Patents

Literature

10877results about "Tubular elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

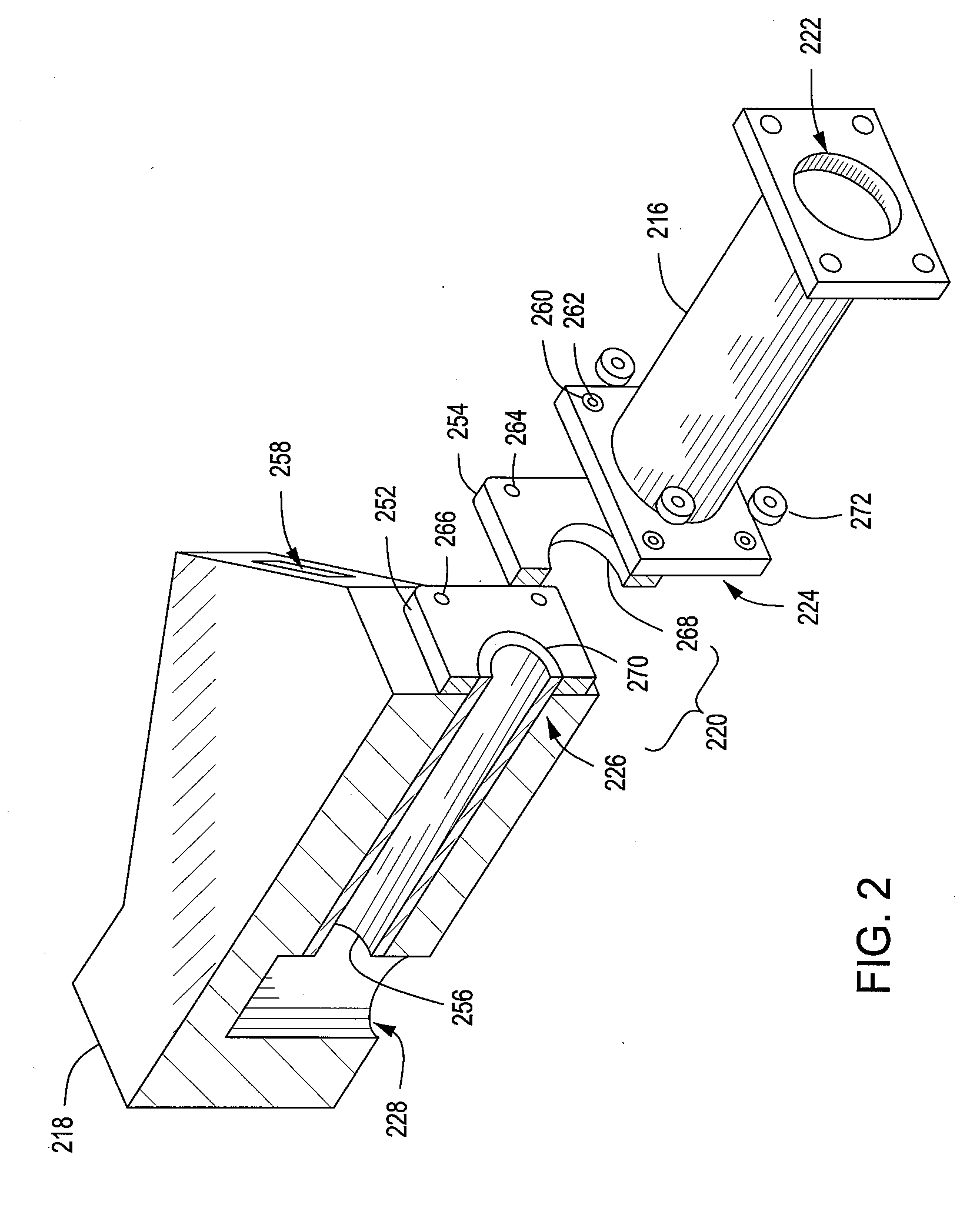

Manifold assembly

Embodiments of a manifold assembly are provided herein. In some embodiments, a manifold assembly includes a first manifold having a first inlet, for coupling to a high temperature fluid source, and a first outlet; a second manifold having a second inlet and a second outlet; and a connector portion coupling the first outlet of the first manifold to the second inlet of the second manifold, the connector portion includes a polymer block; and a thermal isolator disposed between the polymer block and the first manifold.

Owner:APPLIED MATERIALS INC

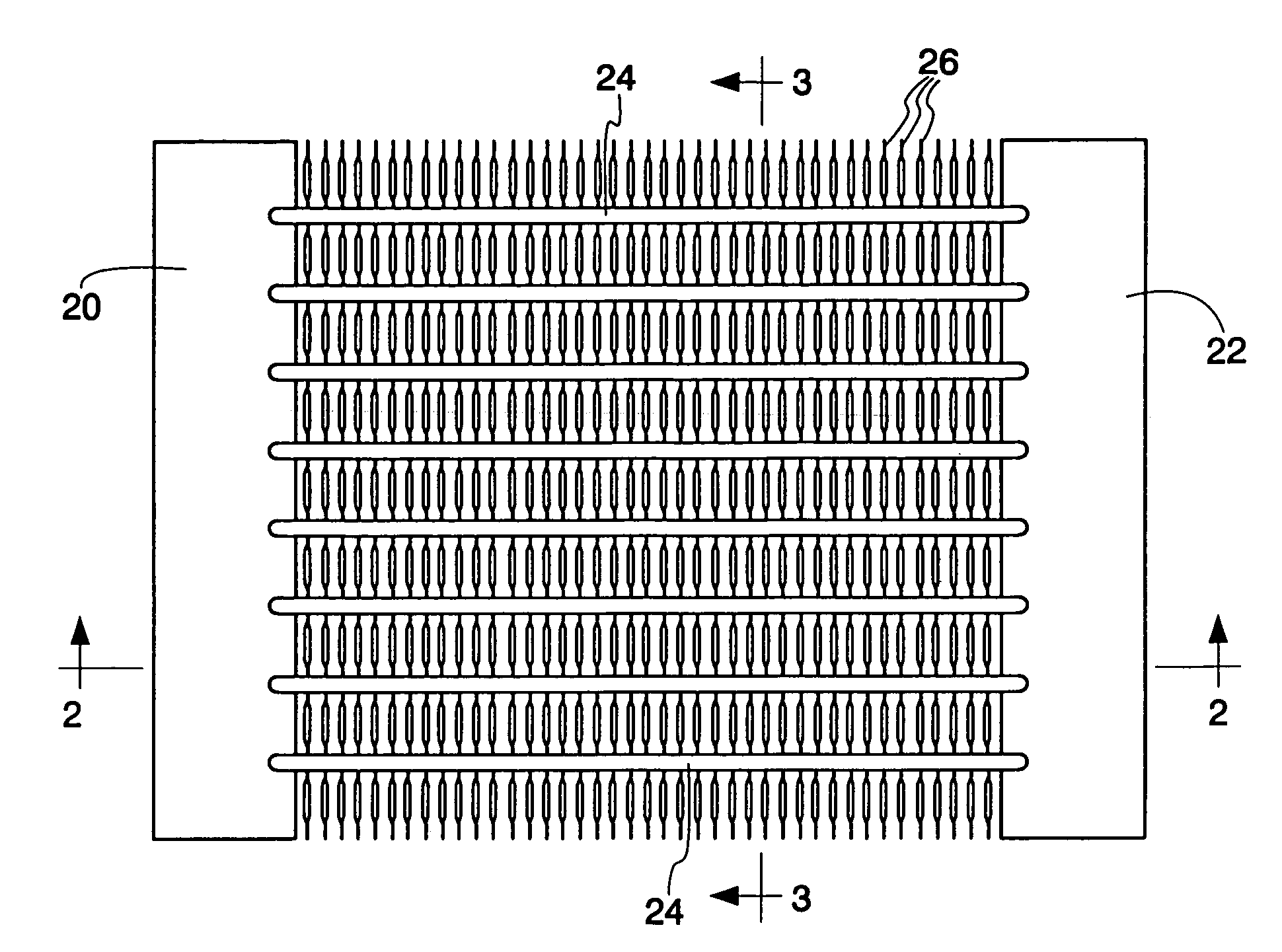

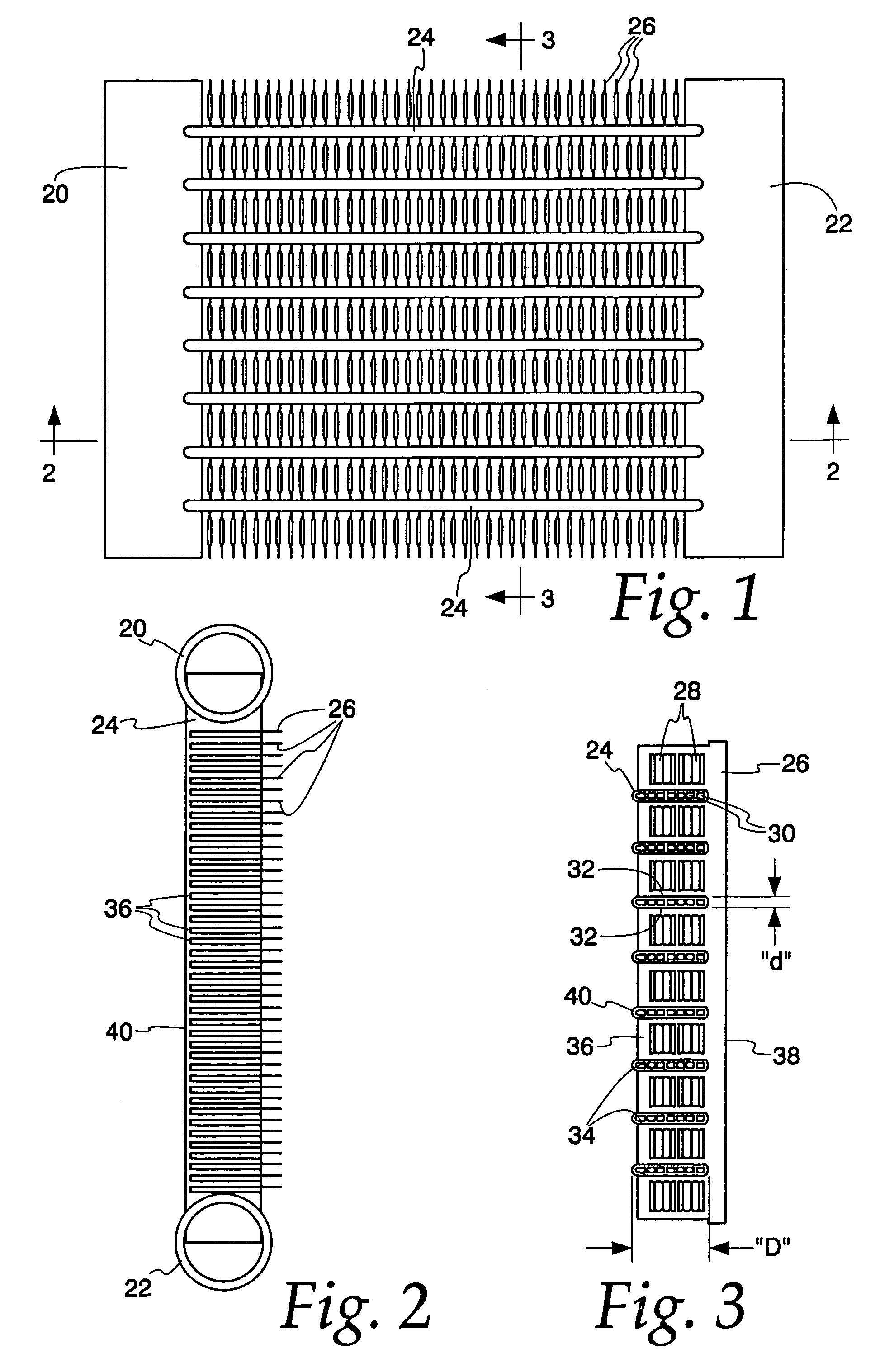

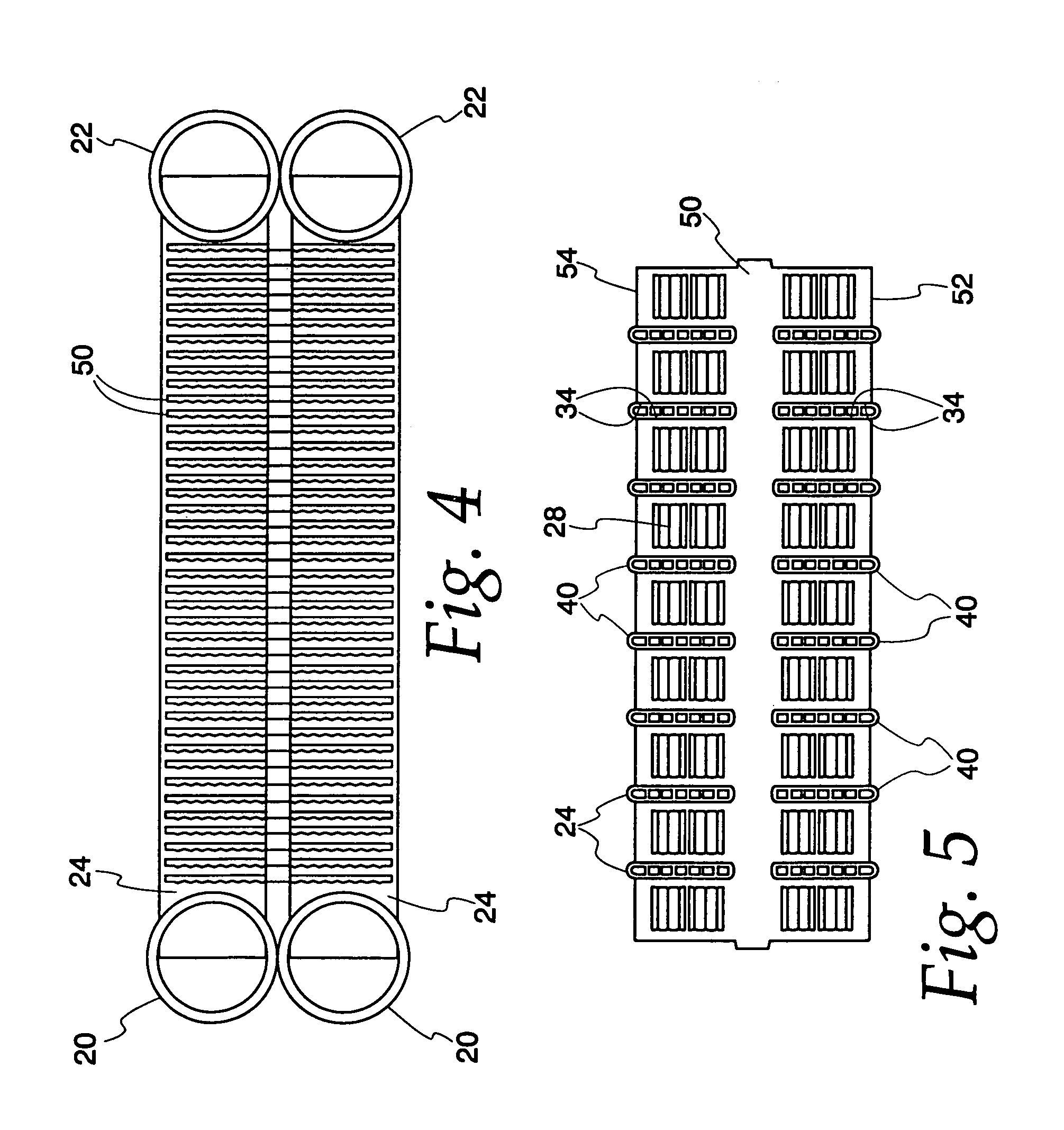

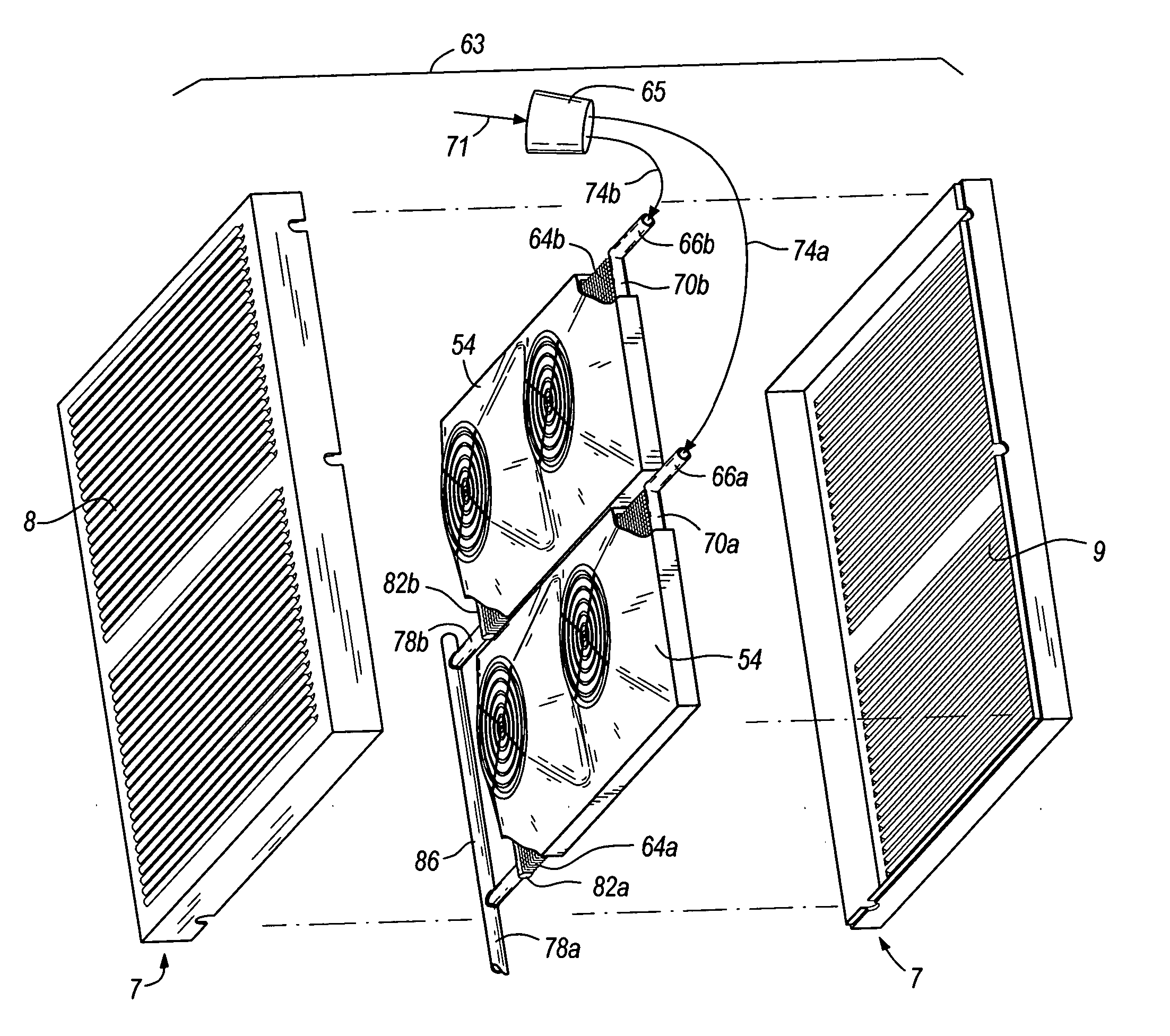

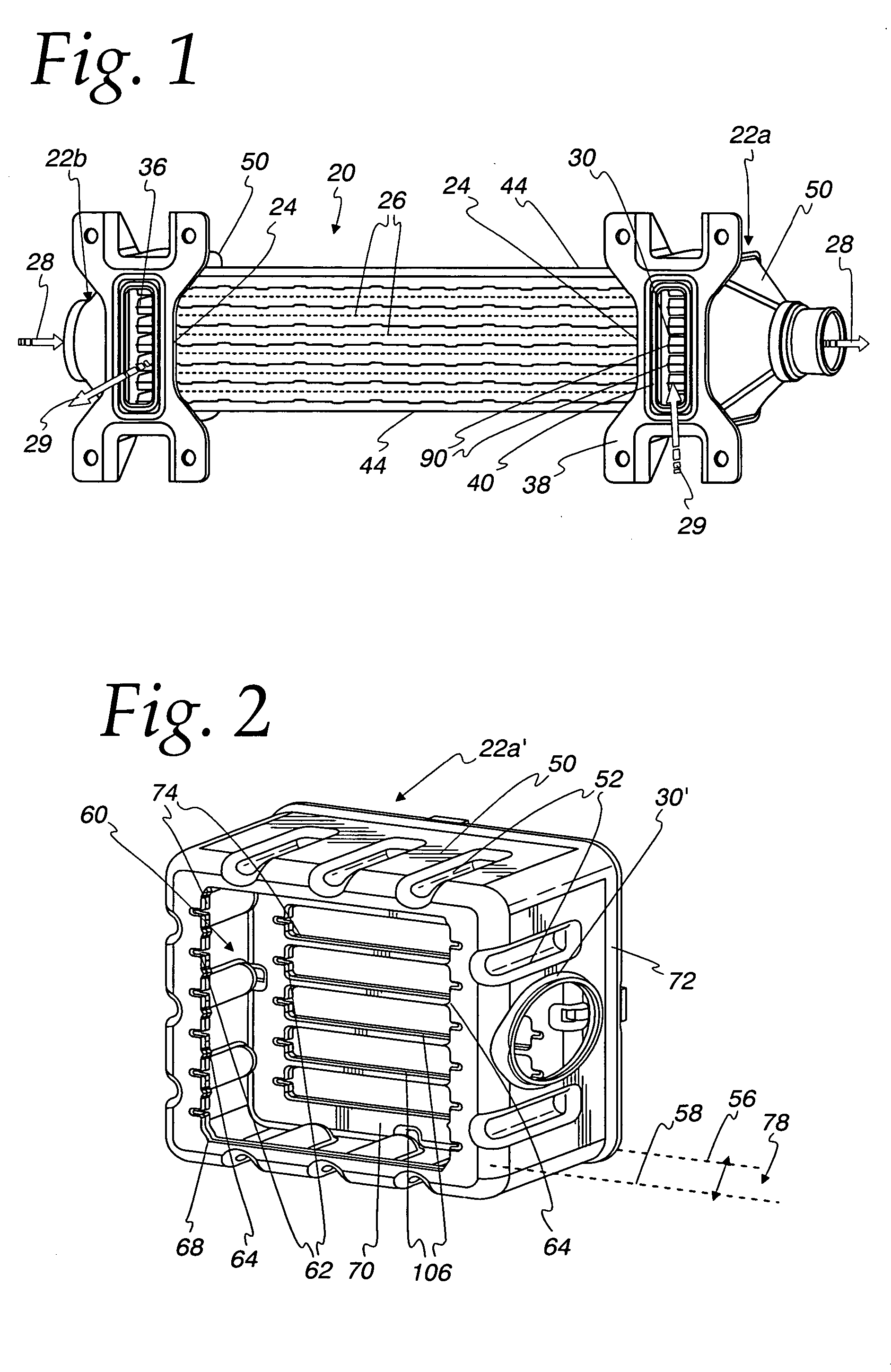

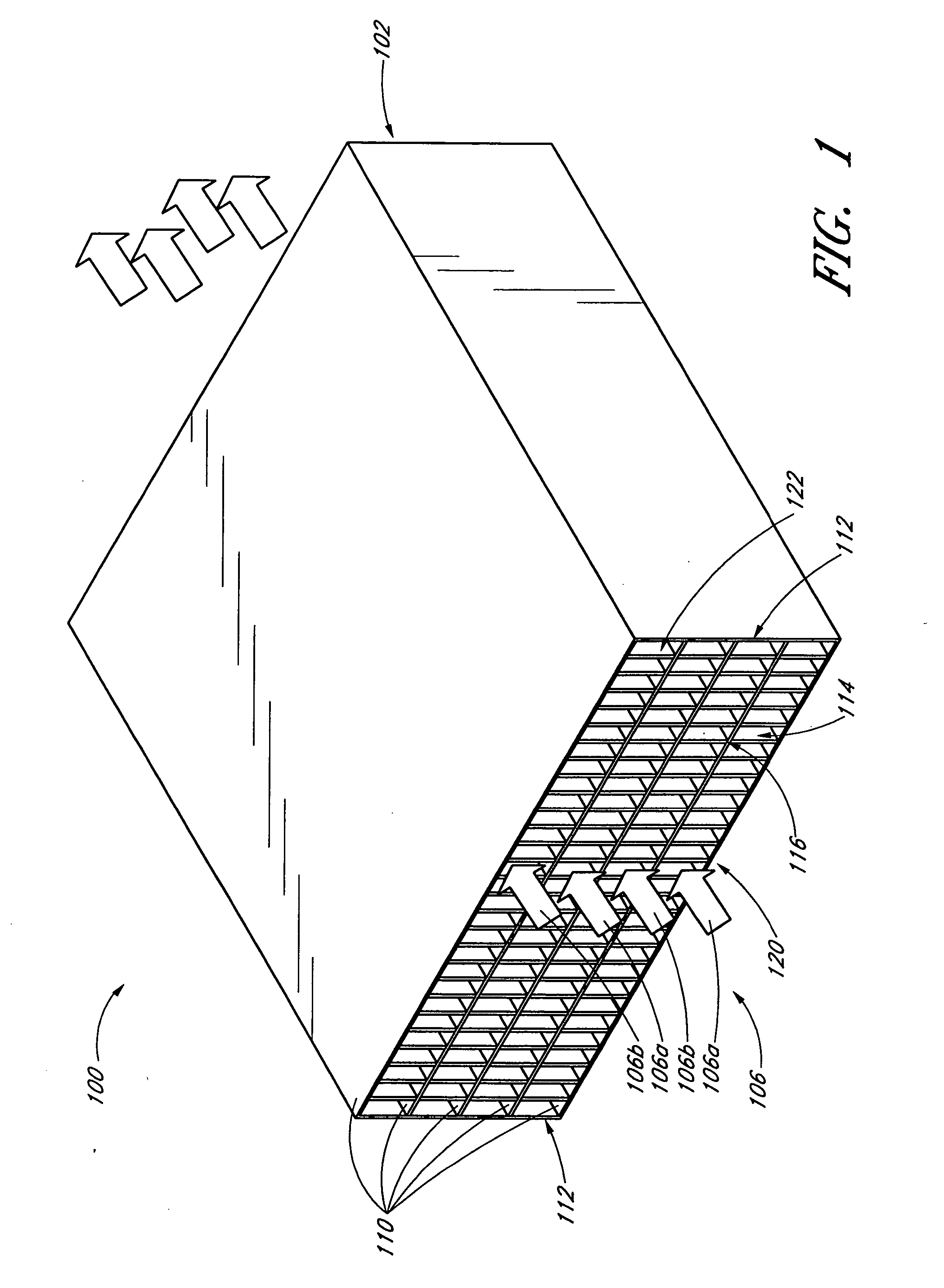

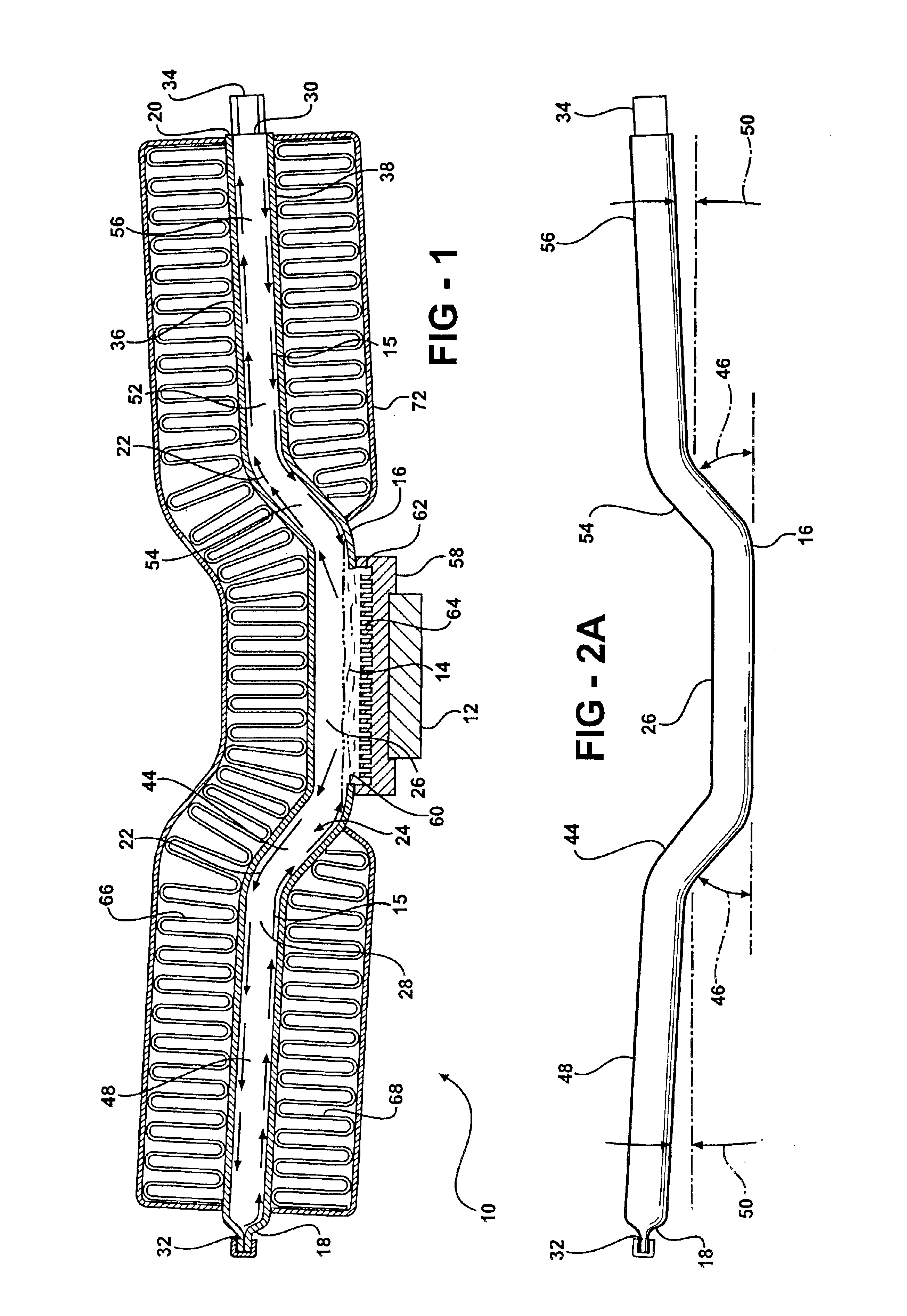

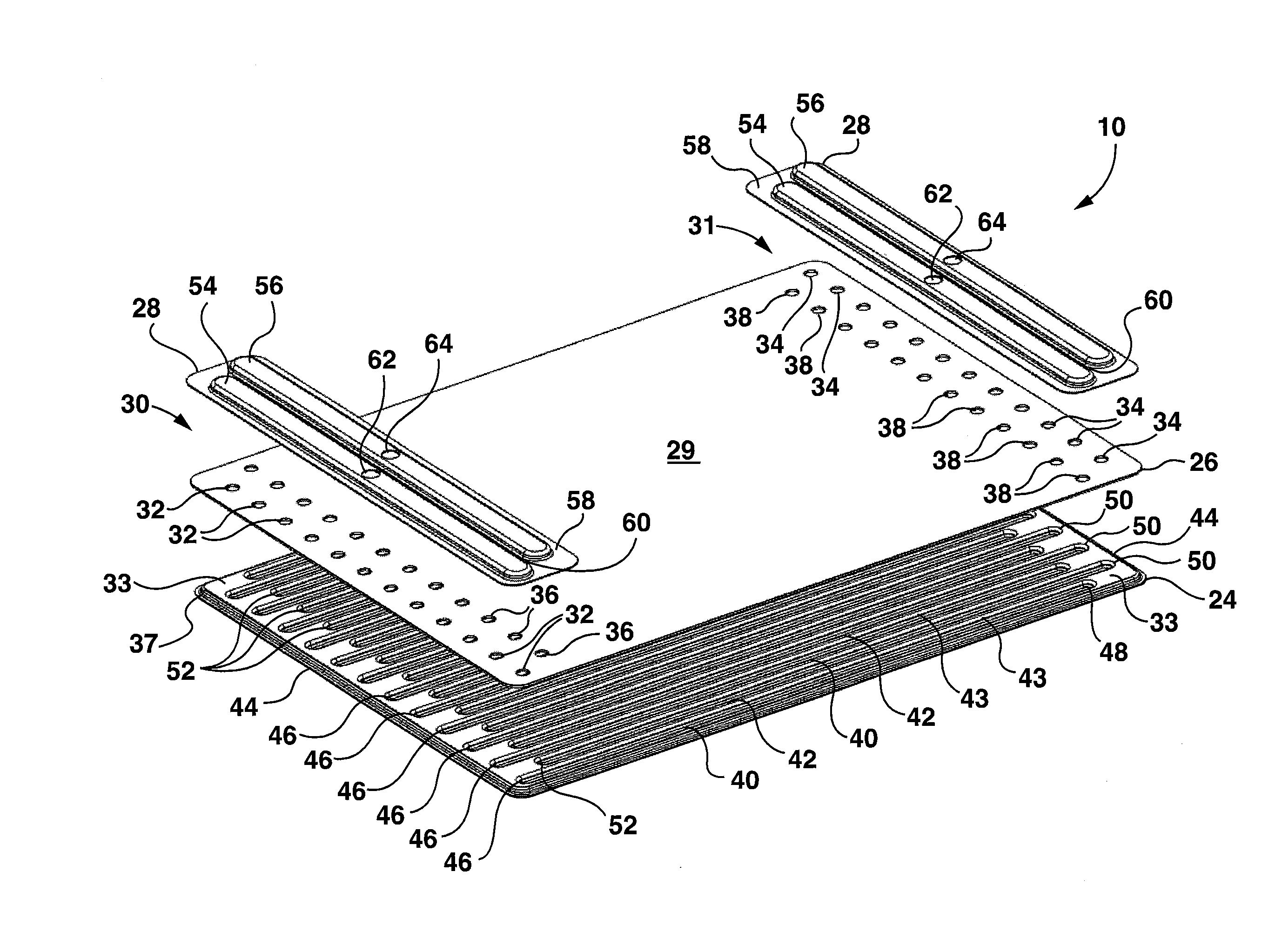

Heat exchanger

InactiveUS6964296B2Eliminate requirementsImprove relationshipSoldering apparatusHeat exhanger finsEngineeringMechanical engineering

Heat exchange inefficiencies found in round tube plate fin heat exchangers are eliminated in an aluminum heat exchanger that includes first and second headers (20), (22) and at least one flattened tube (24), (70) extending between the headers (20), (22). A plurality of generally parallel tube runs are defined and each has opposite edges. A plurality of plate fins (26), (50) are arranged in a stack and each has a plurality of open ended slots (34), one for each run of the tubes (24), (70). Each of the tube runs (24), (70) is nested within corresponding slots (26) and the fins (26), (50) with one of the edges (40) of the tube runs extending outwardly of the corresponding fin (34). The assembly is brazed together.

Owner:MODINE MFG CO

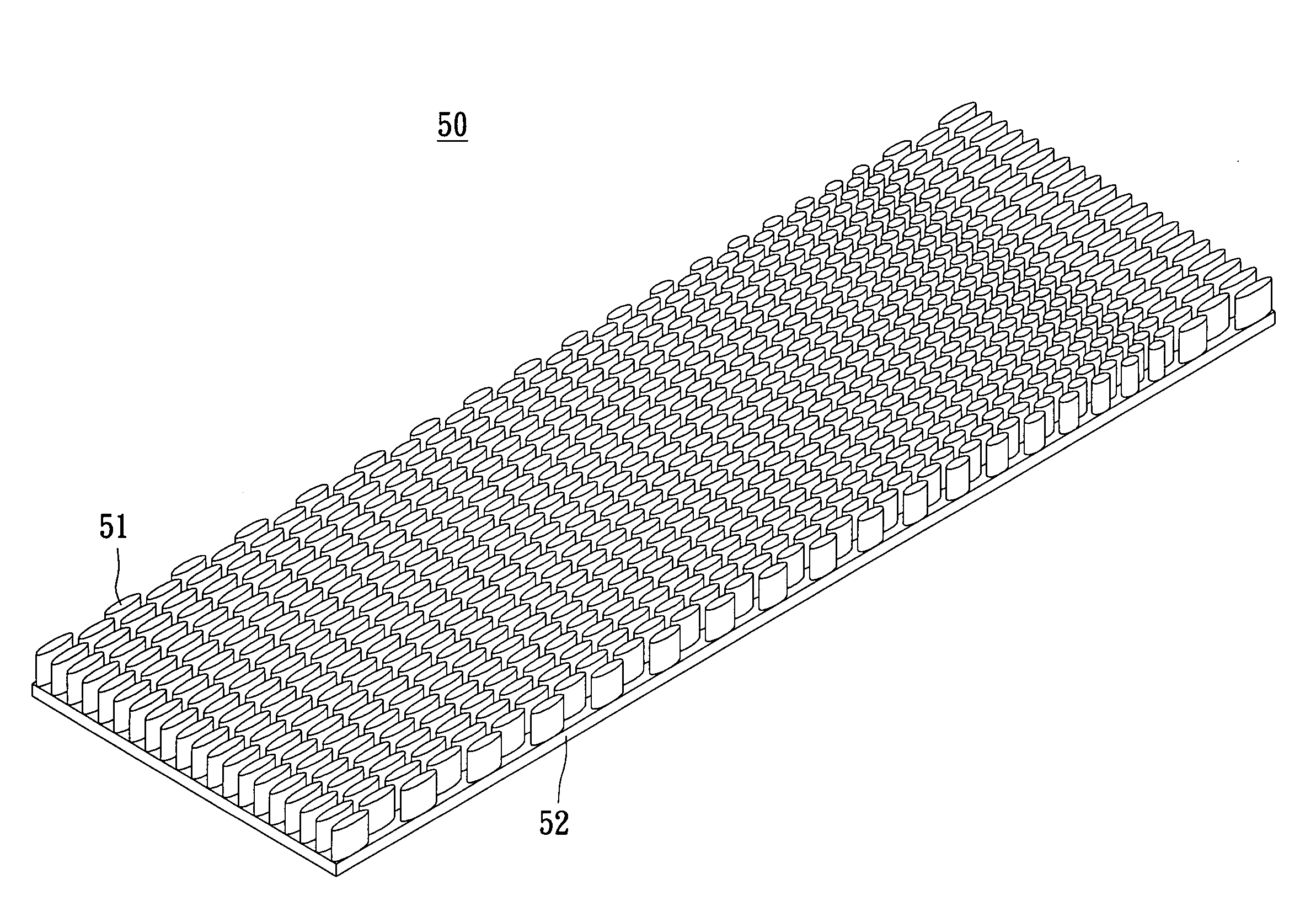

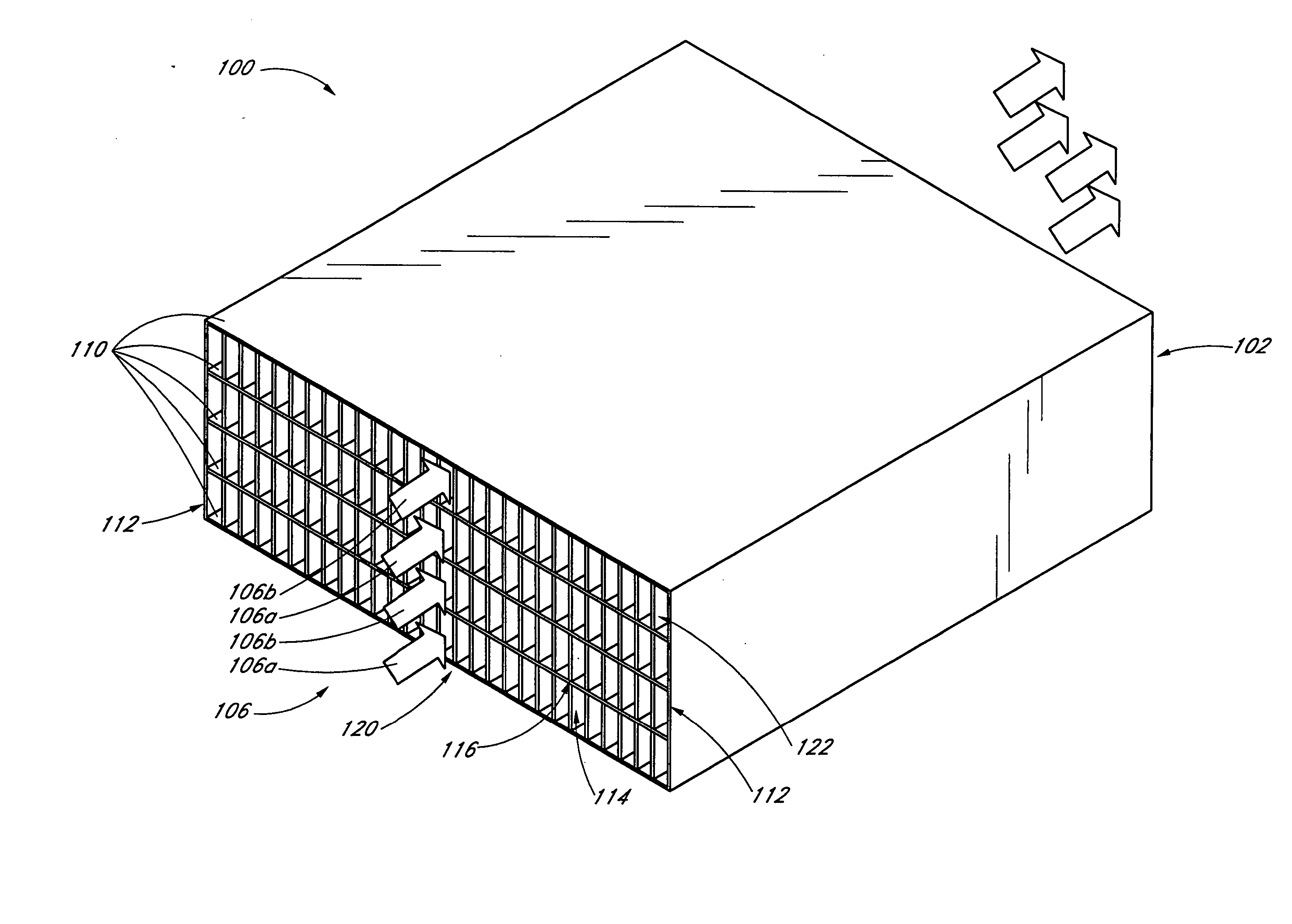

Non-linear fin heat sink

InactiveUS20090145581A1Improve power densityDissipating/removing heatSemiconductor/solid-state device detailsSolid-state devicesCoolant flowEngineering

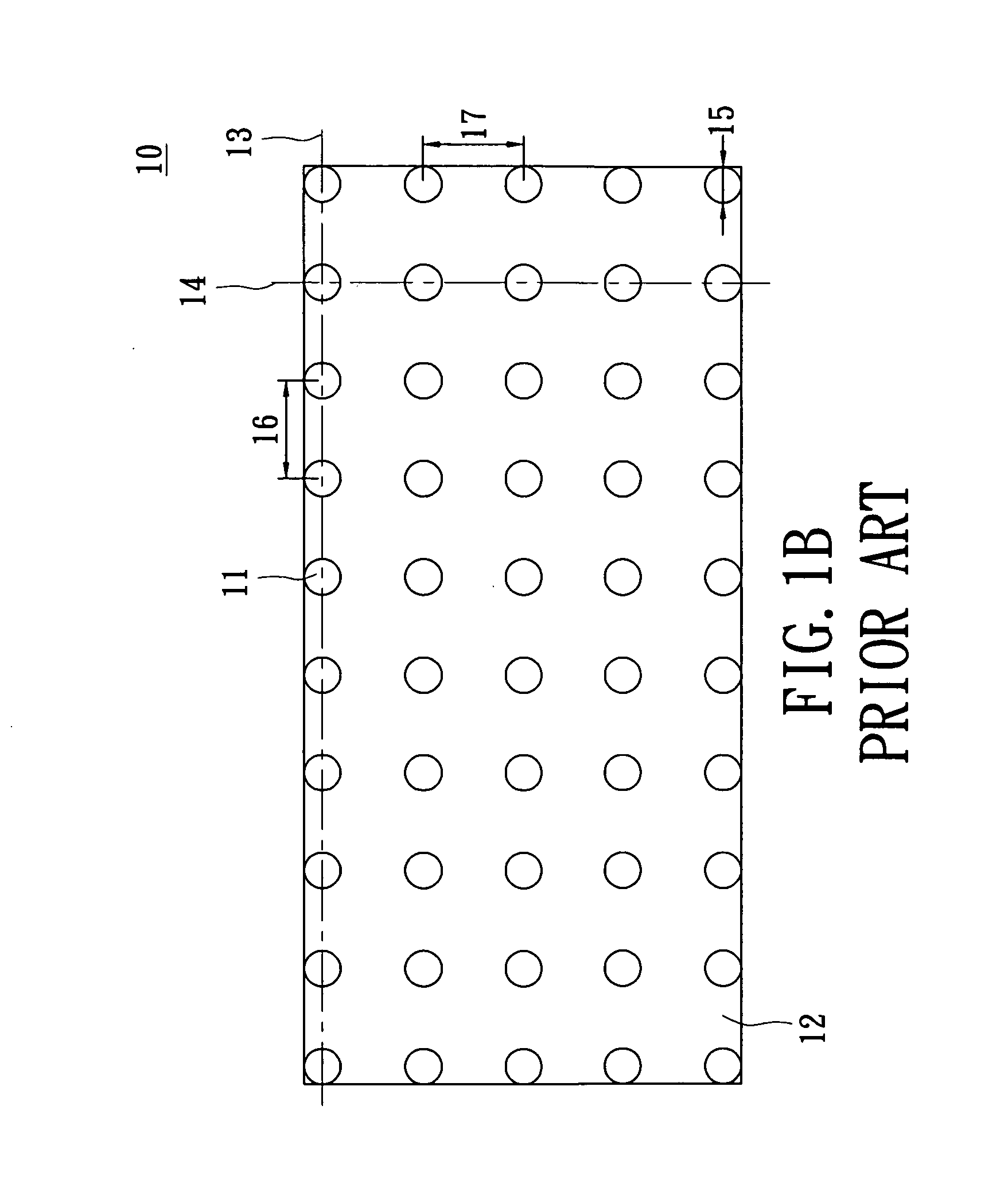

A non-linear fin heat sink is provided for dissipating / removing heat uniformly from a device, where the heat generation is non-uniform over that device, while also providing a small and relatively lightweight heat sink. The heat sink has extended surface protrusions that are optimally shaped in recognition of convective heat transfer, conductive heat transfer, and flow resistance allowing the heat sink to offset the temperature rise of a coolant media and provide enhanced cooling for the coolant temperature, deliver optimized cooling efficiency per the local physical properties of the coolant media, be used with a fluid for effectuating heat transfer; either liquid coolant, gas coolant or a combination thereof. Furthermore the heat sink features turbulence enhancement of the coolant stream by a pin array through which coolant stream passes, such fin array featuring a non-linear shape, spacing, and height pattern to provide optimal cooling while simultaneously reducing volume and flow resistance.

Owner:THERMAL TECH

Automotive lighting assembly cooling system

InactiveUS6910794B2Point-like light sourceLighting heating/cooling arrangementsMobile vehicleEffect light

An automotive lighting assembly cooling system includes a heat pipe with an evaporation area proximate to a heat generating component, such as a Light Emitting Diode (LED), and a condensing area located remote from the evaporation area. Evaporation of fluid within the heat pipe transfers heat away from the heat generating component. The efficiency of the cooling system in one embodiment is increased by including fins associated with the condensing area and placing the fins in an area where air flow external to a moving vehicle assists in cooling the fins.

Owner:GUIDE

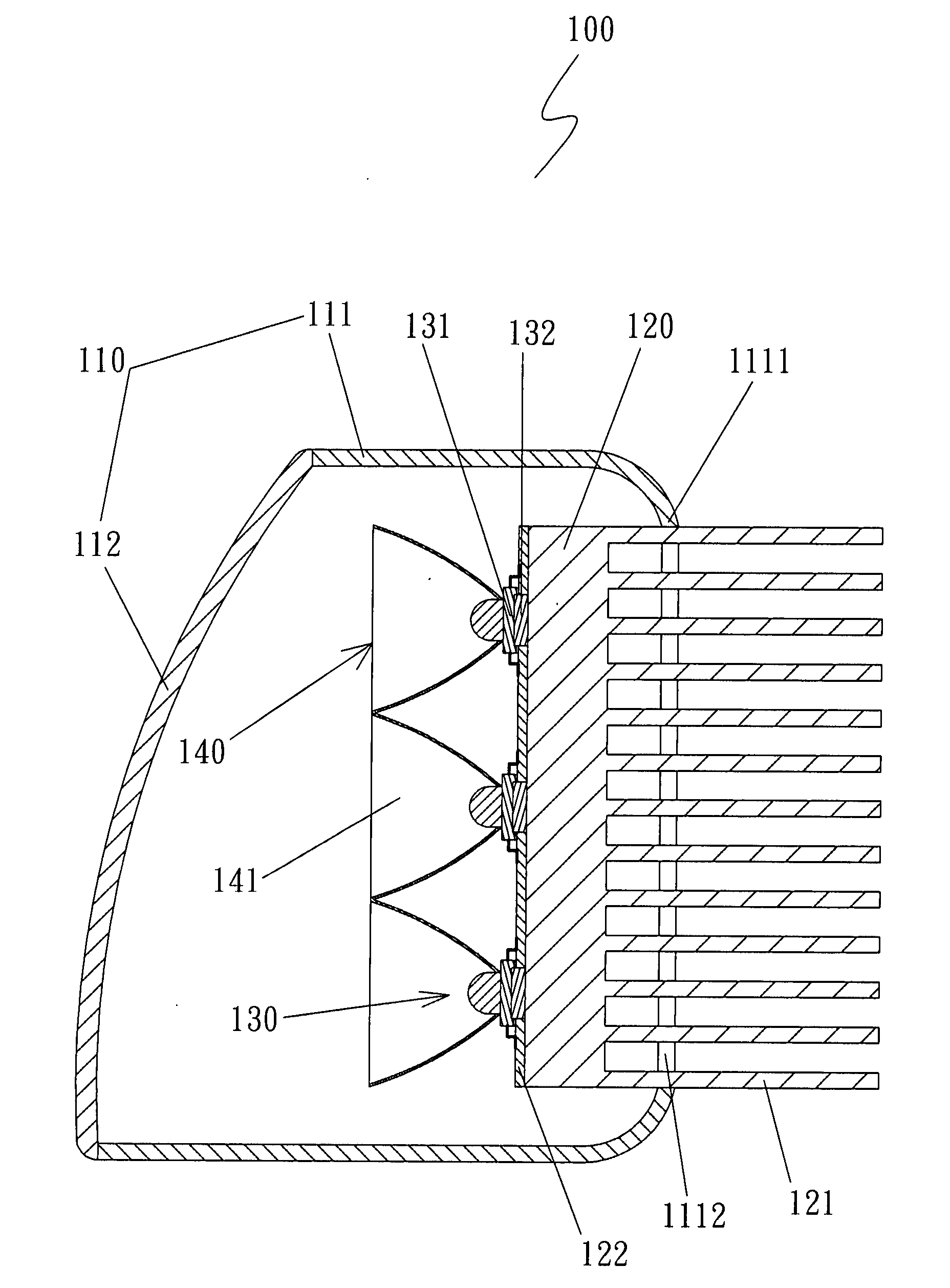

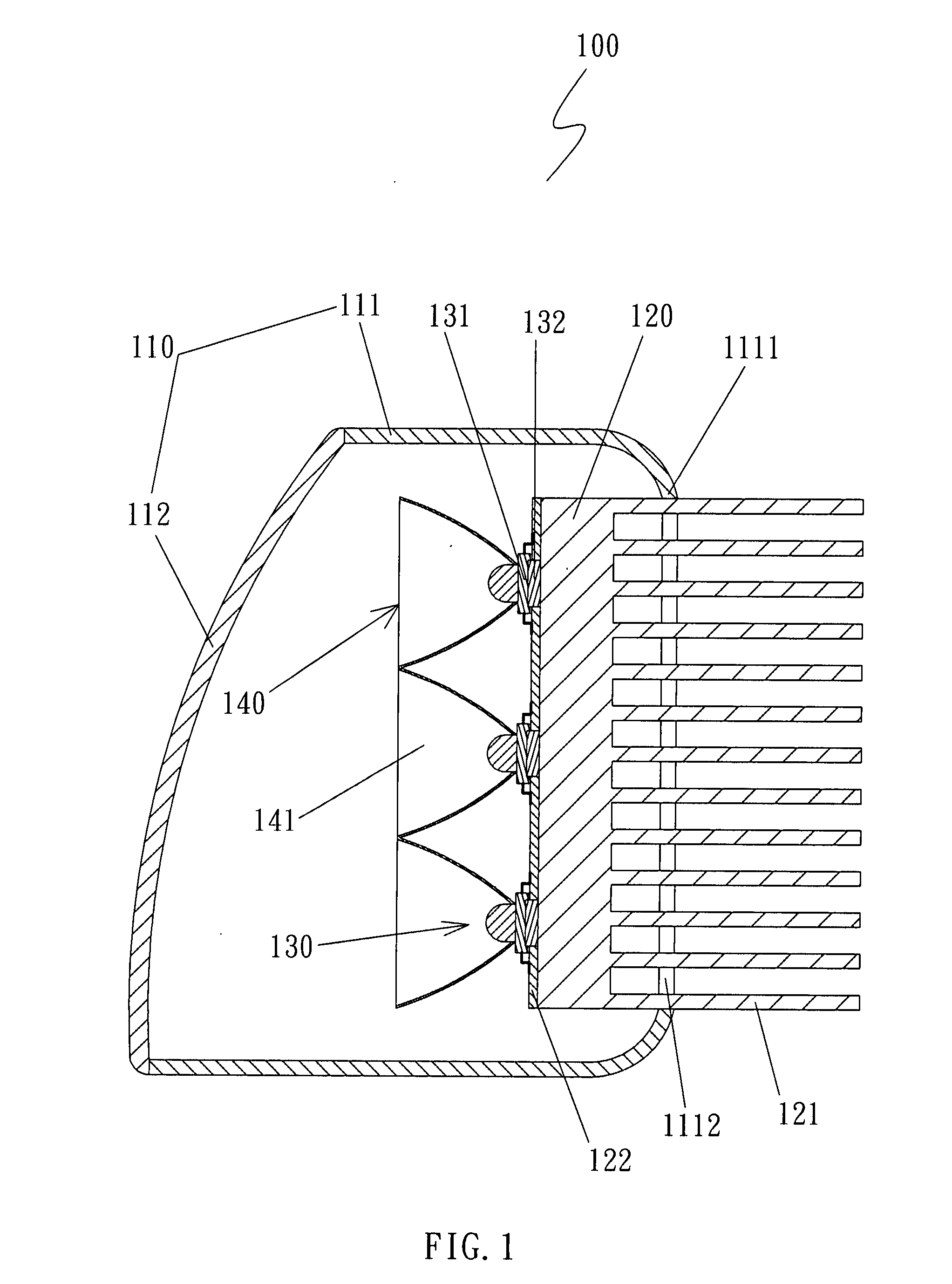

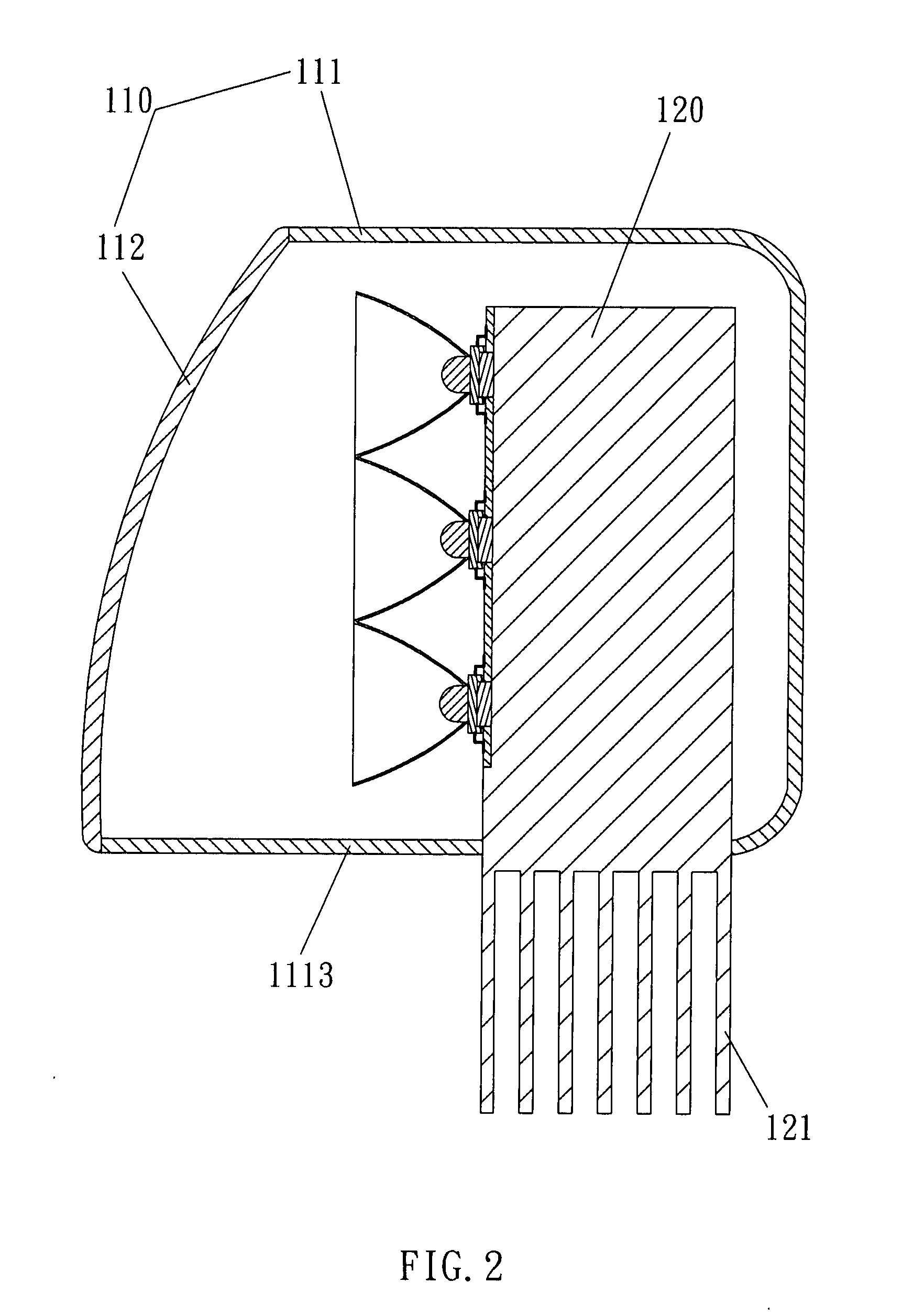

Heat dissipating apparatus for automotive LED lamp

InactiveUS20090059594A1Reduce the temperatureAvoid overall overheatingVehicle headlampsPoint-like light sourceCold airThermal energy

In a heat dissipating apparatus for an automotive LED lamp, the automotive LED lamp includes an automotive lamp set, a heat dissipating module, a plurality of LEDs, and a reflecting unit. The heat dissipating module is wrapped to form an insulation circuit for separating heat energy and electric power of the insulation circuit and heat dissipating module. The LED is electrically connected to the insulation circuit, and a main base of the LED installs a metal conducting plate for conducting the heat produced by the LED to the heat dissipating module. The reflecting unit is installed in the automotive lamp set, so that the heat dissipating module can use a cold air or a liquid coolant as the heat dissipating medium for dissipating heat, preventing a drop of light output caused by an overheat, and avoiding damages to the LED to extend the life expectancy of the automotive LED lamp.

Owner:YIH IND

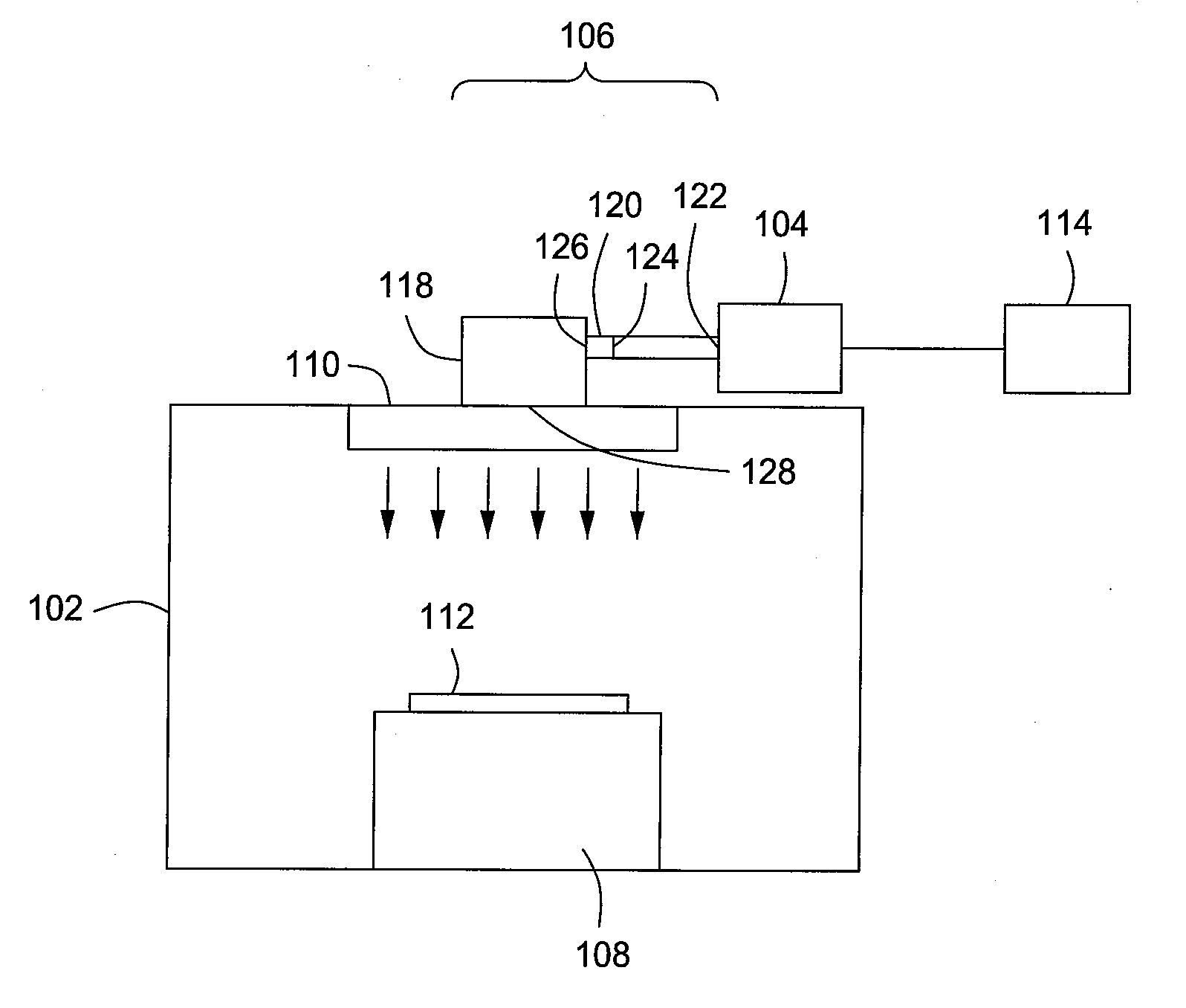

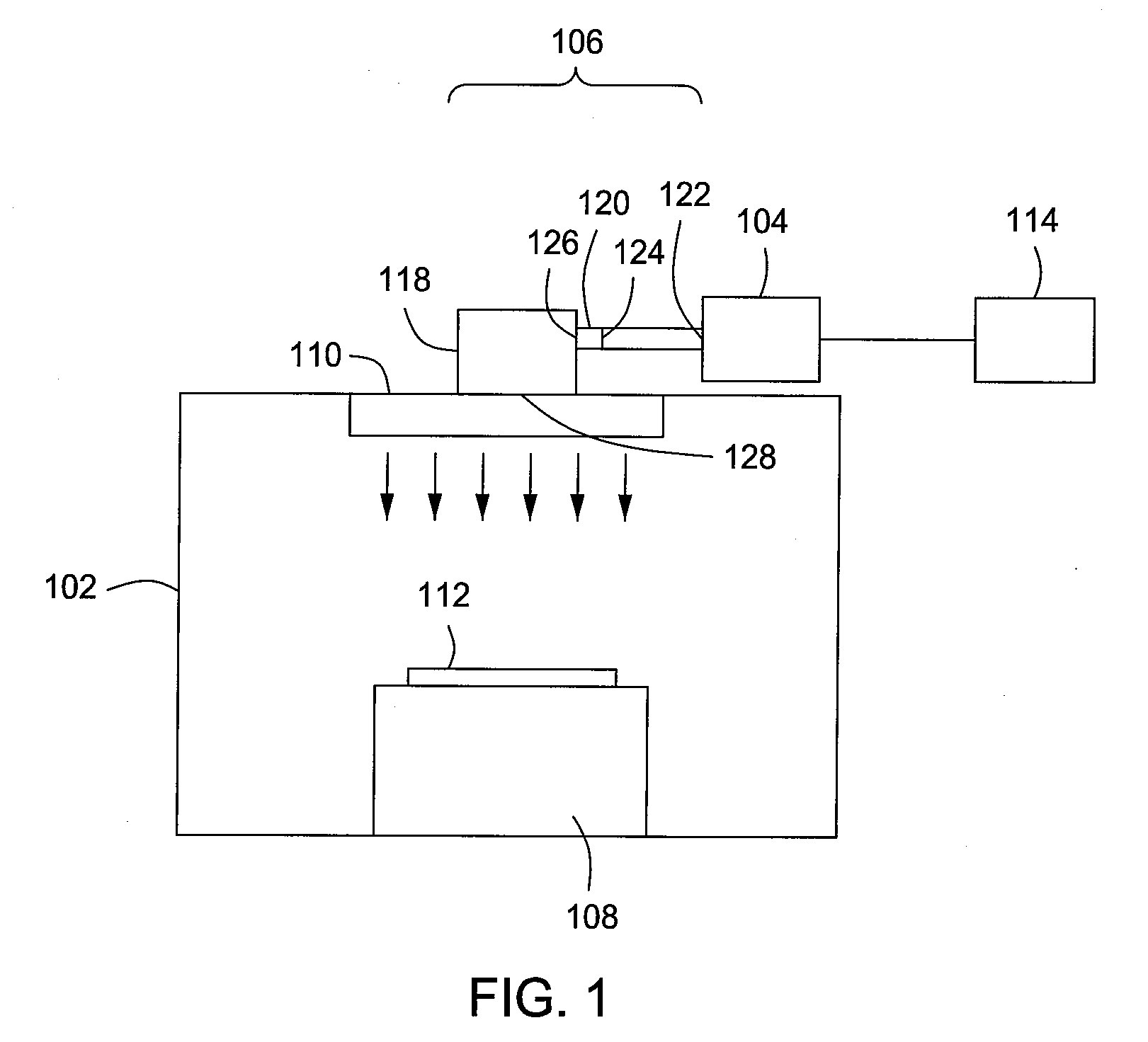

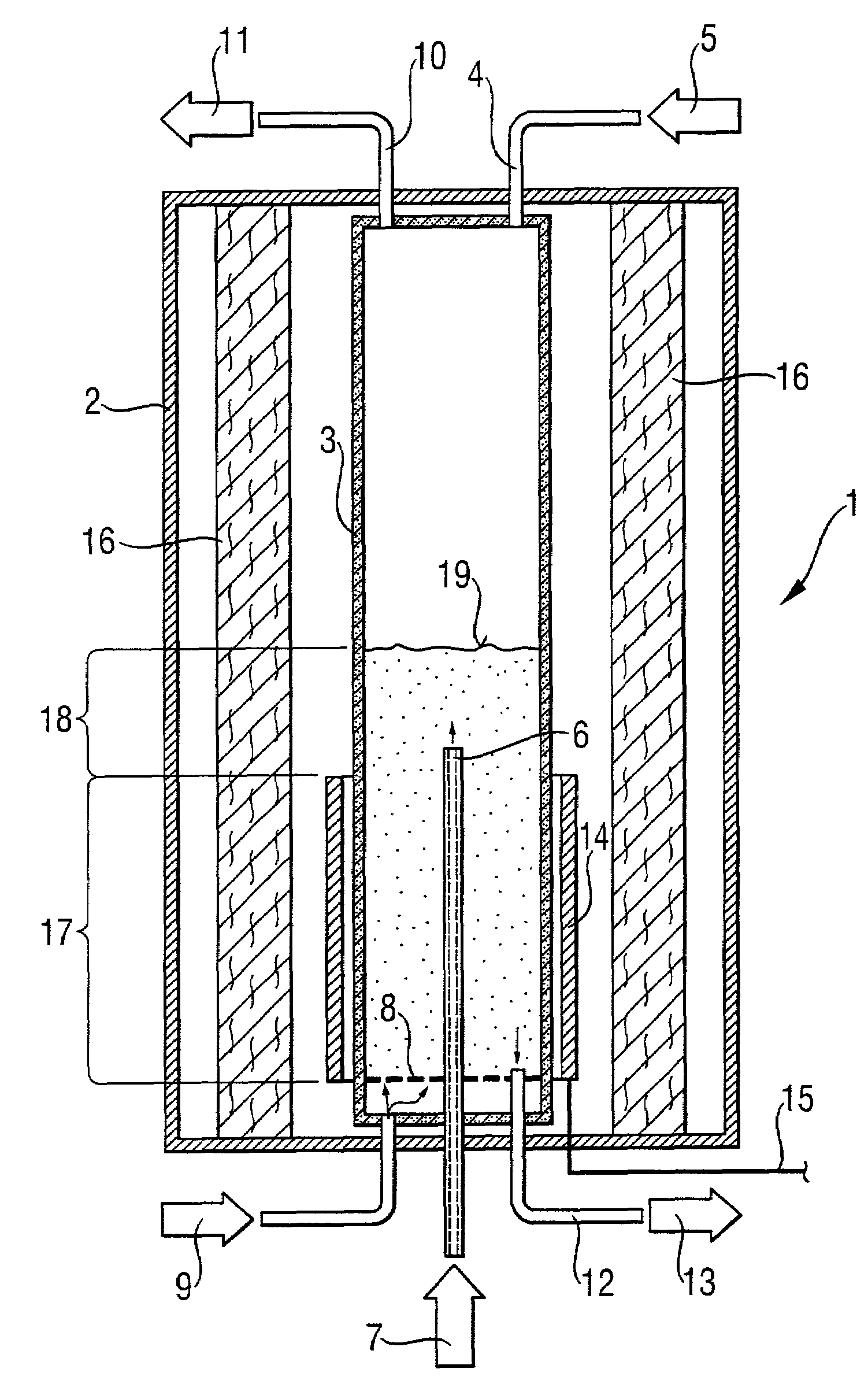

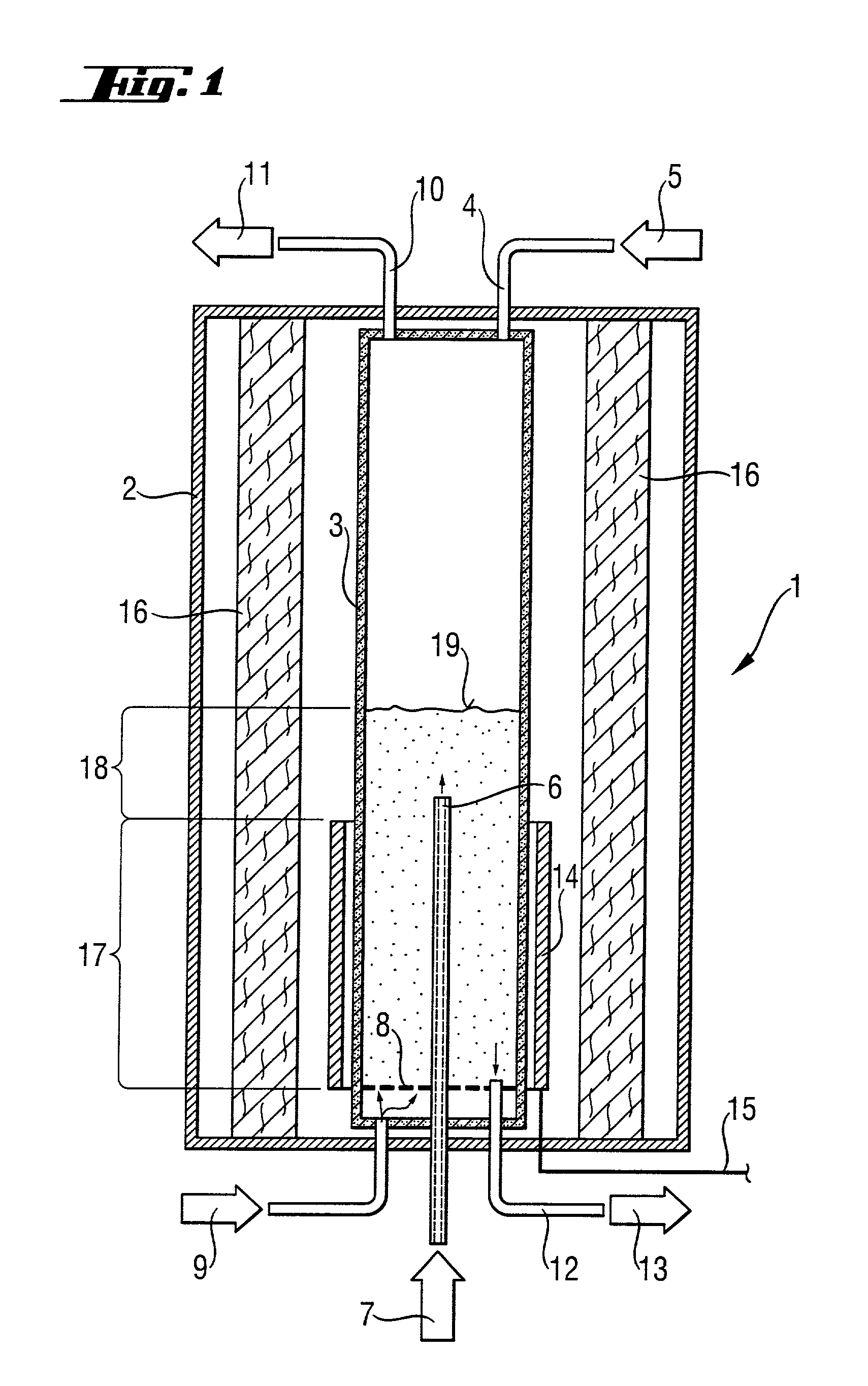

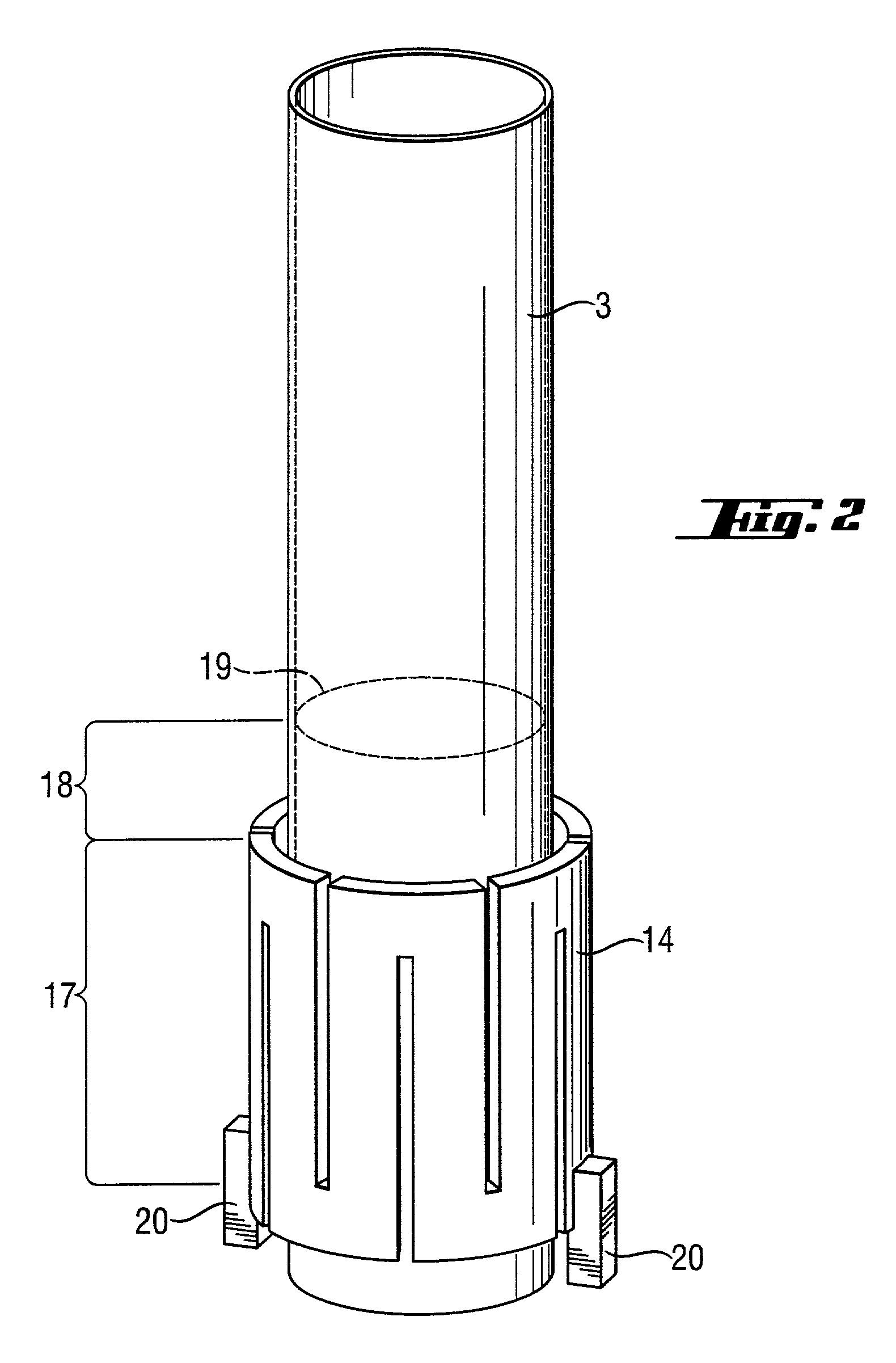

Radiation-heated fluidized-bed reactor

InactiveUS7029632B1Low levelHigh puritySiliconFluidised-bed furnacesFluidized bedReaction temperature

A radiation-heated fluidized-bed reactor and a process for producing high-purity polycrystalline silicon by using this reactor are provided. In this reactor, a heater device (14) is a radiation source for thermal radiation which is arranged outside the inner reactor tube and as a cylinder around the heater zone, without being in direct contact with the inner reactor tube. The inner reactor tube is designed in such a manner that it uses thermal radiation to heat the silicon particles in the heating zone to a temperature which is such that the reaction temperature is established in the reaction zone.

Owner:WACKER CHEM GMBH

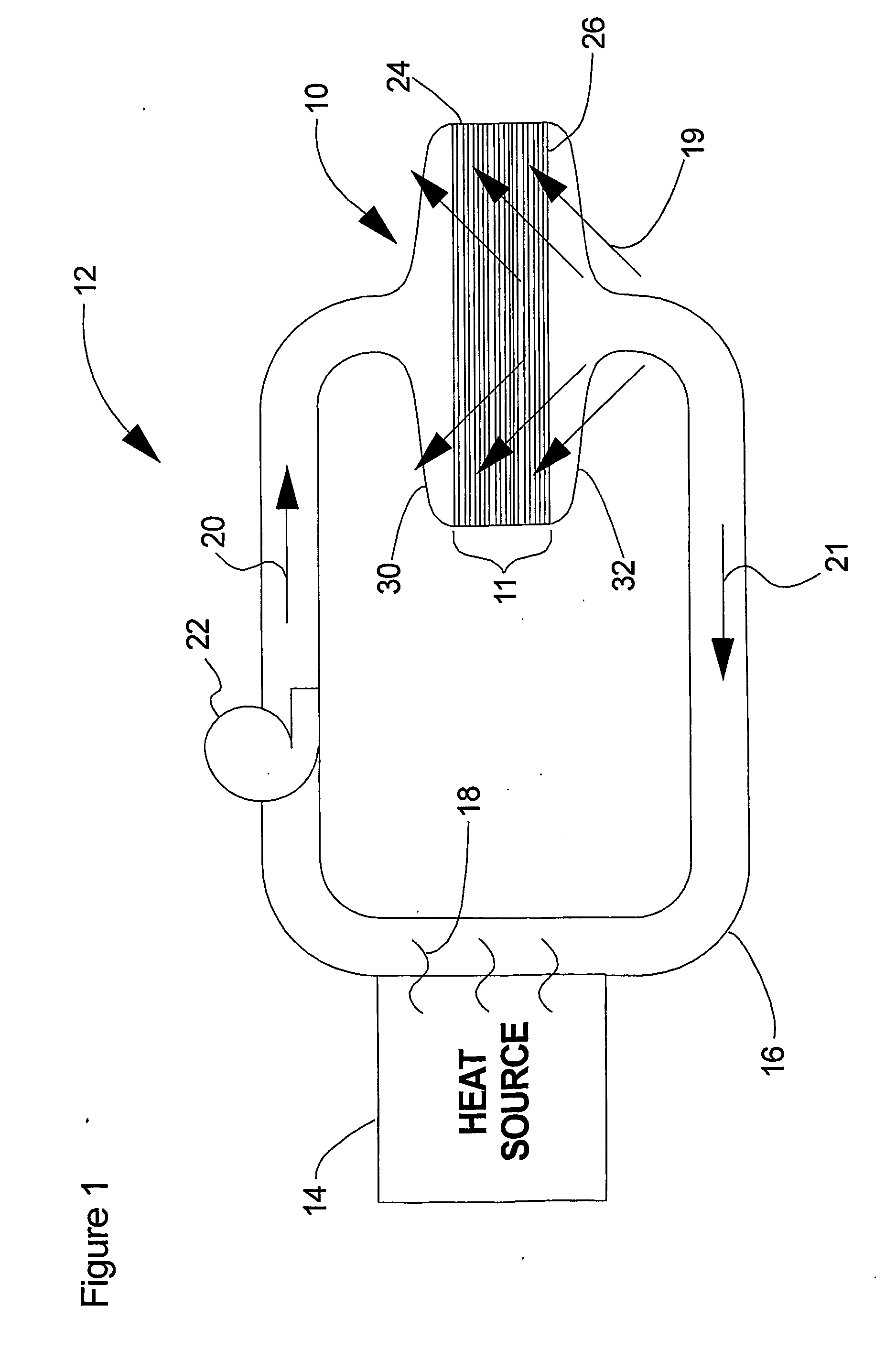

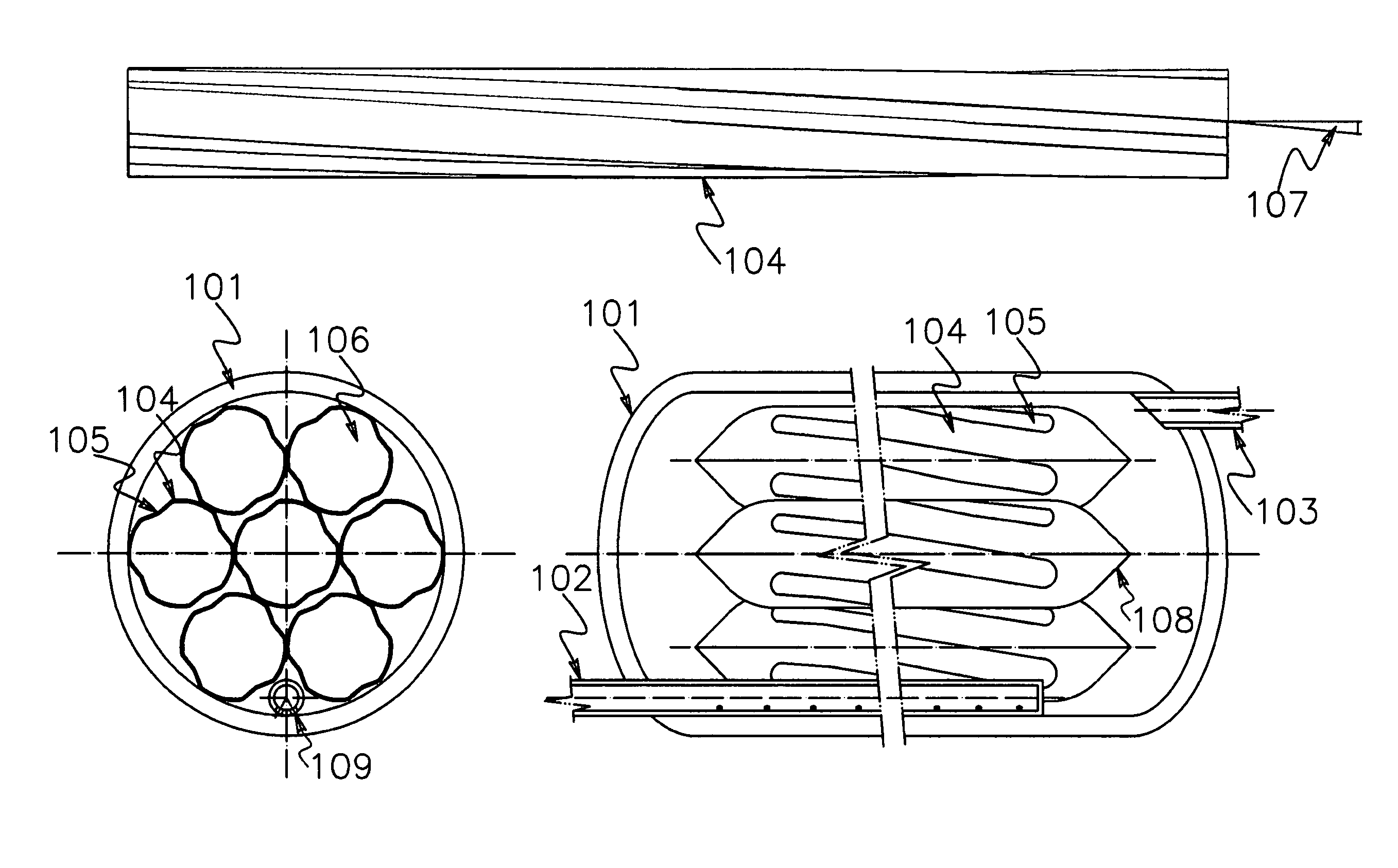

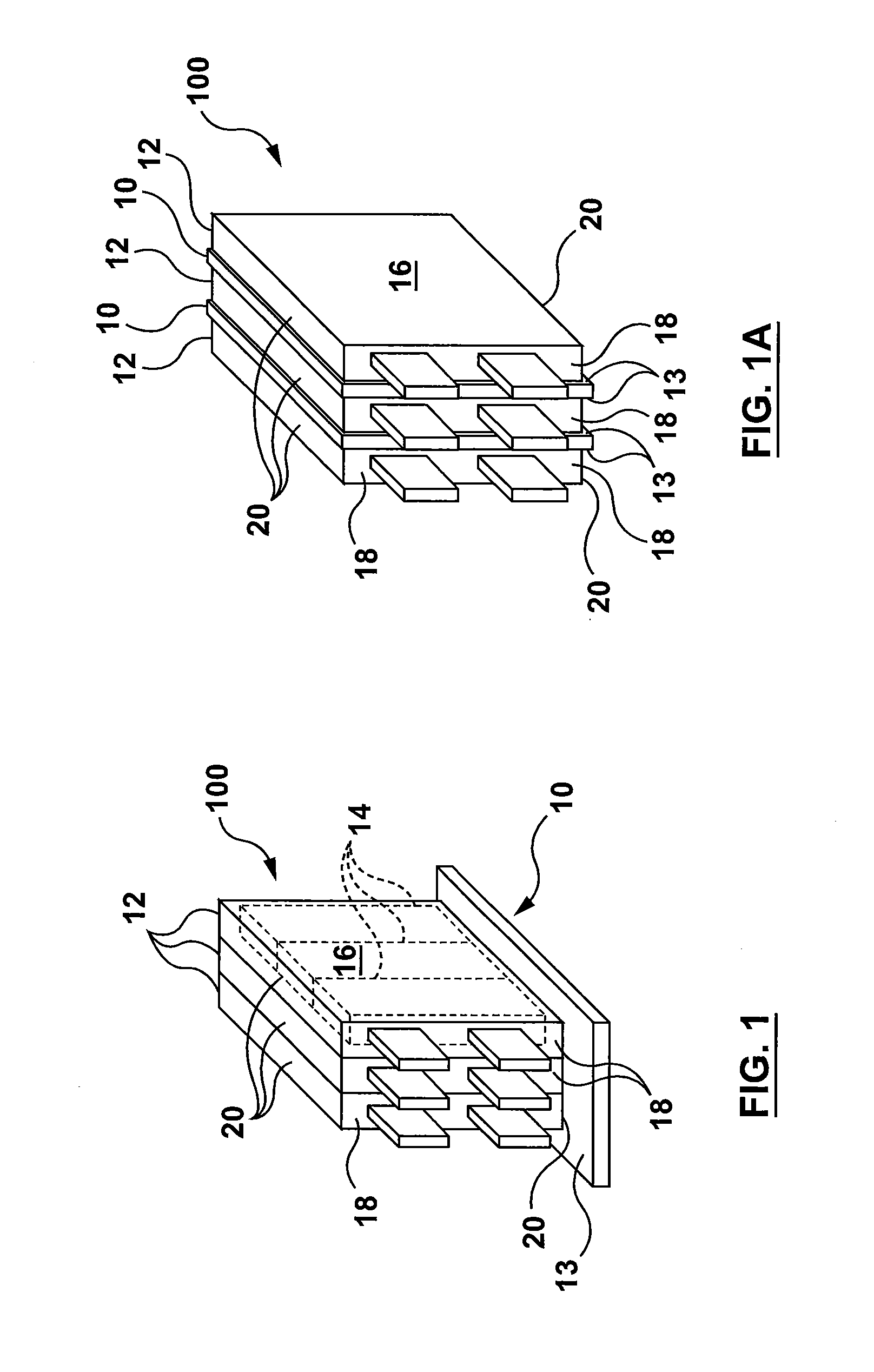

Carbon nanotube heat-exchange systems

InactiveUS20040194944A1Stationary conduit assembliesHeat transfer modificationCarbon nanotubeCooling fluid

A carbon nanotube heat-exchange system (10) and method for producing the same. One embodiment of the carbon nanotube heat-exchange system (10) comprises a microchannel structure (24) having an inlet end (30) and an outlet end (32), the inlet end (30) providing a cooling fluid into the microchannel structure (24) and the outlet end (32) discharging the cooling fluid from the microchannel structure (24). At least one flow path (28) is defined in the microchannel structure (24), fluidically connecting the inlet end (30) to the outlet end (32) of the microchannel structure (24). A carbon nanotube structure (26) is provided in thermal contact with the microchannel structure (24), the carbon nanotube structure (26) receiving heat from the cooling fluid in the microchannel structure (24) and dissipating the heat into an external medium (19).

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

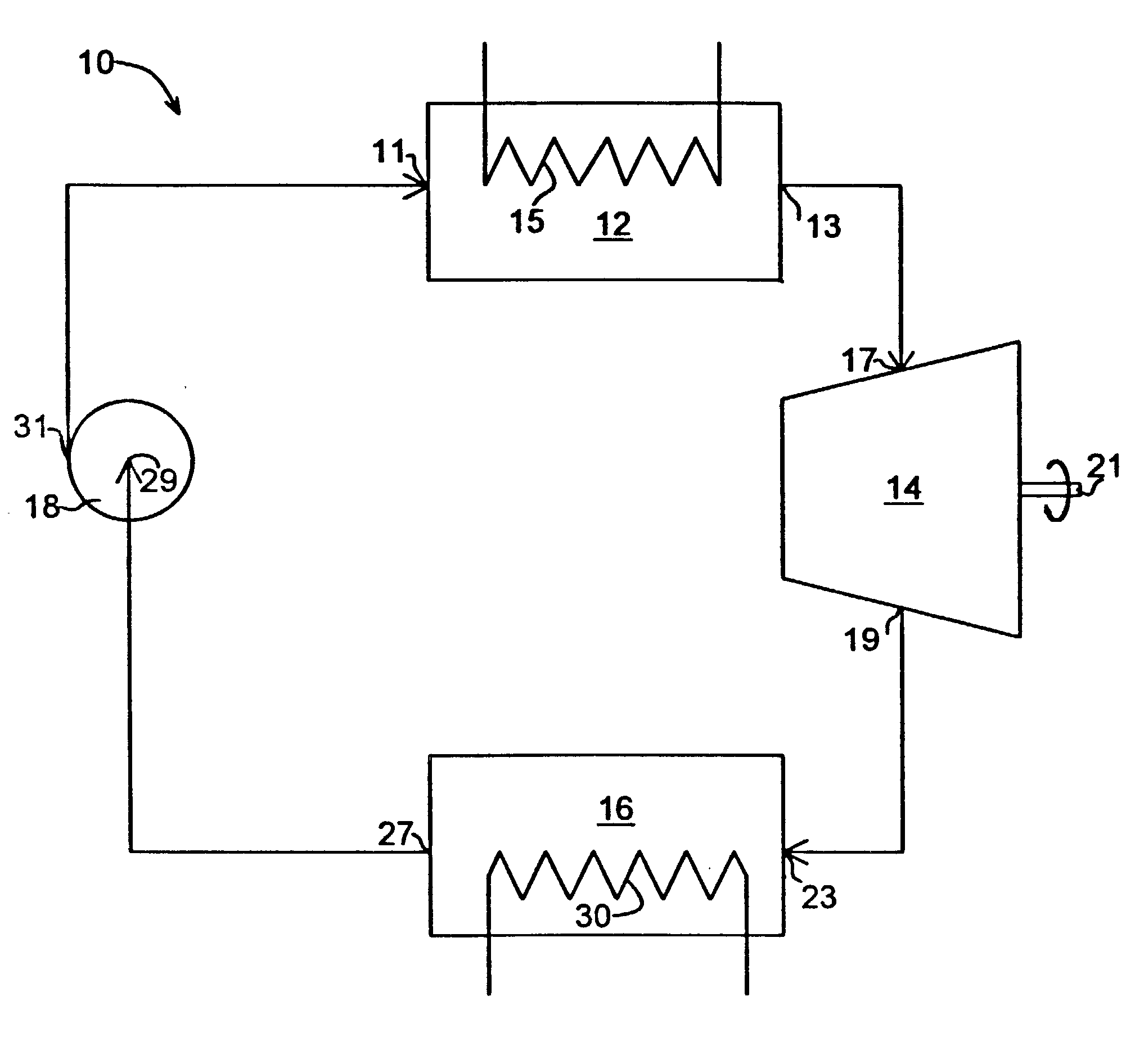

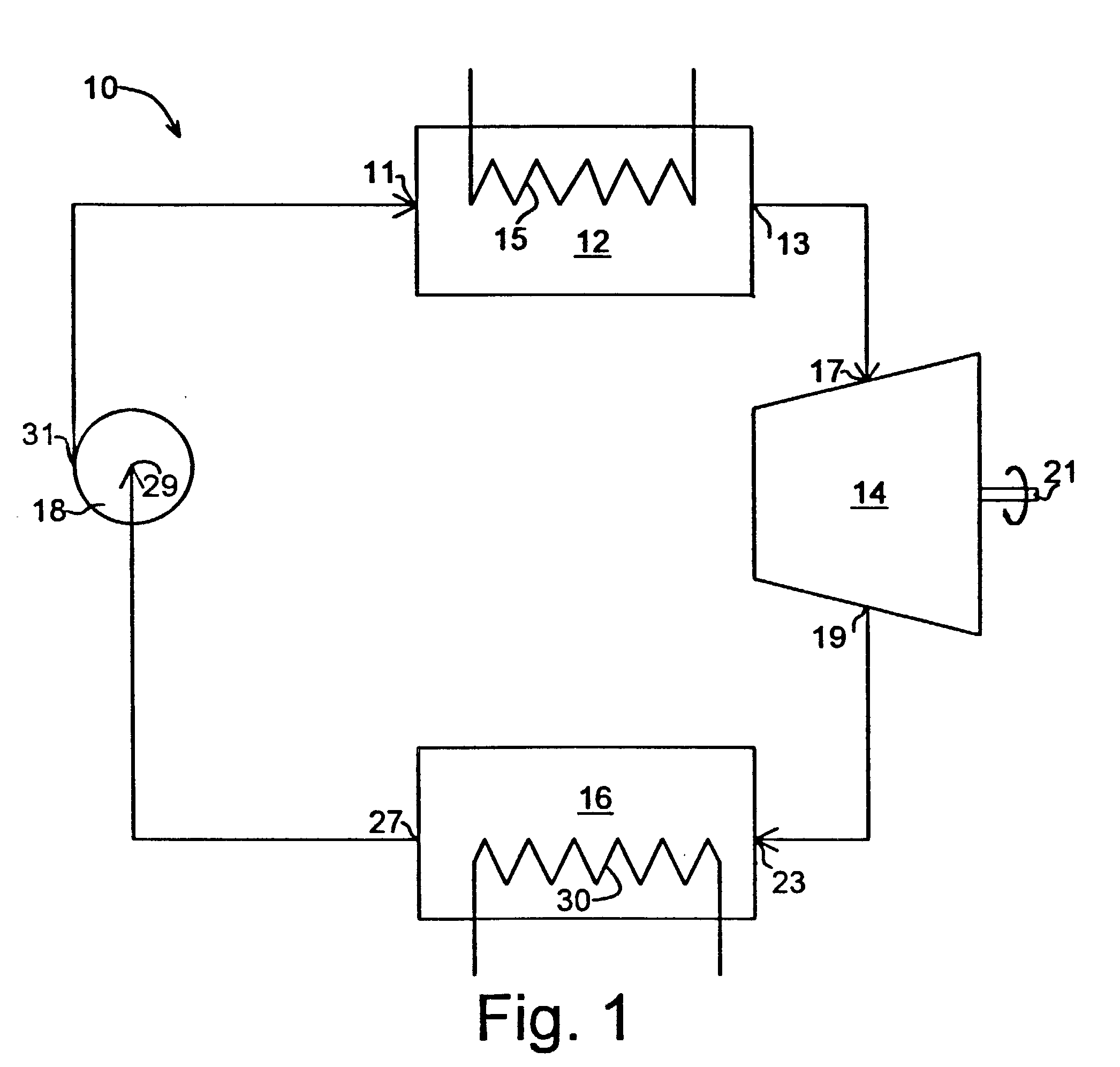

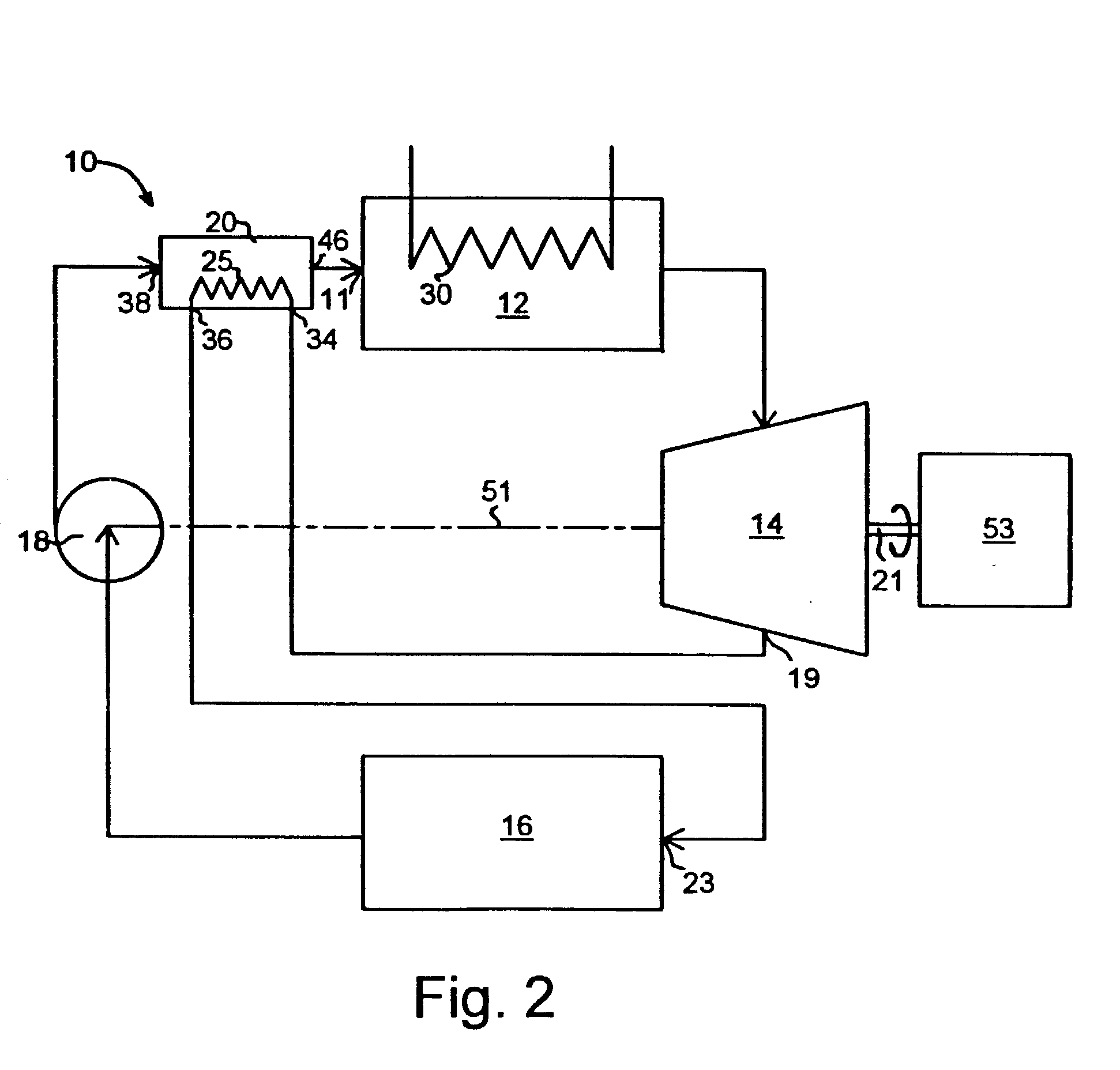

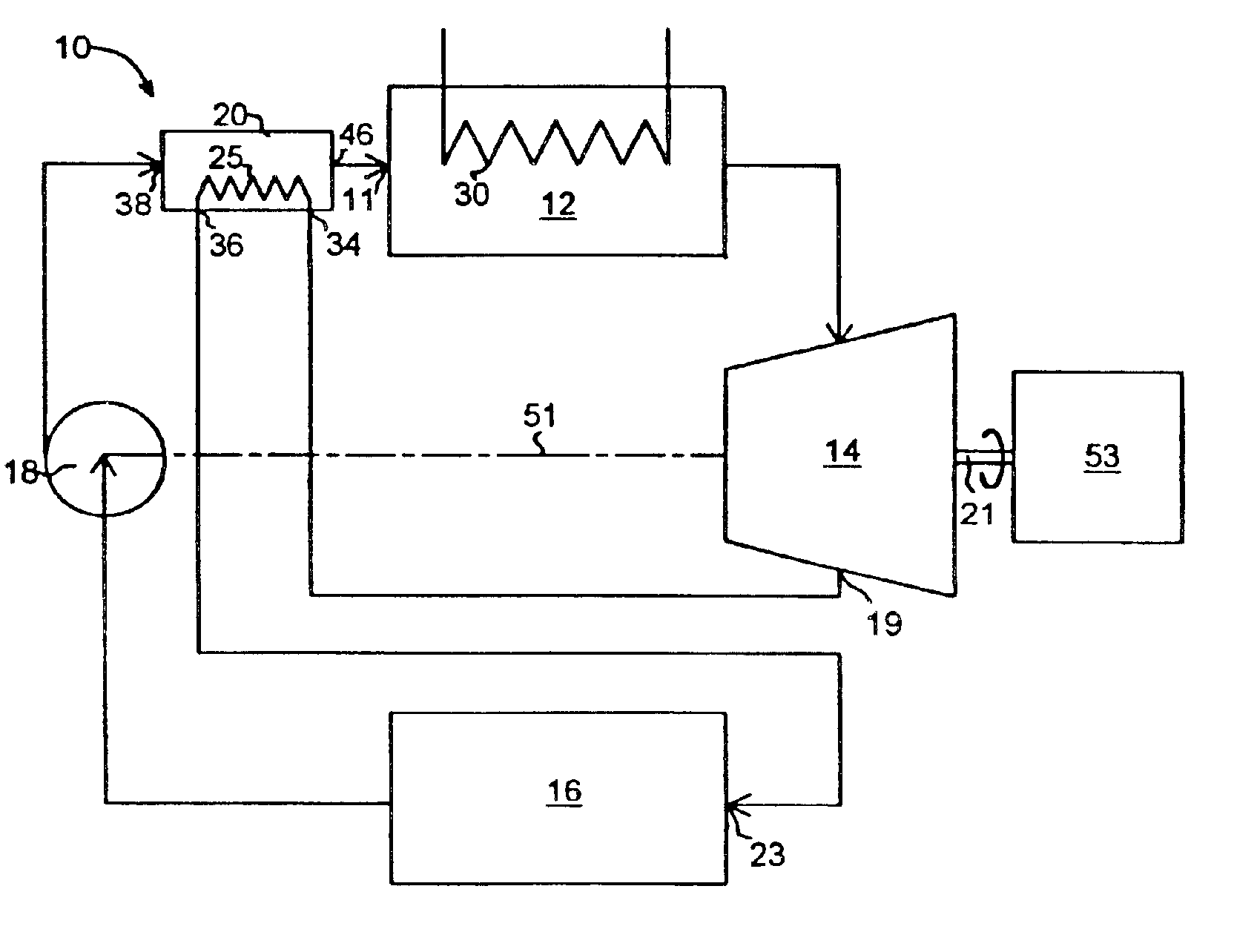

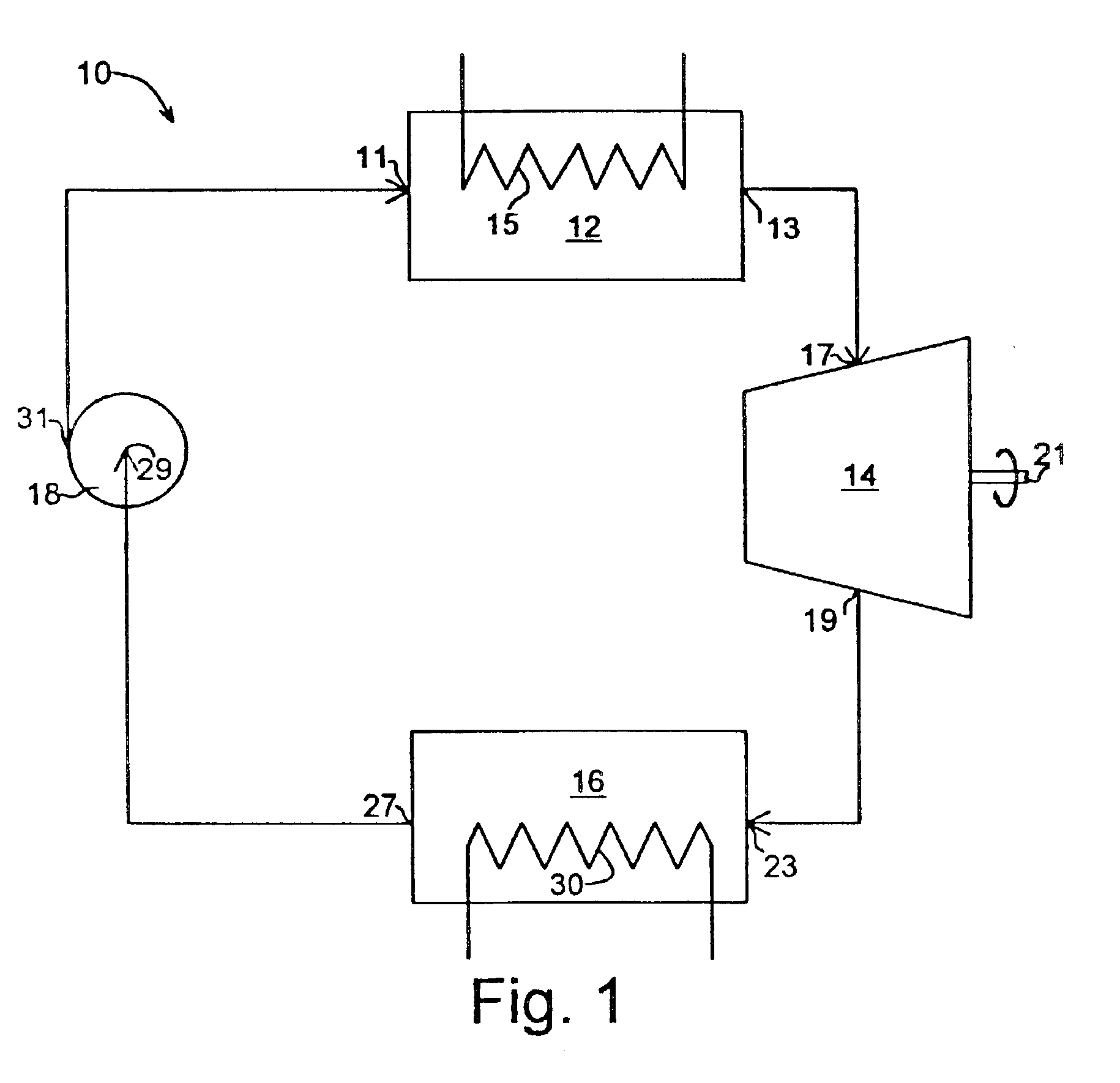

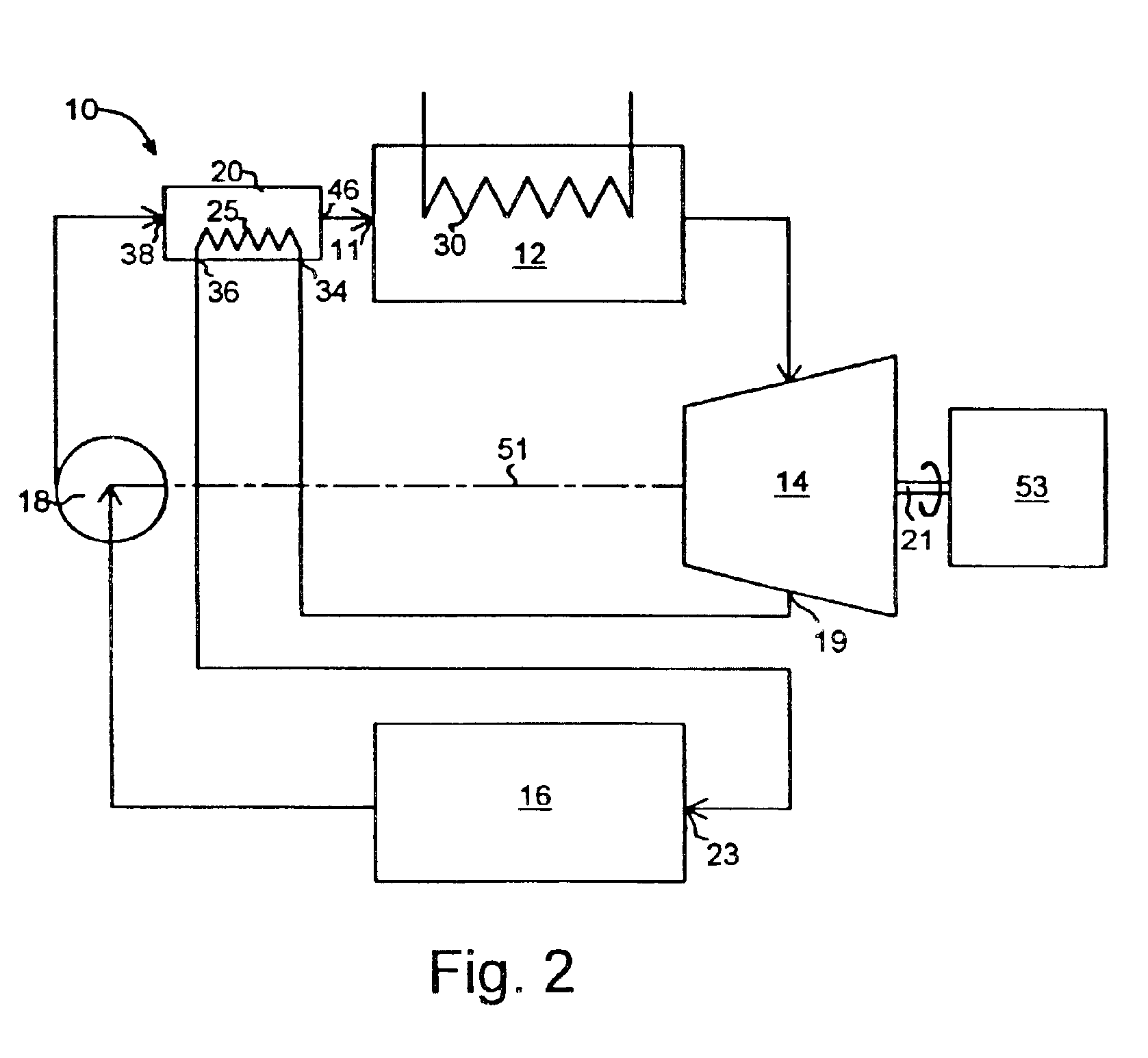

Heat engine

InactiveUS20030000213A1Easy to operateBoilers/analysersClimate change adaptationWorking fluidEngineering

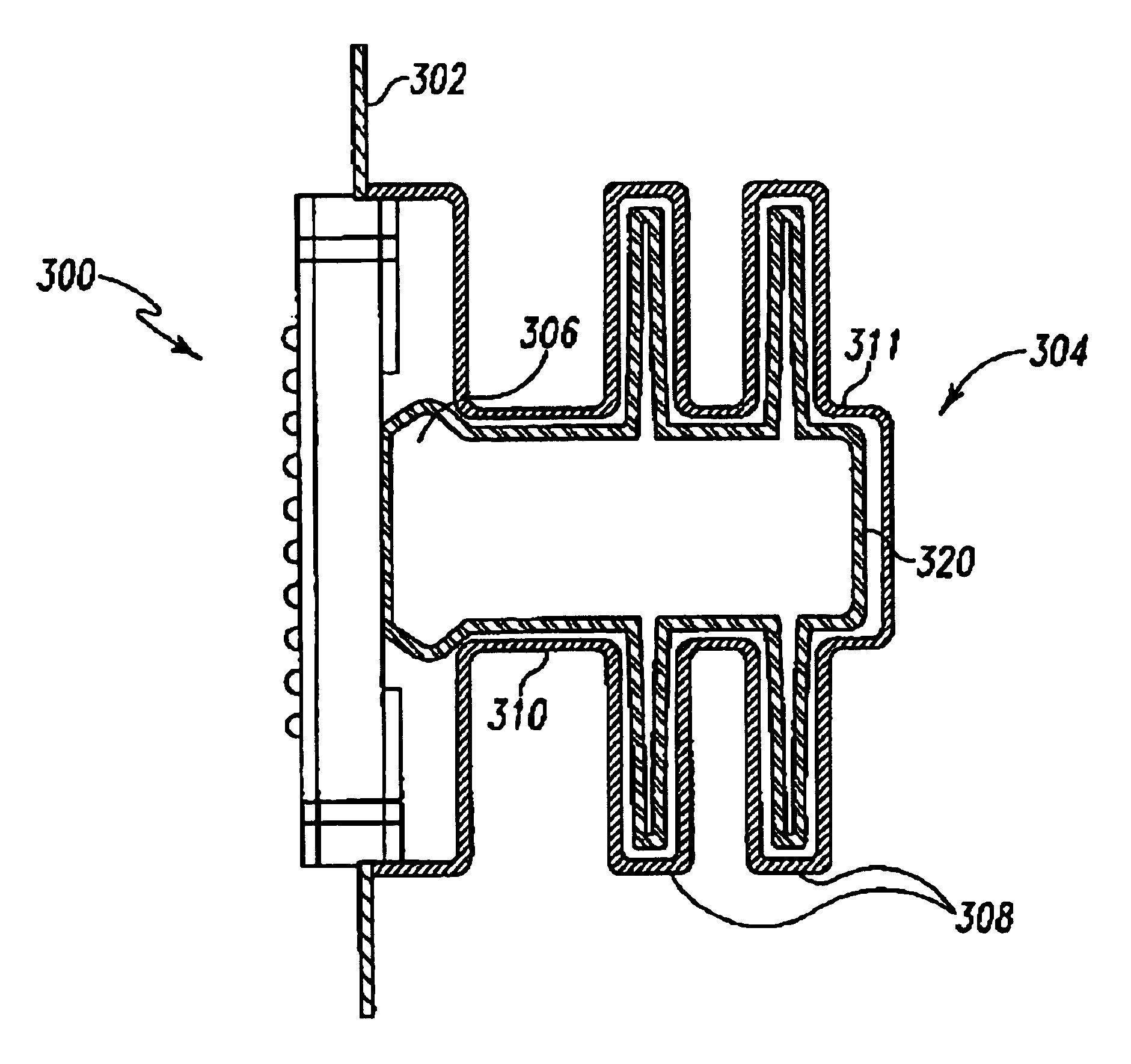

A heat engine (10) achieves operational efficiencies by: 1) recovering waste heat from heat engine expander (14) to preheat heat-engine working fluid, 2) using super-heated working fluid from compressor (402) to pre-heat heat-engine working fluid, and 3) using reject heat from condenser (93) and absorber (95) to heat the heat-engine boiler (12). A dual heat-exchange generator (72) affords continuous operation by using gas-fired heat exchanger (212) to heat generator (72) when intermittent heat source (40), e.g., solar, is incapable of heating generator (72). The combination of heat engine (10) and absorption and compression heat transfer devices (60, 410) allows use of low-temperature heat sources such as solar, bio-mass, and waste heat to provide refrigeration, heating, work output including pumping and heating of subterranean water and electrical generation.

Owner:OHIO STATE INNOVATION FOUND

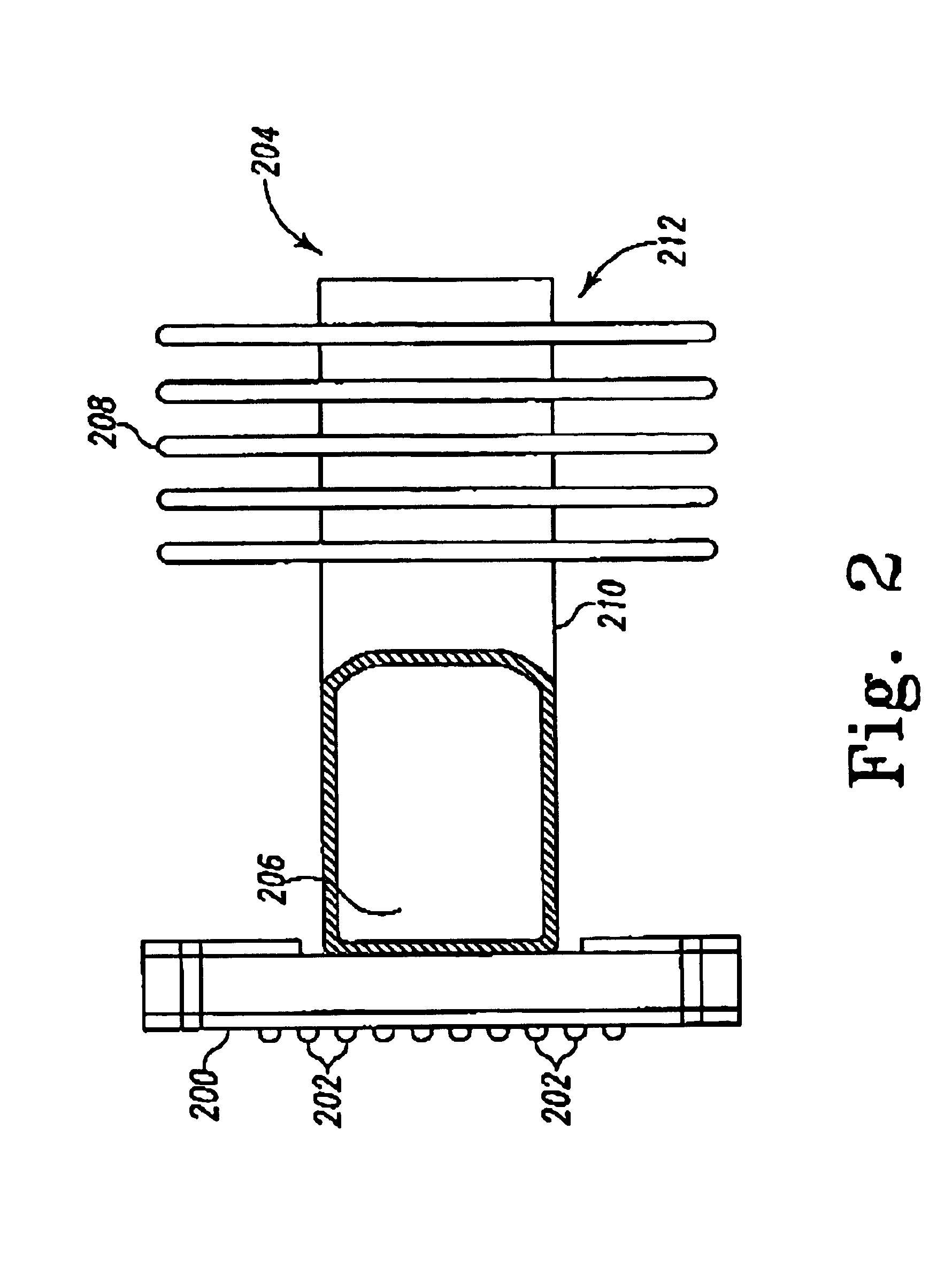

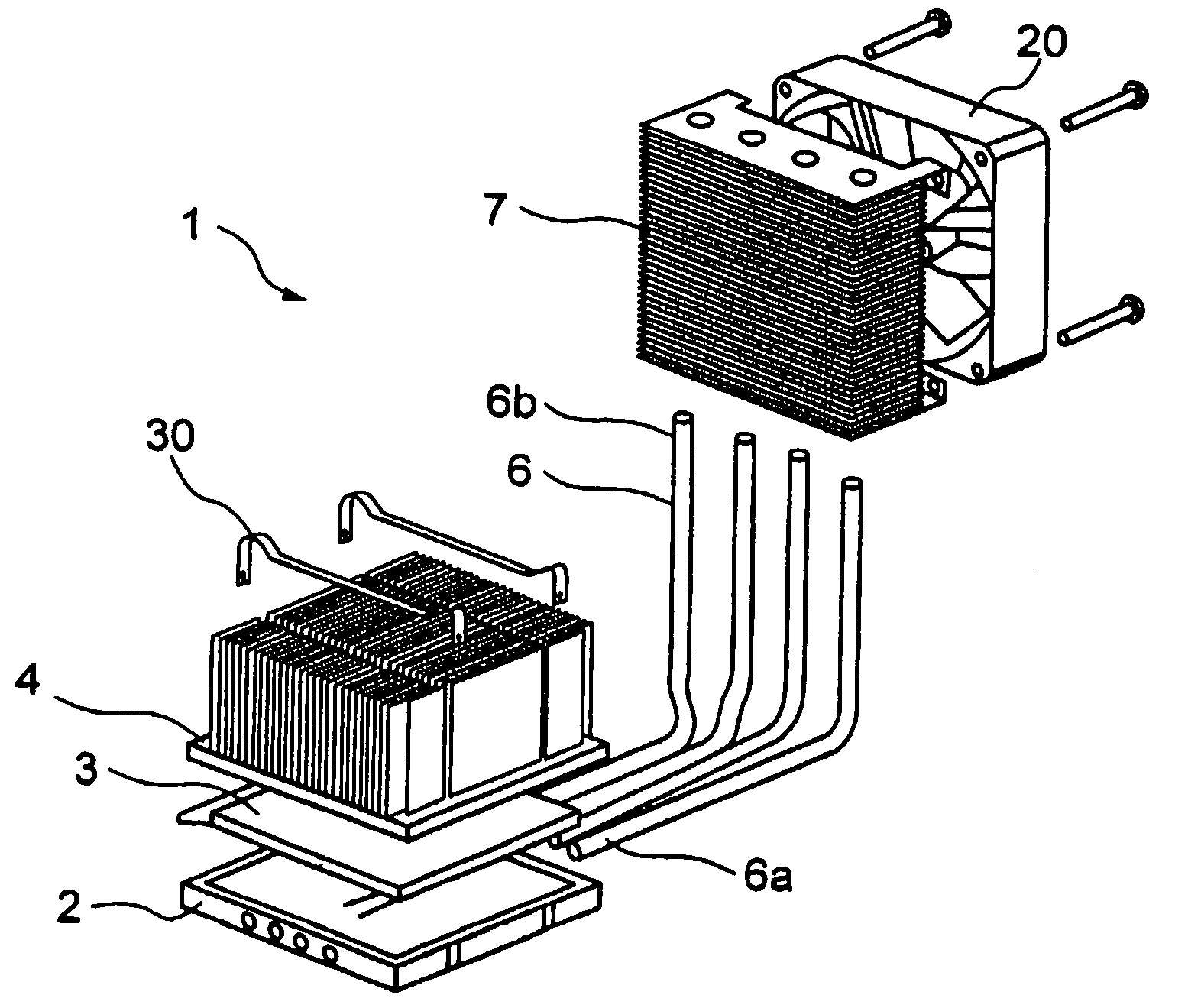

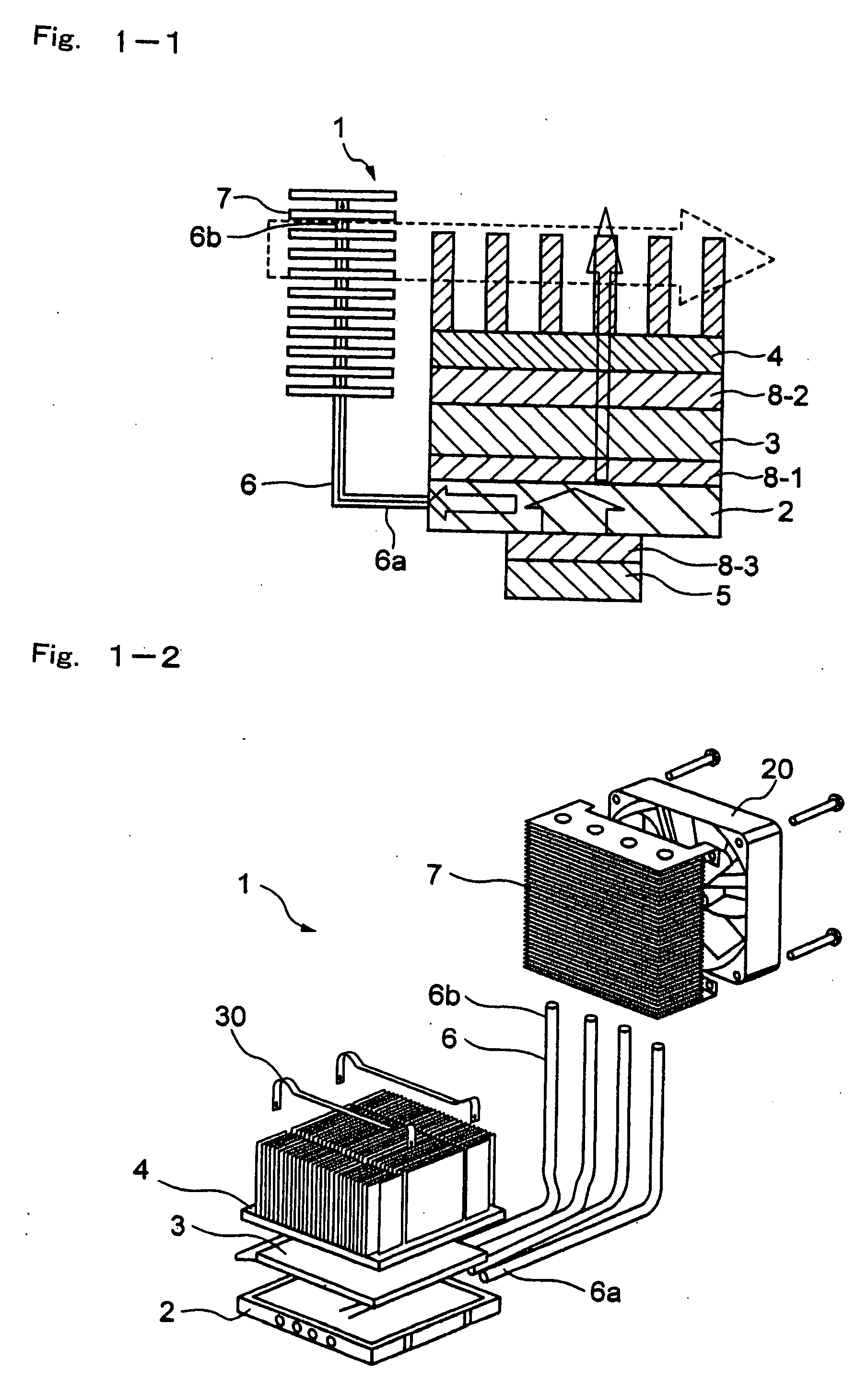

Module for cooling semiconductor device

InactiveUS20050257532A1Improve cooling efficiencyReduce heat gainDomestic cooling apparatusIndirect heat exchangersThermoelectric coolingDevice material

A module for cooling a heat generating element comprising a heat receiving plate thermally connected to at least one heat generating element; a heat transfer device one end portion of which is thermally connected to the heat receiving plate and other end portion of which is thermally connected to a heat dissipating plate; a thermoelectric cooler one face of which is thermally connected to one face of the heat dissipating plate; a first heat sink thermally connected to other face of the heat dissipating plate; and a second heat sink thermally connected to other face of said thermoelectric cooler.

Owner:FURUKAWA ELECTRIC CO LTD

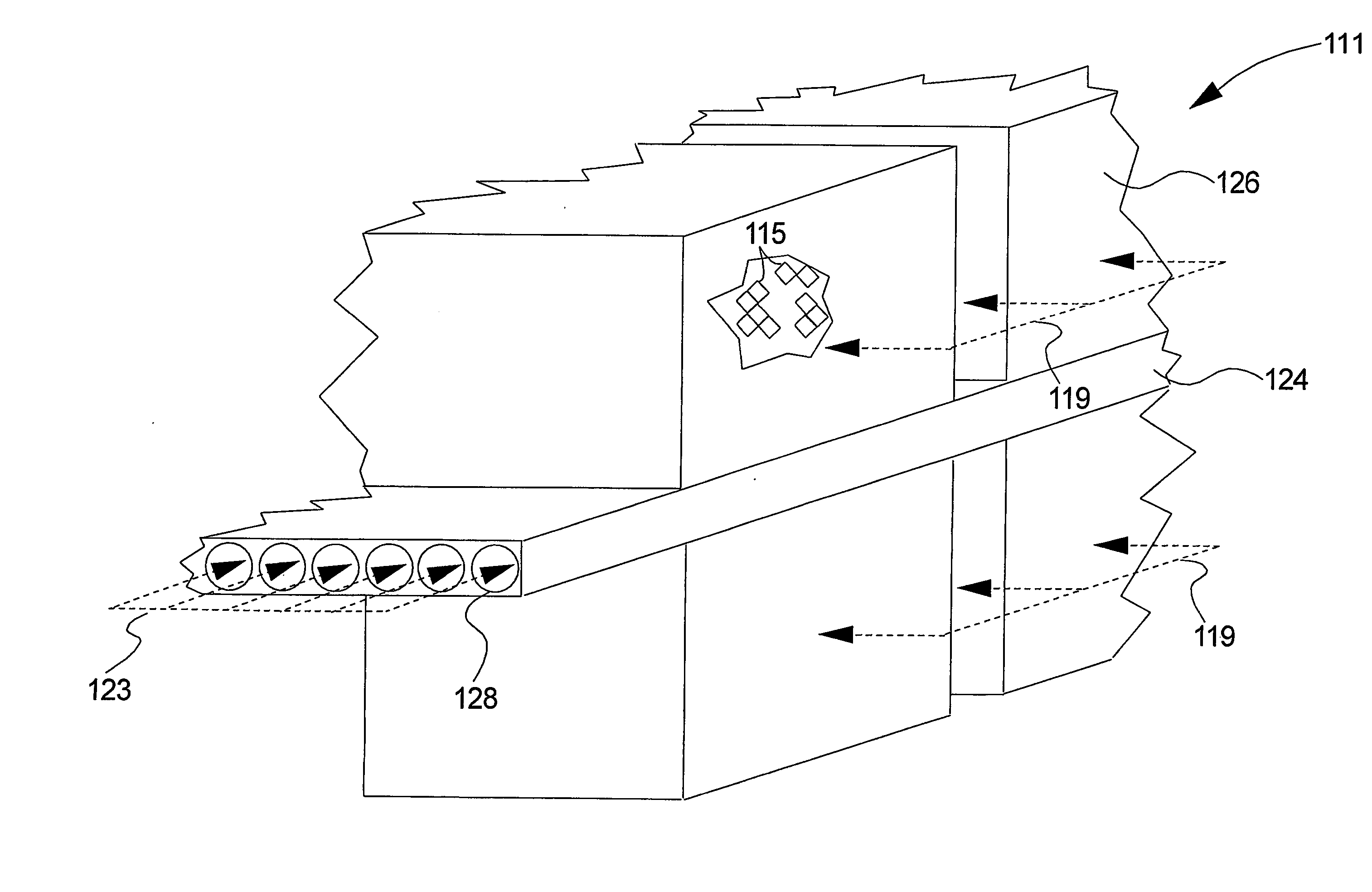

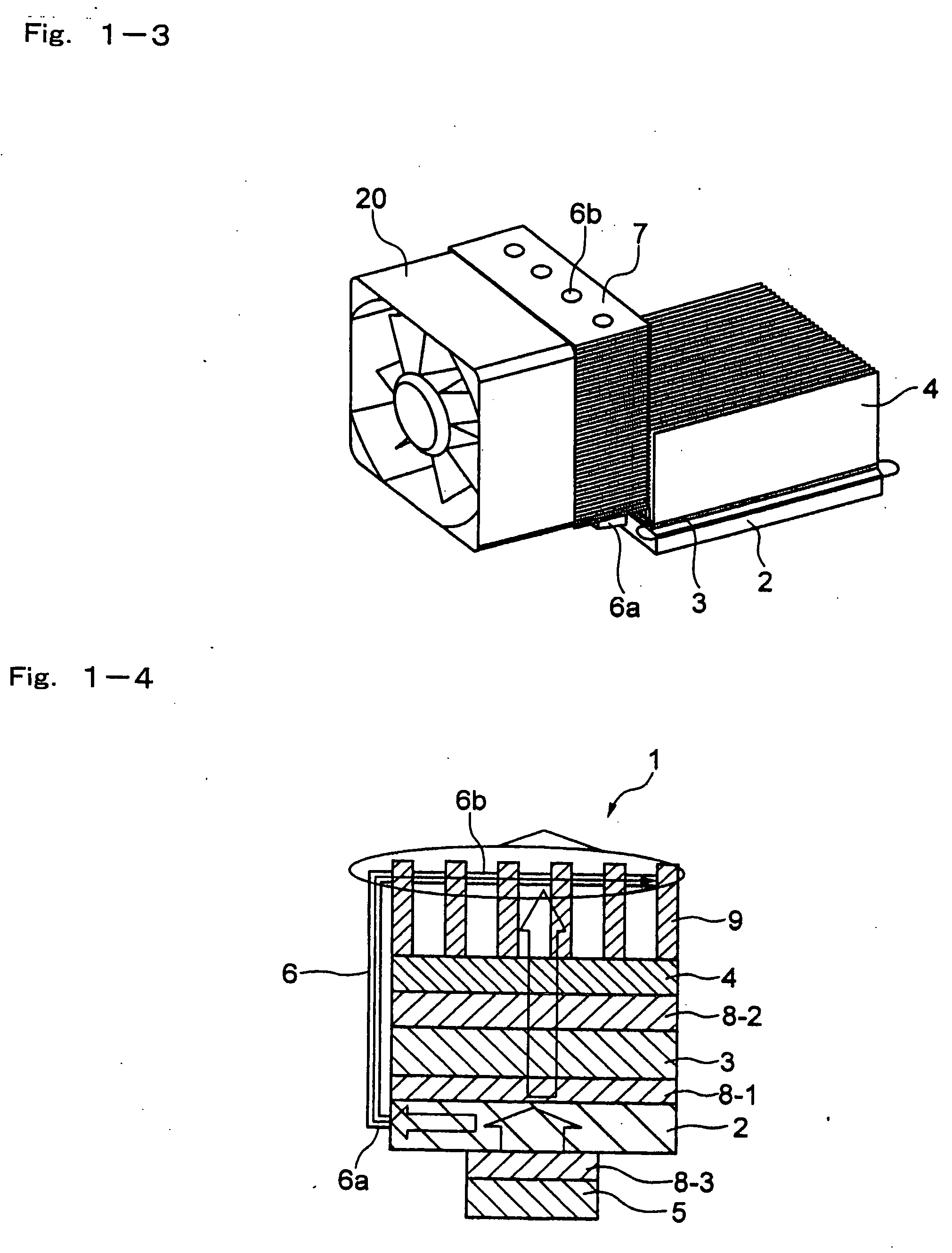

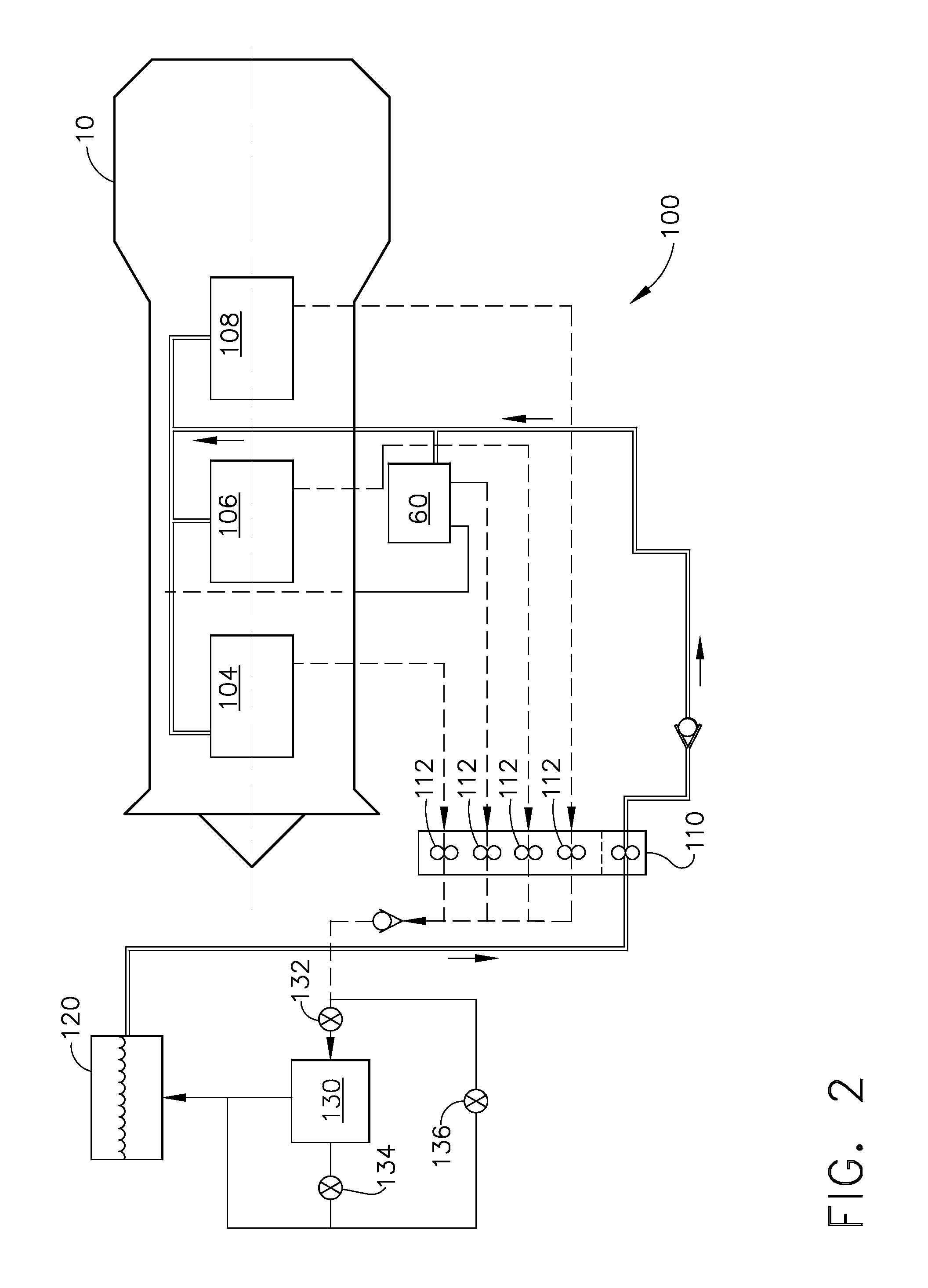

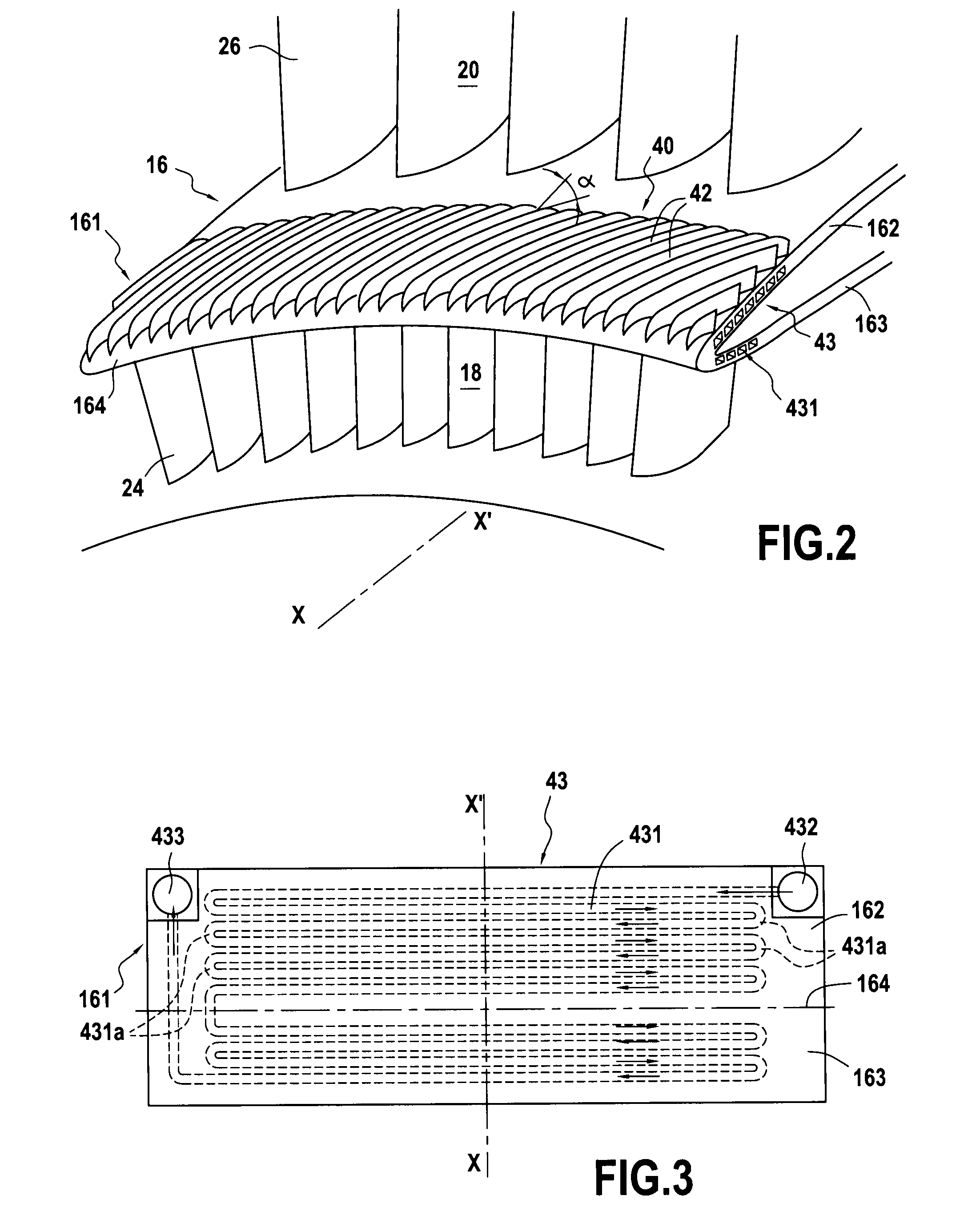

Method and apparatus for operating gas turbine engine heat exchangers

ActiveUS20080095611A1Turbine/propulsion engine coolingEfficient propulsion technologiesEngineeringTurbine

A method for assembling a turbine engine includes assembling a heat exchanger assembly that includes at least a radially inner plate, a radially outer plate, and a heat exchanger coupled between the radially inner and outer plates, forming the heat exchanger assembly such that the heat exchanger assembly has a substantially arcuate shape, and coupling the heat exchanger to a fan casing such that the heat exchanger is positioned upstream or downstream from the fan assembly.

Owner:UNISON INDUSTRIES +1

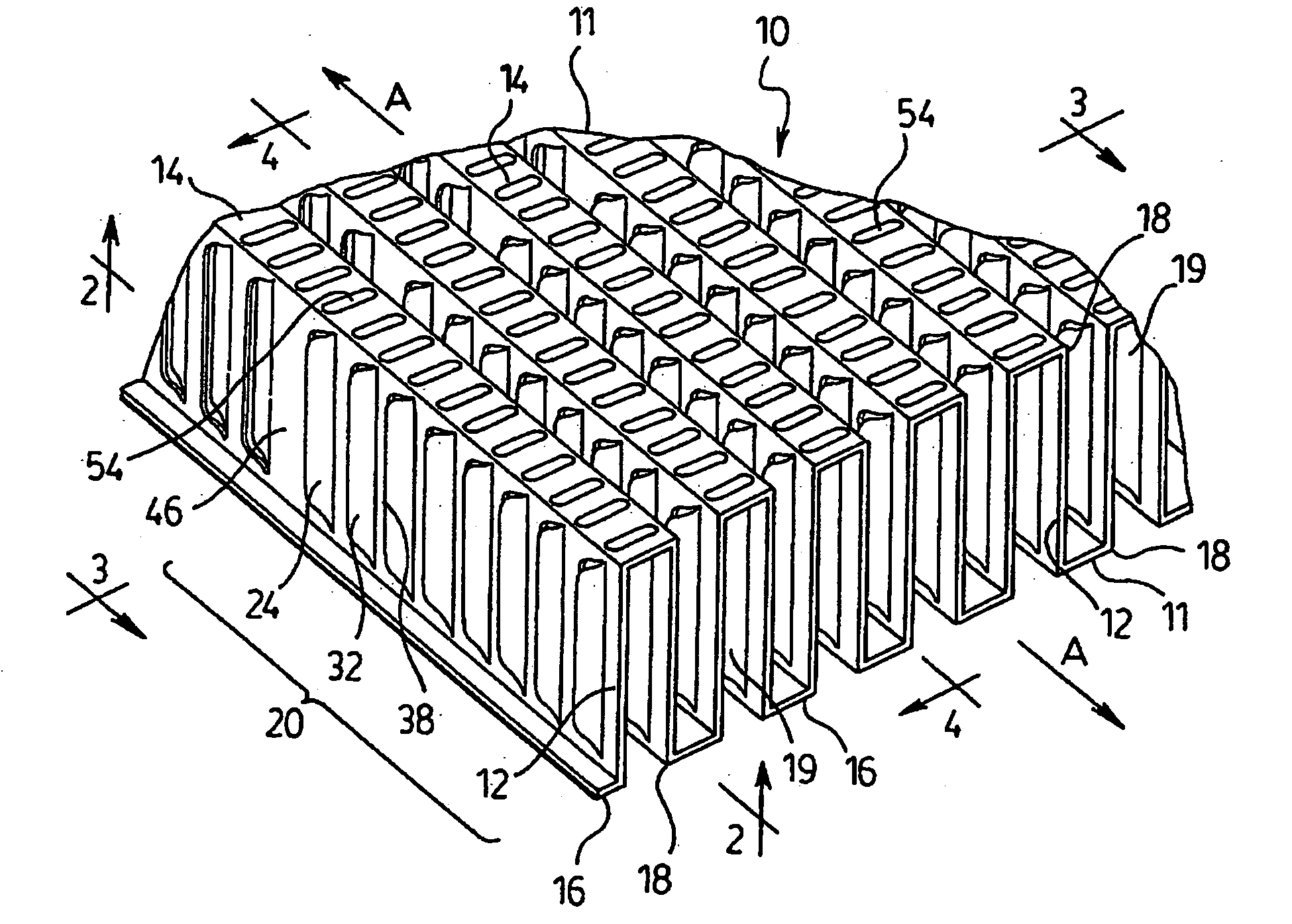

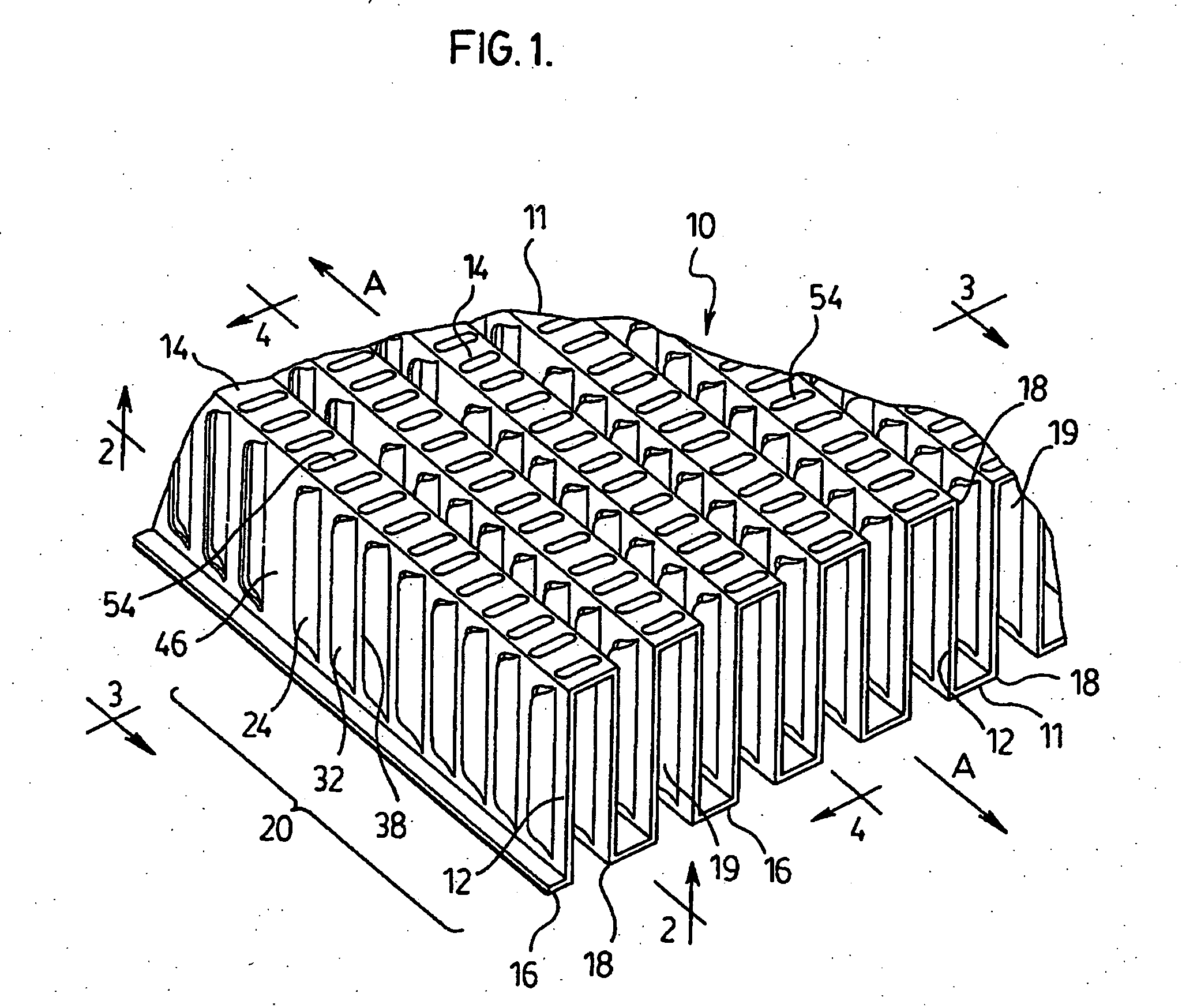

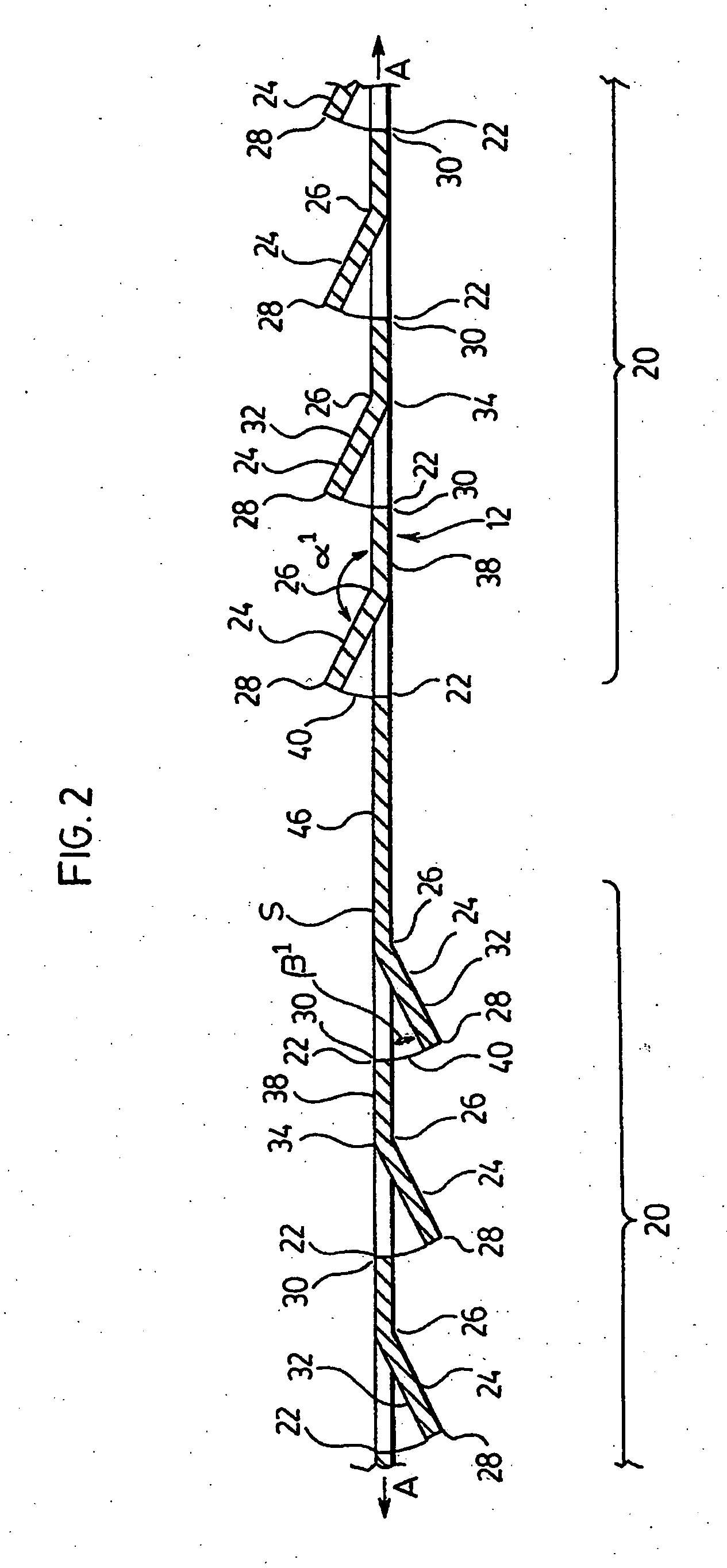

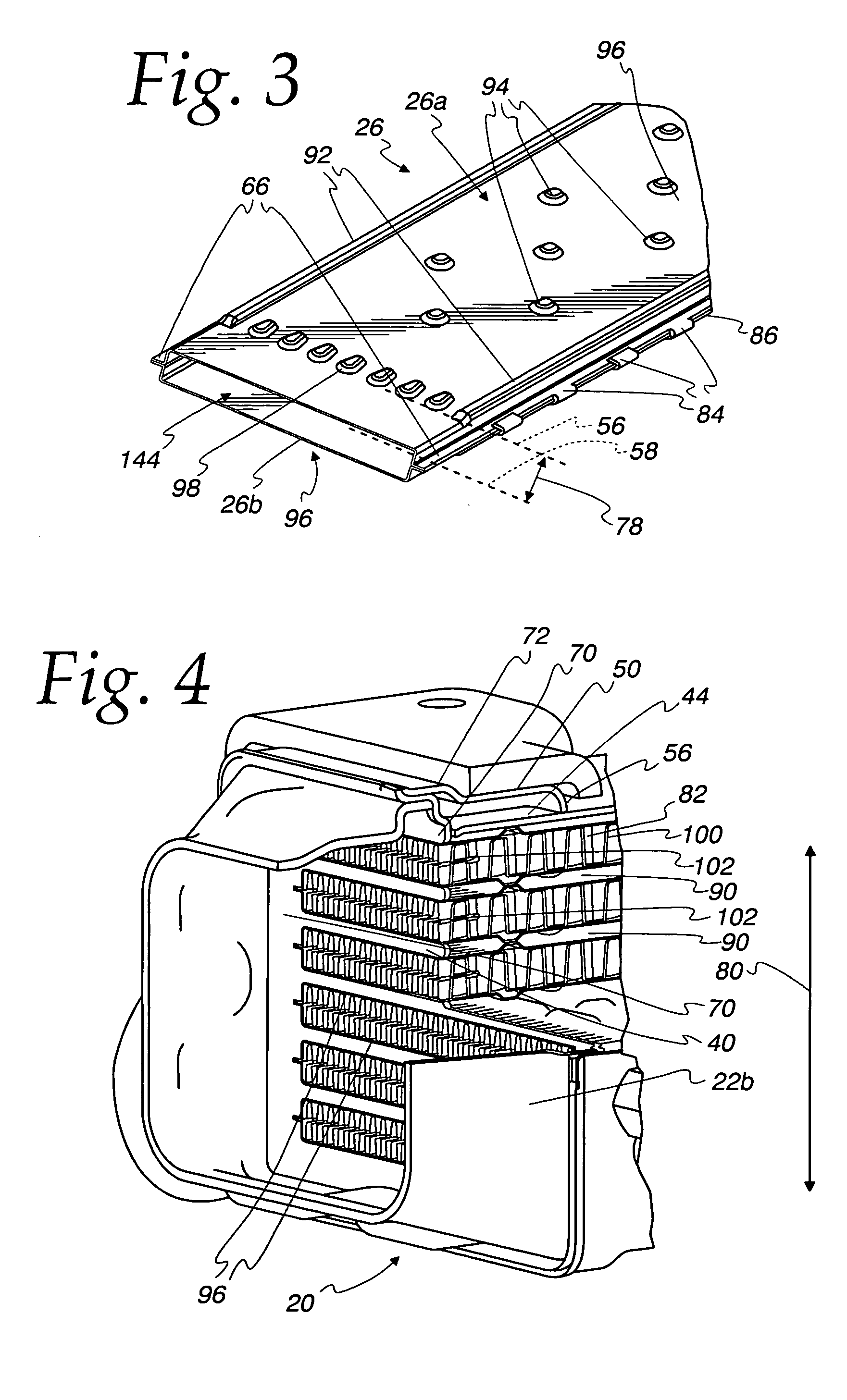

Heat exchangers with corrugated heat exchange elements of improved strength

InactiveUS20070012430A1Heat transfer modificationLaminated elementsEngineeringUltimate tensile strength

A corrugated fin or turbulizer for a heat exchanger comprises a series of corrugations with parallel side walls. The side walls are provided with a series of parallel slits between which one-sided or two-sided louvers are defined. Each of the louvers has first and second edges extending along an adjacent pair of slits, and at least one bend located between the edges, thereby causing at least one of the edges of the louver to project outwardly of the plane of the side wall, and providing the side wall with improved crush resistance. The corrugations may preferably be rectangular or trapezoidal in form, having generally flat top and bottom surfaces defined by two closely-spaced bends. The top and bottom surfaces may preferably be provided with protrusions, at least some of which extend close to the bends. This assists in creating localized areas of weakness along which the bends can be formed cleanly.

Owner:DANA CANADA CORP

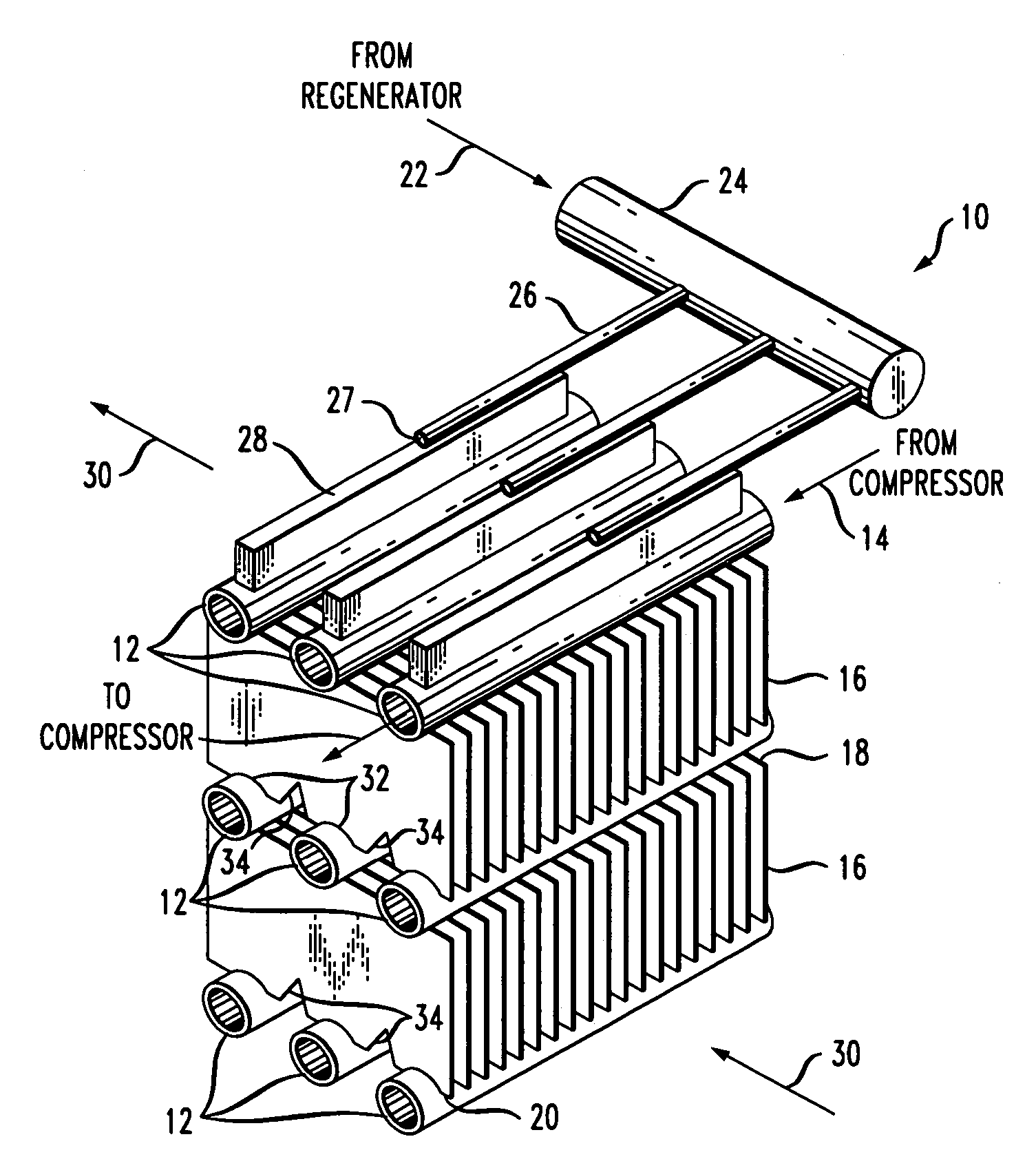

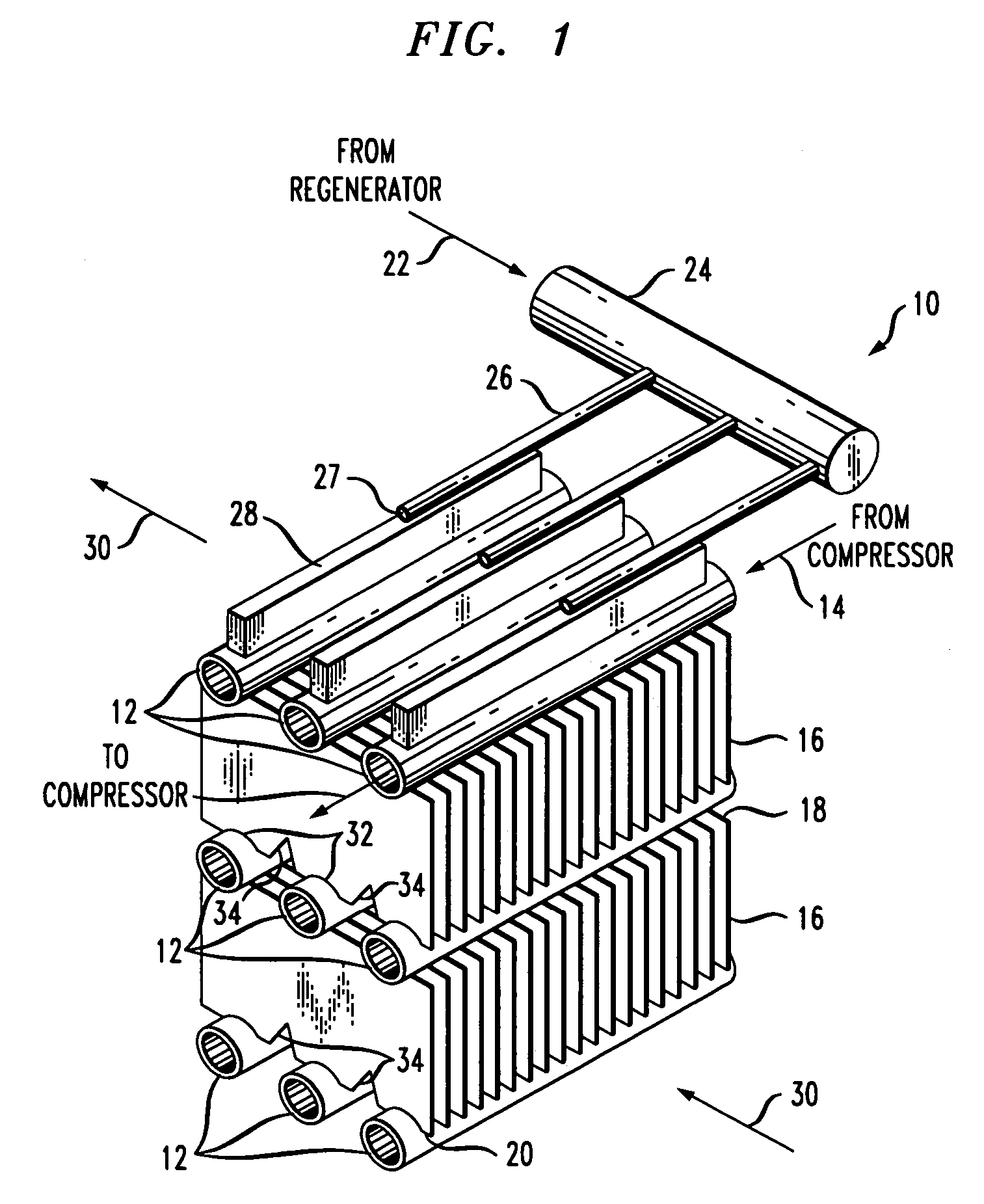

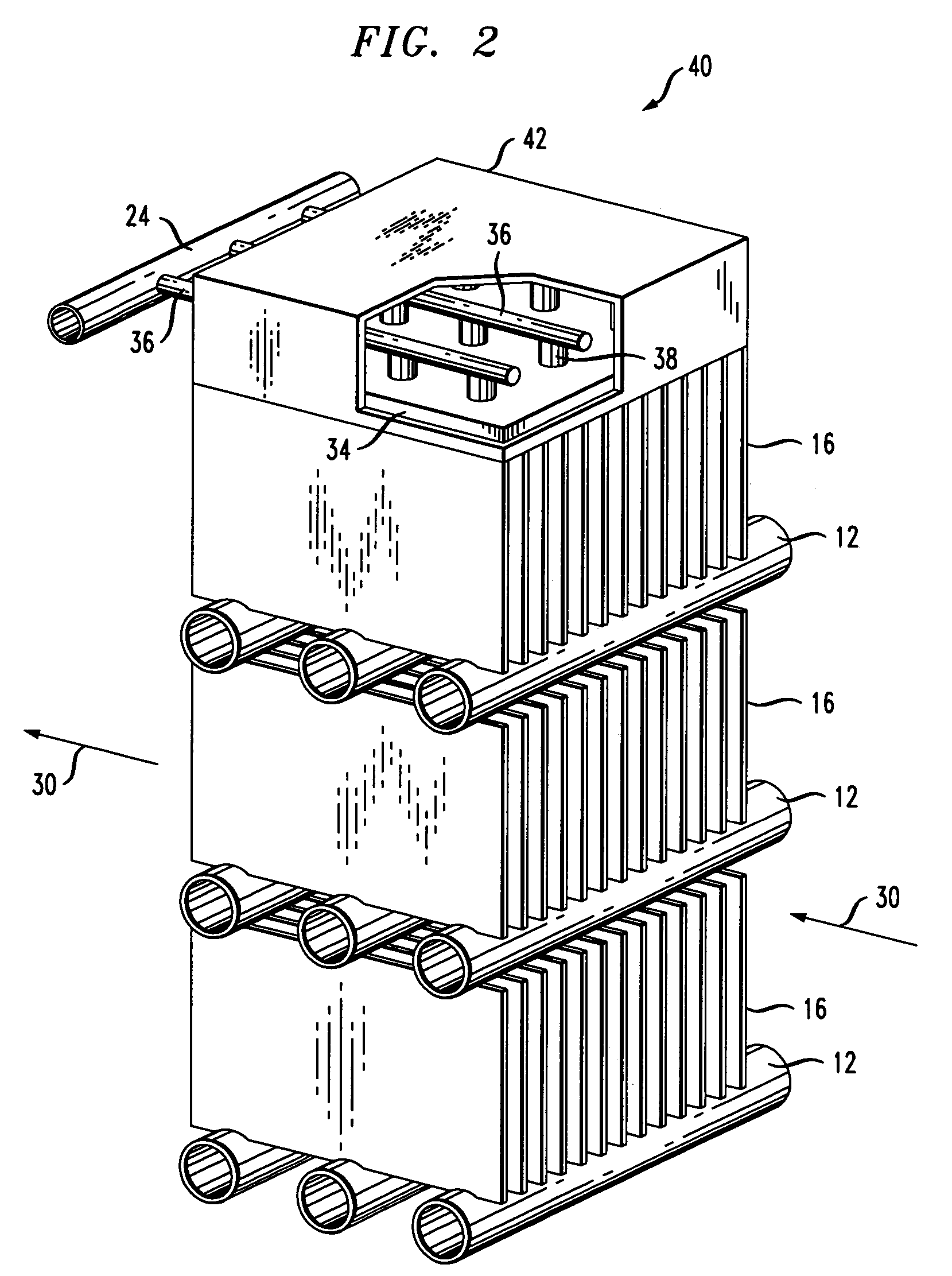

Heat and mass exchanger

ActiveUS7269966B2Additional exchangeEfficient exchangeSpacing meansDomestic cooling apparatusEngineeringContinuous flow

Owner:AIL RES

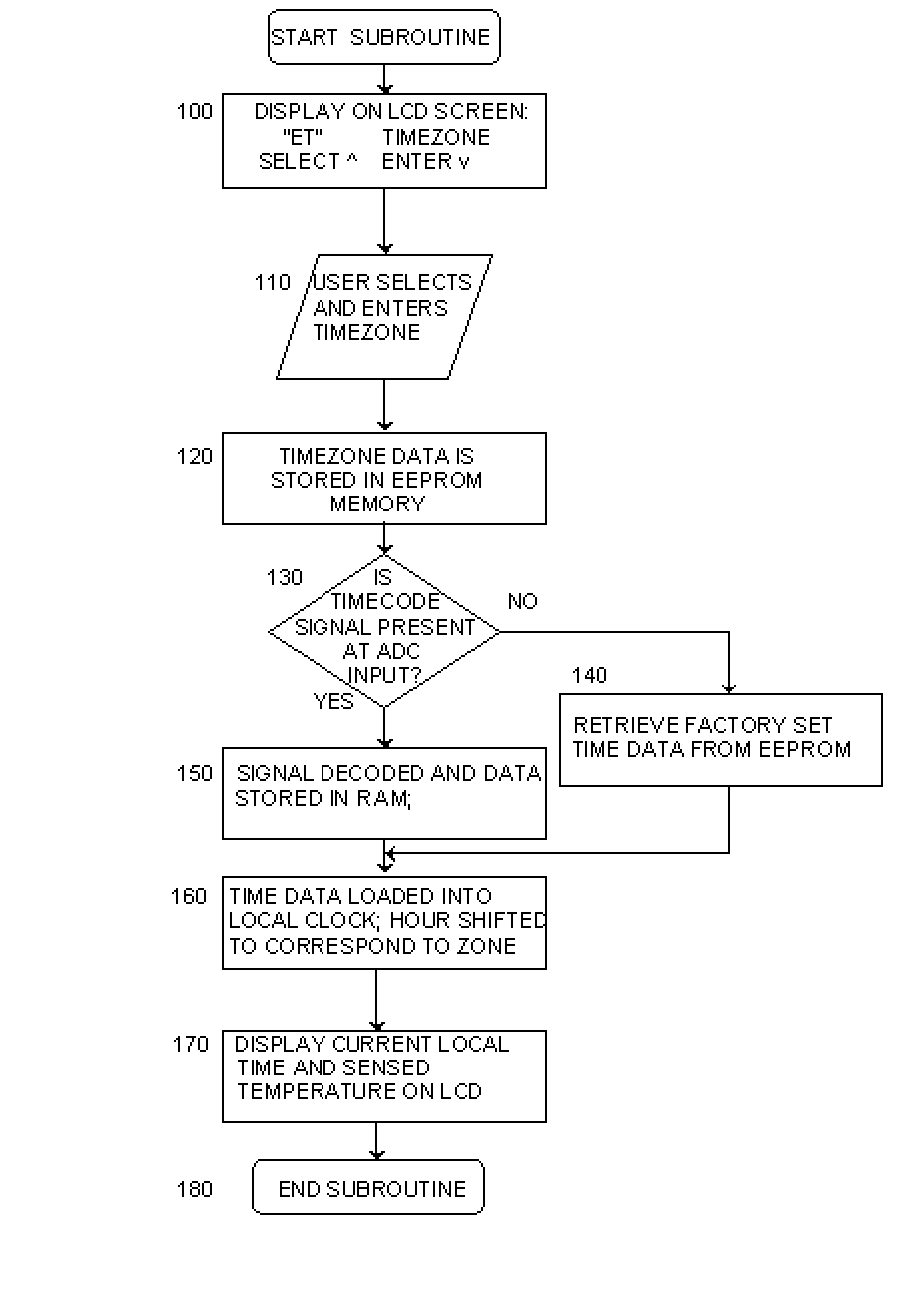

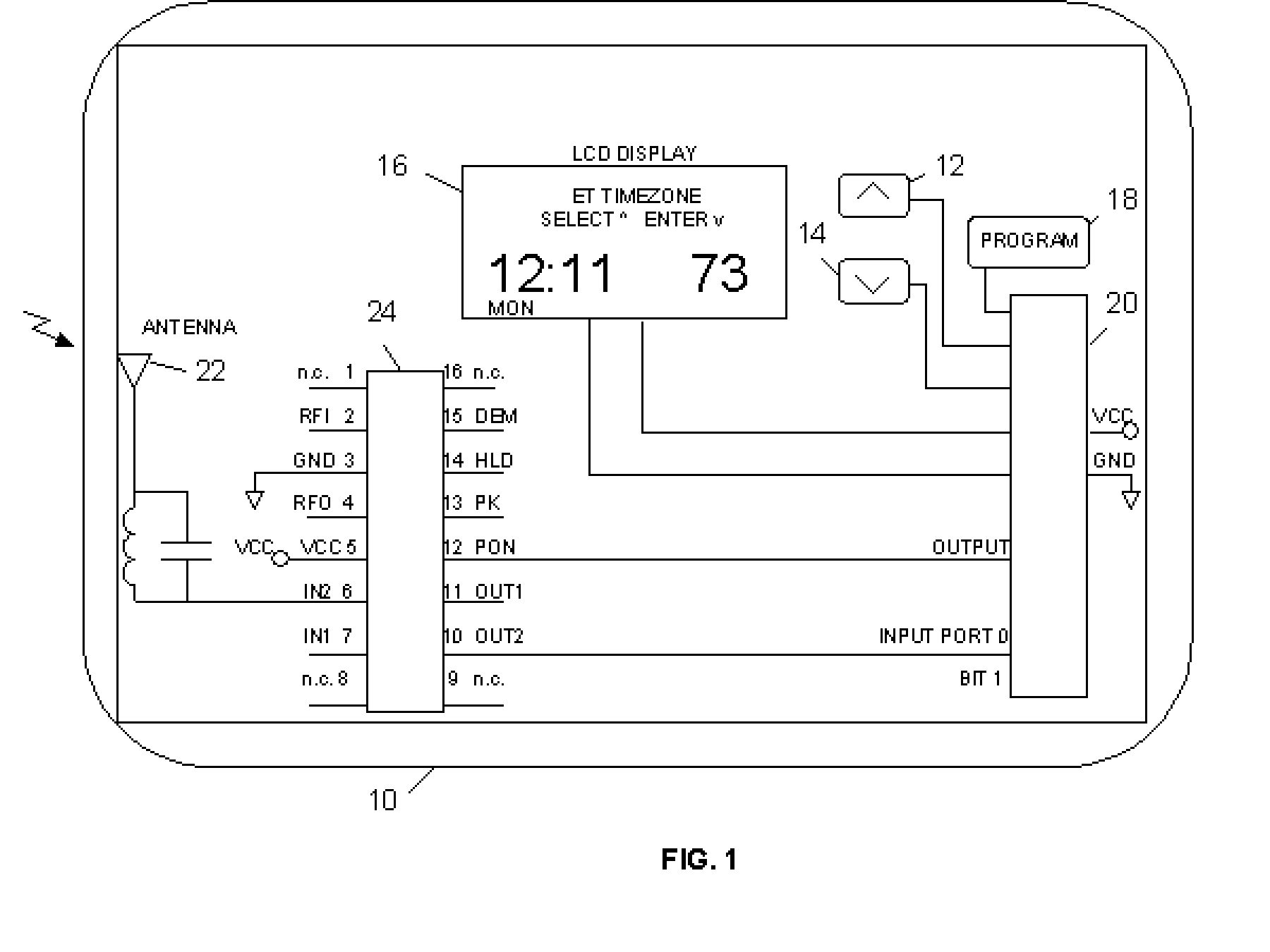

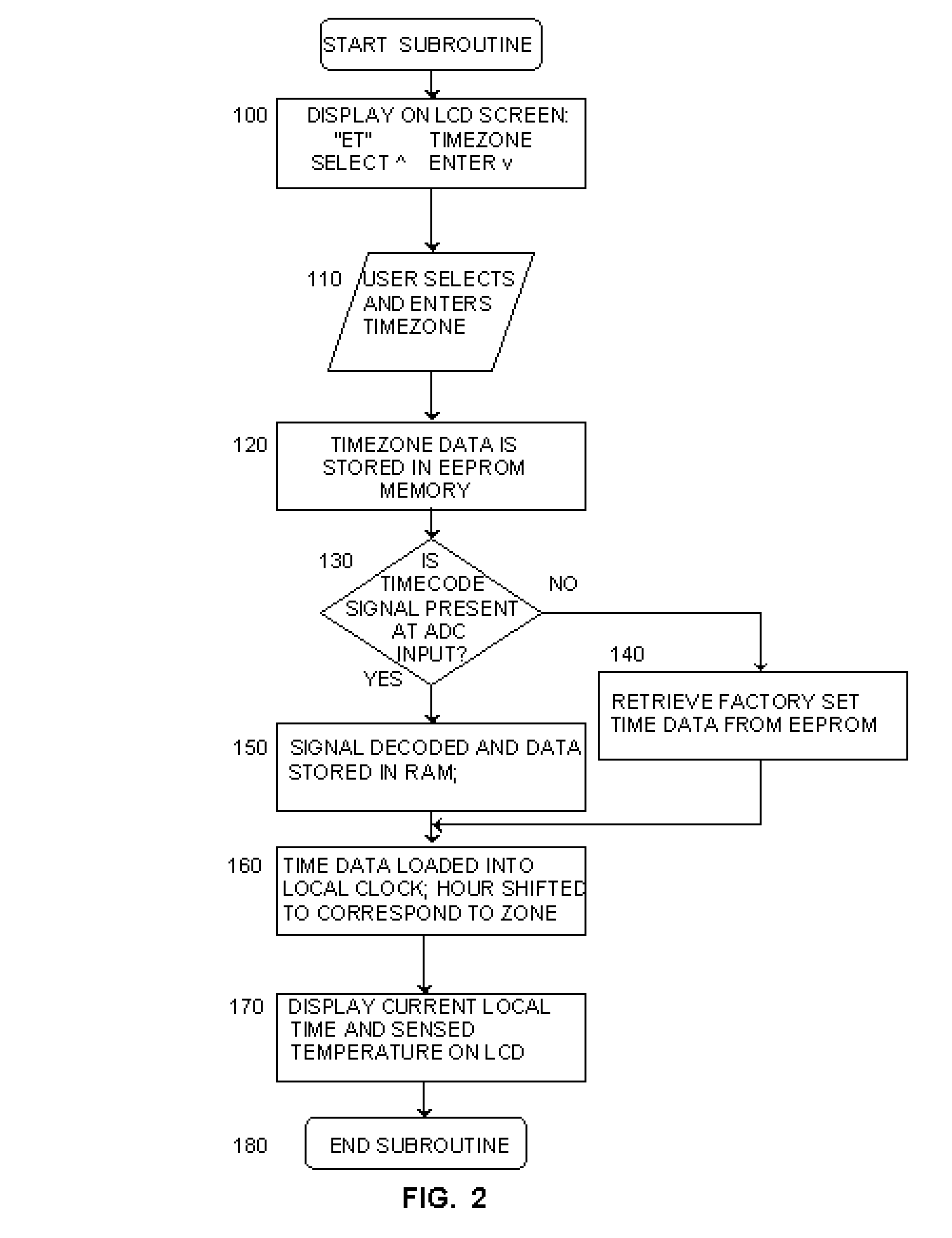

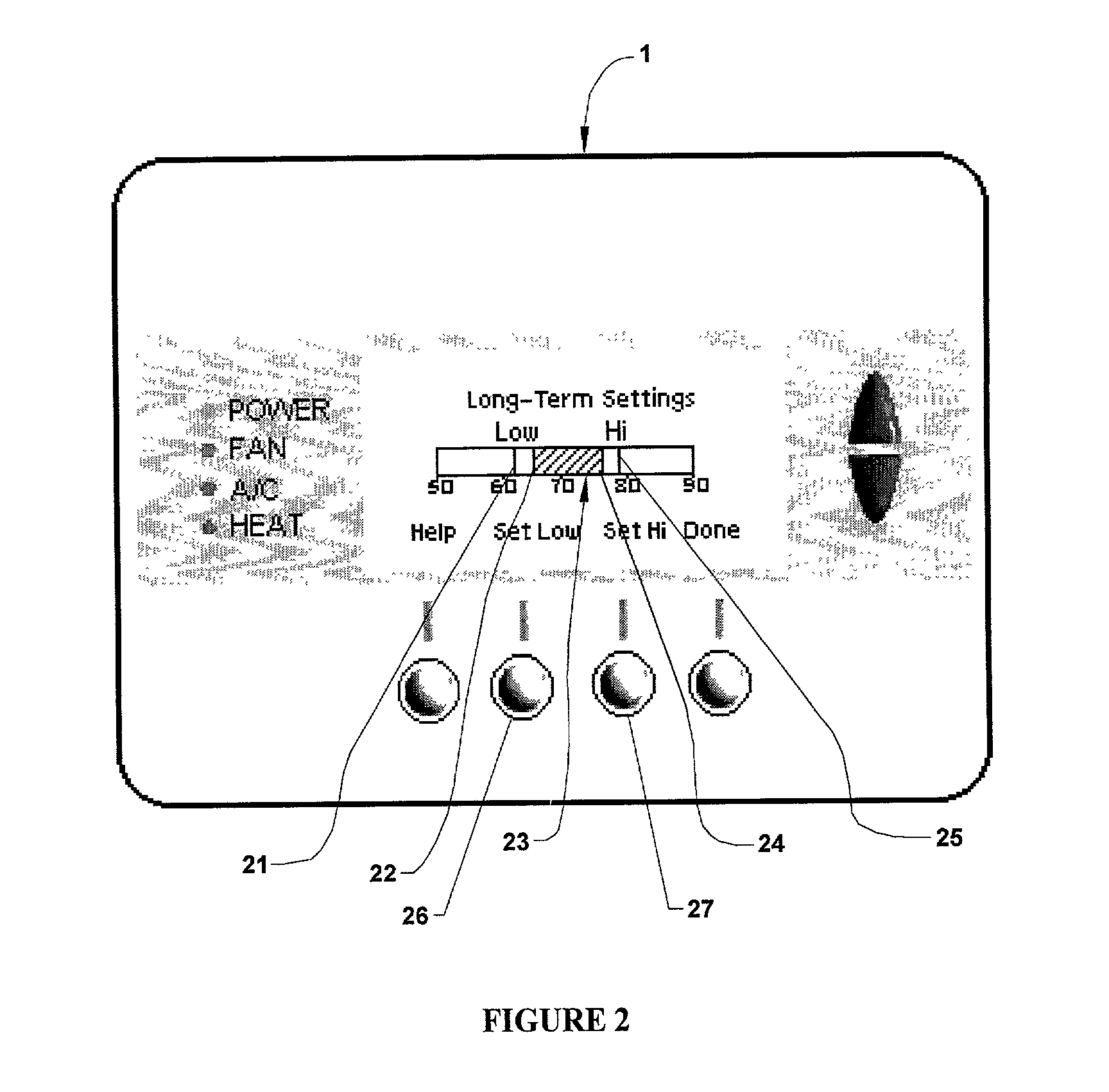

Thermostat With One Button Programming Feature

InactiveUS20030121652A1Easy programmingEasy to startMechanical apparatusSpace heating and ventilation safety systemsTime segmentEngineering

Abstract of Disclosure A digital programmable thermostat comprising up and down temperature adjustment buttons, an LCD display, and a Program button, which a user can simply press once to initiate a single setback program that sets back the last user selected temperature setting during a predetermined setback time period. The thermostat can also automatically set the current time and date, to allow the user to initiate the program without having to set the current time and date.

Owner:COPELAND COMFORT CONTROL LP

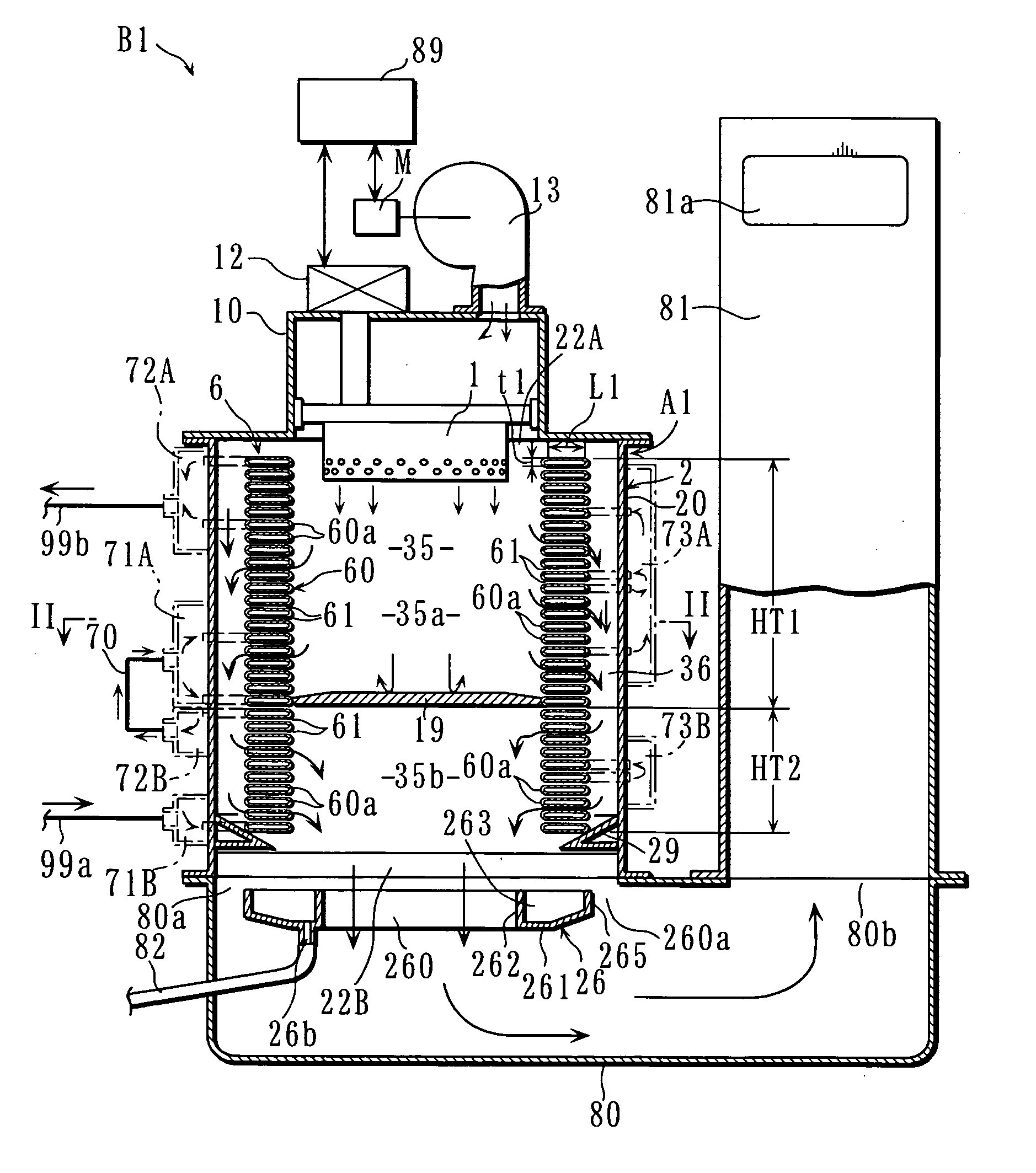

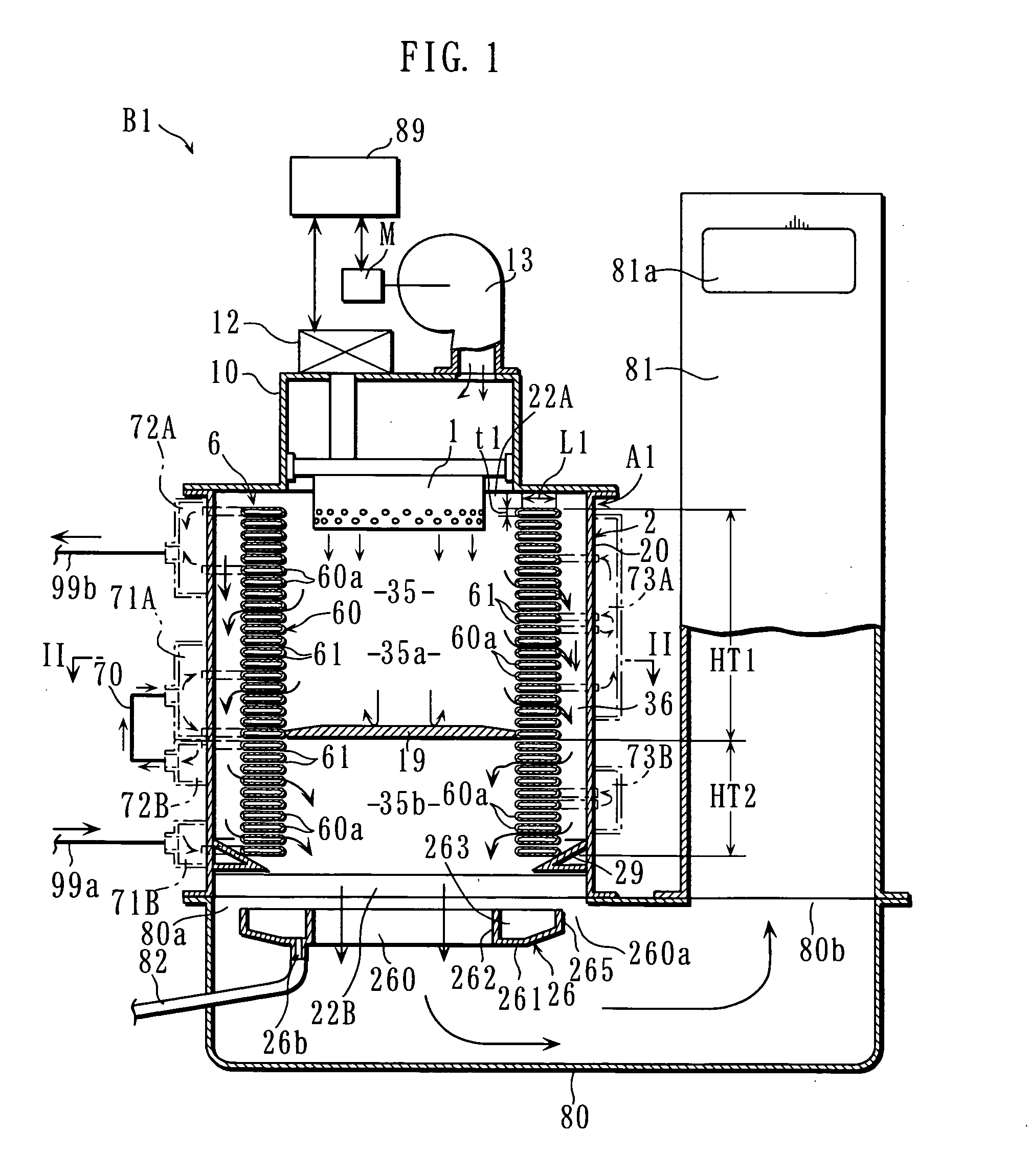

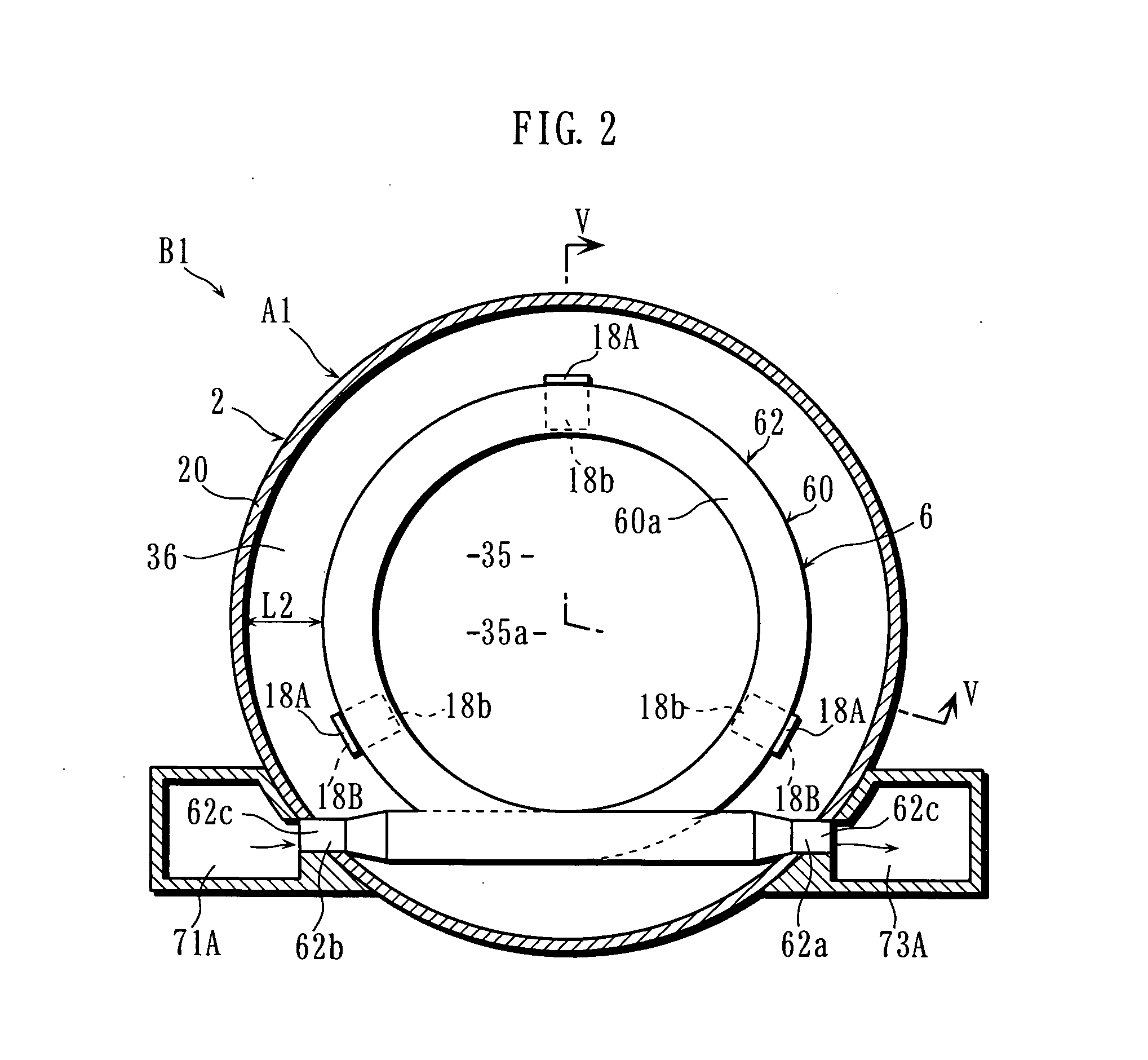

Heat Exchanger and Water Heater

A heat exchanger A1 includes a partition 19 partitioning the space 35 surrounded by a coiled tube 60 at an axially intermediate portion of a housing 2 into a first and a second regions 35a and 35b and partitioning the coiled tube 60 into a first and a second heat exchanging portions HT1 and HT2. The combustion gas supplied to the first region 35a flows to a combustion gas path 36 by passing through a clearance 61 of the first heat exchanging portion HT1 and then passes through a clearance 61 of the second heat exchanging portion HT2. With this structure, the amount of heat recovery is increased, and the heat exchange efficiency is enhanced while simplifying the overall structure of the heat exchanger A1 and reducing the size of the heat exchanger.

Owner:NORITZ CORP

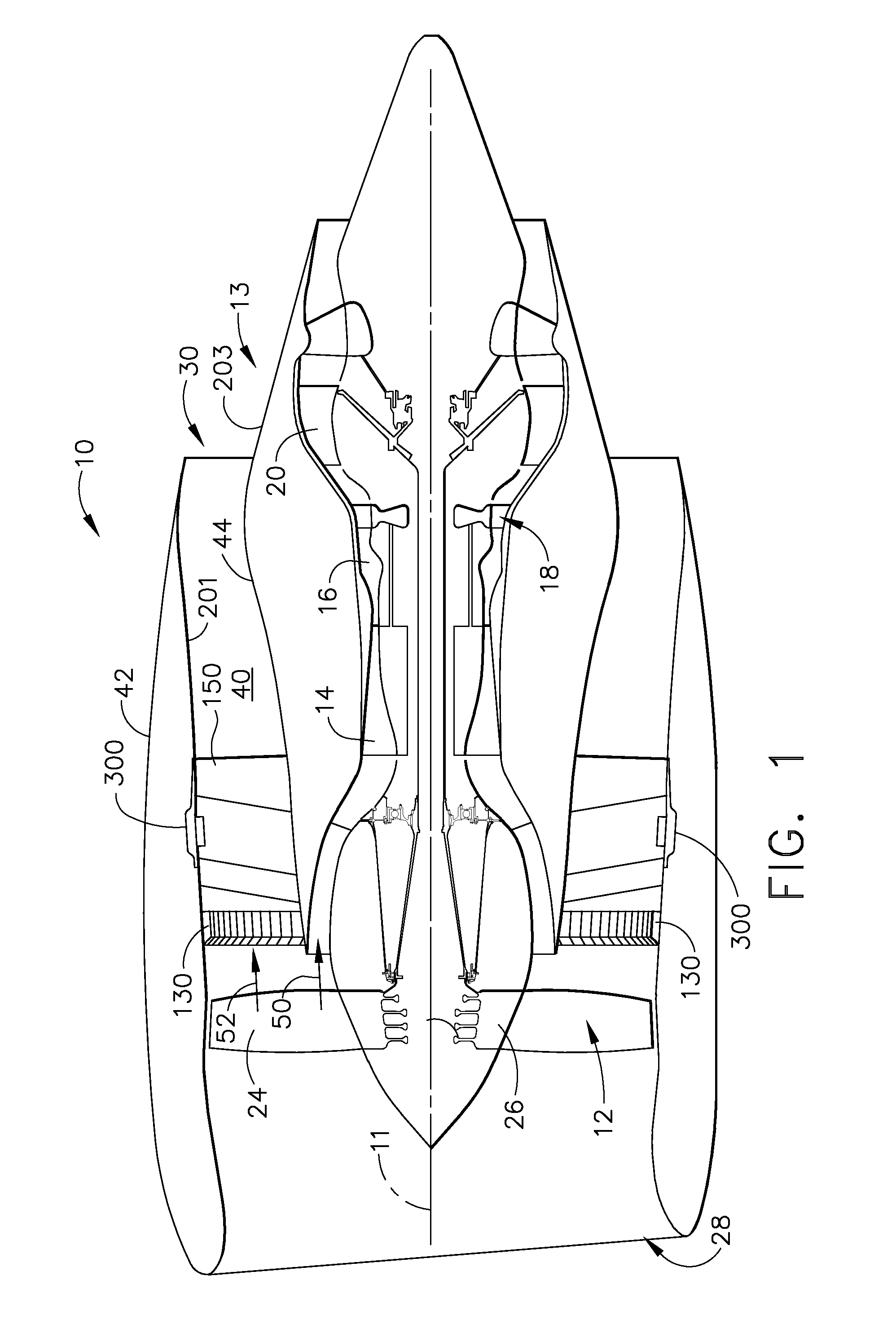

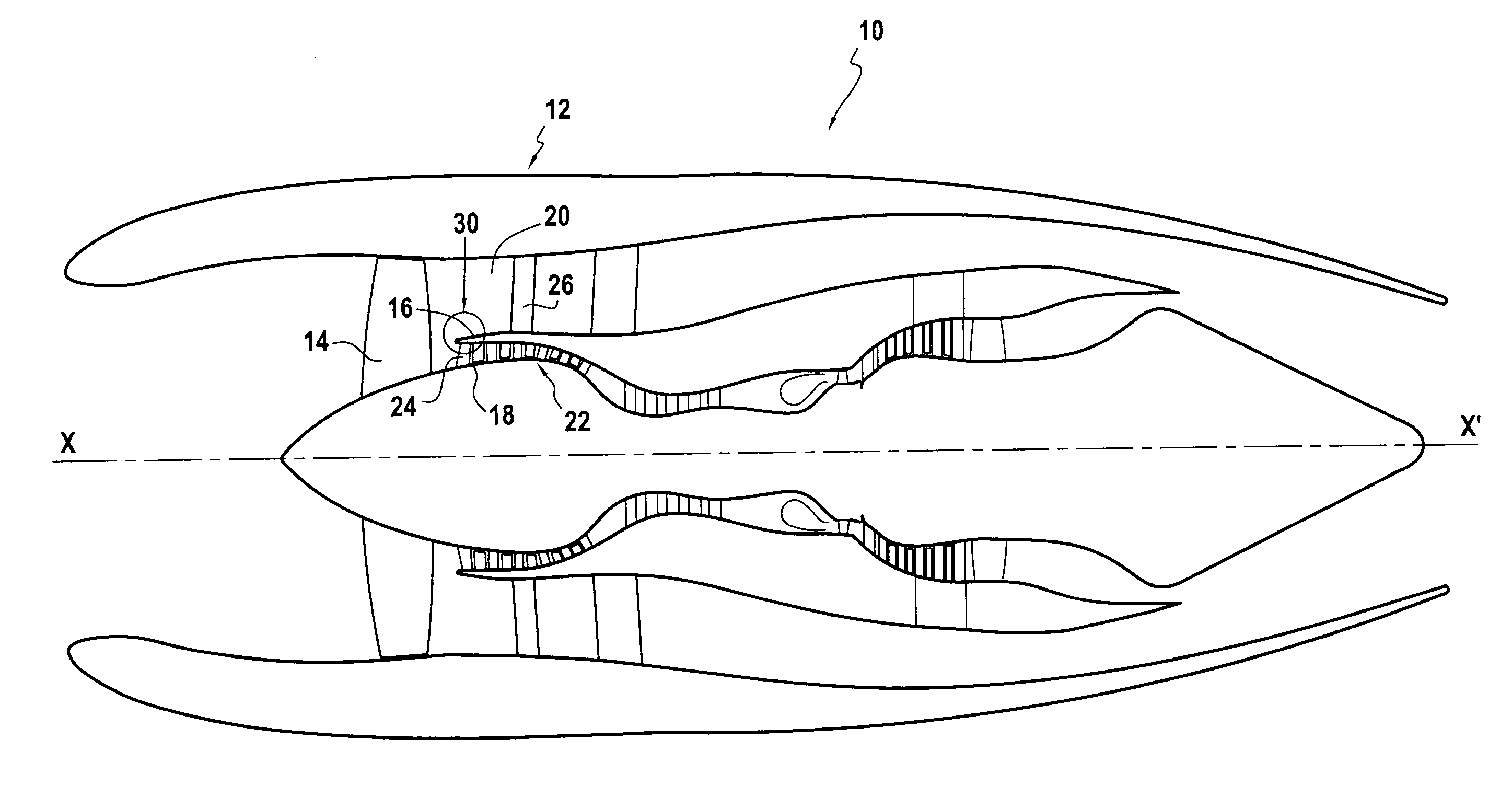

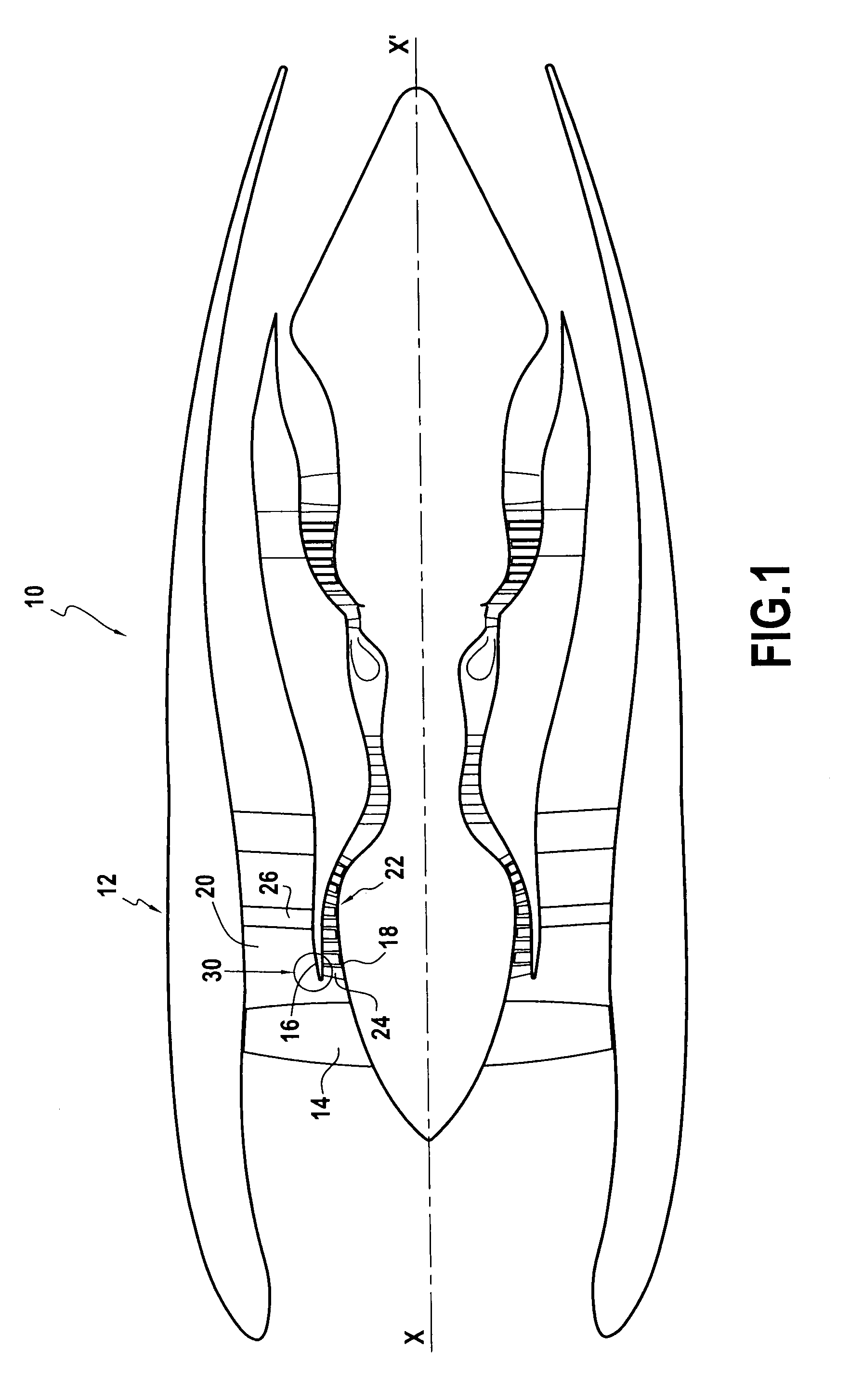

Air-oil heat exchanger placed at the location of the air separator nose of a turbojet, and a turbojet including such an air-oil heat exchanger

InactiveUS20090165995A1Prevent freezingWithout significantly disturbing the air streamExhaust apparatusTurbine/propulsion engine coolingLeading edgeJet engine

The invention relates to an air-oil heat exchanger located at the inner shroud of the secondary duct of a turbojet. In characteristic manner, it comprises an oil circuit placed inside the separator nose and fins placed outside the top wall of the separator nose, between the leading edge of the separator nose and the outlet guide vanes.

Owner:TECHSPACE AERO

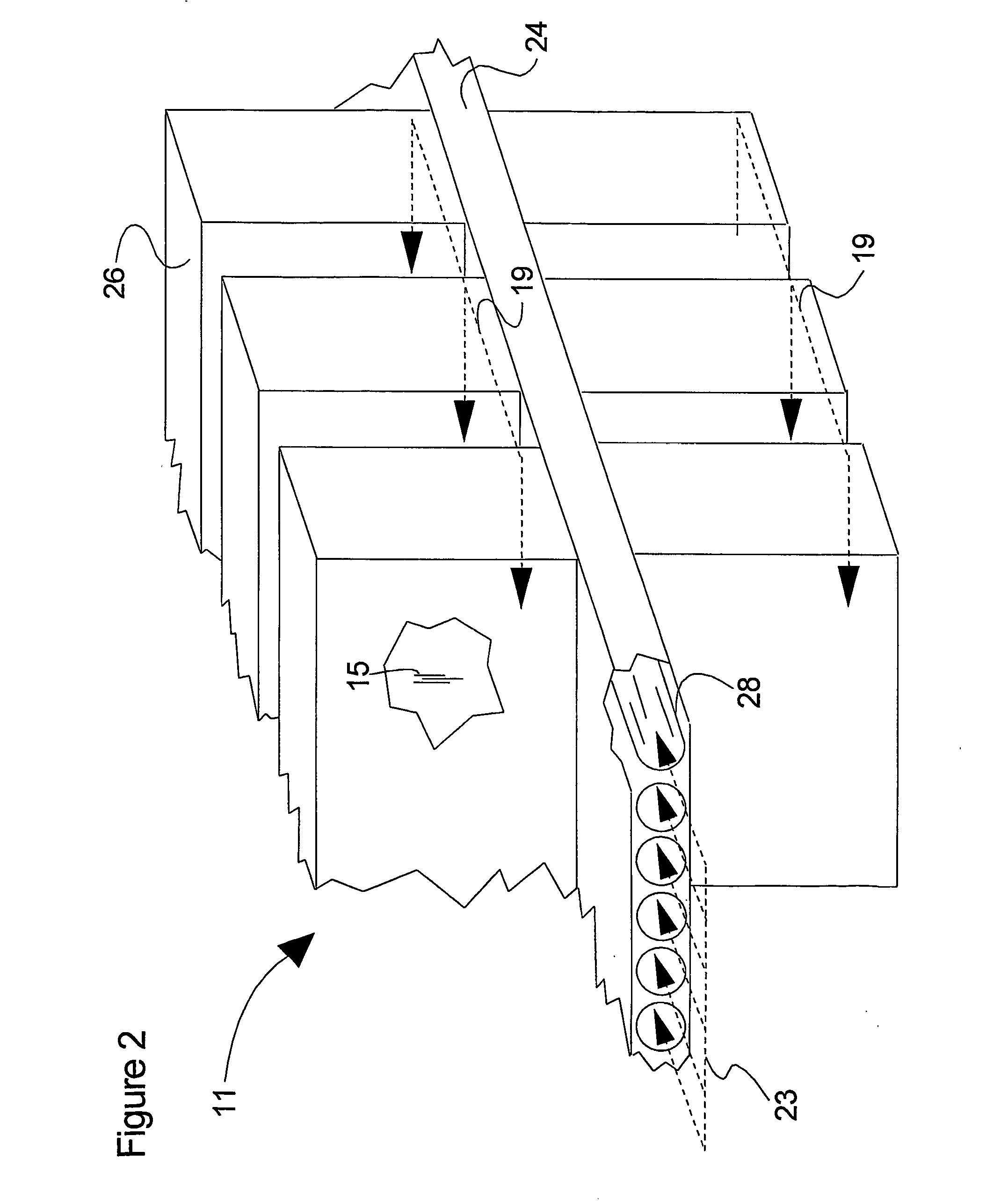

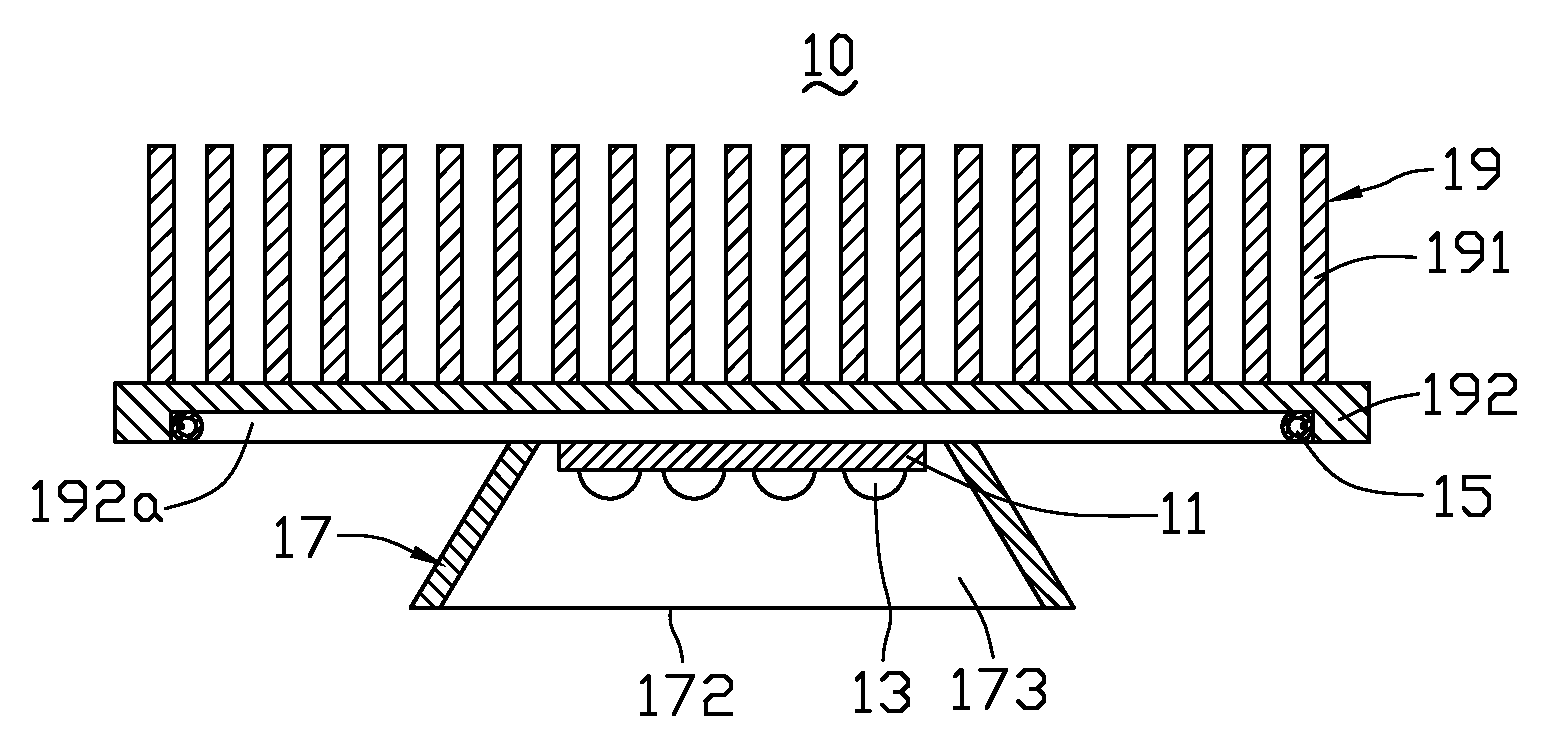

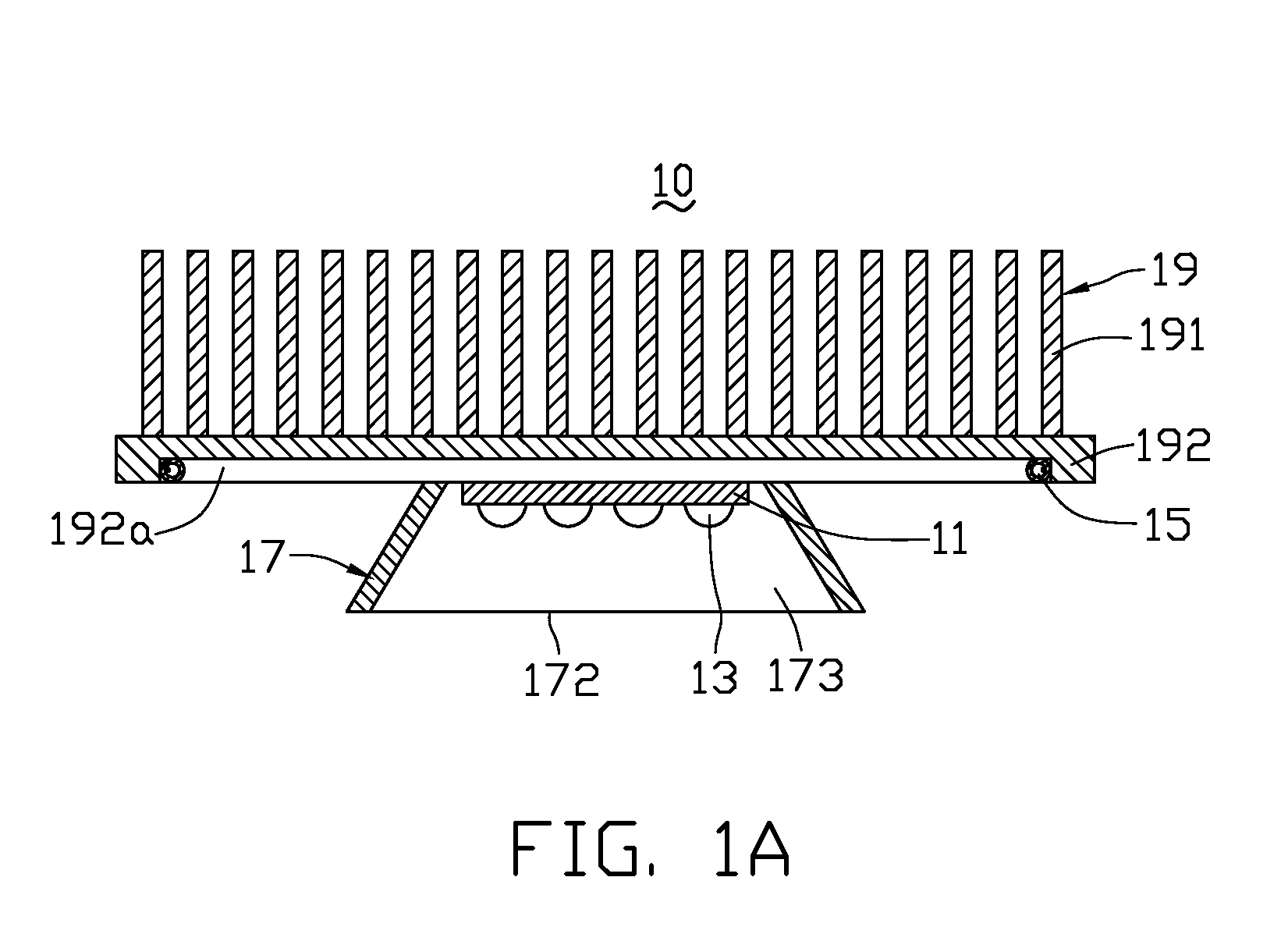

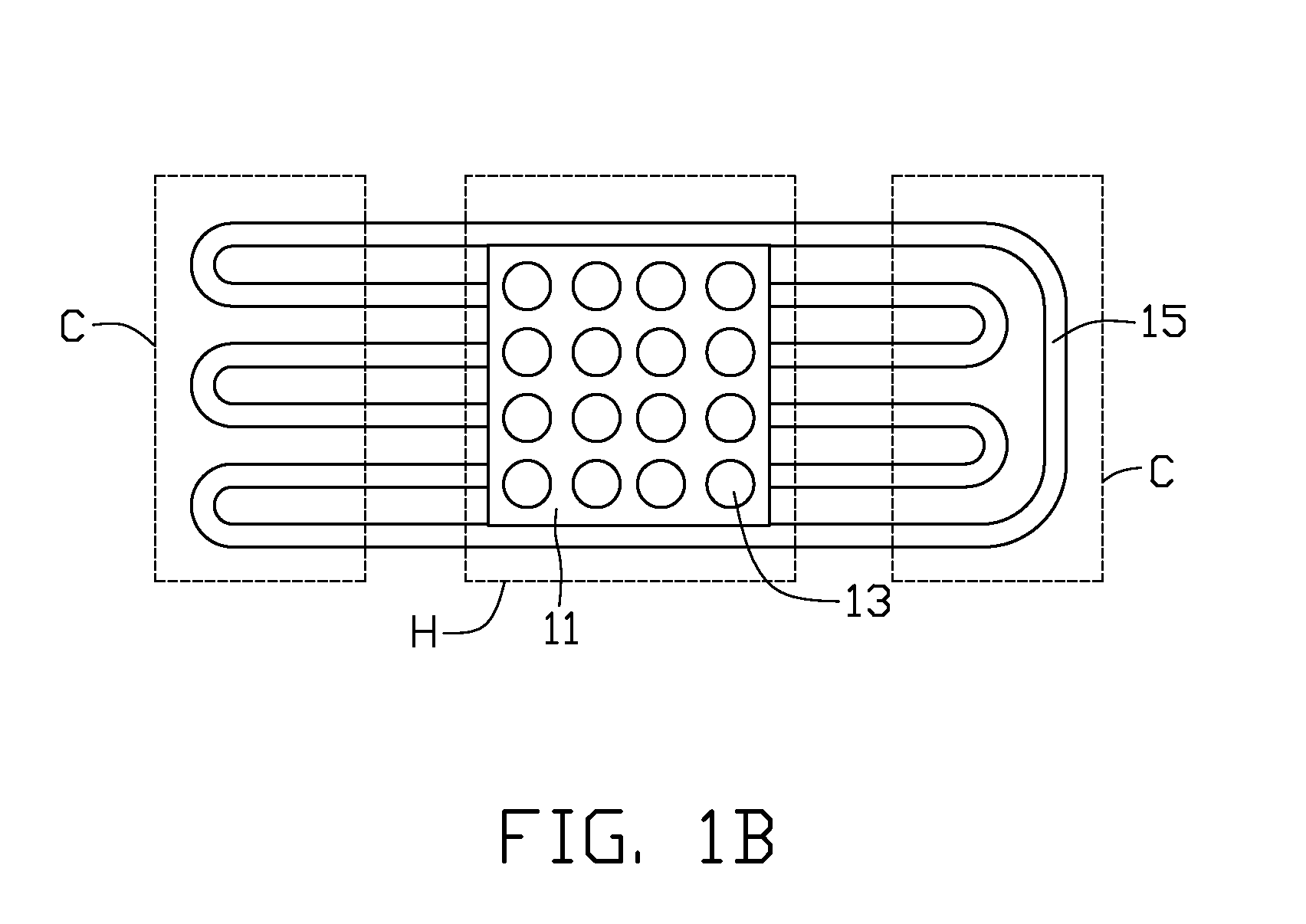

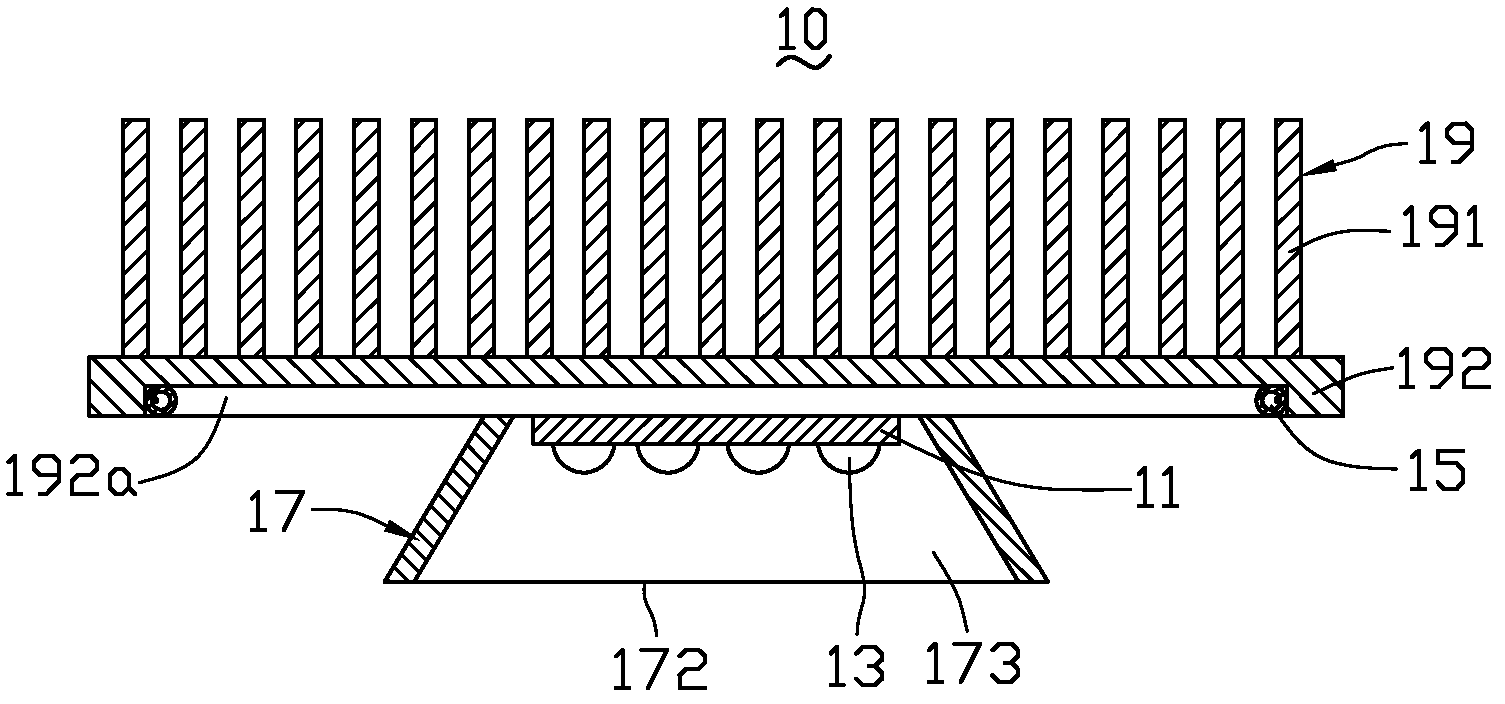

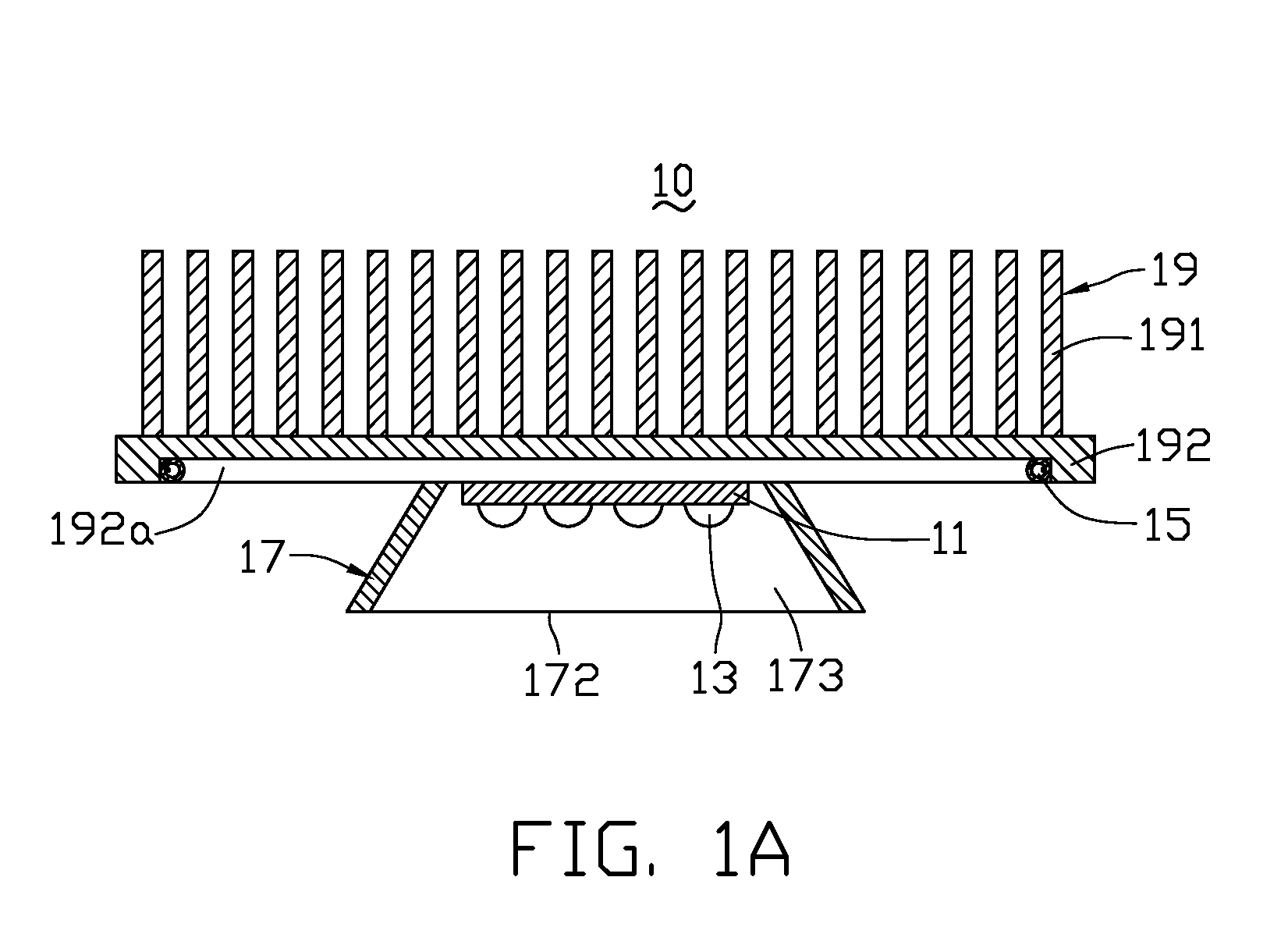

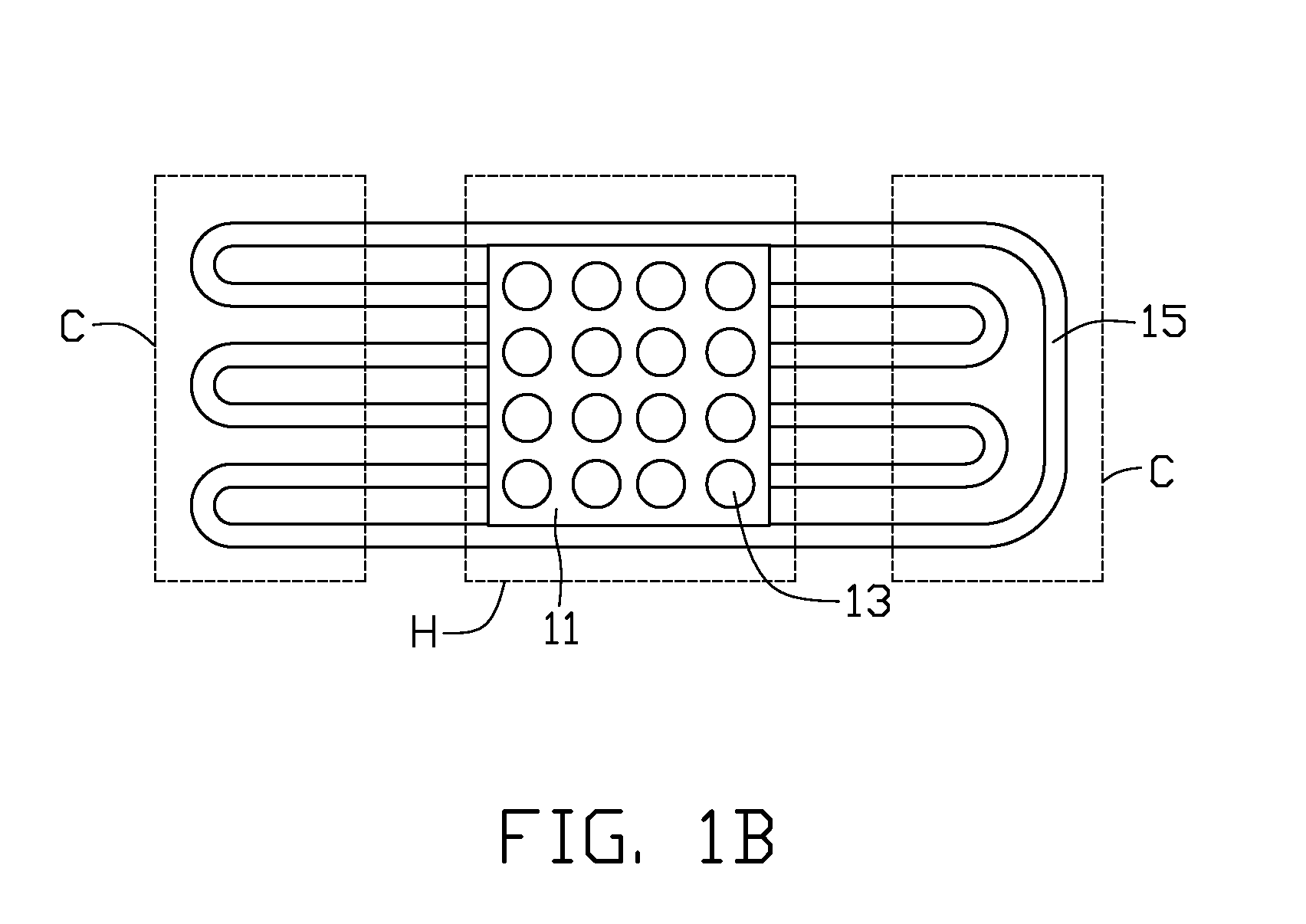

LED lamp cooling apparatus with pulsating heat pipe

InactiveUS20080117637A1Heat dissipationEasy to dry outPlanar light sourcesPoint-like light sourceElectricityWorking fluid

An LED lamp cooling apparatus (10) includes a substrate (11), a plurality of LEDs (13) electrically connected with the substrate, a heat sink (19) for dissipation of heat generated by the LEDs and a pulsating heat pipe (15) thermally connected with the heat sink. The pulsating heat pipe includes a plurality of heat receiving portions (154) and a plurality of heat radiating portions (155), and contains a working fluid (153) therein. The substrate is attached to the heat receiving portions of the pulsating heat pipe and the heat sink is attached to the heat radiating portions of the pulsating heat pipe. The heat generated by the LEDs is transferred from the heat receiving portions to the heat radiating portions of the pulsating heat pipe through pulsation or oscillation of the working fluid in the pulsating heat pipe.

Owner:HON HAI PRECISION IND CO LTD

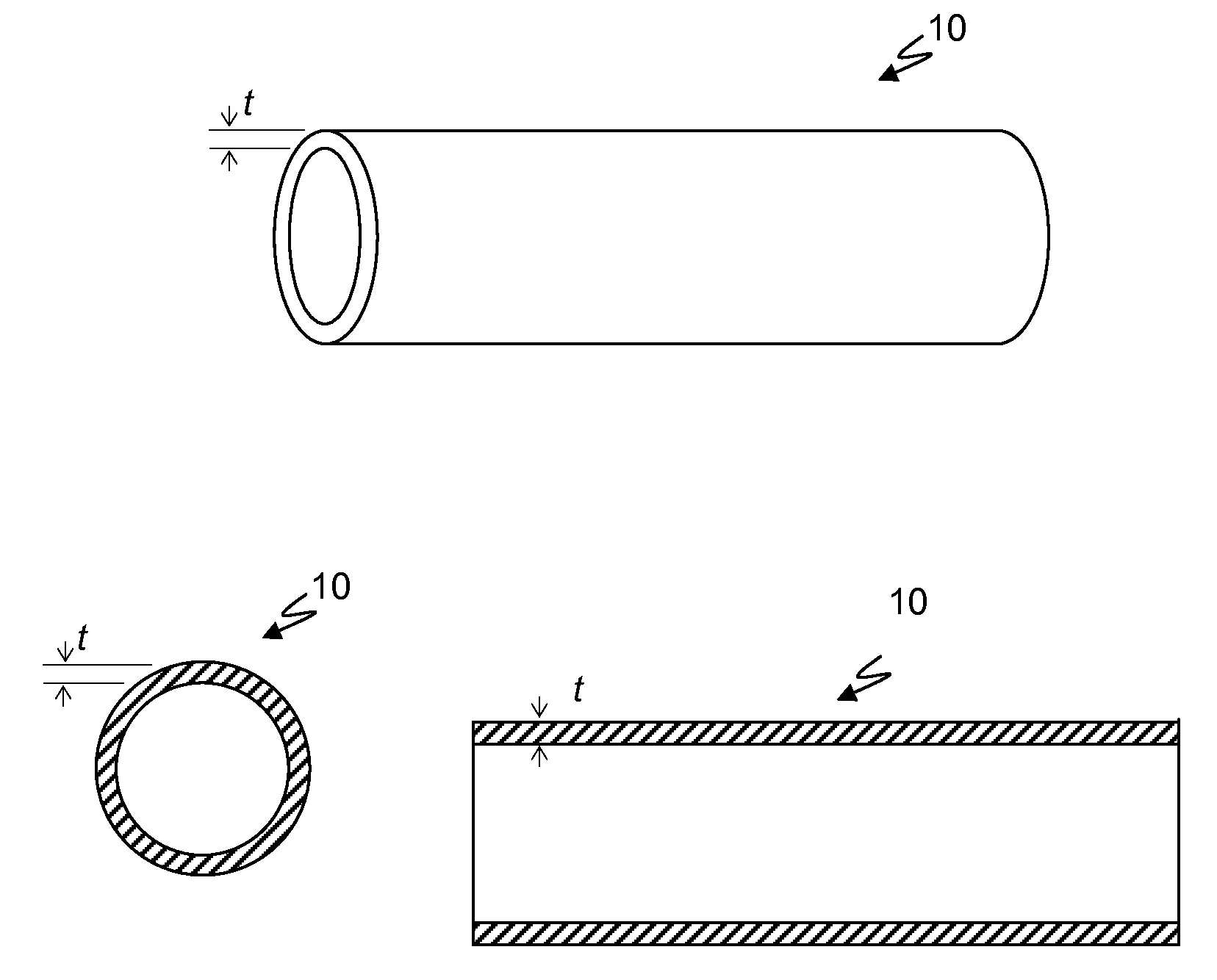

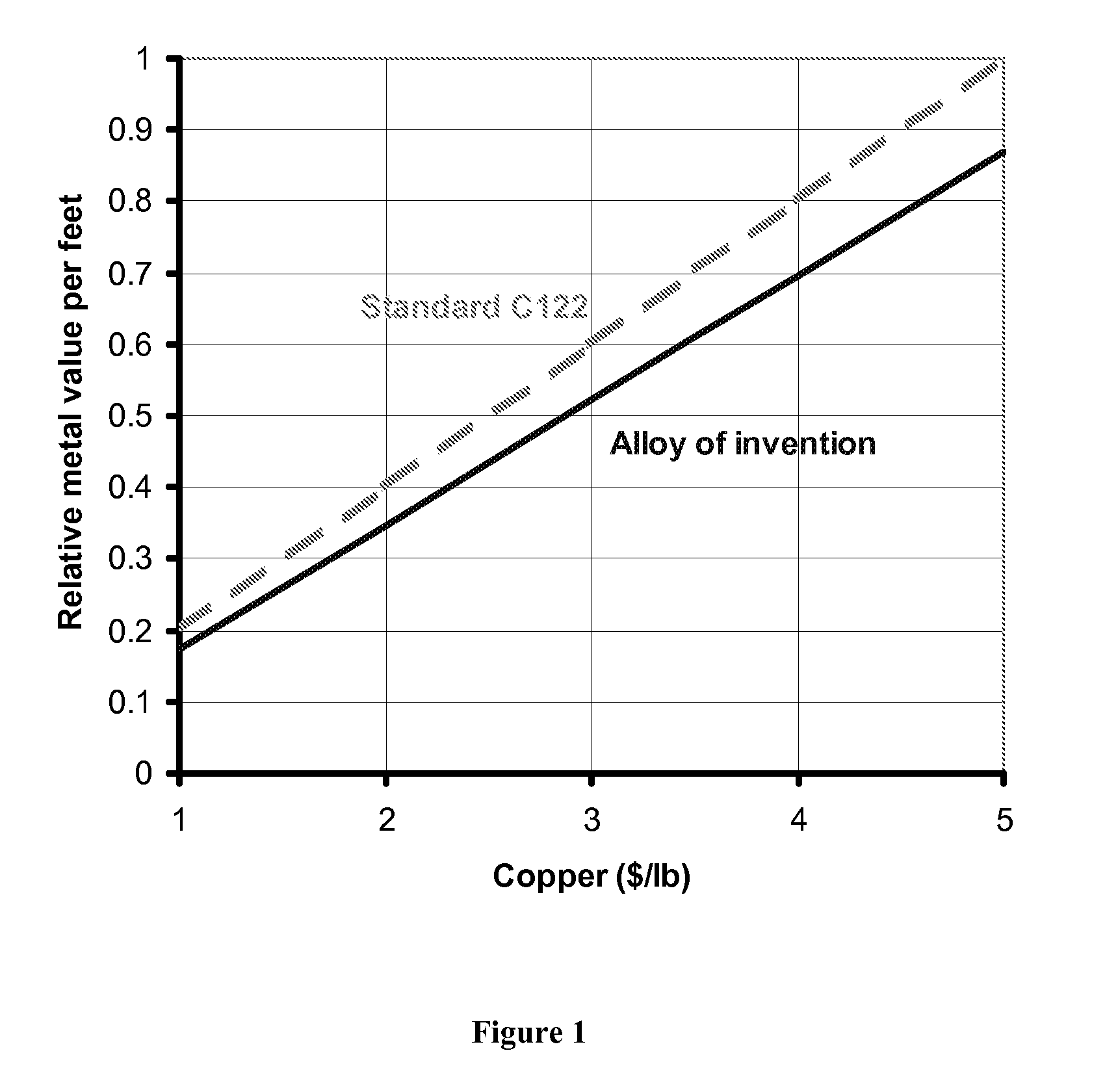

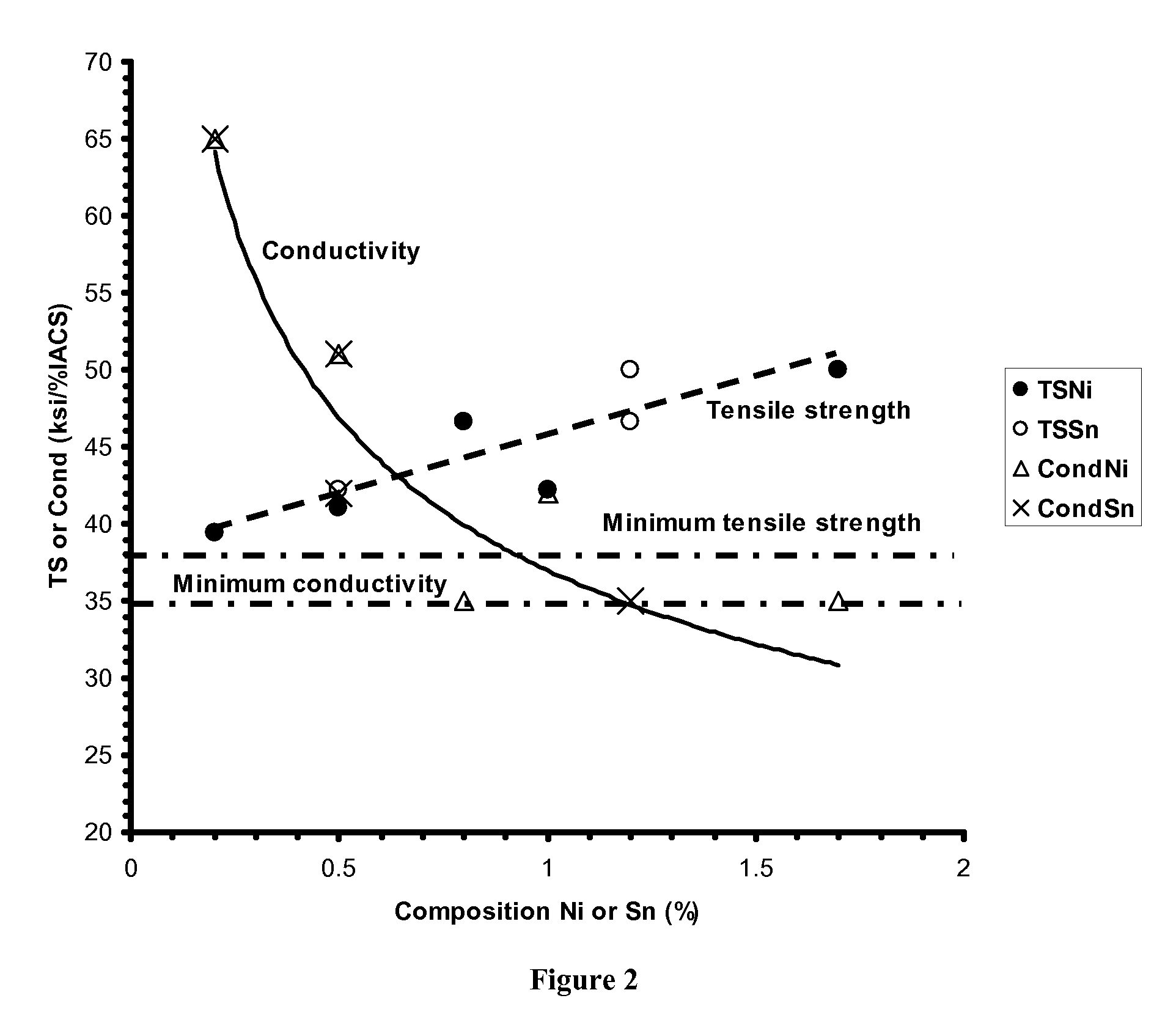

Copper Alloy for Heat Exchanger Tube

InactiveUS20110005739A1High tensile strengthEasy to processTubular elementsPlate heat exchangerHigh pressure

An alloy comprising copper, nickel, tin and, optionally, phosphorus which can be used in, for example, a copper alloy tube for heat exchangers that provides excellent fracture strength and processability for reducing the weight of the tube and for use in high pressure applications with cooling media such as carbon dioxide.

Owner:VIRTUS PRECISION TUBE LLC

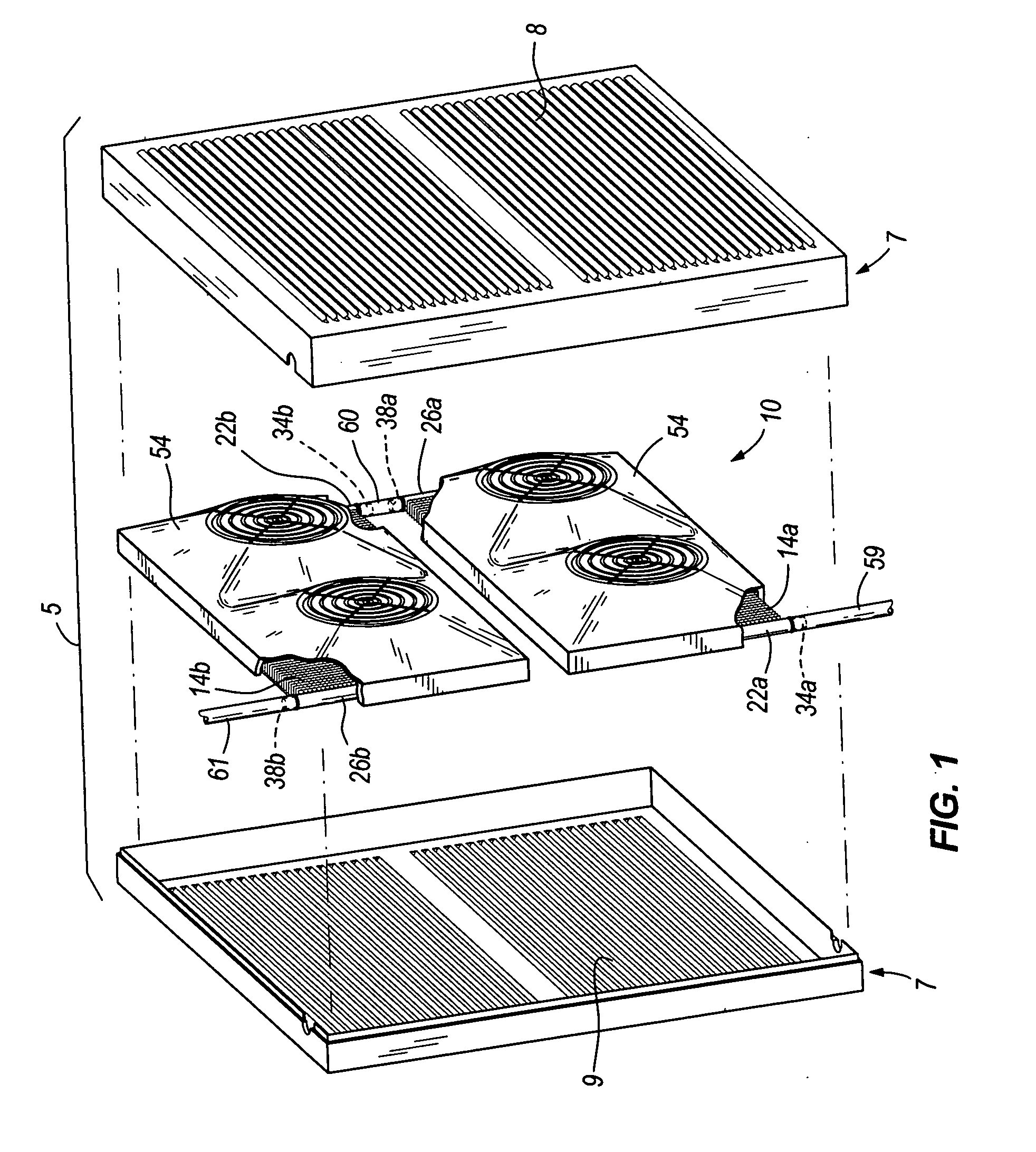

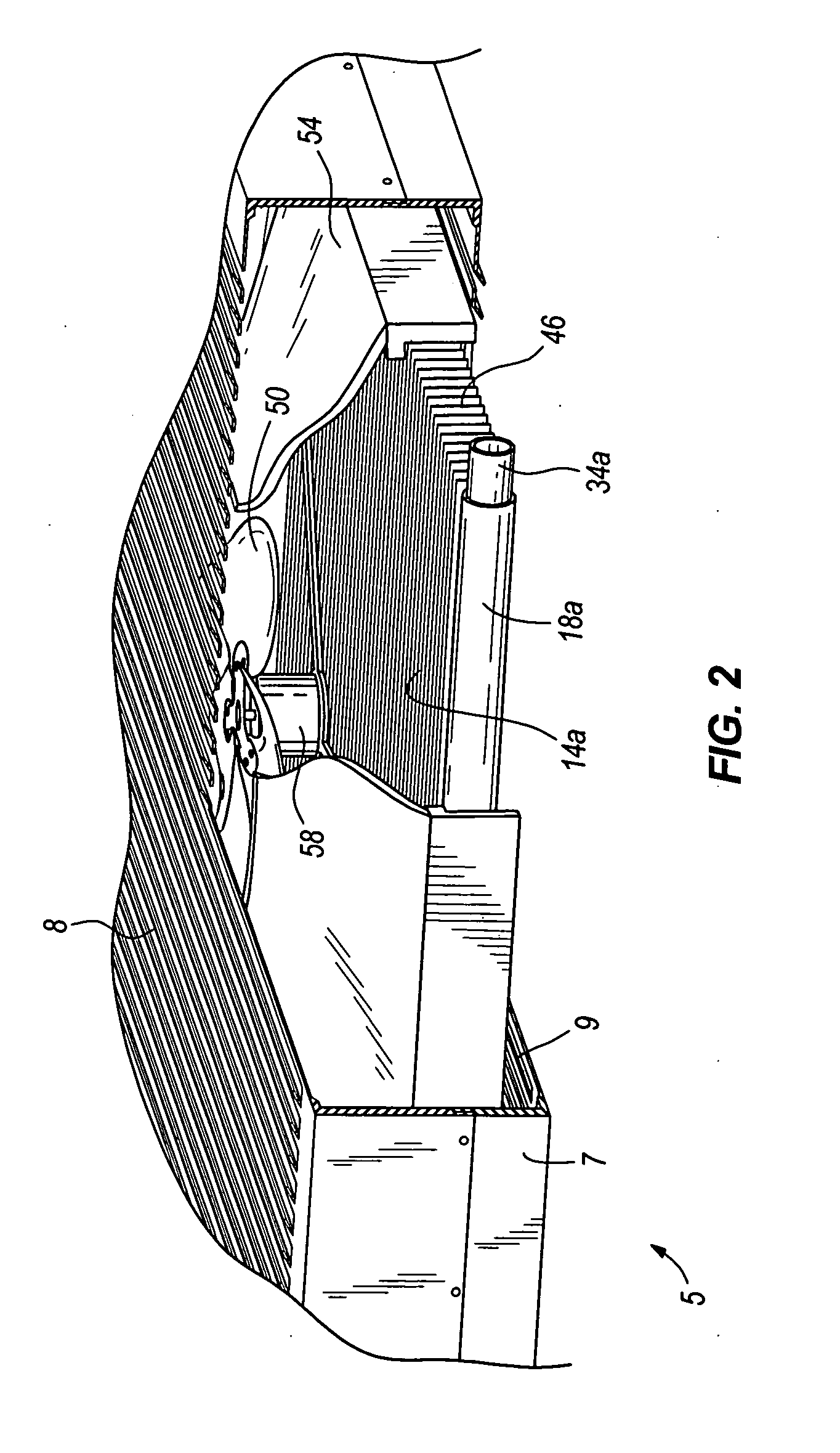

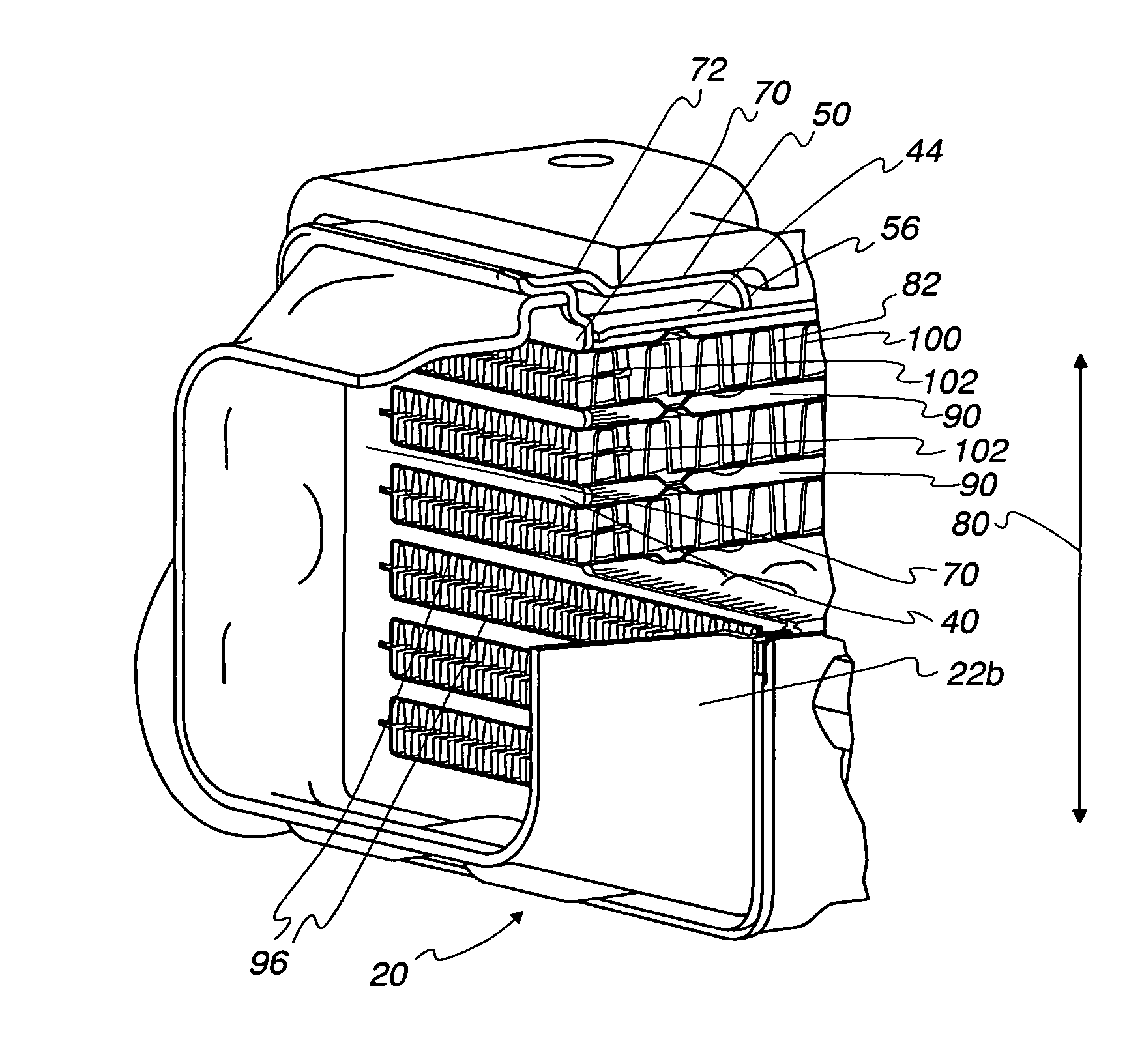

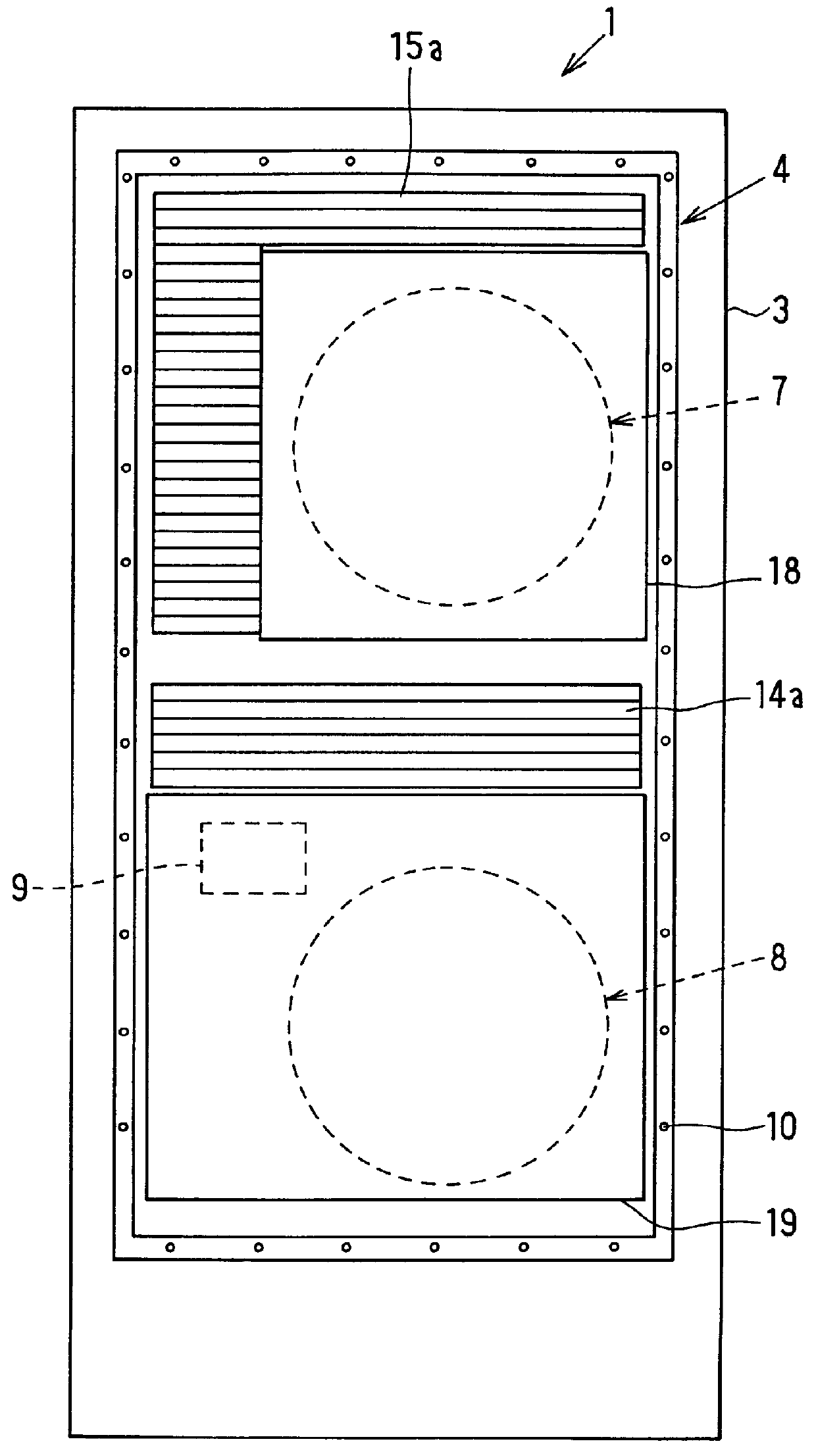

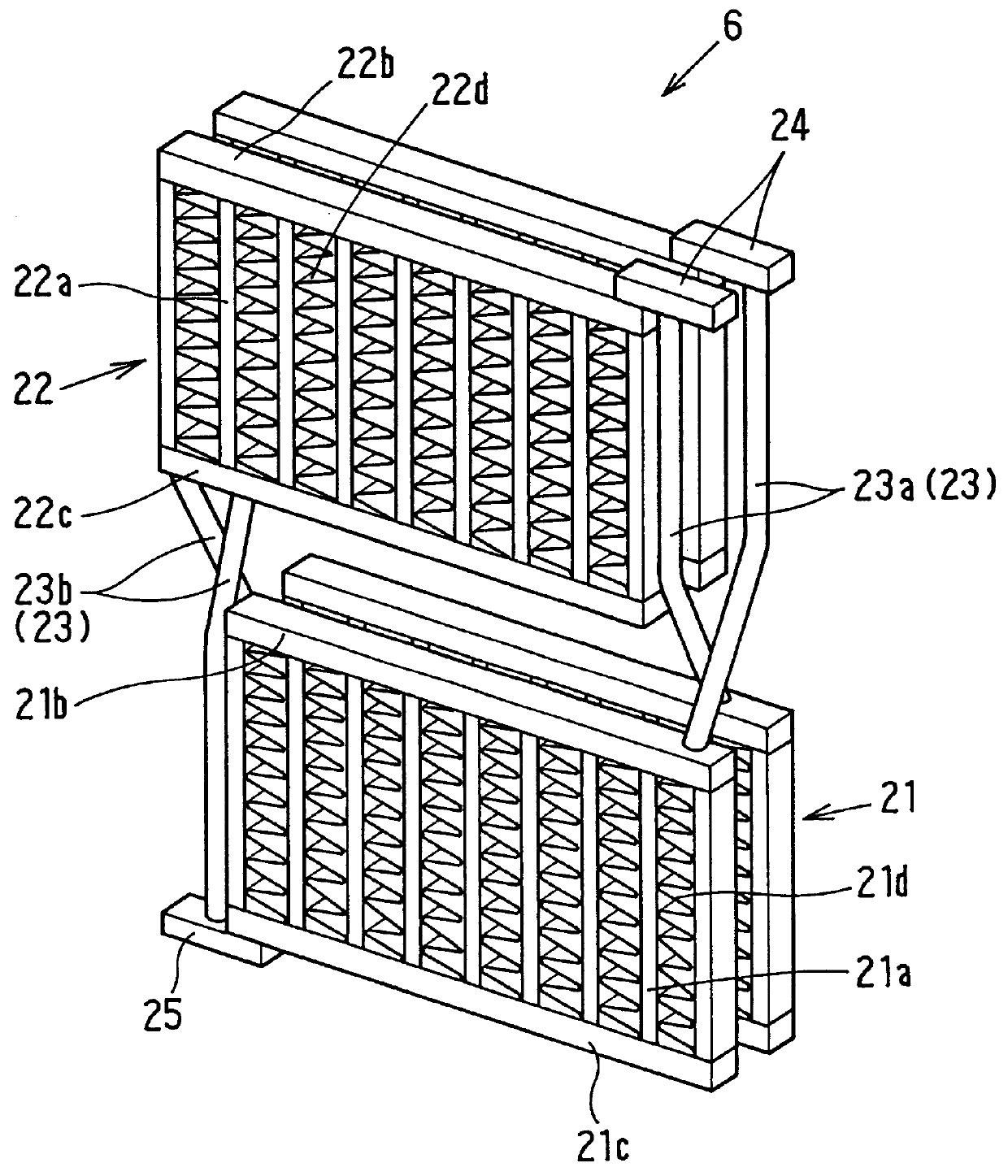

Microchannnel evaporator assembly

The present invention provides a unit cooler adapted for use in a refrigerated environment. The unit cooler includes a housing adapted to be positioned within the refrigerated environment and at least one microchannel evaporator coil supported by the housing. The at least one microchannel evaporator coil includes an inlet manifold and an outlet manifold. The inlet manifold has an inlet port for receiving refrigerant, and the outlet manifold has an outlet port for discharging the refrigerant.

Owner:HUSNN

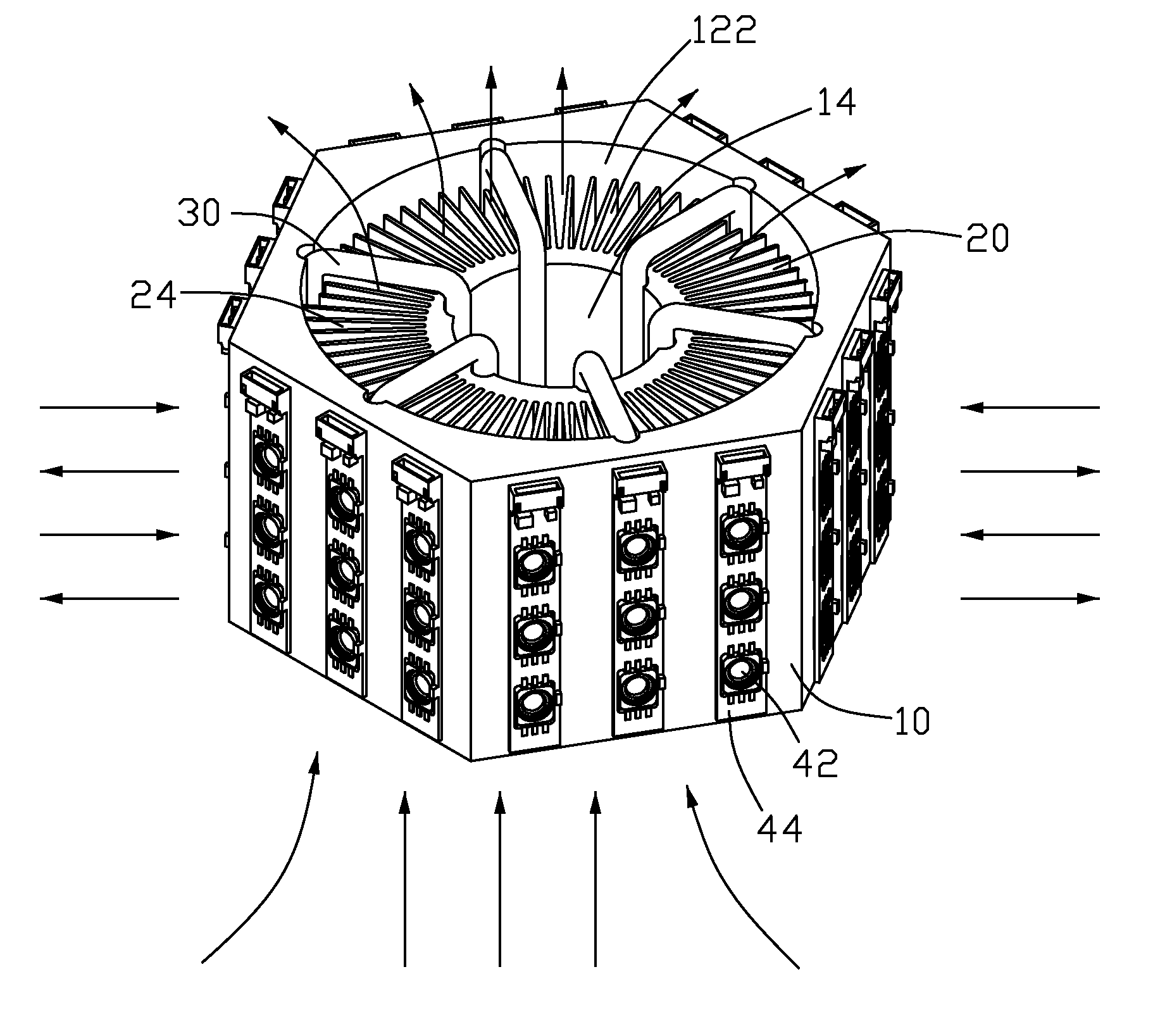

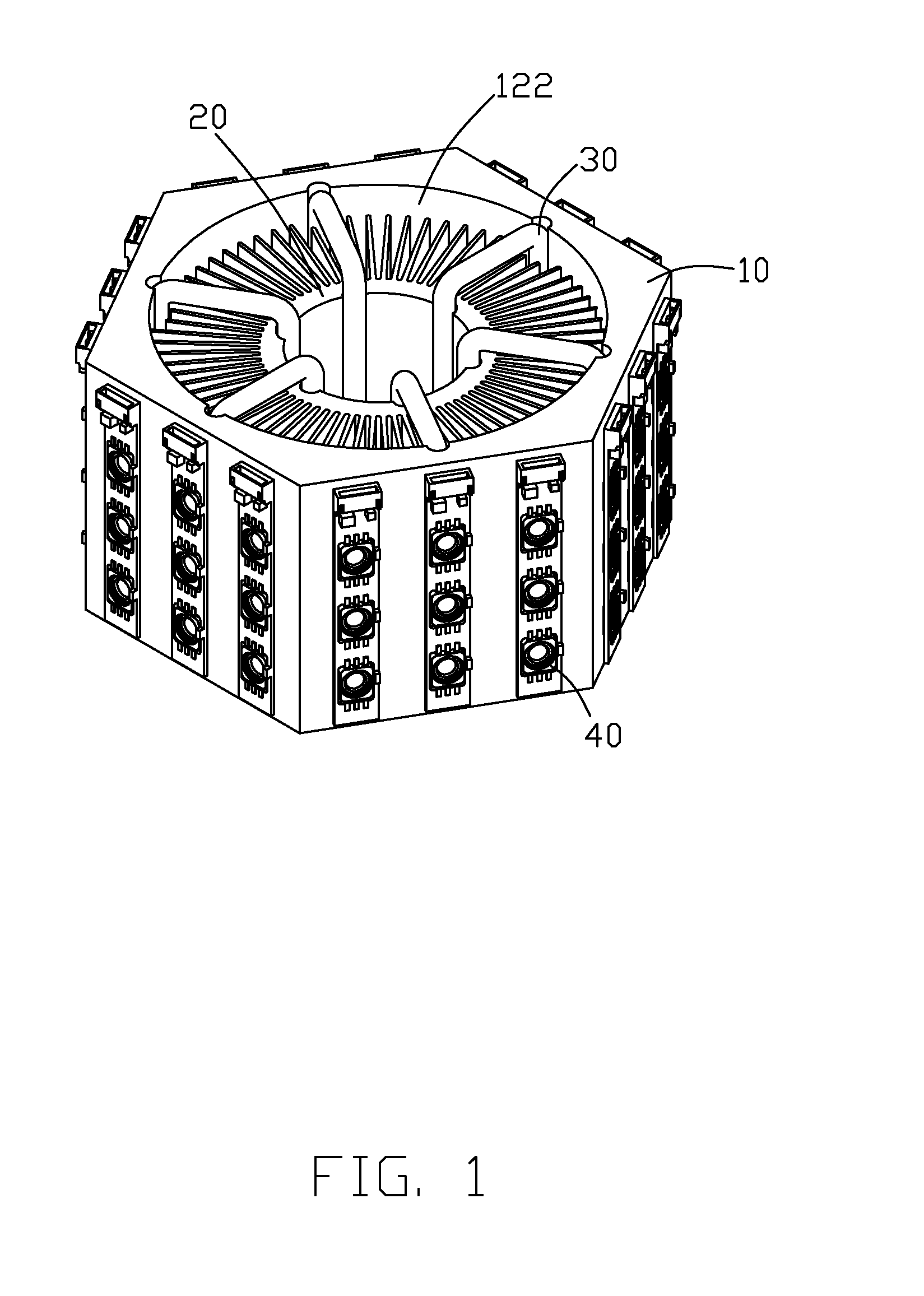

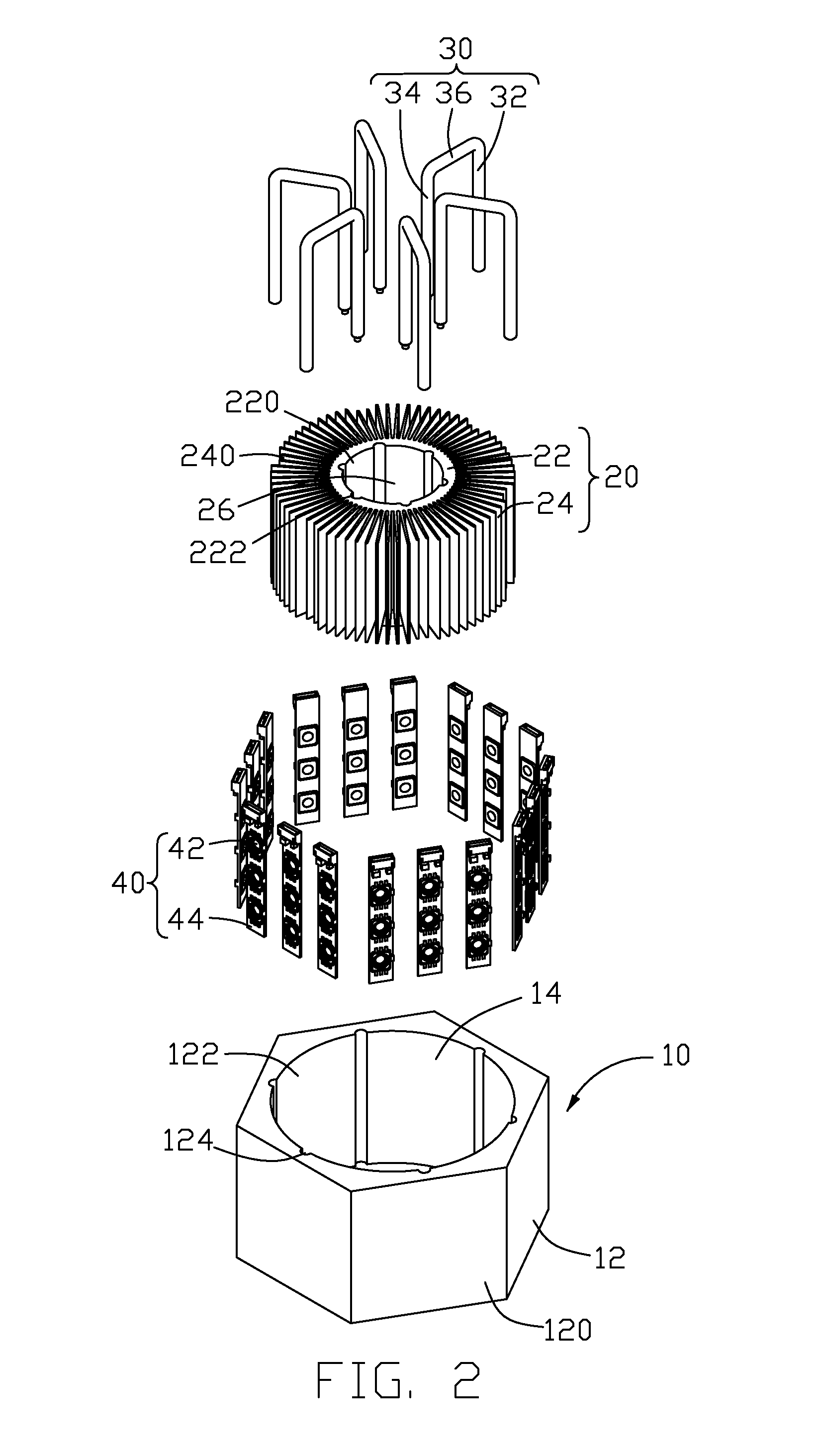

LED lamp with a heat sink assembly

InactiveUS20090040759A1Improve cooling efficiencyPoint-like light sourceLighting support devicesEngineeringLED lamp

An LED lamp includes a hollow first heat sink (10), a plurality of LED modules (40) respectively mounted on outer sidewalls (120) of the first heat sink, a second heat sink (20) being enclosed by the first heat sink, and a plurality of heat pipes (30) connecting the second heat sink to the first heat sink. The second heat sink includes an annular base (22) and a plurality of fins (24, 240) extending outwardly and radially from an outer sidewall of the base. The heat pipes couple the base of the second heat sink with the first heat sink, so that heat generated by the LED modules can be transferred from the first heat sink to the second heat sink via the heat pipes, thereby enhancing a heat dissipating efficiency of the LED lamp.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Heat exchanger with flat tubes

ActiveUS20050161206A1Reinforcing meansInternal combustion piston enginesElectrical and Electronics engineeringHeat exchanger

A heat exchanger with a plurality of stacked flat tubes and a collecting tank having a wall extending around the entire periphery of, and connected to, the end of the stacked flat tubes. A first medium may be distributed through the collecting tank and flat tubes. Internal inserts are in the flat tubes, with the inserts being bonded between the broad sides of the tubes and, in the region of connection of the tubes to the collecting tank, being configured to compensate for length changes in the stacking direction caused by temperature changes, as by recesses in connectors such as wave flanks or by corrugated wave flanks. The flat tubes with inserts such as described may be separately provided for use in manufacture of heat exchangers.

Owner:MODINE MFG CO

LED lamp cooling apparatus with pulsating heat pipe

InactiveUS7547124B2Heat dissipationEasy to dry outPlanar light sourcesPoint-like light sourceElectricityWorking fluid

An LED lamp cooling apparatus (10) includes a substrate (11), a plurality of LEDs (13) electrically connected with the substrate, a heat sink (19) for dissipation of heat generated by the LEDs and a pulsating heat pipe (15) thermally connected with the heat sink. The pulsating heat pipe includes a plurality of heat receiving portions (154) and a plurality of heat radiating portions (155), and contains a working fluid (153) therein. The substrate is attached to the heat receiving portions of the pulsating heat pipe and the heat sink is attached to the heat radiating portions of the pulsating heat pipe. The heat generated by the LEDs is transferred from the heat receiving portions to the heat radiating portions of the pulsating heat pipe through pulsation or oscillation of the working fluid in the pulsating heat pipe.

Owner:HON HAI PRECISION IND CO LTD

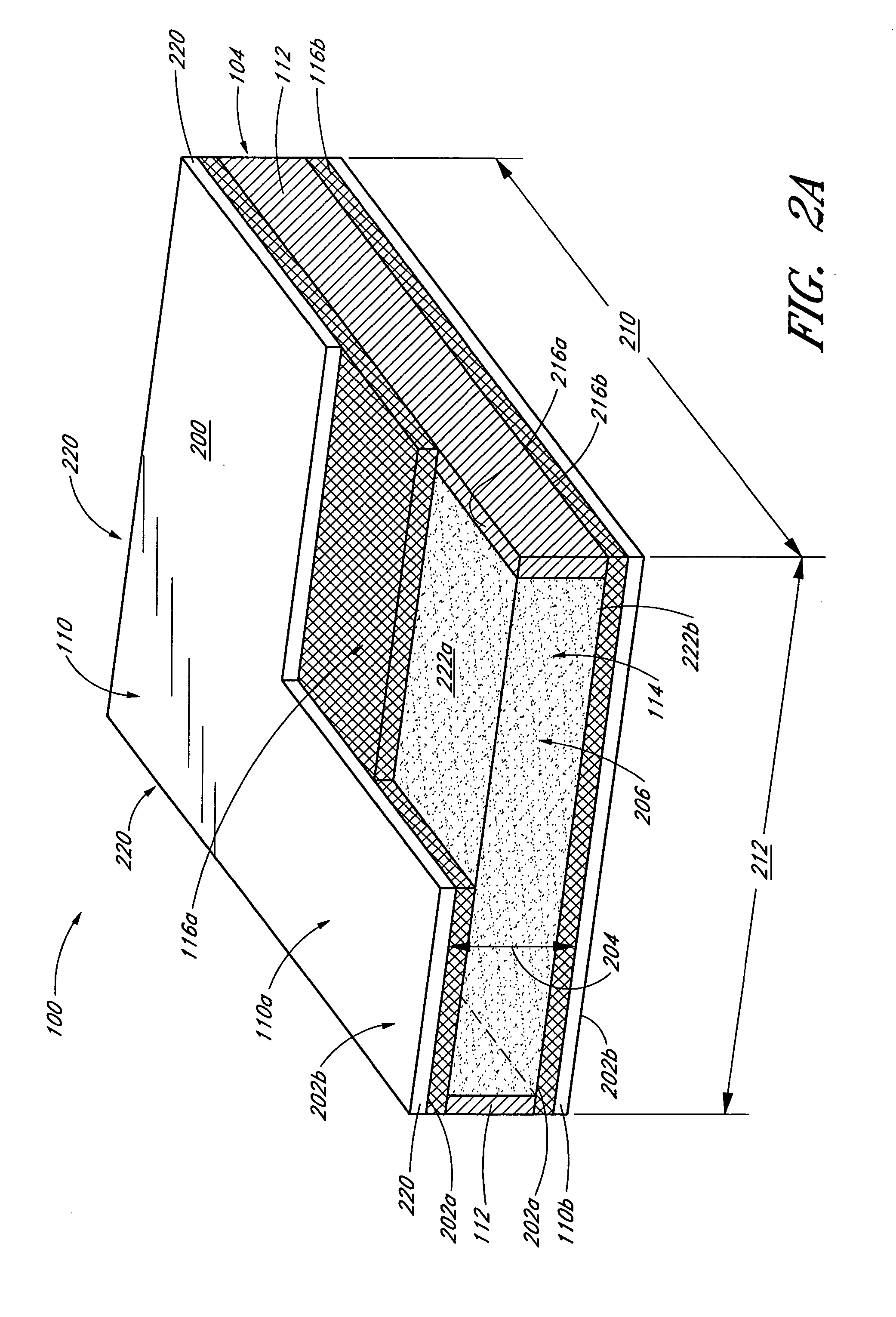

Hybrid heat exchangers

InactiveUS20070284095A1Improve mechanical durabilityLow densityReinforcing meansStationary tubular conduit assembliesCarbon compositesCore component

A light weight hybrid heat exchanger core possessing low density and improved thermal conductivity is disclosed. The hybrid core is comprised of a plurality of parting sheets and interposed by a plurality of high thermal conductivity, light weight bridging elements and enclosure bars. These core members are comprised of dissimilar materials. The parting sheets and bridging elements are interconnected by a specially tailored joint which forms form a substantially strong, high thermal conductivity bond. In particular embodiments, carbon-based bridging elements are bonded to metallic parting sheets using a brazed joint. The parting sheets, in certain embodiments, may comprise titanium or Ni-based superalloys or carbon composites, while the carbon-based bridging elements may comprise fiber-reinforced composites. The carbon-based bridging elements reduce the core weight and increase the core thermal conductivity over conventional all-metal designs, while the brazed joint provides for improved leak resistance over all-composite designs.

Owner:ALLCOMP

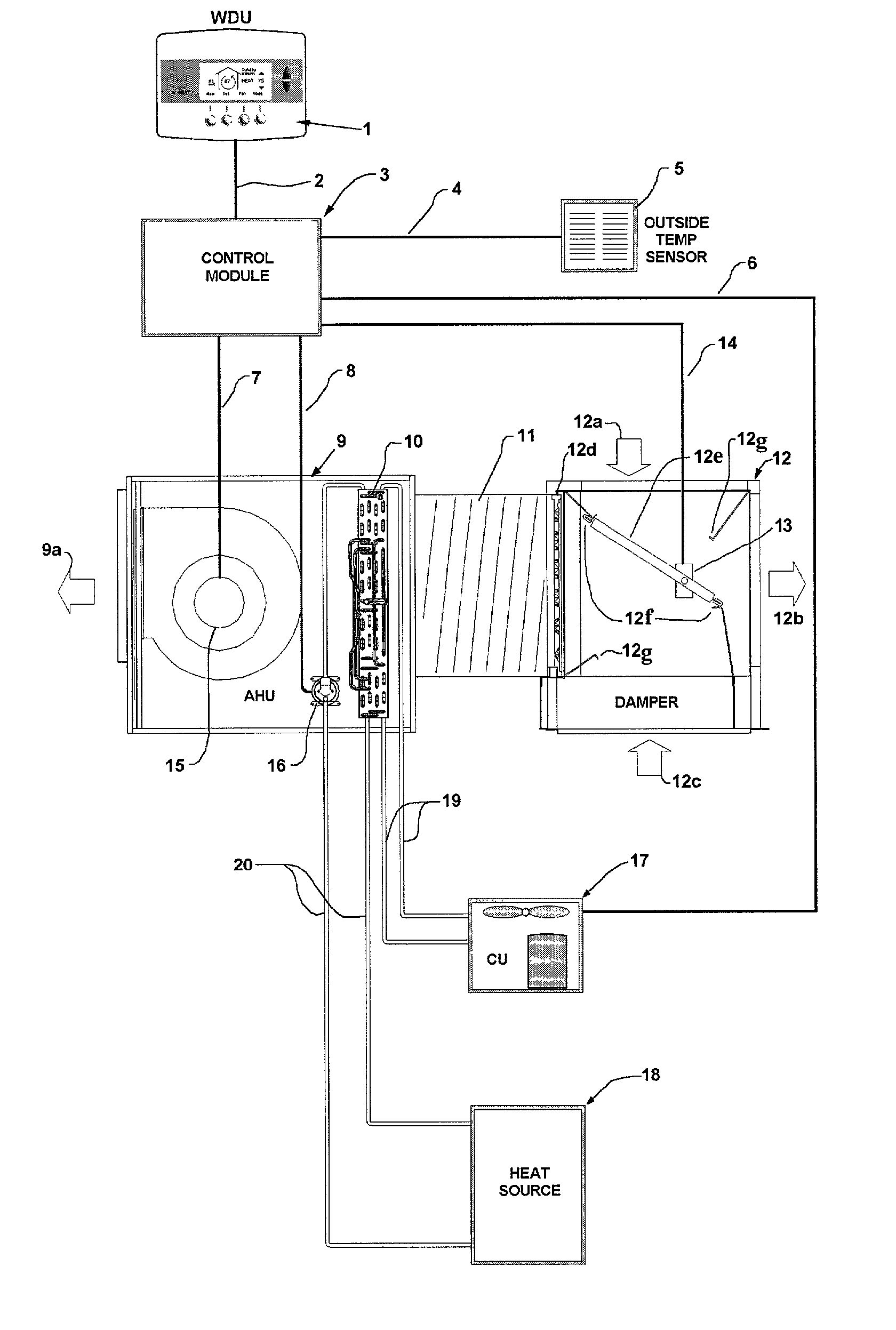

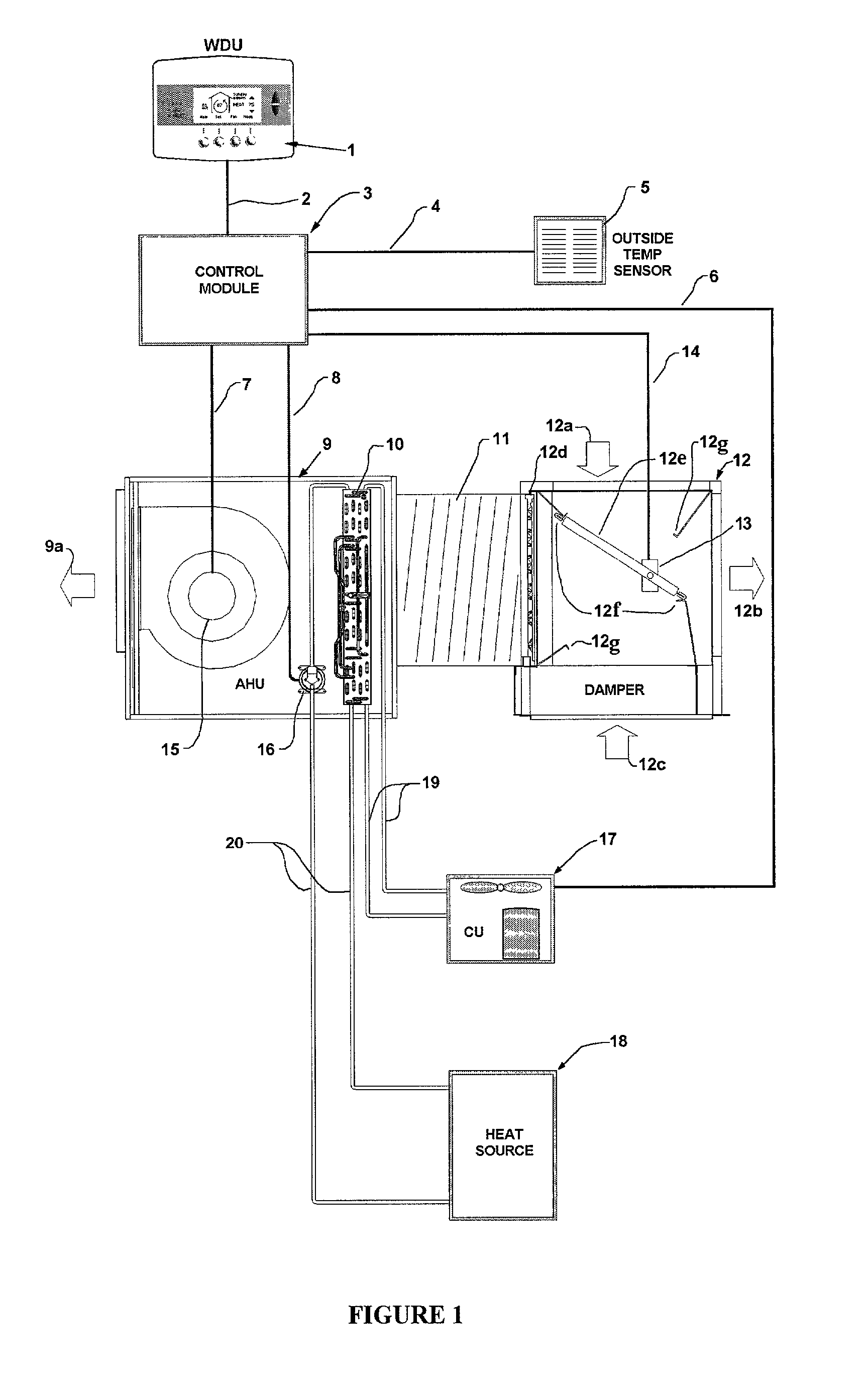

Integrated ventilation cooling system

InactiveUS20020124992A1Reduce energy useEasy temperature controlDucting arrangementsMechanical apparatusIndoor air qualityAir handler

A system and method for cooling and heating of buildings consisting of an integrated assembly of devices, including a variable speed air handler, hot water heating coil, outside air damper, controller, and optional compressor-based air conditioner. During summer the system utilizes nighttime outside air for cooling and uses air temperature predictions to provide information about optimal control settings and to maintain comfort. During winter the system varies airflow with heating demand and ventilates with outside air to maintain indoor air quality.

Owner:NIGHTBREEZE

Heat engine

InactiveUS7062913B2Improve efficiencyBoilers/analysersClimate change adaptationWorking fluidEngineering

Owner:OHIO STATE INNOVATION FOUND

High temperature thermal energy storage system

InactiveUS20120055661A1Large lengthFrom solar energyHeat storage plantsThermal energyThermal energy storage

Owner:FEHER PETER

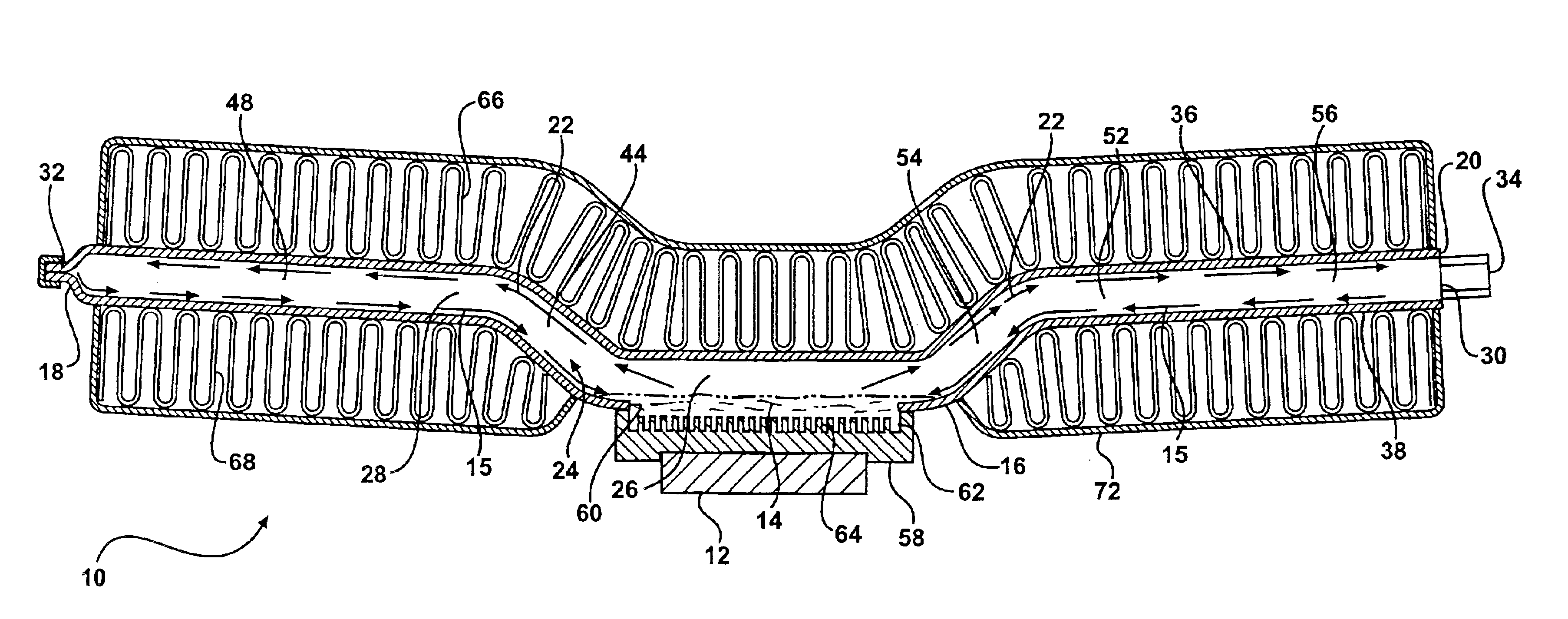

Compact thermosiphon for dissipating heat generated by electronic components

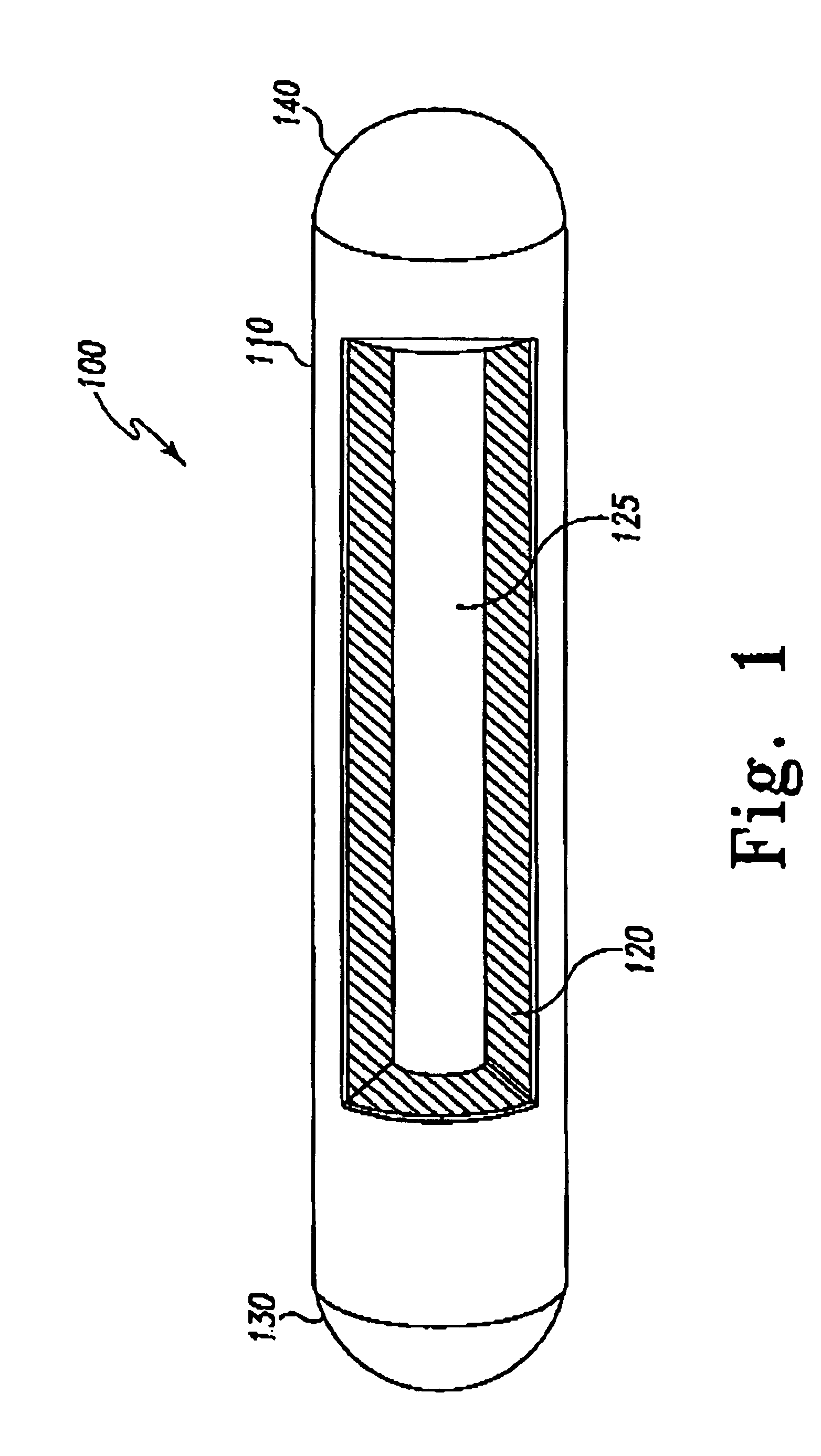

InactiveUS6840311B2Adequate heat dissipationOvercome deficienciesSemiconductor/solid-state device detailsSolid-state devicesWorking fluidEvaporation

A compact thermosiphon assembly for dissipating heat generated by electronic components using a working fluid includes a tube having a first end and a second end and a flat cross section defining an elongated chamber is disclosed. The tube has an evaporation region for receiving heat to evaporate the working fluid into a vaporized working fluid within the chamber disposed between a first condensation region and a second condensation region opposite the first condensation region for condensing the vaporized working fluid back into a liquefied working fluid within the chamber. Each of the condensation regions have a first portion extending upwardly at a first angle from the evaporation region and a second portion extending upwardly at a second angle different than the first angle.

Owner:COOLIT SYSTEMS INC

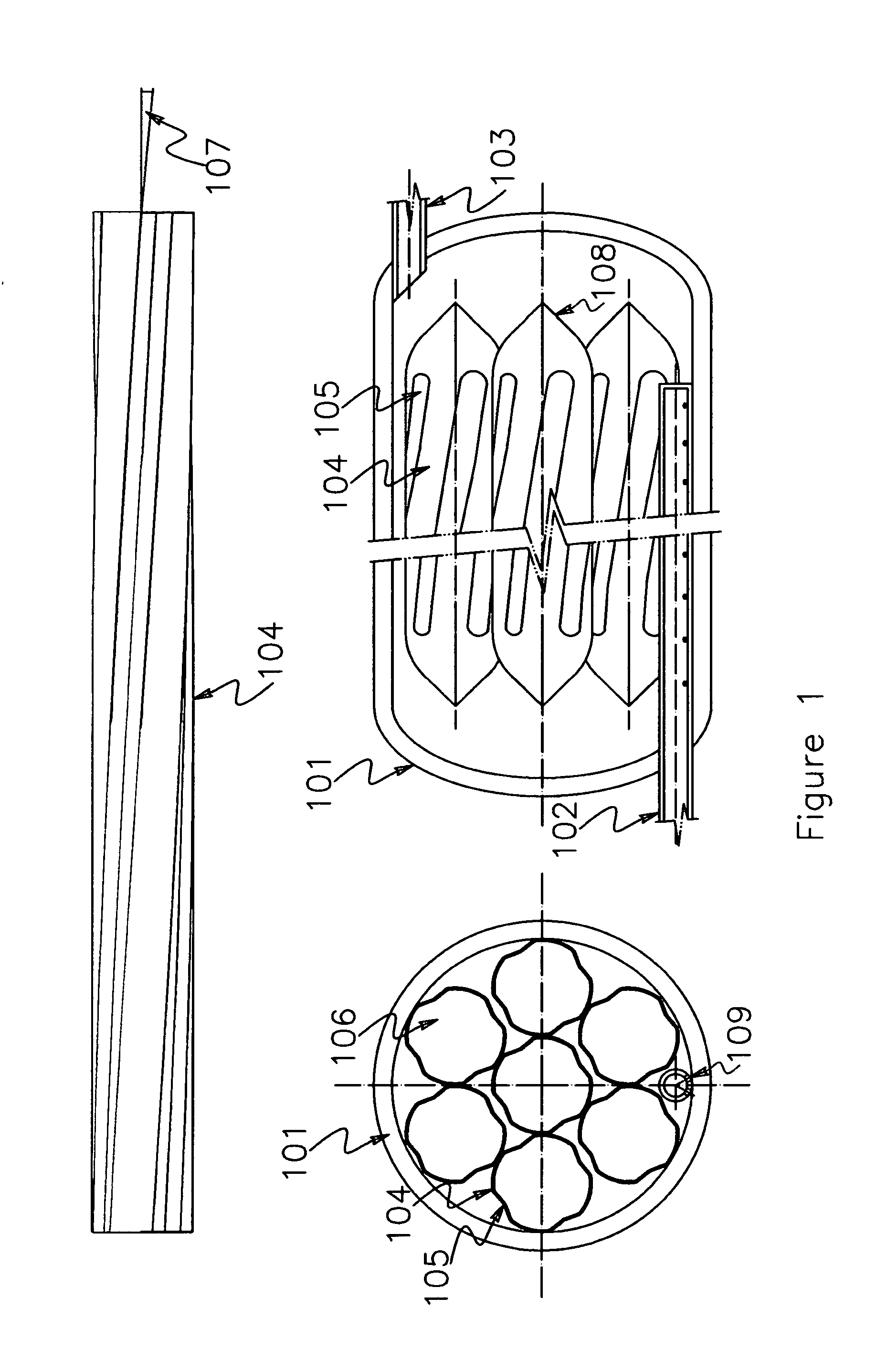

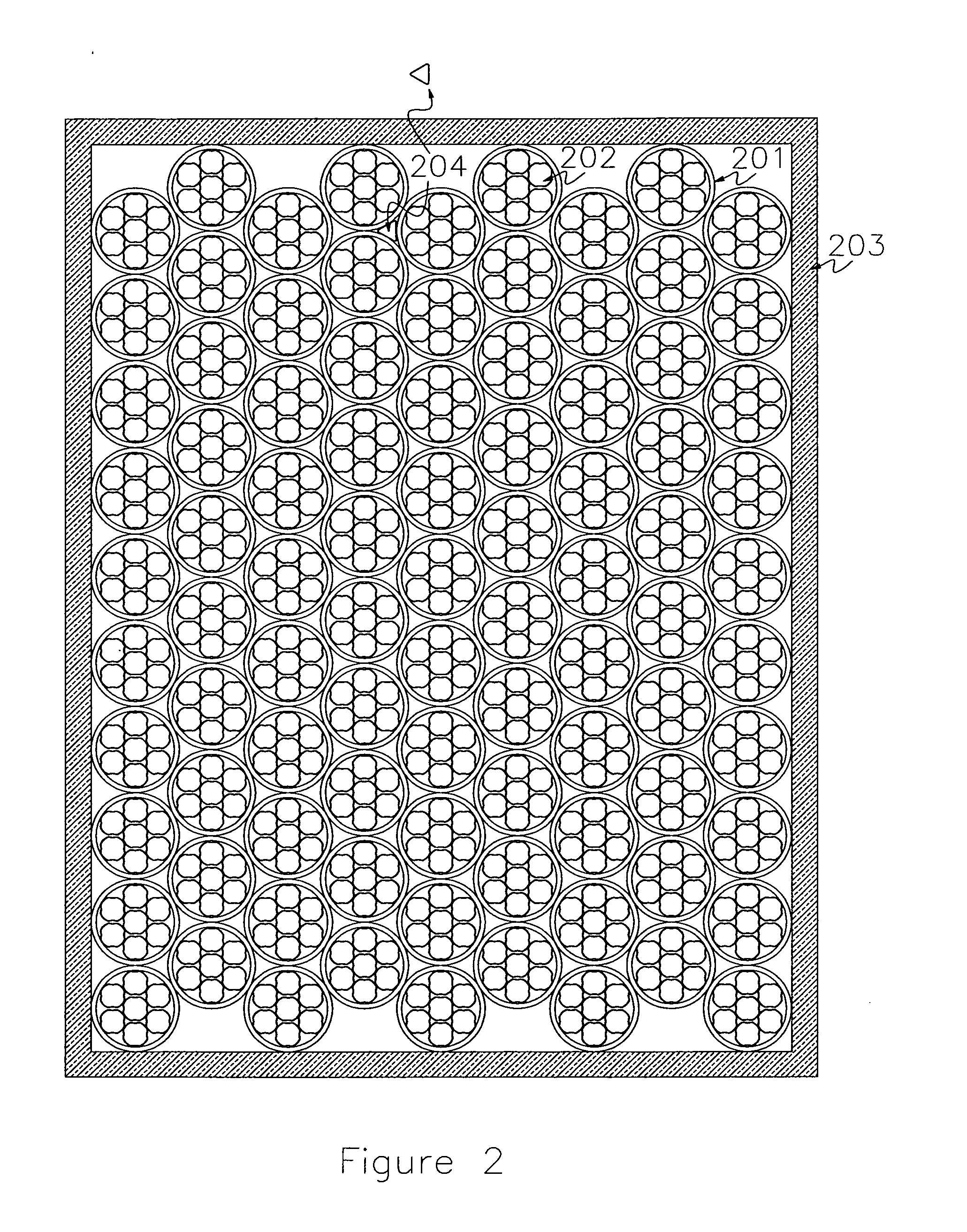

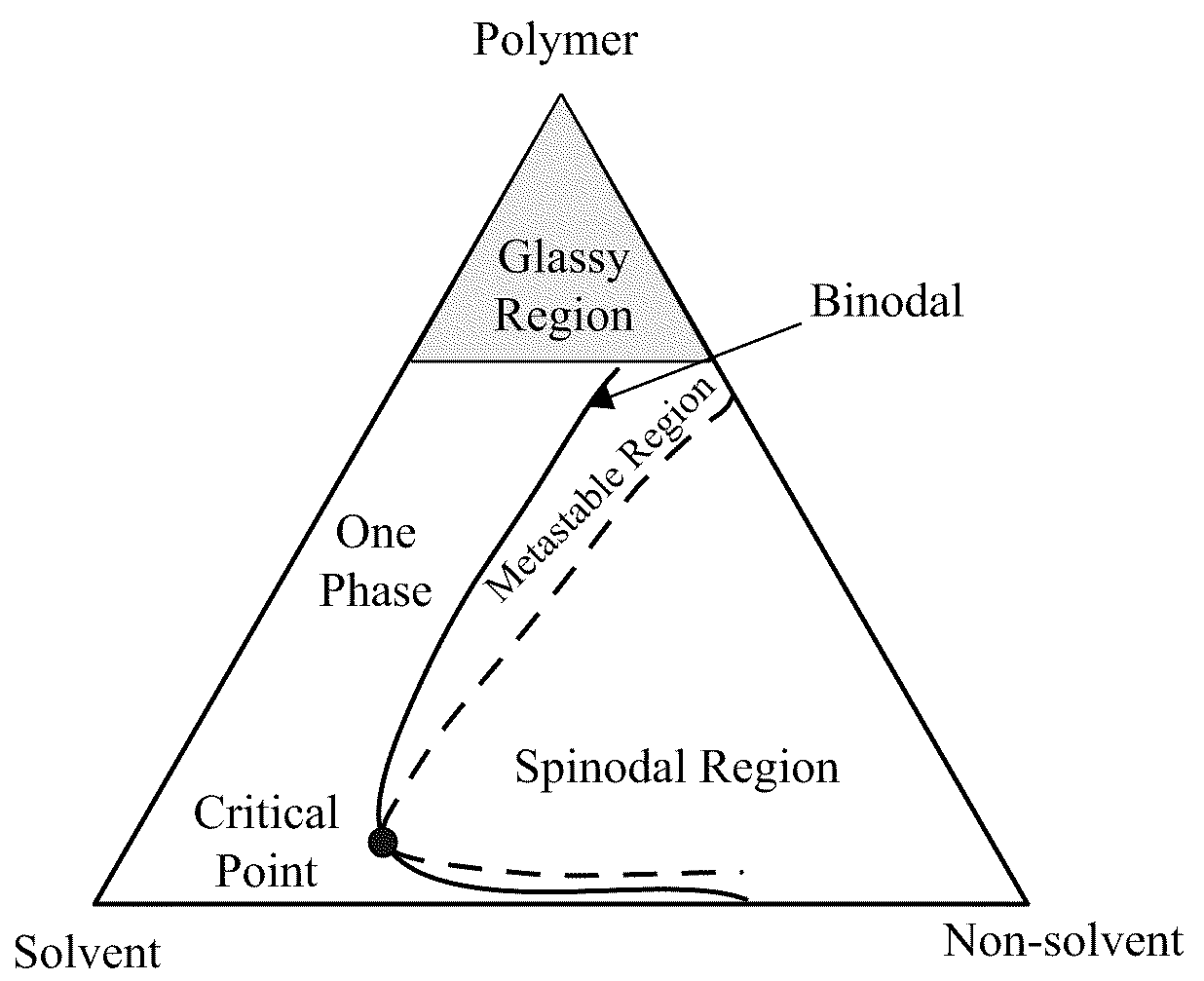

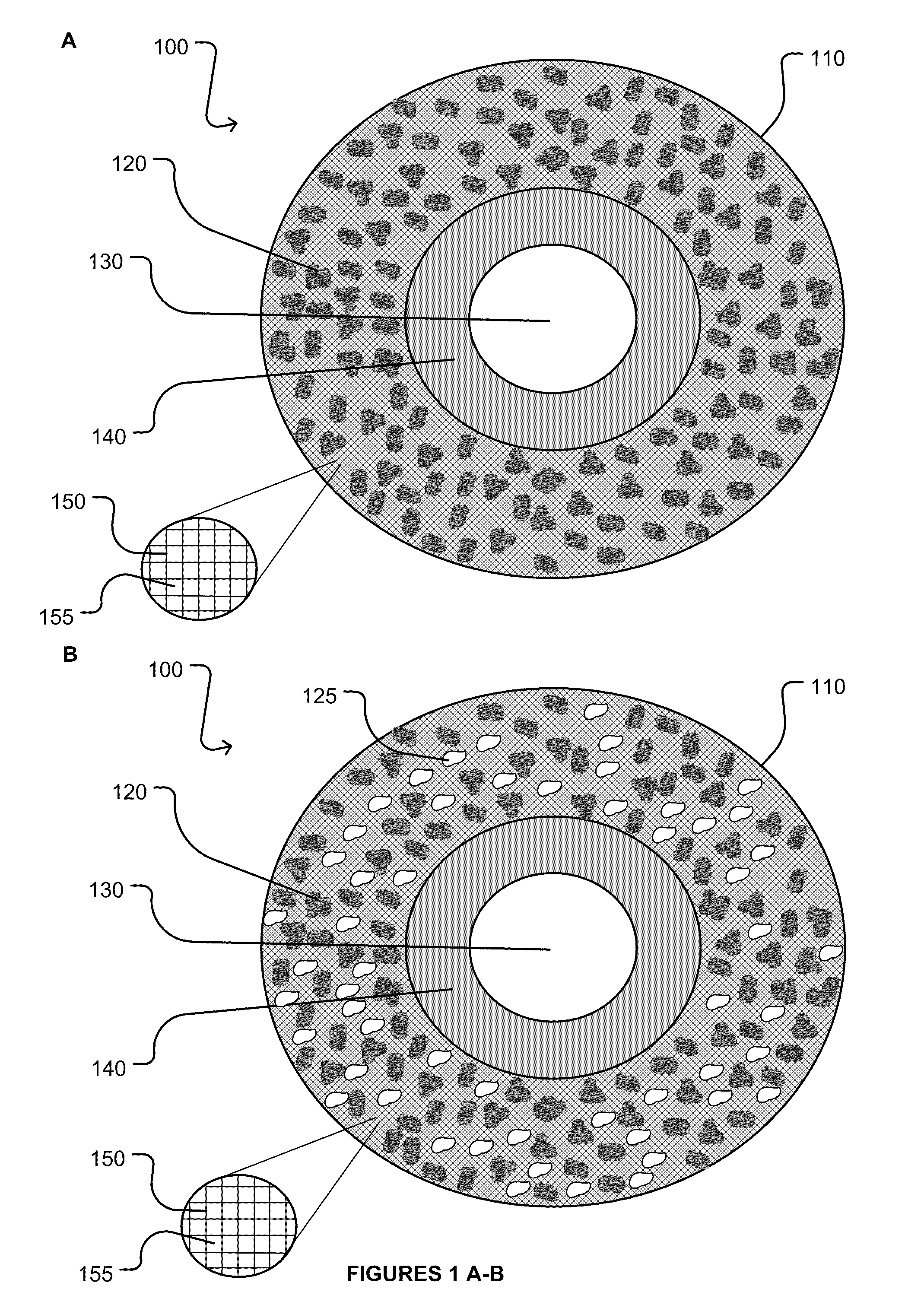

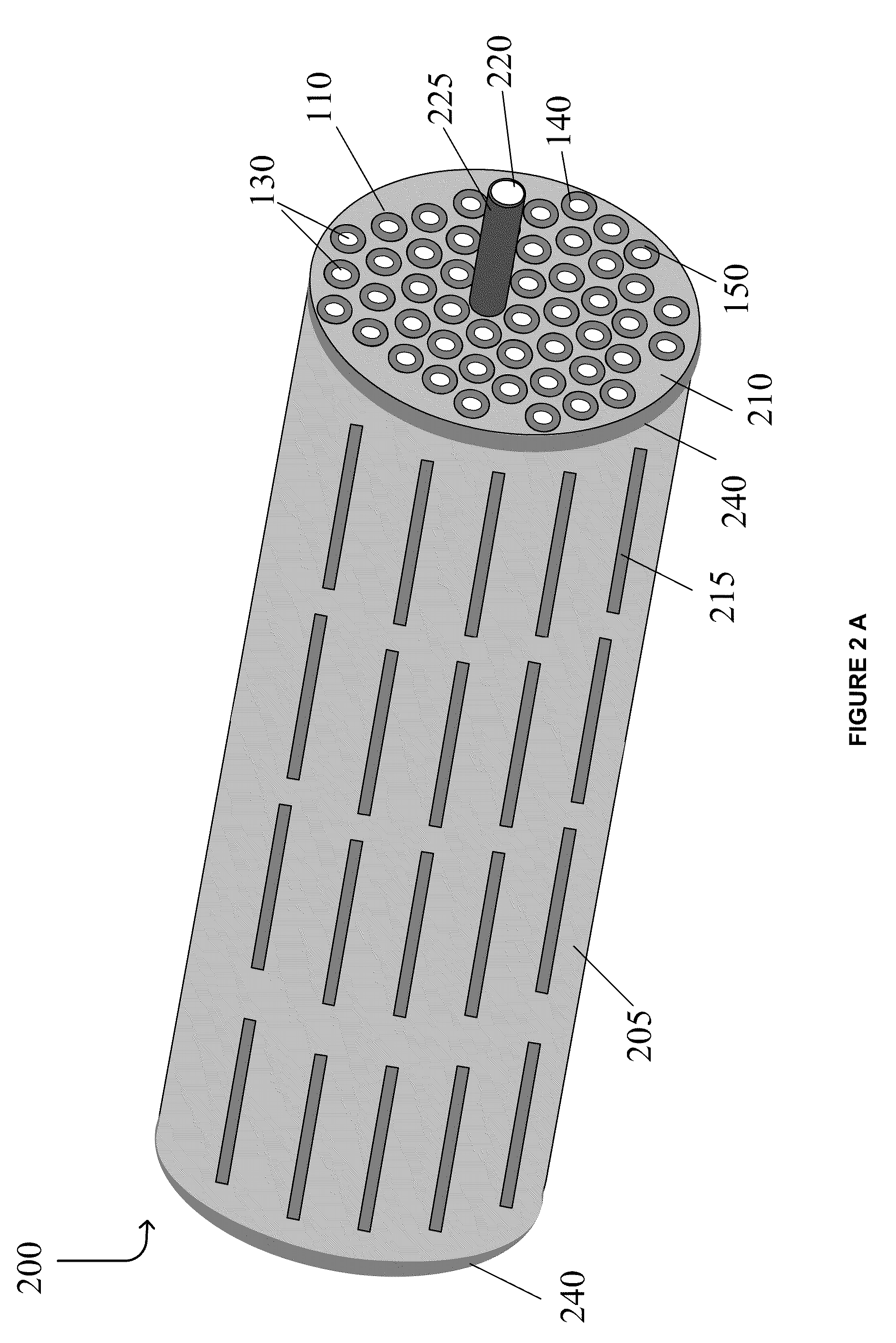

Sorbent fiber compositions and methods of temperature swing adsorption

The various embodiments of the present invention relate to compositions, apparatus, and methods comprising sorbent fibers. More particularly, various embodiments of the present invention are directed towards sorbent fiber compositions for temperature swing adsorption processes. Various embodiments of the present invention comprise sorbent fiber compositions, apparatus comprising a plurality of sorbent fibers, and methods of using the same for the capture of at least one component from a medium, for example CO2 from flue gas.

Owner:GEORGIA TECH RES CORP +1

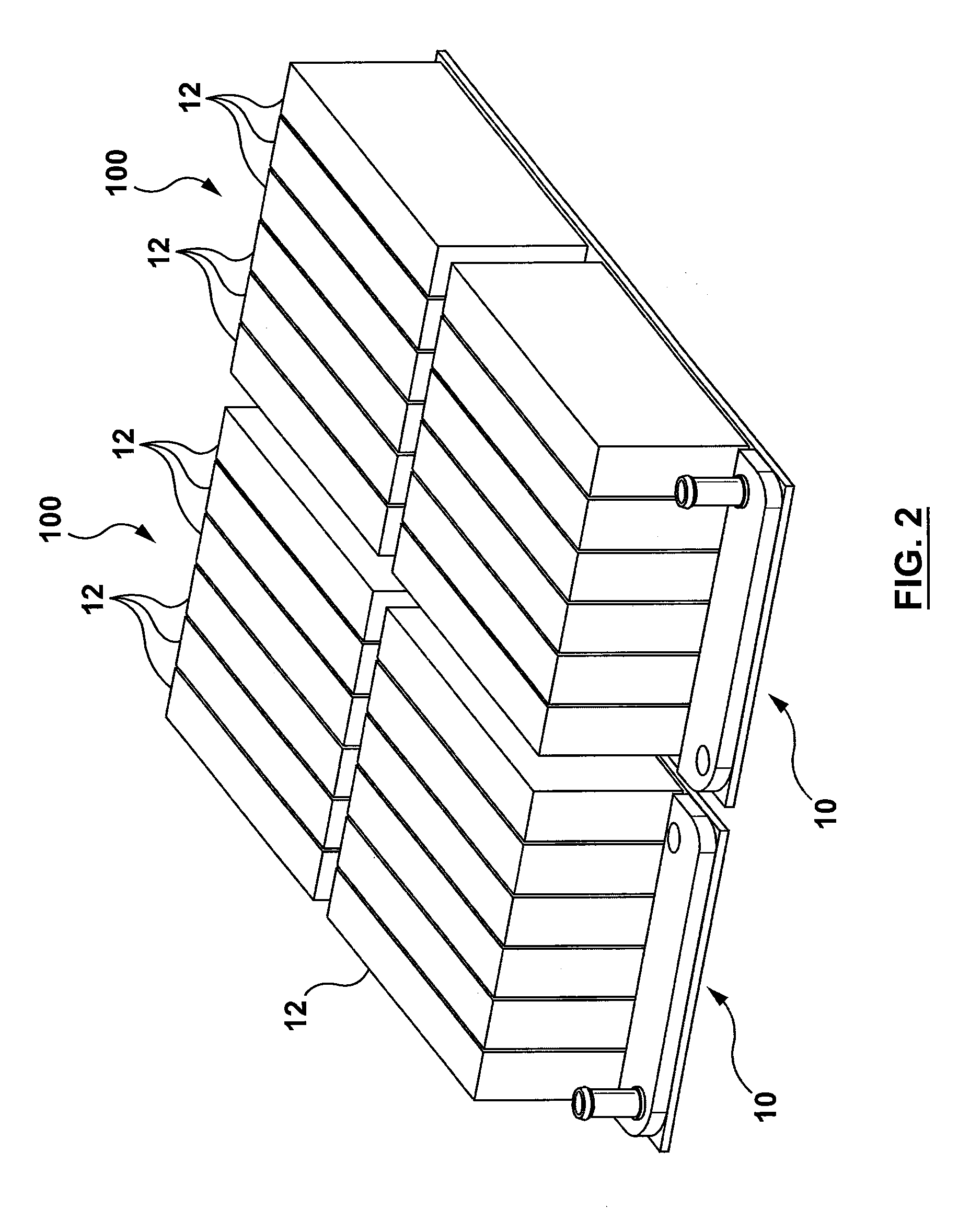

Counter-Flow Heat Exchanger for Battery Thermal Management Applications

A heat exchanger for thermal management of battery units made-up of plurality of battery cells or battery cell containers housing one or more battery cells is disclosed. The heat exchanger has a main body portion defining at least one primary heat transfer surface for surface-to-surface contact with a corresponding surface of at least one of the battery cells or containers. A plurality of alternating first and second fluid flow passages are formed within the main body portion each defining a flow direction, the flow direction through the first fluid flow passages being generally opposite to the flow direction through the second fluid flow passages providing a counter-flow heat exchanger. In some embodiments the heat exchanger has a two pairs of inlet and outlet manifolds, the heat exchanger providing a single-pass, counter-flow arrangement. In other embodiments the first and second fluid flow passages are interconnected by turn portions forming a U-flow, counter-flow heat exchanger.

Owner:DANA CANADA CORP

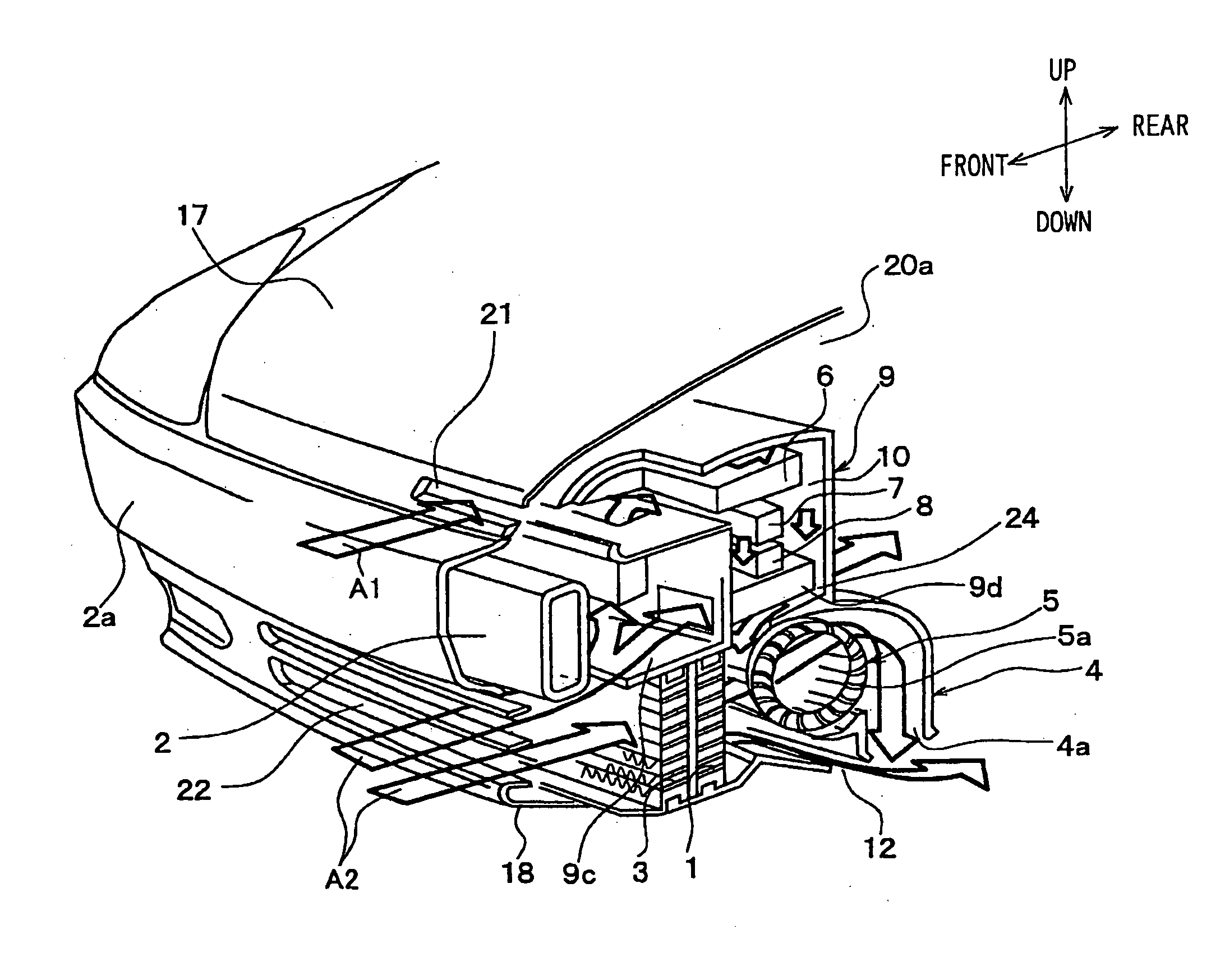

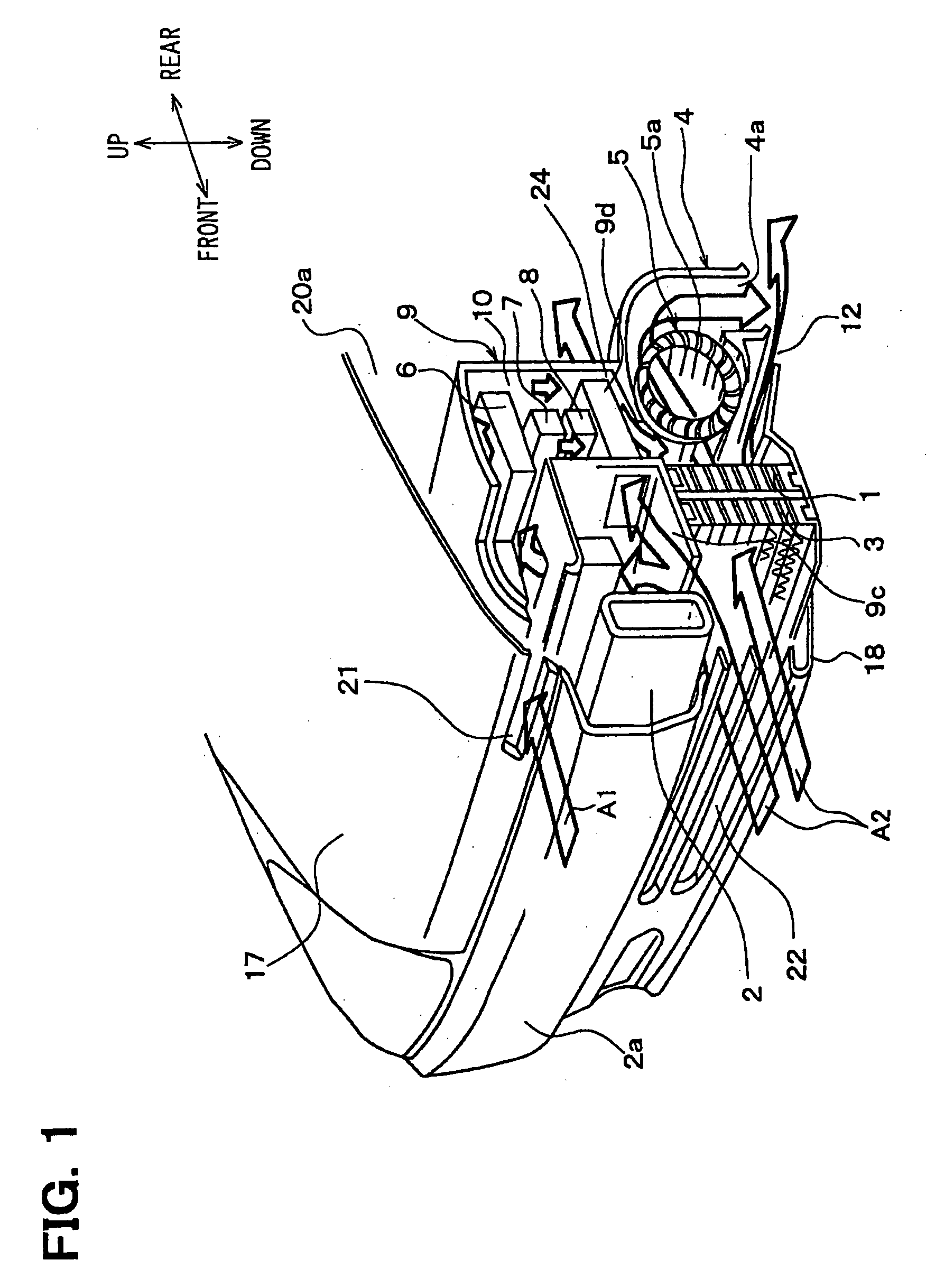

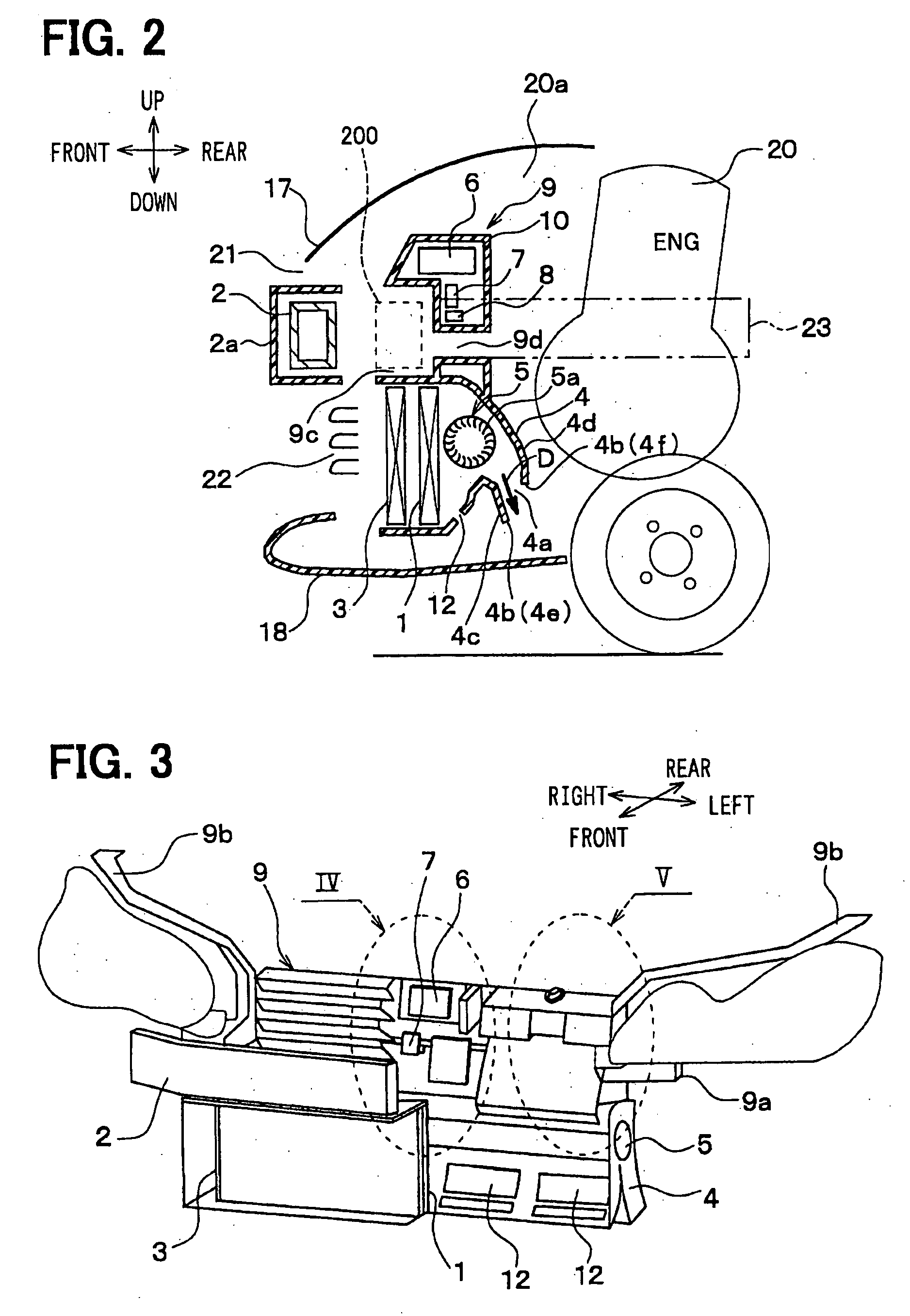

Vehicle front end structure

InactiveUS20050023057A1Lower center of gravityReduce harmLiquid coolingMachines/enginesRadarHeat exchanger

In a front end structure of a vehicle, a heat exchanger is arranged at a position lower than a bumper reinforcement member, so a position of an engine hood is lowered. Electric auxiliary devices such as a radar, electronic control units for lights, and an air cleaner are arranged at a position higher than the bumper reinforcement member or at the rear of the bumper reinforcement member. By this arrangement, the electric auxiliary devices are arranged at a position which is less likely to be affected by the bumper reinforcement member in a case of light frontal crush.

Owner:DENSO CORP

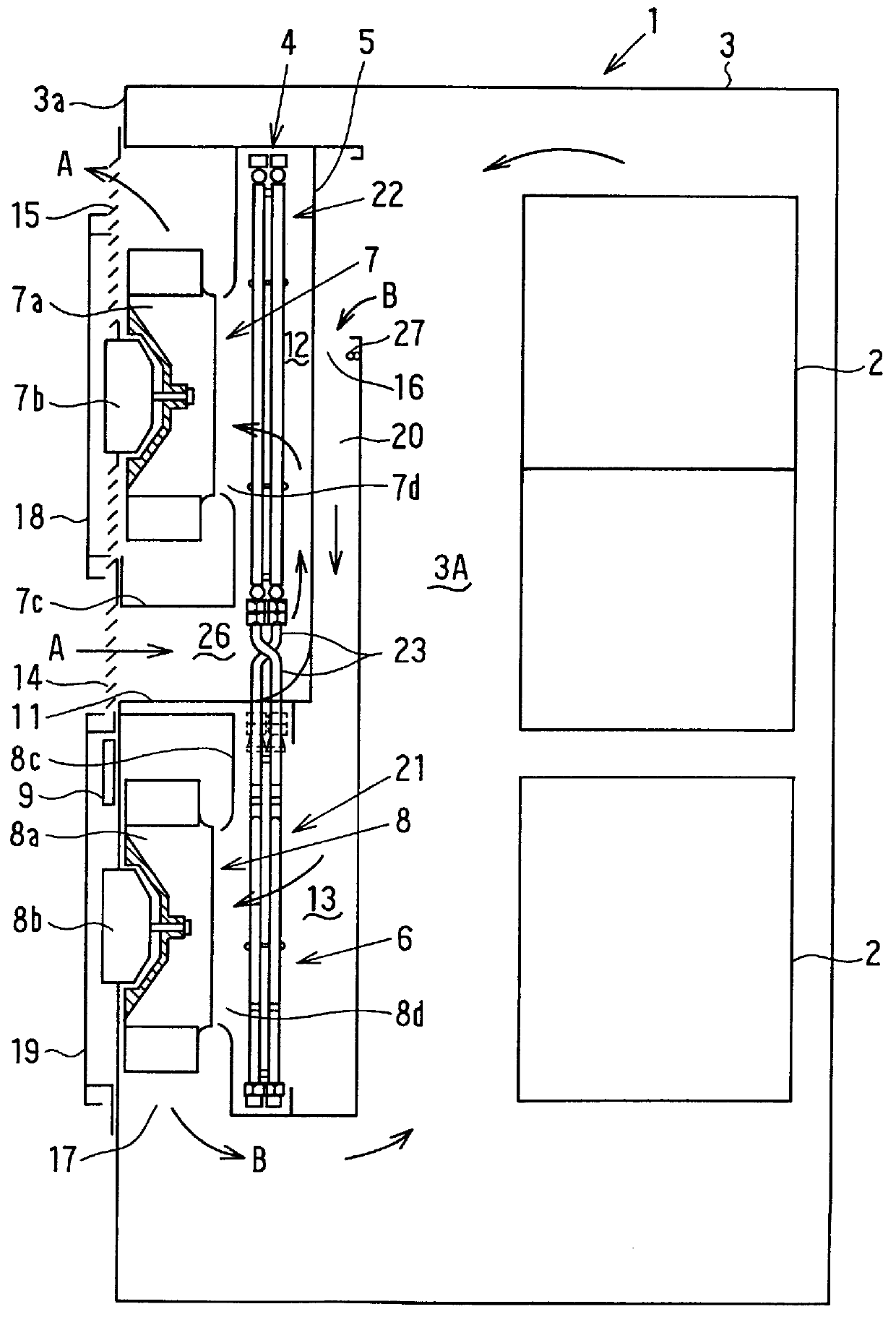

Cooling device boiling and condensing refrigerant

A cooling device includes: a partition plate for partitioning an interior of a case into a first fluid passage through which first fluid having a high temperature flows and a second fluid passage through which second fluid having a low temperature flows; a heat receiving portion disposed in the first fluid passage; a heat radiating portion disposed in the second fluid passage; and a connection pipe for communicating the heat receiving portion and the heat radiating portion. The heat radiating portion is disposed at an upper side of the heat receiving portion in such a manner that the second fluid from a front side of the heat radiating portion flows into a rear side of the heat radiating portion through a pipe space between the heat radiating portion and the heat receiving portion, and further passes through the heat radiating portion from the rear side toward the front side of the heat radiating portion. Thus, the cooling device has a small size while improving the cooling capacity of the cooling device.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com