Method for spinning silk from cocoon of silkworm expressing foreign gene, and product produced by employing the method

A transgenic, raw silk technology, applied in silk fiber production, reeling, surgical instruments, etc., can solve problems such as silk dye affinity and fabric texture damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0139] [Example 1] Silk production using silkworm cocoons expressing foreign genes in silk glands

[0140] 1. Method

[0141] 1.1 Drying steps

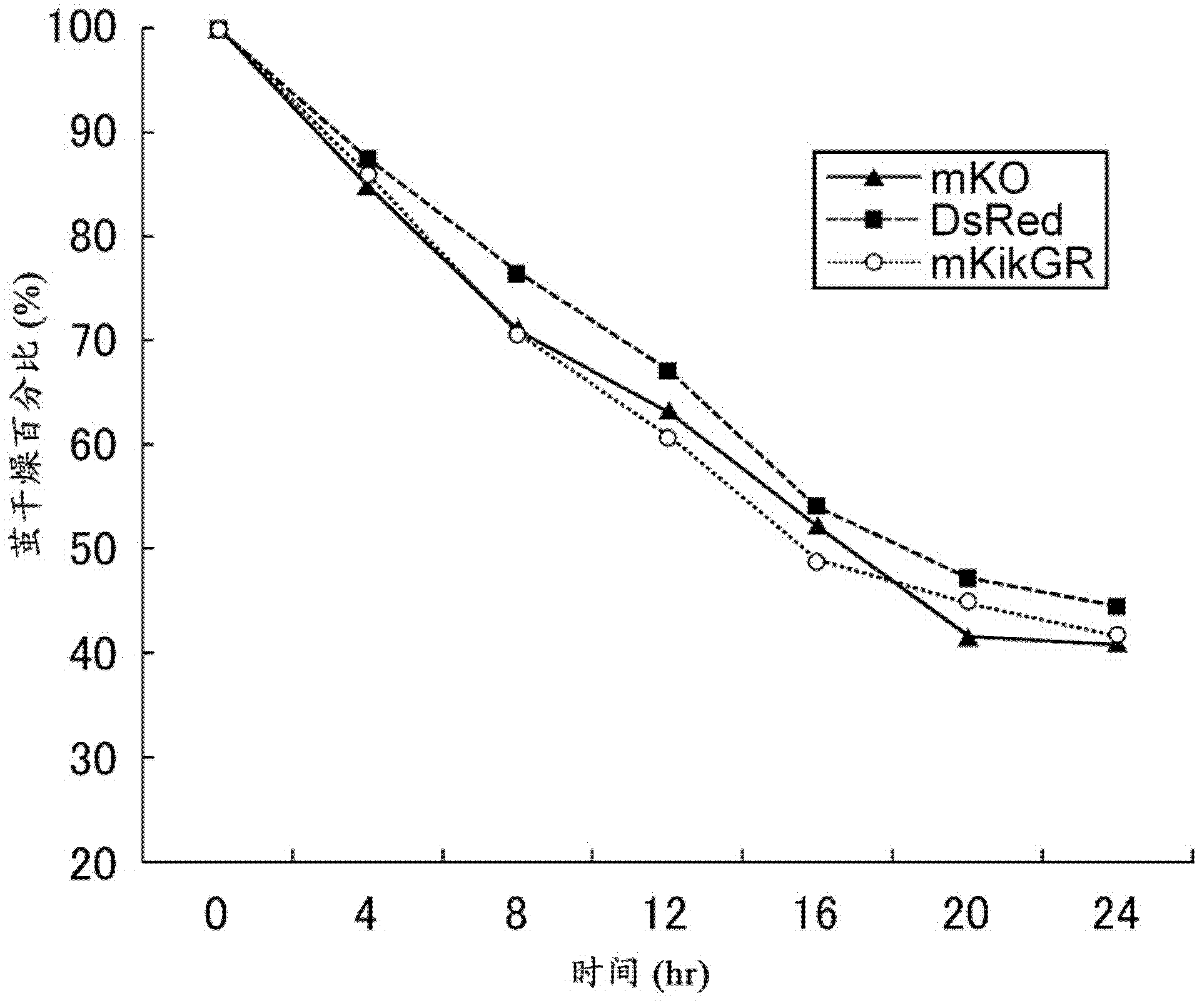

[0142] Typically, the drying process gradually reduces the temperature from a maximum temperature of 115°C to 120°C to 60°C after about 5.5 hours have elapsed. This would give a dry percentage of about 42%. However, in this example, instead of using a temperature gradient, the cocoons were placed in a drier maintained at a constant temperature of 60°C and dried within 20 to 24 hours. As a result, the desired drying percentage ( figure 1 ).

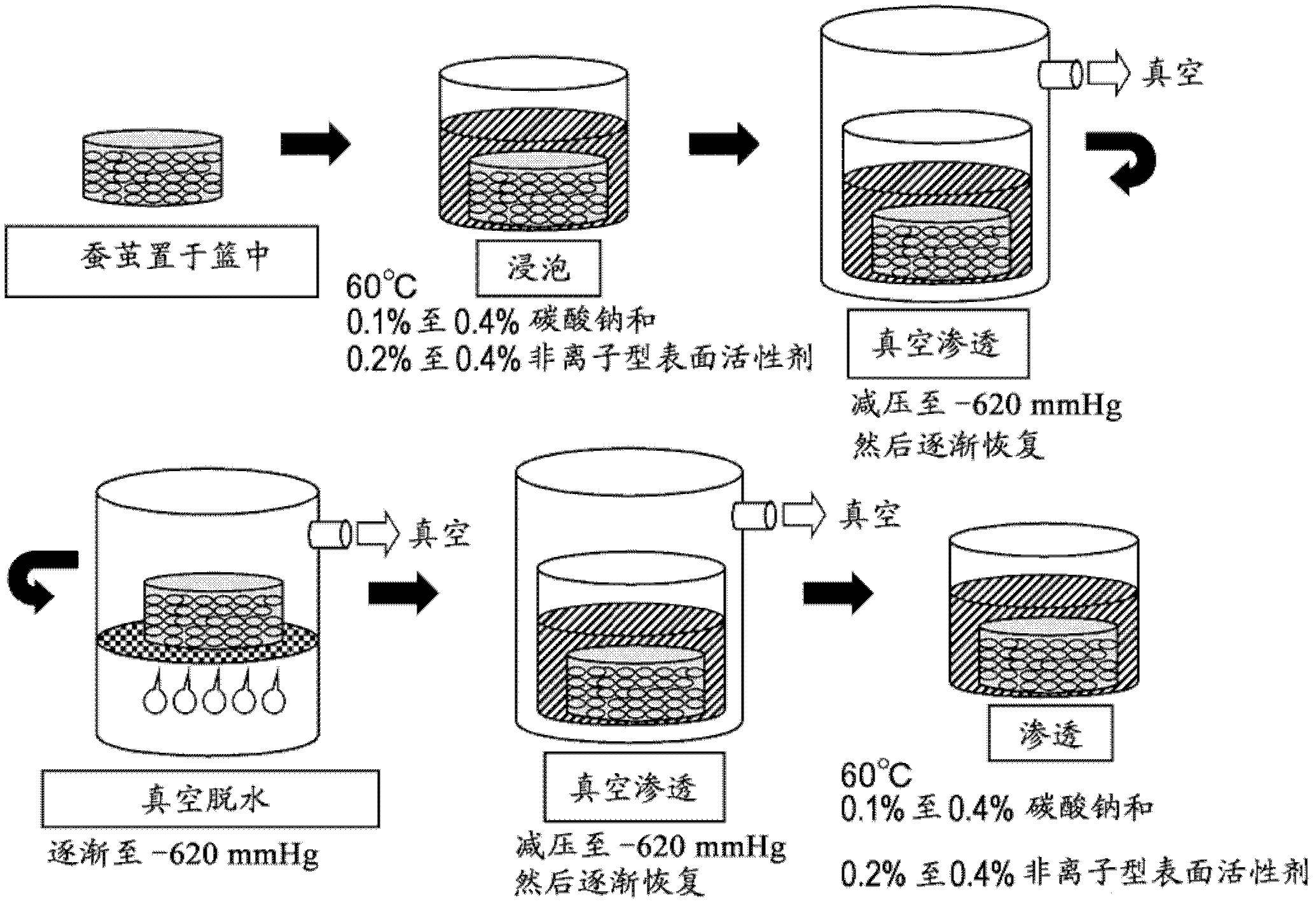

[0143] 1.2 Cocoon cooking steps

[0144] In the present invention, in order to swell and soften cocoon layer sericin under low temperature (60° C. or lower) conditions, cocoon cooking is performed using alkaline agents, surfactants, enzymes, and the like. Examples using alkaline agents and surfactants are given below.

[0145] First, a solution of 0.1% to 0.4% sodium carbonate and 0....

Embodiment 2

[0153] [Example 2] Using fluorescent transgenic cocoon silk as interior accessories material

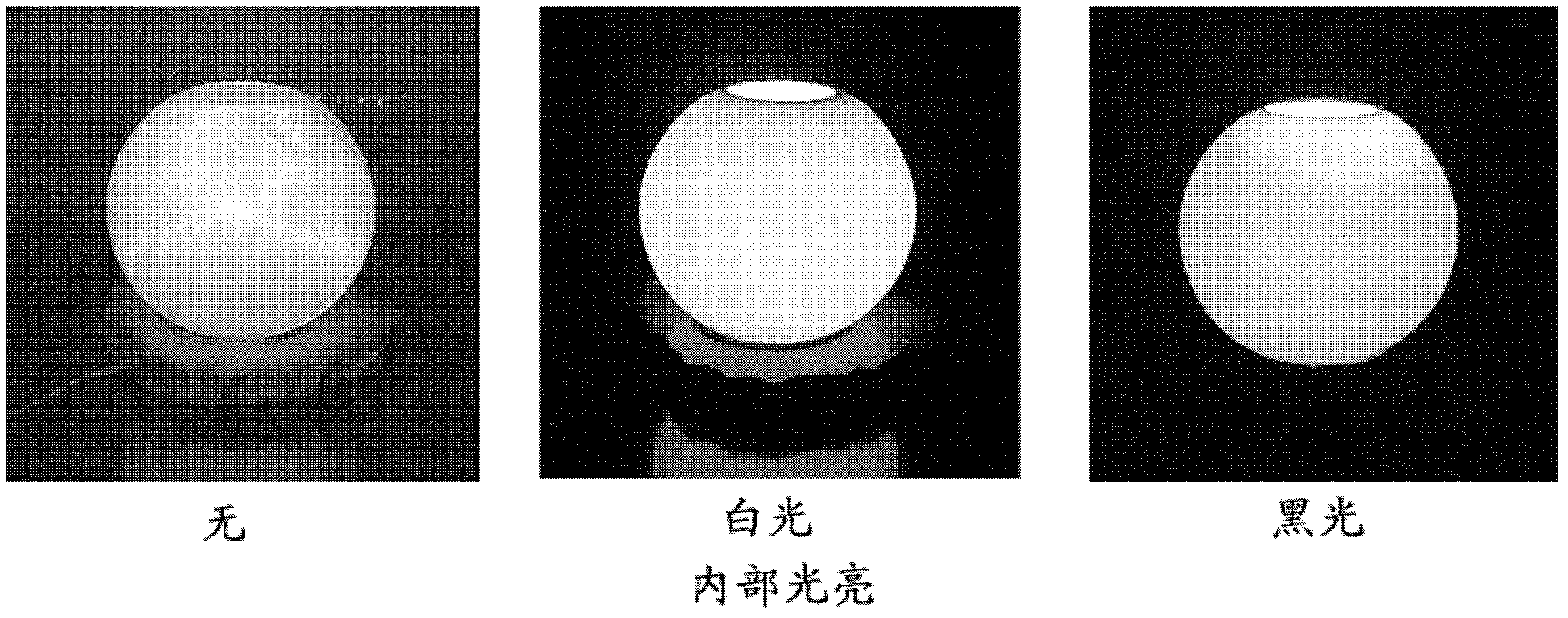

[0154] Fluorescent transgenic cocoon silk is used as a material for interior accessories. The fluorescent transgenic cocoon silk is directly glued and wound around the spherical mold by using the sericin protein carried by the filament itself. Remove from mold when dry. image 3 Interior fittings made by such methods are shown in . exist image 3 , the object on the left has no light source within it (external light only), the object in the middle uses a white light as its light source, and the object on the right uses a black light as its light source. Fluorescent emission due to black light was observed for internal parts made of fluorescent transgenic cocoon silk as the base material.

Embodiment 3

[0155] [Example 3] Application of cell-adhesive cocoons to base materials for artificial blood vessels

[0156] Using transgenic cocoon silk with cell-adhesive properties to generate the base material for artificial blood vessels ( Figure 4 ). Figure 4 The artificial blood vessel shown in has an internal diameter of 1.5mm to 5mm, and the base material is made of raw silk obtained by cocoon drying at 60°C, cocoon boiling at 60°C or below, and silk reeling at 50°C. Figure 5 It shows the artificial blood vessel material made of transgenic cocoon silk and PTFE ( The state when the artificial blood vessel material made of type resin) was transplanted into rats. Figure 6 The state 3 months after transplantation of these materials into rats is shown. Progression of cell growth was observed in the case of artificial vascular material made from transgenic cocoon silk.

[0157] [Reference example] Production of transgenic silkworm cocoons

[0158] To generate fluorescent trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com