Patents

Literature

511results about How to "Increase heat exchange rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

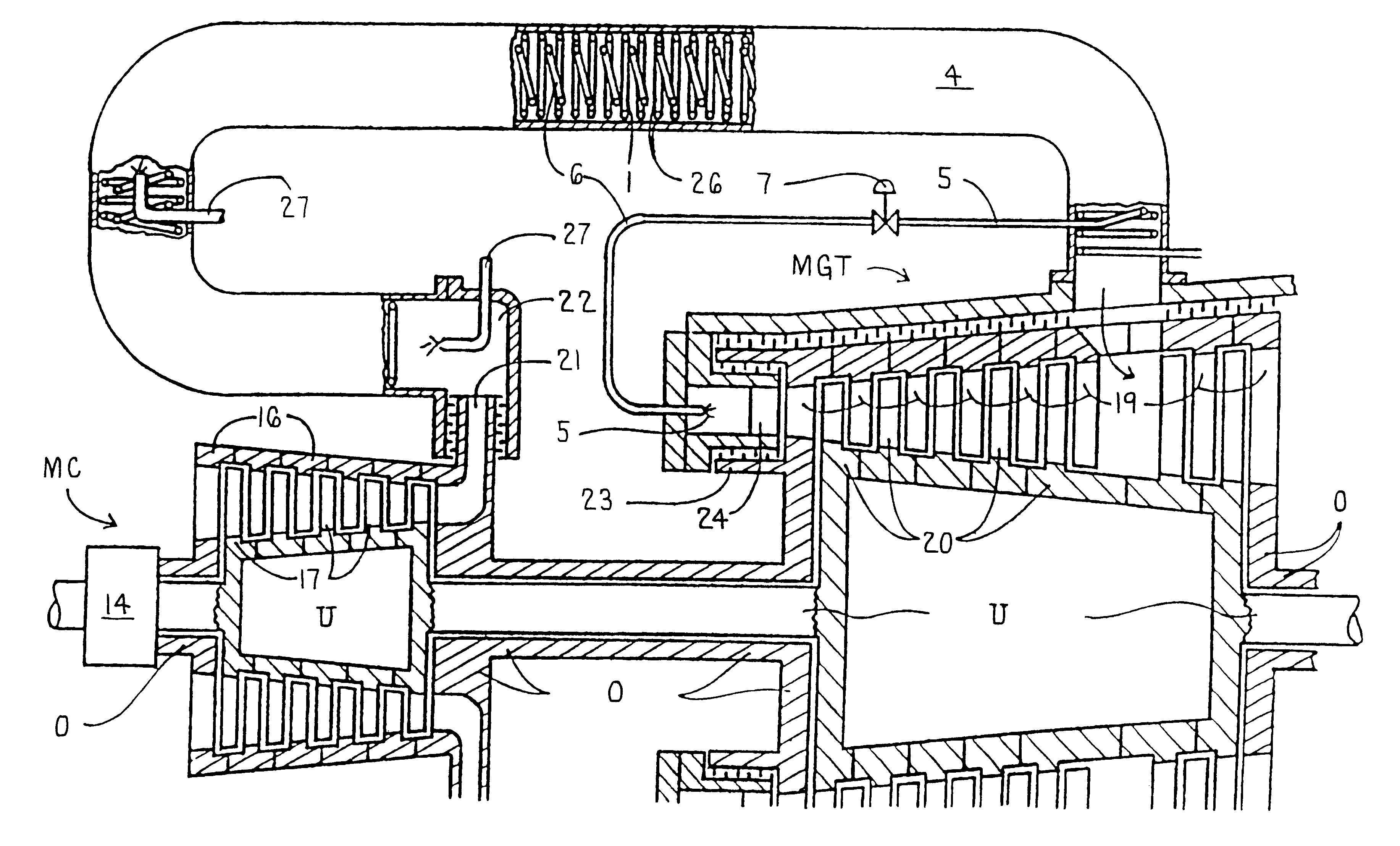

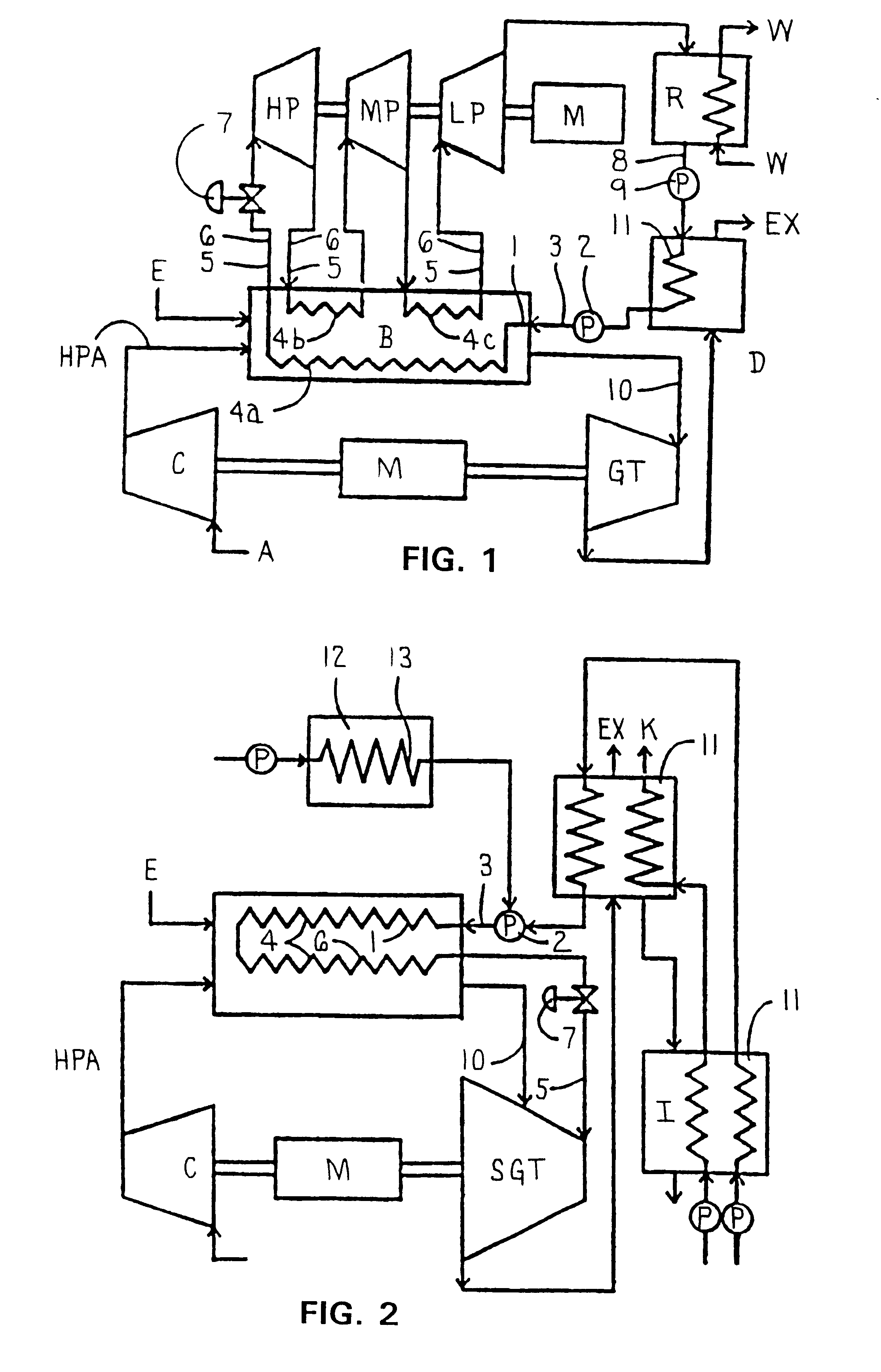

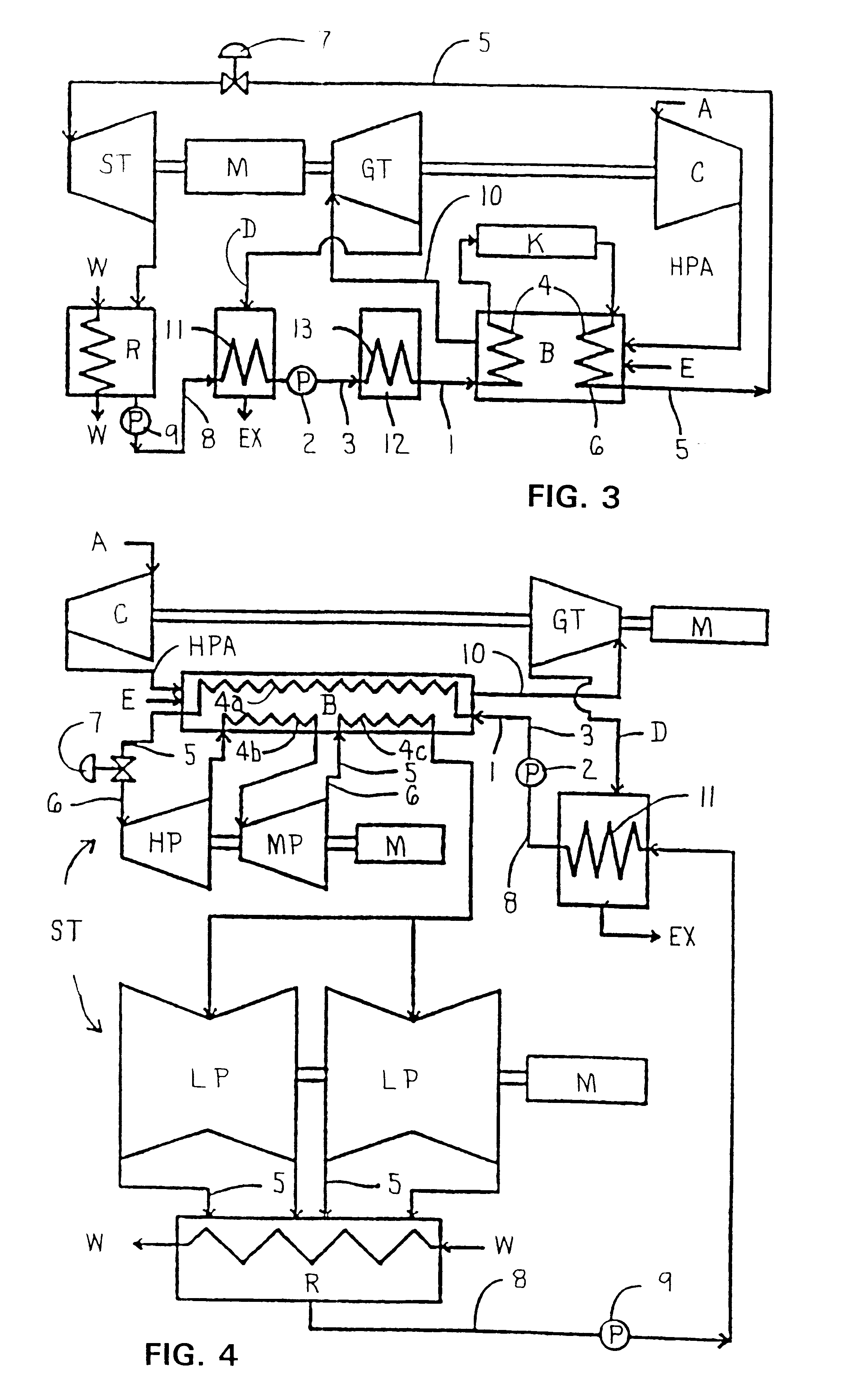

Combined steam and gas turbine engine with magnetic transmission

InactiveUS6263664B1Wide areaImprove system efficiencyContinuous combustion chamberGearingThermal energyCombustion chamber

In a combined steam and gas turbine engine cycle, a combustion chamber is made durable against high pressure and enlarged in length to increase the operation pressure ratio, without exceeding the heat durability temperature of the system while increasing the fuel combustion gas mass flow four times as much as the conventional turbine system and simultaneously for greatly raising the thermal efficiency of the system and specific power of the combined steam and gas turbine engine.Water pipes and steam pipes are arranged inside the combustion chamber so that the combustion chamber can function as a heat exchanger and thereby convert most of the combustion thermal energy into super-critical steam energy for driving a steam turbine and subsequently raising the operation pressure ratio and the thermal efficiencies of the steam turbine cycle and gas turbine cycle. The combustion gas mass flow can be also increased by four times as much as the conventional turbine system (up to the theoretical air to fuel ratio) and the thermal efficiency and the specific power of the gas turbine cycle are considerably increased.Further, the thermal efficiency of the combined system is improved by installing a magnetic friction power transmission system to transmit the power of the system to outer loads.

Owner:TANIGAWA HIROYASU +1

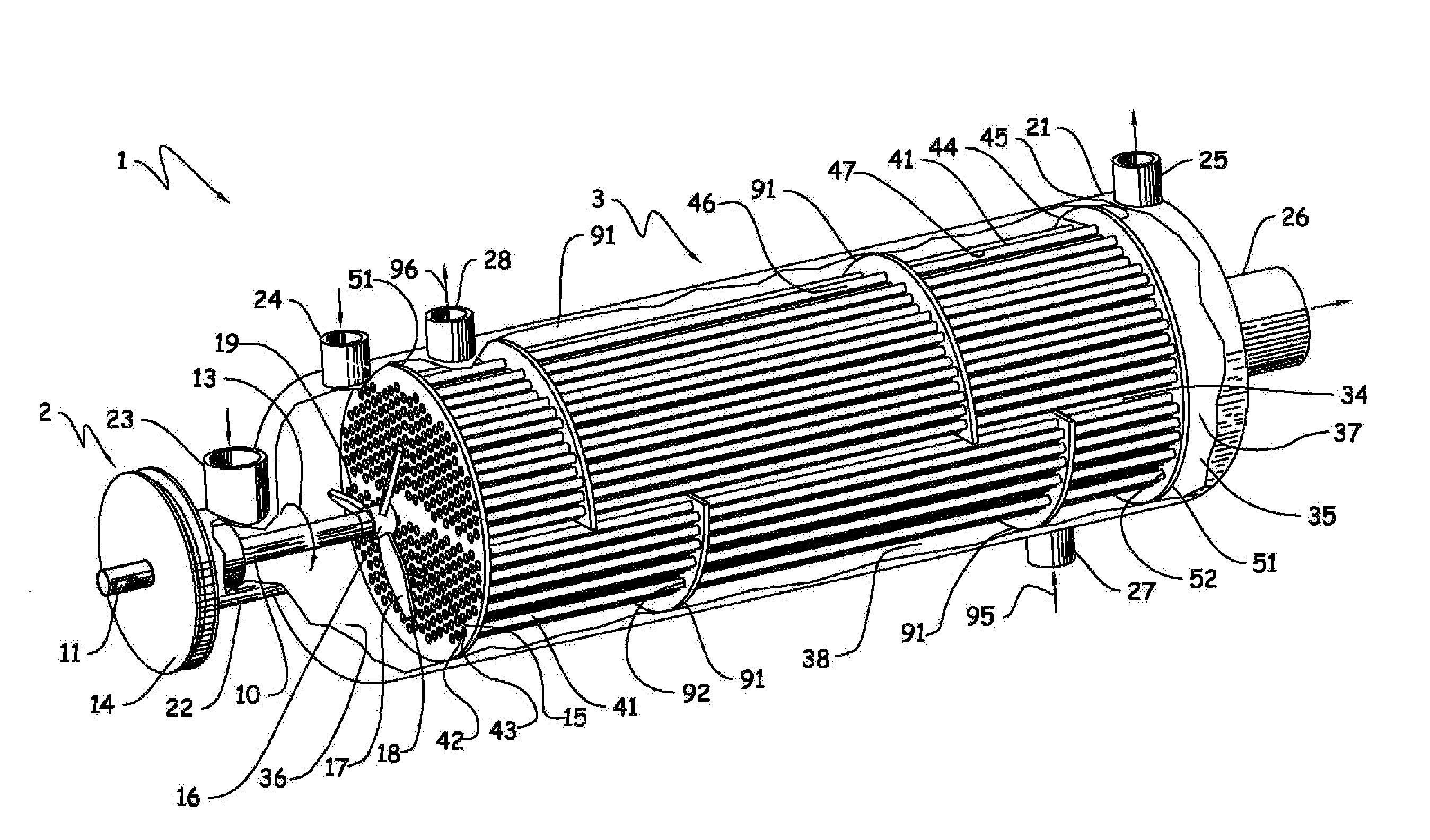

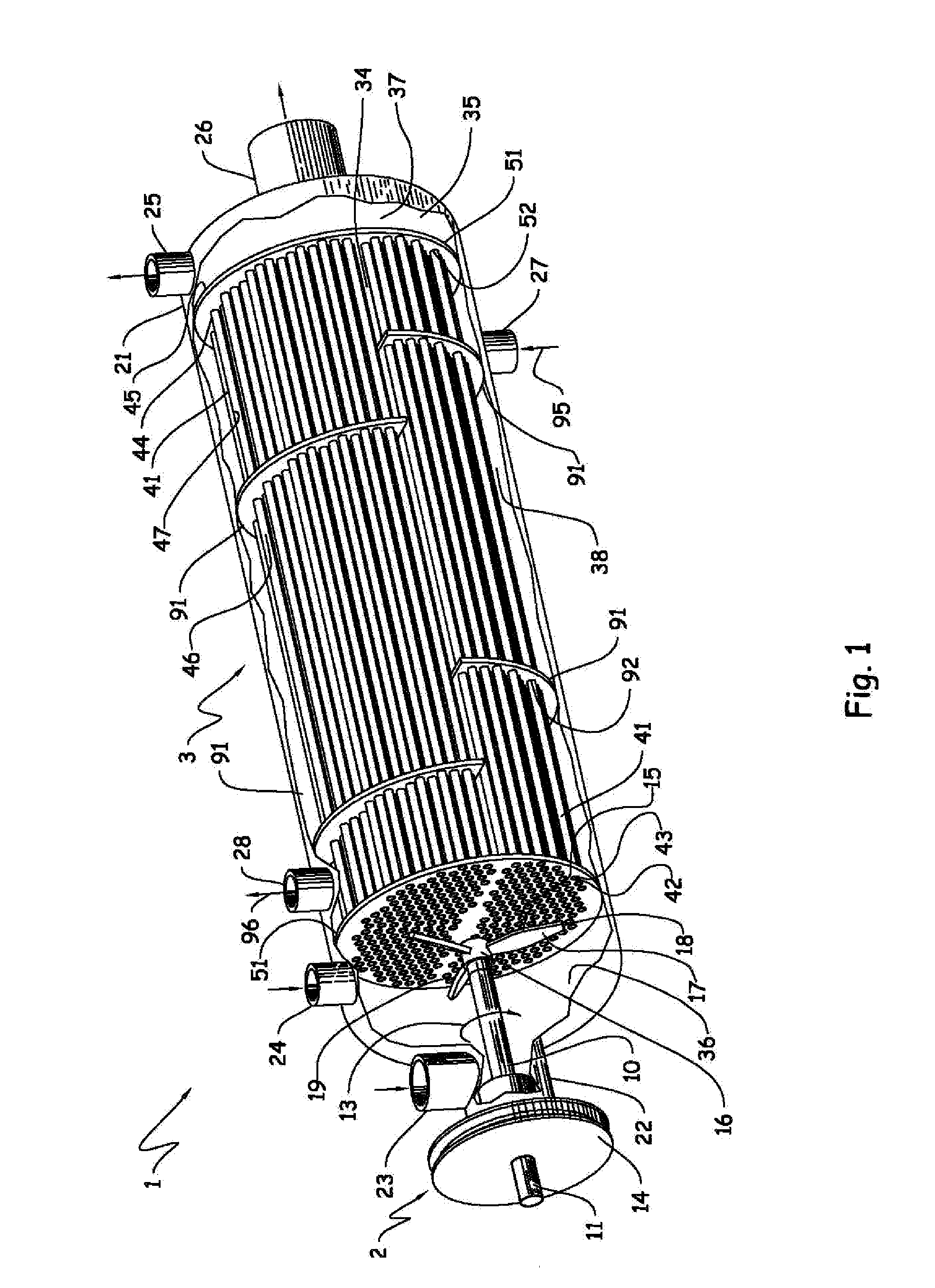

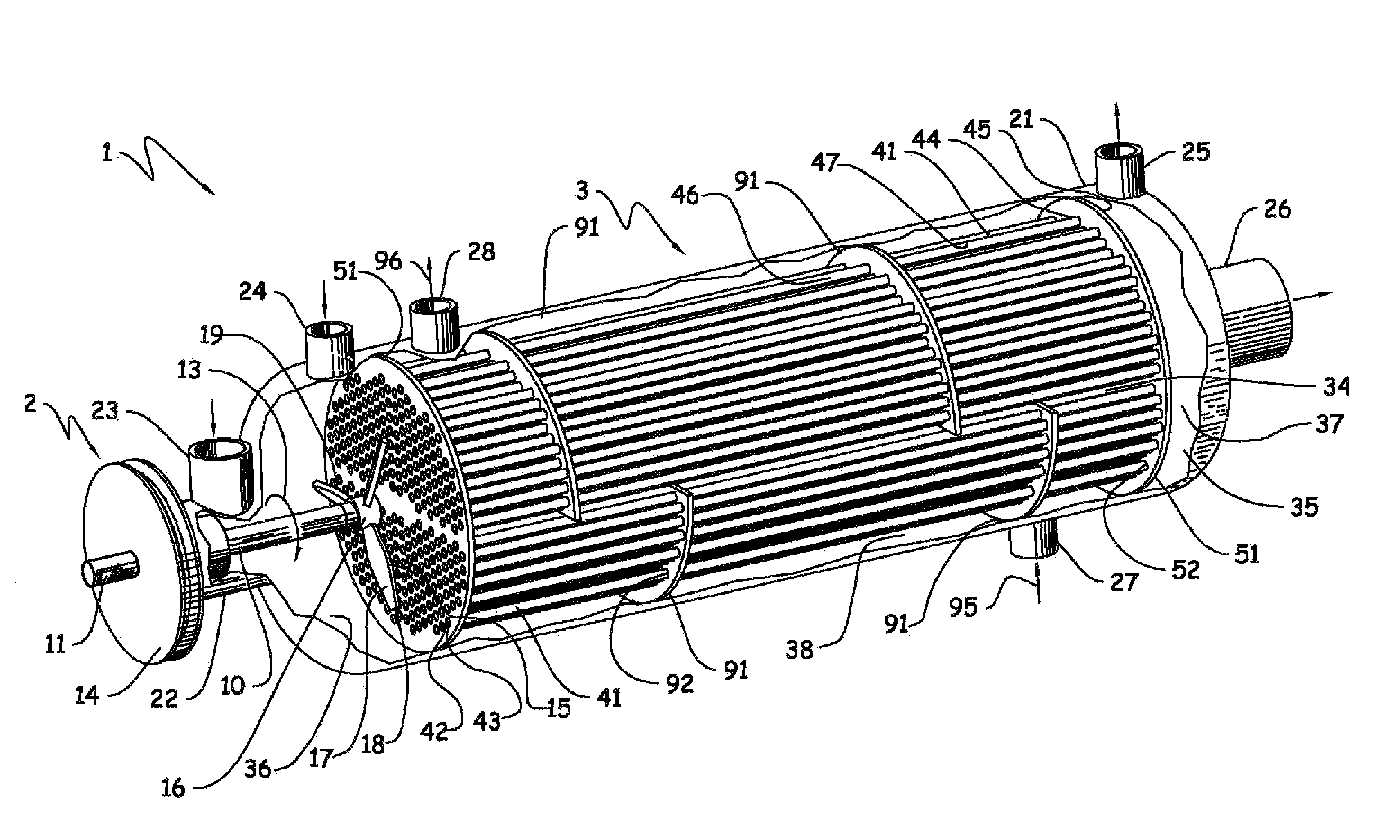

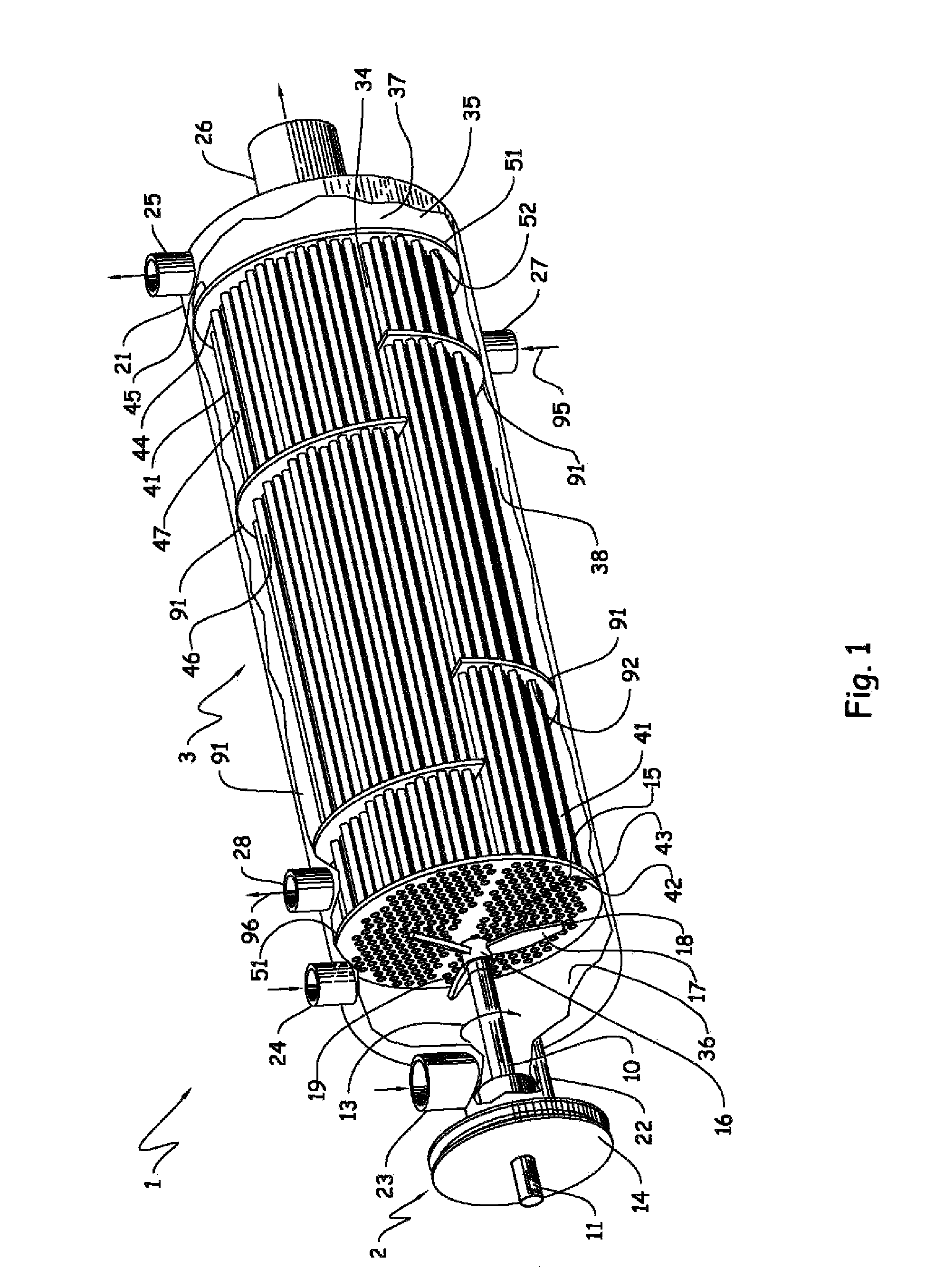

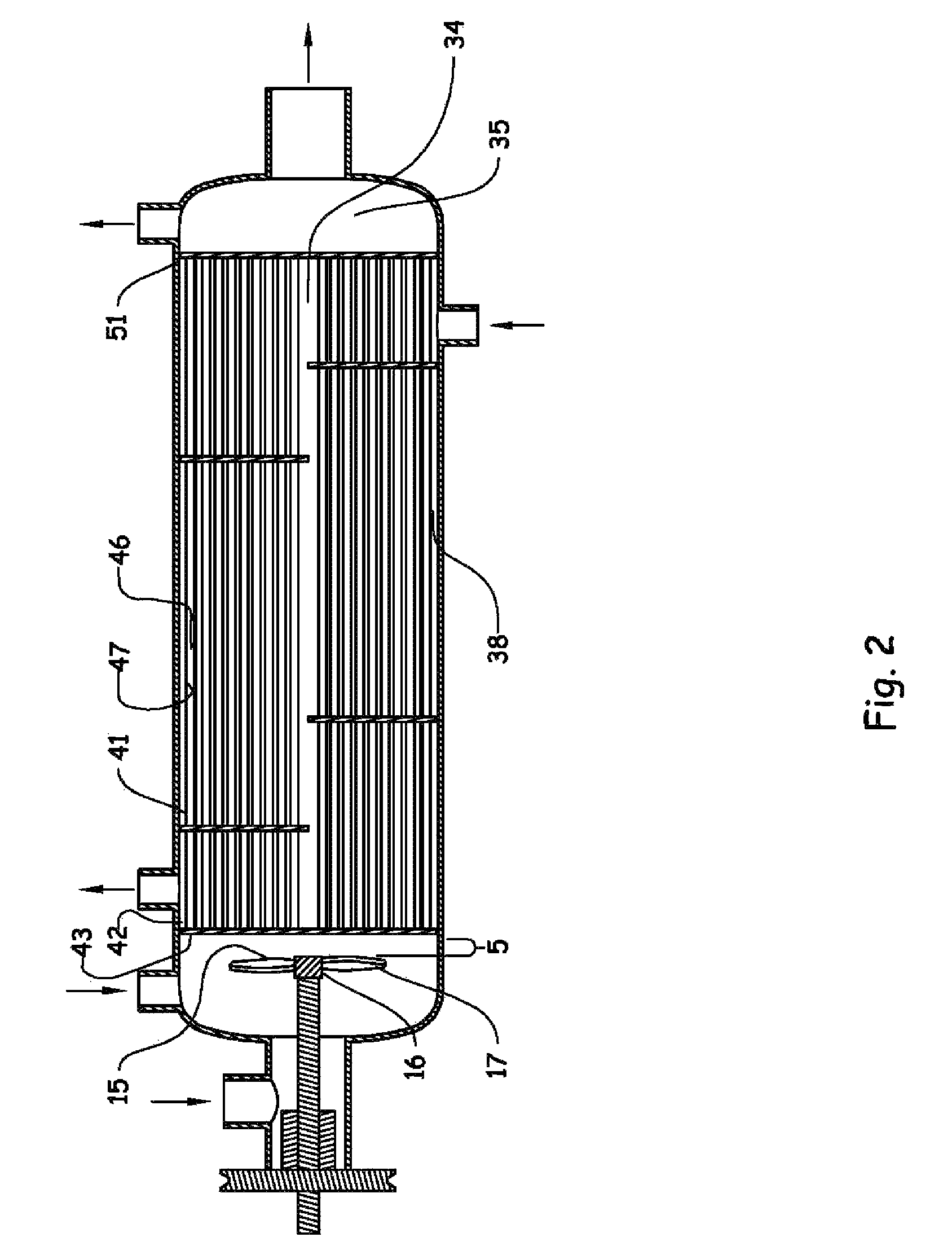

Tube-side sequentially pulsable-flow shell-and-tube heat exchanger appratus, system, and method

ActiveUS20100243208A1Increase heat exchange rateReduce dirtCorrosion preventionStationary tubular conduit assembliesChemical treatmentShell and tube heat exchanger

The present invention relates to a tube-side sequentially pulsable-flow, shell-and-tube heat exchanger apparatus and a chemical processing system comprising and methods of heat exchange employing the same.

Owner:DOW GLOBAL TECH LLC

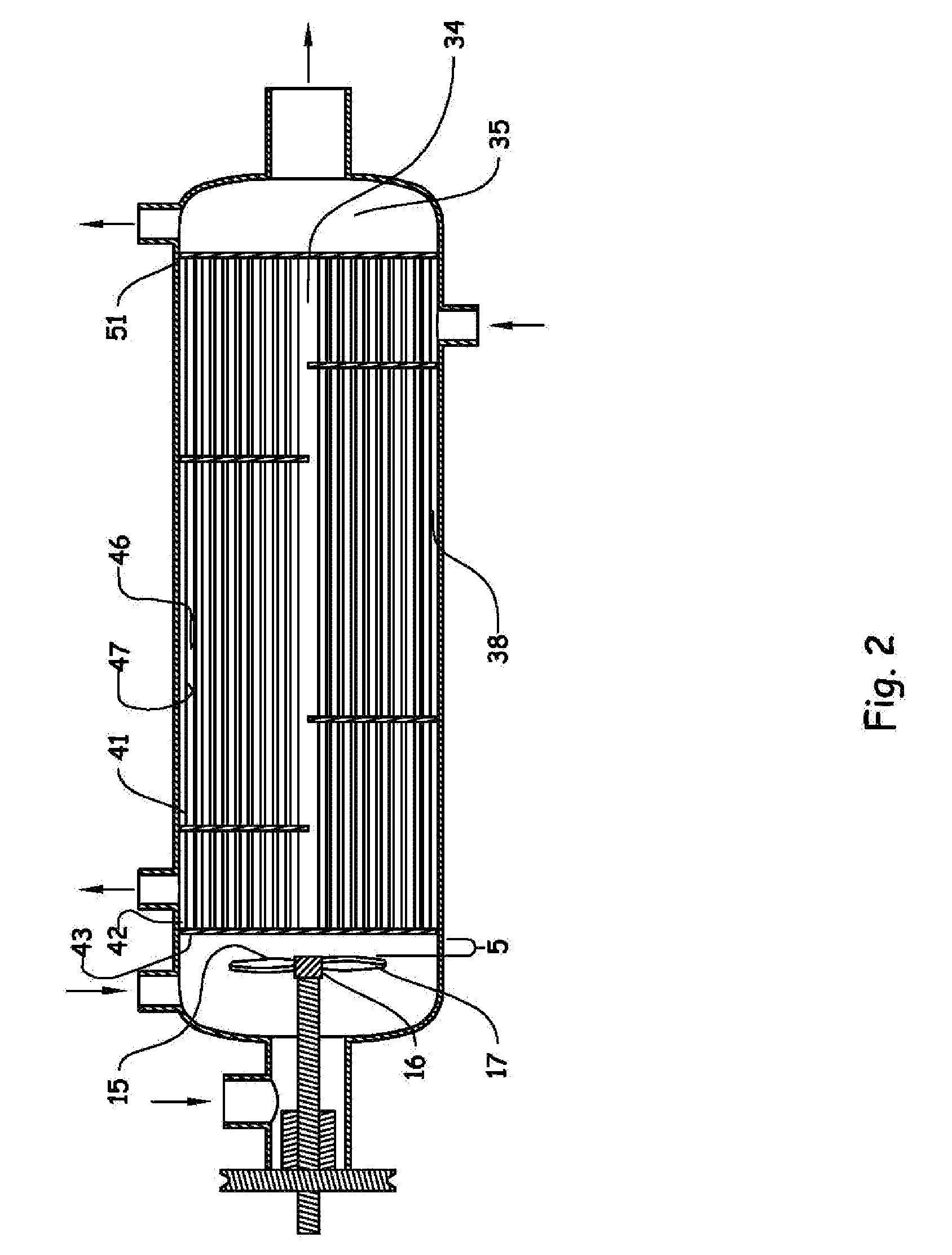

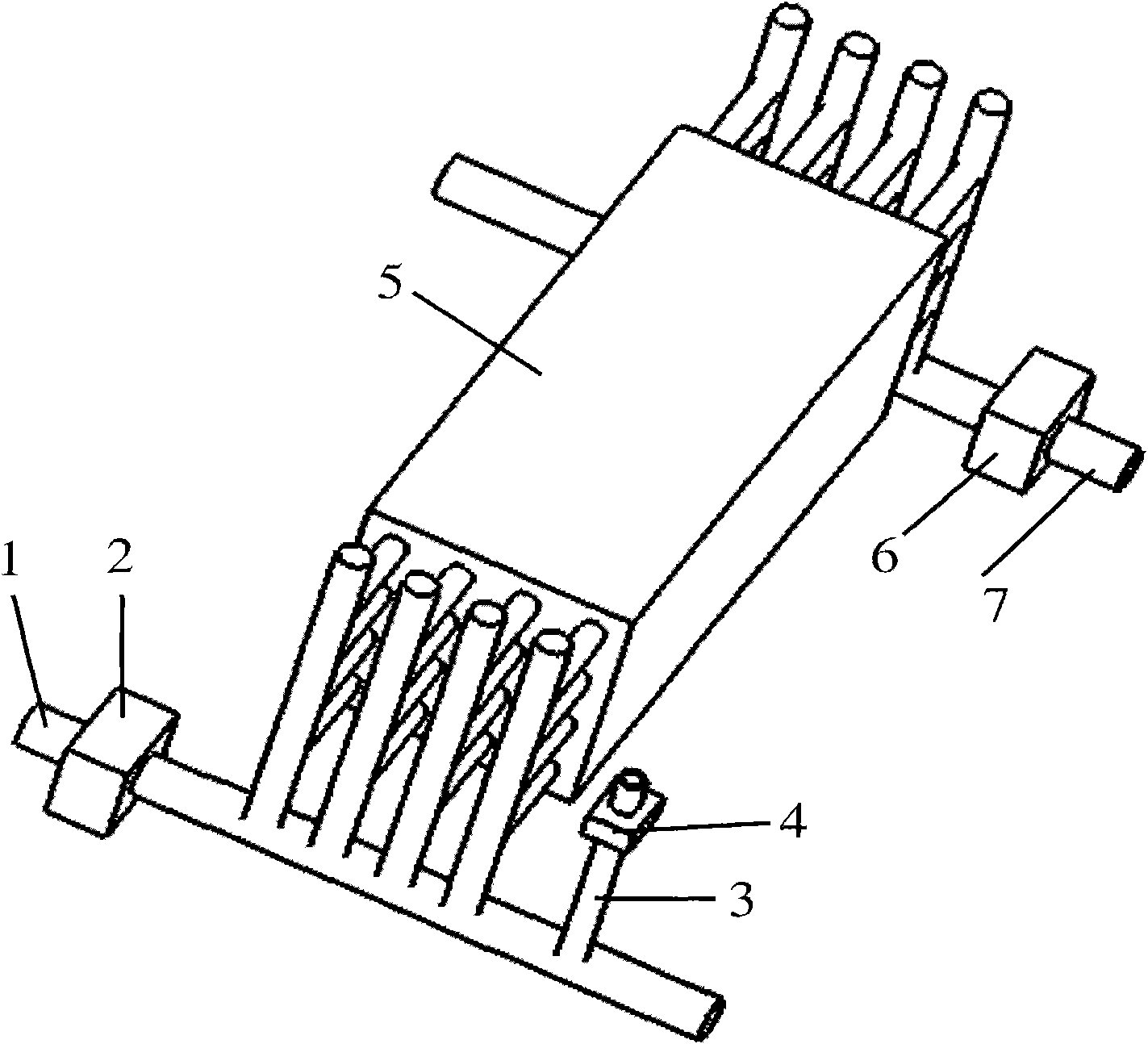

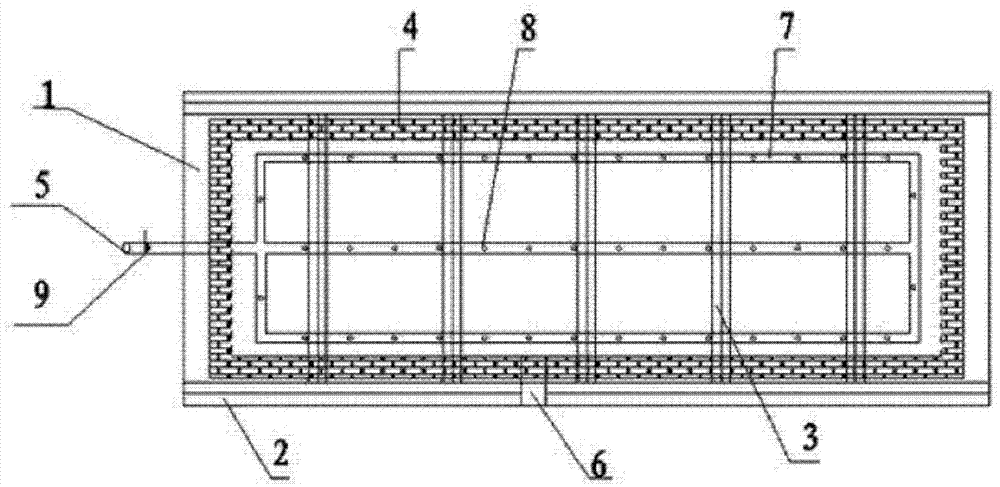

Method for arranging structure of heat exchange pipes of concrete heat storage system for solar thermal power generation

InactiveCN101876488AIncrease heat exchange rateReduce power generation costsSolar heat devicesHeat storage plantsHeat conductingWorking temperature

The invention relates to a method for arranging the structure of heat exchange pipes of a concrete heat storage system for solar thermal power generation, comprising the following steps: arranging a plurality of heat exchange pipes which are arranged equidistantly in a concrete heat storage block (5), connecting two ends of each heat exchange pipe with an inlet pipe (1) and an outlet pipe (7) through a connecting pipe, arranging an inlet control valve (2) and an air inlet and evacuation pipe (3) on each inlet pipe (1), arranging an air inlet and evacuation valve (4) on the air inlet and evacuation pipe (3), and arranging an outlet control valve (6) on each outlet pipe (7). The solar thermal power generation technology is made to be practical due to the adoption of the method. When the structure of the heat exchange pipes, which is arranged by the method, is used, the heat conducting medium is made to flow in the heat exchange pipes from the inlet pipes, then the switch and the flow rate are adjusted through the inlet control valves, the heat is exchanged by the heat exchange pipes and is stored in the concrete heat storage block, and the heat conducting medium is made to flow out of the heat exchange pipes from the outlet pipes. The invention reduces the power generation cost, improves the heat exchange and storage efficiency and ensures that the working temperature of the concrete heat storage system is 600-900 DEG C which is much higher than the use temperature of the prior molten salt.

Owner:WUHAN UNIV OF TECH

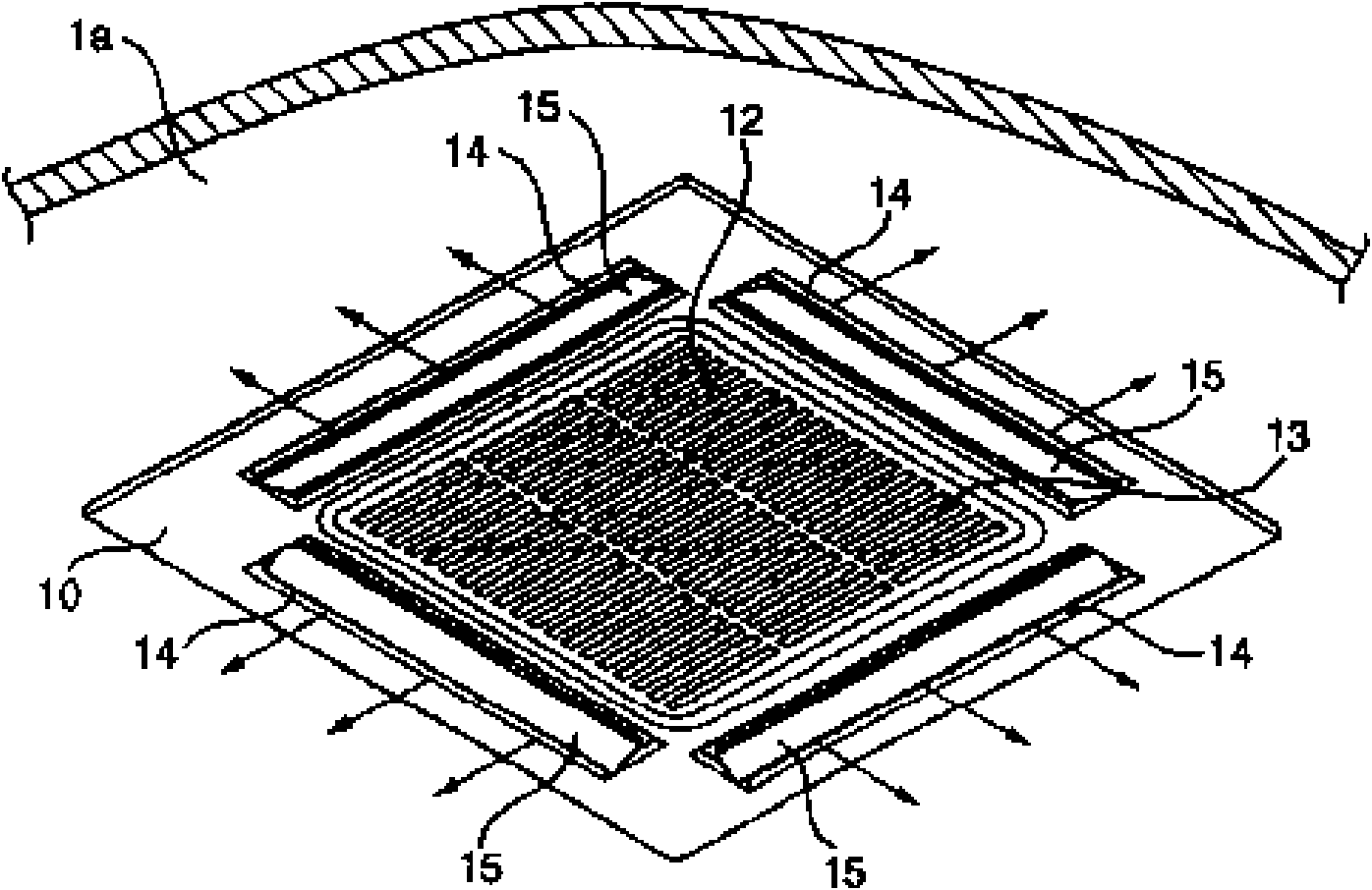

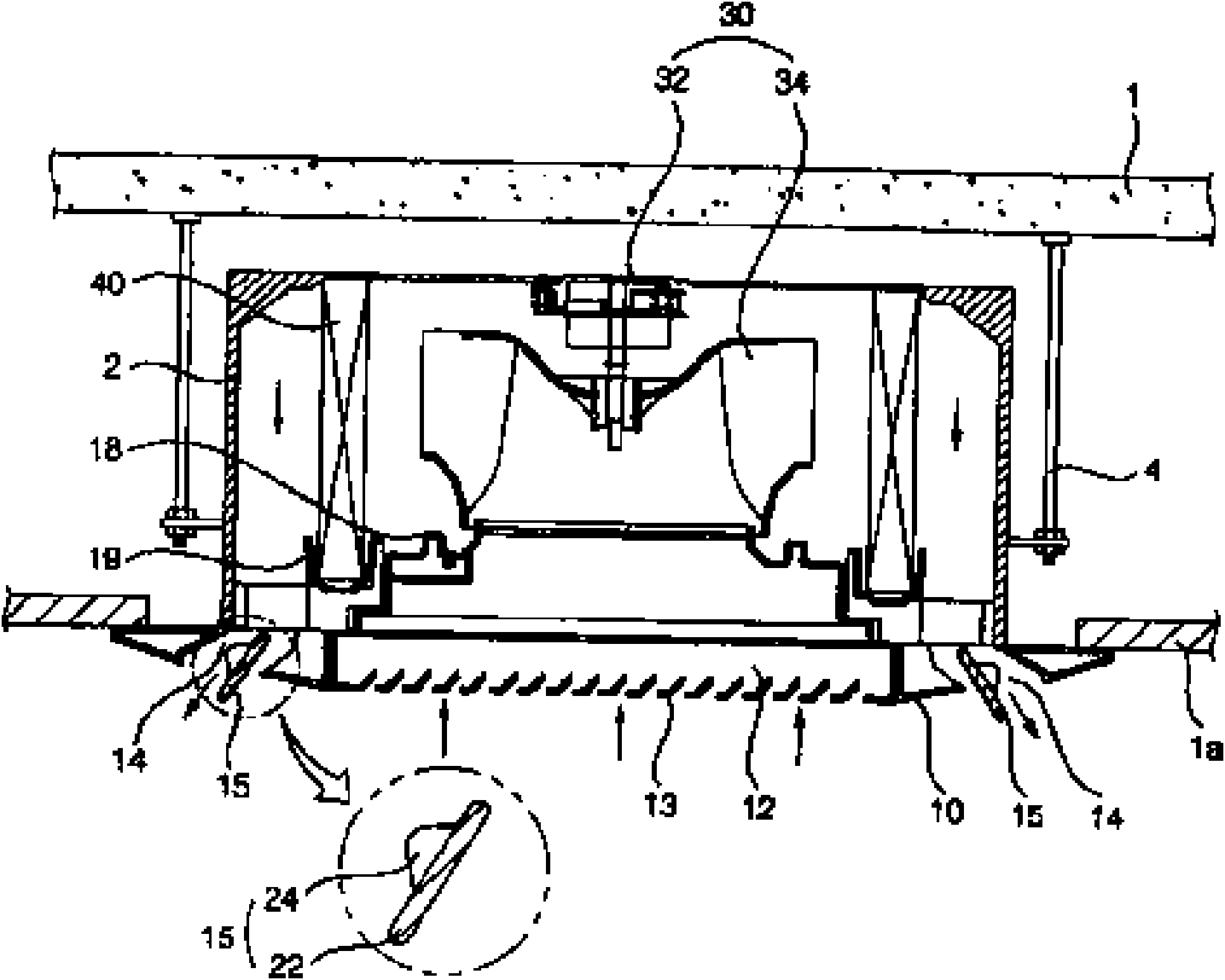

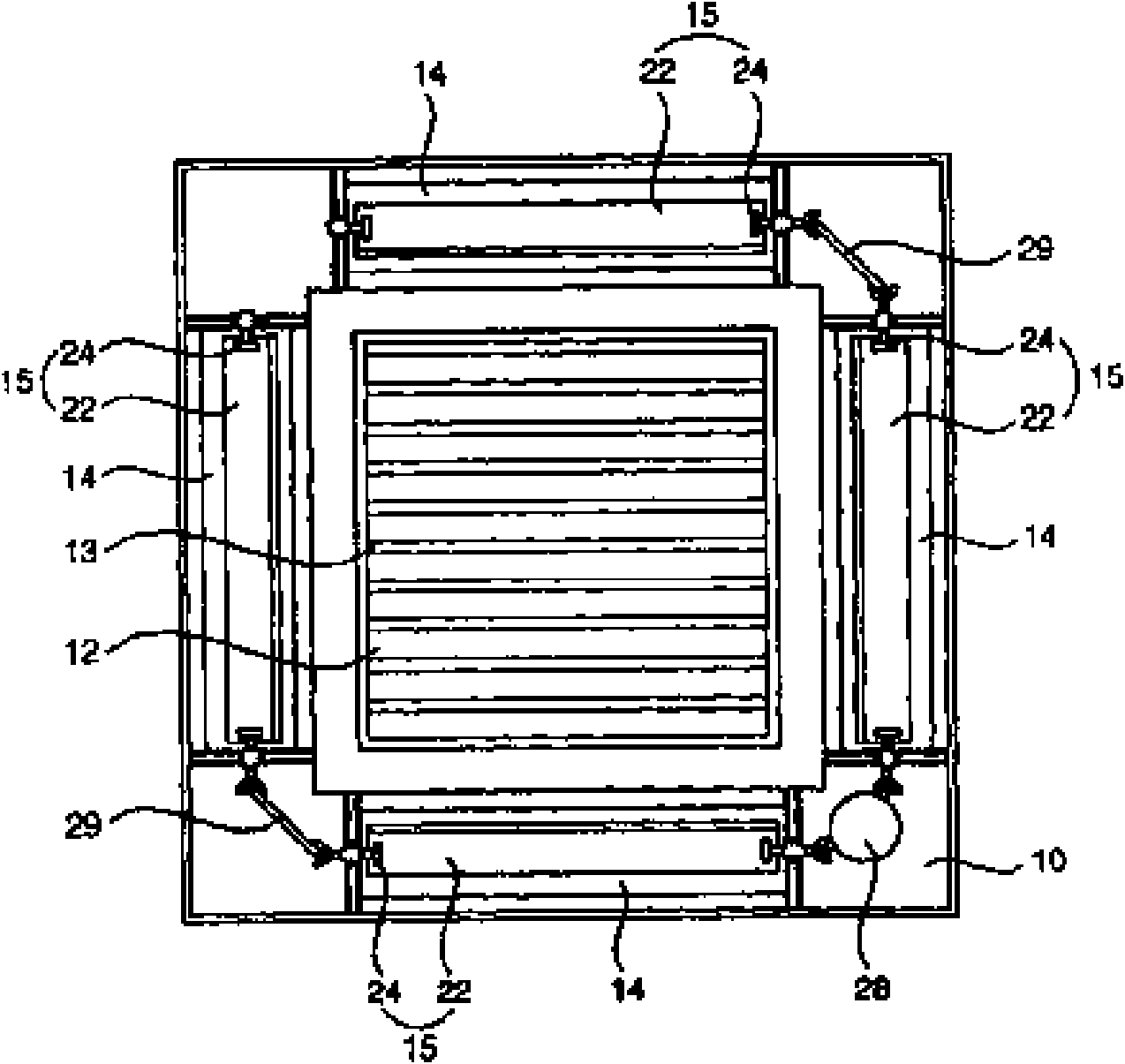

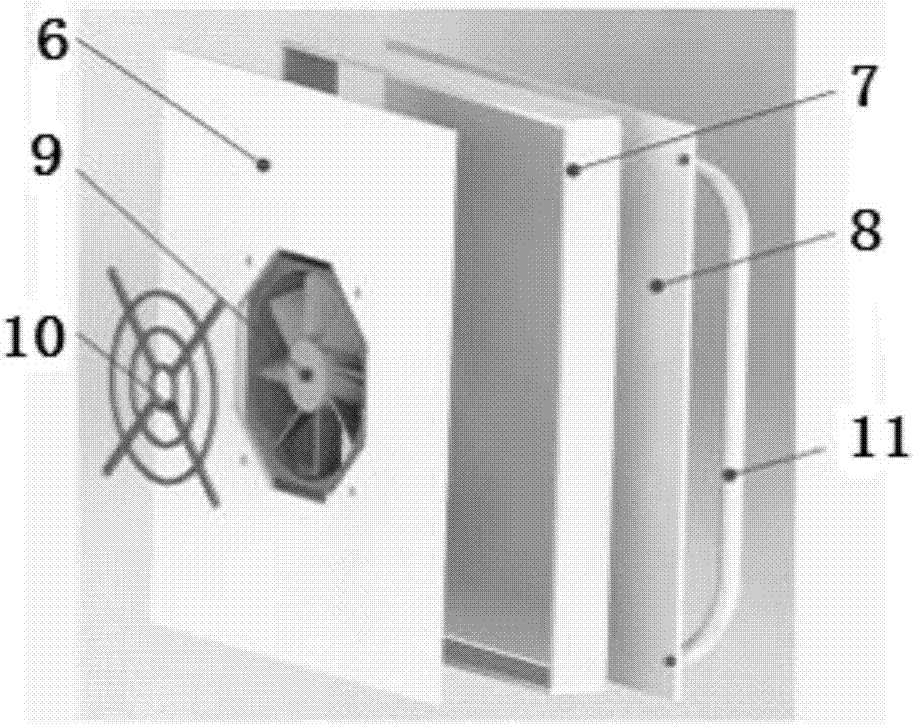

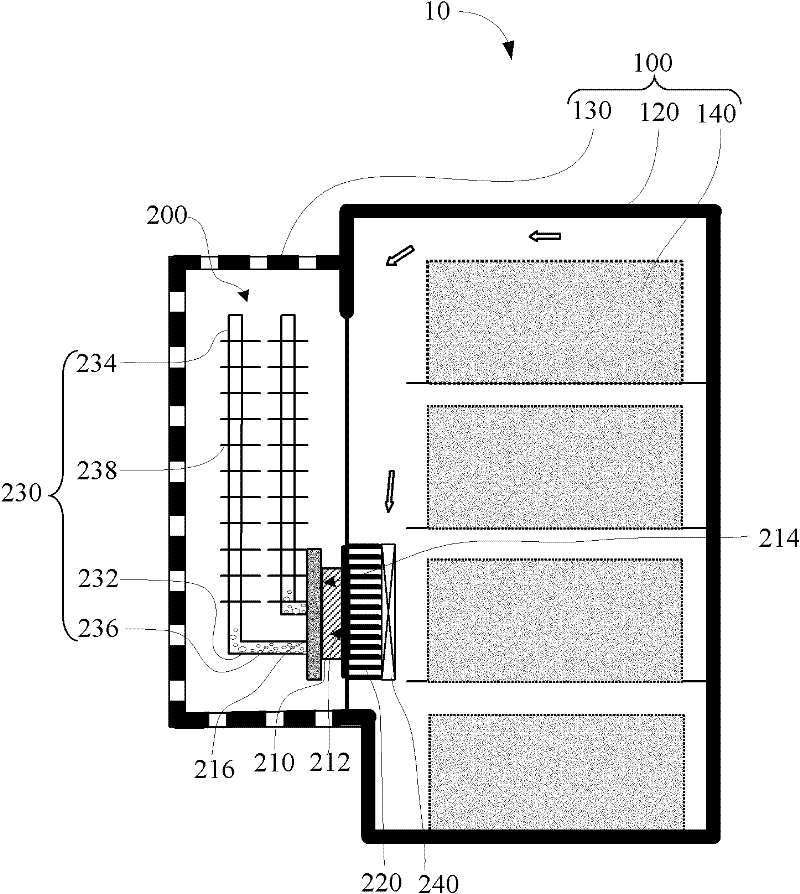

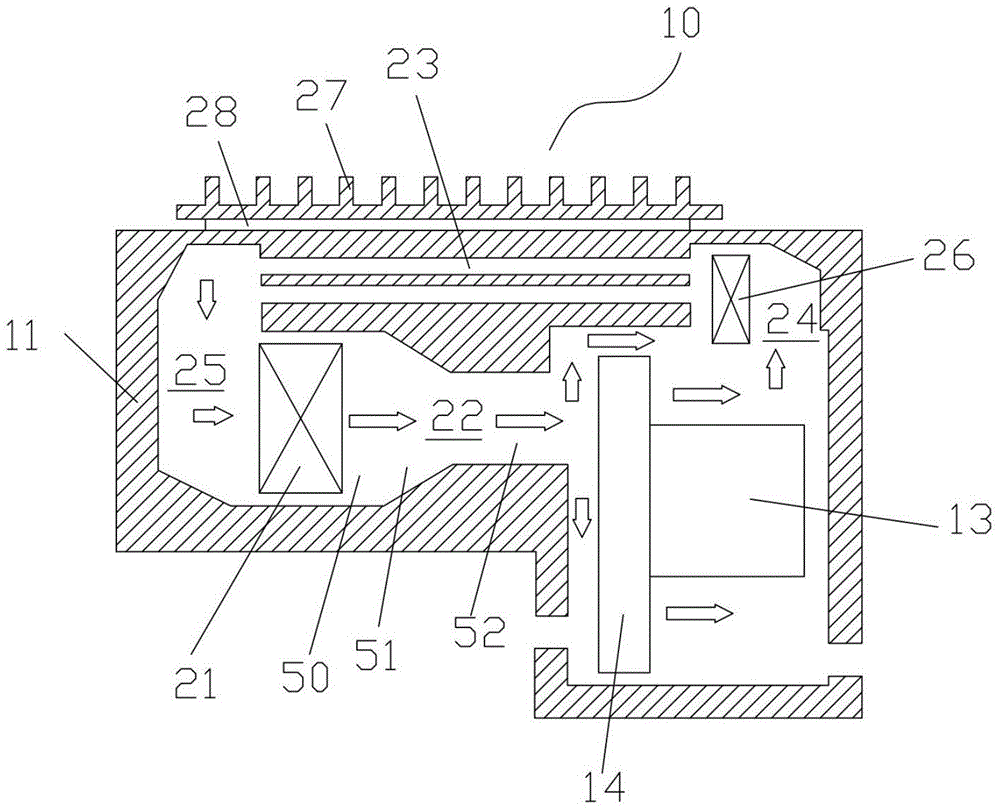

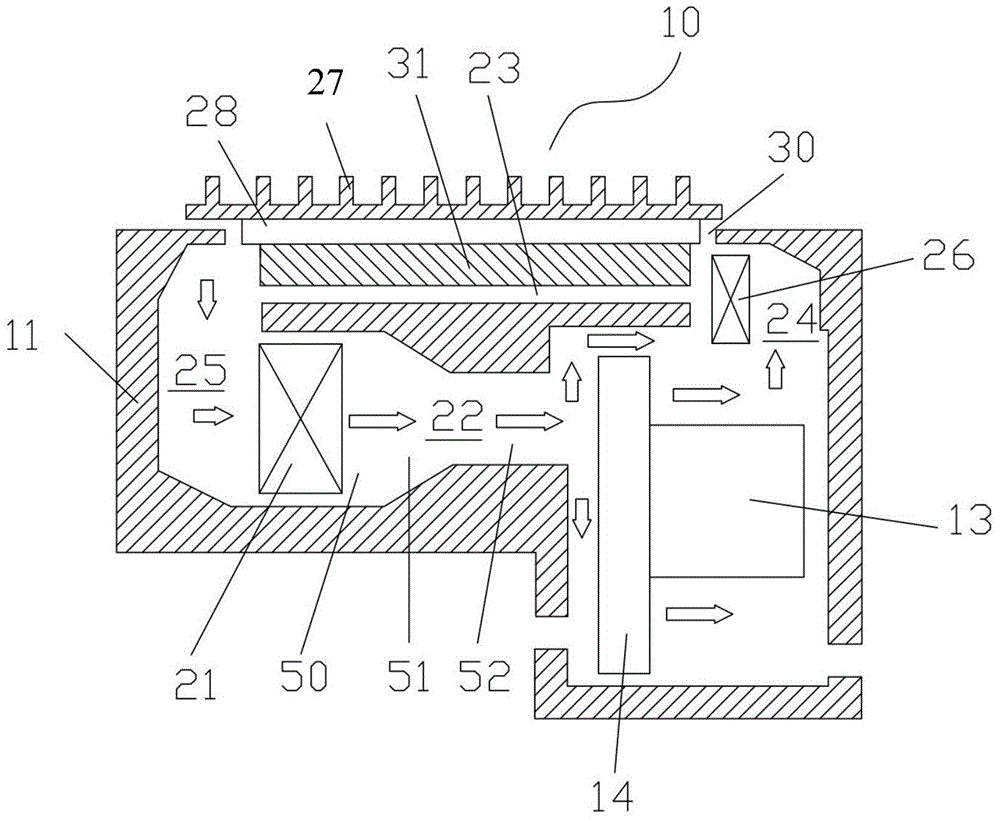

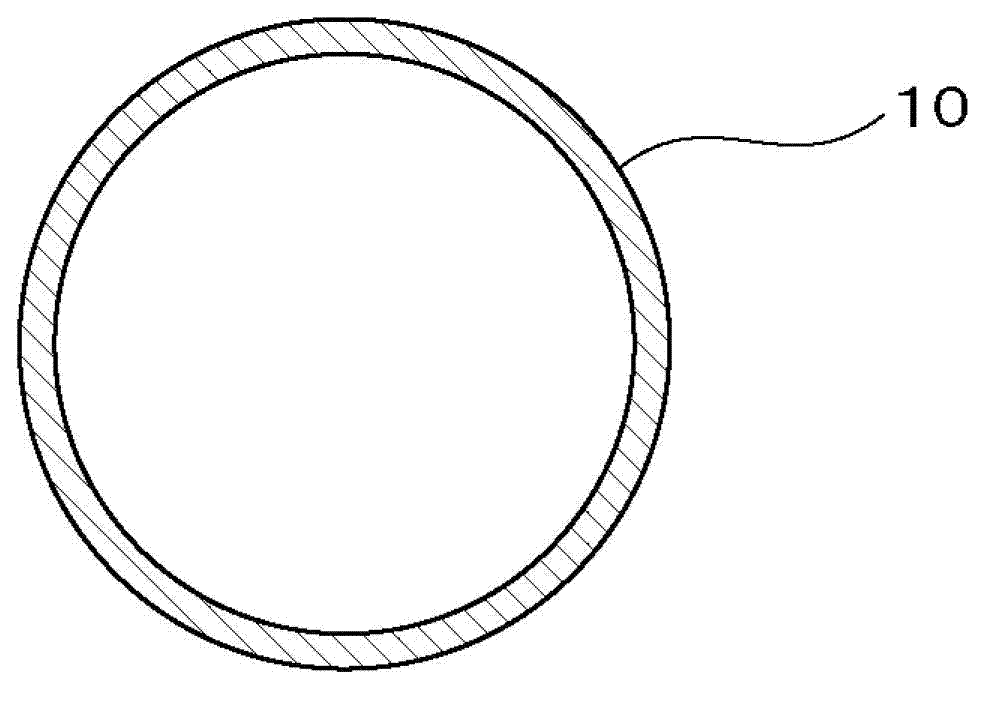

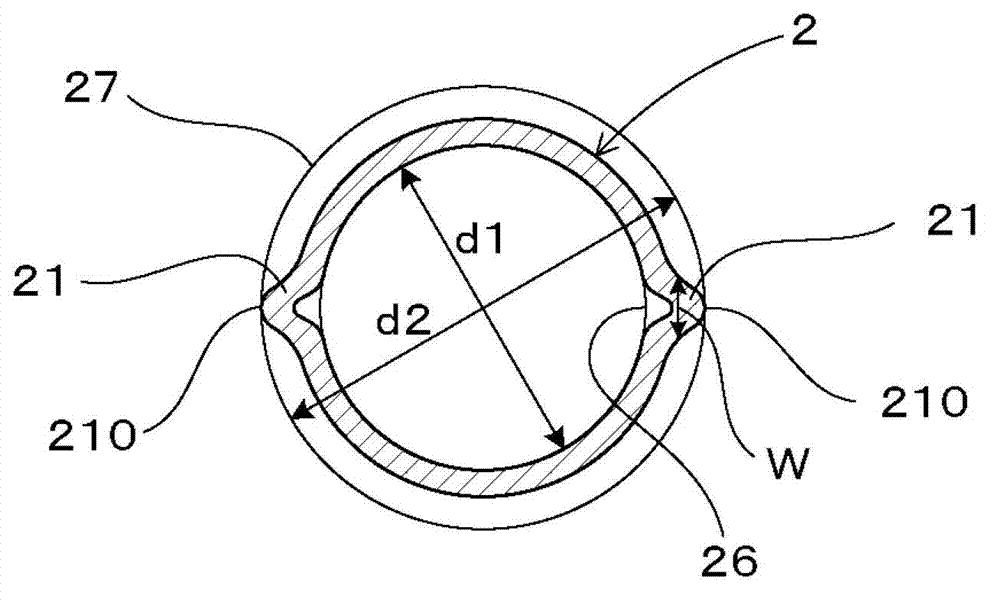

Ceiling type air-conditioning indoor machine

InactiveCN102141266ANovel shapeSmall footprintLighting and heating apparatusHeating and ventilation casings/coversAir conditioningTurbine

The invention discloses a ceiling type air-conditioning indoor machine, which comprises a shell fixedly arranged in a ceiling, a bottom panel which is arranged on the bottom surface of the shell and on which an air suction inlet and an air outlet are formed, and a turbine fan and a heat exchanger which are fixedly arranged inside the shell, wherein the shell has a cylindrical structure; the bottom panel has a circular structure; and the air outlet has an annular structure. In the indoor machine, the panel is design in a more aesthetic circular structure by changing the conventional shape; the indoor machine has novel appearance and further reduced floor area; air can be supplied at the angle of 360 DEG without dead angles; the heat exchanger is correspondingly set to be a cylindrical heat exchanger which is sleeved at the periphery of the turbine fan; and the heat exchange rate can be further increased, the performance of a product can be improved and the competitiveness of the product can be enhanced.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

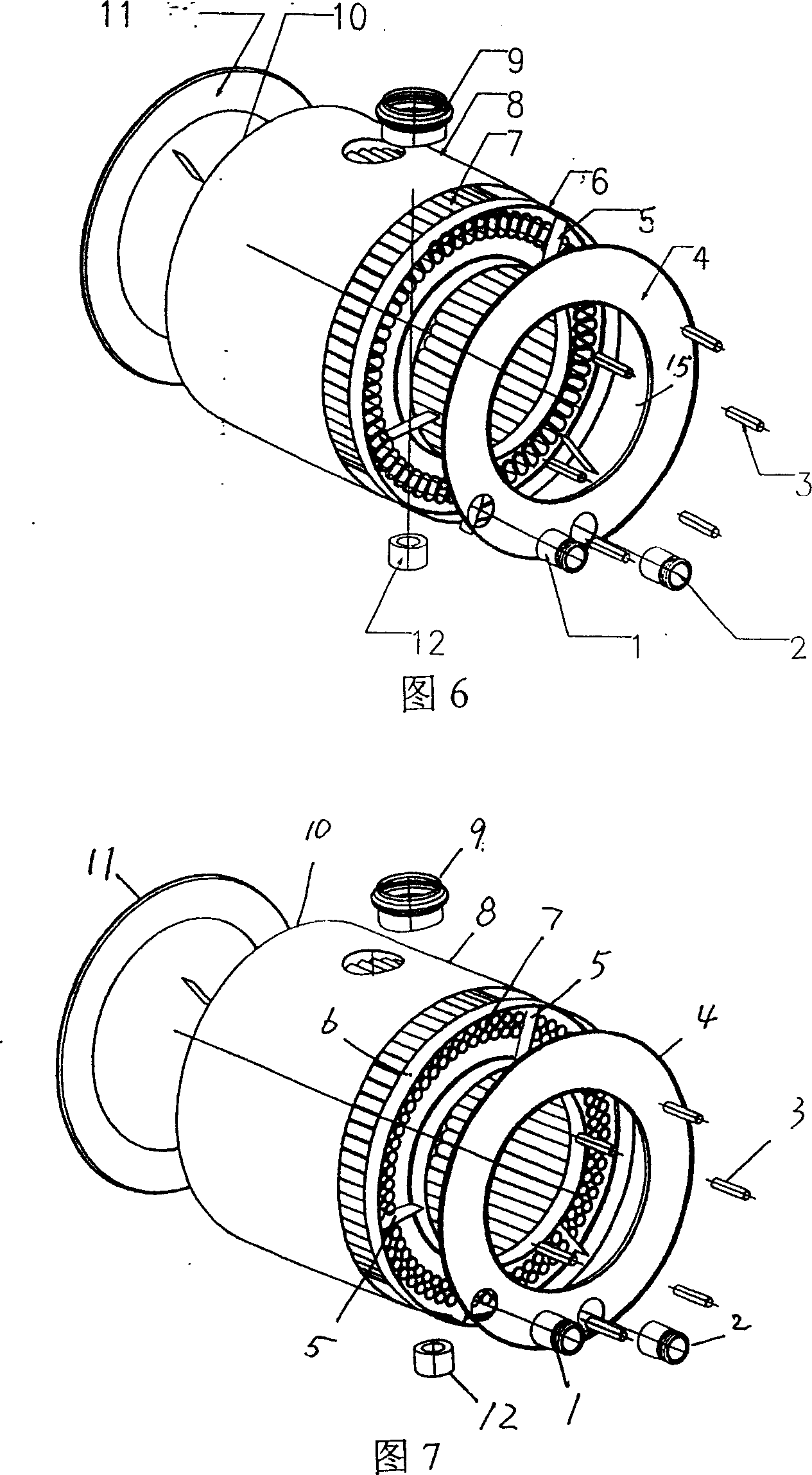

Motor cooling and vibration reducing mechanism

InactiveCN110535282AAvoid damageIncrease heat exchange rateCooling/ventillation arrangementSupports/enclosures/casingsEngineeringWater jacket

The invention discloses a motor cooling and vibration reducing mechanism, and belongs to the technical field of motors. The motor cooling and vibration reducing mechanism comprises a motor main body,a heat dissipation shell and a base, wherein the motor main body is fixedly connected to the interior of the heat dissipation shell through a heat dissipation water jacket, a refrigerant sucking and discharging assembly is fixedly connected to the side wall of a supporting plate, one end, away from a second driving shaft, of a reciprocating mechanism is connected to the refrigerant sucking and discharging assembly, one end, away from the motor main body, of the second driving shaft is connected to a heat dissipation assembly, a push rod is movably connected to the side wall, close to the base,of the heat dissipation shell, and an air diffusion assembly is connected to one end, away from the push rod, of a sliding block. According to the invention, the cooling liquid in the heat dissipation water jacket is sucked out and then pressed back through the refrigerant sucking and discharging assembly to increase the liquid flowing speed so as to improve the heat dissipation efficiency; and under the actions of the buffer assembly and the second spring of the push rod, the motor can be subjected to vibration reducing while the hot gas in the heat dissipation shell can be discharged to dissipate the heat of the motor so as to improve the heat dissipation efficiency and the vibration reducing efficiency.

Owner:山东博发智能科技有限公司

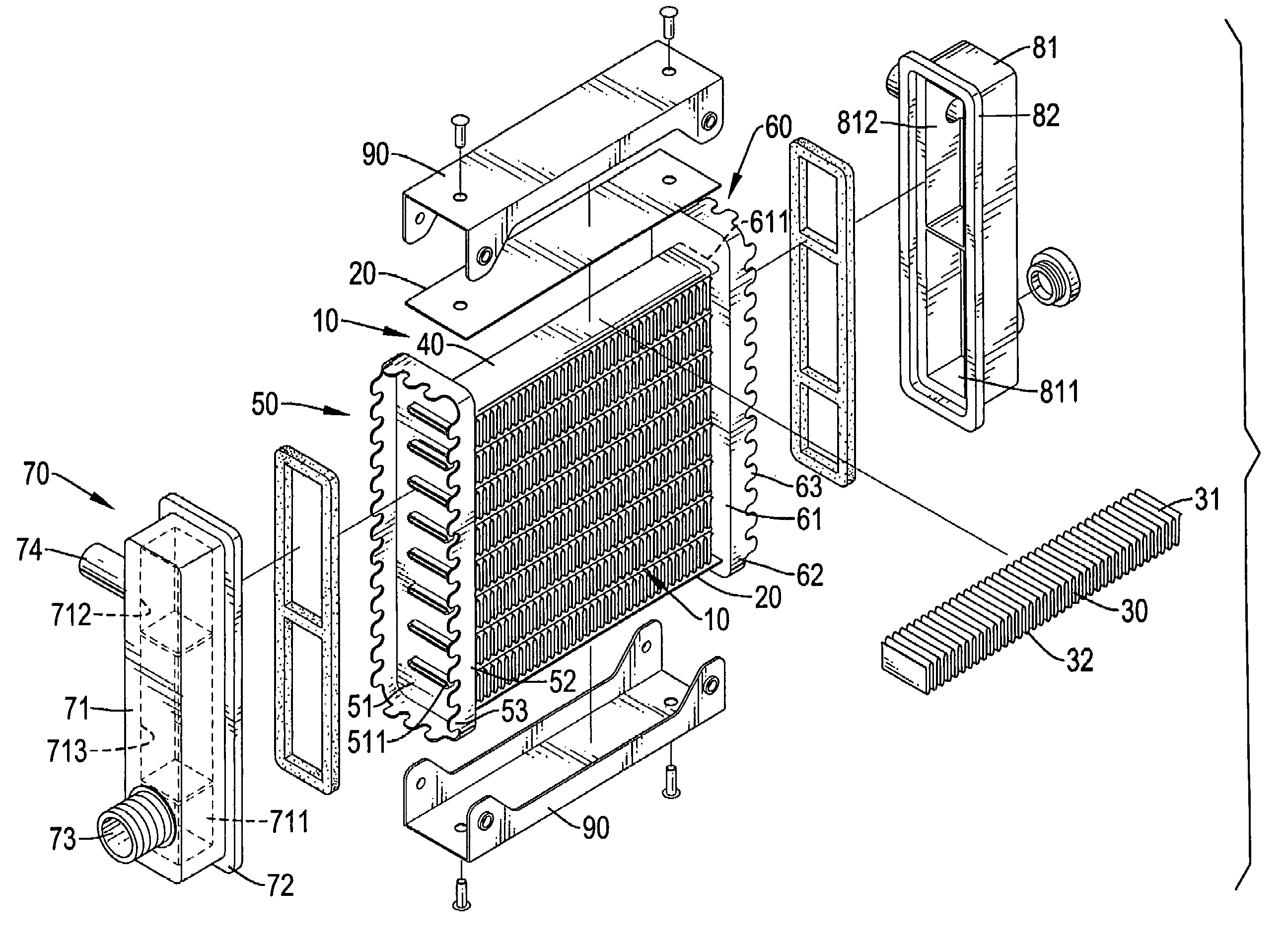

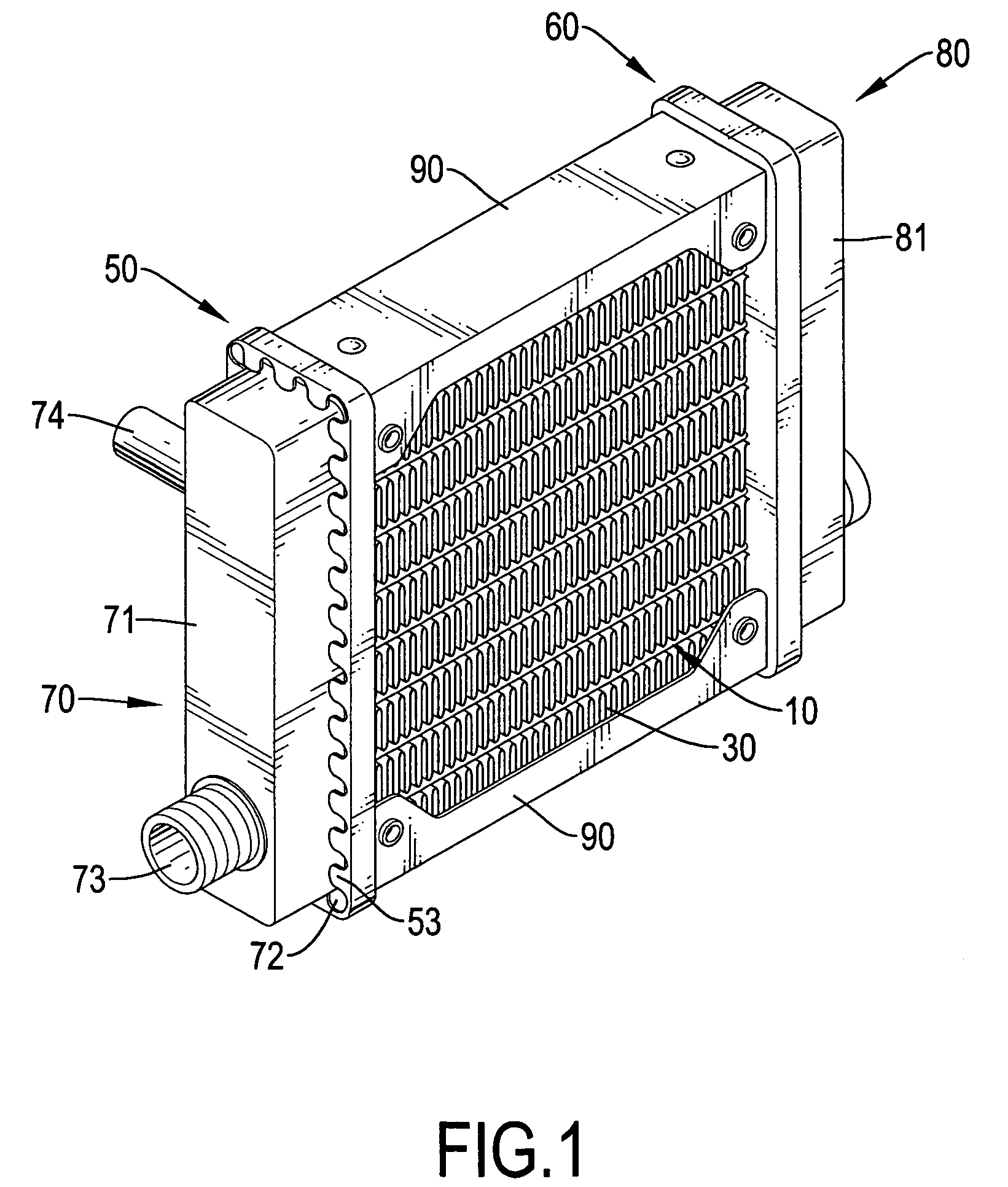

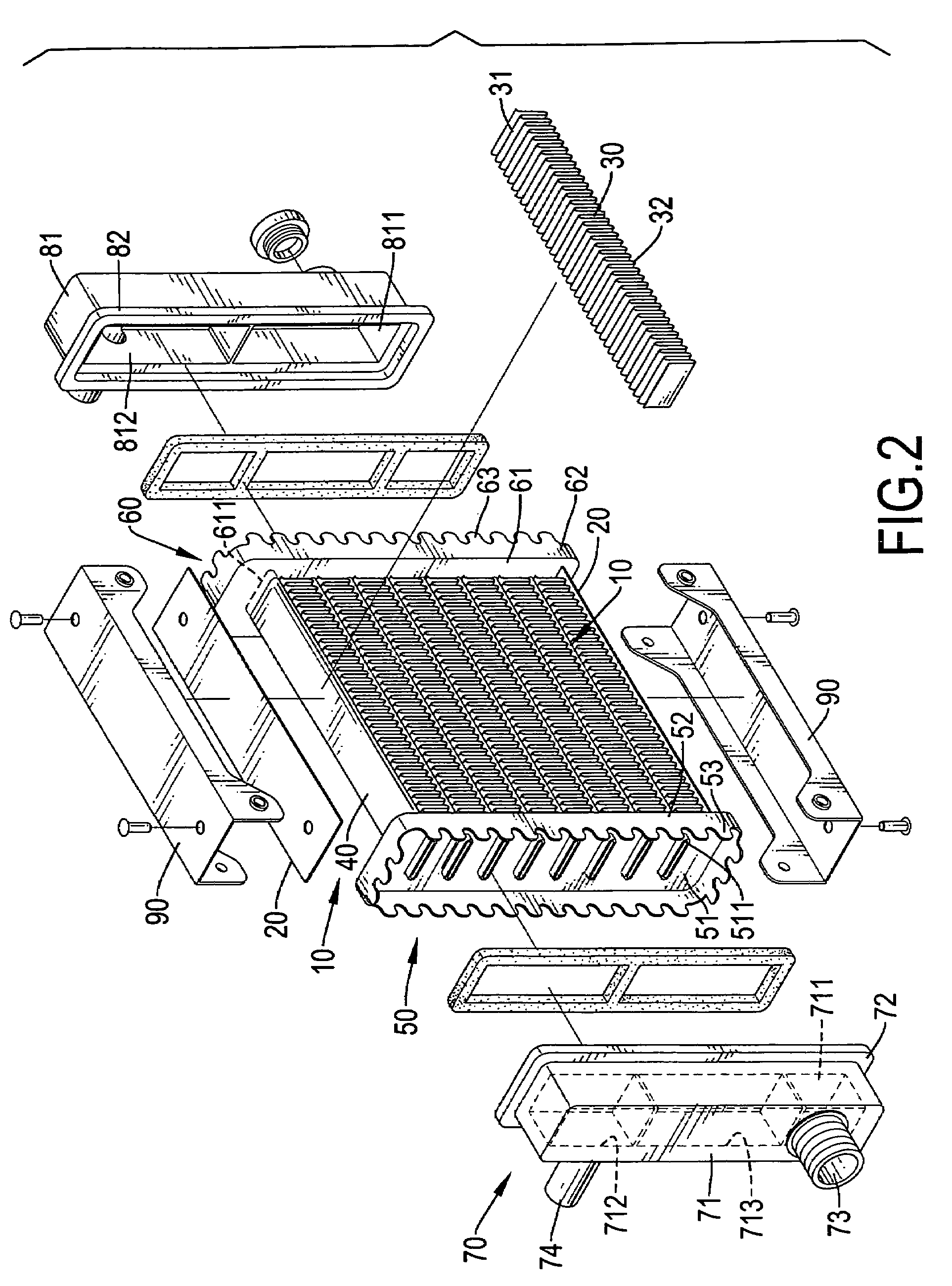

Liquid cooled heat dissipator

InactiveUS20080121384A1Improve cooling efficiencyIncrease heat exchange rateCorrosion preventionStationary conduit assembliesWater channelWater flow

A liquid cooled heat dissipator includes water channels, rows of heat dissipating fins respectively received in a corresponding one of the water channels and each heat dissipating fin having a ridge and a trough, a first water tank mounting seat having first openings defined to respectively communicate with the water channels, a second water tank mounting seat opposite to the first water tank mounting seat and having multiple second openings respectively communicating with the water channels, a first water tank in the first water tank mounting seat and a second water tank mounted in the second water tank mounting seat for turning water flow in the water channels.

Owner:TSENG PO YUNG

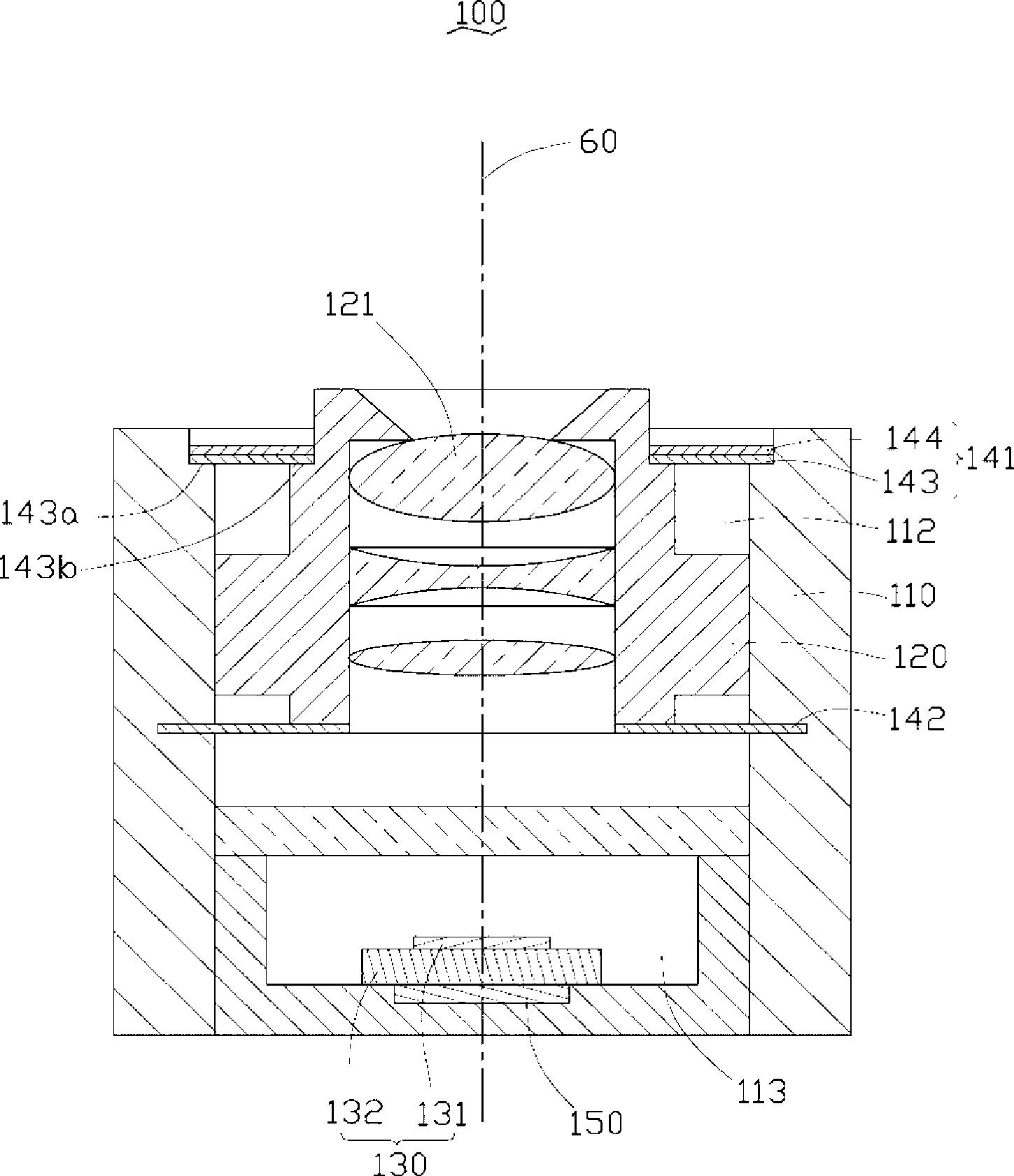

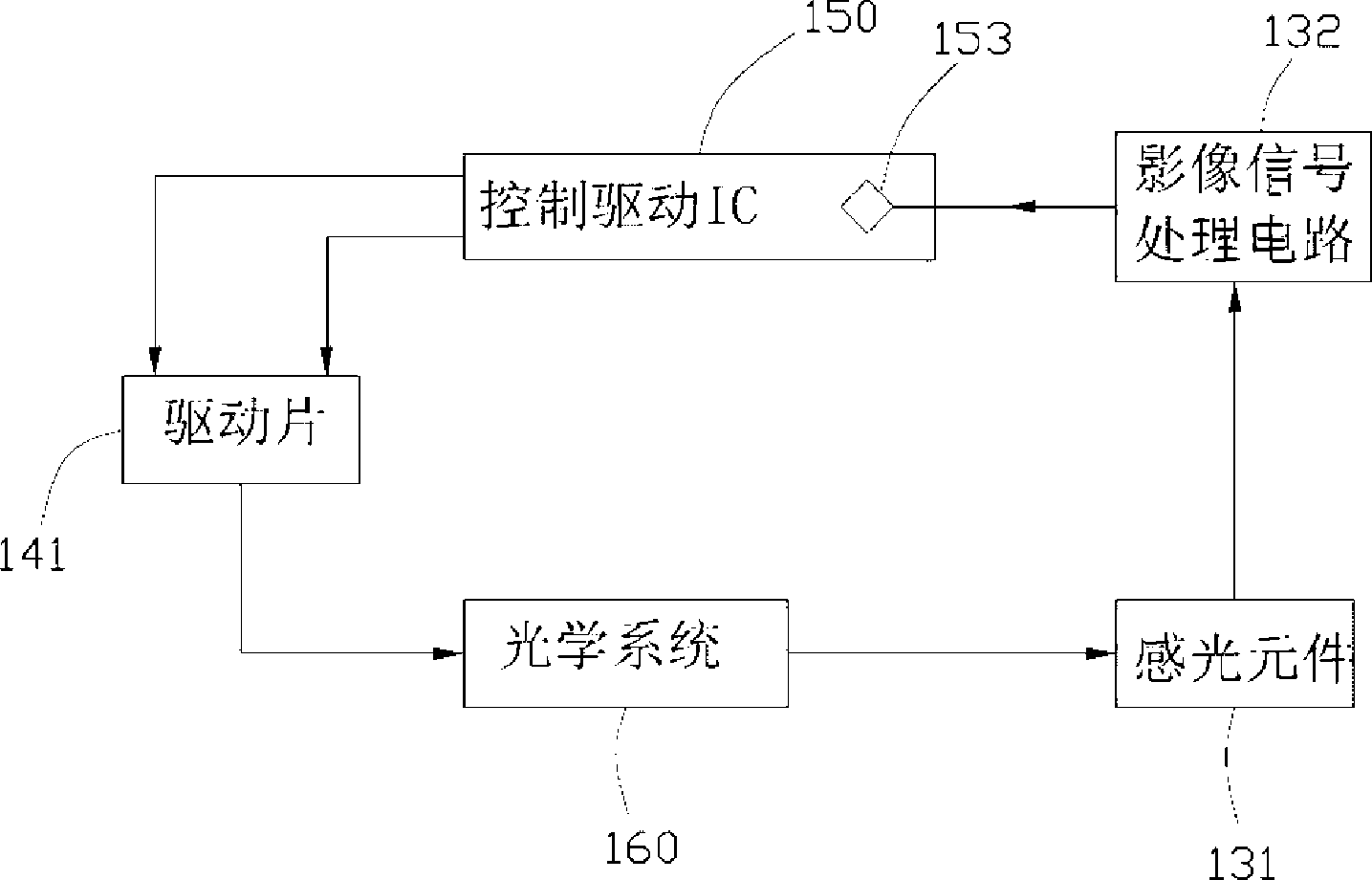

Camera module with automatic focusing function and focusing method thereof

InactiveCN101419379AIncrease surface areaIncrease in sizeTelevision system detailsProjector focusing arrangementDriving currentOptical axis

A camera module comprises a lens base, a lens cone and an image sensor. The lens cone and the image sensor are arranged in the lens base, and an optical component is arranged in the lens cone and coupled with the image sensor. The camera module further comprises at least one drive chip and a corresponding elastic sheet; the drive chip comprises a substrate, a shape memory alloy film arranged on the substrate and a control drive circuit; the control drive circuit supplies a drive current to the shape memory alloy film to cause the film to generate a recovery stress by resistance heating so that the drive chip is bent to drive the lens cone to move along an optical axis; and the control drive circuit stops supplying the drive current to cool the shape memory alloy film and eliminate the recovery stress, thus the elastic sheet rebounds to the lens cone.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

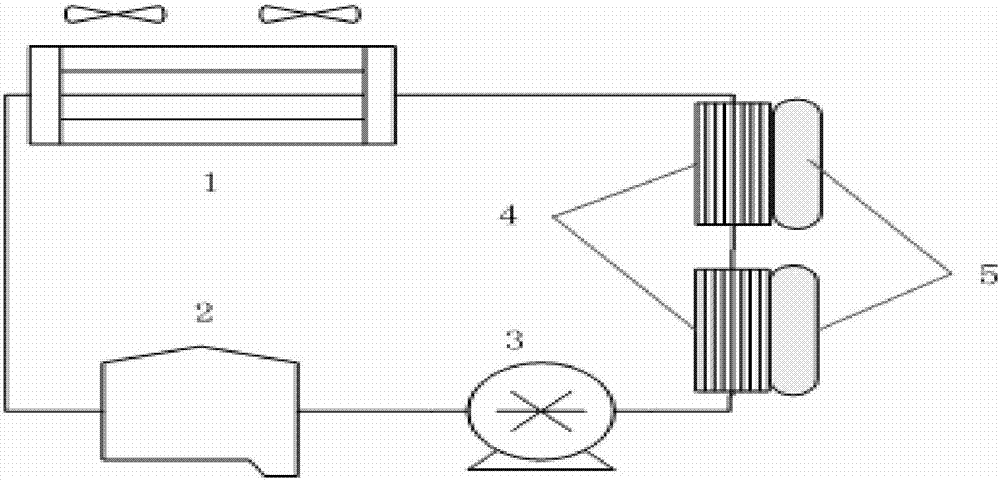

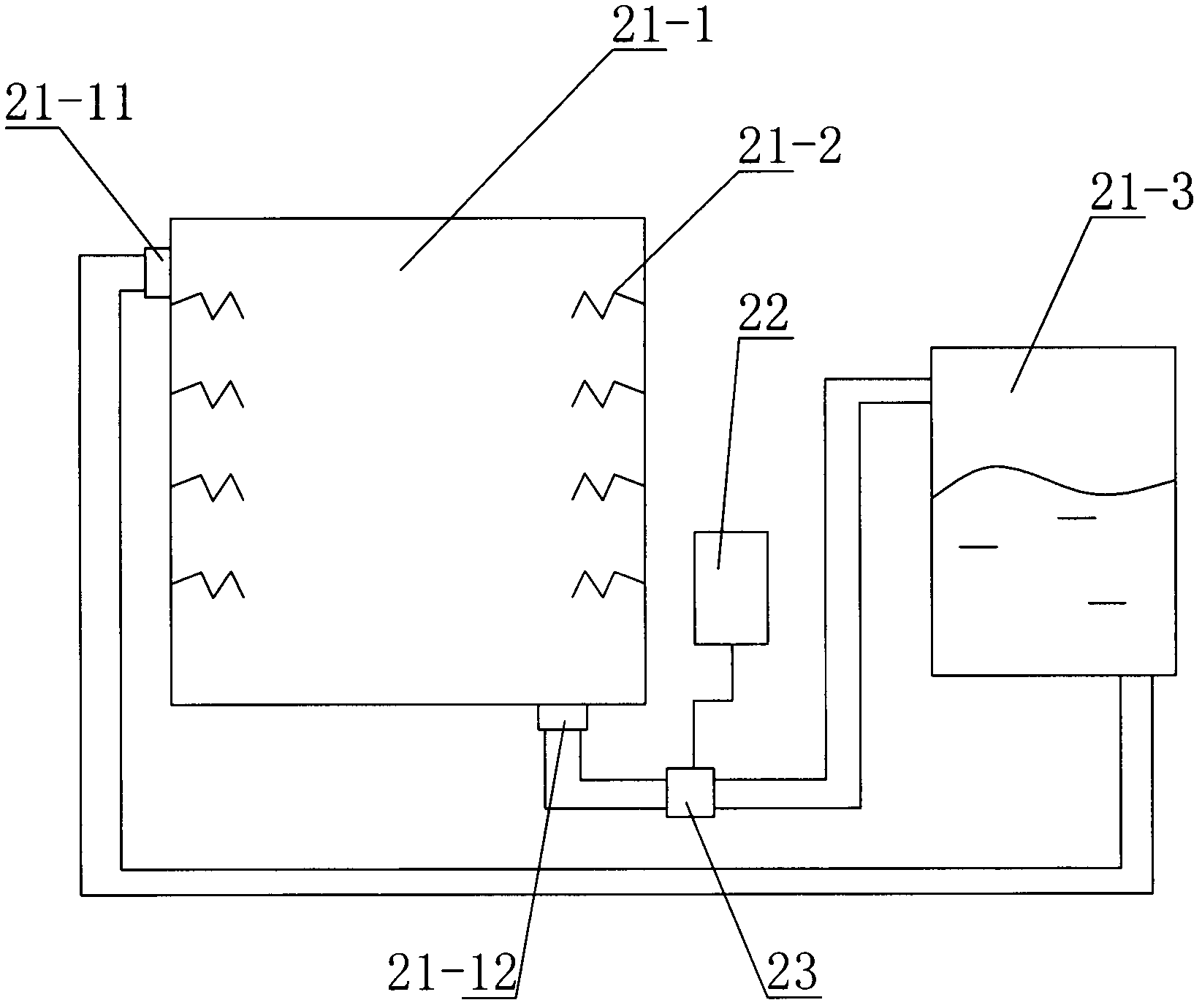

Semiconductor refrigeration temperature control box

PendingCN107461978AExtend the life cycleReduce volumeDomestic refrigeratorsMachines using electric/magnetic effectsEngineeringMicroprocessor

The invention relates to a semiconductor refrigeration temperature control box. Semiconductor refrigeration chips are symmetrically embedded in the side inner wall of a shell; first water cooling heads are arranged at hot ends of the semiconductor refrigeration chips; the water cooling heads are connected with water pumps through water pipes; the other ends of the water pumps are connected with water inlets of circulating water tanks through water pipes; water outlets of the circulating water tanks are connected with air cooling radiators through water pipes; the other ends of the air cooling radiators are connected to second water cooling heads arranged on the semiconductor refrigeration chips through water pipes to form a circulating loop; a temperature sensor is arranged in the shell, and is connected with a microprocessor; the microprocessor is connected with a temperature control module; and the temperature control module is connected with the semiconductor refrigeration chips. The semiconductor refrigeration temperature control box needs no refrigerant, is environment-friendly, free of pollution, small in size, low in weight, low in heat inertia and fast in refrigeration, can normally work no matter in an overweight or weightlessness state and in a horizontal or vertical state or in any angle with the ground, and satisfies the demands of limited space in spaceflight, medical treatment and vehicle carrying.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

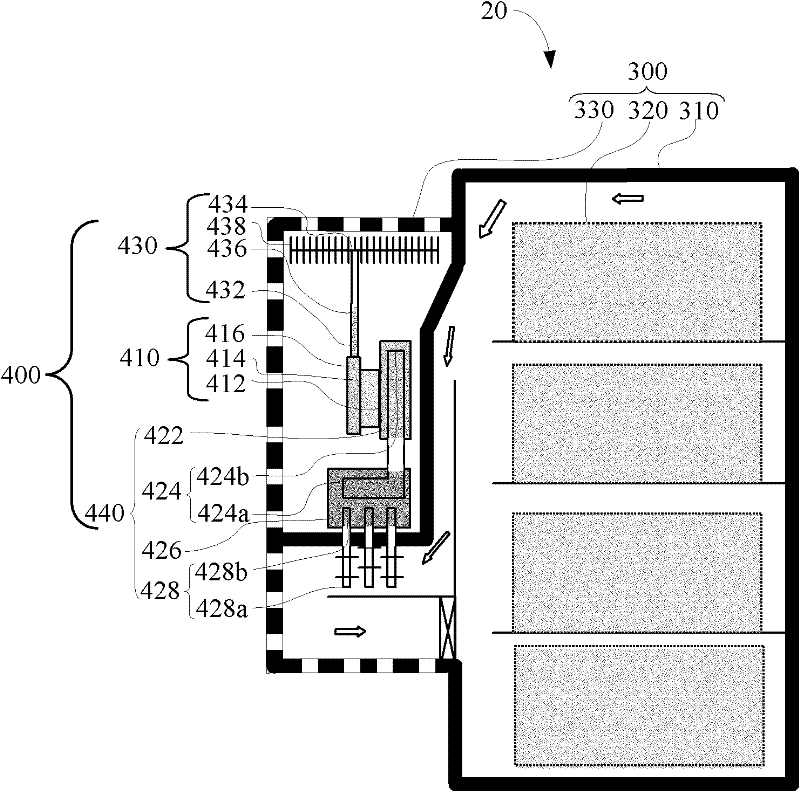

TEC (Thermoelectric Cooling Module) refrigerating device and electrical device using same

InactiveCN102128518ASpeed up heat exchangeIncrease heat exchange rateThermoelectric device with peltier/seeback effectMachines using electric/magnetic effectsEvaporationEngineering

The embodiment of the invention provides a TEC (Thermoelectric Cooling Module) refrigerating device of a thermoelectric refrigeration module; the TEC refrigerating device comprises a TEC module, a first heat exchanger and a second heat exchanger. The TEC module comprises a cold end and a hot end opposite to the cold end. The first heat exchanger is arranged at the cold end of the TEC module and used for exchanging heat with a medium around the cold end of the TEC module. The second heat exchanger is arranged on the hot end of the TEC module and comprises an evaporation end and a condensation end; the second heat exchanger is internally provided with a cooling medium which is used for exchanging heat between the evaporation end and the condensation end in a phase-changing way; and the evaporation end is adjacently connected with the hot end of the TEC module. In the TEC refrigerating device in the embodiment of the invention, the heat exchange with the hot end of the TEC module is accelerated by using the second heat exchanger capable of radiating heat rapidly, so that the heat exchange efficiency is improved, the energy source is saved and the purpose of environmental protection is achieved.

Owner:HUAWEI TECH CO LTD

High efficiency, environmental protection type coal-saving agent, and its prodn. art

An environment protection type coal saving agent is proportionally prepared from sulfur fixating agent, combustion promoter, oxidant, puffing agent, catalyst and water. Its advantages are high effect to decrease consumption of coal and increase thermal efficiency of boiler, and no secondary pollution.

Owner:田立军

Color wheel device, and light source device as well as projection system thereof

ActiveCN104661005AIncrease air flowImprove air heat transfer coefficientPicture reproducers using projection devicesEngineeringProjection system

The invention relates to a color wheel device, and a light source device as well as a projection system thereof. The color wheel device comprises a housing, a color wheel assembly and an airflow driving assembly, wherein an airflow channel is formed in the interior of the housing; the color wheel assembly is arranged in the airflow channel and at least comprises a color wheel disc with a wavelength conversion function; the airflow driving assembly is arranged in the airflow channel; the generated airflow flows from the airflow driving assembly to the surface of the color wheel disc in the direction parallel to the surface of the color wheel disc. According to the color wheel device and the light source device as well as the projection system thereof, the air flowability of the surface of the color wheel disc can be improved, thereby quickly reducing the temperature of the color wheel disc.

Owner:APPOTRONICS CORP LTD

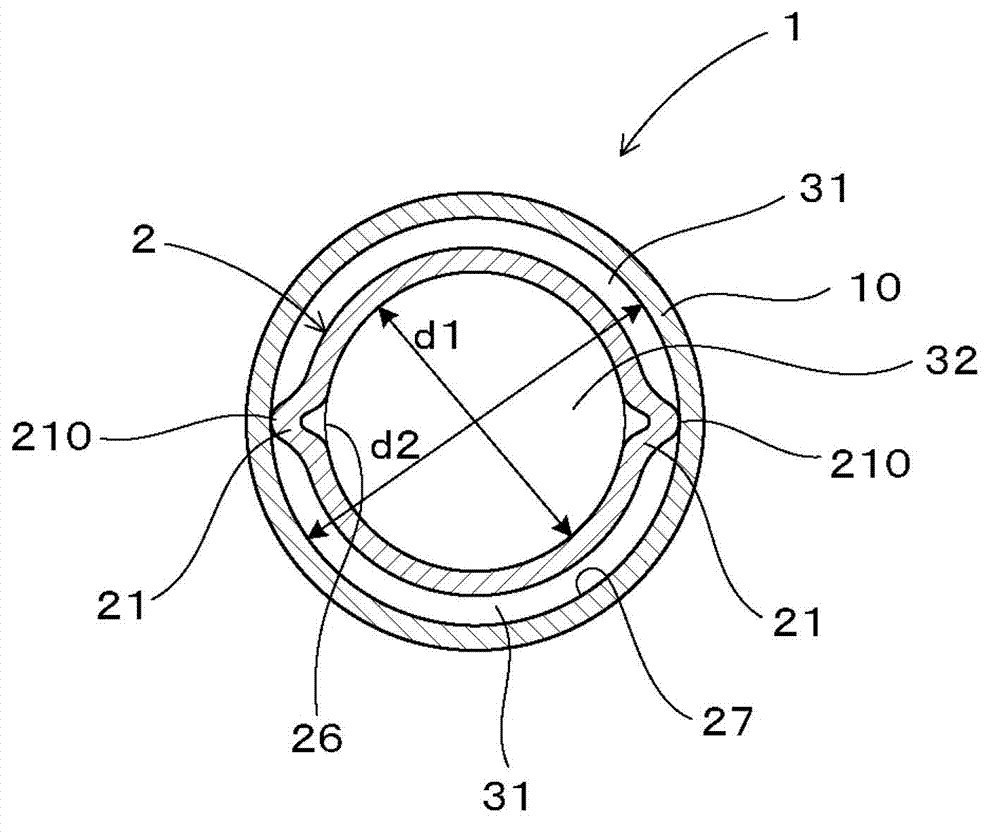

Double pipe for heat exchanger

ActiveCN103245242AIncrease heat exchange rateEfficient heat exchangeStationary tubular conduit assembliesTubular elementsPlate heat exchangerEngineering

Owner:FURUKAWA SKY ALUMINUM CORP

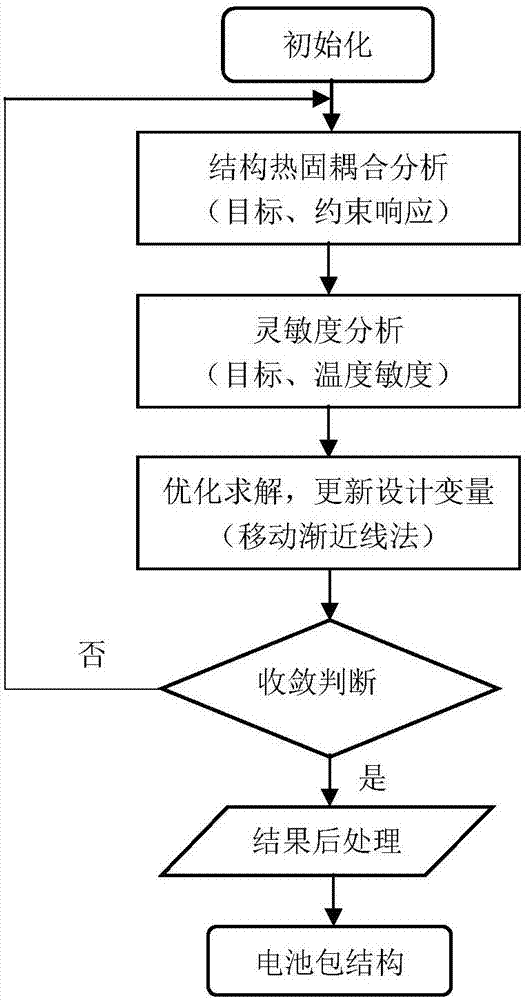

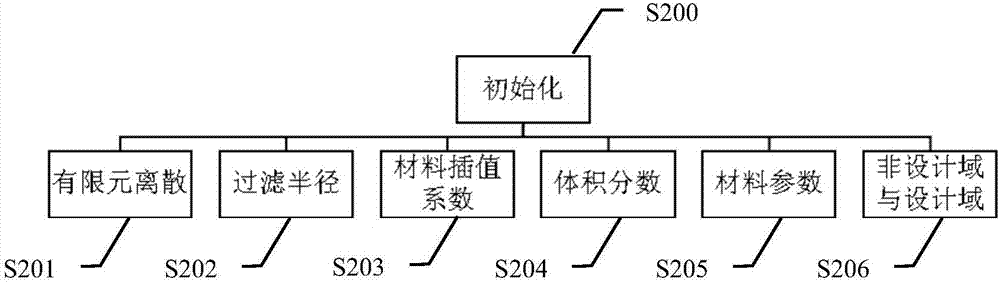

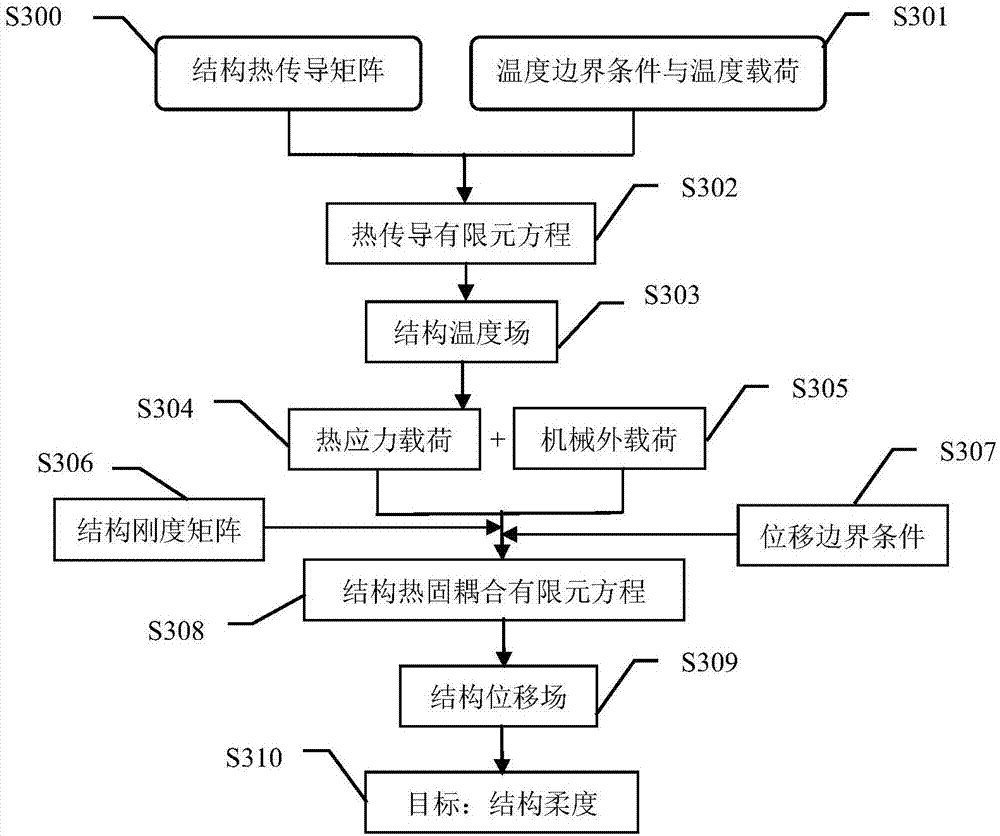

Metal heat dissipation power battery pack structural design method and battery pack

ActiveCN107887669AFree from excessive deformationSimple structureSecondary cellsCell component detailsTopology optimizationField analysis

Disclosed are a metal heat dissipation power battery pack structural design method and a battery pack. The design method comprises the steps of performing material, boundary and load defining, performing non-design region and design region defining, carrying out finite element discrete, solving a structural total heat conduction matrix and total rigidity array, performing structural thermosettingcoupling field analysis, performing structural flexibility and temperature sensitivity analysis, performing flexibility sensitivity analysis, carrying out grid filtering to eliminate a checkboard format, introducing volume constraint and temperature constraint, developing the temperature constraint and performing thermal-mechanical coupling topology optimization, and performing battery pack planarstructure optimization and the like. The battery pack has high and uniform heat dissipation performance and relatively high rigidity, and furthermore, the continuation of the journey and driving safety of an electric vehicle are improved.

Owner:DALIAN UNIV OF TECH

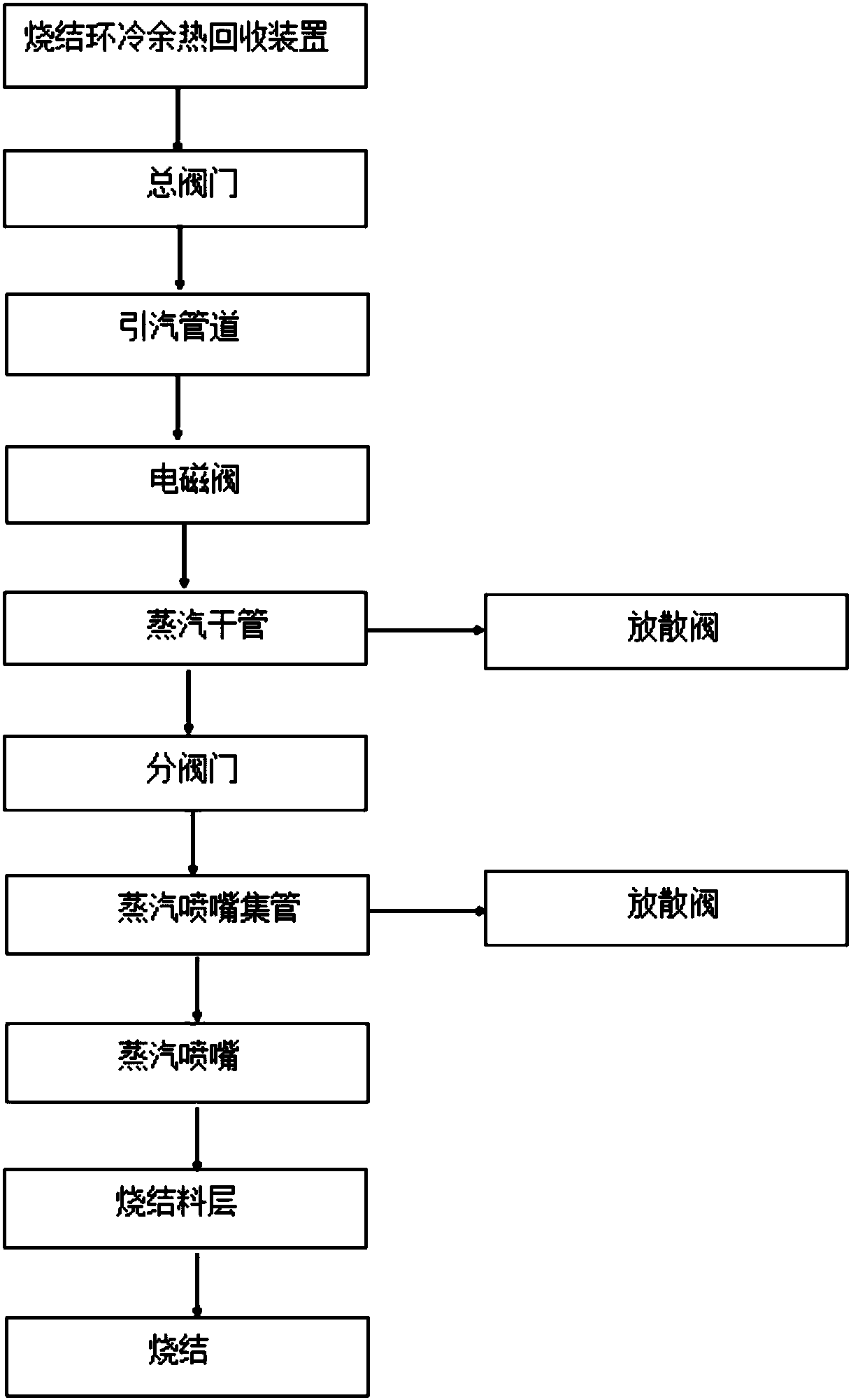

Belt-type sintering machine material layer steam jetting humidifying device and humidifying method

InactiveCN108458593AIncrease heat exchange rateImprove utilization factorFurnace typesNon-combustible gases/liquids supplySolid fuelEngineering

The invention discloses a belt-type sintering machine material layer steam jetting humidifying device and a humidifying method. The belt-type sintering machine material layer steam jetting humidifyingdevice comprises a steam introducing system and a steam jetting system; the steam introducing system comprises a steam introducing pipeline and steam drying pipes; an inlet of the steam introducing pipeline is connected with a steam source; introduced steam enters the steam drying pipes; the steam drying pipes are arranged at the parts, in the advancing direction of a sintering machine, of the two sides of a sintering machine trolley; the steam jetting system comprises a plurality of nozzle collecting pipes; a plurality of steam nozzles are arranged on the nozzle collecting pipes; and the nozzle collecting pipes are arranged on the steam drying pipes. The heat exchange rate of a sintering material layer is increased obviously, the vertical sintering speed of the sintering is increased, and the utilization coefficient of the sintering machine is further increased; and sintering solid fuels are facilitated being thoroughly burnt, heat generated by burning the sintering solid fuels is increased, the quality stability of sintering ore is ensured, and the guarantee is provided for further reducing the sintering solid fuel consumption.

Owner:SHANDONG IRON & STEEL CO LTD

Cooler

InactiveUS20130025837A1Improve cooling effectIncrease in heat transfer coefficientSemiconductor/solid-state device detailsSolid-state devicesCoolant flowEngineering

A cooler includes a plate, a cooling case having a coolant flowing therein, and a plurality of wavy fins having a raised curved portion and a lowered curved portion formed alternately on a side face in a flow direction of the coolant. In this cooler, the coolant flows through between the raised curved portion and the lowered curved portion opposite to each other in a meandering manner. The raised curved portion is provided with a bank creating a flow of coolant from the raised curved portion toward the opposite lowered curved portion. With this bank, a part of a main stream of the coolant can be mixed with the coolant stagnating near the lowered curved portion, whereby the heat transfer coefficient of the wavy fins can be improved. Thus, stagnation of the coolant near the lowered curved portion can be prevented, so that the cooler can have enhanced cooling performance.

Owner:TOYOTA JIDOSHA KK

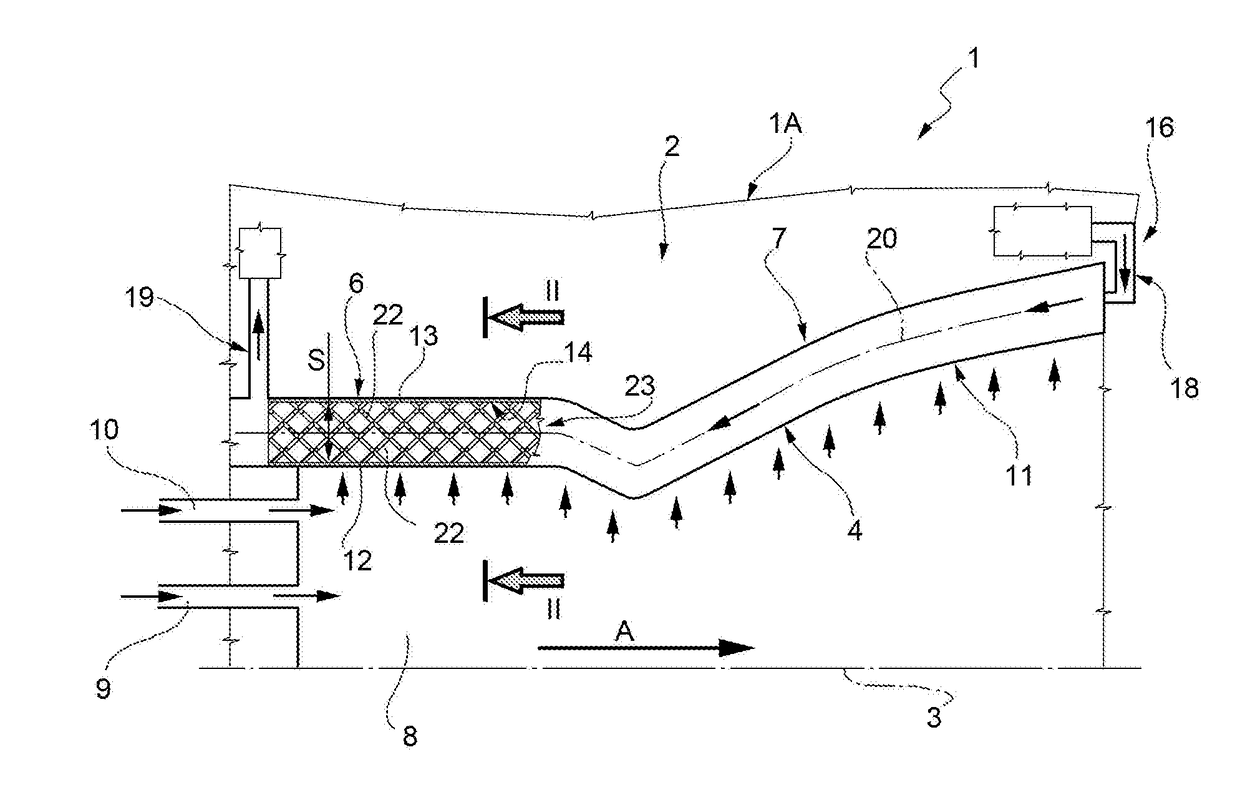

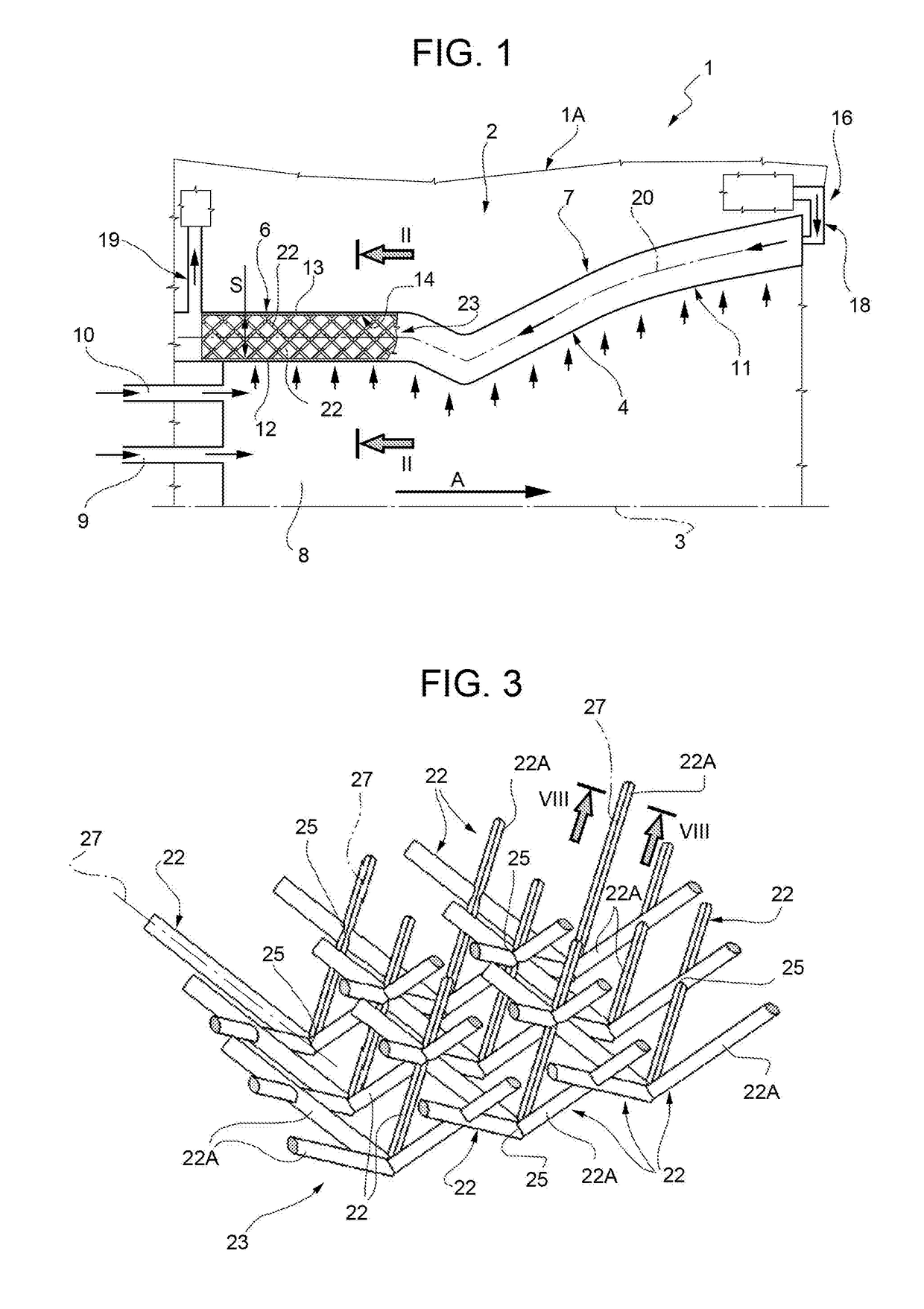

Combustor of a liquid propellent motor

InactiveUS20170122258A1High efficiency and reliabilitySimple and cost-effectiveContinuous combustion chamberHeat exhanger finsCombustion chamberCombustor

A combustor for a liquid propellent motor has an elongated hollow tubular casing having an inner wall delimiting a combustion chamber for the liquid propellent and an outlet nozzle for the combustion products, and an outer wall, both being coaxial to an axis of the casing; the inner and outer walls being spaced apart from each other in radial direction and delimiting at least one guiding conduit of a cooling fluid therebetween; a plurality of bar-shaped elements extending into the guiding conduit, which form a grid for perturbing the cooling fluid, stiffening the casing and increasing the heat exchange surface; the grid being part of a body made in one piece and of a single material along with the inner and outer walls.

Owner:AVIO

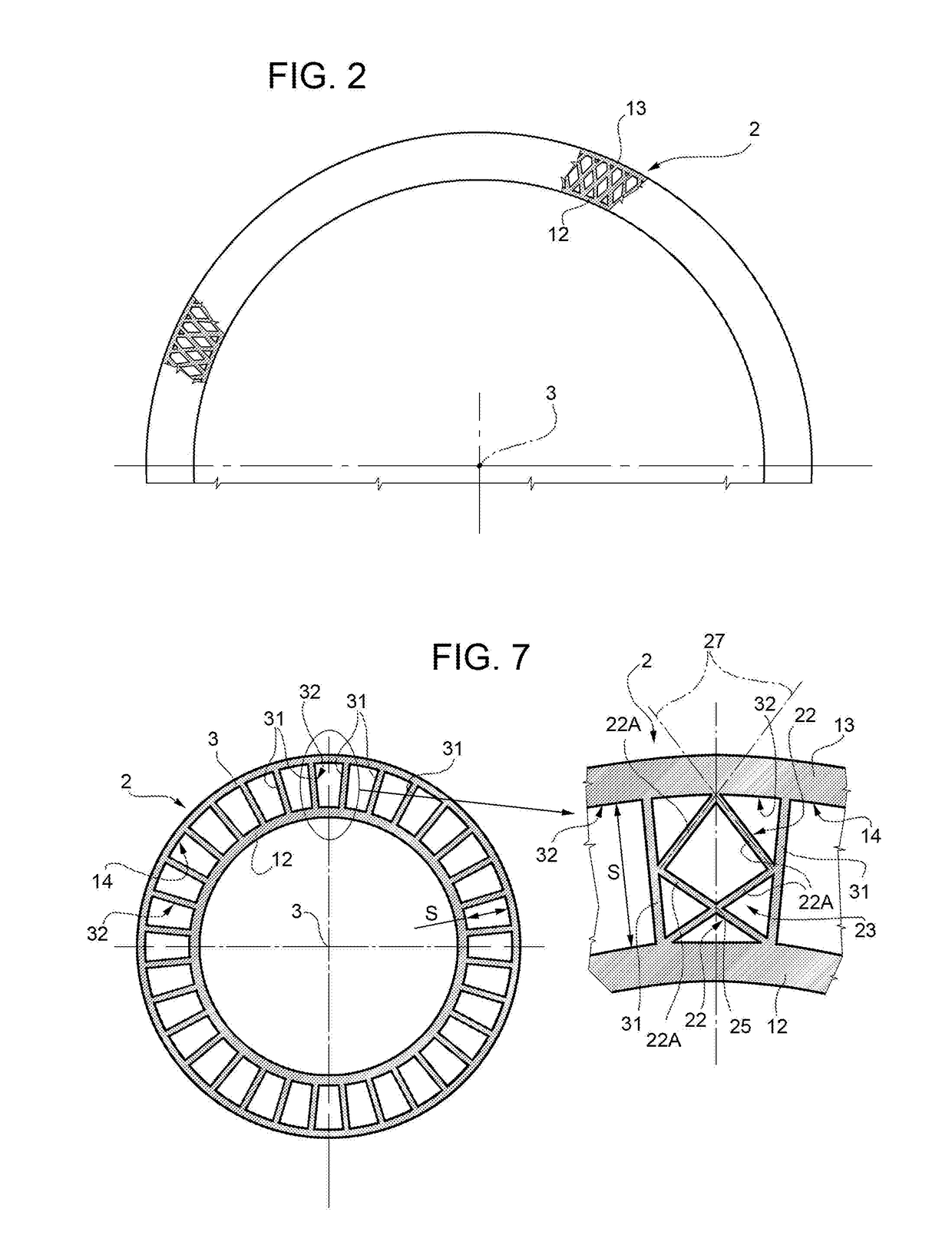

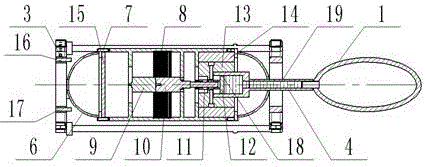

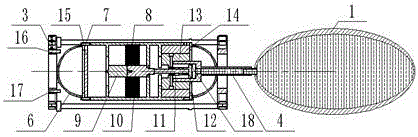

Condensing heat exchanger

InactiveCN101017026ASimple structureEasy to manufactureEnergy efficient heating/coolingAir heatersPlate heat exchangerCombustor

The invention relates to a condensation heat exchanger, related to the heat exchanger of fuel burner, for resolving the problem as low thermal efficiency, wherein a horizontal cylinder frame (8) contains a cylinder (13) formed by coiling or axially arranging heat adsorption tube (7), the outer wall of the cylinder (13) and the inner wall of the frame (8) are arranged with a space between, two ends of the heat adsorption tube (7) are respectively connected with a water inlet connector (1) and a water outlet connector (2), the frame (8) is mounted with a smoke outlet (9) with a condensed water outlet (12) under, the cylinder (13) contains a burning room with a gas burner inside, and at least one of the frame (8) is arranged with a burner mounting hole (15).

Owner:CHENGDU QIANFENG HEAT EXCHANGER

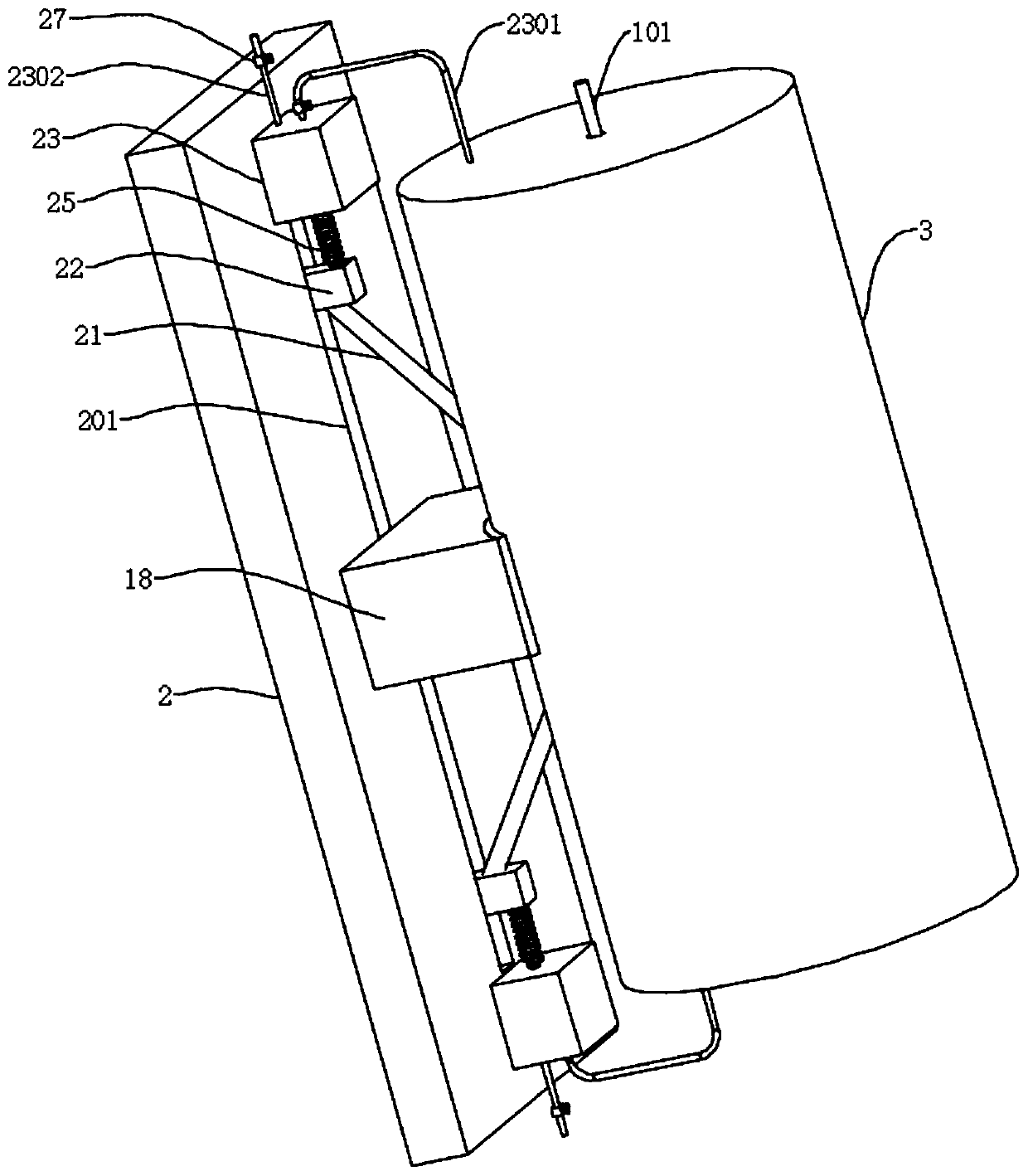

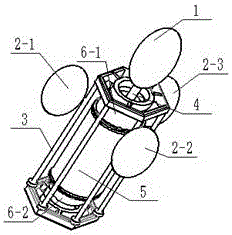

Sea depth high pressure sea water sampler independent buoyancy control equipment

InactiveCN106428487AReduced maximum positive buoyancyLow powerUnderwater vesselsUnderwater equipmentSeawaterDistance detection

The invention relates to sea depth high pressure sea water sampler independent buoyancy control equipment. The equipment mainly includes an outside support, a pressure resistance shell, a pressure resistance shell end cap, an outside oil pocket, a pressure sensor, a underwater distance detection apparatus and a buoyancy control bottle, the buoyancy control bottle is installed outside the outside support, the pressure resistance shell is installed in the cavity of the outside support, the pressure resistance shell is of a thin wall cylinder structure, the two ends of the pressure resistance shell is fixedly connected with the pressure resistance shell end cap, a hydraulic pressure cylinder is installed on the pressure resistance shell, the middle of the outside oil pocket and the hydraulic pressure cylinder is connected through a screw thread, a brushless motor inside the pressure resistance shell is connected with a piston inside the liquid pressure cylinder through a decelerator and a wire rod screw nut; the outside support is also installed with the pressure sensor and the underwater distance detection apparatus. The equipment can carry the sea depth high pressure sea water sampler, adjusts the buoyancy degree of the sea depth high pressure sea water sampler under the water, and achieves an independent unmanned control of the diving depth of the sea depth high pressure sea water sampler.

Owner:ZHEJIANG UNIV

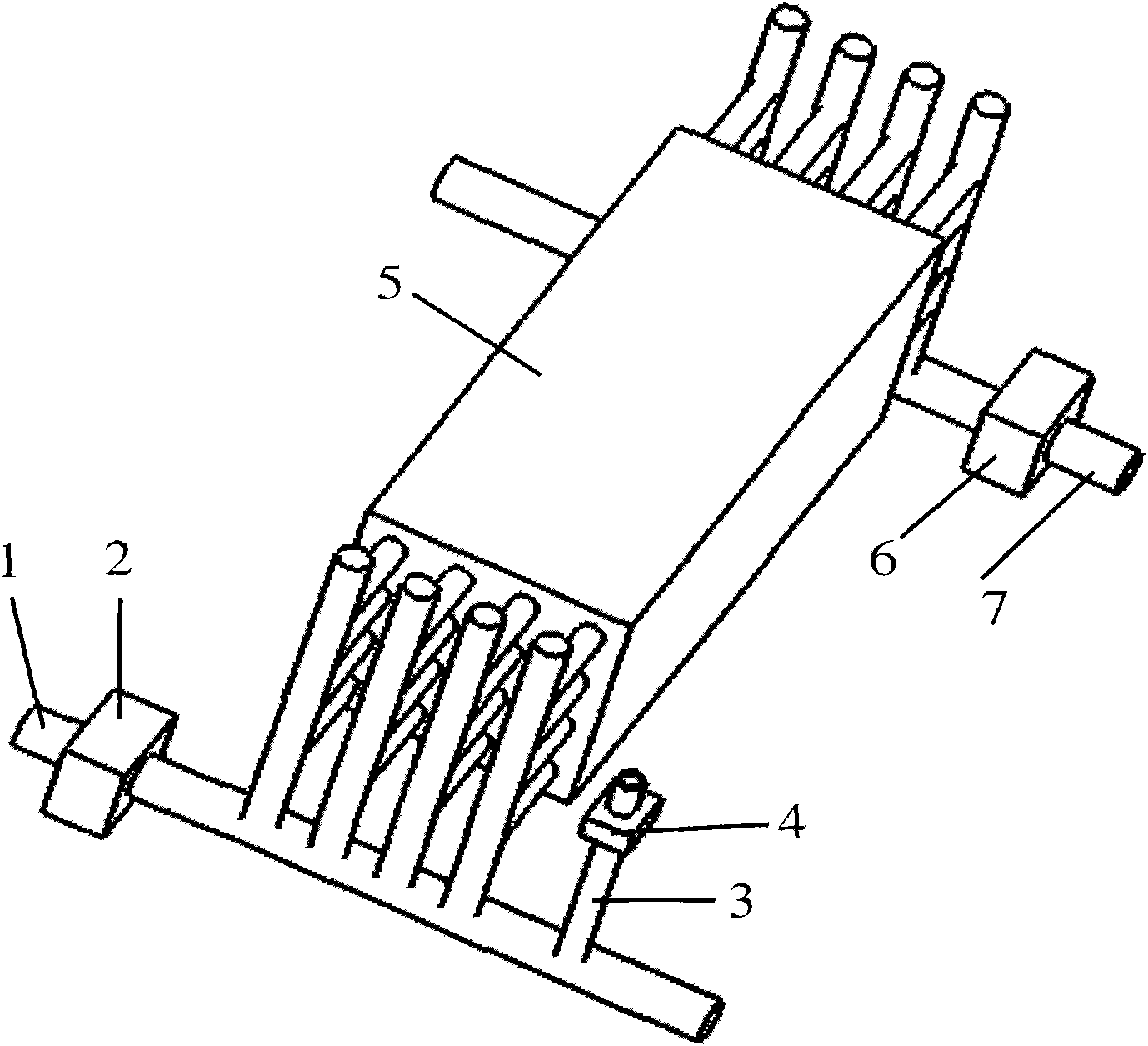

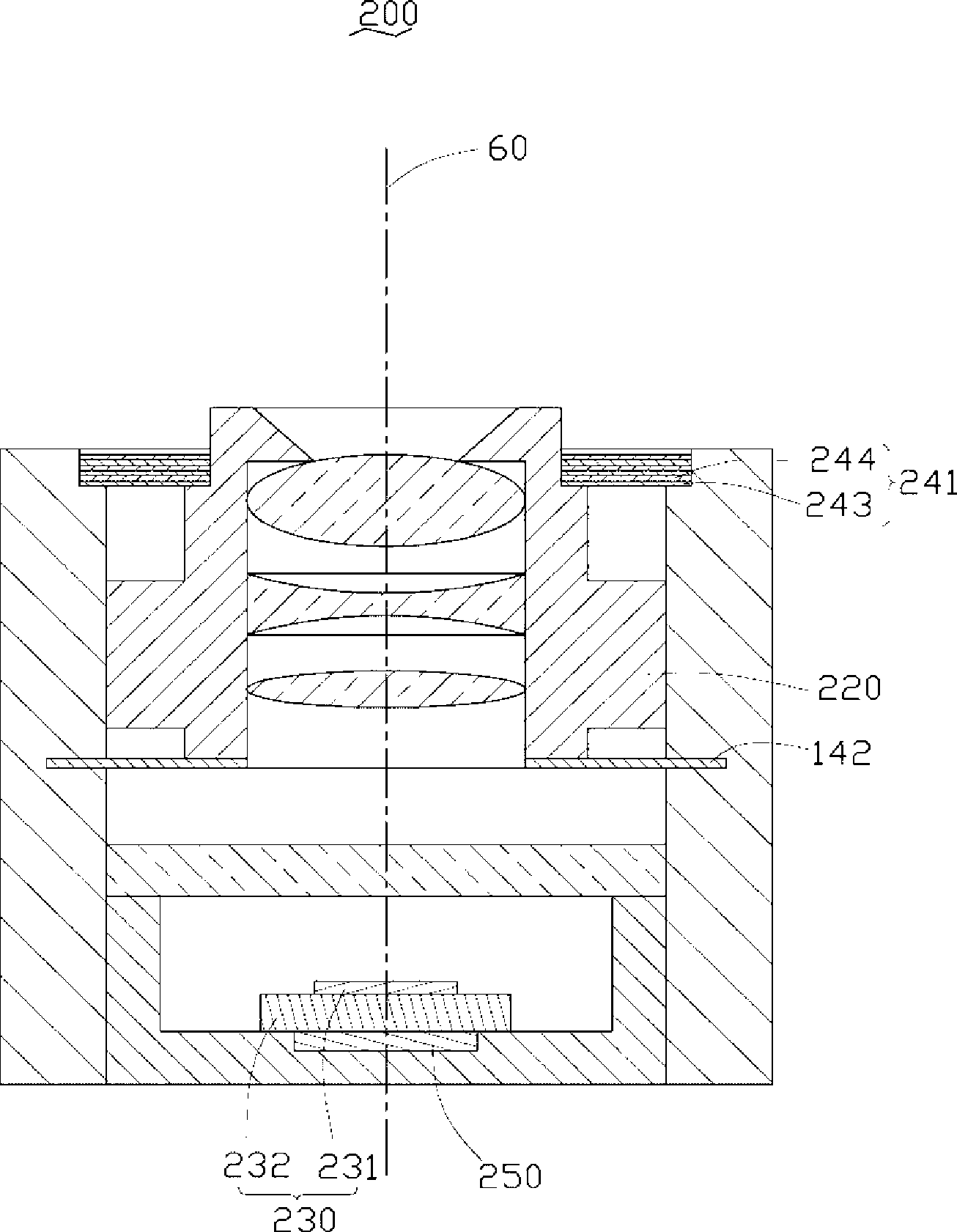

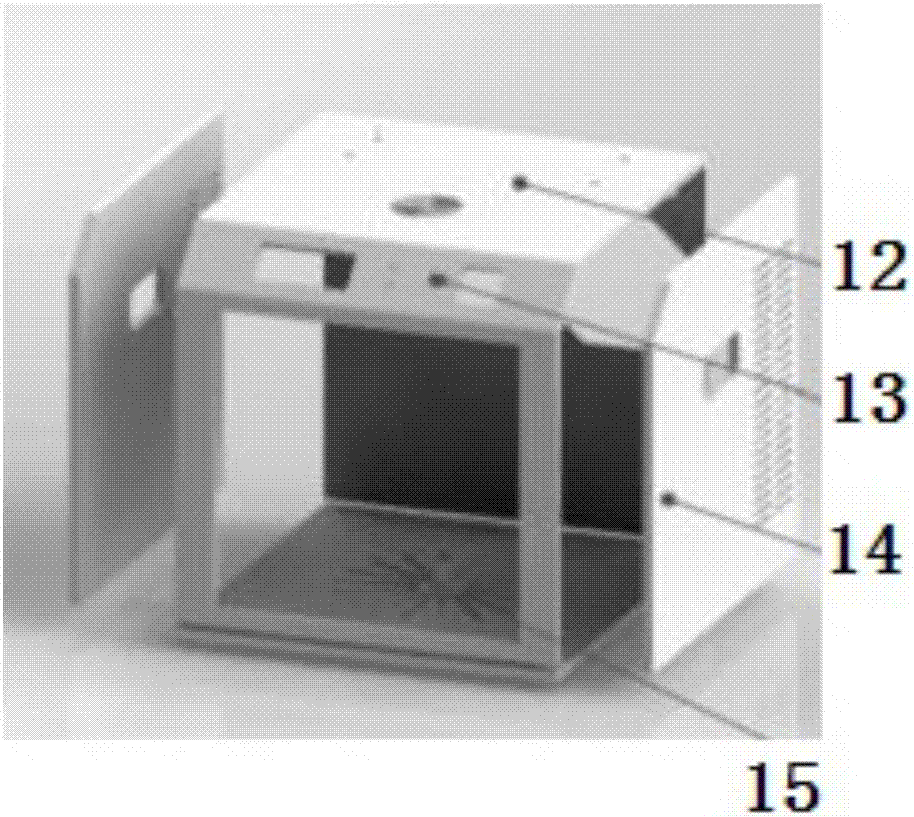

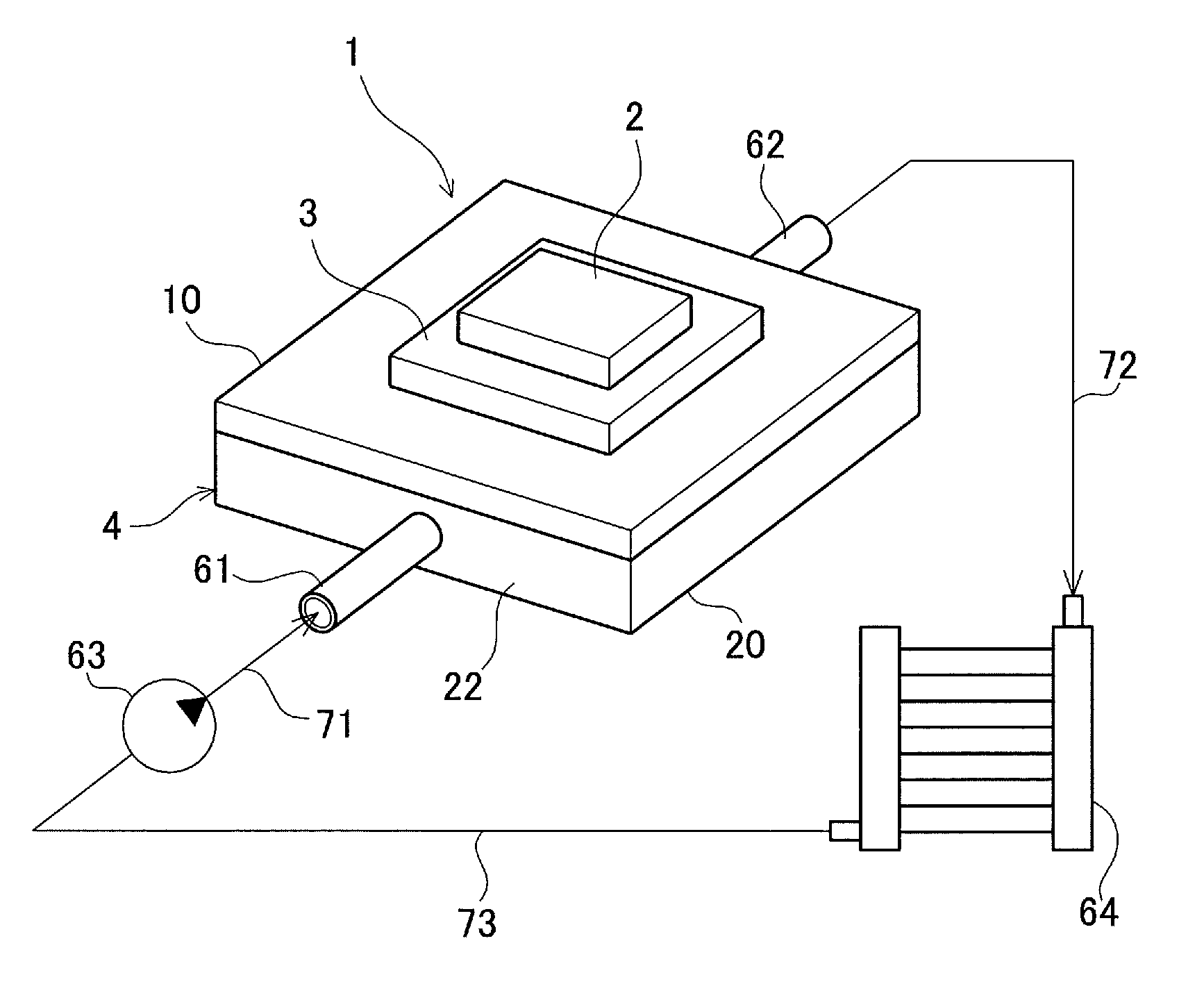

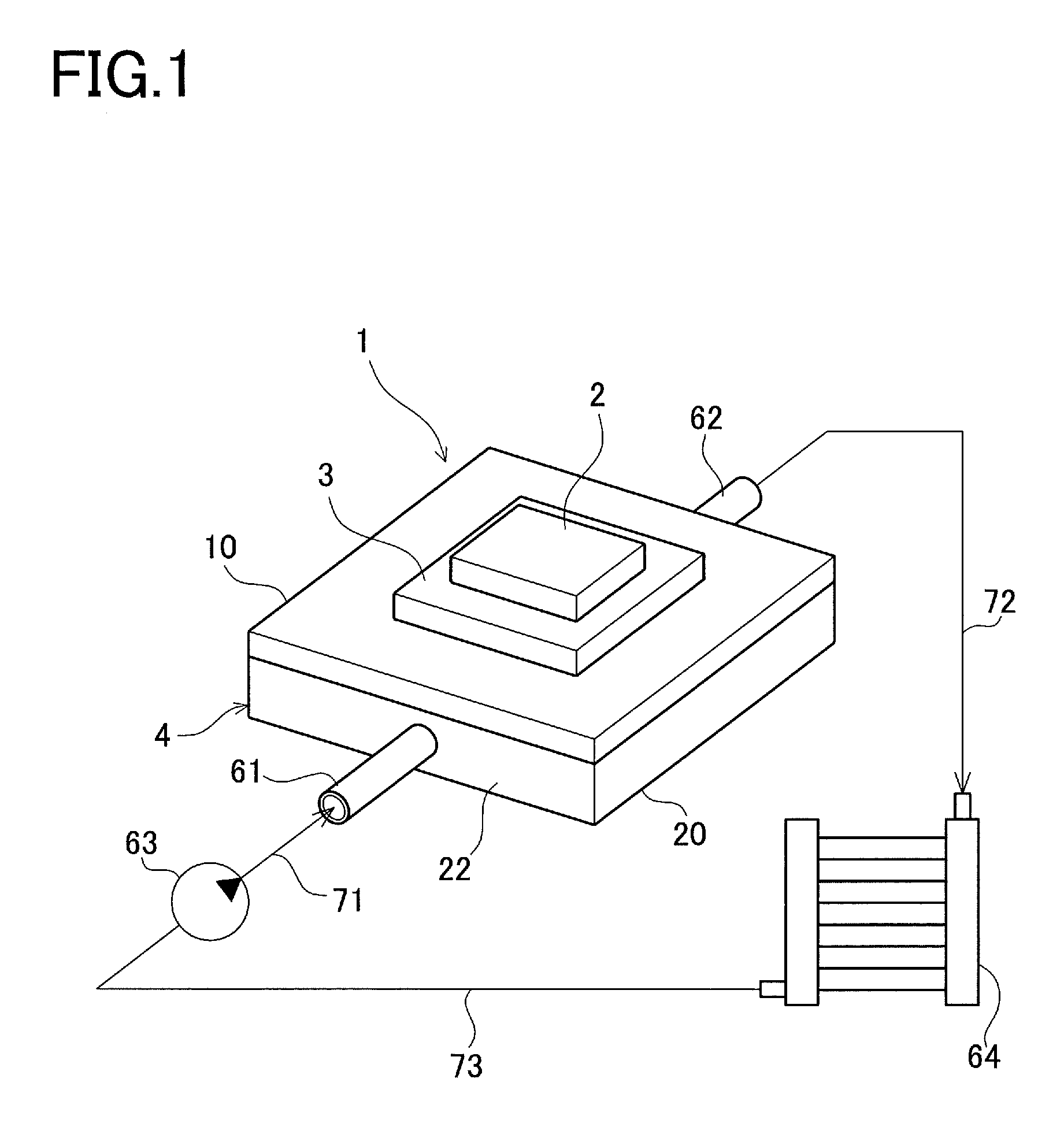

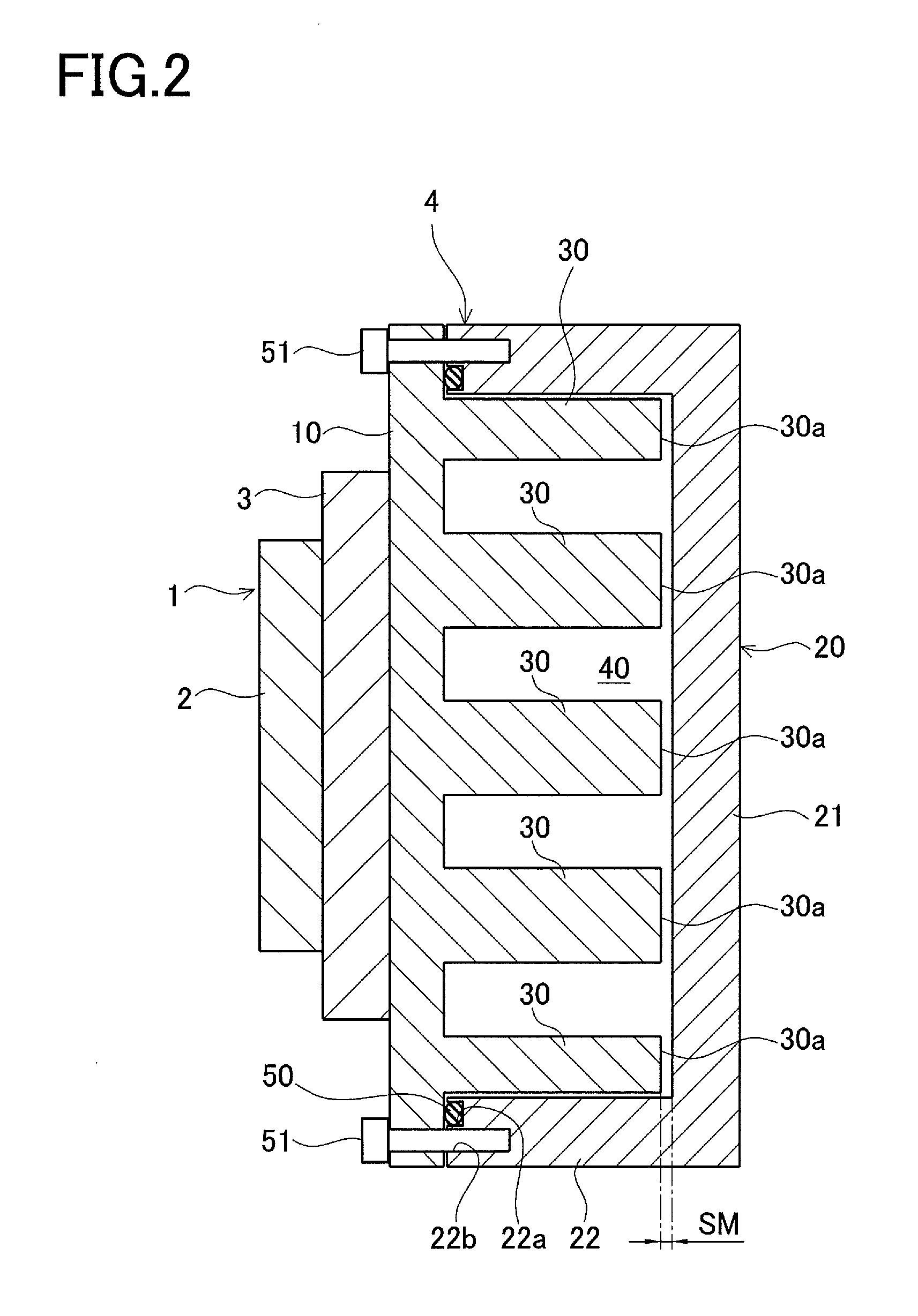

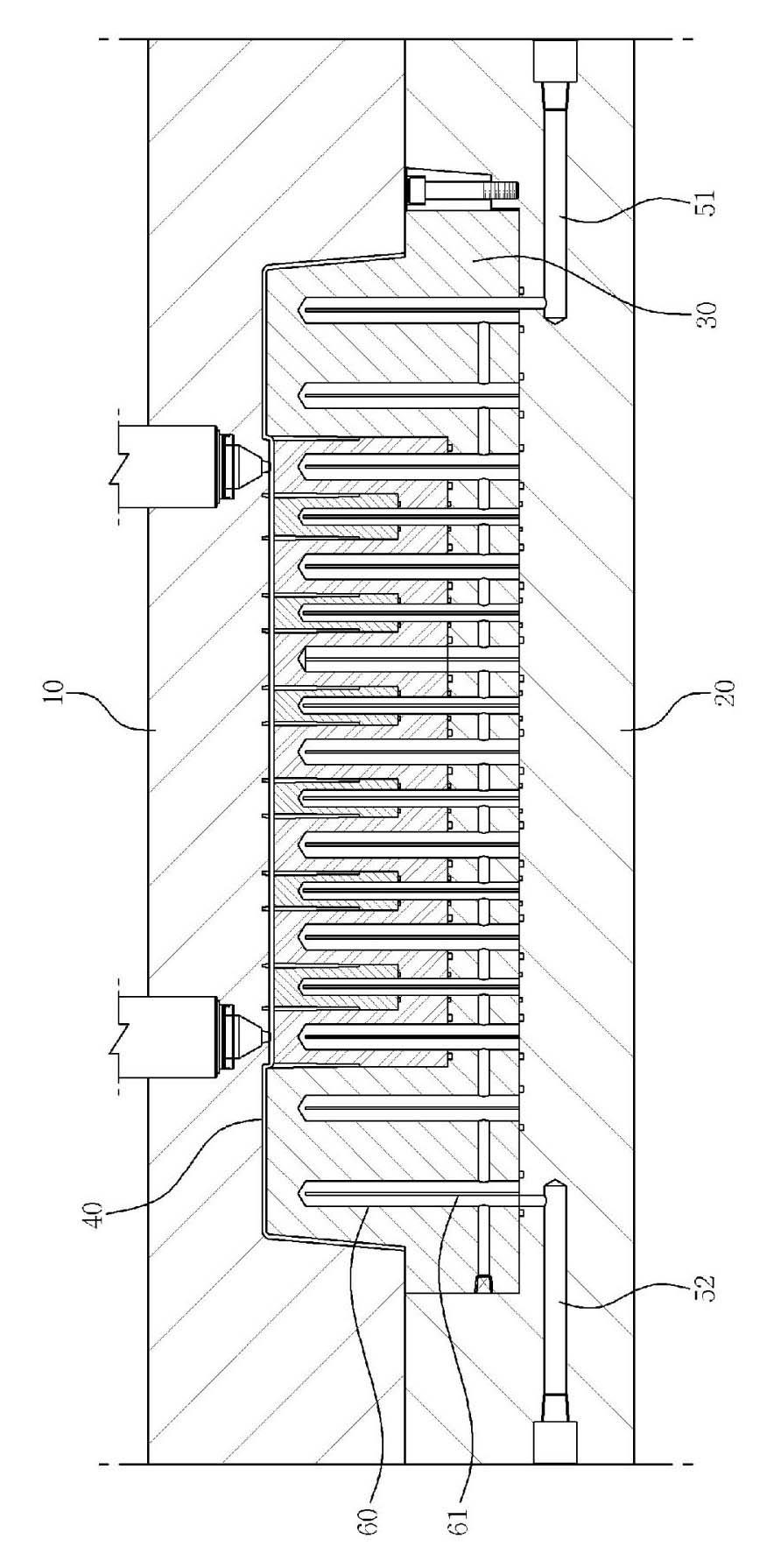

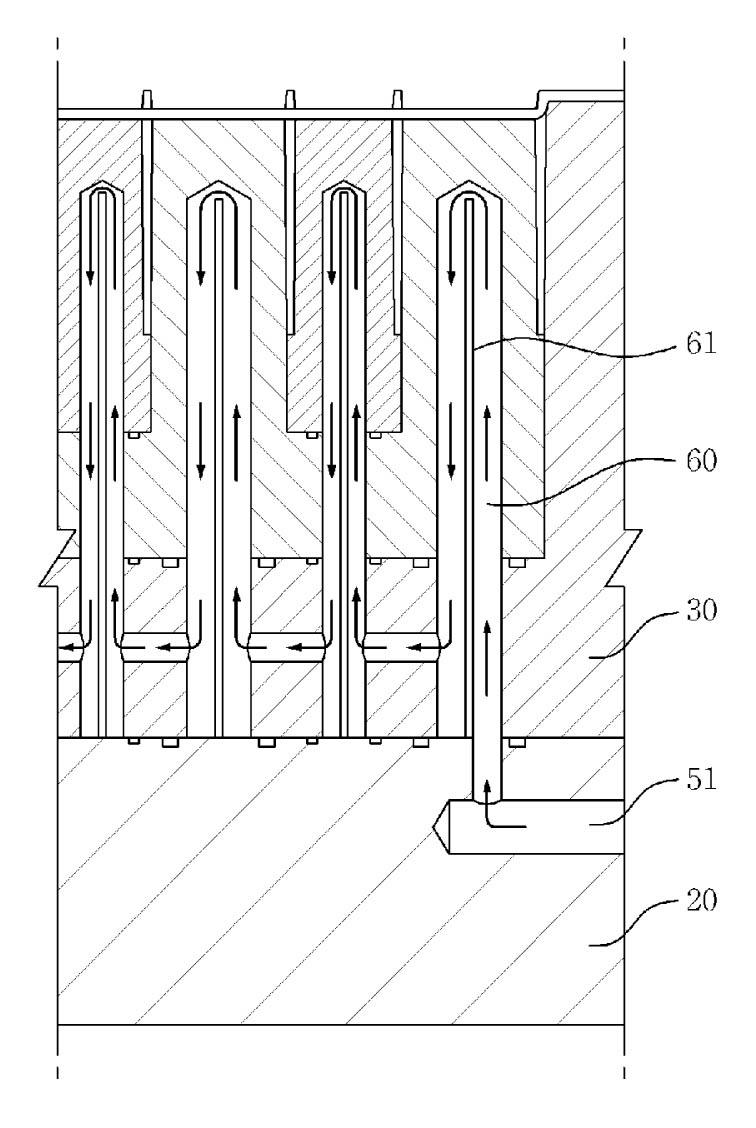

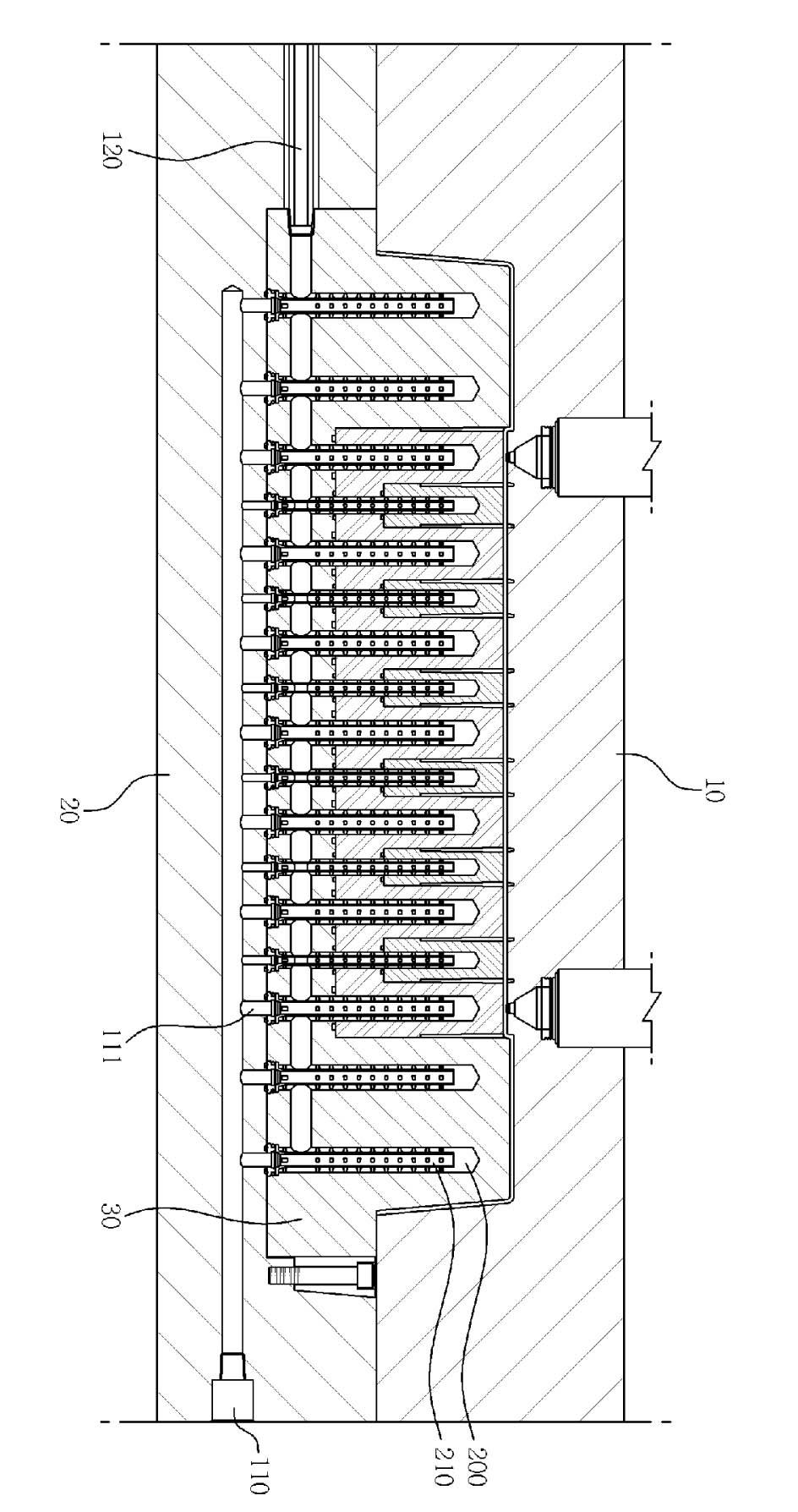

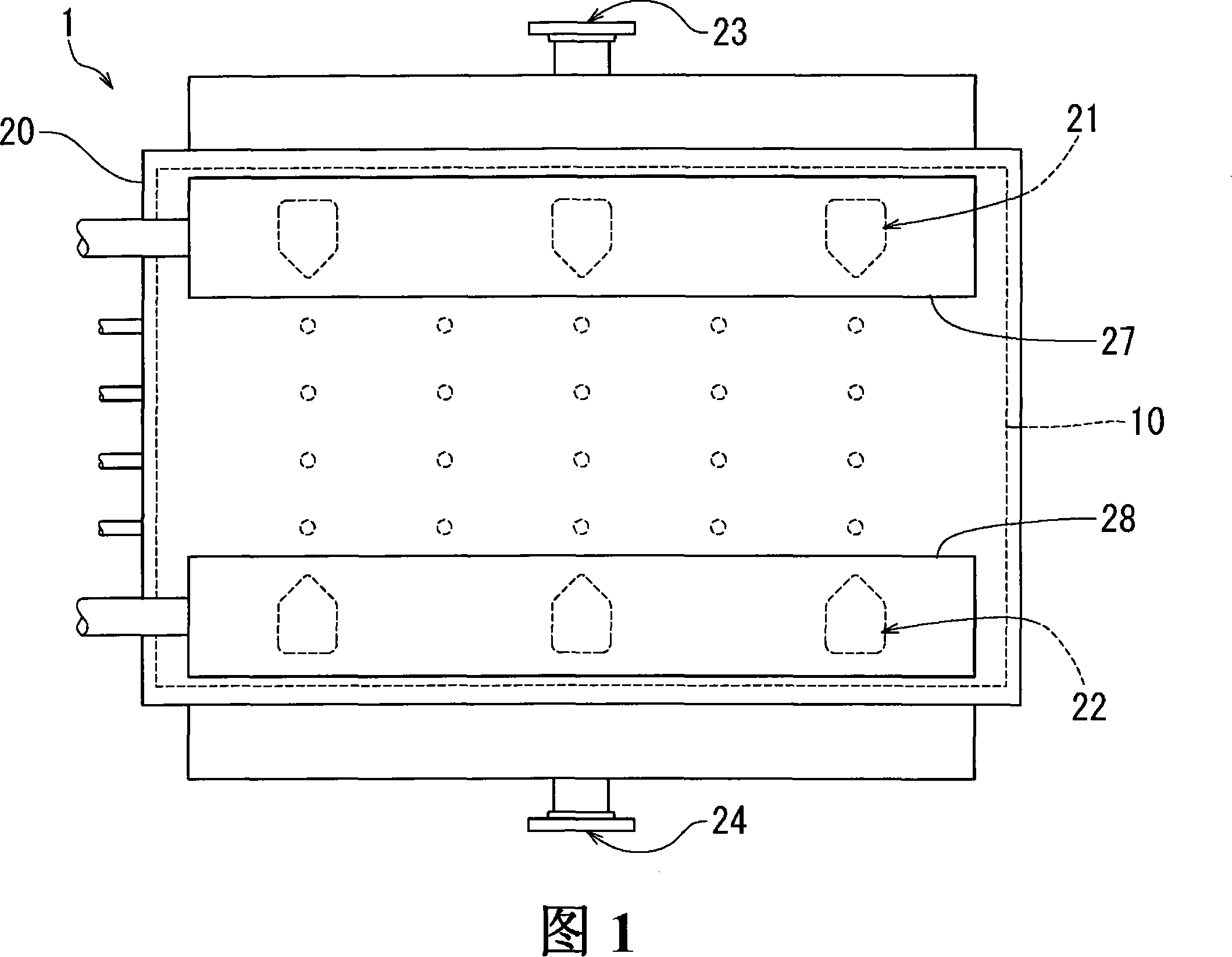

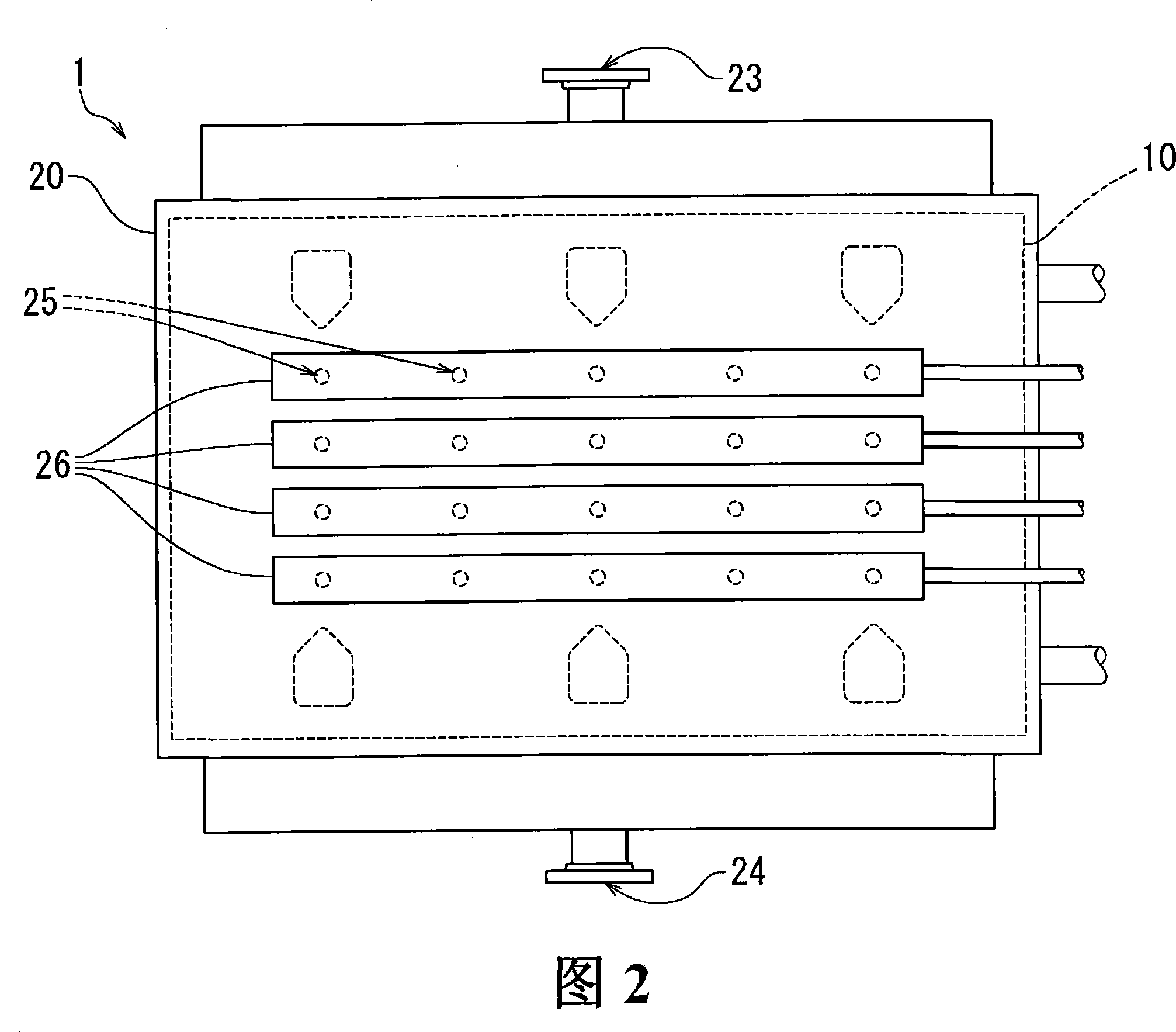

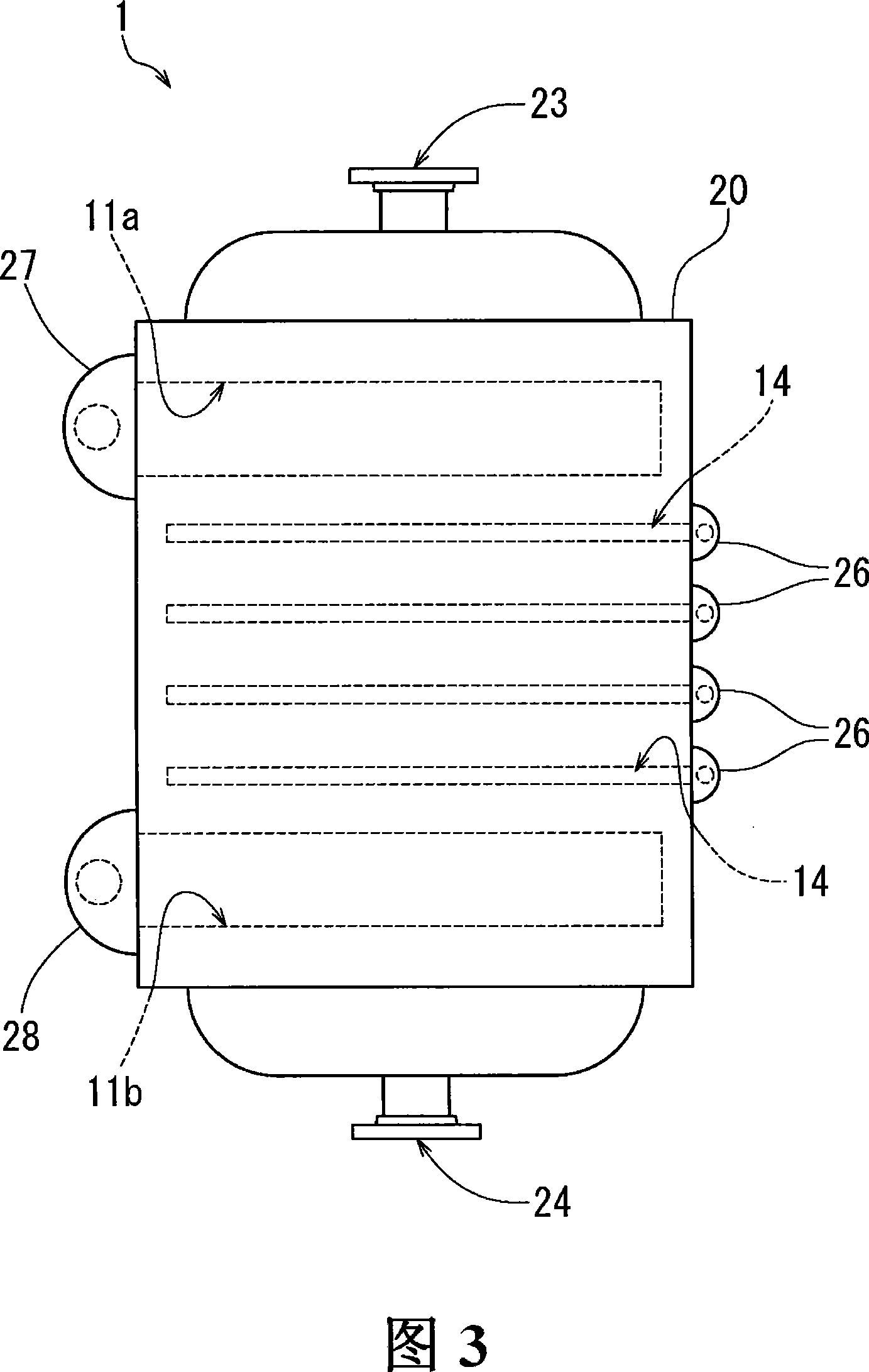

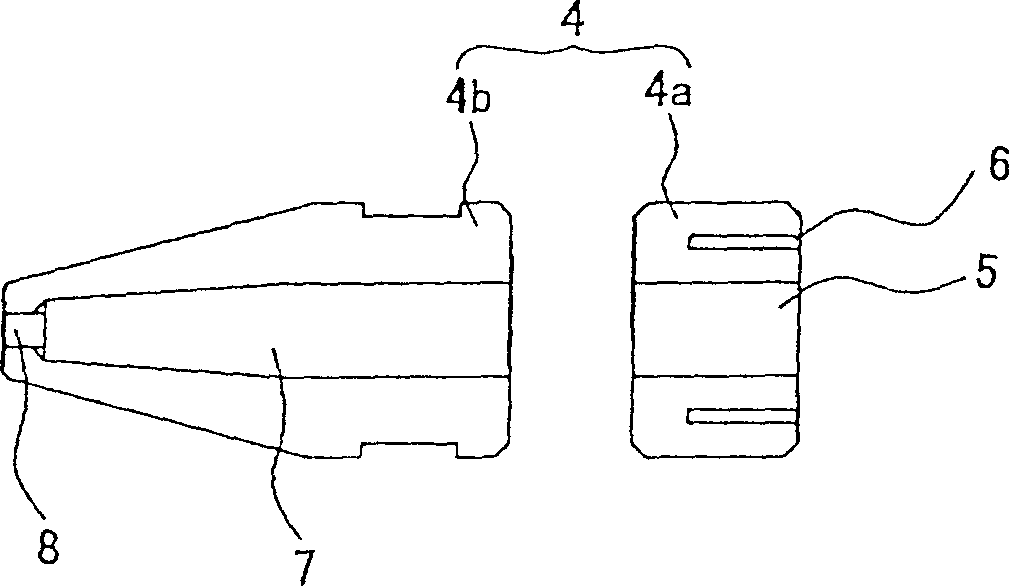

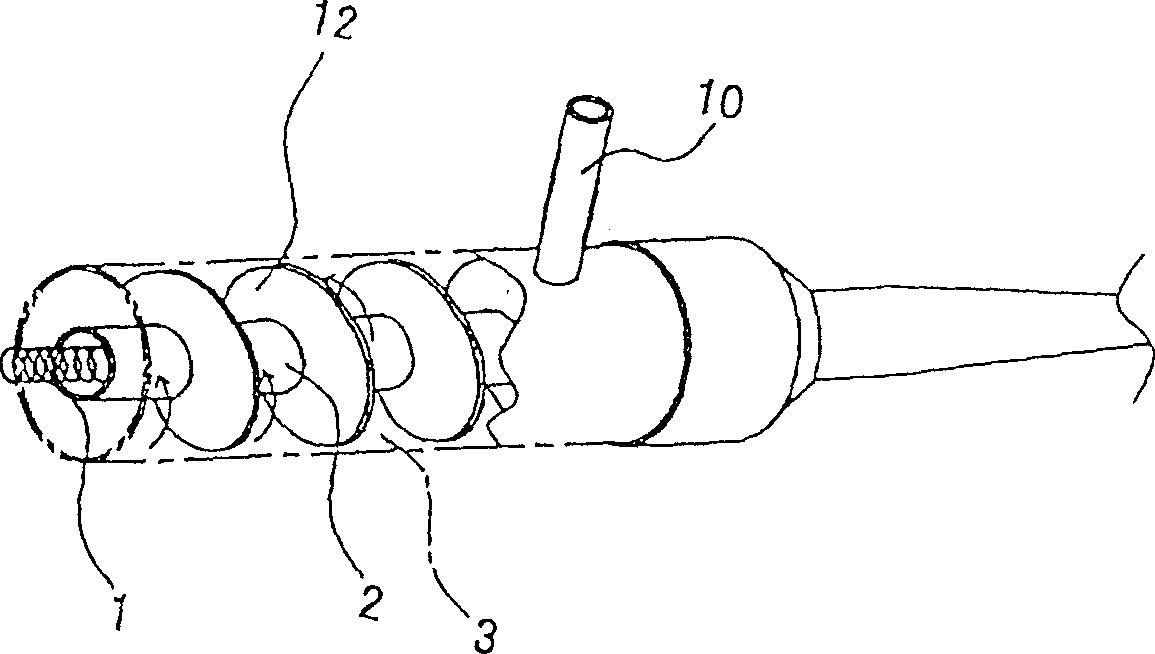

Baffle pipe and core-cooling device for an injection mold

The present invention relates to a core-cooling device for an injection mold which molds plastic injection-molded articles. More particularly, the present invention relates to a core-cooling device for an injection mold, wherein cooling water is efficiently supplied to circulate through a cooling water channel of a core and thus uniformly and quickly cool the core. The core-cooling device for an injection mold according to the present invention comprises: a basic cooling water pipe which is formed on a lower disk (20) and which includes a cooling water inlet (110) and a cooling water outlet (120); and core-cooling water pipes (200) in communication with the cooling water inlet (100) and the cooling water outlet (120) of the basic cooling water pipe so as to enable cooling water to circulate through the interior of a lower core (30).; Baffle pipes (210) divided into left and right sections are coupled to respective core-cooling water pipes (200). The cooling water inlet (110) of the basic cooling water pipe enables cooling water to be simultaneously fed into each of the core-cooling water pipes (200) via distribution pipes (111) connected to the lower ends of baffle pipes (210), respectively. The cooling water outlet (120) of the basic cooling water pipe is connected to lower portions of the core-cooling water pipes (200) so as to discharge, to the outside from the core-cooling device, the cooling water which is fed through the lower ends of the baffle pipes (210), discharged from upper portions of the core-cooling water pipes (200), and falling down toward the lower portions of the core-cooling water pipes (200) in order to cool the lower core (30).

Owner:李在福

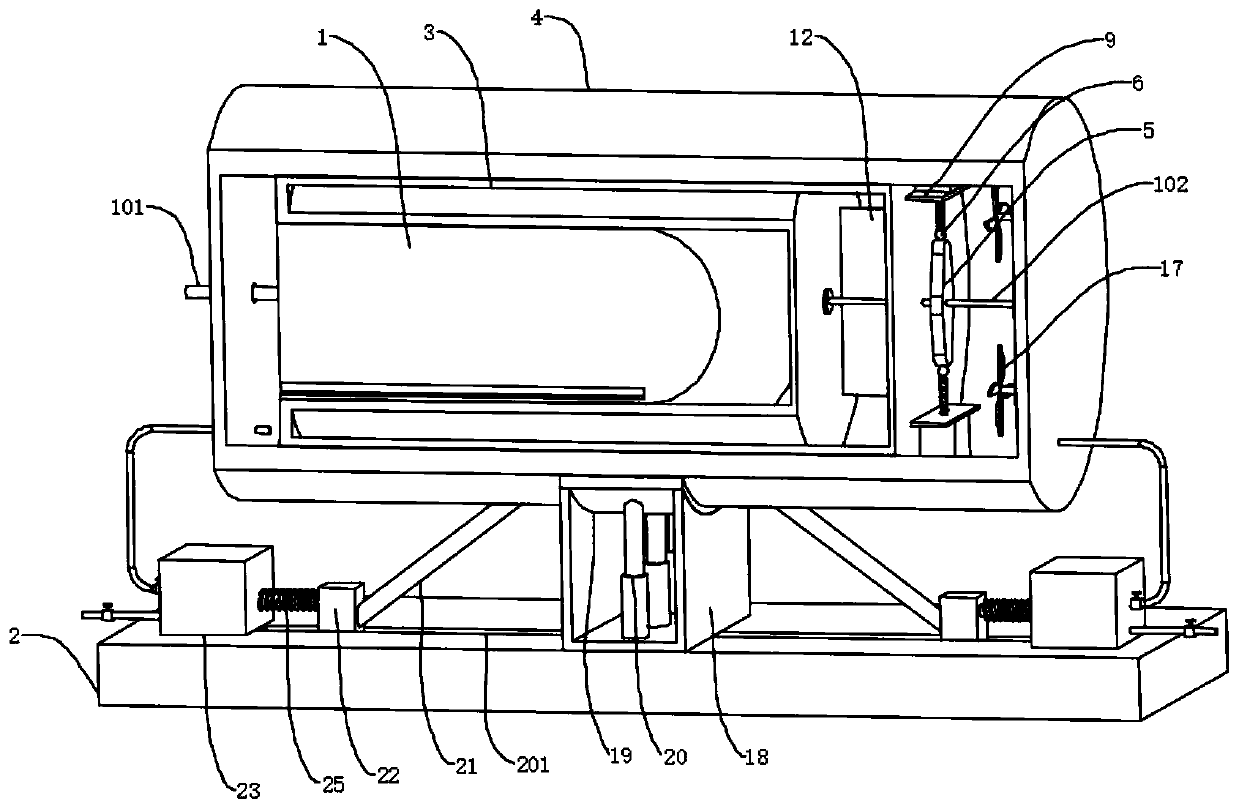

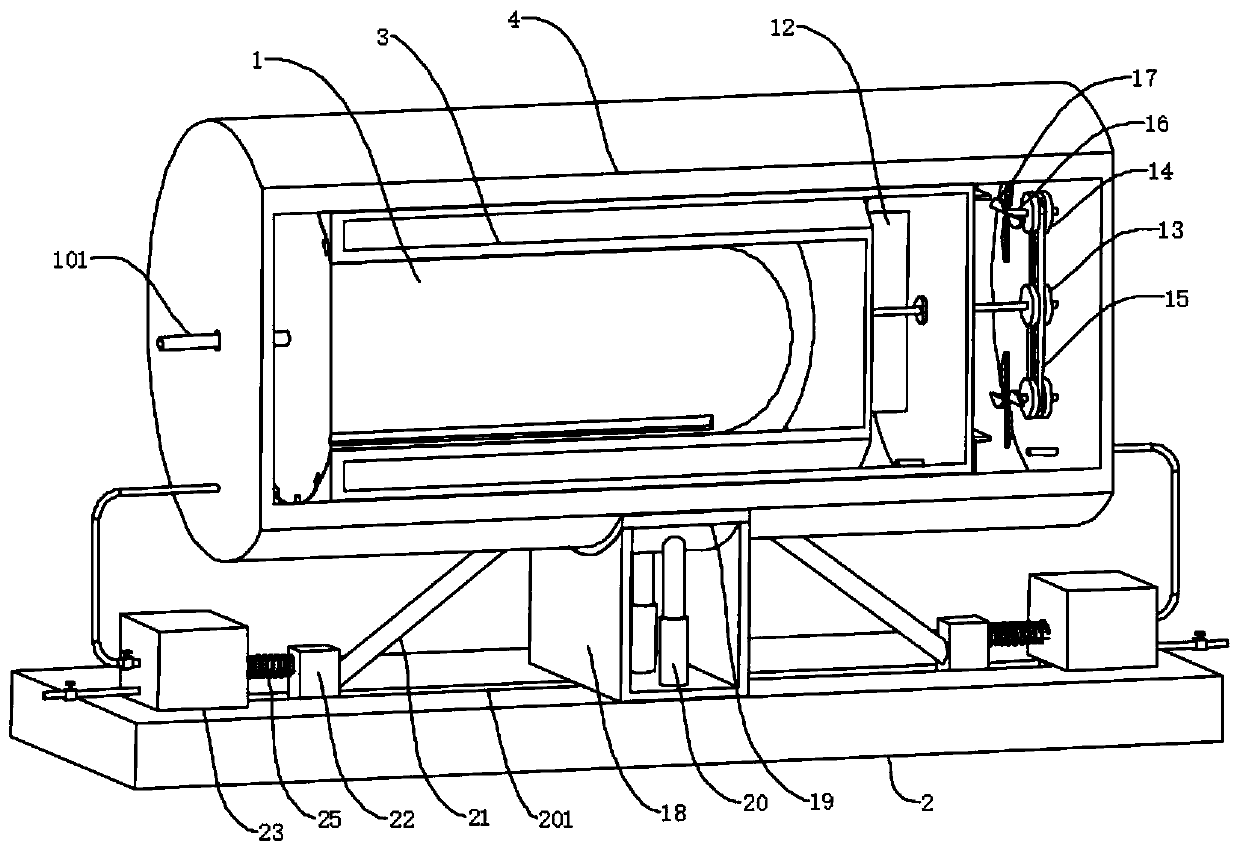

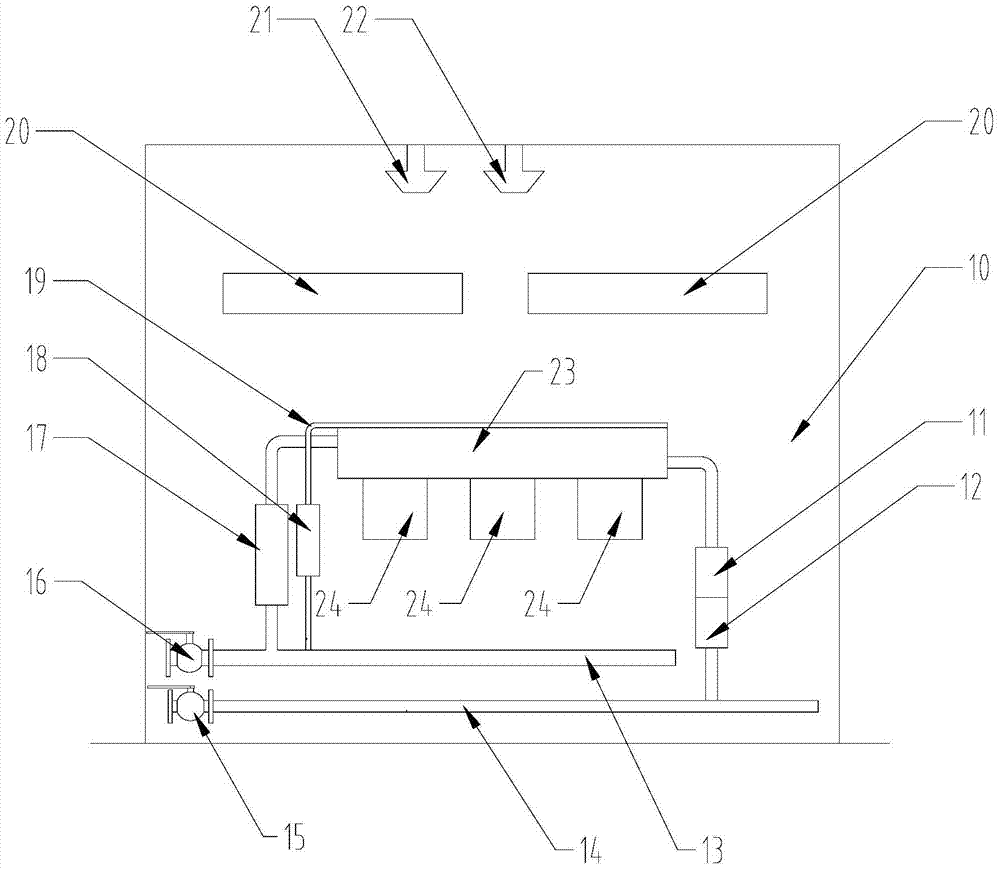

Precast concrete component curing forming device

InactiveCN105437361AImprove qualityDiffusion fastCeramic shaping apparatusEngineeringPrecast concrete

The invention discloses a precast concrete component curing forming device which comprises a curing kiln, a steam pipe, a drain pipe and a radiator, wherein the steam pipe, the drain pipe and the radiator are mounted in the curing kiln; the steam pipe is connected with the inlet of the radiator; the drain pipe is connected with the outlet of the radiator; a humidifying pipe is mounted in the curing kiln and connected with the steam pipe; and a steam hole is formed in the humidifying pipe. According to the precast concrete component curing forming device, the heat exchange rate is increased, the temperature of the curing kiln rises quickly, the temperature and humidity in the curing are even, and the quality of a precast concrete component is improved.

Owner:HUNAN SANY KUAIERJU RESIDENTIAL IND CO LTD

Tube-side sequentially pulsable-flow shell-and-tube heat exchanger appratus, system, and method

ActiveUS9068782B2Increase heat exchange rateReduce dirtCorrosion preventionChemical/physical/physico-chemical stationary reactorsChemical treatmentShell and tube heat exchanger

The present invention relates to a tube-side sequentially pulsable-flow, shell-and-tube heat exchanger apparatus and a chemical processing system comprising and methods of heat exchange employing the same.

Owner:DOW GLOBAL TECH LLC

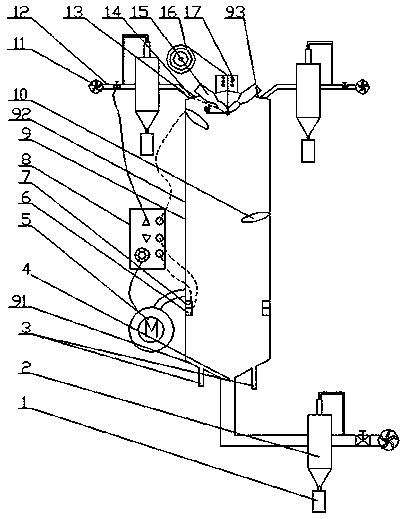

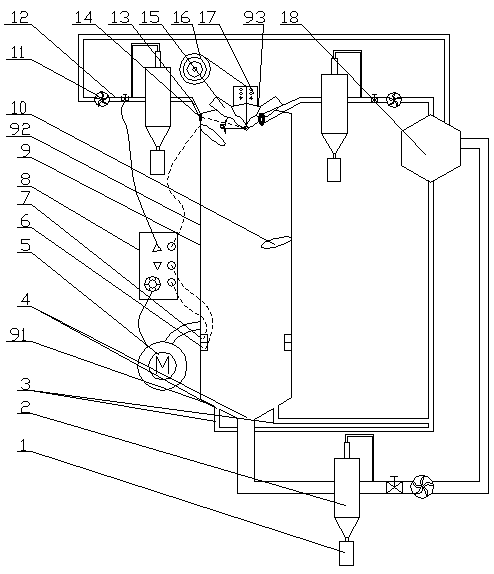

Metal atomization pulverizing equipment with low satellite sphere content

ActiveCN107661983AIncrease heat exchange rateReduce the chance of satellite formationGranularityTower

The invention provides metal atomization pulverizing equipment with low satellite sphere content. The metal atomization pulverizing equipment comprises a metal feeding mechanism, an atomization device, an atomization tower and a powder separation device, wherein the metal feeding mechanism is connected with the atomization device; the atomization device is mounted at the top of the atomization tower; a main powder outlet is formed in the bottom of the atomization tower; the main powder outlet is communicated with the powder separation device; no less than three powder outlet holes are formed in the upper end or a sealing end of a side wall of the atomization tower; the powder outlet holes are formed in the periphery of an atomization powder output and coke collection region at the bottom of the atomization device; the powder outlet holes are connected with the powder separation device through a powder output pipeline. The metal atomization pulverizing equipment with the low satellite sphere content, provided by the invention, is simple in structure and convenient to use; metal atomization powder prepared by the equipment has uniform and small granularity, high spherical degree, good flowability and low satellite sphere content, and performance requirements on various types of metal powder in the market can be met; the equipment is low in manufacturing cost and is convenient forbatch production; urgent requirements on high-performance metal powder at home and abroad can be met.

Owner:HUNAN TIANJI SMART MATERIAL TECH CO LTD

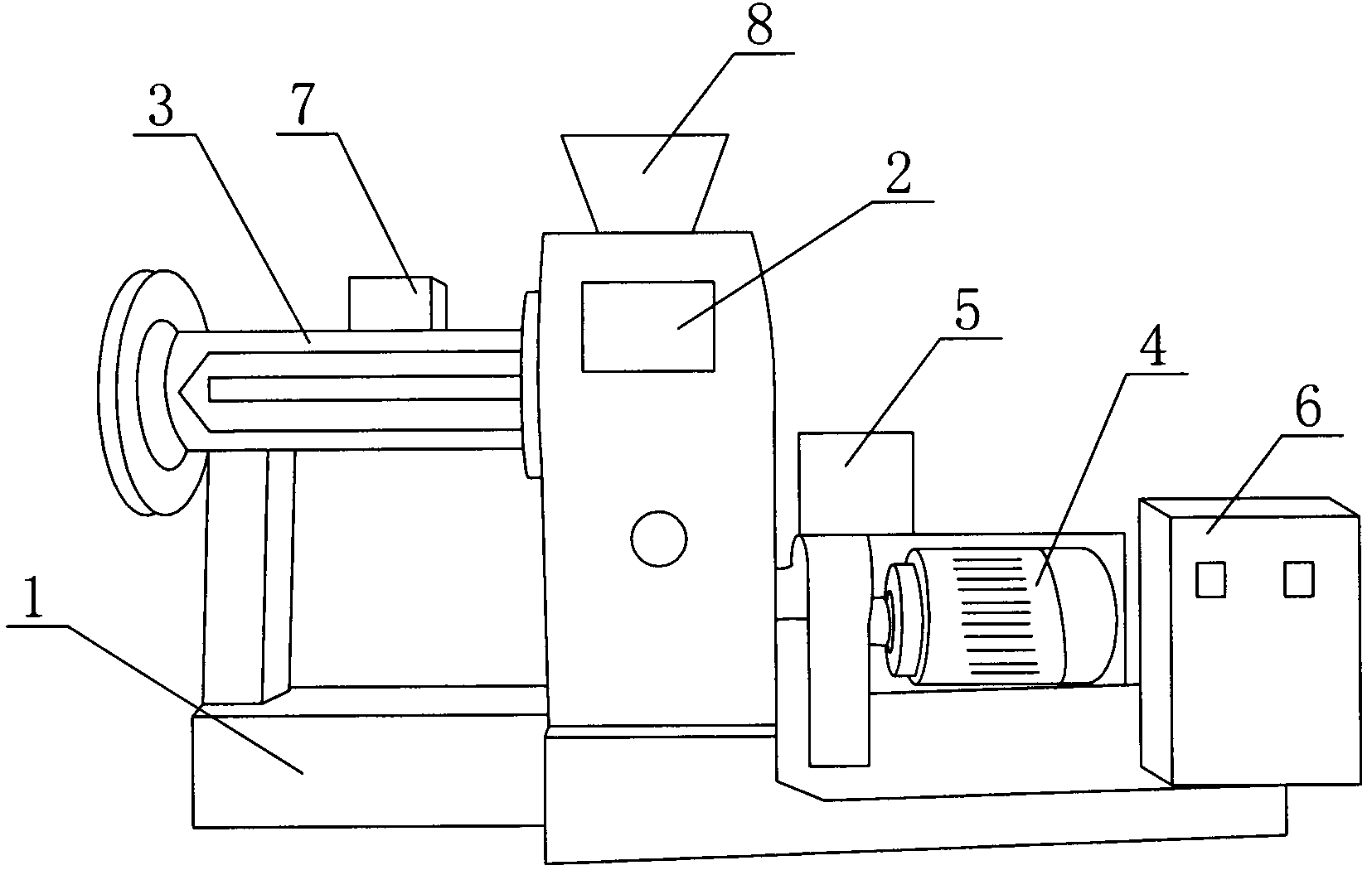

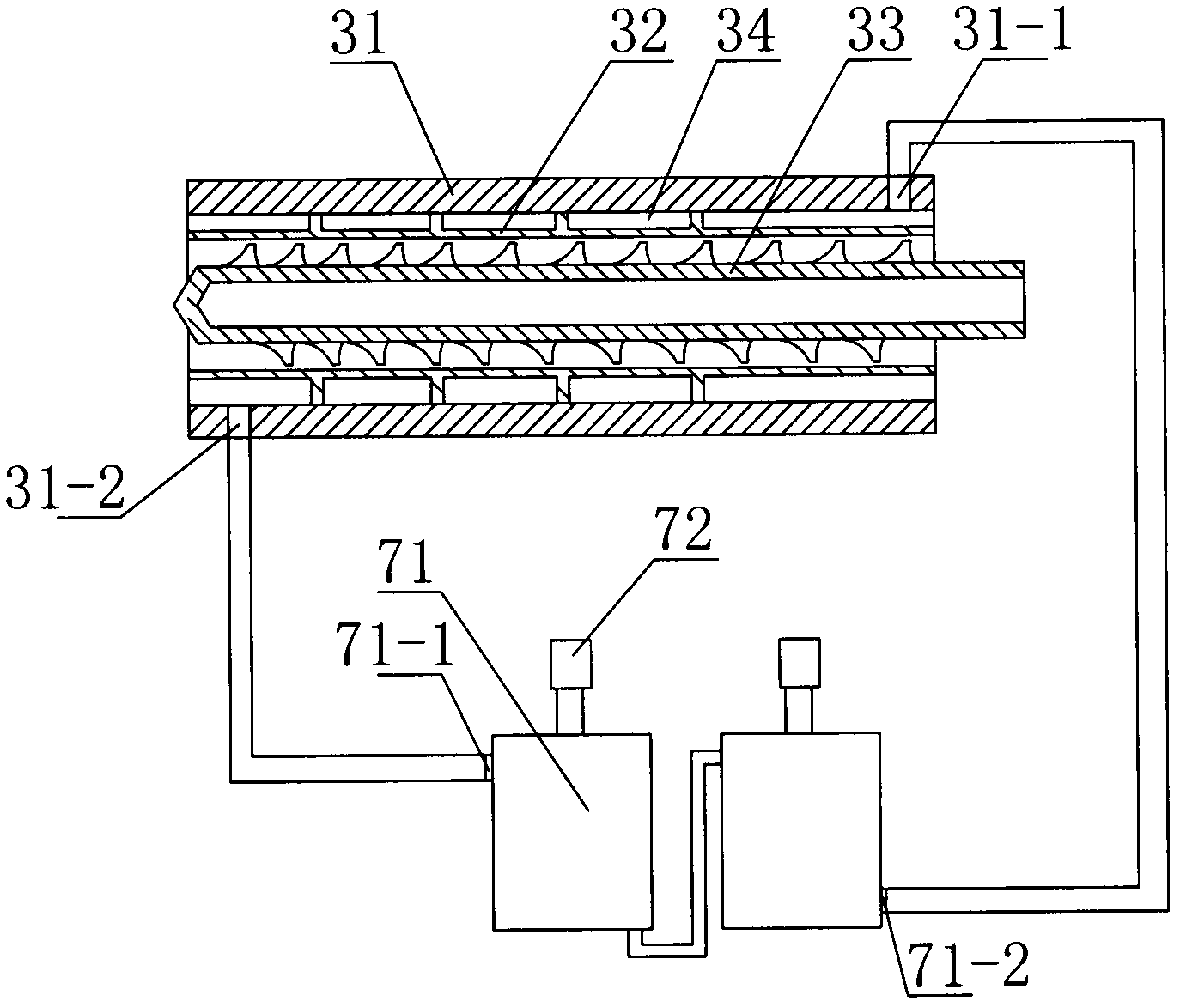

Special extruder for manufacturing rubber

The invention relates to a special extruder for manufacturing rubber, which comprises a base, a temperature control portion, a screw device, a driving motor, a speed reducer and a controller portion. The screw device comprises an outer cylinder, an inner cylinder and a screw, wherein the outer cylinder is fixed onto the base, the inner cylinder is arranged in the outer cylinder, and the screw is arranged in the inner cylinder. A spiral cold water injection cavity is arranged between the inner wall of the outer cylinder and the outer wall of the inner cylinder, a water inlet and a water outlet are respectively arranged on the outer cylinder and communicated with the cold water injection cavity, a cooling device comprises at least one water tank and coolers mounted on the water tanks, two ends of each water tank are connected with a water inlet pipe and a water outlet pipe respectively, the water inlet pipe is communicated with the water outlet, and the water outlet pipe is communicated with the water inlet. The cooling device is added into the screw device of the special extruder for manufacturing the rubber, the temperature of the screw and the rubber can be effectively reduced during extrusion of the rubber, heat exchange rate is increased, and premature melting of the rubber is avoided.

Owner:韦隽彧

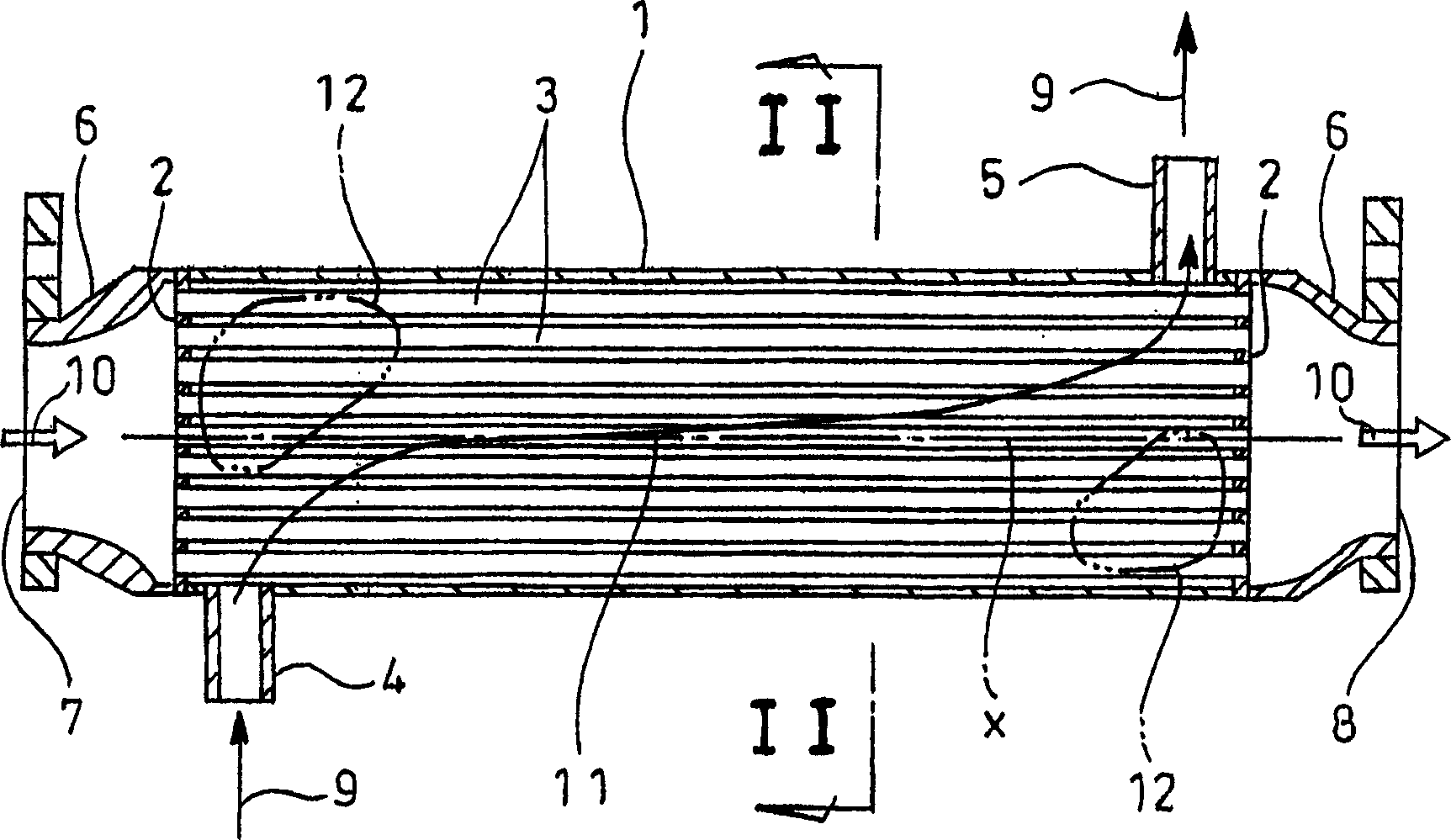

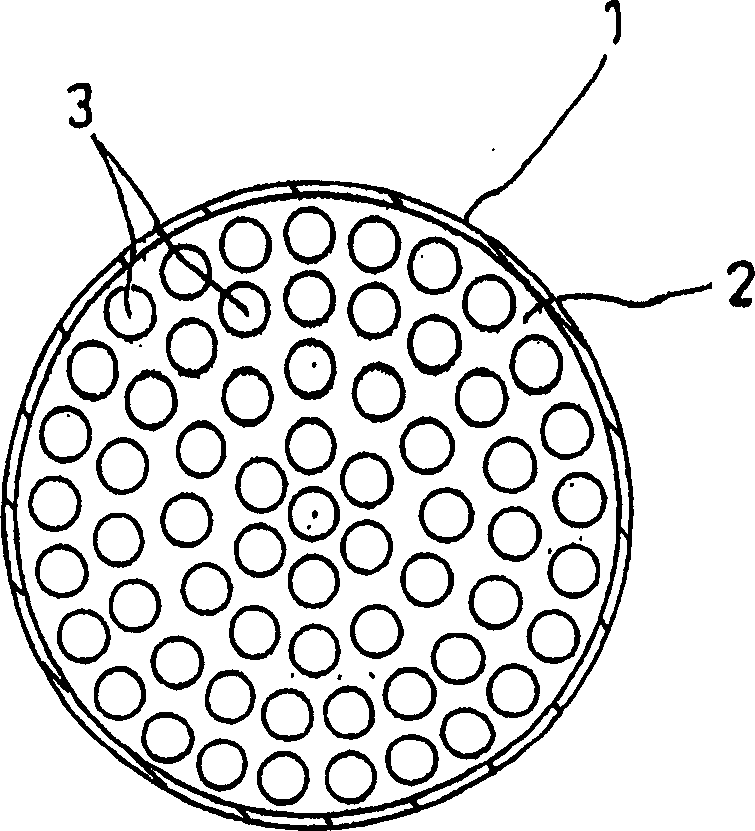

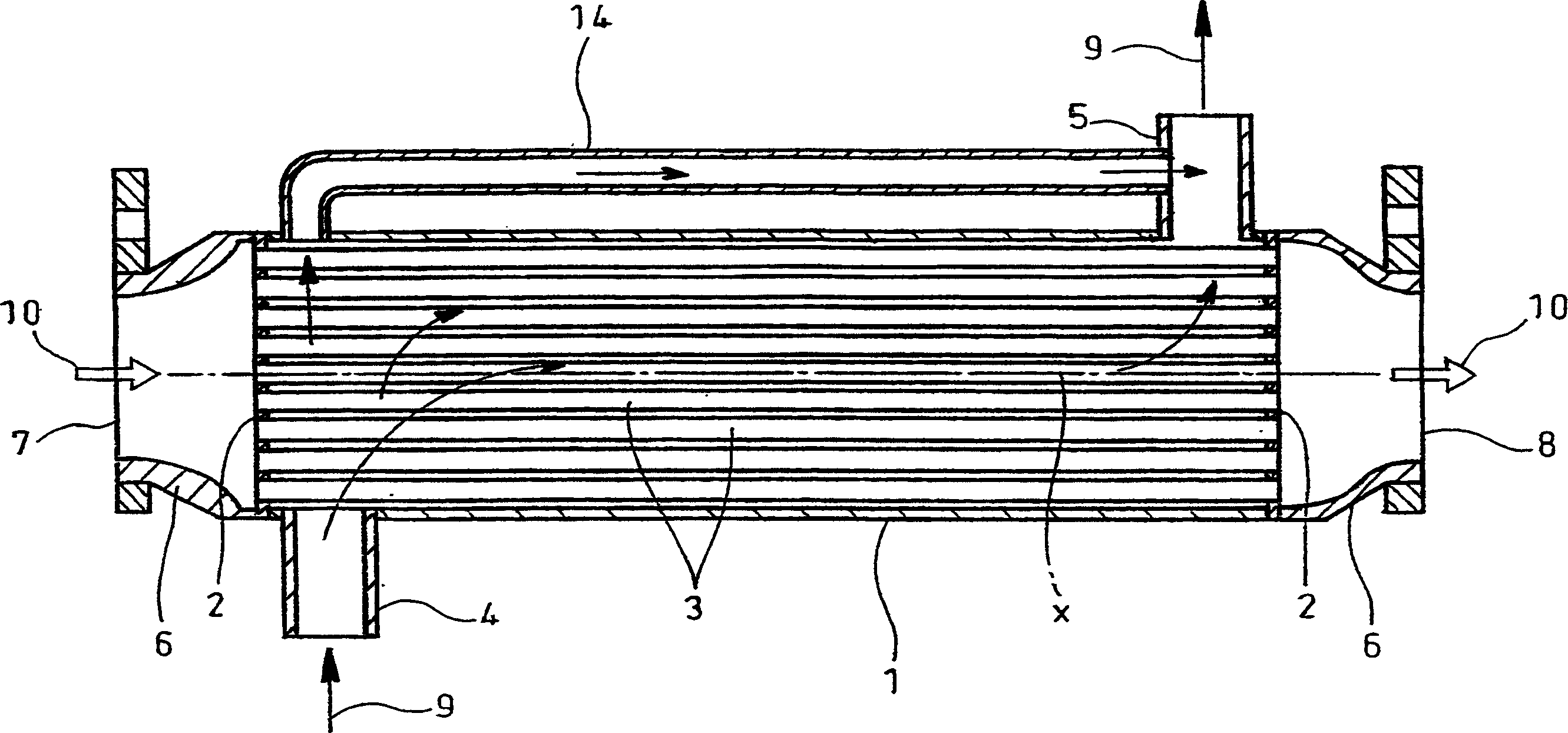

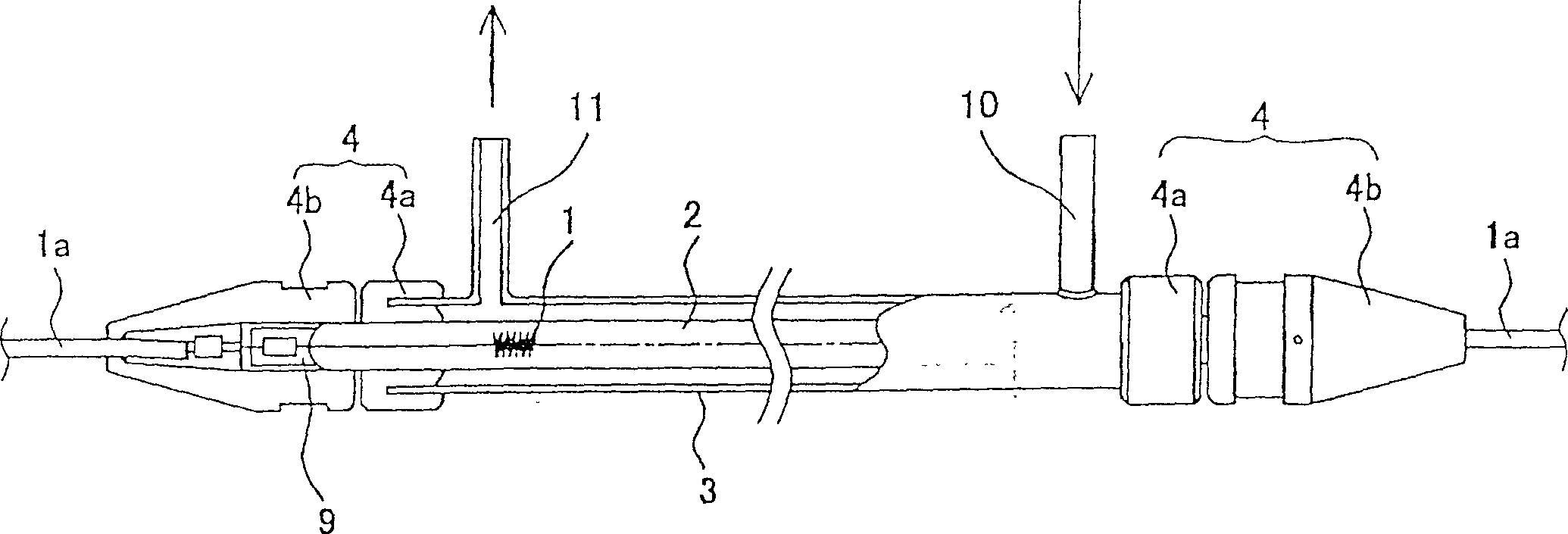

Exhaust gas recirculation cooler

InactiveCN1688804APrevent thermal deformationIncrease heat exchange rateNon-fuel substance addition to fuelInternal combustion piston enginesChillerDiesel engine

The invention provides an EGR cooler comprising tubes (3) and a shell (1) enclosing the tubes (3); cooling water (9) is supplied into and discharged from said shell (1); exhaust gas (10) is guided from a diesel engine into the tubes (3) for thermal exchange of the exhaust gas (10) with the cooling water (9). A bypass flow path for guiding the cooling water (9) is constituted within the shell (1) so as to prevent stagnation of the cooling water (9) in the shell (1).

Owner:HINO MOTORS LTD +1

Condenser

InactiveCN101089536AReduce in quantityAvoid spreadingEvaporators/condensersSteam/vapor condensersElectrical and Electronics engineeringHeat transfer

A condenser has heat exchange plates stacked between which the first and second gap portions are provided alternately. Each plate has a heat transfer section having grooves combined into a V-shape and a hole for discharging condensate. The section has tubular projections formed around the hole on the rear surface of the plate, and tongue-shaped projections formed around the hole on the front surface of the plate. The condenser has a continuous passage which passes linearly through the heat exchange plates in the stacking direction thereof. The passage enables condensate generated in the first gap portions to move in the stacking direction of the heat exchange plates.

Owner:XENESYS

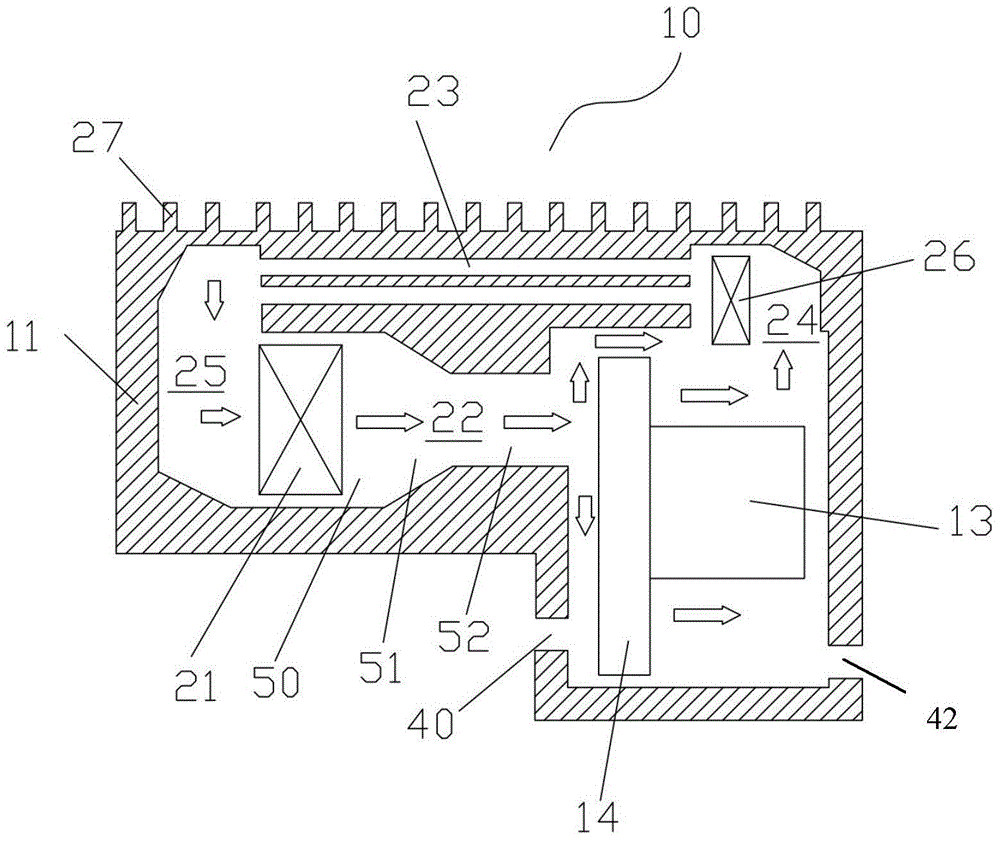

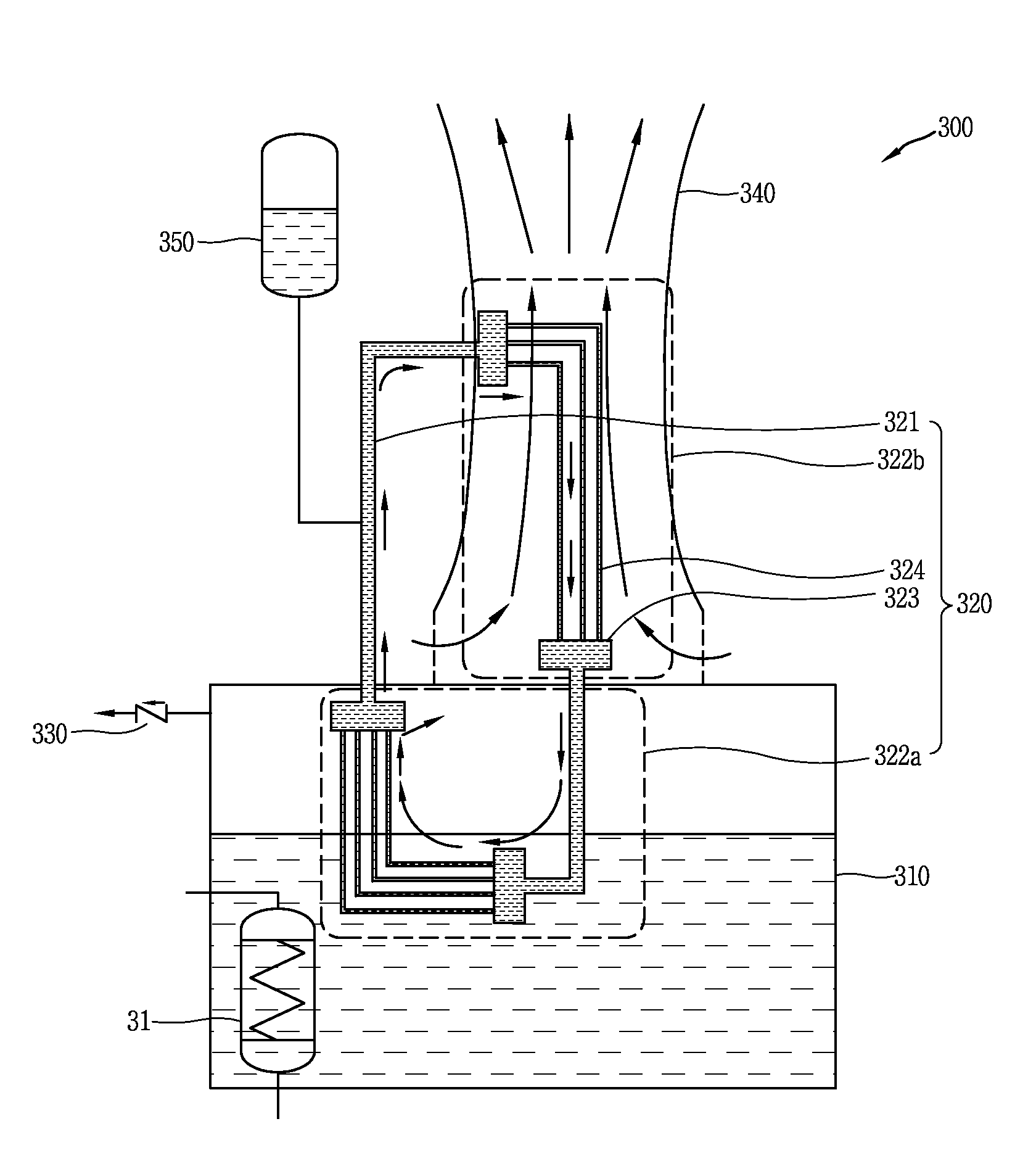

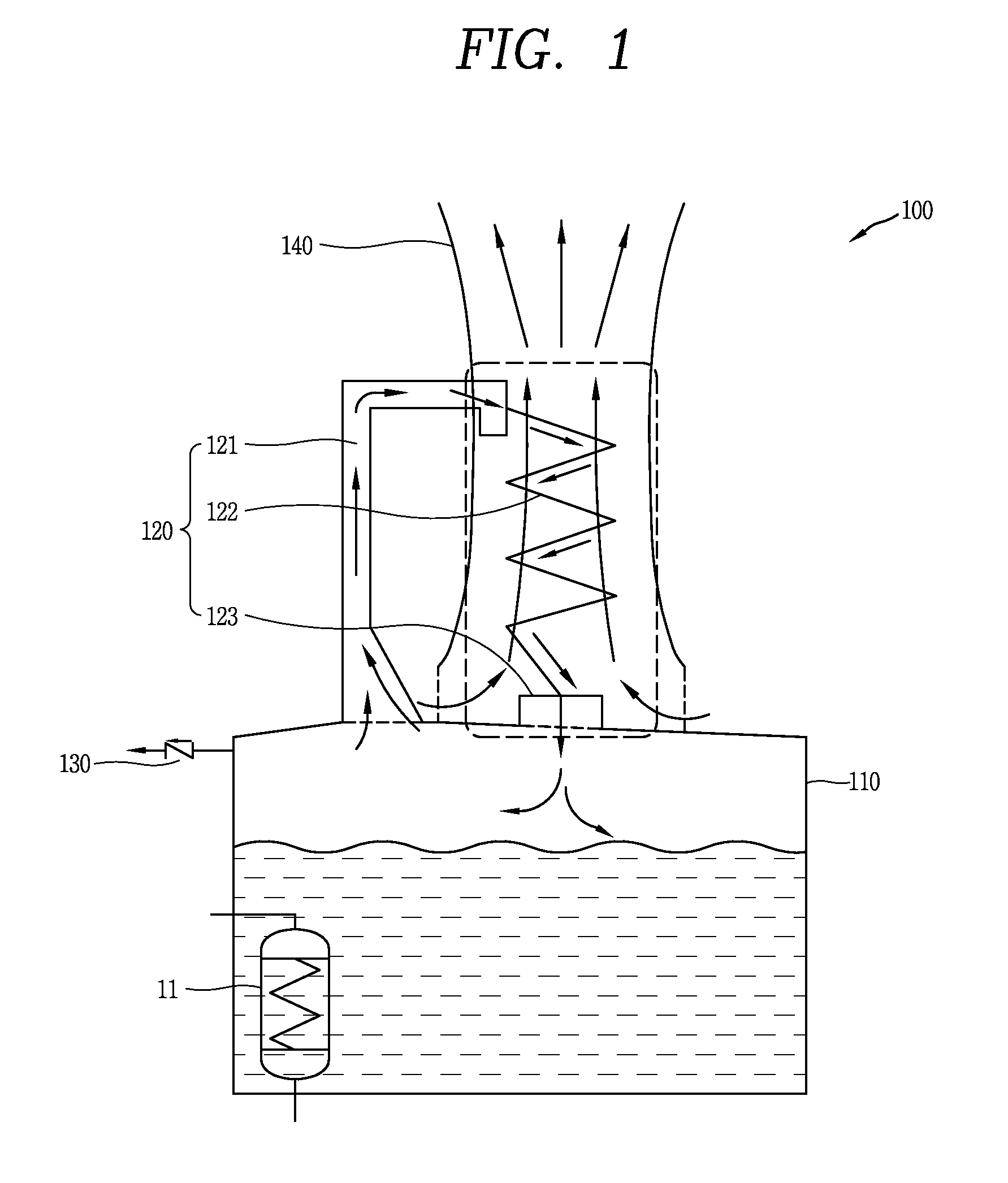

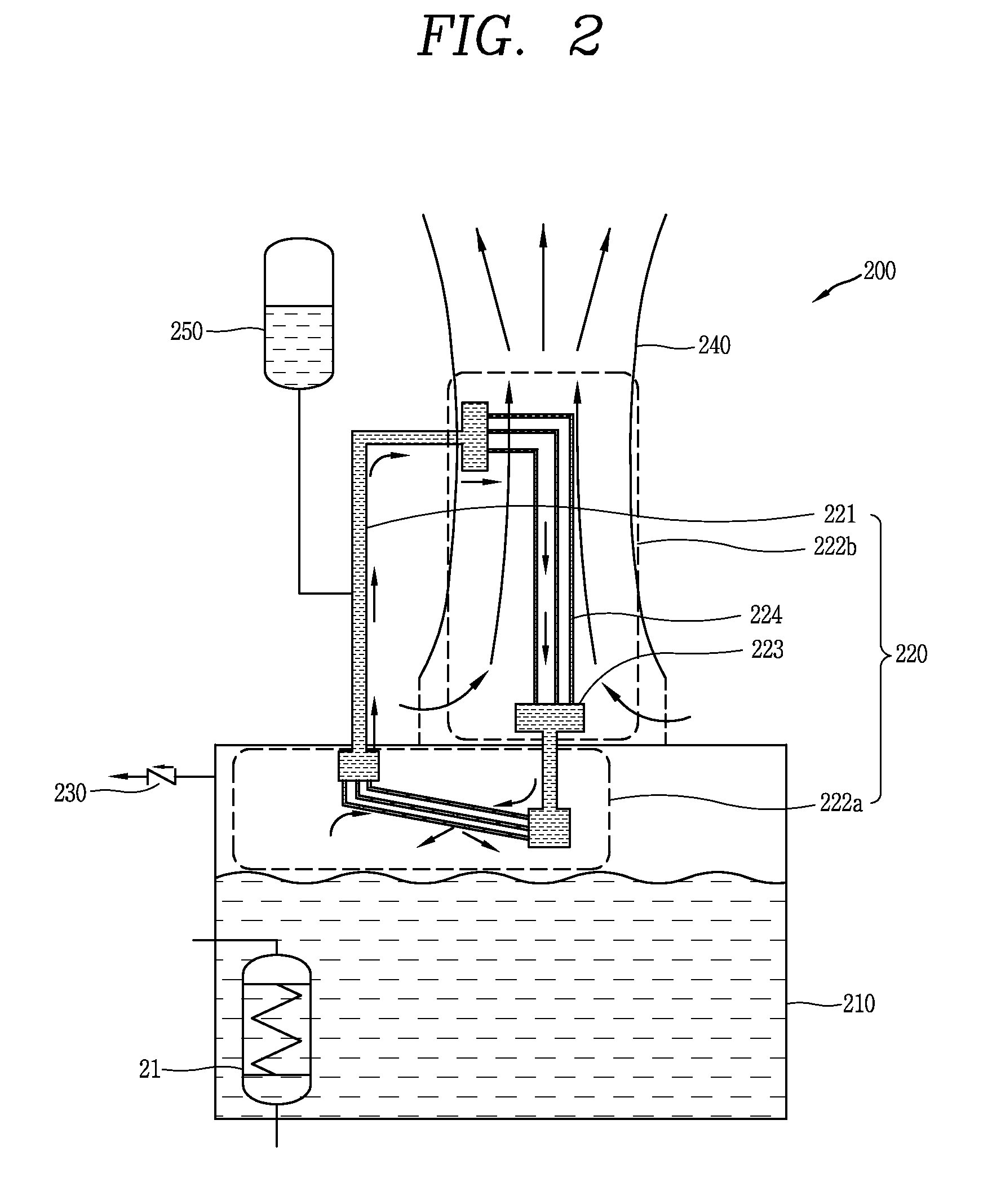

Cooling system of emergency cooling tank and nuclear power plant having the same

ActiveUS20140334590A1Prevent emissionGuaranteed functionPower plant safety arrangementNuclear energy generationNuclear reactorNuclear power plant

The present disclosure provides a cooling system of an emergency cooling tank, which enables long-term cooling without refilling cooling water, in case of the change in a quantity of heat transferred to the emergency cooling tank according to a lapse of time upon an occurrence of an accident of a nuclear reactor, and a nuclear power plant having the same. The emergency cooling tank cooling system includes an emergency cooling tank configured to store cooling water therein, the cooling water receiving heat, transferred from a nuclear reactor or a containment, when an accident occurs in the nuclear reactor, a heat exchanging device installed to be exposed to an outside of the emergency cooling tank to operate in air, and configured to externally emit heat by way of a heat exchange between fluid in the emergency cooling tank and the air such that the operation of the emergency cooling tank is continued even without refilling the cooling water, and an opening and closing unit installed at an upper portion of the emergency cooling tank to be located higher than a water level of the cooling water, and configured to be open by a flow of the fluid generated by an evaporation of the cooling water, the flow being formed due to a pressure difference from external air at pressure higher than a preset pressure, such that some of the fluid is externally emitted when a heat load exceeding a cooling capacity of the emergency cooling tank is transferred.

Owner:KOREA ATOMIC ENERGY RES INST

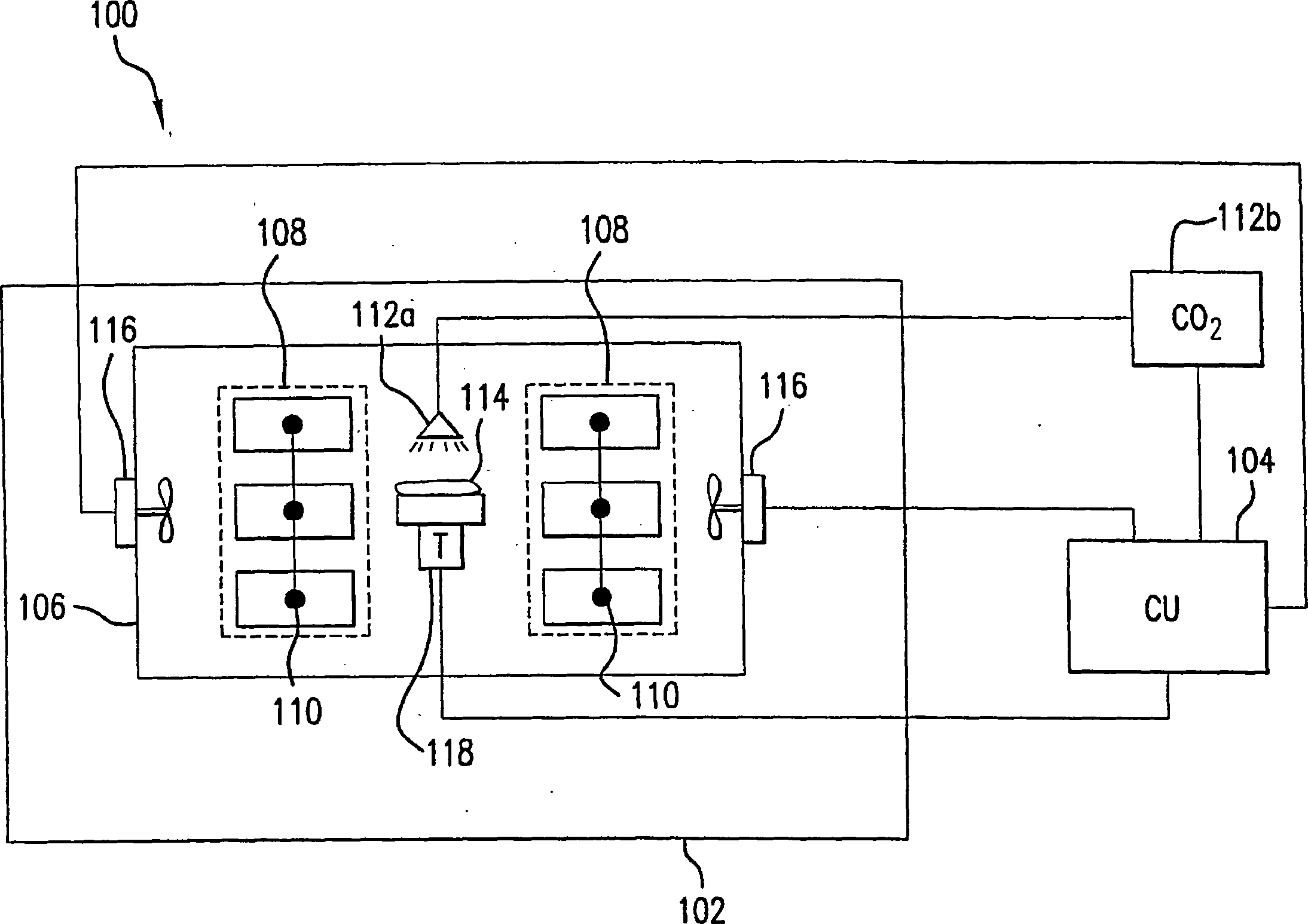

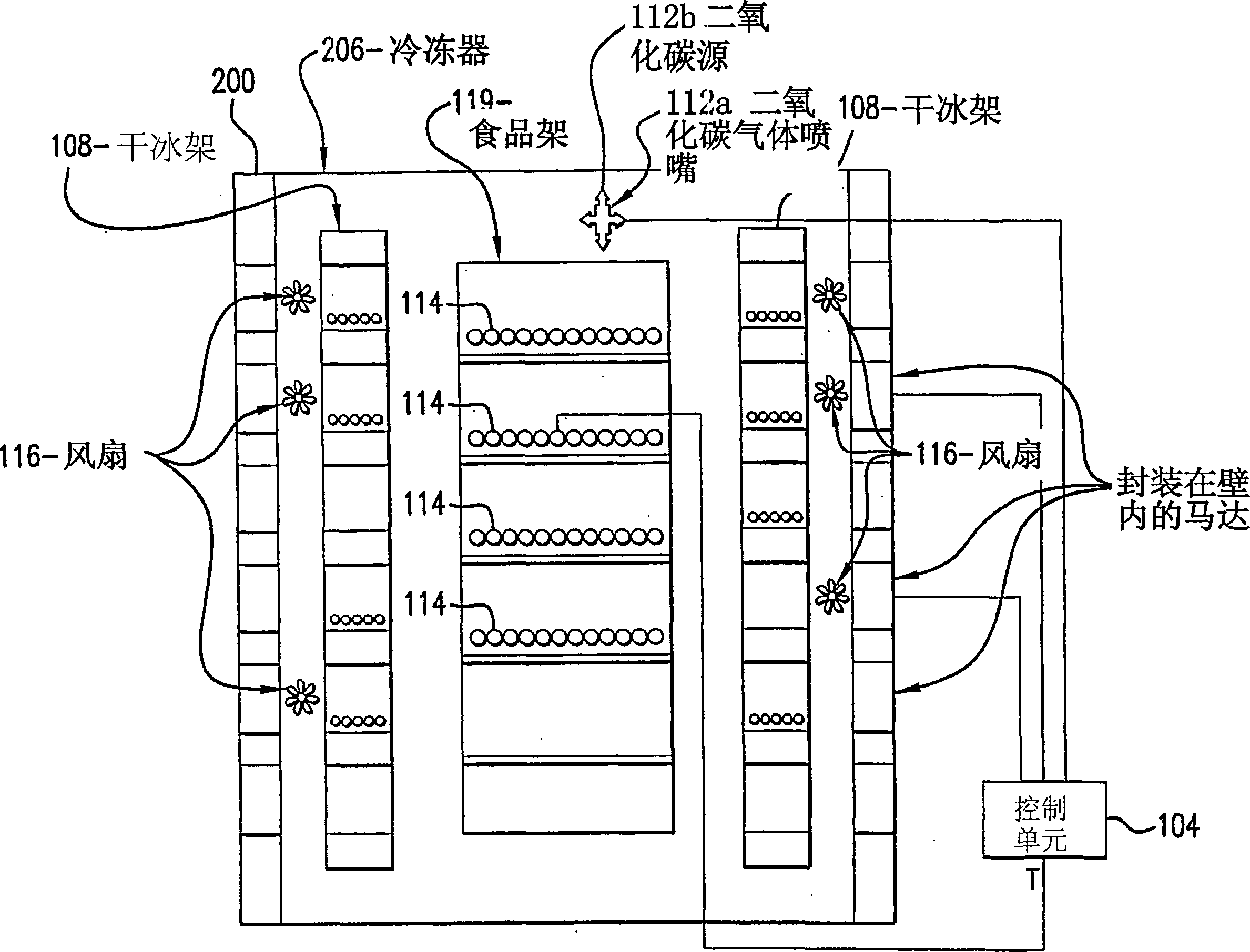

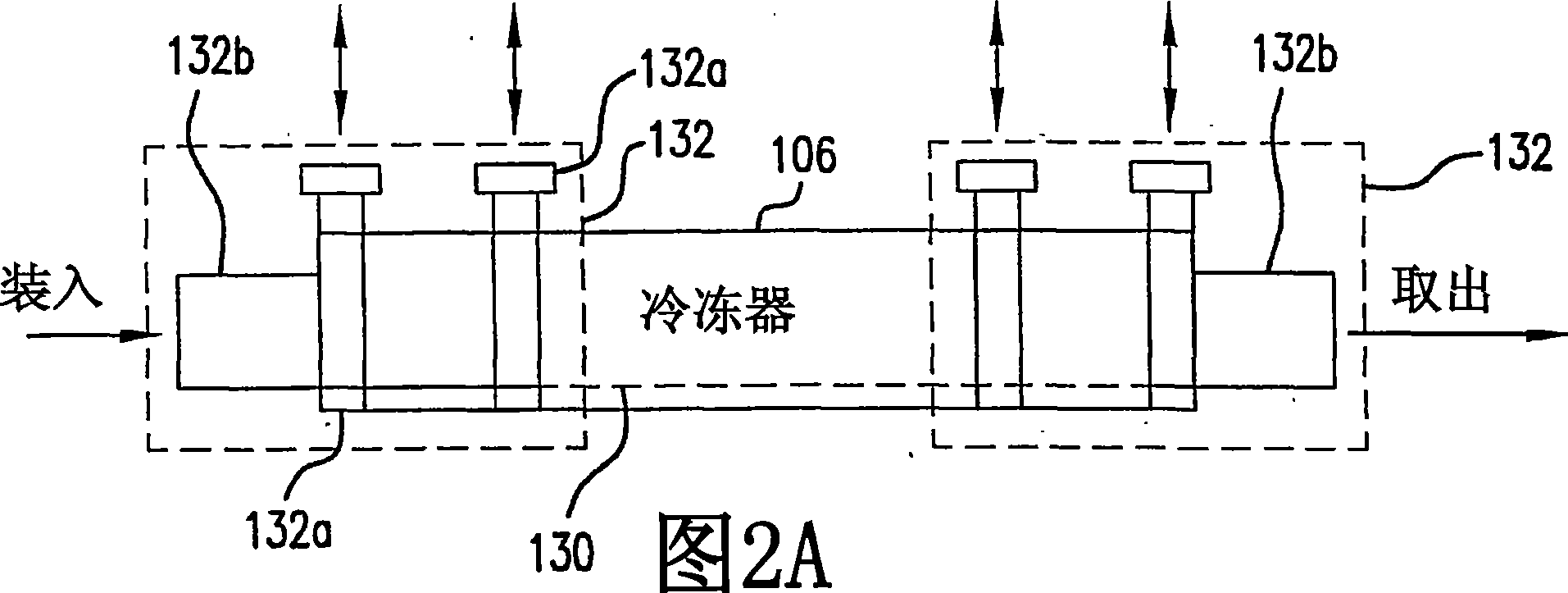

Food freezing and thawing method and apparatus

InactiveCN1917770AKeep it originalOptimal freezing processLighting and heating apparatusMeat/fish preservation by freezing/coolingProcess engineeringIngested food

Owner:大喜多英义

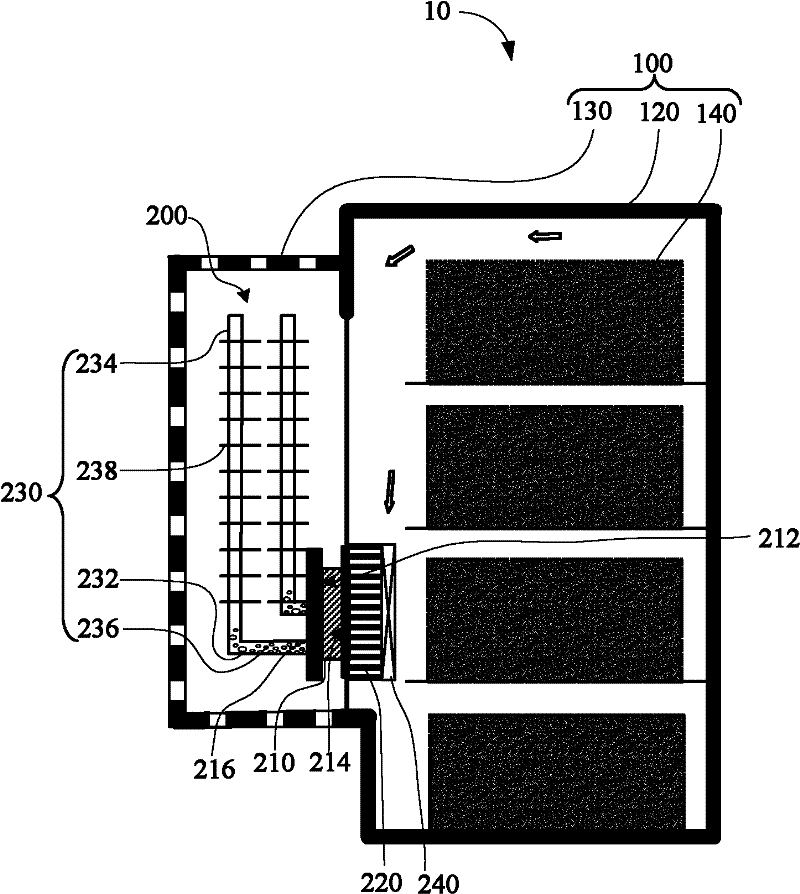

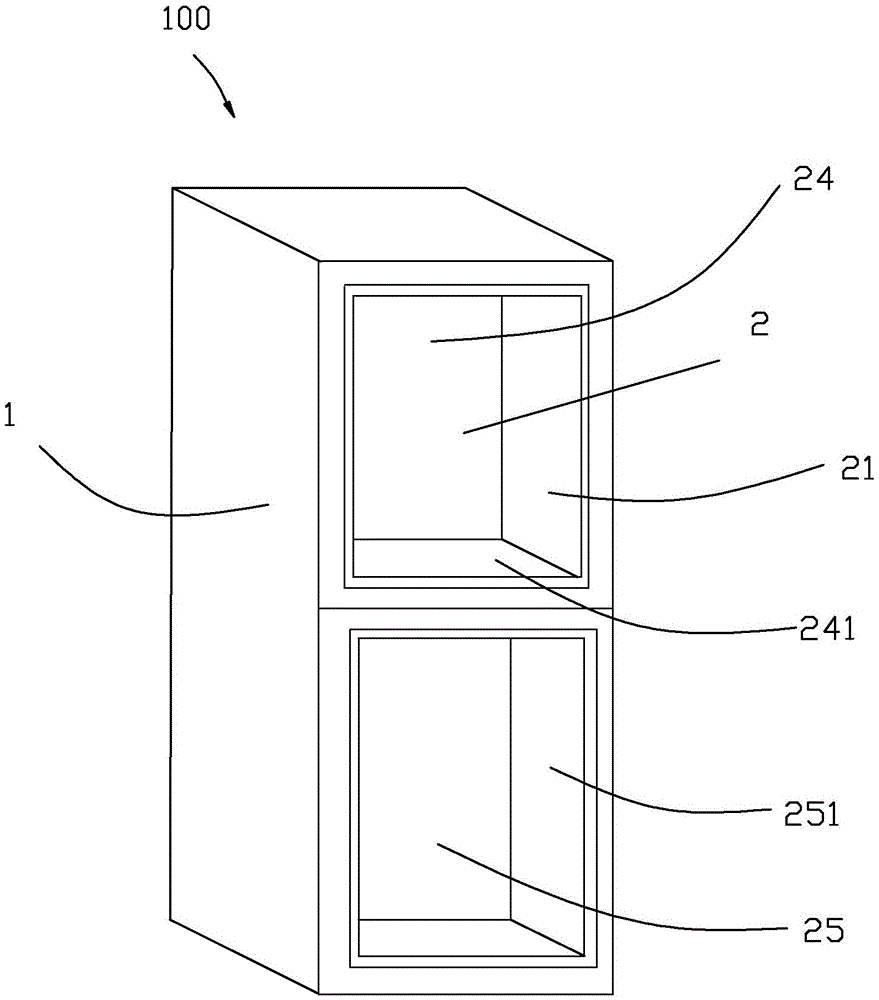

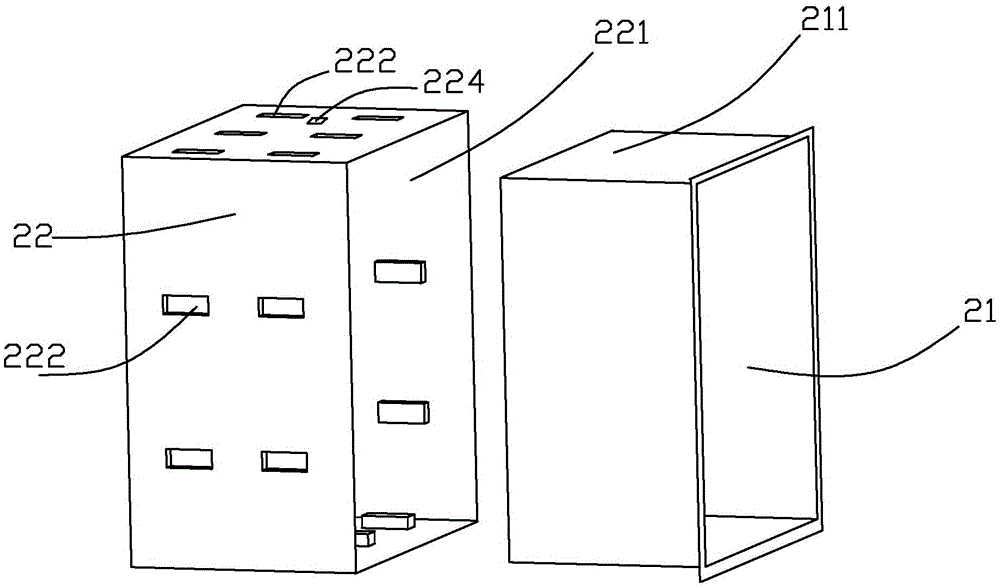

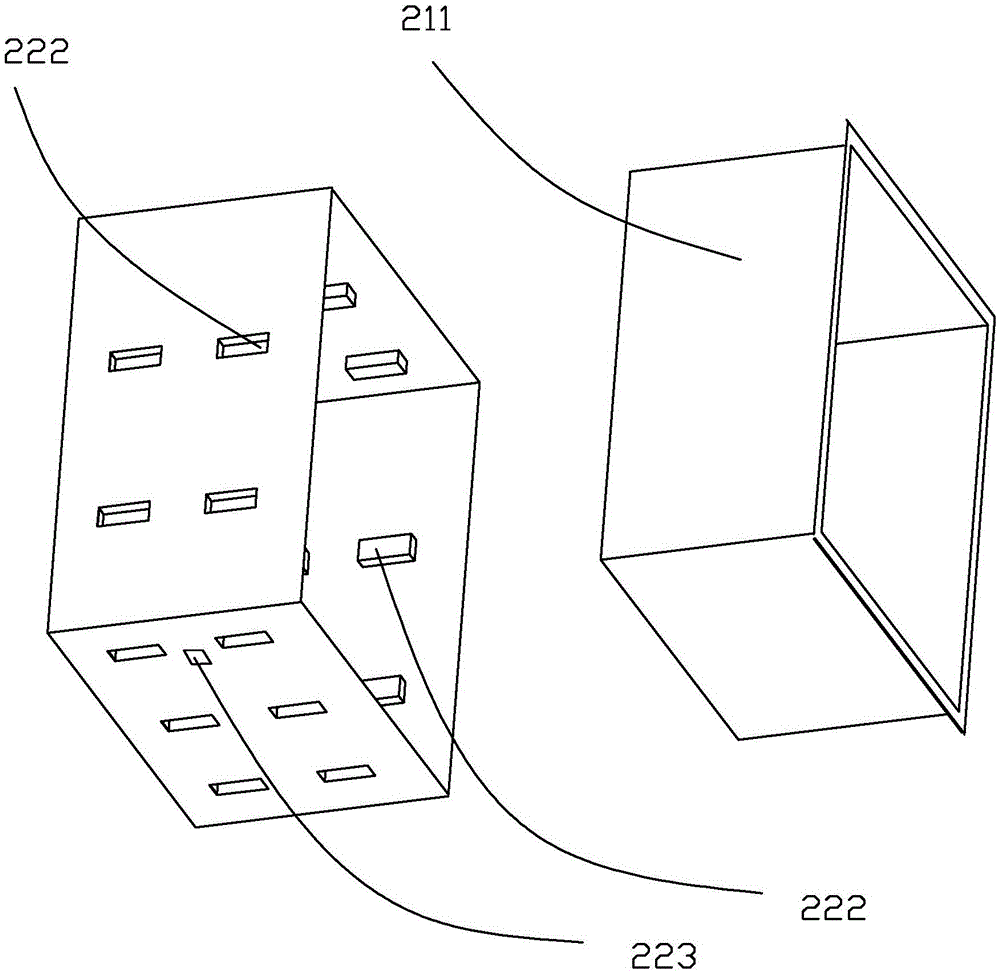

Refrigerator

ActiveCN105091450ANot easy to smellNot easy to dryLighting and heating apparatusDomestic refrigeratorsCold airFrost

The invention discloses a refrigerator. The refrigerator comprises a refrigeration chamber, and a circulating air way for supplying cooling capacity to the refrigeration chamber, wherein the refrigeration chamber is encircled by a first liner and a door body. The refrigerator further comprises a second liner surrounding the outer side of the first liner; openings of the first liner and the second liner are tightly connected; the first liner and the second liner are encircled to form a cavity surrounding the outer side of the first liner; and the second liner is provided with an air inlet communicated with the circulating air way for entering cold air into the cavity and an air return port communicated with the circulating air way for entering the air in the cavity into the circulating air way. The cold air in the cavity performs the heat exchange with the refrigeration chamber through five liner walls of the first liner, so that the refrigeration chamber is synchronously and uniformly refrigerated from five surfaces to achieve effects of improving the heat exchange efficiency and reducing the energy consumption; and meanwhile, the cold air is not directly contacted with foods in the refrigeration chamber to achieve such beneficial effects as difficult food airing, difficult frost damage and difficult tainting by order among all refrigeration chambers.

Owner:SHENYANG HAIER REFRIGERATOR

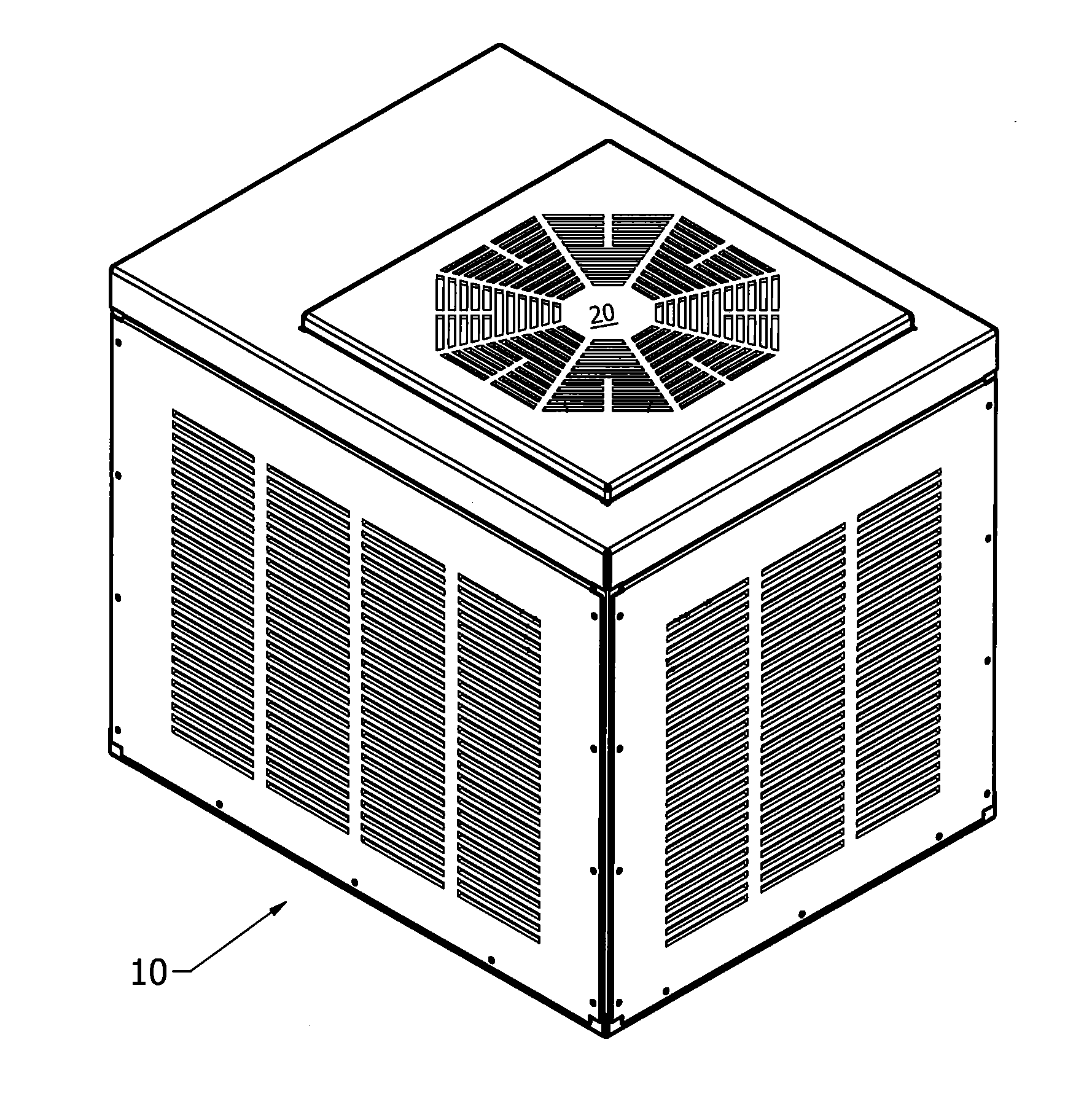

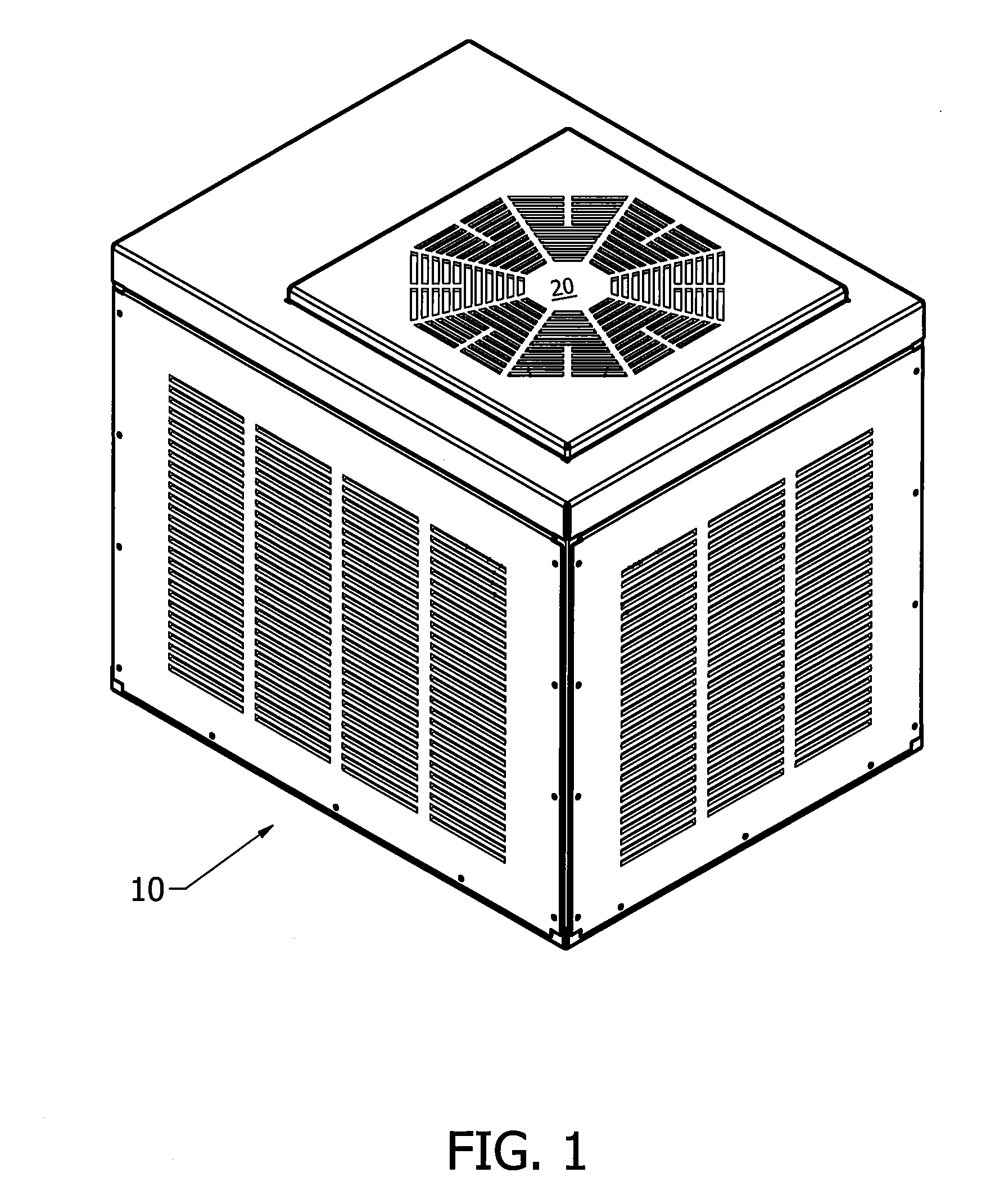

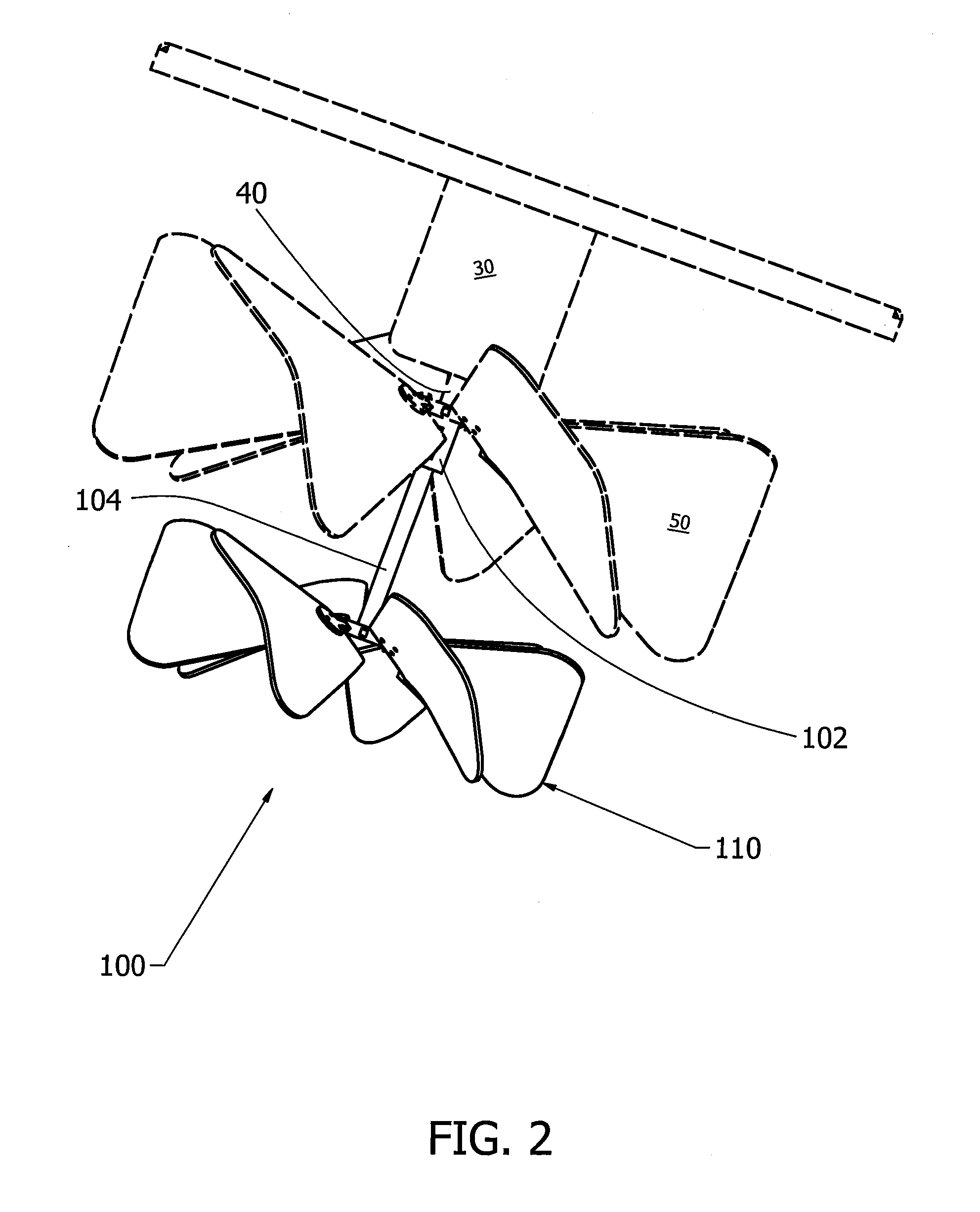

Air Conditioner Condenser Booster

InactiveUS20120222843A1Improve efficiencyOvercome limitationsIndirect heat exchangersPump installationsEngineeringAir conditioning

An architecture is presented that provides a an air conditioner booster device for improving the air flow across the condensing exchanger of an air conditioning unit thereby increasing the efficiency of the air conditioning unit. The air conditioner booster device is intended to increase the air flow created by a traditional air conditioner condenser fan. The air conditioner booster device is easily removably attachable to most conventional air conditioning units.

Owner:MITCHELL JAMES

Liquid heater

InactiveCN1540261ANo energy wastedSimple structureFluid heatersBathroom coversEngineeringThermal water

A fluid heater for generating hot water and hot air in water closet is composed of the coaxial internal tube and external tube with fluid inlet and outlet, tube caps for connecting said two tubes, an electrothermal wire in internal tube, and a cavity between two tubes.

Owner:邹美琴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com