Single silk drying winding system of orice reeling machine

A silk reeling machine and monofilament technology, which is applied in the field of a one-step silk reeling machine monofilament drying and winding system, can solve the problems of undiscovered system disclosure and use, reduce raw silk quality, increase processing costs, etc., and improve energy utilization. , The heating is highly targeted, and the effect of reducing the temperature and humidity of the workshop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with the accompanying drawings.

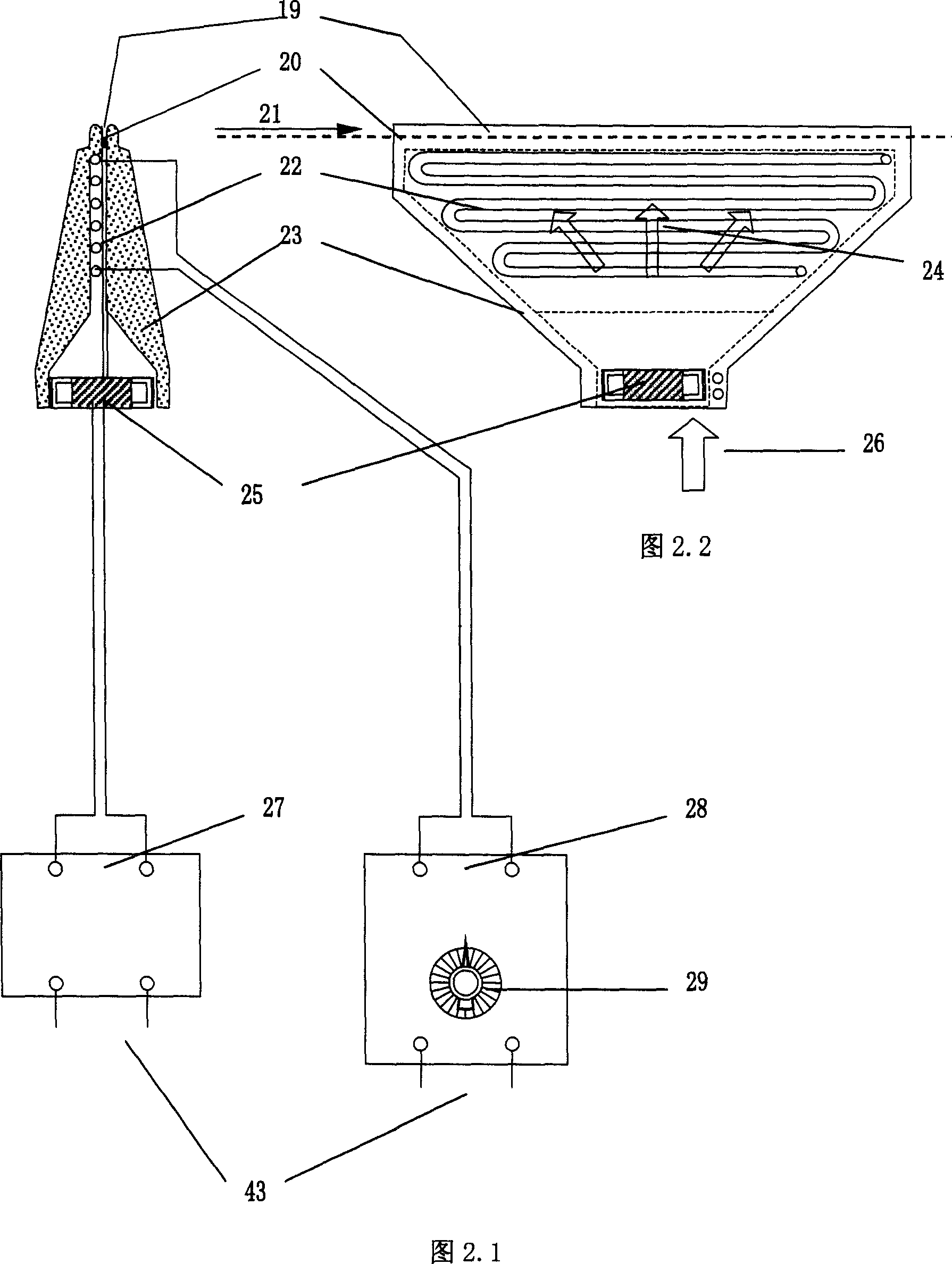

[0068] 1. Monofilament dryer 3

[0069] Change the heating wire to the heating wire.

[0070] As shown in Figure 2, the structure of the monofilament dryer 3 is: in the dryer housing 23, from top to bottom, a stainless steel drying slot 19, an electric heating element 22, a micro fan 25 are arranged in sequence; an electric heating element 22, a power regulator 28. The power supply 43 is electrically connected in sequence; the micro fan 25, the low-voltage DC converter 27, and the power supply 43 are electrically connected in sequence.

[0071] The working process of the monofilament dryer 3 of the present invention is as follows: use standard electric heating elements to heat, use special concrete materials that are fire-resistant, heat-insulating and insulating to form a shell, and stainless steel sheets to form a narrow and smooth thread drying channel, and configu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com