Patents

Literature

36results about How to "Evenly cooked" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

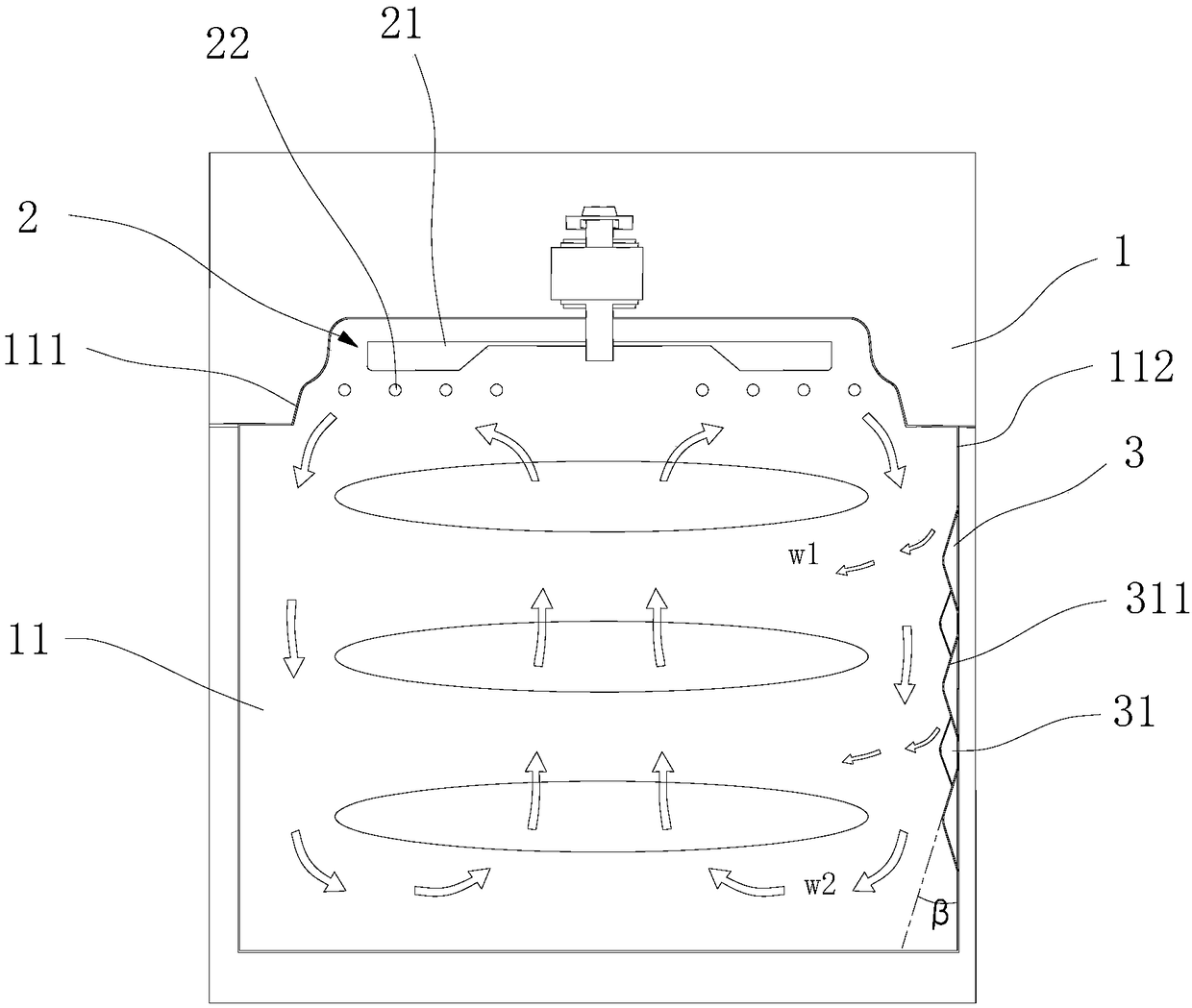

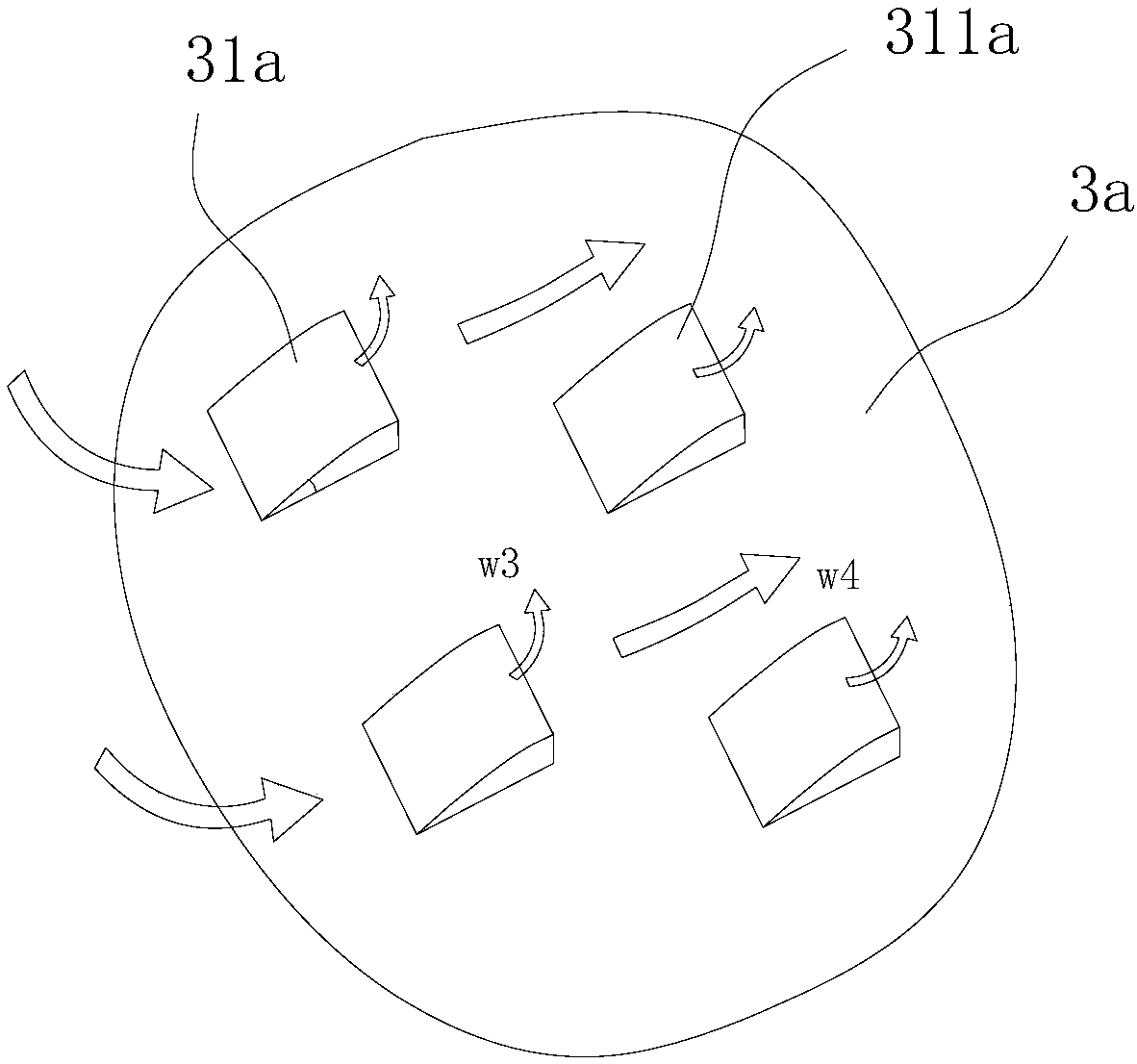

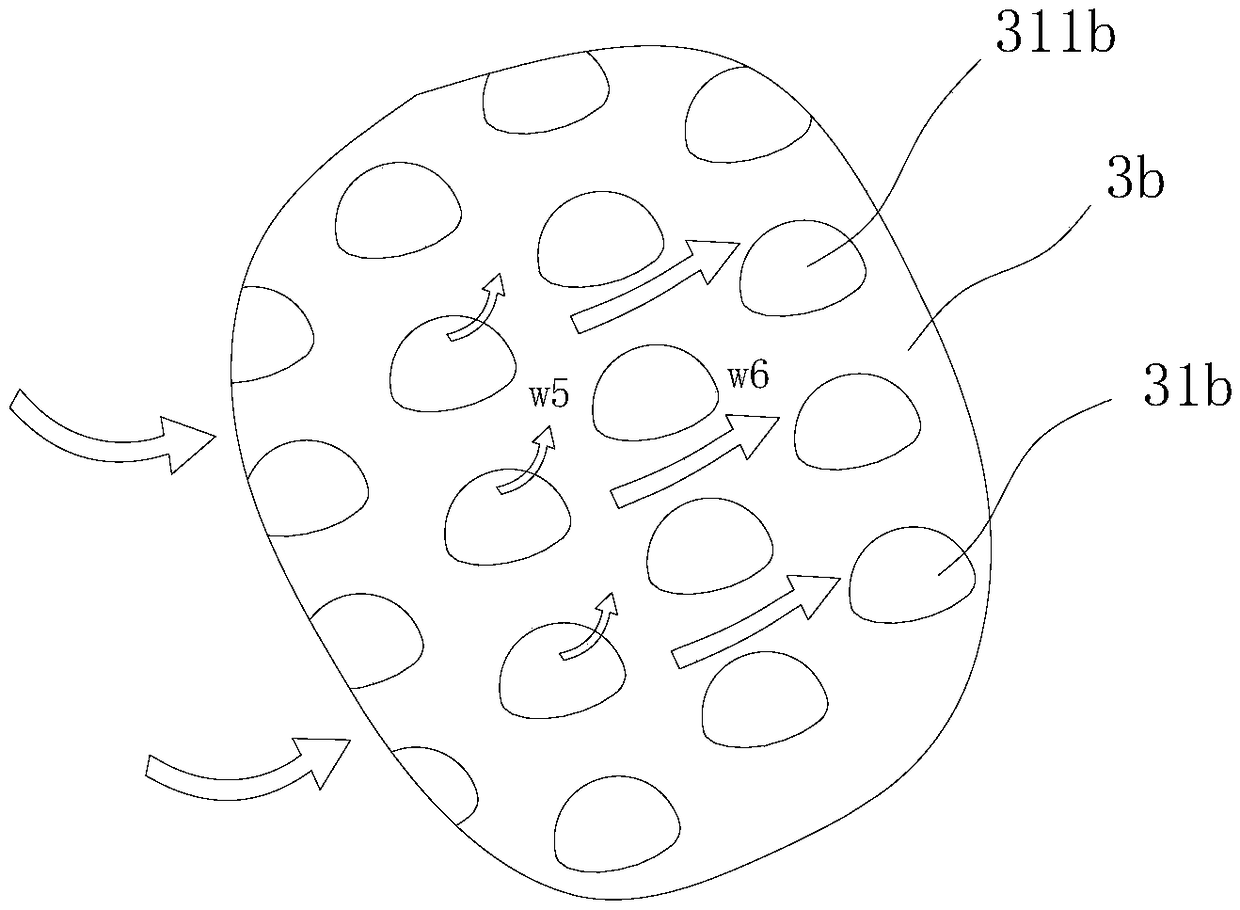

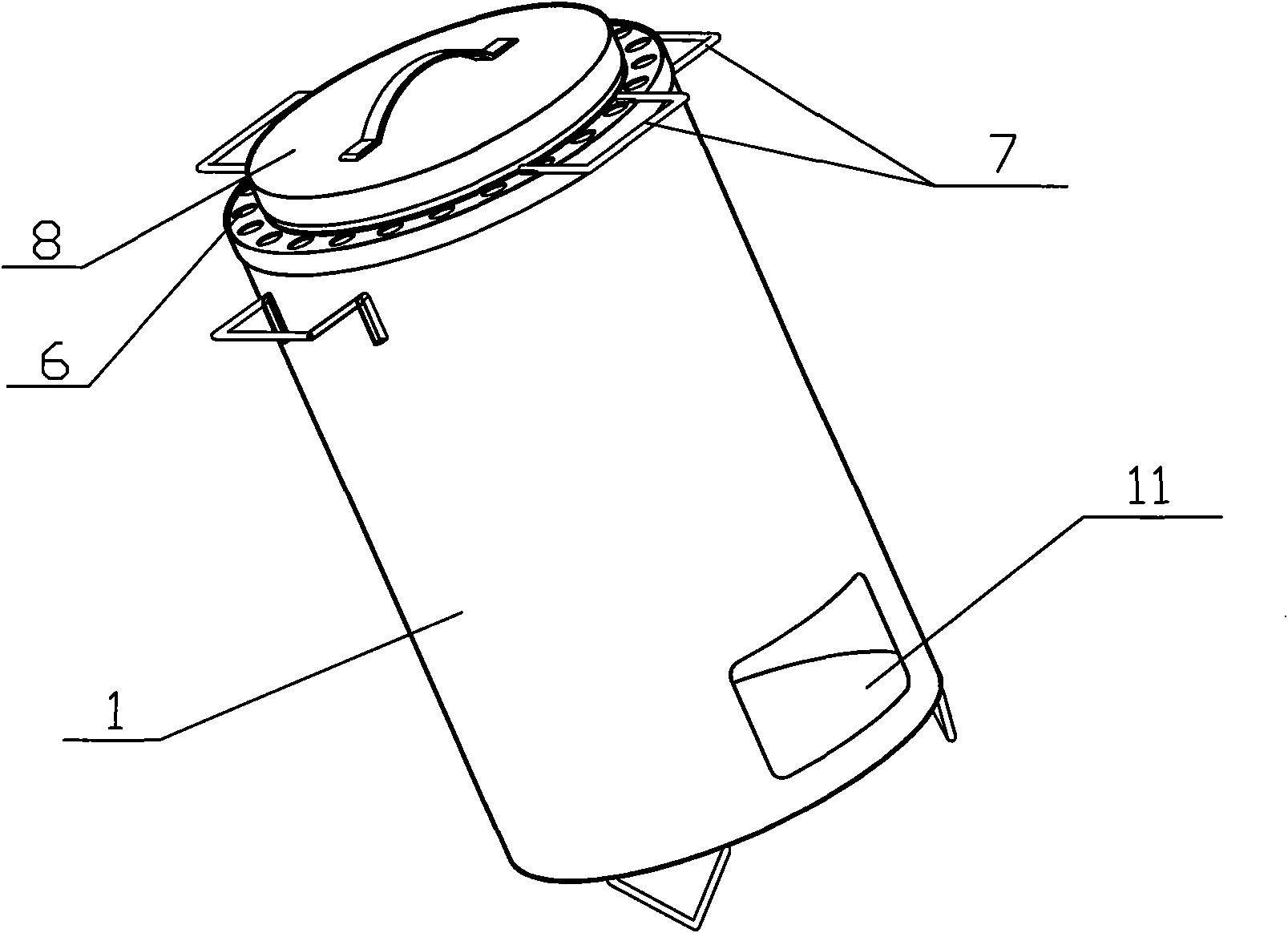

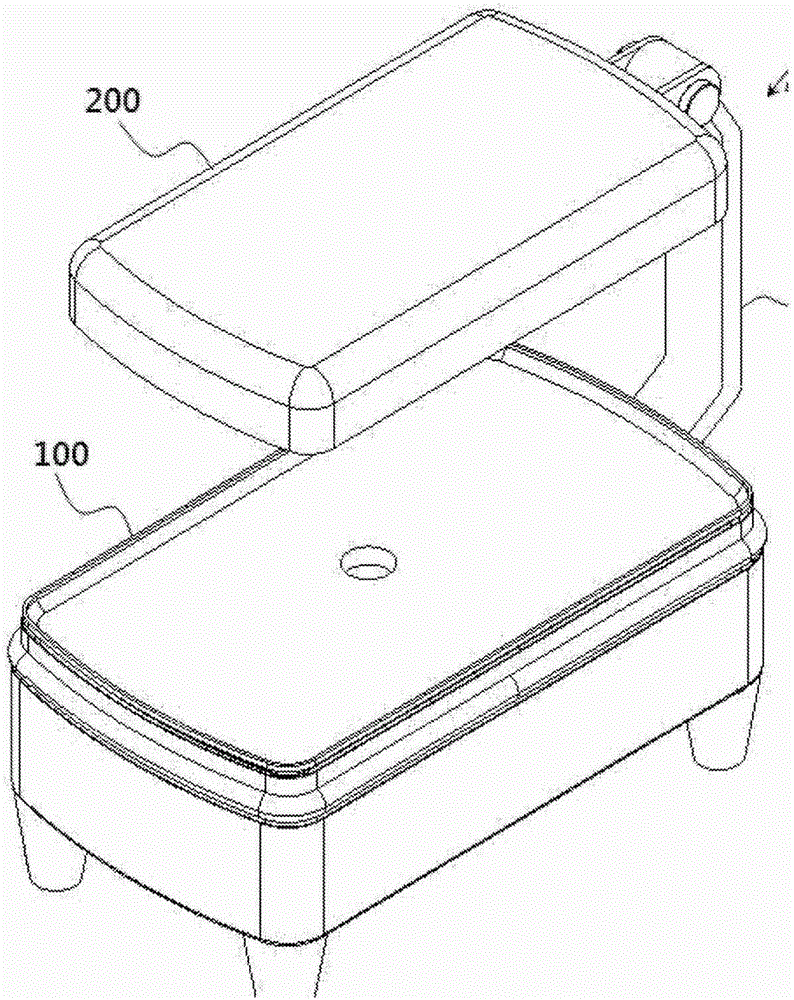

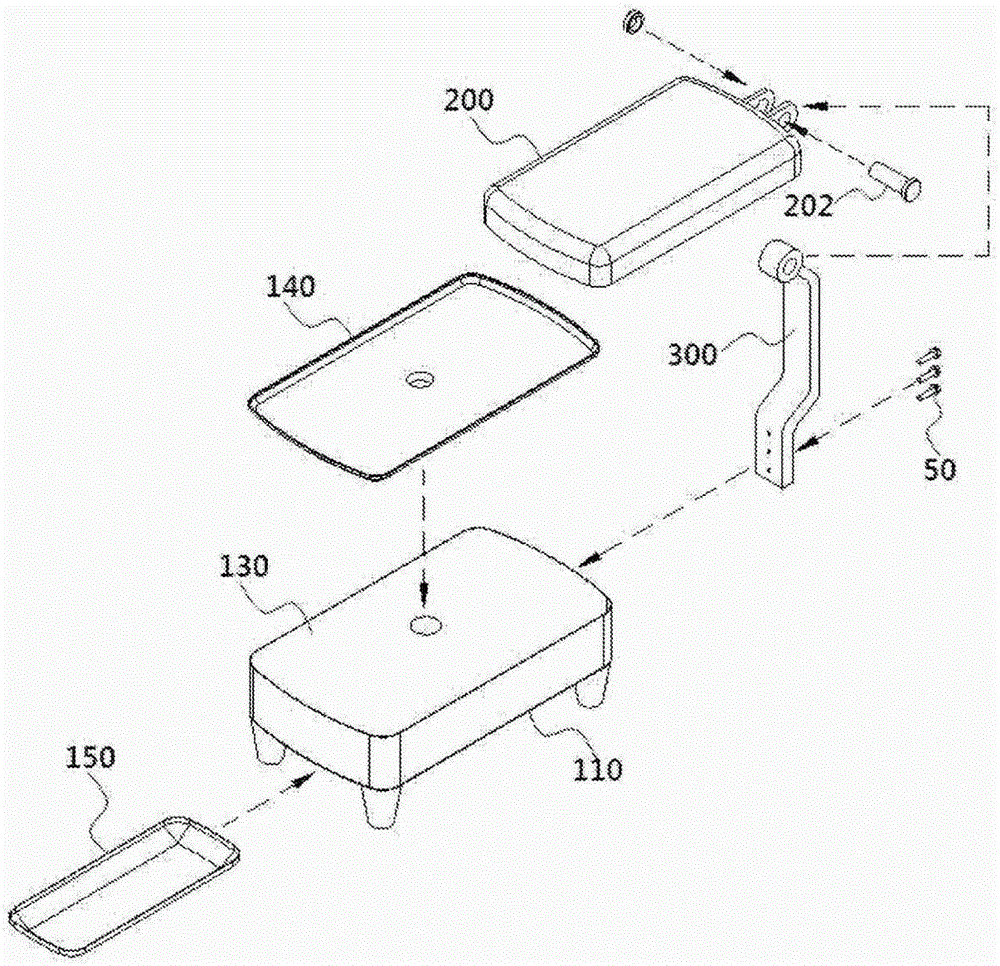

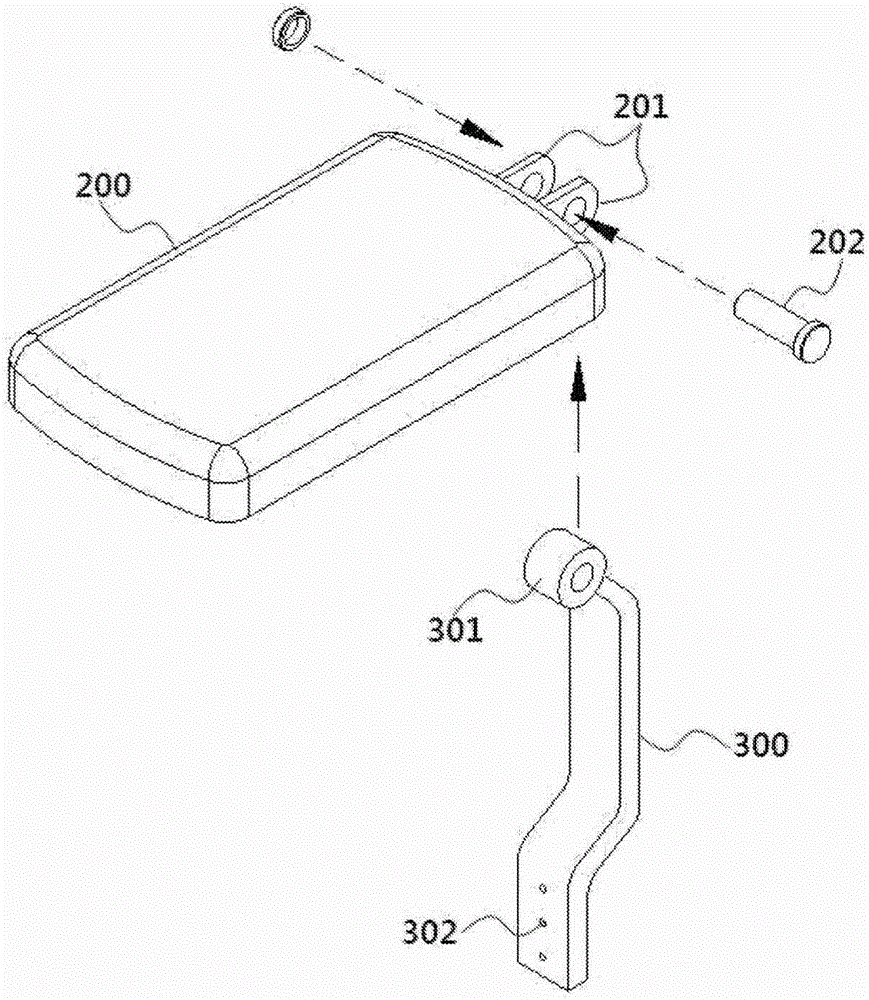

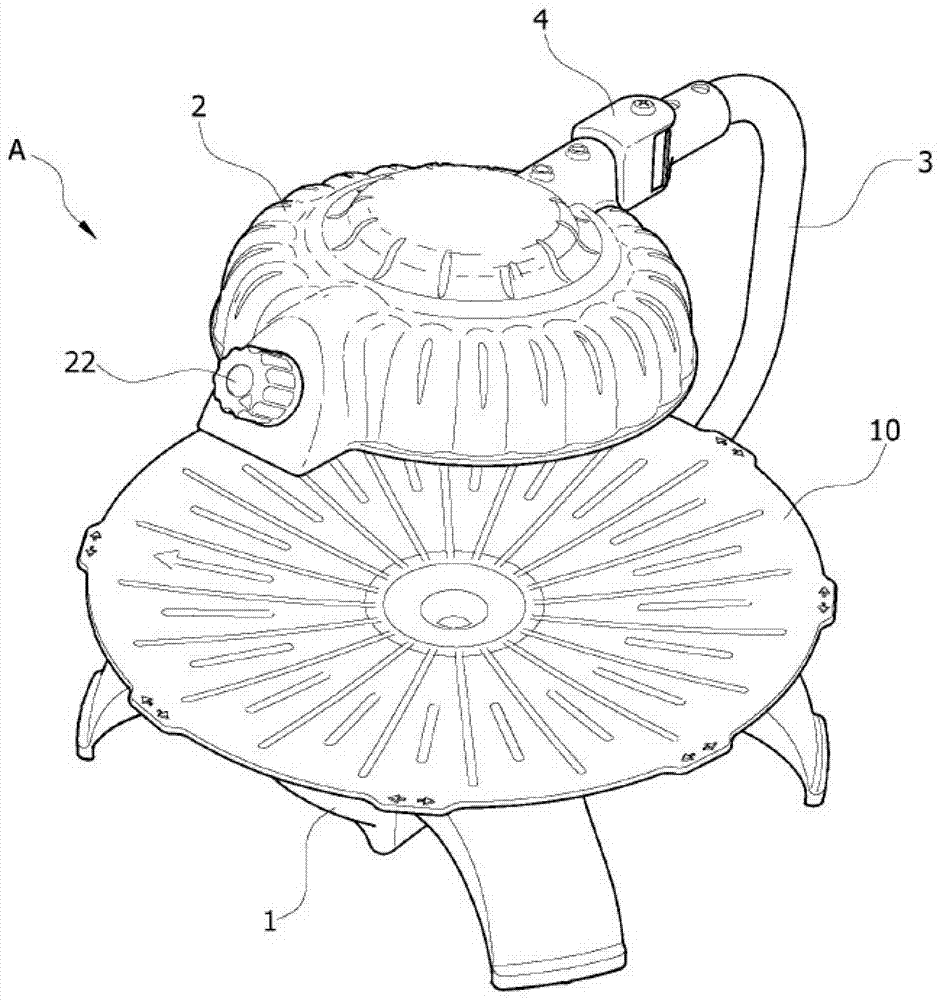

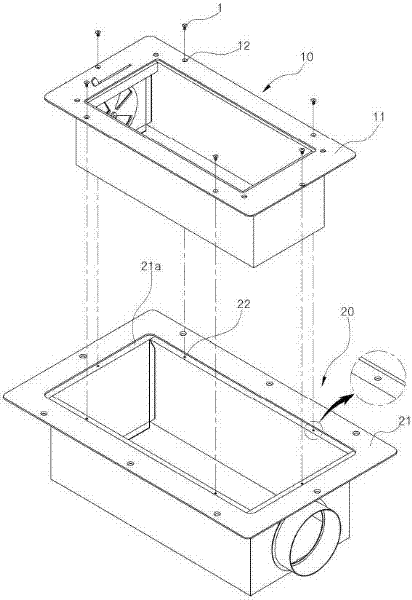

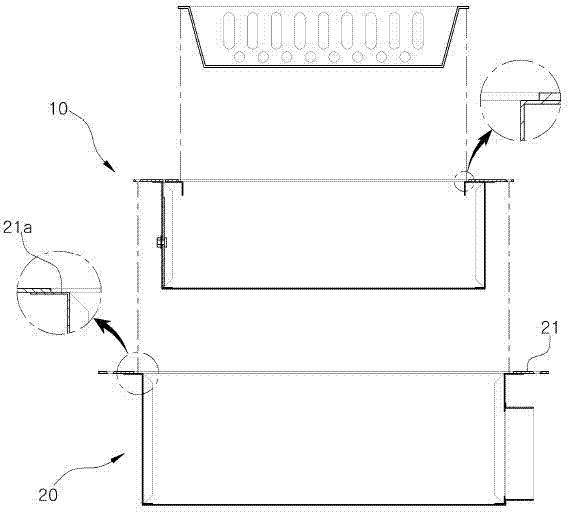

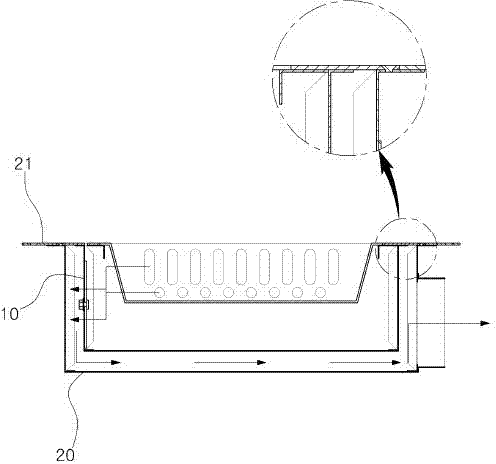

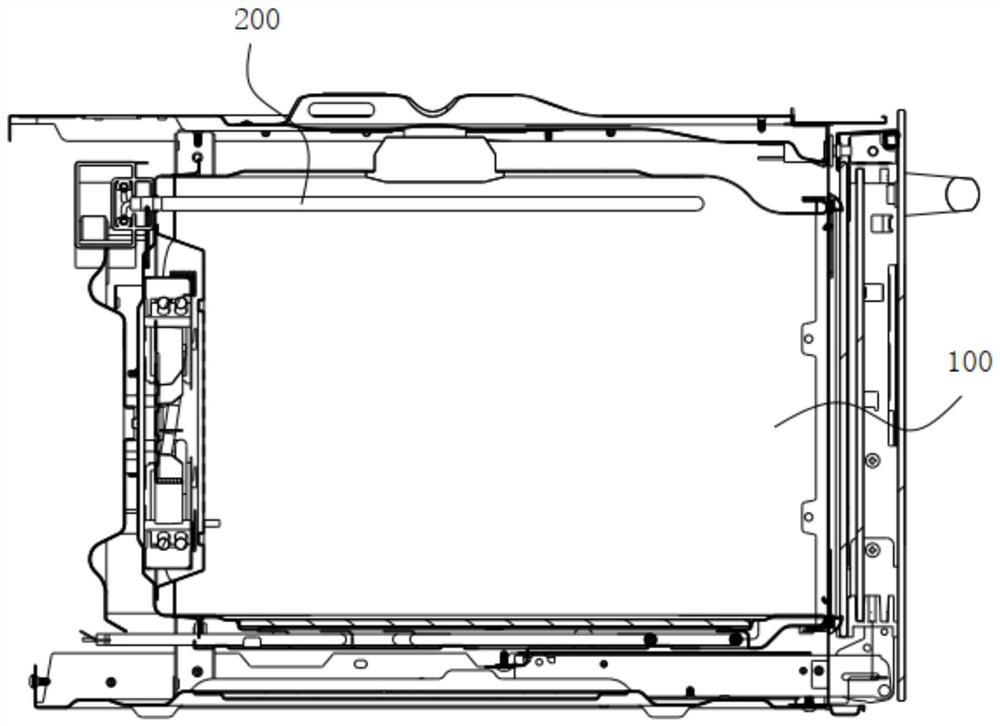

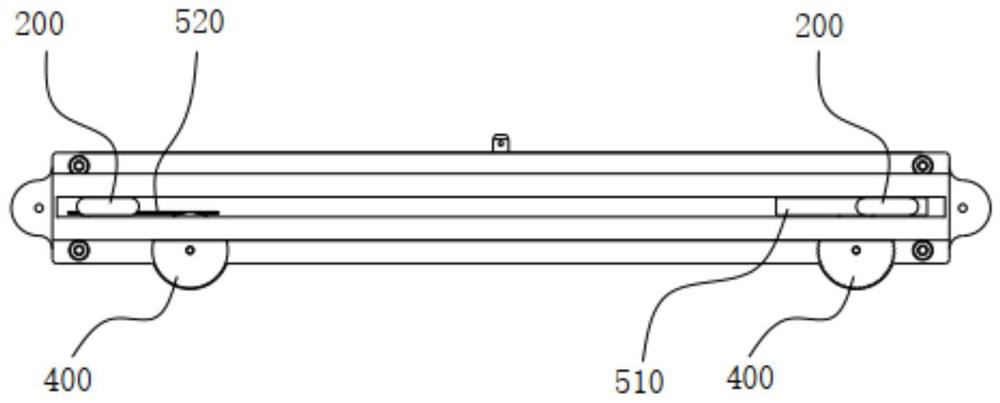

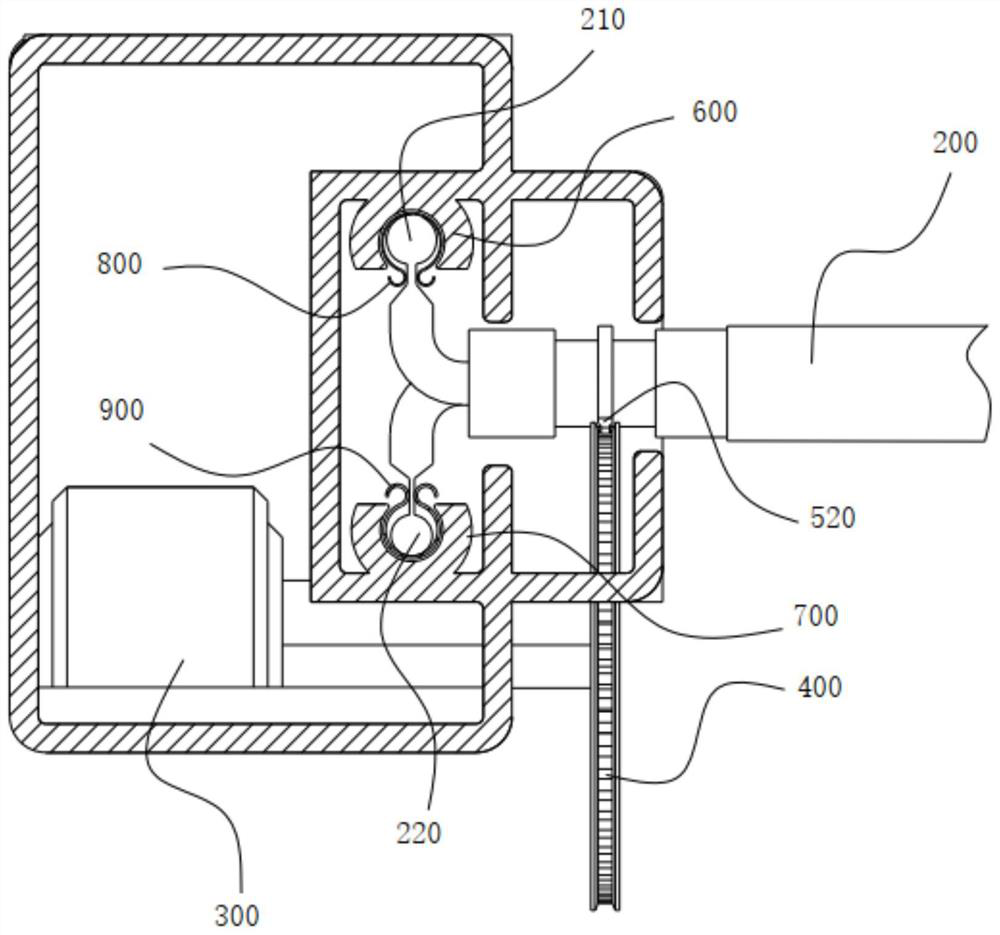

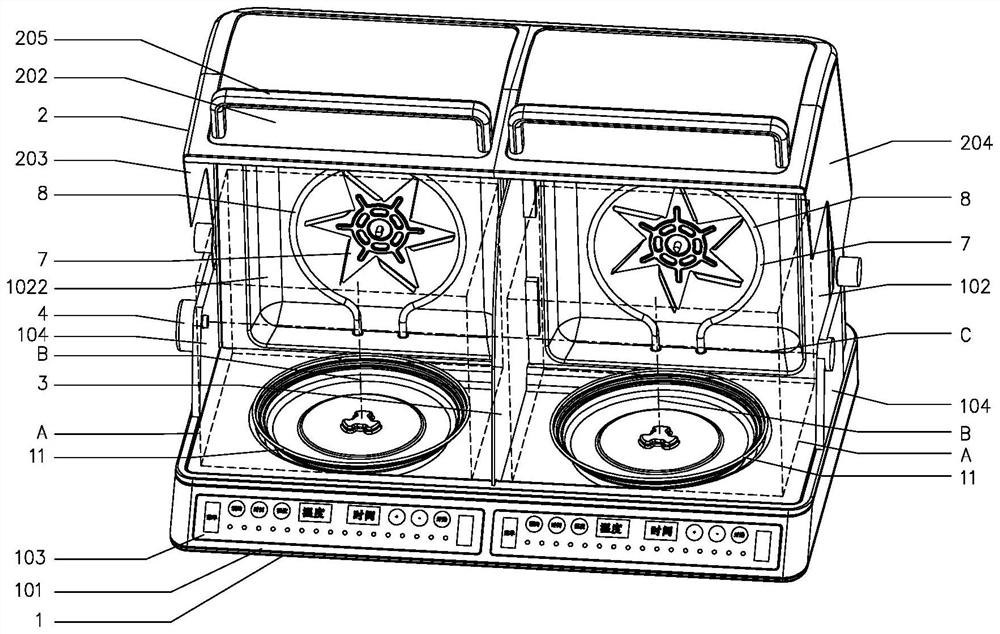

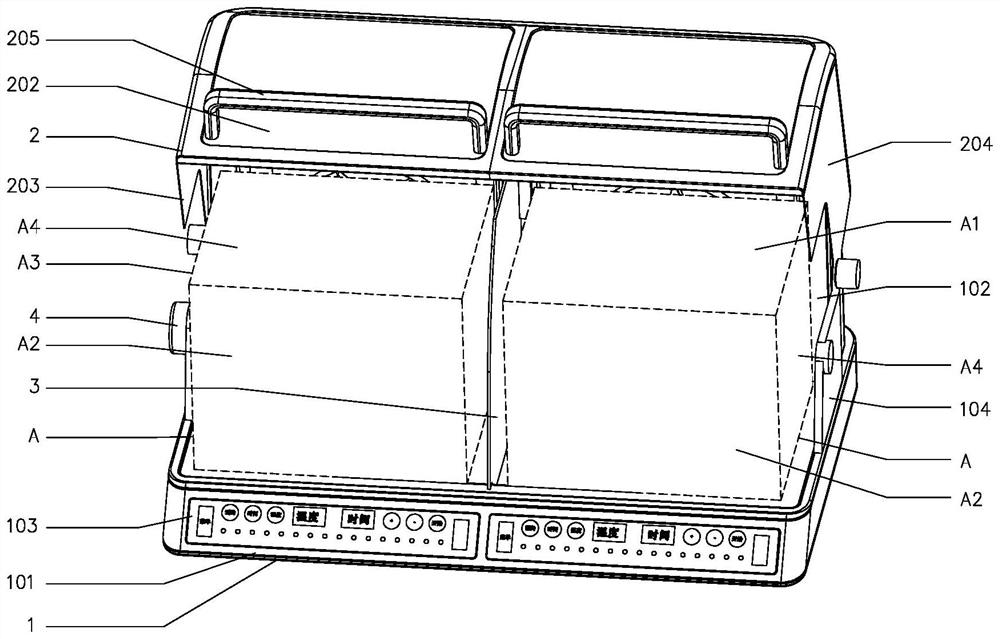

Cooking device

PendingCN108703675AFully heatedImprove cooking resultsRoasting apparatusRoasters/grillsProcess engineeringAirflow

Owner:FOSHAN SHUNDE KUFU ELECTRIC APPLIANCES CO LTD

Method for producing high-elasticity bulked silk-cotton quilt

ActiveCN1743260APromote puffingPuffing treatment can ensure that cocoons are cooked evenly and promoteAnimal fibresUpholstery fillingBoiling processWadding

The invention relates to a method for producing a expanded silk wadding, which includes: sort cocoons, boil at high temperature, degelatinize, shuck the cocoons to remove silkworm, wash, loosen by drawing and make them into silk piece, dewater, dry and draw to make the silk wadding. The invention features that the cocoons before high temperature boiling process are vacuum soaked and expanded by a expanding liquor, concretely the cocoons before high temperature are suctioned into the expanding liquor heated by 80-95 degreeC under vacuum condition, soaked uniformly and expanded in slight boiling state. The said expand is made from amphoteric surfactant. The cocoons after being made into silk pieces and before dewatering are conducted an after finishing by a silk softening agent. Advantages: the patches and stem cubes resulted from un-uniform boiling or in-complete degelatinizing of cocoons are largely reduced; the silk floss is very soft because of full expanding.

Owner:NANTONG LOVER APPL +1

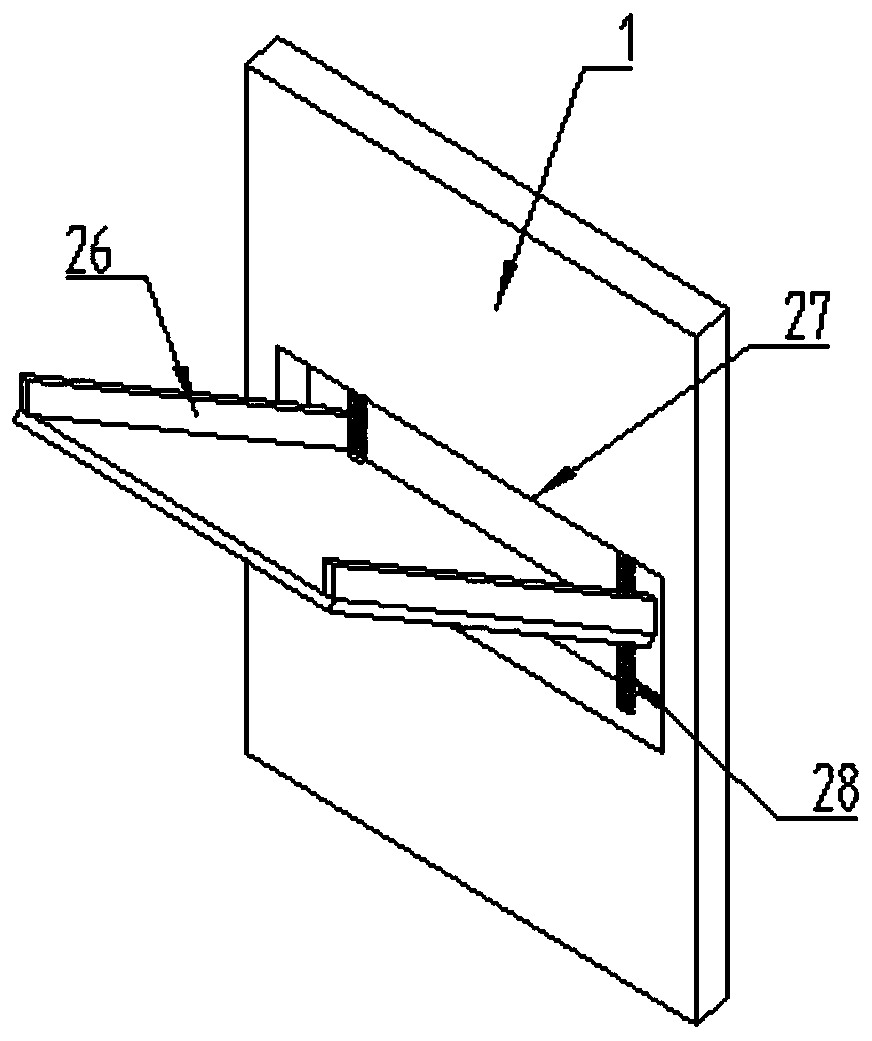

Baking oven with improved structure

The invention discloses a baking oven with an improved structure, belonging to the technical field of food bake. The baking oven comprises an oven body shell which is internally provided with an ovenfurnace; a baking bracket is arranged in the inner cavity of the oven furnace; a combustion chamber is arranged at the bottom space between the oven furnace and the oven body shell; an opening is arranged at the side face of the oven body shell corresponding to the combustion chamber; an edge sealing device which can control the opening size of a ventilation opening thereof is arranged in a cavitybetween the oven furnace and the oven body shell corresponding to the upper end part of the oven furnace and the oven body shell. By controlling the ventilation of the combustion chamber, the invention leads the firepower to be even, the food cooking to be even, the color to be good, the meat quality to be fragrant, smooth, delicious, and original taste and flavor, and the food not to contact with oven fire, thus achieving health and keeping the effect of gravy, and the invention can fully utilize heat energy, saves energy sources, has compact structure design and convenient portability, canbe used for indoor and outdoor baking, and is easy to be popularized.

Owner:梁锁页 +1

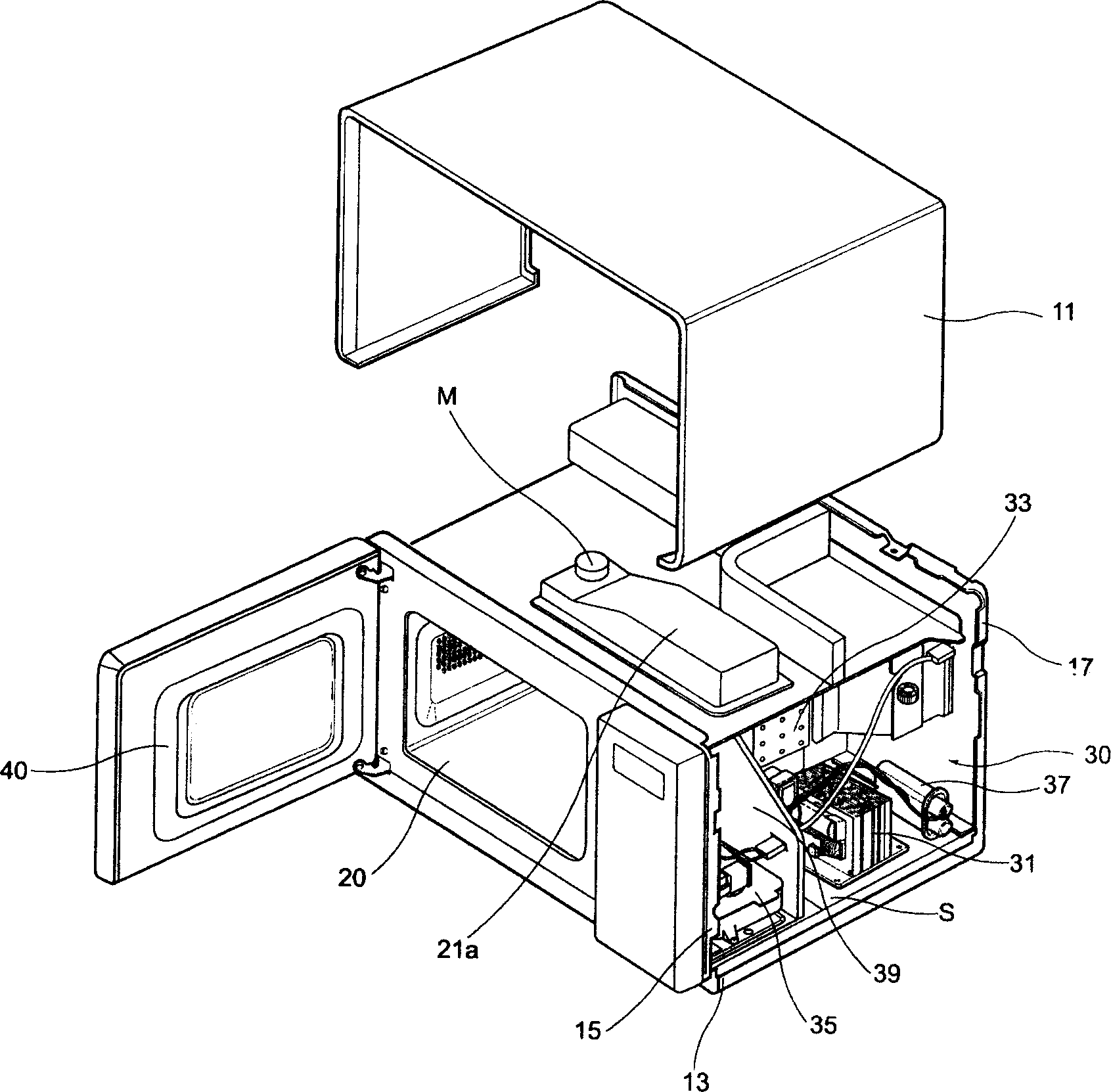

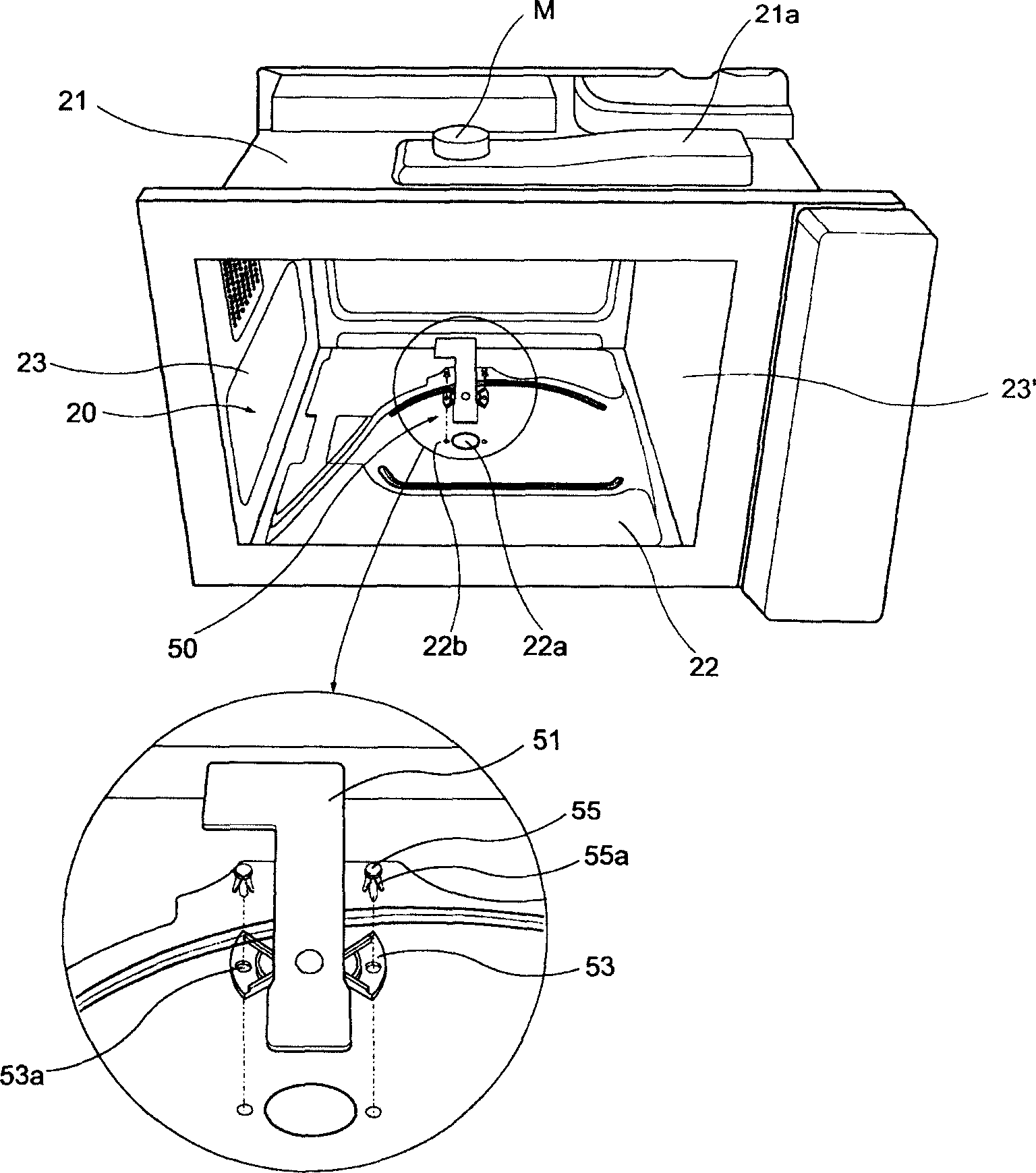

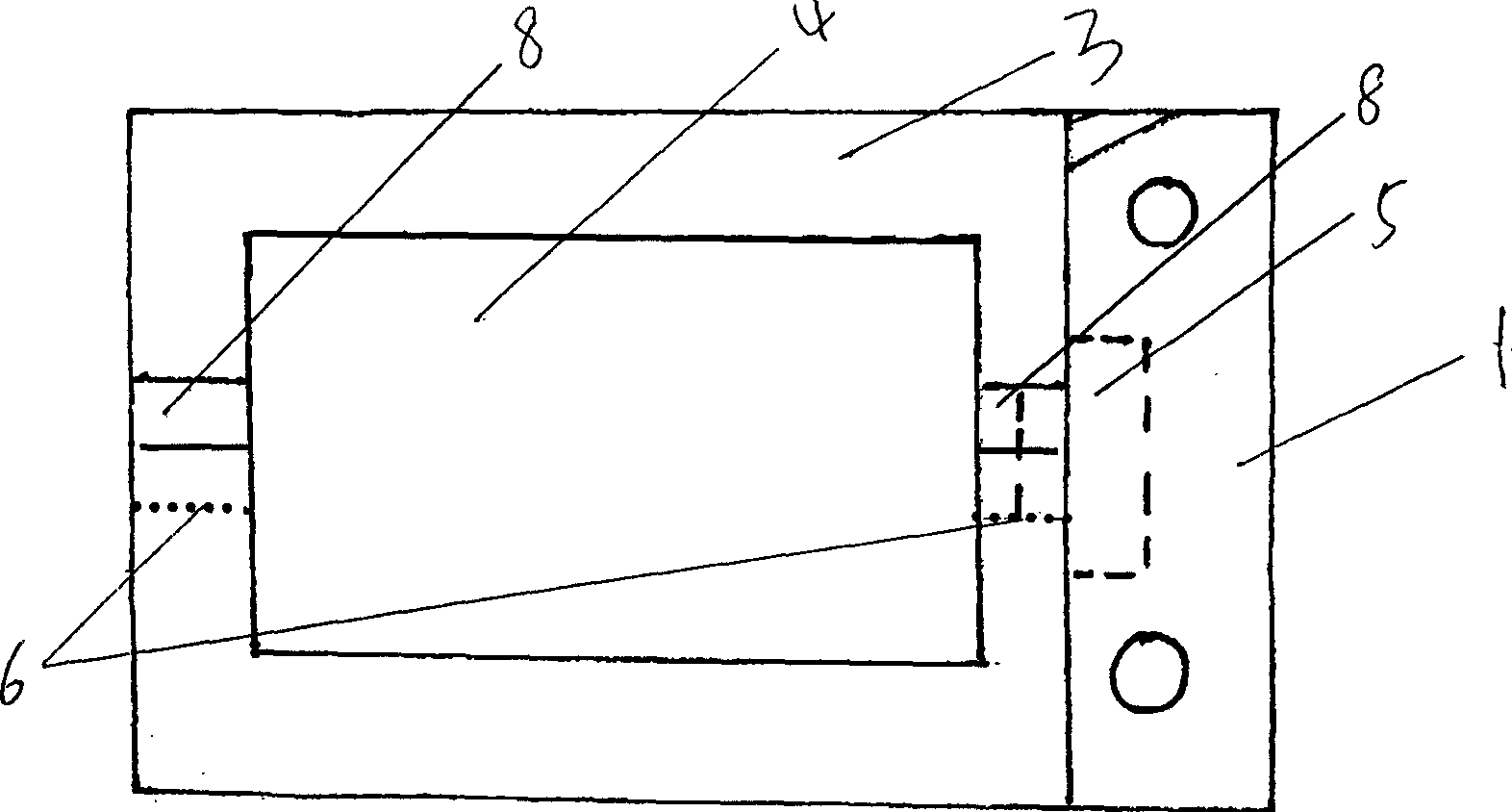

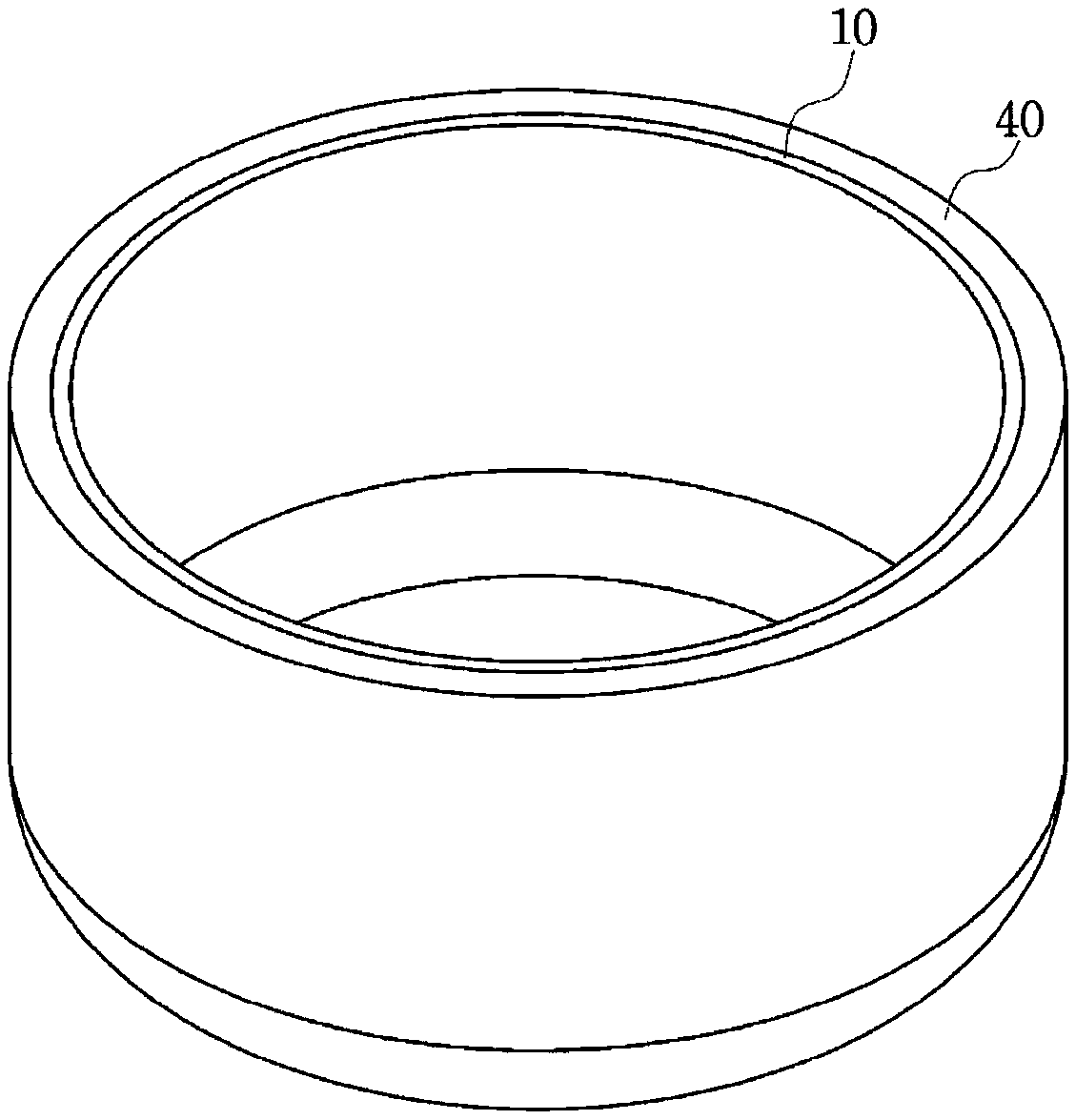

Surface plate structure for bottom of microwave oven chamber

InactiveCN1752529AHeating evenlyEvenly cookedDomestic stoves or rangesLighting and heating apparatusMicrowave ovenSurface plate

The present invention discloses an oven cavity lower portion panel structure of microwave oven, It includes oven cavity for placing cooking material, lower portion panel set in the lower portion of oven cavity and formed into the appearance of lower surface of oven cavity and stirring fan which is fixed on the upper surface of lower portion panel and used for dispersing microwave irradiating oven cavity, on the lower portion panel of oven cavity a forming portion is set, and said stirring fan can utilize the forming portion to reflect microwave towards several directions.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

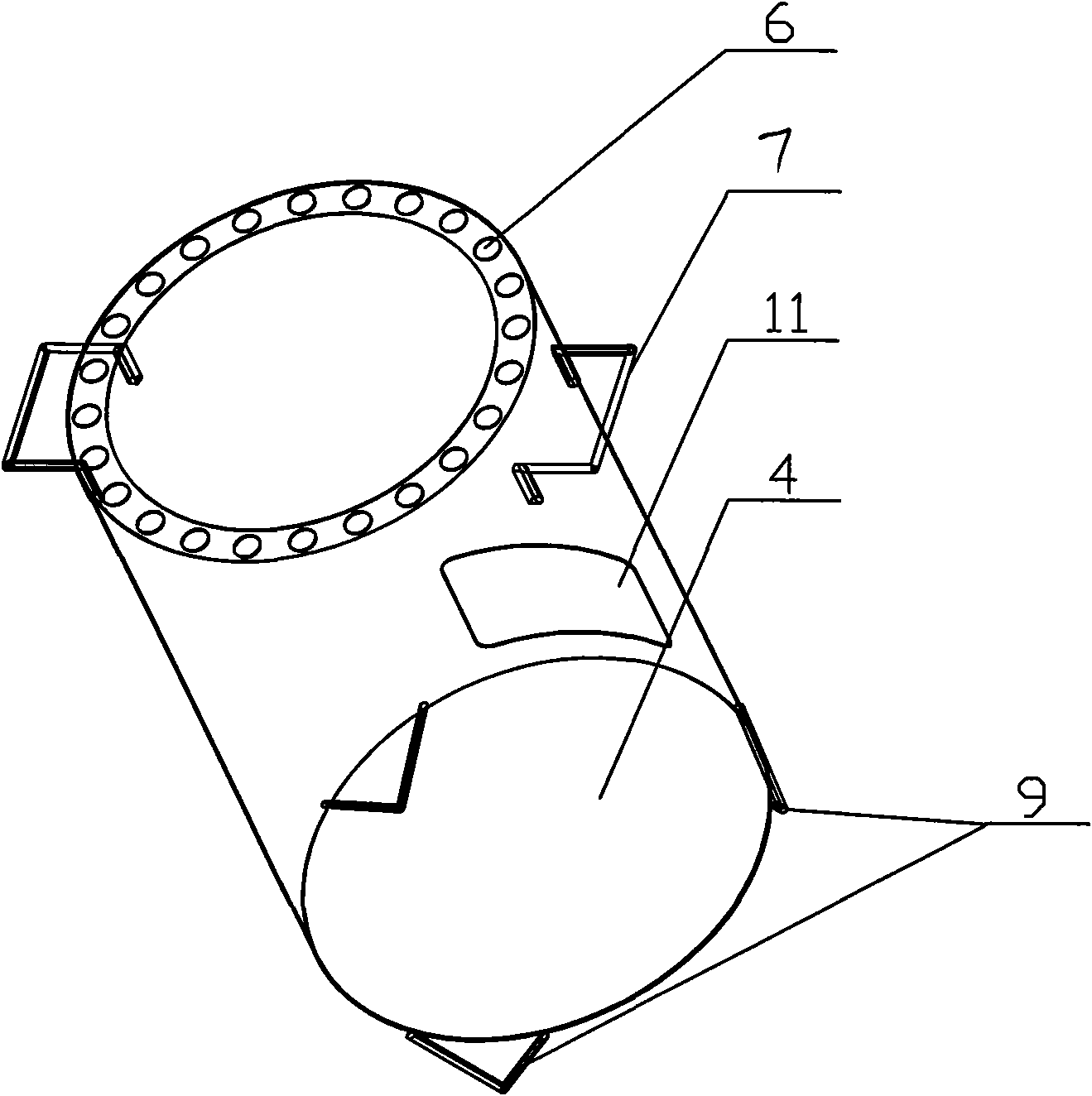

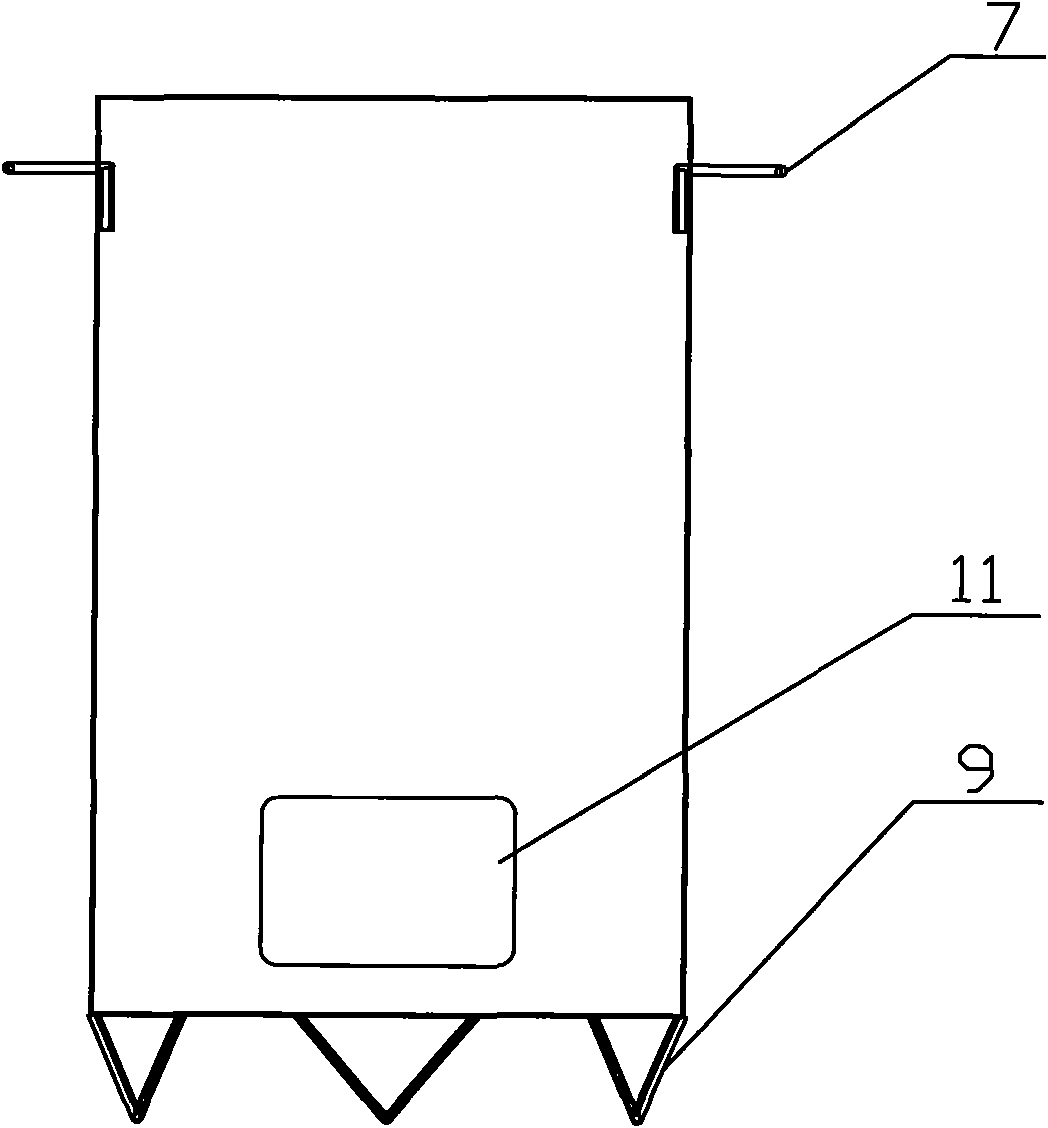

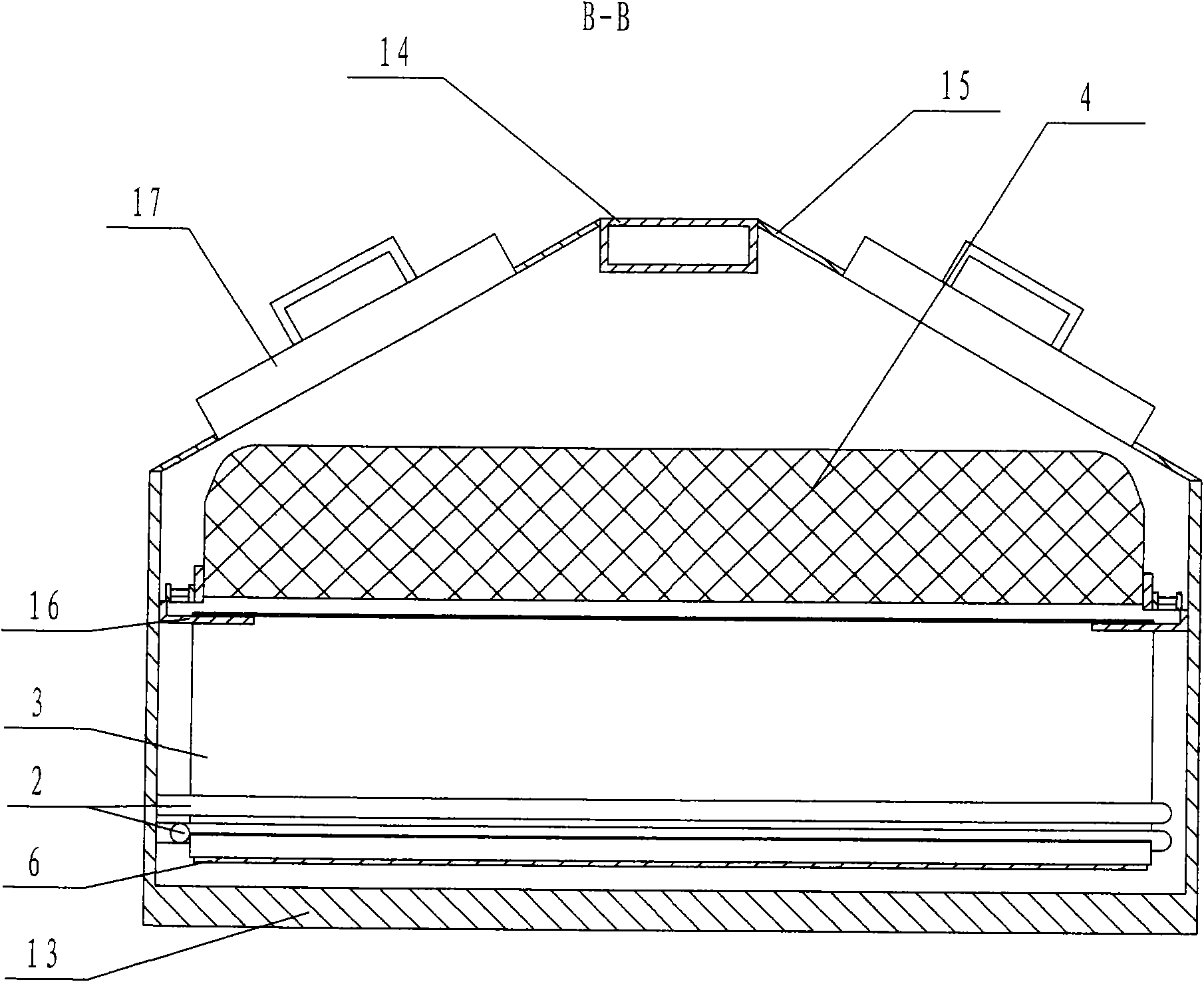

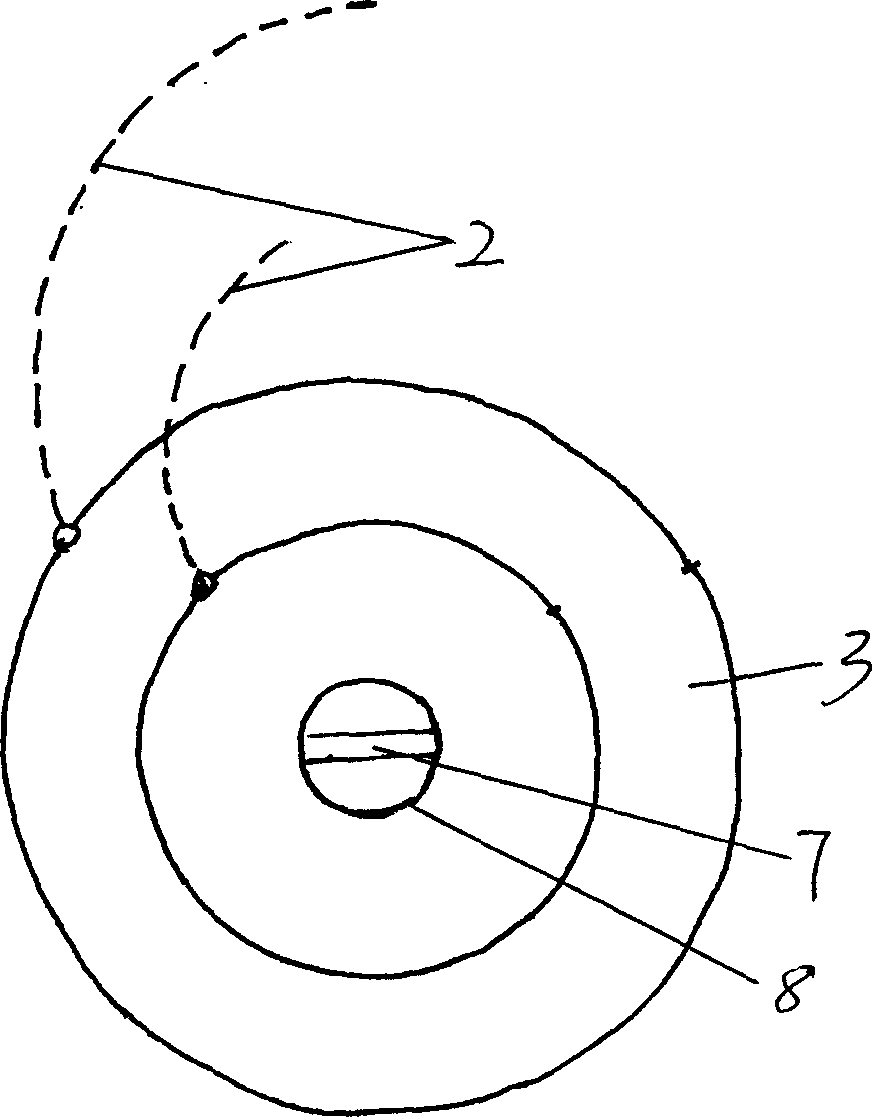

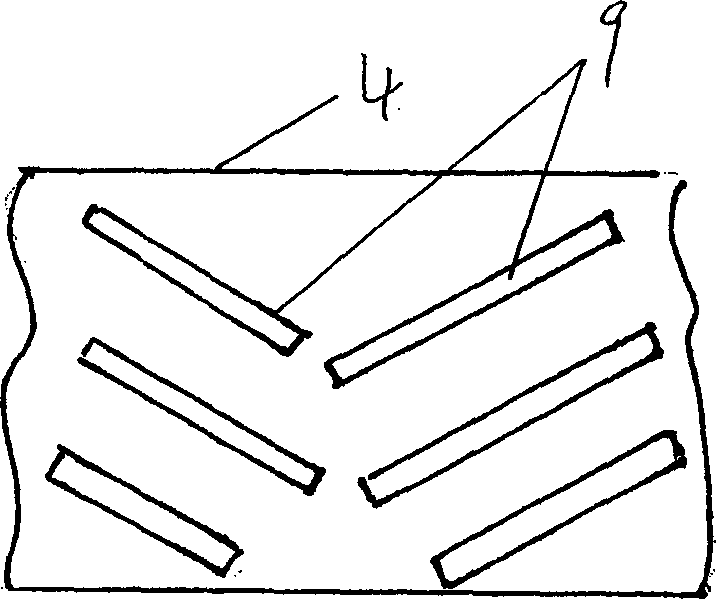

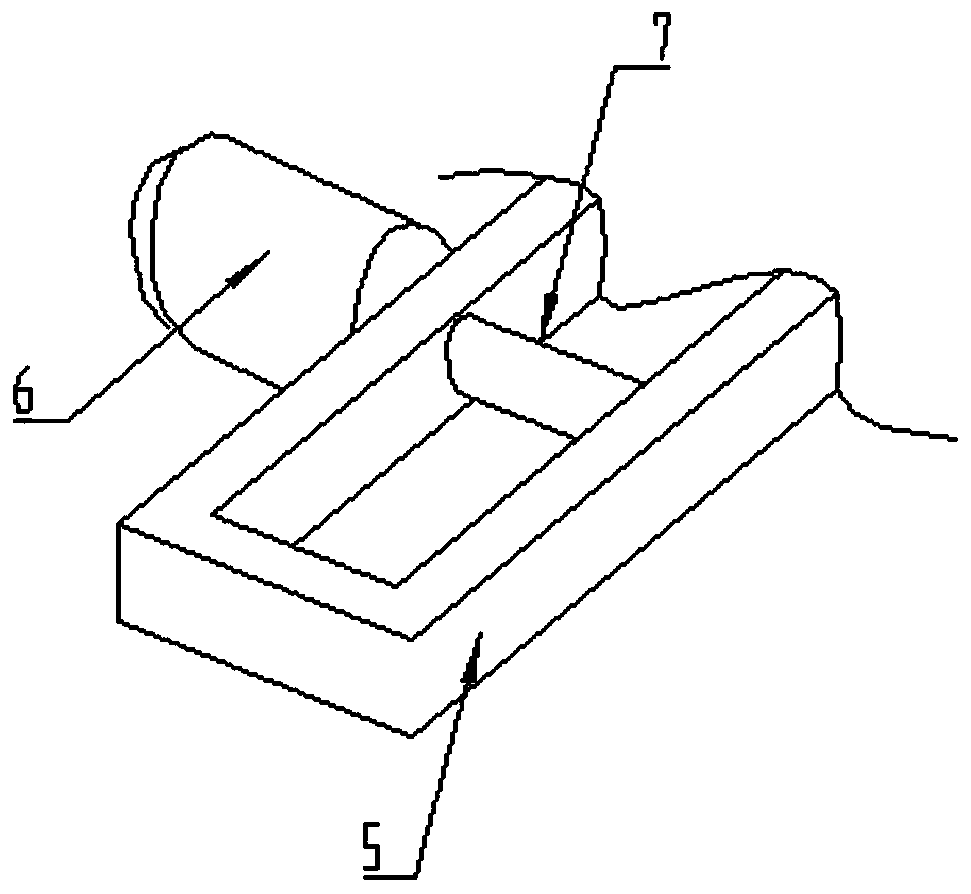

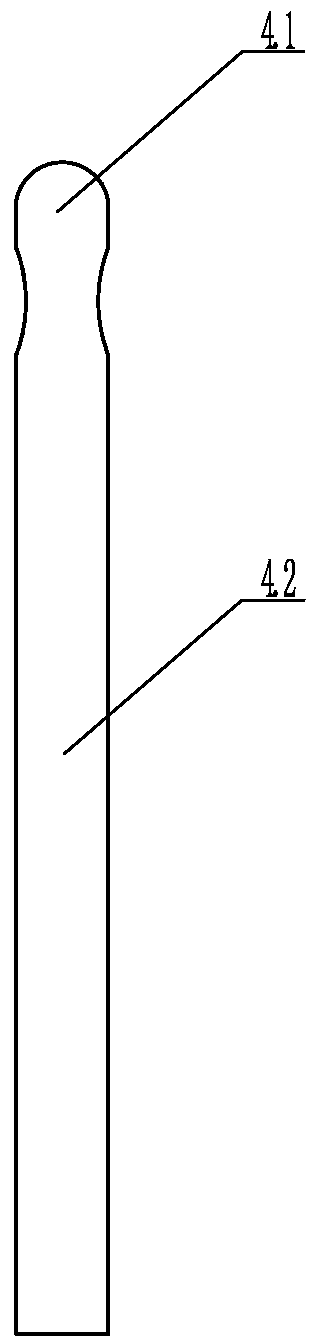

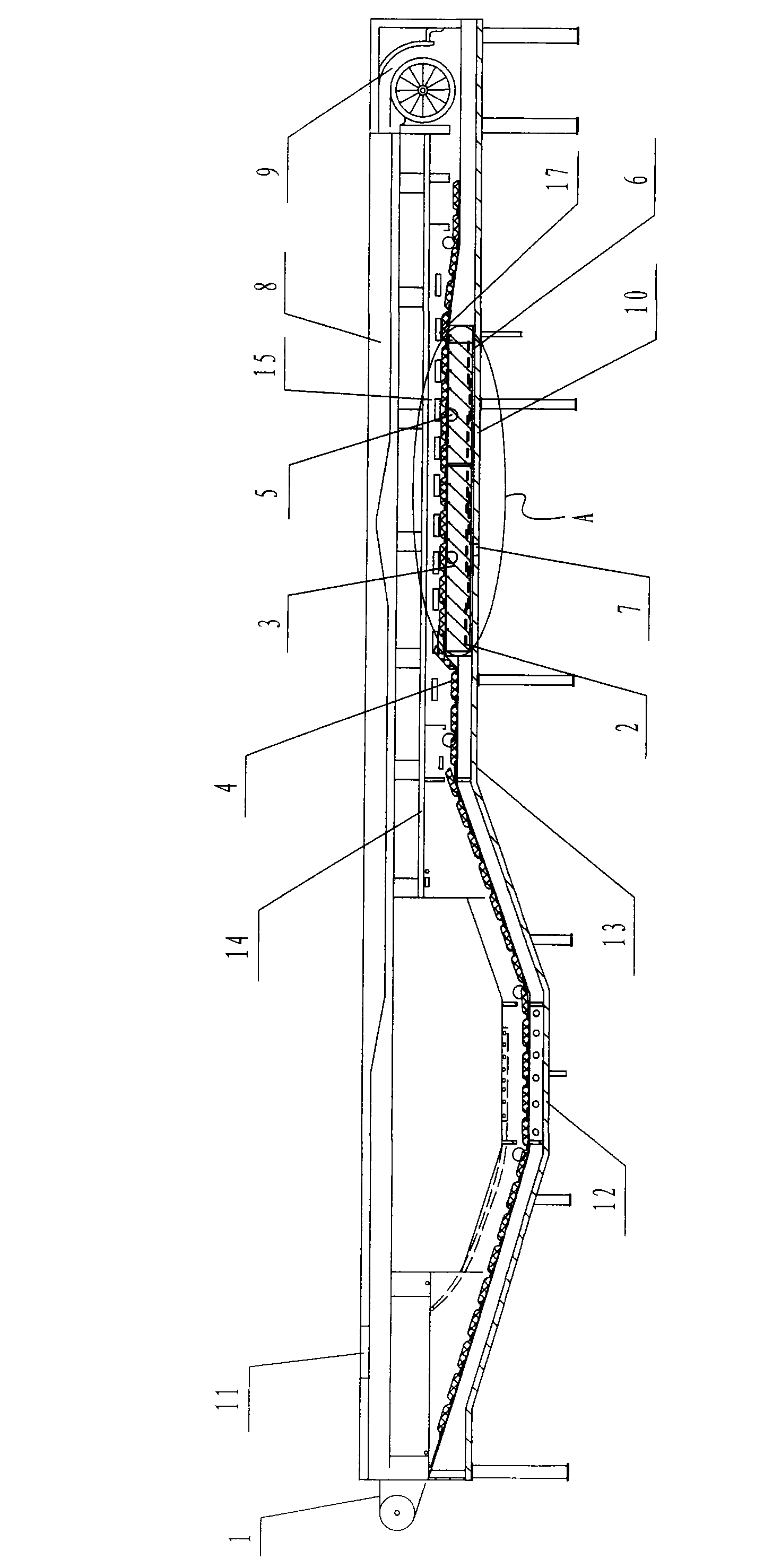

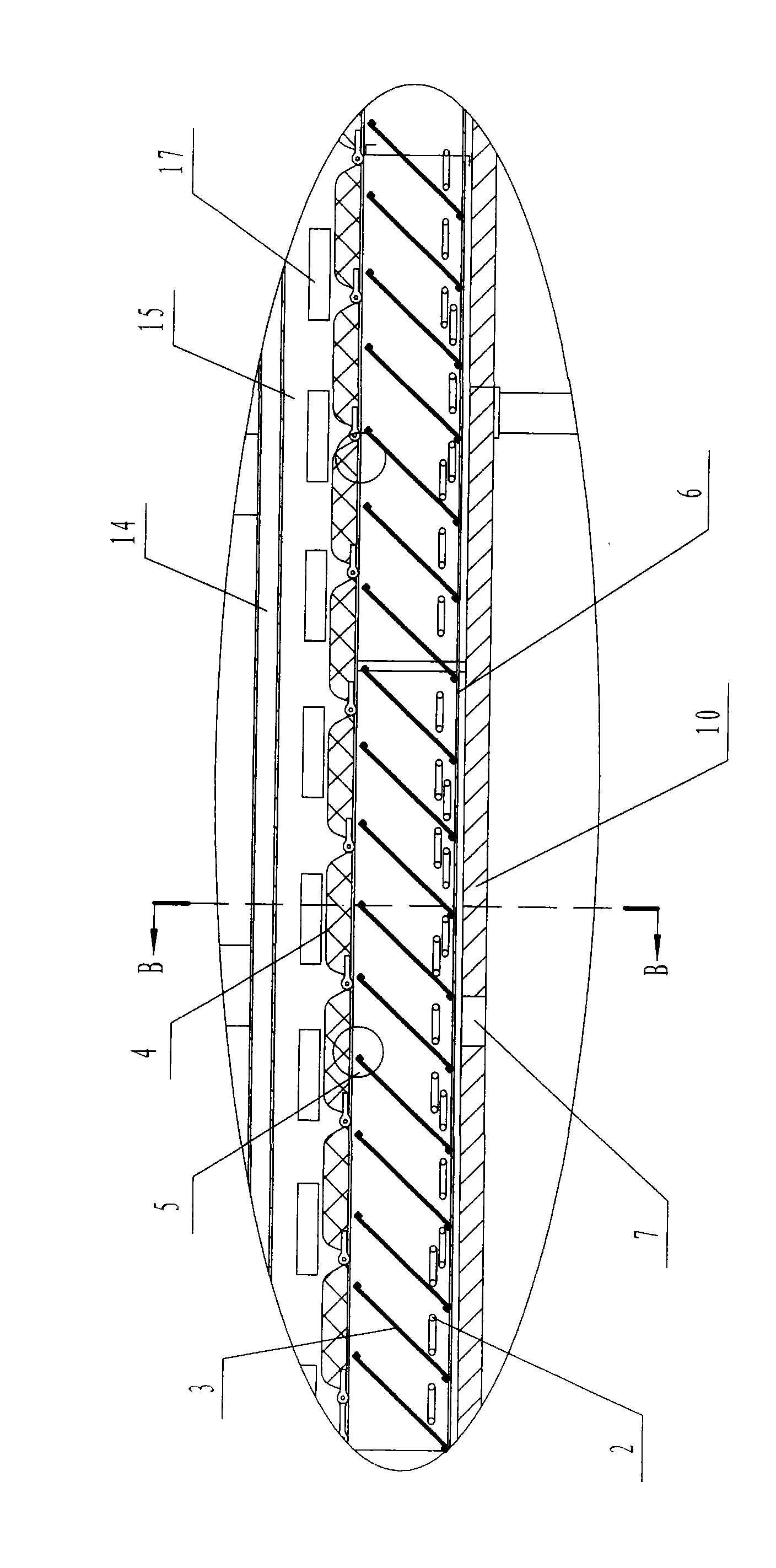

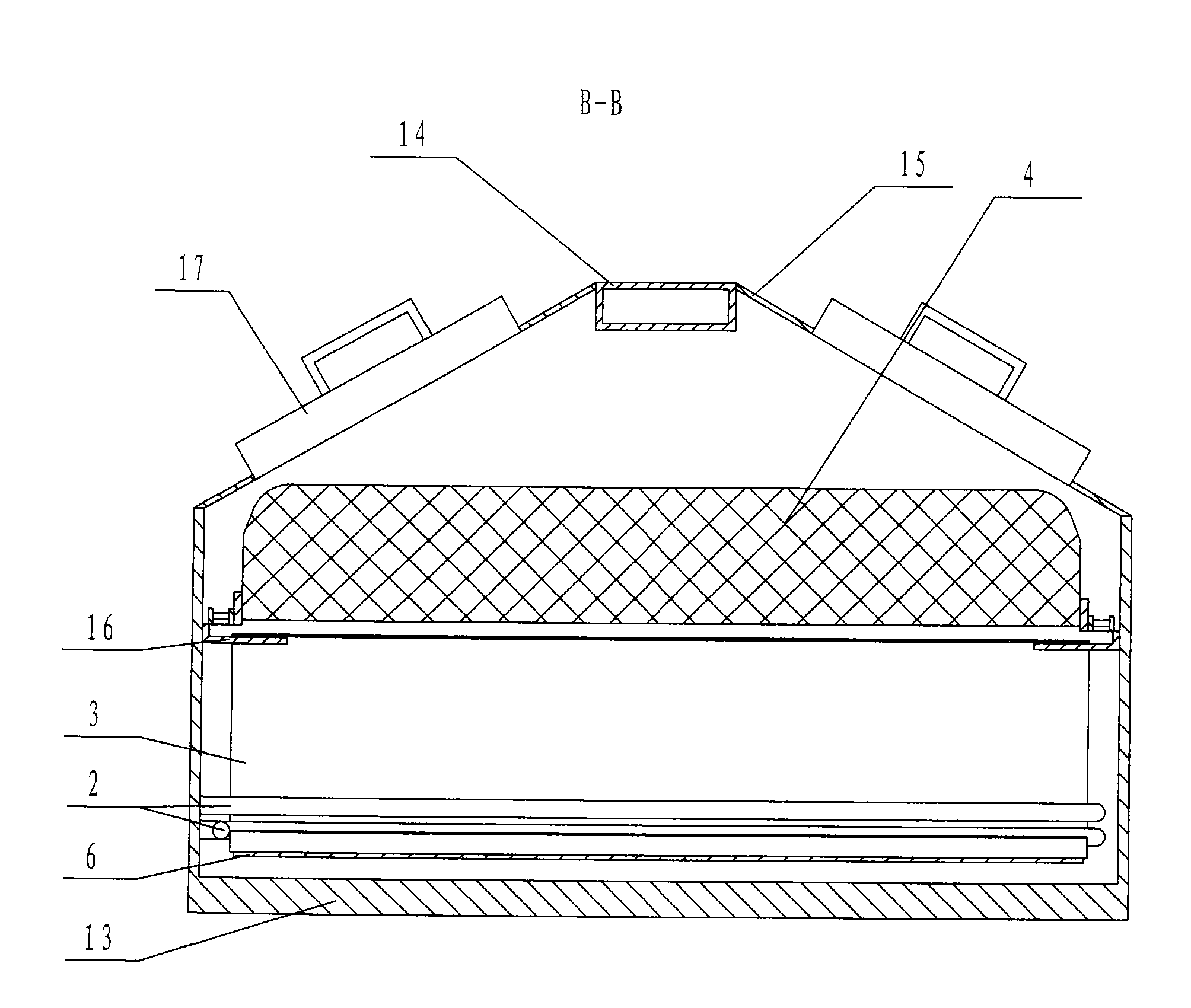

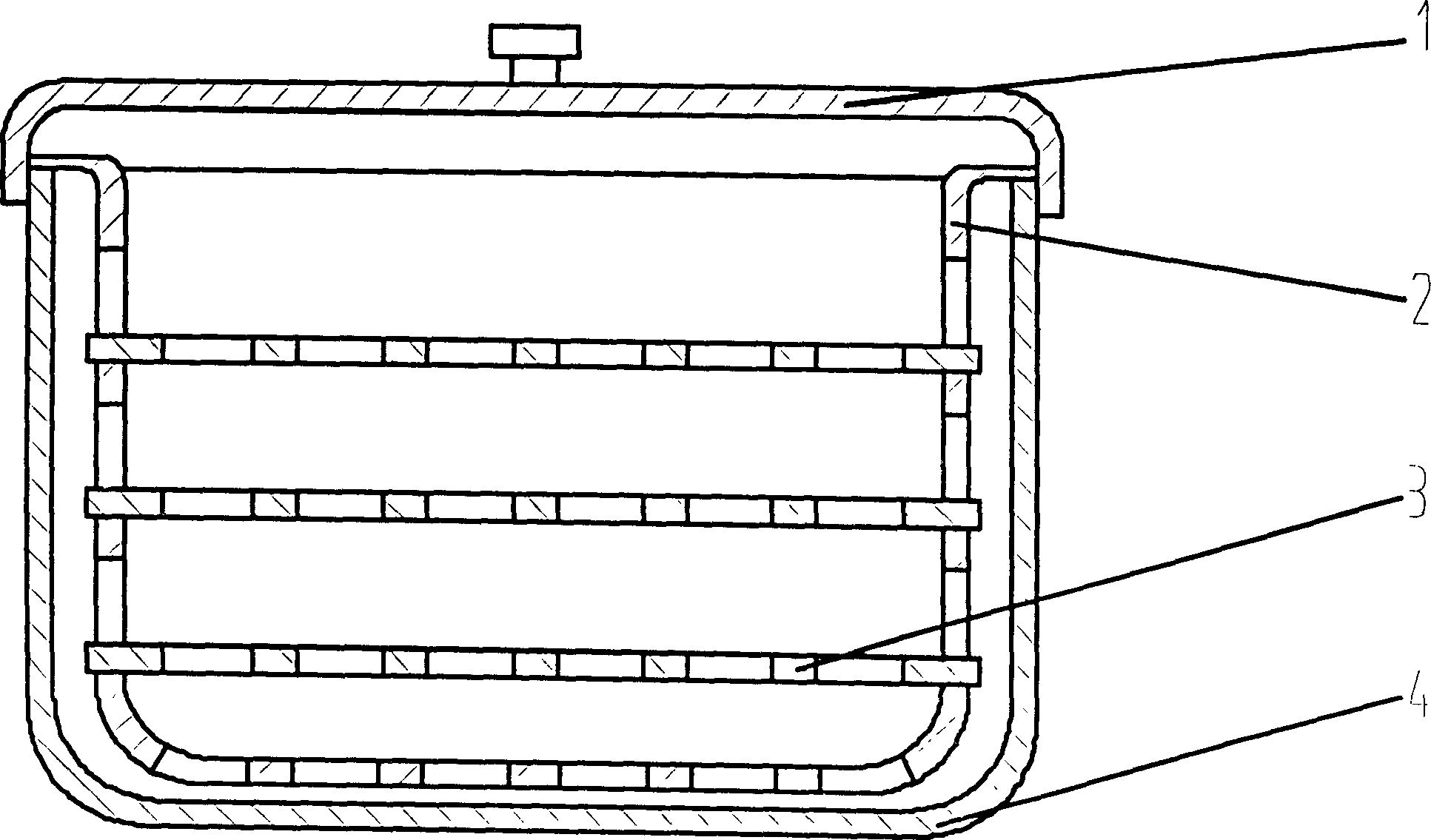

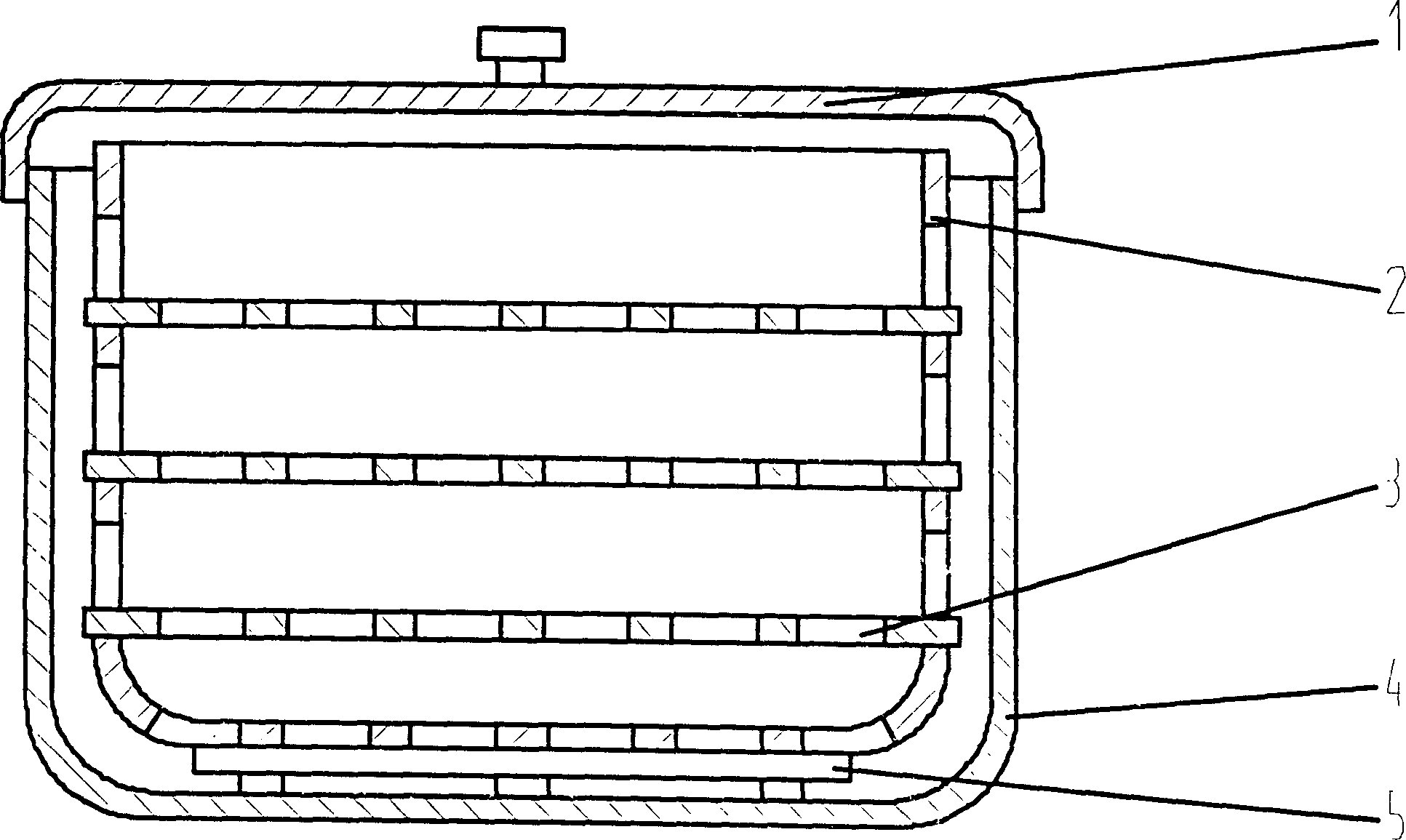

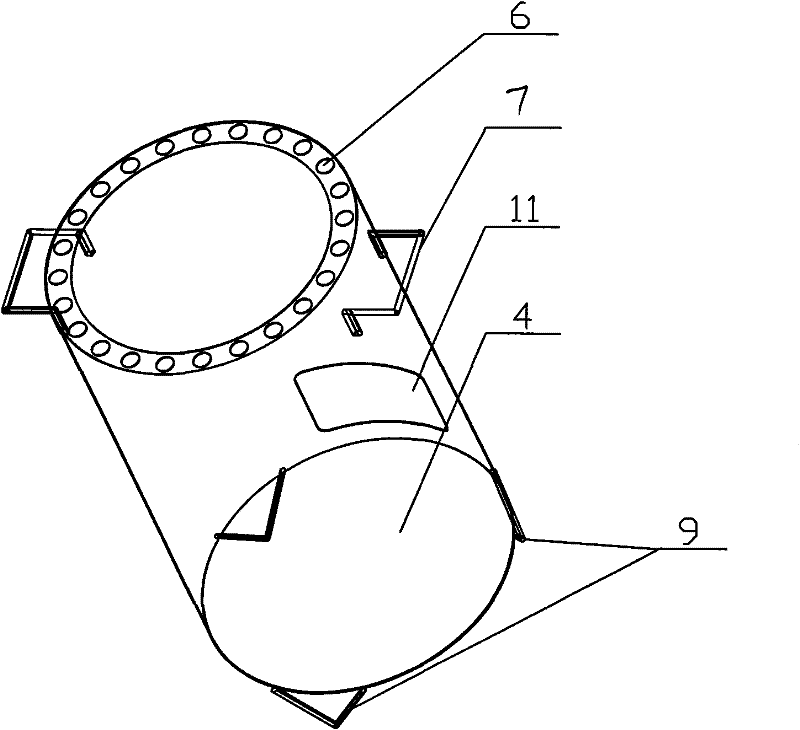

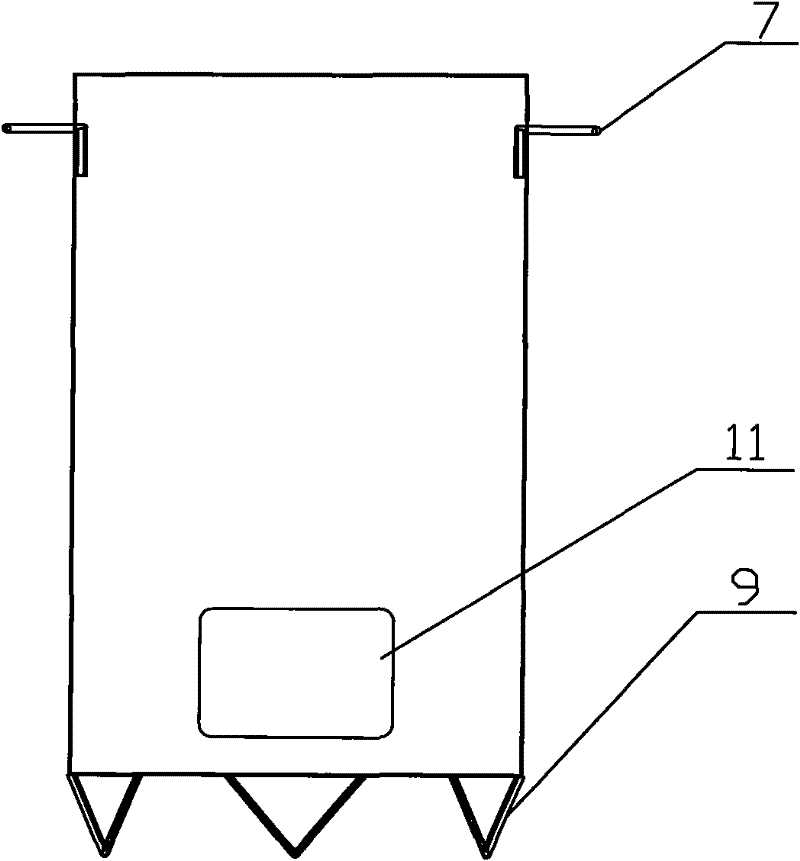

Cooking part device of cocoon cooking machine

InactiveCN101629321AGood adhesionUniform temperatureSilk filament obtainingEngineeringMechanical engineering

The invention relates to a cooking part device of a cocoon cooking machine. A plurality of symmetrical hooks (16) are arranged on both straight walls of a cooking chamber (10) along the length direction, each pair of hooks (16) is respectively positioned on the two straight walls, and inclined plates (3) are hooked on each pair of hooks (16); both the upper ends and the lower ends of all the inclined plates (3) are provided with two folding edges in the same direction; the inclined directions of all the inclined plates (3) are consistent, and the bottoms of all the inclined plates (3) are butted on the upper surface of a reflecting plate (6). Because the guide inclined plates are arranged above a steam elbow pipe, when steam mixed with steam dropping water moves to the positions of the inclined plates, the steam continues to upwards move along the inclined plates due to the function of the inclined plates, and the steam dropping water moves downwards along the inclined plates so as to achieve the aims for separating the steam from the steam dropping water and enabling the steam dropping water to be difficultly attached on silkworm cocoons; the inclined plates and the horizontal plane are in an included angle, and the steam can form circular flow in the cooking chamber, therefore, the temperature in the cooking chamber is more uniform, and the silkworm cocoons in a cocoon cage are uniformly cooked so as to be beneficial to reeling silk.

Owner:童华波

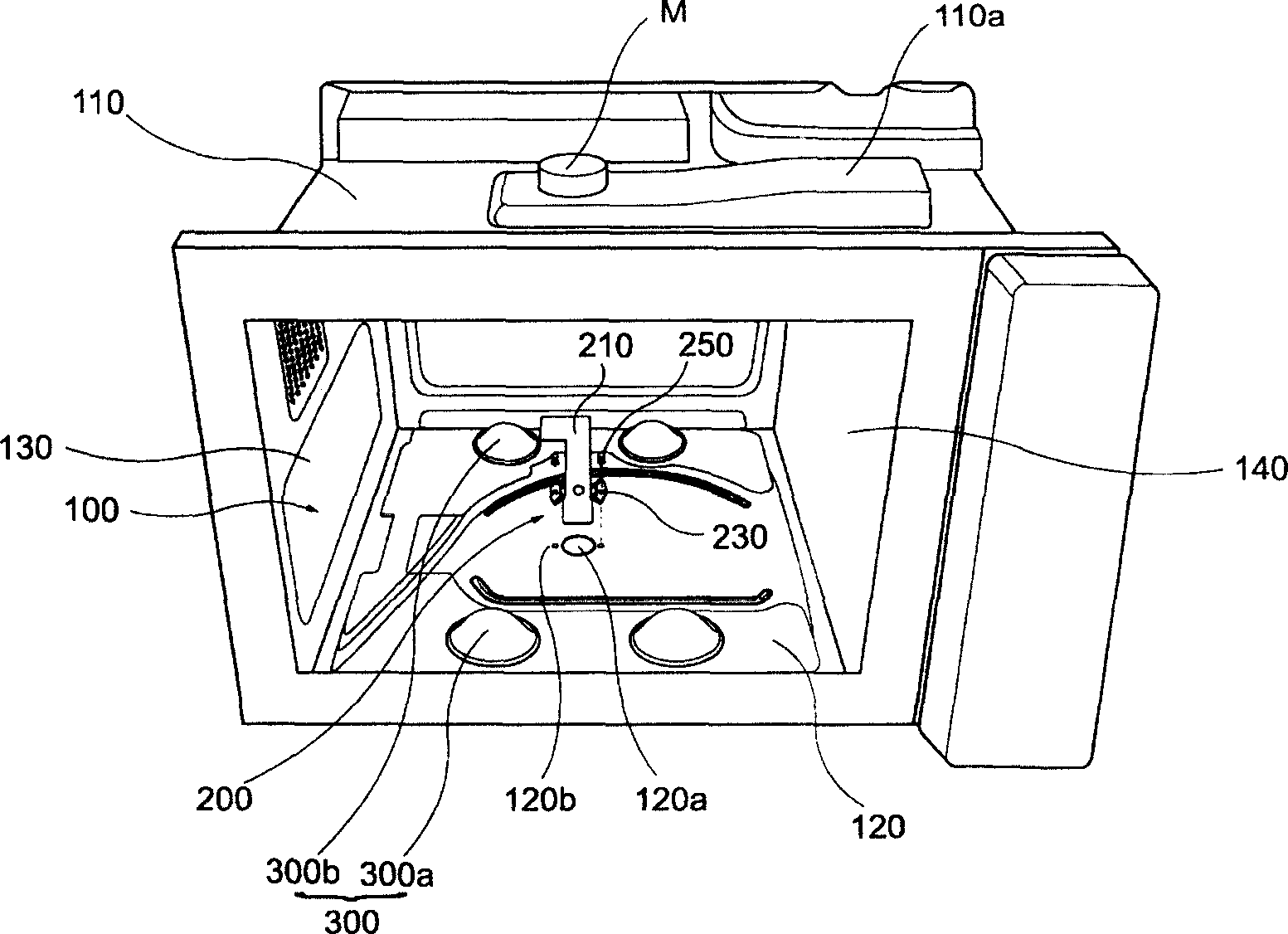

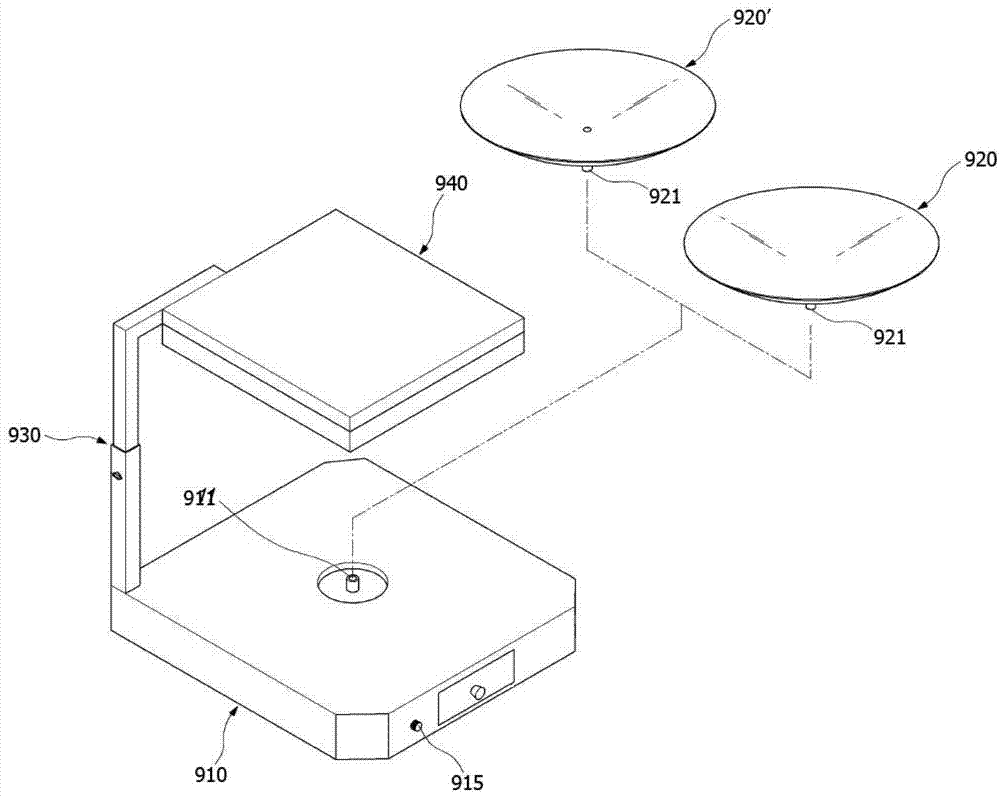

Multi-purpose heating device

InactiveCN105246383AEasy cookingEasy to grabDomestic stoves or rangesLighting and heating apparatusEngineeringElectrical and Electronics engineering

The present invention relates to a multi-purpose heating device comprising: a first heating unit disposed at the bottom thereof; a second heating unit disposed at the top thereof; and a pillar which vertically connects one side end of the first heating unit with one side end of the second heating unit so as to form a space between the first and second heating units, the device being capable of cooking food through the first heating unit disposed at the bottom thereof and at the same time applying heat, through the second heating unit disposed at the top thereof, to the food being cooked by the first heating unit disposed at the bottom thereof, wherein the first and second heating units are controlled by individual power supply and power cut-off and the second heating unit can perform a heating function through up and down rotation on the basis of the pillar.

Owner:李礼顺 +1

Microwave oven with rolled bin

InactiveCN1421644AEvenlyGreat tasteDomestic stoves or rangesLighting and heating apparatusMicrowave ovenProcess engineering

The present invention is one microwave oven with mechanism to make food heated homogeneously and the microwave oven is suitable for producing fried food, roasted food and other food. The microwave oven includes oven body, door, hearth, microwave tube and control mechanism connected to the door and features its rolled bin and its drive shaft and support. The bin may be cylindrical, spindle or roller-shaped. Using the said microwave oven can produce tasty food without color change, so that the present invention may be used in shops and households.

Owner:武雄

Processing technology of silk

ActiveCN108149331AReduce adhesive forceAvoid damageAnimal materialDe-gumming silkSofteningDehydration

The invention discloses a processing technology of silk. The processing technology aims at improving the quality of the silk. The processing technology is characterized by comprising the following steps of high-temperature cocoon cooking, reeling of raw silk from cocoons, degumming, softening, dehydration and drying. The silk produced by the processing technology of the silk is smooth in surface,soft in hand feeling, pure in color and higher in quality.

Owner:桐乡瑞梦蚕桑科技有限公司

Cocoon bedabbling and cooking method

The invention relates to a cocoon bedabbling and cooking method. The method comprises the steps of (1) selecting some silkworm cocoons, weighing the silkworm cocoons, then adopting water for evenly bedabbling the weighed silkworm cocoons, and storing the silkworm cocoons for 1 h to 4 h to enable water to sufficiently permeating the inner layers of the silkworm cocoons; (2) binding the silkworm cocoons stored in the step (1) with a cloth bag, meanwhile, boiling water inside a pot, placing the cloth bag with the bedabbled silkworm cocoons into the pot, then adding sodium hydroxide accounting for 5% to 20% of the silkworm cocoons by weight into the pot, boiling the water in the pot again, and continuously boiling for 0.1 h to 0.5 h; (3) fishing the cloth bag boiled in the step (2) out of the pot, washing the cloth bag with clean water and then airing the cloth bag. According to the cocoon bedabbling and cooking method, the thorough cooking degree of the silkworm cocoons can be uniform, sericin is easy to swell and dissolve, and therefore the bulkiness and softness of silk can reach the best state.

Owner:SUZHOU CIYUN SILK PROD

Nut leisure food processing equipment

InactiveCN111330838AHigh degree of automationImprove processing efficiencySievingGas current separationSnack foodsManufacturing engineering

The invention is suitable for the technical field of food processing equipment and provides nut leisure food processing equipment. The processing equipment comprises a screening box; a feed hopper isarranged at the top of the screening box, a second residue outlet is arranged at the bottom of the screening box, and a first-stage sieve plate and a second-stage sieve plate are sequentially arrangedin the screening box from top to bottom; the first-stage sieve plate and the second-stage sieve plate are movably arranged in the screening box; blanking plates are fixedly arranged at the tail endsof the first-stage sieve plate and the second-stage sieve plate; and the blanking plates are located right above stir-frying boxes, mixed stir-frying mechanisms are arranged inside the stir-frying boxes, screens are arranged below the mixed stir-frying mechanisms, and first residue outlets are formed in the bottoms of the stir-frying boxes. The nut leisure food processing equipment is high in automation degree and high in processing efficiency, the screening box is additionally arranged before stir-frying, the screening purpose is achieved through the first-stage sieve plate and the second-stage sieve plate, uniform cooking is facilitated during stir-frying, and nuts with different sizes can be separately sold, thereby facilitating selling.

Owner:广东锦华泰包装机械科技有限公司

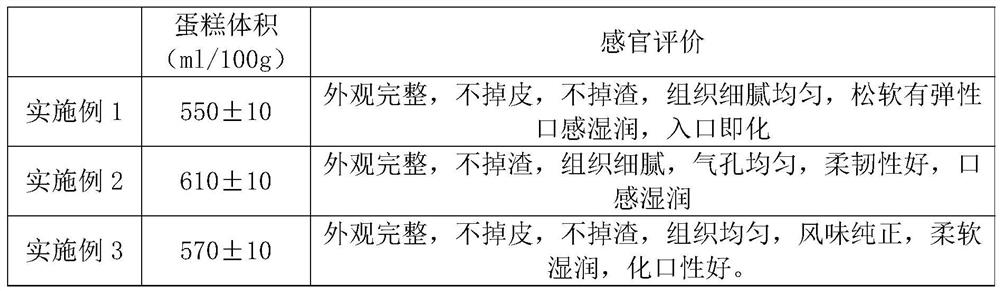

Wheat-flour-free cake and making method thereof

PendingCN113261579AReduce consistencyHigh transparencyDough treatmentDough/pre-mixesBiotechnologyCellulose

The invention relates to the technical field of food baking, in particular to a wheat-flour-free cake and a making method thereof. The formula comprises the following raw materials in parts by weight: 3-8 parts of corn flour, 30-50 parts of eggs, 8-14 parts of white granulated sugar, 6-12 parts of trehalose, 5-10 parts of refined vegetable oil, 1-5 parts of skim milk powder, 0.1-0.5 part of edible salt, 10-20 parts of hydroxyl propyl distarch phosphate, 1-3 parts of a sorbitol solution, 1-3 parts of glycerol, 1-5 parts of a compound emulsifier, 0.5-1.5 parts of a compound leavening agent, 0.1-0.5 part of citric acid, and 0.01 to 0.05 part of sodium dehydroacetate. According to the cake, the corn flour is used for replacing wheat flour, the cake is good in sensory characteristic and taste, and the problem that a wheat bran cake is aged and hardened after being placed for two or three days is solved. The cake is rich in nutrition, contains rich vitamins, trace elements, cellulose, polysaccharide and the like, is suitable for people of all ages, enriches the variety of cake products, and promotes improvement of human dietary fiber structures.

Owner:蔡小强

Brand-new preparation method of feed

The invention discloses a brand-new preparation method of feed. The brand-new preparation method of feed comprises the following steps: 1) selecting 7-9 parts of paddy husks, 15-19 parts of corn cobs, 12-18 parts of sorghum husks and 10-16 parts of straw as the raw materials of the feed; and then pulverizing the raw materials into equidimensional grains and uniformly mixing the grains. The brand-new preparation method of feed realizes the purposes that the paddy husks, the corn cobs and the sorghum husks are prepared into feed, wasting of resources is decreased, and meanwhile the content of cellulose in the raw materials is high and can effectively promote absorption of nutrients by animals; the cost of the raw materials is low, so the manufacturing cost of the feed is low; and because the raw materials are treated and steamed in the manufacturing process, the raw materials can be effectively softened, and the feed prepared from the raw materials is easy to digest.

Owner:浙江贝千喜生物技术有限公司

Silk reeling method adopting dried cocoons

The invention relates to the technical field of silk reeling texture, and discloses a silk reeling method adopting dried cocoons. The problems that a traditional silk reeling adopting dried cocoons islow in production efficiency, raw silk is rough, and the quality is poor are solved. The method comprises the specific steps of soaking dried cocoon shells by adopting clear water, soaking the driedcocoon shells by adopting limewater, conducting vacuum infiltration by adopting mixed infiltrating liquid A, boiling the dried cocoon shells for 20-40 min by adopting alkaline water, adding mixed infiltrating liquid B for infiltrating treatment, soaking the dried cocoon shells by adopting circulating clear water, thoroughly flushing the dried cocoon shells by adopting clear water, and conducting silk reeling after dehydration treatment, the temperature of cocoon beating water is 50-60 DEG C, the temperature of cocoon arranging water and reeling water is 30-35 DEG C, and the pH value is 7-7.5;the silk reeling method adopting the dried cocoons can make cocoon shell sericin swell and dissolve appropriately, the adhesive force among cocoon silk is reduced appropriately, in the later silk reeling process, silkworm cocoons can be subjected to reelability and cocoon beating easily, and raw silk is clean, good in embracing, and unique in gloss, can resist wrinkles, and is good in dyeing performance, high in color fastness and economic value, and low in consumption of raw cocoon materials.

Owner:山西禹珈豪丝业股份有限公司

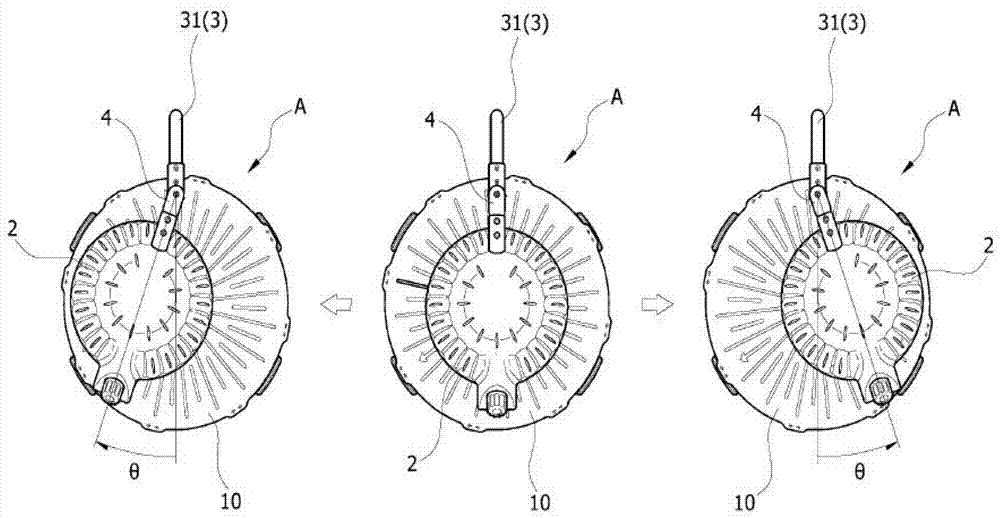

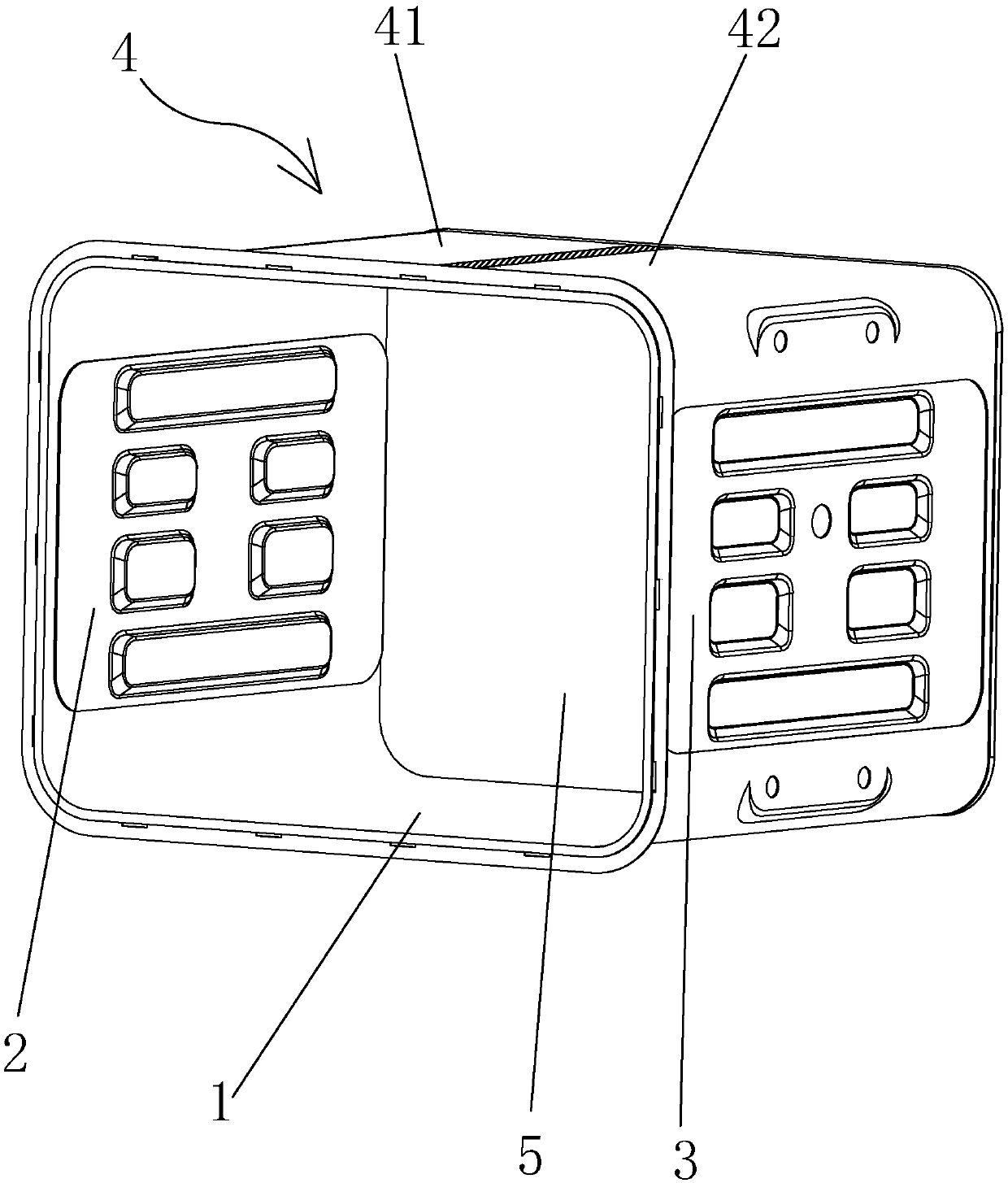

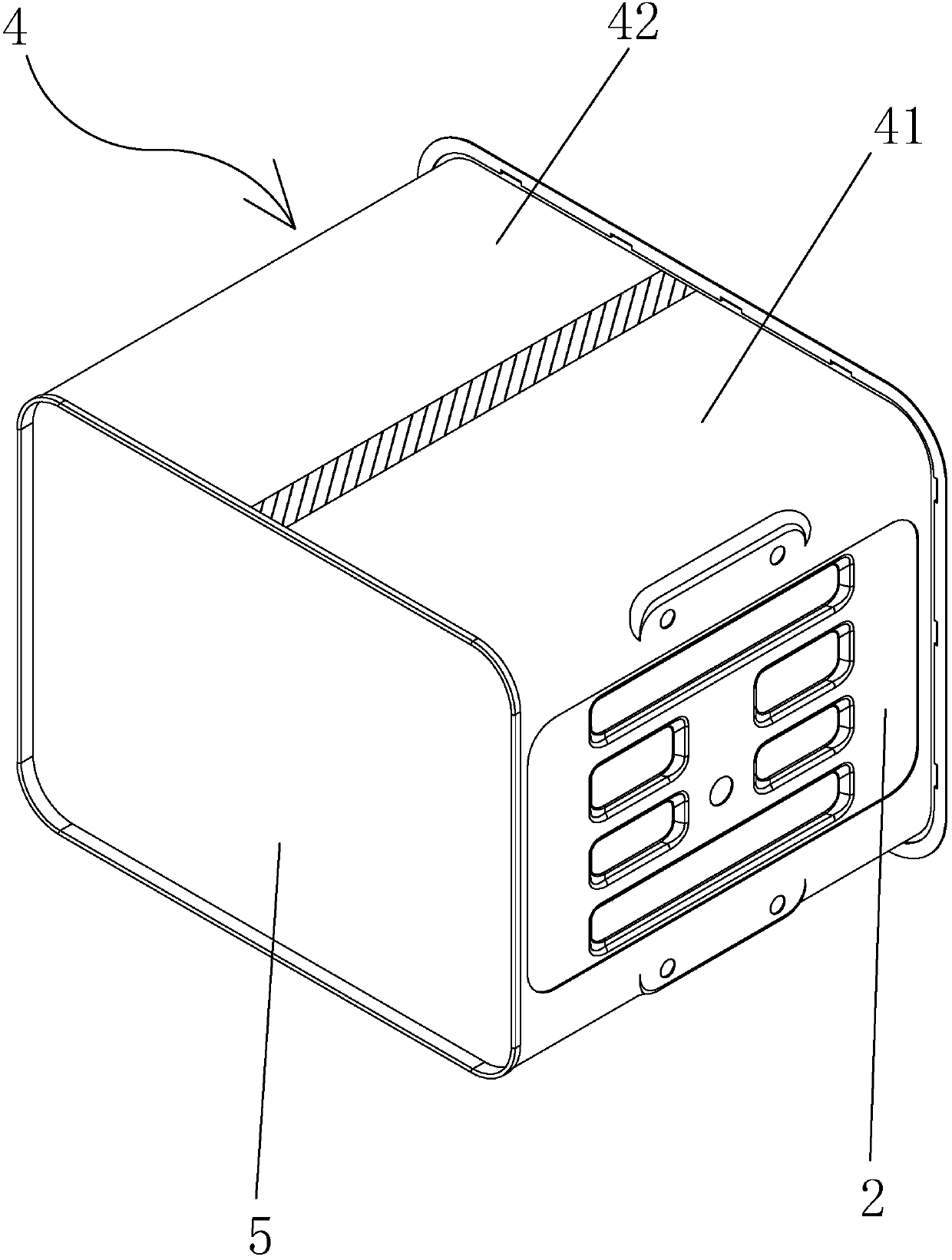

Infrared cooking device with variable heating head position

InactiveCN106859364AEvenly cookedEffectively cookedStoves/ranges foundationsDomestic stoves or rangesEngineeringTemperature difference

The invention discloses an infrared cooking device with a variable heating head position. Through horizontal rotation of a heating head which irradiates heat from top to bottom, temperature difference between different areas of a cooking dish which is configured below the heating head is maximally reduced. Furthermore a rotation limit is kept for restricting the rotating area of the heating head, and furthermore action of a heat source can be automatically stopped according to the requirement.

Owner:ZAIGLE CO LTD

Novel oven inner container

Owner:陈永

Method for preparing multi-flavor soy sauce

InactiveCN107432454ARich tasteAdd seasoning flavorFood ingredient as taste affecting agentFood ingredient as mouthfeel improving agentHigh-fructose corn syrupFood flavor

The invention discloses a method for preparing multi-flavor soy sauce. The method is characterized in that in each 100 kg of fermented and filtered sauce water, the following raw materials are added according to the weight ratio: 2-3 kg of caramel color, 15-30 kg of high fructose corn syrup, 1-2 kg of tsaoko fruit, 0.5-1.5 g of wasabia japonica, 1-2 kg of anise, 1-2 kg of fennel, 2-3 kg of bittern, 3-5 kg of fermented bean curd, and 40-50 kg of salt. The multi-flavor soy sauce has the beneficial effects that the invention provides the preparation method of the multi-flavor soy sauce, the taste of the soy sauce is abundant, at the same time, during a preparation process, multiple adjusting is carried out, the flavoring fragrance of the soy sauce is increased, and the multi-flavor soy sauce is more suitable for market requirement.

Owner:广西顶俏食品科技集团有限公司

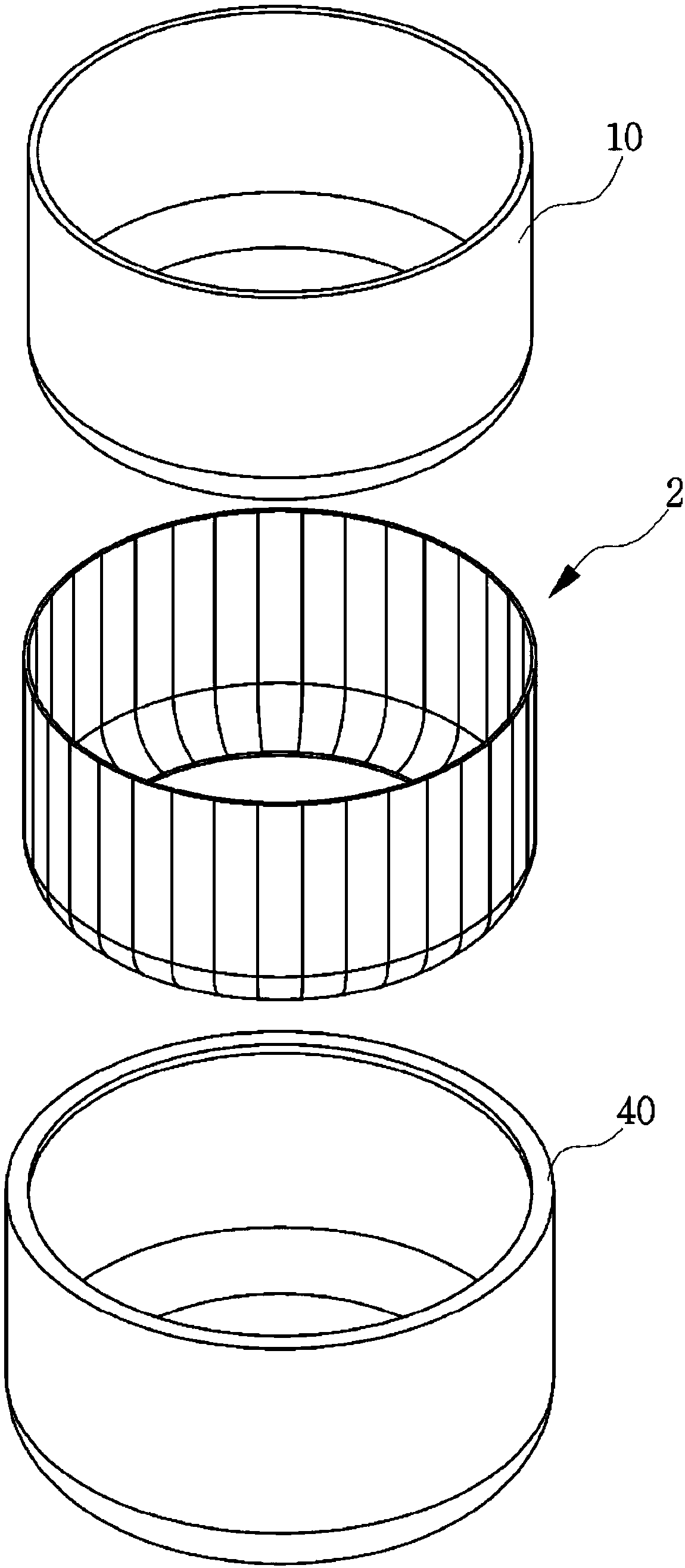

Outdoor cookware using heat pipes

The present invention relates to outdoor cookware, using heat pipes, comprising: an inner receptacle for accommodating contents; heat pipes which are attached to the outer lateral side of the inner receptacle; and an external receptacle which is attached to the outer lateral side of the heat pipes and of which the center part of the lower side is raised and attached to the bottom side of the innerreceptacle. Therefore, since the heat from a burner flame is quickly transmitted to the lateral side of the inner receptacle by means of the heat pipes, the floor side and the lateral side of the outdoor cookware is evenly heated and the contents are evenly cooked.

Owner:에이테크주식회사

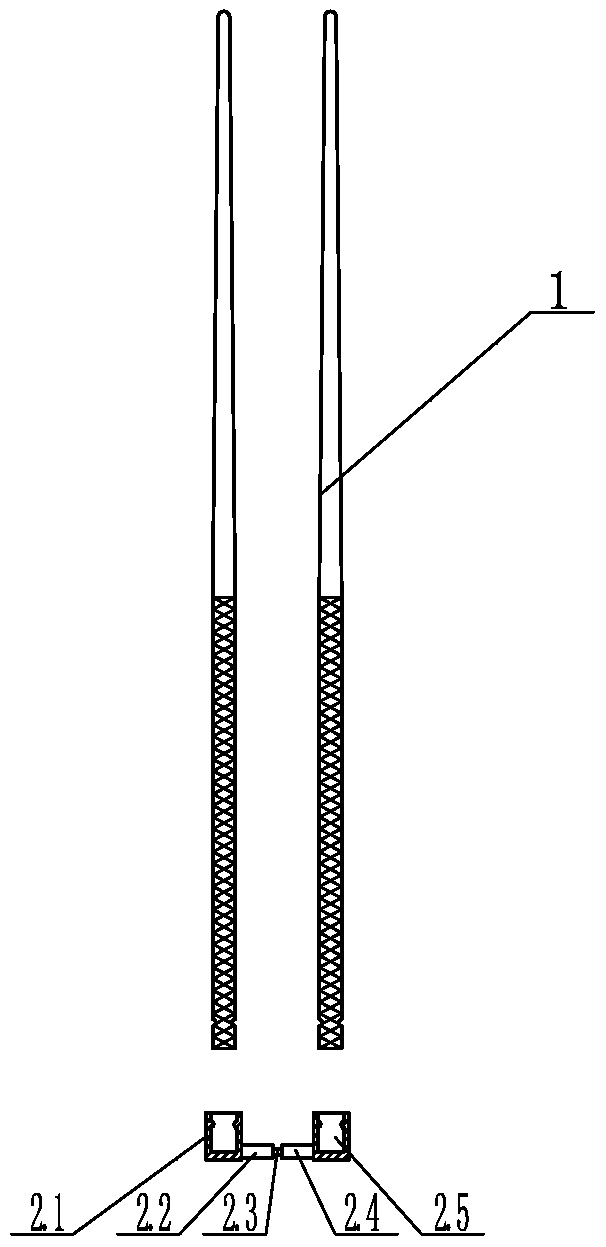

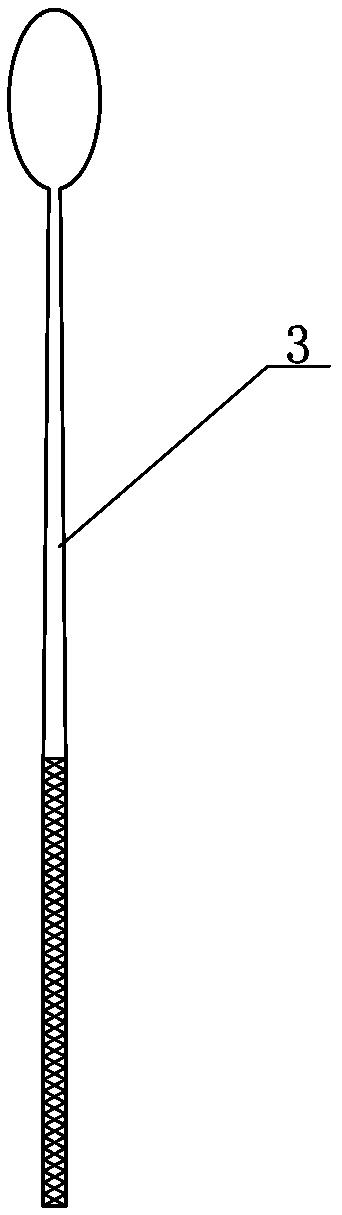

Method for removing bones from round fish

The invention provides a method for removing bones from round fish and belongs to the technical field of kitchen processes. The method comprises the following steps: washing larimichthys crocea to beprocessed for later use; respectively inserting two chopsticks into the abdominal cavity from the fish mouth, rotating the chopsticks to remove the fish gills and fish viscera from the fish belly, tightly clipping the fish gills and fish viscera with the two chopsticks, and removing the fish gills and fish viscera out of the fish mouth; scraping roe and viscera residues out the fish belly with a ladle; scaling two sides of fish bones from the inner side of the fish belly with a hoe scaler; and cutting off the connection of two ends of the fish bones and a fish body, and clamping and taking outthe fish bones. The bone removing process is convenient to operate, does not need skilled operation skills and can be used for quickly removing fish bones by utilizing tools. When the method for removing bones is used for processing larimichthys crocea, about 160 of fish can be processed by green hands each day. The processed fish body has a perfect cylindrical shape, can be filled with soup or filling, has uniform flavor and complete shape after cooking, is suitable for popularization in the industry, and is favorable to inheritance and carrying forward of Chinese traditional cooking skills.

Owner:王胥

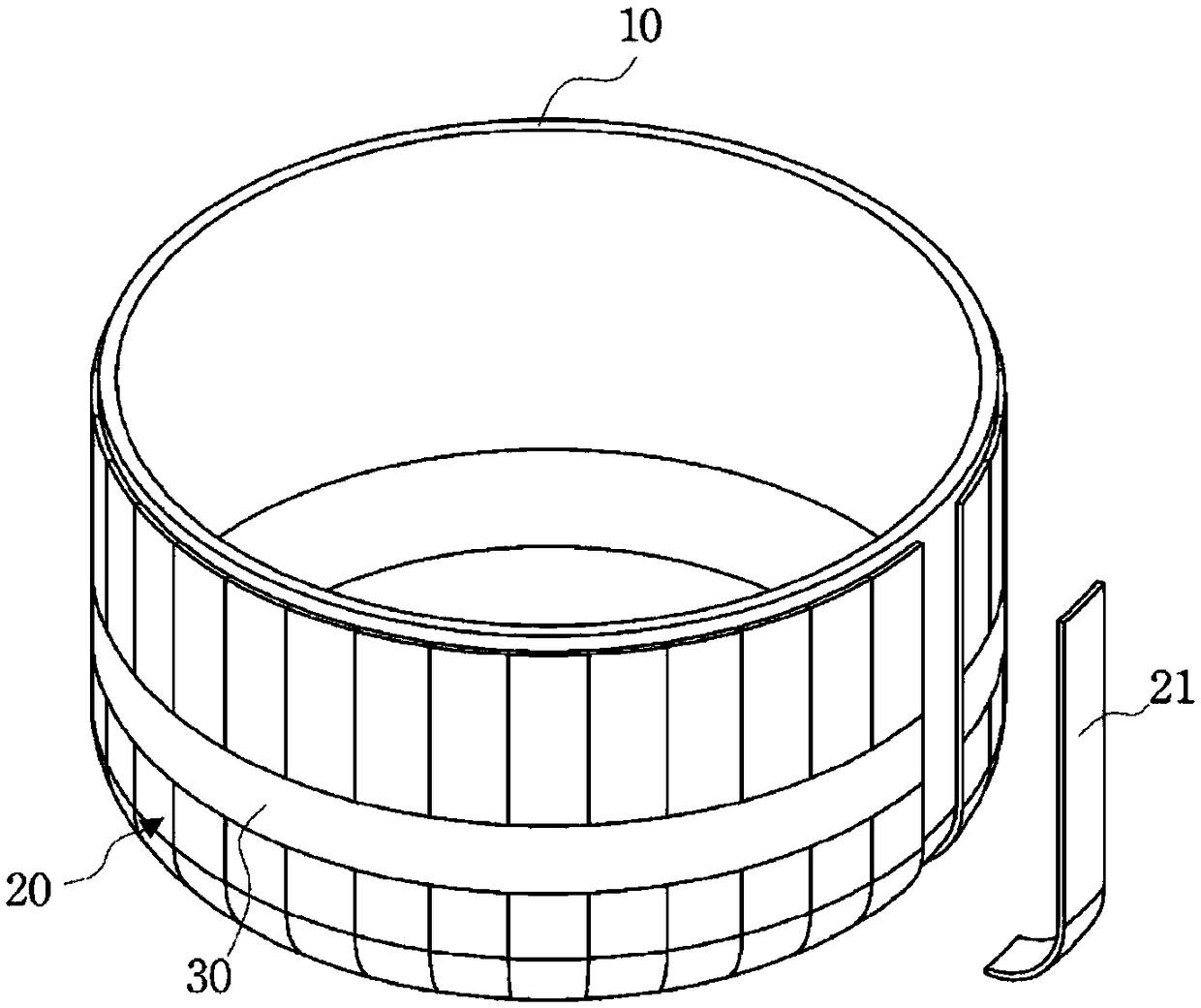

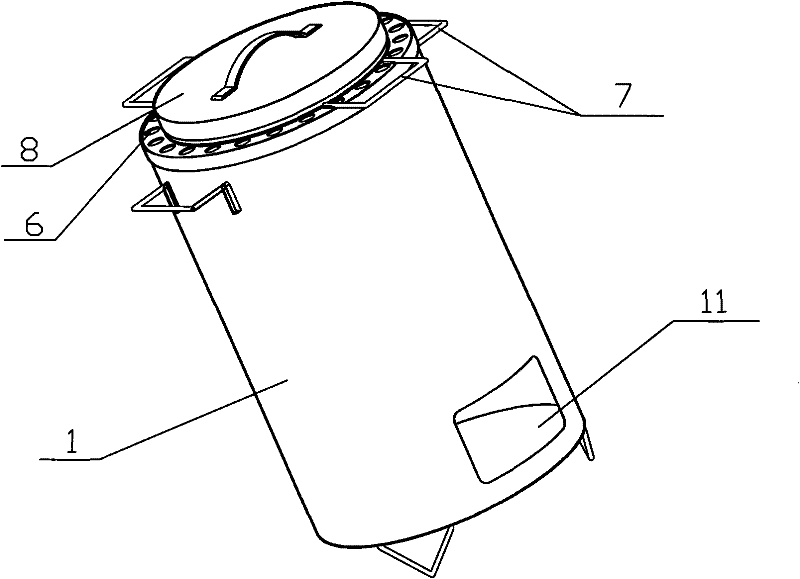

Automatic barbecue machine easy to clean

The invention provides an automatic barbecue machine easy to clean, comprising an inside bucket combined to form a regulator and an outside bucket forming an exhaust port which are combined to form an air duct. In order to place roast rods, a placing table is formed at the flange; the inside bucket and outside bucket respectively form a flange which can separate freely; the inner side of the flange of the outside bucket forms a segment jaw surface which from a space for accommodating the flange of the inner bucket; in a state of combining the inside bucket and outside bucket, the inside bucket and outside bucket from the air duct separated at intervals to keep the flanges at a same horizontal surface. The appearances is beautiful; the inside bucket and outside bucket can be separated and assembled, which is easy to clean oil accumulated in the air duct.

Owner:金锡源

A kind of preparation method of tensile cotton and its products

ActiveCN105133181BPromote puffingEvenly cookedDe-gumming silkNon-woven fabricsMicrocirculationHigh tension

The invention discloses a manufacturing method for tension cotton. The method comprises the following steps: (1) preparing the following raw materials: silkworm cocoons, spandex, elastin, distilled water, natural water, a swelling agent, malic acid, and organosilicon antimicrobials; (2) performing vacuum infiltration processing on the silkworm cocoons; (3) performing expanding treatment on cocoon silk; (4) performing degumming processing on cocoon silk; (5) through cocoon peeling and removing silkworm chrysalis, obtaining cocoon silk fibers, performing antibacterial treatment on the cocoon silk fibers; stretching the cocoon silk fibers and winding the cocoon silk fibers to form silk floss, performing dehydration and drying processing on the silk floss; (6) putting 60-90 parts of silk floss, 10-30 parts of spandex, and 5-20 parts of elastin into a mincing machine to perform mincing processing, to obtain a mixture and manufacture the tension cotton. Also disclosed is high-elasticity tension cotton manufactured by the above method. The tension cotton has high-elasticity and high-tension, and has functions of antibacterial and odor resistant, humidity-absorbing and breathable, and promotes blood microcirculation of human bodies.

Owner:黄文丰

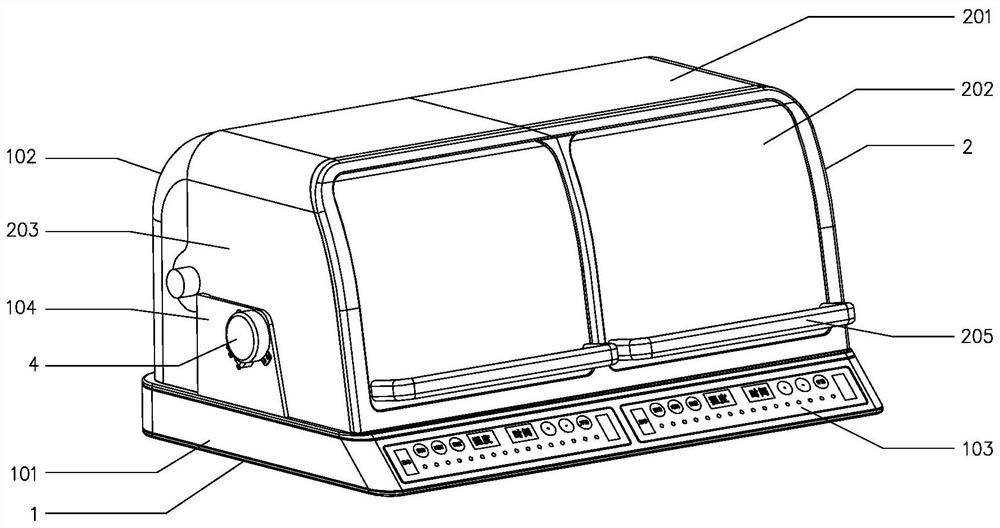

Cooking device with baking function

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

Multipurpose horizontal cooking utensil

The invention relates to a multipurpose horizontal cooking utensil which comprises a machine base and a hot air assembly, wherein the hot air assembly is electrically connected with a control system on the machine base; the machine base is provided with two or more heating cavities used for containing food materials; two or more hot air assemblies are arranged in one-to-one correspondence with the heating cavities; the hot air assemblies correspond to the heating cavities in a front-back mode; the air outlet ends of the hot air assemblies communicate with the heating cavities; the hot air assemblies and the corresponding heating cavities are combined to form cooking modules; a transverse rotating assembly for driving food materials to transversely rotate and / or a frying and baking assembly for frying and baking the food materials are arranged on the machine base; and the transverse rotating assembly and / or the frying and baking assembly are / is electrically connected with a control system. The multipurpose horizontal cooking utensil is diversified in function, reliable in performance and convenient to use, and meets the use requirement of a user for cooking different food materials at the same time.

Owner:RIMOO FOSHAN ELECTRICAL APPLIANCES TECH CO LTD

Processing method of semi-fermented steamed green tea

PendingCN111406808AIncrease contentStrong tasteInorganic/elemental detergent compounding agentsPre-extraction tea treatmentGreen teasProcess engineering

The invention relates to the technical field of tea processing, and provides a processing method of semi-fermented steamed green tea. The processing method comprises the steps of tender picking, withering, stirring, standing, steaming, heat dissipation, dehumidification, rolling, primary drying, secondary rolling, secondary drying and aroma enhancement; the produced tea not only has the advantagesof steaming, but also achieves the effect of converting aroma generated in stir-frying through subsequent aroma enhancement, so that the processed tea is not only rich in inclusion but also rich in taste, and the steaming technology is adopted to solve the problems that the fixation temperature is not easy to regulate and control, the fixation degree is not easy to master, the yield is low due toexcessive water loss of fresh leaves in the fixation process and the like in the existing stir-frying technology.

Owner:温文溪

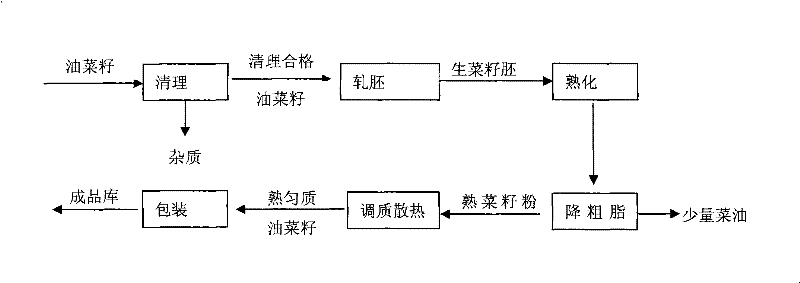

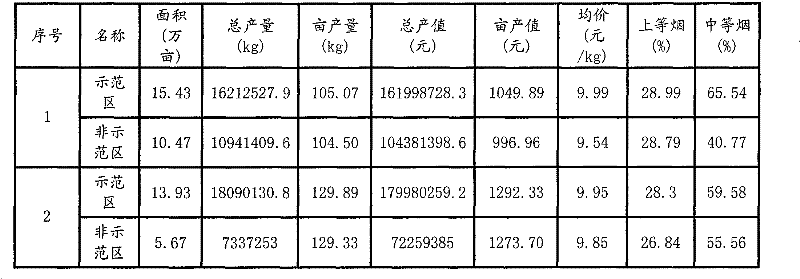

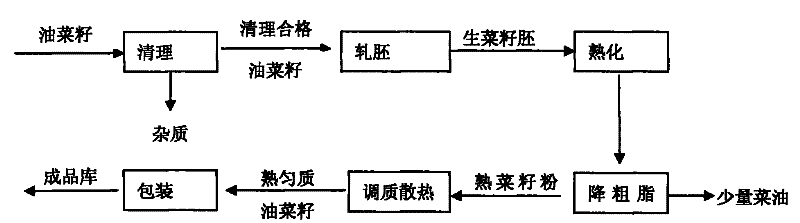

Organic fertilizer for fire-cured tobacco and production method thereof

The invention discloses an organic fertilizer used for cured tobacco and a production method thereof. The production method comprises the following steps: the impurities thereof is in 0.5 percent after rapeseeds are cleared; the germ thickness is 0.5 to 0.35mm, the germinal flake is even and firm, has little powder and does not expose oil, and before rolling, the water content of the rapeseed is regulated to be 5 to 10 percent; the water content of the green germ after the rapeseeds are processed by flaking to be 20 to 25 percent, the rape is steamed to be 60 to 90 DEG C by overheating steam,the water content is controlled to 5 to 10 percent and the time is 80 to 120 minutes; crude fat is reduced: redundant crude fat can be removed by fat-reducing equipment with the temperature of 60 to 90 DEG C and the working pressure of 100 to 500kg / cm<2>, so as to lead the crude fat content in cured rapeseed to be 15 to 25 percent and simultaneously lead the rapeseed not to be caked; by temperingand radiating equipment, the temperature of the rapeseeds is adjusted to 8 to 20 DEG C, the water content is controlled to 10 to 12 percent and the acid value is controlled to 0 to 5; and then package is carried out to obtain the organic fertilizer. The organic fertilizer and the production method thereof can provide nutrients to tobacco plants and soil microorganism, improve quality of tobacco and can be directly applied as base fertilizer by one time.

Owner:GUIZHOU TOBACCO CORP QIANXINAN CORP

Cooking part device of cocoon cooking machine

InactiveCN101629321BNot easy to attachUniform temperatureSilk filament obtainingMechanical engineering

Owner:童华波

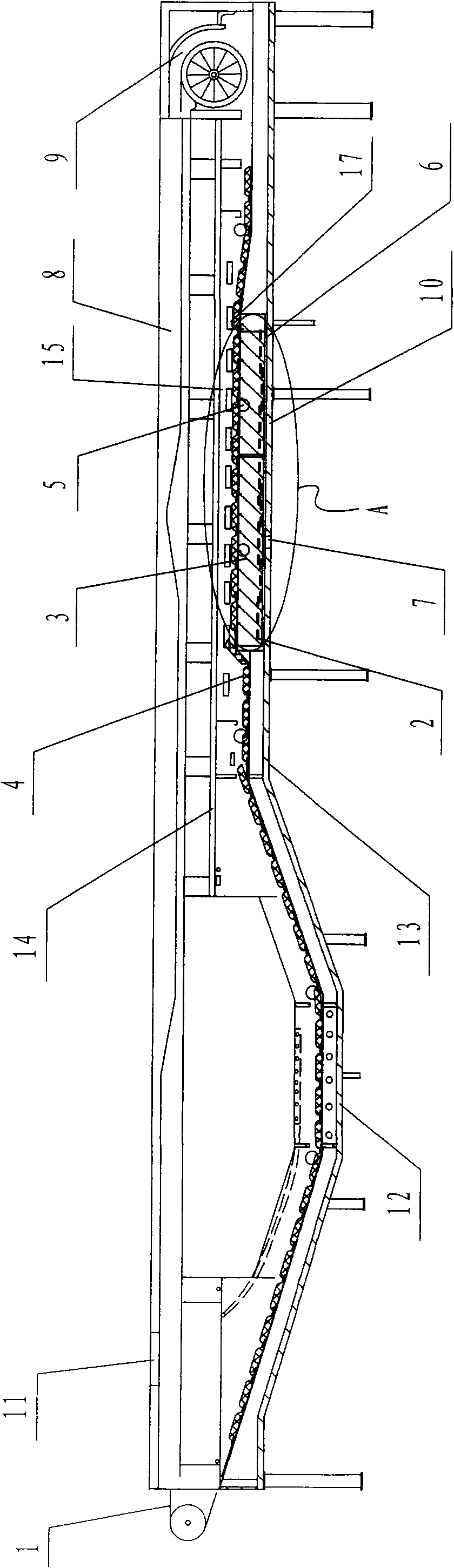

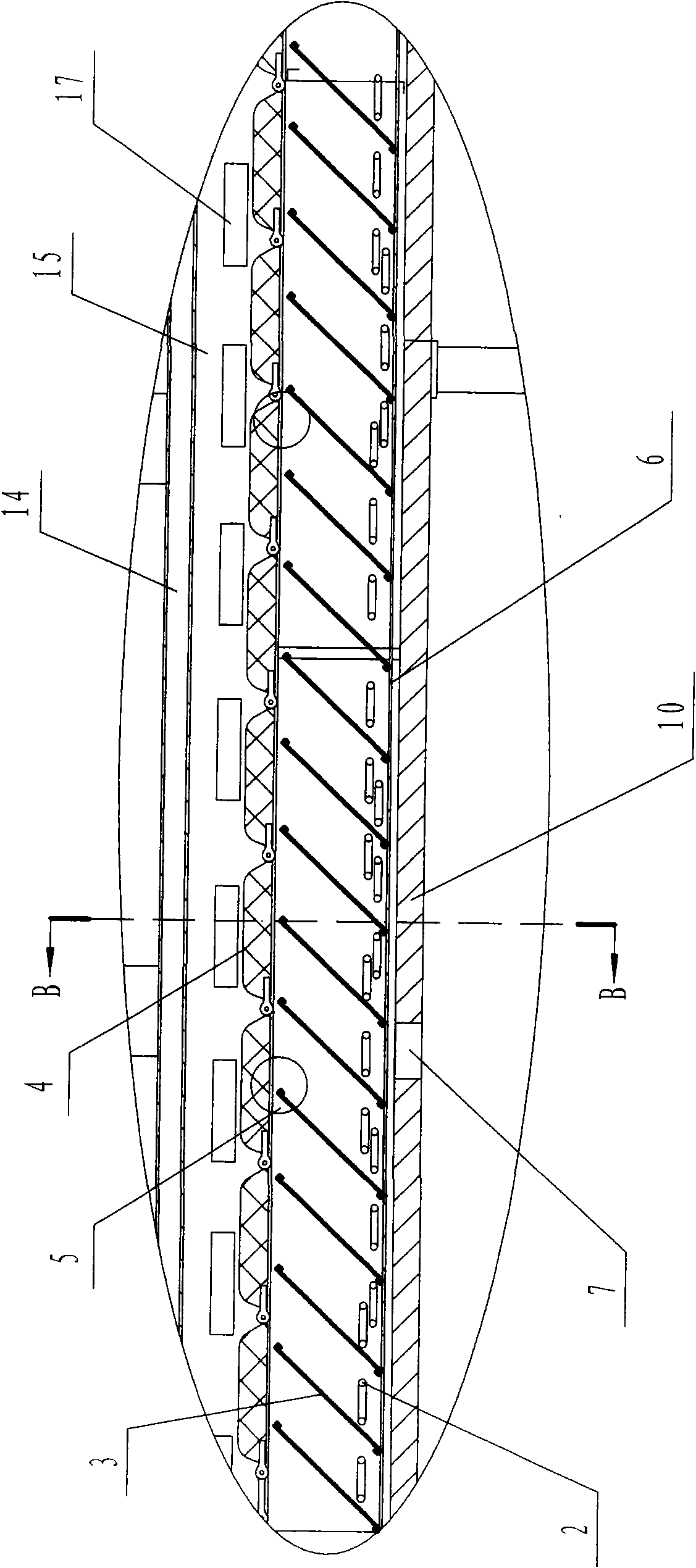

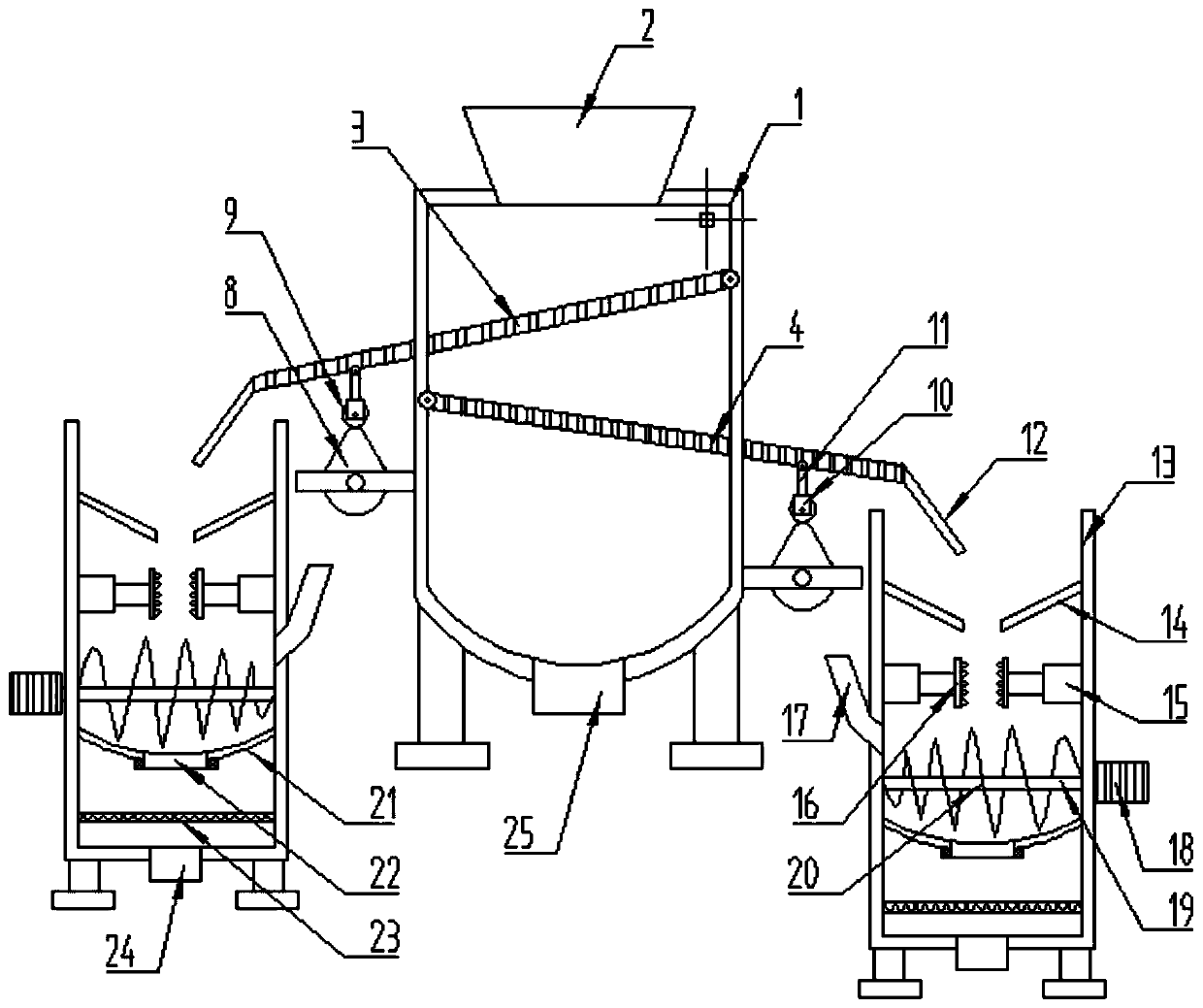

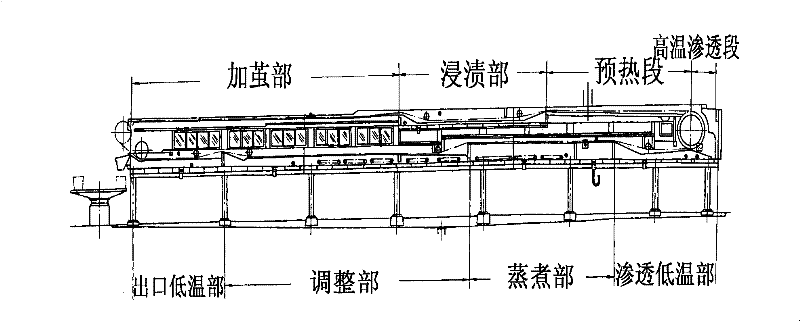

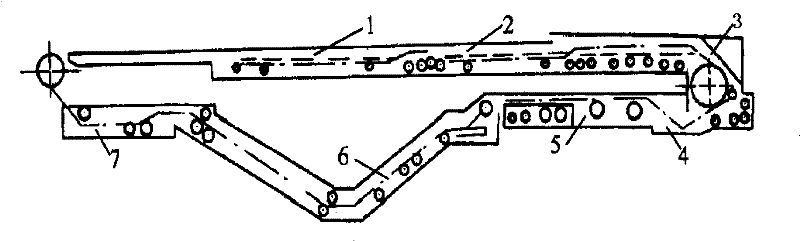

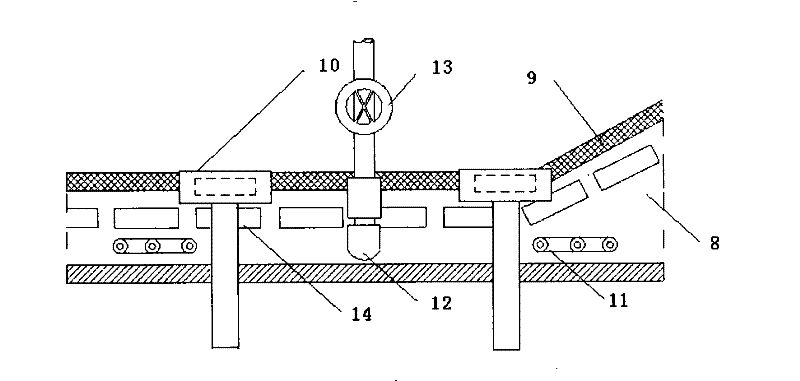

Temperature regulation method for regulation part of cocoon cooking machine and apparatus thereof

InactiveCN101423981BEvenly cookedReduced saddle rateTemperatue controlSilk filament obtainingWater flowEngineering

The invention relates to a temperature adjusting method and a temperature adjusting device for an adjusting part of a cocoon cooking machine, which are capable of effectively improving the cooking evenness of cocoons, and belong to the technical field of textile engineering. The method is as follows: cocoon cooking water temperature is divided into 2 to 6 sections during the adjusting procedure of cocoon cooking; the water temperatures of various sections are from high to low; and the temperature difference of the water temperatures of adjacent sections is between 12 and 16 DEG C. The device consists of a flow injector, overflow openings and heaters, wherein the flow injector is arranged at the bottom of the adjusting part of the cocoon cooking machine; a water curtain which is formed by water flows jetted by the flow injector at a normal temperature and a water pressure of between 0.18 and 0.22 MPa is taken as an isolated body; and the overflow openings and the heaters are arranged inside the various sections respectively to control the water temperatures of the various sections. The temperature adjusting device can greatly reduce the dropping end rate of inner layers in the cooked cocoons, is favorable for uniform cooking of the cocoons, and improves the reelability percentage of the raw material cocoons. The device has a simple structure and low manufacturing cost, can reform the prior cocoon cooking machine, and is favorable for being promoted and applied.

Owner:SUZHOU UNIV

Baking oven with improved structure

The invention discloses a baking oven with an improved structure, belonging to the technical field of food bake. The baking oven comprises an oven body shell which is internally provided with an oven furnace; a baking bracket is arranged in the inner cavity of the oven furnace; a combustion chamber is arranged at the bottom space between the oven furnace and the oven body shell; an opening is arranged at the side face of the oven body shell corresponding to the combustion chamber; an edge sealing device which can control the opening size of a ventilation opening thereof is arranged in a cavity between the oven furnace and the oven body shell corresponding to the upper end part of the oven furnace and the oven body shell. By controlling the ventilation of the combustion chamber, the invention leads the firepower to be even, the food cooking to be even, the color to be good, the meat quality to be fragrant, smooth, delicious, and original taste and flavor, and the food not to contact with oven fire, thus achieving health and keeping the effect of gravy, and the invention can fully utilize heat energy, saves energy sources, has compact structure design and convenient portability, canbe used for indoor and outdoor baking, and is easy to be popularized.

Owner:梁锁页 +1

A kind of cocoon reeling method

ActiveCN109402743BReduce adhesive forceGood relaxing effectSilk reelingAlkaline waterColour fastness

The invention relates to the technical field of silk reeling and textiles, and discloses a cocoon reeling method; it solves the problems of low production efficiency and poor quality of raw silk in traditional cocoon reeling; the specific steps include soaking dry cocoon shells in clear water, soaking in lime water, Vacuum infiltration with mixed permeate A, boil with alkaline water for 20‑40min, add mixed permeate B again for infiltration treatment, then soak in circulating water and rinse with clean water, dehydrate and reel silk, the temperature of the soup is 50 ‑60°C, the temperatures of Lixu soup and reeling soup are both 30‑35°C, and the pH value is 7‑7.5; the cocoon reeling method of the present invention can make the cocoon layer sericin swell and dissolve moderately, and the glue between cocoon silk The effort is appropriately reduced, so the cocoons are easy to loosen and thread during the subsequent silk reeling process. The raw silk is clean and cohesive, with unique luster, wrinkle resistance, good dyeability, high color fastness, high economic value, and low consumption of raw cocoons.

Owner:山西禹珈豪丝业股份有限公司

A kind of silk processing technology

ActiveCN108149331BReduce adhesive forceAvoid damageAnimal materialDe-gumming silkPolymer scienceMachining process

The invention discloses a processing technology of silk. The processing technology aims at improving the quality of the silk. The processing technology is characterized by comprising the following steps of high-temperature cocoon cooking, reeling of raw silk from cocoons, degumming, softening, dehydration and drying. The silk produced by the processing technology of the silk is smooth in surface,soft in hand feeling, pure in color and higher in quality.

Owner:桐乡瑞梦蚕桑科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com