Patents

Literature

470results about "Silk reeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

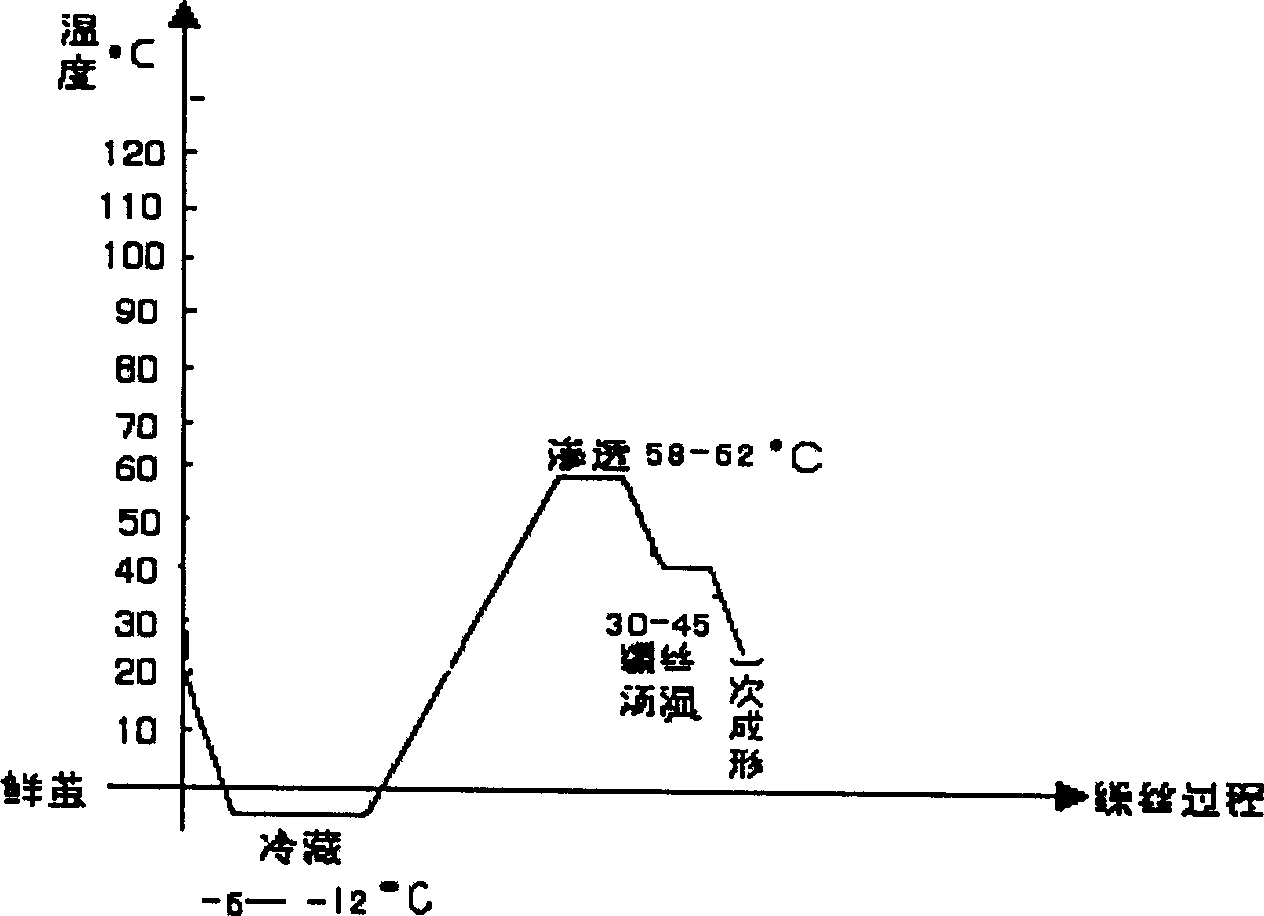

One step filature method for fresh cocoons of silkworms

InactiveCN1446950ASmooth and orderly dissociationReduce man-hour consumptionSilk reelingEngineeringCold storage

The one-step method for reeling the silk of fresh silkworm cocoon includes cold storage, freezing for antistaling, investigating quality of cocoon, screening, vacuumizing, absorbing water, discharging water, reeling silk, heating and winding. Its advantage is high silk quality.

Owner:SICHUAN UNIV TIANYOU BIOLOGIC ENG

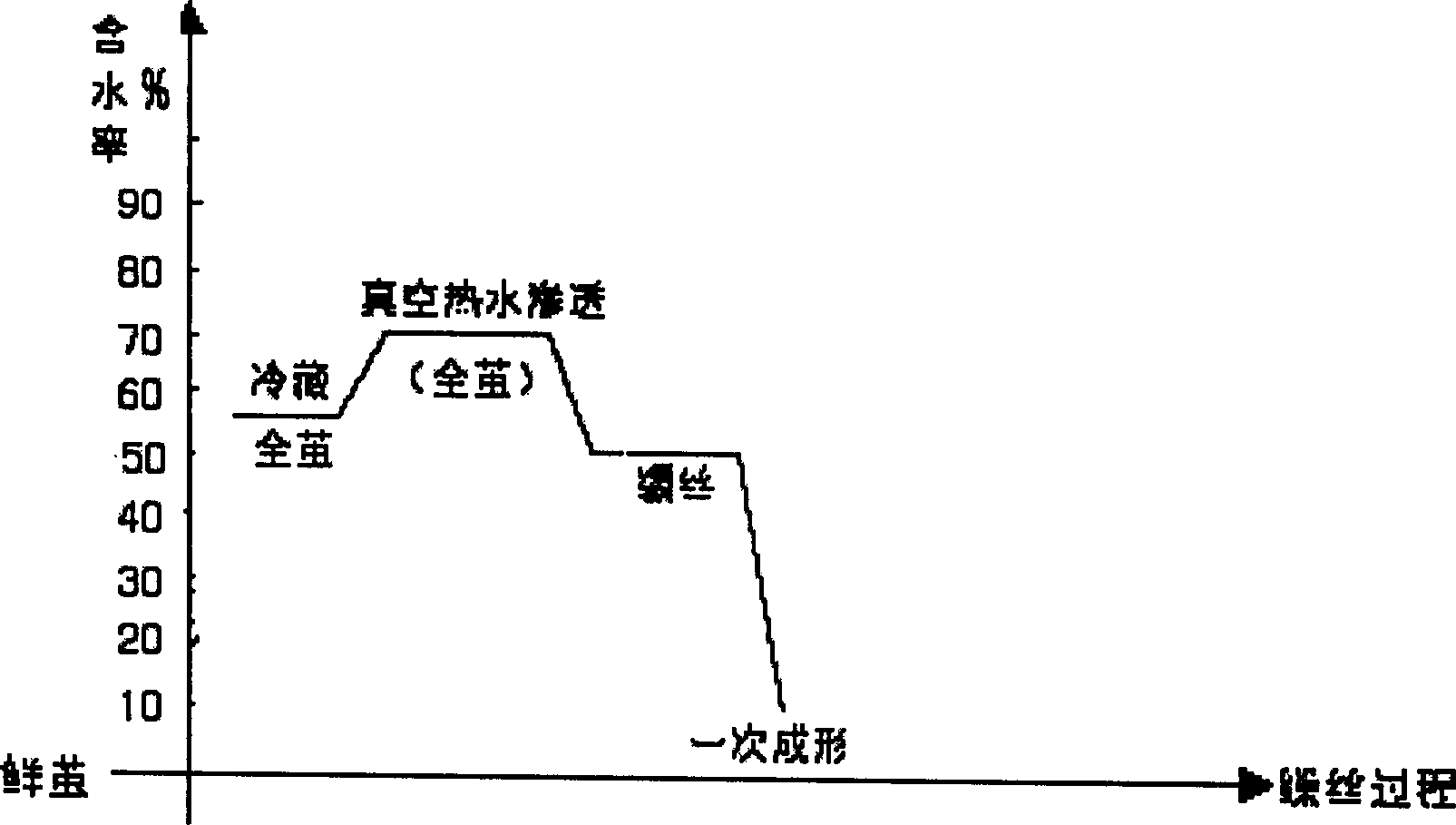

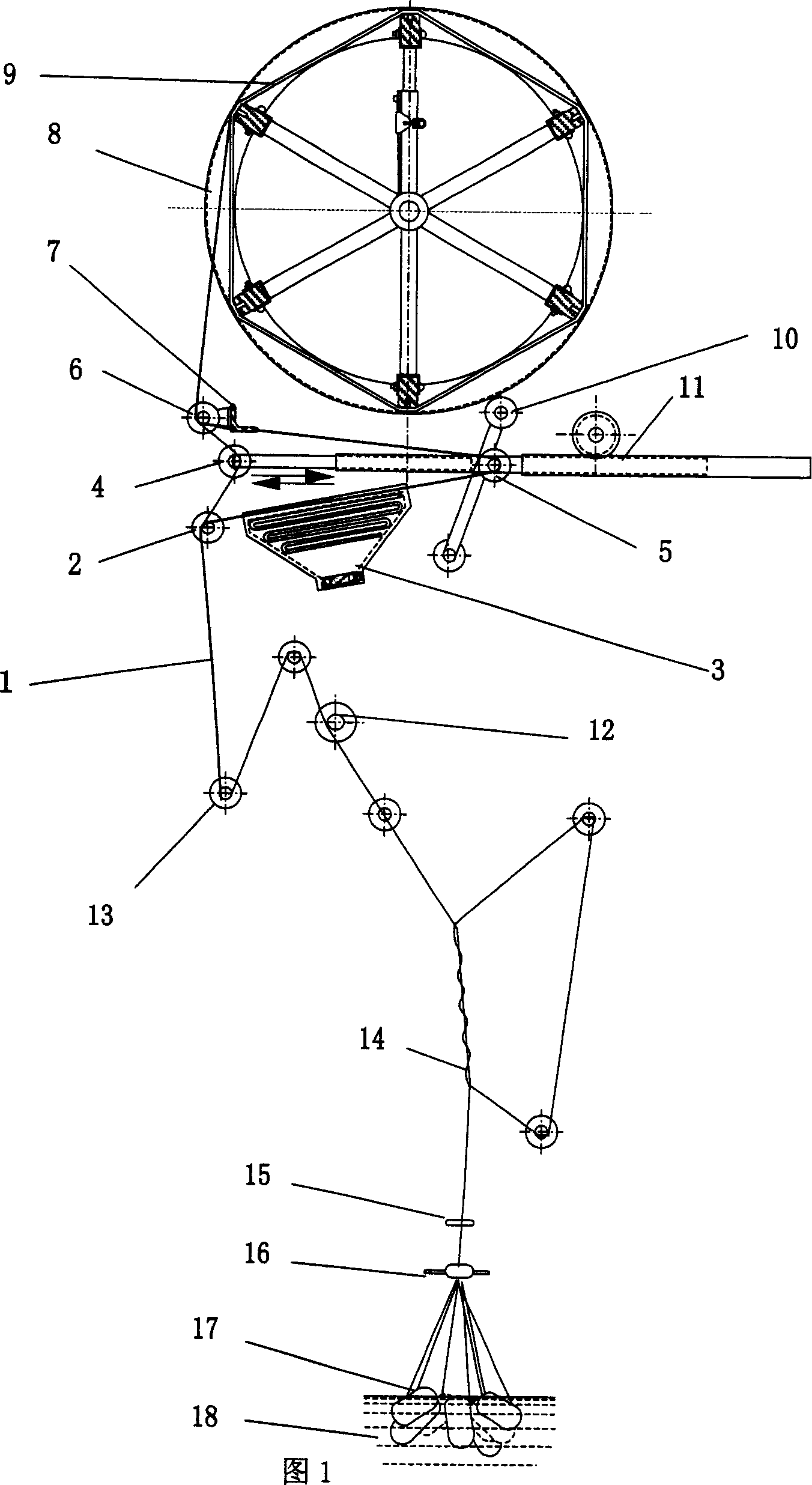

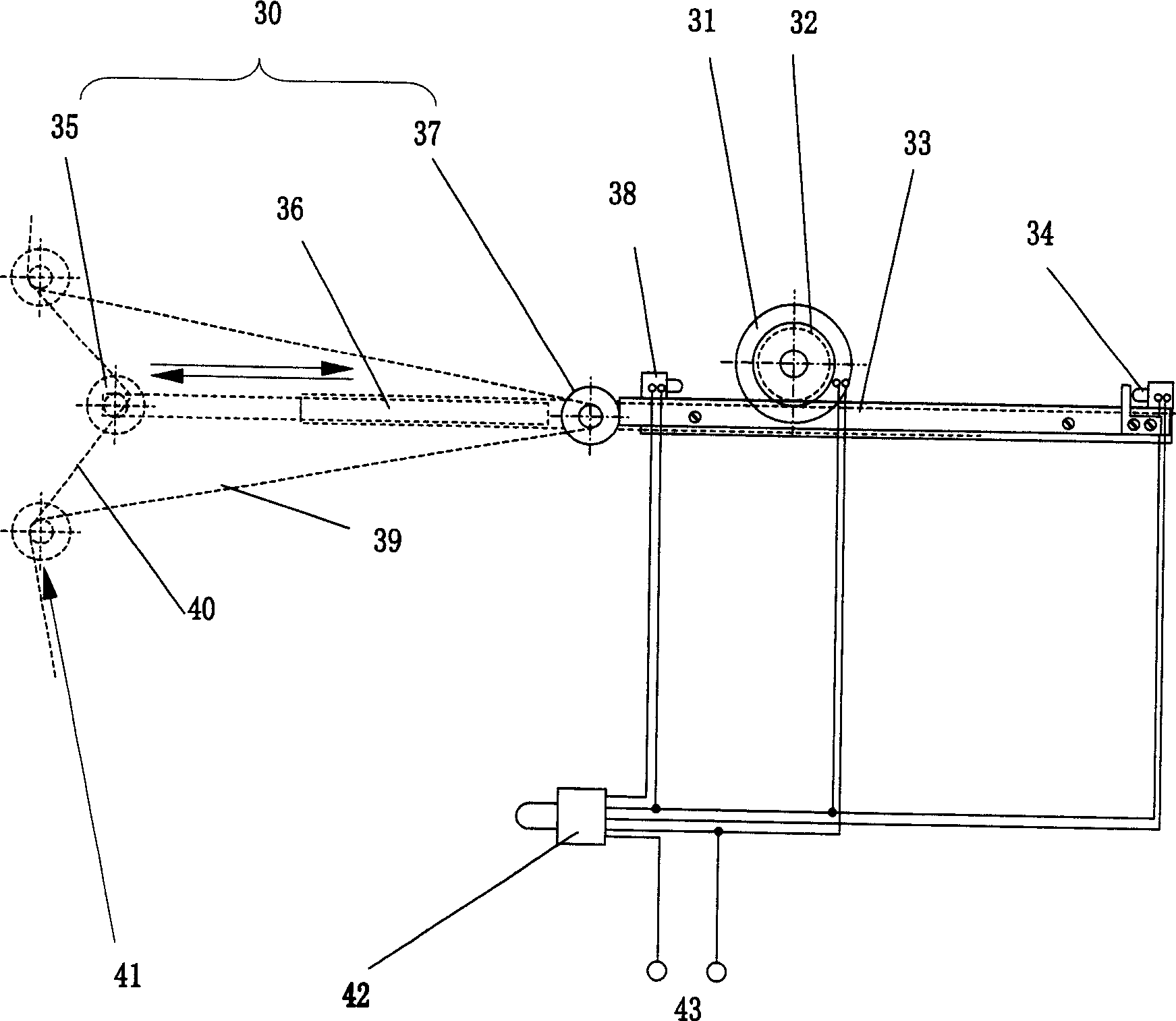

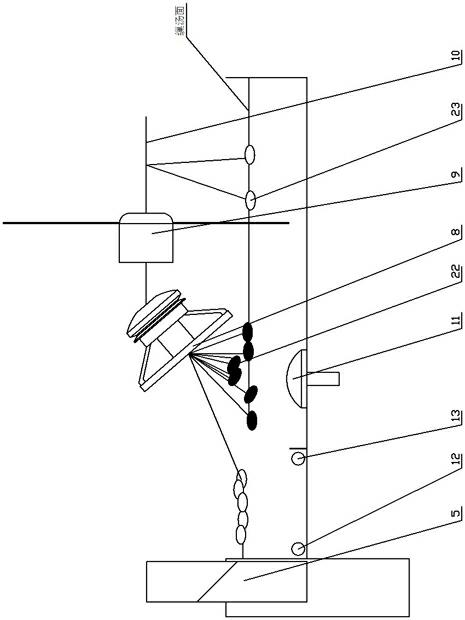

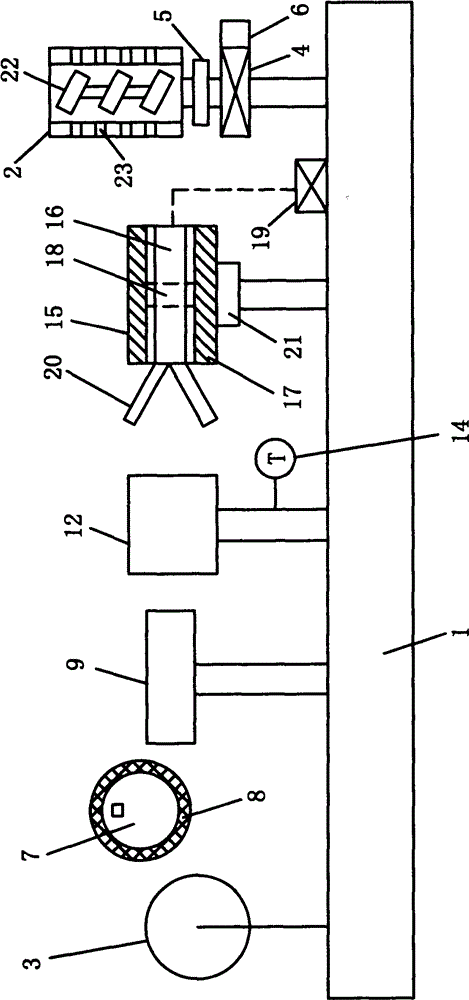

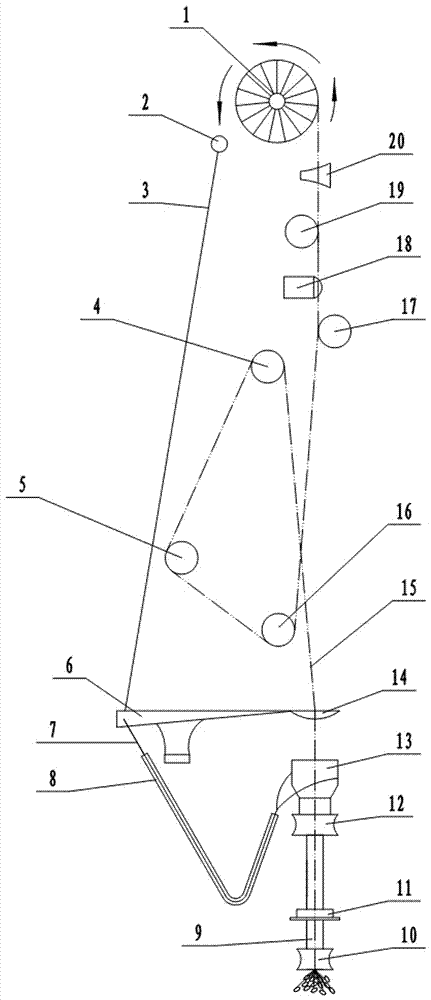

Single silk drying winding system of orice reeling machine

InactiveCN1718873AShorten heating timeReduce production processFilament handlingSilk reelingEngineeringConductor Coil

The present invention discloses a brin drying winding system for reeling machine. In the concrete, it relates to brin dryer, strand silk translation mechanism and single-end rereeling reel. The invented structure is characterized by that according to the running direction of strand silk produced by reeling cocoon in reeling water are successively set cocoon ends thrower, filament guide button, throwing machine and skein machine, denierer, tension buffer drum, positioning drum, brin dryer, strand translation mechanism, traverse drum on the traverse rod, single-end rereeling reel and rereeling reel brake wheel under the single-end rereeling reel.

Owner:SICHUAN UNIV TIANYOU BIOLOGIC ENG

Silk-reeling technology by utilization of tussah fresh cocoon live pupae

The invention relates to a silk-reeling technology by the utilization of tussah fresh cocoon live pupae. The technology includes the steps that vacuum low-temperature permeation is performed on tussah fresh silkworm cocoons of the live pupae after refrigeration and freshness retaining in a vacuum environment at water temperature of 26 DEG C-40 DEG C, wherein the pH value is 6.5-8; according to vacuum low-temperature chemical cocoon reeling, water, sodium carbonate, sodium silicate, sodium borate, hydrogen peroxide and N-coconut oil-potassium glutamate form a reeling solution, and at temperature of 30 DEG C-46 DEG C, vacuumizing is performed for reeling in the pH value of 4-14; according to constant-temperature cocoon blanching, the cocoons are soaked in the reeling solution at temperature of 30 DEG C-40 DEG C for blanching; low-temperature silk reeling is performed, and raw silks are reeled again to be arranged to obtain a finished product. Pupa linings are manually removed from the silkworm pupae after silk reeling, so that the silk-reeling live pupae are obtained. The cocoons are not dried and cooked, silk reeling is directly performed, cost and energy consumption are reduced, and the survival rate of the by-products silk-reeling silkworm pupae is over 95%. Protein, amino acid and other kinds of nutrient active substances of pupa bodies are not affected, the utilization rate of the silk-reeling silkworm pupae is increased, breeding cocoons are provided for a sericulture department to perform orientated breeding, fine-breed breeding is accelerated, and the technology has great significance.

Owner:辽宁柞蚕丝绸科学研究院有限责任公司

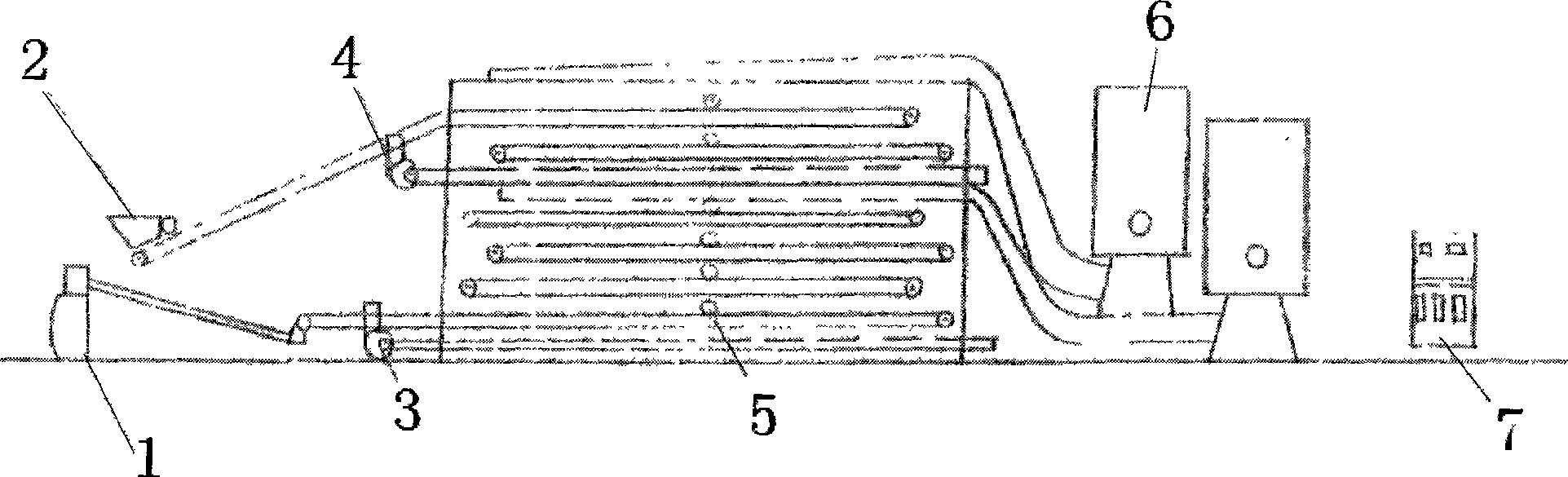

Silk reeling method and exclusive device for reeling raw silk

The invention relates to a silk reeling method and device, particularly to a silk reeling method and an exclusive device for reeling raw silk, which aim to solve the technical problems in the prior art that the energy consumption is large, the technological process is long, and more workers are needed all caused by silk reeling, rereeling and repeated drying; more time and labors are consumed because the bore diameter of a filament guide button is small; during the silk reeling process, the manual manner is adopted to form a silk sheath structure, and the hygrometric state raw silk is gathered by the function of the silk sheath in the method of gathering hygrometric state raw silk, the operation is complicated and the labor productivity is low. According to the invention, bave is processed by a hygrometric state raw silk gathering device after passing through an end feeding wing and a leading-in type filament guide button so as to enable the hygrometric state raw silk to be closely gathered, and moisture in a silk strip to be emitted by extrusion, tiny fouls on the bave surface are eliminated through kneading in a rotary manner, then, the bave is directly wound on a large shade and forms large flourishing yarn sheets through infra-red heating and drying, and the yarn sheets become reeled raw silk after silk falling arrangement.

Owner:ZHEJIANG SCI-TECH UNIV

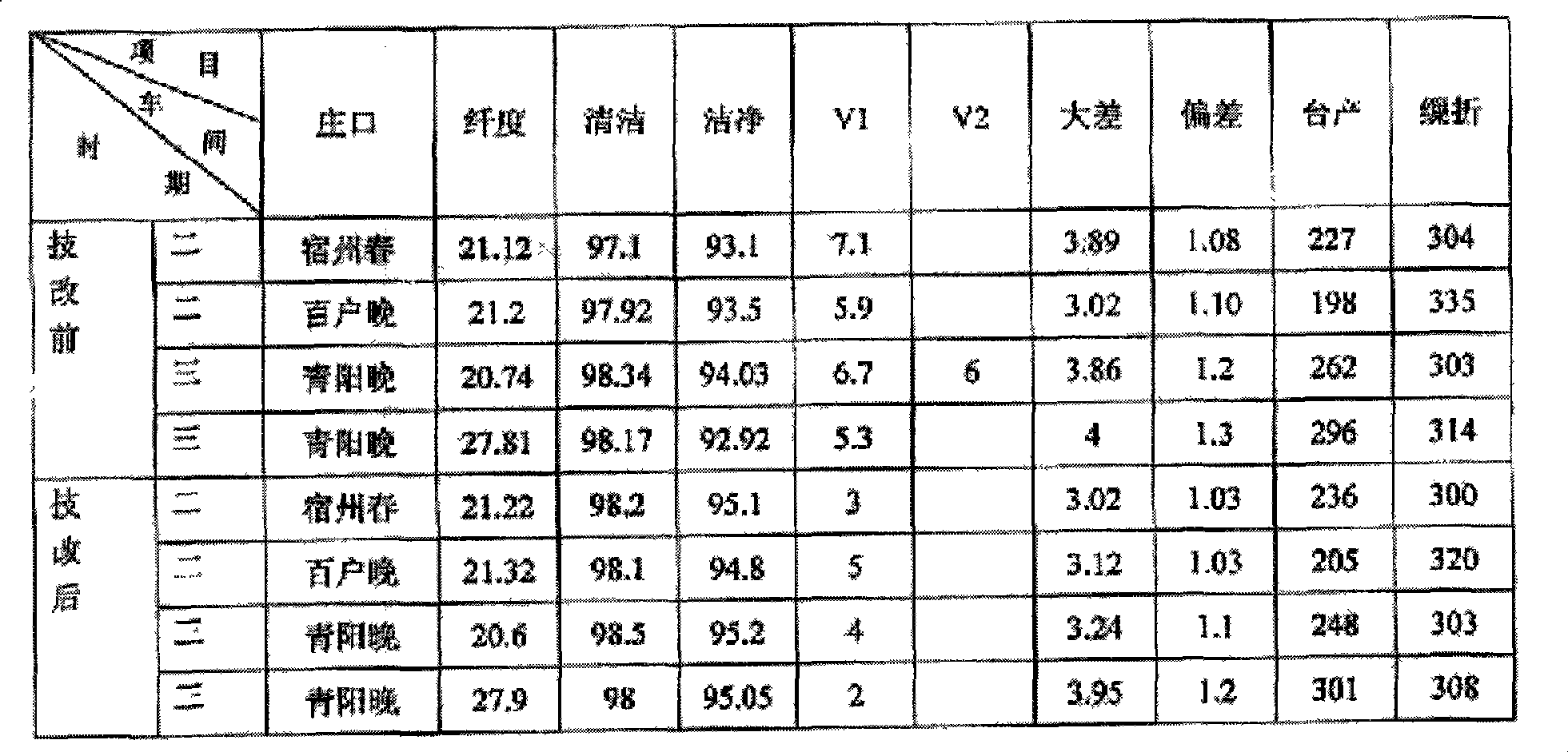

Method for producing super fine silk yarn

InactiveCN1943332ASmall size deviationImprove cleanlinessOrganic active ingredientsSilk reelingYarnFineness

Method for preparing fine silk thread is characterized by inducing tetramolter with superfine agent to tri-molt to produce tetramolter silk, wherein the single yarn fineness is 1 Denier. It has better colored, refraction, and crease-resisting property than tetramolter silk, it has small fibre finess deviation, high lustration, low cost, products made by such silk have improved luster and chromaticity.

Owner:ZHEJIANG UNIV

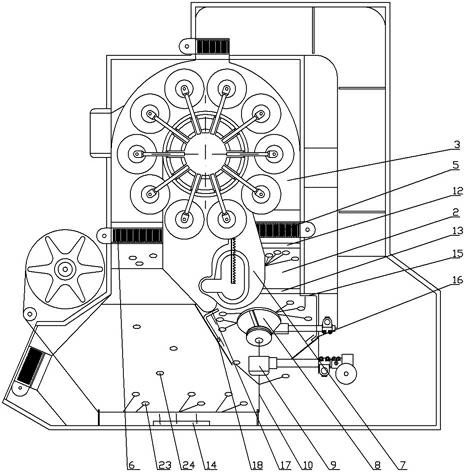

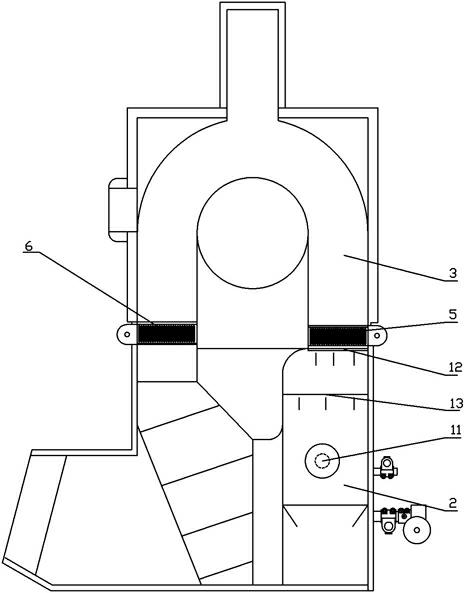

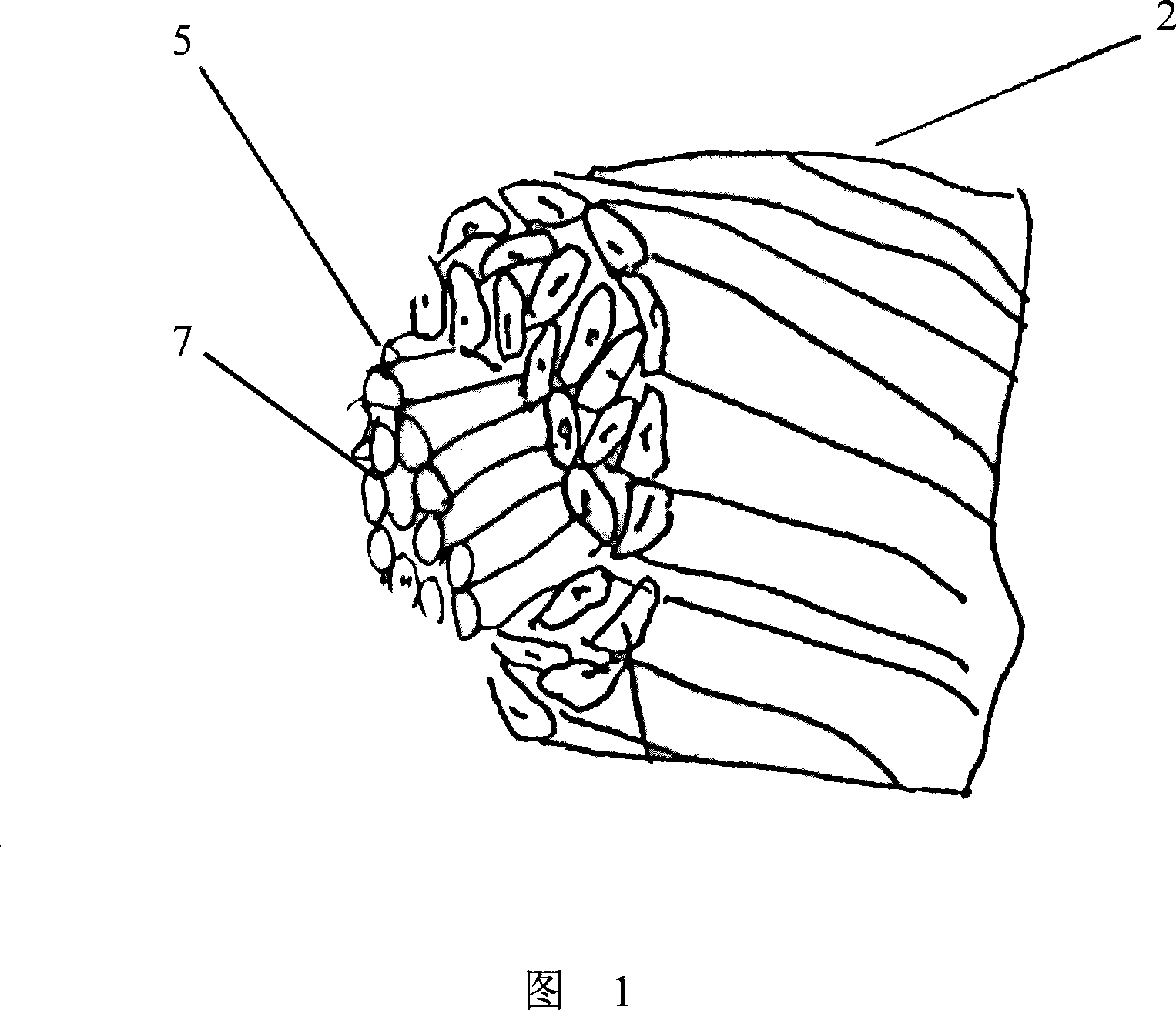

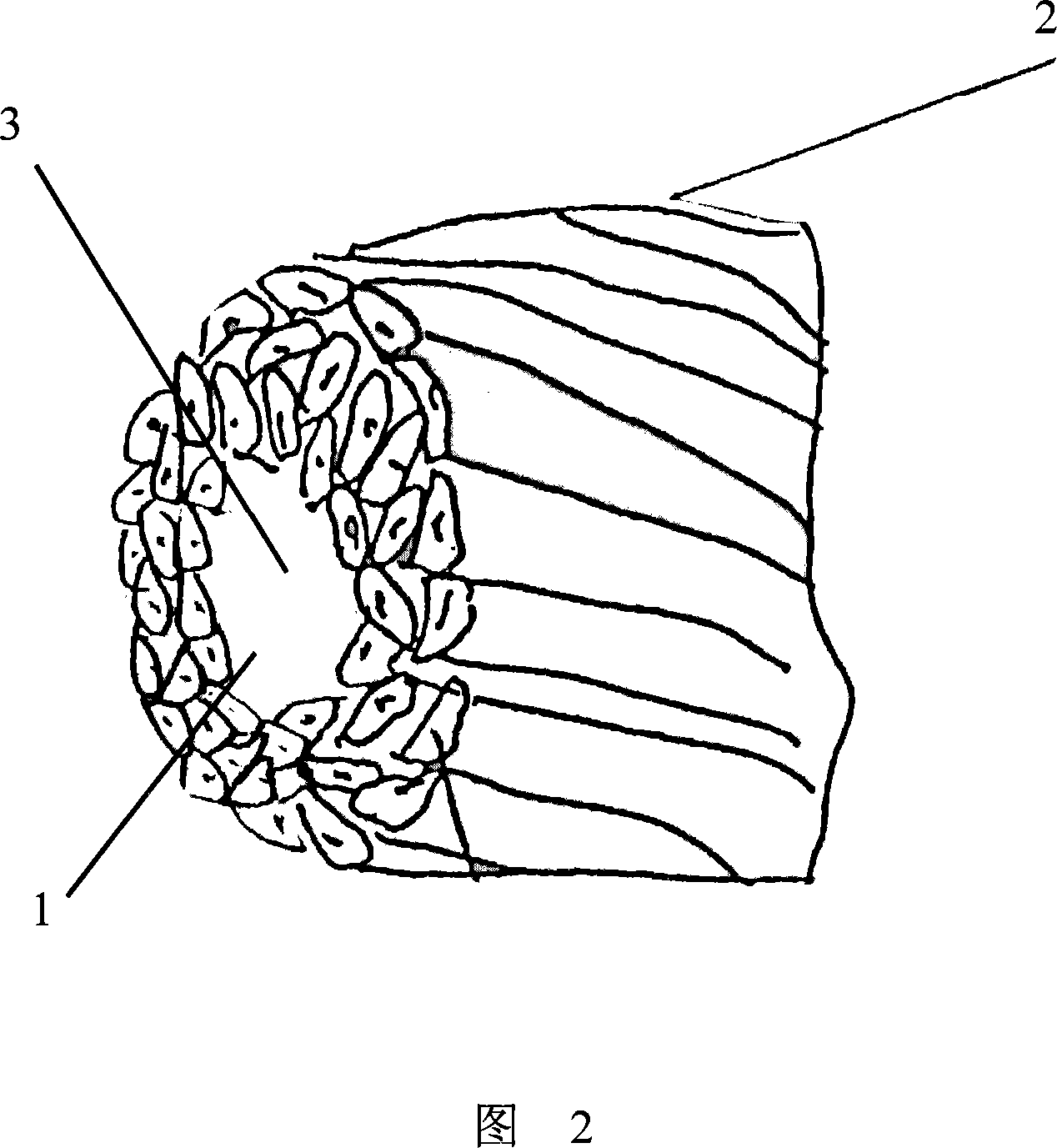

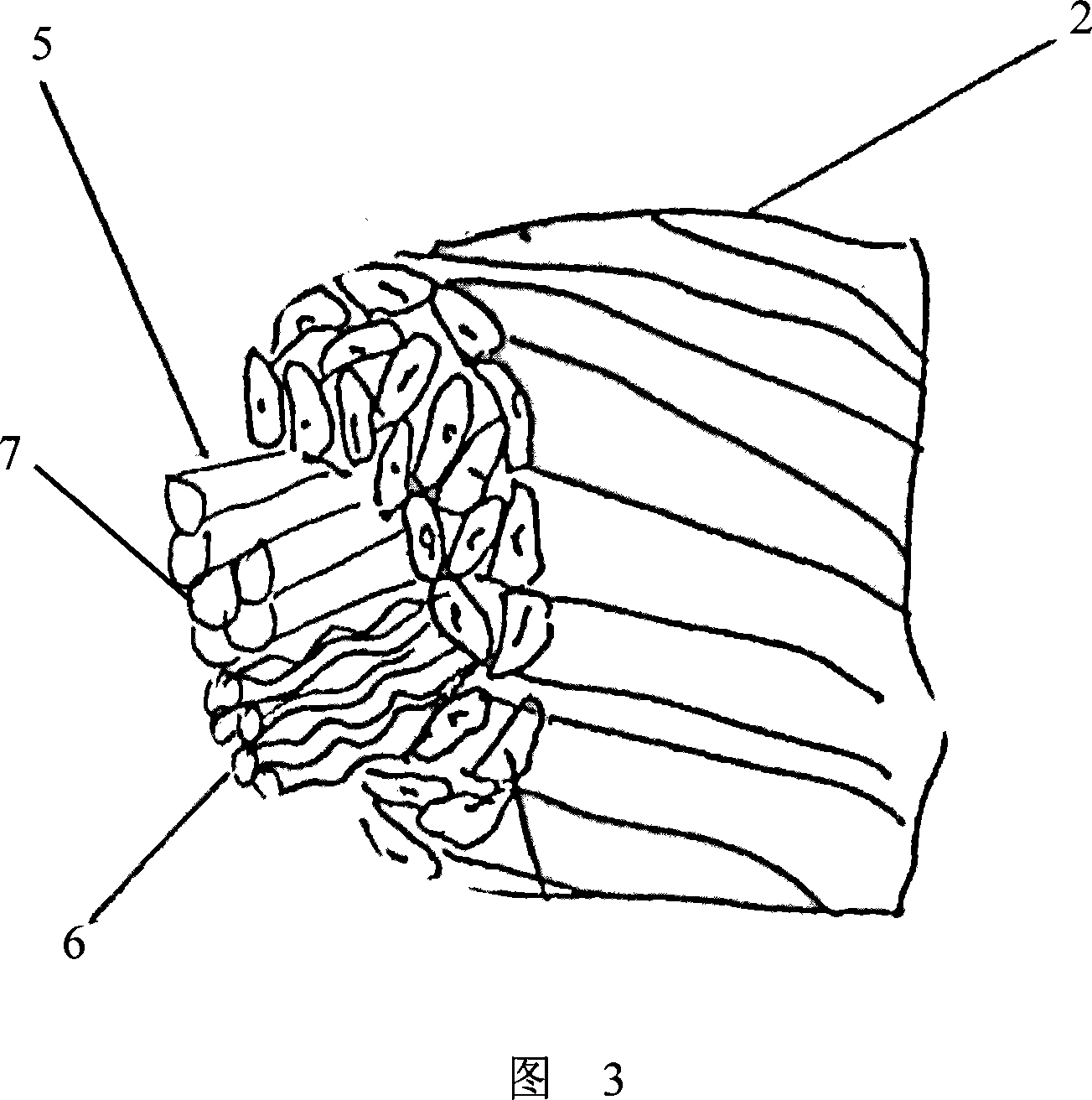

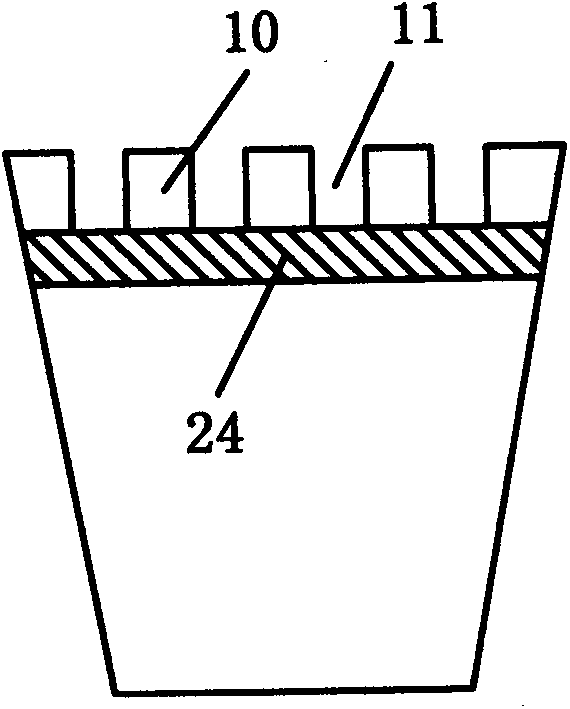

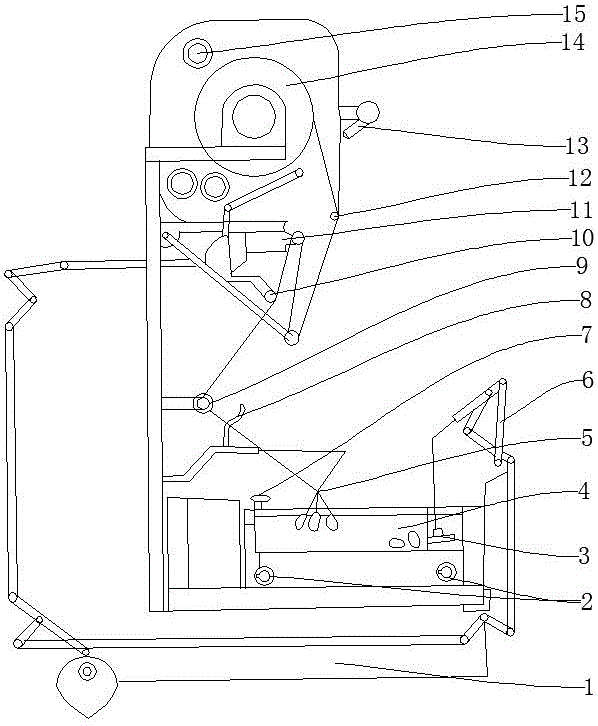

Expansion water flow arranging device for automatic silk reeling machine

The invention relates to a filature machine, in particular to a separating and arranging device for an automatic silk reeling machine. The separating and arranging device mainly solves the technical problems in the prior art that disordered cocoons are not easy to scatter and are further mixed together with ordered cocoons, and the arranging effect is influenced. The separating and arranging device comprises a machine frame (1), and is characterized in that an arranging pot (2) and a beating pot (3) are arranged on the machine frame (1); the arranging pot and the beating pot are integrated and communicated with each other; an ordered cocoon feeding hopper (5) and a disordered cocoon feeding hopper (6) are respectively arranged on the beating pot; an eccentric disc (8) and a fetching needle (9) are sequentially arranged on the machine frame at an inlet of the arranging pot; the eccentric disc is connected with a cocoon silk braid (10) that can transport the ordered cocoons; a sprinkler head (11) that can spray water upwards is arranged at the pot bottom of the arranging pot under the eccentric disc; and a first water adding pipe (12) that can spray water to the inner part of the arranging pot is arranged on the ordered cocoon feeding hopper.

Owner:HANGZHOU TIANFENG TEXTILE MACHINERY

Device and method for replacing croisures

Owner:ZHEJIANG SCI-TECH UNIV +2

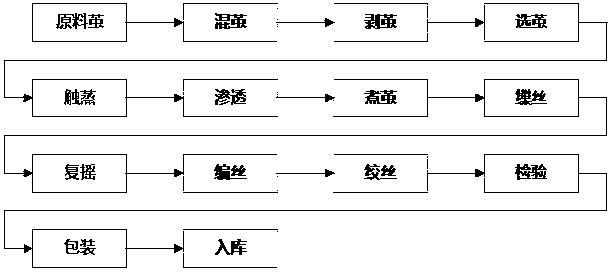

High-quality mulberry silk manufacturing technology

The invention discloses a high-quality mulberry silk manufacturing technology. The technology includes the specific steps of cocoon stripping, cocoon assorting, vacuum steaming, ultrasonic cooperative cocoon cooking, silk reeling, re-reeling, post-processing, testing, packaging, storage and the like. By means of the technology, cleanliness of silk is improved, and silk reeling quality is comprehensively improved, so that under the action of ultrasonic waves, the inside and the outside of a cocoon shell achieve the effects that sericin is uniformly swovlen, shell dropping on the inner layer is reduced, the reelability rate is improved, steaming efficiency is improved, work energy consumption is lowered, neatness and cleanliness of raw silk are improved, and fineness continuous dynamic non-contact detection of the raw silk is achieved. Quality of the raw silk is improved, raw silk drying efficiency is improved, and work energy consumption of equipment is lowered.

Owner:广西隆林嘉利茧丝绸有限公司

Production facility and production process for 6A grade white steam filature

InactiveCN101413144AReduce consumptionStable cocoonSilk reelingSilk cocoons cleaning/classifyingPulp and paper industryHigh pressure

The invention discloses a device for producing a 6A-level white steam filature. According to the sequence of a production process, the device comprises a cocoon drying device, a cocoon assorting device, a cocoon cooking device, a self-silk-reeling device, a silk re-reeling device and the like, wherein the cocoon drying device is provided with a fresh cocoon water ratio detecting device. The technical proposal provided by the invention can effectively solve the following problems: the stable quality of the cocoon is hard to ensure in the production process of cocoon drying by the production technology of the 6A-level white steam filature; the air pressure and the temperature in a digester room are hard to control in the production process of cocoon cooking; and the production process of the white steam filature is lack of monitoring, has low automation level, poor quality stability of the product and the like. At the same time, the technical proposal ensures the stability of the cocoon quality, improves the reelability percentage and the cleanliness index, and promotes the inner layer sericin adhering point to separate instantly to swell at low temperature and at high pressure to the utmost extent; besides, outer surface sericin does not generate dissolving and melting, thus the technical proposal reduces dropped threads in middle and inner layers, reduces the consumption of raw materials, and strengthens the implementation of on-line monitoring in the processes of production and processing at the same time.

Owner:HUANGSHAN HUASHENG SILK GROUP

Method for reeling silk from mulberry silkworm fresh cocoons by virtue of cocoon cooking

The invention discloses a method for reeling silk from mulberry silkworm fresh cocoons by virtue of cocoon cooking. The method is characterized by comprising the process steps of cold storage preservation, cocoon selection, vacuum infiltration, cocoon cooking, silk reeling, treatment of fresh basin residues, and preservation of fresh silkworm chrysalis. The method is simple and convenient, quality indexes such as strength, cohesion, cleanness and purity of raw silk are effectively improved by virtue of the cocoon cooking, and the raw silk is in a grade of being over 4A; silkworm chrysalis can be separated from basin residues through a scutcher to obtain high-quality fresh silkworm chrysalis and silk floss, and therefore the utilization value of byproducts is increased.

Owner:GUANGXI GUIHUA SILK CO LTD

Method for increasing reelability percentage of raw silk

The invention discloses a method for increasing the reelability percentage of raw silk. The method comprises the steps of conducting vacuum penetrating treatment and upper-trough immersion treatment on silkworm cocoons, wherein vacuum penetrating treatment is completed in a vacuum penetrating device, the cocoons and penetrating fluid of which the mass ratio is 1:10-15 are added to the vacuum penetrating device, the penetrating fluid is prepared by mixing a reelability agent and distilled water of which the mass ratio is 1.2-1.5;100, vacuum penetrating treatment is conducted under the conditions that the temperature is 35 DEG C-40 DEG C and the vacuum degree is 0.08 Mpa-0.09 Mpa, the vacuum penetrating device is provided an ultrasonic emission assembly below the fluid level of the penetrating fluid, the ultrasonic emission assembly emits ultrasonic waves to the penetrating fluid during vacuum penetrating treatment, and time for vacuum penetrating treatment ranges from 3 min to 3.5 min. By the adoption of the method for increasing the reelability percentage of the raw silk, the cocoon cooking effect can be effectively improved, it is measured that the average reelability percentage can reach 77.8% after silk reeling, and the average length of non-broken cocoon filaments can reach 854 m.

Owner:SHANGLIN ZHONGXING SILK

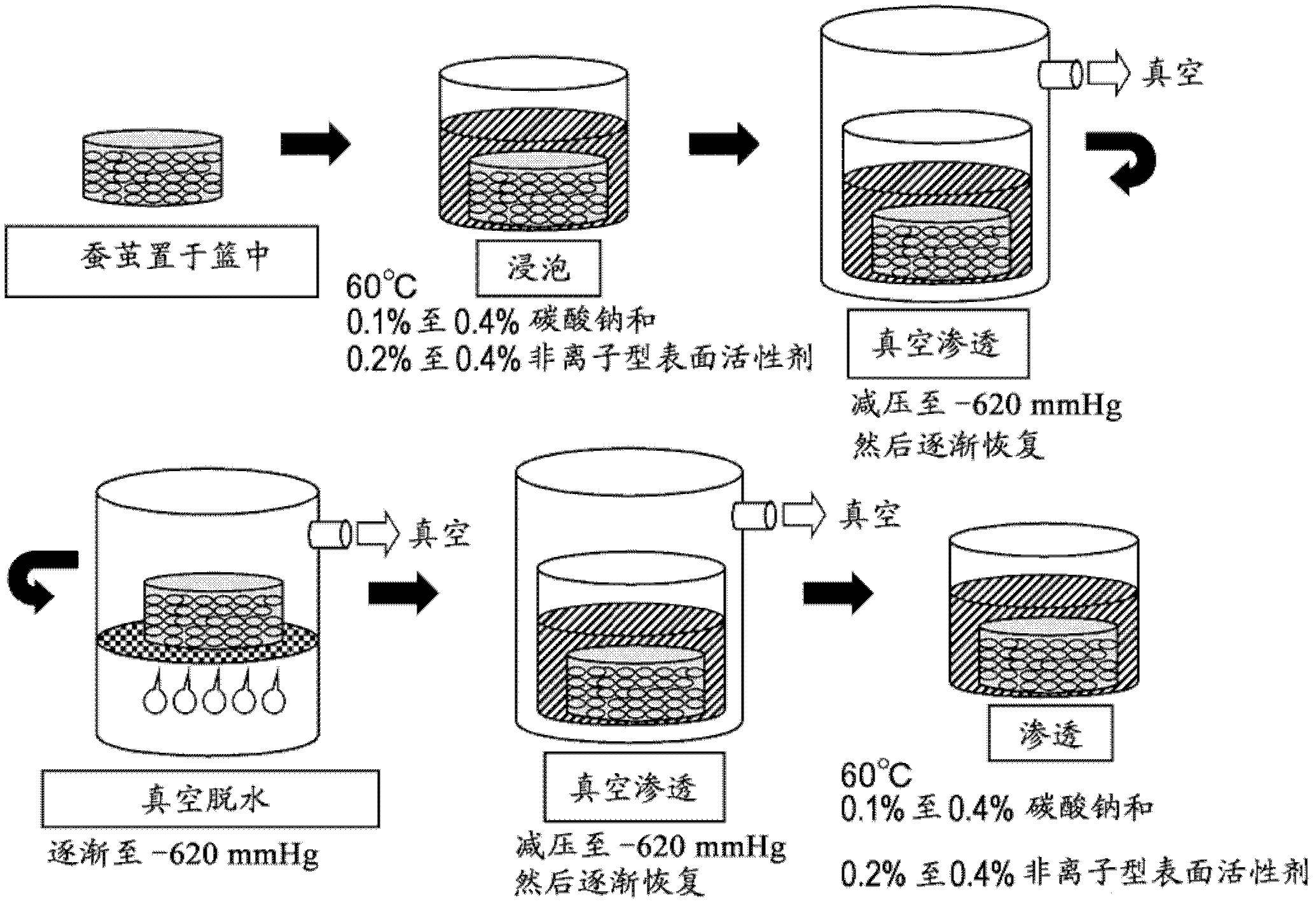

Comprehensive utilization method of fresh cocoons of silkworms

ActiveCN103704181AIncrease release rateHigh economic valueSilk reelingAnimal husbandryEngineeringOrganic chemistry

The invention discloses a comprehensive utilization method of fresh cocoons of silkworms. The method includes the steps of S1, collecting fresh cocoons and storing till pupation occurs; after pupation, placing pupas for 5-6 days; S2, loading the fresh cocoons treated in the step 1, with baskets, cold-preserving the cocoons at the temperature of -5-0 DEG C, under the relative humidity of 60-70%, for 30-90 days; S3, cooking the fresh cocoons, treated in the step 2, by the vacuum penetration sol segregation technique, and reeling silk to obtain raw silk and fresh pupas. By the comprehensive utilization method, fresh pupas of the silkworms can be stored in a long period of time without killing the pupas; silk reeling is performed on the fresh pupas stored by the method to obtain a great amount of fresh pupas; accordingly, high-quality silk can be obtained through the application of silk reeling in fresh cocoons, fresh pupas of high economic value can be obtained, and the method is of great practical significance to post-processing of silkworms.

Owner:SOUTH CHINA AGRI UNIV

Method for preparing mulberry silk containing nanometer TiO2

ActiveCN103952774AIncrease contentEvenly distributedSilk reelingAnimal husbandryBombyx moriChemical agent

The invention discloses a method for preparing mulberry silk containing nanometer TiO2. According to the method, firstly, the nanometer TiO2 is prepared into additive solution with the concentration being 100 too 150mg / L, then, the solution is sprayed onto mulberry leaves according to the use dosage that 1.0L of solution is added to 100kg of mulberry leaves, the mulberry leaves are fed to bombyx mori from the fifth instar stage to the 3rd day after being dried until the mounting, in the produced mulberry silk, the content of Ti element is 440+ / -21 to 500+ / -25ng / g, after the silk is washed for 50 times trough water, the content of Ti element is 418+ / -19 to 465+ / -30ng / g, good combination of nanometer TiO2 and silk protein is shown, and water washing resistance and high stability are realized. The method provided by the invention does not adopt chemical agents, the preparation of the mulberry silk containing nanometer TiO2 is realized, and a new research thought is provided for the mulberry silk modification research. The disclosed method has the advantages that the practicability is high, the operation is convenient, the cost is low, the popularization and the application are easy, and the influence cannot be generated on the environment.

Owner:JIANGSU HUAJIA SILK

Fresh cocoon silk reeling method

InactiveCN104593875AOvercoming poor cohesionOvercome wear resistanceSilk reelingEngineeringPermeation

The invention discloses a fresh cocoon silk reeling method. The method comprises the following steps: stacking and storing fresh cocoons, and then sequentially performing cocoon mixing, cocoon peeling and cocoon selecting according to process requirements to obtain cocoons for silk reeling; putting the cocoons for silk reeling into a closed water tank, and performing low-temperature water suction permeation; cooking the permeated water-sucked cocoons subjected to the low-temperature water suction permeation by using a cocoon cooking machine, performing silk reeling by using an automatic silk reeling machine, and controlling the reeling speed; putting a small net into the water tank, performing negative-pressure water intake and suction, and then performing immersion treatment; finally, performing rereeling finishing, and packaging reeled silks. The fresh cocoon silk reeling method has the advantages of simplicity, quickness and low cost, the defects of an existing fresh cocoon silk reeling method are overcome favorably, the technical problem of influence on the performance of fresh cocoon raw silks caused by lower cohesion and poor abrasion resistance of the raw silks is solved, and the grade of the fresh cocoon raw silks is improved.

Owner:ZHEJIANG UNIV

Processing method of natural colored silk yarn

The invention involves a kind of natural colored mulberry silk the processing method, specially involves a kind of silkworm (bombyx mori) the natural colored cocoon reeling craft. It uses a kind of silkworm natural colored silkworm cocoon and the white silkworm cocoon, or two kind of different colors silkworm natural colored silkworm cocoons matches after the certain proportion the cocoon, then carries on the reeling processing the method, the production from the shallow to the deep different color, the color uniformity and the sense of reality different mulberry silk, satisfies the color and the style which the fabric needs. The method use ordinary silk reeling equipment, craft simple, the ease of operation, is extremely easy to promote, for the natural colored mulberry silkworm cocoon use, provides the green silk product to open the new way.

Owner:SUZHOU UNIV

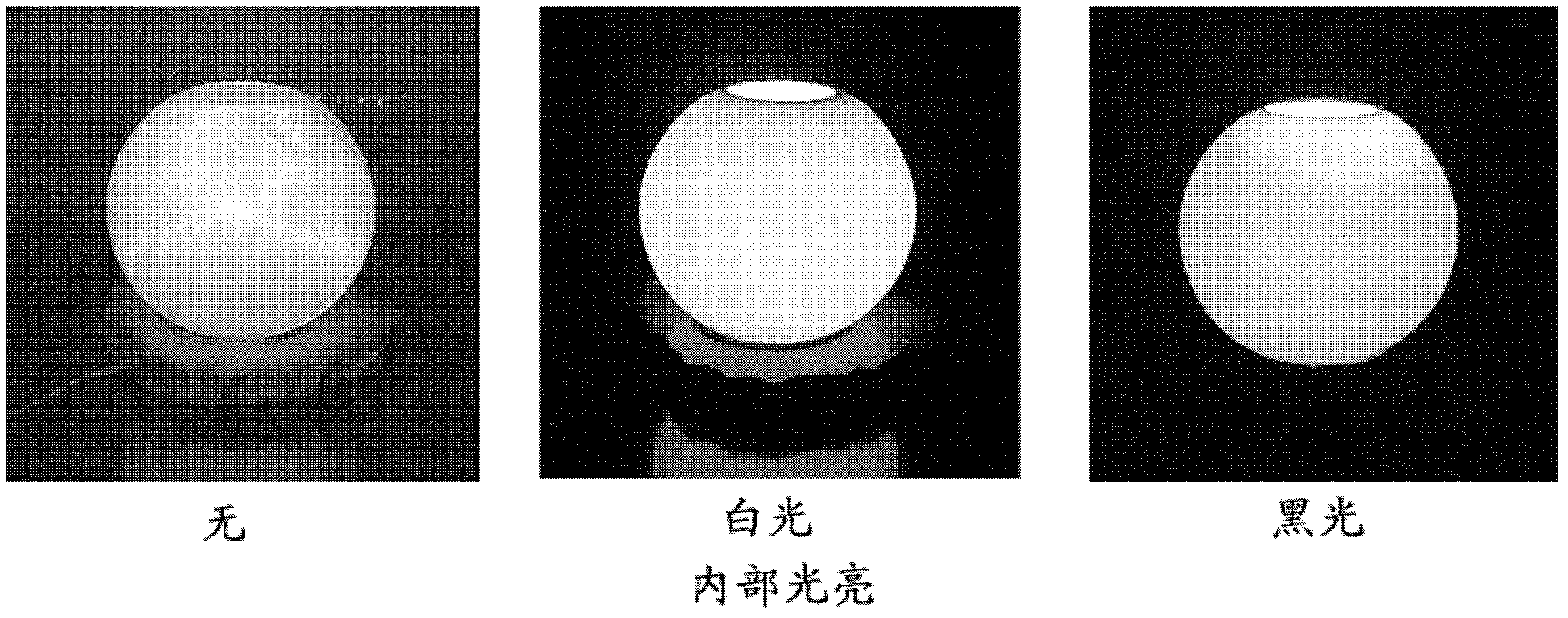

Silk reeling method for GFP family chromoprotein silkworm colourful cocoon

InactiveCN101423980AAddress variabilitySolve puzzles that make colors disappearSilk reelingTemperature controlChemical composition

The invention relates to a silk reeling method for GFP familial chromoprotein silkworm colorful cocoons, wherein cocoon is dried at a temperature of less than 70 DEG C, and obtained dried cocoons are cooked for 30 minutes in a solution containing 0.5 percent of sodium silicate and 0.1 percent of sodium hydroxide at a temperature of 42 DEG C, placed in mild water at a temperature of between 50 and 55 DEG C, and subjected to cocoon brushing and general subsequent technologies such as filament guiding, twisting and ensheathing, cross winding, coiling, drying and silk rereeling to complete the process of silk reeling. The invention skillfully breaks through the technical bottleneck of large-scale silk reeling of the GFP familial chromoprotein silkworm colorful cocoons by utilization of temperature control and change of the chemical compositions of the cocoon cooking solution, establishes a reliable method which is suitable for performing large-scale silk reeling on the GFP familial chromoprotein silkworm colorful cocoons, and provides the novel method for actual practicality of the GFP familial chromoprotein silkworm colorful cocoon varieties.

Owner:SOUTHWEST UNIVERSITY

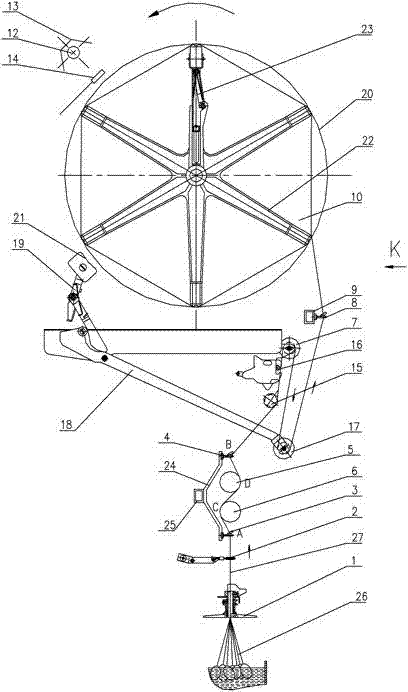

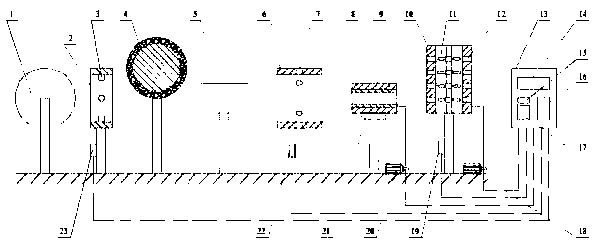

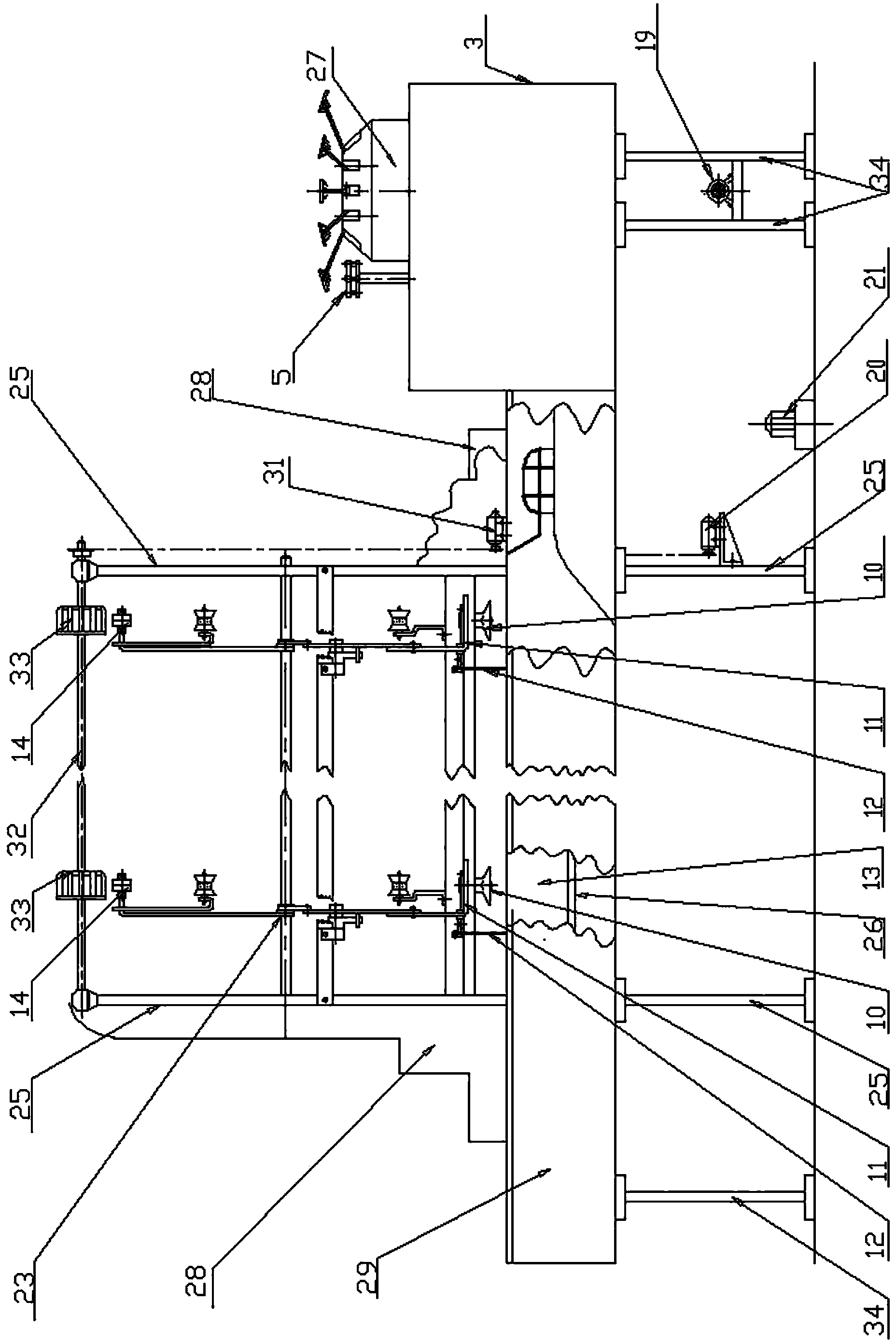

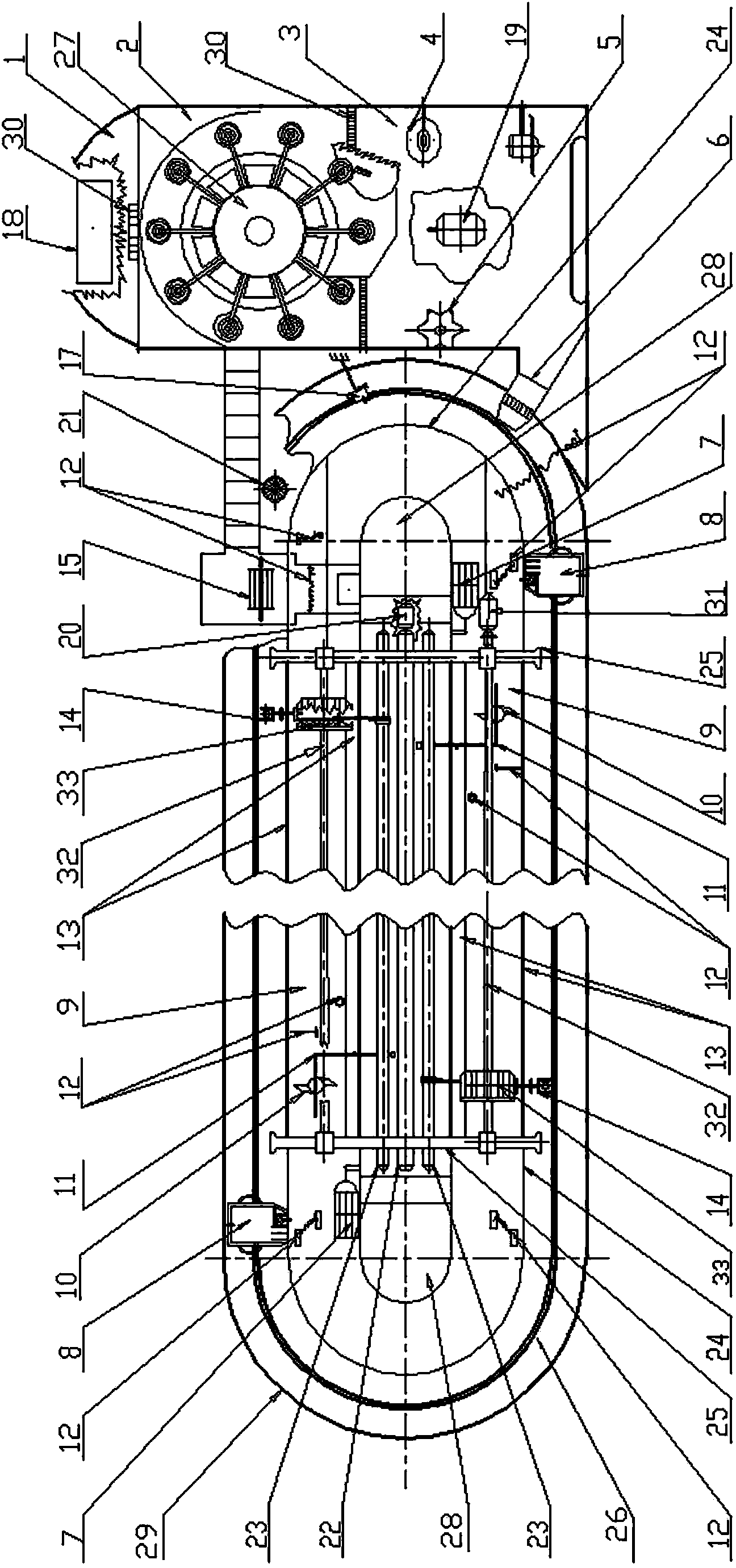

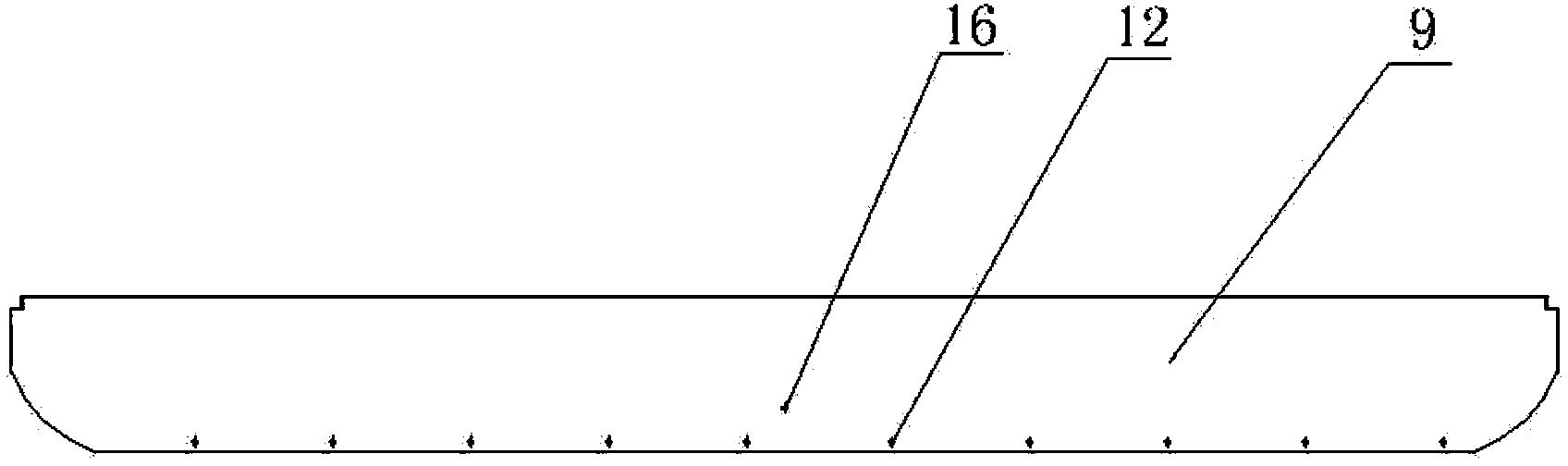

Energy-saving and environmentally-friendly automatic tussah silk reeling machine

ActiveCN103938279AHigh recovery rateEasy to separateSilk reelingTextile/flexible product manufactureAgricultural engineeringElectric machinery

Provided is an energy-saving and environmentally-friendly automatic tussah silk reeling machine. An automatic production line is composed of a cocoon preparing basin, an automatic end groping basin, an automatic end picking bath, an automatic cocoon feeding opening, a reeling basin, automatic cocoon discharging catchers, rotating wings, an automatic end feeding device, an automatic size-fixing device, an automatic basin-residue separating device, a cocoon detecting device, a variable frequency control cabinet, a variable frequency motor, an automatic cocoon feeder and the like. Because cocoon supporting boards and drag horizontal thread interrupters are arranged in the machine, the problem of separation of dropping end cocoons and the problem of drag horizontal threads are well solved, and automatic end groping, automatic end picking, automatic cocoon feeding, automatic sensing, automatic end feeding, automatic winding, automatic cocoon discharging and automatic basin-residue separating are achieved. Thus, labor productivity is improved, labor intensity of operators is reduced, the working environment of the operators is improved, hands of the operators do not need to be soaked in alkaline water for a long time, and the output per man shift is 2.5 times that of a multi-end reeling machine. Meanwhile, the quality of raw silk is higher than the level of 2A, and the recovery rate of reeled silk of tussah cocoons is increased by more than 3%.

Owner:辽宁柞蚕丝绸科学研究院有限责任公司

Method for preparing high grade sexual silk

InactiveCN101054731AImprove silk yieldSilk reelingSilk cocoons cleaning/classifyingFiberUltraviolet lights

The present invention discloses a process for preparing high-quality gender cocoon fibre. Said process comprises the following steps: adopting breeded fluorescent cocoon color to judge breed variety of gender silkworm under ultraviolet light source, respectively measuring sizes of female / male silkworm cocoon and thickness of cocoon layer after separating female silkworm cocoon from male silkworm cocoon, adjusting the cocoon drying technological conditions according to determination of conventional technological condition for cocoon drying and cocoon boiling, wherein for female cocoon, the reducing dry temperature is adjusted to 3-10 DEG C and the shortening reduced speed dry time is adjusted to 0.5-.5 hours, for male cocoon, the prolonging reduced speed dry time is adjusted to 0.5-.5 hours; regulating the technological conditions for cocoon boiling, for female cocoon, the prolonging boiling setting time is 1-3 minutes, for male cocoon, the shortening boiling debug time is 1-3 minutes; then, reeling silks at an auto cocoon cooking machine or an auto fiber-fixed reeling machine to manufacture male silkworm bast silk with a gradation of 6A and female silkworm bast silk with a gradation of 5A-6A. The obtained bast silks is one or two gradations higher than the male / female mixing bast silk, and then realizes the batch silk reeling of cocoon fibre, with high quality.

Owner:SUZHOU UNIV

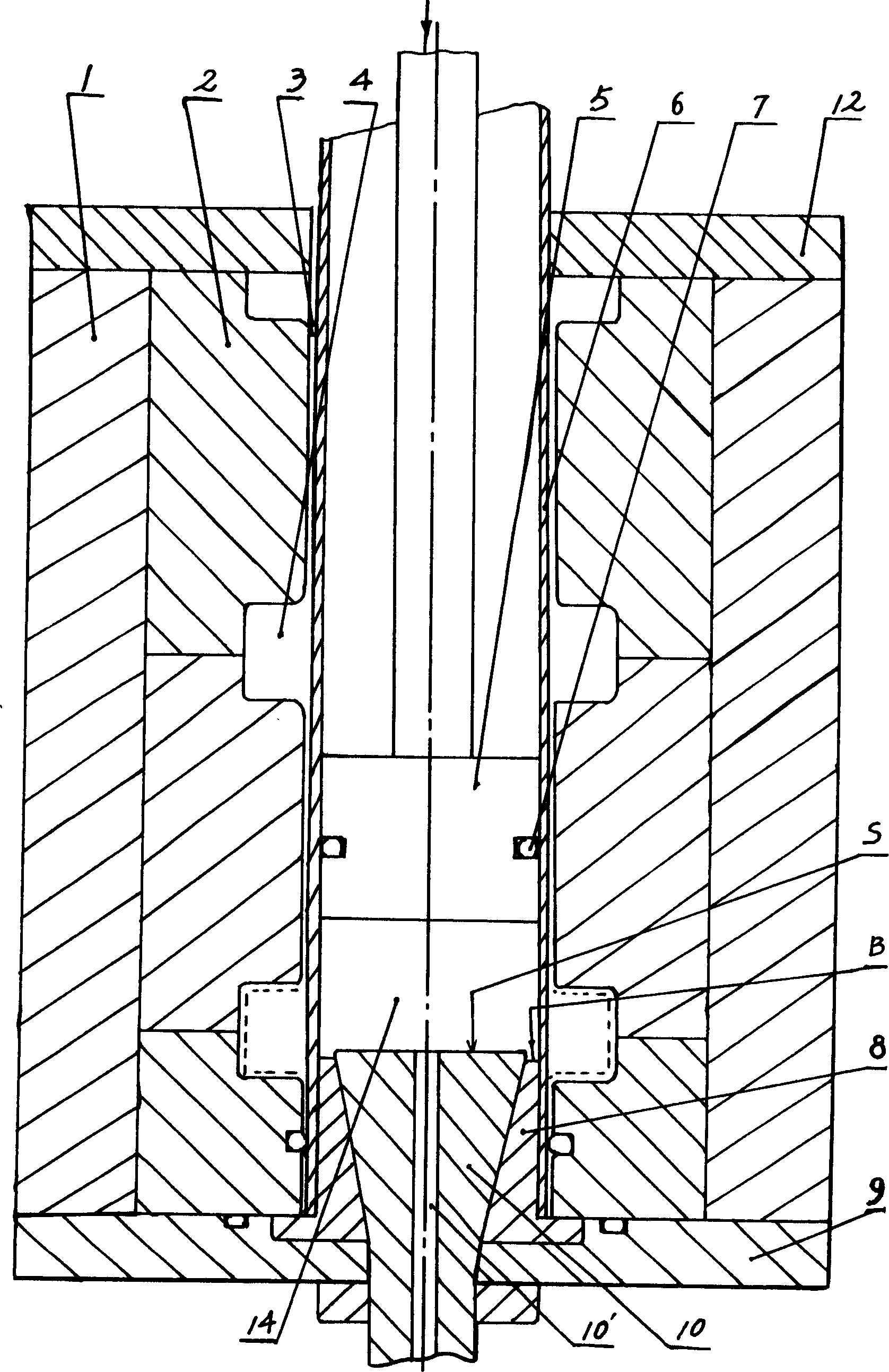

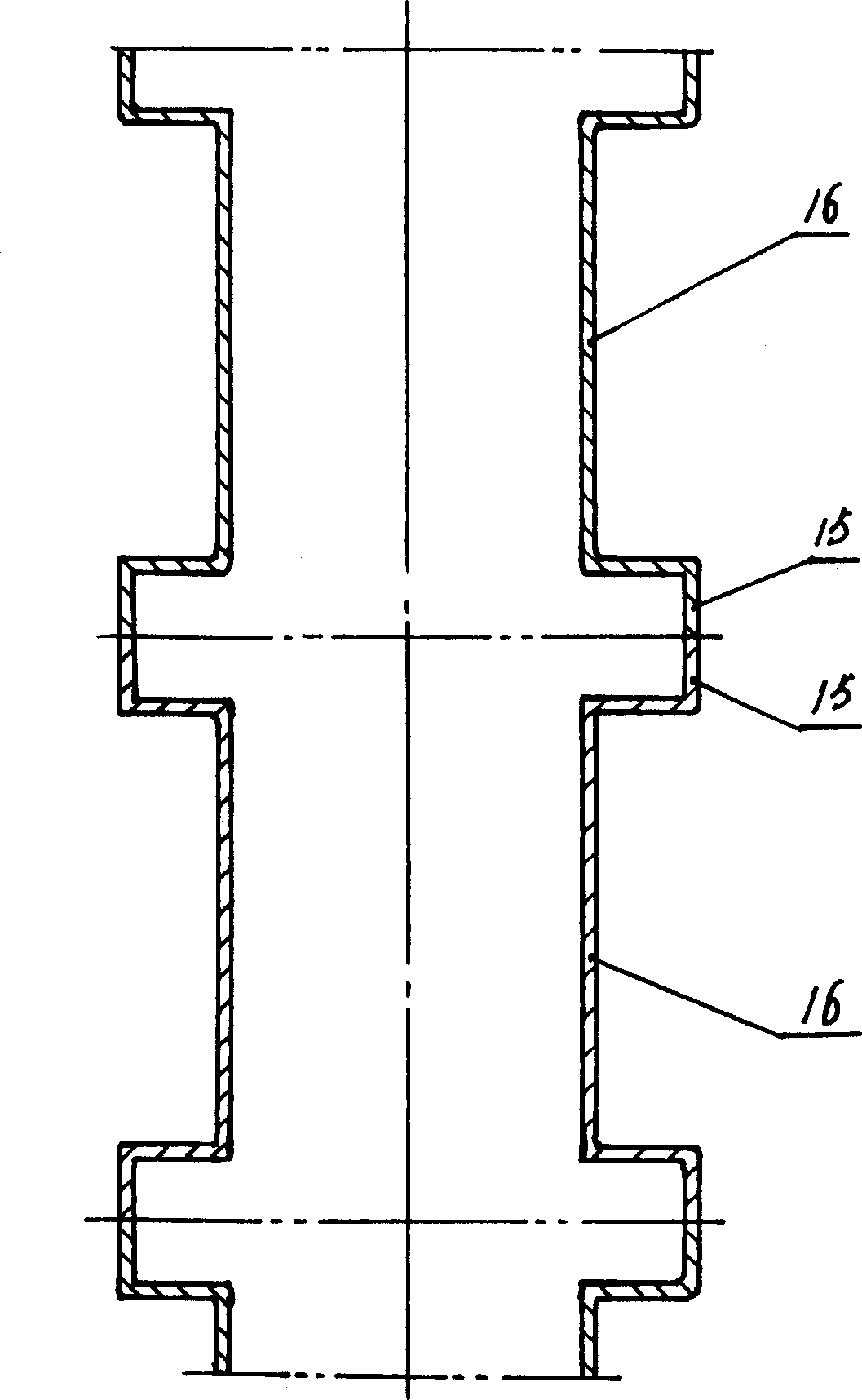

Machining mould and method for stainless nide silk bobbin

A processing die of non-rust steel nest bobbin. The die formed by one or more sectional combination dies has a cavity where a core fit. Cavity is compounded with sectional drum cavity and bulge end cap cavity. Insert a non-rust steel pipe into cavity between die and core. Fit airtight packing between core and non-rust steel pipe. Solid plate is fit on one side of die. Jacked device is fit on outside of core. Fit tamper with topping-up hole in the cavity of one side of solid plate. Topping-up hole connects with fluid cylinder. Fill liquid in impression. Apply pressure to the non-rust steel pipe by fluid power. Make the end cap be expanded to form certain size. Divide the expanding part to obtain the product.

Owner:沈传良

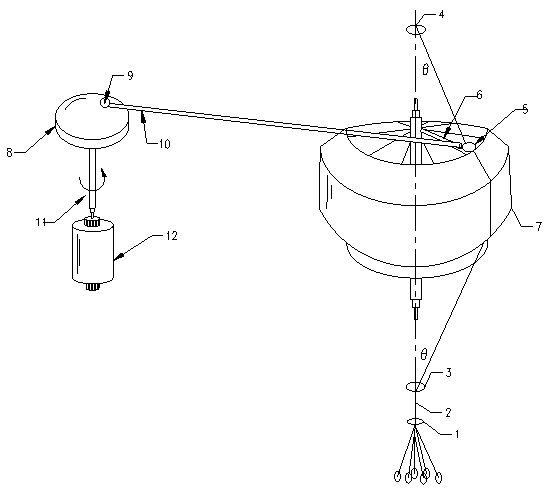

Hollow bulking spun silk and mixed reeling method

InactiveCN101161886AWrinkle recoveryDimensional stabilitySilk reelingYarnPolyvinyl alcoholTactile sensation

The present invention discloses a hollow lofty spun silk and the mixed reeling method thereof. The hollow lofty spun silk comprises a core part and an outer layer outside the core part, and the core part at least comprises part of a middle part formed after core silk which is water-soluble polyvinyl alcohol silk is dissolved out. The mixed reeling method is that: in the silk reeling process of thin silk, a silk through pipe perforating the top and bottom of a silk reeling bath is arranged inside the silk reeling bath; the core silk passes through the silk through pipe; underwater rotor wings rotating alternately and reversely are arranged around the silk through pipe; the underwater rotor wings can cause a reverse water flow alternating slowly, so as to lead cocoon filaments to rotate alternately as well as twine and cover around the core silk. The spun silk of the present invention is lofty and elastic. The novel hollow lofty spun silk can be used to produce tatted goods and knit goods, which have unique elegant luster and hue of the thin silk as well as medium thickness, can be made into outerwear which has the hand feeling with bulkiness and light tactile sensation like wool goods, and also has wrinkle restoring ability as well as dimensional stability.

Owner:富地正招 +2

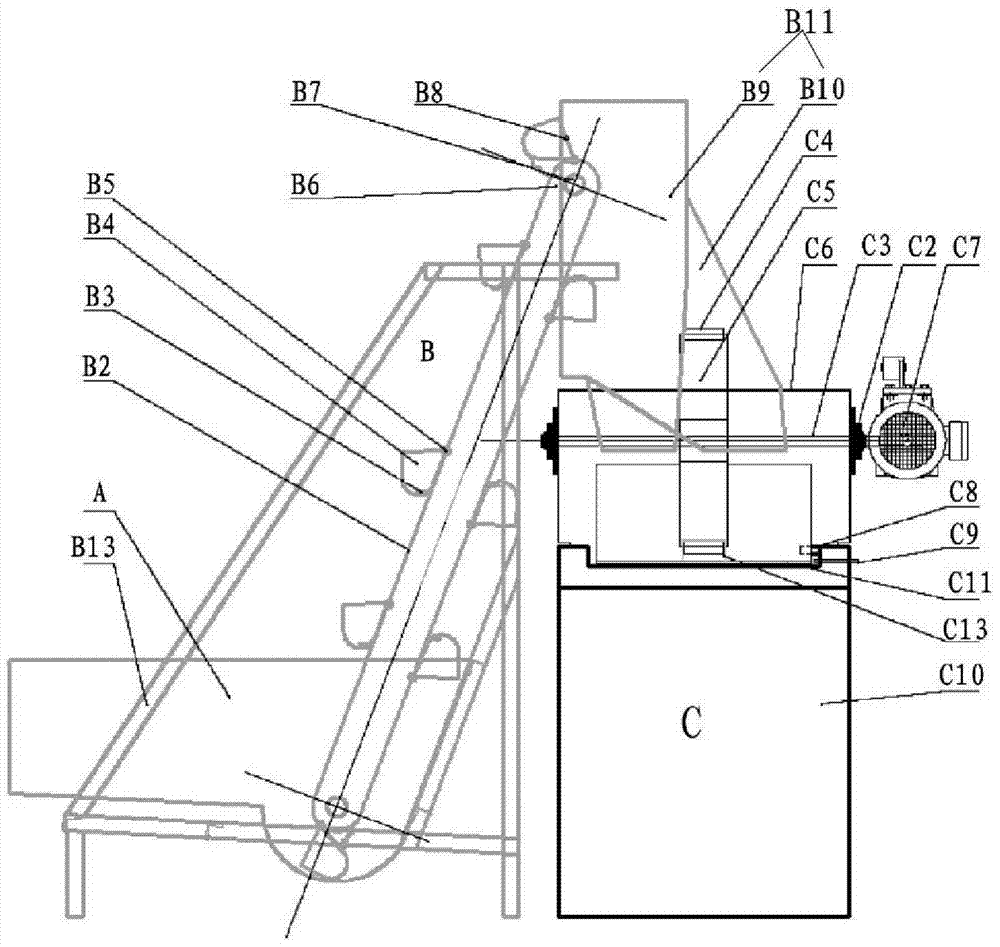

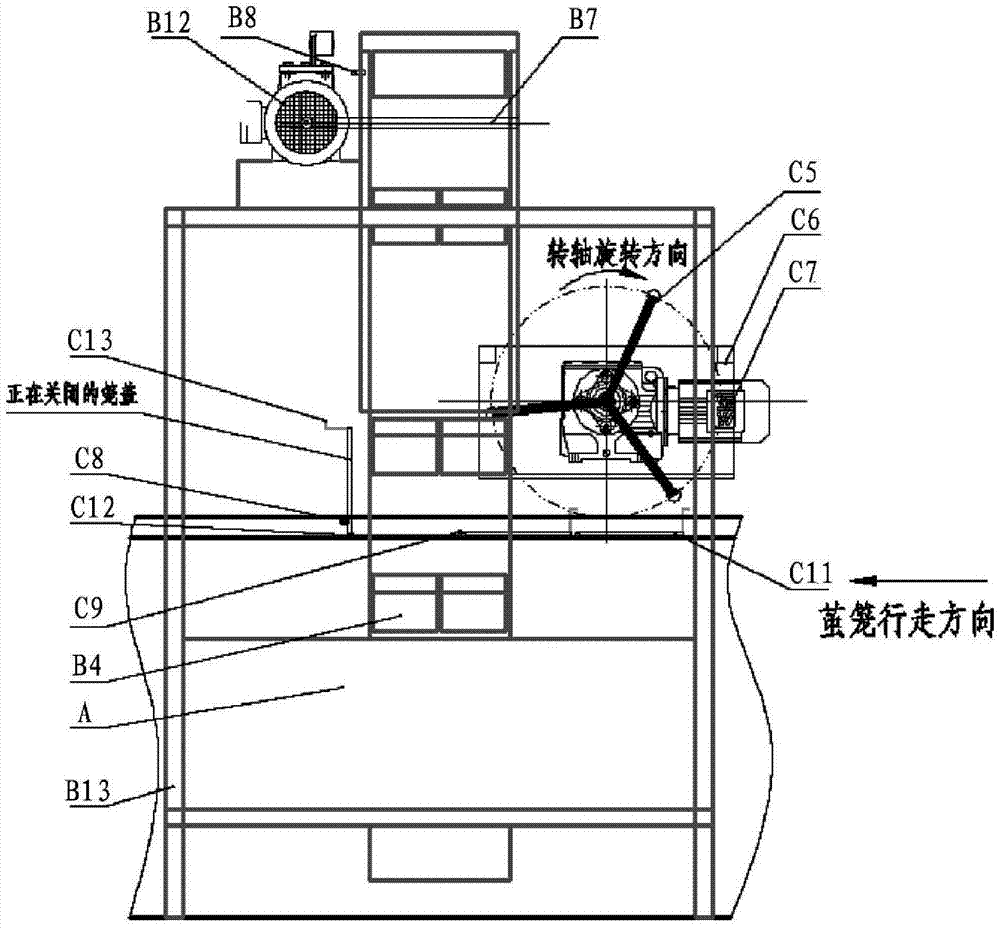

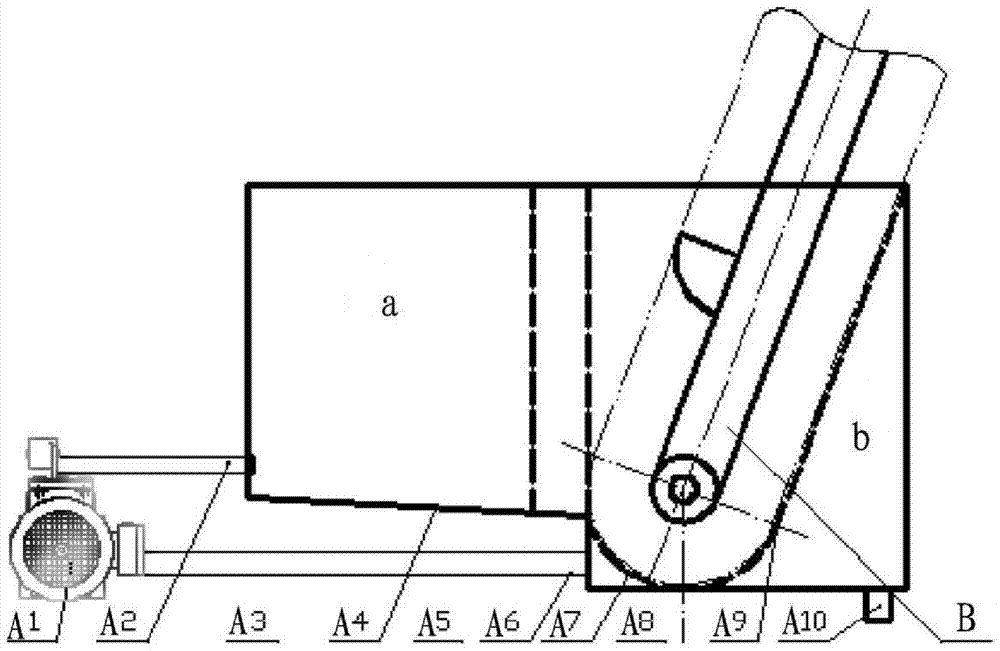

Automatic cocoon feeding machine set

The invention discloses an automatic cocoon feeding machine set. The automatic cocoon feeding machine set is characterized by comprising a silkworm cocoon storage barrel (A), a bucket type lifting quantitative cocoon feeding device (B) and a quick switch cocoon cooking cage cover device (C), wherein the bucket type lifting quantitative cocoon feeding device (B) comprises a rack (B13); the rack (B13) is provided with a circulating motion device; the circulating motion device is provided with at least one cocoon feeding bucket (B4); the cocoon feeding bucket (B4) is used for taking cocoons from the silkworm cocoon storage barrel (A) and carrying out circulating motion along with the circulating motion device; a photoelectric sensor (B8) is arranged at the position of the highest point of the cocoon feeding bucket (B4); the photoelectric sensor (B8) is connected with an automatic control system. The automatic cocoon feeding machine set is convenient to manufacture, and has the advantages of being high in degree of automation and being capable of full-automatic work; all the adopted existing materials can be realized.

Owner:柳州市自动化科学研究所 +1

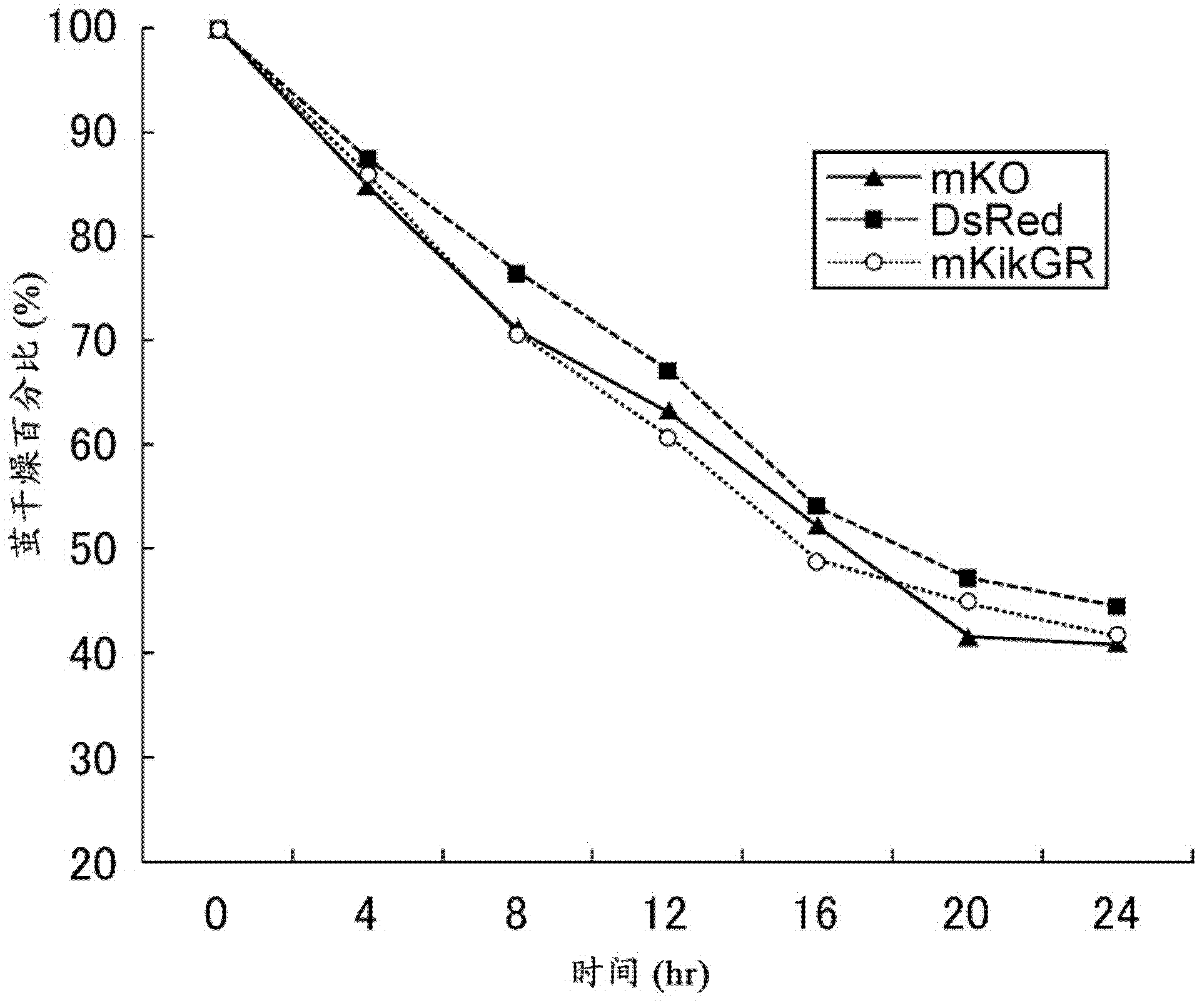

Method for spinning silk from cocoon of silkworm expressing foreign gene, and product produced by employing the method

A cocoon is dried under low temperature (60 DEG C or lower) conditions, rather than the conditions where the temperature is higher than 100 DEG C which has been employed conventionally for the production of a raw silk from a cocoon. Further, the boiling of a cocoon is carried out by employing a vacuum infiltration treatment at a low temperature (a subatmospheric pressure treatment), rather than a high-temperature treatment at 100 DEG C or higher or a treatment with hot water having a temperature around the boiling point which has been employed conventionally. As an alternate cocoon boiling method, a combination of the swelling of sericin with an alkali and the penetration of hot water into a cocoon layer by using a surfactant, an enzyme or the like is carried out. The silk reeling is carried out at a lower temperature than that has been employed conventionally. As a result, it is found that a raw silk can be produced from a cocoon of a silkworm that expresses a foreign gene without deteriorating the properties of a foreign protein contained in the cocoon of the silkworm.

Owner:NAT INST OF AGROBIOLOGICAL SCI

Production method of hand-painted long extra-fine mulberry silk scarves

InactiveCN103704180AMeet diverse needsUnique lusterSilk reelingDyeing processColour fastnessPolymer science

Owner:ZHEJIANG UNIV

Extra-fine mulberry silk twill production method

InactiveCN103710816ABright colorUnique flavorSilk reelingWoven fabricsColour fastnessPolymer science

The invention discloses an extra-fine mulberry silk twill production method. The extra-fine mulberry silk twill production method includes inducing four-molter into three-molter through the drug called 'chaoxisu' to produce high-quality extra-fine silkworm cocoons with the filament number of 1 denier, drying the silkworm cocoons into dried cocoons by a hot-air re-drying process at a low temperature in a long time, cooking the cocoons by a steam cooking process at a low temperature in a short time, reeling extra-fine raw silk in the specification of 9 / 11 denier from ten cocoons quantitatively, knitting an extra-fine mulberry silk fabric by 6+8 pieces of extra-fine raw silk in the specification of 9 / 11 denier, mixing red, yellow and blue acid dyes to form color paste respectively by taking the paste PS-14 as a medium, painting the dye pastes on the degummed and whitened fabric according to the color-separation drawing plates, thereby producing the extra-fine mulberry silk twill products with various patterns. The silk twill produced by the method has the advantages of unique luster, crease resistance, good dyeability, high color fastness, bright color and high economic value, is capable of leading to the improvement of the conventional silk industry, and meets diversified requirements of domestic and foreign markets.

Owner:ZHEJIANG UNIV

Improved reeling machine

The invention discloses an improved reeling machine. The improved reeling machine comprises a machine frame. A silk take-up wheel and a silk feed wheel are arranged on the machine frame, and a drive motor is arranged on the silk take-up wheel. An encoder is arranged on a transmission shaft of the drive motor, and the drive motor is connected with a frequency converter. An eccentric wheel is arranged between the silk take-up wheel and the silk feed wheel, and a rough layer is arranged on the surface of the eccentric wheel. A thread neatening claw is arranged between the eccentric wheel and the silk take-up wheel, and an annular steam jet is arranged between the thread neatening claw and the silk take-up wheel. A plurality of air jet holes are evenly formed inside the annular steam jet. A temperature sensor is arranged on an air inlet pipeline of the annular steam jet. A twister is arranged between the annular steam jet and the silk take-up wheel. The twister comprises an inner cylinder and an outer cylinder, wherein a bearing is arranged between the inner cylinder and the outer cylinder, the inner cylinder is connected with a rotating motor, at least one bypass pipe is arranged in the inlet position of the inner cylinder, and an electromagnetic vibrator is connected with the outer cylinder. By means of the improved reeling machine, the defects in the prior art can be overcome, and the quality of raw silks can be improved.

Owner:上林海润丝业有限公司

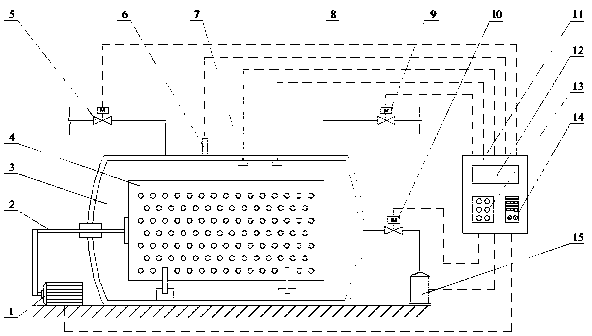

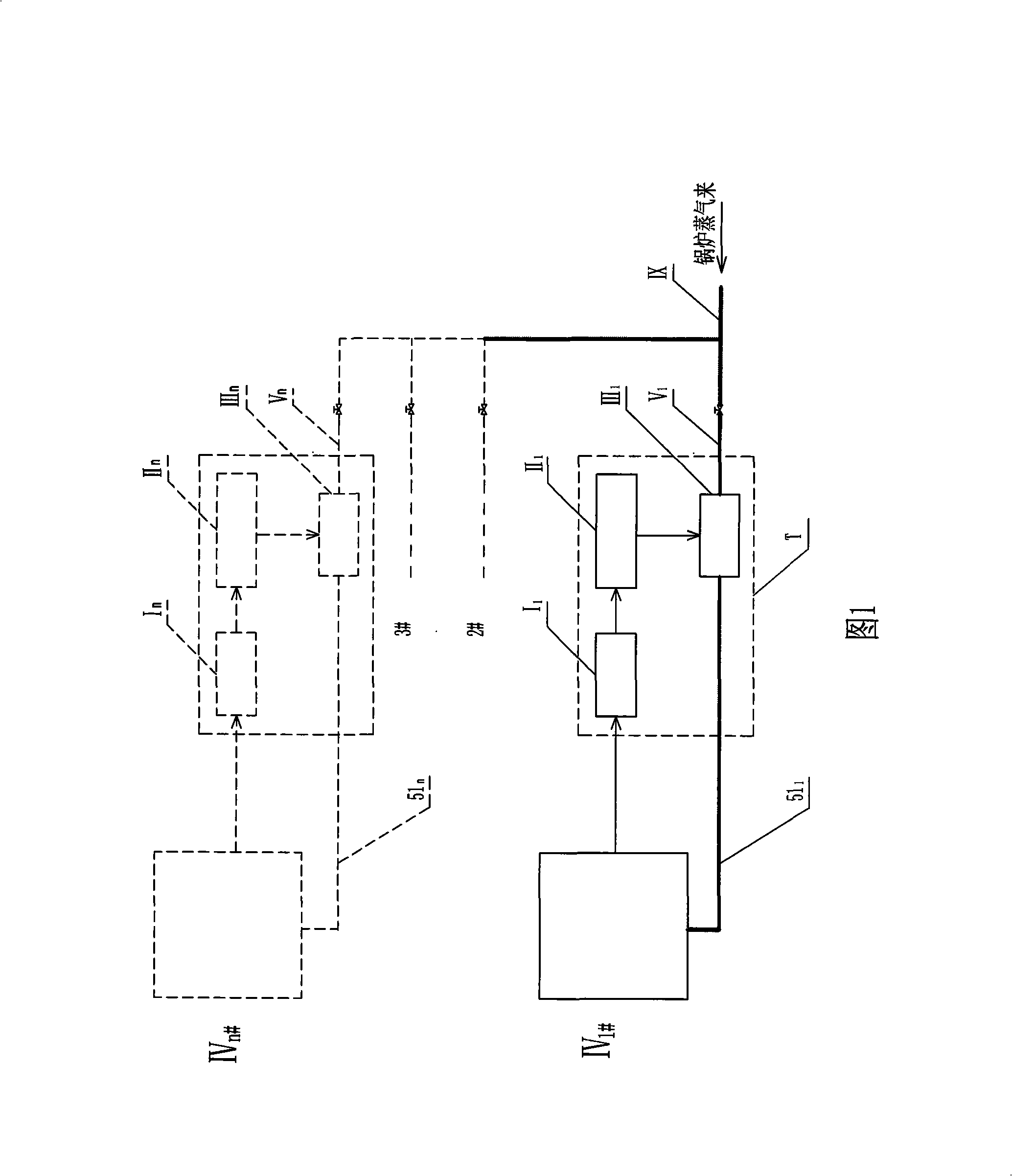

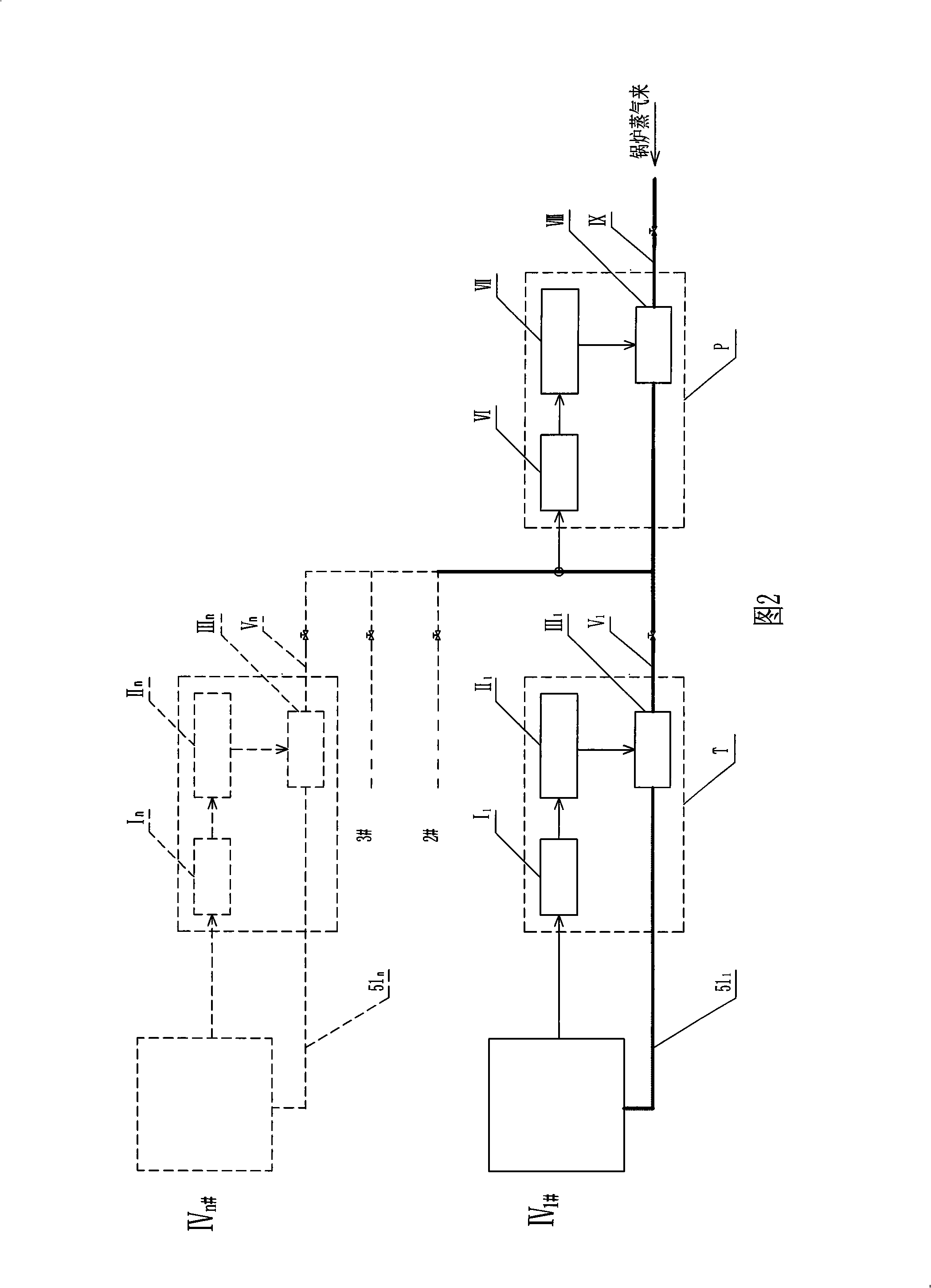

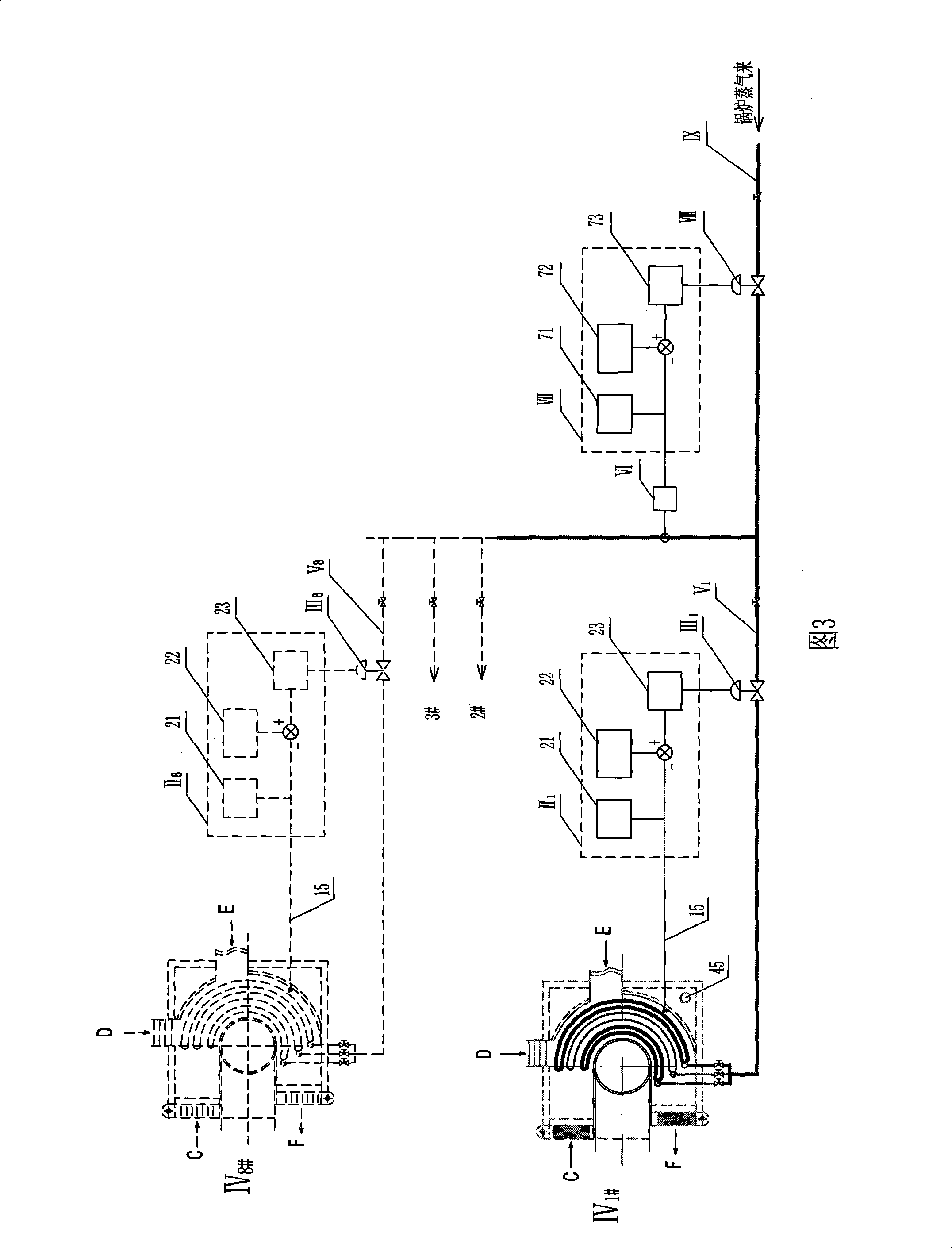

Automatic temperature control apparatus and method in reeling silk production process

InactiveCN101329584AIncrease productivityReduce labor intensityTemperatue controlSilk reelingAuto regulationTemperature control

The invention relates to a temperature automatic control device used in a filature producing process. The device comprises n technological temperature regulating circuits (n is more than or equal to 1 and is less than or equal to 32); and each technological temperature regulating circuit comprises a temperature measuring part, a temperature display and control part and an automatic regulating valve part; simultaneously, the device also comprises a steam pressure regulating circuit which consists of a pressure measuring part, a pressure display and control part and an automatic regulating valve part and is installed before each temperature regulating circuit; a temperature automatic control method by adopting the temperature automatic control device used in the filature producing process is that the pressure in a main pipe of a workshop steam inlet is regulated first by the steam pressure regulating circuit and temperature of technological temperature control points is automatically regulated by the temperature regulating circuit in a graded regulating way. The device and the method can continuously and precisely measure the technological temperature of working procedures and regulate throttle flow by a PID controller and the automatic regulating valve and realize continuous, stable and automatic control of the technological temperature of certain working procedure.

Owner:广西壮族自治区柳州市自动化科学研究所

Method for manufacturing printed scarf from ultrafine mulberry silk

The invention discloses a method for manufacturing a printed scarf from ultrafine mulberry silk. The method includes inducing four-moultinism silkworms to be subjected to triple-moultinism by the aid of 'ultrafine element' medicine and manufacturing ultrafine-fiber-number silkworm cocoons with the filament number of 1 denier; baking the cocoons by a hot-air re-drying process to obtain dry cocoons; cooking the dry cocoons by a steam cocoon cooking process to obtain cooked cocoons; reeling each 10 cocoons to obtain ultrafine raw silk with the size of 9 / 11D; weaving one piece of ultrafine raw silk with the size of 9 / 11D to obtain a fabric made from the ultrafine mulberry silk; mixing red acid dye, yellow acid dye and blue acid dye by paste PS-14 to obtain color paste; printing the color paste on the white fabrics made from the ultrafine mulberry silk according to selected pattern plates, and sorting the fabrics to obtain the printed scarf. The hot-air re-drying process is long in low-temperature time. The steam cocoon cooking process is low in temperature and short in time. The method has the advantages that the printed scarf is ultra-thin and crease-resistant, and is unique in luster, good in dyeing property and high in color fastness and economic value; the traditional natural silk industry can be enhanced, and diversified demands of domestic and foreign markets can be met.

Owner:ZHEJIANG UNIV

Silk reeling machine realizing automatic temperature control

ActiveCN105926048AGuarantee the quality of raw silkTimely detection of broken wiresSilk reelingTemperature controlAutomatic control

The invention discloses a silk reeling machine realizing automatic temperature control. The silk reeling machine comprises a rack and a silk reeling tank, wherein the silk reeling tank is arranged at the upper part of the rack; temperature controllers are arranged below the silk reeling tank; a transmission connection rod is arranged on the rack; a grabbing needle is arranged on the transmission connection rod; a thread bundle and a big reel are arranged on the silk reeling tank; a photoelectric sensor is arranged beside the thread bundle and the big reel; a croisure is arranged above the photoelectric sensor; a transition wheel is arranged above the croisure; a denierer is arranged above the transition wheel; a silk failure anti-cutting wheel is arranged above the denierer; an interlacing ring is arranged beside the silk failure anti-cutting wheel; a length recorder is arranged above the interlacing ring; a silk winding wheel is arranged beside the length recorder; a silk drying tube is arranged beside the silk winding wheel. The silk reeling machine has the benefits as follows: the silk reeling process can be finished in a constant-temperature environment, the quality of raw silk is guaranteed, the silk breaking phenomenon can be found in time, and the amount of reeled silk can be calculated in time.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

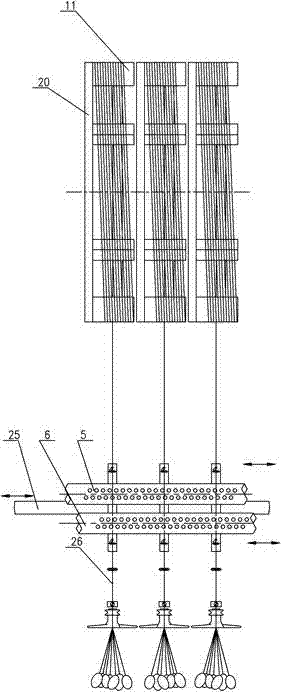

Method of automatically twisting silk threads of raw silks of automatic silk reeling machine

ActiveCN107400931AHighlight substantive featuresSignificant progressSilk reelingConductor CoilMechanical engineering

The invention discloses a method of automatically twisting silk threads of raw silks of an automatic silk reeling machine. The method comprises the steps of (1) lengthening the length of an existing silk passing pipe on a bailing table, additionally installing a friction wheel on the silk passing pipe, and installing a twister on the friction wheel; (2) replacing a single transmission wheel on an existing thread collection wing rotating box by upper and lower dual transmission wheels, driving a thread collector by a revolution rope, and driving the friction wheel so as to enable the friction wheel to drive the twister; (3) heightening the position height of an existing magnetic eyelet frame, installing an ejecting pull rod below the magnetic eyelet frame, and connecting the ejecting pull rod with the twister; and (4) the silk threads entering the silk passing pipe via the thread collector and passing through the twister, the twister twisting the silk threads by rotating clockwise with 1400 revolutions per minute, the twisted silk threads successively passing through an upper drum wheel, a positioning drum wheel and a lower drum wheel and then entering a detecting drum wheel, and then the twisted silk threads passing through the detecting drum wheel and successively passing through a sensor, an upper positioning drum wheel and a cross winding rod to reach a small reel for thread winding. The method has the characteristics that raw silk quality is improved and a manual sheath beating process is prevented.

Owner:上林金鑫丝业有限公司

Reeling agent for automatic silk reeling production

InactiveCN104480536AIncrease release rateFull penetrationSilk reelingCocamidopropyl betaineBright-white

The invention relates to the technical field of silk production and discloses a reeling agent for automatic silk reeling production. The reeling agent comprises the following raw materials of, by weight, 5 to 10 parts of castor oil polyoxyethylene ether, 6 to 9 parts of lauryl sodium sulfate, 6 to 9 parts of polyoxyethylene lauryl ether, 5 to 10 parts of polyoxyethylene fatty alcohol sodium sulfate, 5 to 8 parts of cocamidopropyl betaine, 10 to 15 parts of hydrogen peroxide, and 10 to 15 parts of sodium silicate. The reeling agent is reasonable in formula, capable of effectively increasing the reelability rate of raw silk, improving product quality, fully permeating cocoon shells, performing uniform reeling, and reducing the influence of cocoon quality differences on silk reeling quality, low in production cost, and small in use amount, silk produced through subsequent processes is bright white and soft and smooth in touch, and the use amount of the reeling agent is easy to control.

Owner:安徽省广德新丰丝绸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com