Patents

Literature

47results about How to "Promote puffing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

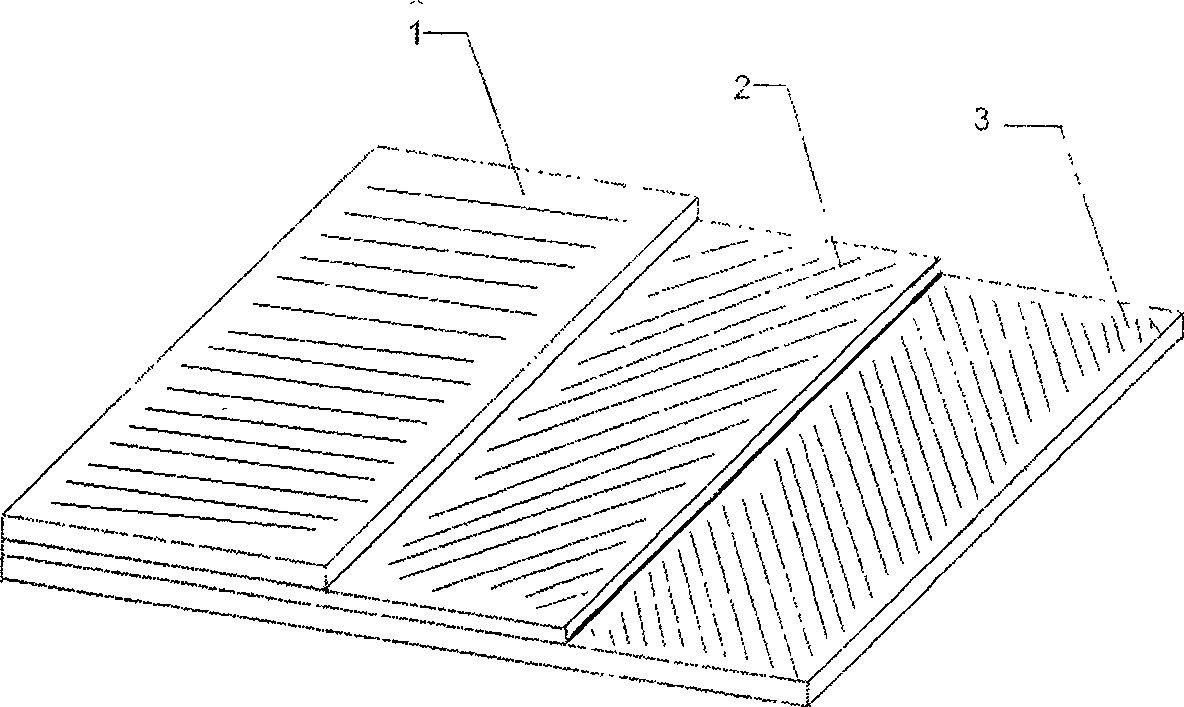

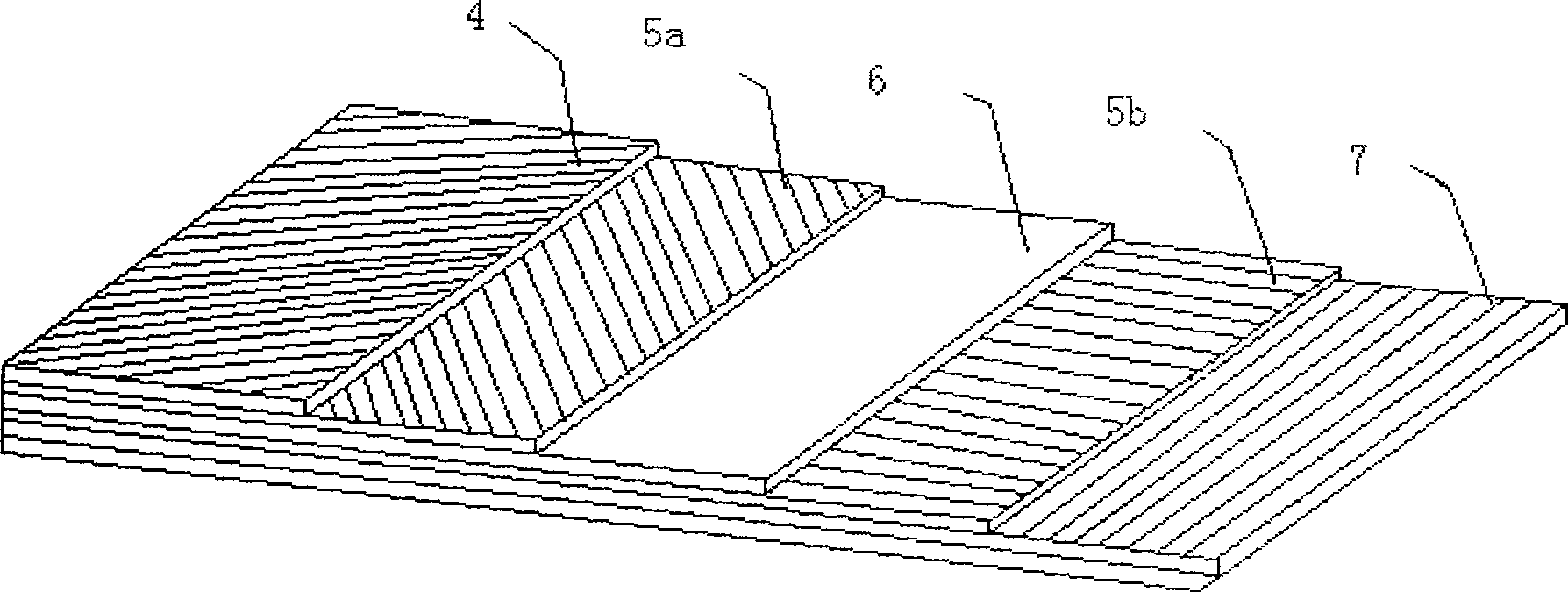

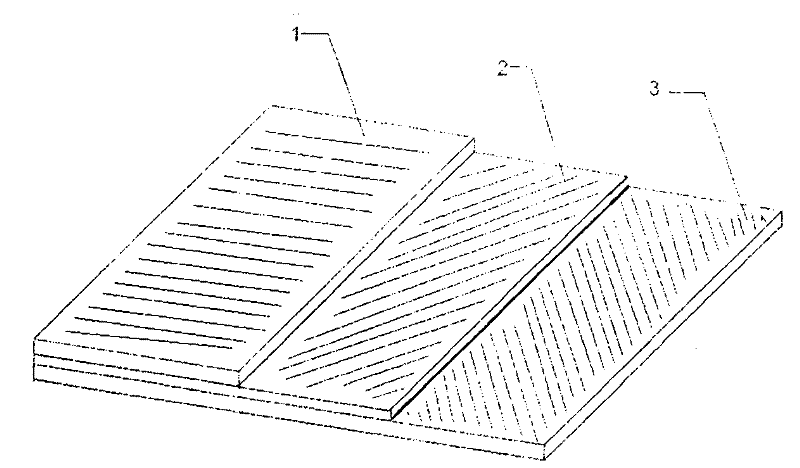

Method for manufacturing light GMT sheet material

InactiveCN101439604APromote puffingImprove heat insulationLayered productsFibre treatmentGlass fiberAlkali free

The invention discloses a method for manufacturing a light GMT board. The method mainly comprises the following steps: making semi-finished felt by a method of mixing chopped modified alkali-free glass fiber and chopped modified polypropylene fiber; producing an evenly impregnated glass fiber chopped mixed felt by dusting, electrostatic impregnation by a dry method and compound needle punching, and making the light GMT board by baking plasticization, fusing impregnation, compound filming, non-woven fabrics covering, continuous rolling, cooling, shaping and edge trimming. The method has the advantages of low energy consumption, high yield, good impregnation uniformity and rapid continuous production speed, the board structure is changed by controlling the content of the glass fiber and resin so that the cost is greatly reduced, and the method is applicable to industrialized production. Meanwhile, the light GMT board can replace wood or steel for environment-friendly recycle. The board also has a sandwich froth layer which enhances expanding, thermal insulation and sound insulation performances of the board, thus achieving unification of light weight and high rigidity.

Owner:黄云清

Method for producing high-elasticity bulked silk-cotton quilt

ActiveCN1743260APromote puffingPuffing treatment can ensure that cocoons are cooked evenly and promoteAnimal fibresUpholstery fillingBoiling processWadding

The invention relates to a method for producing a expanded silk wadding, which includes: sort cocoons, boil at high temperature, degelatinize, shuck the cocoons to remove silkworm, wash, loosen by drawing and make them into silk piece, dewater, dry and draw to make the silk wadding. The invention features that the cocoons before high temperature boiling process are vacuum soaked and expanded by a expanding liquor, concretely the cocoons before high temperature are suctioned into the expanding liquor heated by 80-95 degreeC under vacuum condition, soaked uniformly and expanded in slight boiling state. The said expand is made from amphoteric surfactant. The cocoons after being made into silk pieces and before dewatering are conducted an after finishing by a silk softening agent. Advantages: the patches and stem cubes resulted from un-uniform boiling or in-complete degelatinizing of cocoons are largely reduced; the silk floss is very soft because of full expanding.

Owner:NANTONG LOVER APPL +1

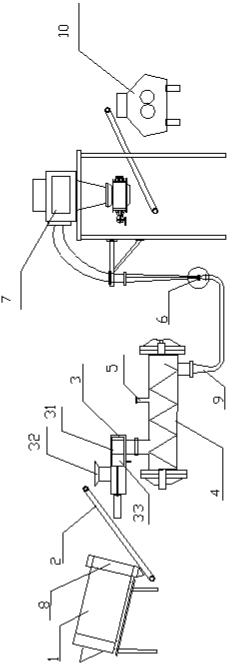

Heterogeneous and synchronous ultramicro original liquid extraction method and apparatus thereof

InactiveCN105169726ATo achieve the effect of separation and extractionLow boiling pointEvaporationActive componentConvection

The invention relates to the technical field of plant extraction, and especially relates to a heterogeneous and synchronous ultramicro original liquid extraction method and an apparatus thereof. The heterogeneous and synchronous ultramicro original liquid extraction method comprises the following steps: heating a plant full of water to 180-230DEG C, and cooling the upper portion of the plant to maintain the temperature in a range of 15-25DEG C and make the upper portion and a lower portion form convection current in order to form vacuum negative-pressure environment; cooling the plant to 75-95DEG C, and maintaining for 10-30h; and collecting the condensate liquid in the cooled position of the upper portion in order to obtain an extract liquid. The invention also provides the apparatus for enforcing the method. The apparatus comprises a raw material bin, an extraction bin, a heating device and a cooling device. A pyrolysis mode is adopted to rapidly puff cells in a raw material in order to make effective active components become micro-molecules easy to extract; the vacuum and negative-pressure low temperature extraction effectively protects nutrients in the raw materials; and fracture of molecular energy bonds supplements energy in the extraction process, so compared with traditional methods, the method disclosed in the invention has the advantages of environmental protection and energy saving.

Owner:陈峰

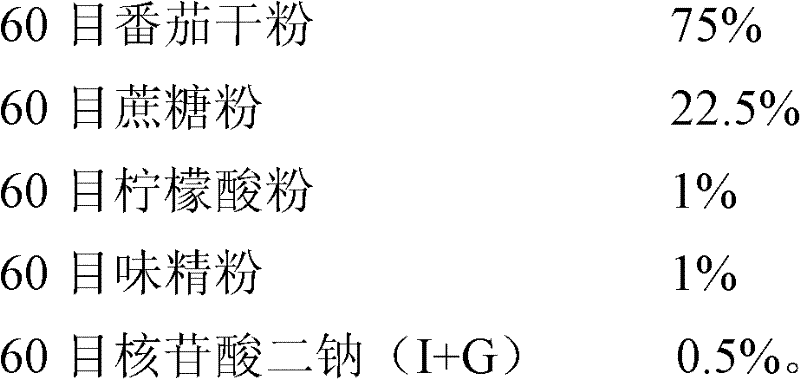

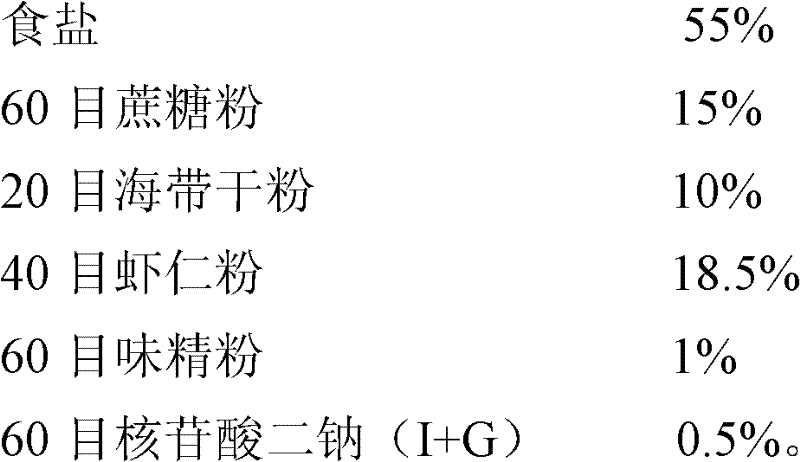

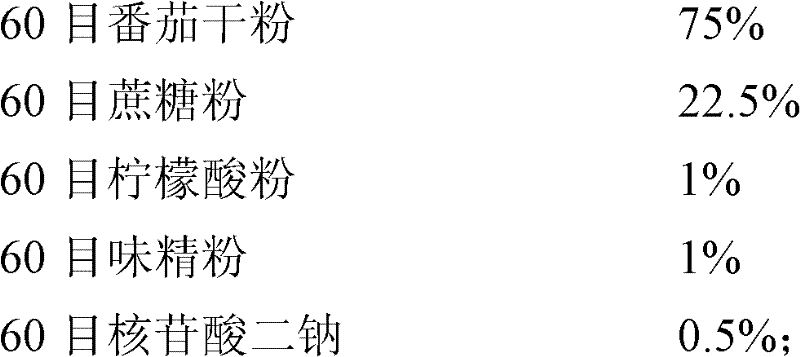

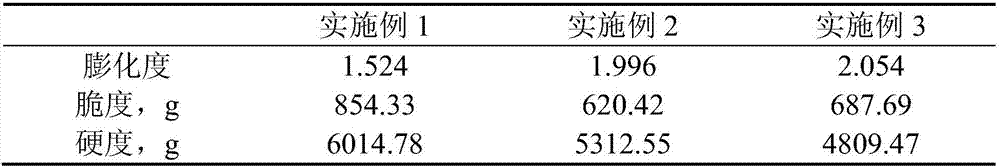

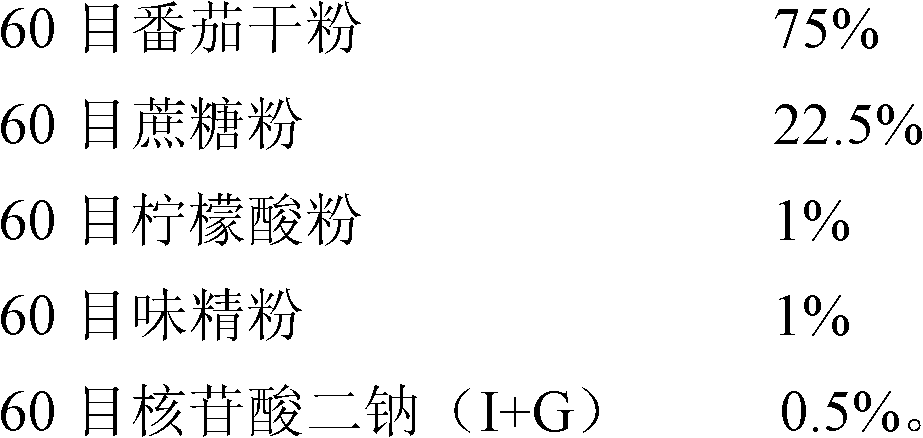

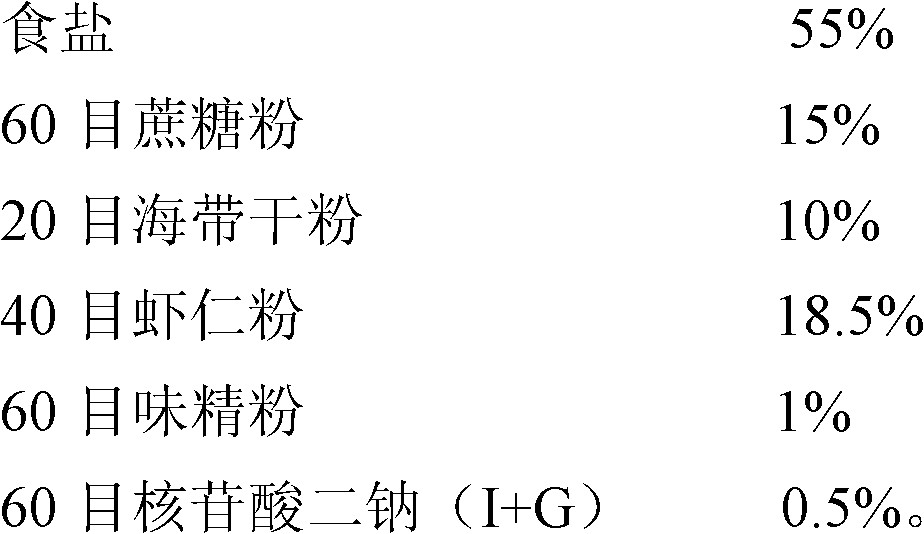

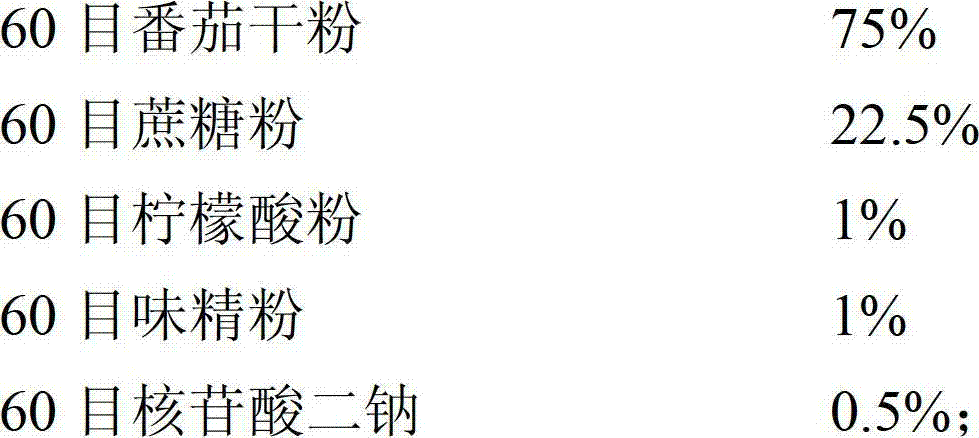

Puffed crispy glutinous rice chips with various tastes and production method thereof

InactiveCN102240000AEasy to operateStrong controllability of product qualityFood preparationChemistrySoya bean

The invention belongs to the technical field of food processing, and discloses puffed crispy glutinous rice chips with various tastes and a production method thereof. The production method comprises the following steps of: mixing glutinous rice flour and isolated soy protein, peanut oil, white granulated sugar or table salt and water, stirring uniformly, blending into a flour dough, pressing the flour dough into slices, cooking and gelatinizing, cooling the gelatinized flour slices, rolling and kneading and stirring uniformly to obtain a dough, rolling the dough into slices, refrigerating, hardening, slicing to obtain rice blanks, drying until the moisture is 20 to 30 percent of the mass of the rice blanks, putting into a closed container and samming, placing on a conveyer belt of a microwave puffing machine in which hot air is aerated and performing microwave puffing, drying, seasoning by using different seasonings, and finally packaging to obtain the puffed crispy glutinous rice chips with various tastes. By using a microwave puffing technology, the product has the characteristics of high puffing rate and pure white color and luster, and is crispy when eaten; moreover, the adding amount of oil is low, so that the product has rich nutrition, and is environment-friendly and healthy; and the crispy chips with various tastes can be produced so as to meet the demand of different consumers.

Owner:GUANGDONG IND TECHN COLLEGE

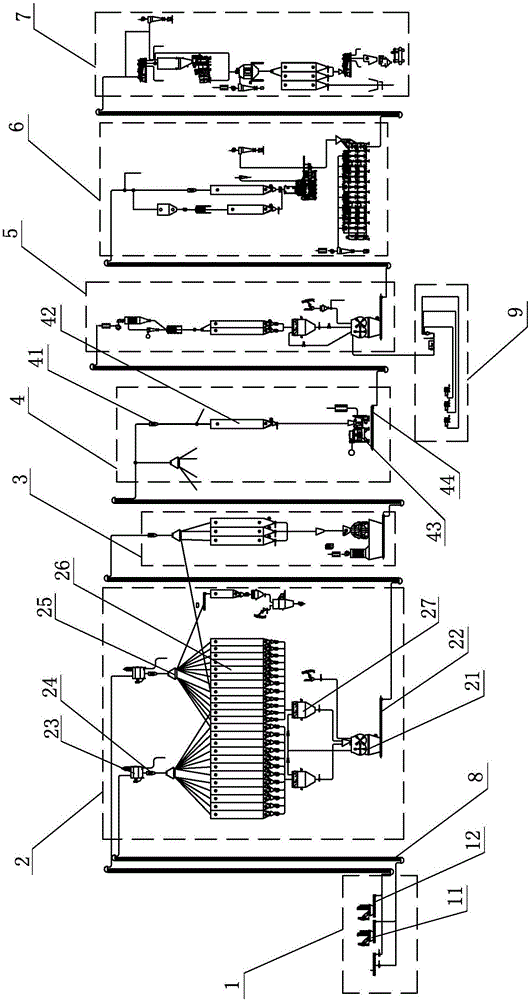

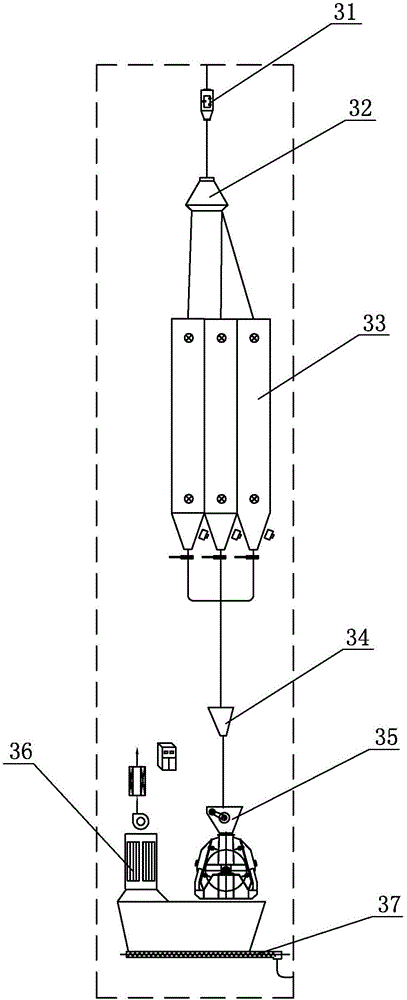

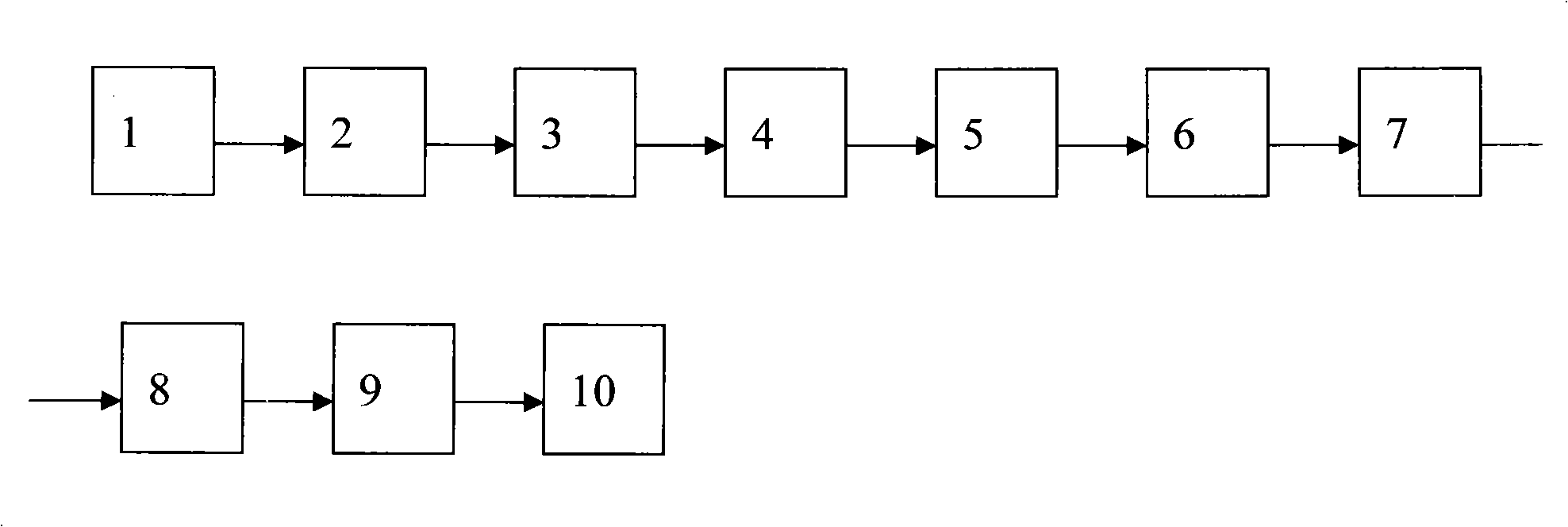

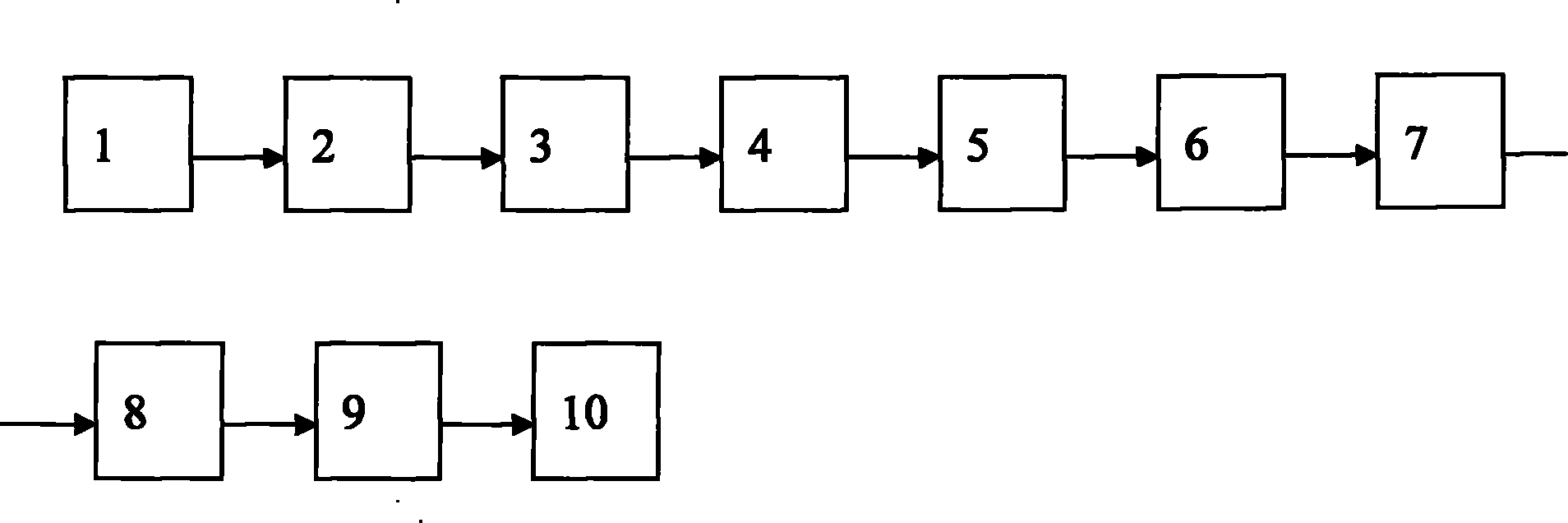

Expanded-feed processing system and processing technology

InactiveCN106690379AQuality assuranceGuaranteed processing efficiencyFeeding-stuffMagnetic separationProduction qualityFeed processing

The invention discloses an expanded-feed processing system. The expanded-feed processing system is characterized by comprising a raw material receiving system, a primary ingredient mixing system, a primary crushing system, a superfine shredding system, a secondary ingredient mixing system, an expansion drying system and an expanded-feed packaging system which are all connected respectively through a raw material elevator. The processing technology includes: 1), primary material mixing; 2), primary crushing; 3), superfine shredding; 4), secondary material mixing; 5), expansion drying; 6), packaging. By the arrangement, production efficiency and production quality of feed are improved.

Owner:宣城市同鼎饲料科技有限公司

Production process of solid composite ferric sulfate polymer

InactiveCN1772642AGood effectBig alumWater/sewage treatment by flocculation/precipitationIron(III) sulfateCinder

The production process of solid composite ferric sulfate polymer includes the following technological steps: the reaction of sulfuric acid cinder, water and concentrated sulfuric acid in certain weight proportion inside a reactor in temperature 100-150 deg.c and pressure not higher than 0.5 MPa for 3.0-5.0 hr; adding additive in certain amount to react for further 20-60 min; cooling to below 80 deg.c, puffing, solidifying, drying and crushing to obtain the product. The present invention obtain solid ferric sulfate polymer product in a short process, and the product may be used in water treatment for pre-treatment, decolorizing, deodorizing, eliminating COD, heavy metal and algae and in treatment of various kinds of waste water. It has obvious treating effect and fast deposition.

Owner:JINAN UNIVERSITY

Processing method of high-quality instant crisp water chestnut chips and crisp water chestnut chips

The invention discloses a processing method of high-quality instant crisp water chestnut chips. The processing method comprises the steps: (1) selecting, peeling and slicing: performing peeling, cleaning and slicing on the selected water chestnuts; (2) color protection: performing color protection treatment on the sliced water chestnuts by using a color protection solution; (3) pre-drying: performing pre-drying treatment on the sliced water chestnuts subjected to the color protection treatment to obtain pre-dried crisp water chestnut chips; (4) airflow puffing: performing airflow puffing treatment on the pre-dried crisp water chestnut chips to obtain the crisp water chestnut chips; and (5) flavoring: flavoring the crisp water chestnut chips. The processing method of the crisp water chestnut chips disclosed by the invention is simple in process and convenient to operate.

Owner:WUHAN POLYTECHNIC UNIVERSITY

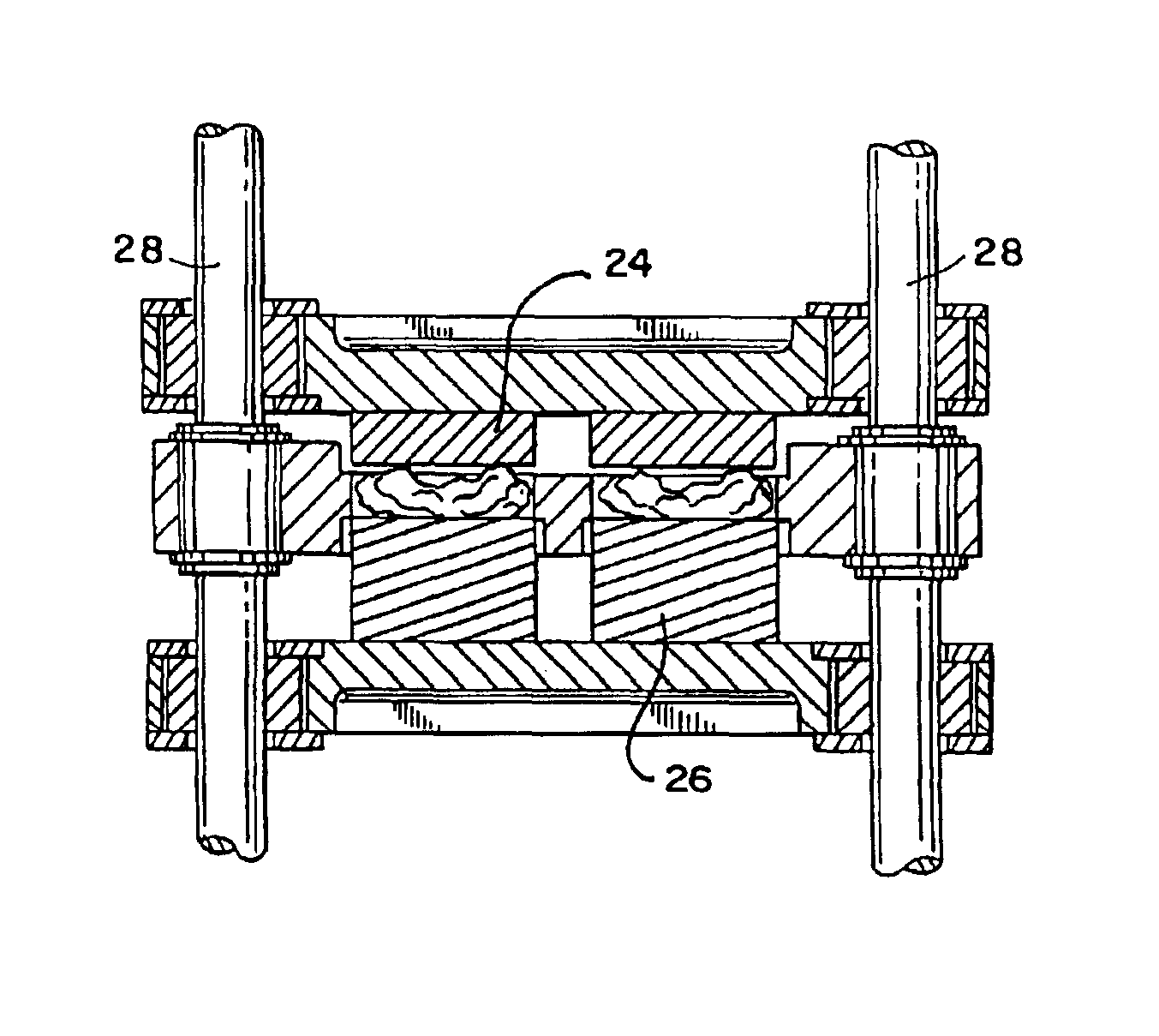

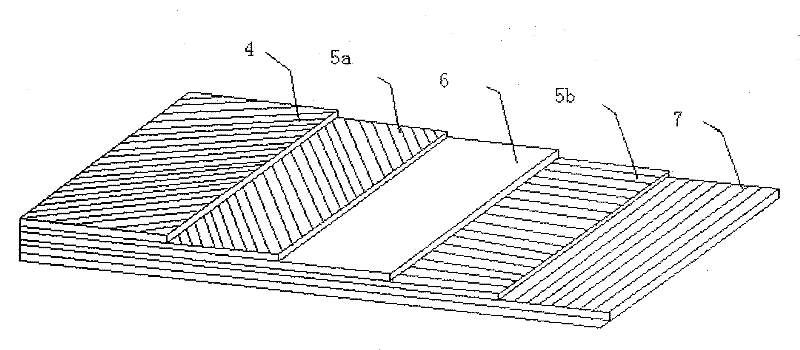

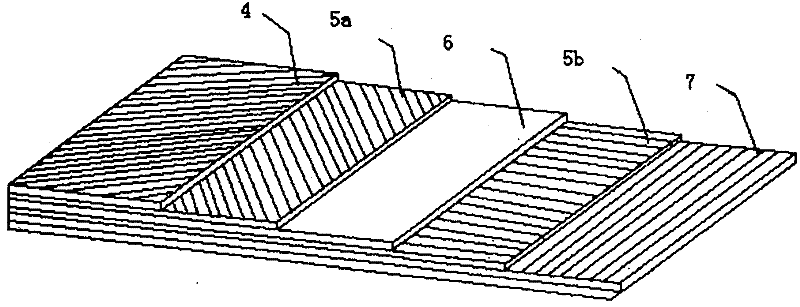

Method for making a puffed food starch product

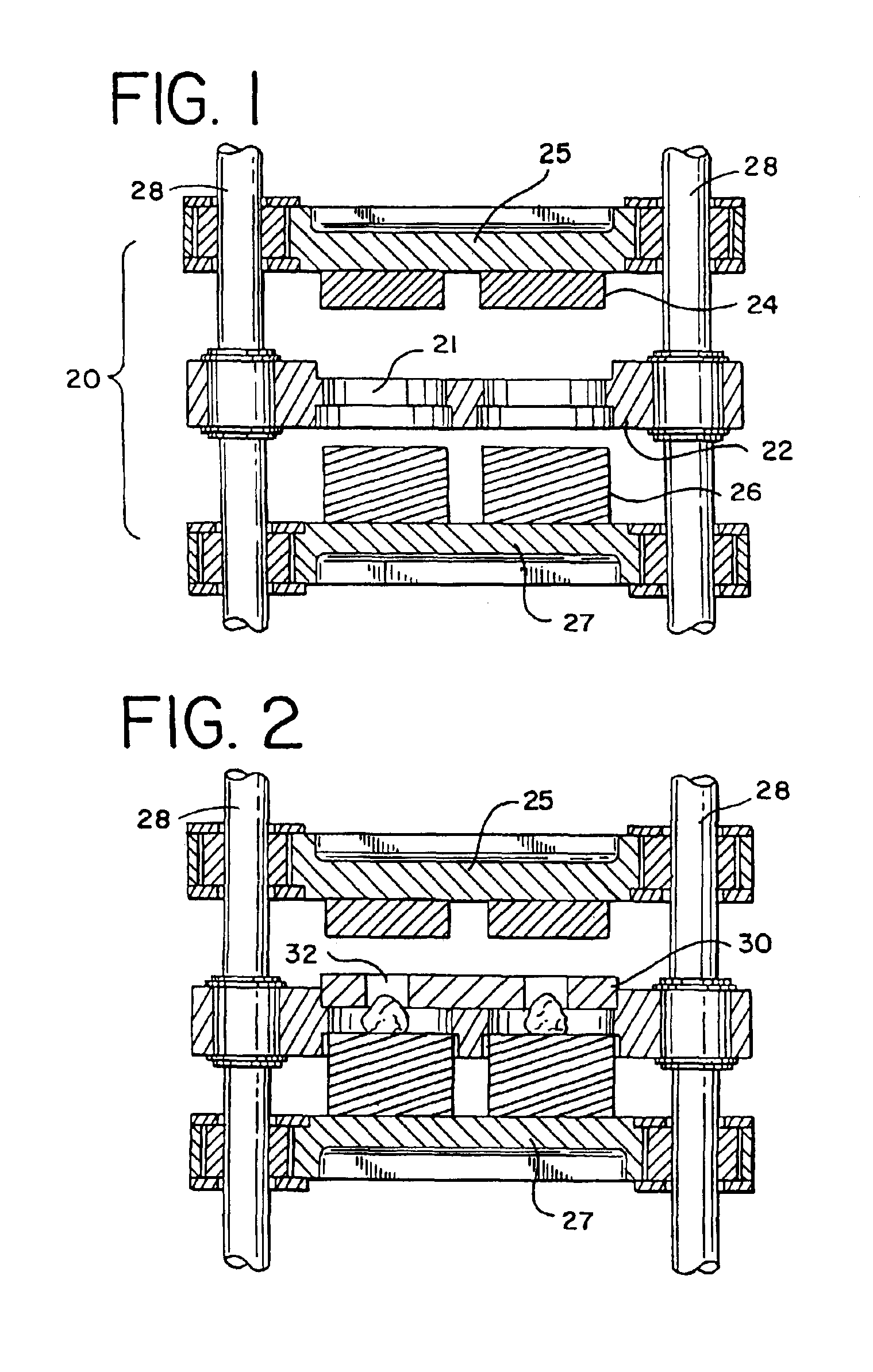

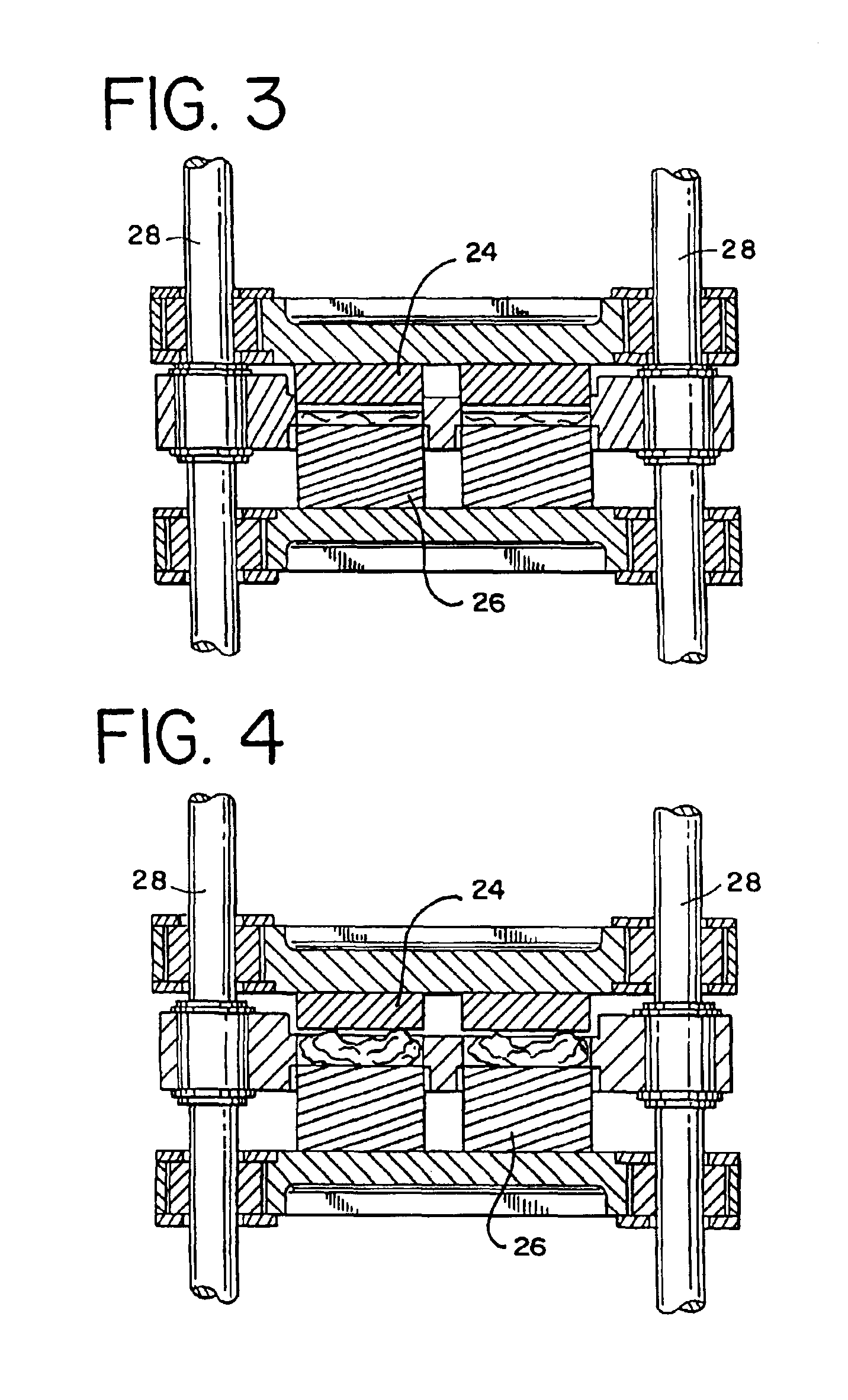

InactiveUS6929813B2Reduce pressurePromote puffingBakery productsFood shapingFood productsFOOD STARCH

The present invention provides a method of making a puffed food starch material product. A food starch material capable of volumetric expansion in three dimensions is placed into a puffing chamber. Expansion of the food starch material includes constraining expansion of the food starch material in at least a first dimension while permitting unconstrained expansion of the food starch material in a second dimension to produce a unitary, puffed food starch material product with at least one surface having a wavy contour.In a method of making a puffed food starch material product of the present invention, a puffing chamber is provided having inner surfaces and a chamber volume. A bulk amount of the food starch material is placed into the puffing chamber. The bulk amount of food starch material is caused to volumetrically expand. The expanding food starch material is constrained in its expansion in at least a first dimension, while permitting expansion of the bulk amount in at least a second dimension.

Owner:THE QUAKER OATS CO

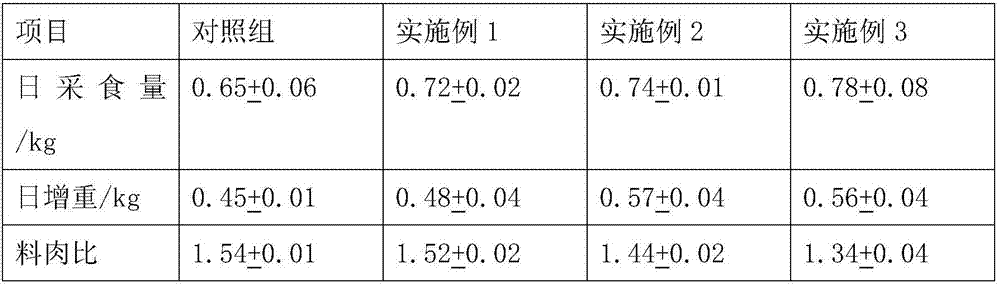

Preparation method of pig feed

InactiveCN107156475AElasticExercise biteAnimal feeding stuffWorking-up animal fodderElderberriesPort access

The invention discloses a preparation method of pig feed, which comprises a preparation method of feed shells and a preparation method of feed pellets. The preparation method comprises the following steps: step I: preparing the feed shells; step II: preparing the feed pellets; step III: forming a port access in the feed shell prepared in the step I, placing the feed pellets prepared in the step II into the feed shell, and respectively adding elderberry pulp, watermelon juice and goat milk into the feed shell; step IV: kneading a planar product in the step I to form a nipple, forming a through hole in the head portion of the nipple, blocking the through hole by using a granular finished product in the step II, and obtaining a suctorial nipple; and step V: inserting the nipple in the step IV into the port access of the step III, thus obtaining the feed finished product. By adopting the pig feed, facial muscles of sow is exercised on one hand, and on the other hand, the chewing force of teeth of the sow can also be exercised, so that the weaning stress of the nursery pig can be effectively alleviated.

Owner:重庆市正品农业发展有限公司

Production process of solid composite ferric sulfate polymer

InactiveCN100335420CIncrease metal ionsPromote destabilizationWater/sewage treatment by flocculation/precipitationSewageIron(III) sulfate

The production process of solid composite ferric sulfate polymer includes the following technological steps: the reaction of sulfuric acid cinder, water and concentrated sulfuric acid in certain weight proportion inside a reactor in temperature 100-150 deg.c and pressure not higher than 0.5 MPa for 3.0-5.0 hr; adding additive in certain amount to react for further 20-60 min; cooling to below 80 deg.c, puffing, solidifying, drying and crushing to obtain the product. The present invention obtain solid ferric sulfate polymer product in a short process, and the product may be used in water treatment for pre-treatment, decolorizing, deodorizing, eliminating COD, heavy metal and algae and in treatment of various kinds of waste water. It has obvious treating effect and fast deposition.

Owner:JINAN UNIVERSITY

Processing method of five-cereal nutrient brewing powder

The invention relates to a processing method of five-cereal nutrient brewing powder. Cellulose in cereals is greatly beneficial for the human body, and is rough in mouthfeel; after being extruded and puffed, some of macromolecular substances are micronized, so that structures are changed, water-soluble dietary fibers are increased and the mouthfeel is improved. Materials generate a series of physical, chemical and biological changes under co-action of high temperature, high pressure and high shearing force in a cavity of an extruder. Physical and chemical properties, nutrient value and sensory quality of expanded products are finally influenceed.

Owner:ANHUI MULONGHU FOOD CO LTD

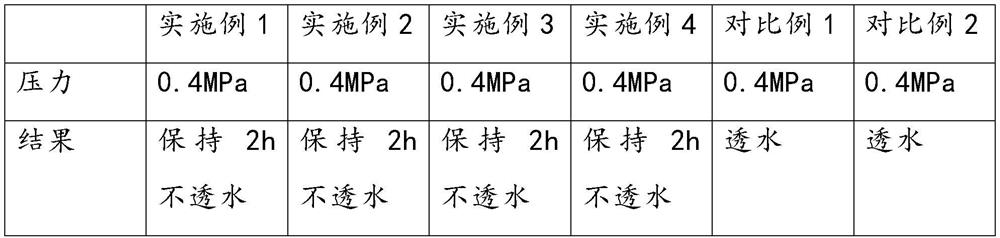

Production process of waterproof willow

ActiveCN113715126APromote puffingImprove bindingPolyurea/polyurethane coatingsPressure impregnationOrganic solventPolyurethane coating

The invention relates to a production process of waterproof willow.The production process comprises the following steps: S1, adding a silane coupling agent into dichloromethane, stirring at a high speed for 15 minutes, heating to 45-50 DEG C, adding willow, soaking for 1 hour, filtering and drying to obtain treated willow; and S2, strengthening the treated willow to obtain strengthened willow; and coating the surface of willow with a prepared mixture, and forming the waterproof willow. Willow is soaked with the silane coupling agent, puffing of willow fibrils is promoted, the coating can be easily combined with willow fibers, the coating stability is improved, the prepared two-component oily polyurethane coating has excellent waterproof performance, no organic solvent is added in the preparation process, and the requirement for environmental protection is met; and finally, the waterproof willow with a waterproof function and excellent mechanical properties is prepared.

Owner:阜南县猛发工艺品有限公司

Energy-saving and emission-reducing assistant for printing and dyeing and production method thereof

InactiveCN102021845ADyeing speed is fastUniform dyeing speedDyeing processDiacetone alcoholRare earth

The invention relates to an energy-saving and emission-reducing assistant for printing and dyeing, which comprises an assistant 1 and an assistant 2, wherein the assistant 1 comprises the following components in parts by weight: methylpyrrolidone, diacetone alcohol, salethyl, isopropyl salicylate and lauryl azone; and the assistant 2 comprises the following components in parts by weight: rare earth oxide, oxalic acid, water and ammonium carbonate. The production process of the assistant 1 comprises the steps of: adding the methylpyrrolidone in a reaction vessel, raising the temperature and then adding the diacetone alcohol, the salethyl,the isopropyl salicylate and the lauryl azone, reacting under the condition of preserving the temperature until the pH value is 6-6.5, and finally obtaining the assistant 1. The production process of the assistant 2 comprises the steps of: adding the oxalic acid and the water into the rare earth oxide La2O3, and then stirring with a high-speed stirring machine, adding the ammonium carbonate and the water, then stirring for 3-6min at a high speed, standing, and storing in a dark place.

Owner:陈家标

Additive for reducing inhibition of seawater on swelling performance of bentonite

The invention discloses an additive for reducing inhibition of seawater on swelling property of bentonite. The additive comprises, by weight, 25-30% of zeolite powder, 30-40% of an ion exchange resinand 35-45% of sodium carbonate. The invention aims to prepare a slurry meeting engineering requirements by utilizing seawater. The method can solve the problem of bentonite mud performance degradationcaused by seawater ions, especially solve the problem of great reduction of bentonite bulking performance in seawater mud, and prepare seawater mud with performance parameters similar to those of fresh water mud, such as viscosity, colloid rate, mud solid particle average particle size D50 and the like. The additive can solve the problem of adaptability of bentonite in seawater, fully utilize seawater resources, save fresh water resources, and has good economic benefits, environmental protection benefits and social benefits.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

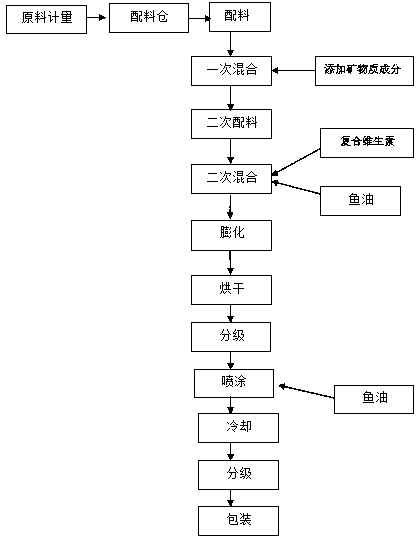

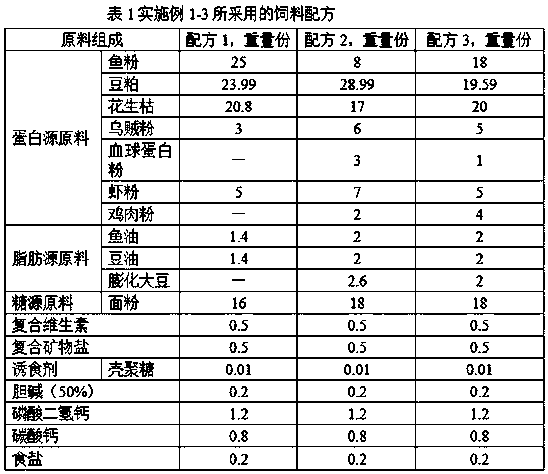

Environmentally protective puffed feed for penaeus vannamei and preparation method thereof

InactiveCN107865193AOvercome imbalanceEmission reductionFood processingClimate change adaptationAmino acidNutrient

The present invention discloses an environmentally protective puffed feed for penaeus vannamei and a preparation method thereof. The environmentally protective puffed feed for the penaeus vannamei isprepared by the following steps: feed raw materials are crushed, the crushed raw materials are mixed to prepare feed base materials, and then water adding, extruding and puffing, granulating and maturing are conducted to prepare a finished product, and the feed consist of the following raw materials in parts by weight: 65-80 parts of protein source raw materials, 2-7 parts of fat source raw materials, 16-20 parts of sugar source raw materials, 0.05-0.2 part of compound vitamin, 0.5-2.0 parts of compound mineral salts and 0-0.2 part of an attractant. According to nutrient requirement characteristics of penaeus vannamei, the animal protein source and plant protein source with high digestibility are selected, and the feed overcomes a problem of an amino acid imbalance of a single protein source, is beneficial to reducing ammonia nitrogen emissions and reduces environmental pollutions, and is simultaneously improved in a formula and conducive to puffing and breeding. A feed coefficient ofthe puffed feed is less than or equal to 1.1, most toxins and anti-nutritional factors are destroyed, the puffed feed is excellent in stability in water, a density of the puffed pellet feed is more than 1.4, a maturing degree is more than 80, and the feed is more comprehensive in nutrients, more palatable than ordinary pellet feeds, and higher in feed efficiency.

Owner:广东凤凰饲料有限公司

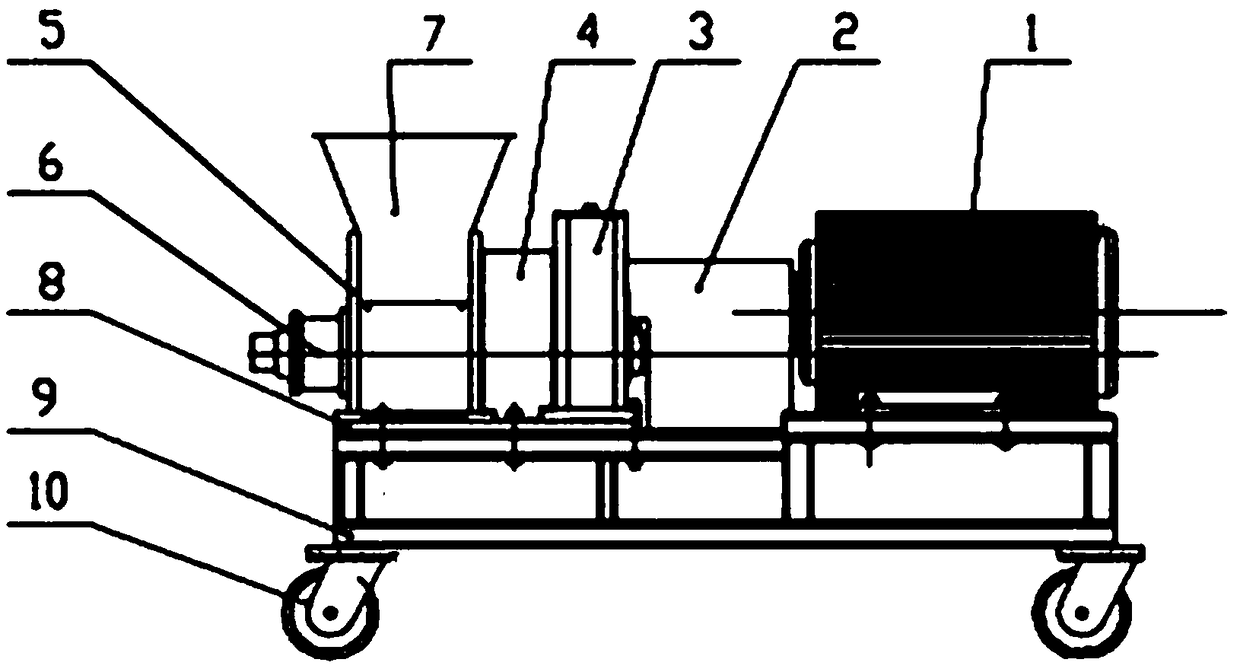

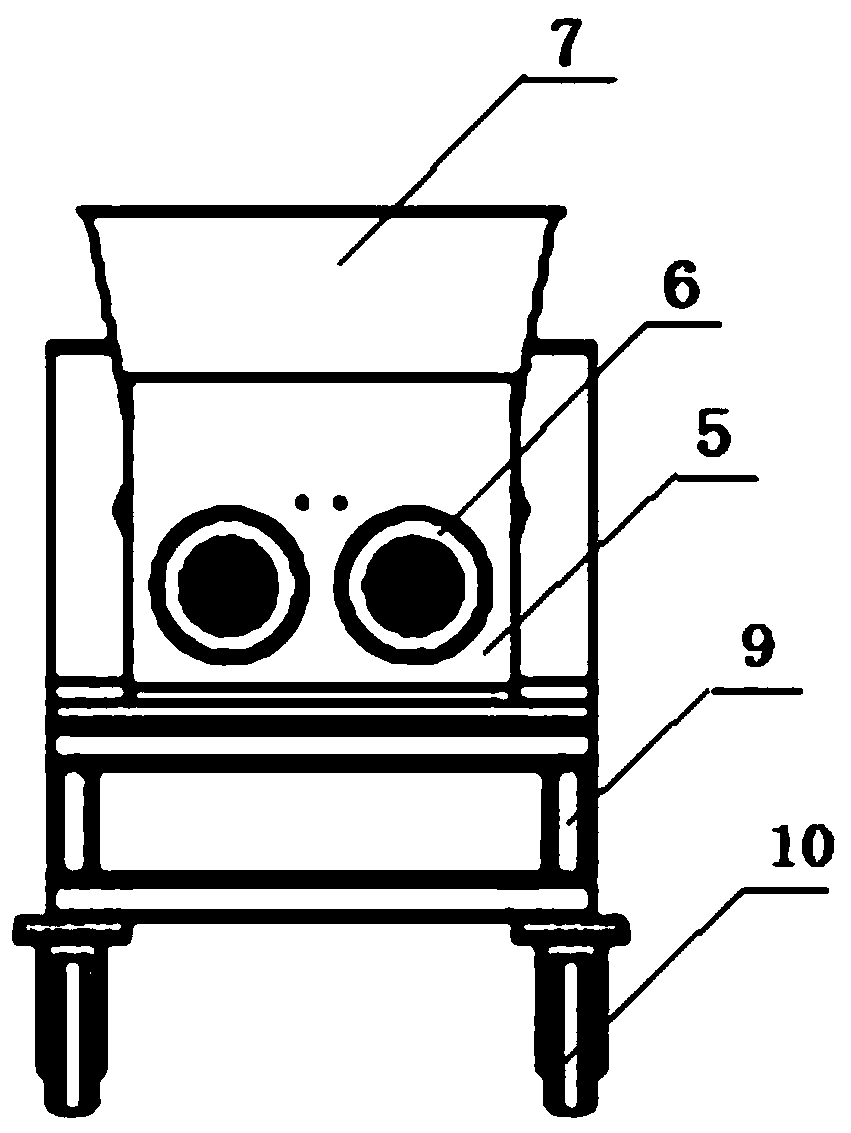

Biomass hopper briquetting machine

ActiveCN104307419AAdd evenlyImprove combustion efficiencyFeeding-stuffBiofuelsHigh densityEngineering

The invention relates to a biomass hopper briquetting machine, in particular relates to a biomass briquette production device capable of uniformly adding an additive and performing high-density compressing on poultry excrement, straws, silage and the like, and belongs to technologies and equipment required by biological energy sources, poultry excrement treatment environment-friendly field and feed field. The device is composed of a biomass hopper, an additive hopper, a mixer and a briquetting machine; the system is internally composed of a feed controller, a dehydrating device, a material uniformizing device, an infrared controller, a dehydrating cabin, a flexible interface, an additive, a helical extruder, and a hot stream coil; and the technical method such as dehydrating, high temperature, high pressure and additive can be provided for producing the biomass briquette.

Owner:新疆西域牧歌农业科技有限公司

Whole Wheat Flour Production Process for Intermediate Extraction and Treatment of Gluten Materials

ActiveCN107125555BEasily brokenIncrease powder yieldFood scienceBiotechnologyBiochemical engineering

The invention discloses a whole wheat flour production process for intermediate extraction and treatment of gluten materials, including impurity removal, wheat tempering, wheat grain grinding, sorting, bran grinding and backfilling. The wheat bran containing part of the endosperm is selected as the raw material of wheat bran, and the raw material of wheat bran is pretreated by extrusion technology, then the raw material of wheat bran is ground, and finally the raw material of wheat bran after grinding is returned to Add and mix with the flour separated from the wheat mill to form wholemeal flour. The invention has a reasonable design, is easy to transform the flour mill, saves energy consumption, and has a good effect on improving the quality of whole wheat flour, is especially suitable for producing high-quality whole wheat flour, can significantly improve its palatability and processing and application characteristics, and prolong the shelf life of whole wheat flour In the long term, it will have good economic benefits after promotion.

Owner:HENAN UNIVERSITY OF TECHNOLOGY +1

Making method of bean product snack foods

The invention relates to the field of processing of bean products, in particular to a making method of puffed bean strips. The method comprises the following steps of (1) selecting superior soybeans,adding water, performing soaking, performing grinding to obtain pulp, and performing filtering to obtain soybean milk; (2) boiling the soybean milk to 95-110 DEG C; (3) when the soybean milk is 80-85DEG C, adding physalis minima for solidifying bean curds, performing heat insulation at 60-65 DEG C, performing standing, performing breaking and feeding, and performing pressurizing to obtain dried bean curds of which the thickness is 0.8-1.2cm; (4) cutting the dried bean curds into semi-finished products of the bean curds of (0.8-1.2)cm*(6.0-8.0)cm; (5) putting the semi-finished products in a fryer for deep frying, controlling the deep-frying temperature to be 140-160 DEG C, and controlling the deep frying time to be 8-10 minutes; and (6) draining oil, performing cooling, performing weighingand performing packing. The invention provides the making method of the puffed bean strips. A modern food processing technology is used for reforming a conventional bean strip making technology, conventional flavor of the bean strips is guaranteed, the production efficiency is improved, and standard large-scale production can be realized.

Owner:湖北田土王食品开发有限公司

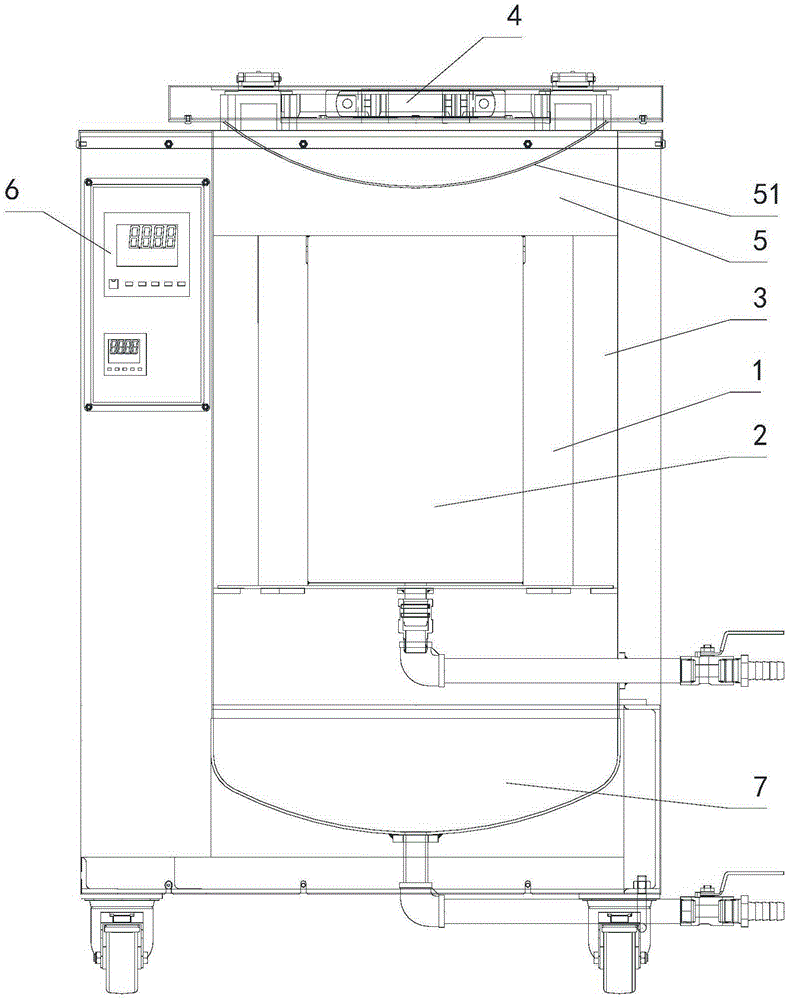

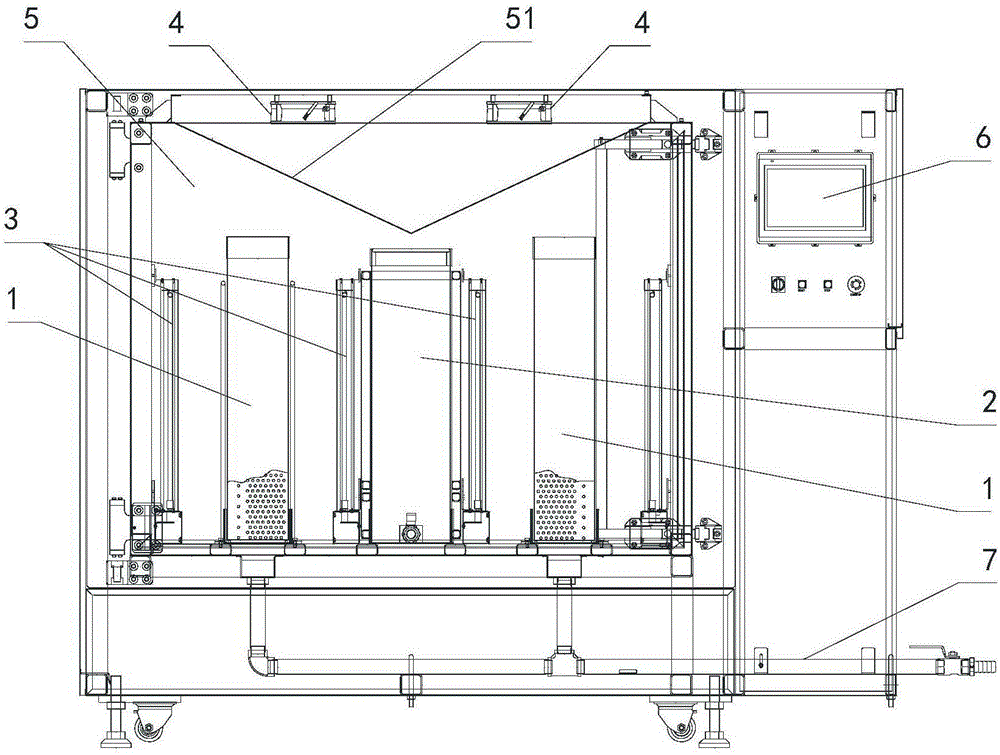

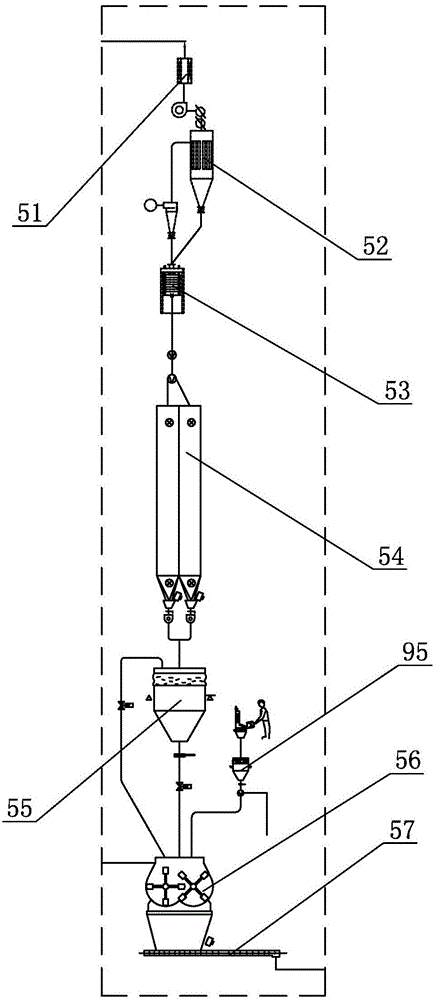

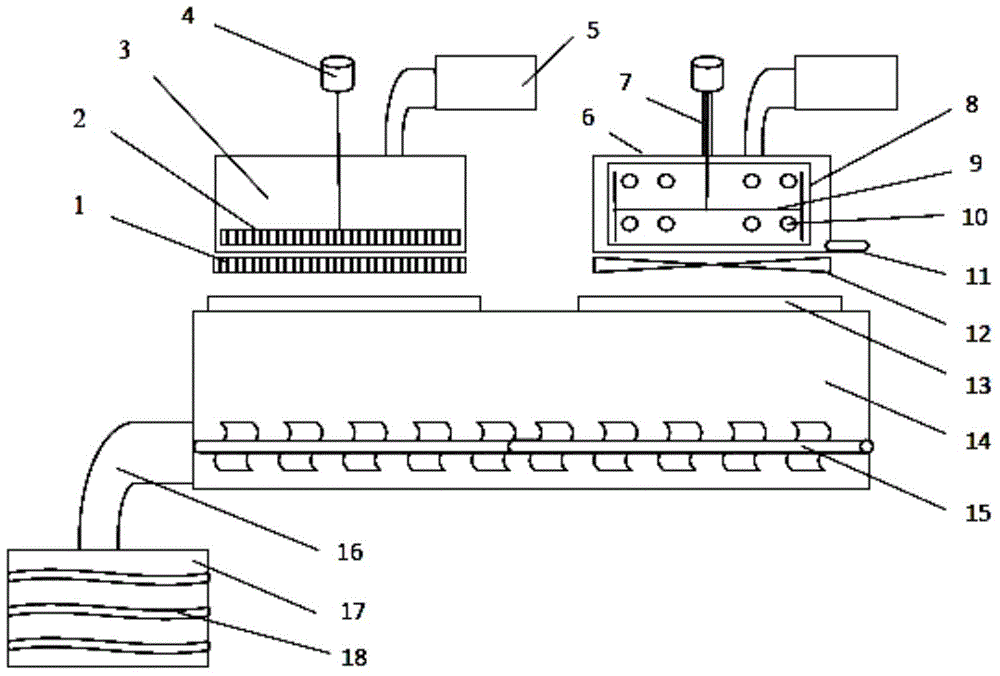

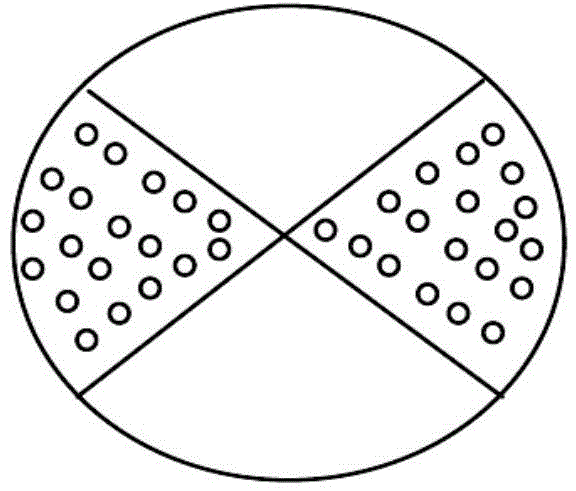

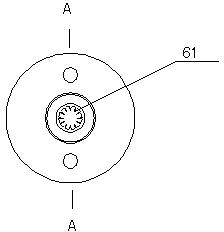

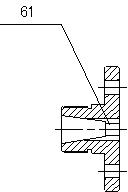

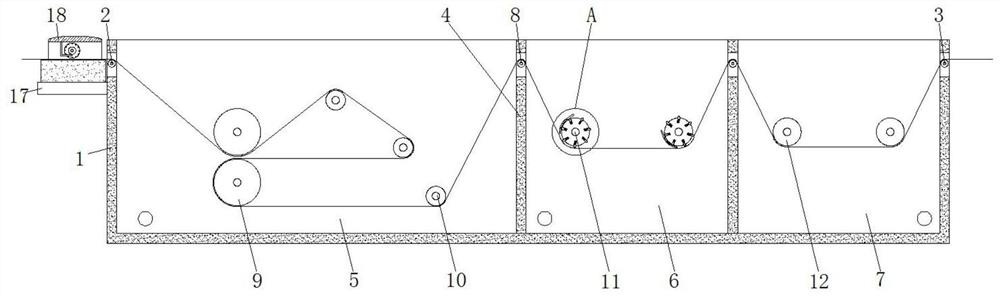

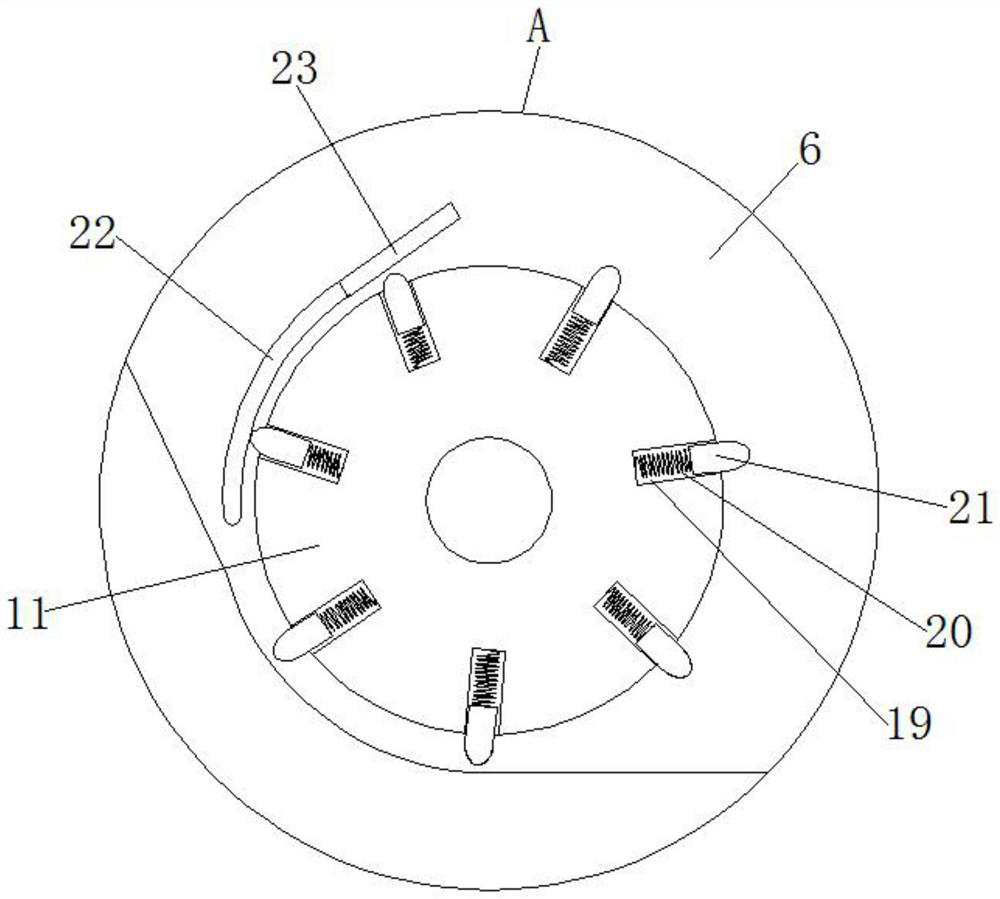

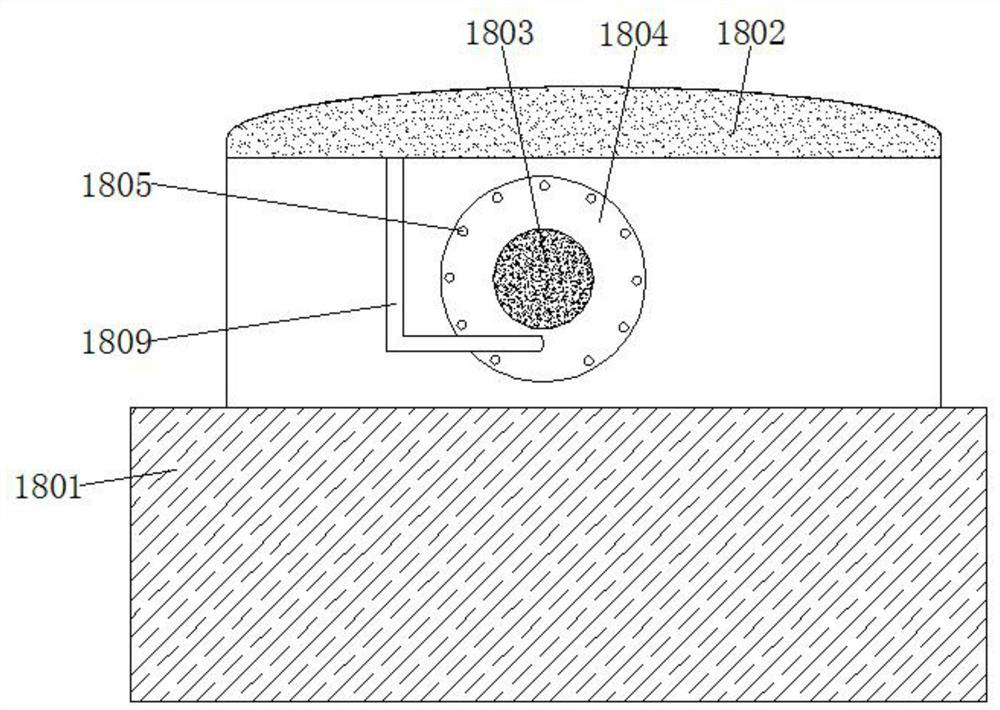

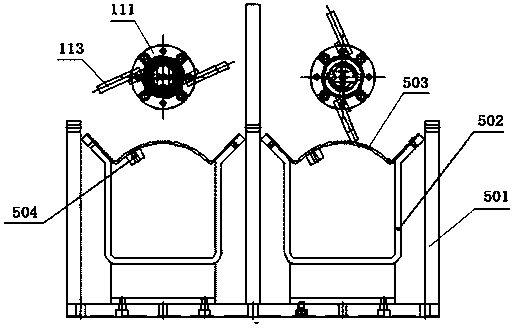

Method and device for preparing cut expanded plant stems

ActiveCN102640975AGuaranteed continuityPromote puffingTobacco preparationPlant stemAgricultural engineering

The invention provides a method and a device for preparing cut expanded plant stems. Threadlike expanded plant stems can be obtained by means of the method and the device. The method comprises the steps of performing moisture regaining treatment to plant stems and controlling moisture content to be 16%-28%; performing exploding treatment to the plant stems regaining moisture through superheated steam and drying, screening and chopping up expanded threadlike expanded plant stems. The device comprises a moisture regaining device, a feeding device, a heating and pressurizing device and an expansion device, wherein the feeding device, the heating and pressurizing device and the expansion device are communicated sequentially. The inner ring surface of a spray nozzle of a venturi expansion pipe is evenly provided with tooth-shaped ribs. A slitting device is a roller splitting machine. The method and the device for preparing the cut expanded plant stems can remarkably improve processibility and utilization ratio of the plant stems.

Owner:NANJING ZHISHENGDA AUTOMATION TECH CO LTD

Easy-to-dye terylene BCF and method for preparing same

Owner:上海繁太实业有限公司

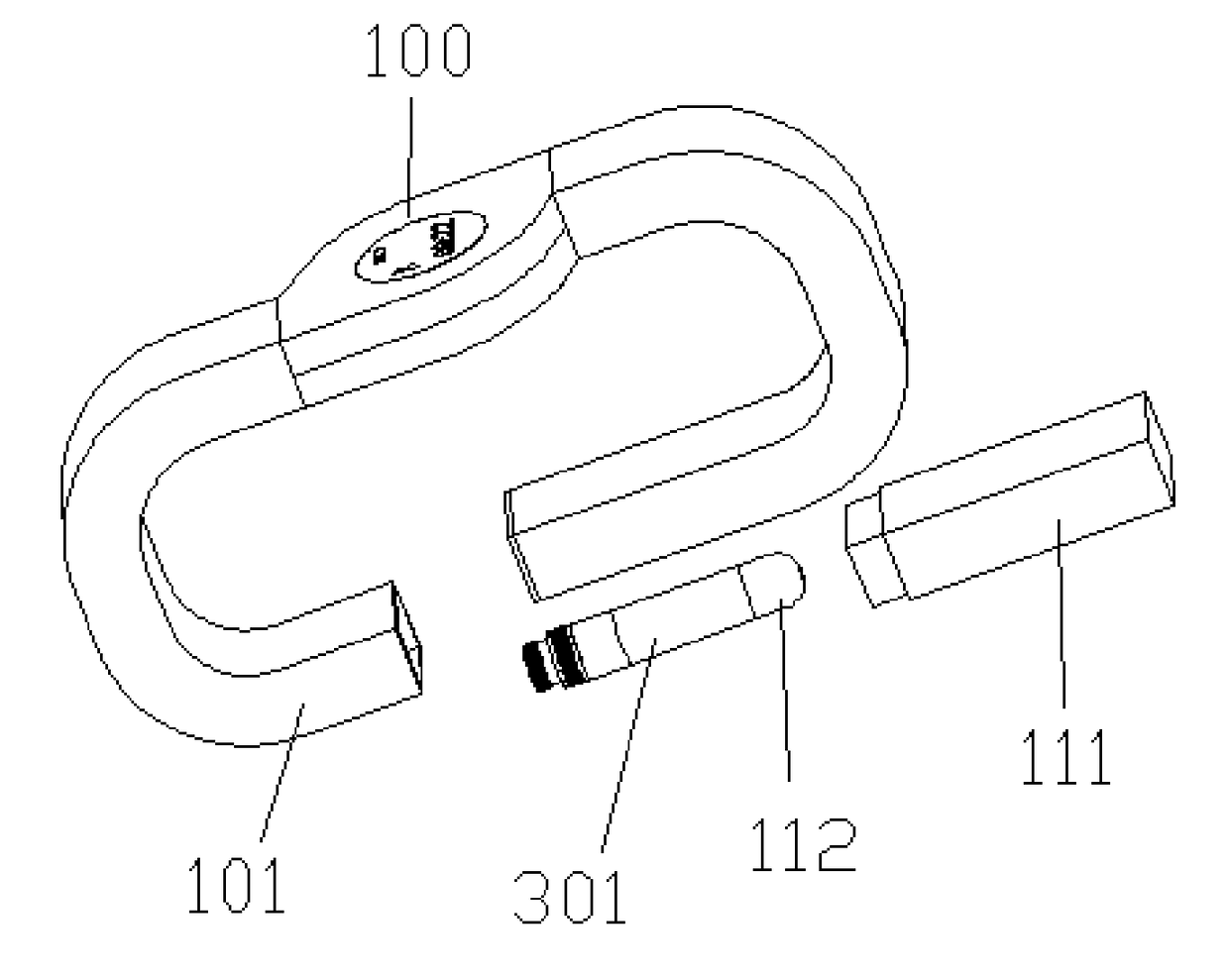

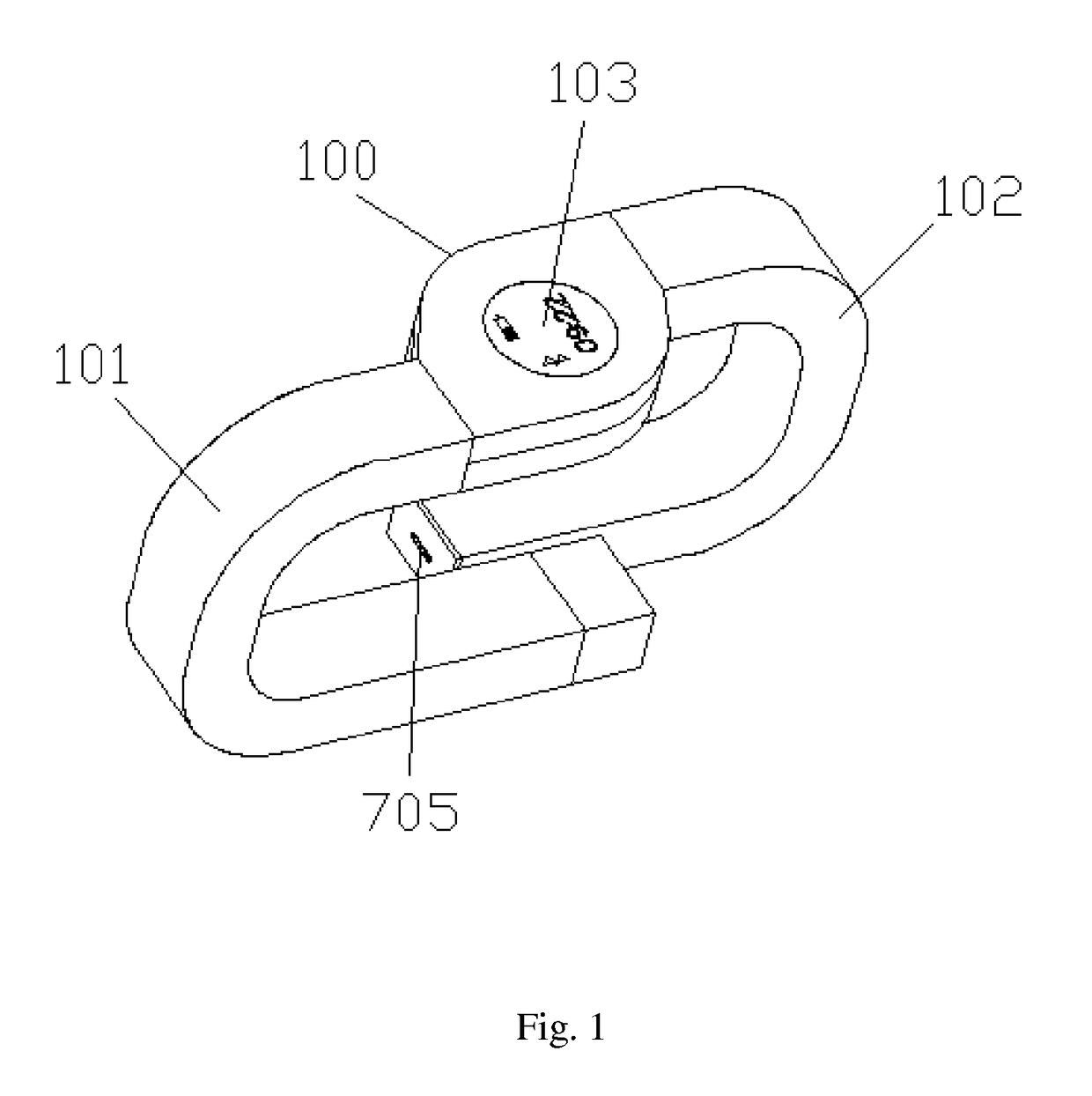

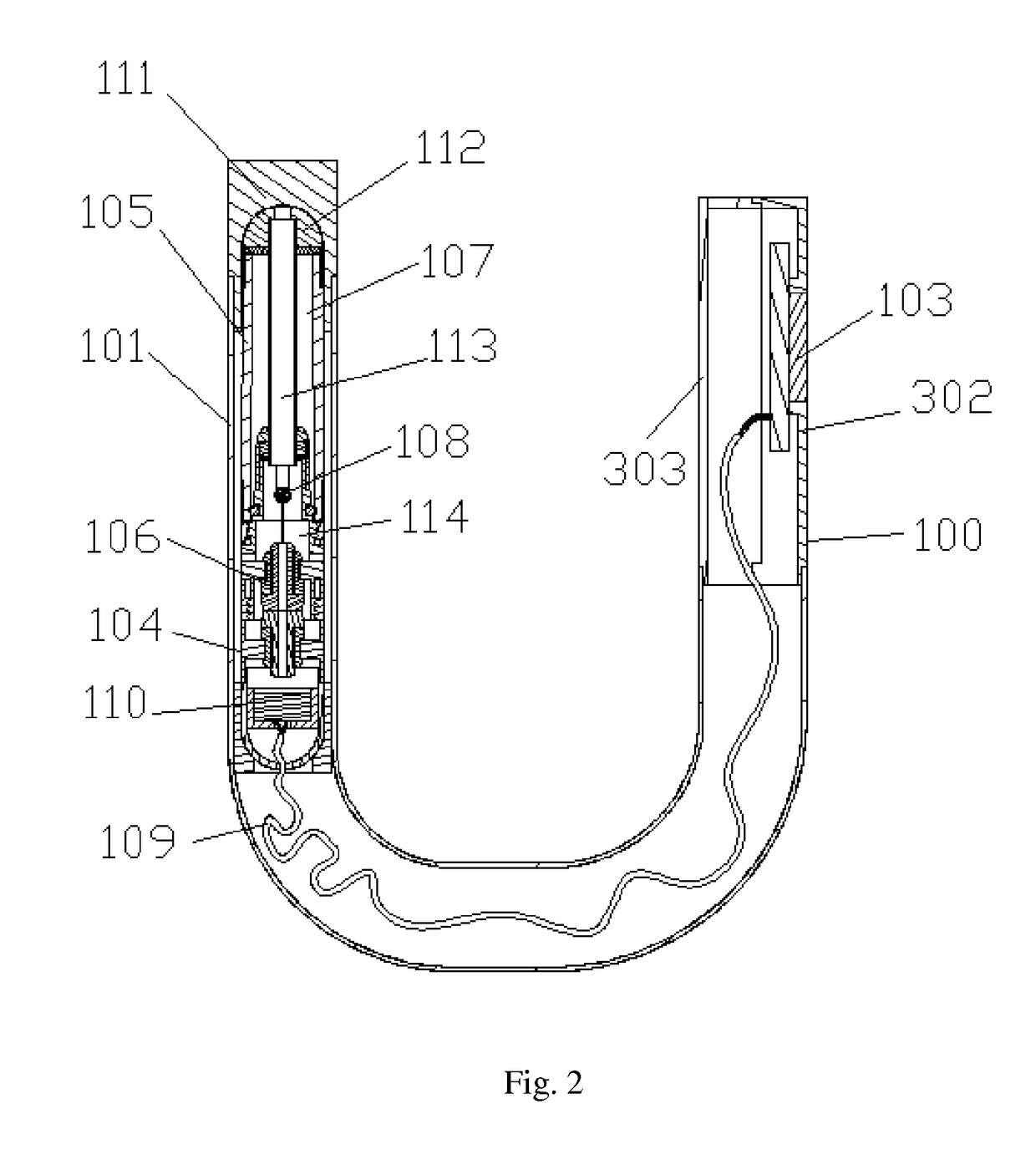

Electronic cigarette

InactiveUS9861137B2Reduce probabilityPromote puffingElectric heatingTobacco devicesElectricityEngineering

An electronic cigarette is provided according to the present application, which includes an annular body. The annular body includes an atomizer assembly, a power supply assembly, a connecting block, a first arc-shaped segment and a second arc-shaped segment. An accommodating chamber is provided in the first arc-shaped segment, and a first electrode connector electrically connected to the power supply assembly is provided in the first arc-shaped segment. The atomizer assembly includes an atomizing sleeve, a second electrode connector, a liquid accommodating space arranged in the atomizing sleeve and an electric heating wire assembly. The electronic cigarette may be worn on the wrist of the user securely, which can avoid falling of the electronic cigarette, and avoid unnecessary loss. Further, may the electronic cigarette can be conveniently carried by wearing it on the wrist, thus the user may puff on the electronic cigarette anytime and anywhere.

Owner:HUIZHOU KIMREE TECH

Puffed crispy glutinous rice chips with various tastes and production method thereof

InactiveCN102240000BEasy to operateStrong controllability of product qualityFood preparationIsolated Soy ProteinSugar

The invention belongs to the technical field of food processing, and discloses puffed crispy glutinous rice chips with various tastes and a production method thereof. The production method comprises the following steps of: mixing glutinous rice flour and isolated soy protein, peanut oil, white granulated sugar or table salt and water, stirring uniformly, blending into a flour dough, pressing the flour dough into slices, cooking and gelatinizing, cooling the gelatinized flour slices, rolling and kneading and stirring uniformly to obtain a dough, rolling the dough into slices, refrigerating, hardening, slicing to obtain rice blanks, drying until the moisture is 20 to 30 percent of the mass of the rice blanks, putting into a closed container and samming, placing on a conveyer belt of a microwave puffing machine in which hot air is aerated and performing microwave puffing, drying, seasoning by using different seasonings, and finally packaging to obtain the puffed crispy glutinous rice chips with various tastes. By using a microwave puffing technology, the product has the characteristics of high puffing rate and pure white color and luster, and is crispy when eaten; moreover, the adding amount of oil is low, so that the product has rich nutrition, and is environment-friendly and healthy; and the crispy chips with various tastes can be produced so as to meet the demand of different consumers.

Owner:GUANGDONG IND TECHN COLLEGE

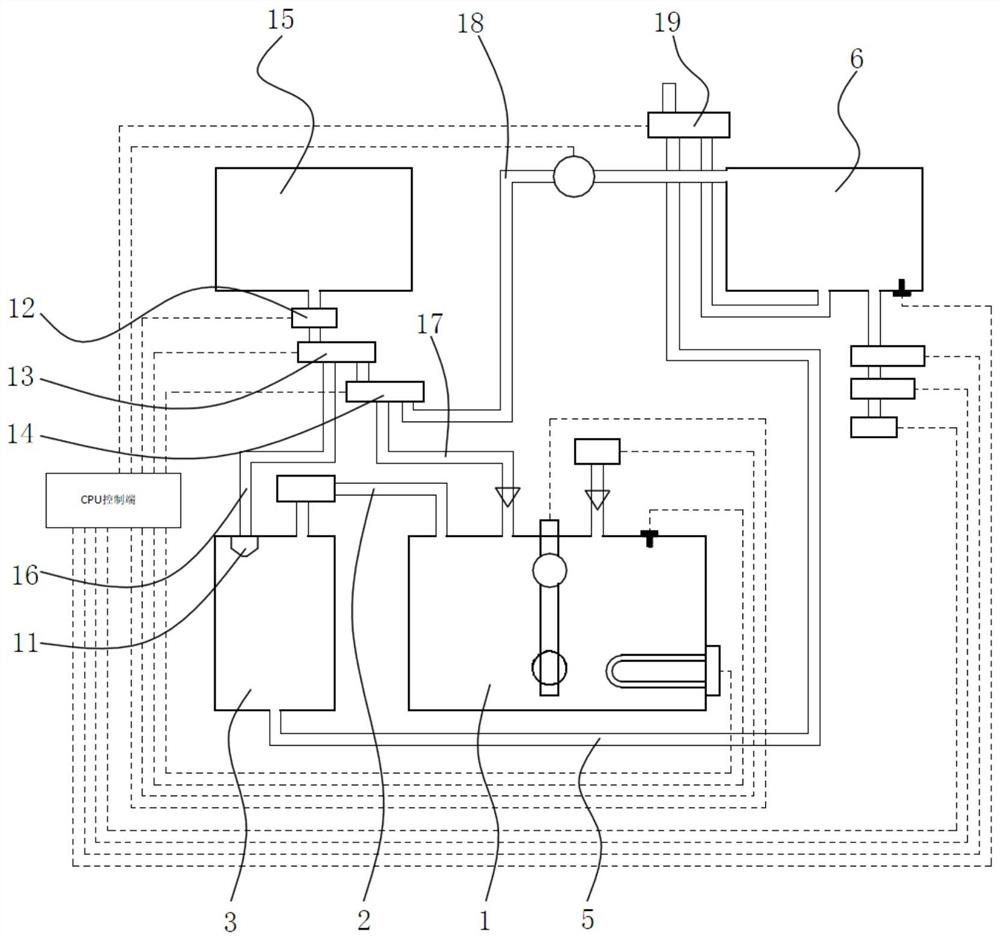

A flame-retardant fabric open-width washing machine and washing method

ActiveCN110747592BPromote infiltrationPossess elastic potential energyTextile treatment containersFabric breaking/softeningFiberEngineering

The present invention relates to the technical field of flat washing machines, and discloses a flame-retardant fabric open-width washing machine and a washing method. The flame-retardant fabric open-width washing machine and washing method, through the fabric pretreatment device, spread the fabric on the pretreatment platform, start the servo motor 2 to drive the rotating rod and the ring to rotate, at this time, the elastic rope and the L-shaped driving rod Contact, the elastic rope rotates continuously with the ring, so that the elastic rope has elastic potential energy, until the elastic rope rotates with the ring to the end of the L-shaped lever, the elastic rope is no longer in contact with the L-shaped lever, and the elastic rope releases its elasticity The potential energy hits the fabric, breaks up the larger raw paste on the fabric, and at the same time makes the fabric fluffy, breaks the raw paste into small particles, can accelerate the puffing of the raw paste, and at the same time, the beating can make the raw paste separate from the fiber, It makes the washing effect better, and the fluffy fabric can also be soaked better, making it easier for the lotion to enter the interior of the fabric.

Owner:SHAOXING SIAN FLAME RETARDANT TECH CO LTD

Production method of puffed bean strips

The invention relates to the field of bean product processing, and especially relates to a production method of puffed bean strips. The method comprises the following steps: 1, selecting high quality soybeans, adding water, immersing, pulping, and filtering to obtain soybean milk; 2, boiling the soybean milk until 95-110DEG C; 3, marinating the soybean milk by using a sour slurry at 80-85DEG C, carrying out heat insulation at 60-65DEG C to form bean curd jelly, breaking the bean curd jelly, feeding the bean curd jelly, and pressurizing to make dried bean curd with the thickness of 0.8-1.2cm; 4, cutting the dried bean curd to form bean curd blanks of 0.8-1.2cm*6.0-8.0cm; 5, putting the blanks in a fryer, and frying at 140-160DEG C for 8-10min; and 6, allowing the fried blanks to stand in order to remove oil, cooling, metering, and packaging. The production method of puffed bean strips is realized through reconstructing a traditional bean strip production technology by using a modern food processing technology, guarantees the traditional flavor of bean strips, improves the production efficiency, and realizes standardized and large scale production.

Owner:吴青平

A kind of preparation method of tensile cotton and its products

ActiveCN105133181BPromote puffingEvenly cookedDe-gumming silkNon-woven fabricsMicrocirculationHigh tension

The invention discloses a manufacturing method for tension cotton. The method comprises the following steps: (1) preparing the following raw materials: silkworm cocoons, spandex, elastin, distilled water, natural water, a swelling agent, malic acid, and organosilicon antimicrobials; (2) performing vacuum infiltration processing on the silkworm cocoons; (3) performing expanding treatment on cocoon silk; (4) performing degumming processing on cocoon silk; (5) through cocoon peeling and removing silkworm chrysalis, obtaining cocoon silk fibers, performing antibacterial treatment on the cocoon silk fibers; stretching the cocoon silk fibers and winding the cocoon silk fibers to form silk floss, performing dehydration and drying processing on the silk floss; (6) putting 60-90 parts of silk floss, 10-30 parts of spandex, and 5-20 parts of elastin into a mincing machine to perform mincing processing, to obtain a mixture and manufacture the tension cotton. Also disclosed is high-elasticity tension cotton manufactured by the above method. The tension cotton has high-elasticity and high-tension, and has functions of antibacterial and odor resistant, humidity-absorbing and breathable, and promotes blood microcirculation of human bodies.

Owner:黄文丰

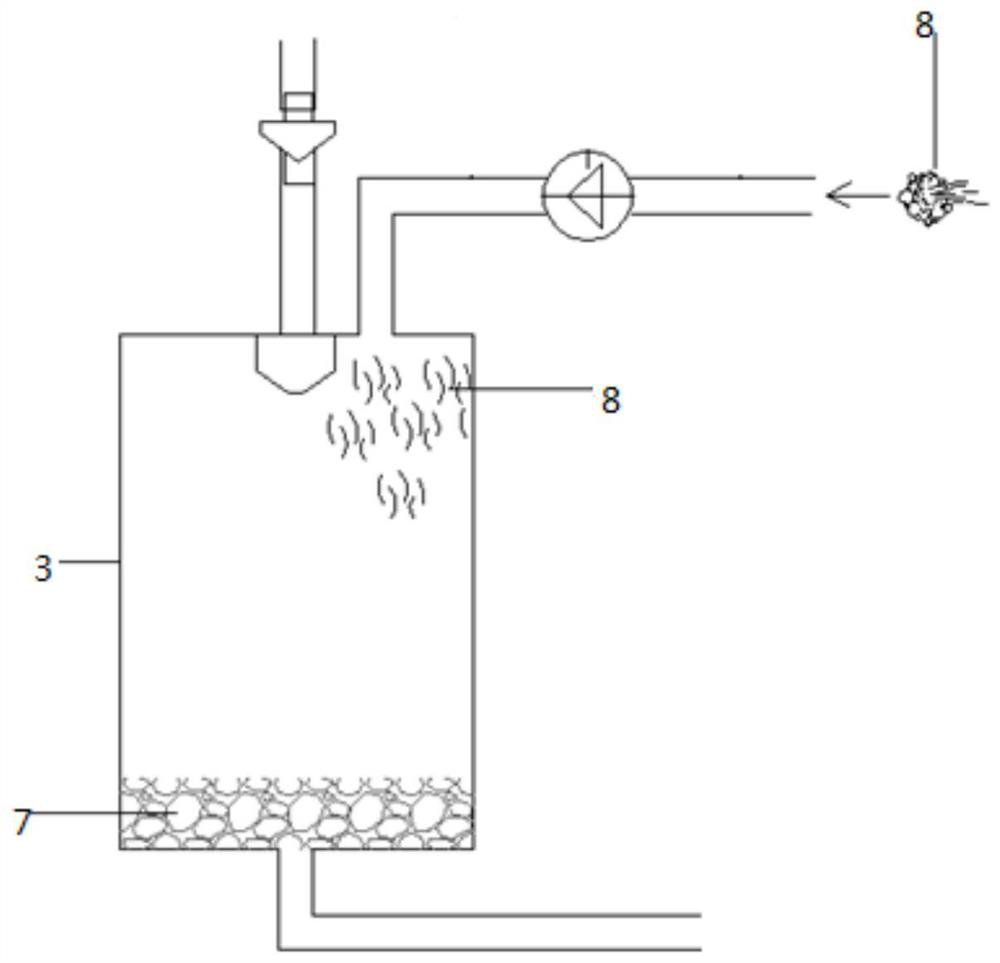

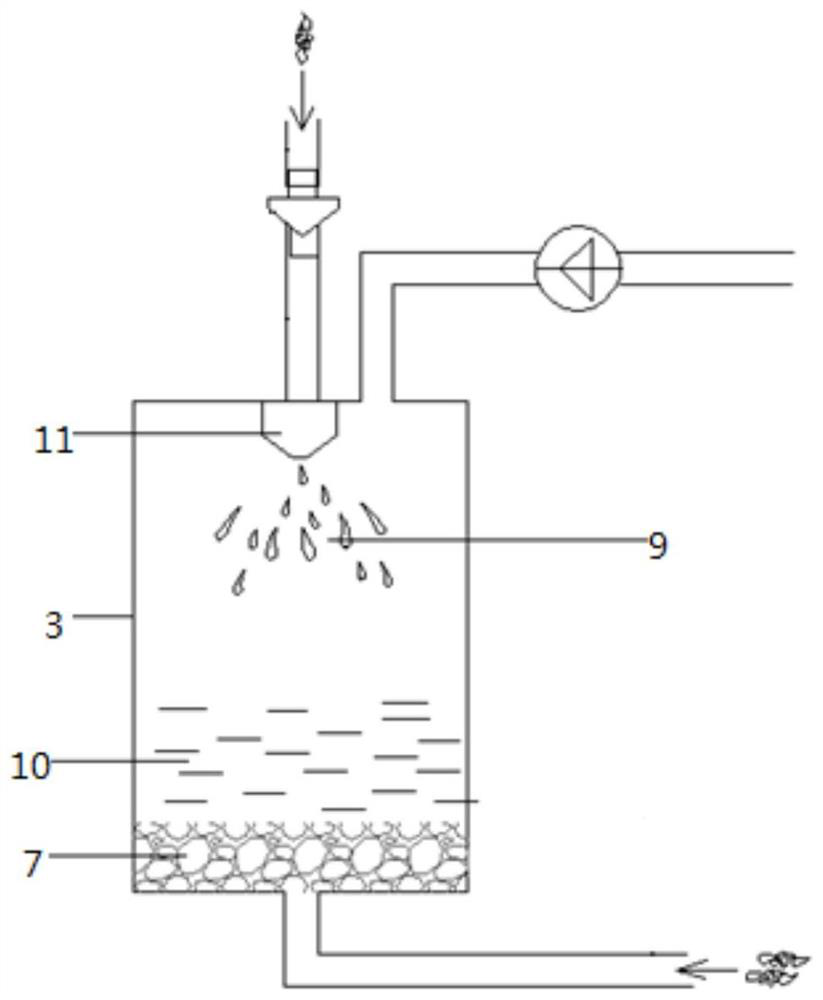

A method and device for preparing a spray solution

ActiveCN109475787BHigh nutritional valuePromote puffingVapor condensationSolid solvent extractionNutritive valuesThermodynamics

Disclosed in the present invention are a method and device for preparing a spray solution. The preparation method comprises: 1) distillation: providing steam to a material chamber, and distilling a liquid preparation material; 2) spray: stop providing high-temperature steam, and spraying the high-temperature steam to quickly form a negative pressure in the material chamber, which makes a solution in a solution vessel instantaneously return to the material chamber and form cold boiling in the material chamber on an instantaneous moment to tear and puff the liquid preparation material; 3) immersion: balancing the negative pressure in the material chamber, and immersing the liquid preparation material in the material chamber by using the reflowed solution; and 4) repetition: continuing to introduce the high-temperature steam into the material chamber, forcing the solution that immerses the liquid preparation material and that is in the material chamber, into the solution vessel, and then repeating the steps 1) to 3) as required. By means of the present invention, nutrients in food ingredients can be fully released, thereby ensuring that the nutritional value of the solution is improved while the food ingredients are not wasted.

Owner:SHENZHEN ZOFU TECH

An additive for reducing the inhibition of seawater on the expansion performance of bentonite

ActiveCN110922947BLarge specific surface areaPromote puffingDrilling compositionIon exchangeSolid particle

The invention discloses an additive for reducing the inhibition of seawater on the swelling performance of bentonite. Based on the total weight of each component, the material is composed of 25% to 30% of zeolite powder, 30% to 40% of ion exchange resin, and 35% to 45% of sodium carbonate. The purpose of the invention is to use seawater to prepare mud that meets engineering requirements. To solve the performance degradation of bentonite mud caused by seawater ions, especially to solve the problem that the swelling performance of bentonite in seawater slurry is greatly reduced, and to formulate viscosity, colloid rate, average particle size of mud solid particles D 50 Seawater slurry whose performance parameters are similar to those of freshwater slurry. The material can solve the adaptability of bentonite in seawater, make full use of seawater resources, save freshwater resources, and has good economic, environmental and social benefits.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Biomass feed extruder

InactiveCN105962398BFully detailedModerate propulsion speedFeeding-stuffPropellerMechanical engineering

Owner:长春长拖农业科技开发有限公司

Method for manufacturing light GMT sheet material

InactiveCN101439604BPromote puffingImprove heat insulationLayered productsFibre treatmentGlass fiberAlkali free

The invention discloses a method for manufacturing a light GMT board. The method mainly comprises the following steps: making semi-finished felt by a method of mixing chopped modified alkali-free glass fiber and chopped modified polypropylene fiber; producing an evenly impregnated glass fiber chopped mixed felt by dusting, electrostatic impregnation by a dry method and compound needle punching, and making the light GMT board by baking plasticization, fusing impregnation, compound filming, non-woven fabrics covering, continuous rolling, cooling, shaping and edge trimming. The method has the advantages of low energy consumption, high yield, good impregnation uniformity and rapid continuous production speed, the board structure is changed by controlling the content of the glass fiber and resin so that the cost is greatly reduced, and the method is applicable to industrialized production. Meanwhile, the light GMT board can replace wood or steel for environment-friendly recycle. The board also has a sandwich froth layer which enhances expanding, thermal insulation and sound insulation performances of the board, thus achieving unification of light weight and high rigidity.

Owner:黄云清

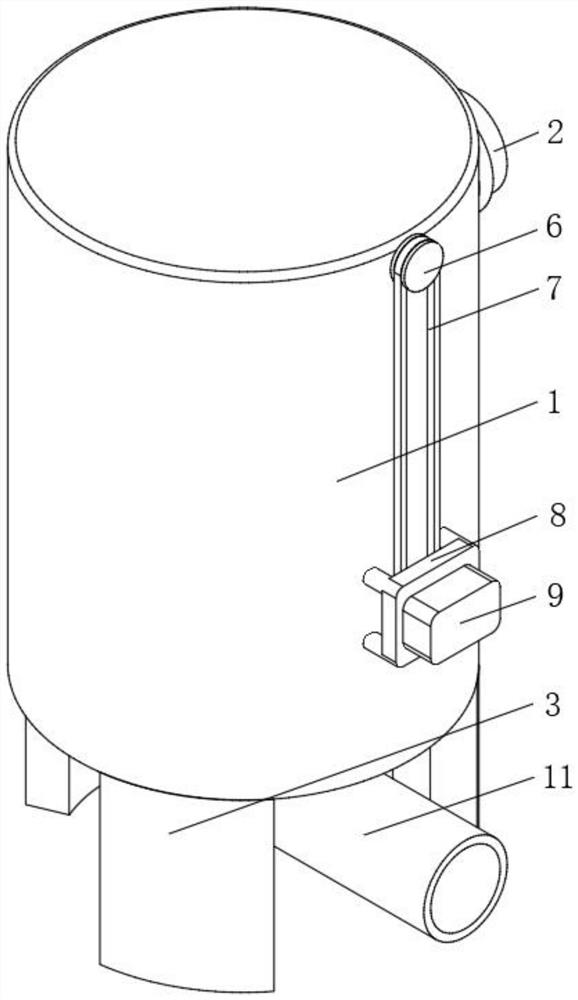

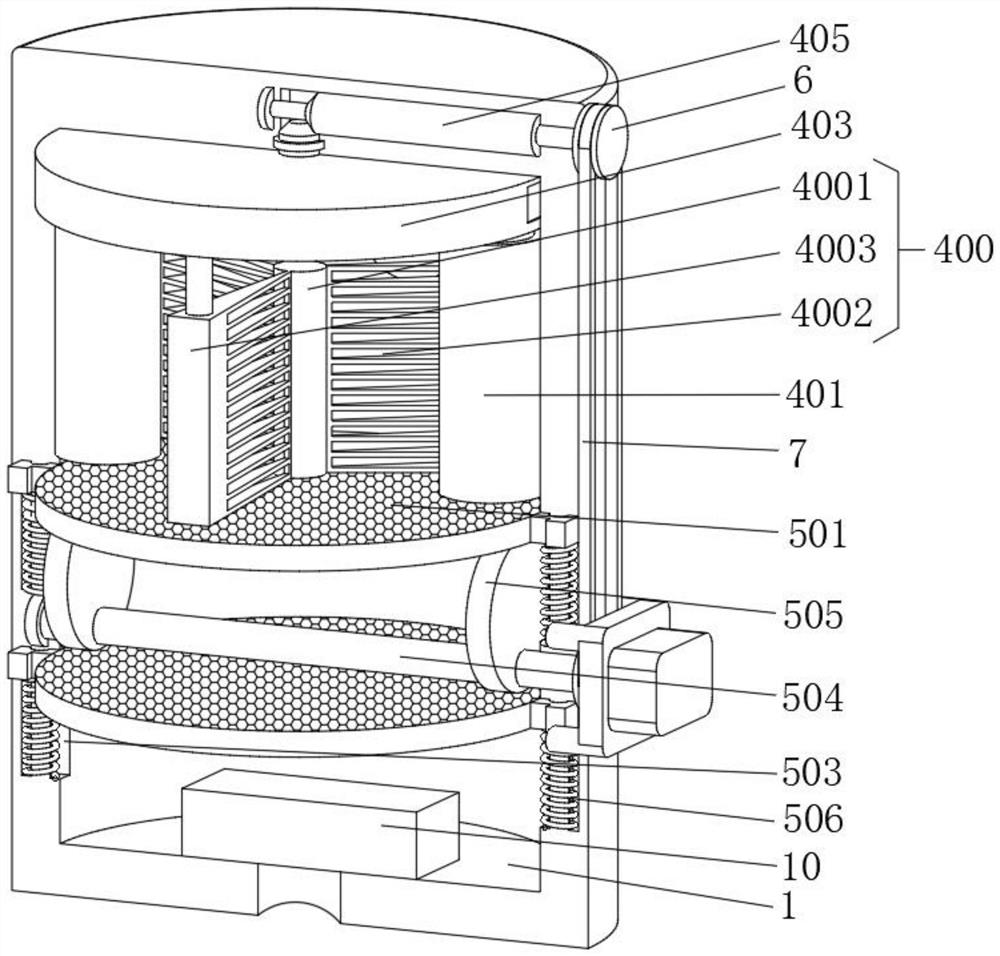

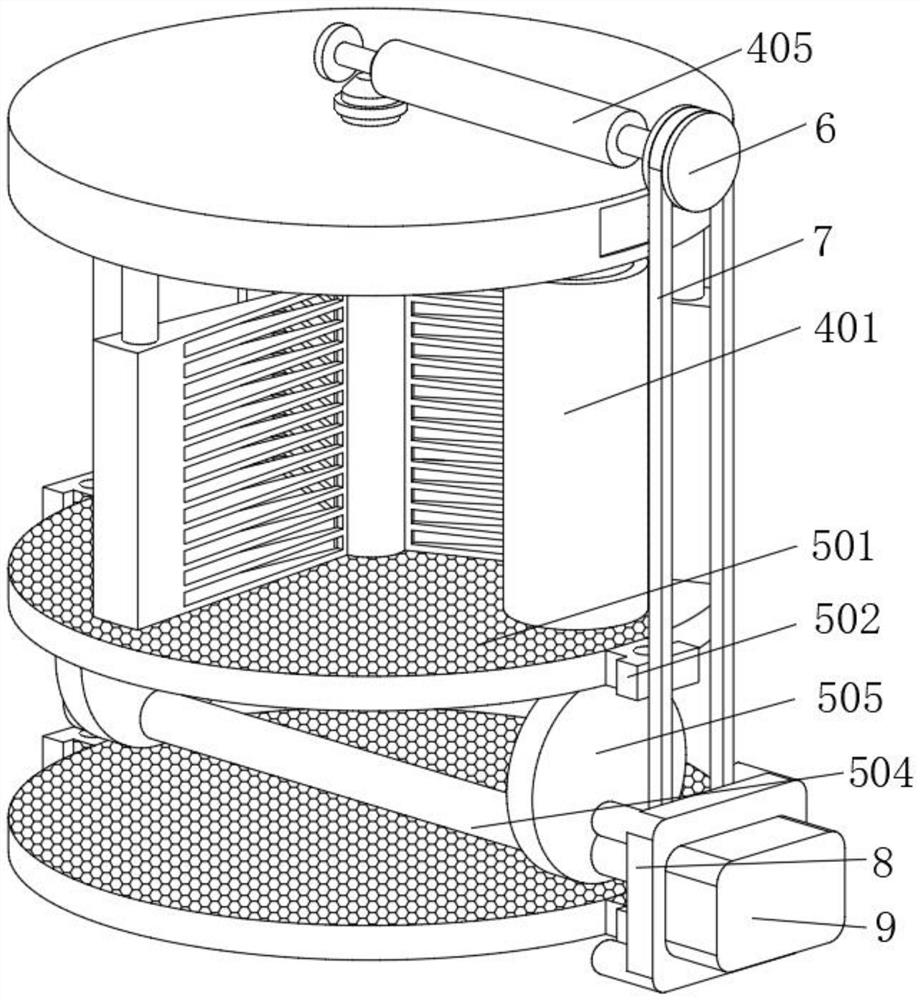

Puffing device for preparing biological feed

According to the technical scheme, the puffing device comprises a machine body, a stirring assembly is arranged at the top of an inner cavity of the machine body, and a filtering assembly is arranged at the bottom of the inner cavity of the machine body; the top of the inner cavity of the machine body is rotatably connected with a connecting shaft through a bearing, the top of the inner cavity of the machine body is provided with a rotating disc, the bottom of the connecting shaft is fixedly connected with the axis of the top of the rotating disc, the two sides of the bottom of the rotating disc are rotatably connected with movable shafts through bearings, and the bottoms of the movable shafts are fixedly connected with the axis of the top of the grinding roller; the filter assembly comprises two filter plates, connecting blocks are fixedly connected to the two sides of each filter plate, sliding grooves are formed in the two sides of the inner wall of the machine body, and the two filter plates are arranged on the two sides of the interior of the sliding grooves correspondingly. And a crushing assembly in the bulking machine is difficult to completely crush the raw materials in a short time.

Owner:江西嘉博生物工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com