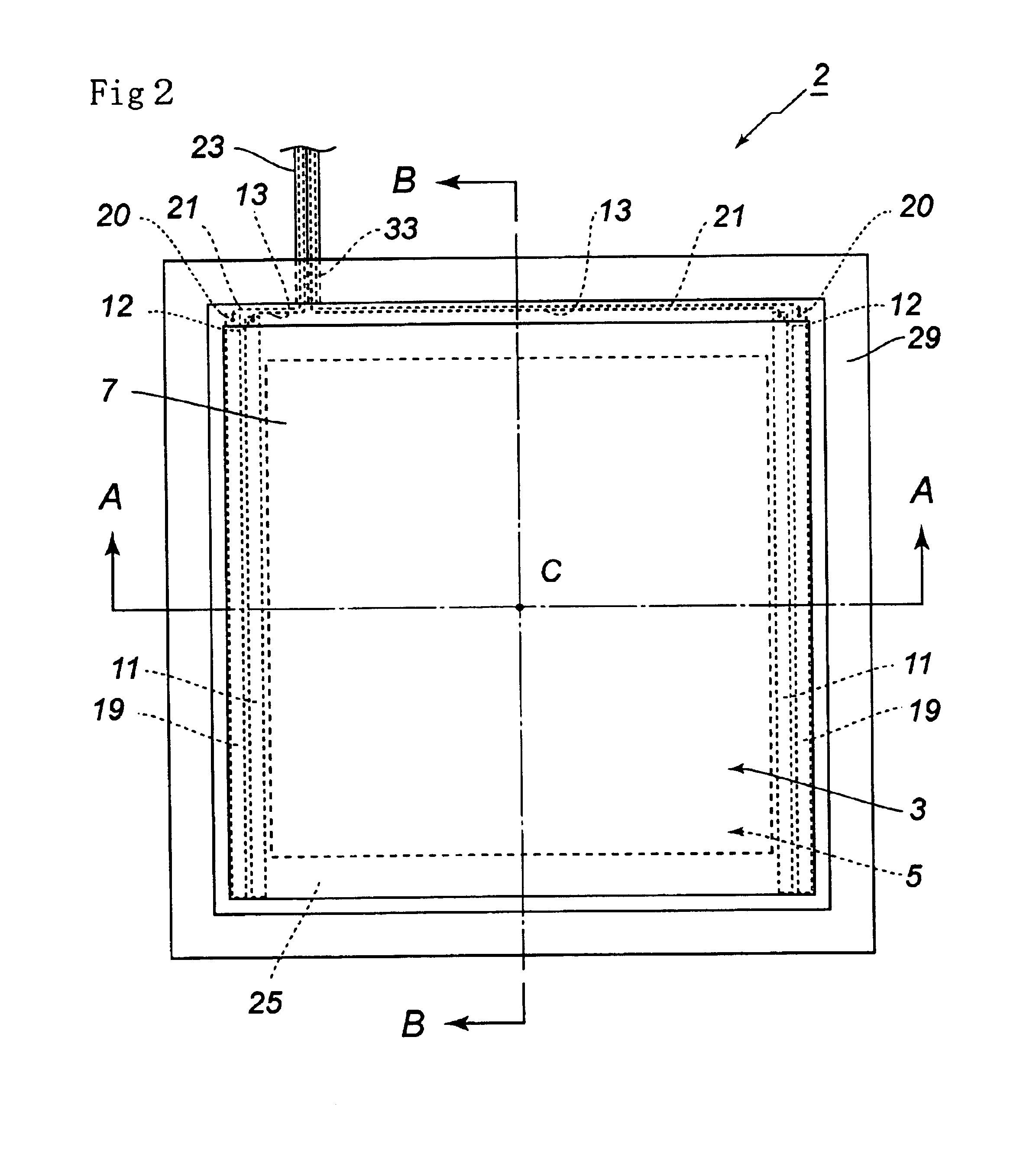

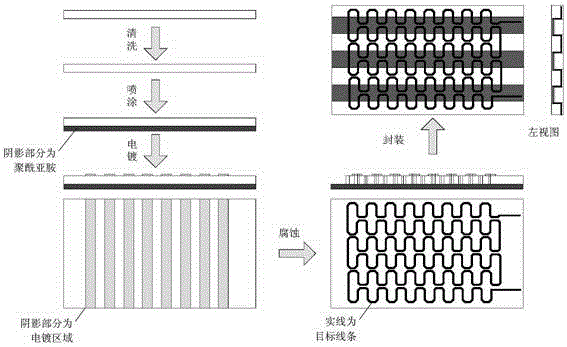

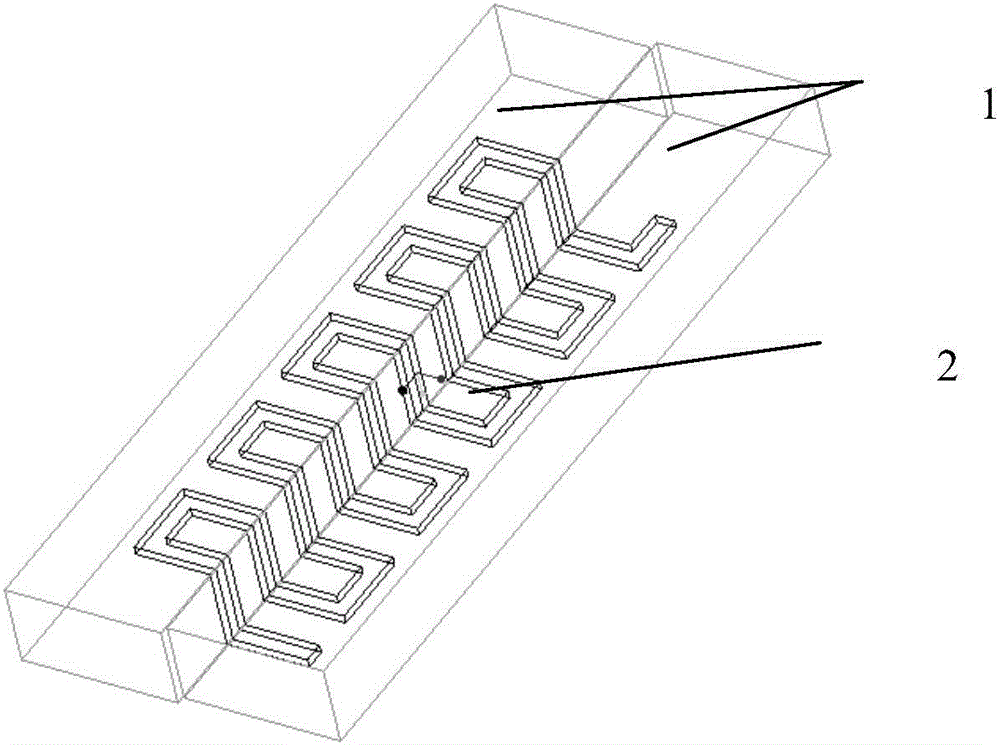

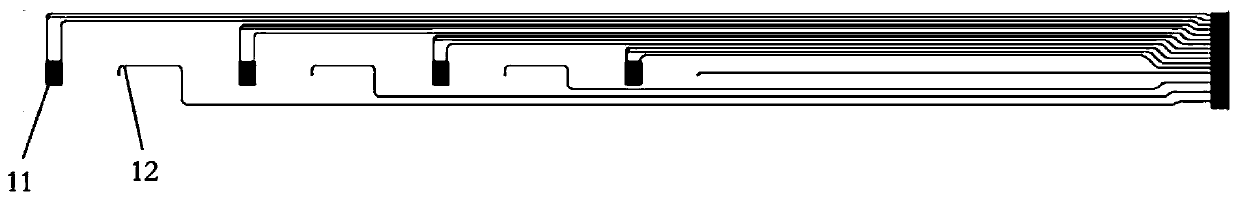

Electronic Device With Flexible Printed Circuit Strain Gauge Sensor

An electronic device may be provided with a flexible printed circuit. The flexible printed circuit may have layers of metal and dielectric. Strain gauge resistors may be formed from a strain gauge metal such as constantan. The strain gauge metal may be formed within the flexible printed circuit layers. A strain gauge may include strain gauge circuitry coupled to a strain gauge bridge circuit. Strain gauge resistors for the bridge circuit may be formed from traces that follow parallel meandering paths in the flexible printed circuit layers. A component such as a fingerprint sensor may overlap the strain gauge resistors. Strain gauge resistors may be formed in different overlapping metal layers in the flexible printed circuit layers or may be formed from the same metal layer. Electroplating techniques may be used to form metal traces to which solder balls or wire bonds are coupled.

Owner:APPLE INC

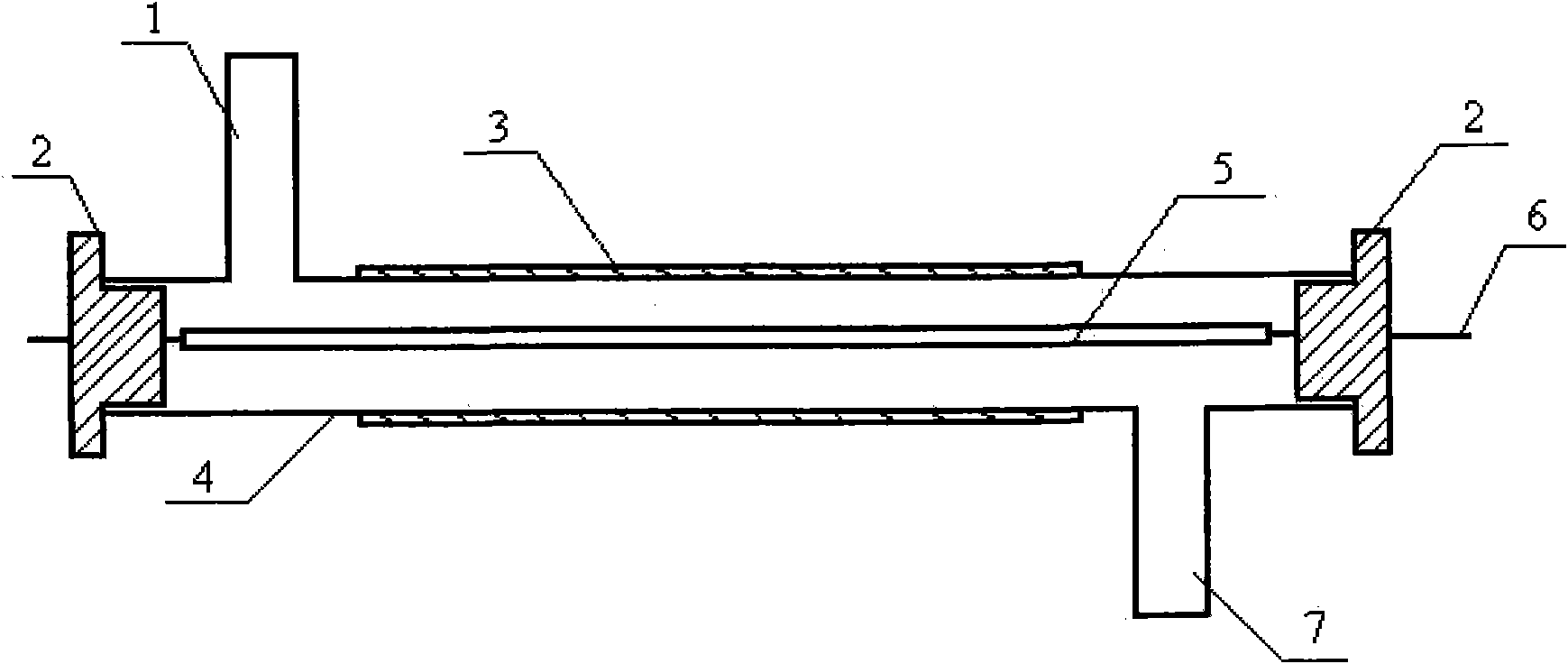

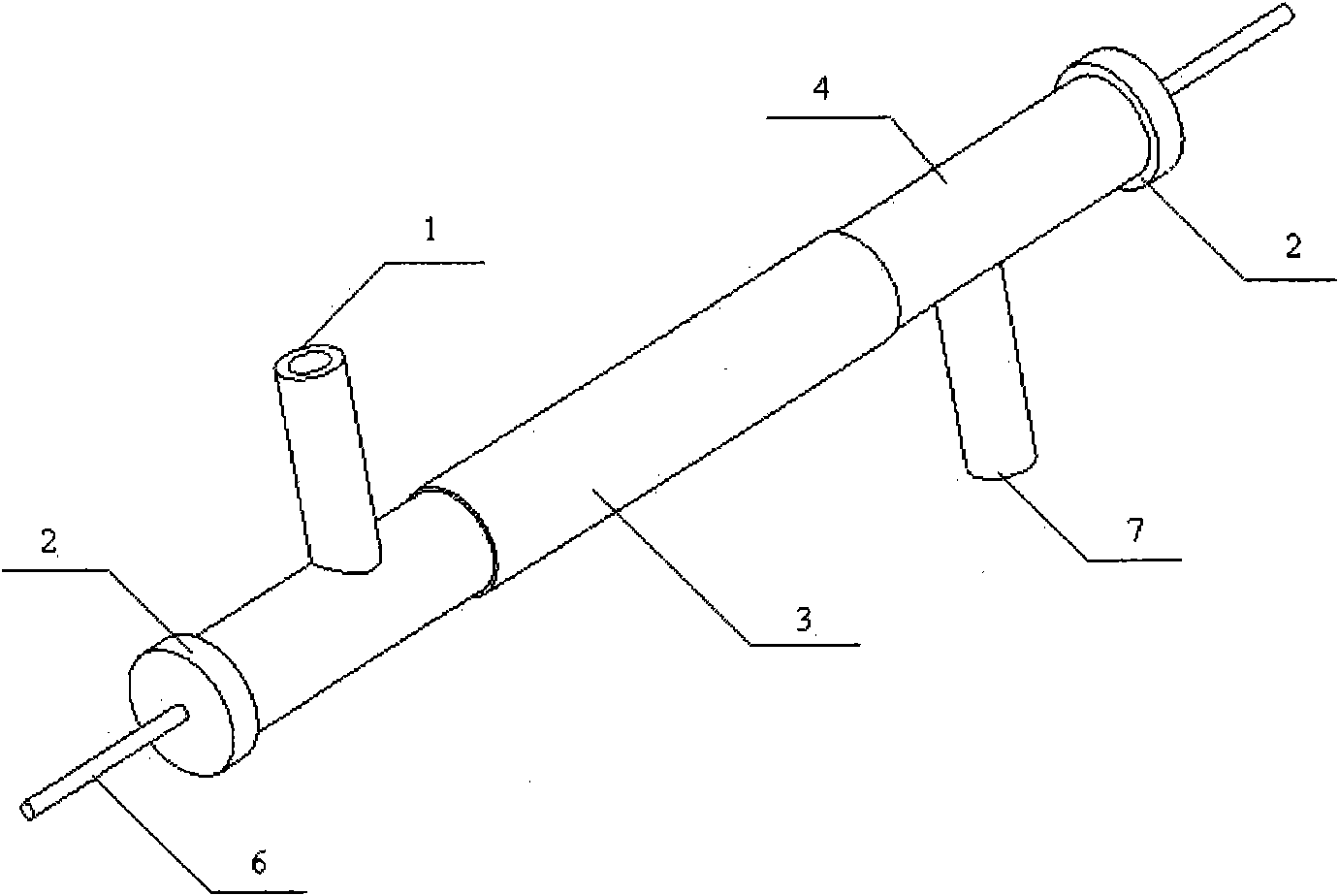

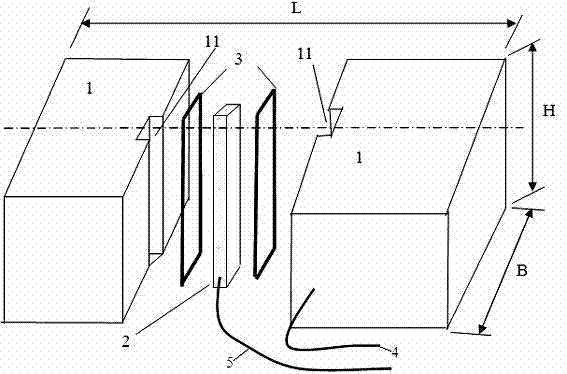

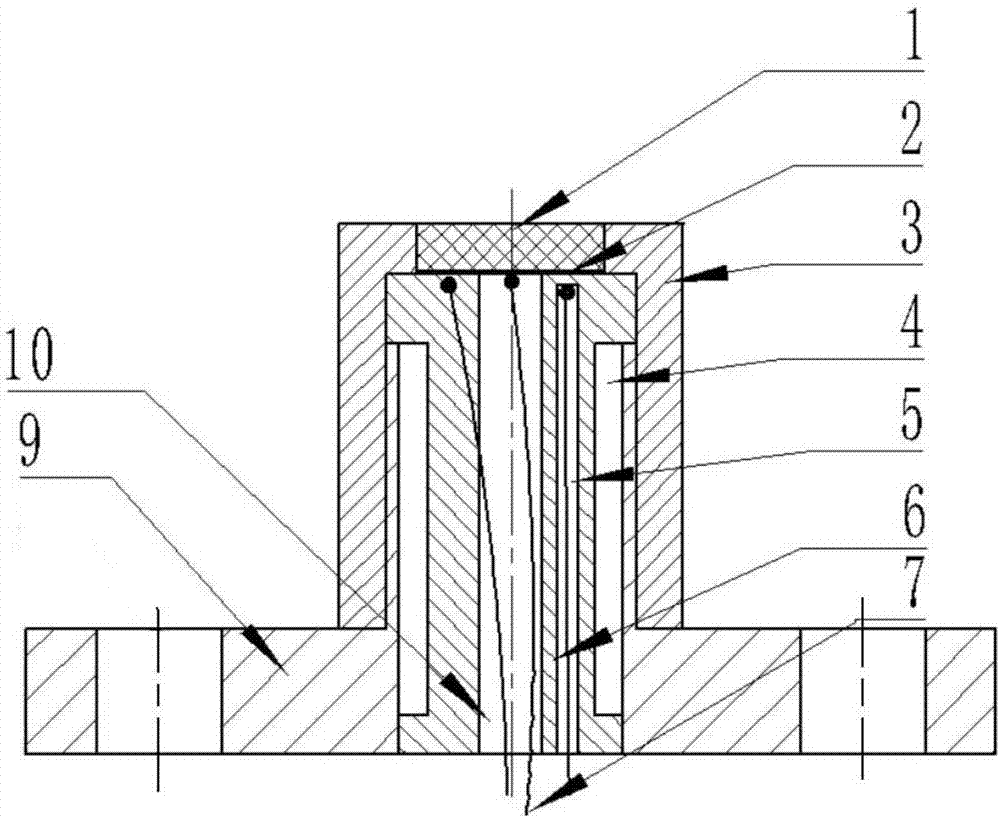

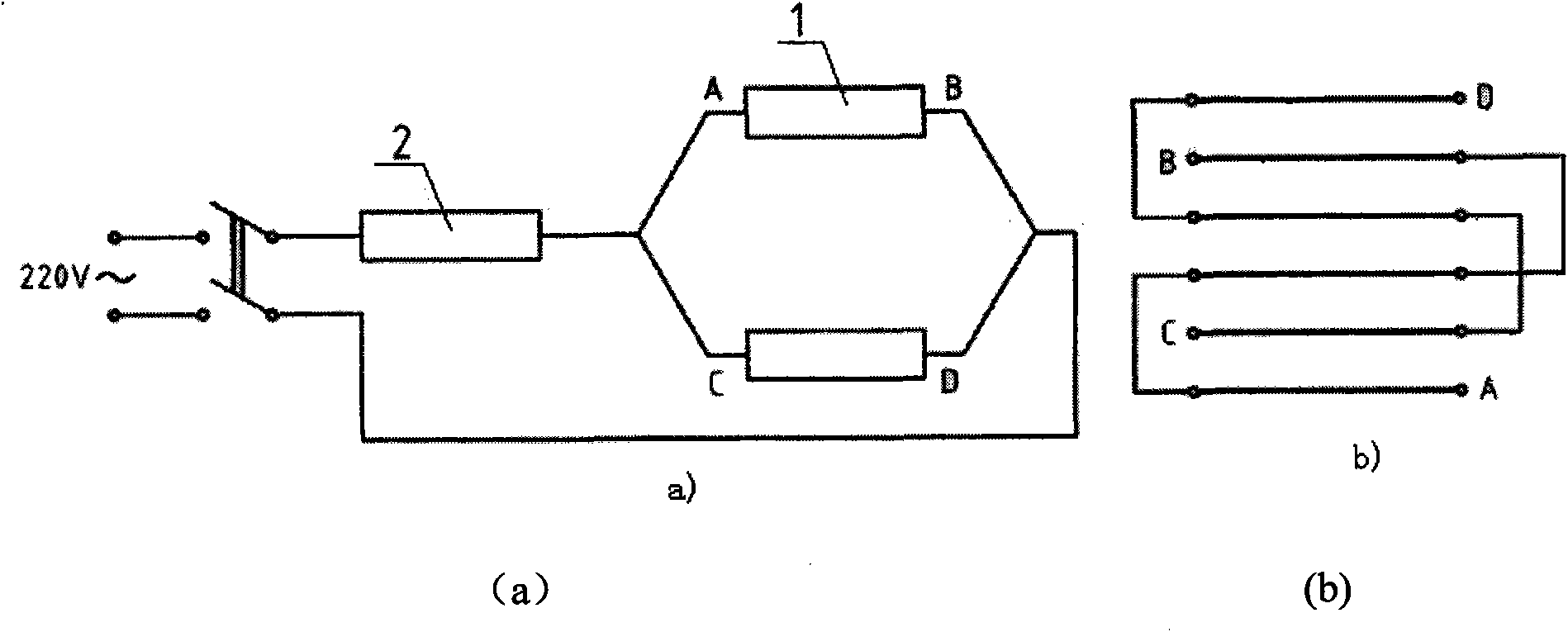

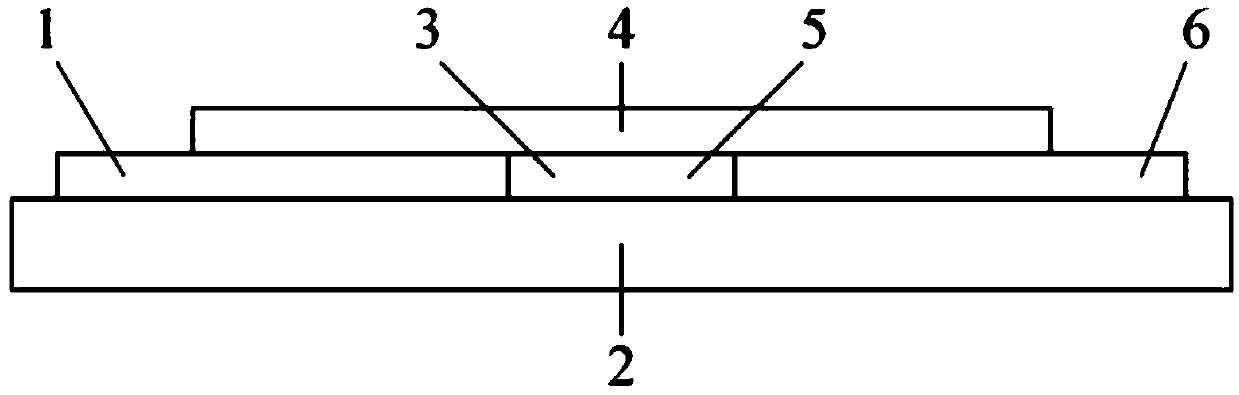

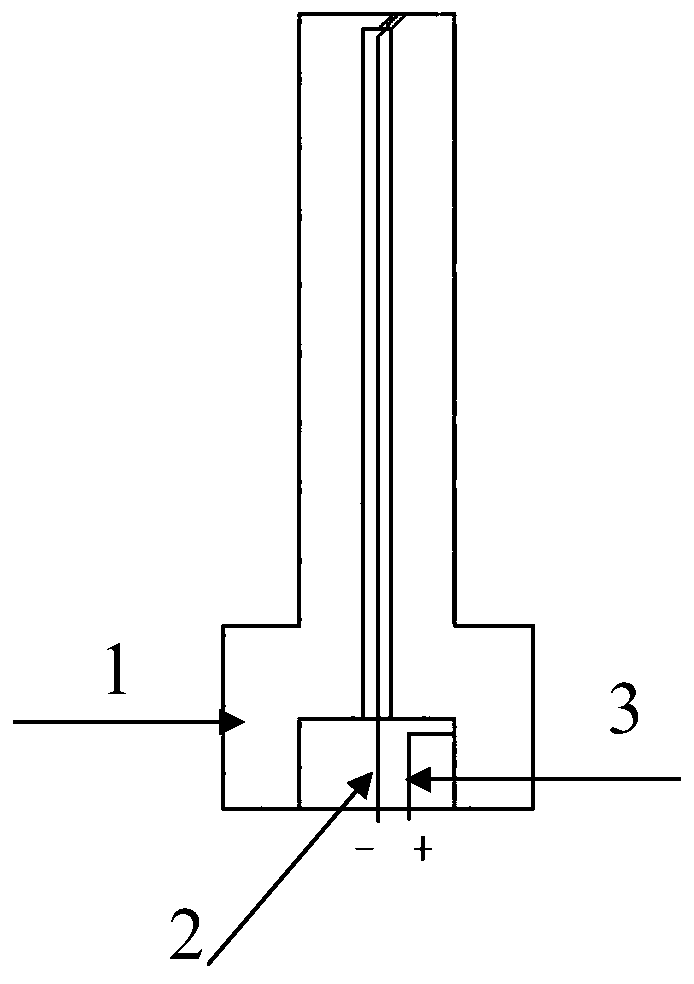

Double-dielectric barrier discharge low-temperature plasma generator

InactiveCN101835336AEvenly distributedImprove conversion efficiencyPlasma techniqueHigh energyLow voltage

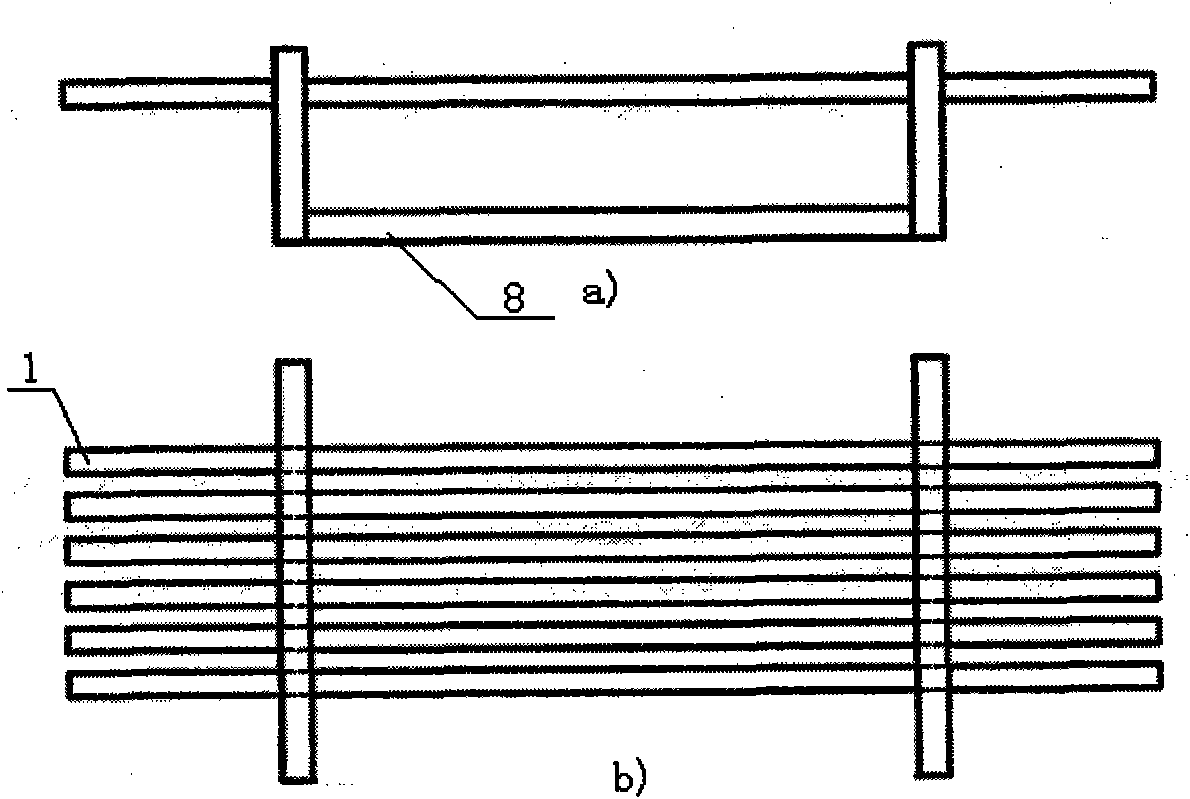

The invention discloses a double-dielectric barrier discharge low-temperature plasma device, and belongs to the field of low-temperature plasma technology. The plasma device comprises an air inlet (1), a polytetrafluoroethylene plug (2), a low voltage electrode (3), a quartz glass tube A (4), a quartz glass tube B (5), a high voltage electrode (6) and an air outlet (7), wherein the outer layer of the high voltage electrode (6) is the quartz glass tube B (5), and the low voltage electrode (3) consists of constantan sheets and is led out by a lead wire and grounded. In the process of treating pollutant gas, the low-temperature plasma generator can effectively reduce the corrosion of air on the high voltage electrode and avoid generating arc discharge and further damaging or breaking down discharge dielectric layers. The formed double-dielectric barrier discharge has high stability and high energy density utilization rate. The low-temperature plasma device can stably work under normal pressure and is applied to the discharge of automotive noxious pollutant gas.

Owner:JIANGSU UNIV

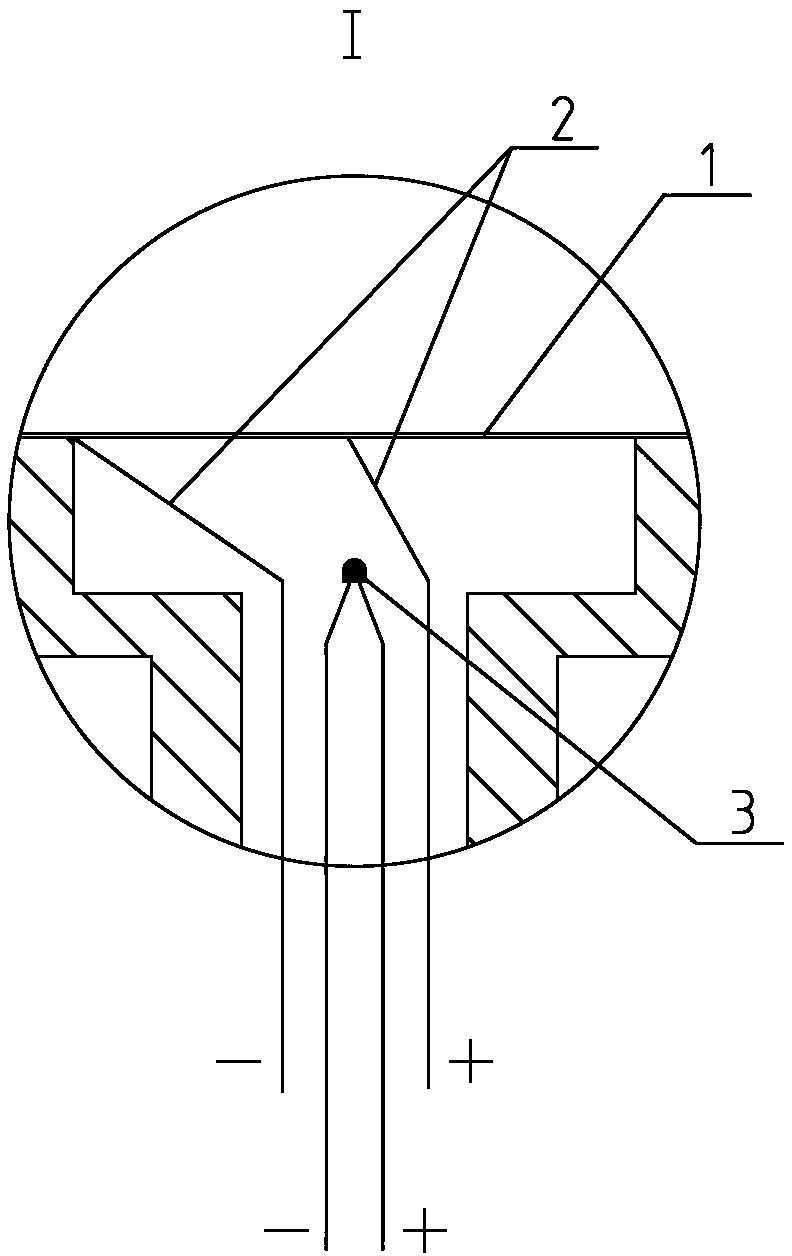

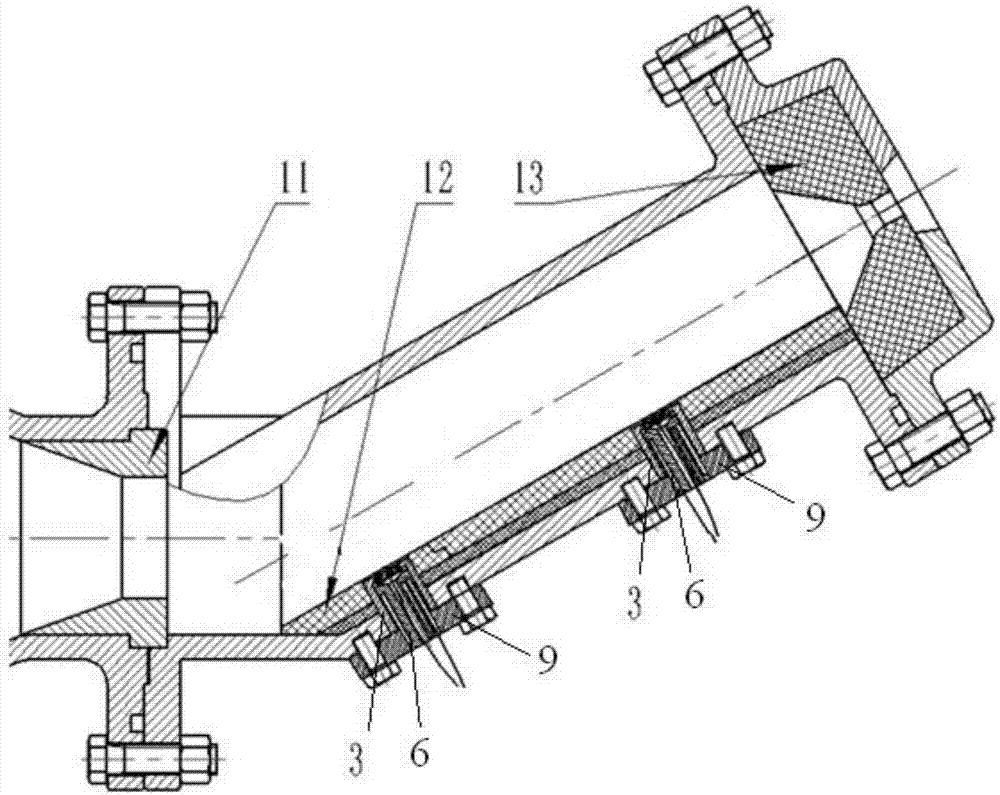

Phase-change heat accumulation type heat flow sensor

ActiveCN103217233AExtended working hoursAbsorb moreThermometers using electric/magnetic elementsUsing electrical meansHeat flowTemperature monitoring

The invention relates to a phase-change heat accumulation type heat flow sensor mainly consisting of a shell, an upper cover, a lower cover, a back cover, a phase-change heat accumulation body, a constantan circular foil, two nickel chrome wires, a thermoelectric couple, a four-hole aluminum oxide ceramic tube and the like, wherein the surface of the constantan circular foil is blacked, the constantan circular foil and the two nickel chrome wires form a measurement end surface sensitive body, the upper cover is welded with the shell after being welded with the measurement end surface sensitive body; after the phase-change heat accumulation body is screwed in, the lower cover is welded with the shell; and the two nickel chrome wires at the constantan circular foil and the thermoelectric couple are drawn out by the back cover in a fastening manner after passing through the four-hole aluminum oxide ceramic tube. According to the phase-change heat accumulation type heat flow sensor disclosed by the invention, by utilizing the phase-change heat accumulation principle, the working time is remarkably prolonged; by utilizing an E-shaped difference thermocouple, the high temperature resistance of the measurement end surface is largely improved; and by utilizing the thermocouple, a measurement end part is added with a temperature monitoring function and the situations that the measurement end part is molten, burn and the like are avoided.

Owner:BEIJING RES INST OF TELEMETRY +1

Strain meter for plastic deformation test and manufacturing and calibration method thereof

ActiveCN103604363ANot easy to break and damageImprove ductilityElectrical/magnetic solid deformation measurementAlloyVacuum annealing

The invention provides a strain meter for a plastic deformation test and a manufacturing and calibration method of the strain meter. The strain meter comprises a substrate, a sensitive grid and a sealing layer, wherein the sensitive grid is obtained by subjecting constantan and tinsel alloy formed in a cold rolling mode to vacuum annealing at 350-550 DEG C for three to six hours. The sensitive grid of the strain meter is obtained by subjecting the constantan and tinsel alloy formed in the cold rolling mode to vacuum annealing, and is good in ductility and elongation and capable of completely meeting measurement requirements of plastic deformation, so that the sensitive grid is not prone to rupture failures in the plastic deformation process.

Owner:ZHONGHANG ELECTRONICS MEASURING INSTR

Transparent face temperature sensor and transparent face temperature controller

InactiveUS6951419B2Measure the transparent surface accuratelyAccurate measurementThermometer detailsThermometers using mean/integrated valuesElectrical and Electronics engineeringElectrically conductive

Owner:TOKAI HITKK

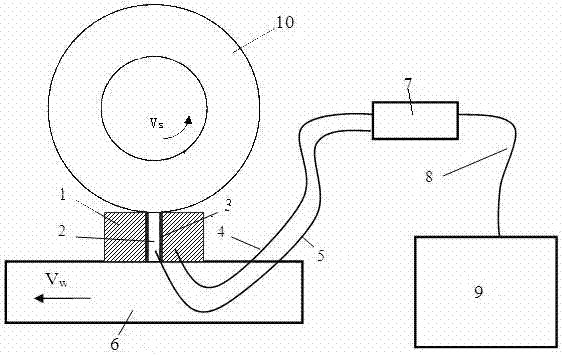

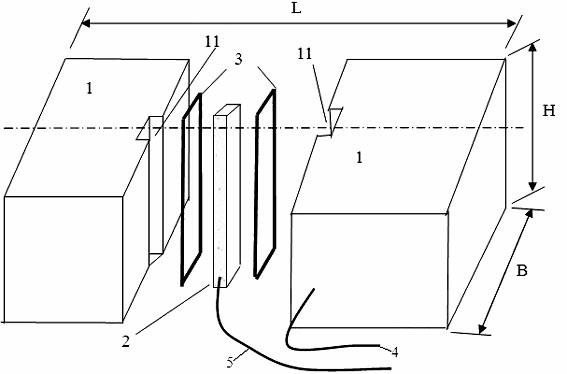

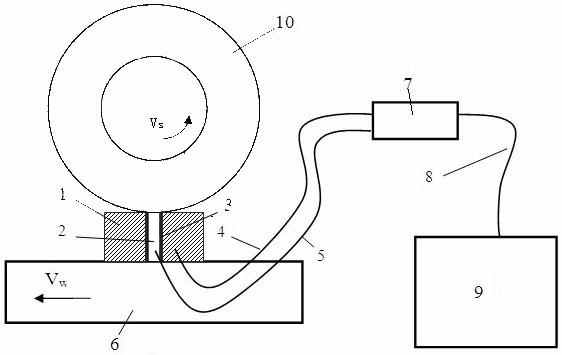

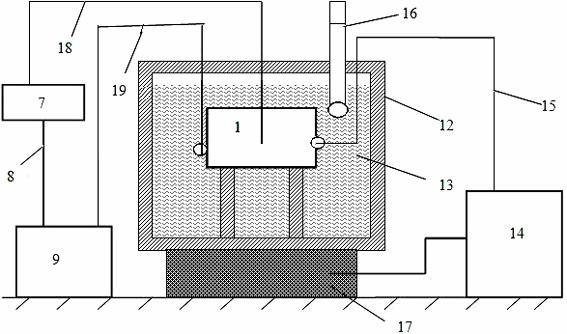

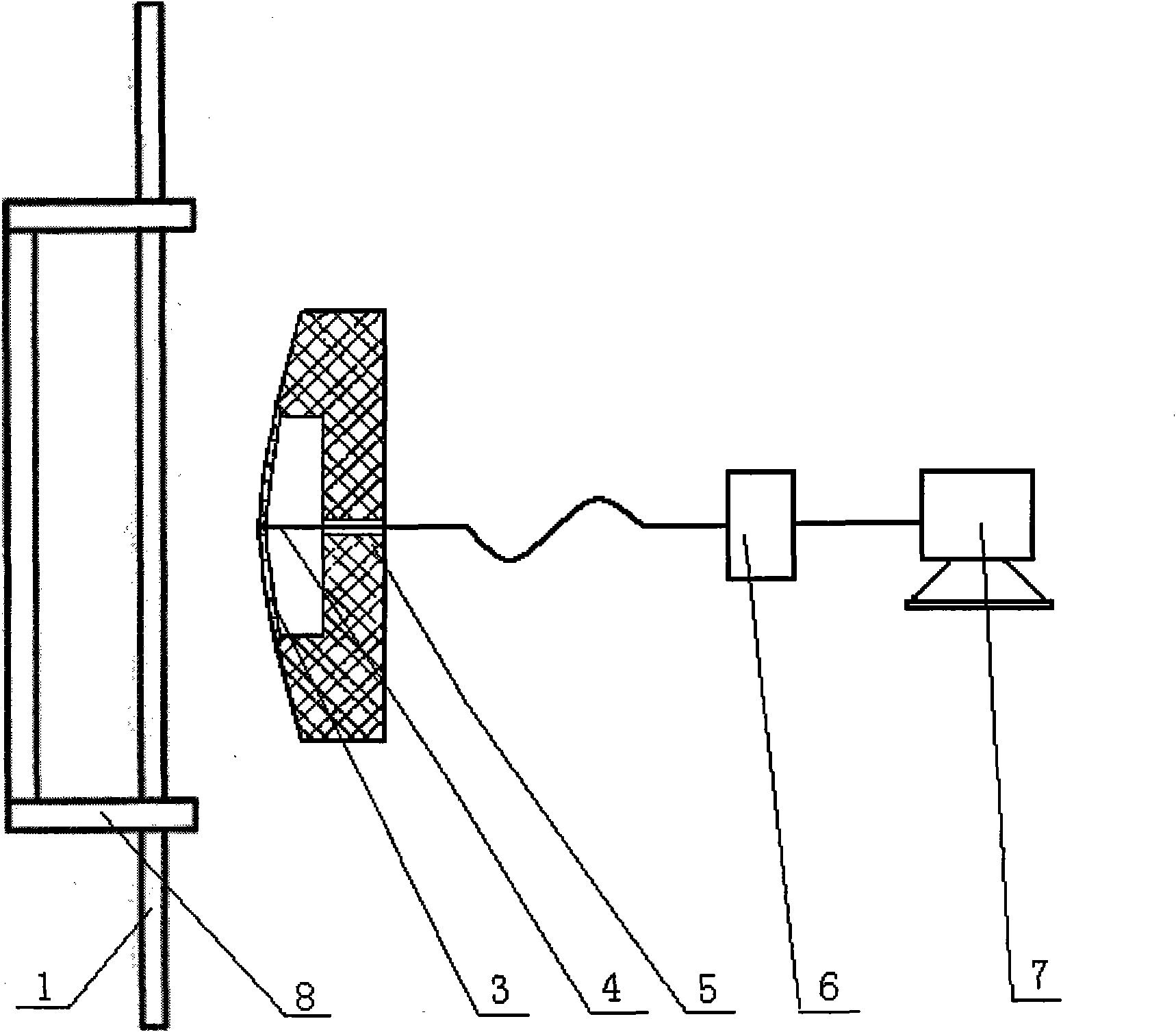

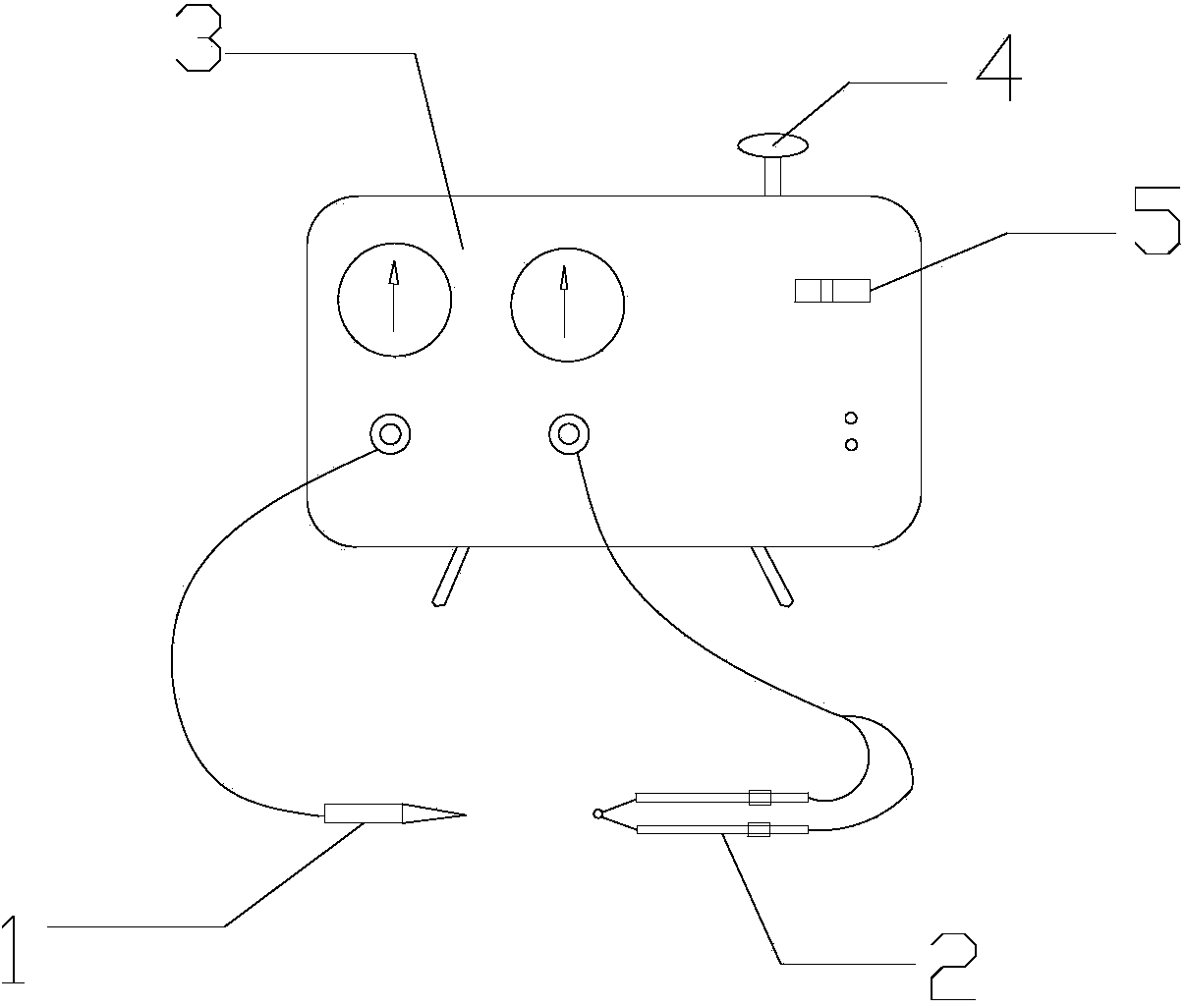

Device for measuring temperature of grinding area during plane grinding

InactiveCN102398220AImprove quality and efficiencyImprove grinding efficiencyThermometers using electric/magnetic elementsGrinding feed controlElectrical conductorEngineering

The invention relates to a device for measuring the temperature of a grinding area during plane grinding. The device comprises a constantan sheet, a mica sheet, an acquisition card and a computer. The device is characterized in that: the constantan sheet and the mica sheet are arranged in grooves on side faces of a grinding workpiece; and the grinding workpiece and the constantan sheet are respectively connected with the computer by using the acquisition card through leads I and II. The device has the advantages that: by using a thermocouple principle, both ends of two conductors with different components are connected into a loop, when the thermocouple temperatures of two connection points are different, an electromotive force can be generated in the loop, and a temperature value which corresponds to the electromotive force generated by thermocouple can be displayed by using a corresponding instrument; the temperature of the grinding area during grinding of the grinding workpiece by using a plane grinding machine can be tested; parameters of a plane grinding process are optimized; and great significance is provided for improvement of the surface quality and grinding efficiency of the grinding workpiece.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

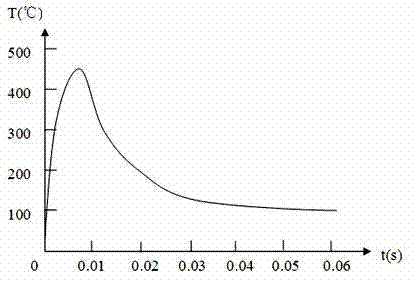

Method for measuring temperature of grinding region of surface grinding

InactiveCN102501173AAccurate measurementAvoid Grinding BurnsThermometers using electric/magnetic elementsGrinding feed controlShielded cableThermodynamics

The invention relates to a method for measuring the temperature of a grinding region of surface grinding. The method comprises the following steps: (1), making a thermocouple temperature sensor, (2), calibrating the thermocouple temperature sensor, and (3), measuring the temperature of the grinding region. During the grinding process, firstly a wire I and a wire II are connected into a collection card with a cold-end compensation function and a computer, then the grinding test is carried out after setting the rotation speed (Vs) of a grinding wheel and the rotation speed (Vw) of a working table, the top part of a ground work piece and the top part of a constantan sheet as thermocouple material are mutually lapped or welded together to form a thermocouple node, and finally the detected value of temperature of the grinding region is displayed and recorded by the computer through the shielded-type collection card with a cold-end compensation function and a shielded cable. The method can measure the temperature of the grinding region relatively and accurately when the work piece is ground by a surface grinding machine, and can protect the work piece from grinding burn and large residual stress by optimizing the process parameters of the surface grinding operation. The method has significance of improving quality of ground surface of the work piece and increasing the grinding efficiency.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

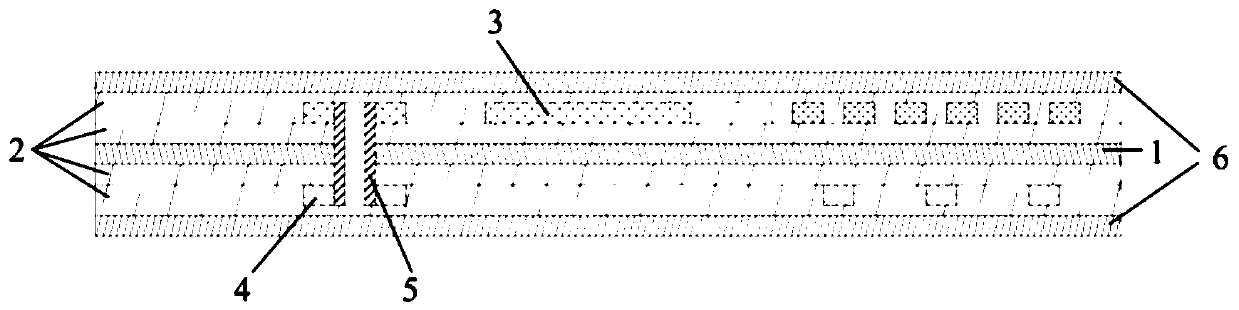

Heat-flow meter for measuring heat flux of aluminium oxide inside solid rocket engine dynamically in real-time

The invention discloses a heat-flow meter for measuring heat flux of aluminium oxide inside a solid rocket engine dynamically in real-time. The heat-flow meter comprises a heat-flow meter body including a cylindrical heat-sink copper piece and a constantan piece that are arranged coaxially. A thermal-insulation ceramic plate that is used for cooling high-temperature heat flux at the surface of the constantan piece is arranged at the top of the constantan piece coaxially; and the outer sides of the thermal-insulation ceramic plate, the constantan piece, and the heat-sink copper piece are coated with a beryllium-oxide ceramic housing and the thermal-insulation ceramic plate is fixed at the top of the constantan piece by the beryllium-oxide ceramic housing. The beryllium-oxide ceramic housing is used for guiding one part of heat flux to the matrix of the heat-sink copper piece. A heat-sink copper hole is formed along the axis direction inside the heat-sink copper piece; and a thermocouple for measuring the top temperature of the heat-sink copper piece is installed approaching the constantan piece inside the heat-sink copper hole. Therefore, a problem that condensed-phase particle washing or density measurement of disposition heat flux inside a solid rocket engine can not be realized on the high-temperature, high-pressure, and high-heat-flux conditions can be solved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

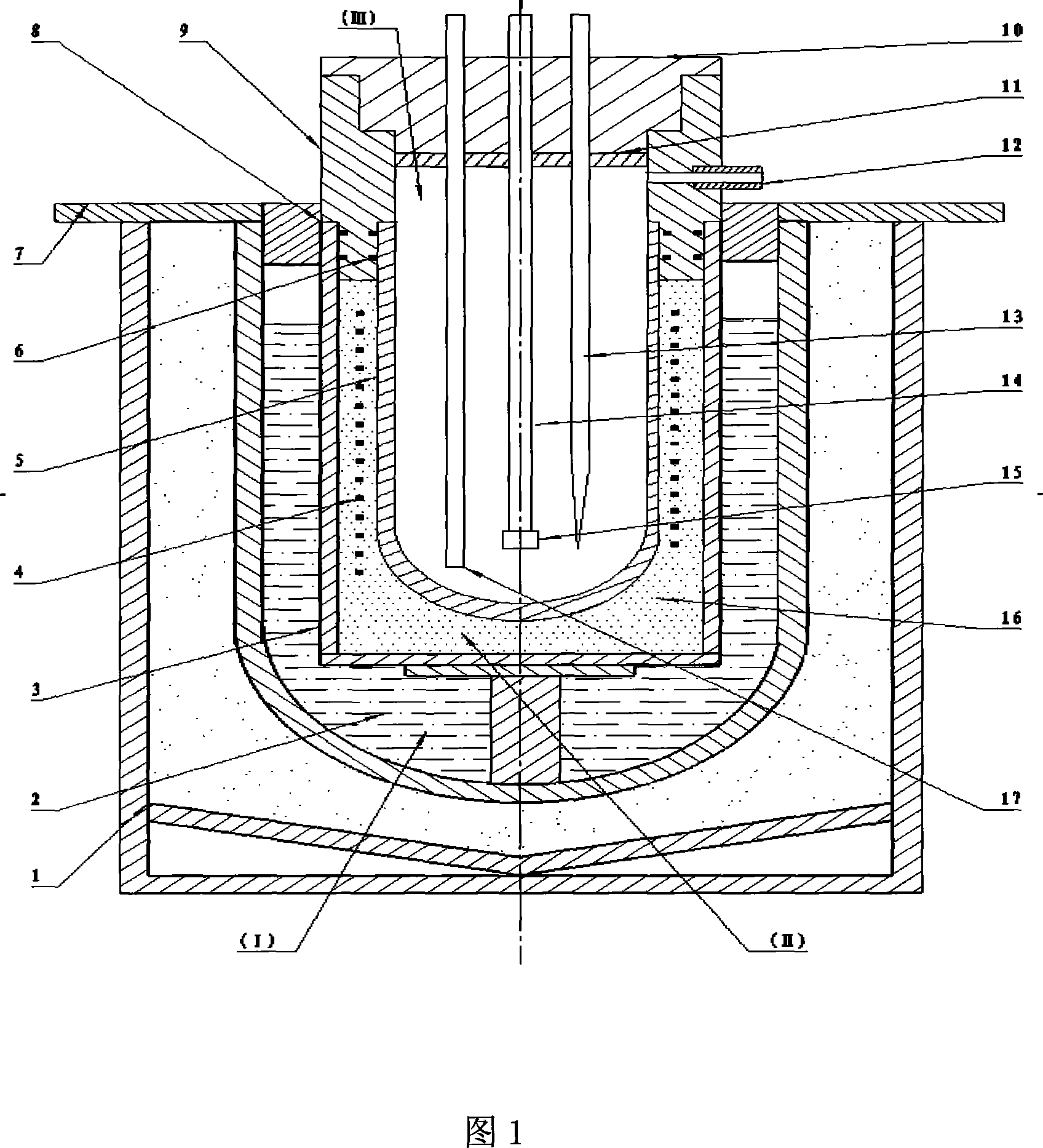

Low-temperature resistance temperature coefficient tester

InactiveCN101021502AAvoid affecting measurement accuracyImprove sealingMaterial resistancePlatinumElectrical resistance and conductance

The invention relates to a device to test temperature coefficient of metal and alloy low-temperature resistance, especially a device to test metal and alloy resistance continuously in -196deg.C-+200deg.C. The device is composed of three parts including thermostatic part, temperature measurement and control and resistance measurement. Thermostatic part contains cold source (I), heater (II), sealing element (III), thermostatic chamber (III) and insulation course (IV) etc. temperature measurement and control contains platinum hot resistance, copper-constantan thermojunction (or platinum hot resistance) and SWP-N intelligent digital apparatus. Resistance measurement adopts double bridge and potentiometer method. The invention can realize measurement of metal and alloy resistance at any temperature in -196 deg.C-+200deg.C by using the same thermostatic container.

Owner:SINO PLATINUM METALS CO LTD

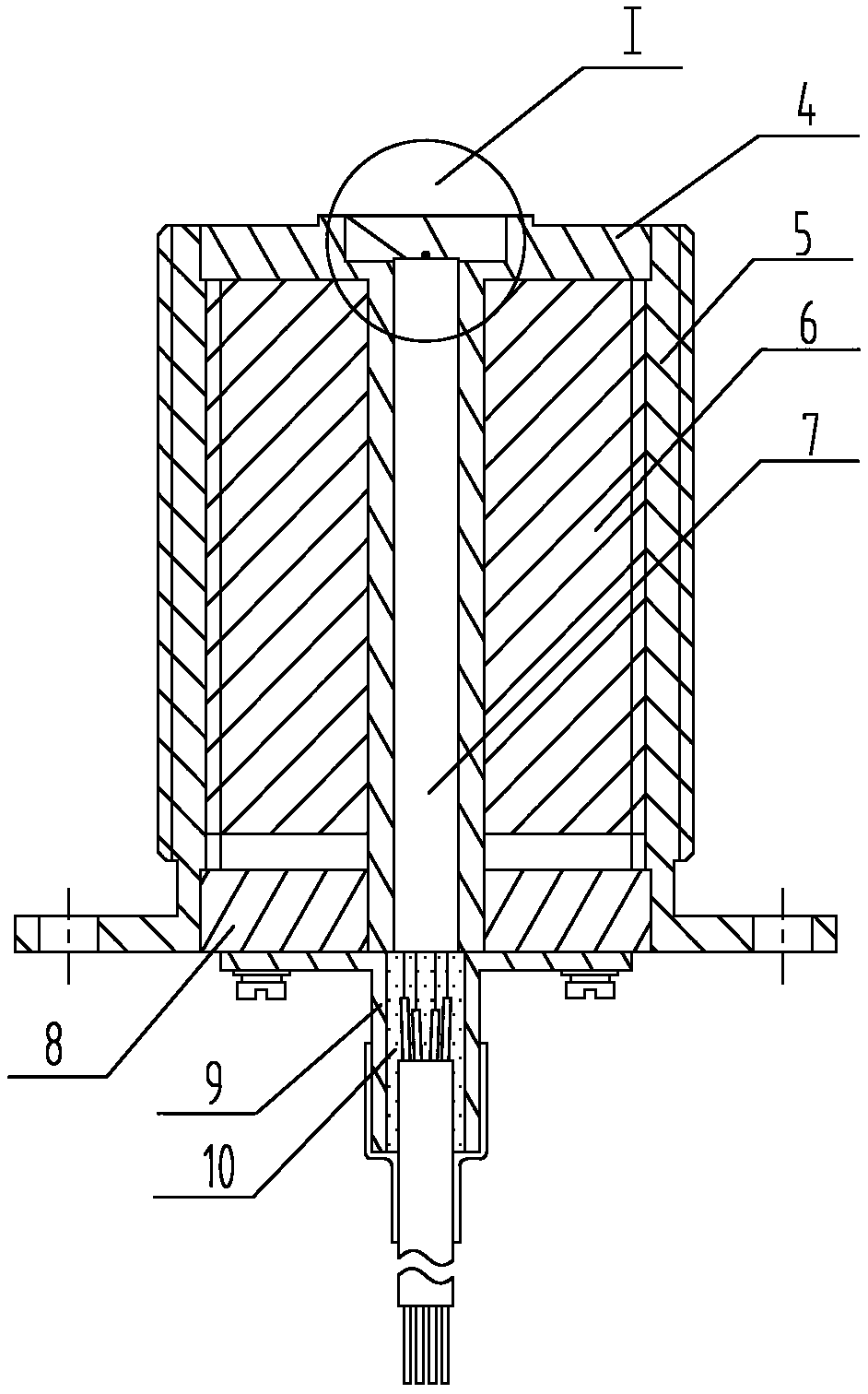

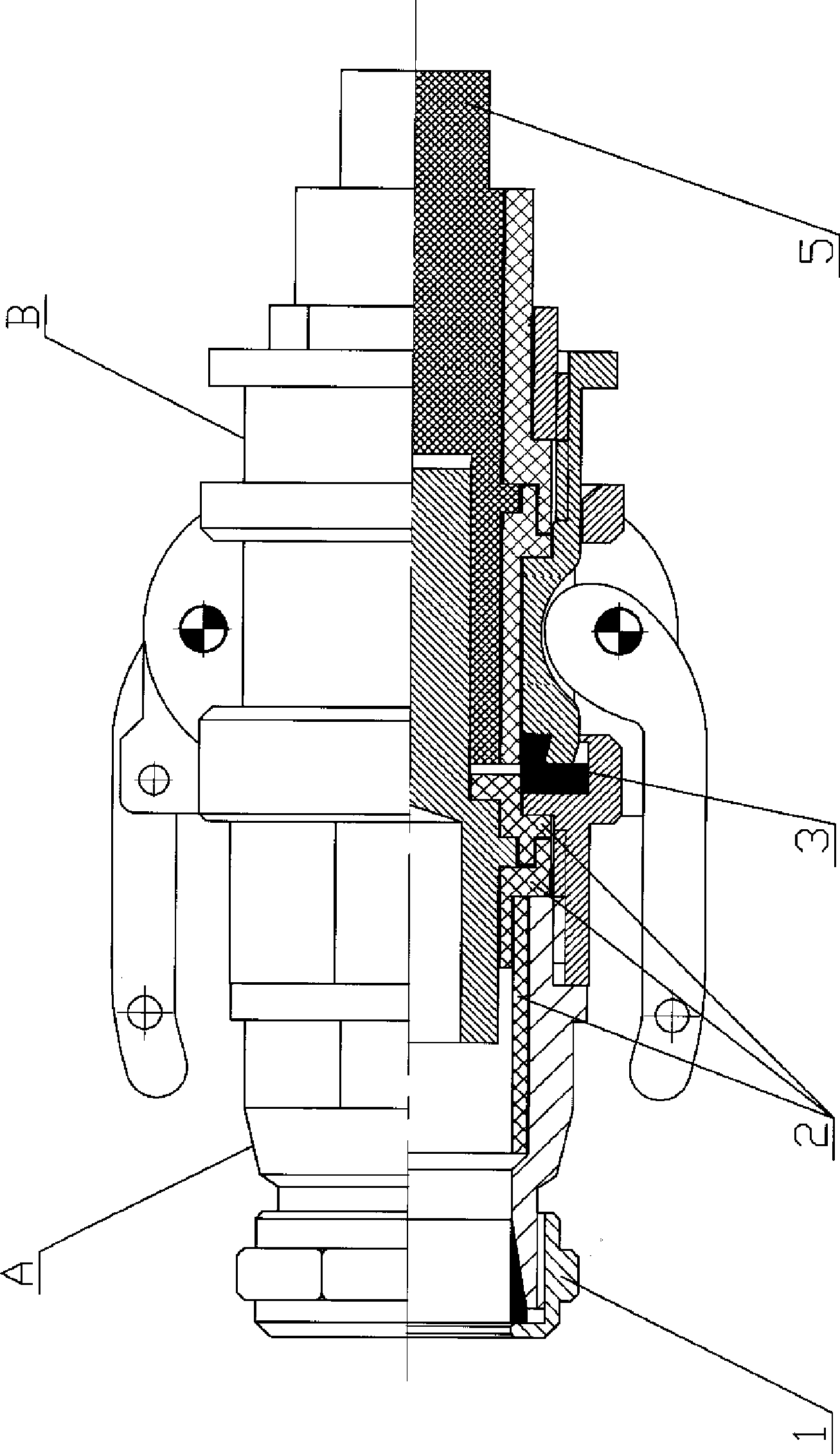

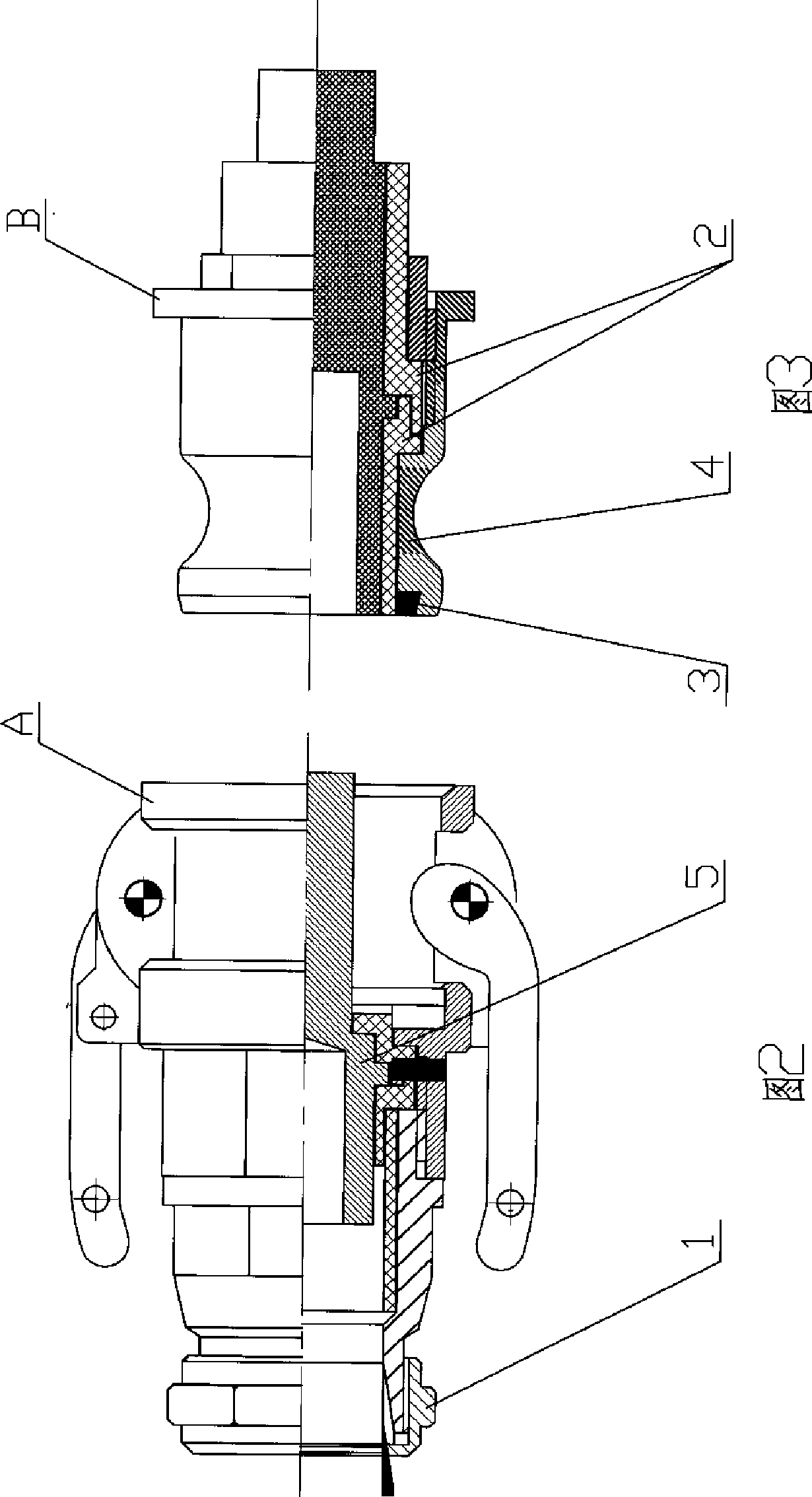

High-current, waterproof and high-temperature resisting cable connector

InactiveCN101521333AEasy to fixImprove sealingCouplings bases/casesMulticonductor cable end piecesEngineeringTemperature resistance

The invention relates to a high-current, waterproof and high-temperature resisting cable connector, comprising an A part and a B part, wherein the A part and the B part are sleeved with each other by fast joints; the A part is a connecting sleeve, one end inside the connecting sleeve is a cavity for fixing and sealing cables, and the end inside the connecting sleeve is an electrode core connected with the B part; the B part is a movable plug bush connected with the electrode core, one end of the movable plug bush is inserted into the A part of the cable connector and is sleeved with the electrode core of the A part of the cable connector, and the other end of the movable plug bush is a fixed embedding end of the electrode core. The invention adopts a waterproof bolt sleeve to fix and seal cables, thereby guaranteeing that the cables are well fixed and sealed, resist high temperature and have good insulation; the invention adopts silicon rubber materials as sealing materials, thereby guaranteeing high temperature resistance, aging resistance and good insulation of the cables; the invention adopts the fast joints of a stainless steel water pipe as a shell, thereby guaranteeing good mechanical strength, high temperature resistance and common standard component of the cables; and the invention adopts silver-bearing copper materials as the electrode core and lining silver-bearing constantan wires as a contact surface, thereby guaranteeing reliable conducting contact and good electric property of the cables.

Owner:HUNAN ZHONGKE ELECTRIC

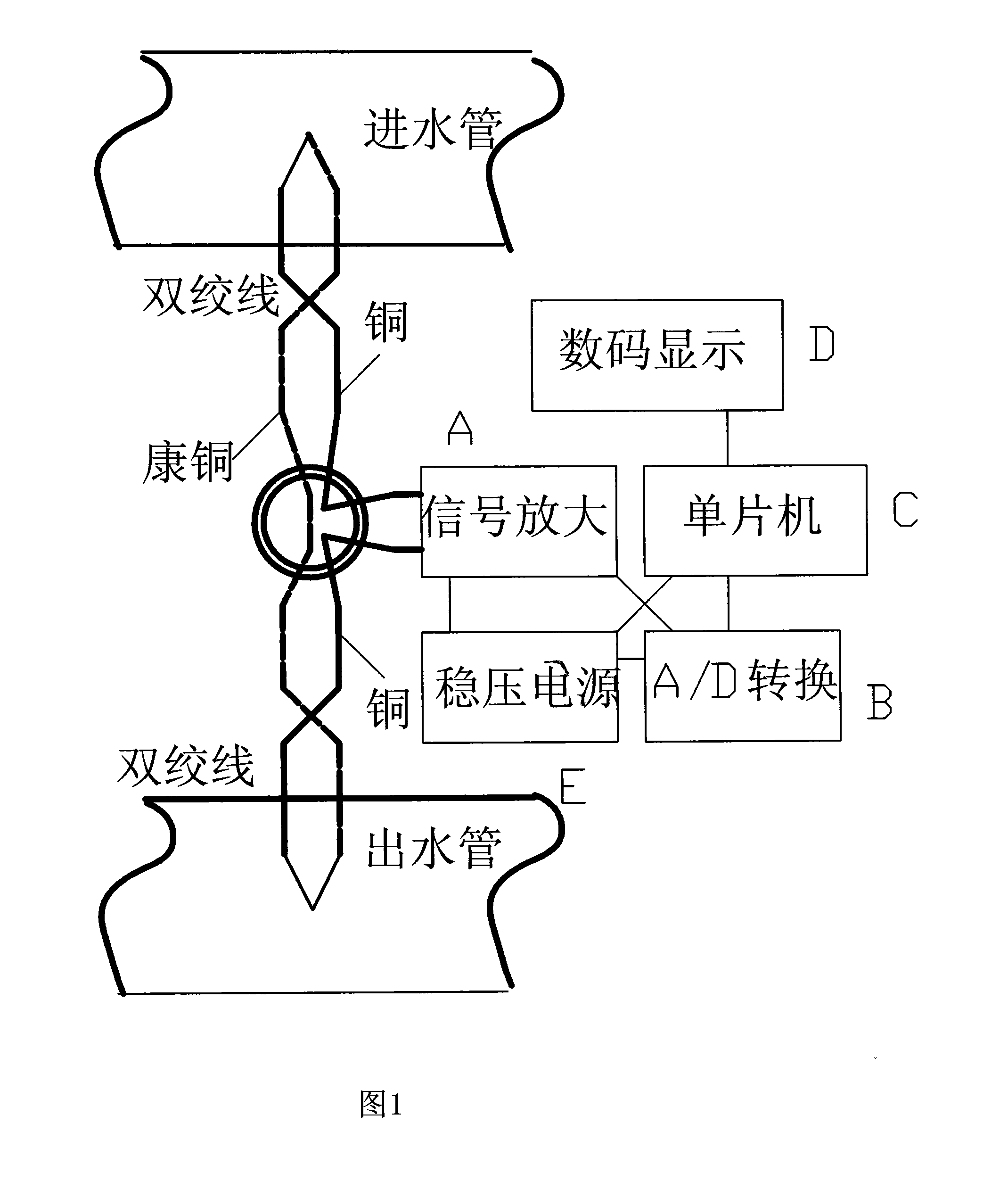

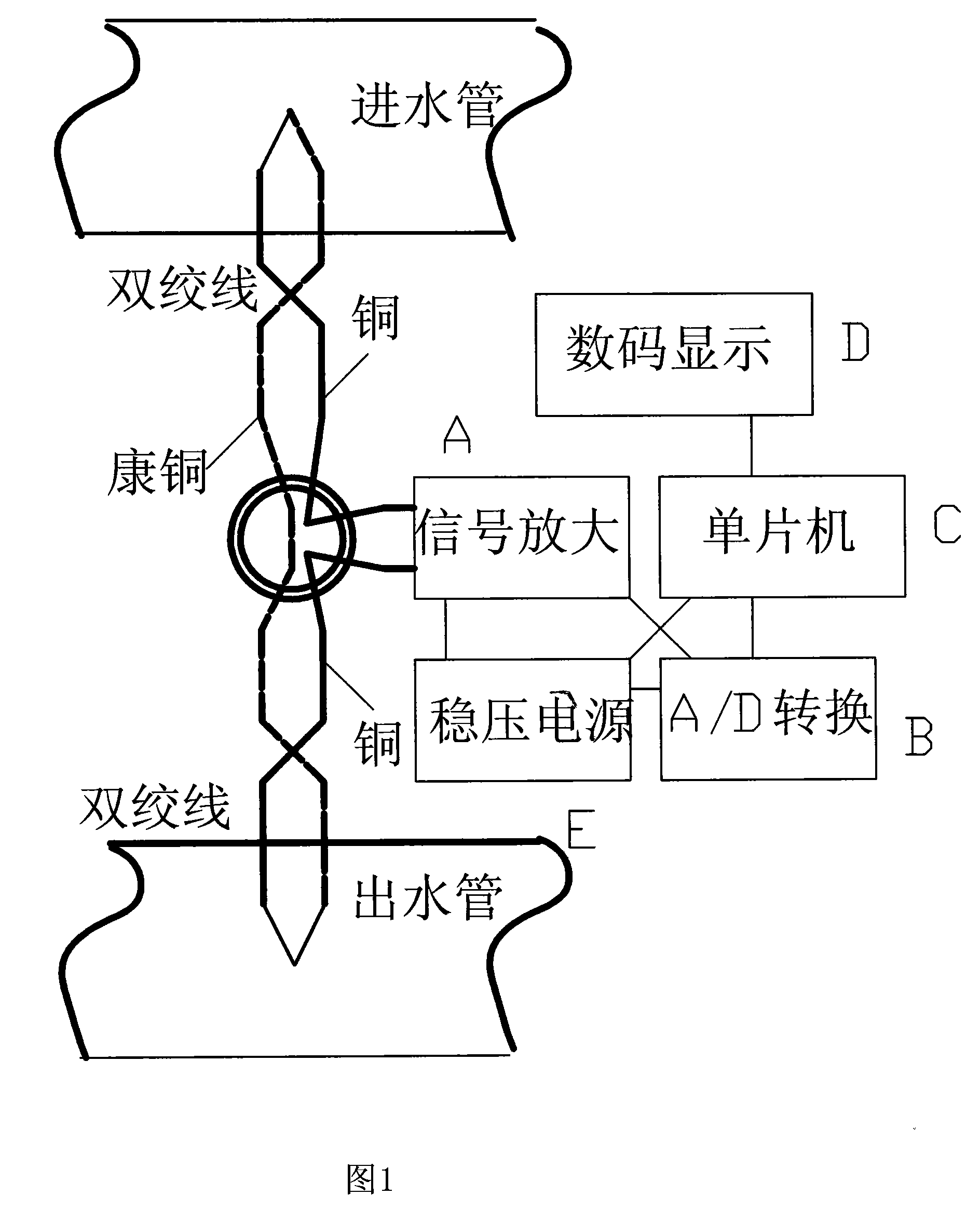

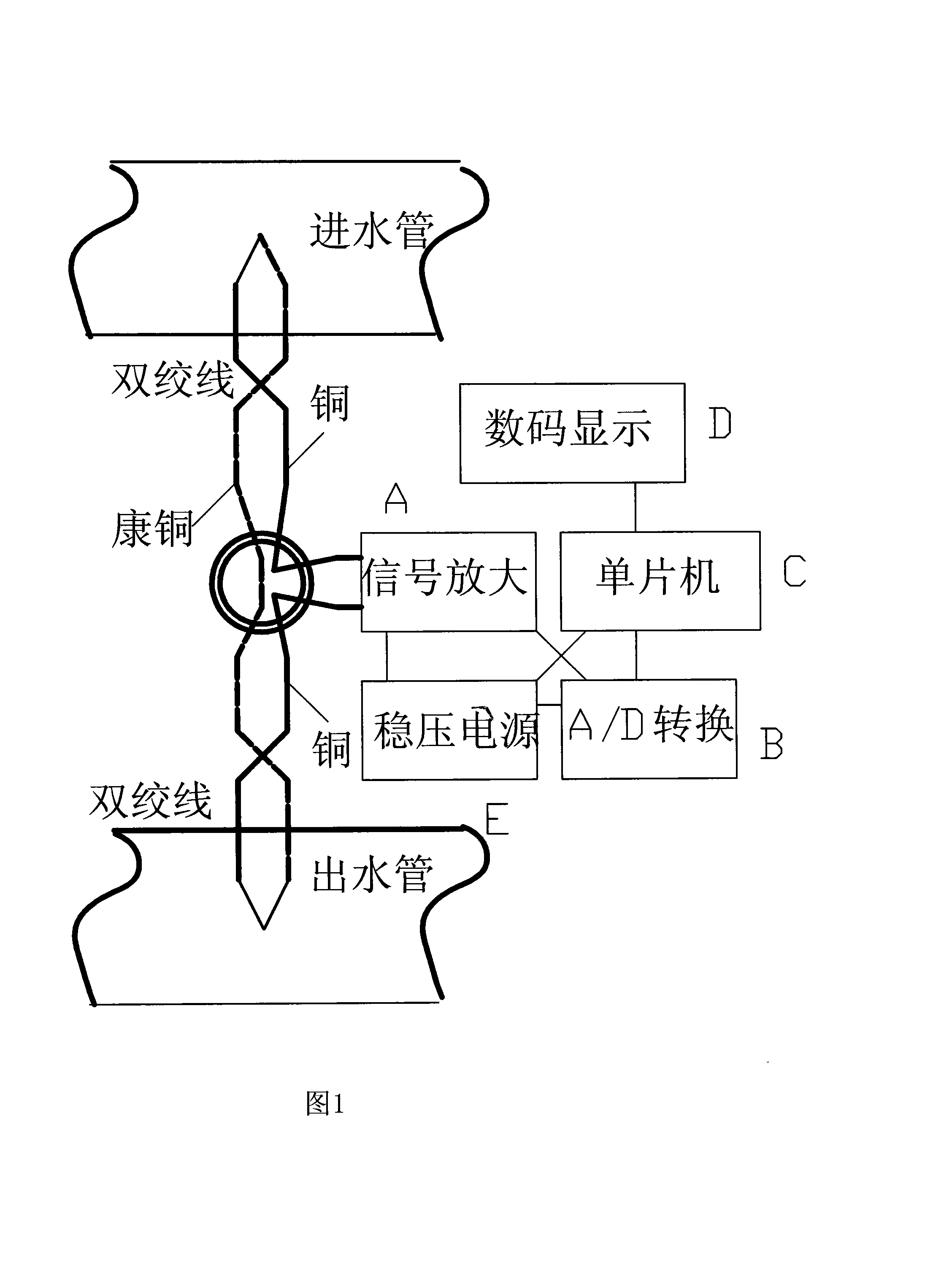

Heating system temperature differential measuring apparatus

InactiveCN101158606ASame temperatureLow costThermometers using electric/magnetic elementsUsing electrical meansSignal conditioning circuitsThermal insulation

The invention relates to a temperature difference measuring device of heating systems pertaining to the technical field of a temperature measuring device. The invention is mainly characterized by composing of a double end thermocouple and a signal conditioning circuit, the two connecting poles of the double end thermocouple are sealed together, assuring insulation and the same temperature; when in operation, both testing ends of the double end thermocouple adopt sealing fixing pedestal are respectively inserted into the inlet and outlet port of a customer heating pipe, both connecting ends are arranged close and are respectively wrapped insulated in thermal insulation material, temperature is assured the same at both the ends, after the double end thermocouple induces the temperature difference at the inlet and the outlet ports, a tiny voltage difference is generated at both ends of the thermocouple, the signal is amplified and displayed by a temperature difference amplifying circuit, the signal multiplies with the flow data acquired by a flowmeter sensor, the double end thermocouple is made of economic and universal thermocouple material copper constantan, the cost is low, the cost is only 1 / 5 of Pt1000 pairing thermocouple. The invention can also be applied to temperature difference measuring of adjacent fields.

Owner:YANGZHOU UNIV

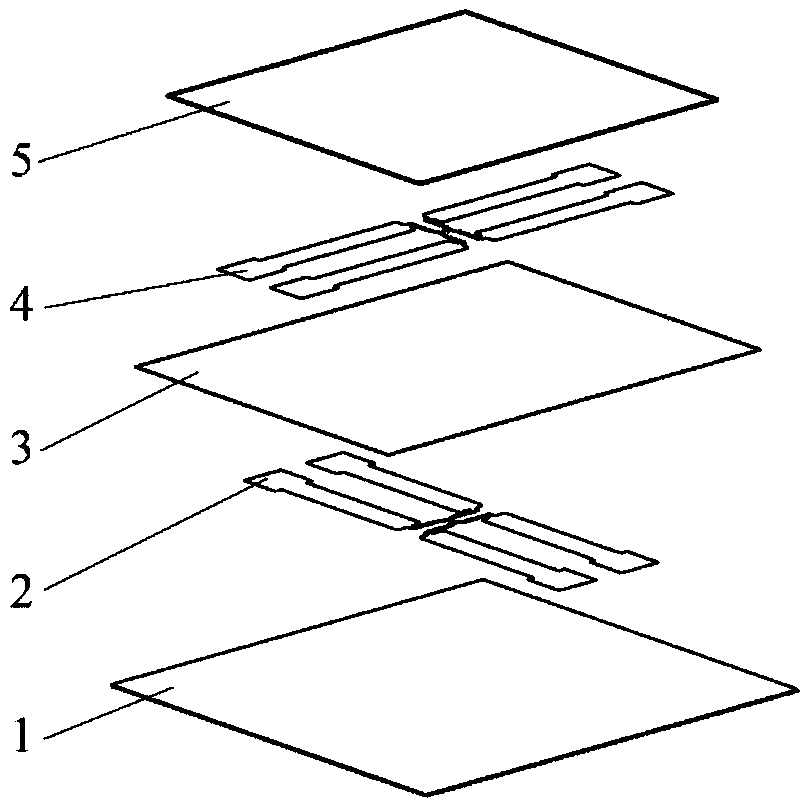

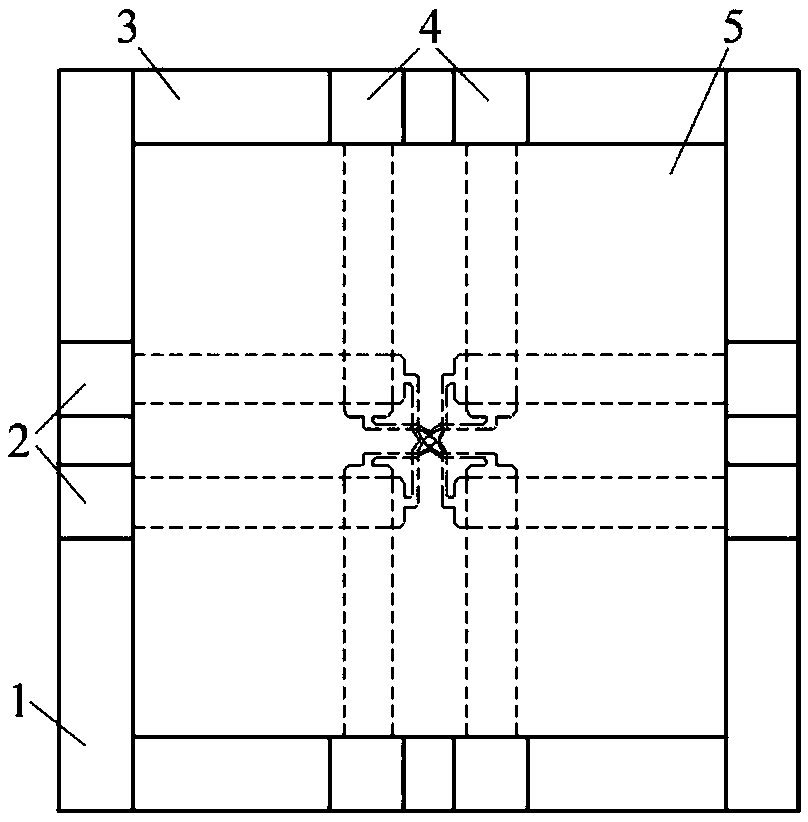

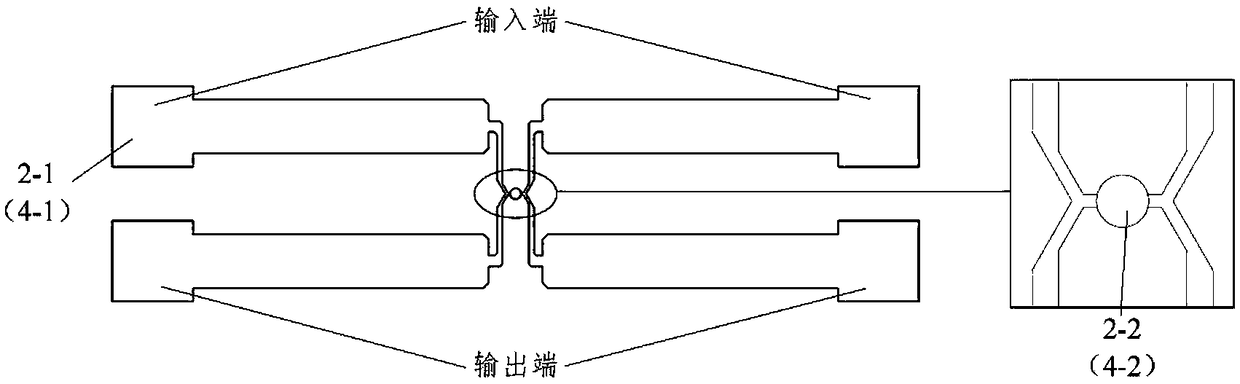

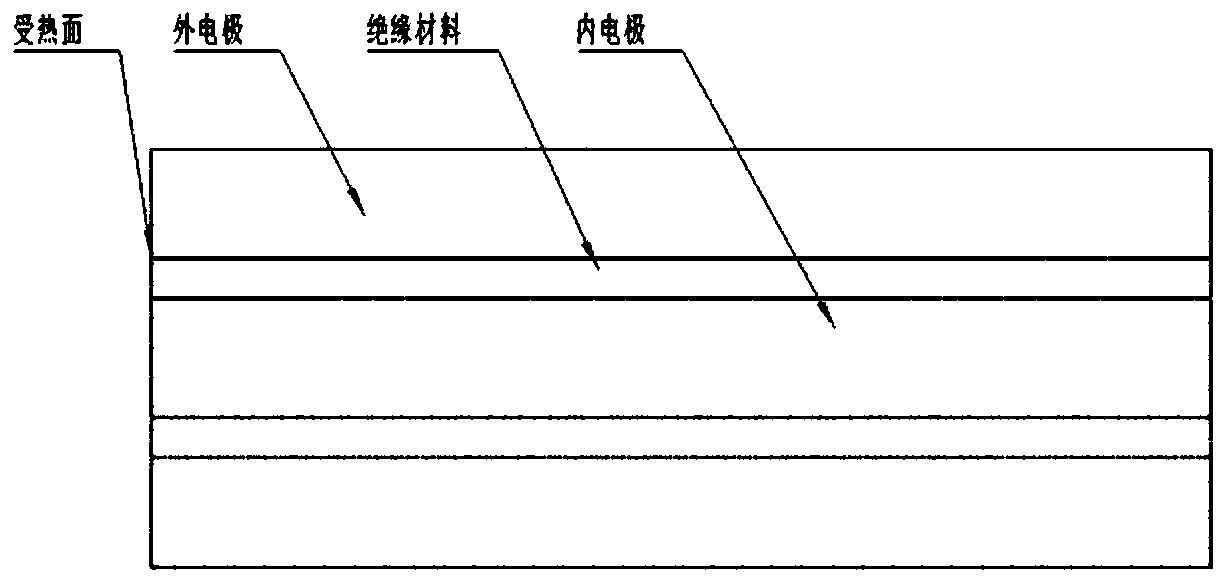

Micro-scale flexible composite ultrahigh pressure sensor and manufacturing method thereof

ActiveCN109163837AReduce flexibilityReduce the impact of detonation wavesForce measurementMeasurement of explosion forceTransverse axisManganin

The invention discloses a micro-scale flexible composite ultrahigh pressure sensor and a manufacturing method thereof. The sensor comprises a substrate; a constantan sensitive element and first electrodes are sputtered on the substrate through an MEMS process; the input end and the output end of the constantan sensitive element are connected with the two first electrodes respectively; the surfacesof the constantan sensitive element and the first electrodes are covered with an insulating layer; a manganin sensitive element and second electrodes are sputtered on the insulating layer through theMEMS process; the input end and the output end of the manganin sensitive element are connected with the two second electrodes respectively; and the manganin sensitive element and the constantan sensitive element are arranged in a vertical alignment mode, the second electrodes and the first electrodes are arranged in a vertical manner of a transverse axis, and the surfaces of the manganin sensitive element and the second electrodes are coated with a protective layer. The sensor has the characteristics of small sizes of the sensitive elements, high measuring range, high precision, large outputsignal, flexibility and the like, is suitable for measurement of micro-scale explosive-loading detonation pressures under multiple working conditions, and also can be expanded to the measurement of other micro-scale axisymmetric dynamic high-pressure flow field pressures.

Owner:XI AN JIAOTONG UNIV

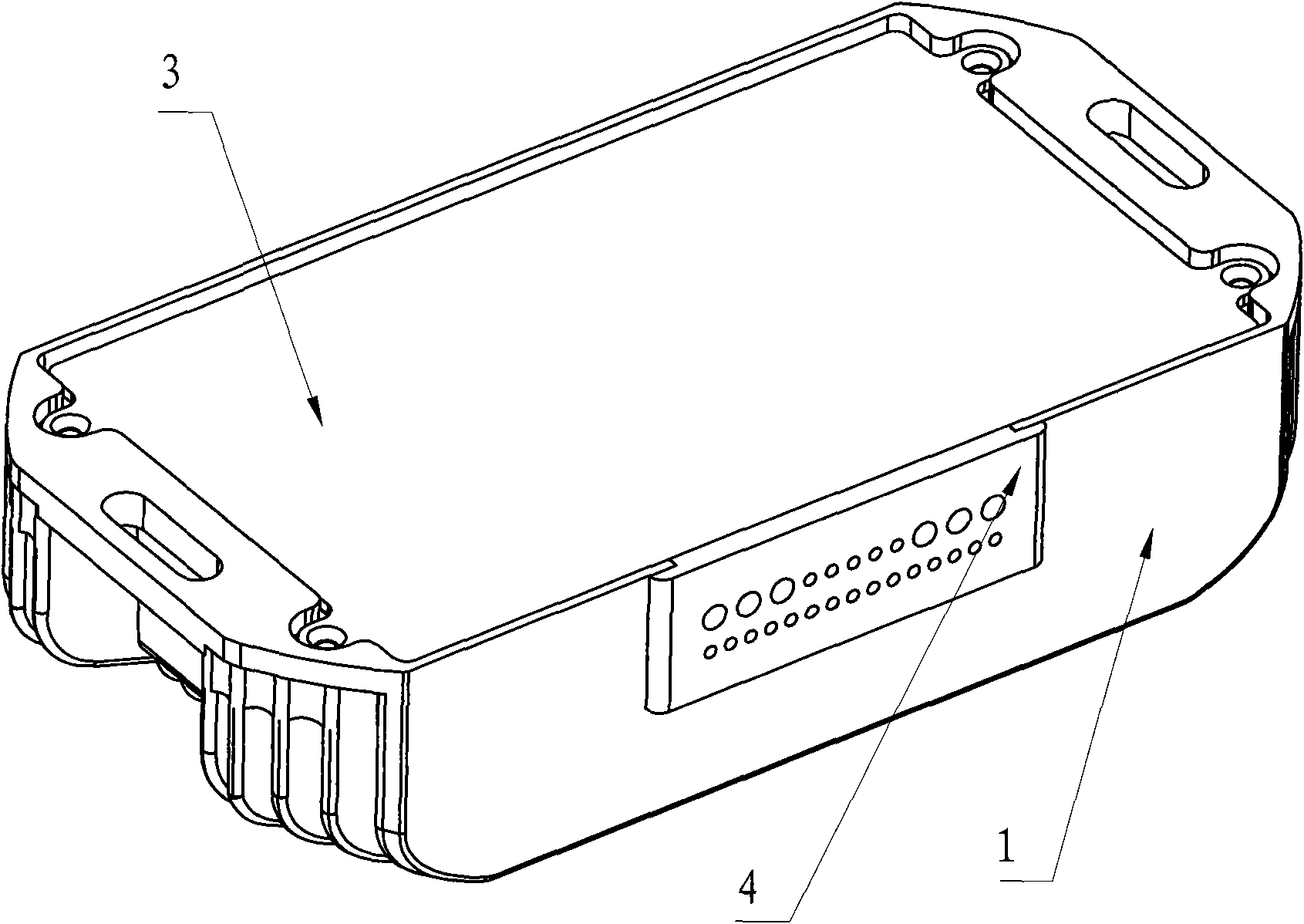

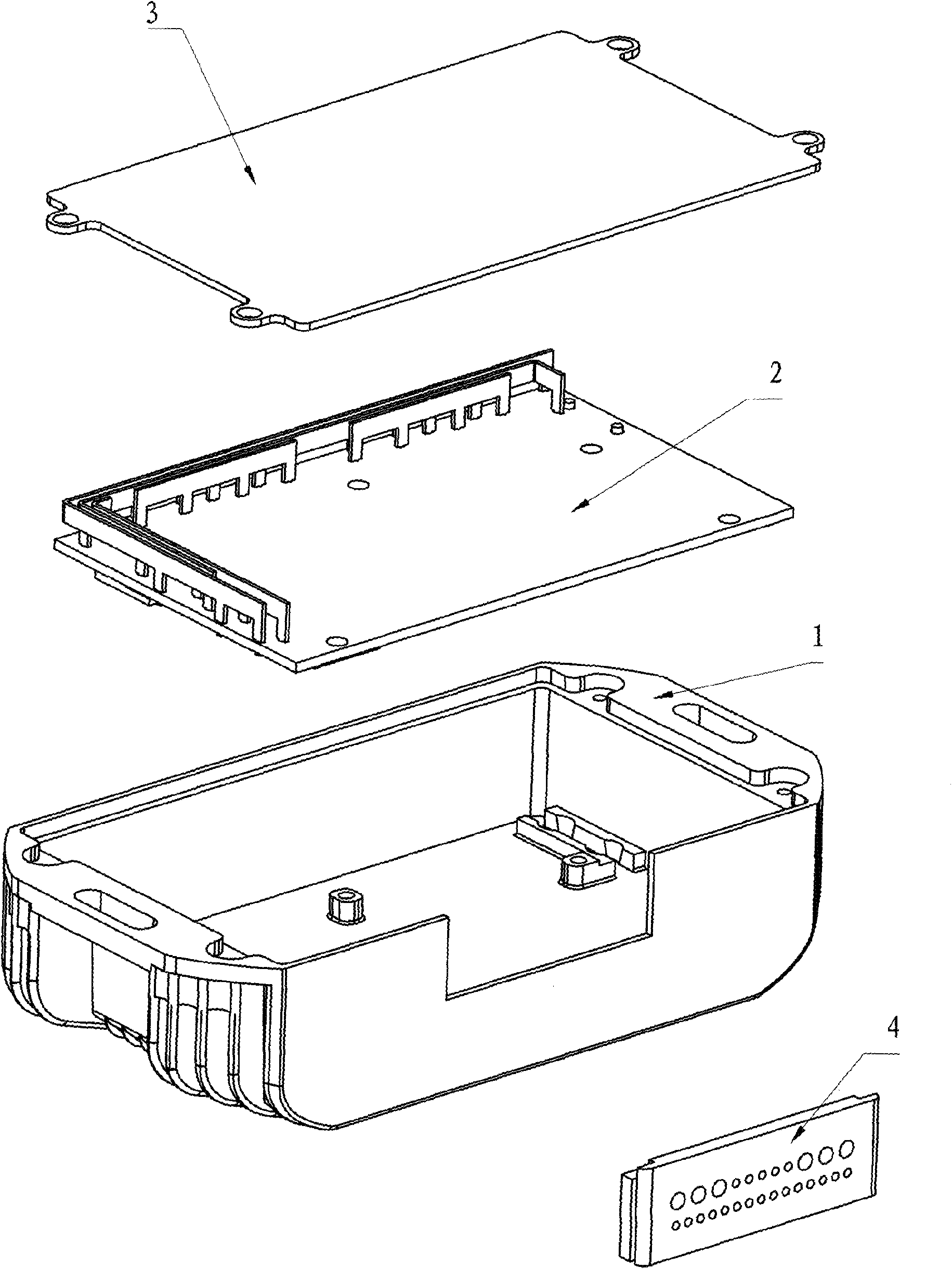

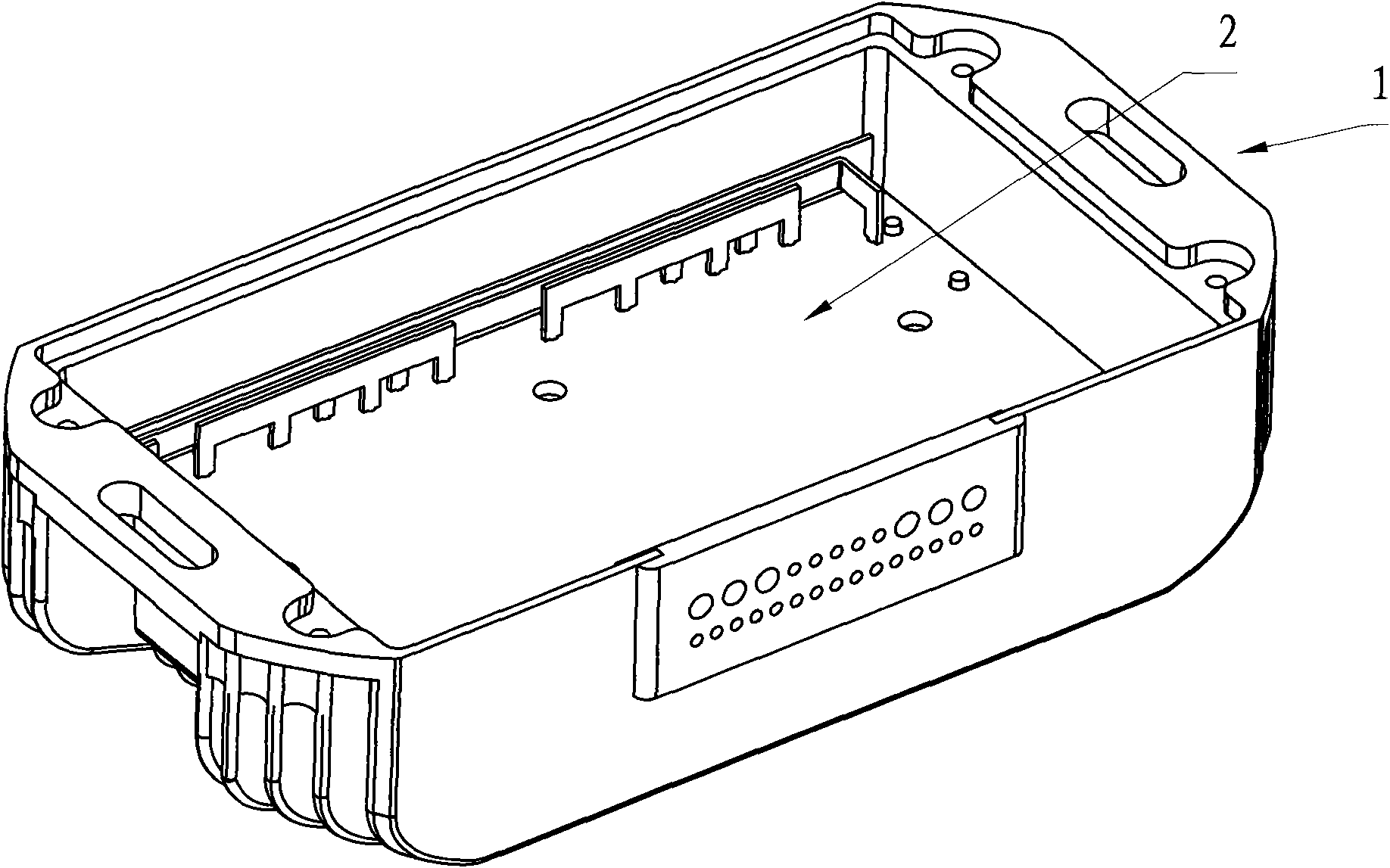

Controller for electric vehicle

InactiveCN101588689AEasy to installReduce processSupport structure mountingElectric/fluid circuitEngineeringElectric vehicle

The invention relates to a controller for electric vehicle, comprising an outer housing and a circuit board mounted in the outer housing, a triode bar, a constantan wire and high current leads, an opening is provided on the edge side of the outer housing, the opening is sealed by a cover board, a mounting plate for mounting the controller on the electric vehicle is provided on one side of the outer housing, a heat radiation slot is arranged on the external side of the other side wall opposite to the mounting plate of the outer housing, characterized in that, the opening and the mounting plate of the outer housing are positioned on the same side, the circuit board is mounted in the outer housing and is fixedly connected with the side wall opposite to the opening of the outer housing by screw nails, the triode bar and the circuit board are in parallel welding, the triode bar and the side wall opposite to the opening of the outer housing is attached tightly. Compared to the prior art, the invention has good heat radiation performance and convenient assembling.

Owner:WENZHOU HUALONG AUTOMOTIVE ELECTRONICS

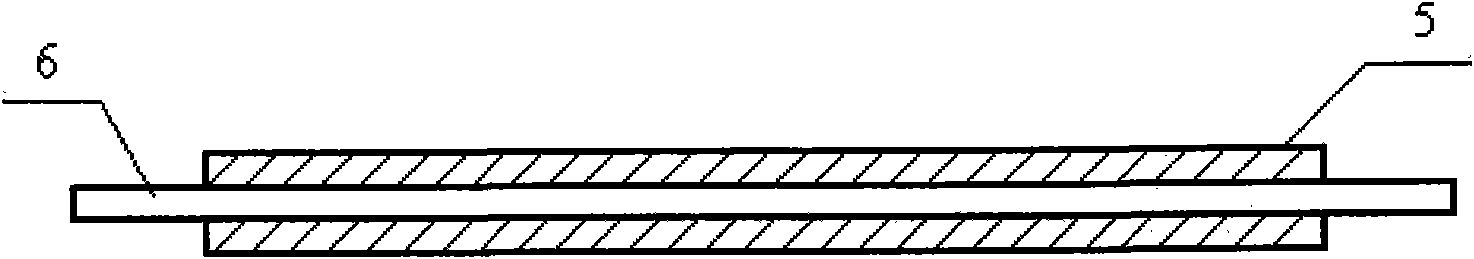

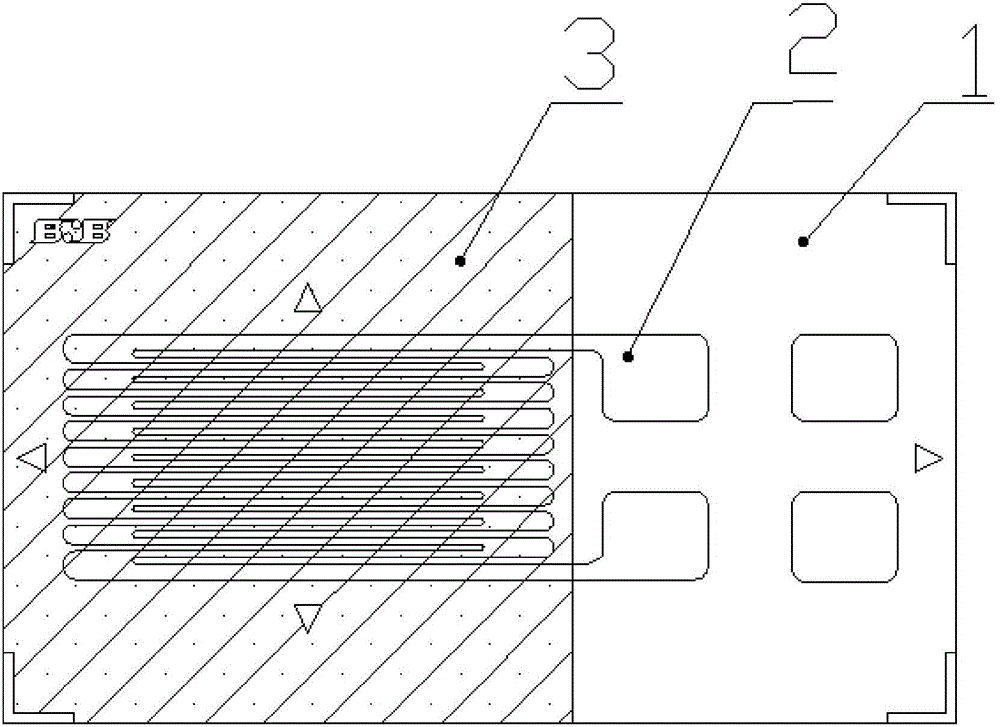

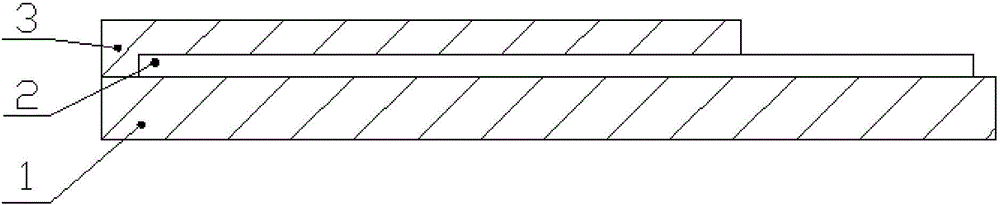

Electric heating piece, electric heating device and equipment

InactiveCN102548064AReduce thicknessReduce weightOhmic-resistance heatingHeat transfer efficiencyEngineering

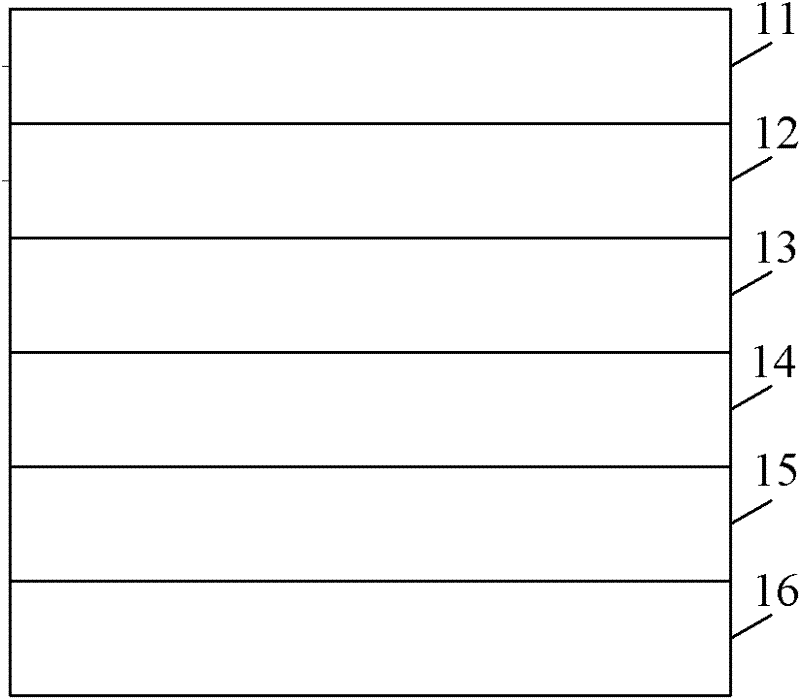

The invention is applicable to the field of heating device design, and provides an electric heating piece, an electric heating device and equipment, wherein the electric heating piece comprises a first insulating layer, a heating layer which is connected with the first insulating layer, a second insulating layer which is connected with the heating layer, a first bonding layer which is connected with the second insulating layer, a uniform heating layer which is connected with the first bonding layer and a second boding layer which is connected with the uniform heating layer, and the heating layer is constantan foil. The electric heating piece selects the constantan foil as the heating layer, so the thickness of the electric heating piece is reduced, and the electric heating piece can be applied in an application range with higher precision; and meanwhile, the heat transfer efficiency of the electric heating piece is also improved, and accordingly, the power and the preheating speed of the electric heating piece are improved.

Owner:SHENZHEN LONGYOO TECH CO LTD

Test device for radiant heat resistance of fabrics

ActiveCN101819171AThe voltage at both ends is stableConform to the requirements of the radiation resistance heat penetration performance testMaterial thermal conductivityMaterial heat developmentData acquisitionOperability

The invention discloses a test device for radiant heat resistance of fabrics, and belongs to the field of safety technology. The test device comprises a radiative heat source, a copperplate calorimeter and a data acquisition system, wherein the radiative heat source consists of two silicone carbide heating rod sets and a resistor; each silicone carbide heating rod set comprises a plurality of silicone carbide heating rods which generate thermal radiation after being electrified; in a circuit, the silicone carbide heating rod sets are formed by serially connecting the silicone carbide heating rods, and the two parallelly connected silicone carbide heating rod sets are connected in series with the resistor and then connected to a 220V power supply; a copper-constantan thermocouple is welded in the center of the internal surface of the arc of a copperplate and then connected to an acquisition card through a through hole at an assembling block; the copperplate is glued to the assembling block through a bonding agent; the data acquisition system consists of the acquisition card and a computer, wherein the acquisition card acquires a temperature signal of the copper-constantan thermocouple and then inputs the temperature signal into the computer for data processing and computation, and the like. The test device is used for testing the radiant heat resistance of the fabrics, has the characteristics of reasonable structure, accurate test and strong operability, and can meet the requirements of the radiant heat resistance tests for the fabrics.

Owner:SHANGHAI FIRE RES INST OF THE MIN OF PUBLIC SECURITY +1

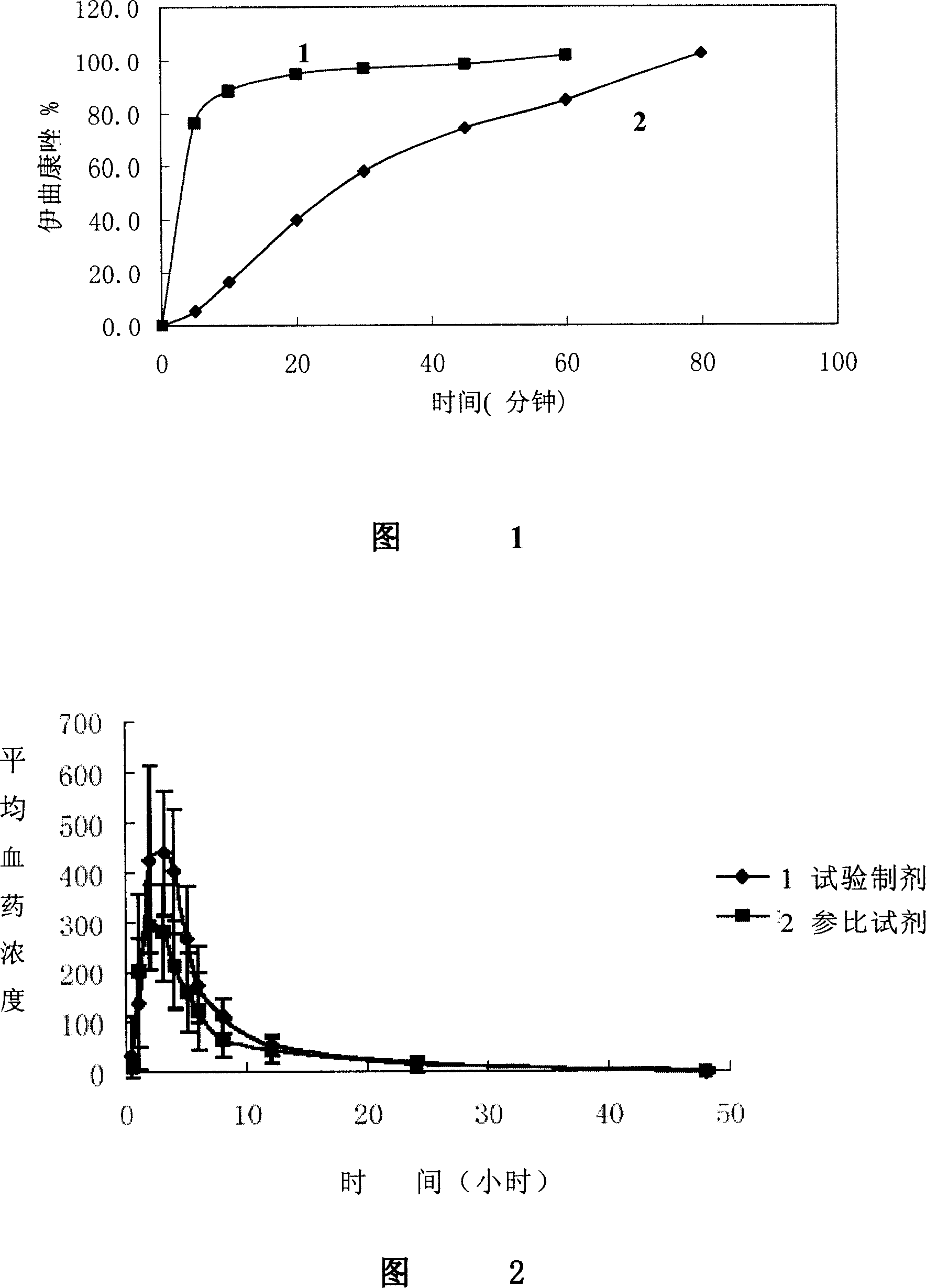

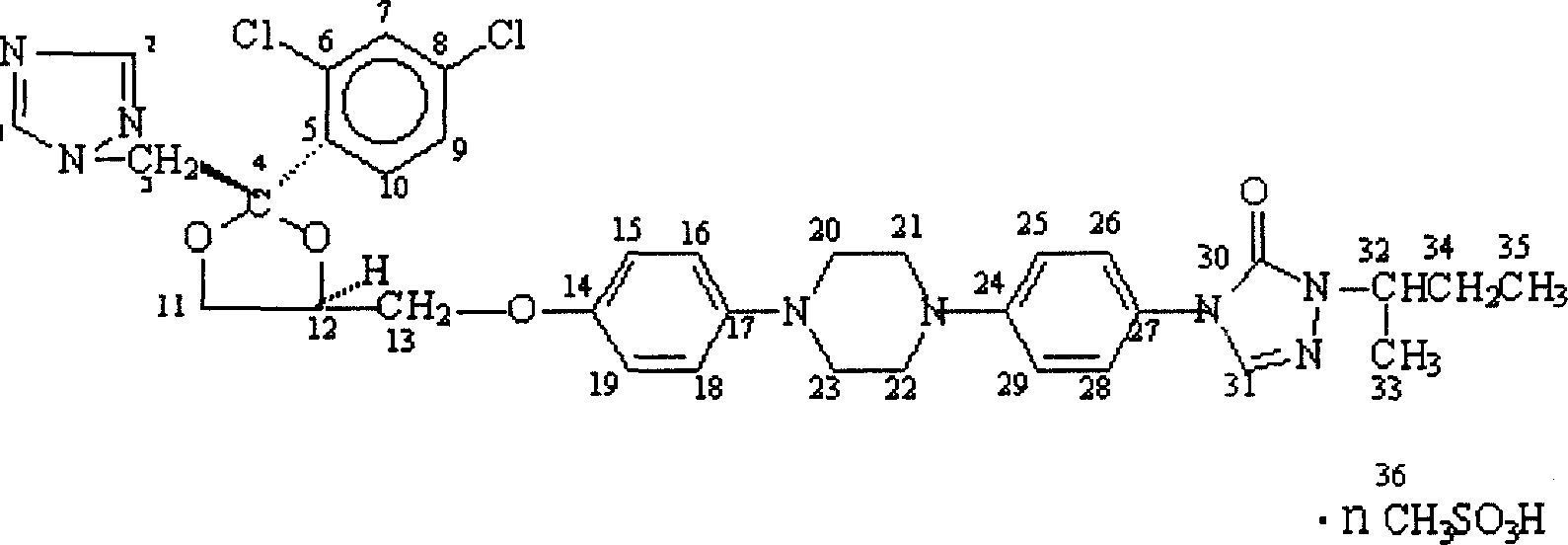

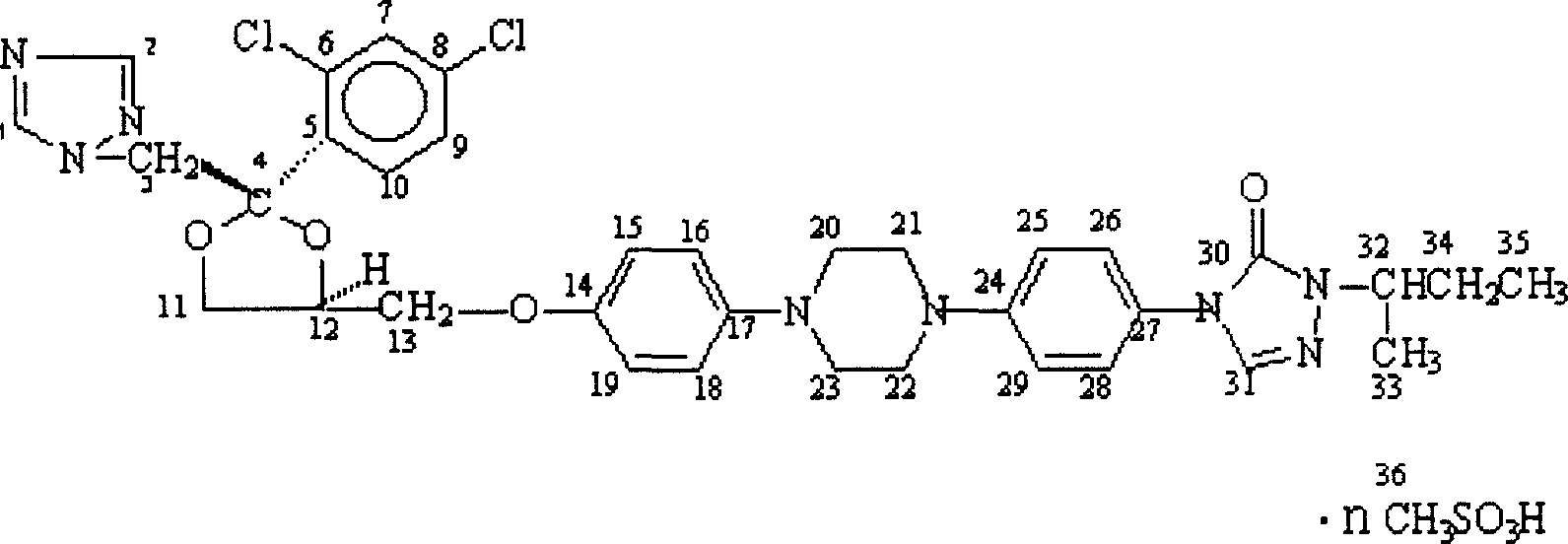

Itraconazole mesylate and its composition and preparation method

InactiveCN1970557AHigh dissolution rateImprove stabilityPowder deliveryOrganic active ingredientsSolubilityFreeze-drying

The invention discloses an eosin constantan methanesulfonic acid salt and component and making method, wherein the eosin constantan methanesulfonic acid salt possesses chemical structural formula (n=1-2), which possesses excellent solubility and stability; the component of eosin constantan methanesulfonic acid salt consists of eosin constantan methanesulfonic acid salt and acceptable carrier, which can prepare kinds of liquid, freeze-drying and film or skin give drug.

Owner:SHANGHAI SEANPHARM

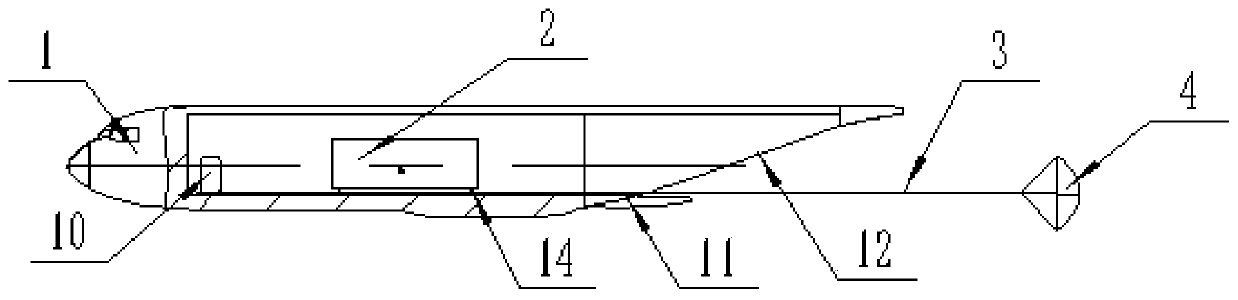

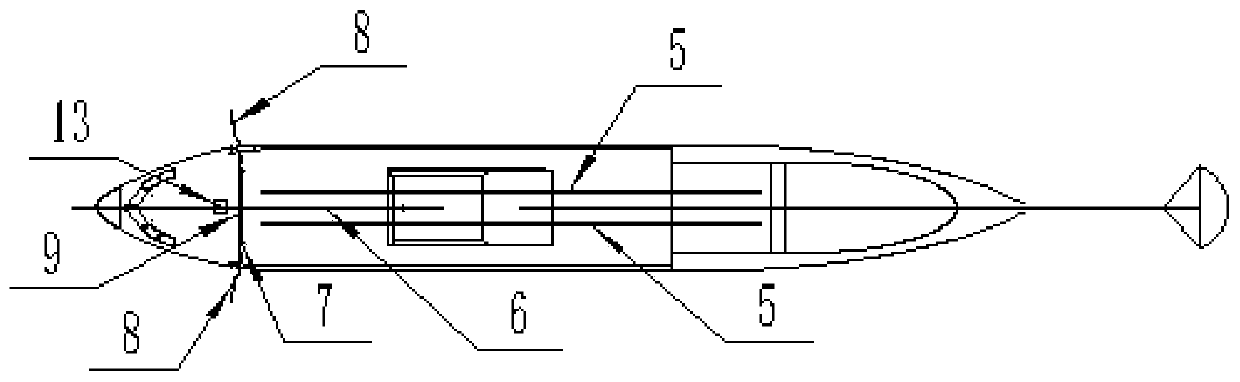

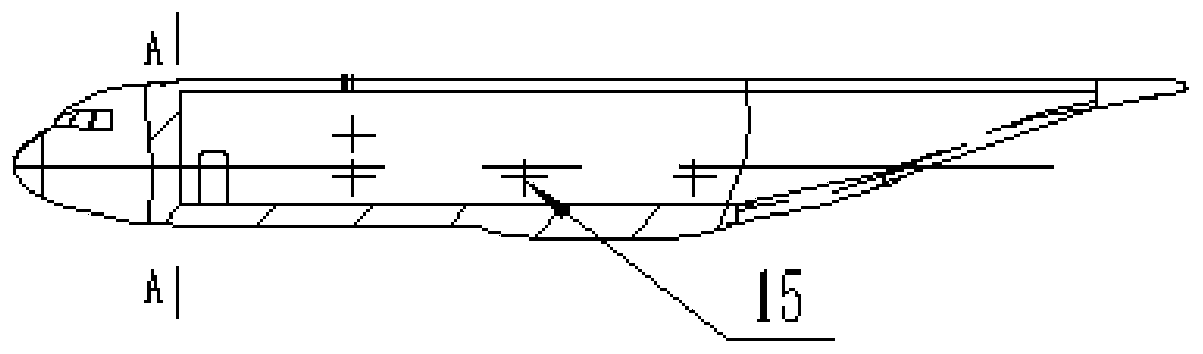

Test method of pressure variation characteristic in transport aircraft large-sized object drop pod

The invention discloses a test method of a pressure variation characteristic in a transport aircraft large-sized object drop pod. An airplane model and an air-dropped material model are included. An air-dropped material model fixing column is arranged on a lower wall near a front wall of an inner cabin of the airplane model. Several fixing columns are arranged on the lower wall near the front wallof the inner cabin of the airplane model. A front portion of the air-dropped material model is connected to a lead. The air-dropped material model is connected and fixed with a constantan wire amongthe fixing columns through the lead. A rear portion of the airplane model is provided with a rear large cabin door. In the invention, a similarity criterion used for a pressure change test in the transport aircraft large-sized object drop pod is determined, a formula of converting pressure in the cabin during testing and corresponding change time to pressure changes in the drop pod during a flightcondition and the corresponding change time is proposed, a parameter calculation and model designing method of the air-dropped material model and extraction parachute model is given, and the method and steps of pressure variation wind tunnel test study in a transport aircraft large-sized object air drop aircraft cabin are established.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

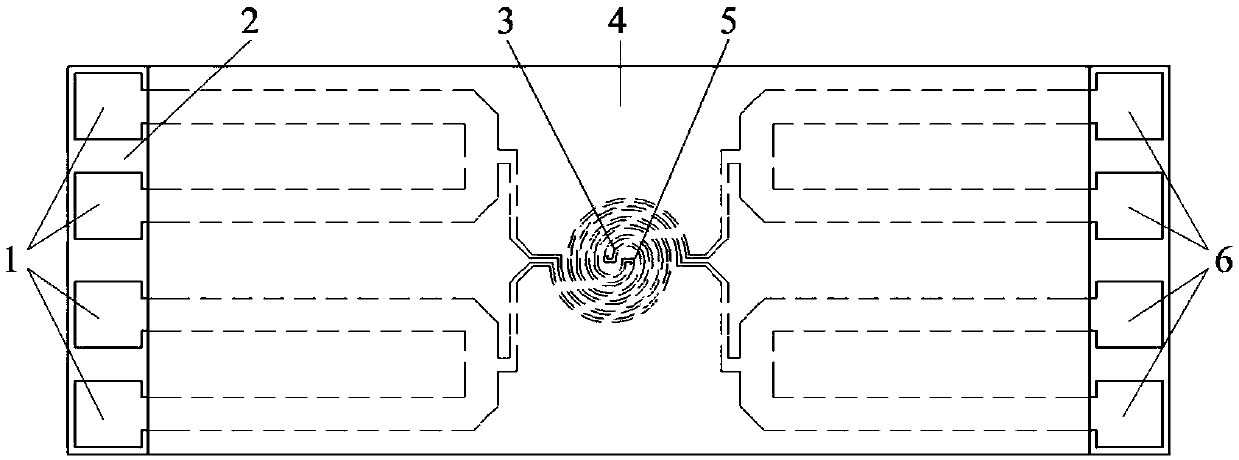

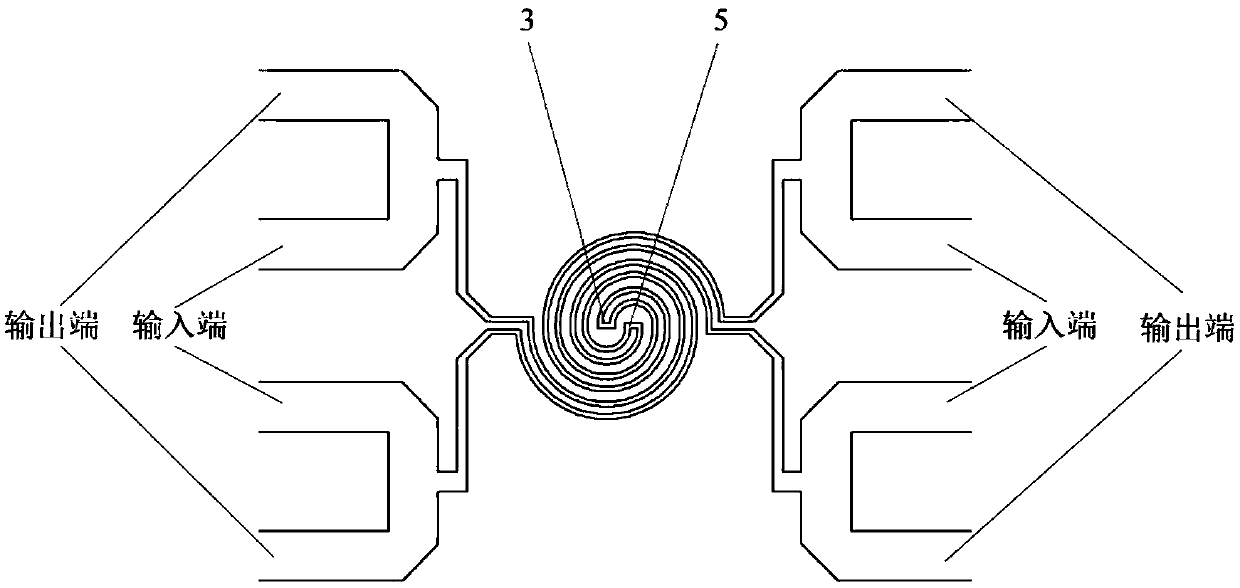

MEMS flexible manganin-constantan composite ultra-high pressure sensor and manufacturing method thereof

ActiveCN108896235AHigh measurement accuracyHigh precisionFluid pressure measurement using ohmic-resistance variationUltra high pressureManganin

The invention relates to an MEMS flexible manganin-constantan composite ultra-high pressure sensor and a manufacturing method thereof. The composite ultra-high pressure sensor comprises a substrate, wherein the substrate is sputtered with a manganin sensitive element, four first electrodes corresponding to the manganin sensitive element, a constantan sensitive element and four second electrodes corresponding to the constantan sensitive element, an input end and an output end of the manganin sensitive element are respectively connected with the two first electrodes, an input end and an output end of the constantan sensitive element are respectively connected with the two second electrodes, and the surfaces of the manganin sensitive element, the constantan sensitive element, the first electrodes and the second electrodes are covered with an insulating layer; and the manganin sensitive element and the constantan sensitive element adopt spiral centrosymmetric distribution, and both the substrate and the insulating layer adopt a polyimide material. The composite ultra-high pressure sensor has the characteristics of high precision, fast response, large output signal and the like.

Owner:XI AN JIAOTONG UNIV

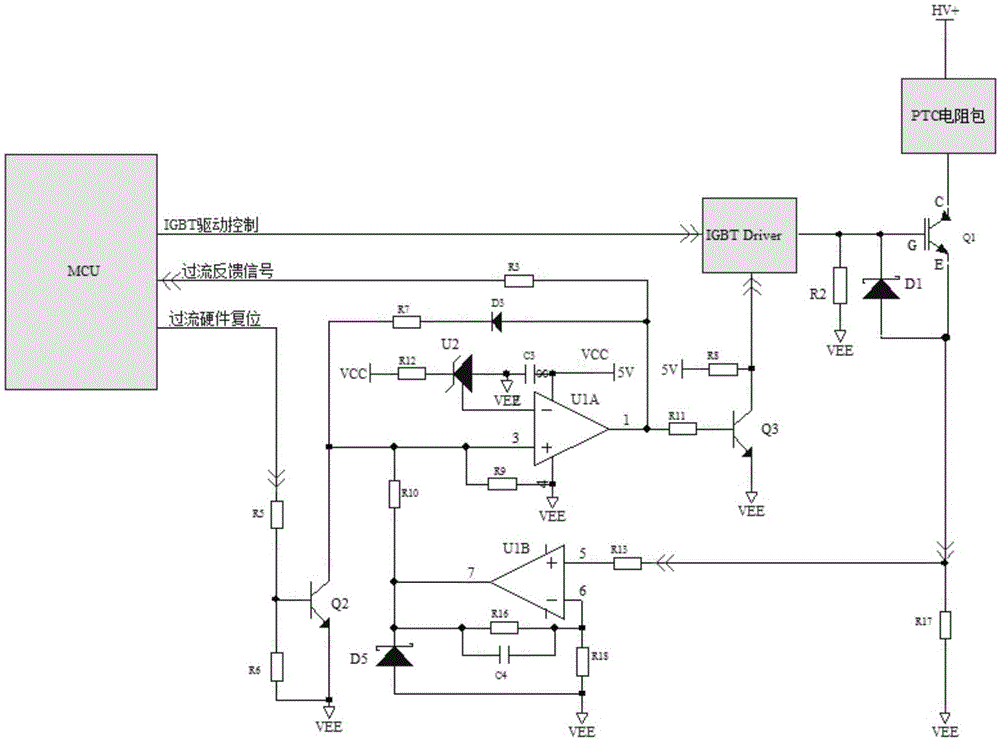

Positive temperature coefficient (PTC) water heater over-current detection software and hardware dual protection circuit

ActiveCN105466032ARealize unlock and reset functionWork lessFluid heatersCurrent/voltage measurementPrinted circuit boardPositive temperature

The invention provides a positive temperature coefficient (PTC) water heater over-current detection software and hardware dual protection circuit which is high in sampling precision, short in response time, capable of providing dual protection for software and hardware and low in requirement for printed circuit board (PCB) Layout. The PTC water heater over-current detection software and hardware dual protection circuit comprises a constantan wire sampling resistor with the precision being one percent, and the constantan wire sampling resistor transfers a current signal into a voltage signal which is sent to an amplifying circuit composed of U1B, R13, R15, R16 and C4. The signal which is amplified by 1+R16 / R15 times is sent to a comparator circuit composed of U1A, U2, R12, R15, R16 and C3. When the voltage is higher than a fiducial voltage stabilizing value (VCC / 2), a comparator outputs a saturation VCC voltage, and the output VCC voltage is fed back to the in-phase end of the operational amplifier U1A through D3 and R7, and thus the comparator is in a state that the saturation voltage VCC is output forwards in a self-locking mode. An audion Q3 is electrified through the output voltage, and then pins can be pulled down through an insulated gate bipolar transistor (IGBT) driving module, so that an IGBT is closed.

Owner:SHANGHAI FENGTIAN ELECTRONICS

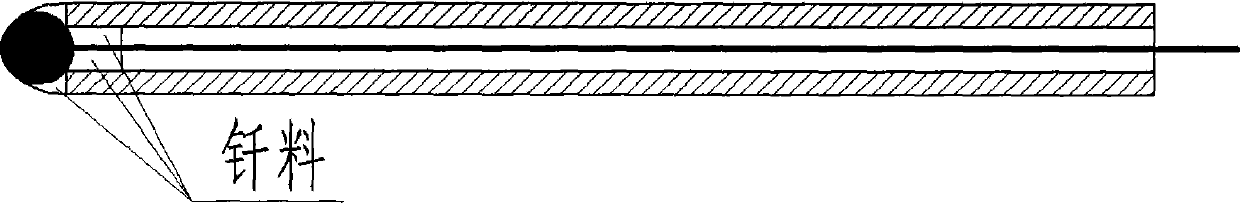

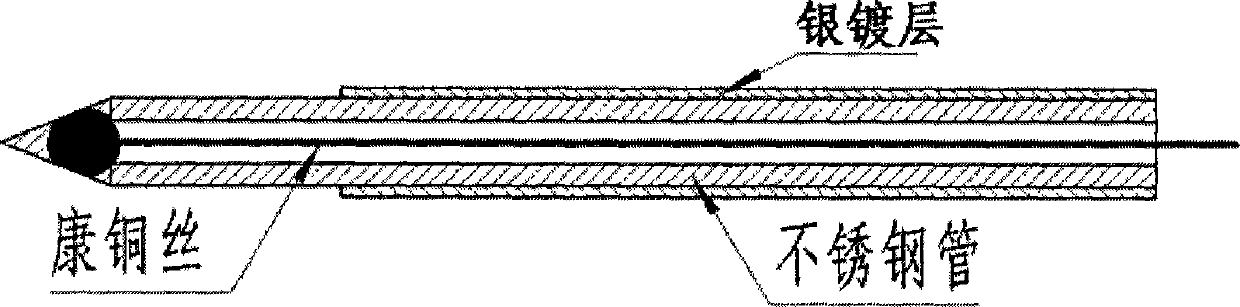

Hot needle with heat concentrated at needle point part, and manufacturing method of hot needle

InactiveCN103801913AIncrease temperatureGood treatment effectAcupunctureKnittingElectrical resistance and conductanceCopper wire

The invention provides a hot needle with heat concentrated at a needle point part, and a manufacturing method of the hot needle. The hot needle has the key points that after braze welding to a stainless steel tube and a constantan wire, electrosilvering is performed on a stainless steel outer surface and in a position far away from the needle point part, so as to form a silver layer; a stainless steel and constantan wire, which are arranged at the tail end of the hot needle, are respectively connected with the two poles of a power source; due to the high conductivity of copper and silver, low pressure drop can be produced when current passes through; the resistance of a part which is near to the needle point and is not silvered is high, so that high pressure drop can be produced when the current passes through and a large amount of hot can be produced, so as to enable input energy to be collected to a part near the needle point. Therefore, the problem of incapability of reaching a curing temperature due to the same temperature of an entire traditional needle can be solved. Under the same heat input conditions, the temperature of a part, inserted into a human body for acupuncture, of the needle is increased, and the curing effect is improved. The hot needle produced by the method has a simple structure, is convenient to use and has a good curing effect.

Owner:HARBIN INST OF TECH

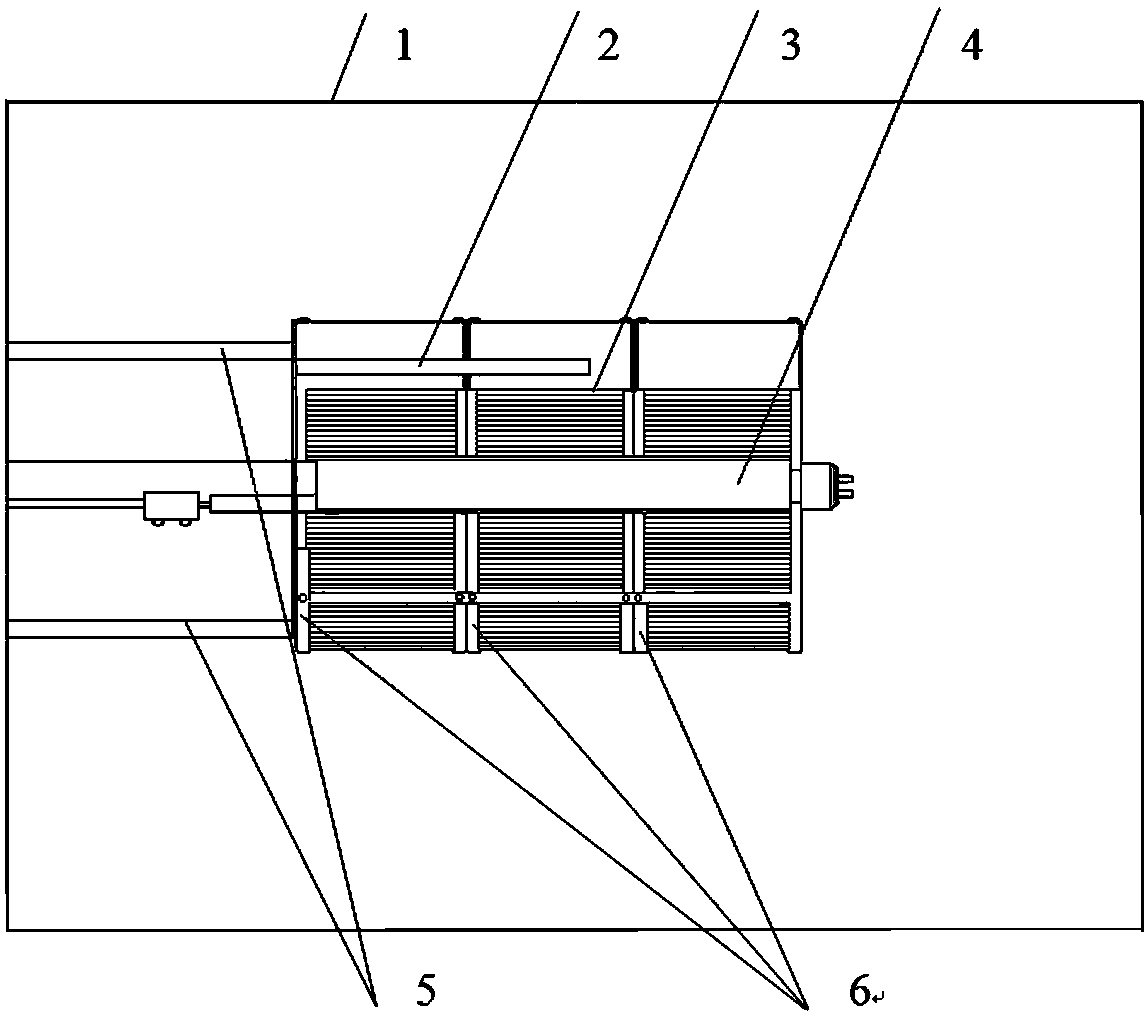

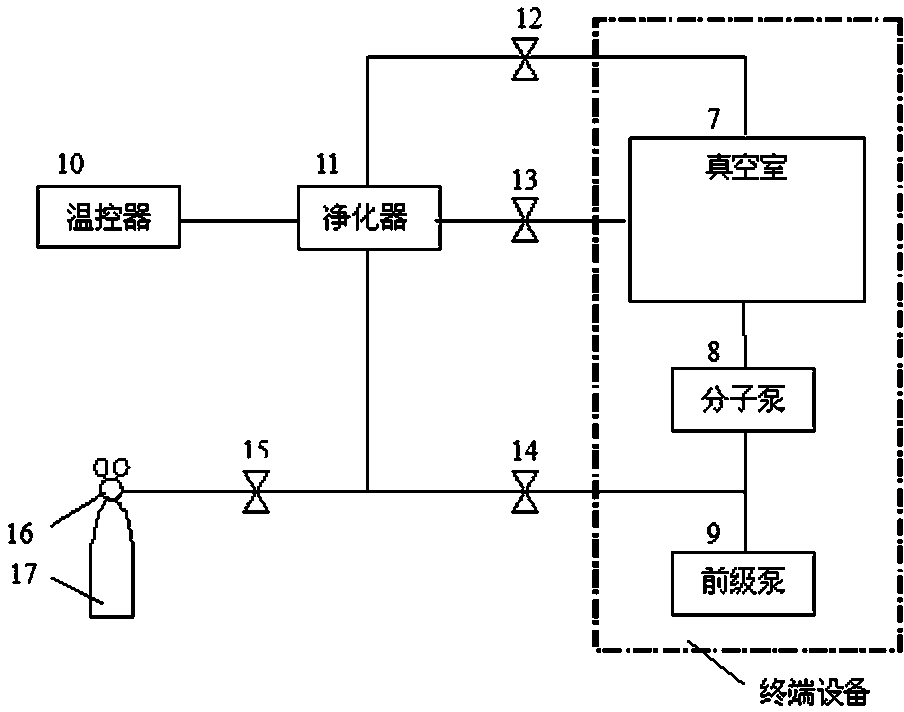

Ultrapure argon online purification system and method

ActiveCN104291284AEliminate pollutionImprove inhalation effectDispersed particle separationNoble gas compoundsControl systemTerminal equipment

The invention discloses an ultrapure argon online purification system and method, belonging to the field of gas purification. According to the technical scheme, the method comprises the following steps: coating a constantan alloy bar with a zirconium-vanadium-iron alloy material, pleating the alloy bar into a folded shape, fixing the alloy bar on a special bracket and framework for a flange plate, arranging the bracket and framework in a stainless steel cylinder, thus forming a non-evapotranspiring argon purification device; connecting the argon purification device with high-purity bottled argon and terminal equipment through related connectors and control valves so as to form an ultrapure argon online purification system; and online activating a getter of the purification device by a vacuum detection and control system of equipment. The application proves that by the system and method, ultrapure argon (99.999999 percent (W / W)) can be obtained on line; the system is good in purification effect, the active and neutral impurity gases in the argon can be reduced from magnitude orders of dozens of ppm to ppb, the operating temperature of the system is low and is generally 160-200 DEG C, water cooling is not needed, and the system and method are safe and convenient to use.

Owner:KUNMING INST OF PHYSICS

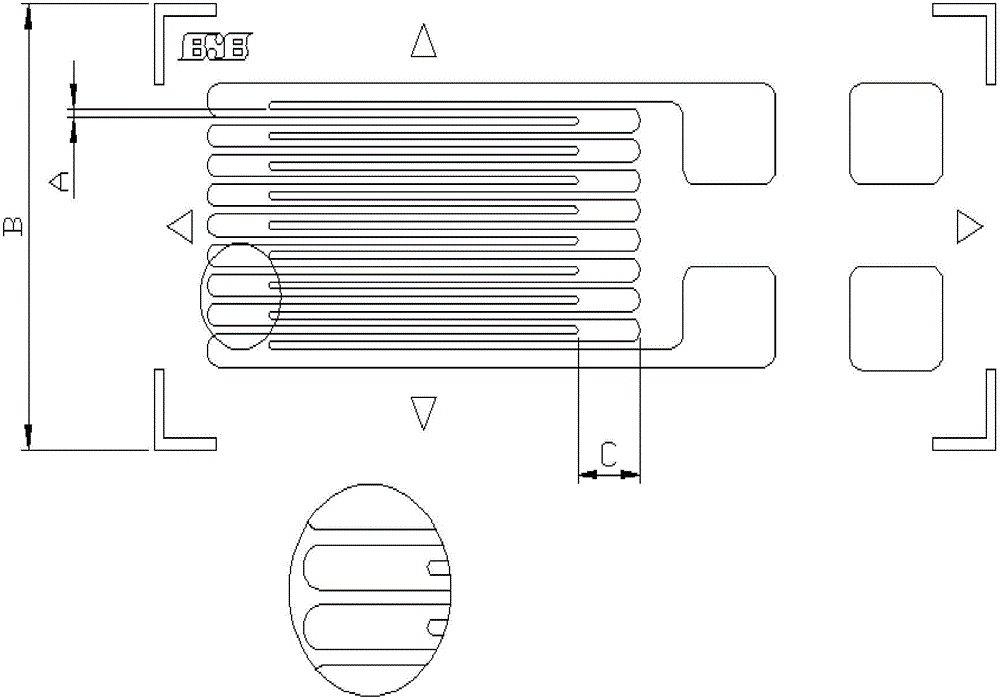

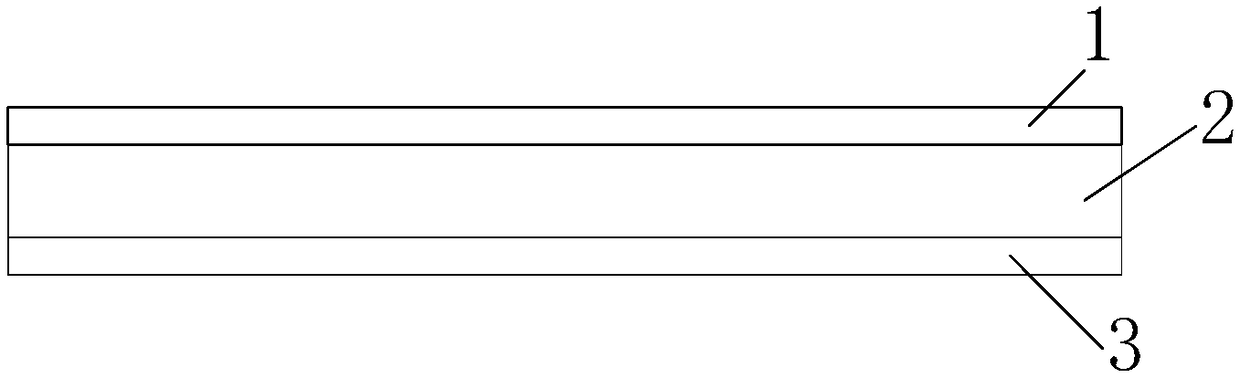

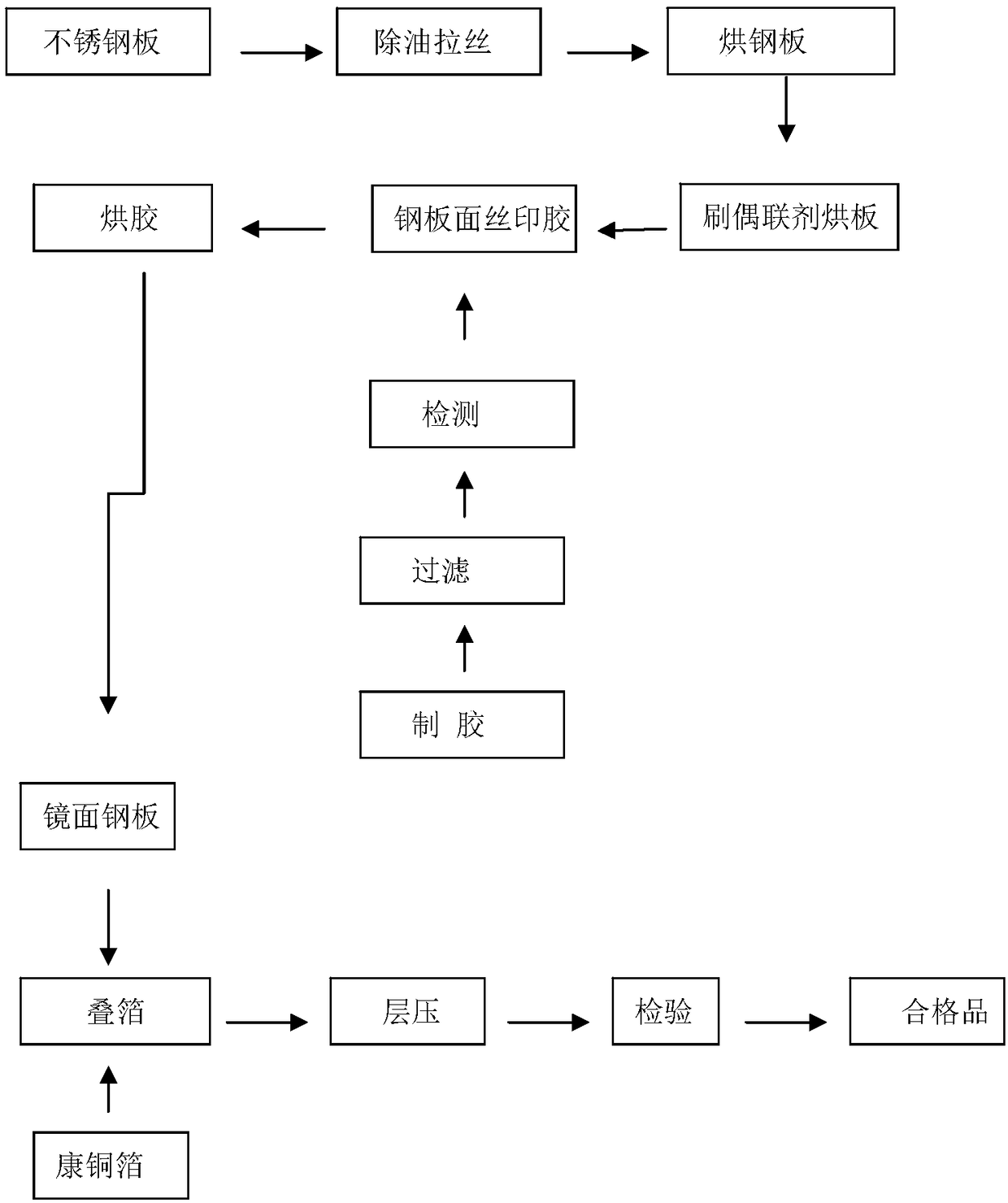

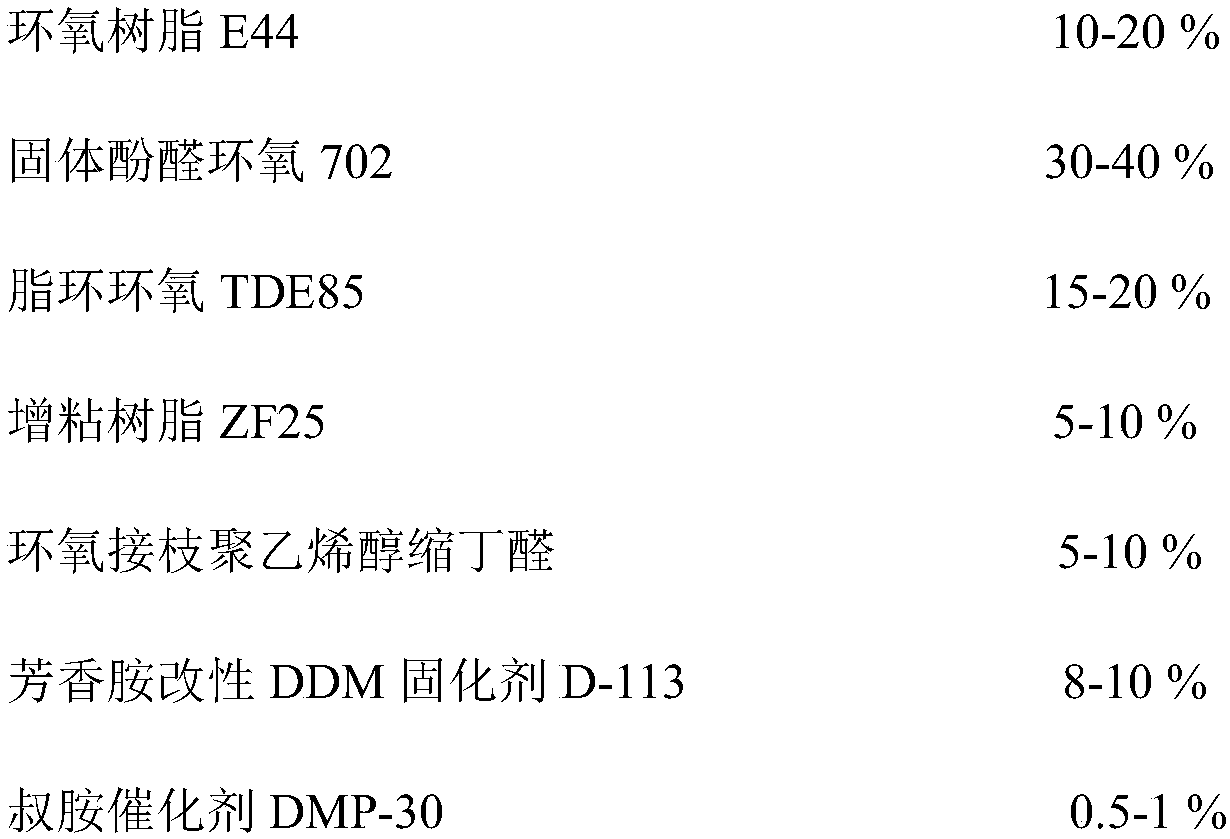

Preparation technology of stainless steel-based plate coated with constantan foil for pressure sensor

ActiveCN108565335AReduced deformabilityHigh thermal conductivityPiezoelectric/electrostrictive device manufacture/assemblyMetal layered productsGlue lineCopper foil

Provided is a preparation technology of a stainless steel-based plate coated with constantan foil for a pressure sensor. A glue solution is printed on the surface of stainless steel after surface treatment is carried out by adopting a screen printing machine, the thickness of a glue line is 60-85 micrometers, and after screen printing is completed, drying is carried out; lastly, a surface dry coating stainless steel surface is covered with constantan foil, and a mirror surface steel plate covers the stainless steel surface, then the stainless steel surface covered with the constantan foil andthe mirror surface steel plate is placed into a vacuum hot press machine for hot pressing, after hot pressing is completed, the temperature is reduced to a room temperature, and the stainless steel-based plate coated with the constantan foil is obtained. The prepared stainless steel-based plate coated with the constantan foil has very low deformability, higher heat conductivity and dielectric strength, a constantan foil shiny side and the stainless steel-based plate have very high bonding strength, the highest bonding strength reaches 2.1 newtons per millimeter, and the stainless steel-based plate coated with the constantan foil has very high heat-resisting stress and other properties. According to the preparation technology of the stainless steel-based plate coated with the constantan foil for the pressure sensor, the constantan foil for preparing the stainless steel-based plate coated with the constantan foil is made into a circuit by etching, an integrated electronic device can be made into the pressure sensor, so the stainless steel-based plate coated with the constantan foil is a pressure sensor special mother board.

Owner:XIANYANG TIANHUA ELECTRONICS SCI & TECH

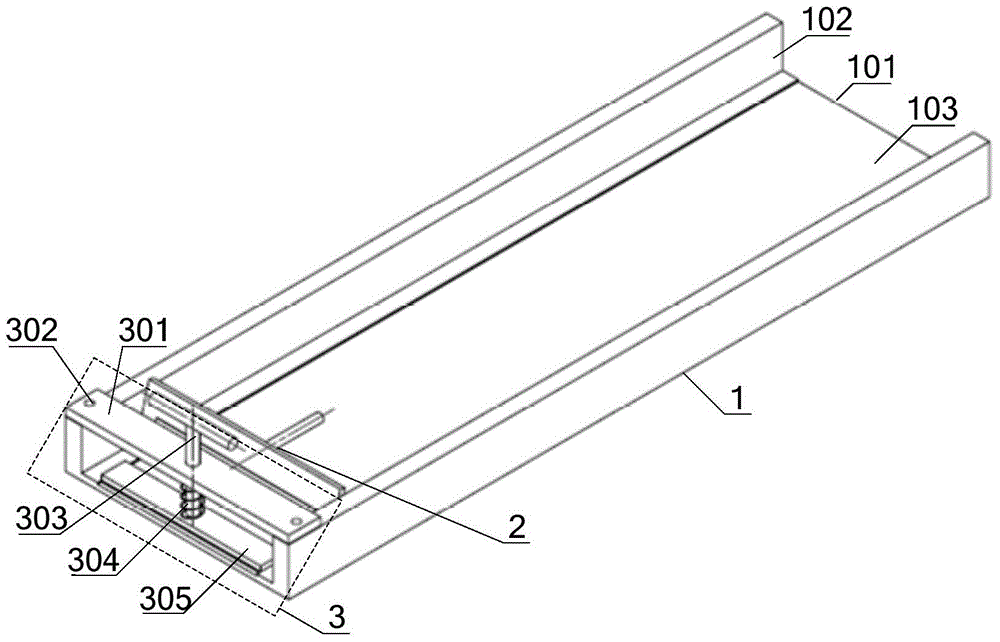

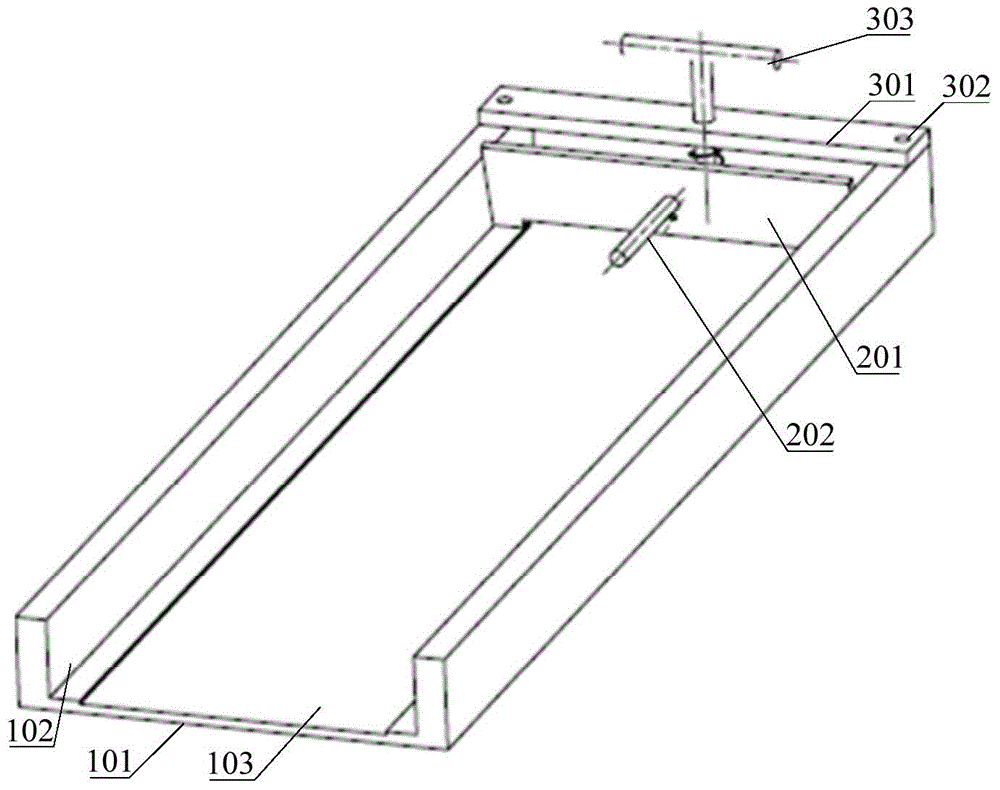

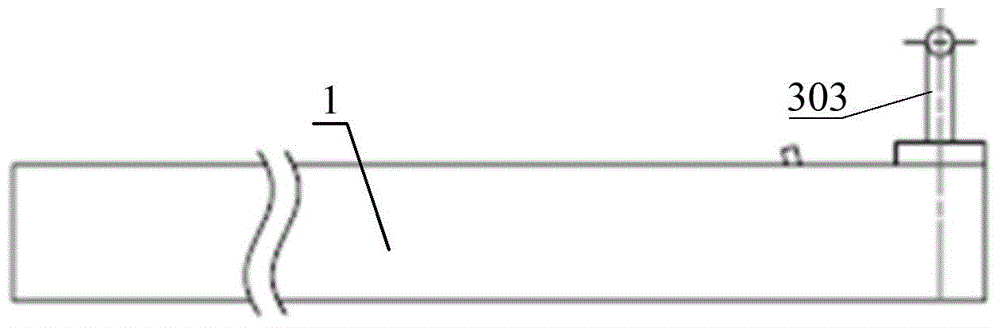

Scraping device for polyimide constantan foil electric heater

The invention discloses a scraping device for a polyimide constantan foil electric heater and belongs to the technical field of photoelectric installation. The invention aims at solving the problems in the prior art that the production efficiency is low, the glue solution thickness cannot be controlled and the glue solution is not uniform. The scraping device disclosed by the invention comprises a bottom table, a pressing device and a scraping structure, wherein the bottom table is of a U-shaped integrated structure and comprises a bottom plate; side walls are arranged on two sides of the bottom plate in the length direction; the bottom plate is of a grooved structure; the scraping structure comprises a scraper and a baffle; the scraping thickness is regulated by the baffle; the pressing device is fixedly arranged at one end of the bottom table, so that a heating plate is fixed; and the scraping structure slides along the side wall of the bottom table so as to realize scraping. According to matching of the fixed pressing plate and the bottom plate, multiple heating plates can be simultaneously pressed, the function of simultaneously scraping the multiple heating plates is realized, and the production efficiency is improved. Moreover, the heating plates are arranged in grooves of the bottom table, the scraping thickness is regulated by the baffle at the front end of the scraper, adjustable glue solution thickness is realized, and the uniformity of the glue solution is guaranteed.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

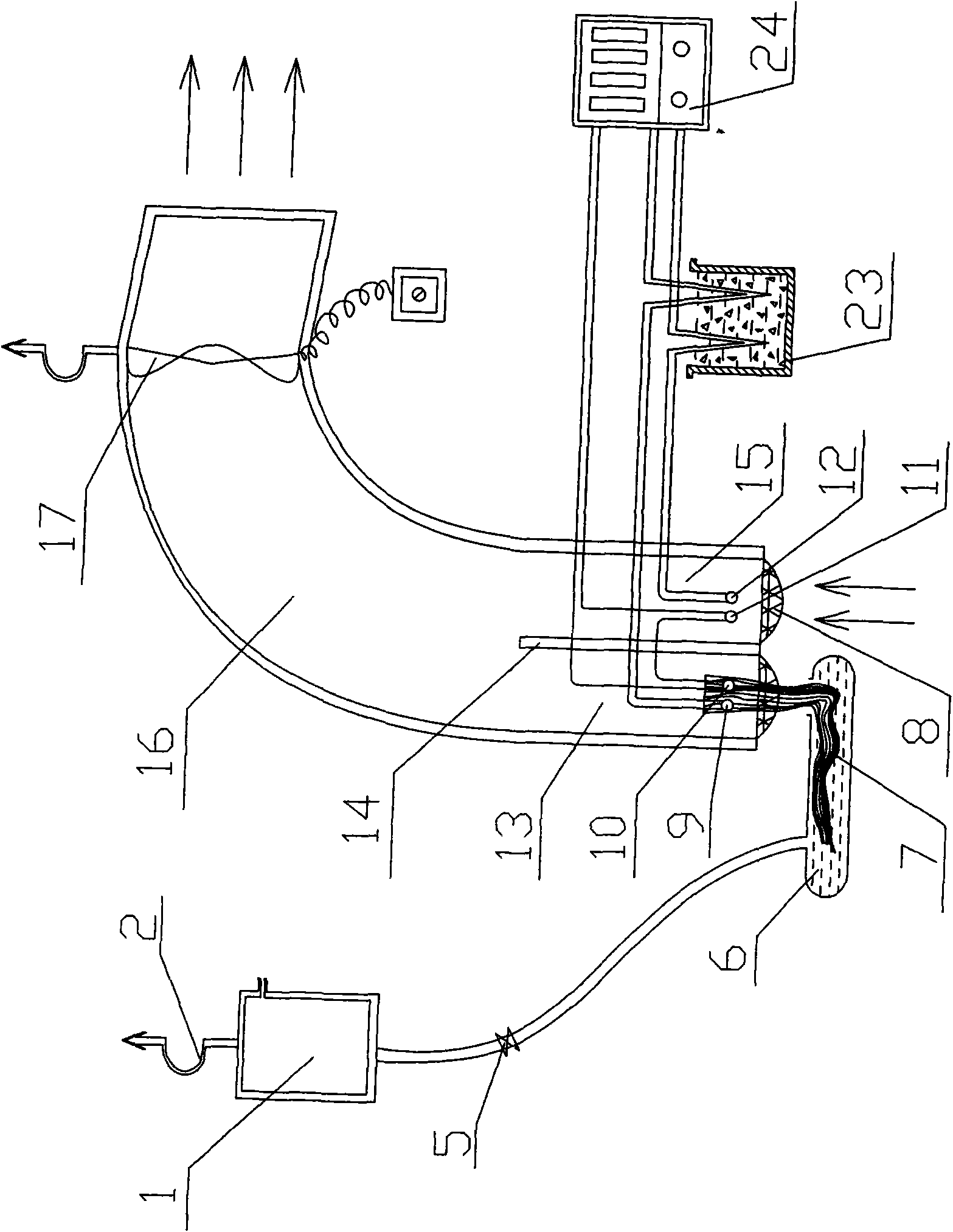

Automatically-recording type ventilating dry humidity device

InactiveCN101644607AHigh sensitivityHigh precisionThermometers using electric/magnetic elementsMaterial moisture contentCopper electrodeThermostat

The invention relates to an automatically-recording type ventilating dry humidity device which comprises a moisturizing device, an air flue (16), a partition plate (14), a fan (17), a thermocouple wetbulb (9), a thermocouple temperature difference wet bulb (10), a thermocouple temperature difference dry bulb (11), a thermocouple dry bulb (12), moisturizing gauze (7), a digital collecting and recording processor (24) and a thermostat (23), wherein a measuring port of the air flue pipe (16) is divided into a measuring cavity I (13) and a measuring cavity II (15) by the partition plate (14); thethermocouple wet bulb (9) and the thermocouple temperature difference wet bulb (10) are arranged in the measuring cavity I (13) of the air flue pipe (16); the thermocouple temperature difference drybulb (11) and the thermocouple dry bulb (12) are arranged in the measuring cavity II (15) of the air flue pipe (16); and the copper electrode output ends of the thermocouple temperature difference wetbulb (10) and the thermocouple temperature difference dry bulb (11), and the copper electrode output ends and the constantan electrode output ends of the thermocouple wet bulb (9) and the thermocouple dry bulb (12) are connected with the inlet end of the digital collecting and recording processor (24), thereby being difficult to lose a limit value and recording and storing a numerical value in the micro-change state process in time.

Owner:SHANDONG INST OF POMOLOGY

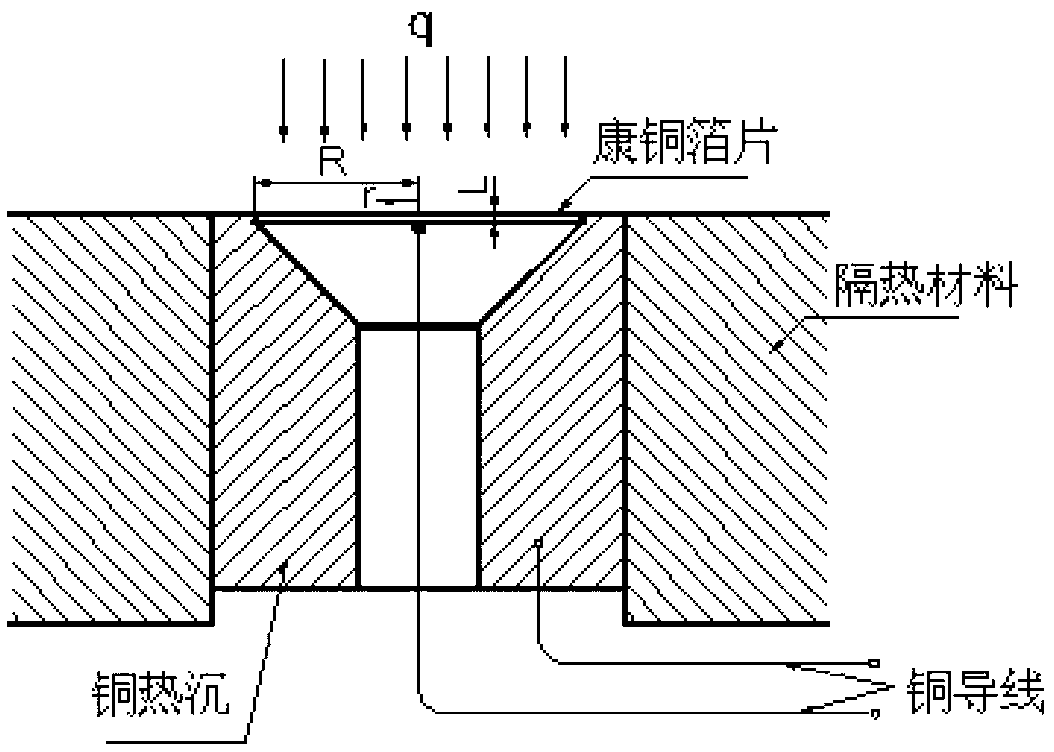

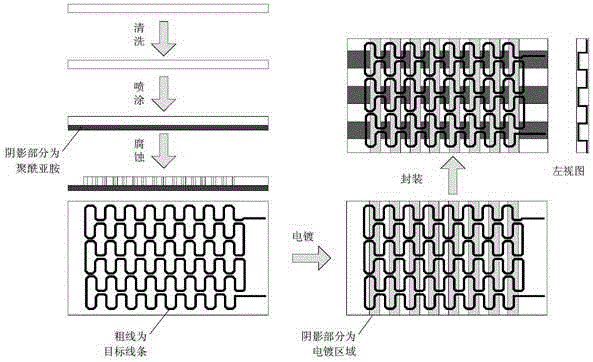

High-sensitivity quick response heat flux sensor

The invention relates to a high-sensitivity quick response heat flux sensor. A curved line is manufactured by using a constantan foil piece, and copper plating is performed on the line through the electroplating technology according to the certain rules. When incident heat flux along the normal direction of sensor heat resistance material appears, the temperature difference generates on the upper and lower planes of the heat resistance material, differential thermocouples output signals and the thermo-electric pile in the sensor is equivalent to accumulation of the output of all the included differential thermocouples so that the sensitivity of the sensor can be enhanced, and the sensor can also quickly respond because of low thickness of the heat resistance material when the incident heat flux is small. Compared with the conventional circular foil heat flux sensor, the high-sensitivity quick response heat flux sensor has the following advantages of being small in the sensor size and low in weight; the sensor is piece-shaped, quick in response and convenient to install and can be directly fit on the measured surface; the sensor has high sensitivity and can cover small range heat flux which cannot be measured by the circular foil heat flux sensor; and the sensor is simple in technology and convenient for batch production.

Owner:BEIJING RES INST OF TELEMETRY +2

Flexible temperature-strain integrated sensor array and preparation method thereof

ActiveCN109855687AFlexibleRealize distributed monitoringMeasurement devicesPrinted circuit detailsSensor arrayCopper foil

The invention discloses a flexible temperature-strain integrated sensor array. The flexible temperature-strain integrated sensor array at least comprises a temperature sensor unit and a strain sensorunit, a positive pole and a negative pole of the temperature sensor unit are formed by imaging a copper foil layer and a constantan foil layer on the two sides of a substrate correspondingly, and thepositive pole and the negative pole are connected through a via hole technology to form a junction; and the strain sensor unit is formed by imaging a constantan foil layer. The sensor array has flexibility and can be directly attached to the surface of a curved surface structure; the temperatures and strain signals of a plurality of measured points can be monitored simultaneously in a distributedmode, and mounting is convenient; a sensitive unit and a lead are integrated on the substrate, no welding point is formed at the test end, and the flexible temperature-strain integrated sensor array especially meets the monitoring demand in a narrow and small space; and a sensor array preparation process is compatible with an FPC process, and high-precision, large-scale and low-cost production canbe achieved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

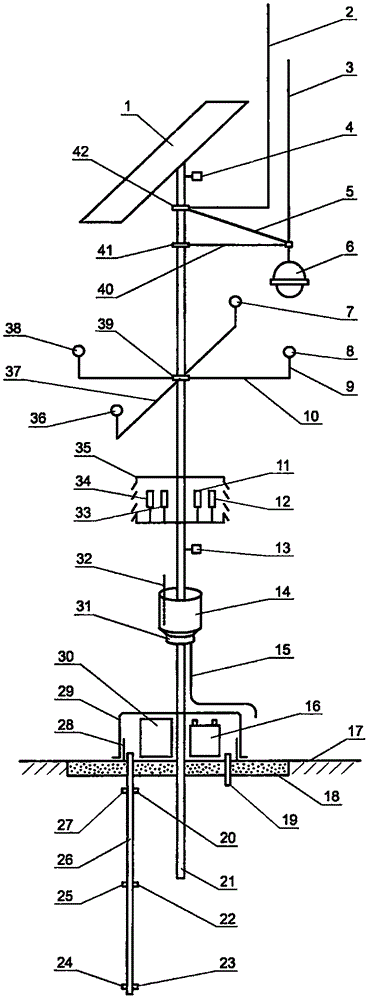

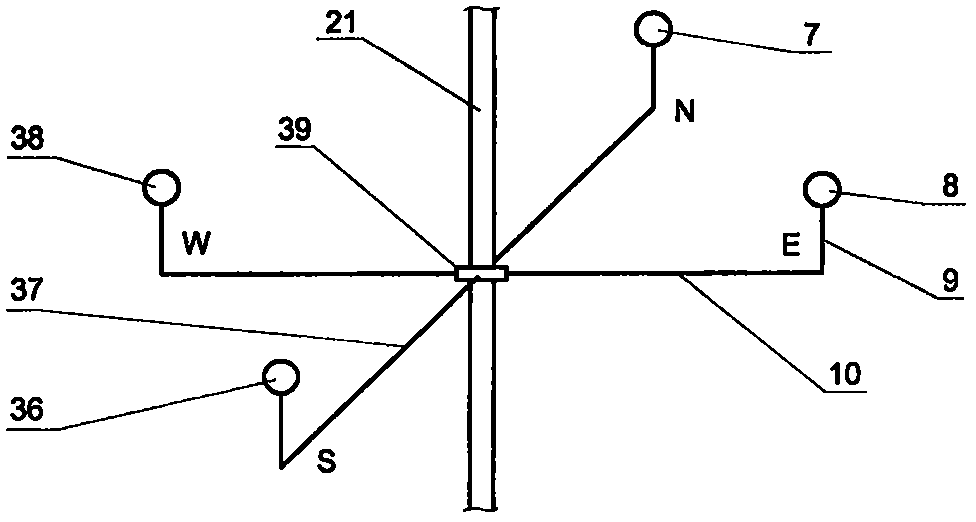

Beach ecological environment factor remote sensing device

InactiveCN105758461ASimple structureLow costMeasurement devicesEcological environmentResource development

The invention provides a beach ecological environment factor remote sensing device comprising a solar cell panel, a luminance sensor, a spherical high definition camera, a loop-shaped constantan wire, an air pressure sensor, an air oxygen content sensor, a water vapor flux sensor, a rain gage cup, a pH value sensor, a humidity sensor and a salinity sensor, wherein the luminance sensor, the air pressure sensor, the environment oxygen content sensor, the water vapor flux sensor, the pH value sensor, the humidity sensor, the salinity sensor and a temperature sensor form an environment factor monitoring mechanism; the loop-shaped constantan wire forms a wind speed and wind direction measuring mechanism. The device is simple in structure, low in manufacture cost, complete in data, full in electronization, strong in generality, fast in measuring response, long in service life, easy in data collection, high in system stability and wide in data coverage. The device can be widely applied to agriculture, forestry, fishery, animal husbandry production, beach aquaculture and land farming, beach environment protection, beach resource development and the like.

Owner:YANCHENG TEACHERS UNIV

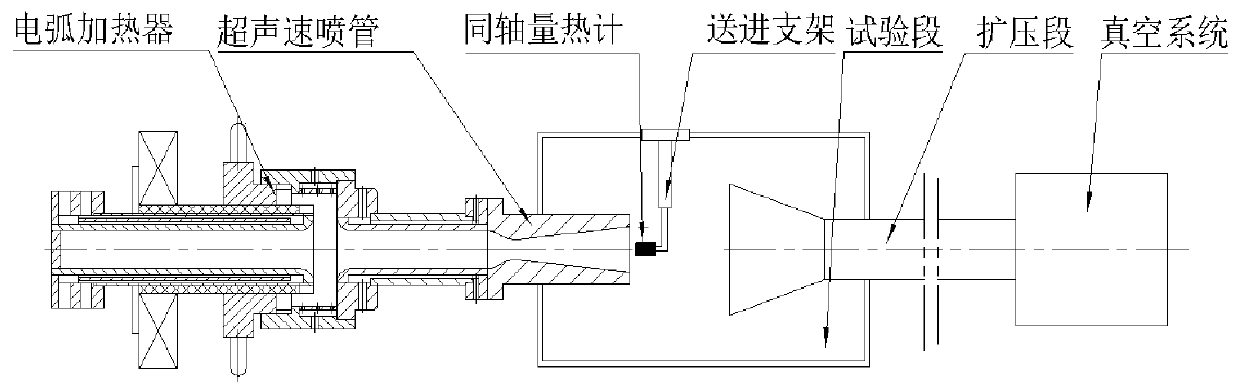

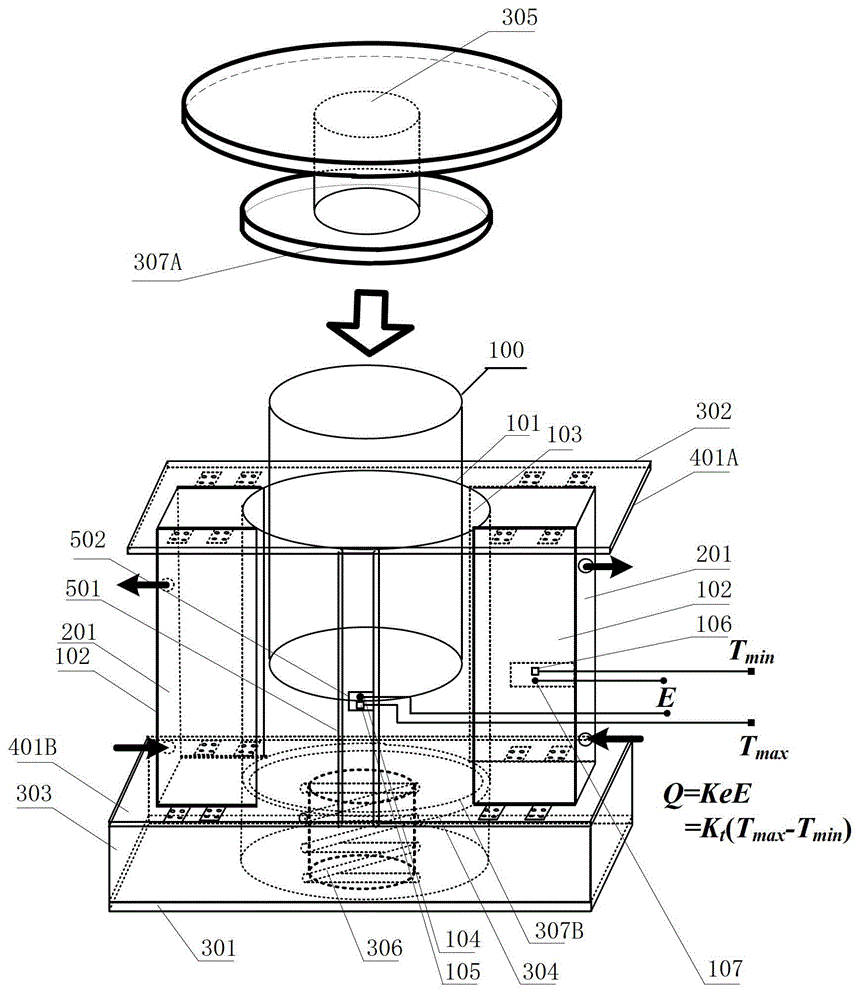

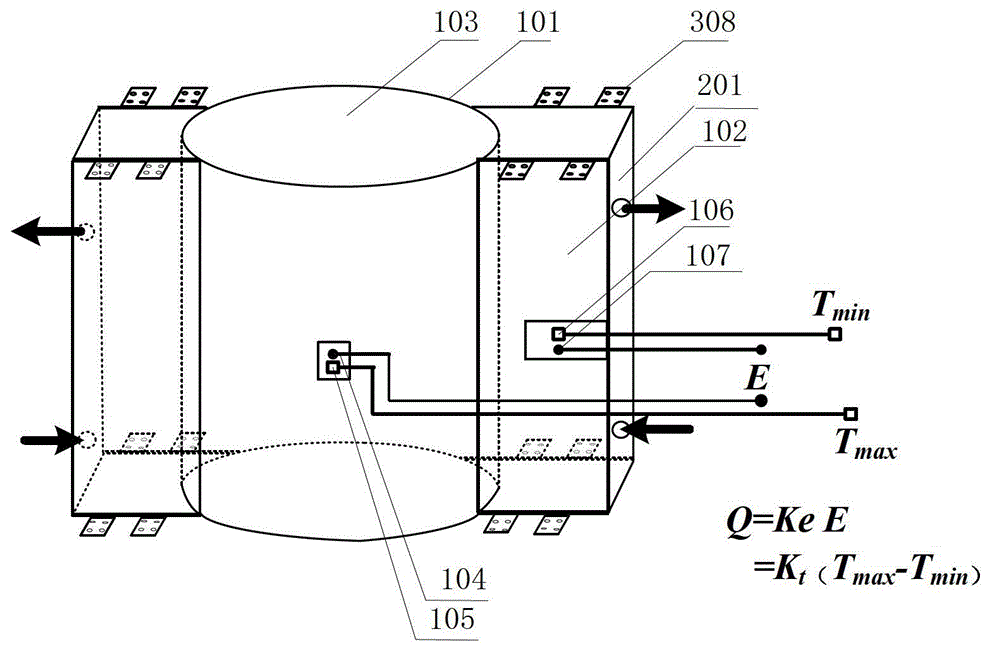

Simple coaxial calorimeter

PendingCN111272314AMeet the needs of precise measurementGood precisionCalorimeterCopper wireEngineering

The inveiton provides a coaxial calorimeter. A shell of the coaxial calorimeter is made of an oxygen-free copper material with high thermal conductivity, a constantan wire with an insulating layer isarranged in a central lead hole of the oxygen-free copper shell, the front end of the constantan wire is riveted near the heated end face of the shell through an inclined hole to form a copper-constantan thermocouple node, and the other copper wire serves as a thermocouple lead to be connected to the oxygen-free copper shell. The coaxial calorimeter has the advantages of being simple in structure,short in response time, resistant to high-temperature gas scouring, small in outer diameter, easy to match with the surface of a model and the like, and a hot contact can be repaired again.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Non-contact nuclear heat source power measurement sensitive device

InactiveCN103335743AProtect the surface stateReduce pollutionCalorimeterThermal insulationEngineering

The invention relates to a non-contact nuclear heat source power measurement sensitive device, which is composed of a constantan sheet, constantan side wings, a fine copper water-cooling head, a thermal insulation material and a support structure, wherein the constantan sheet encircles into a cylindrical test hole, the constantan side wings are symmetrically welded at two sides of the constantan sheet respectively, the fine copper water-cooling head is tightly attached to the constantan side wing, and the constantan sheet and the fine copper water-cooling head form a thermocouple. During measurement, a nuclear heat source is placed in the test hole and not contacted with the hole wall; radiant heat exchanged is carried out between the constantan sheet and the nuclear heat source, the fine copper water-cooling head takes heat absorbed by the constantan sheet away, the temperature of a central position of a waist part of the constantan sheet is the highest, and the temperature of a part which is contacted with the fine copper water-cooling head is the lowest. During heat balance, the maximum temperature difference is proportional to the power of the nuclear heat source, and meanwhile, the temperature difference generates a thermoelectric force in the thermocouple, and the thermoelectric force is proportional to the power of the nuclear heat source. The thermal insulation material is used for reducing the heat loss. According to the invention, the constantan sheet is not contacted with the nuclear heat source, the device not only protects the surface state of the nuclear heat source, but also reduces nuclear pollution to the sensitive device; and the structure is simple, and the performance is reliable.

Owner:BEIHANG UNIV +1

Copper-constantan thermocouple and preparation method thereof

InactiveCN104198074AAccurate measurementThermometers using electric/magnetic elementsUsing electrical meansTransformerCopper wire

The invention discloses a copper-constantan thermocouple and a preparation method thereof. The preparation method includes the steps: A, selecting direct-current arc welding equipment; B, selecting a copper wire and a constantan wire, removing insulating layers at welding ends of the copper wire and the constantan wire, and twin twisting a copper wire welding portion and a constantan wire welding portion; C, connecting the welding ends to an output end of a transformer; contacting a carbon rod tip structure with the twin twisted copper wire and constantan wire welding portion; welding two electrodes of a twin twisted thermocouple by electric arc generated by point discharge; D, judging welding quality after welding; E, selecting an insulating guide tube, penetrating the copper wire and the constantan wire into the insulating guide tube, exposing a welding spot outside the insulating guide tube to serve as a test end, grinding the other ends of the copper wire and the constantan wire to remove the insulating layers, welding to a wiring card and fastening. The preparation method of the copper-constantan thermocouple is available for metal wires with diameters ranging from 0.04mm to 0.2mm, and the outer diameter of the test end of the thermocouple is smaller than 1mm.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com