High-temperature-resistant heteromorphic nanocrystalline aerogel material and preparation method thereof

A nanocrystal and aerogel technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of application limitation, reduction of holes, weakened thermal insulation performance, etc., to achieve assembly and fixation, overcome uncontrollability, The effect of improving temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

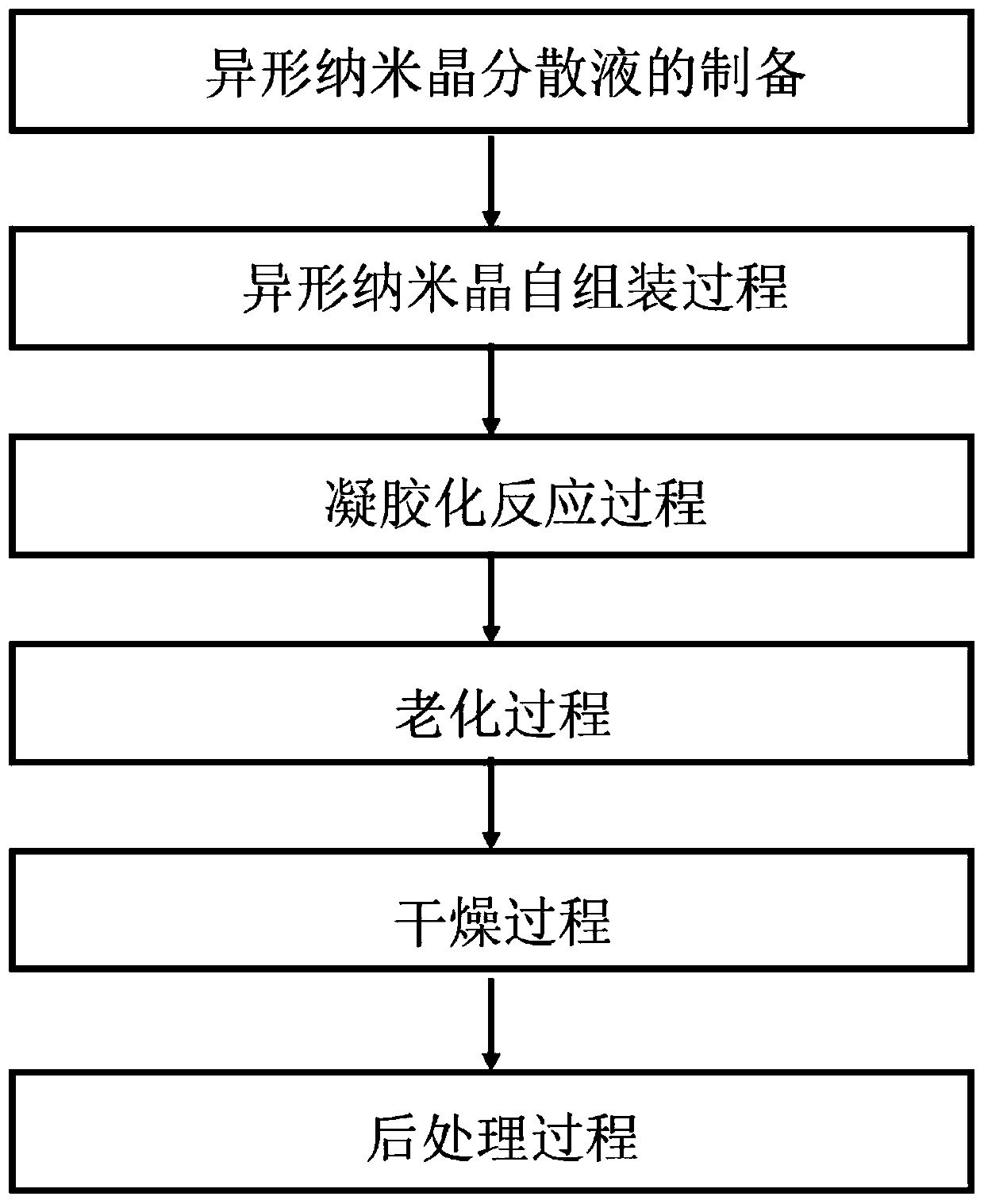

[0038] In a first aspect, the present invention provides a method for preparing a high-temperature resistant special-shaped nanocrystalline airgel material, said method comprising the steps of:

[0039] (1) Mix the aluminum oxide nanopowder and the acidic solution with water to obtain a mixed solution, and then place the mixed solution at 140-340°C (such as 140°C, 150°C, 160°C, 170°C, 180°C, 190°C , 200°C, 210°C, 220°C, 230°C, 240°C, 250°C, 260°C, 270°C, 280°C, 290°C, 300°C, 310°C, 320°C, 330°C or 340°C) for 1~ 10h (such as 1, 1.5, 2, 2.5, 3, 3.5, 4, 4.5, 5, 5.5, 6, 6.5, 7, 7.5, 8, 8.5, 9, 9.5 or 10h), to obtain a special-shaped nanocrystal dispersion; In the present invention, the alumina nanopowder can be, for example, γ-phase alumina nanopowder or alumina oxyhydroxide nanopowder; in the mixed solution, the particle size of a single particle of the alumina nanopowder is, for example, In the scope of 10~200nm; In the present invention, in the process that described mixed sol...

Embodiment 1

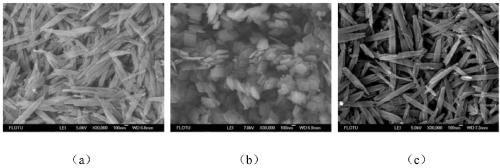

[0065] S1. Preparation of special-shaped nanocrystal dispersion liquid: using alumina nanopowder as raw material, disperse 20g of alumina nanopowder in 500mL aqueous solution, wherein the particle size of a single particle of nanopowder is in the range of 10-200nm; choose 2mol / L 15mL of hydrochloric acid solution as a catalyst (adsorbent) was added to the above-mentioned mixed solution of alumina nanoparticles, the mixed solution was placed in a reaction kettle with polytetrafluoroethylene as a liner, sealed, and reacted at 240°C for 3 hours to obtain the special-shaped nanocrystal dispersion.

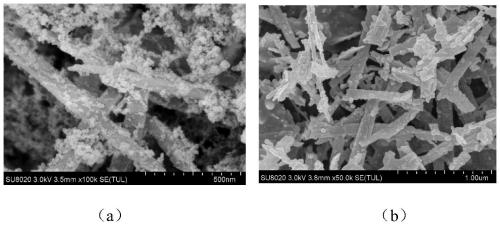

[0066] S2. Self-assembly process of special-shaped nanocrystals: fully mix 30 g of the above-prepared special-shaped nanocrystal dispersions with 20 g of silicic acid with a solid content of 4%, fully stir with magnetons for 5 hours, and then ultrasonicate for 30 minutes to obtain the self-assembled mixture of special-shaped nanocrystals. phase first solution.

[0067] S3. Gelation re...

Embodiment 2

[0075] Example 2 is basically the same as Example 1, except that 20 mL of 2 mol / L acetic acid solution is used as the adsorbent during the preparation of the special-shaped nanocrystal dispersion in step S1.

[0076] The heat insulation performance test was carried out on the high-temperature-resistant special-shaped nanocrystalline airgel material in Example 2, and it was found that the surface of the high-temperature-resistant special-shaped nanocrystalline airgel material has no loss of gloss, no discoloration, and no shedding. Other performance indicators are shown in Table 1. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com