Patents

Literature

66results about How to "Reduce flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

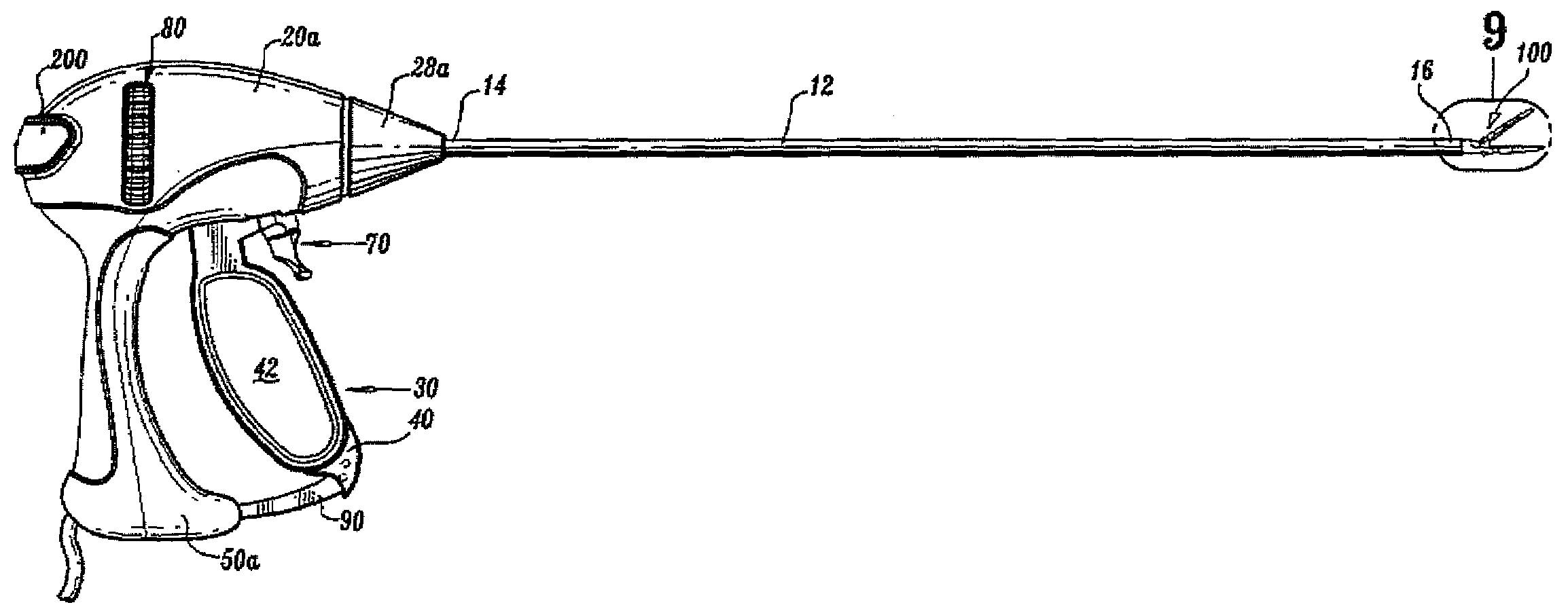

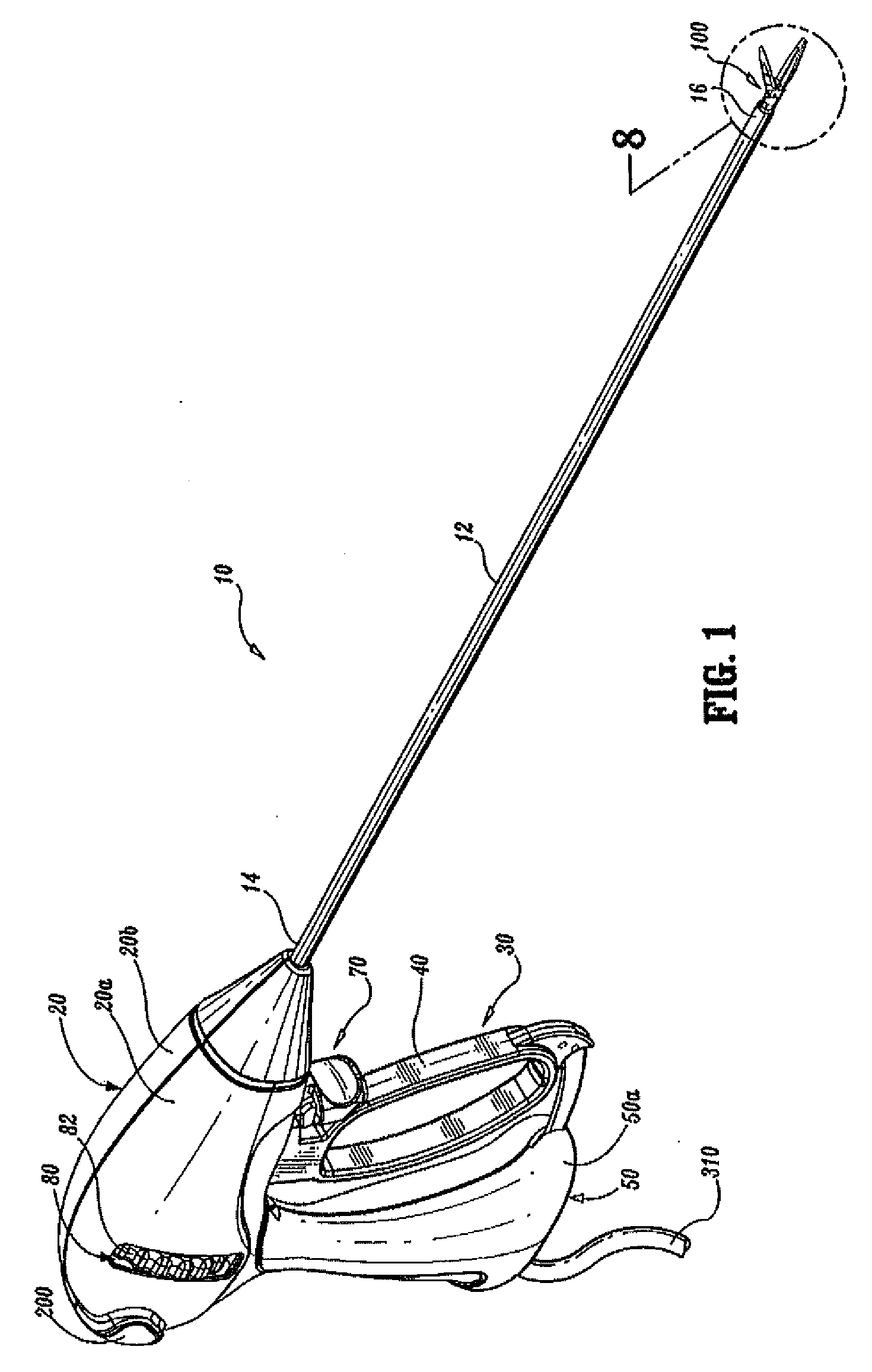

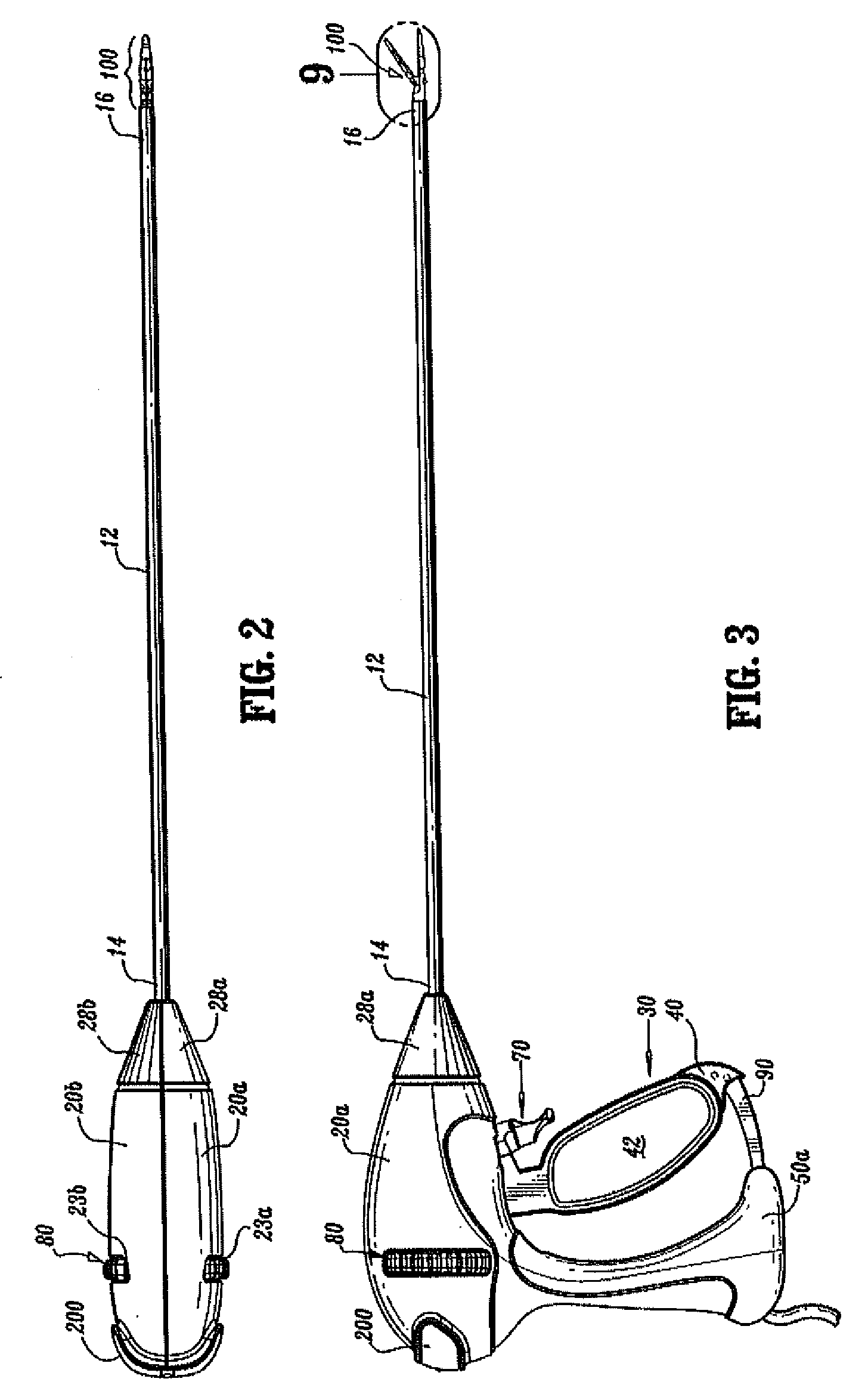

Vessel Sealer and Divider

ActiveUS20100145334A1Reduce flexibilitySeal performance be improveSurgical instrument detailsSurgical forcepsEngineeringKnife blades

An endoscopic bipolar forceps includes a housing and a shaft, the shaft having an end effector assembly at a distal end thereof, which includes two jaw members for grasping tissue therebetween. Each jaw member is adapted to connect to an electrosurgical energy source, enabling them to affect a tissue seal to tissue held therebetween. A drive assembly is included within the housing for moving the jaw members. A movable handle is also included, such that movement of the handle actuates the drive assembly to move the jaw members relative to each other. A knife channel is included within the end effector configured to allow reciprocation of a knife blade within the knife channel. The knife blade includes a proximal edge adapted to engage a proximal edge of the end effector to impede translation of the knife blade when the jaw members are in an open configuration and the knife blade is retracted within the end effector assembly.

Owner:TYCO HEALTHCARE GRP LP

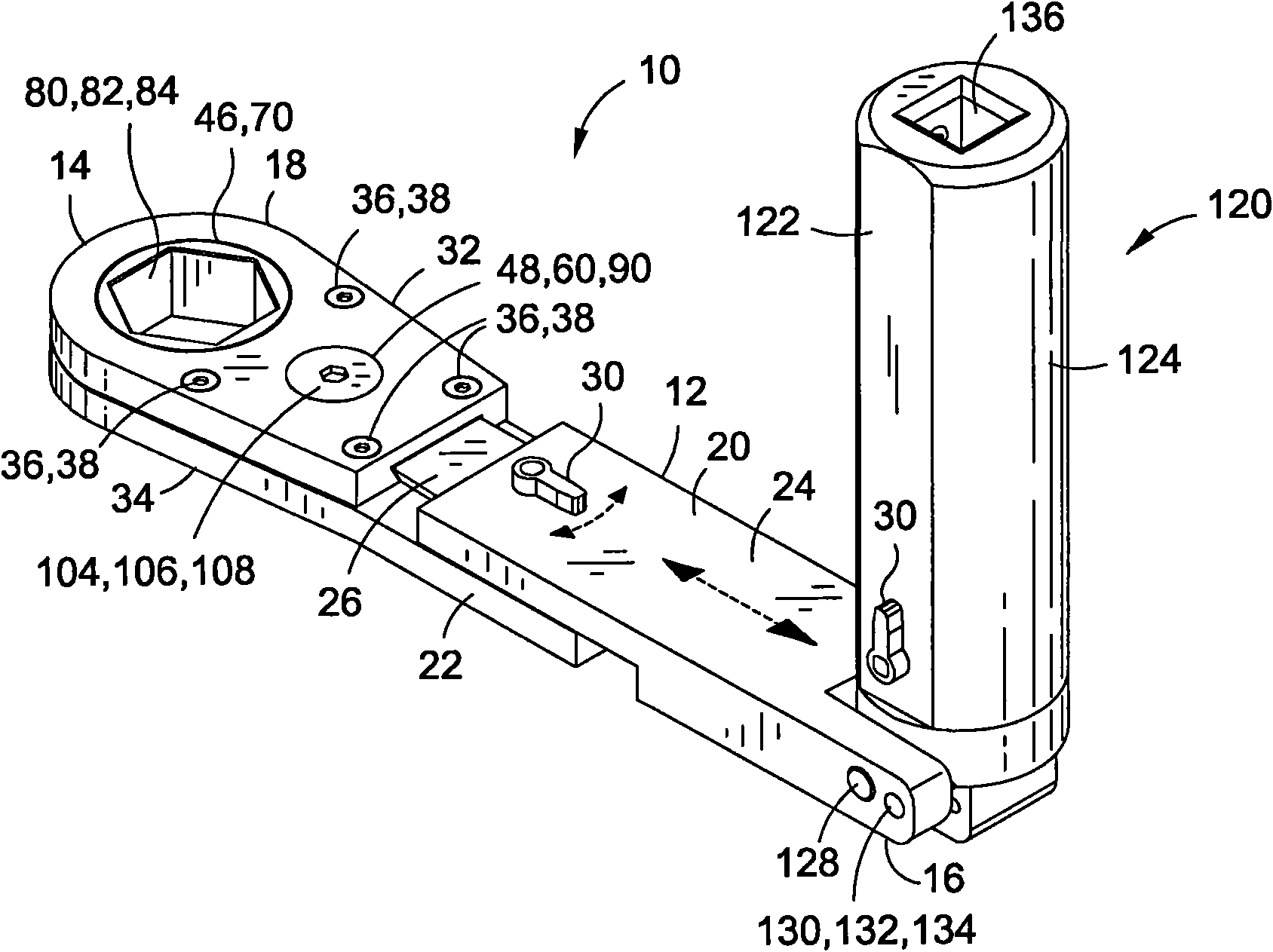

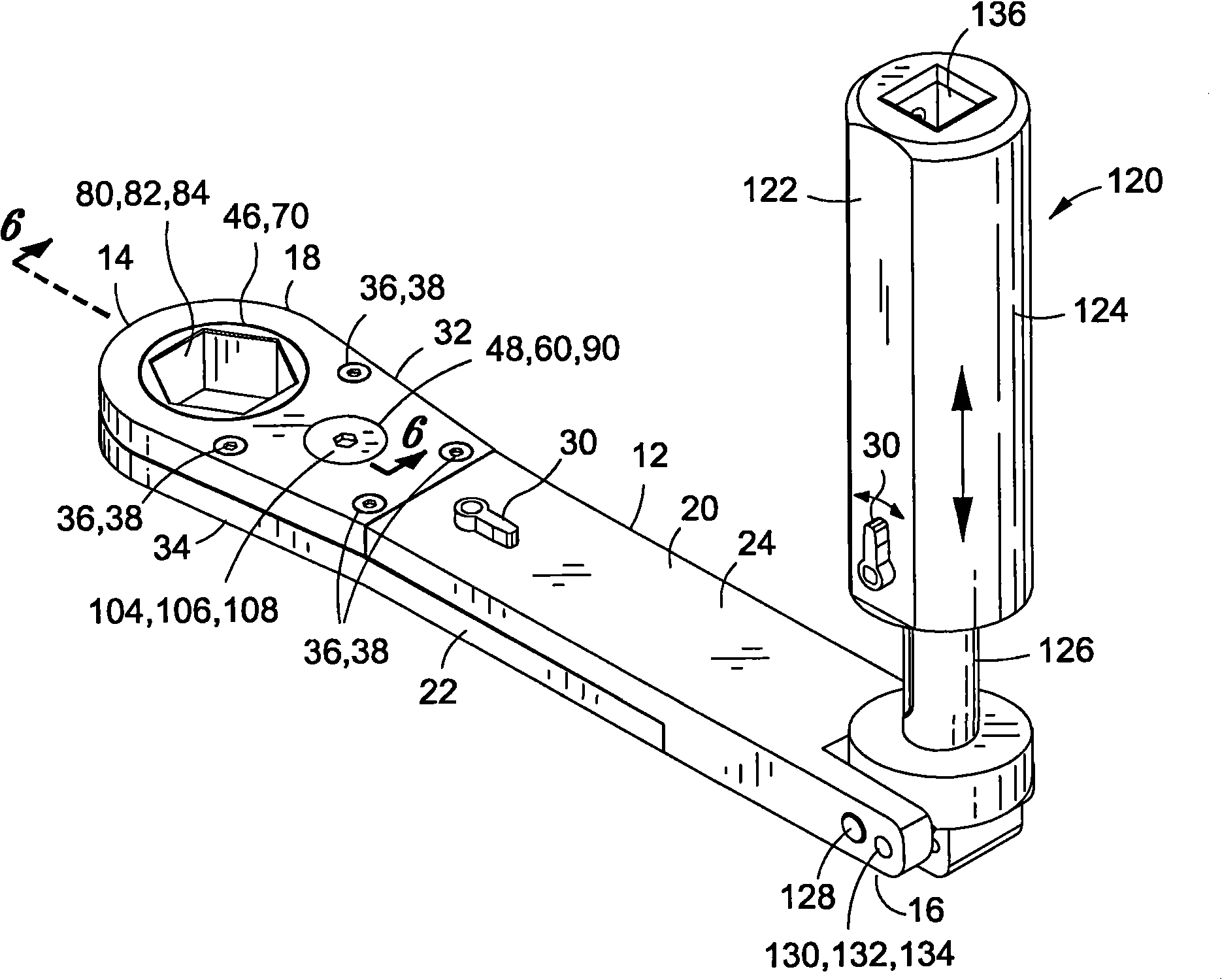

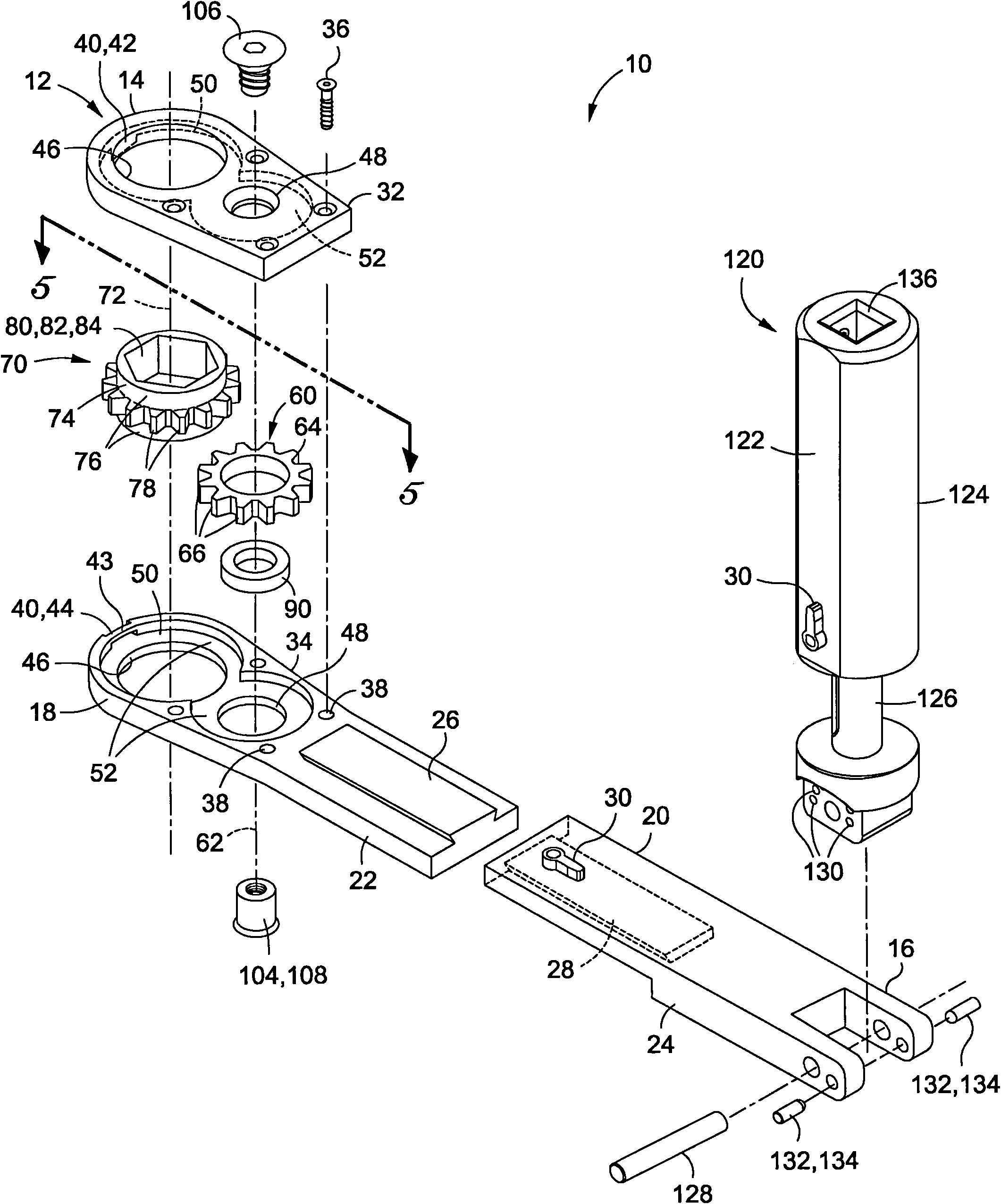

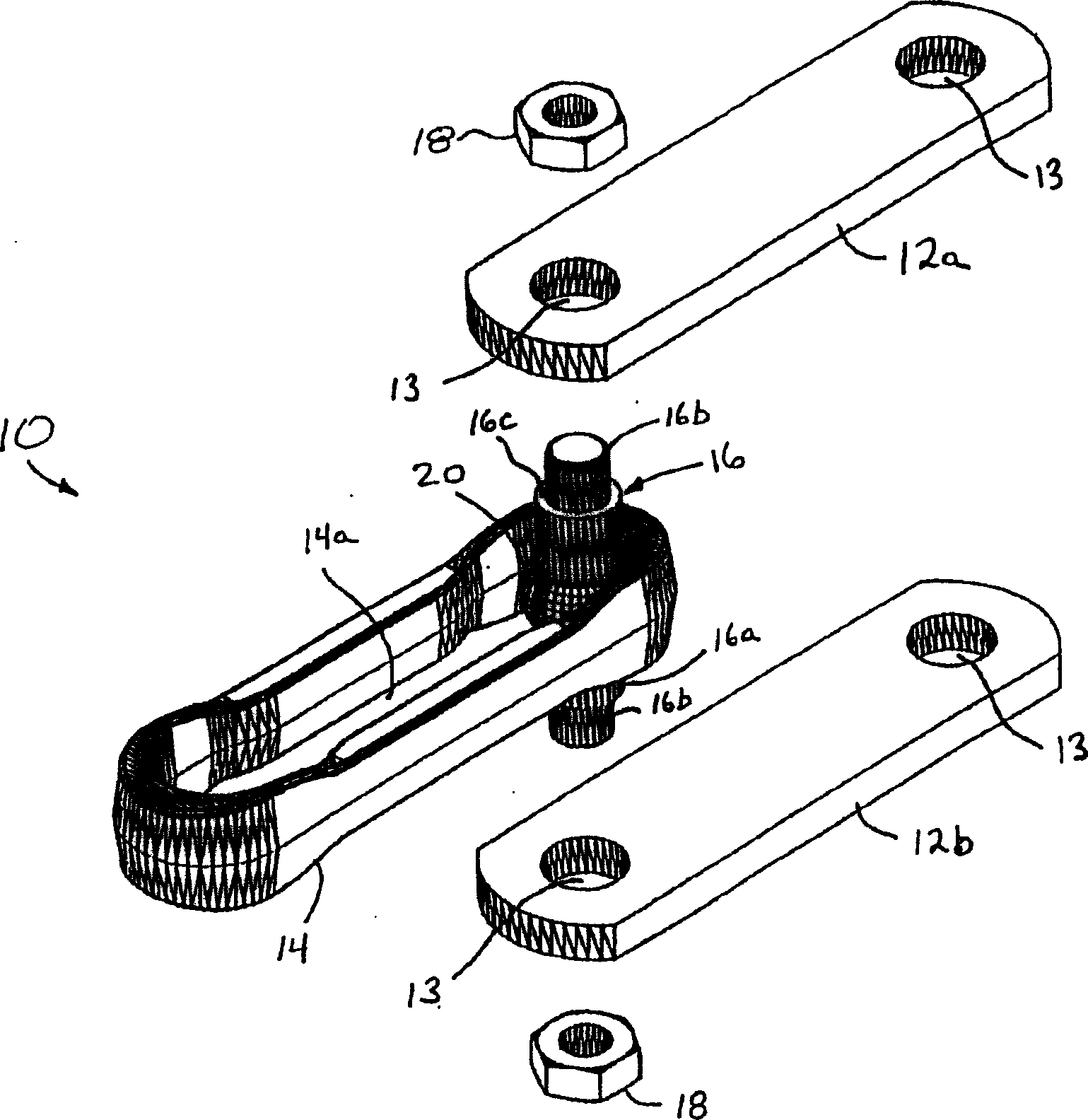

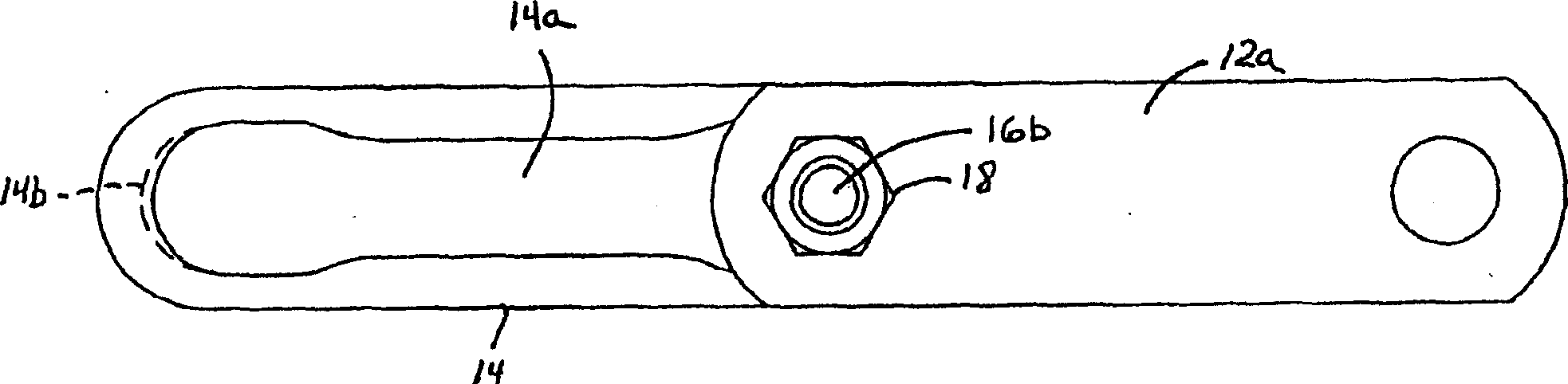

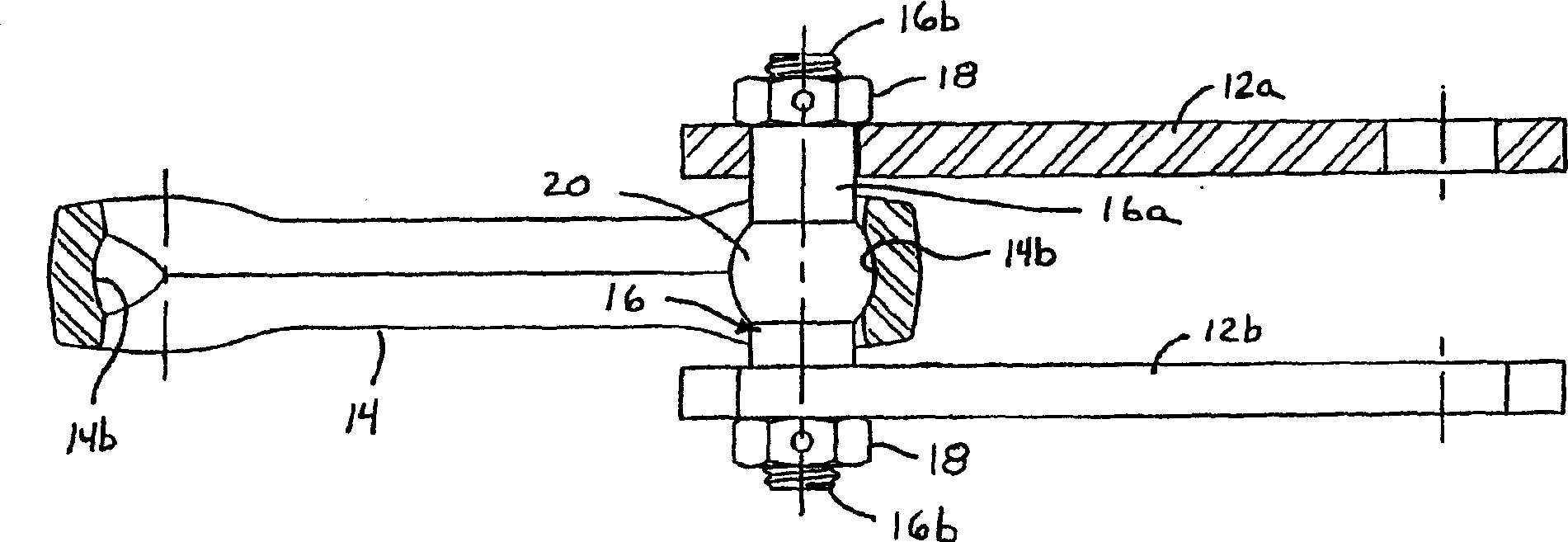

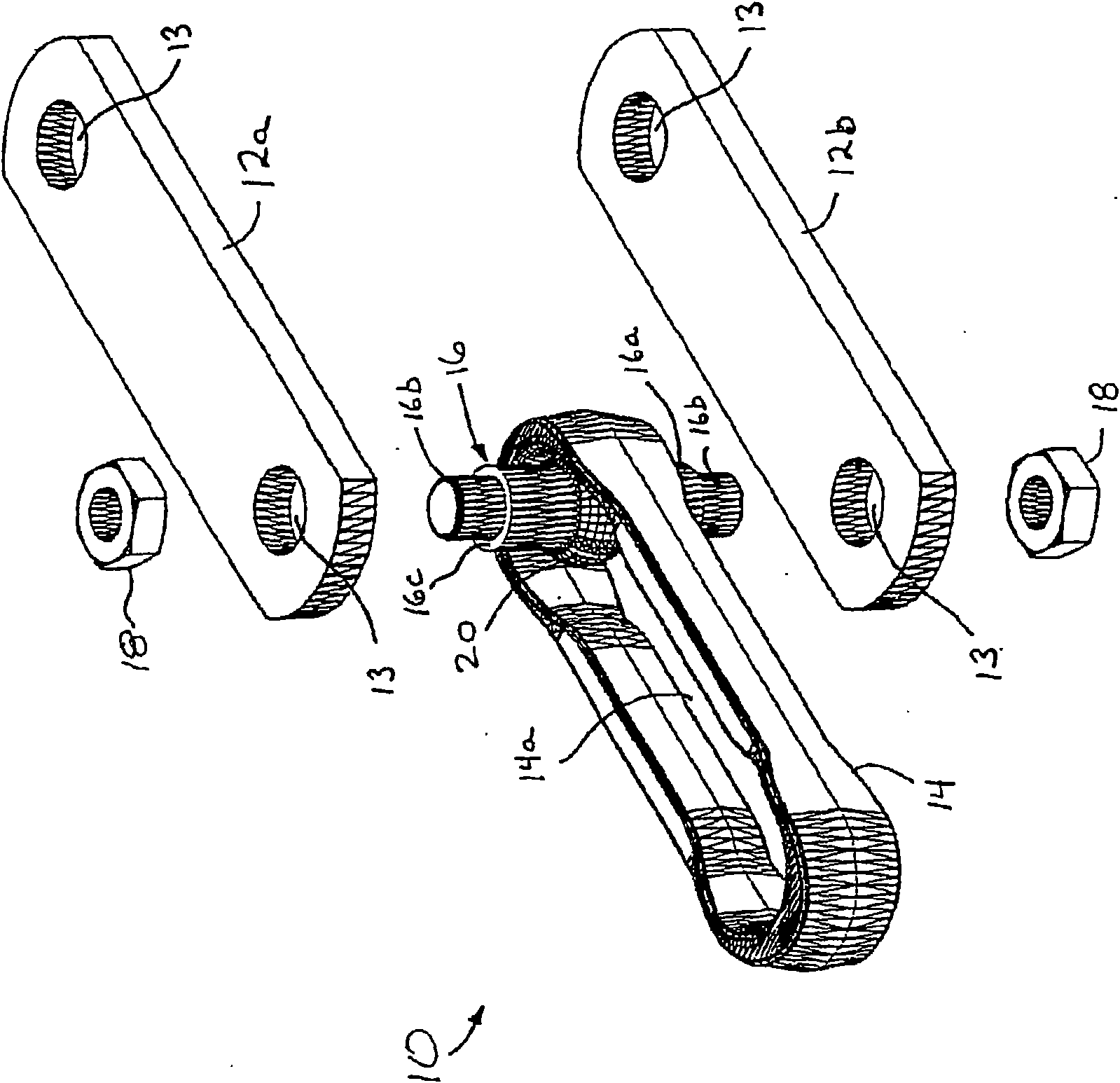

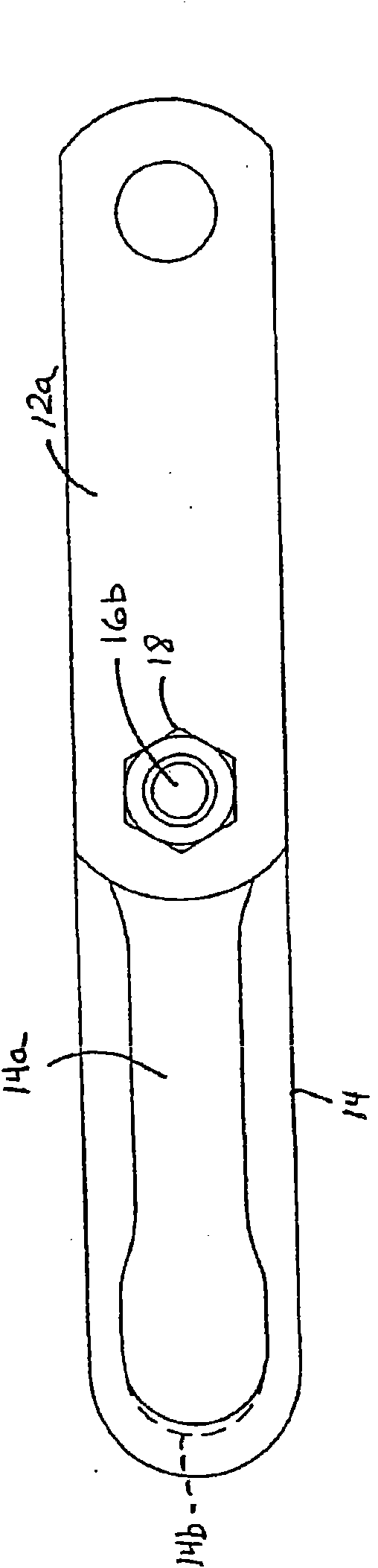

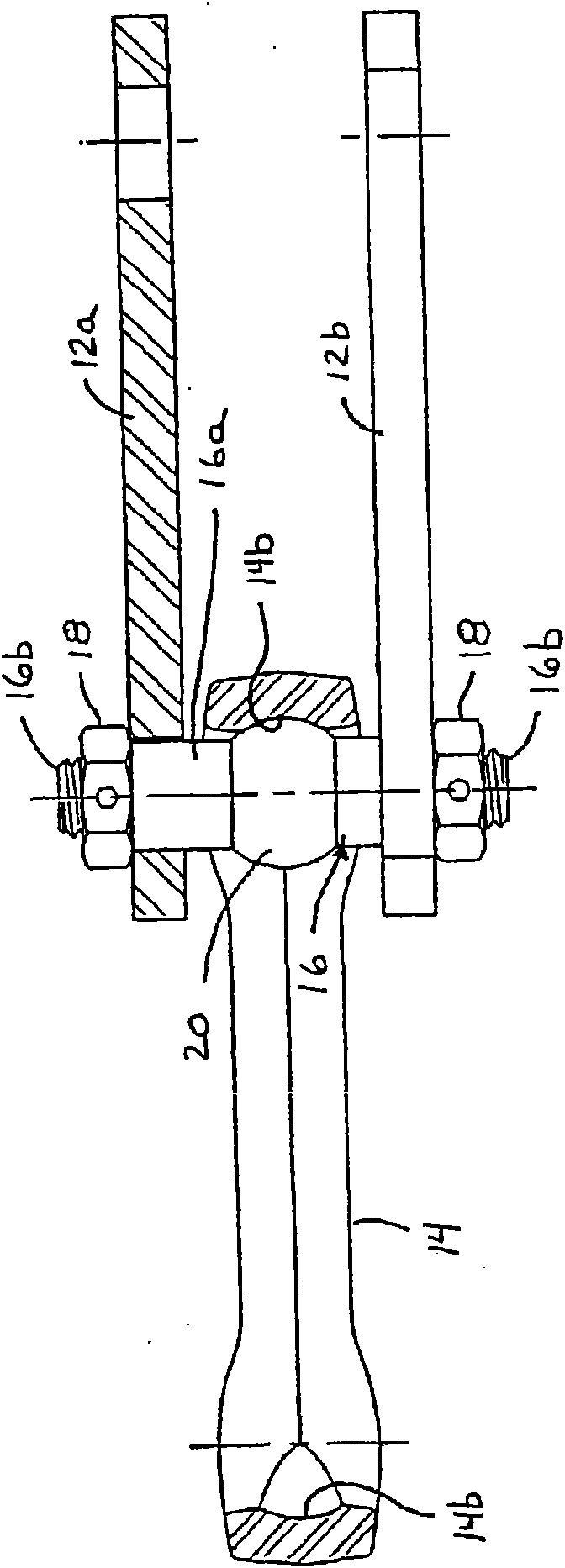

Low profile wrench

A wrench for rotating a member comprises an elongate body having a head portion. The wrench may include a drive mechanism mounted to the head portion. The drive mechanism may comprise a drive gear and a clutch gear. The drive gear may include a drive element for engaging the member. The clutch gear may be operatively coupled to the drive gear and may be rotatably supported by a unidirectional roller clutch.

Owner:THE BOEING CO

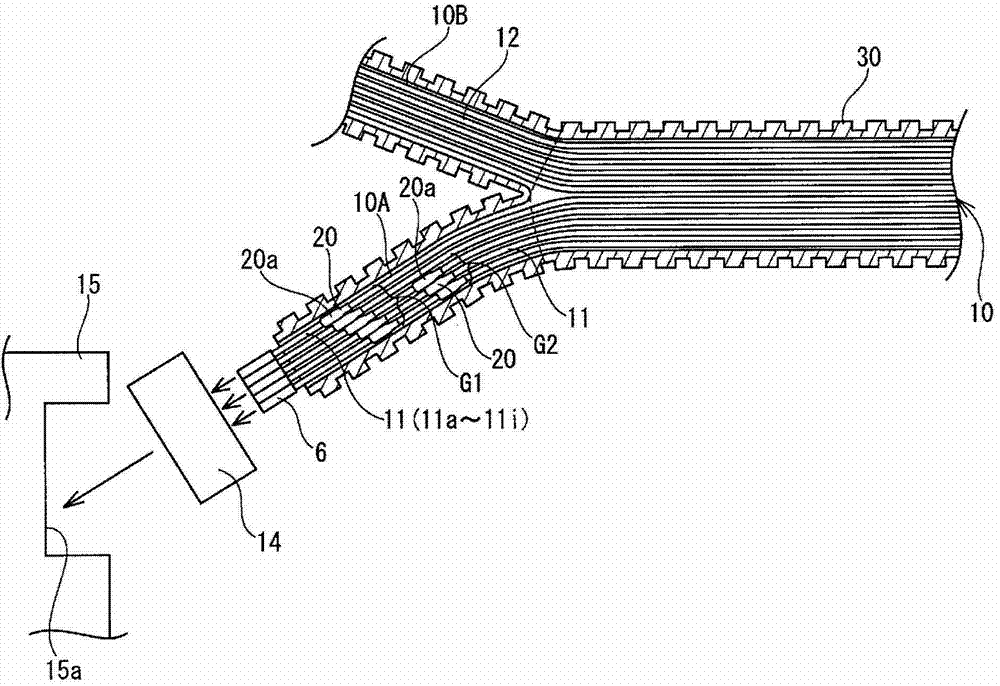

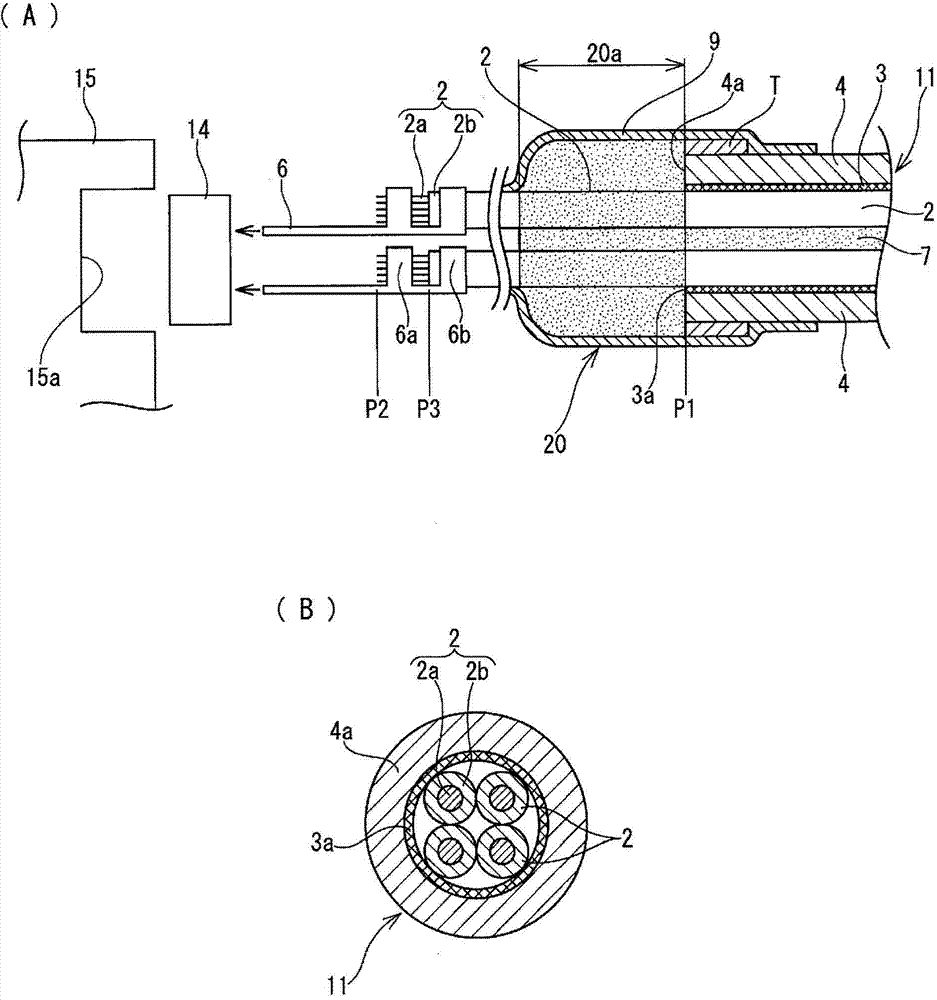

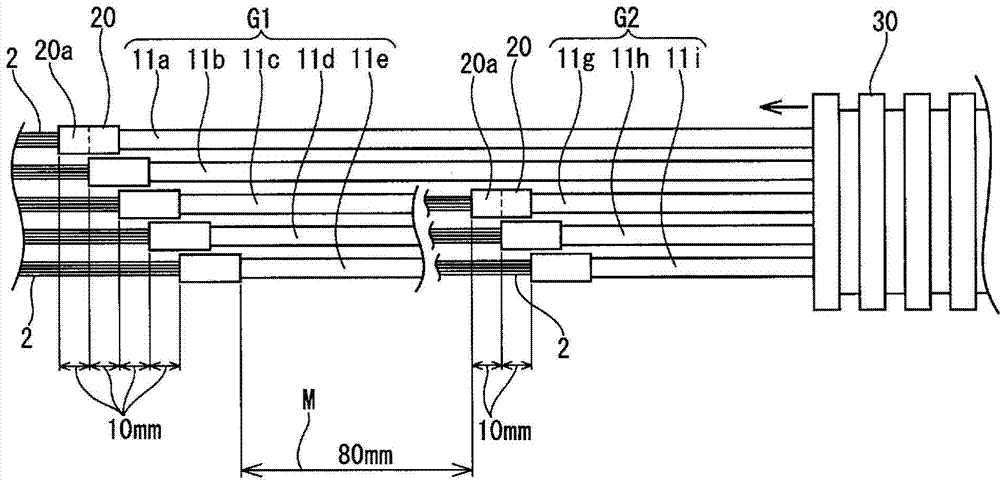

Wire harness waterproof structure

InactiveCN103119662AReduce flexibilitySmall sizeClimate change adaptationInsulated cablesShielded cableEngineering

Provided is a wire harness that suppresses the hardening of waterproofing parts and the enlargement of the outer diameter thereof. In a group of cables configuring one wire harness, a plurality of shielded cables provided with waterproofing parts are divided into a plurality of groups, the positions of the waterproofing parts differ for each group, a prescribed distance is provided between waterproofing parts of different groups, and the waterproofing parts are distributed in the axial direction of the wire harness.

Owner:SUMITOMO WIRING SYST LTD

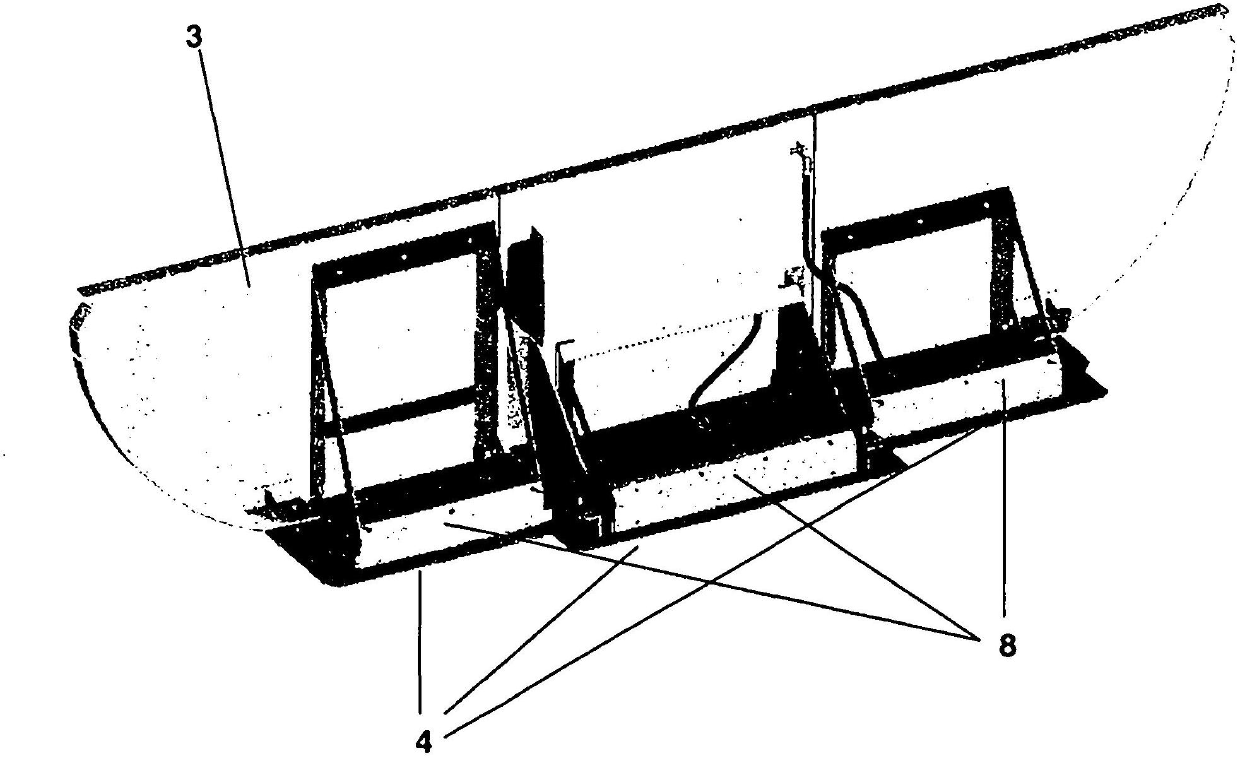

Rail vehicle for a driving operation on track systems having a ballasted superstructure

InactiveCN102639382AReduce flexibilityAvoid accumulationRailway wheel guards/bumpersRailway transportSuperstructureSnow

The invention relates to a rail vehicle for a driving operation on track systems having a ballasted superstructure. The invention is to effectively prevent or at least significantly reduce an agglomeration of snow and ice in cavities of the vehicle underbody. To this end, the rail vehicle comprises at least one flexible membrane (5) in the region of the underbody, said membrane spanning over hollow spaces or supporting framework structures of the underbody of the rail vehicle that are open toward the track system. The membrane (5) can be stimulated as dynamic vibrate during the drive of rail vehicle because of the flexile implementation structure.

Owner:DB FERNVERKEHR +1

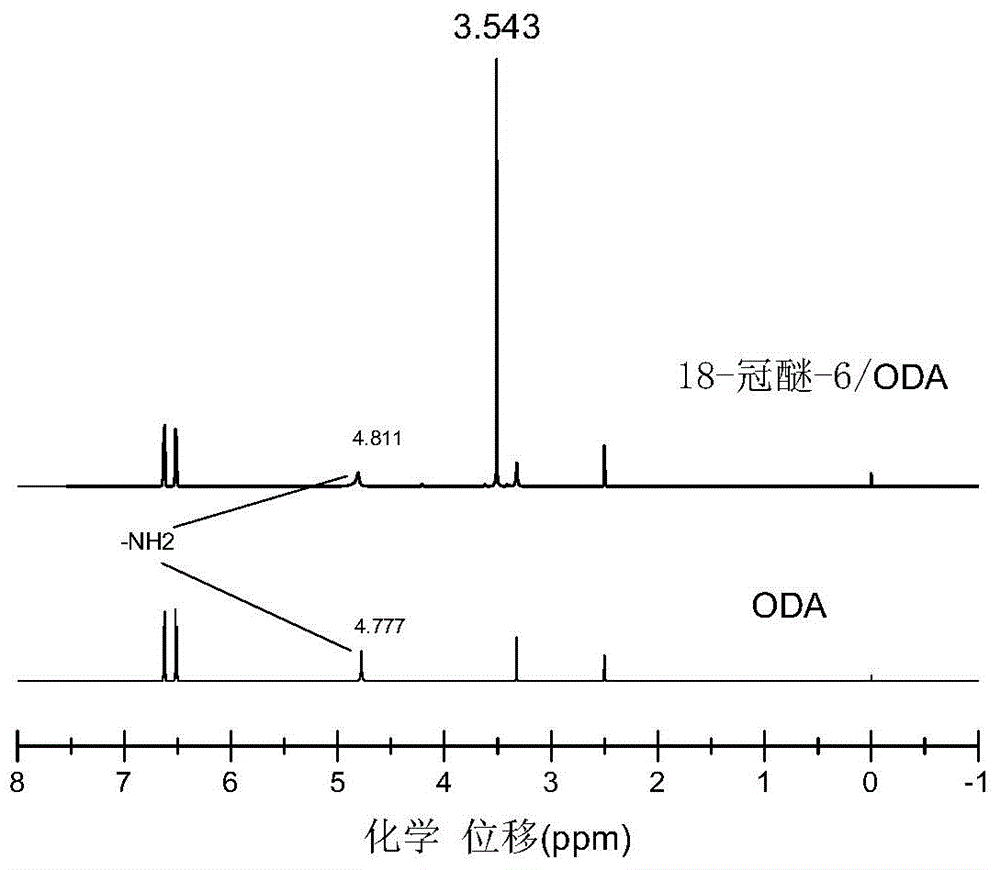

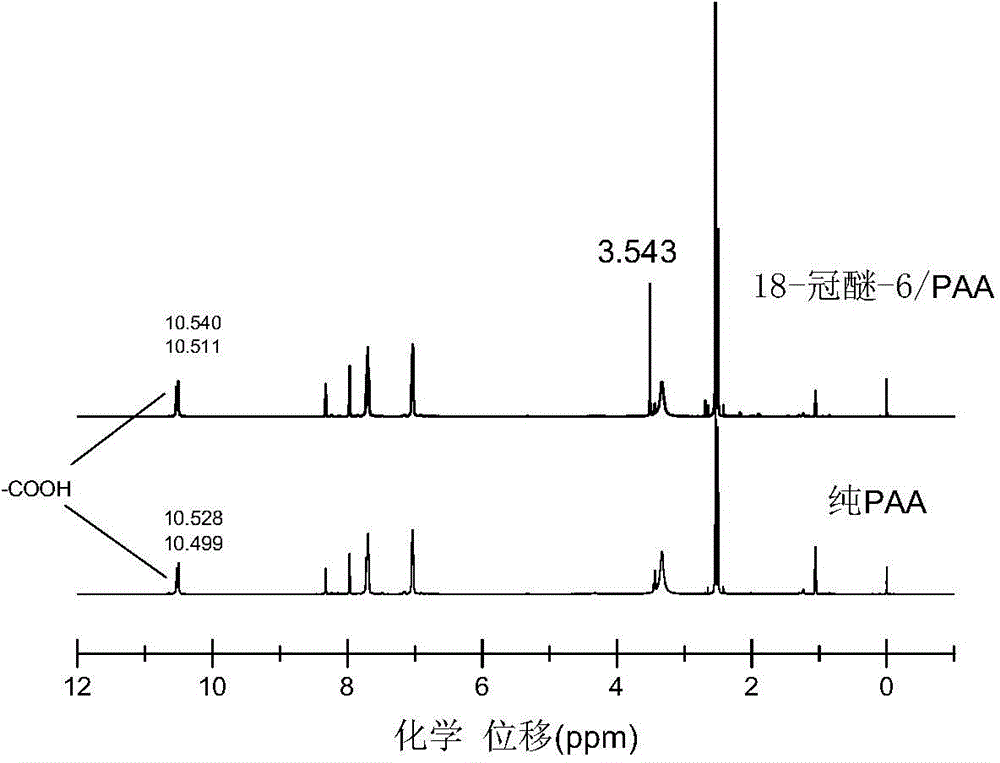

Crown ether modified polyimide hybrid membrane and preparation method thereof

The invention discloses a crown ether modified polyimide hybrid membrane and a preparation method thereof. The preparation method comprises the following steps: under the conditions of the humidity lower than 50%, room temperature and mechanical stirring, in an atmosphere of nitrogen, dissolving crown ether and aromatic diamine into a polarity organic solvent until the crown ether and the aromatic diamine are completely dissolved, continuing to stir to obtain a crown ether / diamine inclusion compound solution, adding aromatic dianhydride to the crown ether / diamine inclusion compound solution, after adding the aromatic dianhydride, continuing stirring to obtain a crown ether modified polyamide acid solution, uniformly smearing the crown ether modified polyamide acid solution on a clean glass sheet, eliminating bubbles, raising the temperature according to the setup program, after treatment, cooling the glass sheet to the room temperature, stripping off the membrane, drying and obtaining the crown ether modified polyimide hybrid membrane. In the invention, the crown ether molecules sleeve the polyamide acid chains to form necklace type supramolecular structures; the polyimide molecular chains are extended to be three-dimensional from two-dimensional type, so that the flexibility of the molecular chains is reduced, and the rigidity is promoted.

Owner:SOUTH CHINA UNIV OF TECH

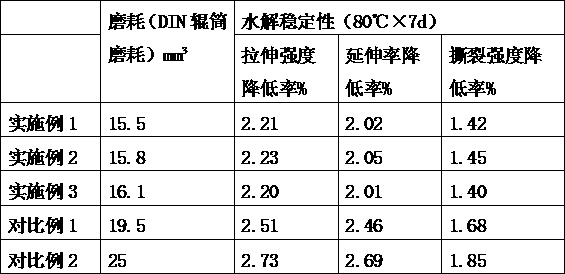

Preparation method of polyurethane sieve plate

The invention discloses a preparation method of polyurethane sieve plate. The method comprises the following steps of: (1) preparing a prepolymer; (2) mixing; (3) casting; (4) precuring and demoulding; and (5) post-curing. The method provided by the invention uses polyester and polyether polyol as raw materials, improves abrasion resistance of the product through introducing nanometer barium sulfate powder, reduces flexibility and improves stiffness of an ether bond through introducing aryl with a steric effect into an ether bond-containing chain extender, thereby enhancing stability to hydrolysis resistance and ensuring various physical and mechanical performances of elastomers at the same time.

Owner:奥斯汀新材料(张家港)有限公司

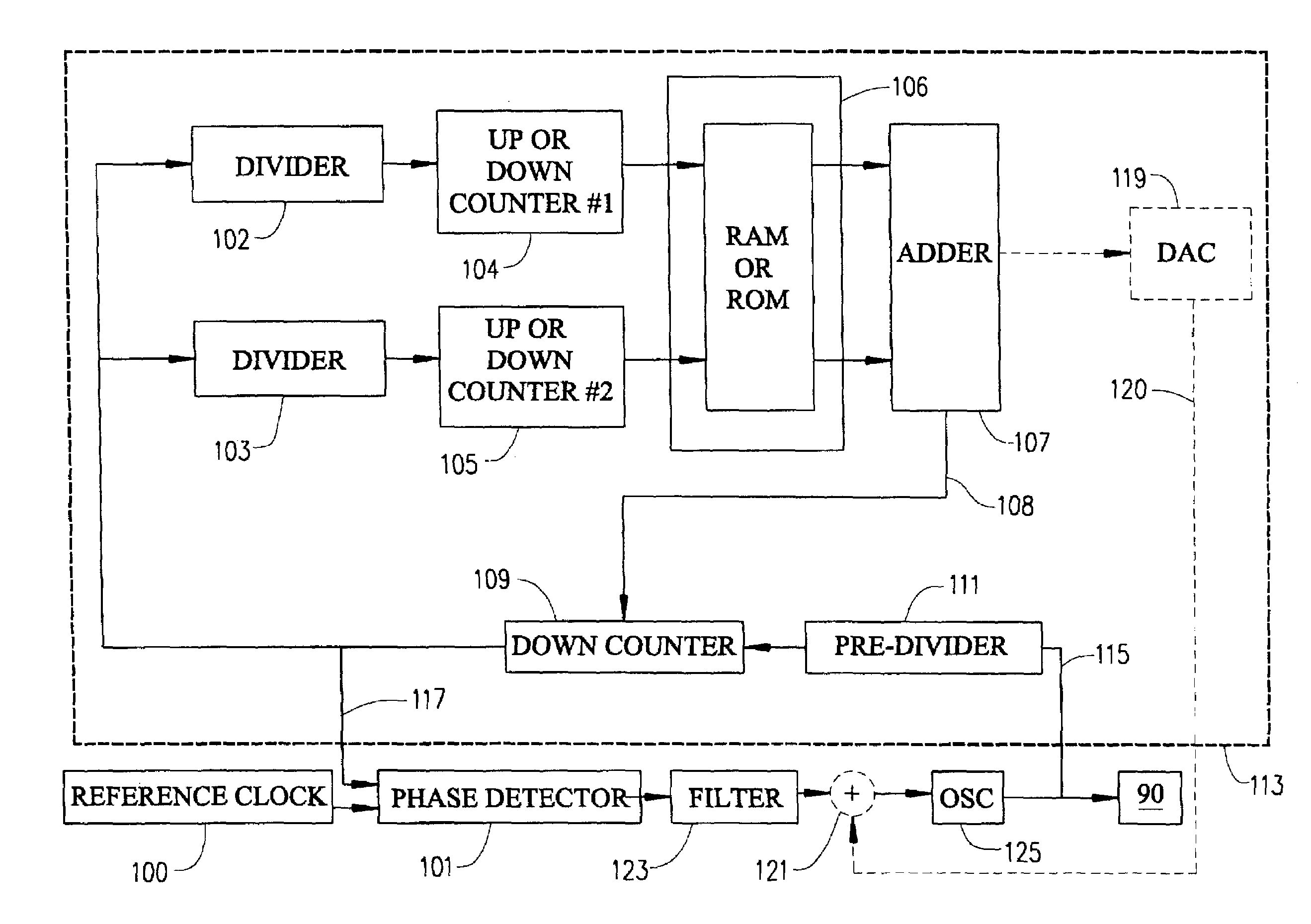

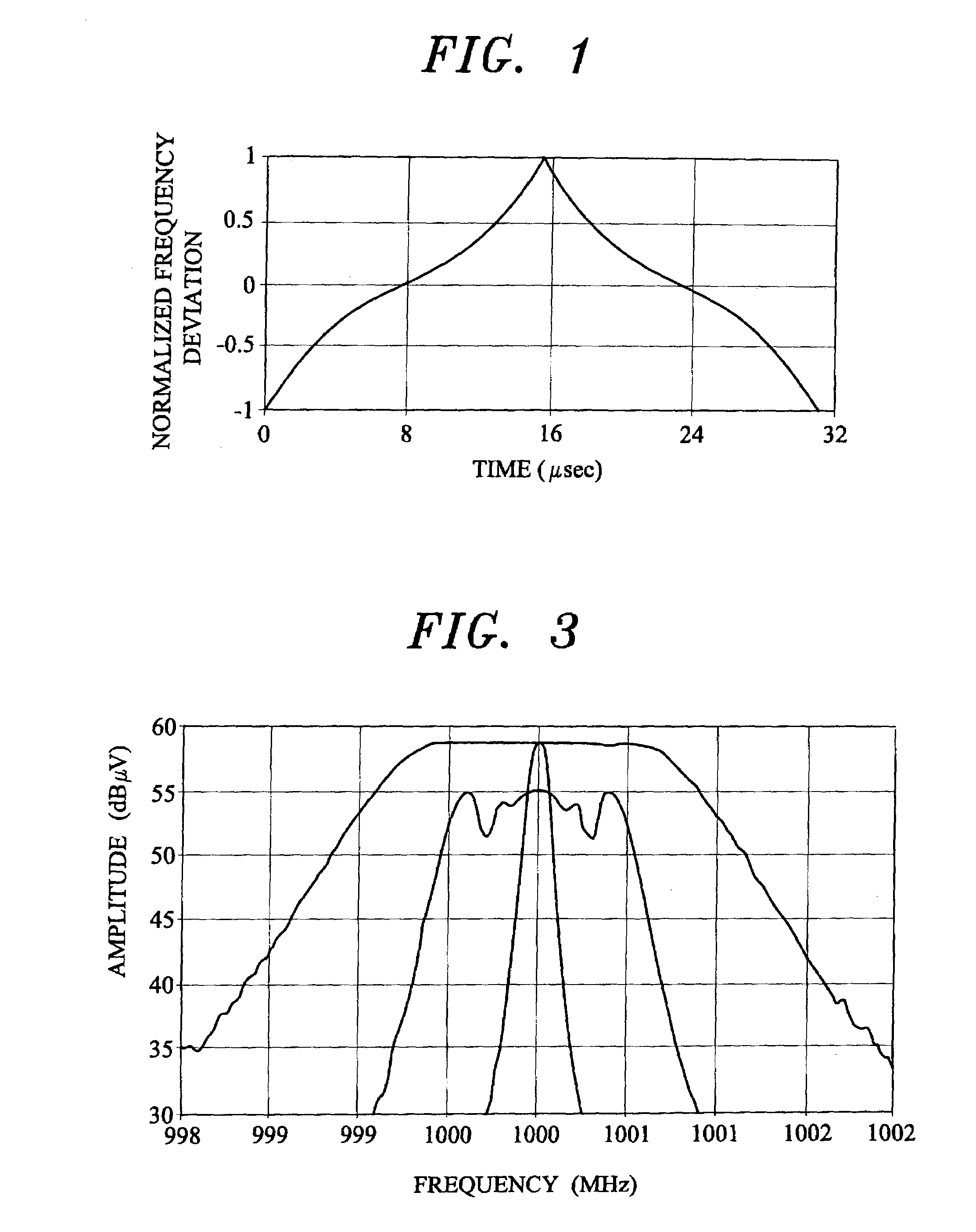

High frequency spread spectrum clock generation

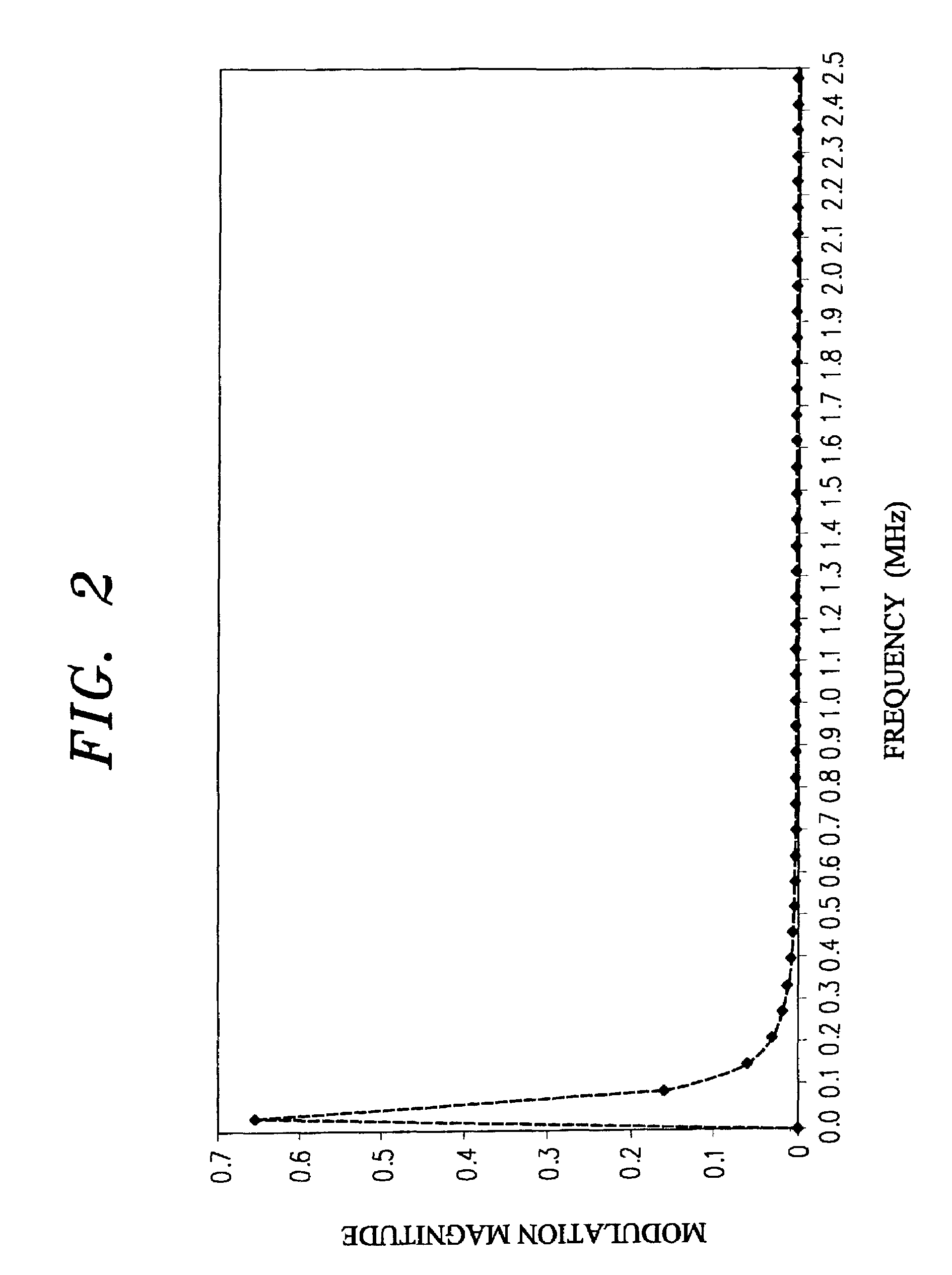

ActiveUS7561652B2Maximum flexibilityReduce flexibilityPulse automatic controlSynchronisation signal speed/phase controlBase frequencyEngineering

Owner:LEXMARK INT INC

Micro-scale flexible composite ultrahigh pressure sensor and manufacturing method thereof

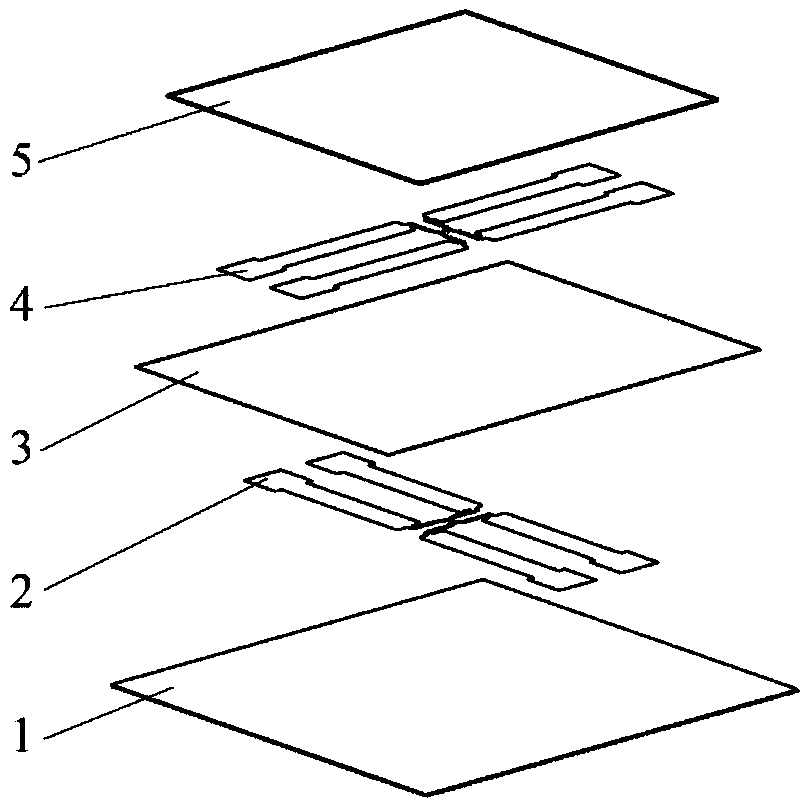

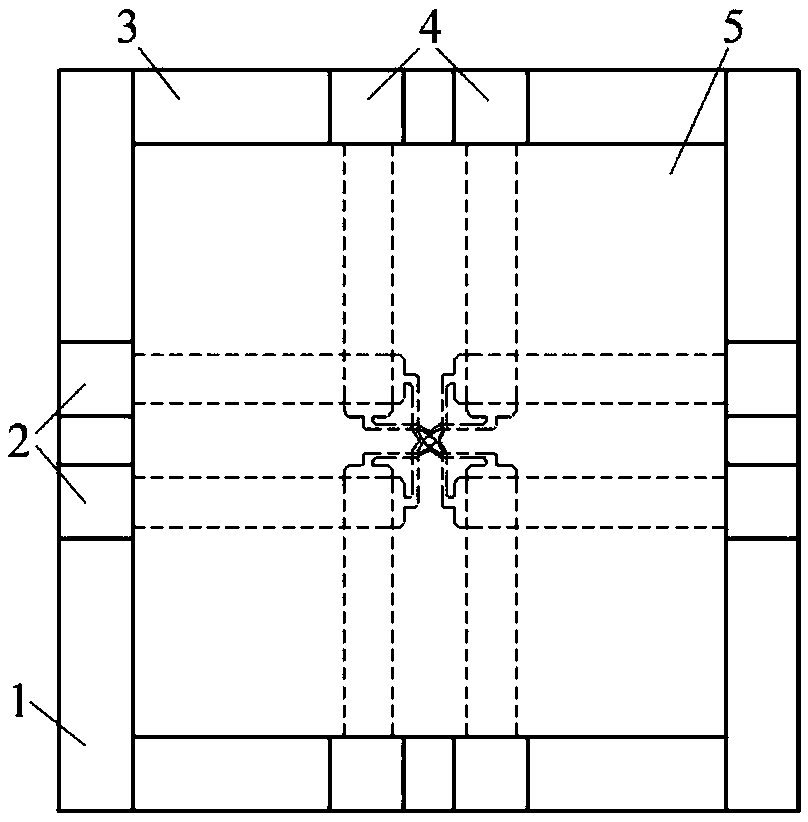

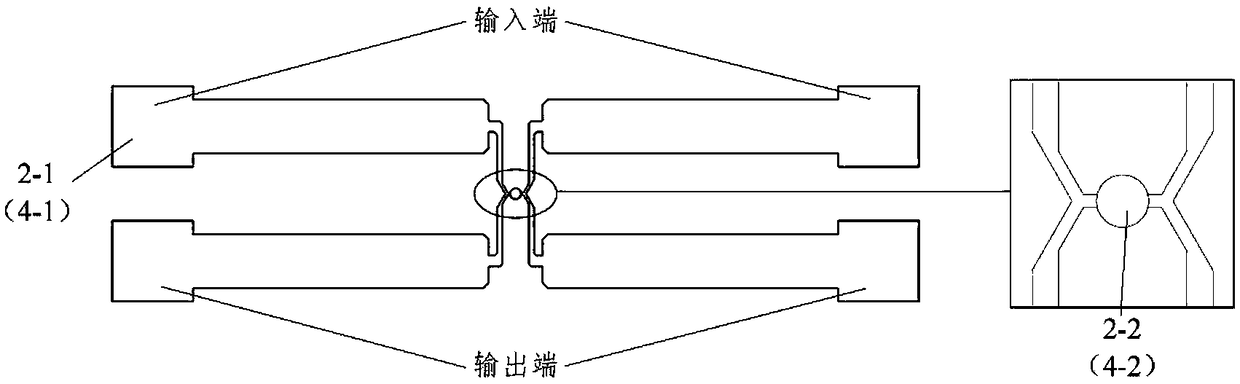

ActiveCN109163837AReduce flexibilityReduce the impact of detonation wavesForce measurementMeasurement of explosion forceTransverse axisManganin

The invention discloses a micro-scale flexible composite ultrahigh pressure sensor and a manufacturing method thereof. The sensor comprises a substrate; a constantan sensitive element and first electrodes are sputtered on the substrate through an MEMS process; the input end and the output end of the constantan sensitive element are connected with the two first electrodes respectively; the surfacesof the constantan sensitive element and the first electrodes are covered with an insulating layer; a manganin sensitive element and second electrodes are sputtered on the insulating layer through theMEMS process; the input end and the output end of the manganin sensitive element are connected with the two second electrodes respectively; and the manganin sensitive element and the constantan sensitive element are arranged in a vertical alignment mode, the second electrodes and the first electrodes are arranged in a vertical manner of a transverse axis, and the surfaces of the manganin sensitive element and the second electrodes are coated with a protective layer. The sensor has the characteristics of small sizes of the sensitive elements, high measuring range, high precision, large outputsignal, flexibility and the like, is suitable for measurement of micro-scale explosive-loading detonation pressures under multiple working conditions, and also can be expanded to the measurement of other micro-scale axisymmetric dynamic high-pressure flow field pressures.

Owner:XI AN JIAOTONG UNIV

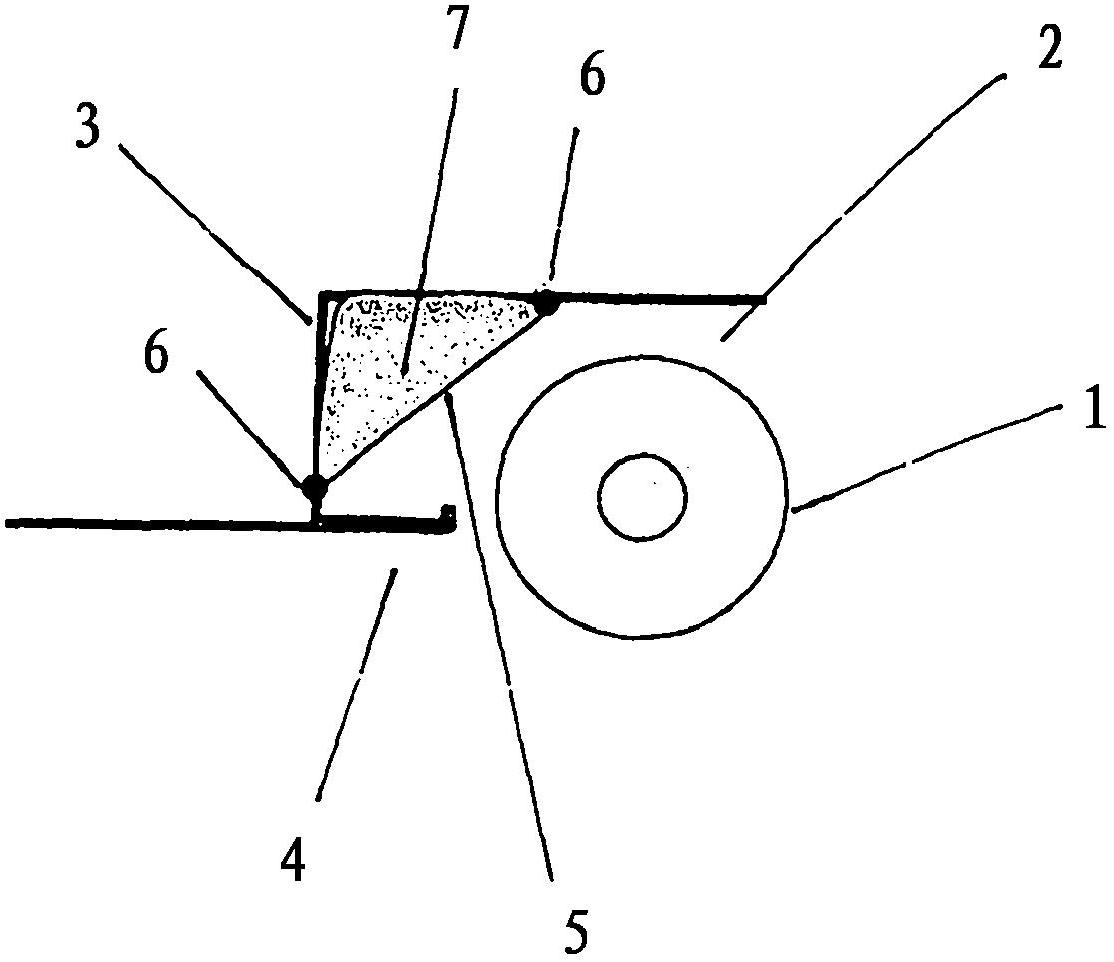

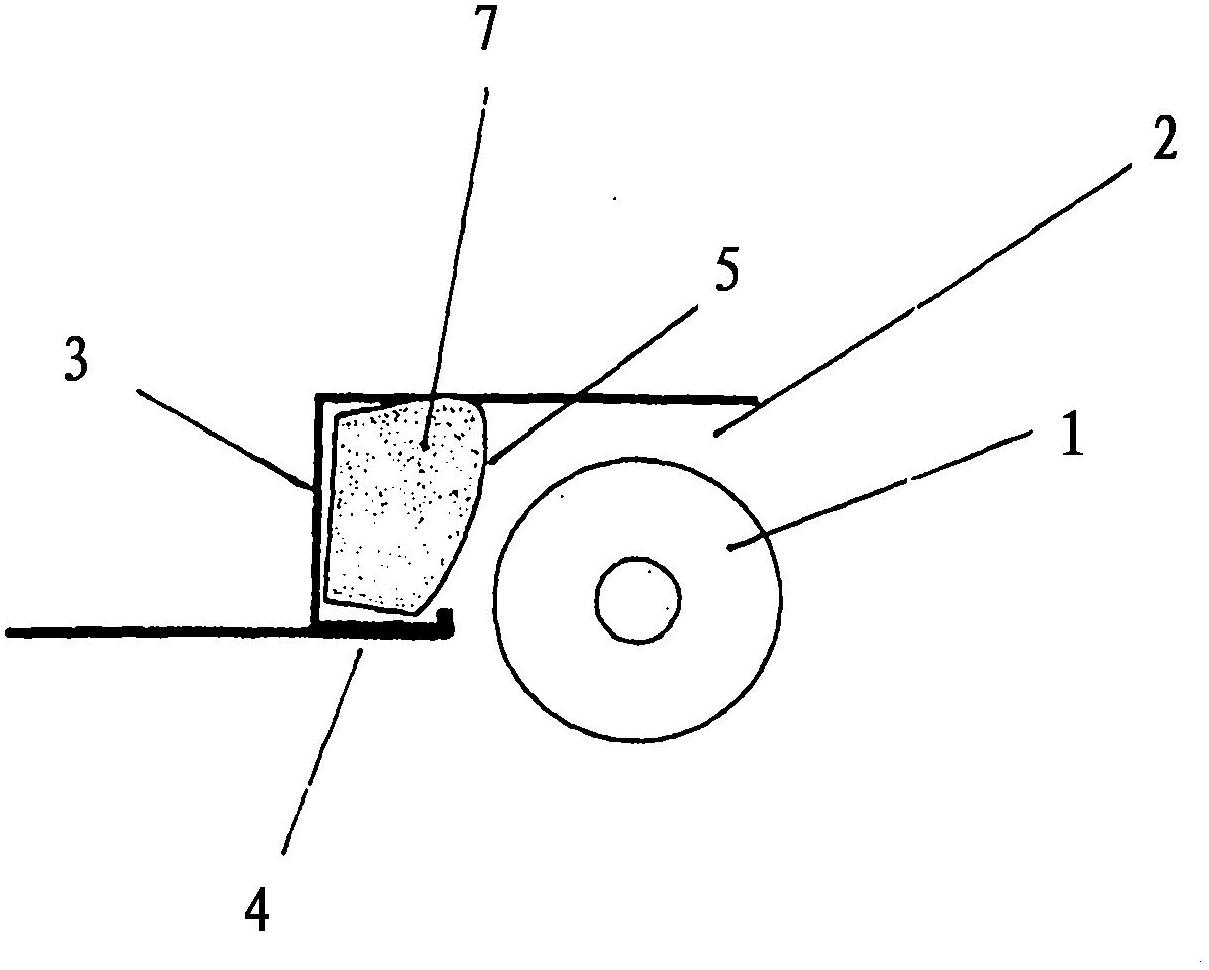

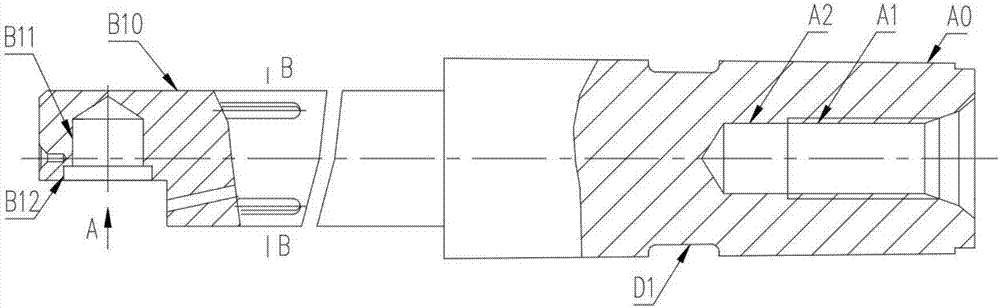

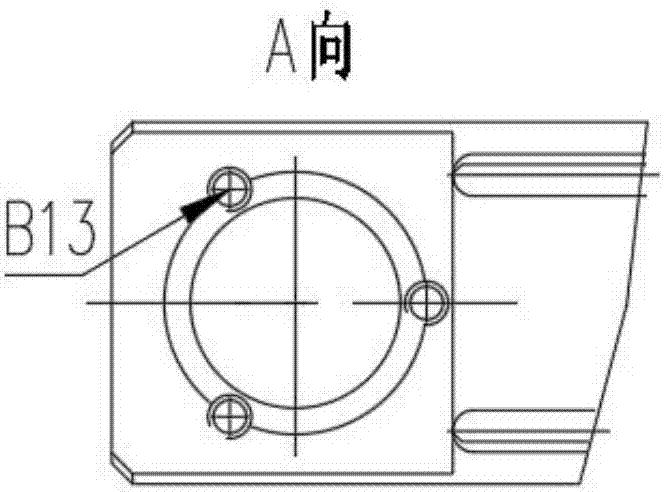

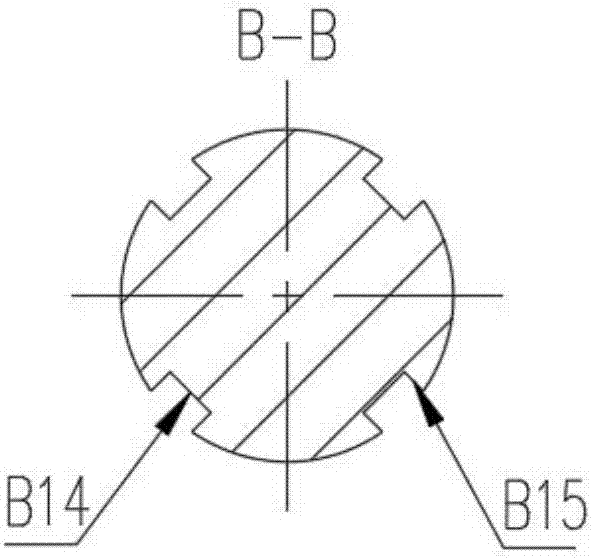

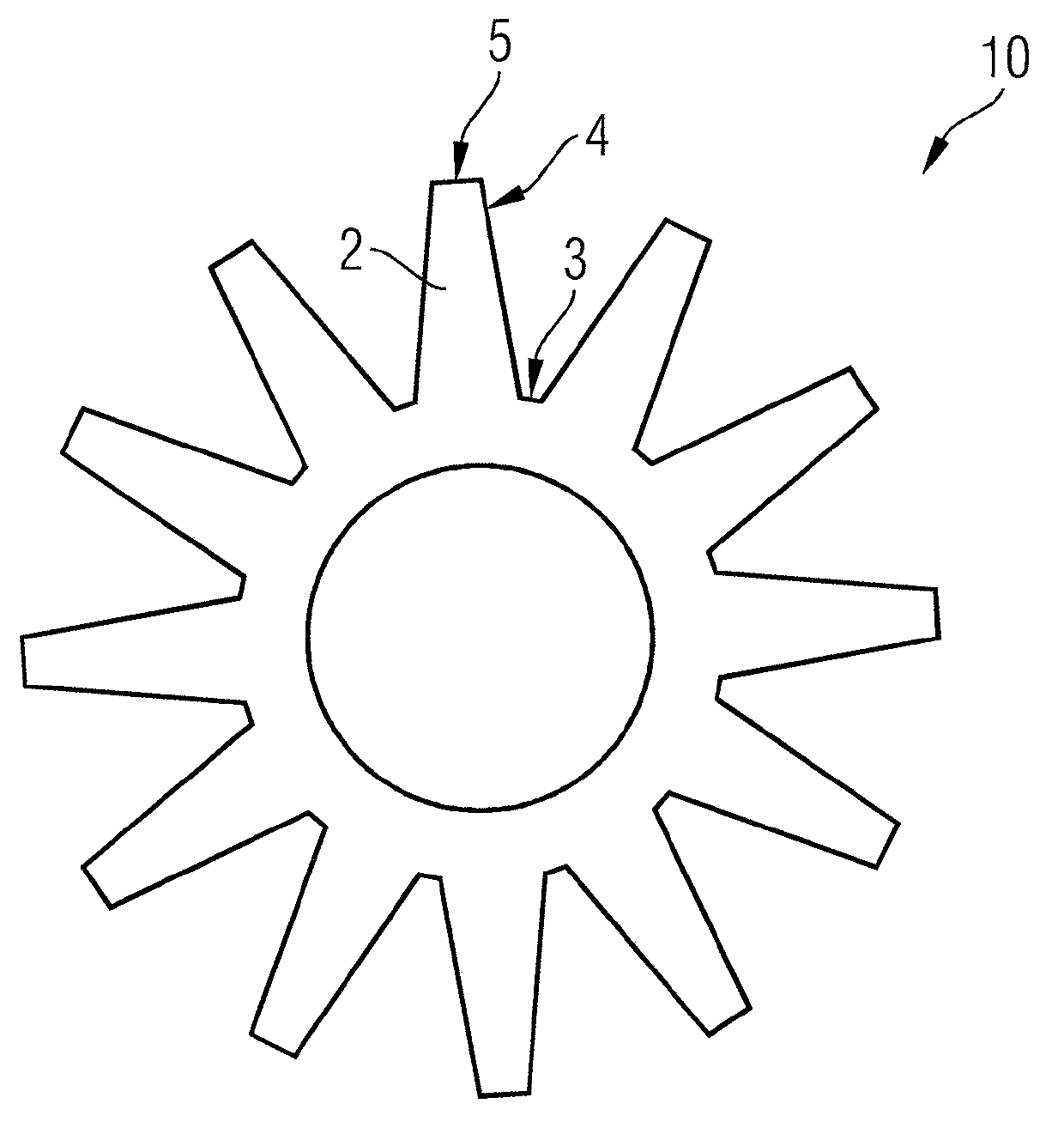

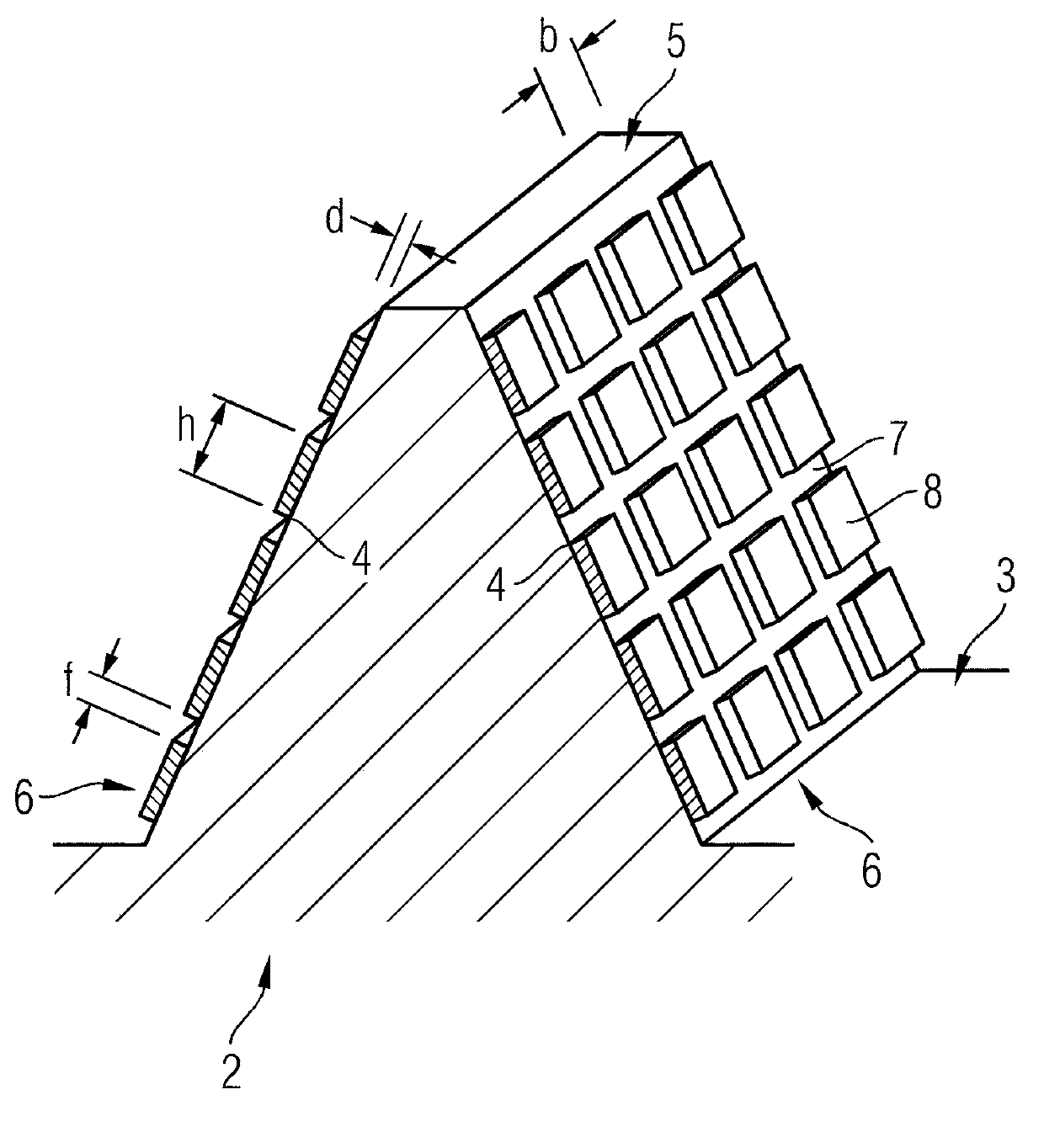

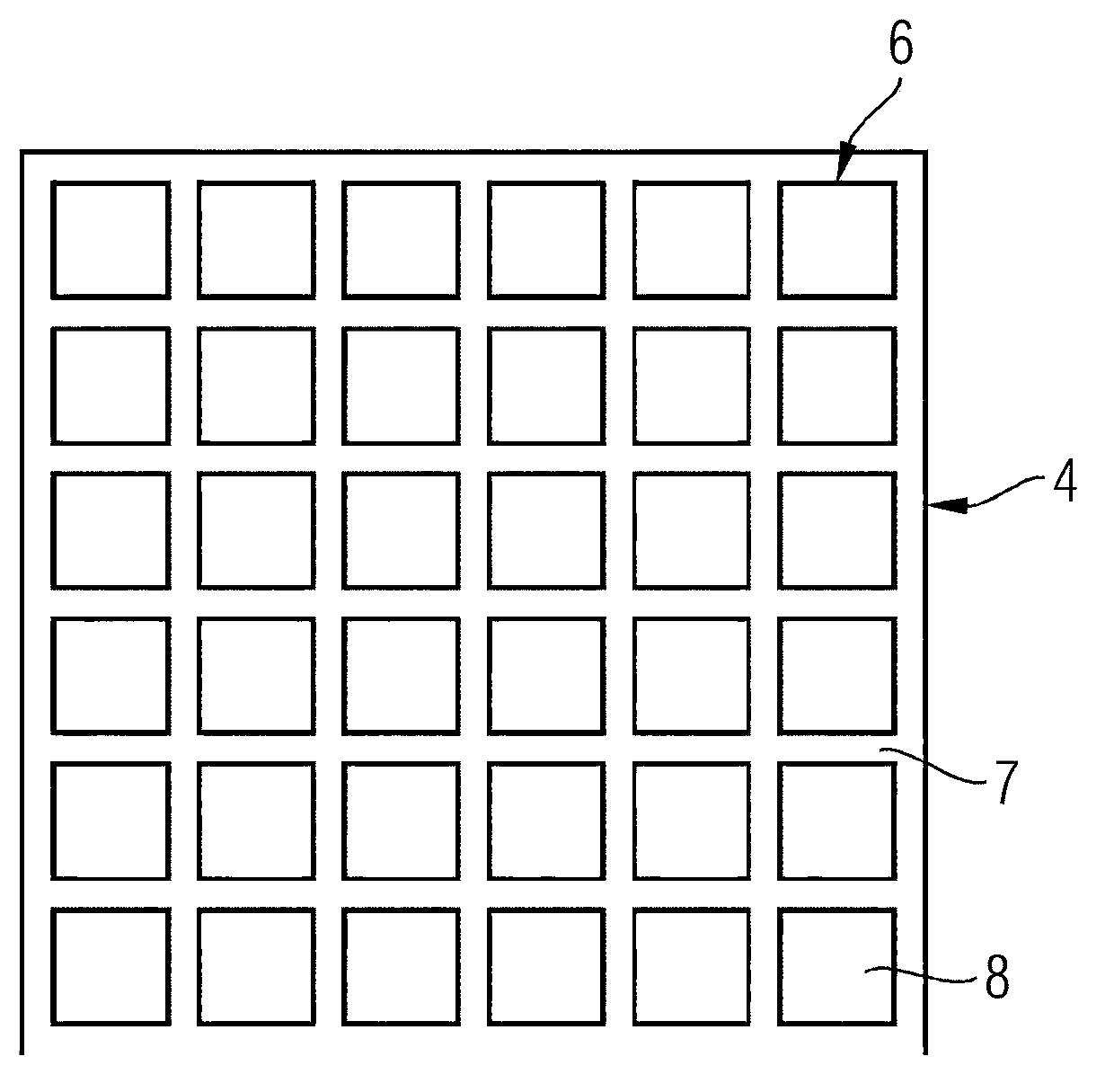

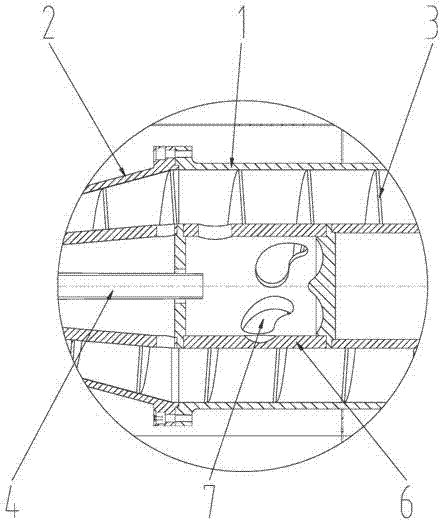

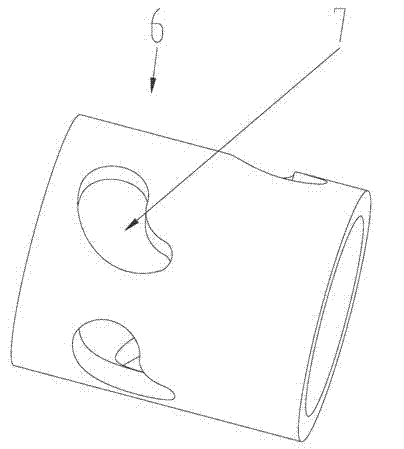

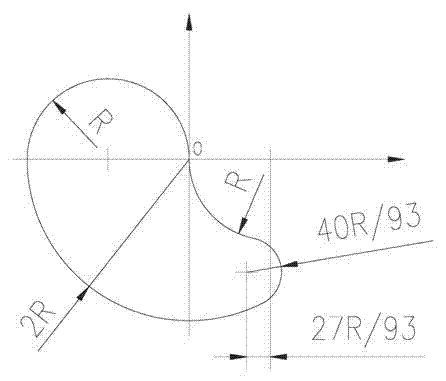

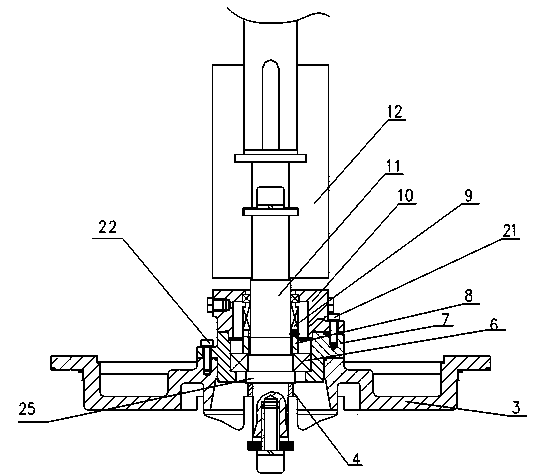

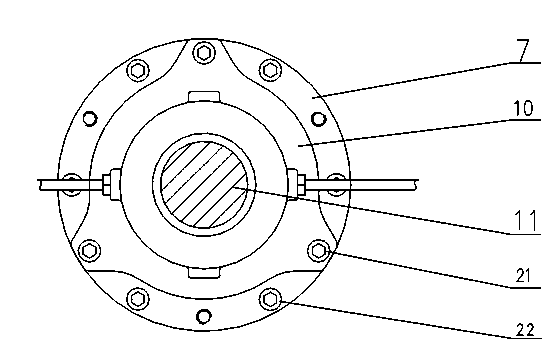

Ultra-deep hole precision boring tool

ActiveCN107186228AImprove rigidityReduce flexibilityBoring barsBoring/drilling machinesDiameter ratioControllability

The invention discloses an ultra-deep hole precision boring tool and machining and using methods thereof. The ultra-deep hole precision boring tool is designed in two modes, namely the non-flat tail mode and the flat tail mode, wherein the non-flat tail tool is composed of a non-flat tail tool handle (1), an abrasion-resistant supporting block (2), a transpositional fine adjustment fine boring head (3), a blade (4), a cushion plate (5), a pull rod (6), a guiding block (7), a nut (8) and the like; and the flat tail tool is composed of a flat tail tool handle (9), an abrasion-resistant supporting block (2), a transpositional fine adjustment fine boring head (3), a blade (4), a supporting plate (10), a locking plate (11) and the like. The ultra-deep hole precision boring tool is a final finish machining tool, the capacity for machining high-precision deep through holes or blind holes with the length-diameter ratio being greater than eight times on common devices such as common turning lathes, milling machines, boring machines and parallel vices can be improved, the stability and controllability of finish machining quality are improved, the normal distribution requirement of hole machining quality is met, and the application range of the devices of the type is enlarged; and the ultra-deep hole precision boring tool is simple in structure, low in production cost and convenient to use.

Owner:贵州凯星液力传动机械有限公司

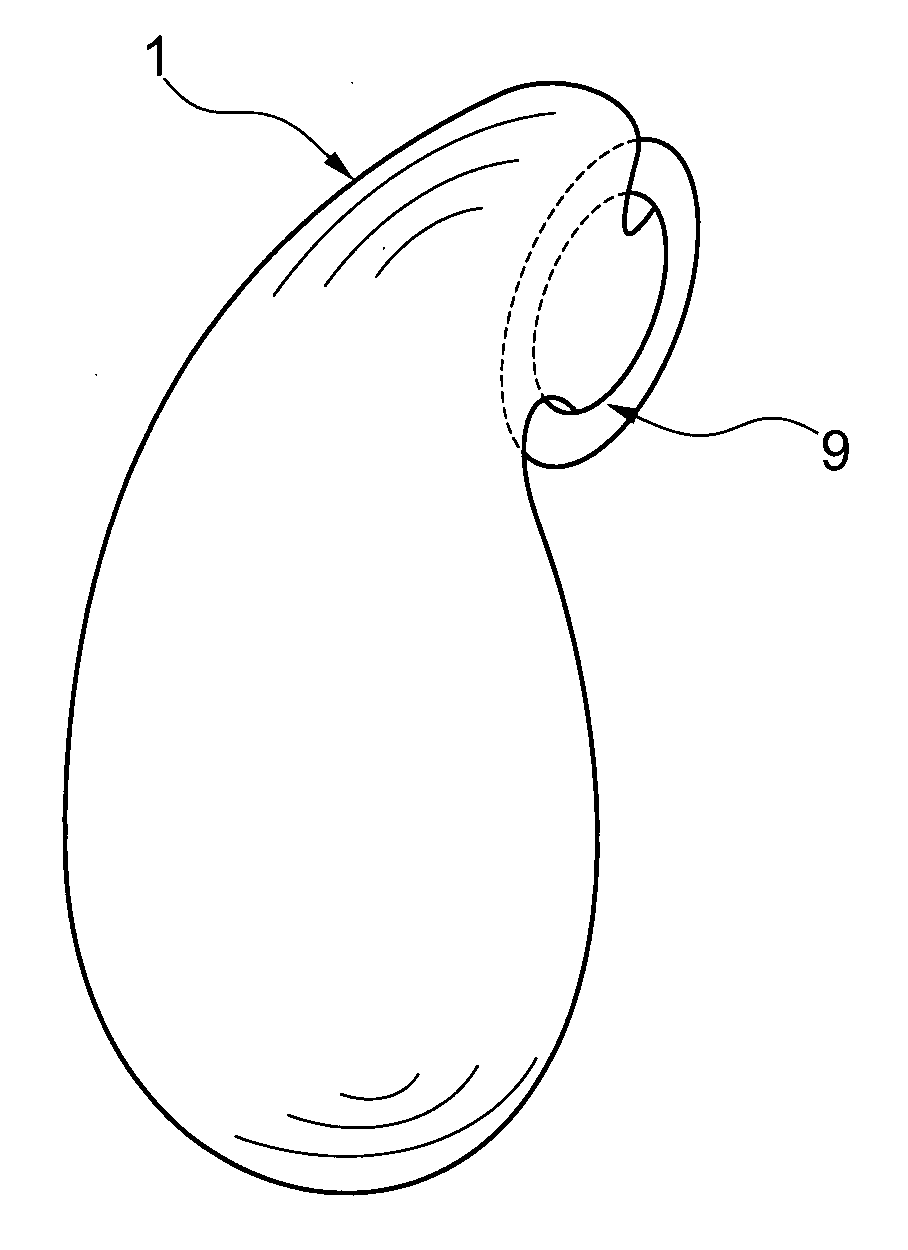

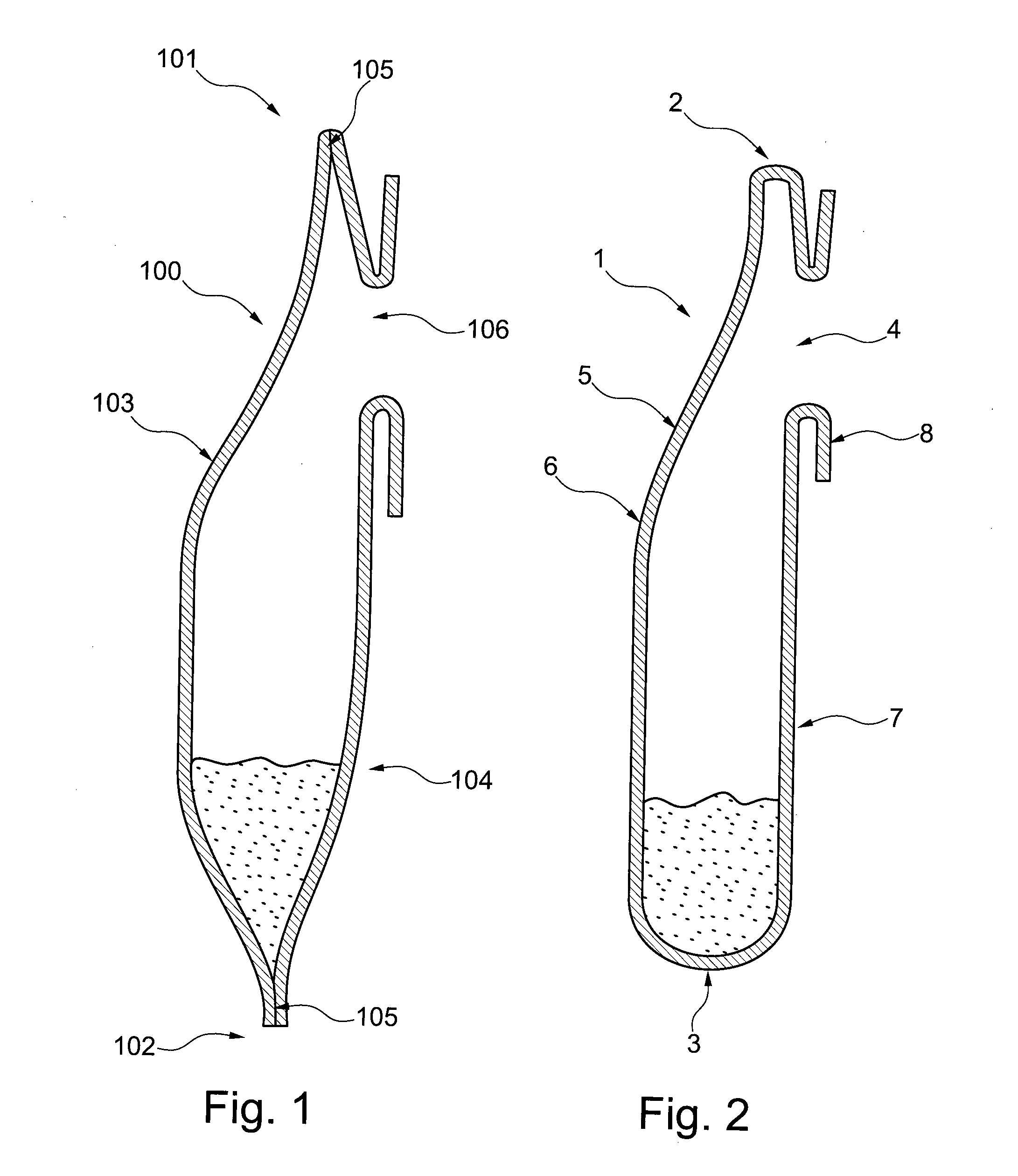

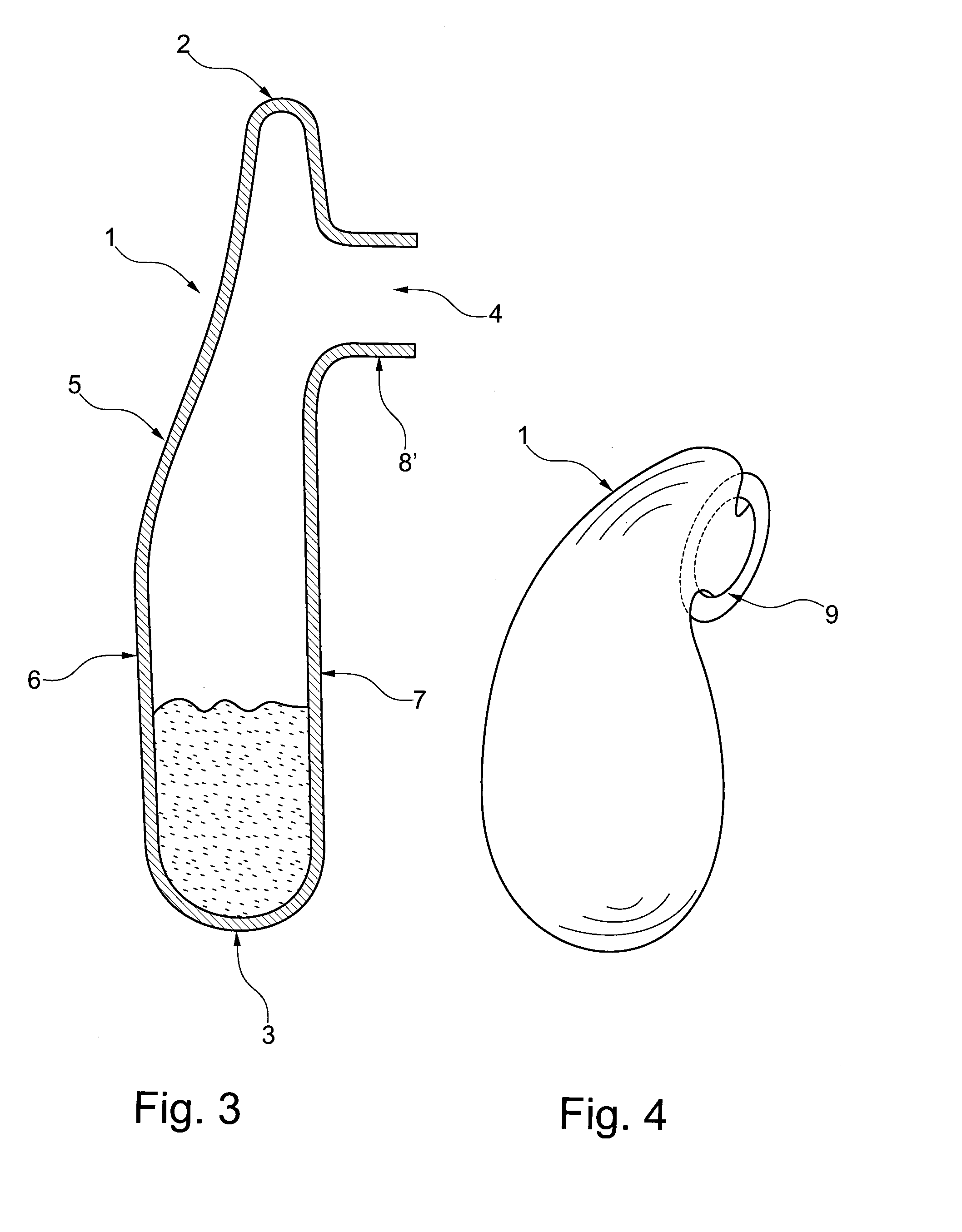

Blow-moulding of ostomy bags

ActiveUS20150265454A1Reduce flexibilityReduced flexibilityNon-surgical orthopedic devicesDomestic articlesEngineeringInjection moulding

An ostomy collecting bag is provided. The collecting bag has a continuous wall with a curvature instead of sealed edges. The collecting bag is truly three-dimensional. The collecting bag may be obtained by injection blow-moulding or extrusion blow-moulding. Methods of producing an ostomy collecting bags by either injection blow-moulding or extrusion blow-moulding is also provided. In injection blow-moulding, a pre-form is injection moulded and subsequently the pre-form is blow-moulded into an ostomy collecting bag. In extrusion blow-moulding, a tube is extruded and subsequently blow-moulded into an ostomy collecting bag. The ostomy collecting bag can thus be made without seals at the edges, which provides a more flexible collecting bag with a larger interior volume.

Owner:COLOPLAST AS

Easy-to-degrade environment-friendly composite material and production process

The invention discloses an easy-to-degrade environment-friendly composite material which is prepared from, by weight, 30-40 parts of wood powder, 20-26 parts of high-density polyethylene, 10-12 partsof vinyl-acrylic copolymer, 10-12 parts of polylactic acid, 23-29 parts of modified filler, 0.4-0.6 part of flame retardant, 0.2-0.3 part of antioxidant and 0.2-0.3 part of toughener. The invention further discloses a production process of the environment-friendly composite material. A wood-plastic composition material is obtained by taking high-density polyethylene and polyvinyl chloride as highpolymer substrates and wood powder as a main filler. Mechanical performance of the composite material is improved by adding the vinyl-acrylic copolymer and the modified filler; by adding the flame retardant, the composite material has good flame-retardant performance; by compounding a small amount of auxiliaries like the antioxidant and the toughener, related performance like antiaging performanceand toughness of the composite material is improved, and the wood-plastic environment-friendly composite material has excellent performance.

Owner:广州益峰尖纸制品有限公司 +1

Low-friction-coefficient antiblocking smooth coating and preparation method thereof

ActiveCN106928798AReduce flexibilityAnti-adhesionAntifouling/underwater paintsPaints with biocidesLow speedIon exchange

The invention relates to a low-friction-coefficient antiblocking smooth coating and a preparation method thereof. The low-friction-coefficient antiblocking smooth coating contains the following components in parts by weight: 90-110 parts of styrene-acrylic emulsion, 15-25 parts of ion exchange silica sol, 10-15 parts of large-particle-size silica sol, 15-25 parts of water, 30-50 parts of ethanol, 2-4 parts of n-butyl alcohol and 0.4-0.6 part of sodium polystyrene sulfonate. The preparation method comprises the following steps: a, by taking styrene-acrylic emulsion with the pH value of 8-9 as a base material, slowly doping silica sol, stirring for 1 hour at a rotating speed of 500rpm, and uniformly mixing materials; b, then adding mixed solution of water and ethanol, slowly adding a n-butyl alcohol defoaming agent, and stirring for 20 minutes at a low speed; and c, finally adding water diluted solution of sodium polystyrene sulfonate, stirring for 10 minutes at a low speed, then filtering by virtue of a 300-mesh filter net, standing, and defoaming for later use. Therefore, the coating has multiple advantages of antistatic property, antiblocking property, good weather resistance, high printing color density, low flexibility and improved paper feeding passing rate of a printing medium, the coating is easy to process and manufacture, and batch production can be carried out.

Owner:江苏耐斯数码科技股份有限公司

Conveyor chain

A section of chain for conveying product along a material handling system includes a pin connecting a center link between two side links. The pin may have a sleeve portion around and at least partially along the shaft portion of the pin. The sleeve portion may engage a center link of the section of chain and may be movable relative to the shaft portion. The sleeve portion may comprise a polymeric material. The sleeve portion may be molded over an I-pin or the like, or may be slid or pressed onto a stud-ended pin or bolt or the like. The pin may include a generally spherical-shaped ball member or portion on the shaft portion to enhance flexibility of the section of chain. The pin may be dialable or selectably positioned at the side links to control and adjust the wear surface of the pin relative to the chain links.

Owner:弗诺斯特链运有限公司

Preparation method of moisture-permeable plasticized polyurethane rubber

InactiveCN108250401ALow temperature resistanceImprove low temperature plasticityPrepolymerSide chain

The invention discloses a preparation method of a moisture-permeable plasticized polyurethane rubber, and belongs to the technical field of rubber preparation. According to the preparation method provided by the invention, 1,4-butanediol is used as an initiator; boron trifluoride diethyl etherate is used as a catalyst; tetrahydrofuran and epoxy chloropropane are polymerized by cationic ring-opening polymerization to form a copolyether of tetrahydrofuran / epoxy chloropropane; then sodium azide is added for the azidation of the copolyether of the tetrahydrofuran / epoxy chloropropane; and a prepolymer is obtained, so that the moisture permeability of polyurethane rubber is improved. The prepolymer provided by the preparation method is a copolyether of tetrahydrofuran / glycidyl azide polymer; themain chain segment of the prepolymer is tetrahydrofuran, so that the glass transition temperature of the copolyether is reduced; the glycidyl azide polymer chain segment hinders the flexibility of the main chain segment due to azide groups on side chains, the low-temperature-resistant lower limit of the glycidyl azide polymer is lower, so that the low-temperature plasticity of the polyurethane rubber is improved; and the glycidyl azide polymer is used as an adhesive, so that the mechanical property of the polyurethane rubber is improved, and the application prospect is wide.

Owner:仇颖莹

Coated cogwheel

InactiveCN103216602AAvoid splittingPrevent peelingLayered productsPortable liftingEngineeringMechanical engineering

The cogwheel has a main portion which is made from basis material with lesser hardness. A layer (6) is arranged on portion of cogwheel main portion and provided with greater hardness. The layer is subdivided by seams (7) into multiplicity of segments (8) in spaced-apart relationship. The layer is arranged on tooth flank (4) of cogwheel main portion. The seams are sized to cut completely through layer and to extend into cogwheel main portion. An independent claim is included for a method for producing coated cogwheel.

Owner:SIEMENS AG

Special sealing plate material for automobile engine and gearbox

InactiveCN101696727AImprove creep resistanceReduce stress relaxation rateEngine sealsAcrylonitrileStress relaxation

The invention discloses a special sealing plate material for an automobile engine and a gearbox, comprising the following raw materials by weight percent: 5-8% of aramid pulp, 20-25% of plant fiber, 23-28% of mineral fiber, 5-10% of nylon fiber, 15-35% of silicate filler, 8-12% of butadiene-acrylonitrile rubber, 10-15% of natural rubber, 1-3% of coupling agent and 0.5-2.5% of vulcanizing system. Compared with the prior art, the invention improves the creep resistance of sealing products, reduces the stress relaxation rate, improves ageing-resistant performance and compactness, changes the proportion of horizontal and longitudinal arrangements of the fiber, and reduces the difference of the longitudinal direction and the horizontal direction so as to improve the tightness.

Owner:南阳天一密封股份有限公司

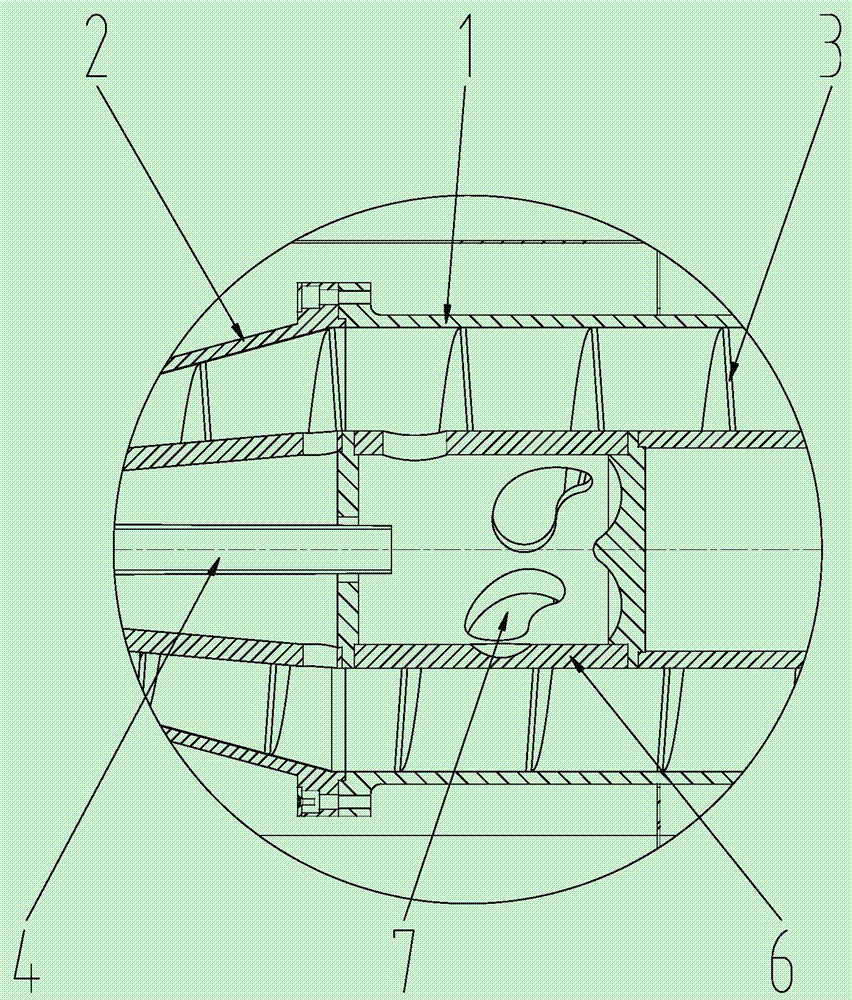

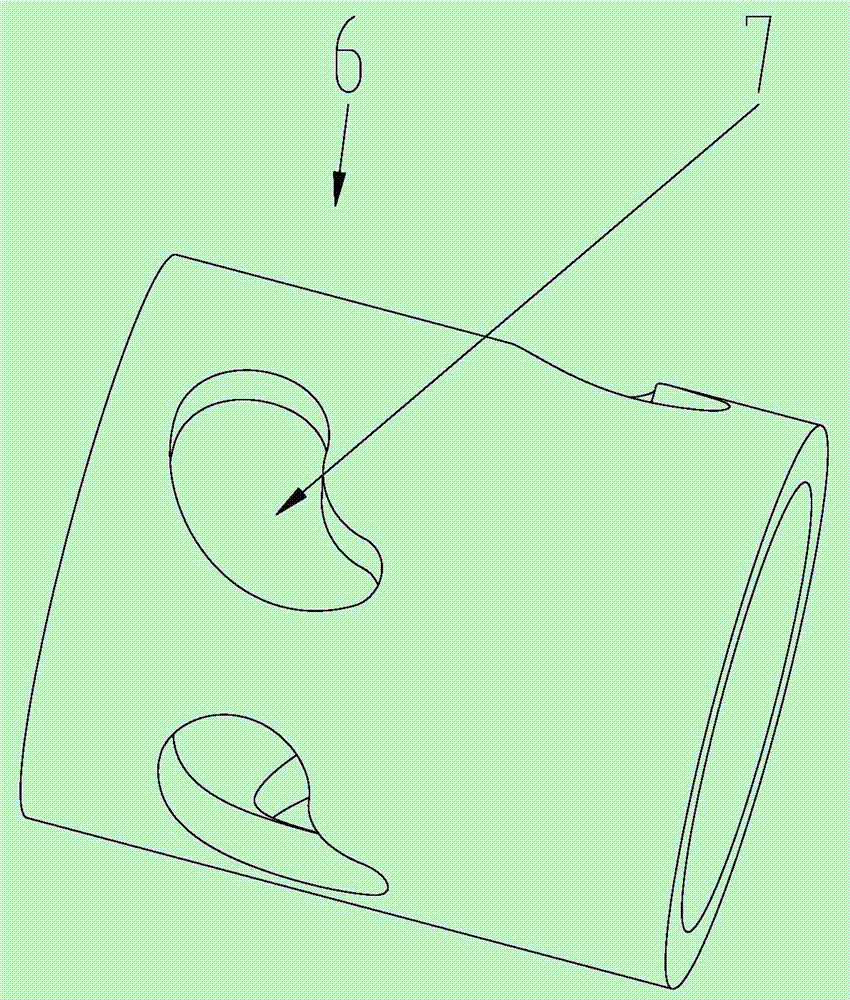

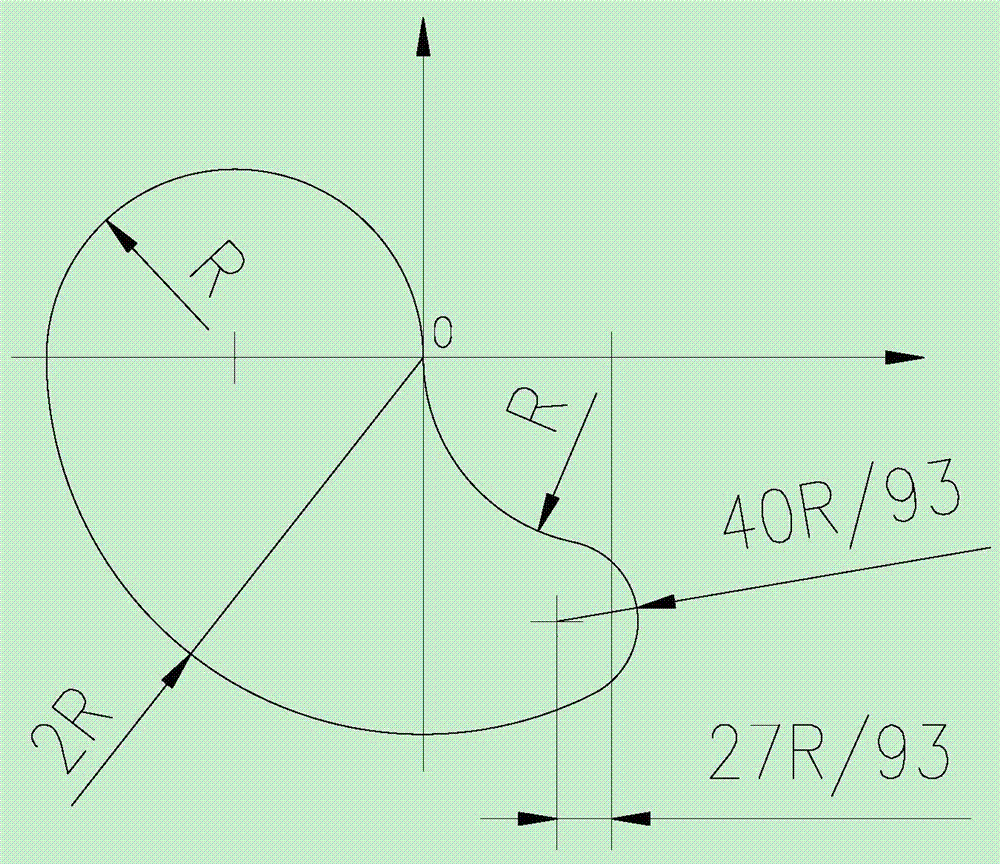

Horizontal spiral discharge sedimentary centrifuge and feeding pipe barrel thereof

ActiveCN104741250AComply with hydraulic distributionQuality improvementRotary centrifugesSpiral bladeEngineering

The invention discloses a feeding pipe barrel of a horizontal spiral discharge sedimentary centrifuge. The feeding pipe barrel comprises a barrel body. A plurality of discharge openings are formed in the barrel body and are in a streamline shape. All the discharge openings are distributed in a spiral mode. The invention further discloses the horizontal spiral discharge sedimentary centrifuge. The horizontal spiral discharge sedimentary centrifuge comprises a straight drum, a conical drum and a spiral body, wherein the conical drum is installed at one end of the straight drum, and the spiral body is arranged inside the conical drum. Spiral blades are arranged on the peripheral wall of the spiral body. A feeding pipe is arranged inside the spiral body. The feeding pipe barrel communicated with the feeding pipe is arranged inside the spiral body. The disturbance influence formed by fluid on a sedimentary separation area during suspension liquid discharging can be effectively reduced, and the centrifugal separation effect is improved.

Owner:GREEN WATER SEPARATION EQUIP

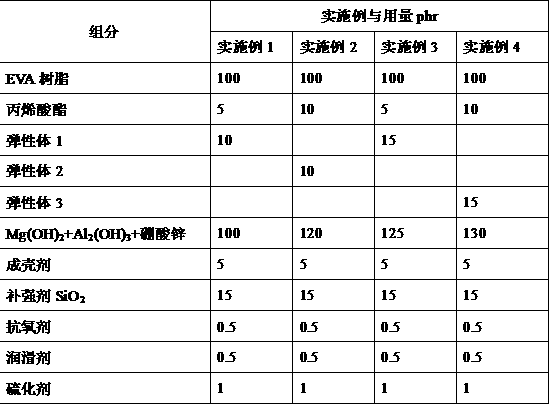

Crust-type high-elongation low-smoke halogen-free flame-retardant polyolefin cable material and preparation method thereof

InactiveCN109251401ANo significant decrease in elongation at breakNo significant reduction in flexibilityPlastic/resin/waxes insulatorsElastomerPolyolefin

The invention provides a crust-type high-elongation low-smoke halogen-free flame-retardant polyolefin cable material, which is characterized in that raw materials of the cable material comprise the following ingredients (by weight): 40-70 parts of an ethylene-vinyl acetate copolymer, 2-10 parts of acrylate rubber, 5-20 parts of ethylene propylene rubber, 2-20 parts of an elastomer, 100-120 parts of a flame retardant, 10-30 parts of an anti-smoke flame retardant, 0.1-2 parts of an antioxidant, 0.1-2 parts of a lubricant, 0.5-2 parts of a vulcanizing agent, 5-20 parts of a reinforcing agent, and1-5 parts of a crust-forming agent. The invention also provides a preparation method of the cable material. The cable material can help reduce toxic fumes.

Owner:ANHUI HUALING CABLE GRP

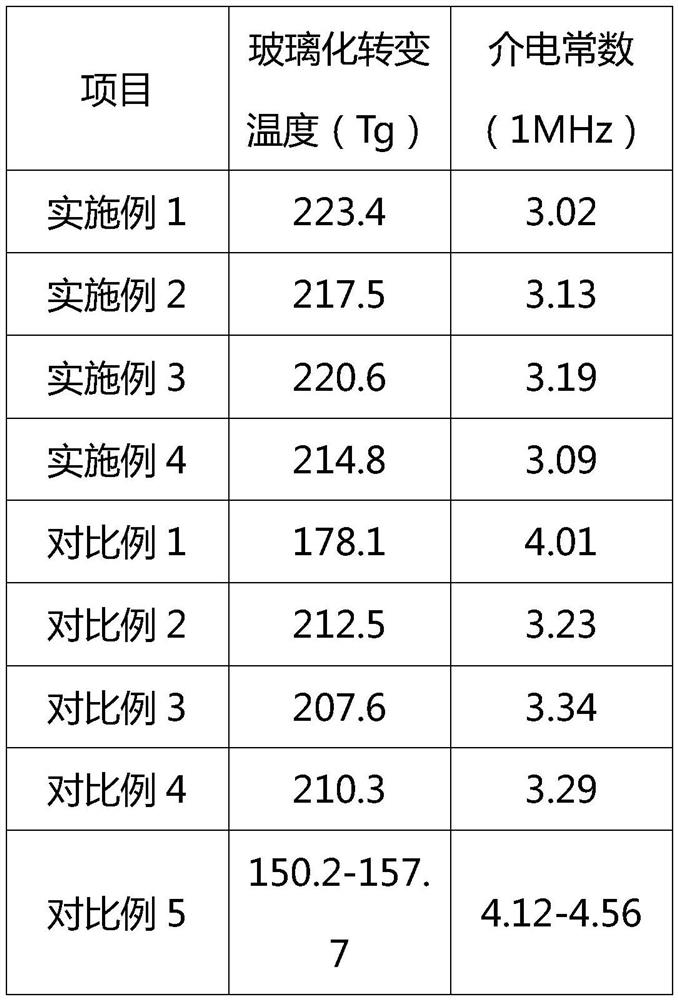

High-performance acrylic resin type photosensitive circuit board ink and preparation method thereof

ActiveCN112175444AHigh glass transition temperatureLower glass transition temperatureInksPhotosensitive materials for photomechanical apparatusPolymer scienceAcrylic resin

The invention provides a high-performance acrylic resin type photosensitive circuit board ink and a preparation method thereof, and belongs to the technical field of ink. The ink comprises the following components in parts by weight: 120-160 parts of epoxy acrylate resin, 25-40 parts of cyanate ester prepolymer, 12-40 parts of N-phenylmaleimide, 1.2-2.4 parts of maleic anhydride, 2-4 parts of styrene, 8-12 parts of acrylic acid, 1-5 parts of epoxy resin curing agent, 5-7 parts of photosensitive monomer, 0.5-0.7 part of wetting agent, 0.2-0.6 part of dispersing agent, 1.2-1.8 parts of defoamingagent, 2.5-4.5 parts of drier, 0.3-0.5 part of thixotropic agent, 10-12 parts of water-based photoinitiator, 0.4-0.6 part of pigment, 25-38 parts of filler and 2-5 parts of water. Under the mutual cooperation of the epoxy acrylate resin, the cyanate ester prepolymer and the N-phenyl maleimide, the dielectric property and the thermal stability of the ink are synergistically improved.

Owner:连云港百利合新材料发展有限公司

Crosslinked laminated wrapping film and container box therefor

InactiveCN1265962CExcellent Adhesive PropertiesEasy to pull outSynthetic resin layered productsFlat article dispensingLow-density polyethyleneLinear low-density polyethylene

The present invention relates to wrap films, especially wrap films for food. More specifically, the present invention pertains to crosslinked laminated polyethylene wrap films which are excellent in clinging property, pulling-out ease from a dispenser box and heat resistance, does not emit much odor, permits suitable food wrapping and can be produced efficiently. Specifically, the present invention provides a crosslinked laminated wrap film having, at least, two surface layers and one intermediate layer, wherein the two surface layers each comprises 20 to 90% by weight of a linear low density polyethylene and 80 to 10% by weight of a high pressure process low density polyethylene, wherein the intermediate layer has at least one layer comprising 50 to 95% by weight of a high density polyethylene and 50 to 5% by weight of a high pressure process low density polyethylene, and wherein the surface layers and intermediate layer each has 0.050 to 0.800 part by weight of glycerin monofatty acid ester based on 100 parts by weight in total of the two polyethylenes constituting the respective layer.

Owner:ASAHI KASEI KK

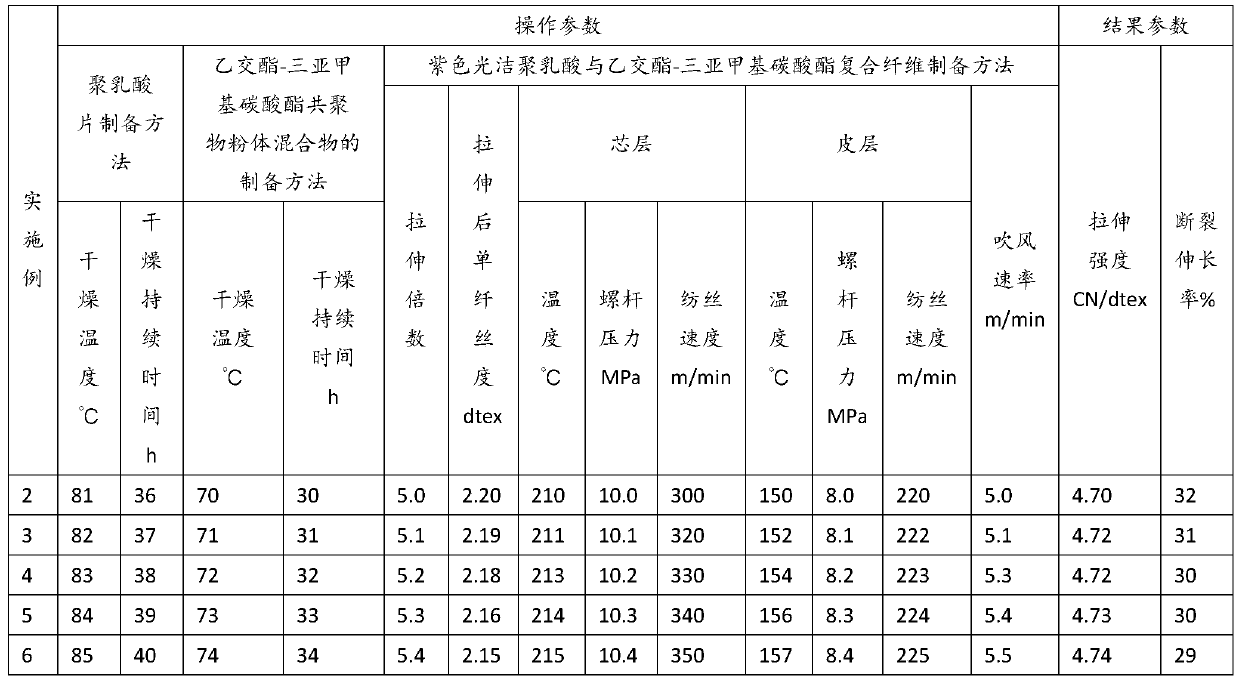

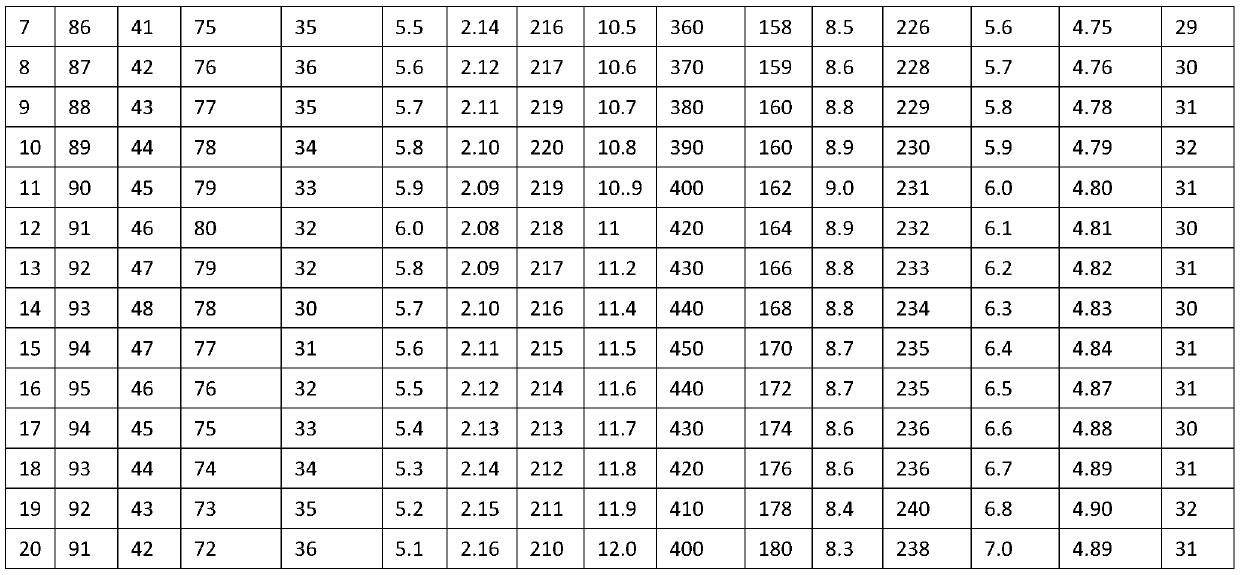

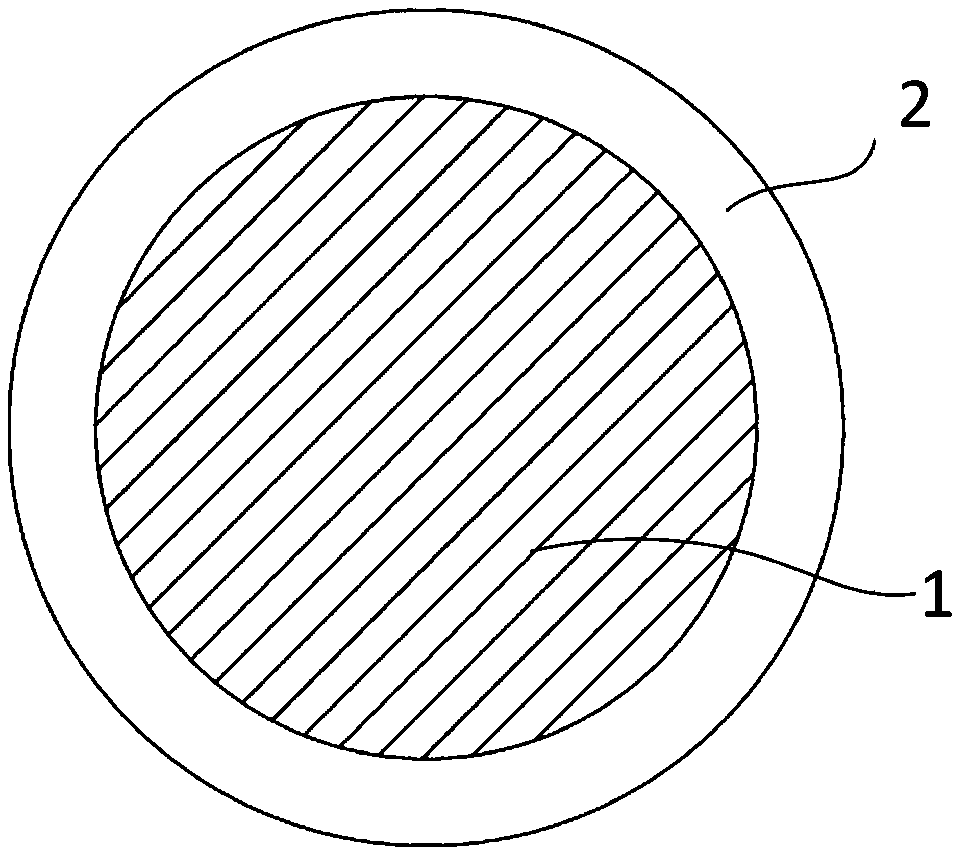

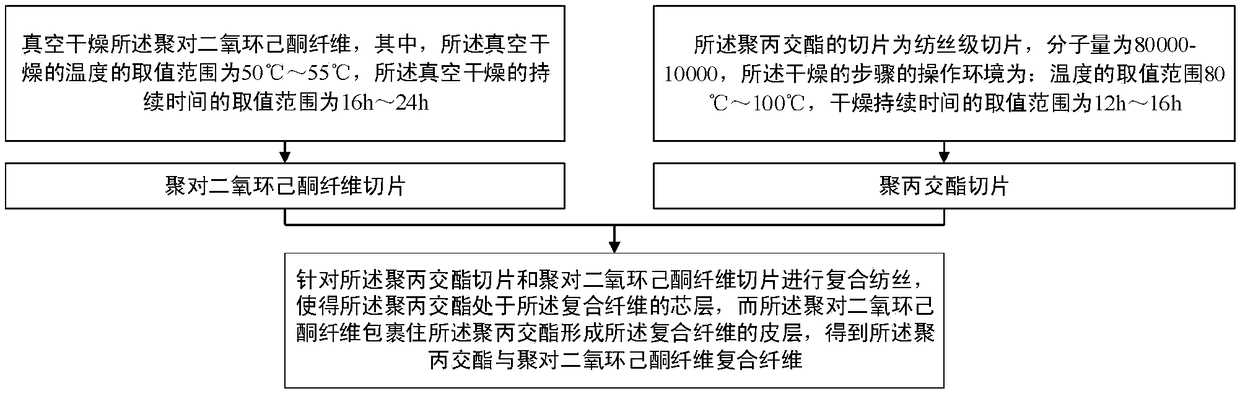

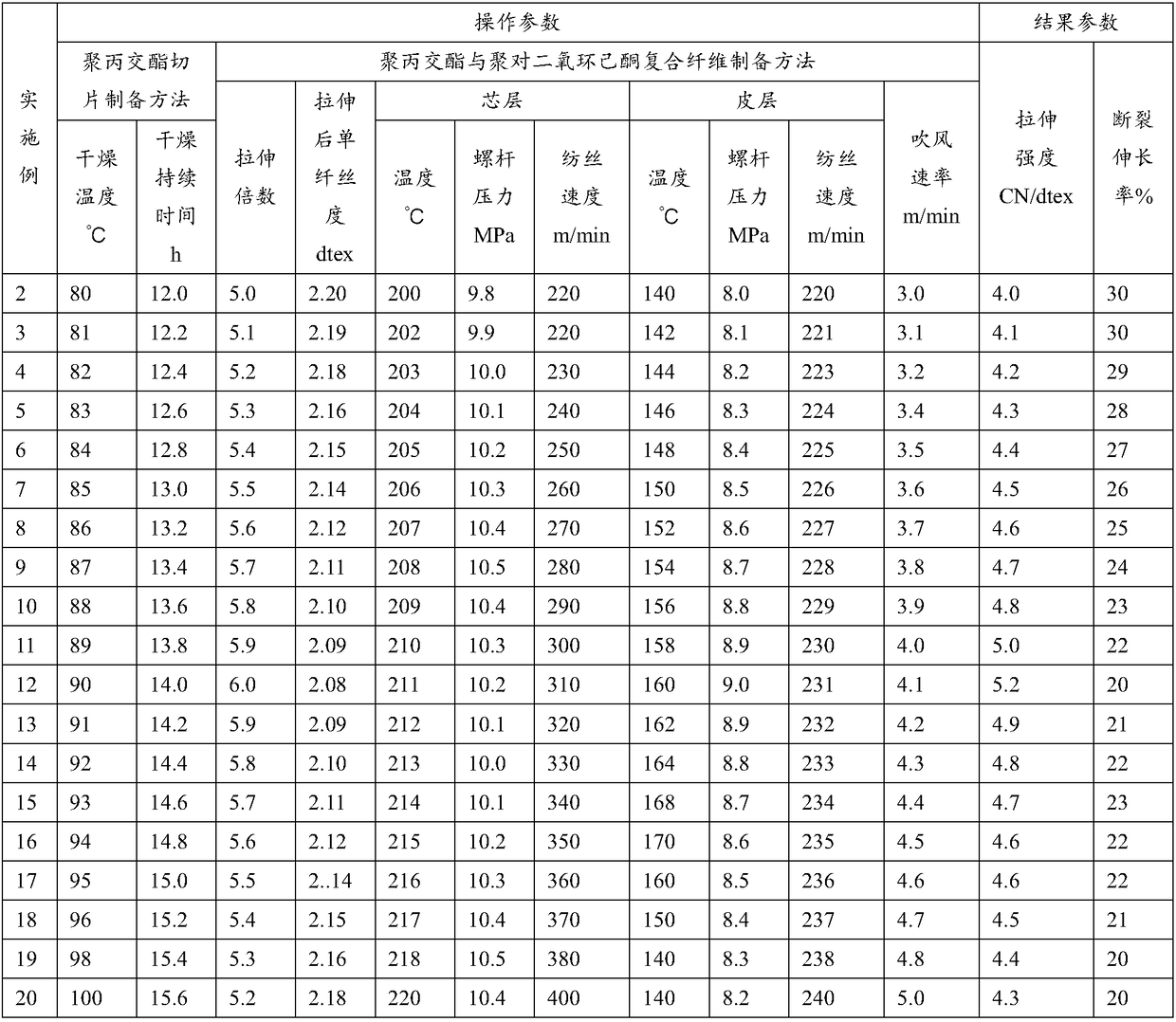

Colorful polylactic acid and glycolide-trimethylene carbonate copolymer composite fiber and preparation method thereof

PendingCN110592721AReduce flexibilitySlow down degradationFilament/thread formingConjugated synthetic polymer artificial filamentsFiberPowder mixture

The invention discloses a colorful polylactic acid and glycolide-trimethylene carbonate copolymer composite fiber and a preparation method thereof. The composite fiber comprises a glycolide-trimethylene carbonate copolymer powder mixture and a polylactic acid composite fiber, after the composite fiber is formed, the polylactic acid fiber forms a core layer of the composite fiber, and the colorfulglycolide-trimethylene carbonate copolymer forms a skin layer of the composite fiber. The preparation method comprises the steps that the glycolide-trimethylene carbonate copolymer powder mixture andpolylactic acid slices are obtained respectively; the raw materials are subjected to composite spinning, the polylactic acid is located in the core layer of the composite fiber, the polylactic acid iscoated with the colorful glycolide-trimethylene carbonate copolymer to form the skin layer of the composite fiber, and the colorful composite fiber is obtained. The colorful composite fiber preparedby using the method can meet the requirements for a surgical suture, the colorful composite fiber is softer, and the cost is lower.

Owner:CHINESE TEXTILE ACAD

Polylactide-p-dioxanone composite fiber, preparation method thereof, application and surgical suture

ActiveCN109234843AIncreased biodegradation rateGood biocompatibilitySuture equipmentsFilament/thread formingP-dioxanoneFiber

The invention discloses a polylactide-p-dioxanone composite fiber, a preparation method thereof, application and a surgical suture. In the composite fiber, a polylactide fiber serves as a core layer of the composite fiber, and p-dioxanone serves as a skin layer of the composite fiber. The preparation method comprises the following steps: respectively obtaining a polylactide slice and a p-dioxanoneslice; performing composite spinning on the polylactide slice and the p-dioxanone slice, so that polylactide is located at the core layer of the composite fiber, and the p-dioxanone is used for packaging the polylactide to form the skin layer of the composite fiber, so as to obtain the polylactide-p-dioxanone composite fiber. The composite fiber can be used for the surgical suture. The surgical suture is prepared from the composite fiber. The value range of the tensile strength of the composite fiber is 4.0CN / dtex-5.2CN / dtex, and the value range of the breakage elongation is 20%-30%, so thatthe composite fiber can meet the requirements of the surgical suture and is low in manufacturing cost.

Owner:CHINESE TEXTILE ACAD

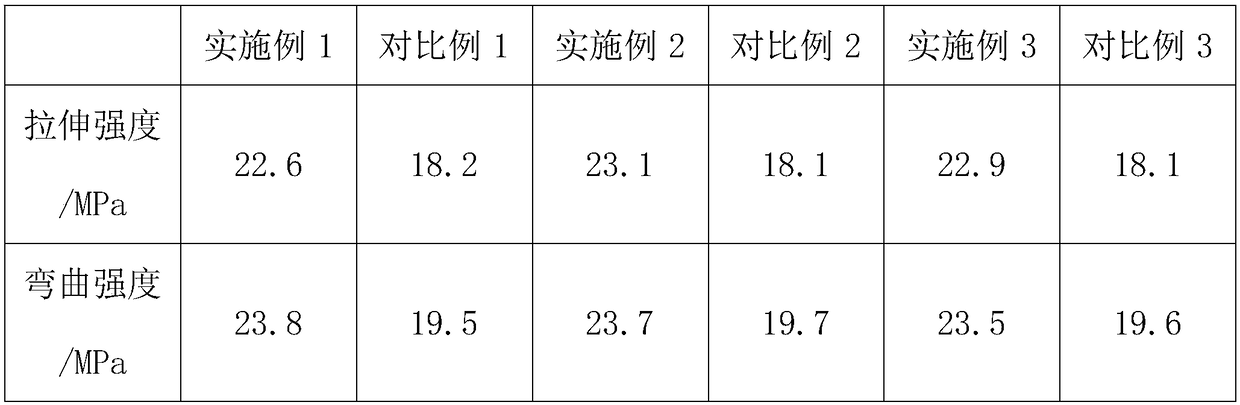

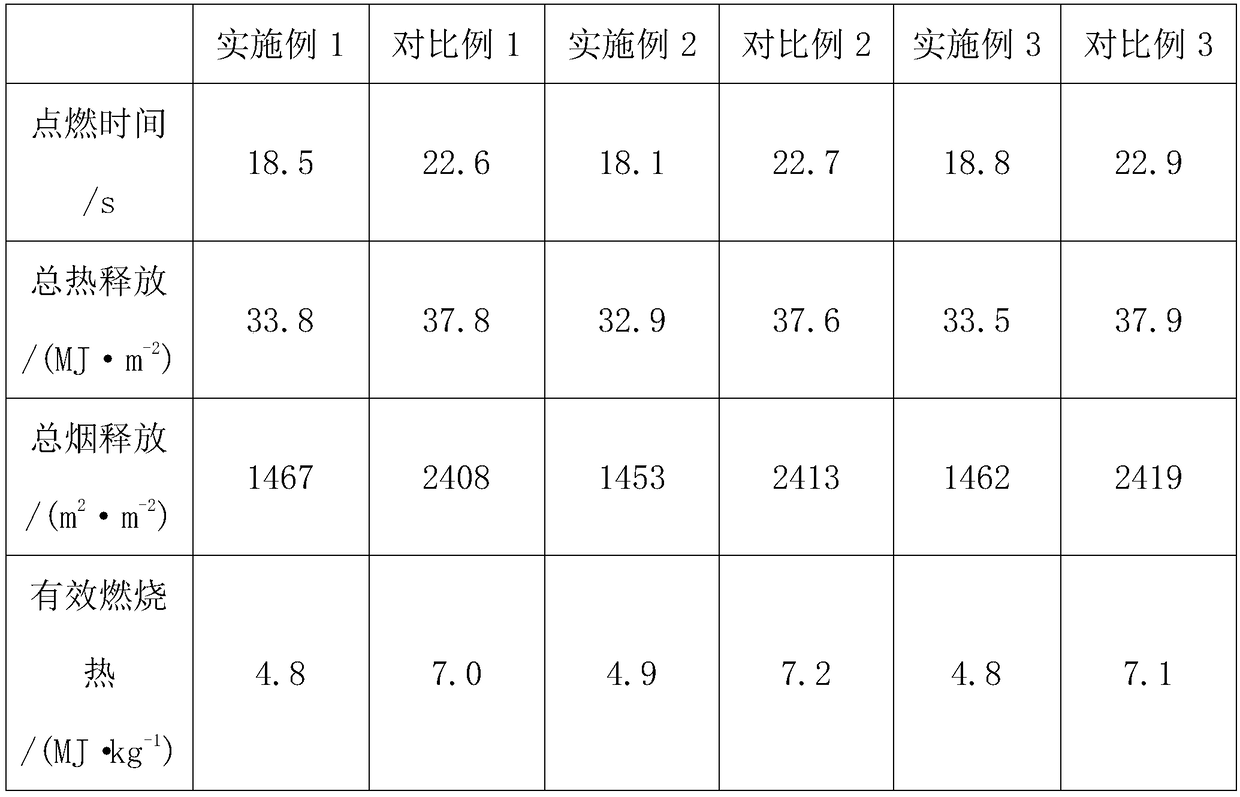

Flame-retardant and wear-resistant polypropylene pipe

The invention discloses a flame-retardant and wear-resistant polypropylene pipe. The pipe is prepared from, by weight, 95-100 parts of random copolymerization polypropylene, 9-12 parts of liquid polysulfide rubber, 5-9 parts of ethylene-vinyl acetate copolymer, 3-4 parts of styrene-butadiene thermoplastic elastomer, 17-20 parts of kaolin, 15-18 parts of organic bentonite, 7-10 parts of flame-retardant modified zeolite powder, 13-16 parts of expandable graphite, 2-3 parts of paraffin, 1-2 parts of tributyl citrate, 1-2 parts of epoxy tall oil, 2-4 parts of stabilizer and 1-3 parts of anti-aging agent. The flame-retardant and wear-resistant polypropylene pipe is excellent in flame retardance, and good in impact resistance and wear resistance.

Owner:ANHUI ZHENGSHI NEW BUILDING MATERIAL

Polyurethane lining plate and preparation method thereof

The invention relates to a polyurethane lining plate and a preparation method thereof, and belongs to the field of wear-resistance protection of equipment. The polyurethane lining plate consists of a prepolymer and a curing agent containing an ether bond at a weight ratio of 100 to (8-12), wherein the prepolymer is prepared from the following raw materials in parts by weight of 100 parts of polyhydric alcohol, 35-50 parts of isocyanate, 5-10 parts of silicon carbide particles, 0.3-0.8 part of an organotin catalyst and 0.04-0.15 part of a coupling agent. With the adoption of the polyurethane lining plate provided by the invention, the structural strength of a polyurethane elastomer is improved and the hydrolysis property of the polyurethane elastomer is reduced; the wear resistance of the product is effectively improved; the softness of the ether bond is improved and the rigidity of the ether bond is realized, so that not only can various physical and mechanical properties of the elastomer be ensured, but also the hydrolysis resistance stability and strength of the polyurethane lining plate are improved, the impact deformation is prevented and the more firm structure is realized; the mounting and dismounting processes are simple and convenient, the processing intensity of an inner liner of the equipment is reduced, and the lining plate is convenient to replace; the shut-down time for maintenance of the equipment is shortened, the investment cost caused by equipment production is reduced, and the production efficiency is improved.

Owner:BIRTLEY TIANJIN IND EQUIP

Conveyor chain

A section of chain for conveying product along a material handling system includes a pin connecting a center link between two side links. The pin may have a sleeve portion around and at least partially along the shaft portion of the pin. The sleeve portion may engage a center link of the section of chain and may be movable relative to the shaft portion. The sleeve portion may comprise a polymeric material. The sleeve portion may be molded over an I-pin or the like, or may be slid or pressed onto a stud-ended pin or bolt or the like. The pin may include a generally spherical-shaped ball member or portion on the shaft portion to enhance flexibility of the section of chain. The pin may be dialable or selectably positioned at the side links to control and adjust the wear surface of the pin relative to the chain links.

Owner:弗诺斯特链运有限公司

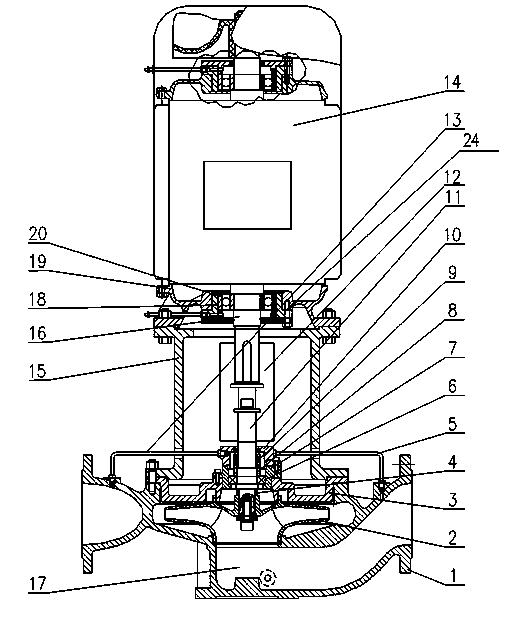

Easy-to-disassemble type single-stage single-suction vertical centrifugal pump

InactiveCN104110389AExtended service lifeImprove volumetric efficiencyPump componentsPump installationsSingle stageCoupling

The invention discloses an easy-to-assemble type single-stage single-suction vertical centrifugal pump which comprises a pump shaft, a coupler and a motor shaft. The pump shaft and the motor shaft are connected through the coupler, and the coupler is a clamp-type coupler. The easy-to-assemble type single-stage single-suction vertical centrifugal pump has the advantage that the parts are convenient to replace.

Owner:上海申宝泵业有限公司

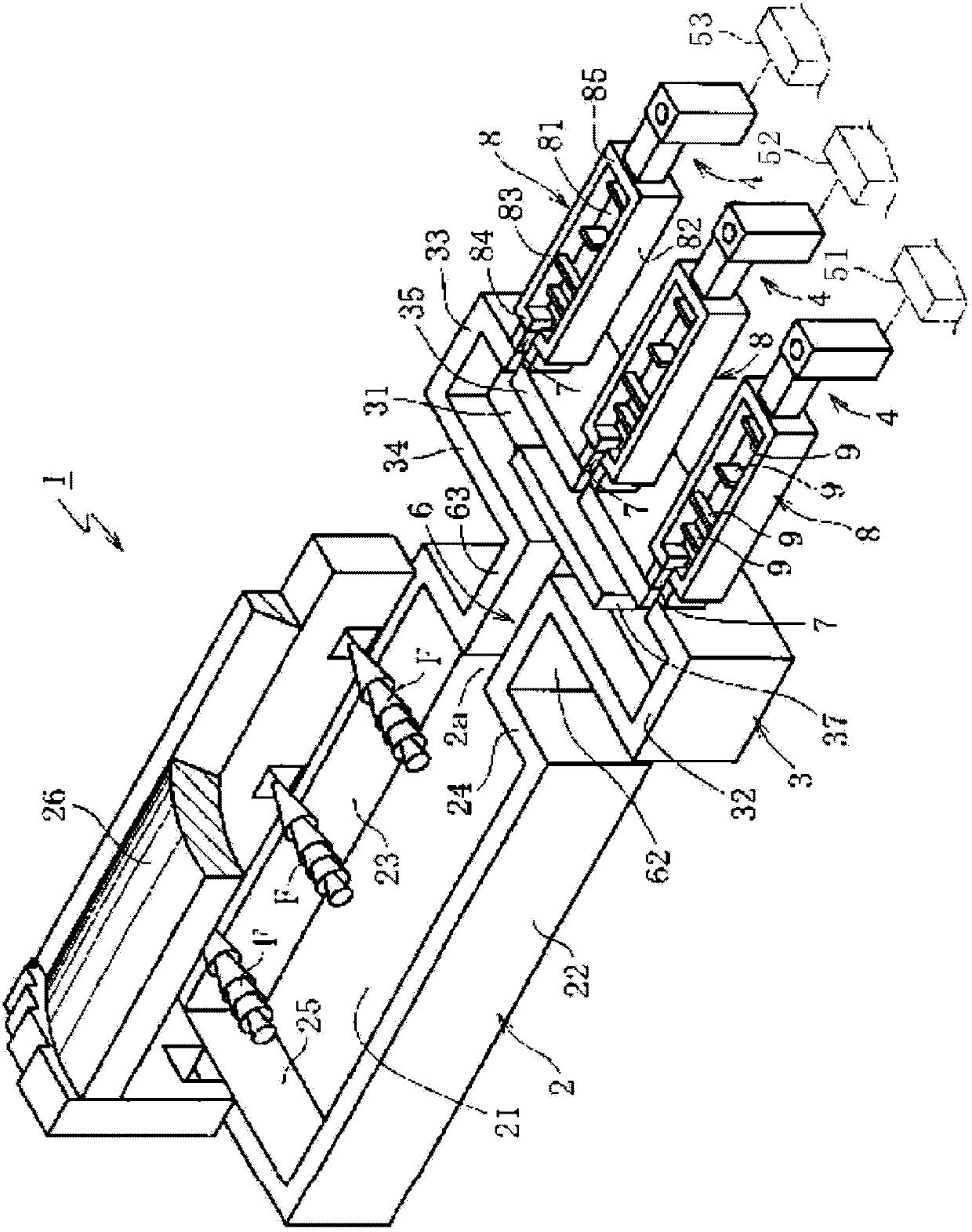

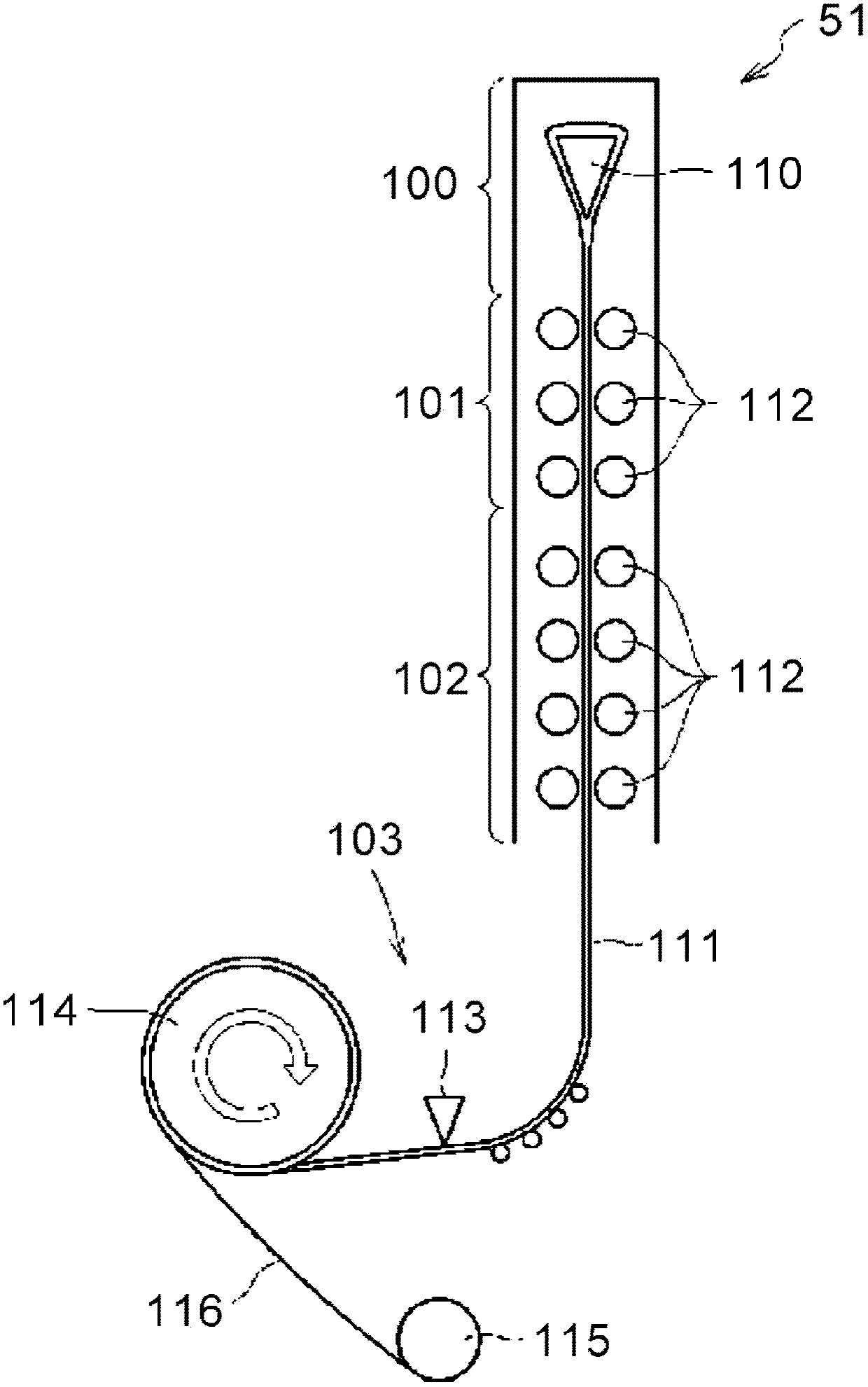

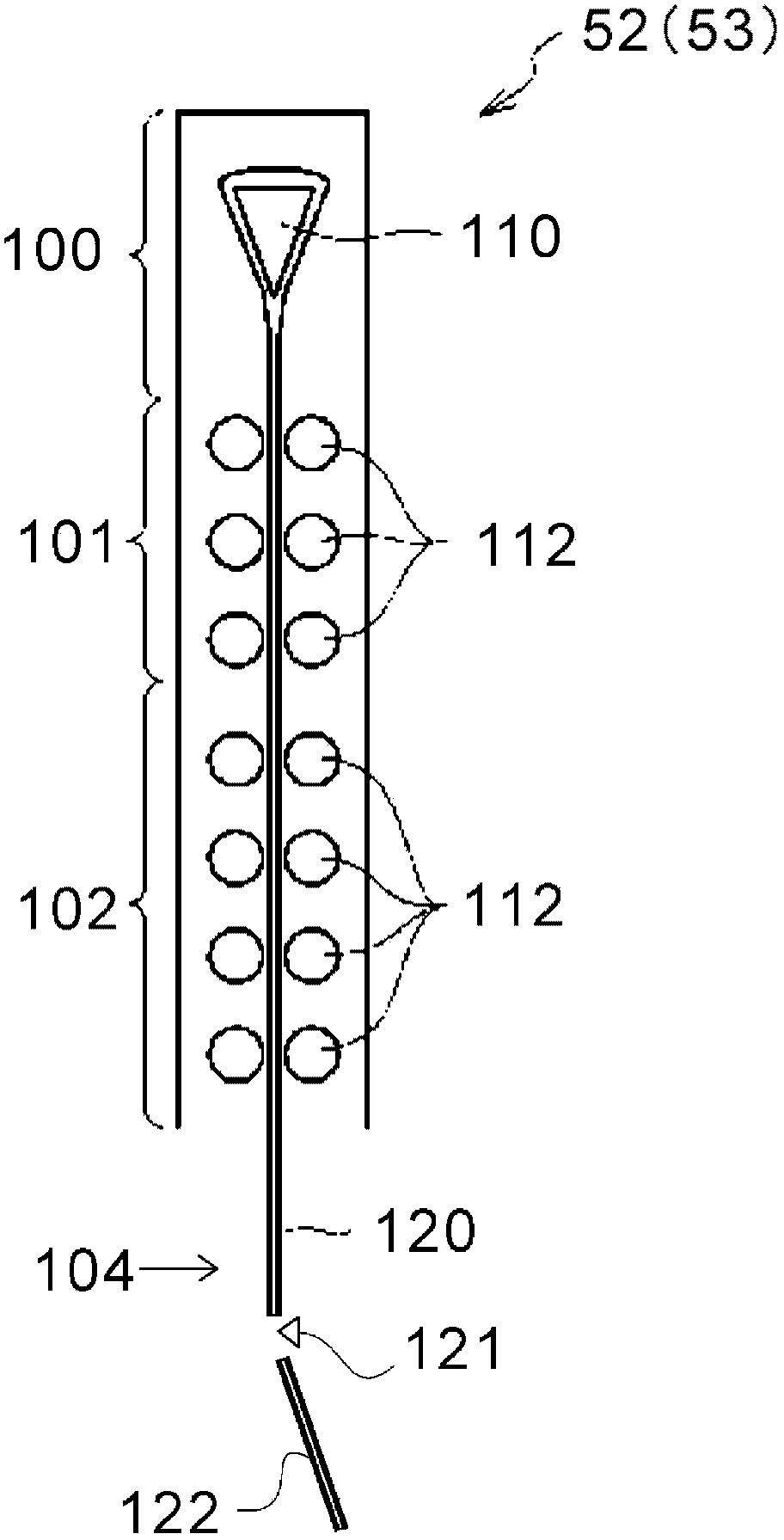

Method for producing glass film

Provided is a method, including: a melting step of melting glass in a melting furnace 2; a distribution step of supplying the molten glass in the melting furnace 2 to a plurality of branched channels 4; and a forming step of supplying the molten glass flowing out from each of the plurality of branched channels 4 to one of a plurality of forming apparatuses 51 to 53 communicating with the plurality of branched channels 4, respectively, and forming the molten glass into a plate-shaped glass by a down-draw method, in which one or more of the plurality of forming apparatuses 51 to 53 are used to form a glass film having a thickness of 1 to 200 μm.

Owner:NIPPON ELECTRIC GLASS CO LTD

Horizontal screw discharge sedimentation centrifuge and its feed tube

ActiveCN104741250BComply with hydraulic distributionQuality improvementRotary centrifugesSpiral bladeEngineering

The invention discloses a feeding pipe barrel of a horizontal spiral discharge sedimentary centrifuge. The feeding pipe barrel comprises a barrel body. A plurality of discharge openings are formed in the barrel body and are in a streamline shape. All the discharge openings are distributed in a spiral mode. The invention further discloses the horizontal spiral discharge sedimentary centrifuge. The horizontal spiral discharge sedimentary centrifuge comprises a straight drum, a conical drum and a spiral body, wherein the conical drum is installed at one end of the straight drum, and the spiral body is arranged inside the conical drum. Spiral blades are arranged on the peripheral wall of the spiral body. A feeding pipe is arranged inside the spiral body. The feeding pipe barrel communicated with the feeding pipe is arranged inside the spiral body. The disturbance influence formed by fluid on a sedimentary separation area during suspension liquid discharging can be effectively reduced, and the centrifugal separation effect is improved.

Owner:GREEN WATER SEPARATION EQUIP

Preparation method of polyurethane sieve plate

The invention discloses a preparation method of a polyurethane sieve plate, and relates to the technical field of polyurethane sieve plate. The preparation method comprises the following steps: (1) preparation of prepolymer, (2) mixing, (3) pouring, (4) pre-curing and demolding, and (5) post curing. Polyester and polyether polyol are used as raw materials, hydrolysis resistance stability of the polyurethane sieve plate is improved by an ether-linkage-containing diamines chain extender, the polyurethane prepolymer is prepared from polyester and polyether blended polyol, and thus, the hydrolysispossibility is reduced while the strength of polyurethane elastomer is improved; the ether-linkage-containing diamines chain extender is used; and aryl with steric effect is introduced in the ether-linkage-containing chain extender, the flexibility of ether linkage is reduced so that the ether linkage is rigid, and the hydrolysis resistance stability of the polyurethane sieve plate is improved while various physical properties and mechanical properties of the elastomer are ensured.

Owner:安徽屹翔滤材有限公司

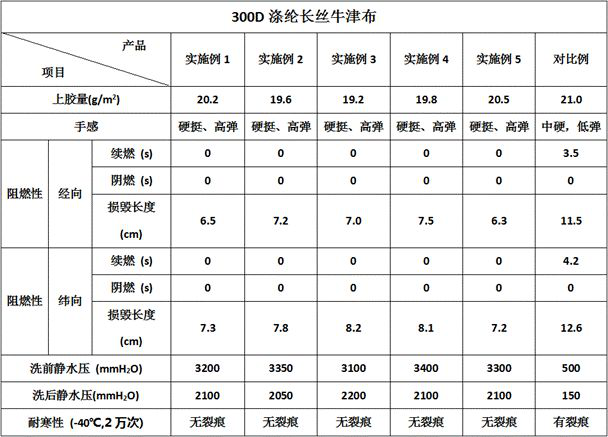

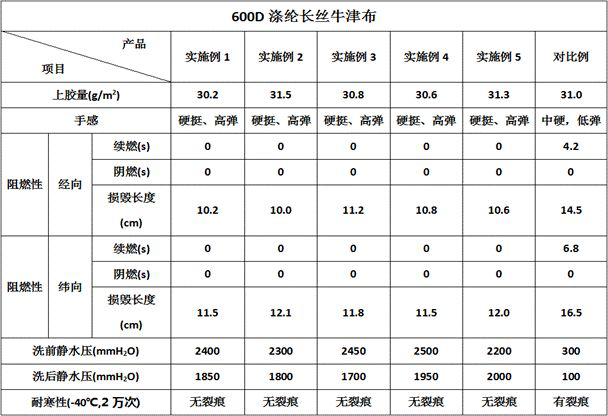

Preparation method of water-based flame-retardant water-pressure-resistant polyurethane emulsion for fabrics

The invention relates to a preparation method of a water-based flame-retardant water-pressure-resistant polyurethane emulsion, which is prepared from isophorone diisocyanate, hydrogenated phenylmethane diisocyanate, polyoxypropylene triol, tris(dipropylene glycol)phosphite, linear dihydroxyalkyl siloxane, melamine cyanurate, dimethylolpropionic acid, 2-methyl-1,3-propylene glycol, triethylamine, hydrazine hydrate and deionized water through a prepolymerization reaction, a neutralization reaction, an emulsification reaction and a chain extension reaction. The fabric is stiff and dry in hand feeling and is high in elasticity, high in fastness, cold-resistant, high in water pressure resistance, good in flame retardance, environmentally friendly and low in production cost.

Owner:LIAONING FIXED STAR FINE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com