Method for degrading organic contaminant catalyzed by ultrasonic wave

A technology for catalytic degradation of organic pollutants, applied in the field of ultrasonic catalytic degradation of organic pollutants, can solve the problems of limited improvement in the efficiency of ultrasonic catalytic degradation of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

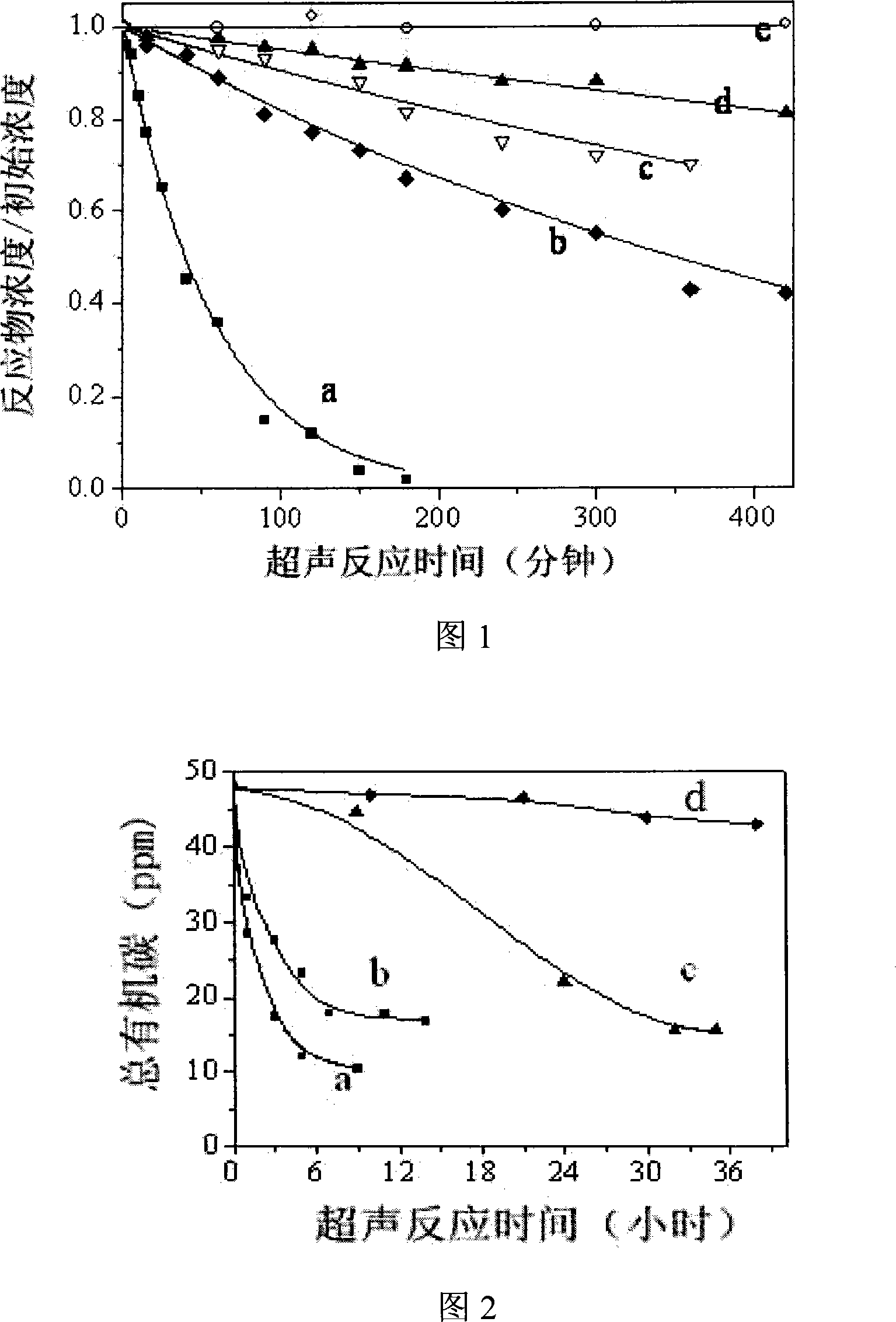

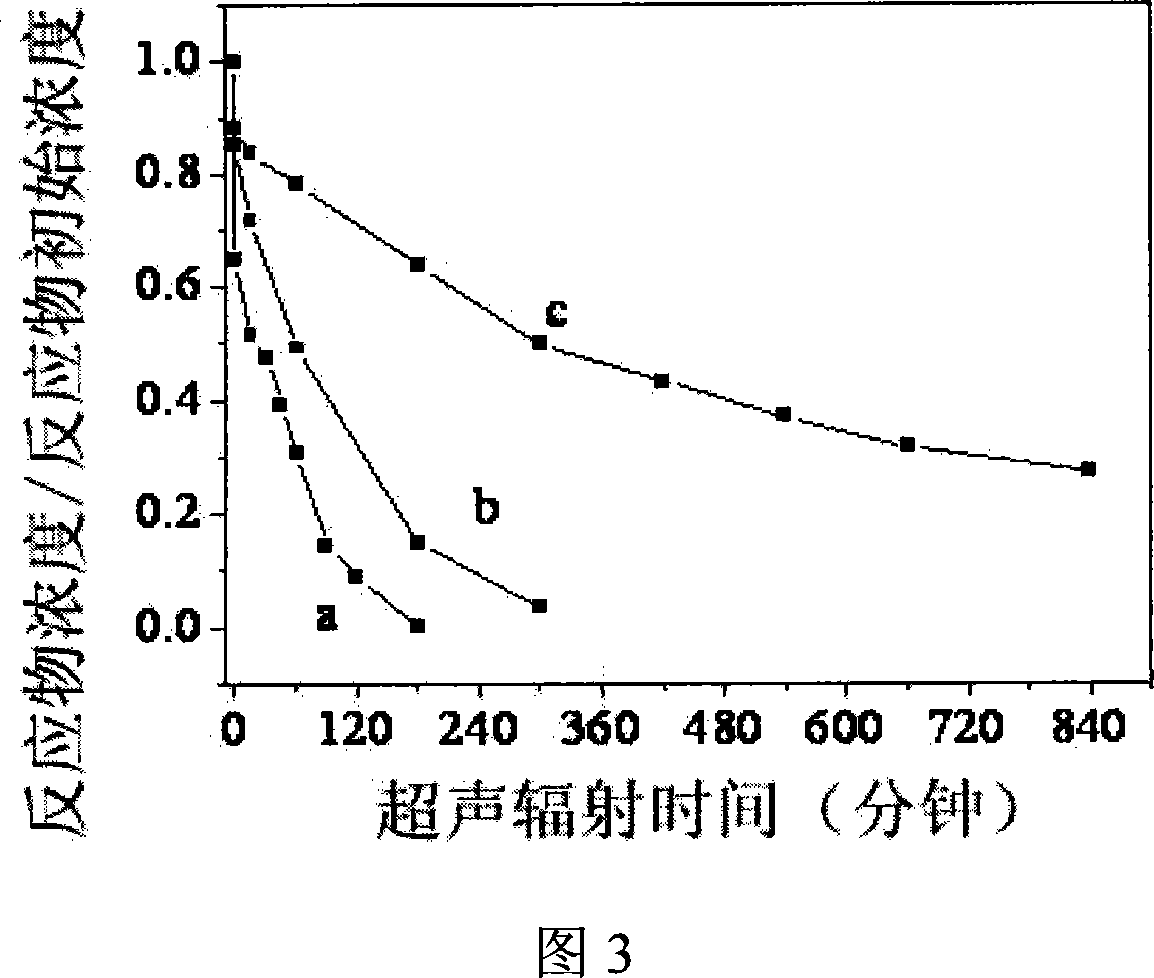

Embodiment 1

[0051]Take 10 grams of zirconium dioxide (average particle size: 25 nanometers) and place it in an oven at 150°C for 12 hours; then take 2 grams and disperse it in a 200 ml round bottom flask, add 200 ml of double distilled water, and ultrasonically break it for one hour. Add 31.5 mg of silver nitrate, use 1 mol / liter of chloric acid to adjust the pH value to 3.0, then place in the dark and stir for 30 minutes to achieve adsorption / desorption equilibrium while passing Ar to remove air. 500W xenon lamp was irradiated for 4 hours, and the silver nitrate was converted into elemental nanoparticles and loaded on the zirconia carrier. Centrifuge the catalyst, dry it at 100° C. for 10 hours, and grind it into powder to prepare a nano-silver (average particle size: 3 nm) / zirconia (average particle size: 25 nm) composite solid-phase catalyst.

[0052] The round-bottomed flask contains 1.0 grams of nano-silver / zirconia composite solid-phase catalyst (loading capacity 1.0%, mass fraction...

Embodiment 2

[0055] Take 10 grams of ferric oxide (average particle size: 280 nanometers), put it in an oven and dry it at 150°C for 12 hours; then take 2 grams and disperse it in a 200 ml round bottom flask, add 200 ml of twice distilled water, and ultrasonically break it for one hour. Add 50 mg of potassium chloroplatinate, use 1 mol / liter of chloric acid to adjust the pH value to 3.0, then place in the dark and stir for 30 minutes to achieve adsorption / desorption equilibrium while passing Ar to remove air. The 500W xenon lamp was irradiated for 4 hours, and the potassium chloroplatinate was converted into simple nanoparticles and loaded on the ferric oxide carrier. Centrifuge the catalyst, dry it at 100°C for 10 hours, and grind it into powder to prepare nano-platinum (average particle size 5nm) / ferric oxide (average particle size 280 nm) composite solid-phase catalyst.

[0056] The round bottom flask contains 0.5 gram of nanometer platinum / ferric oxide composite solid-phase catalyst (l...

Embodiment 3

[0059] Take 10 grams of chromium trioxide (average particle size: 165 nanometers), put it in an oven and dry it at 150°C for 12 hours; then take 2 grams and disperse it in a 200 ml round bottom flask, add 200 ml of twice distilled water, and ultrasonically break it for one hour. Add 42 mg HAuCl 4 , using 1 mol / liter of chloric acid to adjust the pH value to 3.0, then placed in the dark and stirred for 30 minutes to achieve adsorption / desorption equilibrium while passing Ar to remove air. 500W xenon lamp irradiation for half an hour, the HAuCl 4 It is converted into simple nanometer particles and loaded on the chromium trioxide carrier. The catalyst was separated by centrifugation, dried at 100°C for 10 hours, and ground into powder to obtain a composite solid-phase catalyst of nano-gold (average particle size: 2nm) / chromium trioxide (average particle size: 165 nm).

[0060] The round-bottomed flask contains 4.0 g of nano-gold / chromium trioxide composite solid-phase catalyst ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com