Patents

Literature

4387 results about "Nanometer particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Optical element with nanoparticles

InactiveUS7046439B2Effective lightingBrighter backlit displaysDiffusing elementsProjectorsMicrometerNanoparticle

Owner:SKC HI TECH & MARKETING CO LTD CO REGISTRATION NO 161511 0225312

Nanoparticle releasing medical devices

Owner:ABBOTT CARDIOVASCULAR

Preparation of Nanoparticle Materials

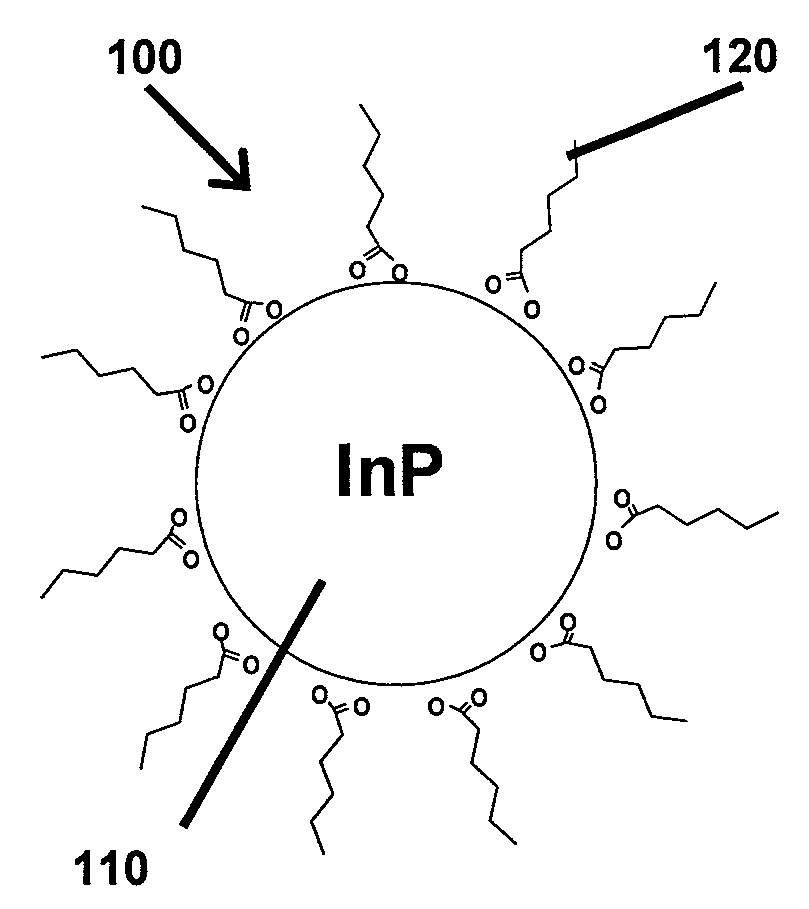

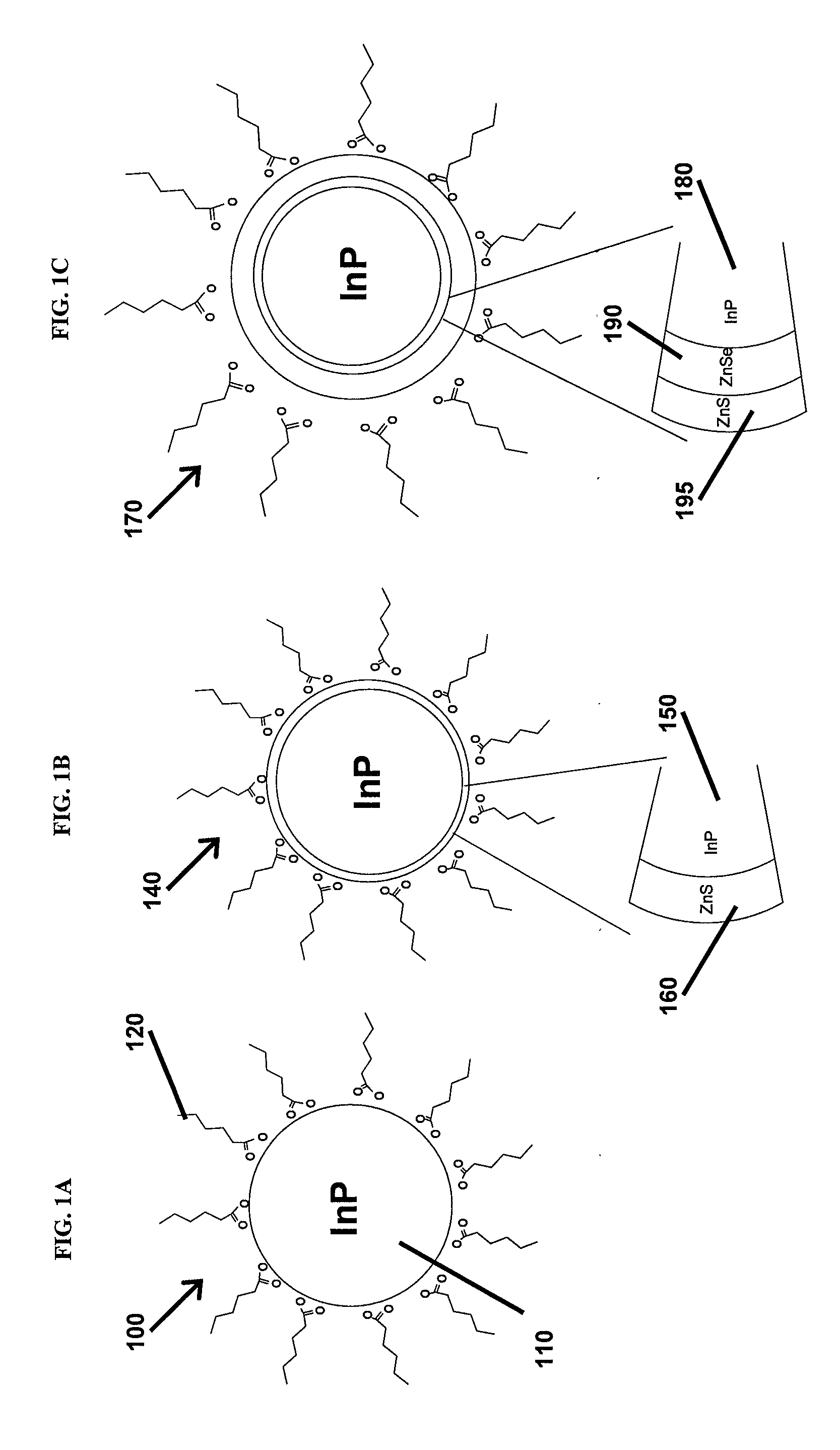

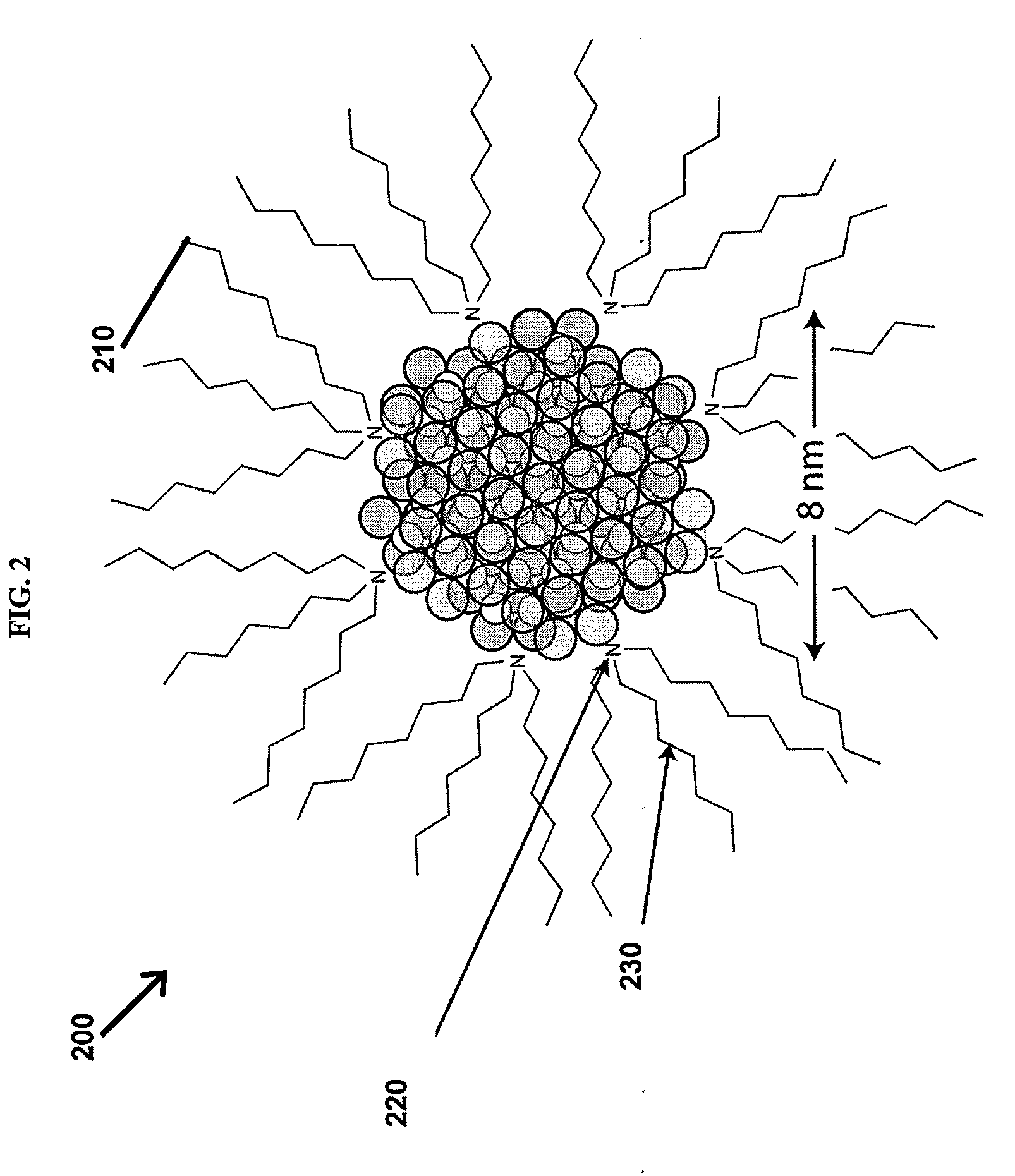

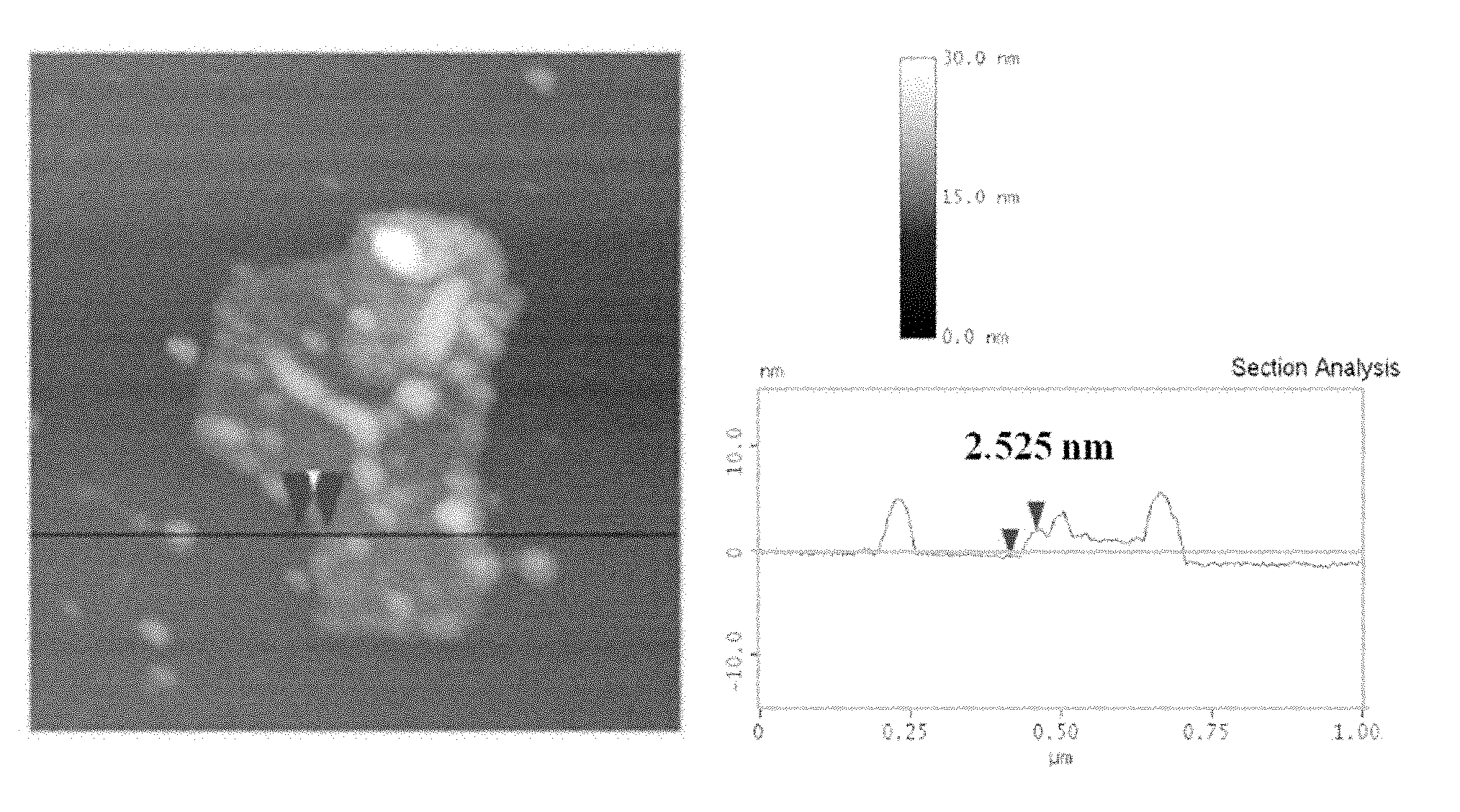

ActiveUS20080160306A1Easily scaled-upLiquid surface applicatorsGlass/slag layered productsSemiconductor materialsMolecular cluster

Nanoparticles including a molecular cluster compound incorporating ions from groups 12 and 16 of the periodic table, as well as a core semiconductor material incorporating ions from groups 13 and 15 of the periodic table, are fabricated. The core semiconductor material is provided on the molecular cluster compound.

Owner:NANOCO TECH LTD

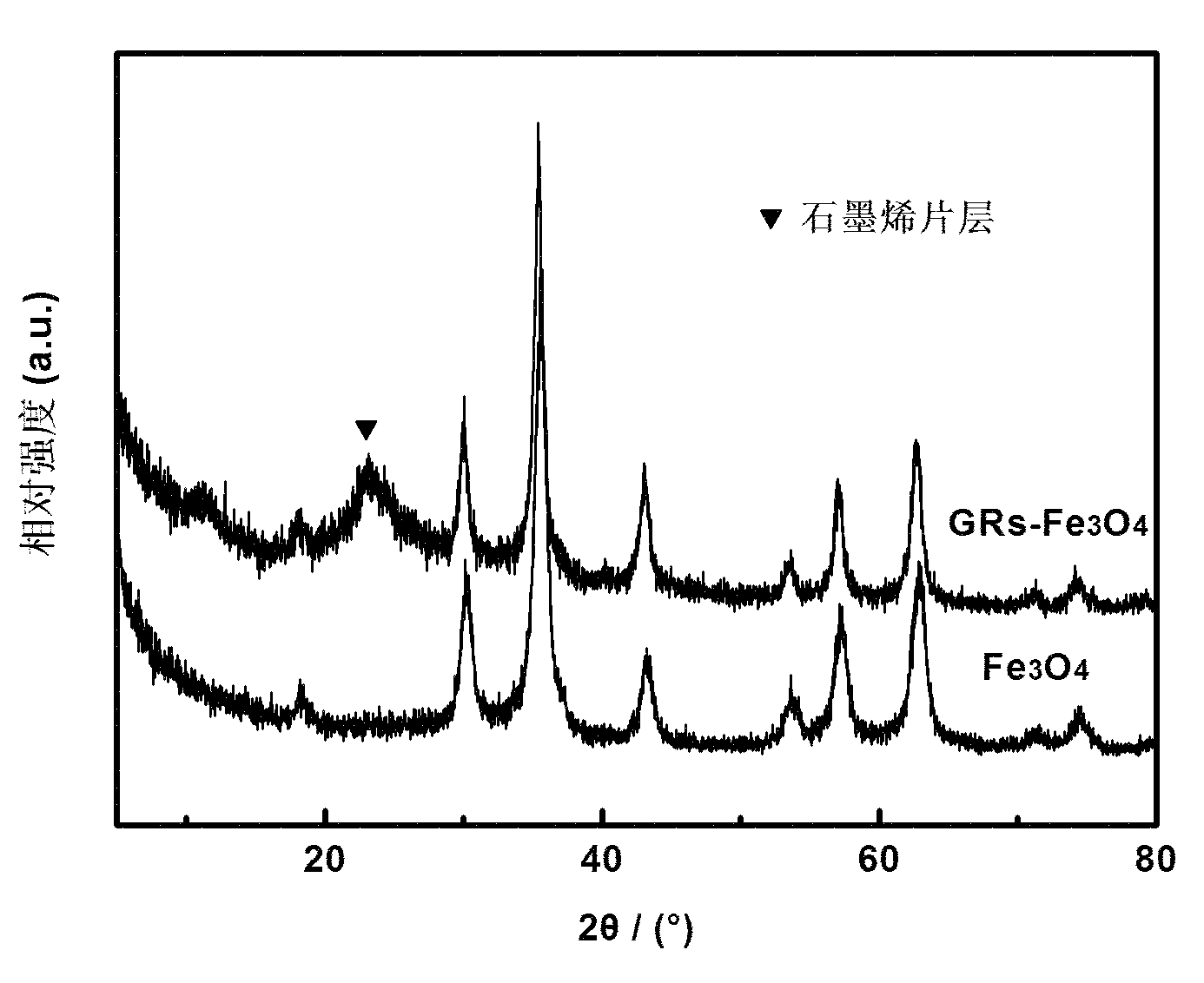

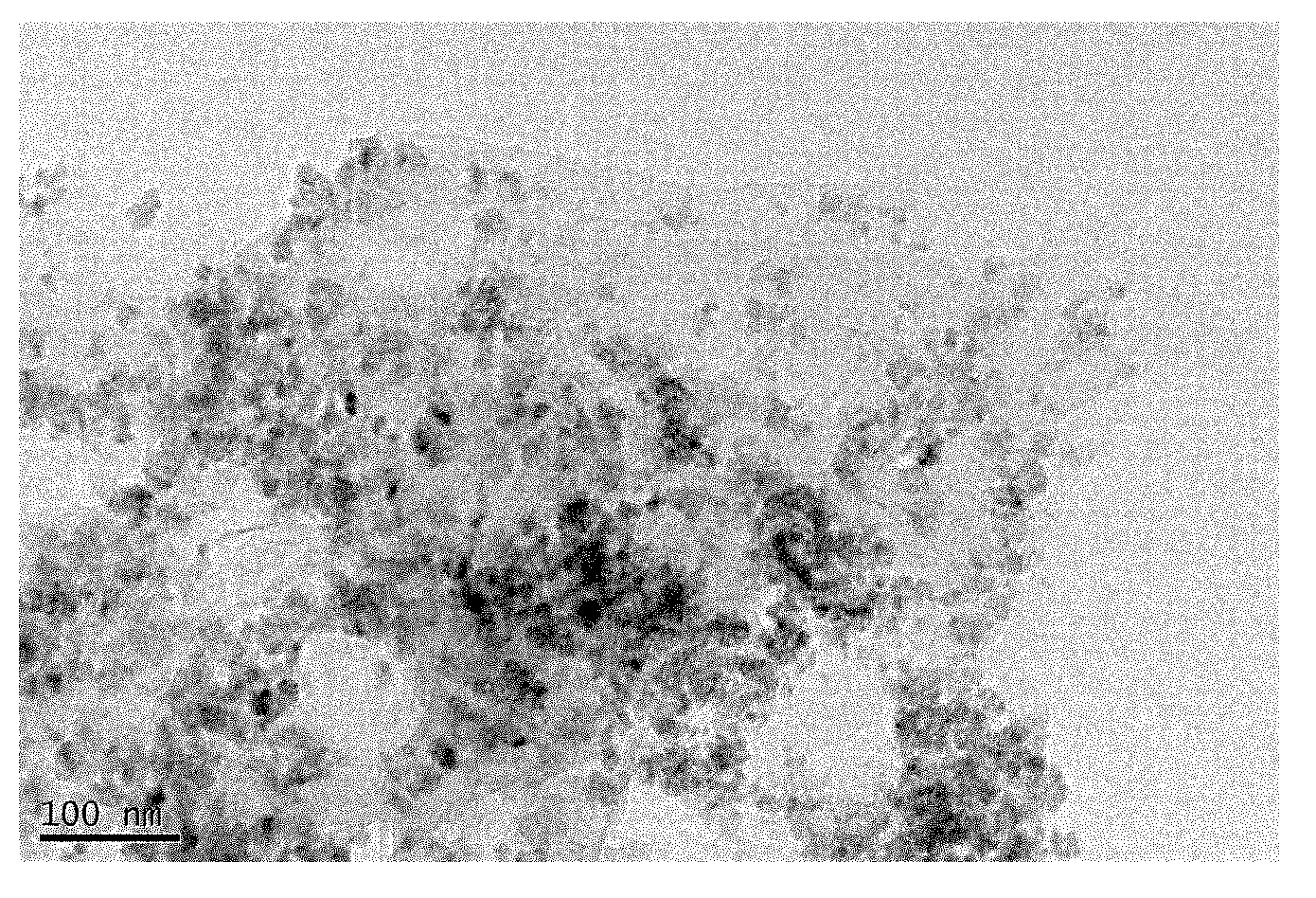

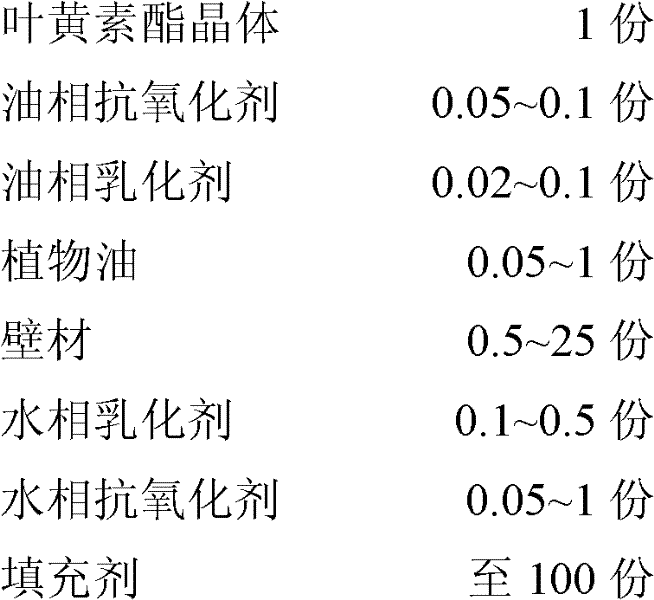

Method for preparing graphene loaded ferroferric oxide magnetic nanometer particle composite material

InactiveCN101941842AGood dispersionPromote crystallizationMaterial electrochemical variablesElectrodesHydrazine compoundNitrogen gas

The invention relates to a method for preparing a graphene loaded ferroferric oxide magnetic nanometer particle composite material. The method comprises the following steps of: (1) dispersing graphite oxide into deionized water, pouring into a vessel after ultrasonic and centrifuging, putting the vessel into an oil-bath pan, adding hydrazine hydrate and an anionic surfactant for heating, condensing and refluxing, and cooling and drying to obtain modified graphene; and (2) dispersing the graphene into aqueous solution, and ultrasonically stirring and centrifuging to obtain modified graphene dispersion liquid; and weighing a soluble trivalent ferric salt and divalent ferric salt, dissolving the salt into the deionized water, introducing nitrogen, pouring into the modified graphene dispersion liquid, dripping ammonia after uniform ultrasonic stirring, heating for reaction, washing and collecting a product, and drying the product. The method is simple and easy for industrial production; and the prepared composite material has the advantages of pure crystal phase, uniform distribution and excellent electrocatalytic activity.

Owner:DONGHUA UNIV

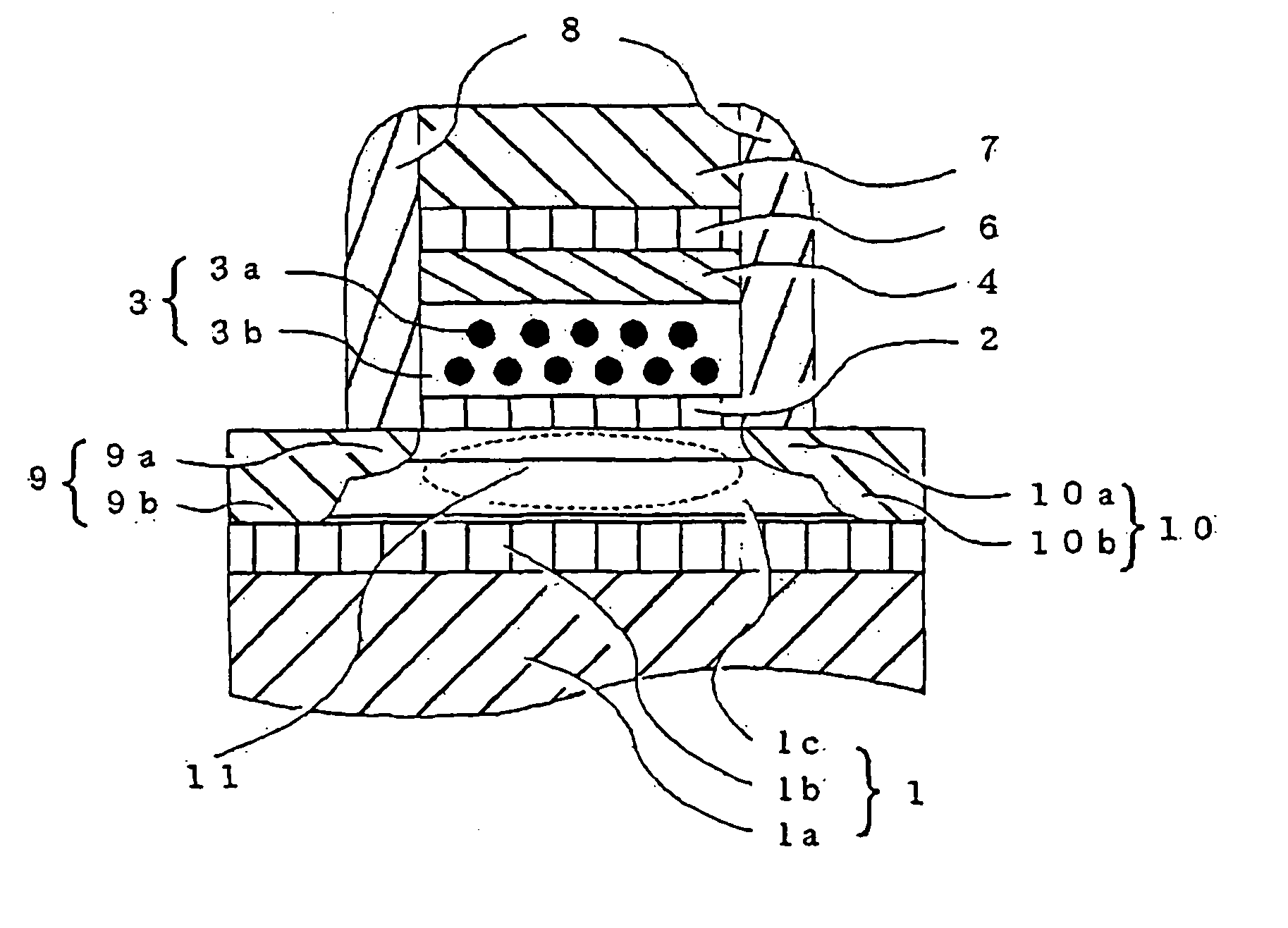

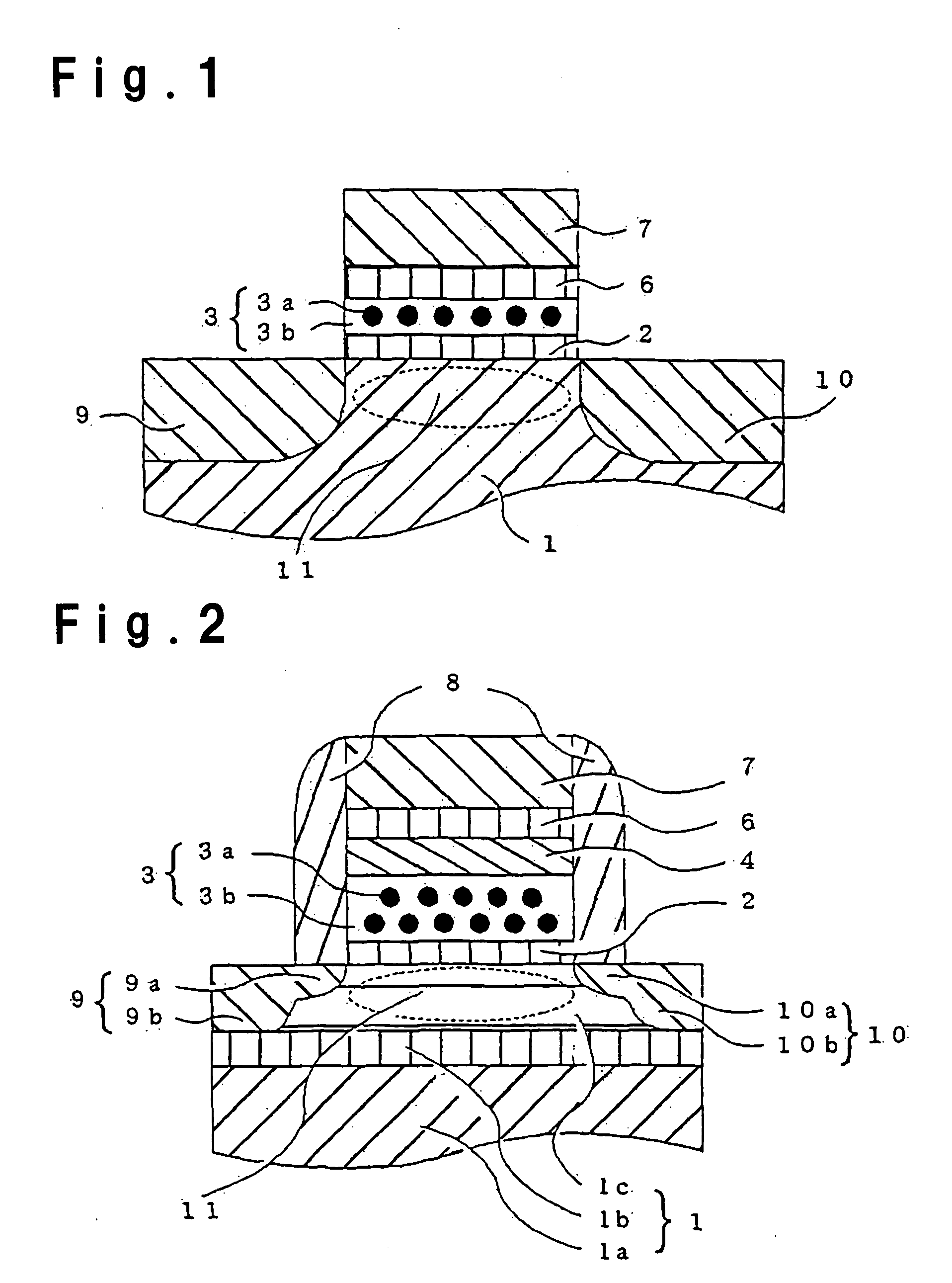

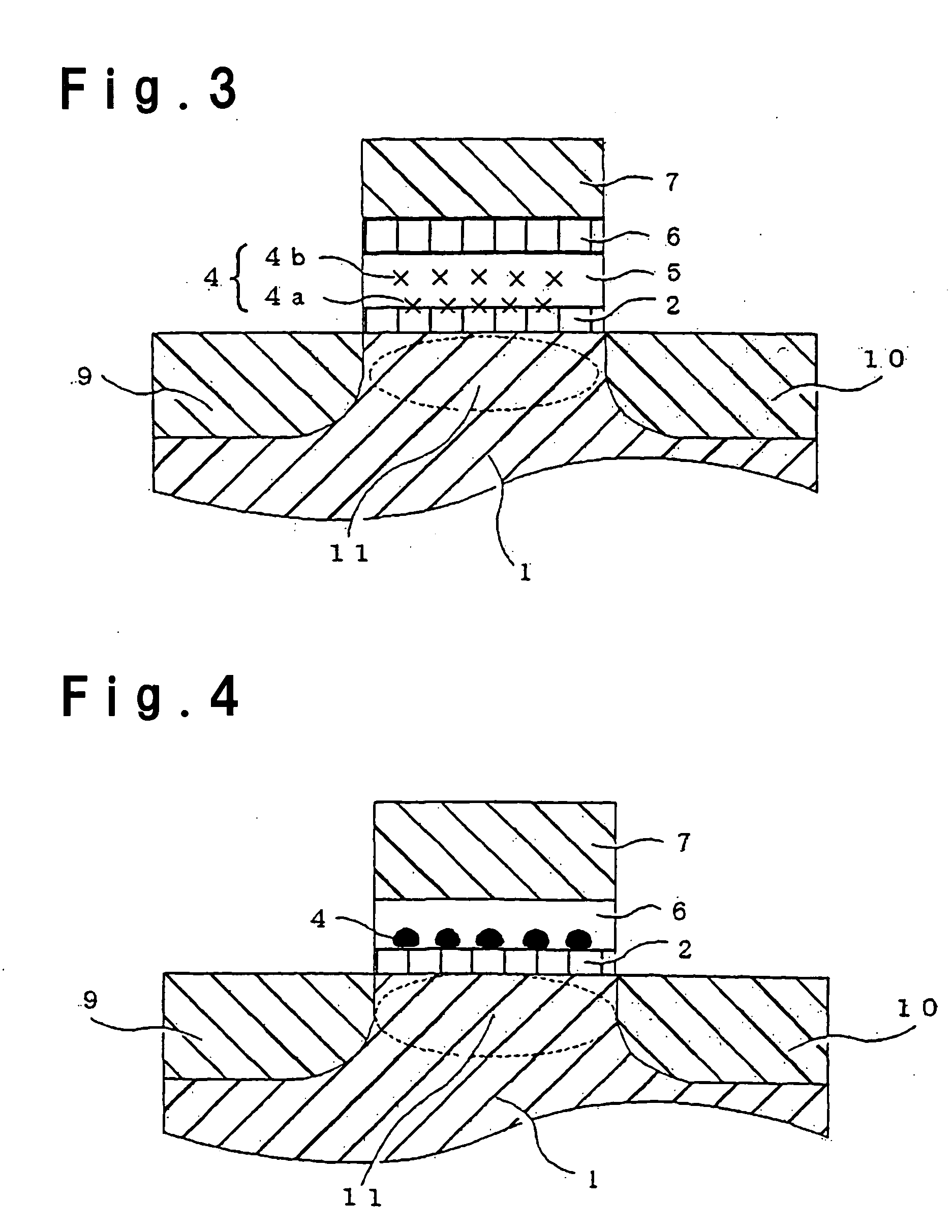

Novolatile semiconductor memory device and manufacturing process of the same

There is provided a nonvolatile semiconductor memory device which can shorten data writing and erasing time, significantly improve the endurance characteristic and be activated with low power consumption. The nonvolatile semiconductor memory device comprises an insulating layer 3b with electric insulation, wherein, a charge retention layer 3 formed adjacent to a tunnel insulating film 2 contains nano-particles 3a comprised of a compound which is constituted from at least one single-element substance or chemical compound having a particle diameter of at most 5 nm functions as a floating gate, and which are independently dispersed with a density of from 10+12 to 10+14 particles per square centimeter.

Owner:ASAHI GLASS CO LTD +1

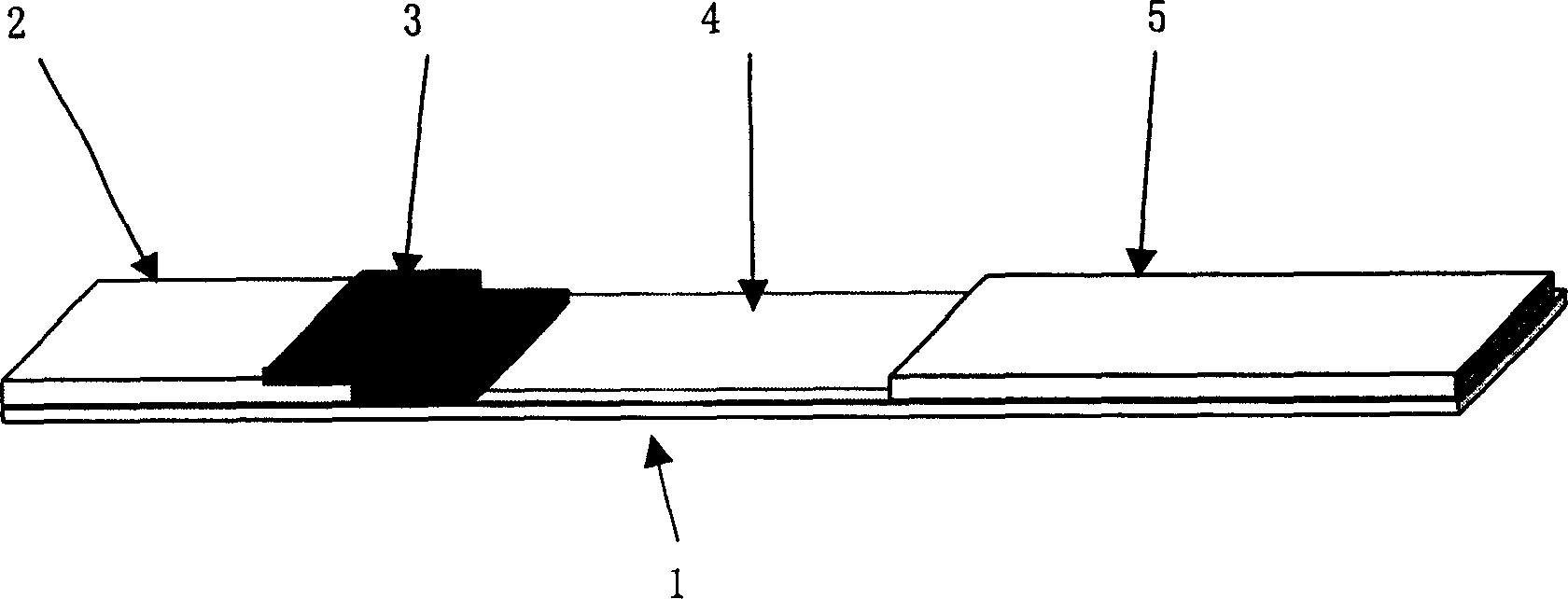

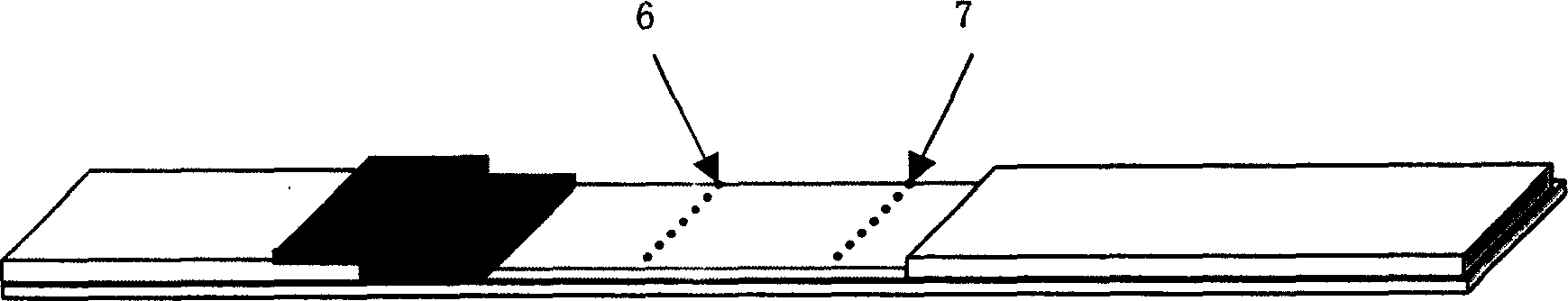

Wood plastic composite material composection and formed board thereof and their preparation process

The present invention provides one kind of wood-plastic composition, which contains wood powder and resin as well as nanometer particle of size below 100 nm. The wood-plastic composition with nanometer particle has hardness greater than 56HRR and heat distortion temperature higher than 105 deg.c. It may be produced into plate used widely for building, transportation, packing, household decoration and daily use article.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

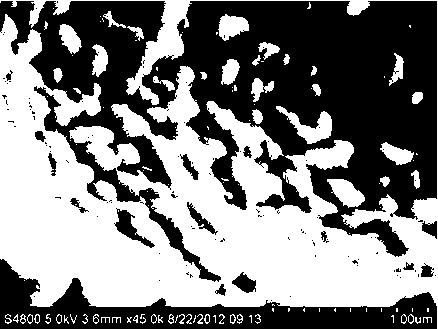

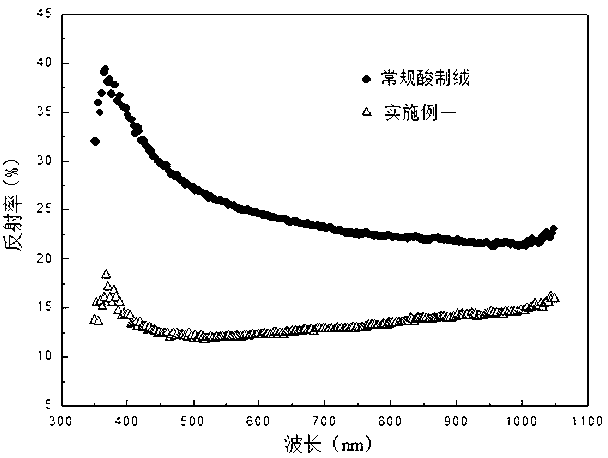

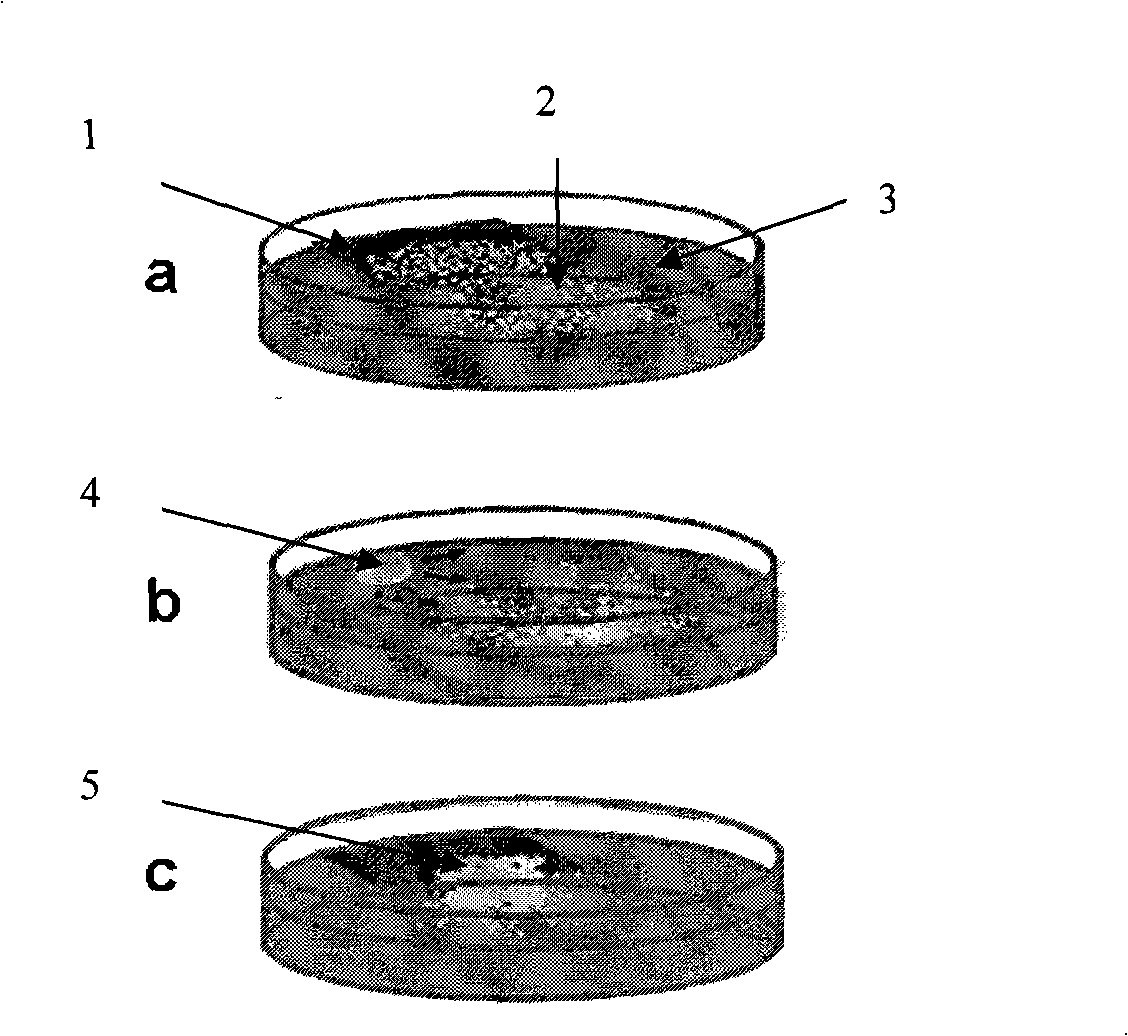

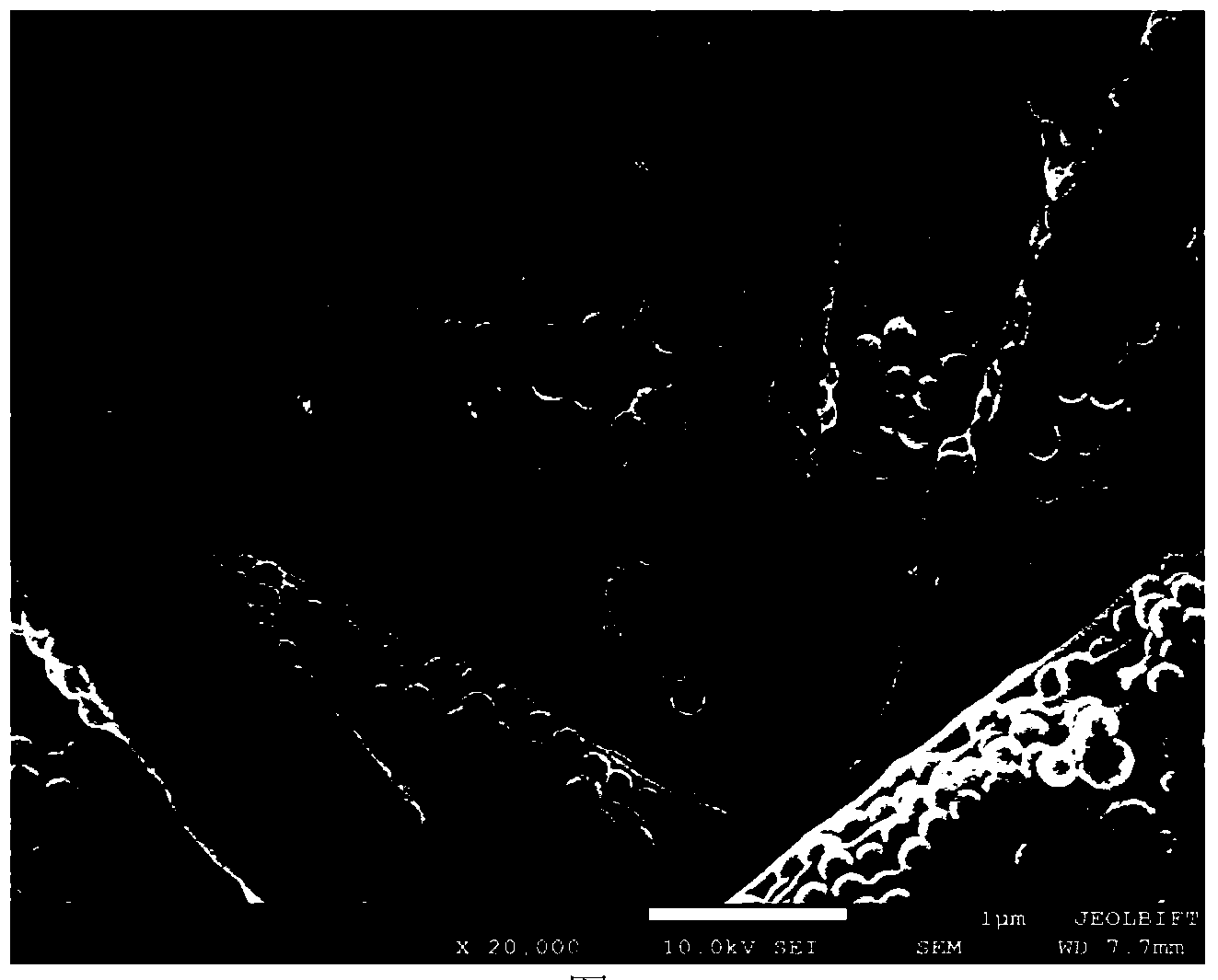

Textured structure of crystalline silicon solar cell and preparation method thereof

ActiveCN103219428AImprove conversion efficiencySimple manufacturing methodPhotovoltaic energy generationSemiconductor devicesMicrometerSpins

The invention discloses a preparation method of a textured structure of a crystalline silicon solar cell. The method includes the steps of (1) cleaning and texture preparation, (2) soaking a silicon wafer in a solution containing metal ions to enable the surface of the silicon wafer to be coated with a layer of metal nanometer particles, (3) corroding the surface of the silicon wafer to form a nanometer-grade texture, (4) cleaning to remove the metal particles, (5) carrying out microstructure amendment etching in second chemical corrosive liquid, and (6) cleaning and spin-drying. As is proved by a test, the size of the textured structure is between 100nm-500nm; the textured structure is of a nanopore shape with a large hole diameter and a small depth, or a nanometer pyramid with edge angles, or of a nanometer pit shape structure with an edge angle nanometer cone body or with an edge angle; and compared with a nanometer-micrometer composite textured structure disclosed in CN102610692A, the textured structure enables conversion efficiency of a cell piece to be improved by about 0.2%-0.5%, and an unexpected effect is achieved.

Owner:SUZHOU UNIV +1

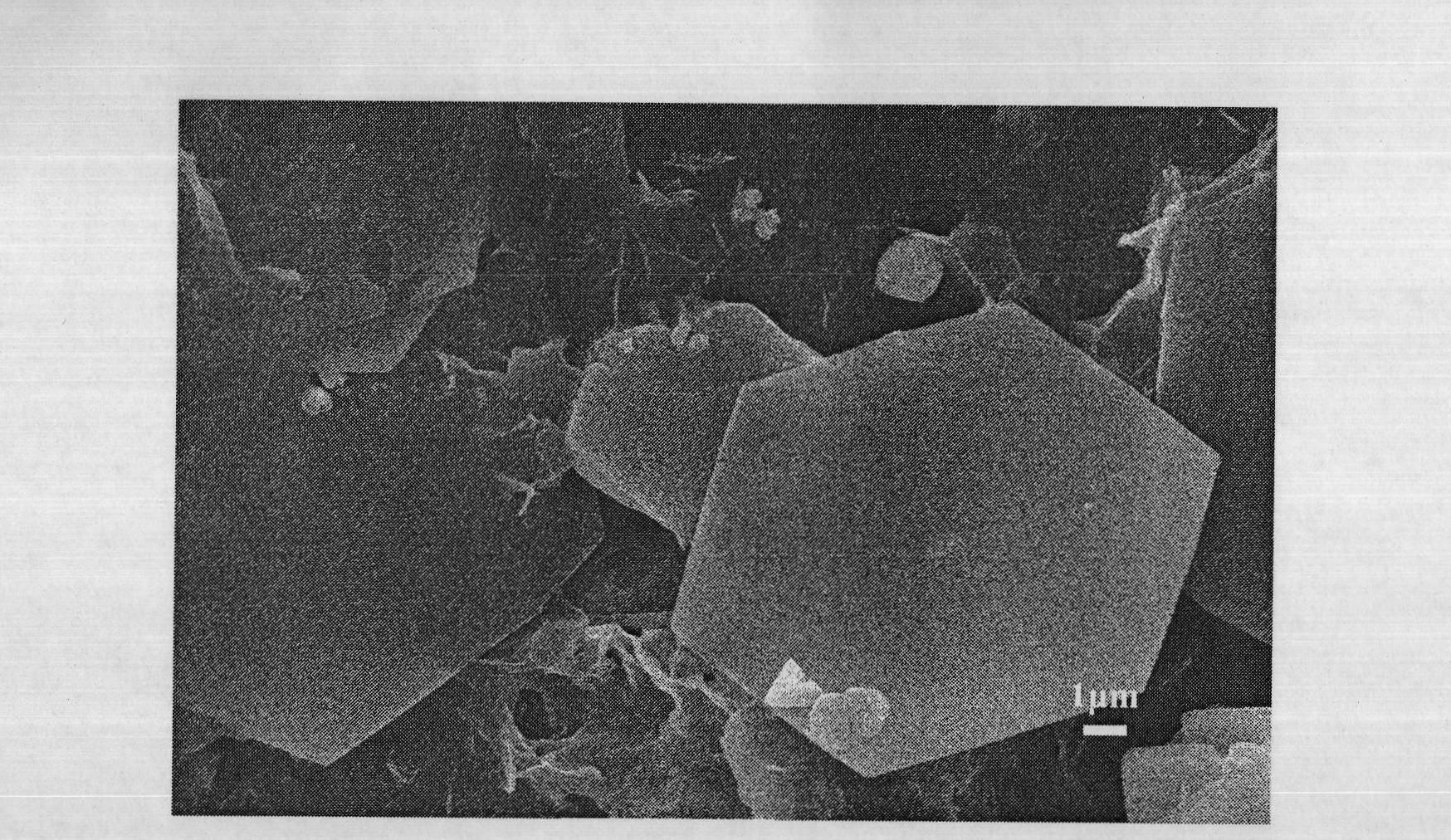

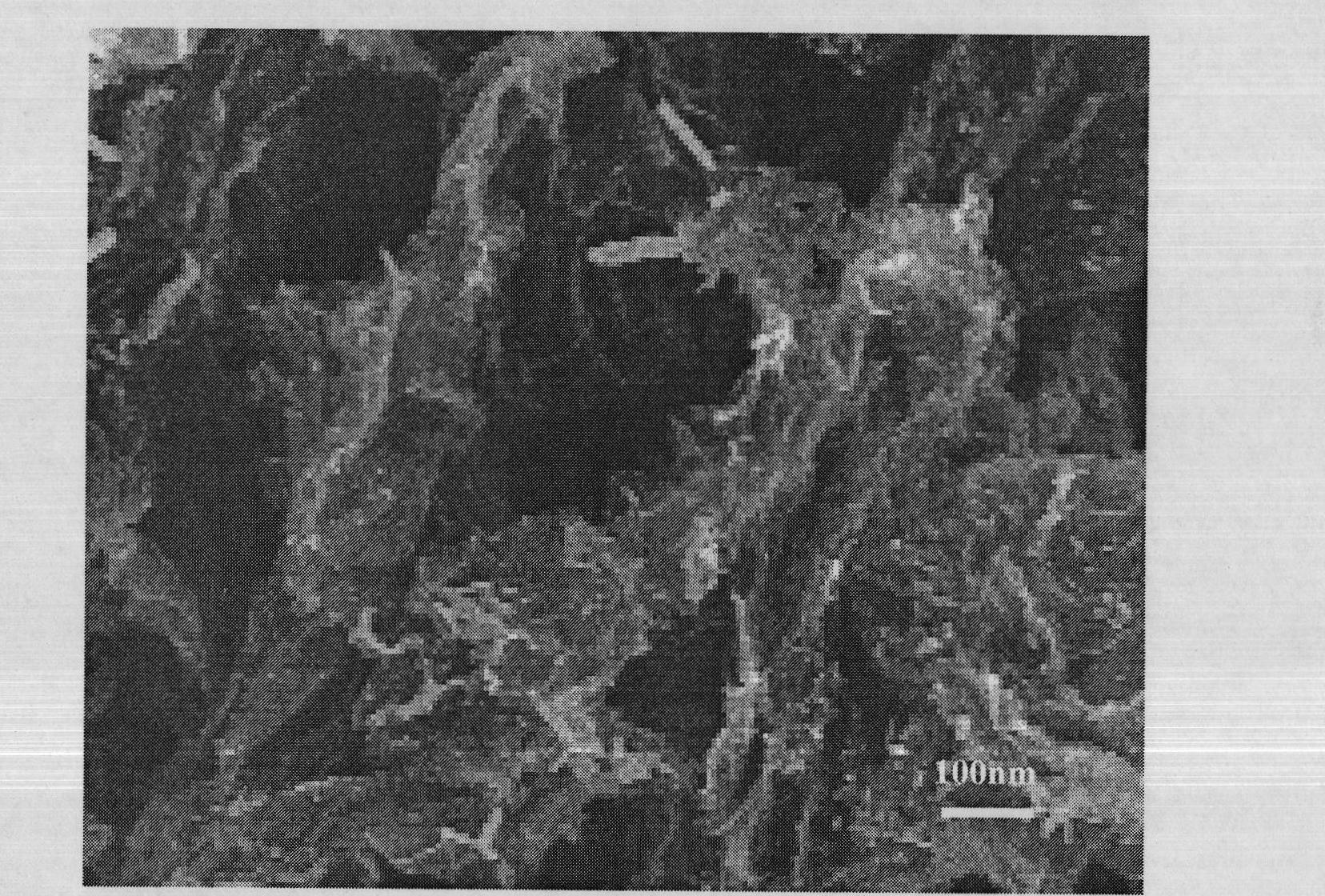

Preparation method of large-area and continuous graphen/zinc oxide composite structure

ActiveCN101857222AThickness is easy to controlSimple processZinc oxides/hydroxidesNanoparticleThree-dimensional space

The invention relates to a method for preparing continuous graphen / zinc oxide composite structure in large area, which belongs to the preparation field of the novel nanometer material, and is applicable to the fields such as sensor, solar panel, novel nanometer part and the like. The method comprises the following three steps that: first step: uniformly dispersing graphen or graphene oxide in liquid phase; second step: utilizing a hydrothermal process to ensure the zinc oxide nanometer structure and the graphen two-dimensional sheet to form a continuous structure in a three-dimensional space; third step: transferring the prepared composite structure onto a substrate to be dried. The method has simple process and low device requirement since the composite structure is synthesized in the solution; the process repeatability is strong, and the process parameter can be well controlled; the prepared graphen / zinc oxide composite structure has large area and is continuous, the generated zinc oxide nanometer sheet layer, nanometer particle and nanometer line are connected with each other and intersected with each other under the effect of the graphen so as to form a continuous porous structure in the three-dimensional space.

Owner:如东文园投资开发有限公司

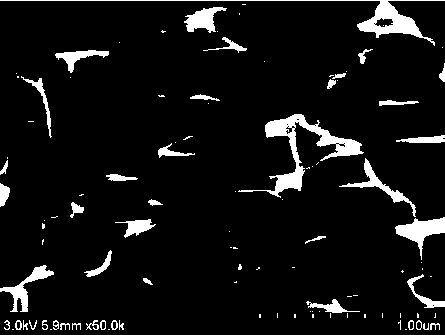

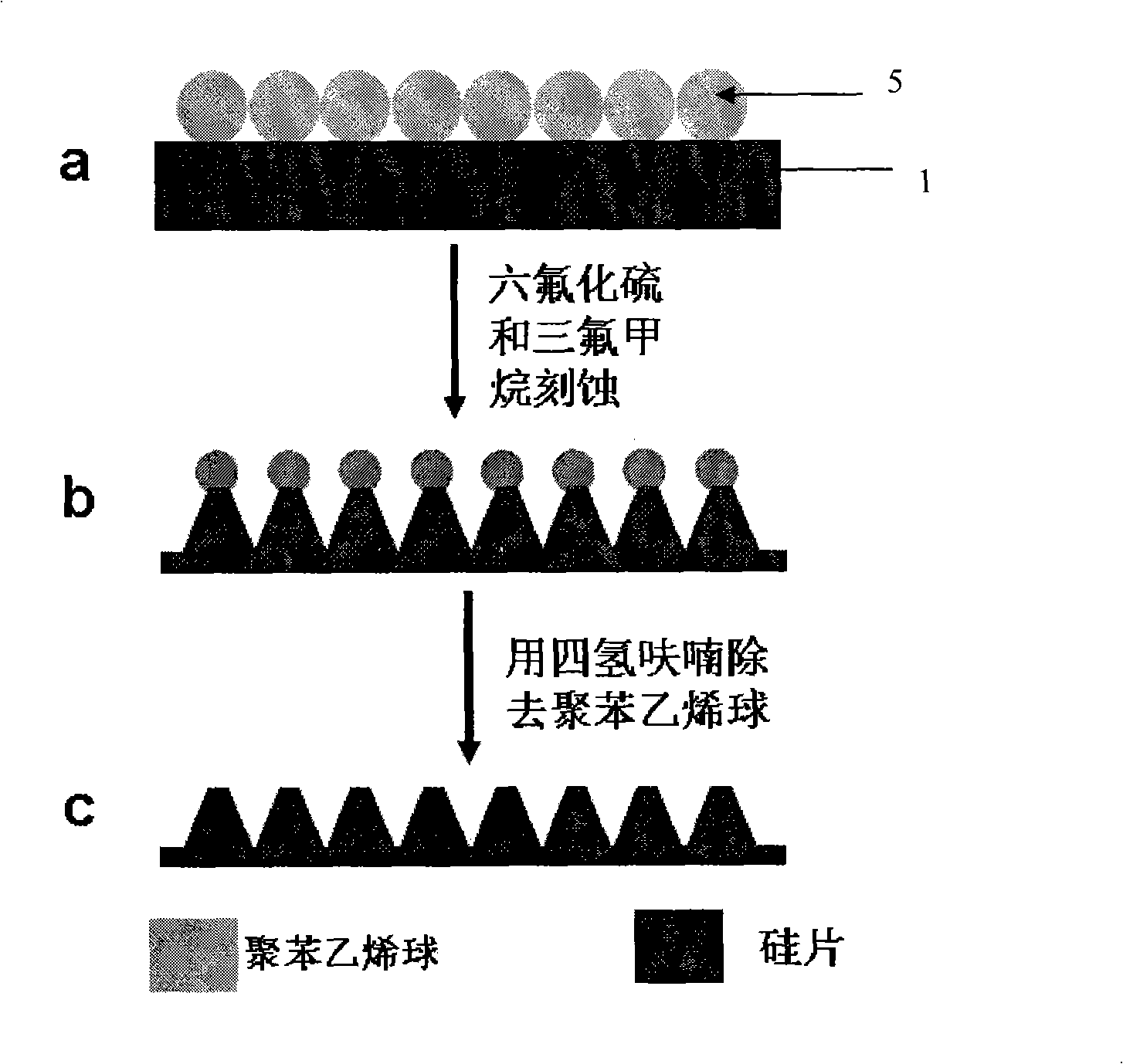

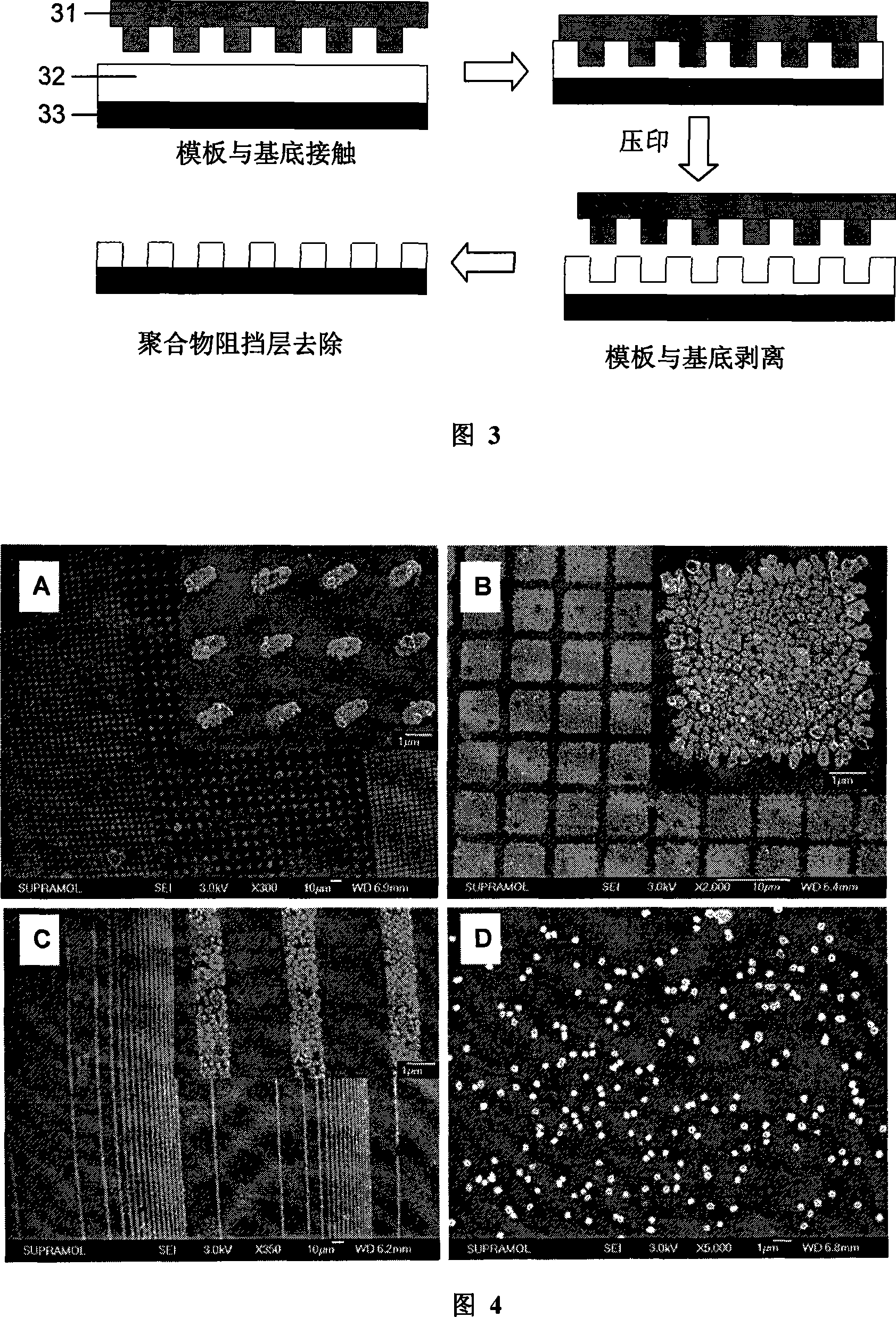

Method for constructing anti-reflection microstructure using single layer nanometer particle as etching blocking layer

InactiveCN101308219ASimple methodBase variableSemi-permeable membranesVolume/mass flow by thermal effectsSurface patternLight energy

The invention belongs to the surface patterning microstructure construction technique, which relates to a method for constructing a microstructure with anti-reflection performance on a foundation base by combining the self-assembly technique with the reactive ion beam etching technique. The method is to take monolayer polymeric micro-spheres, silicon dioxide micro-spheres and nano-particles of metal or metal oxides as a barrier layer and implement the RIE etching to the foundation base, then an approximate cone-shaped microstructure is constructed on the foundation base, and the structure has extreme high anti-reflection performance, thereby effectively improving the light energy utilization rate, reducing the interference of veiling glare in an optical system, increasing the optical transmittance, and further improving the sensitivity and stability of the optical system, and the method can be used for constructing large-area anti-reflection structures. The method of the invention has advantages of simple operation, changeable foundation base, strong applicability, good repeatability, low cost, high efficiency, adjustable anti-reflective applied wavelength and conformity to industrialized standards, and can be used for making photoelectric devices such as solar batteries and white light sensors.

Owner:JILIN UNIV

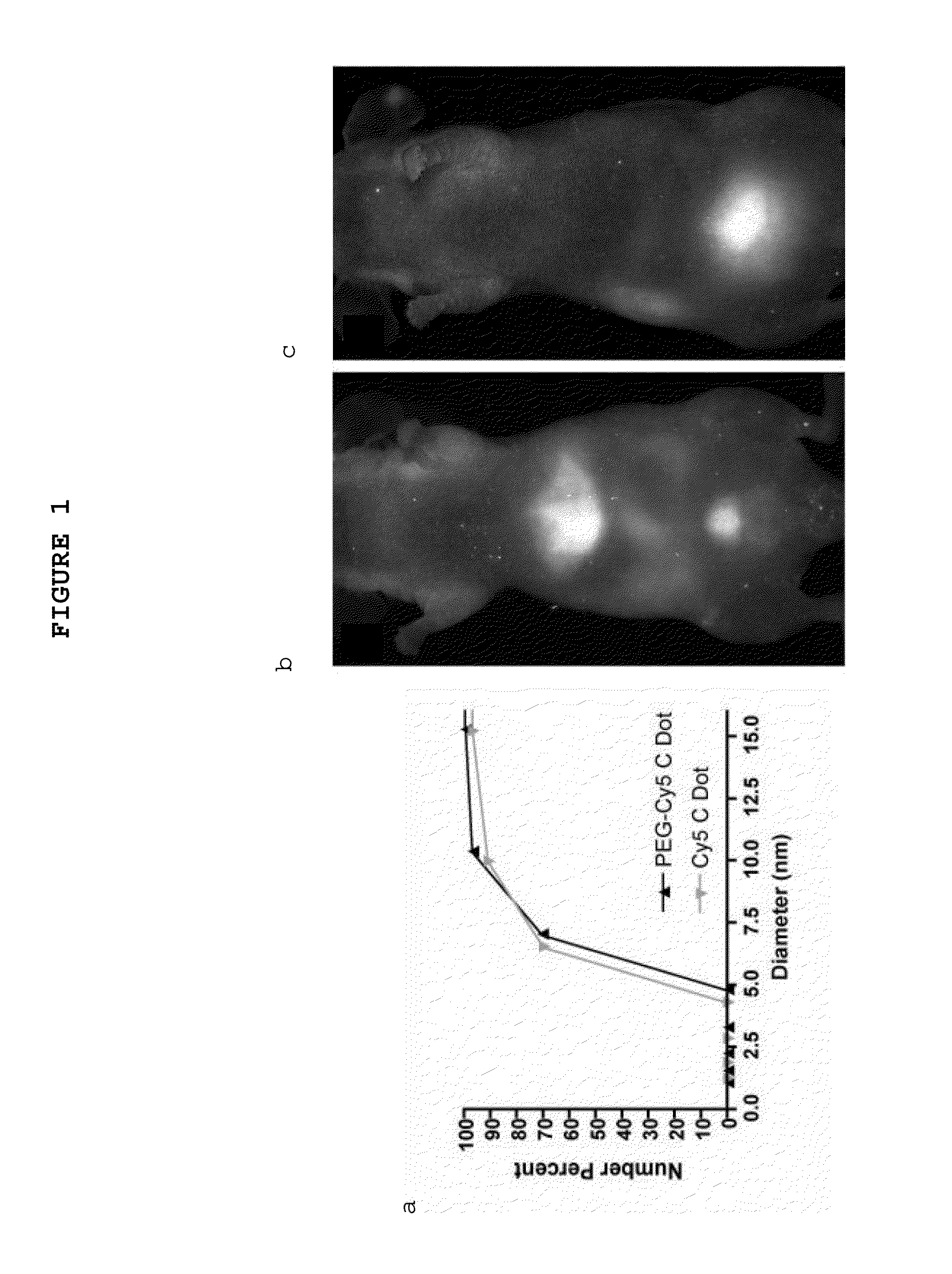

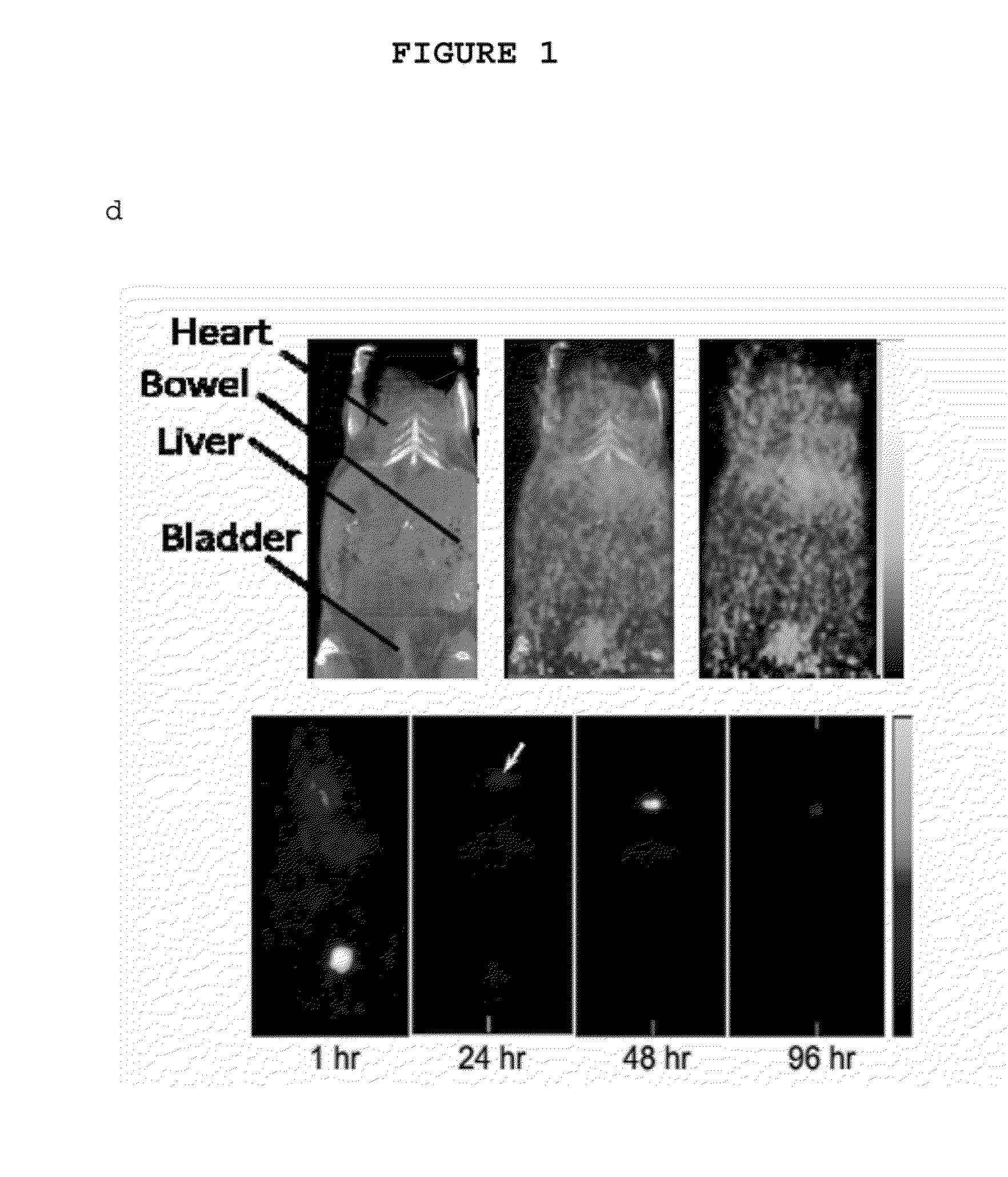

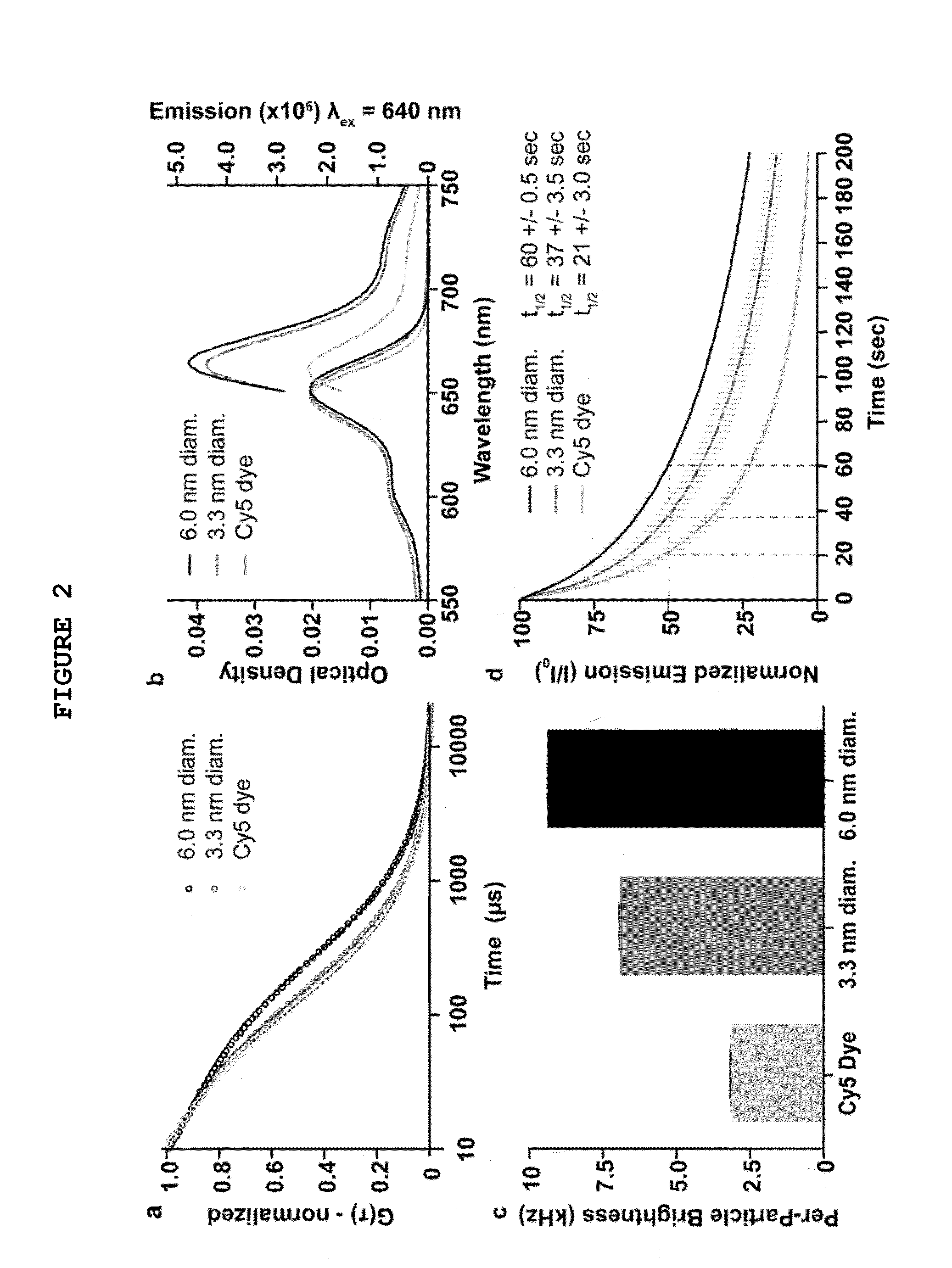

Multimodal silica-based nanoparticles

ActiveUS20140248210A1Ultrasonic/sonic/infrasonic diagnosticsPowder deliveryCellular componentDisease

The present invention provides a fluorescent silica-based nanoparticle that allows for precise detection, characterization, monitoring and treatment of a disease such as cancer. The nanoparticle has a range of diameters including between about 0.1 nm and about 100 nm, between about 0.5 nm and about 50 nm, between about 1 nm and about 25 nm, between about 1 nm and about 15 nm, or between about 1 nm and about 8 nm. The nanoparticle has a fluorescent compound positioned within the nanoparticle, and has greater brightness and fluorescent quantum yield than the free fluorescent compound. The nanoparticle also exhibits high biostability and biocompatibility. To facilitate efficient urinary excretion of the nanoparticle, it may be coated with an organic polymer, such as poly(ethylene glycol) (PEG). The small size of the nanoparticle, the silica base and the organic polymer coating minimizes the toxicity of the nanoparticle when administered in vivo. In order to target a specific cell type, the nanoparticle may further be conjugated to a ligand, which is capable of binding to a cellular component associated with the specific cell type, such as a tumor marker. In one embodiment, a therapeutic agent may be attached to the nanoparticle. To permit the nanoparticle to be detectable by not only optical fluorescence imaging, but also other imaging techniques, such as positron emission tomography (PET), single photon emission computed tomography (SPECT), computerized tomography (CT), bioluminescence imaging, and magnetic resonance imaging (MRI), radionuclides / radiometals or paramagnetic ions may be conjugated to the nanoparticle.

Owner:SLOAN KETTERING INST FOR CANCER RES +1

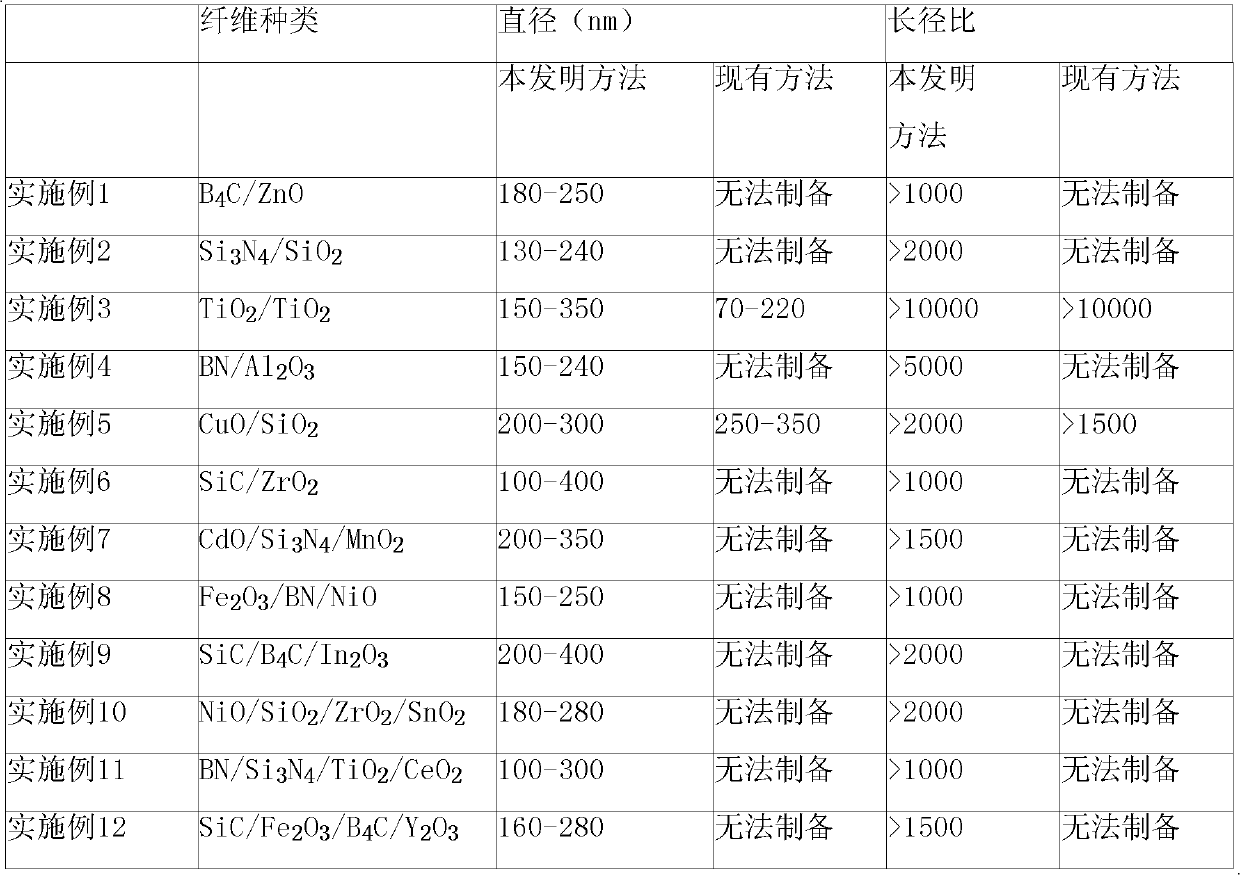

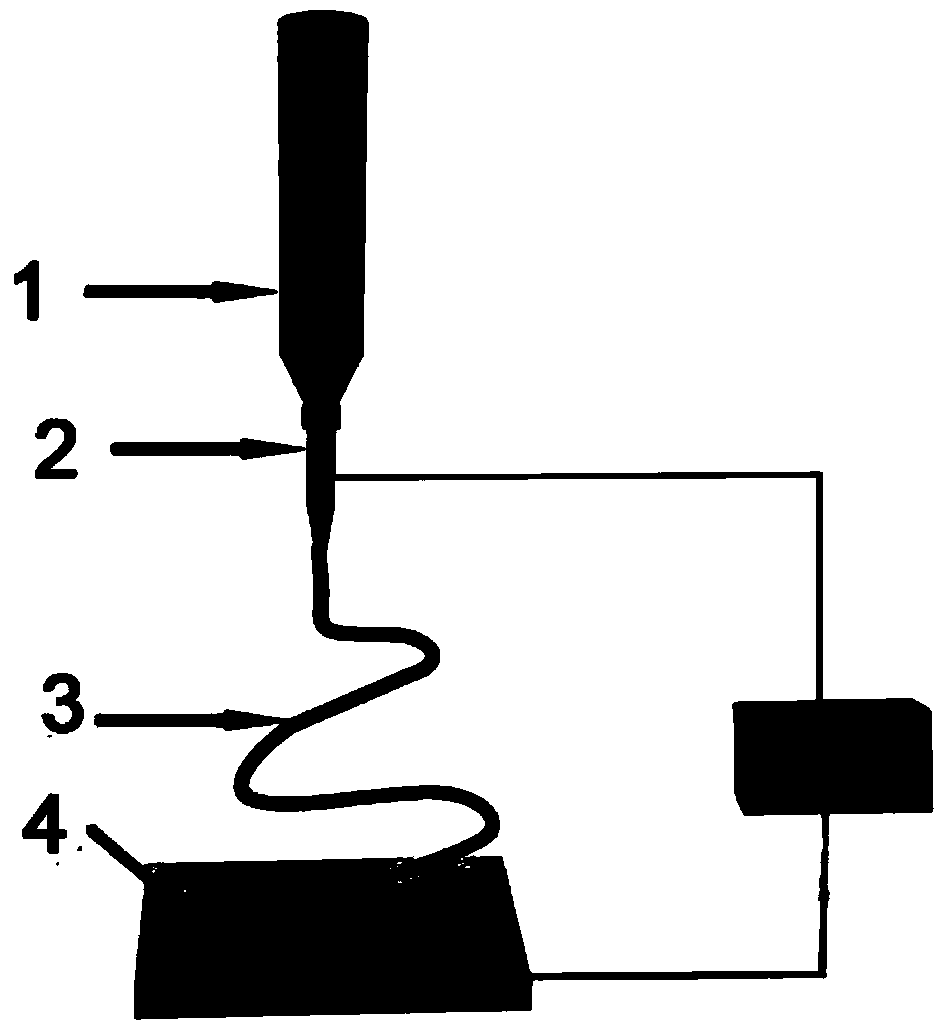

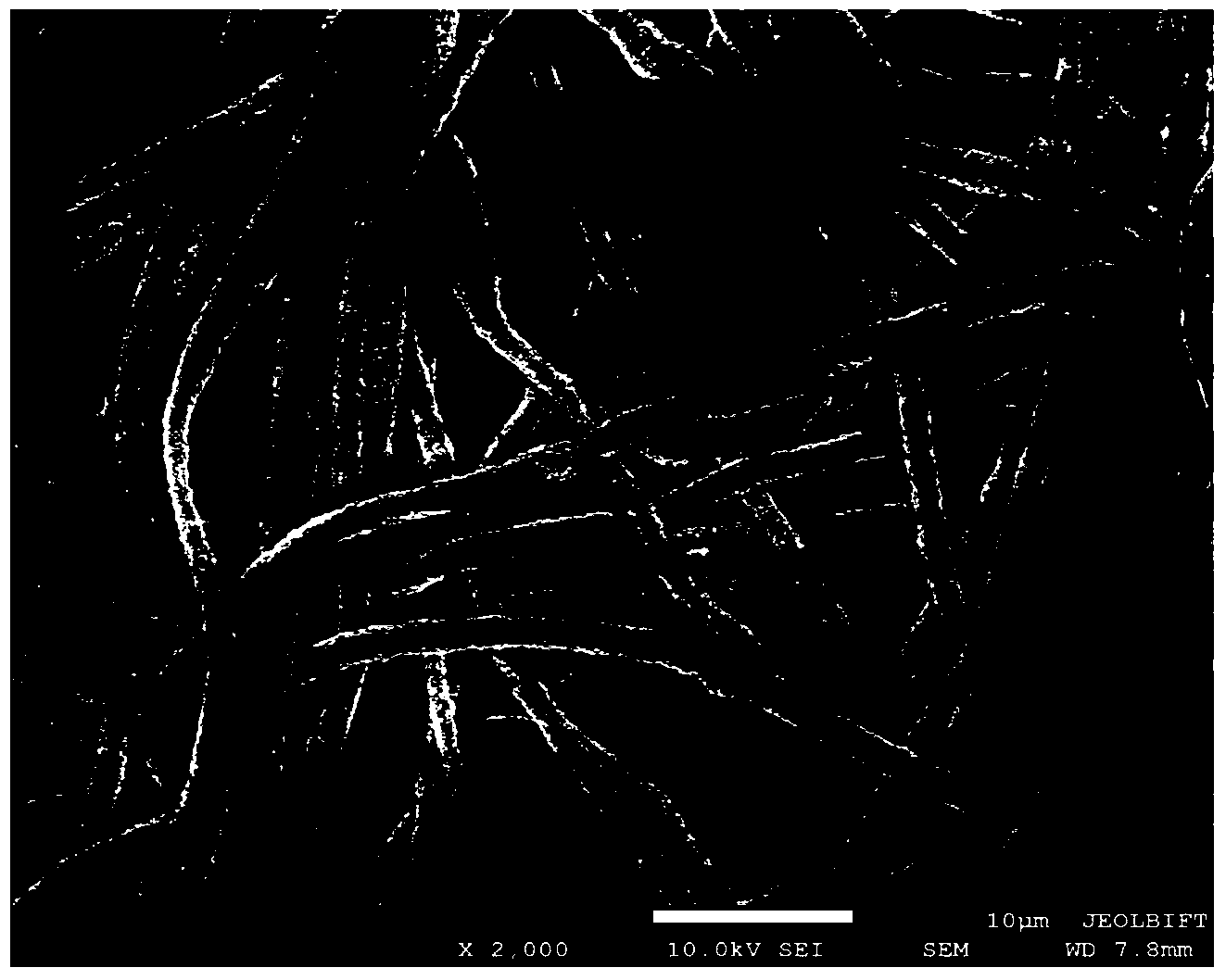

Electrostatic spinning preparation method of ceramic nanometer composite fibers

The invention discloses an electrostatic spinning preparation method of ceramic nanometer composite fibers, comprising the following concrete steps of: firstly, according to volume percentage, weighing 3-10 percent of ceramic nanometer particles with the partilce size of 10-300 nm, 3-20 percent of ceramic precursor, 5-30 percent of spinnable polymer and 40-89 percent of solvent with the total volume of 100 percent; secondly, adding the spinnable polymer into the solvent, heating in water bath and magnetically stirring; thirdly, adding the ceramic precursor into the spinnable polymer solution obtained in the second step, heating in water bath, magnetically stirring and ageing; fourthly, adding the ceramic nanometer particles into the ceramic precursor spinnable solution obtained in the third step, heating at constant temperature in the water bath and forming a spinning solution by carrying out ultrasonic dispersion and constant temperature swelling; fifthly, preparing composite nanometer fibers by the spinning solution according to an electrostatic spinning technology; and sixthly, obtaining the ceramic nanometer composite fibers by sintering the composite nanometer fibers. In the method, raw materials have wide selection conditions and wide optional range.

Owner:XIAN UNIV OF TECH

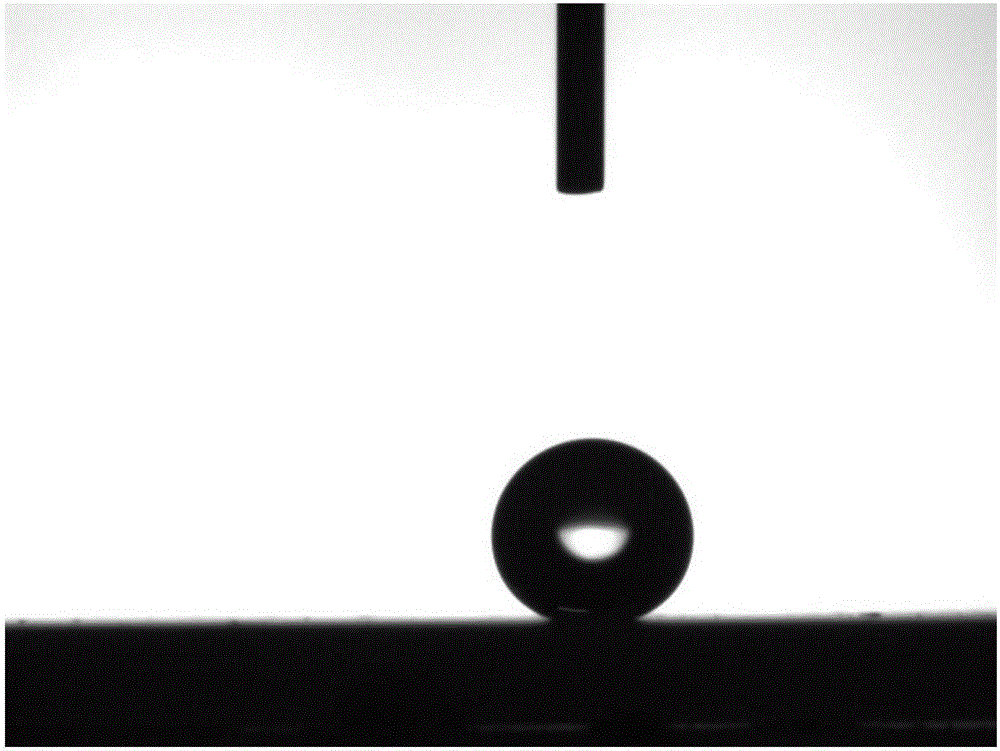

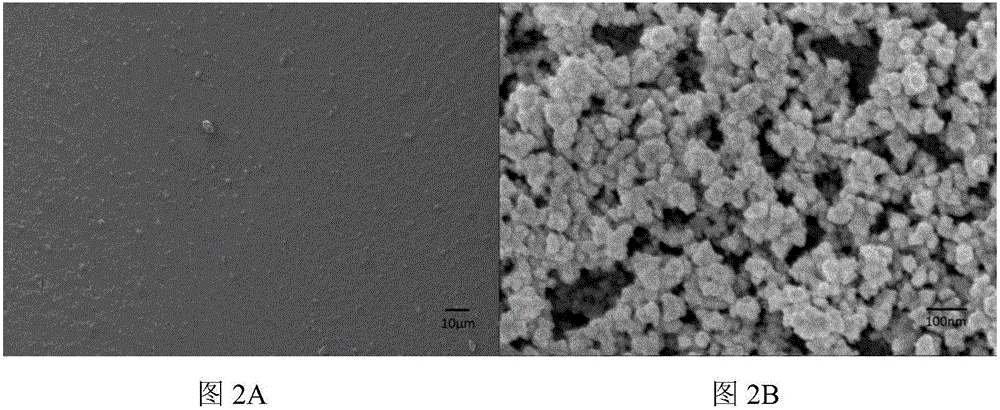

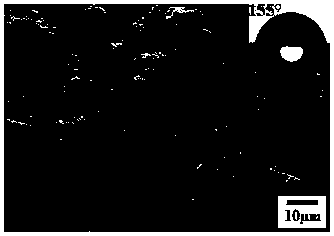

Super-hydrophobic nanometer transparent coating and preparation method thereof

ActiveCN104987520AExcellent superhydrophobic propertiesHigh transparencyCoatings with pigmentsFibre treatmentOrganic solventUltrasonic dispersion

The invention provides a super-hydrophobic nanometer transparent coating and a preparation method thereof and belongs to the technical field of super-hydrophobic paint. The method includes the steps that firstly, a first category of inorganic nanometer particles are added into an organic solution, and ultrasonic dispersion is performed; secondly, dispersing agents and a second category of inorganic nanometer particles are added, and ultrasonic dispersion is performed so that a dispersion solution can be obtained; crosslinking agents and additives are added in the dispersion solution, ultrasonic dispersion is performed, finally, low-surface energy polymers are added, mixtures are evenly mixed, and transparent and clear super-hydrophobic paint is obtained; the surface of a solid base materials is coated with the transparent and clear super-hydrophobic paint, and the super-hydrophobic nanometer transparent coating is obtained through low-temperature thermal drying and curing. The super-hydrophobic performance of the super-hydrophobic nanometer transparent coating prepared through the method is excellent, the contact angle can be 160 degrees, the rolling angle is 1-7 degrees, the super-hydrophobic nanometer transparent coating can be sprayed to the surfaces of most of common materials, the morphology of the surfaces of the materials are not changed, and the application prospects and the application potency are very wide.

Owner:BEIHANG UNIV

Process for producing nanometer particles by fluid bed spray-drying

Nanometer particles of poorly water-soluble or substantially water-insoluble compound are produced by finely-spraying a non-aqueous solution of said compound into a heated and fluidized bed of carrier excipient. The resulting product consists of a free flowing mixture of relatively large particles of carrier excipient and nanometer sized particles (less than 3 μm)) of compound.

Owner:KERKHOF NICHOLAS J

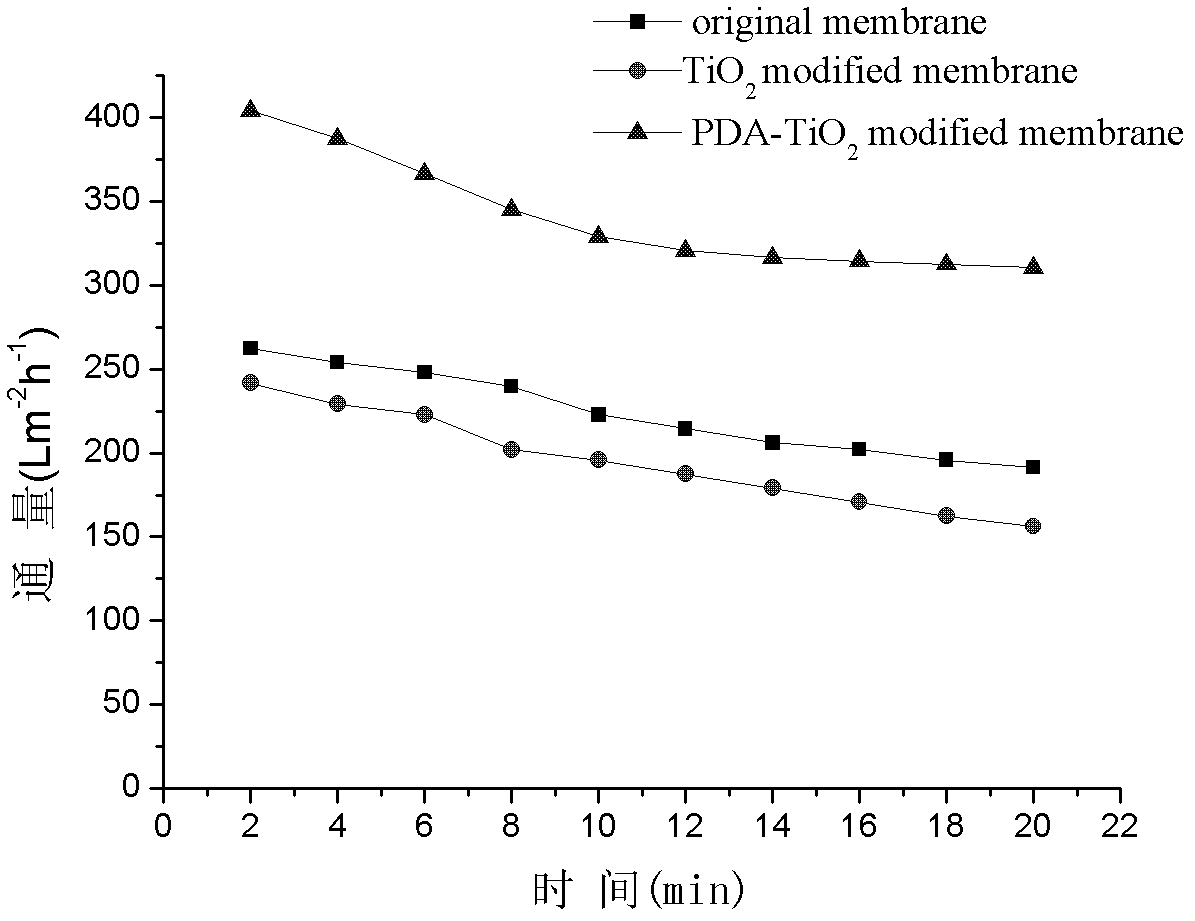

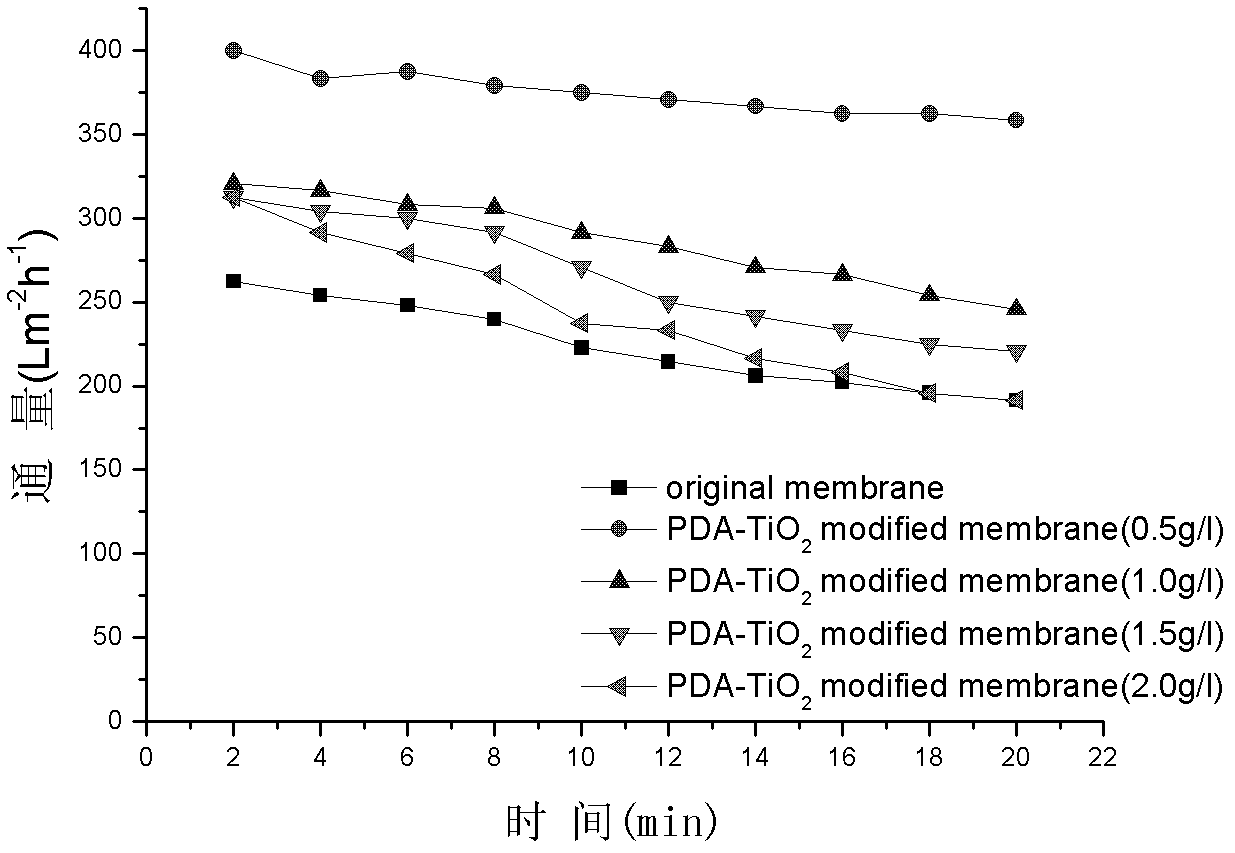

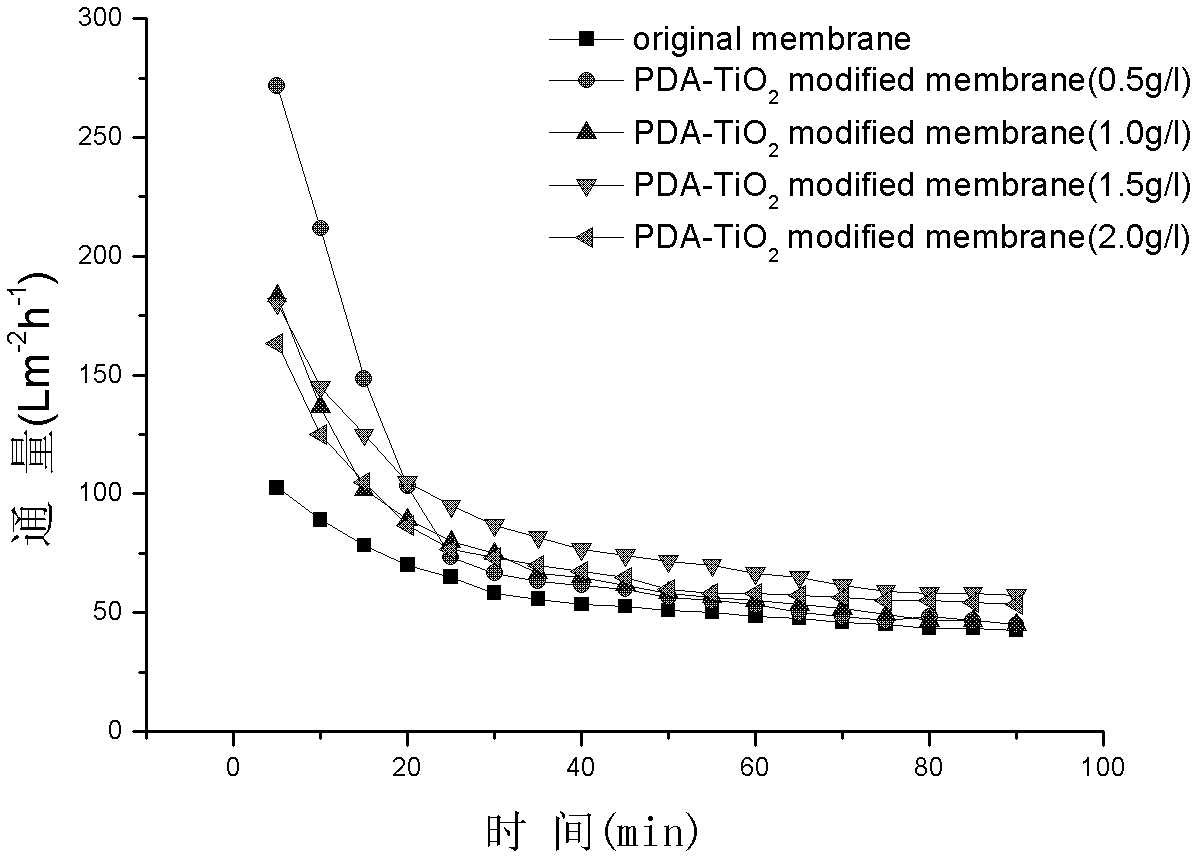

Method for preparing high-flux composite membrane from dopamine-modified nanometer material

InactiveCN102614783AImprove hydrophilicityImprove pollutionSemi-permeable membranesPigment treatment with macromolecular organic compoundsOrganic solventHigh flux

The invention relates to a method for preparing a high-flux composite membrane from a dopamine-modified nanometer material and belongs to the technical field of modification of membrane materials. The method is characterized by comprising the following steps of: forming an active poly-dopamine composite layer on the surfaces of titanium dioxide nanometer grains by utilizing automatic polymerization of dopamine, selecting different concentrations of dopamine-modified titanium dioxide grains, and adding the modified nanometer grains utilized as additives into a membrane casting solution, in which the mass fraction of PVDF (Polyvinylidene Fluoride) is 13% and the mass fraction of PVP (Polyvinyl Pyrrolidone) is 4%, so as to bend and modify according to different proportions, thus obtaining a composite membrane prepared from dopamine-modified nanometer titanium dioxide. The method for preparing the high-flux composite membrane from the dopamine-modified nanometer material, disclosed by the invention, has the advantages that dopamine-modified titanium dioxide can be greatly dispersed in an organic solvent to form a uniform dispersed phase; the additive can be used for effectively improving the hydrophilcity and anti-pollution capability of the high-flux composite membrane; and the dopamine modification method is simple, the condition is gentle, the flux of the prepared membrane is large and the anti-pollution capability is strong.

Owner:DALIAN UNIV OF TECH

Process for preparing novel formulation of integrative traditional Chinese medicine and production method thereof

InactiveCN102100661AWide distribution of targetsStrong slow and controlled release performancePharmaceutical delivery mechanismPlant ingredientsHigh pressureIndustrial scale

The invention relates to a process for preparing a novel formulation of an integrative traditional Chinese medicine and a production method thereof. Traditional Chinese medicine simple recipe, traditional Chinese medicine compound recipe, integrated Chinese and western medicine compound recipe and integrated Chinese and western medicine composition are prepared by utilizing a nanometer vector combination process. The production method comprises the following steps of extracting with alcohol-water, crushing and extracting in an ultrasonic manner, extracting in a microwave manner, decocting in water and condensing, spraying and drying, homogenizing under high pressure, grinding to be nanometer particles, preparing the nanometer particles and the like. The invention pays attention to the advantages of nanometer traditional Chinese medicine, such as multiple synergism, multiple targets and the like. After the novel formulation disclosed by the invention is produced in an industrial scale, the production cost can be greatly reduced, the quality of the product can be improved, and the target performance and the controlled release performance of the medicines are stronger.

Owner:SUZHOU ZHIWEITANG BIOLOGICAL TECH +1

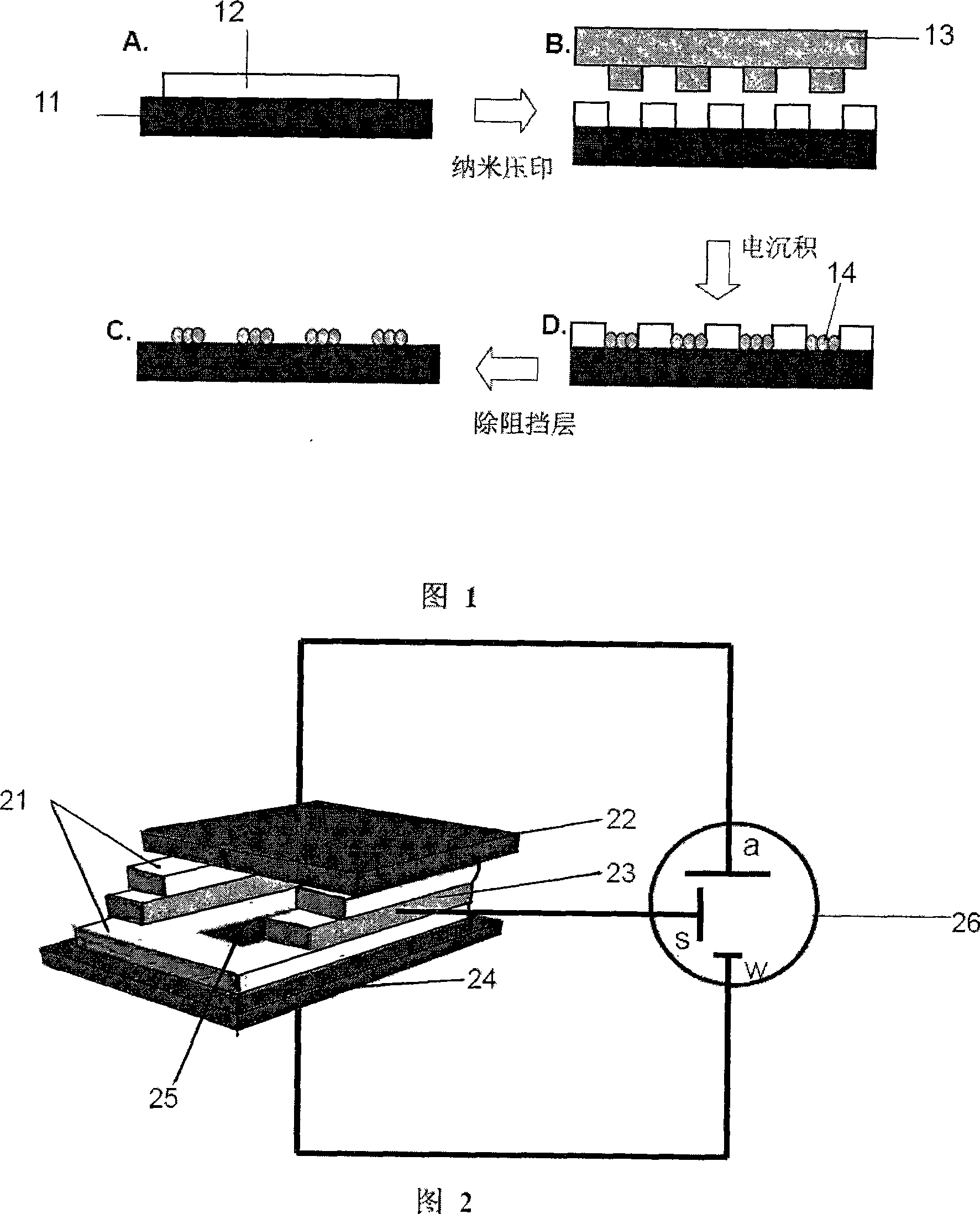

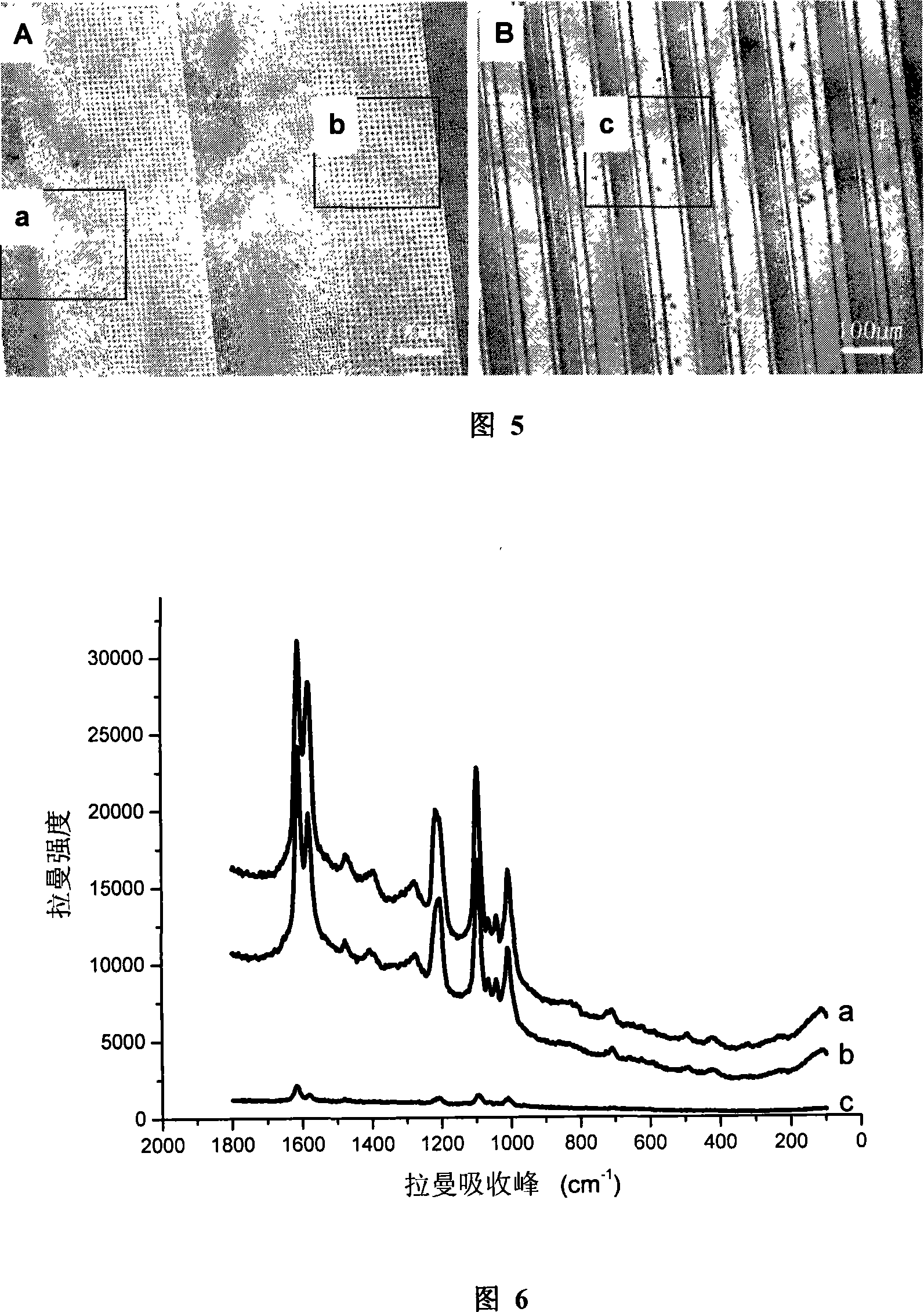

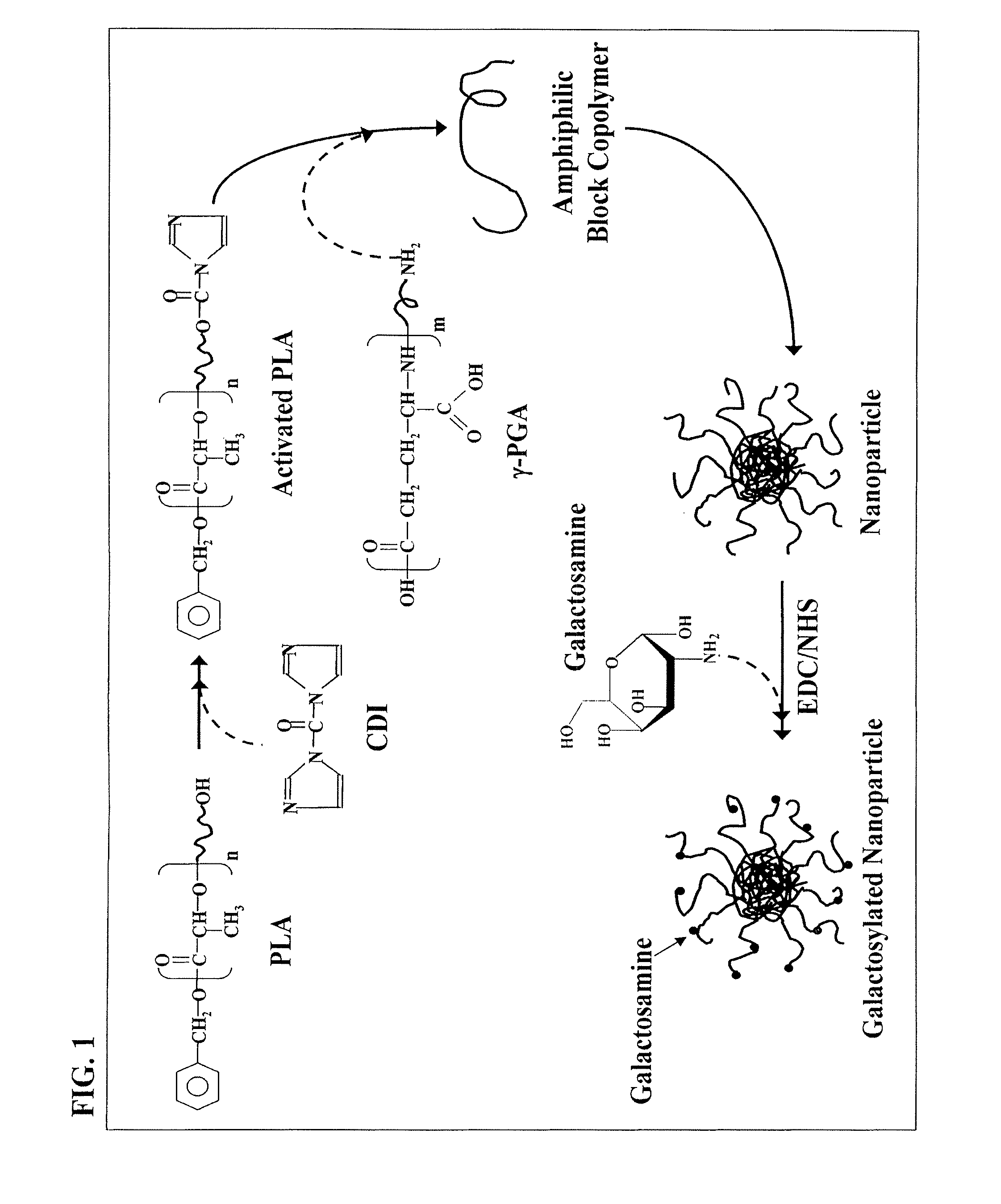

Constituting method for metal ordered structure surface reinforced base

The invention relates to a method to construct ordered structure on base, and the application of using the base to construct metal ordered structure. The method includes the following steps: adopting inorganic base or polymer base, taking base surface process to make it could conduct electricity, construct ordered microstructure of different functional group or macromolecule barrier layer; assembling the metal nanometer particle into the ordered structure to gain metal nanometer ordered structure. The invention could be widely used in making high sensitive metal sensor and detector.

Owner:JILIN UNIV

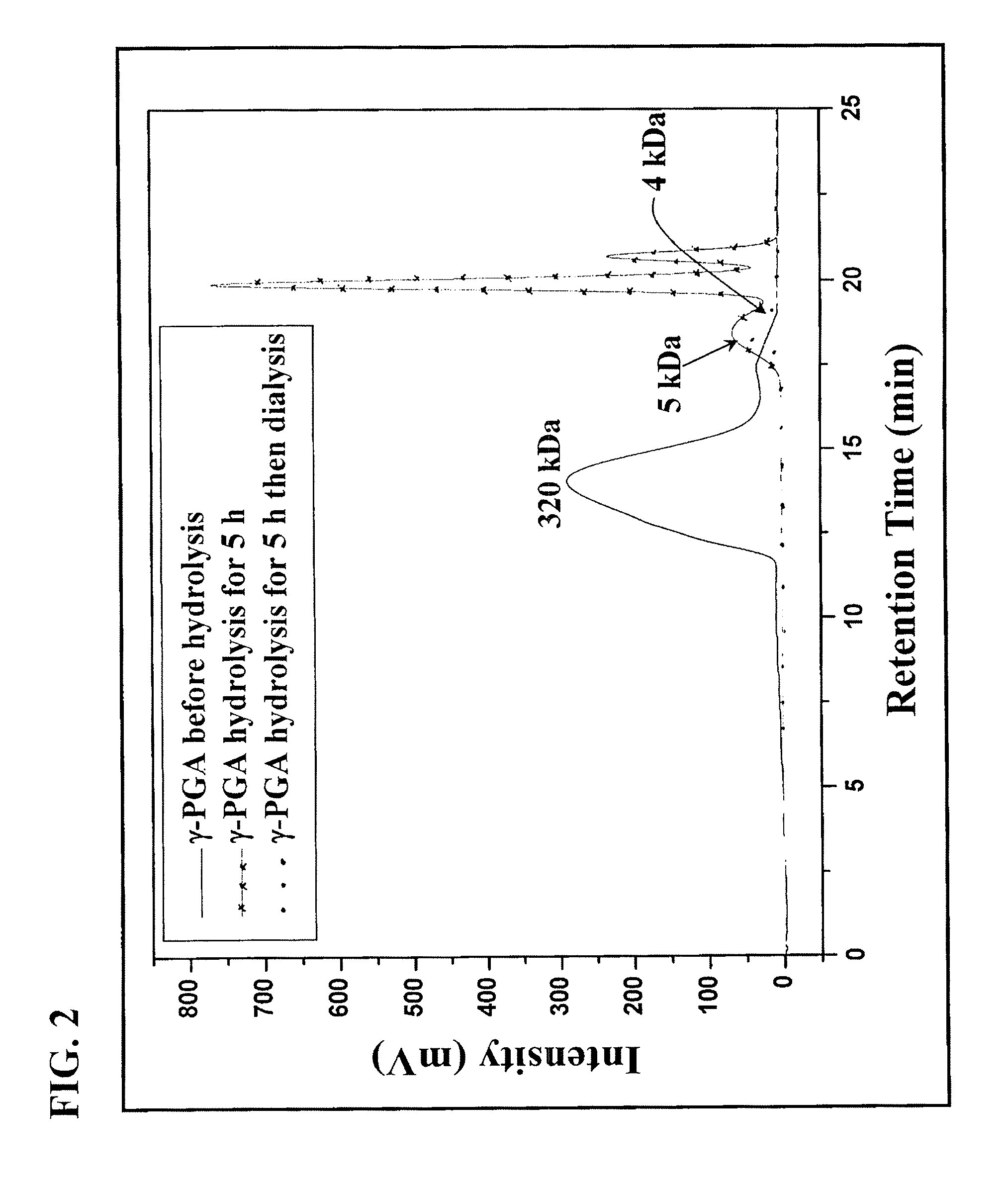

Pharmaceutical composition of nanoparticles

InactiveUS8663599B1Accelerated phase transitionIn-vivo radioactive preparationsPeptide/protein ingredientsMedicineNanoparticle

The invention discloses a pharmaceutical composition of pH-sensitive liposome nanoparticles for lodging in a target tissue cell in situ of an animal subject, the nanoparticles comprising a proton-releasing photosensitive compound that releases protons upon photolysis, wherein the compound is in vesicles of the liposomes. A light or UV light is provided to induce the photosensitive compound to release the protons, thus the released protons causing the pH-sensitive liposome to decompose.

Owner:GP MEDICAL

Lithium ion battery anode material manganese lithium phosphate and preparation method thereof

ActiveCN101320809AImprove electronic conductivityEvenly dispersedElectrode manufacturing processesPhosphorus compoundsCapacitanceLithium iron phosphate

The invention discloses a manganese / lithium phosphate of lithium iron battery positive pole material and a production method thereof, the technical issue to be solved is to improve electrochemical performances of the positive pole material. The material of the invention includes substrates of manganese / lithium phosphate which are covered by a carbon material covering layer, the lithium covering the manganese / lithium phosphate behind the carbon material covering layer is spherical and has microscopic characteristics of being near spherical, rhombic, tapered, tabular, layered or / and block-shaped as well as of having 0.5-30 mum long and short axles. The production method comprises the following steps of: production of nanometer particles, liquid phase mixed reaction, production of precursor, sintering treatment, covering organic substances. Compared with the prior art, the invention improves the electron conductivity of the manganese / lithium phosphate by covering with carbon liquid phase, the carbon sufficiently covers active materials to efficiently prevent particle aggregation, the invention has the characteristics of about 4V of discharge voltage, high discharge and charge capacitance, excellent circulation stability, high safety, simple process, low cost and little influence on the environment.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

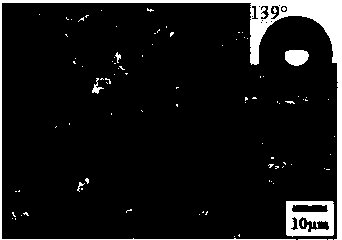

Photocatalytic type self-repairing super-hydrophobic coating and preparation method thereof

ActiveCN103409028ASimple preparation processWith super weather resistancePolyurea/polyurethane coatingsPolyester coatingsSuperhydrophobeOrganic solvent

The invention belongs to the technical field of new chemical materials and relates to a photocatalytic type self-repairing super-hydrophobic coating and a preparation method thereof. The coating comprises the following materials: 10-50 percent of thermoplastic film-forming resin, 5-20 percent of low-surface energy material, 1-10 percent of photocatalytic active nano particles, 5-40 percent of hydrophobicity nano particles and 20-60 percent of organic solvent. The preparation method comprises the following steps: firstly, allowing nano particles to be subjected to fluorosilane modification to obtain the hydrophobicity nano particles; then, weighing all components of the coating for mixing, and performing high-speed shearing dispersing to obtain the coating provided by the invention. The coating can be applied to the surfaces of base materials such as steel material, aluminium alloy, plastic and composite in the way of brushing, spraying and the like, and a lotus leaf type super-hydrophobic coating can be obtained through drying. The coating can realize super-hydrophobic self-repairing through UV irradiation after being polluted by organic pollutant or subjected to mechanical wear by external forces, so that the coating has extremely good super-hydrophobic performance and perdurability, and the long-term using performance under the outdoor environments is also ensured.

Owner:FUDAN UNIV

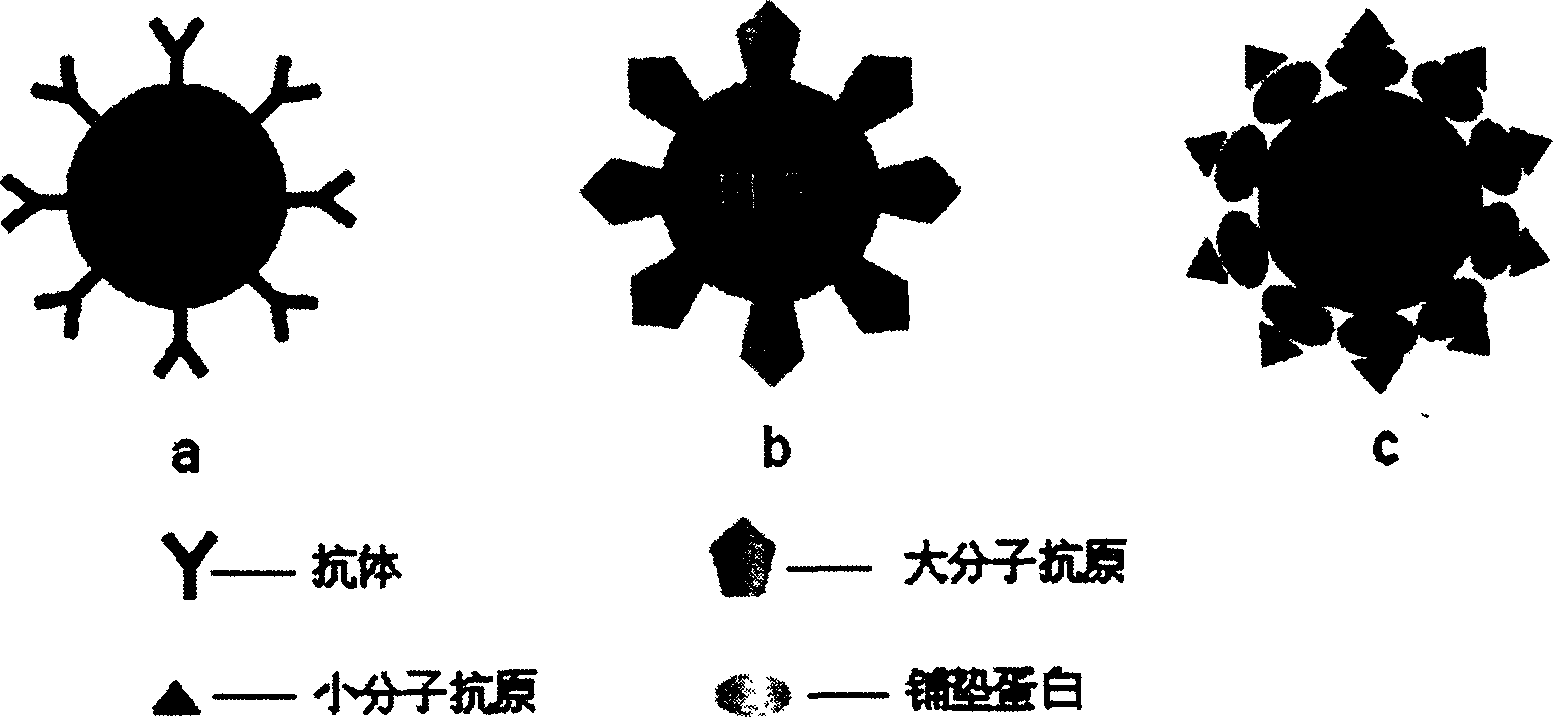

Immune chromatography with fluorescent rare earth nanometer particle as marker and detecting testing paper strip

InactiveCN1645146ASimple and fast operationHigh sensitivityBiological testingFluorescence/phosphorescenceAntigenNanoparticle

An immune chromatographic method includes fixing capture antigen or antibody directly on chromatographic film (PH) by physical absorption means, adding sample liquid and label antibody on sample cushion side of PF and forming immmune composite through immune reaction, detecting formed detection and control belts, sticking PE, sample loading cushion, label cushion and water absorption cushion in sequence on backing. The test paper is also disclosed.

Owner:XIAMEN UNIV

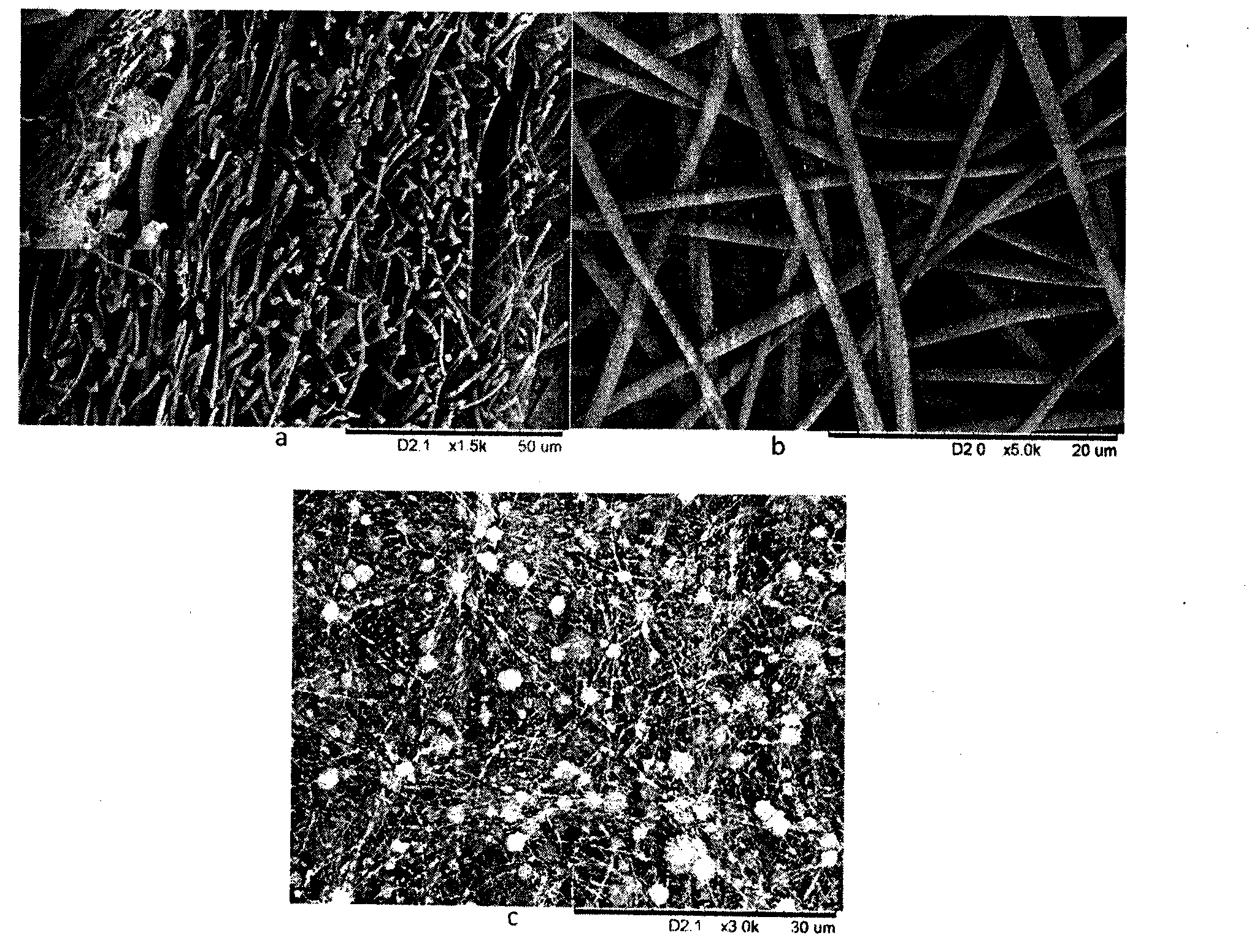

Efficient oil and water separation composite fiber film and preparation method thereof

InactiveCN103866492ASelf-supportingRealize multiple reuseFilament/thread formingNon-woven fabricsFiberHydrophobic polymer

The invention discloses an efficiency oil and water separation composition fiber film and a preparation method thereof, and belongs to the field of functional nanometer fiber materials. Hydrophobic polymers such as polyurethane, polystyrene and polymethyl methacrylate or polycaprolactone are used as the main raw materials of the fiber film, the main raw materials are dissolved in an organic solvent to form a polymer solution, hydrophobic nanometer particles are added into the polymer solution in the preparation process, after the mixture is evenly mixed, electro-spinning is conducted on the mixed solution by means of the electrostatic spinning method, and then a fiber film material which is formed by micro-nanometer composite structures and is in the shape of non-woven fabric is obtained. The electro-spun fiber film of the micro-nanometer structure has super-hydrophobic / super-oleophylic property in the air and excellent oil adsorption performance, and the contact angle to oil is nearly zero. The efficient oil and water separation composite fiber film is simple in preparation method, low in energy consumption, high in efficiency, high in oil and water separation speed, and capable of being widely used in the fields such as oily water efficient purification.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

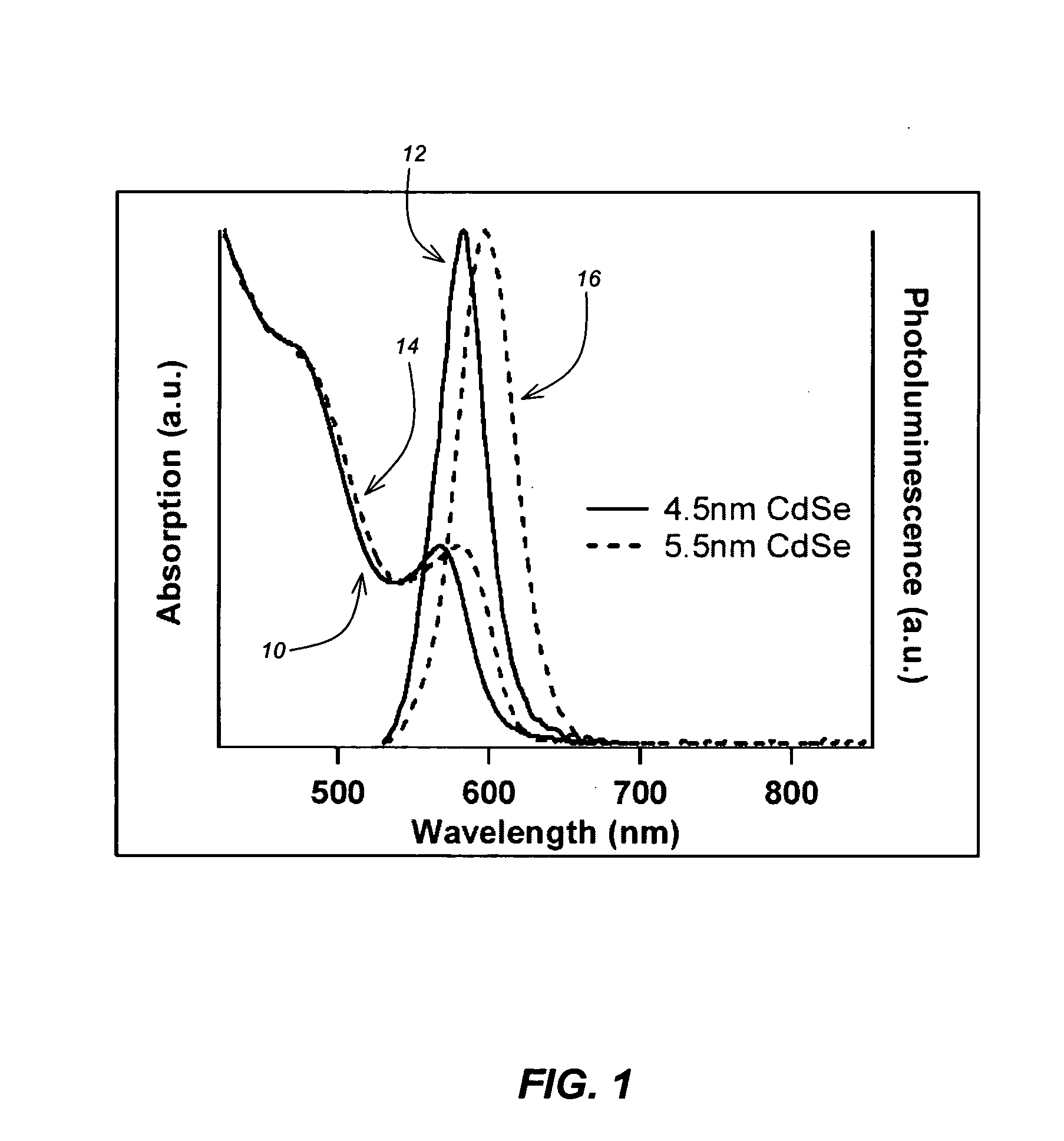

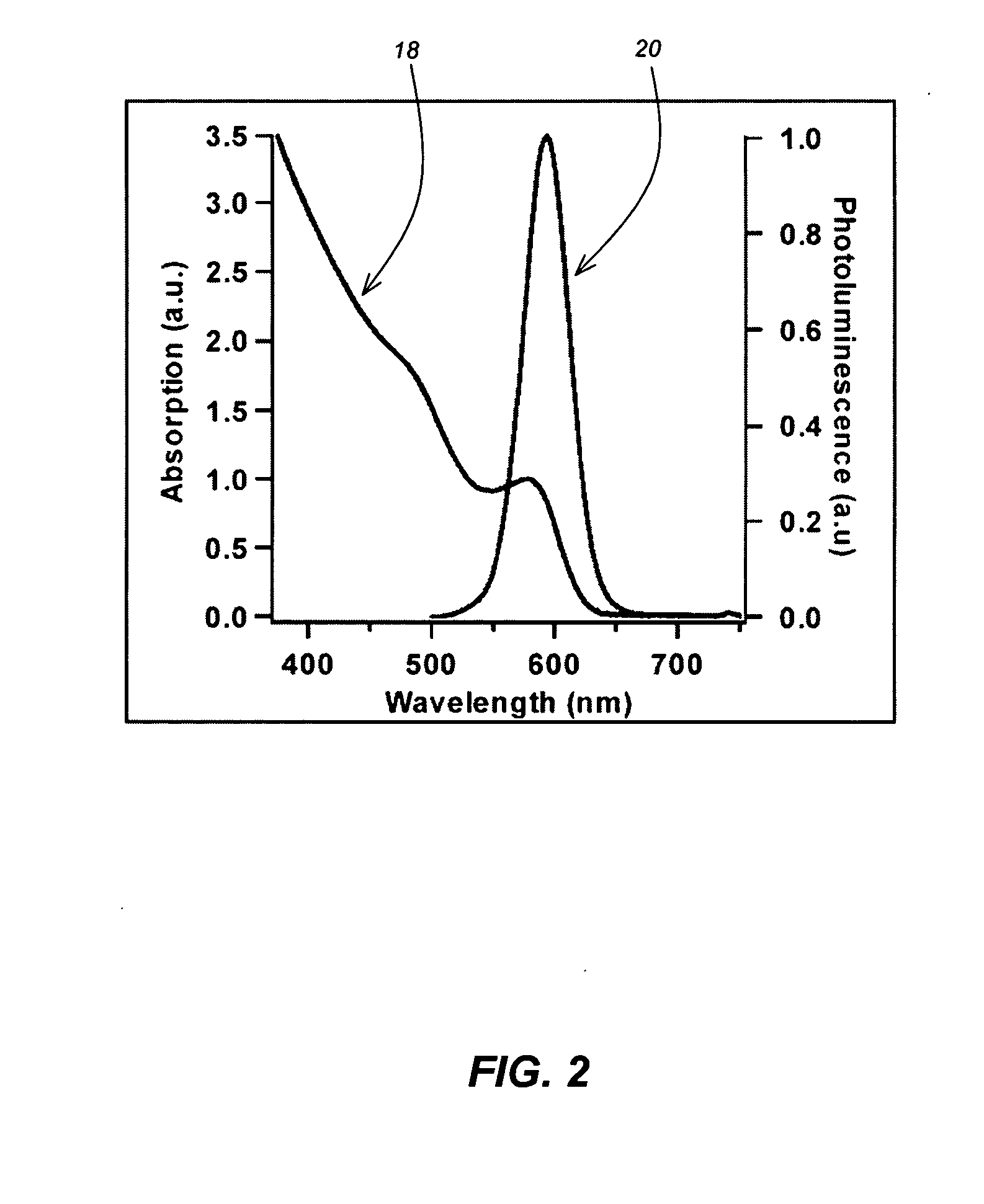

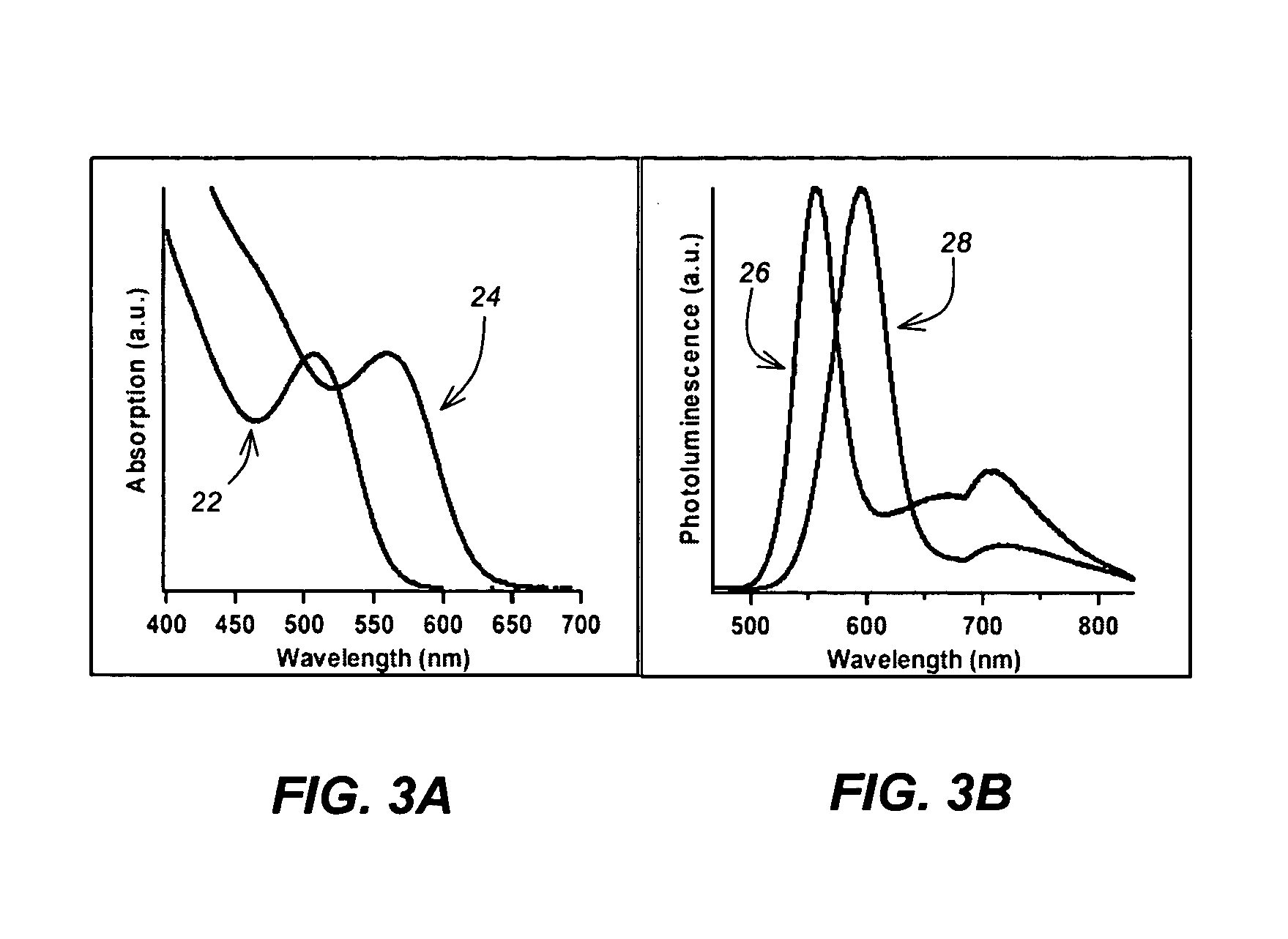

Method for synthesis of colloidal nanoparticles

InactiveUS20060061017A1High crystallinityLarge-scale, safe, convenient, reproducible, and energy-efficient productionDielectric heatingMaterial nanotechnologyContinuous flowColloidal nanoparticles

A method for synthesis of high quality colloidal nanoparticles using comprises a high heating rate process. Irradiation of single mode, high power, microwave is a particularly well suited technique to realize high quality semiconductor nanoparticles. The use of microwave radiation effectively automates the synthesis, and more importantly, permits the use of a continuous flow microwave reactor for commercial preparation of the high quality colloidal nanoparticles.

Owner:RGT UNIV OF CALIFORNIA

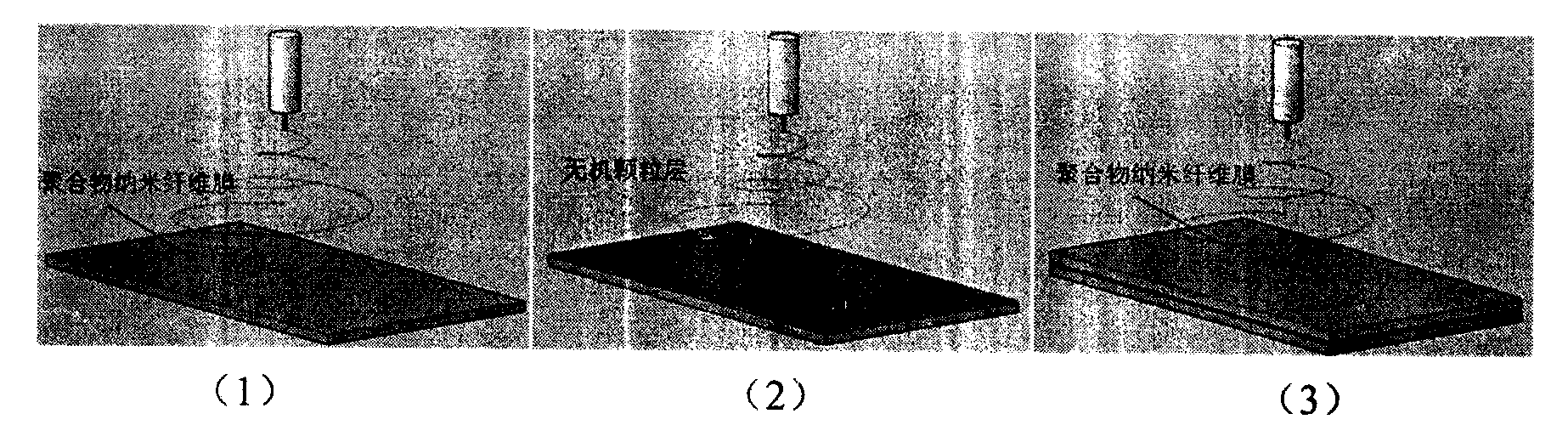

Method for preparing composite lithium-ion battery separator through electrostatic spinning/electrostatic spraying

InactiveCN103474610AExcellent heat shrinkage resistanceIncrease fluid retentionCell component detailsNon-woven fabricsFiberOrganic solvent

The invention relates to the field of lithium-ion batteries, in particular to a method for preparing a composite lithium-ion battery separator through electrostatic spinning / electrostatic spraying. The method specifically includes the steps of firstly, adding high molecular polymer into an organic solvent, dissolving the high molecular polymer through mechanical stirring to form a transparent solution, and obtaining an electrostatic spinning solution; secondly, mixing inorganic nanometer particles with the high molecular polymer and adding the mixture into the organic solvent, and conducting mechanical stirring to obtain inorganic nanometer particle suspension liquid; thirdly, conducting electrostatic spinning on the spinning solution prepared in the first step to prepare a lower layer nanometer fiber film, and enabling the inorganic nanometer particle suspension liquid prepared in the second step to be deposited on the lower layer nanometer fiber film through electrostatic spraying to obtain an interlayer; finally, receiving an electrostatic spun nanometer fiber layer on an inorganic particle layer to obtain the composite lithium-ion battery separator. The composite lithium-ion battery separator has the high imbibing rate and good electrochemical stability under the room temperature and has good heat shrinkage resistance performance at the same time.

Owner:TIANJIN POLYTECHNIC UNIV

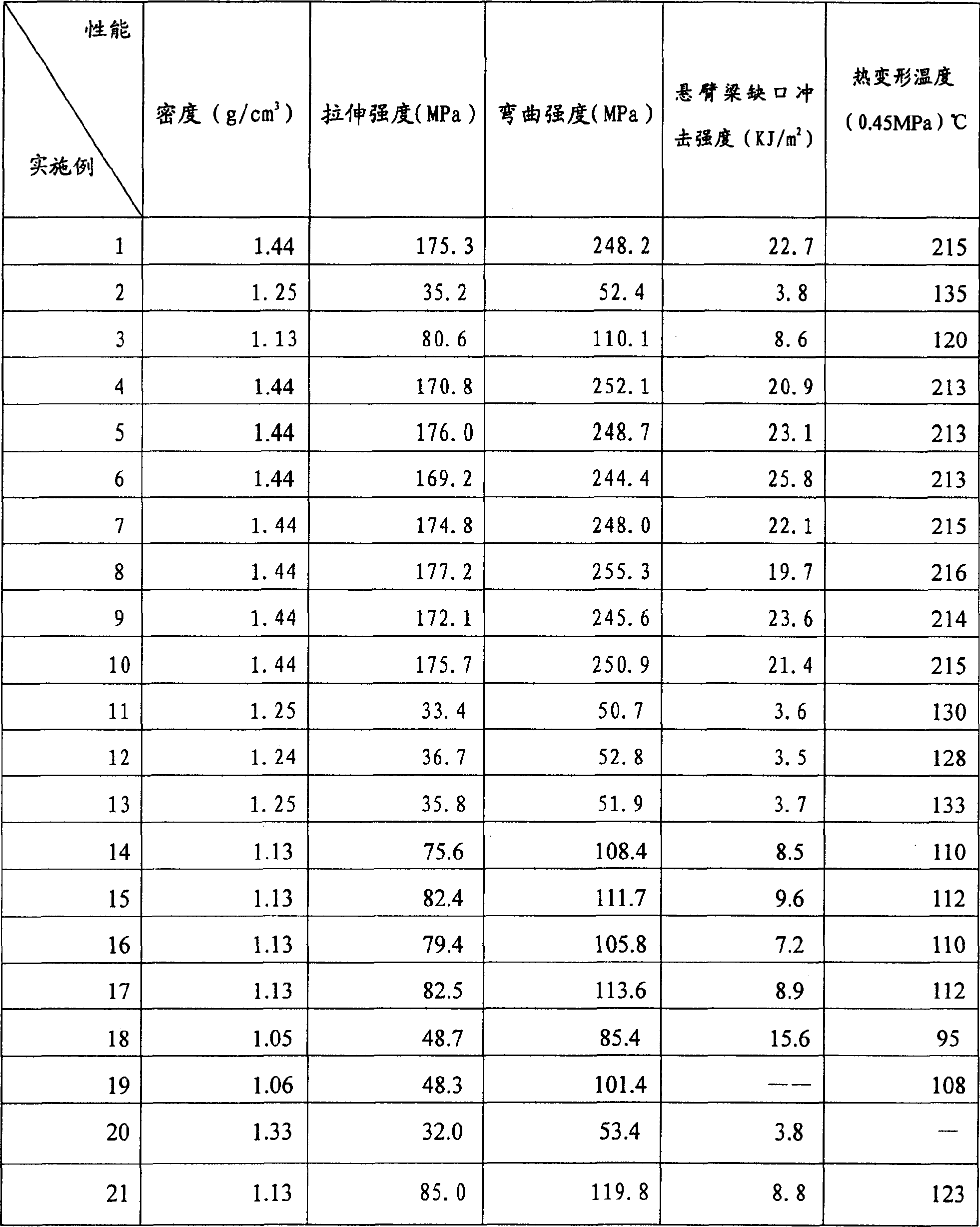

Inorganic nano particle modified high performance recovery plastic and its preparing process

InactiveCN1858101AHigh tensile strengthImprove bending strengthPlastic recyclingGlass fiberAlkali free

The inorganic nanometer particle modified high performance regenerated plastic consists of recovered plastic 5-98 wt%, new plastic in the same type 0-93 wt%, inorganic nanometer particle 1-30 wt%, flexibilizer and compatilizer 1-30 wt%, and alkali free glass fiber 0-45 wt%, and the surface of the alkali free glass fiber is treated with silane coupler in the amount of 0.2- 5% of the added alkali free glass fiber. The said components are mixed homogeneously through stirring, melted and extruded to form.

Owner:NANJING JULONG SCI&TECH CO LTD

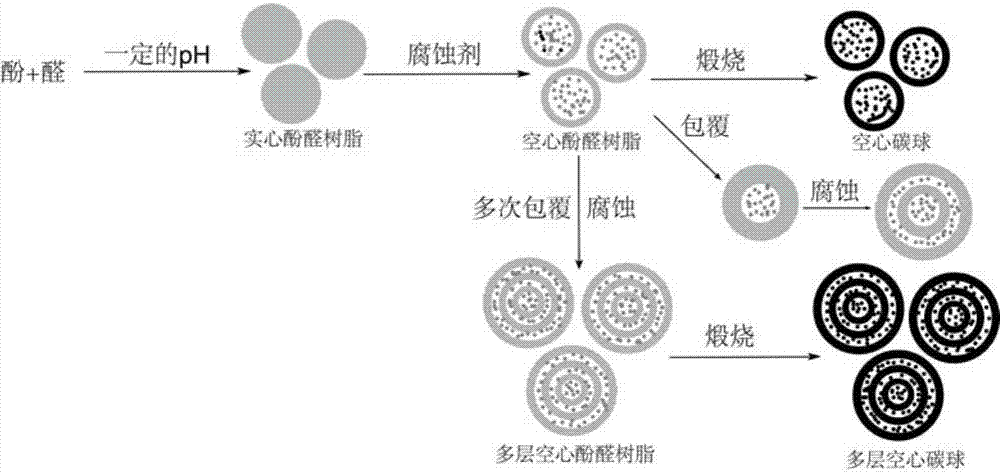

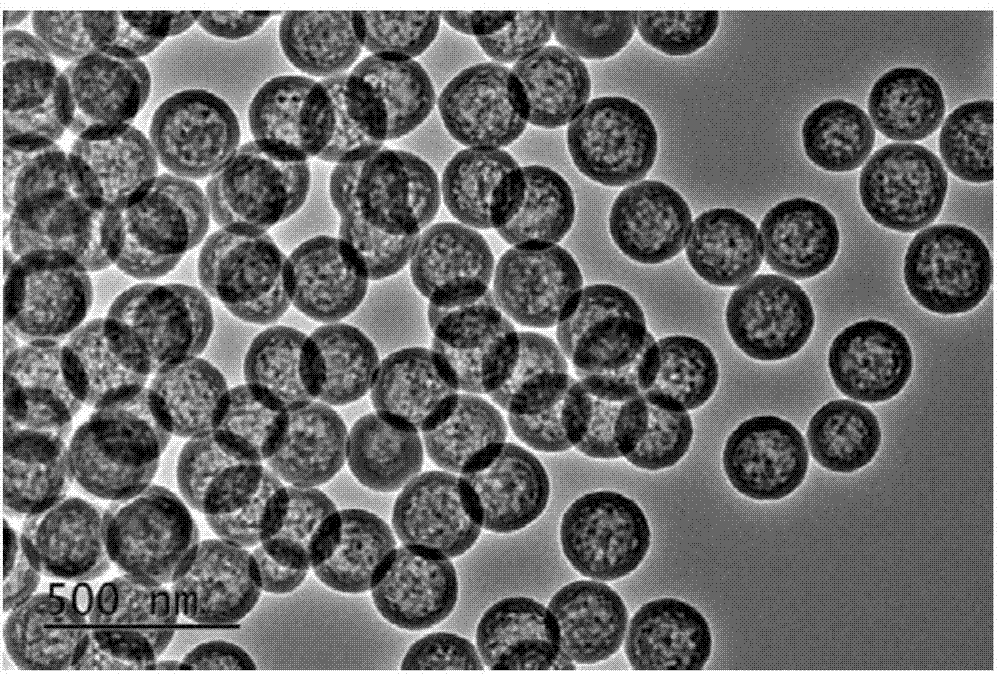

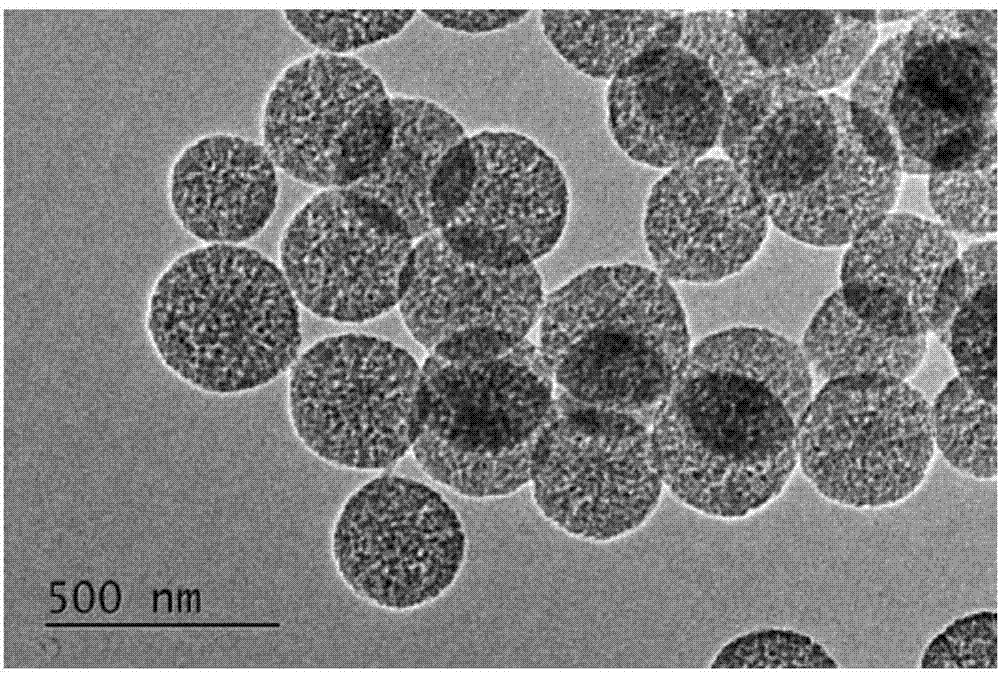

Single-layer and multi-layer hollow carbon nanosphere and preparation method and application thereof

ActiveCN104843665AEasy to operateMild reaction conditionsMaterial nanotechnologySolubilityIn situ polymerization

The invention discovers and proposes a characteristic that interior species of phenolic resin are nonuniform in distribution in a polymerization process, and discloses a method for preparing a hollow carbon sphere by utilizing the characteristic of phenolic resin. The method comprises: (1) putting phenol into water or a solvent, adjusting the pH, then adding aldehyde and stirring at a certain temperature for a period of time; (2) adding a corrosive agent in a reaction system, stirring at a certain temperature, and selectively removing a part with a relatively low polymerization degree inside a polymer by utilizing a solubility difference of interior species for different solvents, to obtain an intermediate product, that is, a hollow sphere of phenolic resin polymer; and (3) calcining the intermediate product that is obtained in step (2) in an inertia or reducing atmosphere, naturally cooling to room temperature, and thus completing preparation of the hollow carbon sphere. The method is simple and practicable, and the prepared hollow carbon sphere is uniform in shape and controllable in dimension. Moreover, by utilizing a characteristic that the phenolic resin can be in-situ polymerized on surfaces of different nanometer particles, on one hand, a multi-layer hollow structure can be prepared in a multi-cladding and layer-by-layer corrosion manner, and on the other hand, the different nanometer particles can also be packaged in a cavity in an in-situ mode, so as to prepare a nuclear shell or egg yolk-nuclear structure. The prepared hollow carbon sphere has a potential application value in aspects of silicon-carbon negative electrode material, Li-S battery, supercapacitor, heavy metal ion adsorption, and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Tannin-chitosan composites

ActiveUS20110059162A1Improve mechanical propertiesImprove efficiencyAntibacterial agentsOrganic active ingredientsAdjuvantHydrogel film

Owner:WISCONSIN ALUMNI RES FOUND

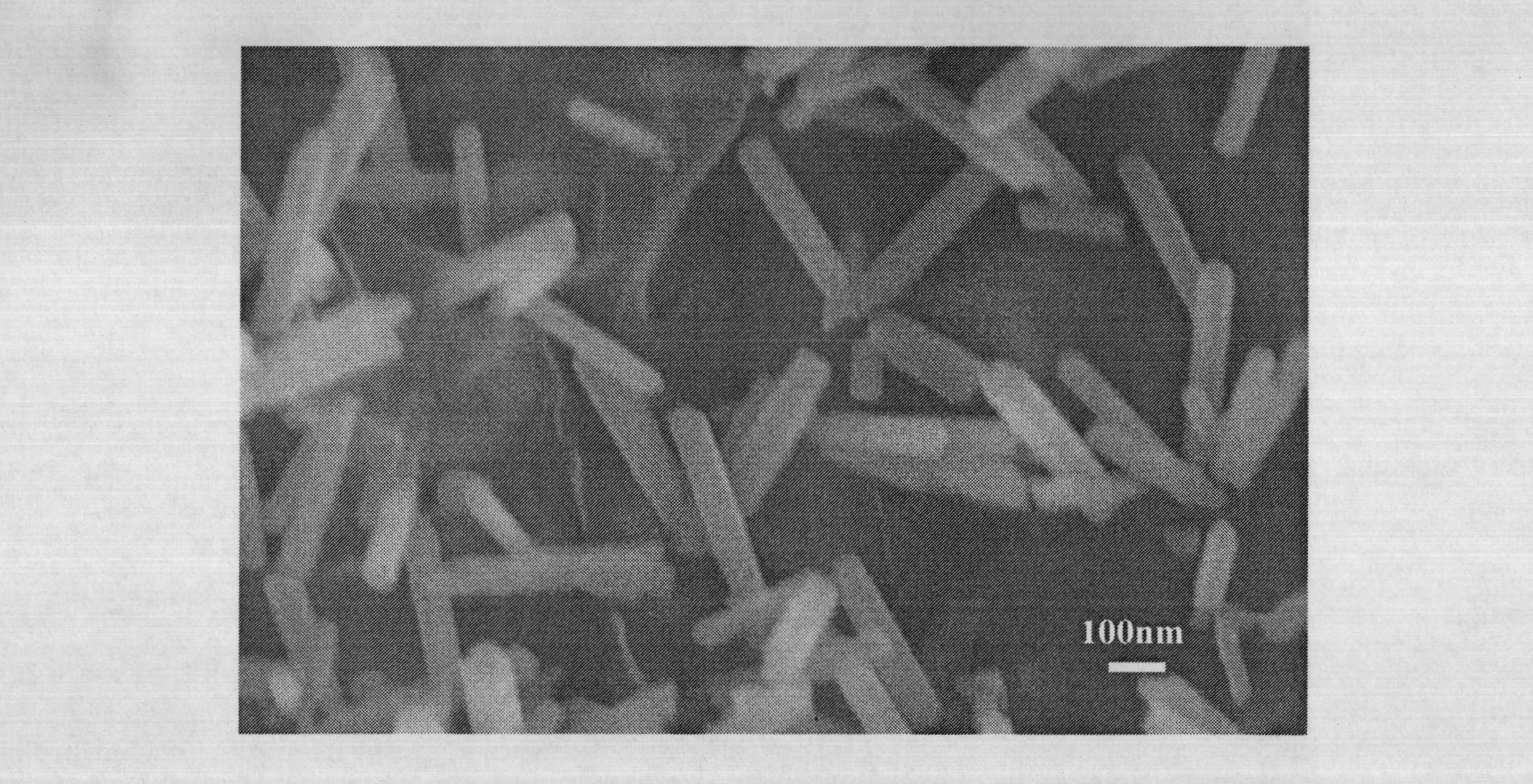

Glycerin based synthesis of silver nanoparticles and nanowires

The present invention includes compositions and methods for the production of noble metal nanoparticles and nanowires conjugated to polyols or polymers. The present invention allows the incorporation of noble metal nanoparticles to a wide range of products such as body care products to exploit the biocidal properties of silver nanoparticles against bacteria, viruses and fungi.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Preparing method of nanometer particle carbon nanotube compound catalyst

InactiveCN101224434AEasy to operateGood catalyticOrganic-compounds/hydrides/coordination-complexes catalystsModified carbonElectrostatic interaction

The invention relates to a preparation method of a nano particle carbon nanotube compound catalyst. The carbon nanotube with electric charges on surface is obtained from the materials which can generate non-covalent action with the carbon nanotube. Then nano particle with opposite electric charges on surface to that of the non-covalent modified carbon nanotube is added and completely mixed, and excess nano particle is removed to finally obtain the nano particle carbon nanotube catalyst compound. A plurality of nano particle carbon nanotube catalyst compounds can be prepared by the invention, all of which represent very good catalytic activities. The invention adopts the method of non-covalent modified carbon nanotube to obtain carbon nanotube with perfect surface. Meanwhile, the invention provides the nano particle, in particular, the morphology controllable nano particle on the load of carbon nanotube with an effective way by utilizing the electrostatic interaction of carbon nanotube and namo particle, thus extending the applications of morphology controllable nano particle in catalytic field.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

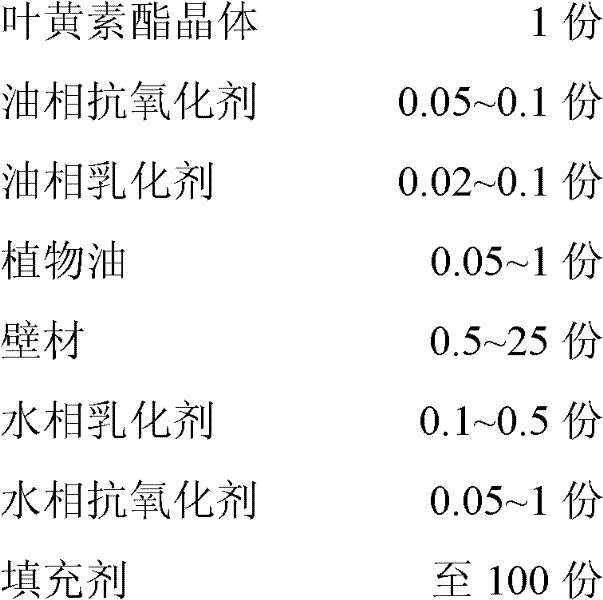

Lutein ester microcapsule powder and preparation method thereof

ActiveCN102389108AInstant highGood self-emulsifying performanceFood preparationAntioxidantFiller Excipient

The invention discloses lutein ester microcapsule powder and a preparation method thereof. The preparation method comprises the following steps of: preparing an oil phase solution and a water phase solution respectively, and mixing and emulsifying the oil phase solution and the water phase solution; and non-water raw materials comprise the following components in part by weight: 1 part of lutein ester crystal, 0.05 to 0.1 part of oil phase antioxidant, 0.02 to 0.1 part of oil phase emulsifying agent, 0.05 to 1 part of plant oil, 0.5 to 25 parts of wall material, 0.1 to 0.5 part of water phaseemulsifying agent, 0.05 to 1 part of water phase antioxidant, and the balance of filler. In the preparation method for the lutein ester microcapsule powder, the oil-soluble lutein ester is fully dispersed in cold water in the form of sub nanometer particles, and the product can be self-emulsified in water, and is good in instant capacity and self-emulsification capacity, and high in stability, and has uniform and durable color; and the phenomena of oil floating, precipitation, adhesion to a bottle wall and the like are avoided during application. Organic solvents are not introduced in the powder, so solvent residues are avoided in the product. The production process is environment-friendly, simple and practicable, expensive equipment is not needed, and the microcapsule powder can be industrially produced easily and conveniently.

Owner:INNOBIO CORP LTD

Method for achieving high-melting-point material 3D printing through nanometer ink together with laser melting

InactiveCN103407296AWide range of choicesLarge specific surface areaOther printing apparatusDevice formInk printer

The invention discloses a method for preparing the nanometer ink through ceramics, metal, semiconductors, glass and other high-melting-point materials, carrying out 3D printing and utilizing the laser heating sintering in the process of printing to obtain 3D devices formed by combining the ceramics, the metal, the semiconductors and other composite. The method comprises the first step of processing raw materials needed to prepare the device into nanometer particles of 1-500nm, the second step of preparing the particles into ink jet printing ink, the third step of carrying out 3D printing by utilizing an improved ordinary ink printer and adopting the laser heating sintering in the process of printing, and the fourth step of achieving the melting and sintering molding of the nanometer particles. According to the method, micron-level precision devices with any complex shape can be directly prepared, the high surface energy of the nanometer particles is utilized, the sintering temperature is lowered, high density is achieved, and a superior property is obtained. The method can be used for manufacturing automobile metal ceramic composite pistons, aviation engine tail pipes, and ceramic bearings and ceramal composite precise components of watches and other precision instruments and for directly printing a circuit board.

Owner:南京鼎科纳米技术研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com