Patents

Literature

49results about How to "Increased biodegradation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

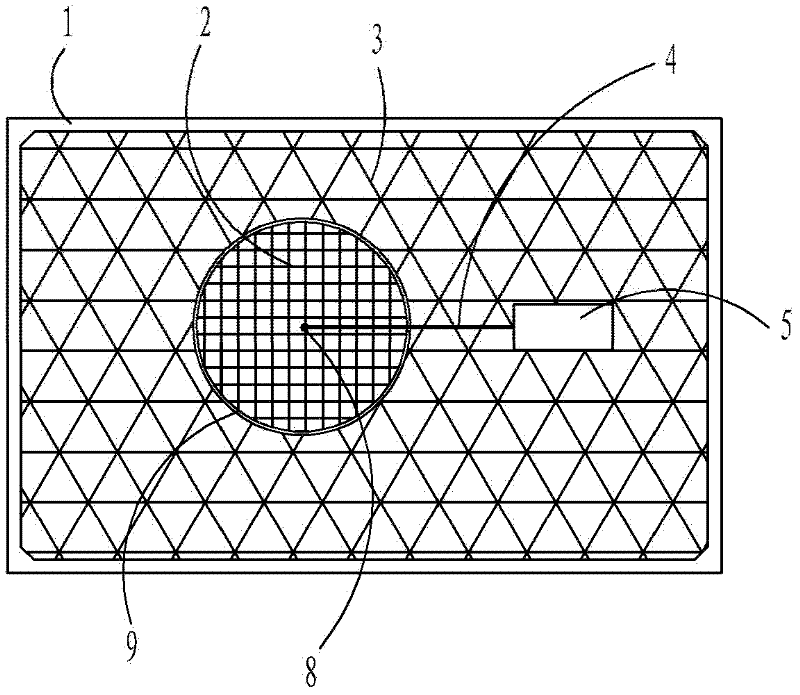

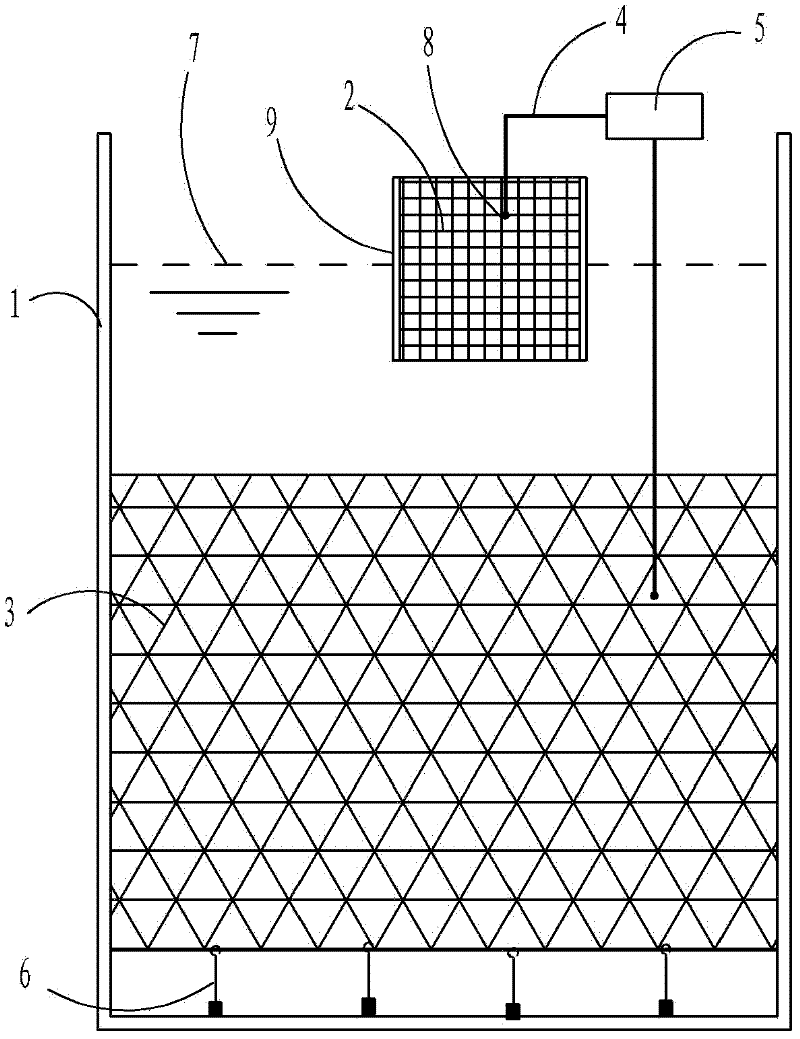

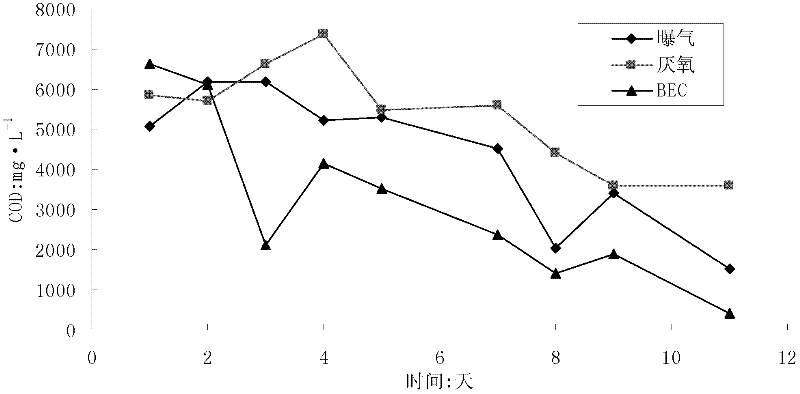

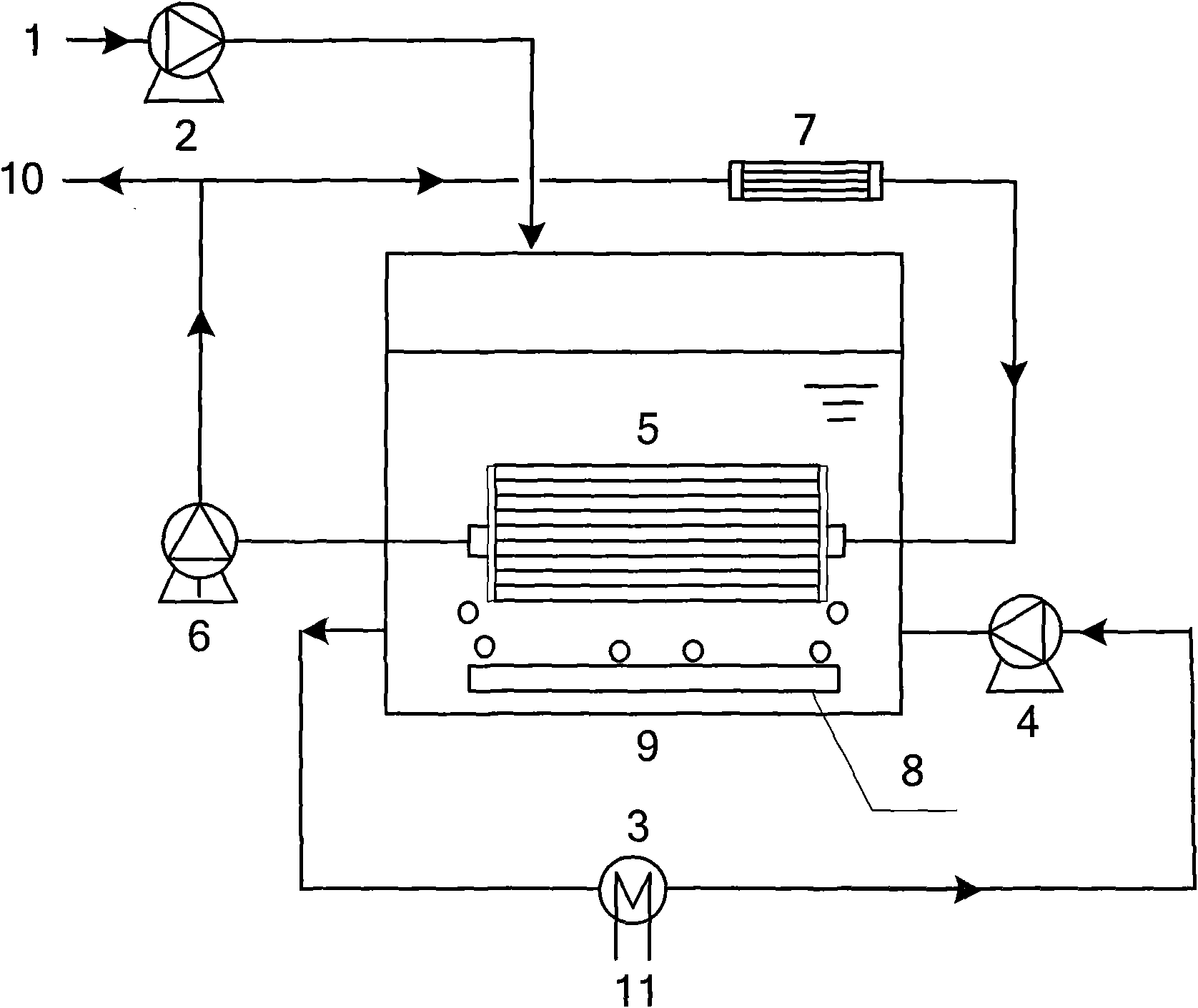

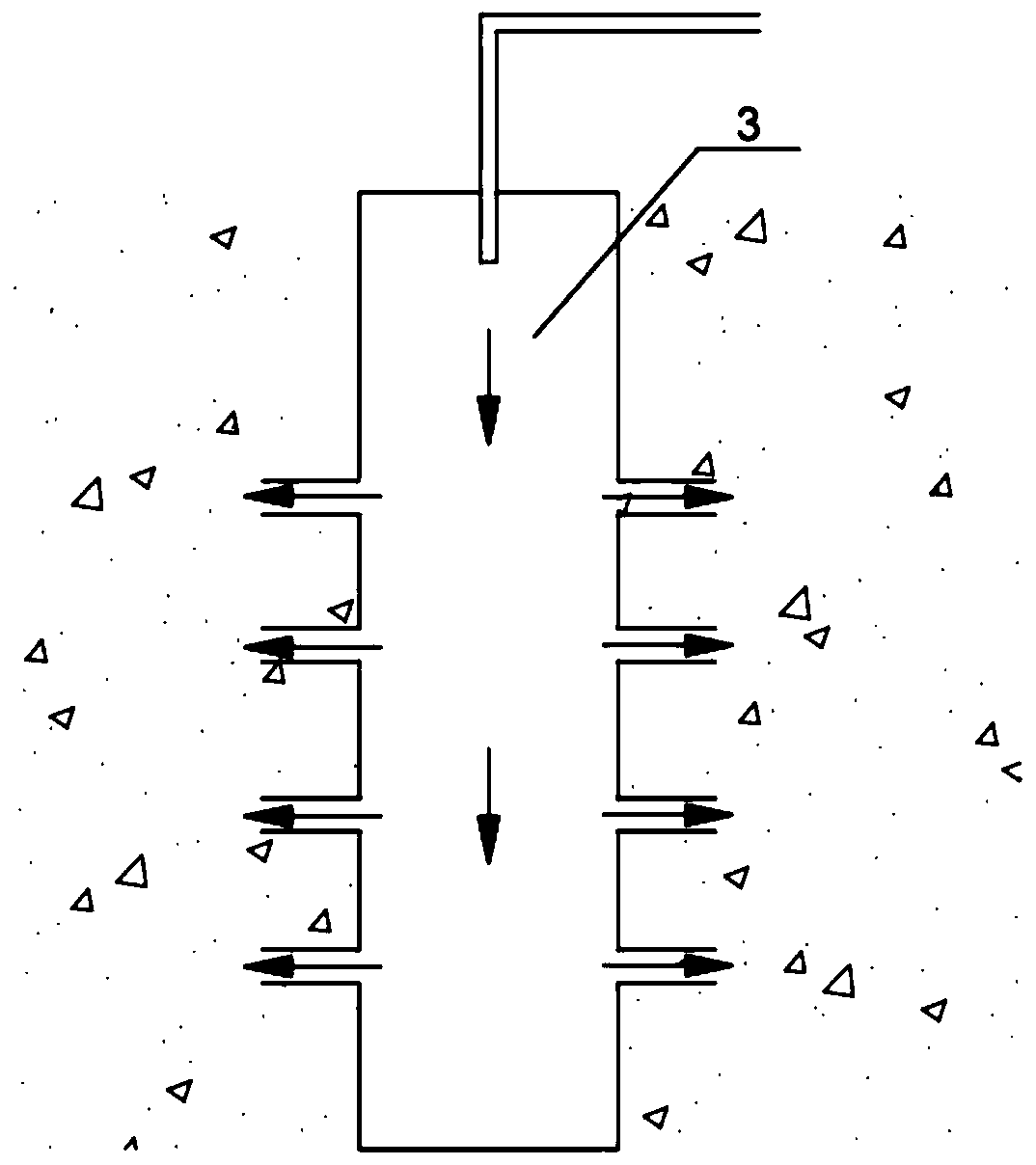

Bio-electrochemical enhanced waste water treatment device

InactiveCN102249397AEasy to handleReduce energy consumptionTreatment using aerobic processesSustainable biological treatmentBioelectrochemistryResistor

The invention discloses a bio-electrochemical enhanced waste water treatment device, which is characterized in that: anodes which are soaked in water and are uniformly distributed are fixedly arranged in an aeration basin; the anodes are connected with cathodes which float on the surface of a water body through leads; and a resistor is connected in series to the leads. In the treatment device, electrochemical and biochemical treatment technologies are integrated, molecular oxygen in the air can be directly utilized, and aeration in the biological treatment process of waste water is eliminated or reduced, so that the treatment device has the advantages of good waste water treatment effect, low energy consumption, long electrode service life and small investment.

Owner:HEFEI UNIV OF TECH

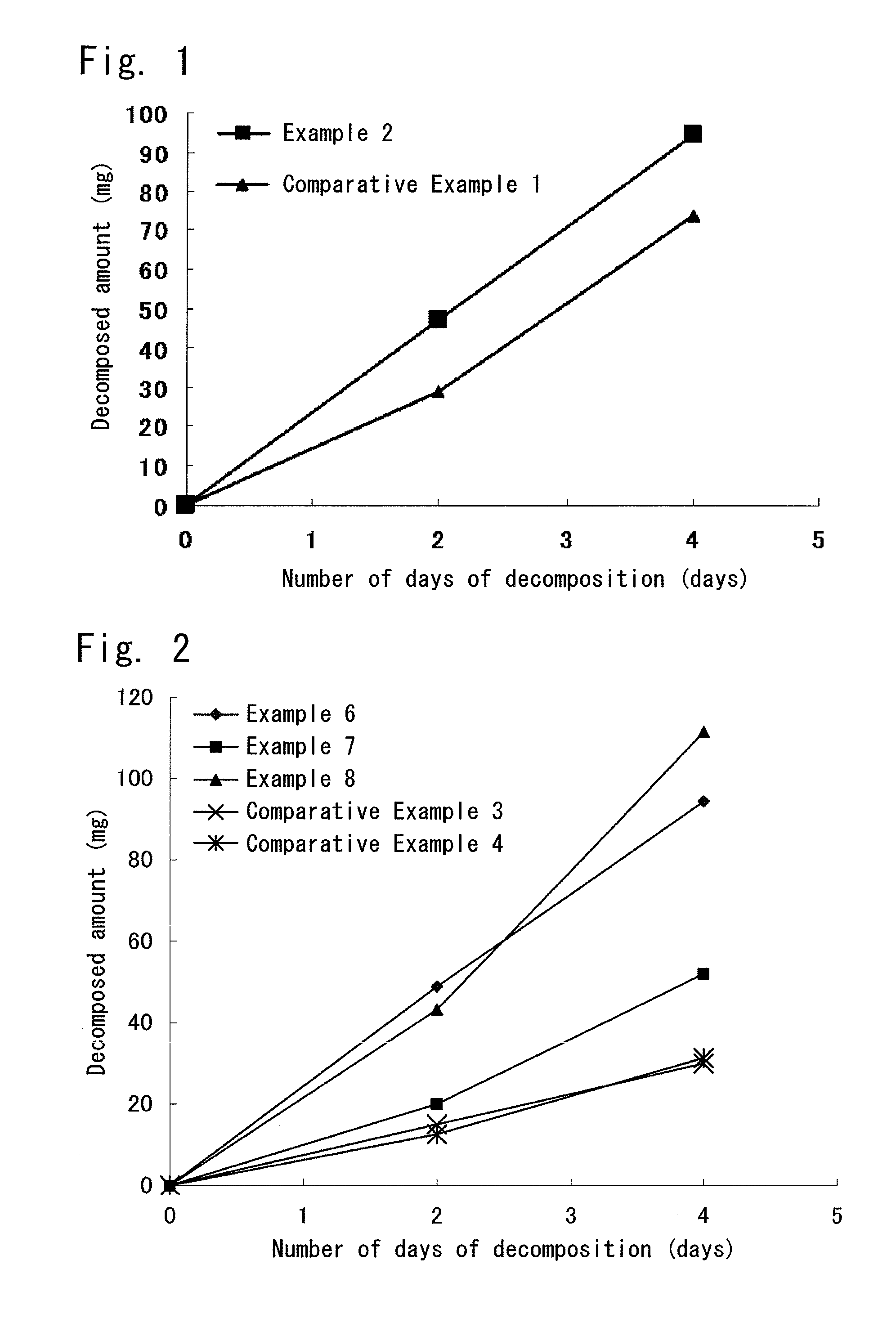

Biodegradable resin composition

InactiveUS20130184415A1Rate of hydrolysis becomes smallSmall rateBio-packagingDecompositionPolyethylene glycol

[Problem] To provide a biodegradable resin composition which permits the biodegradable resin to quickly decompose.[Means for Solution] The biodegradable resin is blended with a polyglycolic acid and an ester decomposition promoter of an inorganic particulate material that promotes the hydrolysis of the polyglycol.

Owner:TOYO SEIKAN KAISHA LTD +1

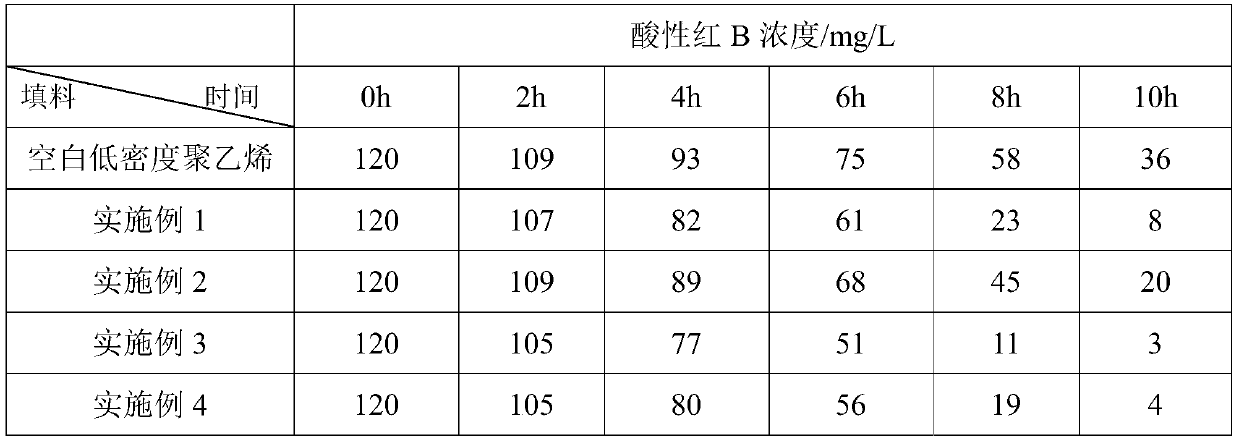

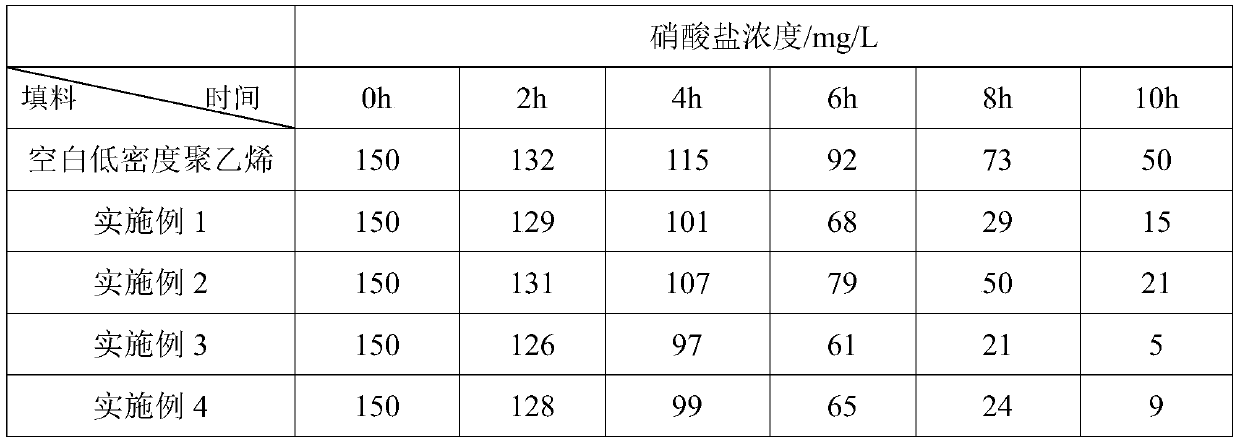

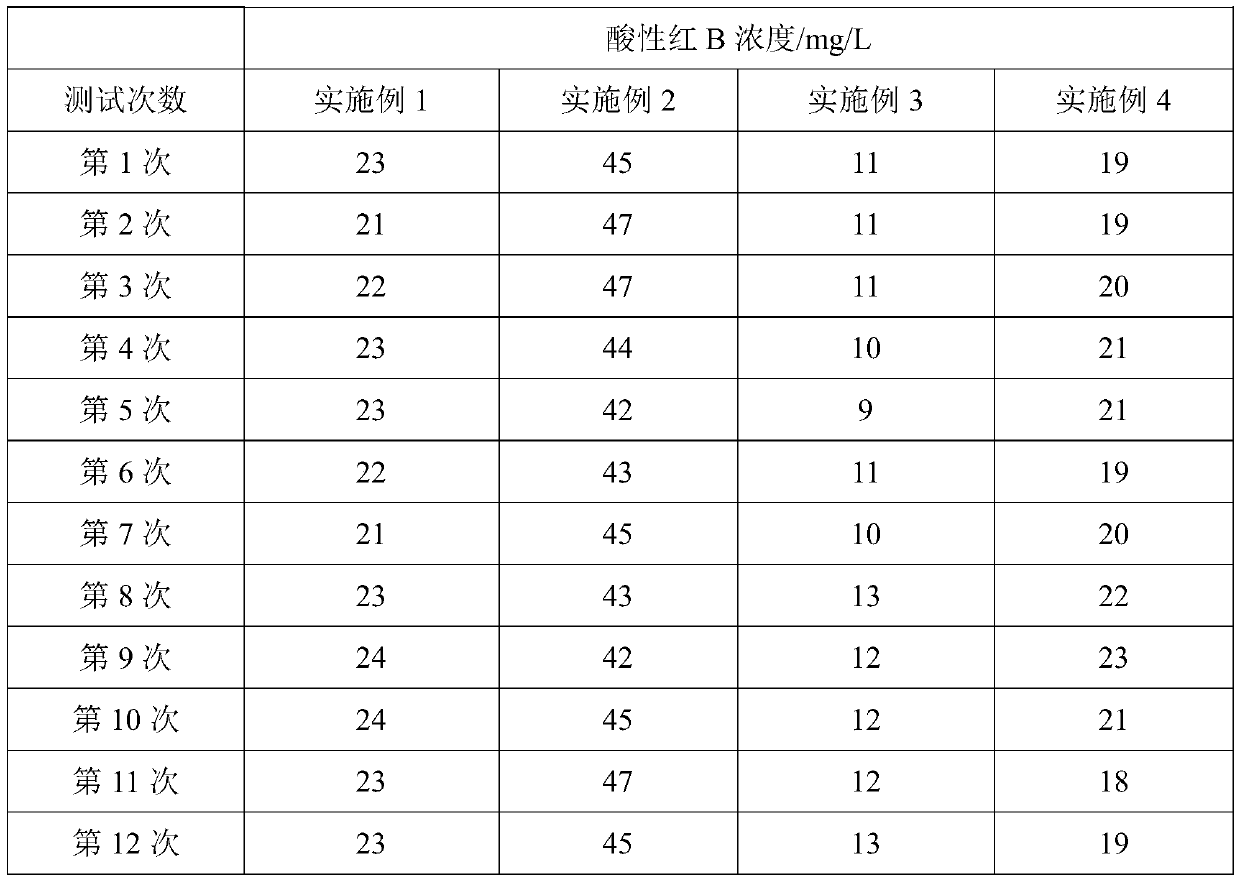

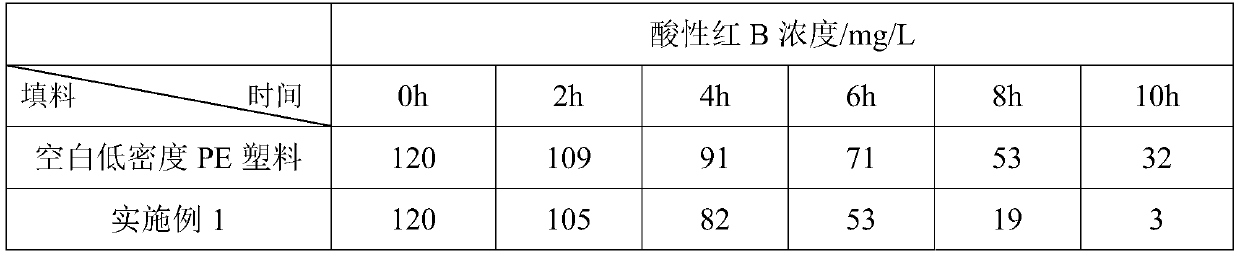

Preparation method and application of plastic with anthraquinone compound-grafted surface

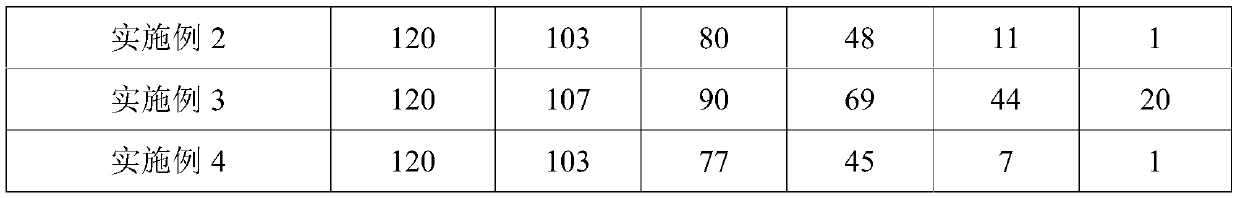

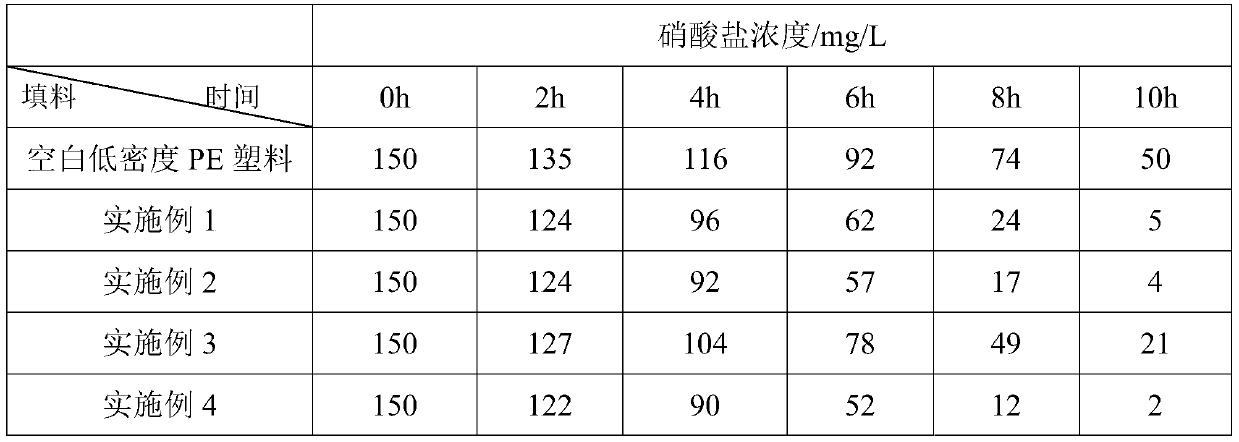

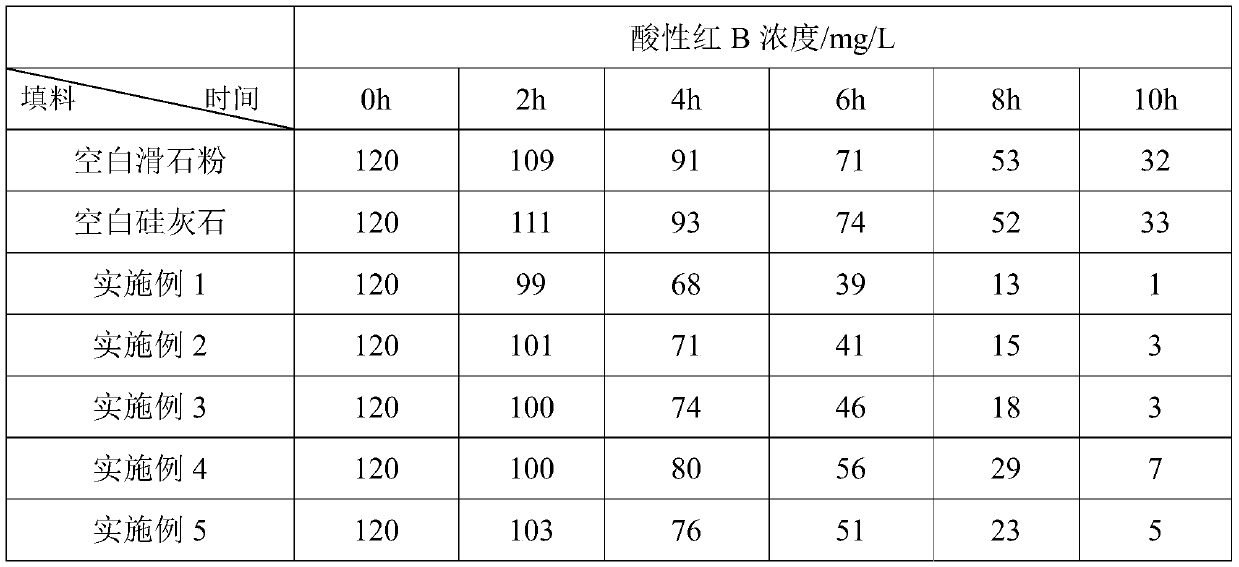

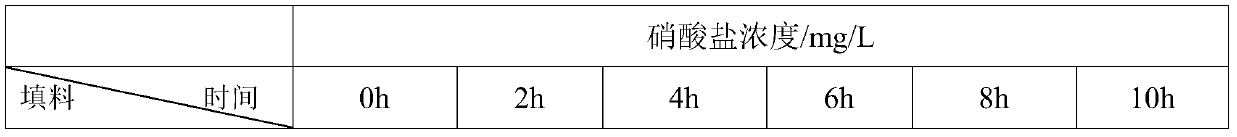

ActiveCN110157031ALow costWide variety of sourcesWater contaminantsBiological water/sewage treatmentEpoxyNitrate

The invention belongs to the field of water treatment, relates to the field of treatment of wastewater containing pollutants, and concretely relates to a preparation method and an application of a plastic with an anthraquinone compound-grafted surface. The preparation method comprises the following steps: a plastic is hydrophilically treated with plasma, a strong oxidant, ozone, gamma-ray, an electron beam or an ion beam, and then is treated with an epoxy silane coupling agent to obtain an epoxy modified plastic; and the epoxy modified plastic is reacted with an amino group-containing anthraquinone compound to obtain the plastic with the anthraquinone compound-grafted surface. The plastic with the anthraquinone compound-grafted surface can accelerate the biodegradation of azo dyes, nitrates and the like, can be recycled and reused, can be reused after being simply treated, can be reused for 10 times or above, and can be used to treat wastewater containing azo dyes, nitrates and the like.

Owner:XIAMEN UNIV OF TECH

Membrane distillation bioreactor device and method

InactiveCN101659495ASimple processEasy maintenance and operationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentLiquid wasteSteam pressure

The invention provides a membrane distillation bioreactor device and a method for treating wastewater or waste liquid by using the device. In the membrane distillation bioreactor device, membrane distillation technology and biological degradation technology are combined, a hydrophobic microporous membrane component is immersed in a biological reactor, latent heat resources such as solar energy andwaste heat are used to heat wastewater to be treated to produce a steam pressure difference between two sides of the membrane to recover water resource, operation energy consumption is saved greatly,and operation cost is saved. A high temperature condition is favorable for improvement in the activity of microorganisms and the biological degradation speed. In the process, a membrane separation process is free from the influences of biological degradation degree, system operation starting requires short time, and effluent is stable and high in quality and meets the standards for reverse osmosis water. The device has the outstanding advantages of simple structure, simple process, low operation energy consumption, small floor area occupation, high biological degradation speed and the like and has a great practical value for the improvement and development of high organic wastewater treatment and high-purity water preparation technology.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

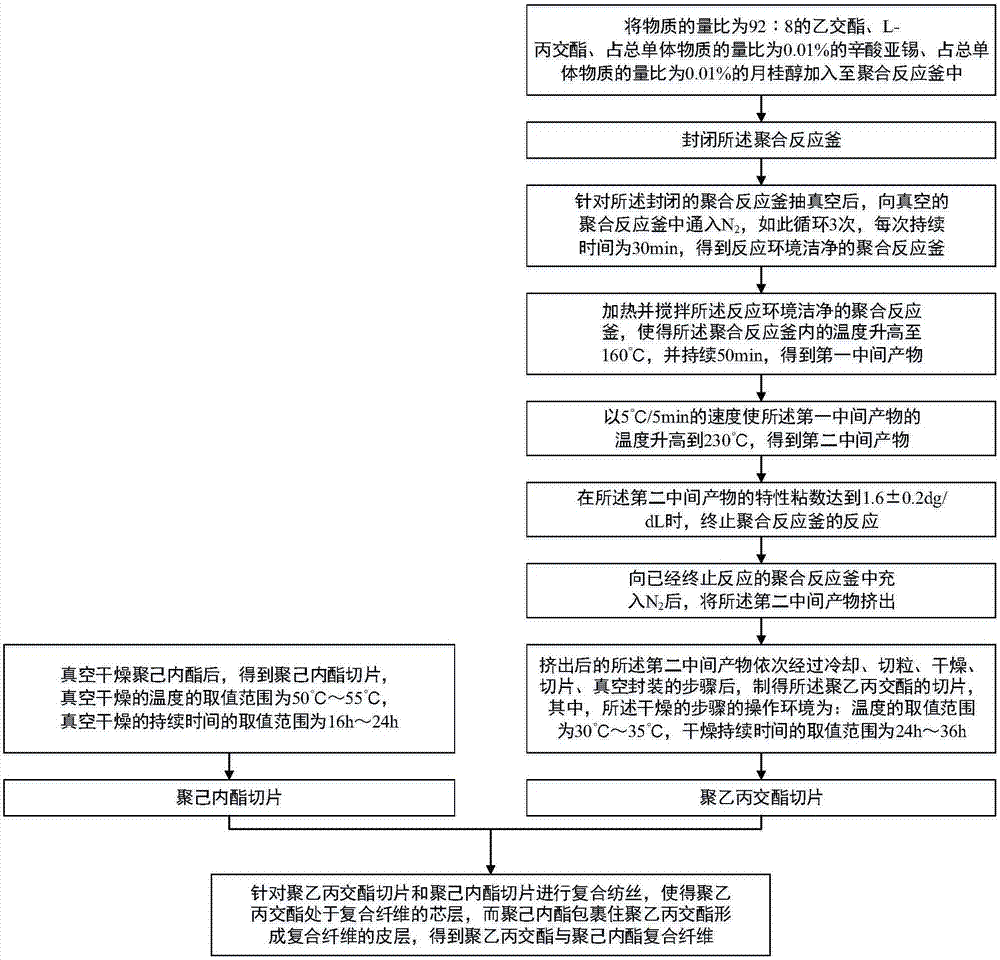

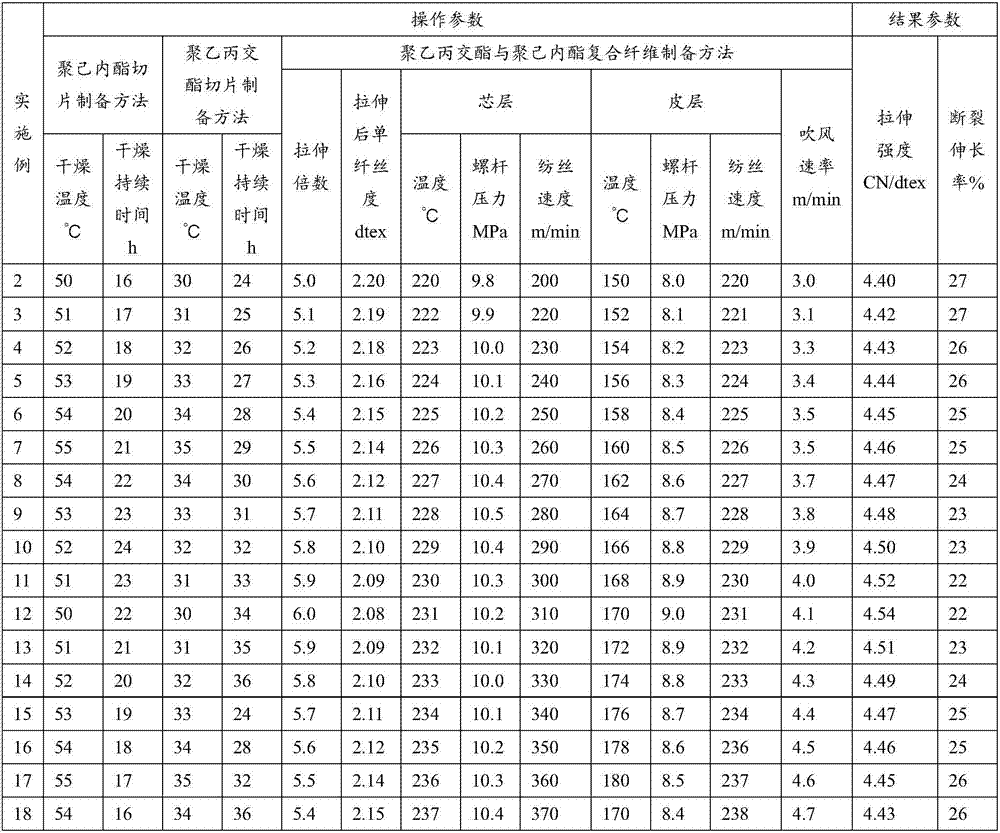

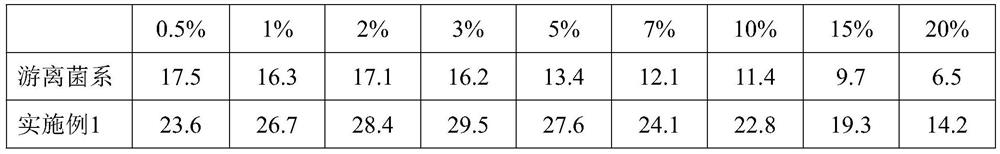

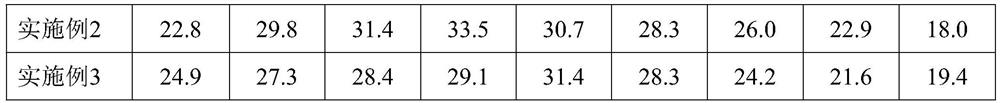

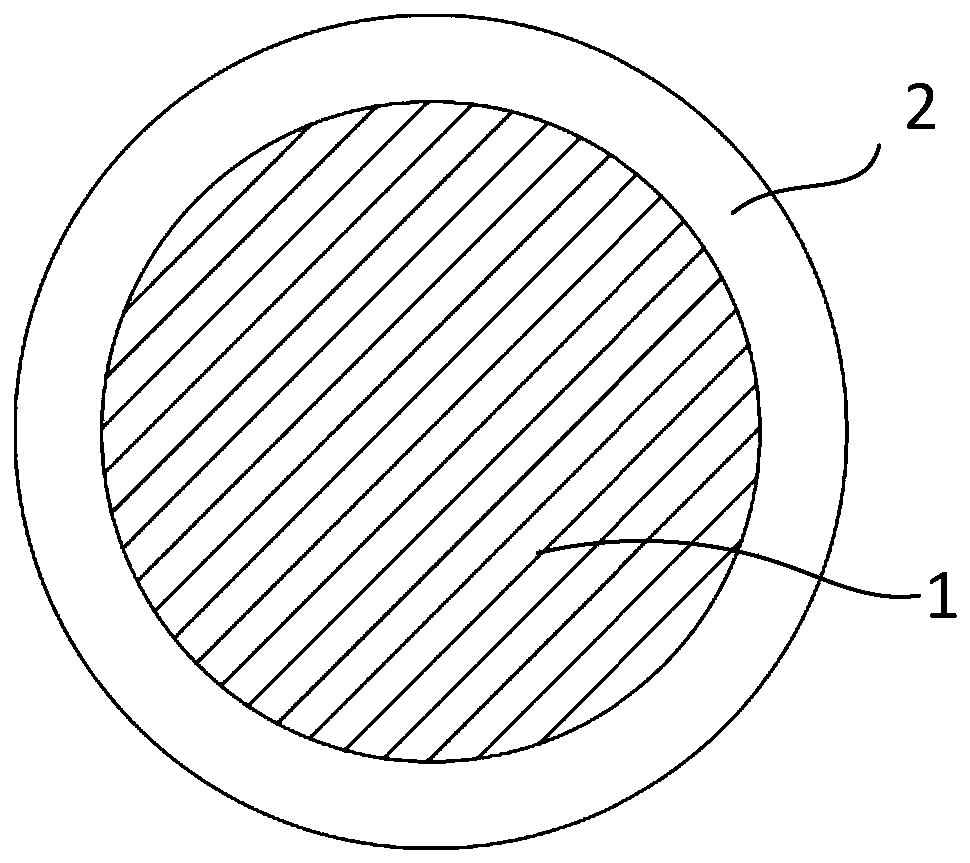

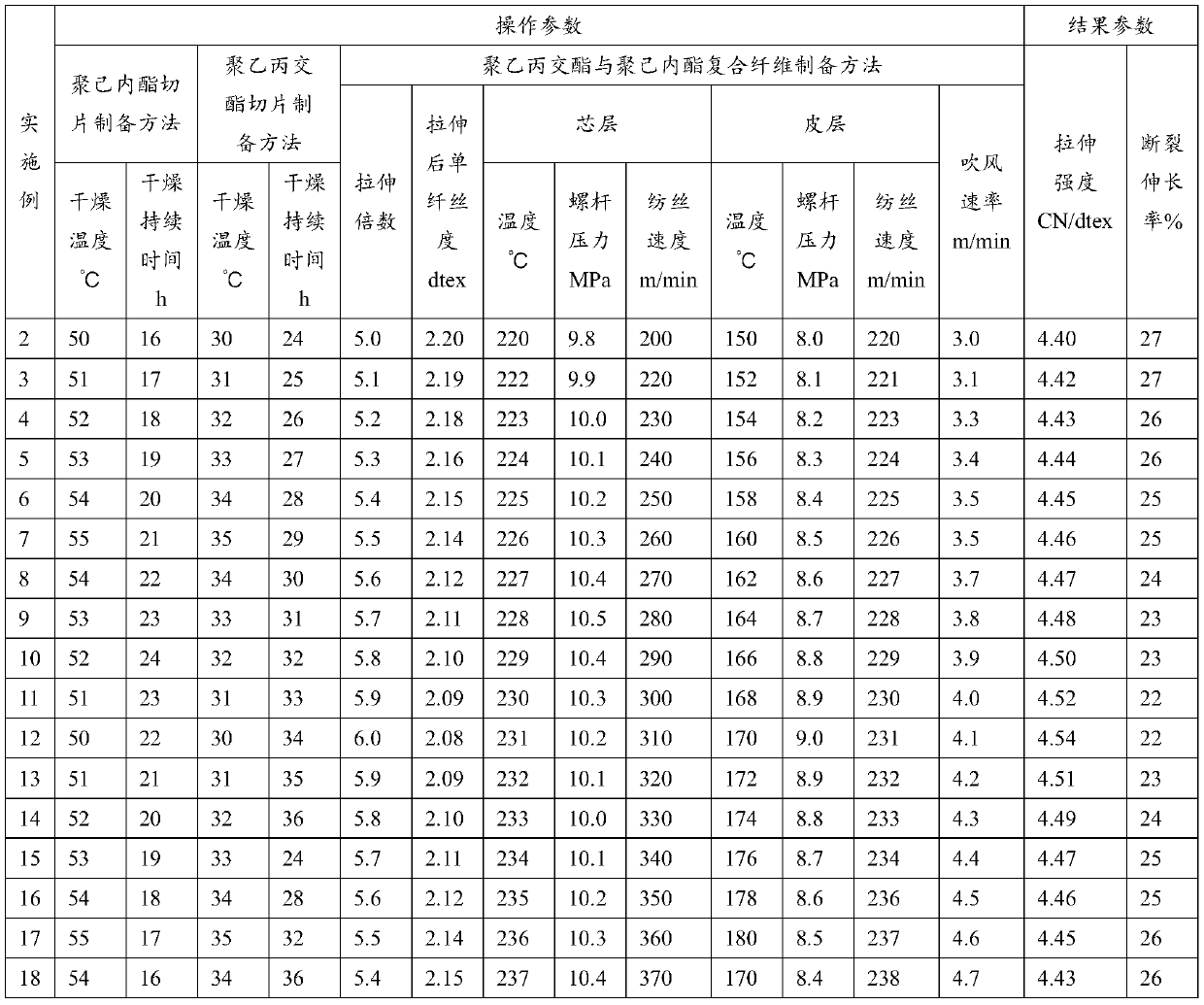

Poly lactate geycollic acid and polycaprolactone complex fiber, preparation method and application thereof, and operation suture line

ActiveCN107059158AFeel goodImprove flexibilitySuture equipmentsFilament/thread formingChemistrySurgical suture

The invention discloses a poly lactate geycollic acid and polycaprolactone complex fiber, a preparation method and application thereof, and an operation suture line. The complex fiber comprises a poly lactate geycollic acid fiber and a polycaprolactone complex fiber, wherein the poly lactate geycollic acid fiber is used as a core layer of the complex fiber, and the polycaprolactone fiber is used as a skin layer of the complex fiber. The preparation method comprises the following steps: obtaining poly lactate geycollic acid slices and polycaprolactone slices respectively; and performing composite spinning on the poly lactate geycollic acid slices and the polycaprolactone slices, wherein the poly lactate geycollic acid is used as the core layer, and the polycaprolactone covers the poly lactate geycollic acid to form the skin layer of the complex fiber so as to obtain the poly lactate geycollic acid and polycaprolactone complex fiber. The composite fiber can be used for the operation suture line. The operation suture line is prepared from the complex fiber. The complex fiber can not only alleviate the characteristic of easy degradation of the poly lactate geycollic acid fiber, but also can enhance the flexibility of the poly lactate geycollic acid fiber.

Owner:CHINESE TEXTILE ACAD

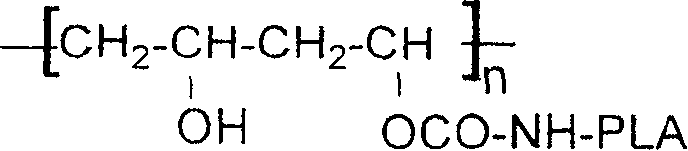

Polyhydroxy alkanoates graft polymer and preparation method thereof

ActiveCN101747476AChange molecular structureImprove thermal stabilityPolymer scienceFilling materials

The invention discloses a polyhydroxy alkanoates graft polymer and a preparation method thereof; the polyhydroxy alkanoates graft polymer is prepared by the following ingredients by weight parts: 100 parts of polyhydroxy alkanoates, 01-15 parts of grafting monomer, 0-5 parts of initiator and 0-5 parts of antioxidants. The polyhydroxy alkanoates graft polymer changes the molecular structure of thepolyhydroxy alkanoates, improves the heat stability thereof and further quickens the biological degrading ratio; in addition, the compatibility of the polyhydroxy alkanoates graft polymer and inorganic filling materials, such as CaCO3, talcum powder and the like and the polarity blending material is improved, and the polyhydroxy alkanoates graft polymer has high practical and economical values.

Owner:山东省意可曼科技有限公司

Preparation method and application of plastic with surface being grafted with graphene and anthraquinone compound

ActiveCN110157007ALow costWide variety of sourcesWater contaminantsTreatment with microorganism supports/carriersSulfonyl chlorideGraphite oxide

The invention belongs to the field of water treatment, relates to the field of treatment of wastewater containing pollutants, and concretely relates to a preparation method and an application of a plastic with the surface being grafted with graphene and an anthraquinone compound. The surface of a plastic is hydrophilically modified to obtain active groups such as a hydroxyl group and a carboxyl group, the reactive groups react with an amino group-containing silane coupling agent to make the surface of the plastic have the amino group, the amino group reacts with the carboxyl group on the surface of the graphene oxide, the remaining hydroxyl group, carboxyl group or secondary amino group and a sulfonyl chloride group-containing anthraquinone compound undergo a dehydrochlorination reaction,and the graphene oxide is further reduced to obtain the plastic with the surface being grafted with graphene and the anthraquinone compound. The plastic obtained in the invention can significantly accelerate the biodegradation of azo dyes, nitrates and the like, can be reused for 10 times or more, and can be widely used in the field of sewage treatment.

Owner:XIAMEN UNIV OF TECH

Method for enhancing high-concentration ethylbenzene waste gas treatment by using biological trickling filter

ActiveCN103170238ARich varietyHigh level of biodiversityDispersed particle separationAir quality improvementHigh concentrationSludge

The invention discloses a method for enhancing high-concentration ethylbenzene waste gas treatment by using a biological trickling filter. According to the invention, a biological trickling filter device is inoculated by using active sludge; domestication is carried out under low-concentration ethylbenzene waste gas; when domestication is finished, the ethylbenzene is regulated to a high concentration range; when high-concentration ethylbenzene removing efficiency is stabilized, a non-ionic surfactant and an inorganic salt cosolvent are added into a nutrient solution; with a solubilization effect of the surfactant, a mass transfer process of slightly soluble organics between three phases of gas, liquid, and bio-membrane is promoted. Therefore, bioavailability is improved, and degradation efficiency is improved. With the method provided by the invention, running device and other running conditions are not changed, and operation process continuous long-time running can be ensured. The method is economical, and has the advantages of high efficiency, environment friendliness, and convenient operation and maintenance.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

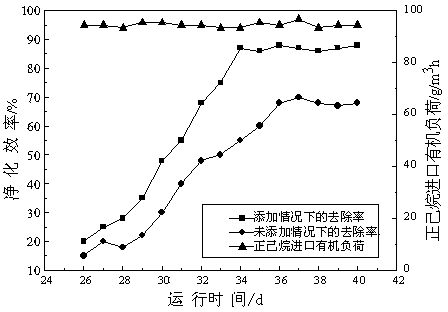

Method for improving processing of high-load n-hexane waste gas by biotrickling filter

InactiveCN103463968AImprove purification effectStrong resistance to shock loadsDispersed particle separationAir quality improvementActivated sludgeActive agent

The invention belongs to the technical field of biological purification for organic waste gas, and discloses a method for improving the processing of high-load n-hexane waste gas by a biotrickling filter. According to the method, activated sludge is adopted to carry out inoculation on the biotrickling filter, domestication is conducted under low-load n-hexane waste gas, after the domestication is finished, the n-hexane waste gas is improved to be within the range of a high load, microorganisms which are domesticated well under the low load are exposed out of the high-load n-hexane waste gas, a bio-surfactant is added in a nutrient solution of the biotrickling filter, the nutrient solution is evenly distributed on padding in the biotrickling filter through a spraying device, and the microorganisms decompose the n-hexane into CO2, H2O and cytoplasm. According to the method, shock load resistance is strong, on the condition that an operation device and the operation condition are not changed for an existing biotrickling filter, the purification effect of the biotrickling filter on the hydrophobe n-hexane waste gas can be improved, the biodegradation rate is increased, the removal efficiency is improved, the operation cost is low, and operation is easy and stable.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

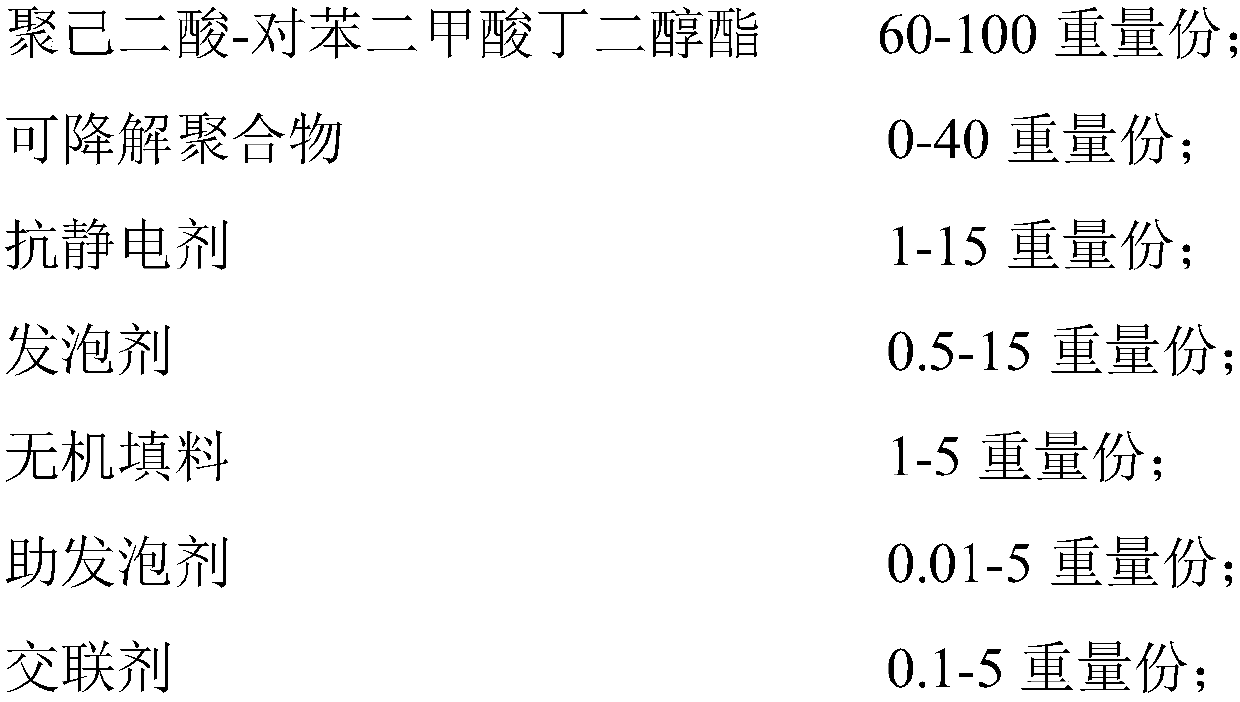

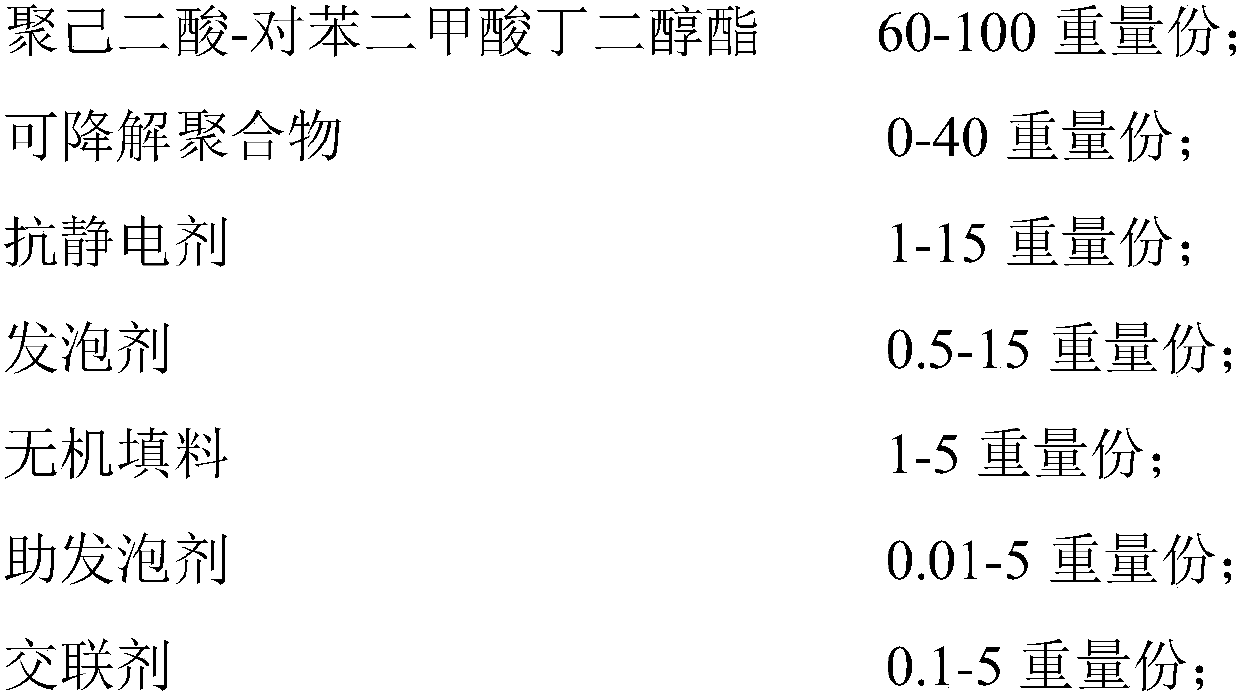

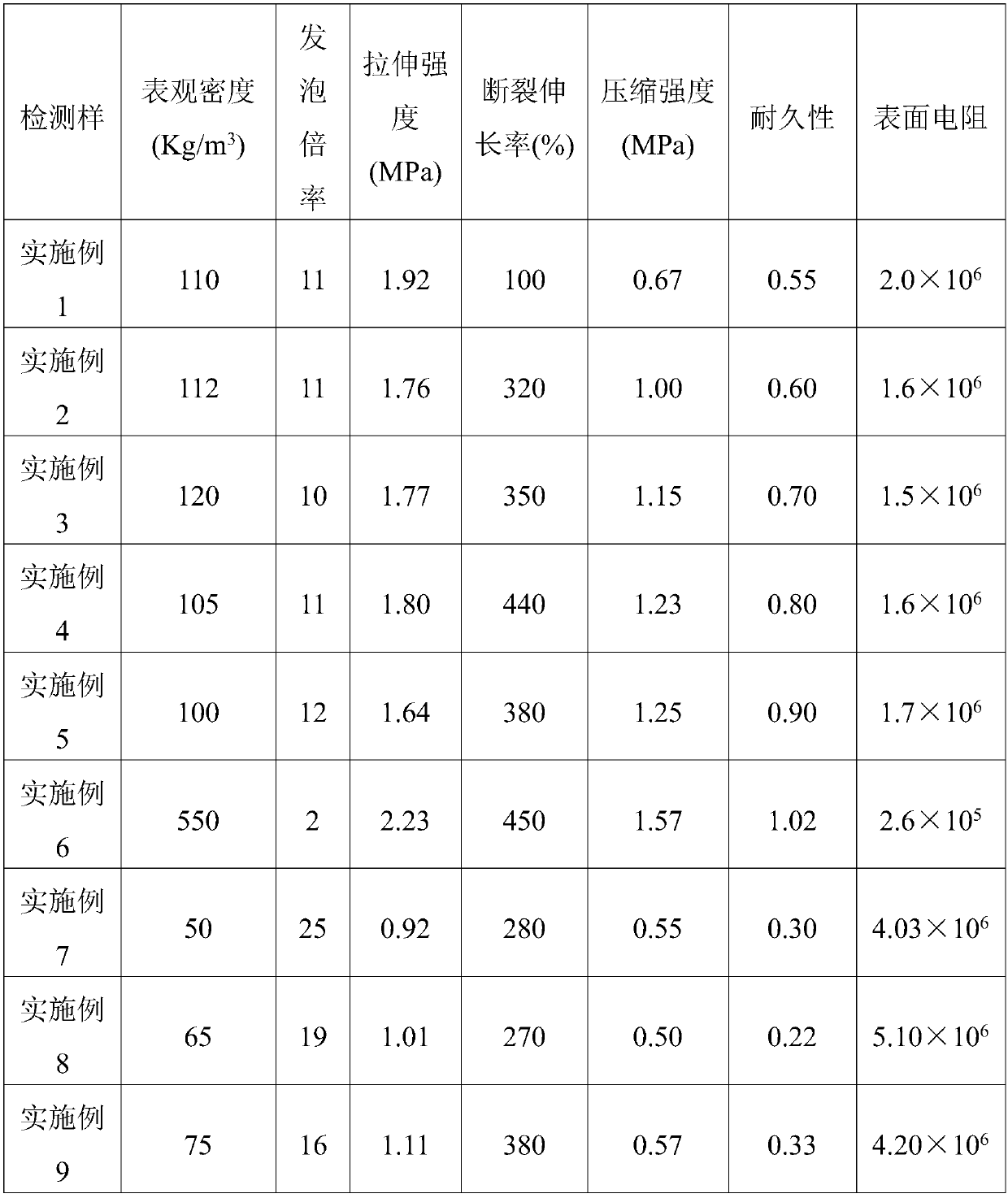

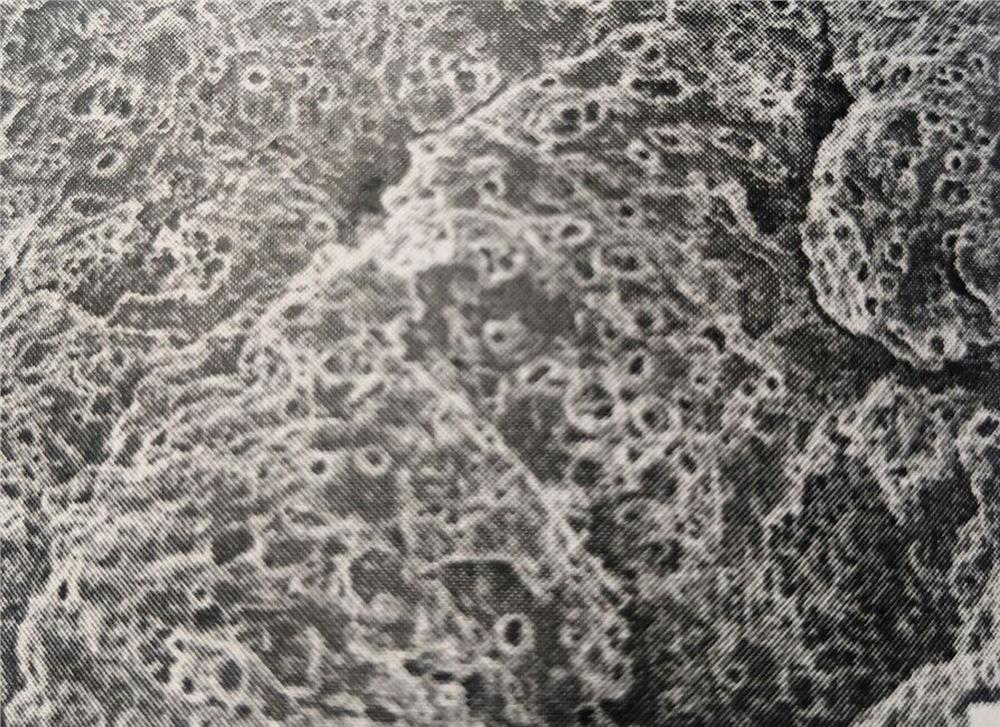

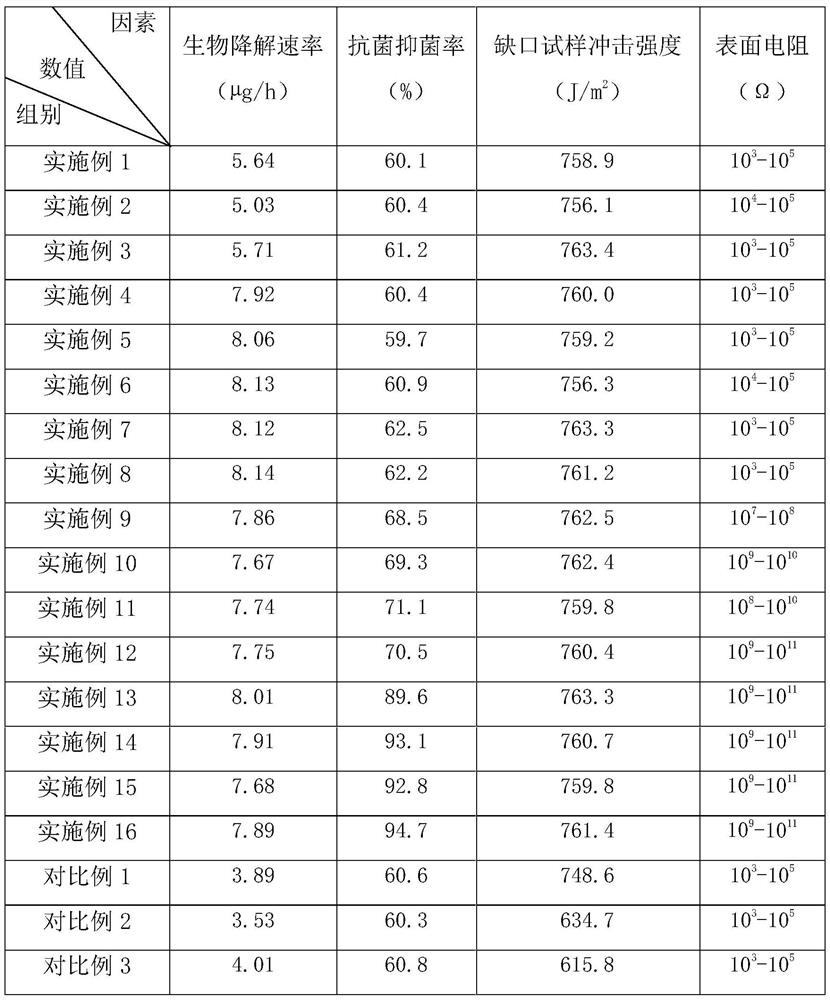

Antistatic biodegradable foaming material and preparation method thereof

InactiveCN107857978AImprove antistatic performanceGood physical propertiesFoaming agentAntistatic agent

The invention relates to an antistatic biodegradable foaming material and a preparation method thereof and belongs to the technical field of foaming material, which solves the problem of declining ofmechanical property of material due to adding a large ratio of antistatic agent when the method of the antistatic property of the poly(p-butyleneadipate-co-terephthalate) foaming material needed to beimproved in the prior art. The antistatic biodegradable foaming material is prepared from the following components in parts by weight: 60 to 100 parts of poly(p-butyleneadipate-co-terephthalate), 0 to 40 parts of biodegradable polymer, 1 to 15 parts of antistatic agent, 1 to 5 parts of inorganic filler, 0.5 to 15 parts of foaming agent, 0.01 to 5 parts of foaming additive, and 0.1 to 5 parts of crosslinking agent. The antistatic biodegradable foaming material has the advantages that the antistatic property is excellent, the physical property is excellent, the water-resistant property is good,the durability is good, the foaming rate is higher, and the mechanical property can be regulated in the wide range.

Owner:长春中科应化生态材料有限公司

Wood-plastic composite material for 3D printing and preparation method and application thereof

ActiveCN112063032AImprove the lubrication effectImprove liquidityAdditive manufacturing apparatusThermoplasticPtru catalyst

The invention discloses a wood-plastic composite material for 3D printing and a preparation method and application thereof. The wood-plastic composite material is mainly prepared from the following raw materials: wood flour, lignin, bamboo powder or straw powder, thermoplastic plastic, a coupling agent, a compatilizer, an antioxidant, a lubricating agent, a toughening agent and a functional additive. The composite material is good in mechanical property, excellent in lubricating property and flowability, beneficial to smooth 3D printing process, smooth in surface of a printed piece, strong ininterlayer bonding force, and excellent in wear resistance and toughness, and solves the problem of printing failure caused by high shrinkage rate and easiness in curling of polypropylene and the like; the production cost is low; the microstructure is characterized by having mutually communicated pore channels so that heat and mass transfer, ventilation and reaction are facilitated; the weight islow, and the degradation period is controllable; the material can also be used as a filler and a catalyst carrier, and has potential application prospects in the fields of filtration, adsorption, tower internals and other transfer processes, ventilation, reaction engineering and biological tissue engineering; and the material is also suitable for manufacturing lightweight accessories of unmanned aerial vehicles and automobiles and packaging materials for recycling.

Owner:HUNAN UNIV

Methods for extinguishing petroleum-based fires, suppressing petroleum-released vapors and cleaning petroleum-contaminated surfaces

InactiveUS7223362B2Trend downPromote degradationOrganic detergent compounding agentsTransportation and packagingPetroleum productNon ionic

Compositions and methods for emulsifying a petroleum product that has been spilled upon a portion of the earth's surface or that is burning are based upon use of a nonionic, primary surfactant composition comprising a first ethoxylated sorbitol oleate and, preferably, a second ethoxylated sorbitol oleate, and a nonionic, secondary surfactant that is capable of stabilizing and solubilizing the primary surfactant composition such that the resulting emulsifying compositions have a hydrophilic / lipophilic balance between about 12.0 and about 13.5.

Owner:HANS P ACHTMANN REVOCABLE TRUST

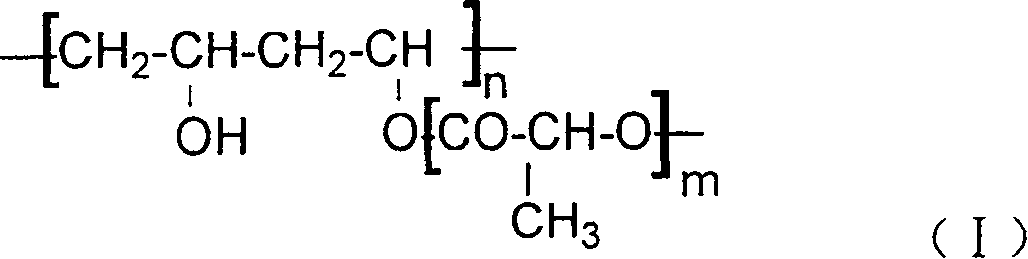

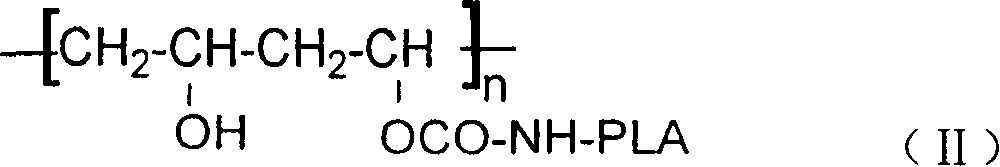

Blend material of vinol/polylactic acid graft copolymer and starch, their preparing method and application

This invention provides a polyvinyl alcohol / polylactic acid branch copolymer prepared directly from lactic acid and polyvinyl alcohol or from end-capped polylactic acid and polyvinyl alcohol. The copolymer has a glass transition temperature of 51~65 deg. C, a melting point of 104~165 deg. C and a molecular weight of 10000~600000. This invention also provides the blend of polyvinyl alcohol / polylactic acid copolymer and starch, its application and the method to prepare polyvinyl alcohol / polylactic acid copolymer. As the glass transition temperature and the melting point of the copolymer are of great difference, the copolymer can be used as a kind of completely biodegradable thermoplastics, which expands the application of polylactic acid. Addition of starch not only greatly lowers the cost but also accelerates the biodegradation of the copolymer. The blend of polyvinyl alcohol / polylactic acid copolymer and starch also performs good mechanical properties and can be especially made into membranes by direct blow molding.

Owner:SICHUAN UNIV

Method for grafting redox mediator on surface of inorganic filler and application

ActiveCN110040842ALow costWide variety of sourcesWater contaminantsTreatment with anaerobic digestion processesChemical reactionHazardous substance

The invention belongs to the field of water treatment, relates to the field of treatment of pollutant-containing wastewater and particularly relates to a method for grafting a redox mediator on the surface of inorganic filler and application. The method comprises the following steps: taking a thiopropyl silane coupling agent and the inorganic filler to react, so as to obtain thiopropyl modified inorganic filler; then carrying out mercapto-ene click chemical reaction on the thiopropyl modified inorganic filler and an allyl-containing redox mediator to obtain the inorganic filler with the surface grafted with the redox mediator. The inorganic filler with the surface grafted with the redox mediator, prepared by the method provided by the invention, can be used for rapidly accelerating the degradation of azo dyestuffs and can be repeatedly utilized; the method has the advantages of wide source of raw materials, few reaction steps and low cost; raw materials which easily produce toxic and harmful substances after being in contact with moisture are not needed; the inorganic filler can be widely applied to the treatment of wastewater containing the azo dyestuffs and nitrate.

Owner:XIAMEN UNIV OF TECH +1

Starch acetate-polydioxanone graft copolymer/inorganic particulate nano composite material and preparation method thereof

The invention discloses a starch acetate-polydioxanone graft copolymer / inorganic particulate nano composite material which is prepared from a starch acetate-polydioxanone graft copolymer base material and nanometer inorganic particulates, wherein the weight ratio of starch acetate to graft copolymers is 1 to 40:100, and the weight ratio of the nanometer inorganic particulates to the starch acetate-polydioxanone graft copolymers is 0.5 to 10:100. The invention also discloses a preparation method of the starch acetate-polydioxanone graft copolymer / inorganic particulate nano composite material. Because the starch acetate and the nanometer inorganic particulates are introduced into the copolymer, the production cost is reduced, the thermal property, the mechanical property and the biodegradation rate of the polydioxanone are increased, and the preparation method has lower requirements for a monomer and a reaction condition and has simple operation, high production efficiency and no environment pollution.

Owner:SICHUAN UNIV

Bamboo powder coated paper

InactiveCN111719333AHigh tensile strengthGood compatibilityVegetable material additionPaper coatingPolymer scienceAdipic acid

The invention provides a bamboo powder coated paper. The coated paper comprises raw paper and a composite coated material; the composite coated material comprises a coated layer, and the preparation components of the coated layer comprise bamboo powder and degradable plastic; the degradable plastic is prepared from polylactic acid, poly(butylene succinate) and a copolymer of butylene adipate and butylene terephthalate. The bamboo powder and the degradable plastic including polylactic acid (PLA), polybutylene succinate (PBS) and the copolymer (PBAT) of butylene adipate and butylene terephthalate are used as main raw materials, and undergo processes of blending, extrusion or pressing and the like to prepare the composite material. The coated film obtained from the material prepared in the invention is water-proof and oil-proof, overcomes the defects of low variability, low strength and the like of bamboo, has the excellent characteristics of low water absorptivity, easiness in regeneration and recovery, corrosion resistance and the like, and has a wide market prospect.

Owner:福建益百利包装材料有限公司

High-temperature-resistant biologically-soluble ceramic fiber and preparation method thereof

Owner:WUHAN UNIV OF SCI & TECH

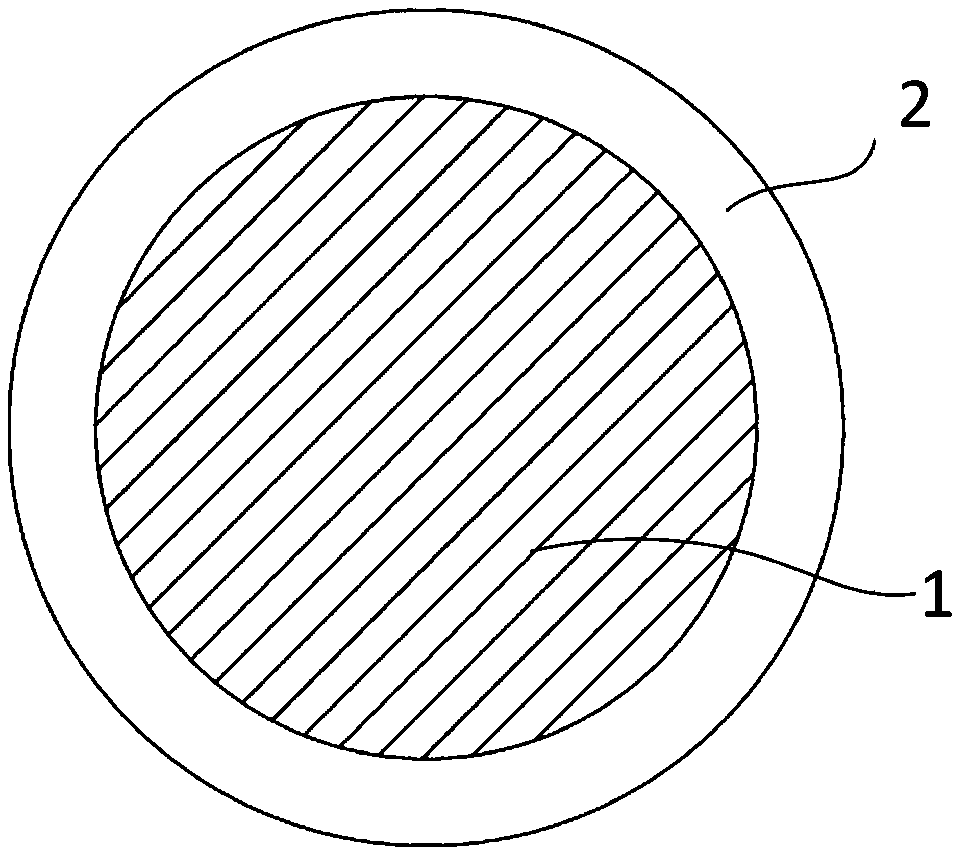

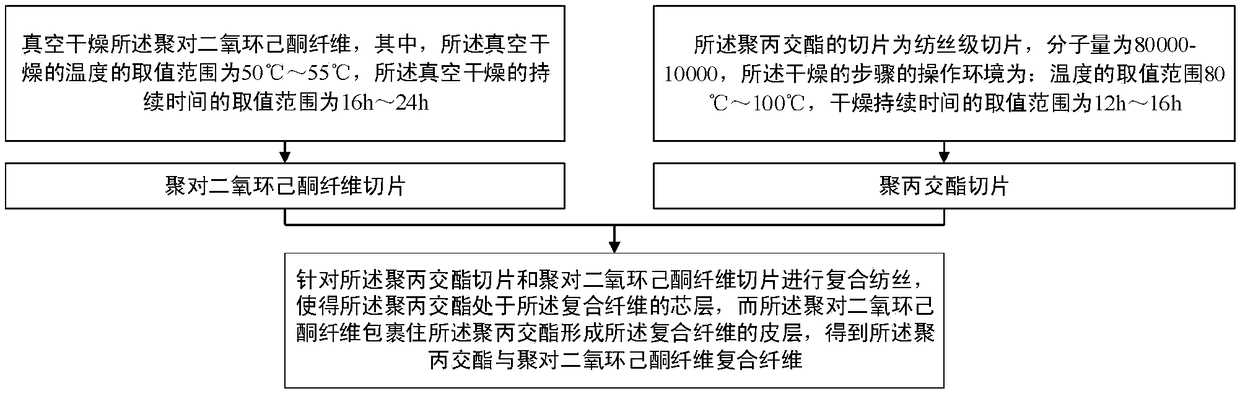

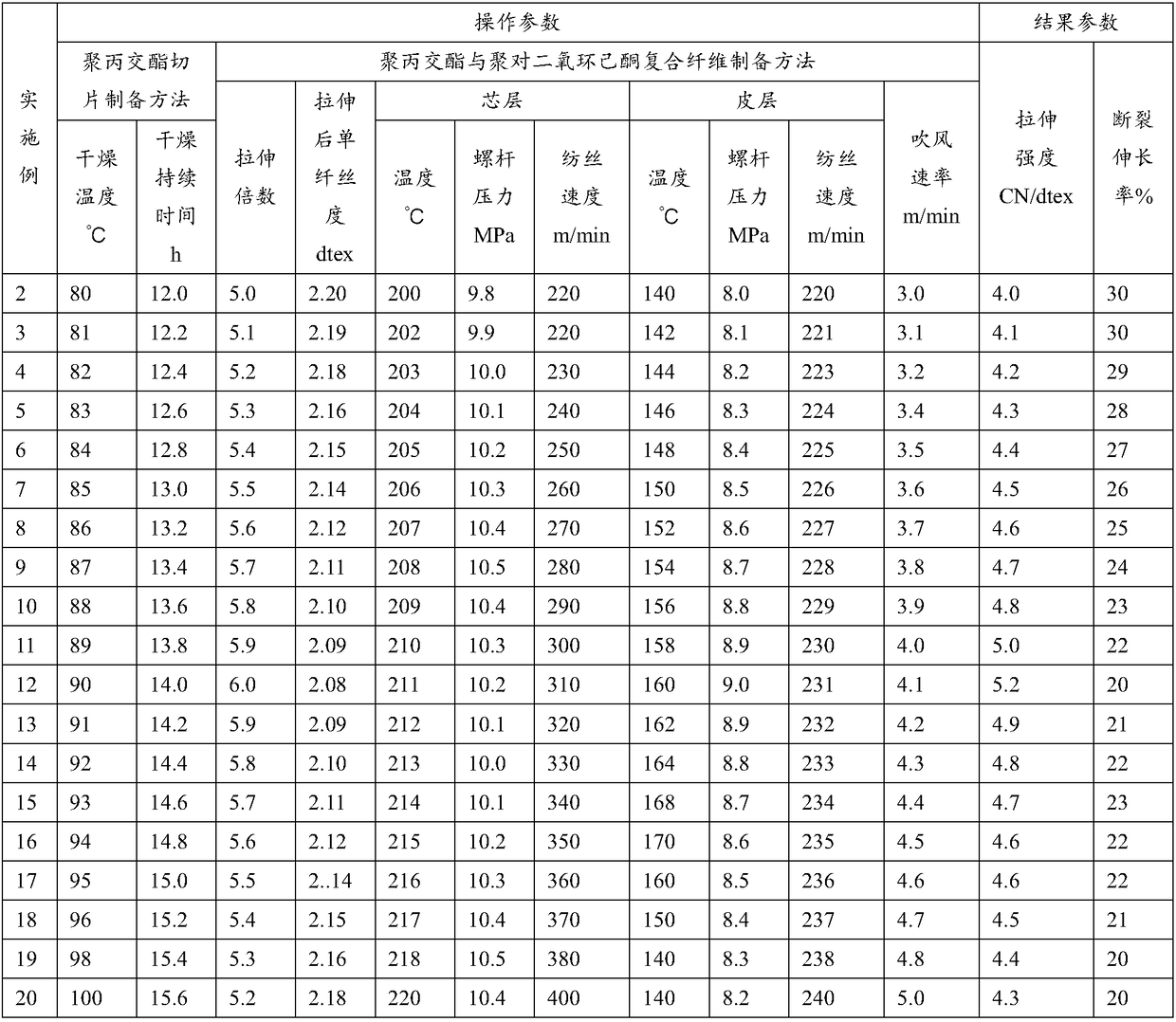

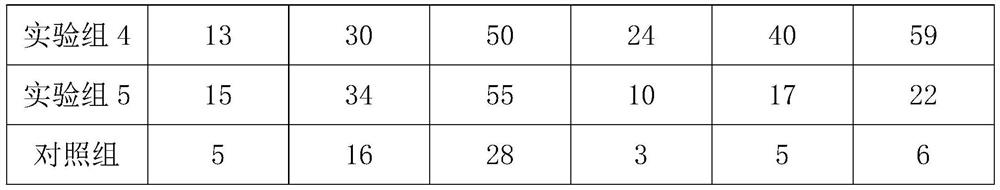

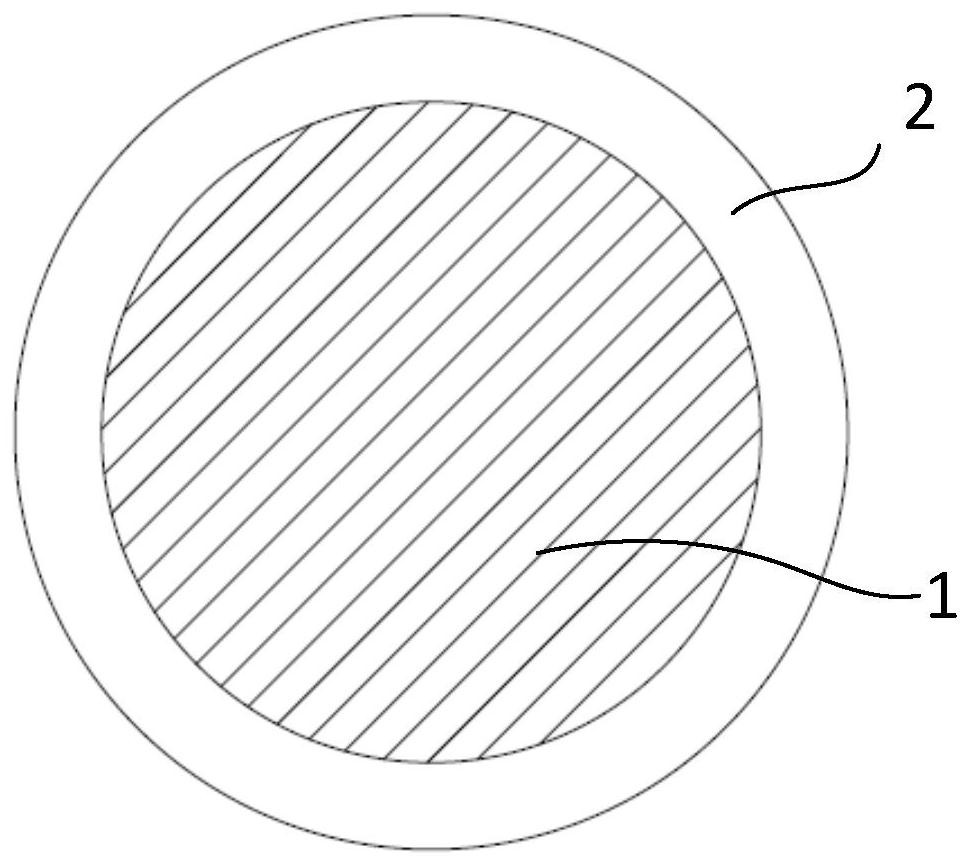

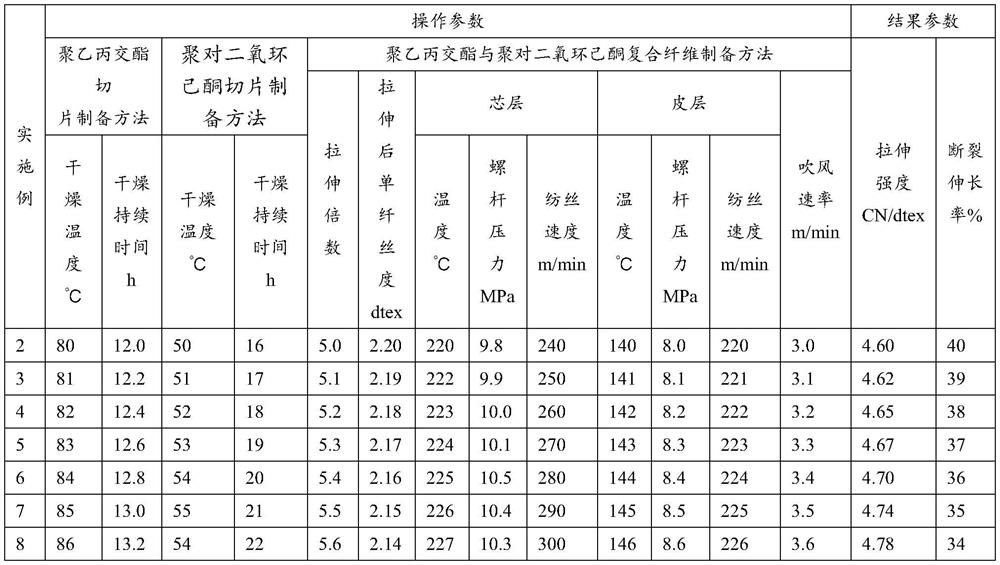

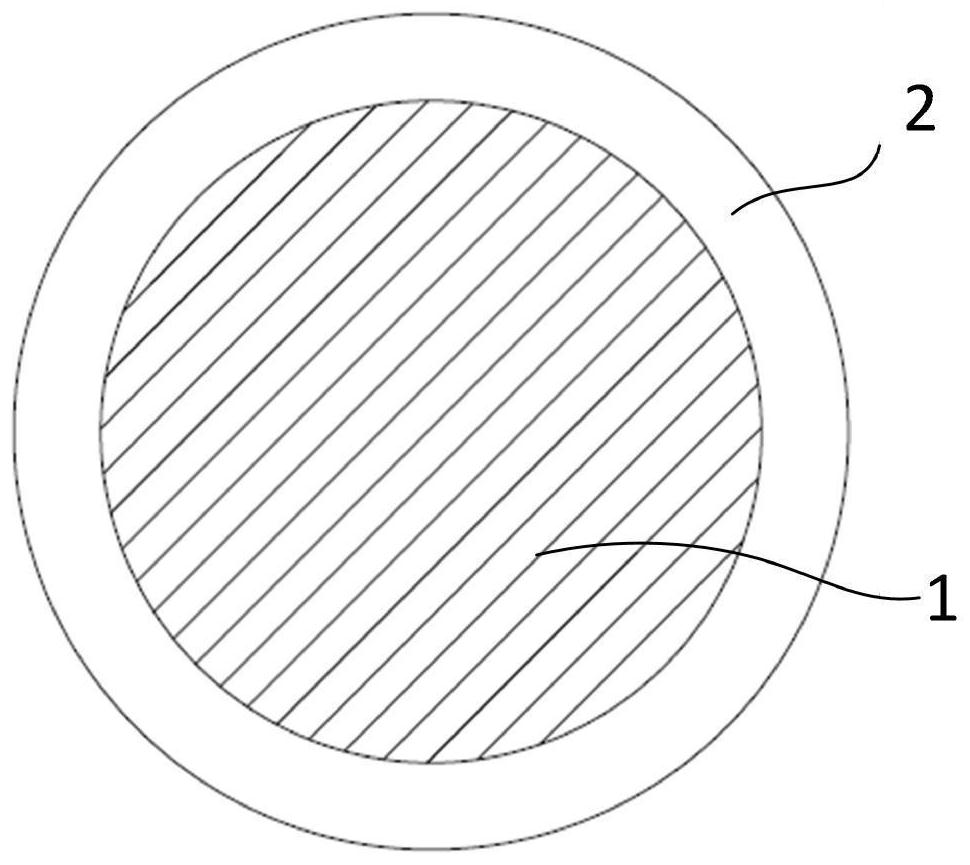

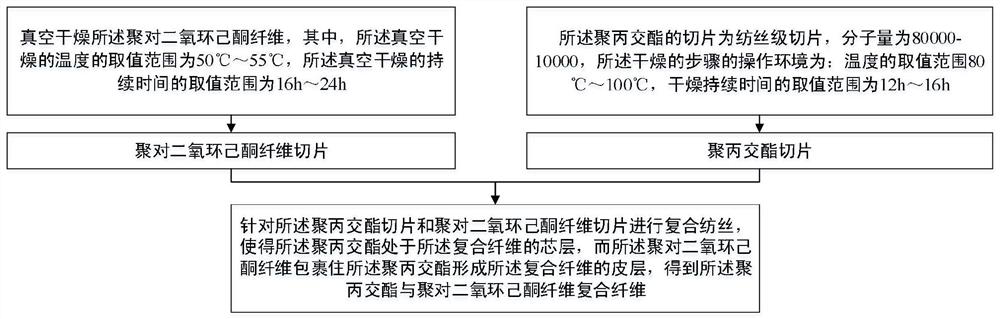

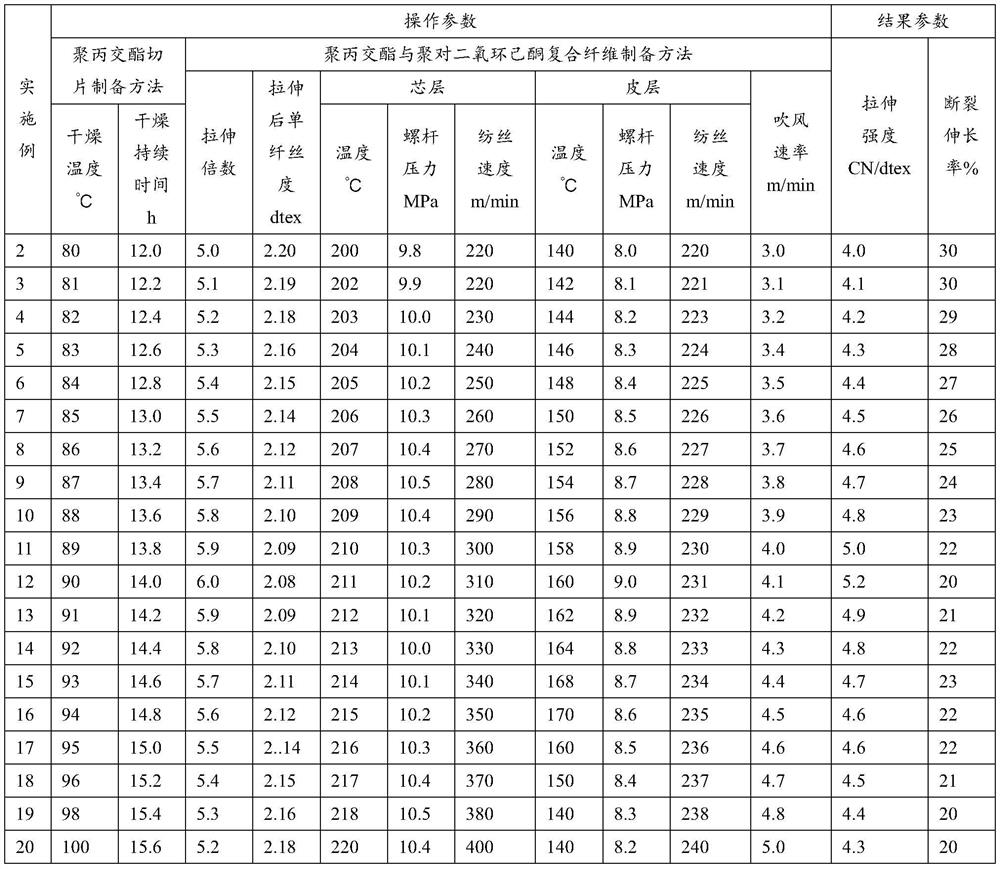

Polylactide-p-dioxanone composite fiber, preparation method thereof, application and surgical suture

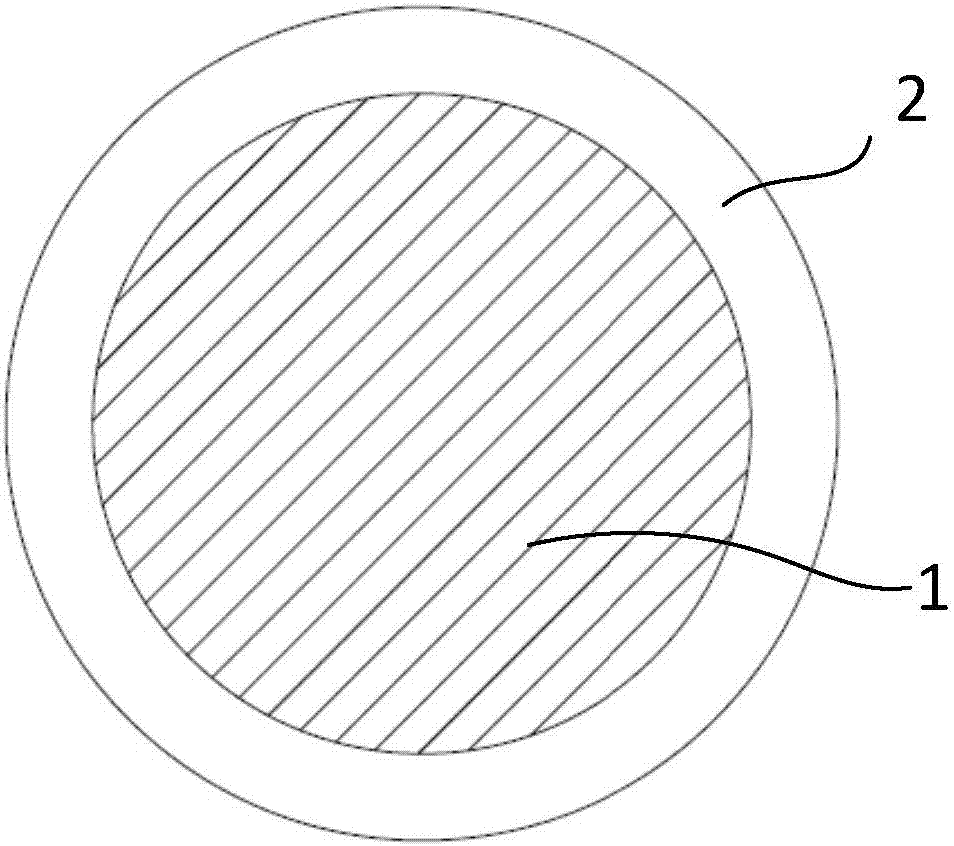

ActiveCN109234843AIncreased biodegradation rateGood biocompatibilitySuture equipmentsFilament/thread formingP-dioxanoneFiber

The invention discloses a polylactide-p-dioxanone composite fiber, a preparation method thereof, application and a surgical suture. In the composite fiber, a polylactide fiber serves as a core layer of the composite fiber, and p-dioxanone serves as a skin layer of the composite fiber. The preparation method comprises the following steps: respectively obtaining a polylactide slice and a p-dioxanoneslice; performing composite spinning on the polylactide slice and the p-dioxanone slice, so that polylactide is located at the core layer of the composite fiber, and the p-dioxanone is used for packaging the polylactide to form the skin layer of the composite fiber, so as to obtain the polylactide-p-dioxanone composite fiber. The composite fiber can be used for the surgical suture. The surgical suture is prepared from the composite fiber. The value range of the tensile strength of the composite fiber is 4.0CN / dtex-5.2CN / dtex, and the value range of the breakage elongation is 20%-30%, so thatthe composite fiber can meet the requirements of the surgical suture and is low in manufacturing cost.

Owner:CHINESE TEXTILE ACAD

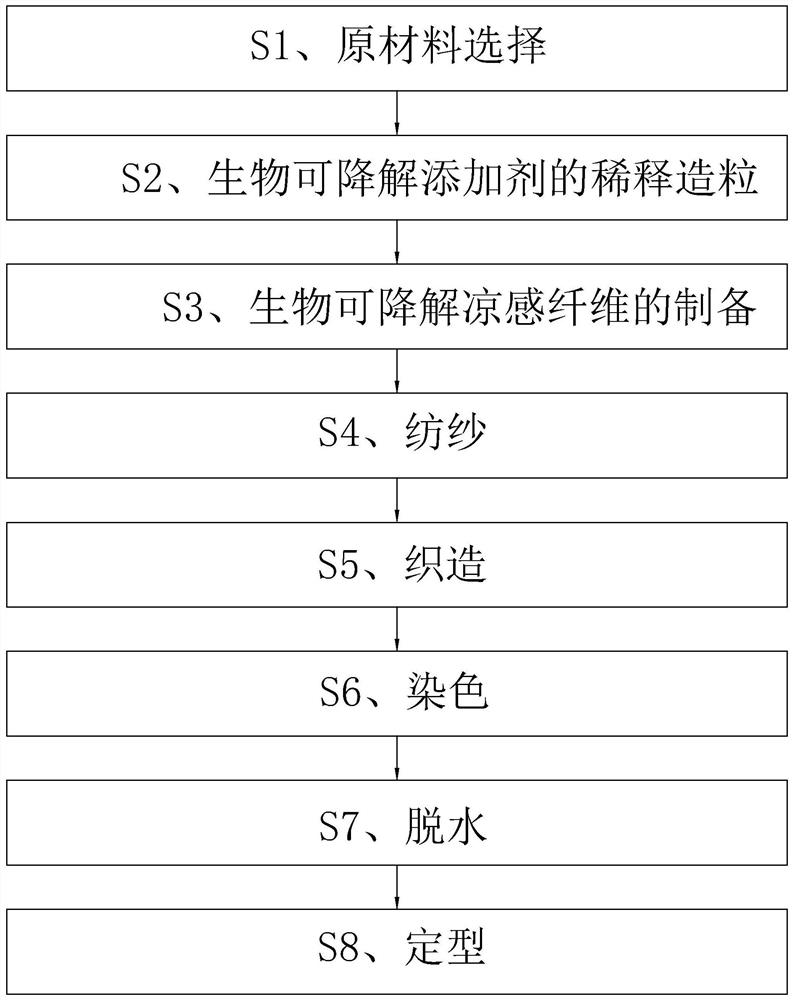

Preparation method of biodegradable cool fabric

PendingCN112779656AImprove the problem of biodegradation rate declineIncreased biodegradation rateWeft knittingLiquid/gas/vapor removalPolymer chemistryBiodegradable additives

The invention discloses a preparation method of a biodegradable cool fabric, and belongs to the technical field of weft knitted fabric preparation. According to the key points of the technical scheme, the method comprises the following steps of S1, selection of raw materials including a base material, a biodegradable additive and a cool additive; S2, dilution and granulation of the biodegradable additive; S3, preparation of biodegradable cool fibers; S4, spinning; S5, weaving; S6, dyeing; S7, dewatering; and S8, setting. According to the preparation method of the biodegradable cool fabric, the biodegradable cool fabric has better biodegradability and wearing comfort.

Owner:无锡恒隆纺织品有限公司

Full-biodegrade composite material taking oriented poly butylene succinate as nucleating agent and preparation method of full-biodegrade composite material

InactiveCN106009537AImprove machinabilityIncreased biodegradation ratePoly(butylene succinate)Materials science

The invention provides a full-biodegrade composite material taking oriented poly butylene succinate as a nucleating agent and a preparation method of the full-biodegrade composite material. The full-biodegrade composite material comprises the following components in mass percent: 30-70% of poly butylene succinate and 70-30% of poly ethylene succinate. The preparation method comprises the following steps: 1) drying poly ethylene succinate in vacuum at 25-40 DEG C, and drying poly butylene succinate in vacuum at 60-100 DEG C; 2) putting 0-100% of poly ethylene succinate and 0-100% of poly butylene succinate into a screw extruder, and carrying out blending and extruding to obtain a composite material; 3) carrying out single-side rolling and plate pressing on the composite material of poly ethylene succinate and poly butylene succinate at appropriate processing temperature; and 4) taking out the molded composite material, and carrying out heat treatment on the molded composite material at the temperature below the melting point of poly ethylene succinate, so as to obtain the composite material. The full-biodegrade composite material is simple and feasible in process, low in cost, easy to realize industrialization and obvious in economic value.

Owner:SHAANXI UNIV OF SCI & TECH

Degradable cotton swab and preparation method thereof

PendingCN114015206ABiodegradableImprove mechanical propertiesWithdrawing sample devicesPolymer scienceButanedioic acid

The invention relates to a degradable cotton swab and a preparation method, and relates to the field of medical supplies, the degradable cotton swab is prepared from the following raw materials by weight: 110-130 parts of poly (butylene succinate), 70-90 parts of polylactic acid, 15-25 parts of a filler, 5-10 parts of a flexibilizer, 3-5 parts of a compatilizer, and 1-2 parts of a degradation accelerator; the preparation method of the degradable cotton swab comprises the following steps: S1, heating the poly (butylene succinate), the polylactic acid, the filler, the flexibilizer, the compatilizer, the degradation accelerant, an anti-static additive and an antibacterial agent to 120-150 DEG C according to a set proportion, and stirring for 20-25 minutes to obtain a blended material; S2, extruding and cooling the blended material to obtain a raw material rod; S3, cutting the raw material rod to obtain a formed cotton swab. The handle of the cleaning verification cotton swab can be degraded, and the cleaning verification cotton swab can have the antistatic and antibacterial effects at the same time.

Owner:深圳市华晨阳科技有限公司

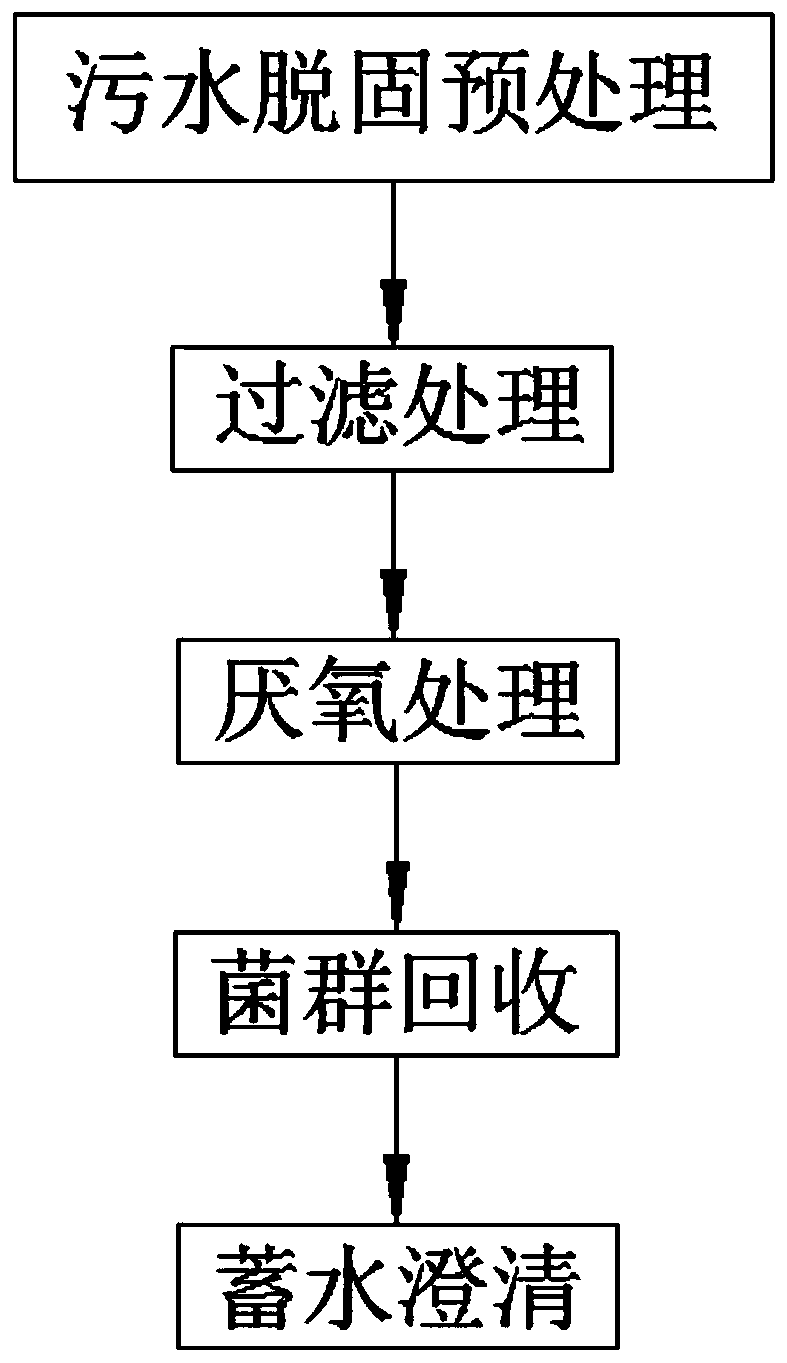

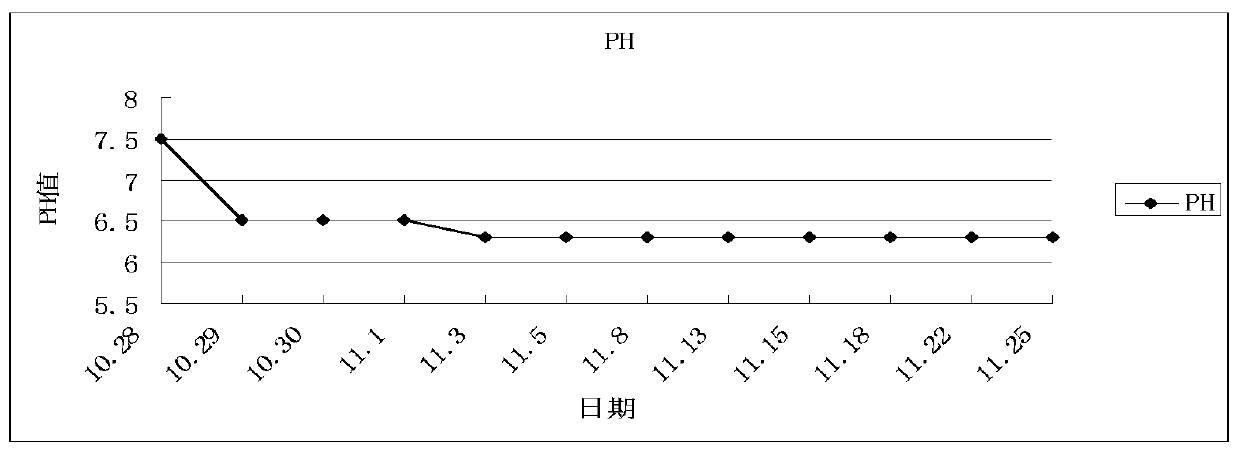

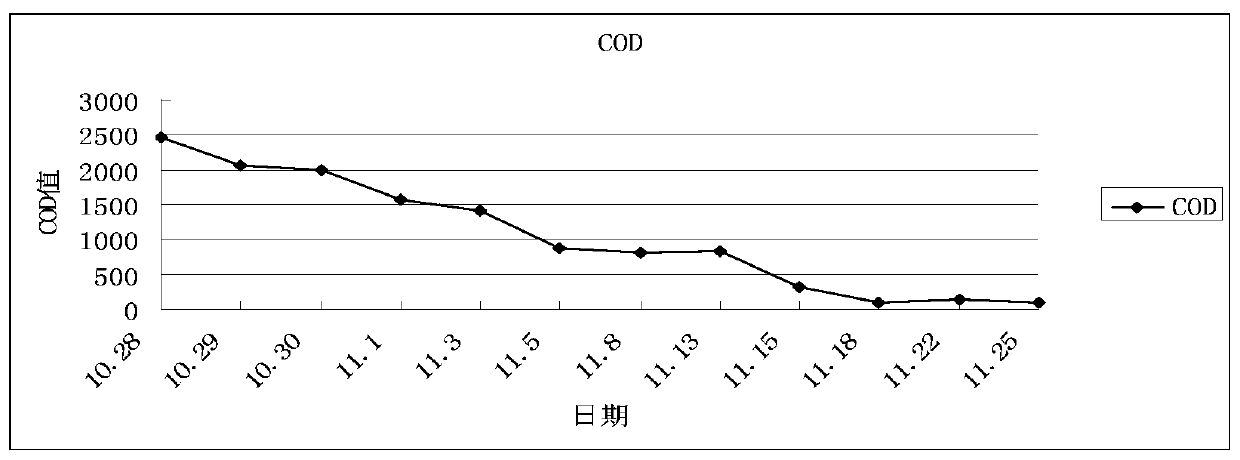

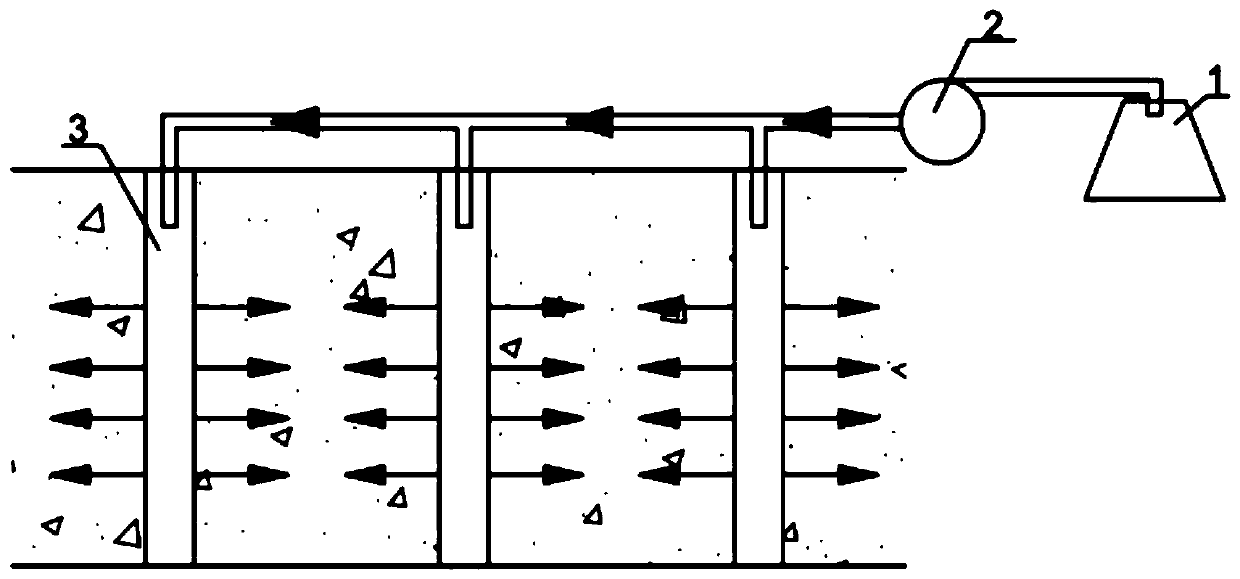

Zero-discharge combination process for livestock and poultry breeding sewage

InactiveCN110436702AAvoid churnLow costWater/sewage treatment by centrifugal separationWater treatment parameter controlFiltrationPre treatment

The invention discloses a zero-discharge combination process for livestock and poultry breeding sewage. The zero-discharge combination process comprises the following steps that sewage is subjected tode-solidification pre-treatment, specifically, flushing sewage is introduced into a rolling sieve, the flushing sewage is subjected to solid-liquid separation through the centrifugal force of the rolling sieve and a screen of the rolling sieve, filtration treatment is performed, specifically, the sewage after de-solidification is sequentially filtered through a first filter and a second filter, anaerobic treatment is performed, specifically, the secondary filtered sewage is introduced into a fixed bed biological anaerobic reaction device, and an obligate ammonia addicting bacteria is added tothe fixed bed biological anaerobic reaction device to remove phosphorus from the sewage. The zero-discharge combination process effectively prevents the loss of biological bacteria, improves the biodegradation rate, shortens the reaction time and reduces the engineering cost, and the obligate bacteria come from the environment of the project, professionalism and adaptability are high, and targeted selection of strains for biological systems is realized.

Owner:HAINAN CHENGTAI ENVIRONMENT ENG

Soil and underground water in-situ synergistic repair method

InactiveCN110170510AMeet growth needsImprove metabolic activityContaminated soil reclamationPetroleumPollution

The invention discloses a soil and underground water in-situ synergistic repair method. The method comprises the steps that a carbon element, a nitrogen element and a phosphorus element are added intoreinjection water, the weight ratio of the carbon element to the nitrogen element to the phosphorus element (C:N:P) is 100:5:1, a petroleum degradation bacterium with the concentration being 5,000-10,000 mg / L accounting for 0.5-1.2% of the total volume of the reinjection water is added into the reinjection water, meanwhile, aeration is performed on the reinjection water, the aeration amount is kept at 1.5-2 mg / L, and therefore final reinjection water is formed; a liquid charge pump extracts the final reinjection water from a biological enhancement adjusting tank, and reinjects the reinjectionwater into a stratum through reinjection, and in-situ synergic repair of soil and underground water is achieved. The biology growth speed is high, the biologic degrading speed is high, contaminated soil and underground water can be rapidly repaired, the repair effect is good, the repair technology is simple, the repair cost is low, contaminated soil does not need to be excavated in large area, alarge number of water resources are saved, and no secondary pollution is caused.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

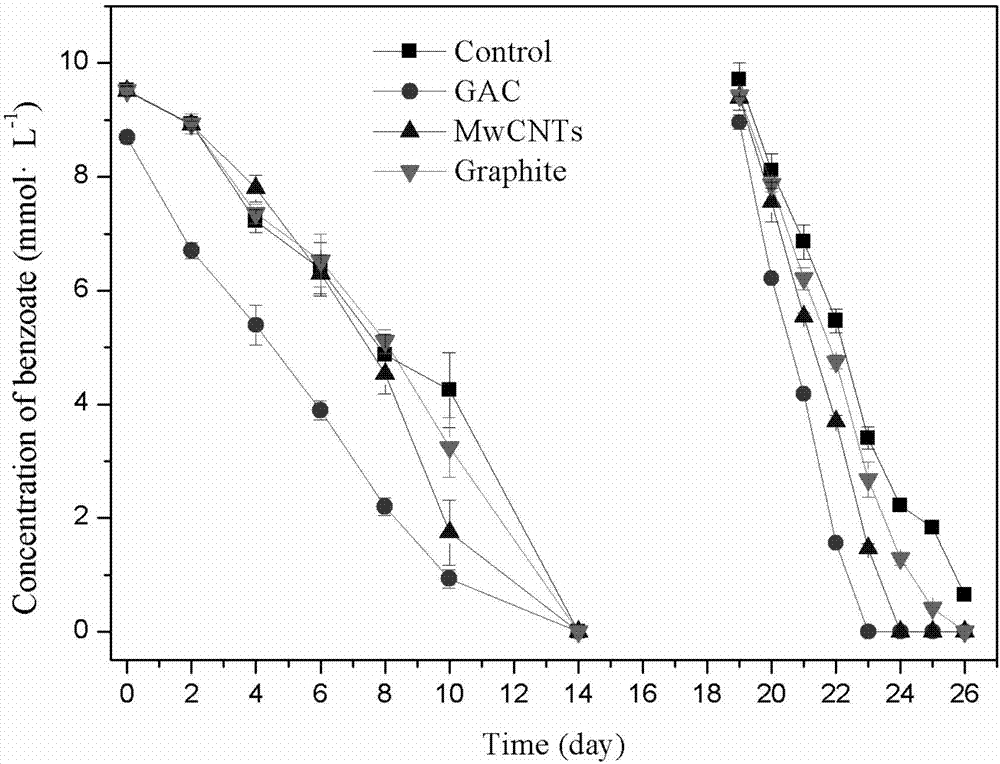

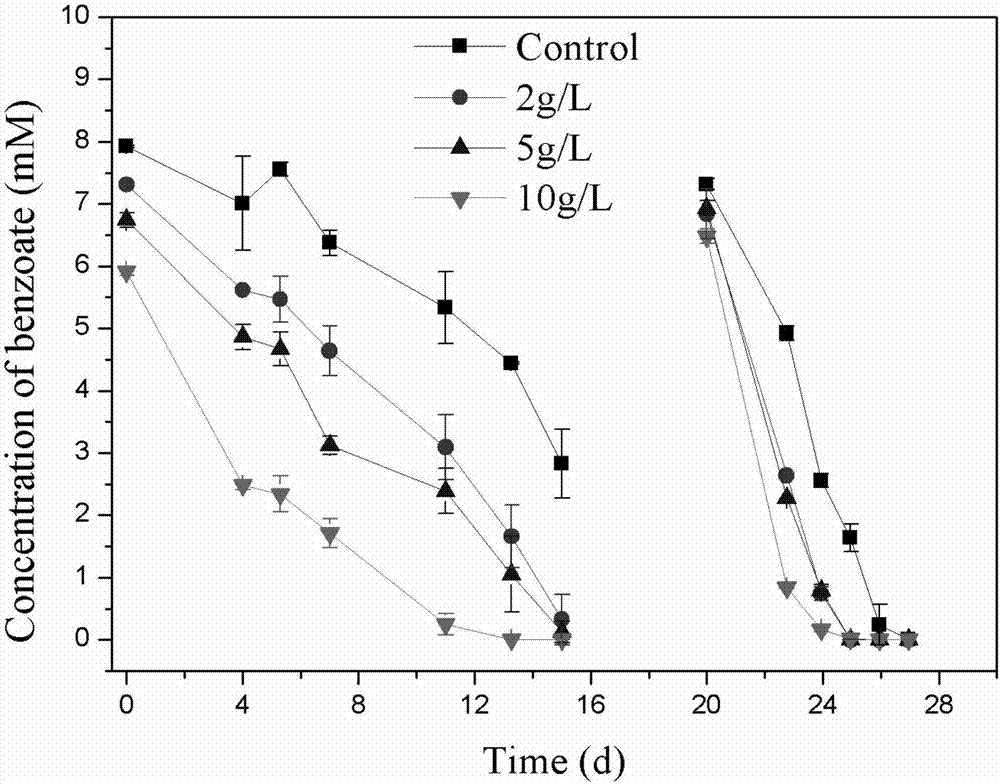

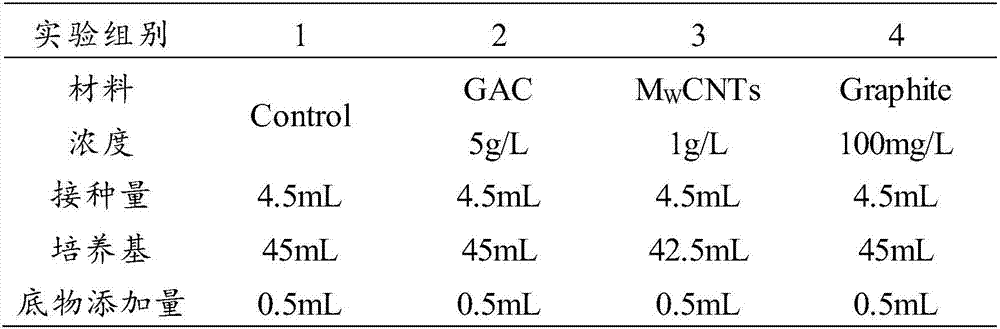

Method for treating benzoic-acid-containing waste water and anaerobic biodegradation method for benzoic acid

InactiveCN107500406APromote anaerobic degradationIncrease the rate of anaerobic degradationWater contaminantsTreatment with anaerobic digestion processesBenzoic acidWastewater

The invention provides an anaerobic biodegradation method for benzoic acid. The anaerobic biodegradation method for benzoic acid comprises the step of carrying out anaerobic biodegradation on the benzoic acid by using benzoic acid degrading bacteria in the presence of a conductive carbon material. The conductive carbon material is added in a benzoic acid anaerobic degradation process, the benzoic acid anaerobic degradation speed can be increased, the method can be used for treating the benzoic-acid-containing waste water, and can also be used for treating benzoic-acid-containing solid wastes, the treatment speed is increased, and the treatment ability is improved. Experimental results show that by the conductive carbon material, anaerobic degradation of the benzoic acid can be promoted, and along with increasing of the concentration of the conductive carbon material, the biodegradation speed of the benzoic acid is increased.

Owner:UNIV OF SCI & TECH OF CHINA

Biodegradable foamed polypropylene and preparation method thereof

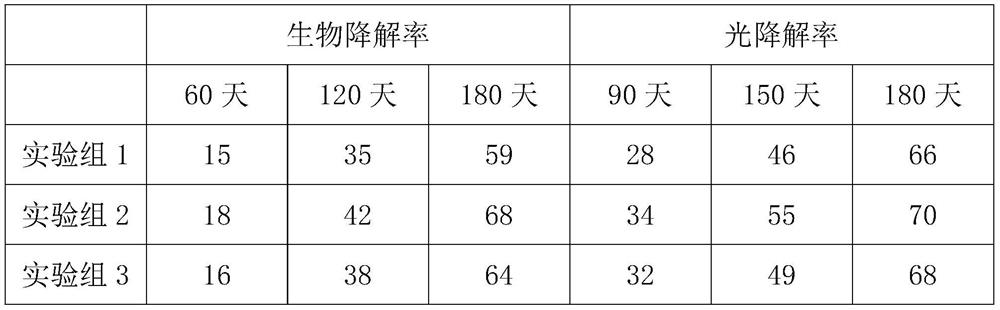

The invention discloses biodegradable foamed polypropylene, and particularly relates to the technical field of high polymer materials. The biodegradable foamed polypropylene is prepared from the following raw materials: a polypropylene resin, starch, calcium hydroxide, vinyl acetate, a dispersing agent, an antioxidant, a foaming nucleating agent, a photodegradation agent and a toughening agent. According to the invention, calcium hydroxide and the vinyl acetate are used for modifying starch, an alkaline earth metal calcium hydroxide is used for primarily modifying the starch so as to improve the compatibility of the starch, and then ceric ammonium nitrate is used for carrying out graft copolymerization reaction on the vinyl acetate and the starch so as to greatly improve the compatibility of the modified starch after graft copolymerization, so that the mixing effect of the starch and the polypropylene is good so as to effectively improve the biodegradation rate of the polypropylene material; the photodegradation rate of the polypropylene material can be effectively improved by adding the photodegradation agent while the foamed polypropylene material is treated by utilizing biodegradation and photodegradation so as to greatly improve the degradation rate of the foamed polypropylene material.

Owner:JIANGSU HAOSHENG PLASTIC IND TECH CO LTD

Polyhydroxy alkanoates graft polymer and preparation method thereof

ActiveCN101747476BChange molecular structureImprove thermal stabilityPolymer scienceOrganic chemistry

The invention discloses a polyhydroxy alkanoates graft polymer and a preparation method thereof; the polyhydroxy alkanoates graft polymer is prepared by the following ingredients by weight parts: 100 parts of polyhydroxy alkanoates, 01-15 parts of grafting monomer, 0-5 parts of initiator and 0-5 parts of antioxidants. The polyhydroxy alkanoates graft polymer changes the molecular structure of the polyhydroxy alkanoates, improves the heat stability thereof and further quickens the biological degrading ratio; in addition, the compatibility of the polyhydroxy alkanoates graft polymer and inorganic filling materials, such as CaCO3, talcum powder and the like and the polarity blending material is improved, and the polyhydroxy alkanoates graft polymer has high practical and economical values.

Owner:山东省意可曼科技有限公司

Composite fiber of polyglycolide and polydioxanone, its preparation method, application and surgical suture

ActiveCN109137135BImprove flexibilityIncreased biodegradation rateSuture equipmentsFilament/thread formingFiberSpinning

Owner:CHINESE TEXTILE ACAD

Composite fiber of polylactide and polydioxanone, its preparation method, application and surgical suture

ActiveCN109234843BIncreased biodegradation rateGood biocompatibilitySuture equipmentsFilament/thread formingFiberSpinning

Owner:CHINESE TEXTILE ACAD

Bioremediation agent for oil-contaminated saline-alkali soil and application of bioremediation agent

PendingCN114479867ALow costWill not cause secondary pollutionContaminated soil reclamationOrganic fertilisersAlkali soilNutrition

The invention relates to the technical field of soil remediation, in particular to a bioremediation agent for oil-contaminated saline-alkali soil and application of the bioremediation agent. The bioremediation agent is prepared from the following components in parts by mass: 22 to 45 parts of biomass filler; 42 to 78 parts of immobilized microspheres; 3-10 parts of a nutrition activator; wherein the biomass filler is prepared from wood chips, rice chaff, straws, cow dung, wheat bran and walnut shells; the immobilized microspheres are composed of saline-alkaline tolerant hydrocarbon-philic bacteria, biological enzyme, nano urea peroxide particles, sodium alginate and activated carbon. The nutrition activating agent is prepared from yeast powder, NH4Cl, urea and K2HPO4. All the components are low in price and easy to obtain, the processing and using method is simple, and the cost for repairing the oil-contaminated saline-alkali soil can be effectively reduced. The oil content of the remedied oil-contaminated soil is lower than 0.2%, the national environmental protection standard requirement is met, and the remediation period is shortened to be within 2 months from original 6 months or above.

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite fiber of polyethylene lactide and polycaprolactone, its preparation method, use and surgical suture

ActiveCN107059158BIncreased biodegradation rateGood biocompatibilitySuture equipmentsFilament/thread formingFiberLactide

The invention discloses a poly lactate geycollic acid and polycaprolactone complex fiber, a preparation method and application thereof, and an operation suture line. The complex fiber comprises a poly lactate geycollic acid fiber and a polycaprolactone complex fiber, wherein the poly lactate geycollic acid fiber is used as a core layer of the complex fiber, and the polycaprolactone fiber is used as a skin layer of the complex fiber. The preparation method comprises the following steps: obtaining poly lactate geycollic acid slices and polycaprolactone slices respectively; and performing composite spinning on the poly lactate geycollic acid slices and the polycaprolactone slices, wherein the poly lactate geycollic acid is used as the core layer, and the polycaprolactone covers the poly lactate geycollic acid to form the skin layer of the complex fiber so as to obtain the poly lactate geycollic acid and polycaprolactone complex fiber. The composite fiber can be used for the operation suture line. The operation suture line is prepared from the complex fiber. The complex fiber can not only alleviate the characteristic of easy degradation of the poly lactate geycollic acid fiber, but also can enhance the flexibility of the poly lactate geycollic acid fiber.

Owner:CHINESE TEXTILE ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com