Patents

Literature

619 results about "Wadding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wadding is a disc of material used in guns to seal gas behind a projectile or to separate powder from shot. Wadding can be crucial to a gun's efficiency, since any gas that leaks past a projectile as it is being fired is wasted. A harder or more carefully designed item which serves this purpose is often called a sabot. Wadding for muzzleloaders is typically a small piece of cloth, or paper wrapping from the cartridge.

Beverage portioned package for preparing a foamy beverage from soluble powder

InactiveUS20050158426A1Sufficient pressureSufficient amountPackaging foodstuffsWater insolubleWadding

A beverage portioned package for preparing a beverage in an extraction device of which the package is held or clamped between a water supplying part and a receiver of the device. The package has a first surface for the water to be forced to flow there through under pressure when the package is held or clamped in the device; a second surface for the flow of beverage to be forced to flow there through so to be collected in the receiver, wherein the package contains a portion of water-soluble beverage material and a portion of a filler. The filler comprising water insoluble material adapted to maintain the extraction pressure above the pressure created by the sole resistance of the first and second surfaces when the package is emptied of said soluble material.

Owner:NESTEC SA

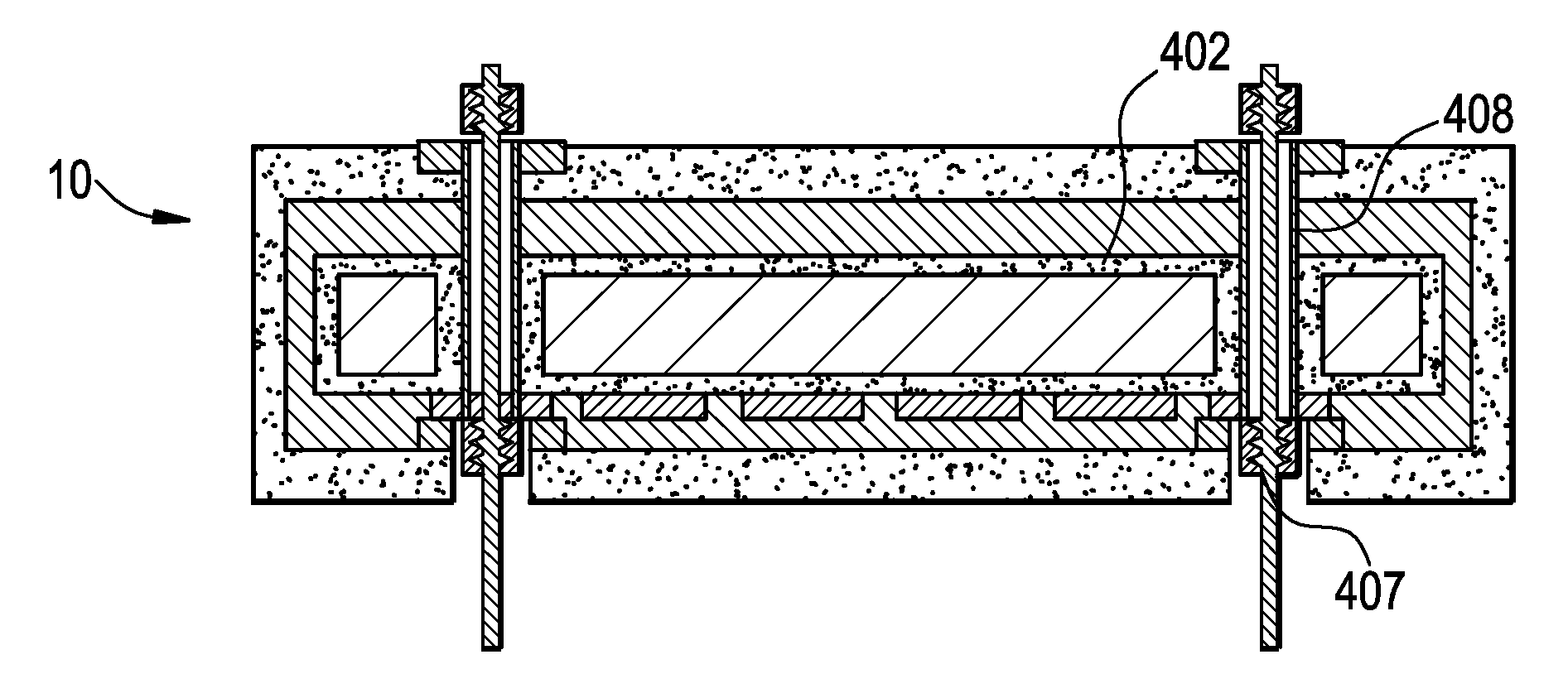

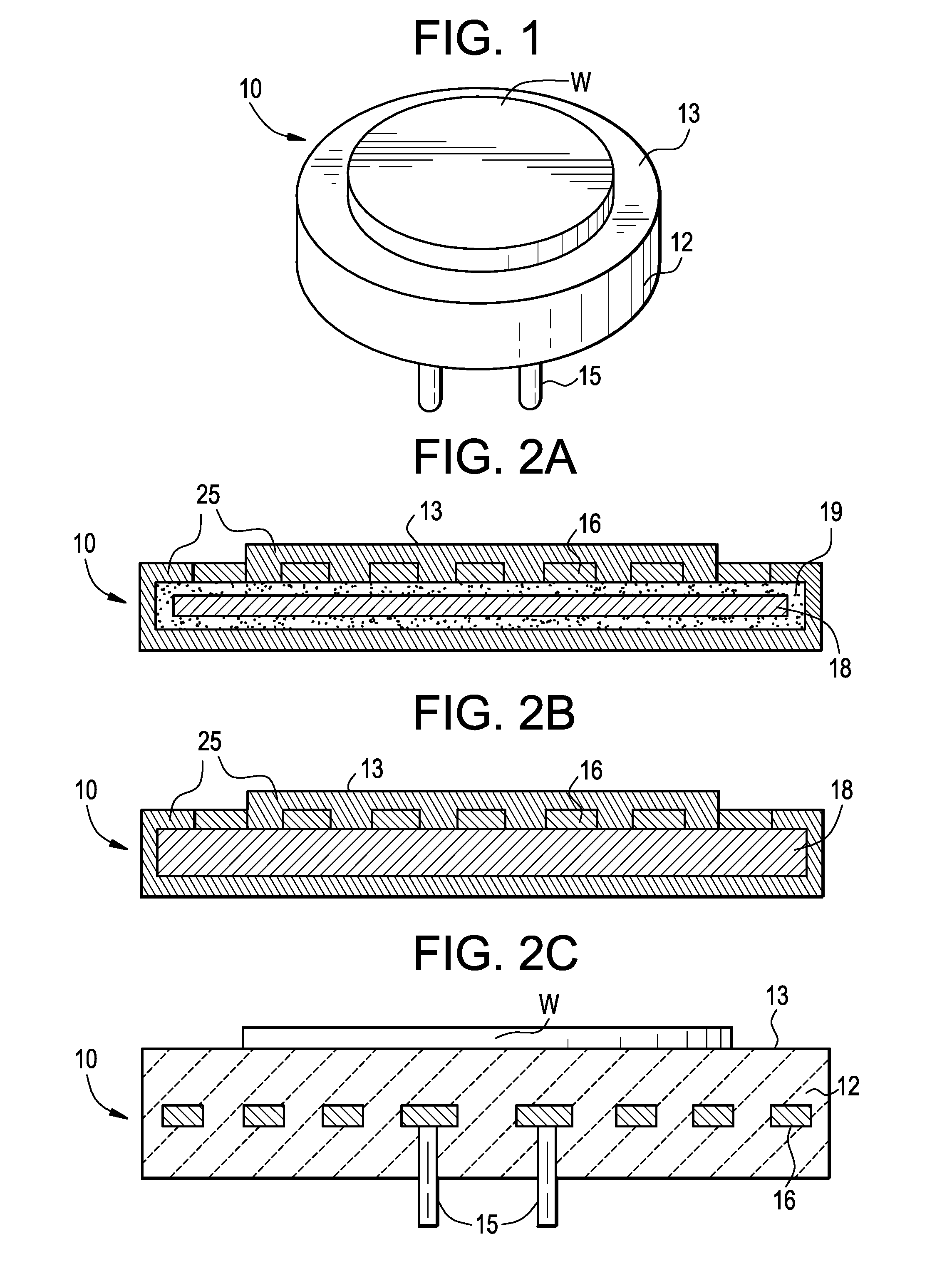

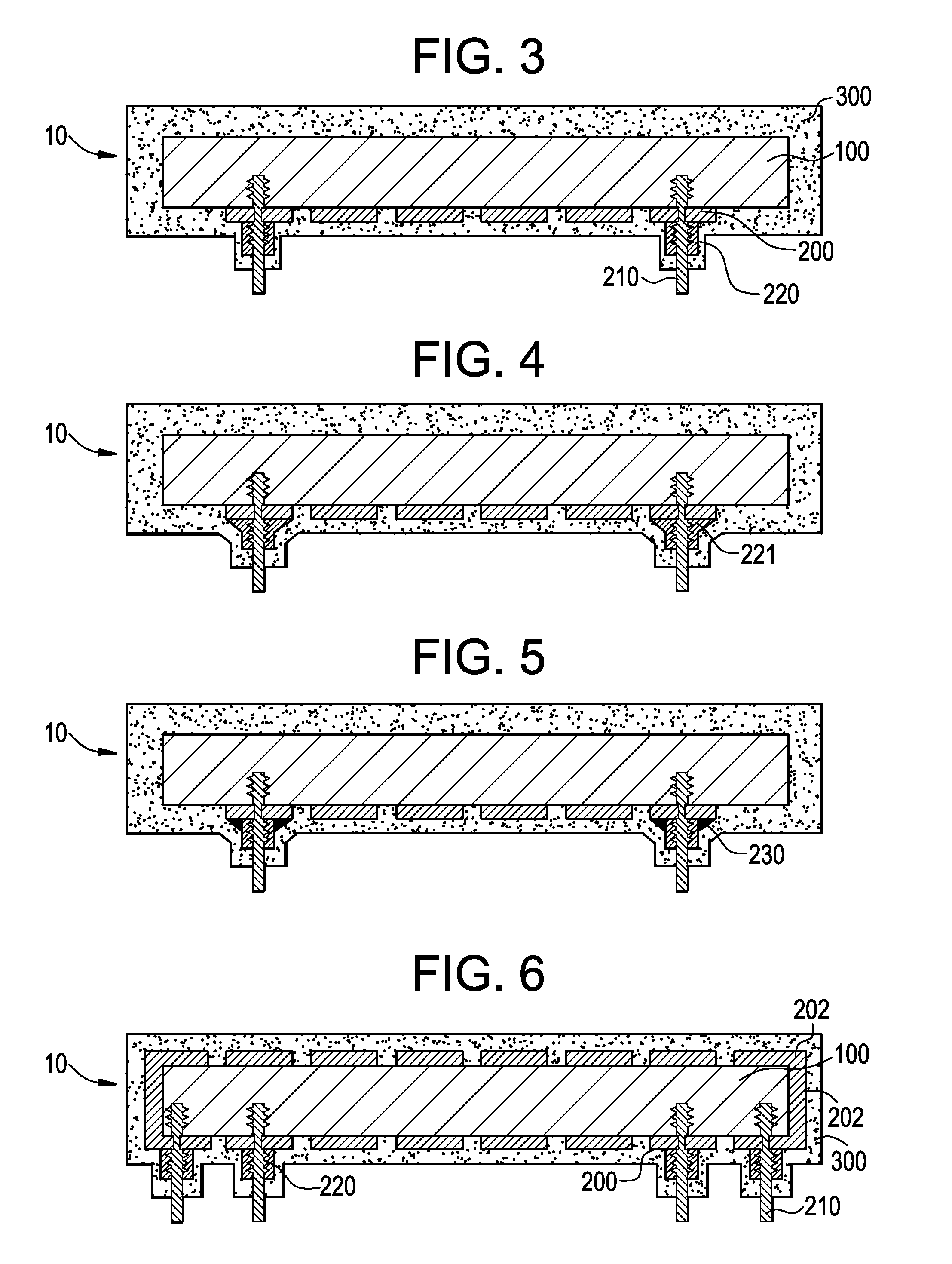

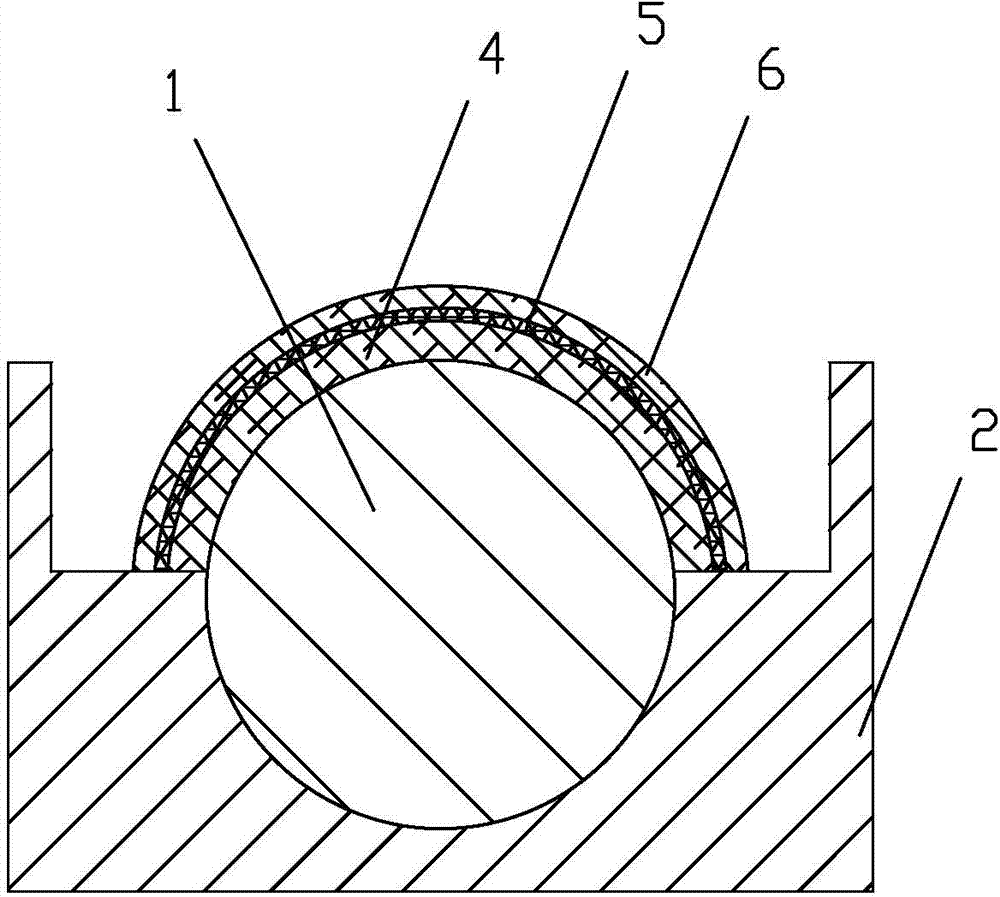

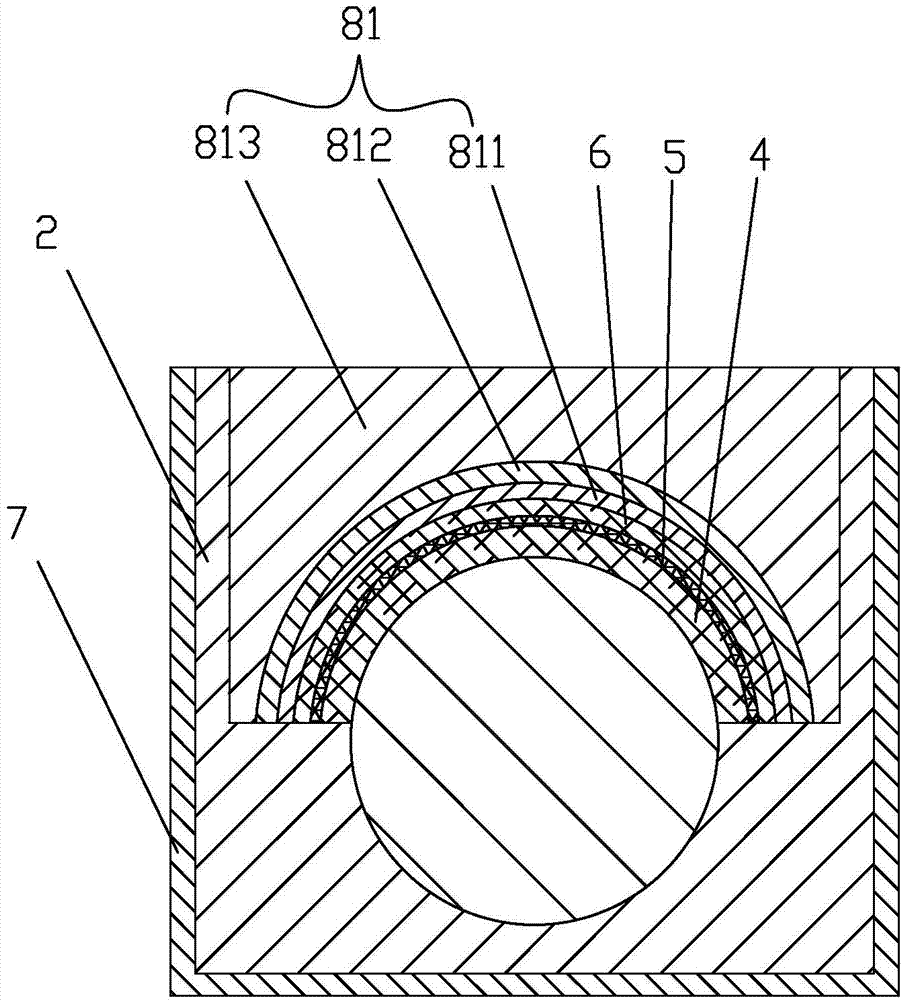

Corrosion resistant wafer processing apparatus and method for making thereof

InactiveUS20080016684A1Line/current collector detailsSemiconductor/solid-state device manufacturingElectrical connectionWadding

A wafer processing apparatus characterized by having corrosion resistant connections for its electrical connections, gas feed-through channels, recessed areas, raised areas, MESA, through-holes such as lift-pin holes, threaded bolt holes, blind holes, and the like, with the special configurations employing connectors and fillers having excellent chemical resistant properties and optimized CTEs, i.e., having a coefficient of thermal expansion (CTE) that closely matches the CTE of the base substrate layer, the electrode(s), as well as the CTE of coating layer. In one embodiment, a nickel plated molybdenum insert is employed.

Owner:GENERAL ELECTRIC CO

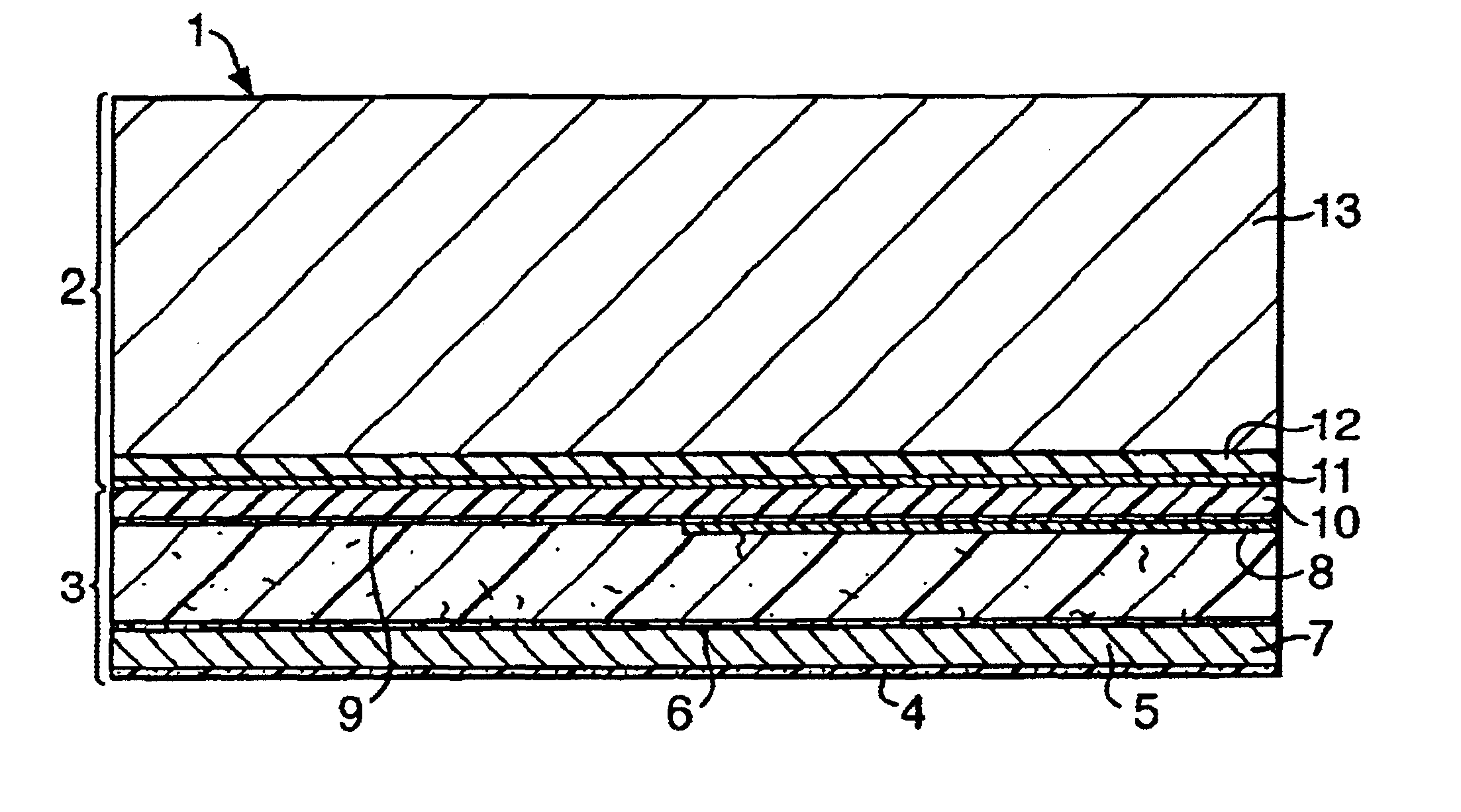

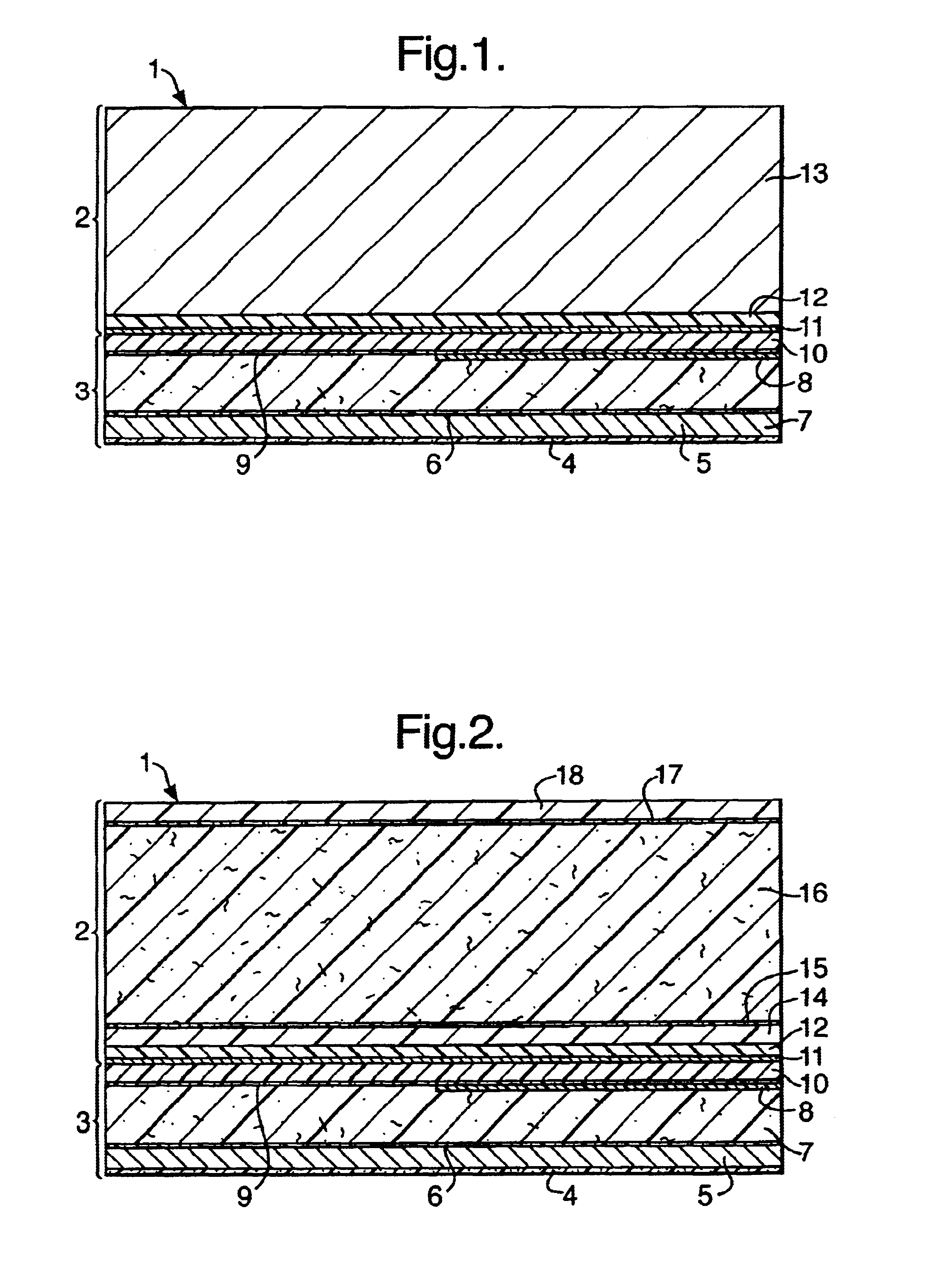

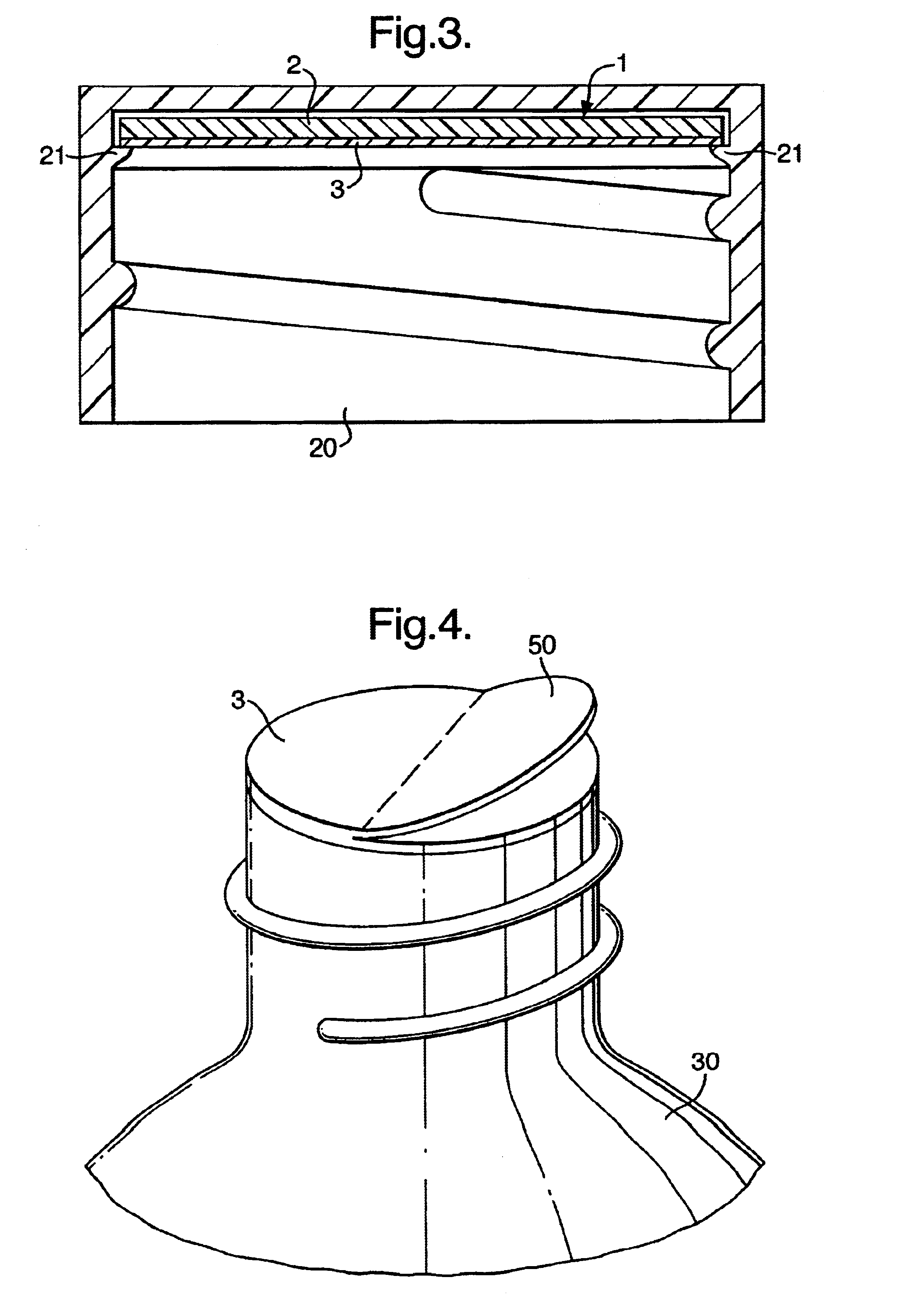

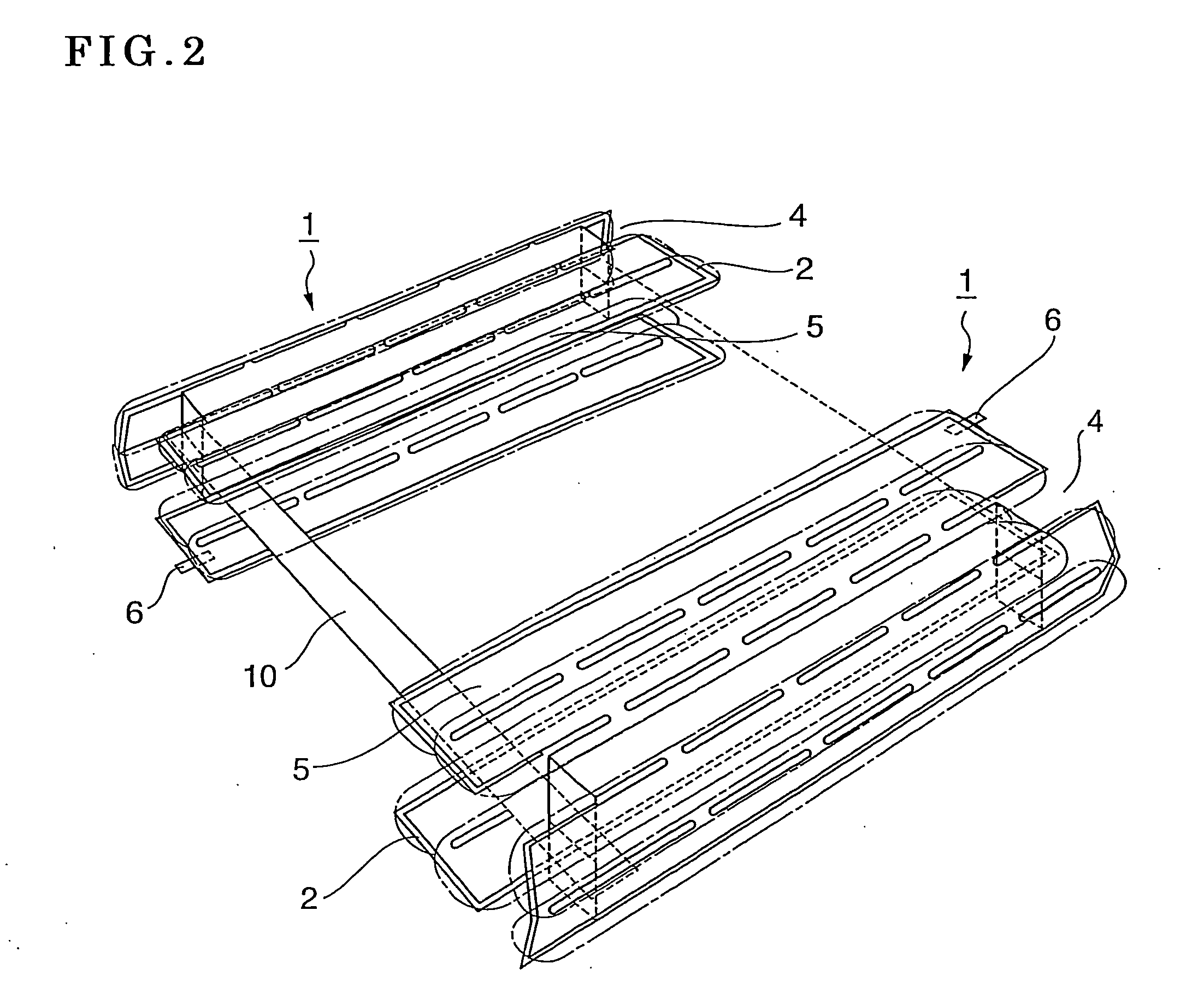

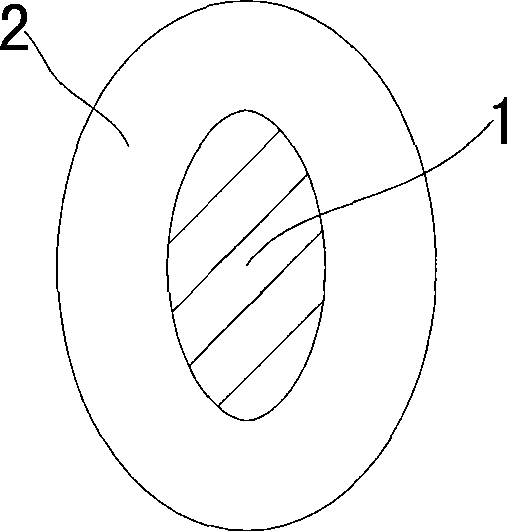

Container closure

InactiveUS6902075B2Achieve stabilizationHigh elongationCapsThreaded caps applicationWaddingEngineering

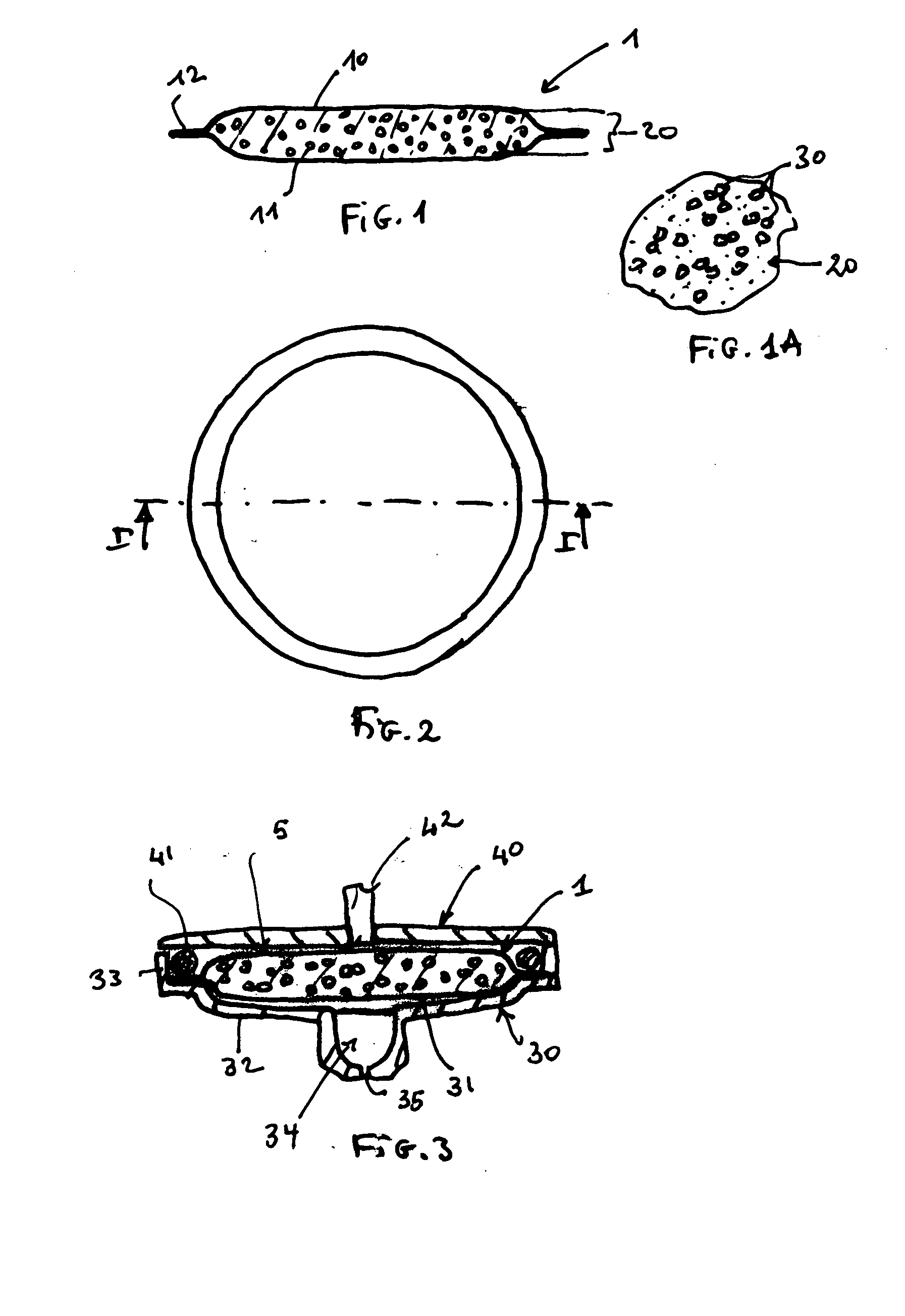

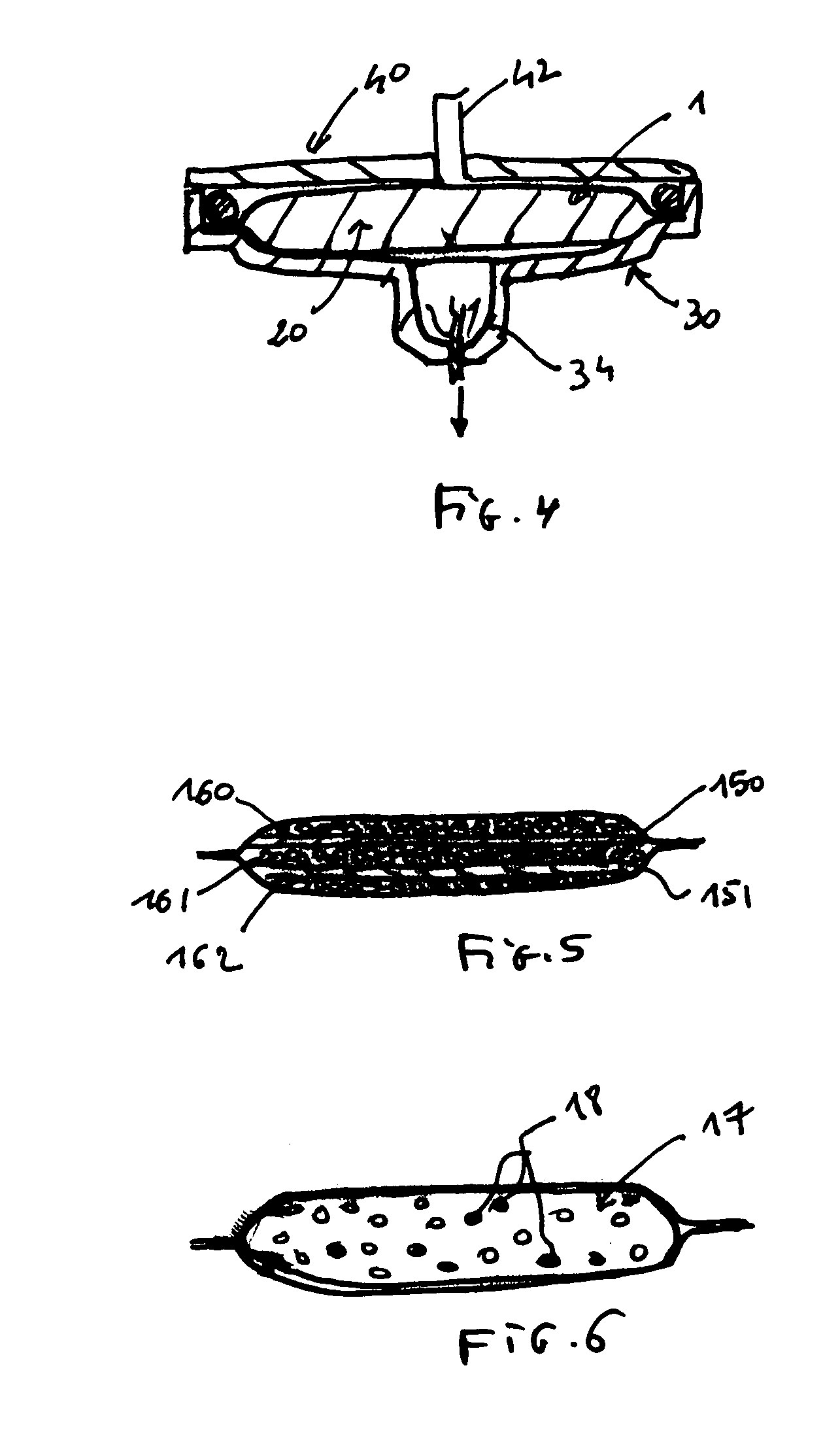

A one-component seal and wadding system (1) for a screw-cap includes a seal (3) having lower layers (4,5) forming an induction heating sealable system for attaching the seal (3) to the neck of a container, a seal substrate (6) including a free tab (50) lying wholly within the circumference of the seal, a layer of liner (2), and an attachment element (10,11,12) including a release layer (11) for attaching the seal substrate (7) including the tab (50) to the wadding (2).

Owner:SELIG SEALING PROD INC

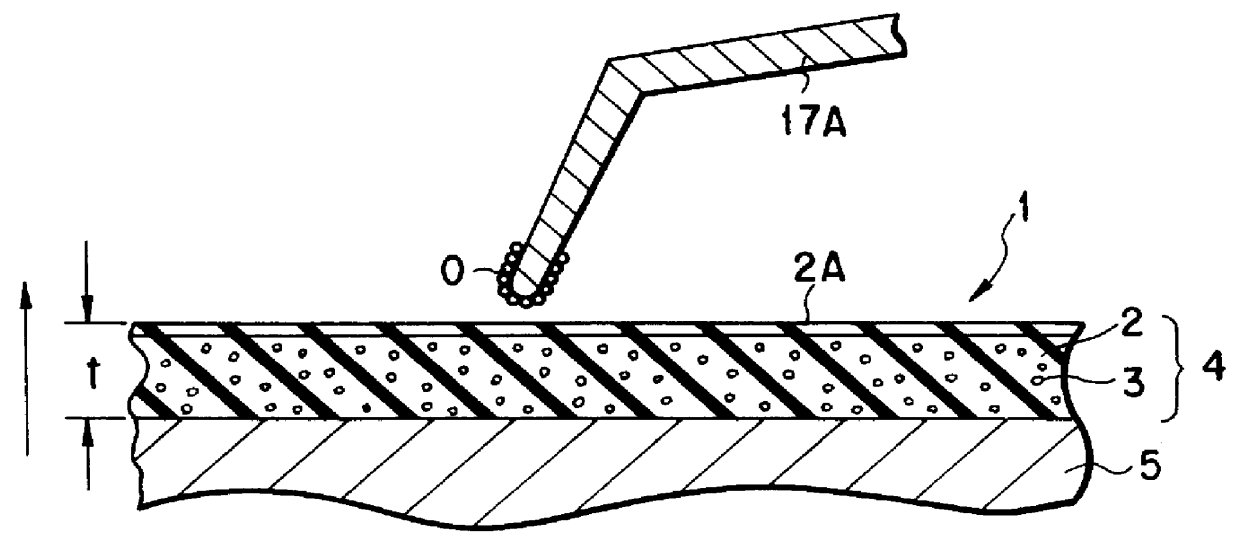

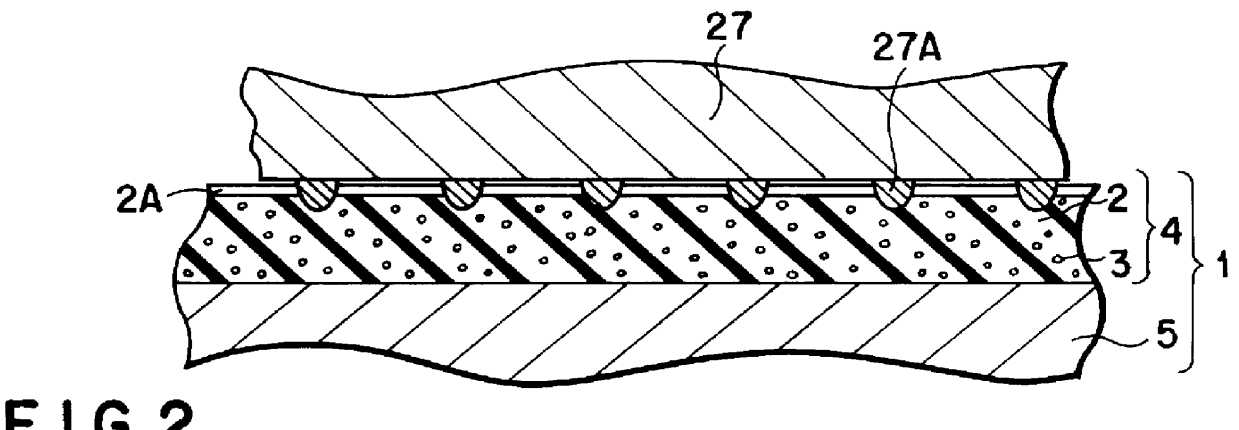

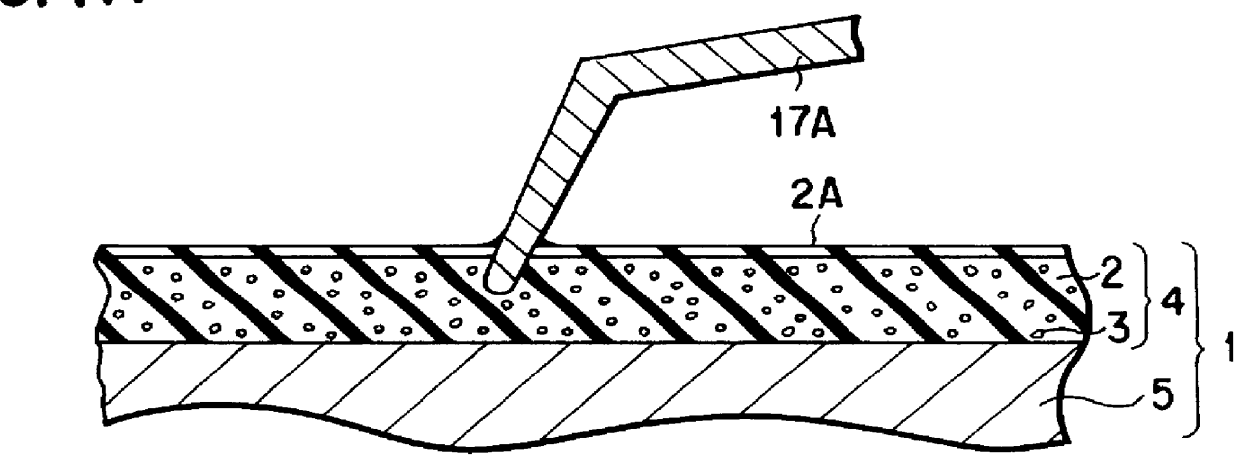

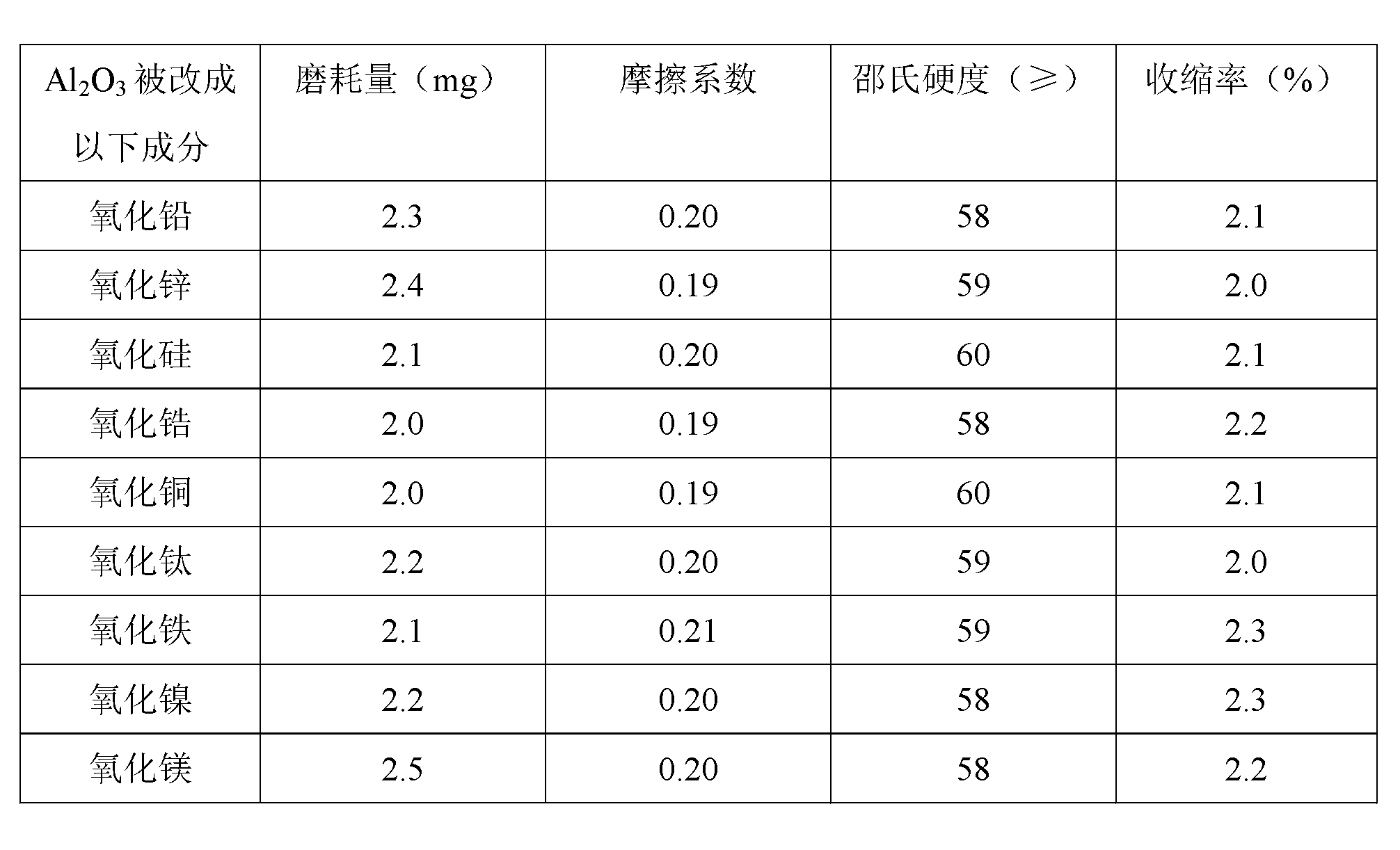

Cleaner for inspecting projections, and inspection apparatus and method for integrated circuits

InactiveUS6130104AImprove surface conditionAnalog circuit testingSemiconductor/solid-state device testing/measurementWaddingBiomedical engineering

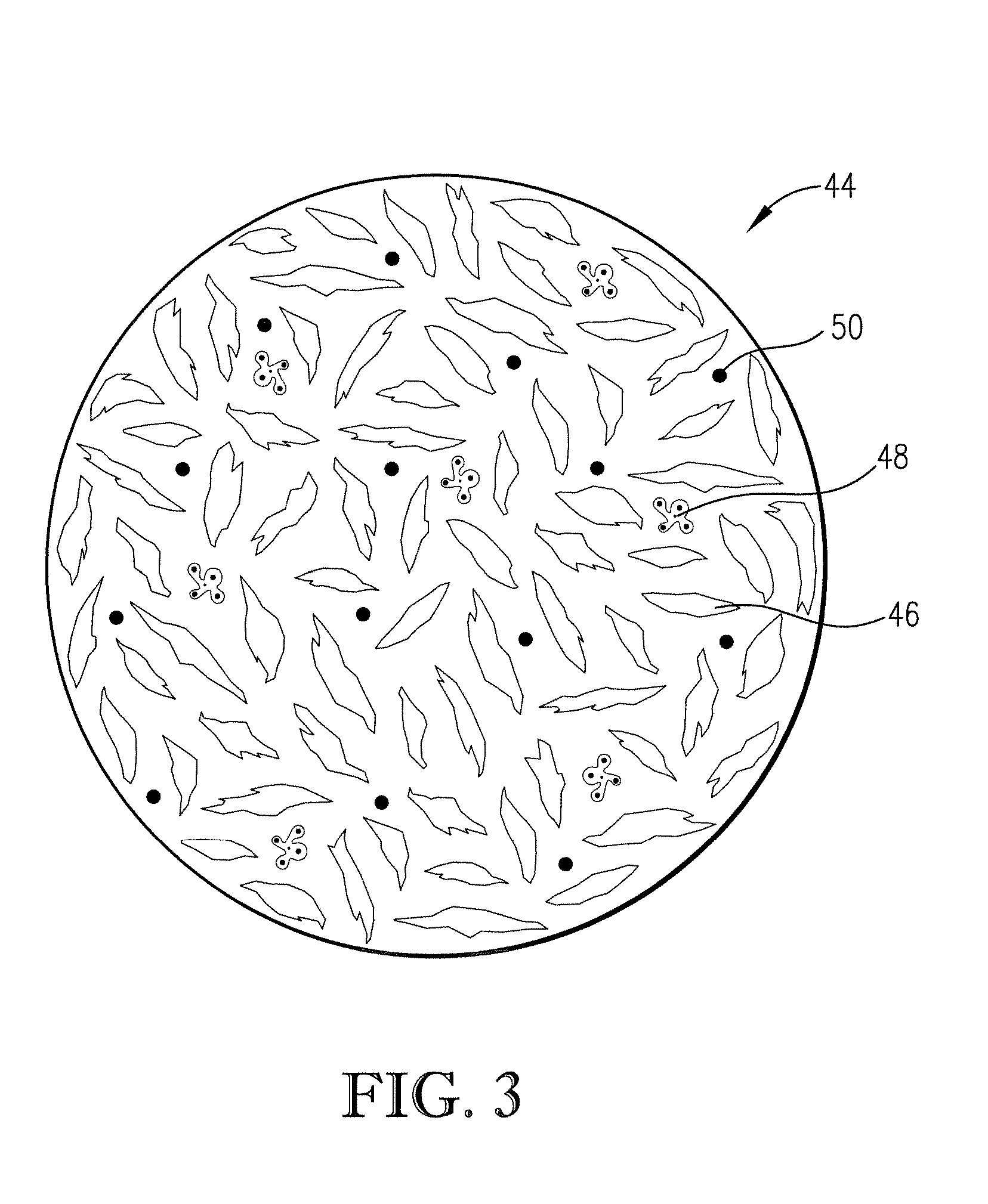

A cleaner of this invention is a cleaner for inspecting projections and removes any substance, e.g., aluminum oxide, which attaches to needle points of probe needles, when the probe needles pierce into the cleaner. The cleaner has a cleaner layer and a substrate. The cleaner layer is constituted by an elastic material layer, and a filler having a surface state improving function of the inspecting projections and dispersed in the elastic material layer. As the filler having a surface state improving function, a powder including at least one of ceramic materials, e.g., sand, glass, alumina, Carborundum (trade name), and the like, or a fiber layer made of an inorganic fiber or organic fiber can be employed.

Owner:TOKYO ELECTRON LTD

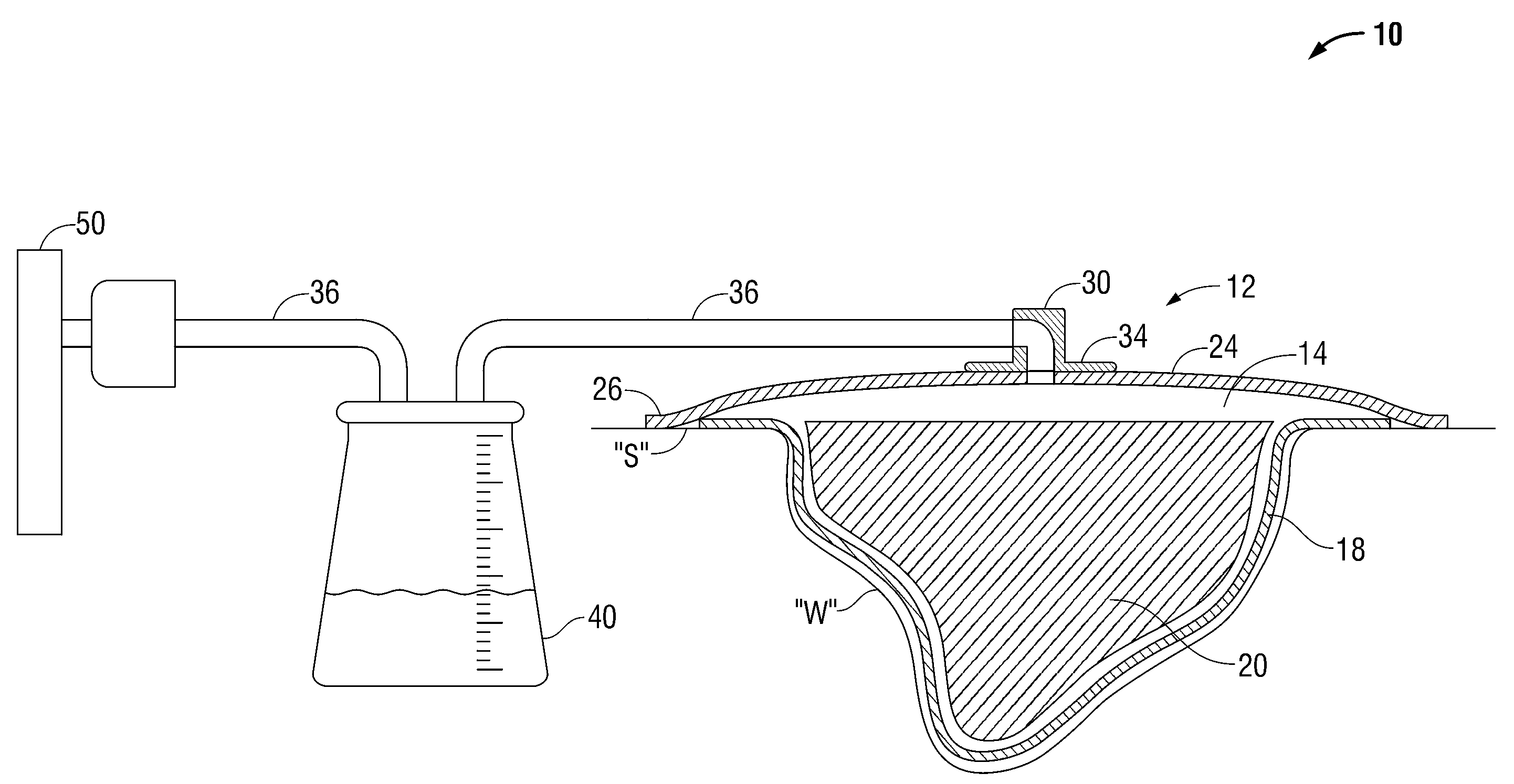

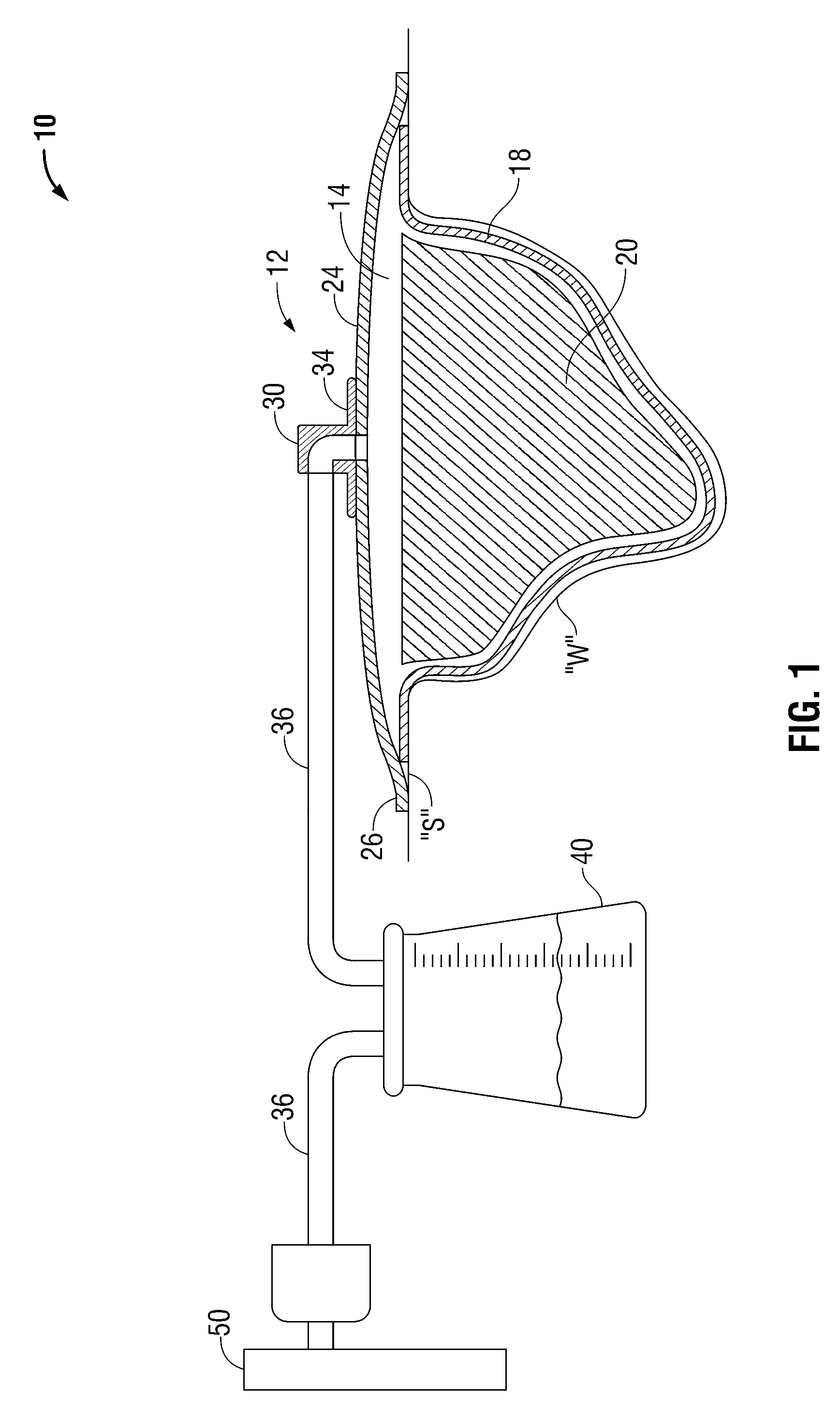

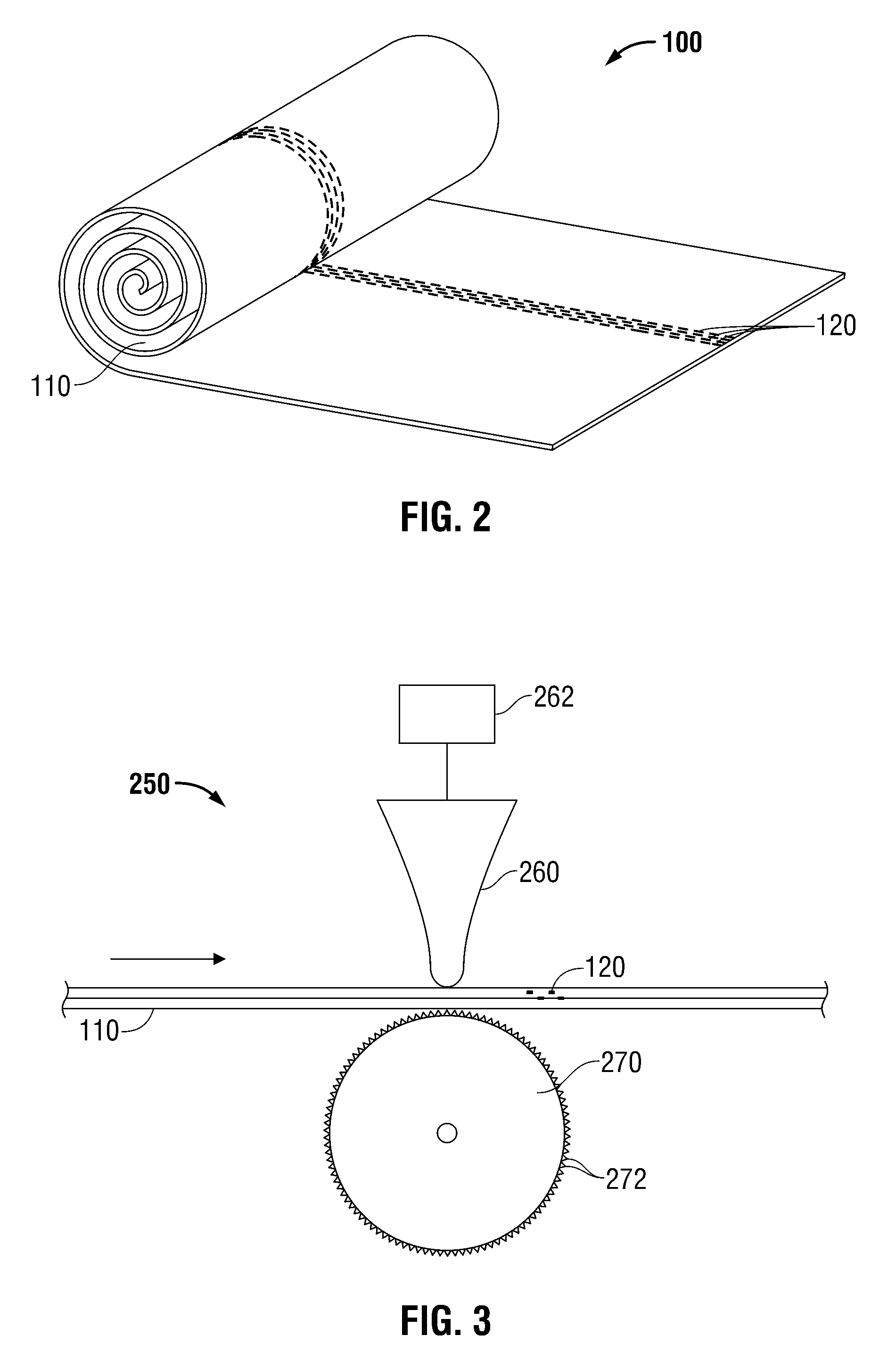

Fibrous Wound Filler Material for Negative Pressure Wound Therapy

An apparatus for promoting the healing of an exuding wound includes a wound cover for defining a reservoir over a wound in which a negative pressure may be maintained. The cover may form a substantially fluid-tight seal around the wound and permit fluid communication between the reservoir and a vacuum source suitable for providing an appropriate negative pressure to the reservoir to stimulate healing of the wound. A wound filler positioned between the wound and the wound cover includes a nonwoven material at least partially perforated by sonic welding.

Owner:TYCO HEALTHCARE GRP LP

Methods of placing treatment chemicals

Methods of treating a subterranean formation comprising placing a solid treatment chemical and a tacky polymer onto a solid substrate to create a coated solid substrate; placing the coated solid substrate into a portion of a subterranean formation; and, allowing the tacky polymer to degrade and allowing the solid treatment chemical to be released into the portion of the subterranean formation. Methods of creating a particulate pack comprising a treatment chemical in a subterranean formation comprising placing a solid treatment chemical and a tacky polymer onto a particulate to create a coated particulate; creating a slurry comprises the coated particulates slurried into a treatment fluid; placing the slurry into a portion of a subterranean formation so a to create a particulate pack; and, allowing the tacky polymer to degrade and allowing the solid treatment chemical to be released into the portion of the subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

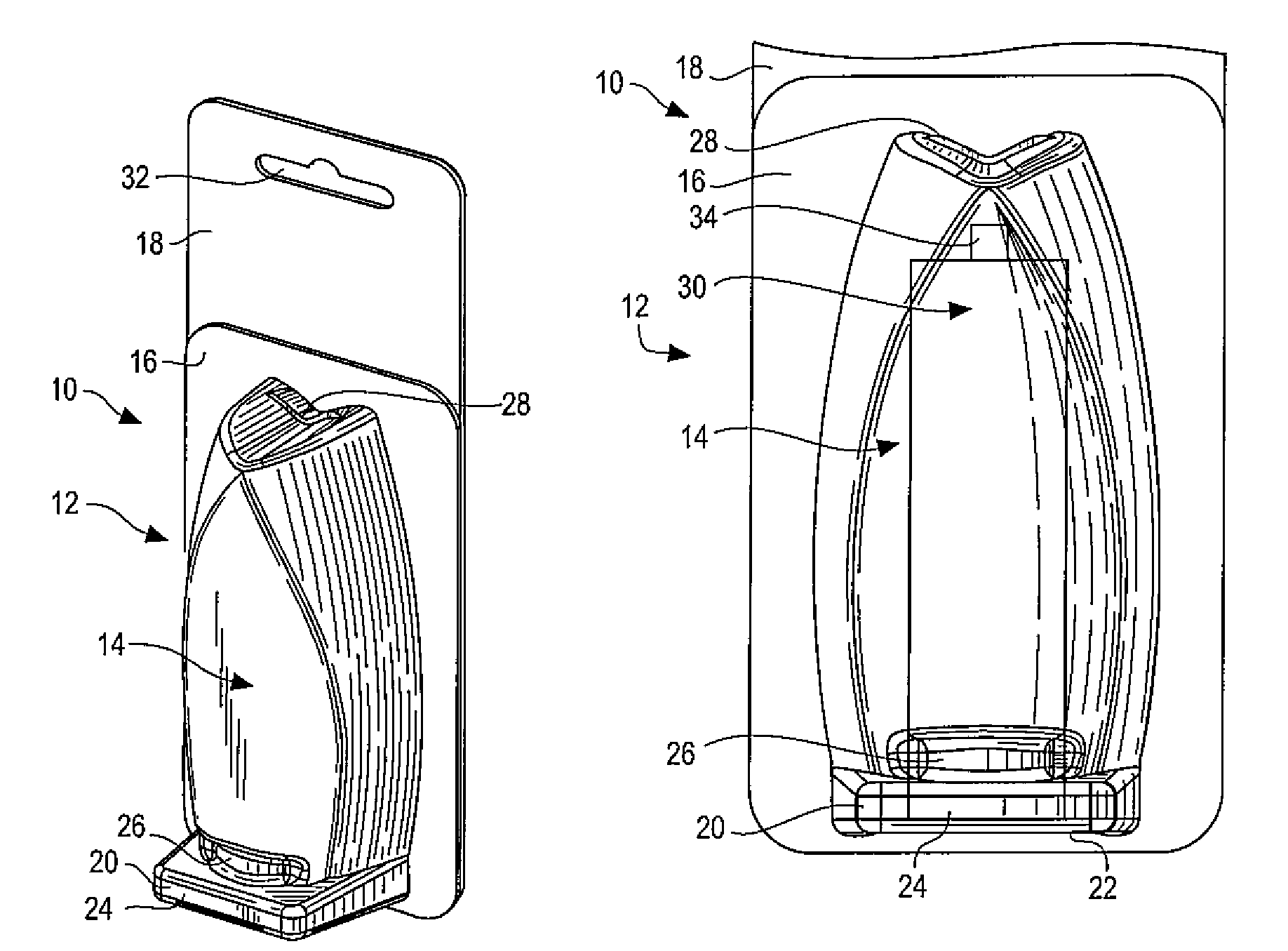

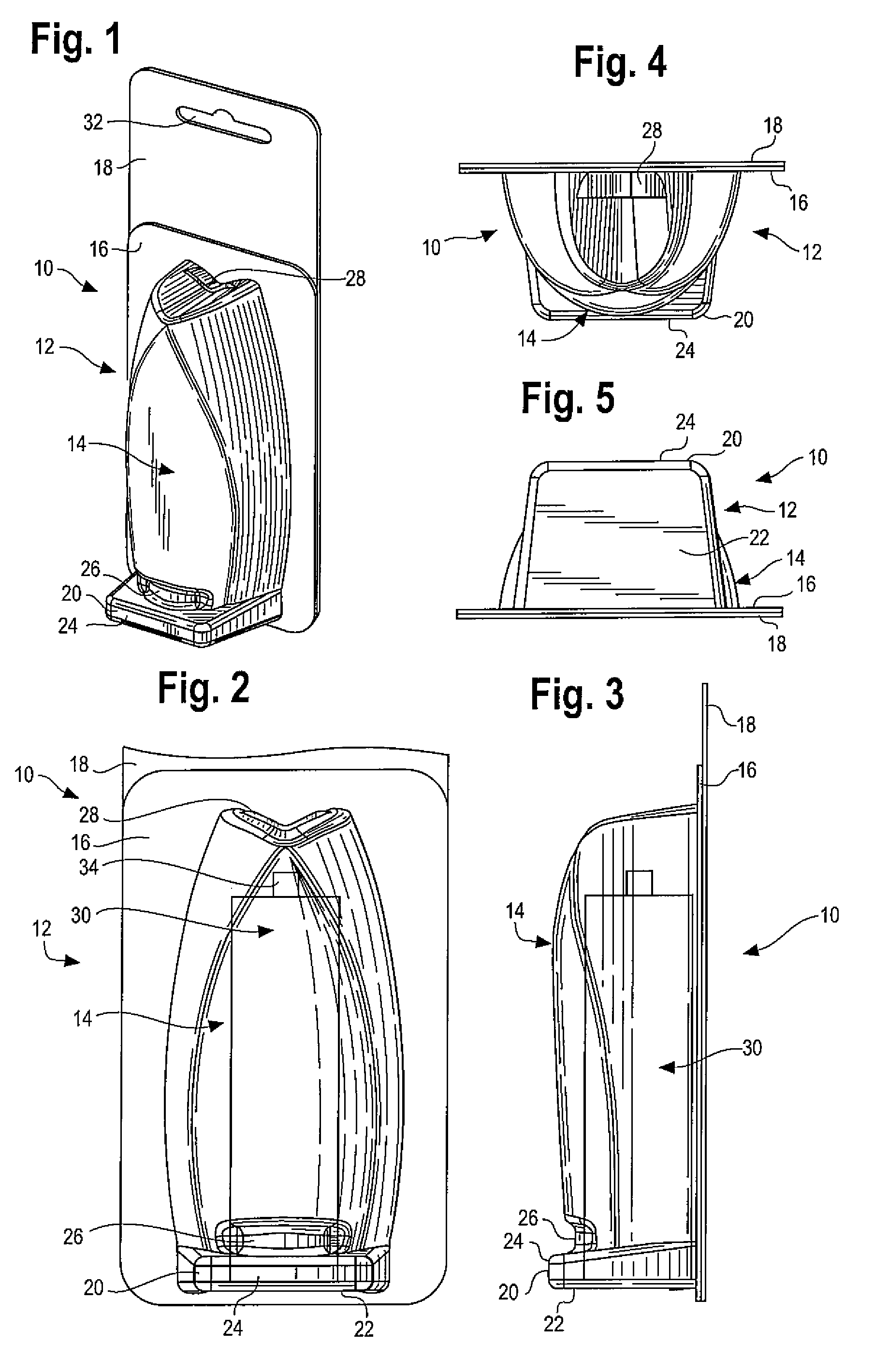

Shaped packaging for a refill

A package includes a refill for a device and a configuration of the package that resembles at least a portion of the device with which the refill functionally interacts. The configuration of the package is indicative of the device and does not include same. In addition, a method of identifying a renewable item for a rechargeable device includes the steps of providing a package including a structural configuration that resembles at least a portion of the rechargeable device with which the renewable item interacts and packaging the renewable item within the package. The rechargeable device is not carried by the structural configuration. Further, a packaging includes a first item and a structure that carries the first item and that resembles at least one portion of a second item with which the first item functionally interacts. A characteristic of the structure identifies the second item. The second item is not carried by the structure.

Owner:SC JOHNSON & SON INC

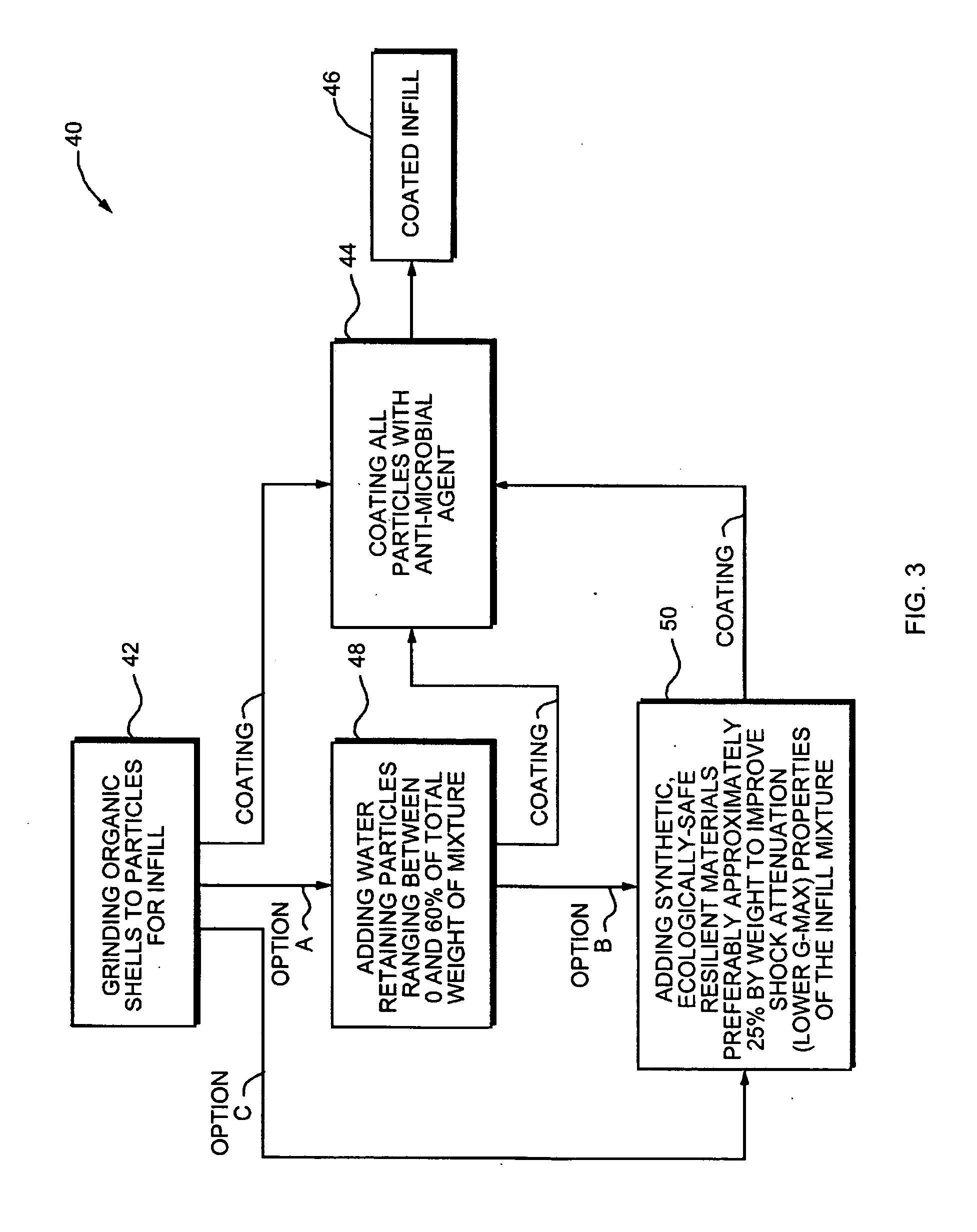

Artificial turf infill

InactiveUS20100055461A1High albedoImprove retention capacitySynthetic resin layered productsCellulosic plastic layered productsWalnut NutUltrasound attenuation

An artificial turf infill comprising an organic material including ground walnut shells having each organic particle completely coated with an anti-microbial agent. Water-retaining particles are added to the infill ranging between 0 and 60% of total weight of the mixture. Synthetic, ecologically-safe resilient granules preferably between approximately 20% and 25% by weight may be added to the infill to improve shock attenuation (lower G-max) properties of the infill mixture. The water-retaining particles and synthetic resilient granules within the infill are completely coated with the anti-microbial agent.

Owner:DALUISE DANIEL A +1

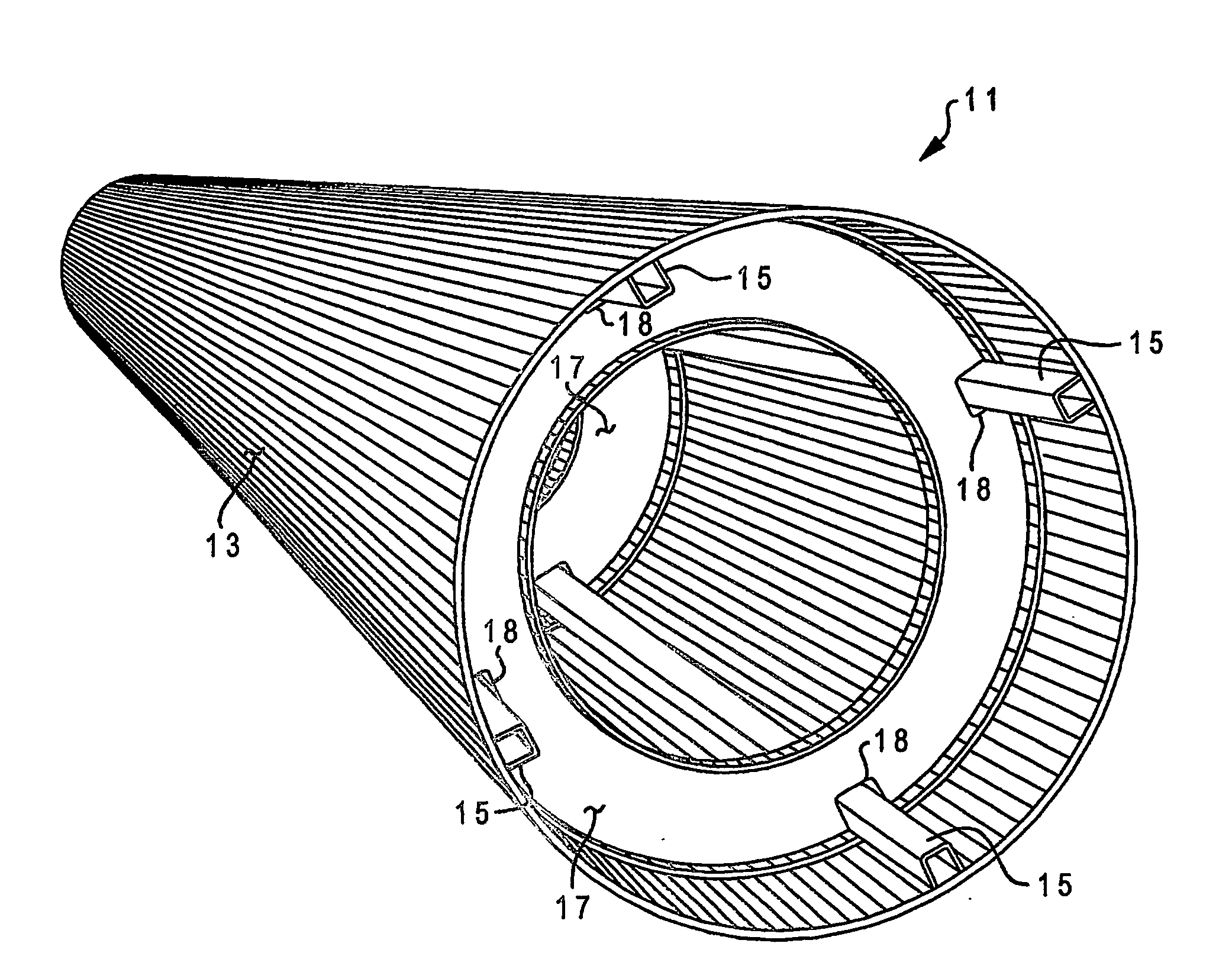

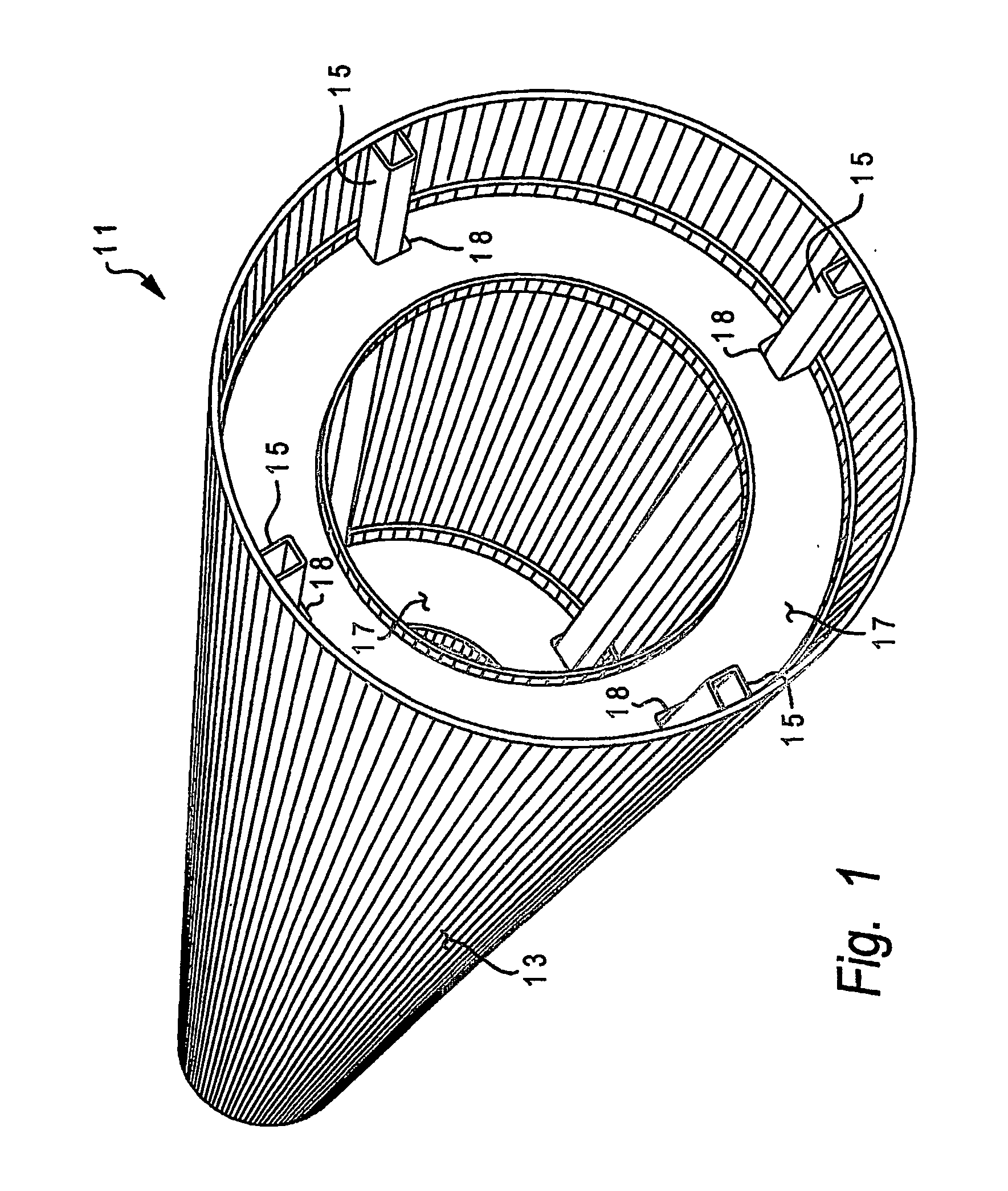

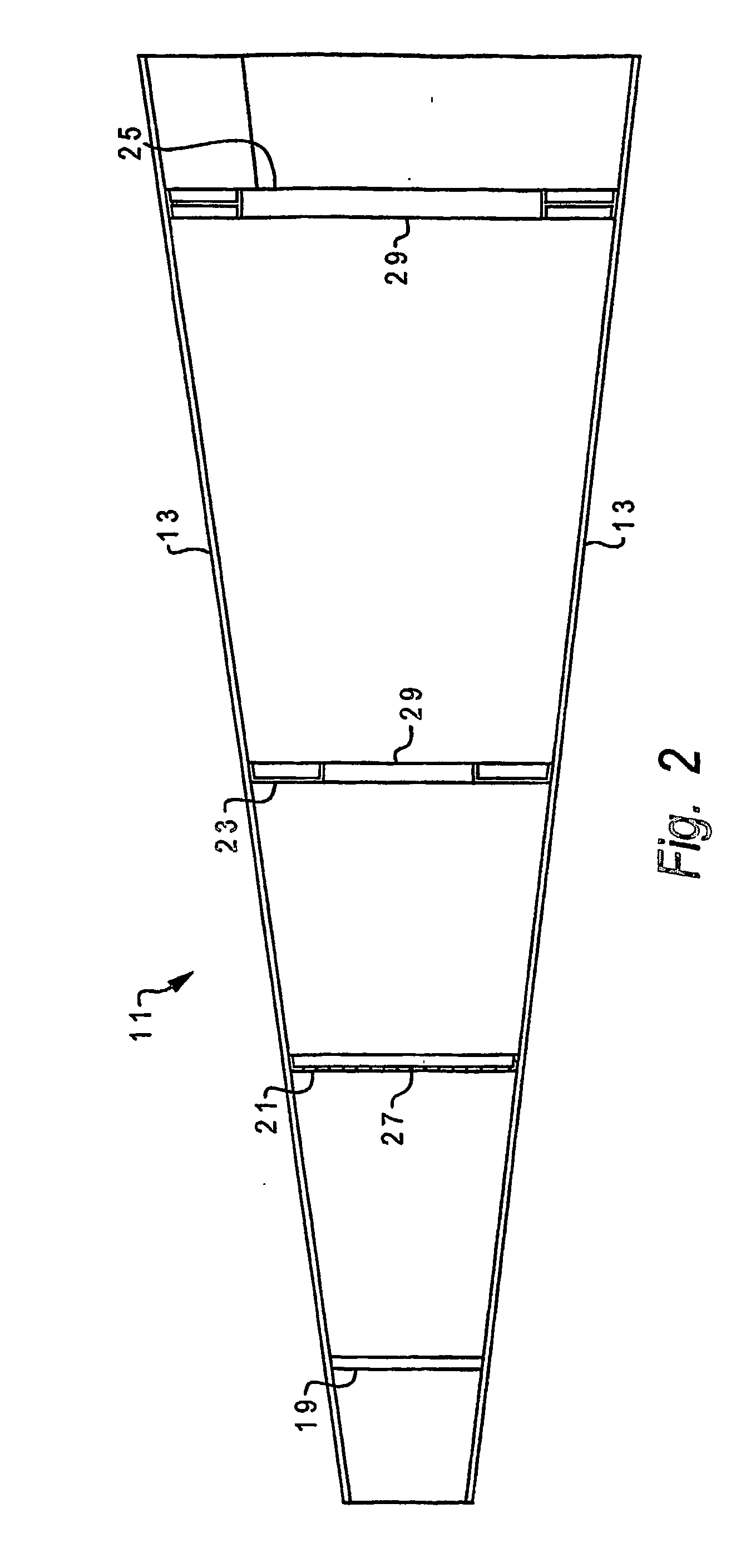

Contact stiffeners for structural skins

ActiveUS20070011970A1Reduce manufacturing costBulky assemblyAircraft stabilisationSpars/stringersAdhesiveFilling materials

An internal stiffening member of varying configurations in which the stiffening elements support the skin using a compression-only load path is dislcosed. In the preferred embodiment, the stiffening element has a peripheral edge that is adapted to be press fit into contact with the skin. The stiffening member may be held in place by various retention devices. Another configuration is a slip-in rib having a flange with a peripheral channel in which a filler material is disposed. The rib is inserted into an assembled structural box beam, and the filler material is used to fill any gaps between the slip-in rib and the interior surface of the structural box beam. The filler material is preferably an expandable material, such as an expandable foam-type material. However, in situations where a slip-in rib forms a primary structural rib, the filler material is preferably a structural adhesive or liquid shim material. A solid adhesive or filler would not crush under the clamping forces from fasteners or bolts at localized fitting attachments.

Owner:BELL HELICOPTER TEXTRON INC

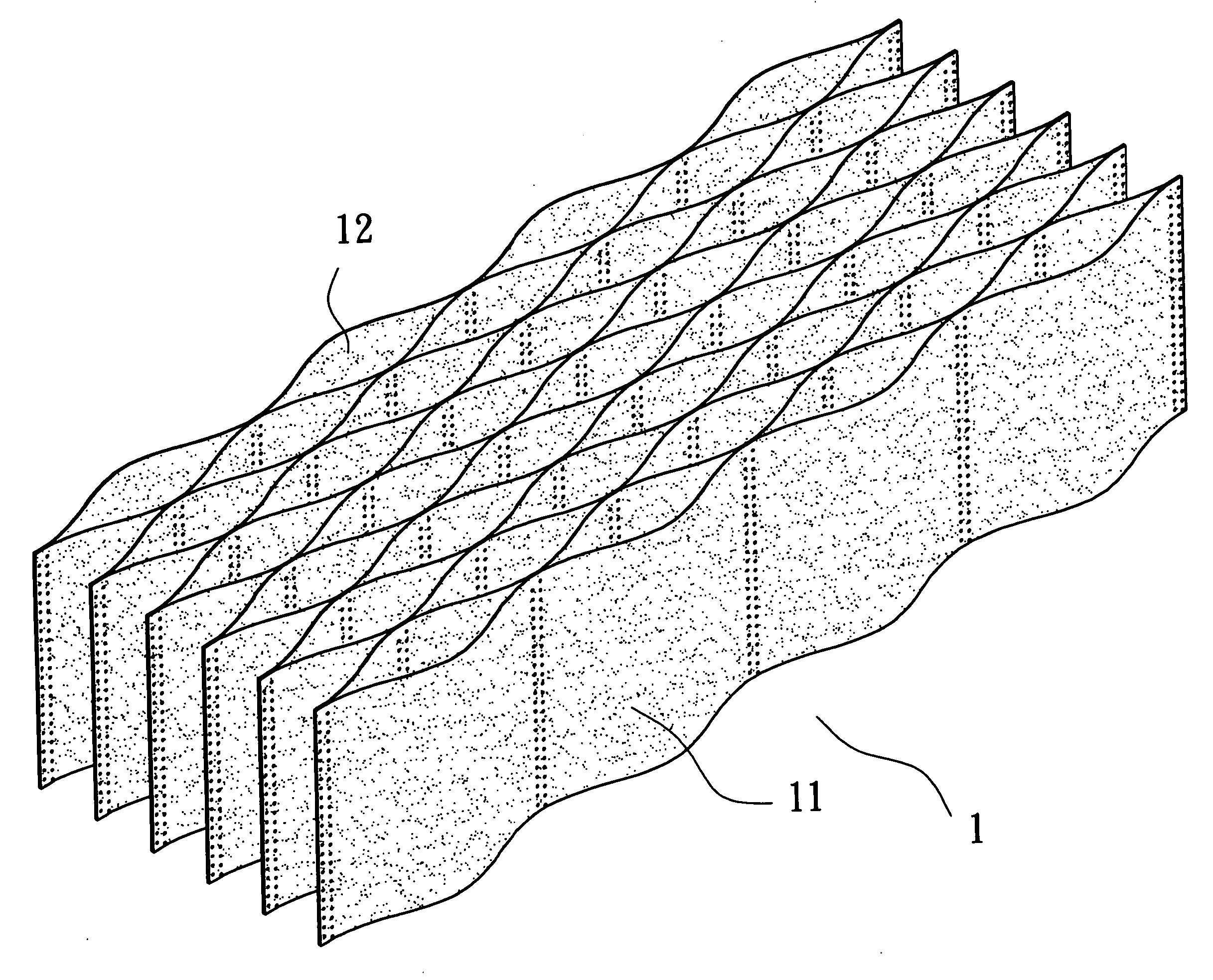

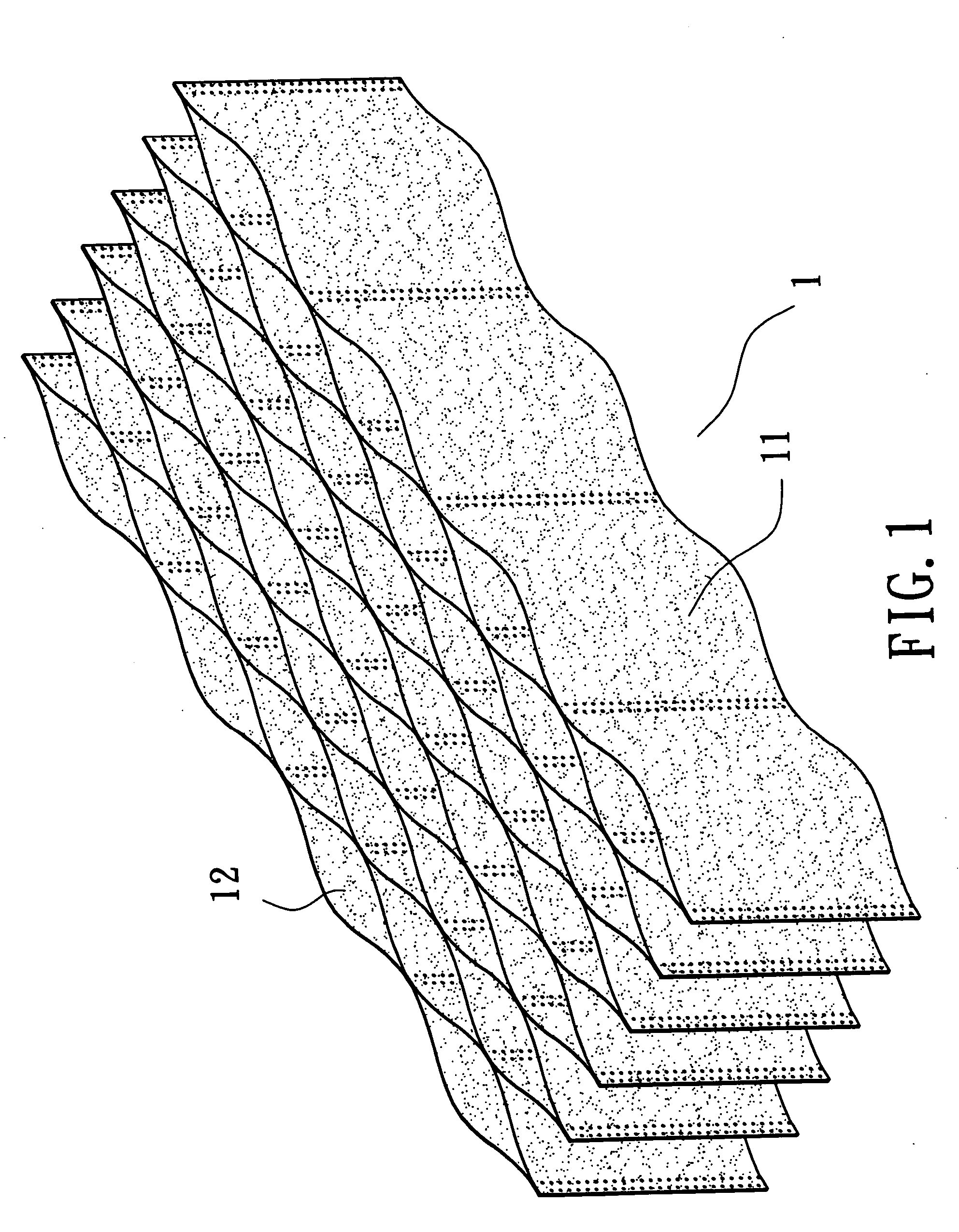

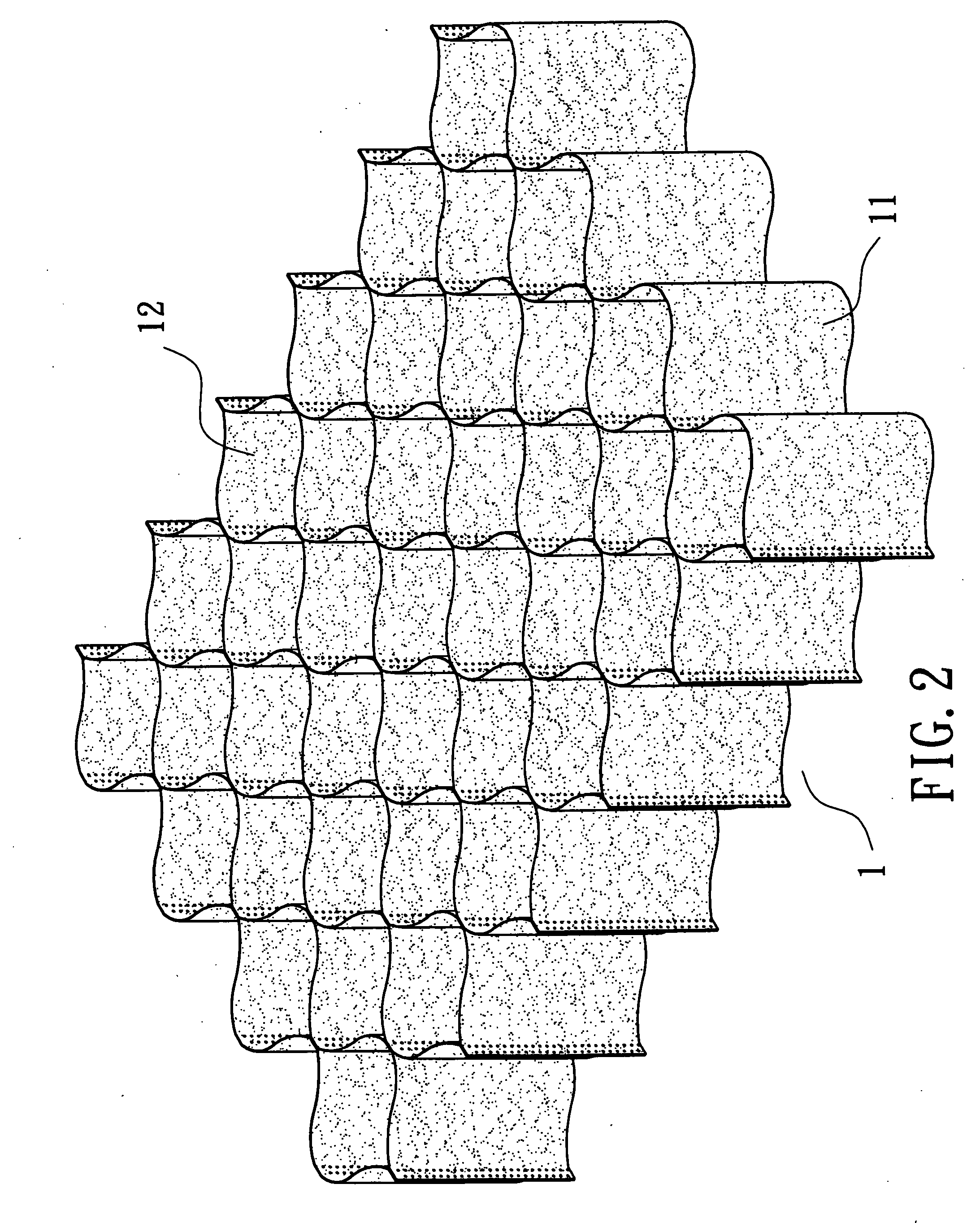

Textured geocell

A geocell for retaining infill in geotechnical structure, e.g. a protection construction on an unstable slope in mountainous areas, construction foundation, and green-making with plants, consists of several plastic plates; every two adjacent plastic plates are connected together at several spaced apart elongated joints by means of ultrasonic welding, each of which elongate joints includes several aligned points; thus, the geocell can be expanded into a honeycomb shape, and cells are formed therein for containing backfill therein; the plastic plates are formed with rough finishes so as to increase the backfill retaining capability of the present geocell.

Owner:HUIKWANG CORP

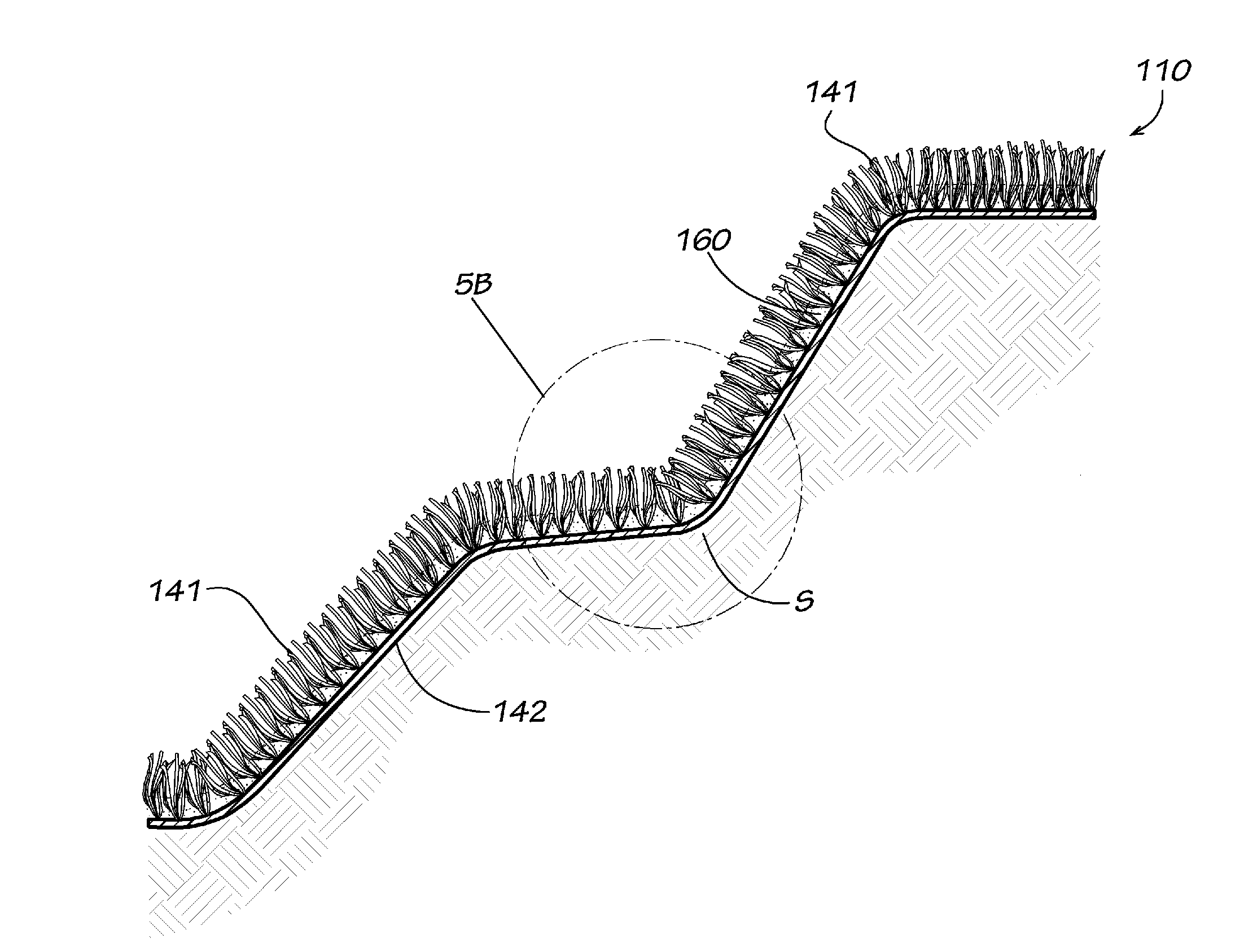

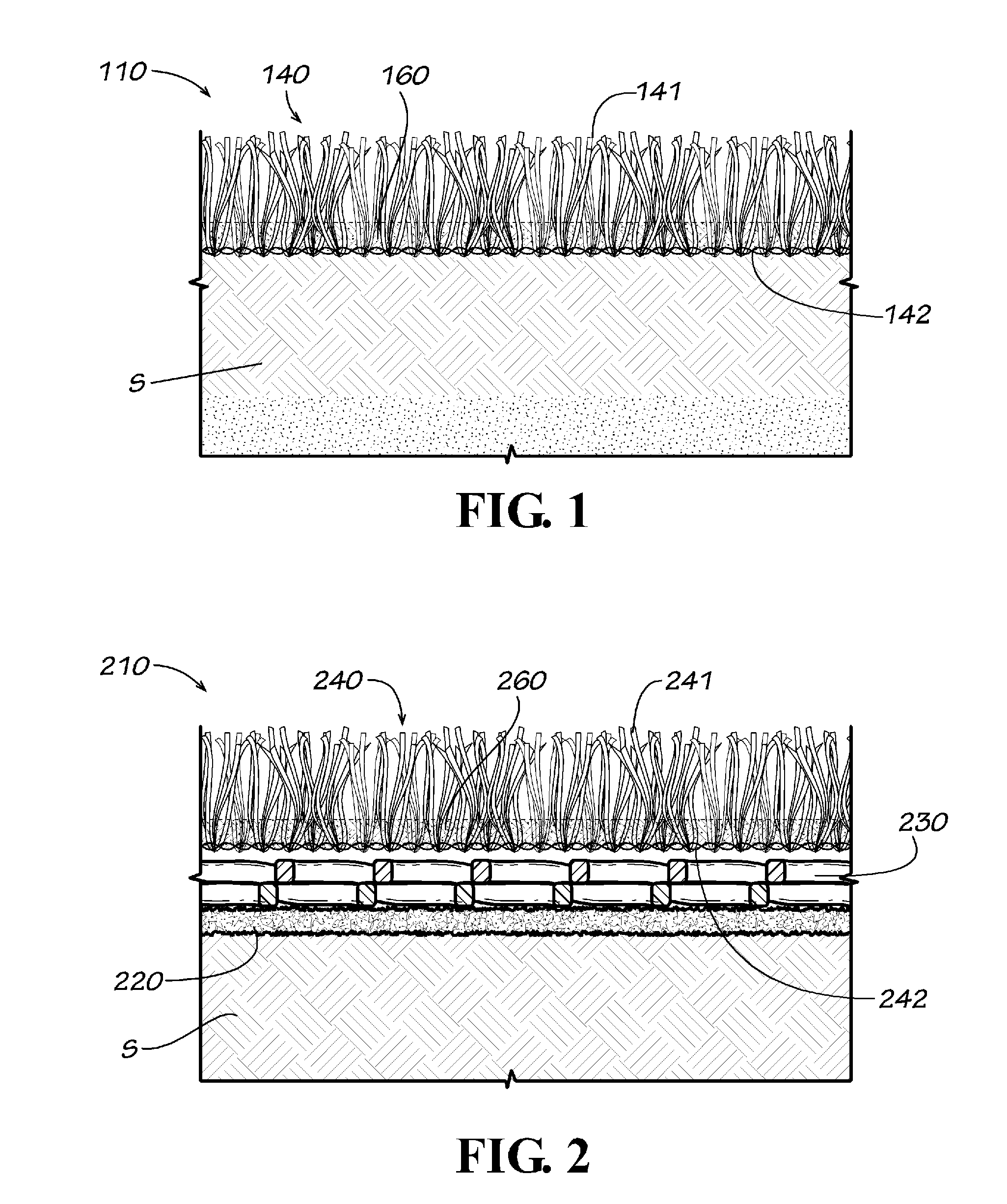

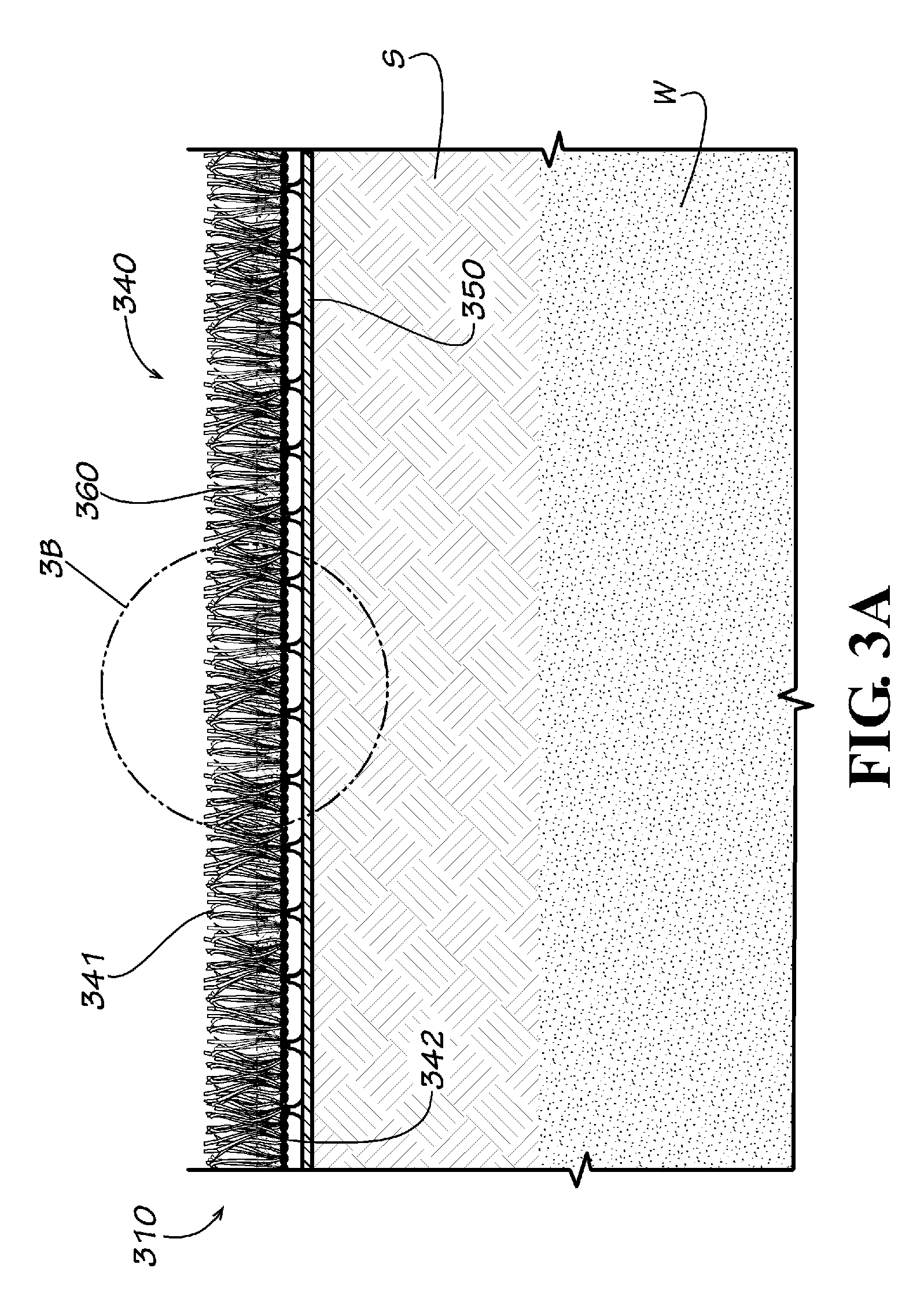

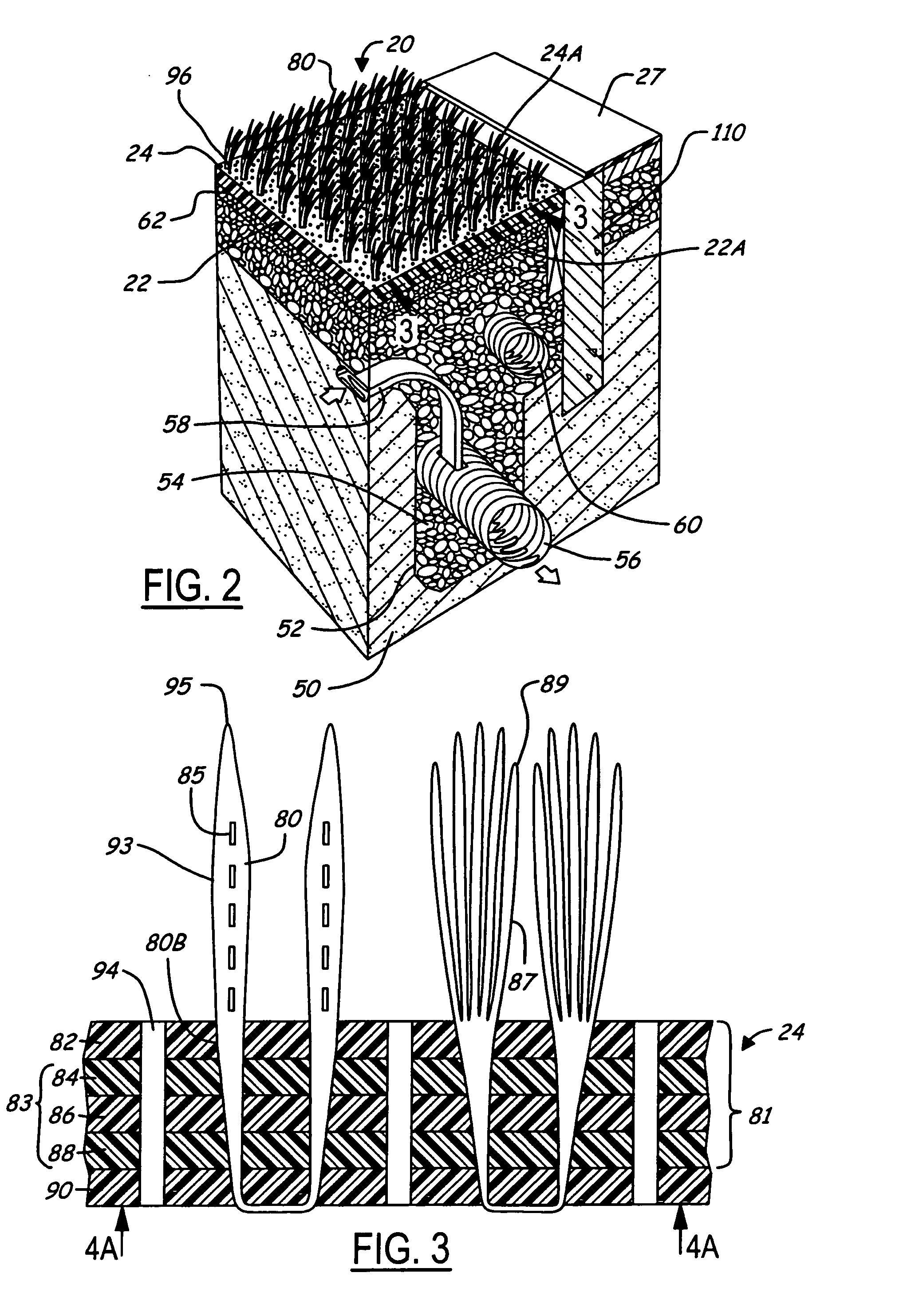

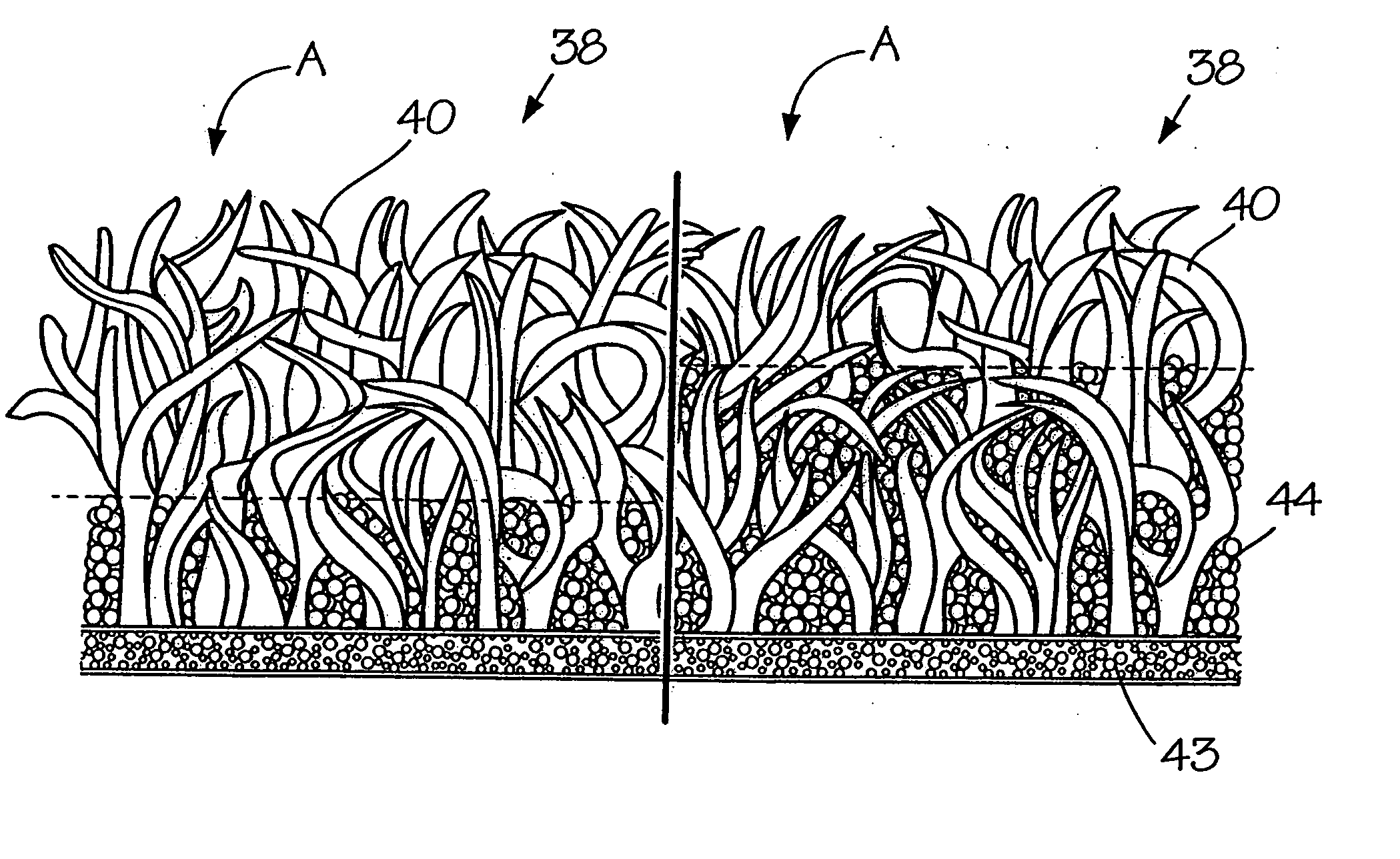

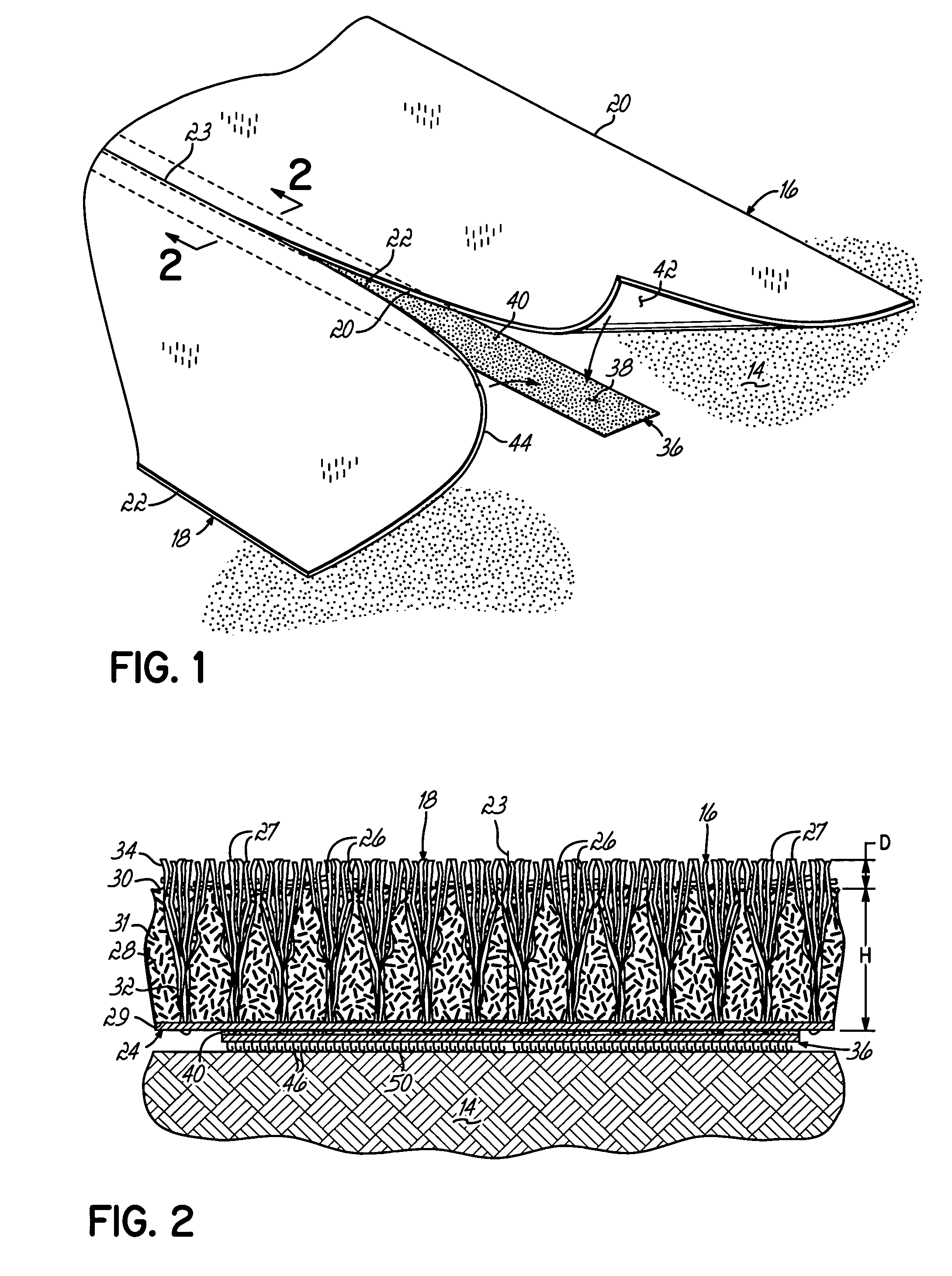

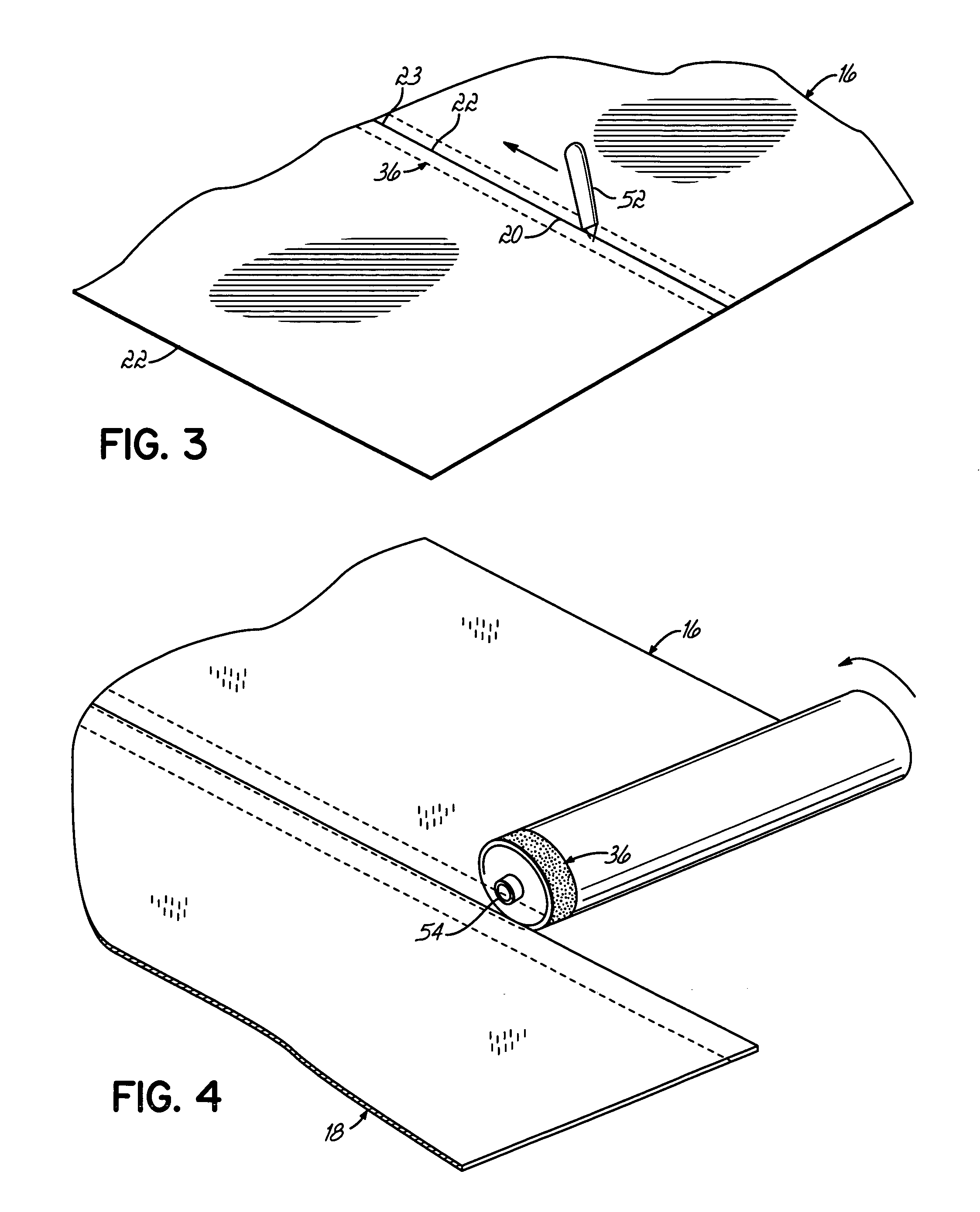

Synthetic ground cover system with binding infill for erosion control

A synthetic ground cover system for erosion control to be placed atop the ground, including a synthetic grass which comprises a composite of one or more geo-textiles tufted with synthetic yarns. The synthetic ground cover also includes a sand / soil infill ballast applied to the synthetic grass and a binding agent applied to the sand / soil infill to stabilize the sand / soil infill against high velocity water shear forces.

Owner:WATERSHED GEOSYNTHETICS

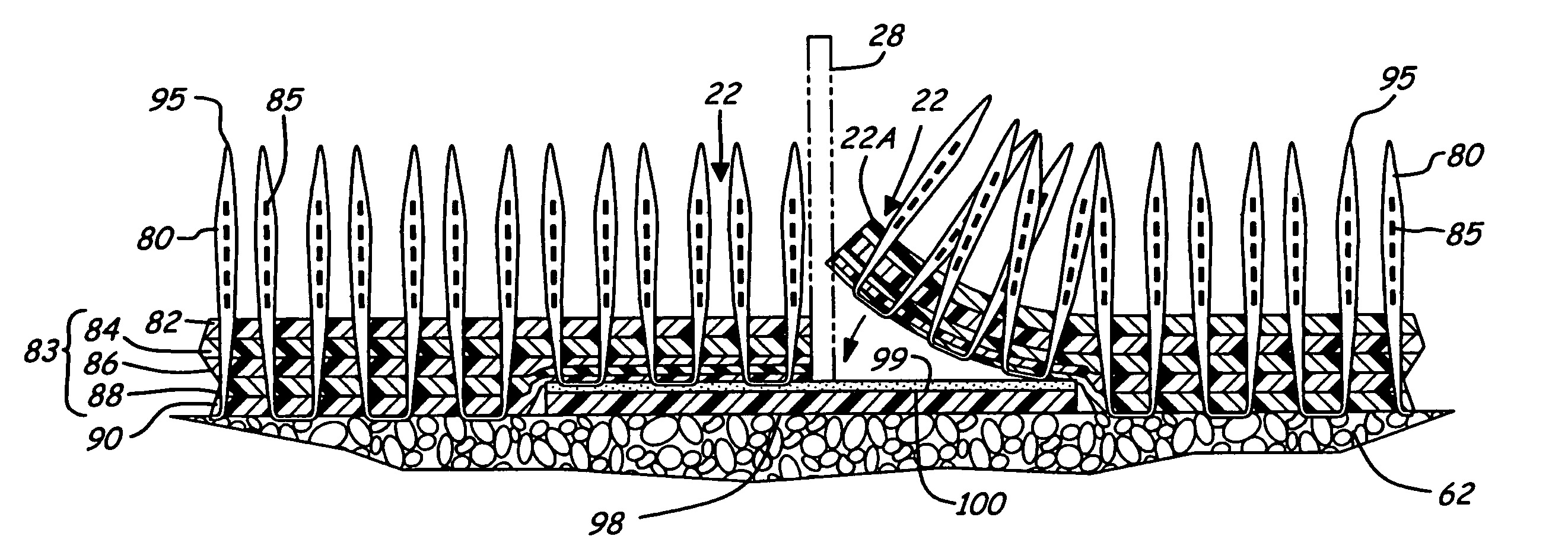

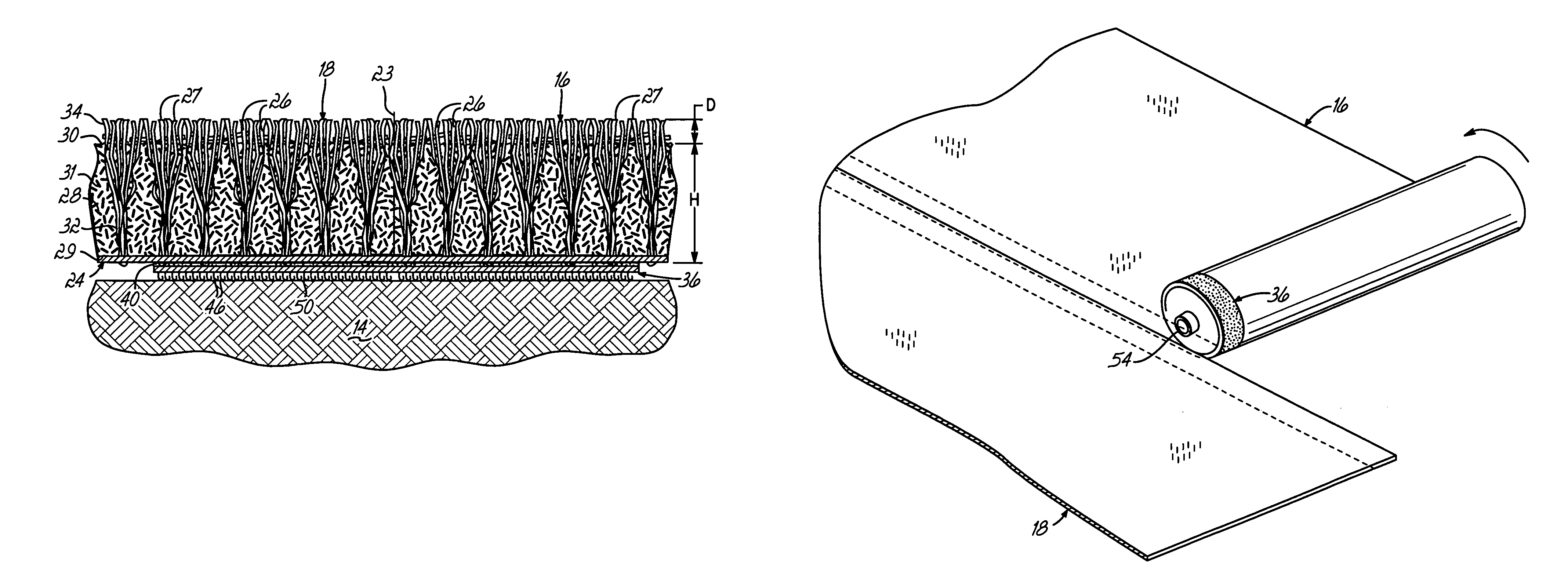

Synthetic sports turf having improved playability and wearability

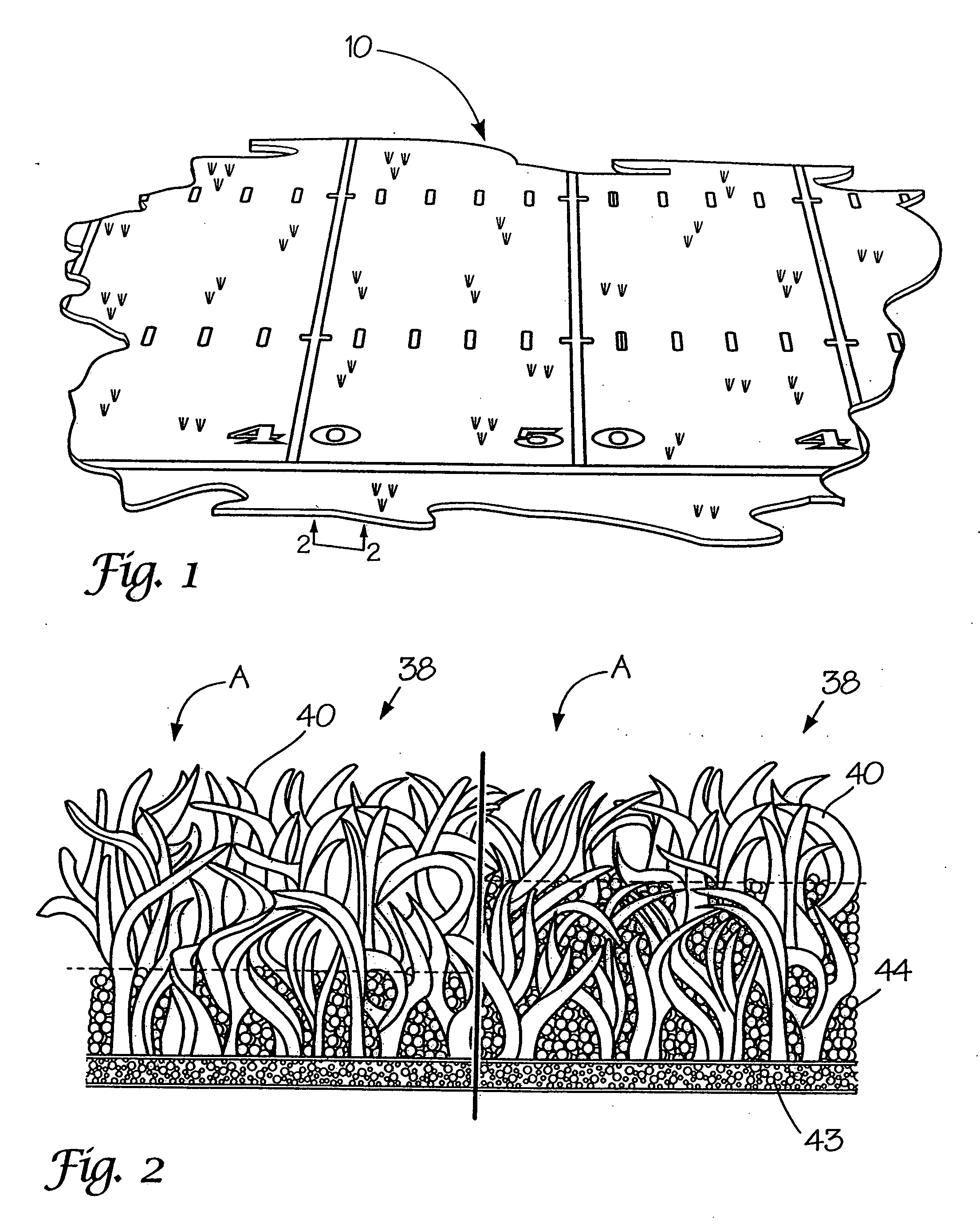

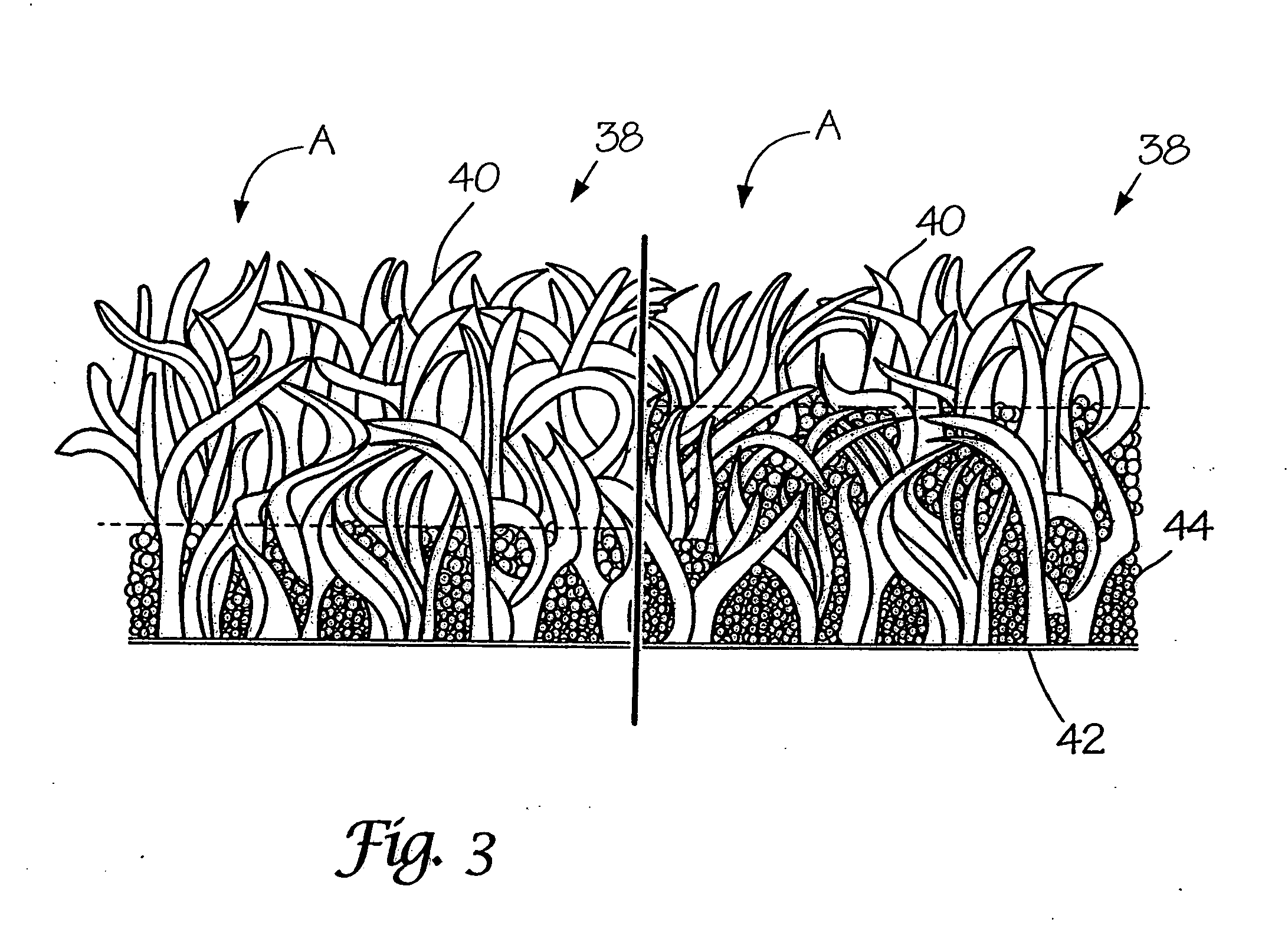

A durable and wear resistant synthetic sports field having at least one strip having a plurality of fibrillated polypropylene strands tufted within a multilayer backing material. The strands are tufted in a wide variety of pile heights, patterns, gauges, and stitch patterns depending upon end use. The multiplayer backing material has a top mesh polypropylene layer at least three layers of a backing material coated with a secondary coating used to contain the ends of the plurality of strands. The strips are placed onto a fine aggregate layer placed over a coarse aggregate layer and a geotextile fabric. The geotextile fabric is placed onto a compacted and leveled subgrade. A ground rubber infill, with or without sand particles and diatomaceous earth, is introduced onto the strips. In alternative arrangements, a series of perforated drains and drain tiles may be introduced to the coarse aggregate layer to promote drainage.

Owner:ASTROTURF

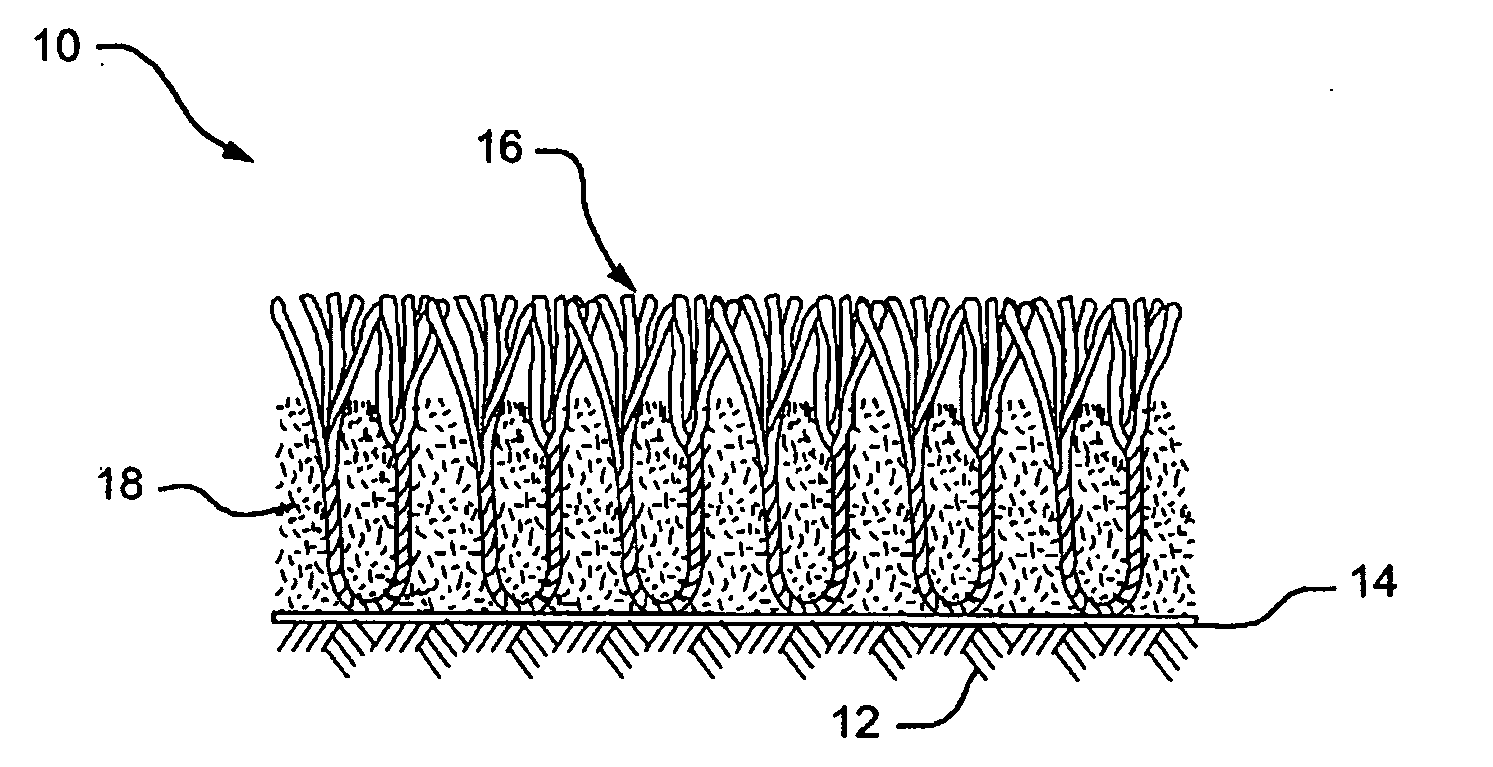

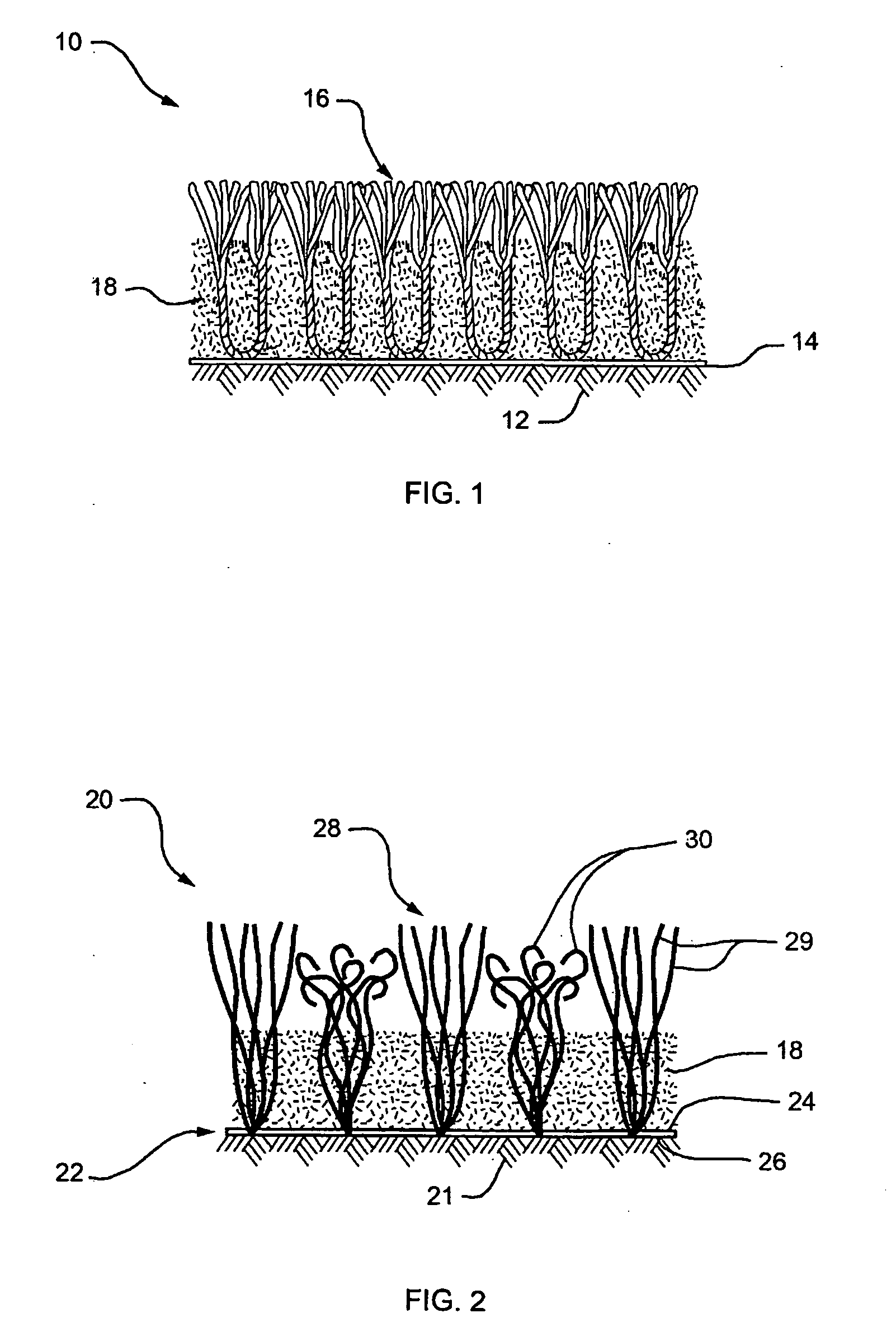

Filler for artificial turf system

ActiveUS20070160800A1Improve abilitiesLiquid surface applicatorsDead plant preservationPorosityArtificial turf

Artificial turf for use with an artificial turf system, which may also include a base layer and a support layer. The artificial turf comprising a backing supporting pile tufts of between ¼″ to 4″ in length, in position on its upper surface. The backing may comprise a porous synthetic foam or backing sheet. A filler of particles shaped to have no sharp edges and of substantially equal size are interspersed over the backing and about the tufts up to at least half thick length. The artificial turf substantially retains its resiliency, porosity and equal density throughout.

Owner:USGREENTECH L L C

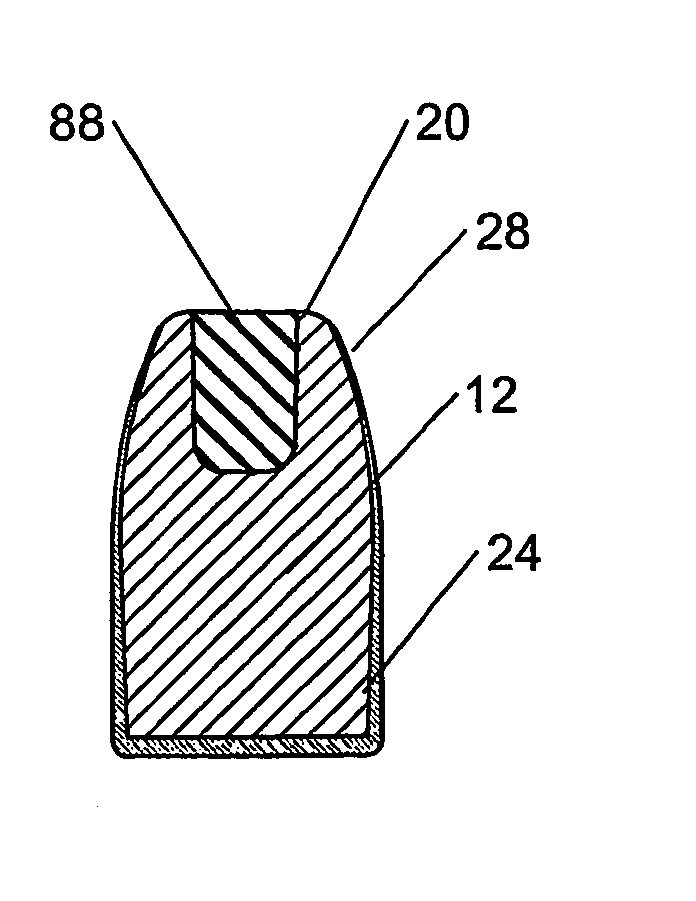

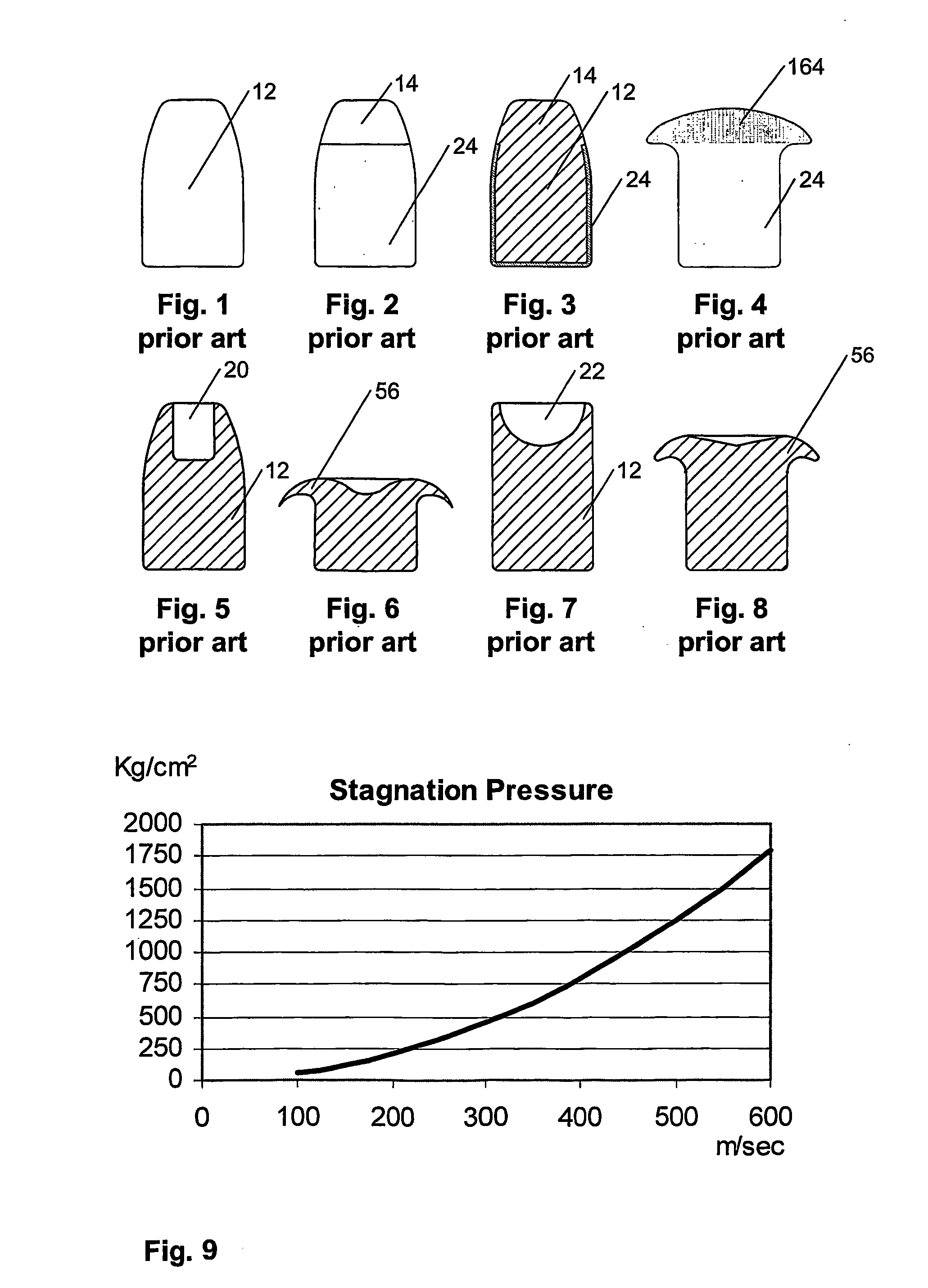

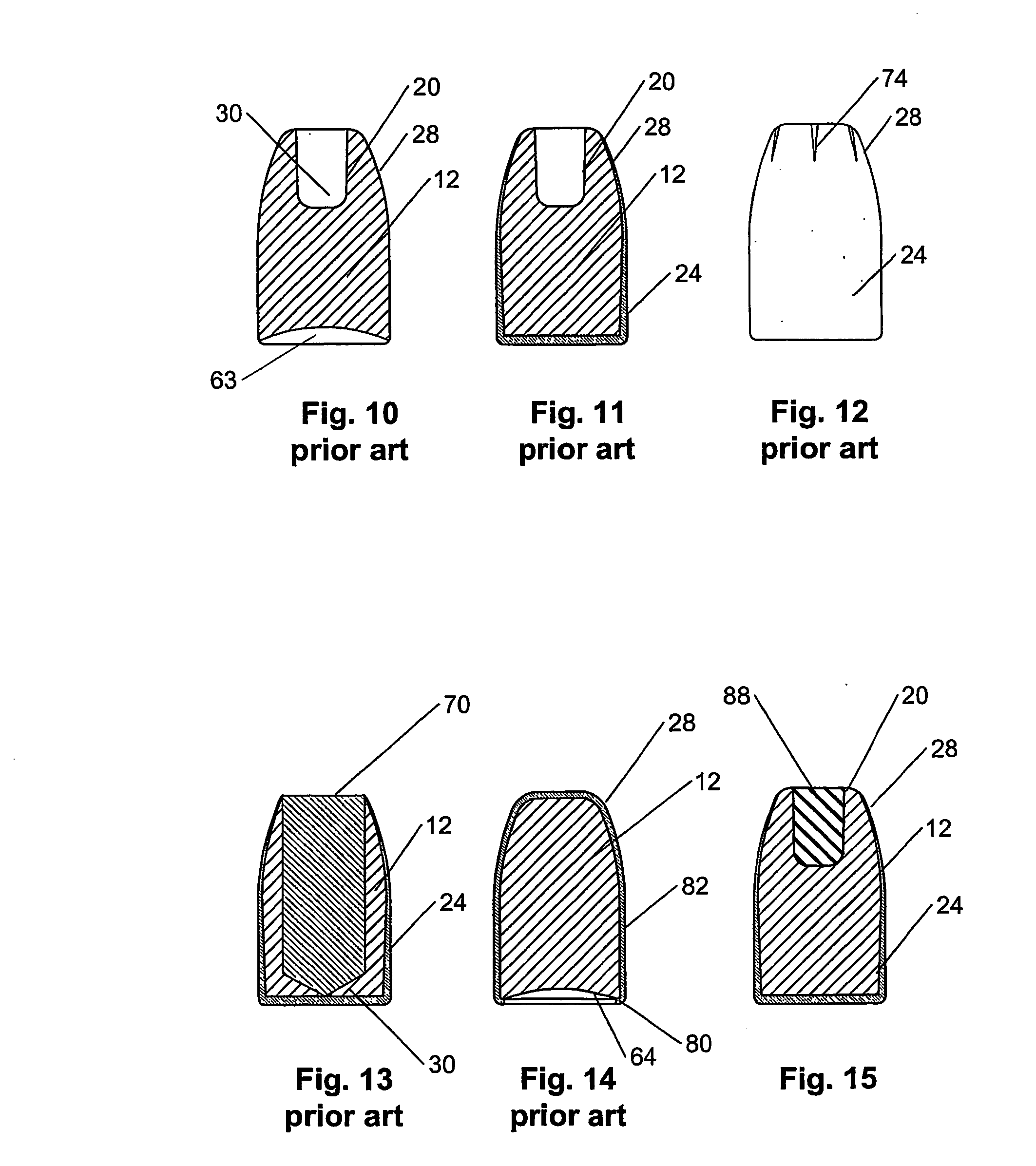

Bullet with booster filling and its manufacture

InactiveUS20050126422A1Preventing pointIncrease heightAmmunition projectilesTraining ammunitionElastomerEngineering

A bullet having a cavity in its forward end that is open at that end and a filling situated within said cavity. Preferably, the filling comprises an elastomer. Preferably, the elastomer filling is vulcanized. More preferably, the vulcanized elastomer filling has a Shore hardness in the range from about 6 to about 90. Alternatively, the filling is a colored rigid polymer filling, if a non-expanding training hollow point bullet is desired. In particular, the invention is a filling and its application to hollow point bullets for the purposes of: improving bullet expansion during the penetration of liquid targets; preventing clogging with debris from intermediate targets; increasing expansion during the perforation of hard materials; preventing the expansion of training bullets; and allowing users to identify different cartridge designs. The invention is also devices and methods for introducing the filling into the cavity.

Owner:LAMM CHARLES ROBERT EMILE

Manufacturing method of simulation tree mould

The invention discloses a manufacturing method of a simulation tree mould. The method comprises the following steps: manufacturing a mould clamping fixture, and making a simulation tree by mixed resin; manufacturing an upper mould, namely, laying oil sludge on the ground, leveling the laid oil sludge, enabling half of the simulation tree to be embedded into the oil sludge, defining a frame made of the oil sludge around the simulation tree to form a pouring tank, coating the simulation tree with a layer of vaseline, coating the vaseline layer with a silica gel layer, covering the silica gel layer by an abrasive cloth layer, pouring silica gel into the pouring tank to form a second silica gel layer, manufacturing a box body, removing the oil sludge around the simulation tree, framing the simulation tree by the box body, injecting filler into the box body, forming a filling layer on the second silica gel layer, and standing still until the layer is cured; manufacturing a lower mould, wherein the method of manufacturing the lower mould is the same as that of manufacturing the upper mould. With the method, the manufacturing cost of the simulation tree mould is very low, and thus the method is suitable for popularization.

Owner:李东礼

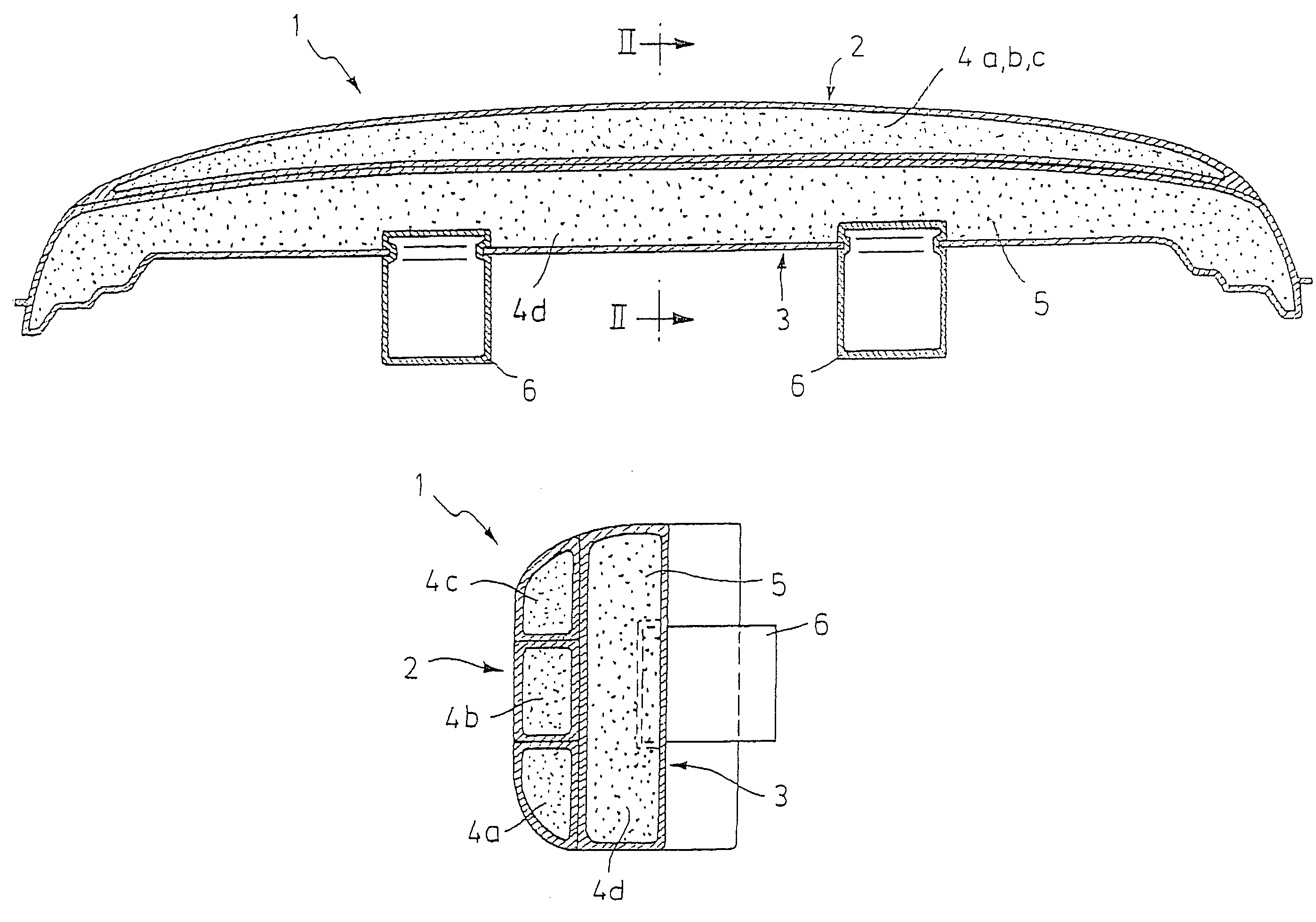

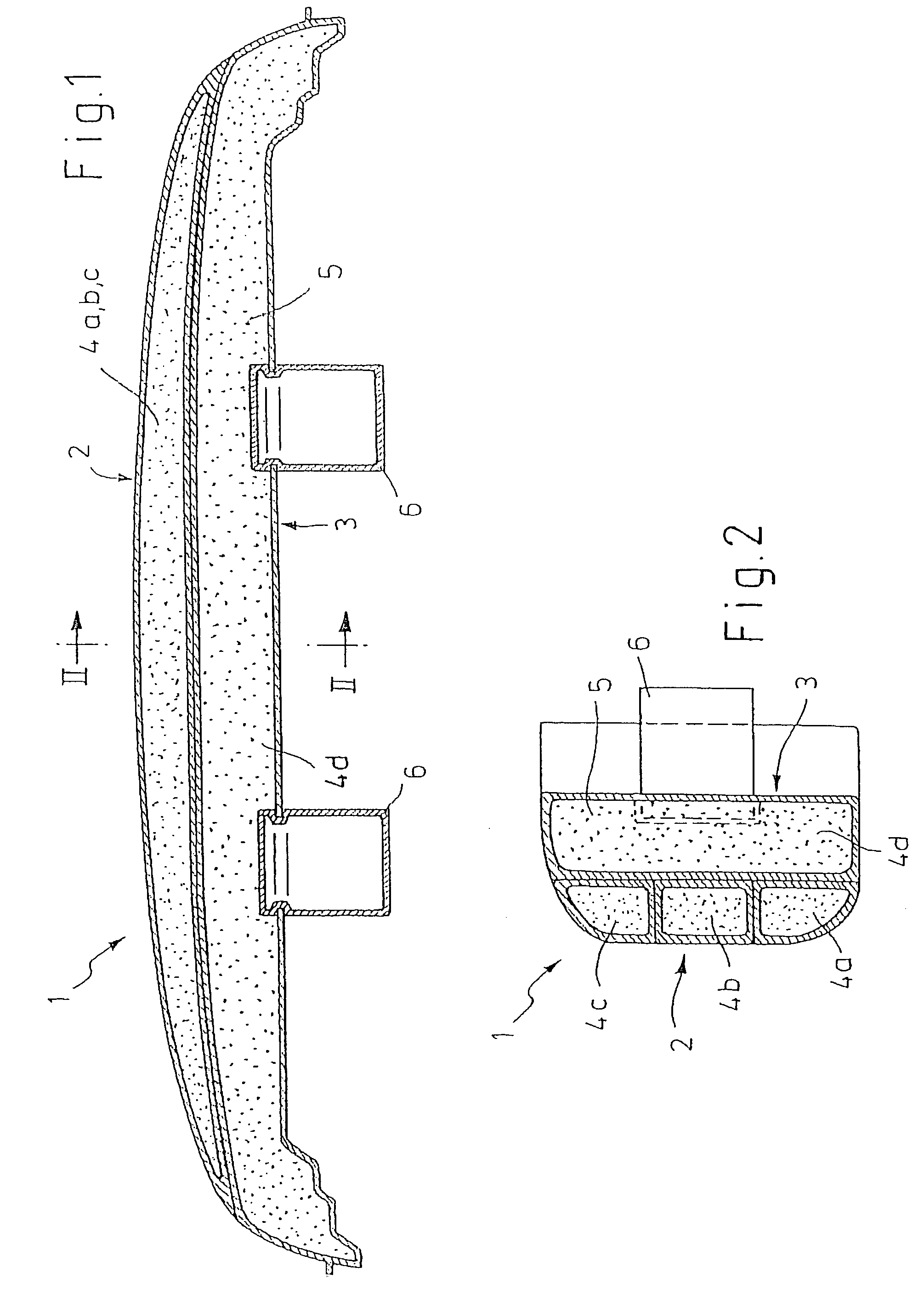

Energy-absorbent component

InactiveUS7044514B2Easy to manufactureStrong stable load-bearing structurePedestrian/occupant safety arrangementBumpersMobile vehicleEnergy absorption

Described is an energy-absorbent component for a motor vehicle, for example as a bumper, which is in the form of a blow-molded hollow body of thermoplastic material enclosing a foam filling on all sides. The hollow body comprises a plurality of chambers therein. The chambers are each closed in themselves and they each respectively accommodate a foam filling affording a differing energy absorption capability.

Owner:KAUTEX TEXTRON

Synthetic Sports Turf Having Improved Playability And Wearability

InactiveUS20070137017A1Easy to drainDead plant preservationArtificial flowers and garlandsInfillWear resistant

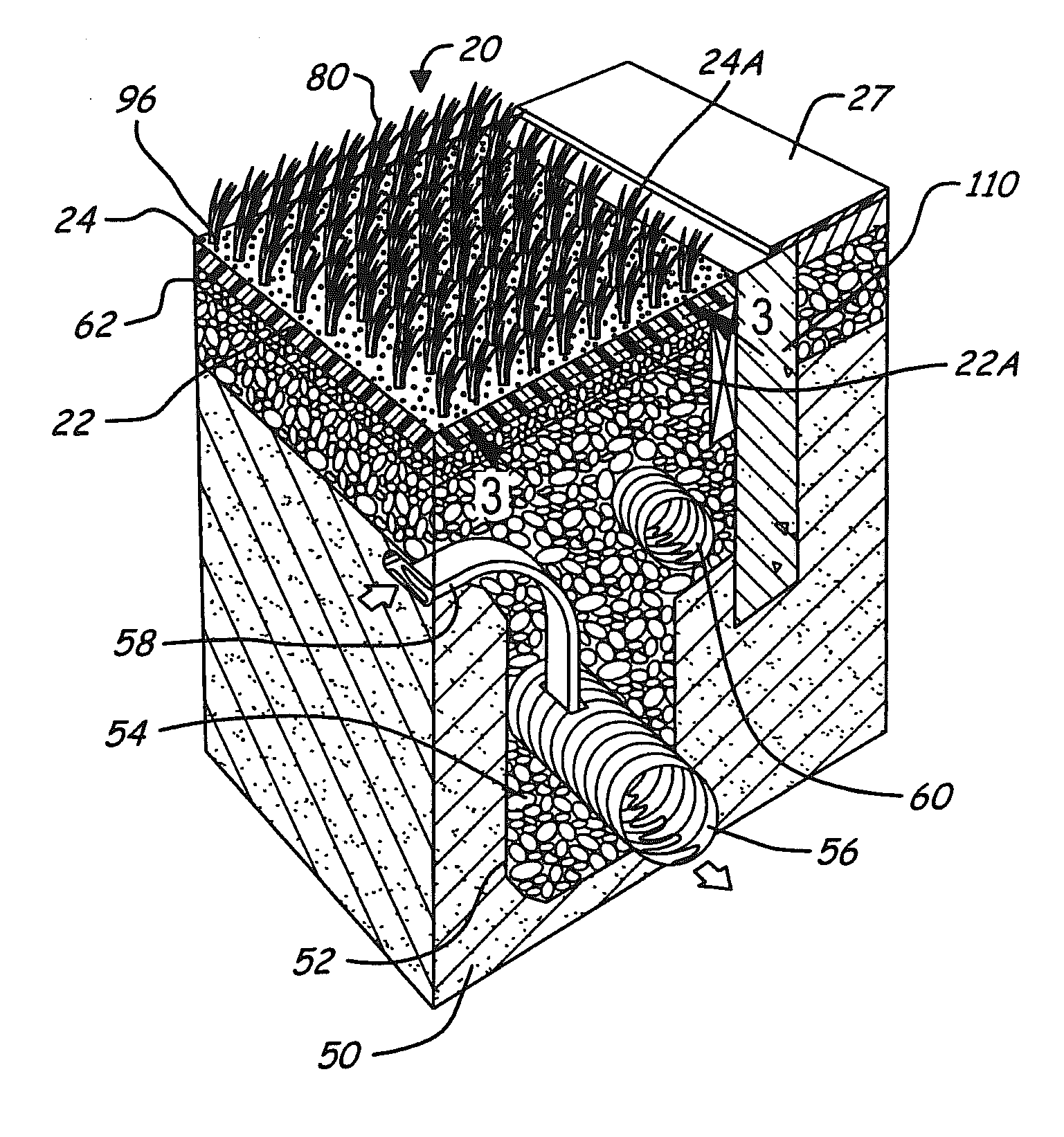

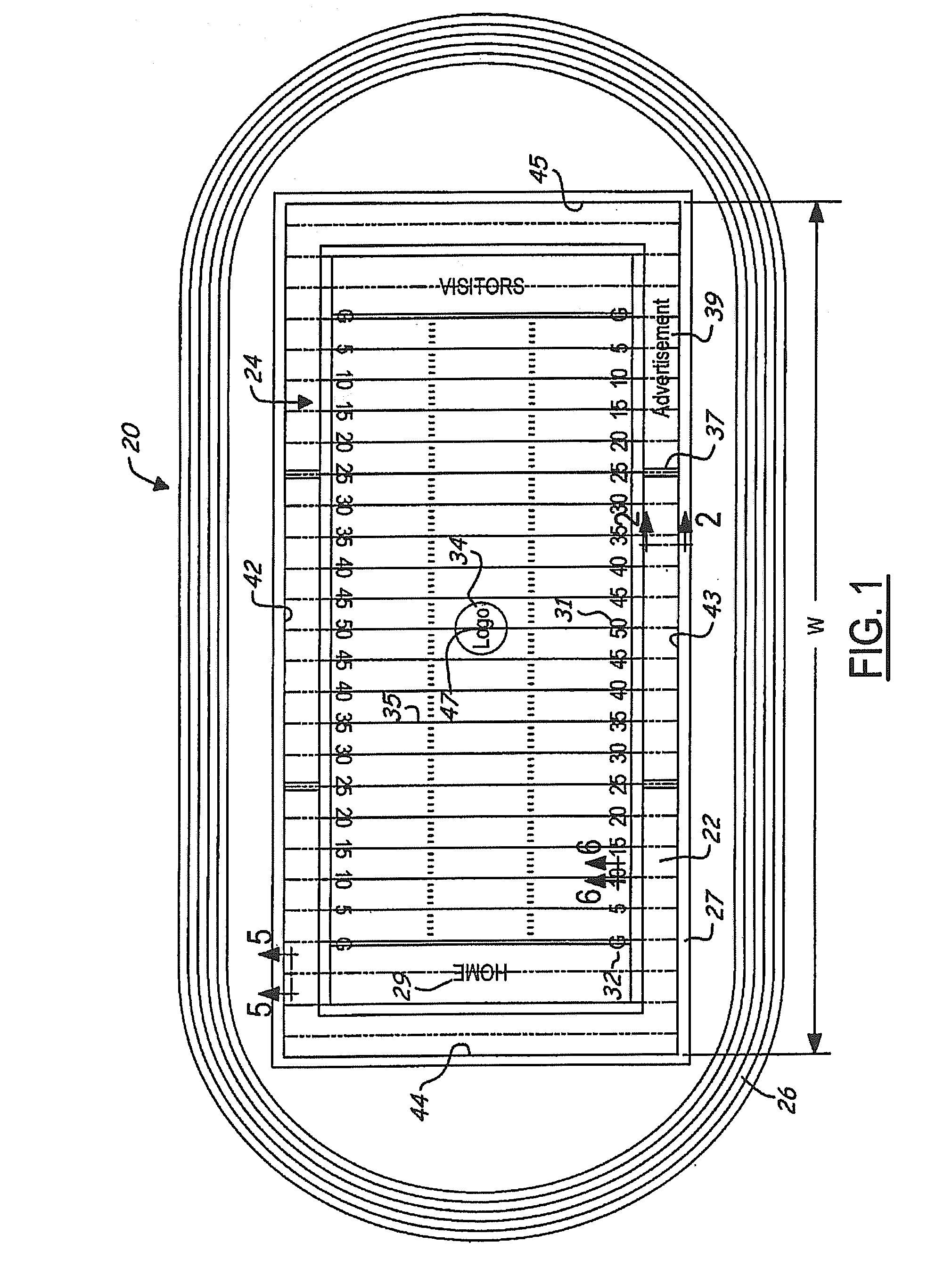

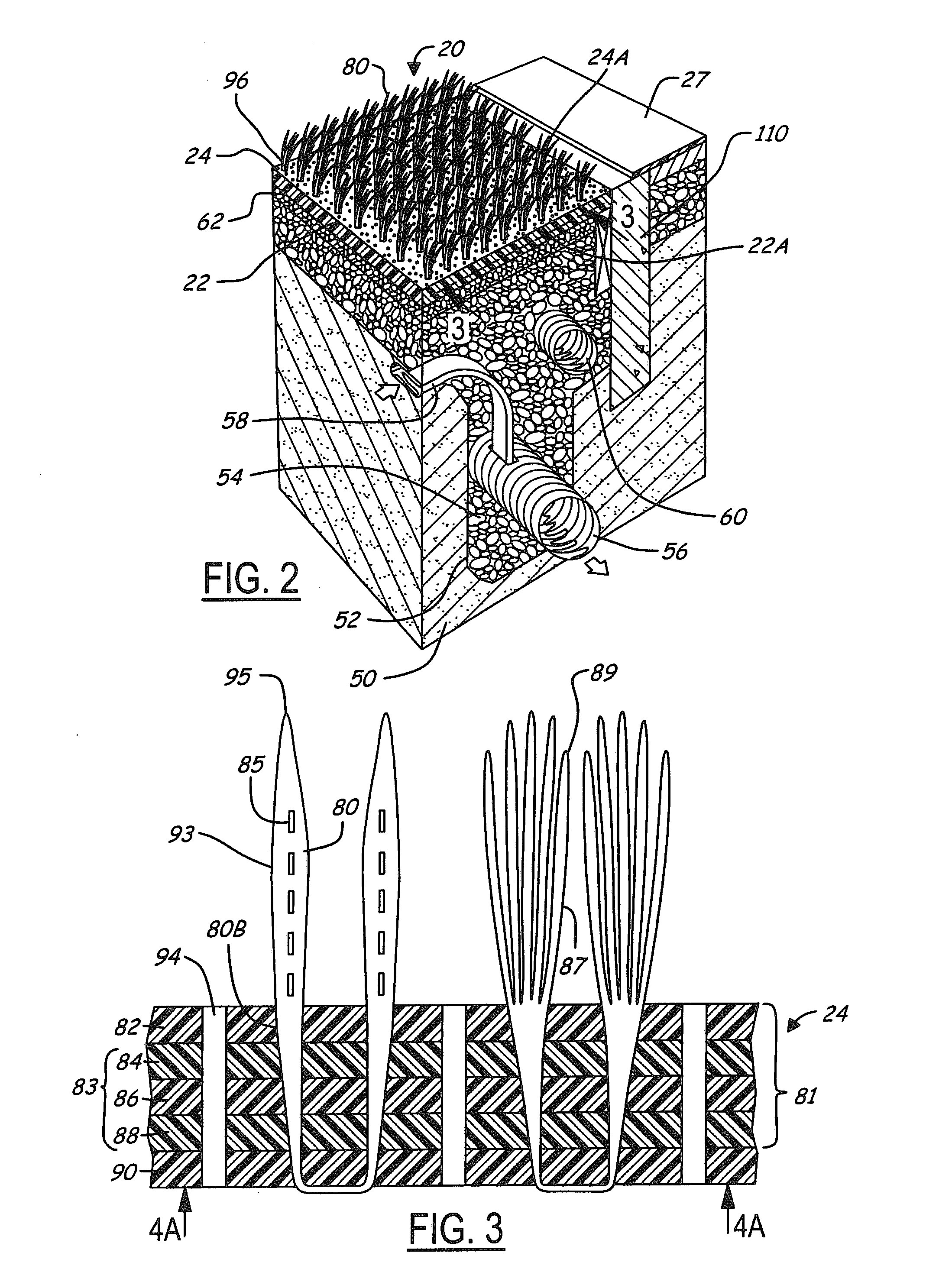

A durable and wear resistant synthetic sports field having at least one strip having a plurality of fibrillated polypropylene strands tufted within a multilayer backing material. The strands are tufted in a wide variety of pile heights, patterns, gauges, and stitch patterns depending upon end use. The multiplayer backing material has a top mesh polypropylene layer at least three layers of a backing material coated with a secondary coating used to contain the ends of the plurality of strands. The strips are placed onto a fine aggregate layer placed over a coarse aggregate layer and a geotextile fabric. The geotextile fabric is placed onto a compacted and leveled subgrade. A ground rubber infill, with or without sand particles and diatomaceous earth, is introduced onto the strips. In alternative arrangements, a series of perforated drains and drain tiles may be introduced to the coarse aggregate layer to promote drainage.

Owner:GENERAL SPORTS VENUE

Method for producing high-elasticity bulked silk-cotton quilt

ActiveCN1743260APromote puffingPuffing treatment can ensure that cocoons are cooked evenly and promoteAnimal fibresUpholstery fillingBoiling processWadding

The invention relates to a method for producing a expanded silk wadding, which includes: sort cocoons, boil at high temperature, degelatinize, shuck the cocoons to remove silkworm, wash, loosen by drawing and make them into silk piece, dewater, dry and draw to make the silk wadding. The invention features that the cocoons before high temperature boiling process are vacuum soaked and expanded by a expanding liquor, concretely the cocoons before high temperature are suctioned into the expanding liquor heated by 80-95 degreeC under vacuum condition, soaked uniformly and expanded in slight boiling state. The said expand is made from amphoteric surfactant. The cocoons after being made into silk pieces and before dewatering are conducted an after finishing by a silk softening agent. Advantages: the patches and stem cubes resulted from un-uniform boiling or in-complete degelatinizing of cocoons are largely reduced; the silk floss is very soft because of full expanding.

Owner:NANTONG LOVER APPL +1

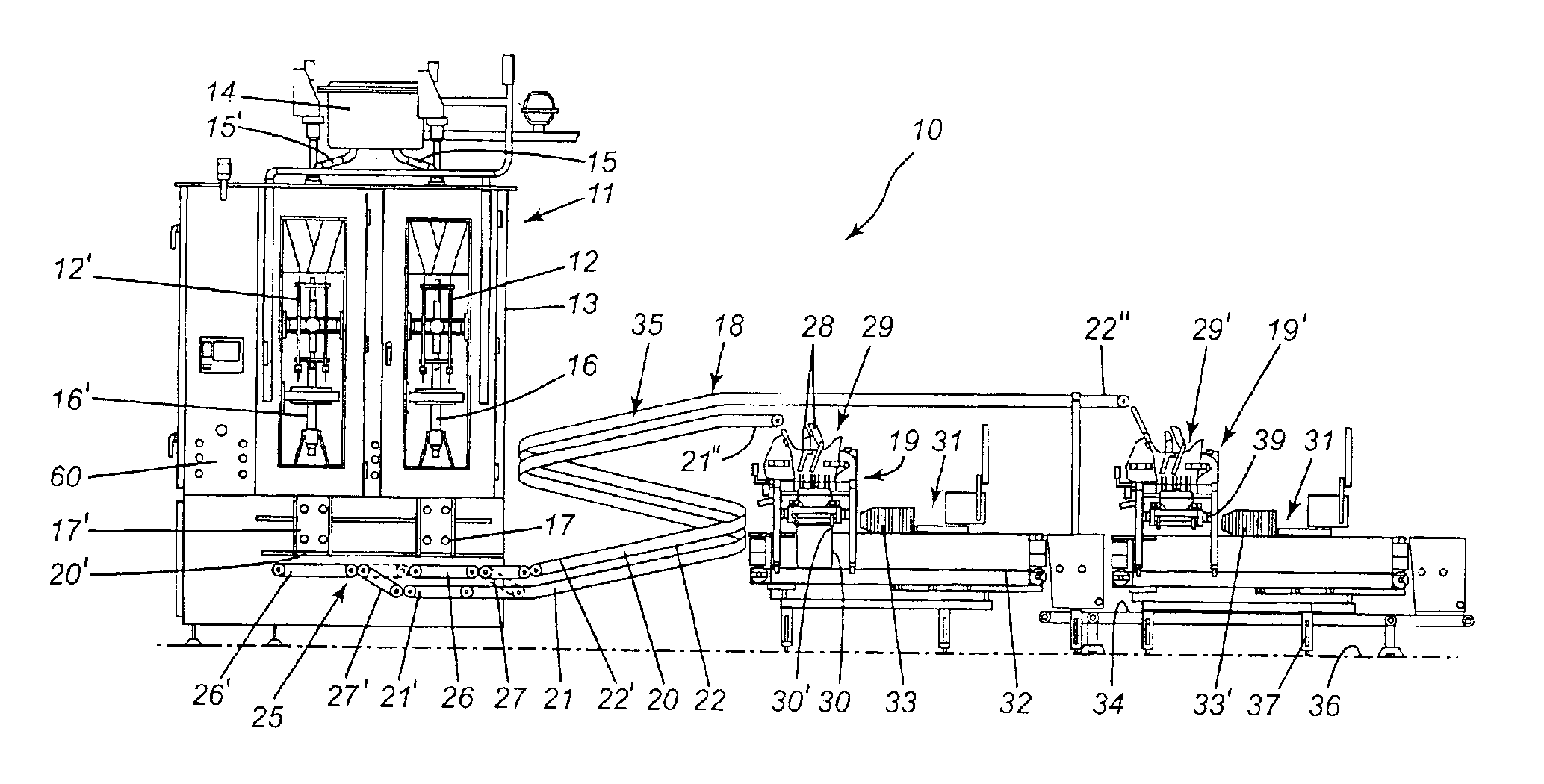

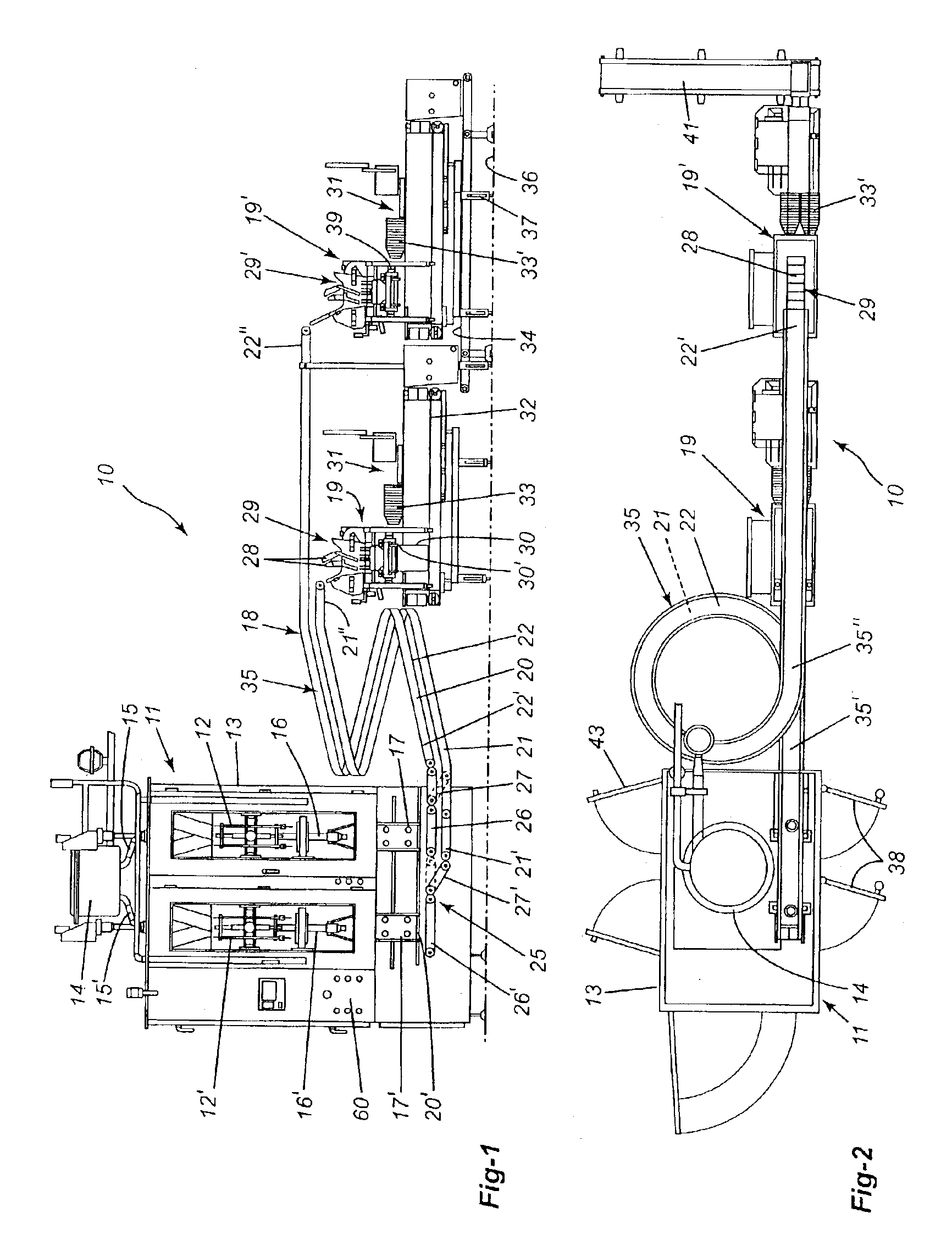

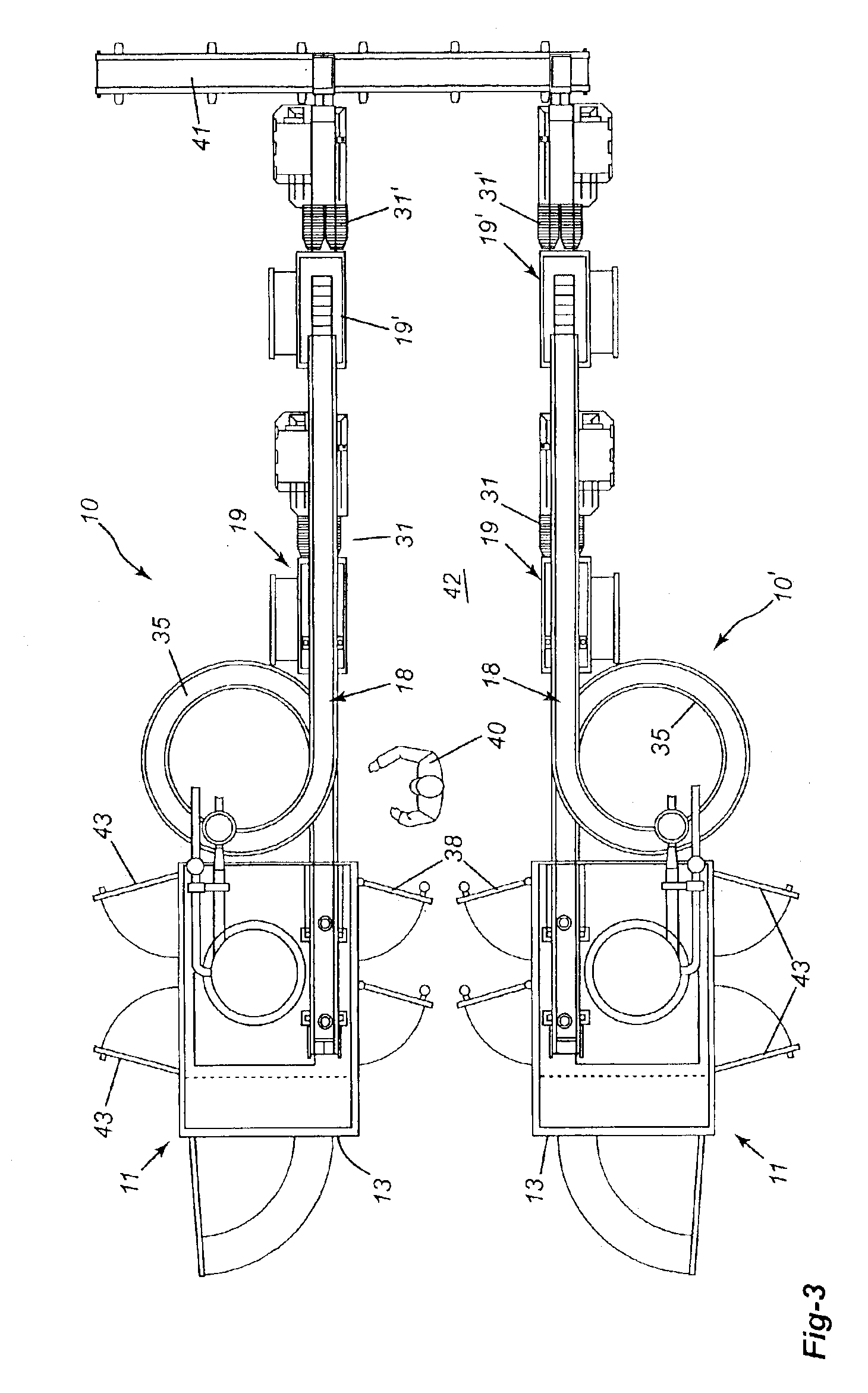

High speed bagging system and method

InactiveUS6874299B2Increase the output speedHigh outputWrapping material feeding apparatusMultiple wrapper applicationLiquid productWork cycle

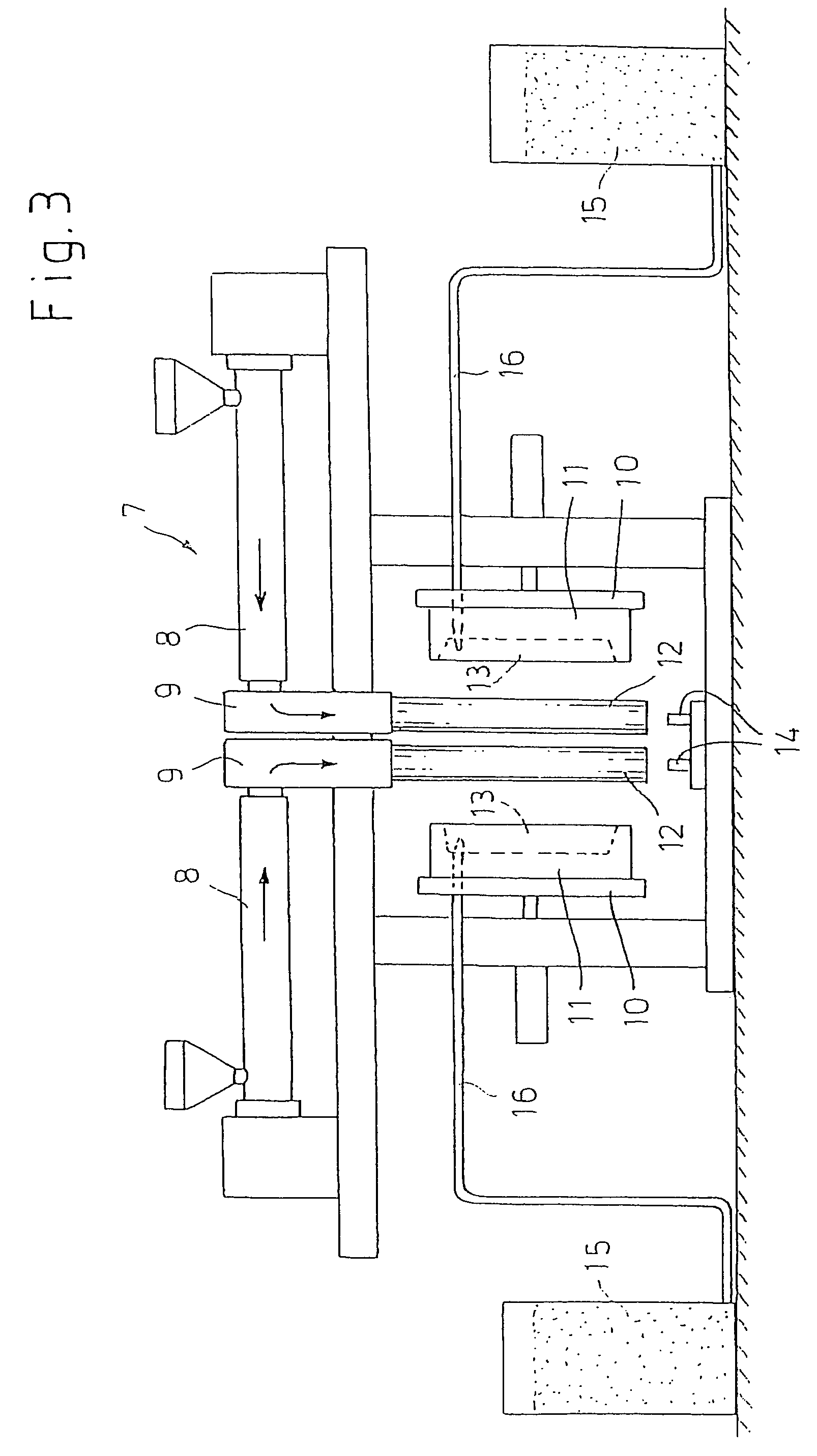

A high speed bagging system and a method for placing a liquid product into a bag and placing at least two of these bags into a pouch is described. The system comprises at least two bag fillers housed in a common filler housing and operating simultaneously to place the liquid product in respective bags on a continuous basis during a working cycle. Filled bags are simultaneously conveyed on a two lane conveyor system. The two-lane conveyor is configured to optimize floor space area. Each conveyor belt has an outlet end associated with a respective bagging machine at a bagging station. The bagging machines are adapted to place at least two of the bags into a pouch on a continuous basis during the working cycle. The bagging machines feed a respective pouch closure device to close a mouth opening of the pouches which are then discharged on a discharge conveyor.

Owner:GLOPAK INC

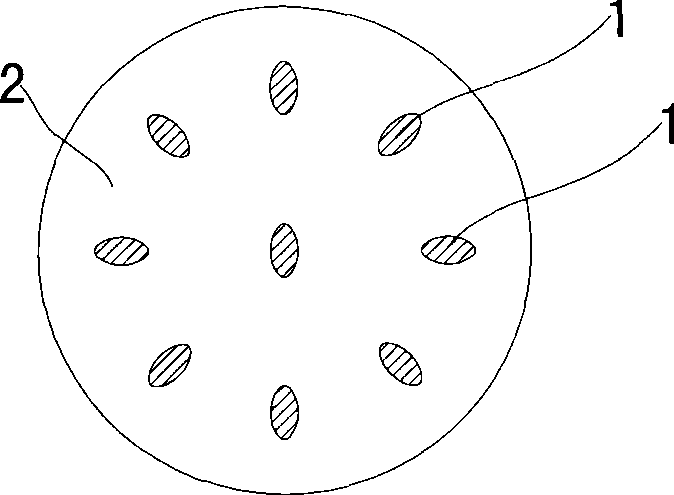

Biodegradale polyurethane capsules and manufacturing method thereof

InactiveUS20040084791A1Improve responsePromote decompositionSynthetic resin layered productsCellulosic plastic layered productsCoated surfaceThermal insulation

The present invention relates to biodegradable polyurethane capsules for molded product of polyurethane foam and to methods for manufacturing the same, the inventive biodegradable polyurethane capsule comprises a powder made from a biodegradable material, first coating layer of calcium alginate gel formed on the surface of said power and second coating layer of foamable polyurethane resin formed on the surface of said first coating layer. Products manufactured from the biodegradable polyurethane capsule according to the present invention can be widely used as heat isolating materials and heat isolating structural materials because the basic physical properties such as heat insulation are good. And, since the biodegradable material inside the capsule is decomposed by microbes in the nature after a certain period, the efficiency of destruction is considerably improved, so it is possible to minimize the conventional problems of soil, air, and sea pollution caused by fill-in or incineration of the wastes of polyurethane molded foam product.

Owner:BIOREPLA CORP

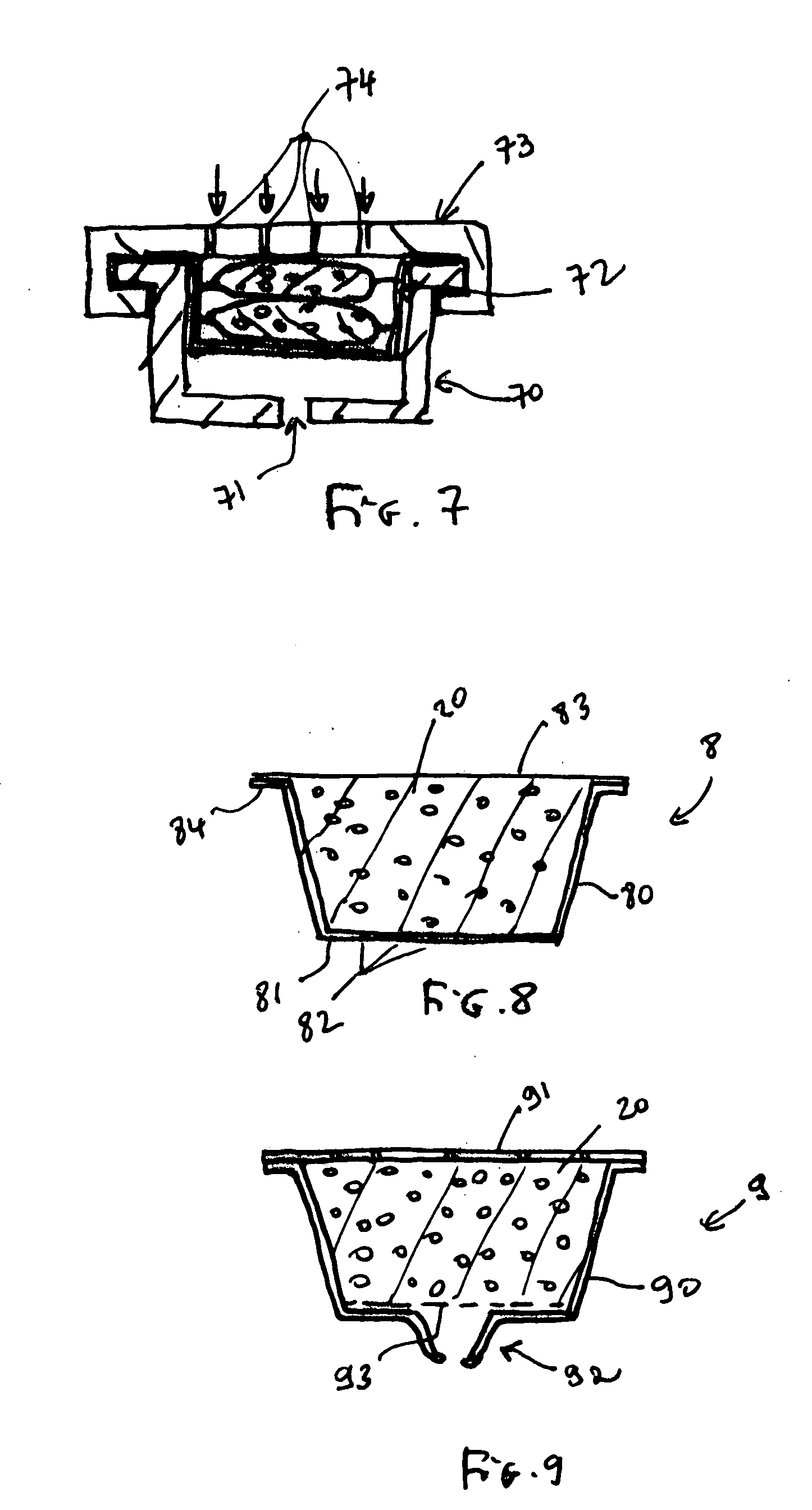

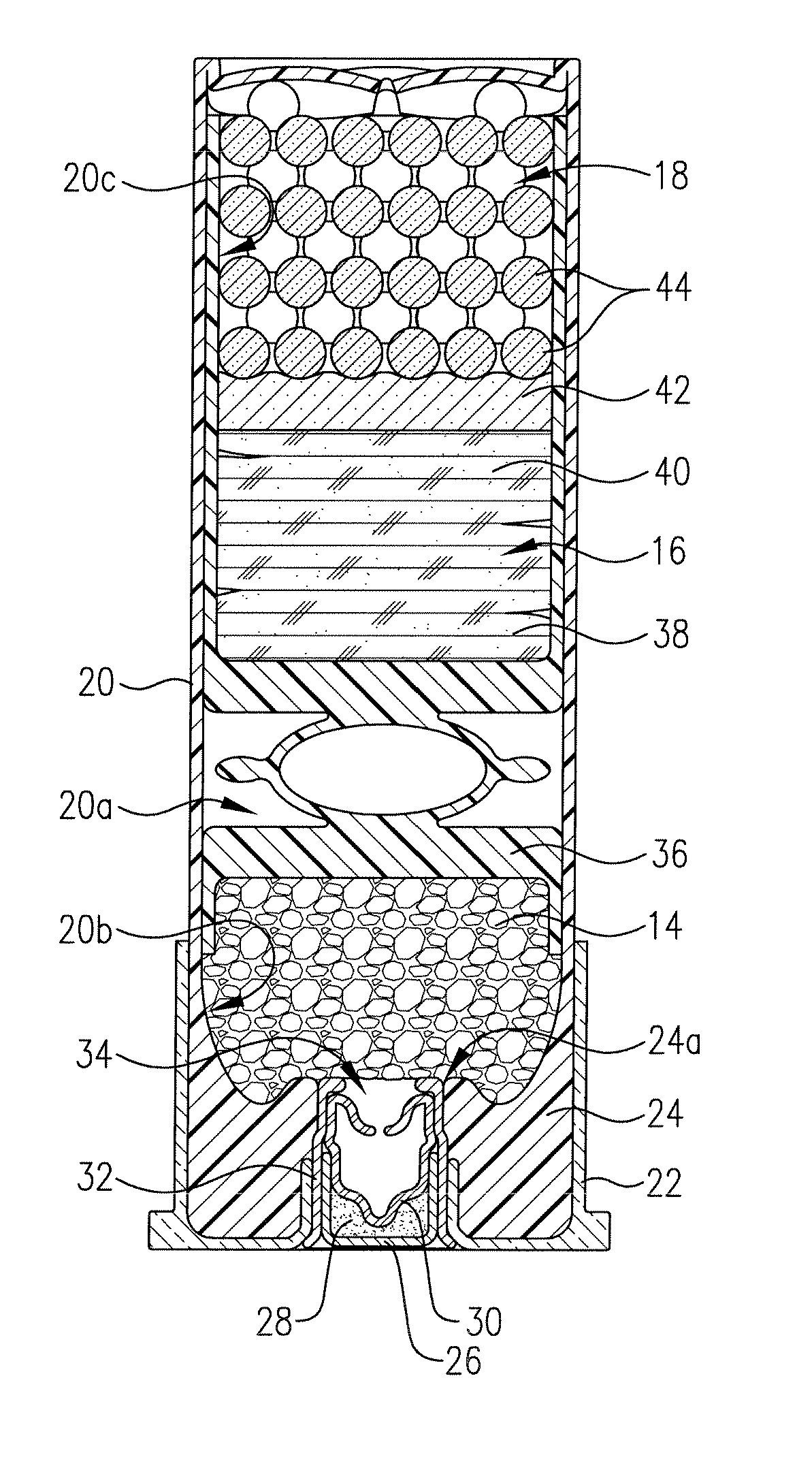

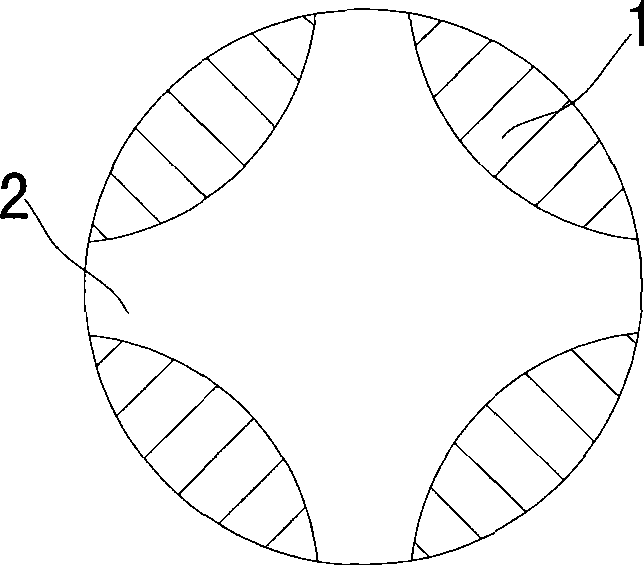

High density cartridge and method for reloading

InactiveUS20070084375A1Reduce loadReduce chargeAmmunition projectilesShotgun ammunitionHigh densityGram

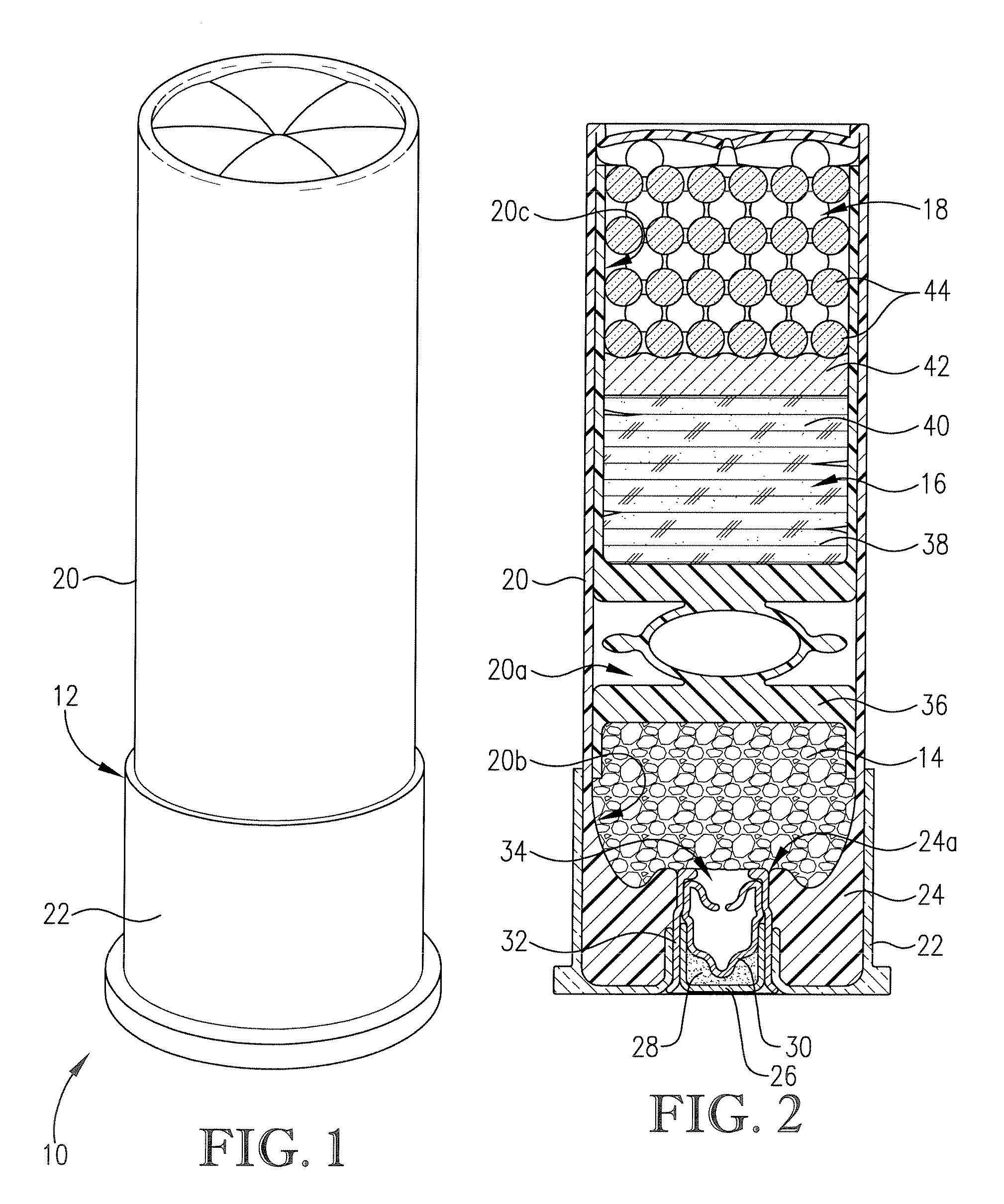

A cartridge (10), constructed in accordance with the principles of a preferred embodiment of the present invention and configured for use in a firearm (not shown), such as a traditional 12-gauge shotgun, broadly includes a shell (12), powder (14) housed within the shell (12), wadding (16) separating the powder (14) within the shell (12), and high density, non-toxic, non-steel shot (18) received within the wadding (16). The high density shot (18) includes a plurality of pellets (44), each including tungsten (46) and presenting a density between about sixteen and nineteen grams per cubic centimeter. Each of the pellets (44) present a uniform, smooth spherical shape. The high density shot (18) is a non-toxic, non-steel shot that patterns well even at long range applications while providing the desired lethality without the need for relatively large payloads.

Owner:SMITH KYLE STEVEN

Universal air-cushioning material

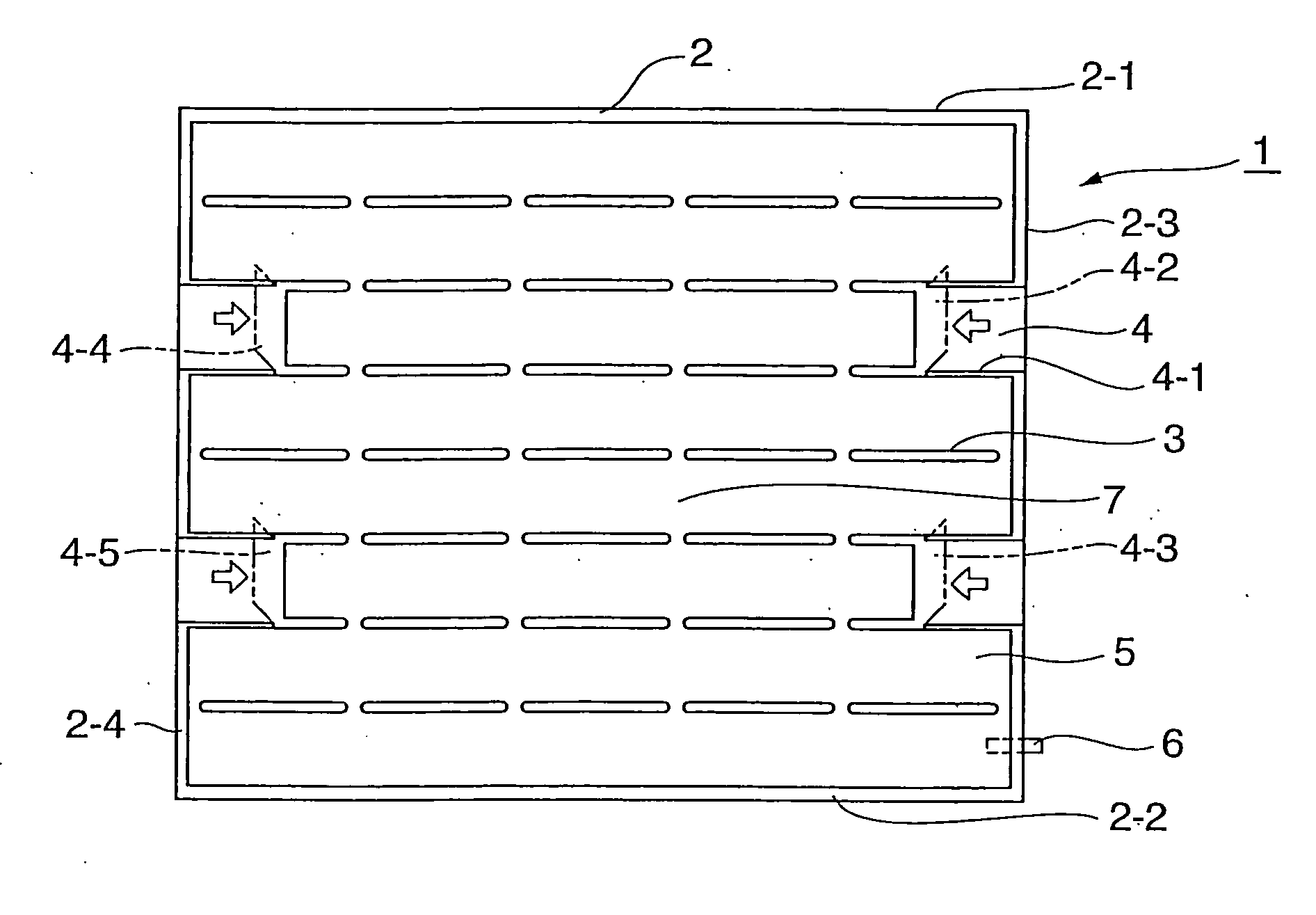

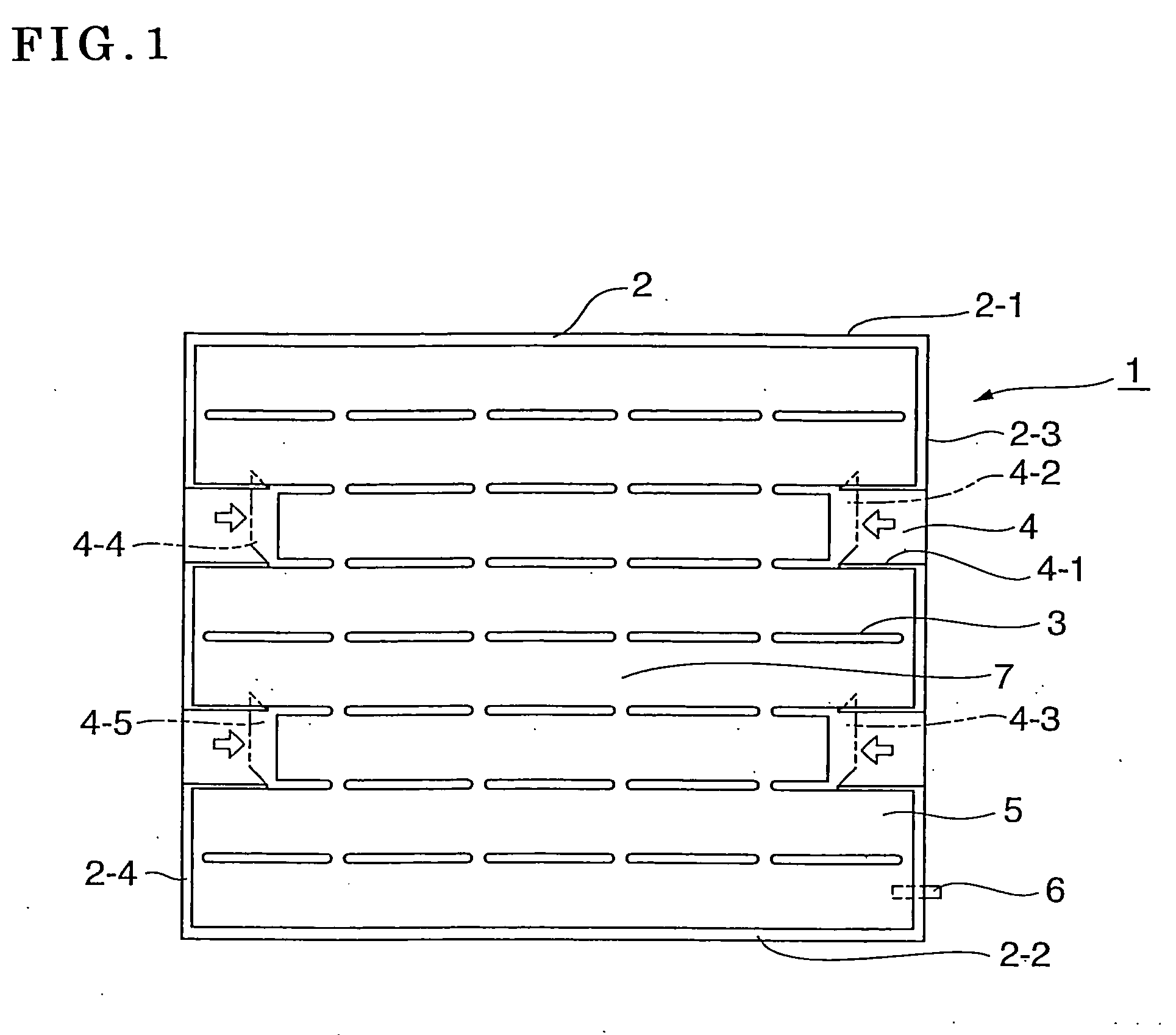

InactiveUS20070131575A1Broad mutual contact areaStable cushioning functionBagsSacksCushioningWadding

The invention intends to cheaply provide a cushioning material that can pack articles to be packed different in shapes and dimensions with a simple structure and stably and that can withstand transportations for long periods under severe conditions. A universal air cushioning material is formed in such a manner that side portions forming end portions of above and below and left and right external frames of two superposed rectangular synthetic resin films made of a same raw material are thermally fused and, between the side portions, an intermediate portion thereof is arbitrarily thermally fused in accordance with a dimension and shape of the article to be packed to dispose a plurality of partitioned peripheral portions; at arbitrary positions in the vicinity of the side portions of the peripheral portions, at least a pair of notches is disposed horizontally symmetrically in accordance with a dimension and shape of the article to be packed and, in the peripheral portions, at least one air passage port is disposed to form a plurality of mutually communicated air chambers to enable to arbitrarily vary a contact area between the air chambers and the article to be packed or an inner wall of the transporting vessel; to at least one of the air chambers an air inlet port is disposed to inject air from the air inlet port to expand an entirety of the air chambers; and thereby an inside thereof is pressed against the article to be packed and an outside thereof is pressed against an inner wall of the transporting vessel.

Owner:ABE TOMEMATSU

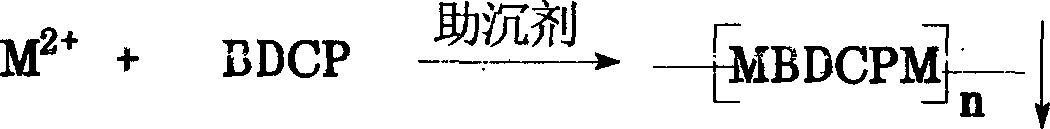

Heavy metal precipitating agent

ActiveCN1603249AImprove sedimentation efficiencyEfficient removalWater/sewage treatmentWaddingPhysical chemistry

The invention discloses a heavy metal precipitator. It conquers the disadvantages of low utilization factor of raw material, and weak complexation ability, incompact wadding and slow speed to deposit existed in the heavy metal precipitator in existing.Especially for the stability complexation heavy metal ion wasting water, it can remove stability heavy metal ion. Moreover, it has decolor function and can be used in the process for heavy metal ion.

Owner:GUANGDONG ZHONGDA ENVIRONMENTAL PROTECTION TECH INVESTMENT

Functional silk non-woven xysma and producing process thereof

InactiveCN1552972AImprove insulation effectIncrease elasticityDe-gumming silkNon-woven fabricsCross-linkEmulsion

Functional silk non-woven wadding is prepared from natural silk, plant resin emulsion and inorganic nano bactericidal. The said emulsion is of self cross-linked anion resin, co-polymerized from acrylic diester, arylonitrile itaconic acid and N hydroxy acrylamide as cross-linking agent. The ratio of emulsion : silk is 100: (1.5-5.0) by dry weight. Silver ion nano bactericidal is also added into the wadding with the ratio of the bactericidal : silk is 100: (0.5-15.0). The product is soft and light, moisture-absorbing and gas permeable, high thermal insulation, elastic, water washing resistance, safety and usable widely.

Owner:丁永华

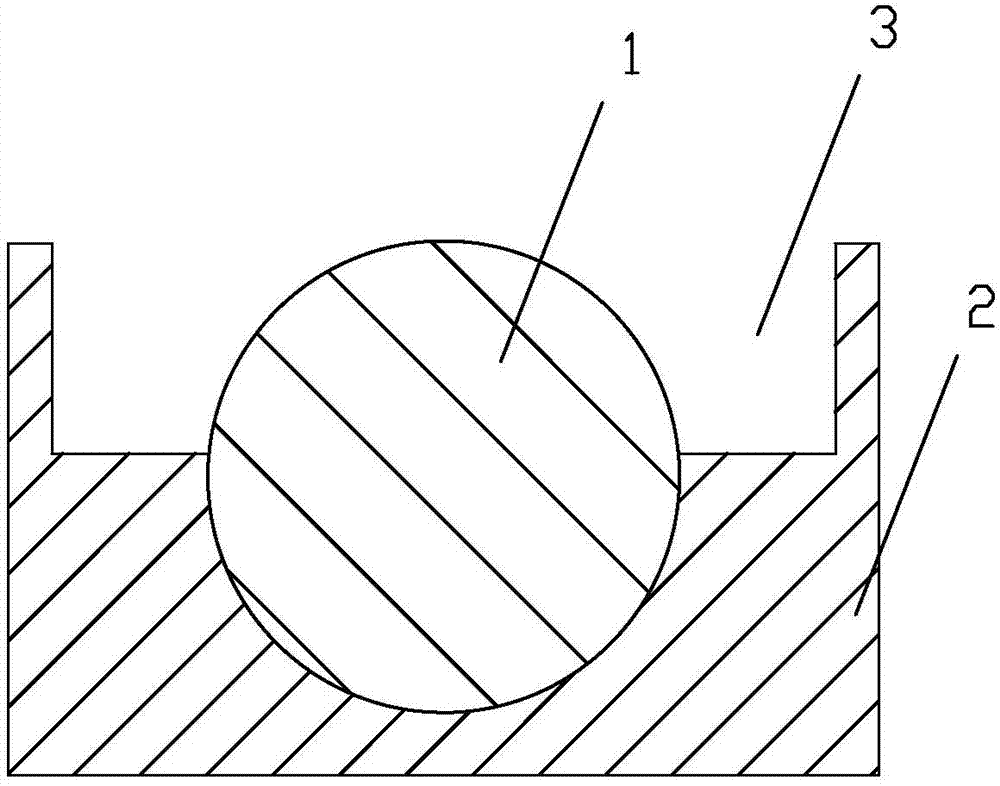

Method for preparing ultrafine zeolite powder filling PTFE (polytetrafluoroethylene) composite material

The invention discloses a method for preparing an ultrafine zeolite powder filling PTFE (polytetrafluoroethylene) composite material. The method comprises the steps of 1) proportioning materials, i.e. mixing polytetrafluoroethylene, ultrafine zeolite powder, a filler I and a filler II according to the ratio; 2) uniformly mixing the mixture proportioned and then carrying out cold press forming under the pressure of 20-40 Mpa; 3) putting the formed object obtained in the step 2) into a high temperature sintering furnace, heating to 330-380 DEG C with the speed of 30-100 DEG C / hour and preserving heat for 0.5-2 hours; and 4) naturally cooling sintering products obtained in the step 3) to the room temperature to obtain the ultrafine zeolite powder filling PTFE (polytetrafluoroethylene) composite material. The ultrafine zeolite powder filling PTFE (polytetrafluoroethylene) composite material prepared according to the method has excellent performance, the wear resistance of the composite material is improved upon the premise of not remarkably reducing the matrix friction coefficient of PTFE, and the application range of the composite material is wide.

Owner:ZHEJIANG UNIV

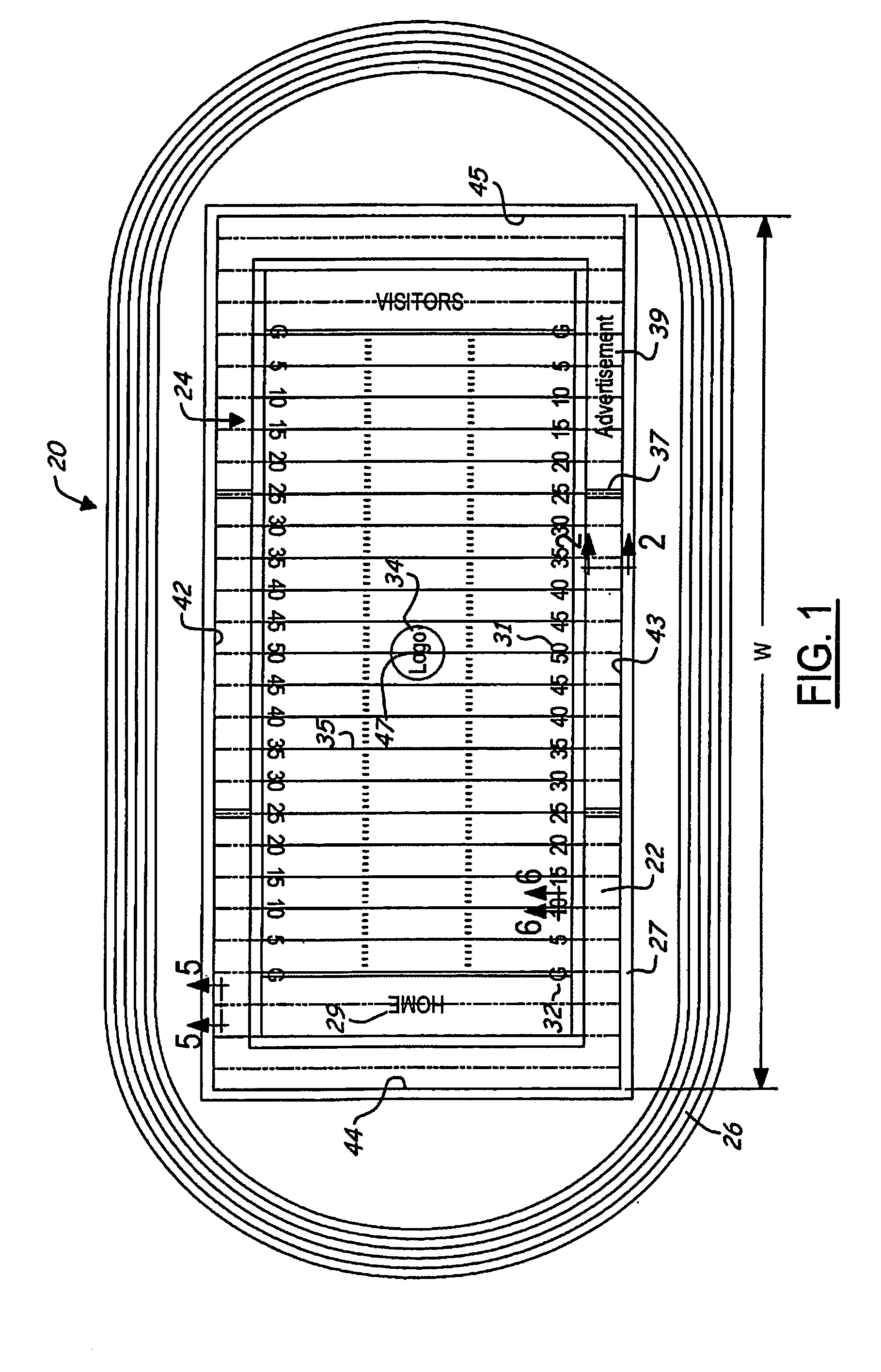

Roll up artificial turf

A filled artificial turf includes a plurality of filled artificial turf sections which can be disconnected, rolled up and stored and then later unrolled and reconnected, thereby to enable a facility to accommodate a wide variety of sporting and non-sporting events, with no adverse effects on the playability of the turf. Each of the sections includes a backing, fibers secured to the backing, and a particulate fill with the fibers being of sufficient density and texture so as to substantially hold the particulate fill to the backing during rolling and unrolling. The sections also include hook and loop fasteners along the edges thereof, to facilitate simple and cost-effective connection and disconnection of the sections.

Owner:HELLAS CONSTR INC

Silk-floss wadded quilt producing process

The present invention discloses silk-floss wadded quilt producing process, and aims at providing one kind of silk-floss wadded quilt capable of resisting vacuum compression. The silk-floss wadded quilt producing process includes the steps of: soaking silkworm cocoon in hot water, machine drawing silk, boiling, high temperature refining, cold rinsing, neutralizing to soften, adding special puffing agent and drying agent, quick high temperature roasting, physical puffing, making wadding, vacuuming and sealing, and packing the product. The silk-floss wadded quilt product has small size and after unpacking, it restores its puffed soft ventilating state.

Owner:潘新平

Conductive polymer resin and core-sheath composite structure dyeable antistatic fiber

InactiveCN101434739ALower glass transition temperatureLow melting pointElectroconductive/antistatic filament manufactureFilament/thread formingPolymer scienceConductive polymer

The invention discloses a conductive high molecular resin and a stainable antistatic fiber with a sheath-core composite structure prepared by the resin. The fiber comprises the conductive high molecular resin and resins of PBT, PET, PTT, PA, PP and the like; wherein, the weight ratio of the conductive high molecular resin and the resins of PBT, PET, PTT, PA, PP and the like is about 5 percent-50 percent to 95 percent-50 percent. The fiber prepared is characterized by being easy to be shaped and dyed in processing. Fabrics processed by the fiber has good static eliminating feature, can remarkably improve the electrostatic and electrification phenomena of chemical fibers, wool textiles and non-woven fabrics and is applicable to various civilian costume fabrics, short fiber fillings, wool fabrics, antistatic working uniforms, etc.

Owner:POLYNOVA MATERIALS SUZHOU +1

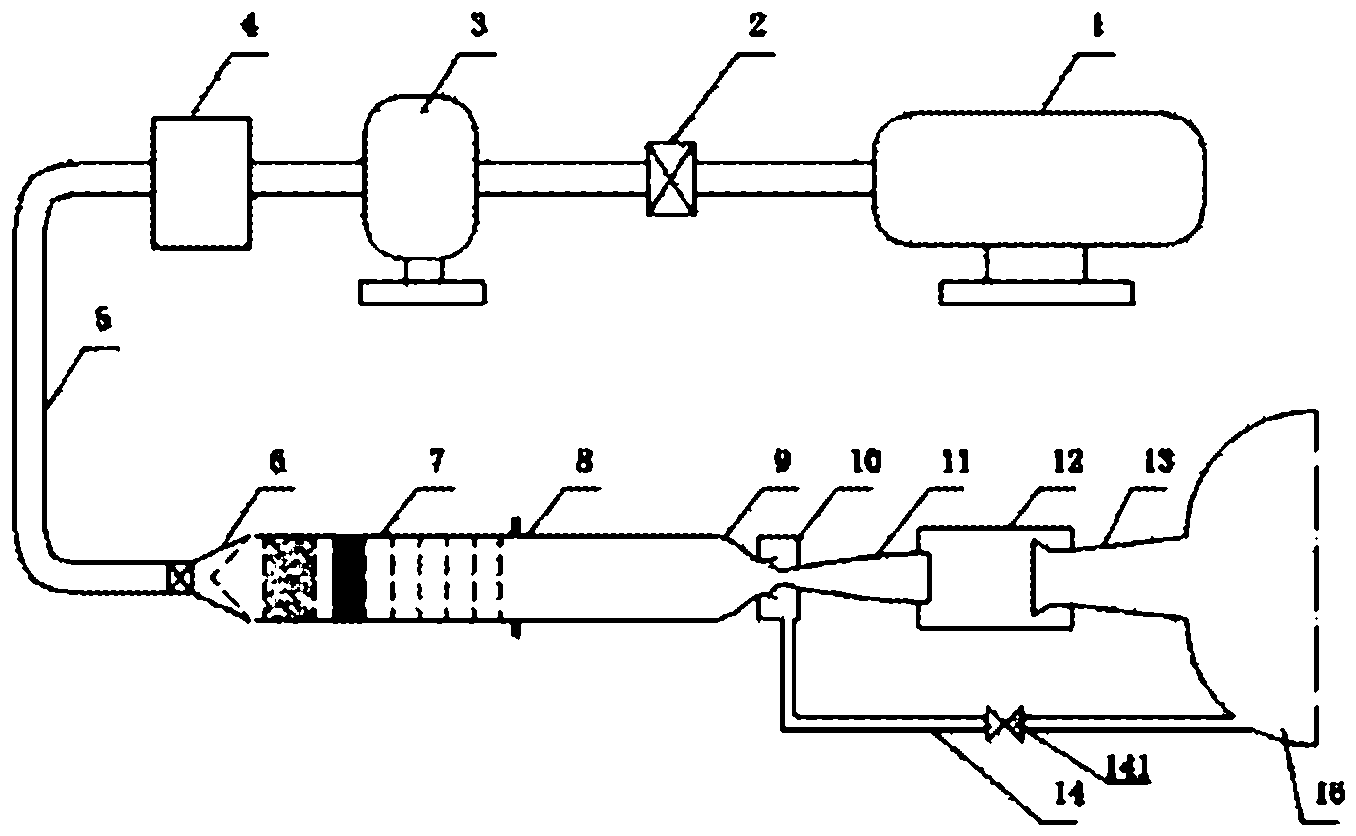

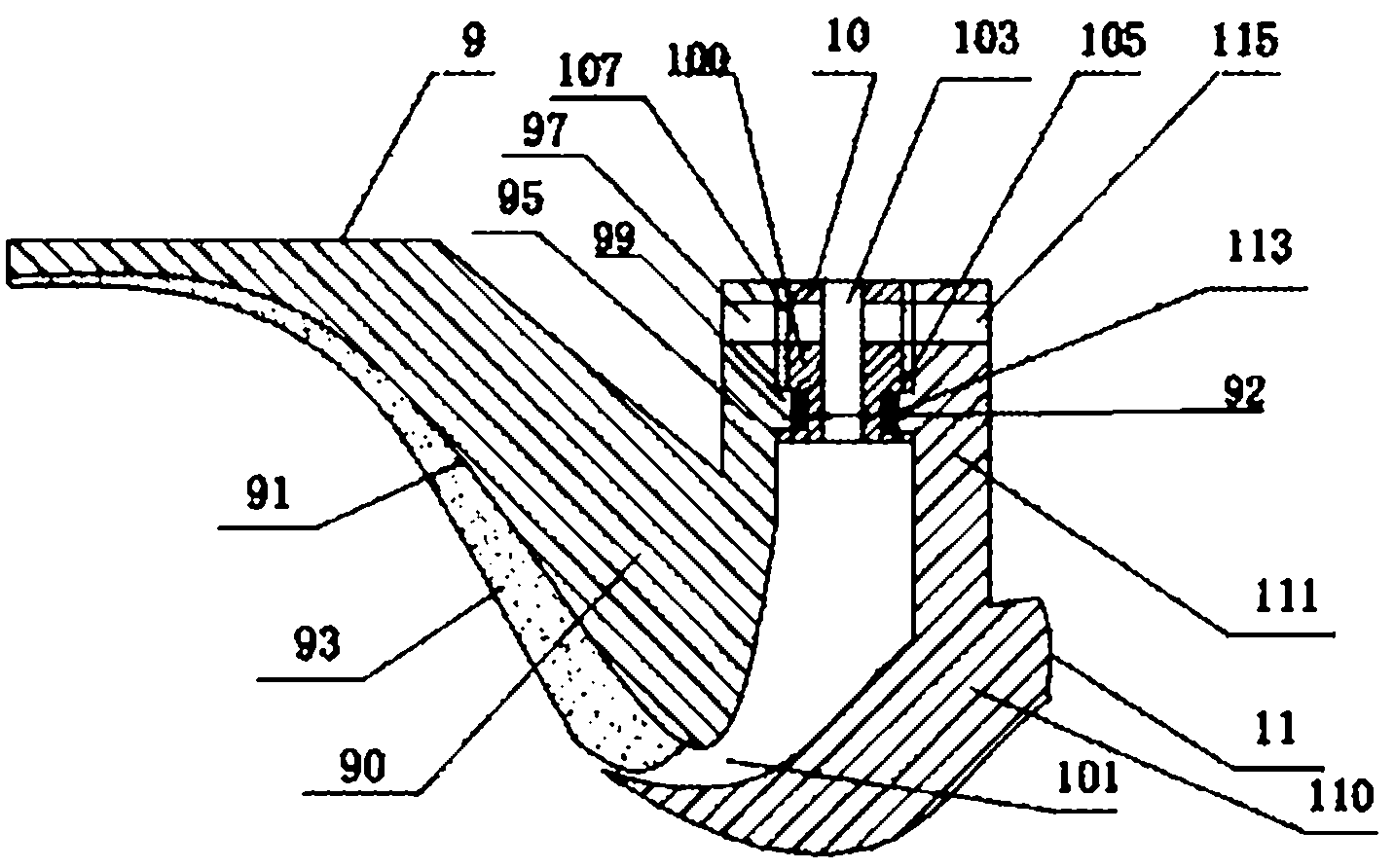

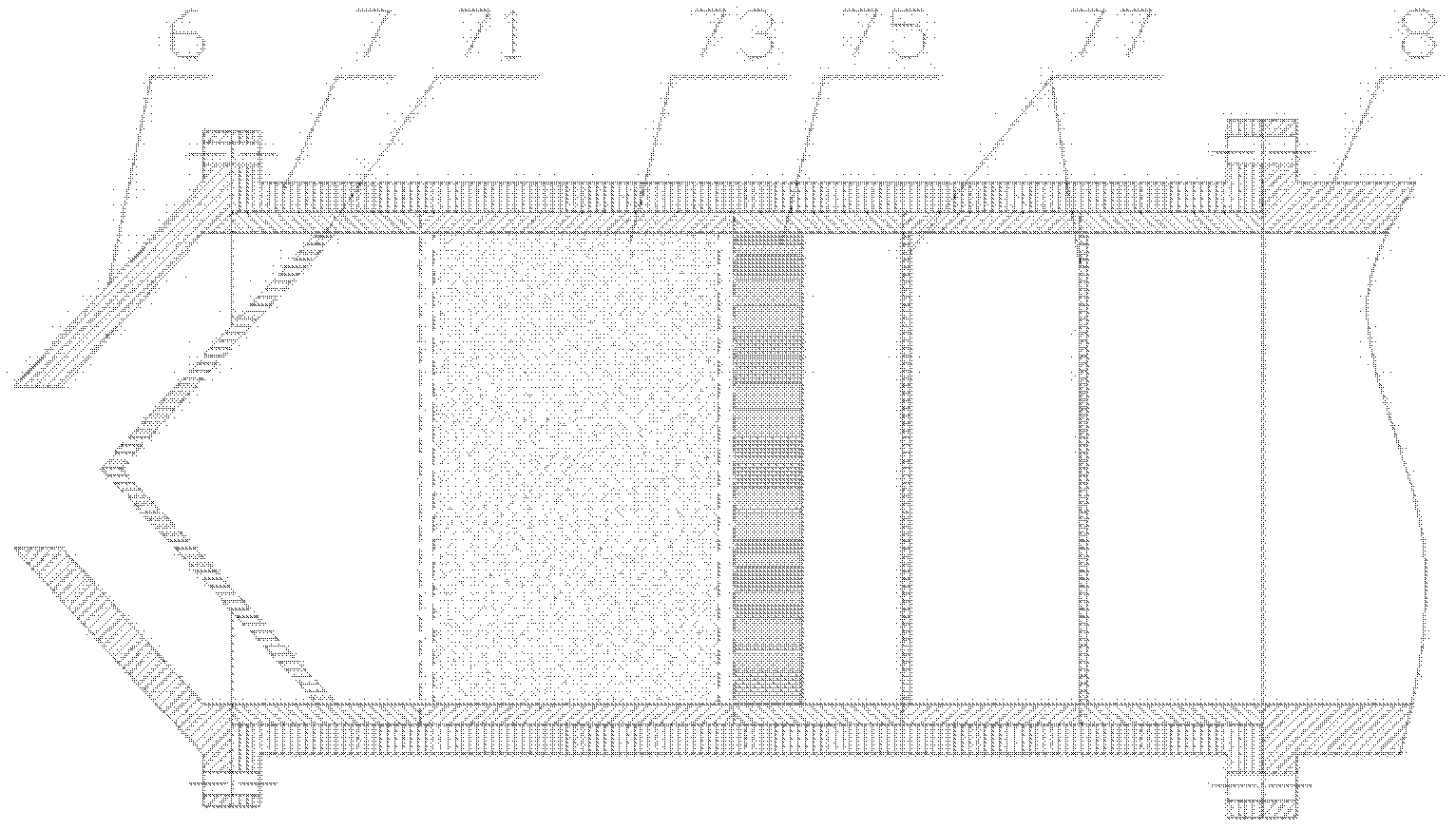

Supersonic wind tunnel with variable quality of flow field

The invention discloses a supersonic wind tunnel with variable quality of a flow field. A boundary layer sucking and removal device is arranged on the supersonic wind tunnel, and a turbulent boundary layer on the inner wall of the outlet end of a contraction section is sucked and removed by using the boundary layer sucking and removal device to change the quality of the flow field; meanwhile, a separation prevention cone, a stainless steel silk wadding noise elimination part, a sintering net plug and a multi-layer damping net are selectively arranged at a front stabilization section so as to change the quality of the flow field. The supersonic wind tunnel can solve the problems that experiment cost is increased, the work amount is large, and the reliability of an experiment result is low when the supersonic wind tunnel realizes the quality of different flow fields so as to achieve the effects of reducing experiment cost, and work amount and improving the reliability of the experiment result.

Owner:NAT UNIV OF DEFENSE TECH

Fiber wadding for filling bone defects

ActiveUS8853298B2Speedup (acceleration)Improve adhesionImpression capsSurgical adhesivesFiberWadding

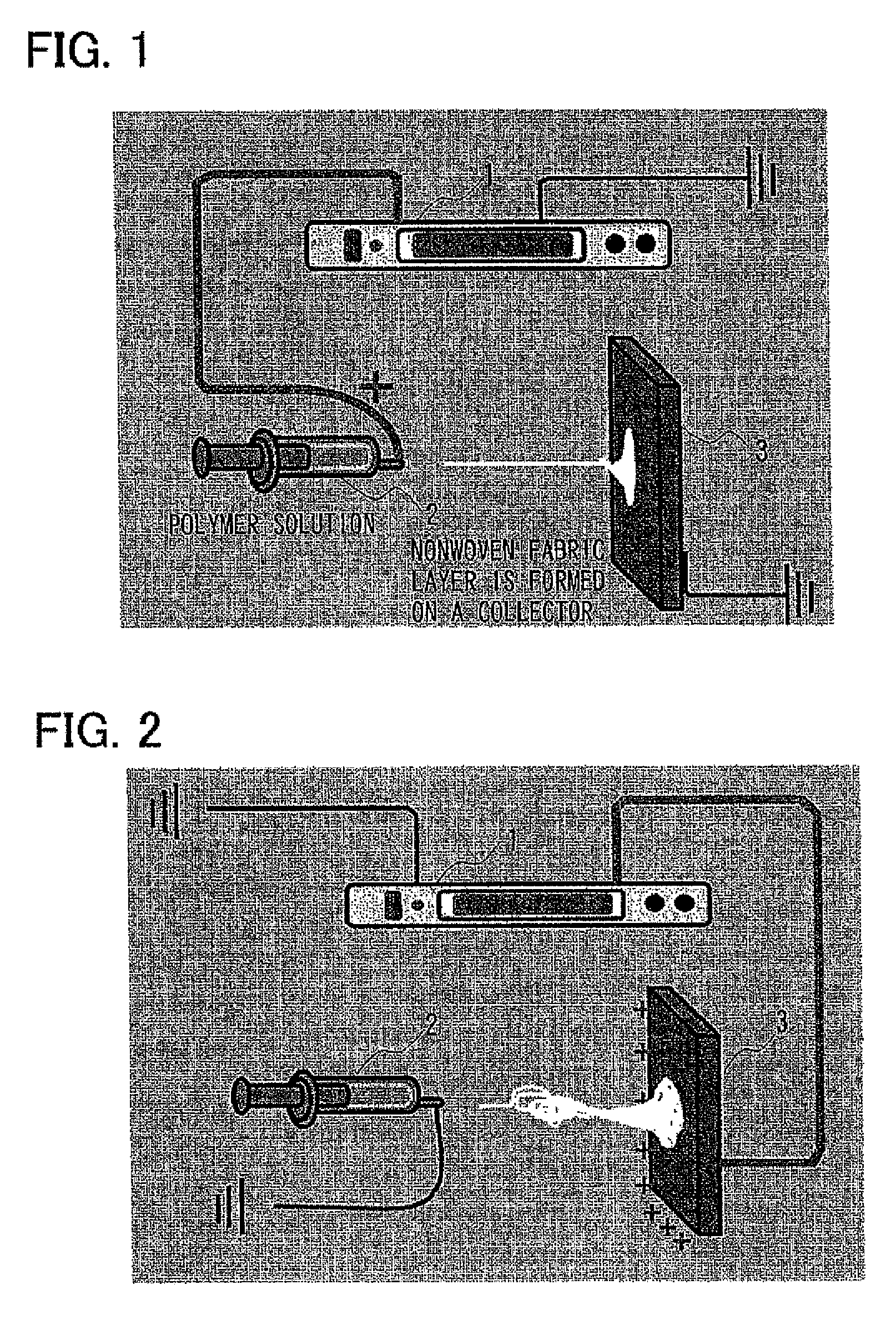

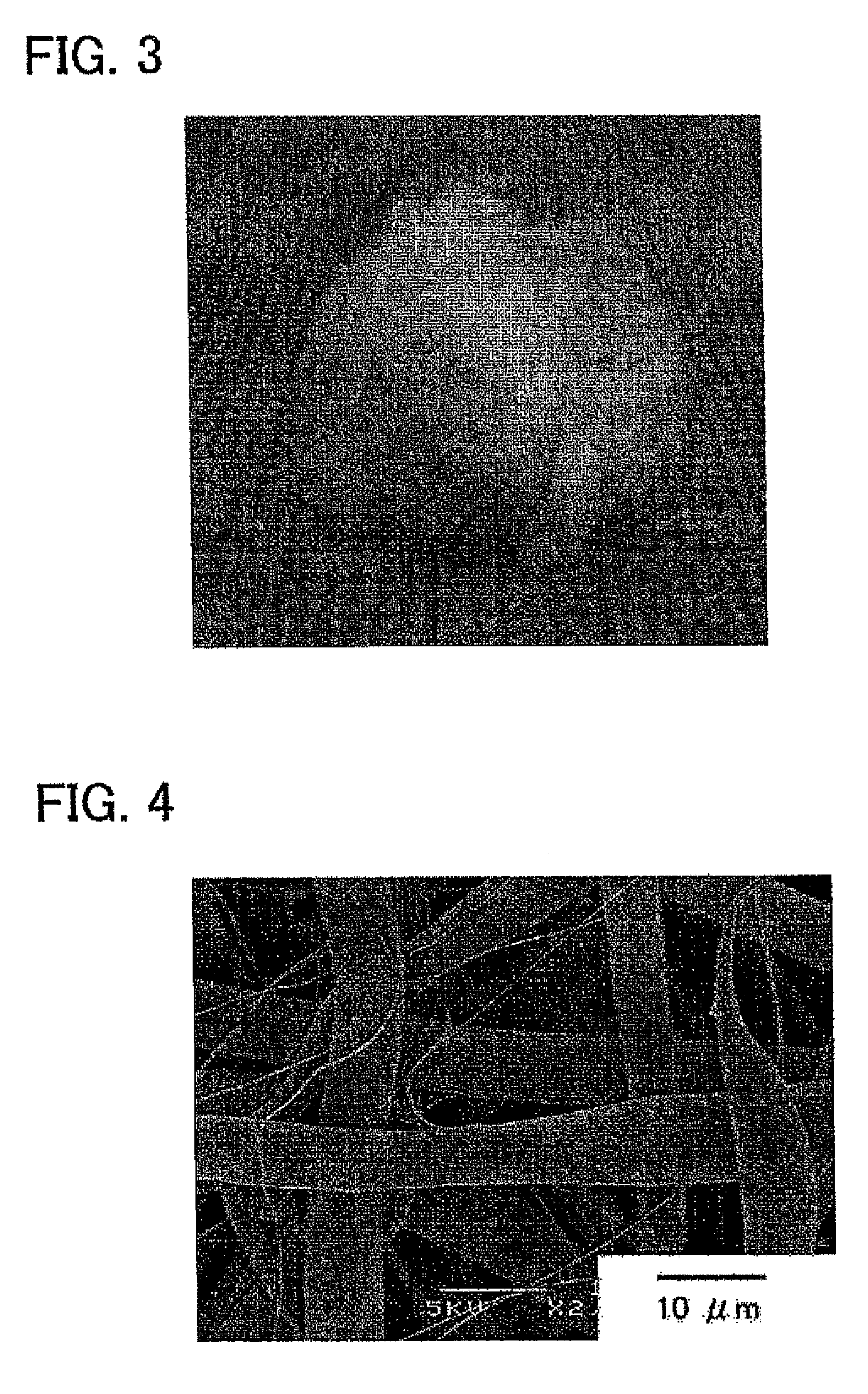

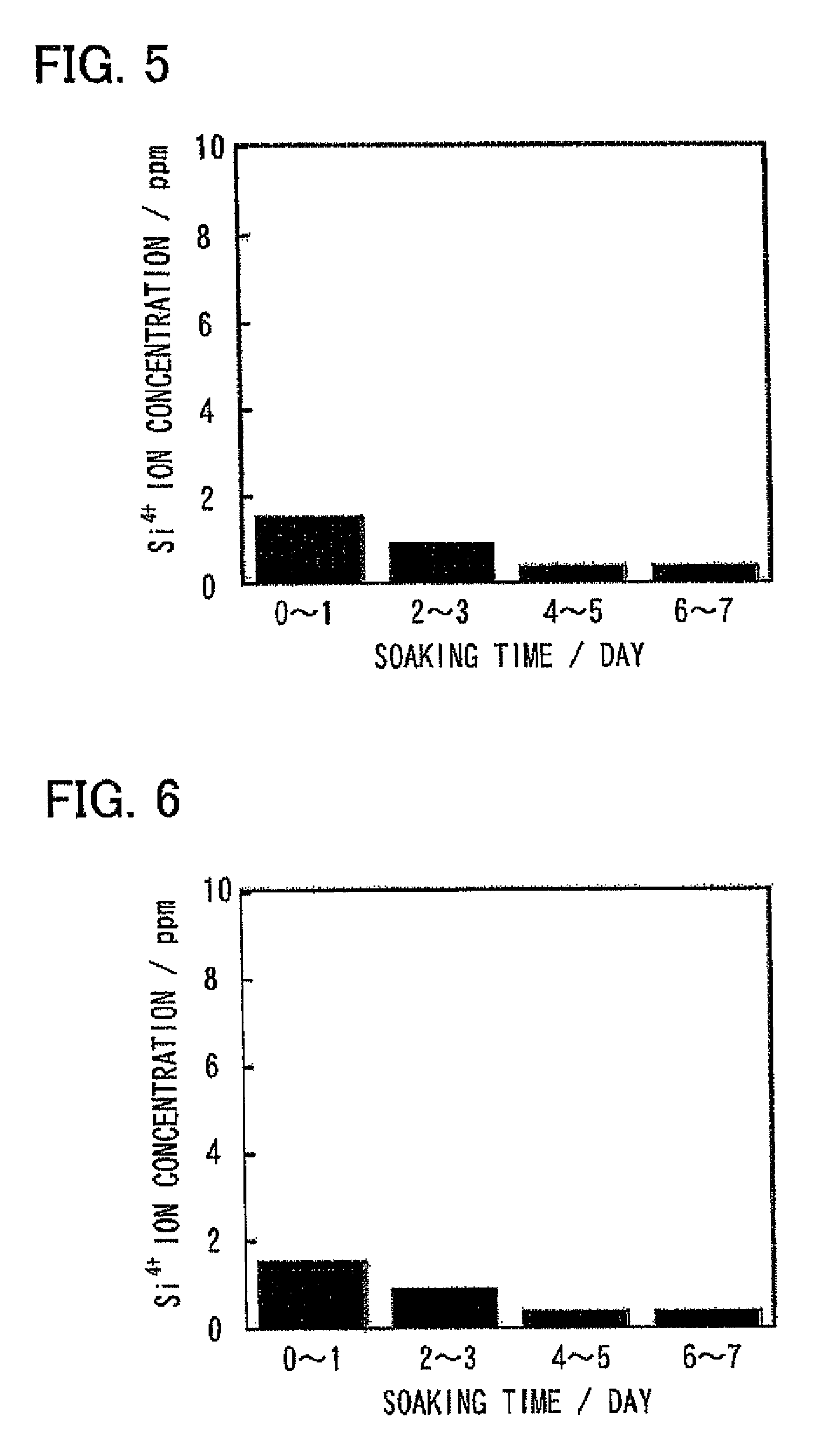

A fiber wadding for filling bone defects having a flocculent three-dimensional structure is disclosed. The fiber wadding includes a plurality of fibers that contain a biodegradable resin as a principal component and a siloxane. Outside diameter of the plurality of fibers of the wadding is from about 0.05 μm to about 30 μm. Bulk density of the fiber wadding is about 0.005-0.3 g / cm3.

Owner:NAGOYA INSTITUTE OF TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com