Patents

Literature

8330results about How to "Improve thermal efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

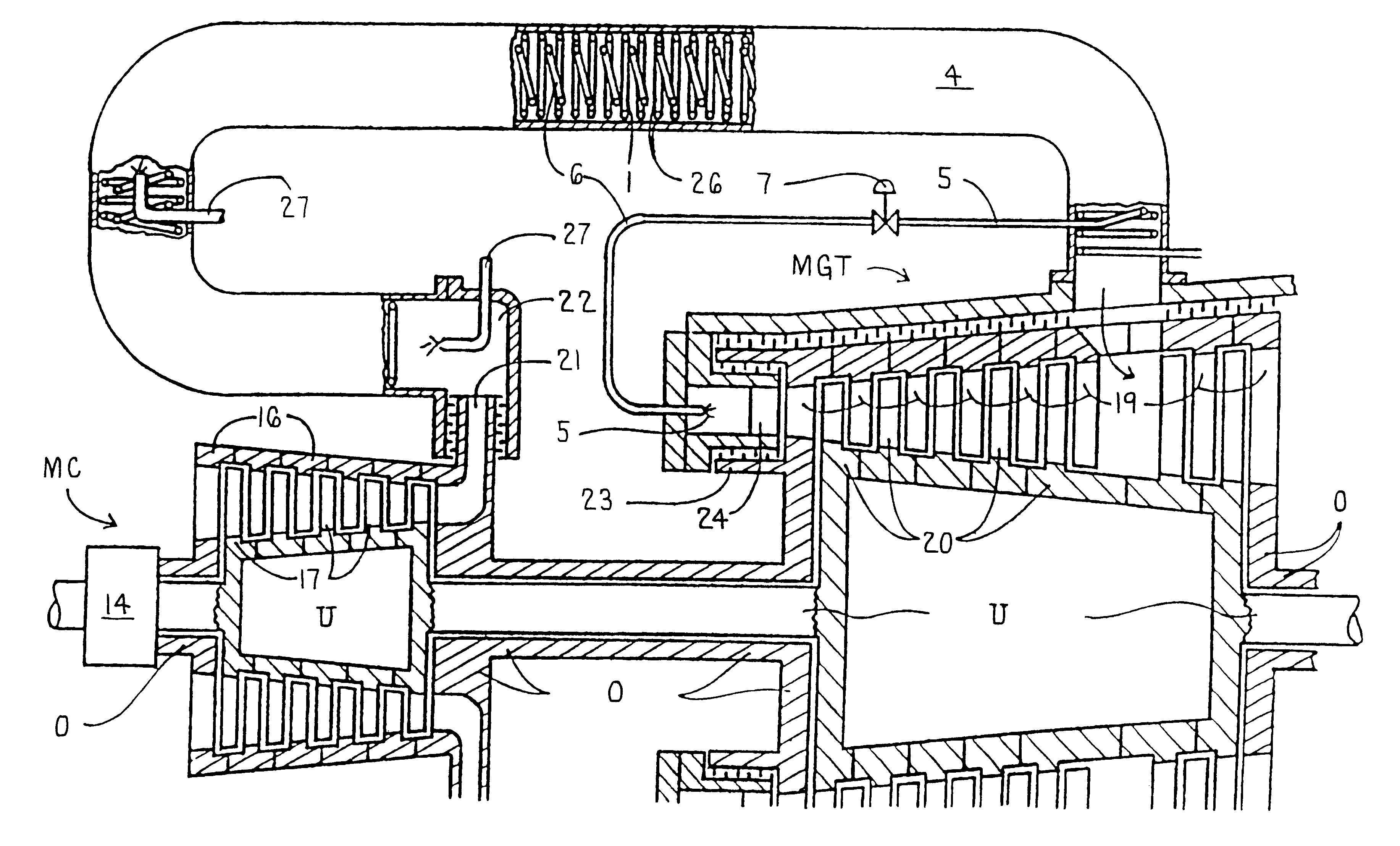

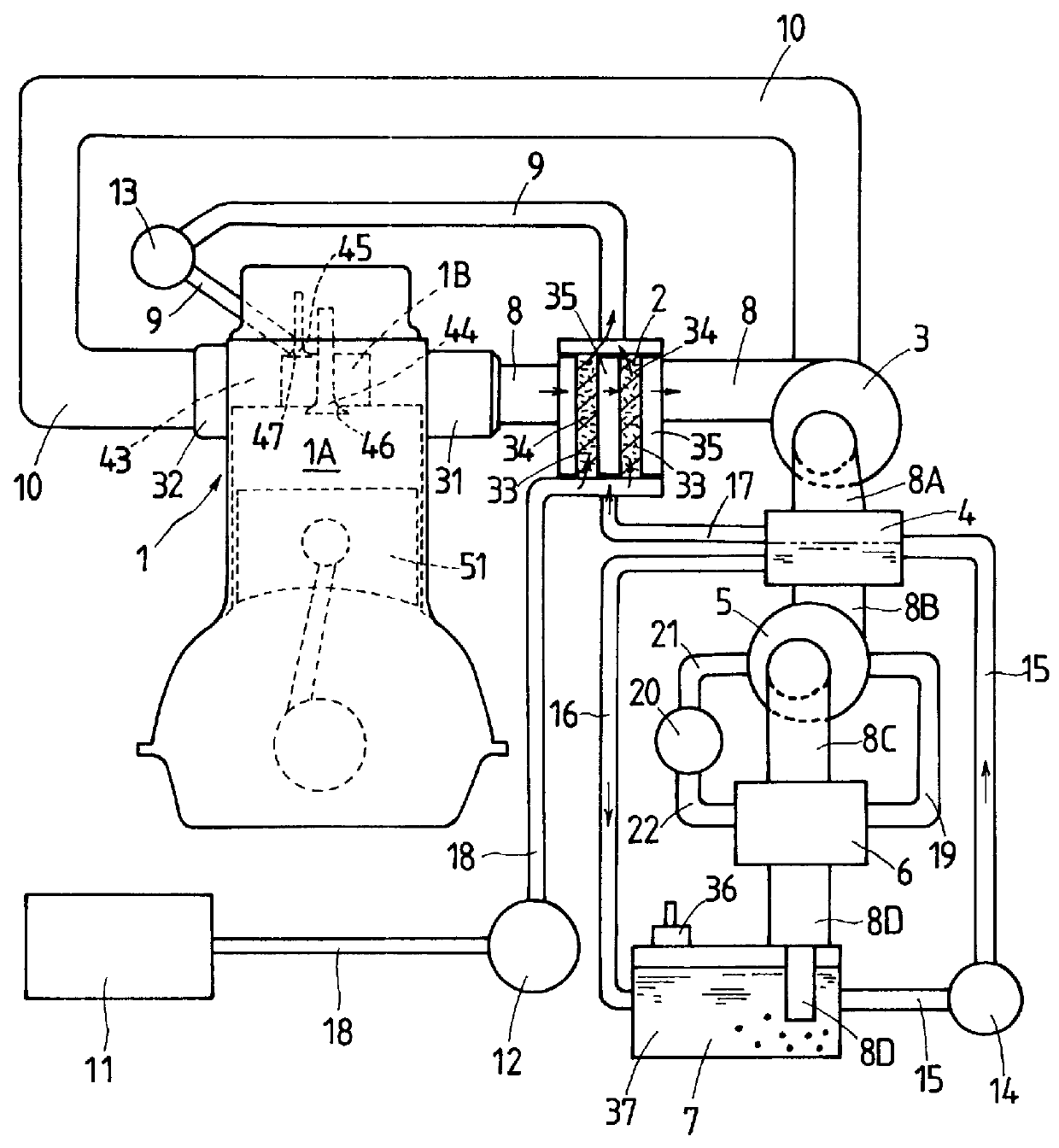

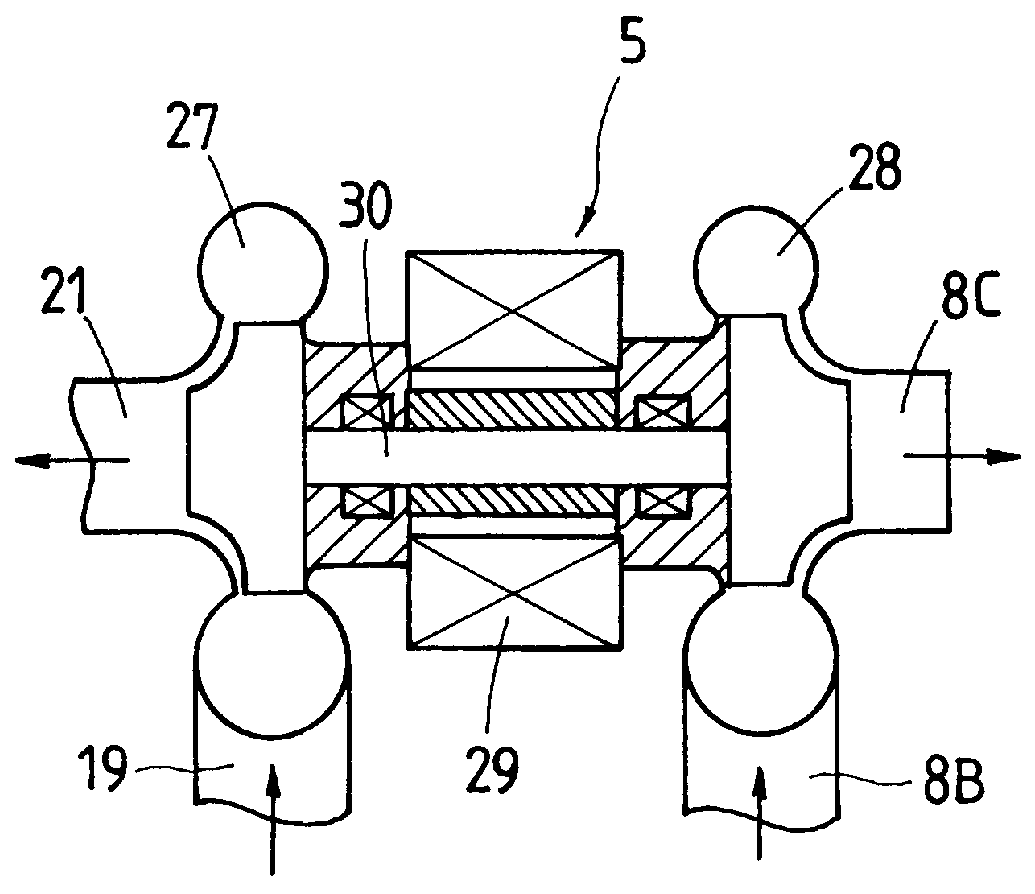

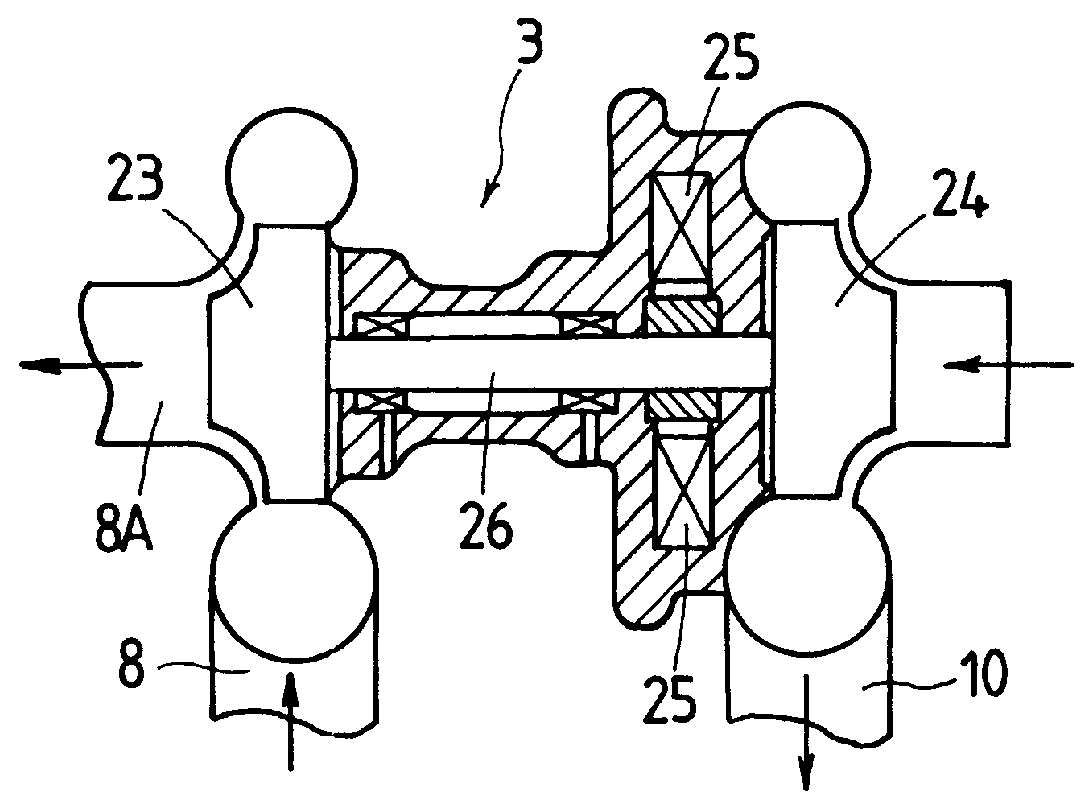

Combined steam and gas turbine engine with magnetic transmission

InactiveUS6263664B1Wide areaImprove system efficiencyContinuous combustion chamberGearingThermal energyCombustion chamber

In a combined steam and gas turbine engine cycle, a combustion chamber is made durable against high pressure and enlarged in length to increase the operation pressure ratio, without exceeding the heat durability temperature of the system while increasing the fuel combustion gas mass flow four times as much as the conventional turbine system and simultaneously for greatly raising the thermal efficiency of the system and specific power of the combined steam and gas turbine engine.Water pipes and steam pipes are arranged inside the combustion chamber so that the combustion chamber can function as a heat exchanger and thereby convert most of the combustion thermal energy into super-critical steam energy for driving a steam turbine and subsequently raising the operation pressure ratio and the thermal efficiencies of the steam turbine cycle and gas turbine cycle. The combustion gas mass flow can be also increased by four times as much as the conventional turbine system (up to the theoretical air to fuel ratio) and the thermal efficiency and the specific power of the gas turbine cycle are considerably increased.Further, the thermal efficiency of the combined system is improved by installing a magnetic friction power transmission system to transmit the power of the system to outer loads.

Owner:TANIGAWA HIROYASU +1

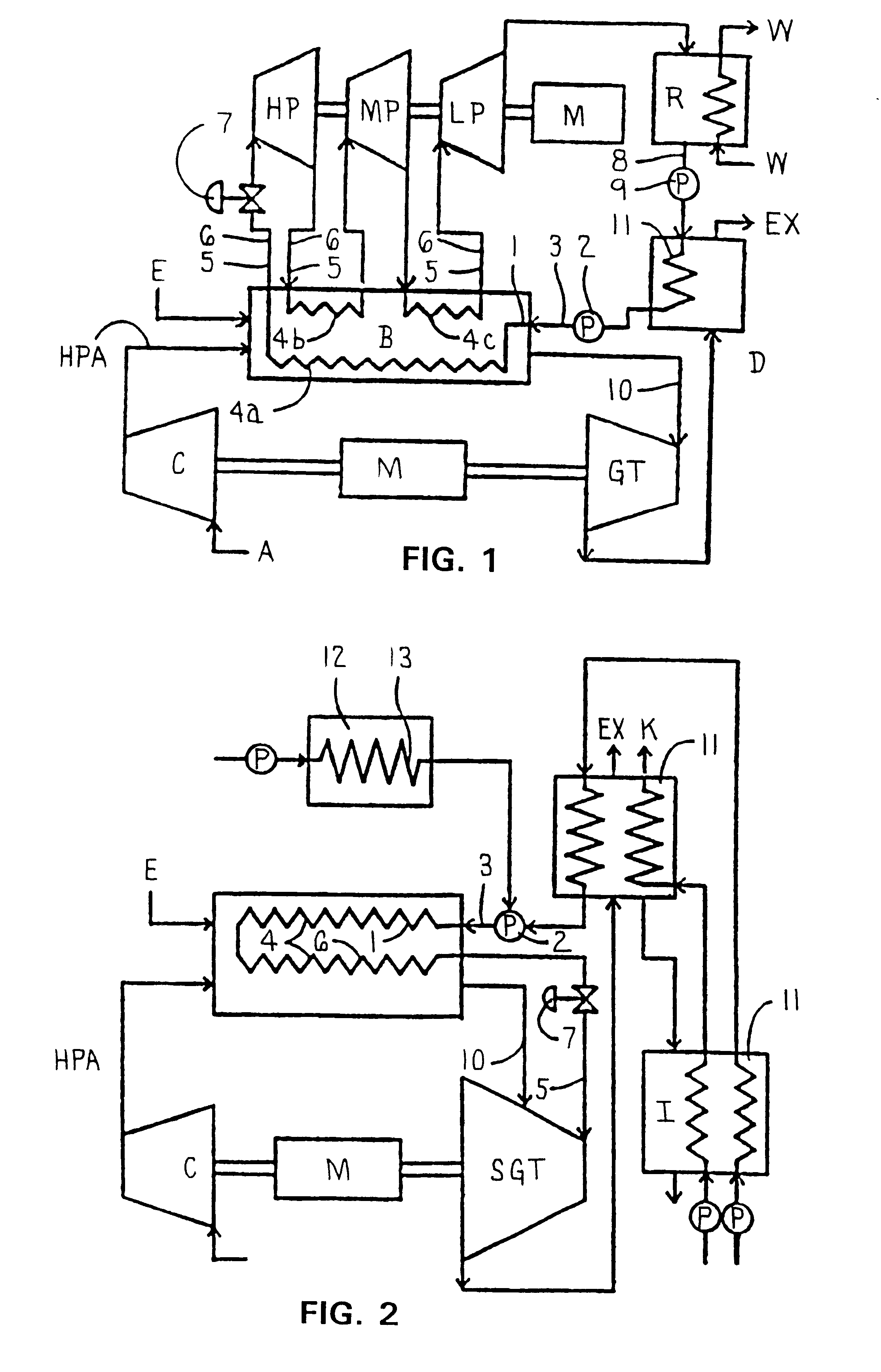

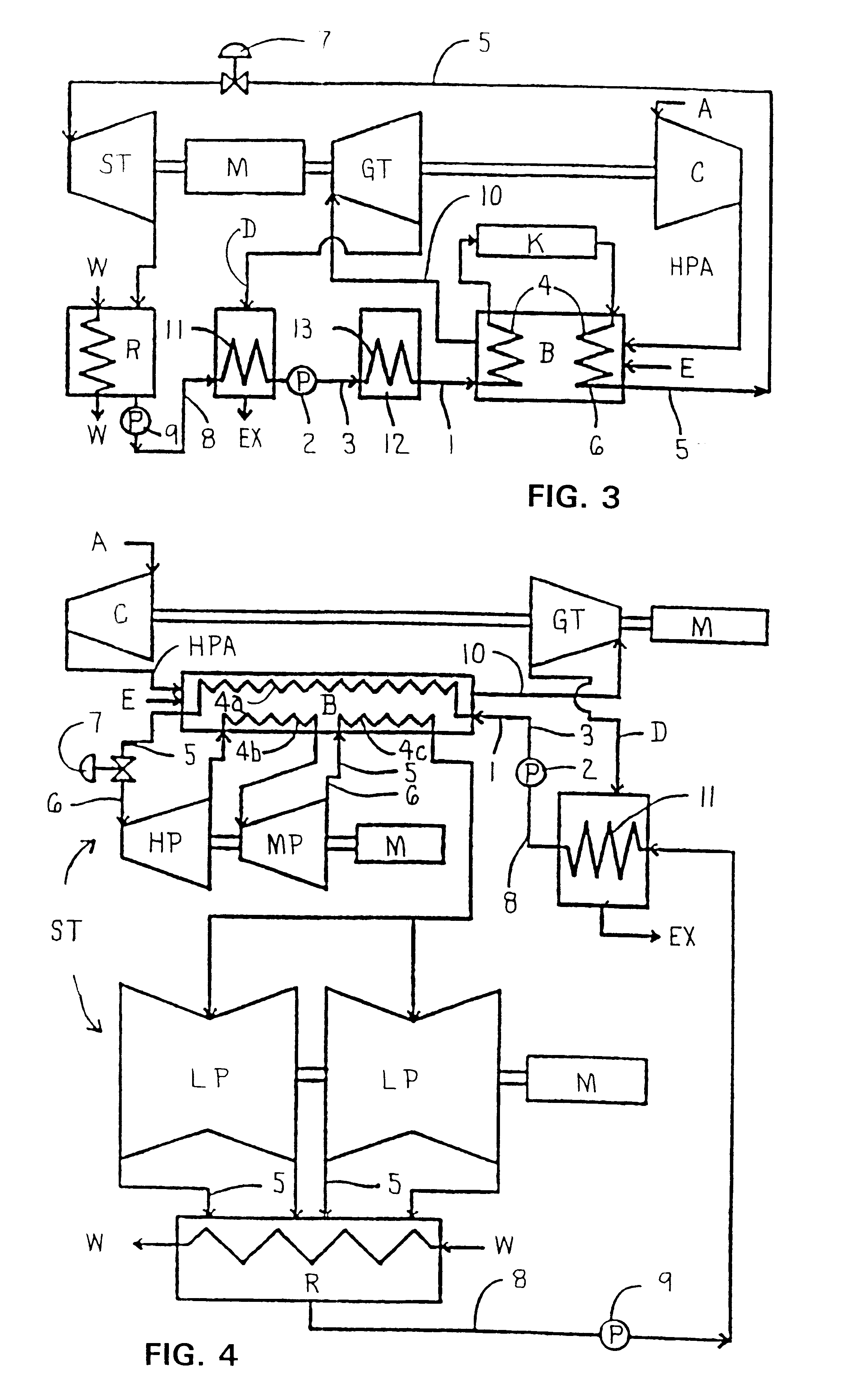

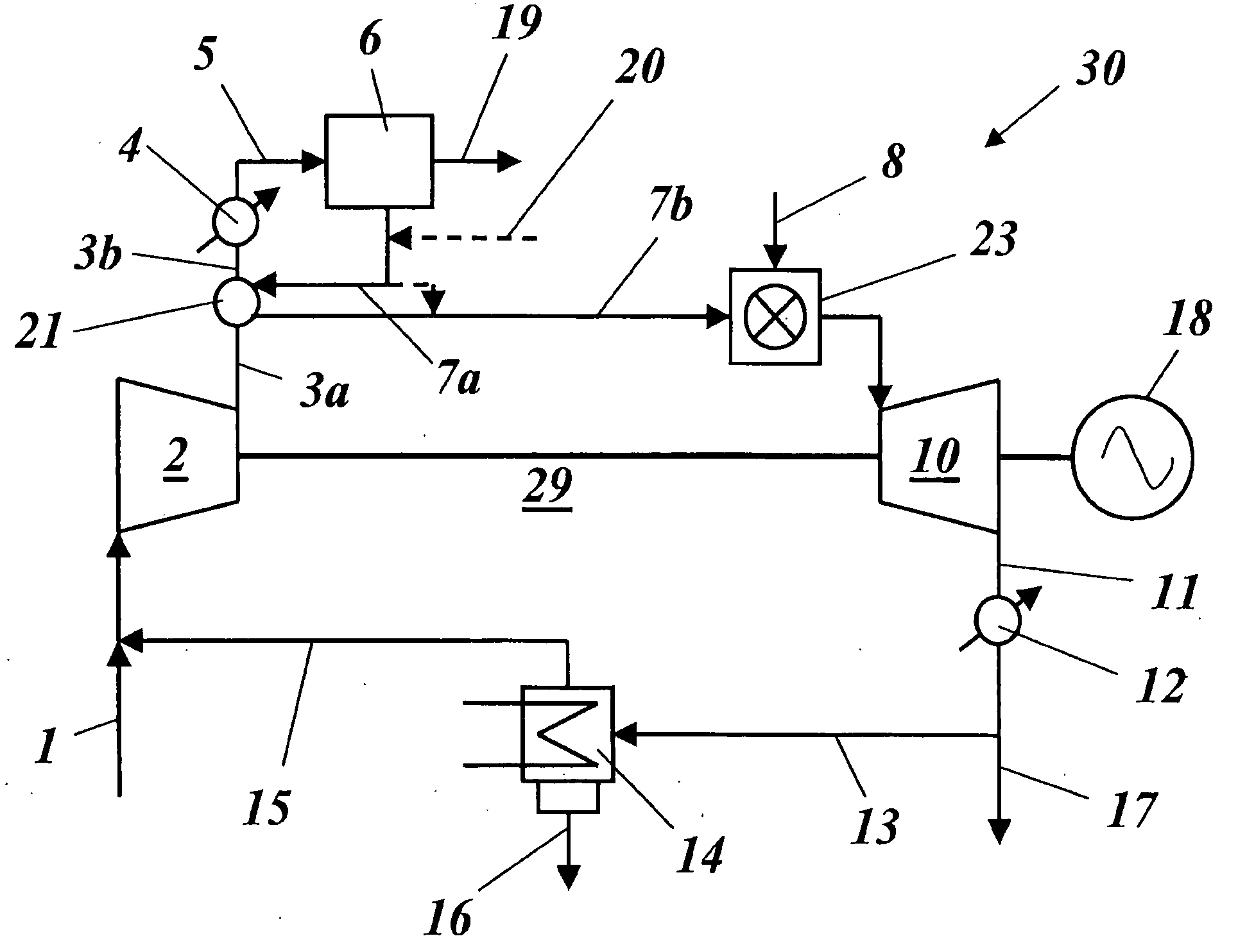

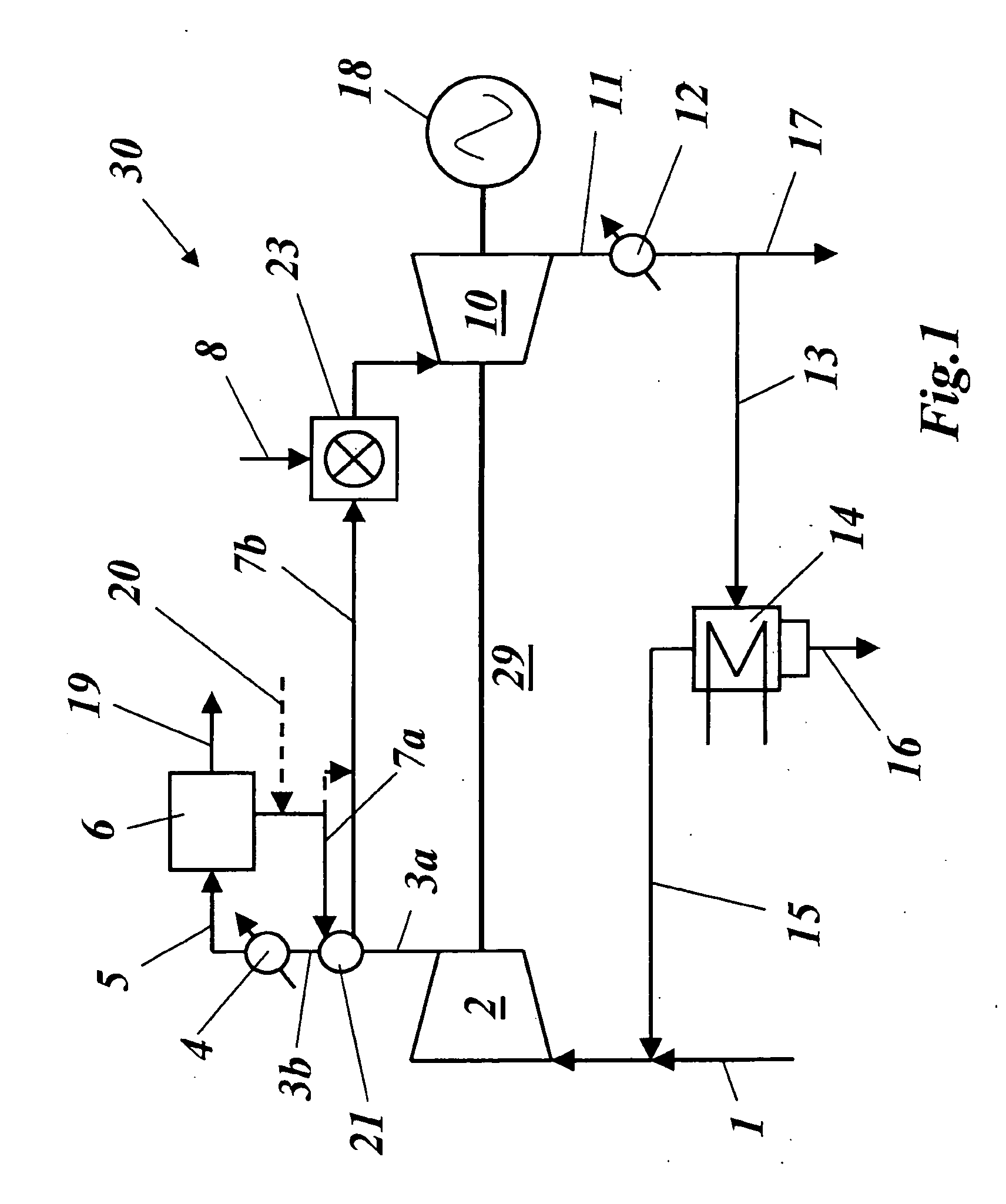

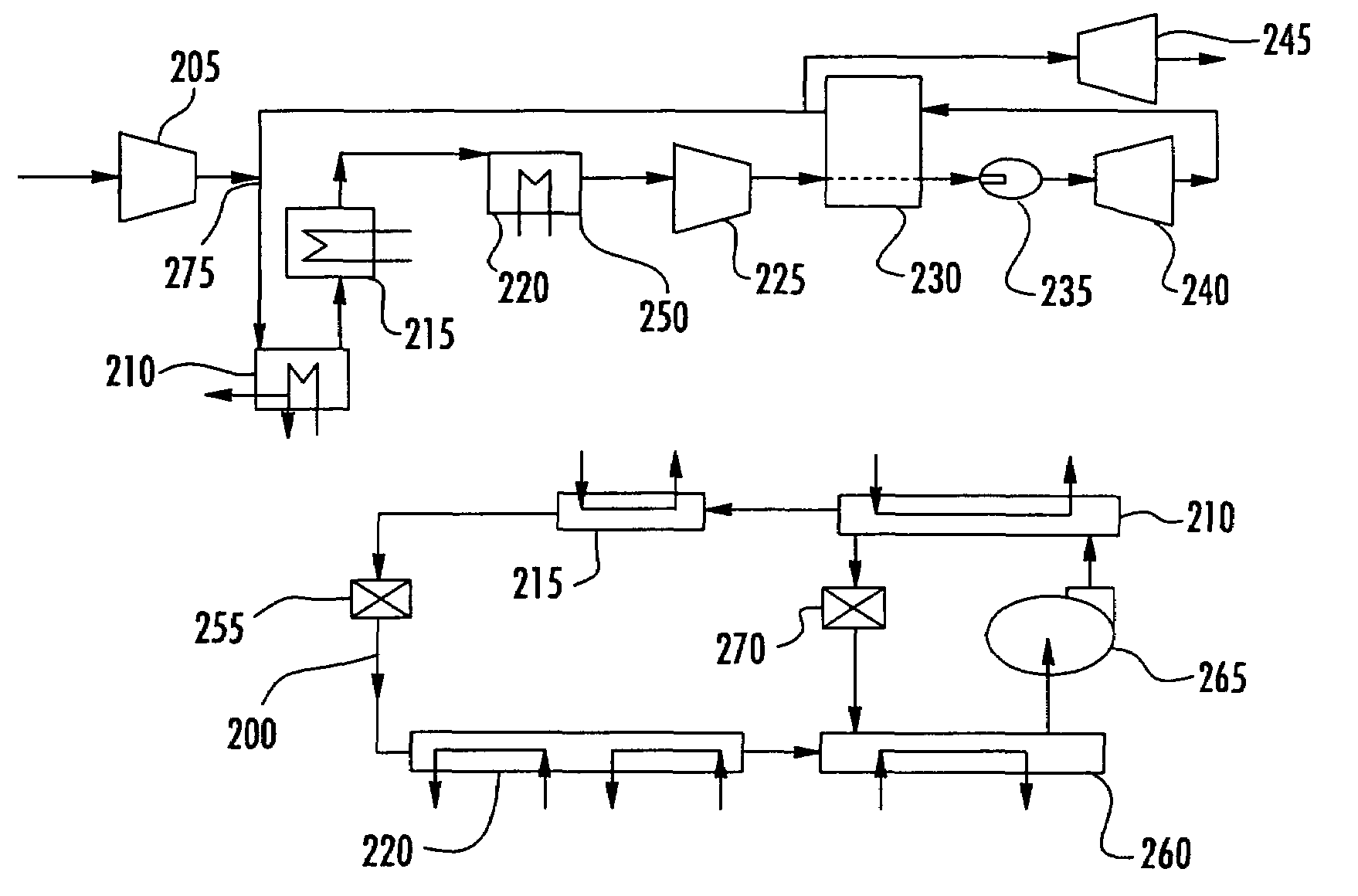

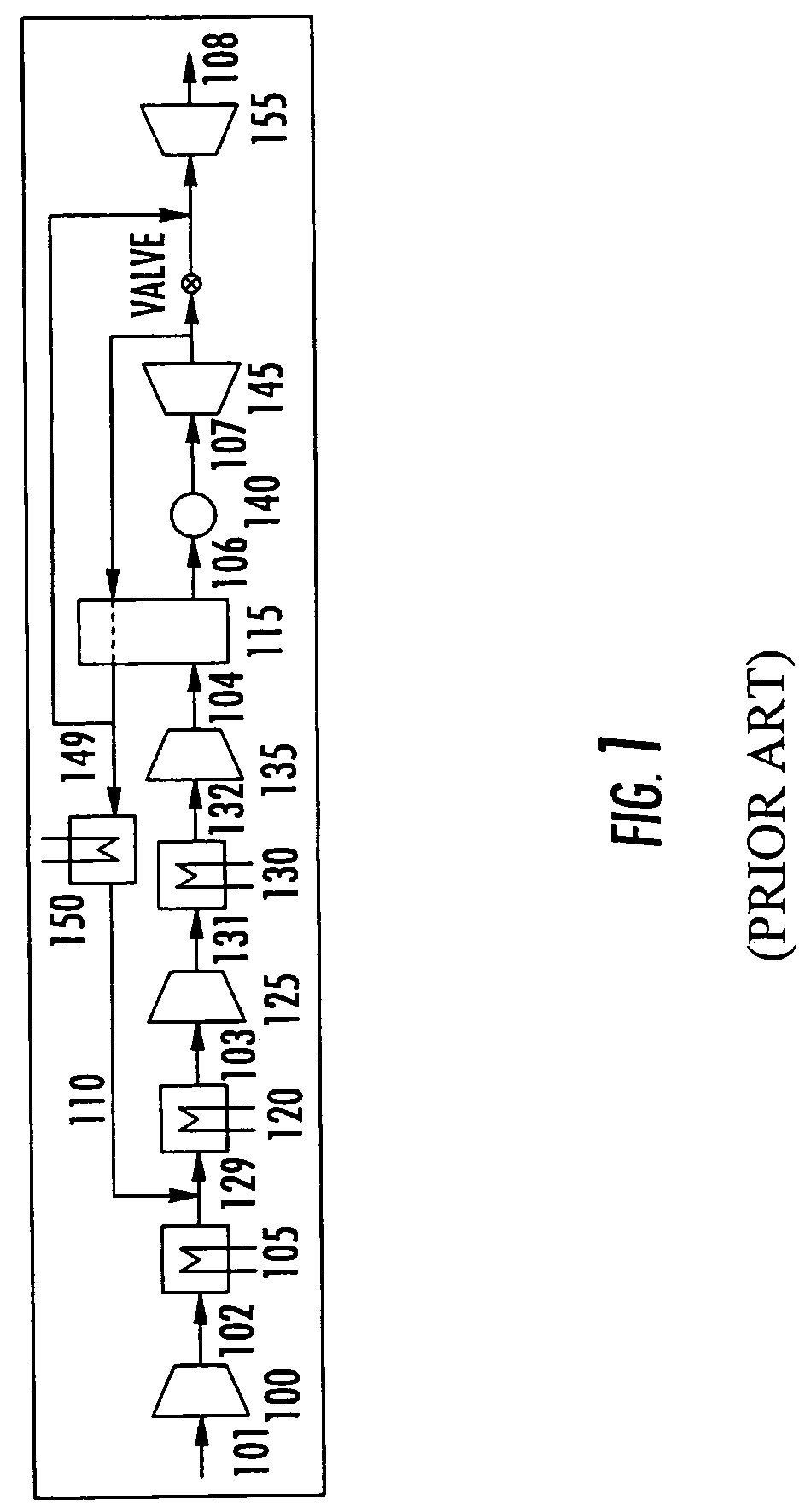

Method of generating energy in a power plant comprising a gas turbine, and power plant for carrying out the method

InactiveUS20050028529A1Small sizeLow costContinuous combustion chamberDispersed particle separationPower stationCombustor

A method of generating energy in a power plant (30) having a gas turbine (29), includes a first step a gas containing air (1) is compressed in a first compressor (2) of the gas turbine (29), a second step the compressed gas (3, 3a, 3b; 5; 7a, 7b) is fed to a combustion process with the addition of fuel (8) in a combustor (23), a third step the hot flue gas (9) from the combustor (23) is expanded in an expander or a turbine (10), driving a generator (18), of the gas turbine (29) while performing work, and a fourth step a partial flow of the expanded flue gas (11) is recirculated to the inlet of the first compressor (2) and admixed with the gas containing air (1). Carbon dioxide (CO2) is separated from the compressed gas (3, 3a, 3b; 5; 7a, 7b) in a CO2 separator (6) before the third step. In such a method, the overall size and energy costs are reduced by virtue of the fact that, to permit increased CO2 concentrations in the CO2 separator (6), not more than about 70% of the carbon dioxide contained in the compressed gas (3, 3a, 3b; 5, 5a, 5b; 7a, 7b) is removed from the compressed gas (3, 3a, 3b; 5, 5a, 5b; 7a, 7b).

Owner:ALSTOM TECH LTD

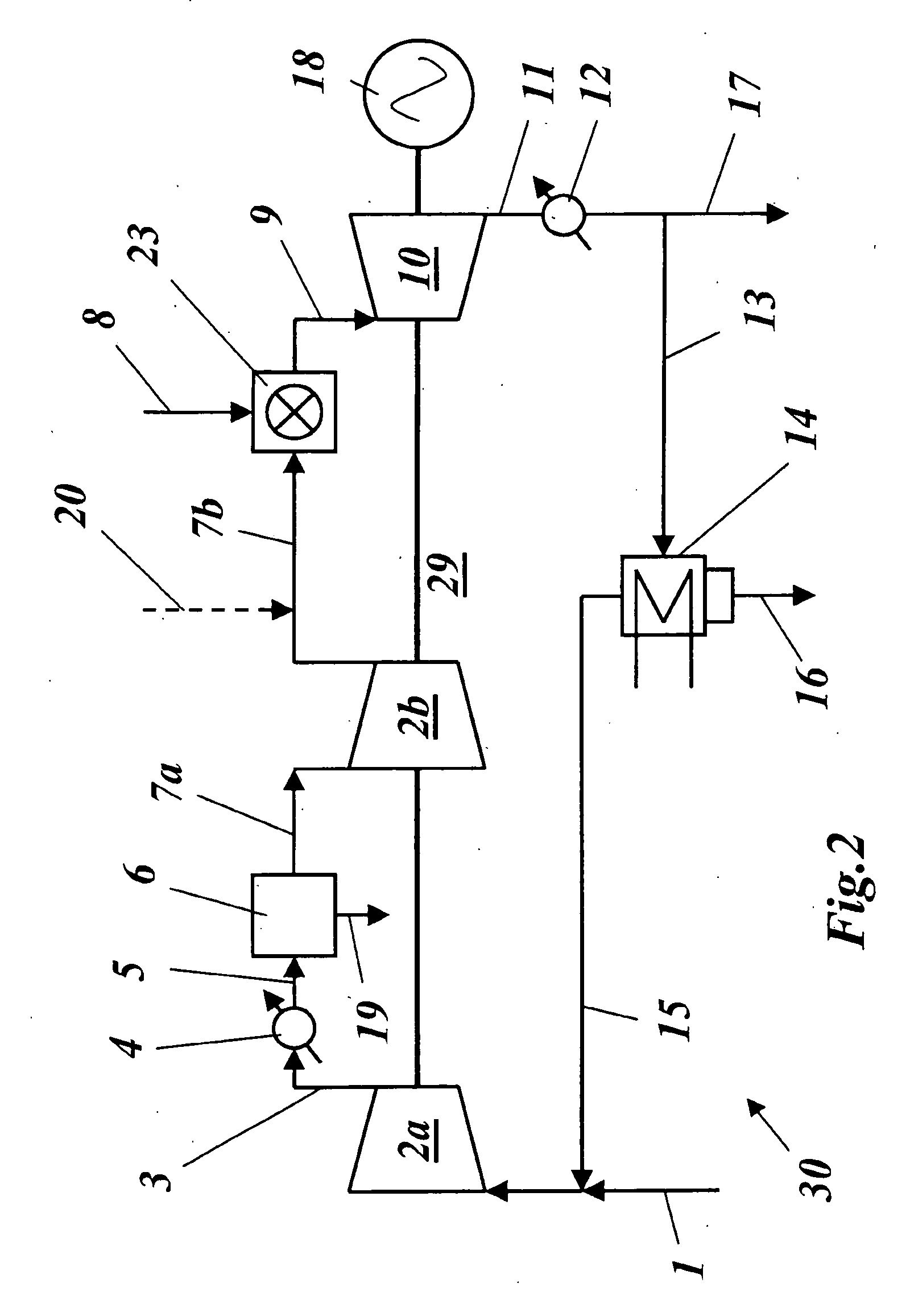

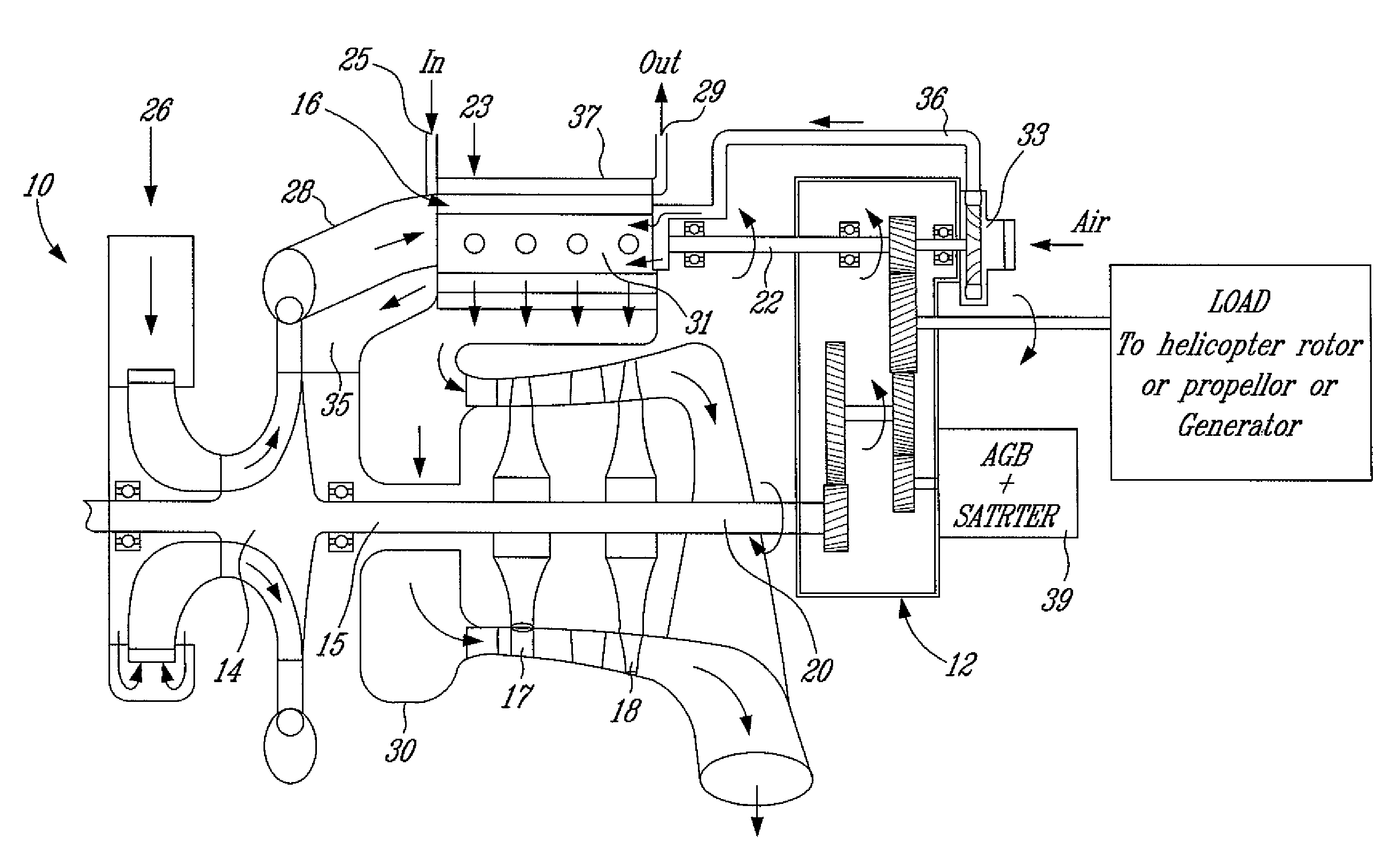

Low volumetric compression ratio integrated turbo-compound rotary engine

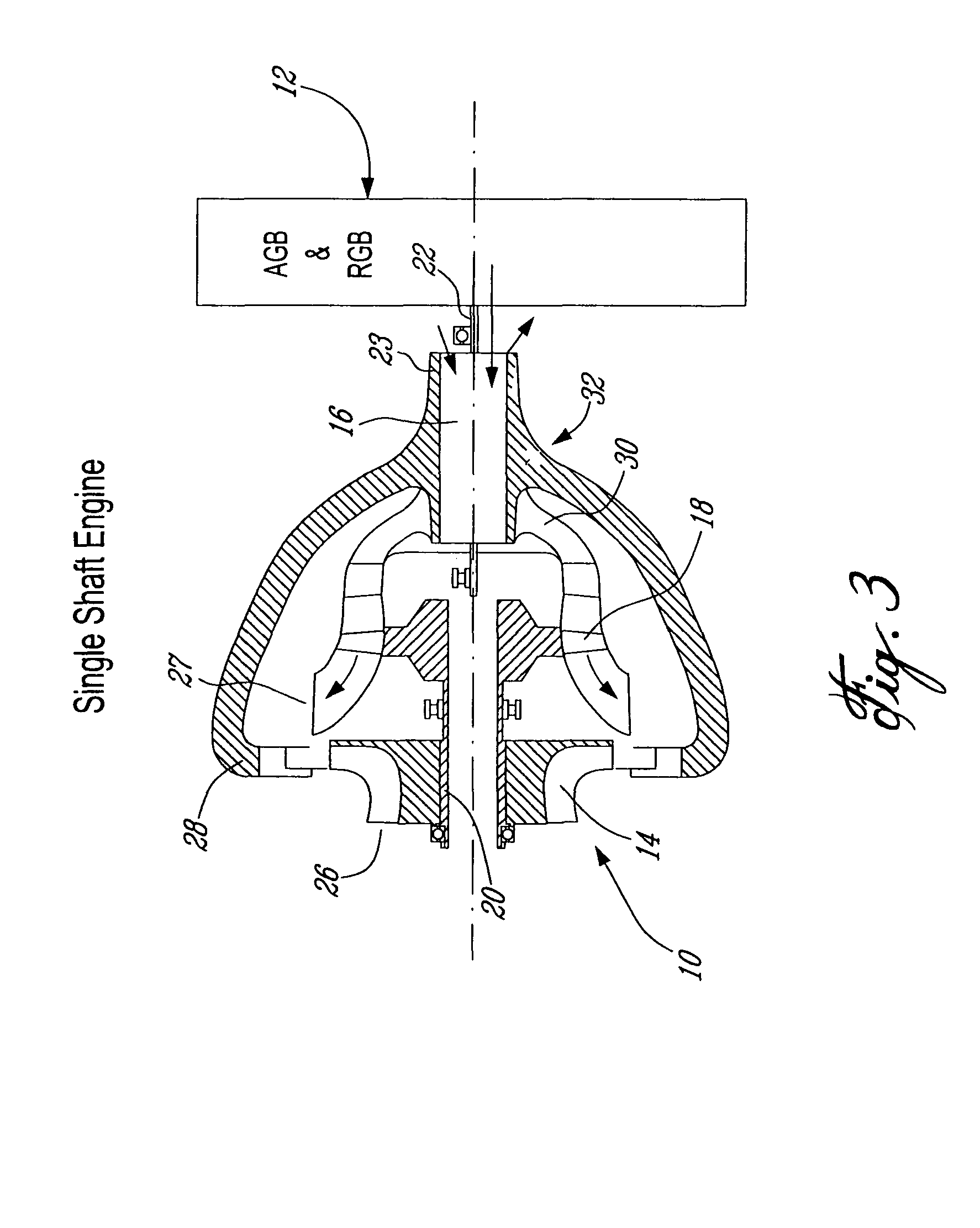

ActiveUS7775044B2Reduce the compression ratioImprove thermal efficiencyGas turbine plantsEfficient propulsion technologiesAir cycleRotary engine

Owner:PRATT & WHITNEY CANADA CORP

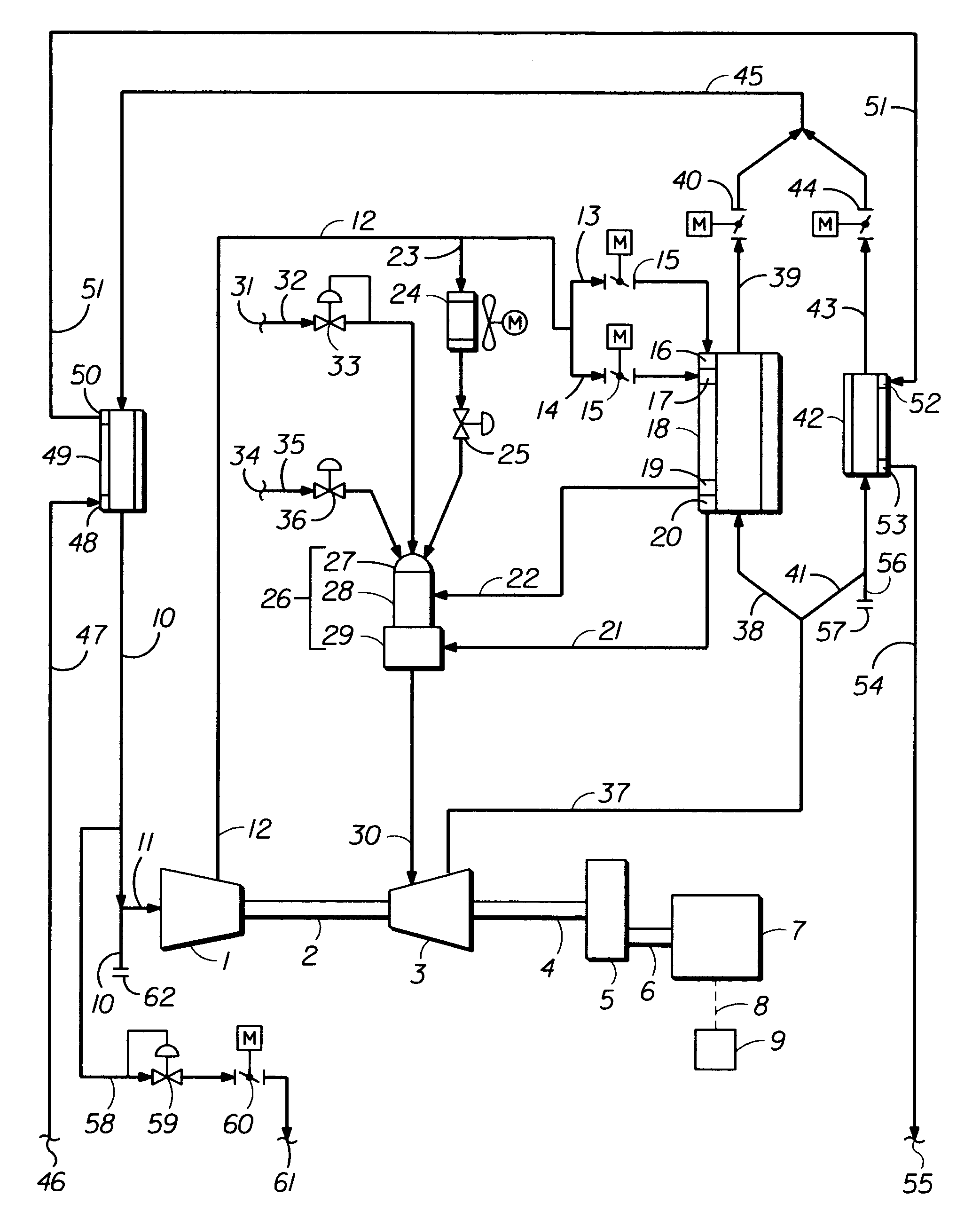

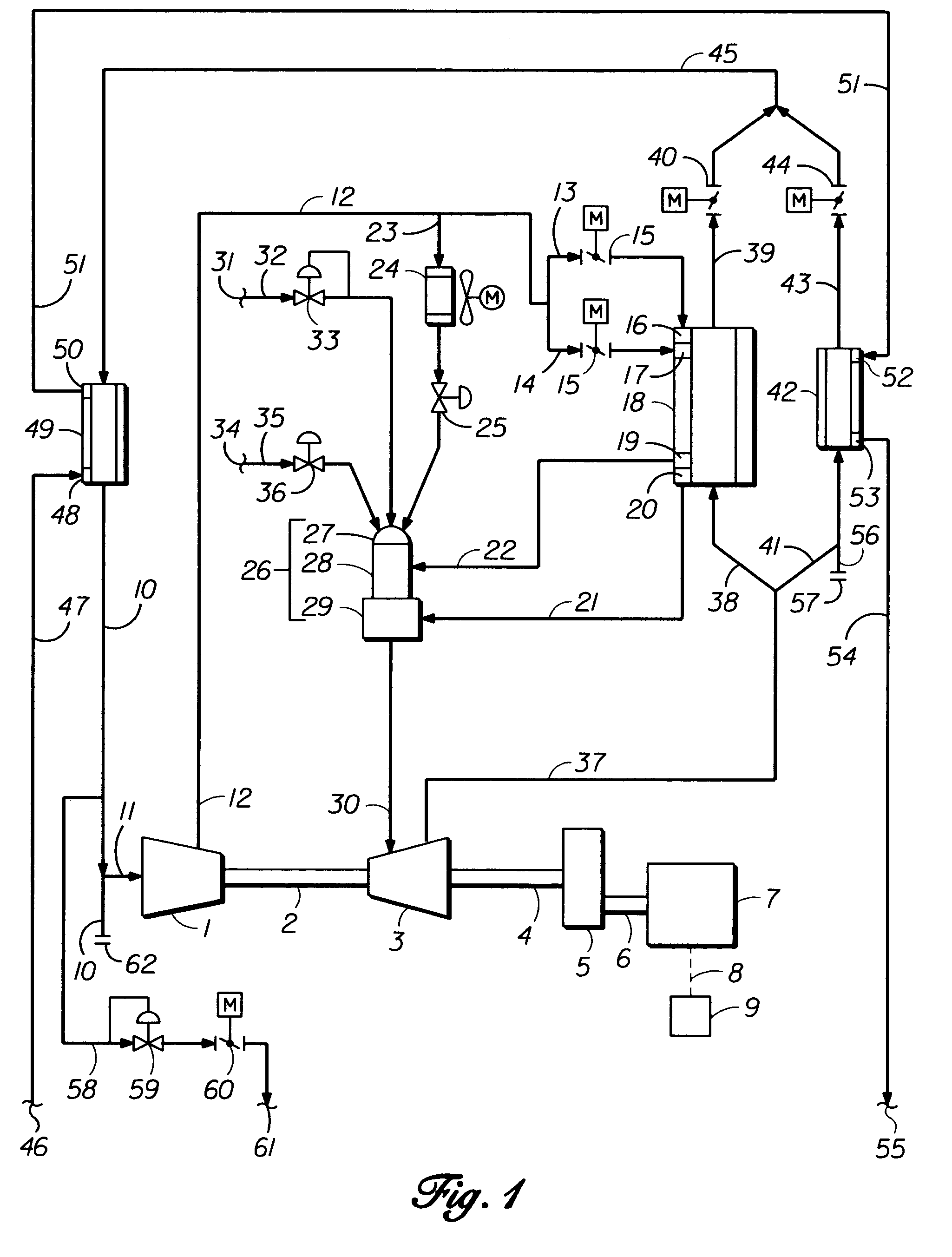

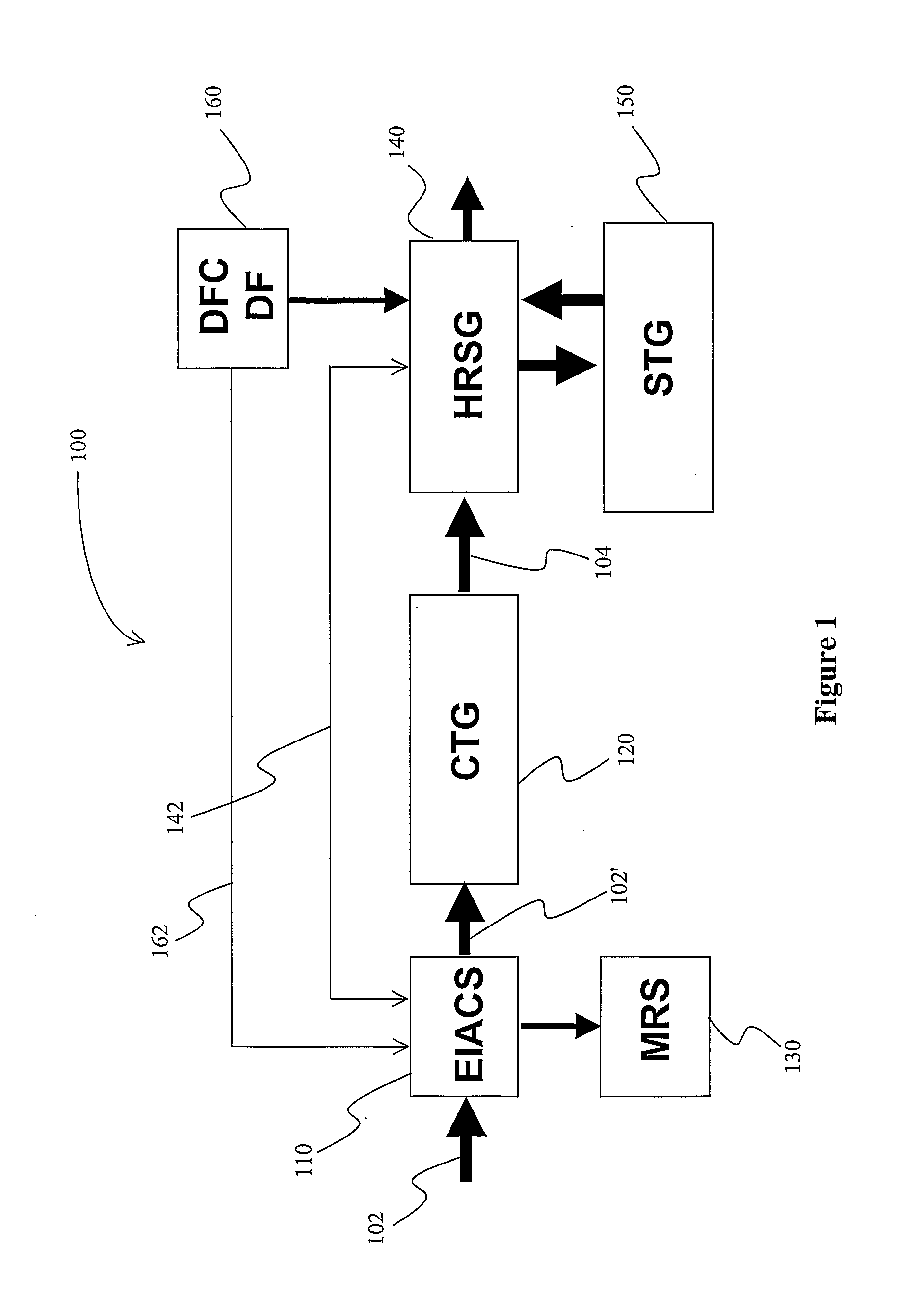

Power cogeneration system and apparatus means for improved high thermal efficiencies and ultra-low emissions

InactiveUS7124589B2Improve thermal efficiencyGas turbine plantsCombined combustion mitigationThermal energyCogeneration

A power cogeneration system employing a partially-open gaseous fluid cycle method and apparatus devices for oxy-fuel combustion conversion of a given hydrocarbon composition fuel's heat-value energy into mechanical or electrical power energy, and transferred useful heat energy, with accompanying large reductions of consumed fuel and undesirable exhaust emissions.

Owner:AES DEV CO

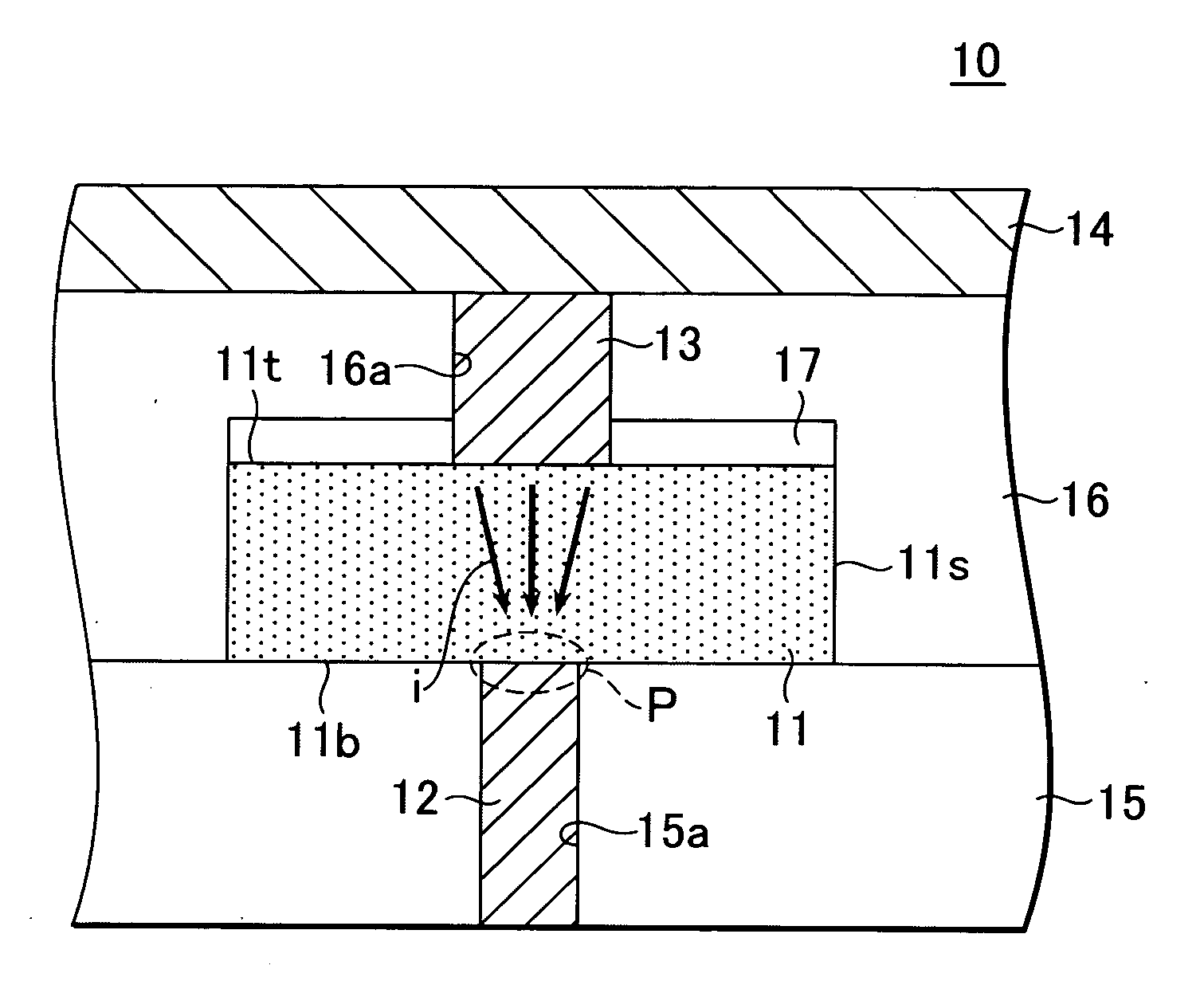

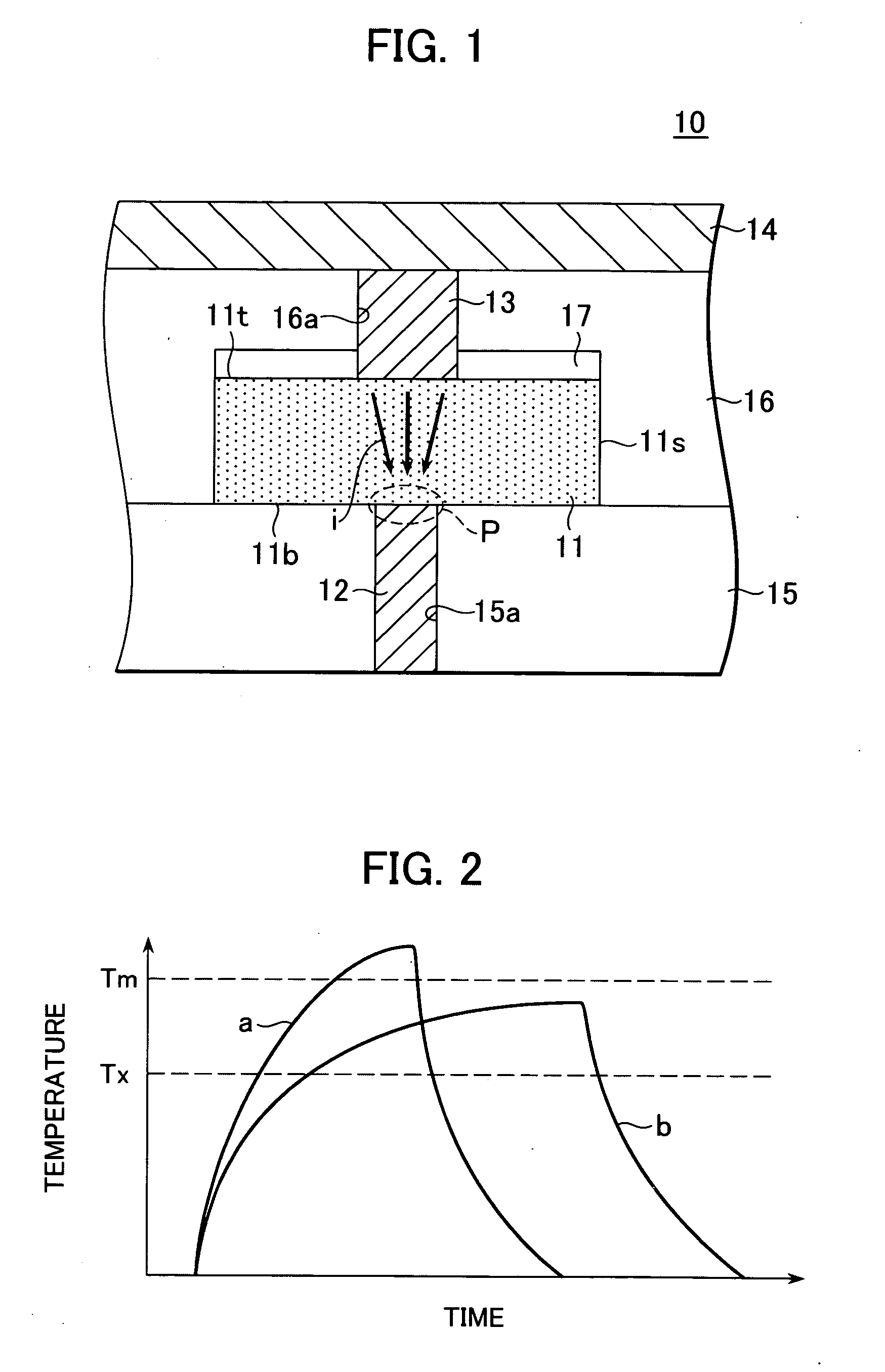

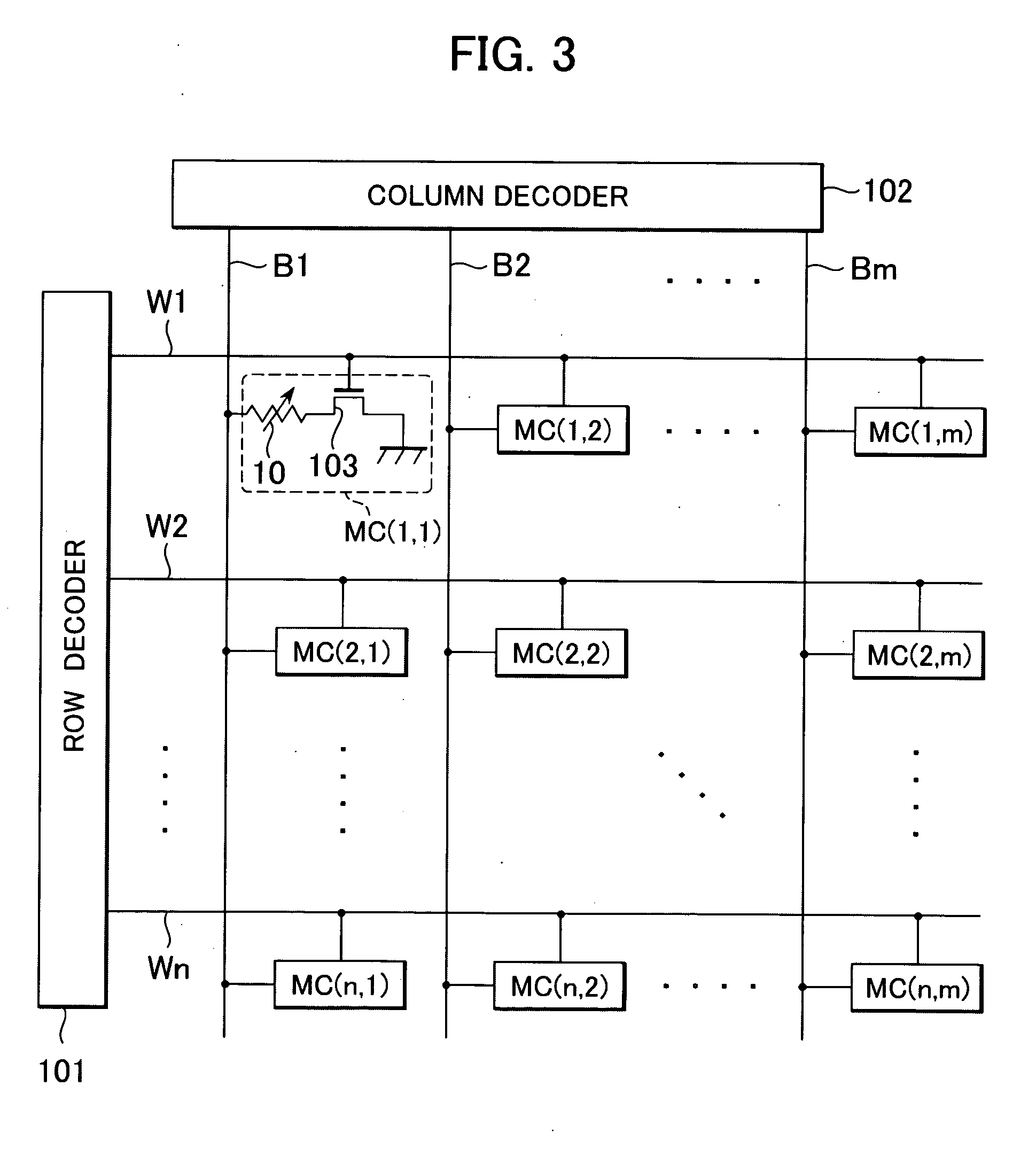

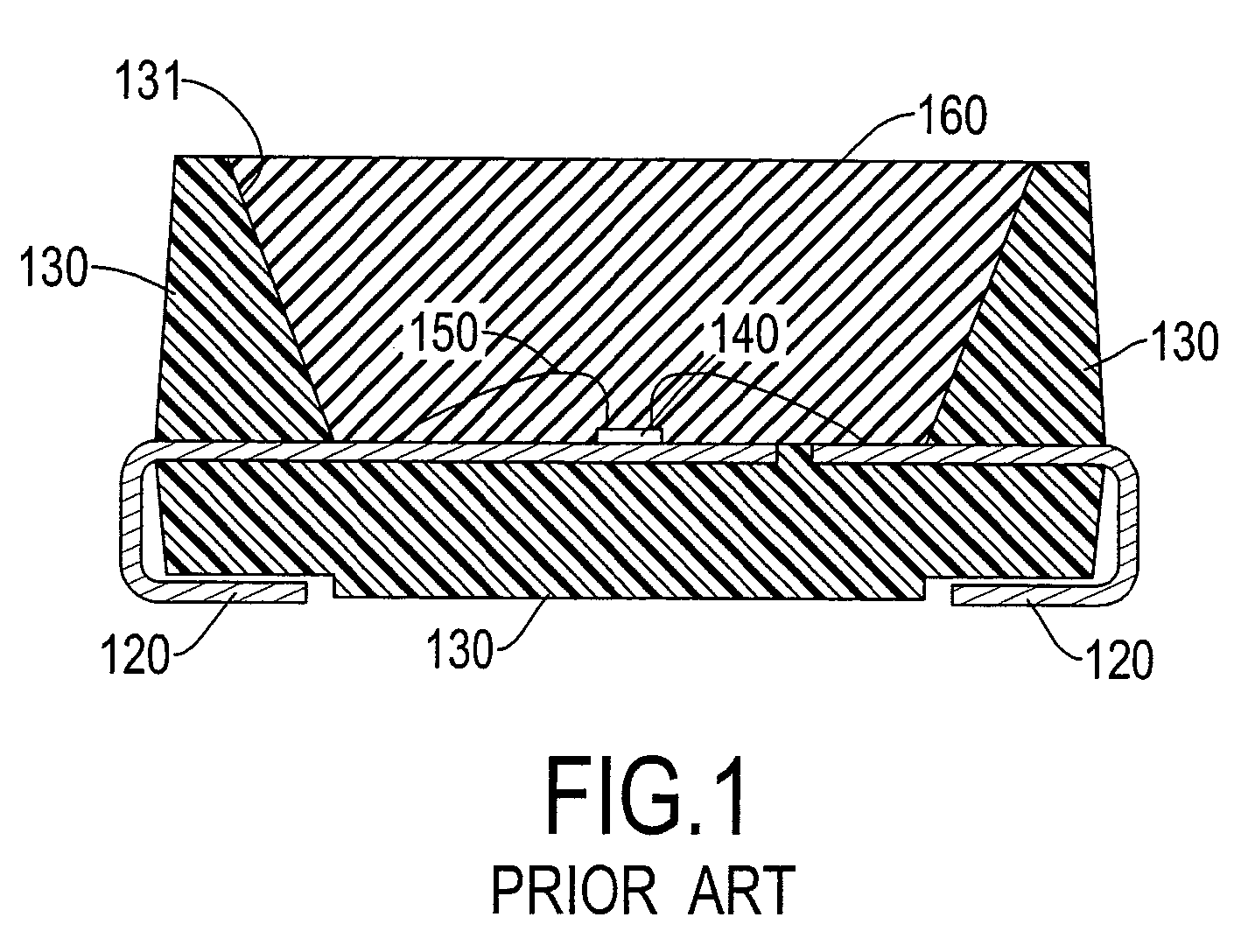

Electrically rewritable non-volatile memory element and method of manufacturing the same

InactiveUS20070063180A1Minimizing damageImprove thermal efficiencySolid-state devicesBulk negative resistance effect devicesEngineeringRecording layer

A non-volatile memory element includes a recording layer that includes a phase change material, a lower electrode provided in contact with the recording layer, an upper electrode provided in contact with a portion of the upper surface of the recording layer, a protective insulation film provided in contact with the other portion of the upper surface of the recording layer, and an interlayer insulation film provided on the protective insulation film. High thermal efficiency can thereby be obtained because the size of the area of contact between the recording layer and the upper electrode is reduced. Providing the protective insulation film between the interlayer insulation film and the upper surface of the recording layer makes it possible to reduce damage sustained by the recording layer during patterning of the recording layer or during formation of the through-hole for exposing a portion of the recording layer.

Owner:ELPIDA MEMORY INC

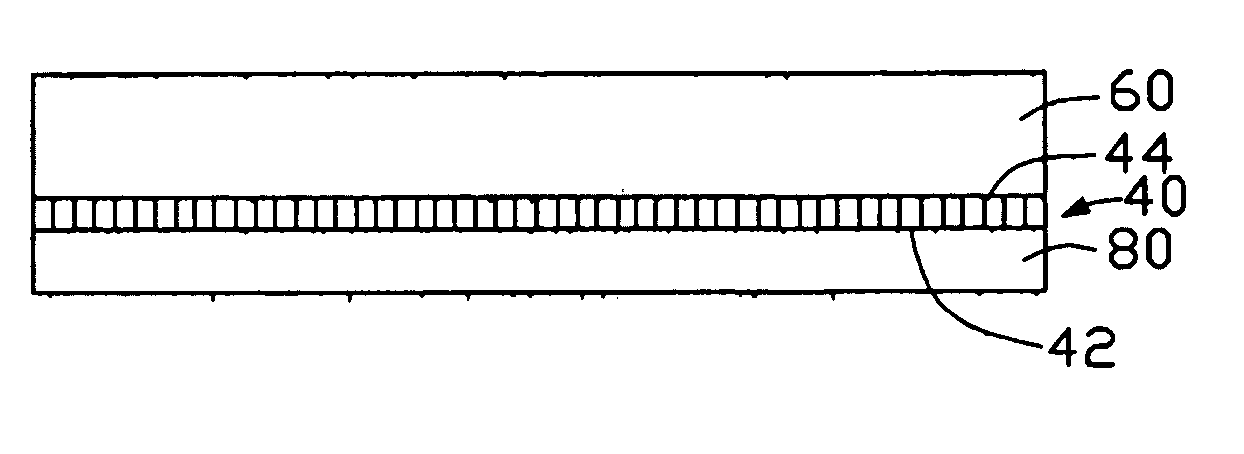

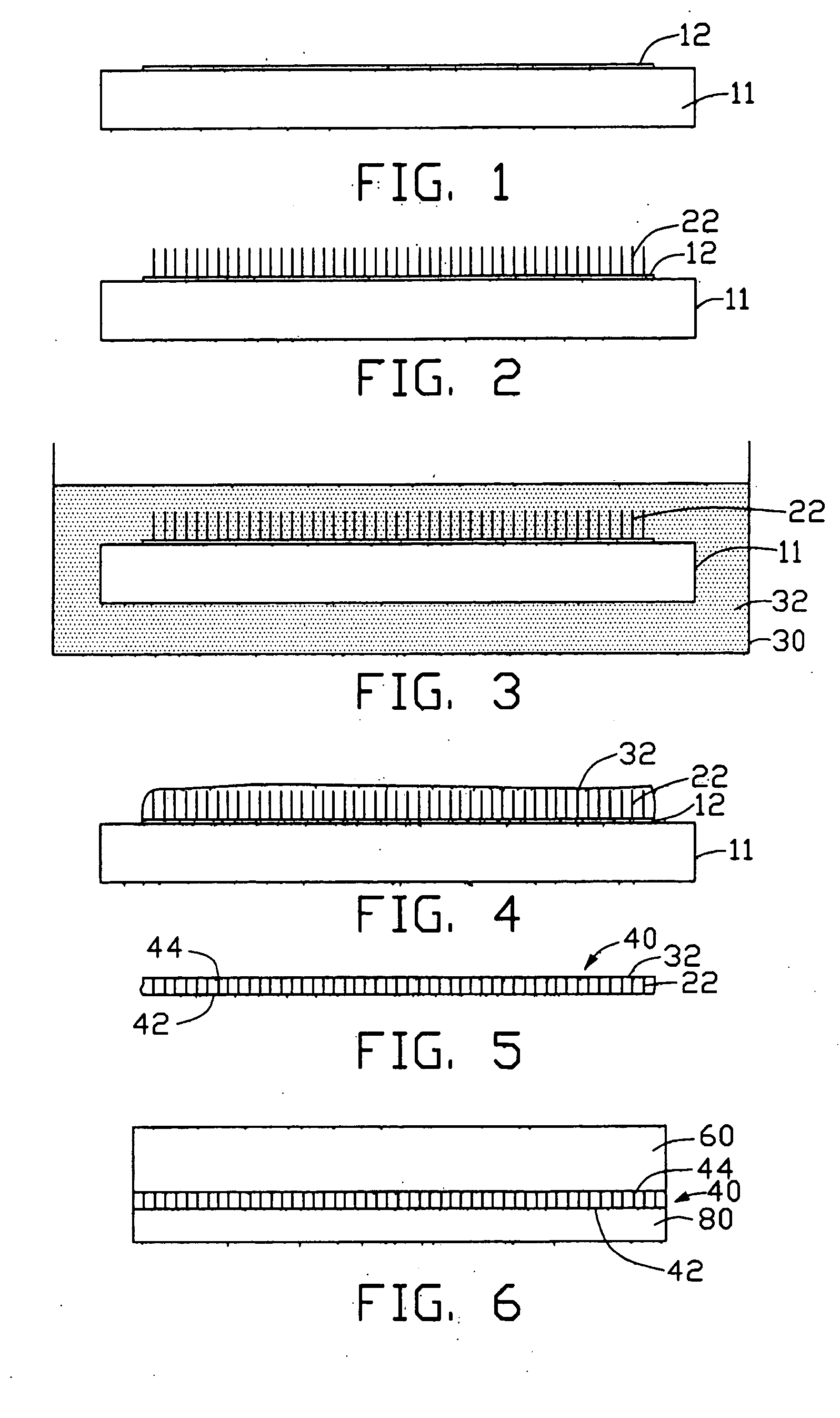

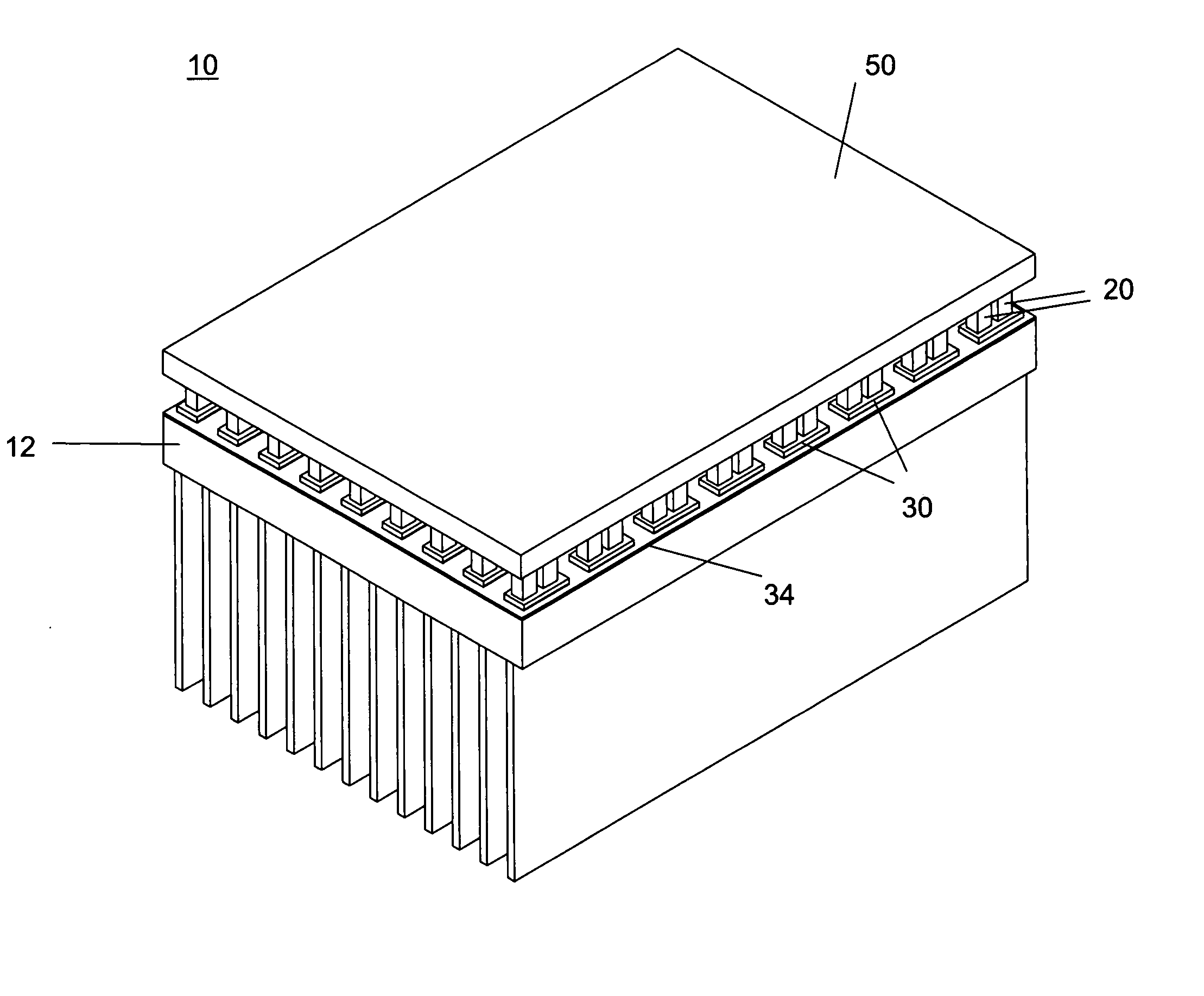

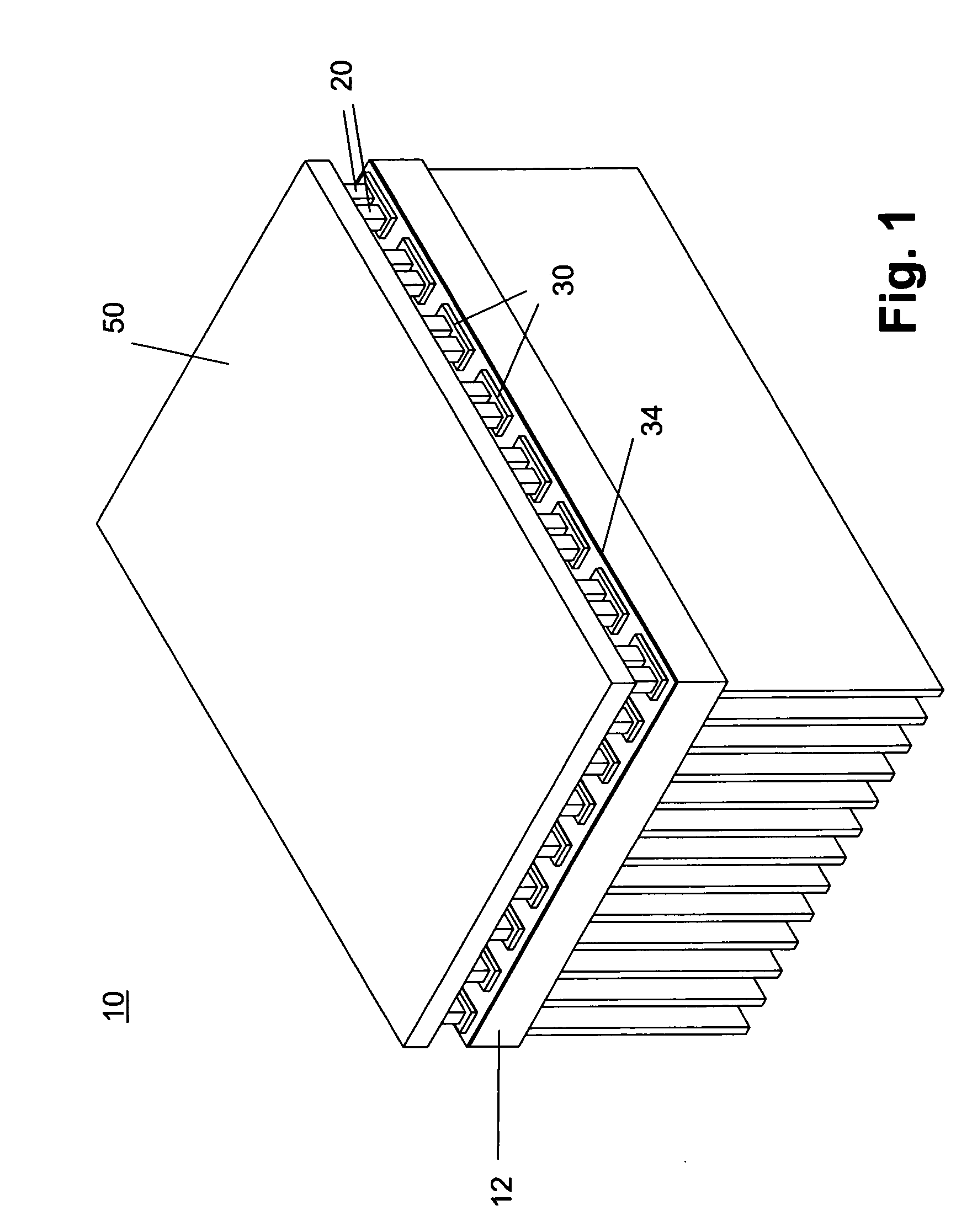

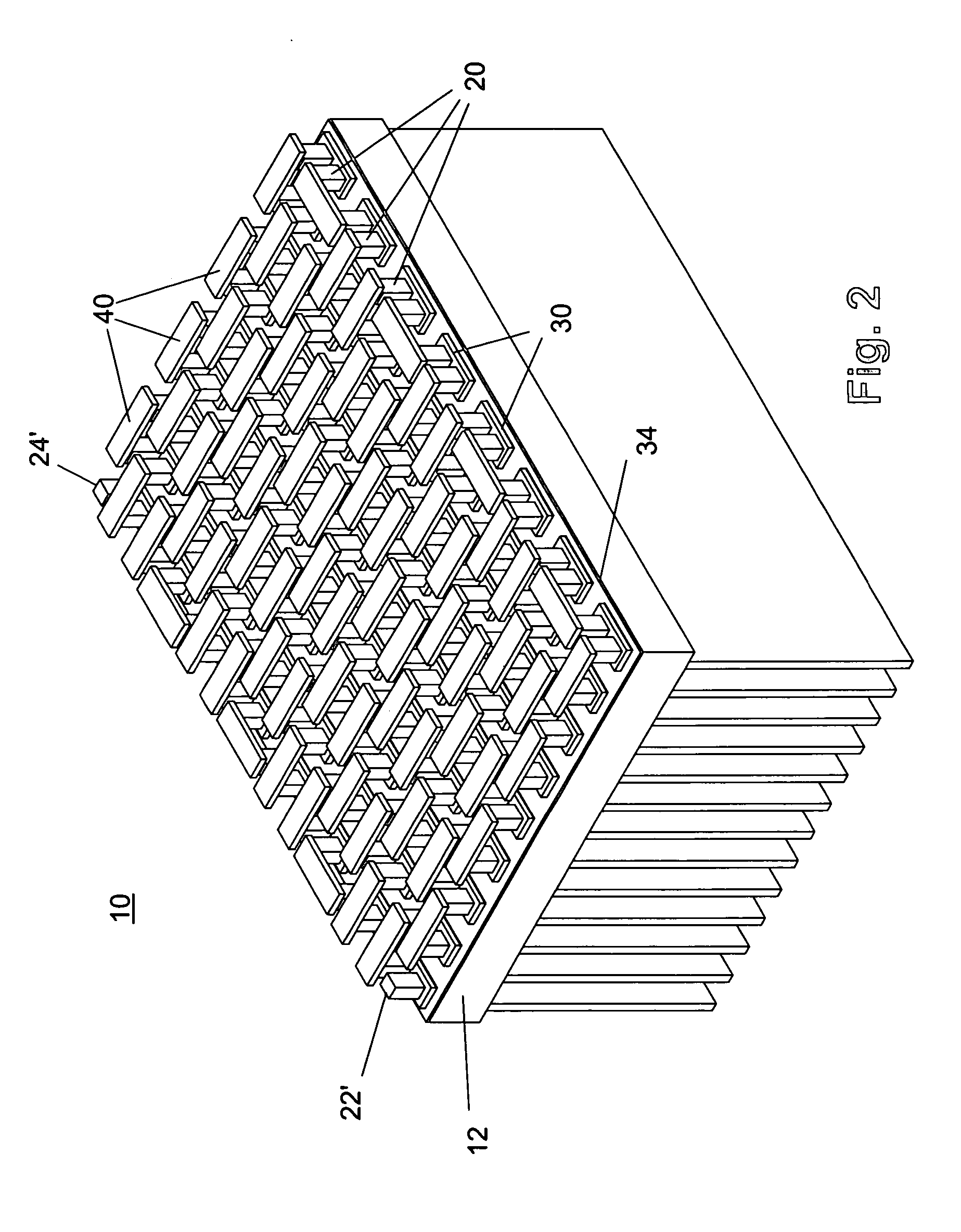

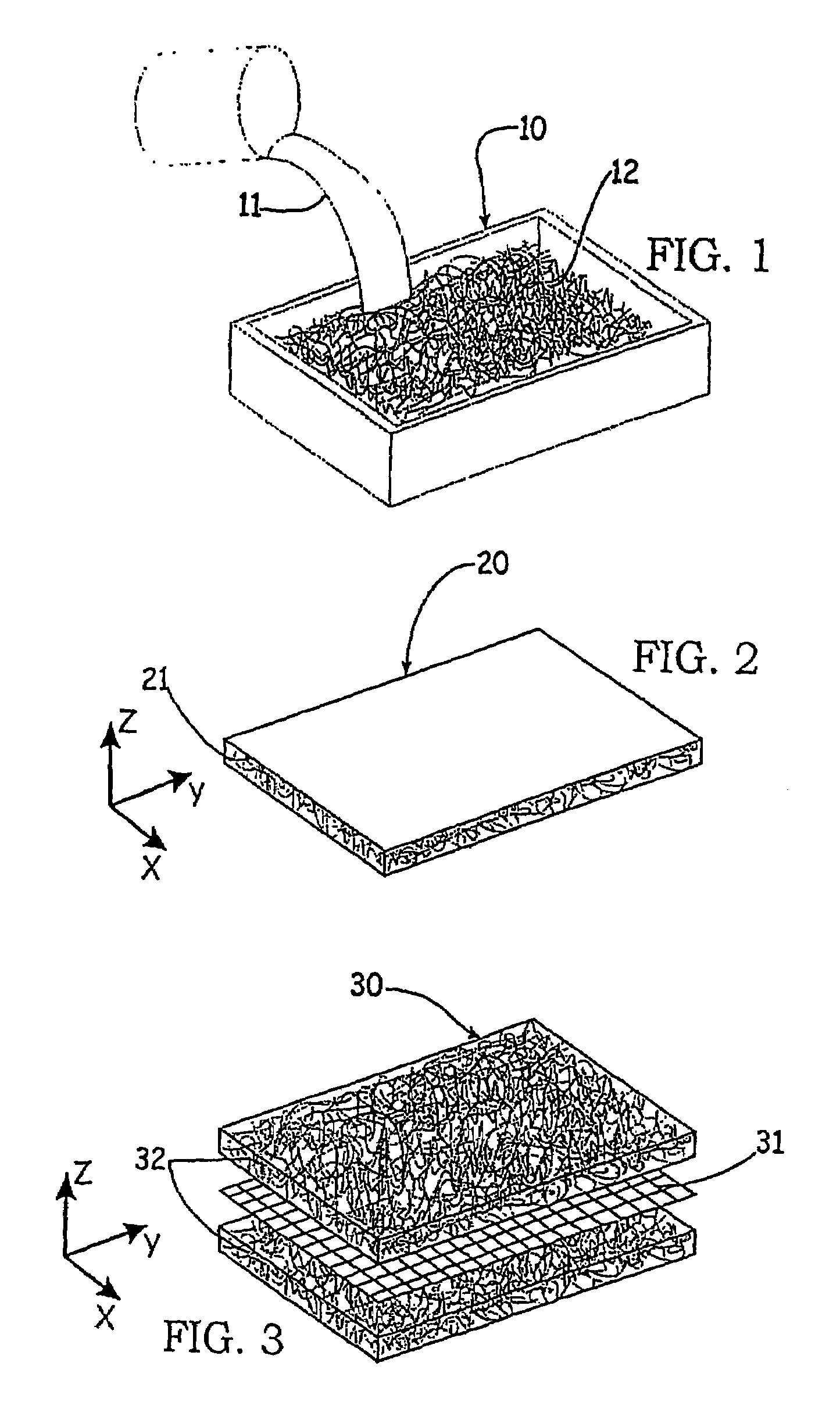

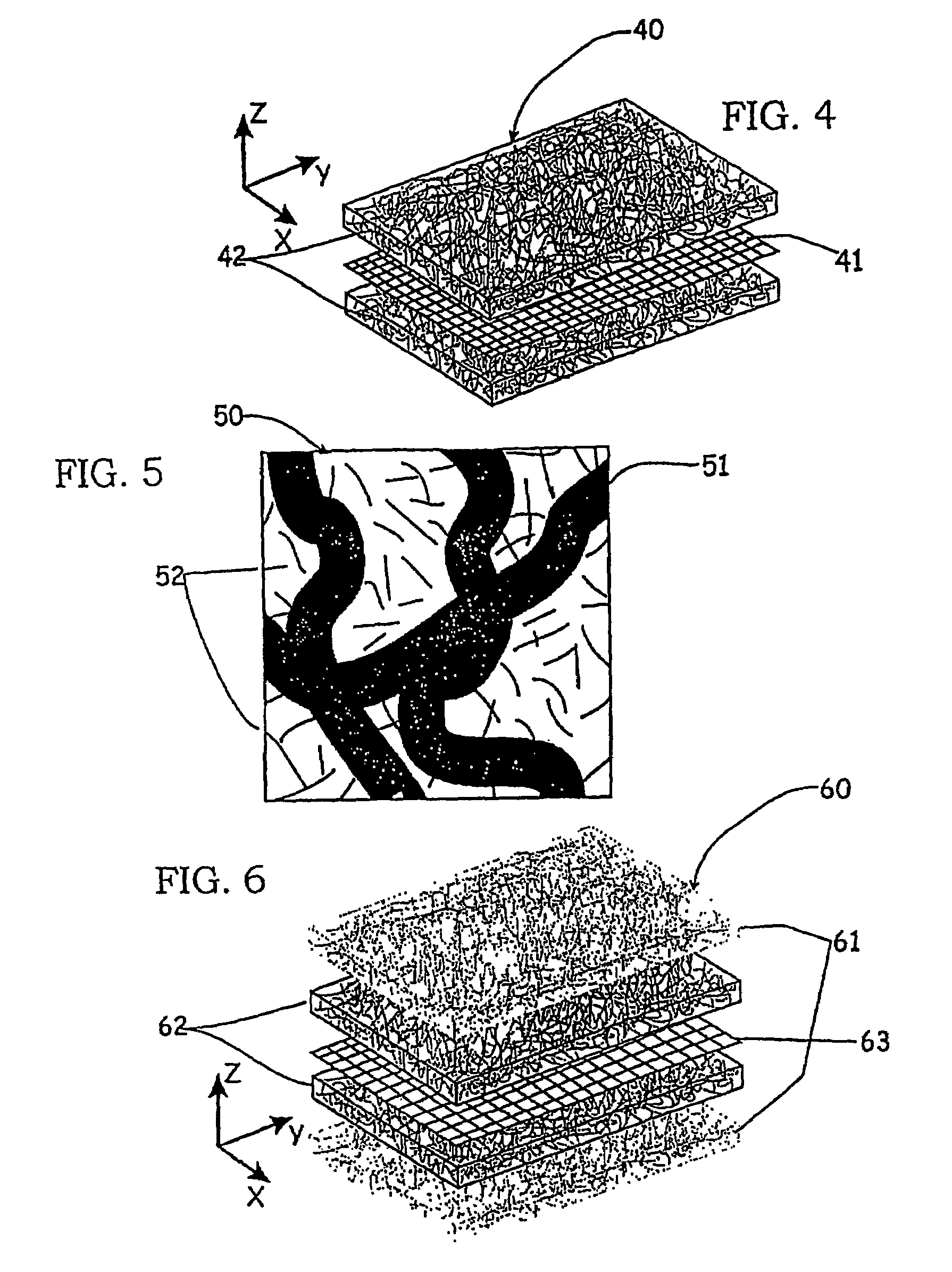

Thermal interface material and method for manufacturing same

ActiveUS20050167647A1Reduce thicknessSmall resistanceMaterial nanotechnologySemiconductor/solid-state device detailsLiquid stateCarbon nanotube

A thermal interface material (40) includes a macromolecular material (32), and a plurality of carbon nanotubes (22) embedded in the macromolecular material uniformly. The thermal interface material includes a first surface (42) and an opposite second surface (44). Each carbon nanotube is open at both ends thereof, and extends from the first surface to the second surface of the thermal interface material. A method for manufacturing the thermal interface material includes the steps of: (a) forming an array of carbon nanotubes on a substrate; (b) submerging the carbon nanotubes in a liquid macromolecular material; (c) solidifying the liquid macromolecular material; and (d) cutting the solidified liquid macromolecular material to obtain the thermal interface material with the carbon nanotubes secured therein.

Owner:TSINGHUA UNIV +1

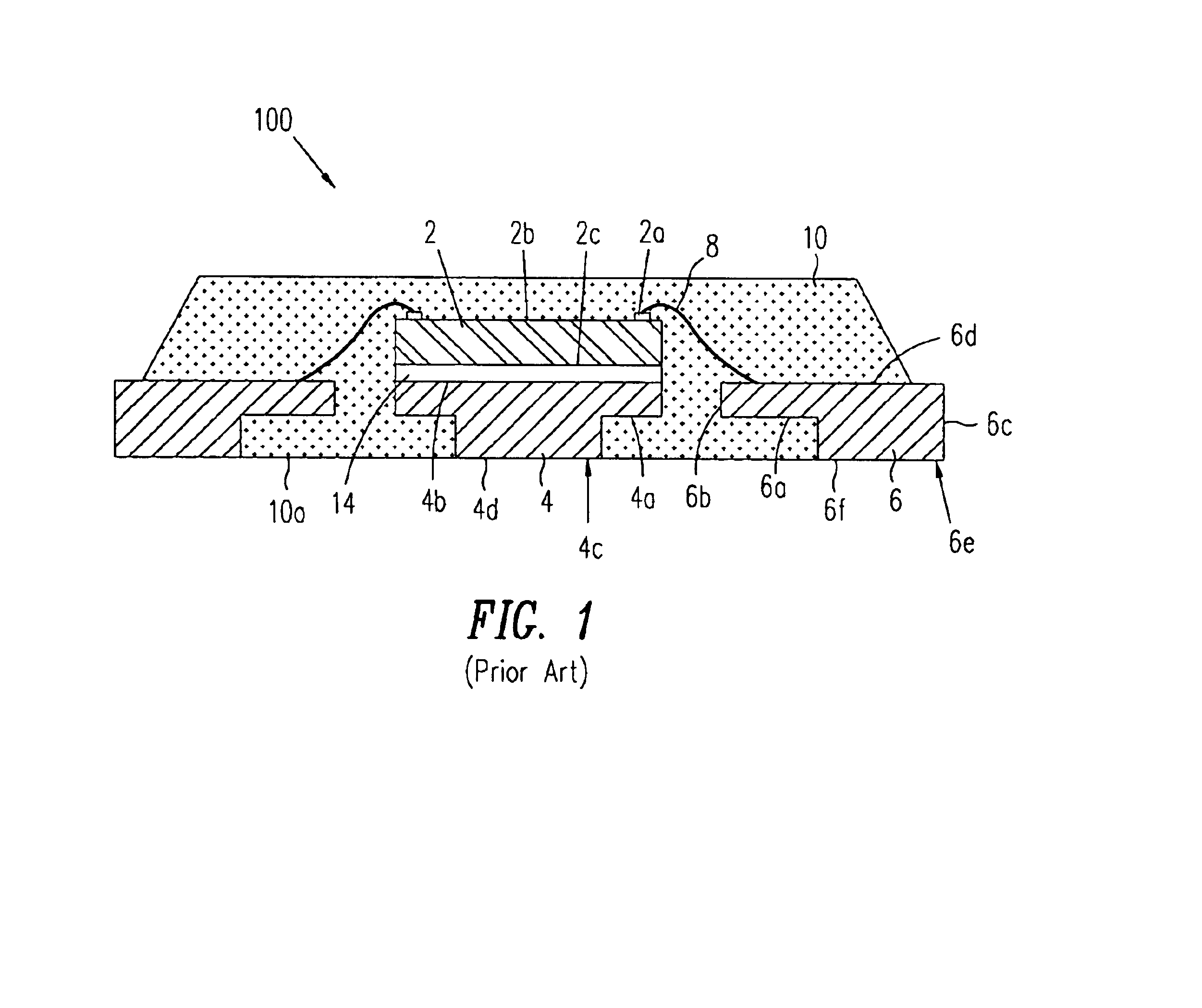

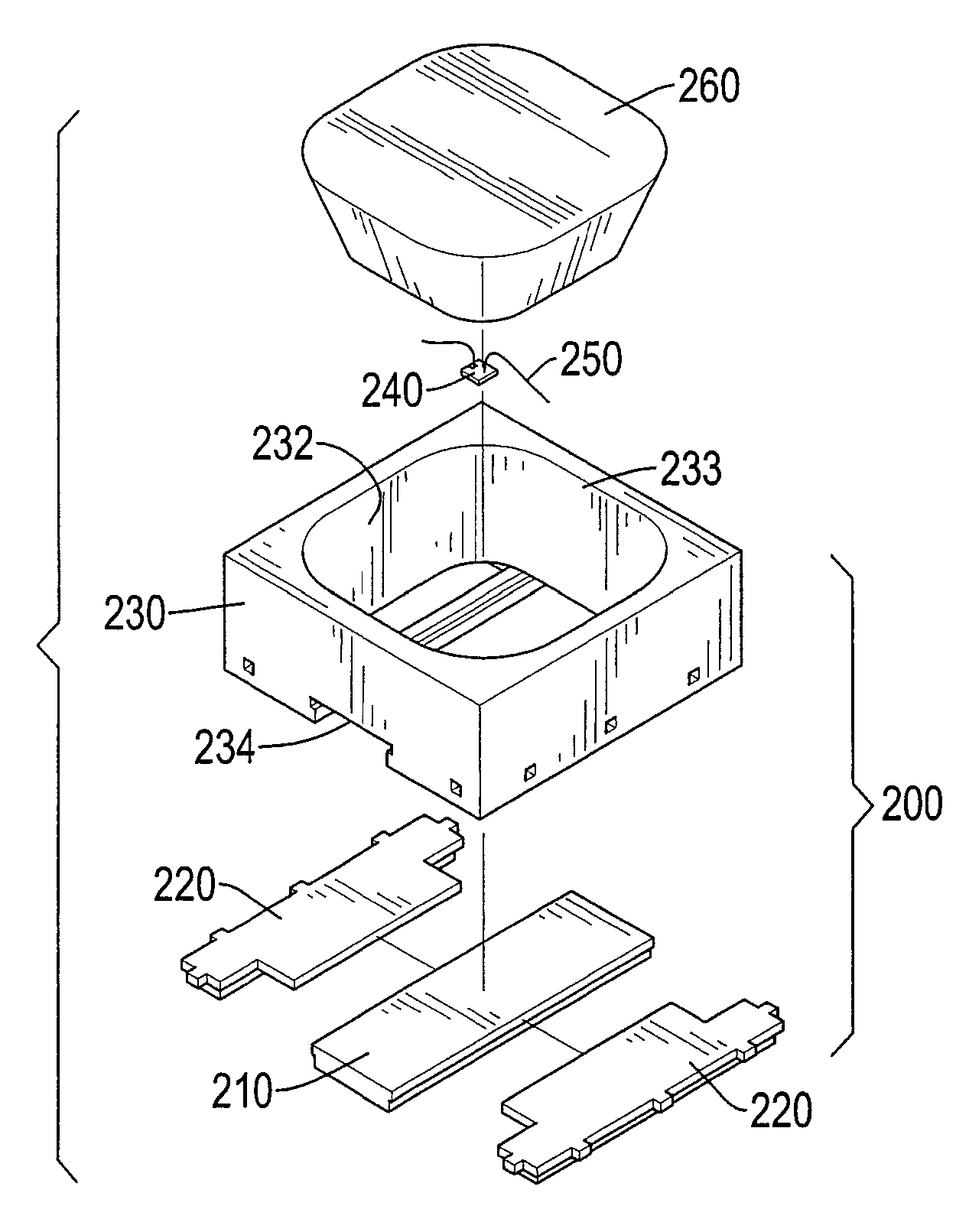

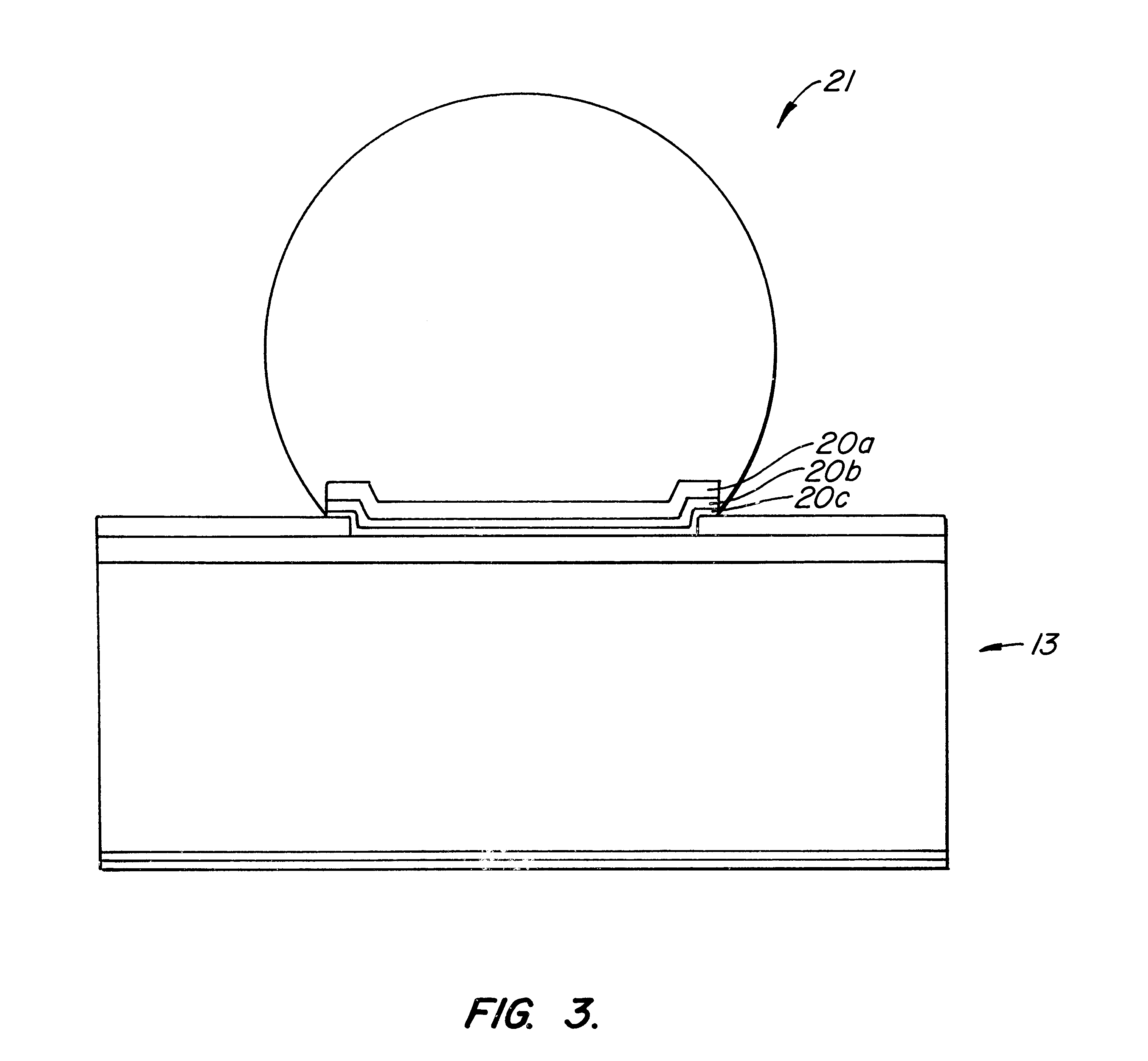

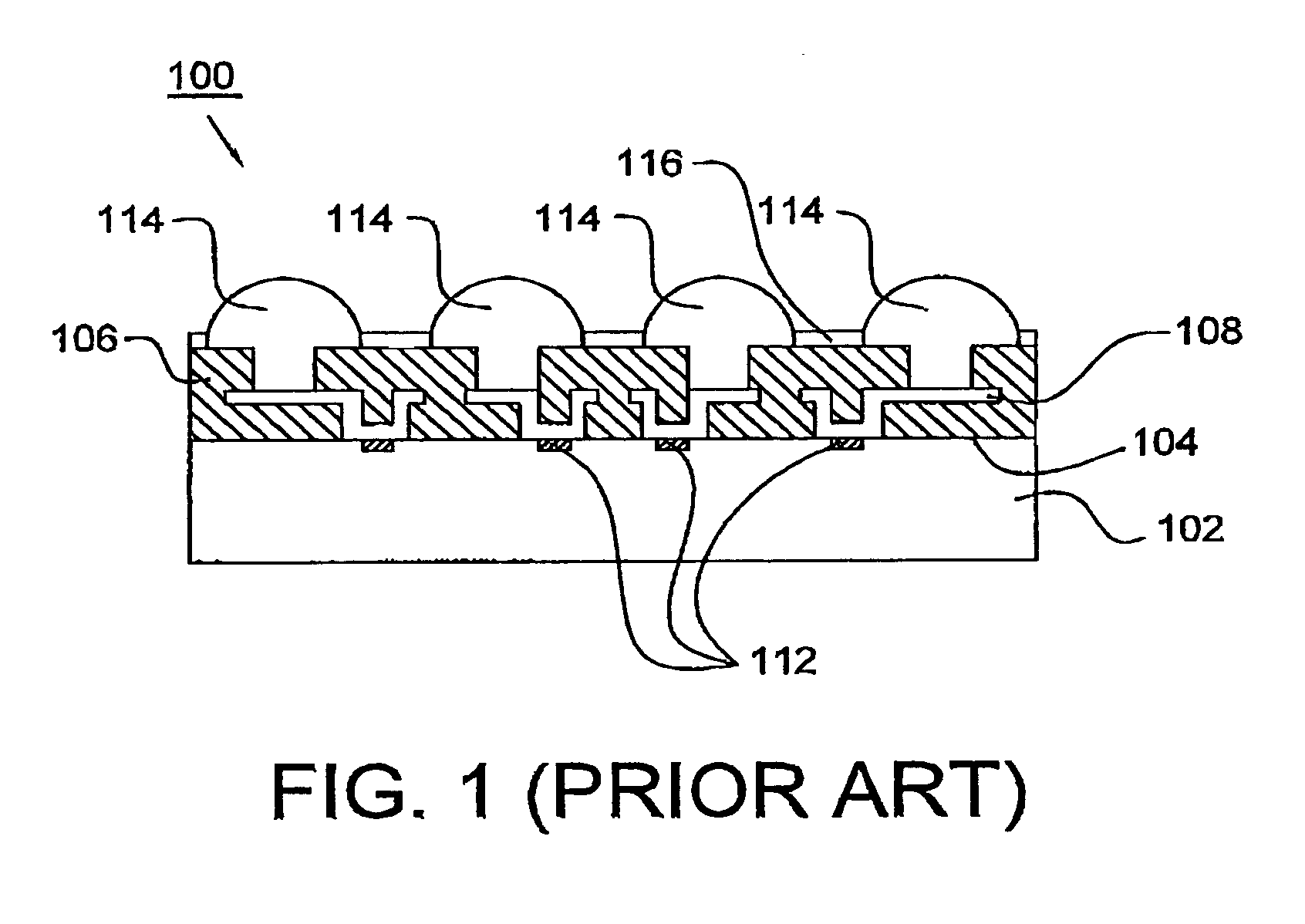

Semiconductor package

InactiveUS6858919B2Lesser mounting heightLesser footprintSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSemiconductor package

A semiconductor package is disclosed that bonds a semiconductor chip to a leadframe using a flip chip technology. An exemplary semiconductor package includes a semiconductor chip having a plurality of input-output pads at an active surface thereof. A plurality of leads are superimposed by the bond pads and active surface of the semiconductor chip. The leads have at least one exposed surface at a bottom surface of the package body. A plurality of conductive connecting means electrically connect the input-output pads of the chip to the leads. A package body is formed over the semiconductor chip and the conductive connecting means. The bottom surface portions of the leads are exposed to the outside.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

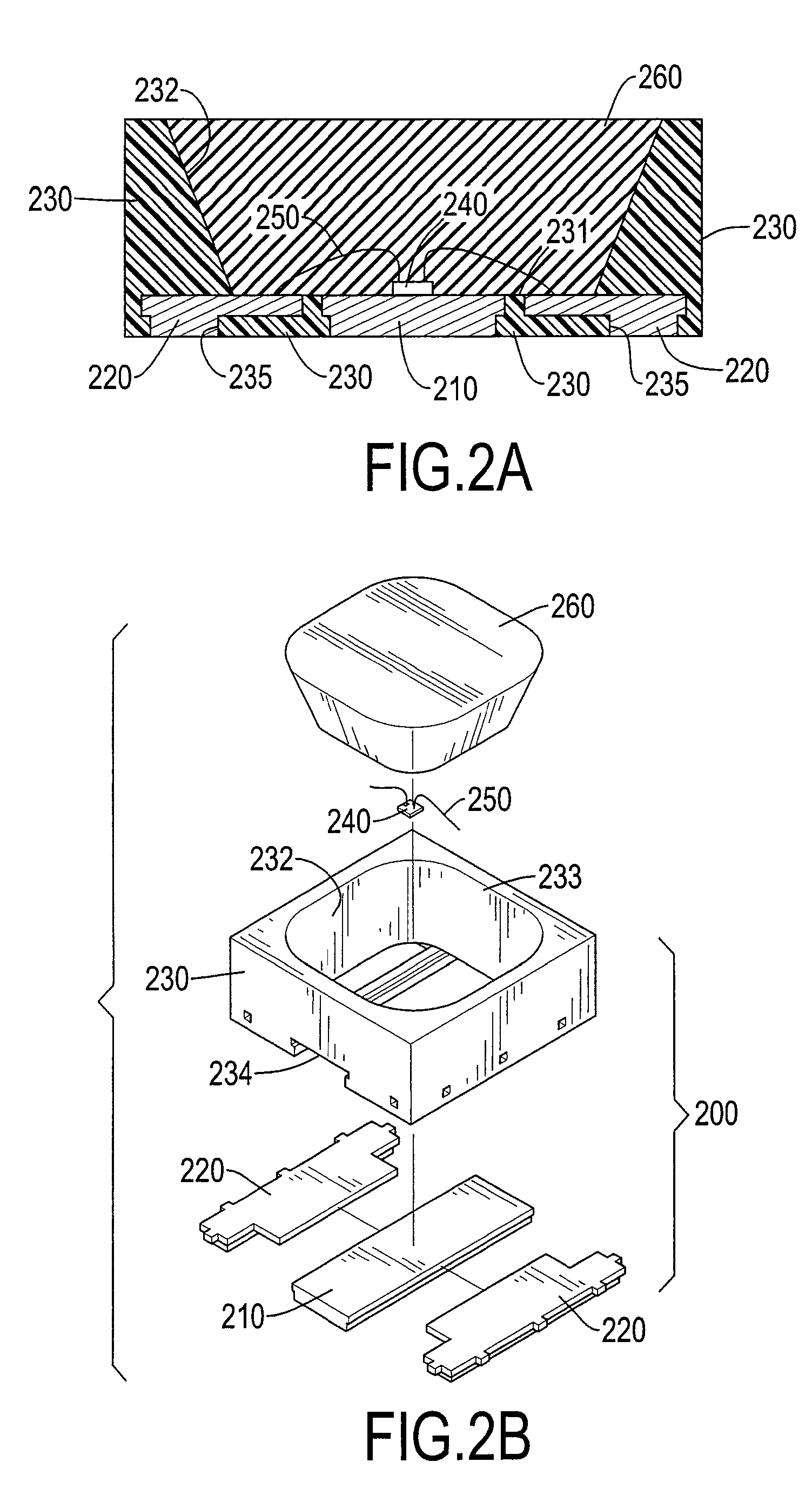

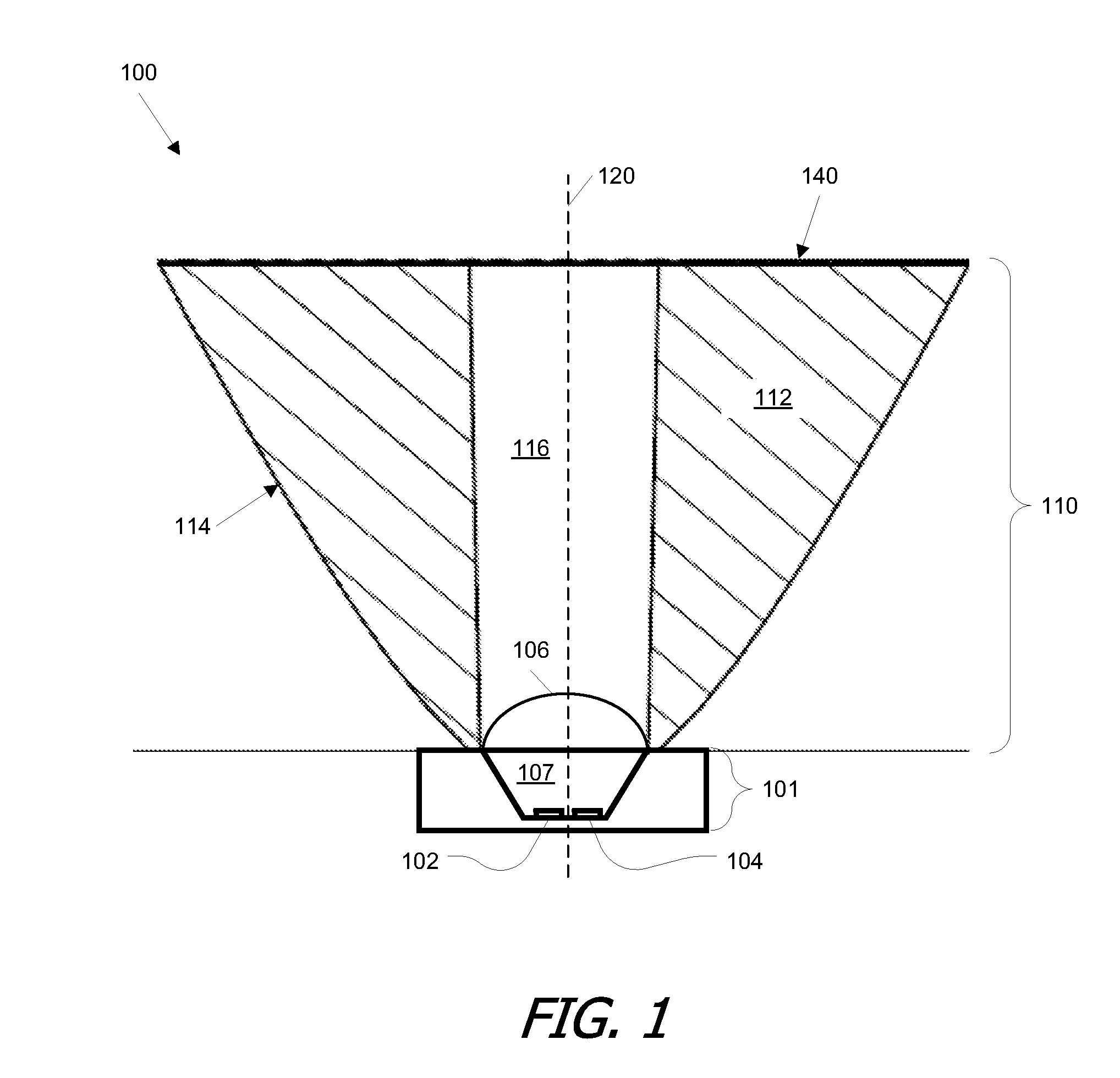

Package for a high-power light emitting diode

InactiveUS20080258162A1Improve thermal efficiencyBroaden applicationSolid-state devicesSemiconductor devicesEngineeringSealant

A package for a high-power light emitting diode (LED) has a packaging substrate, at least one LED chip, at least one pair of conductive wires and an encapsulant. The packaging substrate has a reflective base with a recess, a dissipating board and at least one pair of electrodes. The electrodes and dissipating board are mounted in the reflective base and have upper surfaces. The LED chip is adhered to the dissipating board. The conductive wires connects electrodes of the LED chip and the electrodes. The encapsulant is transparent and fills the recess of the reflective base. Most heat from the LED chip is conducted via the dissipating board, thereby improving thermal conduction efficiency and allowing more powerful or numerous LED chips in the package. Therefore, the package provides different pass ways for conducting heat and electricity to improve heat conduction of the LED.

Owner:KOUNG CHIA YIN +1

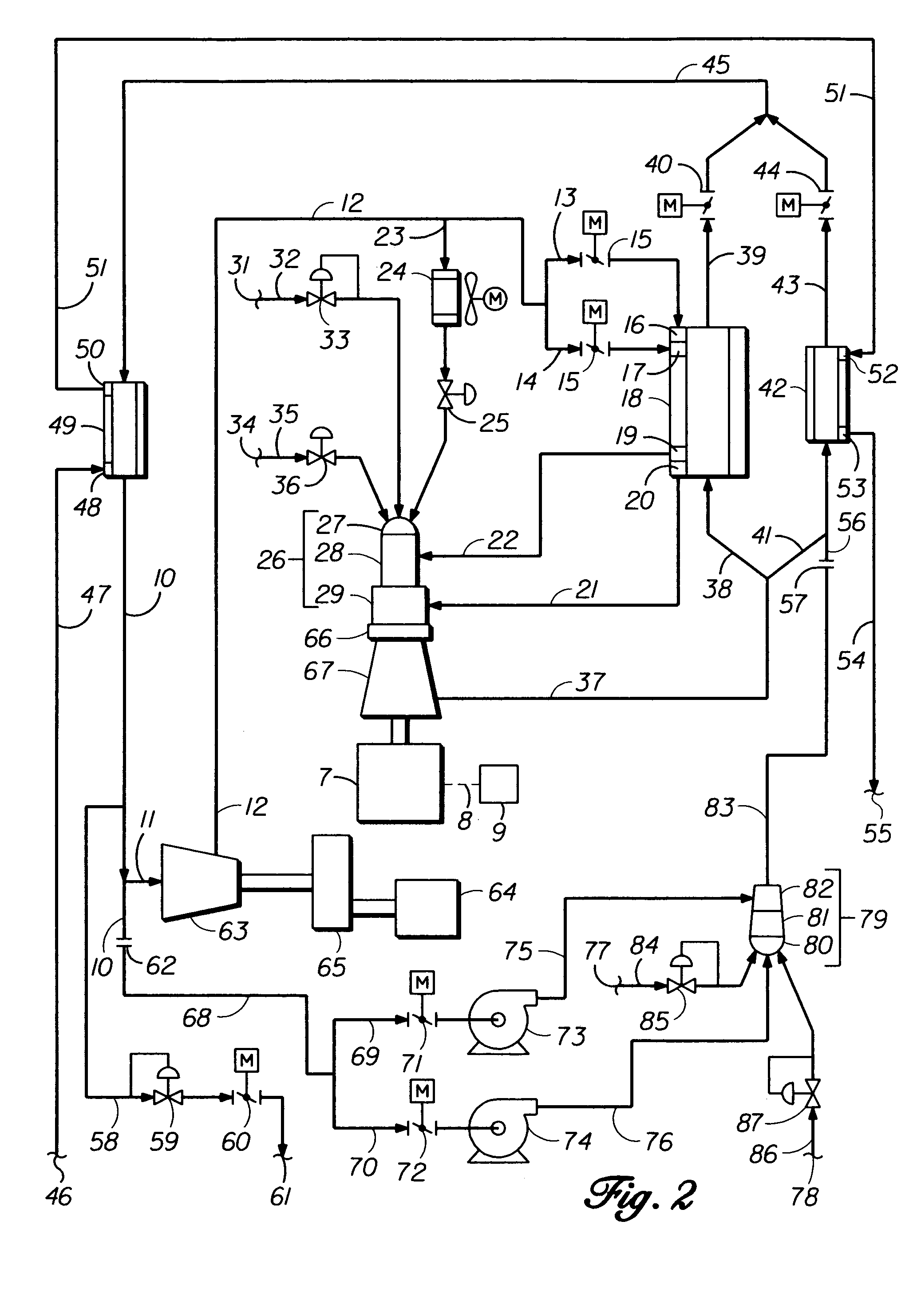

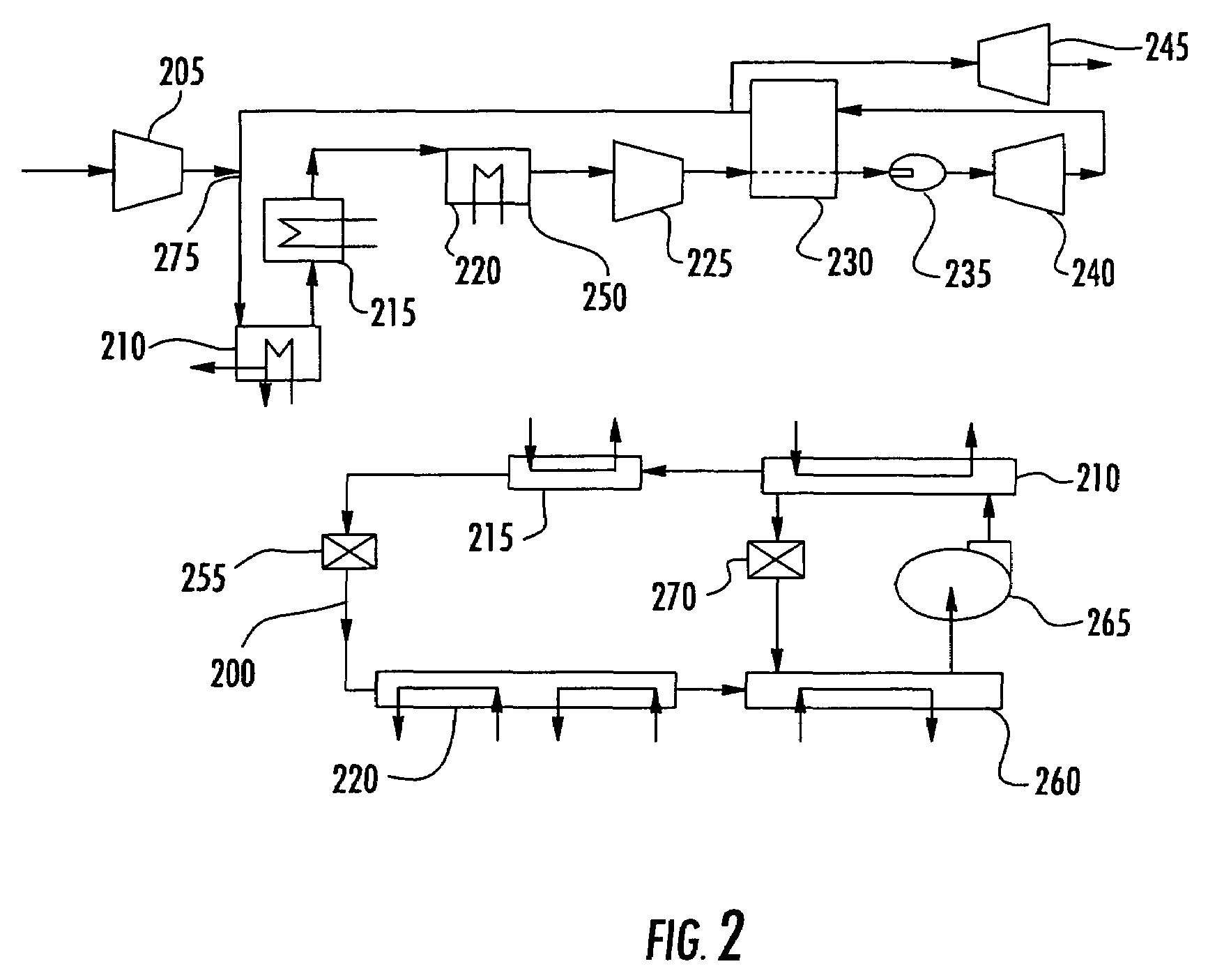

Combined cooling and power plant with water extraction

InactiveUS7472550B2Work lessImprove thermal efficiencyEngine fuctionsGas turbine plantsPower stationEngineering

A turbine engine system and a method for using the turbine engine system that includes at least one low-pressure compressor, at least one high-pressure compressor, at least one low-pressure turbine, and at least one high-pressure turbine. In addition, the turbine engine system includes an absorption refrigeration system that is used to pre-cool an air-gas mixture before it enters the high-pressure compressor. As such, the pre-cooled mixture is easier to compress, thereby increasing the thermal efficiency of the turbine engine. Additionally, the exhaust heat from the air-gas mixture that is pre-cooled may be used to drive the absorption refrigeration system. Lastly, water, may be extracted from the evaporator of the absorption refrigeration cycle.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

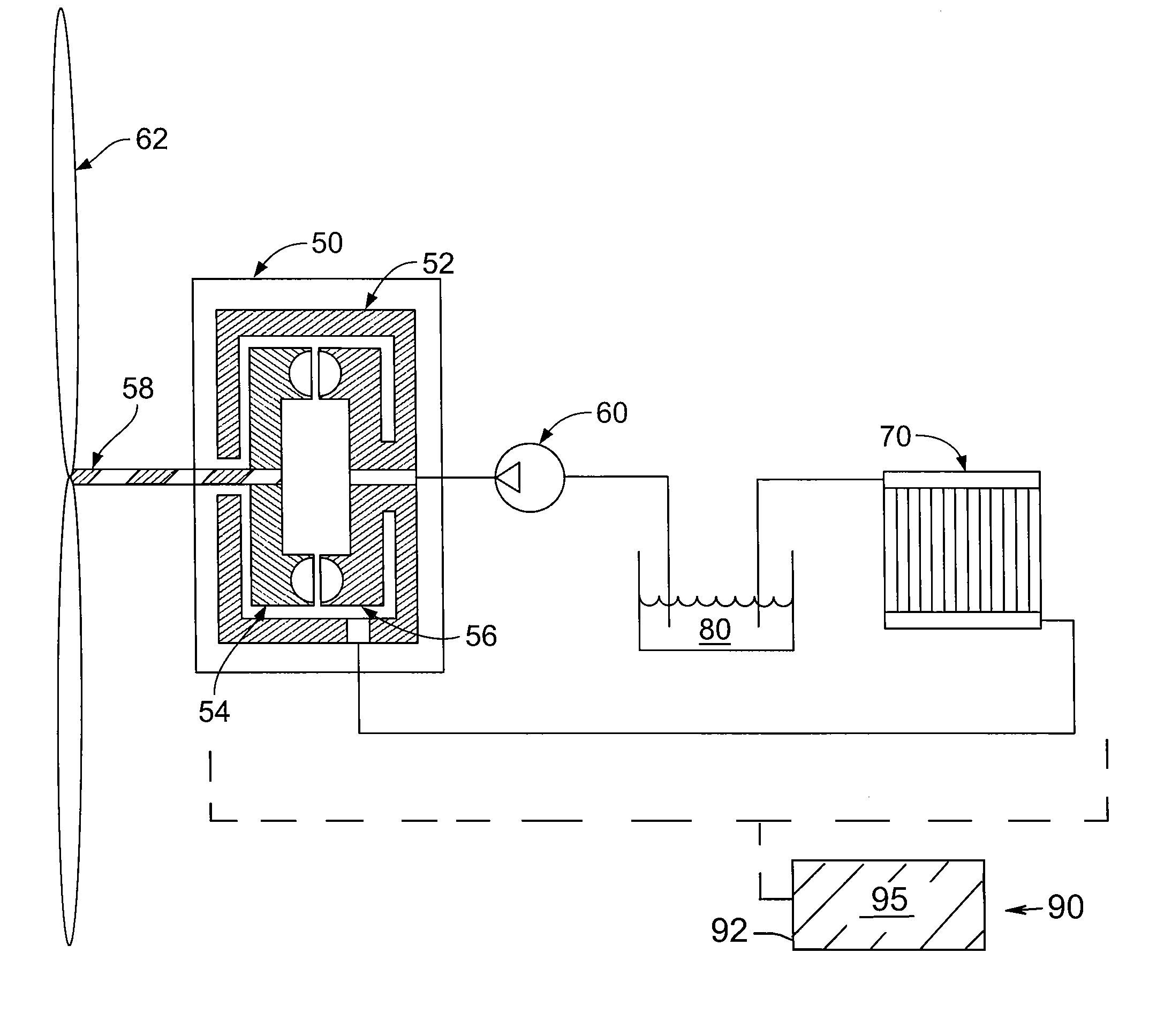

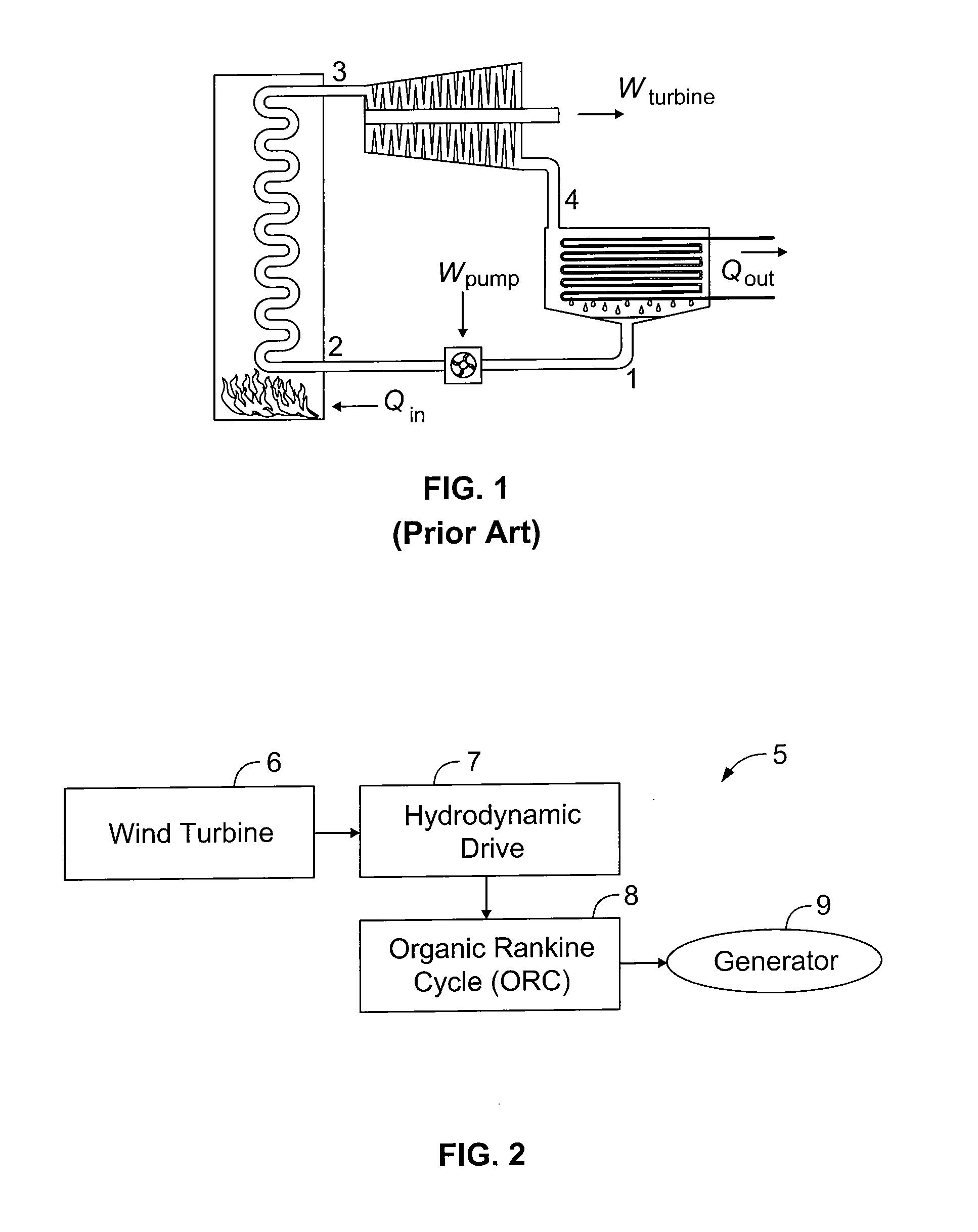

Power generator using a wind turbine, a hydrodynamic retarder and an organic rankine cycle drive

InactiveUS20120001436A1Facilitates easy inspectionEasy maintenanceWind energy with garvitational potential energyEnergy industryElectricityOrganic Rankine cycle

An electric power generating system is provided that uses a wind turbine to generate waste-heat that is utilized in an organic Rankine Cycle drive that converts heat energy into rotation of a generator rotor for generating electricity. A hydrodynamic retarder may be provided that dissipates heat into a hot fluid by directing the flow of the fluid through the hydrodynamic retarder in a manner that resists rotation of blades of the wind turbine. The hot fluid circulating in the hydrodynamic retarder is a thermal heat source for vapor regeneration of organic heat exchange fluid mixture(s) used in the Rankine cycle, expansion of the organic heat exchange fluid being converted into rotation of the generator rotor.

Owner:SAMI SAMUEL DR

Disposable and biodegradable paper cup

InactiveUS6926197B2Improve thermal performanceHigh biodegradabilityFlexible coversWrappersPaper sheetPhase transition

Owner:HED AHARON ZEEV +1

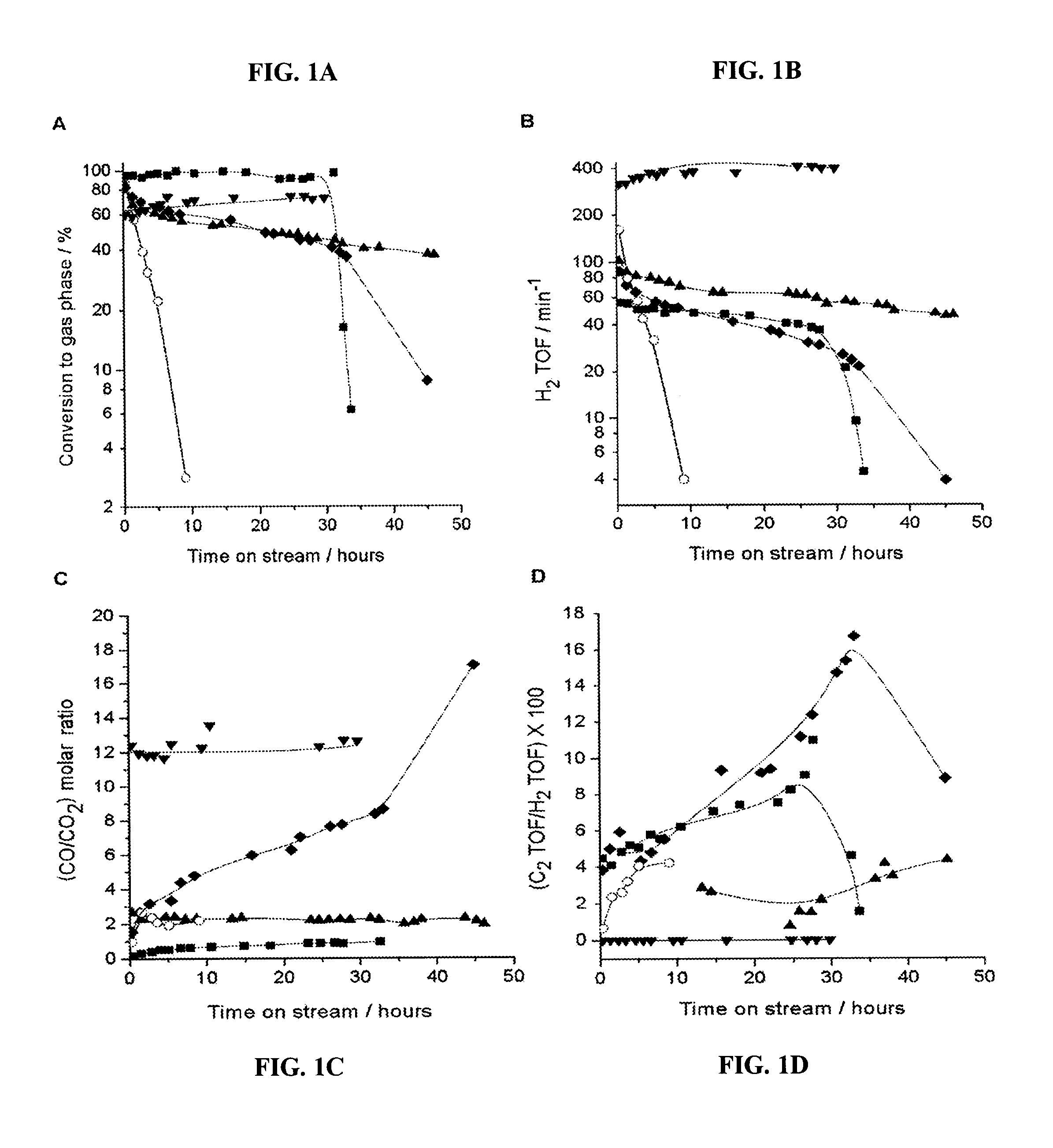

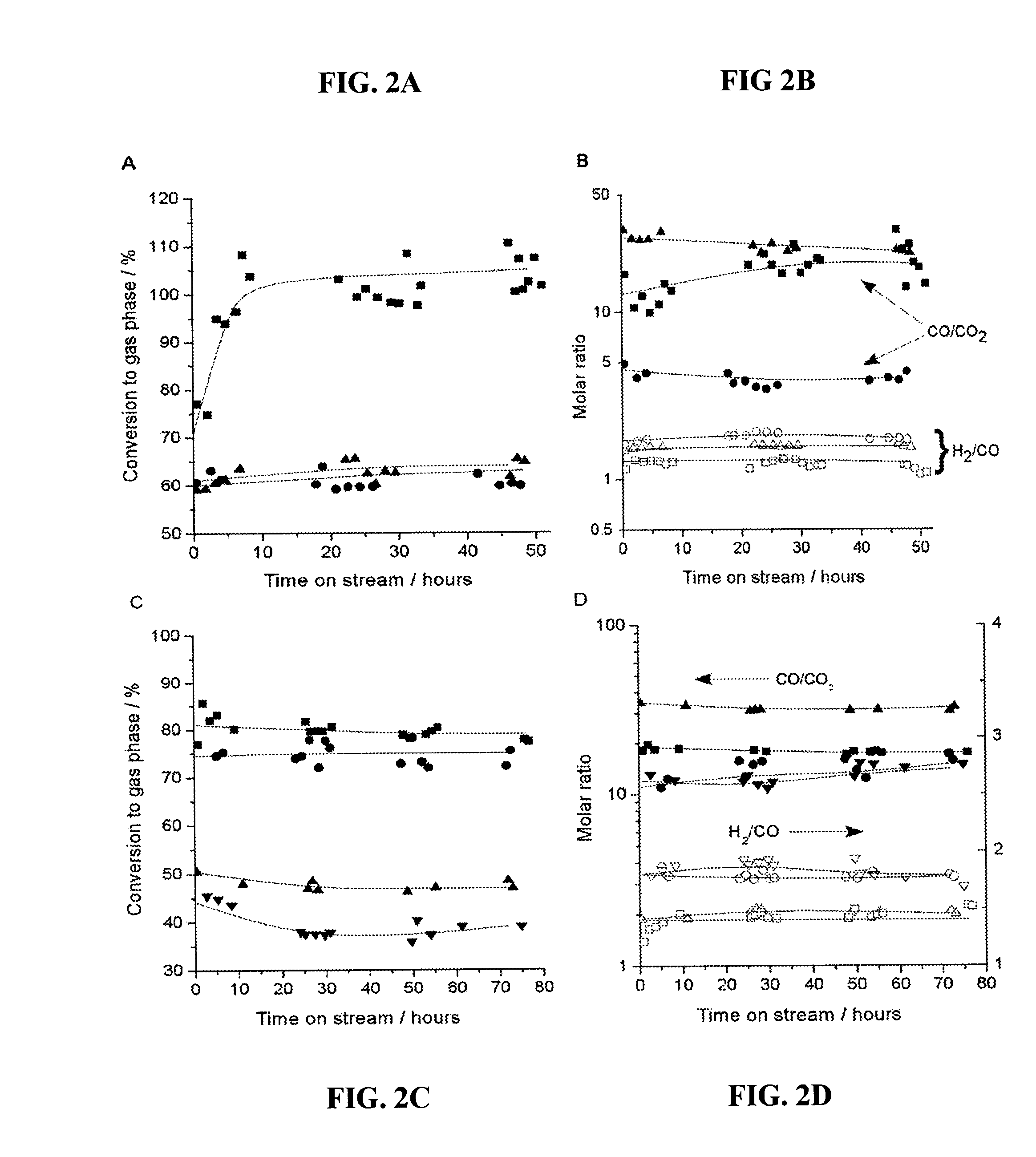

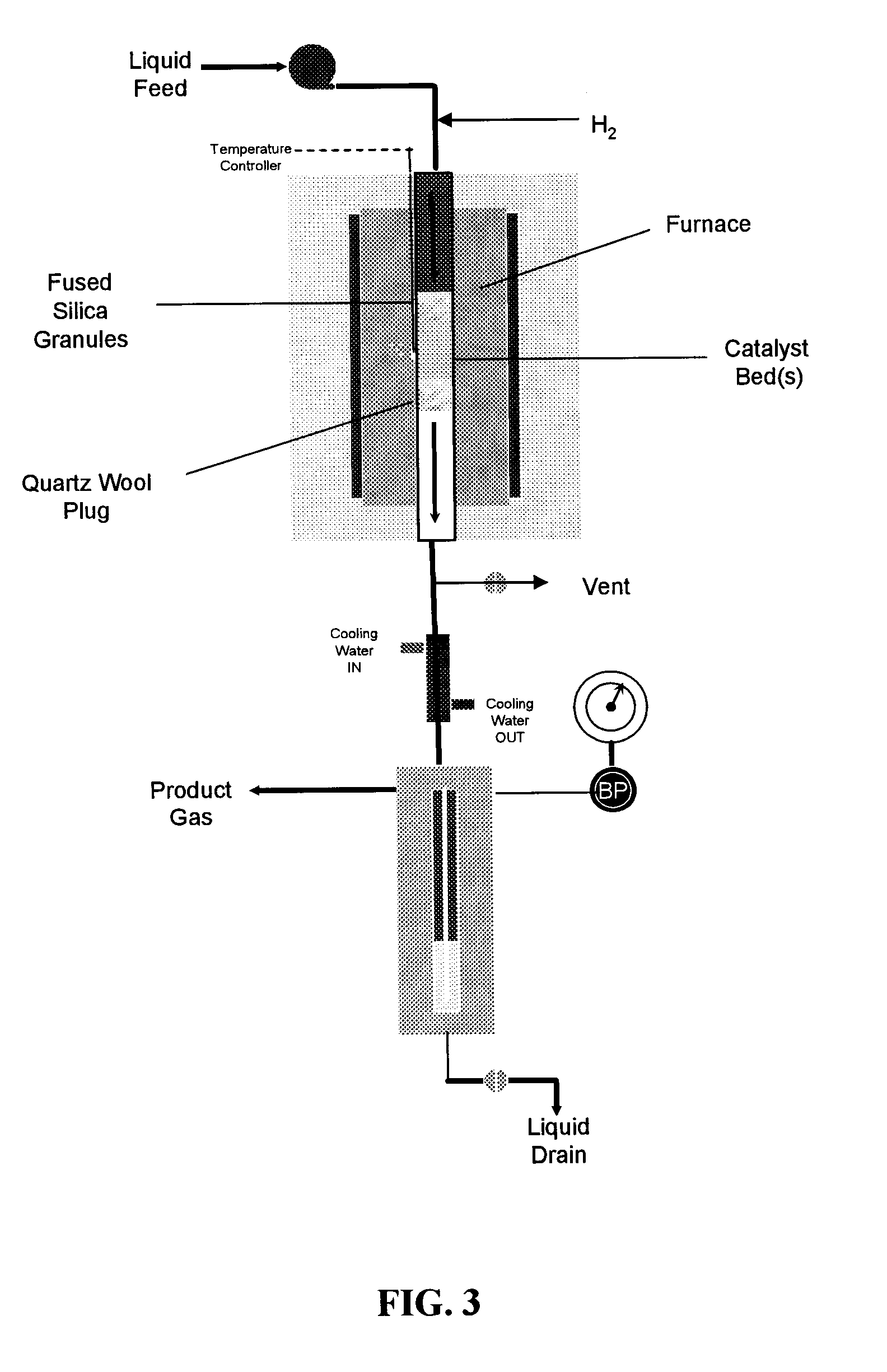

Method for producing bio-fuel that integrates heat from carbon-carbon bond-forming reactions to drive biomass gasification reactions

ActiveUS20070225383A1Improve thermal efficiencyImprove economyCatalytic crackingBiofuelsSyngasBiodiesel

A low-temperature catalytic process for converting biomass (preferably glycerol recovered from the fabrication of bio-diesel) to synthesis gas (i.e., H2 / CO gas mixture) in an endothermic gasification reaction is described. The synthesis gas is used in exothermic carbon-carbon bond-forming reactions, such as Fischer-Tropsch, methanol, or dimethylether syntheses. The heat from the exothermic carbon-carbon bond-forming reaction is integrated with the endothermic gasification reaction, thus providing an energy-efficient route for producing fuels and chemicals from renewable biomass resources.

Owner:VIRENT +1

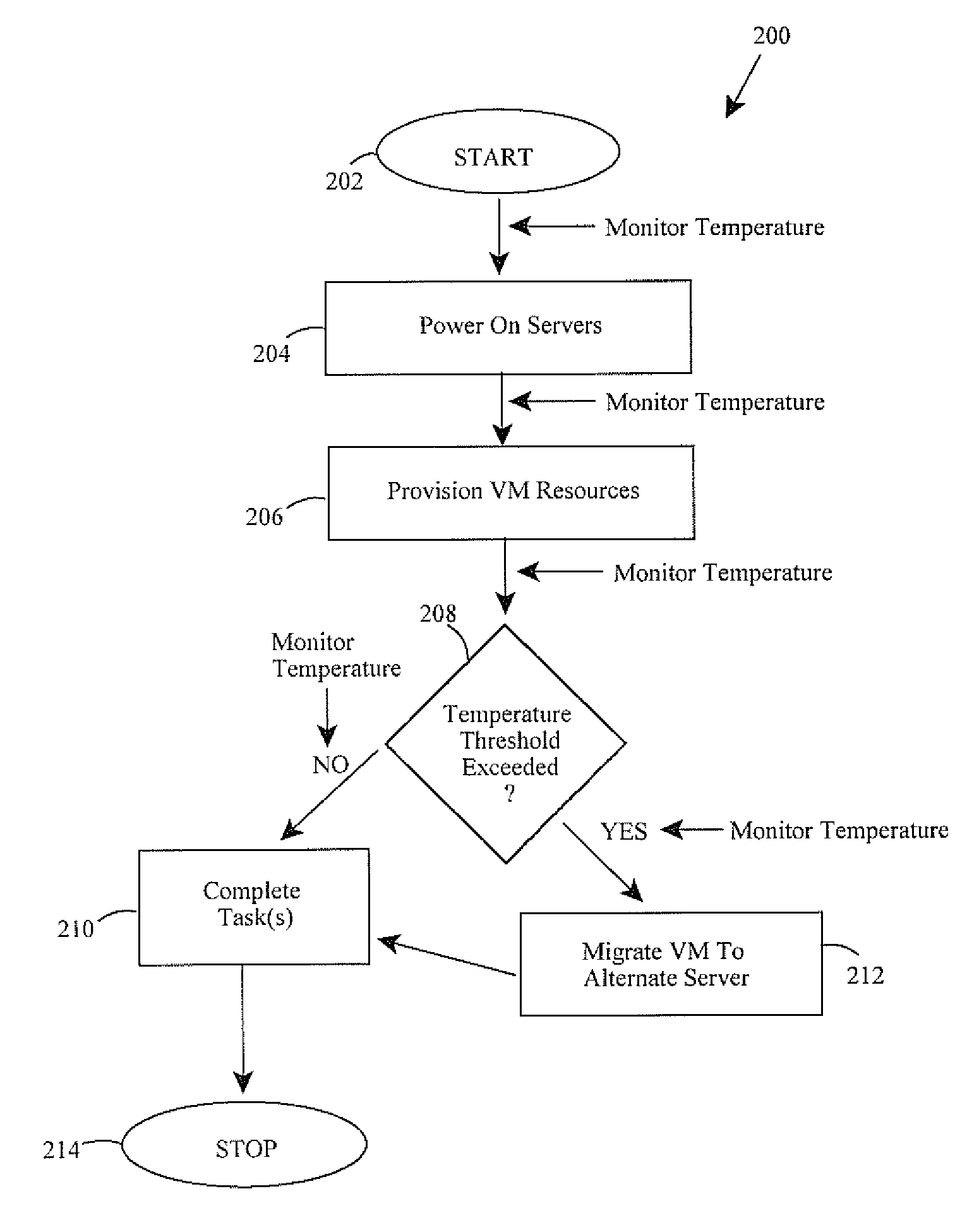

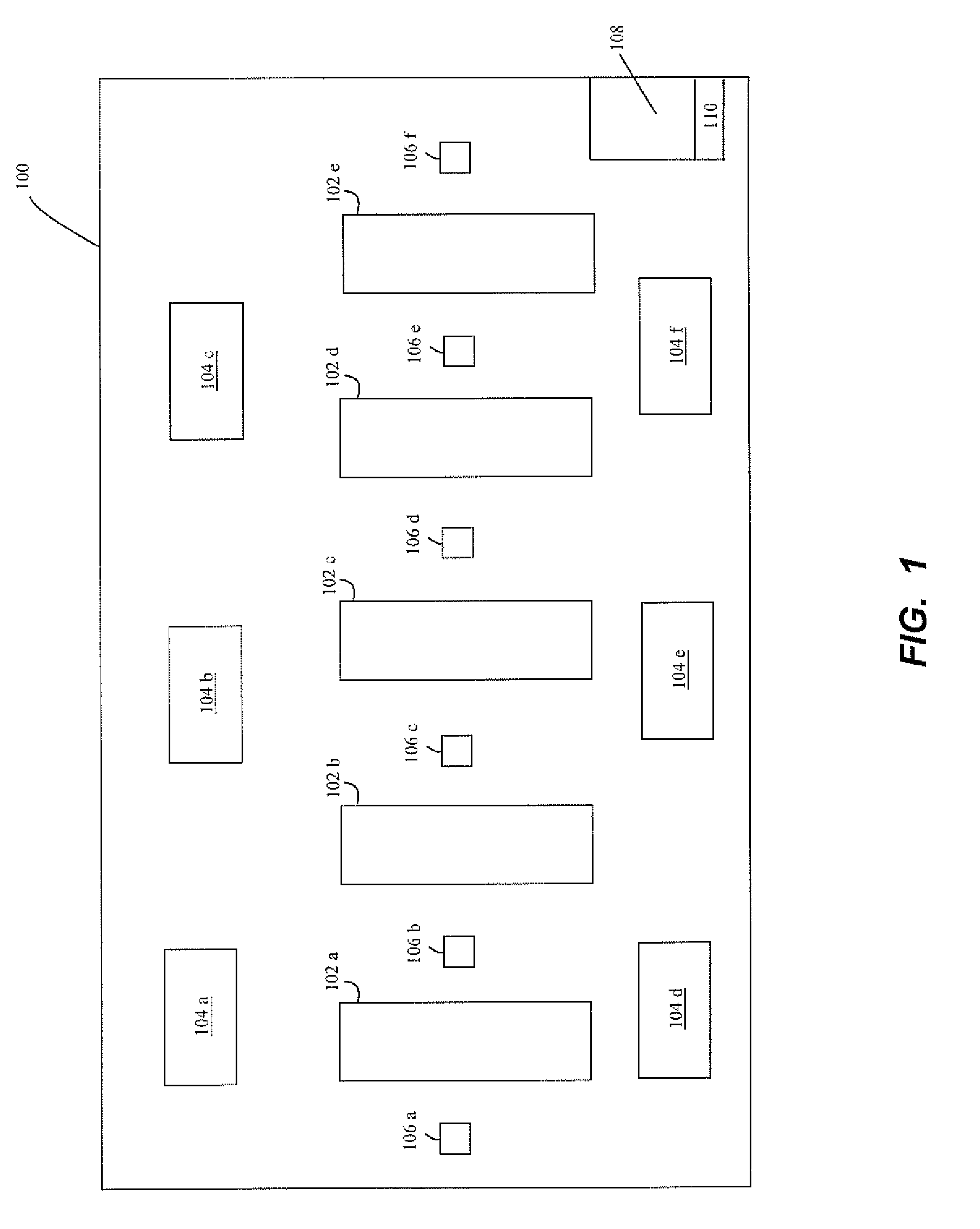

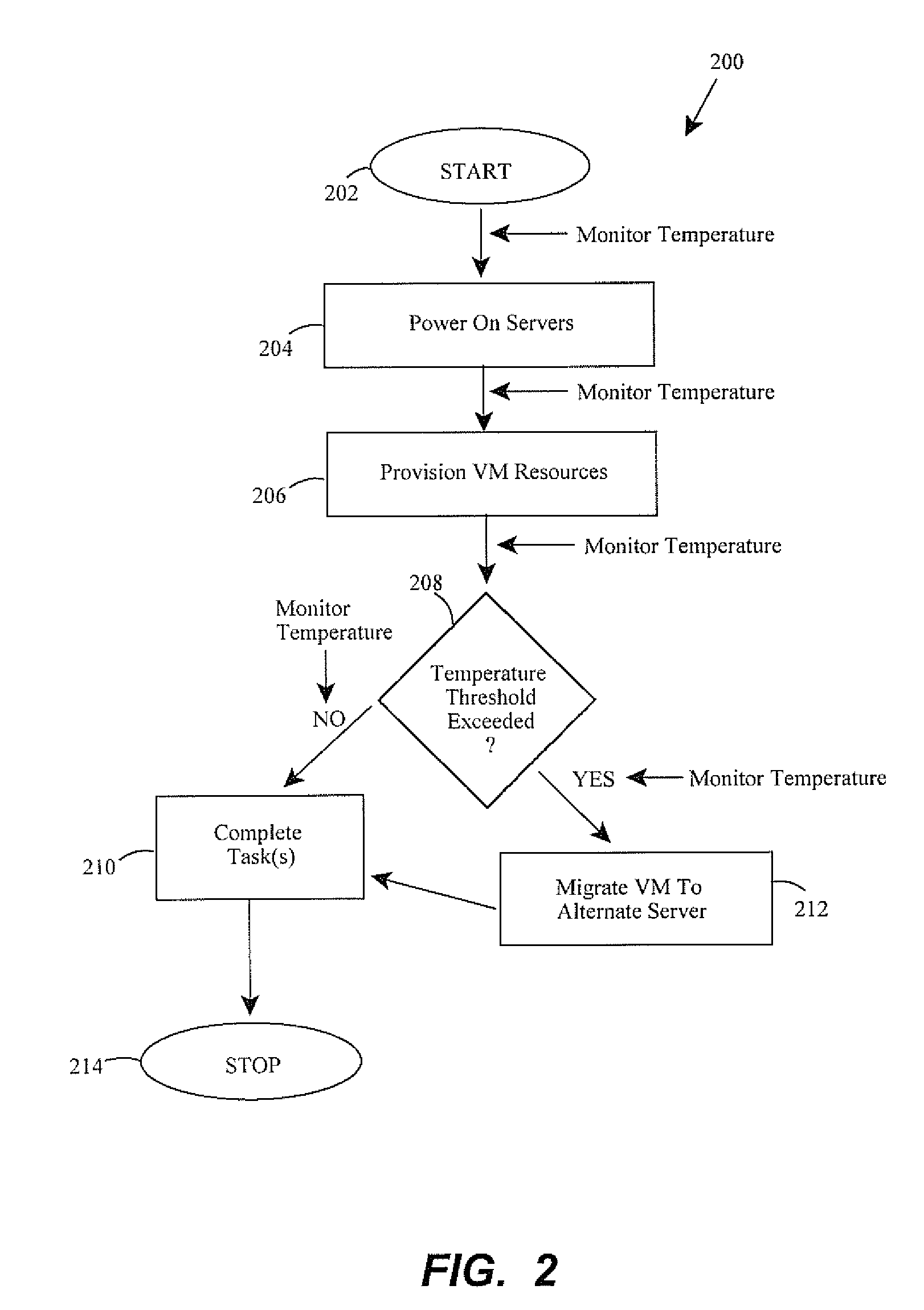

Dynamic thermal load balancing

ActiveUS20100217454A1Inhibit migrationImprove thermal efficiencyThermometer detailsTemperatue controlData centerComputerized system

A method for improving thermal efficiency in one or more data centers includes measuring a temperature at one or more computing devices having allocated thereto one or more computing workloads and determining whether the measured temperature exceeds a predetermined temperature threshold. If the predetermined temperature threshold is exceeded, sufficient computing workloads are migrated to one or more alternate computing devices to reduce the temperature at one or more of the computing devices to less than or equal to said predetermined temperature threshold. In accomplishing the method, there is provided a data orchestrator configured at least for receiving data concerning the measured temperature, determining whether the measured temperature exceeds the predetermined temperature threshold, and migrating one or more of the computing workloads to one or more alternate computing devices. Computer systems and computer programs available as a download or on a computer-readable medium for installation according to the invention are provided.

Owner:SUSE LLC

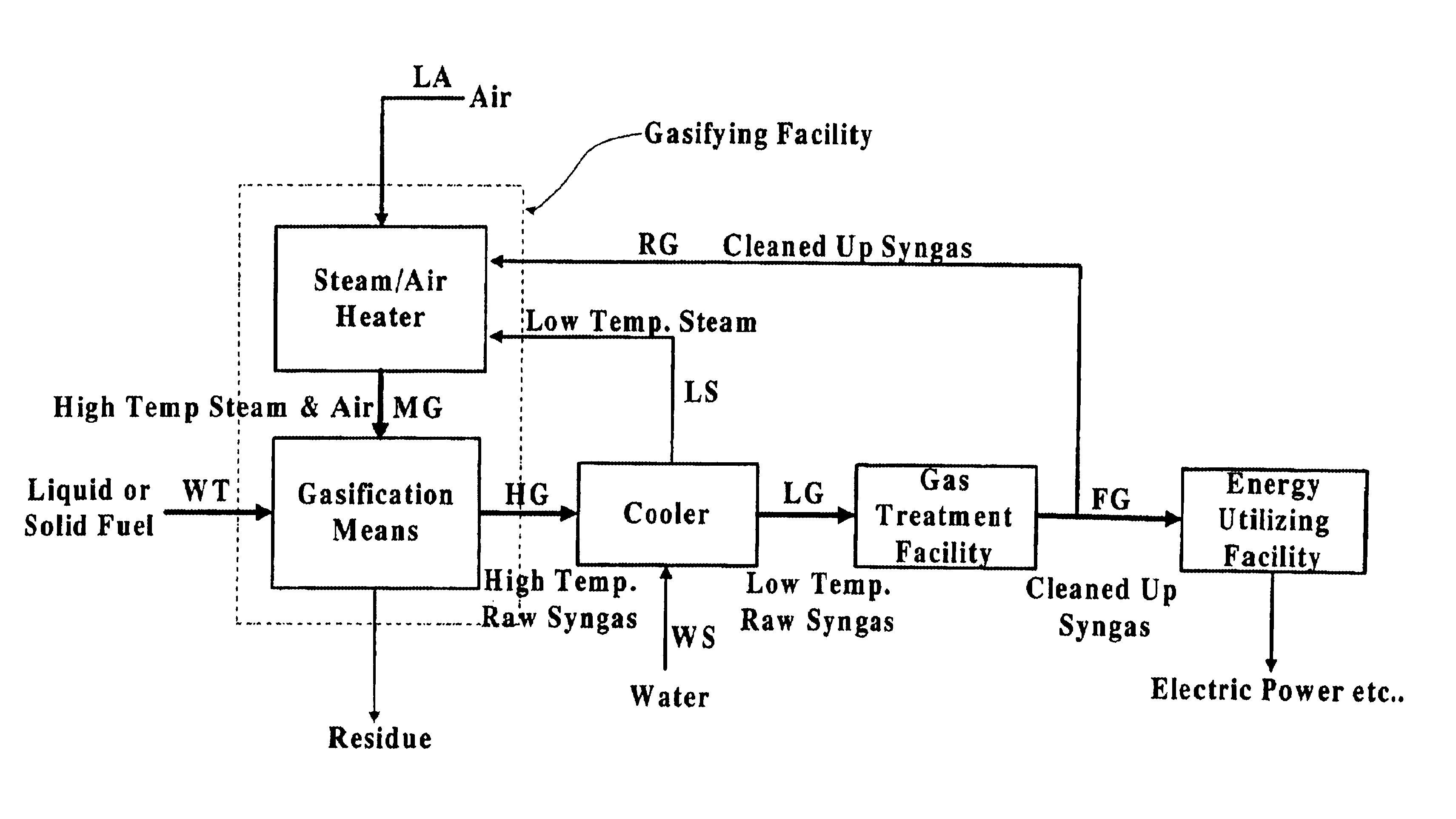

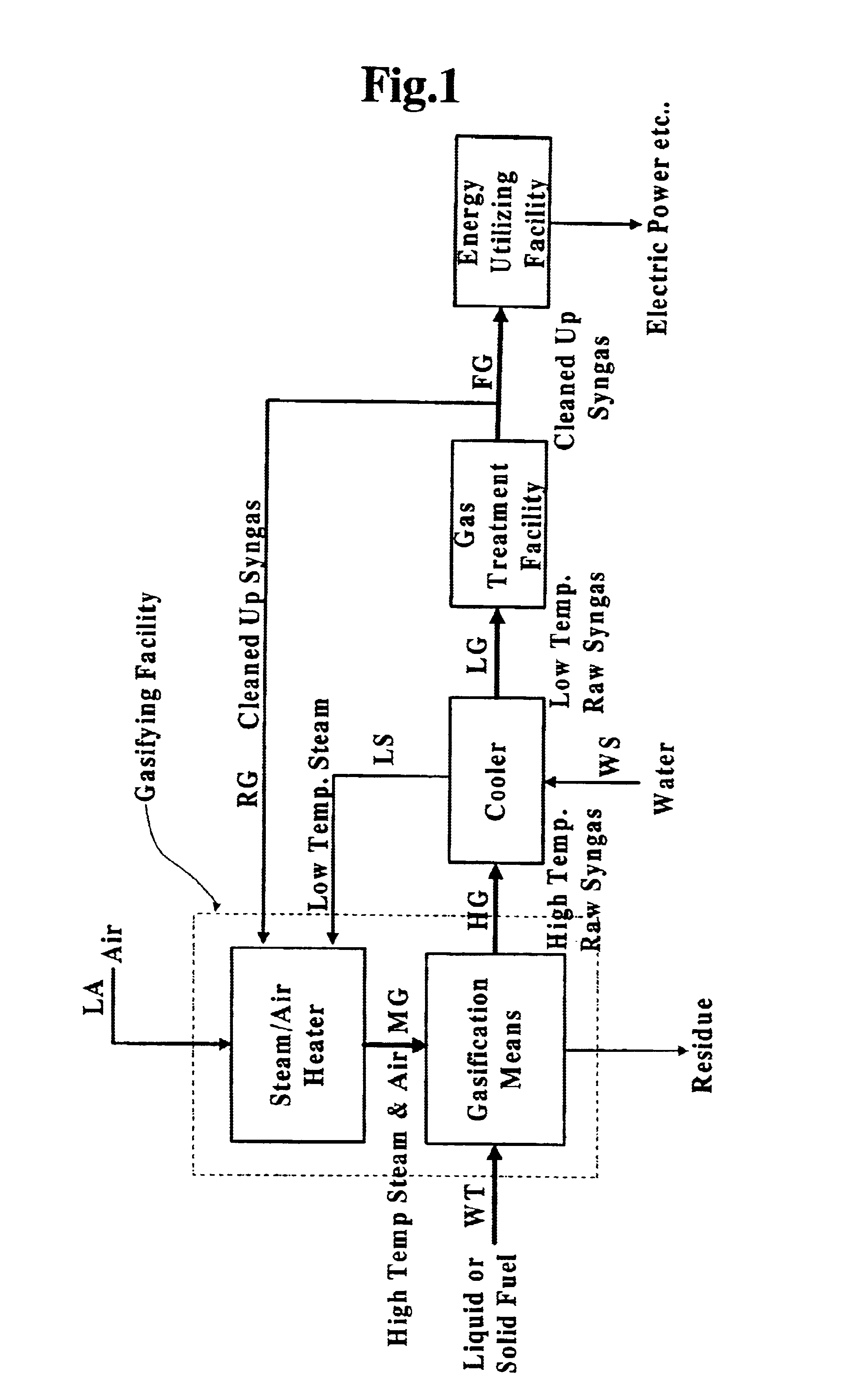

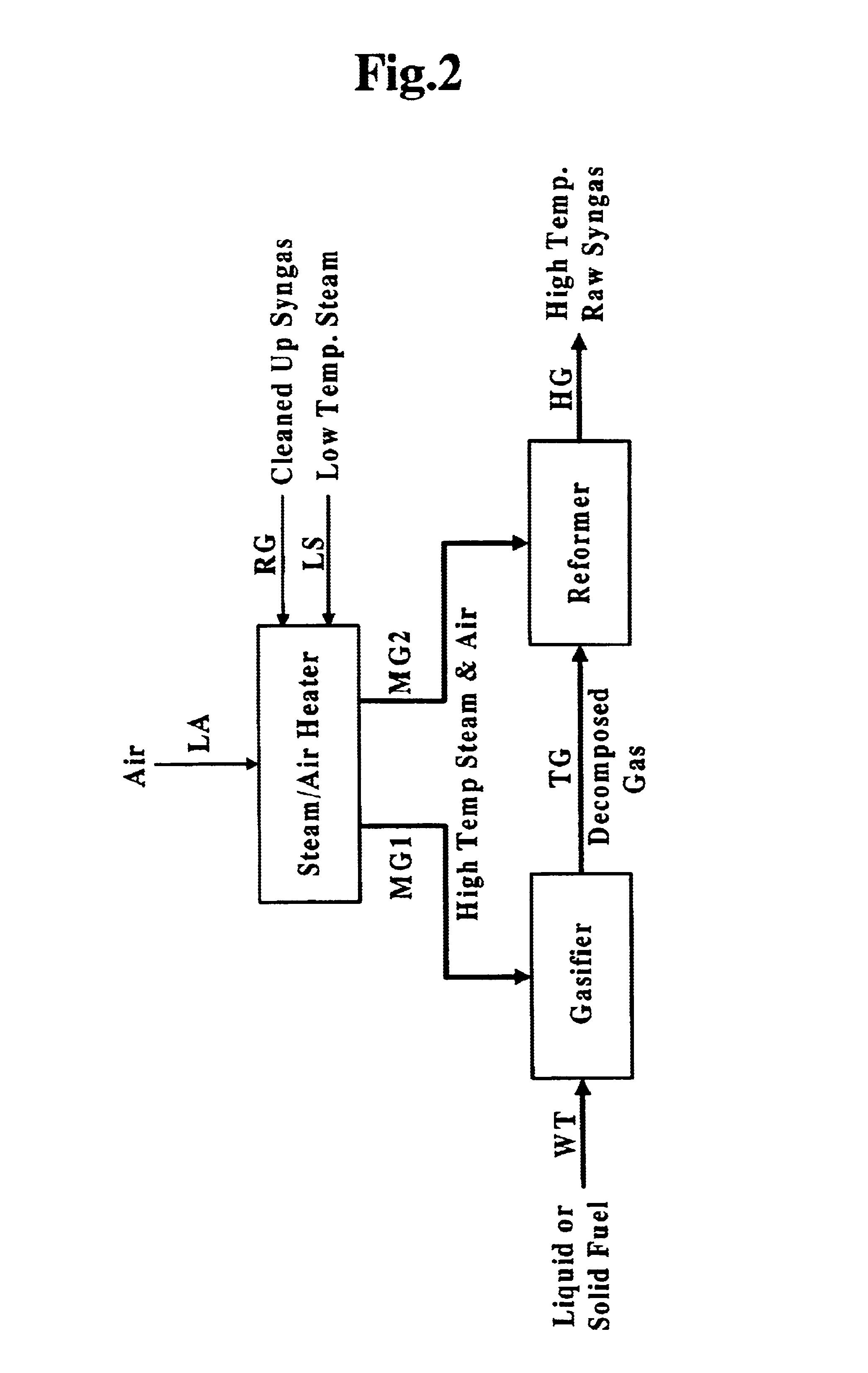

Apparatus and method for gasifying liquid or solid fuel

InactiveUS6837910B1Quality improvementAmount of heat can be ensuredHydrogenGaseous fuelsSyngasExothermic reaction

A gasifying apparatus comprises a gasifier, a reformer and a heating device. The gasifier produces a thermal decomposed gas with use of a thermal decomposition reaction of a liquid or solid fuel such as waste or coal, and the heating device heats a low-temperature steam and air so as to be a high-temperature steam and air, which have a temperature equal to or higher than 700 deg. C. The gasifying apparatus has feeding means including fluid passages for feeding the high-temperature steam and air to the gasifier and the reformer. In a thermal decomposition area of the gasifier, the liquid or solid fuel is thermally decomposed to produce the thermal decomposed gas with sensible heat of the high-temperature steam and air and with the heat generated by an exothermic oxidation reaction between the high-temperature air and the liquid or solid fuel. In the reformer, the thermal decomposed gas is reformed in the existence of the high-temperature steam so as to be a high-temperature syngas. The steam reforming reaction of the liquid or solid fuel is carried out with an exothermic reaction between the high-temperature air and hydrocarbon contained in the thermal decomposed gas and with an endothermic reaction between the hydrocarbon and the high-temperature steam.

Owner:NIPPON FURNANCE IND KAISHA +1

Thermoelectric module with directly bonded heat exchanger

InactiveUS20050121065A1Improve thermal efficiencyReduce thermal resistanceThermoelectric device with peltier/seeback effectEngineeringThermoelectric element

A thermoelectric device with an improved thermal efficiency has an object to be heated or cooled having a surface, at least one electrically conductive lower pad bonded directly to the surface of the object using a thermally conductive dielectric material, at least one thermoelectric element coupled on one end to the electrically conductive pad, at least one electrically conductive upper pad coupled to an opposite end of the thermoelectric element, and electrical power connections coupled to the device.

Owner:FERROTEC USA CORP

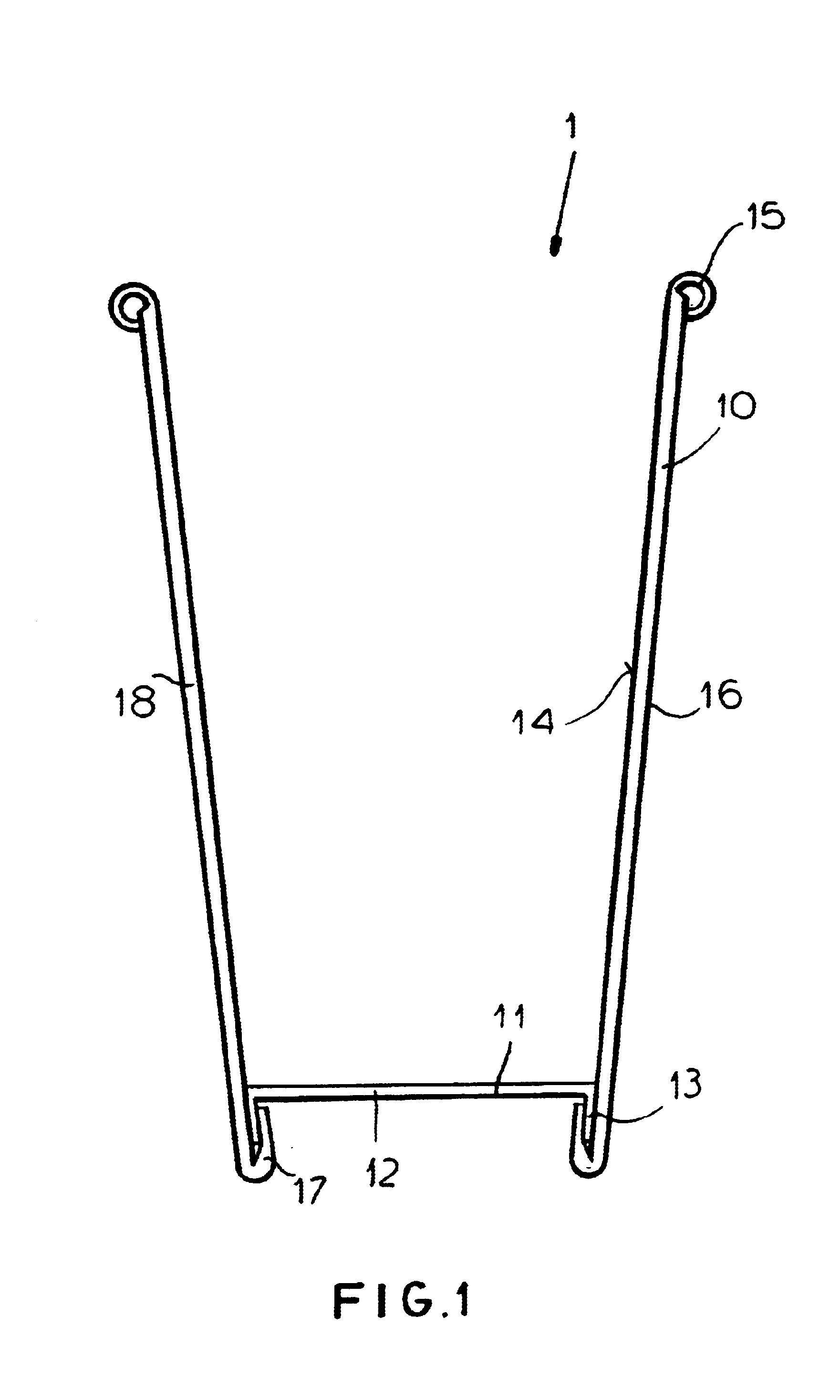

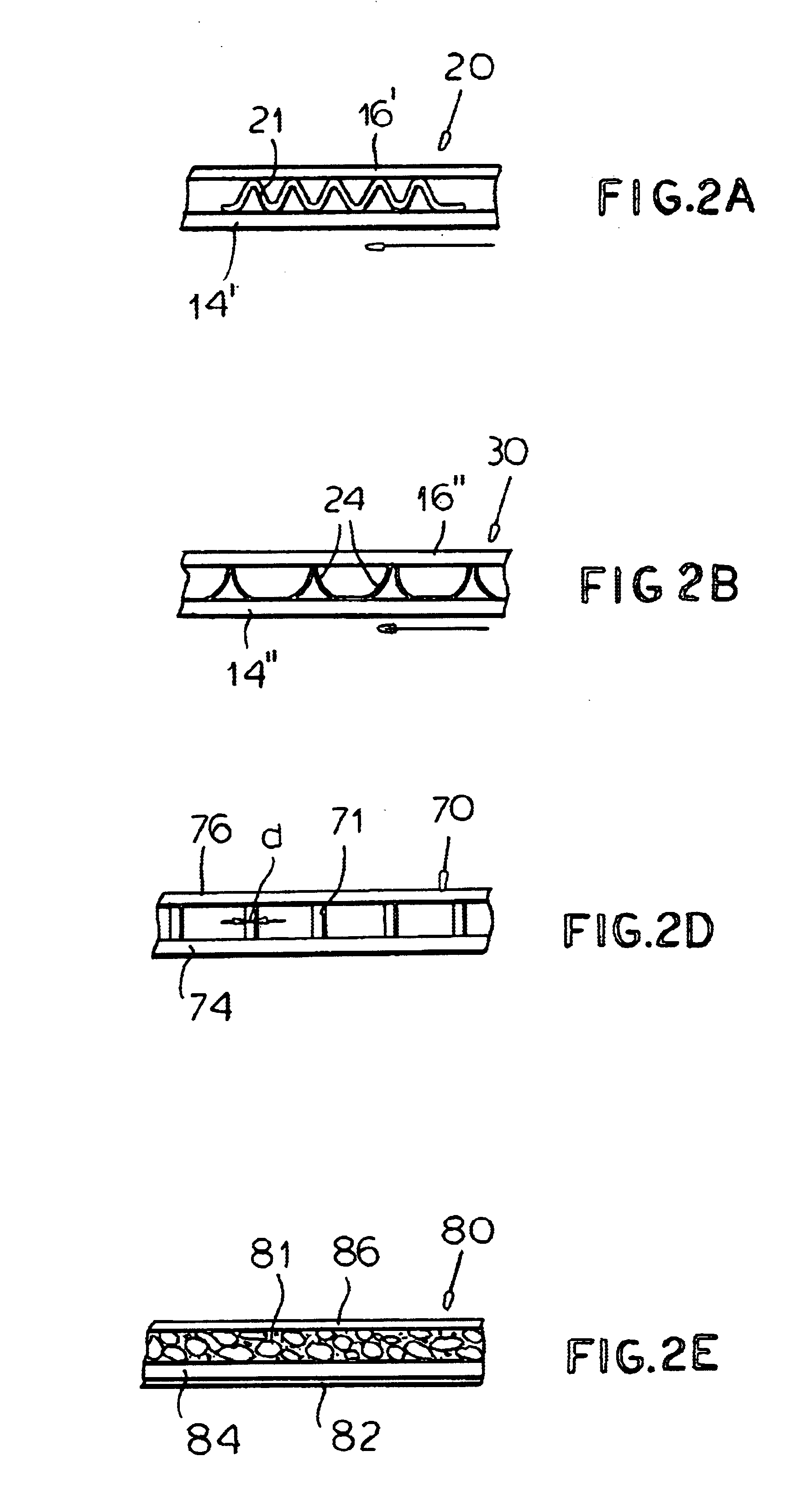

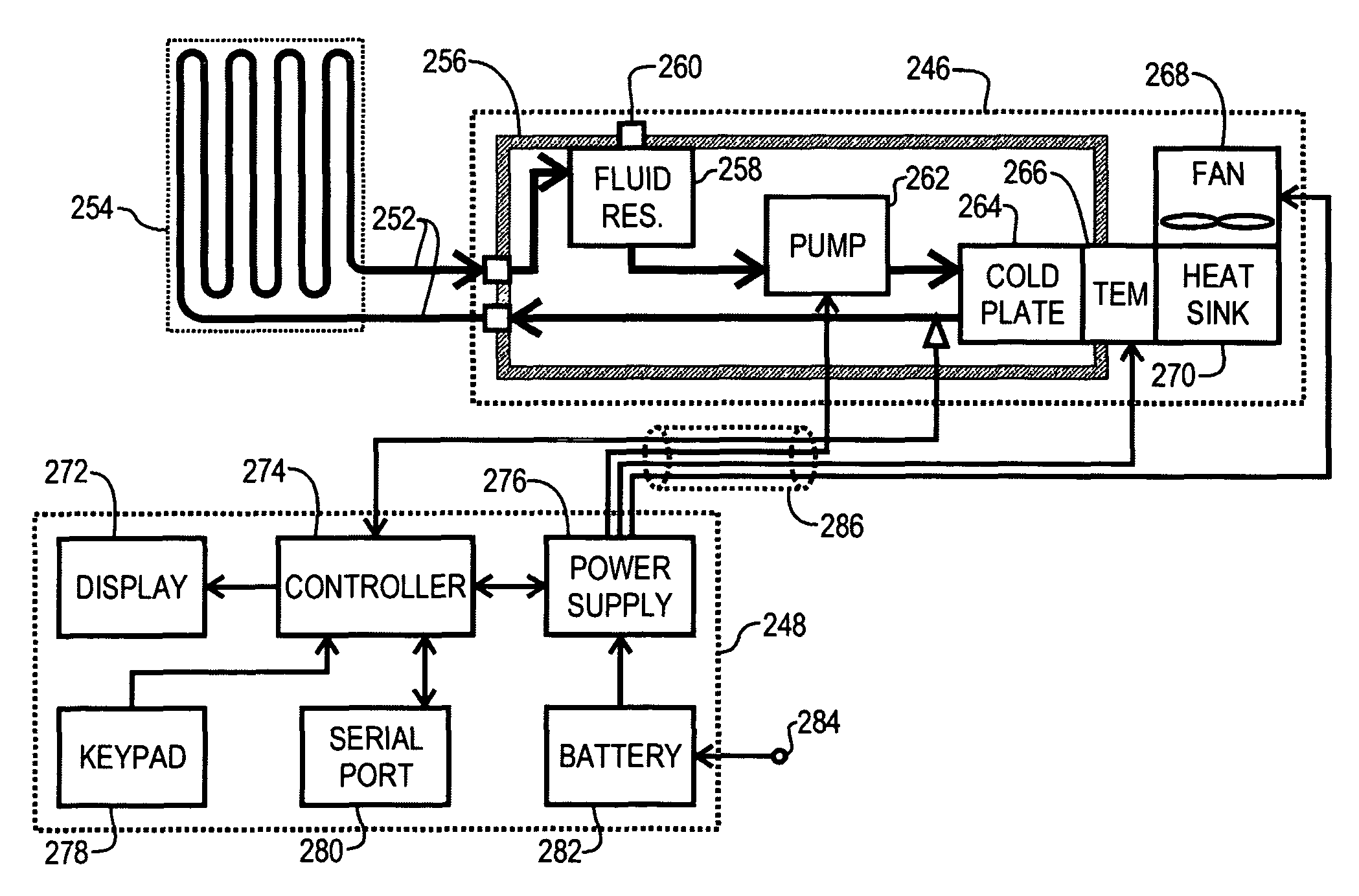

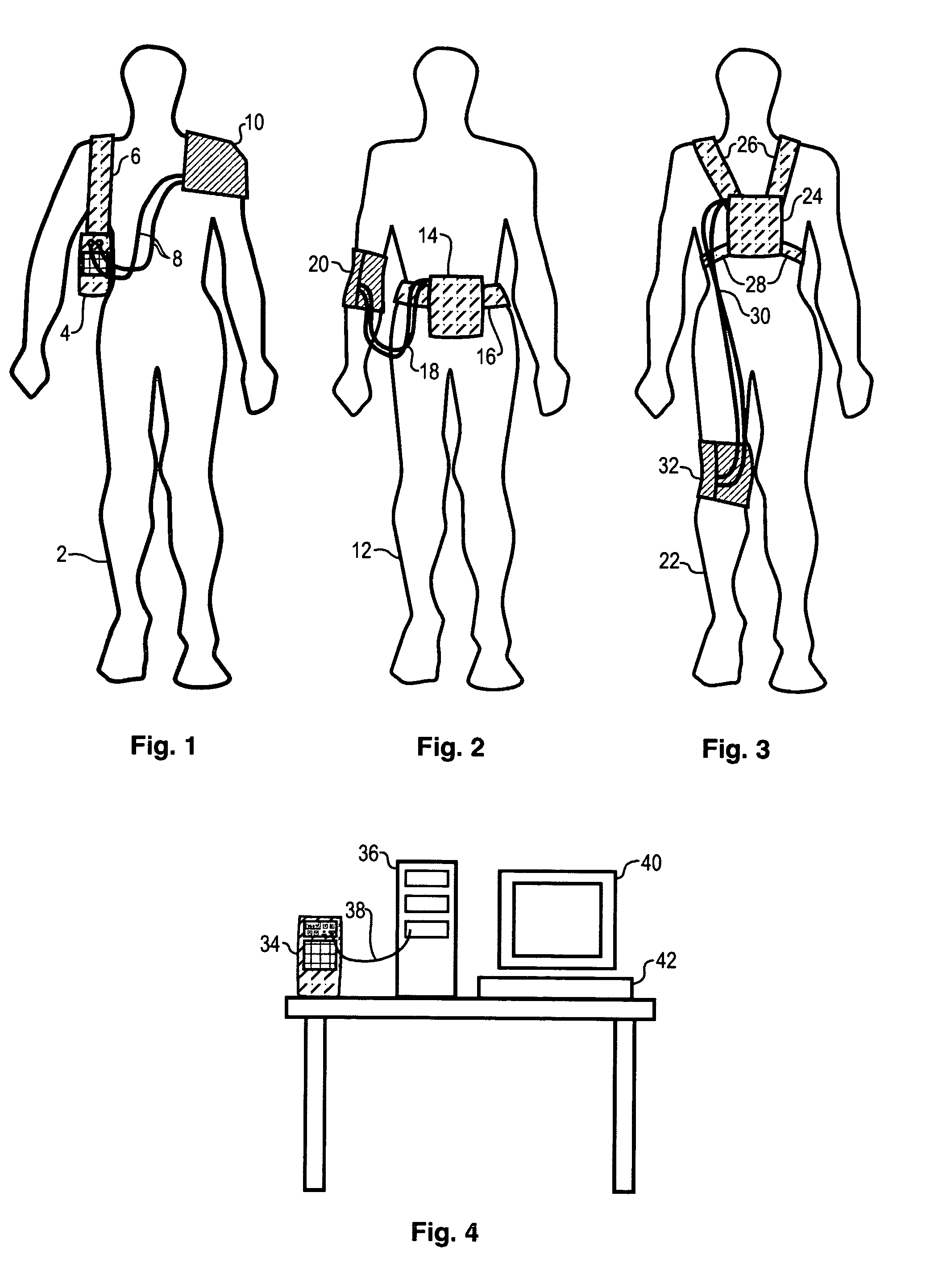

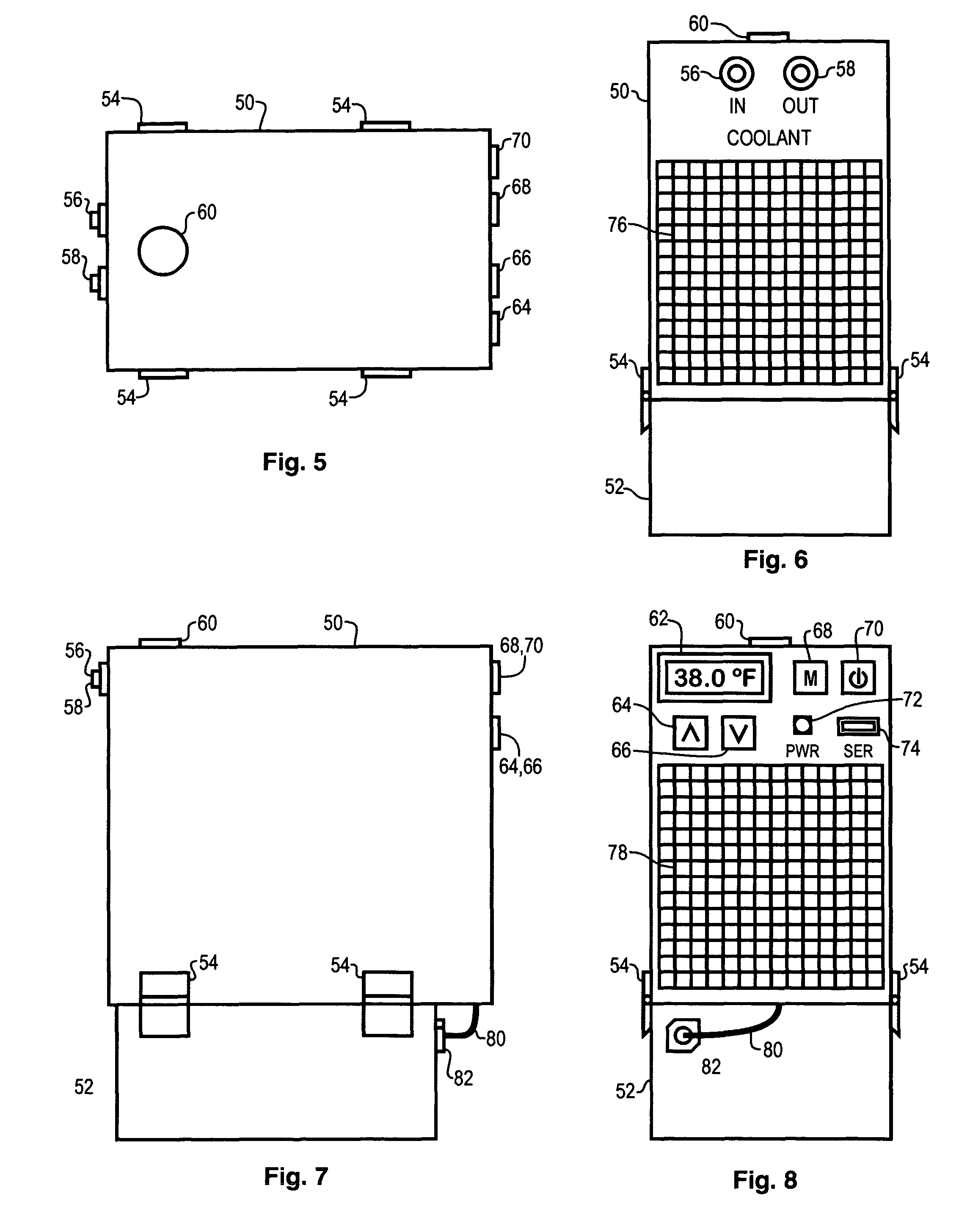

Portable thermal therapeutic apparatus and method

ActiveUS7959657B1Improve thermal efficiencyTherapeutic coolingTherapeutic heatingHeat transfer fluidHeat spreader

A portable thermal therapeutic apparatus, adapted to transfer heat between a creature and the atmosphere by circulating heat transfer fluid within a conduit held in contact with the creature. The apparatus includes a housing with a support structure that is particularly adapted for portable use. A heat pump is disposed within the housing, and operates to transfer heat between a first portion and a manifold. A heat sink is thermally coupled to the first portion, and transfers heat between the first portion and the atmosphere. A pump is disposed within the housing and circulates the fluid through the manifold and the conduit. A power supply is disposed within the housing and drives the pump, thereby causing the fluid to circulate within the manifold and the conduit. The power supply is also provides direct current to the heat pump, thereby causing heat to flow from the manifold to the first portion.

Owner:CRYODYNAMICS

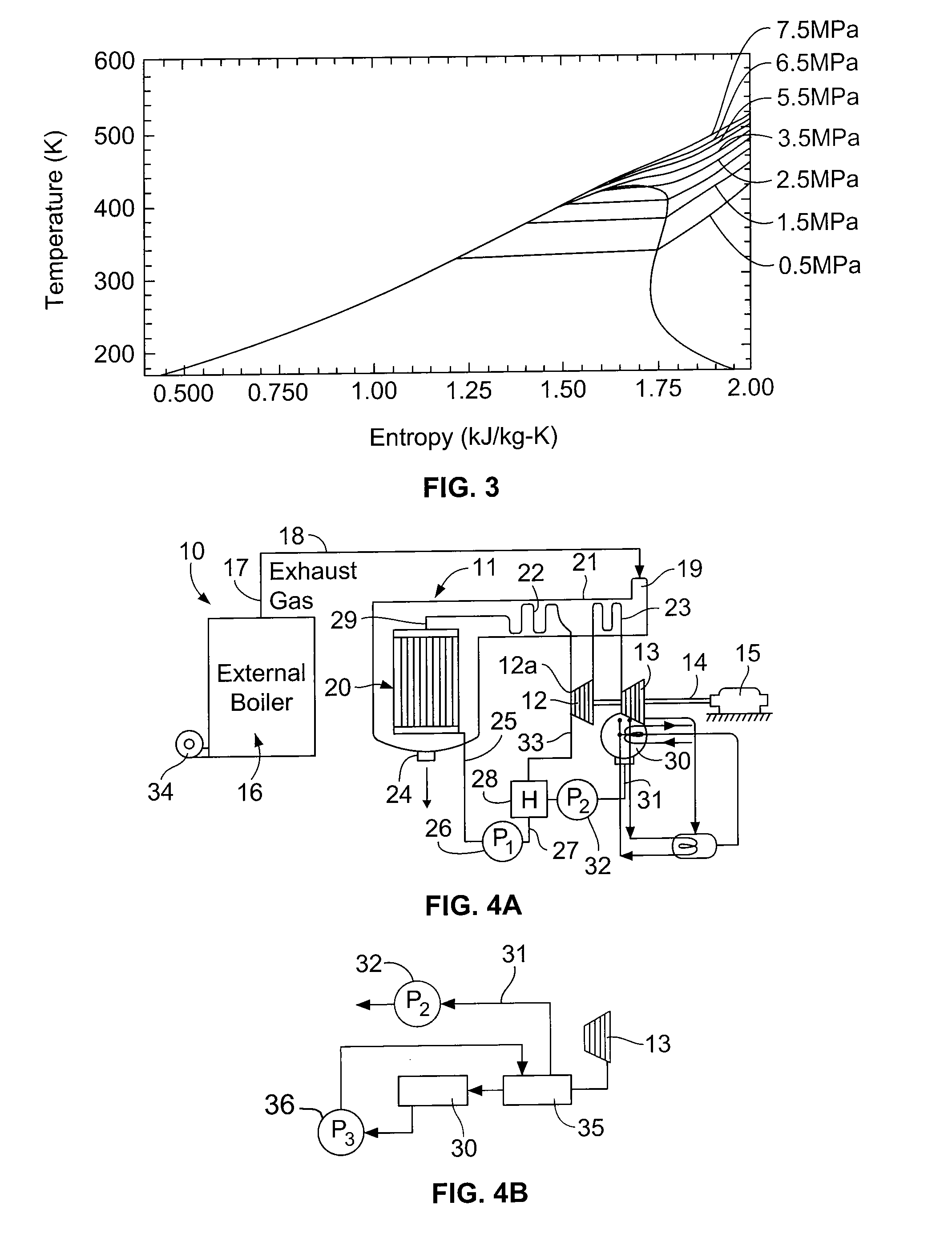

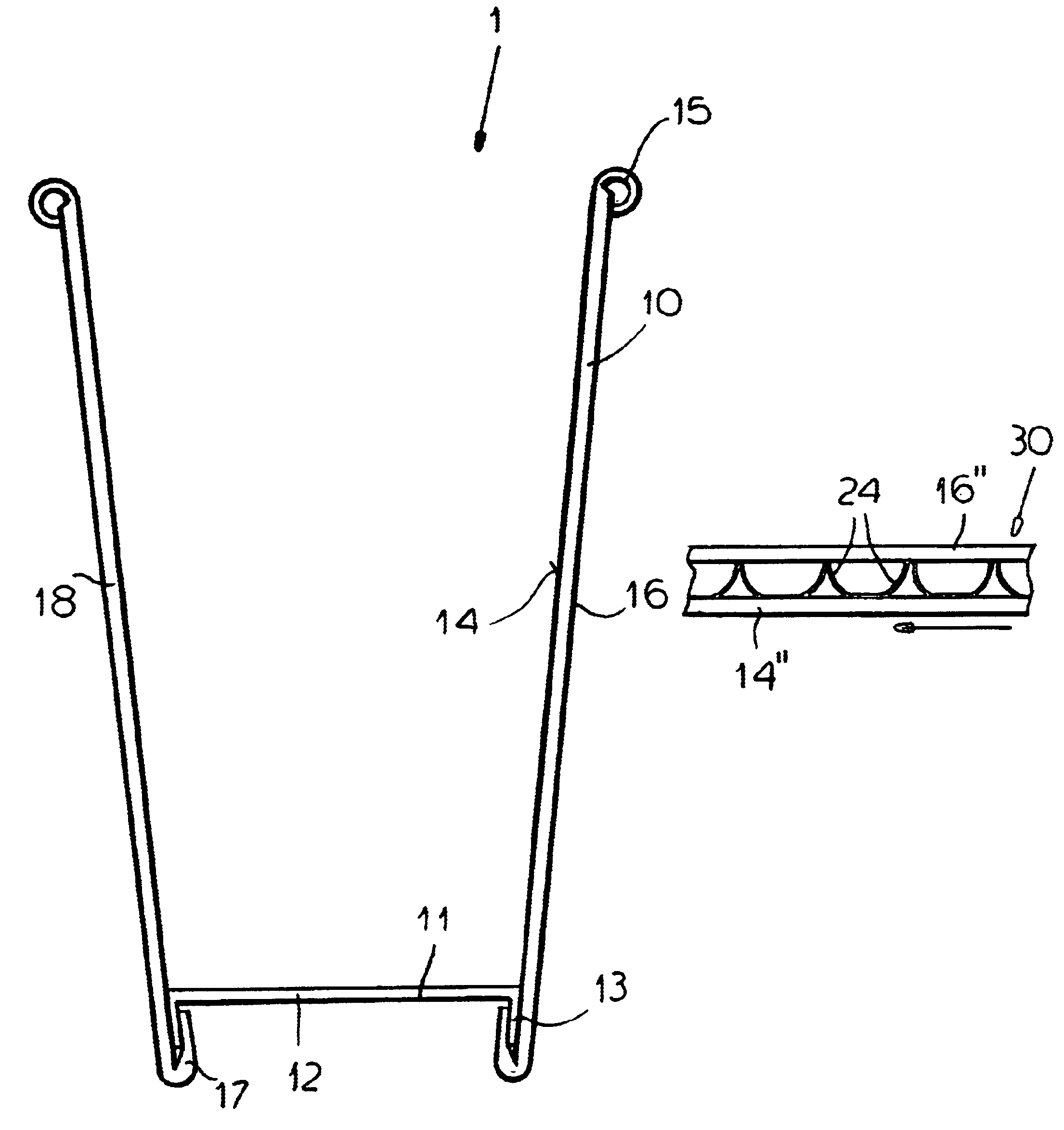

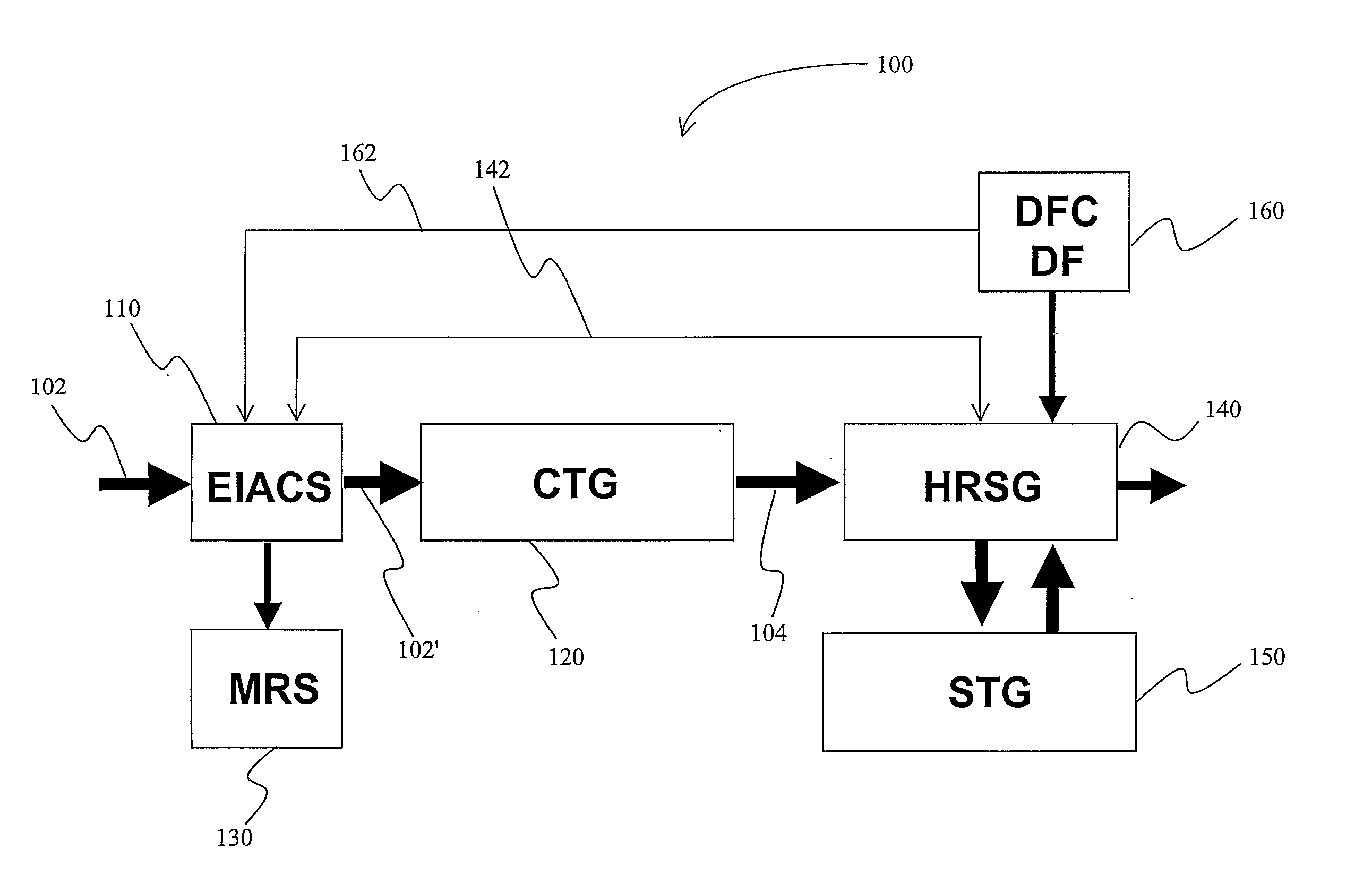

Triple Cycle Power Plant

InactiveUS20080034727A1High power outputQuality improvementGas turbine plantsSteam engine plantsPower stationNuclear engineering

Abstract: A refrigeration cycle is integrated into a combined cycle power plant to form a triple cycle power plant in which gas turbine generator inlet air is chilled and dehydrated to increase the mass flow of the inlet air, and in which duct firing in HRSG is increased in dependence of the increased mass flow. In further preferred integration aspects, the heat from the inlet chiller refrigerant is provided to the HRSG.

Owner:FLUOR TECH CORP

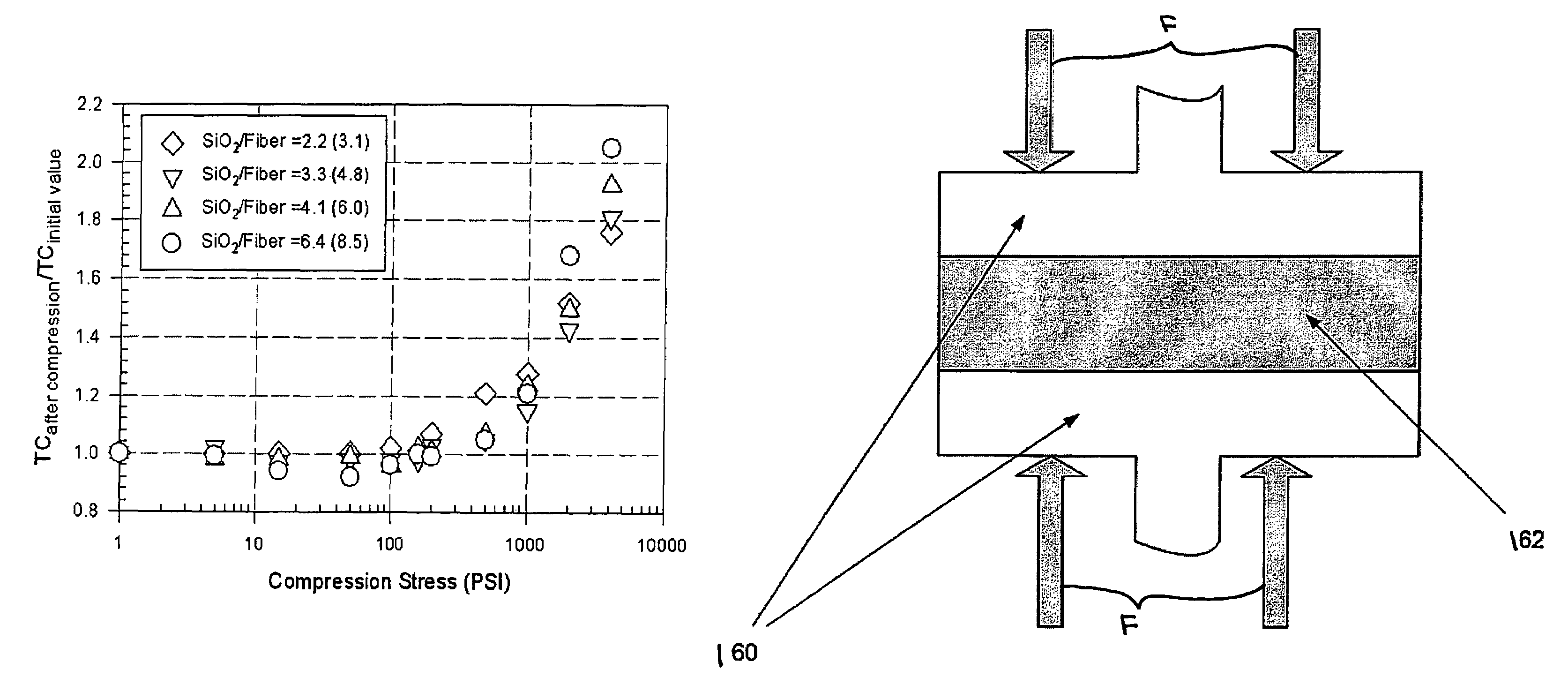

High strength, nanoporous bodies reinforced with fibrous materials

ActiveUS7560062B2High modulusHigh strengthLayered productsOrnamental structuresFlexural strengthHigh intensity

This invention discloses improvements that can be achieved in thermal or mechanical performance of aerogel composites via densification. Densified aerogels and aerogel composites can display higher compressive strength, modulus, flexural strength, and maintains or insubstantially increases the thermal conductivity relative to the pre-densified form. In the special case of fiber reinforced aerogel composites densification via mechanical compression can prove highly beneficial.

Owner:ASPEN AEROGELS INC

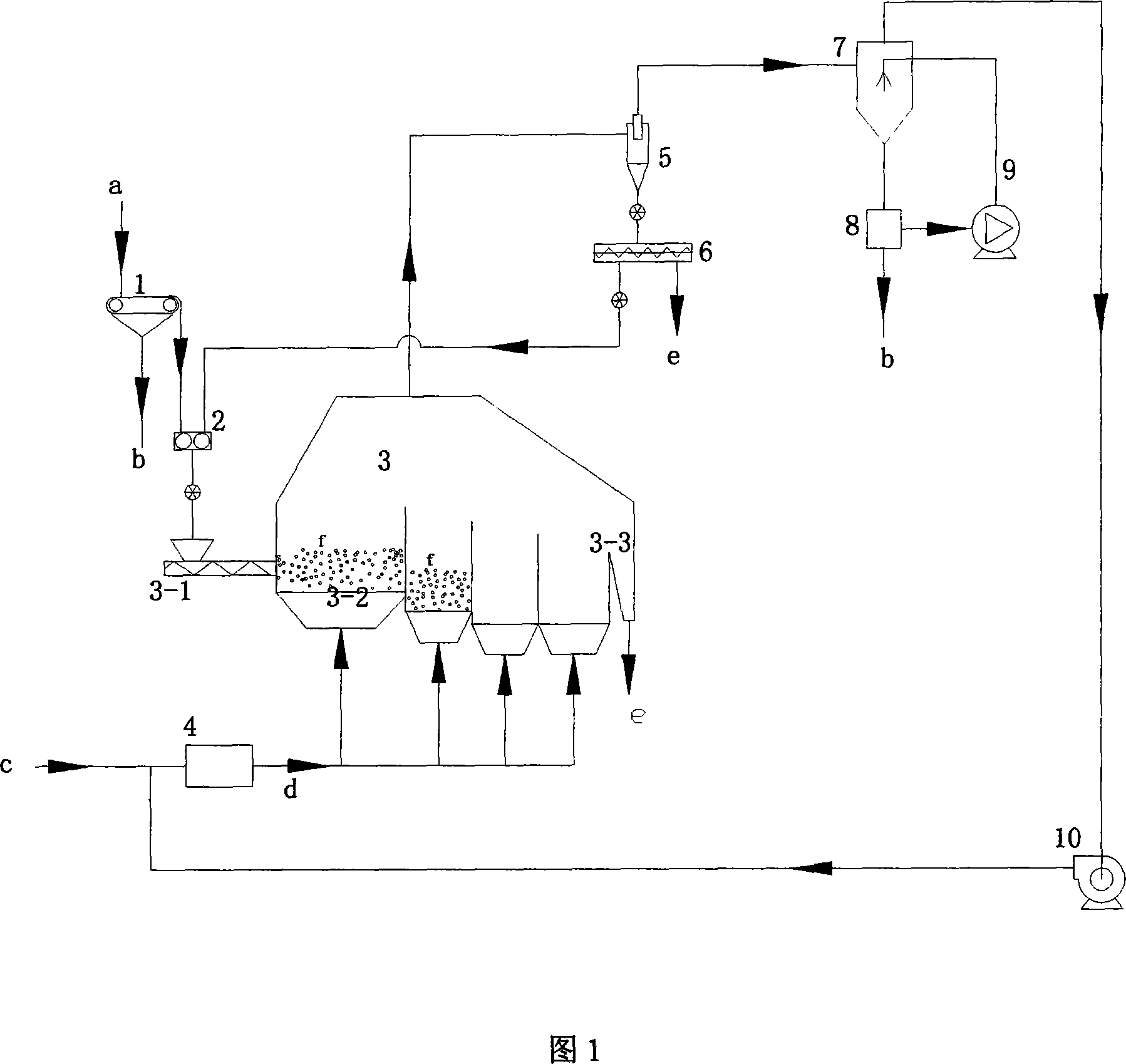

Enclosed multi-chamber fluidized bed drying method for sludge

InactiveCN101186422AUniform humidityReduce breakageSludge treatment by de-watering/drying/thickeningLiquid wasteFluidized bed drying

A closed multi-room fluidized bed sludge drying method is provided, which is a sludge drying method having the advantages of simple equipment structure, convenient operation, strong sludge adaptability, high thermal efficiency, safety, continuity, stability, etc. After the mechanically dewatered sludge is mixed with the back-mixed sludge, the mixture is dried room by room in an inert particles multi-room fluidized bed dryer (3). The first room and the second room of the inert particles multi-room fluidized bed dryer (3) adopt inert particles (f) as heat storage medium. Gas from a cyclone separator (5) goes through a spray tower (7) and returns into an air heating unit (4) through a circulating fan (10). Part of dried sludge (e) at the lower part of the cyclone separator (5) enters the inert particles multi-room fluidized bed dryer (3) through the back-mixing in a mixer (2). Waste liquid from the bottom of the spray tower (7) enters a waste liquid circulating pool (8), with part of waste liquid circulating into the spray tower (7) and part into a sewage treatment system.

Owner:SOUTHEAST UNIV

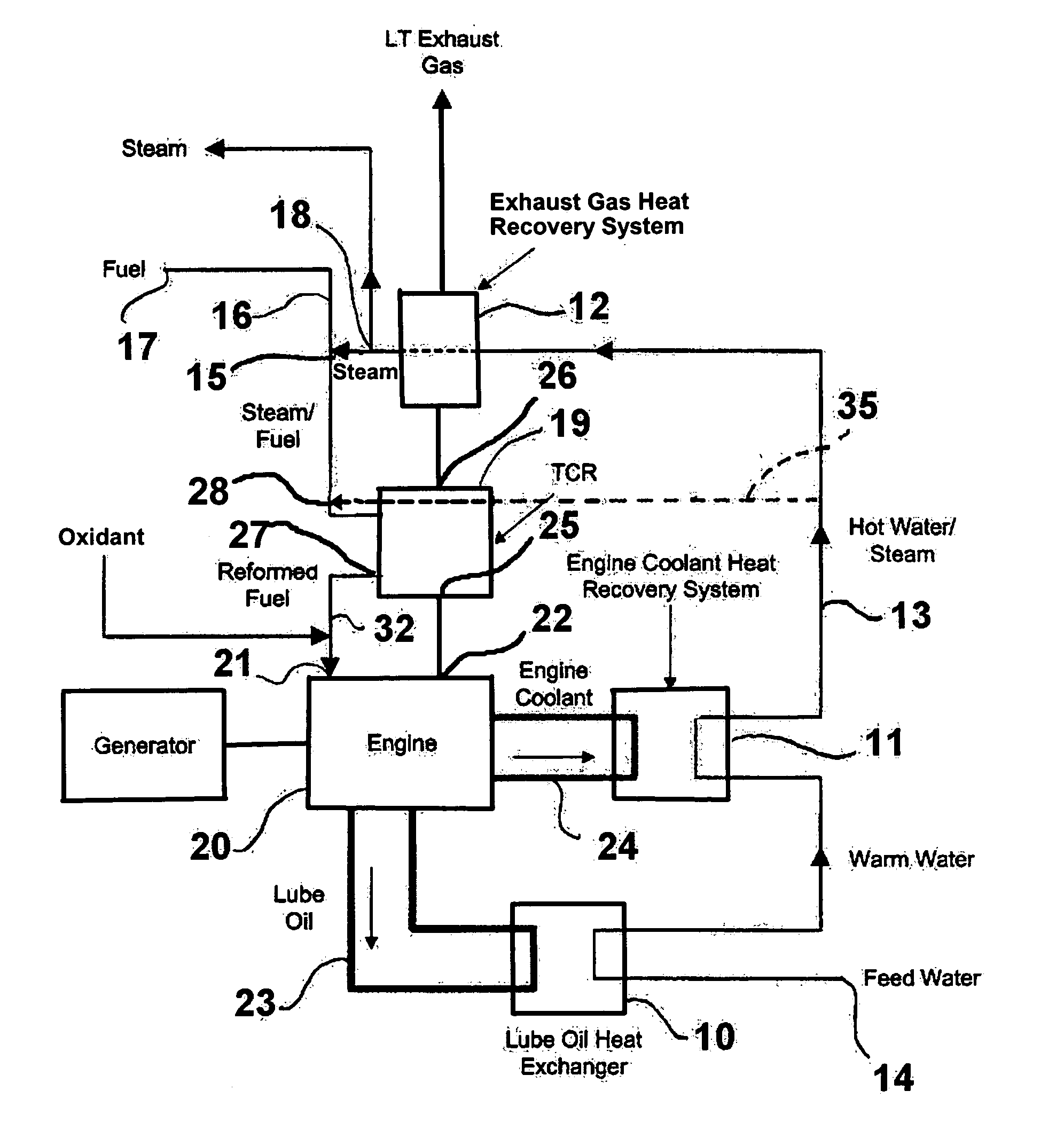

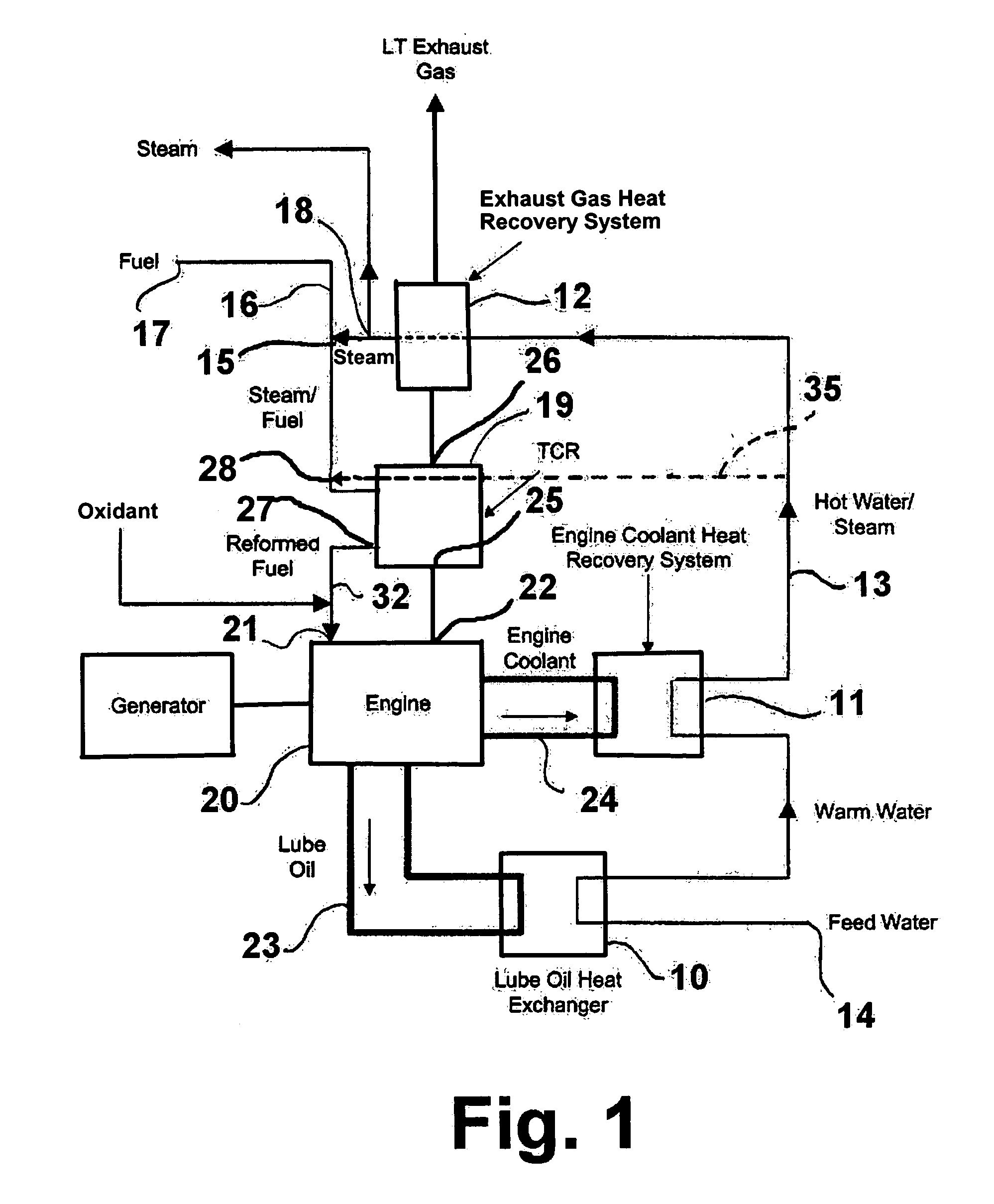

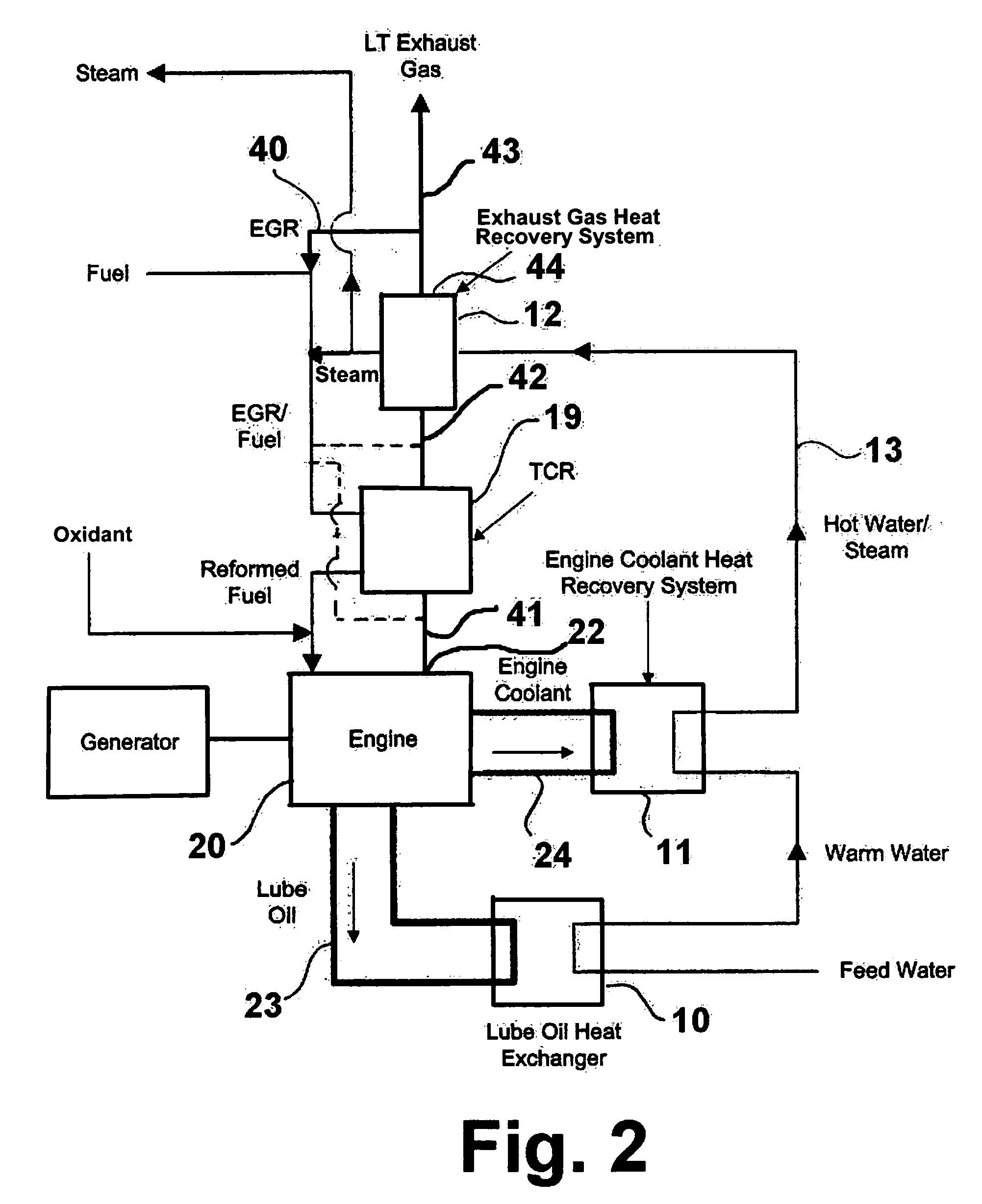

Advanced high efficiency, ultra-low emission, thermochemically recuperated reciprocating internal combustion engine

ActiveUS7210467B2Emission reductionImprove efficiencyInternal combustion piston enginesExhaust apparatusExternal combustion engineEngineering

An apparatus including a reciprocating internal combustion engine and a thermochemical recuperator in which a fuel is reformed. The thermochemical recuperator is heated by exhaust gases from the reciprocating internal combustion engine and steam for the reforming process is produced by passing feed water through an engine lubricating oil heat exchanger, an engine cooling system heat recovery system and an exhaust gas heat recovery system arranged in series.

Owner:GAS TECH INST

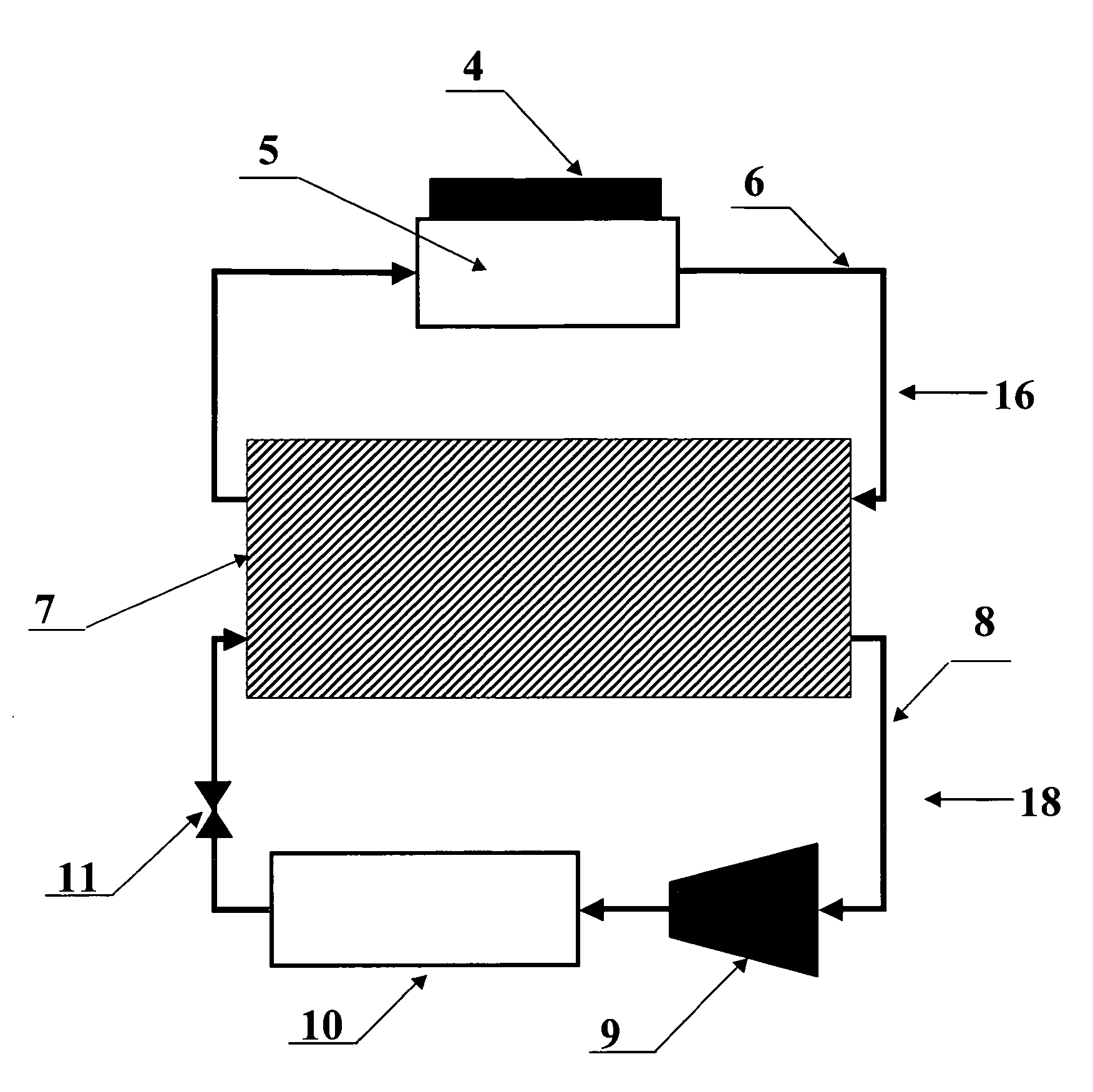

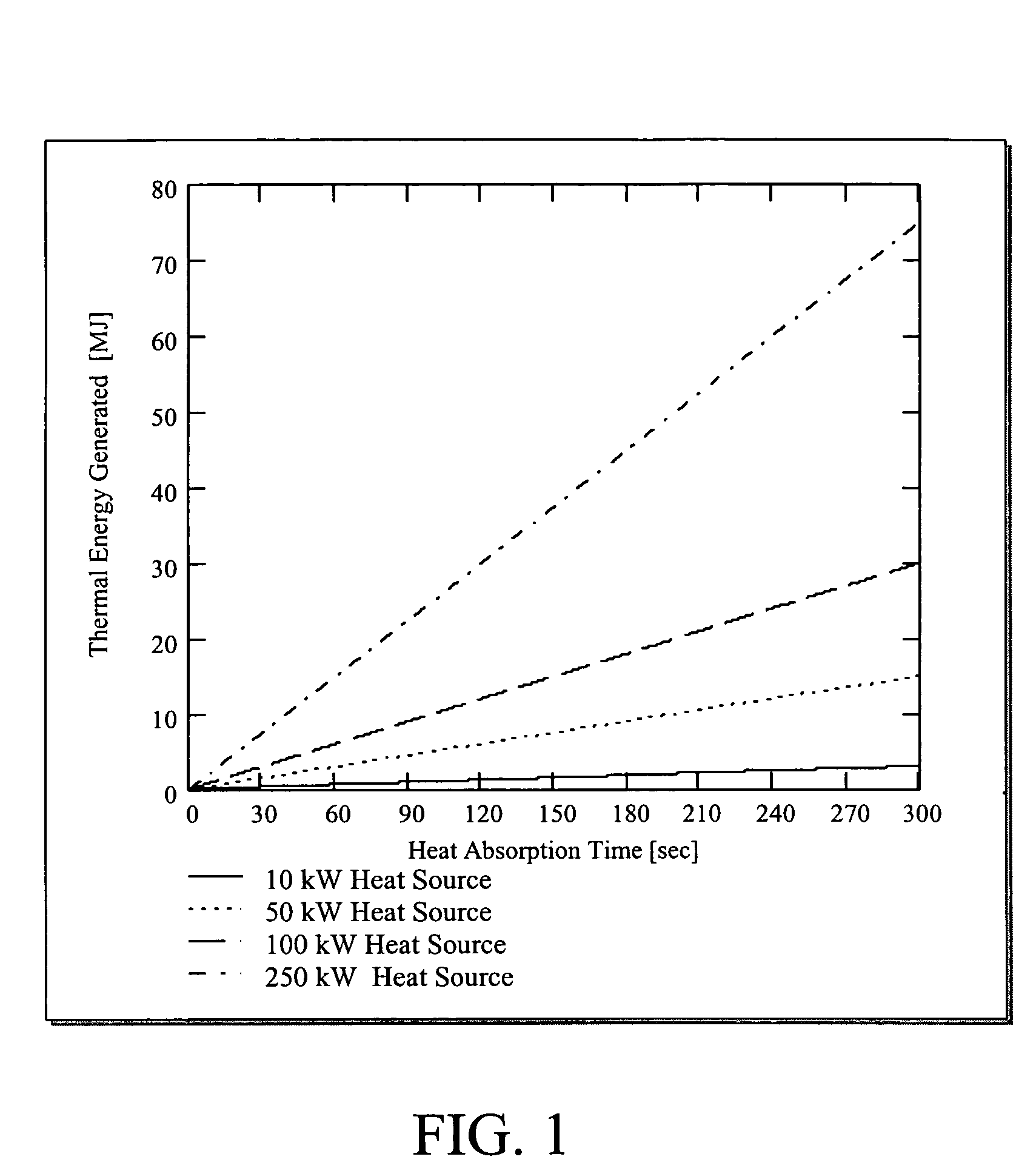

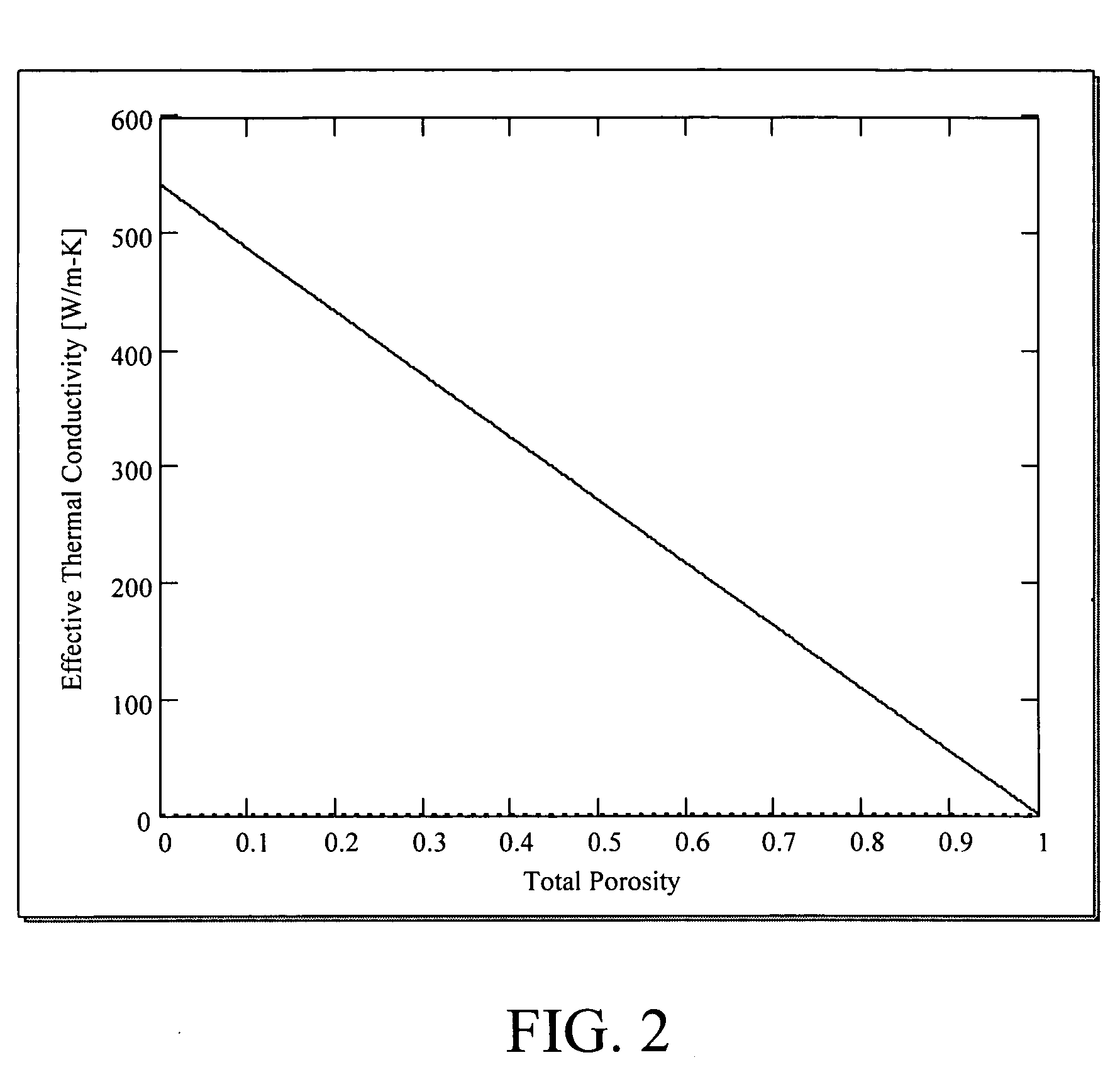

Method and apparatus for absorbing thermal energy

ActiveUS7316262B1Improve thermal efficiencyHigh effective thermal conductivityHeat storage plantsHeat exchange apparatusThermal energyPhase-change material

The subject invention pertains to a method and apparatus for storing thermal energy. The subject thermal energy storage apparatus can function as a heat absorber in a cooling system. A cooling system can incorporate a cooling cycle that utilizes thermal energy storage and has two coolant loops. The primary cooling loop acquires the waste heat from a heat source, such as an electronic device, by heat transfer to the primary coolant via, for example, a sensible heat process (where sensible heat is heat absorbed or transmitted by a substance during a change in temperature which is not accompanied by a change of state) or by evaporating the primary coolant through a latent heat phase change process. The waste heat absorbed by the primary coolant is transferred to the host material of the heat absorber. The subject invention uses a high thermal conductivity host material to house a lower thermal conductivity phase change material, in order to achieve a thermal energy absorber that has a high effective thermal conductivity. In a specific embodiment, the high thermal conductivity host material has have voids within the structure that can be filled by the phase change material. The increased surface area of phase change material in thermal contact with the host material per volume of phase change material allows the thermal energy to be stored or released quickly, because of the enhanced effective thermal conductivity.

Owner:RINI TECH

Gas engine with a gas fuel reforming device

InactiveUS6079373AReduce air pollutionMinimize formationInternal combustion piston enginesExhaust apparatusThermal energyCO2 content

The gas engine with a gas fuel reforming device thermally decomposes CH4, a major component of natural gas, into a reformed fuel of CO and H2 to increase the heat produced and thereby reduce the CO2 content in the exhaust gas and prevent the formation of NOx. The gas engine mixes CH4 with CO2 and sends the gas mixture to the catalyst reactor installed in the exhaust passage where the gas mixture is thermally decomposed into a reformed fuel by using the thermal energy of the exhaust gas. CO2 is extracted from the exhaust gas by the CO2 supply device which in turn sends the CO2 to the catalyst reactor. The CO2 supply device comprises a CO2 dissolving device that accommodates a solution to dissolve CO2 of low-temperature exhaust gas and a CO2 delivery device installed in the exhaust passage through which high-temperature exhaust gas flows and adapted to release CO2 from the solution supplied from the CO2 dissolving device. The CO2 supply device can be formed of a CO2 separation membrane that separates CO2 from the exhaust gas.

Owner:ISUZU MOTORS LTD

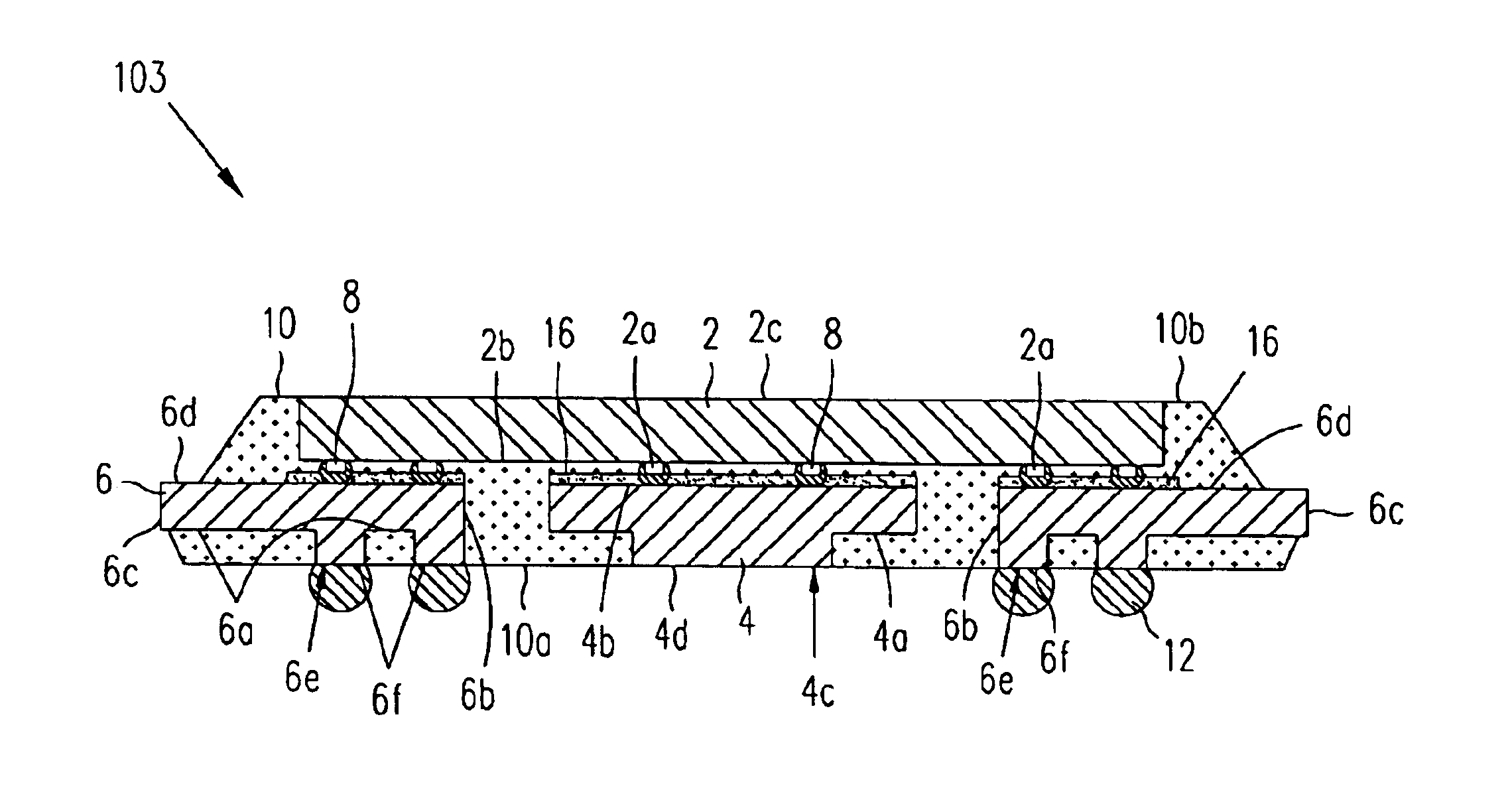

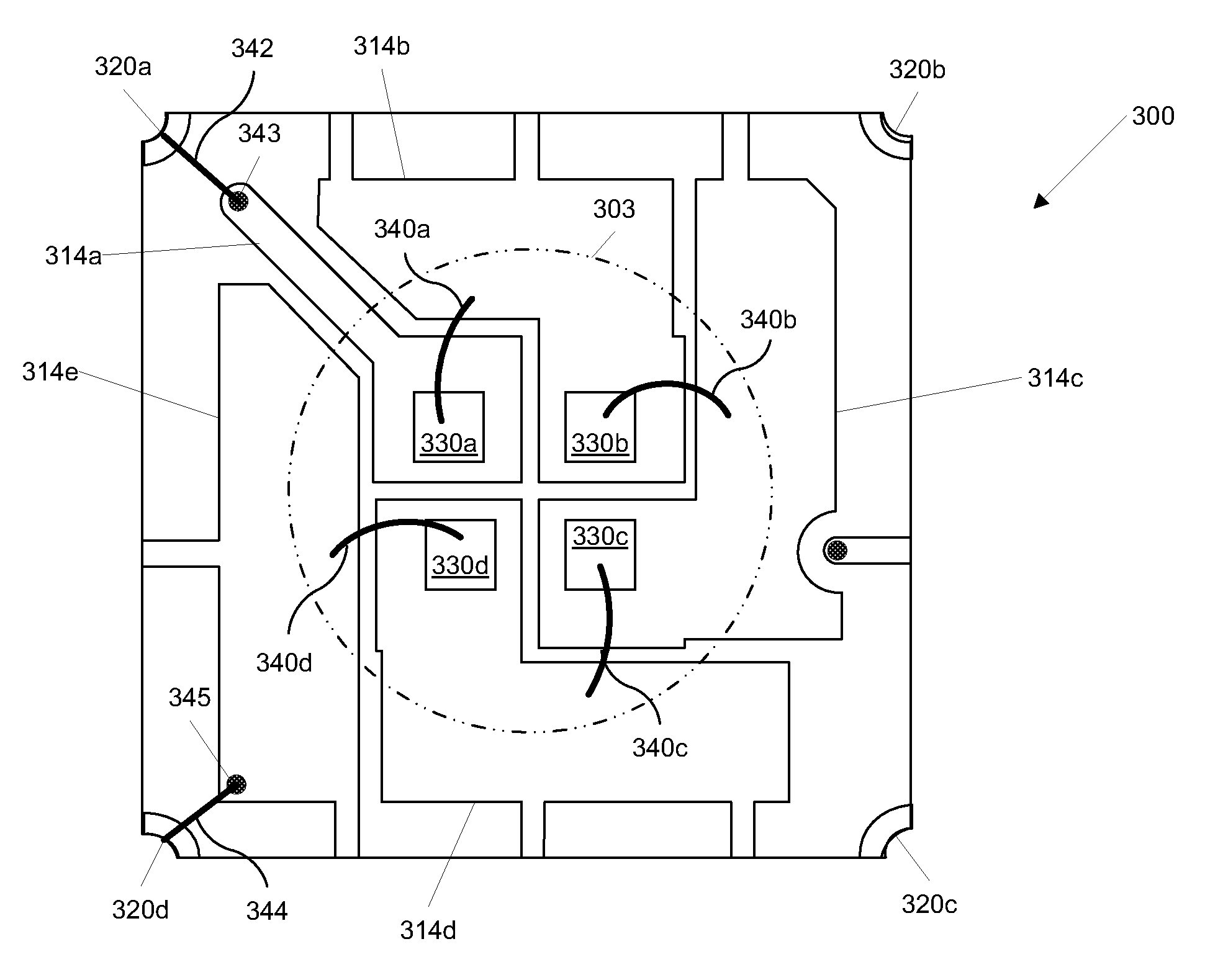

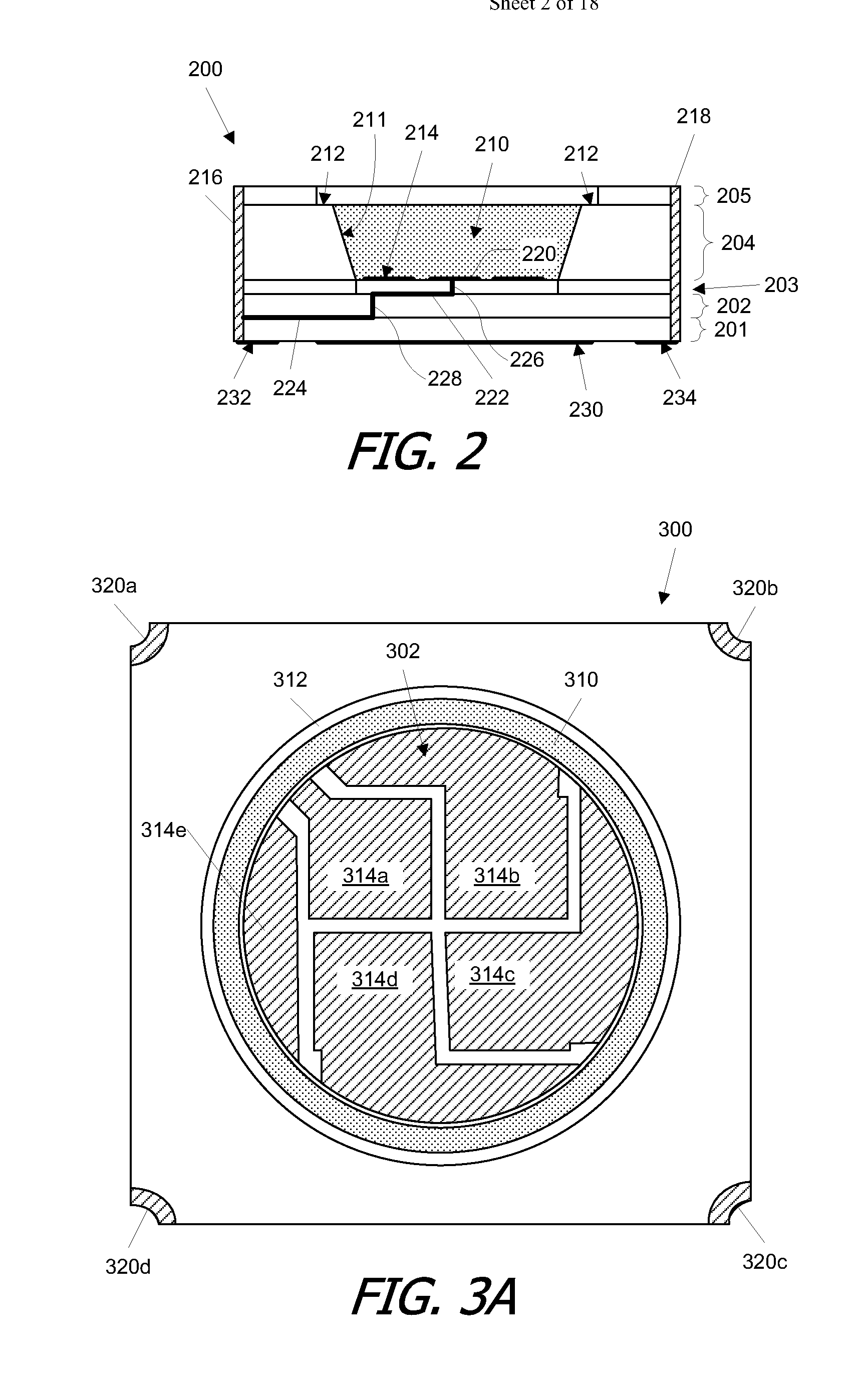

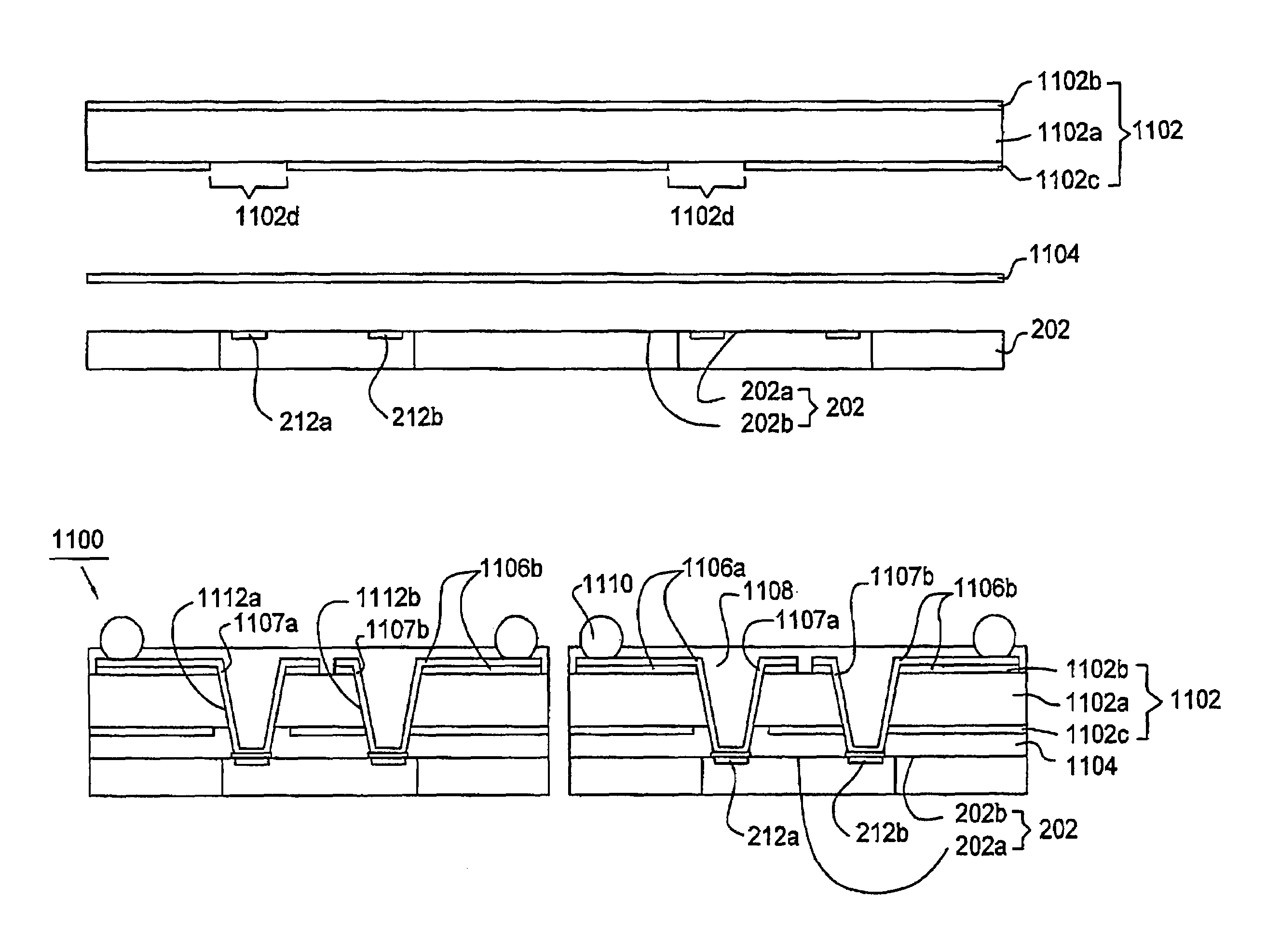

Package for multiple light emitting diodes

ActiveUS20100259930A1Improve controlImprove thermal efficiencyLighting support devicesPoint-like light sourceElectricityLight-emitting diode

Substrates and packages for LED-based light devices can significantly improve thermal performance and provide separate electrical and thermal paths through the substrate. One substrate includes multiple electrically insulating base layers. On a top one of these layers are disposed top-side electrical contacts, including light device pads to accommodate a plurality of light devices. External electrical contacts are disposed on an exterior surface of the substrate. Electrical paths connect the top-side electrical contacts to the external electrical contacts. At least portions of some of the electrical paths are disposed between the electrically insulating base layers. The electrical paths can be arranged such that different subsets of the light device pads are addressable independently of each other. A heat dissipation plate can be formed on the bottom surface of a bottom one of the base layers.

Owner:LEDENGIN

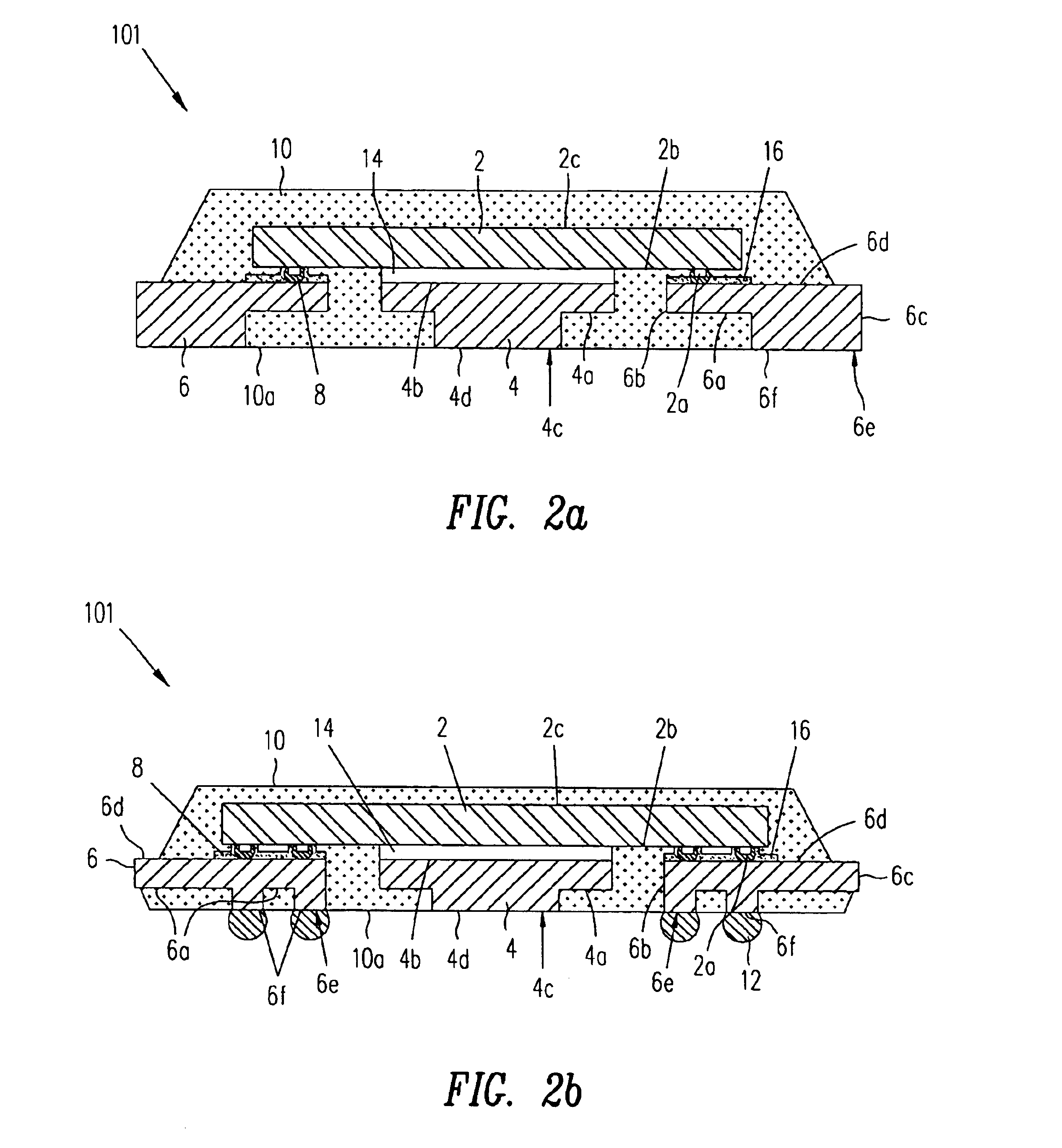

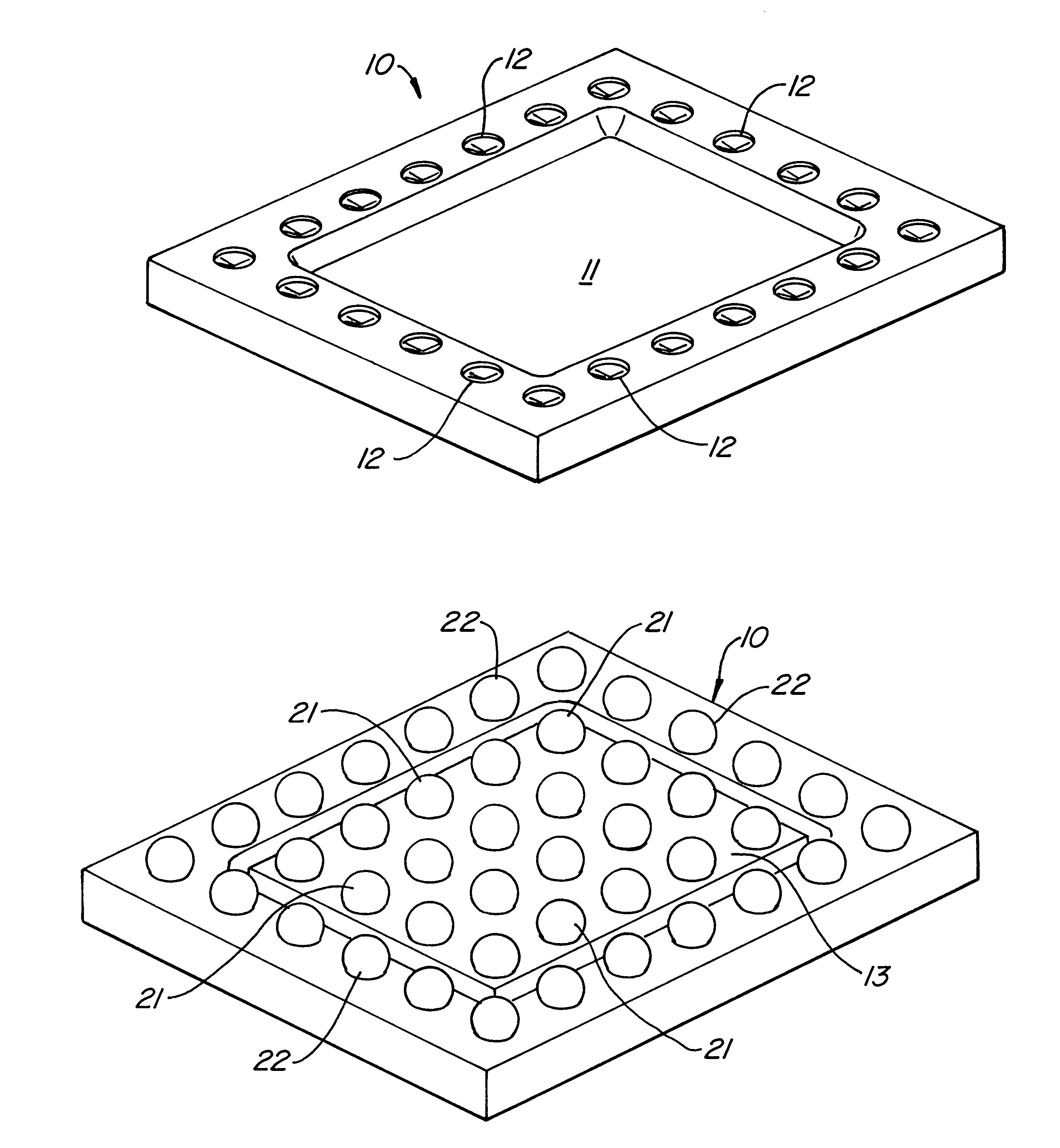

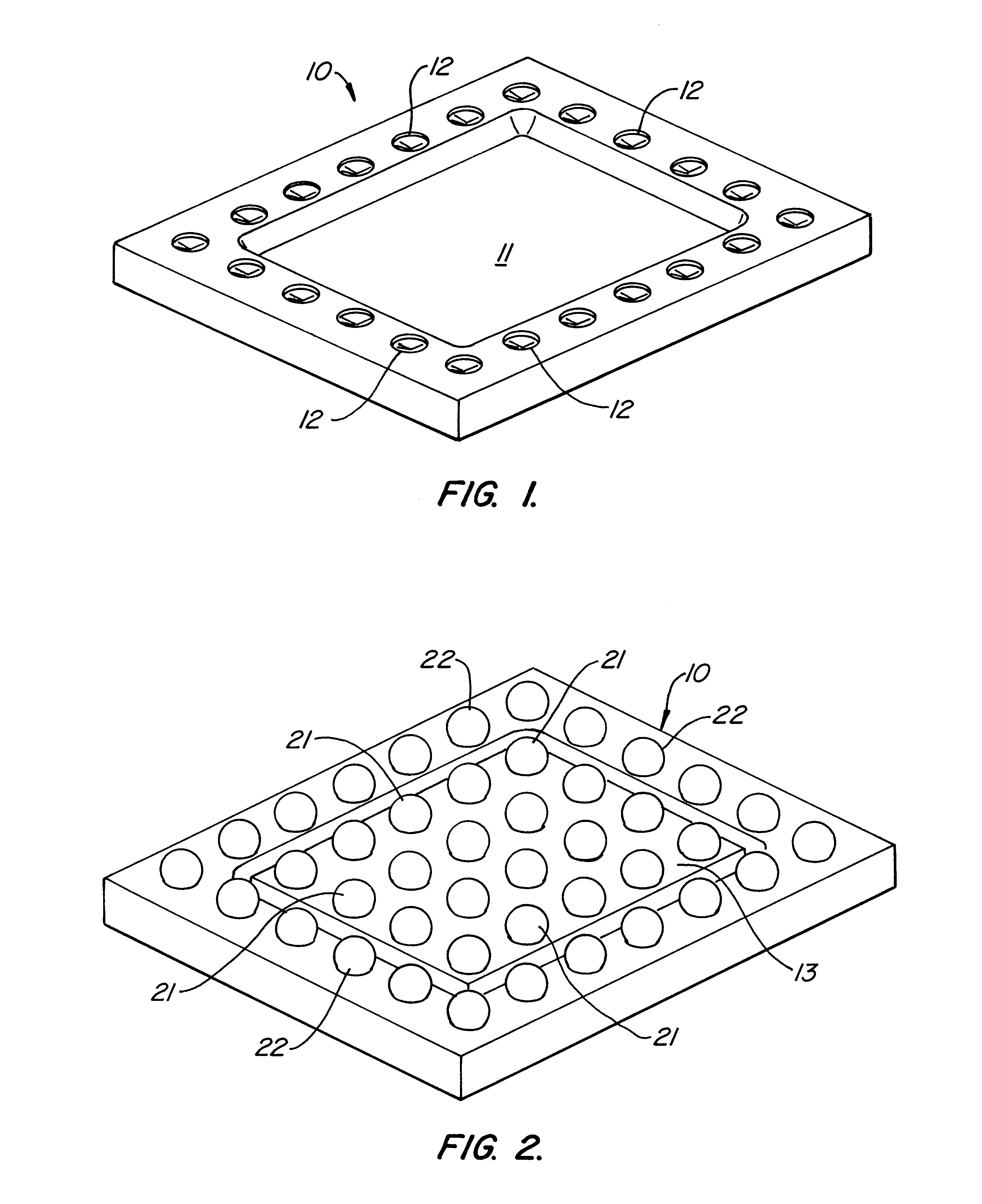

Flip chip substrate design

InactiveUS6661082B1Improve thermal efficiencySimple manufacturing processSemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineeringFlip chip

A chip device that includes a leadframe that has a die attach cavity. The memory device further includes a die that is placed within the die attach cavity. The die attach cavity is substantially the same thickness as the die. The die is positioned within the cavity and is attached therein with a standard die attachment procedure.

Owner:SEMICON COMPONENTS IND LLC

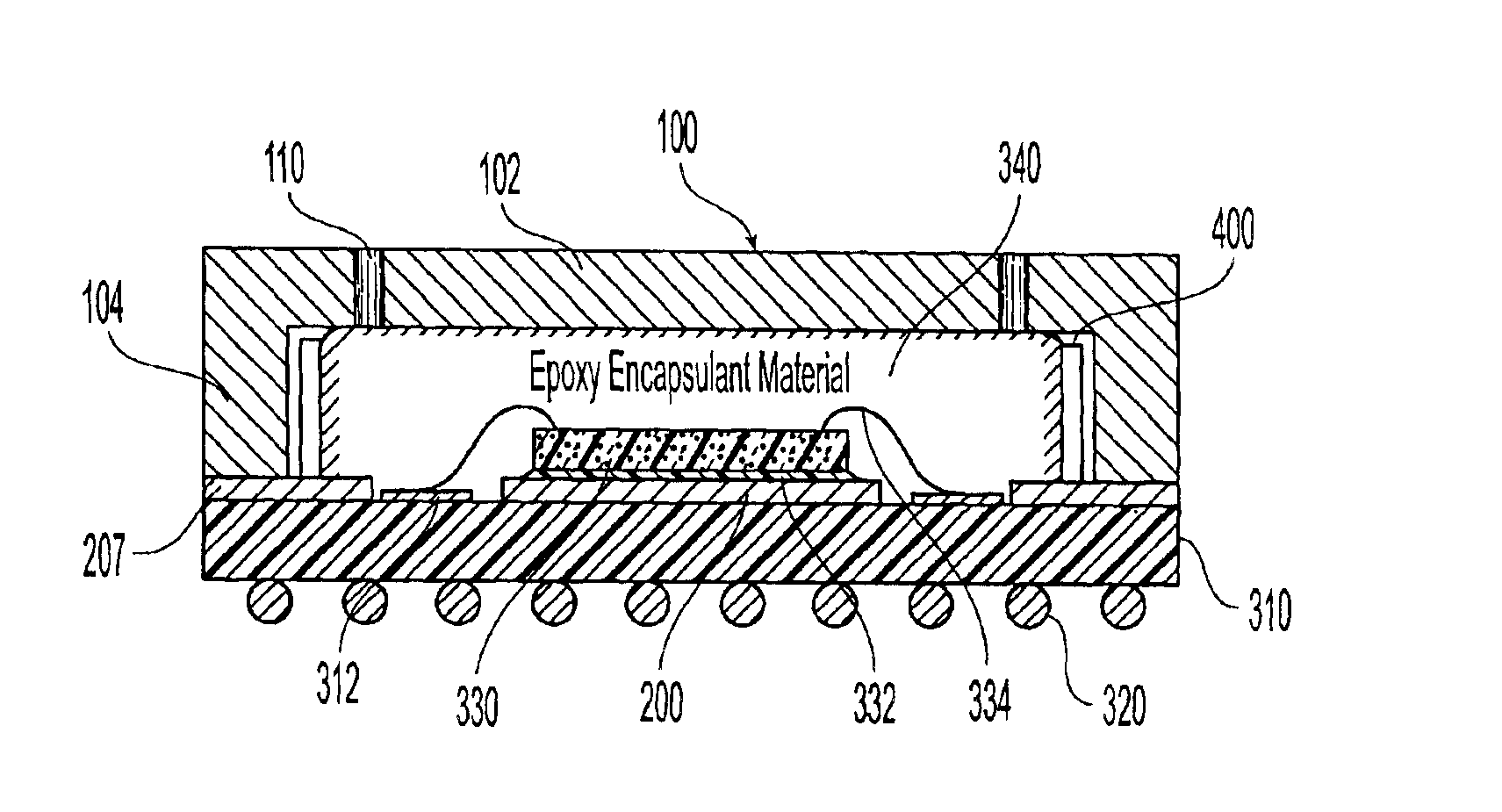

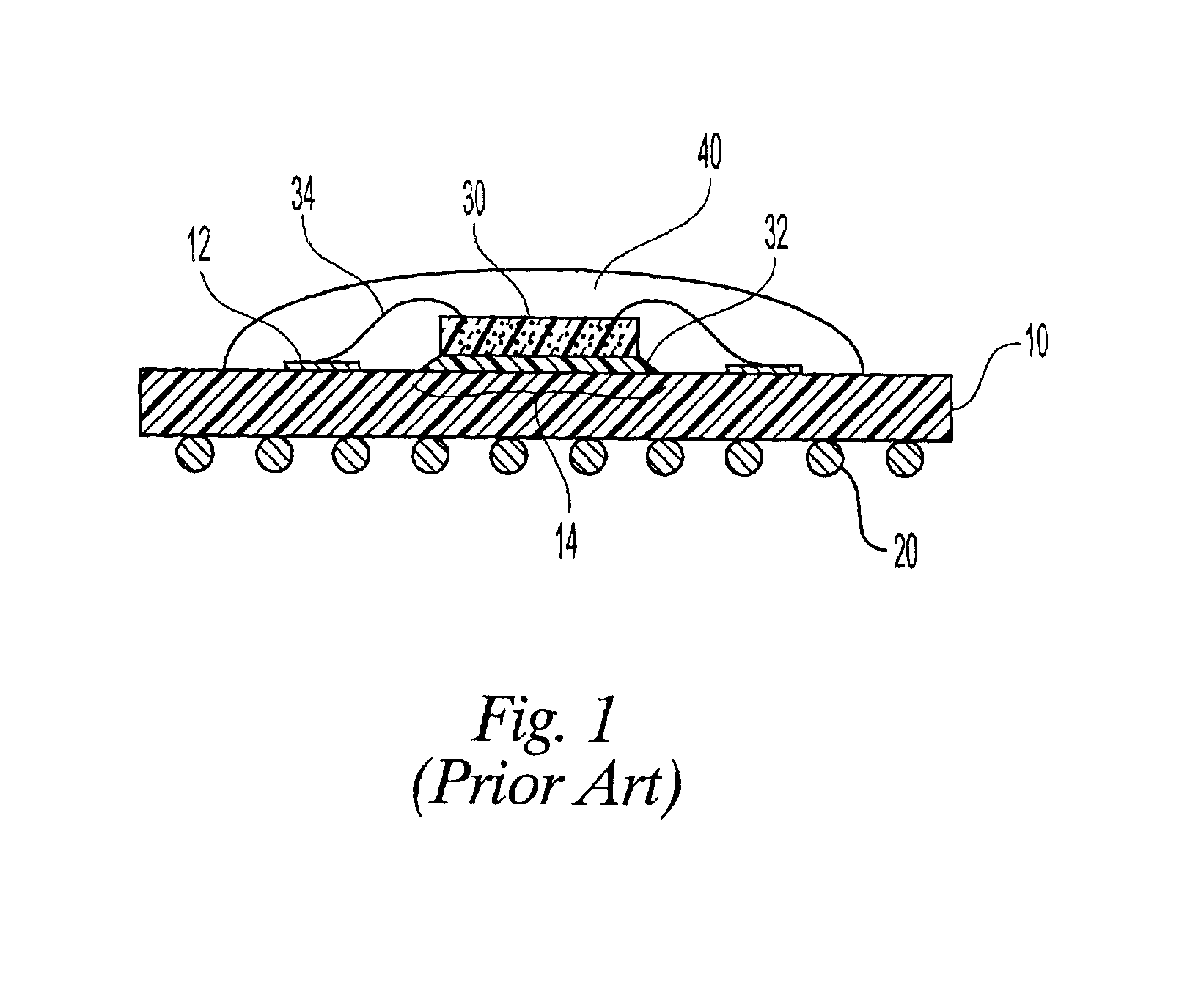

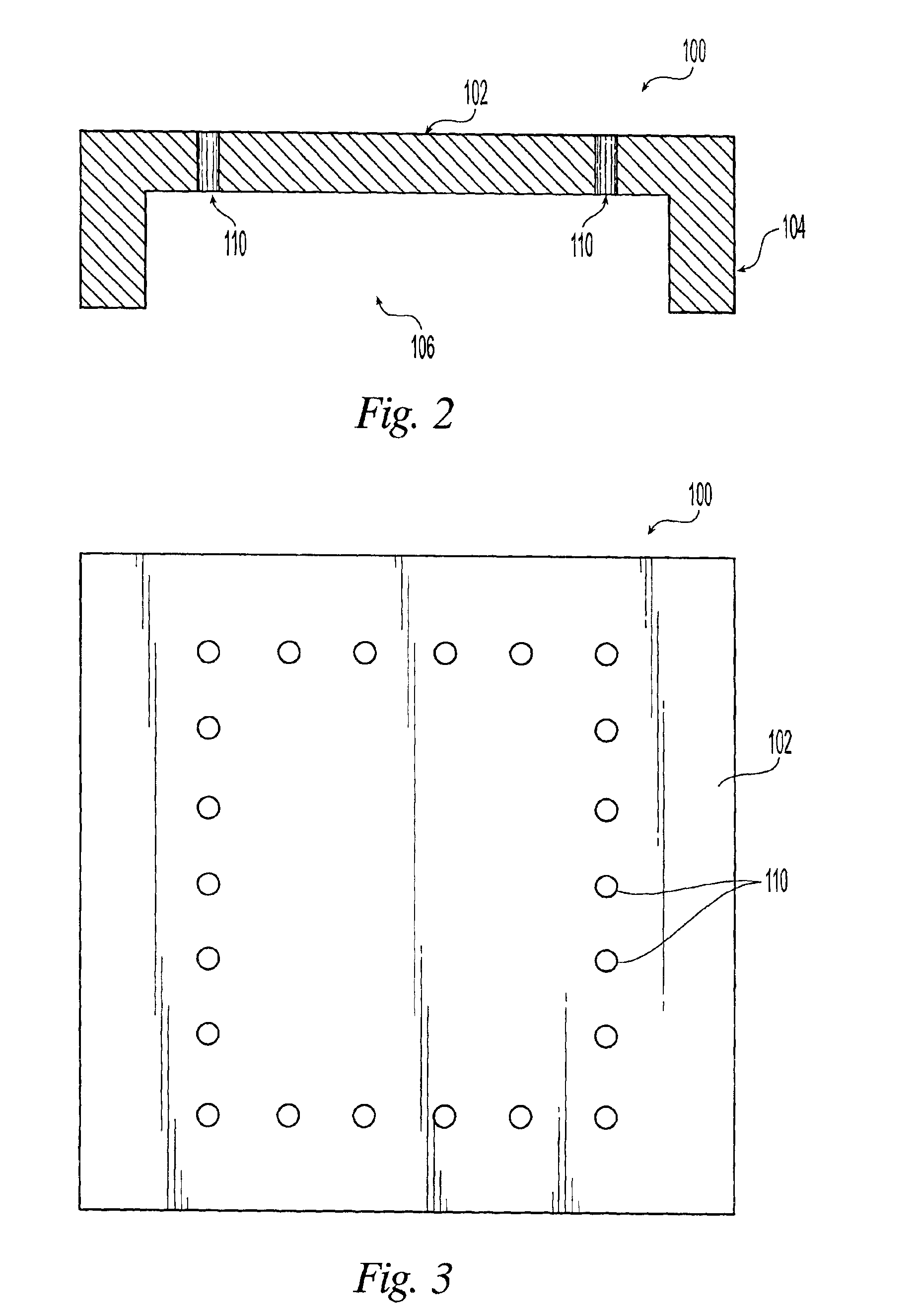

Thermally enhanced metal capped BGA package

InactiveUS6882041B1Improve abilityEnhance thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesElectrical and Electronics engineeringMetal

A thermally enhanced wirebond BGA package having a laminate substrate, an IC device mounted on the substrate, and a metal cap defining a cavity inside the package between the IC device and the metal cap. A substantial portion of the cavity is filled with a thermally enhanced epoxy encapsulant establishing a thermal conduction path between the IC device and the metal cap. The BGA package may be further enhanced by bonding a metal heat slug on the laminate substrate and mounting the IC device on the slug.

Owner:ALTERA CORP

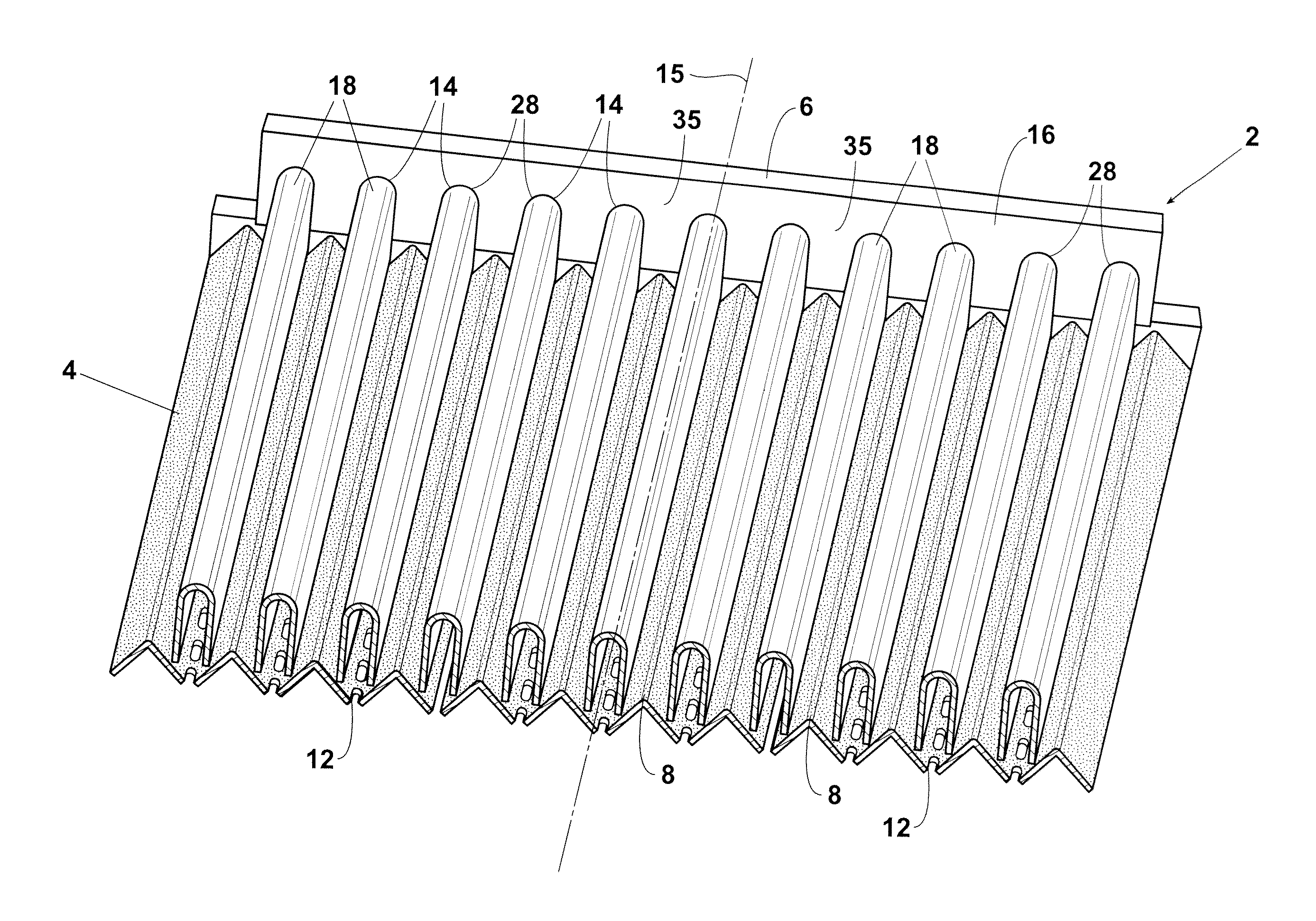

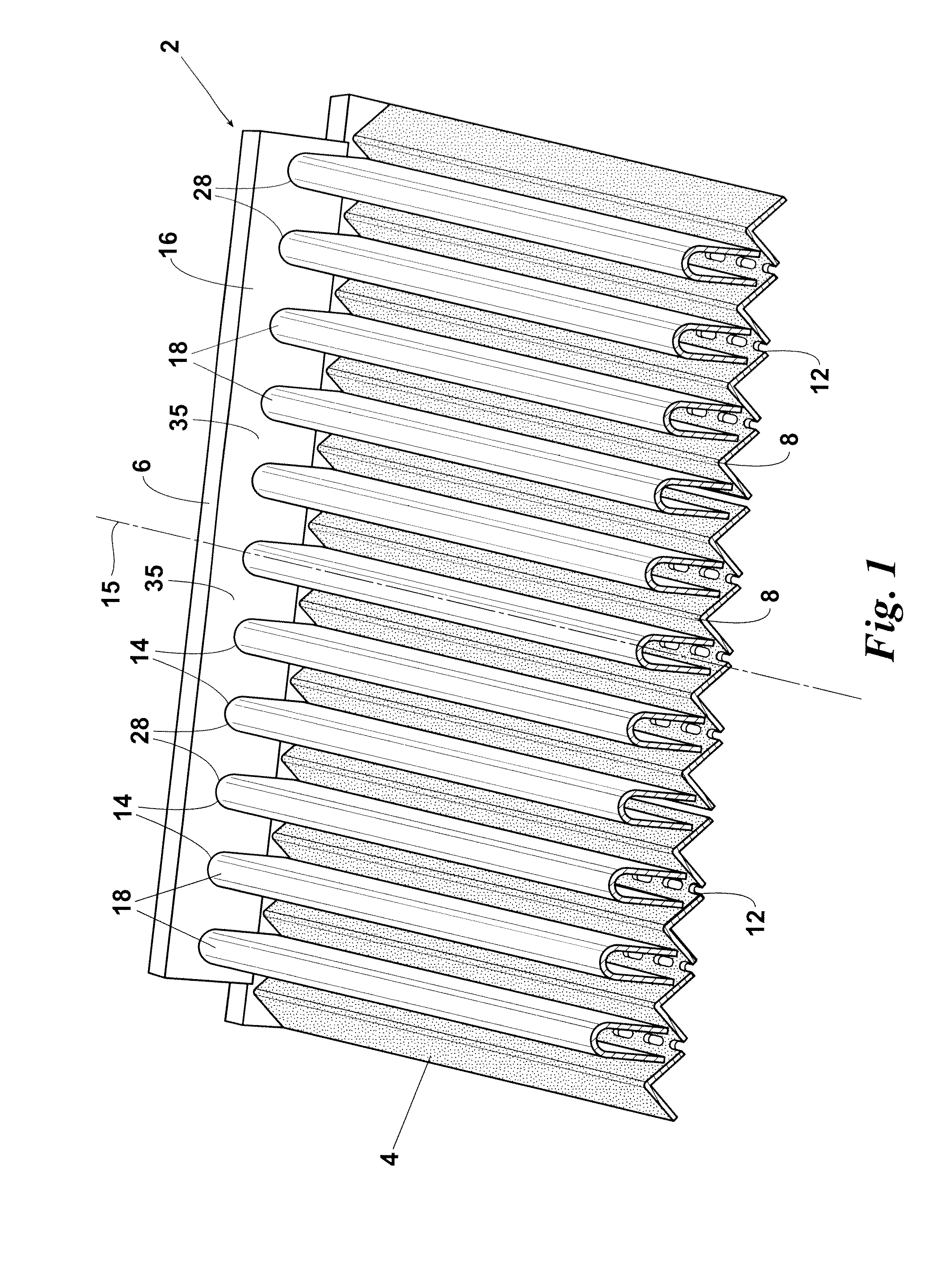

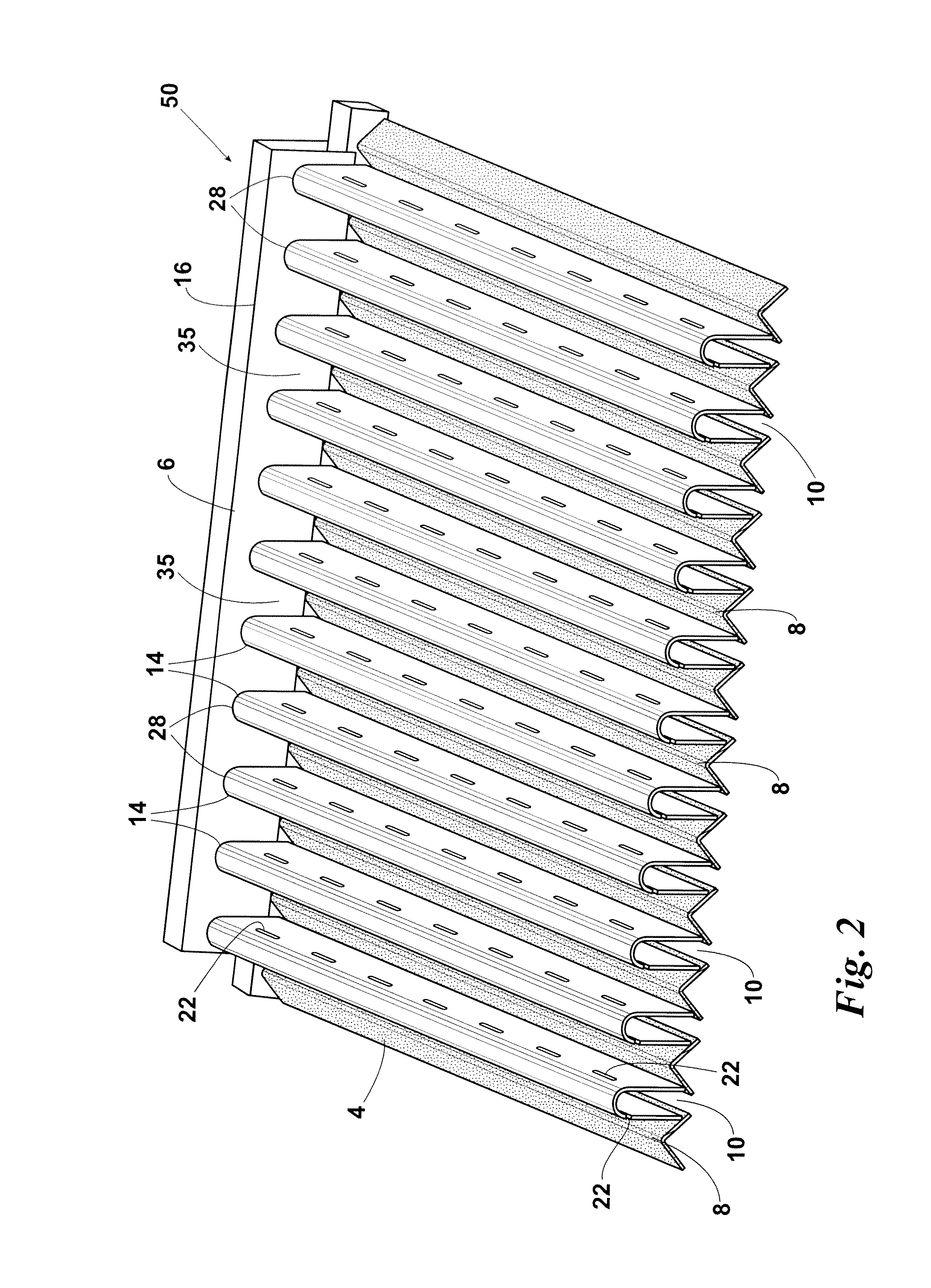

Cooking grate and cooking apparatus

InactiveUS20120318149A1Shorten warm-up timeBeneficialCooking vesselsRoasters/grillsCombustionEngineering

A cooking grate and a grill assembly having one or more of the cooking grates therein. The cooking grate can be a one-piece structure but is preferably a two-piece structure wherein the upper piece comprises longitudinally extending food support ribs having hollow interiors. The ribs will be positioned over and cover open areas in the lower structure so that combustion gases flowing through the open areas of the lower structure will flow into the hollow interiors of the food support ribs.

Owner:W C BRADLEY CO

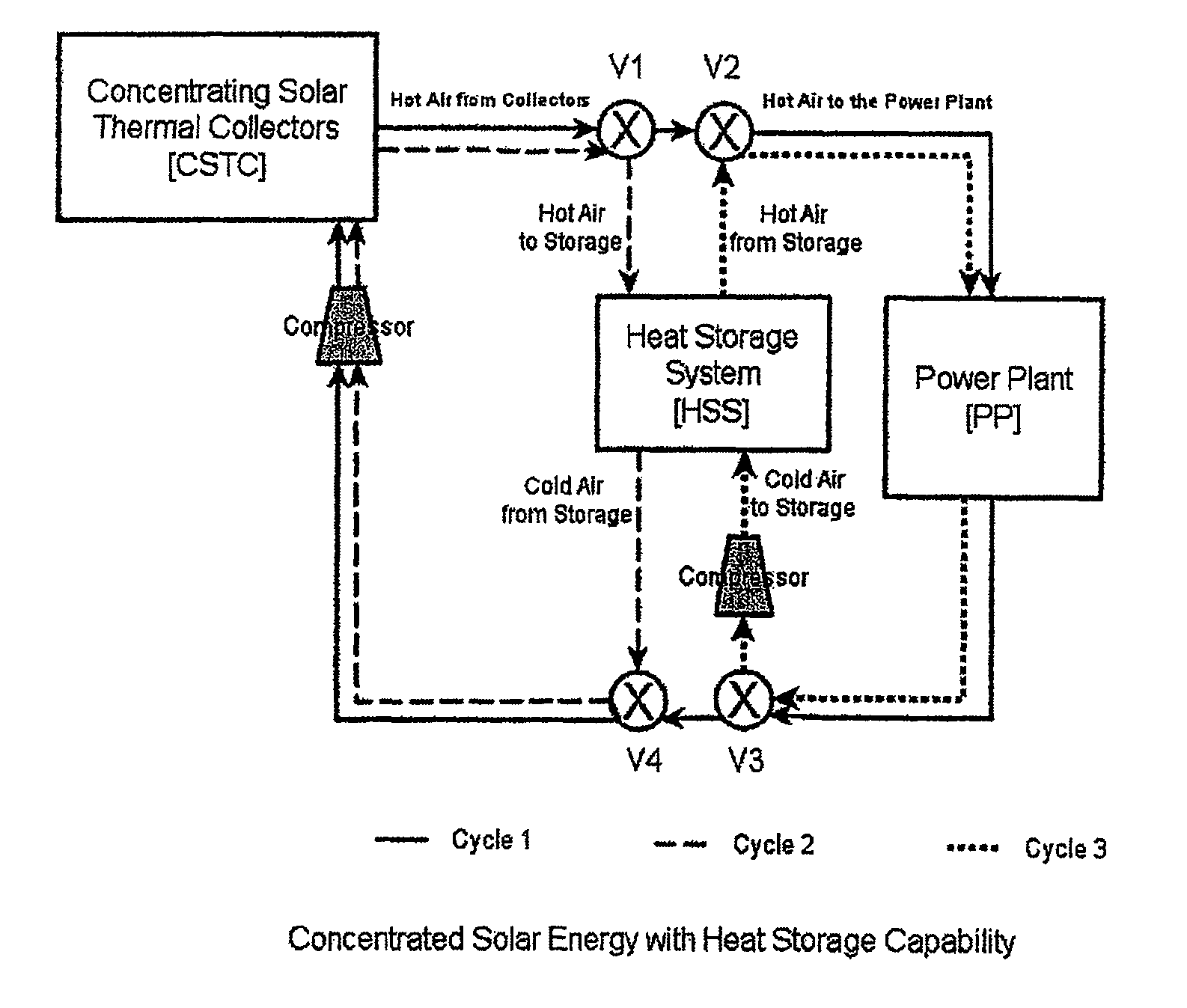

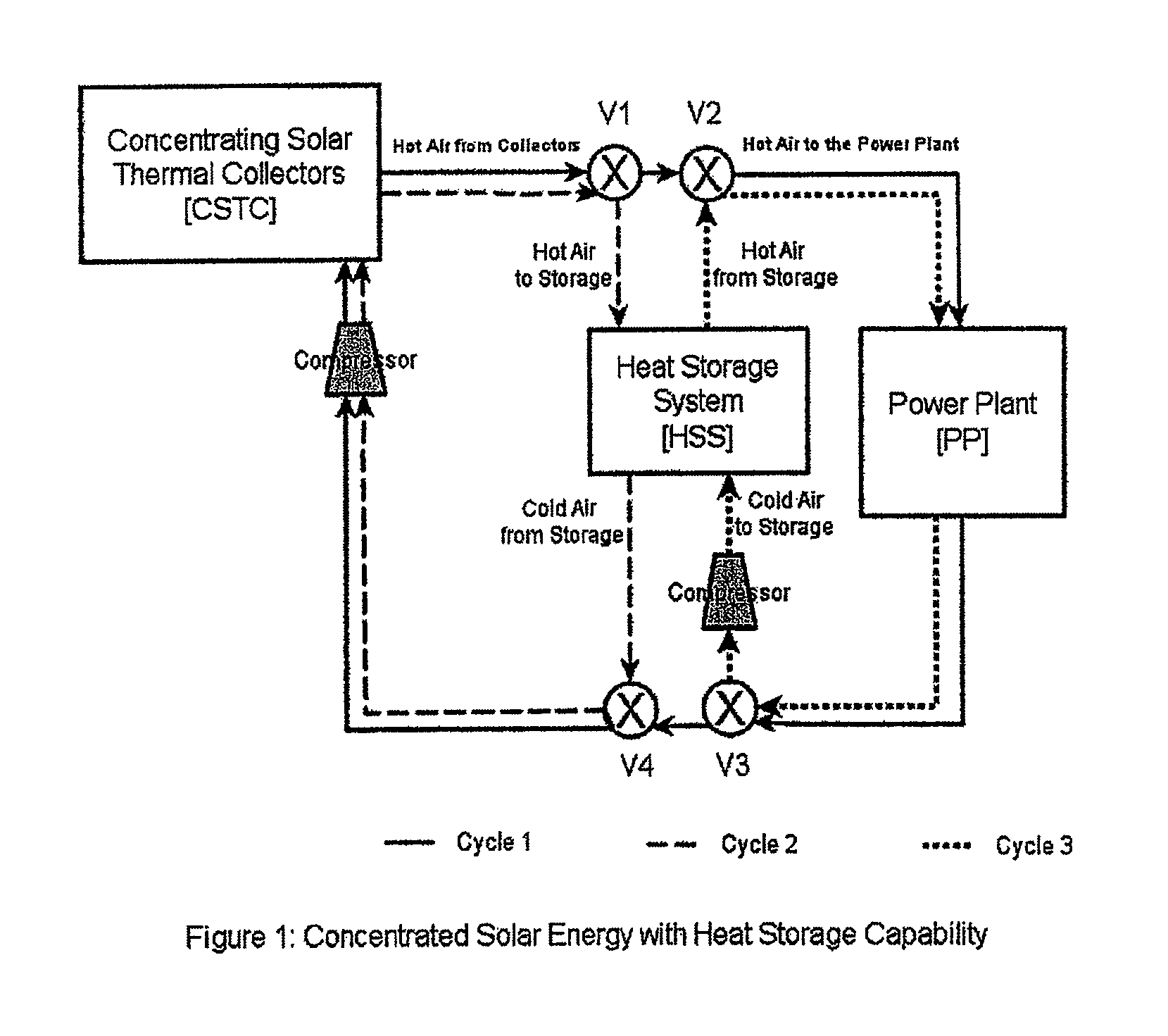

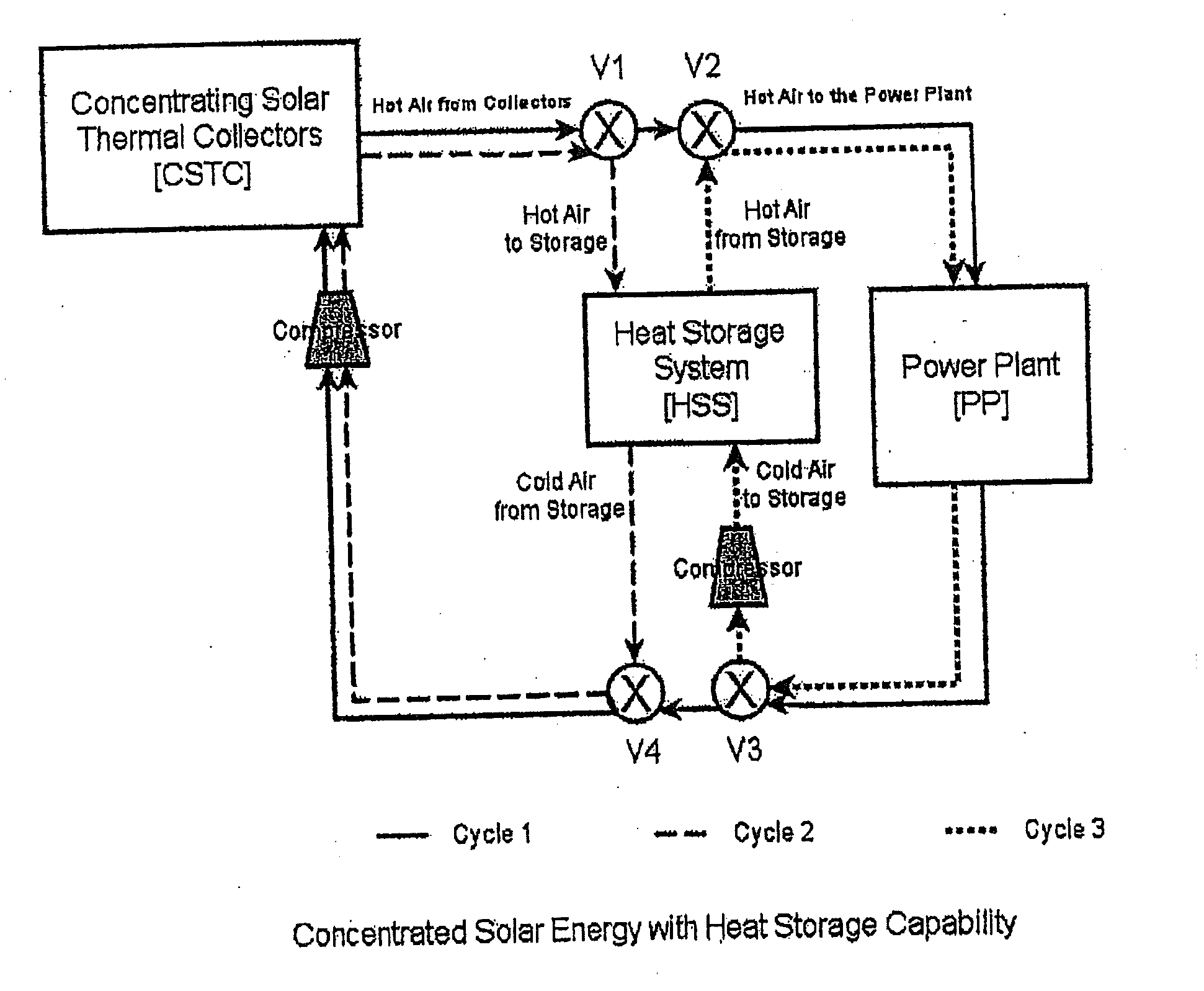

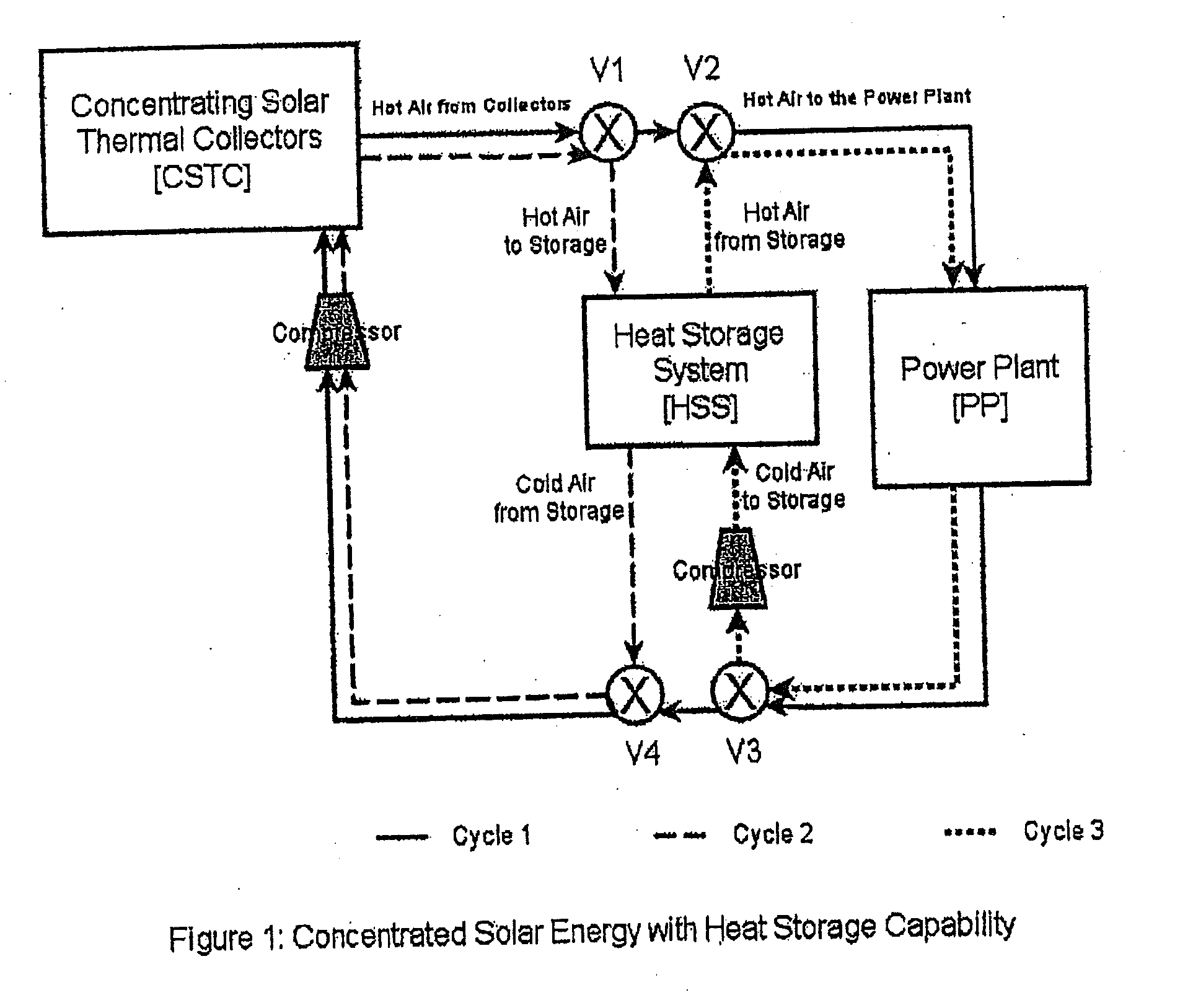

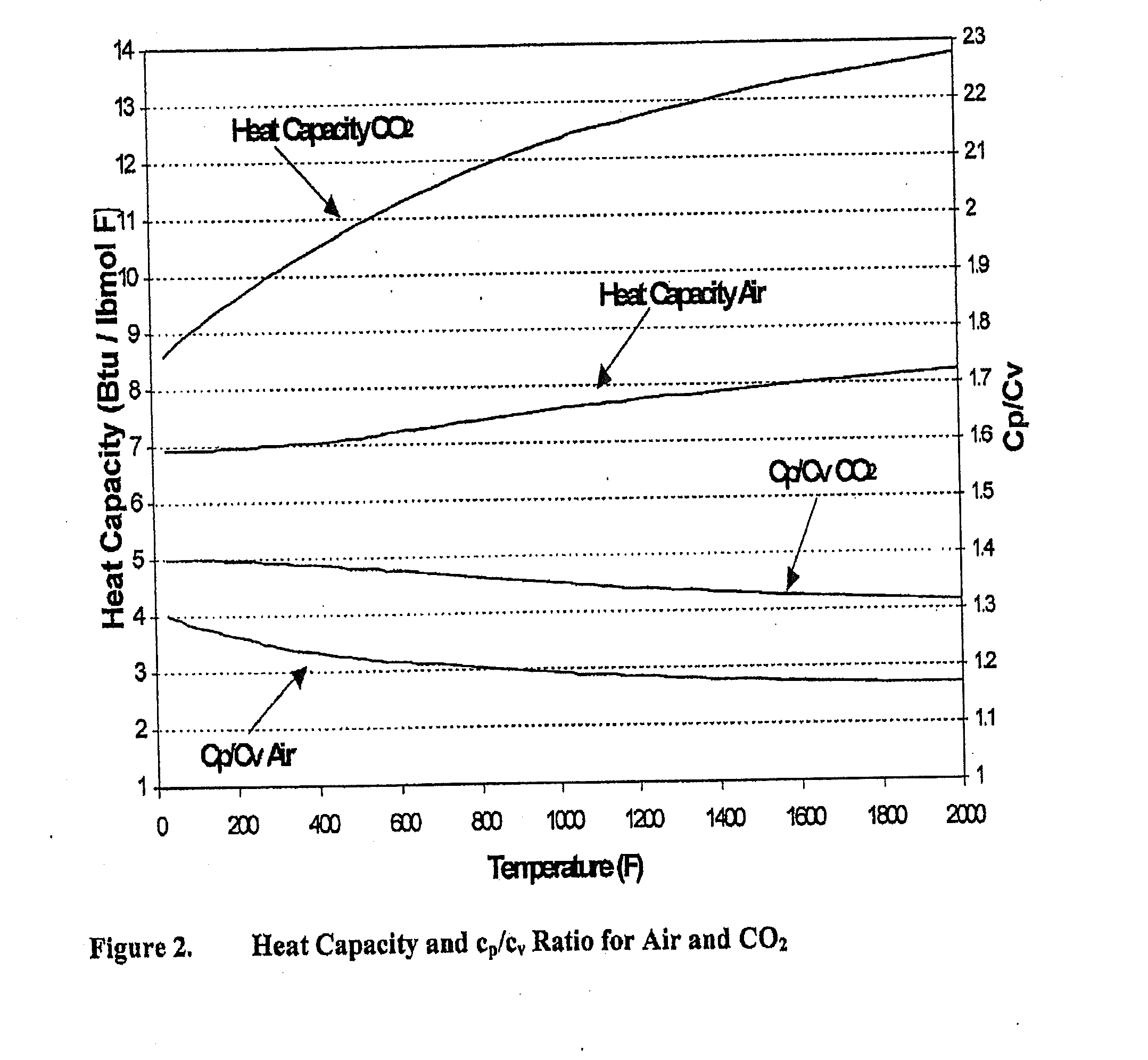

Solar power plant and method and/or system of storing energy in a concentrated solar power plant

ActiveUS7954321B2Big advantageLower energy requirementsSolar heating energyAuxillary drivesPower stationEngineering

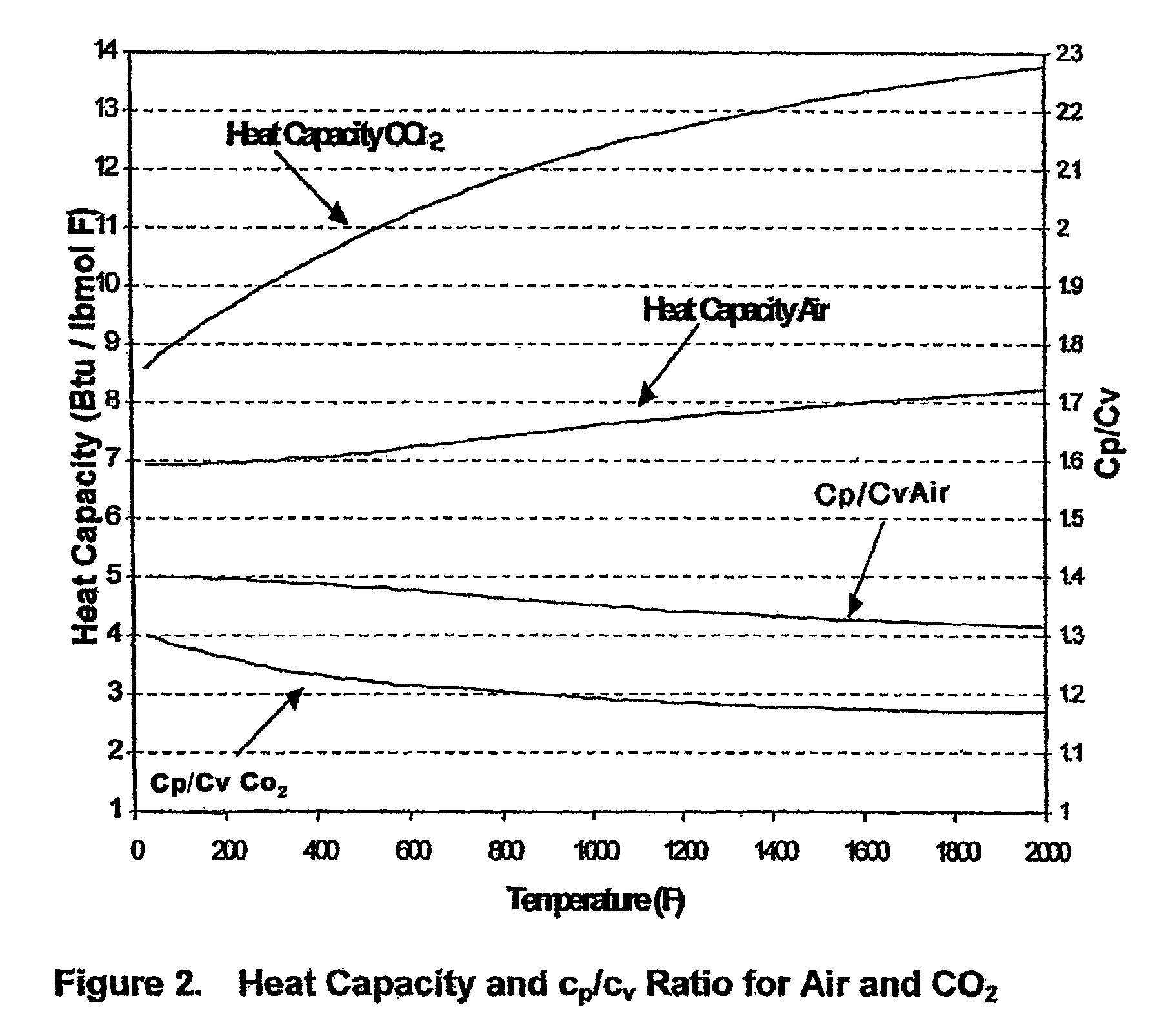

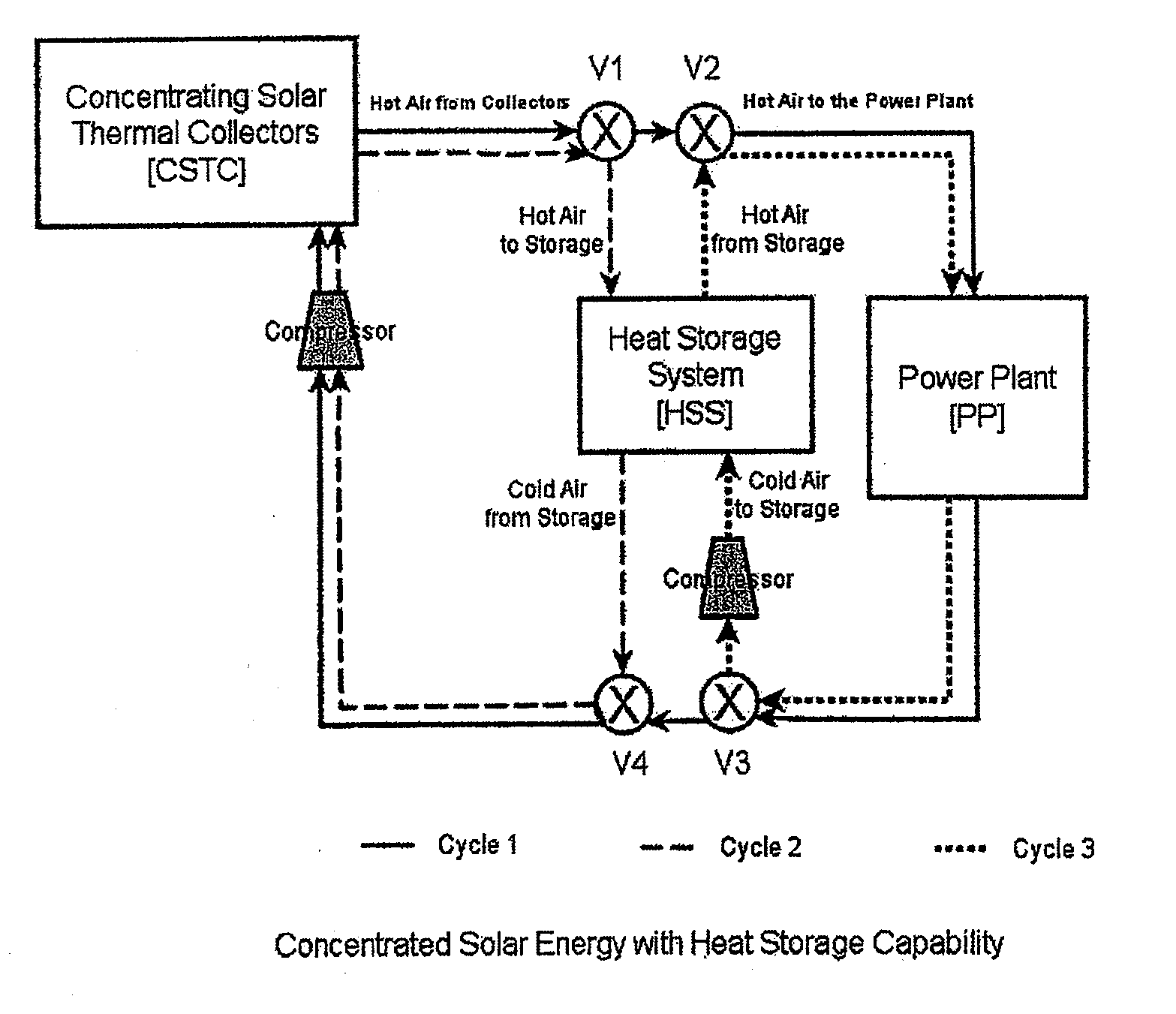

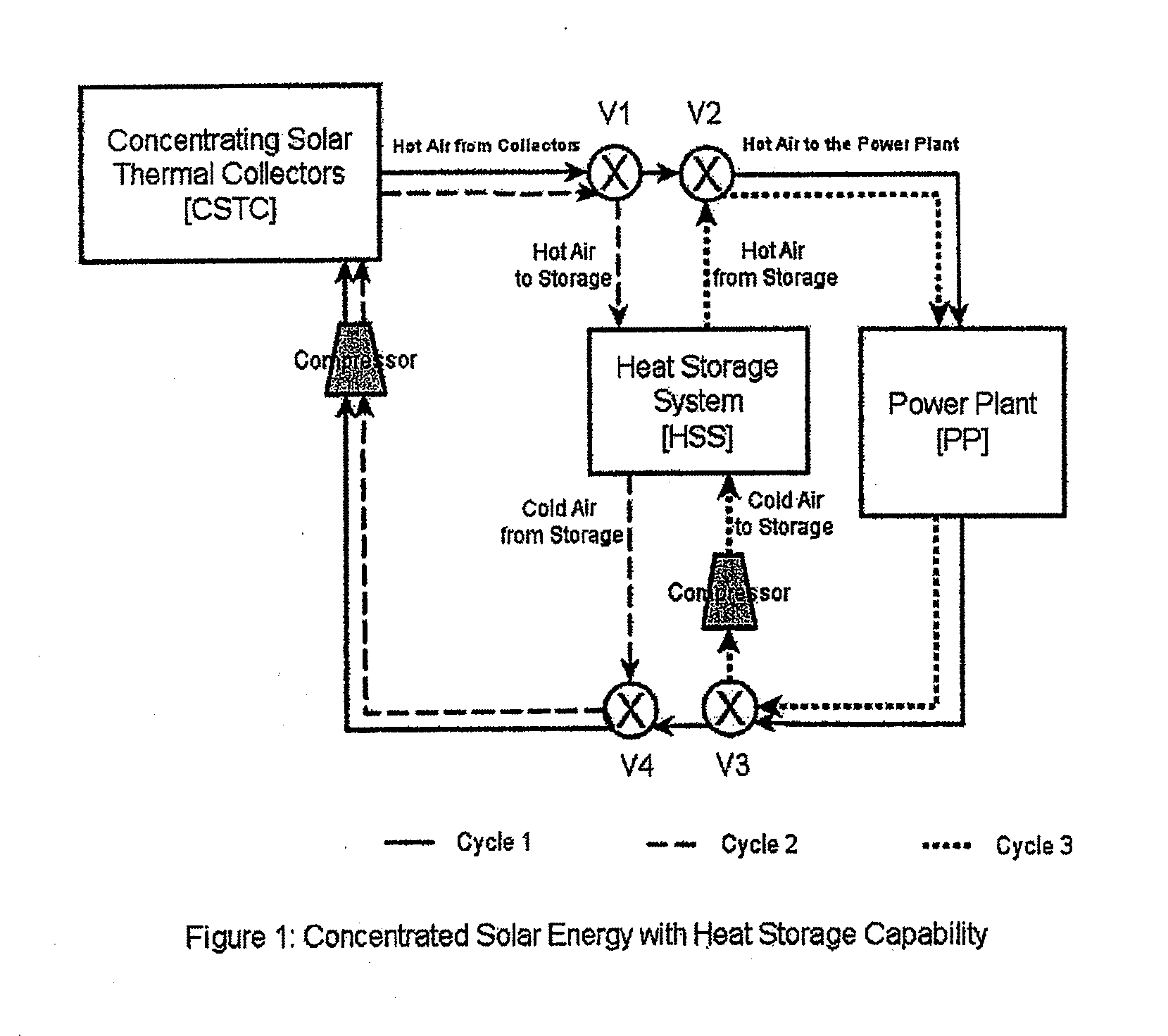

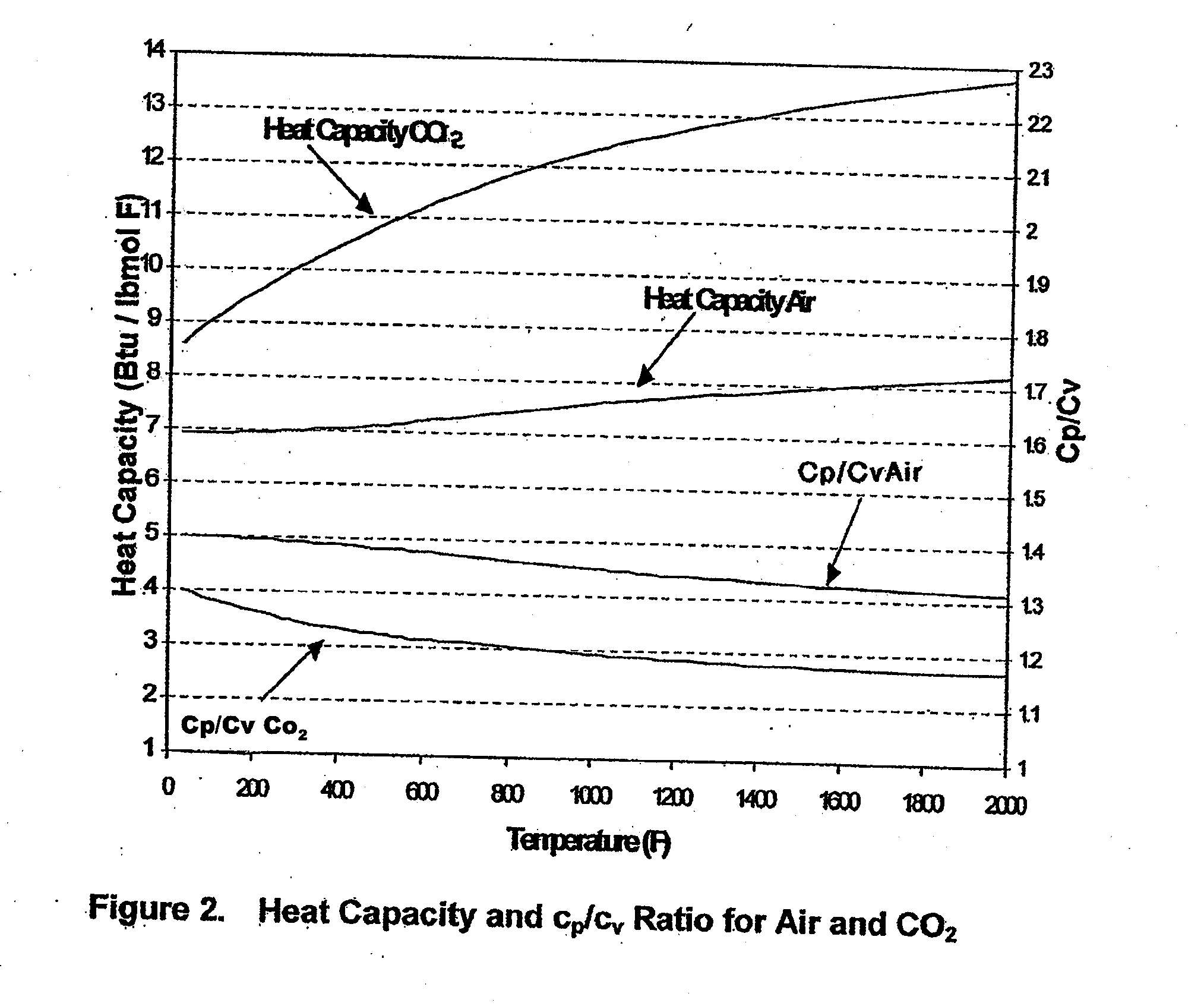

A method for storing heat from a solar collector CSTC in Concentrating Solar Power plants and delivering the heat to the power plant PP when needed. The method uses a compressed gas such as carbon dioxide or air as a heat transfer medium in the collectors CSTC and transferring the heat by depositing it on a bed of heat-resistant solids and later, recovering the heat by a second circuit of the same compressed gas. The storage system HSS is designed to allow the heat to be recovered at a high efficiency with practically no reduction in temperature. Unlike liquid heat transfer media, our storage method itself can operate at very high temperatures, up to 3000° F., a capability which can lead to greater efficiency. Due to material constraints and cost considerations in the rest of the system the maximum temperature is presently limited to between 1700° F. and 2000° F. The method can be applied to all current solar collector designs. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

Solar power plant and method and/or system of storing energy in a concentrated solar power plant

ActiveUS20100176602A1Big advantageLower energy requirementsSolar heating energyAuxillary drivesPower stationEngineering

A method for storing heat from a solar collector CSTC in Concentrating Solar Power plants and delivering the heat to the power plant PP when needed. The method uses a compressed gas such as carbon dioxide or air as a heat transfer medium in the collectors CSTC and transferring the heat by depositing it on a bed of heat-resistant solids and later, recovering the heat by a second circuit of the same compressed gas. The storage system HSS is designed to allow the heat to be recovered at a high efficiency with practically no reduction in temperature. Unlike liquid heat transfer media, our storage method itself can operate at very high temperatures, up to 3000° F., a capability which can lead to greater efficiency. Due to material constraints and cost considerations in the rest of the system the maximum temperature is presently limited to between 1700° F. and 2000° F. The method can be applied to all current solar collector designs. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

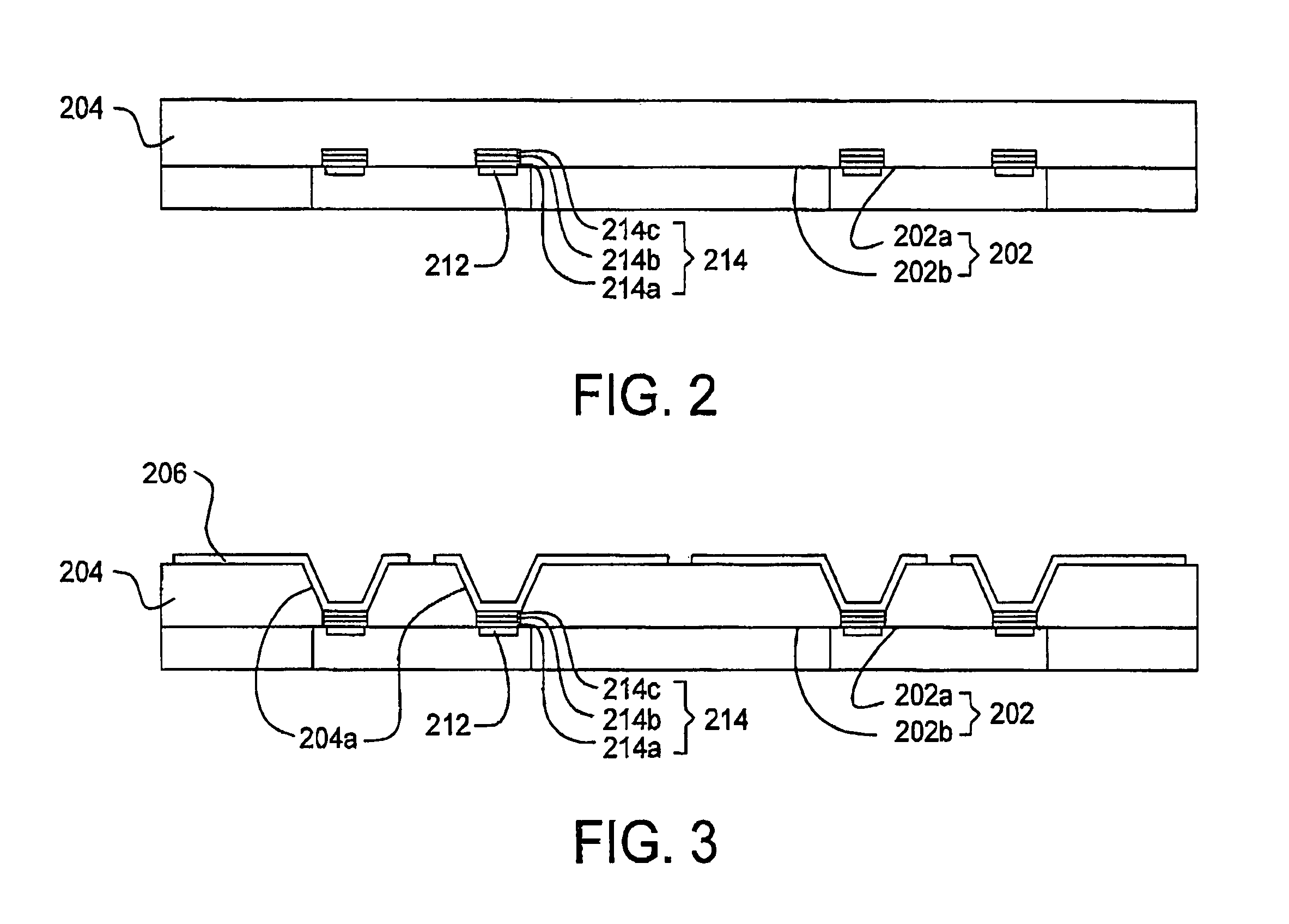

Semiconductor chip package and method for making the same

ActiveUS7041534B2Improve thermal efficiencyImprove thermal performanceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageSemiconductor chip

A semiconductor chip package mainly includes a semiconductor chip, a first dielectric layer disposed on the semiconductor chip, a plurality of conductive traces electrically connected to the semiconductor chip, a second dielectric layer disposed on the conductive traces and the first dielectric layer wherein a portion of the conductive traces are exposed from the second dielectric layer, and a plurality of contacts for external connection formed on the exposed portion of the conductive traces. The semiconductor chip has a surface including an active area, a dummy area surrounding the active area, and a plurality of bonding pads disposed on the active area. The bonding pads are electrically connected to the contacts by the conductive traces. The present invention further provides methods for manufacturing the semiconductor chip package.

Owner:ADVANCED SEMICON ENG INC

Solar power plant and method and/or system of storing energy in a concentrated solar power plant

ActiveUS20110277471A1Big advantageLower energy requirementsSolar heating energyFrom solar energyPower stationEngineering

A method for storing heat from a solar collector CSTC in Concentrating Solar Power plants and delivering the heat to the power plant PP when needed. The method uses a compressed gas such as carbon dioxide or air as a heat transfer medium in the collectors CSTC and transferring the heat by depositing it on a bed of heat-resistant solids and later, recovering the heat by a second circuit of the same compressed gas. The storage system HSS is designed to allow the heat to be recovered at a high efficiency with practically no reduction in temperature. Unlike liquid heat transfer media, our storage method itself can operate at very high temperatures, up to 3000° F., a capability which can lead to greater efficiency.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com