Patents

Literature

252results about How to "Self-supporting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

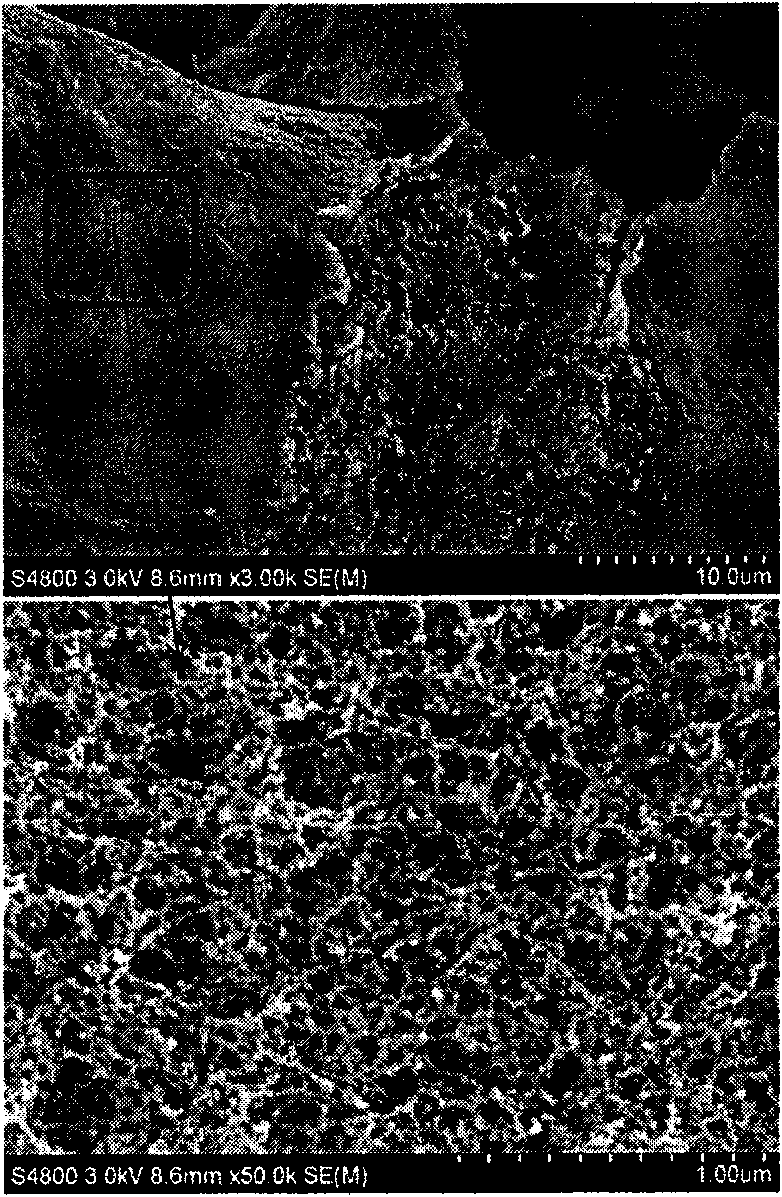

Bi*WO*/oxide fiber cloth with multistage heterogeneous structure, method and application

InactiveCN101623630ASelf-supportingEvenly distributedBiocideDispersed particle separationFiberAlcohol

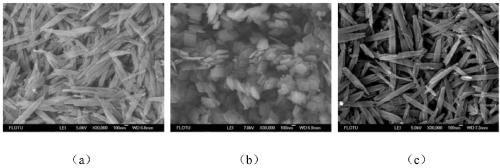

The invention relates to Bi2WO6 / oxide nanofiber cloth with a multistage heterogeneous structure, a prepration method and an application. The method combines the electrospinning and alcohol-thermal synthesis technology and prepares the Bi2WO6 / TiO2 or Bi2WO6 / ZnO fiber cloth with the multistage heterogeneous structure, Bi2WO6 nanosheets with the side length of 50-200nm and the thickness of 10-40nm are grown on mutually orderly interwoven TiO2 fiber or ZnO fiber with the diameter of 100-500nm in an inclined manner, wherein, the Bi2WO6 nanosheets consist of Bi2WO6 nanoparticles with the dimension of 10-40nm. The Bi2WO6 / TiO2 or ZnO fiber cloth with the multistage heterogeneous structure has the advantages of greater strength, smaller particle size, larger specific surface area and the multistage heterogeneous structure, thereby having important applications in solar cells, photocatalysis, self-cleaning and other aspects.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Ultraviolet-curing and semi-interpenetrating network-structure polycarbonate-based solid-state polymer electrolyte and preparation method thereof

ActiveCN107768717AEasy to prepareHigh conductivity at room temperatureSolid electrolytesFinal product manufactureCross-linkPolymer science

The invention discloses an ultraviolet-curing and semi-interpenetrating network-structure polycarbonate-based solid-state polymer electrolyte and a preparation method thereof. The ultraviolet-curing and semi-interpenetrating network-structure polycarbonate-based solid-state polymer electrolyte is characterized in that a crosslinking agent is automatically cross-linked to form a framework, polycarbonate is taken as a solid-state polymer substrate uniformly filled in the framework, a lithium salt is dispersed in the solid-state polymer substrate, the weight ratio of the lithium salt and the polycarbonate is (4:6)-(9:1), and the crosslinking agent accounts for 5-50% of total weight of the solid-state polymer electrolyte. The solid-state polymer electrolyte is simple in preparation method, high in room-temperature electrical conductivity and good in electrochemical and interface stability, can be self-supported and can be used as an electrolyte of a lithium ion battery, and the oxygenolysis potential is larger than 4.5V.

Owner:HARBIN INST OF TECH WUXI RES INST OF NEW MATERIALS +1

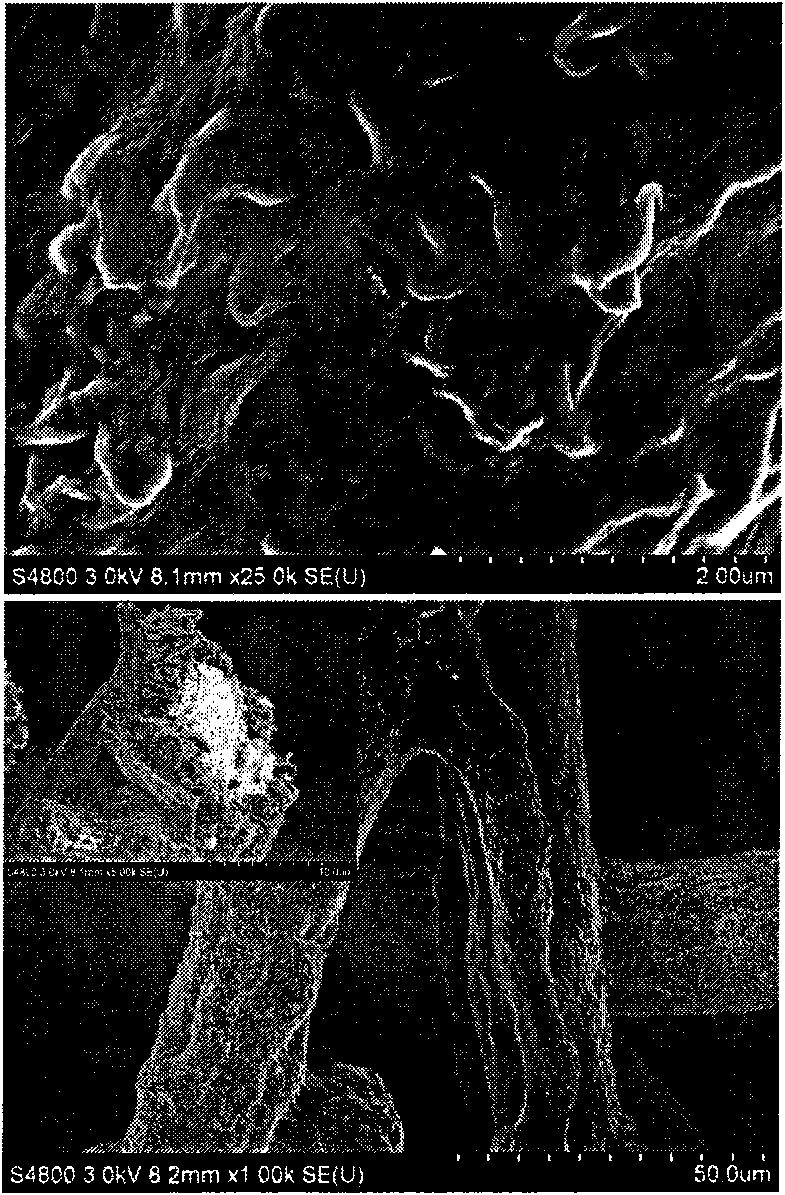

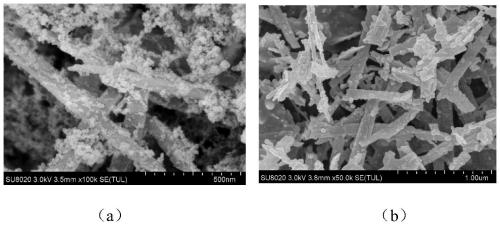

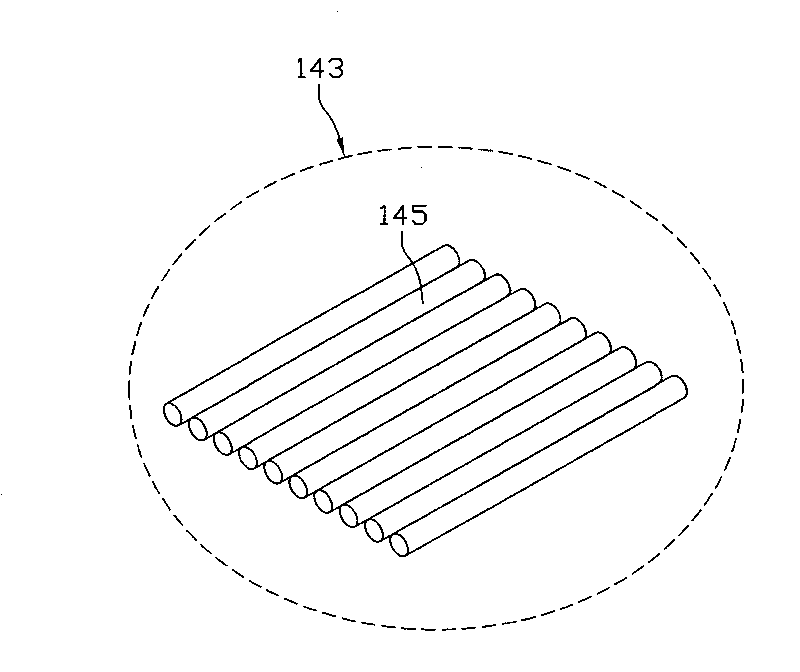

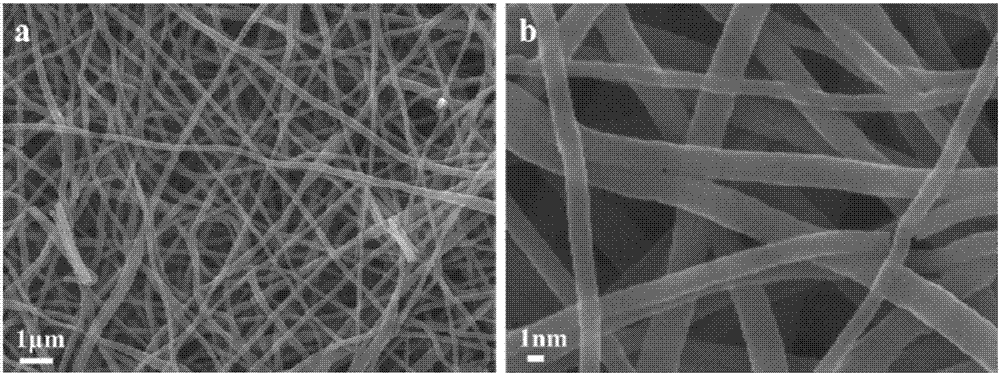

Metal fiber-nanometer carbon fiber-carbon aerogel composite material and preparation method and use thereof

InactiveCN101661839ASelf-supportingGood for electrolyte storageElectrode manufacturing processesHybrid capacitor electrodesMetal fiberInternal resistance

The invention discloses a metal fiber-nanometer carbon fiber-carbon aerogel composite material and a preparation method and a use thereof, wherein, the material contains metal fiber, nanometer carbonfiber and carbon aerogel; a binding point of the metal fiber is sintered on a tri-dimensional net structure, the nanometer carbon fiber grows on the metal fiber, and the carbon aerogel is coated on the nanometer carbon fiber. The preparation method comprises the following steps: sintering the metal fiber net structure in a large area on a selected thin layer; allowing the nanometer carbon fiber togrow by catalyzing a selected chemical vapor phase deposition method of a carbon-containing compound under a specified condition; then coating a selected organic polymer on the nanometer carbon fiber, and carbonizing the polymer at a certain temperature to obtain the metal fiber-nanometer carbon fiber-carbon aerogel composite material. The material can be taken as an electrode material of a novelchemical power supply; and the material has a self-supporting integral structure without an organic polymer macromolecular binding agent, has a tri-dimensional layered hole structure which is beneficial to ion transmission and storage, and has high electrical conductivity, small internal resistance and good chemical energy storage performance.

Owner:EAST CHINA NORMAL UNIV

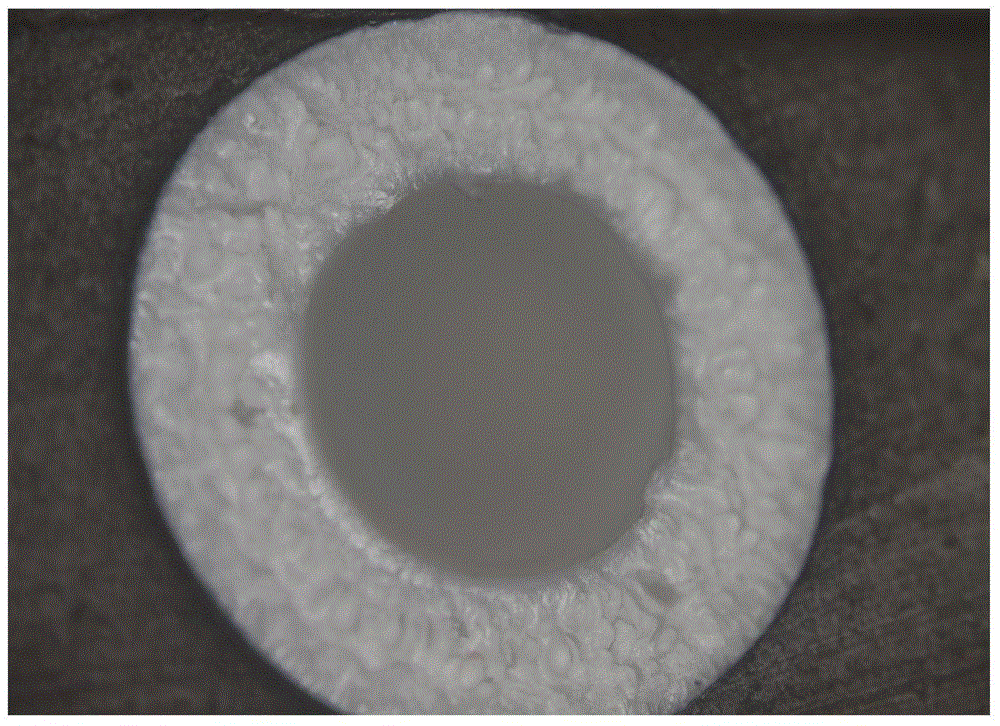

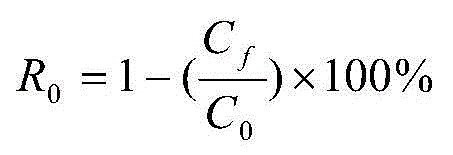

A heavy metal ion adsorption type PS hollow fiber ultrafiltration membrane and a preparing method thereof

ActiveCN104587852AImprove adsorption capacitySelf-supportingSemi-permeable membranesOther chemical processesFiberUltrafiltration

A heavy metal ion adsorption type PS hollow fiber ultrafiltration membrane and a preparing method thereof are disclosed. After a spinning solution is prepared, the hollow fiber ultrafiltration membrane is prepared by a dry-wet spinning method. The spinning solution comprises polysulfone, additives, a solvent and a pore forming agent. Compared with the prior art, the heavy metal ion adsorption type hollow fiber ultrafiltration membrane belongs to hollow fiber ultrafiltration membranes, has characteristics of a self-supporting property, large membrane area of an assembly, large flux, and the like, and is good in pressure resistance and high in adsorptive property for heavy metal ions. A preparing process of the membrane is simple, stable and prone to industrialization. The adsorption effects for heavy metal ions are obvious.

Owner:VONTRON TECH CO LTD

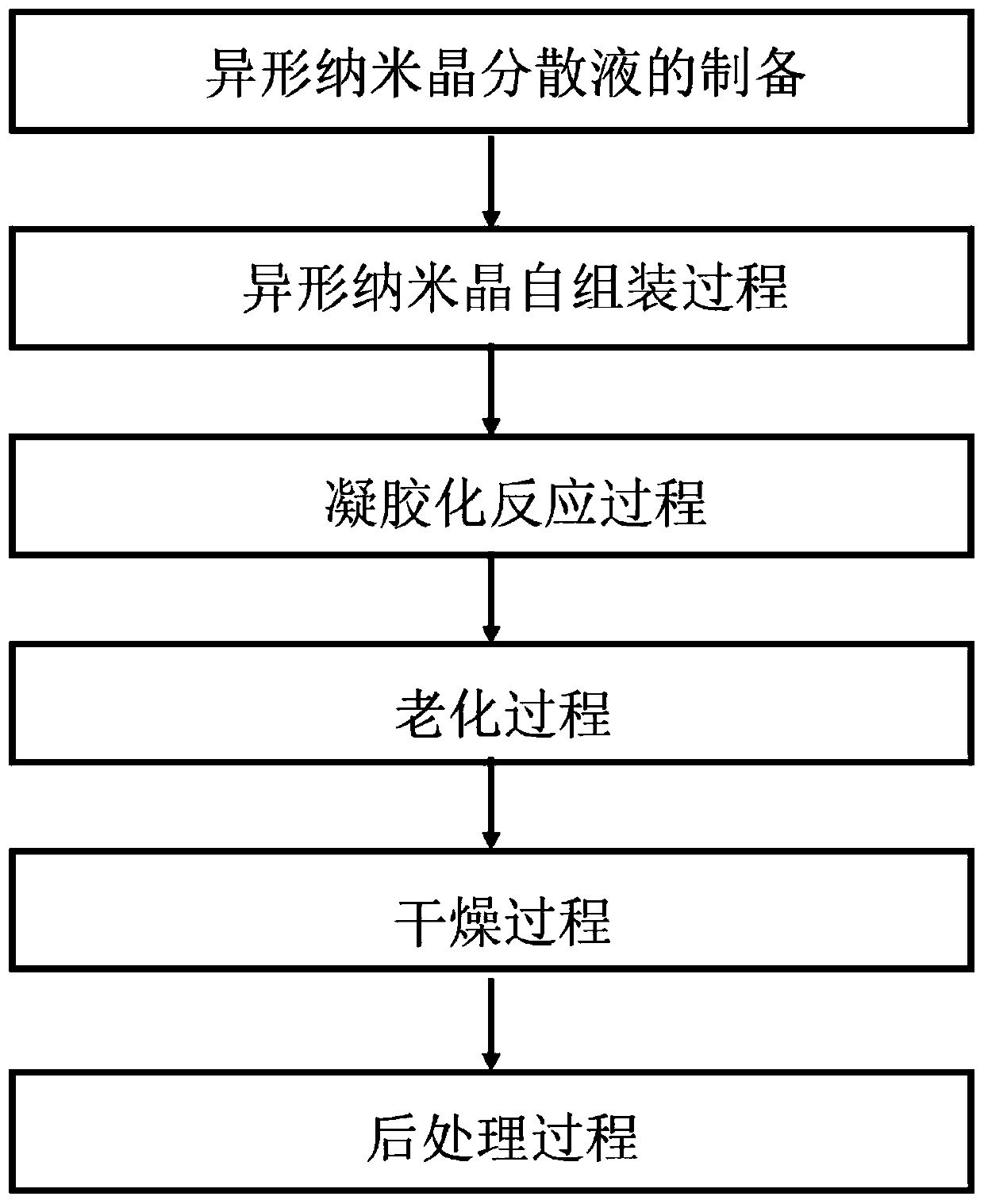

High-temperature-resistant heteromorphic nanocrystalline aerogel material and preparation method thereof

The invention relates to a high-temperature-resistant heteromorphic nanocrystalline aerogel material and a preparation method thereof. The method is as follows: preparing heteromorphic nanocrystal dispersion liquid; mixing the heteromorphic nanocrystal dispersion liquid and an assembly agent evenly by stirring and ultrasonic treatment to obtain a mixture phase first solution; then adding a catalyst solution, performing a gelation reaction process by stirring and ultrasonic treatment, and then performing a vacuum pumping process to obtain gelation reaction liquid; and performing an aging step and a drying step to obtain a heteromorphic nanocrystalline aerogel material; the heteromorphic nanocrystalline aerogel material is subjected to post-treatment in two or more different temperature stages to obtain the high temperature-resistant heteromorphic nanocrystalline aerogel material. The invention performs a staged heat treatment process on the aerogel material in the post-treatment process, thereby realizing the strengthening and toughening of themicrostructure of the aerogel material, so that the structural strength of the aerogel material is remarkably improved, the high temperature resistance performance and the large specific surface area after the heat treatment are realized, and the preparation of the high-temperature-resistant heteromorphic nanocrystalline aerogel material capable of high-efficient heat insulation is realized.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

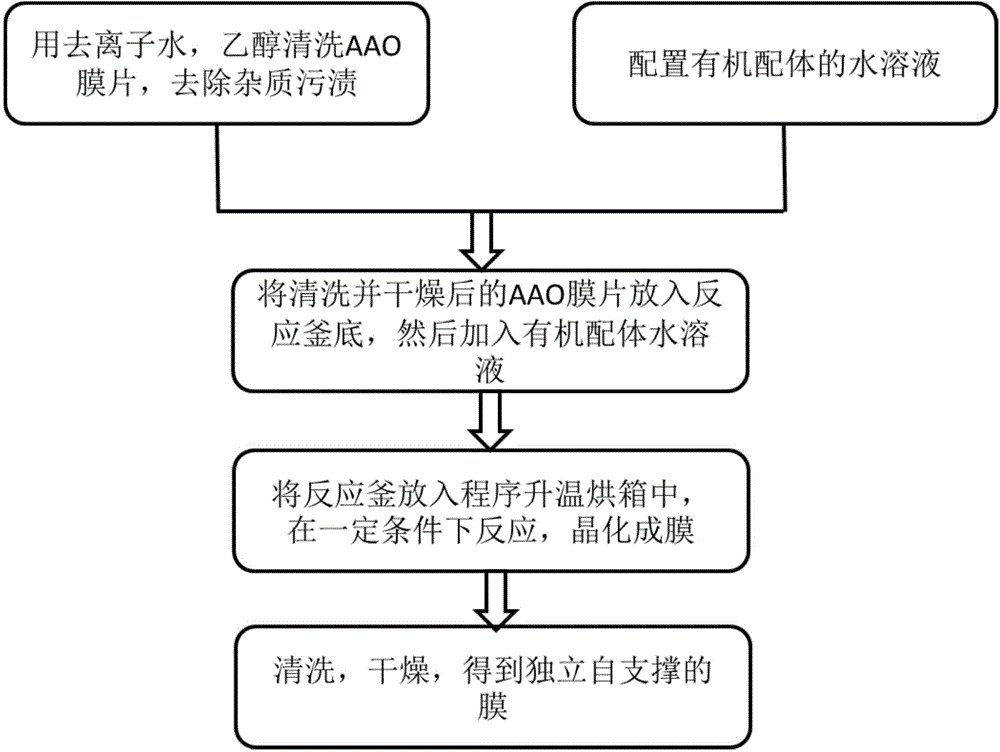

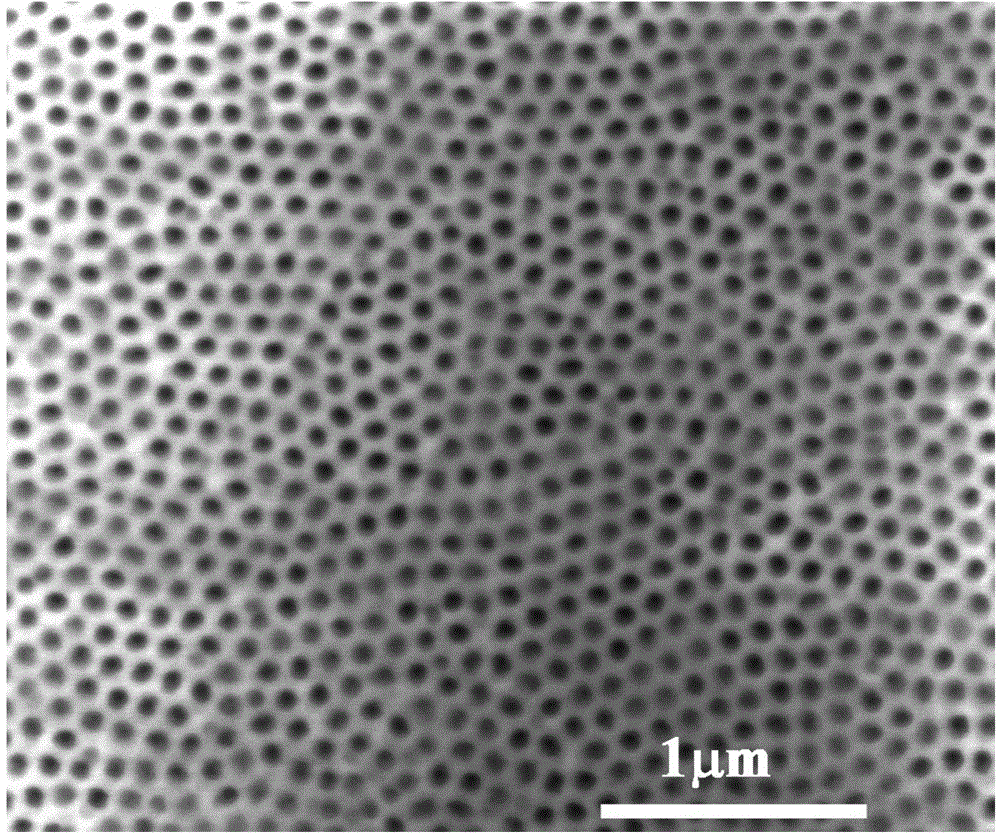

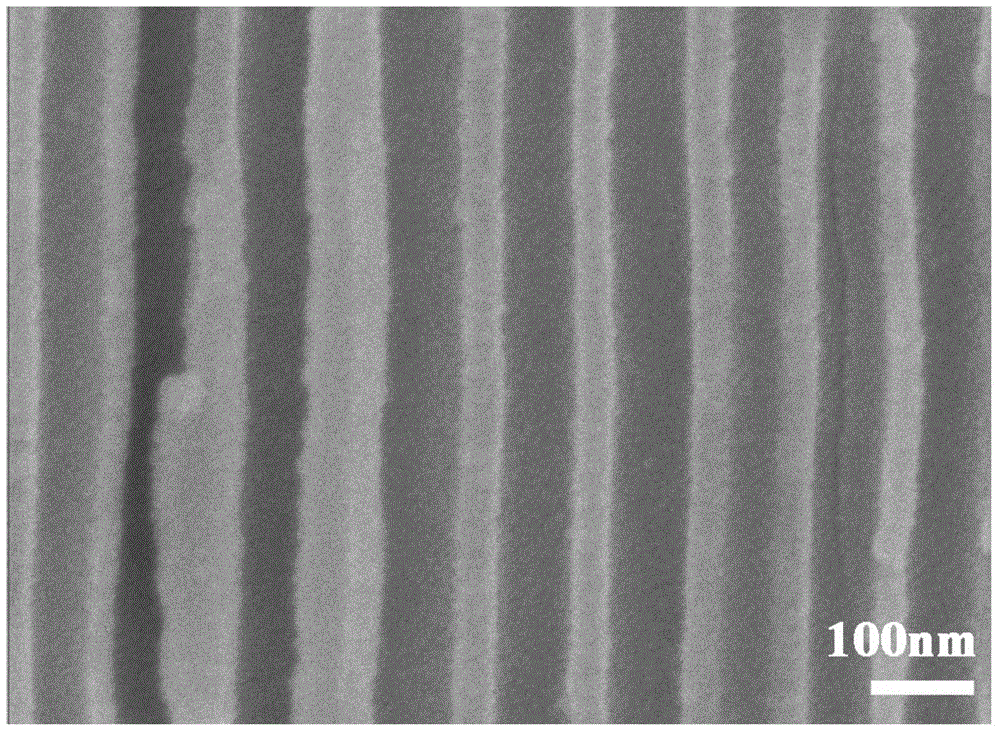

Preparation method of individually-self-supporting MIL-53 metal-organic framework membrane material

InactiveCN103977715ASimple processEasy to operateSemi-permeable membranesPre treatmentCarbon dioxide

The invention discloses a preparation method of an individually-self-supporting MIL-53 metal-organic framework membrane material. The preparation method comprises the following steps: a precursor pretreatment, organic ligand solution preparation, film preparation through a hydrothermal reaction, and a washing and drying treatment after the film forming. Specifically, the method comprises one step of soaking a metal oxide material into a water solution of an organic ligand, during this process, the organic ligand enters the channels of the metal oxide material, and then the metal oxide carries out reactions with the organic ligand so as to obtain continuous and individually-self-supporting MOF membrane. A hydrothermal method is adopted, the preparation is simple, and the target product is obtained only through a one-step reaction. The MIL-53 membrane can be used to separate carbon dioxide gas in the aerospace field.

Owner:BEIHANG UNIV

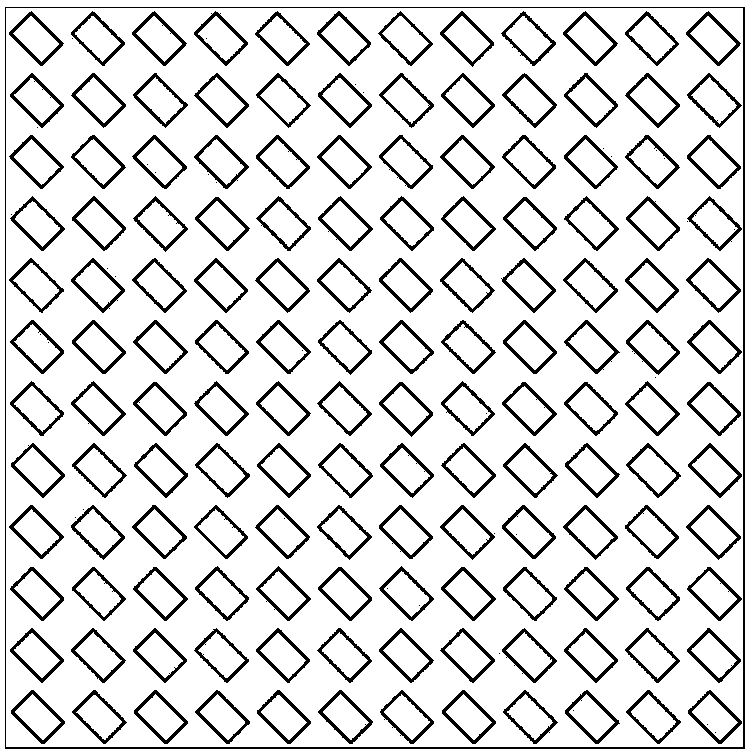

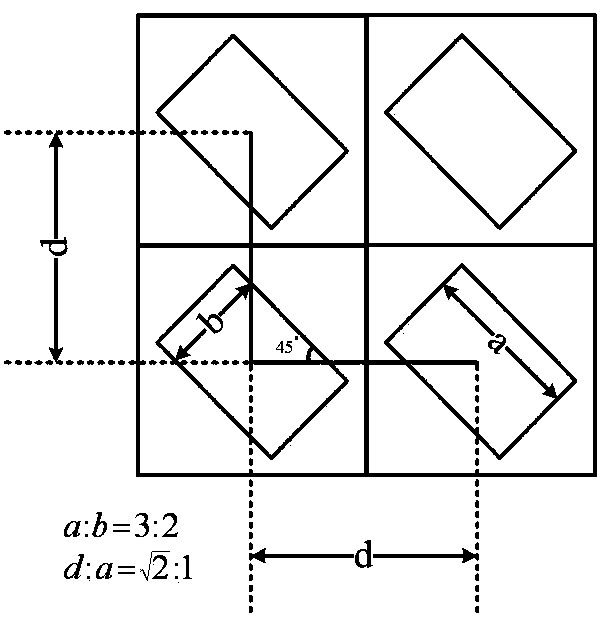

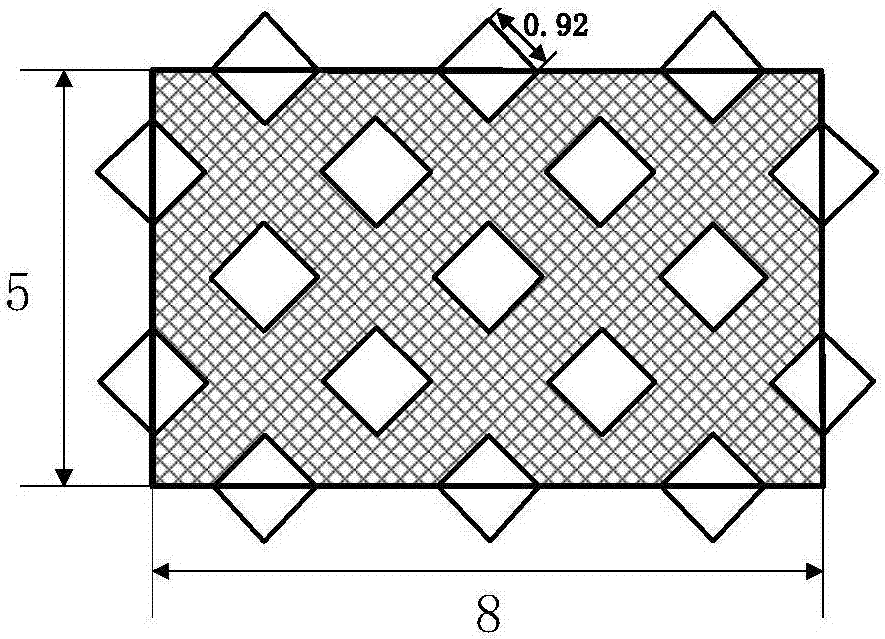

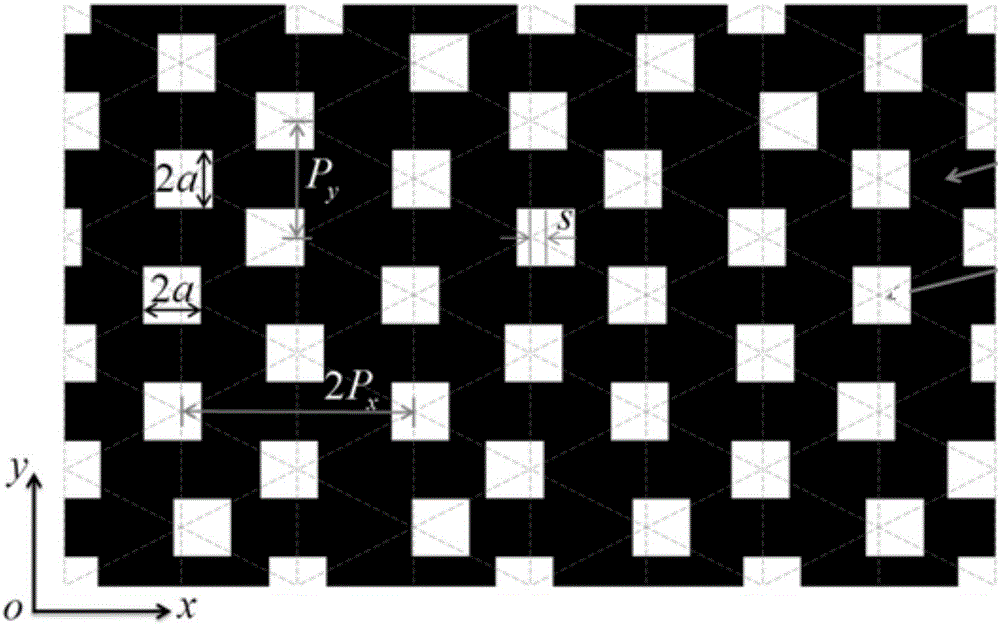

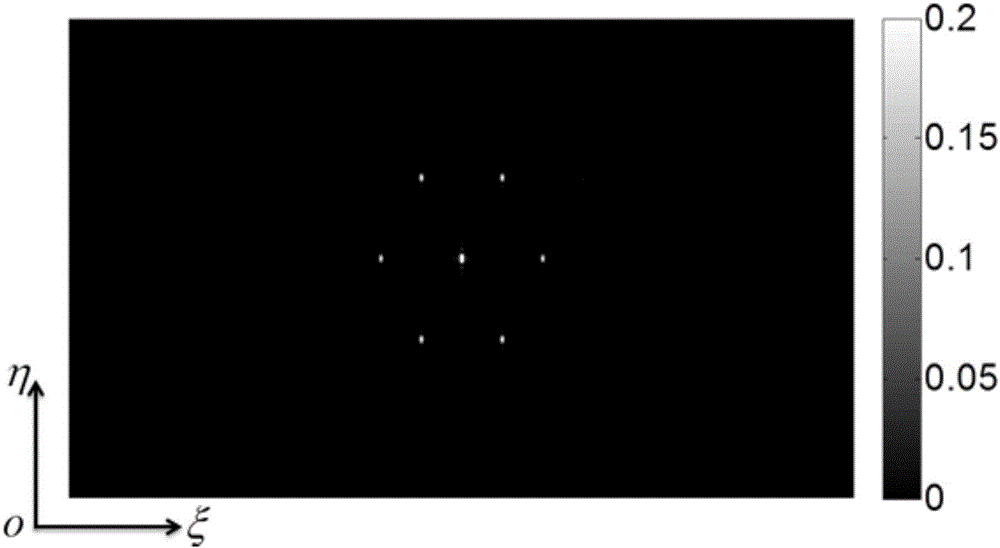

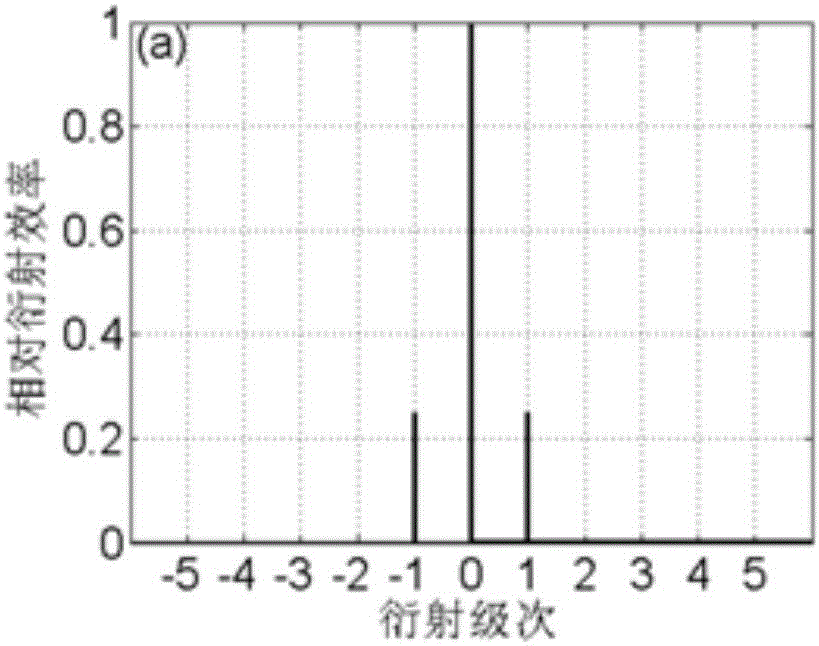

Rectangular-hole single-stage diffraction grating

ActiveCN103901519ASelf-supportingImprove efficiencyDiffraction gratingsRectangular apertureMaterials science

The invention provides a rectangular-hole single-stage diffraction grating. The grating is formed by repeatedly arranging regular light-pervious rectangular hole modules on a light-impervious substrate periodically in the two-dimensional direction, the length-width ratio of each module rectangular hole of the grating is 3:2, the long edge of each rectangular hole and the one-dimensional axis direction form an included angle of 45 degrees, and the proportion of the distance between diagonal line intersection points of every two adjacent rectangular holes in the same dimension to the length of the long edge of each rectangular hole is shown in the instruction. Compared with an existing grating, the single-stage diffraction grating can effectively inhibit high-level diffraction, 2n-level and 3n-level diffraction can be eliminated, n is an integer except zero, and five-level and higher-level diffraction can be inhibited to be 0.16% or lower than 0.16% of first-level diffraction. The single-stage diffraction grating can achieve self-supporting, has higher diffraction efficiency and has a binaryzation feature; the regular rectangular hole modules are arranged in order, and accordingly the grating is easy to manufacture and popularize and use in practice.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

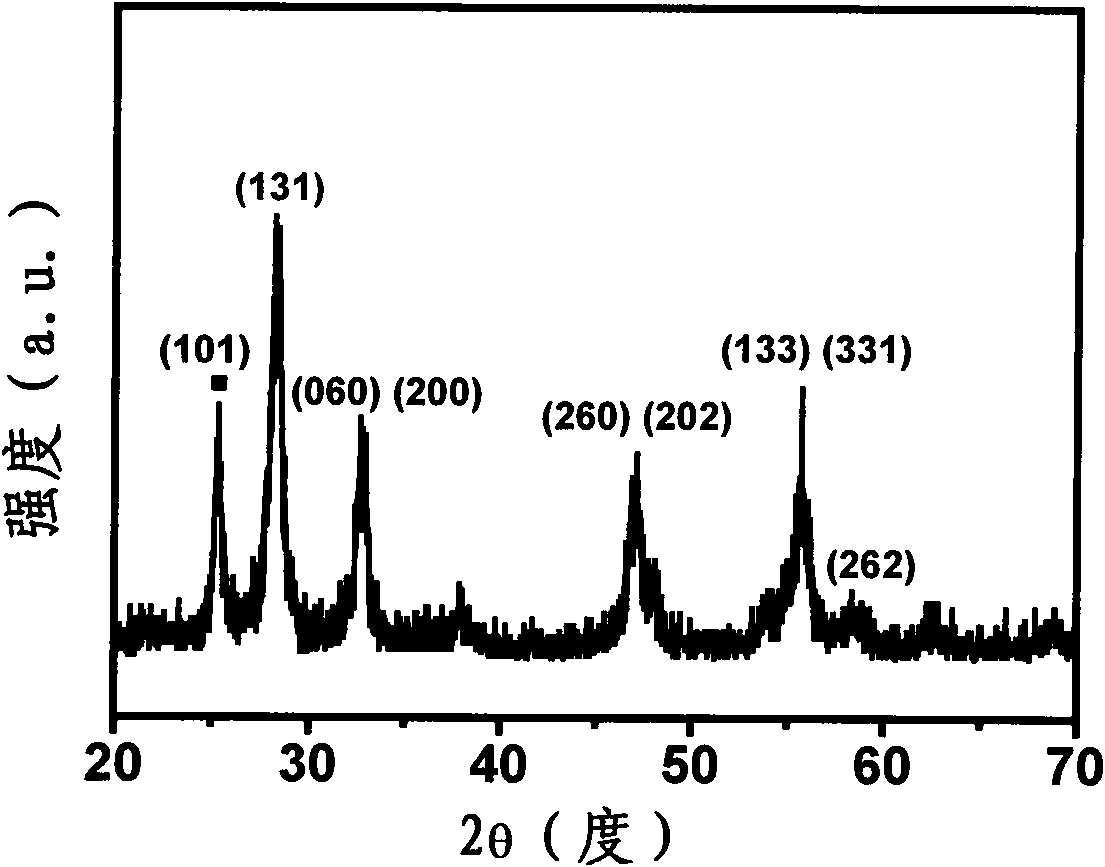

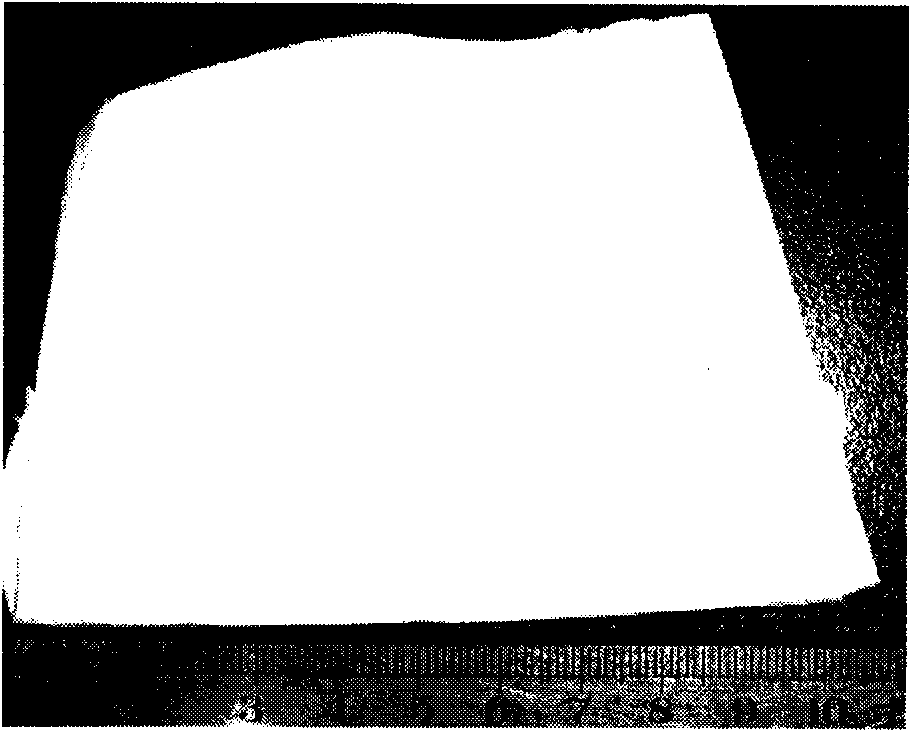

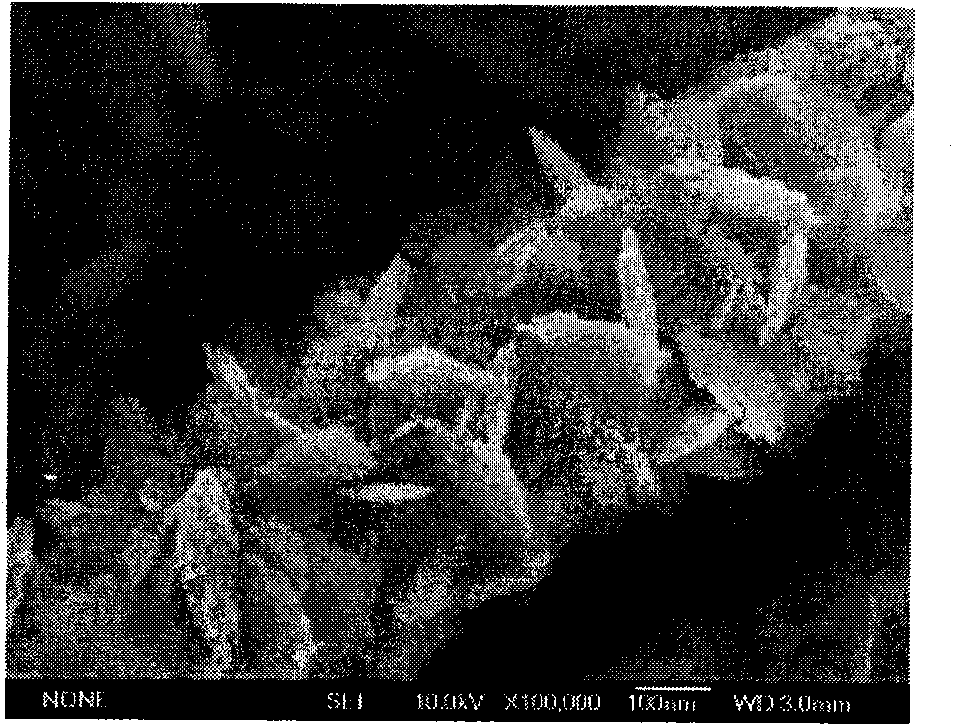

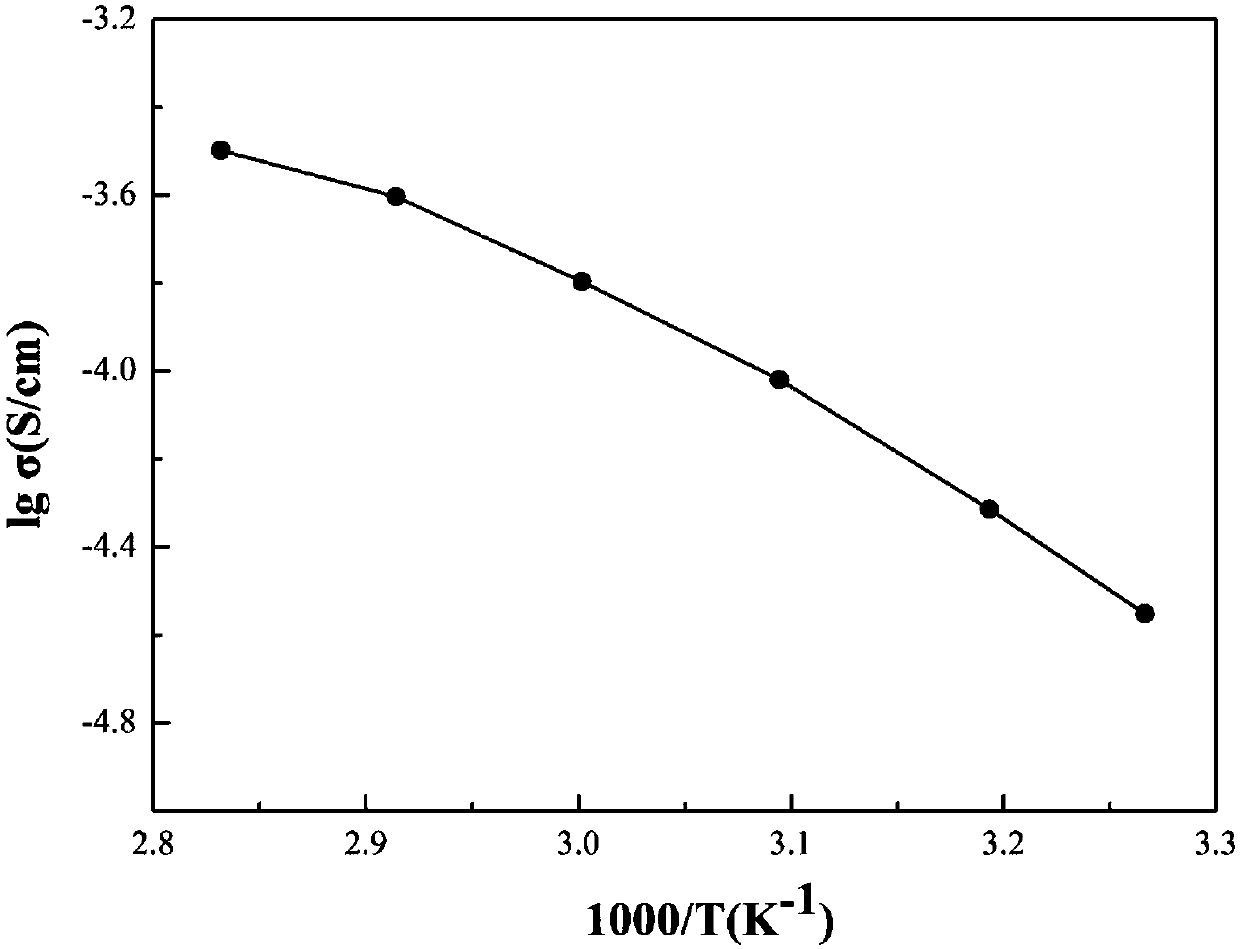

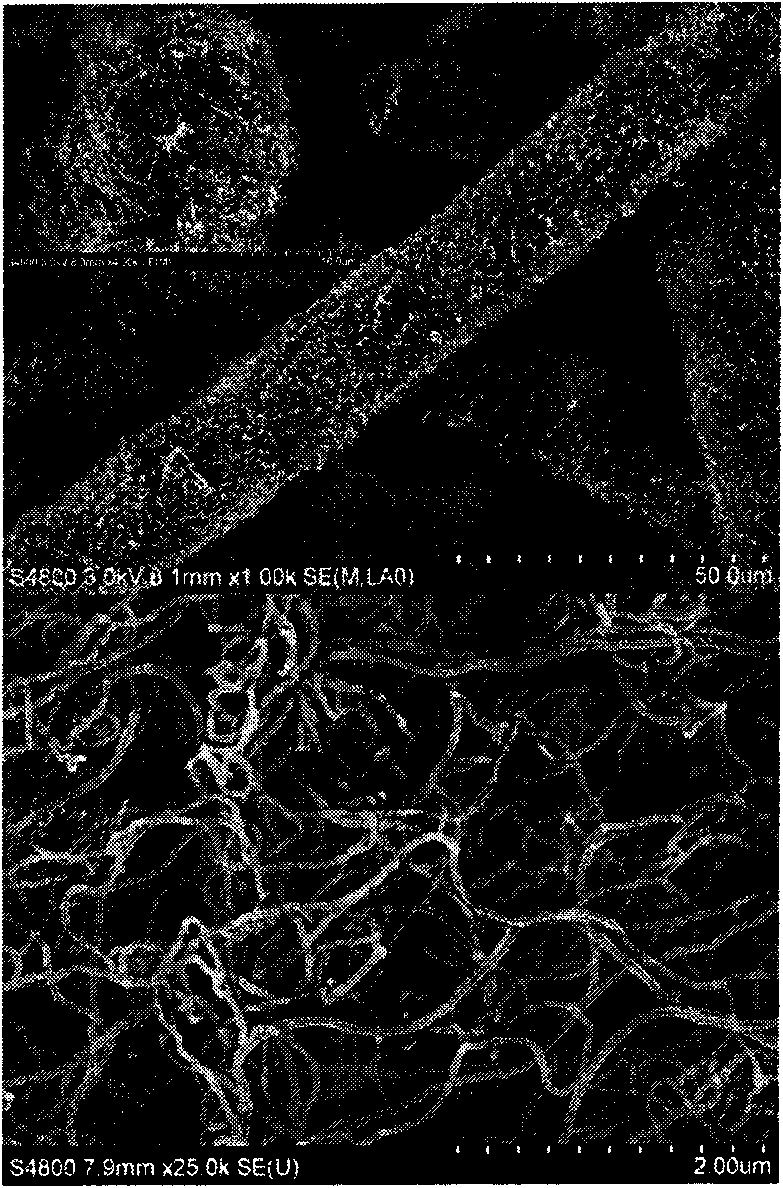

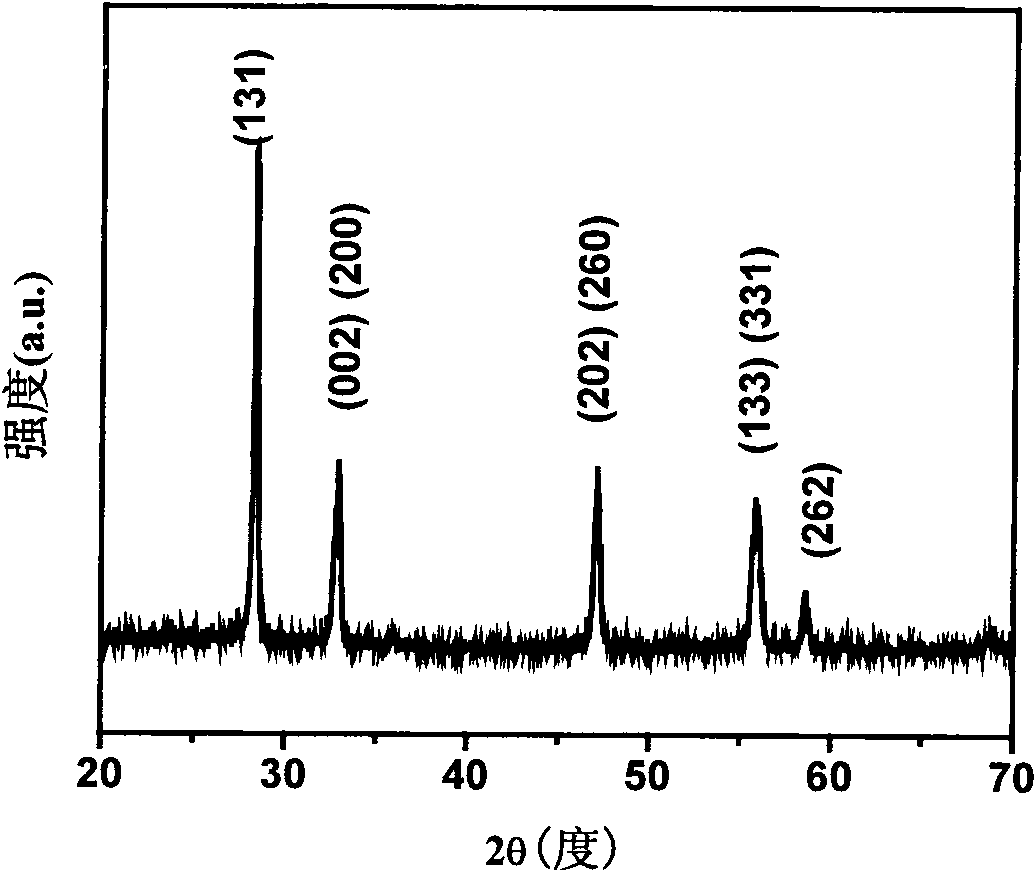

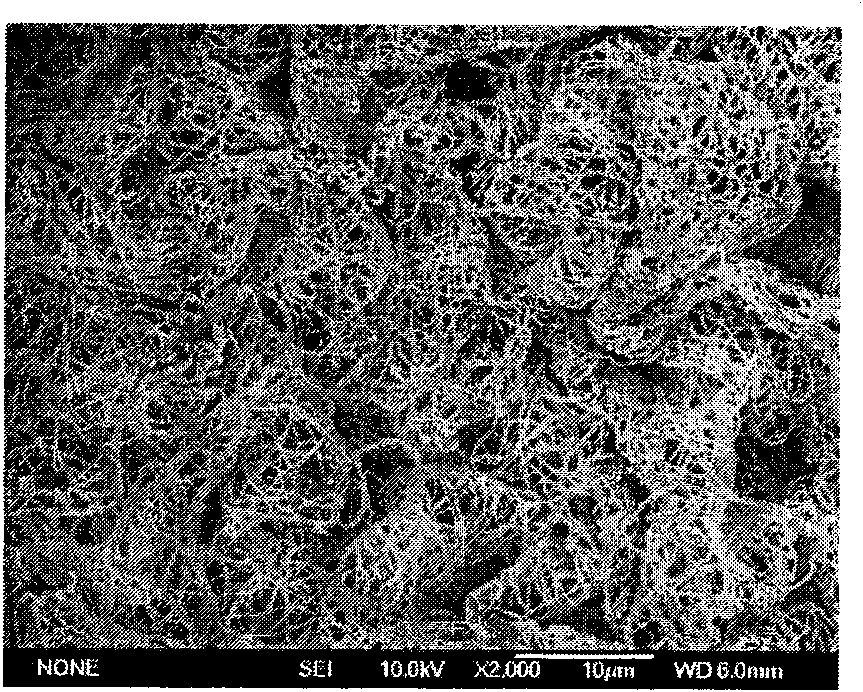

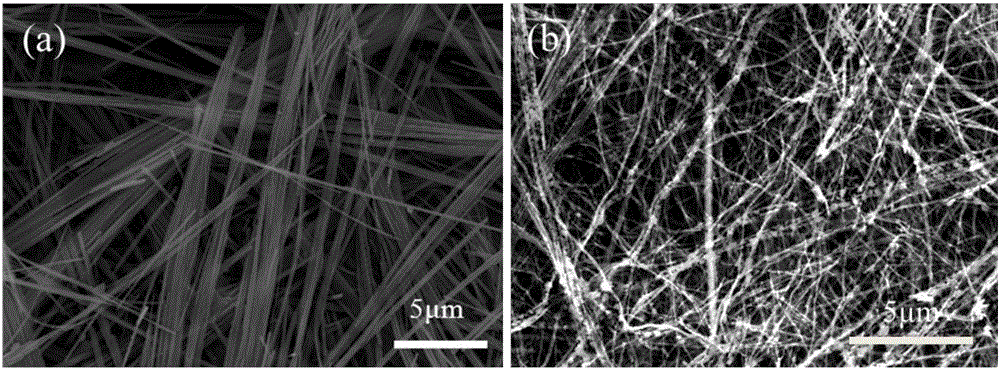

Bi2WO6 nano-fiber cloth and preparation method and application thereof

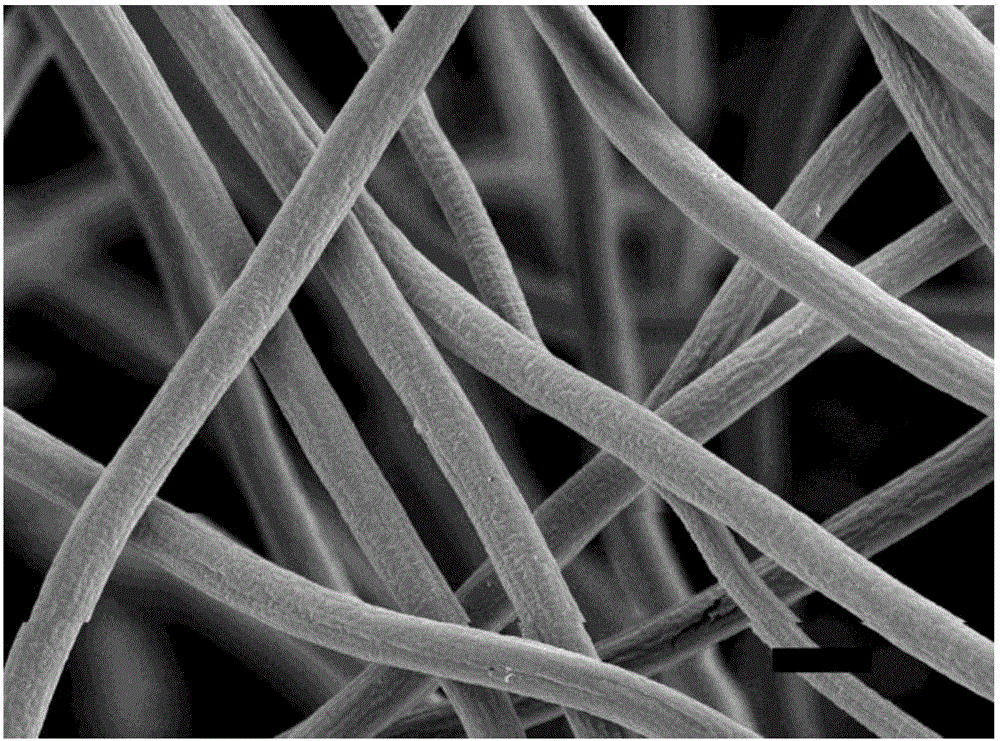

InactiveCN101612565ASimple preparation processShort cycleCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsFiberPolymer science

The invention relates a Bi2WO6 nano-fiber cloth and a preparation method and an application thereof. The nano-fiber cloth is characterized in that the nano-fiber is prepared from Bi2WO6 nano-fiber with a length of hundreds of microns and a diameter of 30-400nm by electrostatic spinning; wherein, a defined amount of reactants are mixed and stirred according to a stoichiometry ratio, then proper tackifier is added to obtain Bi2WO6 precursor with proper viscosity and charge quantity, and finally Bi2WO6 nano-fiber cloth with controllable size, crystal type and morphology can be obtained through the control of the proportioning of each material in the precursor solution and the conditions of the electrostatic spinning. The Bi2WO6 nano-fiber cloth prepared by the electrostatic spinning used as photocatalyst has high specific area and crystallinity so that the visible light activity of the cloth is high, a certain kind of organic pollutants can be degraded in short time, and meanwhile, the catalyst can be recycled and reused very conveniently so that the problem of practical application of photocatalyst is solved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Hollow fiber compound nanofiltration membrane and preparation method thereof

InactiveCN104607056AHigh removal rateImprove removal effectSemi-permeable membranesPolyetherimidePolyvinyl alcohol

The invention relates to a hollow fiber compound nanofiltration membrane. The nanofiltration membrane takes a porous supporting layer as an inner layer and a separating function layer as an outer layer. A casting membrane solution of the porous supporting layer contains an inner layer macromolecular polymer which is selected from one or more of polysulfone, polyether sulfone, polyvinylidene fluoride, polyvinyl chloride and polyacrylonitrile; a casting membrane solution of the separating function layer contains an outer layer macromolecular polymer which is selected from one or more of polyetherimide, polyether-ether-ketone, sulfonated polyether-ether-ketone, polymethyl methacrylate and polyvinyl alcohol; a preparation method comprises the following steps: synchronously extruding and molding the inner layer casting membrane solution and the outer layer casting membrane solution; solidifying to obtain a membrane filament in a nascent state; and carrying out an oxidizing agent aqueous solution to obtain the hollow fiber compound nanofiltration membrane. The invention further provides the preparation method of the nanofiltration membrane correspondingly. According to the hollow fiber compound nanofiltration membrane provided by the invention, the flux of the nanofiltration membrane is remarkably improved, and moreover, the nanofiltration membrane further has the certain desalinization rate.

Owner:HUNAN OVAY TECH CO LTD

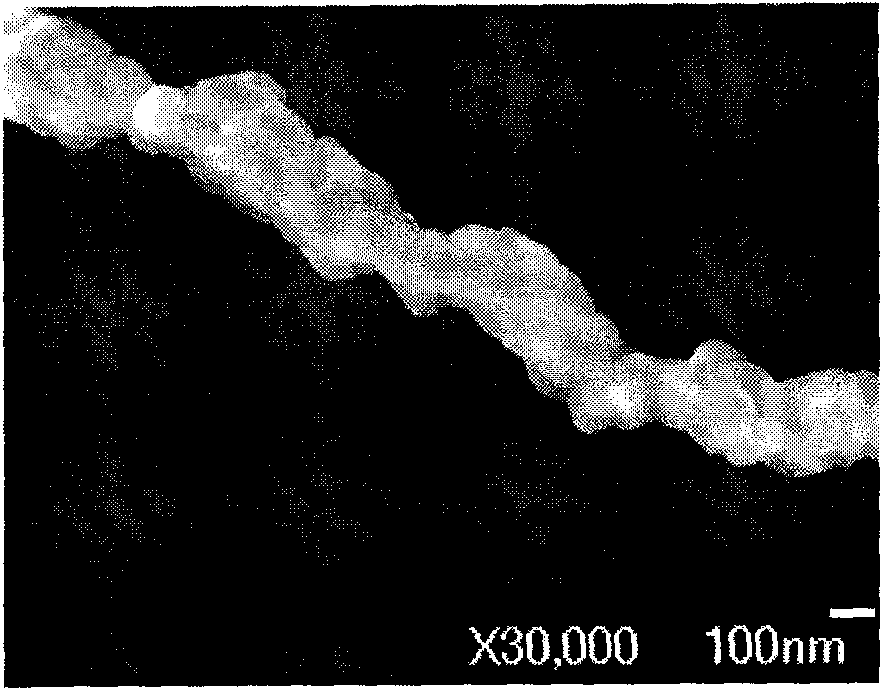

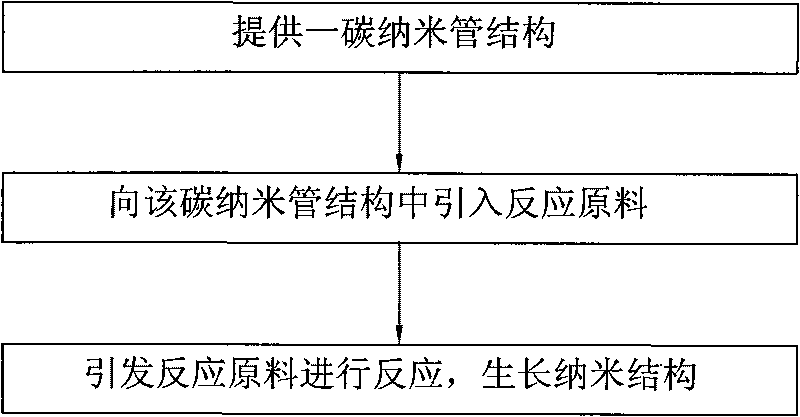

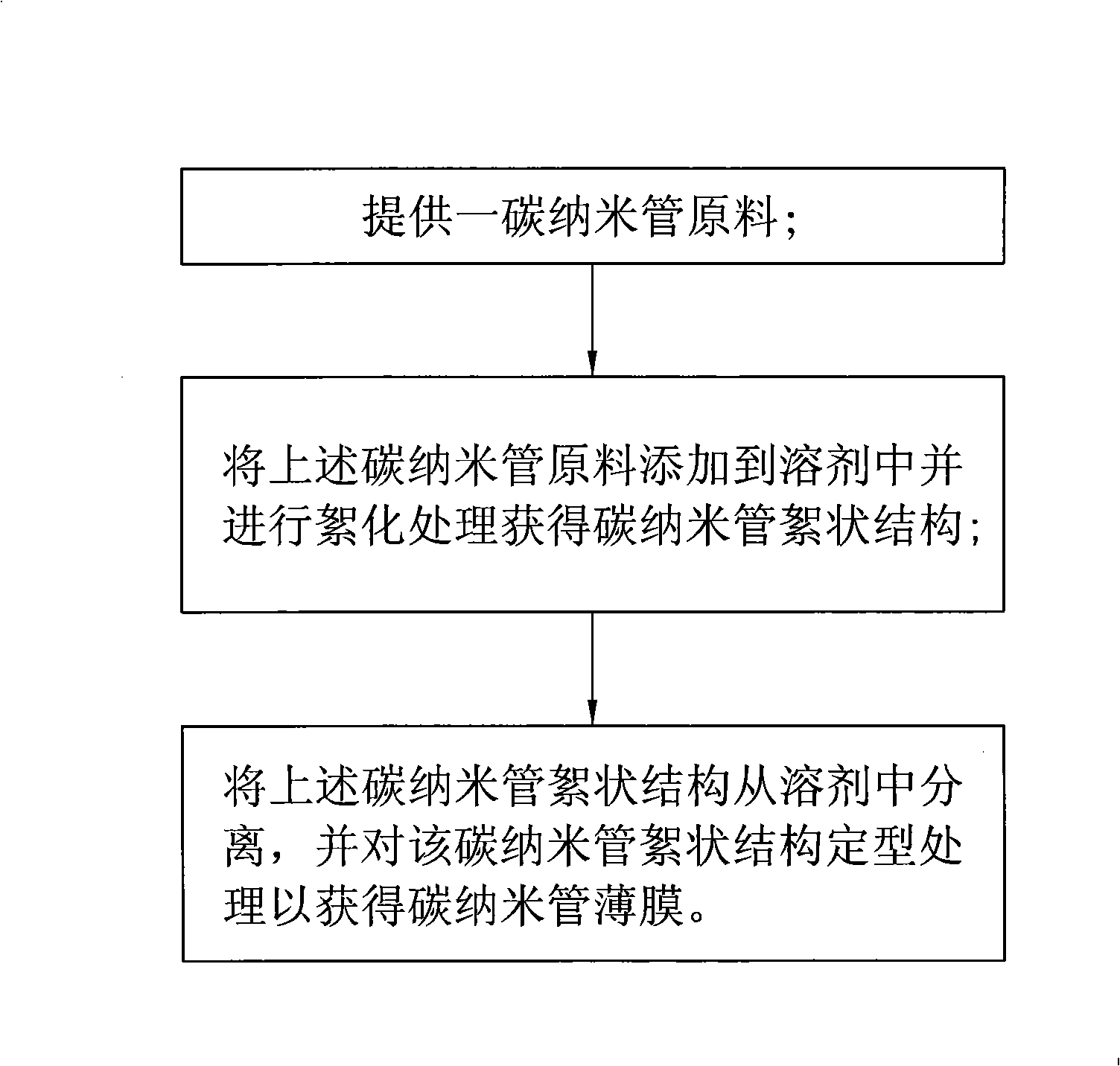

Preparation method of nanostructure

The invention relates to a preparation method of a nanostructure, comprising the following steps of: providing a carbon nanotube at least of which a part is arranged in a suspending way; introducing reaction materials into the carbon nanotube; initiating the reaction materials to react, and forming the nanostructure on the surface of the carbon nanotube structure.

Owner:TSINGHUA UNIV +1

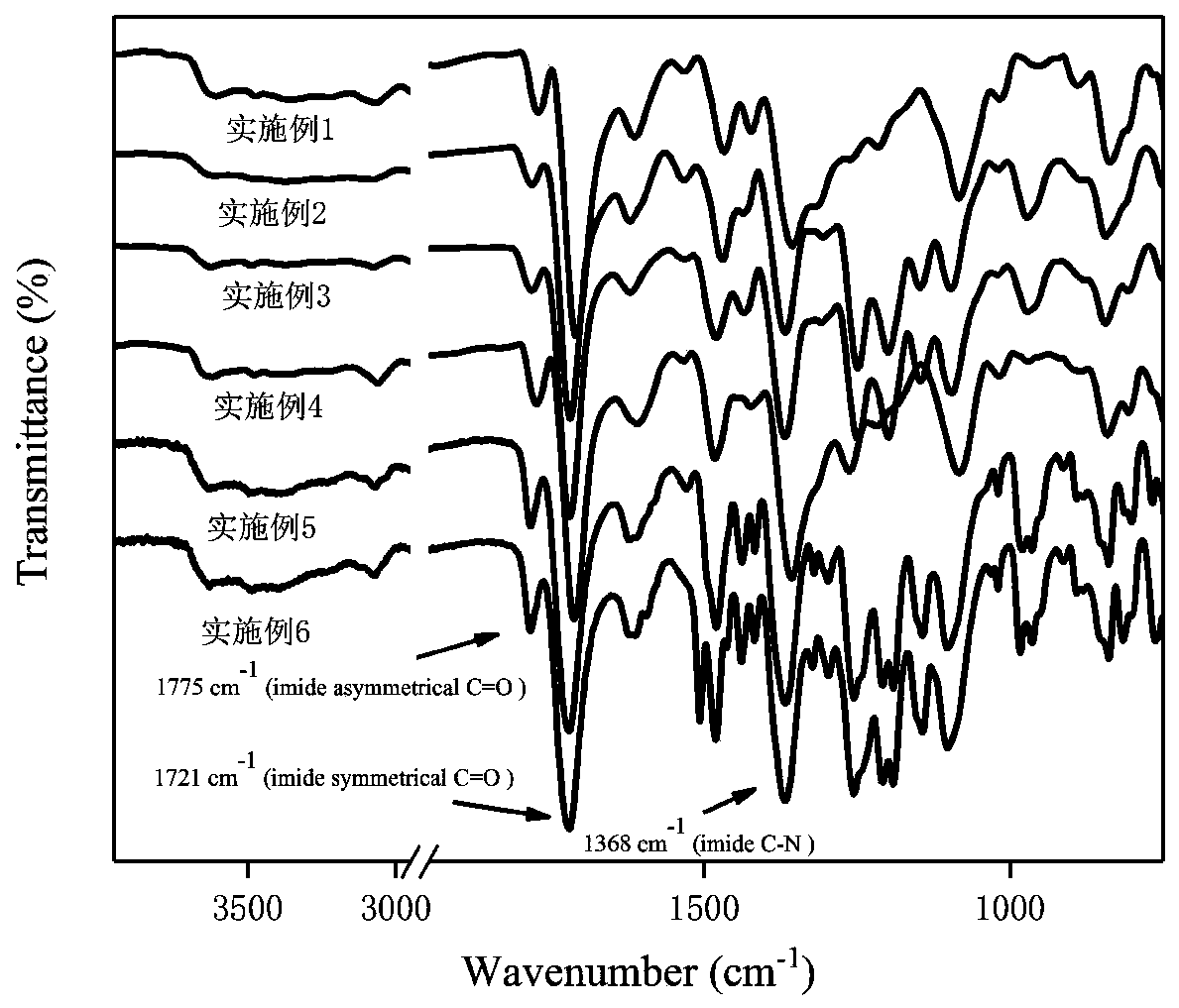

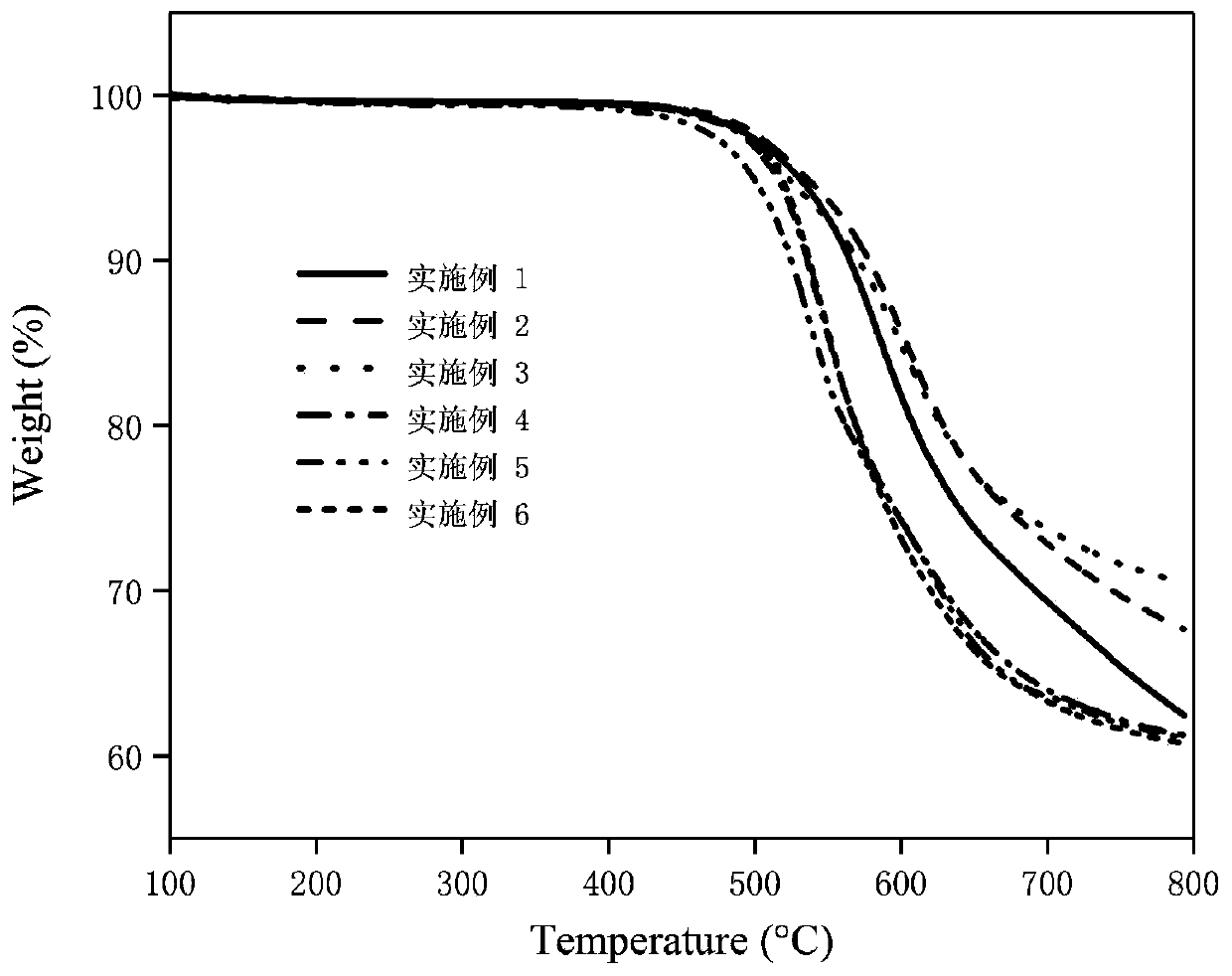

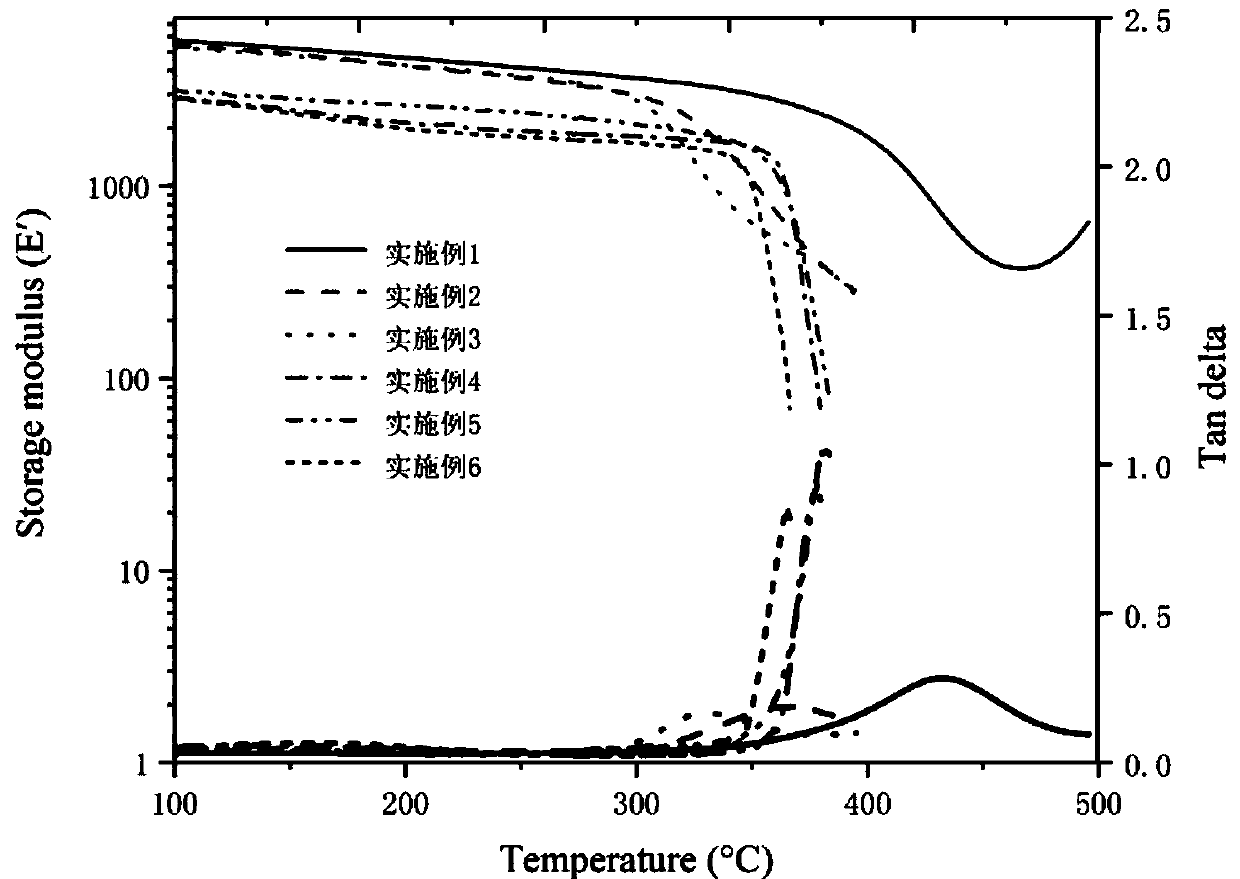

Benzimidazole-substituted polyimide, preparation method thereof, benzimidazole-substituted polyimide film, and preparation method and application of film

The invention provides a benzimidazole-substituted polyimide, a preparation method thereof, a benzimidazole-substituted polyimide film, and a preparation method and an application of the film, and belongs to the technical field of polyimide materials. The glass transition temperature of the benzimidazole-substituted polyimide film is 328-431 DEG C, the 5% thermal decomposition temperature is 498-537 DEG C, the tensile strength is 69-190 MPa, the tensile modulus is 3.5-6.2 GPa, the water absorption rate is 1.12-1.78%, the thermal expansion coefficient is 2.5-48.0 ppm / K, and the film is thermally soluble in m-cresol, N-methylpyrrolidone, dimethyl sulfoxide, N,N-dimethylformamide, N,N-dimethylacetamide and tetrahydrofuran organic solvents. The benzimidazole-substituted polyimide film providedby the invention has the advantages of high thermal stability, good dimensional stability, low water absorption rate, excellent mechanical properties, and good solubility in organic solvents.

Owner:DONGHUA UNIV

Lithium ion battery cathode, preparation method thereof and lithium ion battery applying the same

InactiveCN101409338AImprove conductivityNot self-supportingElectrode manufacturing processesActive material electrodesElectrical batteryCarbon nanotube

Owner:TSINGHUA UNIV +1

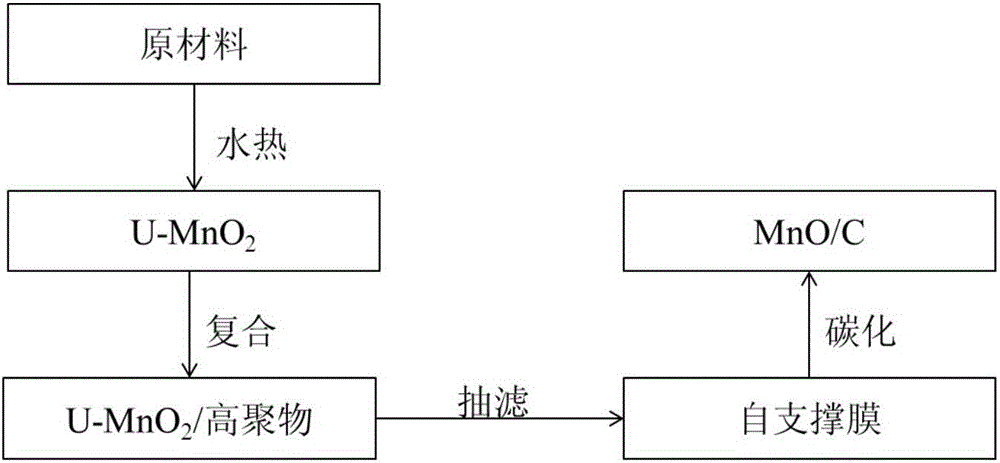

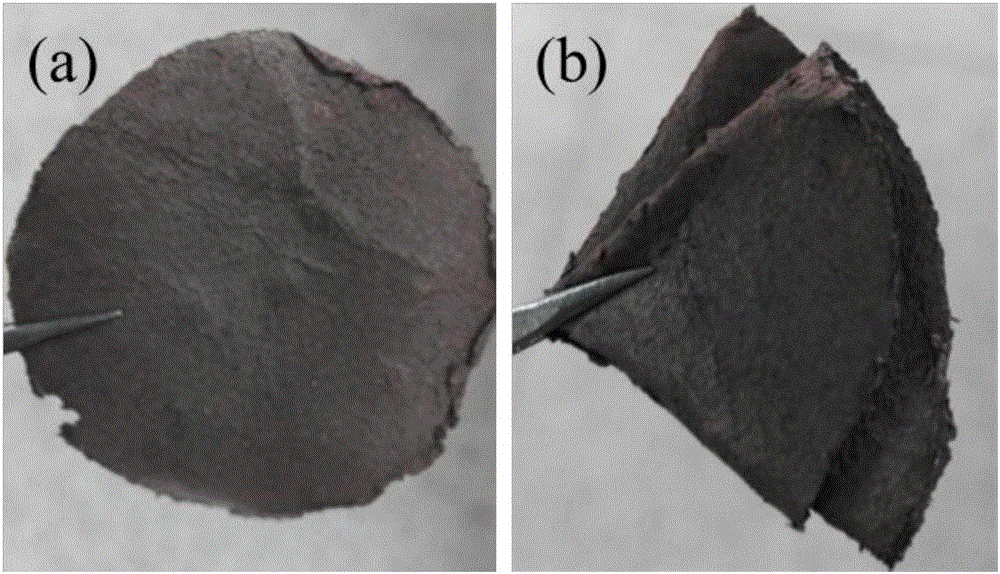

Preparation method of self-support lithium ion battery cathode material

InactiveCN104993143ASimple preparation processImprove structural stabilityCell electrodesSecondary cellsNanowireFiltration

The invention relates to a preparation method of a self-support lithium ion battery cathode material. The method includes: making a manganese salt, an oxidant and a solvent into an ultralong one-dimensional manganese dioxide (U-MnO2) nanowire by a hydrothermal technique, dispersing the U-MnO2 in an acidic solution and adding a proper amount of an organic monomer to obtain a U-MnO2@high polymer compound, carrying out cleaning, pumping filtration and drying to obtain a self-support membrane, and carrying out high temperature heat treatment to obtain the self-support carbon coated MnO(MnO@C) electrode material. The MnO@C prepared by the method can be directly used as the cathode material of a lithium ion battery without additional current collector, conductive additive and binder. The material has the characteristics of simple preparation process, high structure stability, self-current collection, excellent electrochemical performance and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

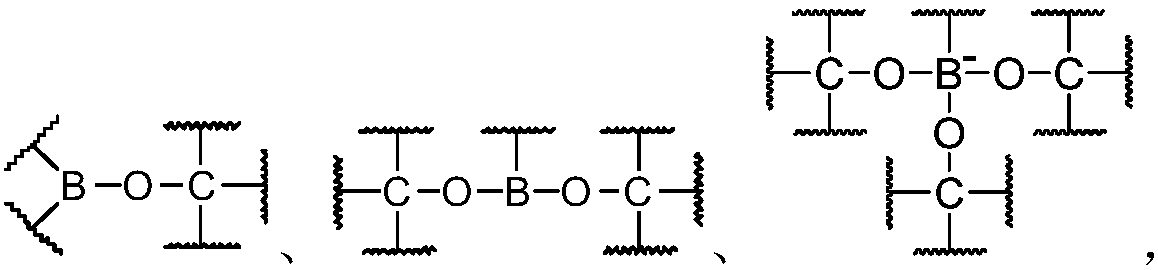

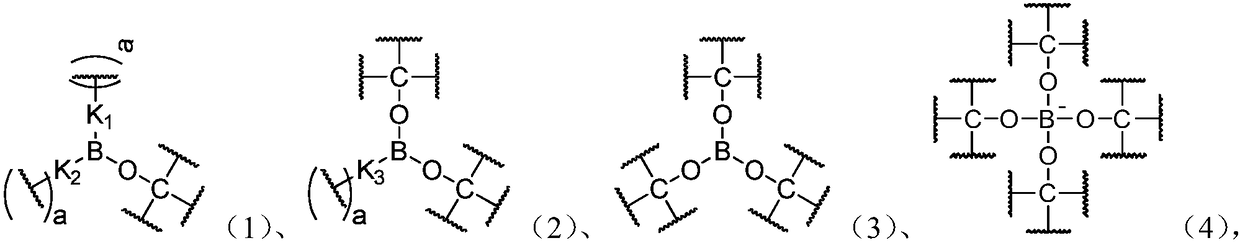

Dynamic polymer with hybrid cross-linked network and application thereof

The invention discloses a dynamic polymer with a hybrid cross-linked network. The dynamic polymer contains common covalent cross-linking and dynamic covalent organic borate bonds. The dynamic polymerintegrates the respective advantages of the dynamic covalent organic borate bonds and the common covalent cross-linking, and polymeric materials of abundant structures and with diversified propertiescan be prepared by regulating the structures of reactants. The high dynamic reversibility of the dynamic covalent organic borate bonds in the dynamic polymer allows the polymer to present the functional characteristics of stimulation responsiveness, self repair performance; the common covalent cross-linking endows the dynamic polymer with certain strength and stability; moreover, based on the dynamic nature of the dynamic organic borate bonds, the dynamic polymer has the characteristics of energy dissipation and energy absorption and the good functions of damping, shock absorption, sound insulation, impact resistance, high toughness and the like. The dynamic polymer can be used for preparing damping and buffering materials, anti-impact protection materials, self-repairing materials, toughmaterials, force transducers, etc.

Owner:厦门天策材料科技有限公司

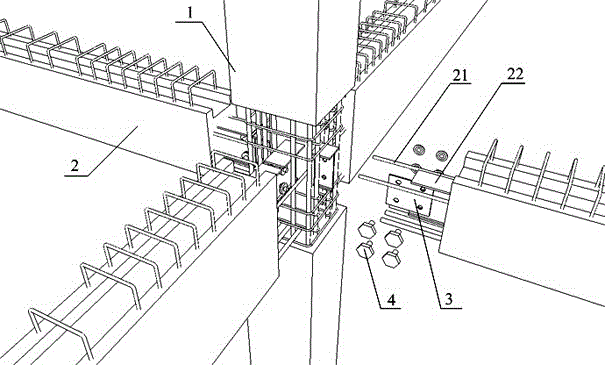

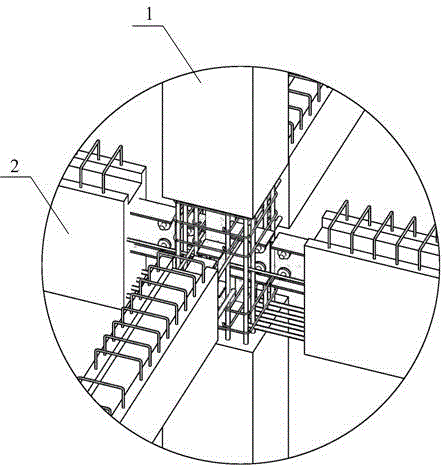

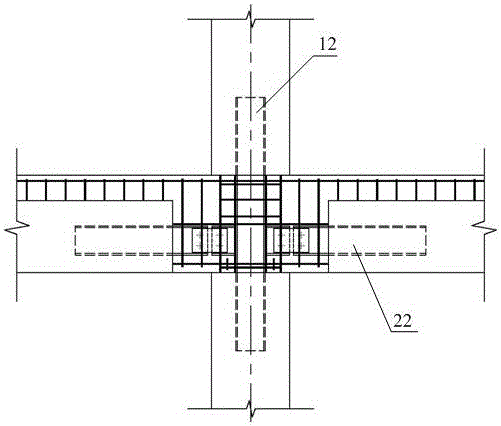

Prefabricated concrete frame structure and manufacturing method thereof

ActiveCN106149873AEnsure continuityEnsure integrityBuilding constructionsShear capacityAgricultural engineering

The invention discloses a prefabricated concrete frame structure which comprises prefabricated columns and prefabricated beams. Each prefabricated column is connected with one end of the corresponding prefabricated beam, a node area is formed at a joint of each prefabricated column and the corresponding prefabricated beam, each prefabricated beam is divided into an upper-layer column body and a lower-layer column body by the corresponding node area, each upper-layer column body and the corresponding lower-layer column body are connected through longitudinal reinforcing steel embedded in the prefabricated column in the corresponding node area, and column body longitudinal rebars are embedded in each prefabricated column and are continuous in the corresponding node area; beam end reinforcing steel is embedded at one end, connected with the corresponding prefabricated column, of each prefabricated beam, and the longitudinal reinforcing steel and the beam end reinforcing steel are connected through bolts. The invention further discloses a manufacturing method of the prefabricated concrete frame structure. Nodes of the prefabricated concrete frame structure are equivalent to cast-in-place concrete frame nodes in anti-seismic performance and energy dissipating capacity, anti-seismic concept design of 'strong nodes and weak components', 'strong shear capacity and weak bending capacity' and 'strong columns and weak beams' is realized, and construction process and difficulty can be reduced.

Owner:FOSHAN ELECTRIC POWER DESIGN INST +1

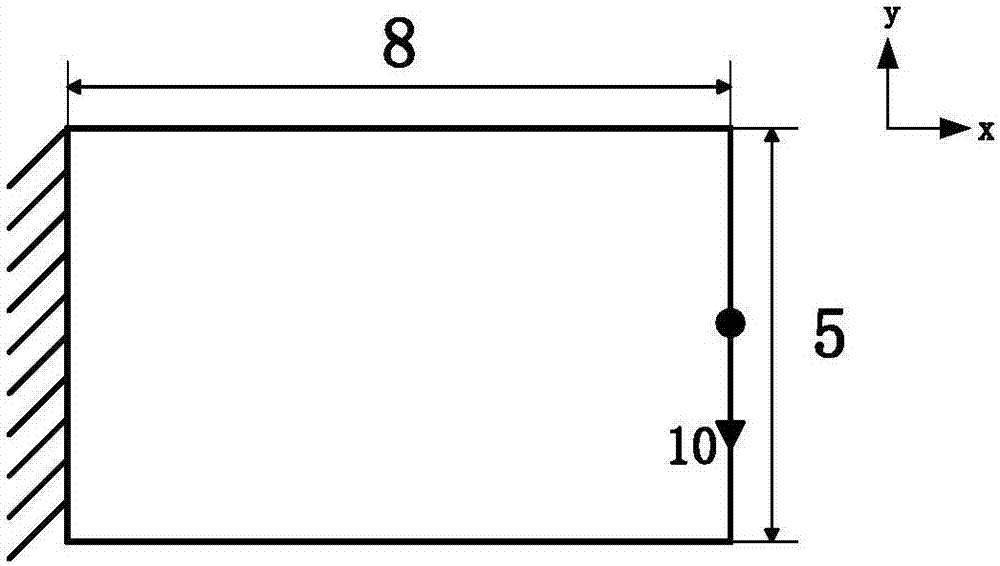

Topological optimization design method of self-supporting structure in additive manufacturing

ActiveCN107391824ASelf-supportingReduce the numberDesign optimisation/simulationSpecial data processing applicationsModel reconstructionTopology optimization

The invention discloses a topological optimization design method of a self-supporting structure in additive manufacturing and aims at solving the technical problem of low practicability of the topological optimization design method of an existing self-supporting structure. The design method is characterized in that a certain number of closed polygonal holes are formed in a physical design area, and the topological layout evolution of the structure is driven by actions, such as movement, deformation, fusion, reduction, expansion and the like, of the holes. Furthermore, relative positions among apexes of all polygons are controlled, so that the inclined angle of the suspended portion of the overall structure is larger than the critical angle value, and accordingly self-supporting of the structure is achieved. Compares with a design method of the background technology, the topological optimization design method sacrifices less flexibility for achieving self-supporting of the structure. Furthermore, design variables are independent of units, small in number, little in calculation amount and easy to convergence. In addition, the designed structure boundaries are smooth, no intermediate density unit exists inside, and the design method is beneficial to later processing processes such as model reconstruction conducted by engineering designers and is high in practicability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

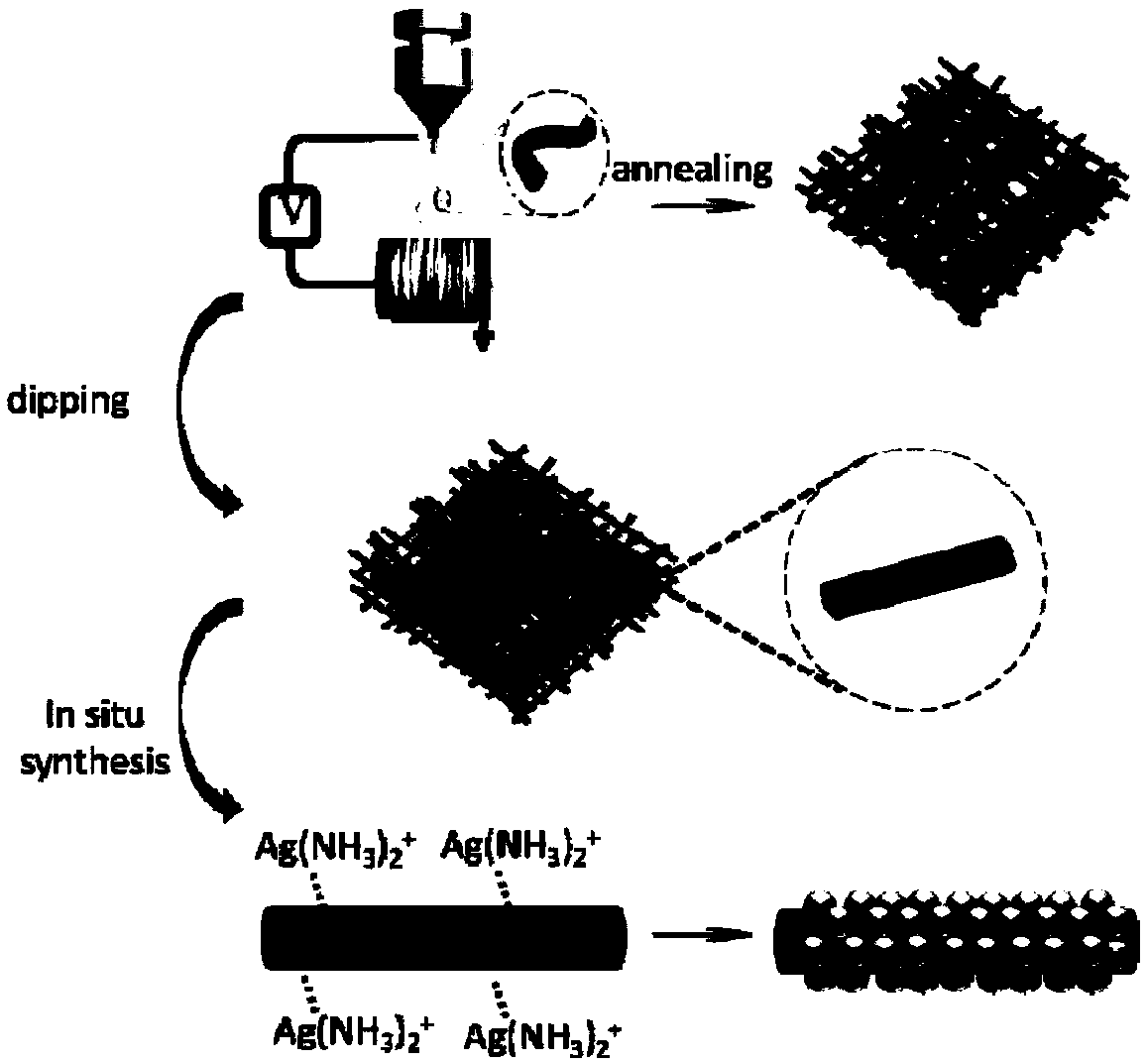

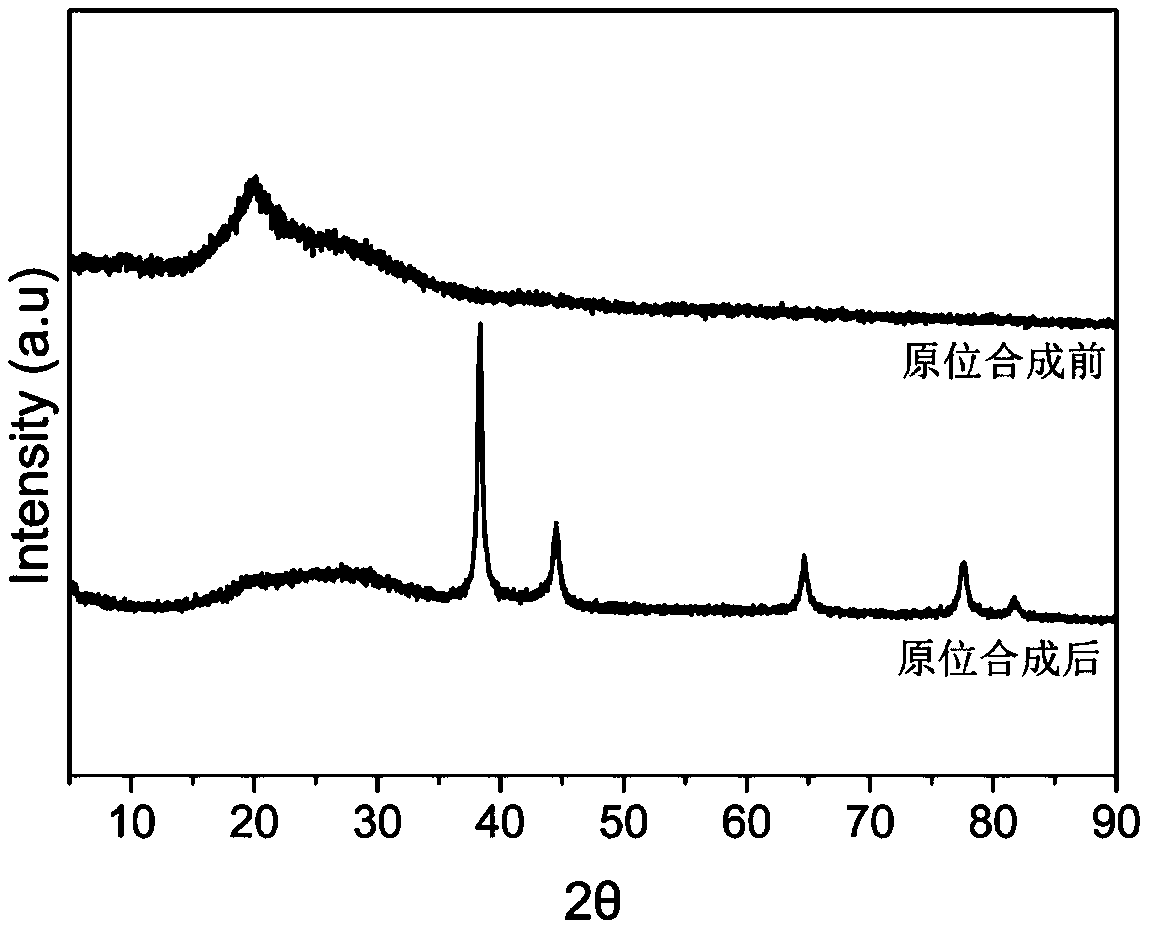

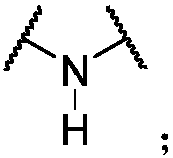

Flexible thermoelectric nanofiber thin film and preparation and application thereof

ActiveCN109295707AExcellent flexibilityGood mechanical strengthFibre typesMonocomponent synthetic polymer artificial filamentElectrospinningNanometre

The invention relates to a flexible thermoelectric nanofiber thin film and preparation and an application thereof, wherein the flexible thermoelectric nanofiber thin film is a PEDOT:PSS-based nanofiber thin film having the surface coated with silver nanoparticles. The preparation includes the steps: the PEDOT:PSS-based nanofiber thin film is obtained by an electrostatic spinning technology; the nanofiber thin film is annealed and then impregnated in a PEDOT:PSS solution, the excess solution on the surface is washed away, and then drying is performed; and the surface of the nanofibers is coatedwith silver nanoparticles by in situ synthesis. The thin film not only has good thermoelectric properties, but also has good mechanical properties and flexibility, and is easily processed into flexible thermoelectric devices. The method provides a new way for preparing the flexible thermoelectric thin film, and has important significance for development of the flexible thermoelectric devices.

Owner:DONGHUA UNIV

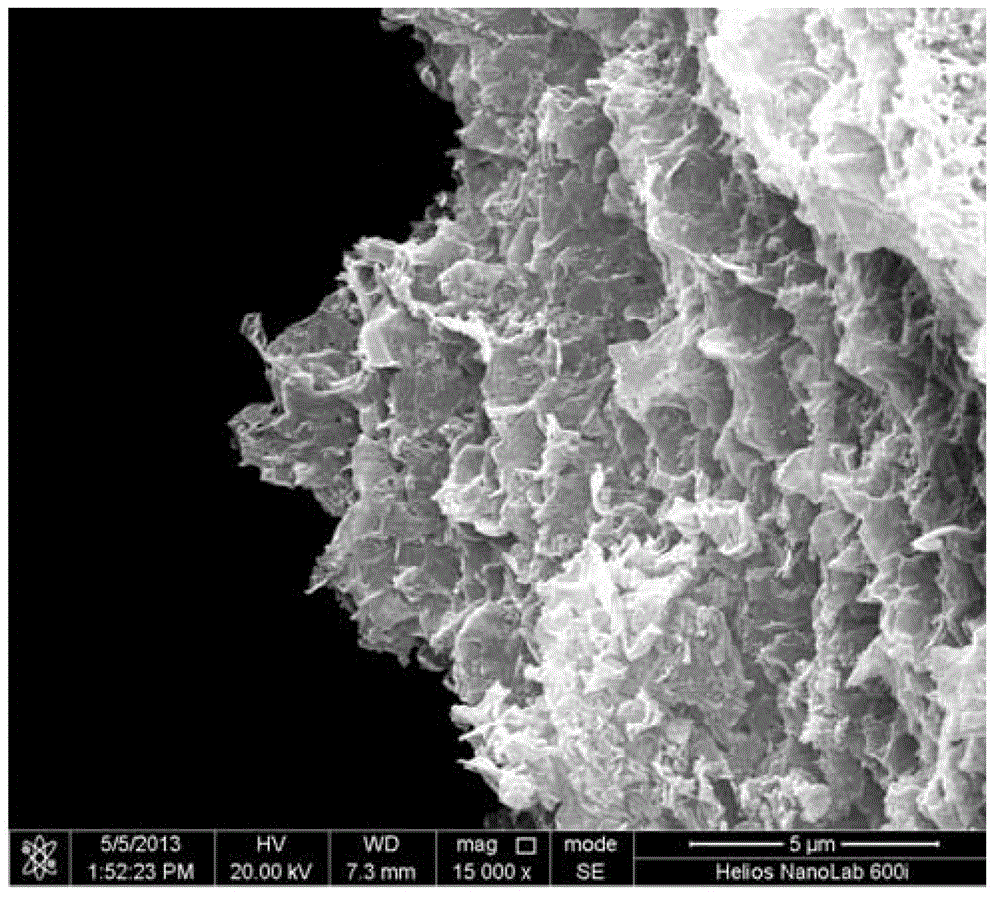

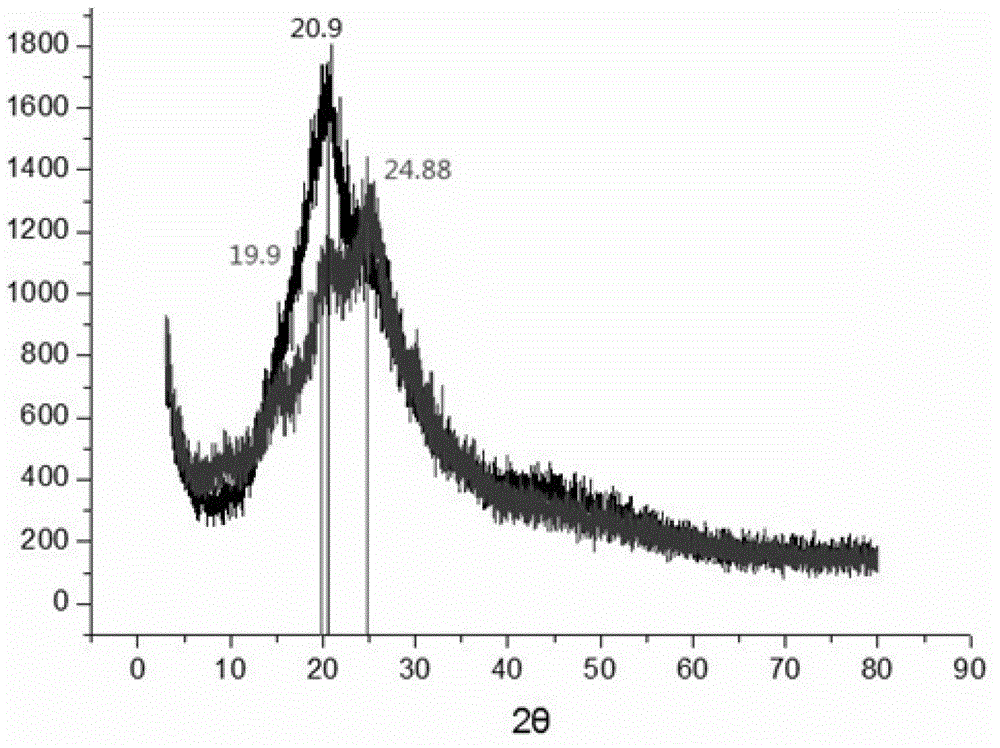

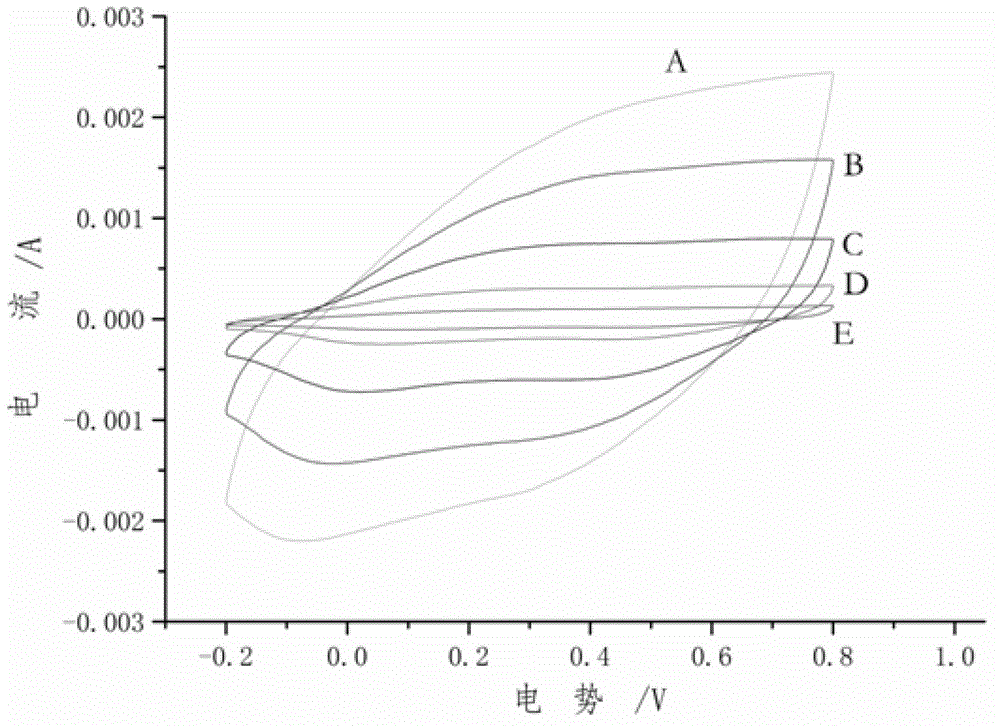

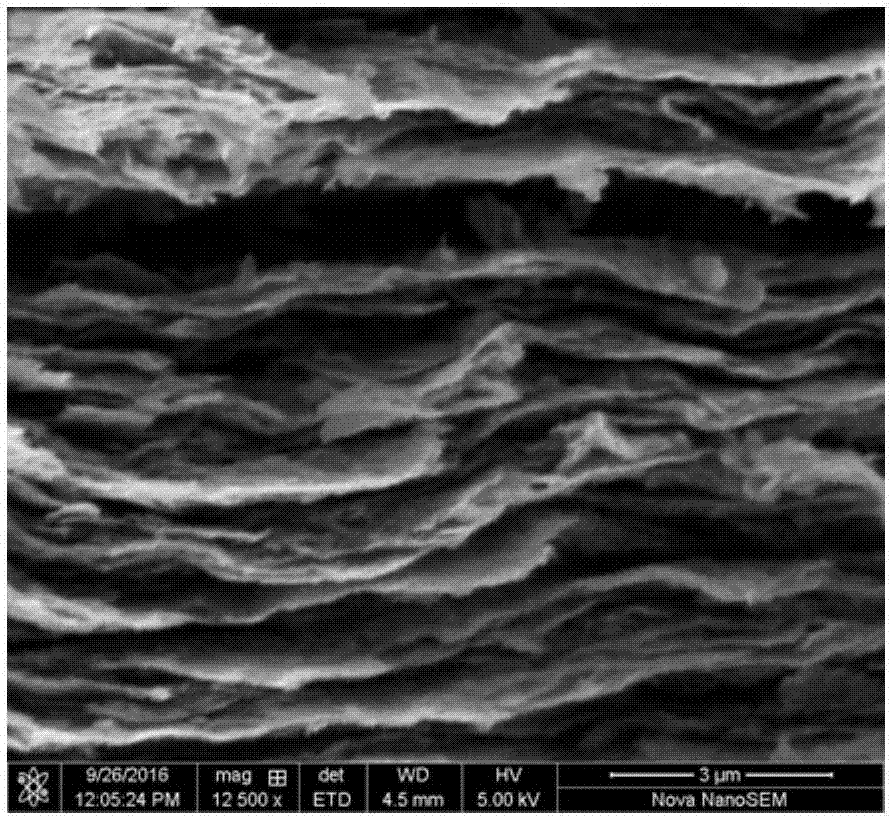

Preparation method for well-organized high-capacity self-supporting film based on epitaxial growth of polyaniline on graphene surface

ActiveCN103337377AGood size controlThickness is easy to controlHybrid capacitor electrodesHybrid/EDL manufactureFilm baseElectric capacity

The invention discloses a preparation method for a well-organized high- capacity self-supporting film based on epitaxial growth of polyaniline on a graphene surface and relates to the preparation method for the self-supporting film. The method that solves the problems that an oxidized graphene / polyaniline composite prepared by a conventional method is poor in stability and disordered in structure comprises the following steps: first, preparing the oxidized graphene; second, performing aniline acidation; third, preparing powder with the graphene / polyaniline micron-sized composite structure; and fourth, dissolving the powder obtained in the third step into the water, followed by sedimentation by utilizing an electrodeposition method, a vertical pulling method, a natural sedimentation method, a suction filtration sedimentation method or a spin-coating sedimentation method, thereby obtaining the film. According to the method, various directional sedimentation methods are adopted for film forming, the film with the layered ordered structure is obtained; the prepared film has favorable self-supporting performance from the aspect of macroscopic performance, and is proved to be high in electric capacity up to 323 F / g by a cyclic voltammetry, and be good in stability. The method belongs to the field of electrode material preparation.

Owner:HARBIN INST OF TECH

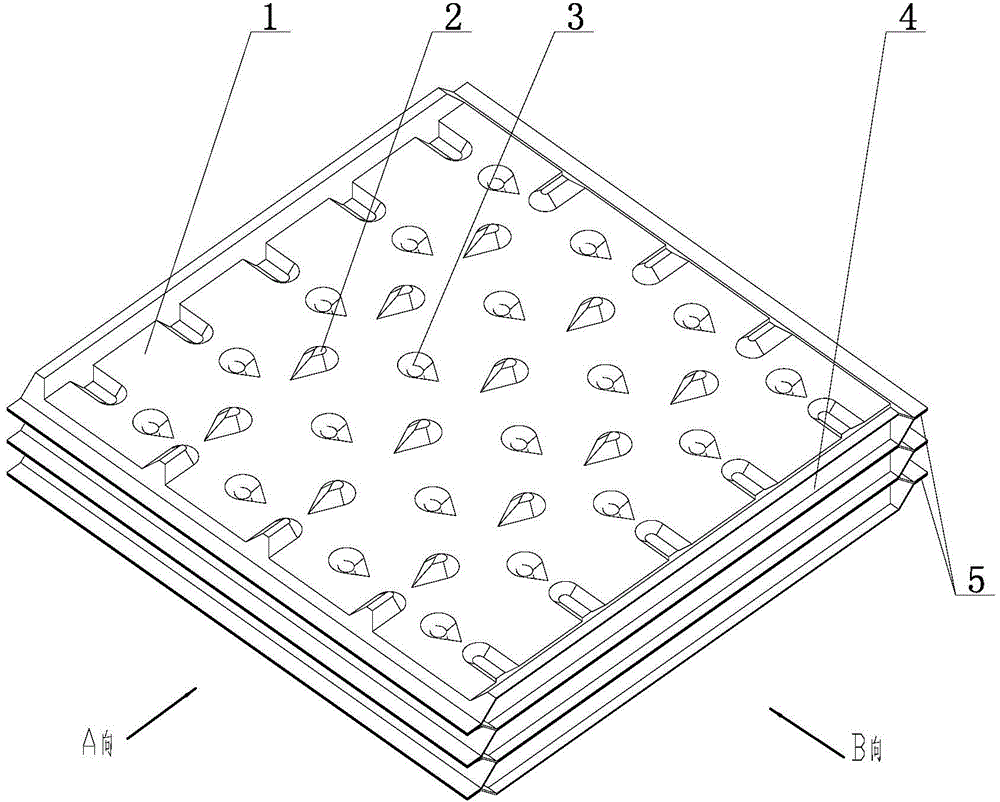

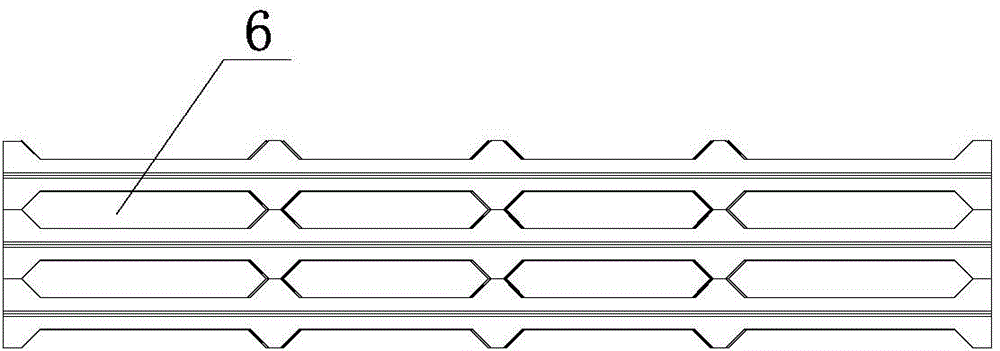

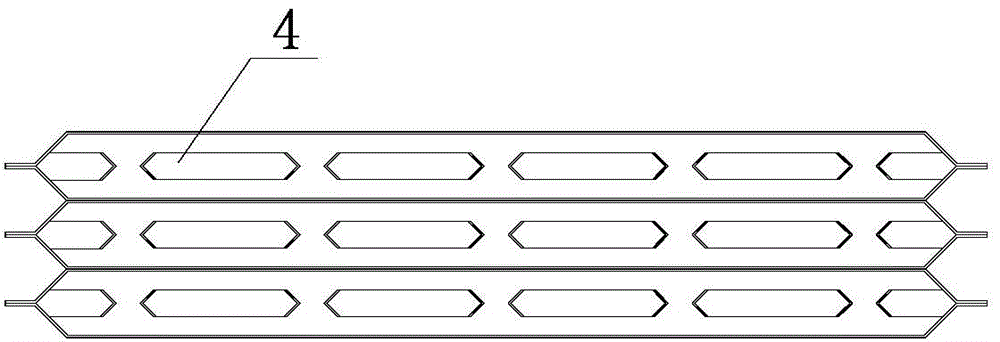

Self-supporting wide gap heat exchanging element

ActiveCN104696983ASelf-supportingReduce manufacturing costCombustion processIndirect carbon-dioxide mitigationFlue gasWide gap

The invention is applicable to the field of air cold medium pre-heating and particularly relates to a self-supporting wide gap heat exchanging element. The self-supporting wide gap heat exchanging element comprises a plurality of plate pairs which are overlapped layer by layer; each plat pair comprises upper and lower plate sheets which are arranged oppositely; a plurality of rows of convex ripples and concave ripples are distributed on the upper surfaces of the plate sheets along the same axis direction; the convex ripples and concave ripples are obtained by upwards and downwards pressing and molding the plate sheets; the convex ripples and concave ripples are distributed at intervals; the positions of the convex ripples and concave ripples on the upper plate sheets in the plate pairs correspond to the positions of the convex ripples and concave ripples on the lower plate sheets in the plate pairs; one group of opposite edges of the plate sheets are upwards folded and are transited into planes; the other group of opposite edges of the plate sheets are downwards folded and are transited into planes; the two adjacent folding edges in each plate pair are welded to form an air channel; the two adjacent plate pairs are symmetrical up and down, and the adjacent folding edges between the two adjacent plate pairs are welded to form a flue gas channel. The self-supporting wide gap heat exchanging element has the advantages that a wide gap channel can be combined, dirt and dust are not easy to deposit, the resistance fall also can be reduced and the heat exchanging efficiency is sufficiently improved.

Owner:SHANDONG WINTECH TECH CO LTD

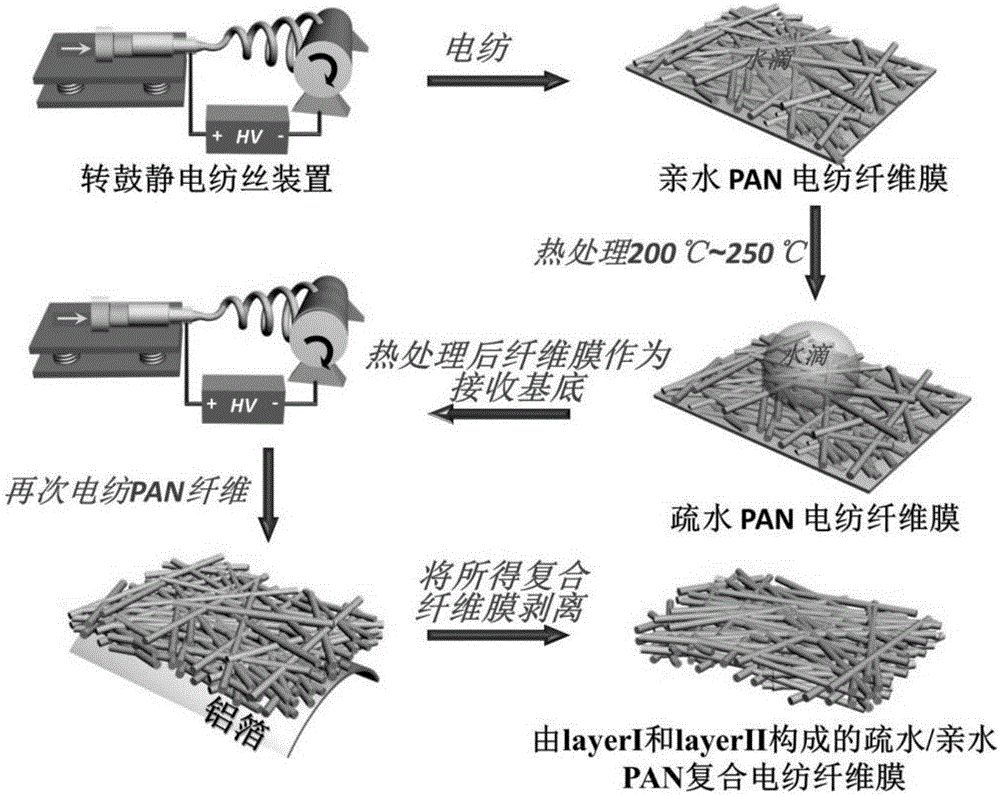

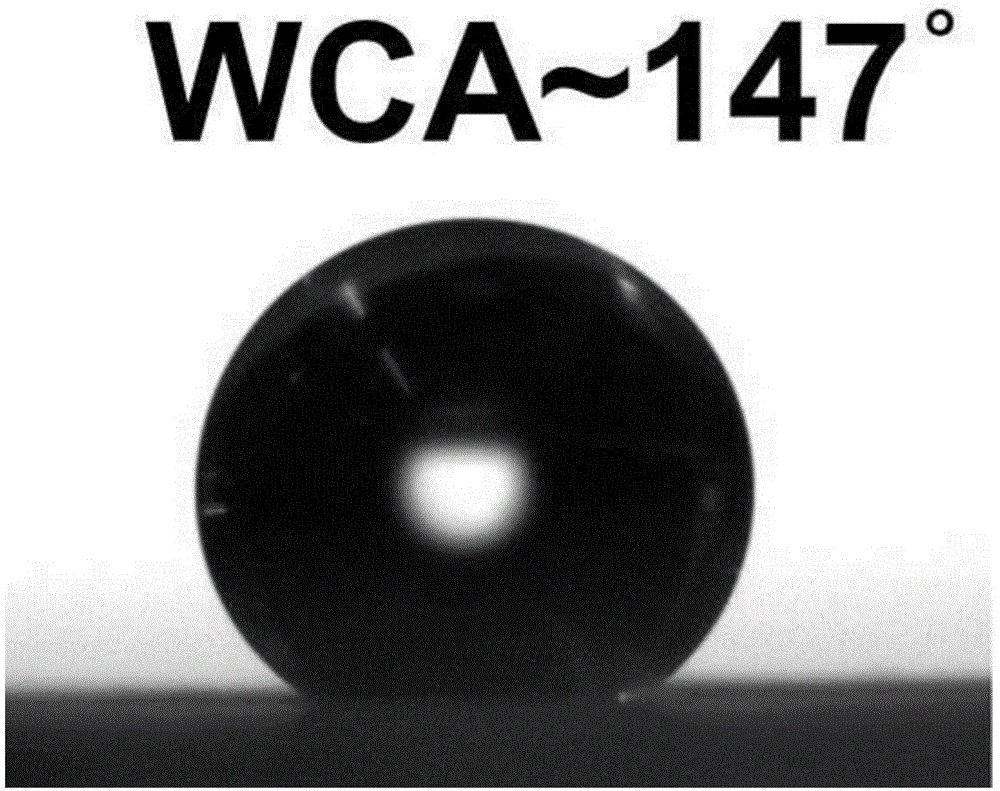

Composite fibrous membrane having hydrophobic/hydrophilic wettability difference and preparation method thereof

ActiveCN106283389AEfficient captureEfficient Collection CapabilityHeating/cooling textile fabricsNon-woven fabricsMicro nanoPolymer science

The invention discloses a composite fibrous membrane having hydrophobic / hydrophilic wettability difference and a preparation method thereof and belongs to the technical field of functional micro-nano composite fibrous materials. The composite fibrous membrane is provided with two fibrous membrane layers. Firstly, an electrostatic spinning solution A serves as a precursor solution to prepare the fibrous membrane PAN-I by adopting an electrostatic spinning method, a heat treatment method is combined to make the fibrous membrane PAN-I have hydrophobicity; then, an electrostatic spinning solution B serves as a precursor solution to prepare the fibrous membrane PAN-II, and then a receiving substrate is stripped to obtain the composite fibrous membrane. The preparation method is simple, low in energy consumption and high in efficiency. The fiber diameter of the composite fibrous membrane can be controlled by adjusting process parameters. Compared with simple hydrophobic or hydrophilic micro / nano fibrous membrane material, the composite fibrous membrane has efficient water drop capture and collection capability under the driving of hydrophobic / hydrophilic difference and can be used in the fields of water collection or mist collection from the air and the like.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Method for preparing carbon nanofiber non-woven fabric by coal hydroliquefaction residue base asphalt alkene substances

ActiveCN107988713AExpand the range of high value-added applicationsSimple manufacturing processHeating/cooling textile fabricsNon-woven fabricsCarbon fibersCarbon nanofiber

The invention discloses a method for preparing a carbon nanofiber non-woven fabric by coal hydroliquefaction residue base asphalt alkene substances. Coal hydroliquefaction residues are extracted sequentially by n-hexane and tetrahydrofuran to obtain asphalt base alkene substances, the asphalt base alkene substances are dissolved in tetrahydrofuran solvents, spinning additives are dissolved in N-N-dimethyl formamide solution, the solution is mixed, electrostatic spinning is performed at normal temperature to obtain a nascent fiber non-woven fabric, and the nascent fiber non-woven fabric is preoxidized and carbonized to obtain the carbon nanofiber non-woven fabric. The method has the advantages that high value-added application of the coal hydroliquefaction residues is enlarged, the preparation process of raw materials is simplified, and obtained carbon fibers are carbon nanofibers and have a certain self-supporting property.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Energy-absorbing method based on hybrid cross-linked network dynamic polymer

The invention discloses an energy-absorbing method based on a hybrid cross-linked network dynamic polymer. The method is characterized in that the hybrid cross-linked network dynamic polymer containing common covalent cross-linking, a dynamic covalent bond and an optional supramolecular hydrogen bond is used as an energy-absorbing material for energy-absorbing protection, wherein the dynamic covalent bond is an inorganic borate bond. The dynamic polymer provided by the invention integrates the respective advantages of the common covalent cross-linking and the dynamic covalent bond; the commoncovalent cross-linking endows the dynamic polymer with certain strength and stability; the dynamic covalent bond in the dynamic polymer has good dynamic reversibility, so the dynamic polymer has the characteristics of energy dissipation and energy absorption and can provide the functions of damping, shock absorption, sound insulation, impact resistance, noise abatement, impact resistance, high toughness and the like as an energy-absorbing material; and the dynamic polymer is especially applicable to the body protection of people during exercises, daily life and working, the body protection ofthe military police, explosion prevention, protection in airborne landing and aerial delivery, collision prevention of automobiles, anti-impact protection of electronic products and electric appliances, etc.

Owner:厦门逍扬运动科技有限公司

Graphene-based flexible composite electrode material and preparation method and application thereof

InactiveCN106935813AHigh strengthImprove electrochemical performanceHybrid capacitor electrodesCell electrodesComposite electrodeSolvent

The invention provides a graphene-based flexible composite electrode material and a preparation method and an application thereof. The graphene-based flexible composite electrode material is a flexible thin film prepared from graphene and an active material, wherein the active material is a nanosheet-shaped two-dimensional active material; and the graphene and the two-dimensional active material are alternately stacked and arranged. The preparation method for the graphene-based flexible composite electrode material comprises the following steps of providing the graphene and the two-dimensional active material separately; dispersing the graphene and the two-dimensional active material into a solvent to form a mixed dispersion liquid; performing layer-by-layer assembling processing on the mixed dispersion liquid to obtain the graphene-based flexible composite electrode material; or after performing layer-by-layer assembling processing on the mixed dispersion liquid, performing heat treatment to obtain the graphene-based flexible composite electrode material.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

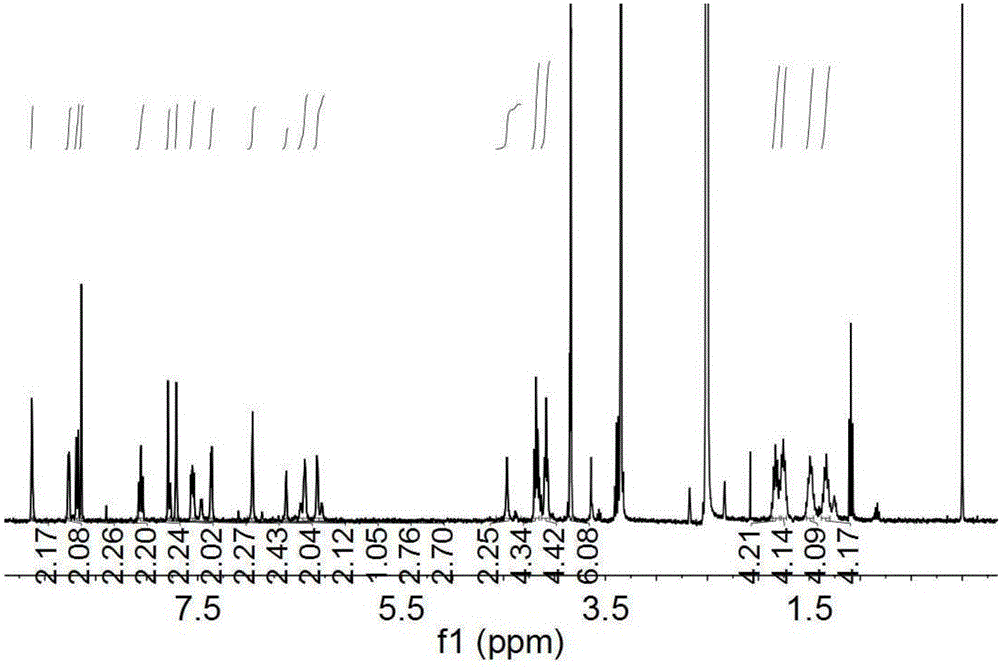

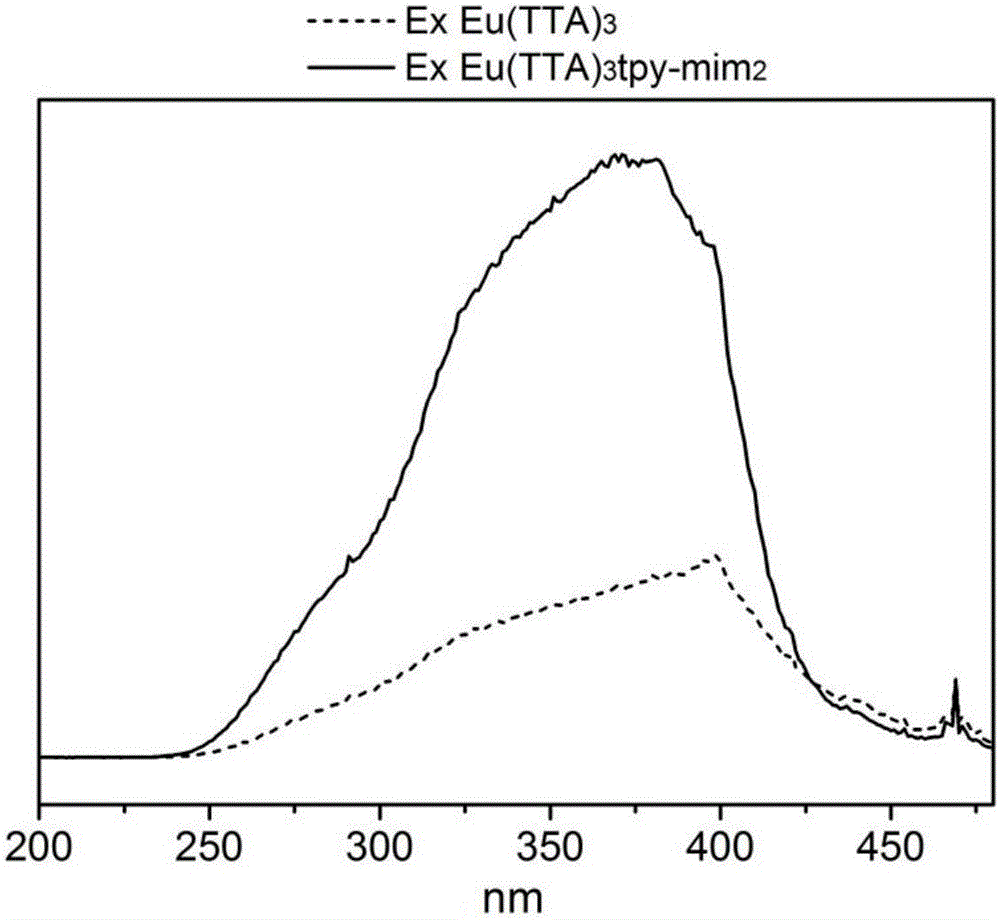

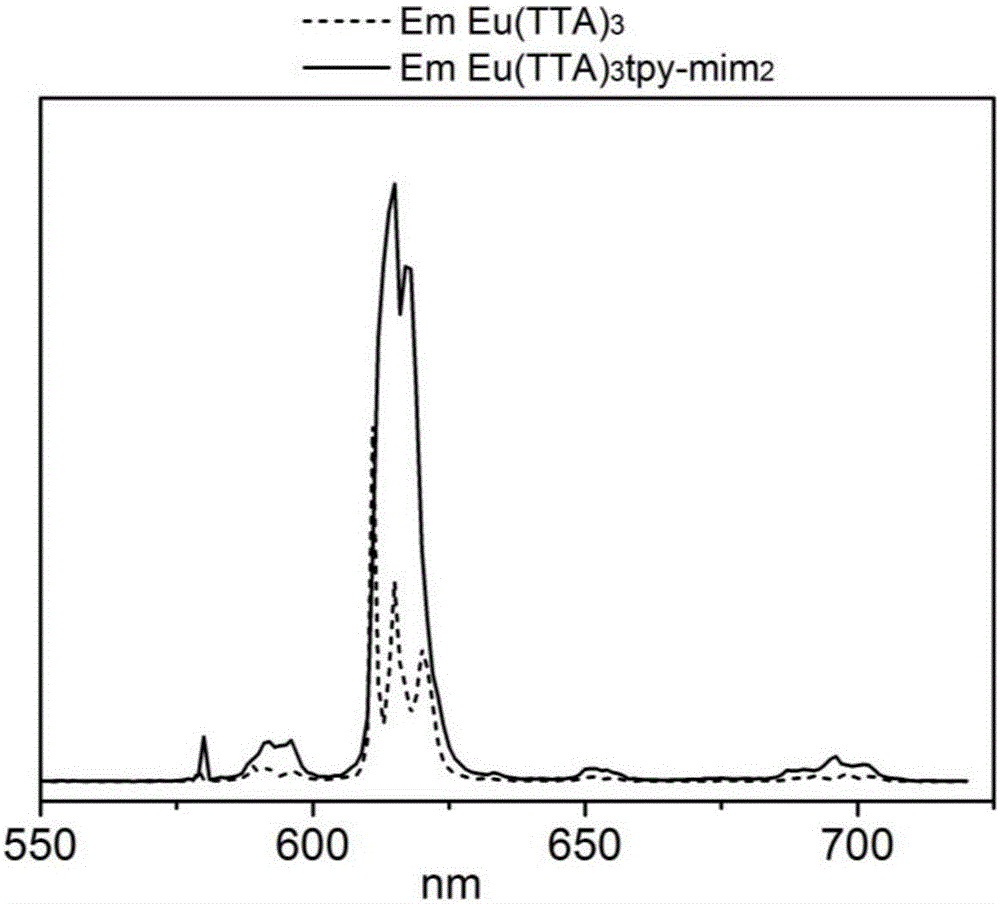

Ternary rare earth complex and application of complex in preparing high-strength hybrid luminous hydrogel

ActiveCN106432297AHigh transparencyHigh mechanical strengthGroup 3/13 organic compounds without C-metal linkagesLuminescent compositionsEnvironmental resistanceStructural formula

The invention provides a ternary rare earth complex and application of the complex in preparing high-strength hybrid luminous hydrogel. The chemical structural formula of the ternary rare earth complex is shown as follows. First terpyridyl bridged imidazolium salt is used for being combined with a rare earth beta-diketone complex to form a ternary complex, the ternary complex can be self-assembled in water to form a micellar structure, and then rare earth ions and ASPA are isolated through the collaborative protection on the rare earth ions by the ternary complex and the micellar structure, so that the aim of preparing a hydrogel which is good in luminescence property and high in mechanical strength is achieved. The hydrogel uses water as a medium, the preparation method is simple, easy and environmentally friendly, and a volatile organic solvent is avoided from being used. Please see the formula in the description.

Owner:HEBEI UNIV OF TECH

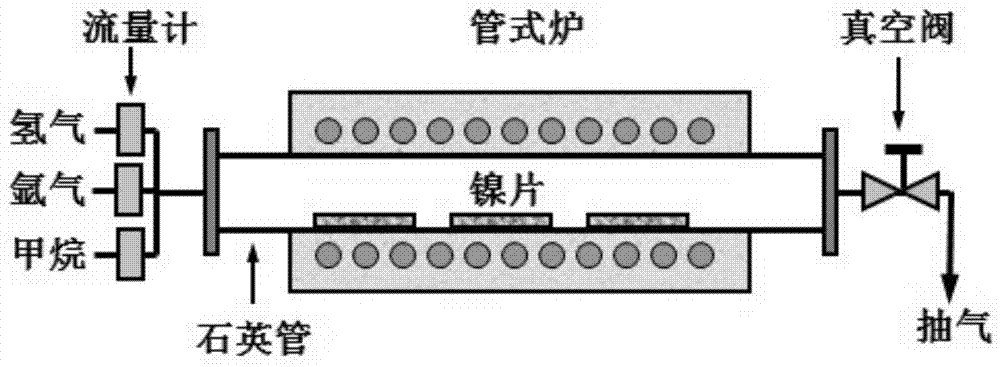

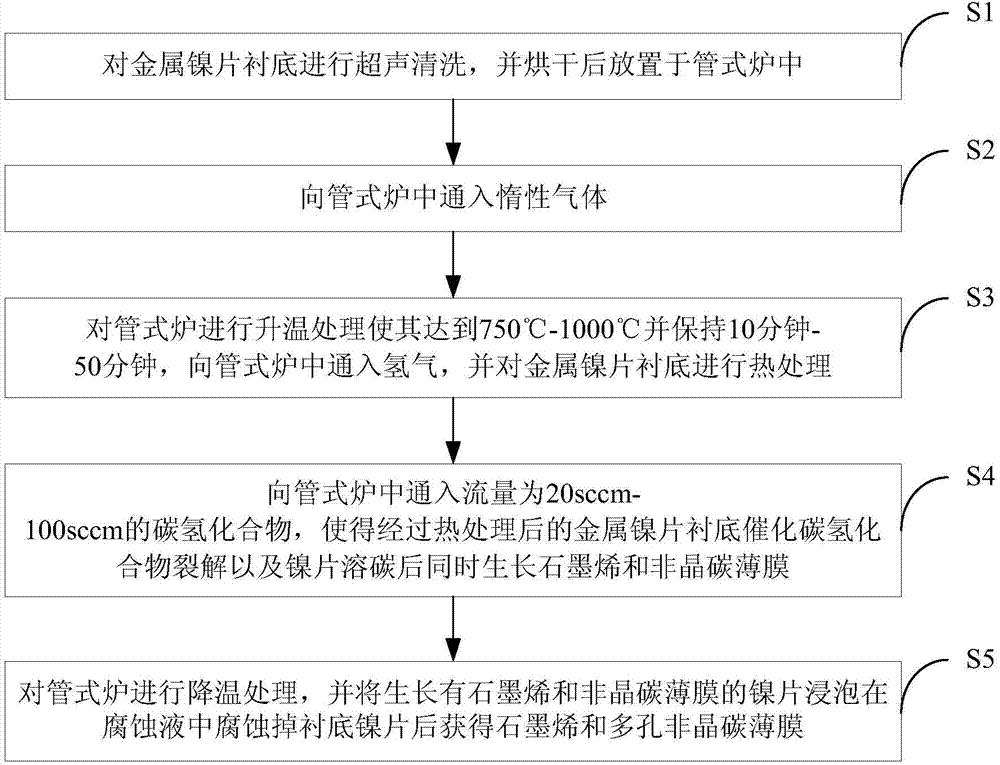

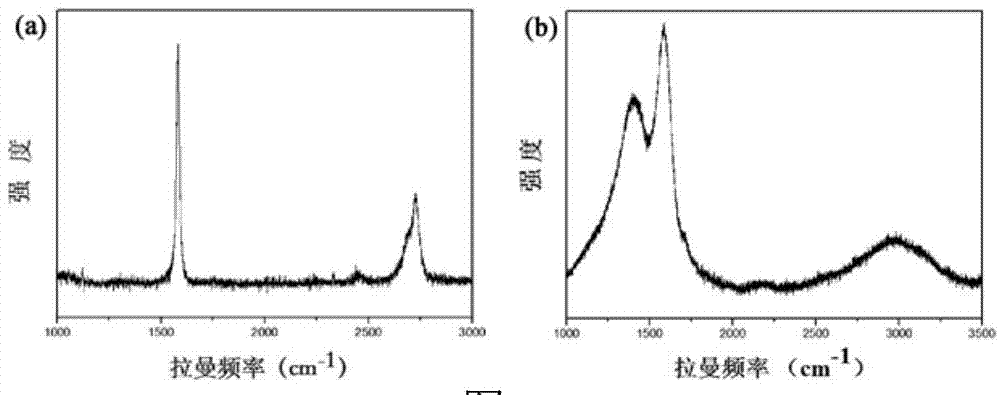

Method for preparing graphene and porous amorphous carbon films simultaneously

InactiveCN103613094ASimple equipmentLow costGrapheneCarbon preparation/purificationHydrogen compoundsCvd graphene

The invention discloses a method for preparing graphene and porous amorphous carbon films simultaneously. The method comprises the following steps: S1, ultrasonically cleaning a metal nickel sheet substrate, drying the metal nickel sheet substrate and placing the metal nickel sheet substrate into a tube furnace; S2, introducing inert gases into the tube furnace; S3, heating the tube furnace to 750 to 1,000 DEG C and maintaining for 10 to 50 minutes, introducing hydrogen into the tube furnace, and performing heat treatment on the metal nickel sheet substrate; and S4, introducing hydrocarbon compounds with the flow quantity of 20 to 100 sccm into the tube furnace, cracking the hydrocarbon compounds under the catalysis of the metal nickel sheet substrate subjected to heat treatment, dissolving carbon by a nickel sheet, and growing graphene and porous amorphous carbon films simultaneously; and S5, cooling the tube furnace, soaking the nickel sheet, on which the graphene and the porous amorphous carbon films grow, into corrosive liquid, and corroding the substrate nickel sheet to obtain the graphene and the porous amorphous carbon films. The hydrocarbon compounds serve as carbon sources, the adsorption cracking of the carbon sources on the surface of the substrate nickel sheet under the high temperature condition is controlled, and carbon atoms are dissolved into the nickel sheet, so that the graphene and the porous amorphous carbon films can be obtained simultaneously.

Owner:HUAZHONG UNIV OF SCI & TECH

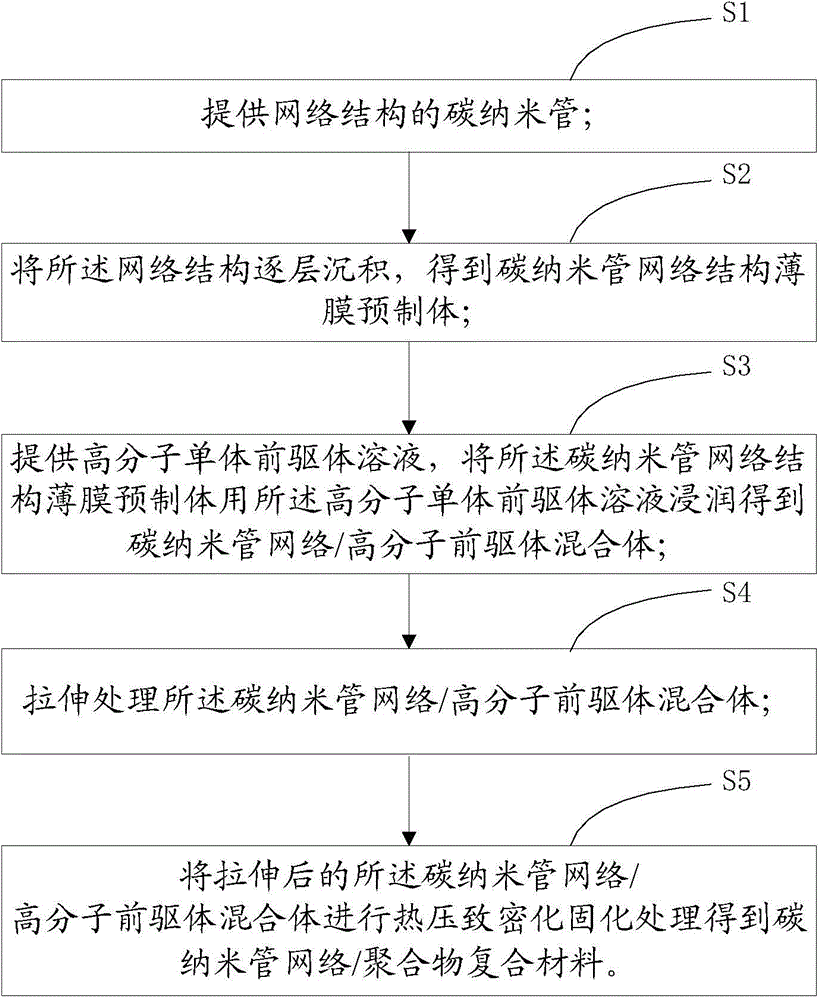

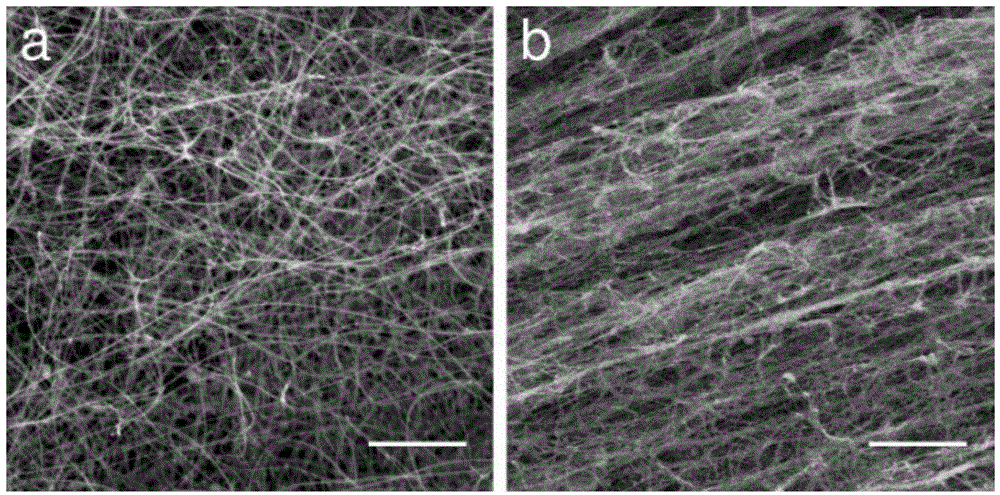

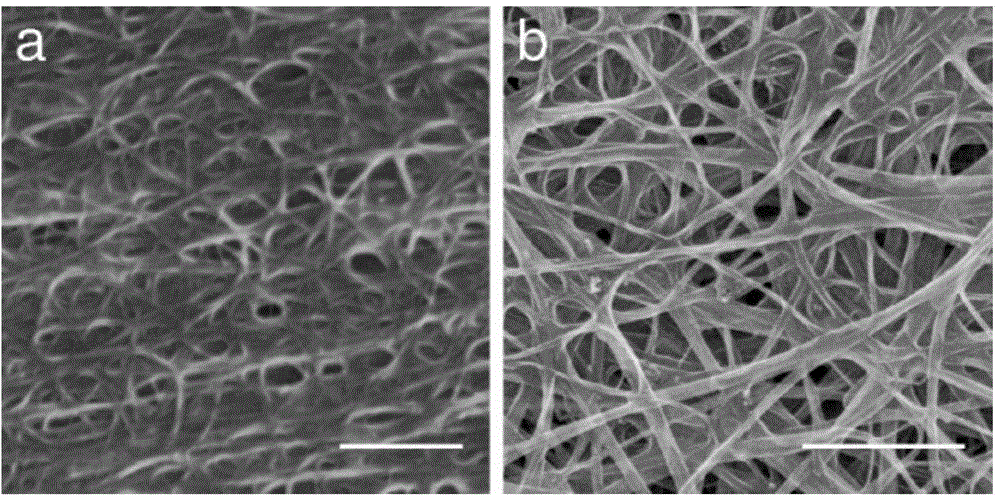

Carbon nano-tube network/polymer composite material and preparation method thereof

The invention discloses a carbon nano-tube network / polymer composite material. The carbon nano-tubes are mutually tangled to form a network structure, wherein the outer surface of the carbon nano-tube is uniformly wrapped with a polymer, and the carbon nano-tube and the polymer are all independently existed in a non-aggregated state. Compared with the prior art, the carbon nano-tube is existed in a non-aggregated state and the polymer is existed in a non-enriched state; by adopting the carbon nano-tube network / polymer composite material, the shortcomings of the traditional carbon nano-tube composite material such as the agglomeration of the carbon nano-tubes and the low content are solved, meanwhile, the excellent mechanical property, electrical property and thermal property of the carbon nano-tube are kept, and the carbon nano-tube is excellent in self-supporting property and is easy to process in the using process and has a wide application future in the fields such as the electromagnetic shielding materials, functional intelligent materials and electrode materials.

Owner:SUZHOU CREATIVE CARBON NANOTECH

Single-stage diffraction grating

ActiveCN106094087AEliminate Harmonic PollutionHigh resolutionDiffraction gratingsImage resolutionHarmonic pollution

The invention provides a single-stage diffraction grating. The diffraction grating comprises an opaque thin film and n light transmitting holes. The n light transmitting holes are distributed on the opaque thin film in the form of quasi-inclined square grids at a preset probability density. The sizes of the light transmitting holes and the period of the quasi-inclined square grids are set according to a preset proportion. In this way, the n light-transmitting holes are distributed on the opaque thin film in the form of quasi-inclined square grids at the preset probability density, so that only the 0-order diffraction and the + / -1-order diffraction are achieved without any high-order diffraction. The harmonic pollution can be eliminated, and the resolution ratio is improved. Furthermore, the accuracy of the analysis result is ensured and the shot spectrum precision is improved. Moreover, the optical grating can realize the self-supporting function, so that the loss caused by a substrate can be eliminated. In addition, since the structure of the grating is only provided with a light-transmitting part and an opaque part, so that the binary structure is easy to machine.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

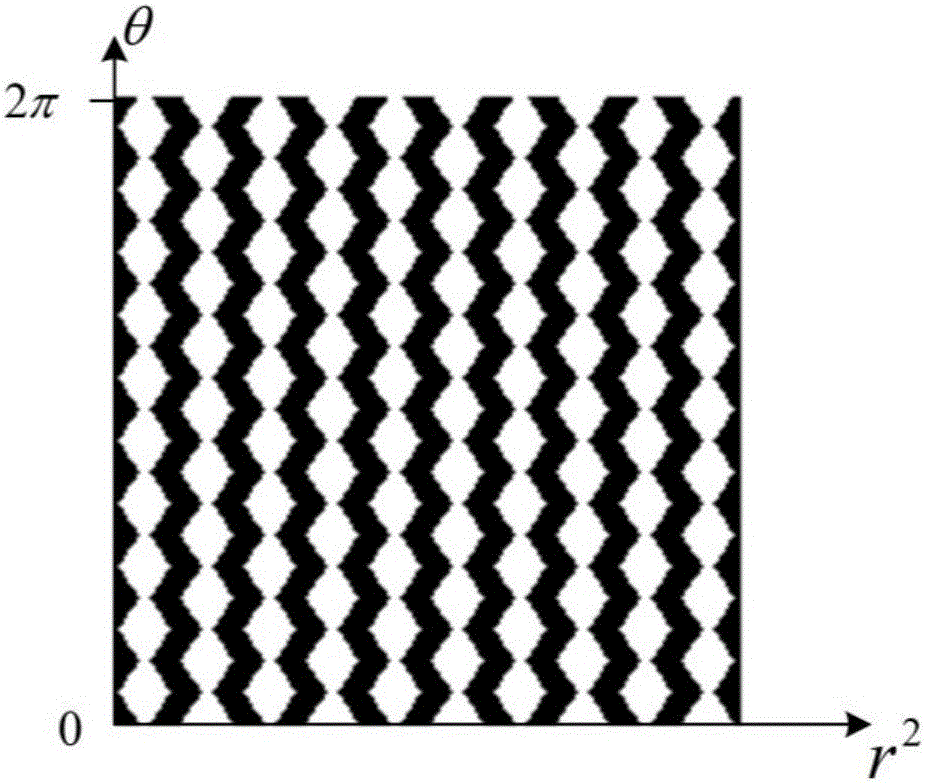

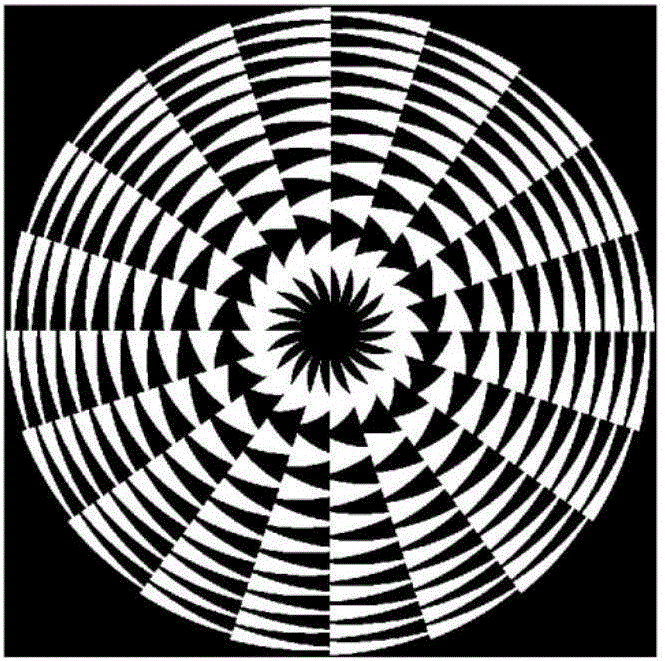

Trapezoidal wave zone plate with quasi-single-stage focusing characteristic

InactiveCN105866870ASelf-supportingDoes not affect diffraction resultsDiffraction gratingsIsosceles trapezoidSingle stage

The invention discloses a trapezoidal wave zone plate with a quasi-single-stage focusing characteristic. The trapezoidal wave zone plate comprises a light-proof substrate and a plurality of ring-shaped wave zones which are sequentially arranged from inside to outside by taking the substrate as a center, wherein each ring-shaped wave zone comprises at least two spiral trapezoidal hole light transmission units which are formed by twisting isosceles-trapezoid-shaped hole light transmission units, and are sequentially connected; the radial light transmittance of the wave zone plate meets a formula shown in the description. Compared with a common Fresnel wave zone plate, the trapezoidal wave zone plate can restrain the diffraction efficiency of a senior focus very well, also can reduce the peak strength of the senior focus. Moreover, when a ratio of the top edge of the original trapezoid to the bottom edge of the original trapezoid is equal to 1 to 5, the trapezoidal wave zone plate further has the effect of eliminating a 3n-level focus, and also restrains the efficiency of a 5-level focus to 0.16% of a 1-level focus (insulating efficiency being 6.93%). Compared with a Gabor wave zone plate, the 1-level focus efficiency is higher than the focusing efficiency of the Gabor wave zone plate, and the trapezoidal wave zone plate is easier to manufacture in comparison with a plurality of binaryzation Gabor wave zone plates.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Preparation method of graphene/active carbon composite film

InactiveCN106531459ASelf-supportingBendableHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceActivated carbon

The invention discloses a preparation method of a graphene / active carbon composite film. Active carbon is subjected to acid modification treatment, and is then mixed with a graphene oxide dispersion liquid, then the graphene / active carbon mixed solution is subjected to freezing treatment, then a solid mixture after freezing treatment is dried, thermal reduction of a graphene oxide is performed to obtain graphene / active carbon aerogel, finally a roller press or tablet press are adopted to mechanically press the graphene / active carbon aerogel to obtain a graphene / active carbon composite film, active carbon particles are uniformly dispersed in a graphene framework, and the film material has a self-supporting characteristic and has bendability. The preparation method can eliminate a re-stacking phenomenon in the graphene film preparation process, provides an efficient conductive carrier for active carbon, and the prepared composite film material can be separately used as a supercapcitor electrode under the condition of not adding a binder, and has relatively high specific capacitance and stable cycle performance.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

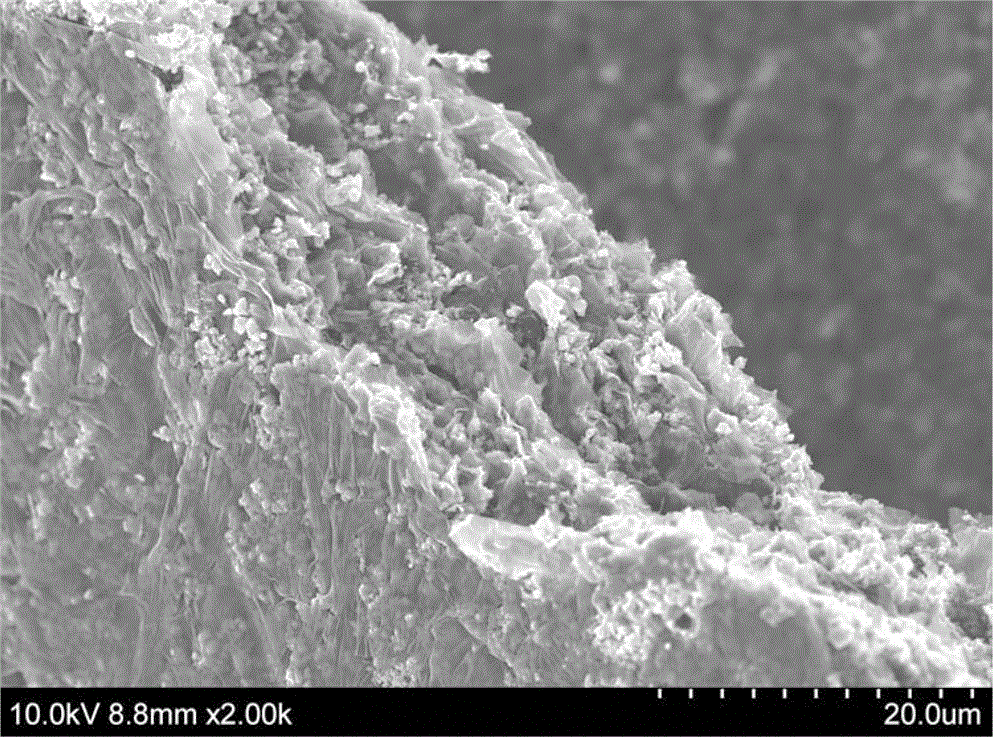

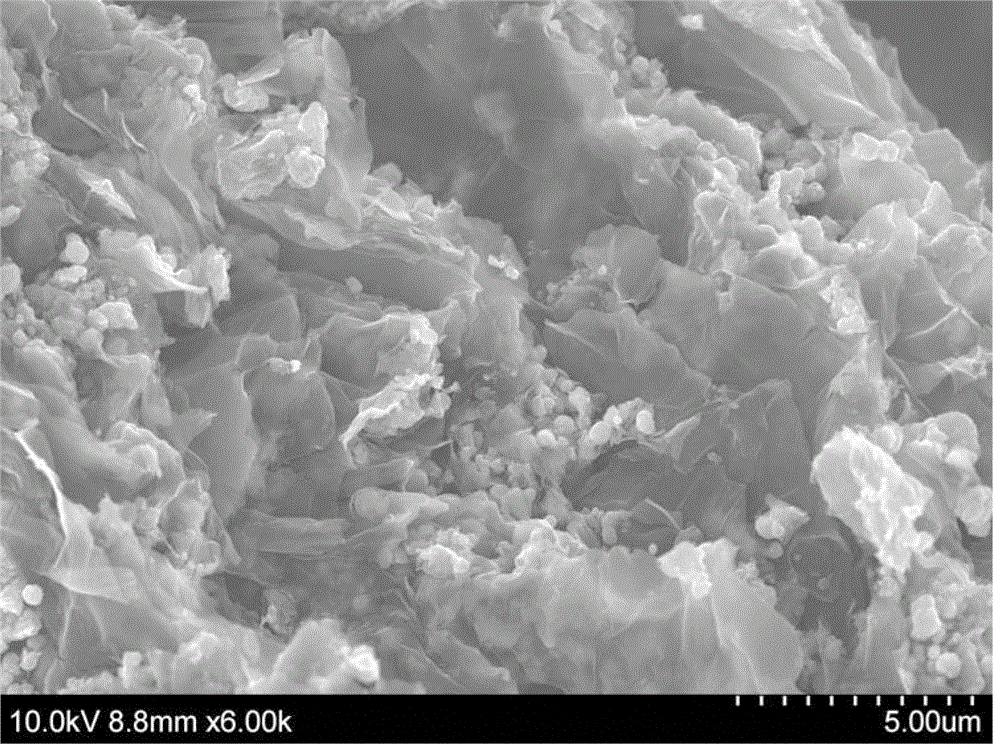

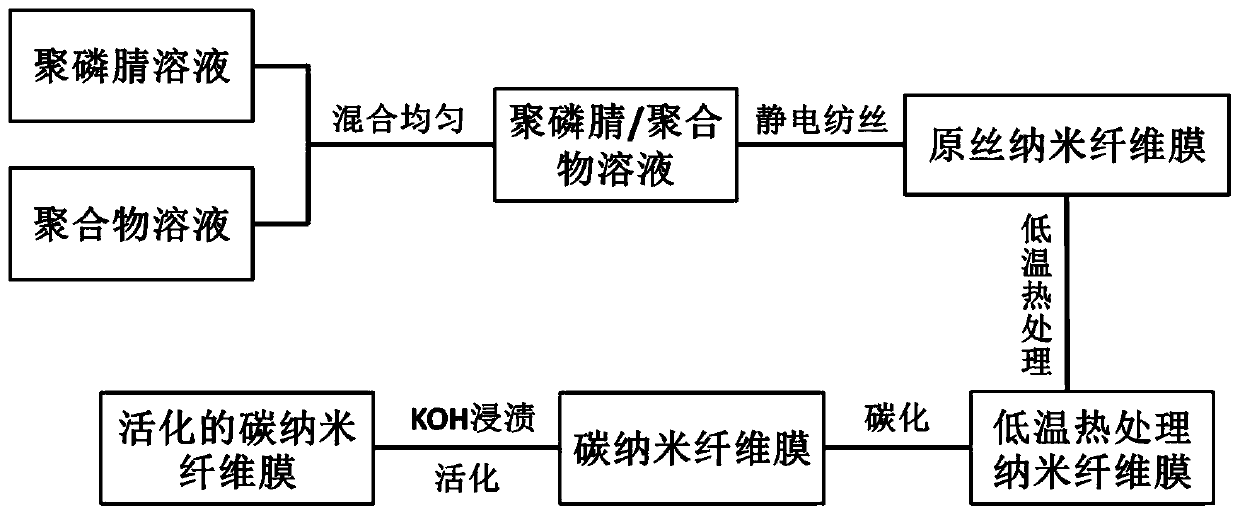

Self-supporting flexible super capacitor electrode material and preparation method

InactiveCN109727781AHigh specific capacitanceIncrease mesoporeHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceFiber

The invention relates to a self-supporting flexible super capacitor electrode material and a preparation method, and belongs to the technical field of super capacitor electrode materials. The method comprises the following concrete steps that a polyphosphazene and polymer mixed solution is prepared, the mixed solution is used to prepare a polymer / polyphosphazene nanometer fiber film via a static spinning method, and a nitrogen and phosphor doped self-supporting flexible carbon nanometer fiber film is obtained from the polymer / polyphosphazene nanometer fiber film by means of low-temperature heat treatment, high-temperature carbonization and potassium hydrate activation, and can be applied to a flexible super capacitor electrode material. According the method, extra conductive additive and binder are not needed, the electrode material can be used directly, the carbon fiber film electrode material doped with nitrogen and phosphor includes a meso-structure and fake capacitance at the sametime, the specific capacitance can reach 176F / g, the carbon fiber film is highly flexible, and the material can be widely applied to the flexible and wearable electronic fields.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com