Temperature regulation method for regulation part of cocoon cooking machine and apparatus thereof

An adjustment device and a technology of a cocoon cooking machine, which are applied in the directions of temperature control, mechanical treatment, control/regulation system, etc., can solve the problems of high occupied space, unfavorable promotion and application, complex structure of the cocoon cooking machine, etc. The effect of improving the relaxation rate and reducing the rate of fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

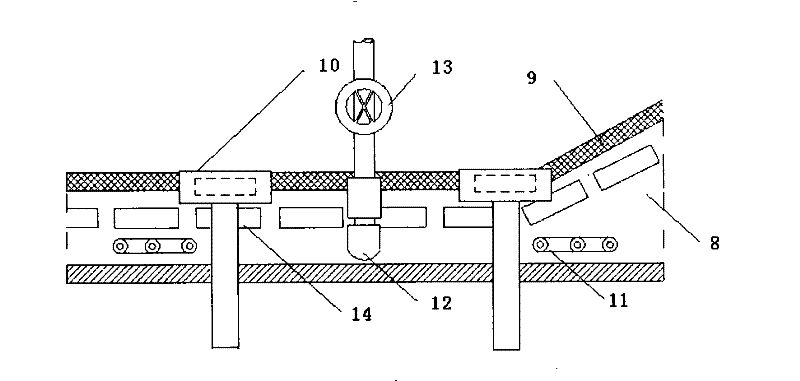

[0017] See attached image 3 , which is a structural schematic diagram of the temperature adjustment device of the adjustment part of the cocoon cooking machine in this embodiment. It consists of a water jet, an overflow 10 and a heater 11. The water jet is installed at the bottom of the adjustment part of the cocoon cooking machine. It is composed of a water spray pipe 12 and a water inlet control valve 13. The diameter of the water spray pipe is 25 mm, and the upper part has a small hole with a diameter of 2.5 mm. The center of each small hole The distance is 5mm, and the water spray pipe can be inserted from the side opening of the adjusting part tank 8, and the upper cover plate 9 of the tank is provided with an overflow port, and the heater is a steam pipe, which is arranged in the adjusting part tank of the cocoon cooking machine. Open the water inlet control valve, and the small hole on the upper part of the water spray pipe sprays water upward with a normal temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com