Biodegradable foamed polypropylene and preparation method thereof

A foamed polypropylene and biodegradable technology is applied in the field of polymer materials to achieve the effects of reducing costs, increasing the rate of biodegradation, and increasing the rate of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

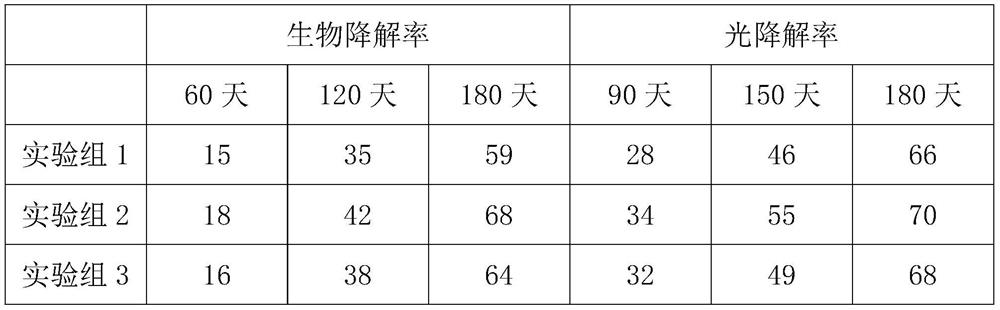

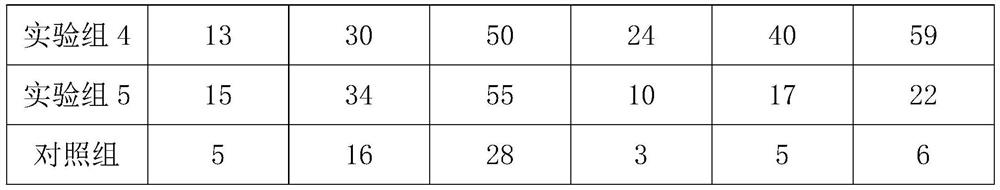

Examples

Embodiment 1

[0025] The invention provides a biodegradable foamed polypropylene, comprising the following raw materials in parts by weight: 40 parts of polypropylene resin, 30 parts of starch, 1 part of calcium hydroxide, 20 parts of vinyl acetate, 2 parts of dispersant, 1 part of oxygen agent, 1 part of foaming nucleating agent, 1 part of photodegradation agent and 4 parts of toughening agent.

[0026] In a preferred embodiment, the starch is one of potato starch, sweet potato starch or corn starch, the dispersant is aluminum sulfate, and the antioxidant is an alkyl monophenol antioxidant or azapine Cyclic polyphenol antioxidant, the photodegradant is iron stearate, the toughening agent is maleic anhydride grafted polypropylene or maleic anhydride grafted EVA, and the foaming nucleating agent is bicarbonate sodium.

[0027] The present invention also provides a preparation method of biodegradable foamed polypropylene, the specific preparation steps are as follows:

[0028] Step 1: Put t...

Embodiment 2

[0038] Different from Example 1, the present invention provides a biodegradable foamed polypropylene, including the following raw materials in parts by weight: 50 parts of polypropylene resin, 40 parts of starch, 3 parts of calcium hydroxide, 30 parts of vinyl acetate 4 parts, 4 parts of dispersant, 3 parts of antioxidant, 2 parts of foam nucleating agent, 3 parts of photodegradant and 7 parts of toughening agent.

Embodiment 3

[0040] All different from Examples 1-2, the present invention provides a biodegradable foamed polypropylene, comprising the following raw materials in parts by weight: 60 parts of polypropylene resin, 50 parts of starch, 5 parts of calcium hydroxide, acetic acid 40 parts of vinyl ester, 6 parts of dispersant, 5 parts of antioxidant, 3 parts of foaming nucleating agent, 5 parts of photodegradant and 10 parts of toughening agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com