Microchannnel evaporator assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

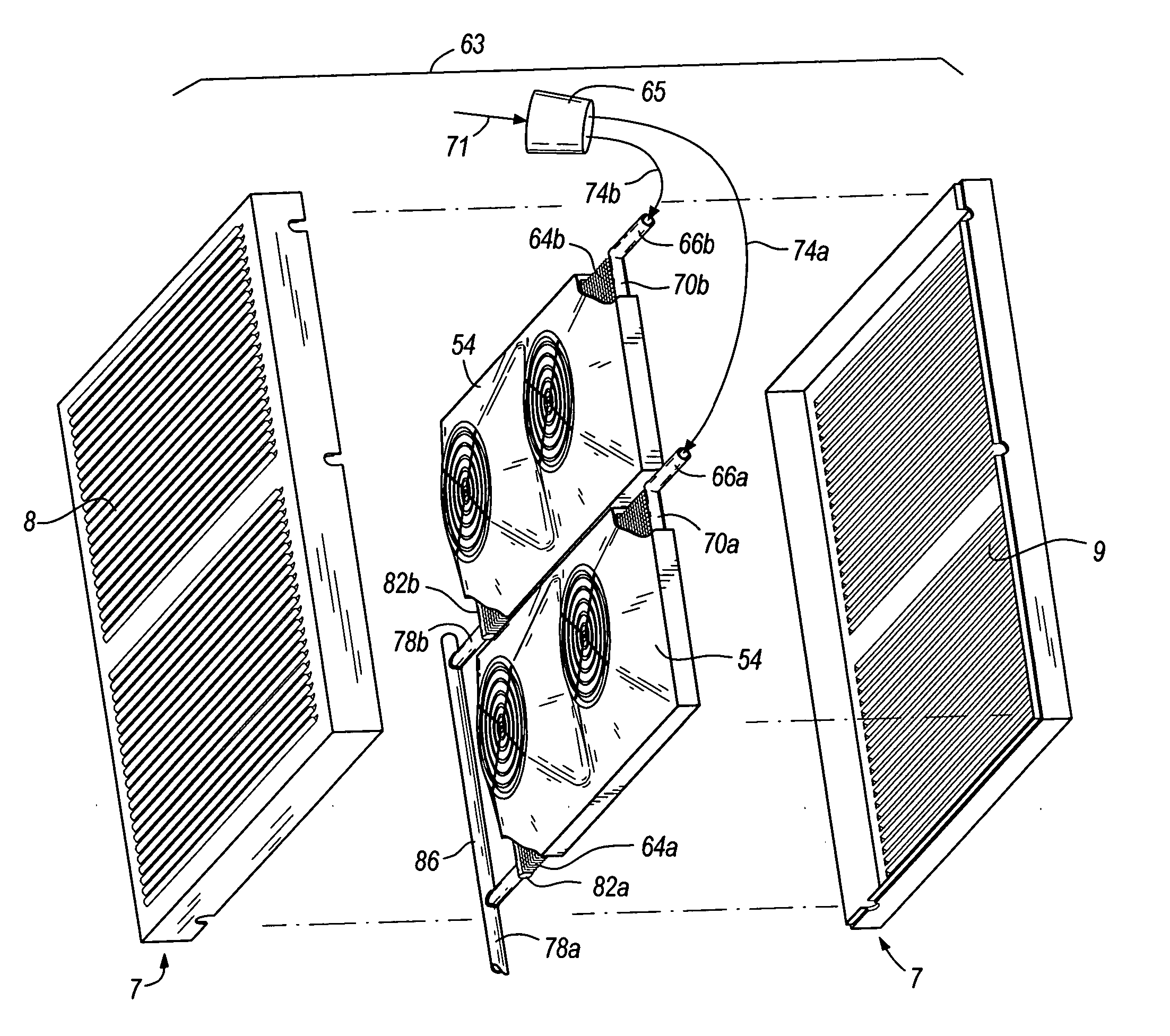

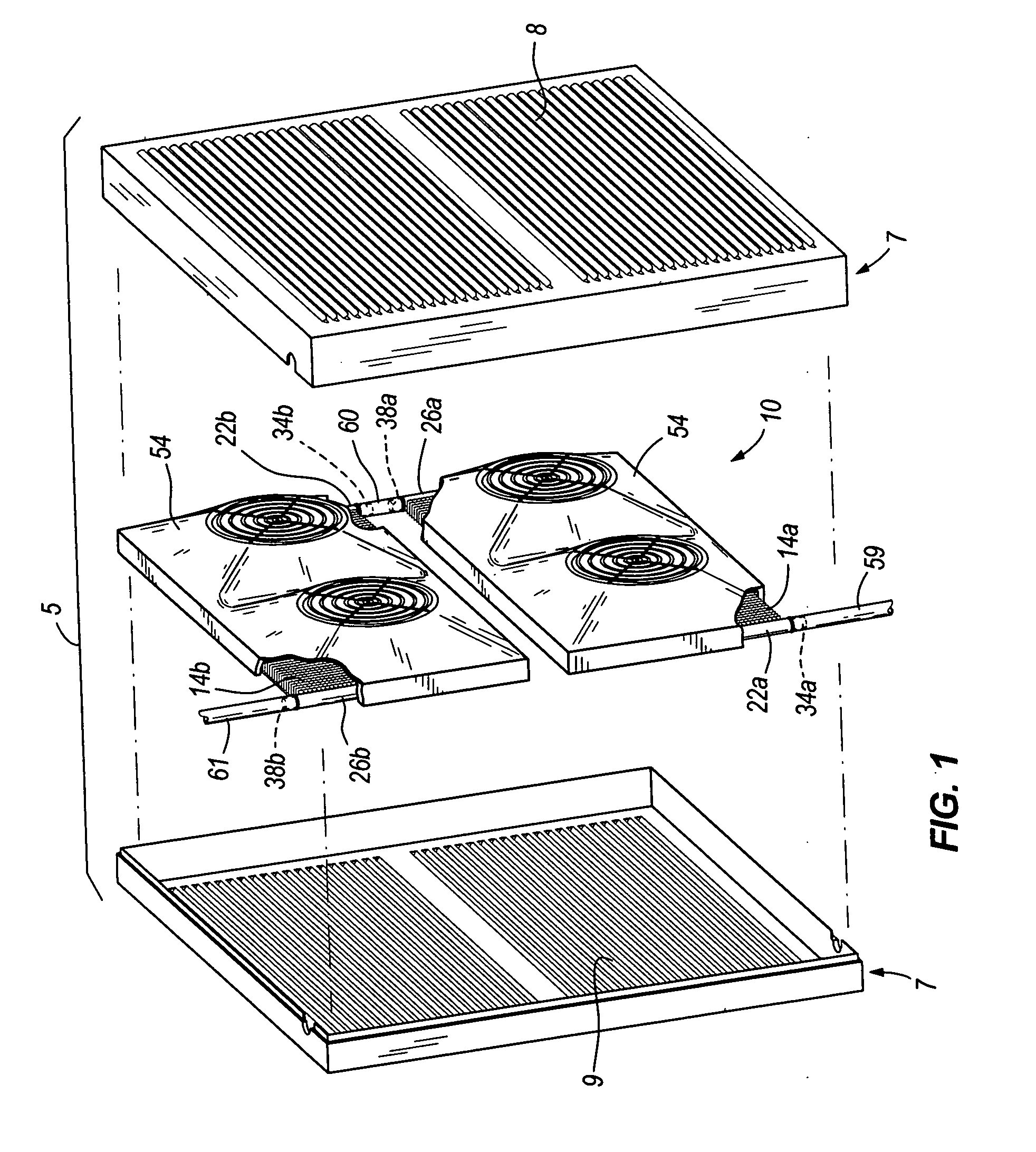

[0028] With reference to FIG. 1, a unit cooler 5 including a first configuration of an evaporator assembly 10 is shown. The unit cooler 5 may be used in a large-scale refrigeration system or a large-scale refrigerated environment, such as a walk-in cooler and a refrigerated warehouse, for example. The evaporator assembly 10 in the unit cooler 5 may therefore recirculate the air in the refrigerated environment to provide a refrigerated airflow to products stored in the walk-in cooler or refrigerated warehouse.

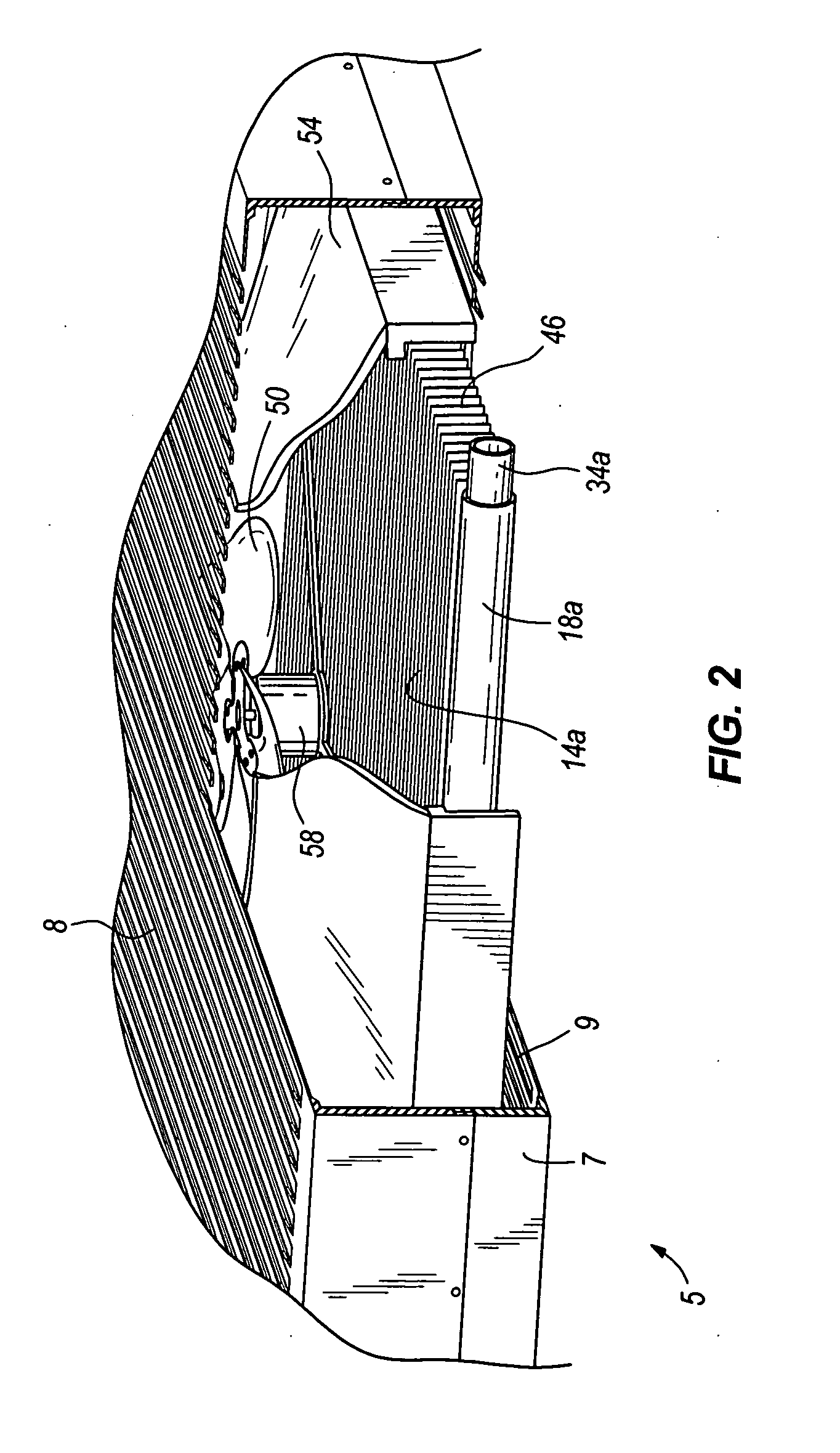

[0029] In a two-phase refrigeration system, the role of the evaporator assembly 10 is to receive low-pressure liquid refrigerant, remove heat from an airflow passing through the evaporator assembly 10, and discharge gaseous refrigerant to one or more compressors (not shown) remotely located from the evaporator assembly 10. The low-pressure liquid refrigerant evaporates as it passes through the evaporator assembly 10, such that the refrigerant passes through a substantial portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com